hnc HNC-18, HNC-19M Operator Manual

CENTURY STAR MILLING CNC SYSTEM

HNC-18/19M OPERATOR’S MANUAL

V2.01

Wuhan Huazhong Numerical Control Co., Ltd.

CONTENT

PRECAUTIONS................................................................................I

1 INTRODUCTION...........................................................................1

OVERALL LAYOUT ............................................................................ 1

MACHINE CONTROL KEYS ................................................................2

ALPHA NUMERIC KEYBOARD............................................................. 8

MENU TREE................................................................................... 10

2 SET UP.......................................................................................17

POWER ON.................................................................................... 18

RESET/ EMERGENCY STOP ............................................................ 19

HOMING (REFERENCE–POINT APPROACH).......................................20

SOFTWARE LIMITS DEFINITION......................................................... 22

TOOL DATA SETTING ....................................................................... 24

ORIGIN OFFSET............................................................................. 27

3 MANUAL OPERATION...............................................................29

JOG FEED.....................................................................................30

INCREMENTAL FEED ....................................................................... 35

MANUAL HANDWHEEL .................................................................... 39

SPINDLE OPERATIONS ................................................................... 42

AUXILIARY OPERATIONS................................................................. 45

4 AUTOMATIC OPERATION ......................................................47

PROGRAM LOADING.......................................................................49

PROGRAM TESTING ....................................................................... 51

RUNNING CONTROL ....................................................................... 53

REAK POINT OPERATION ............................................................... 57

B

MDI

OPERATION ........................................................................... 62

5 PROGRAM OPERATION ...........................................................65

PEN A PROGRAM ......................................................................... 66

O

C

REATE A NEW FILE ....................................................................... 67

ELETE AN EXISTED FILE ................................................................ 69

D

E

DIT A PROGRAM FILE .................................................................... 70

PROGRAM FORMAT ........................................................................ 72

6 DATA EXCHANGE VIA RS232...................................................73

CONFIGURATION............................................................................ 74

SET UP THE RS232 CONNECTION ...................................................76

I

UPLOAD DATA FILE TO NC..............................................................77

DOWNLOAD DATA FILE FROM NC .................................................... 80

7 SETTING AND DISPLAYING .....................................................83

POSITION AND COORDINATES CHOICE............................................. 83

VIEW OPTIONS .............................................................................. 84

8 DIAGNOSIS................................................................................88

ALARM DIAGNOSIS ........................................................................ 89

I/O CHECK....................................................................................90

REGISTERS WATCH........................................................................ 91

9 PARAMETERS...........................................................................93

PARAMETERS BROWSING ............................................................... 95

PARAMETERS OPERATION .............................................................. 96

PARAMETERS DESCRIPTION ............................................................99

II

Precautions

This section enumerates safety precautions for protecting the user

and preventing damage to the machine. Read the contents of this

part thoroughly before attempting to use the machine.

1. The working temperature for the Numerical Control (NC) unit

and its cable cabinet is 0 to 45°C (32°F to 113°F). No freezing is

allowed. The temperature variation should be less than 1.1°C/min

(2°F/min). Humidity should be kept below 90% Relative Humidity,

non-condensing and without frost; 75% Relative Humidity or lower is

more desirable.

2. For storage, the temperature range should be kept within

–20°C to 60°C (-4°F to 140°F) non-condensing and without frost.

All devices should be placed indoors and away from sunshine, dust,

eroding gases and moisture.

3. Impact during transportation or other situations should be less

than 5.9 m/s (0.6 g) for vibrations in the range between 10 to 60 Hz.

4. Correct grounding is critical for the NC unit and other electrical

devices. No grounding or incorrect grounding may injure the

operator or damage components of the NC devices. If the devices

are not correctly grounded, inductive interference from electric

motors and appliances can give errors and unexpected results.

5. Filters are used on cooling fans to prevent dust from entering

into devices. However, after time filters become clogged, preventing

adequate cooling. Clean the filters every three months. In dusty

environments such as wood routers, clean the filters more often.

6. After a long period of non-operation, NC devices should be

cleaned and dried. Also check the wiring and ground connections.

Once power is resumed after non-operation, observe the operation

for several hours to make sure there is no unexpected behavior.

7. Never machine a workpiece without first checking the

I

machine's status. Before using the machine for a production run,

make sure that the machine operates correctly by doing a trial run

including, for example, a single block with a feedrate override or a

machine lock function. Another possibility is to do the trial run

without a tool or workpiece mounted. Failure to confirm the

correct operation with a trial run may result in unexpected motion or

behavior that can damage the workpiece, damage the machine, or

injure the operator.

8. Before operating the machine, thoroughly check the entered

data, including parameters, program and settings. Operating the

machine with incorrectly specified data may also result in

unexpected motion or behavior that can damage the workpiece,

damage the machine, or injure the operator.

9. Ensure that the specified feedrate is appropriate for the

intended operation. The appropriate feedrate varies with the

operation. Generally each machine has a maximum allowable

feedrate found in the machine's operation manual. If a machine is

run at other than the correct feedrate or if the maximum allowable

feedrate is exceeded, unexpected motion or behavior may result that

can damage the workpiece, damage the machine, or injure the

operator.

10. When using the tool compensation function, thoroughly check

the direction and amount of compensation for each tool. Operating

the machine with incorrectly specified data may produce unexpected

motion or behavior that can damage the workpiece, damage the

machine, or injure the operator.

11. Usually, there is no need to change the factory-set

parameters of the NC unit and PMC. However, when there is no

choice other than to change a parameter, be sure you fully

understand the function of the parameter before making any change.

Failure to set a parameter correctly may produce unexpected motion

or behavior that can damage the workpiece, damage the machine,

or injure the operator.

12. Immediately after switching on the power, do not touch any of

II

the keys on the Manual Data Input (MDI) panel until the position

display or alarm screen appears on the NC unit. Since some of the

keys on the MDI panel are dedicated to maintenance or other special

operations, pressing any of these keys may prevent the NC unit from

entering its normal state. Starting the machine in the wrong state

may cause unexpected motion or behavior.

13. While the operator’s manual supplied with an NC unit provides

an overall description of the machine’s functions, some functions are

specific for that machine alone and may not be available for another

model. Check the specification of the machine if in doubt as to its

machine-specific functions.

III

HNC-18/19T Operator’s Manual

1 Introduction

Overall layout

The user operates the mill either through the Numerical Control Unit

(NCU) or a Hand Pendant (optional). RS232 allows the user to

exchange data between the NCU and other computers. A PS/2

connector in the Data Exchange Port lets the user plug in a

keyboard.

LCD

Screen

Alpha

numeric

keyboard

Soft keys

-+

Machine

control

keys

Front face of Numerical Control Unit (NCU)

MPG(Manual pulse

generator) unit is a hand

pandent that compose of

an Emergency Stop

button, an axis switch

and a pulse generator. It

can be used for the user

to operate the machine at

a convenient place.

1

HNC-18/19T Operator’s Manual

There are four main areas on the front face of NCU: LCD Screen,

Soft keys, Alpha numeric keyboard and Machine Control keys.

These are shown in detail below.

a) LCD Screen

The LCD screen in the upper right displays the machine’s status, the

tool’s position, the program’s content and other information.

b) Menu keys

Beneath the LCD screen are the “Soft keys” from F1 to F10. They

change their function depending on which menu is being used.

c) Alpha numeric keyboard

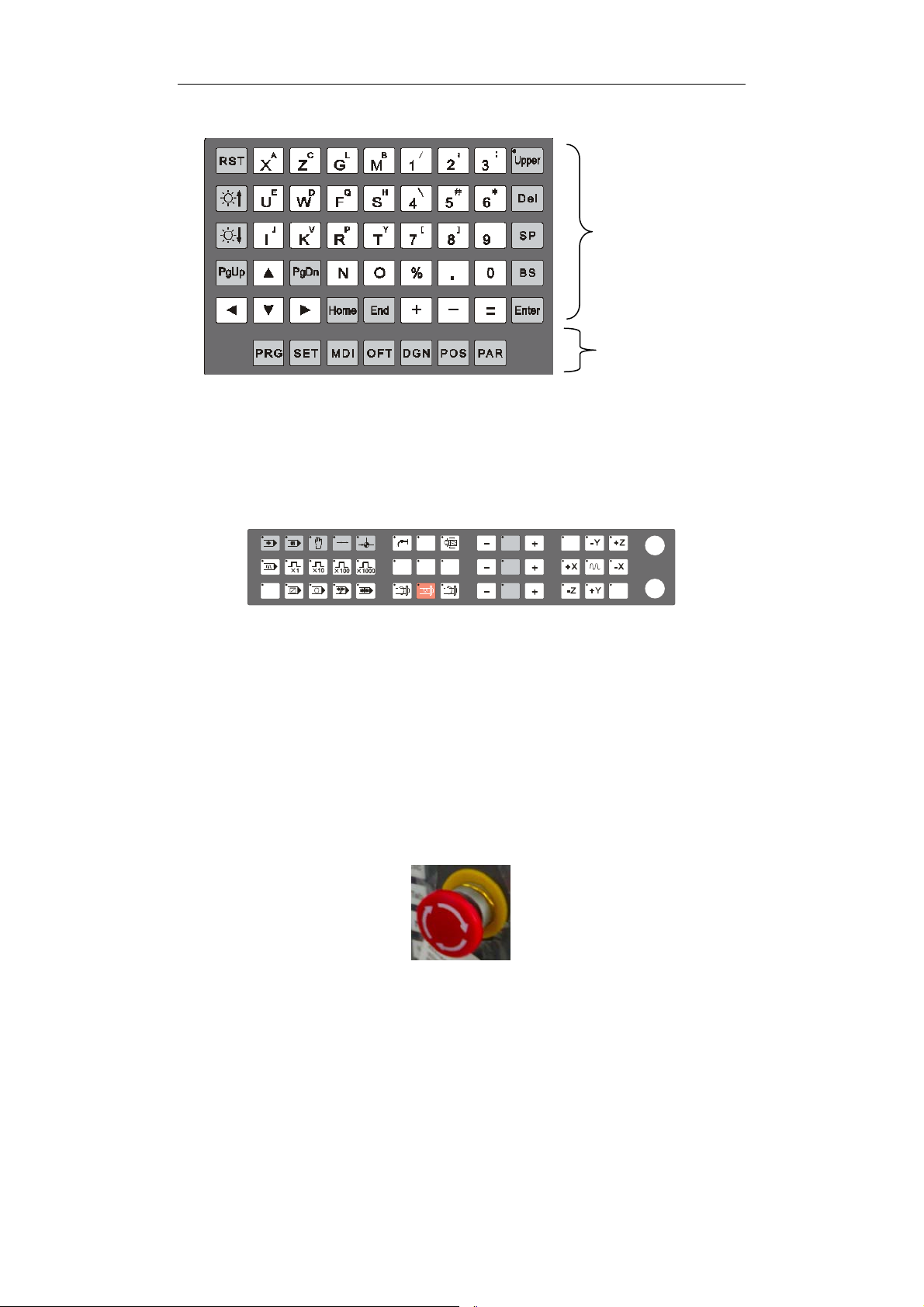

On the right side of the LCD screen is the Alphabetic keyboard.

These keys are used for editing a program, as well as changing or

viewing parameters.

1

HNC-18/19T Operator’s Manual

N

Alpha

umerical

keys

Function keys

d) Machine Control keys

At the bottom of the front panel are the Machine Control keys.

These keys operate the machine directly.

e) Other Controls

An emergency stop button is on the front panel to deal with abnormal

situations. Pushing down on the button stops the machine from any

further motion and sets the electronic brakes on the motor axes and

spindle. Pulling upon a stopped button resets the software system

and the machine can operate again under computer or manual

control

1

HNC-18/19T Operator’s Manual

A green “Cycle Run” button starts the automatic machining process.

A red “Feed Hold” button pauses machining under computer control.

1

1 Introduction

Machine Control Keys

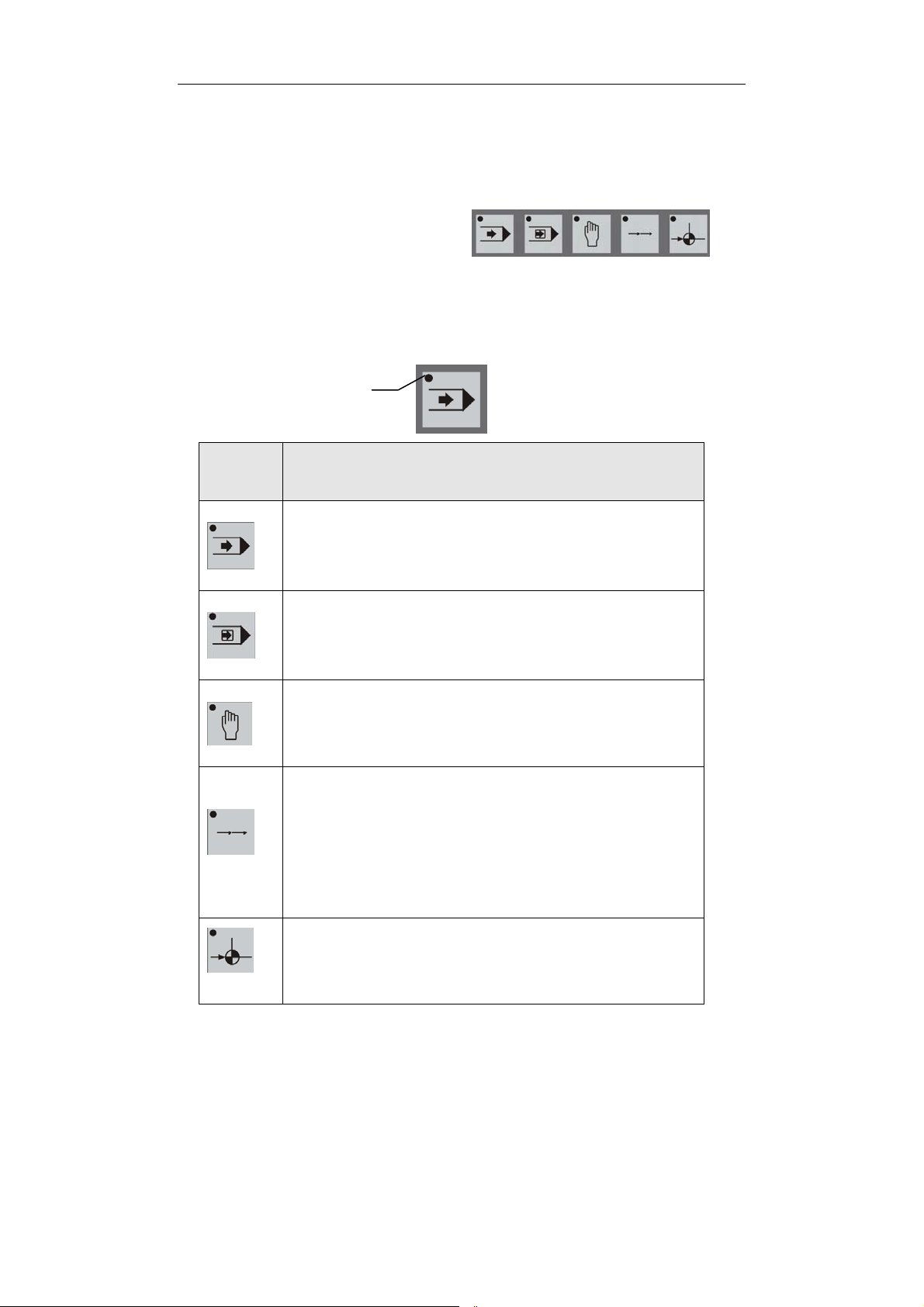

a) Mode Selection Switches.

To the right are shown the five

switches that select the operation

mode of the machine. Note that the small LED “activation” light on

the upper left of each key indicates in which mode the machine is

working.

KEY DESCRIPTION

Activation light

Automatic (AUTO) mode key: Pressing this key

switches to Auto mode. In AUTO mode,

workpiece can be machined automatically from a

program.

Single Block (SBL) mode key: Pressing this

key switches to “SBL” mode. In SBL mode, a

program can be run block by block.

Manual (MAN) mode key: Pressing this key

switches to manual operation or “jog” mode. In

manual mode, any axis of the tool can be

manually controlled.

Incremental (INC) mode key: Pressing this key

switches to “INC” operation mode. In INC

mode, the tool can be moved a number of steps

along any axis by either the Axis keys or the hand

wheel (Manual Pulse Generator). The number

of steps depends on which of the multiple-step

keys is selected.

Reference (REF) mode key: Pressing this key

switches to “Reference” mode. In Reference

mode, each motion axis can home exactly on its

reference position.

2

HNC-18/19T Operator’s Manual

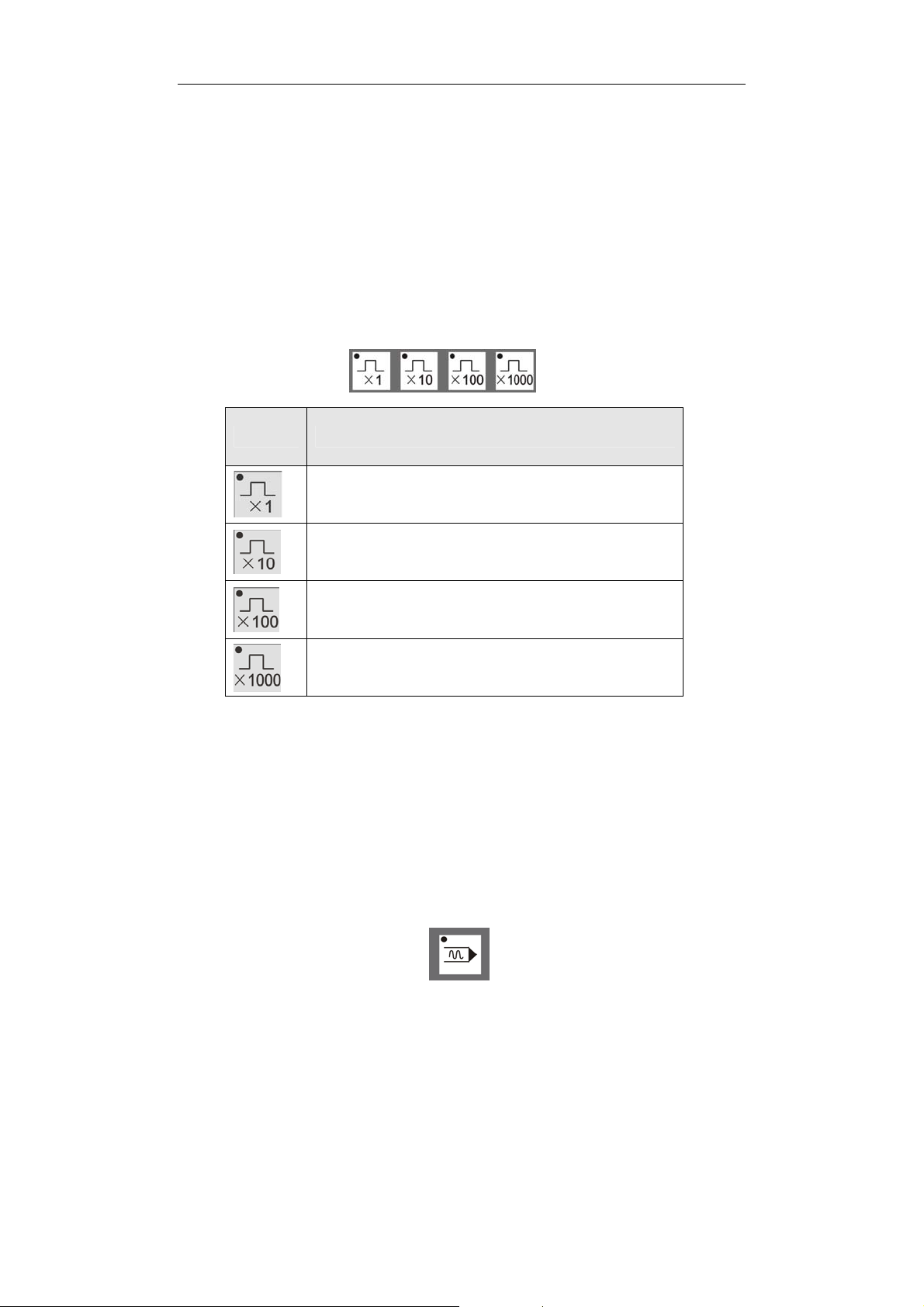

b) Multiple Step Keys:

Shown on the right are the four multiple step selection keys used

during incremental operation. Again, the LED light on the key’s

upper-left corner indicates the corresponding multiple selected.

First the INC key is pushed to set the Incremental Mode, then the

desired number of multiple steps is pressed and finally the desired

Axis key is pressed.

The multiple step selection keys are:

KEY DESCRIPTION

Each key push moves that axis one step

Each key push moves that axis 10 steps

Each key push moves that axis 100 steps

Each key push moves that axis 1000 steps

A step is equal to one micrometer (1 μm) for each linear axis (X, Y, Z)

and 0.001 degrees for each rotational axis.

On the same row as the Multiple Step keys, is the Verify key used in

conjunction with the Automatic Mode key. When the Verify key is

activated, a program runs at a higher speed than during normal

machining. The operator can run a program quickly be sure the

program performs the proper function.

3

1 Introduction

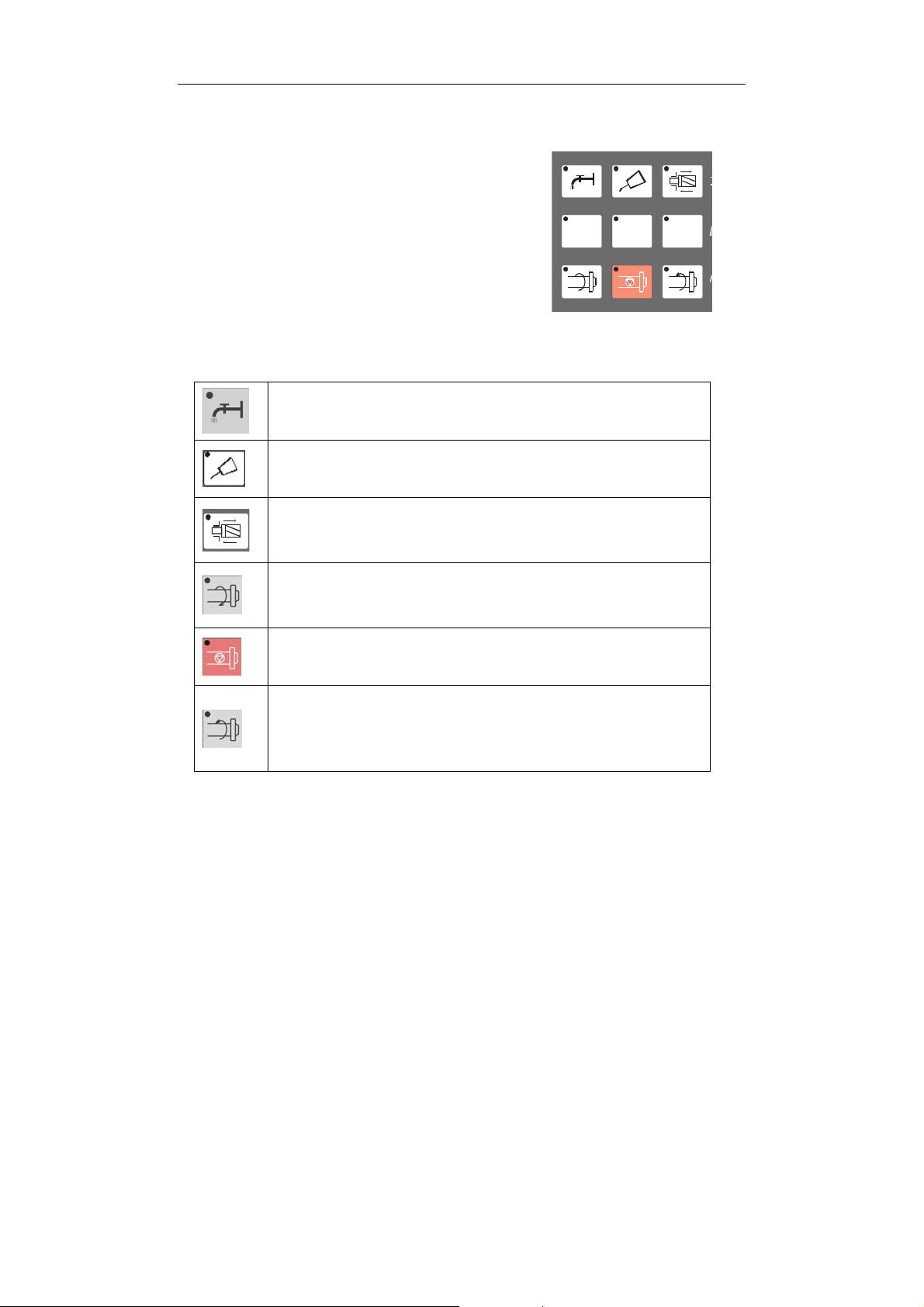

c) Spindle and Auxiliary Operation keys:

These nine keys usually function in Manual

mode. They control spindle, turret tool

selection, coolant and chuck functions.

These functions are activated only when no

program is running.

Details of the keys are shown below:

Coolant Switch key: This key opens or closes

the coolant flow

Lubrication key: Turn on the lubrication system

with this key.

Tool lock/unlock: After pressing this key, the tool

will be release if it is locked before and will be

locked if it is to be replaced in.

Spindle Clockwise Rotation key: Pressing this

key begins spindle rotation in the clockwise

direction (top of workpiece moves toward operator).

Spindle Stop key: Stop the spindle rotation by

pressing this key.

Spindle Counter-clockwise Rotation key:

Pressing this key begins spindle rotation in the

counter-clockwise direction (top of workpiece

moves away from operator).

4

HNC-18/19T Operator’s Manual

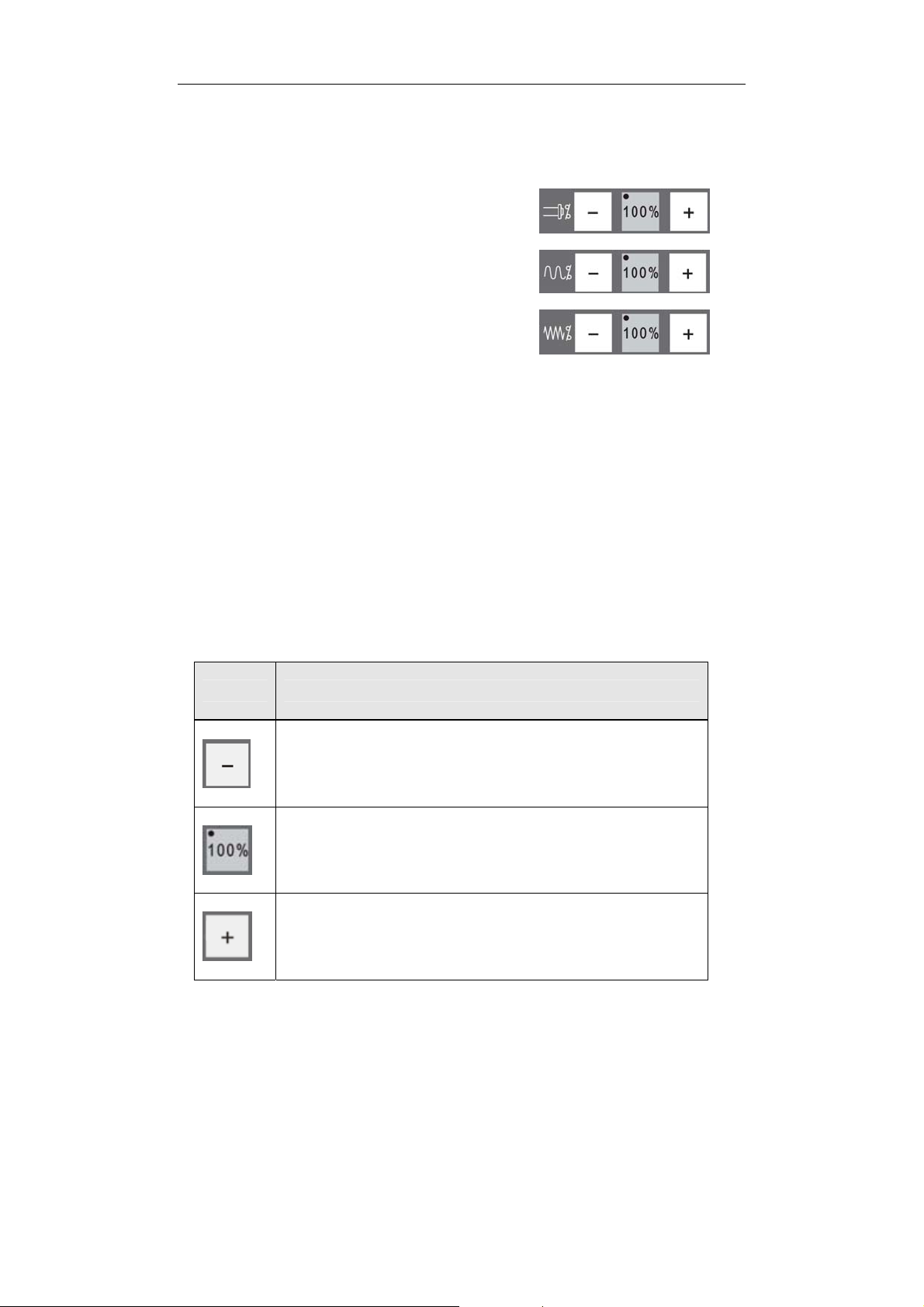

d) Speed Adjustment keys:

By pressing these keys the spindle speed,

rapid traverse rate and feed rate

(machining speed) can be adjusted. The

first row controls the spindle speed, the

second row controls the rapid traverse

speed and the bottom row controls feed

rate.

These keys work by adjusting the speed relative to a ”base” speed.

Different modes (Automatic, Single Block and Manual) may have

different base speeds. The base speed is set by the G-code

program or the parameter setting.

For each row, pressing the center key sets the speed at 100% of the

base speed; the LED light in the key’s upper-left corner is lit to signify

that the machine is running in base speed. Pressing the minus (-)

key, decreases the base speed by a fixed percent; pressing the plus

(+) key, increases the base speed by a fixed percent. Below is an

example where the speeds are changed by 2%:

KEY DESCRIPTION

Pressing this key decreases the speed 2% for

each press. The current speed or rate is displayed

on the LCD screen.

Once this key is pressed, the override ratio is set

to 100%. The LED light indicates that the current

speed is the base speed.

Pressing this key increases the speed 2% for each

press. The current speed or rate is displayed on

the LCD screen.

5

1 Introduction

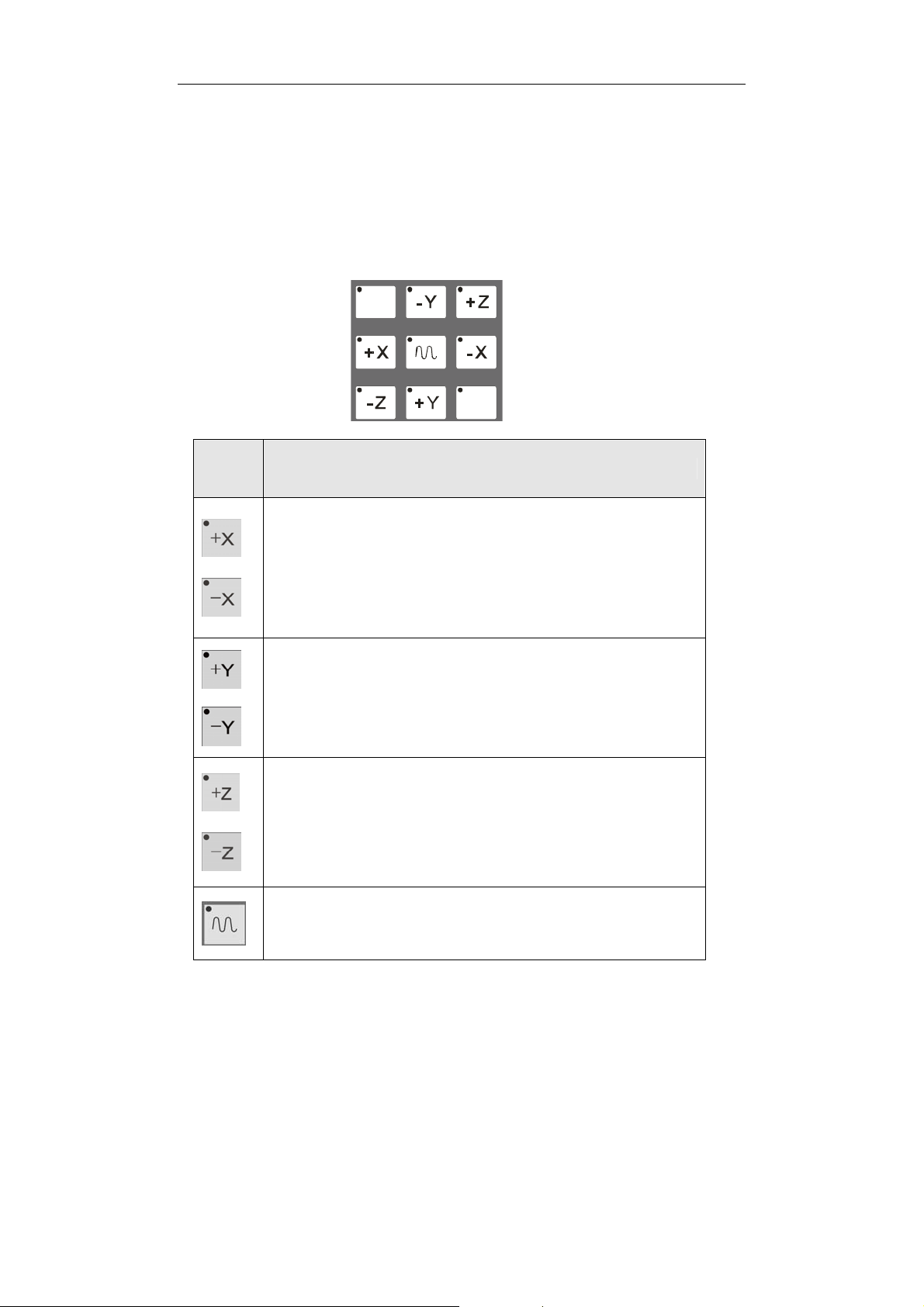

e) Axis Operation keys:

These five keys select 1) the desired axis and 2) the direction of

motion in various modes. These keys only function in Manual

Mode, INC Mode and Reference Mode. The LED light in the

upper-left corner specifies which axis or direction is selected.

KEY

DESCRIPTION

In INC mode or Manual Mode, the tool moves the X

axis in the positive direction while +X is pressed

and in the negative direction while –X is pressed.

In Reference mode, pressing the +X key homes the

X axis (finds the machine reference on the X axis).

In INC mode or Manual Mode, the tool moves the Y

axis in the positive direction while +Y is pressed

and in the negative direction while –Y is pressed.

In Reference mode, pressing the +Y key homes the

Y axis (finds the machine reference on the Y axis).

In INC mode or Manual Mode, the tool moves the Z

axis in the positive direction while +Z is pressed and

in the negative direction while –Z is pressed. In

Reference mode, pressing the +Z key homes the Z

axis (finds machine reference on the Z axis).

This key speeds up tool motion in Manual mode. It

must be pressed in conjunction with one of the Axis

keys.

6

HNC-18/19T Operator’s Manual

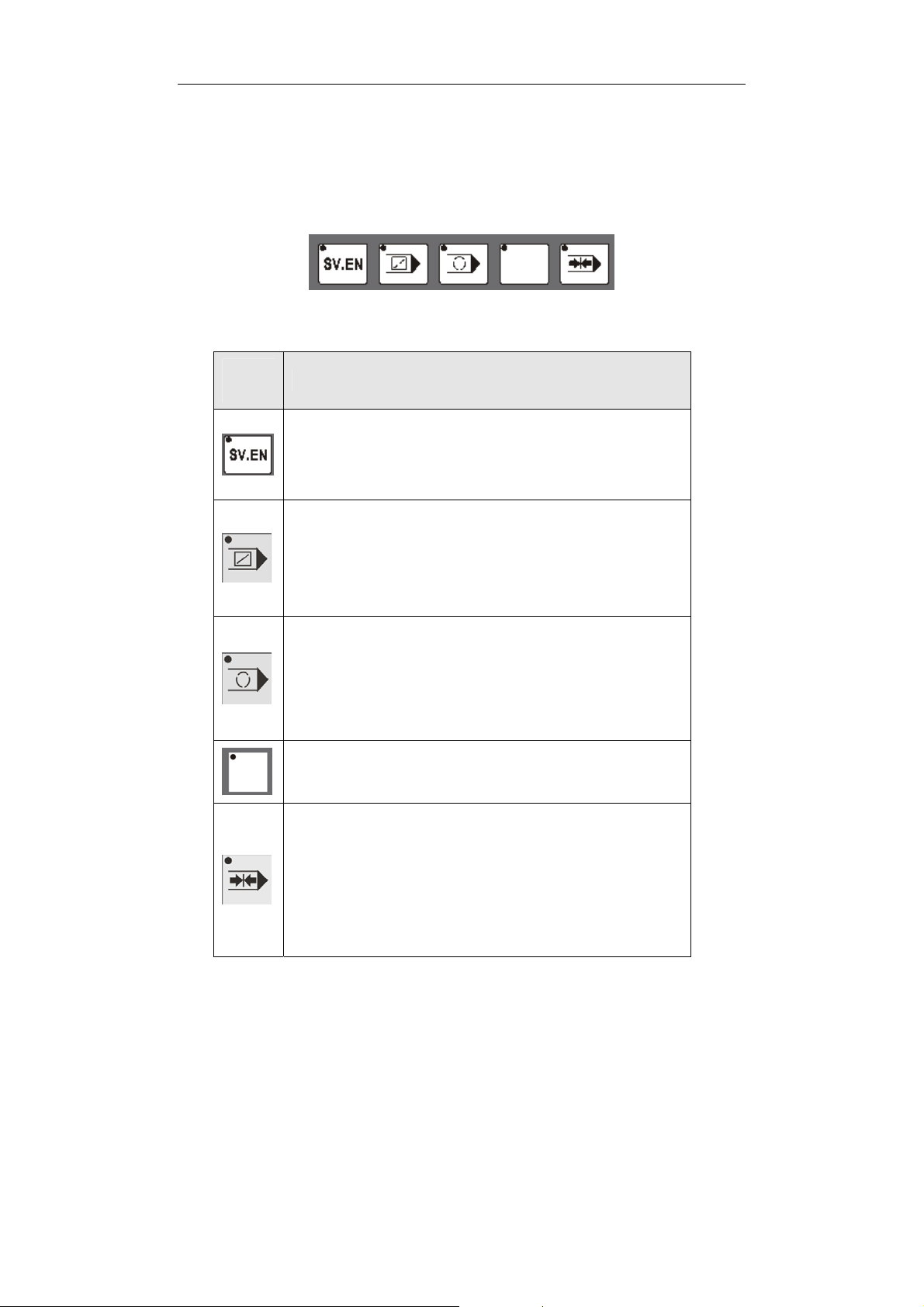

f) Other keys:

The five keys below are other keys that control various machining

functions.

KEY

DESCRIPTION

Servo enable key: Press this key to enable

or disable the servo.

Block Bypass key: Activating this key

bypasses program blocks that start with a “/”

character

Program Stop key: Activating this key

enables the M01 G-code stop function,

stopping the program at a desired block.

Not used.

Machine Lock key: Activating this key

prevents any motion from the spindle, the tool

changer turret or any axis; it is used for system

testing

7

1 Introduction

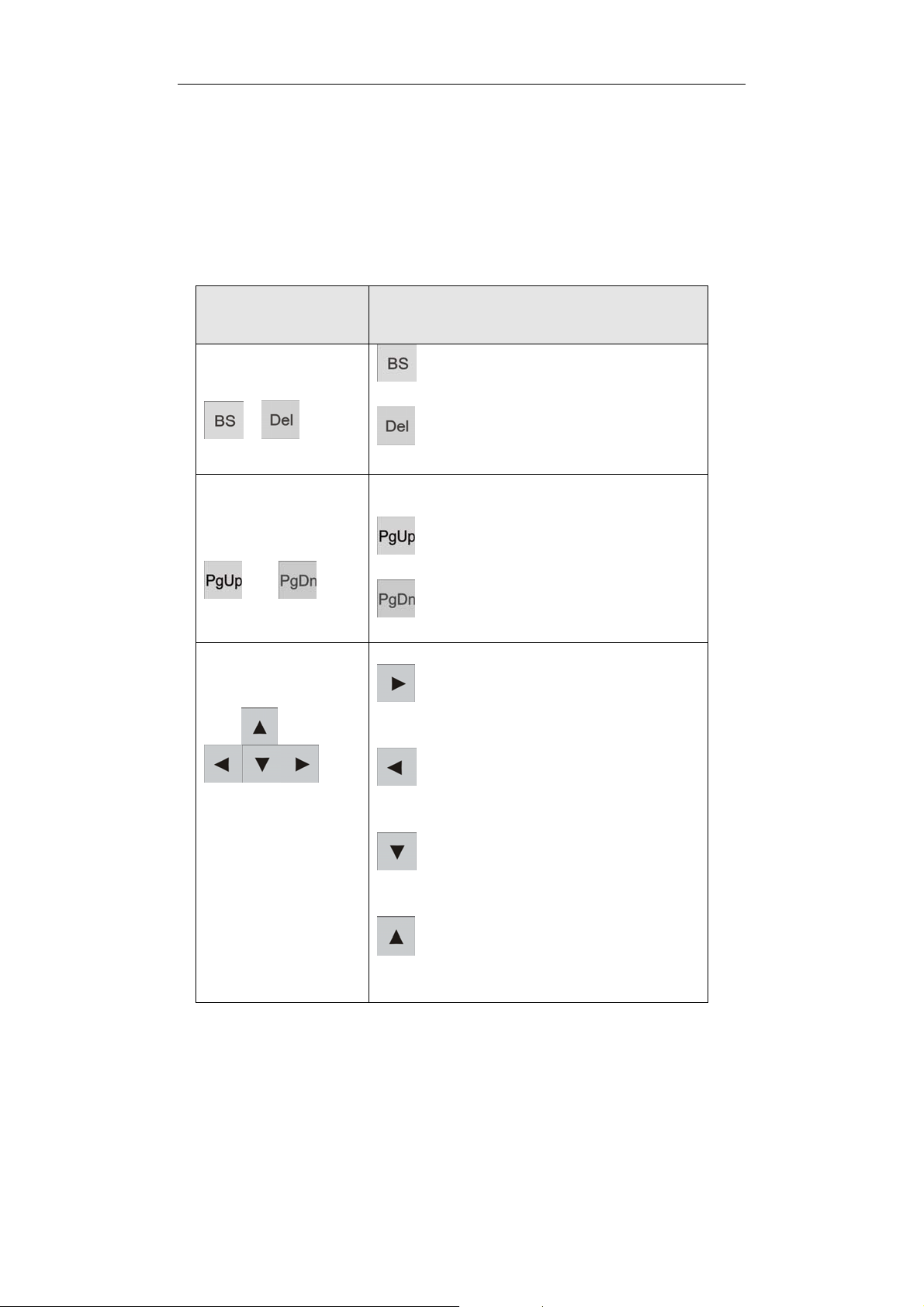

Alpha Numeric Keyboard

The Alpha Numeric keyboard lets the operator input either letters or

numbers for programs, parameters or conversational commands.

KEY

Delete keys

Page change keys

Cursor keys

DESCRIPTION

Backspace key deletes the

character in front of the cursor

Delete key deletes the character

at the cursor

There are two kinds of page change

keys:

PageUp key moves the page one

screen up

PageDown key moves the page

one screen down.

Right key: moves the cursor to

the right, selects a soft key to the right

or selects a column to the right.

Left key: moves the cursor to

the left, selects a soft key to the left or

selects a column to the left.

Down key: moves the cursor

down, selects a soft key on the bottom

or selects a row on the bottom.

Up key: moves the cursor up,

selects a soft key on the top or selects

a row on the top.

8

HNC-18/19T Operator’s Manual

Shift Up key

The Shift Up key toggles the status of

double-character keys in the Alpha

Numeric keyboard. The LED light in the

upper-left corner indicates whether the

upper character is selected. When

the LED light is on, the upper character

is selected, otherwise the lower

character will be input. For example,

“X” will be input if is pressed

when LED light of

is off, while

“A” will be input when the LED light is

on.

9

1 Introduction

Menu tree

For HNC-18/19 CNC system, there are seven function keys below

the alpha numeric keyboard that bahave as seven different function

keys.

They are:

KEY

DESCRIPTION

PROGRAM submenu key: Press this key to do

operations related with program such as open, edit

or test a part program.

SETTING submenu key: Press this key to

activate setting submenu.

MDI submenu key: Press this key to switch to

MDI (Manual Data Input) submenu.

OFFSET submenu key: Press this key to enter

into OFFSET submenu which enable the operator

to set a tool’s offset data.

DIAGONOSIS submenu key: Activating this key

will present DIAGONOSIS submenus, which can

help user to tell what is the cause of faults

happened.

POSITION submenu key: This key will bring up

the POSITION submenus. Which allow the

operator to choose different axes coordinates type

to monitor.

PARAMETER submenu key: Press this key to

enter into PARMAETER submenu, where the user

can check or modify the system’s parameters.

10

HNC-18/19T Operator’s Manual

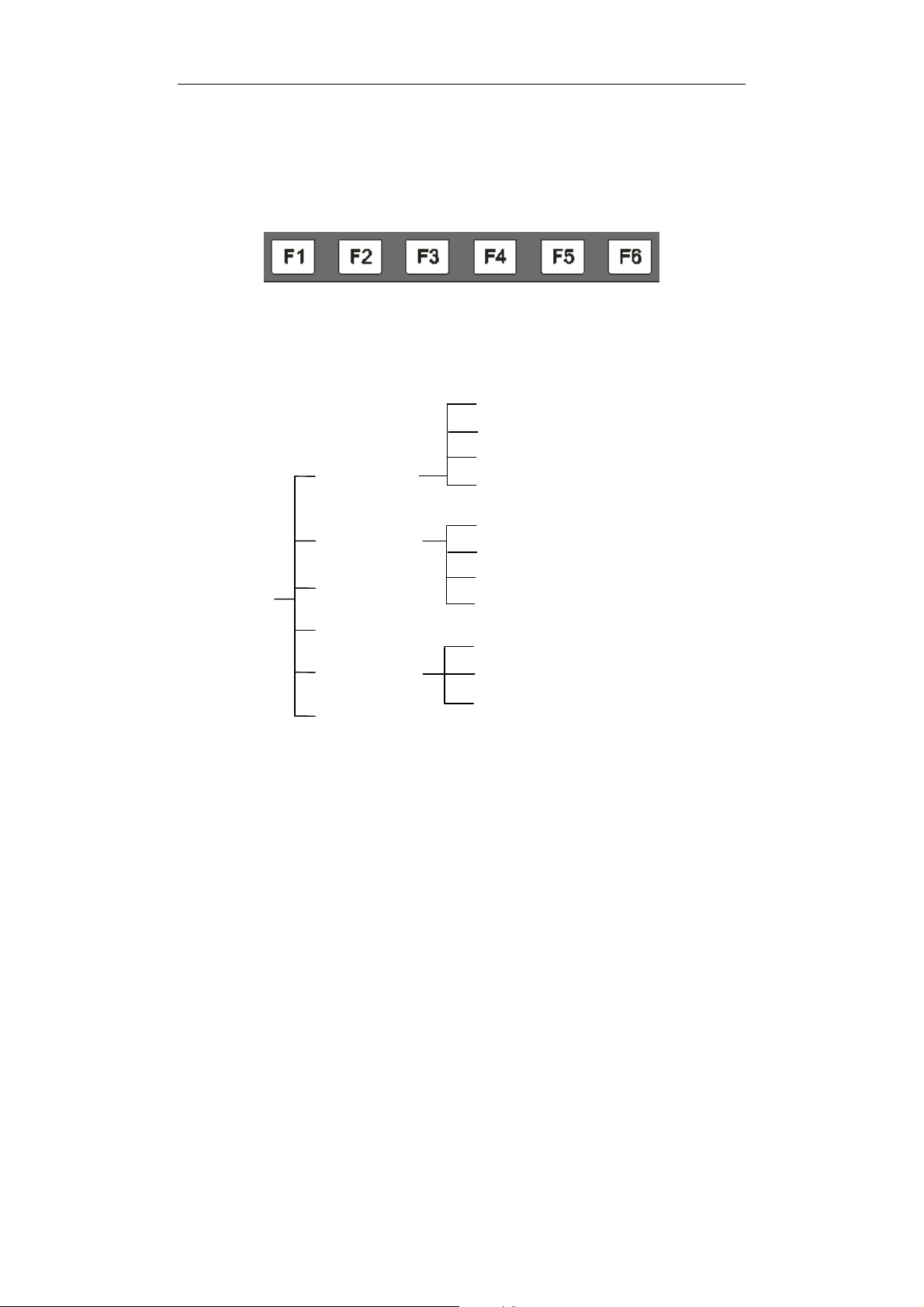

There are six soft keys to navigate each of the above key. The

functions of the soft keys change according to which function key is

active.

Each function is corresponding to one submenu. Let’s go through the

seven submenus one by one.

a) PROGRAM SUBMENU

OPEN (F1)

TST (F3)

REW (F4)

BP (F5)

DNC (F6)

EDIT (F2)

NEW (F3)

SAVE (F4)

PRG

TST (F3)

REW (F4)

BP (F5)

ROW (F5)

STOP (F6)

SAVE BP (F1)

LOAD BP (F2)

DNC (F6)

BACK (F6)

The key “PRG” has six submenus.

F1, corresponding to OPEN, picks which program is to be run or

edited. By default or switched from EDIT to OPEN, F3~F6 are

attached with TST, REW, BP and DNC.

TST, stands for PROGRAM TEST, verifies whether the opened

program has correct syntax and tool path.

REW, abreviation of REWIND, restarts a program from the first

block.

11

1 Introduction

Y

Y

BP, means breakpoint operation, has three submenus, SAVE

BP(Save the break point information to a file), LOAD BP(Load

the break point information from a file) and BACK(Back to OPEN

function menus).

DNC, enable the NC to receive program from a computer.

F2, corresponding to EDIT, allows the user to do edit operation and

some running process control operation. When EDIT is active,

F3~F6 are used for NEW, SAVE, ROW and STOP(Stop the program

from running)

NEW, creates a new program.

SAVE, saves the current program.

ROW, allows the user to run the program from a specified row

rather than from the first.

STOP, Stop the program from running.

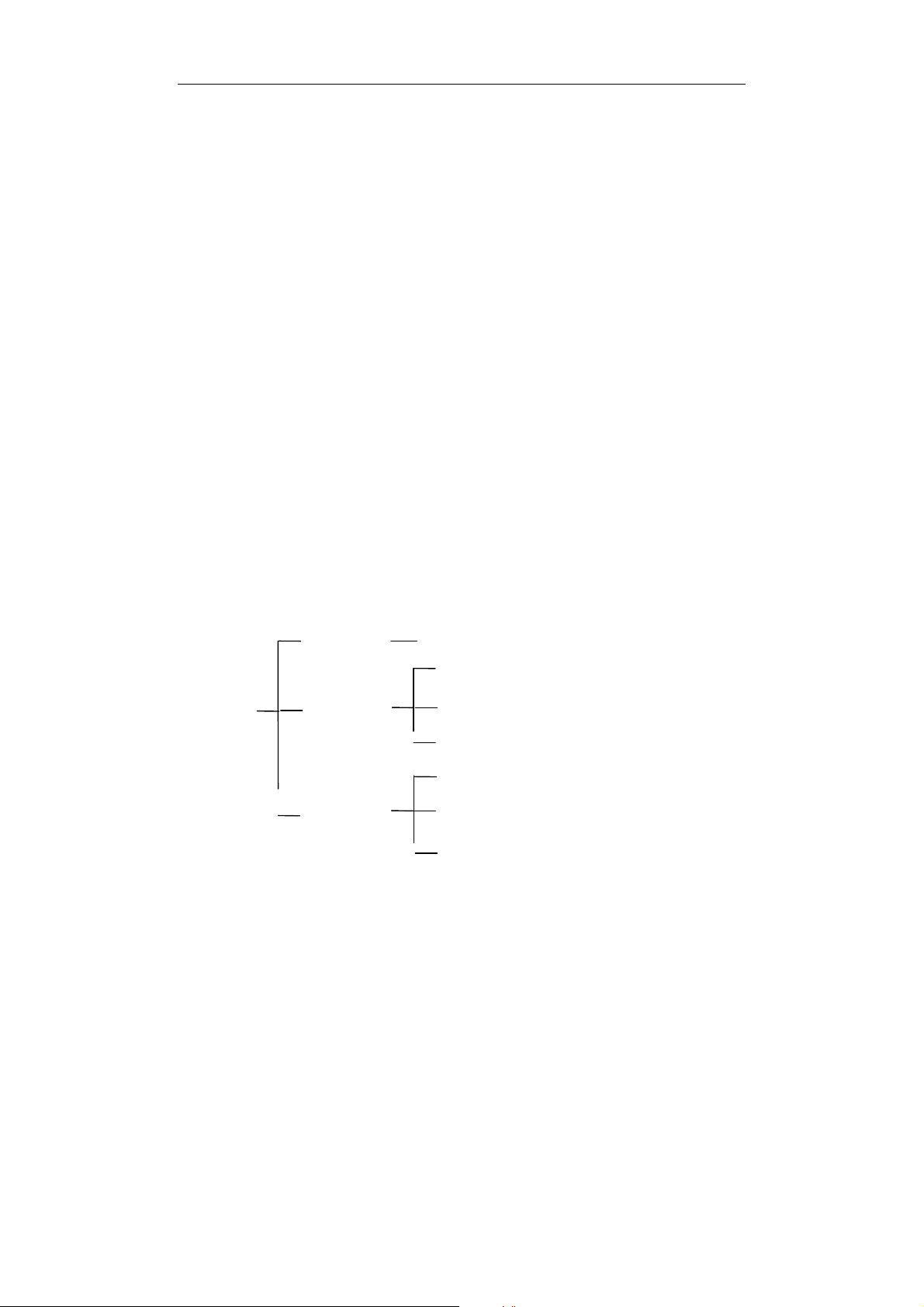

b) SETTING SUBMENU

SET

WCS (F1) G54~G59, RCS(PgUp PgDw)

X RST (F4)

RCS (F2)

RST (F5)

Z RST (F6)

X HPI (F4)

HPI (F3)

HPI (F5)

Z HPI (F6)

The key “SET” has three submenus.

F1, WCS, workpiece coordinate system. Lets the user to set

coordinates system’s origin offset for G54 to G59 and RCS.

F2, RCS, relative coordinate system. This function has two

12

HNC-18/19T Operator’s Manual

A

submenus: X RST, resets the X position of RCS’s origin. Y RST,

resets the Y position of RCS’s origin. Z RST, resets the Z position of

RCS’s origin.

F3, corresponding to HPI(Home position input), also has three

submenus: X HPI, resets the X position of home point. Y HPI, resets

the Y position of home point. Z HPI, resets the Z position of home

point.

c) MDI SUBMENU

MDI

BAK.BP (F5)

LIGN TOOL (F6)

The key “MDI” has two submenus.

F5, corresponding to BAK BP, lets the tool go back to the break point

after an interactive intervention during automatic machining.

F6, corresponding to ALGN TOOL, allow operator to re-align the

tool’s dimension.

d) OFFSET SUBMENU

LEN Comp (F1)

OFT

DIAComp (F2)

The key “OFT” has two submenus.

F1, corresponding to Len Comp, allows the user to measure and set

the tool’s length compensation value.

13

1 Introduction

A

F2, corresponding to DIA Comp, used for the user to input the tool’s

diameter compensation value.

e) DIAGNOSIS SUBMENU

I/O (F1)

REG. (F2)

DGN MSG(F3)

BT(F5)

JOB NOTE (F6)

NEW JOB (F3)

RST JOB (F4)

BACK (F6)

The key “DGN” has five submenus.

F1, corresponding to IO, displays the status of I/O points.

F2, corresponding to REG, presents the value of the system

registers.

F3, corresponding to MSG, lists the contents of alarms.

F5, corresponding to ABT(ABOUT), presents version information of

the software.

F6, corresponding to JOB NOTE, is a statistic function which has

three submenus, NEW JOB, RST JOB and BACK.

NEW JOB, allows the user to set the planned workpieces

number.

RST JOB, lets the user to reset the statistic value.

BACK, back to the previous menu.

14

HNC-18/19T Operator’s Manual

A

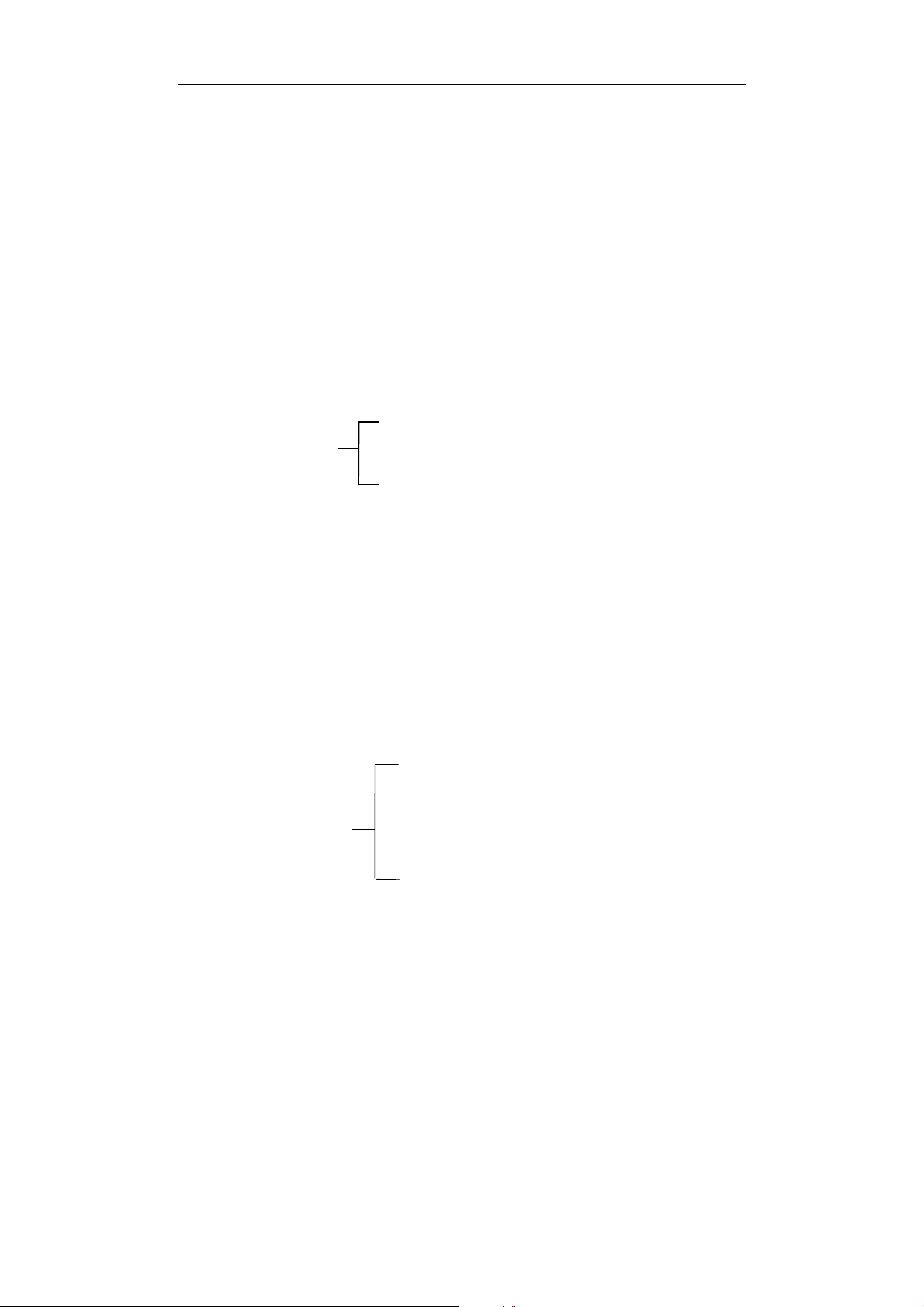

f) POSITION SUBMENU

POS

MCS (F1)

WCS (F2)

LL (F3)

TEXT (F4)

GRPH (F5)

GRPH PARM (F6)

The key “POS” has six submenus.

F1, corresponding to MCS, displays machine coordinate system.

F2, corresponding to WCS, displays workpiece coordinates system.

F3, corresponding to ALL, displays overall information of the axes.

F4, corresponding to TEXT, displays the G code of the program.

F5, corresponding to GRPH, displays the graphical figure of the part.

F6, corresponding to GRPH PARM, allows the user to set graphical

figure’s parameters.

g) PARAMETER SUBMENU

BACK PARM (F1)

LOAD PARM (F2)

PAR

DNC PARM (F3)

PASSWORD (F4)

BACK PLC (F5)

LOAD PLC (F6)

15

1 Introduction

The key “PAR” has five submenus.

F1, corresponding to BACK PARM, makes a backup parameters.

F2, corresponding to LOAD PARM, loads a saved parameter file.

F3, DNC PARM, used to set the DNC parameters.

F4, PASSWORD, inputs the password to access the parameters.

F5, corresponding to BACK PLC, backs up the PLC program.

F6, corresponding to LOAD PLC, loads a saved PLC program.

16

Loading...

Loading...