Page 1

Century

Century

Century

Century Star

Star

Star

Star Milling

Milling

Milling

Milling CNC

CNC

CNC

CNC System

System

System

System

Programming

Programming

Programming

Programming Guide

Guide

Guide

Guide

V

V

V

V 3.3

December

December

December

December ,

Wuhan

Wuhan

Wuhan

Wuhan Huazhong

© 2007 Wuhan Huazhong Numerical Control Co., Ltd

Huazhong

Huazhong

Huazhong Numerical

Numerical

Numerical

Numerical Control

3.3

3.3

3.3

,

2007

,

2007

, 2007

2007

Control

Control

Control Co.,

Co.,

Co.,

Co., Ltd

Ltd

Ltd

Ltd

Page 2

Preface

Preface

Preface

Preface

Preface

Organization

Organization

Organization

Organization of

1. General

2. Preparatory Function

3. Interpolation Function

4. Feed Function

5. Coordinate System

6. Spindle Speed Function

7. Tool Function

8. Miscellaneous Function

9. Functions to Simplify Programming

10. Comprehensive Programming Example

11. Custom Macro

Applicability

Applicability

Applicability

Applicability

This Programming Guide is applicable to the following CNC system:

HNC-18iM/19iM v4.0

of

documentation

of

documentation

of documentation

documentation

HNC-18xp/M

HNC-19xp/M

HNC-21MD/22MD v05.62.07.10

Internet

Internet

Internet

Internet Address

http://www.huazhongcnc.com/

Address

Address

Address

i

Page 3

Table of Contents

Table

Table

Table

Table of

Preface ............................................................................................................................................. i

1 General ................................................................................................................................... 1

2 Preparatory Function (G code) ............................................................................................. 20

3 Interpolation Functions ......................................................................................................... 24

4 Feed Function ....................................................................................................................... 43

5 Coordinate System ................................................................................................................ 51

of

Contents

of

Contents

of Contents

Contents

1.1 CNC Programming ..................................................................................................... 2

1.2 Interpolation ................................................................................................................ 4

1.2.1 Linear Interpolation ........................................................................................ 4

1.2.2 Circular Interpolation ...................................................................................... 4

1.2.3 Helical Interpolation ....................................................................................... 5

1.3 Feed Function ............................................................................................................. 6

1.4 Coordinate System ...................................................................................................... 7

1.4.1 Reference Point ............................................................................................... 7

1.4.2 Machine Coordinate System ........................................................................... 8

1.4.3 Workpiece Coordinate System ........................................................................ 9

1.4.4 Setting Two Coordinate Systems at the Same Position ................................ 10

1.4.5 Absolute Commands ..................................................................................... 11

1.4.6 Incremental Commands ................................................................................ 12

1.4.7 Polar Coordinates .......................................................................................... 13

1.5 Spindle Speed Function ............................................................................................ 14

1.6 Tool Function ............................................................................................................ 15

1.6.1 Tool Selection ............................................................................................... 15

1.6.2 Tool Offset .................................................................................................... 15

1.7 Miscellaneous Function ............................................................................................ 17

1.8 Program Configuration ............................................................................................. 18

1.8.1 Structure of an NC Program ......................................................................... 18

1.8.2 Main Program and Subprogram .................................................................... 19

2.1 G code List ................................................................................................................ 21

3.1 Positioning (G00) ..................................................................................................... 25

3.2 Single Direction Positioning (G60) .......................................................................... 26

3.3 Linear Interpolation (G01) ........................................................................................ 27

3.4 Circulation Interpolation (G02, G03) ....................................................................... 29

3.5 Helical Interpolation (G02, G03) .............................................................................. 35

3.6 Virtual Axis (G07) and Sine Interpolation ................................................................ 38

3.7 Tapping (G34) ........................................................................................................... 40

4.1 Rapid Traverse (G00) ............................................................................................... 44

4.2 Cutting Feed (G94, G95) .......................................................................................... 45

4.3 Dwell (G04) .............................................................................................................. 46

4.4 Exact Stop (G09, G61) ............................................................................................. 47

4.5 Cutting Mode (G64) ................................................................................................. 49

5.1 Reference Position Return (G28) .............................................................................. 52

5.2 Auto Return from Reference Position (G29) ............................................................ 53

5.3 Setting a Workpiece Coordinate System (G92) ........................................................ 55

5.4 Selecting a Machine Cooridinate System (G53) ....................................................... 56

5.5 Selecting a Workpiece Coordinate System (G54~G59) ............................................ 57

5.6 Plane Selection (G17, G18, G19) ............................................................................. 59

5.7 Absolute and Incremental Programming (G90, G91) ............................................... 60

5.8 Dimension Selection (G20, G21, G22) ..................................................................... 62

ii

Page 4

Table of Contents

5.9 Polar Coordinates ..................................................................................................... 63

6 Spindle Speed Function ........................................................................................................ 66

7 Tool Function ........................................................................................................................ 67

7.1 Tool Selection and Tool Offset (T code) ................................................................... 68

7.2 Tool Radius Compensation (G40, G41, G42) ........................................................... 69

7.3 Tool Length Compensation (G43, G44, G49) .......................................................... 74

7.4 RTCP (Rotation Tool Center Point Programming) ................................................... 76

8 Miscellaneous Function ........................................................................................................ 77

8.1 M code List ............................................................................................................... 78

8.2 CNC M-Function ...................................................................................................... 79

8.2.1 Program Stop (M00) ..................................................................................... 79

8.2.2 Optional Stop (M01) ..................................................................................... 79

8.2.3 End of Program (M02) .................................................................................. 79

8.2.4 End of Program with return to the beginning of program (M30) ................. 79

8.2.5 Subprogram Control (M98, M99) ................................................................. 80

8.3 PLC M Function ....................................................................................................... 81

8.3.1 Spindle Control (M03, M04, M05) ............................................................... 81

8.3.2 Tool Selection (M06) .................................................................................... 81

8.3.3 Coolant Control (M07, M08, M09) .............................................................. 81

9 Functions to Simplify Programming .................................................................................... 82

9.1 Mirror Image (G24, G25) ......................................................................................... 83

9.2 Scaling (G50, G51) ................................................................................................... 85

9.3 Coordinate System Rotation (G68, G69) .................................................................. 87

9.4 Canned Cycles .......................................................................................................... 89

9.4.1 Return to the Initial Point/R point Level (G98, G99) ................................... 90

9.4.2 High-speed Peck Drilling Cycle (G73) ......................................................... 91

9.4.3 Left-hand Tapping Cycle (G74) .................................................................... 93

9.4.4 Fine Boring Cycle (G76) .............................................................................. 95

9.4.5 Drilling Cycle, Spot Drilling (G81) .............................................................. 97

9.4.6 Drilling Cycle, Counter Boring Cycle (G82) ................................................ 99

9.4.7 Peck Drilling Cycle (G83) .......................................................................... 101

9.4.8 Tapping Cycle (G84) .................................................................................. 103

9.4.9 Boring Cycle (G85) .................................................................................... 105

9.4.10 Boring Cycle (G86) .................................................................................... 107

9.4.11 Back Boring Cycle (G87) ........................................................................... 109

9.4.12 Manual Boring Cycle (G88) ........................................................................ 111

9.4.13 Boring Cycle (G89) ..................................................................................... 113

9.4.14 Canned Cycle Cancel (G80) ....................................................................... 114

9.5 Summary ................................................................................................................. 115

10 Custom Macro ............................................................................................................ 121

10.1 V ariables ................................................................................................................. 122

10.1.1 Type of Variables ........................................................................................ 122

10.1.2 System Variables ........................................................................................ 123

10.2 Constant .................................................................................................................. 130

10.3 Operators and Expression ....................................................................................... 131

10.4 Assignment ............................................................................................................. 132

10.5 Selection statement

IF,

ELSE,ENDIF ..................................................................... 133

10.6 Repetition Statement WHILE, ENDW ................................................................... 134

10.7 Macro Call .............................................................................................................. 135

10.8 Example .................................................................................................................. 137

iii

Page 5

1. General

1

General

1

General

1

1 General

General

This chapter is to introduce the basic concepts in Computerized Numerical Control (CNC)

system: HNC-21M /22 M, HNC-18iM/19iM, HNC-18xp/M, HNC-19xp/M.

1

Page 6

1.1

CNC

1.1

CNC

1.1

1.1 CNC

CNC Programming

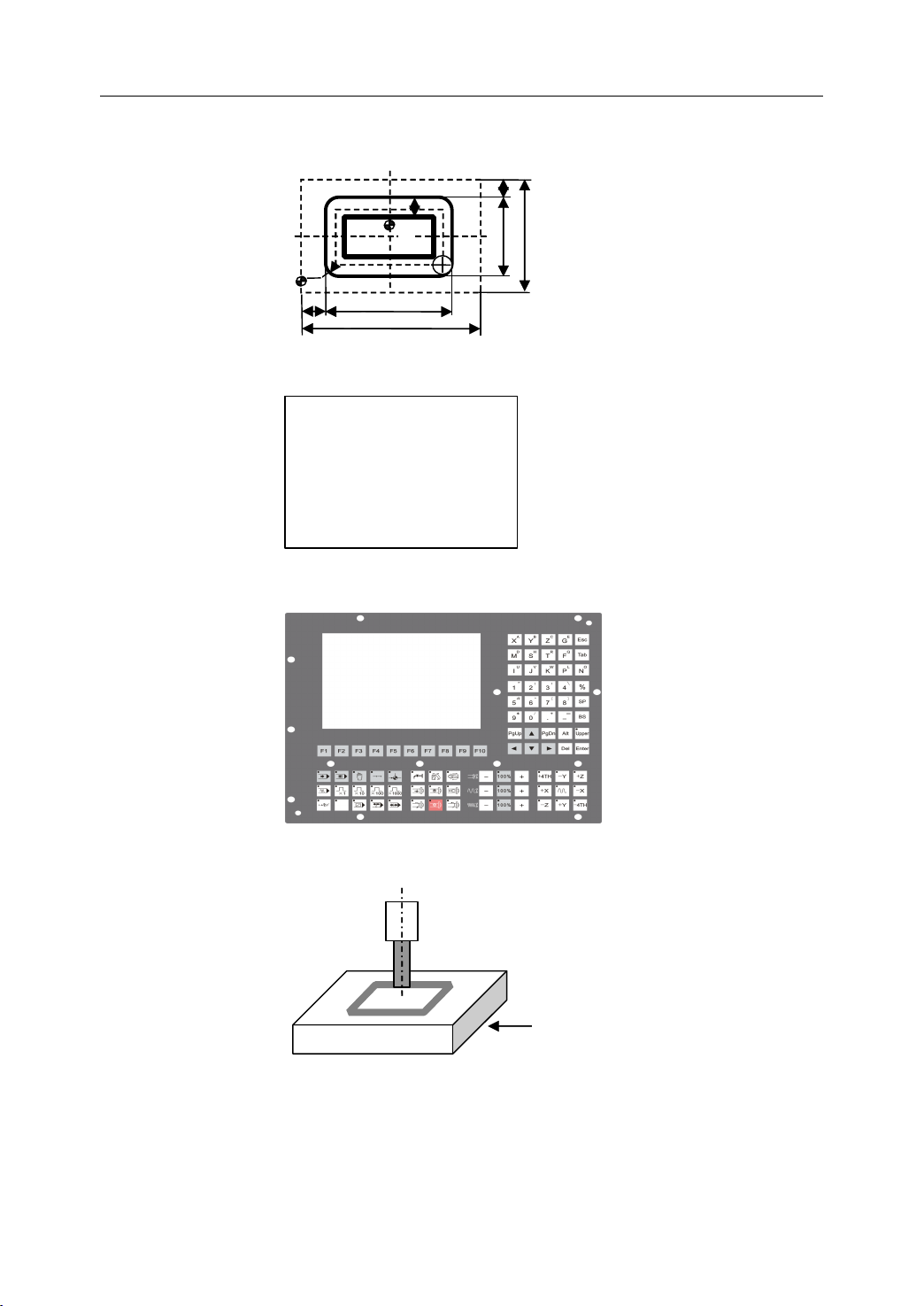

To

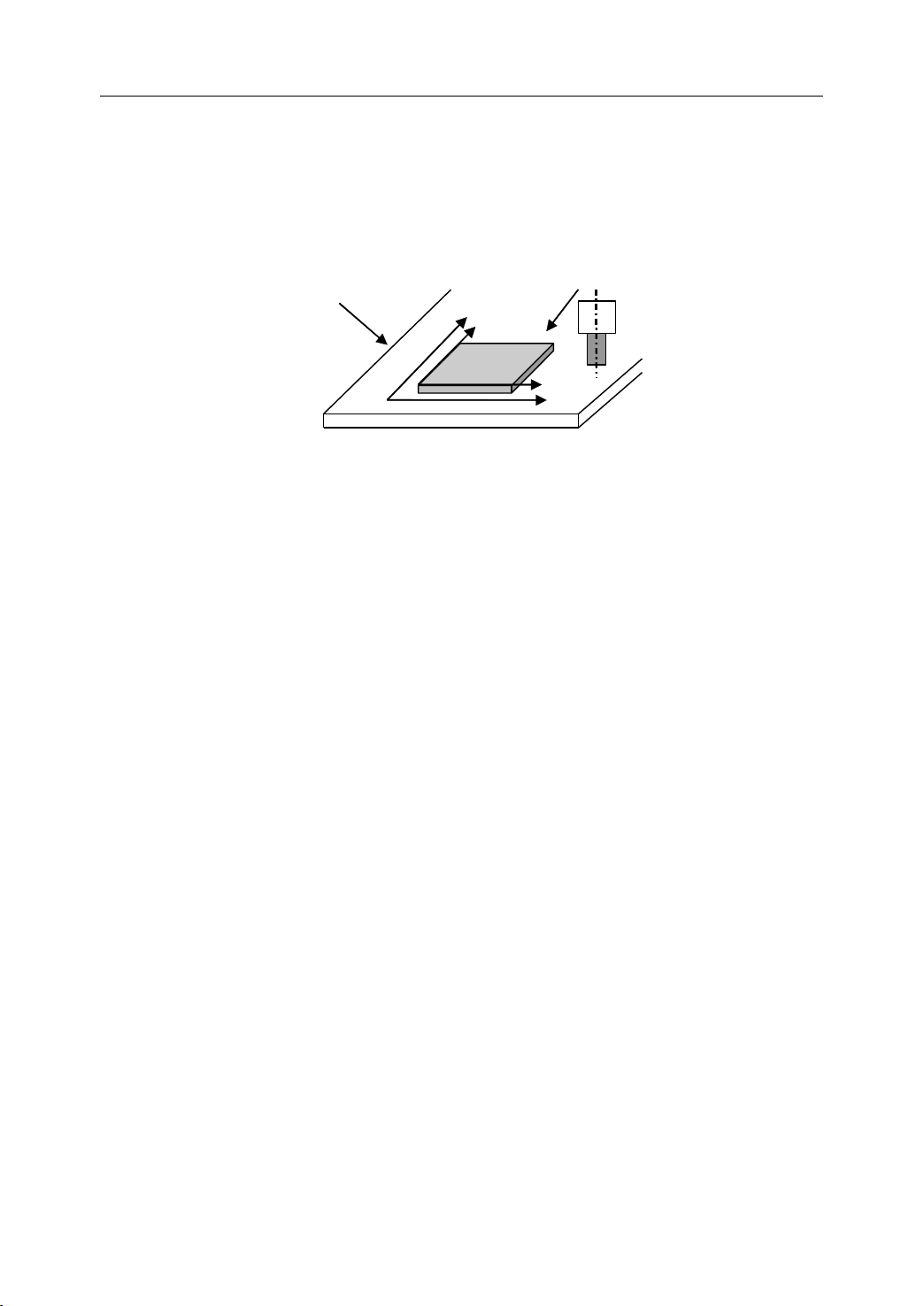

operate CNC machine tool, the first step is to understand the part drawing and produce a

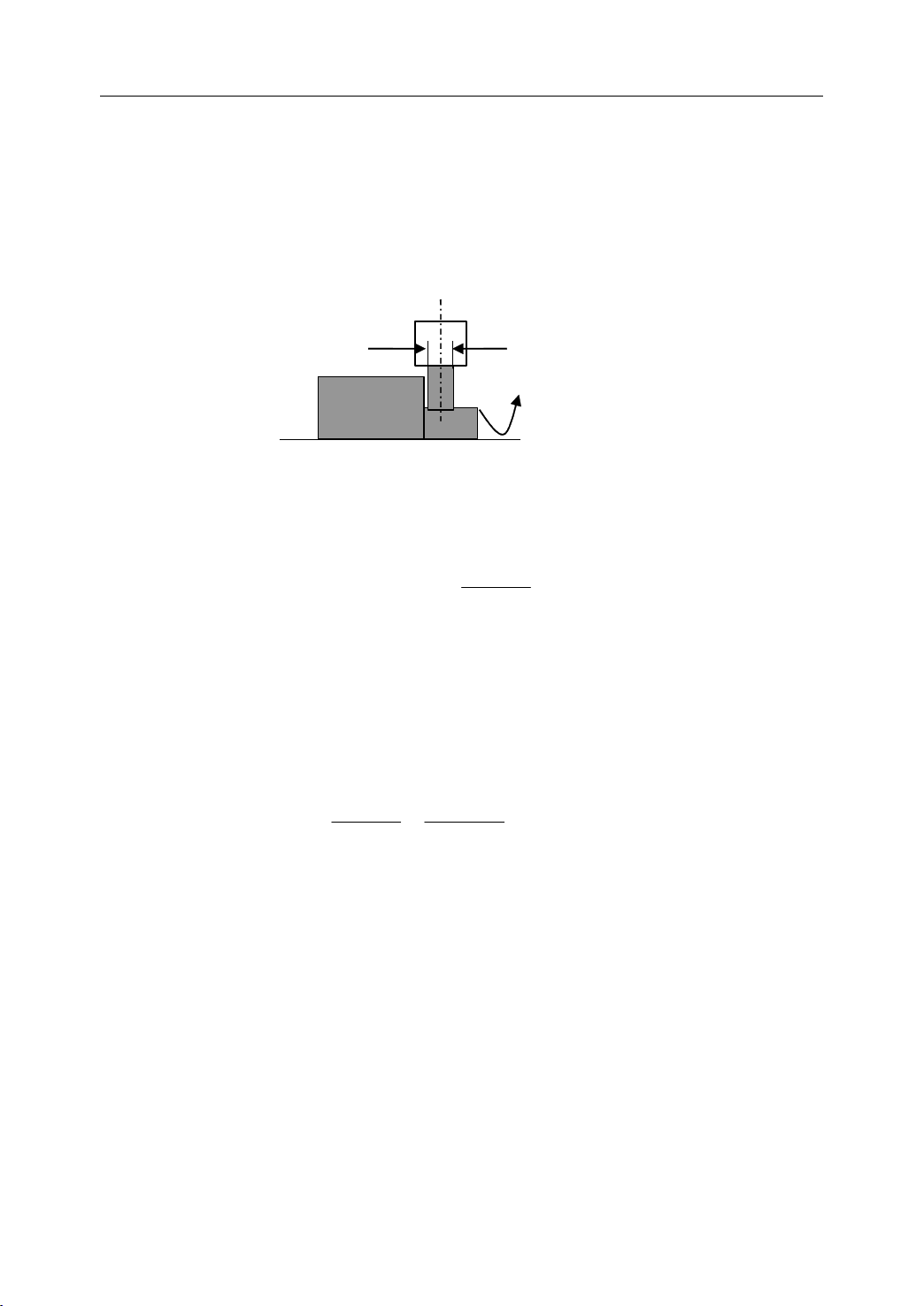

program manual script. The procedure for machining a part is as follows (Figure 1.1):

1) Read drawing

2) Produce the program manual script

3) Input the program manual script by using the machine control panel

4) Manufacture a part

Programming

Programming

Programming

1. General

2

Page 7

1. Reading drawing

1. General

R

B

1

10

0

2. Programming

%3308 (the origin is on A)

N1 G92 X0 Y0 Z50

N2 M03 S500

N3 G00 X-31

N4 Z5

N5 G01 Z-3 F40

… .

3. Inputting program

8

A

7

0

Y-26

1

6

8

4. Manufacturing

Workpiece

Figure 1 . 1 The workflow of operation of CNC machine tool

3

Page 8

1. General

1.2

Interpolation

1.2

Interpolation

1.2

1.2 Interpolation

Interpolation

Interpolation refers to an operation in which the machine tool moves along the workpiece

parts. There are five methods of interpolation: linear, circular, helical, parabolic, and cubic.

Most CNC machine can provide linear interpolation and circular interpolation. The other

three methods of interpolation (helical, parabolic, and cubic interpolation) are usually used

to manufacture the complex shapes, such as aerospace parts.

1.2.1

1.2.1

1.2.1

1.2.1 L

Linear interpolation refers to the tool movement along a straight line.

1.2.2

1.2.2

1.2.2

1.2.2 Circular

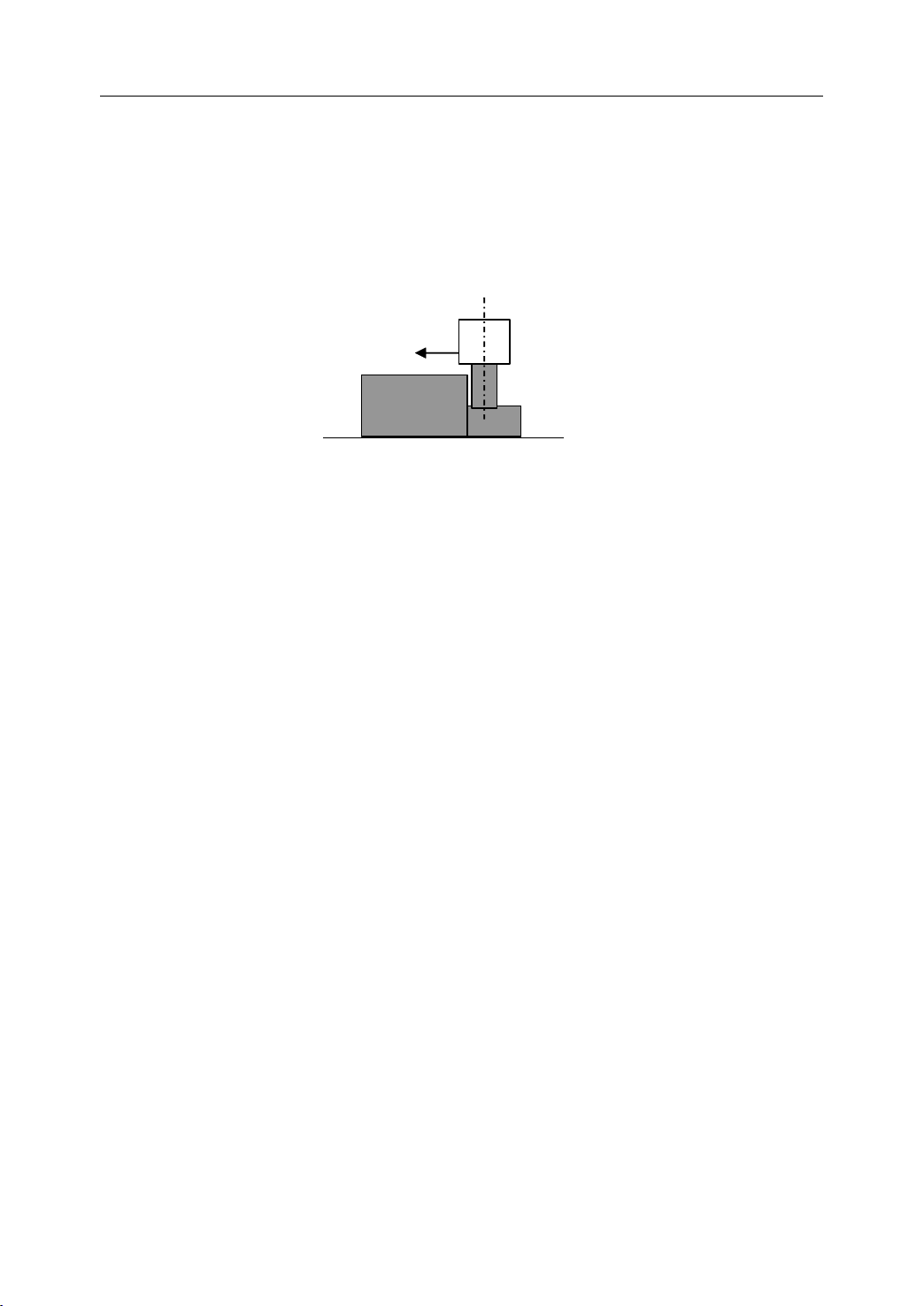

Figure 1.3 shows a tool movement along an arc.

L

inear

L

inear

L inear

inear Interpolation

Circular

Circular

Circular Interpolation

Interpolation

Interpolation

Interpolation

Interpolation

Interpolation

Interpolation

Figure 1 . 2 Linear Interpolation

tool

workpiece

tool

workpiece

Figure 1 . 3 Circular Interpolation

Note:

Note:

Note:

Note:

In this manual, it is assumed that tools are moved against workpieces.

4

Page 9

1. General

1.2.3

1.2.3

1.2.3

1.2.3 Helical

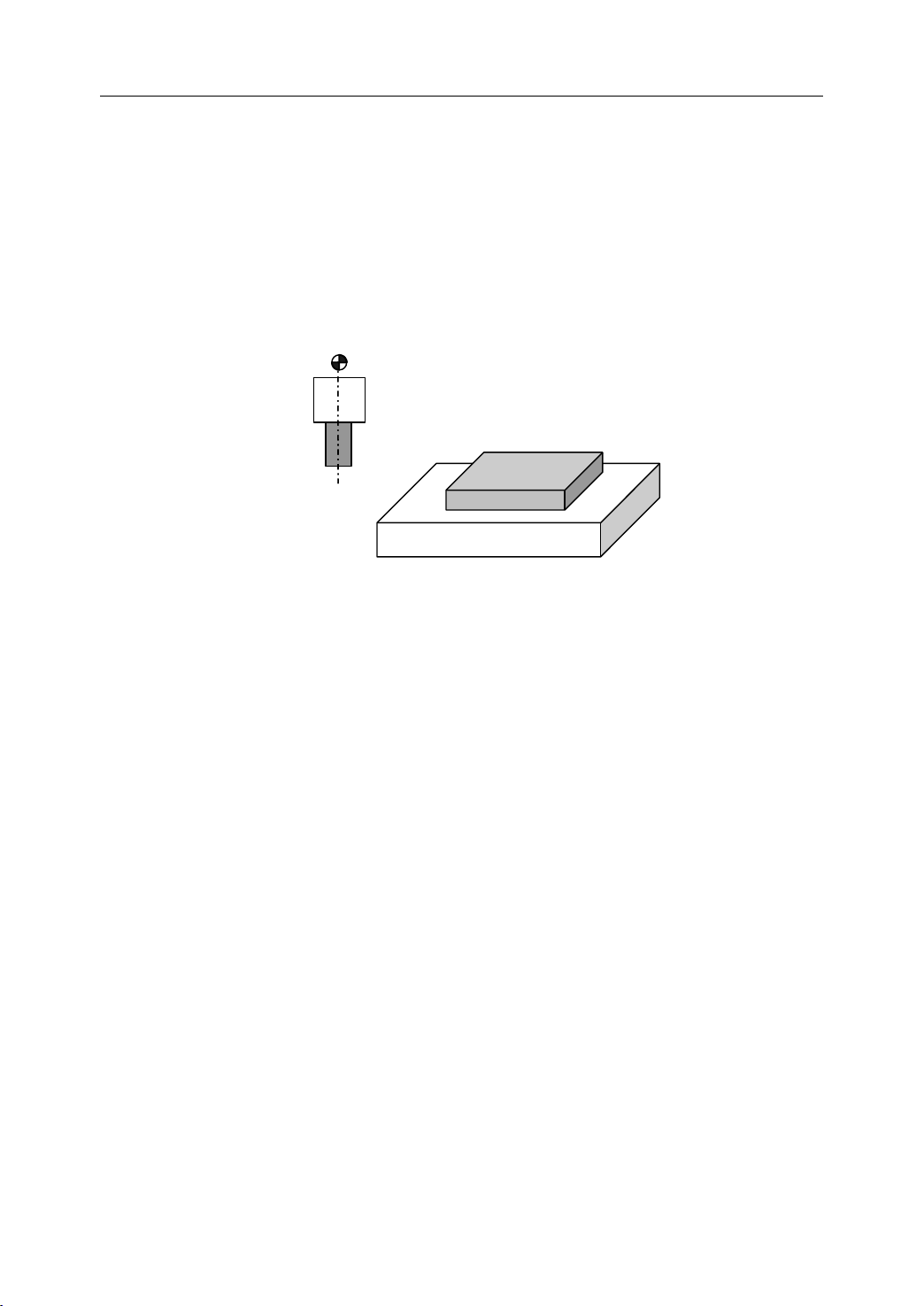

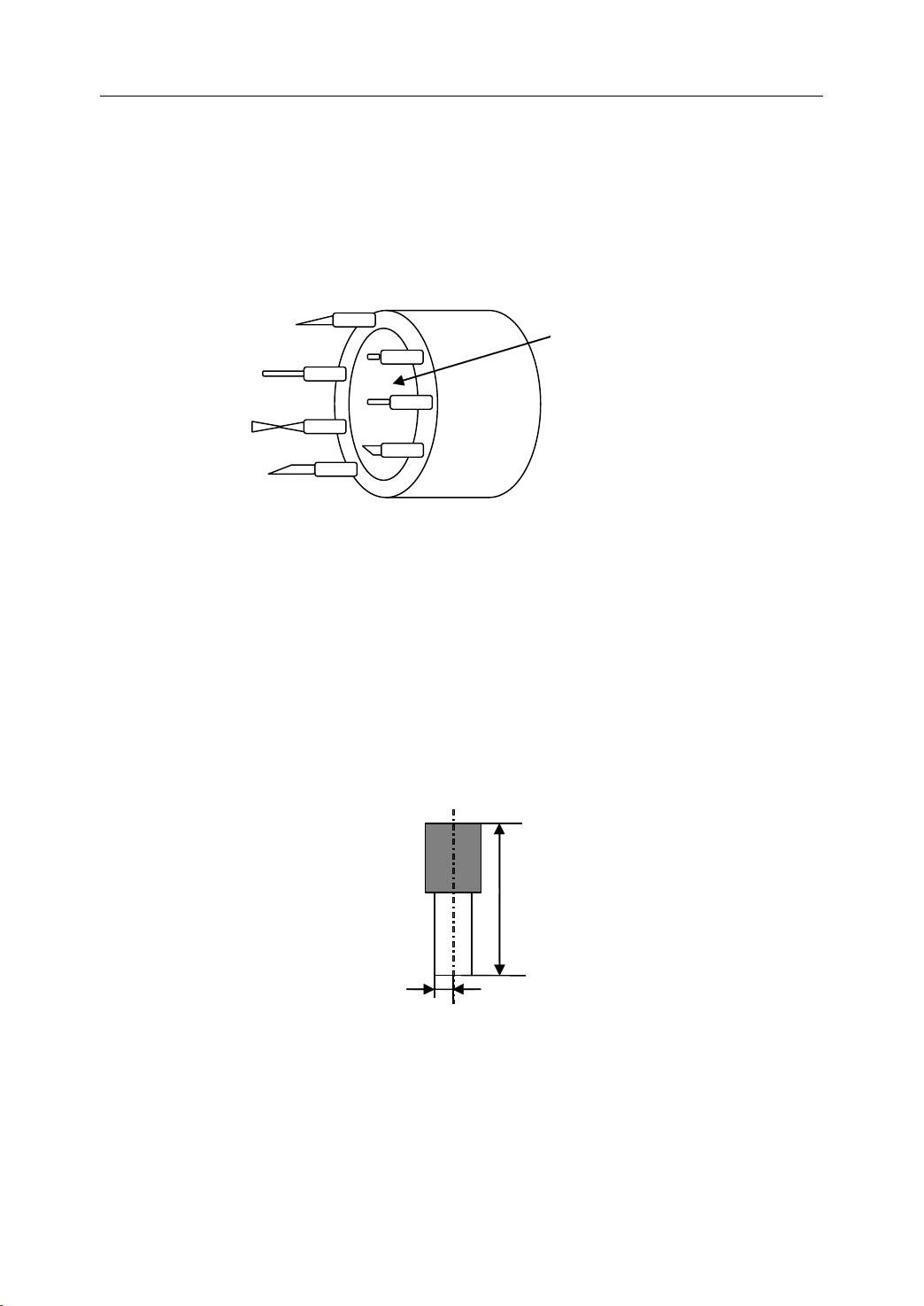

Helical interpolation can be used to manufacture threads on a workpiece.

Helical

Helical

Helical Interpolation

Interpolation

Interpolation

Interpolation

Figure 1 . 4 Helical Interpolation

5

Page 10

1. General

1.3

Feed

1.3

Feed

1.3

1.3 Feed

Feed Function

- Feed refers to an operation in which the tool moves at a specified speed to cut a

workpiece.

- Feedrate refers to a specified speed, and numeric is used to specified the fe e drate .

- Feed function refers to an operation to control the fe e drate .

Function

Function

Function

m m/min

F

workp iece

T

able

Figure 1 . 5 Feed Function

For example:

F150.0 //feed the tool at 150mm/min, while the workpiece makes one turn

Tool

6

Page 11

1.4

Coordinate

1.4

Coordinate

1.4

1.4 Coordinate

Coordinate System

System

System

System

1. General

1.4.1

1.4.1

1.4.1

1.4.1 Reference

Reference point is a fixed position on CNC machine tool, which is determined by cams and

measuring system. Generally, it is used when the tool is required to exchange or the

coordinate system is required to set.

There are two ways to move to the reference point:

- Manual reference position return: The tool is moved to the reference point by operating

Reference

Reference

Reference Point

Point

Point

Point

Reference Position

Tool

workp iece

Table

Figure 1 . 6 Reference Point

the button on the machine control panel. It is only used when the machine is turned on.

- Automatic reference position return: It is used after the manual reference position return

has been used. In this manual, this would be introduced.

7

Page 12

1. General

+

X

+

X

+

Y

'

+Z+

Y

+

Z

+Y+

C

+

Z

'

+A +

B

+

C

+ X +Y +

Z

+

A

+

B

+

X

'

1.4.2

1.4.2

1.4.2

1.4.2 Machine

Machine

Machine

Machine Coordinate

Coordinate

Coordinate

Coordinate System

System

System

System

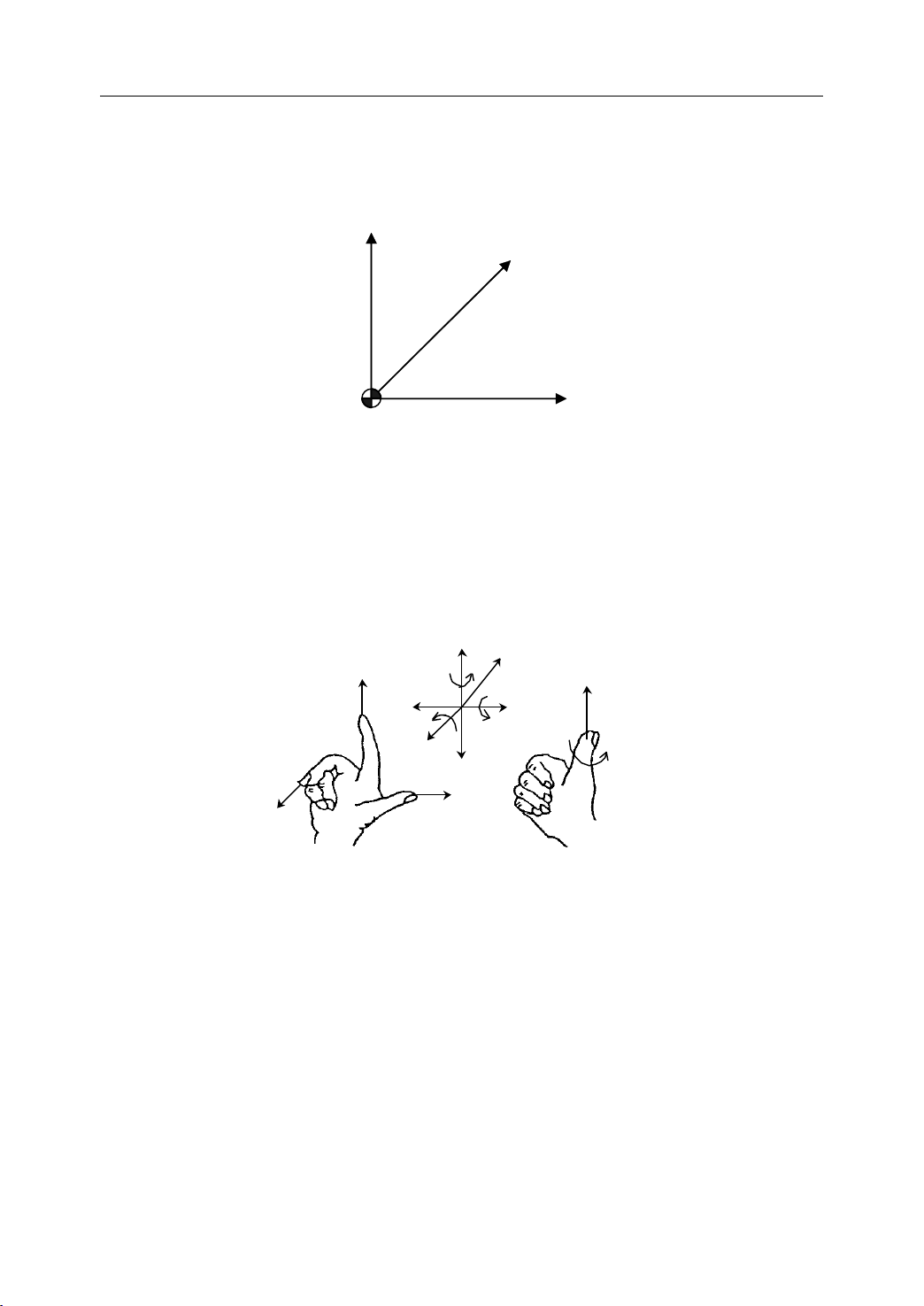

The coordinate system is set on a CNC machine tool. Figure 1.7 is a machine coordinate

system of milling machine, and shows the direction of axes:

Zm

Ym

M

Figure 1 . 7 Machine Coordinate System

In general , three basic linear coordinate axes of motion are X,

Xm

Y,

Z. Moreover, X,

Y,

Z axis

of rotation is named as A, B, C cor respond ently. Due to different types of milling machine,

the axis direction can be decided by following the rule – “ three finger rule ” of the right

hand.

Figure 1 . 8 “ three finger rule ”

- The thumb points the X axis. X axis controls the cross motion of the cutting tool.

“ +X ” means that the tool is away from the spindle centerline

- T he index points the Y axis. Y axis is usually a virtual axis.

- T he middle finger points the Z axis. Z axis controls the motion of the cutting tool.

“ +Z ” means that the tool is away from the spindle.

8

Page 13

1. General

1.4.3

1.4.3

1.4.3

1.4.3 Workpiece

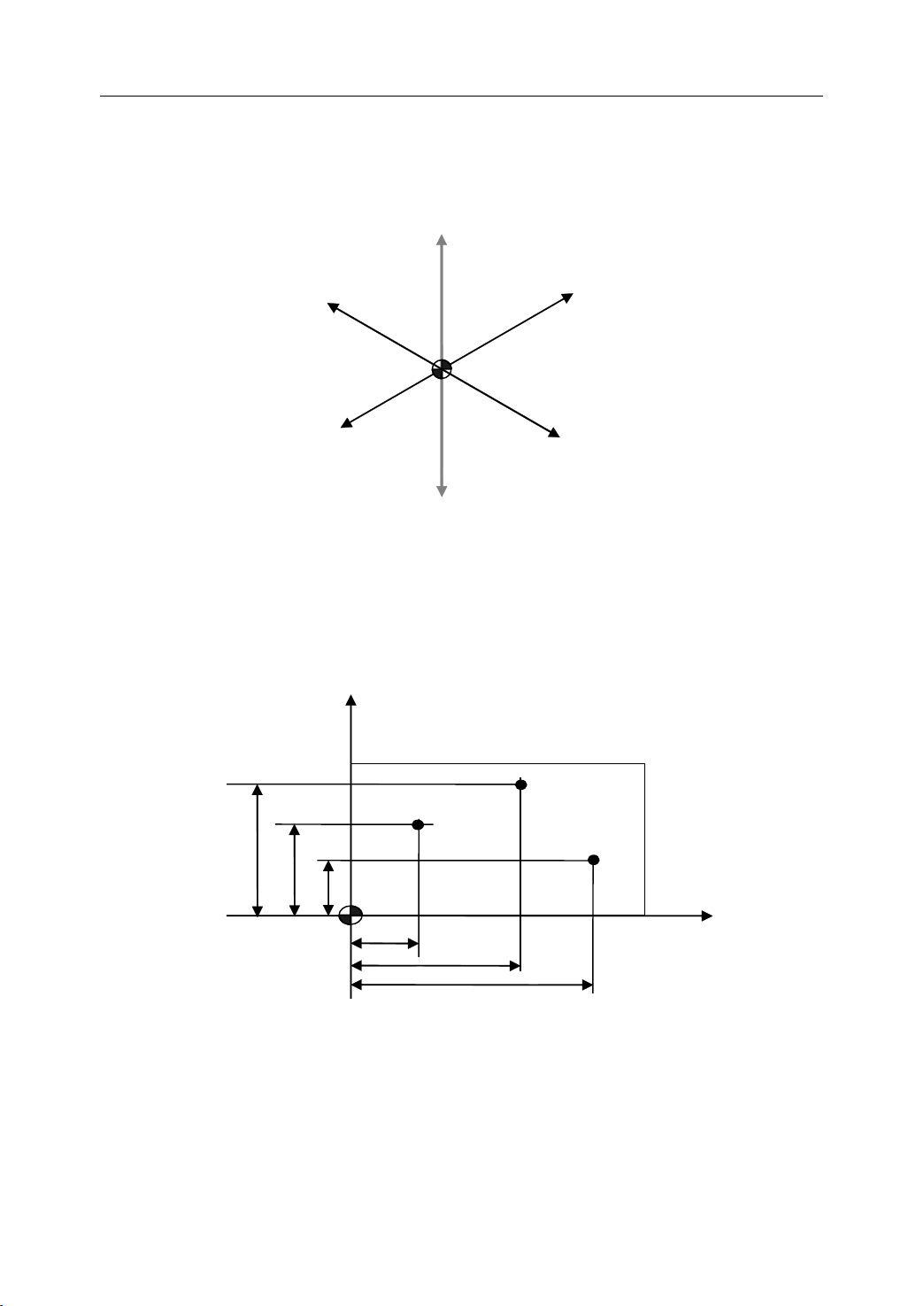

The coordinate system is set on a workpiece. The data in the NC program is from the

workpiece coordinate system.

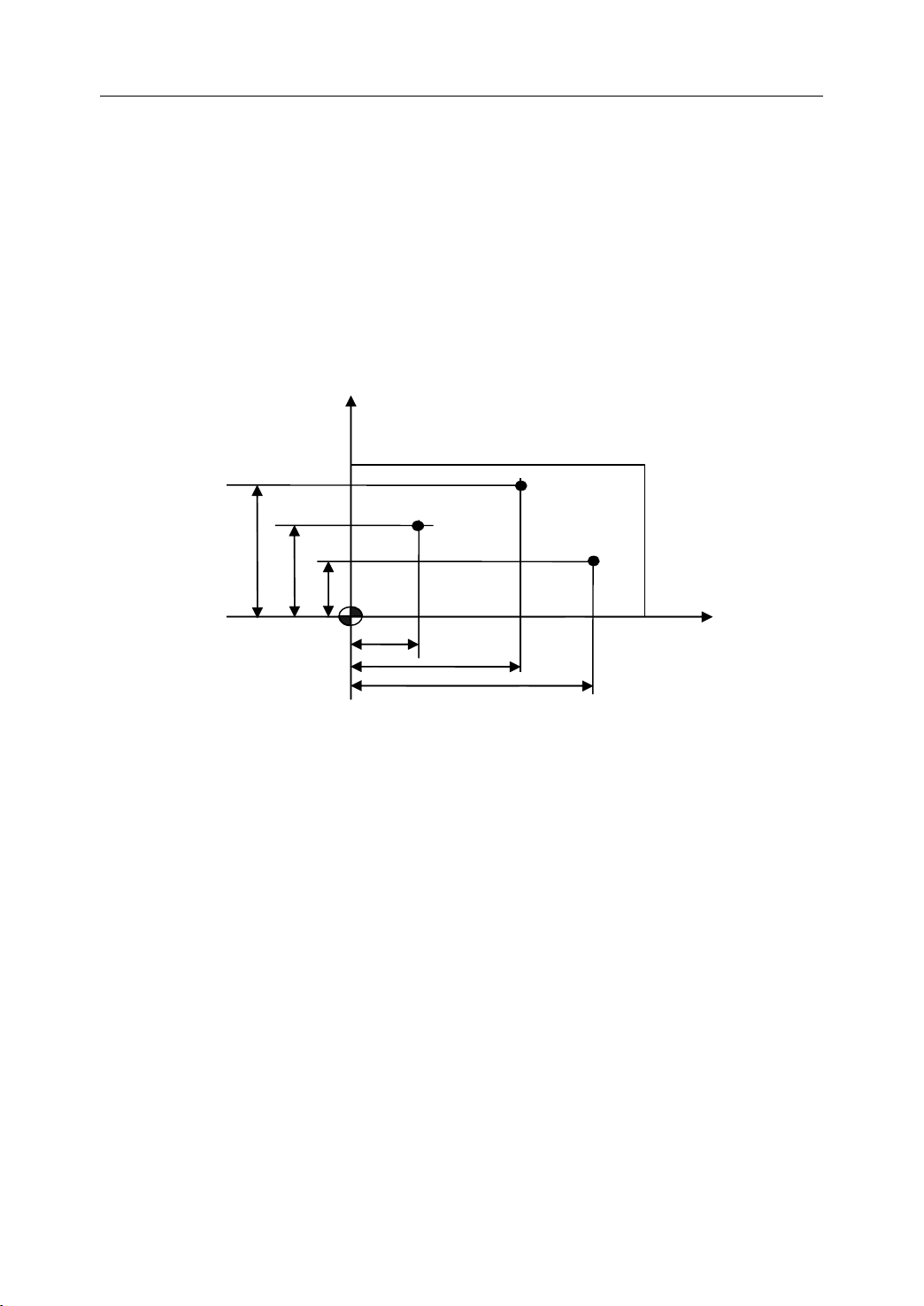

Example: Those three points can be defined on workpiece coordinate system:

Workpiece

Workpiece

Workpiece Coordinate

P1 corresponds to X20 Y35

Coordinate

Coordinate

Coordinate System

Figure 1 . 9 Workpiece Coordinate System

System

System

System

Z+

X-

W

W

W

W

Y-

Z-

Y+

X+

P2 corresponds to X50 Y60

P3 corresponds to X70 Y20

Y

P2

P1

60

35

20

20

50

70

Figure 1 . 10 Example of defining points on workpiece coordinate system

P3

X

9

Page 14

1. General

1.4.4

1.4.4

1.4.4

1.4.4 Setting

When a workpiece is set on the table, the positional relation between machine coordinate

system and workpiece coordinate system are set.

According to the command program based on the workpiece coordinate system, the tool

moves on the coordinate system specified by CNC, and cuts a workpiece.

Setting

Setting

Setting Two

Two

Coordinate

Two

Coordinate

Two Coordinate

Coordinate Systems

Coordinate system

specified by the CNC

established on the table

Figure 1 .11Setting two coordinate systems at the same position

Systems

Systems

Systems at

Y

Y

workpiece

Table

at

the

at

at the

Same

the

Same

the Same

Same Position

Coordinate system on

part drawing established

on the work-piece

X

X

Position

Position

Position

10

Page 15

1. General

1.4.5

1.4.5

1.4.5

1.4.5 Absolute

The absolute dimension describes a point at “ the distance from zero point of the coordinate

system ” .

E xample: These three point in absolute dimensions are the following:

Absolute

Absolute

Absolute Commands

P1 corresponds to X20 Y35

P2 corresponds to X20 Y60

P3 corresponds to X70 Y20

60

Commands

Commands

Commands

35

20

Y

P2

P1

P3

X

20

50

70

Figure 1 . 12 Absolute Dimension

11

Page 16

1. General

1.4.6

1.4.6

1.4.6

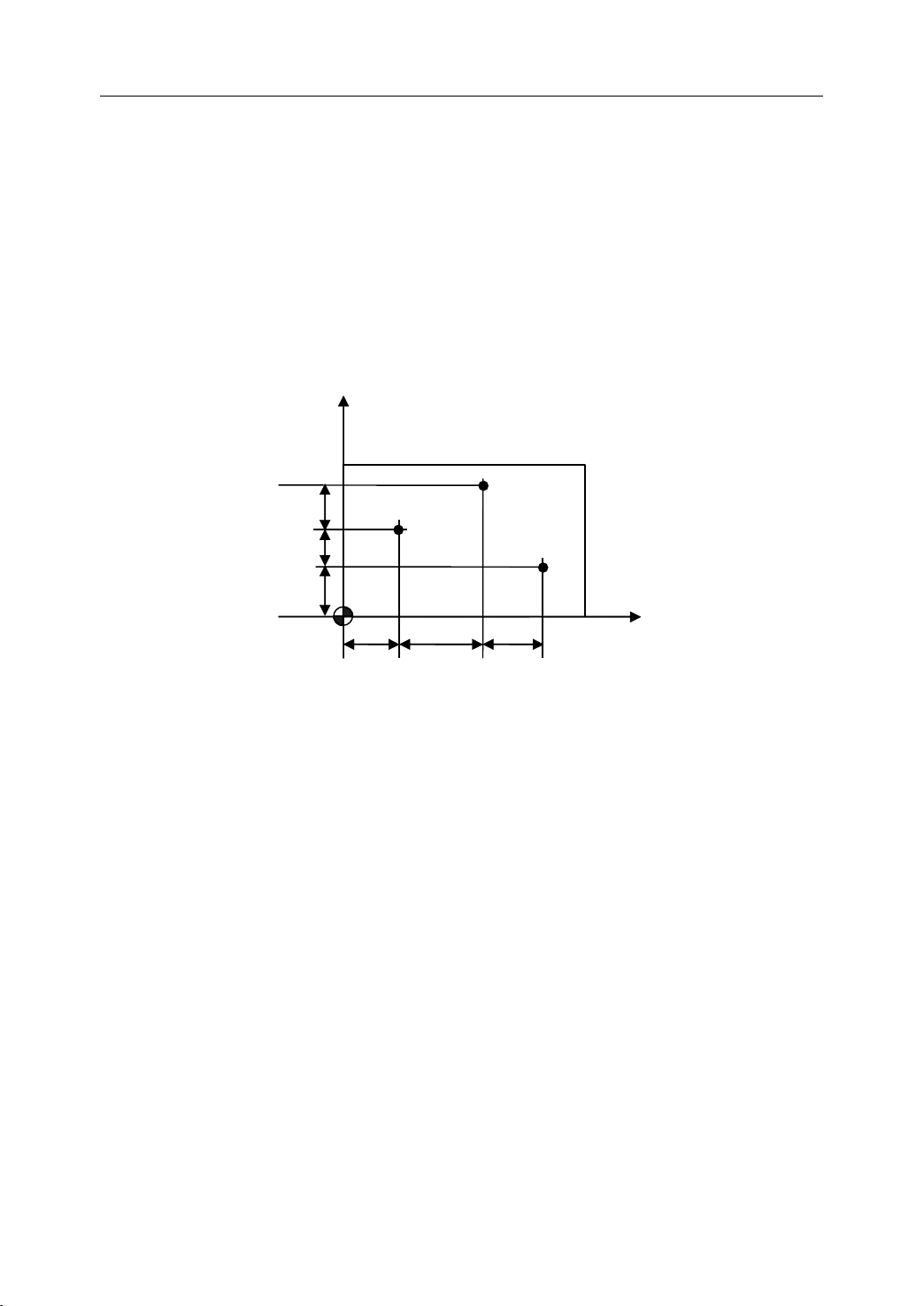

1.4.6 Incremental

The incremental dimension describes a distance from the previous tool position to the next

tool position.

Example: These three point in incremental dimensions are the following:

Incremental

Incremental

Incremental Commands

P1 corresponds to X20 Y35 //with reference to the zero point

P2 corresponds to X30 Y20 //with reference to P1

P3 corresponds to X20

Commands

Commands

Commands

Y-35

Y

20

15

20

P1

//with reference to P2

P2

P3

3020

20

X

Figure 1 . 13 Incremental Dimension

12

Page 17

1. General

1.4.7

1.4.7

1.4.7

1.4.7 Polar

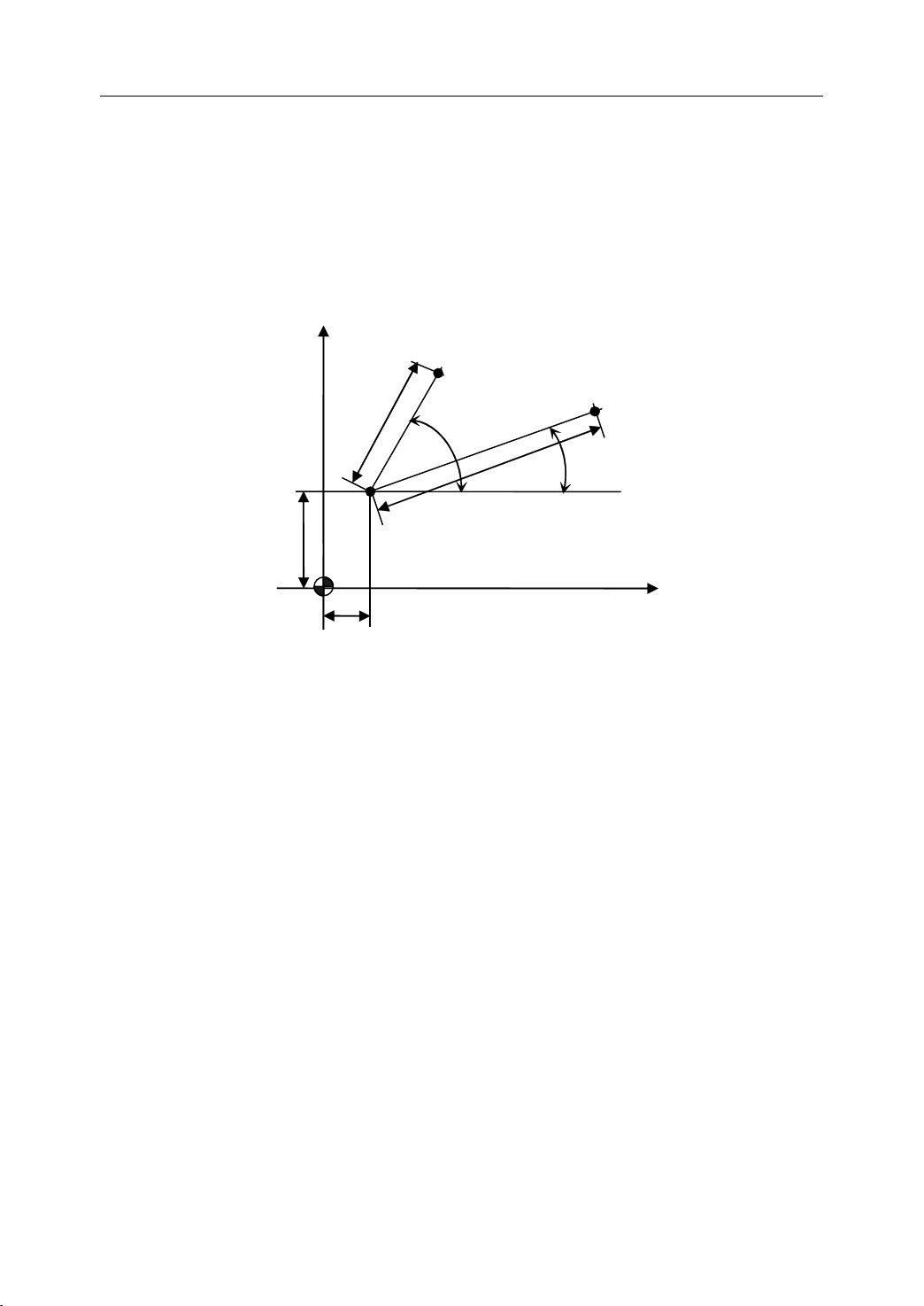

Beside the “ Cartesian coordinate system ” , another way to specify coordinates is “ polar

coordinates ” . The polar coordinate method is useful only if there is radius and angle

measurements on a workpiece.

Example: Two points P1 and P2 with reference to the pole are described as follows.

Polar

Polar

Polar Coordinates

Coordinates

Coordinates

Coordinates

Y

30

Pole

P2

P1

60

75 °

100

15

30 °

X

Figure 1 . 14 Polar Coordinates

P1 corresponds to radius=100 plus angle=30 °

P2 corresponds to radius=60 plus angle=75 °

13

Page 18

1. General

1.5

Spindle

1.5

Spindle

1.5

1.5 Spindle

Spindle Speed

The cutting speed (v) refers to the speed of the tool with respect to the workpiece when the

workpiece is cut. The unit of the cutting speed is m/min. As for the CNC, the cutting speed

can be specified by the spindle speed (N) in min-1.

The formula to get the spindle speed is:

Speed

Speed

Speed Function

Spindle speed N

Figure 1 . 15 Cutting Speed and Spindle Speed

Function

Function

Function

-1

m in

workpiece

T

Tool

Tool diameter

D mm

V: Cutting speed m/min

able

v

N

∗=1000

D

π

N: the spindle speed

v: cutting speed

D: diameter value of the workpiece

Example: When the diameter of workpiece is 100mm, and the cutting speed is 80m/min,

v

then the spindle speed:

N

=

∗

=

D

The constant surface speed refers to the speed even when the workpiece diameter is changed,

and the CNC changes the spindle speed. At this time, the spindle speed is the cutting speed.

8010001000

∗

≈

100

∗

ππ

mr

/250

14

Page 19

1.6

Tool

1.6

Tool

1.6

1.6 Tool

Tool Function

Function

Function

Function

1. General

1.6.1

1.6.1

1.6.1

1.6.1 Tool

It is necessary to select a suitable tool when drilling, tapping, boring or the like is performed.

As it is shown in Figure 1.16, a number is assigned to each tool. Then this number is used in

the program to specify that the corresponding tool is selected.

1.6.2

1.6.2

1.6.2

1.6.2 Tool

When writing a program, the operator just use the workpiece dimensions according to the

dimensions in the part drawing. The tool nose radius center and the tool length are not taken

Tool

Selection

Tool

Selection

Tool Selection

Selection

Tool

Offset

Tool

Offset

Tool Offset

Offset

01

01

01

01

02

02

02

02

Figure 1 . 16

Tool

Tool number

Selection

into account. However, when machining a workpiece, the tool path is affected by the tool

geometry. There are two kinds of tool offset: tool length compensation and tool radius

compensation.

Length

Radius

Figure 1 . 17 Length compensation and Radius compensation

15

Page 20

1. General

Tool Length Compensation

There are two kind of ways to specify the value of tool length compensation.

- Absolute value of tool compensation (the distance between tool tip and machine

reference point)

- Incremental value of tool compensation (the distance between tool tip and the

standard tool)

Tool Radius Compensation

Figure 1. 18 shows the difference between the programmed contour and the corrected tool

path.

Programmed contour

Corrected tool path

Figure 1 . 18 Difference between programmed contour and corrected tool path

16

Page 21

1. General

1.7

Miscellaneous

1.7

Miscellaneous

1.7

1.7 Miscellaneous

Miscellaneous Function

Miscellaneous function refers to the operation to control the spindle, feed, and coolant. In

general, it is specified by an M code.

When a move command and M code are specified in the same block, there are two ways to

execute these commands:

1) Pre-M function

M command is executed before the completion of move command

2) Post-M function

M command is executed after the completion of move command.

The sequence of the execution depends on the specification of the machine tool builder.

Function

Function

Function

17

Page 22

1. General

Program

1.8

Program

1.8

Program

Program Configuration

1.8

1.8

1.8.1

1.8.1

1.8.1

1.8.1 Structure

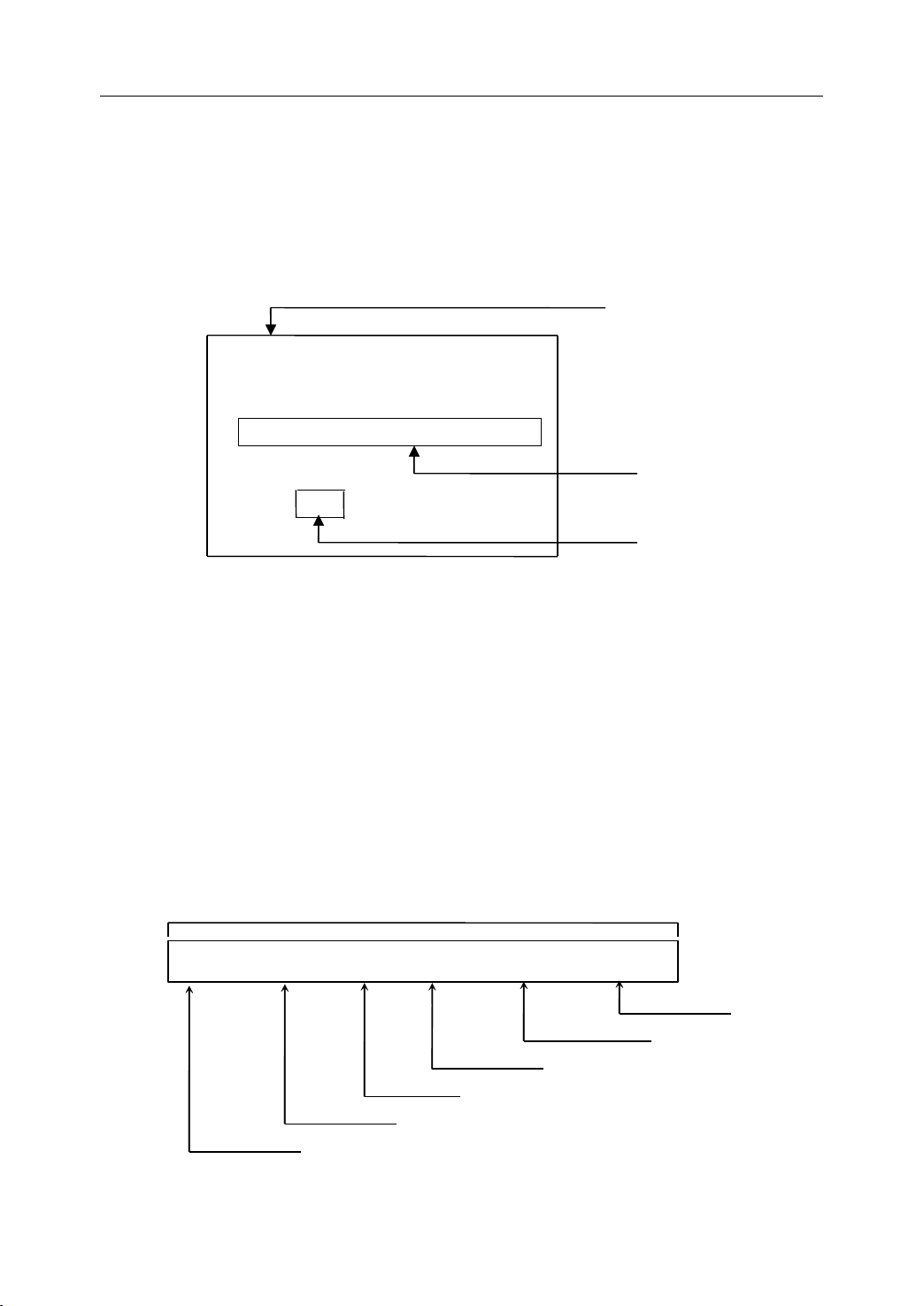

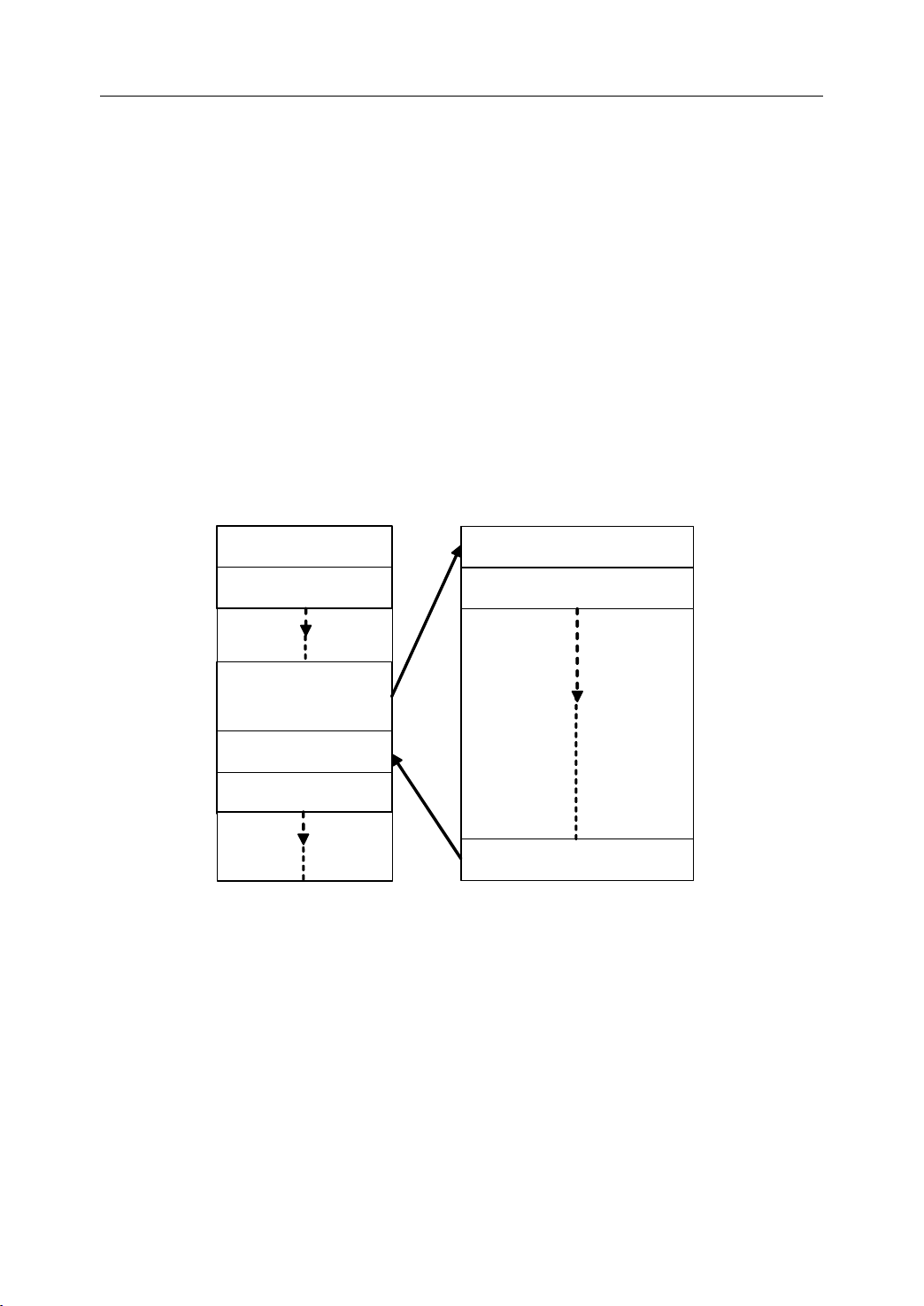

As it is shown in Figure 1.19, an NC program consists of a sequence of NC blocks

block is one of machining steps. Commands

Structure

Structure

Structure of

- Format of program

Configuration

Configuration

Configuration

of

an

NC

of

an

of an

an NC

%1000

N01 G91 G00 X50 Y60

N10 G01 X100 Y500 F150 S300 M03

N...... ;COMMENT

N200 M30

Figure 1 . 19 Structure of an NC Program

program

program

program name

name

name

name

Program

NC

Program

NC Program

Program

Commands

Commands

Commands in each block are the instruction.

Program

Program block

Command character

blocks

blocks

blocks . Each

The program name must be specified in the format OXXXX (X could be letters or

numbers).

program

- Format of program

T he program number should be started with %XXXX or OXXXX (X could be numbers

only).

- Format of blocks

A

block starts with the program block number.

N.. G.. X … Y …

program

program number

blocks

blocks

blocks

Program block number

number

number

number

Program block

F..

Feed Function

Coordinate - Dimension word

Preparatory function

Figure 1 . 20 Structure of Block

M.. S..

Spindle function

Miscellaneous function

18

Page 23

end

Instruction 1

Instruction 2

Instruction n

Instruction n+1

Follow the direction

of the subprogram

Instruction 1

Instruction 2

Return to the main program

Main program

Subprogram

of

- Format of end

The last block should contain M02 or M03 to indicate the end of program.

- Format of Comments

All information after the “ ; ” is regarded as comments.

All information between “ ( ) ” is regarded as comments.

end

end of

Comments

Comments

Comments

program

of

program

of program

program

1. General

1.8.2

1.8.2

1.8.2

1.8.2 Main

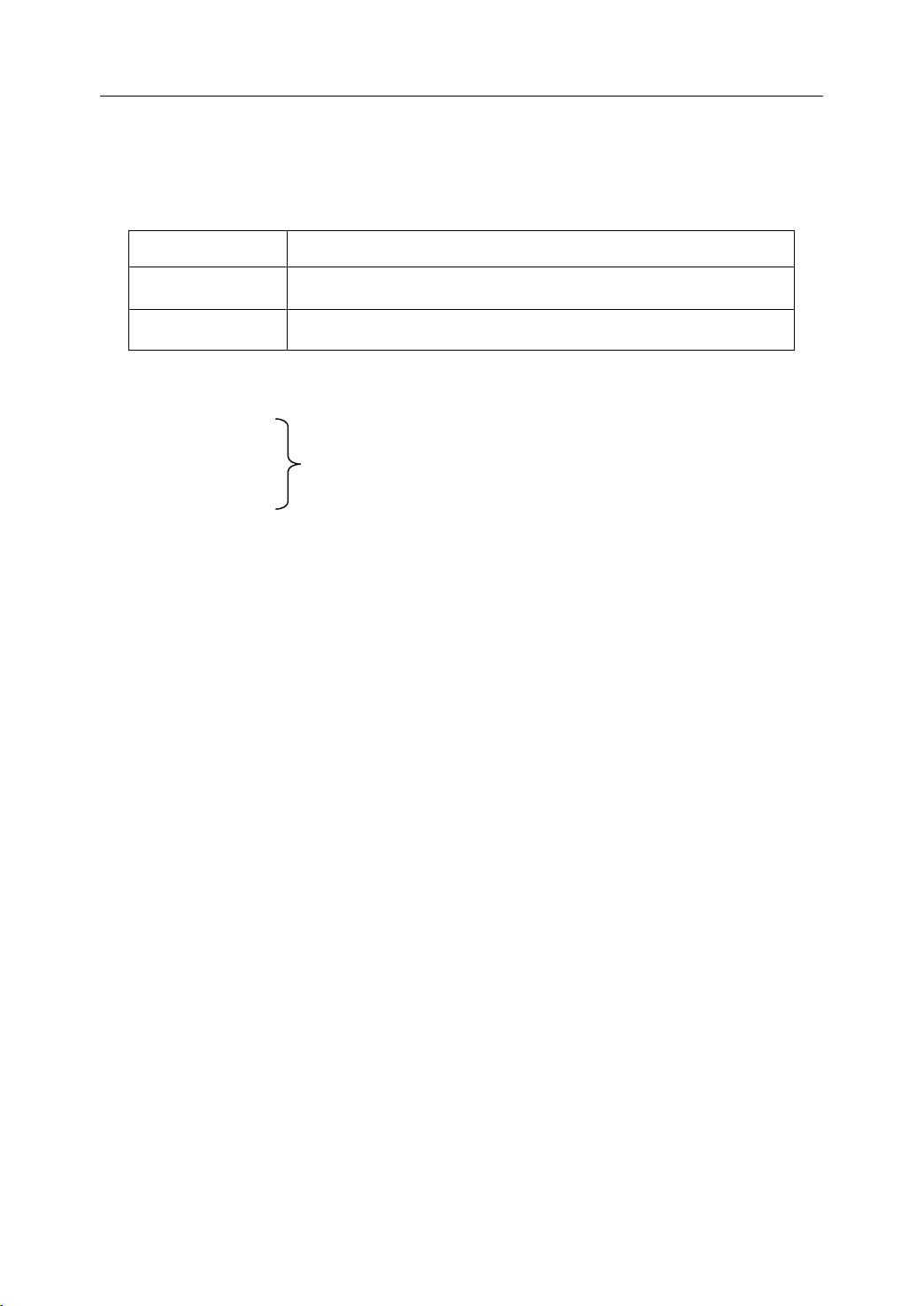

There are two type of program: main program and subprogram. The CNC operates

according to the main program. When a execution command of subprogram is at the

execution line of the main program, the subprogram is called. When the execution of

subprogram is finished, the system returns control to the main program.

Main

Main

Main Program

Program

Program

Program and

and

Subprogram

and

Subprogram

and Subprogram

Subprogram

Note:

Note:

Note:

Note:

Main program and its subprogram must be written in a same file with a different program

codes.

Figure 1 . 21 Main program and subprogram

19

Page 24

2

Preparatory

2

Preparatory

2

2 Preparatory

Preparatory Function

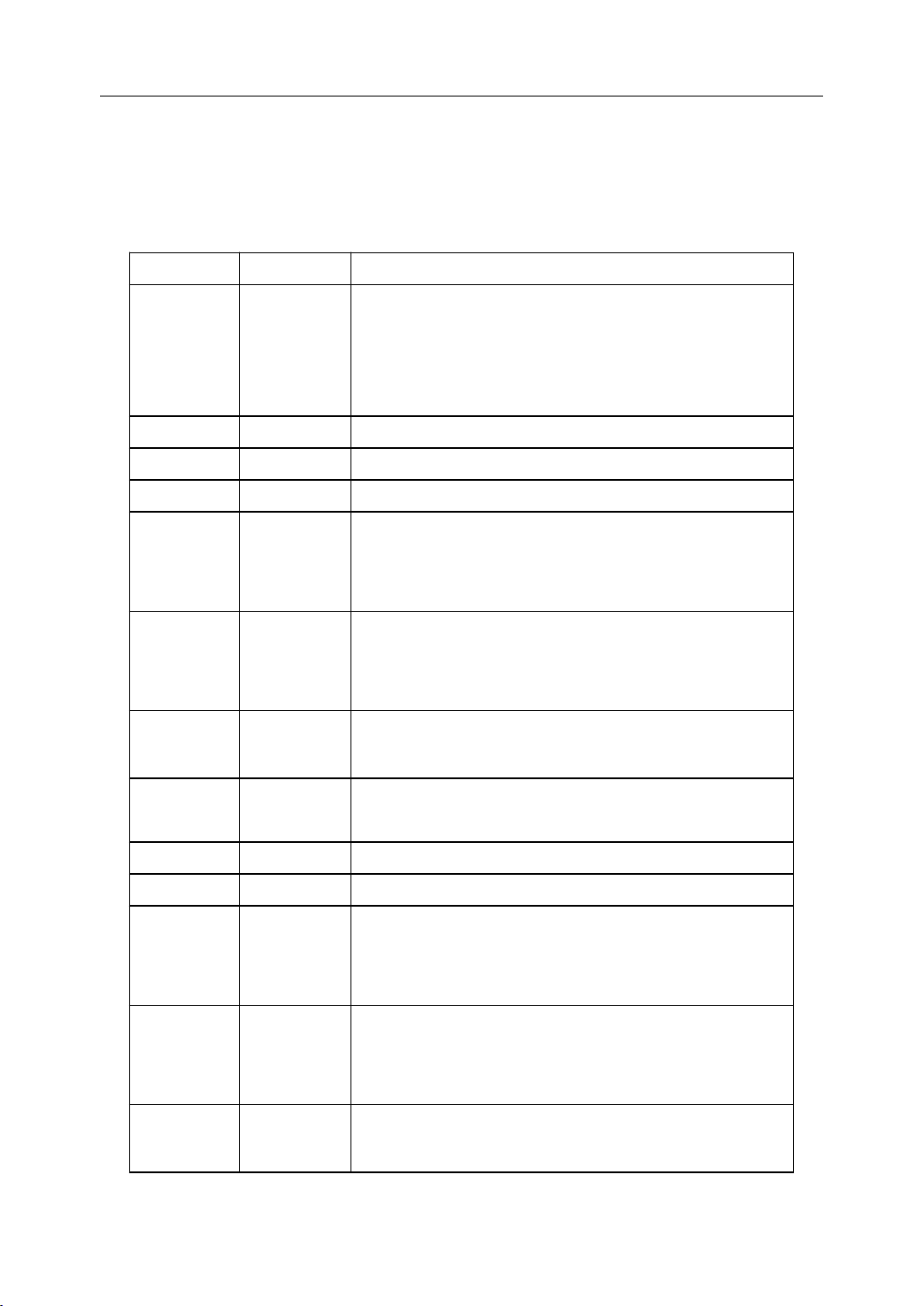

There are two types of G code: one-shot G code, and modal G code.

Type

Type

Type

Type Meaning

One-shot G code The G code is only effective in the block in which it is specified

Modal G code The G code is effective until another G code is specified.

Example : G01 and G00 are modal G codes.

N10 G01 X 100;

Meaning

Meaning

Meaning

Function

Function

Function (G

Table 2 1 Type of G code

(G

(G

(G code)

code)

code)

code)

2. Preparatory Function

N20 Y200 X200;

N30 X300;

N40 G00 Y100;

G01 is effective from N10 to N30

20

Page 25

2.1

G

2.1

2.1

2.1 G

code

G

code

G code

code List

List

List

List

The following table is the list of G code in HNC system.

Table 2 2 G code list

G

code

G

code

G

G code

code G

G

roup

G

roup

G roup

roup function

function

function

function

2. Preparatory Function

G00

◣ G01

G02 Circular interpolation/Helical interpolation CW

G03 Circular interpolation/Helical interpolation CCW

G04 00 Dwell

G07 00 Virtual axis

G09 00 Exact stop

◣ G17

G18 ZX plane selection

G19 YZ plane selection

G20

◣ G21

G22 Input in i mpulses equivalent weight

G24

◣ G25

G28

G29 Return from reference point

01

02

08

03

00

Rapid positioning

Linear interpolation

XY plane selection

Input in inch es

Input in m etrics

Programmable mirror image

Programmable mirror image cancel

Return to reference point

G34 00 Thread tapping

G38 00 Polar Coordinates

◣ G40

G41 Cutter compensation left

G42 Cutter compensation right

G43

G44 Tool length compensation - direction

◣ G49

◣ G50

G51 Scaling

09

10

04

Cutter compensation cancel

Tool length compensation +direction

Tool length compensation cancel

Scaling cancel

21

Page 26

G53 00 Machine coordinate system selection

2. Preparatory Function

22

Page 27

G54

Workpiece coordinate system 1

G55 Workpiece coordinate system 2

2. Preparatory Function

G56 Workpiece coordinate system 3

11

G57 Workpiece coordinate system 4

G58 Workpiece coordinate system 5

G59 Workpiece coordinate system 6

G60 00 Single direction positioning

◣ G61

Exact stop mode

12

G64 Cutting mode

G68

Coordinate rotation

05

◣ G69

G73

Coordinate rotation cancel

High-speed drilling cycle

G74 Left-hand tapping cycle

G76 Fine boring cycle

◣ G80

Canned cycle cancel

G81 Drilling cycle , Spot drilling

G82 Drilling cycle , Counter boring cycle

G83 Peck drilling cycle

06

G84 Tapping cycle

G85 Boring cycle

G86 Boring cycle

G87 Back boring cycle

G88 Manual Boring cycle

G89 Boring cycle

◣ G90

Absolute command

13

G91 Increment command

G92 00 Setting for work coordinate system

◣ G94

Feed per minute

14

G95 Feed per r otation

◣ G98

Return to initial point in canned cycle

15

G99 Return to R point in canned cycle

23

Page 28

2. Preparatory Function

Explanation:

Explanation:

Explanation:

Explanation:

1) G codes in 00 group are one-shot G code, while the other groups are modal G

code.

2)

3) Multiple G codes from different groups can be specified in the same block. If

means that it is default setting.

◣

multiple G codes from the same group are specified in the same block, only the

last G code specified is valid .

24

Page 29

3

Interpolation

3

Interpolation

3

3 Interpolation

Interpolation Functions

This chapter would introduce:

1) Positioning Command (G00)

2) Single Direction Positioning (G60)

3) Linear Interpolation (G01)

4) Circular Interpolation (G02, G03)

5) Helical Interpolation (G02, G03)

6) Thread Tapping (G34)

Functions

Functions

Functions

3. Interpolation Function

25

Page 30

3.1

Positioning

3.1

Positioning

3.1

3.1 Positioning

Positioning (G00)

Programming

Programming

Programming

Programming

G00 X_Y_Z_A_

(G00)

(G00)

(G00)

3. Interpolation Function

Explanation

Explanation

Explanation

Explanation of

X,Y,Z, A Coordinate value of the end point in the absolute command or incremental

command

Function

Function

Function

Function

The tool is moved at the highest possible speed (rapid traverse). I f the rapid traverse

movement is required to execute simultaneously on several axes, the rapid traverse speed is

decided by the axis which takes the most time. Thus, the tool path is nonlinear. The operator

can use this function to position the tool rapidly, to travel around the workpiece, or to

approach the tool change position.

Example

Example

Example

Example

Move tool from

of

the

parameters

of

the

parameters

of the

the parameters

parameters

A

(20, 15) to B (90, 45) at the rapid traverse speed.

Non linear interpolation

Y

positioning

C

B

Absolute programming:

G00 X90 Z45

Incremental programming:

G00 X70 Y30

15

O

Figure 3 . 1 Positioning (Rapid Traverse)

A

20 90

50

26

X

Page 31

3.2

Single

3.2

Single

3.2

3.2 Single

Single Direction

Programming

Programming

Programming

Programming

G60 X_ Y_ Z_ A_

Direction

Direction

Direction Positioning

Positioning

Positioning

Positioning (G60)

(G60)

(G60)

(G60)

3. Interpolation Function

Explanation

Explanation

Explanation

Explanation of

X,Y,Z, A Coordinate value of the end point in the absolute command or incremental

command

Function

Function

Function

Function

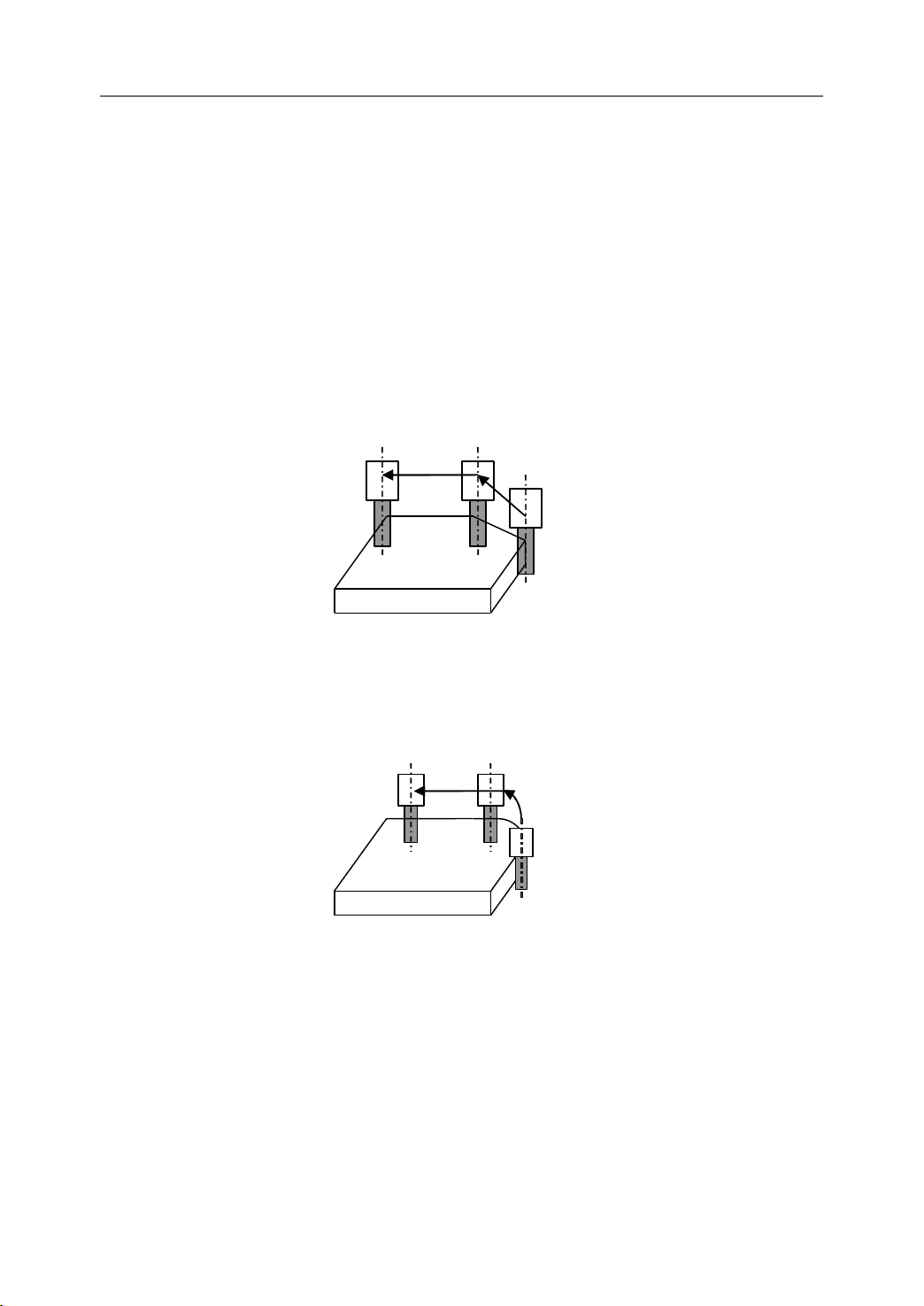

At first, move the tool from the start point to the intermediate point at the rapid traverse

speed. Then, tool is moved from the intermediate point to the end point at the specified

fe e drate .

of

the

parameters

of

the

parameters

of the

the parameters

parameters

Start position

Overrun

intermediate point

Start position

End position

Figure 3 . 2 Single Direction Positioning (G60)

Note:

Note:

Note:

Note:

The direction and distance from the intermediate point to the end point are set by machine

parameter – single direction positioning offset. When the value of the parameter is less than

0, the direction is negative. When the value of the parameter is more than 0, the direction is

positive.

27

Temporary stop

Page 32

3.3

Linear

3.3

Linear

3.3

3.3 Linear

Linear Interpolation

Programming

Programming

Programming

Programming

G01 X_ Y_ Z_ A_ F_

Interpolation

Interpolation

Interpolation (G01)

(G01)

(G01)

(G01)

3. Interpolation Function

Explanation

Explanation

Explanation

Explanation of

X,Y,Z, A Coordinate value of the end point in the absolute command or incremental

command

F Feedrate. It is effective until a new value is specified.

Function

Function

Function

Function

The tool is moved along the straight line at the specified fe e drate .

Example

Example

Example

Example 1

Move tool from

of

of

of the

1

1

1

the

parameters

the

parameters

the parameters

parameters

A

(20, 15) to B (90, 45) at the rapid traverse speed.

Y

15

O

linear interpolation

A

20 90

45

Figure 3 . 3 Linear Interpolation – Example 1

B

X

A bsolute programming

G01 X90 Y45 F800

Incremental programming

G01 X70 Y30 F800

28

Page 33

Example

Example

Example

Example 2

2

2

2

Use the tool (Φ8) to machine a groove (3mm) on a workpiece.

8

A

R4

B

15

Figure 3 . 4 Linear Interpolation – Example 2

70

100

3. Interpolation Function

10

60

80

%3308 (the origin is on A)

N1 G92 X0 Y0 Z50

N2 M03 S500

N3 G00 X-31

Y-26

N4 Z5

N5 G01 Z-3 F40

N6 Y26 F100

N7 X31

N8

Y-26

N9 X-31

N10 G00 Z50

N11 X0 Y0

N12 M05

N13 M30

%3309 (the origin is on B)

N1 G92 X0 Y0 Z50

N2 M03 S50 0

N3 G00 X19 Y14

N4 Z5

N5 G01 Z-3 F40

N6 Y66 F100

N7 X81

N8 Y14

N9 X19

N10 G00 Z50

N11 X0 Y0

N12 M05

N13 M30

29

Page 34

3.4

Circulation

3.4

Circulation

3.4

3.4 Circulation

Circulation Interpolation

Programming

Programming

Programming

Programming

Interpolation

Interpolation

Interpolation (G02,

(G02,

(G02,

(G02, G03)

G03)

G03)

G03)

3. Interpolation Function

G02

⎫

⎧

G17

⎨

⎩

⎧

G18

⎨

⎩

⎧

G19

⎨

⎩

Explanation

Explanation

Explanation

Explanation of

G17 The working plane is

G18 The working plane is XZ, and the infeed direction is Y

G19 The working plane is YZ, and the infeed direction is X

G02 a circular path in c lockwise direction (CW) (Figure 3.5)

G03 a circular path in counterc lockwise direction ( C CW)

G02 and G03 are defined when the working plane is specified. Figure 3.5 shows the

direction of circular interpolation.

G03

G02

G03

G02

G03

⎬

⎭

⎫

⎬

⎭

⎫

⎬

⎭

X_Y_

X_ Z_

Y_ Z_

I_J_

⎧

⎨

R_

⎩

I_ K_

⎧

⎨

R_

⎩

J_ K_

⎧

⎨

R_

⎩

of

the

parameters

of

the

parameters

of the

the parameters

parameters

⎫

F_

⎬

⎭

⎫

F_

⎬

⎭

⎫

F_

⎬

⎭

XY,

and the infeed direction is Z

Y

G02

G 17

Figure 3 . 5 Direction of circular interpolation

X, Y/X,

the specific working plane. For an incremental command, the coordinate values of the

circle end point with reference to the circle starting point in the specific working plane.

Z/Y,

Z For an absolute command, the coordinate values of the circle end point in

X

G03

G02

X

30

G03

G 18

Z

G03

G02

Z

G 19

Y

Page 35

3. Interpolation Function

I, J/I, K/J, K Coordinate values of the circle center point with reference to the circle

starting point in incremental command. (Figure 3.6)

Y

1

1

1

1

R Circle radius. When the arc is less than 180 ° (minor arc) , R is positive . If

the arc is more than 180 ° (major arc), R is negative.

F Feedrate along the circle

Function

Function

Function

Function

The tool is moved along a full circle or arcs.

E nd point (X, Y)

X

Centre

Start

point

I

Figure 3 . 6 Distance from the start point to the circle centre point

X

5

5

5

5

3

3

3

3

J

E nd point (X, Z)

Z

4

4

4

4

Centre

Z

Start

point

I

K

2

2

2

2

End point

Y

Centre

(Y,

Z)

Start

point

J

K

Note:

Note:

Note:

Note:

1) When it is full circle programming, R can not be used in the program. I, J, K can

only be used in this case.

2) When it is not full circle programming, the operator can select R or I, J, K to

program. I f I, J, K, and R addresses are all specified in the program , R tak es

precedence and the other are ignored.

31

Page 36

Example

Example

Example

Example 1

1

1

1

Use G02 to program the minor arc a and the major arc b.

3. Interpolation Function

(i) Arc a

G91 G02 X30 Y30 R30 F300

G91 G02 X30 Y30 I30 J0 F300

G90 G02 X0 Y30 R30 F300

b

R

30

a

a

Start point

Figure 3 . 7 Circular Interpolation – Example 1

Y

End

point

R30

X

6

6

6

6

G90 G02 X0 Y30 I30 J0 F300

(ii) Arc b

G91 G02 X30 Y30 R- 30 F300

G91 G02 X30 Y30 I0 J30 F300

G90 G02 X0 Y30 R- 30 F300

G90 G02 X0 Y30 I0 J30 F300

32

Page 37

Example

Example

Example

Example 2

2

2

2

Use G02/G03 to program the full circle.

Figure 3 . 8 Circular Interpolation – Example 2

3. Interpolation Function

Y

R

30

X

O

B

A

i ) Clockwise circle from

A

to A

G90 G02 X30 Y0 I- 30 J0 F300

G91 G02 X0 Y0 I- 30 J0 F300

(ii) Counterclockwise circle from B to B

G90 G03 X0

Y-

30 I0 J30 F300

G91 G03 X0 Y0 I0 J30 F300

33

Page 38

Example

Example

Example

Example 3

3

3

3

Use the tool (Φ8) to machine a groove (3mm) on a workpiece.

R10

R10

20

20

R20

R20

30

30

Figure 3 . 9 Circular Interpolation – Example 3

R20

R20

%3314

N1 G92 X0 Y0 Z50

3. Interpolation Function

R10

R10

N2 M03 S500

N3 G00 X10 Y30

N4 Z5

N5 G01 Z-3 F40

N6 X30

N7 G02 X38.66 Y25 R10

(N7 G02 X38.66 Y25 J-10)

N8 G01 X47.32 Y10

N9 G02 X30

(N9 G02 X30

Y-20

Y-20

R20

J-10 I-17.32)

N10 G01 X0

N11 G02 X0 Y20 R20

(N11 G02 X0 Y20 J20)

N12 G03 X10 Y30 R10

(N13 G03 X10 Y30 J10)

N14 G00 Z50

N15 X0 Y0

N16 M30

34

Page 39

Example

Example

Example

Example 4

Use the tool (Φ8) to machine a groove (3mm) on a workpiece.

%3315

N1 G92 X0 Y0 Z50

4

4

4

20

20

R10

R10

R20

R20

Figure 3 . 10 Circular Interpolation – Example 4

3. Interpolation Function

N2 M03 S500

N3 G00 X-25 Y-8.66

N4 Z5

N5 G01 Z-3 F40

N6 G02 X-25 Y8.66 R10

N7 G01 X-10 Y17.32

N8 G02 X-10 Y-17.32 R-20

N9 G01 X-25 Y-8.66

N10 G00 Z50

N11 X0 Y0

N12 M05

N13 M30

3.5

Helical

3.5

Helical

3.5

3.5 Helical

Helical Interpolation

Interpolation

Interpolation

Interpolation (G02,

(G02,

(G02,

(G02, G03)

35

G03)

G03)

G03)

Page 40

Programming

Programming

Programming

Programming

3. Interpolation Function

G02

⎫

⎧

G17

⎨

⎩

⎧

G18 Y_F_

⎨

⎩

⎧

G19 X_F_

⎨

⎩

Explanation

Explanation

Explanation

Explanation of

G17 The working plane is

G18 The working plane is XZ, and the infeed direction is Y

G19 The working plane is YZ, and the infeed direction is X

G02 a circular path in c lockwise direction (CW) (Figure 3.5)

G03 a circular path in counterc lockwise direction ( C CW)

X, Y/X,

the specific working plane. For an incremental command, the coordinate values of the

X_Y_

⎬

G03

⎭

G02

⎫

X_Z_

⎬

G03

⎭

G02

⎫

Y_Z_

⎬

G03

⎭

Z/Y,

I_J_

⎫

⎧

⎬

⎨

R_

⎭

⎩

I_K_

⎧

⎨

⎩

⎧

⎨

⎩

of

the

of

the

of the

the parameters

Z For an absolute command, the coordinate values of the circle end point in

⎫

⎬

R_

⎭

J_K_

⎫

⎬

R_

⎭

parameters

parameters

parameters

Z_F_

L

L

L

XY,

and the infeed direction is Z

circle end point with reference to the circle starting point in the specific working plane.

I, J/I, K/J, K Coordinate values of the circle center point with reference to the circle

starting point in incremental command.

R Circle radius. When the arc is less than 180 ° (minor arc) , R is positive . If

the arc is more than 180 ° (major arc), R is negative.

Z, Y, X The coordinate value of the end point with reference to the starting point on

the third axis in the incremental command.

F Feedrate along the circle

L Number of circles on a workpiece

Figure 3 .11Helical Interpolation (G02, G03)

Function

Function

Function

Function

Helical interpolation can be used to manufacture threads on the workpiece.

36

Page 41

3. Interpolation Function

Example

Example

Example

Example 1

Use G03 to program.

Absolute programming

1

1

1

G90 G17 F300

G03 X0 Y30 R30 Z10

Z

10

O

30

Start point

X

7

7

7

7

Figure 3 . 12 Helical Interpolation – Example 1

End point

30

Y

Incremental programming

G91 G17 F300

G03 X-30 Y30 R30 Z10

37

Page 42

3. Interpolation Function

Example

Example

Example

Example 2

2

2

2

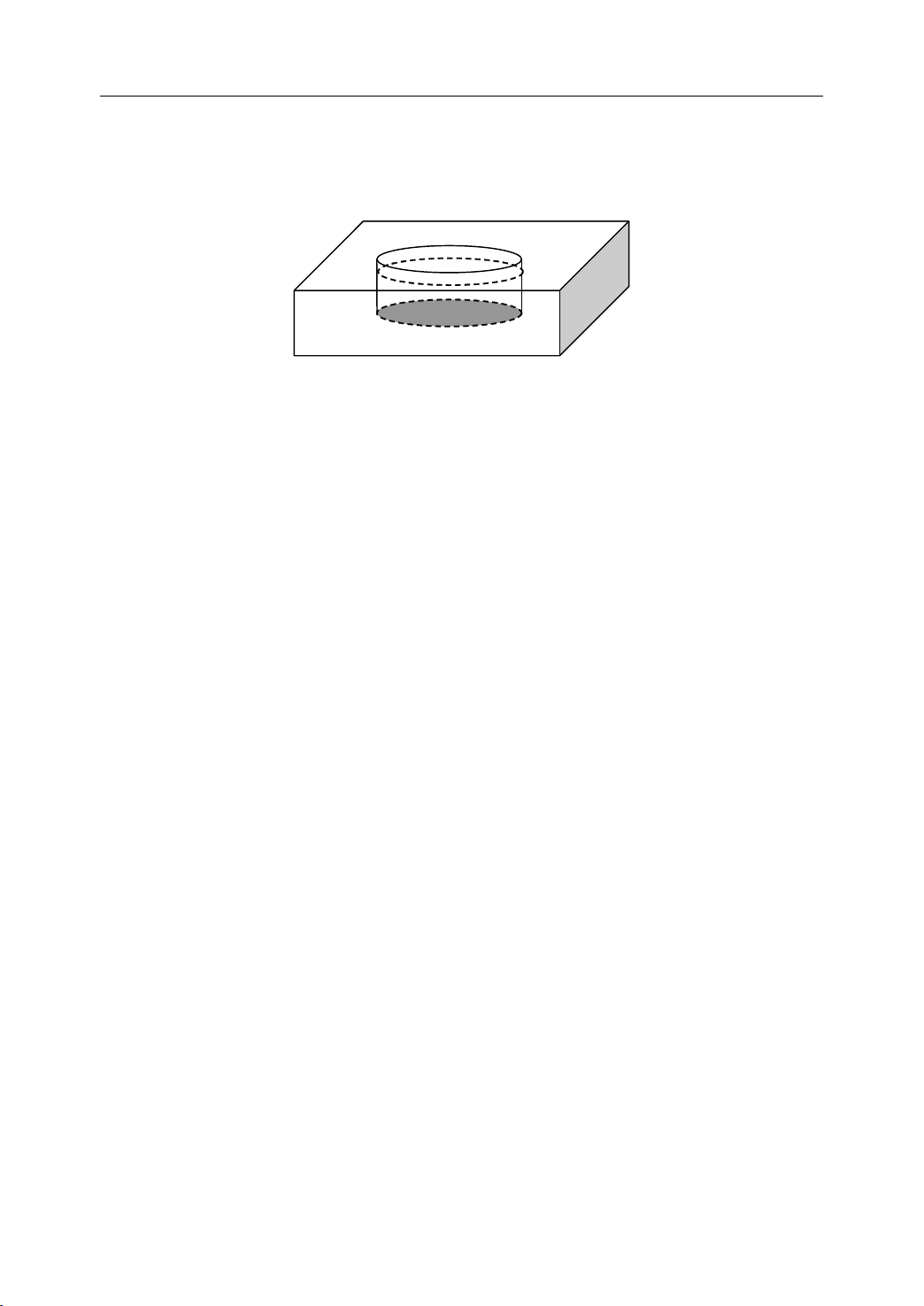

Use the tool (Φ10mm) to machine a hole (the diameter is 50mm, and the height is 10mm)

on a workpiece.

R25

10

Figure 3 . 13 Helical Interpolation – Example 2

%3317

N1 G92 X0 Y0 Z30

N2 G01 Z11 X20 F200

N3 G91 G03 I-20 Z-1 L11

N4 G03 I-20

N5 G90 G01 X0

N6 G00 Z30

N7 X30

Y-50

N8 M30

38

Page 43

3.6

Virtual

3.6

Virtual

3.6

3.6 Virtual

Virtual Axis

Programming

Programming

Programming

Programming

G07 X_Y_Z_A

Axis

Axis

Axis (G07)

(G07)

(G07)

(G07) and

and

and

and Sine

Sine

Sine

Sine Interpolation

Interpolation

Interpolation

Interpolation

3. Interpolation Function

Explanation

Explanation

Explanation

Explanation of

X,Y,Z, A One of axes is set as the virtual axis.

If it is set to 0, then that axis is the virtual axis. If it is set to 1, then that axis is the actual

axis.

Function

Function

Function

Function

G07 command can be used with helical interpolation command (G02, G03). The operation

combined G07 and G02/G03 is called sine interpolation.

Note

Note

Note

Note

The tool would not be moved along the virtual axis.

Example

Example

Example

Example 1

Use G03 to program

of

of

of the

1

1

1

the

parameters

the

parameters

the parameters

parameters

Y

100

G90 G00 X-50 Y0 Z0

G07 X0 G91

G03 X0 Y0 I0 J50 Z60 F800

50

Z

O

Figure 3 . 14 Sine Interpolation – Example 1

39

60

Page 44

Example

Example

Example

Example 2

To

2

2

2

implement the sine interpolation on the working plane

Z × Z+Y × Y = R × R (R: radius)

Y=R SIN ( 2 π× X/L ) (L: the distance on Z axis for each cycle)

3. Interpolation Function

XY.

%3319

N01 G92 X0 Y0 Z0

N02 G07 Z0

N03 G19 G90 G03

N04 G07 Z1

N05 M30

Y

R5

Y.0

Y

10

5

Z

50

Figure 3 . 15 Sine Interpolation – Example 2

0

Z0 J5 K0 X20.0 F100

X

40

Page 45

3.7

Tapping

3.7

Tapping

3.7

3.7 Tapping

Tapping (G34)

Programming

Programming

Programming

Programming

G34 K _ F _ P _

(G34)

(G34)

(G34)

3. Interpolation Function

Explanation

Explanation

Explanation

Explanation of

K The distance from the starting point to the bottom of the hole

F Thread lead. If it is positive , the spindle turns clockwise during tapping. If it is negative,

the spindle turns counterclockwise during tapping.

P Dwell time at the bottom of a hole. (The unit is seconds.)

Function

Function

Function

Function

With this command, the operator can rigid tap a thread.

Note

Note

Note

Note

1) When the spindle turns clockwise during tapping, the spindle would turn

2) When the spindle turns counterclockwise during tapping, the spindle would turn

In general, there is overshoot of the tap at the bottom of the thread during the

of

the

parameters

of

the

parameters

of the

the parameters

parameters

counterclockwise during retraction.

clockwise during retraction.

spindle-braking portion of the tapping cycle. It can be set by PMC parameters (Table 3-1) to

eliminate the overshoot errors.

41

Page 46

Table 3 1 PMC parameters

CNC

system

CNC

system

CNC

CNC system

system PMC

#0062 Maximum spindle speed during tapping

PMC

parameters

PMC

parameters

PMC parameters

parameters

3. Interpolation Function

HNC 18/19i

#0063 Minimum spindle speed during tapping

#0064

#0065

Dwell unit for tapping

Optional dwell unit for tapping

#0017 Maximum spindle speed during tapping

#001 8 Minimum spindle speed during tapping

HNC 21/22

#001 9

#00 30

Dwell unit for tapping

Optional dwell unit for tapping

Optional dwell unit for tapping is only effective when “ dwell unit for tapping ” is assigned to

“ 0 ” . Moreover, it is not necessary to restart the system.

The following formular is to calculate the dwelled unit (X):

D = (S * S / C) * X / 10000 = L * 360 / F

D dwell amount

S spindle speed

C Transmission gear ratio

X dwell unit

L overshoot error

F thread lead

.

42

Page 47

Example

Example

Example

Example

Use G34 to program.

3. Interpolation Function

%0002

G92 X-20

Y-20

2-M10××

2-M10

20

20

20

20

12

12

12

12

20

20

20

20

20

20

20

20

Figure 3 . 16 T apping - Example

1.5

1.5

80

80

80

80

80

80

80

80

Z50

M03 S200

G 00 X20 Y12

Z5

G34 K-27 F1.5

G00 X100

G34 K-27 F1.5

G00 Z50

X-20

Y-20

M05

M30

43

Page 48

4

Feed

4

Feed

4

4 Feed

Feed Function

This chapter would introduce:

1) Rapid Traverse

The tool is moved at the rapid traverse speed set in CNC.

2) Cutting Feed

The tool is moved at the programmed cutting feedrate.

3) Dwell

4) Exact Stop

5) Cutting Mode

Function

Function

Function

4. Feed Function

44

Page 49

4. Feed Function

4.1

Rapid

4.1

Rapid

4.1

4.1 Rapid

Rapid Traverse

Positioning command (G00) is to move the tool at the rapid traverse speed (the highest

possible speed).

This rapid traverse speed can be controlled by the machine control panel. For more detailed

information, please refer to turning operation manual.

Traverse

Traverse

Traverse (G00)

(G00)

(G00)

(G00)

45

Page 50

4.2

Cutting

4.2

Cutting

4.2

4.2 Cutting

Cutting Feed

Programming

Programming

Programming

Programming

G94 [F_ ]

G95 [F_ ]

Feed

Feed

Feed (G94,

(G94,

(G94,

(G94, G95)

G95)

G95)

G95)

4. Feed Function

Explanation

Explanation

Explanation

Explanation of

G94 feedrate per minute.

On linear axis, the unit of feedrate is mm/min, or in/min.

On rational axis, the unit of feedrate is degree/min.

G95 feedrate per revolution

The unit of feedrate is mm/rev, or in/rev.

Note:

Note:

Note:

Note:

1) G94 is the default setting

2) G95 is only used when there is spindle encoder.

Function

Function

Function

Function

The feedrate can be set by G94 or G95.

of

the

parameters

of

the

parameters

of the

the parameters

parameters

46

Page 51

4.3

Dwell

4.3

Dwell

4.3

4.3 Dwell

Dwell (G04)

Programming

Programming

Programming

Programming

G04 P_

(G04)

(G04)

(G04)

4. Feed Function

Explanation

Explanation

Explanation

Explanation of

P dwell time (specified in seconds)

Function

Function

Function

Function

It can be used to interrupt machining to get the smooth surface. I t can be used to control the

groove cutting, drilling, and turning path.

Example

Example

Example

Example

Use G04 to get the smooth surface.

of

the

parameters

of

the

parameters

of the

the parameters

parameters

Z

X

2

4

Figure 4 . 1 Dwell – Example

%0004

G92 X0 Y0 Z0

G91 F200 M03 S500

G43 G01 Z-6 H01

G04 P5

G49 G00 Z6 M05 M30

47

Page 52

4.4

Exact

4.4

Exact

4.4

4.4 Exact

Exact Stop

Programming

Programming

Programming

Programming

G09

G61

Stop

Stop

Stop (G09,

(G09,

(G09,

(G09, G61)

G61)

G61)

G61)

4. Feed Function

Explanations

Explanations

Explanations

Explanations of

The tool is moved to the end point of a block, then the position of the end point is checked.

Then, the next block is proceeded.

The difference between G09 and G61 is that G09 is one-shot G code. A nd G61 is modal G

code.

Function

Function

Function

Function

G09 or G61 can be used to machine a sharp edge.

of

the

parameters

of

the

parameters

of the

the parameters

parameters

Y

(2)

(1)

Figure 4 . 2 Exact Stop (G09/G61) – tool path from block (1) to block (2)

Position check

X

48

Page 53

Example

Example

Example

Example

Use G61 to program.

%0061

G92 X0 Y0 Z0

G91 G00 G43 Z-10 H01

G41 X50 Y20 D01

G01 G61 Y80 F300

Y

100

30

2 0

50

Figure 4 . 3 Exact Stop - Example

8

8

8

8

4. Feed Function

X

150

X100

…

49

Page 54

4.5

Cutting

4.5

Cutting

4.5

4.5 Cutting

Cutting Mode

Programming

Programming

Programming

Programming

G64

Mode

Mode

Mode (G64)

(G64)

(G64)

(G64)

4. Feed Function

Explanation

Explanation

Explanation

Explanation of

The tool is moved to the end point of a block. Then, the next block is proceeded. The tool

path is shown in the following figure.

Function

Function

Function

Function

G64 command can make the tool move smoothly between two blocks.

of

the

parameters

of

the

parameters

of the

the parameters

parameters

Y

(2)

(1)

O

Figure 4 . 4 Cutting Mode (G64) – tool path from block (1) to block (2)

X

50

Page 55

Example

Example

Example

Example

Use G64 to program.

%0064

G92 X0 Y0 Z0

G91 G00 G43 Z-10 H01

G41 X50 Y20 D01

G01 G64 Y80 F300

Y

100

A ctual

tool path

30

2 0

15050

Figure 4 . 5 Cutting Mode – Example

9

9

9

9

4. Feed Function

X

X100

…

51

Page 56

5

Coordinate

5

Coordinate

5

5 Coordinate

Coordinate System

This chapter would introduce:

1) Reference Position Return (G28)

2) Auto Return from Reference Position (G29)

3) Setting a Workpiece Coordinate System (G92)

4) Selecting a Machine Coordinat System (G53)

5) Selecting a Workpiece Coordinate System (G54~G59)

6) Plane Selection (G17, G18, G19)

7) Absolute and Incremental Programming (G90, G91)

8) Dimension Selection (G20, G21, G22)

9) Polar Coordinates (G38)

System

System

System

5. Coordinate System

52

Page 57

5.1

Reference

5.1

Reference

5.1

5.1 Reference

Reference Position

Programming

Programming

Programming

Programming

G28 X_ Y_ Z_ A_

Position

Position

Position Return

Return

Return

Return (G28)

(G28)

(G28)

(G28)

5. Coordinate System

Explanation

Explanation

Explanation

Explanation of

X,Y,Z, A Coordinate values of the intermediate point in absolute command/incremental

command

Function

Function

Function

Function

The tool is moved to the intermediate point rapidly, and then returned to the reference point.

Note:

Note:

Note:

Note:

1) In general, G28 is used to change tools or cancel the mechanical error. Tool radius

of

the

parameters

of

the

parameters

of the

the parameters

parameters

R(Reference position)

B(Intermediate position)

A(Start position for Reference position return)

Figure 5 . 1 Reference Position Return (G28)

compensation and tool length compensation should be cancelled when G28 is

executed.

2) G28 can not only make the tool move to the reference point, but also can save the

intermediate position to be used in G29.

3) When the power is on and manual reference position return is not available, G28 is

same as the maunaul reference position return. The direction of this reference

position return (G28) is set by the axis parameter – reference approach direction.

4) G28 is one-shot G code.

53

Page 58

5.2

Auto

5.2

Auto

5.2

5.2 Auto

Auto Return

Programming

Programming

Programming

Programming

G29 X_ Y_ Z_ A_

Return

Return

Return from

from

from

from Reference

Reference

Reference

Reference Position

5. Coordinate System

Position

Position

Position (G29)

(G29)

(G29)

(G29)

Explanation

Explanation

Explanation

Explanation of

X,Y,Z, A Coordinate value of the end point in absolute command/incremental

command

Function

Function

Function

Function

The tool is moved rapidly from the intermediate point defined in G28 to the end point. Thus,

G29 is generally used after G28 is defined.

of

the

parameters

of

the

parameters

of the

the parameters

parameters

R(Reference position)

B(Intermediate position)

C(Destination of return from the reference position)

Figure 5 . 2 Auto Return from Reference Position (G29)

Note:

Note:

Note:

Note:

G29 is one-shot G code.

54

Page 59

Example

Example

Example

Example

5. Coordinate System

Use G28, G29 command to program the track shown in. It moves from the starting point

to the intermediate point B , and then return s to the reference point R. At last, it moves from

the reference point R to the end point C through the intermediate point B.

R

Reference position

11

Intermediate point

C

X

10

10

10

10

70

50

30

…

G91 G28 X100 Y20 ;A

Y

B

A

30

Figure 5 . 3 Reference Position – Example

B

R

→

→

130 180

A

M06 T02 ;Changing the tool

G29 X50

…

Y-

40 ;R

B

C

→

→

55

Page 60

5.3

Setting

5.3

Setting

5.3

5.3 Setting

Setting a

Programming

Programming

Programming

Programming

G92 X_ Y_ Z_ A_

a

Workpiece

a

Workpiece

a Workpiece

Workpiece Coordinate

Coordinate

Coordinate

Coordinate System

5. Coordinate System

System

System

System (G92)

(G92)

(G92)

(G92)

Explanation

Explanation

Explanation

Explanation of

X,Y,Z, A Coordinate values of the tool position in the workpiece coordinate system.

Functions

Functions

Functions

Functions

G92 can set a workpiece coordinate system based on the current tool position (X_ Y_ Z_

A_ ).

Example

Example

Example

Example

Use G92 to set a workpiece coordinate system.

of

the

parameters

of

the

parameters

of the

the parameters

parameters

Z

20.0

Y

30.0

X

30.0

G92 X30.0 Y30.0 Z20.0

Figure 5 . 4 Setting a Workpiece Coordinate System – Example

56

Page 61

5.4

Selecting

5.4

Selecting

5.4

5.4 Selecting

Selecting a

Programming

Programming

Programming

Programming

G53 X_ Y_ Z_ A_

a

Machine

a

Machine

a Machine

Machine Cooridinate

Cooridinate

Cooridinate

Cooridinate System

5. Coordinate System

System

System

System (G53)

(G53)

(G53)

(G53)

Explanation

Explanation

Explanation

Explanation of

X,Y,Z, A Absoulte coordinate values of a point in the machine coordinate system.

Function

Function

Function

Function

A

machine coordinate system is selected, and the tool moves to the position at the rapid

traverse speed.

Note:

Note:

Note:

Note:

1) Absolute values must be specified in G53. The incremental values would be

2) G53 is one-shot G code.

of

the

of

the

of the

the parameters

ignored by G53.

parameters

parameters

parameters

57

Page 62

5.5

Selecting

5.5

Selecting

5.5

5.5 Selecting

Selecting a

(G54~G59)

(G54~G59)

(G54~G59)

(G54~G59)

Programming

Programming

Programming

Programming

54

G

⎫

⎧

⎪

⎪

55

G

⎪

⎪

⎪

⎪

56

G

⎪

⎪

⎨

G

⎪

⎪

G

⎪

⎪

G

⎩

⎬

57

⎪

⎪

58

⎪

⎪

59

⎭

X_ Y_ Z_ A_

a

Workpiece

a

Workpiece

a Workpiece

Workpiece Coordinate

Coordinate

5. Coordinate System

Coordinate

Coordinate System

System

System

System

Explanation

Explanation

Explanation

Explanation of

X,Y,Z, A Coordinate values of the point with reference to the origin of machine in

absolute command

Function

Function

Function

Function

There are six workpiece coordinate system to be selected. If one coordinate system is

selected, the tool is moved to a specified point.

Note:

Note:

Note:

Note:

1) The workpiece coordinate system must be set before using these commands

2) Reference position must be returned before these commands (G54~G59) are

3) G54 is the default setting.

of

the

parameters

of

the

parameters

of the

the parameters

parameters

(G54~G59). The workpiece coordinate system can be set by using the MDI panel.

For detailed information, please refer to the milling operation manual.

executed.

58

Page 63

Example

Example

Example

Example

5. Coordinate System

Select one of workpiece coordinate system, and the tool path is Current point→A

Origin

-186.327

Y

40

G54

O

1

Figure 5 . 5 Workpiece Coordinate System – Example

-117.452

Y

30

A

G59

X

30

B

O

X

30

2

Machine

-63.948

-98.359

% 1000

N01 G54 G00 G90 X 30 Y4 0

N02 G59

N03 G00 X30 Y 30

N04 G54

N05 X0 Y0

B.

→

N06 M30

59

Page 64

5.6

Plane

5.6

Plane

5.6

5.6 Plane

Plane Selection

Programming

Programming

Programming

Programming

G17

G18

G19

Selection

Selection

Selection (G17,

(G17,

(G17,

(G17, G18,

G18,

G18,

G18, G19)

G19)

G19)

G19)

5. Coordinate System

Explanation

Explanation

Explanation

Explanation of

G17 working plane is

G18 working plane is ZX , infeed direction is Y

G19 working plane is YZ , infeed direction is X

Function

Function

Function

Function

The working plane is specified and used for tool radius compensation and circular

interpolation.

Note:

Note:

Note:

Note:

Move command is not related with the plane selection. For example, in the command G17

G01 Z10, Z axis does still move.

of

the

parameters

of

the

parameters

of the

the parameters

parameters

XY,

infeed direction is Z

60

Page 65

5.7

Absolute

5.7

Absolute

5.7

5.7 Absolute

Absolute and

G91)

G91)

G91)

G91)

Programming

Programming

Programming

Programming

G90 X_ Y_ Z_ A_

G91 X_ Y_ Z_ A_

and

and

and Incremental

Incremental

Incremental

Incremental Programming

5. Coordinate System

Programming

Programming

Programming (G90,

(G90,

(G90,

(G90,

Explanation

Explanation

Explanation

Explanation of

G90 Absolute programming

X,Y,Z, A Coordinate values of the point with reference to the origin of programming

G91 Incremental programming

X,Y,Z, A Coordinate values of the point with reference to the previous position

Function

Function

Function

Function

The tool is moved to the specified position.

of

the

parameters

of

the

parameters

of the

the parameters

parameters

61

Page 66

5. Coordinate System

Example

Example

Example

Example

Move the tool from point 1 to point 2 through point 3, and then return to the current point.

Y

G90 programming

%0001

M03 S500

N01 G92 X0 Y0 Z10

N02 G01 X20 Y15

N03 X40 Y45

N04 X60 Y25

N05 X0 Y0 Z10

N06 M30

45

25

15

O

20

Figure 5 . 6 Absolute and Incremental Programming – Example

2

3

1

40

X

60

G91 programming

%0001

M03 S500

N01 G92 X0 Y0 Z10

N02 G91 G01 X20 Y15

N03 X20 Y30

N04 X20

Y-20

N05 G90 X0 Y0

N06 M30

62

Page 67

5.8

Dimension

5.8

Dimension

5.8

5.8 Dimension

Dimension Selection

Programming

Programming

Programming

Programming

G20

G21

G22

Selection

Selection

Selection (G20,

(G20,

(G20,

(G20, G21,

G21,

G21,

G21, G22)

G22)

G22)

G22)

5. Coordinate System

Explanation

Explanation

Explanation

Explanation of

G20: Inch input

G21: Metric input

G22: I mpulses equivalent weight input

The units of linear axis and circular axis are shown in the following table

Metric system (G21) Mm Degree

Function

Function

Function

Function

Depending on the part drawing, the workpiece geometries can be programmed in metric

measures, inches, or i mpulses equivalent weight .

of

the

parameters

of

the

parameters

of the

the parameters

parameters

Table 5 1

Inch system (G20) Inch Degree

Pulse system (G22) I mpulses equivalent weight I mpulses equivalent weight

. Unit of Linear axis and Circular axis

Linear axis Circular axis

63

Page 68

5.9

Polar

5.9

Polar

5.9

5.9 Polar

Polar Coordinates

Programming

Programming

Programming

Programming

G38 X_ Y_

G01 AP=_ RP=_

G02 / G03 AP=_ RP=_ R_

Coordinates

Coordinates

Coordinates

5. Coordinate System

Explanation

Explanation

Explanation

Explanation of

G38 Setting a polar coordinate system

X, Y Coordiante value of the pole in the workpiece coordinate system

AP Polar angle

RP Polar radius

R Circle radius

Function

Function

Function

Function

The polar coordinate method is useful only if there is radius and angle measurements on a

workpiece.

Note

Note

Note

Note

These commands can be used with commands of workpiece coordinate system.

of

the

parameters

of

the

parameters

of the

the parameters

parameters

64

Page 69

Example

Example

Example

Example 1

1

1

1

Use polar coordinates command to program.

R42

Figure 5 . 7 Polar Coordinates – Example 1

%3326

G92 X 0 Y 0 Z 10

5. Coordinate System

50

84

G00 X -50

Y

-60

G00 Z -3

G01 G41 X -42 D 01 F 1000

Y0

G38 X 0 Y 0

G02 AP=0 RP=42 R42

G01

Y

-50

X -50

G00 G40

Y

-60

Z10

G00 X0 Y0

M30

65

Page 70

5. Coordinate System

Example

Example

Example

Example 2

2

2

2

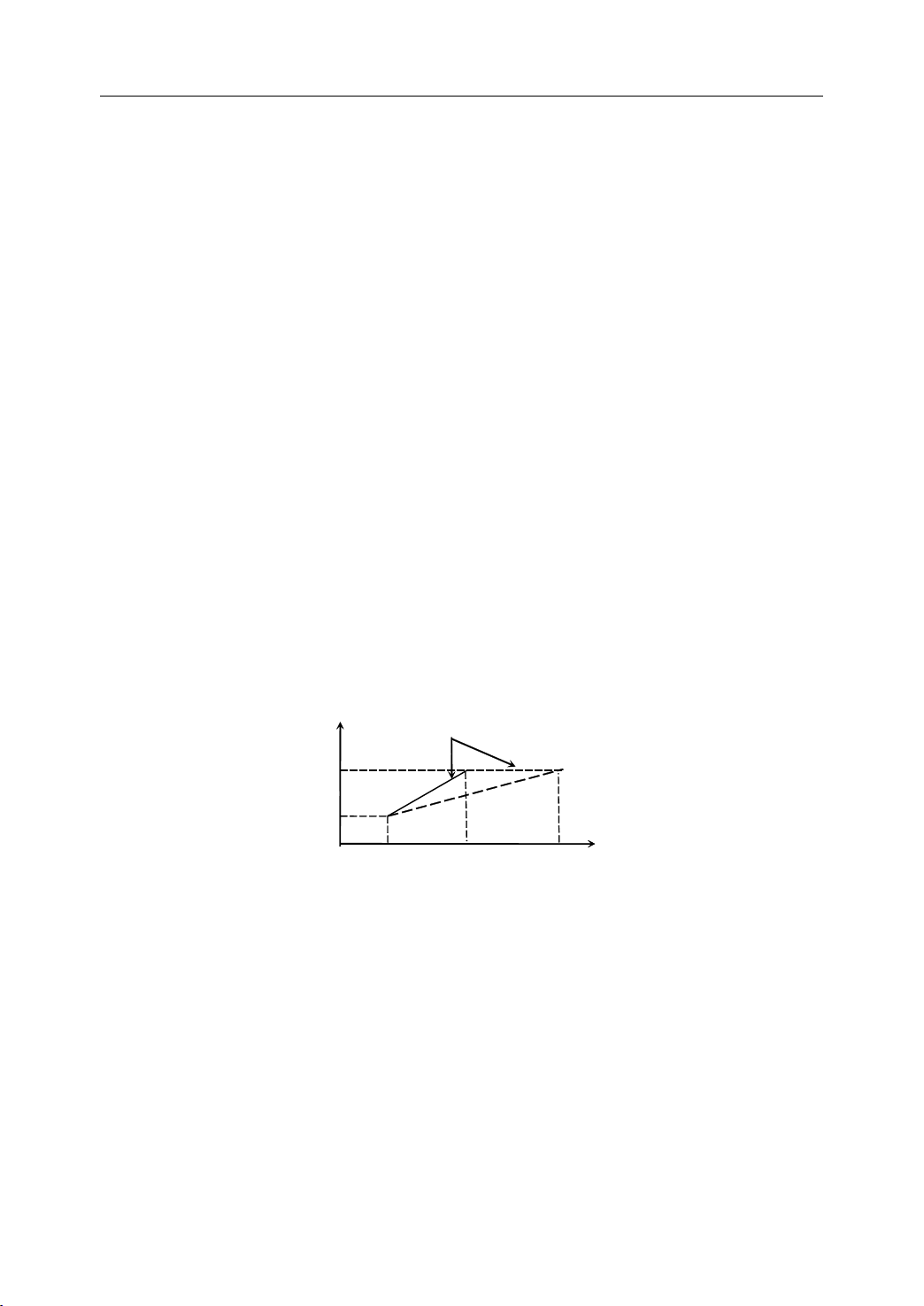

W hen the tool is turning clockwise, the polar radius increases 2mm as the the polar angle

increases 10 ° .

50

42

Figure 5 . 8 Polar Coordinate – Example 2

%0001

G54 G00 X -15

G00 Z -3

G01 G41 X 0 D 01 F 1000

Y50

G38 X 42 Y 50

#0=180

#1=42

while #0 gt 0

G01 AP=[#0] RP=[#1]

#0=#0-10

#1=#1+2

Endw

G01 AP=0 RP=78

Y 0

X -15

G00 G40

Y

-15

Y

-15 Z 10

Z10

M30

66

Page 71

6. Spindle Speed Function

6

Spindle

6

Spindle

6

6 Spindle

Spindle Speed

Spindle function controls the spindle speed (S), the unit of spindle speed is r/min. S is modal