Page 1

TM-528

Revised 032495

OPERATION AND MAINTENANCE

MANUAL

for

TRUCK/TRAILER-MOUNTED GENERATOR SET

140-KVA, 400-HZ, 115/200-V AC, 3-PHASE

with

DETROIT DIESEL ENGINE

TYPE 8V-71N

5566B

Model Numbers

140G17K (Truck Mounted Unit)

140G17P (Trailer Mounted Unit)

140G17P (With Special Accessories)

Manufactured by

L

.!

HOBART BROTHERSCOMPANY "

POWER SYSTEMS DIVISION

j”i

TROY, OHIO 45373

1

U.S.A.

Page 2

Page 3

SAFETY INSTRUCTIONS AND WARNINGS FOR ELECTRICAL POWER EQUIPMENT

ELECTRIC SHOCK can kill. Do not touch live electrical parts.

ELECTRIC ARC FLASH can injure eyes burn skin cause equipment damage and

I

ignite combustible material. Do not use power cabies to

brekk load and prevent tools from causing short circuits.

IMPROPER PHASE CONNECTION,! PARALLELING, OR USE can damage this and attached

equipment.

IMPORTANT: - Protect all oderating personnel.

Read, understand, and follow

ail instructions in the Operating/Instruction Manual before

installing, operating,

or servicing the equipment.

Keep the manual

available for future use by all operators.

A.

GENERAL

Equipment that supplies electrical power can cause serioueinjury or death,

or damage to other equipment or property.

observe all safety rules and take precautionary actions.

The operator must strictlv

Safe practices

have been developed from past experience in the use of power source equipment.

While certain practices below apply only to electrically-powered equipment,

other practices apply to engine-driven equipment,

B.

SHOCK PREVENTION

Bare conductors,

electrically-live

or terminals in the output circuit, or ungrounded,

equipment can fatally shock a person.

and some practices to both.

Have a certified

electrician verify that the equipment is adequately grounded and learn what

terminals and parts are electrically HOT.

Avoid hot spots on machine. Use'

proper safety clothing, procedures, and test equipment.

The electrical resistance

dangerous currents to

equipment, do not work in damp areas.

dry wood,

use insulating gloves when dampness or sweat cannot be avoided.

of the body is decreased when wet, permitting

flow through it.

When inspecting or servicing

Stand on a drv rubber mat or

Keep clothing dry, and never work alone.

./

1

1. Installation and Grounding of Electrically Powered Equipment

Equipment driven by electric motors (rather than by diesel or gasoline

engines) must be installed and maintained in accordance with the ?lational

Electrical Code, ANSI/XFPA 70, and other applicable codes.

A power

disconnect switch or circuit breaker must be located at the equinment.

Check the nameplate for volta e,

only 3-phase power is

availab e,

to only two wires of the 3-phase line.

frequency, and phase requirements.

F

connect any single-phase rated equipment

DO NOT CONNECT the equipment

grounding conductor (lead) to the third live wire of the 3-phase line

this makes the eauipment frame electrically HOT, which can cause a fa;aF

-iniT&.-Always connect the grounding lead

if supplied in a power line cable,

to tne grounded switch box or building ground,

separate groundin

of the grounding

situation.

details.

Refer to the National Electrical Code .ANSI/NFPA 70 for

Do not remove plug ground prongs. Use correctly mating

lead.

!T

ead will be adequate for the worst

Ensure that the current

-m-e-

If not provided, use a

(am erage)

P

ault current

capacity

receptacles.

2.

Output Cables and Terminals

Inspect cables frequently for damage to the insulation and the

connectors.

not overload

Re lace or repair cracked or worn cables immediately. Do

ca les. 1

Do not touch output terminal while equipment is

energized.

Service and Maintenance

3.

,

This equipment must be maintained in good elec&?ical and mechanical

condition to avoid hazards stemming from disrepair. Report,any

equipment defect or safet

use of the eluigm ent unti its safety has been assured.

should be ma e'

y qualified personnel only.

hazard to the supervisor and di.z;.z;fmre

1

>

If

Instruction 910082

Feb 25/86 Revised

Page 1

Page 4

?I.

TC)XIC FUME PREVENTION

E.

c

- .

Before inspecting or servicing eledtricallp-powered equiment,

take the following precautions:

a. Shut OFF all power at the

disconnectin

before inspecting or servicing the

f

switch or line breaker

equ pment.

b.

Lock switch OPEN (or remove line fuses) so that power cannot be

turned ON accidentally.

c. Disconnect power to equipme.nt if it is out of service.

d. If troubleshooting must be 'done with the unit ener

another person present who is trained in turning o

9

zed, have

f the equipment

and'providing or calling far first aid.

FIRE AND EXPLOSION PREVENTION'

Fire and explosion are caused hy electrical short circuits, combustible

material nea,r engine exhaust &ping, misuse of batteries and' fuel, or

unsafe operating or fueling conaitlons.

1.

2.

3.

Electrical Short Circuits and Overloads

Overloaded or shorted equipment can become

hot enough to cause fires

either by self destruction or causing nearby combustibles to ignite.

For electrically-powered equipment, in particular,

"1

rotide primary

~input protection to remove short circuited or heavi y overloaded

equipment from the line.

Batteries

Batteries may explode and/or give off flammable hydro en

and arcing from a ruptured battery can cause fires

an

3 ad%%oni?e acid

failures.

When servicing, do not smoke, cause sparking, or use open

flame near the battery.

Engine Fuel

Use only approved fuel container or fueling system.

Fires and

explosions can occur if the fuel tank is not grounded prior to ;g duping

fuel transfer. Shut unit DOWN before removing fuel tank cap.

completely fill tank, because heat from the eouipment may cause fuel

expansion overflow.

Remove all spilled fuel IMMEDIATELY, including any .

that penetrates the unit. After clean-up,

fumes away with compressed air.

open equipment doors and blow

Carbon monoxide - Engine exhaust fumes can kill and cause,health problems.

Pipe or vent the exhaust fumes to a suitable exhaust duct or outdoors.

Never locate engine exhausts near intake ducts of air conditioners.

BODILY INJURY PREVENTION

Serious inju

Y

can result from contact with fans inside some equipment.

Shut DOWN sue

equipment for inspection and routine maintenance.

When

equipment is in oneration use extreme care in doing necessary troubleshooting

and adjustment.

Do not remove guards while equipment.is operating.

MEDICAL AND FIRST AID TREATMENT

First'aid facilities and a qualified first aid person should be available

for each shift for immediate treatment of all injury victims. Electric

shock victims should be checked by a ph

sician and taken to a hospital

immediately if any abnormal signs are

o served. i:

EMERGENCY FIRST AID I

Call physician immediately.

Seek additional assistance and use First Aid

techniques recommended by American Red Cross until medical help arrives.

./

;EzREATHING IS DIFFICULT give oxy en,

FOR ELECTRICAL SHOCK, turn o

F

if available, and have victim lie

f power, Remove victim; if not

breaihing, begin artificial respiration, preferably mouth"to-mouth. If

I no detectable pulse,

Squad immediately,.

begin external heart massage. Calll.$mergency Rescue

G.1 EQUIPMENT PRECAUTIONARY LABELS

h:;E:::e 3 YeCau==ona

Order and

abels

ry Aabe's on the equi

that cannot be easily rea

F

ent monthly.

.

!,

Page 2

Instruction 910082

Revised Feb 25/86

Page 5

TABLE OF CONTENTS

SUBJECT

I

Introduction

,

Description/Operation ,

/

Identification

1.

General

2. Model Number

3.

Optional Equipment

A.

Trucks

B.

Truck Body Kits

C.

Trailer

D.

Transformer-Rectifiers

E.

T-R Mounting Kits

F.

Test Box

G.

Revolving Light

Description

1.

General

2.

Orientation

3.

Special Features

A. Protective Monitor System

B.

Pullout Trays

C. Voltage Regulator

D.

Test Receptacle Connector

1

./

/‘Ii

Jan 22181

1

CHAPTER/SECTION

PAGE

1-o

1

l-l

1

1

1

2

2

2

2

2

2

2

314

l-2

1

1

Contents

Page 1

Page 6

TABLE OF CONTENTS CONTINUED

SUBJECT

CHAPTER/SECTION

E . Test Box

,

l-2

F. Dual Output

I

).

4., Canopy

5. Engine, Generator and Controlls Assembly

A. General

3. Generator

C. Engine

D. Governor

E. Engine Safety Shutdown System

(1) General

(2) Air shutoff valve

(3) Engine fault sensing devices

(a) General

(b) Emergency-stop solenoid valve

F. Air Cleaner

G. Control Box

(1) Voltage regulator tray

(a) Gantrols

(b) Protection

(c) Components

(2) Protective relay tray

1

Contents

Page 2

) b’i

TM-528

PAGE

3

3

3

6

6

7

9

9

10

10

10

10

12

I;

Revised Jan 22/81

Page 7

I

i

i

/

!

/

I

/

f

I

!

/

I

,

I

/

!&

1

TABLE OF CONTENTS CONTINUED

SUBJECT

CHAPTER/SE CT ION

‘, (a) S

ensing relays 1’

(b) Protective monitor module

I

,I

(c) indicating I ights

(d) Plug interlock relay

(e) Test-bank switch

(f) Resistor

(g) Fuse interlock relay

(h) Connector

(i) Diode,

capacitor and terminal board

(k) Overload relay

(I) Fuses

(3) Generator control tray

(a) Resistors

16

(b) Generator output meters 16

(c) Meter and I ine switches

16

18

18

18

(d) Receptacle connect0 r

(4 Tray

(f) Manual voltage control

H. Engine and Generator Control Panel

(1) Engine gages and meters

(a) 0 i I pressure gage and diaphragm switch

l-2

1

Li

I t

TM-528

PAGE

12

12

14

14

14

15

15

15

15

15

15

16

18

18

18

Jan 22/8 T Revised

Contents

Page 3

Page 8

TABLE OF CONTENTS CONTINUED

TM-528

SUBJECT

I (b) Ammeter : ,

(c) Temperature gage

(d) Hourmeter

(2) Panel lights

(3) Indicating I ights

(a) Engine ON indicating light

(b) locd contactor indicating I ights

(4) Switches

(a) Air valve (starting) switch

(b) Starter switch

!_

,

CHAPTE R/SE CT 10 N

1-2

PAGE

18

20

20

20

20

20

20

21

21

21

(c) Speed control switch

(d) Light switch

(e) Load contactor control switches

(f) Push-to-build-up-voltage switch

(5) Excitationtdeenergization relay

(6) Fuse

(7) Test receptacle connector

(8) Speed control cable

(9) Cold weather starting aid

(10) Terminal boards

.I

J. Special Engine and Generator Control Panel

t

l,‘i

21

21

21

22

22

22

22

22

22

23

23

) General

!

Contents

Page 4

(1

23

Revised Jan 22/81

Page 9

I

m

1

TABLE OF CONTENTS CONTINUED

SUBJECT

(2) Receptacle, connector and circuit breaker

I

<’

(3) Emergency-stop switch

,(4) Ho urme ter d iaphragm switch

(5) Locd contactor switches operating handle

(6) Low fuel warning and shutdown system

K. Power Module

(1) Capacitor

CHAPTER/SECTION

1-2

(2) Line-drop current transformer

(3) Ammeter current transformer

(4) Locd contactor

(5) Diode panel

(6) Resistors (line drop)

(7) Overload current transformer

(8) Overlood board

(9) Indicating light relc

(10) Terminal board

’ L. Output Terminal Panel

Preparation for Use

,l . Generator Set

A. General

B. Inspection/Check

ys and blocking diode

l-3

C. Output Cables Installation

Jan 22/81 Revised

TM-528

PAGE

23

23

23

23

25

25

25

25

25

26

26

26

26

26

28

28

28

1

1

1

1

3/4

Contents

Page 5

Page 10

TM-528

SUBJECT

CHAPTER/SECTION

PAGE

TABLE OF CONTENTS CONTINUED

(l), Cable requirements

3

(2) Cable connection ’

Operation

1. General

2. Operating the Truck

A. General Operating Instructions

8. Starting the Truck Engine

C. Positioning the Truck

3. Operating the Trailer

A. General

B. Operating the Brakes

C. Drawbar

4. Operating the Generator Set

A. General

8. Connecting Output Cables

C. Preparation for Power Delivery

(1) Voltage regulator trcy

(2) Protective relay tray

1 (3) Generator control tray

(4) Engine and generator control panei

D. Normal Engine Starting

1

E. Cold Weather Engine Starting

Contents

Page 6

1-3

3/4

3/4

l-4

1

1

1

1

1

2

2

2

2

2

2

2

3

3

3

3

4

4

,

4

(#Ii

7 :

Revised Jan 22/81

Page 11

I

m

I 1

TM-528

I

I

TABLE OF CONTENTS CONTINUED

SUBJECT

CH APTE R/SE CT IO N

PAGE

--

F., Power Delivery (Automatic Voltage Cantroi)

l-4

9

G. Power Delivery (Manual Voltage Gntrol)

H.. Stop Power Deliver&

10

10

J. Stop Engine

K. Emergency Stop (Special)

5. Operating Instructions for Optional T-Rs

A. Transformer-Rectifier Operation

(1) Direct current power delivery

(2) Simultaneous 28.5-V and 35-V DC power delivery

(3) Simultaneous 28.5-V DC and 115-V AC power delivery

(4) Simultaneous 35-V DC or 112-V DC

-

Servicing

2-o

Maintenance

2-l

1. General

10

10

11

11

11

11

12

12

2. Maintenance Schedule

1

A. General

1

B.

Maintenance Schedule Check Sheet

1

C. Time lntemais

1

D. Identification of Interval Periods

1:

3. Air Cleaner Cartridge Replacement

3

A. Removal

,

3

ii

B. Installation

4

Jan 22/8 1 Revised :

i.

Contents

Page 7

Page 12

TM-528

TABLE OF CONTENTS CONTINUED

SUBJECT CHAPTER/SE CT ION

PAGE

4. Electrical System (24-‘V and

I

A. Lights

B. Fuses

C. Wiring and Gpnections

D . Battery Service

(1) General

12-W DC) , 2-l 5

(2) Battery location and accessibility

(3) Battery care

(4) Liquid level

(5) Cleaning the battery

5. Electrical System (115-V AC)

A. Monitoring Instruments

B. Indicating Lights

C. Protective Relays

D. Wiring and Connections

6. Lubrication

A. General

B. AC Generator

C. Generator Controls

D. Diesel Engine

(1) Lubrication schedule

t:

ontents

5

5

5

s 5

5

5

5

7

7

8

8

8

8

9

9

9

1

)“i

9 .

-

!,

Revised Jan 22/81

Page 8

Page 13

SUBJECT

.

w

1

I

TM-528

TABLE OF CONTENTS CONTINUED

CHAPTER/SE CT IO N

PAGE

I

(2) Oil specification

2-l

9

I

(3) Oil viscosity

10

(4) Changing engine oil

10

(5) Changing oil filter elements

10

(6) Lubrication procedures

7. Generator Maintenance

10

13

A. Cleaning

B . Ad i ustment

8. Engine Mcintenance

A. General

3. Cleaning

Ad iustment/Test

1. General

2. Testing

13

13

13

2-2

13

13

1

1

1

A. Preoperational Test Procedures

1

B. Operational Test

4

3. Adjustment

7

A. Engine Governor

7

B. Generator

8

C. Generator Control Adiustments

8

(1) Adjust manual voltage co,ntrol variable $$istor

9

Jan 22/81 Revised

:

i>

Contents

Page 9

Page 14

TABLE OF CONTENTS CONTINUED

TM-528

SUBJECT

CHAPTER/SE CT 10 N

I (2) Adjust generator ove?load relay

balast resistor I

(3) Adjust 115-V AC voltage regulator

),

(a) Adiust generator output voltage

(b) Adiust cable length and size

compensation rheostats

(c) Adjust damp and rate potentiometers

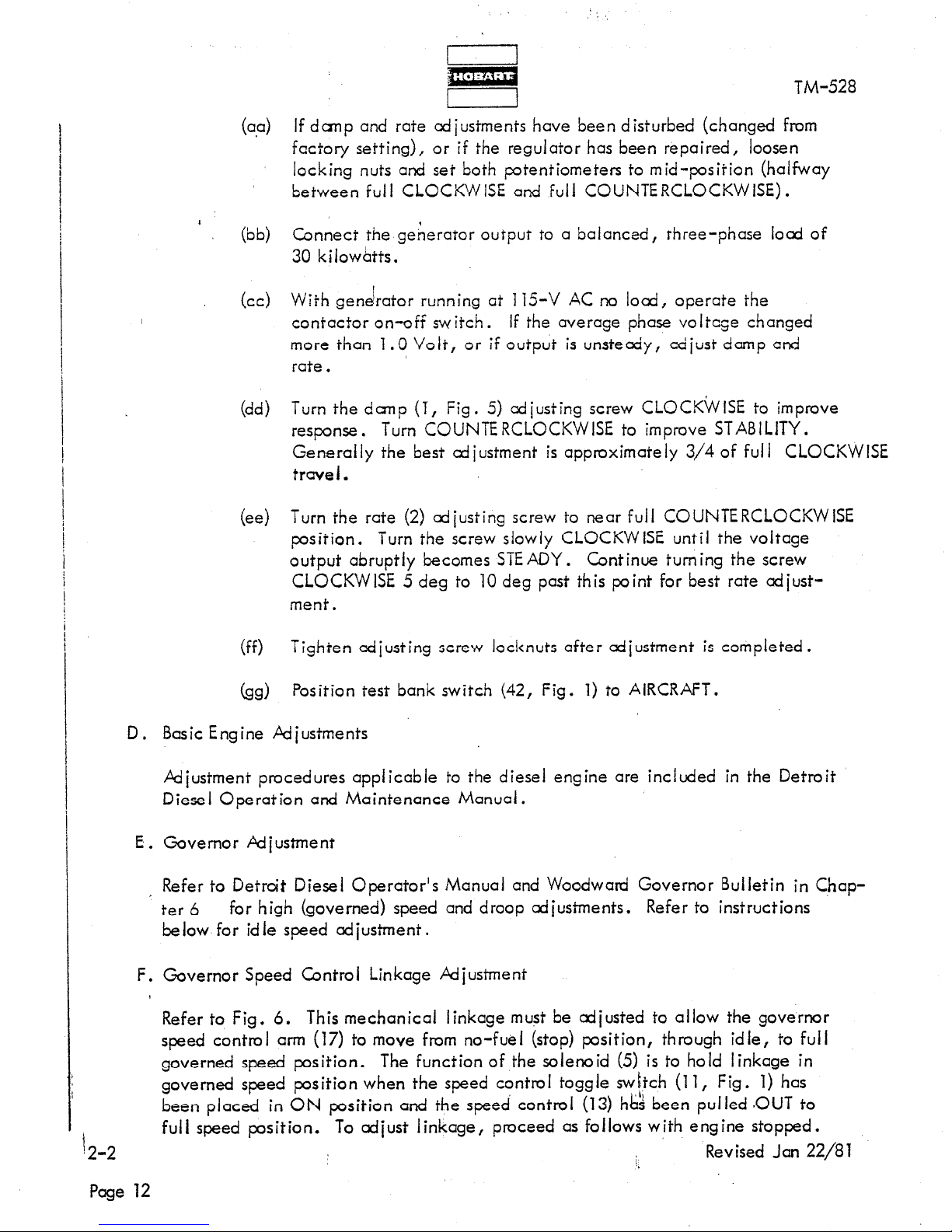

D. Basic Engine Adiustrnents

E. Governor Adiustment

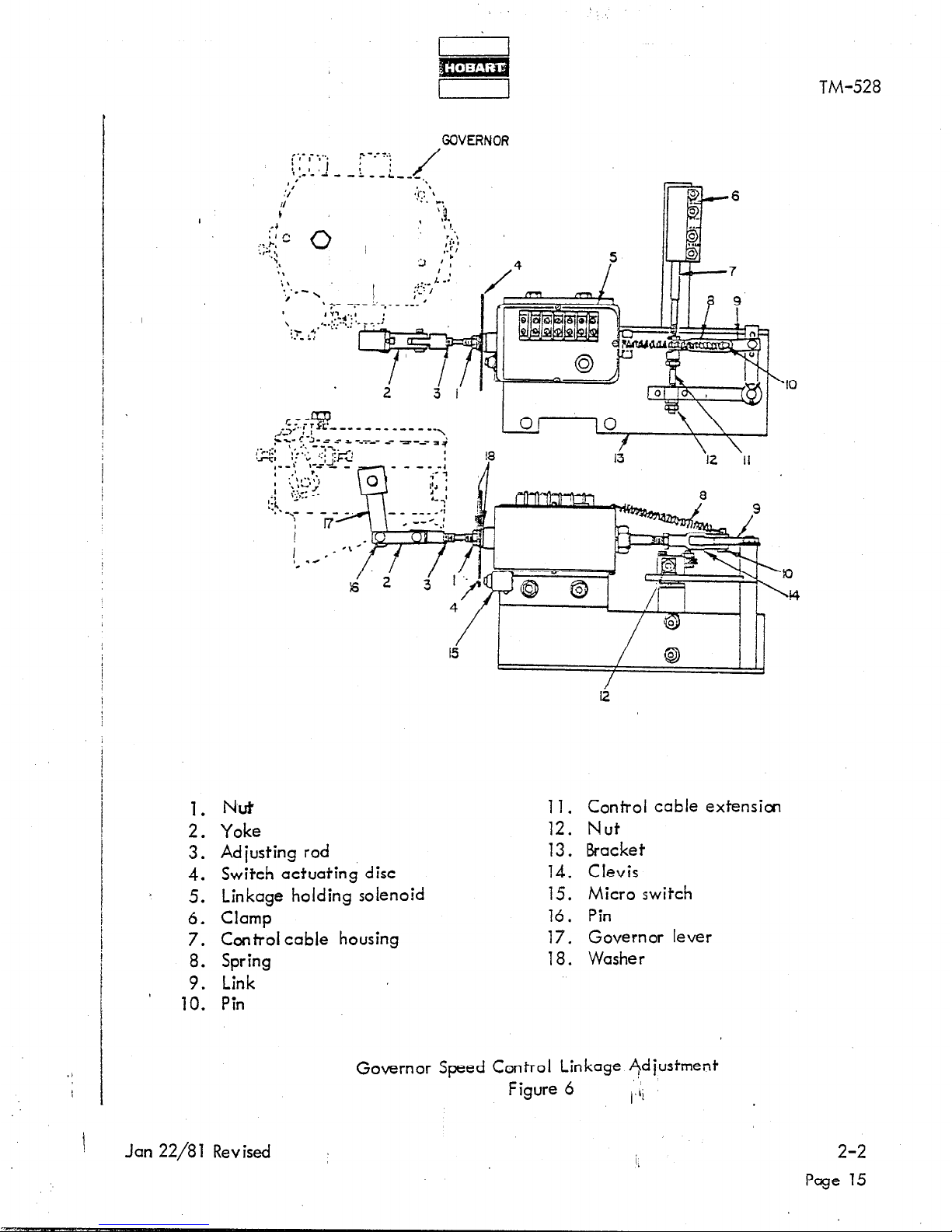

F. Covernor Speed Control Linkage Adiustment

(i) Adjust switch operating disc position

2-2

PAGE

9

10

10

El0

11

12

12

12

14

(2) Adjust solenoid linkage

(3) Ad just eng ine id le speed

(4) Adjust engine governed (high) speed

Troubleshooting

Troubleshooting Procedures

1. General

2. Troubleshooting Chart

A. Description

8. Use of the Troubleshooting Chart

3. Wiring Diagrams

II lustrated Parts List

3-o

3-l

4-o ,,ii

14

14

16

1

1

1

1

ontents

c!

Page 10

j, Revised Jan 22/81

Page 15

I 1

TM-528

TABLE OF CONTENTS CONTINUED

SUBJECT

Intro#uct ion

1. General

I

2. ,Purpose

3. Arrangement

CHAPTER/SECTION PAGE

1

4-l 1

4. Explanation of Parts List

A. Contents

B. Parts List Form

(1) Figure-Item No. Column

(2) Hobart Part Number Column

(3) Nomenclature Column

(4) Eff (Effective) Column

(5) Units per Assembly Column

Manufacturer’s Codes

1. Explanation of Manufacturer’s (Vendor) Code List

Parts List

1. Explanation of Parts List Arrangement

2. Symbol s and Abbreviations

Numerical Index

1 1. Explanation of Numerical Index

Optional Equipent

Manufacturer’s Literature

Jan 22/81 Revised :

4-2

4-3

1

4-4

1

5-o

1

6-O

Li

1

l/2

l/2

i;

Contents

Page 11

Page 16

I

(’

j CHAPTER/

j SECTION

l-l

l-2

l-2

l-2

l-2 !

l-2

l-2

l-2

l-2,

l-2

l-2

l-2

l-2

l-3

l-4

l-4

l-4

l-4

2-l

2-l

2-l

2-l

2-l

2-l

2-l

2-l

2-2

2-2

2-2

2-2 1

2-2

2-2

2-2

3-l

3-l I

3-1

3-l

3-l

.I

3-l

1 4-3

FIGURE

NUMBER

I

,l

1

2

3

4

5

6

7

8

9

10

11

12

1

1

1

2

3

1

1

2

3

4

5

6

7

1

1

2

3

4

5

6

1

2

3

4

5

6

1

1

‘&

I

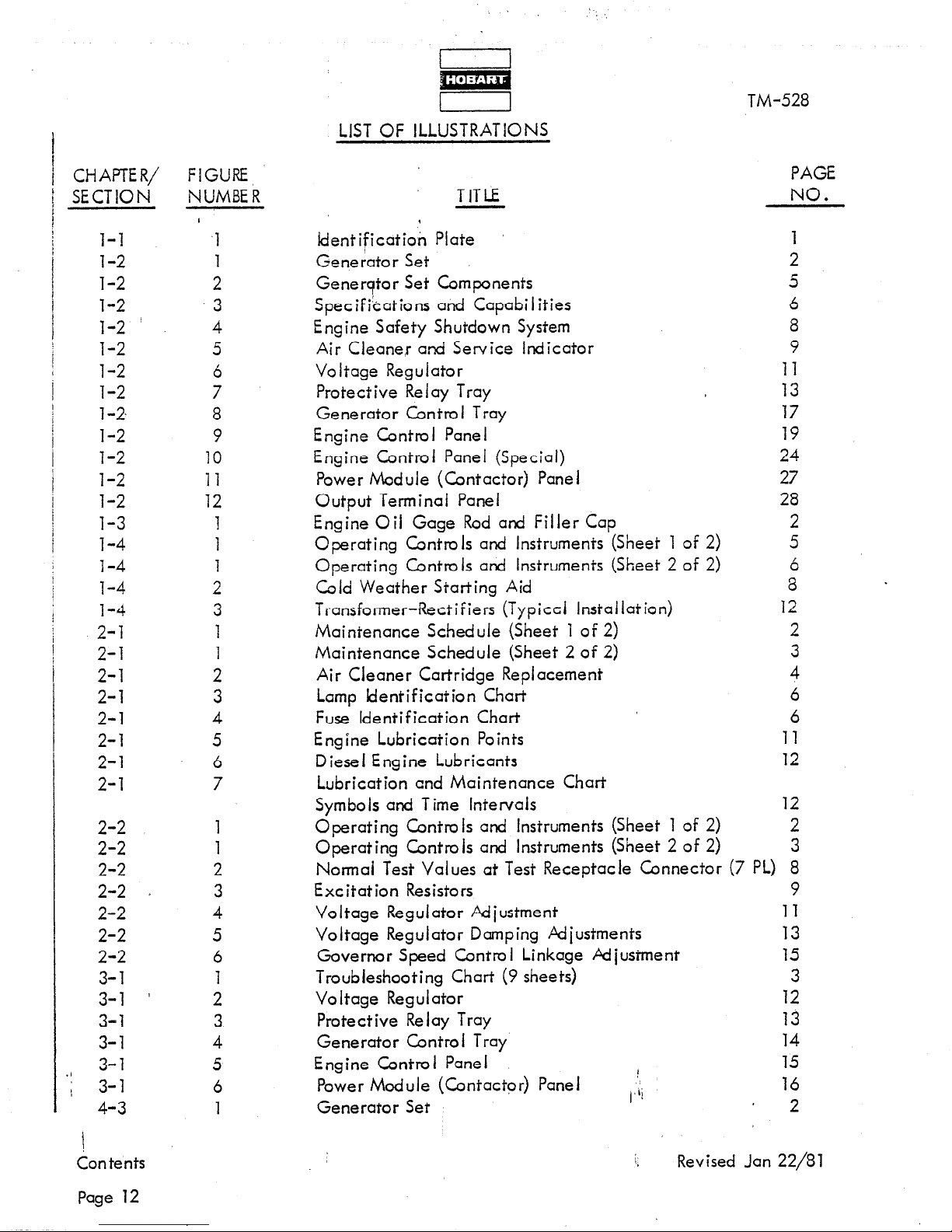

LIST OF ILLUSTRATIONS

TITLE

Identification Plate ’

Generator Set

Generator Set Components

Specifications and Capabilities

Engine Safety Shutdown System

Air Cleane,r and Service Indicator

Voltage Regulator

Protective Relay Tray

Generator Control Tray

Engine Control Panel

Engine Control Panel (Special)

Power Module (Contactor) Panel

Output Terminal Panel

Engine Oil Gage Rod and Filler Cap

Operating Controls and Instruments (Sheet 1 of 2)

Operating Controls and Instruments (Sheet 2 of 2)

Cold Weather Starting Aid

Transformer-Rectifiers (Typiccl Installation)

Maintenance Schedule (Sheet 1 of 2)

Maintenance Schedule (Sheet 2 of 2)

Air Cleaner Cartridge Replacement

Lamp Identification Chart

Fuse Identification Chart

Engine Lubrication Points

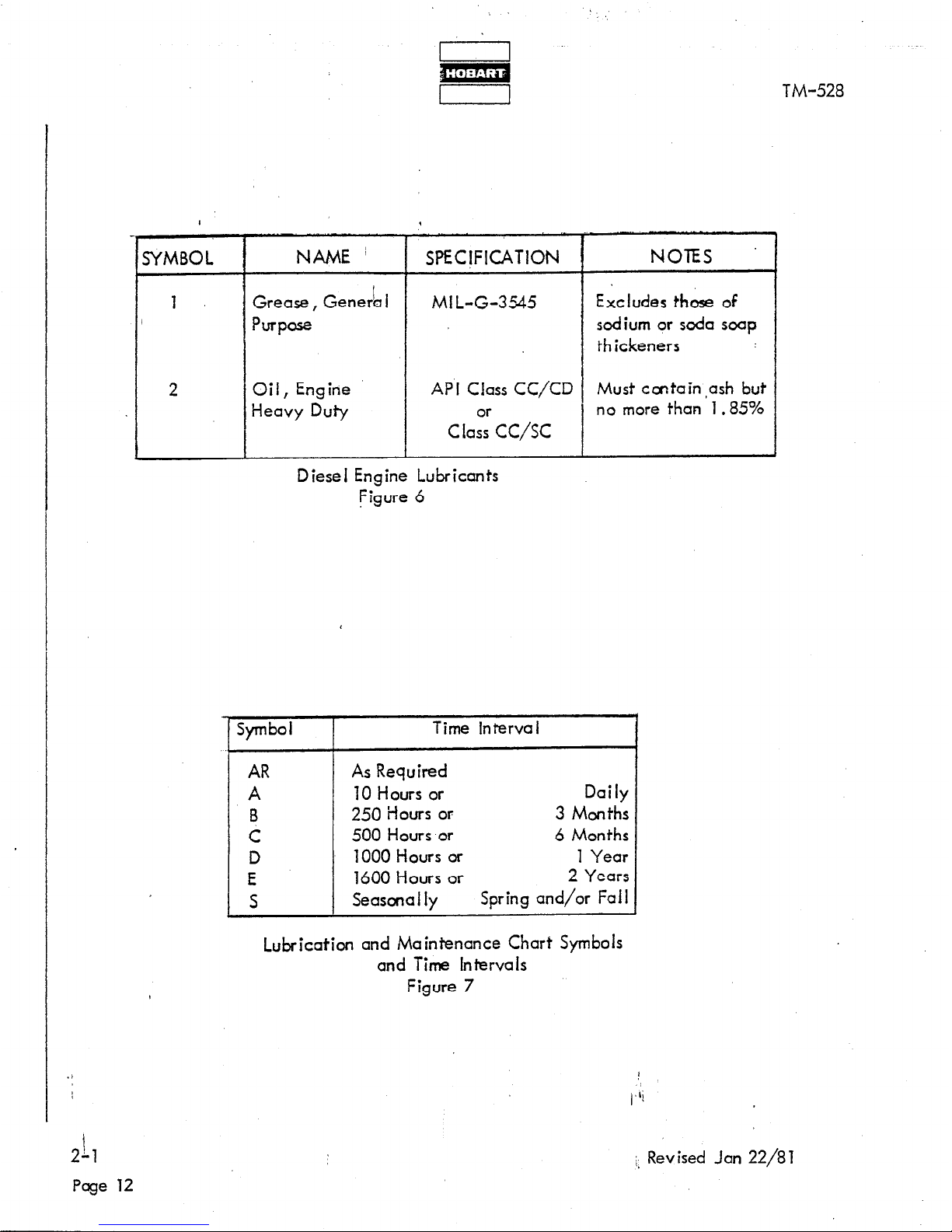

Diesel Engine Lubricants

Lubrication end Maintenance Chart

Symbols and T ime Intervals

Operating Controls and Instruments (Sheet 1 of 2)

Operating Controls and Instruments (Sheet 2 of 2)

Normal Test Values at Test Receptacle Connector (7 PL) 8

Excitation Resistors 9

Voltage Regulator Adiustment

Voltage Regulator Damping Adiustments 13

Governor Speed Control Linkage Adiustment

Troubleshooting Chart (9 sheets) 3

Voltage Regulator

Protective Relay Tray 13

Generator Control Tray 14

Engine Control Panel

Power Module (Contactor) Panel

Generator Set

I

/;i

TM-528

11

13

17

19

24

27

28

8

12

11

12

12

11

15

12

15

16

PAGE

NO.

1

2

5

6

8

9

2

5

6

2

3

4

6

6

2

3

2

!

Con tents

Page 12

5

Revised Jan 22/81

Page 17

./

!

CHAPTER/

FIGURE

SECTION

NUMBER

4-3

4-3

4-3

4-3

4-3

4-3

4-3

4-3

4-3

4-3

11

4-3 12

4-3

13

4-3

14

4-3 15

4-3 16

4-3 17

4-3 17A

4-3

18

4-3 19

4-3 20

1

!/r

I,

LIST OF ILLUSTRATIONS (CONTINUED)

2 ~

3

4

5

6

7

8

9

10

<’

TITLE

I

.

Canopy Assembly

Generator Set Without Canopy

Control Box Assembly

Voltage Regulator Tray Assembly

, Protective Relay Tray Assembly

Generator Control Tray Assembly

Control Box and Internal Components Group

Engine Control Panel Assembly

Engine Controi Panel Assembly

(Special)

‘Power Module Panel Assembly

Output Terminal Panel Assembly

Air Cleaner Group

Generator Group

Red iator and Coo I ing System

Engine Group

Governor Oil Filter Lines Group

Lines, Oil, Emergency Shut Down

Governor Linkage Group

Exhaust System

Frame Group

TM-528

PAGE

NO.

4

6

8

10

12

16

20

22

26

30

34

36

38

40

44

48

50

52

54

56

r

Jan 22/8 1 Revised :

Contents

Page 13/14

Page 18

Page 19

id

I

i,NTRODUCTiON

This manual contains operation and, maintenance information for a 400-Hz Generator Set

which may be either truck or trail&r mounted,.

Brothers Company,

The purpose of the manual is!to provide operators and maintenance personnel with instructions

and information which will guide and ,assist them in the efficient operation and maintenance

of the ground power equipment.

these instructions and familiarize’ themselves with the characteristi’cs, capabilities, and

limitations of the unit.

The manual is divided into six chapters. Each chapter is d ivided into as many sections as

required .

section begins with Page one and the first illustration in each section is Figure 1.

Should this manual contain additional information required to cover optional equipment,

modifications, changes and updated designs, added after the original manual was released,

this information will be added at the end of a Section where it would normally be found.

Added or changed information is indicated by a solid black line in the left-hand margin

of the page, opposite the new or revised material.

Pages and illustrations are not numbered consecutively through the manual. Each

Power Sjstems Division, Troy, Ohio 45373.

Ail personnel responsible for the equipment should read

1

These units are manufactured by Hobart

TM-528

Always refer to the Table of Contents, or to the last page (s) of a Section to determine

if special information hcs been added for your particular machine.

Refer to Chapter 1, Section 1 for an explanation of how to identify generator sets.

Chapter 5 lists ail options available for use with the basic generator set.

lists ail pertinent,manufacturer’s literature which is furnished with this manual, including

schematic and connection diagrams.

Chapter 6

!

Jan 22/81 Revised

:

I)

Introduction

Page l/2

Page 20

.,

Page 21

TM-523

CHAPTER 1. DESCRiPTlON AND OPERATION

SECTION 1. IDENTIFICATION

I

9

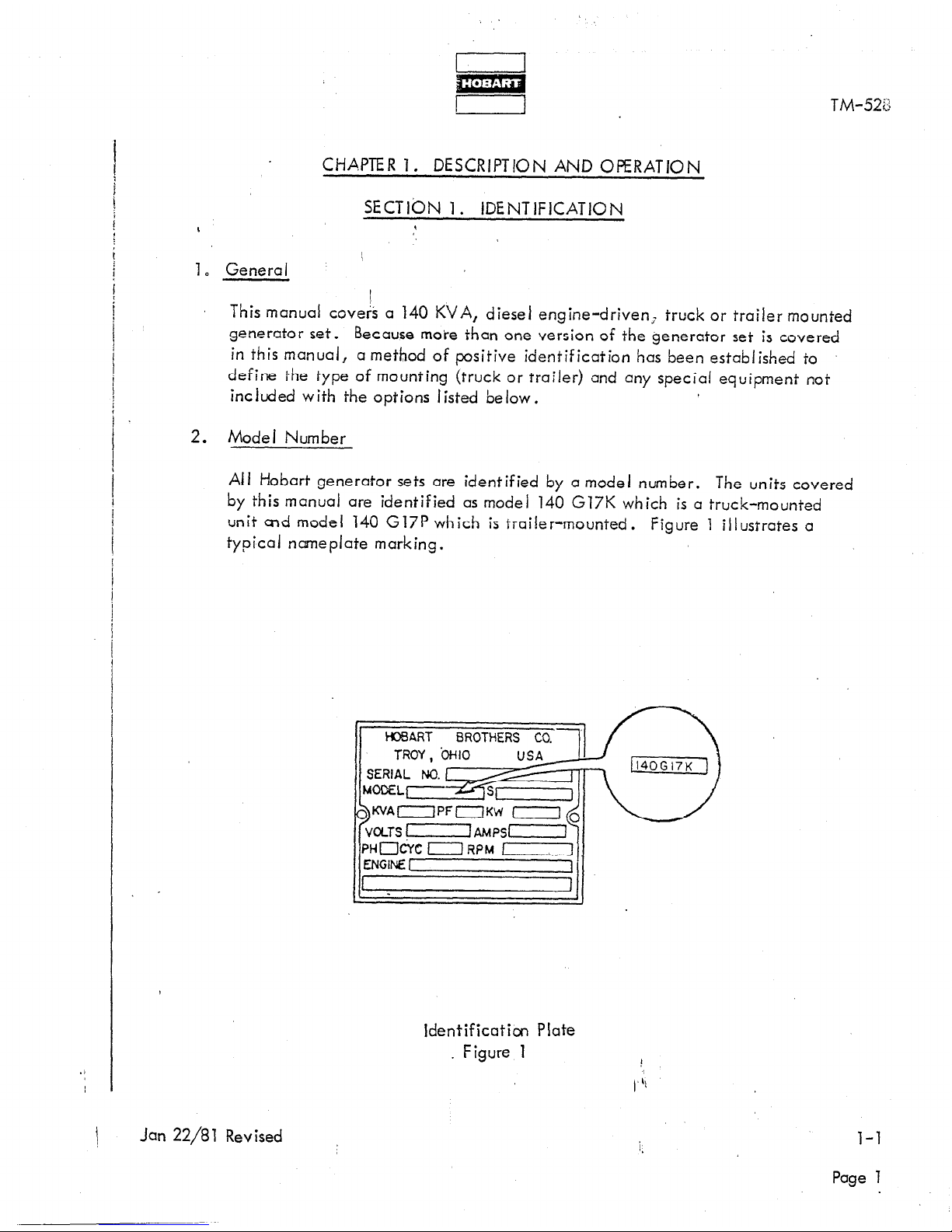

1. General

This manual coveA a 140 KVA, diesel engine-driven; truck or trailer mounted

generator set.

Because more than one version of the generator set is covered

in this manual, a method of positive identification has been established to

define the type of mounting (truck or trailer) and any special equipment not

included with the options I isted below.

2. Model Number

Ail Hobart generator sets are identified by a model number. The units covered

by this manual are identified as model 140 G17K which is a truck-mounted

unit end model 140 G17P which is trailer-mounted. Figure 1 illustrates a

typical nameplate marking.

1 WART BROTHERS CO. 1

If-Y

K’JAOPFOKW

Identification Plate

. Figure 1

\

Jan 22/81 Revised

Page 1

Page 22

TM-528

140G17K defines a generator set mounted on any of the truck options listed below.

140G17P defines a generator set mounted on the optional trailer.

140G17P (special) ‘defines a trailer-mounted generator set which includes special equipment.

3. Optional Eqbi,pment

Optional equipment consists of trucks,

transformer-rectifier mounting kitk, a revolving amber light and a test box.

/

A. Trucks

The truck options consist of Chevrolet model CS-51403, Ford model F-500, GMC

model CS-51403 and Dodge model D-500.

B. Truck Body Kits

Truck body kits, part number 482150, are available for mounting the basic generator

set, with or without transformer-rectifiers, on any of the available truck options. These

kits are described and illustrated in TO-110.

I

C. Trailer

I

The optional trailer, part number 482158,

TO-106.

,

truck body kits, trailer, transformer-rectifiers,

is covered by an instruction manual

D. Transformer-Rectifiers

Transfomler-rectifiers are available to change the 115-V AC generator output to 28.5,

35 and 112 V DC. The 28.5 volt unit is covered in TM-597, the 112 volt unit is covered

in TM-598 and the 35 vo It unit is covered in TM-599.

E. T-R Mounting Kits

Transformer-rectifier mounting kits, part number 482163, are available for mounting

any combination of T-R units on the optional trucks at-d trailer. These kits are covered

in TO-111.

F. Test Box

The optional test box, part number 388318-4, is available to check voltage levels at

critical points throughout the circuitry.

It plugs into the test receptacle connector

on the engine control panel of each unit. This option is covered in TO-112.

Page 2

\;

Revised Jan 22/81

Page 23

I

I

TM-528

G. Revo iving Light (Truck-Mounted Units)

This emergency warning iigbt revolves through 3600. Central iy mounted on top

of the truck cab, it has an ‘on-off switch located on the dashboard. This option

is covered in TO-1 13.

1

Jan 22/81 Revised ;

i.

l-l

Page 3/4

Page 24

Page 25

!d

r I

SECT1 ON 2. DESCRIPTION

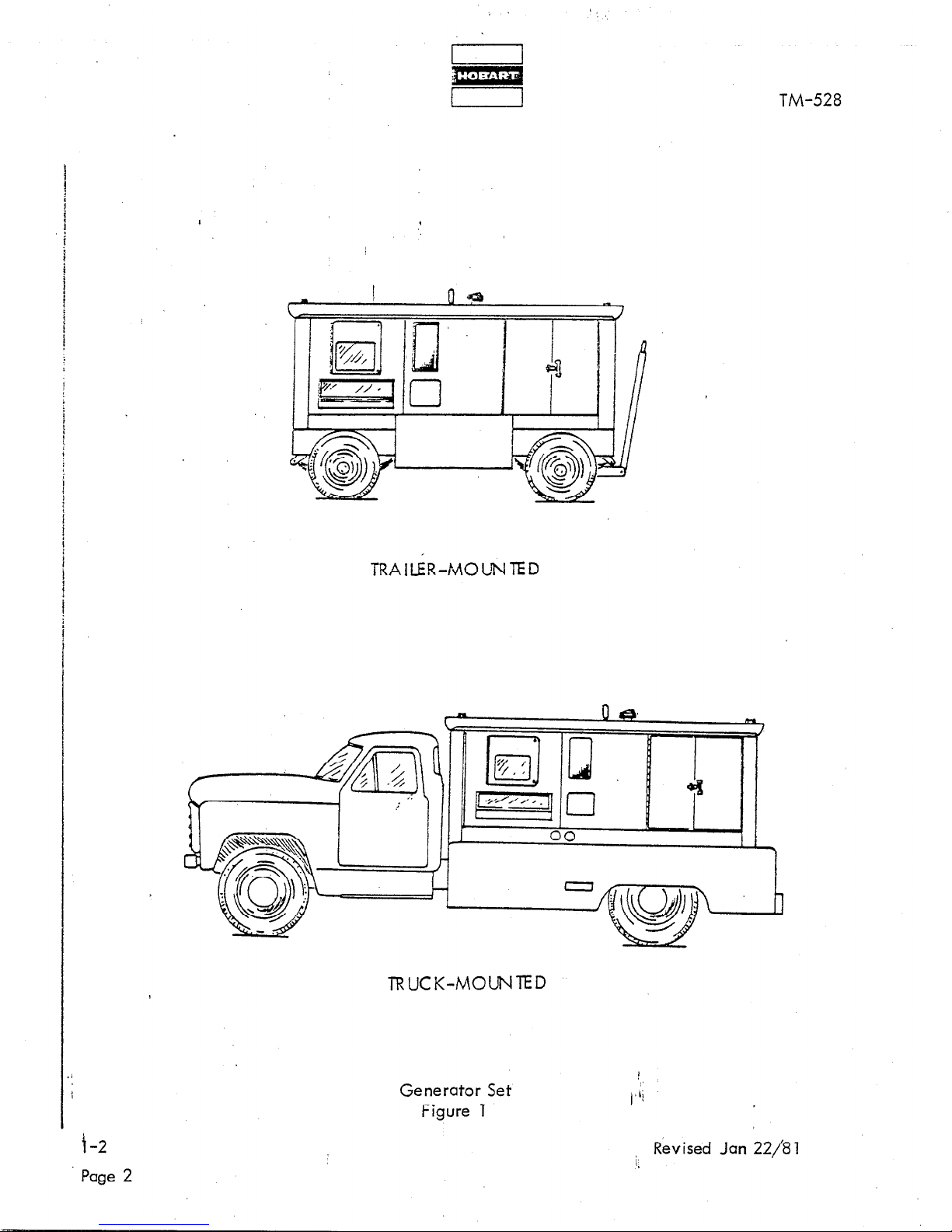

1. General

The generator set covered by this manual is a diesel engine-driven unit,

enclosed by a canopy and designed for mounting on a truck or trailer

(See Fig. 1). ’

TM-528

/

The purpose of the generator set is to produce and deliver regulated, 400-Hz,

115/200-V AC power to one o,r two parked aircraft for operation of the air-

craft’s electrical equipment when the on-board generators are not running.

Orientation

2.

For purposes of orientat ion and to fcm ii iarize operators and maintenance

personnel with the location of components, the radiator is considered to

be at the FRONT of the unit. The generator and controls are at the REAR.

RIGHT and LEFT are determined by standing at the rear and facing the

math ine .

and engine control panel are mounted on the RIGHT side at the REAR of

the unit.

NOTE: When the generator set is mounted on a truck, the rcdictor or

FRONT end of the generator set is at the REAR of the truck.

Operating controls are then on the LEFT, or driver’s side, of

the truck. When the generator set is mounted on a trailer,

the radiator is at the drawbar, FRONT end.

3. Special Features

Thus, the generator control box, output receptacle connector,

The generator has many special features which are described more fully

under the assemblies in which they appear. Some of the main features

are mentioned here and described briefly.

A. Protective Monitor System

A single, solid-state device (1, Fig.

the fault sensing units in the generator output circuit and functions

to cause the load to be disconnected from the generator if an abnormal

condition of voltage,

Pullout Trays

B.

The control box is equipped with pullout, drawer-type trays which

provide easy access to controls and equipment md,unted in them.

Each tray may be removed as an assembly by disbbnnecting a single

quick-disconnect connector and tripping two safety latches.

Jan 22/81 Revised :

7) receives signals from ail of

frequency or load develops.

1,

l-2

Page 1

Page 26

/

I

m

I 1

TM-528

TRAILER-MOLNTED

TRUCK-MOUNTED

Generator Set

Figure 1

f-2

Page 2

i Revised Jan 22/81

Page 27

TM-528

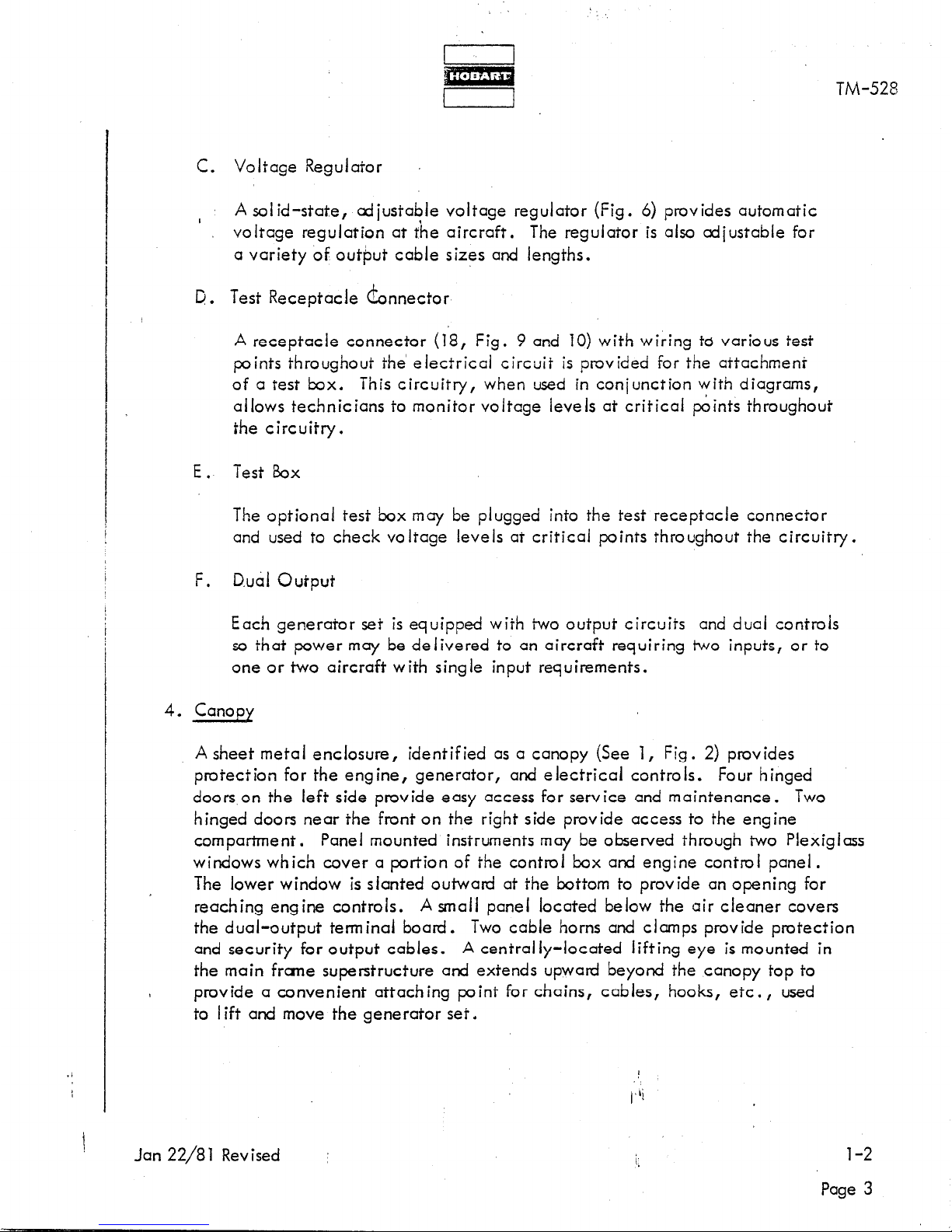

C. Voltage Regulator

I

A solid-state, adiustabie voltage regulator (Fig. 6) provides automatic

voltage regulation at f’he aircraft.

The regulator is also adiustabie for

a variety of output cable sizes and lengths.

D. Test Receptacle Connector

A receptacle connector (18, Fig. 9 and 10) with wiring ta various test

points throughout the eiectricai circuit is provided for the attachment

of a test box. This circuitry, when used in conjunction with diagrams,

allows technicians to monitor voltage levels at critical points throughout

the circuitry.

E.

Test bx

The optional test box may be plugged into the test receptacle connector

and used to check voltage levels at critical points throughout the circuitry.

F.

D.uai Output

Each generator set is equipped with two output circuits and dual controls

so that power may be delivered to an aircraft requiring two inputs, or to

one or two aircraft with single input requirements.

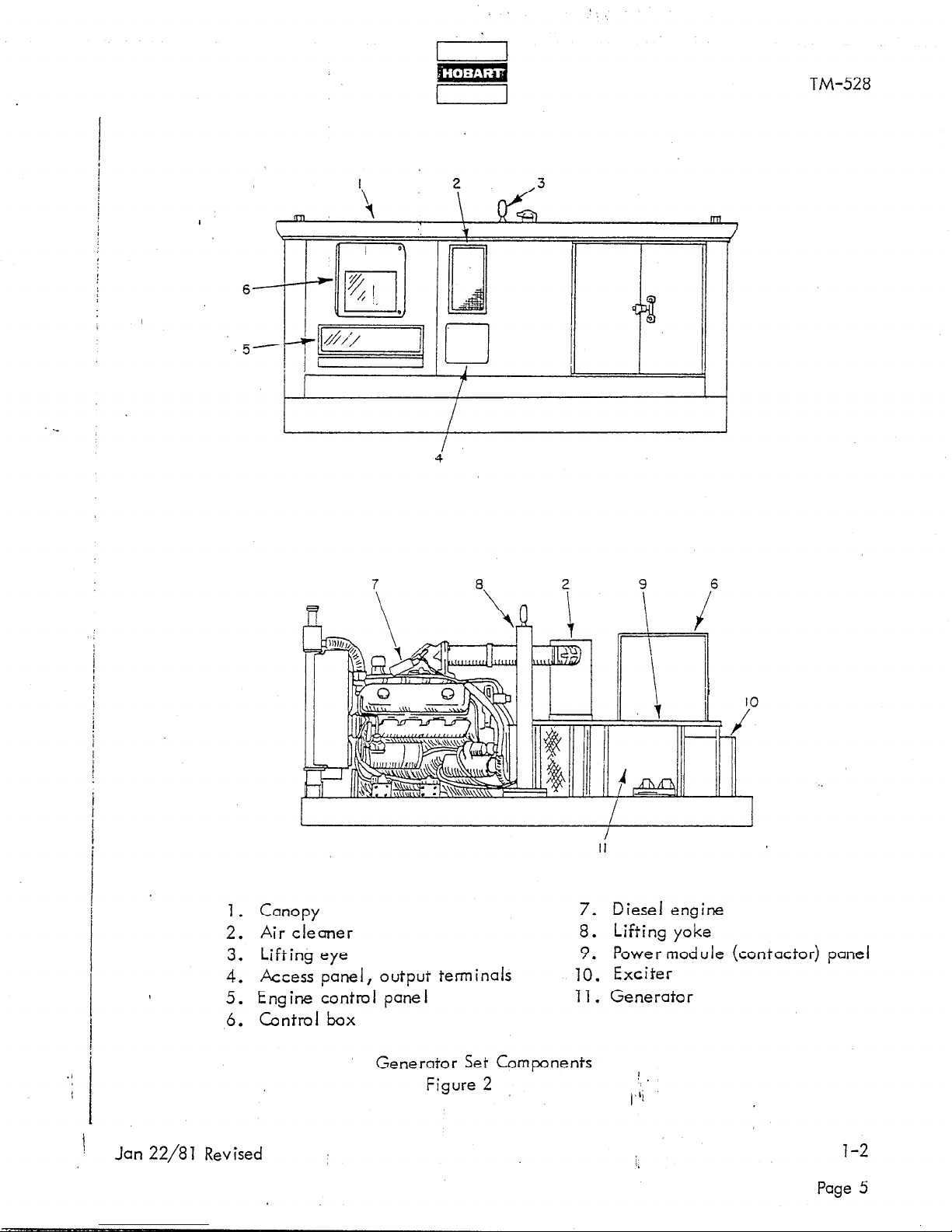

4. Canopy

A sheet metal enclosure,

identified as a canopy (See 1, Fig. 2) provides

protection for the engine, generator, and electrical controls. Four hinged

doors on the left side provide easy access for service and maintenance. Two

hinged doors near the front on the right side provide access to the engine

corn partme nt .

Panel mounted instruments may be observed through two Plexiglass

windows which cover a portion of the control box and engine control panel.

The lower window is slanted outward at the bottom to provide an opening for

reaching engine controls.

A small panel located below the air cleaner covers

the dual-output terminal board.

Two cable horns and clamps provide protection

and security for output cables.

A central iy-located lifting eye is mounted in

the main frcrne superstructure and extends upward beyond the canopy top to

provide a convenient attaching point for chains, cables, hooks, etc., used

to I ift and move the generator set.

Jan 22/81 Revised

:

i;

l-2

Page 3

Page 28

m

I 1

TM-528

L

I

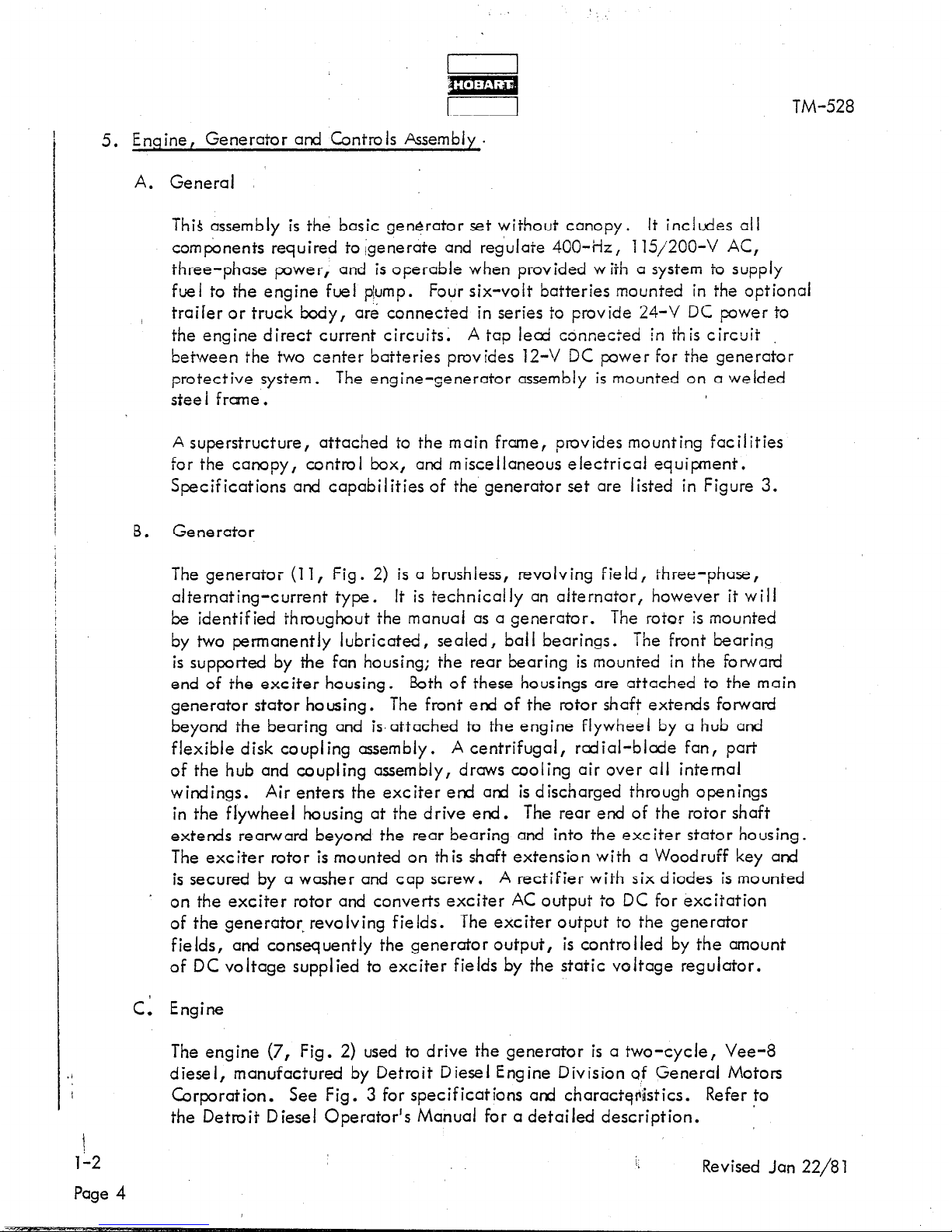

5. Engine, Generator and Controls Assembly.

A. General

This assembly is the basic generator set without canopy.

It includes all

components required to igenerate and reg’ulate 400-iiz, 115/200-V AC,

three-phase power,

and is operable when provided with a system to supply

fuel to the engine fuel plump.

Four six-volt batteries mounted in the optional

/

trailer or truck body, are connected in series to provide 24-V DC power to

the engine direct current circuits:

A tcp lecd connected In this circuit

between the two center batteries provides 12-V DC power for the generator

protective system.

The engine-generator assembly is mounted on a welded

stee I f rme .

A superstructure,

attached to the main frame, provides mounting facilities

for the canopy, control box,

and m isceiianeous electrical equipment.

Specifications and capabilities of the’generator set are listed in Figure 3.

8.

Gene rato r

The generator (11, Fig. 2) is a brushless, revolving field, three-phase,

alternating-current type.

It is technically an alternator, however it will

be identified throughout the manual as a generator. The rotor is mounted

by two permanently lubricated, sealed, bail bearings. The front bearing

is supported by the fan housing; the rear bearing is mounted in the forward

end of the exciter housing.

Both of these housings are attached to the main

generator stator housing.

The front end of the rotor shaft extends forward

beyond the bearing and is. attached to the engine flywheel by a hub and

flexible disk coupling assembly.

A centrifugal, radial-blade fan, part

of the hub and coupling assembly, draws cooling air over ail internal

windings.

Air enters the exciter end and is discharged through openings

in the flywheel housing at the drive end. The rear end of the rotor shaft

extends rearward beyond the rear bearing and into the exciter stator housing.

The exciter rotor is mounted on this shaft extension with a Woodruff key and

is secured by a washer and cap screw.

A rectifier with six diodes is mounted

on the exciter rotor and converts exciter AC output to DC for excitation

of the generator revolving fields.

The exciter output to the generator

fields, and consequently the generator output, is controlled by the amount

of DC voltage supplied to exciter fields by the static voltage regulator.

C. Engine

The engine (7, Fig. 2) used to drive the generator is a two-cycle, Vee-8

diesel, manufactured by Detroit Diesel Engine Division af General Motors

Corporation. See Fig.

3 for specifications and characterh’stics. Refer to

the Detroit Diesel Operator’s Manual for a detailed description. ’

112

Revised Jan 22/81

Page 4

Page 29

f

n Ili=l n I 1

i i

I 1

u

r 1

TM-528

/

II

1. Canopy 7. Diesel engine

2. Air cleaner 8. Lifting yoke

3. Lifting eye

9. Power module (contactor) panei

4. Access panel, output terminals 10. Exciter

5. Engine control panel 11. Generator

6. Control box

Generator Set Components

Figure 2

1

.

(‘Ii

!

Jan 22/8 1 Revised

l-2

Page 5

Page 30

GENERATOR

I I

TM-528

Output power rating

0 utput voltage

Rated lo&I capacity

Overload capacity (125% of lrated load) ’

Frequency (cycles-per-second)

0 utput ki iowatts

Po,wer factor

Duty cycle

Operating speed (at 400 Hz)

Output cable size (each of four conductors)

ENGINE

Manufacturer

,

I

,.

Detroit Diesel Engine Div.

140 KVA

115/200-v

404-A

505-A

400 Hz

172 KW

0.8 PF

100%

T7P4 RPM

210

General Motors Corp.

Type

Model

Displacement

Bore and stroke

Governed speed

Horsepower at 1714 RPM

Id!e speed

Overspeed governor trip

Coolant system capacity (approx.)

Lubricating oil capacity (without filters change) (approx.) 23 quarts (21 liters)

Lubricating oil capacity (with filters change) (approx.) 26 quarts (25 liters)

567 cubic inches (9291 c.m3)

4-l/2 x 5 inches (115 mmx 127 mm)

1900 to 2025 RPM

19-l/2 gals. (74 liters)

8V-77 N diesel

7083-7000

1714 RPM

253 HP

800 to 850 RPM

D. Governor

The mechanical-hydraulic governor (4, Fig. 4) is identified as a Woodward

Model PSG. Instructions and an ii iustrated parts list for the governor are

included in Woodward Bulletin which is supplied with this manual in Chapter 6.

Engine Safety Shutdown System

E.’

(1) General

The automatic, electric, shutdown system is designed to stop t& engine if there is a loss of oil

pressure, overheating of engine coolant, or engine overspeed.

Page 6

Specifications and Capabilities

Figure 3

Page 31

TM-528

(8) Air shutoff valve

The principal component in the safety shutdown system is the air shutoff valve. The valve

consists of a circular, hinged plate which is mounted in the engine air inlet housing (2). The

valve is mounted on a cross-shaft (5) which is spring-loaded in a direction to close the valve.

’ (9) Engine Safety devices :’ ’

General

All fault sensing devi es have a common characteristic. They are basically normally-closed

hydraulic valves. Th 8 ,y also perform a common function: they release oil pressure to the

/

shutdown valve bellows when an engine operating fault occurs. As stated above, this pressure

release allows the bellows assehbly to unlatch and thus close the shutdown valve. Sensing

devices are series-connected in the oil supply line to the bellows assembly so that the operation

of any device will release pressure to the bellows. Fault sensing devices are described in detail

in the Detroit Diesel Operators Manual.

a. Overspeed governor

The overspeed governor is a mechanical fly-weight type, mounted at the rear of the engine

and driven through an adapter by the camshaft. Electrical contacts in the governor are

connected in parallel with other engine shutdown devices. The governor is adjusted to close

the contacts and actuate the shutdown solenoid when an engine speed of 1950 RPM is

reached. The governor must be manually reset, after tripping, by pushing a button located on

the governor head.

b. Temperature sensing safety switch

This switch is mounted in the engine water manifold and is identified as an “Alarmstat”. It

is very sensitive to temperature changes and functions to protect the engine against

overheating caused by low coolant level, broken fan belt, etc. It sends a signal which

activates the shut-down solenoid to stop the engine when temperature in the cooling system

reaches 205 deg. F.

c. Start circuit cut-out switch

This is a Micro-type switch, mounted just below the air-valve operating lever. The switch

is electrically connected in series with the starter switch. In normal operation the switch is

CLOSED. In the event the shutdown solenoid is actuated to stop the engine, the shutdown

switch is OPENED to prevent operation of the engine starter until the shutdown air valve is

LATCHED in OPEN position.

cf. Start circuit solenoid switch

This switch is mounted on a bracket on the left side of the engine below the time delay

relay. This soleniod type switch functions to conduct 24-V DC power to the engine starter

solenoid when the panel mounted pushbutton start switch is pushed. The soleniod switch

serves to by-pass and protect the start circuit cut-out switch against the heavy load current of

the starter.

e. Low oil pressure switch.

This switch is mounted on the engine block. It sends a signal to the time delay relay when

engine oil pressure drops below 10 psi. The time delay relay serves to delay for

approximately 10 seconds the activation of the shutdown solenoid.

!

March 24/95 Revised

1-2

Page 7

Page 32

LEFT SIDE OF ENGINE

TM-528

RIGHT SIDE OF SHUTDOWN VALVE

1.

Bellows assembly

2. Shutoff valve housing

3.

Overspeed

4.

Engine

5.

1 Valve shaft

governor

governor

./

1-b

Page 8

6. Shutdown valve operating solenoid

7. Low coolant and high temperature

valve

8. Emergency shutdown solenoid valve

Engine Safety Shutdown System

Figure 4.

t

‘I

(#hi

i Revised Jan 22/8 1

Page 33

F.

Air Cleaner

I

I

TM-528

The diesel-engine air cleaner (Fig. 5) is a dry-cartridge type.

It is equipped

with a moisture eiiminator and a service indicator. The indicator functions

to ‘signal the operator when the cartridge needs changing. A red cylindrical

flag (2) is forced upward in a glass enclosed viewing chamber (7) when air

I

pressure within the air:!cleaner housing drops below the outside air pressure.

As the cartridge becomes loaded with dirt and air pressure within the cleaner

lessens, the flag gradually rises higher in the glass viewing chamber. When

the flag reaches the top of the chamber,

it locks in that position to warn the

operator that the cartridge must be changed.

The flag is reset (unlocked) by

pushing the reset button (3) located on the bottom of the indicator.

G. Control box

The control box (6, Fig. 2)

is a sheet metal enclosure which houses and provides

mounting facilities for generator controls and electrical equipment. The box

is equipped with three drawer-type trays which contain generator output control

devices and monitoring instruments.

Trays slide in ard out on nylon rollers for

easy access to internally mounted components. Each tray is easily removcble

by disconnecting an amphenol connector, unlocking the safety latches, and

sliding the complete tray assembly out of the control box.

F /- .

1. Viewing chamber

2. Indicating flag

3. Reset button

1

(‘Ii

Jan 22/8 1 Revised

Air Cleaner and Service lnd icator

I

Figure 5

!,

1-2

Page 9

Page 34

TM-528

Two shielded instrument panel iights’are mounted on the left side of the control box

front panel to iliwninate controls and instruments in the trays.

(1) Voltage regulator tray

I

1

1

!

,

,

i

1

1

I

!

The voltage regulator! tray is the topmost in the control box.

regulator manual is supplied with the generator set, a brief, working description

is given here.

The voltage regulator is designed to provide 1% voltcge regulation with 0.25second recovery time for a,ll loads up to 100% of rated load on a three-phase,

fo ur-w ire,

field excitation power for the rotary exciter,

voltage by varying the exciter field power as required to meet varying load

conditions. Thus, the generator output is held at a constant voltage. The

maximum continuous rating of this regulator is 4.0 Amperes at 140 Volts DC.

Any deviation of the generator output voltage from its set, regulated level

is sensed by the voltcge detection and comparison circuits.

from the comparison circuit into the transistorized pre-amp1 ifier, cmpl ified,

and used to drive the magnetic cmplifier. The magnetic unpiifier output

changes in response to this signal,

exciter enough to return the generator voltage to its regulated value. The

voltage at which the generator is regulated may be odiusted w

adjustment rheostat (2, Fig. 6).

115/200-Volt, 400-Hz, brushless generator. This regulator provides

I

and regulates generator output

chcnging the field power of the rotary

Although a separate

A signal is fed

,ith the vo I tage

i-2

(a) Contro is

The rheostat (2, Fig. 6)

of the generator output.

potentiometer (4).

another potentiometer (3).

OFF by a toggle switch (5).

be ON. An instruction plate under the potentiometer knobs indicates

pmper setting for various cable sizes and lengths. Regulator stability

is adjusted by the damping circuit gain potentiometer (8). Regulator

response time is adiusted by the damping circuit rate potentiometer (10).

(b) Protection

Internal circuitry of the voltage regulator is protected by a cartridge

type, 5 Ampere fuse (12).

(c) Components

See Fig. 6. Refer to Operation and Maintenance”Manual No. T*M-759 for

a detailed description of the voltage regulator.

is used to adjust the regulated voltage value

Compensation for cable size is adiusted by a

Cable length is compensated for by adiustment of

Cable compensation may be turned ON or

For this application the switch must always

1

Revised Jan 22/8 1

Page 10

Page 35

m

1

1

TM-528

i

1. Resistor (1000 Ohms, 25 Watts)

2. Regulator rheostat

3.

Cable length compensation rheostat

4.

Cable size compensation rheostat

5.

On-Off switch, line drop compensation

6. Line drop compensation, chassis assembly

7.

Receptacle connector

8.

Damping circuit gain potentiometer

9. Receptacle connector

0.

Damping circuit rate potentiometer

11. Receptacle connector

12. Fuse (5A)

13. Fuseholder

14. Receptacle connector

15. Sensing and preamplifier chassis

assembly

16. High-phase sensing board assembly

17. Reactor

18, Chassis

19. Terminal board

Voltage Regulator

Figure 6

1

( ,‘ii

Jan 22/81 Revised

:

l-2

1,

Page 11

Page 36

(2) Protective relay tray

TM-528

Refer to Fig. 7.

The center tray in the control box is identified as the protective

relay tray and contains electrical and electronic safety devices designed to pro-

‘tect the aircraft electrical systems against damcge which could result from over-

voltage, undervo ltqge, or underfrequency.

The tray also contains devices for

the protection and control of the generator output electrical system. The Generator Schematic Diagram shows how the protective devices are located in the

electrical system. ”

(a) Sensing relays

The overvoltage relay (3), undervoltage reiay (4), underfrequency relay

(5), and over-frequency relay (6)

are connected to the generator output

lecds between the generator and the load contactor. These relays sense

any abnormal condition of voltage or frequency and signal the soiid-state

circuitry of the protective monitor module (I) to open the load contactor

holding circuit and disconnect the generator output to the aircraft.

Solid-state overload signaling devices (one for each output) are also

connected to the protective monitor module and perform a function

similar to the sensing relays.

/

t

‘1-2

Page 12

Trip values for the sensing relays and overload devices are as follows:

Overvoltage relay trips at 130 V to 134 V.

UndeNoltage relay trips at 93 V to 103 V.

Overfrequency relay trips at 415 Hz to 425 Hz.’

Underfrequency relay trips at 375 Hz to 385 Hz.

Overload device trips at any value over 125% rated load capacity.

(b) Protective monitor module

The protective monitor (1) is a solid-state device with a hermetically-

sealed, reed-type, relay.

The solid-state, printed circuit board or card

replaces five latching relays and a time delay relay which were formerly

used. SCIRs (

si icone-controlled rectifiers) are used, one each for over-

I

frequency, underfrequency, overvoltage, under-voltage, and overlood.

The board includes five memory circuits and an odiustable time delay

circuit.

device (overload module, overvoltage relay, etc.).

Each memory circuit is connected to a corresponding sensing

All of the circuits

are connected to the module relay coil, and any one of the circuits can

energize the coil to open the relay contacts. Thus, when a sensing

device energizes any one of the module circuits,, the module relay is

also energized to break the load contactor hoI@g circuit and allow

the load contactor to open.

All circuits, except the undervoitage

circuit, function immediately to open the load contactor.

Revised Jan 22/8 1

Page 37

TM-528

1.

Protective monitor module

2. Fuse interlock relay

3.

Overvo I tage sensing relay

4.

Under-voltage sensing relay

) 5. Underfrequency sensing relay

6. Over-frequency sensing relay

7; Generator overload relay

8.

Tray fastener

( 9. Overlood indicating I ight

10.

Reset SW itch

11. Undervoltage indicating light

12.

No. 1 resistor, 100 Ohm, 25 Watt

13.

Overvoltage indicating light

14. No. 2 resistor, 100 Ohm,

25

Watt

15. Under-frequency indicating light

16. interlock relay fuse, 2A

17. Underfrequency indicating light

18. Load contactor circuit fuse, 2A

19. Test bank switch

20. Capacitor, 6.8 MFD, 35 V

21. Terminal board

22. Diode, 400 V RV, 1.5 A

.’

23. Receptacle connector

24. No. 1 plug-interlock relay

25. No. 2 plug-interlock relay

Protective Relay Tray

Jan 22/81 Revised

Figure 7

l-2

Page 13

Page 38

TM-528

A time delay system is designed into the under-voltage circuit to prevent nuisance

opening of the contactor under conditions of momentary under-voltage in the

generator output.

An undervoltage condition which continues uninterrupted

for a period of 4,to 12 seconds will cause the time delay circuit to open the

load contactor. Each of the five circuits is connected to a corresponding

indicating light (9.,, T 1, 13, 15,

and 17) wh ich is turned on when a fault

occurs.

I

)_

The module relay will remain energized (OFEN) and the light will remain ON

until the reset switch (10) ,is pushed to break the module 12-V DC circuit, and

allow the relay to return to normal, CLOSED position.

(c) Indicating I ights

The function of these lights (9, 11, 13, 15 and 17) is to indicate, to the

operator, the abnormal condition of overvoltage, underfrequency, etc.,

which caused the protective monitor system to function. Each of the five

lights is connected to an actuating circuit within the memory and time delay

module. When one of the circuits is activated, it turns on th,e applicable

ind icating light.

The light will remain on until the reset switch (10) is

pushed. These are press-to-test type lights in which the lamps (bulbs) may

be tested by pressing the lens holder momentarily.

(d) Plug interlock relay

The function of the plug interlock relay (24) is to cause the No. 1 output

load contactor to open in the event the cable plug connector becomes

accidentally disconnected from the aircraft during power delivery, or

if an attempt is made to deliver power when the output cable is not

connected to the aircraft.

Twenty-eight Volt direct current for operation

of the relay is supplied from the aircraft either through an on-board

transformer-rectifier, or from a twenty-eight Volt electrical system.

Connection from the aircraft to the interlock relay is made through

terminals E and F on the cable connectors. Another relay (25) functions

in the scme manner for No. 2 output load contactor.

(e) Test-bank SW itch

A sp st, toggle switch (19) provides a means of bypassing the interlock

relays (24 and 25) h

w en supplying power to a load bank or to aircraft

not equipped with a plug interlock system.

In the TEST BANK position

the interlock relays are bypassed. In AIRCRAFT position, they are

switched back into the circuit.

t

T-2

i* Revised Jan 22/8 1

Page 14

Page 39

TM-528

(f) Resistor

I

A 100 Ohm, ,25 Watt resistor (12) is connected in series with the plug

interlock relay (24) to ptotect the relay in the event that phase C contacts

in the No. 1 load contactor should fail to close when the generator ON

switch is pushed. An identica’l resistor (14) perfons the same function

for No. 2 relay (24).

/

(g) Fuse interlock relay

I

I

I

The function of the fuse interlock relay (2) is to interrupt the locd contactor

holding coil circuit and remove the load in case of a bldwn fuse (16) in the

protective relay coil circuit.

(h) Connector

A twenty-six contact connector, (23) provides a quick-disconnect facility

for all wiring to the trays electrical components so that the complete tray

assembly may be removed quickly and easily.

(i) Diode, capacitor and terminal board

A terminal board (21)

is used to mount and connect a diode (22) and

capacitor (20) into the fuse-interlock relay coil circuit. Their purpose

is to prevent an inductive spike in the 12-V DC circuit from triggering

an SCR in the protective monitor module (1) and turning on an indicating

light when no fault exists.

(k) Overload relay

This overload relay (7) is a thermal type with manual reset.

its function

is to protect the generator in case both output circuits are operated to

capacity at the same time.

The relay signals the protective monitor

module to open both loach contactors in approximately 5 minutes when

the generator is operated at 125% to 127% rated load .

(I) Fuses

A fuse (18) is located in the load contactor hold circuit to protect the

power module in case of a rectifier failure. Another fuse (16) protects

the 12-V DC protective monitor circuit.

Jan 22/81 Revised :

T-2

Page 15

Page 40

1

j

,

I

i

t

i

I

,

i

,

!

f

I

!

/

(3)

./

t

l-2

Page 16

.

Generator control tray

The generator control tray (Fig. 8) is the bottom tray in the

contains ‘instruments and controls for monitoring at-id control

output.

4

TM-528

control box. It

ling 5

(a) Res iston

’

Two 25 Ohm,

TOO !Watt, ballast resistors (1) are connected

the generator DC field circuit.

:nerator

n series in

A 50 Ohm, 100 Watt variable resistor (12) is connected in series between

the manual control rectifier (15) and rheostat (14). Its purpose is to adiust

the DC voltage to the rheostat.

This odiustment determines the generator

output voltage control range of the rheostat e

(b) Generator output meters

The generator output is monitored by three instruments; a frequency meter

(8), a voltmeter (7), and an cmmeter (6). The frequency meter is a

resonant-reed type, and indicates the frequency of the generator output

alternating current in the range of 380 to 420 Hz (cycles per second).

The voltmeter indicates the generator output voitage in each phase-to-

neutral (A-N, B-N and C-N)

or phase-to-phase (A-B, B-C and C-A)

as selected by the meter selector switch (5) and the line selector switch

(4). (These switches are described below .) The voltmeter has a 3-1/2inch (89 mm) face and the scale is graduated 0 to 300 V. The ammeter

is also 3-l/2-inch size and is graduated 0 to 500 Ai The crnperage value

in each of the three phases may be read on the cmmeter by selecting the

desired phase with switch (5). Th

ree ammeter current transformers (4,

Fig. 11) lower the output load current to a lesser value, of definite

ratio, which will operate the ammeter movement without damage. The

ammeter dial scale is grcduated and numbered so that the pointer will

indicate the true load current value rather than the meter movement current.

(c) Meter and line switches

These switches provide a means of selecting and determining which phase

of voltage and current is indicated on the voltmeter and ammeter and

whether the voltage is line-to-neutral or line-to-line. The meter switch

(5) is a four-position, rotary type. A nameplate (3), located under the,

switch knob, is marked and lettered to indicate the three functional

positions of the meter switch.

(When the knob is pointing straight down,

the switch is OFF.) The line switch (4) is a two-posi!tion, toggle switch

used to select either line-to-neutral or line-to-line (@Itage to the voltmeter.

The nameplate is also marked to indicate the position of this

SW itch.

i,

Revised Jan 22/81

Page 41

I

1

1.

2.

3.

4.

5.

6.

7.

8.

m

I

1

8

7

TM-528

Resistor (25 Ohm, 100 Watt)

Fastener

Instruction plate

Line selector toggle switch

Meter selector rotary switch

AC Ammeter

Voltmeter :

Frequency meter

TO.

11.

1-2.

13.

14.

15.

Generator Control Tray

Figure 8

Nylon roller

Receptacle connector

Tray

Resistor (50 Ohm, 100 Watt)

Automatic-manual switch

Manual voltage control rheostat

Rectifier

), Ii

Jan 22/81 Revised

1

l-2

Page 17

Page 42

TM-528

(d) Receptacle connector

An Amphenol connector (10) provides a means of quickly disconnecting

all wires to generator control tray components.

(h)’ Tray

,

I

The tray (11) slides in and out on nylon rollers (9). It

is secured in place

I

by two captive screw fasteners (2).

(f) Manual voltage control

When the automatic manual switch (13)

Is placed n MANUAL position,

AC power is supplied to the rectifier (75) rather than to the automatic

voltage regulator.

The DC output of the rectifier is routed to the exciter

fie Id through a rheostat (14).

The generator output voltage is thereby

manually controlled by adiustment of the rheostat.

H. Engine and Generator Control Panel (140Gl7K and 14OGl7P)

Refer to Fig. 9.

The engine and generator control panel assembly is mounted

directly below the generctor control box.

lnstrwnents and controls are protected

by a clear Plexiglass panel which is mounted in a frune that extends outward

and downward at an angle over the contra I panel.

Instruments may be observed

through the Plexiglass panel and controls may be operated by reaching under

the pane I.

(1) Engine gages and meters

(a) 0 il pressure gage and diaphragm switch

The oil pressure gage (7)

is a bourdon tube type and indicates engine

I ubricat ing oil pressure.

It is graduated from 0 to 75 psi (0 to 517 kPa).

Adiaphragm type switch (8) is mounted in the oil line directly behind

the oil gage. Th

is switch is closed by engine oil pressure and connects

24-V DC to the hourmeter, throttle holding solenoid, and-excitation-

deenergization relay only when the engine is running.

(b) Ammeter

The ammeter (6) indicates the d irection and the value of the current

flow in the engine 24-V DC electrical system. Its graduated range

is from -30 Amperes through 0, to +30 Amperes.

\

l-2

[I Revised Jan 22/8 1

Page 18

Page 43

, ,

:‘.

_

a:

I

TM-528

1. Excitation-deenergization relay

2. Panel light

3. Push-to-build-up-voltage switch

4. Fuse, lights and excitation circuit (IOA)

5. Light switch

6. Ammeter, DC circuit

,7. Oil pressure gage

8. Diaphram switch, hourmeter and

excitation circuit

9. Coolant temperature gage

10. Hourmeter

1’1. Speed control switch

12.

DELETED

13. Engine speed control cable

14.

Start switch

15.

DELETED

16.

Terminal board

17. Engine running indicating light

18. Test receptacle connector

19.

No. 2 contactor

indicating

light

20.

No. 1 contactor

indicating

light

21.

No. 1 contactor

operating

switch

22.

No. 1 contactor

operating

switch

Engine Control Panel (140G17K and 140G17P)

Figure 9

1

Ii

March 24/95 Revised

1-2

Page 19

Page 44

I

m

r

(c) Temperature gage

The temperature gage (9) is of one piece construction ard consists

8

of a panel mounted indicating mechanism which is connected to an

engine-mounted bulb by a capil’lary tube. The gage indicates

engine coolant temperature ‘in a range of 1000 F to 220’ F ( 38O C

to m” C).. 1

(d) Houneter

The hourmeter (70) is electrically driven from the 24-V battery

system. The hourmeter measures and records elapsed runhing

time when the engine is operating.

actual operating time which is required for meeting maintenance

schedules.

NOTE: The houneter used on 140G17P (Special) is a 12-V DC unit.

,.

Its function is to record

TM-528

Panel lights

(2)

Two shielded instrument panel lights (2) provide illumination for

instruments and controls during night-time operation.

(3) Indicating lights

There are three indicating lights mounted on the control panel.

(a) Engine ON indicating light

This light (77) gl ows green when the engine is running and

engine lubricating oil pressure is holding the diaphragm switch

(8) closed.

(b) Load contactor indicating I ights

Each output load contactor holding coil circuit has an indicating

light (19 and 20) h’ h I w IC g ows red when the circuit is energized

and is holding the contactor closed. When the lood contactor

opens for any reason,

the I ight is turned OFF.

NOTE: Fault indicating lights in the protective relay tray are

described in Para. 5, G, (2), (c).

t

l-2

Page 20

1

(‘Ii

eevised Jan 22/81

Page 45

TM-528

(4) Switches

a. Starter switch

This is a pushbutton switch (14, Fig. 9) which connects a 24-V DC power signal to the starter

solenoid. The solenoid then engages the starter and supplies power for cranking the engine.

I

b. Speed control switch -1

This is a single-throw, on-off toggle switch (11) used to connect DC power to a solenoid in the

governor speed control linkage. When the switch is ON, the solenoid functions to hold the

linkage in governed speed position for normal generator operation. This toggle switch also

connects power tothe excitation-deenergization relay circuit.

c. Light switch

Panel lights (2) and clearance lights are controlled by another single-throw toggle switch (5).

d. Load contactor control switches

Each load contactor is controlled by a toggle switch. No. 1 output contactor is controlled by

switch (21). No. 2 output contactor is controlled by switch (22). These are three-position

switches which are spring-loaded in the top “ON” position. When placed in the spring-loaded

ON position, the switch provides 115-V AC power directly to a rectifier which supplies DC

power for closing the load contactor. When released, it returns to the normal ON position and

continues to provide power to the rectifier. But in this switch positionAC power must pass

through the plug interlock and fuse interlock relays. In OFF position, the switch opens the AC

circuit to the rectifier, thereby cutting off the source of DC power to the contactor coil abd

allows the contactor to open.

March 24/95 Revised

1-2

Page 21

Page 46

I

r:

I

(e) Push-to-build-up-voltage switch

TM-528

This is a pushbutton switch (3) that connects initial power to the excitation-

deenergization relay (1) at generator startup.

It is functional only if the

speed control switch (11)

is ON and the engine is operating at governed

,

speed..

(5) Excitation-deenergization relay

’ This relay (1) is mounted on the back of the engine control panel. Its function

is to connect AC power to the voltage regulator so that the regulator may supply

excitation to the exciter fields.

The relay is only functional when the engine

is running at governed speed,

and the engine speed control switch (11) is in 0 N

position.

(6) Fuse

A 10-A fuse (4) protects the 24-V DC, light and engine-generator speed control

circuit.

(7) Test receptacle connector

This Amphenol connector (18) provides an attaching point for leads which are

connected to selected test points throughout the

engine and generator electrical

systems.

Connection and schematic diagrams indicate points at which the lecds

are connected.

This receptacle connector is designed to mate with a test box

plug connector.

It is protected by a dust cap.

The test box, part number 388318-4,

is available from Hobart Brothers Company at a nom inal kharge. Refer to 2-2;

Para. 2. B. (29) for a description of its use.

(8) Speed control cable

This push-pull control cable (13)

is connected to the engine governor linkage

and is used to position the linkage for the engine speed desired. It is also used

for normal engine shutdown.

A hinged latch, mounted on the panel behind the

1 control cable knob, holds the control out sufficiently for normal idle speed when

the latch is held in UP position,

the control is allowed to move to its ful I IN

position which allows governor linkage and fuel racks to go to NO-FUEL position

and stop the engine.

. l’-2

Page 22

;,Rev ised Jan 22/8 1

Page 47

.

‘.

ti

m

L

I

TM-528

(10) Terminal boar+&

,.

Three terminal boards (16)

are mounted on the back of the control panel

near the lower ed’ge.

They provide convenient connection terminals for

wires leading to and from control panel components.

J.

Special Engine and Generator Controf Panel (140G17P Special)

(1) General (See Fig. 10)

Only those items are described here which are added to the standanf control

panel. Note that some standard items are located differently. item numbers

‘I through 22 on Fig.

10 identify the same parts that’they did in Fig. 9. New

items 23 through 31 have been added at the end of the list 0

(2) Receptacle connector ard circuit breaker

A twist-lock type receptacle connector (29) provides a convenient outlet

connection for a light or small hand tool requiring 115-V, 400-Hz power.

This output circuit is protected by a 20-A circuit breaker (23).

(3) Emergency-stop switch

A single-throw,

toggle switch (24)

connects power to a solenoid valve in

the engine safety shutdown system.

When activated the valve releases

pressure in the engine air valve latching system and causes the air valve

to close and stop the engine.

(4) Hourmeter diaphragm switch

Another diaphragm switch (25) is added behind the oil pressure gage to

connect 12-V DC to the hourmeter (lo), only when the engine is running.

This circuit is protected by a 2-A fuse (28).

(5) Load contactor switches operating handle

A special handle (30)

is mounted on the load, contactor switches to operate

both switches simultaneously., If both outpuplicable plugs are not’connected

to an aircraft, only the contactor in the circuit being used wi,ll remain

closed .

Jan 22/81- Revised ’

l-2

Page. 23,

Page 48

TM-528

16

26 30 19

16 I8

1. Excitation-deenergization relay

2. Panel light

3. Push-to-build-up-voltage switch

4. Fuse, lights and excitation circuit (1 OA)

5. Light switch

6. Ammeter, DC circuit

7. Oil pressure gage

8. Diaphram switch, hourmeter and

excitation circuit

9. Coolant temperature gage

10. Hourmeter

11. Speed control switch

12. DELETED

13. Engine speed control cable

14. Start switch

15. DELETED

16. Terminal board

17. Engine running indicating light

18. Test receptacle connector

i7

28

19. No. 2 contactor indicating light

20. No. 1 contactor indicating light

21. No. 1 contactor operating switch

22. No. 1 contactor operating switch

23. Circuit breaker, convenience output

circuit

24. Emergency stop switch

25. Hourmeter operating diaphragm

switch

26. Low fuel (engine stopped) warning

light (red

27. Push switch, low fuel system test

28. Fuse, fuel warning system test

29. Convenience output receptacle

(115-V, 400-Hz

30. Load contactor switches

operating handle

31. Fuel warning system relay

Engine Control Panel (140G17P Special)

;!I

Figure 10

(,I1

‘9

Pzige 24

March 24/95 Revised

j>

Page 49

I 1

(6) Low fuel warning and shutdown system

This system warns the operator when engine fuel is low and also automatically

stops the engine before the tank is completely empty.

Two sensing devices (not shown) are mounted in the fuel tank. The uppermost

device sends’a signal to q relay (31) w h en fuel in the tank reaches a low

level which will allow only cpproximateiy 30 minutes of operation.

relay (37) fu&ions to turn on a flashing,

mounted on the canopy top. If the tank is not filled when the warning light

comes on, the lower sensing device will activate the emergency shutdown

solenoid to stop the engine before the tank is emptied. A red warning

light (26) indicates to the operator that the engine has been stopped due

to low fuel (if blue flashing light is also on), or an emergency. The fuel

warning system is protected by a 2-A fuse (28). A push switch (27) is

used for testing the flashing light circuit.

After a low-fuel shutdown, fuel must be odded in tank to turn off warning

I ights.

rotating warning light which is

TM-528

The

K. Power Module

The power module, or contactor pane I (Fig.

position above the generator below the control box.

power module panel assembly are identified as follows:

(1) Capacitor

The function of the three capacitors (l), which are connected to the

generator output leads at the bus bar (3) terminals, is to eliminate radio

frequency interference before it is transmitted along the 400-Hz output

cables.

(2) Line-drop current transformer

The three line-+rop current transformers (2), in conjunction with the

burden resistors (8), detect the magnitude and power factor of current

flowing from the generator to the load, and feed a signal to the voltage

regulator which interprets the signal and alters the exciter field current

as required to maintain a constant predetermined voltage at the load.

(See Voltage Regulator Manual TM-759) ,,

11) is mounted in a horizontal

Components of the

(3) Ammeter current transformer

The three ammeter current transformers (4) low&r the output load current

to a lesser value of definite ratio which will ‘$erate the ammeter movement without damage .,

so that t.he ammeter pointer w iii ind icate the true load current value

rather than the meter movement current..

Jan 22/81 Revised

The ammeter dial scale is graduated,and numbered

1,

l-2

Page 25

Page 50

Page 51

.

‘4

1

TM-528

SECTION 3. PREPARATION FOR USE

1.

Generator Set

A., General

,

The generator s&t is shipped i’n operating condition and is ready for use

after inspection dnd check.

CAUTION: READ ORRAi-lNG INSTRUCTIONS IN’ CHAPTER 1,

SECTION 4, BEFORE OPERATING THE UNIT.

B.

Inspect ion/Check

Inspect at-xi check the generator set thoroughly before operating.

(1) Remove crating, blocking, banding, ties, and other securing

and protective material.

(2) Inspect exterior for shipping damage such as broken’glass, dcmaged

sheet metal, etc.

(3) Open all canopy doors and inspect interior for foreign material

such as rags, tools, shipping papers, etc.

(4) Check fuel, coolant, and oil hoses and connections for visible

leaks. Check the ground surface under the unit for evidence

of leaks. If leaks are discovered, correct by tightening hose

clamps, tube fittings, etc., as required.

(5) Check security of attaching and retaining hardware.

(6) Check f II

0 owing for sufficient quantity.

(a) Diesel fuel tank capacity is as follows:

Trailer -

approximately 65 gallons (246 liters).

Truck

- approximately 89 gallons (337 I iters).

(b) Engine coolant level should be approximately one inch

(25 mm) below the fillerneck to allow a sufficient

capacity for coolant expansion.

CAUTION: BE SURE THE COOLING SYSTEM ANTIFREEZE

SOLUTION ,IS ADEQUATE v-F0 PROTECT BELOW

LOWEST TEMPERATURE EXPECTED.

Jan 22/81 Revised :

l-3

Page 1

Page 52

I I

m

1

TM-528

/

(c) The oil’gage rod (Fig.

See 2-1, Fig.

6, or Detroit Diesel Operator’s Manual for oil recommendations.

1) has F (ful I) and L (low) level marks to indicate

lubricating oil level in the oil pan.

Oil level should be kept as near

tlhe F mark as possible.

$:

I

CAUTION: NEVER OFERATE THE ENGINE WITH OIL LEVEL BELOW THE

LOW-E/‘/EL MARK OR ABOVE FULL-LEVEL MARK.

(7) The air cleaner (Sect. 1-2, Fig. 5) is a dry type. Be sure there are no papers,

tapes, or other materials covering the air inlet area.

(8) Check fluid I