Hobart 140G17K, 140G17P Operation And Maintenance

TM-528

Revised 032495

OPERATION AND MAINTENANCE

MANUAL

for

TRUCK/TRAILER-MOUNTED GENERATOR SET

140-KVA, 400-HZ, 115/200-V AC, 3-PHASE

with

DETROIT DIESEL ENGINE

TYPE 8V-71N

5566B

Model Numbers

140G17K (Truck Mounted Unit)

140G17P (Trailer Mounted Unit)

140G17P (With Special Accessories)

Manufactured by

L

.!

HOBART BROTHERSCOMPANY "

POWER SYSTEMS DIVISION

j”i

TROY, OHIO 45373

1

U.S.A.

SAFETY INSTRUCTIONS AND WARNINGS FOR ELECTRICAL POWER EQUIPMENT

ELECTRIC SHOCK can kill. Do not touch live electrical parts.

ELECTRIC ARC FLASH can injure eyes burn skin cause equipment damage and

I

ignite combustible material. Do not use power cabies to

brekk load and prevent tools from causing short circuits.

IMPROPER PHASE CONNECTION,! PARALLELING, OR USE can damage this and attached

equipment.

IMPORTANT: - Protect all oderating personnel.

Read, understand, and follow

ail instructions in the Operating/Instruction Manual before

installing, operating,

or servicing the equipment.

Keep the manual

available for future use by all operators.

A.

GENERAL

Equipment that supplies electrical power can cause serioueinjury or death,

or damage to other equipment or property.

observe all safety rules and take precautionary actions.

The operator must strictlv

Safe practices

have been developed from past experience in the use of power source equipment.

While certain practices below apply only to electrically-powered equipment,

other practices apply to engine-driven equipment,

B.

SHOCK PREVENTION

Bare conductors,

electrically-live

or terminals in the output circuit, or ungrounded,

equipment can fatally shock a person.

and some practices to both.

Have a certified

electrician verify that the equipment is adequately grounded and learn what

terminals and parts are electrically HOT.

Avoid hot spots on machine. Use'

proper safety clothing, procedures, and test equipment.

The electrical resistance

dangerous currents to

equipment, do not work in damp areas.

dry wood,

use insulating gloves when dampness or sweat cannot be avoided.

of the body is decreased when wet, permitting

flow through it.

When inspecting or servicing

Stand on a drv rubber mat or

Keep clothing dry, and never work alone.

./

1

1. Installation and Grounding of Electrically Powered Equipment

Equipment driven by electric motors (rather than by diesel or gasoline

engines) must be installed and maintained in accordance with the ?lational

Electrical Code, ANSI/XFPA 70, and other applicable codes.

A power

disconnect switch or circuit breaker must be located at the equinment.

Check the nameplate for volta e,

only 3-phase power is

availab e,

to only two wires of the 3-phase line.

frequency, and phase requirements.

F

connect any single-phase rated equipment

DO NOT CONNECT the equipment

grounding conductor (lead) to the third live wire of the 3-phase line

this makes the eauipment frame electrically HOT, which can cause a fa;aF

-iniT&.-Always connect the grounding lead

if supplied in a power line cable,

to tne grounded switch box or building ground,

separate groundin

of the grounding

situation.

details.

Refer to the National Electrical Code .ANSI/NFPA 70 for

Do not remove plug ground prongs. Use correctly mating

lead.

!T

ead will be adequate for the worst

Ensure that the current

-m-e-

If not provided, use a

(am erage)

P

ault current

capacity

receptacles.

2.

Output Cables and Terminals

Inspect cables frequently for damage to the insulation and the

connectors.

not overload

Re lace or repair cracked or worn cables immediately. Do

ca les. 1

Do not touch output terminal while equipment is

energized.

Service and Maintenance

3.

,

This equipment must be maintained in good elec&?ical and mechanical

condition to avoid hazards stemming from disrepair. Report,any

equipment defect or safet

use of the eluigm ent unti its safety has been assured.

should be ma e'

y qualified personnel only.

hazard to the supervisor and di.z;.z;fmre

1

>

If

Instruction 910082

Feb 25/86 Revised

Page 1

?I.

TC)XIC FUME PREVENTION

E.

c

- .

Before inspecting or servicing eledtricallp-powered equiment,

take the following precautions:

a. Shut OFF all power at the

disconnectin

before inspecting or servicing the

f

switch or line breaker

equ pment.

b.

Lock switch OPEN (or remove line fuses) so that power cannot be

turned ON accidentally.

c. Disconnect power to equipme.nt if it is out of service.

d. If troubleshooting must be 'done with the unit ener

another person present who is trained in turning o

9

zed, have

f the equipment

and'providing or calling far first aid.

FIRE AND EXPLOSION PREVENTION'

Fire and explosion are caused hy electrical short circuits, combustible

material nea,r engine exhaust &ping, misuse of batteries and' fuel, or

unsafe operating or fueling conaitlons.

1.

2.

3.

Electrical Short Circuits and Overloads

Overloaded or shorted equipment can become

hot enough to cause fires

either by self destruction or causing nearby combustibles to ignite.

For electrically-powered equipment, in particular,

"1

rotide primary

~input protection to remove short circuited or heavi y overloaded

equipment from the line.

Batteries

Batteries may explode and/or give off flammable hydro en

and arcing from a ruptured battery can cause fires

an

3 ad%%oni?e acid

failures.

When servicing, do not smoke, cause sparking, or use open

flame near the battery.

Engine Fuel

Use only approved fuel container or fueling system.

Fires and

explosions can occur if the fuel tank is not grounded prior to ;g duping

fuel transfer. Shut unit DOWN before removing fuel tank cap.

completely fill tank, because heat from the eouipment may cause fuel

expansion overflow.

Remove all spilled fuel IMMEDIATELY, including any .

that penetrates the unit. After clean-up,

fumes away with compressed air.

open equipment doors and blow

Carbon monoxide - Engine exhaust fumes can kill and cause,health problems.

Pipe or vent the exhaust fumes to a suitable exhaust duct or outdoors.

Never locate engine exhausts near intake ducts of air conditioners.

BODILY INJURY PREVENTION

Serious inju

Y

can result from contact with fans inside some equipment.

Shut DOWN sue

equipment for inspection and routine maintenance.

When

equipment is in oneration use extreme care in doing necessary troubleshooting

and adjustment.

Do not remove guards while equipment.is operating.

MEDICAL AND FIRST AID TREATMENT

First'aid facilities and a qualified first aid person should be available

for each shift for immediate treatment of all injury victims. Electric

shock victims should be checked by a ph

sician and taken to a hospital

immediately if any abnormal signs are

o served. i:

EMERGENCY FIRST AID I

Call physician immediately.

Seek additional assistance and use First Aid

techniques recommended by American Red Cross until medical help arrives.

./

;EzREATHING IS DIFFICULT give oxy en,

FOR ELECTRICAL SHOCK, turn o

F

if available, and have victim lie

f power, Remove victim; if not

breaihing, begin artificial respiration, preferably mouth"to-mouth. If

I no detectable pulse,

Squad immediately,.

begin external heart massage. Calll.$mergency Rescue

G.1 EQUIPMENT PRECAUTIONARY LABELS

h:;E:::e 3 YeCau==ona

Order and

abels

ry Aabe's on the equi

that cannot be easily rea

F

ent monthly.

.

!,

Page 2

Instruction 910082

Revised Feb 25/86

TABLE OF CONTENTS

SUBJECT

I

Introduction

,

Description/Operation ,

/

Identification

1.

General

2. Model Number

3.

Optional Equipment

A.

Trucks

B.

Truck Body Kits

C.

Trailer

D.

Transformer-Rectifiers

E.

T-R Mounting Kits

F.

Test Box

G.

Revolving Light

Description

1.

General

2.

Orientation

3.

Special Features

A. Protective Monitor System

B.

Pullout Trays

C. Voltage Regulator

D.

Test Receptacle Connector

1

./

/‘Ii

Jan 22181

1

CHAPTER/SECTION

PAGE

1-o

1

l-l

1

1

1

2

2

2

2

2

2

2

314

l-2

1

1

Contents

Page 1

TABLE OF CONTENTS CONTINUED

SUBJECT

CHAPTER/SECTION

E . Test Box

,

l-2

F. Dual Output

I

).

4., Canopy

5. Engine, Generator and Controlls Assembly

A. General

3. Generator

C. Engine

D. Governor

E. Engine Safety Shutdown System

(1) General

(2) Air shutoff valve

(3) Engine fault sensing devices

(a) General

(b) Emergency-stop solenoid valve

F. Air Cleaner

G. Control Box

(1) Voltage regulator tray

(a) Gantrols

(b) Protection

(c) Components

(2) Protective relay tray

1

Contents

Page 2

) b’i

TM-528

PAGE

3

3

3

6

6

7

9

9

10

10

10

10

12

I;

Revised Jan 22/81

I

i

i

/

!

/

I

/

f

I

!

/

I

,

I

/

!&

1

TABLE OF CONTENTS CONTINUED

SUBJECT

CHAPTER/SE CT ION

‘, (a) S

ensing relays 1’

(b) Protective monitor module

I

,I

(c) indicating I ights

(d) Plug interlock relay

(e) Test-bank switch

(f) Resistor

(g) Fuse interlock relay

(h) Connector

(i) Diode,

capacitor and terminal board

(k) Overload relay

(I) Fuses

(3) Generator control tray

(a) Resistors

16

(b) Generator output meters 16

(c) Meter and I ine switches

16

18

18

18

(d) Receptacle connect0 r

(4 Tray

(f) Manual voltage control

H. Engine and Generator Control Panel

(1) Engine gages and meters

(a) 0 i I pressure gage and diaphragm switch

l-2

1

Li

I t

TM-528

PAGE

12

12

14

14

14

15

15

15

15

15

15

16

18

18

18

Jan 22/8 T Revised

Contents

Page 3

TABLE OF CONTENTS CONTINUED

TM-528

SUBJECT

I (b) Ammeter : ,

(c) Temperature gage

(d) Hourmeter

(2) Panel lights

(3) Indicating I ights

(a) Engine ON indicating light

(b) locd contactor indicating I ights

(4) Switches

(a) Air valve (starting) switch

(b) Starter switch

!_

,

CHAPTE R/SE CT 10 N

1-2

PAGE

18

20

20

20

20

20

20

21

21

21

(c) Speed control switch

(d) Light switch

(e) Load contactor control switches

(f) Push-to-build-up-voltage switch

(5) Excitationtdeenergization relay

(6) Fuse

(7) Test receptacle connector

(8) Speed control cable

(9) Cold weather starting aid

(10) Terminal boards

.I

J. Special Engine and Generator Control Panel

t

l,‘i

21

21

21

22

22

22

22

22

22

23

23

) General

!

Contents

Page 4

(1

23

Revised Jan 22/81

I

m

1

TABLE OF CONTENTS CONTINUED

SUBJECT

(2) Receptacle, connector and circuit breaker

I

<’

(3) Emergency-stop switch

,(4) Ho urme ter d iaphragm switch

(5) Locd contactor switches operating handle

(6) Low fuel warning and shutdown system

K. Power Module

(1) Capacitor

CHAPTER/SECTION

1-2

(2) Line-drop current transformer

(3) Ammeter current transformer

(4) Locd contactor

(5) Diode panel

(6) Resistors (line drop)

(7) Overload current transformer

(8) Overlood board

(9) Indicating light relc

(10) Terminal board

’ L. Output Terminal Panel

Preparation for Use

,l . Generator Set

A. General

B. Inspection/Check

ys and blocking diode

l-3

C. Output Cables Installation

Jan 22/81 Revised

TM-528

PAGE

23

23

23

23

25

25

25

25

25

26

26

26

26

26

28

28

28

1

1

1

1

3/4

Contents

Page 5

TM-528

SUBJECT

CHAPTER/SECTION

PAGE

TABLE OF CONTENTS CONTINUED

(l), Cable requirements

3

(2) Cable connection ’

Operation

1. General

2. Operating the Truck

A. General Operating Instructions

8. Starting the Truck Engine

C. Positioning the Truck

3. Operating the Trailer

A. General

B. Operating the Brakes

C. Drawbar

4. Operating the Generator Set

A. General

8. Connecting Output Cables

C. Preparation for Power Delivery

(1) Voltage regulator trcy

(2) Protective relay tray

1 (3) Generator control tray

(4) Engine and generator control panei

D. Normal Engine Starting

1

E. Cold Weather Engine Starting

Contents

Page 6

1-3

3/4

3/4

l-4

1

1

1

1

1

2

2

2

2

2

2

2

3

3

3

3

4

4

,

4

(#Ii

7 :

Revised Jan 22/81

I

m

I 1

TM-528

I

I

TABLE OF CONTENTS CONTINUED

SUBJECT

CH APTE R/SE CT IO N

PAGE

--

F., Power Delivery (Automatic Voltage Cantroi)

l-4

9

G. Power Delivery (Manual Voltage Gntrol)

H.. Stop Power Deliver&

10

10

J. Stop Engine

K. Emergency Stop (Special)

5. Operating Instructions for Optional T-Rs

A. Transformer-Rectifier Operation

(1) Direct current power delivery

(2) Simultaneous 28.5-V and 35-V DC power delivery

(3) Simultaneous 28.5-V DC and 115-V AC power delivery

(4) Simultaneous 35-V DC or 112-V DC

-

Servicing

2-o

Maintenance

2-l

1. General

10

10

11

11

11

11

12

12

2. Maintenance Schedule

1

A. General

1

B.

Maintenance Schedule Check Sheet

1

C. Time lntemais

1

D. Identification of Interval Periods

1:

3. Air Cleaner Cartridge Replacement

3

A. Removal

,

3

ii

B. Installation

4

Jan 22/8 1 Revised :

i.

Contents

Page 7

TM-528

TABLE OF CONTENTS CONTINUED

SUBJECT CHAPTER/SE CT ION

PAGE

4. Electrical System (24-‘V and

I

A. Lights

B. Fuses

C. Wiring and Gpnections

D . Battery Service

(1) General

12-W DC) , 2-l 5

(2) Battery location and accessibility

(3) Battery care

(4) Liquid level

(5) Cleaning the battery

5. Electrical System (115-V AC)

A. Monitoring Instruments

B. Indicating Lights

C. Protective Relays

D. Wiring and Connections

6. Lubrication

A. General

B. AC Generator

C. Generator Controls

D. Diesel Engine

(1) Lubrication schedule

t:

ontents

5

5

5

s 5

5

5

5

7

7

8

8

8

8

9

9

9

1

)“i

9 .

-

!,

Revised Jan 22/81

Page 8

SUBJECT

.

w

1

I

TM-528

TABLE OF CONTENTS CONTINUED

CHAPTER/SE CT IO N

PAGE

I

(2) Oil specification

2-l

9

I

(3) Oil viscosity

10

(4) Changing engine oil

10

(5) Changing oil filter elements

10

(6) Lubrication procedures

7. Generator Maintenance

10

13

A. Cleaning

B . Ad i ustment

8. Engine Mcintenance

A. General

3. Cleaning

Ad iustment/Test

1. General

2. Testing

13

13

13

2-2

13

13

1

1

1

A. Preoperational Test Procedures

1

B. Operational Test

4

3. Adjustment

7

A. Engine Governor

7

B. Generator

8

C. Generator Control Adiustments

8

(1) Adjust manual voltage co,ntrol variable $$istor

9

Jan 22/81 Revised

:

i>

Contents

Page 9

TABLE OF CONTENTS CONTINUED

TM-528

SUBJECT

CHAPTER/SE CT 10 N

I (2) Adjust generator ove?load relay

balast resistor I

(3) Adjust 115-V AC voltage regulator

),

(a) Adiust generator output voltage

(b) Adiust cable length and size

compensation rheostats

(c) Adjust damp and rate potentiometers

D. Basic Engine Adiustrnents

E. Governor Adiustment

F. Covernor Speed Control Linkage Adiustment

(i) Adjust switch operating disc position

2-2

PAGE

9

10

10

El0

11

12

12

12

14

(2) Adjust solenoid linkage

(3) Ad just eng ine id le speed

(4) Adjust engine governed (high) speed

Troubleshooting

Troubleshooting Procedures

1. General

2. Troubleshooting Chart

A. Description

8. Use of the Troubleshooting Chart

3. Wiring Diagrams

II lustrated Parts List

3-o

3-l

4-o ,,ii

14

14

16

1

1

1

1

ontents

c!

Page 10

j, Revised Jan 22/81

I 1

TM-528

TABLE OF CONTENTS CONTINUED

SUBJECT

Intro#uct ion

1. General

I

2. ,Purpose

3. Arrangement

CHAPTER/SECTION PAGE

1

4-l 1

4. Explanation of Parts List

A. Contents

B. Parts List Form

(1) Figure-Item No. Column

(2) Hobart Part Number Column

(3) Nomenclature Column

(4) Eff (Effective) Column

(5) Units per Assembly Column

Manufacturer’s Codes

1. Explanation of Manufacturer’s (Vendor) Code List

Parts List

1. Explanation of Parts List Arrangement

2. Symbol s and Abbreviations

Numerical Index

1 1. Explanation of Numerical Index

Optional Equipent

Manufacturer’s Literature

Jan 22/81 Revised :

4-2

4-3

1

4-4

1

5-o

1

6-O

Li

1

l/2

l/2

i;

Contents

Page 11

I

(’

j CHAPTER/

j SECTION

l-l

l-2

l-2

l-2

l-2 !

l-2

l-2

l-2

l-2,

l-2

l-2

l-2

l-2

l-3

l-4

l-4

l-4

l-4

2-l

2-l

2-l

2-l

2-l

2-l

2-l

2-l

2-2

2-2

2-2

2-2 1

2-2

2-2

2-2

3-l

3-l I

3-1

3-l

3-l

.I

3-l

1 4-3

FIGURE

NUMBER

I

,l

1

2

3

4

5

6

7

8

9

10

11

12

1

1

1

2

3

1

1

2

3

4

5

6

7

1

1

2

3

4

5

6

1

2

3

4

5

6

1

1

‘&

I

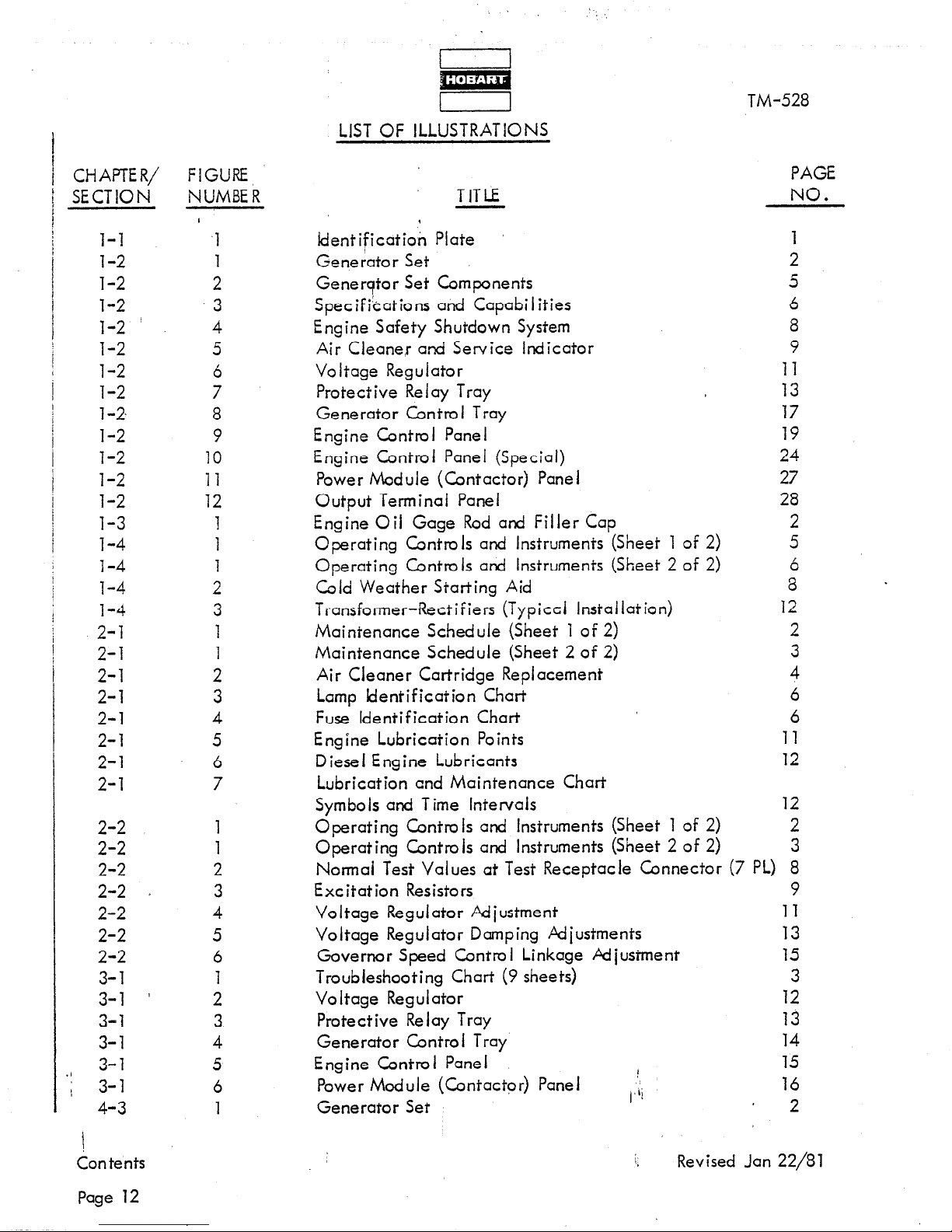

LIST OF ILLUSTRATIONS

TITLE

Identification Plate ’

Generator Set

Generator Set Components

Specifications and Capabilities

Engine Safety Shutdown System

Air Cleane,r and Service Indicator

Voltage Regulator

Protective Relay Tray

Generator Control Tray

Engine Control Panel

Engine Control Panel (Special)

Power Module (Contactor) Panel

Output Terminal Panel

Engine Oil Gage Rod and Filler Cap

Operating Controls and Instruments (Sheet 1 of 2)

Operating Controls and Instruments (Sheet 2 of 2)

Cold Weather Starting Aid

Transformer-Rectifiers (Typiccl Installation)

Maintenance Schedule (Sheet 1 of 2)

Maintenance Schedule (Sheet 2 of 2)

Air Cleaner Cartridge Replacement

Lamp Identification Chart

Fuse Identification Chart

Engine Lubrication Points

Diesel Engine Lubricants

Lubrication end Maintenance Chart

Symbols and T ime Intervals

Operating Controls and Instruments (Sheet 1 of 2)

Operating Controls and Instruments (Sheet 2 of 2)

Normal Test Values at Test Receptacle Connector (7 PL) 8

Excitation Resistors 9

Voltage Regulator Adiustment

Voltage Regulator Damping Adiustments 13

Governor Speed Control Linkage Adiustment

Troubleshooting Chart (9 sheets) 3

Voltage Regulator

Protective Relay Tray 13

Generator Control Tray 14

Engine Control Panel

Power Module (Contactor) Panel

Generator Set

I

/;i

TM-528

11

13

17

19

24

27

28

8

12

11

12

12

11

15

12

15

16

PAGE

NO.

1

2

5

6

8

9

2

5

6

2

3

4

6

6

2

3

2

!

Con tents

Page 12

5

Revised Jan 22/81

./

!

CHAPTER/

FIGURE

SECTION

NUMBER

4-3

4-3

4-3

4-3

4-3

4-3

4-3

4-3

4-3

4-3

11

4-3 12

4-3

13

4-3

14

4-3 15

4-3 16

4-3 17

4-3 17A

4-3

18

4-3 19

4-3 20

1

!/r

I,

LIST OF ILLUSTRATIONS (CONTINUED)

2 ~

3

4

5

6

7

8

9

10

<’

TITLE

I

.

Canopy Assembly

Generator Set Without Canopy

Control Box Assembly

Voltage Regulator Tray Assembly

, Protective Relay Tray Assembly

Generator Control Tray Assembly

Control Box and Internal Components Group

Engine Control Panel Assembly

Engine Controi Panel Assembly

(Special)

‘Power Module Panel Assembly

Output Terminal Panel Assembly

Air Cleaner Group

Generator Group

Red iator and Coo I ing System

Engine Group

Governor Oil Filter Lines Group

Lines, Oil, Emergency Shut Down

Governor Linkage Group

Exhaust System

Frame Group

TM-528

PAGE

NO.

4

6

8

10

12

16

20

22

26

30

34

36

38

40

44

48

50

52

54

56

r

Jan 22/8 1 Revised :

Contents

Page 13/14

id

I

i,NTRODUCTiON

This manual contains operation and, maintenance information for a 400-Hz Generator Set

which may be either truck or trail&r mounted,.

Brothers Company,

The purpose of the manual is!to provide operators and maintenance personnel with instructions

and information which will guide and ,assist them in the efficient operation and maintenance

of the ground power equipment.

these instructions and familiarize’ themselves with the characteristi’cs, capabilities, and

limitations of the unit.

The manual is divided into six chapters. Each chapter is d ivided into as many sections as

required .

section begins with Page one and the first illustration in each section is Figure 1.

Should this manual contain additional information required to cover optional equipment,

modifications, changes and updated designs, added after the original manual was released,

this information will be added at the end of a Section where it would normally be found.

Added or changed information is indicated by a solid black line in the left-hand margin

of the page, opposite the new or revised material.

Pages and illustrations are not numbered consecutively through the manual. Each

Power Sjstems Division, Troy, Ohio 45373.

Ail personnel responsible for the equipment should read

1

These units are manufactured by Hobart

TM-528

Always refer to the Table of Contents, or to the last page (s) of a Section to determine

if special information hcs been added for your particular machine.

Refer to Chapter 1, Section 1 for an explanation of how to identify generator sets.

Chapter 5 lists ail options available for use with the basic generator set.

lists ail pertinent,manufacturer’s literature which is furnished with this manual, including

schematic and connection diagrams.

Chapter 6

!

Jan 22/81 Revised

:

I)

Introduction

Page l/2

.,

TM-523

CHAPTER 1. DESCRiPTlON AND OPERATION

SECTION 1. IDENTIFICATION

I

9

1. General

This manual coveA a 140 KVA, diesel engine-driven; truck or trailer mounted

generator set.

Because more than one version of the generator set is covered

in this manual, a method of positive identification has been established to

define the type of mounting (truck or trailer) and any special equipment not

included with the options I isted below.

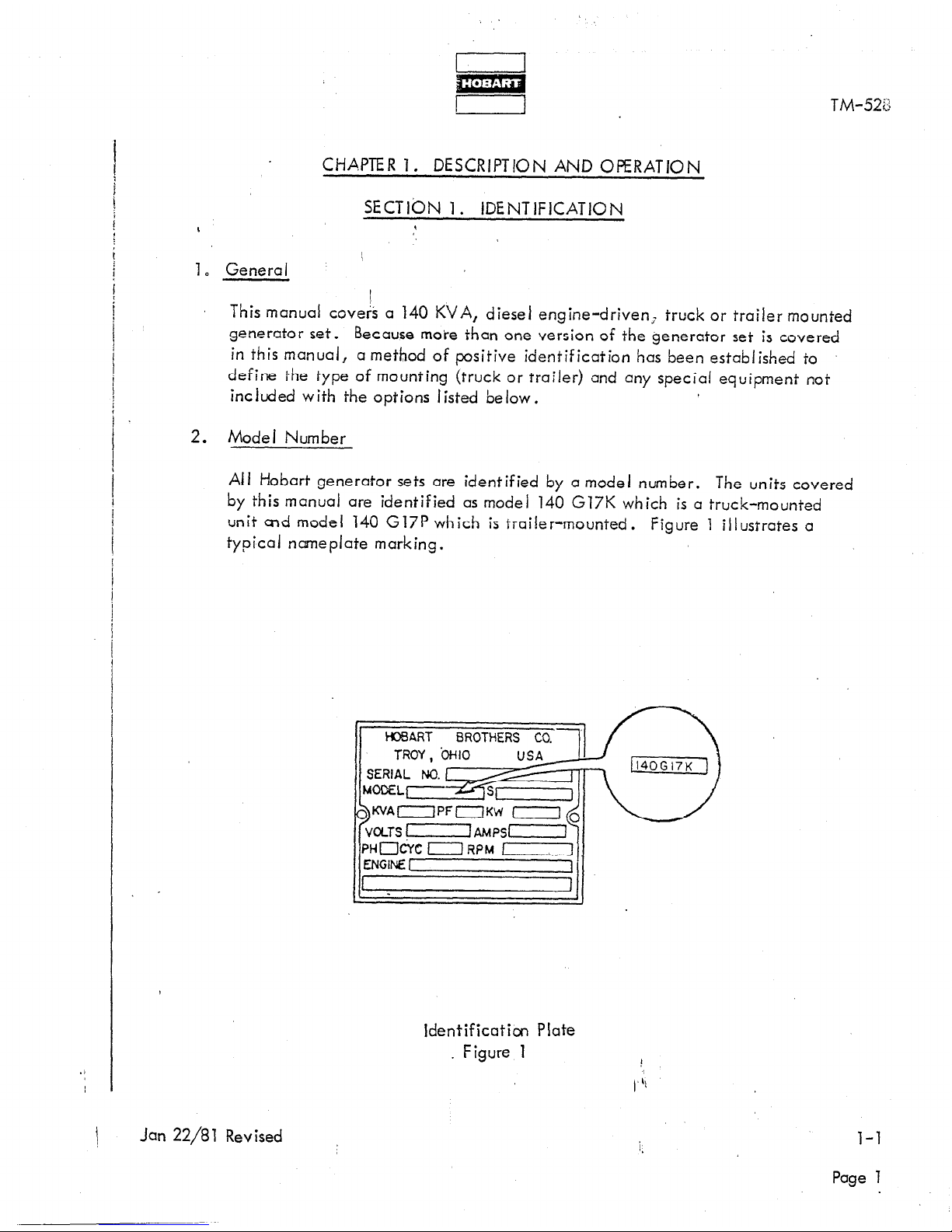

2. Model Number

Ail Hobart generator sets are identified by a model number. The units covered

by this manual are identified as model 140 G17K which is a truck-mounted

unit end model 140 G17P which is trailer-mounted. Figure 1 illustrates a

typical nameplate marking.

1 WART BROTHERS CO. 1

If-Y

K’JAOPFOKW

Identification Plate

. Figure 1

\

Jan 22/81 Revised

Page 1

TM-528

140G17K defines a generator set mounted on any of the truck options listed below.

140G17P defines a generator set mounted on the optional trailer.

140G17P (special) ‘defines a trailer-mounted generator set which includes special equipment.

3. Optional Eqbi,pment

Optional equipment consists of trucks,

transformer-rectifier mounting kitk, a revolving amber light and a test box.

/

A. Trucks

The truck options consist of Chevrolet model CS-51403, Ford model F-500, GMC

model CS-51403 and Dodge model D-500.

B. Truck Body Kits

Truck body kits, part number 482150, are available for mounting the basic generator

set, with or without transformer-rectifiers, on any of the available truck options. These

kits are described and illustrated in TO-110.

I

C. Trailer

I

The optional trailer, part number 482158,

TO-106.

,

truck body kits, trailer, transformer-rectifiers,

is covered by an instruction manual

D. Transformer-Rectifiers

Transfomler-rectifiers are available to change the 115-V AC generator output to 28.5,

35 and 112 V DC. The 28.5 volt unit is covered in TM-597, the 112 volt unit is covered

in TM-598 and the 35 vo It unit is covered in TM-599.

E. T-R Mounting Kits

Transformer-rectifier mounting kits, part number 482163, are available for mounting

any combination of T-R units on the optional trucks at-d trailer. These kits are covered

in TO-111.

F. Test Box

The optional test box, part number 388318-4, is available to check voltage levels at

critical points throughout the circuitry.

It plugs into the test receptacle connector

on the engine control panel of each unit. This option is covered in TO-112.

Page 2

\;

Revised Jan 22/81

I

I

TM-528

G. Revo iving Light (Truck-Mounted Units)

This emergency warning iigbt revolves through 3600. Central iy mounted on top

of the truck cab, it has an ‘on-off switch located on the dashboard. This option

is covered in TO-1 13.

1

Jan 22/81 Revised ;

i.

l-l

Page 3/4

!d

r I

SECT1 ON 2. DESCRIPTION

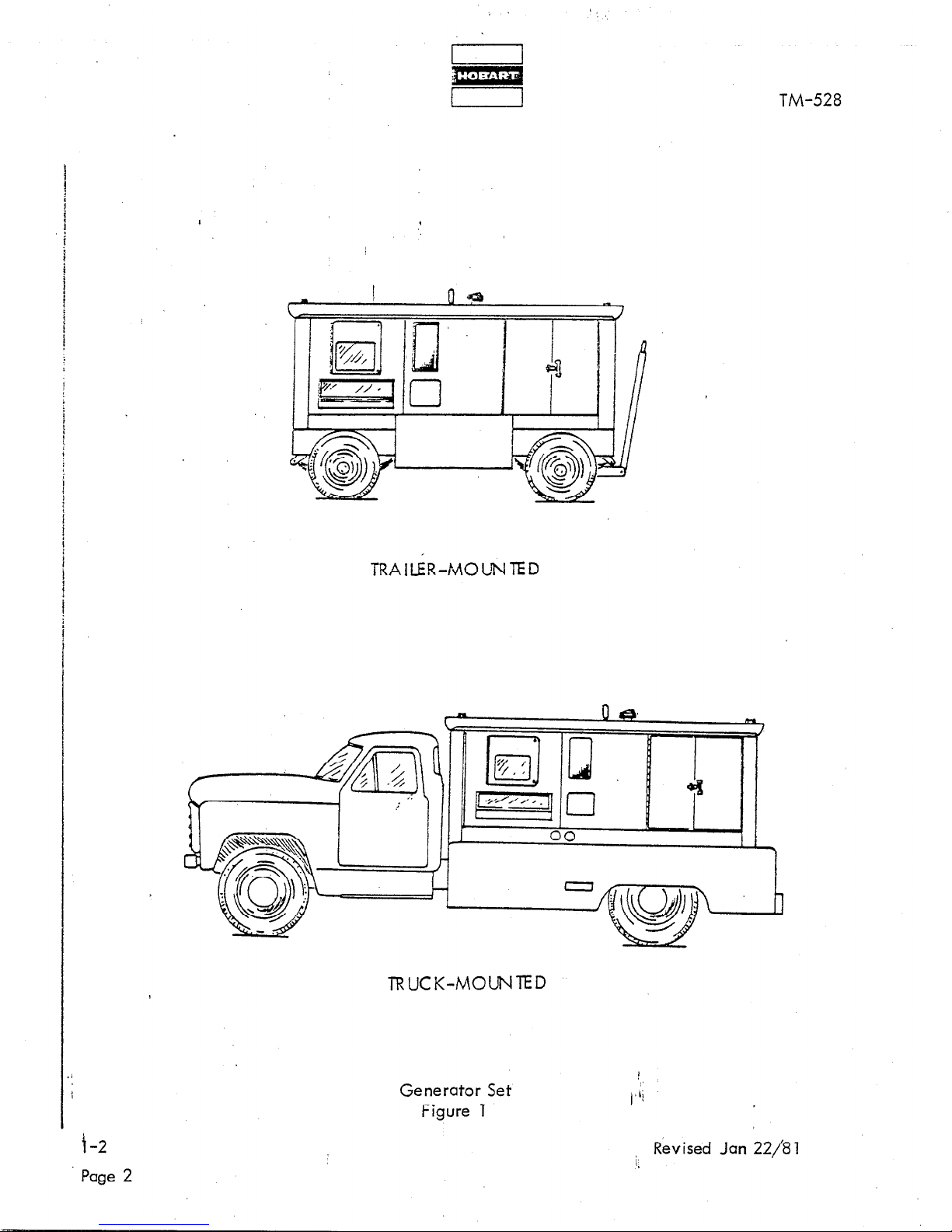

1. General

The generator set covered by this manual is a diesel engine-driven unit,

enclosed by a canopy and designed for mounting on a truck or trailer

(See Fig. 1). ’

TM-528

/

The purpose of the generator set is to produce and deliver regulated, 400-Hz,

115/200-V AC power to one o,r two parked aircraft for operation of the air-

craft’s electrical equipment when the on-board generators are not running.

Orientation

2.

For purposes of orientat ion and to fcm ii iarize operators and maintenance

personnel with the location of components, the radiator is considered to

be at the FRONT of the unit. The generator and controls are at the REAR.

RIGHT and LEFT are determined by standing at the rear and facing the

math ine .

and engine control panel are mounted on the RIGHT side at the REAR of

the unit.

NOTE: When the generator set is mounted on a truck, the rcdictor or

FRONT end of the generator set is at the REAR of the truck.

Operating controls are then on the LEFT, or driver’s side, of

the truck. When the generator set is mounted on a trailer,

the radiator is at the drawbar, FRONT end.

3. Special Features

Thus, the generator control box, output receptacle connector,

The generator has many special features which are described more fully

under the assemblies in which they appear. Some of the main features

are mentioned here and described briefly.

A. Protective Monitor System

A single, solid-state device (1, Fig.

the fault sensing units in the generator output circuit and functions

to cause the load to be disconnected from the generator if an abnormal

condition of voltage,

Pullout Trays

B.

The control box is equipped with pullout, drawer-type trays which

provide easy access to controls and equipment md,unted in them.

Each tray may be removed as an assembly by disbbnnecting a single

quick-disconnect connector and tripping two safety latches.

Jan 22/81 Revised :

7) receives signals from ail of

frequency or load develops.

1,

l-2

Page 1

/

I

m

I 1

TM-528

TRAILER-MOLNTED

TRUCK-MOUNTED

Generator Set

Figure 1

f-2

Page 2

i Revised Jan 22/81

TM-528

C. Voltage Regulator

I

A solid-state, adiustabie voltage regulator (Fig. 6) provides automatic

voltage regulation at f’he aircraft.

The regulator is also adiustabie for

a variety of output cable sizes and lengths.

D. Test Receptacle Connector

A receptacle connector (18, Fig. 9 and 10) with wiring ta various test

points throughout the eiectricai circuit is provided for the attachment

of a test box. This circuitry, when used in conjunction with diagrams,

allows technicians to monitor voltage levels at critical points throughout

the circuitry.

E.

Test bx

The optional test box may be plugged into the test receptacle connector

and used to check voltage levels at critical points throughout the circuitry.

F.

D.uai Output

Each generator set is equipped with two output circuits and dual controls

so that power may be delivered to an aircraft requiring two inputs, or to

one or two aircraft with single input requirements.

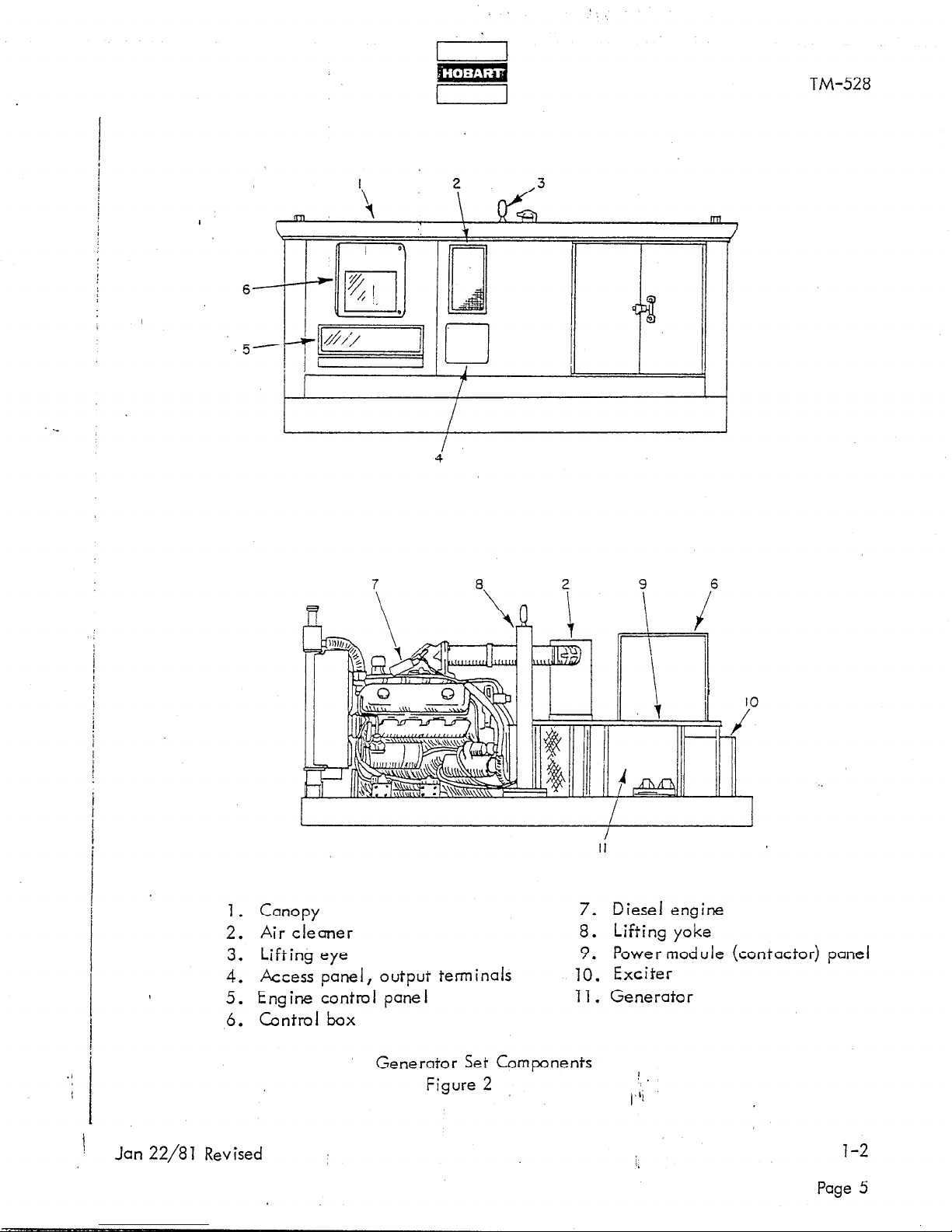

4. Canopy

A sheet metal enclosure,

identified as a canopy (See 1, Fig. 2) provides

protection for the engine, generator, and electrical controls. Four hinged

doors on the left side provide easy access for service and maintenance. Two

hinged doors near the front on the right side provide access to the engine

corn partme nt .

Panel mounted instruments may be observed through two Plexiglass

windows which cover a portion of the control box and engine control panel.

The lower window is slanted outward at the bottom to provide an opening for

reaching engine controls.

A small panel located below the air cleaner covers

the dual-output terminal board.

Two cable horns and clamps provide protection

and security for output cables.

A central iy-located lifting eye is mounted in

the main frcrne superstructure and extends upward beyond the canopy top to

provide a convenient attaching point for chains, cables, hooks, etc., used

to I ift and move the generator set.

Jan 22/81 Revised

:

i;

l-2

Page 3

m

I 1

TM-528

L

I

5. Engine, Generator and Controls Assembly.

A. General

This assembly is the basic generator set without canopy.

It includes all

components required to igenerate and reg’ulate 400-iiz, 115/200-V AC,

three-phase power,

and is operable when provided with a system to supply

fuel to the engine fuel plump.

Four six-volt batteries mounted in the optional

/

trailer or truck body, are connected in series to provide 24-V DC power to

the engine direct current circuits:

A tcp lecd connected In this circuit

between the two center batteries provides 12-V DC power for the generator

protective system.

The engine-generator assembly is mounted on a welded

stee I f rme .

A superstructure,

attached to the main frame, provides mounting facilities

for the canopy, control box,

and m isceiianeous electrical equipment.

Specifications and capabilities of the’generator set are listed in Figure 3.

8.

Gene rato r

The generator (11, Fig. 2) is a brushless, revolving field, three-phase,

alternating-current type.

It is technically an alternator, however it will

be identified throughout the manual as a generator. The rotor is mounted

by two permanently lubricated, sealed, bail bearings. The front bearing

is supported by the fan housing; the rear bearing is mounted in the forward

end of the exciter housing.

Both of these housings are attached to the main

generator stator housing.

The front end of the rotor shaft extends forward

beyond the bearing and is. attached to the engine flywheel by a hub and

flexible disk coupling assembly.

A centrifugal, radial-blade fan, part

of the hub and coupling assembly, draws cooling air over ail internal

windings.

Air enters the exciter end and is discharged through openings

in the flywheel housing at the drive end. The rear end of the rotor shaft

extends rearward beyond the rear bearing and into the exciter stator housing.

The exciter rotor is mounted on this shaft extension with a Woodruff key and

is secured by a washer and cap screw.

A rectifier with six diodes is mounted

on the exciter rotor and converts exciter AC output to DC for excitation

of the generator revolving fields.

The exciter output to the generator

fields, and consequently the generator output, is controlled by the amount

of DC voltage supplied to exciter fields by the static voltage regulator.

C. Engine

The engine (7, Fig. 2) used to drive the generator is a two-cycle, Vee-8

diesel, manufactured by Detroit Diesel Engine Division af General Motors

Corporation. See Fig.

3 for specifications and characterh’stics. Refer to

the Detroit Diesel Operator’s Manual for a detailed description. ’

112

Revised Jan 22/81

Page 4

f

n Ili=l n I 1

i i

I 1

u

r 1

TM-528

/

II

1. Canopy 7. Diesel engine

2. Air cleaner 8. Lifting yoke

3. Lifting eye

9. Power module (contactor) panei

4. Access panel, output terminals 10. Exciter

5. Engine control panel 11. Generator

6. Control box

Generator Set Components

Figure 2

1

.

(‘Ii

!

Jan 22/8 1 Revised

l-2

Page 5

GENERATOR

I I

TM-528

Output power rating

0 utput voltage

Rated lo&I capacity

Overload capacity (125% of lrated load) ’

Frequency (cycles-per-second)

0 utput ki iowatts

Po,wer factor

Duty cycle

Operating speed (at 400 Hz)

Output cable size (each of four conductors)

ENGINE

Manufacturer

,

I

,.

Detroit Diesel Engine Div.

140 KVA

115/200-v

404-A

505-A

400 Hz

172 KW

0.8 PF

100%

T7P4 RPM

210

General Motors Corp.

Type

Model

Displacement

Bore and stroke

Governed speed

Horsepower at 1714 RPM

Id!e speed

Overspeed governor trip

Coolant system capacity (approx.)

Lubricating oil capacity (without filters change) (approx.) 23 quarts (21 liters)

Lubricating oil capacity (with filters change) (approx.) 26 quarts (25 liters)

567 cubic inches (9291 c.m3)

4-l/2 x 5 inches (115 mmx 127 mm)

1900 to 2025 RPM

19-l/2 gals. (74 liters)

8V-77 N diesel

7083-7000

1714 RPM

253 HP

800 to 850 RPM

D. Governor

The mechanical-hydraulic governor (4, Fig. 4) is identified as a Woodward

Model PSG. Instructions and an ii iustrated parts list for the governor are

included in Woodward Bulletin which is supplied with this manual in Chapter 6.

Engine Safety Shutdown System

E.’

(1) General

The automatic, electric, shutdown system is designed to stop t& engine if there is a loss of oil

pressure, overheating of engine coolant, or engine overspeed.

Page 6

Specifications and Capabilities

Figure 3

Loading...

Loading...