Page 1

SP-520 PLUS Electronic Speed Controller

Thank you for purchasing the HITEC SP-520 PLUS electronic speed controller

with reverse. This unit features competition grade performance with reversing speeds

in a fully proportional mode. It can handle stock and modified class motors, with

internal TEMPFET sensors to prevent overheating and damaging the unit.

Additionally, the unit is polarity protected to prevent damage in the case of an

accidental reversed hook-up. The SP-520 has the highest power output and best

power transfer efficiency in its class.

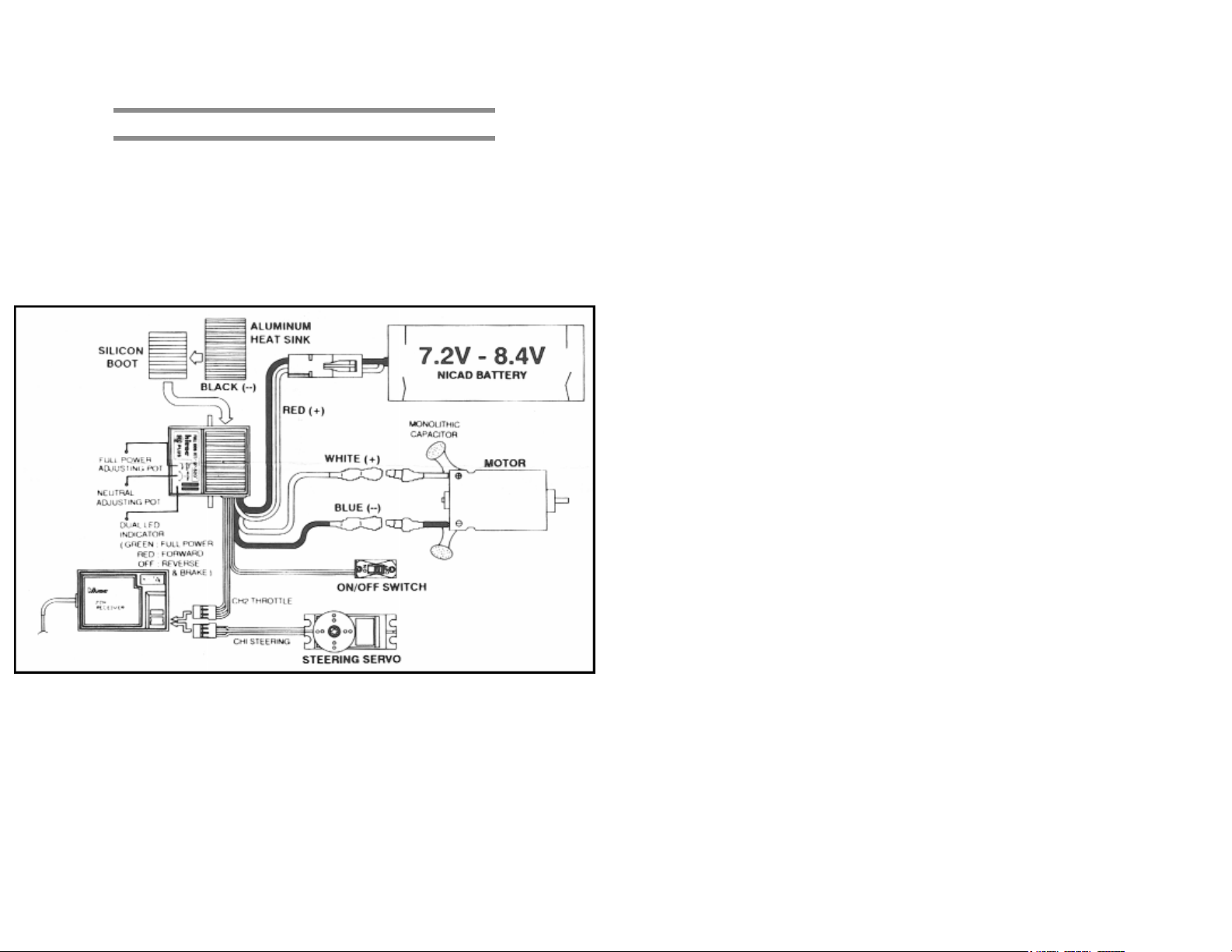

WIRING DIAGRAM

FEATURES

•

MOSFETs provide high effciency with minimum power loss.

• TEMPFET protction prevenst damge due to overheating.

• Wide operating range of 6.0 to 8.4 volts with BEC. (5-7 cells)

• Light weight aluminum heatsink with new patented heat conductive silicon

boot. (PAT # 4528)

• Polarity protected circuit.

• Reverse delayed system (0.45 second delay time)

SPECIFICATIONS

FORWARD REVERSE

• Peak amperage capability 560A 240A

• Continuous amperage capability 140A 60A

• Voltage loss 0.0125 ohm 0.025 ohm

• BEC voltage output 5.6V

• TEMPFET cutoff point 250 degrees F (120 C)

• Dimensions 1.77x2.16x0.78 inch (45x55x20mm)

• Weight (with heat sink) 2.6oz (75g)

INSTALLING THE SP-520 POWER

1. MOUNTING LUGS

Installation of the SP-520 is made easy for the car driver with the use of the servo

style mounting lugs. These lugs are also removable by separating the case halves of

the contoller and allowing the mounting lugs to slide out.

2. CONNECTORS

If you have TAMYIA style connectors on your car, the SP-520 will be an exact match

for you. However, if you choose to use different connectors for your SP-520, please

see the section of these instructions which describe the wiring diagram and how to

hookup the SP-520.

3. MOUNTING & CONNECTING

Mount the SP-520 into place within the chassis of your car, using the mounting lugs

or double sided tape on the back of the case. Please insure that the controller is

securely held in place. Once the controller is in place, disconnect the motor wires and

connect the main battery wires from the car battery to the controller.

Note: Always check the polarity of the wires prior to plugging in the battery to the

controller. Reversing the polarity may result in damage to the controller, despite the

reverse polarity protection within the SP-520. If you do accidentally connect the

controller in reverse polarity, immediately disconnect the wires and allow the

controller to rest for at least one minute. Check for the correct polarity and then

reconnect the main battery wires using the correct polarity. The SP-520 should now

operate normally.

Once the main battery and controller are connected, turn the car radio and

transmitter to the “ON” position. Check to see if the red or green indicator light on the

SP-520 comes “ON” when you advance the throttle stick forward. If not, the

transmitter reversing switch should be used to correct the direction. Check the

operation of the steering servo for proper movement too. If the radio functions

correctly, place the car on a block or car stand so that the rear wheels are not touching the ground. Connect the motor wires and be aware that the motor may begin

running at this time.

Page 2

4. NEUTRAL SETTING

If the motor begins running, you must set the neutral position of the controller. Make

sure you set the throttle on the transmitter to neutral and the trim lever for throttle in

the middle. Using the supplied tuning wand, insert the wand into the neutral

adjustment hole on the SP-520 controller. Slowly turn the neutral controller

potentiometer one direction or the other until the motor stops, and the red indicator

light on the controller just goes out. This is the correct position for the neutral

adjustment. The motor should now move the wheels in the correct direction when the

red or green indicator light comes “ON” while advancing the throttle stick forward. If

yes, the motor wires were cross connected. Correct it by changing the polarity of the

motor wires in reverse. If no light comes “ON”, correct the direction by using the

reversing switch of the transmitter.

5. HIGH SPEED SETTING

To adjust the high speed setting, again disconnect the motor wires. With the motor

disconnected, give the throttle on the transmitter full throttle position. You should see

a green light on the SP-520 controller. If not, use the tuning wand to adjust the “FULL

POWER” potentiometer until the light comes “ON” when full power is commanded

from the transmitter. To take full advantage of the power band of the SP-520, adjust

the full power setting so that the green light will come only when the very last bit of

throttle is added to the transmitter. This will give you a broad mid-range power band

which allows far better control of the car. You may now reconnect the motor to the car.

6. REVERSE

To use the reverse function of the SP-520 PLUS, simply move the throttle stick or

trigger on your transmitter the opposite direction of full throttle. There will be a very

slight delay before reverse power is applied to the motor from the controller, and this

is to prevent damage to the gears of the car. If you cannot get the reverse speeds to

work, you may have to readjust the throttle position on the transmitter to allow for

additional movement in the reverse direction.

TEMPFET PROTECTION

Your SP-520 controller is protected from overheating by a built in TEMPFET device.

The TEMPFET is designed to prevent the controller from being damaged due to

excessive heat. Some high performance modified motors and running a car in grass,

mud or deep sand can cause the motor to work very hard. This causes overheating to

the motor, controller and batteries. Should you overheat the SP-520, it will

automatically stop the car until the controller cools down. If you should experience

this, you should take the time to find the cause of the car working so hard. This could

be dragging parts, jammed wheels, too tight of a gear mesh, and broken parts. Always

check the car carefully before continuing to run the car. The SP-520 will return to

normal operation in a few minutes.

ALUMINUM HEAT SINK AND SILICON BOOT

In any case where high speed running is done, rough terrain is encountered, or high

powered motors are used, always place the aluminum heatsink on the controller to

assit in cooling the controller. The SP-520 will be more efficient when it runs cooler.

Also, the SP-520 has a silicon heatsink boot which not only helps the heatsink to

attach to the controller, but it also transfers the heat away from the controller and

keeps the MOSFETs separated. Please leave the silicon boot in place at all times.

ADDITIONAL TIPS

1. MONOLITHIC CAPACITORS

Motors on model cars generate static electricity which interfere with radio control

equipment. To prevent this from happening, it is necessary to place at least two (2)

monolithic capacitors to the motor of the car. These are supplied with the SP-520.

Solder one end of a capacitor to the positive (+) pole of the motor endbell and the

other end to metal casing of the motor. With the second capacitor, solder one end to

the negative (-) pole of the motor endbell to the same place on the casing as the first

capacitor.

2. AIR CIRCULATION

You can expect some heat to be felt by the heatsink of the SP-520. This is quite

normal. Because the SP-520 operates more efficient when it is cool, always place the

controller on the car chassis in a position where it will receive plenty of air circulation.

3. POWER LOSS PROTECTION

Although the connectors on the SP-520 are already mounted to the 15 gauge wires,

we recommend that you keep the wires as short as possible to get best results. If you

are capable of soldering these wires, the best connection possible will be to connect

the motor wires directly to the motor, leaving the bullet style motor wire connectors off

completely.

ALTERNATE WIRING AND WIRING DIAGRAM

The SP-520 can be adapted for use with other wire connectors. If you find that you

must change the connectors, please study the wiring diagram carefully. The red wire

is for battery positive (+), the black is battery negative (-), white is motor positive (+)

and blue is motor negative (-). The receiver connector is suitable for use with

FUTABA, JR PROPO, and HITEC systems. When changing connectors, always use

a high grade rosin core solder only, and insulate all connections with heat shrink

tubing. Now, go hit the track and good racing!

Loading...

Loading...