Page 1

H&K EUROPE

User manual

Filet Freezer 804048V

Filet Chiller 804800

Please keep in the McDonald’s store equipment manual for future reference

Page 2

Contents

Warning 3

Introduction 4

Manufacturer’s details 4

Warranty 5

Purchase record 5

Installation 6

Operation 6

Technical information 6

Maintenance 7

Troubleshooting 8

Setting operational temperature MTR12 8

Controller configuration LAE MTR12 9

Controller configuration FK207T 10

Setting operational temperature FK207T 11

Fault codes FK207T 11

Replacement parts 12

Wiring schematic 13

Issue 1:1 31.10.2002

2

Page 3

Warning

Do not operate, maintain or repair the filet freezer without first reading this manual

Care should be taken when moving the unit as it is of considerable

weight

Alteration of the controller may result in operating difficulties

Disconnect power source before maintaining or repairing the unit

Do not steam clean, jet wash or use high-pressure hoses on, or in the

vicinity of, this unit.

A poorly maintained condenser loses its warranty cover and can result in

compressor failure and freezer inefficiency

Repairs should be undertaken by a qualified engineer

Only genuine H&K Ltd replacement parts should be used

Issue 1:1 31.10.2002

3

Page 4

Introduction

The Filet Freezer and Filet Chiller holding cabinets have been specifically

designed for the McDonald’s corporation to hold food products at regulated

temperatures.

Pre-frozen products are held in the Filet freezer at the regulated temperature

of -18°C to -24°C and chilled products are held at 1°C to 4°C in the Filet

Chiller.

Manufacturer’s details

H&K (Rugby)

1 Cosford Lane

Swift Valley

Rugby

CV21 1QN

United Kingdom

Tel: +44 (0) 1788 554000

Fax: +44 (0) 1788 554100

H&K (Dublin)

Cherry Orchard Industrial Estate

Ballyfermont Road

Dublin 10

Ireland

Tel: +353 (1) 6055400

Fax: +353 (1) 6055466

The CE mark indicates that this product complies with the European

requirements on safety, health, environment and customer protection.

Issue 1:1 31.10.2002

4

Page 5

Warranty

Equipment manufactured by H&K Ltd is guaranteed for a period of one year

from date of purchase. H&K Ltd warranty terms covers labour charges and

replacement of defective parts within this period. Claims for defective

equipment will be accepted if the defect is a result of manufacturing error or of

a part’s non-compliance. H&K Ltd does not accept responsibility for defects

caused by the mishandling, abuse or neglect of equipment. Parts replaced

after the one-year period has elapsed are covered under warranty for 90 days.

Purchase record

This information should be entered upon receipt of Filet Freezer/Chiller

Date installed……………………………………

H&K Ltd quality number………………………..

Filet 1

H&K Ltd electrical number……………………..

Date installed……………………………………

H&K Ltd quality number……………………….

Filet 2

H&K Ltd electrical number…………………….

Date installed……………………………………

H&K Ltd quality number……………………….

Filet 3

H&K Ltd electrical number…………………….

These numbers are to the left of the condenser fins – access through the top

access panel (see picture on page 13)

Please quote them in any relevant correspondence

Issue 1:1 31.10.2002

5

Page 6

Installation

Upon receipt of equipment inspect for damage. Any damaged parts should

be reported to H&K Ltd within 24 hours of receiving the unit.

The unit must be kept upright at all times (i.e. in working position) and must

be securely fixed to the wall using the Mounting Bracket provided.

Temperature settings on the controller have been factory pre-set and should

not require adjustment.

Before initial start-up leave the unit to stand for 2 hours without power. This

is to prevent any damage to the internal refrigeration components.

The Product Shelf can be positioned in the unit. The Shelf Brackets can be

adjusted to allow for three different height positions within the unit.

Operation

At daily start-up, after switching on, allow 1 to 2 hours for the unit to reach

operating temperature. The door must be closed during this chill-down period.

Freezer: When operating temperature has been reached (-18 to -24°C), food

product (which must be at least -18°C prior to loading) may be loaded into the

Freezer. Chiller: When operating temperature has been reached (1°C to 4°C),

food product may be loaded into the Chiller.

The exterior of the unit should be cleaned daily with a damp cloth rinsed in a

mild soap and water mixture. Do not use abrasive cleaners as they will

damage the finish of the stainless steel.

The interior of the unit should be cleaned daily, with a mild soap and water

mixture.

Technical information

Dimensions length 780mm x width 470mm x height 895mm

Weight 75kg

Capacity 94 litres

Refrigerant R404A

Refrigerant charge 300 grams

Electrical supply 230V single phase, 50 Hz, 2A running, 6A protection

Issue 1:1 31.10.2002

6

Page 7

Maintenance

Ensure power is disconnected before attempting any maintenance work

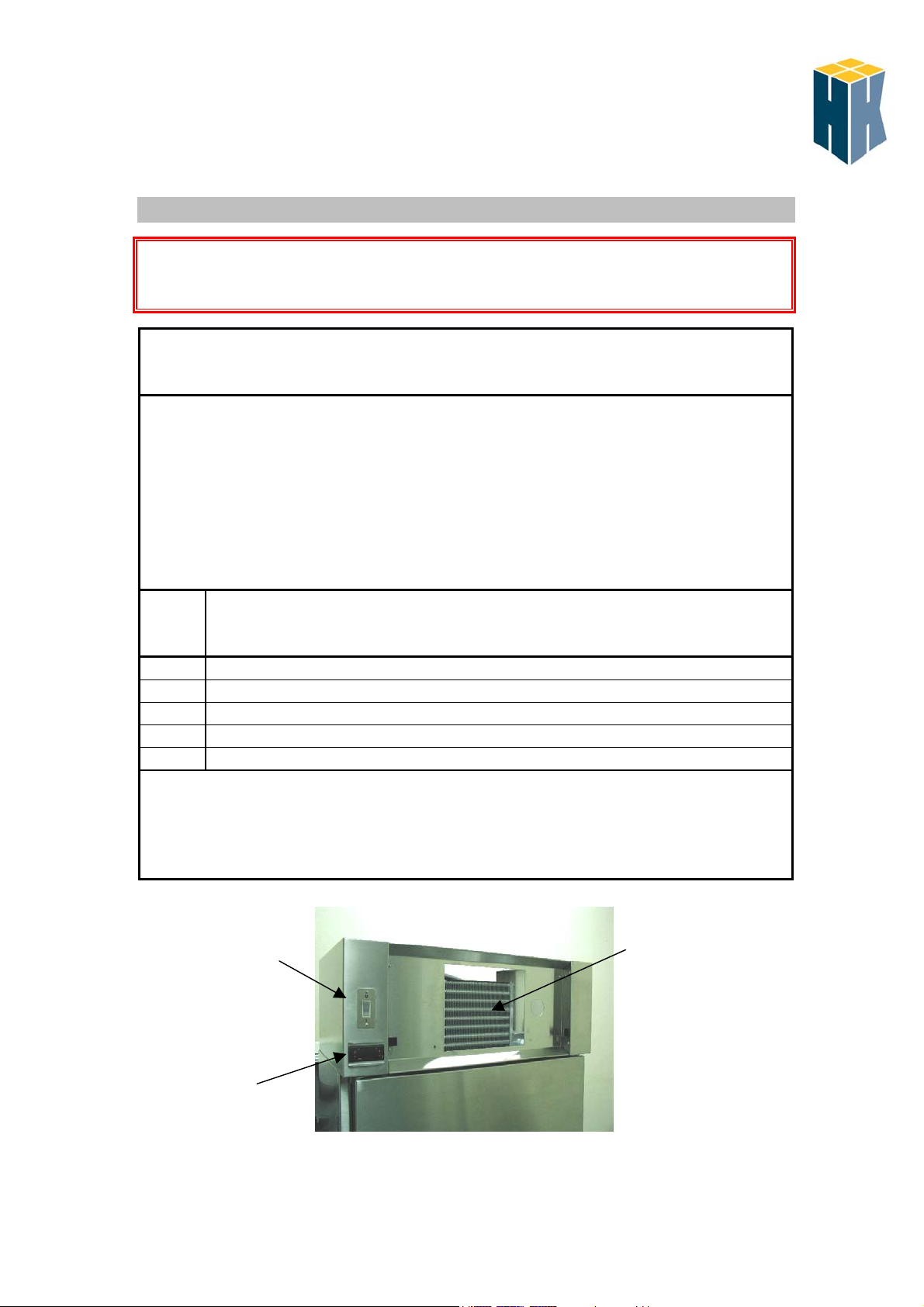

Cleaning the condenser

The condenser (pictured below) must be kept clean in order to maintain a

clear passage through which air may pass. Air is continually drawn through

the condenser fins, along with dust, lint, paper, grease, etc. Do not allow this

dirt to build up and block vision through the fins. A clean condenser will

minimise operating, maintenance and repair expenses.

The condenser fins are likely to require cleaning at least once a month but

the frequency will depend on unit usage and operating conditions.

Step Action

1 Isolate power and unplug the unit

2 Remove the protective grill from the front of the unit

3 Gently brush or vacuum the dirt from the condenser fins

4 Re-align the fins using a fin comb (H&K Ltd part number S06084)

5 Replace the cover panel

If there is a significant dirt build-up that is difficult to remove, contact a

refrigeration service company who will be able blow out the condenser with

pressurised air, CO

or nitrogen.

2

On/off

switch

Controller

Issue 1:1 31.10.2002

Condenser

fins

7

Page 8

Troubleshooting

Problem Cause Repair

Unit will not start

Unit will not reach operating temperature

Issue 1:1 31.10.2002

1. Unit not plugged in

2. No power to unit

(controller display not

1. Plug unit into relevant

socket

2. Check store power supply

(isolator breaker tripped)

illuminated)

3. Unit still not operating

1. Loaded with product prior

to unit reaching operating

temperature. Product

loaded above -18°C.

2. Condenser fins dirty

3. Operating temperature

set point incorrect

4. Unit still not operating

3 Contact service company

1. Remove product until unit

has reached operating

temperature. Ensure

product is at correct

temperature prior to loading.

2. Clean fins (see

Maintenance)

3. Check controller setting

(see Setting operational

4. Contact service company

WARNING!

Electricity can kill

temperature)

Setting operational temperature MTR12

Setting the operating temperature of the unit

Unit must be switched on

Press

Filet Freezer Filet Chiller

Set

Adjust display

(¿ and À keys)

to read

-24 01

8

Page 9

Information for service company

LAE MTR12 controller configuration

Read following instructions fully before commencing any alterations

Set key

Display

Step Press Display

Programming the controller to the Filet Freezer and Chiller units

Commence with unit switched off

Adjust display

(¿ and À keys)

reads

Press Display

reads

Adjustment

to read

keys

Filet Freezer Filet Chiller

1 ¿ and À

simultaneously,

hold both and

switch unit on.

2 Set USP Set previous

3 Set ∩SP Set previous

4 Set RT1 Set previous

5 Set PF1 Set previous

6 Set ADJ Set previous

7 Set HY1 Set previous

8 Set - - - - -

On completion of the preceding steps the controller will adopt the new settings once the unit is

PAR -

-

-

-24

setting

(sets lowest

temperature)

-24

setting

(sets high point)

2

setting

(sets for delayed

start)

Off

setting

(switches off unit

if probe fails )

-4

setting

3

setting

switched off and then switched back on again.

(minimises

temperature

overshoot)

-

00

(sets lowest

temperature)

02

(sets high point)

2

(sets for delayed

start)

Off

(switches off unit

if probe fails )

00

2

(minimises

temperature

overshoot)

Issue 1:1 31.10.2002

9

Page 10

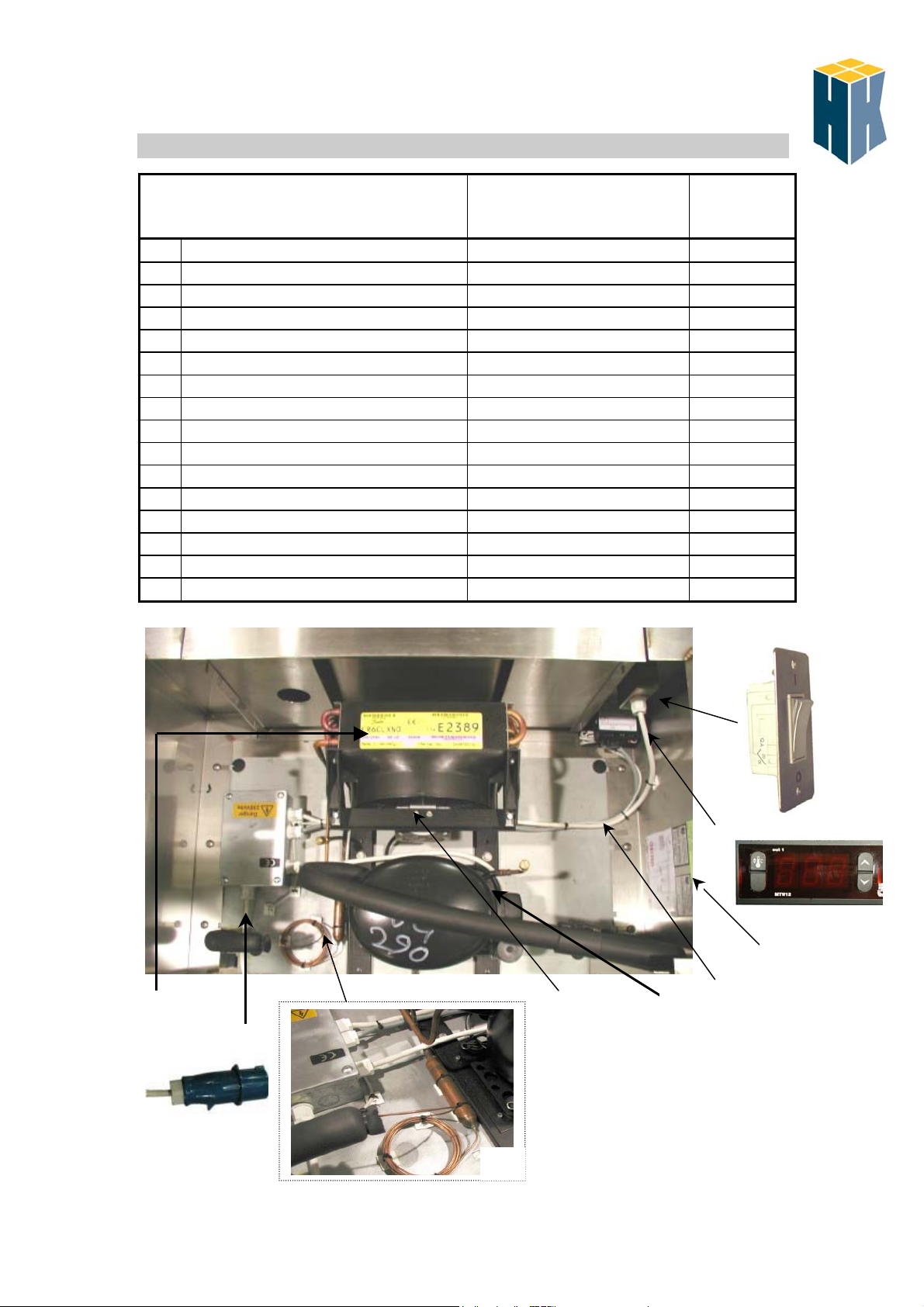

Read following instructions fully before commencing any alterations

Display

Set key

If before all of the proceeding steps are completed no key action is detected for 60 seconds

the controller will revert back to its running mode.

Step Press Display

1

2

¿ and À

simultaneously and

hold for approx. 4sec.

¿ and À

simultaneously

hold for approx. 4sec.

3 À key

4 À key

5 À key

6 À key

7 À key

8 À key

9 À key

10 À key

11 À key

12 À key

13 À key

On completion of the proceeding steps press ¿ and À keys simultaneously. The controller will

Issue 1:1 31.10.2002

FK 207T Controller configuration

Programming the controller

Commence with the unit switched on

Press Display

reads

PA

/ 1

/ 6

r0

r1

r2

c2

c7

c8

c9

d0

d3

d6

Set

Set

Set

Set

Set

Set

Set

Set

Set

Set

Set

Set

Set

adopt the new settings.

reads

0

previous

setting

previous

setting

previous

setting

previous

setting

previous

setting

previous

setting

previous

setting

previous

setting

previous

setting

previous

setting

previous

setting

previous

setting

Adjust display

(¿ and À keys)

to read

FREEZER UNIT

Adjustment keys

Adjust display

(¿ and À keys)

to read

-19

-32

CHILLER UNIT

-19

-32

0 0

3 2

-24 0

-24 2

2 2

90 90

100 100

1 1

0 0

0 0

1 1

10

Page 11

Setting the operating temperature FK207T

Press and hold Set key

Unit must be switched on

Adjust ¿ and Àkey

Fault codes FK207T

Adjustment

parameters

FREEZER

UNIT

-24°C

CHILLER

UNIT

01°C

This new controller has a fault indication program that aid’s in

recognising problem’s that may occur with the refrigeration aspects.

A simple code, listed below, will show on the controller display.

Code Reasons Remedies

E2

Corrupted

memory

data

E0

Cabinet

probe

alarm

E1

Evaporator

probe

alarm

COH

CSd

Issue 1:1 31.10.2002

• There is the

• Probe type incorrect

• Probe fault

• Probe type incorrect

• Probe fault

• The evaporator

• Condenser fins dirty

• The condenser

• Condenser fins dirty

• The condenser

corruption of the

configuration data of

the memory of the

instrument

temperature is

outside the limits of

the controller

temperature is

outside the limit set

within the parameter

C7

temperature is

outside the limit set

within the parameter

C8

• Switch off the power supply for 2minutes.

Reconnect the power supply; if error code still

displayed replace the unit.

• Fit correct probe type

• Check probe connections

• Fit correct probe type

• Check probe connections

• Test the temperature close to the probe to

ensure its between the set operating range

• Clean the condenser fins (see page 7)

• Check temperature close to the probe and

adjust parameter C7

• Clean the condenser (See page 7)

• Turn unit off

• Check temperature close to the probe and

adjust parameter C8

11

Page 12

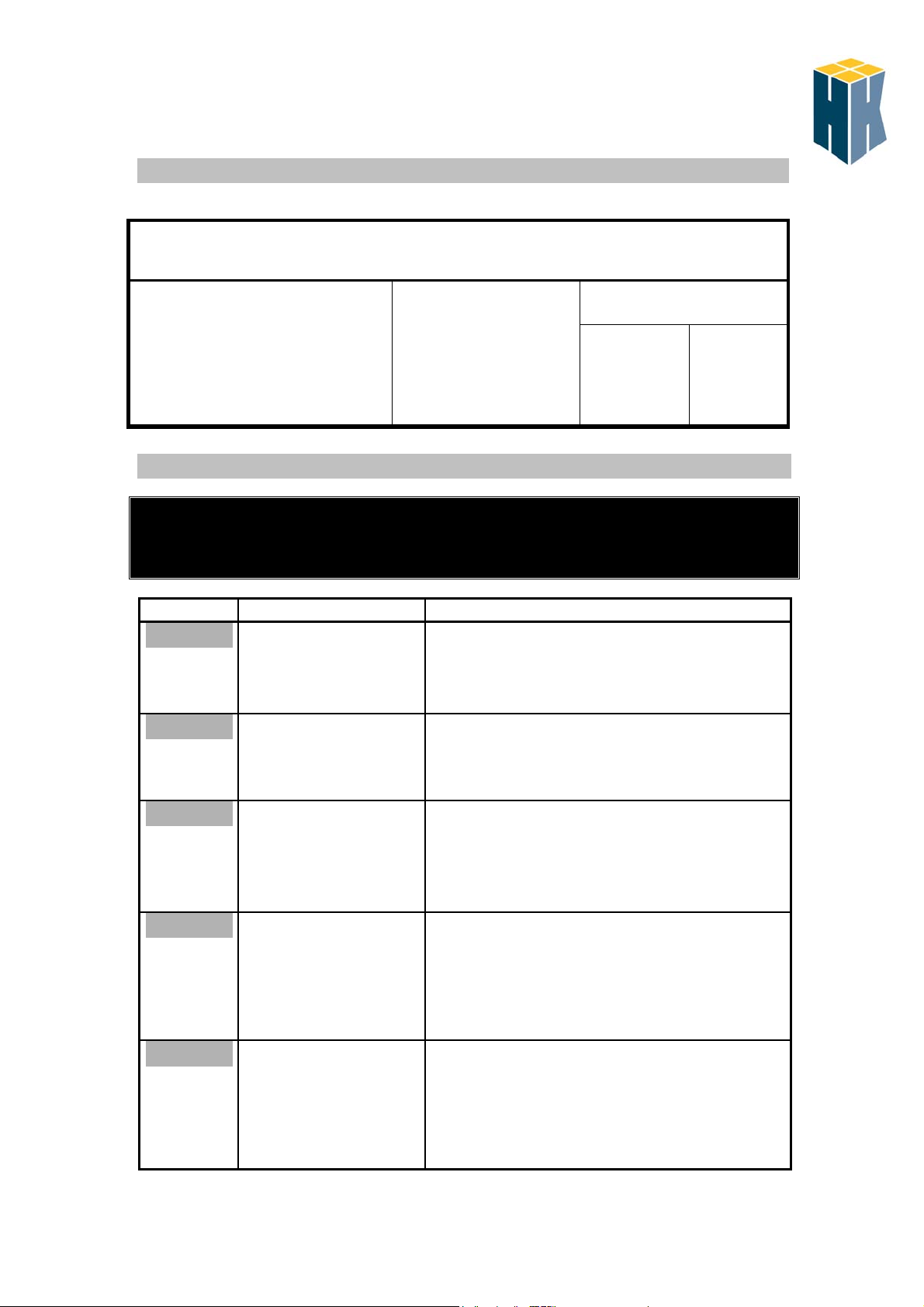

Description

On/off Switch E11020 1

1

LAE MTR12 Controller (Freezer) 1000-R02010 1

2

LAE MTR12 Controller (Chiller) 1002-R02010 1

2

Fk207T controller (Freezer) 1000-R02012 1

2

Fk207T controller (Chiller) 1001-R02012 1

2

Probe R02009 1

3

Compressor R01112 1

4

Capillary Tube and Drier R01201 1

5

Condenser Fan Motor R01020 1

6

Condenser Fan Blade R01021 1

7

Mains Cable E06126 3m

8

Plug E10021 1

9

Compressor assembly number - -

10

Quality and electrical numbers - -

11

Internal fan E20007 1

Door Gasket T03084 2

10

8 & 9

Replacement parts

Part number

6 & 7 4

5

Quantity

1

2

11

3

Issue 1:1 31.10.2002

12

Page 13

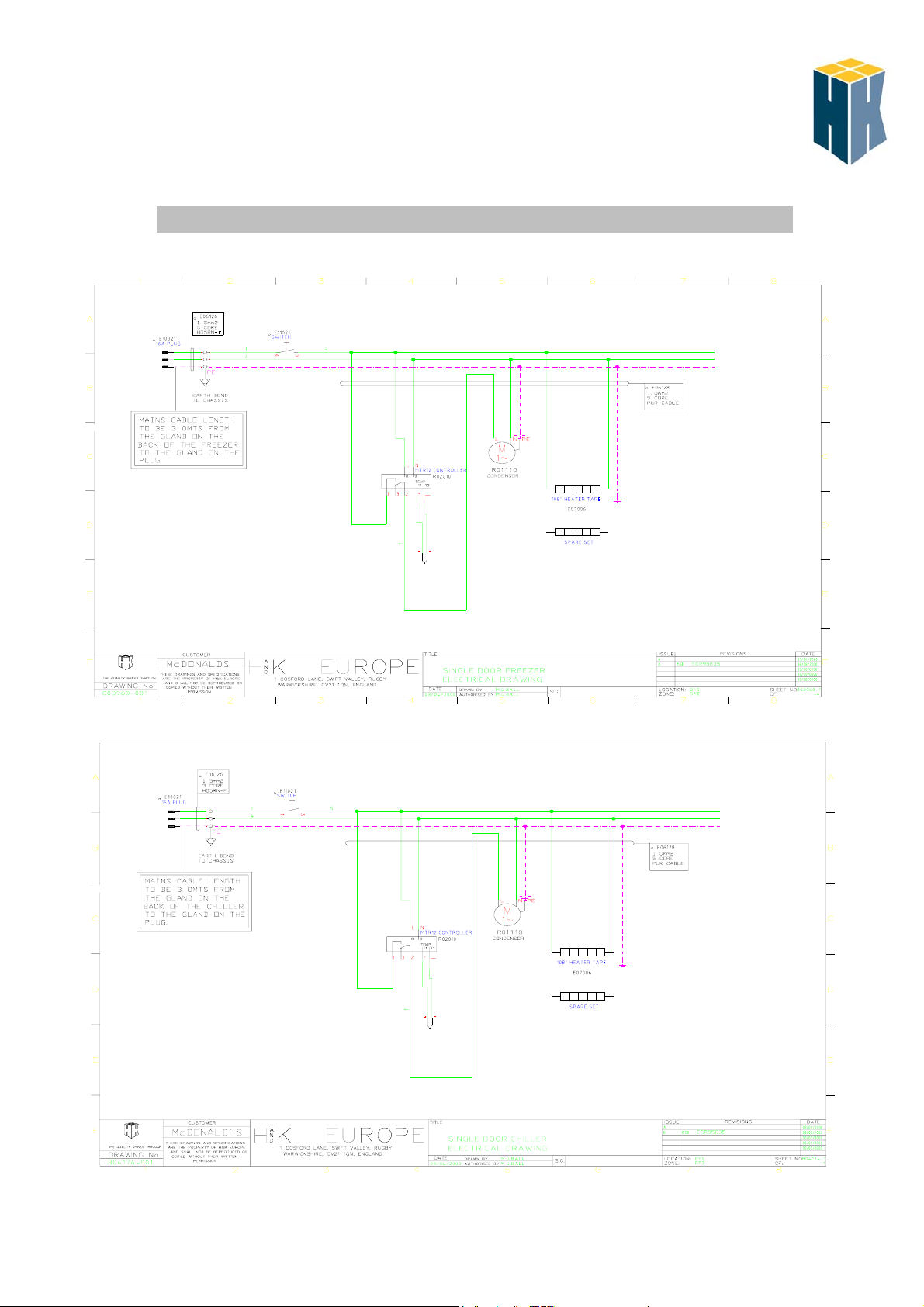

Freezer

Wiring schematic

Chiller

Issue 1:1 31.10.2002

13

Loading...

Loading...