Page 1

EVO 7

Cable Tie Application Tools

Documentation Provided By HMC Electronics

33 Springdale Ave. Canton, MA 02021

http://www.hmcelectronics.com

(800) 482-4440

Page 2

It began with a simple question: Could we create a new cable tie tool

designed to reduce the risks of repetitive-stress injuries to users while

actually increasing their productivity?

THE EVO 7 WITH TLC TECHNOLOGY.

YE

S

It ended with a definitive answer:

Documentation Provided By HMC Electronics

33 Springdale Ave. Canton, MA 02021

http://www.hmcelectronics.com

(800) 482-4440

Page 3

1

REVOLUTIONARY

Introducing the next evolution of cable tie

tools, featuring ergonomically-enhanced

comfort, safety and performance.

Documentation Provided By HMC Electronics

33 Springdale Ave. Canton, MA 02021

http://www.hmcelectronics.com

(800) 482-4440

Page 4

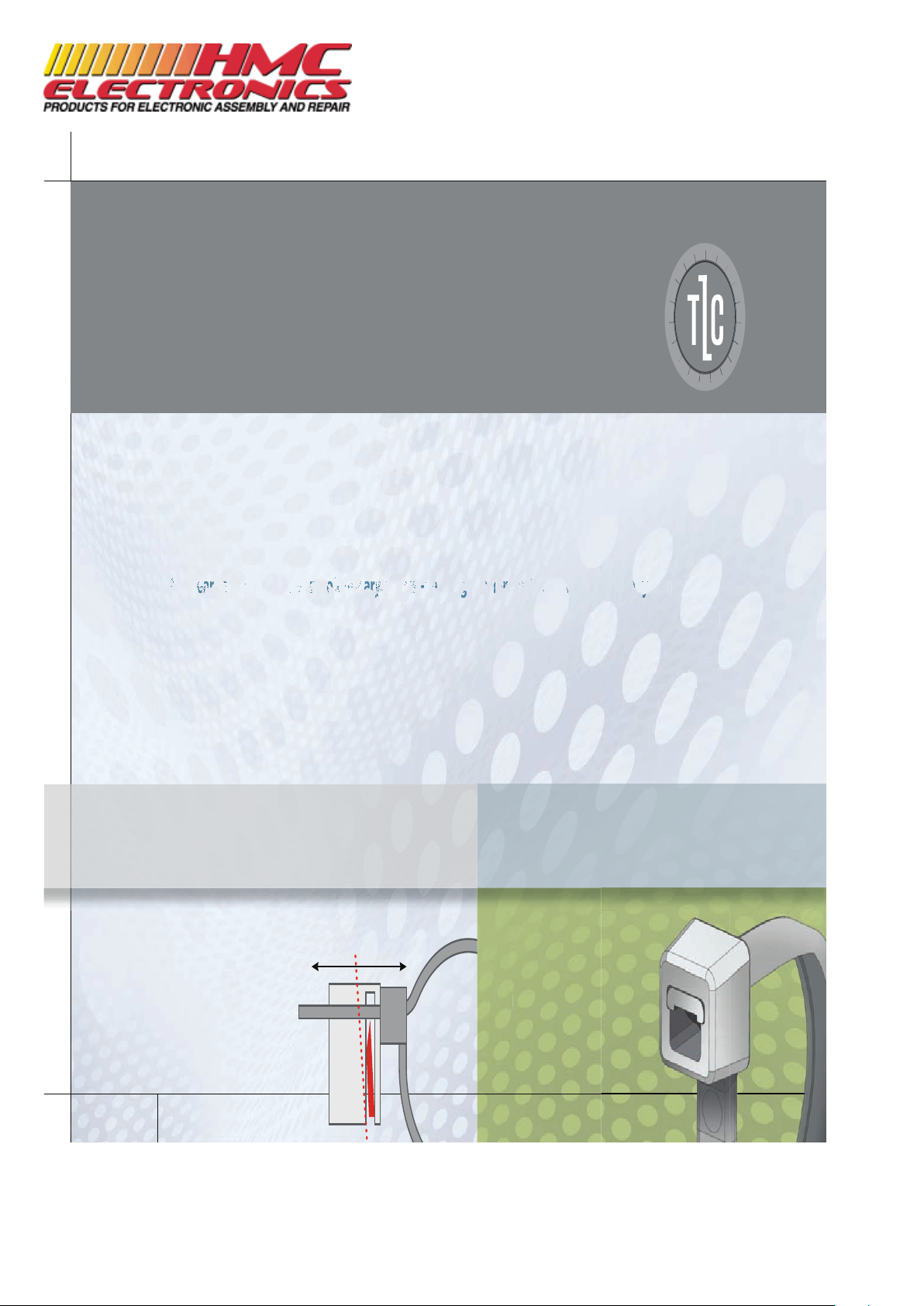

The heart of EVO 7

TLC TECHNOLOGY

Continual dynamic tension

allows potential for lateral

movement throughout the

cutting process. When the tie

is cut, it snaps abruptly, jarring

the users hand, resulting in a

protruding, sharp edge.

• No jarring impact

• Clean, fl ush cut

• Minimal hand force needed

• No overstressing of

cable tie

No, in this case, TLC doesn’t literally stand for “tender lovin

g

care”. But you can be sure plent

y

went into its development. In fact, our

engineers incorporated the advice and feedback of leadin

g ergo

nomic experts to perfect a tool

sp

ecifi cally designed to protect users from

the risks of repetitive-stress injuries. All of this results in healthier workers and better installations – TLC at its best.

AA

tt tthhee hheeaartt

oof t

he EVO

O 77 lie

s rreevvoollluu

ttionna

r

y

y

,

pp

aattenntt

p

p

eddin

g

g

TTnsso//Lo

c/Cuutt

(

(

T

T

LC) technol

o

y

y

that

dramatically

changes how cable ties are cut. The ke

y

is TLC’s ability to lock each tie in place at the desired tension prior to cuttin

g

. Because the tension is

fi xed at the tri

gg

er when squeezin

g

begins, only a minimum of hand force and a shorter ran

g

e of motion is required to cut throu

g

h each

tie. hat’s more, there’s no jarring impact after the cut. Also, because each tie is cut at a consistent level of tension with less movement

,

there’s less wear on internal components, resultin

g

in longer tool life

.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

T

E

N

S

I

O

N

.

L

O

C

K

.

C

U

T

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2

Tie movement can cause blade angle

WITH TLC TECHNOLOGY...

EVO 7

WITHOUT TLC TECHNOLOGY...

STANDARD CUTTING TOOL

eeded

Documentation Provided By HMC Electronics

33 Springdale Ave. Canton, MA 02021

http://www.hmcelectronics.com

(800) 482-4440

Page 5

TENSION

Want to select a specifi c level of tie tension for bundling? Simply rotate the tension knob

to any of the easy-to-read, pre-set tension settings. Standard cable tie installation tools

stretch the tie while cutting, causing the tie end to retract into the head, or leave a

protruded edge. But with EVO 7, the tie is cut at precisely the tension you select for a

clean, fl ush cut at the tie head – without overstressing the tie.

LOCK

With TLC Technology, the patent-pending locking mechanism detects when the desired

tension is met, and locks the tie in place prior to cutting. At that moment, all force applied

to the trigger is directed to cutting the tie. That means the trigger only needs to be pulled

far enough to cut the tie, reducing the range of motion and subsequent strain on the hand

and arm.

Once the tie is locked in place, the tool operator needs only to advance the trigger

enough to cut the tie. Since there is no dynamic tension (stretching) on the cable tie, all

energy is focused on driving the blade through the tie, resulting in a clear, fl ush cut, time

after time – all with no jarring motion to the hand or arm.

CUT

3

LOCK

Documentation Provided By HMC Electronics

33 Springdale Ave. Canton, MA 02021

http://www.hmcelectronics.com

(800) 482-4440

Page 6

4

TWO GRIP SPANS

Because hands come in different sizes, so

does EVO 7. Choose from a standard grip

span or short grip span, for smaller hands.

From the inside out, the EVO 7 was designed with user comfort and safety in mind. That’s

because the more you use a tool, the more you’re at risk to suffer a repetitive-stress injury.

According to the U.S. Bureau of Labor Statistics, repetitive-stress injuries account for two-

thirds of all occupational injuries and result in the longest absences from work – a median of

18 days missed! The resulting costs are astronomical.

No wonder our engineers made ergonomics their highest priority. Of course, their focus

began with the development of TLC technology, which signifi cantly reduces the amount of

strain and impact on the user’s muscles and tendons. But there’s much more.

The EVO 7 is lightweight, with a handle designed to keep the wrist in an upright, neutral

position. Contoured to fi t the palm of the hand, the handle is crafted from soft, non-slip

material with a built-in air cushion to reduce pressure points. The soft-touch trigger even

features individual fi nger grips for greater comfort and control. Add it all up and the

EVO 7 is one very handy tool, indeed.

Getting a grip on

ERGONOMICS

4

TWO

GRIP

SP

ause hands c

o

s EVO 7.

Cho

o

span or short g

rip

om t

ca

us

Accord

thirds

o

days wongan

strain

a

Th

e EV

positi

o

m

at

fea E

VO

etting

3.1 ˝ (80mm)3.5 ˝ (90mm)

STANDARD SHORT SPAN

Documentation Provided By HMC Electronics

33 Springdale Ave. Canton, MA 02021

http://www.hmcelectronics.com

(800) 482-4440

Page 7

Yo

u’u’llll

b b

e e

abab to o cocount t onon EVO 7’s s

super

ioio

r r

pepe

ormama

ncnc

e

jo

b after job. That’s because the EVO

7

d d

esesnene

d dfo

r

ma

xi

x

mu

m

dudubi

tyty

. .

s s

ad

ad

va

nc

ed

composite housing is both

i

mp

acact

an

an

chemic

al

sisistst

anan

t t and d

bubu

ililt

toto s s

tatandnd uu

p

p

to the most demanding industrial environs.

WhWhenen u u

sesed d

c c

bibination

with HellermannTyton’s su

rior line

of

h

ig

y-

y-

en

en

gi

neneed

cable ties, the

O O

sesetsts t

t

hehe

n newew s stataar

ar

fo

safe and effi cient cable tie ins

taatat

io

io

n. B tn, w

ould you

e

xp

p

ecect

t

ytyt

l l

eses

s s

frfr

omom t t

hehe

g g

babaad

er in cable tie hand tool design

f

or o o

vevethe

e

de

de

cades?

c

onsist

en

cycy

is th

e

mark o

f

gr

eatnes

s, the EVO 7 more than m

easures s

up

up

t

t

o the

stst

andard. Thanks to

tent-pending Tension/Lock/Cut (TLC) technology, the EVO 7 effossly c

uts to

t

t

p

p

recise selected

tension, tie after tie, job after job. What’s more, every

EVO O 7 7 ill

y y

ca

ca

li

l

brated at our factory,

ensuring consistent performance from too

to too

l, a

o o

veveth

e e lili

fefe

o of

each individual tool

.

that’s a cut above the rest

PERFORMANCE

5 (20)09 (38)112 (51)215 (68)319 (85)423 (104)528 (125)632 (143)737 (165)

8

AVERAGE TENSION CUT-OFF FORCE - LBS. (N)

TENSION SETTING

Documentation Provided By HMC Electronics

33 Springdale Ave. Canton, MA 02021

http://www.hmcelectronics.com

(800) 482-4440

Page 8

TENSION

ADJUSTMENT

SYSTEM

Finally, a system that lets you

adjust tension without causing any.

The EVO 7 features the industry’s

widest tension range, with 33

precisely calibrated, easy-to-read,

pre-set tension settings, allowing

for the most precise and perfectly

applied cable tie available. Simply

rotate the tension knob until your

desired setting clicks into place.

There’s no guesswork, no fi ne

tuning. The tension for each setting

always remains the same. Want

to lock in a desired tension? Just

remove the screw from the thumb

lock and place it in the provided

lock hole. It’s just that easy!

B

A

TENSION LOCK

MECHANISM

To lock the tension,

remove the screw

from its storage

position (A) and

insert into the EVO 7

lock mechanism (B).

6

Documentation Provided By HMC Electronics

33 Springdale Ave. Canton, MA 02021

http://www.hmcelectronics.com

(800) 482-4440

Page 9

T

ension Knob

:

ate

th

th

e ke k

nob

nob

to

an

an

y o

y o

f 3

f 3

3 p

3 p

p

rec

rec

ise

pre

-se

t t

ens

ens

ion

ion

se

tti

heshes

e e

e e

asy

asy

-to

-re

ad

ad

set

set

tintin

gs

gs

em

ain

co co

nst

ant

an

d c

ons

ist

ist

ent

ent

fr fr

om

too

l t

o t

ool

.

ong Narrow

e:

All

ows yo

u

to to

cutcut

ca

ble

ti

es

in

the tightest

of

spa

spa

cesces

qu qu

ly ly

and

ea

sil

y.

Easy Blade

eplacement:

One

-wa

-wa

y b

y b

lad

lad

e i

nsnsal-

al-

ionion

ma

ma

keskes

on

on

-s-s

te

de

rep

rep

lac

eme

emena

a

snap. There’

s n

o n

eed

to send the tool in

and

youy’re

upp and r

un

ing

agaaga

in

in

no

tim

e.

ontoured Ergonomically-Engineered Handle:

fte

d f

so

ft-gri

p,

non

-sl-sl

matmat

eri

eri

al,

th

e g

e g

rip

rip

feafea

tur

es

an integrate

d a

ir

cuscus

hio

hio

n t

n t

hathat

co

to

you

you

r h

r h

and

for maximum co

mfo

rt.

Trigger:

ade from soft-

gri

p,

p,

non

-sl

-sl

ip ip

eri

al,

th

e c

ont

ont

ourour

ed

ed

fulful

engeng

th

th

tri

tri

gge

gge

r r

orp

orp

ora

ora

tes

tes

in

div

idu

al

fi n

ger

g

grips

to

a

ccommodate

mul

tip

le hand sizes.

Thumb Lock

:

To

unl

unl

ock

th

e t

ensens

ionion

kn

kn

ob,

sl

sl

th

the -sl-sl

ip

thumb

loc

k fk f

orworw

ard

dju

dju

st

to to

des

de

ired tension

set

tin

g a

g a

nd

nd

eas

eas

e tehe

thu

mb

loc

k t

k t

o l

o

ockoc in

pl

p

ace

ace..

nt

egr

ated H

ang

er Hoo

k:

Allows easy

sto

rag

rag

e

e

and

ac

ces

sib

ili

ili

ty.

ty.

Wider Tapered Tie E ntry: Per mits

easy i

nse

rti

on

of of

eaceac

h th t

so

so

yo

yo

u c

an

e f

rom

ti

e t

o t

fas

fas

ter

ter

th

an

eve

r.

FEATURES

Impact-Res

i

stant Hous

ing:

e f

rom

du

du

rab

rab

le,

le,

li

li

ght

ght

ght

weiwei

ghtght

co

mpo

site,

the

EV

EV

O 7

we

igh

s 9

s 9

.7

.7

oz.

oz.

(.

(.

275

275

kg

kgg),

),

),

ist

s c

hemhem

icaica

l cl c

ontont

amianat

ion

an

d id i

s b

s b

uil

t t

o s

tan

d ud u

to

to

the

the

to

to

ugh

est

in

dus

dus

tri

tri

al

env

iro

nme

nts

nts

T

op

Vi

ew

of

unitnt

Viewof

uni

t

7

Documentation Provided By HMC Electronics

33 Springdale Ave. Canton, MA 02021

http://www.hmcelectronics.com

(800) 482-4440

Page 10

TESTIMONIALS

“It used to be that at the end of a day of working on small harnesses, my hand would just ache.

With EVO 7, that’s no longer an issue. I also like the numbered tension settings and the screw

hole so you can lock in your setting. It’s the best tool I’ve ever used!”

MIKE T. Installer - Wire Harness Assembler

“It just fi ts my hand. Cutting is much smoother, too. None of that jerking motion like with other

tools. Much easier on my hands and arms. And the cuts are clean—I don’t have to go back and

trim at all. The work goes much easier and much faster. It’s the best tool I’ve ever tried.”

MICHELE B. Installer - Major Aeronautics Manufacturer

“I can barely feel it when I cut the tie strap. It’s much easier on my wrist. Adjusting the tension is

easy, too. You just twist the knob to the number you want and it clicks in. With other tools, you’re

always guessing. If I were rating them, other tools would be a ‘5’. EVO 7 is a ‘10’!”

LUZ L. Installer - Major Aeronautics Manufacturer

“The difference is amazing. This tool is much easier to squeeze and very smooth. Everybody

likes it. It’s good for morale and good for our people, long-term. The EVO 7 also cuts very fl ush.

In our business, that’s important for quality and safety. We can’t leave any sharp edges. Our

cuts have never been so clean.”

AL A. President - AF Technologies

LEADING TIER SUPPLIER TO THE AEROSPACE INDUSTRY

SUPPLIER TO THE POWER GENERATION INDUSTRY

SUPPLIER TO THE UNITED STATES DEPT. OF DEFENSE

8

Documentation Provided By HMC Electronics

33 Springdale Ave. Canton, MA 02021

http://www.hmcelectronics.com

(800) 482-4440

Page 11

HellermannTyton Cable Ties

BETTER BY DESIGN

Innovation. Performance. Durability. The qualities that went

into creating the EV

O

7 are the same ones that go into

making HellermannTyton cable ties the fi nest in the industry.

Wh

en HellermannTyton’s industry-leading cable ties

are used in combination with the EV

O

7, you can be

confi dent that each tie has been precisely tensioned and

cut, ensuring the longest and safest life in its application.

ellermannTyton cable ties are engineered to our exact

ing

standards and manufactured from high-grade materials f

or

ong-lasting relia

bili

ty and superior tensile strength.

Add i

n our comm

i

tment to work closely with you to meet

the unique tie and tool needs of

y

our operation, and we

think you

’ll

agree: HellermannTyton ties it all together

.

ORDERING INFORMATION

Part No. Type Description

Cable Tie Installation Tools

110-70083 EVO7 Standard hand span 3.5” (90mm) can be used with all variations of

HellermannTyton’s 18-80 lb cable ties

110-70084 EVO7SP Short hand span 3.1” (80mm) can be used with all variations of

HellermannTyton’s 18-80 lb cable ties

Replacement Parts/Accessories

110-70106 BLADEKT Blade replacement kit for EV07 and EVO7SP. Contains: (1) Blade &

(1) Nose piece Screw

110-70091 T8SD T8 Star Driver for removal/insertion of tension lock out screw

110-70089 CALTOOL Calibration Tool to be used for removal of cap at back of tension knob

and for calibrating tool on site

110-99000 UC200

UC200 Tension Gauge for tensile read outs when calibrating tools

on site

Most Popular Cable Ties

T18R9M4 T18R 18 pound cable tie, 4˝ long, PA66, natural, 1000/bag

T18R0M4 T18R 18 pound cable tie, 4˝ long, PA66, black, 1000/bag

T30R9M4 T30R 30 pound cable tie, 6˝ long, PA66, natural, 1000/bag

T30R0M4 T30R 30 pound cable tie, 6˝ long, PA66, black, 1000/bag

T50R9M4 T50R 50 pound cable tie, 8˝ long, PA66, natural, 1000/bag

T50R0M4 T50R 50 pound cable tie, 8˝ long, PA66, black, 1000/bag

For our complete selection, go to www.hellermann.tyton.com • 1.800.537.1512 • corp@htamericas.com

Documentation Provided By HMC Electronics

33 Springdale Ave. Canton, MA 02021

http://www.hmcelectronics.com

(800) 482-4440

Page 12

www.hellermann.tyton.com

1.800.537.1512

TOOL WARRANTY

HellermannTyton offers a 90-day warranty with the purchase of any cable tie installation tool. An extended

one year warranty is available by registering the tool online at www.hellermann.tyton.com/warranty after

receipt of the tool.

HellermannTyton warrants our mechanical hand tools (EVO 7, EVO 7SP, MK7, MK7HT, MK9, MK9HT, MK9SST,

MK9RC, MK9REF) to be free from defects in manufacturer workmanship and material under normal conditions

of use and service for a period of 90 days from initial delivery to the purchaser. Purchaser shall notify

HellermannTyton of any warranty claim within ten (10) business days after discovery, but not later than the

expiration of the above warranty period or such claim shall be deemed waived.

The foregoing warranties and remedies are exclusive and in lie of all other warranties and remedies

whatsoever, expressed or implied, including, but not limited to, any warranties of merchantability or fi tness

for a particular purpose, which HellermannTyton expressly disclaims. All warranties are deemed void if tool

is opened or tampered with.

HellermannTyton North American

Corporate Headquarters

7930 N Faulkner Rd.

P.O. Box 245017

Milwaukee, WI 53224-9517

Phone: 414.355.1130, 1.800.537.1512

Fax: 414.355.7341, 1.800.848.9866

Email: corp@htamericas.com

TS16949:2002, ISO 9001:2000 and

ISO 14001 certifi ed

HellermannTyton Canada

205 Industrial Parkway North, Unit #4

Aurora, Ontario L4G 4C4 Canada

Phone: 1.800.661.2461

Fax: 1.800.390.3904

Email: sales@hellermanntyton.ca

HellermannTyton Mexico

Anillo Periférico Sur 7980 Edifi cio 2 - D

Parque Industrial Tecnológico II

Santa María Tequepexpan

Tlaquepaque, Jalisco, México 45601

Teléfono: 011.52.33.3133.9880

Fax: 011.52.33.3133.9861

Email: info@hellermanntyton.com.mx

MADE IN THE USA

LITPD246

GENERAL WARRANTY

HellermannTyton products are warranted to be free from defects in material and workmanship

at the time sold by us; but our obligation under this warranty and that of the seller is limited to

the replacement of the product, and neither we nor the seller are bound by any other warranty,

expressed, implied or statutory.

Under no circumstances are we or the seller liable for any loss, damage or expenses or

consequential damages of any kind arising out of the use or inability to use these products. All

are sold with the understanding that the user will test them in actual use and determine their

adaptability for the intended uses.

EXTENDED TOOL WARRANTY

S

T

ANDARD

EXTENDE

D

90 Days

Year

Register online to appl

y

is

ter productonne w

it

i

n 1

m

ontistration notice

e-m

ail

w

ill

be

sent

e

e Ye

ar

o

f

W

arr

a

y

eas

Documentation Provided By HMC Electronics

33 Springdale Ave. Canton, MA 02021

http://www.hmcelectronics.com

(800) 482-4440

Loading...

Loading...