Page 1

Service Documents

Confidential, for authorized service technicians only!

Do not disclose this information to or share these documents

with third parties.

Vertraulich! Nur für autorisierte Servicetechniker!

Nicht zur Weitergabe an Dritte freigegeben!

TECHNICAL SERVICE:

Stamer Musikanlagen GmbH • Magdeburger Str. 8 • 66606 St.Wendel • Germany

Music & Sales P.E. GmbH • Leipziger Str. 3 • 66606 St.Wendel • Germany

Note!

The components used in this product - particularly parts affecting

safety as well as speakers and transformers - were developed and

manufactured to certain specifications. Please use original spare

parts only to ensure the product remains fully functional and safe.

Achtung!

Die in diesem Produkt verwendeten Komponenten, insbesondere

sicherheitsrelevante Teile, Lautsprecher und Transformatoren

wurden nach spezifischen Vorgaben entwickelt und gefertigt.

Bitte benutzen Sie ausschließlich Original-Ersatzteile – nur so ist

die volle Funktionalität und Sicherheit gewährleistet.

HK1805

CTA

118 SUB

2006/10/25

Page 2

Directory

features page: 3-13

drawing-numbers-example page: 14

standard for single wire confection page: 15

HK1805-CTA-Subwoofer page: 16

exploded drawings: complete Rev.: 1B page: 17-18

front grille Rev.: 1B page: 19

chassis/ cabling Rev.: 1D page: 20-23

display Rev.: 1A page: 24

mainboard Rev.: 1C page: 25

PWM-modul Rev.: page: 26

dolly Rev.: 1A page: 27

stacking plate Rev.: 1A page: 28-29

spare parts list Rev.: 1A page: 30-32

circuit diagrams preamp Rev.: 1C page: 33-35

inputboard Rev.: 1B page: 36

powerfilter 230V Rev.: 1A page: 37

powerfilter 100-120V Rev.: 1A page: 38

layout diagrams mainboard Rev.: 1C page: 39

Page 3

ConTour Array™ 1.0

B. ConTour Array™ Speakers

1. The CTA 208 Mid/High Unit

Fig. 1: CTA 208

Design and Construction

The CTA 208 Mid/High unit‘s top and bottom

panels slope at an angle of 4.5°. Water-repellent,

black PU lacquer coats the enclosure made of 18mm, 13-ply birch plywood. Your choices of array

curving angles (or splay) are 0° and 9°. The baffle

board cover consists of a metal grille; found behind

it are two CD horns equipped with acoustical lens

for the four 1" drivers.

The CTA 208 weighs 29 kg. It is 51 cm wide, 52.5

cm high and 34.6 cm deep (including rigging

attachments). Two grips on the side panels simplify

transport and set-up.

Fully integrated rigging attachments comprising

three quick-release pins and three rigging

connectors, two mounted on the sides and one in

the rear, serve to fly the mid/high units.

Electrical and Acoustical Data

The CTA 208 enclosure features two 8" cone chassis

speakers and four 1" B&C high frequency drivers

with a front-mounted acoustical lens in a CD horn

configuration. An internal passive crossover with a

crossover frequency of 2 kHz addresses the drivers

via a special acoustic lens. The CTA 208 enclosure‘s

nominal electrical power-handling is 500 watts

RMS at 8 ohms impedance. It produces 105 dB

(1W@1m) sound pressure, measured under halfspace conditions. Maximum SPL measured under

the same conditions at one meter is 134 dB at 10%

THD. The CDR 108 radiates at a horizontal angle of

100°. Frequency response ranges from 95 Hz to 19

kHz (±3 dB).

1.1 Specifications, CTA 208

A professional two-way system featuring cylindrical

wave technology, this cabinet serves to set up

vertical line arrays and project a coherent wavefront

across the entire frequency range. The precisiontuned enclosure sports two 8" midrange speakers.

Four 1" high-frequency drivers address two constant

directivity horns with 100° horizontal directivity via

a special acoustic lens. Vertical directivity depends

on the number of CT A 208s in use.

The housing is made of 15/18-mm birch plywood

coated with black PU varnish. Its fully integrated

rigging hardware adjusts to two 0° and 9° angles

for setting up line arrays. An integrated pole mount

offers two tilt angles of 3° and 11°. An impactresistant steel grille covers the front.

The active CTA 118 Sub system subwoofer with

an integrated DDO-Pro™ Controller drives the

enclosure. CTA 208‘s frequency response (+- 3dB)

ranges from 95 hertz to 19 kHz. Axial sensitivity is

105 dB, measured under half-space conditions at @

1W / 1m. Maximum SPL measured under the same

conditions with two CTA 208s is 134 dB at 10%

THD. Each unit‘s nominal power handling is 500

watts RMS at 8 ohms.

Connectors: 1 Neutrik NL 4 Speakon.

Dimensions (W x H x D): 51 x 52.5 x 34.6 cm

Weight: 29 kg

Model: HK Audio CTA 208

Connections

The ports are out of harm‘s way on a recessed

connector panel on the CTA 208‘s back. It offers

one Speakon NL 4 connector. Pin assignments are

pin 1+ = mid/high +, 1- = mid/high-.

Page 4

1.2 The CTA 208 Enclosures‘ Technical Data

Nominal power handling/program/peak: .................. 500W RMS /1000W/ 1500W

Frequency response -10 dB 3): .................................... 80 Hz - 20 kHz

Frequency response+/-3 dB 3): ................................... 95 Hz - 19 kHz

Directivity: .................................................................. 100° horizontal

Sensitivity 1W@1m 1): ................................................ 105 dB

Max. SPL calculated 1): .............................................. 138 dB 2)

Max. SPL peak 1): ....................................................... 136 dB 3)

Max. SPL 1): ............................................................... 134 dB @ 10% THD (200 Hz- 5 kHz) 3)

Nominal impedance: .................................................. 8 ohms

Woofer/midrange speaker: ......................................... 2x 8"

High-frequency driver: ............................................... 4x 1", 2" voice coil

Crossover frequency: .................................................. 2 kHz, 12 dB/ octave

Connectors: ................................................................ 1 Speakon(r) NL 4

Housing (birch): ........................................................ 15/18 mm (1/2"), 9/13-ply

Angles up: .................................................................. 2x 4.5°

Finish: ........................................................................ Black 2-component PU lacquer

Grille: ......................................................................... Metal grille with black acoustic foam

Handles: .................................................................... Two slot grips routed into the side panels

Rigging hardware: ...................................................... DualCurve™, integrated with quick-release pins

Pole mount: ............................................................... HK Audio DuoTilt™

Weight: ....................................................................... 29 kg/ 63.8 lbs.

Dimensions (W x H x D): ........................................... 51 x 52.5 x 34.6 cm; 20" x 20 2/3" x 13 2/3"

Accessories: ............................................................... Touring flight case (2 CTA 208), rigging frame

25

English

1) Measured under half-space conditions2) Based on peak power handling 3) Measured with 2 CTA 208s

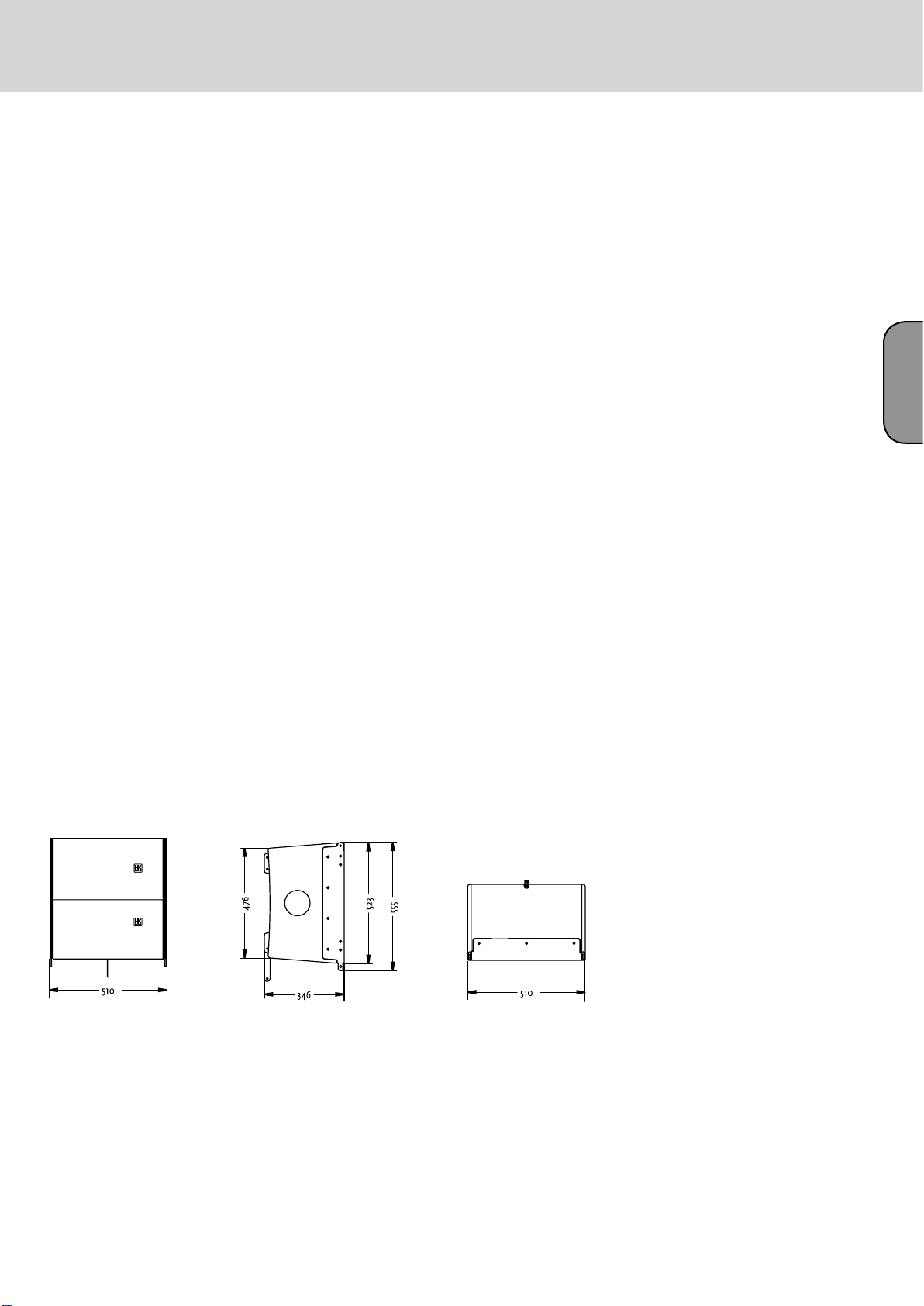

Fig. 2: CTA 208 housing dimensions in mm

English

Page 5

ConTour Array™ 1.0

2. CTA 118 Sub

Fig. 3: CTA 118 Sub

Design and Construction

Made of 18-mm 13-ply birch plywood, waterrepellent, black PU lacquer coats the CTA 118

Sub enclosure. A robust metal grille backed with

laminated acoustic foam rubber covers the baffle

board.

The CTA 118 Sub weighs 59 kg. It is 51 cm wide, 73

high and 71 cm deep. Three slot grips routed into

the side panels enable easy transport and set-up; a

recessed handle is on the lid. The active circuitry

resides in a separate chamber at the back of the

enclosure. A removable dolly protects the electronic

components and simplifies transport.

Electrical and Acoustical Data

The CTA 118 Sub enclosure features an 18" woofer.

The CTA 118 Sub enclosure‘s nominal electrical

power-handling is 700 watts RMS at 8 ohms

impedance. It produces 101 dB (1W@1m) sound

pressure, measured under half-space conditions.

Maximum SPL measured under the same conditions

at one meter is 130 dB at 10% THD. The CTA 118

Sub‘s frequency response ranges from 42 Hz to fx

(+/-3 dB). The two integrated PWM power amps

for the subwoofer and the mid/high output deliver

1000W RMS each.

2.1 Specifications, CTA 118 Sub

A professional active subwoofer equipped with a

DDO-Pro™ Controller and a 1000W RMS PWM

power amp, the CTA 118 Sub delivers excellent

impulse response and exceedingly dynamic lowfrequency response. It features an 18" woofer

mounted in a precision-tuned bass reflex enclosure.

Another 1000W RMS PWM power amp drives

HK Audio CTA 208 or ConTour Series™ speakers.

The rectangular block housing is made of 18-mm

birch plywood coated with black PU lacquer. An

impact-resistant steel grille covers the front. A

removabledolly protects the electronic components

and simplifies transport

Its frequency response ranges from the crossover

frequency down to 42 Hz (-3 dB) and 36 Hz (-10 dB).

Maximum SPL under half-space conditions is 130 dB

at 10% THD.

Connectors: 1 Neutrik NL 4 Speakon output, 1 XLR

female, 1 XLR male, 2 Powercon, 2 RJ45 Ethercon

Dimensions (W x H x D): 51 x 73 x 71 cm

Weight: 59 kg

Model: HK Audio CTA 118 Sub

Connections

Ports are out of harm‘s way on a recessed connector

panel on the CTA 118 Sub‘s back. It offers one

Speakon NL 4 connector. Pin assignments are pin

1+ = mid/high +, 1- = mid/high- . A Powercon mains

socket with another Powercon output connects to

the power supply. A female XLR and a male XLR port

serve to route signals. Two Neutrik Ethercon ports

serve to network several CTA 118 Subs.

Page 6

2.2 Technical Data, CTA 118 Sub

Integrated Power Amps:

Output power, Subwoofer: ...........................................1000 W RMS, Class D

Output power, Mid/High: ............................................1000 W RMS, Class D

Protection circuits: .......................................................DDO Pro™ Limiter, thermal protect, short-circuit

Line In/ Through: ........................................................ Female XLR, electronically balanced & floating

Mid/High Out: .............................................................1 Speakon(r) NL 4

Mains In/ Out: .............................................................2 Powercon

Networking/ Communication: .....................................DDO Pro™ Net/RS 485 Ethercon

Woofer: ........................................................................18"

Frequency response - 10 dB: ........................................36 Hz - fx

Frequency response+/- 3 dB: ........................................ 42 Hz - fx

Sensitivity 1W@1m 1): .................................................101 dB

Max. SPL calculated 1): ................................................134 dB 2)

Max. SPL peak 1): .........................................................133 dB

Max. SPL 1): .................................................................130 dB @ 10% THD (50 Hz- 200Hz)

Housing (birch): ..........................................................18 mm (3/4"), 13-ply

Surface coating: ...........................................................Black 2-component PU lacquer

Grille: ...........................................................................Metal grille with black acoustic foam

Handles: ......................................................................6 slot grips routed into the side panels, 1 on the lid

Pole mount: .................................................................M20

Weight: .........................................................................59 kg/ 129.8 lbs.

Dimensions (W x H x D): .............................................51 x 73 x 71 cm, 20" x 28 3/4" x 27 7/8"

Accessories: ................................................................. Protective cover, stack base plate

27

English

1) Measured under half-space conditions 2) Based on peak power handling

Fig. 4: CTA 118 Sub housing dimensions in mm

Page 7

ConTour Array™ 1.0

C. Rigging ConTour Array™ Enclosures

1. Components and Applications of

ConTour Array™ Rigging Hardware

Please also read the Notes on Rigging Safety in Chapter A of this manual.

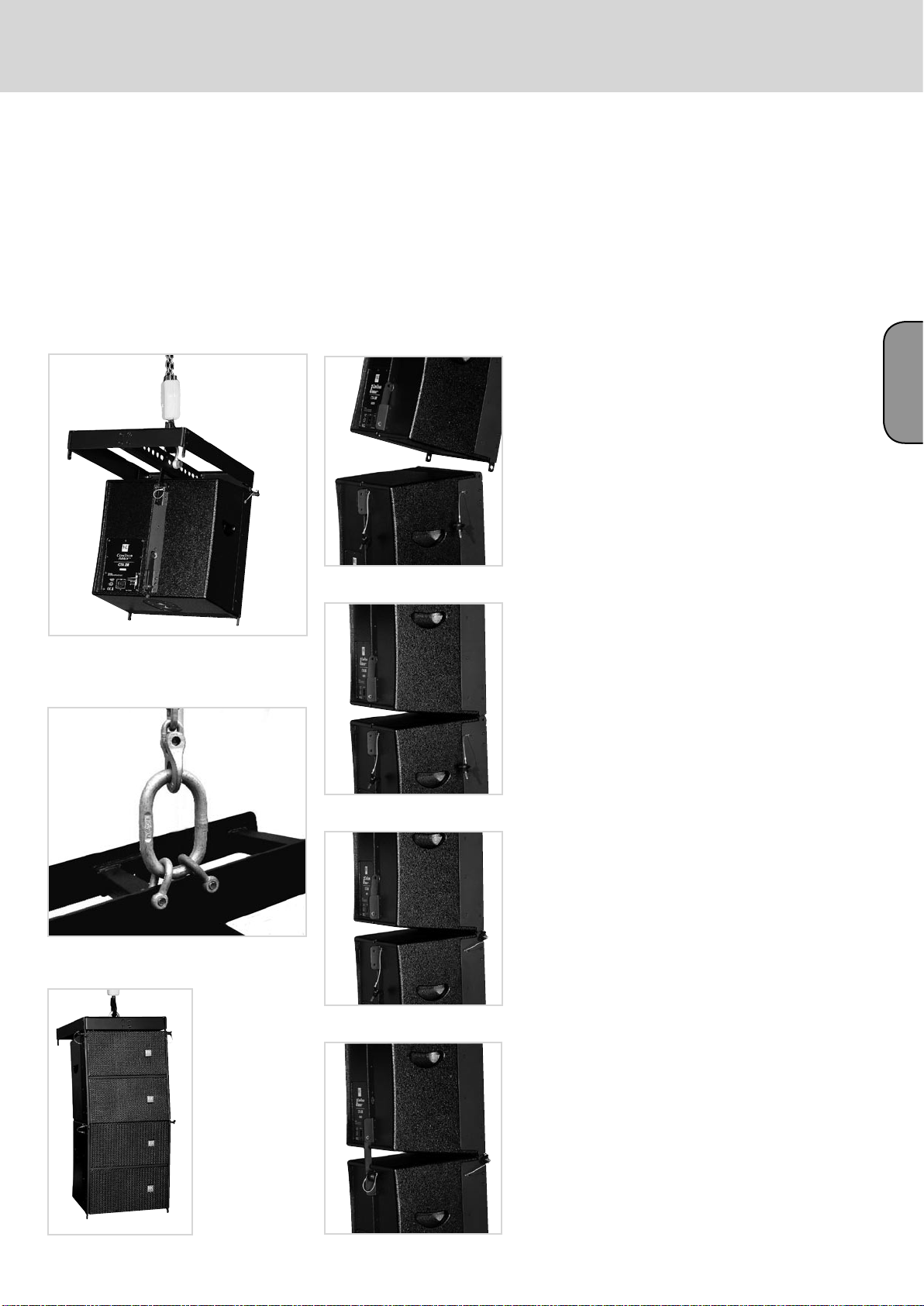

Fig. 5: Integrated rigging attachments

Fig. 6: ConTour Array™ rigging frame

Fig. 7: Shackles for attaching motors, chain hoists

ConTour Array™ rigging hardware consists of the

following parts:

• a rigging frame with two shackles for attaching

motors or chain hoists.

• integrated rigging points on the side and back for

flying ConTour Array™ CTA 208 Mid/High units.

• three quick-release pins per CTA 208 for

connecting the enclosure to the rigging frame.

Important note on pins: Quick-release pins connect

rigging hardware and speaker enclosures, and their

proper function must be tested and verified. Pins

must always engage fully in the (fitted) hole. Under

no circumstances may these pins release on their

own when subjected to tractional forces. The nib in

the center of the pinhead must always be depressed

to insert pins; it releases the ball detents in front.

Once the pin engages in the hole, the nib must ease

back to its initial position.

1.1 Mounting the Rigging Frame

It takes two people to perform these tasks. Remove

the quick-release pins from the enclosure. Set the

rigging frame on the enclosure. First attach the two

front connectors. Turn the rigging frame‘s connector

component down and slide it into the rear rigging

connector.

Insert the rear pin through the hole labeled 0°.

Attach to the rigging frame the shackle that accepts

the motor hook. Your choice of pick point depends

on how sharply you aim to curve the array later.

Tip: If you intend to rig additional enclosures, we

recommend that you attach all the required speaker

cords to the rigging frame now because this task

becomes more difficult as the array grows higher.

Be sure to use cords of sufficient length!

1.2 Setting the DualCurve™ Angle

Curve the two CTA 208 cabinets using the rear

connector component. You have two angles to

choose from, 0° and 9°. Remove the pin on the rear,

insert lead the connector into the rigging track and

secure the connector component with the pin as

pictured.

1.3 Rigging Additional

CTA 208 Mid/High Enclosures

Hoist the mounted CTA 208 Mid/High cabinets to a

height that allows you to roll a second case holding

two enclosures under the array. Remove the two

front pins from the enclosure you wish to mount.

Move the second case with two additional CTA 208s

into position. Slowly lower the top two cabinets

until the two front connectors engage. Insert the

two front pins first, ensuring they engage fully and

securely (see Figure 12 a). You may have to shift

the two enclosures slightly to ease the pins into

position. To attach the rear connector component,

you must swivel it out of the track and ensure it

faces down (see Figure 12 b). Insert the pin through

the hole labeled 0° or 9° as required.

Note: Depending on application, you may not be

able to select a pick point with a shackle. In this

case, use two shackles and a suitable O-ring as

shown in Figure 10.

Check all pins on the top rigging frame to ensure

they seat firmly. Attach the motor to the shackle.

Important: Ensure the motor‘s chain bag hangs

freely and does not rest on the rigging frame!

Engage the motor to lift the cabinet from the case.

Roll the case off to the side. Remove the two front

pins from the enclosure you wish to mount and fold

down its connector component. Now you can rig

further cabinets.

Hoist the array consisting of four CTA 208

enclosures high enough to remove it fully from the

case. Secure the hoisted array against blasts of wind

or unintentional twisting to prevent it from moving.

Page 8

29

English

Fig. 8: Mounting the rigging frame

Fig. 9: Setting an intermediate angle

Fig. 10: Hoisting the mounted CTA 208 enclosure

Fig. 11 a, b, c, d, e: Rigging additional CTA 208 enclosures

Page 9

ConTour Array™ 1.0

2. Groundstacking

3. Mains and Generator

Power Supply

Fig. 12 a, b: ConTour Array™ ground-stack connectors

Depending on application, use two or three

ConTour Array™ subwoofers as the stack‘s base. Set

the desired number of subwoofers on top of one

another.

Caution:

Secure the ground stack to prevent it from tipping!

Use the M10 bushings on the back of the CTA 118

subwoofer and the ground-stack connectors to do

this.

Mount mid/high units individually, one after

another, on the top CTA 118 Sub. Use the ConTour

Array™ stack plate as the base and connector to

the subwoofer. Attach it to the CTA 118 Sub’s pole

mount using the M20 thumb screw. The stack plate

lets you easily adjust mid/high units without having

to move the subwoofer. On this stack plate, you can

freely select the desired down-tilt between 0° and 9°

in 1.5° increments.

Connect no more than two CTA 118 Subs to one

mains phase (16 A). If you use the Powercon Link

port, connect no more than one further CTA 118

Sub. The 13-A limit on maximum input current (see

label) applies to Great Britain because UK power

cables are approved to 13 A only. 16-A current is

permissible in other countries using EU power

cables.

Caution: If you must power the CTA 118 Sub with a

generator, ensure the generator is running before

you switch the system on. Never switch systems

off and on with the help of the generator! This can

damage the PWM power amps’ switching power

supply!

Note: The Powercon Link is not available for 100120-volt units.

Fig. 13: ConTour Array™ stack plate

Fig. 14 a, b: Attaching the stackplate to the CTA 118 Sub

Fig. 15 a,b,c: CTA 208 Mid/High stack

Page 10

D. The ConTour Array™ DDO-Pro™ Controller

1. The DDO-Pro™ Net Port

31

Net Ports link several CTA 118 Subs in a

communication network. Use CAT 5 network cables

or professional Ethercon cables with a metal plug

to do this. Connect the first CTA 118 Sub’s output to

the next unit’s input, and so forth.

Note: This is purely a data interface. The DDO-Pro™

Net Port does not send audio signals.

If you wish to adjust controller settings (for example,

filter, gain or delay), you can do this on any CTA 118

Sub’s control panel. Automatically, the unit becomes

the master controller and sends parameter changes

to all networked CTA 118 Subs (up to 32 units).

Note: It does not send "Utilities" menu settings.

Caution: If you wish to use another CTA 118 Sub

and a ConTour Series™ cabinet (CT 108, CT 112, CT

115) for near-fill or in-fill applications alongside CTA

208 speakers in a larger rig, DO NOT network it!

Otherwise the connected CT 108, CT 112 or CT 115 will

adopt the settings entered for the mid/high array.

2. Audio Signal Routing

3.1 Level

You can adjust input levels from -96 dB to + 6dB in

0.5 dB steps. Use the Up or Down keys to select the

gain setting and confirm your selection with Enter.

Note: The Level parameter adjusts the level after the

analog-to-digital converter to balance out varying

(system) levels. Level does not influence the input

signal’s volume in front of the analog-to-digital

converter. If the display reads “Digital Clip ?! Check

Input !” be sure to reduce the level at the mixing

console. In this case, the signal is saturating the

analog-to-digital converter, distorting the signal’s

rectangular waveform to create square waves. This

sounds extremely annoying and will eventually

destroy the power amp and speakers.

Tip: If you wish to reduce the volume of the lower

mid/high unit in the array – say, because it hangs

low and listeners are close to this unit – you can

use Level to do this. However, Level also affects the

subwoofer’s volume. Increase Sub Level by the same

value to compensate for the difference.

3.2 Key Lock

English

Fig. 16: DDO-Pro™ network

Use an XLR cord to connect the signal source to

the first CTA 118 Sub’s signal input. If you wish to

connect further CTA 118 Subs to the source, do this

using the Signal Through ports. The XLR port’s pin

assignments are: pin 1 = ground, 2=+, 3=-.

Be sure to read section 3.1 covering maximum input

signal level and digital clip error and heed these

guidelines.

3. Handling the

DDO-Pro™ Controller

Four keys operate the device - Menu, Enter, Up and Down.

Menu/ Esc:

This key accesses the controller’s menu structure

and exits a menu level.

Enter:

This key confirm changes and access menu levels.

Up and Down:

These keys navigate within a menu level and

increase and decrease displayed values. Please refer

to the menu structure quick guide at the end of the

chapter to learn more.

3.3 Utilities

Sync Remote

When you confirm the Sync Remote command, the

unit sends the current settings to all networked

controllers. The control panel currently in use is the

master. This feature comes in handy if the network

connection fails.

Noise Reduction

You can activate Noise Reduction on demand. It

mutes signal paths when the rig is off-line. The unit

ships with this feature deactivated.

LCD Contrast

Adjust the display’s contrast to taste using the Up or

Down keys. Confirm your selection with Enter.

Factory Reset

When you confirm this function, ALL settings reset

to their factory defaults. For example, you could use

it to set all delays to 0 ms and levels to 0 dB.

Fig. 17: DDO-Pro™ Controller panel

The AD converter’s Digital Clip indicator

Page 11

ConTour Array™ 1.0

2 x CT108 1 x CT112

Delay Base

Select the preferred delay display reading - meters

(m), feet (ft) or milliseconds (ms). Select the

option with the Up or Down keys and confirm your

selection with Enter.

3.4 Sub Delay

Sub Delay is a time alignment tool, that is, it

compensates differences in mid/high units’ and

subwoofers’ response times. Like Sub Level, Sub

Delay controls subwoofers’ and mid/high units’

relative delay.

For example, if you place subwoofers well in front

of mid/high units, you must delay the subwoofers

accordingly. Do this by adjusting a positive

delay value in the Sub Delay menu. If you place

subwoofers well behind mid/high units, you must

enter negative values to compensate.

Caution: Negative Sub Delay values delay the signal

path from the subwoofer to the mid/high unit,

causing overall system latency! Experience has

shown that this method compensates differences of

15 ms or 5 m without latency problems. The control

range sweeps from -30 ms to 29.6 ms.

3.6 Sub Level

You can adjust the balance of volumes between the

subwoofer and mid/high unit from -12 dB to + 6dB

in 0.5 dB steps. Use the Up or Down keys to select

the Sub Level and confirm your selection with Enter.

3.7 System Setup

A special filter preset is available for each

configuration (see fig. 19 a-f). Be sure to assign

the same preset to each DDO-PRO™ controller for

every configuration (1 to 4 CTA 208s). Use the Up

or Down keys to select the right preset and confirm

your selection with Enter.

1 x CT115 1 x CTA208

4 x CTA208

Fig. 18 a, b, c, d, e, f: System Setups

3.5 Delay

Delay controls the overall delay of a system

comprised of subwoofers and mid/high units. The

highest setting is 72.6 ms.

Page 12

3.8 Quick Guide to the V1.01 Controller’s Menu Structure

33

English

Fig. 19: Menu structure of the DDO-PRO™ Controller

English

Page 13

E. Service

1. Maintenance

35

Regularly check the vents to ensure air flows freely

in and out. Clean the foam rubber filters whenever

necessary. Remove the vent grille on the back to do

this.

2. ConTour Array™

Spare Parts

Note:

• If your equipment needs service, please turn to

your HK Audio dealer or the HK Audio distributor in

your country. They stock the required spare parts.

• In the event of a defect, always indicate the

defective device’s serial number. This way the HK

Audio service team can immediately find out if an

update is available for your product.

• Use only original HK Audio replacement speakers

and parts! Most were developed especially for HK

Audio products and are not available direct from

speaker manufacturers!

3. Replacing Loudspeakers

and Voice Coils

3.1 1", 8" and 18" Speakers

Proceed as follows to replace the given speaker:

• Unfasten and remove the Phillips screws holding

the grille in place. Remove the grille. These screws

are on the CT 118 Sub’s front panel and the CTA

208’s side and bottom panels.

• Unfasten and remove the hex head bolts holding

the speaker in place.

• The speaker is now detached. Disconnect the

speaker wires.

3.2 The Drivers’ Voice Coils

Proceed as follows to replace the drivers’ voice coils:

• Remove the front grille as described above.

• Unfasten the four screws holding the horn yoke

and remove the horn and driver from the baffle.

Disconnect the wires connecting the driver. Ensure

correct polarity when installing and connecting

a replacement speaker! Red= positive, black =

negative

• Unfasten the voice coil housing’s hex head bolts

using a 3-mm wrench.

• Take the lid off the voice coil housing.

• Replace the voice coil.

Important note: Replace the voice coil in a clean

working environment only. Be sure to keep dust

and dirt out of the open driver. If despite your

precautions particles manage to get in, use a strip

of adhesive tape to remove them or carefully blow

compressed air into the back of the driver to whisk

the particles out. When installing the new voice

coil, ensure it is centered properly. Proceed as

follows to check this:

Close the cover of the voice coil housing and

reconnect the cords (red = positive, black =

negative). Feed a sine wave signal with a frequency

between 1000 Hz and 1500 Hz into the mid/high

enclosure’s input. Sweep through the frequency.

If you hear abrasive noises like crackling or

scratching, the voice coil is not centered properly.

Reopen the voice coil chassis and turn the voice coil

a bit until it renders the signal cleanly!

4. Checking Speakers’ Phase

As a precaution, always check the components’

phase using a suitable phase-checker after replacing

speakers. To do this, connect the CTA 208 mid/high

unit to the CTA 118 Sub using a Speakon cord.

Note: If you are checking the CTA 208 mid/high

unit in passive mode with an external power amp,

you will get a different phase reading! Therefore

always use the CTA 118 Sub for phase checks.

Connect the phase-checker to the CTA 118’s signal

input. It may be advisable to lower the input level on

the DDO-Pro™ Controller!

The speakers’ phases should read as follows:

With CTA 118 Sub:

18" woofer: In phase (+)

8" speaker: Out of phase (-)

1" driver: In phase (+)

CTA 208 passive:

8" speaker: In phase (+)

1" driver: Out of phase (-)

English

Caution: When installing and connecting a

replacement speaker, ensure the polarity is correct!

Red= positive, black = negative

Page 14

DRAWING-NUMBERS

EXAMPLE

HK0106-EX-R01-1A

VERSION

SERIAL NUMBER

DEPARTMENT:

R = R&D

REVISION

PROJECT-NR.:

HK = HK AUDIO

HU = HUGHES&KETTNER

MP = MINDPRINT

CHARACTER:

BL = SHEET METAL / BLECH

EX = EXPLODED DRAWING / EXPLOSIONSZEICHNUNG

HZ = CABINET / HOLZGEHÄUSE

KU = PLASTIC / KUNSTSTOFF

LP = PCB / LEITERPLATTEN

SO = MISCELLANEOUS / SONSTIGES

SP = SCHEMATIC / SCHALTPLÄNE

TR = TRANSFORMER / TRANSFORMATOR

GK = WIRING DIAGRAM / GERÄTEVERKABELUNG

Page 15

Stand

W

Y

r

Standard for single wire confection.

16 B 150 638 I - 485 W Z I 1015

style 1015 according UL specifications

I = completely insulated with black shrinktube or appropriate sleeve

IT = partly insulated; only crimp connection insulated.

no marking = without insulation

Z = with additional junction

no marking = without additional junction

W = angled faston

no marking = straight faston

17. Jun 04

Faston connector brass tin-plated DIN 46245

638 = 6,3 * 0,8 [mm]

488 = 4,8 * 0,8 [mm]

485 = 4,8 * 0,5 [mm] if fully insulated (I) insulation with blue shrinktube

if partly insulated (IT) use IF 602 485 .

288 = 2,8 * 0,8 [mm]

285 = 2,8 * 0,5 [mm] if fully insulated (I) insulation with blue shrinktube

if partly insulated (IT) use IF 602 485

abiso = 5mm bared and tin-plated (teilabzug)

text for special constructions, (for example. 4mm ringshaped faston)

the larger faston connector always mentioned at first. (Nathan drawing number controlling)

lenght in mm within a 50 mm raster

colour

B = black (phase conductor)

R = red

BR = brown

BL = blue (neutral conductor)

= white

G = yellow-green (ground bonding/ earthing connection)

cross section

16 = AWG 16 (prefered usage)

Q1.5 = H07VK 1,5mm² (prefered usage)

wire designation:

P + lfd Nr. = AWG single wire black, red, blue, brown or white

E + lfd Nr. = AWG single wire green- yellow

L + lfd N

FQL + lfd Nr. = crossover wiring H07VK

Regarding special wirings like wiring harness or similar, drawings will be prepared and appropriate

. = twisted AWG double wire, lenght specification always in twisted condition

drawing numbers will be stored in the article archive.

Page 16

Confidential, for authorized service technicians only! Do not disclose

this information to or share these documents with third parties.

TECHNICAL SERVICE:

Stamer Musikanlagen GmbH • Magdeburger Str. 8 • 66606 St.Wendel • Germany

Music & Sales P.E. GmbH • Leipziger Str. 3 • 66606 St.Wendel • Germany

Service Documents

HK1805

CTA

CTA 118 SUB

SUBWOOFER

Page 17

2 E 400280

10E 974220

17E 976115

HK1805-HZ-R02-1D

13 E 974501

16E 976094

4 E 970760

18

8 E 974145

15 E 976010

7 E 974020

11

3 E 502198

HK1805-EX-R03-1D

19E 976162

1E 1134

HK1805-EX-R02-1B

11E 974232

18 E 976159

4

12E 974272

ÄNDERUNG

INDEX

drawing-nr. update C. Loris

1B-240506

ZEICHNER

13

5 E 972008

HK1805-SO-R04-1A

14 E 976009

9 E 974218

TITEL:

6E 974012

66606 St. Wendel / Germany

22 E 994199

ZEICHNUNGS-NR.:

ERSTELLT VON:

GEPRÜFT/

FREIGEGEBEN VON:

WERKSTOFF:

DATEINAME:

HK1805-EX-R04-1B

C. LORIS 1

HK1805-EX-R04-1B-Bass-gesamt

HK1805-SUB COMPLETE

EXPLODED DRAWING

OBERFLÄCHE:

VERSION:

AM:

24.05.2006

AM:

/

REVISION:

BLATT:

2

B1

BLÄTTER

Page 18

Pos. part-no. 1 description Beschreibung quantity

1 1134 HK1805-bass front grill assembly HK1805-Frontgitterbaugruppe Bass 1

2 400280 HK1805-bass cabinet HK1805-Bass Holzgehäuse 1

3 502198 Electronic-Chassis HK1805-Elektronikchassis 1

4 970760 plate for butterfly lock CT 118 Blech Schliessplatte CT118 2

5 972008 damping wool Dämmwolle Hochbauschvlies 1

6 974012 hexagon socket head cap screw, M6x30, black Inbusschraube M6*30 sw 8

7 974020 hexagon socket head cap screw, M5x20, black Inbusschraube M5x20sw 17

8 974145 ABC-Spax-S chipboard screw, panhead Z, 5x25, black Pan Head-Z ABC-Spax sw 5*25 4

9 974218 ABC-Spax-S chipboard screw, panhead Z, 5x20, black Pan Head-Z ABC-Spax sw 5*20 4

10 974220 hexagon socket countersunk head screw, M6x40, black Inbussenkschraube M6x40 sw 4

11 974232 ABC-Spax-S chipboard screw, panhead Z, 3.5x12, zinc plated Pan Head-Z ABC-Spax vz 3,5*12 12

12 974272 cross recessed raised countersunk screw, M5x10, black Linsensenkschraube M5*10 sw 4

13 974501 hexagon socket countersunk head screw, M4x16, black Inbussenkschraube M4x16 sw 4

14 976009 rubber foot D38*H11 [mm] Gummifuss D38*H11 [mm] 4

15 976010 rubber foot D38*H20 [mm] Gummifuss D38*H20 [mm] 4

16 976094 plastic dish 3403 HKBS! DART ! Griffschale 3403 HKBS! DART ! 1

17 976115 connector plate Befestigungsplatte M20 1

18 976159 plastic dish Premium One Griffinnenschale Premium One 6

19 976162 rubberbuffer d=18 h=40mm Gummipuffer d=18 h=40 Typ B 4

20* 982037 sealing tape 2x6mm Iso-Zell-Band fadenvers. 2*6mm 0,54 lfdm

21* 982044 sealing tape 2x15mm Iso-Zell-Band fadenvers. 2*15mm 3,70 lfdm

22 994199 SICA LP 470.100_3300WT 8 Ohm SICA LP 470.100_3300WT 8 Ohm 1

ÄNDERUNG

INDEX

drawing-nr. update C. Loris

1B-240506

ZEICHNER

66606 St. Wendel / Germany

ZEICHNUNGS-NR.:

ERSTELLT VON:

GEPRÜFT/

FREIGEGEBEN VON:

WERKSTOFF:

DATEINAME:

HK1805-EX-R04-1B

C. LORIS 2

HK1805-EX-R04-1B-Bass-gesamt

TITEL:

HK1805-SUB COMPLETE

EXPLODED DRAWING

VERSION:

AM:

AM:

OBERFLÄCHE:

24.05.2006

/

REVISION:

BLATT:

2

B1

BLÄTTER

Page 19

Pos. part-no. 1 description Beschreibung quantity

1 970815 HK1805-bass front grid HK1805-Frontgitter-Bass 1

2 972086 acoustics foam anthracite 5mm Akustikschaum Anthrazit 5mm 1

3 980251 logo 'hk'ConTourSer. 35x35x3mm Logo 'hk'ConTourSer. 35x35x3mm 1

ÄNDERUNG

INDEX

1B-240506 PPI 15, drawing-nr. update C. Loris

ZEICHNER

2 E 972086

HK1805-SO-R02-1B

TITEL:

3E 980251

1 E 970815

HK1805-BL-R24-1C

66606 St. Wendel / Germany

ZEICHNUNGS-NR.:

ERSTELLT VON:

GEPRÜFT/

FREIGEGEBEN VON:

WERKSTOFF:

DATEINAME:

HK1805-EX-R02-1B

C. Loris 1

HK1805-EX-R02-1B-FRONTGITTER-BASS

HK1805-BASS-FRONT GRILLE

EXPLODED DRAWING

OBERFLÄCHE:

VERSION:

AM:

24.05.2006

AM:

/

REVISION:

BLATT:

1

B1

BLÄTTER

Page 20

17E 974102

27E 976135

19

13E 970814

HK1805-BL-R28-1A

1E 547058

5E 931304

5

10 E 970811

HK1805-BL-R26-1E

18 E 974103

3E 600090

HK1805-LP-R03-1A

19

27

21 E 974290

23E 974392

20E 974157

25E 974521

25

ÄNDERUNG

INDEX

1B-240506 drawing-nr. update C. Loris

1C-300506 replacement of cables

1D-120906 assembly revised

ZEICHNER

F. Sitter

F. Sitter

12E 970813

HK1805-BL-R13-1D

2E 600090

HK1805-LP-R04-1A

16E 974051

14E 972009

HK1805-SO-R01-1B

15 E 972041

9 E 959052

11E 970812

HK1805-BL-R27-1A

28 E 976141

19

4 E 600091

22 E 974362

19 E 974110

6E 952141

8E 952305

16

14

24E 974444

11

23

26 E 976007

7E 952153

66606 St. Wendel / Germany

ZEICHNUNGS-NR.:

ERSTELLT VON:

GEPRÜFT/

FREIGEGEBEN VON:

WERKSTOFF:

DATEINAME:

TITEL:

HK1805-BASS-CHASSIS

EXPLODED DRAWING

HK1805-EX-R03-1D

C. LORIS 1

HK1805-EX-R03-1D-CHASSIS

OBERFLÄCHE:

VERSION:

AM:

12.09.2006

AM:

/

REVISION:

BLATT:

4

BLÄTTER

D1

Page 21

Pos. part-Nor. 1 description Beschreibung quantity

1 547058 mainboard PCB complete Mainboardplatine fertigbestückt 1

2 600090 Networkinterfaceboard is part of Inputboard Interfaceplatine als Teil von Inputplatine 1

3 600090 Inputboard 54_Inputplatine fertigbestückt 1

4 600091 mains filter assembly 220-240V 60 Netzfilter CTA 118 220-240V 1

5 931304 ferrite teroid core, 25x15x12 Ferritring, geschlossen 25x15x12 3

6 952141 mains inlet PowerCon Netzbuchse Power Con Inlet 1

7 952153 mains outlet PowerCon Netzbuchse Power Con Outlet 1

8 952305 speakon chassis connector, NL4MP-3 Speakonbuchse 4pol eckig, NL4MP-3 1

9 959052 PWM amp module 100-240V PWM Endstufe 100-240Volt 2

10 970811 HK1805 air guide HK1805_Lüftungshaube_PWM 2

11 970812 HK1805 ventilation grill HK1805_Lüftungsgitter 2

12 970813 HK1805 sheet metal chassis HK1805_Blechchassis 1

13 970814 ribbon connector safety lock HK1805_Pfostensteckverbinder-Schutzblech 1

14 972009 acoustic foam anthracite 5mm, PPI20 Akustikschaum Anthrazit 5mm, PPI20 2

15 972041 rubber punching 25x25x15mm Zellkaut. -Stanzteil 25x25x15mm 1

16 974051 plastic PCB spacer, 4.2x8x5, Polyamid black Dist.Hülse PE 4,2*8*5 [mm] 12

17 974102 hexagon nut, class 8, M3, zinc plated Sechskantmutter M3 vz 2

18 974103 toothed lock washer, D=4.3, AZ, zinc plated Fächer-Scheibe az, 4,3 vz 2

19 974110 self locking hexagon nut with plastic insert, M3, zinc plated Stopmutter M3 vz 19

20 974157 cross recessed raised countersunk tapping screw, 2.9x9.5, black Blechschr. Senk-Li 2,9*9,5 sw 4

21 974290 self locking hexagon nut with plastic insert, M4, zinc plated Stopmutter M4 vz 8

22 974362 hexagon PCB spacer, type B, M3x12, zinc plated Dist. Bol Innen/Außengew. M3*12 vz 3

23 974392 hexagon socket oval head screw, M3x8, black Linsenschr.m.Innens. M3*8 sw 12

24 974444 cross recessed raised countersunk screw, M3x12, black Linsensenkschraube M3*12 sw 4

25 974521 cross rec. raised counters. tap. screw w. cutting slot, 2.9x9.5, black Senkschr. f. Kunststoff 2,9*9,5, sw 6

26 976007 cable tie 2,5x100 (mm) Kabelbinder natur 2,5x100 (mm) 14

27 976135 socket for cable tie Schraubsockel 5

28 976141 rubberbuffer 15x15 B Gummipuffer GM-Puffer 15x15 B 8

29* 982044 sealing tape 2x15mm Iso-Zell-Band fadenvers. 2*15mm 0,20 lfdm

30* 986019 adhesive tape, double-sided, clear Kleebeband, doppelseitig, klar 0,20 lfdm

ÄNDERUNG

INDEX

1B-240506 drawing-nr. update C. Loris

1C-300506 replacement of cables

1D-120906 assembly revised

ZEICHNER

F. Sitter

F. Sitter

66606 St. Wendel / Germany

ZEICHNUNGS-NR.:

ERSTELLT VON:

GEPRÜFT/

FREIGEGEBEN VON:

WERKSTOFF:

DATEINAME:

HK1805-EX-R03-1D

C. LORIS 2

HK1805-EX-R03-1D-CHASSIS

TITEL:

HK1805-BASS-CHASSIS

EXPLODED DRAWING

AM:

AM:

OBERFLÄCHE:

VERSION:

12.09.2006

/

REVISION:

BLATT:

4

D1

BLÄTTER

Page 22

9

2

4

1

ÄNDERUNG

INDEX

1B-240506 drawing-nr. update C. Loris

1C-300506 replacement of cables

1D-120906 assembly revised

ZEICHNER

F. Sitter

F. Sitter

3

9

TITEL:

HK1805-BASS-CHASSIS

66606 St. Wendel / Germany

ZEICHNUNGS-NR.:

ERSTELLT VON:

GEPRÜFT/

FREIGEGEBEN VON:

WERKSTOFF:

DATEINAME:

HK1805-EX-R03-1D

C. LORIS 3

HK1805-EX-R03-1D-CHASSIS

EXPLODED DRAWING

OBERFLÄCHE:

VERSION:

AM:

12.09.2006

AM:

/

REVISION:

BLATT:

4

D1

BLÄTTER

Page 23

E 962346, stranded wire P 42

AWG14/16 Style 1015

HK0502-KA-R04-XX

E 964052, powercable DIVA

Y-stranded wire

HK1805-KA-R01-XX

E 962288, stranded wire E3

16-YG-200-638-485 1015, AWG

962314 stranded wire E18

16-YG-200-638-eyelet, AWG

E 962038, stranded wire E4

16-YG-120-638-638 1015, AWG

E 962054, stranded wire 2*JST 3pol,

140mm AWG 26 Style 1007

E 965618, flat ribbon cable 20-2-360mm , Typ 6

AWG 28 flexible grey RM1,27

ÄNDERUNG

INDEX

1B-240506 drawing-nr. update C. Loris

1C-300506 replacement of cables

1D-120906 assembly revised

ZEICHNER

F. Sitter

F. Sitter

E 962262, stranded wire FQL17

Q1.5-R-1000-488I-bared

E 962263, stranded wire FQL17

Q1.5-B-1000-488I-bared

E 962337, stranded wire P39

CABLING 230V

Pos. part-no. 1 part-no. 2 part-no. 3 description Beschreibung quantity

1 962038 str anded wi re E4 16-YG-120-638-638 1015, A WG Litze E 4 16-YG-120-638- 638 1015, AWG 3

2 962054 s tranded w ire 2xJST 3pol, 140mm AW G26 Style 1007 Litze 2xJST 3pol, 140mm A WG26 Styl e 1007 2

3 962262 s tranded w ire FQL17 Q1.5- R-1000-488I- bared Litze FQL17 Q1.5-R- 1000-488I-bared 1

4 962263 s tranded w ire FQL17 Q1.5- B- 1000-488I-bar ed Litze FQL17 Q1.5-B-1000-488I-bared 1

5 962288 stranded wire E3 16-YG-200- 638-485 1015, A WG Litze E 3 16-YG-200-638-485 1015, A WG 2

6 962314 stra nded wir e E18 16-Y G-200-638- eyelet, AW G stranded wi re E18 16- YG-200- 638-eyelet, AW G 2

7 962337 strande d w ir e P39 16-R-600- 488I-485IT 1015, AW G Litze P39 16-R-600-488I-485IT 1 015, AW G 1

8 962338 stranded wir e P39 16-B-600-488I-485I 1015, AWG Litz e P39 16-B-600-488I-485I 1015, AW G 1

9 962346 (230V) stranded wir e P42 AWG14/16 Style 1015 HK0502-KA- R04-xx Litze P42 AW G14/16 Style 1015 HK0502-KA- R04-xx 2

10 964052 powerca ble DIVA, Y-s tranded w ire HK1805- KA-R01 -xx Powerkabe l DIVA, Y -Litze HK1805-KA- R01-xx 1

11 965618 f lat ri bbon cabl e 20-2-360, Typ 6, AWG 28 F lachbandkabel 20- 2-360, Typ 6, A WG 28 1

12 965626 fla t ribbon c able 20-2-200, Typ 5, AWG 28 Flac hbandka bel 20-2-200, Typ 5, AW G 28 1

16-R-600-488I-485IT 1015, AWG

E 962338, stranded wire P39

16-B-600-488I-485I 1015

66606 St. Wendel / Germany

ZEICHNUNGS-NR.:

ERSTELLT VON:

GEPRÜFT/

FREIGEGEBEN VON:

WERKSTOFF:

DATEINAME:

HK1805-EX-R03-1D

C. LORIS 4

HK1805-EX-R03-1D-CHASSIS

E 965626, flat ribbon cable 20-2-200mm Typ 5,

AWG 28 flexible grey RM1,27

E 962054, stranded wire 2*JST 3pol,

140mm AWG 26 Style 1007

E 962038, stranded wire E4

16-YG-120-638-638 1015, AWG

TITEL:

HK1805-BASS-CHASSIS

EXPLODED DRAWING

OBERFLÄCHE:

VERSION:

AM:

12.09.2006

AM:

/

REVISION:

BLATT:

4

D1

BLÄTTER

Page 24

pos. part-no. 1 description Beschreibung quantity

1 547058 ConTour CTA 118 Mainboard ConTour CTA 118 Mainboard 1

2 966010 push-bottom cylindric, black Knopf-Taster rund/zyl. schwarz 1

3 966046 plunger type key top, 9*9, B32-1210 Knopf-Taster 9*9 B32-1210 4

4 970800 plexiglas CTA Operating panel Plexiglas CTA Operating panel 1

5 974110 self locking hexagon nut with plastic insert, M3, zinc plated Stopmutter M3 vz 4

6 974212 hexagon PCB spacer, type B, M3x15, zinc plated Dist. Bol Innen/Außengew. M3*15 vz 4

7E 974221

7 974221 hexagon socket countersunk head screw, M3x8, zinc plated Inbussenkschraube M3x8 vz 4

4E 970800

6E 974212

INDEX CHANGES

2E 966010

3 E 966046

1E 547058

TITLE:

HK1805-CTA DISPLAY

5E 974110

RESP.

66606 St. Wendel / Germany

DRAWING-NO.:

DRAWN BY:

CHECKED BY:

MATERIAL:

FILENAME:

HK1805-EX-R11-1A

C. LORIS 1

HK1805-EX-R11-1A-DISPLAY

EXPLODED DRAWING

VERSION:

DATE:

12.09.2006

DATE:

FINISH:

REVISION:

PAGE:

A1

PAGES

Page 25

2

3

5

1

6

2

9

4

INDEX CHANGES

RESP.

9

7 9

Spa re Parts List for: HK1805-NZ-R01-1C

Project: CTA

Project Number: HK1805

As sembly: Mainboard

pos. part no. de scription Bezeichnung refe rence de signators quantity

1 936010 LED 5mm grün s tandard dif fused LED 5mm grün Standard dif fused LD3, LD2 2

2 936041 LED 5mm blau semi diff used LED 5mm blau semi diff used LD1, LD10-12, LD6-9, LD13-14 10

3 936046 LED 5mm orange, s tandard LED 5mm orange, Standar d LD5, LD4 2

4 946009 NAIS TQ2-12V DC print, miniature relais Relais NAIS TQ2-12V DC print REL1 1

5 950021 tac tile push button B3F-4055 Taster Tac-Sw itch B3F-4055 SW4, SW3, SW2, SW1 4

6 950083 pus h button sw itch, v ertical, 2x UM (2 Pols) Drucks chalter ohne LED 11,25mm SW5 1

7 952021 con nector SEK18 2*8pol Wannenstec ker 2*8pol Gprint JP13 1

8 952053 JST, 3-pol, vert ., print, B 3B-EH-A Stif tleiste JST 3pol Gprint JP3, JP1 2

9 952150 con nector SEK18 2*10pol. Wannenst ecker 2*10pol Gprint JP6, JP5 2

66606 St. Wendel / Germany

DRAWING-NO.:

DRAWN BY:

CHECKED BY:

MATERIAL:

FILENAME:

HK1805-LP-R01-1C

C. LORIS 1

HK1805-LP-R01-1C-MAINBOARD

TITLE:

HK1805-CTA

MAINBOARD

FINISH:

VERSION:

DATE:

DATE:

12.10.2006

REVISION:

PAGE:

A1

PAGES

Page 26

E 959052

PWM Amp Module 100-240V

To ensure the procedure of our quality assurance

(burn-in-test, quality-test,...) please send the complete

module to our technical service for replacement.

For customer inquiry please contact our service-team.

Page 27

Pos. part-no. 1 description Beschreibung quantity

1 400282 finished board fertiges Rollbrett aus Schreinerei 1

2 974099 Mechanical locking screw, TENSILOCK W151, M6x20 Sperrzahnschraube M 6*20 vz, Tensilock W151 16

3 974225 cross recessed panhead screw, M4x10, zinc plated Linsenschraube M4 x 10 vz 10

4 976143 Butterfly 170290 Butterfly 170290 2

5 976158 castor 100mm, blue Lenkrolle 100mm, blau 4

2 E 974099

5 E 976158

INDEX

ÄNDERUNG

ZEICHNER

3E 974225

4E 976143

1E 400282

HK1805-HZ-R04-1A

TITEL:

HK1805 CTA DOLLY

66606 St. Wendel / Germany

ZEICHNUNGS-NR.:

ERSTELLT VON:

GEPRÜFT/

FREIGEGEBEN VON:

WERKSTOFF:

DATEINAME:

HK1805-EX-R01-1A

C. LORIS 1

HK1805-EX-R01-1A-ROLLBRETT

EXPLODED DRAWING

OBERFLÄCHE:

VERSION:

AM:

15.03.2006

AM:

/

REVISION:

BLATT:

1

A1

BLÄTTER

Page 28

8 E 974114

16 E 976010

15 E 976009

12 E 974524

7 E 974091

18E 976157

2E 970828

4E 970830

1E 598005

9

5 E 970831

INDEX

ÄNDERUNG

13

7

ZEICHNER

2

9

9

12

18

3 E 970829

11

12

9 E 974168

11E 974453

13 E 974525

7

11

14 E 974526

17 E 976106

TITEL:

HK1805-CTA-STACKING PLATE

EXPLODED DRAWING

66606 St. Wendel / Germany

ZEICHNUNGS-NR.:

10E 974320

6E 970842

ERSTELLT VON:

GEPRÜFT/

FREIGEGEBEN VON:

WERKSTOFF:

DATEINAME:

HK1805-EX-R10-1A

C. LORIS 1

HK1805-EX-R10-1A-Groundstack

OBERFLÄCHE:

VERSION:

AM:

15.05.2006

AM:

N/A

REVISION:

BLATT:

2

A1

BLÄTTER

Page 29

Pos. part-no. 1 description Beschreibung quantity

1 598005 spare tightening knob M20 Gewinde mit Anschlag M20 1

2 970828 HK1805-groundstack front block HK1805-Groundstack Frontklotz 2

3 970829 HK1805-groundstack mounting plate HK1805-Groundstack Montageplatte 1

4 970830 HK1805-groundstack left mounting part HK1805-Groundstack Halterung links 1

5 970831 HK1805-groundstack right mounting part HK1805-Groundstack Halterung rechts 1

6 970842 sheet metal CTA subwoofer-connector Blech CTA Bass-Verbinder 2

7 974091 toothed lock washer, D=5.3, AZ, zinc plated Fächer-Scheibe az, 5,3 vz 6

8 974114 self locking hexagon nut with plastic insert, M5, zinc plated Stopmutter M5 vz 2

9 974168 washer, form A, 5.3*12, zinc plated Unterleg-Scheibe 5,3*12 vz 6

10 974320 cross recessed countersunk screw, M5x30, zinc plated Senkschrauben M5*30 vz 2

11 974453 hexagon socket countersunk head screw, M5x16, black Inbussenkschraube M5x16 sw 5

12 974524 hexagon domed cap nut, M5, zinc platec Hutmutter M5 vz 6

13 974525 hexagon socket head cap screw, M5x14, black Inbusschraube M 5x14 sw 2

14 974526 hexagon socket countersunk head screw, M5x12, black Inbussenkschraube M 5x12 sw 3

15 976009 rubber foot D38*H11 [mm] Gummifuss D38*H11 [mm] 2

16 976010 rubber foot D38*H20 [mm] Gummifuss D38*H20 [mm] 2

17 976106 spare tightening knob Molpen M10x27mm Knopfschraube Molpen M10x27mm 4

18 976157 self locking clamping pin KSB2234 8x17 Kugelsperrbolzen KSB2234 8x17 2

INDEX

ÄNDERUNG

ZEICHNER

66606 St. Wendel / Germany

ZEICHNUNGS-NR.:

ERSTELLT VON:

GEPRÜFT/

FREIGEGEBEN VON:

WERKSTOFF:

DATEINAME:

HK1805-EX-R10-1A

C. LORIS 2

HK1805-EX-R10-1A-Groundstack

TITEL:

HK1805-CTA-STACKING PLATE

EXPLODED DRAWING

VERSION:

AM:

15.05.2006

AM:

OBERFLÄCHE:

N/A

REVISION:

BLATT:

2

A1

BLÄTTER

Page 30

HK1805-EX-R04-1B-SUB-COMPLETE

G

x

Article No. 1 (230V) Article No. 2 (117V) Article No. 3 (100V) Description Bezeichnung Quantity

1134 HK1805-bass front grill assembly HK1805-Frontgitterbaugruppe Bass 1

400280 HK1805-bass cabinet HK1805-Bass Holzgehäuse 1

502198 Electronic-Chassis HK1805-Elektronikchassis 1

970760 plate for butterfly lock CT 118 Blech Schliessplatte CT118 2

972008 damping wool Dämmwolle Hochbauschvlies 1

974012 hexagon socket head cap screw, M6x30, black Inbusschraube M6*30 sw 8

974020 hexagon socket head cap screw, M5x20, black Inbusschraube M5x20sw 17

974145 ABC-Spax-S chipboard screw, panhead Z, 5x25, black Pan Head-Z ABC-Spax sw 5*25 4

974218 ABC-Spax-S chipboard screw, panhead Z, 5x20, black Pan Head-Z ABC-Spax sw 5*20 4

974220 hexagon socket countersunk head screw, M6x40, black Inbussenkschraube M6x40 sw 4

974232 ABC-Spax-S chipboard screw, panhead Z, 3.5x12, zinc plated Pan Head-Z ABC-Spax vz 3,5*12 12

974272 cross recessed raised countersunk screw, M5x10, black Linsensenkschraube M5*10 sw 4

974501 hexagon socket countersunk head screw, M4x16, black Inbussenkschraube M4x16 sw 4

976009 rubber foot D38*H11 [mm] Gummifuss D38*H11 [mm] 4

976010 rubber foot D38*H20 [mm] Gummifuss D38*H20 [mm] 4

976094 plastic dish 3403 HKBS! DART ! Griffschale 3403 HKBS! DART ! 1

976115 connector plate Befestigungsplatte M20 1

976159 plastic dish Premium One Griffinnenschale Premium One 6

976162 rubberbuffer d=18 h=40mm Gummipuffer d=18 h=40 Typ B 4

982037 sealing tape 2x6mm Iso-Zell-Band fadenvers. 2*6mm 0,54 lfdm

982044 sealing tape 2x15mm Iso-Zell-Band fadenvers. 2*15mm 3,70 lfdm

994199 SICA LP 470.100_3300WT 8 Ohm SICA LP 470.100_3300WT 8 Ohm 1

HK1805-EX-R02-1B-SUB-FRONTGRILLE-ASSEMBLY

Article No. 1 (230V) Article No. 2 (117V) Article No. 3 (100V) Description Bezeichnung Quantity

970815 HK1805-bass front grid HK1805-Frontgitter-Bass 1

972086 acoustics foam anthracite 5mm Akustikschaum Anthrazit 5mm 1

980251 logo 'hk'ConTourSer. 35x35x3mm Logo 'hk'ConTourSer. 35x35x3mm 1

HK1805-EX-R03-1D-CHASSIS/CABLIN

Article No. 1 (230V) Article No. 2 (117V) Article No. 3 (100V) Description Bezeichnung Quantity

547058 mainboard PCB complete Mainboardplatine fertigbestückt 1

600090 Networkinterfaceboard is part of Inputboard Interfaceplatine als Teil von Inputplatine 1

600090 Inputboard 54_Inputplatine fertigbestückt 1

600091 mains filter assembly 220-240V 60 Netzfilter CTA 118 220-240V 1

931304 ferrite teroid core, 25x15x12 Ferritring, geschlossen 25x15x12 3

952141 mains inlet PowerCon Netzbuchse Power Con Inlet 1

952153 mains outlet PowerCon Netzbuchse Power Con Outlet 1

952305 speakon chassis connector, NL4MP-3 Speakonbuchse 4pol eckig, NL4MP-3 1

959052 PWM amp module 100-240V PWM Endstufe 100-240Volt 2

962038 stranded wire E4 16-YG-120-638-638 1015, AWG Litze E4 16-YG-120-638-638 1015, AWG 3

962054 stranded wire 2xJST 3pol, 140mm AWG26 Style 1007 Litze 2xJST 3pol, 140mm AWG26 Style 1007 2

962262 stranded wire FQL17 Q1.5-R-1000-488I-bared Litze FQL17 Q1.5-R-1000-488I-bared 1

962263 stranded wire FQL17 Q1.5-B-1000-488I-bared Litze FQL17 Q1.5-B-1000-488I-bared 1

962288 stranded wire E3 16-YG-200-638-485 1015, AWG Litze E3 16-YG-200-638-485 1015, AWG 2

962314 stranded wire E18 16-YG-200-638-eyelet, AWG stranded wire E18 16-YG-200-638-eyelet, AWG 2

962337 stranded wire P39 16-R-600-488I-485IT 1015, AWG Litze P39 16-R-600-488I-485IT 1015, AWG 1

962338 stranded wire P39 16-B-600-488I-485I 1015, AWG Litze P39 16-B-600-488I-485I 1015, AWG 1

962346 stranded wire P42 AWG14/16 Style 1015 HK0502-KA-R04-xx Litze P42 AWG14/16 Style 1015 HK0502-KA-R04-x

2

Page 31

964052 powercable DIVA, Y-stranded wire HK1805-KA-R01-xx Powerkabel DIVA, Y-Litze HK1805-KA-R01-xx 1

Y

965618 flat ribbon cable 20-2-360, Typ 6, AWG 28 Flachbandkabel 20-2-360, Typ 6, AWG 28 1

965626 flat ribbon cable 20-2-200, Typ 5, AWG 28 Flachbandkabel 20-2-200, Typ 5, AWG 28 1

970811 HK1805 air guide HK1805_Lüftungshaube_PWM 2

970812 HK1805 ventilation grill HK1805_Lüftungsgitter 2

970813 HK1805 sheet metal chassis HK1805_Blechchassis 1

970814 ribbon connector safety lock HK1805_Pfostensteckverbinder-Schutzblech 1

972009 acoustic foam anthracite 5mm, PPI20 Akustikschaum Anthrazit 5mm, PPI20 2

972041 rubber punching 25x25x15mm Zellkaut. -Stanzteil 25x25x15mm 1

974051 plastic PCB spacer, 4.2x8x5, Polyamid black Dist.Hülse PE 4,2*8*5 [mm] 12

974102 hexagon nut, class 8, M3, zinc plated Sechskantmutter M3 vz 2

974103 toothed lock washer, D=4.3, AZ, zinc plated Fächer-Scheibe az, 4,3 vz 2

974110 self locking hexagon nut with plastic insert, M3, zinc plated Stopmutter M3 vz 19

974157 cross recessed raised countersunk tapping screw, 2.9x9.5, black Blechschr. Senk-Li 2,9*9,5 sw 4

974290 self locking hexagon nut with plastic insert, M4, zinc plated Stopmutter M4 vz 8

974362 hexagon PCB spacer, type B, M3x12, zinc plated Dist. Bol Innen/Außengew. M3*12 vz 3

974392 hexagon socket oval head screw, M3x8, black Linsenschr.m.Innens. M3*8 sw 12

974444 cross recessed raised countersunk screw, M3x12, black Linsensenkschraube M3*12 sw 4

974521 cross rec. raised counters. tap. screw w. cutting slot, 2.9x9.5, black Senkschr. f. Kunststoff 2,9*9,5, sw 6

976007 cable tie 2,5x100 (mm) Kabelbinder natur 2,5x100 (mm) 14

976135 socket for cable tie Schraubsockel 5

976141 rubberbuffer 15x15 B Gummipuffer GM-Puffer 15x15 B 8

982044 sealing tape 2x15mm Iso-Zell-Band fadenvers. 2*15mm 0,20 lfdm

986019 adhesive tape, double-sided, clear Klebeband, doppelseitig, klar 0,20 lfdm

HK1805-EX-R11-1A-DISPLA

Article No. 1 (230V) Article No. 2 (117V) Article No. 3 (100V) Description Bezeichnung Quantity

547058 ConTour CTA 118 Mainboard ConTour CTA 118 Mainboard 1

966010 push-bottom cylindric, black Knopf-Taster rund/zyl. schwarz 1

966046 plunger type key top, 9*9, B32-1210 Knopf-Taster 9*9 B32-1210 4

970800 Plexiglas CTA Operating panel Plexiglas CTA Operating panel 1

974110 self locking hexagon nut with plastic insert, M3, zinc plated Stopmutter M3 vz 4

974212 hexagon PCB spacer, type B, M3x15, zinc plated Dist. Bol Innen/Außengew. M3*15 vz 4

974221 hexagon socket countersunk head screw, M3x8, zinc plated Inbussenkschraube M3x8 vz 4

HK1805-LP-R01-1C-MAINBOARD

Article No. Ref.Destricption Description Bezeichnung Quantity

936010 LD3, LD2 LED 5mm grün standard diffused LED 5mm grün Standard diffused 2

936041 LD1, LD10-12, LD6-9,

LD13-14

936046 LD5, LD4 LED 5mm orange, standard LED 5mm orange, Standard 2

946009 REL1 NAIS TQ2-12V DC print, miniature relais Relais NAIS TQ2-12V DC print 1

950021 SW4, SW3, SW2, SW1 tactile push button B3F-4055 Taster Tac-Switch B3F-4055 4

950083 SW5 push button switch, vertical, 2xUM (2 Pols) Druckschalter ohne LED 11,25mm 1

952021 JP13 connector SEK18 2*8pol Wannenstecker 2*8pol Gprint 1

952053 JP3, JP1 JST, 3-pol, vert., print, B 3B-EH-A Stiftleiste JST 3pol Gprint 2

952150 JP6, JP5 connector SEK18 2*10pol. Wannenstecker 2*10pol Gprint 2

LED 5mm blau semi diffused LED 5mm blau semi diffused 10

Page 32

HK1805-EX-R01-1A-DOLL

Y

E

Article No. 1 (230V) Article No. 2 (117V) Article No. 3 (100V) Description Bezeichnung Quantity

400282 finished board fertiges Rollbrett aus Schreinerei 1

974099 Mechanical locking screw, TENSILOCK W151, M6x20 Sperrzahnschraube M 6*20 vz, Tensilock W151 16

974225 cross recessed panhead screw, M4x10, zinc plated Linsenschraube M4 x 10 vz 10

976143 Butterfly 170290 Butterfly 170290 2

976158 castor 100mm, blue Lenkrolle 100mm, blau 4

HK1805-EX-R10-1A-STACKING PLAT

Article No. 1 (230V) Article No. 2 (117V) Article No. 3 (100V) Description Bezeichnung Quantity

598005 spare tightening knob M20 Gewinde mit Anschlag M20 1

970828 HK1805-groundstack front block HK1805-Groundstack Frontklotz 2

970829 HK1805-groundstack mounting plate HK1805-Groundstack Montageplatte 1

970830 HK1805-groundstack left mounting part HK1805-Groundstack Halterung links 1

970831 HK1805-groundstack right mounting part HK1805-Groundstack Halterung rechts 1

970842 sheet metal CTA subwoofer-connector Blech CTA Bass-Verbinder 2

974091 toothed lock washer, D=5.3, AZ, zinc plated Fächer-Scheibe az, 5,3 vz 6

974114 self locking hexagon nut with plastic insert, M5, zinc plated Stopmutter M5 vz 2

974168 washer, form A, 5.3*12, zinc plated Unterleg-Scheibe 5,3*12 vz 6

974320 cross recessed countersunk screw, M5x30, zinc plated Senkschrauben M5*30 vz 2

974453 hexagon socket countersunk head screw, M5x16, black Inbussenkschraube M5x16 sw 5

974524 hexagon domed cap nut, M5, zinc platec Hutmutter M5 vz 6

974525 hexagon socket head cap screw, M5x14, black Inbusschraube M 5x14 sw 2

974526 hexagon socket countersunk head screw, M5x12, black Inbussenkschraube M 5x12 sw 3

976009 rubber foot D38*H11 [mm] Gummifuss D38*H11 [mm] 2

976010 rubber foot D38*H20 [mm] Gummifuss D38*H20 [mm] 2

976106 spare tightening knob Molpen M10x27mm Knopfschraube Molpen M10x27mm 4

976157 self locking clamping pin KSB2234 8x17 Kugelsperrbolzen KSB2234 8x17 2

Page 33

4321

Date Modification Revision Name

13.12.05 1st draft 1A A. Peter

30.01.06 see logfile 1B F. Sitter

D

29.03.06 see logfile 1C F. Sitter

D

Analog_Interface

HK1805-SP-R01-1C-02AnalogIO.Sch

C

AGND

-15V

+15V

B

INPUT

TOP_OUTPUT

TOP_OUTPUT

SUB_OUTPUT

SUB_OUTPUT

PROTECT_T

PROTECT_S

LIMIT_T

LIMIT_S

MUTE

GND_LIFT

IN_SENS

DGND

+5V

CHASSIS

Digital_Interface

HK1805-SP-R01-1C-03DigitalIO.Sch

INPUT

TOP_OUTPUT

TOP_OUTPUT

SUB_OUTPUT

SUB_OUTPUT

PROTECT_T

PROTECT_S

LIMIT_T

LIMIT_S

MUTE

GND_LIFT

IN_SENS

CHASSIS

DGND

+5V

AGND

-15V

C

+15V

B

NA = not assembled part ----- EX = exclusive part, no alternative allowed

HT = high temperature part, assemble with distance from PCB

Title:

HK1805 Preamp

66606 St. Wendel / Germany

Number: Version: Revision:1HK1805-SP-R01-1C C

A

Drawn by: Date:

Alexander Peter

F. Sitter

All rights reserved. No part of this schematic may be reproduced, stored in a retrieval system, transmitted in any form or

by any means, electronic, mechanical, photocopying, recording or otherwise, without the prior permission of the author. Filename: HK1805-SP-R01-1C-01Main.Sch

1 2 3 4

PCB No.:

HK1805-NZ-R01, always use latest revision

Date:

14.12.05

19.04.06

Page:

3Checked by:

1

Pages

A

Page 34

+15V +15V

D1

C1

D6

1N4148

NA

B

G

R

47p/100V-K

47p/100V-K

REL2

+

1

10

-

TQ2-12V

NA

47p/100V-K

FB1

BL01RN1A1F1J

FB2

BL01RN1A1F1J

C2

C5

FB3

BL01RN1A1F1J

JP1

3

R

JST-B03B-EH-A

R8

240R

NA

2

G

1

B

JP7

1

2

3

JST-B03B-EH-A

NA

D

Analog In/Thru connector panel

+15V

Q2

BC546B

NA

R12

C

GND_LIFT

10K

NA

2

3

4

9

8

7

C3

47p/100V-K

C7

10u/63V

C8

10u/63V

C4

47p/100V-K

C6

47p/100V-K

C11

47n/250V

R22

47R/1W

SW5A

2 1

LTV75-SD11.25-CS

SW5B

5 6

LTV75-SD11.25-CS

3

4

C9

1N4148D31N4148

47p/100V-K

R1

12K

R2

12K

D2

1N4148D41N4148

-15V -15V

12

13

+15V

R10

10K

R11

10K

R14

10K

R13

10K

+15V

U3B

MC33079N(ST)

5

+

6

7

-

-15V

R20

8K2

C14

22p/100V-K

DDO Top Output

TOP_OUTPUT

TOP_OUTPUT

B

BR1

+15V

-15V

+5V

+15V

A

AGND

DGND

+15V

0R0

BR3

-15V

0R0

BR4

+5V+5V

0R0

+5V

DDO Sub Output

+15V

-15V

-15V

DGND

MUTE

SUB_OUTPUT

SUB_OUTPUT

R16

10K

R17

10K

CHASSIS

All rights reserved. No part of this schematic may be reproduced, stored in a retrieval system, transmitted in any form or by any means, electronic, mechanical, photocopying, recording or otherwise, without the prior permission of the author. Filename: HK1805-SP-R01-1C-02AnalogIO.Sch

R3

12K

R5

4K7

+15V

U1A

84

MC33078N(ST)

3

VCC

+

2

-

VEE

-15V

R6

4K7

C10

47pF/100V-K

U3D

MC33079N(ST)

+

-

R18

8K2

C12

22p/100V-K

5

+

6

-

U1B

MC33078N(ST)

R32

3K9

R25

47R

INPUT

1

R4

12K

INPUT

C42

47p/100V-K

FB6

BL01RN1-A62

C43

-15V+

R23

14

47R

R33

7

560R

R34

560R

+15V

411

MC33079N(ST)

3

VCC

+

2

-

VEE

-15V

R21

8K2

C15

22p/100V-K

U3C

MC33079N(ST)

10

+

9

D8

1N4148

D9

1N4148

U3A

1

8

-

R19

8K2

C13

22p/100V-K

U6

LTV817

U7

LTV817

R26

47R

47p/100V-K

REL1

2

3

+

4

9

8

-

7

TQ2-12V

+15V

C44

47p/100V-K

C45

+15V+

47p/100V-K

R24

47R

+15V

+15VSub

1

10

FB7

BL01RN1-A62

PROTECT_T

LIMIT_T

PROTECT_S

LIMIT_S

R7

240R

D5

1N4148

JP3

B

G

R

JST-B03B-EH-A

C16

47p/100V-K

C17

47p/100V-K

RESTART_TOP

Top_Output_neg

Top_Output_pos

RESTART_SUB

Sub_Output_neg

Sub_Output_pos

+15V

1

2

3

Q1

BC546B

R9

10K

IN_SENS

DGND+5V-15V

FB4

BL01RN1-A62

JP5

1 2

DGND+

3 4

+5V+

5 6

GNDT GNDT

7 8

-15V+ -15V+

9 10

+15V+ +15V+

11 12

13 14

15 16

17 18

19 20

SEK18-20P

DGND+

+5V+

TOP OUT

R28 1K0

+5V

R29 1K0

+5V

R30 1K0

+5V

R31 1K0

+5V

SUB OUT

JP6

1 2

3 4

5 6

GNDB GNDB

7 8

9 10

11 12

13 14

15 16

17 18

19 20

SEK18-20P

NA = not assembled part ----- EX = exclusive part, no alternative allowed

HT = high temperature part, assemble with distance from PCB

66606 St. Wendel / Germany

Number: Version: Revision:1HK1805-SP-R01-1C C

A. Peter

Drawn by: Date:

F. Sitter

Checked by:

PCB No.:

HK1104-NZ-R01, always use latest revision

1 2 3 4 5 6 7 8

C30

47p/100V-K

FB5

BL01RN1-A62

C31

47p/100V-K

47p/100V-K

FB8

BL01RN1-A62

47p/100V-K

FB9

BL01RN1-A62

47p/100V-K

47p/100V-K

FB10

BL01RN1-A62

47p/100V-K

DGND

Title:

C46

C48

C49

C51

C50

HK1805 Preamp

14.12.2005

19.04.06

Date:

87654321

D

C

B

A

2

Page:

3

Pages

Page 35

HO16

21

21

21

21

U10

VCC

WP

VSS

M24256-B

NA

LD1

5MM-B/50X100°

5MM-B/50X100°

LD6

R59

680R

R54

10K

DGND +5V

R47

10K

1

2

3

4

HO28

DK-R70-B30

DK-R70-B30

HO8

DK-R17-B09

HO9

DK-R17-B09

HO22

DK-R17-B09

HO23

DK-R17-B09

HO24

DK-R17-B09

HO25

DK-R17-B09

HO14

DK-R17-B09

HO15

DK-R17-B09

HO29

DK-R70-B30

DK-R70-B30

A0

A1

A2

SDA

SCL

NA

JP2

JST-B03B-EH-A

B1G2R

3

R60

220R

NA

R46

10K

RXD

RX-EN

TX-EN

TXD

HO27

DGND

1

2

3

5

6

JP12

JST-B03B-EH-A

B1G2R

R61

330R

NA

NA

3

+15V

-15V

JP8

SL-08P08X1-SW97

R51

10K

NA

R52

10K

NA

R53

10K

NA

U5B

1C

7C

9C

3C

8

DGND

7

6

5

4

3

2

1

1D

DBG1 DBG2

3D

DBG3 DBG4

DBG5 DBG6

5D

7D

DBG7 DBG8

DBG9 DBG10

9D

11D

DBG11 DBG12

DBG13 DBG14

13D

15D

DBG15 DBG16

+15V

AGND

AGND

-15V

RIGHT_OUTPUT

RD0304-LP-R01-4

U5C

ISP_MISO

ISP_SCK

RESET

DSP_SS

PD1-TXD

PD7-SDA

PD6-SCL

RESET

RD0304-LP-R01-4

LEFT_INPUT

RIGHT_INPUT

SUB_OUTPUT

SUB_OUTPUT2

LEFT_OUTPUT

ISP_MOSI

DETECT

PD0-RXD

WP_EEP

C1

C2

+5V

DGND

DGND

SCL

SDA

K_UP

K_DOWN

K_ENTER

K_MENU

LED_LT

LED_ST

LED_SS

LED_LS

LCD_DB6

LCD_DB7

LCD_DB4

LCD_DB5

LCD_RS

LCD_EN

LIMIT_S

LIMIT_T

SCL

SDA

TX-EN

RX-EN

LED_ST

R41

330R

LD2

5MM-G

3A

4A

5A

6A

7A

8A

9A

10A

20A

19A

18A

17A

16A

15A

14A

13A

25A

26A

27A

28A

41A

42A

43A

50A

49A

LED_LT

R42

330R

LMO12D

DGND DGND DGND DGND

+5V

DGND

+5V

DGND

U5D

CHASSIS

CHASSIS

RD0304-LP-R01-4

U5A

GPIO0

GPIO1

GPIO2

GPIO3

GPIO4

GPIO5

GPIO6

GPIO7

XDATA0

XDATA1

XDATA2

XDATA3

XDATA4

XDATA5

XDATA6

XDATA7

CTRL_SCL

CTRL_SDA

PC2

PC3

XSPI_OUT

XSPI_IN

XSPI_CLK

CHASSIS

CHASSIS

RD0304-LP-R01-4

LD4

4C

2C

6C

5C

10C

8C

2D

4D

6D

8D

10D

12D

14D

16D

CHASSIS

CHASSIS

RESET

MUTE_OUT

AUX1

AUX2

WP_EEPROM

PD0-RXD

PD1-TXD

PD2-INT0

PD3-INT1

PD4-OC1B

PD5-OC1A

PD6-ICP

PD7-OC2

DGND

DGND

DGND

DGND

DGND

DGND

LED_SS

R43

330R

LD3

5MM-G

INPUT

SUB_OUTPUT

SUB_OUTPUT

TOP_OUTPUT

TOP_OUTPUT

1 2

DBG1 DBG2

3 4

DBG3 DBG4

DBG5 DBG6

5 6

7 8

DBG7 DBG8

DBG9 DBG10

9 10

11 12

DBG11 DBG12

DBG13 DBG14

13 14

15 16

DBG15 DBG16

C3

C4

11A

+5V

12A

+5V

29A

+5V

30A

+5V

31A

+5V

32A

+5V

23A

24A

GND_LIFT

45A

IN_SENS

47A

48A

RXD

33A

TXD

34A

MUTE

35A

36A

PROTECT_T

37A

PROTECT_S

38A

BL_DIM

39A

LCD_CONTR

40A

1A

2A

21A

22A

44A

46A

DGND

LED_LS

R44

330R

NA = not assembled part ----- EX = exclusive part, no alternative allowed

LD5

HT = high temperature part, assemble with distance from PCB

LMO12D

BR2

0R0

JP13

SEK18-16P

+5V

66606 St. Wendel / Germany

Number: Version: Revision:1HK1805-SP-R01-1B C

A. Peter

Drawn by: Date:

F. Sitter

Checked by:

PCB No.:

HK1104-NZ-R01, always use latest revision

R38

4606M-10K-B

PT1

C18

DGND

D

22u/16V-T

U8

GND

Vo

VCC

RS

R/W

E

DB0

DB1

LCD 16x2

DB2

DB3

DB4

DB5

DB6

DB7

LED-A

LED-K

SUNLIKE-162ABWT

C

PT10LH-10K NA

+5V

+

1

DGND

3

3

2

+5V

4

5

DGND

6

7

7

8

8

9

9

10

10

11

12

13

14

15

15

16

16

R49

68R

DGND

DGND

LR

C19

2u2/35V-T

R39

10R

Q3

BC546B

DGND

+

R48

LCD_CONTR

100R

LCD_RS

LCD_EN

LCD_DB4

LCD_DB5

LCD_DB6

LCD_DB7

+5V

R45

10K

BL_DIM

K_UP

K_DOWN

K_ENTER

K_MENU

12345

6

+5V

DGND

JP4

1

2

3

4

5

6

7

8

SL-08P08X1-SW97

DGND

+15V

LD12

LD13

+5V

+15V

-15V

DGND

IN_SENS

MUTE

GND_LIFT

PROTECT_T

PROTECT_S

LIMIT_T

LIMIT_S

JP11

R

G

B

JST-B03B-EH-A

5MM-B/50X100°

5MM-B/50X100°

5MM-B/50X100°

5MM-B/50X100°

BL_DIM

R55

10K

Q4

BC546B

DGND DGND

LD11

LD14

R35

R15

680R

680R

R56

10K

R36

10K

DGNDDGND

DGND

R50

100R

R40

100R

3

2

1

DGND

8

+5V

6

7

5

B

IN_SENS

MUTE

GND_LIFT

PROTECT_T

PROTECT_S

LIMIT_T

LIMIT_S

+5V

+15V

-15V

A

AGND

DGND

CHASSIS

HO7

DK-R17-B09

HO21

DK-R17-B09

HO17

DK-R17-B09

HO18

DK-R17-B09

HO19

DK-R17-B09

HO20

DK-R17-B09

HO26

DK-R17-B09

HO10

DK-R17-B09

+5V

DBG14

DGND

C24

47p/100V-K

FB12

BL01RN1-A62

LD10

5MM-B/50X100°

5MM-B/50X100°

5MM-B/50X100°

5MM-B/50X100°

LD9

R27

680R

R57

10K

R37

Q5

10K

BC546B

DGNDDGND

C25

+5V DGND

100n/63V-K

U9

VCC

A

B

GND

SN65176BP

LD7

LD8

R58

680R

RE

DE

SW1

B3F-4055

SW2

B3F-4055

SW3

B3F-4055

SW4

B3F-4055

R

D

8

7

4

C52

47p/100V-K

Q6

BC546B

All rights reserved. No part of this schematic may be reproduced, stored in a retrieval system, transmitted in any form or by any means, electronic, mechanical, photocopying, recording or otherwise, without the prior permission of the author. Filename: HK1805-SP-R01-1C-03DigitalIO.Sch

1 2 3 4 5 6 7 8

87654321

Mechanics / Ref-Points / Filtering

JP9

JP10

+5V

C39

100n/63V-K

DGND

+15V -15V

+

C27

2u2/35V-T

+15V -15V

C32

100n/63V-K

-15V

C36

100n/63V-K

HO2

DK-R70-B32

HO6

NDK-R0-B40

14.12.2005

19.04.06

JP14

FASTON-6.3-ST

+5V

100n/63V-K

DGND

+5V

100n/63V-K

DGND

+

C28

C33

100n/63V-K

C37

100n/63V-K

HO3

DK-R70-B32

HO11

NDK-R0-B40

FASTON-6.3-ST

C20

C40

2u2/35V-T

Page:

3

FASTON-6.3-ST

FASTON-6.3-ST

+5V

C38

100n/63V-K

DGND

+15V -15V

+

C26

2u2/35V-T

+15V

C23

100n/63V-K

+15V -15V

C35

100n/63V-K

HO1

DK-R70-B32

HO5

NDK-R0-B40

HO13

NDK-R0-B40

Title:

HK1805 - Preamp

Date:

JP15

+5V

100n/63V-K

+5V

100n/63V-K

DGND

+

C29

+15V

C34

100n/63V-K

HO4

DK-R70-B32

HO12

NDK-R0-B40

3

Pages

C21

C41

2u2/35V-T

D

C

B

A

Page 36

4321

D

D

DDO Pro NET PORT ANALOG PORT

J2

C

NE8FAH

J3

B

NE8FAH

SHLD

SHLD

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

FB1

FB2

FB3

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

DIG_CHASSIS

C1

BL01RN1-A62

BL01RN1-A62

BL01RN1-A62

C2

C3

47p/100V-K

47p/100V-K

47p/100V-K

JP5

FASTON-6.3-ST

JP3

3

R

2

G

1

B