Page 1

#12 TIN CHOPPER ATTACHMENT

WITH ROUND PAN

AFC

12 TIN-C/EPAN 295746

701 S. RIDGE AVENUE

TROY, OHIO 45374-0001

937 332-3000

www.hobartcorp.com

FORM 37017 (July 2012)

Page 2

Assembly, Care, and Operation of

Chopper Attachment with Round Pan

SAVE THESE INSTRUCTIONS

GENERAL

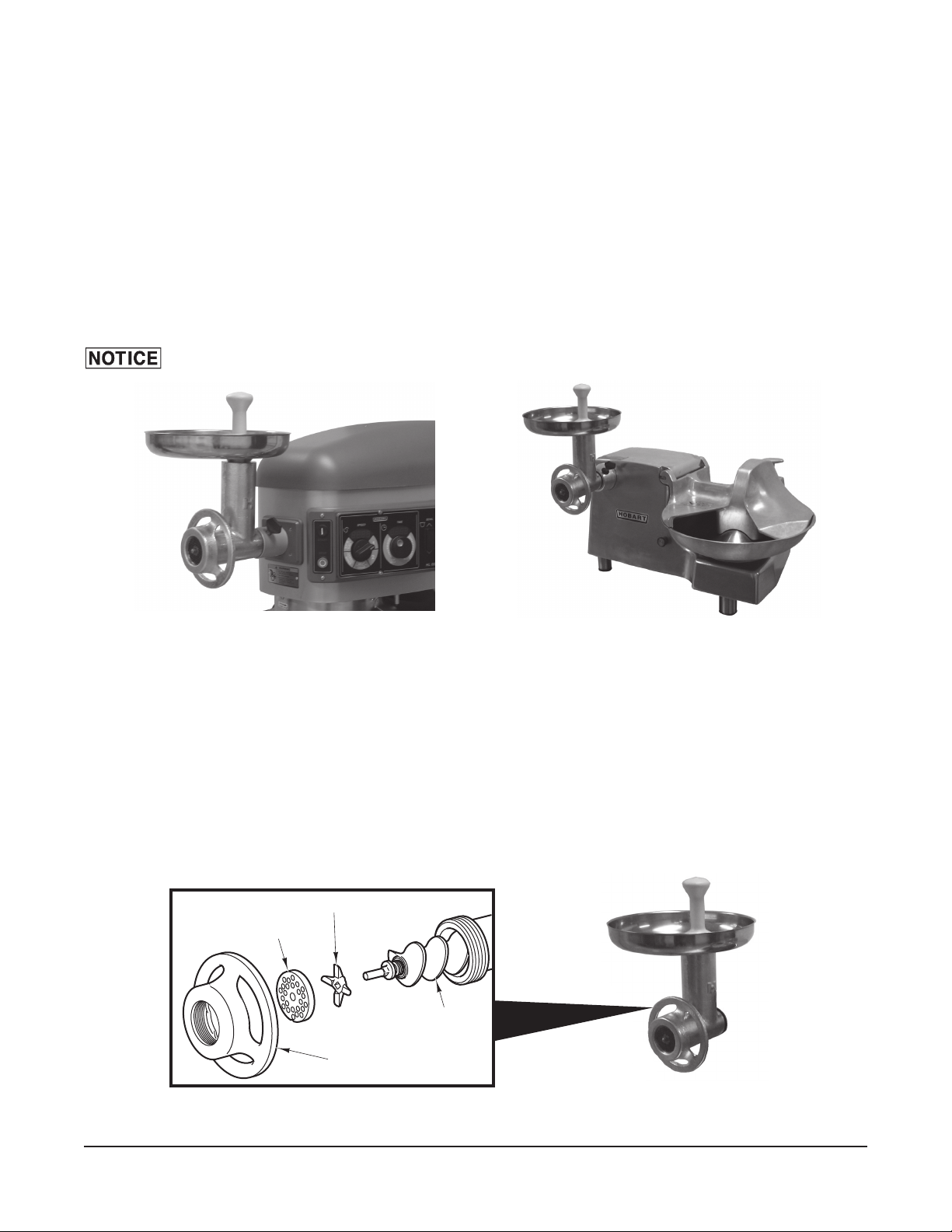

The Chopper Attachment allows you to prepare many additional foods with your Hobart Mixer (Fig.1) or

Food Cutter (Fig. 2). The #12 Tin Chop End is designed to use a #12 size knife and plate. The knife and

plate (which has

plates are available with hole sizes

This product must not be used for preparation of bread crumbs.

1

/8" holes) come with the Chopper Attachment when shipped from the factory. Other

5

/64, 3/16, 1/4, 3/8, 1/2, 5/8 and 11/16" for ne to coarse chopping.

CHOPPER ATTACHMENT on a MIXER

Fig. 1

CHOPPER ATTACHMENT on a FOOD CUTTER

Fig. 2

ASSEMBLY

UNPACKING

Immediately after unpacking, check for possible shipping damage. If the Chopper Attachment is found to

be damaged, save the packaging material and contact the carrier within 15 days of delivery.

The Chopper Attachment must be thoroughly cleaned and sanitized before assembly and operation. Refer

to the cleaning section.

KNIFE

PLATE

WORM

ASSEMBLY

ADJUSTING RING

© HOBART, 2012

Fig. 3

– 2 –

Page 3

CYLINDER

Check to ensure the hub and hub drive are clean and clear of any obstruction. Insert the cylinder assembly

with a slight twisting motion toward the left. The cylinder stop pin will contact the side of the hole that

receives it. Tighten the thumb screw.

NOTE: Upon disassembly it is only necessary to loosen the thumb screw about three turns.

WORM, KNIFE, & PLATE

Slide the worm into the cylinder and rotate until the square shank of the worm locks into the hub drive.

Install the knife with cutting edges facing out, and the plate, making sure the notch aligns with the pin in

the bottom of the cylinder.

ADJUSTING RING, FEED PAN, & FEED STOMPER

Thread the adjusting ring on hand tight. Do not adjust the hand wheel too tight; if the knife and plate

are both sharp, only a moderate pressure will be needed. Knives and plates must be sharp and true for

proper cutting action. Rub a little fat or a light coating of food grade mineral oil over newly-sharpened

plates before use.

The knife and plate depend on meat for lubrication. Therefore, the chopper attachment must

never be operated without meat or some type of lubrication.

Install the feed pan and feed stomper.

OPERATION

USING THE CHOPPER ATTACHMENT

The feed pan should be kept in place in the cylinder for ease of feeding. Cut meat into strips and feed

it into the Chopper Attachment using the feed stomper only as needed. If the strips are cut to proper

size, they will feed without assistance from the feed stomper. When running meat through the Chopper

Attachment a second time, more speed is attained by feeding small quantities at a time. Do not try to force

large amounts through with the feed stomper. Substances that could become packed tight in the chopper

like bread crumbs are not recommended. If material in the cylinder stalls the Mixer or Food Cutter, stop

machine at once. Do not attempt to restart. Remove the adjusting ring, knife, plate and worm and clear

the obstruction.

MIXER SPEEDS

For the Classic Series Mixers: Use 2nd or 3rd speeds.

(A120, A200, D300, D330, D340,

H600, P660, & L800 Mixers)

For the Legacy Series Mixers: Use 3rd speed for 3 speed mixers.

Use 2nd speed for 4 speed mixers.

– 3 –

Page 4

CLEANING

Unplug the electrical cord.

Before using the Chopper Attachment, wash each component thoroughly with mild soap and water.

Sanitize with a solution consisting of one tablespoon of sodium hypochlorite bleach (5.25%) to one gallon

of water. Rinse with clean water. Apply tasteless food grade mineral oil to the bare metal areas of the

worm assembly, cylinder, and adjusting ring. The knife and plate need some preliminary lubrication; rub

fat or a light coating of tasteless food grade mineral oil over the cutting faces of these parts.

MAINTENANCE

Unplug the electrical cord.

MIXER & FOOD CUTTER ATTACHMENT HUB DRAINS

Always keep the Mixer attachment hub drain slot and the Food Cutter attachment hub drain hole clean,

clear, and free of obstruction. Refer to their respective product catalogs for further instruction.

CYLINDER DRAIN

A drain hole at the bottom end of the cylinder (Fig. 4) allows

any meat juices to drain. This hole should be inspected

periodically to make sure that it is free of obstructions.

A small wire can be used to remove any material which

may have accumulated.

SERVICE

Contact your local Hobart-authorized Service Ofce for

any repairs or adjustments needed on this equipment.

Fig. 4

TROUBLESHOOTING

SYMPTOM POSSIBLE CAUSE

Chopper Attachment will not operate. Electrical power not connected.

Circuit Breaker tripped or fuse blown.

If the above suggestions do not remedy the situation,

contact Service.

Product has poor appearance,

comes out soft and mushy.

Damaged Knife and/or Plate Adjusting Ring is too tight - only moderate pressure

Knife and/or Plate worn, replace Knife and Plate or

Adjusting Ring loose, tighten end ring, hand tight

only.

is needed.

FORM 37017 (July 2012) PRINTED IN U.S.A.

– 4 –

Loading...

Loading...