Page 1

3

3M™Scotch-Weld™Structural Adhesives

Product

1

Matching 3M structural adhesives

to your performance requirements

Selection

Guide

Documentation Provided By HMC Electronics

33 Springdale Ave. Canton, MA 02021

http://www.hmcelectronics.com

(800) 482-4440

Page 2

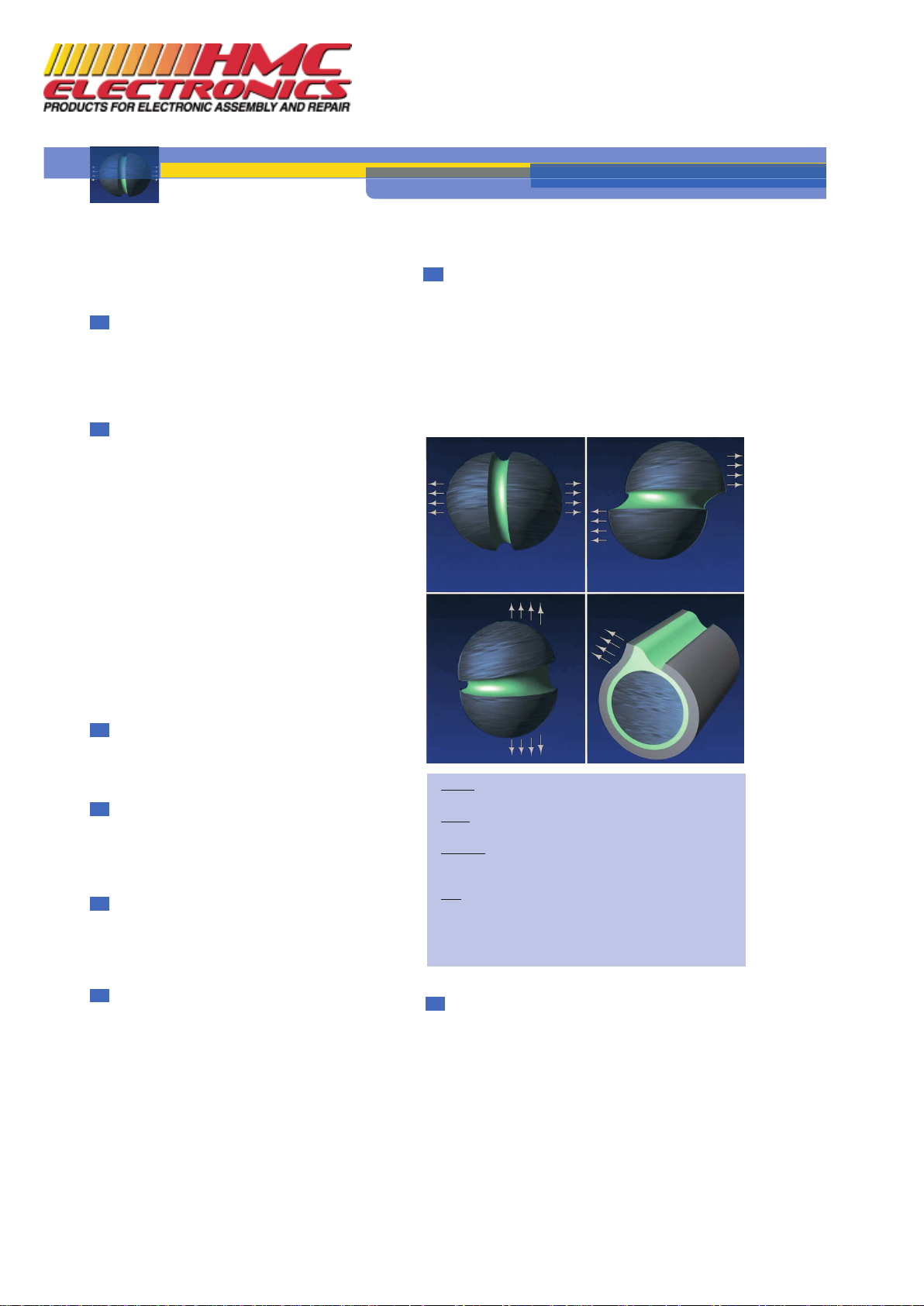

Tensile Shear

Peel

Cleavage

Tensile is pull exerted equally over the entire joint. Pull

direction is straight and away from the adhesive bond.

Shear

is pull directed across the adhesive, forcing the substrates

to slide over each other.

Cleavage

is pull concentrated at one edge of the joint, exerting

a prying force on the bond. The other edge of the joint is

theoretically under zero stress.

Peel

is concentrated along a thin line at the edge of the bond

where one substrate is flexible. The line is the exact point where

an adhesive would separate if the flexible surface were peeled

away from its mating surface. Once peeling has begun, the

stress line stays out in front of the advancing bond separation.

Simplifying adhesive decisions for your application

The following questions will help you narrow adhesive choices to

two or three possibilities for evaluation.

Q1 What surfaces are to be bonded?

Understanding surface conditions is the first step to determining

how much bonding strength will be needed and which adhesives

may work best. For example, is the surface painted and with what

kind of paint? If the material is a plastic

, what kind? For bare metals,

will the surface be clean?

Q2 What are the general characteristics of the structural

adhesive types?

As a rule of thumb, 3M

™

Structural Strength Adhesives bond the

load-bearing parts of a product with a minimum of 1,000 psi overlap

shear strength.

• Epoxy adhesives in one and two-part formulations

provide the highest strength at elevated temperature and

chemical resistance of all 3M adhesives.

• Acrylic adhesives bond the widest variety of substrates including

hard-to-bond plastics and oily metal. The distinction is high

strength bonding without the surface preparation needed for

epoxies and urethanes

• Urethane adhesives are generally lower cost and cure quickly to an

elastic bond in applications requiring flexibility between dissimilar

materials. Impact resistance is a distinctive characteristic.

• Cyanoacrylate adhesives are high strength liquid formulations

known as instant adhesives. On rigid plastic, glass, metal, rubber

,

and other low porosity substrates, they harden in seconds

through reaction with surface moisture.

Q3 What is the present bonding or joining method?

When the answer provides likes/dislikes and advantages/disadvantages

of the current method, it is easier to determine if structural adhesive

can improve the end product quality and/or the production process.

Q4 What is the preferred bonding range?

This is often the biggest clue to help understand which product will

work best. Start with worklife – the amount of time you have to

apply and reposition – and then ask about time to handling strength

and full cure.

This could lead to productivity improvements.

Q5 Can simple surface preparation be included in the

production process?

Maximum bond strength and environmental resistance can be easily

achieved by cleaning with IPA/water (50:50 mix) and abrading with

Scotch-Brite

®

Surface Conditioning Products if the surface is very smooth.

Q6 What is the joint design and how will parts fit together?

For the best adhesive bond, there should be at least a .003"-.005"

gap between the parts for shear and 0.015" - 0.020" for peel. The

gap should be as consistent as possible.

Q7 To what types of environments and stresses

will the bond be subjected?

Consider bond line stresses, inside/outside end use, UV

exposure,

chemical exposure, moisture, and temperature ranges.

Strength can be readily matched to the substrate and stress

characteristics to which the bond will be subjected. Most adhesives

and tapes perform better when the primary stress is tensile or shear.

In most industrial applications, however, a combination of stresses

are involved that may include cleavage and peel.

In general, epoxies hold up best to harsh environments.

Q8 What is the preferred method of application?

Depending on formulation, 3M structural adhesives are available in

a variety of cartridge sizes, 5-gallon pails, and 55-gallon drums.

You

can apply manually or with automated bulk systems.

2

1

Documentation Provided By HMC Electronics

33 Springdale Ave. Canton, MA 02021

http://www.hmcelectronics.com

(800) 482-4440

Page 3

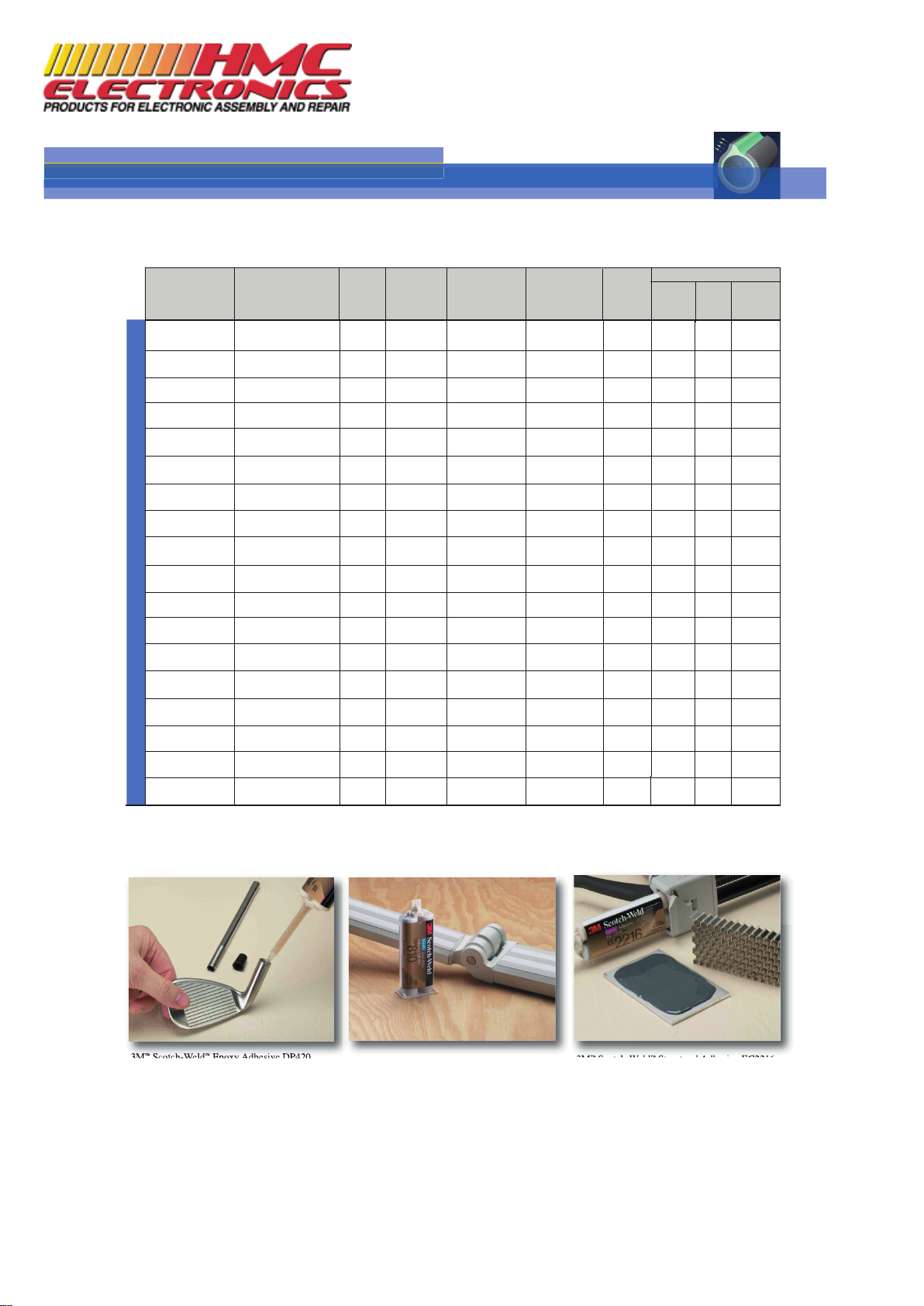

Product

(Color)

Key

Features

Mix Ratio

(Volume)

B:A

Approximate

Viscosity

75°F (24°C)

(cps)

Approximate

Mixed Worklife

at 75°F (24°C)

Approximate

Time to Handling

Strength at 75°F

(24°C)

Average

T-Peel at

75°F (24°C)

(piw)

Overlap Shear (psi)

-67°F

(-55

°C)

75°F

(24°C)

180°F

(82°C)

1:1

13,000 5 minutes

20 minutes

2

900 1,500 300

1:1

8,500 4 minutes

20 minutes

10

3,000 3,500 200

1:1

95,000 5 minutes

20 minutes

2

900 1,500 300

1:1

80,000 6 minutes

20 minutes

2

1,250 2,200 800

1:1

6,500 5 minutes

20 minutes

35

3,500 2,000 150

1:1

55,000 8 minutes

20 minutes

20

2,700 3,500 250

1:1

50,000 8 minutes

20 minutes

20

2,500 2,500 200

1:1

52,500 25 minutes

2.5 hours

35

3,400 4,300 400

1:1

15,000 25 minutes

2.5 hours

35

4,000 2,500 150

1:1

80,000 90 minutes

10 hours

20

1,500 2,500 400

1:1

10,000 80 minutes

6 hours

20

3,500 1,200 150

3M™Scotch-Weld™Structural Adhesives in Duo-Pak Cartridges and Bulk

Epoxy

3M™ Scotch-Weld™ Structural Adhesive EC2216

bonds honeycomb to aluminum for common

applications in aerospace and transportation.

3M™ Scotch-Weld™ Epoxy Adhesive DP420

bonds the stainless steel shaft into the stainless

steel head of a golf club with handling strength

in two hours.

3M™ Scotch-Weld™ Low Odor Acrylic Adhesive

DP810 requires minimal surface preparation for

bonding metal hinges into awning frames.

Note: The technical information and data on these pages should be considered representative or typical only and should not be used for specification purposes.

* Available in Duo-Pak Cartridges only.

Duo-Pak Cartridges continued on next page.

General Purpose

Rigid bonds

Very flexible

Colorless

General Purpose

Non-sag

Flame Retardant

UL94 V-0 rating

Very flexible

Colorless

General Purpose

Flexible bonds

General Purpose

Flexible bonds

High Performance

Very flexible bonds

High Performance

Very flexible bonds

High Performance

Flexible bonds

High Performance

Flexible bonds

High Performance

Very flexible bonds

Rigid potting compound

Non-corrosive

Tough durable bonds

High impact resistance

Tough durable bonds

High impact resistance

Tough durable bonds

Non-sag

Tough durable bonds

High impact resistance

Tough durable bonds

Non-sag

DP100

(Clear)

DP100 Plus

(Clear)

DP100NS

(Translucent)

DP100FR

(White)

DP105

(Clear)

DP110

(Gray)

DP110

(Translucent)

DP125

(Gray)

DP125

(Translucent)

DP190

(Gray)

DP190

(Translucent)

EC2216*

(Gray)

DP270

(Black, Clear)

DP420

(Off-White)

DP420

(Black)

DP420NS

(Black)

DP460

(Off-White)

DP460NS

(Off-White)

3

2:3

80,000 90 minutes

10 hours

25

3,000 3,200 400

1:1

12,000 60 minutes

3 hours

2

1,200 2,500 300

2:1

30,000 20 minutes

2 hours

50

4,500 4,500 450

2:1

30,000 20 minutes

2 hours

50

4,500 4,500 1,250

2:1

180,000 20 minutes

2 hours

50

4,500 4,500 1,250

2:1

30,000 60 minutes

4 hours

60

4,500 4,500 700

2:1

125,000 60 minutes

4 hours

60

4,900 4,650 1,350

2

3

4

Documentation Provided By HMC Electronics

33 Springdale Ave. Canton, MA 02021

http://www.hmcelectronics.com

(800) 482-4440

Page 4

Urethane

DP600

(Gray)

Concrete repair

Self-leveling

1:1 6,000 1 minute 4 minutes 2,300

DP600NS

(Gray)

Concrete repair

Non-sag

1:1 Paste 1 minute 2 minutes 2,300

DP601

(Gray)

Flexible

Self-leveling

1:1 6,000 1 minute 4 minutes 2,300

DP601NS

(Gray)

Flexible

Non-sag

1:1 Paste 1 minute 2 minutes 2,300

DP604NS

(Black)

Flexible

Non-sag

1:1 Paste 4 minutes 20 minutes 900

DP605NS

(Off-White)

Semi-rigid

Non-sag

1:1 150,000 5 minutes 20 minutes 1,350

DP608

(Black)

Flexible

Non-sag

1:1 Paste 10 minutes 90 minutes 2,000

DP620NS

(Black)

Flexible

Non-sag

1:1 Paste 20 minutes 4 hours 2,500

DP640*

(Brown)

Tough flexible bonds

Non-sag

1:1 25,000 40 minutes 8 hours 2,000

DP5001

(Black)

Flexible

Conveyor belt repair

1:1 100,000 1 minute 15 minutes 600

DP5003

(Black)

Non-sag

Vertical applications

1:1 Paste 3 minutes 60 minutes 500

DP5105

(Gray)

Low temperature flexibility

Expansion joint seals

1:1 32,000 5 minutes 9 hours 150

DP5106

(Gray)

High strength

Control joint seals

1:1 34,000 4 minutes 40 minutes 1,100

Product

(Color)

Key

Features

Mix Ratio

(Volume)

B:A

Approximate

Viscosity

75°F (24°C)

(cps)

Approximate

Mixed Worklife

at 75°F (24°C)

Approximate

Time to Handling

Strength at 75°F

(24°C)

Average

T-Peel at

75°F (24°C)

(piw)

Overlap Shear (psi)

-67°F

(-55°C)

75°F

(24°C)

180°F

(82°C)

3M™Scotch-Weld™Structural Adhesives in Duo-Pak Cartridges and Bulk (continued)

DP805

(Light Yellow)

Fast strength build

Minimal surface prep

1:1 110,000 3 minutes 10 minutes 35 2,500 3,500 2,200

DP810

(Tan, Black)

Tough durable bonds

High impact resistance

1:1 20,000 10 minutes 20 minutes 30 1,200 3,600 500

DP810NS

(Tan)

Tough durable bonds

Non-sag

1:1 95,000 10 minutes 20 minutes 20 1,200 4,000 500

DP820*

(Light Yellow)

Tough durable bonds

Minimal surface prep

1:1 55,000 15 minutes 40 minutes 20 3,100 3,150 1,900

DP8005

(Off-White,

Black)

Bonds polyolefins and low

surface energy materials

10:1 25,000 3 minutes 3 hours 10 2,400 300

DP8010

(Off-White)

Bonds polyolefins and low

surface energy materials

10:1 20,000 10 minutes 2 hours 35 1,800 400

Acrylic

DP8010NS Bonds polyolefins and low 10:1 65,000 10 minutes 2 hours 30 2,400 400

(Off-White) surface energy materials

Note: The technical information and data on these pages should be considered representative or typical only and should not be used for specification purposes.

* Available in Duo-Pak Cartridge only.

4

3M™ Concrete Repair DP600 Self-Leveling sets quickly to anchor bolts and repair

deep cracks and spalls in concrete.

With no surface preparation,

3M

™

Scotch-Weld™Structural

Acrylic Adhesive DP8010

bonds the mitered corners of

a simulated-wood composite

plastic P.O.P. display,

eliminating nails that would

compromise appearance.

5

6

7

Documentation Provided By HMC Electronics

33 Springdale Ave. Canton, MA 02021

http://www.hmcelectronics.com

(800) 482-4440

Page 5

1386

(Cream)

High temperature strength

Impact resistance

150,000 60 350/177 10 10 3,000 5,500 4,500 2,500

1469

(Cream)

High temperature strength

Low viscosity

60,000 120 350/177 10 2 3,150 3,700 3,700 3,600

2086

(Gray)

High temperature strength

High viscosity

Paste 60 350/177 10 5 3,000 5,000 5,000 2,200

2214 Regular

(Gray)

High temperature strength

Low temp curing

Paste 60 250/121 10 5 3,000 4,500 4,500 1,500

2214 Hi-Density

(Gray)

High temperature strength

Deaerated, dense bonds

Paste 60 250/121 10 5 3,000 4,500 4,500 1,700

2214 Hi-Temp

Original (Gray)

High temperature strength and

environmental resistance

Paste 60 250/121 10 2 2,000 2,000 3,000 2,500

2214 Hi-Temp

New Formula (Gray)

High temperature strength and

environmental resistance

Paste 60 250/121 10 2 2,800 2,800 2,800 2,500

2214 Non-Metallic

Filled (Cream)

High temperature strength

Higher insulation value

Paste 60 250/121 10 7 3,000 4,000 4,500 1,500

2290

(Amber)

Low solids liquid coating for

metal laminations

60 30 350/177 50 10 5,000 5,000 3,500 1,200

Product

(Color)

Key Features Approximate

Viscosity

75°F (24°C)

(cps)

Time

(min)

Temperature

(°F/°C)

Pressure

(psi)

Average

T-Peel

at 75°F (24°C)

(piw)

-67°F

(-55°C)

75°F

(24°C)

180°F

(82°C)

250°F

(121°C)

Cure Conditions Overlap Shear (psi)

3M™Scotch-Weld™One-Part Epoxy Adhesives and Metal Primers

Product (Color) Description Viscosity (cps) Comments

3901 Adhesion promoter 5 A primer for film and liquid adhesives for improved metal and glass adhesion or improved resistance

(Red) Organo-silane base to environmental exposure with epoxy and urethane adhesives. Protects cleaned surfaces until bonding

Brush or spray can be completed. Imparts improved corrosion protection to metal.

Primer

Epoxy

Note: The technical information and data on these pages should be considered representative or typical only and should not be used for specification purposes.

3M™Scotch-Weld™Two-Part Structural Adhesives

Epoxy

Note: The technical information and data on these pages should be considered representative or typical only and should not be used for specification purposes.

Product

(Color)

Key

Features

Mix Ratio

(Volume)

B:A

Approximate

Viscosity

75°F (24°C)

(cps)

Approximate

Mixed Worklife

at 75°F (24°C)

Approximate

Time to Handling

Strength at 75°F

(24°C)

Average

T-Peel at

75°F (24

°

C)

(piw)

Overlap Shear (psi)

-67°F

(-55°C)

75°F

(24°C)

180°F

(82°C)

3532 B/A Multi-purpose 1:1 30,000 10 minutes 90 minutes 25 2,500 2,000 300

(Brown) Semi-rigid bonds

3535 B/A Multi-purpose 1:1 30,000 3 minutes 30 minutes 25 2,500 2,000 300

(Off-White) Semi-rigid bonds

3549 B/A Tough Flexible bonds

(Brown) Non-sag

1:1 30,000 60 minutes 8 hours 25 2,500 2,000 300

Urethane

1838 B/A Multi-purpose 4:5 400,000 60 minutes 8 hours 4 1,500 3,000 500

(Green) Rigid bonds

1838 B/A Multi-purpose 5:6 250,000 60 minutes 8 hours 4 1,500 2,000 500

(Tan) Rigid bonds

1838L B/A Multi-purpose 1:1 10,000 60 minutes 8 hours 4 2,000 2,500 300

(Translucent) Rigid bonds

2158 B/A Multi-purpose 1:1 375,000 2 hours 10 hours 3 1,500 2,000 400

(Gray) Rigid bonds

2216 B/A High performance 2:3 80,000 90 minutes 10 hours 25 3,000 3,200 400

(Gray) Very flexible bonds

2216 B/A General purpose 1:1 10,000 2 hours 14 hours 25 3,000 1,700 140

(Translucent) Very flexible bonds

2216 B/A NS High performance 2:3 350,000 2 hours 10 hours 25 2,000 2,500 400

(Tan) Non-sag

3501 B/A Multi-purpose 1:1 500,000 7 minutes 25 minutes 4 1,500 2,400 300

(Gray) Rigid bonds

5

1751 B/A Excellent void filler 3:2 700,000 45 minutes 10 hours 4 1,400 2,000 500

(Gray) Rigid bonds

Documentation Provided By HMC Electronics

33 Springdale Ave. Canton, MA 02021

http://www.hmcelectronics.com

(800) 482-4440

Page 6

6

3M™ EPX Applicators for Duo-Pak Cartridges

For low volume applications and take-it-to-the-job convenience,

the 3M

™

EPX Plus II and EPX metal manual applicators comfortably

dispense any of the many 3M

™

Scotch-Weld™ Duo-Pak

Structural Adhesives.

For higher volume, select the 200ml manual dispenser or the

200ml or 400ml pneumatic dispenser.

For concrete repair, you also have manual or pneumatic options.

Manual Applicators

Pneumatic Applicators

Helical 35ml 10:1

and 250ml 10:1

Helical and

square gold 37ml

2:1, 50ml 1:1,

and 43ml 2:1

Helical and square

gold 200/400ml

1:1 and 2:1

Concrete repair

helical

3M

™

EPX Nozzles simultaneously mix, meter,

and dispense 3M

™

Scotch-Weld™ 2-Part

Adhesives or Concrete Repair from Duo-Pak

cartridges. Extended reach helical nozzle is

shown here bonding ABS components of a

pump housing.

Concrete repair

square for 8.4 oz.

cartridge

3M™Nozzles for EPX Applicators and Duo-Pak Cartridges

Choose either the square gold or helical nozzle.

With the unique chambered design of the square gold, the two parts

of the adhesive cascade through the nozzle with just low pressure to

mix and apply even higher viscosity adhesives.

The helical design is your choice whenever you want extended reach

for convenience and access.

EPX Plus II Applicator

35ml with10:1 plunger

37ml with 2:1 plunger*

50ml with 1:1 plunger*

EPX Metal Applicator

with 2:1 plunger*

EPX 200ml Applicator

with 2:1 and 1:1 plunger*

Concrete repair 12-ounce

cartridge applicator

* Included with applicator

EPX 50ml Applicator

for 50ml 1:1 and for 37ml

2:1 low viscosity products

EPX 200ml Applicator

for 200ml 1:1 and 2:1, and

250ml 10:1 (conversion kit)

EPX 400ml Applicator

for 1:1 and 2:1

Concrete repair 12-ounce

cartridge applicator

8

9 10

11

12

13 14

15

16

17 18

19

20

21

Documentation Provided By HMC Electronics

33 Springdale Ave. Canton, MA 02021

http://www.hmcelectronics.com

(800) 482-4440

Page 7

3M™Scotch-Weld™Instant Adhesives

3M™Scotch-Weld™Instant Adhesive CA8 is a multi-purpose product

for use in a variety of assembly applications.

3M

™

Scotch-Weld™CA40 Instant Adhesive works on many problem

surfaces where other adhesives may fail, such as EPDM rubber.

For wood and veneer repair, 3M

™

Scotch-Weld™Instant Adhesive

CA40H is a high viscosity liquid for a fast void-filling bond.

For repair of fiberglass/concrete cast pottery, 3M™Scotch-Weld™Instant Adhesive CA50 Gel bonds with high tensile and shear strength.

Non-sagging for neat application.

7

Note: The technical information and data above should be

considered representative or typical only, and should not

be used for specification purposes.

(1) The time it takes assembled parts to reach a

strength where further handling and processing

can take place. Times will depend on surface to be

bonded, temperature and humidity.

(2) Tested per ASTM D 1876-61T.

(3) Tested per ASTM D 1002-64.

*

Substrate failure.

Time

(1)

Average

(2)

Overlap Shear Strength

(3)

To T-Peel @ 75°F (24°C) (PSI)

Handling At 75°F

Strength Viscosity (24°C) Alumi- Nitrile Neoprene Rigid

Product Description Base (Sec.) (cps) (PIW) Steel num Rubber Rubber ABS PVC

CA4 • Fast setting for a variety of plastics and rubbers ethyl 5-40 150 1-2 2300 2800 35* 55* 800* 800*

CA5 • Higher viscosity, slower setting version ethyl 15-60 2000 1-2 2500 650 35* 55* 800* 800*

of CA4 for filling gaps

• Meets CID A-A-3097, Type II, Class 3

CA7 • Very fast setting methyl 1-30 15-40 2-4 2500 2400 35* 55* 900* 1000*

• Excellent adhesion to metals, plastics, and rubbers

CA8 • Slower setting than CA7 ethyl 5-40 70-130 2-4 2000 2100 35* 55* 900* 1000*

• Excellent adhesion to metals, plastics and rubbers

• Meets CID A-A-3097, Type II, Class 2

CA9 • Slower setting version of CA8 for wire ethyl 20-70 1000- 2-4 2000 2400 35* 55* 900* 1000*

tacking and coil terminating 1700

• Meets CID A-A-3097, Type II, Class 3

CA40 • Very fast setting ethyl 3-20 20 1-2 1700 2600 35* 55* 800* 800*

• Excellent adhesion to many substrates including

flexible vinyl and EPDM rubber

CA40H • Higher viscosity version of CA40 ethyl 5-40 400-600 1-2 1500 1500 35* 55* 900* 1000*

• Better void filling capabilities.

CA50 • High-viscosity, non-sag gel ethyl 60-120 45,000- 1-2 2000 900 105* 130* 800* 600*

Gel • Less sensitive to acidic surfaces. 85,000

CA100 • High peel and impact strength ethyl 20-70 2500- 15 2000 2900 95* 120* 600* 700*

• High thermal shock and heat resistance

4500

Surface • Clear, colorless organic-based liquid helps speed curing and prime surfaces

Activator • Comes with brush and spray pump

22

23

24

25

Instant Adhesives

Documentation Provided By HMC Electronics

33 Springdale Ave. Canton, MA 02021

http://www.hmcelectronics.com

(800) 482-4440

Page 8

DP605NS

Off-White

50ml

200ml

400ml

00-021200-82252-0

00-021200-87853-4

00-021200-87854-1

62-3592-1435-0

62-3592-3830-0

62-3592-3530-6

605NS

Off-White

5 gallon pail B

5 gallon pail A

00-021200-82253-7

00-021200-82254-4

62-3592-8530-1

62-3692-8530-9

DP608

Black

50ml

12 oz

00-021200-96418-3

00-021200-56607-3

62-3268-5030-2

62-3268-1231-0

608

Black

5 gallon pail B

5 gallon pail A

50 gallon drum B

50 gallon drum A

00-021200-96513-5

00-021200-96514-2

00-021200-96515-9

00-021200-96516-6

62-3268-8530-8

62-3368-8530-6

62-3268-9530-7

62-3368-9530-5

DP620NS

Black

50ml

12 oz

00-021200-96416-9

00-021200-56685-1

62-2645-5030-2

62-2645-1232-8

620NS

Black

5 gallon pail B

5 gallon pail A

50 gallon drum B

50 gallon drum A

00-021200-96449-7

00-021200-96450-3

00-021200-96505-0

00-021200-96506-7

62-2645-8530-8

62-2745-8530-6

62-2645-9530-7

62-2745-9530-5

DP640

Brown

50ml

200ml

400ml

00-021200-89543-2

00-021200-89545-6

00-021200-89544-9

62-3549-1435-0

62-3549-3830-0

62-3549-3530-6

DP805 Yel-

low

50ml

200ml

400ml

00-021200-83758-6

00-021200-87828-2

00-021200-87829-9

62-3288-1435-5

62-3288-3830-5

62-3288-3530-1

805

Yellow

5 gallon pail B

5 gallon pail A

00-021200-87233-4

00-021200-87234-1

62-3288-8530-6

62-3388-8530-4

DP810

Tan

50ml

200ml

400ml

00-021200-31310-3

00-021200-31311-0

00-021200-31312-7

62-3298-1435-4

62-3298-3830-4

62-3298-3530-0

810

Tan

20 liter pail B

20 liter pail A

00-021200-45230-7

00-021200-45233-8

62-3298-8730-1

62-3398-8730-9

DP810

Black

50ml 00-021200-49077-4 62-2788-1435-5

DP810NS 50ml 00-021200-49082-8 62-2799-1435-2

810NS

Tan

20 liter pail B

20 liter pail A

00-021200-49085-9

00-021200-49086-6

62-2799-8730-9

62-2899-8730-7

DP820

Yellow

50ml

200ml

400ml

00-021200-89347-6

00-021200-89348-3

00-021200-89349-0

62-3277-1435-8

62-3277-3830-8

62-3277-3530-4

420

Black

5 gallon pail B

5 gallon pail A

55 gallon drum B

55 gallon drum A

00-021200-41531-9

00-021200-41532-6

00-021200-41533-3

00-021200-41534-0

62-2778-8530-7

62-2878-8530-5

62-2778-9530-6

62-2878-9530-4

420

Off-White

5 gallon pail B

5 gallon pail A

00-021200-82238-4

00-021200-82239-1

62-3280-8530-3

62-3380-8530-1

DP420NS

Black

37ml

200ml

00-021200-39285-6

00-021200-39286-3

62-3299-1435-2

62-3299-3832-8

420NS

Black

5 gallon pail B

5 gallon pail A

55 gallon drum B

55 gallon drum A

00-021200-56587-8

00-021200-31309-7

00-048011-58132-3

00-048011-58133-0

62-3299-8535-2

62-3399-8530-1

62-3299-9530-2

62-3399-9530-0

DP460

Off-White

37ml

200ml

400ml

00-021200-82225-4

00-021200-87830-5

00-021200-87831-2

62-3593-1435-8

62-3593-3830-8

62-3593-3530-4

460

Off-White

Quart Kit

5 gallon pail B

5 gallon pail A

00-021200-82226-1

00-021200-82227-8

00-021200-82228-5

62-3593-6430-4

62-3593-8530-9

62-3693-8530-7

DP460NS

Off-White

37ml

200ml

400ml

00-021200-43670-3

00-021200-43671-0

00-021200-43672-7

62-2792-1435-7

62-2792-3830-7

62-2792-3530-3

460NS

Off-White

5 gallon pail B

5 gallon pail A

00-021200-43673-4

00-021200-43674-1

62-2792-8530-8

62-2892-8530-6

DP600

Gray /

Self-Leveling

50ml

12 oz

00-021200-56602-8

00-021200-56599-1

62-2649-5030-4

62-2649-1230-4

600

Concrete Repair

8.4 oz 00-021200-96596-8 62-2649-1233-8

600

Gray /

Self- Leveling

5 gallon pail B

5 gallon pail A

50 gallon drum B

50 gallon drum A

00-021200-96574-6

00-021200-96575-3

00-021200-96576-0

00-021200-96577-7

62-2649-8535-9

62-2749-8535-7

62-2649-9535-8

62-2749-9535-6

DP600NS

Gray

50ml

12 oz

00-021200-56603-5

00-021200-56606-6

62-2652-1230-8

62-2652-5030-8

600NS

Gray

5 gallon pail B

5 gallon pail A

50 gallon drum B

50 gallon drum A

00-021200-96578-4

00-021200-96579-1

00-021200-96580-7

00-021200-96581-4

62-2652-8535-3

62-2752-8535-1

62-2652-9535-2

62-2752-9535-0

DP601

Gray

50ml

12 oz

00-021200-96410-7

00-021200-96411-4

62-2649-5031-2

62-2649-1232-0

601

Gray

5 gallon pail B

5 gallon pail A

50 gallon drum B

50 gallon drum A

00-021200-96451-0

00-021200-96452-7

00-021200-96507-4

00-021200-96508-1

62-2649-8530-0

62-2749-8530-8

62-2649-9530-9

62-2749-9530-7

DP601NS

Gray

50ml

12 oz

00-021200-96407-7

00-021200-96408-4

62-2652-5031-6

62-2652-1231-6

601NS

Gray

5 gallon pail B

5 gallon pail A

50 gallon drum B

50 gallon drum A

00-021200-96453-4

00-021200-96454-1

00-021200-96509-8

00-021200-96510-4

62-2652-8530-4

62-2752-8530-2

62-2652-9530-3

62-2752-9530-1

DP604NS

Black

50ml

12 oz

00-021200-96412-1

00-021200-56598-4

62-2648-5030-6

62-2648-1230-6

604NS

Black

5 gallon pail B

5 gallon pail A

50 gallon drum B

50 gallon drum A

00-021200-96461-9

00-021200-96462-6

00-021200-96531-9

00-021200-96532-6

62-2648-8530-2

62-2748-8530-0

62-2648-9530-1

62-2748-9530-9

DP605NS

Off-White

50ml

200ml

400ml

00-021200-82252-0

00-021200-87853-4

00-021200-87854-1

62-3592-1435-0

62-3592-3830-0

62-3592-3530-6

605NS

Off-White

5 gallon pail B

5 gallon pail A

00-021200-82253-7

00-021200-82254-4

62-3592-8530-1

62-3692-8530-9

DP608

Black

50ml

12 oz

00-021200-96418-3

00-021200-56607-3

62-3268-5030-2

62-3268-1231-0

608

Black

5 gallon pail B

5 gallon pail A

50 gallon drum B

50 gallon drum A

00-021200-96513-5

00-021200-96514-2

00-021200-96515-9

00-021200-96516-6

62-3268-8530-8

62-3368-8530-6

62-3268-9530-7

62-3368-9530-5

DP620NS

Black

50ml

12 oz

00-021200-96416-9

00-021200-56685-1

62-2645-5030-2

62-2645-1232-8

620NS

Black

5 gallon pail B

5 gallon pail A

50 gallon drum B

50 gallon drum A

00-021200-96449-7

00-021200-96450-3

00-021200-96505-0

00-021200-96506-7

62-2645-8530-8

62-2745-8530-6

62-2645-9530-7

62-2745-9530-5

DP640

Brown

50ml

200ml

400ml

00-021200-89543-2

00-021200-89545-6

00-021200-89544-9

62-3549-1435-0

62-3549-3830-0

62-3549-3530-6

DP805

Yellow

50ml

200ml

400ml

00-021200-83758-6

00-021200-87828-2

00-021200-87829-9

62-3288-1435-5

62-3288-3830-5

62-3288-3530-1

805

Yellow

5 gallon pail B

5 gallon pail A

00-021200-87233-4

00-021200-87234-1

62-3288-8530-6

62-3388-8530-4

DP100

Clear

50ml

200ml

400ml

00-021200-22648-9

00-021200-87260-0

00-021200-87261-7

62-3575-1435-5

62-3575-3830-5

62-3575-3530-1

100

Clear

5 gallon pail B

5 gallon pail A

00-021200-82344-2

00-021200-82345-9

62-3575-8531-4

62-3675-8531-2

DP100 Plus

Clear

50ml

200ml

400ml

00-021200-87195-5

00-021200-87266-2

00-021200-87267-9

62-3272-1435-9

62-3272-3830-9

62-3272-3530-5

100 Plus

Clear

5 gallon pail B

5 gallon pail A

00-021200-87197-9

00-021200-87198-6

62-3272-8530-0

62-3372-8530-8

DP100FR

Off-White

50ml

200ml

400ml

00-048011-56742-6

00-048011-56744-0

00-048011-56743-3

62-3531-1435-8

62-3531-3830-8

62-3531-3530-4

100FR

Off-White

5 gallon pail B

5 gallon pail A

00-048011-57229-1

00-048011-57230-7

62-3531-8530-9

62-3631-8530-7

DP100NS

Translucent

50ml

200ml

400ml

00-021200-82255-1

00-021200-87264-8

00-021200-87265-5

62-3265-1435-3

62-3265-3830-3

62-3265-3530-9

100NS

Translucent

5 gallon pail B

5 gallon pail A

00-021200-82256-8

00-021200-82257-5

62-3265-8530-4

62-3365-8530-2

DP105

Clear

50ml

200ml

400ml

00-021200-87203-7

00-021200-87270-9

00-021200-87271-6

62-3287-1435-7

62-3287-3830-7

62-3287-3530-3

105

Clear

5 gallon pail B

5 gallon pail A

00-021200-87205-1

00-021200-87206-8

62-3287-8530-8

62-3387-8530-6

DP110

Gray

50ml

200ml

400ml

00-021200-82470-8

00-021200-87274-7

00-021200-87275-4

62-3533-1434-7

62-3533-3830-4

62-3533-3530-0

110

Gray

5 gallon pail B

5 gallon pail A

00-021200-82471-5

00-021200-82472-2

62-3533-8531-3

62-3633-8531-1

DP110

Translucent

50ml

200ml

400ml

00-021200-82465-4

00-021200-87846-6

00-021200-87847-3

62-3563-1434-4

62-3563-3830-1

62-3563-3530-7

110

Translucent

5 gallon pail B

5 gallon pail A

00-021200-82466-1

00-021200-82467-8

62-3563-8531-0

62-3663-8531-8

DP125

Gray

50ml

200ml

400ml

00-021200-87215-0

00-021200-87844-2

00-021200-87845-9

62-3293-1435-5

62-3293-3830-5

62-3293-3530-1

125

Gray

5 gallon pail B

5 gallon pail A

00-021200-87217-4

00-021200-87218-1

62-3293-8530-6

62-3393-8530-4

DP125

Translucent

50ml

200ml

400ml

00-021200-87211-2

00-021200-87842-8

00-021200-87843-5

62-3291-1435-9

62-3291-3830-9

62-3291-3530-5

DP190

Gray

50ml

200ml

400ml

00-021200-22647-2

00-021200-87840-4

00-021200-87841-1

62-3553-1435-2

62-3553-3830-2

62-3553-3530-8

DP190

Translucent

50ml

200ml

400ml

00-021200-87219-8

00-021200-87838-1

00-021200-87839-8

62-3286-1435-9

62-3286-3830-9

62-3286-3530-5

DP270

Black

50ml

200ml

400ml

00-021200-82262-9

00-021200-87836-7

00-021200-87837-4

62-3266-1435-1

62-3266-3830-1

62-3266-3530-7

270

Black

Gallon Kit

5 gallon pail B

5 gallon pail A

00-021200-82263-6

00-021200-82264-3

00-021200-82265-0

62-3266-7430-6

62-3266-8530-2

62-3366-8530-0

DP270

Clear

50ml

200ml

400ml

00-021200-82248-3

00-021200-87834-3

00-021200-87835-0

62-3262-1435-0

62-3262-3830-0

62-3262-3530-6

270

Clear

5 gallon pail B

5 gallon pail A

00-021200-82250-6

00-021200-82251-3

62-3262-8530-1

62-3362-8530-9

DP420

Black

37ml

200ml

400ml

00-021200-41528-9

00-021200-41530-2

00-021200-41529-6

62-2778-1435-6

62-2778-3830-6

62-2778-3530-2

420

Black

5 gallon pail B

5 gallon pail A

5 gallon drum B

55 gallon drum A

00-021200-41531-9

00-021200-41532-6

00-021200-41533-3

00-021200-41534-0

62-2778-8530-7

62-2878-8530-5

62-2778-9530-6

62-2878-9530-4

DP420

Off-White

37ml

200ml

400ml

00-021200-82236-0

00-021200-87832-9

00-021200-87833-6

62-3280-1435-2

62-3280-3830-2

62-3280-3530-8

420

Off-White

5 gallon pail B

5 gallon pail A

00-021200-82238-4

00-021200-82239-1

62-3280-8530-3

62-33808530-1

DP420NS

Black

37ml

200ml

00-021200-39285-6

00-021200-39286-3

62-3299-1435-2

62-3299-3832-8

420NS

Black

5 gallon pail B

5 gallon pail A

55 gallon drum B

55 gallon drum A

00-021200-56587-8

00-021200-31309-7

00-04801158132-3

00-048011-58133-0

62-3299-8535-2

62-3399-8530-1

62-3299-9530-2

62-3399-9530-0

DP460

37ml

200ml

00-021200-82225-4

00-021200-87830-5

62-3593-1435-8

62-3593-3830-8

Product Size

Product UPC List

*

*

8

*

Large Buy

Product Size UPC Stock #

DP420 37ml 00-021200-82236-0 62-3280-1435-2

Off-White 200ml 00-021200-87832-9 62-3280-3830-2

400ml 00-021200-87833-6 62-3280-3530-8

Blue indicates non-stocked items

Blue indicates non-stocked items

DP810NS

Tan

50ml

200ml

400ml

810NS

Tan

20 liter pail B

20 liter pail A

DP820

Yellow

50ml

200ml

400ml

1386

Cream

1 quart

5 gallon pail

1469

Cream

1 quart

5 gallon pail

1751

Gray

2 Oz tube kit

pint kit

quart kit

gallon kit

5 gallon pail B

5 gallon pail A

1838

Green

2 Oz tube kit

pint kit

quart kit

gallon kit

5 gallon pail B

5 gallon pail A

1838

Tan

quart kit

5 gallon pail B

5 gallon pail A

1838L

Translucent

2 Oz tube kit

quart kit

5 gallon pail B

5 gallon pail A

2158

Gray

pint kit

quart kit

gallon kit

5 gallon pail B

5 gallon pail A

2214

Gray / Regular

6 Oz cartridge

1 quart

5 gallon pail

2214

Gray / Hi-Density

6 Oz cartridge

5 gallon pail

2214

Gray / Hi-Temp

New Formula

6 Oz cartridge

5 gallon pail

2214

Gray / Hi-Temp

Original Formula

6 Oz cartridge

2214

Cream /

Non Metallic

2 Oz tube

6 Oz cartridge

2216

Gray

2 Oz tube kit

pint kit

quart kit

gallon kit

5 gallon pail B

5 gallon pail A

50 gallon drum B

50 gallon drum A

2216

Translucent

2 Oz tube kit

pint kit

quart kit

gallon kit

5 gallon pail B

5 gallon pail A

50 gallon drum B

50 gallon drum A

2216

Tan / Non-Sag

5 gallon pail B

5 gallon pail A

EC2216

Gray (Duo-Pak)

43ml

2290

Amber

gallon container

5 gallon pail

54 gallon drum

3501

Gray

2 Oz tube kit

pint kit

gallon kit

3532

Brown

2 Oz kit

quart kit

5 gallon pail B

5 gallon pail A

3535

Off-White

2 Oz kit

quart kit

3549

Brown

2 Oz kit

quart kit

5 gallon pail B

5 gallon pail A

3901

Red

1/2 pint

Product Size UPC Stock #

Documentation Provided By HMC Electronics

33 Springdale Ave. Canton, MA 02021

http://www.hmcelectronics.com

(800) 482-4440

Page 9

*Large Buy

EPX Pneumatic Applicator 00-021200-83528-5 62-9781-9930-5E

EPX Mixing Nozzle - 00-021200-85801-7 62-9742-9938-0

Helical - Bulk

EPX Mixing Nozzle - 00-021200-50008-4 62-9171-9153-8

Square Gold

EPX Mixing Nozzle - 00-021200-50009-1 62-9171-9953-1

Square Gold - Bulk

EPX Plus II 00-021200-31381-3 62-9164-9930-4

Mixing Nozzle 10:1

EPX Plus II 00-021200-31382-0 62-9164-9931-2

Mixing Nozzle

10:1 Bulk

EPX 200ml 00-021200-87977-7 62-9136-9930-2

Manual Applicator

EPX Plunger - 200ml 00-021200-87981-4 62-9136-9938-5

EPX 200ml 00-021200-87978-4 62-9140-9930-4

Pneumatic Applicator

10:1 Conversion kit - 00-021200-31385-1 62-9174-9932-9

200ml Pneumatic

Applicator (250ml)

EPX 400ml Pneumatic 00-021200-87979-1 62-9145-9930-3

Applicator

EPX 200ml / 400ml 00-021200-87982-1 62-9142-9930-0

Mixing Nozzle - Helical

EPX 200ml / 400ml 00-021200-97331- 62-9176-9127-1

Mixing Nozzle Square Gold

EPX 250ml 00-021200-39200-9 62-9165-9930-1

Mixing Nozzle 10:1

EPX 12oz Manual 00-021200-96200-4 62-9600-9935-6

Dispenser

EPX 12oz Pneumatic 00-021200-96206-6 62-9602-9935-2

Dispenser

12oz Blunt End Mix Tip 00-051131-04901-7 62-9606-9935-3

12oz Tapered End Mix Tip 00-051131-04902-4 62-9607-9935-1

8.4oz Cartridge Mix Tip 00-048011-53382-7 62-9637-9935-8

*

*

*

EPX Plus II Applicator

00-021200-50004-6 62-9170-9930-1

1:1 Plunger EPX Plus II

00-021200-50005-3 62-9170-9911-1

2:1 Plunger EPX Plus II

00-021200-50006-0 62-9170-9921-0

10:1 Plunger

EPX Plunger II

00-021200-50007-7 62-9170-9910-3

EPX Metal Applicator

00-021200-21789-0 62-9740-9935-0

2:1 Plunger Metal

00-021200-82314-5 62-9744-9935-0

EPX Pneumatic

Applicator

00-021200-83528-5 62-9781-9930-5

EPX Mixing

Nozzle - Helical

00-021200-21791-3 62-9742-9935-6

UPC Stock # Product UPC Stock #

*

3M™ Sco

tch-Weld™Epoxy Adhesive 2214 bonds and seals refrigerant coils with overlap shear strength of 4500 psi. One

part eliminates metering and mixing.

9

*

Large Buy

Blue indicates non-stocked items

Blue indicates non-stocked items

DP5001

Black

50ml

12 oz

00-021200-96414-5

00-021200-96415-2

62-3528-5032-5

62-3528-1238-2

5001

Black

5 gallon pail B

5 gallon pail A

50 gallon drum B

50 gallon drum A

00-021200-96521-0

00-021200-96522-7

00-021200-96523-4

00-021200-96524-1

62-3528-8530-5

62-3628-8530-3

62-3528-9530-4

62-3628-9530-2

DP5003

Black

50ml

12 oz

00-021200-96395-7

00-021200-56616-5

62-3514-5030-9

62-3514-1230-9

5003

Black

5 gallon pail B

5 gallon pail A

50 gallon drum B

50 gallon drum A

00-021200-96455-8

00-021200-96456-5

00-021200-96511-1

00-021200-96512-8

62-3514-8530-5

62-3614-8530-3

62-3514-9530-4

62-3614-9530-2

DP5105

Gray

12 oz 00-021200-56618-9 62-2678-1230-3

5105

Gray

5 gallon pail B

5 gallon pail A

50 gallon drum B

50 gallon drum A

00-021200-96566-1

00-021200-96567-8

00-021200-96568-5

00-021200-96569-2

62-2678-8535-8

62-2754-8535-7

62-2678-9535-7

62-2754-9535-6

DP5106

Gray

12 oz 00-021200-56611-0 62-3527-1230-1

5106

Gray

5 gallon pail B

5 gallon pail A

50 gallon drum B

50 gallon drum A

00-021200-96582-1

00-021200-96583-8

00-021200-96584-5

00-021200-96585-2

62-3527-8535-6

62-3627-8535-4

62-3527-9535-5

62-3627-9535-3

DP8005

Translucent

35ml

250ml

00-021200-41547-0

00-021200-41548-7

62-2786-0430-1

62-2786-3930-7

8005

Translucent

1 gallon

container A

5 gallon pail B

5 gallon pail A

50 gallon drum B

00-021200-41552-4

00-021200-41550-0

00-021200-41553-1

00-021200-41551-7

62-2886-7530-9

62-2786-8530-0

62-2886-8530-8

62-2786-9530-9

DP8005

Black

35ml

250ml

00-021200-45167-6

00-021200-45168-3

62-2779-0430-6

62-2779-3930-2

8005

Black

1 gallon

container A 5

gallon pail B

5 gallon pail A

50 gallon drum B

00-021200-45171-3

00-021200-45169-0

00-021200-45172-0

00-021200-45170-6

62-2879-7530-4

62-2779-8530-5

62-2879-8530-3

62-2779-9530-4

DP8010

Off-White

35ml

250ml

00-021200-49110-8

00-021200-49111-5

62-2783-0430-8

62-2783-3930-4

8010

Off-White

1 gallon

container A

5 gallon pail B

5 gallon pail A

50 gallon drum B

00-021200-49113-9

00-021200-49112-2

00-021200-49115-3

00-021200-49114-6

62-2883-7530-6

62-2783-8530-7

62-2883-8530-5

62-2783-9530-6

DP8010NS

Off-White

35ml

250ml

00-021200-96309-4

00-021200-96310-0

62-2798-0430-6

62-2798-3930-2

8010NS

Off-White

5 gallon pail B

5 gallon pail A

50 gallon drum B

50 gallon drum A

00-021200-96312-4

00-021200-96311-7

00-021200-96313-1

00-021200-96314-8

62-2898-8530-3

62-2798-8530-5

62-2898-7530-4

62-2798-9530-4

CA4 2 gm tube

1 oz bottle

1 lb bottle

00-021200-96601-9

00-021200-96600-2

00-021200-96597-5

62-3801-0230-1

62-3801-0330-9

62-3801-3830-5

CA5 1 oz bottle

1 lb bottle

00-021200-74289-7

00-021200-74288-0

62-3802-0330-7

62-3802-3830-3

CA8 2 gm tube

1 oz bottle

1 lb bottle

00-021200-21065-5

00-021200-21066-2

00-021200-21067-9

62-3815-0130-3

62-3815-0330-9

62-3815-3830-5

CA9 1 oz bottle

1 lb bottle

00-021200-21068-6

00-021200-21069-3

62-3817-0330-5

62-3817-3830-1

CA40 1 oz bottle

1 lb bottle

00-021200-74290-3

00-021200-74291-0

62-3803-0330-5

62-3803-3830-1

CA40H 1 oz bottle

1 lb bottle

00-021200-21073-0

00-021200-21074-7

62-3829-0330-0

62-3829-3830-6

CA50 20 gm tube

200 gm tube

00-021200-82332-9

00-021200-83737-1

62-3872-0330-0

62-3872-3630-0

CA100 1 oz bottle

1 lb bottle

00-021200-82334-3

00-021200-82335-0

62-3873-0330-8

62-3873-3830-4

Surface Activator 2 oz bottle

1 gallon

container

00-021200-87937-1

00-021200-87963-0

62-3804-0830-2

62-3804-7530-1

Product Size UPC Stock #

00-021200-49082-8

00-021200-49084-2

00-021200-49083-5

62-2799-1435-2

62-2799-3830-2

62-2799-3530-8

00-021200-49085-9

00-021200-49086-6

62-2799-8730-9

62-2899-8730-7

00-021200-89347-6

00-021200-89348-3

00-021200-89349-0

62-3277-1435-8

62-3277-3830-8

62-3277-3530-4

00-021200-19917-2

00-021200-19919-6

62-1386-6525-2

62-1386-8525-0

00-021200-19949-3

00-021200-19950-9

62-1469-6525-6

62-1469-8525-4

00-021200-20100-4

00-021200-20101-1

00-021200-20103-5

00-021200-20105-9

00-021200-20108-0

00-021200-20120-2

62-1751-0530-3

62-1751-5430-1

62-1751-6430-0

62-1751-7430-9

62-1751-8530-5

62-1752-8530-3

00-021200-20148-6

00-021200-20150-9

00-021200-20152-3

00-021200-20154-7

00-021200-20155-4

00-021200-20160-8

62-1838-0530-8

62-1838-5430-6

62-1838-6430-5

62-1838-7430-4

62-1838-8530-0

62-1839-8530-8

00-021200-22599-4

00-021200-22600-7

00-021200-22603-8

62-1614-6435-9

62-1614-8535-4

62-1752-8535-2

00-021200-22645-8

00-021200-22646-5

00-021200-82634-4

00-021200-82635-1

62-3520-0535-9

62-3520-6435-6

62-3520-8531-0

62-3620-8531-8

00-021200-20258-2

00-021200-20260-5

00-021200-20262-9

00-021200-20264-3

00-021200-20269-8

62-2158-5430-8

62-2158-6430-7

62-2158-7430-6

62-2158-8530-2

62-2159-8530-0

00-021200-20344-2

00-021200-20345-9

00-021200-23047-3

62-2214-2930-1

62-2214-6530-5

62-2214-8530-3

00-021200-20813-3

00-021200-20814-0

62-3414-2930-6

62-3414-8530-8

00-021200-20833-1

00-021200-20835-5

62-3491-2830-6

62-3491-8530-6

00-021200-20806-5 62-3402-2930-1

00-021200-20802-7

00-021200-25496-3

62-3401-0830-7

62-3401-2934-5

00-021200-20351-0

00-021200-20354-1

00-021200-20356-5

00-021200-20358-9

00-021200-20360-2

00-021200-20365-7

00-021200-20361-9

00-021200-20366-4

62-2216-0530-6

62-2216-5430-4

62-2216-6430-3

62-2216-7430-2

62-2216-8530-8

62-2217-8530-6

62-2216-9530-7

62-2217-9530-5

00-021200-20851-5

00-021200-20852-2

00-021200-20854-6

00-021200-20856-0

00-021200-64980-6

00-021200-64981-3

00-021200-20859-1

00-021200-20927-7

62-3508-0530-5

62-3508-5430-3

62-3508-6430-2

62-3508-7430-1

62-3508-8535-6

62-3608-8535-4

62-3508-9530-6

62-3608-9530-4

00-021200-87179-5

00-021200-87180-1

62-3278-8530-7

62-3378-8530-5

00-021200-56659-2

62-2216-1435-7

00-021200-76225-3

00-021200-76227-7

00-021200-76228-4

62-3847-7530-0

62-3847-8531-7

62-3847-9530-8

00-021200-20842-3

00-021200-20843-0

00-021200-20846-1

62-3501-0530-0

62-3501-5430-8

62-3501-7430-6

00-021200-20878-2

00-021200-20879-9

00-021200-20881-2

00-021200-20935-2

62-3532-0515-6

62-3532-6430-2

62-3532-8515-8

62-3632-8516-4

00-021200-20887-4

00-021200-20888-1

62-3535-0515-9

62-3535-6430-5

00-021200-20901-7

00-021200-20902-4

00-021200-20904-8

00-021200-20942-0

62-3549-0501-0

62-3549-6401-7

62-3549-8501-2

62-3649-8501-0

00-021200-21087-7 62-3901-3525-9

26

Documentation Provided By HMC Electronics

33 Springdale Ave. Canton, MA 02021

http://www.hmcelectronics.com

(800) 482-4440

Page 10

Wet Thickness Square Ft per gal. Approx. gal.reqd.

per 1000 Square Ft. (approx.) per 1000 Square Ft.

1/2 in. 3.2 312.0

1/8 in. 12.8 78.0

1/16 in. 25.6 39.0

1/32 in. 51.2 20.0

25 mils 64.0 16.0

1 mil 1600.0 0.62

Bead Size Approx. Lineal Approx. gal. per

Dimension* Ft. per gal. 1000 Lineal Ft.

1/2 in. 196 5.0

3/8 in. 350 3.0

1/4 in. 785 1.3

1/8 in. 3,130 0.32

1/16 in. 12,420 0.08

Bead Size Linear Ft. Linear Ft. Linear Ft. Linear Ft. Linear Ft. Linear Ft. Linear Ft. Linear Ft. Linear Ft.

Dimension* per 35 ml per 37 ml per 43 ml per 50 ml per 200 ml per 250 ml per 250 ml per 12 fl. oz. (355 ml) per 400 ml

(10:1 Cart.) (2:1 Cart.) (3:2 Cart.) (1:1 Cart.) (1:1 & 2:1 Cart.) (10:1 Cart.) (1:1 Caulk Cart.) (1:1 & 2:1 Cart.) (1:1 & 2:1 Cart.)

1/2 in. 1.9 2.0 2.2 2.5 10 12.5 12.5 19 21

3/8 in. 3.3 3.5 3.9 4.5 18 22.5 22.5 33 37

1/4 in. 7.5 8.0 9.0 10.5 41 52 52 75 83

1/8 in. 29.3 31.0 35.7 41.5 165 205 205 298 331

1/16 in. 115.2 122.0 142.0 165.0 656 825 825 1182 1313

Approximate Coverages for 3M™ Scotch-Weld™ Adhesives in Duo-Pak Cartridges

Coverages per Gallon for Various Thicknesses of

100% Solids 3M Adhesives

Coverages per Gallon for Various

Bead Sizes of 100% Solids 3M Adhesives

* Bead size is semi-circular bead with width equal to size noted and

height at center of bead equal to 1/2 the width.

NOTE: The technical information and data provided here should be considered representative or typical only and should not be used for specification purposes.

3M™Scotch-Weld™Structural Adhesives Coverage Guide

Industrial Adhesives and Tapes Division

3M Center Bldg. 21-1W-10

900 Bush Ave.

St. Paul, MN 55144

1-800-362-3550

www.3M.com/adhesives

Printed in U.S.A.

© 2008 3M

78-9236-7114-9

PRODUCT USE: All statements, technical information and recommendations contained in this document are based upon tests or experience that 3M believes

are reliable. However, many factors beyond 3M’s control can affect the use and performance of a 3M product in a particular application, including the

conditions under which the product is used and the time and environmental conditions in which the product is expected to perform. Since these factors

are uniquely within the user’s knowledge and control, it is essential that the user evaluate the 3M product to determine whether it is fit for a particular

purpose and suitable for the user’s method of application. WARRANTY AND LIMITED REMEDY: 3M warrants that each 3M product meets the

applicable specifications at the time 3M ships the product. 3M MAKES NO OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, BUT NOT

LIMITED TO, ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OR ANY IMPLIED WARRANTY ARISING

OUT OF A COURSE OF DEALING, CUSTOM OR USAGE OF TRADE. User is responsible for determining whether the 3M product is fit for a particular

purpose and suitable for user’s application. If the 3M product is defective, your exclusive remedy and 3M’s and seller’s sole obligation will be, at 3M’s

option, to repair or replace the product or refund the purchase price. LIMITATION OF LIABILITY: Except where prohibited by law, 3M and seller will

not be liable for any loss or damage arising from the 3M product, whether direct, indirect, special, incidental or consequential, regardless of the legal

theory asserted, including warranty, contract, negligence or strict liability.

3M, Scotch-Weld

and Scotch-Brite are

trademarks of 3M Company.

Surface Preparation Tips

The following surface preparation steps

are generally recommended for most

substrates and structural adhesives:

Metals

1. Wipe surface with isopropyl alcohol

(IPA) or methyl ethyl ketone (MEK)

using a clean cloth. A heavier degreaser

may be needed if the substrate contains

a layer of processing oil.

2. Lightly abrade surface with sandblasting,

fine grit sandpaper, or 3M

™

Scotch-Brite

™

7447 maroon pads.

3. Wipe surface with IPA or MEK to

remove debris.

4. Allow solvent to evaporate before

applying adhesive.

Plastics and Rubbers

1. Lightly abrade surface with sandblasting,

fine grit sandpaper, or 3M

™

Scotch-Brite

™

7447 maroon pads.

2. Wipe surface with IPA using a clean

cloth to remove debris.

3. Allow solvent to evaporate before

applying adhesive.

Glass

1. Wipe surface using a clean cloth with

acetone or MEK containing 0.5 wt%

silane adhesion promoter.

2. Allow solvent to evaporate before

applying adhesive.

Documentation Provided By HMC Electronics

33 Springdale Ave. Canton, MA 02021

http://www.hmcelectronics.com

(800) 482-4440

Loading...

Loading...