WJ200

Series Inverter

Instruction Manual

• Single-phase Input 200V class

• Three-phase Input 200V class

• Three-phase Input 400V class

Manual Number: NT325X

May 2010

Hitachi Industrial Equipment Systems Co., Ltd.

After read this manual,

Keep it handy for future reference.

Safety Messages

For the best results with the WJ200 Series inverter, carefully read this manual and all

of the warning labels attached to the inverter before installing and operating it, and

follow the instructions exactly. Keep this manual handy for quick reference.

Definitions and Symbols

A safety instruction (message) includes a “Safety Alert Symbol” and a signal word or

phrase such as WARNING or CAUTION. Each signal word has the following meaning:

HIGH VOLTAGE: This symbol indicates high voltage. It calls your attention to items or

operations that could be dangerous to you and other persons operating this equipment.

Read the message and follow the instructions carefully.

WARNING: indicates a potentially hazardous situation that, if not avoided, can result in

serious injury or death.

CAUTION: Indicates a potentially hazardous situation that, if not avoided, can result in

minor to moderate injury or serious damage to the product. The situation described in

the CAUTION may, if not avoided, lead to serious results. Important safety measures

are described in CAUTION (as well as WARNING), so be sure to observe them.

Step 1: Indicates a step in a series of action steps required to accomplish a goal. The

number of the step will be contained in the step symbol.

NOTE: Notes indicates an area or subject of special merit, emphasizing either the

product’s capability or common errors in operation or maintenance.

TIP: Tips give a special instruction that can save time or provide other benefits while

installing or using the product. The tip calls attention to an idea that may not be

obvious to first-time users of the product.

i

Hazardous High Voltage i

HIGH VOLTAGE: Motor control equipment and electronic controllers are connected to

hazardous line voltages. When servicing drives and electronic controllers, there may be

exposed components with housing or protrusions at or above line potential. Extreme

care should be taken to protect against shock.

Stand on an insulating pad and make it a habit to use only one hand when checking

components. Always work with another person in case an emergency occurs. Disconnect

power before checking controllers or performing maintenance. Be sure equipment is

properly grounded. Wear safety glasses whenever working on electronic controllers or

rotating machinery.

Caution when using Safe Stop Function

When using Safe Stop function, make sure to check whether the safe stop function

properly works when installation (before starting operation). Please carefully refer to

page Appendix E

ii

General Precautions – Read These First!

WARNING: This equipment should be installed, adjusted, and serviced by qualified

electrical maintenance personnel familiar with the construction and operation of the

equipment and the hazards involved. Failure to observe this precaution could result in

bodily injury.

WARNING: The user is responsible for ensuring that all driven machinery, drive train

mechanism not supplied by Hitachi Industrial Equipment Systems Co., Ltd., and

process line material are capable of safe operation at an applied frequency of 150% of

the maximum selected frequency range to the AC motor. Failure to do so can result in

destruction of equipment and injury to personnel should a single-point failure occur.

WARNING: For equipment protection, install a ground leakage type breaker with a fast

response circuit capable of handling large currents. The ground fault protection circuit

is not designed to protect against personal injury.

WARNING: HAZARDOUS OF ELECTRICAL SHOCK. DISCONNECT INCOMING

POWER BEFORE WORKING ON THIS CONTROL.

WARNING: Wait at least five (5) minutes after turning OFF the input power supply

before performing maintenance or an inspection. Otherwise, there is the danger of

electric shock.

CAUTION: These instructions should be read and clearly understood before working on

WJ200 series equipment.

CAUTION: Proper grounds, disconnecting devices and other safety devices and their

location are the responsibility of the user and are not provided by Hitachi Industrial

Equipment Systems Co., Ltd.

CAUTION: Be sure to connect a motor thermal disconnect switch or overload device to

the WJ200 series controller to assure that the inverter will shut down in the event of an

overload or an overheated motor.

HIGH VOLTAGE: Dangerous voltage exists until power light is OFF. Wait at least five

(5) minutes after input power is disconnected before performing maintenance.

WARNING: This equipment has high leakage current and must be permanently (fixed)

hard-wire to earth ground via two independent cables.

WARNING: Rotating shafts and above-ground electrical potentials can be hazardous.

Therefore, it is strongly recommended that all electrical work conform to the National

Electrical Codes and local regulations. Installation, alignment and maintenance should

be performed only by qualified personnel.

CAUTION:

a) Class I motor must be connected to earth ground via low resistive path (<0.1)

b) Any motor used must be of a suitable rating.

c) Motors may have hazardous moving path. In this event suitable protection must be

provided.

CAUTION: Alarm connection may contain hazardous live voltage even when inverter is

disconnected. When removing the front cover for maintenance or inspection, confirm

that incoming power for alarm connection is completely disconnected.

CAUTION: Hazardous (main) terminals for any interconnection (motor, contact breaker,

filter, etc.) must be inaccessible in the final installation.

CAUTION: This equipment should be installed in IP54 or equivalent (see EN60529)

enclosure. The end application must be in accordance with BS EN60204-1. Refer to the

section “Choosing a Mounting Location” on page 2-7

suitably amended for your application.

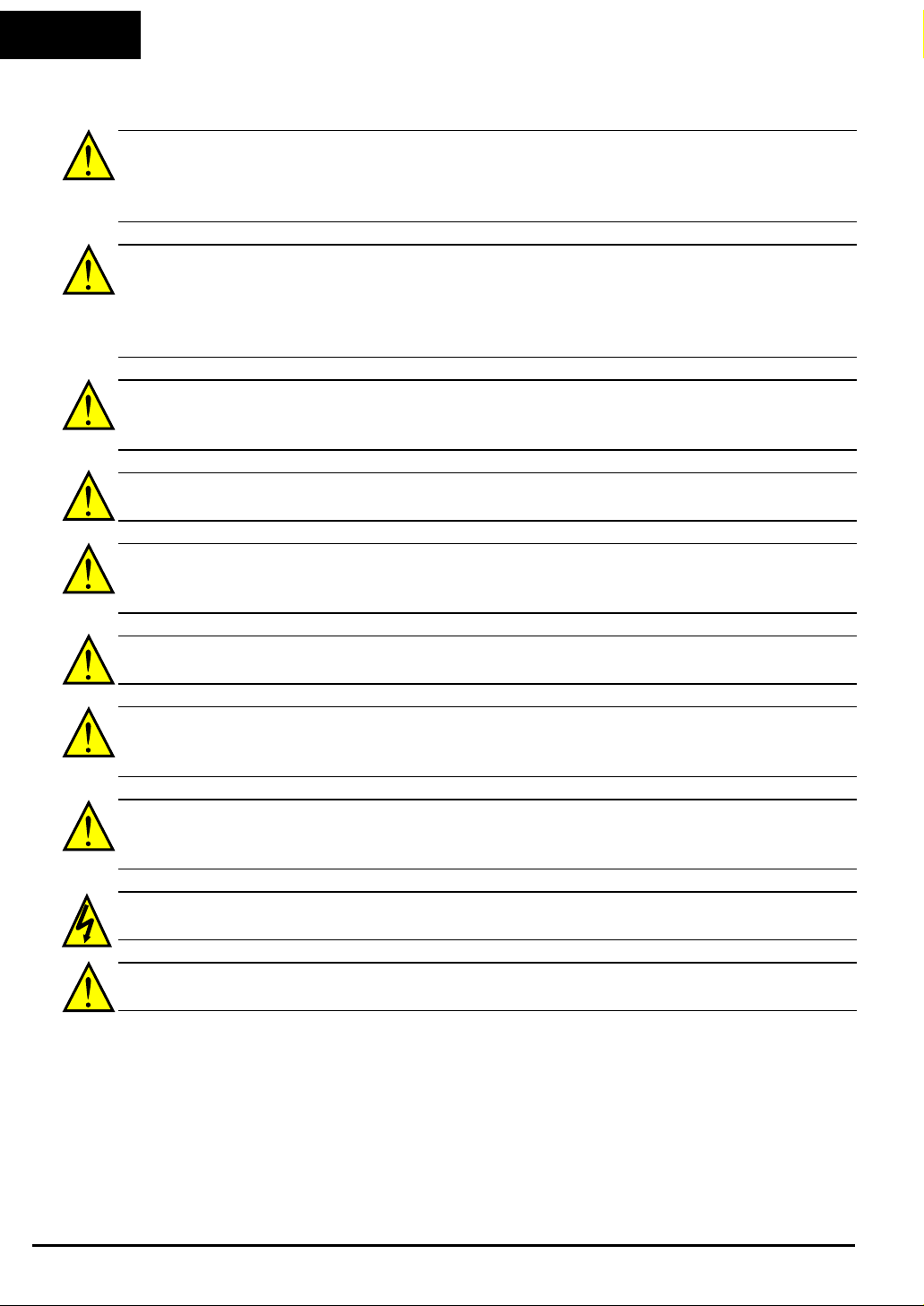

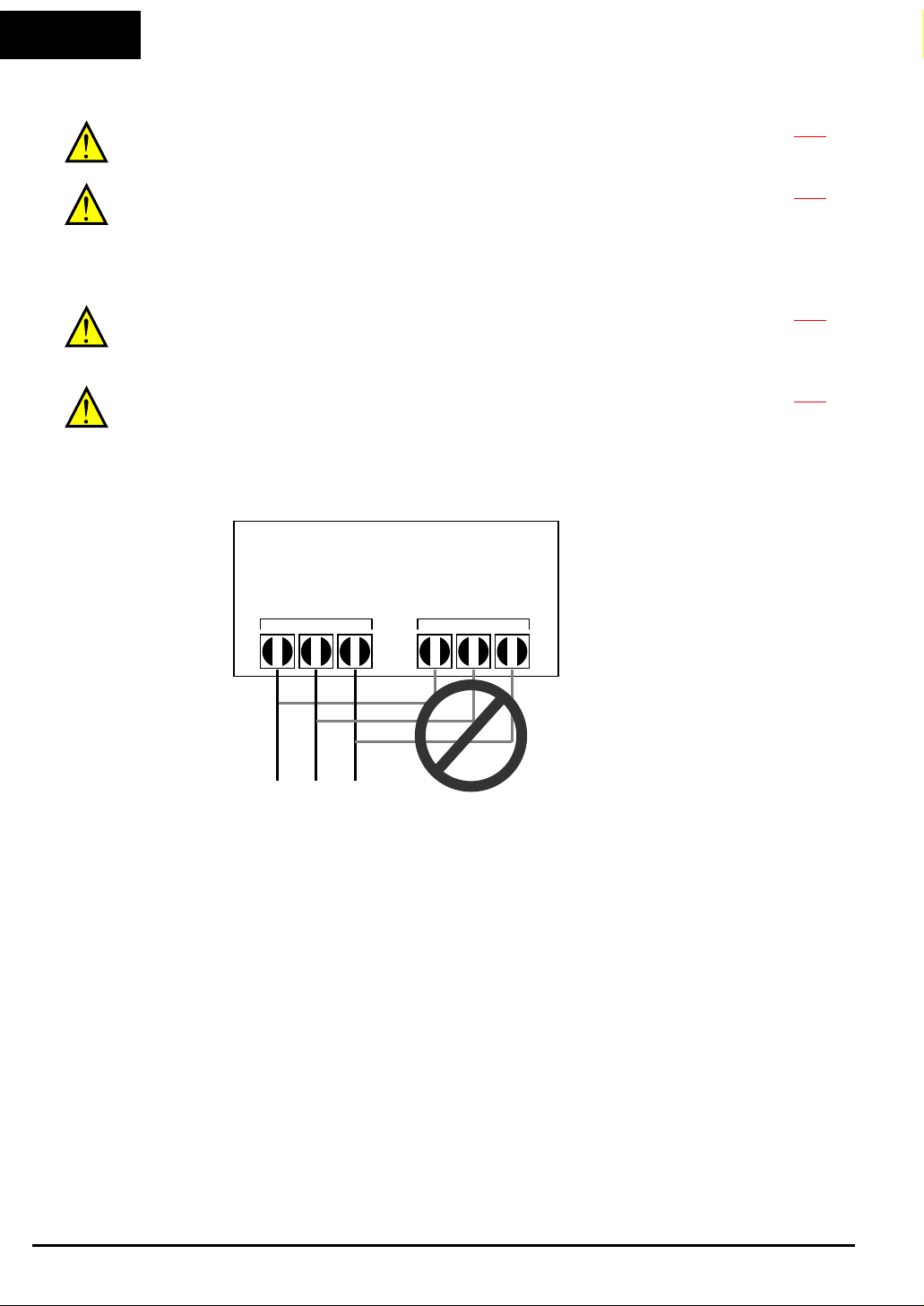

CAUTION: Connection to field wiring terminals must be reliably fixed having two

independent means of mechanical support. Use a termination with cable support (figure

below), or strain relief, cable clamp, etc.

CAUTION: A double-pole disconnection device must be fitted to the incoming main

power supply close to the inverter. Additionally, a protection device meet IEC947-1/

IEC947-3 must be fitted at this point (protection device data shown in “Determining

Wire and Fuse Sizes” on page 2-16).

NOTE: The above instructions, together with any other requirements highlighted in

this manual, must be followed for continue LVD (European Low Voltage Directive)

compliance.

. The diagram dimensions are to be

iii

iv

Index to Warnings and Cautions in This Manual iv

Cautions and Warnings for Orientation and Mounting Procedures

HIGH VOLTAGE: Hazard of electrical shock. Disconnect incoming power before

working on this control. Wait five (5) minutes before removing the front cover.

HIGH VOLTAGE:

Hazard of electrical shock. Never touch the naked PCB

(printed circuit board) portions while the unit is powered up. Even for switch

portion, the inverter must be powered OFF before you change.

WARNI NG : In the cases below involving a general-purpose inverter, a large peak

current can flow on the power supply side, sometimes destroying the converter module:

1. The unbalance factor of the power supply is 3% or higher.

2. The power supply capacity is at least 10 times greater than the inverter capacity (or

the power supply capacity is 500kVA or more).

3. Abrupt power supply changes are expected, due to the conditions such as:

a. Several inverters are interconnected with a short bus.

b. A thyristor converter and an inverter are interconnected with a short bus.

c. An installed phase advance capacitor opens and closes.

CAUTION: Be sure to install the unit on flame-resistant material such as a steel plate.

Otherwise, there is the danger of fire.

CAUTION: Be sure not to place any flammable materials near the inverter. Otherwise,

there is the danger of fire.

CAUTION: Be sure not to let the foreign matter enter vent openings in the inverter

housing, such as wire clippings, spatter from welding, metal shavings, dust, etc.

Otherwise, there is the danger of fire.

CAUTION: Be sure to install the inverter in a place that can bear the weight according

to the specifications in the text (Chapter 1, Specifications Tables). Otherwise, it may fall

and cause injury to personnel.

CAUTION: Be sure to install the unit on a perpendicular wall that is not subject to

vibration. Otherwise, it may fall and cause injury to personnel.

CAUTION: Be sure not to install or operate an inverter that is damaged or has missing

parts. Otherwise, it may cause injury to personnel.

CAUTION: Be sure to install the inverter in a well-ventilated room that does not have

direct exposure to sunlight, a tendency for high temperature, high humidity or dew

condensation, high levels of dust, corrosive gas, explosive gas, inflammable gas,

grinding-fluid mist, salt damage, etc. Otherwise, there is the danger of fire.

CAUTION: Be sure to maintain the specified clearance area around the inverter and to

provide adequate ventilation. Otherwise, the inverter may overheat and cause

equipment damage or fire.

…2-3

…2-4

…2-8

…2-9

…2-9

…2-9

…2-9

…2-9

…2-9

…2-9

…2-10

v

Wiring – Warnings for Electrical Practice and Wire Specifications

WARNI NG : “USE 60/75C Cu wire only” or equivalent. For models WJ200-001L, -002L,

-004L, -007L, -015S, -022S, -004H, -007H, -015H, -022H and -030H.

WARNI NG : “USE 75C Cu wire only” or equivalent. For models WJ200-001S, -002S,

-004S, -007S, -015L, -022L, -037L, -055L, -075L, -110L, -150L, -037H, -040H, -055H,

-075H, -110H and -150H.

WARNI NG : “Open Type Equipment.”

WARNI NG : “Suitable for use on a circuit capable of delivering not more than 100k rms

symmetrical amperes, 240V maximum when protected by Class CC, G, J or R fuses or

circuit breaker having an interrupting rating not les than 100,000 rms symmetrical

amperes, 240 volts maximum”. For models with suffix S, N or L.

WARNI NG : “Suitable for use on a circuit capable of delivering not more than 100k rms

symmetrical amperes, 480V maximum when protected by Class CC, G, J or R fuses or

circuit breaker having an interrupting rating not les than 100,000 rms symmetrical

amperes, 480 volts maximum.” For models with suffix H.

HIGH VOLTAGE: Be sure to ground the unit. Otherwise, there is a danger of electric

shock and/or fire.

HIGH VOLTAGE: Wiring work shall be carried out only by qualified personnel.

Otherwise, there is a danger of electric shock and/or fire.

HIGH VOLTAGE: Implement wiring after checking that the power supply is OFF.

Otherwise, you may incur electric shock and/or fire.

HIGH VOLTAGE: Do not connect wiring to an inverter operate an inverter that is not

mounted according to the instructions given in this manual.

Otherwise, there is a danger of electric shock and/or injury to personnel.

WARNI NG : Make sure the input power to the inverter is OFF. If the drive has been

powered, leave it OFF for five minutes before continuing.

CAUTION: Power terminal assignment is different compared to old models such as

L100, L200 series, etc,. Pay attention when wiring the power cable.

…2-18

…2-18

…2-18

…2-18

…2-18

…2-18

…2-18

…2-23

…2-11

~21

vi

Wiring – Cautions for Electrical Practice

CAUTION: Fasten the screws with the specified fastening torque in the table

below. Check for any loosening of screws. Otherwise, there is the danger of fire.

CAUTION: Be sure that the input voltage matches the inverter specifications;

Single phase 200V to 240V 50/60Hz (up to 2.2kW) for SFEF model

Single/Three phase 200V to 240V 50/60Hz (up to 2.2kW) for NFU model

Three phase 200V to 240V 50/60Hz (7.5kW) for LFU model

Three phase 380V to 480V 50/60Hz (up to 7.5kW) for HFx model

CAUTION: Be sure not to power a three-phase-only inverter with single phase

power. Otherwise, there is the possibility of damage to the inverter and the danger

of fire.

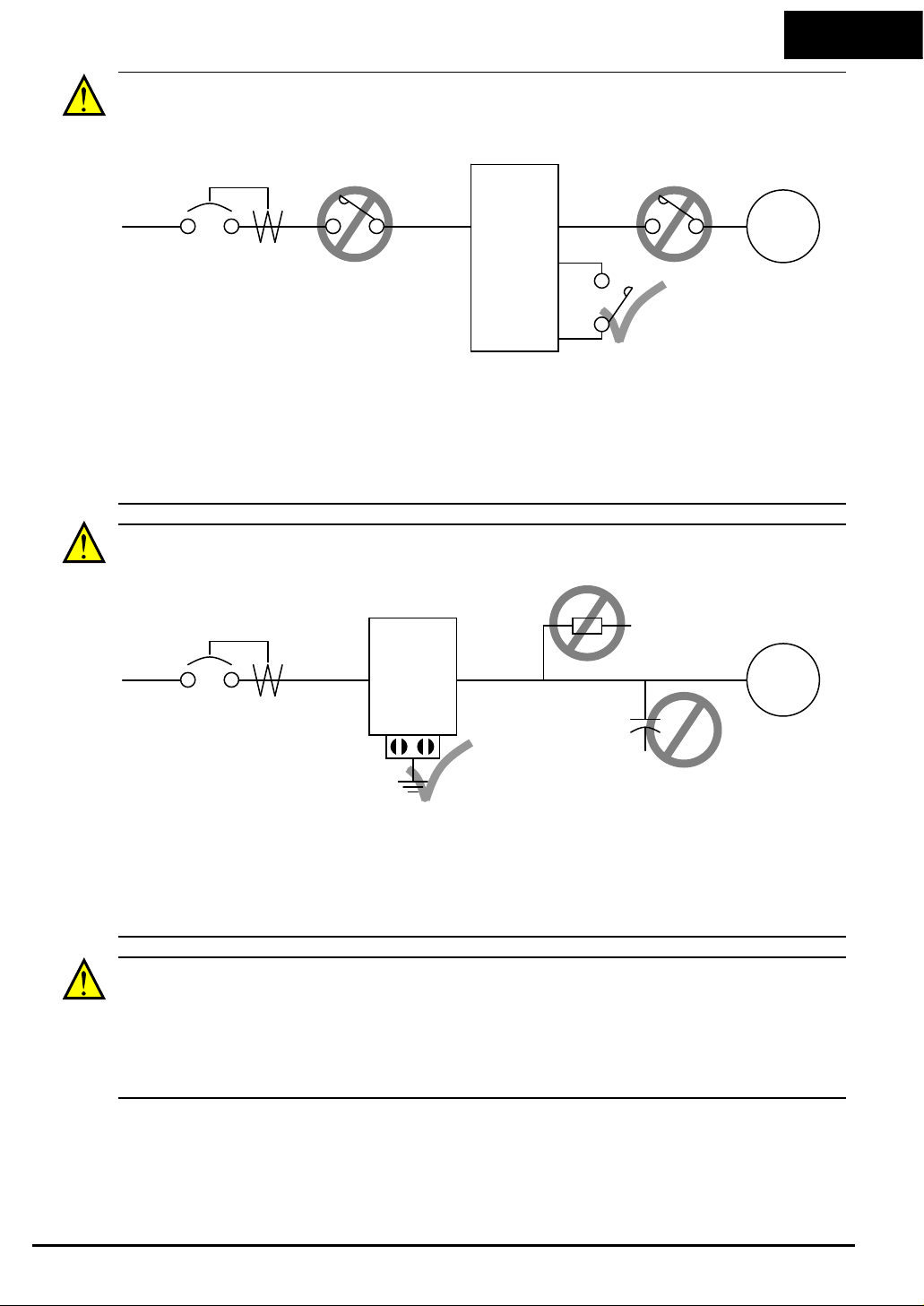

CAUTION: Be sure not to connect an AC power supply to the output terminals.

Otherwise, there is the possibility of damage to the inverter and the danger of

injury and/or fire.

WJ200 Inverter

Output to Motor

Power Input

… 2-18

… 2-20

… 2-20

… 2-20

Powerup Test Caution Messages

CAUTION: Remarks for using ground fault interrupter breakers in the main

power supply: Adjustable frequency inverter with integrated CE-filters and

shielded (screened) motor cables have a higher leakage current toward earth GND.

Especially at the moment of switching ON this can cause an inadvertent trip of

ground fault interrupters. Because of the rectifier on the input side of the inverter

there is the possibility to stall the switch-off function through small amounts of DC

current.

Please observe the following:

Use only short time-invariant and pulse current-sensitive ground fault

interrupters with higher trigger current.

Other components should be secured with separate ground fault interrupters.

Ground fault interrupters in the power input wiring of an inverter are not an

absolute protection against electric shock.

CAUTION: Be sure to install a fuse in each phase of the main power supply to the

inverter. Otherwise, there is the danger of fire.

CAUTION: For motor leads, ground fault interrupter breakers and

electromagnetic contactors, be sure to size these components properly (each must

have the capacity for rated current and voltage). Otherwise, there is the danger of

fire.

CAUTION: The heat sink fins will have a high temperature. Be careful not to

touch them. Otherwise, there is the danger of getting burned.

CAUTION: The operation of the inverter can be easily changed from low speed to

high speed. Be sure to check the capability and limitations of the motor and

machine before operating the inverter. Otherwise, there is the danger of injury.

CAUTION: If you operate a motor at a frequency higher than the inverter

standard default setting (50Hz/60Hz), be sure to check the motor and machine

specifications with the respective manufacturer. Only operate the motor at

elevated frequencies after getting their approval. Otherwise, there is the danger of

equipment damage and/or injury.

CAUTION: Check the following before and during the Powerup test. Otherwise,

there is the danger of equipment damage.

Is the shorting bar between the [+1] and [+] terminals installed? DO NOT power

or operate the inverter if the jumper is removed.

Is the direction of the motor rotation correct?

Did the inverter trip during acceleration or deceleration?

Were the rpm and frequency meter readings as expected?

Were there any abnormal motor vibration or noise?

… 2-20

… 2-20

… 2-20

… 2-23

… 2-23

… 2-23

… 2-29

… 2-23

vii

viii

Warnings for Configuring Drive Parameters

Cautions for Configuring Drive Parameters

Warnings for Operations and Monitoring

WARNI NG : When parameter b012, level of electronic thermal setting, is set to

motor FLA rating (Full Load Ampere nameplate rating), the inverter provides solid

state motor overload protection at 115% of motor FLA or equivalent. If parameter

B012 exceeds the motor FLA rating, the motor may overheat and damaged.

Parameter B012, level of electronic thermal setting, is a variable parameter.

CAUTION: Be careful to avoid specifying a braking time that is long enough to

cause motor overheating. If you use DC braking, we recommend using a motor

with a built-in thermistor, and wiring it to the inverter’s thermistor input (see

“Thermistor Thermal Protection” on page 4-24). Also refer to the motor

manufacturer’s specifications for duty-cycle recommendations during DC braking.

HIGH VOLTAGE: When set RDY function ON, there will be a voltage appear at

motor output terminals U, V and W even if the motor is in stop mode. So never

touch the inverter power terminal even the motor is not running.

CAUTION: Do not change Debug mode for safety reasons. Otherwise unexpected

performances may occur.

WARNI NG : Be sure to turn ON the input power supply only after closing the front

case. While the inverter is energized, be sure not to open the front case. Otherwise,

there is the danger of electric shock.

WARNI NG : Be sure not to operate electrical equipment with wet hands.

Otherwise, there is the danger of electric shock.

WARNI NG : While the inverter is energized, be sure not to touch the inverter

terminals even when the motor is stopped. Otherwise, there is the danger of

electric shock.

WARNI NG : If the retry mode is selected, the motor may suddenly restart after a

trip stop. Be sure to stop the inverter before approaching the machine (be sure to

design the machine so that safety for personnel is secure even if it restarts.)

Otherwise, it may cause injury to personnel.

WARNI NG : If the power supply is cut OFF for a short period of time, the inverter

may restart operating after the power supply recovers if the Run command is

active. If a restart may pose danger to personnel, so be sure to use a lock-out

circuit so that it will not restart after power recovery. Otherwise, it may cause

injury to personnel.

WARNI NG : The Stop Key is effective only when the stop function is enabled. Be

sure to enable the Stop Key separately from the emergency stop. Otherwise, it may

cause injury to personnel.

WARNI NG : During a trip event, if the alarm reset is applied and the Run

command is present, the inverter will automatically restart. Be sure to apply the

alarm reset only after verifying the Run command is OFF. Otherwise, it may cause

injury to personnel.

… 3-34

… 3-19

… 3-47

… 3-62

… 4-3

… 4-3

… 4-3

… 4-3

… 4-3

… 4-3

… 4-3

… 4-3

WARNI NG : Be sure not to touch the inside of the energized inverter or to put any

conductive object into it. Otherwise, there is a danger of electric shock and/or fire.

WARNI NG : If power is turned ON when the Run command is already active, the

motor will automatically start and injury may result. Before turning ON the power,

confirm that the RUN command is not present.

WARNI NG : When the Stop key function is disabled, pressing the Stop key does not

stop the inverter, nor will it reset a trip alarm.

WARNI NG : Be sure to provide a separate, hard-wired emergency stop switch when

the application warrants it.

WARNI NG : If the power is turned ON and the Run command is already active, the

motor starts rotation and is dangerous! Before turning power ON, confirm that the

Run command is not active.

WARNI NG : After the Reset command is given and the alarm reset occurs, the motor

will restart suddenly if the Run command is already active. Be sure to set the alarm

reset after verifying that the Run command is OFF to prevent injury to personnel.

Cautions for Operations and Monitoring

CAUTION: The digital outputs (relay and/or open collector) available on the drive

HIGH VOLTAGE: Dangerous voltage exists even after the Safe Stop is activated.

CAUTION: The heat sink fins will have a high temperature. Be careful not to touch

them. Otherwise, there is the danger of getting burned.

CAUTION: The operation of the inverter can be easily changed from low speed to

high speed. Be sure to check the capability and limitations of the motor and

machine before operating the inverter. Otherwise, it may cause injury to personnel.

CAUTION: If you operate a motor at a frequency higher than the inverter standard

default setting (50Hz/60Hz), be sure to check the motor and machine specifications

with the respective manufacturer. Only operate the motor at elevated frequencies

after getting their approval. Otherwise, there is the danger of equipment damage.

CAUTION: It is possible to damage the inverter or other devices if your application

exceeds the maximum current or voltage characteristics of a connection point.

CAUTION: Be sure to turn OFF power to the inverter before changing the short

circuit bar position to change SR/SK. Otherwise, damage to the inverter circuitry

may occur.

CAUTION: Be careful not to turn PID clear ON and reset the integrator sum when

the inverter is in Run mode (output to motor is ON). Otherwise, this could cause the

motor to decelerate rapidly, resulting in a trip.

HIGH VOLTAGE: When set RDY function ON, there will be a voltage appear at

motor output terminals U, V and W even if the motor is in stop mode. So never

touch the inverter power terminal even the motor is not running.

must not be considered as safety related signals. The outputs of the external safety

relay must be used for integration into a safety related control/command circuit

It does

NOT

mean that the main power has been removed.

… 4-3

… 4-3

… 4-3

… 4-11

… 4-22

… 4-2

… 4-2

… 4-2

… 4-4

… 4-8

… 4-26

… 4-31

… 4-32

… 4-34

ix

x

Warnings and Cautions for Troubleshooting and Maintenance

CAUTION: Do not connect the megger to any control circuit terminals such as

CAUTION: Never test the withstand voltage (HIPOT) on the inverter. The inverter

WARNI NG : Wait at least five (5) minutes after turning OFF the input power

supply before performing maintenance or an inspection. Otherwise, there is the

danger of electric shock.

WARNI NG : Make sure that only qualified personnel will perform maintenance,

inspection, and part replacement. Before starting to work, remove any metallic

objects from your person (wristwatch, bracelet, etc.). Be sure to use tools with

insulated handles. Otherwise, there is a danger of electric shock and/or injury to

personnel.

WARNI NG : Never remove connectors by pulling on its wire leads (wires for cooling

fan and logic P.C.board). Otherwise, there is a danger of fire due to wire breakage

and/or injury to personnel.

CAUTION: Do not connect the megger to any control terminals such as intelligent

I/O, analog terminals, etc. Doing so could cause damage to the inverter.

CAUTION: Never test the withstand voltage (HIPOT) on the inverter. The inverter

has a surge protector between the main circuit terminals above and the chassis

ground.

intelligent I/O, analog terminals, etc. Doing so could cause damage to the inverter.

has a surge protector between the main circuit terminals above and the chassis

ground.

HIGH VOLTAGE: Be careful not to touch wiring or connector terminals when

working with the inverters and taking measurements. Be sure to place the

measurement circuitry components above in an insulated housing before using

them.

… 6-2

… 6-2

… 6-2

… 6-10

… 6-10

… 6-10

… 6-10

… 6-14

General Warnings and Cautions iv

WARNI NG : Never modify the unit. Otherwise, there is a danger of electric shock and/or injury.

CAUTION: Withstand voltage test and insulation resistance tests (HIPOT) are executed before

the units are shipped, so there is no need to conduct these tests before operation.

CAUTION: Do not attach or remove wiring or connectors when power is applied. Also, do not

check signals during operation.

CAUTION: Be sure to connect the grounding terminal to earth ground.

CAUTION: When inspecting the unit, be sure to wait five minutes after turning OFF the power

supply before opening the cover.

CAUTION: Do not stop operation by switching OFF electromagnetic contactors on the primary

or secondary side of the inverter.

Power

Input

When there has been a sudden power failure while an operation instruction is active, then the

unit may restart operation automatically after the power failure has ended. If there is a

possibility that such an occurrence may harm humans, then install an electromagnetic contactor

(Mgo) on the power supply side, so that the circuit does not allow automatic restarting after the

power supply recovers. If the optional remote operator is used and the retry function has been

selected, this will also cause automatic restarting when a Run command is active. So, please be

careful.

CAUTION: Do not insert leading power factor capacitors or surge absorbers between the output

terminals of the inverter and motor.

Power

Input

When there has been a sudden power failure while an operation instruction is active, then the

unit may restart operation automatically after the power failure has ended. If there is a

possibility that such an occurrence may harm humans, then install an electromagnetic contactor

(Mgo) on the power supply side, so that the circuit does not allow automatic restarting after the

power supply recovers. If the optional remote operator is used and the retry function has been

selected, this will also cause automatic restarting when a Run command is active. So, please be

careful.

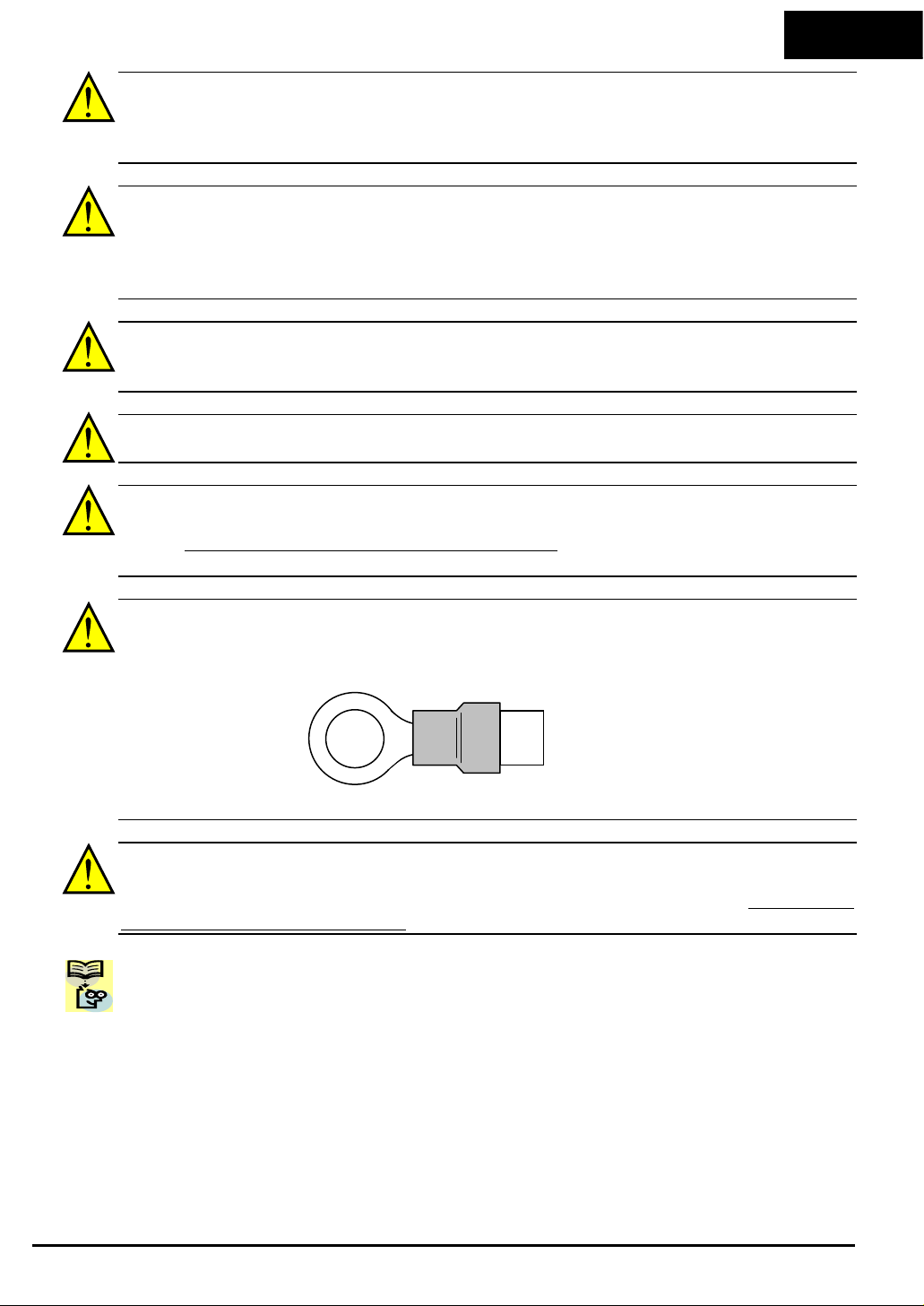

CAUTION: MOTOR TERMINAL SURGE VOLTAGE SUPPRESSION FILTER

(For the 400V CLASS)

In a system using an inverter with the voltage control PWM system, a voltage surge caused by

the cable constants such as the cable length (especially when the distance between the motor

and the inverter is 10m or more) and cabling method may occur at the motor terminals. A

dedicated filter of the 400V class for suppressing this voltage surge is available. Be sure to

install a filter in this situation.

Ground fault

interrupter

Ground fault

interrupter

L1, L2, L3

L1, L2, L3

Inverter

GND lug

Inverter

U, V, W

U, V, W

PCS

FW

Surge absorber

Motor

Motor

Leading power

factor capacitor

xi

xii

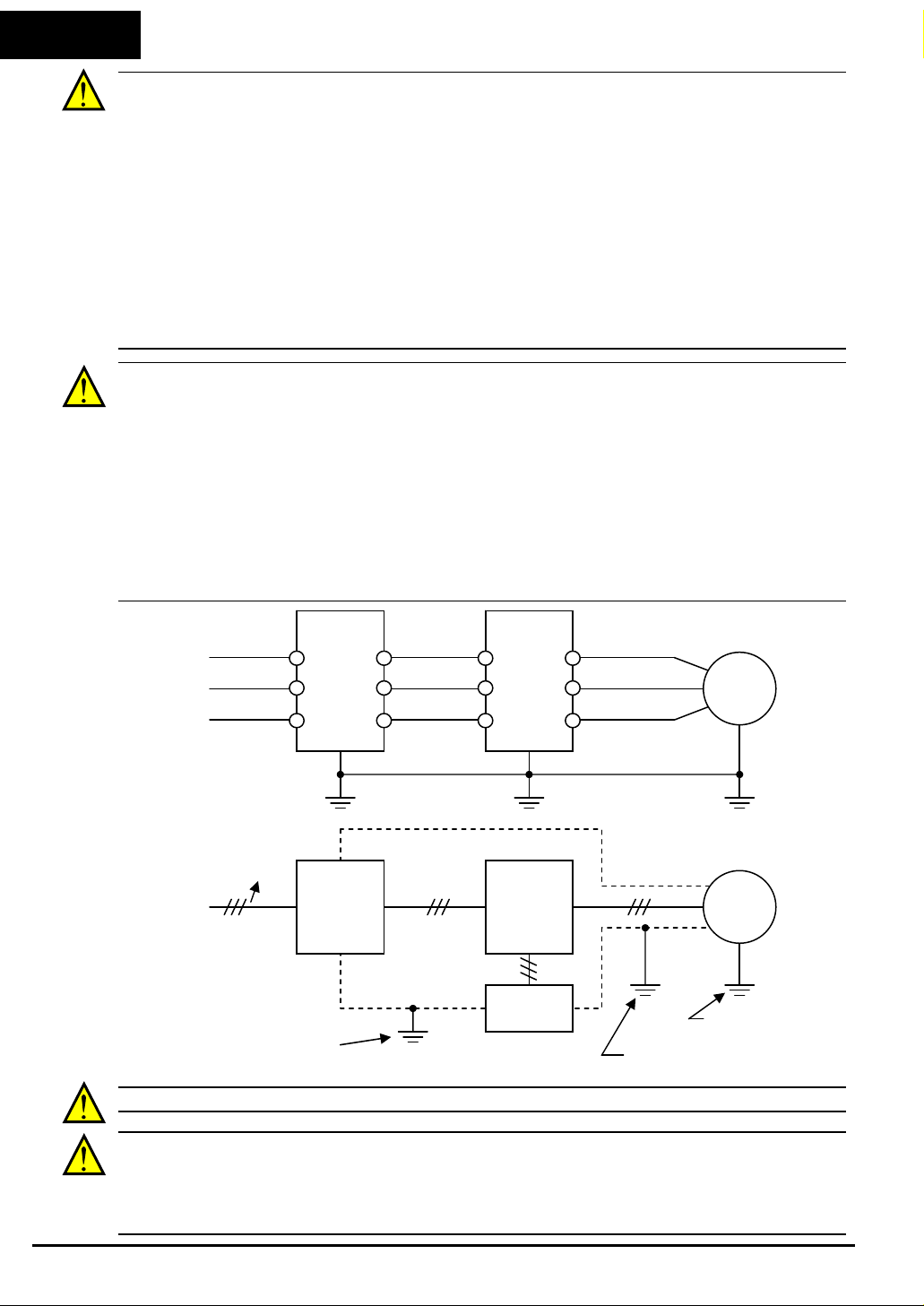

CAUTION: EFFECTS OF POWER DISTRIBUTION SYSTEM ON INVERTER

In the case below involving a general-purpose inverter, a large peak current can flow on the

power supply side, sometimes destroying the converter module:

1. The unbalance factor of the power supply is 3% or higher.

2. the power supply capacity is at least 10 times greater than the inverter capacity (or the

power supply capacity is 500kVA or more).

3. Abrupt power supply changes are expected, due to conditions such as:

a. Several inverters are interconnected with a short bus.

b. A thyristor converter and an inverter are interconnected with a short bus.

c. An installed phase advance capacitor opens and closes.

Where these conditions exist or when the connected equipment must be highly reliable, you

MUST install an input side AC-reactor of 3% (at a voltage drop at rated current) with respect to

the supply voltage on the power supply side. Also, where the effects of an indirect lightening

strike are possible, install a lightening conductor.

CAUTION: SUPPRESSION FOR NOISE INTERFERENCE FROM INVERTER

The inverter uses many semiconductor switching elements such as transistors and IGBTs. Thus,

a radio receiver or measuring instrument located near the inverter is susceptible to noise

interference.

To protect the instruments from erroneous operation due to noise interference, they should be

used well away from the inverter. It is also effective to shield the whole inverter structure.

The addition of an EMI filter on the input side of the inverter also reduces the effect of noise

from the commercial power line on external devices.

Note that the external dispersion of noise from the power line can be minimized by connecting

an EMI filter on the primary side of the inverter.

SFEF model has integrated filter complies to EN61800-3 category C1.

HFEF model has integrated filter complies to EN61800-3 category C2.

EMI Filter

R1

S1

T1

noise

Completely ground the

enclosure panel, metal

screen, etc. with as short

a wire as possible.

EMI Filter Inverter

R2

S2

T2

Inverter

L1

L2

L3

Remote

Operator

U

V

W

Conduit or shielded cable

-- to be grounded

Motor

Motor

Grounded frame

CAUTION: When the EEPROM error E08 occurs, be sure to confirm the setting values again.

CAUTION: When using normally closed active state settings (C011 to C017) for externally

commanded Forward or Reverse terminals [FW] or [RV], the inverter may start automatically

when the external system is powered OFF or disconnected from the inverter! So do not use

normally closed active state settings for Forward or Reverse terminals [FW] or [RV] unless your

system design protects against unintended motor operation.

CAUTION: In all the instrumentations in this manual, covers and safety devices are

occasionally removed to describe the details. While operating the product, make sure that the

covers and safety devices are placed as they were specified originally and operate it according to

UL Cautions, Warnings and Instructions xii

Warnings and Cautions for Troubleshooting and Maintenance

the instruction manual.

CAUTION: Do not discard the inverter with household waste.

Contact an industrial waste management company in your area who can

treat industrial waste without polling the environment.

The warnings and instructions in this section summarizes the procedures necessary to ensure

an inverter installation complies with Underwriters Laboratories

WARNI NG : Use 60/75C Cu wire only. (for models: WJ200-001L, -002L, -004L, -007L, -015S,

-022S, -004H, -007H, -015H, -022H and -030H)

WARNI NG : Use 75C Cu wire only. (for models: WJ200-001S, -002S, -004S, -007S, -015L, -022L,

-037L, -055L, -075L, -110L, -150L, -040H, -055H, -075H, -110H and -150H)

WARNI NG : Suitable for use on a circuit capable of delivering not more than 100,000 rms

Symmetrical Amperes, 240 or 480V maximum.

WARNI NG : When protected by CC, G, J, or R class Fuses, or when Protected By A Circuit

Breaker Having An Interrupting Rating Not Less Than 100,000 rms Symmetrical Amperes, 240

or 480 Volts Maximum.

WARNI NG : Install device in pollution degree 2 environment.

WARNI NG : Maximum Surrounding Air Temperature 50C

WARNI NG : Solid state motor overload protection is provided in each model

WARNI NG : Integral solid state short circuit protection does not provide branch circuit

protection. Branch circuit protection must be provided in accordance with the National Electric

Code and any additional local codes

guidelines.

xiii

xiv

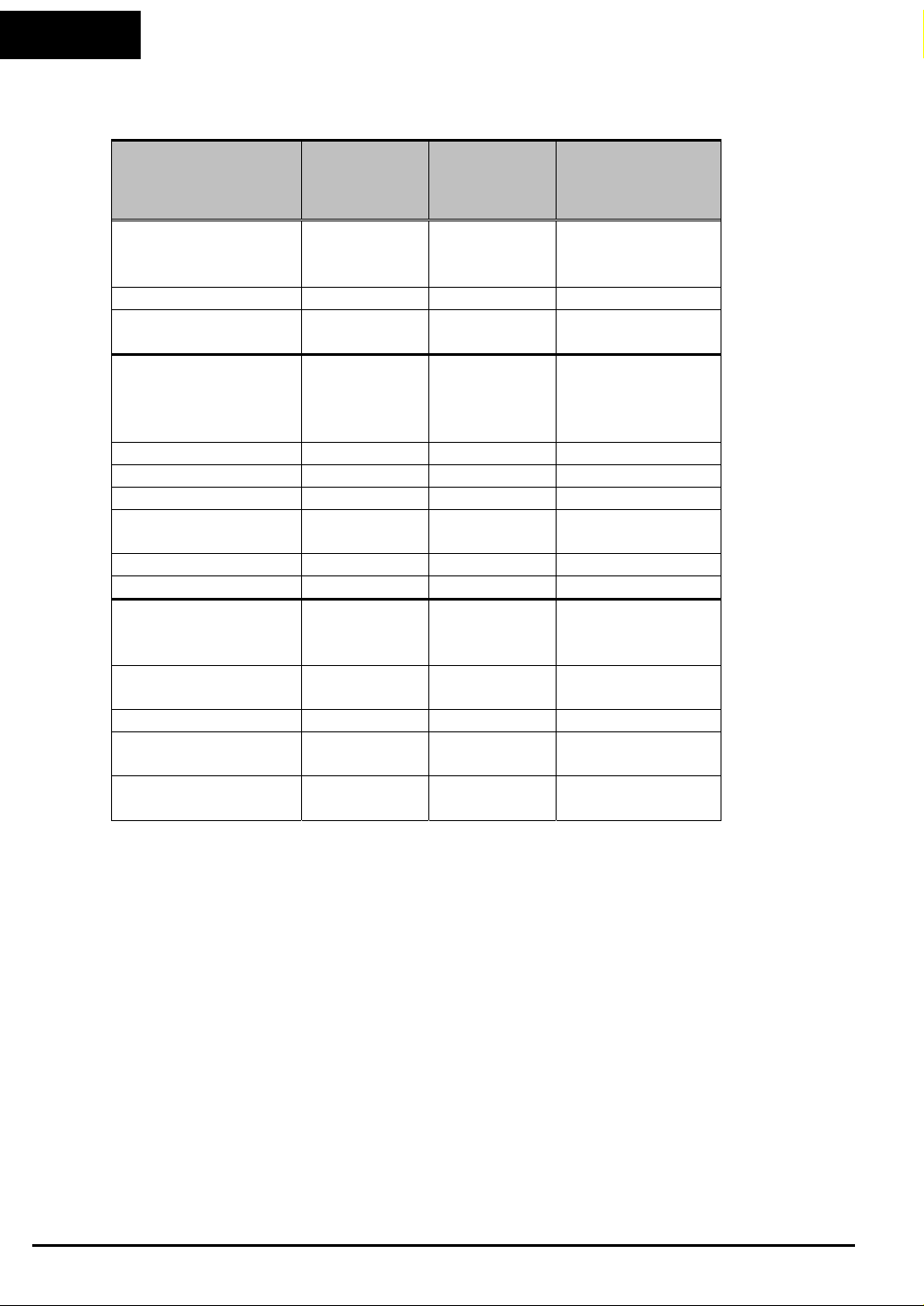

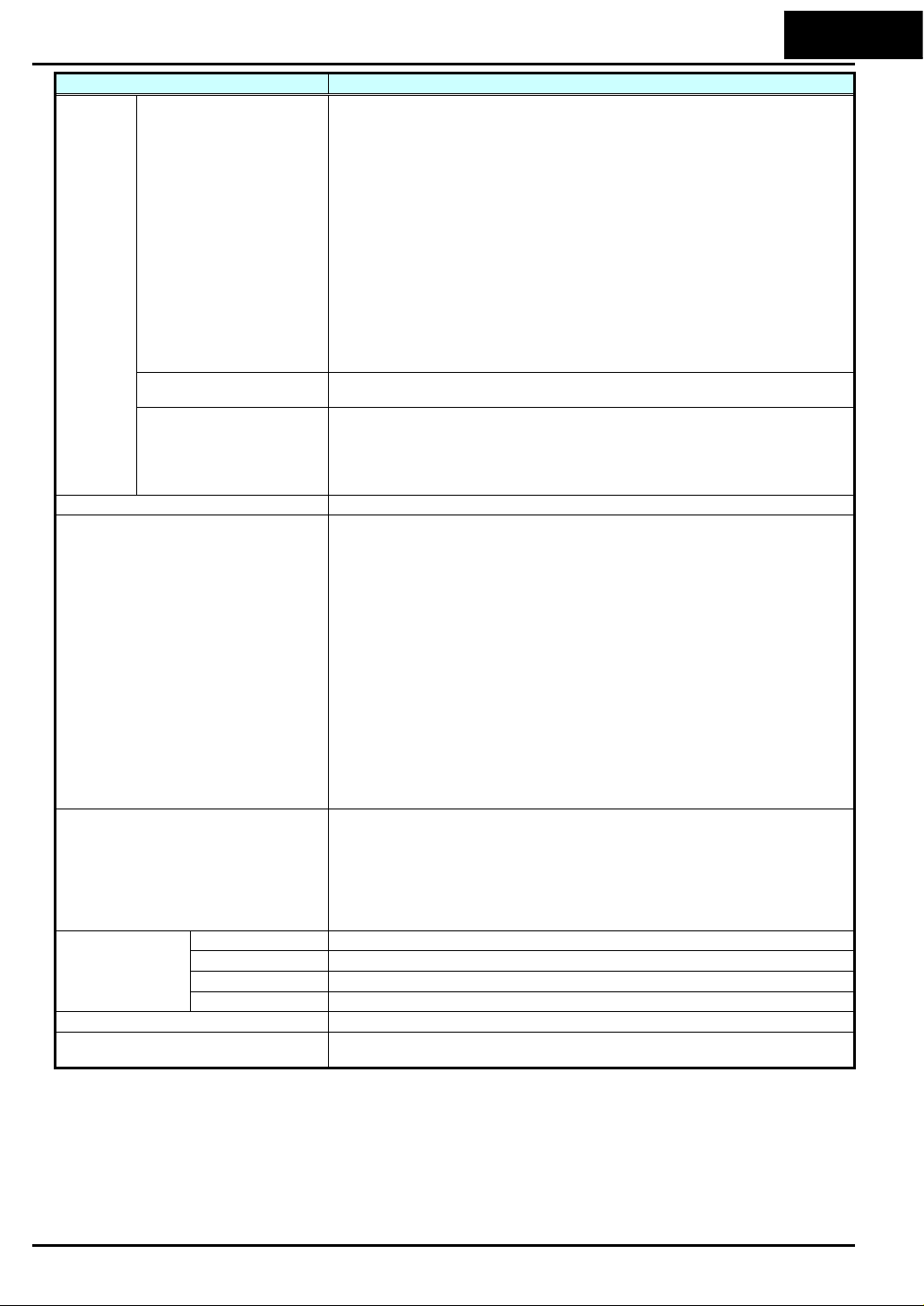

Terminal symbols and Screw size

Inverter Model Screw Size

Required

Torque (N-m)

Wire range

WJ200-001S

2

WJ200-002S

M3.5 1.0 AWG16 (1.3mm

)

WJ200-004S

WJ200-007S M4 1.4 AWG12 (3.3mm2)

WJ200-015S

WJ200-022S

M4 1.4 AWG10 (5.3mm

2

)

WJ200-001L

WJ200-002L

WJ200-004L

M3.5 1.0 AWG16 (1.3mm

2

)

WJ200-007L

WJ200-015L M4 1.4 AWG14 (2.1mm2)

WJ200-022L M4 1.4 AWG12 (3.3mm2)

WJ200-037L M4 1.4 AWG10 (5.3mm2)

WJ200-055L

WJ200-075L

M5 3.0 AWG6 (13mm

2

)

WJ200-110L M6 5.9 to 8.8 AWG4 (21mm2)

WJ200-150L M8 5.9 to 8.8 AWG2 (34mm2)

WJ200-004H

2

WJ200-007H

M4 1.4 AWG16 (1.3mm

)

WJ200-015H

WJ200-022H

WJ200-030H

M4 1.4 AWG14 (2.1mm

2

)

WJ200-040H M4 1.4 AWG12 (3.3mm2)

WJ200-055H

WJ200-075H

WJ200-110H

WJ200-150H

M5 3.0 AWG10 (5.3mm

M6 5.9 to 8.8 AWG6 (13mm

2

)

2

)

xv

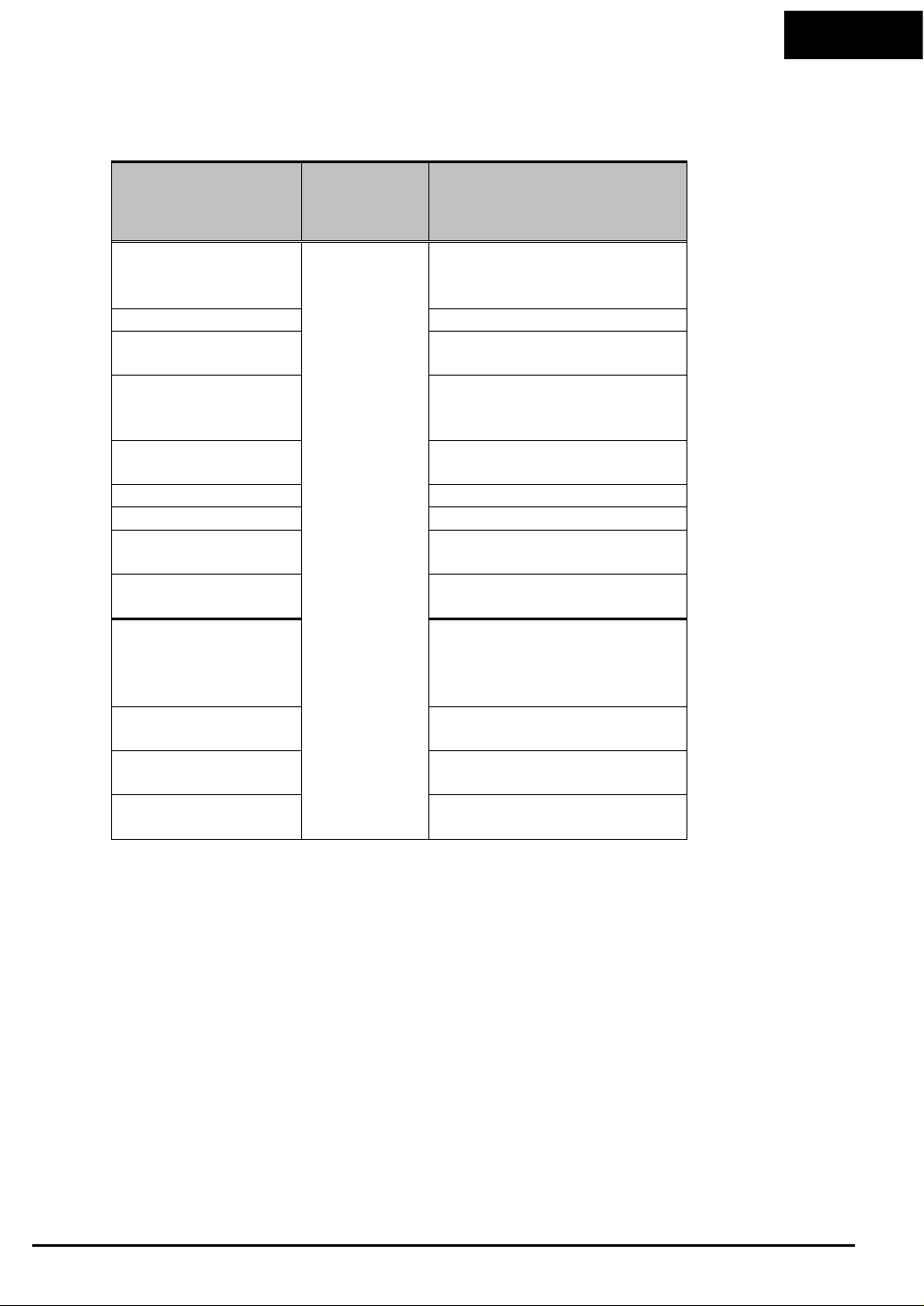

Fuse Sizes

The inverter shall be connected with a UL Listed Cartridge Nonrenewable fuse,

rated 600Vac with the current ratings as shown in the table below.

Inverter Model Type Rating

WJ200-001S

WJ200-002S

WJ200-004S

WJ200-007S 15A, AIC 200kA

WJ200-015S

WJ200-022S

WJ200-001L

WJ200-002L

WJ200-004L

WJ200-007L

WJ200-015L

WJ200-022L 20A, AIC 200kA

WJ200-037L 30A, AIC 200kA

WJ200-055L

WJ200-075L

WJ200-110L

WJ200-150L

WJ200-004H

WJ200-007H

WJ200-015H

WJ200-022H

WJ200-030H

WJ200-040H

WJ200-055H

WJ200-075H

WJ200-110H

WJ200-150H

Class J

10A, AIC 200kA

30A, AIC 200kA

10A, AIC 200kA

15A, AIC 200kA

40A, AIC 200kA

80A, AIC 200kA

10A, AIC 200kA

15A, AIC 200kA

20A, AIC 200kA

40A, AIC 200kA

xvi

Table of Contents

Safety Messages

Hazardous High Voltage ............................................................................................................... i

General Precautions – Read These First! ................................................................................. ii

Index to Warnings and Cautions in This Manual .................................................................... iv

General Warnings and Cautions ................................................................................................. x

UL Cautions, Warnings and Instructions .............................................................................. xiii

Circuit Breaker and Fuse Sizes ................................................................................................ xv

Table of Contents

Revisions ............................................................................................................................... xviii

Contact Information ............................................................................................................... xix

Chapter 1: Getting Started

Introduction ............................................................................................................................ 1-2

WJ200 Inverter Specifications .............................................................................................. 1-4

Introduction to Variable-Frequency Drives ........................................................................ 1-18

Frequently Asked Questions ............................................................................................... 1-23

Chapter 2: Inverter Mounting and Installation

Orientation to Inverter Features .......................................................................................... 2-2

Basic System Description ...................................................................................................... 2-4

Step-by-Step Basic Installation ............................................................................................ 2-6

Powerup Test ........................................................................................................................ 2-23

Using the Front Panel Keypad ........................................................................................... 2-25

Chapter 3: Configuring Drive Parameters

Choosing a Programmable Device ........................................................................................ 3-2

Using the Keypad Devices ..................................................................................................... 3-3

“D” Group: Monitoring Functions ......................................................................................... 3-7

“F” Group: Main Profile Parameters ................................................................................... 3-11

“A” Group: Standard Functions .......................................................................................... 3-12

“B” Group: Fine Tuning Functions ..................................................................................... 3-44

“C” Group: Intelligent Terminal Functions ........................................................................ 3-83

“H” Group: Motor Constants Functions ........................................................................... 3-104

“P” Group: Other Parameters ............................................................................................ 3-111

Chapter 4: Operations and Monitoring

Introduction ............................................................................................................................ 4-2

Connecting to PLCs and Other Devices ............................................................................... 4-4

Control Logic Signal Specifications ...................................................................................... 4-6

Intelligent Terminal Listing ................................................................................................ 4-10

Using Intelligent Input Terminals ...................................................................................... 4-12

Using Intelligent Output Terminals ................................................................................... 4-51

Analog Input Operation ....................................................................................................... 4-87

Pulse Train Input Operation ............................................................................................... 4-89

Analog Output Operation ...................................................................................................... 4-90

Chapter 5: Inverter System Accessories

Introduction ............................................................................................................................ 5-2

Component Description ......................................................................................................... 5-3

Chapter 6: Troubleshooting and Maintenance

Troubleshooting ...................................................................................................................... 6-2

Monitoring Trip Events, History, & Conditions ................................................................... 6-8

Restoring Factory Default Settings .................................................................................... 6-14

Maintenance and Inspection ............................................................................................... 6-15

Warranty ............................................................................................................................... 6-22

Appendix A: Glossary and Bibliography

Glossary .................................................................................................................................. A-2

Bibliography ........................................................................................................................... A-8

Appendix B: ModBus Network Communications

Introduction ............................................................................................................................ B-2

Connecting the Inverter to ModBus ..................................................................................... B-3

Network Protocol Reference .................................................................................................. B-5

ModBus Data Listing ........................................................................................................... B-24

Appendix C: Drive parameter Setting Tables

Introduction ............................................................................................................................ C-2

Parameter Settings for Keypad Entry .................................................................................. C-2

Appendix D: EMC installation guidance

Appendix E: Safety

xvii

xviii

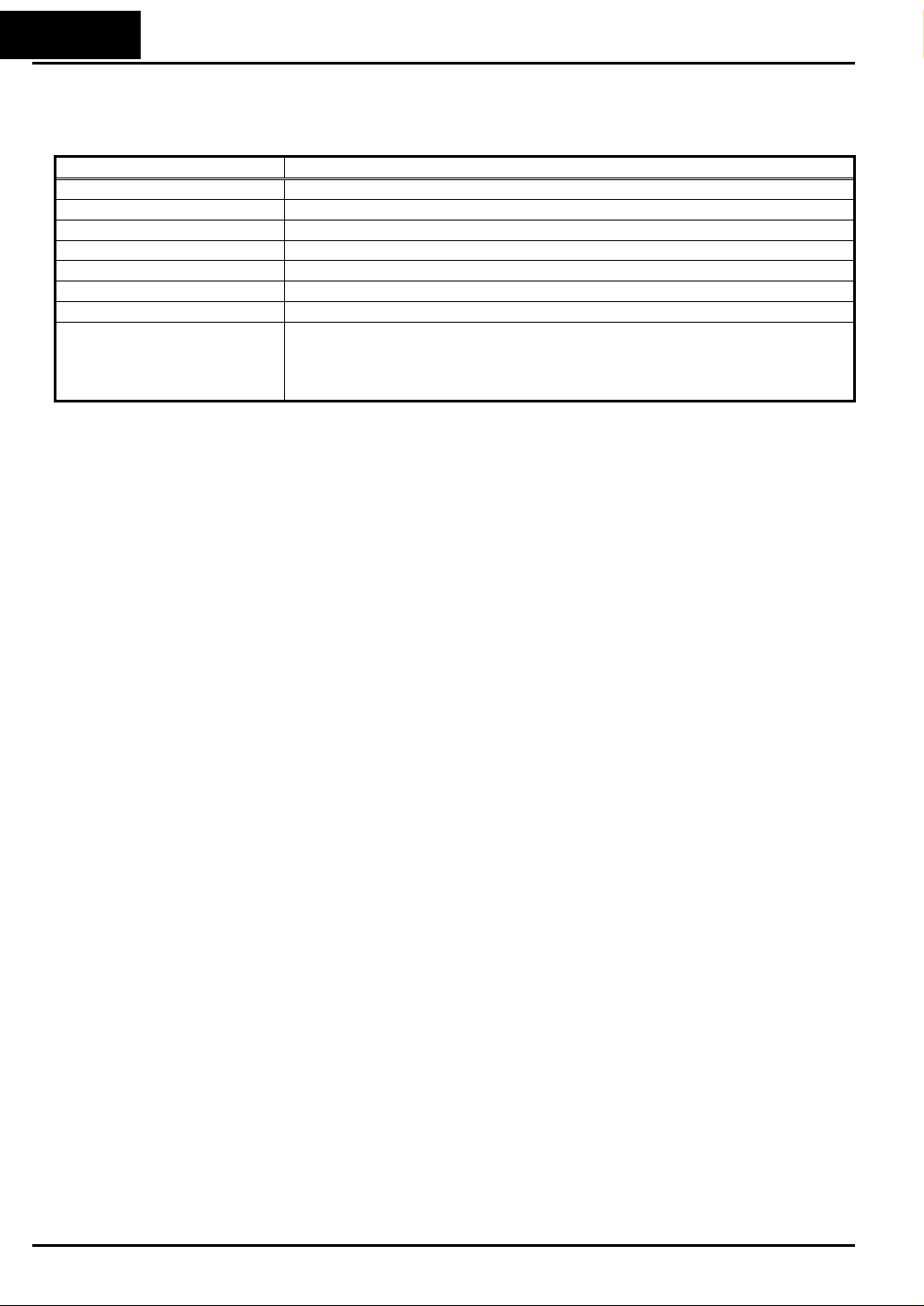

Revisions

Revision History Table

No. Revision Comments

Date of

Issue

Manual No.

Operation

Contact Information

Hitachi America, Ltd.

Power and Industrial Division

50 Prospect Avenue

Tarrytown, NY 10591

U.S.A.

Phone: +1-914-631-0600

Fax: +1-914-631-3672

Hitachi Europe GmbH

Am Seestern 18

D-40547 Dusseldorf

Germany

Phone: +49-211-5283-0

Fax: +49-211-5283-649

Hitachi Asia Ltd.

16 Collyer Quay

#20-00 hitachi Tower, Singapore 049318

Singapore

Phone: +65-538-6511

Fax: +65-538-9011

Hitachi Asia (Hong Kong) Ltd.

7th Floor, North Tower

World Finance Centre, Harbour City

Canton Road, Tsimshatsui, Kowloon

Hong Kong

Phone: +852-2735-9218

Fax: +852-2735-6793

NOTE: To receive technical support for the Hitachi inverter you purchased, contact the

Hitachi inverter dealer from whom you purchased the unit, or the sales office or

factory contact listed above. Please be prepared to provide the following inverter

nameplate information:

1. Model

2. Date of purchase

3. Manufacturing number (MFG No.)

4. Symptoms of any inverter problem

If any inverter nameplate information is illegible, please provide your Hitachi contact

with any other legible nameplate items. To reduce unpredictable downtime, we

recommend that you stock a spare inverter.

xix

Hitachi Australia Ltd.

Level 3, 82 Waterloo Road

North Ryde, N.S.W. 2113

Australia

Phone: +61-2-9888-4100

Fax: +61-2-9888-4188

Hitachi Industrial Equipment Systems Co., Ltd.

AKS Building, 3, kanda Neribei-cho

Chiyoda-ku, Tokyo, 101-0022

Japan

Phone: +81-3-4345-6910

Fax: +81-3-4345-6067

Hitachi Industrial Equipment Systems Co., Ltd.

Narashino Division

1-1, Higashi-Narashino 7-chome

Narashino-shi, Chiba 275-8611

Japan

Phone: +81-47-474-9921

Fax: +81-47-476-9517

Getting Started

1−1

In This Chapter… page

- Introduction ...................................................................................... 2

- WJ200 Inverter Specifications ........................................................ 4

- Introduction to Variable-Frequency Drives .................................. 18

- Frequently Asked Questions ........................................................ 23

1

1−2

Introduction

Main Features

Congratulation on your purchase of an WJ200 Series Hitachi inverter! This inverter

drive features state-of-the-art circuitry and components to provide high performance.

The housing footprint is exceptionally small, given the size of the corresponding motor.

The Hitachi WJ200 product line includes more than a dozen inverter models to cover

motor sizes from 1/8 horsepower to 20 horsepower, in either 240VAC or 480VAC power

input versions.

The main features are:

• 200V and 400V class, 0.1 to 15kW inverters having dual rating

• US or EU versions available

• EzSQ (simple programming function) integrated

• Built-in RS485 MODBUS RTU as standard, other FieldBus optional

• New current suppressing function

• Sixteen programmable speed levels

• PID control adjusts motor speed automatically to maintain a process variable value

• Password protection to avoid unexpected parameter change

The design in Hitachi inverters overcomes many of the traditional trade-offs between

speed, torque and efficiency. The performance characteristics are:

• High starting torque of 200% at 0.5Hz

• Continuous operation at 100% torque within a 1:10 speed range (6/60Hz / 5/50Hz)

without motor derating.

• Fan has ON/OFF selection to provide longer life for cooling fan.

A full line of accessories from Hitachi is available to complete your motor application:

• Integrated USB port for PC communication

• Digital remote operator keypad

• Integrated brake chopper

• EMC filter (footprint type C1) optional

A

_

A _

Inverter Specification Label

The Hitachi WJ200 inverters have product labels located on the right side of the

housing, as pictured below. Be sure to verify that the specifications on the labels match

your power source, and application safety requirements.

Model name

Input ratings

Output ratings

MFG number

Inverter Specification Label

-001SF

200 -240

200

05A _T1 2345

-240

-001

1−3

Ver:2.0

2.0/1.3

1.2 /1. 0

1005

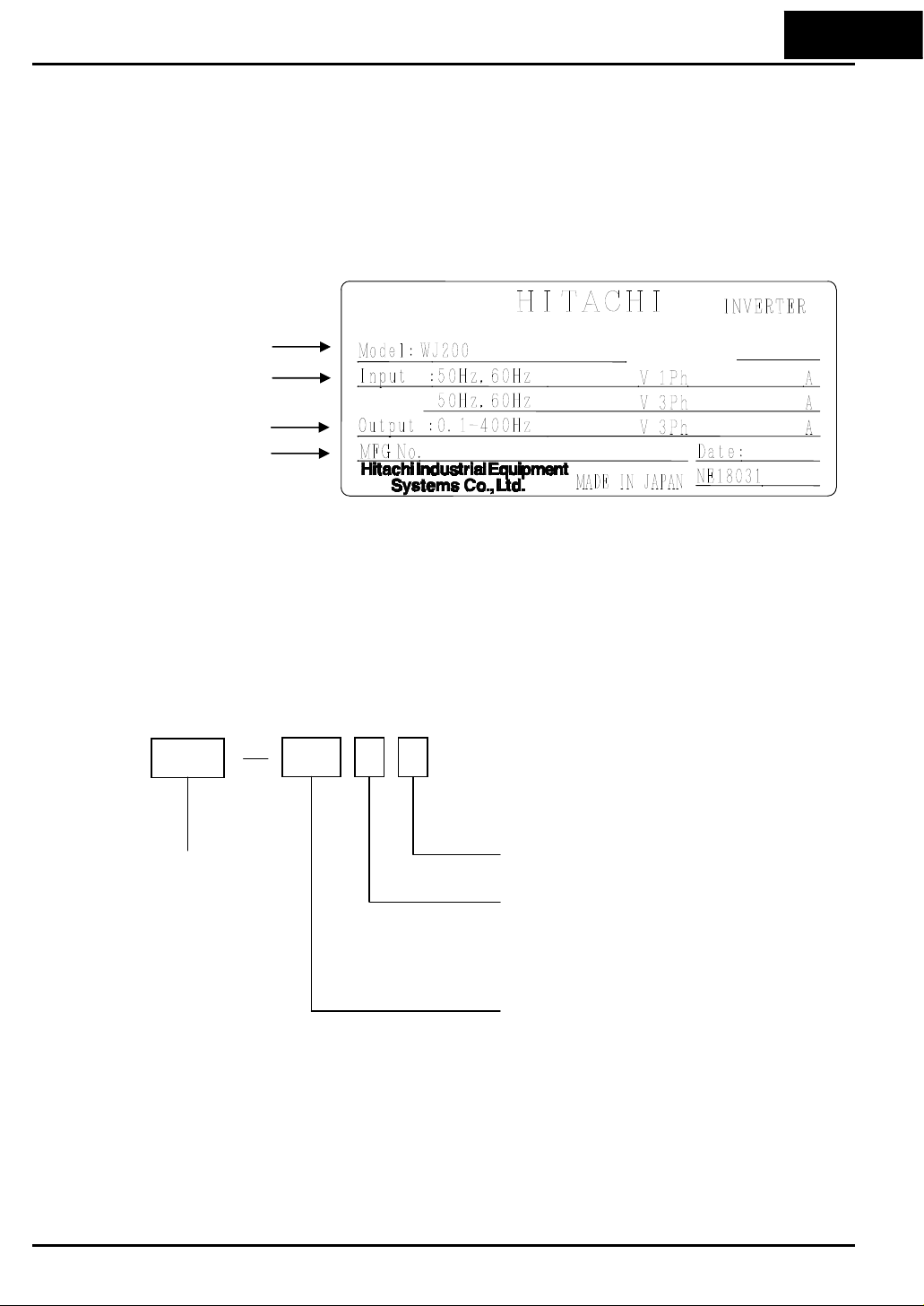

The model number for a specific inverter contains useful information about its

operating characteristics. Refer to the model number legend below:

WJ200

Series name

001 S F

Configuration type

F=with keypad

Input voltage:

S=Single-phase 200V class

L=Three-phase 200V class

H=Three-phase 400V class

pplicable motor capacity in kW

001=0.1kW 037=3.7kW

002=0.2kW 040=4.0kW

004=0.4kW 055=5.5kW

007=0.75kW 075=7.5kW

015=1.5kW 110=11kW

022=2.2kW 150=15kW

030=3.0kW

≤

≤

1−4

WJ200 Inverter Specifications

Model-specific tables for 200V and 400V class inverters

The following tables are specific to WJ200 inverters for the 200V and 400V class model

groups. Note that “General Specifications” on page in this chapter

class groups. Footnotes for all specification tables follow the table below.

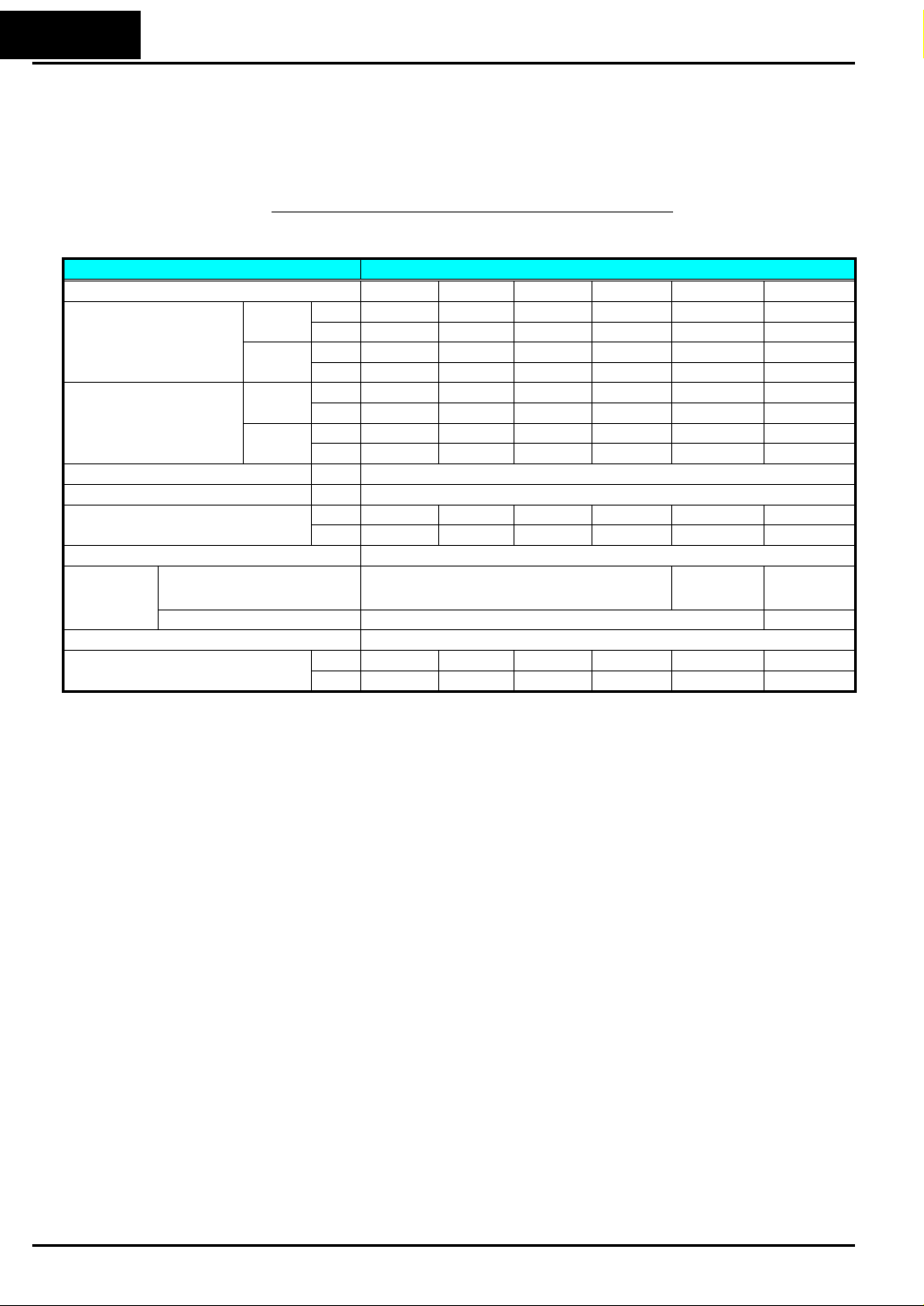

Item Single-phase 200V class Specifications

WJ200 inverters, 200V models 001SF 002SF 004SF 007SF 015SF 022SF

Applicable motor size

*2

Rated capacity (kVA) 200V VT 0.4 0.6 1.2 2.0 3.3 4.1

Rated input voltage

Rated output voltage *3 3-phase: 200 to 240V (proportional to input voltage)

Rated output current (A) VT 1.2 1.9 3.5 6.0 9.6 12.0

Starting torque *6 200% at 0.5Hz

Braking Without resistor

With resistor 150% 100%

DC braking Variable operating frequency, time, and braking force

Weight kg 1.0 1.0 1.1 1.6 1.8 1.8

kW VT 0.2 0.4 0.55 1.1 2.2 3.0

CT 0.1 0.2 0.4 0.75 1.5 2.2

HP VT 1/4 1/2 3/4 1.5 3 4

CT 1/8 1/4 1/2 1 2 3

CT 0.2 0.5 1.0 1.7 2.7 3.8

240V VT 0.4 0.7 1.4 2.4 3.9 4.9

CT 0.3 0.6 1.2 2.0 3.3 4.5

Single-phase: 200V-15% to 240V +10%, 50/60Hz ±5%

CT 1.0 1.6 3.0 5.0 8.0 11.0

100%:

50%:

lb 2.2 2.2 2.4 3.1 4.0 4.0

50Hz

60Hz

apply to both voltage

70%: 50Hz

≤

50%: 60Hz

20%: 50Hz

20%:

≤

≤

≤

60Hz

Footnotes for the preceding table and the tables that follow:

Note1: The protection method conforms to JEM 1030.

Note2: The applicable motor refers to Hitachi standard 3-phase motor (4p). When

using other motors, care must be taken to prevent the rated motor current

(50/60Hz) from exceeding the rated output current of the inverter.

Note3: The output voltage decreases as the main supply voltage decreases (except

when using the AVR function). In any case, the output voltage cannot exceed

the input power supply voltage.

Note4: To operate the motor beyond 50/60Hz, consult the motor manufacturer for

the maximum allowable rotation speed.

Note5: For achieving approved input voltage rating categories:

• 460 to 480VAC – Over-voltage category 2

• 380 to 460VAC – Over-voltage category 3

To meet the Over-voltage category 3, insert an EN or IEC standard

compliant isolation transformer that is earth grounded and star connected

(for Low Voltage Directive).

Note6: At the rated voltage when using a Hitachi standard 3-phase, 4-pole motor.

Note7: The braking torque via capacitive feedback is the average deceleration

torque at the shortest deceleration (stopping from 50/60Hz as indicated). It is

not continuous regenerative braking torque. The average deceleration torque

varies with motor loss. This value decreases when operating beyond 50Hz. If

a large regenerative torque is required, the optional regenerative braking

unit and a resistor should be used.

1−5

Note8: The frequency command is the maximum frequency at 9.8V for input voltage

0 to 10VDC, or at 19.6mA for input current 4 to 20mA. If this characteristic

is not satisfactory for your application, contact your Hitachi representative.

Note9: If the inverter is operated outside the region shown in the graph in the

derating curve, the inverter may be damaged or its service life may be

shortened. Set Β083 Carrier Frequency Adjustment in accordance with the

expected output current level. See derating curve section for the detailed

information of the inverter operating range.

Note10: The storage temperature refers to the short-term temperature during

transportation.

Note11: Conforms to the test method specified in JIS JIS C 60068-2-6 :2010(IEC

60068-2-6:2007). For the model types excluded in the standard specifications,

contact your Hitachi sales representative.

Note12: Watt losses are calculated values based on specification of main

semi-conductors. You must take suitable margin when designing cabinet

based on these values. Otherwise there is a possibility of heating trouble.

≤

≤

≤

≤

1−6

WJ200 Inverter Specifications, continued…

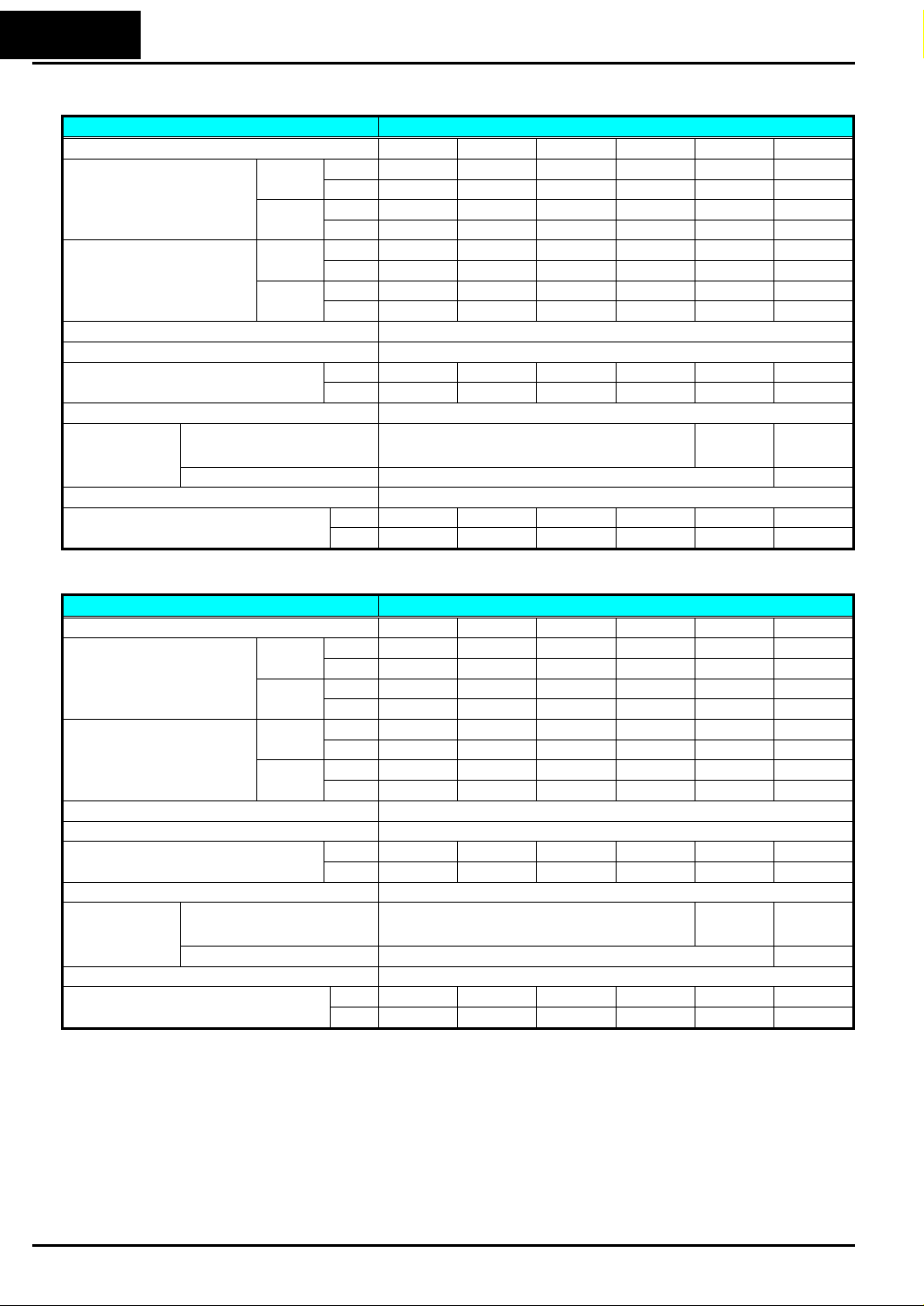

Item Three-phase 200V class Specifications

WJ200 inverters, 200V models

Applicable motor size

*2

Rated capacity (kVA) 200V VT 0.4 0.6 1.2 2.0 3.3 4.1

Rated input voltage

Rated output voltage *3 Three-phase: 200 to 240V (proportional to input voltage)

Rate d o utpu t c urre n t ( A) VT 1.2 1.9 3.5 6.0 9.6 12.0

Starting torque *6 200% at 0.5Hz

Braking Without resistor

With resistor 150%

DC braking Variable operating frequency, time, and braking force

Weight kg 1.0 1.0 1.1 1.2 1.6 1.8

kW V T 0.2 0.4 0.75 1.1 2.2 3.0

CT 0.1 0.2 0.4 0.75 1.5 2.2

HP VT 1/4 1/2 1 1.5 3 4

CT 1/8 1/4 1/2 1 2 3

CT 0.2 0.5 1.0 1.7 2.7 3.8

240V VT 0.4 0.7 1.4 2.4 3.9 4.9

CT 0.3 0.6 1.2 2.0 3.3 4.5

CT 1.0 1.6 3.0 5.0 8.0 11.0

lb 2.2 2.2 2.4 2.6 3.5 4.0

Item Three-phase 200V class Specifications

WJ200 inverters, 200V models

Applicable motor size

*2

Rated capacity (kVA) 200V VT 6.7 10.3 13.8 19.3 20.7

Rated input voltage

Rated output voltage *3 Three-phase: 200 to 240V (proportional to input voltage)

Rated output current (A) VT 19.6 30.0 40.0 56.0 69.0

Starting torque *6 200% at 0.5Hz

Braking Without resistor

With resistor 150%

DC braking Variable operating frequency, time, and braking force

Weight Kg 2.0 3.3 3.4 5.1 7.4

kW VT 5.5 7.5 11 15 18.5

CT 3.7 5.5 7.5 11 15

HP VT 7.5 10 15 20 25

CT 5 7.5 10 15 20

CT 6.0 8.6 11.4 16.2 20.7

240V VT 8.1 12.4 16.6 23.2 24.9

CT 7.2 10.3 13.7 19.5 24.9

CT 17.5 25.0 33.0 47.0 60.0

lb 4.4 7.3 7.5 11.2 16.3

001LF 002LF 004LF 007LF 015LF 022LF

Three-phase: 200V-15% to 240V +10%, 50/60Hz ±5%

70%: 50Hz

100%:

50%:

037LF 055LF 075LF 110LF 150LF

Three-phase: 200V-15% to 240V +10%, 50/60Hz ±5%

100%:

50%:

50Hz

60Hz

50Hz

60Hz

≤

50%: 60Hz

≤

70%: 50Hz

≤

50%: 60Hz

≤

≤

≤

≤

≤

1−7

WJ200 Inverter Specifications, continued…

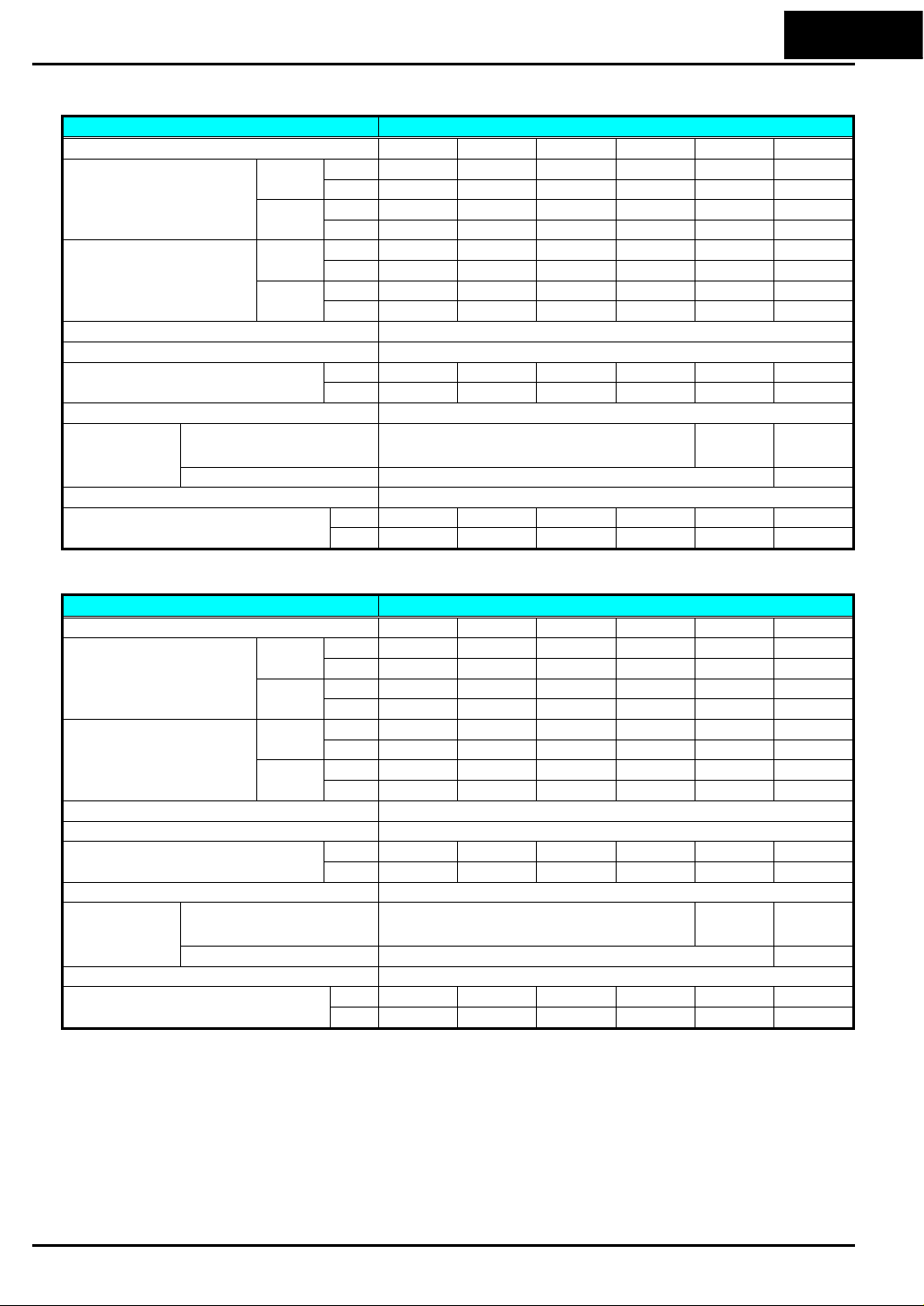

Item Three-phase 400V class Specifications

WJ200 inverters, 400V models

Applicable motor size

*2

Rated capacity (kVA) 380V VT 1.3 2.6 3.5 4.5 5.7 7.3

Rated input voltage

Rated output voltage *3 Three-phase: 400 to 480V (proportional to input voltage)

Rate d o utpu t c urre n t ( A) VT 2.1 4.1 5.4 6.9 8.8 11.1

Starting torque *6 200% at 0.5Hz

Braking Without resistor

With resistor 150%

DC braking Variable operating frequency, time, and braking force

Weight kg 1.5 1.6 1.8 1.9 1.9 2.1

kW V T 0.75 1.5 2.2 3.0 4.0 5.5

CT 0.4 0.75 1.5 2.2 3.0 4.0

HP VT 1 2 3 4 5 7.5

CT 1/2 1 2 3 4 5

CT 1.1 2.2 3.1 3.6 4.7 6.0

480V VT 1.7 3.4 4.4 5.7 7.3 9.2

CT 1.4 2.8 3.9 4.5 5.9 7.6

CT 1.8 3.4 4.8 5.5 7.2 9.2

lb 3.3 3.5 4.0 4.2 4.2 4.6

004HF 007HF 015HF 022HF 030HF 040HF

Three-phase: 400V-15% to 480V +10%, 50/60Hz ±5%

70%: 50Hz

100%:

50%:

50Hz

60Hz

≤

50%: 60Hz

≤

Item Three-phase 400V class Specifications

WJ200 inverters, 400V models

Applicable motor size

*2

Rated capacity (kVA) 380V VT 11.5 15.1 20.4 25.0

Rated input voltage

Rated output voltage *3 Three-phase: 400 to 480V (proportional to input voltage)

Rated output current (A) VT

Starting torque *6 200% at 0.5Hz

Braking Without resistor

With resistor 150%

DC braking Variable operating frequency, time, and braking force

Weight kg 3.5 3.5 4.7 5.2

kW V T 7.5 11 15 18.5

CT 5.5 7.5 11 15

HP VT 10 15 20 25

CT 7.5 10 15 20

CT 9.7 11.8 15.7 20.4

480V VT 14.5 19.1 25.7 31.5

CT 12.3 14.9 19.9 25.7

CT

lb 7.7 7.7 10.4 11.5

055HF 075HF 110HF 150HF

Three-phase: 400V-15% to 480V +10%, 50/60Hz ±5%

17.5 23.0 31.0 38.0

14.8 18.0 24.0 31.0

100%:

50%:

50Hz

60Hz

1−8

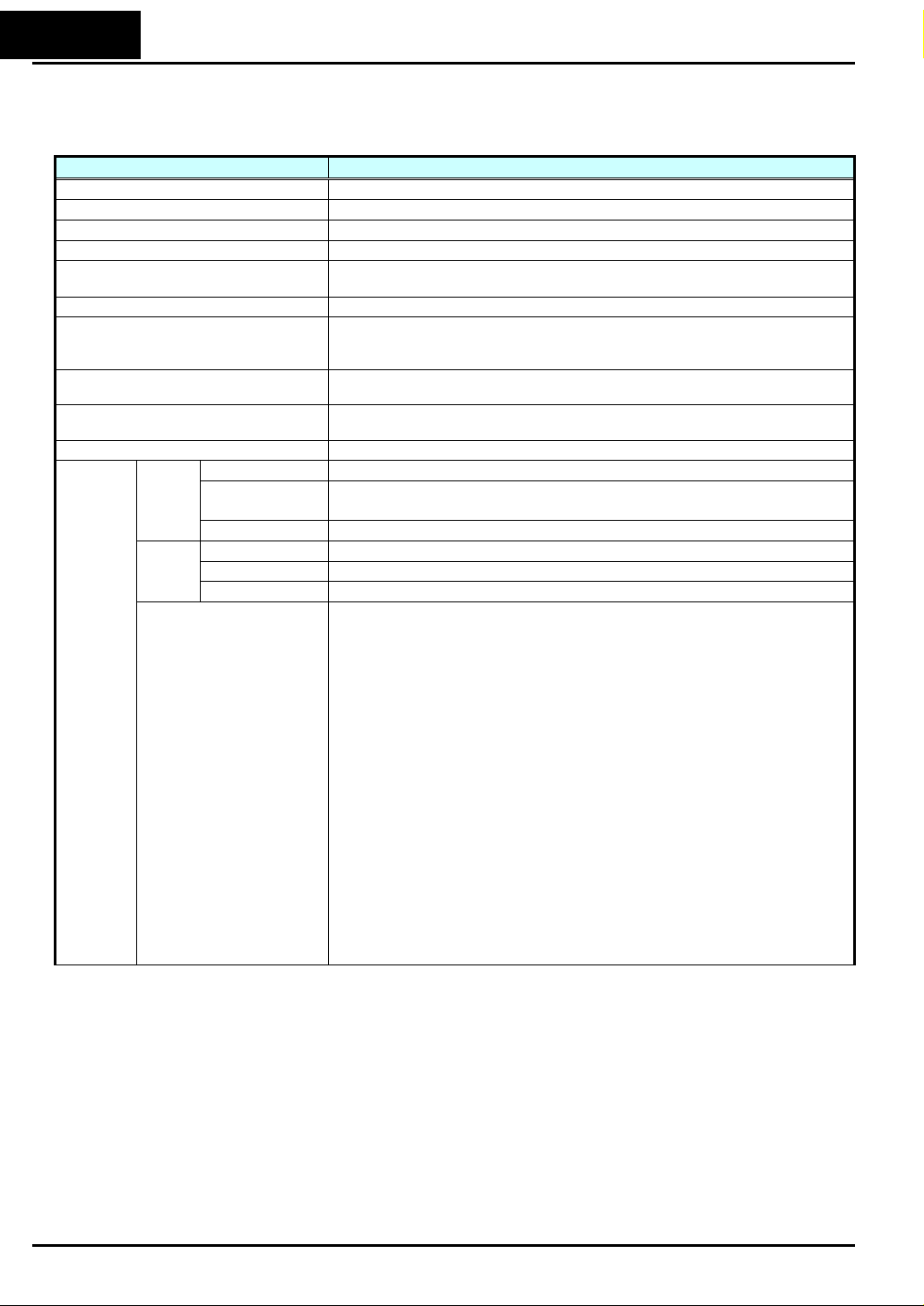

General Specifications

The following table applies to all WJ200 inverters.

Item General Specifications

Protective housing *1

Control method

Carrier frequency

Output frequency range *4

Frequency accuracy

Frequency setting resolution

Volt./Freq. characteristic

Overload capacity

Acceleration/deceleration time

Starting torque

Input

signal

Freq.

setting

Operator panel

External signal

*8

Via network

FWD/

REV run

Operator panel

External signal

Via network

Intelligent input

terminal

Seven terminals,

sink/source changeable

by a short bar

68 functions assignable

IP20

Sinusoidal Pulse Width Modulation (PWM) control

2kHz to 15kHz (derating required depending on the model)

0.1 to 400Hz

Digital command: ±0.01% of the maximum frequency

Analog command: ±0.2% of the maximum frequency (25°C ± 10°C)

Digital: 0.01Hz; Analog: max. frequency/1000

V/f control (constant torque, reduced torque, free-V/F): base freq.

30Hz~400Hz adjustable,

Sensorless vector control, Closed loop control with motor encoder feedback

Dual rating: CT(Heavy duty) : 60 sec. @150%

VT(Normal duty) : 60 sec. @120%

0.01 to 3600 seconds, linear and S-curve accel/decel, second accel/decel

setting available

200% @0.5Hz (sensorless vector control)

Up and Down keys / Value settings

0 to 10 VDC (input impedance 10k Ohms), 4 to 20mA (input impedance 100

Ohms), Potentiometer (1k to 2k Ohms, 2W)

RS485 ModBus RTU, other network option

Run/Stop (Forward/Reverse run change by command)

Forward run/stop, Reverse run/stop

RS485 ModBus RTU, other network option

FW (forward run command), RV (reverse run command), CF1~CF4

(multi-stage speed setting), JG (jog command), DB (external braking), SET

(set second motor), 2CH (2-stage accel./decel. command), FRS (free run stop

command), EXT (external trip), USP (startup function), CS (commercial

power switchover), SFT (soft lock), AT (analog input selection), RS (reset),

PTC (thermistor thermal protection), STA (start), STP (stop), F/R

(forward/reverse), PID (PID disable), PIDC (PID reset), UP (remote control

up function), DWN (remote control down function), UDC (remote control

data clear), OPE (operator control), SF1~SF7 (multi-stage speed setting; bit

operation), OLR (overload restriction), TL (torque limit enable), TRQ1

(torque limit changeover1), TRQ2 (torque limit changeover2), BOK (Braking

confirmation), LAC (LAD cancellation), PCLR (position deviation clear),

ADD (add frequency enable), F-TM (force terminal mode), ATR (permission

of torque command input), KHC (Cumulative power clear), MI1~MI7

(general purpose inputs for EzSQ), AHD (analog command hold), CP1~CP3

(multistage-position switches), ORL (limit signal of zero-return), ORC

(trigger signal of zero-return), SPD (speed/position changeover), GS1,GS2

(STO inputs, safety related signals), 485 (Starting communication signal),

PRG (executing EzSQ program), HLD (retain output frequency), ROK

(permission of run command), EB (rotation direction detection of B-phase),

DISP (display limitation), NO (no function)

Item General Specifications

Output

signal

Alarm output contact

Other functions

Protective function

Operating

environment

Coating color

Options

Intelligent output

terminal

48 functions assignable

Monitor output (analog)

Pulse train output

(0~10Vdc, 32kHz max.)

Temperature

Humidity

Vibration *11

Location

1−9

RUN (run signal), FA1 ~FA5 (frequency arrival signal), OL,OL2 (overload

advance notice signal), OD (PID deviation error signal), AL (alarm signal),

OTQ (over/under torque threshold), UV (under-voltage), TRQ (torque limit

signal), RNT (run time expired), ONT (power ON time expired), THM

(thermal warning), BRK (brake release), BER (brake error), ZS (0Hz

detection), DSE (speed deviation excessive), POK (positioning completion),

ODc (analog voltage input disconnection), OIDc (analog current input

disconnection), FBV (PID second stage output), NDc (network disconnect

detection), LOG1~LOG3 (Logic output signals), WAC (capacitor life

warning), WA F (cooling fan warning), FR (starting contact), OHF (heat sink

overheat warning), LOC (Low load), MO1~MO3 (general outputs for EzSQ),

IRDY (inverter ready), FWR (forward operation), RVR (reverse operation),

MJA (major failure), WCO (window comparator O), WCOI (window

comparator OI), FREF (frequency command source), REF (run command

source), SETM (second motor in operation), EDM (STO (safe torque off)

performance monitor), OP (option control signal), NO (no function)

Output freq., output current, output torque, output voltage, input power,

thermal load ratio, LAD freq., heat sink temperature, general output (EzSQ)

[PWM output]

Output freq., output current, output torque, output voltage, input power,

thermal load ratio, LAD freq., heat sink temperature, general output (EzSQ)

[Pulse train output]

Output frequency, output current, pulse train input monitor

ON for inverter alarm (1c contacts, both normally open or closed available.)

Free-V/f, manual/automatic torque boost, output voltage gain adjustment,

AVR function, reduced voltage start, motor data selection, auto-tuning,

motor stabilization control, reverse running protection, simple position

control, simple torque control, torque limiting, automatic carrier frequency

reduction, energy saving operation, PID function, non-stop operation at

instantaneous power failure, brake control, DC injection braking, dynamic

braking (BRD), frequency upper and lower limiters, jump frequencies, curve

accel and decel (S, U, inversed U,EL-S), 16-stage speed profile, fine

adjustment of start frequency, accel and decel stop, process jogging,

frequency calculation, frequency addition, 2-stage accel/decel, stop mode

selection, start/end freq., analog input filter, window comparators, input

terminal response time, output signal delay/hold function, rotation direction

restriction, stop key selection, software lock, safe stop function, scaling

function, display restriction, password function, user parameter,

initialization, initial display selection, cooling fan control, warning, trip

retry, frequency pull-in restart, frequency matching, overload restriction,

over current restriction, DC bus voltage AVR

Over-current, over-voltage, under-voltage, overload, brake resistor overload,

CPU error, memory error, external trip, USP error, ground fault detection at

power on, temperature error, internal communication error, driver error,

thermistor error, brake error, safe stop, overload at low speed, modbus

communication error, option error, encoder disconnection, speed excessive,

EzSQ command error, EzSQ nesting error, EzSQ execution error, EzSQ user

trip

Operating (ambient): -10 to 40°C(*10), / Storage: -20 to 65°C(*11)

20 to 90% humidity (non-condensing)

5.9m/s2 (0.6G), 10 to 55 Hz

Altitude 1,000m or less, indoors (no corrosive gasses or dust)

Black

Remote operator unit, cables for the units, braking unit, braking resistor, AC

reactor, DC reactor, EMC filter, fieldbus

1−10

Signal Ratings

Detailed ratings are in “Control Logic Signal Specifications” in chapter 4.

Signal / Contact Ratings

Built-in power for inputs 24VDC, 100mA maximum

Discrete logic inputs 27VDC maximum

Discrete logic outputs 50mA maximum ON state current, 27 VDC maximum OFF state voltage

Analog output 10bit / 0 to 10VDC, 2mA

Analog input, current 4 to 19.6 mA range, 20mA nominal

Analog input, voltage

+10V analog reference 10VDC nominal, 10mA maximum

Alarm relay contacts 250 VAC, 2.5A (R load) max., 0.2A (I load, P.F.=0.4) max.

0 to 9.8 VDC range, 10VDC nominal, input impedance 10kΩ

100 VAC, 10mA min

30 VDC, 3.0A (R load) max., 0.7A (I load, P.F.=0.4) max.)

5 VDC, 100mA min.

Loading...

Loading...