Page 1

®

Operators Manual

In a world of compromise, some don’t.

HK USC Carbine

.45 ACP

Page 2

USC

Universal Self-loading

Carbine

Operators Manual

CAUTION: Read the safety rules before handling the

USC Carbine!

© Heckler & Koch, Inc., 11/99 (revised June 2001)

All rights reserved

HK, Inc., 21480 Pacific Blvd.

Sterling, Virginia 20166-8903

United States of America

Telephone (703) 450-1900

Specifications and models subject to change without notice.

.45 ACP

®

Page 3

5

TABLE OF CONTENTS

4

TABLE OF CONTENTS

Troubleshooting Guide ......................................................................33

Carrying Sling ....................................................................................35

Sights ..................................................................................................36

Exploded Diagram and Parts List........................................................38

Specifications ......................................................................................40

Firearms Service Record ....................................................................41

Safety Rules on the Use of the HK USC ..............................................6

General ................................................................................................8

Assembly Groups ................................................................................10

Description of Assembly Groups ........................................................11

Assembly Group 1 Upper Receiver with barrel..................................11

Assembly Group 2 Bolt Group ..........................................................12

Assembly Group 3 Lower Receiver with trigger mechanism ............13

Assembly Group 4 Buttstock with pistol grip......................................15

Assembly Group 5 Magazine ............................................................15

Accessories ........................................................................................16

Carrying Sling......................................................................................16

Cleaning Kit ........................................................................................16

Mounting Rails for Aiming Devices according to MIL-STD-1913........16

Handling and Operation ....................................................................17

Filling the Magazine ..........................................................................17

Emptying the Magazine ......................................................................17

Insertion and Removal of the Magazine ............................................17

Loading the USC ................................................................................18

Forward Assist ....................................................................................19

Storage of the USC ............................................................................20

Disassembly ........................................................................................21

Safety Check ......................................................................................21

Disassembly into Assembly Groups ..................................................23

Disassembly and Assembly of the Bolt Group....................................23

Disassembly and Assembly of the Magazine ....................................24

Reassembly of the USC ....................................................................25

Function Check ..................................................................................26

Cleaning & Maintenance ....................................................................27

Normal Cleaning ..............................................................................28

Major Cleaning ..................................................................................30

Operator Inspection ............................................................................30

Lubrication ..........................................................................................31

Ammunition..........................................................................................32

Stoppages ..........................................................................................32

Page 4

7

USC SAFETY RULES

6

USC SAFETY RULES

• Before handling and cleaning the carbine check to ensure that:

- The bolt is locked to the rear

- The carbine is unloaded (cartridge chamber empty)

- The barrel is free of obstructions

- The magazine is empty.

• Keep your finger off the trigger when loading, unloading or

otherwise handling the carbine. Always place the trigger finger

outside of the trigger guard.

• Never use force when handling, disassembling, cleaning and

assembling the carbine.

• Disassemble the carbine only as far as described in this

manual.

• A handstop is provided with each USC to keep the nonfiring

hand or fingers away from the barrel of the carbine. This

handstop should be used at all times and can be mounted on

the USC with or without the mounting rails attached.

• Always wear eye protection when using the carbine.

• Always wear hearing protection when using the carbine.

• Take into account the fact that bystanders are also endangered.

Ensure bystanders are also wearing ear and eye protection.

• Only use ammunition designed to SAAMI specifications that is

factory-loaded, undamaged, and of the correct caliber. The use

of low powered cartridges (including wadcutter and semiwadcutters bullets) could lead to functional stoppages

(including bullets stuck in the barrel) and is not recommended.

• Always mind that the muzzle area is free of obstacles during

firing.

• Store the USC and ammunition in separate places.

• Discharging firearms in poorly ventilated areas, cleaning

firearms, or handling ammunition may result in exposure to

lead, a substance known to be associated with birth defects,

reproductive harm, and other serious injury. Have adequate

ventilation at all times. Wash hands thoroughly after exposure.

• Heckler & Koch does not assume liability for events due to

disregarding this manual, improper handling, negligence,

improper treatment, unauthorized exchange of parts, or

manipulations of the carbine.

• Remember, firearms safety begins with you. Read this operators

manual and be familiar with the safe handling of this firearm

before using it. Store all firearms in a safe and secure location.

Keep firearms away from children. Always be a safe shooter.

Keep this manual with the carbine.

Safety Rules on the use of the HK USC carbine.

Clear the firearm! Before handling the carbine, “clear it!” Do so by:

• Make sure fingers are outside of the trigger guard and the

weapon is pointed in a safe direction at all times!

• ON SAFE – Rotate the safety/selector lever to the “Safe”

position. (With the safety/selector lever set at the white box with

a white bullet symbol inside.)

• REMOVE MAGAZINE – Depress the magazine release lever and

remove the magazine from the magazine well.

• COCKING LEVER – Rotate the ejection port towards the ground

and pull the cocking lever rearward one or more times to insure

the chamber is empty. Watch for a live round or empty case to

be ejected. Rotate the cocking lever upward slightly and lock it

into the indent in the cocking lever housing to lock the bolt

open.

• INSPECT CHAMBER – Inspect chamber for the presence of a

live round or empty case.

Visually – View chamber through open ejection port.

Physically – Insert index finger through magazine well or

ejection port and feel for the presence of a round or cartridge

case in the chamber.

Remove any live rounds or empty cases from the chamber or

from within the firearm or magazine before handling the USC

further.

The HK USC carbine is now considered “Clear”.

WARNINGS

• Carefully read this operators manual before handling the

carbine.

• Only use the carbine after you have fully reviewed and

understand these instructions.

• Observe all notes on handling and operation. Failure to do so

may result in injury or death of the operator or bystanders.

• Do not use any firearm if you have recently ingested alcohol or

drugs.

• When passing the carbine between persons, the weapon must

be clear and the bolt should be open.

• Always treat the carbine as if it were loaded and ready to fire.

• Never point the carbine at anyone during handling.

• Always point the carbine in a safe direction.

• Place your finger on the trigger only when your sights are

aimed at the target.

Page 5

9

GENERAL

8

USC CARBINE

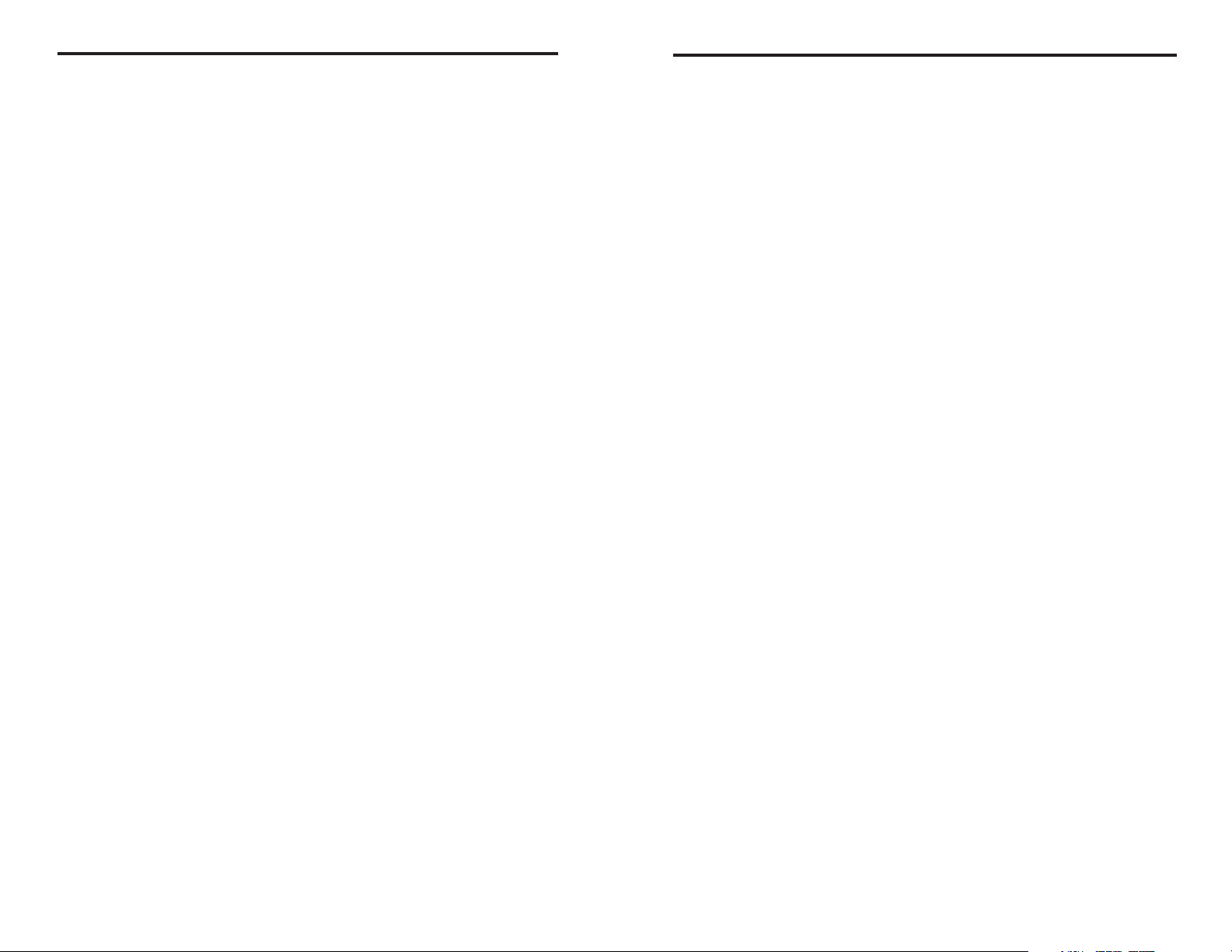

Fig. 2 USC (right side view)

Fig. 3 USC oblique (rear, left side view)

General

The USC Carbine is a semi-automatic small arm designed and

constructed according to the latest methods of advanced technology.

The upper receiver, magazine, lower receiver, and buttstock are made of

high strength polymer. The USC is a simple blowback operated weapon

with a fixed barrel capable of semi-automatic fire.

The USC offers maximum safety and accuracy as it fires from the closed

bolt position. The USC is easily disassembled into its main assembly

groups for cleaning and care without the use of tools.

Accessories

The following accessories are available:

• mounting rails for aiming devices

• handstop

• multi-purpose carrying sling

• tactical lights

NOTE: Photographs throughout this manual show the USC carbine

with the accessory Picatinny rail mounted on the top of the upper

receiver.

Other accessories may also be available, please contact HK for more

information.

Fig. 1 USC (left side view)

Page 6

11

DESCRIPTION OF ASSEMBLY GROUPS

10

USC CARBINE

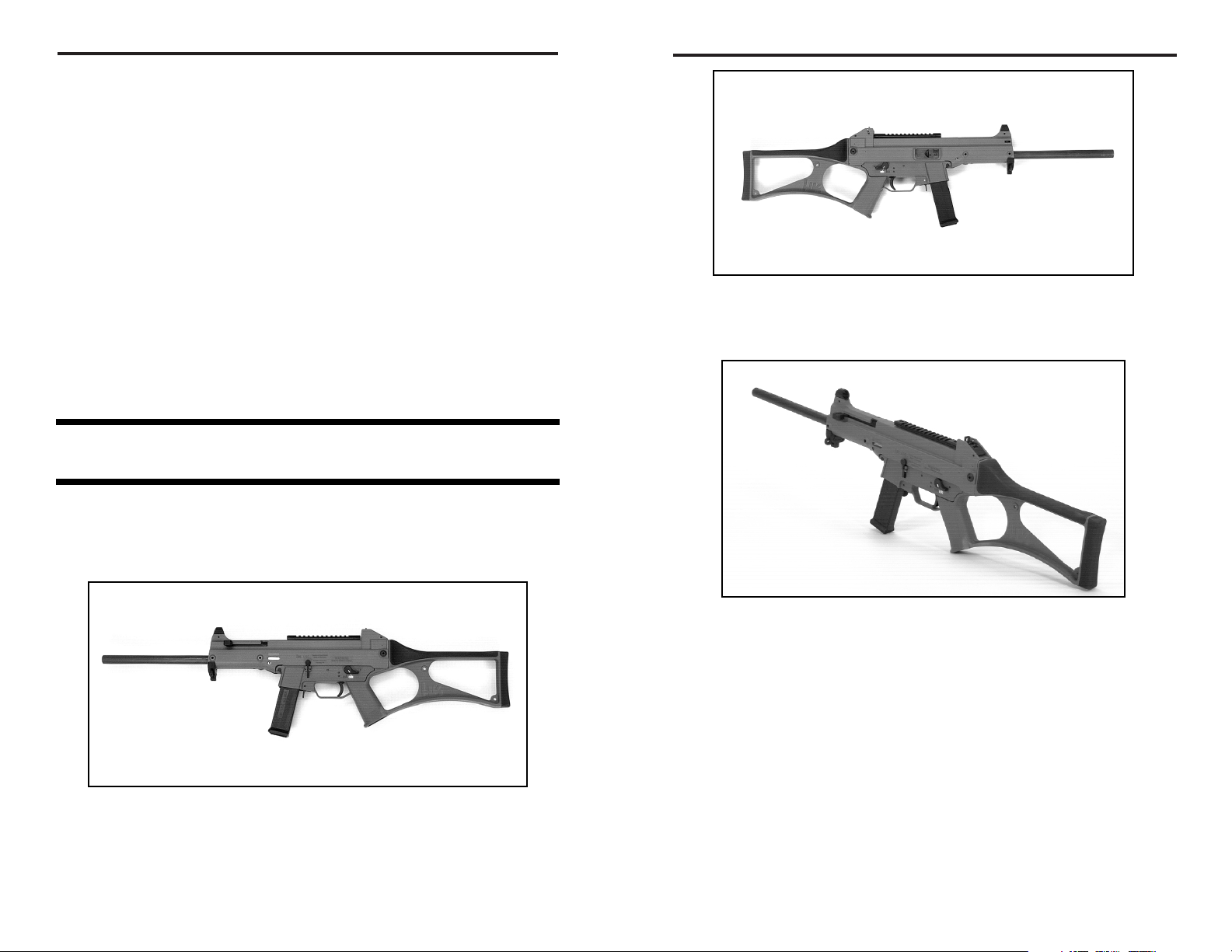

Assembly Group 1 Upper receiver with barrel

The upper receiver is produced using fiber-reinforced plastics and

houses other subassemblies. The inside of the upper receiver contains

metal guideways for the bolt group as well as attachment points for the

lower receiver with magazine well and the buttstock.

The barrel is inserted into and pinned to the upper receiver. The cocking

lever of the carbine is located above the barrel. It also serves to

manually lock the bolt in its open position. The right side of the upper

receiver contains the ejection port.

The bottom part of the upper receiver includes the support bolts for the

lower receiver and a handstop with dual mounting points for the carrying

sling.

The sights are fastened to the top of the upper receiver. They consist of

a flip-up type rear sight with diopter (peep) and u-notch apertures as

well as of the front sight post with front sight hood. A Picatinny rail is

mounted on the top of the receiver. Six additional hard points are

molded into the receiver on the left, right, and on the bottom sides.

These hard points allow for the easy installation of additional rails.

Fig. 5 Upper Receiver with barrel and attachment components

1 Upper receiver 5 Flip-up rear sight

2 Barrel 6 Accessory Picatinny rail

3 Front sight 7 Handstop

4 Cocking lever 8 Hardpoints

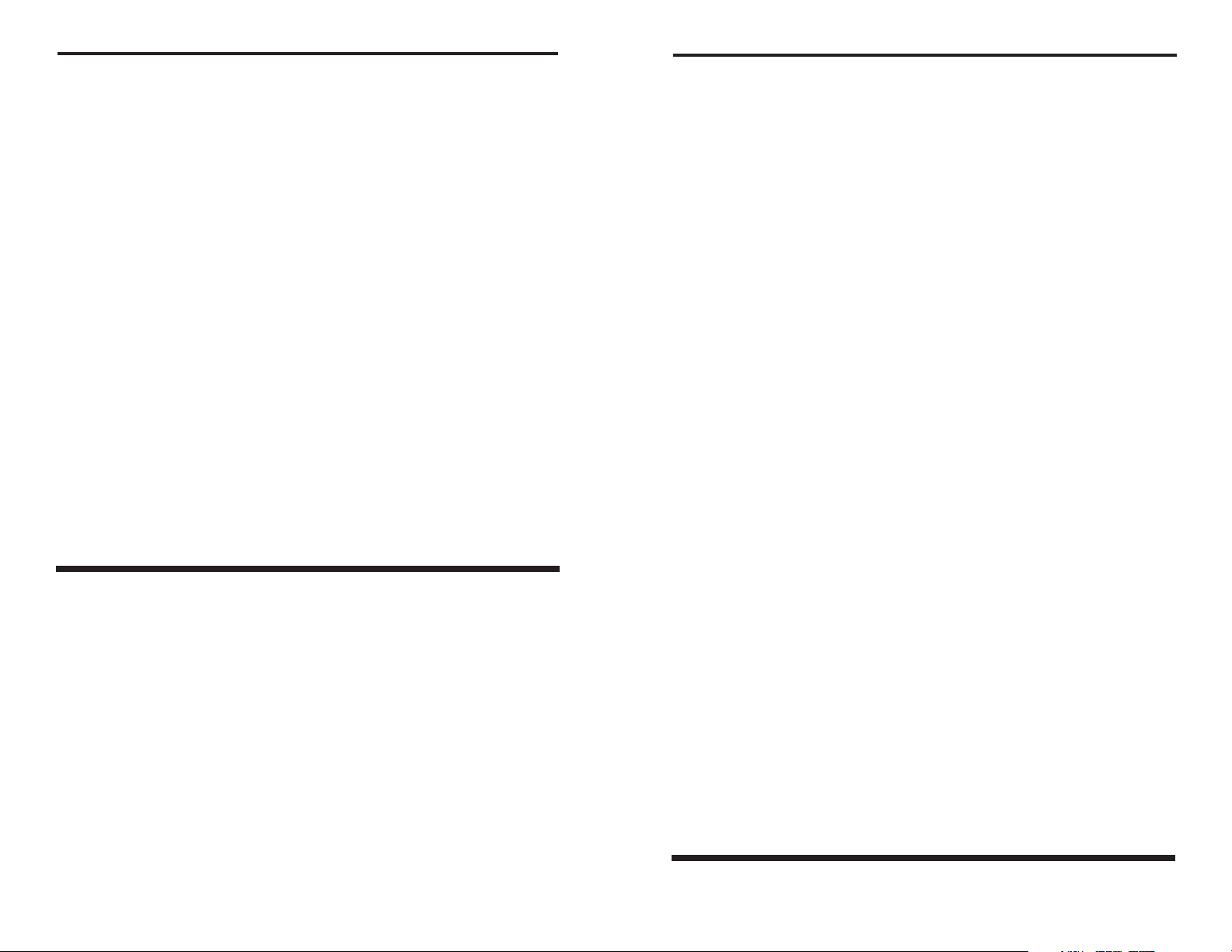

Assembly Groups

1 Upper receiver with barrel, folding buttstock and

attachment components

2 Bolt Group with recoil spring assembly, complete

3 Lower receiver with trigger mechanism, backplate and

magazine well

4 Buttstock with pistol grip

5 Magazine

For accessories see pages 15-16

Fig. 4 USC Assembly Groups

Page 7

13

DESCRIPTION OF ASSEMBLY GROUPS

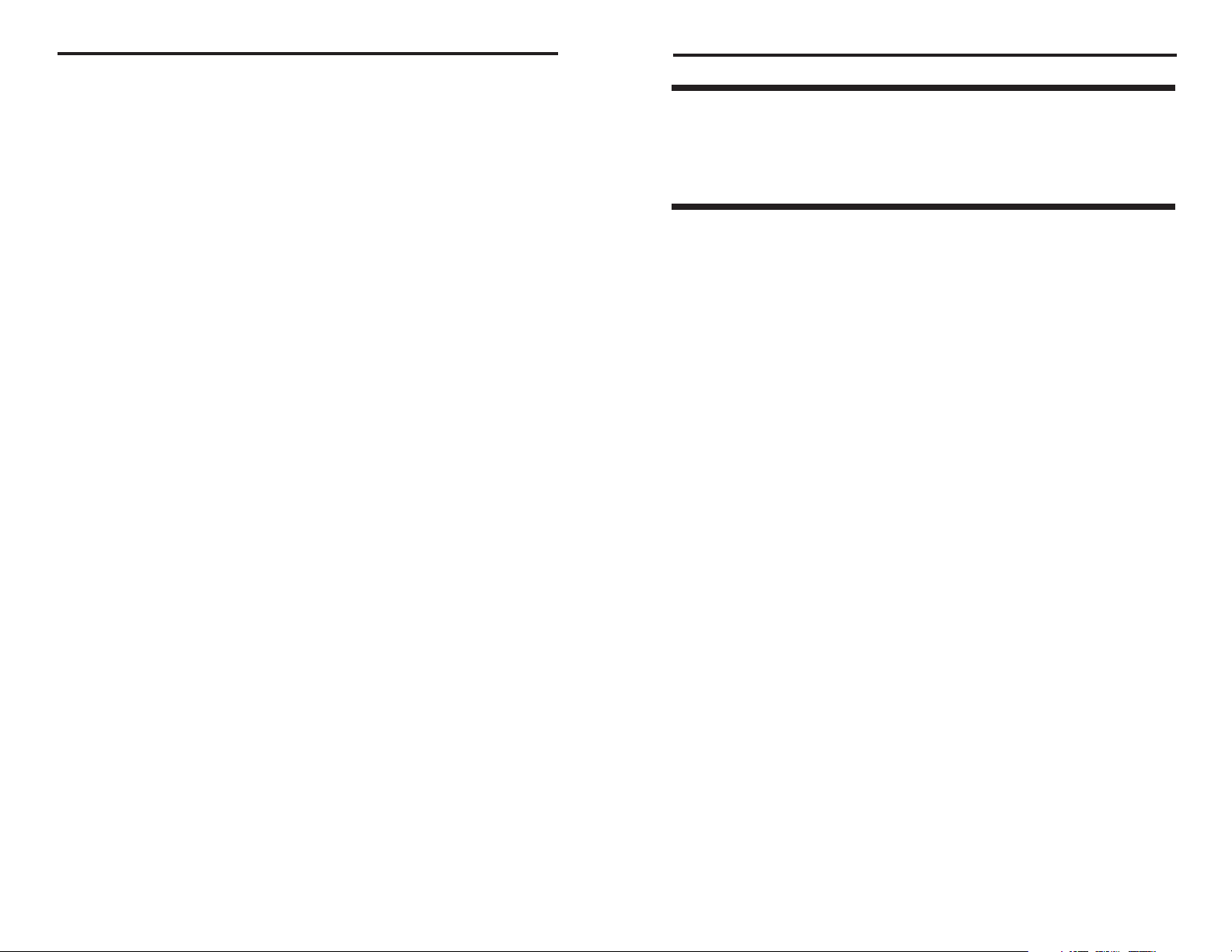

Assembly Group 3 Lower receiver with trigger mechanism

The lower receiver houses the trigger mechanism with ambidextrous

safety/selector levers, the magazine well, magazine release lever and

bolt catch. The forward portion of the lower receiver is hooked to the

upper receiver. The rear portion is fastened to the upper receiver using

guide rails in the pistol grip of the buttstock.

The safety/selector levers are fitted on both sides of the pistol grip.

The forward portion of the lower receiver has lugs for attachment to the

upper receiver. Behind these lugs is the magazine well with the

magazine release lever.

Above the magazine release lever is the bolt catch. It serves to hold the

bolt rearward when the last round is fired and to release the bolt from

the open position after an empty magazine has been replaced with a

loaded magazine.The rear side of the lower receiver includes the

integrated backplate with buffer and support for the recoil spring

assembly.

Fig. 10 Lower receiver with trigger mechanism and magazine well

1 Trigger 5 Bolt catch

2 Magazine release lever 6 Safety/Selector lever

3 Magazine well 7 Hammer

4 Attachment lugs 8 Trigger guard

12

USC CARBINE

Assembly Group 2 Bolt Group

The bolt group, together with the recoil spring assembly, is contained

inside the upper receiver. The reciprocal movement of the bolt group

provides for feeding and ignition of the cartridge, for extraction and

ejection of the spent case as well as for cocking of the hammer. The

right side of the bolt has a thumb recess for manual closing of the bolt

(forward assist).

The recoil spring assembly pushes the bolt forward into the firing

position. The cone-shaped support for the recoil spring assembly is

housed in the backplate of the lower receiver. The longitudinally

movable guide ring supports itself within the bolt.

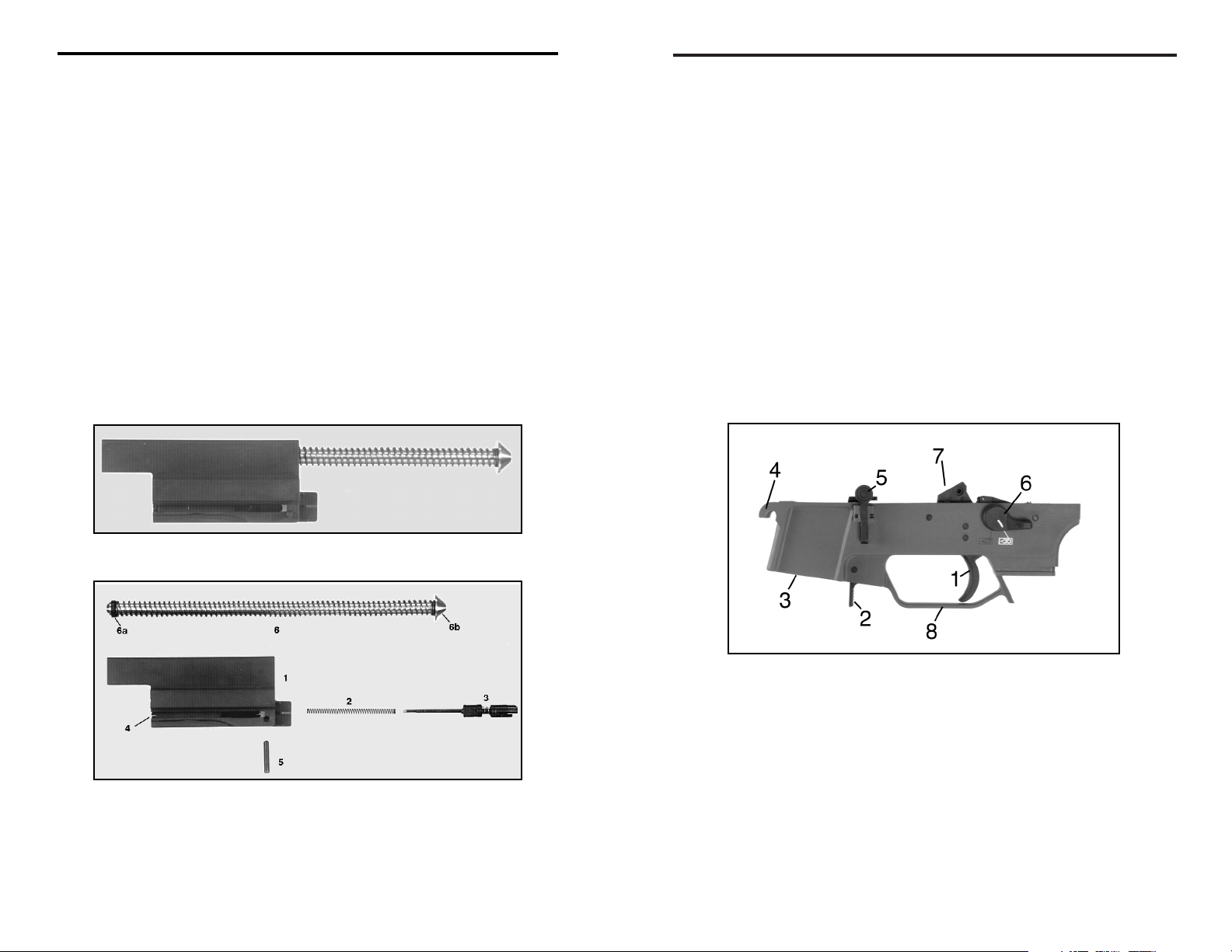

The bolt group (Fig. 8 and 9) consists of:

1 bolt 5 firing pin retaining pin

2 firing pin spring 6 recoil spring assembly, complete

3 firing pin assembly 6a guide ring

4 extractor 6b support

Fig. 8 Bolt Group, assembled

Fig. 9 Bolt Group, disassembled

Page 8

14

USC CARBINE

15

DESCRIPTION OF ASSEMBLY GROUPS

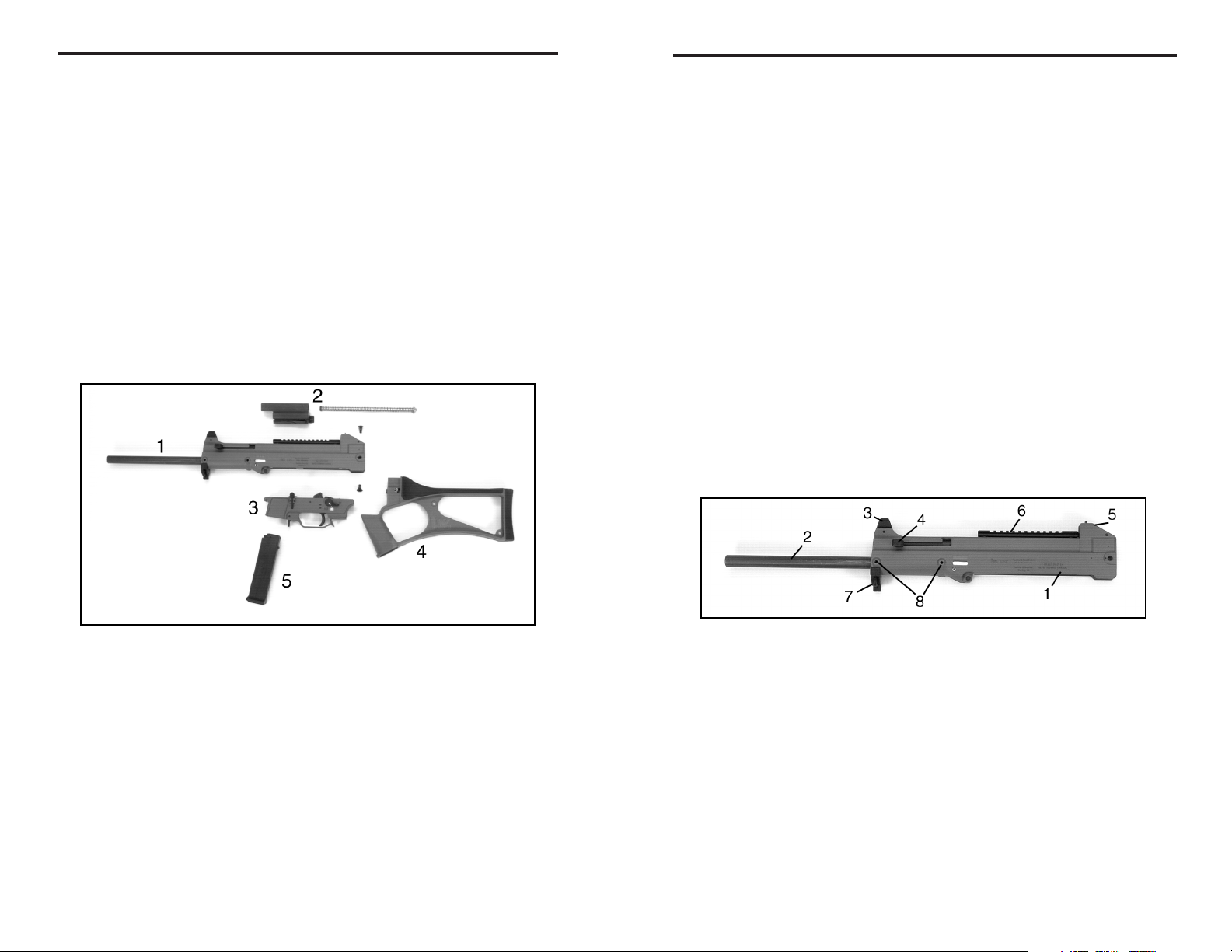

Assembly Group 4 Buttstock with pistol grip

The buttstock is attached to the receiver by the means of two hex head

screws which can be installed or removed by using the HK tool.

Fig. 11 Buttstock with pistol grip

The buttstock holds the upper and lower receiver together. A rubber

cheek rest and buttplate are molded onto the polymer frame of the

buttstock.

Assembly Group 5 Magazine

The magazine housing is constructed from plastic. The magazine

consists of: magazine housing, magazine floor plate, follower, follower

spring and locking plate.

Fig. 12 Magazine, complete Fig. 13 Magazine, disassembled

1 Magazine housing 4 Follower spring

2 Magazine floor plate 5 Locking plate

3 Follower

safe semi-automatic fire

The safety/selector lever of the USC trigger mechanism has two

positions :

Position = Safe

Position = Semi Automatic fire

Page 9

17

HANDLING & OPERATION

16

USC CARBINE ACCESSORIES

Filling the Magazine

• Grasp magazine.

• Slide individual cartridges under the magazine lips one by one (Fig. 20).

• Repeat this process until the required number of cartridges has been

inserted or the magazine is full (maximum 10 rounds).

Fig. 17 Filling the magazine

NOTE: Loading more than the prescribed number of rounds will

prevent the magazine from being inserted in the weapon with the

bolt forward.

Emptying the Magazine

• Grasp magazine.

• With your thumb, push cartridges forward out of the magazine into the

palm of the other hand

OR

• Grasp magazine and hold it with the points of the bullets pointing

towards the bottom.

• Use a piece of wood to slide the cartridges out of the magazine.

Insertion and removal of magazine

• Put the USC safety/selector on (Safe).

• Insert magazine into the magazine well (Fig. 18). The magazine catch

has to engage audibly in the process. Tug on the magazine to ensure

it is fully engaged.

• For removal of the magazine, push magazine catch forward (Fig 19)

and remove magazine downward.

Fig. 18 Insert magazine Fig. 19 Remove magazine

Carrying sling

The carrying sling (Fig.14) enables the shooter to carry the USC carbine

securely in a wide variety of positions.

Fig. 14 Sling

Cleaning Kit The cleaning kit includes:

1 Transport case 5 Oil bottle

2 Cleaning patches 6 Bore brush

3 Cleaning brush 7 Patch holder

4 Cleaning rod with folding handle

Fig. 15 Cleaning Kit

Mounting rails (MIL-STD-1913) for aiming devices

The mounting rail (Picatinny Rail) is screwed onto the molded-in hard

points provided either on top of the receiver, below the forearm or on the

right or left sides of the forearm.

Fig. 16 Mounting rails

Page 10

19

LOADING THE USC

18

USC CARBINE

Starting Situation 2: There is an empty magazine in the carbine.

The bolt is held back by the bolt catch.

• Put the USC safety/selector on (Safe).

• Push magazine catch forward and remove empty magazine.

• Insert the filled magazine into the magazine well until the magazine

catch engages audibly. Tug to check.

• Depress upper end of bolt catch (Fig. 21), thus releasing the bolt and

allowing it to snap forward chambering a round.

WARNING:The USC is now fully loaded and with the safety on.

FIg. 21 Depress bolt catch to release the bolt

With heavy external fouling of the USC, (sand, sludge) or to load the

firearm quietly, the thumb recess on the bolt may be used as a forward

assist (Fig 25A). To do so use the thumb recess, push bolt forwards until

it is in the forward most position.

FIg. 22 Forward Assist

Starting Situation 1: No magazine is present in the carbine. The bolt

is forward.

• Put the USC safety/selector on (Safe).

• Insert the loaded magazine into the magazine well until the magazine

catch engages audibly. Tug downward to ensure it is properly seated.

• The USC is partially loaded and with the safety on.

• Pull cocking lever backwards as far as it will go and let bolt snap back

to its forward position chambering a round. In the process do not ride

the cocking lever forward.

WARNING:The USC is now fully loaded and with the safety on.

or

• Pull cocking lever backwards as far as it will go, (Fig. 20 ) and swivel it

upwards (engage it in the indent) into the open position.

• Insert the loaded magazine into the magazine well until the magazine

catch engages audibly. Tug to check.

• With the open palm of the non-firing hand "slap" the cocking lever

downward and forward to chamber a round. During this process do

not ride the cocking lever forwards.

WARNING:The USC is now fully loaded and with the safety on.

FIg. 20 Pull cocking lever backwards

Page 11

21

DISASSEMBLY

20

USC STORAGE

NOTE:The USC is easily disassembled and reassembled with the HK

Tool. Do not use force in any of the disassembly procedures.

Disassembly beyond the procedures outlined in this manual is not

recommended and may void the HK Warranty. Disassembly beyond

the operators level described here may be carried out by qualified

maintenance personnel only. Contact HK for more information.

Clear the carbine! Before handling the firearm, “clear it!” Do so by:

1 • Make sure fingers are outside of the trigger guard and the

weapon is pointed in a safe direction at all times!

2 • ON SAFE – Rotate the safety/selector lever to the “Safe”

position. (With the safety/selector lever set at the white box with

a white bullet symbol inside.)

3 • REMOVE MAGAZINE – Depress the magazine release lever and

remove the magazine from the magazine well.

4 • COCKING LEVER – Rotate the ejection port towards the ground

and pull the cocking lever rearward one or more times to insure

the chamber is empty. Watch for a live round or empty case to

be ejected. Rotate the cocking lever upward slightly and lock it

into the indent in the cocking lever housing to lock the bolt

open.

5 • INSPECT CHAMBER – Inspect chamber for the presence of a

live round or empty case.

Visually – View chamber through open ejection port.

Physically – Insert index finger through magazine well or

ejection port and feel for the presence of a round or cartridge

case in the chamber.

Remove any live rounds or empty cases from the chamber or

from within the firearm or magazine before handling the USC

further.

The HK USC is now considered “Clear.” Once clear, let the bolt move

forwards.

1. Store the carbine clean and lubricated.

2. Store the carbine without a round in the chamber.

3. Store the carbine with the cocking lever forward and the hammer

down (at rest).

4. After no more than twelve (12) months unload all loaded magazines

and replace the ammunition with fresh ammunition.

5. Clean and lubricate the carbine and magazines every twelve (12)

months while in storage.

6. Store the carbine is a clean, dry environment with regulated

temperature controls.

Page 12

23

DISASSEMBLY INTO ASSEMBLY GROUPS

22

USC CARBINE

Disassembly of the Bolt

1 • Push and hold firing pin forward.

2 • Pull out firing pin assembly retaining pin to the left (Fig. 28).

3 • Remove firing pin assembly and firing pin spring to the rear. To

do this, push the locking catch to the right (Fig. 29). With your

thumb prevent the firing pin assembly with firing pin spring from

springing out.

Fig. 28 Fig. 29

Pull out firing pin retaining pin Push locking catch to the right

WARNING: Never disassemble the firing pin. It is possible to

assemble the firing pin assembly incorrectly and in doing so,

disabling the USC firing pin safety. Contact HK for more information.

Assembly of the Bolt

1 • Place firing pin spring onto firing pin.

2 • Insert firing pin spring and firing pin assembly into the bolt from

the rear and push them forwards (Fig. 30).

3 • Using any pointed object push the rear end of the firing pin

forwards (Fig. 31).

4 • Insert firing pin retaining pin from the left to retain firing pin

assembly in the bolt.

Fig. 30 Fig. 31

Insert firing pin spring Push firing pin forwards

and firing pin assembly

locking

catch

Stripping into assembly groups

1 • Detach carrying sling

2 • Use the 5 mm Allen wrench of the HK tool and remove the hex

headed Allen screws located on the left and right sides of at the

rear end of the receiver

3 • Pull the buttstock straight backwards out of the guiding rails of

the lower the receiver.

4 • Swivel the lower receiver downwards at an angle of

approximately 45° and detach it from the support bolts of the

upper receiver (figures 23 & 24).

Fig. 23 Detaching lower receiver Fig. 24 (Detail) lower receiver

5 • Pull back the cocking lever and remove the recoil spring

assembly and the bolt to the rear (figure 25).

Fig. 25 Removing recoil spring

Page 13

25

ASSEMBLY

24

USC CARBINE

Reassembly of the USC

1 • With the cocking lever forward, insert the bolt and recoil spring

assembly to the receiver from the rear.

2 • From below, engage lower receiver (hammer between cocked

and released positions) into the support bolts on the upper

receiver and swivel it upwards (Fig. 32).

Fig. 32

3 • Hold the upper and lower receiver firmly together. Slide buttstock

guiding rails horizontally into the appropriate slots of the lower

receiver (Fig. 33).

Fig. 33

Pushing buttstock into upper and lower receiver

4 • Fasten the buttstock to the upper receiver by means of the two

Allen screws with the HK tool (do not use excessive force to

tighten the screws down).

5 • Put the USC safety/selector on (Safe).

6 • Insert empty magazine.

7 • Carry out a function check as described on page 26.

8 • Attach carrying sling (Fig. 34)

Disassembly of the Magazine

1 • Depress locking plate through magazine floor plate and slide

magazine floor plate to the rear (fig. 30).

2 • Detach magazine floor plate to the rear.

3 • Remove follower spring with locking plate and follower.

Fig. 30

CAUTION: Magazine floor plate is under spring tension. With your

thumb secure locking plate with follower spring to prevent it from

springing out.

Assembly of Magazine

1 • Insert follower and follower spring with locking plate into the

magazine housing from below.

2 • Fully depress follower spring and locking plate (Fig. 31) and

slide magazine floor plate onto magazine housing from the rear.

3 • Push magazine floor plate forwards as far as it will go.

4 • Check that the floorplate is fully seated and secured in place by

the tab of the locking plate.

Fig. 31

Page 14

27

CLEANING & MAINTENANCE

26

USC CARBINE

Operator Cleaning

• The functional performance of any mechanical device varies greatly

on the quality and frequency of the maintenance performed on that

item. Firearms are no exception. The operator spends most of the time

with the weapon and therefore has the best opportunity to perform the

necessary upkeep required to insure top performance at all times.

• Metal components of new USC are coated in a thick, oily preservative

that should be removed prior to the weapon being used or fired. This

preservative oil, applied by HK personnel prior to the shipment of the

weapons from the manufacturing facility in Germany, guarantees that

the weapons and accessories will remain corrosion-free during

storage and transport. However, this preservative fluid is not

considered a lubricant and therefore should be removed and replaced

with a high-quality weapons lubricant whenever possible. This

preservative fluid attracts debris and dirt and possesses little or no

lubrication qualities.

• Cleaning the USC, especially with its polymer construction, need not

take hours and a great deal of effort. With the right equipment a very

fouled USC should be able to be thoroughly cleaned in less than 10

minutes. A solvent tank where the parts can be immersed in and

scrubbed will save a great deal of time and effort as will compressed

air to blow off the fouling and solvent or to spread the lubricant. There

are companies, such as Safety-Kleen, that sell or rent such solvent

tanks and will exchange the solvent on a regular basis at a

reasonable price.

NOTE: If using ultra sonic cleaning machines, do not immense the

painted portion of the USC, specifically the color pictogram firing

mode markings on the lower receiver. Ultra sonic cleaning or strong

solvents will remove the markings!

• If such a set up is not available to you, a complete weapons cleaning

kit specially designed for the HK USC will reduce your cleaning time

and make the job easier.

• Any quality weapons solvent or oil can be used to clean the USC.

Basically, if it’s safe to put your bare hands into it won’t hurt the

surfaces of the weapon. Break-Free (CLP), Ballistol, Militec or any

of the other brand-name cleaners or lubricants specifically designed

for use with weapons will work well on the USC.

• At HK we recommend two types of operator cleaning. Normal cleaning

and Major cleaning.

Fig. 34

Attaching carrying sling

NOTE: A Function Check should be performed anytime the carbine

is reassembled. This quick check indicates whether or not the

carbine has been properly assembled and/or assembled with all

components. A properly executed Function Check can also reveal

many of the more obvious malfunctions that could occur between

the interactive components of the carbine. ALWAYS clear the

carbine before performing the Function Check! ENSURE the

carbine is clear!

1 • Clear the carbine!

2 • Place the cocking lever and bolt group in the forward position.

3 • With the carbine on “Safe”, pull the trigger. Hammer should not fall.

4 • Place the weapon on “Semi-automatic”. Pull the trigger and hold

the trigger back. Hammer should fall.

5 • Still holding the trigger back, recock the carbine. Release the

trigger. Listen for the “click” of the trigger and sear resetting. Pull

the trigger. Hammer should fall.

6 • The Function Check is now complete.

Page 15

29

CLEANING

28

USC CARBINE

• Chamber – Apply a liberal amount of solvent to the appropriate bore

brush. Insert the brush through the back of the receiver into the

chamber. DO NOT push the brush past the chamber! Work the brush

back and forth in the chamber at least three times. Remove the brush

and let the solvent go to work on the fouling for a few minutes while you

work on other components.

• Chamber face – This area is easily tackled using the special Chamber

Face brush available in the HK Field Cleaning Kit for the USC carbine.

Attach this brush to the cleaning rod and lock the handle so that the rod

and brush can be turned together. Apply a liberal amount of solvent to

the bristles of the brush. Insert the brush through the back of the receiver

until it makes contact with the area surrounding the opening to the

chamber and bore. With slight inward pressure, rotate the brush in a

clockwise direction to break up the carbon fouling built-up on the face of

the chamber. Continue this procedure until you are satisfied with your

efforts.

• Upper Receiver – Apply a few drops of solvent to a toothbrush and

scrub the area around the chamber face and along the length of the

receiver rails to break-up the carbon fouling. Remove all of the fouling,

carbon, and visible debris from the entire upper receiver using a solvent

tank and compressed air or swabs, patches, rags, etc. Run al least three

clean patches of the appropriate size all the way through the bore in the

direction of bullet travel to remove the loose fouling and solvent.

• Muzzle – Use a nylon bristle toothbrush and a small amount of solvent

to remove any fouling from the muzzle.

Bolt group Scrub all parts of the bolt group with a toothbrush and solvent

where carbon is visible, especially around the face of the bolt and the

extractor. Do not attempt to remove the extractor for cleaning!

There is no functional need to remove the extractor for normal

cleaning. Remove the loose fouling from all parts using a rag, swabs or

compressed air.

Magazine Don’t forget the magazines! They are very important and very

often overlooked during cleaning. Many stoppages occur as a result of

improperly maintained magazines. Apply a few drops of solvent to a

toothbrush and scrub the top of the magazine to remove any visible

carbon fouling or loose debris. Pay special attention to the front edge of

the housing, feed lips, and the follower. Remove the solvent and loose

fouling from the magazine using a rag, swabs or compressed air.

Normal cleaning

Performed after each firing or every twelve (12) months.

Major cleaning

Often referred to as “detailed cleaning”. Performed on a USC after 1,000

rounds or when the weapon is exposed to or excessively laden with

sand, dust, water or other visible contaminants or foreign matter.

• The cleaning intervals listed here are recommendations only!

• Your intervals between cleaning will vary greatly depending on many

factors to include the type of ammunition used, the environment in

which the weapon is used, and the thoroughness of your cleaning, etc.

Normal cleaning

1. CLEAR THE CARBINE!

2. Disassemble the weapon into the major assembly groups.

Multi-purpose carrying sling The nylon webbing and plastic components

of the multi-purpose carrying sling can be cleaned using warm water and

a soft bristled brush. Allow the sling material to dry completely before

storage or use. Avoid getting the metal sling components wet.

Buttstock Simply remove any foreign debris from the exterior polymer and

rubber surface of the buttstock using a toothbrush, rag, swabs or

compressed air when available.

Lower receiver Remove any foreign debris from the plastic pistol grip

using a tooth-brush, rag, swabs or compressed air. Scrub the top of the

hammer, ejector and the area around the front of the ejector with a small

amount of solvent or oil to break up the carbon fouling. Remove the

loose fouling and debris by rinsing the components in the a solvent tank

or by using rags, swabs, or compressed air.

Forearm / foregrip Remove any foreign debris from the forearm or

optional foregrip using a toothbrush, rag or compressed air.

Upper receiver with barrel Start with the bore and chamber.

• Bore – Apply a liberal amount of solvent to a bronze bristle bore brush of

the appropriate caliber. Always insert the bore brush from the chamber end

and push it all the way through the barrel in the direction that the bullet

travels. Pull the brush back through the barrel. DO NOT use stainless steel

brushes as they will damage the USC’s rifling. DO NOT allow the brush to

stop in the bore or it may get stuck! Repeat this in/out procedure for a

minimum of three complete trips. Remove the bore brush and let the solvent

work in the bore for a few minutes while you clean other components.

Page 16

31

LUBRICATION

30

USC CARBINE

Lubrication

Any type of high-quality, medium-weight lubricant (oil) specifically

designed for use on firearms such as Break-Free (C.L.P.) Ballistol, or

Militec will work well on the HK USC carbine. DO NOT use

lubricants/cleaners that boast of their ability to penetrate metal (i.e.

WD-40, Tri-Flow, etc.) as these substances may deaden primers.

Where and how much?

No Lube – (surface is dry and not slippery to the touch)

• Sling material

• Plastic components

Light Lube – (finger run across surface yields little or no lube)

• Bore and chamber

• All metal parts (except sound suppressor)

• Muzzle

• Magazine spring

• Axles of all operating controls (cocking lever, bolt

catch, safety/selector lever, magazine catch, etc.)

• Rear sight assembly

• All metal accessories

Medium Lube – (finger run across surface yields some lube but lube

does not run down surface when held in a vertical position)

• Bolt group with recoil spring and guide rod

Heavy Lube – (Lube runs down surface when held in a vertical

position) No heavy lube is required on the HK USC!

• Reapply lubrication to the bolt of the USC periodically during firing as

it burns off from the heat.

• Apply lubricant using a shaving brush, swabs, patches, or rag. A spray

bottle also works well using compressed air to circulate the lubricant

into all parts and to remove the excess.

Major Cleaning

As mentioned earlier, Major cleaning should be performed after 1,000

rounds are fired through a USC. Major cleaning is also performed when

the weapon has been immersed in water or is laden with large amounts

of visible foreign matter or fouling.

During major cleaning, all firearm components except the painted

surfaces (firing modes symbols) and the carrying sling, should be rinsed

with or immersed in solvent and scrubbed thoroughly with a brush. This

includes the magazine and it’s parts. The components can then be dried

using a rag or swabs, though compressed air is preferable for Major

cleaning.

If any assembly groups require a more thorough cleaning, an “ultra-

sonic” cleaning machine can be used containing any solvent that it is

safe to place your bare hands in, as a general rule.

However, avoid placing painted surfaces such as the firing mode

markings on the lower receiver into an ultra-sonic cleaner, as this may

remove the colored markings. Further disassembly of any assembly

group(s) beyond the level described above must be performed by, or at

a minimum supervised by, an HK factory-trained armorer.

Operator inspection

During or after cleaning the operator should inspect the firearm and it’s

components for any irregularities that may causes problems during it’s

operation. If any potential deficiencies are noted, they should be

corrected immediately and/or brought to the attention of the unit

armorer. In general, the operator should keep a watchful eye out for the

following discrepancies both in the weapon as a whole and in each

assembly group.

• Improper function

• Missing parts

• Cosmetic flaws (cracks, dents, burrs, rust, etc.)

• Improper assembly

• Loss of spring tension (where applicable)

• Unusual looseness (where applicable)

• Cracked welds

• Excessive wear

• Absence of protective finish (where applicable)

• Absence of proper lubrication

Also check these more areas where problems may begin in the USC.

Page 17

33

TROUBLESHOOTING GUIDE

32

USC CARBINE

1. Put the USC safety/selector on (Safe).

2. Remove the magazine.

3. Pull rearward on the cocking lever and lock the bolt open.

4. Ensure that barrel, cartridge chamber and receiver are free of

obstructions.

5. Next, determine and eliminate the cause of the stoppage. The items

indicated in the following tables do not cover all stoppages

theoretically possible. A given stoppage may also have been caused

by other reasons than the ones indicated.

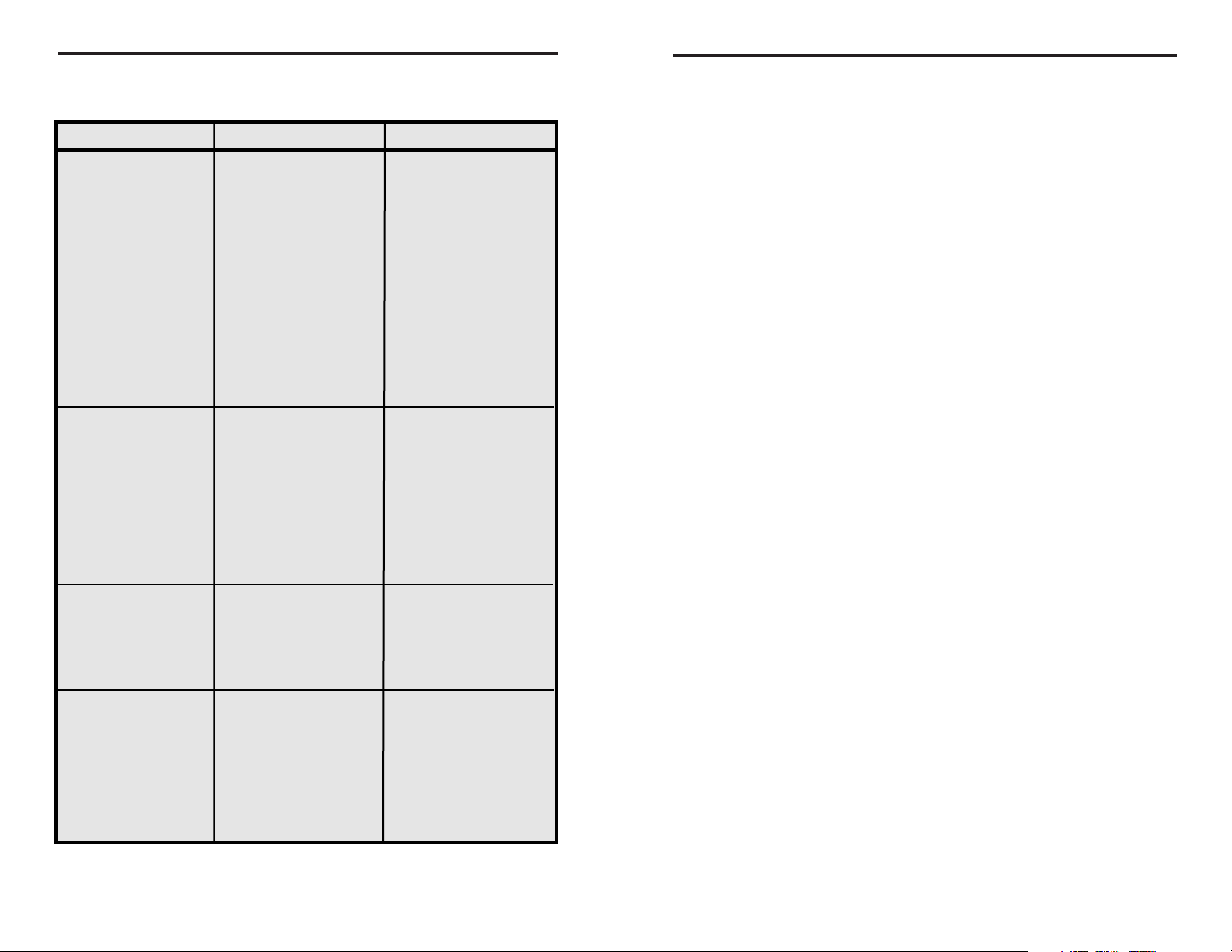

Stoppage Cause Remedy

Cartridge not ignited Ammunition fault Replace round

(Dud round)

Firing pin damaged Take USC to

or broken maintenance shop

Hammer spring Take USC to

damaged or broken maintenance shop

Bolt did not stay open on Cartridge case stuck in Unload. Retract bolt to

the last shot chamber because it is eject spent case. Clean

deformed or the chamber if fouled. If required take

is dirty USC to maintenance shop

Cartridge case not Chamber is dirty Clean cartridge chamber

extracted or ejected

Extractor broken Take USC to

maintenance shop

Ejector damaged Take USC to

maintenance shop

Insufficient bolt recoil Unload. Retract cocking

lever to eject spent

case. Check for smooth

movement of bolt and

check chamber for fouling.

Clean if required.

Ammunition

The USC carbine was designed to use ammunition made to NATO or

SAAMI specifications. Like an automobile engine, you cannot expect top

performance by using poor quality fuel. The same applies to firearms.

There are a number of general considerations that should be made

when choosing the type of ammunition you plan to use in the USC.

DO USE

• Ammunition of the appropriate caliber and of recent manufacture

• Clean burning ammunition

• Non-corrosive ammunition

• Jacketed Hollow Point (JHP), “Silver-Tip”, ball, truncated cone, “Hydra

Shok”, +P, etc.

DO NOT USE

• Reloads or remanufactured ammunition. Beware of military surplus,

foreign or outdated ammunition.

• Non-jacketed or exposed lead ammunition

• Corrosive ammunition (primer and/or propellant)

• Empty cases as “dummy“ (inert) rounds, as damage may result to the

weapon, especially the synthetic magazines employed in the USC.

Use complete dummy rounds available for training purposes.

• Any ammunition that exceeds NATO or S.A.A.M.I. pressure limits

WARNING: Only use ammunition designed to SAAMI specifications

that is factory-loaded, undamaged, and of the correct caliber. The

use of low powered cartridges (including wadcutter and semiwadcutters bullets) could lead to functional stoppages (including

bullets stuck in the barrel) and is not recommended.

Stoppages

In the event of stoppages on the USC, the carbine is to be considered

loaded until the actual cause of the stoppage has been determined.

During the elimination of stoppages, safety precautions are to be taken

into account.

In the event of stoppages on the USC, for example the cartridge fired

from the USC is not ignited, the bolt assembly does not close

completely, or the spent cartridge case is not ejected, the following

immediate steps have to be taken:

Page 18

35

CARRYING SLING

34

USC CARBINE

Carrying sling

The carrying sling enables the USC to be carried in several ways. The

carrying sling is attached to the mounting points on the receiver,

handstop, or buttstock via the carbine hooks.

Length Adjustment

1 • Close coupler

2 • Rest the carrying sling between thumb and index finger and let

the USC hang down in a horizontal position. Adjust the length in

such a way that there is a space of approximately 10 cm (4

inches) between your forearm and the USC.

For adjustment

1 • Slide the forward buckle and coupler with the sewn-up end as

far as possible up to the front carbine.

2 • Somewhat loosen the belt loop in the rear buckle.

3 • To shorten the carrying sling, pull the upper loop forwards

4 • To lengthen the carrying sling, pull the upper loop to the rear.

5 • Tighten loop in the buckle

6 • Tighten carrying sling

Routing the Carrying sling

In order to carry the USC laterally against the body or in front of the

body (ready position), or on the back, the carrying sling must be

properly routed. To do so:

1 • Pull the two halves of the carrying sling apart and upwards.

2 • Place the upper part of the carrying sling onto your shoulder

over your head.

Stoppage Cause Remedy

No cartridge fed by bolt. Magazine not properly Insert magazine properly

inserted

Magazine loose Check magazine catch and

tab on magazine. If

required take USC to

maintenance shop.

Follower spring lame Replace magazine or

follower spring and take to

maintenance shop.

Magazine lips damaged Replace magazine or

magazine housing and

take the damaged one to

maintenance shop

Bolt not fully closed. Car tridge chamber dirty Clean cartridge chamber

Cartridge not fully fed

Cartridge damaged Replace cartridge

Recoil spring lame Take USC to maintenance

shop

Improperly cocked Allow cocking lever to snap

forward. On releasing

cocking lever do not ride it

forward.

Bolt does not stay open Magazine spring lame Replace magazine and

after last shot take damaged one to the

maintenance shop

Bolt catch damaged Take USC to maintenance

shop

Magazine stuck in Magazine damaged Replace magazine housing

magazine well and take damaged one to

to the maintenance shop

Magazine catch defective Take USC to maintenance

shop

Page 19

37

SIGHT ALIGNMENT

36

USC CARBINE

Correct point of aim

Even circle of light

Fig. 42 Sight pictures

Point of aim

Rear sight

Aperture

Circle of light

Front sight holder

Front sight post

Impact as with incorrectly

centered front sight = right

Impact as with full sight

= high

Impact as with fine sight

= low

Impact as with incorrectly

centered front sight = left

Sight Adjustment

If the point of impact has to be corrected, this will be done by adjustment

of the rear sight using the Allen wrench provided with the weapon.

The USC is zeroed at the factory to hit the point of aim at 25 meters

(27.3 yards).

Elevation adjustment

• To lower the weapon’s point of impact, turn the elevation adjustment

screw clockwise.

• To raise the weapon’s point of impact, turn the elevation adjustment

screw counterclockwise.

NOTE: 1 revolution of the elevation adjustment screw changes the

point of impact by 4.5 centimeters (1.77 inches) at a range of 25

meters (27.3 yards).

Windage adjustment

• To move the weapon’s point of impact to the left, turn the windage

adjustment screw counterclockwise.

• To move the weapon’s point of impact to the right, turn the windage

adjustment screw clockwise.

NOTE: 1 click of the windage adjustment screw changes the point of

impact by 1.15 centimeters (.45 inches) at a range of 25 meters (27.3

yards).

Fig. 40 Elevation adjustment Fig. 41 Windage adjustment

Page 20

39

EXPLODED DIAGRAM & PARTS LIST

38

USC CARBINE

Item Description Part No. Item Description Part No.

36 Locking lever spring 214616

37 Locking lever 219095

38 Bolt 214615

39 Locking lever housing 214613

40 Elbow spring right 217946

41 Elbow spring left 205201

42 Hammer 217936

43 Hammer spring, left 217533

44 Hammer spring, right 217585

45 Notched disk 217614

46 Compression spring 205418

47 Index plate 205419

48 Axle, locking lever 219521

49 Safety lever, left 217945

50 Safety lever, right 205437

51 Magazine release 219530

52 Magazine release spring 217536

53 Magazine release axle 219549

54 Bolt catch 217540

55 Bolt catch spring 217539

56 Roll pin,bolt catch, 2 x 12 mm 928080

57 Allen screw, buttstock (2) 217903

* Magazine complete .45 (58 - 62) 219486

58 Magazine housing, .45 ACP 219522

59 Follower .45 ACP 219523

60 Magazine spring .45 ACP 219524

61 Locking plate .45 ACP 219525

62 Floor plate 219526

* Picatinny rail, short, complete with screws 219662

63 Picatinny rail, short 219660

64 Cylindrical screw (2x) 219413

* Picatinny rail, long, complete (66 - 67) 219663

65 Picatinny rail, long 219661

66 Cylindrical screw (2x) 219413

* HK tool 988496

67 Carrying sling, USC complete 214085

* Adaptor for UTL* 219693

* not pictured

* Upper receiver with barrel, complete (I - 21)

1 Upper receiver, incomplete 219492

2 Front sight 217506

3 Roll pin, front sight, 4 x 144 mm 928747

* Rear sight, complete (4 - 10) 217513

4 Sight suppor t 217504

5 Flat spr ing 217515

6 Rear sight 217516

7 Windage adjustment screw 217517

8 Rear sight spr ing 217518

9 Sight suppor t spring 217503

10 Elevation adjustment screw 217505

11 Roll pin, sight support, 4 x 30 mm 987695

12 Cocking lever 217519

13 Cocking lever spring 217508

14 Cocking lever support 217507

15 Roll pin, cocking lever support, 4 x 16 mm 986546

16 Barrel .45 ACP 219497

17 Roll pin, barrel, 6 x 32 mm 988425

18 Ejector 219399

* Hand stop, complete. (19-21) 219364

19 Hand stop, incomplete 219342

20 Insert plate, handstop 219343

21 Cylindrical screw, handstop 5 x 16 mm 219414

* Buttstock, complete (24- 25) 219496

22 Buttstock 217528

23 Buffer 217544

* Bolt, complete .45 ACP (24 - 29) 219495

24 Bolt, incomplete, .45 ACP 219499

25 Extractor .45 ACP 217573

26 Firing pin assembly, complete 217555

27 Firing pin spring 217523

28 Firing pin retaining pin 217587

29 Recoil spring assembly, complete 217548

* Lower receiver, complete (30-56) 219487

30 Lower receiver, incomplete 219491

31 Trigger 205420

32 Trigger spring 217918

33 Axle (3x) 217532

34 Sear, complete 205439

35 Sear spring 217917

* Locking lever complete 219094

Fig. 43 USC

.45 ACP

Item Description Part No. Item Description Part No.

Page 21

41

FIREARM SERVICE RECORD

Firearm Type ________________ Serial Number ________________

Number of Cumulative Total Maintenance &

Date Rounds Fired of Rounds Fired Users Name Remarks

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

40

USC CARBINE

Specifications

Caliber . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45 ACP

Operating principle . . . . . . . .Simple blow back, firing from a closed bolt position

Dimensions

Overall length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 900 mm (35.43 in)

Overall width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55 mm (2.17 in)

Overall height with magazine . . . . . . . . . . . . . . . . . . . . . . . . . . 243 mm (9.75 in)

Barrel length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 406 mm (16 in)

Twist length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 406 mm (16 in)

Sight radius . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 327 mm (12.87 in)

Weights

USC without magazine . . . . . . . . . . . . . . . . . . . . . approximately 2.715 kg (6 lb.)

Magazine, empty (10 rounds) . . . . . . . . . . . . . . . . . . . . . . . . 0.098 kg (.216 lb.)

Carrying sling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.10 kg (.22 lb.)

Other Data

Firing modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Semi -automatic

Sights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Modular approach,

Standard adjustable mechanical sight,

Accessory mounting rails for optional aiming devices

Bore profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6x polygonal, right-hand twist

Page 22

Page 23

Heckler & Koch, Inc.

21480 Pacific Blvd.

Sterling,Virginia 20166-8903

United States of America

Tel. (703) 450-1900

Fax (703) 450-8160

www.hecklerkoch-usa.com

In a world of compromise, some don’t.

Heckler & Koch GmbH

D-78722 Oberndorf/Neckar

Postfach 1329

Germany

Tel. 011-49-7423/79-0

Fax 011-49-7423/2280

www.heckler-koch.de

HK USA 6/01 #701474

®

Remember, firearms safety begins with you. Read and follow all safety information in the

operators manual. Store all firearms in a safe and secure location. Keep firearms away from

children. Always be a safe shooter.

Loading...

Loading...