COMBI OVENS

COMBI PLUS

GAS & ELECTRIC

MANUFACTURERS INSTRUCTIONS

Part C: Operating manual

- WARRANTY

-

To ensure the guarantee on this equipment, you should comply with the MANUFACTURER’S

INSTRUCTIONS in this manual.

However if you cannot undertake the required maintenance operations, our installation and service

network is available to provide you with a personalized contract.

- WARNING

-

•

The product delivered to you complies with current standards. If any modifications are made

the manufacturer cannot accept any responsibility whatsoever.

The manufacturer cannot be held responsible in the event of inappropriate use of the

equipment.

•

This equipment is intended for use by suitably trained professionals.

•

Read all the documentation before user.

•

Keep your documents for future reference.

•

Translation of the original manual

3HE3909

96E

U

Page 1 3HE390996EU – 01/17

HOBART GmbH

Registered office:

Robert Bosch Str. 17,

77656 Offenburg - Germany

CONTENT

COMBI PLUS

GAS & ELECTRIC

1. RECOMMANDATIONS ........................................................................................................................... 3

2. COMPOSITION OF THE APPLIANCES .................................................................................................. 6

2.1 6 AND 10 LEVEL OVENS ..................................................................................................................................... 6

2.2 20 LEVEL OVENS ................................................................................................................................................ 6

2.3 ACCESSORIES .................................................................................................................................................... 7

3. PRACTICAL OPERATING ADVISE ........................................................................................................ 9

3.1 BEFORE FIRST USE ........................................................................................................................................... 9

3.2 LOAD LIMITS ........................................................................................................................................................ 9

3.3 USING THE SUPPORTS (Runners, modules and trolleys) ................................................................................. 9

3.4 POSITIONING AND STORAGE OF THE CORE PROBE .................................................................................. 10

3.5 USE LIMITS ........................................................................................................................................................ 10

3.6 PREHEATING (20 level oven) ............................................................................................................................ 11

3.7 USE OF OVENWARE ......................................................................................................................................... 11

4. USING THE CONTROL PANEL ............................................................................................................ 12

4.1 GENERAL ........................................................................................................................................................... 12

4.2 GENERAL ACTIONS .......................................................................................................................................... 12

4.3 MANUAL MENU ................................................................................................................................................. 13

4.4 AUTO MENU: Automatic / programmed recipes ................................................................................................ 14

4.5 TOOL BOX MENU .............................................................................................................................................. 18

5. GUIDANCE AND INFO ABOUT THE CONTROL SCREEN .................................................................. 23

6. TOOLS FOR OPTIMAL COOKING ....................................................................................................... 25

6.1 CORE PROBE .................................................................................................................................................... 25

6.2 LOW TEMPERATURE COOKING ..................................................................................................................... 25

8. USB PORT SOCKET ............................................................................................................................. 27

9. ERROR MESSAGES ............................................................................................................................. 28

9.1 ERROR SCREENS ............................................................................................................................................. 28

9.2 ERROR MESSAGES .......................................................................................................................................... 28

10. MAINTENANCE ................................................................................................................................. 29

10.1 INFORMATION ABOUT STAINLESS STEELS .................................................................................................. 29

10.2 THE COMMONEST CAUSES OF CORROSION: .............................................................................................. 29

11. MAINTENANCE OF THE OVEN ........................................................................................................ 31

11.1 MAINTENANCE OF EXTERNAL SURFACES ................................................................................................... 31

11.2 CLEANING THE ELECTRONIC COMPARTMENT VENTILATION OPENINGS ............................................... 31

11.3 CLEANING THE CAVITY GASKET .................................................................................................................... 31

11.4 MAINTENANCE OF INTERNAL SURFACES .................................................................................................... 32

Page 2 3HE390996EU – 01/17

HOBART GmbH

Registered office:

Robert Bosch Str. 17,

77656 Offenburg - Germany

11.5 MATERIAL USED FOR COOKING CORROSIVE PRODUCTS ........................................................................ 35

11.6 UNLOCKING THE ROTATING DUCT ................................................................................................................ 35

12. LES CONSUMABLES ....................................................................................................................... 36

12.1 GENERAL ........................................................................................................................................................... 36

12.2 CLEANING PRODUCT ....................................................................................................................................... 36

13. GUARANTEE ..................................................................................................................................... 37

Page 3 3HE390996EU – 01/17

HOBART GmbH

Registered office:

Robert Bosch Str. 17,

77656 Offenburg - Germany

1. RECOMMANDATIONS

♦ These appliances are for professional use, only appropriately trained personnel should use them.

♦ These appliances are intended to be used for commercial applications, for example in kitchens of restaurants,

canteens, hospitals and in commercial enterprises such as bakeries, butcheries, etc., but not for continuous mass

production of food.

♦ These appliances must be installed with sufficient ventilation to prevent the formation of an excessive concentration

of substances harmful for health within the premises in which they are installed.

♦ The rate of new air required for combustion is 2m3/h per kW of heating power.

♦ The equipment is not designed to work in an explosive atmosphere. Accordingly it must not be installed in an area

covered by the ATEX directive.

♦ Never block the condensate exhaust flue, because the pressure could rise in the appliance and pose a risk of

explosion.

♦ If an error message appears consult the list of error messages and follow the ADVICE given

♦ When cleaning high pressure jets or lances should never be used.

♦ NEVER start the oven WITHOUT HAVING POSITIONED AND LOCKED the ventilation duct.

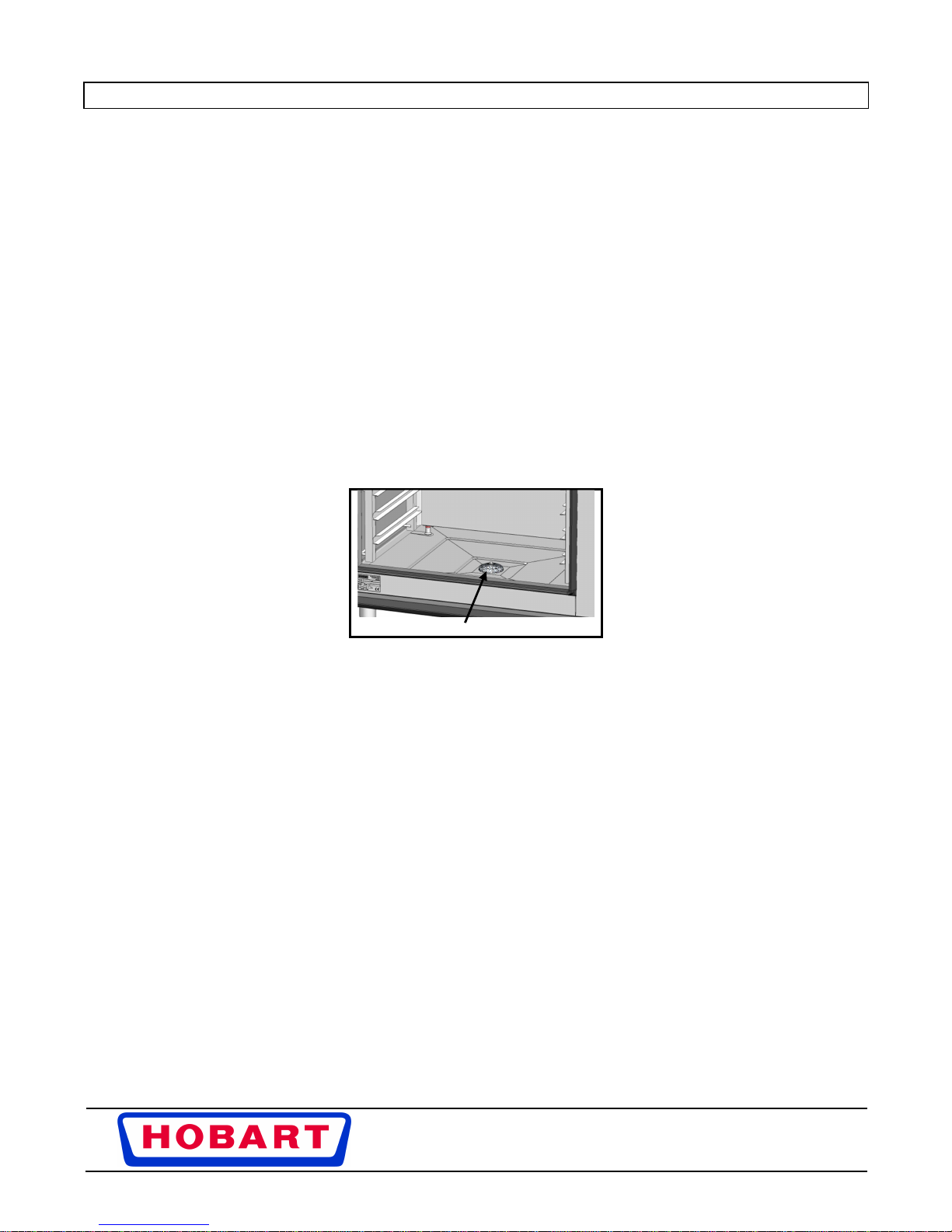

♦ Do not remove the ventilation duct and the drain grid located in the oven. If this grid is missing do not start the oven.

Drain grid

♦ Always use a qualified technician to install the equipment and if necessary change the oven from one gas to

another.

♦ IMPORTANT: Please be aware that when cooking dishes prepared with alcohol (coq au vin, pears in wine, etc.…).

Vapour saturated with alcohol may when heated cause an explosion in the oven and due to the sealed door, create

a momentary overpressure which may cause an irreversible deformation of the panels. This risk is further increased

when the user adds alcohol to the products near the end of the cooking cycle and closes the door to complete

cooking.

♦ The appliance must be isolated electrically during cleaning or maintenance and when replacing parts.

♦ The control panel is operated via a serigraphic touch screen using your fingers. We recommend the exclusive use of

your fingers and no other items such as knives, forks or spoons etc.

♦ For long term reliability and safety it is advisable to have the unit serviced twice a year by suitably qualified

technicians (Dismantling of burners, inspection and cleaning of venturis, cleaning nozzles, adjustment of air rings,

cleaning vents, checking for possible leaks, checking control elements, regulating and safety accessories…).

♦ The oven must be meticulously maintained on a DAILY basis (see the “Maintenance” chapter). In particular,

the fans, heating elements and walls must be kept clean, without accumulation of grease and mineral

deposits (lime or other).

♦ Preheating (20 level ovens): Whatever the cooking mode, these ovens are designed to be preheated with the trolley

in place. See « Practical operating advice ».

♦ Using a trolley or preheating plate (optional) is compulsory for automatic cleaning of 20 level ovens.

♦ It is strictly forbidden to open the door of the oven during the cleaning cycle.

♦ Never place the core probe behind the ventilation duct (the probe could be damaged by the fan, an element or the

gas heat exchange).

Page 4 3HE390996EU – 01/17

HOBART GmbH

Registered office:

Robert Bosch Str. 17,

77656 Offenburg - Germany

♦ THE APPLICATION OF ANY CLEANING PRODUCT ONTO A HOT SURFACE, OVER 60°C, IS STRICTLY

FORBIDDEN. The surface will be damaged beyond repair (darkened, virtually black).

♦ Combination ovens should be cleaned with specific products which can resist temperature of up to 70°C. An

inappropriate cleaning or descaling product may have a slightly corrosive effect.

♦ The detergent chemical risk should not exceed 3 in accordance with EN 1717 (Toxicological information FDS: LD50

> 200mg/kg).

♦ We strongly recommend the use of cleaning products supplied by the manufacturer to ensure good results and

optimize the service life of its components.

Except for the UK market: No detergent product is recommended or supplied. Any detergent used with this

appliance must have been verified to represent no greater risk than Fluid Category 3. If the detergent used

represents a Fluid Category risk greater than Fluid Category 3 alternative backflow protection to the double check

valve supplied with the appliance will be required immediately upstream of the appliance. The backflow protection

used must be appropriate to the risk posed by the detergent.

♦ For maximum efficiency of the descaling product without damaging the material and components of the oven, you

should use an appropriate descaler. The use of certain acids has an irreversible destructive effect that may cause

significant damage. The descaling product must contain corrosion inhibitors to prevent metal attack. It must also

comply with legal requirements, in particular for material intended to come into contact with foodstuffs.

Chemical products containing nitric acid are strictly prohibited. Recommended composition:

- Phosphoric acid <50%

- Corrosion inhibitor

♦ The automatic cleaning system is exclusively designed to achieve an introduction of cleaning and degreasing

chemical. Never use a descaling agent. This would damage the hydraulic system of the oven irreversibly.

♦ The manufacturer certifies that the packaging meets the provision 94/62/CE (relating to packaging and packaging

waste of 20.12.94) and requests that the final installer (or user) observes the rules relating to the removal of the

packaging (recycling or reuse).

♦ « According to article 6 of the decree of 20 July 2005 a marking giving the identity of the manufacturer and the

market release date must appear on equipment after 13 August 2005».

« The Manufacturer has filled in the National Register. »

As per the legal provisions in force (article 21 & 22 of the decree 2005-829), the customer is responsible for the

obligations relating to the elimination of electric and electronic waste, namely:

- he is to deal with selective treatment, reconditioning and destruction of residue arising from electric and

electronic equipment, selectively collected in the installations meeting the technical requirements or in any

other installation authorised for the purpose, in another member State of the European Union, or in another

State so far the transfer of these residues out of France is made according to the provisions of the

Regulation of 1st February 1993 indicated above.

- he must make sure that all fluids of electric and electronic equipment are drained according to the

requirements of the provisions.

- he must make sure that the information relating to the removal and treatment of these residues is forwarded

to any further acquirer.

♦ The warranty will not cover problems caused by failure to comply with these recommendations

Warning! Danger! Caution!

♦ Cooking appliances may reach 250°C. BE CAREFUL not to burn yourself when using or handling INNER

ACCESSORIES (Plates, modules, filter, duct...).

♦ The surface temperature of the door can exceed 60°C. BEWARE OF THE RISK OF BURNS.

♦ Loading and unloading containers and ovenware: The height of the top shelf or runner can be 1.75 m. If

unloading manually be careful. ATTENTION: splashes and spillages pose a risk of scalding.

♦ When using the core probe be aware that it can be very hot, always use suitable protection to avoid burns

♦ Remember the dangers identified on the safety data sheet for detergent

- Harmful if swallowed.

Page 5 3HE390996EU – 01/17

HOBART GmbH

Registered office:

Robert Bosch Str. 17,

77656 Offenburg - Germany

- Can result in serious burns.

- Irritates the eyes.

- Irritates the respiratory tracts.

- Risk of serious eye lesions.

♦ Danger of irritation to the skin and eyes or acid burns.

Detergents will cause irritation and possible burns if in direct contact with the skin or eyes.

- Do not inhale the mist or spray

- Avoid direct contact with these products

- Never open the oven door during the automatic cleaning cycle

- Wear protective clothing, gloves and hermetic protective goggles in accordance with the safety data

sheet.

♦ Remember the safety advice provided by the safety data sheet for each detergent

- Do not eat or drink when using these products.

- Do not inhale their vapours.

- If case of contact with eyes rinse immediately with plenty of water and seek medical advice.

- Wear appropriate protective clothing, gloves and face and eye protective gear.

- In the event of an accident or sickness seek immediate medical attention

- Dispose of the product and its container as hazardous waste.

Page 6 3HE390996EU – 01/17

HOBART GmbH

Registered office:

Robert Bosch Str. 17,

77656 Offenburg - Germany

2. COMPOSITION OF THE APPLIANCES

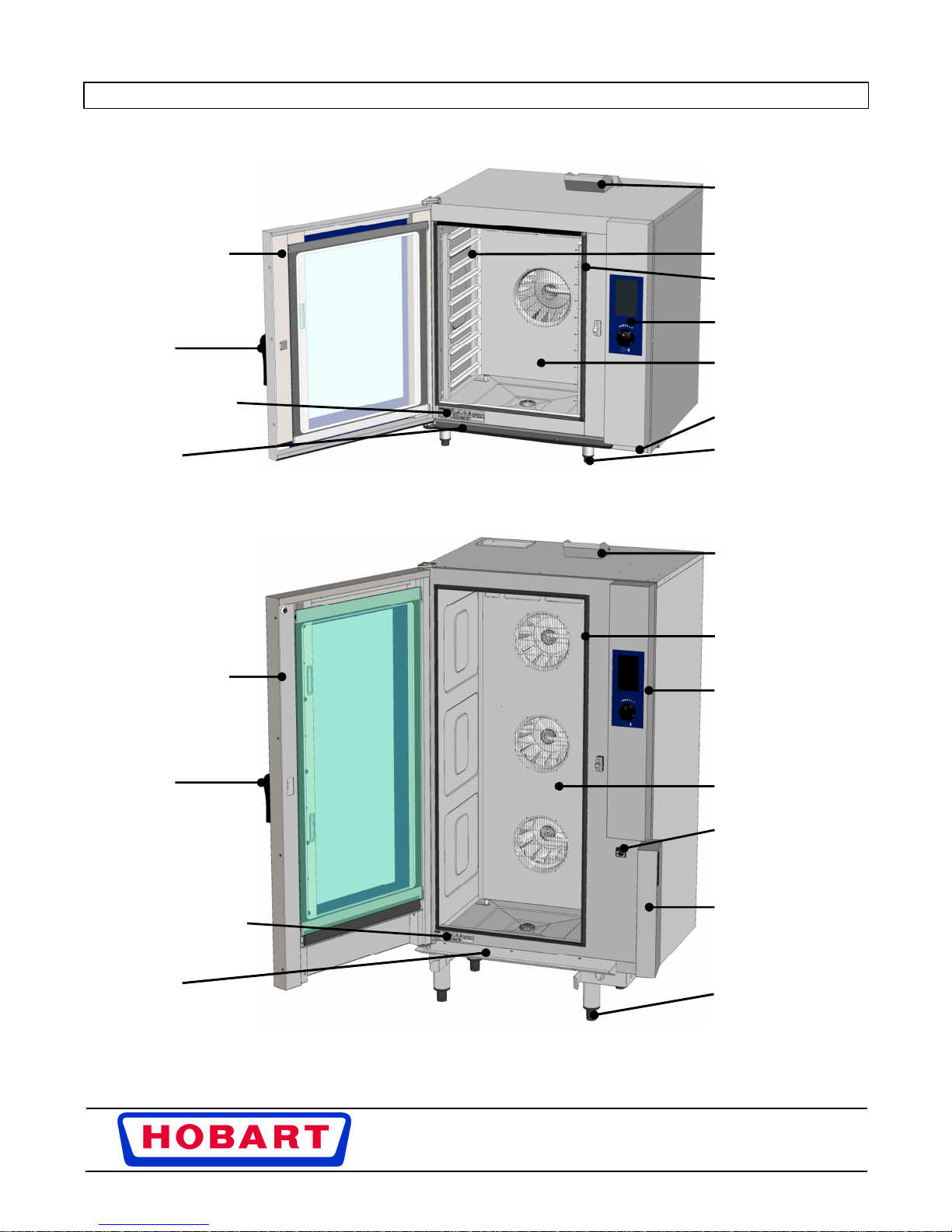

2.1 6 AND 10 LEVEL OVENS

Motorised vent valve

Double glazed door

(unlocked from the inside)

Runners

Cavity seal

Control panel

Door handle

Wire or sheet duct

Data plate

(visible with the

door open)

USB port

Oven legs

height

adjustable

Door channel

2.2 20 LEVEL OVENS

Motorised vent valve

Cavity seal

Double glazed door

(unlocked from the inside)

Control panel

Door handle

Sheet duct

USB port

Access door

Data plate

(visible with the

door open)

Door channel

Oven legs

height adjustable

Page 7 3HE390996EU – 01/17

HOBART GmbH

Registered office:

Robert Bosch Str. 17,

77656 Offenburg - Germany

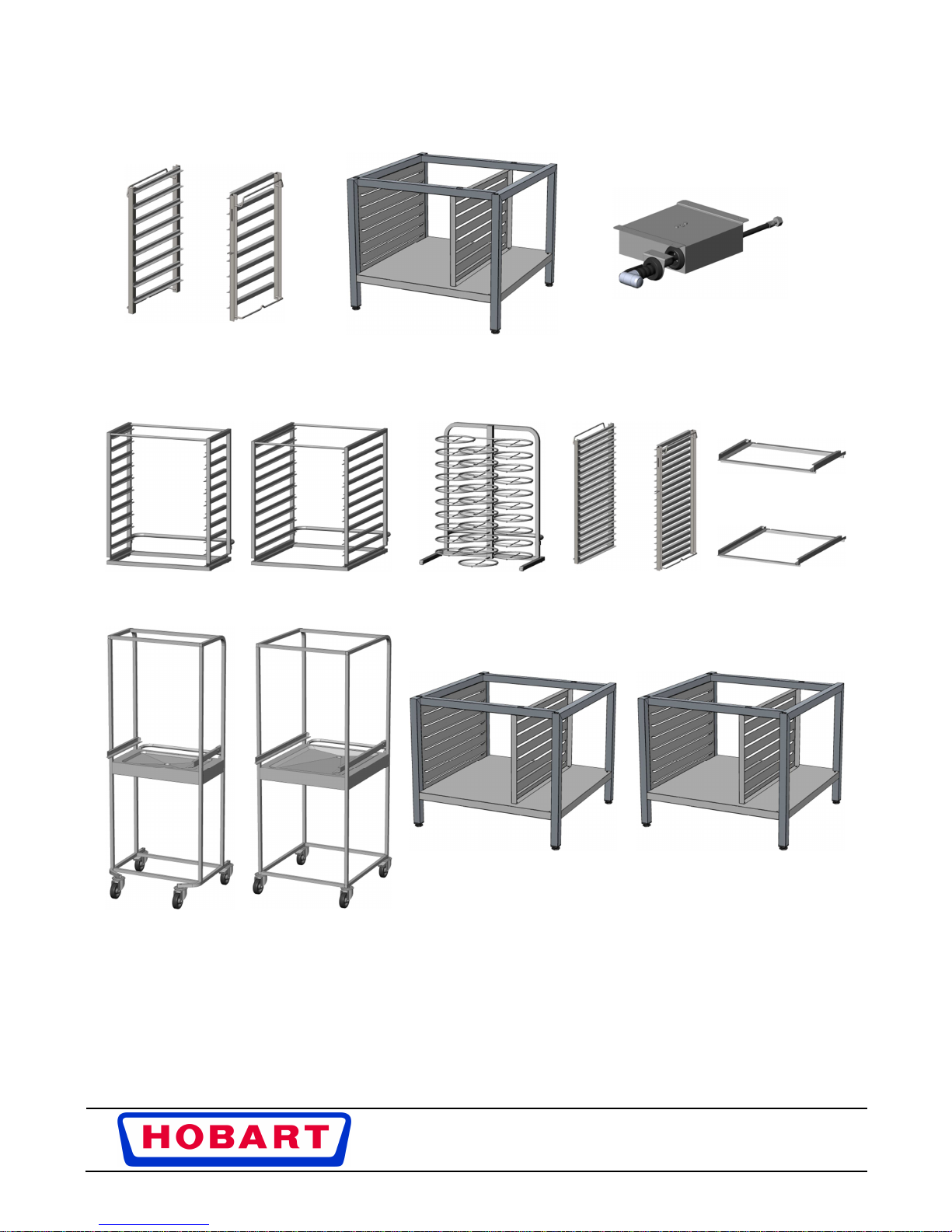

2.3 ACCESSORIES

2.3.1 6 LEVEL OVENS

Runners 8 level GN1/1 stand Rolling Spray Kit

GN1/1 Stand Door Kit

2.3.2 10 LEVEL OVENS

GN1/1 Banqueting

runner Device

GN1/1 Runners Trolley

spaced 65

GN2/1 Runners Trolley

spaced 65

GN1/1 Banqueting Trolley

30 plates spaced 66

GN1/1 runners kit

20 level

GN2/1 Banqueting

runner Device

GN1/1 Banqueting

Trolley Table

GN2/1 Banqueting

Trolley Table

GN1/1 stand GN2/1 stand

GN1/1 Stand Door Kit GN2/1 Stand Door Kit

Banqueting isothermic Hoodt

Page 8 3HE390996EU – 01/17

HOBART GmbH

Registered office:

Robert Bosch Str. 17,

77656 Offenburg - Germany

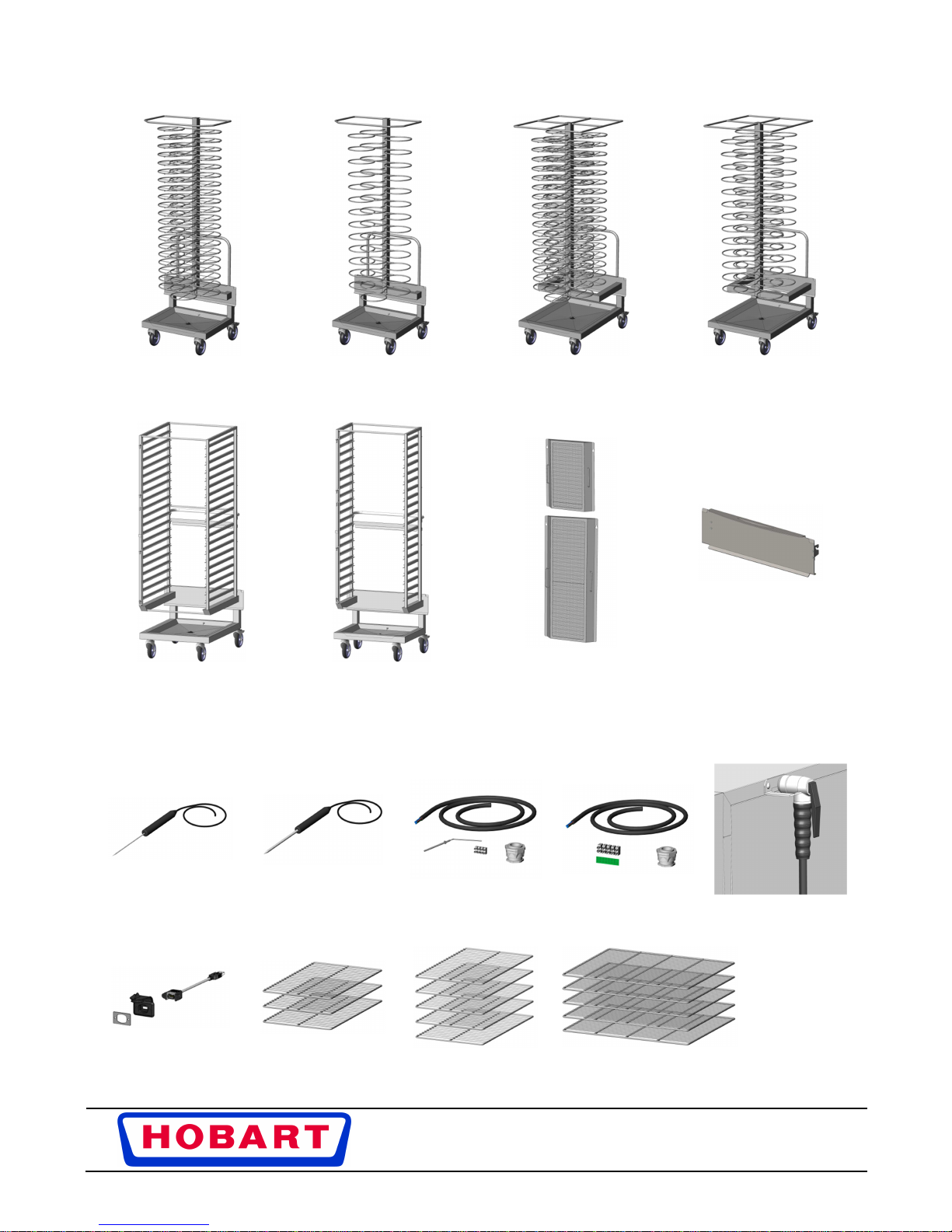

2.3.3 20 LEVEL OVENS

GN1/1 Banqueting Trolley 60

plates spaced 66

GN1/1 Banqueting Trolley 40

plates spaced 100

GN2/1 Banqueting Trolley 102

plates spaced 75

GN2/1 Banqueting Trolley 78

plates spaced 100

Banqueting isothermic Hood Banqueting isothermic Hood Banqueting isothermic Hood Banqueting isothermic Hood

GN1/1 Runners Trolley spaced

65

GN2/1 Runners Trolley spaced

65

Grease Filter Kit Preheat Plate

Banqueting isothermic Hood Banqueting isothermic Hood

2.3.1 ALL MODELS

Core Probe Kit Delicate

products 1 pt dia.1.7x100mm

Core Probe Kit Standard

3 pts dia.4.5x100mm

2x10m PT100 Recorder

Connection. Kit

Energy Management

Connection Kit

Independent Spray Kit

USB Socket Kit GN1/1 Kit 3 grills GN1/1 Kit 5 grills GN2/1 Kit 5 grills

Page 9 3HE390996EU – 01/17

HOBART GmbH

Registered office:

Robert Bosch Str. 17,

77656 Offenburg - Germany

3. PRACTICAL OPERATING ADVISE

3.1 BEFORE FIRST USE

After manufacture units are tested and their accessories and instruction manuals put inside the oven cavity.

A thorough clean should be undertaken before use.

Using domestic washing up liquid and hot water will give good results, rinse thoroughly and dry.

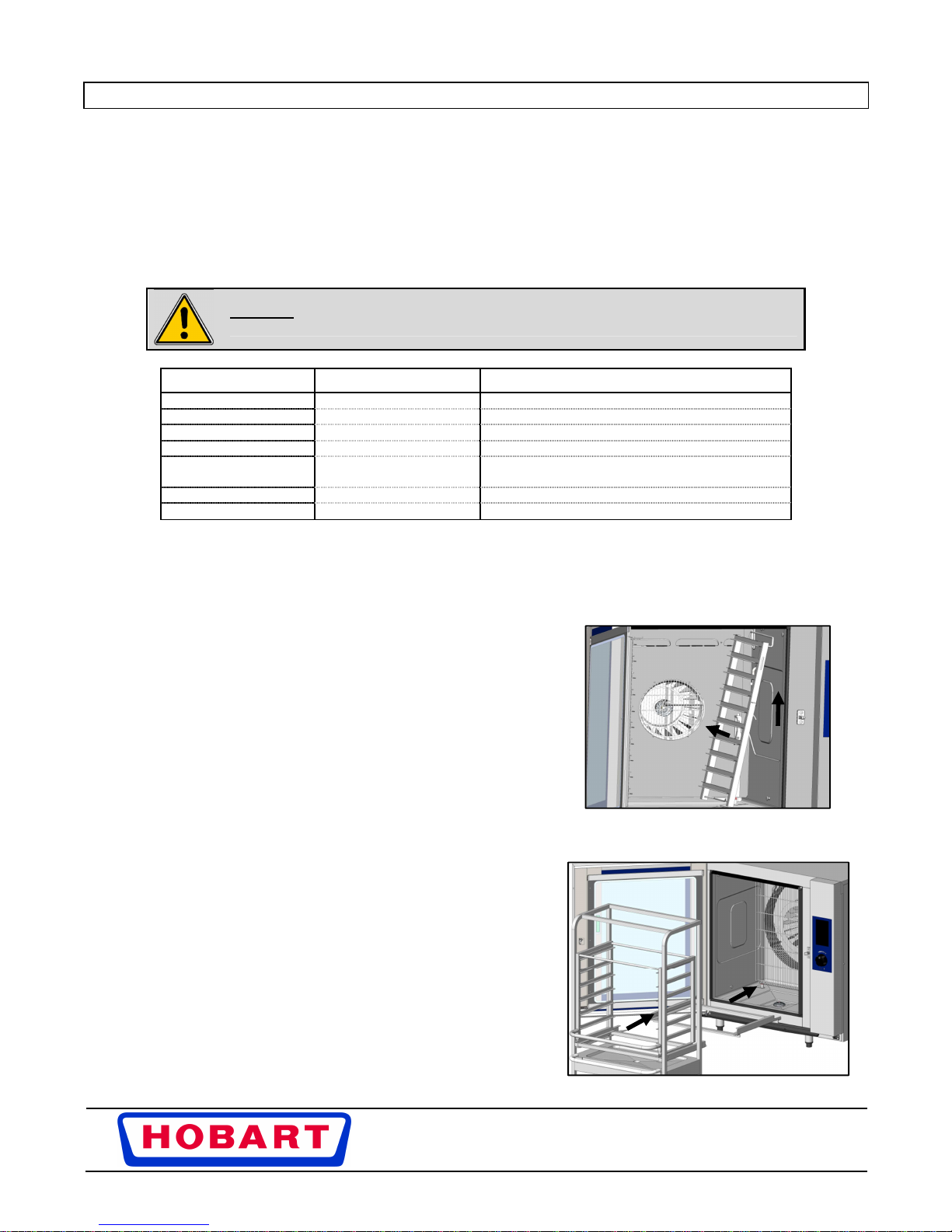

3.2 LOAD LIMITS

Attention: For your safety and that of the equipment always comply with these load

limits.

Model Maximum quantity Support

6 level GN 1/1 24 Kg Runners

10 level GN 1/1 40 Kg Runners and Banqueting or runners trolley

10 level GN 2/1 80 Kg Runners and Banqueting or runners trolley

6+6 level GN 1/1 24 Kg (per cavity) Runners

6+10 level GN 1/1 24 Kg (upper oven

40 Kg (lower oven)

Runners

Runners and Banqueting or runners trolley

20 level GN 1/1 80 Kg Banqueting or Runners trolley

20 level GN 2/1 160 Kg Banqueting or Runners trolley

3.3 USING THE SUPPORTS (Runners, modules and trolleys)

3.3.1 SUSPENDED RUNNERS

On 6 and 10 level ovens

To remove the suspended runners from each side of the oven

cavity:

- Lift gently by the middle.

- Then lift off the front and back pegs

- Swing the runners towards the middle of the oven and

remove them.

Attention: if a core probe kit is fitted remove this before removing

the right hand runners

To refit reverse the above instructions

3.3.2 RUNNER OR BANQUETING TROLLEYS

On 10 level ovens

Remove the suspended runners as explained in the paragraph

« Suspended runners ».

- Locate the rolling frame in the base of the oven

Attention: the oven must be at the exact same height as

the trolley table.

- Move the table transporting the runner module or

banqueting frame so it is in front of the oven.( Always

ensure the module is securely locked in place during

transport)

- Position the trolley in front of the oven and release the catch

- Push the module onto the rolling frame.

To remove it reverse these instructions

Page 10 3HE390996EU – 01/17

HOBART GmbH

Registered office:

Robert Bosch Str. 17,

77656 Offenburg - Germany

On 20 level ovens

- Place the trolley in front of the oven.

- Push it carefully into the cooking cavity

3.4 POSITIONING AND STORAGE OF THE CORE PROBE

♦ Do not put the core probe behind the ventilation duct (risk of severe deterioration

against a fan, a heating element or the gas heat exchange).

♦ When using the core probe, NOTE it may be very hot. Use appropriate protection if

there is a chance it may be hot.

No cooking or with a core temperature not programmed:

Ovens with runners:

Store the probe in the holder on the runner

upright if it isn’t being used (see drawing

opposite).

Ovens with trolley (20 level)

Store the probe in the holder provided on the

ventilation duct (see drawing opposite).

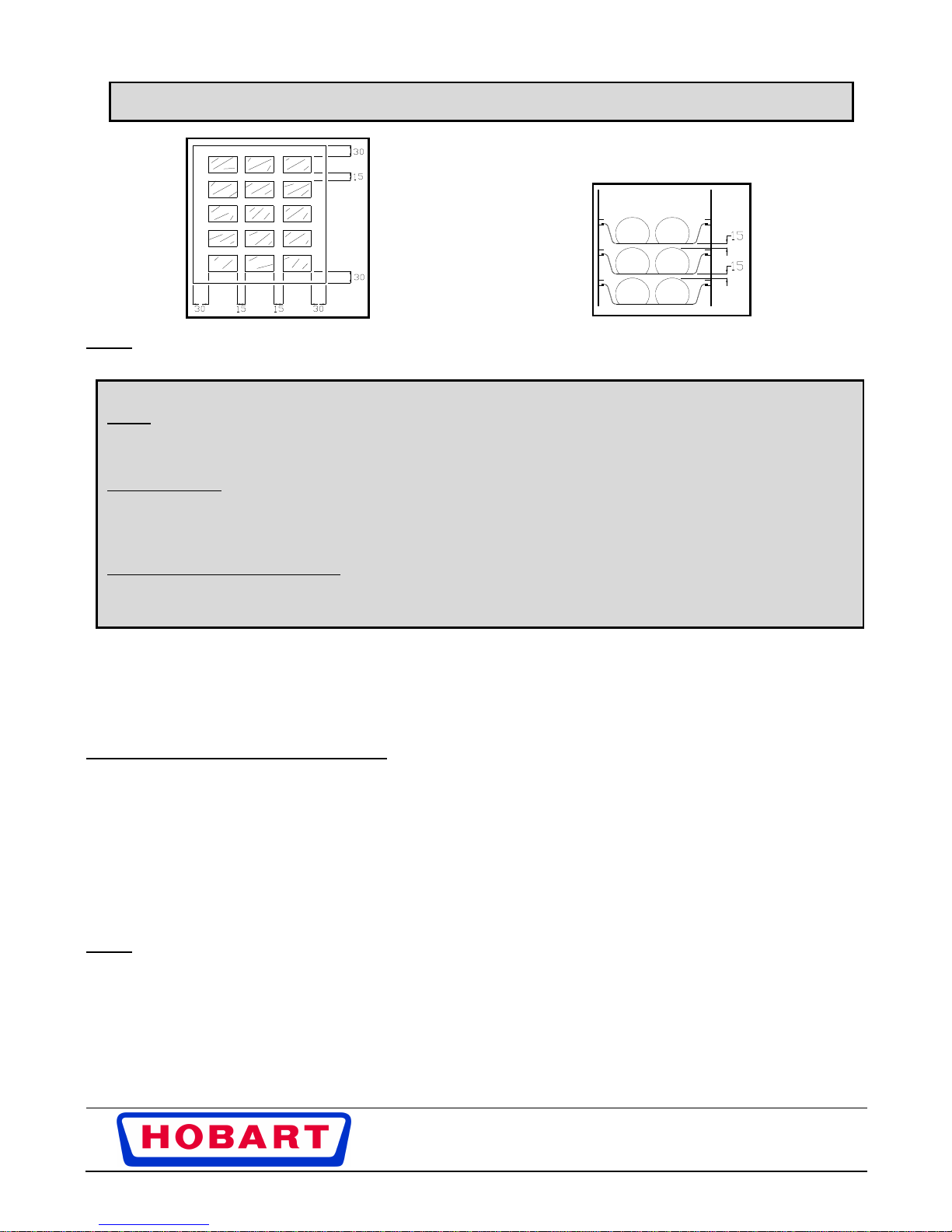

During cooking or with a core temperature programmed:

Oven fitted with a module or trolley

Always inset the probe from the centre rear

to avoid it being pulled out when the trolley is

removed

3.5 USE LIMITS

Internal oven capacity:

MODEL 6 GN1/1 10 GN1/1 10 GN2/1 6+6 GN 1/1 6+10 GN 1/1 20 GN1/1 20 GN2/1

GN 1/1 trays (325 x 530) 6 10 20 6 + 6 6 + 10 20 40

GN 2/1 trays (650 x 530) - - 10 - - - 20

Number of levels 6 10 10 6 + 6 6 + 10 20 20

Spacing between levels (mm) 83 67 67 83 83 / 67 67 67

6 / 10

level

ovens

20 level

ovens

Page 11 3HE390996EU – 01/17

HOBART GmbH

Registered office:

Robert Bosch Str. 17,

77656 Offenburg - Germany

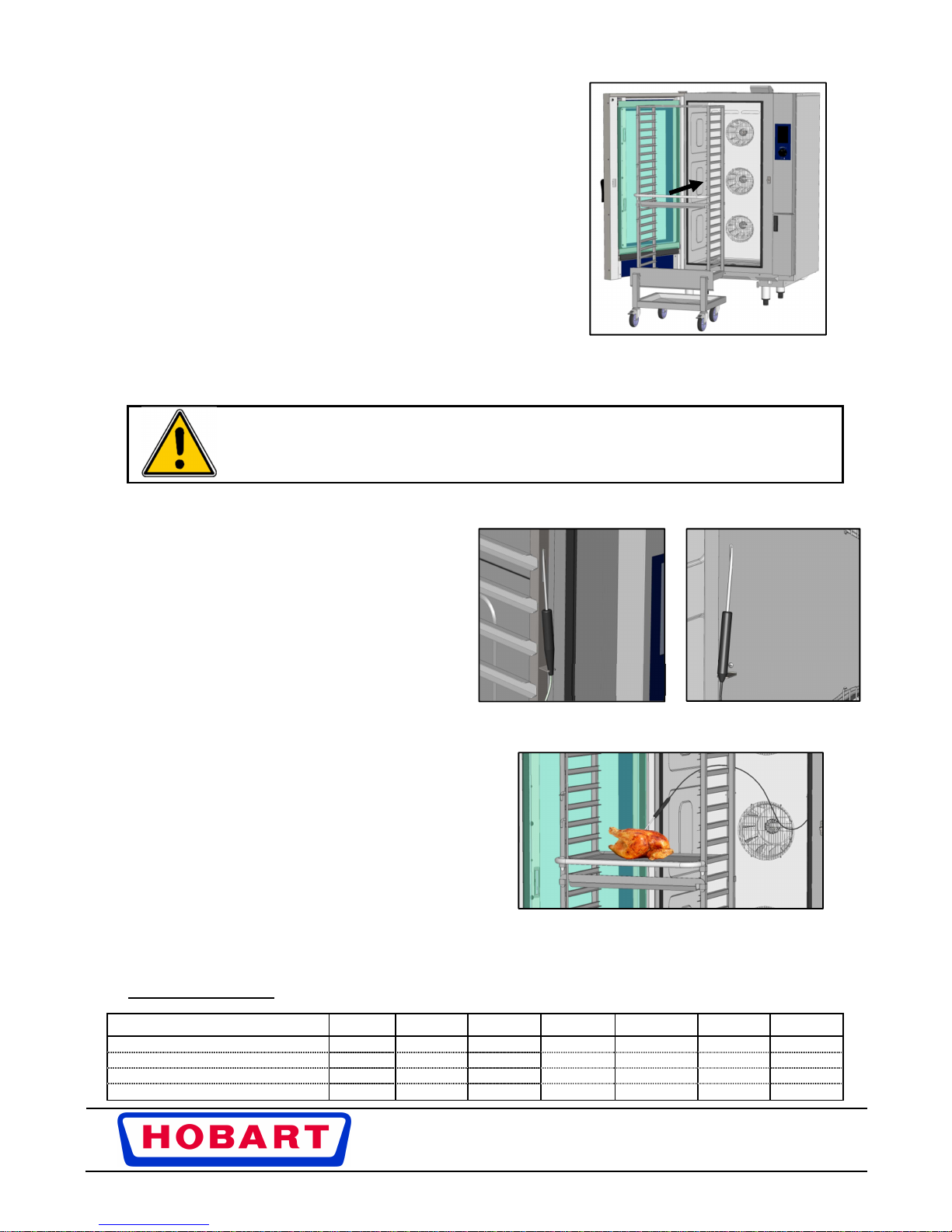

IMPORTANT: The number of levels used for the product to be cooked, as well as the number of portions to

be placed on a given level should comply with the following rules.

15mm between cooked products

and the plate above

min 15mm between

cooked products

min 30mm between

cooked products and

the tray edges

NOTE: Depending on how these rules are observed, the number of levels used can be reduced (example: 1 level out of

2) depending on the size of the products treated.

UNEVEN COOKING OF PRODUCT ON TRAYS ARISES FROM THREE FACTORS:

LOAD:

Even cooking requires the correct circulation of air between products. These, when cooked, must be

sufficiently spaced to allow this.

Too big a load may lead to excessive moisture, generating cooking differences.

TEMPERATURE:

- Preheating: The shorter and more delicate the cooking (less than 15 min), the closer the preheating

temperature should be to the cooking temperature.

- Cooking temperature: It is always better to have a lower temperature than a higher one. In case of

problems, lower temperature in 10°C steps.

DISCHARGE OF EXCESS STEAM:

Whilst cooking products loose a proportion of their moisture as steam. If this amounts to more than the oven

can discharge this will result in uneven browning and inconsistent results.

reduce the load to obtain good results (after selecting Convection mode with Vent open)

3.6 PREHEATING (20 level oven)

Irrespective of the mode, these ovens are intended to be preheated "AWITH THE TROLLEY IN PLACE or

with the optional "Preheating plate fitted".

If a trolley or the optional plate is not available:

- Dry mode:

Adjust the required preheating temperature, but stop the oven or put the trolley in place, once

the REQUIRED TEMPERATURE is reached.

- Combi mode:

DO NOT USE. Always preheat in DRY mode to the required temperature (see above). Move

to Combi mode for cooking with the trolley in place (Instantaneous steam production)

- Steam mode /

Injection oven

:

DO NOT USE: Always preheat in DRY mode to 105°C. Switch to Steam for

cooking with the trolley in place (Instantaneous steam production)

- Steam mode:

Preheat the boiler only FOR THE FIRST USE OF THE DAY then stop heating or put the

trolley in place when the oven reaches a TEMPERATURE OF 80°C (Steam coming out of

the base of the oven) (Equajet boiler model).

NOTE: The NON-OBSERVANCE of these RECOMMENDATIONS will create problems for which the Manufacturer

cannot be held responsible.

3.7 USE OF OVENWARE

* PASTRIES / VIENNOISERIE: Use backing trays for pastry

* ROASTS: Use gastronorm containers for meat preparations in sauces or for braising….

For roasting, cook the products directly on the grills (chicken, roast beef, sausages….). In this case

place a gastronorm container (20mm deep) on the bottom level to catch the cooking juices.

Loading...

Loading...