Thu Jul 21 2011 14:14 GMT+0900

NT3261_Cover1.indd 1 11/07/27 18:03

1

UL Cautions, Warnings and Instructions xii

Warnings and Cautions for Troubleshooting and Maintenance

The warnings and instructions in this section summarize the procedures necessary to ensure an

inverter installation complies with Underwriters Laboratories

guidelines.

WARNING: Use 60/75C Cu wire only.

WARNING: Suitable for use on a circuit capable of delivering not more than 100,000 rms

Symmetrical Amperes, 120V maximum.

WARNING: When protected by J class Fuses, or when Protected by Type E

Combination Motor

Controller Having An Interrupting Rating Not Less Than 100,000 rms Symmetrical Amperes, 120

Volts Maximum.

WARNING: Install device in pollution degree 2 environment.

WARNING: Maximum Surrounding Air Temperature 45C (004M),50C(007M).

WARNING: Solid state motor overload protection is provided in each model

WARNING: Integral solid state short circuit protection does not provide branch circuit protection.

Branch circuit protection must be provided in accordance with the National Electric Code and any

additional local codes

2

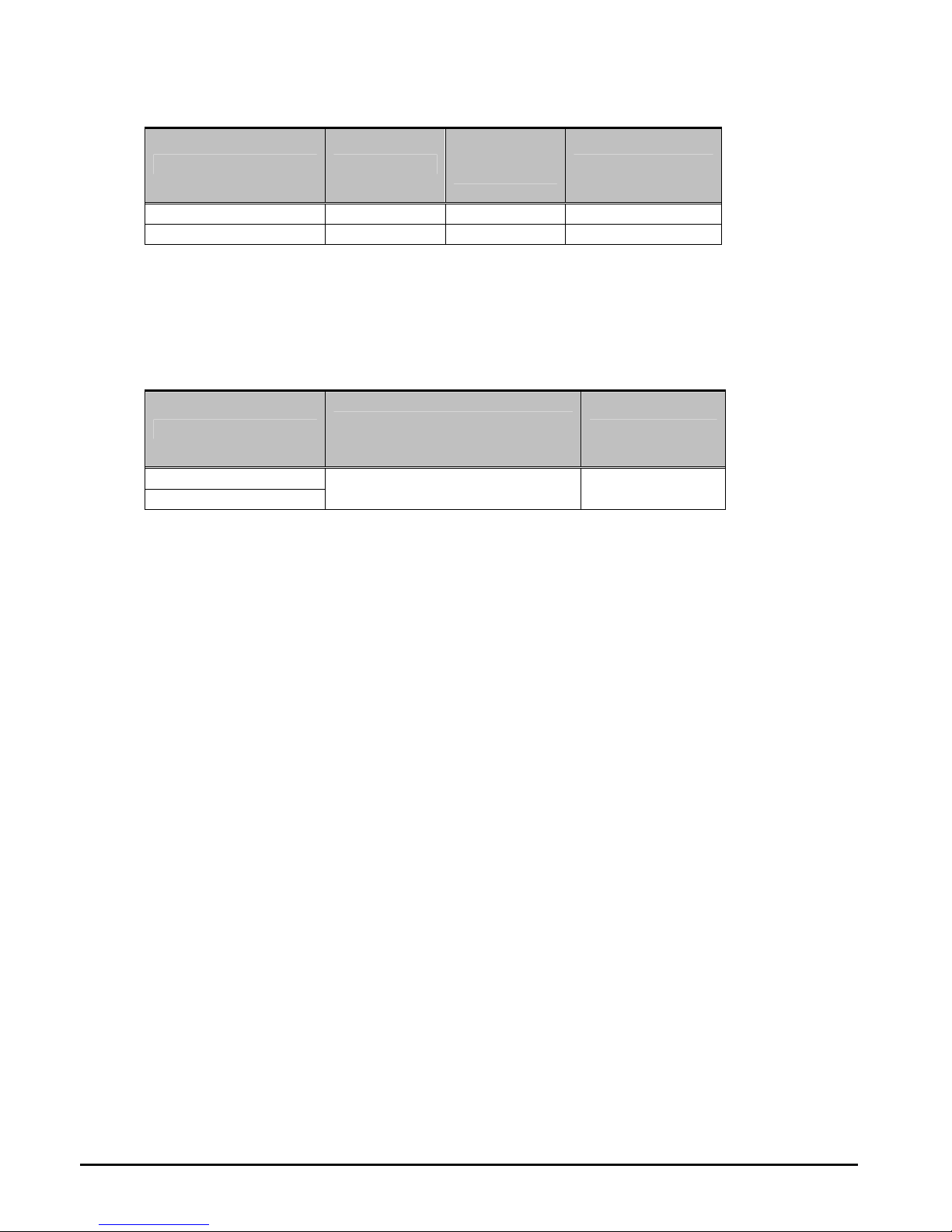

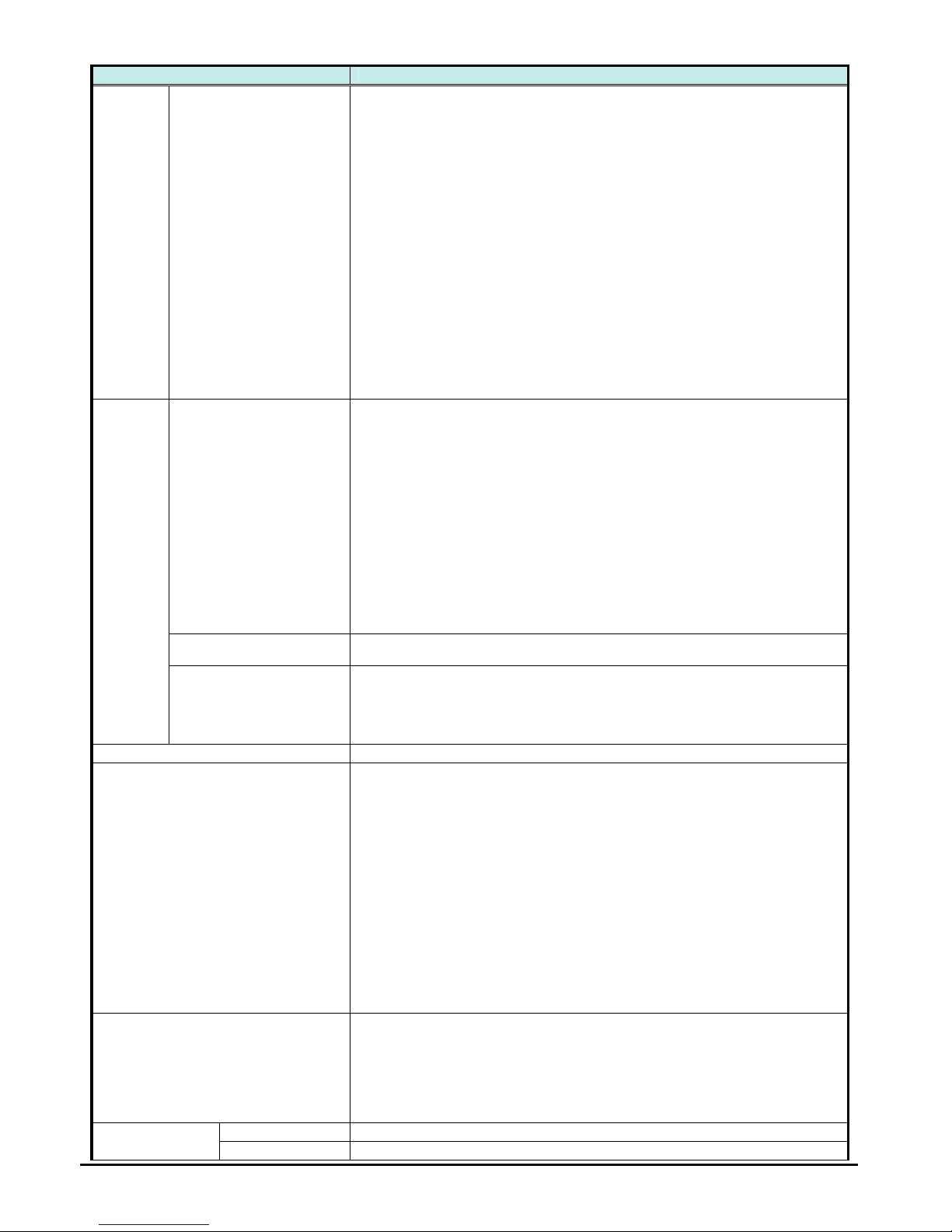

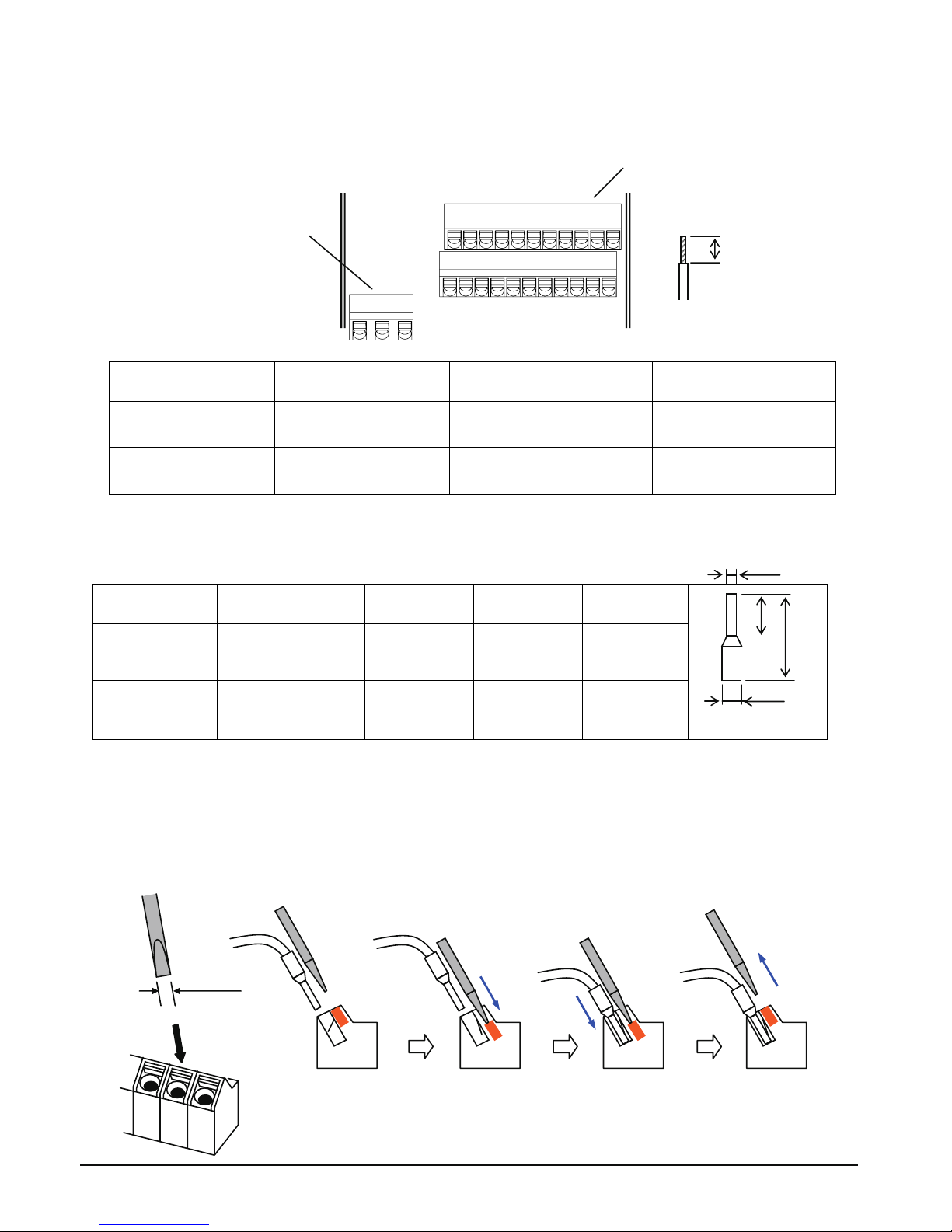

Terminal symbols and Screw size

Inverter Model Screw Size

Required

Torque (N-m)

Wire range

WJ200-004M M3.5 1.2 AWG12 (3.3mm2)

WJ200-007M M4 1.4 AWG10 (5.3mm2)

Fuse Sizes

The inverter shall be connected with a UL Listed Cartridge Nonrenewable fuse, rated 600Vac

with the current ratings as shown in the table below or Type E Combination Motor Controller

marking is to indicate that the unit shall be connected with, LS Industrial System Co., Ltd, Type E

Combination Motor Controller MMS Series with the ratings as shown in the table below:

Inverter Model

Fuse (UL-rated, class J, 600V ,

Maximum allowable current)

Type E C.M.C.

WJ200-004M

WJ200-007M

50A, AIC 200kA

MMS-32H,

120 V, 40 A

3

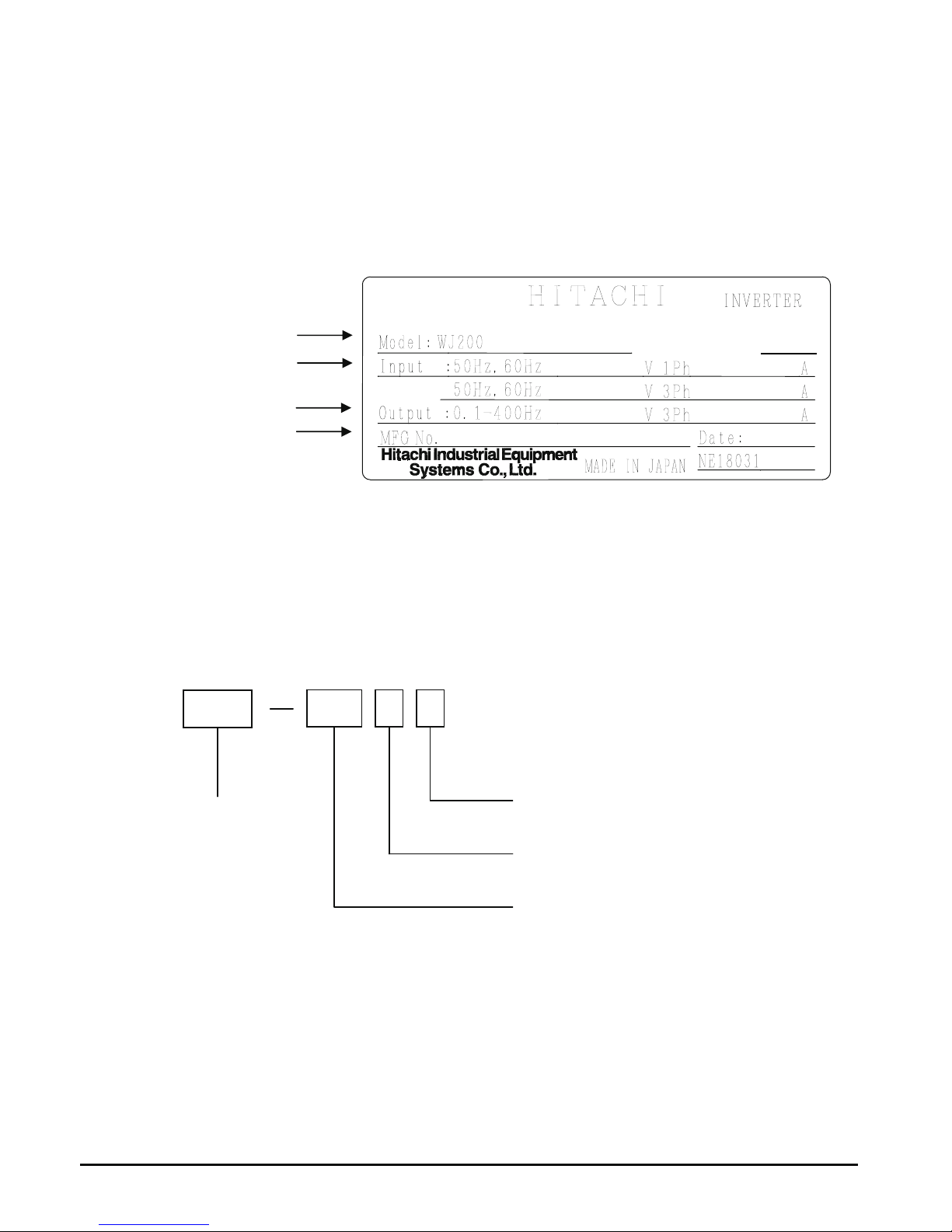

Inverter Specification Label

The Hitachi WJ200 inverters have product labels located on the right side of the housing,

as pictured below. Be sure to verify that the specifications on the labels match your power

source, and application safety requirements.

Inverter Specification Label

The model number for a specific inverter contains useful information about its operating

characteristics. Refer to the model number legend below:

100-120

200-240

14.0

3. 0

1104

14A_T12345_A_-001

-004MF

Model name

Input ratings

Output ratings

MFG number

Ver:2.0

WJ200

004 M F

Series name

Configuration type

F=with keypad

Input voltage:

M=Single-phase 100V class

A

pplicable motor capacity in kW

004=0.4kW

007=0.75kW

4

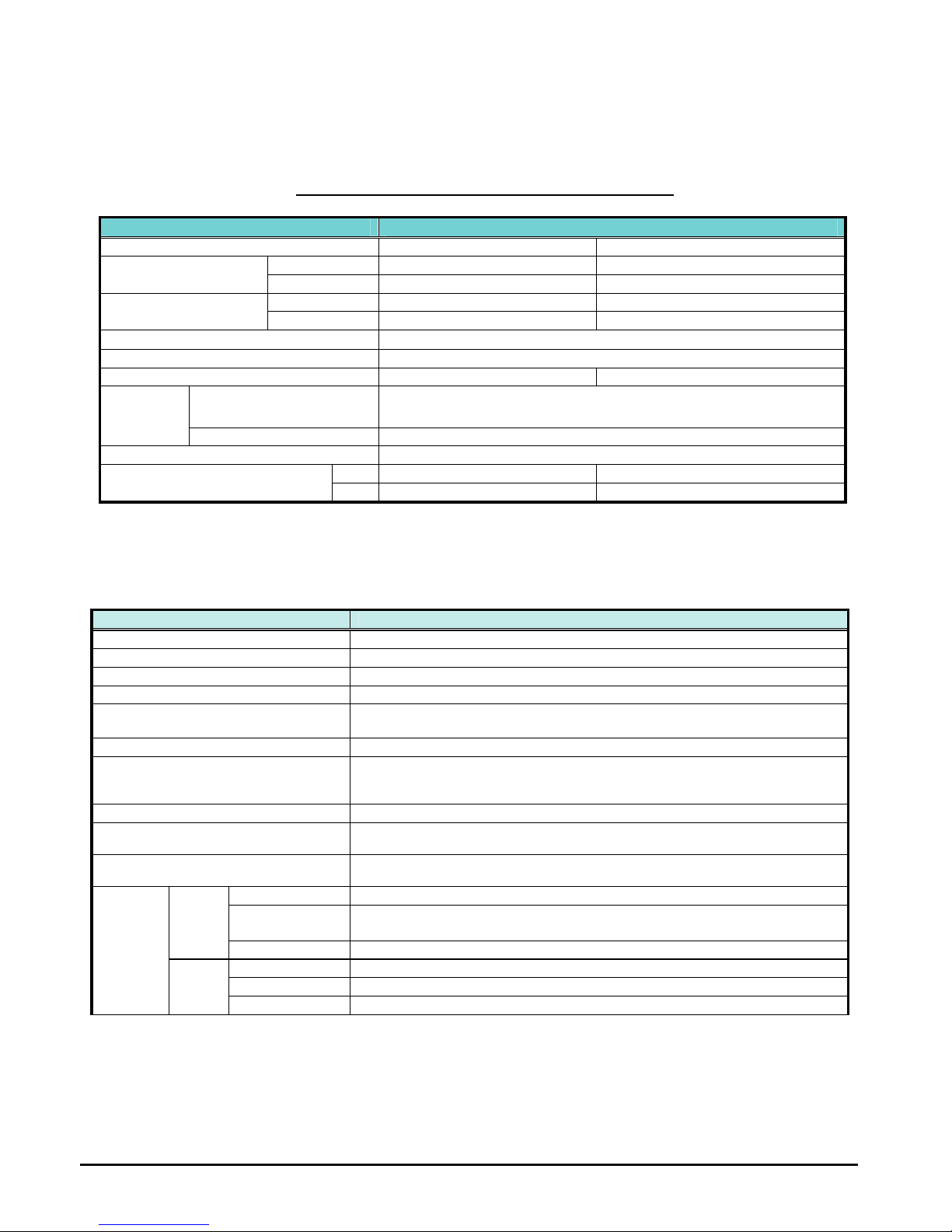

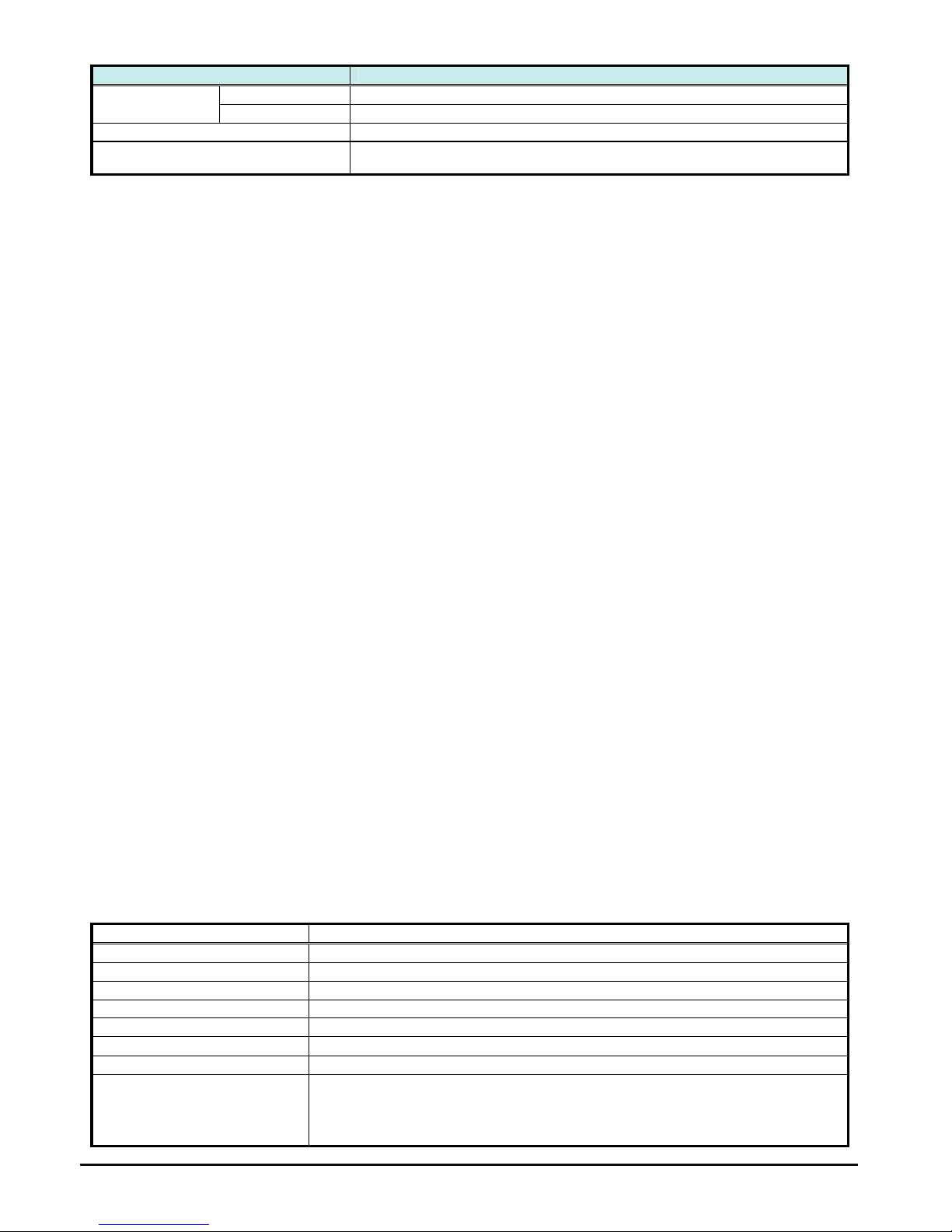

WJ200 Inverter Specifications

Model-specific tables for the Single-phase 100V class inverters

The following tables are specific to WJ200 inverters for the Single-phase 100V class model

groups. Note that “General Specifications” on page in this chapter

apply to both voltage

class groups. Footnotes for all specification tables follow the table below.

Item Single-phase 100V class Specifications

WJ200 inverters, 100V models 004MF 007MF

kW 0.4 0.75 Applicable motor size

HP

1/2 1

100V 1.0 1.7 Rated capacity (kVA)

120V 1.2 2.0

Rated input voltage

Single-phase: 100V to 120V 10%, 50/60Hz 5%

Rated output voltage *3 Three-phase: 200 to 240V (proportional to input voltage)

Rated output current (A) *12 3.0 (2.6) 5.0 (4.0)

Without resistor *6

100%:

50Hz

50%:

60Hz

Braking

With resistor 150%

DC braking Variable operating frequency, time, and braking force

kg 1.1 1.6 Weight

lb 2.4 3.5

General Specifications

The following table applies to Single-phase 100V class WJ200 inverters.

Item General Specifications

Protective housing *1

IP20

Control method

Sinusoidal Pulse Width Modulation (PWM) control

Carrier frequency

2kHz to 15kHz (derating required depending on the model)

Output frequency range *4

0.1 to 400Hz

Frequency accuracy

Digital command: 0.01% of the maximum frequency

Analog command: 0.2% of the maximum frequency (25C 10C)

Frequency setting resolution

Digital: 0.01Hz; Analog: max. frequency/1000

Volt./Freq. characteristic

V/f control (constant torque, reduced torque, free-V/F): base freq. 30Hz~400Hz

adjustable,

Sensorless vector control, Closed loop control with motor encoder feedback

Overload capacity

60 sec. @150%

Acceleration/deceleration time

0.01 to 3600 seconds, linear and S-curve accel/decel, second accel/decel

setting available

Starting torque *5

200% @0.5Hz (IM: sensorless vector control)

50% @10% of base frequency (PM: sensorless vector control)

Operator panel

Up and Down keys / Value settings

External signal

*7

0 to 10 VDC (input impedance 10k Ohms), 4 to 20mA (input impedance 100

Ohms), Potentiometer (1k to 2k Ohms, 2W)

Freq.

setting

Via network

RS485 ModBus RTU, other network option

Operator panel

Run/Stop (Forward/Reverse run change by command)

External signal

Forward run/stop, Reverse run/stop

Input

signal

FWD/

REV run

Via network

RS485 ModBus RTU, other network option

5

Item General Specifications

Intelligent input terminal

Seven terminals,

sink/source changeable

by a short bar

68 functions assignable

FW (forward run command), RV (reverse run command), CF1~CF4 (multi-stage

speed setting), JG (jog command), DB (external braking), SET (set second

motor), 2CH (2-stage accel./decel. command), FRS (free run stop command),

EXT (external trip), USP (startup function), CS (commercial power switchover),

SFT (soft lock), AT (analog input selection), RS (reset), PTC (thermistor thermal

protection), STA (start), STP (stop), F/R (forward/reverse), PID (PID disable),

PIDC (PID reset), UP (remote control up function), DWN (remote control down

function), UDC (remote control data clear), OPE (operator control), SF1~SF7

(multi-stage speed setting; bit operation), OLR (overload restriction), TL (torque

limit enable), TRQ1 (torque limit changeover1), TRQ2 (torque limit

changeover2), BOK (Braking confirmation), LAC (LAD cancellation), PCLR

(position deviation clear), ADD (add frequency enable), F-TM (force terminal

mode), ATR (permission of torque command input), KHC (Cumulative power

clear), MI1~MI7 (general purpose inputs for EzSQ), AHD (analog command

hold), CP1~CP3 (multistage-position switches), ORL (limit signal of zero-return),

ORC (trigger signal of zero-return), SPD (speed/position changeover),

GS1,GS2 (STO inputs, safety related signals),

485 (Starting communication

signal), PRG (executing EzSQ program), HLD (retain output frequency), ROK

(permission of run command), EB (rotation direction detection of B-phase),

DISP (display limitation), NO (no function)

Intelligent output terminal

48 functions assignable

RUN (run signal), FA1~FA5 (frequency arrival signal), OL,OL2 (overload

advance notice signal), OD (PID deviation error signal), AL (alarm signal), OTQ

(over/under torque threshold), UV (under-voltage), TRQ (torque limit signal),

RNT (run time expired), ONT (power ON time expired), THM (thermal warning),

BRK (brake release), BER (brake error), ZS (0Hz detection), DSE (speed

deviation excessive), POK (positioning completion), ODc (analog voltage input

disconnection), OIDc (analog current input disconnection), FBV (PID second

stage output), NDc (network disconnect detection), LOG1~LOG3 (Logic output

signals), WAC (capacitor life warning), WAF (cooling fan warning), FR (starting

contact), OHF (heat sink overheat warning), LOC (Low load), MO1~MO3

(general outputs for EzSQ), IRDY (inverter ready), FWR (forward operation),

RVR (reverse operation), MJA (major failure), WCO (window comparator O),

WCOI (window comparator OI), FREF (frequency command source), REF (run

command source), SETM (second motor in operation), EDM (STO (safe torque

off) performance monitor), OP (option control signal), NO (no function)

Monitor output (analog)

Output freq., output current, output torque, output voltage, input power, thermal

load ratio, LAD freq., heat sink temperature, general output (EzSQ)

Output

signal

Pulse train output

(0~10Vdc, 32kHz max.)

[PWM output]

Output freq., output current, output torque, output voltage, input power, thermal

load ratio, LAD freq., heat sink temperature, general output (EzSQ)

[Pulse train output]

Output frequency, output current, pulse train input monitor

Alarm output contact

ON for inverter alarm (1c contacts, both normally open or closed available.)

Other functions

Free-V/f, manual/automatic torque boost, output voltage gain adjustment, AVR

function, reduced voltage start, motor data selection, auto-tuning, motor

stabilization control, reverse running protection, simple position control, simple

torque control, torque limiting, automatic carrier frequency reduction, energy

saving operation, PID function, non-stop operation at instantaneous power

failure, brake control, DC injection braking, dynamic braking (BRD), frequency

upper and lower limiters, jump frequencies, curve accel and decel (S, U,

inversed U,EL-S), 16-stage speed profile, fine adjustment of start frequency,

accel and decel stop, process jogging, frequency calculation, frequency

addition, 2-stage accel/decel, stop mode selection, start/end freq., analog input

filter, window comparators, input terminal response time, output signal

delay/hold function, rotation direction restriction, stop key selection, software

lock, safe stop function, scaling function, display restriction, password function,

user parameter, initialization, initial display selection, cooling fan control,

warning, trip retry, frequency pull-in restart, frequency matching, overload

restriction, over current restriction, DC bus voltage AVR

Protective function

Over-current, over-voltage, under-voltage, overload, brake resistor overload,

CPU error, memory error, external trip, USP error, ground fault detection at

power on, temperature error, internal communication error, driver error,

thermistor error, brake error, safe stop, overload at low speed, modbus

communication error, option error, encoder disconnection, speed excessive,

EzSQ command error, EzSQ nesting error, EzSQ execution error, EzSQ user

trip

Temperature

Operating (ambient): -10 to 40C(*8), / Storage: -20 to 65C(*9)

Operating

environment

Humidity

20 to 90% humidity (non-condensing)

6

Item General Specifications

Vibration *10

5.9m/s2 (0.6G), 10 to 55 Hz

Location

Altitude 1,000m or less, indoors (no corrosive gasses or dust)

Coating color

Black

Options

Remote operator unit, cables for the units, braking unit, braking resistor,

fieldbus

Footnotes for the preceding table and the tables that follow:

Note1: The protection method conforms to JIC C 0920.

Note2: The applicable motor refers to Hitachi standard 3-phase motor (4p). When using other

motors, care must be taken to prevent the rated motor current (50/60Hz) from exceeding the

rated output current of the inverter.

N

ote3: The output voltage decreases as the main supply voltage decreases (except when using

the AVR function). In any case, the output voltage cannot exceed the input power supply voltage.

In any case, the output voltage cannot exceed two times the input power supply voltage

Note4: To operate the motor beyond 50/60Hz, consult the motor manufacturer for the maximum

allowable rotation speed.

Note5: At the rated voltage when using a Hitachi standard 3-phase, 4-pole motor.

Note6: The braking torque via capacitive feedback is the average deceleration torque at the

shortest deceleration (stopping from 50/60Hz as indicated). It is not continuous regenerative

braking torque. The average deceleration torque varies with motor loss. This value decreases

when operating beyond 50Hz. If a large regenerative torque is required, the optional

regenerative braking unit and a resistor should be used.

Note7: The frequency command is the maximum frequency at 9.8V for input voltage 0 to

10VDC, or at 19.6mA for input current 4 to 20mA. If this characteristic is not satisfactory for

your application, contact your Hitachi representative.

Note8: If the inverter is operated outside the region shown in the graph in the derating curve,

the inverter may be damaged or its service life may be shortened. Set B083 Carrier Frequency

Adjustment in accordance with the expected output current level. See derating curve section

for the detailed information of the inverter operating range.

Note9: The storage temperature refers to the short-term temperature during transportation.

Note10: Conforms to the test method specified in JIS JIS C 60068-2-6 :2010(IEC

60068-2-6:2007). For the model types excluded in the standard specifications, contact your

Hitachi sales representative.

Note11: Watt losses are calculated values based on specification of main semi-conductors. You

must take suitable margin when designing cabinet based on these values. Otherwise there is a

possibility of heating trouble.

Note12: “When the ambient temperature exceeds 40C, output current must be limited to the

value in ( ).

Signal Ratings

Detailed ratings are in “Control Logic Signal Specifications” in Page 16.

Signal / Contact Ratings

Built-in power for inputs 24VDC, 100mA maximum

Discrete logic inputs 27VDC maximum

Discrete logic outputs 50mA maximum ON state current, 27 VDC maximum OFF state voltage

Analog output 10bit / 0 to 10VDC, 2mA

Analog input, current 4 to 19.6 mA range, 20mA nominal

Analog input, voltage

0 to 9.8 VDC range, 10VDC nominal, input impedance 10k

+10V analog reference 10VDC nominal, 10mA maximum

Alarm relay contacts 250 VAC, 2.5A (R load) max., 0.2A (I load, P.F.=0.4) max.

100 VAC, 10mA min

30 VDC, 3.0A (R load) max., 0.7A (I load, P.F.=0.4) max.)

5 VDC, 100mA min.

7

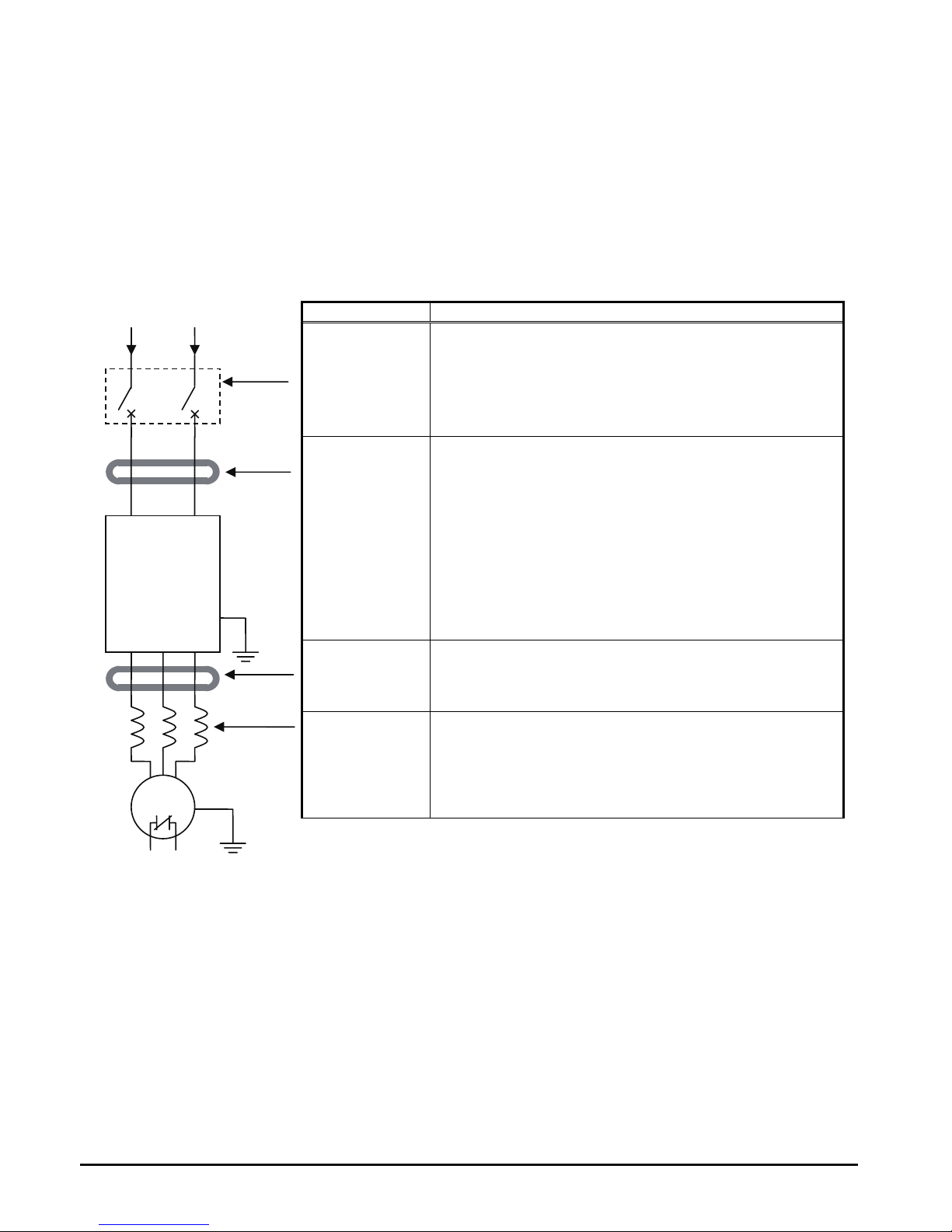

Basic System Description

A motor control system will obviously include a motor and inverter, as well as a circuit

breaker or fuses for safety. If you are connecting a motor to the inverter on a test bench

just to get started, that’s all you may need for now. But a system can also have a variety of

additional components. Some can be for noise suppression, while others may enhance the

inverter’s braking performance. The figure and table below show a system with all the

optional components you might need in your finished application.

Name Function

Breaker /

disconnect

A molded-case circuit breaker (MCCB), ground fault

interrupter (GFI), Type E Combination Motor

Controller(Type E C.M.C) or a fused disconnect device.

NOTE: The installer must refer to the NEC and local codes

to ensure safety and compliance.

Radio noise filter

Electrical noise interference may occur on nearby

equipment such as a radio receiver. This magnetic choke

filter helps reduce radiated noise (can also be used on

output).

Radio noise filter

Electrical noise interference may occur on nearby

equipment such as a radio receiver. This magnetic choke

filter helps reduce radiated noise (can also be used on

input).

Output-side

AC Reactor

This reactor reduces the vibration in the motor caused by

the inverter’s switching waveforms, by smoothing the

waveform to approximate commercial power quality. It is

also useful to reduce harmonics when wiring from the

inverter to the motor is more than 10m in length.

From power supply

Breaker,

MCCB or

GFI

M

Thermal

switch

L1 N

T1 T2 T3

Inverter

GND

8

Determining Wire and Fuse Sizes

The maximum motor currents in your application determines the recommended wire size.

The following table gives the wire size in AWG. The “Power Lines” column applies to the

inverter input power, output wires to the motor, the earth ground connection, and any other

components shown in the “Basic System Description” on page 7. The “Signal Lines”

column applies to any wire connecting to the two green connectors just inside the front

cover panel.

Motor Output Wiring Applicable equipment

kW HP

Inverter Model

Power

Lines

Signal Lines

Fuse (UL-rated,

class J, 600V ,

Maximum

allowable

current)

Typ e E

C.M.C.

0.4 1/2

WJ200-004MF

AWG12 /

3.3mm2

50A

MMS-32H,

120 V, 40 A

0.75

1

WJ200-007MF

AWG10 /

5.3mm

2

18 to 28

AWG / 0.14

to 0.75 mm

2

shielded wire

(see Note 4)

50A

MMS-32H,

120 V, 40 A

Note 1: Field wiring must be made by a UL-Listed and CSA-certified closed-loop terminal

connector sized for the wire gauge involved. Connector must be fixed by using

the crimping tool specified by the connector manufacturer.

Note 2: Be sure to consider the capacity of the circuit breaker to be used.

Note 3: Be sure to use a larger wire gauge if power line length exceeds 66ft. (20m).

Note 4: Use 18 AWG / 0.75mm

2

wire for the alarm signal wire ([AL0], [AL1], [AL2]

terminals).

Note 5: Type E Combination Motor Controller marking is to indicate that the unit shall be

connected with, LS Industrial System Co., Ltd, Type E Combination Motor

Controller MMS Series .

9

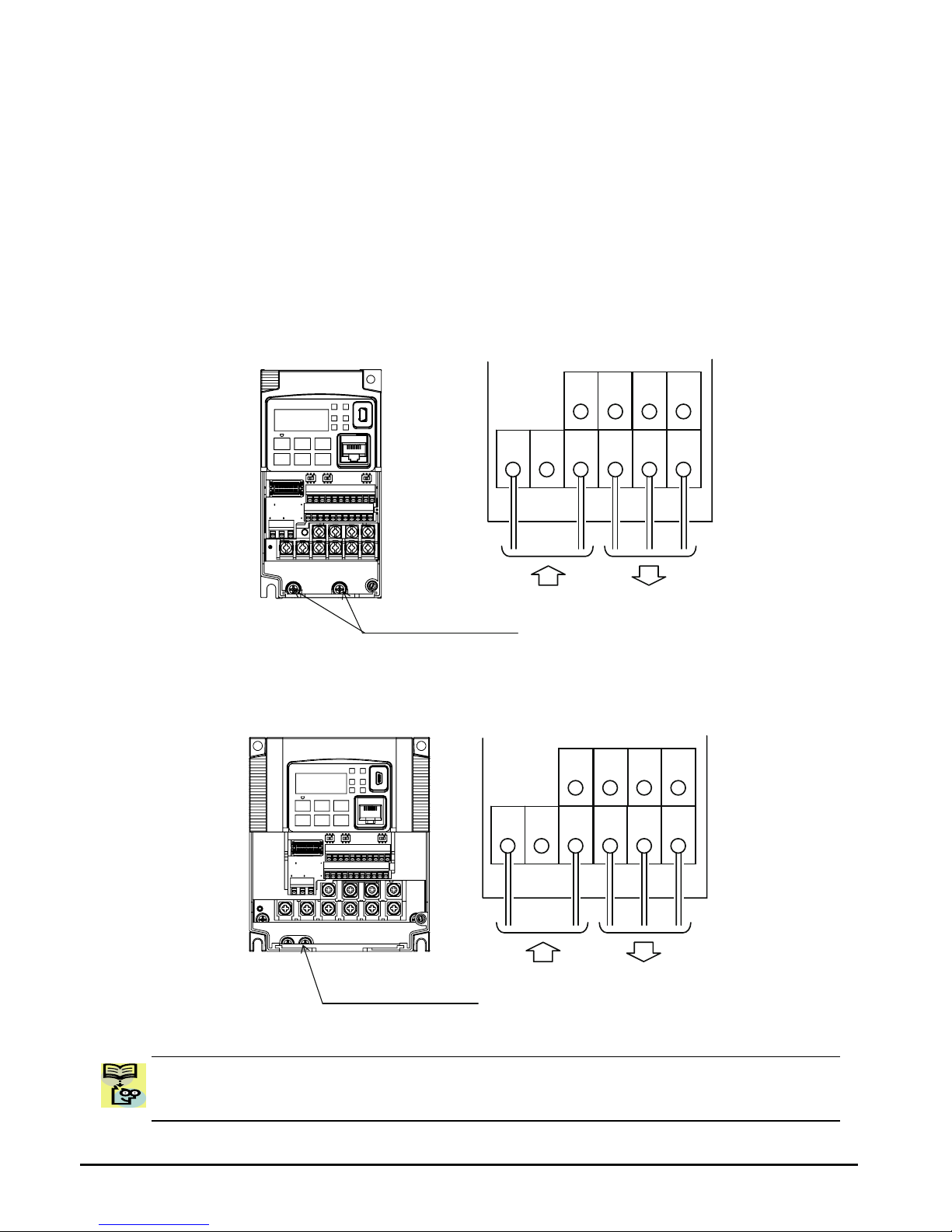

Wire the Inverter Input to a Supply

In this step, you will connect wiring to the input of the inverter. This Inverter is single-phase

power only. The power connection terminals are [L1] and [N]. So you must refer to the

specifications label (on the side of the inverter) for the acceptable power source

types!

Single-phase inverter models will have no connection to the [S/L2] terminal.

This is only used for three-phase models.

Note the use of ring lug connectors is

recommended

for a secure connection.

Single-phase 100V 0.4kW

Single-phase 100V 0.75kW

NOTE: An inverter powered by a portable power generator may

cause a distorted power

waveform, overheating the generator. In general, the generator capacity should be five

times that of the inverter (kVA).

Chassis Ground (M4)

Chassis Ground (M4)

Single-phase

L1

Power input Output to Motor

N U/T1 V/T2 W/T3

RB

P/+

-

Single-phase

Power input Output to Motor

L1

N U/T1 V/T2 W/T3

RB P/+

-

10

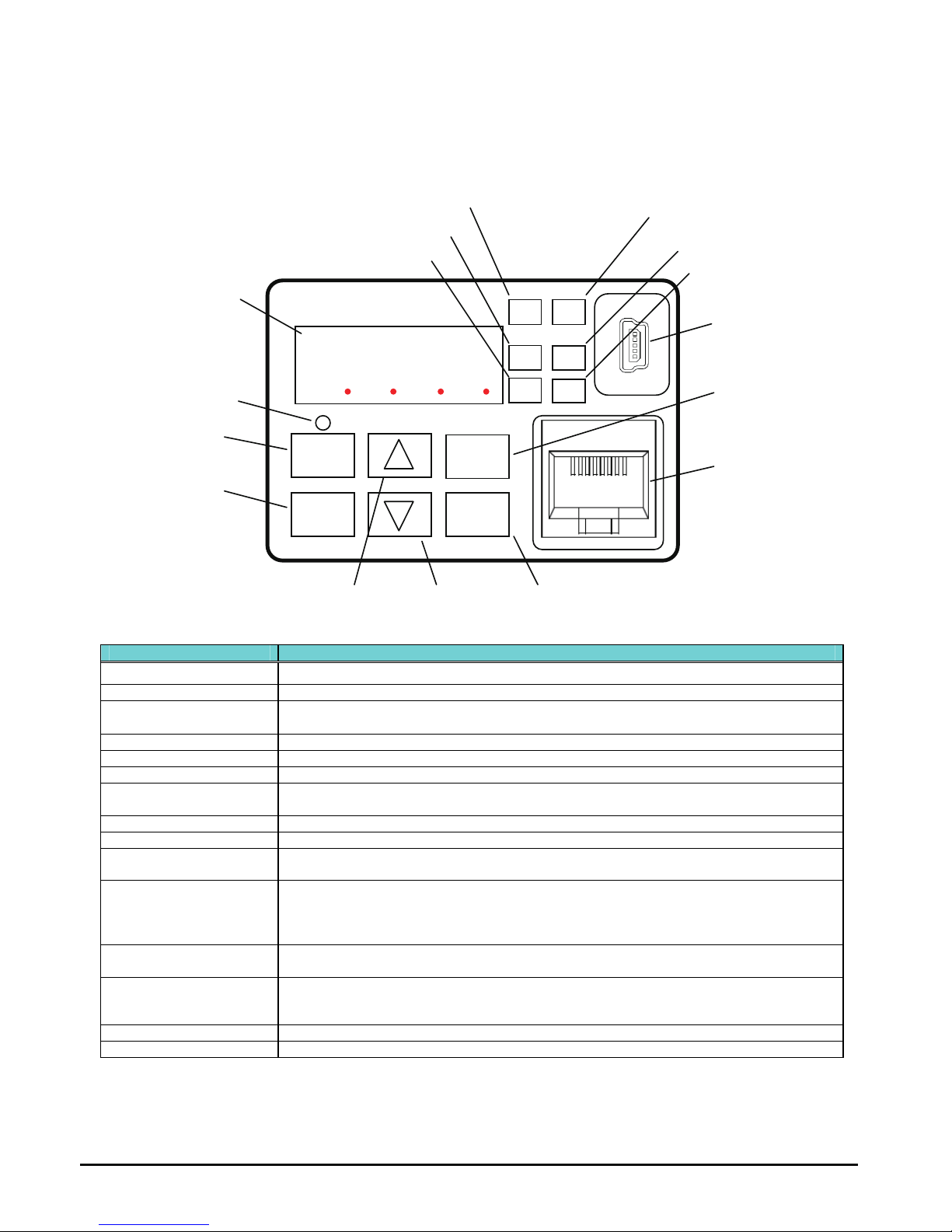

Using the Front Panel Keypad

Please take a moment to familiarize yourself with the keypad layout shown in the figure

below. The display is used in programming the inverter’s parameters, as well as monitoring

specific parameter values during operation.

Key and Indicator Legend

Items Contents

(1) POWER LED Turns ON (Green) while the inverter is powered up.

(2) ALARM LED Turns ON (Red) when the inverter trips.

(3) Program LED

¾ Turns ON (Green) when the display shows changeable parameter.

¾ Blinks when there is a mismatch in setting.

(4) RUN LED Turns ON (Green) when the inverter is driving the motor.

(5) Monitor LED [Hz] Turns ON (Green) when the displayed data is frequency related.

(6) Monitor LED [A] Turns ON (Green) when the displayed data is current related.

(7) Run command LED

Turns ON (Green) when the RUN command source is set to the operator. (Run key is

effective.)

(8) 7-seg LED Shows each parameter, monitors etc.

(9) RUN key Makes inverter run.

(10) STOP/RESET key

¾ Makes inverter stop, according to parameter setup.

¾ Reset the inverter when it is in trip situation

(11) ESC key

¾ Go to the top of next function group, when a function mode is shown

¾ Cancel the setting and return to the function code, when a data is shown

¾ Moves the cursor to a digit left, when it is in digit-to-digit setting mode

¾ Pressing for 1 second leads to display data of d001, regardless of current display.

(12) Up key

(13) Down key

¾ Increase or decrease the data.

¾ Pressing the both keys at the same time gives you the digit-to-digit edit.

(14) SET key

¾ Go to the data display mode when a function code is shown

¾ Stores the data and go back to show the function code, when data is shown.

¾ Moves the cursor to a digit right, when it is in digit-to-digit display mode

(15) USB connector Connect USB connector (mini-B) for using PC communication

(16) RJ45 connector Connect RJ45 jack for remote operator

1

2

RUN

ESC

STOP/

RESET

SET

8888

RUN

Hz A

PWR

ALM

PRG

(1) POWER LED

(2) ALARM LED

(8) 7-seg LED

(4) RUN LED

(10) STOP/RESET key

(15) USB connector

(3) Program LED

(16) RJ45 connector

(14) SET key

(13) Down key (12) Up key

(11) ESC key

(9) RUN key

(7) Run command LED

(5) Monitor LED [Hz]

(6) Monitor LED [A]

11

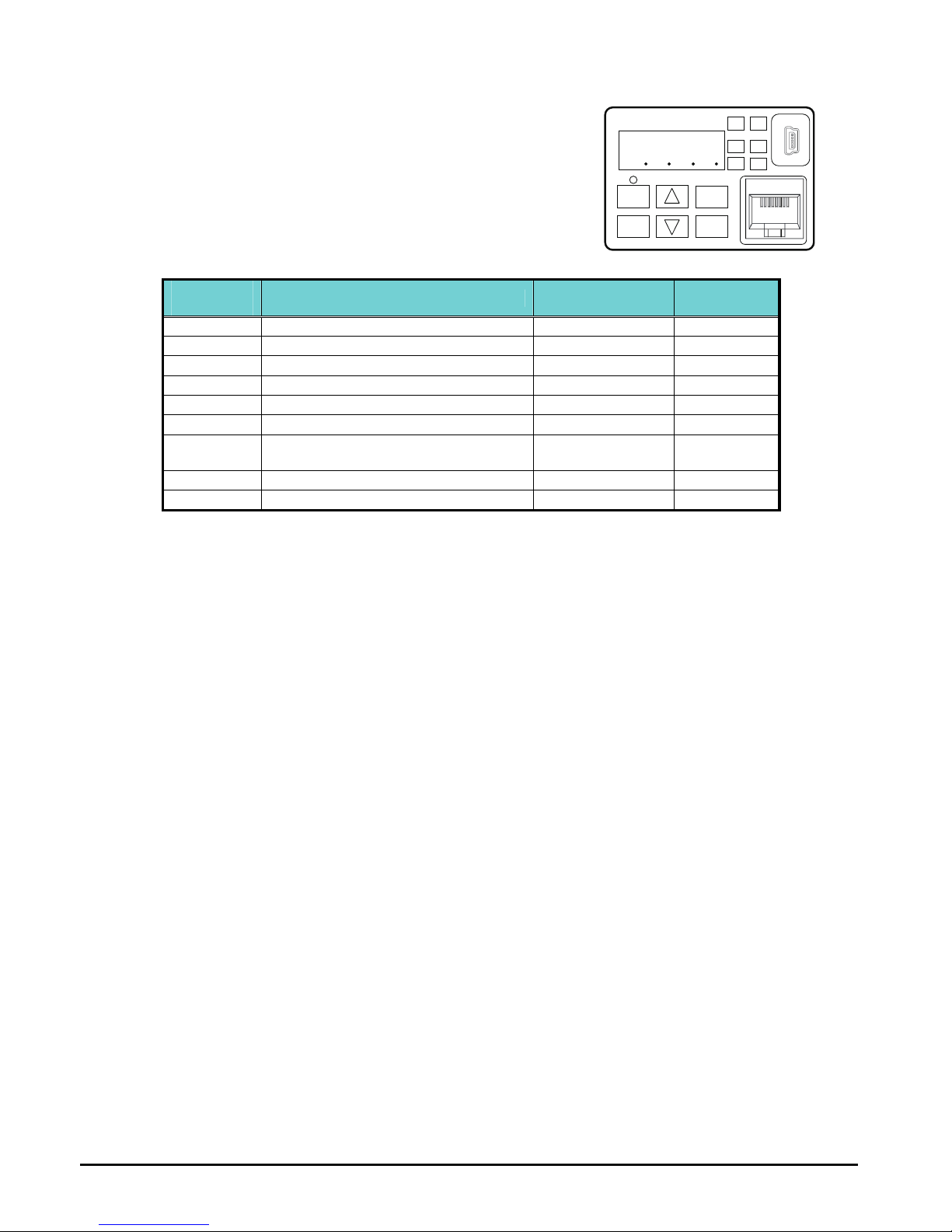

Keys, Modes, and Parameters

The purpose of the keypad is to provide a way to

change modes and parameters. The term function

applies to both monitoring modes and parameters.

These are all accessible through function codes that are

primary 4-character codes. The various functions are

separated into related groups identifiable by the

left-most character, as the table shows.

Function

Group

Type (Category) of Function Mode to Access

PRG LED

Indicator

“d” Monitoring functions Monitor

“F” Main profile parameters

Program

z

“A” Standard functions

Program

z

“b” Fine tuning functions

Program

z

“C” Intelligent terminal functions

Program

z

“H” Motor constant related functions

Program

z

“P” Pulse train input, torque, EzSQ, and

communication related functions

Program

z

“U” User selected parameters

Program

z

“E” Error codes

You can see from the following page how to monitor and/or program the parameters.

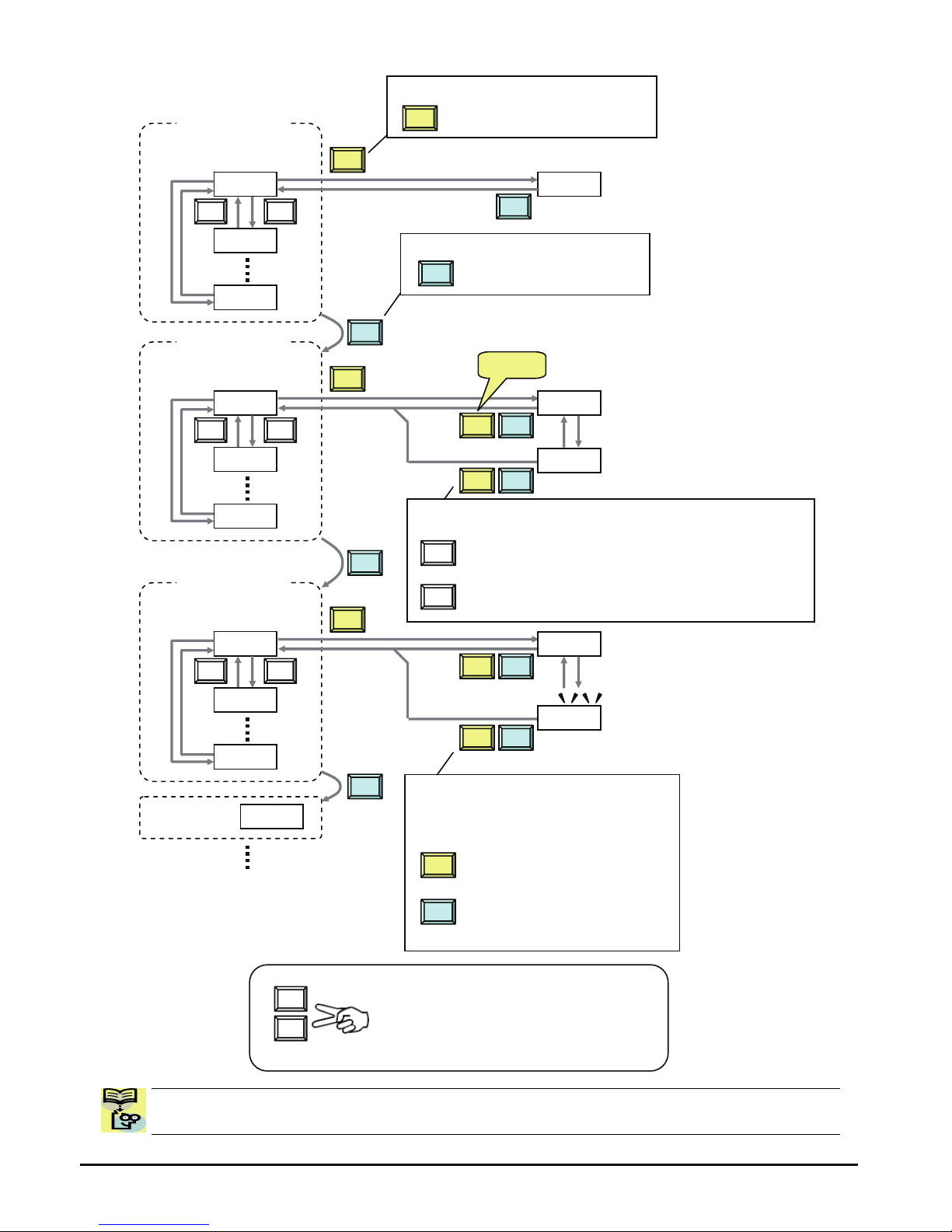

Keypad Navigation Map

The WJ200 Series inverter drives have many programmable functions and parameters.

Chapter 3 will cover these in detail, but you need to access just a few items to perform the

powerup test. The menu structure makes use of function codes and parameter codes to

allow programming and monitoring with only a 4-digit display and keys and LEDs. So, it is

important to become familiar with the basic navigation map of parameters and functions in

the diagram below. You may later use this map as a reference.

1

2

RUN

ESC

STOP/

RESET

SET

8888

RUN

Hz

A

PWR

ALM

PRG

12

NOTE: Pressing the [ESC] key will make the display go to the top of next function group,

regardless the display contents. (e.g. A021 Æ [ESC] Æ b001)

U

V

Press the both up and down key at the same

time in func. code or data display, then

single-digit edit mode will be enabled.

Refer to 2-34 for further information.

d001

V U

ESC

SET

Group "d"

Func. code display

0.00

d002

d104

F001

V U

Group "F"

Func. code display

F002

F004

50.00

50.01

SET

SET ESC

SET ESC

Save

A001

V U

Group "A"

Func. code display

A002

A165

00

01

SET

SET ESC

SET ESC

Data display

When data is changed, the display

starts blinking, which means that

new data has not been activated yet.

: Saves the data in EEPROM and

returns to func. code display.

: Cancels the data change and

returns to func. code display.

SET

ESC

Group "b"

b001

ESC

Func. code display

: Jumps to the next group

ESC

Func. code display

: Moves to data display

SET

ESC

ESC

Data display (F001 to F003)

Data does not blink because of real time synchronizing

: Saves the data in EEPROM

and returns to func. code display.

: Returns to func. code display without saving data.

SET

ESC

13

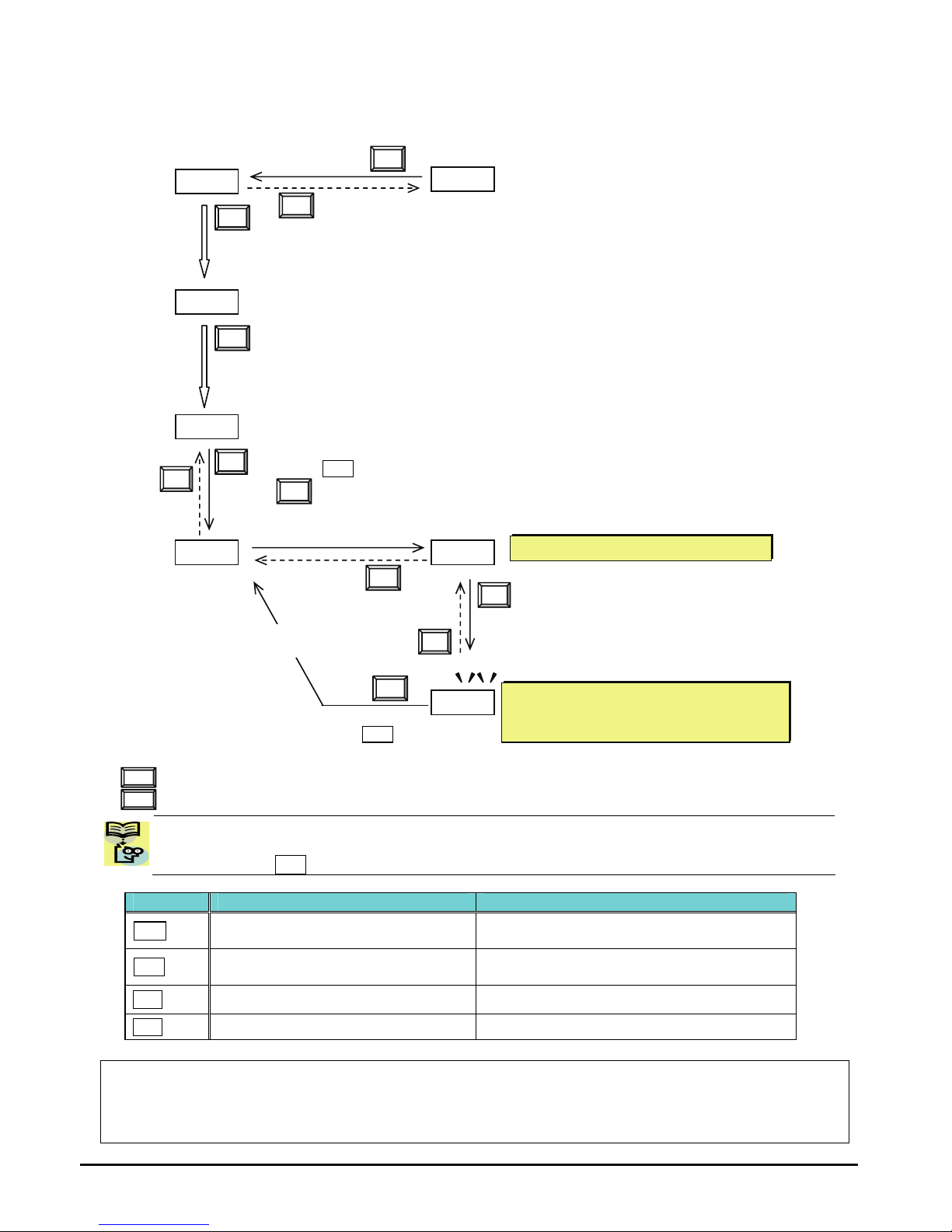

[Setting example]

After power ON, changing from 0.00 display to change the b083 (carrier frequency) data.

Function code dxxx are for monitor and not possible to change.

Function codes Fxxx other than F004 are reflected on the performance just after changing the data

(before pressing SET key), and there will be no blinking.

When a function code is shown… When data is shown…

ESC key Move on to the next function group

Cancels the change and moves back to the

function code

SET key Move on to the data display

Fix and stores the data and moves back to

the function code

U key

Increase function code Increase data value

V key

Decrease function code Decrease data value

Note

Keep pressing for more than 1 second leads to d001 display, regardless the display situation. But note that

the display will circulates while keep pressing the [ESC] key because of the original function of the key.

(e.g. F001 Æ A001 Æ b001 Æ C001 Æ …Æ displays 50.00 after 1 second)

b001

b083 5.0

Display is lit solidy

12.0

F001

d001

0.00

c Data of d001 will be shown on the

display after the first power ON

d Press [ESC] key to show

the function code

e Press [ESC] key to move

on to the function group F001

f Press [ESC] key twice to move

on to the function group b001.

g Press Up key to change increase

function code (b001

Æ b083)

h Press SET key to display the data of b083

i Press SET key to set

and save the data

When data is changed, the display

starts blinking, which means that new

data has not been activated yet.

ESC

U

V

SET

ESC

ESC

SET

ESC

U

V

:Fix and stores the data and moves back to the function code

:Cancels the change and moves back to the function code

SET

ESC

SET

i Press up key to increase the

data (5.0 Æ 12.0)

14

Connecting to PLCs and Other Devices

Hitachi inverters (drives) are useful in many types of applications. During installation, the

inverter keypad (or other programming device) will facilitate the initial configuration. After

installation, the inverter will generally receive its control commands through the control

logic connector or serial interface from another controlling device. In a simple application

such as single-conveyor speed control, a Run/Stop switch and potentiometer will give the

operator all the required control. In a sophisticated application, you may have a

programmable logic controller (PLC) as the system controller, with several connections to

the inverter.

It is not possible to cover all the possible types of application in this manual. It will be

necessary for you to know the electrical characteristics of the devices you want to connect

to the inverter. Then, this section and the following sections on I/O terminal functions can

help you quickly and safely connect those devices to the inverter.

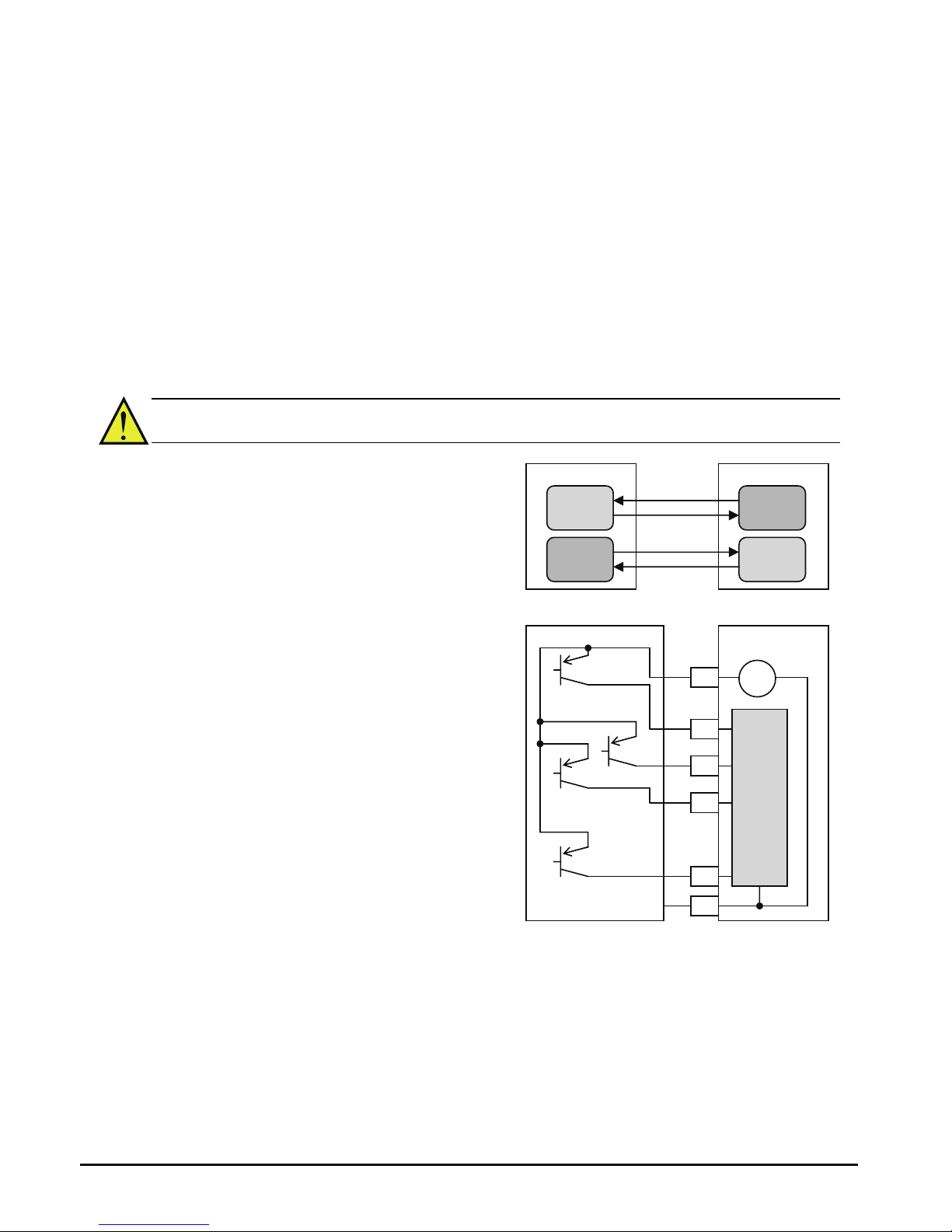

CAUTION: It is possible to damage the inverter or other devices if your application

exceeds the maximum current or voltage characteristics of a connection point.

The connections between the inverter and

other devices rely on the electrical input/output

characteristics at both ends of each connection,

shown in the diagram to the right.

The inverter’s configurable inputs accept either

a sourcing or sinking output from an external

device (such as PLC). This chapter shows the

inverter’s internal electrical component(s) at

each I/O terminal. In some cases, you will

need to insert a power source in the interface

wiring.

In order to avoid equipment damage and get

your application running smoothly, we

recommend drawing a schematic of each

connection between the inverter and the other

device. Include the internal components of

each device in the schematic, so that it makes

a complete circuit loop.

After making the schematic, then:

1. Verify that the current and voltage for each

connection is within the operating limits of

each device.

2. Make sure that the logic sense (active high or active low) of any ON/OFF connection is

correct.

3. Check the zero and span (curve end points) for analog connections, and be sure the

scale factor from input to output is correct.

4. Understand what will happen at the system level if any particular device suddenly

loses power, or powers up after other devices.

Other device

Input

circuit

Output

circuit

WJ200 inverter

Input

circuit

Output

circuit

signal

return

signal

return

Other device WJ200 inverter

Input

circuits

P24

1

2

3

7

L

24V

+ -

GND

…

…

15

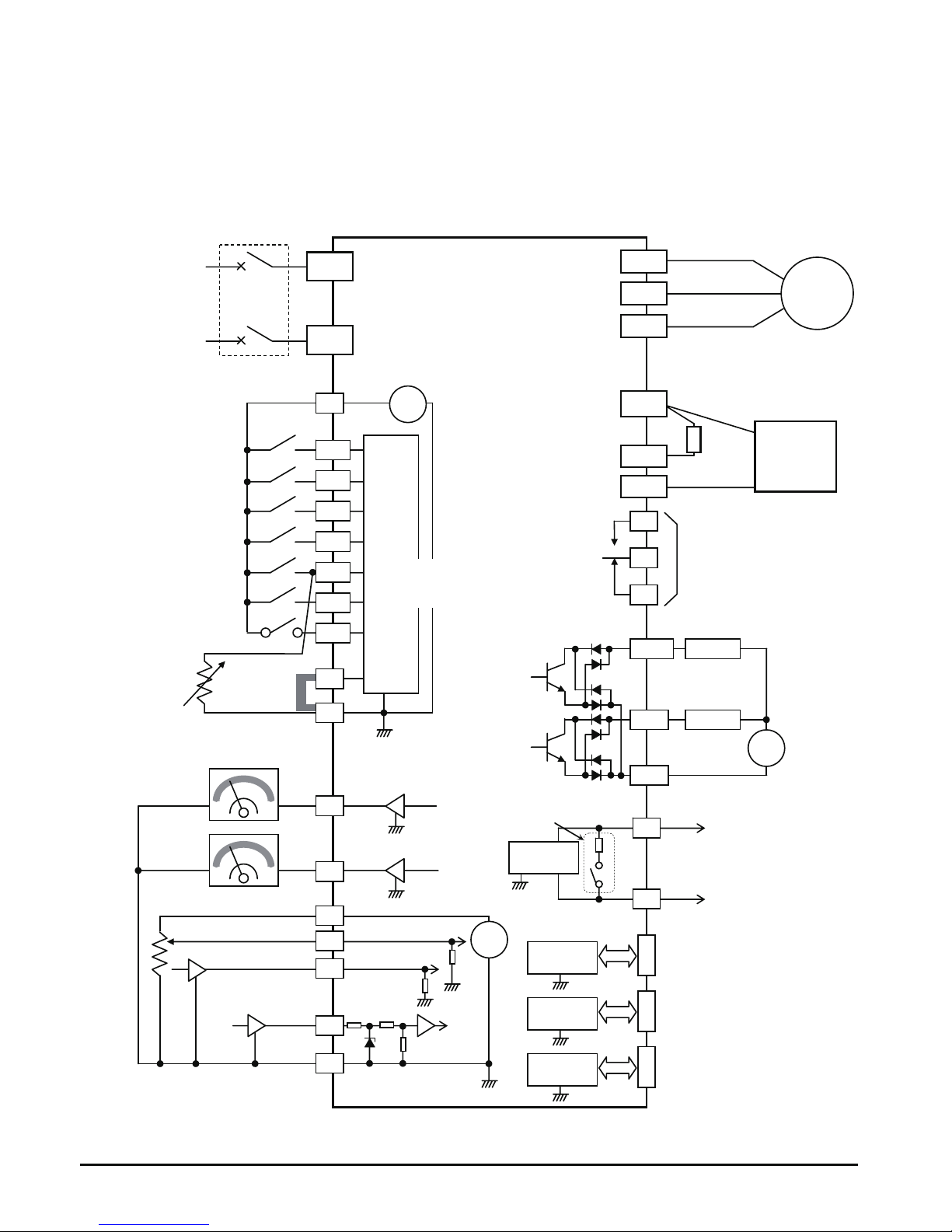

Example Wiring Diagram

The schematic diagram below provides a general example of logic connector wiring, in

addition to basic power and motor wiring converted in Chapter 2. The goal of this chapter

is to help you determine the proper connections for the various terminals shown below for

your application needs.

Breaker, MCCB

or GFI

Power source,

1-phase,

inverter model

Input

circuits

24V

P24

+ -

1

2

3/GS1

4/GS2

5/PTC

Forward

Thermistor

Intelligent inputs,

7 terminals

GND for logic inputs

NOTE: For the wiring

of intelligent I/O and

analog inputs, be sure

to use twisted pair /

shielded cable. Attach

the shielded wire for

each signal to its

respective common

terminal at the inverter

end only.

Input impedance of

each intelligent input is

4.7k

[5] configurable as

discrete input or

thermistor input

AM

Meter

H

L

A

nalog reference

0~10VDC

4~20mA

GND for analog signals

WJ200

Moto

r

P/+

L1

N

U(T1)

V(T2)

W(T3)

-

AL1

AL0

AL2

Relay contacts,

type 1 Form C

6

7/EB

EO

Meter

Pulse train input

24Vdc 32kHz max.

RB

Brake

resistor

(optional)

11/ EDM

Load

Freq. arrival signal

Open collector output

Output circuit

GND for logic outputs

12

Load

+

CM2

L

L

+

O

OI

EA

A

pprx.10k

10Vdc

A

pprx.100

RS485

transceiver

RJ45 port

(Optional operator port)

USB

transceiver

USB (mini-B) port

(PC communication port)

USB power: Self power

L

L

Option port

controller

Option port connector

L

L

L

L

L

SP

SN

RS485

transceiver

Termination resistor (200)

(Change by slide switch)

Serial communication port

(RS485/ModBus)

L

PLC

Short bar

(Source type)

NOTE: Common for

RS485 is “L”.

Braking

unit (optional)

16

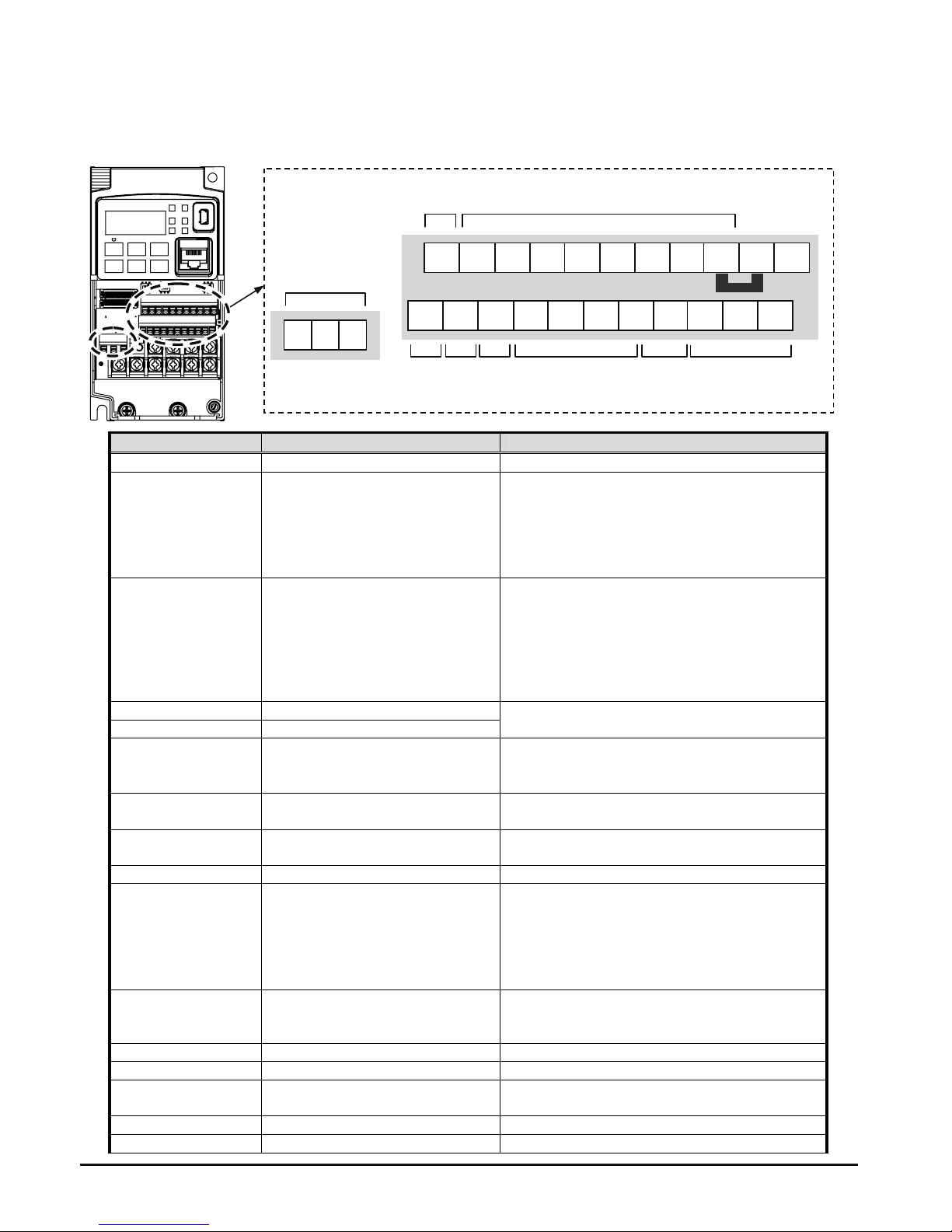

Control Logic Signal Specifications

The control logic connectors are located just behind the front housing cover. The relay

contacts are just to the left of the logic connectors. Connector labeling is shown below.

Terminal Name Description Ratings

P24 +24V for logic inputs 24VDC, 100mA. (do not short to terminal L)

PLC Intelligent input common To change to sink type, remove the short bar

between [PLC] and [L], and connect it

between [P24] and [L]. In this case,

connecting [L] to [1]~[7] makes each input

ON. Please remove the short bar when using

external power supply.

1

2

3/GS1

4/GS2

5/PTC

6

7/EB

Discrete logic inputs

(Terminal [3],[4],[5] and [7]

have dual function. See

following description and

related pages for the details.)

27VDC max. (use PLC or an external supply

referenced to terminal L)

GS1(3) Safe stop input GS1

GS2(4) Safe stop input GS2

Functionality is based on ISO13849-1

See appendix for the details.

PTC(5) Motor thermistor input Connect motor thermistor between PTC and

L terminal to detect the motor temperature.

Set 19 in C005.

EB(7) Pulse train input B 2kHz max.

Common is [PLC]

EA Pulse train input A 32kHz max.

Common is [L]

L (in upper row) *1 GND for logic inputs Sum of input [1]~[7] currents (return)

11/EDM Discrete logic outputs [11]

(Terminal [11] has dual

function. See following

description and related pages

for the details.)

50mA max. ON state current,

27 VDC max. OFF state voltage

Common is CM2

In case the EDM is selected, the functionality

is based on ISO13849-1

4VDC max. ON state voltage depression

12 Discrete logic outputs [12] 50mA max. ON state current,

27 VDC max. OFF state voltage

Common is CM2

CM2 GND for logic output 100 mA: [11], [12] current return

AM Analog voltage output 0~10VDC 2mA maximum

EO Pulse train output 10VDC 2mA maximum

32kHz maximum

L (in bottom row) *2 GND for analog signals Sum of [OI], [O], and [H] currents (return)

OI Analog current input 4 to 19.6 mA range, 20 mA nominal,

Analog

out

p

ut

Logic inputs

Logic

out

p

ut

Short bar

PLC

Analog

in

p

ut

Pulse

Train

input

Pulse

Train

out

put

RS485

comm.

RS485

comm.

P24 1 L 3 2

5 4 6

SN 7

12 11 AM CM2

OI L H O EA

SP EO

AL2AL1A

L0

Relay

contacts

17

Terminal Name Description Ratings

input impedance 100

O Analog voltage input 0 to 9.8 VDC range, 10 VDC nominal,

input impedance 10 k

H +10V analog reference 10VDC nominal, 10mA max.

SP, SN Serial communication terminal For RS485 Modbus communication.

AL0, AL1, AL2 *3 Relay common contact 250VAC, 2.5A (R load) max.

250VAC, 0.2A (I load, P.F.=0.4) max.

100VAC, 10mA min.

30VDC, 3.0A (R load) max.

30VDC, 0.7A (I load, P.F.=0.4) max.

5VDC, 100mA min.

Note 1: The two terminals [L] are electrically connected together inside the inverter.

Note 2: We recommend using [L] logic GND (to the right) for logic input circuits and [L]

analog GND (to the left) for analog I/O circuits.

Note 3: Refer to page 39 for details of trip signals.

Wiring sample of control logic terminal (source logic)

Note: If relay is connected to intelligent output, install a diode across the relay coil

(reverse-biased) in order to suppress the turn-off spike.

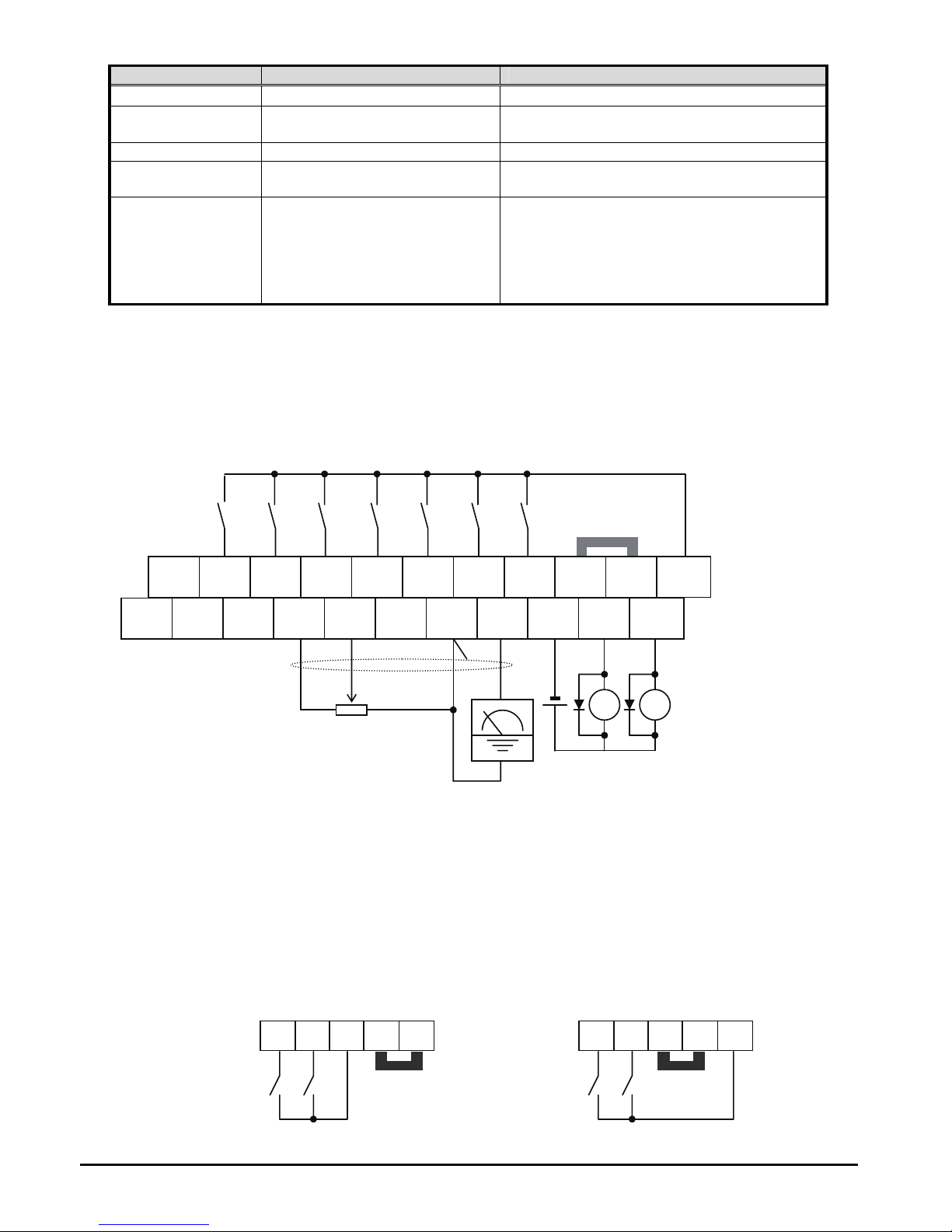

Sink/source logic of intelligent input terminals

Sink or source logic is switched by a short bar as below.

SP EO EA H O OI L AM CM2 12 11/EDM

Freq. meter

Variable resistor

for freq. setting

(1k

-2k

)

Short bar

(

source logic

)

RY

SN 7/EB 6 5/PTC 4/GS2 3/GS1

1 L PLC P24

RY

Short bar

PLC P24

L 1 2

Sink logic

Short bar

PLC P24 L

1 2

Source logic

18

Wire size for control and relay terminals

Use wires within the specifications listed below. For safe wiring and reliability, it is recommended

to use ferrules, but if solid or stranded wire is used, stripping length should be 8mm.

Solid

mm

2

(AWG)

Stranded

mm2 (AWG)

Ferrule

mm2 (AWG)

Control logic

terminal

0.2 to 1.5

(AWG 24 to 16)

0.2 to 1.0

(AWG 24 to 17)

0.25 to 0.75

(AWG 24 to 18)

Relay terminal

0.2 to 1.5

(AWG 24 to 16)

0.2 to 1.0

(AWG 24 to 17)

0.25 to 0.75

(AWG 24 to 18)

Recommended ferrule

For safe wiring and reliability, it is recommended to use following ferrules.

* Supplier: Phoenix contact

Crimping pliers: CRIPMFOX UD 6-4 or CRIMPFOX ZA 3

How to connect?

(1) Push down the orange actuating lever by a slotted screwdriver (width 2.5mm max.).

(2) Insert the conductor.

(3) Pull out the screwdriver then the conductor is fixed.

Wire size

mm

2

(AWG)

Model name of

ferrule *

L [mm] Φd [mm] ΦD [mm]

0.25 (24) AI 0.25-8YE 12.5 0.8 2.0

0.34 (22) AI 0.34-8TQ 12.5 0.8 2.0

0.5 (20) AI 0.5-8WH 14 1.1 2.5

0.75 (18) AI 0.75-8GY 14 1.3 2.8

Control logic terminal

Relay output terminal

8mm

Push down the

orange actuating

lever.

2.5mm

Insert in the

conductor.

Pull out the

screwdriver to fix

the conductor.

8

L

Φd

ΦD

19

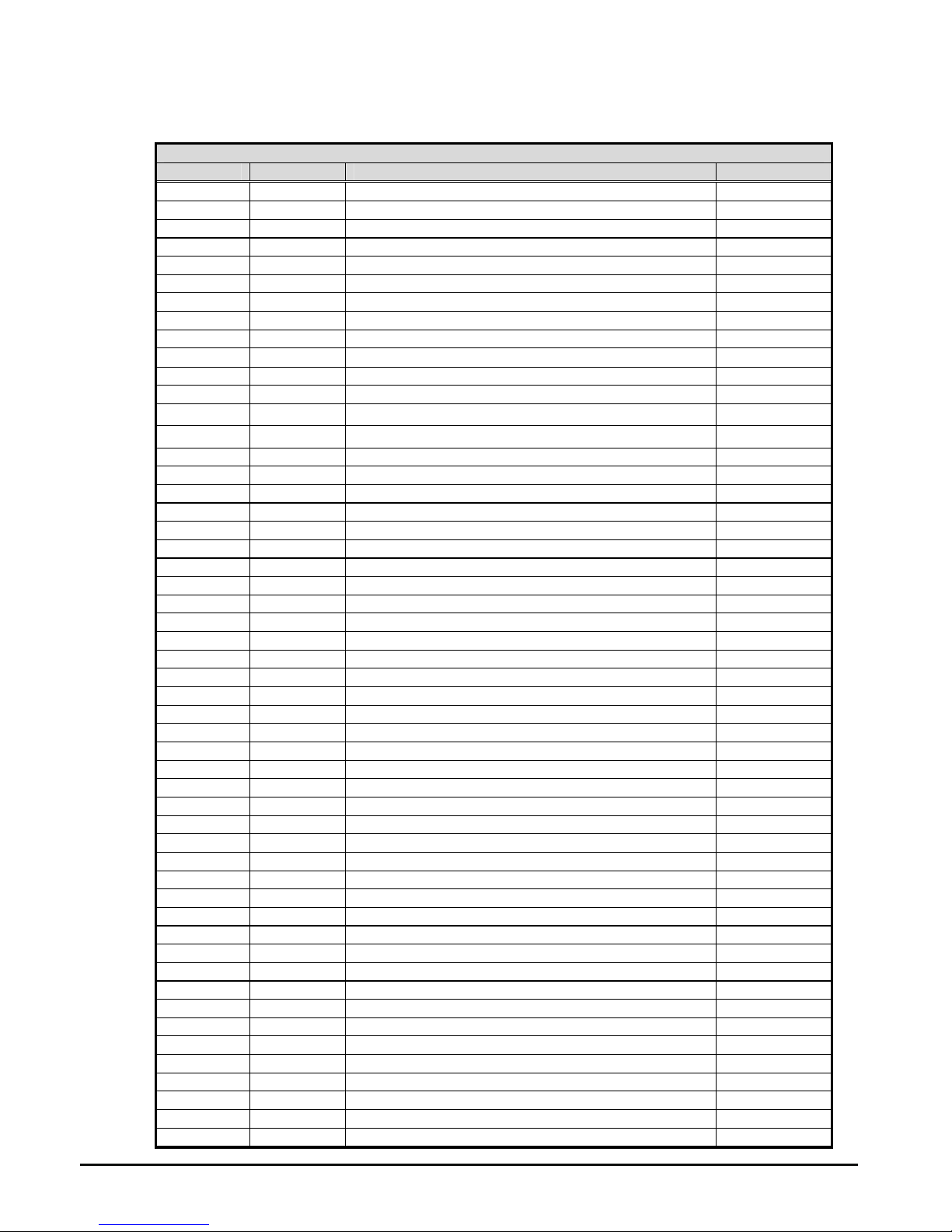

Intelligent Terminal Listing

Intelligent Inputs

Use the following table to locate pages for intelligent input material in this chapter.

Input Function Summary Table

Symbol Code Function Name Page

FW 00 Forward Run/Stop

RV 01 Reverse Run/Stop

CF1 02 Multi-speed Select, Bit 0 (LSB)

CF2 03 Multi-speed Select, Bit 1

CF3 04 Multi-speed Select, Bit 2

CF4 05 Multi-speed Select, Bit 3 (MSB)

JG 06 Jogging

DB 07 External DC braking

SET 08 Set (select) 2nd Motor Data

2CH 09 2-stage Acceleration and Deceleration

FRS 11 Free-run Stop

EXT 12 External Trip

USP 13 Unattended Start Protection

CS 14 Commercial power source switchover

SFT 15 Software Lock

AT 16 Analog Input Voltage/Current Select

RS 18 Reset Inverter

PTC 19 PTC thermistor Thermal Protection

STA 20 Start (3-wire interface)

STP 21 Stop (3-wire interface)

F/R 22 FWD, REV (3-wire interface)

PID 23 PID Disable

PIDC 24 PID Reset

UP 27 Remote Control UP Function

DWN 28 Remote Control Down Function

UDC 29 Remote Control Data Clearing

OPE 31 Operator Control

SF1~SF7 32~38 Multi-speed Select,Bit operation Bit 1~7

OLR 39 Overload Restriction Source Changeover

TL 40 Torque Limit Selection

TRQ1 41 Torque limit switch 1

TRQ2 42 Torque limit switch 2

BOK 44 Brake confirmation

LAC 46 LAD cancellation

PCLR 47 Pulse counter clear

ADD 50 ADD frequency enable

F-TM 51 Force Terminal Mode

ATR 52 Permission for torque command input

KHC 53 Clear watt-hour data

MI1~MI7 56~62 General purpose input (1)~(7)

AHD 65 Analog command hold

CP1~CP3 66~68 Multistage-position switch (1)~(3)

ORL 69 Limit signal of zero-return

ORG 70 Trigger signal of zero-return

SPD 73 Speed/position changeover

GS1 77 STO1 input (Safety related signal)

GS2 78 STO2 input (Safety related signal)

485 81 Starting communication signal

PRG 82 Executing EzSQ program

HLD 83 Retain output frequency

ROK 84 Permission of Run command

EB 85 Rotation direction detection (phase B)

20

Use the following table to locate pages for intelligent input material in this chapter.

Input Function Summary Table

Symbol Code Function Name Page

DISP 86 Display limitation

NO 255 No assign

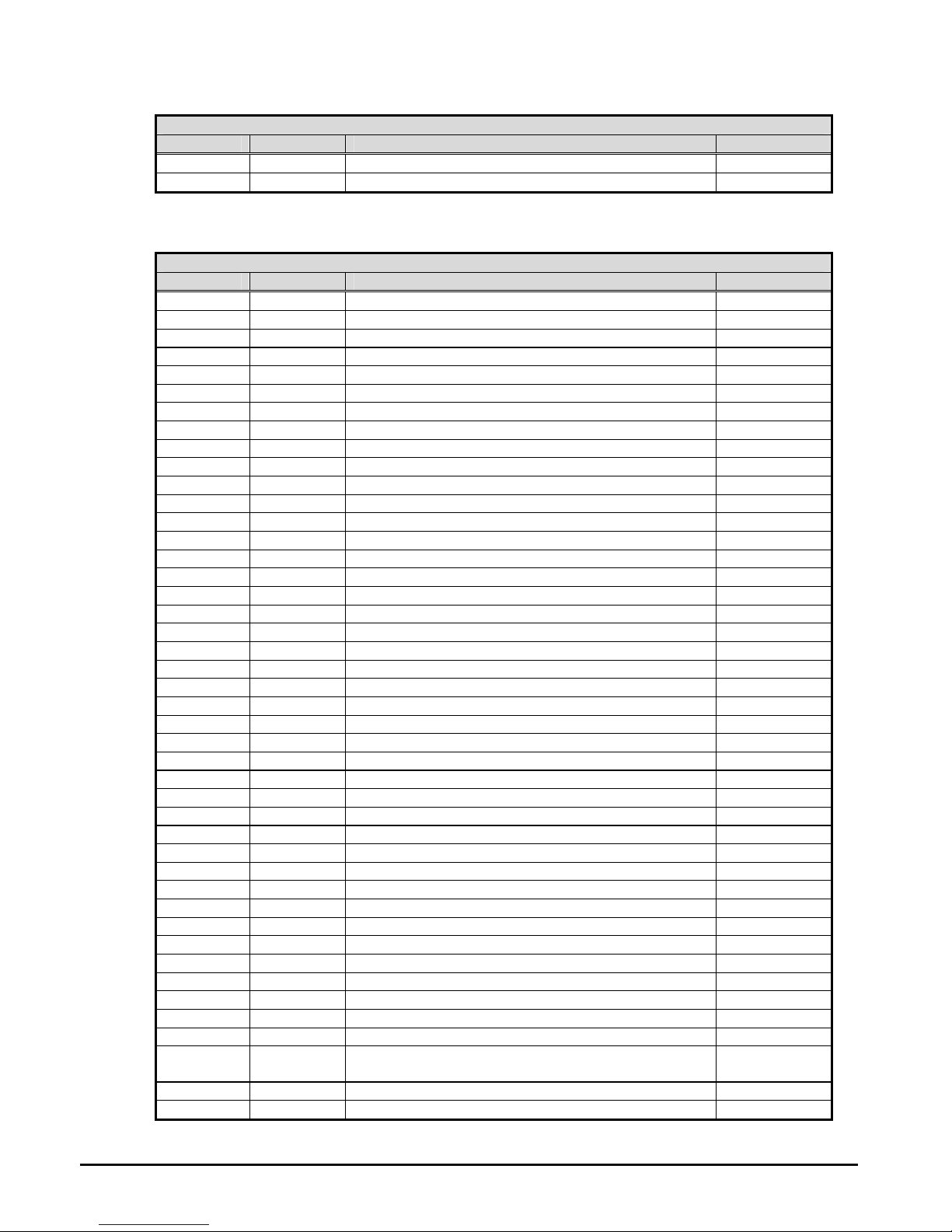

Intelligent Outputs

Use the following table to locate pages for intelligent output material in this chapter.

Input Function Summary Table

Symbol Code Function Name Page

RUN 00 Run Signal

FA1 01 Frequency Arrival Type 1–Constant Speed

FA2 02 Frequency Arrival Type 2–Over frequency

OL 03 Overload Advance Notice Signal

OD 04 PID Deviation error signal

AL 05 Alarm Signal

FA3 06 Frequency Arrival Type 3–Set frequency

OTQ 07 Over/under Torque Threshold

UV 09 Undervoltage

TRQ 10 Torque Limited Signal

RNT 11 Run Time Expired

ONT 12 Power ON time Expired

THM 13 Thermal Warning

BRK 19 Brake Release Signal

BER 20 Brake Error Signal

ZS 21 Zero Hz Speed Detection Signal

DSE 22 Speed Deviation Excessive

POK 23 Positioning Completion

FA4 24 Frequency Arrival Type 4–Over frequency

FA5 25 Frequency Arrival Type 5–Set frequency

OL2 26 Overload Advance Notice Signal 2

ODc 27 Analog Voltage Input Disconnect Detection

OIDc 28 Analog Voltage Output Disconnect Detection

FBV 31 PID Second Stage Output

NDc 32 Network Disconnect Detection

LOG1~3 33~35 Logic Output Function 1~3

WAC 39 Capacitor Life Warning Signal

WAF 40 Cooling Fan Warning Signal

FR 41 Starting Contact Signal

OHF 42 Heat Sink Overheat Warning

LOC 43 Low load detection

MO1~3 44~46 General Output 1~3

IRDY 50 Inverter Ready Signal

FWR 51 Forward Operation

RVR 52 Reverse Operation

MJA 53 Major Failure Signal

WCO 54 Window Comparator for Analog Voltage Input

WCOI 55 Window Comparator for Analog Current Input

FREF 58 Frequency Command Source

REF 59 Run Command Source

SETM 60 2nd Motor in operation

EDM 62

STO (Safe Torque Off) Performance Monitor

(Output terminal 11 only)

OP 63 Option control signal

no 255 Not used

21

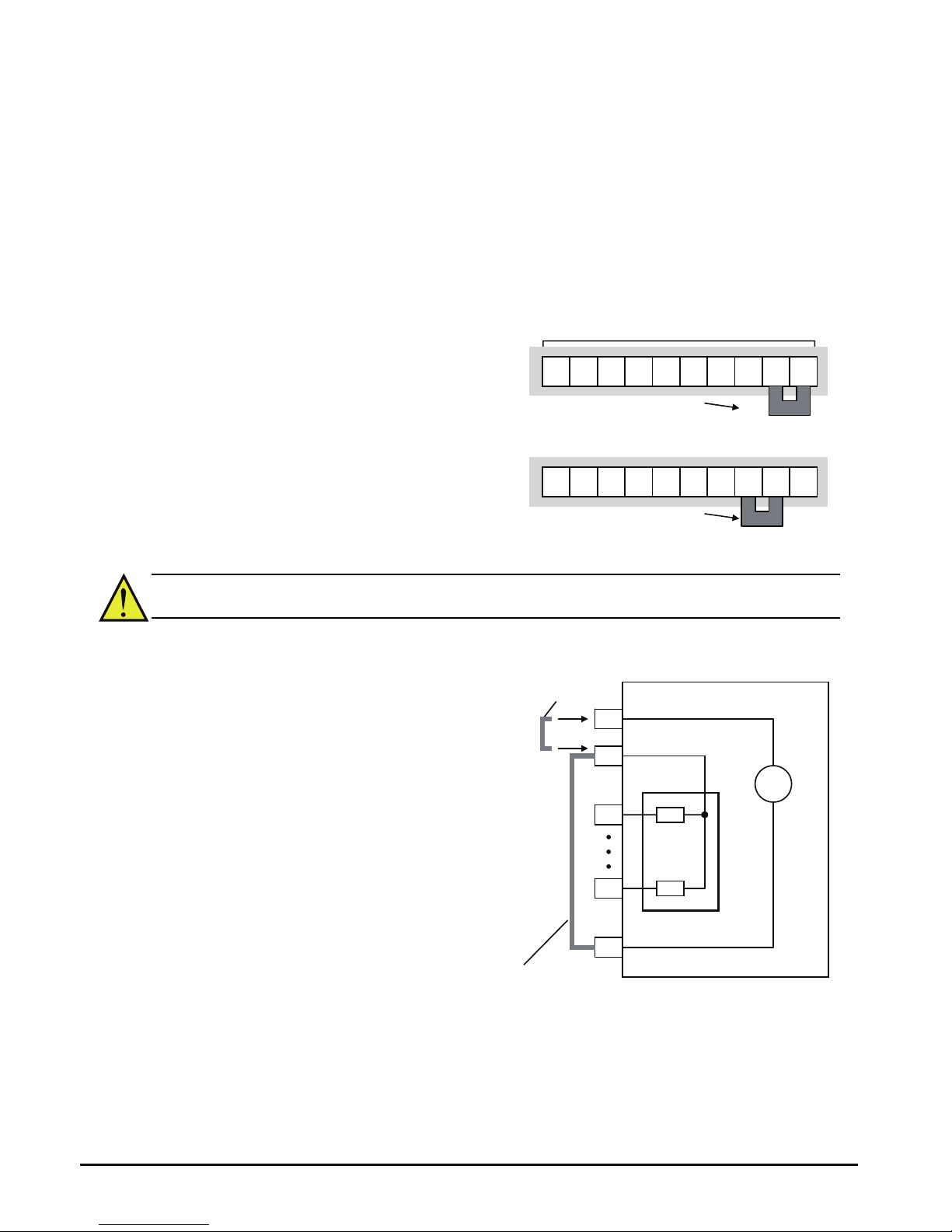

Using Intelligent Input Terminals

Terminals [1], [2], [3], [4], [5], [6] and [7] are identical, programmable inputs for general use.

The input circuits can use the inverter’s internal (isolated) +24V field supply or an external

power supply. This section describes input circuits operation and how to connect them

properly to switches or transistor outputs on field devices.

The WJ200 inverter features selectable sinking or sourcing inputs. These terms refer to the

connection to the external switching device–it either sinks current (from the input to GND)

or sources current (from a power source) into the input. Note that the sink/source naming

convention may be different in your particular country or industry. In any case, just follow

the wiring diagrams in this section for your application.

The inverter has a short bar (jumper) for

configuring the choice of sinking or sourcing

inputs. To access it, you must remove the

front cover of the inverter housing. In the

figure to the top right, the short bar is shown

as attached to the logic terminal block

(connector). If you need to change to the

source type connection, remove the short bar

and connect it as shown in the figure at the

bottom right.

CAUTION: Be sure to turn OFF power to the inverter before changing the short circuit bar

position. Otherwise, damage to the inverter circuitry may occur.

[PLC] Terminal Wiring – The [PLC]

terminal (Programmable Logic Control

terminal) is named to include various

devices that can connect to the inverter’s

logic inputs. In the figure to the right, note

the [PLC] terminal and the short bar

(jumper). Locating the short bar between

[PLC] and [L] sets the input logic source

type, which is the default setting for EU

and US versions. In this case, you

connect input terminal to [P24] to make it

active. If instead you locate the short bar

between [PLC] and [P24], the input logic

will be sink type. In this case, you

connect the input terminal to [L] to make

it active.

The wiring diagram on the following pages show the four combinations of using sourcing or

sinking inputs, and using the internal or an external DC supply.

WJ200 inverter

P24

1

7

L

24V

PLC

Input

circuits

+

-

Logic GND

Input common

Short bar for

sink logic

Short bar for

source logic

Logic inputs

5 4 3 2 1 L

PLC P24

Source logic connection

Short bar

7 6

5 4 3 2 1 L

PLC P24

Sink logic connection

Short bar

7 6

22

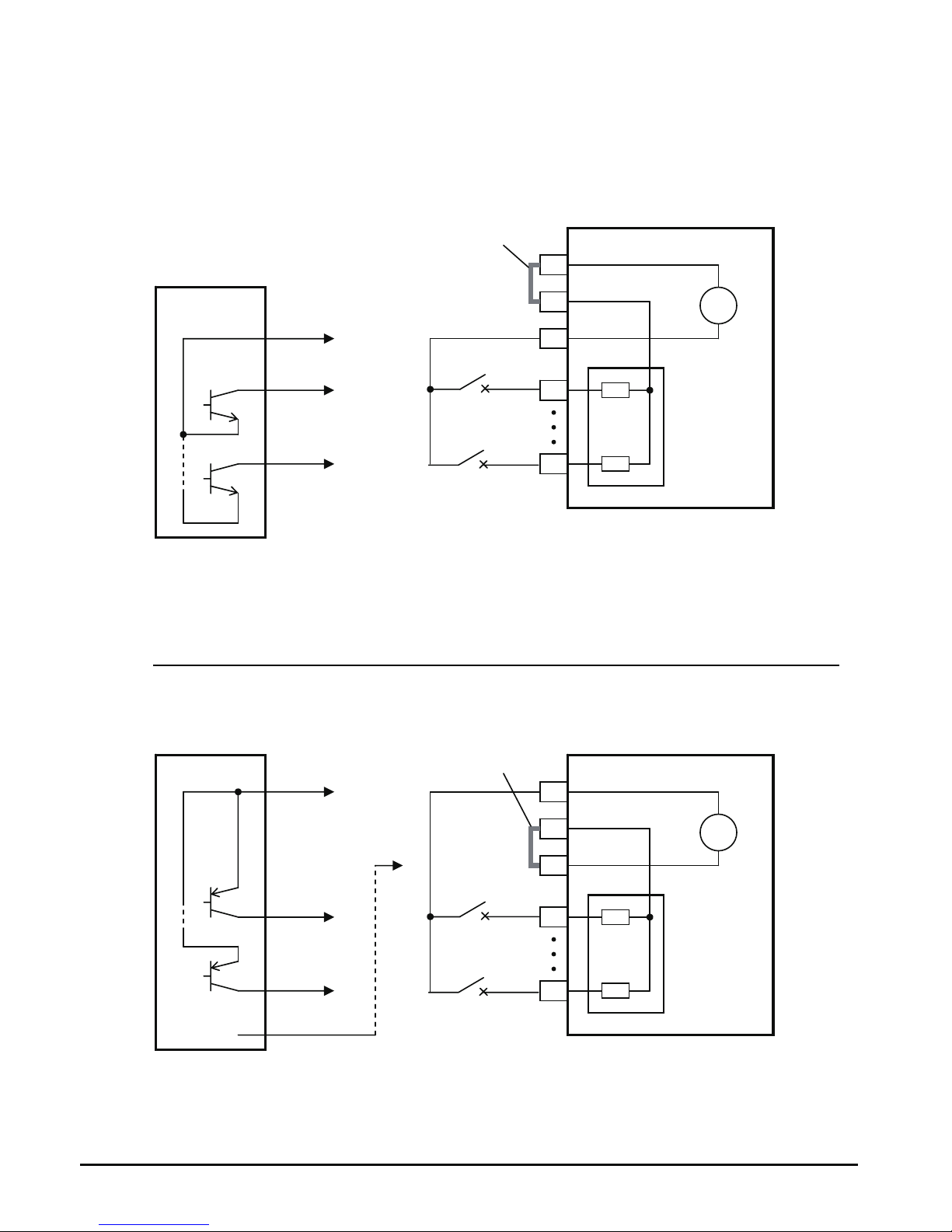

The two diagrams below input wiring circuits using the inverter’s internal +24V supply.

Each diagram shows the connection for simple switches, or for a field device with

transistor outputs. Note that in the lower diagram, it is necessary to connect terminal [L]

only when using the field device with transistors. Be sure to use the correct connection of

the short bar shown for each wiring diagram.

Sinking Inputs, Internal Supply

Short bar = [PLC] – [P24] position

GND

7

1

Field device

Open collector outputs,

NPN transistors

WJ200

P24

1

7

24V

PLC

Input

circuits

+

Logic GND

Input common

Short bar

Input switches

L

Sourcing Inputs, Internal Supply

Short bar = [PLC] – [L] position

Common to

[P24]

7

1

Field device

PNP transistor

sousing outputs

WJ200

P24

1

7

24V

PLC

Input

circuits

+

Logic GND

Input common

Short bar

Input switches

L

GND

to PNP bias

circuits

23

The two diagrams below show input wiring circuits using an external supply. If using the

“Sinking Inputs, External Supply” in below wiring diagram, be sure to remove the short bar,

and use a diode (*) with the external supply. This will prevent a power supply contention in

case the short bar is accidentally placed in the incorrect position. For the “Sourcing Inputs,

External Supply”, please connect the short bar as drawn in the diagram below.

Sinking Inputs, External Supply

Short bar = Removed

GND

7

1

Field device

Open collector outputs,

NPN transistors

WJ200

P24

1

7

24V

PLC

Input

circuits

+

Logic GND

Input common

Input switches

L

24V

+

+

24V

*

* Note: Make sure to remove the short circuit bar in case of

using an external power supply.

Sourcing Inputs, External Supply

Short bar = Removed

7

1

Field device

WJ200

P24

1

7

24V

PLC

Input

circuits

+

Input common

Input switches

L

GND

PNP transistor

sourcing outputs

24V

+

24V

+

24

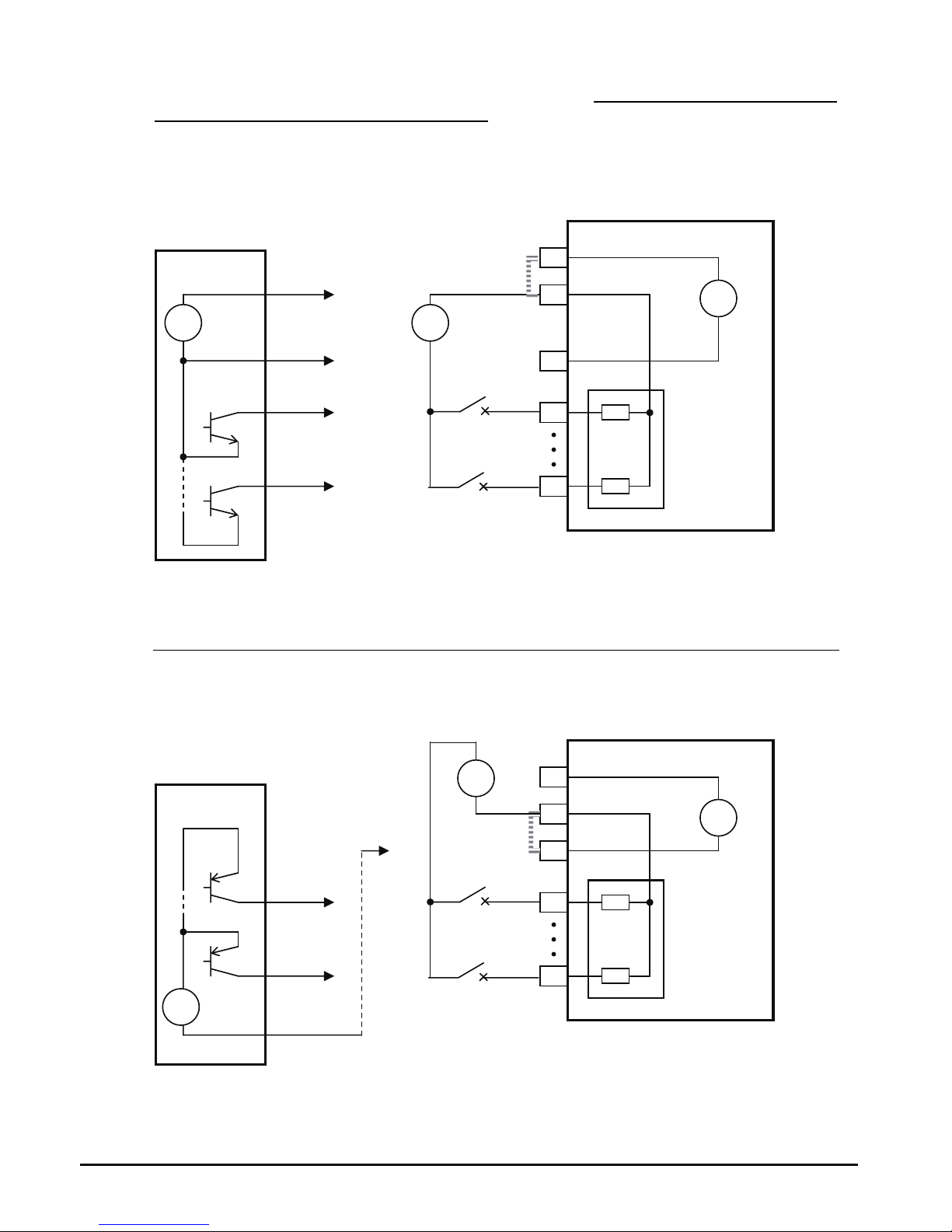

CAUTION: Be sure to install a diode in between "P24" and "PLC" when connecting

multiple inverters with digital input wiring in common.

The power to the inverter control

circuits can be supplied externally as shown below. It is

possible to read and write parameters via the keypad with control power supplied in

this way, even though the drive itself is not powered. However it is NOT possible to

drive the motor.

To allow this capability, the inverter does not block current inflow to the control inputs.

When two or more inverters are connected together with common I/O wiring in this way,

it may result in unwanted activation of inputs. The use of diodes (rated 50V, 0.1A) as

shown will avoid this problem.

Short

bar

Inserting

diode

PLC

L

1

P24

PLC

L

1

Switch

OFF

Power ON

Power OFF

Input

ON

P24

PLC

L

P24

PLC

L

1

Switch

OFF

Power ON

Power OFF

Input

OFF

Short

bar

1

Switch

OFF

Switch

OFF

Input

OFF

Input

ON

P24

PLC

L

P24

PLC

L

P24

PLC

L

P24

PLC

L

1

1

1

Short

bar

In case of Source logic

Short

bar

25

Forward Run/Stop and Reverse Run/Stop Commands:

When you input the Run command via the terminal [FW], the inverter executes the Forward

Run command (high) or Stop command (low). When you input the Run command via the

terminal [RV], the inverter executes the Reverse Run command (high) or Stop command

(low).

Option

Code

Terminal

Symbol

Function Name State Description

ON Inverter is in Run Mode, motor runs forward

00

FW Forward Run/Stop

OFF Inverter is in Stop Mode, motor stops

ON Inverter is in Run Mode, motor runs reverse

01

RV Reverse Run/Stop

OFF Inverter is in Stop Mode, motor stops

Valid for inputs:

C001~C007

Required settings

A002 = 01

Notes:

When the Forward Run and Reverse Run

commands are active at the same time, the

inverter enters the Stop Mode.

When a terminal associated with either [FW] or

[RV] function is configured for normally closed,

the motor starts rotation when that terminal is

disconnected or otherwise has no input voltage.

Example (default input configuration shown see

page 59):

See I/O specs on page 16,17.

NOTE: The parameter F004, Keypad Run Key Routing, determines whether the single Run

key issues a Run FWD command or Run REV command. However, it has no effect on the

[FW] and [RV] input terminal operation.

WARNING: If the power is turned ON and the Run command is already active, the motor

starts rotation and is dangerous! Before turning power ON, confirm that the Run command

is not active.

RV FW

7654321L

PCS

P24

PLC

26

Multi-Speed Select ~Binary Operation

The inverter can store up to 16 different target

frequencies (speeds) that the motor output uses for

steady-state run condition. These speeds are accessible

through programming four of the intelligent terminals as

binary-encoded inputs CF1 to CF4 per the table to the

right. These can be any of the six inputs, and in any

order. You can use fewer inputs if you need eight or

fewer speeds.

NOTE: When choosing a subset of speeds to use,

always start at the top of the table, and with the

least-significant bit: CF1, CF2, etc.

The example with eight speeds in the

figure below shows how input switches

configured for CF1–CF3 functions can

change the motor speed in real time.

NOTE: Speed 0 depends on A001

parameter value.

Option

Code

Terminal

Symbol

Function Name State Description

ON Binary encoded speed select, Bit 0, logical 1

02

CF1 Multi-speed Select,

Bit 0 (LSB)

OFF Binary encoded speed select, Bit 0, logical 0

ON Binary encoded speed select, Bit 1, logical 1

03

CF2 Multi-speed Select,

Bit 1

OFF Binary encoded speed select, Bit 1, logical 0

ON Binary encoded speed select, Bit 2, logical 1

04

CF3 Multi-speed Select,

Bit 2

OFF Binary encoded speed select, Bit 2, logical 0

ON Binary encoded speed select, Bit 3, logical 1

05

CF4 Multi-speed Select,

Bit 3 (MSB)

OFF Binary encoded speed select, Bit 3, logical 0

Valid for inputs:

C001~C007

Required settings

F001, A001=02,

A020 to A035

Notes:

When programming the multi-speed settings,

be sure to press the SET key each time and then

set the next multi-speed setting. Note that when

the key is not pressed, no data will be set.

When a multi-speed setting more than 50Hz

(60Hz) is to be set, it is necessary to program the

maximum frequency A004 high enough to allow

that speed

Example (some CF inputs require input

configuration; some are default inputs):

See I/O specs on page 16,17.

Multi-

speed

Input Function

CF4 CF3 CF2 CF1

Speed 0 0 0 0 0

Speed 1 0 0 0 1

Speed 2 0 0 1 0

Speed 3 0 0 1 1

Speed 4 0 1 0 0

Speed 5 0 1 0 1

Speed 6 0 1 1 0

Speed 7 0 1 1 1

Speed 8 1 0 0 0

Speed 9 1 0 0 1

Speed 10 1 0 1 0

Speed 11 1 0 1 1

Speed 12 1 1 0 0

Speed 13 1 1 0 1

Speed 14 1 1 1 0

Speed 15 1 1 1 1

Speed

0th

4th

6th

1st

2nd

5th

7th

3rd

1

0

1

0

1

0

1

0

[CF1]

[CF2]

[CF3]

[FW]

CF4 CF3 CF2 CF1

7654321L

PCS

P24

PLC

27

Two Stage Acceleration and Deceleration

When terminal [2CH] is turned ON, the inverter

changes the rate of acceleration and

deceleration from the initial settings (F002 and

F003) to use the second set of acceleration/

deceleration values. When the terminal is

turned OFF, the inverter is returned to the

original acceleration and deceleration time

(F002 acceleration time 1, and F003

deceleration time 1). Use A092 (acceleration

time 2) and A093 (deceleration time 2) to set

the second stage acceleration and deceleration

times.

In the graph shown above, the [2CH] becomes active during the initial acceleration. This

causes the inverter to switch from using acceleration 1 (F002) to acceleration 2 (A092).

Option

Code

Terminal

Symbol

Function Name State Description

ON Frequency output uses 2nd-stage acceleration and

deceleration values

09

2CH Two-stage Accelera-

tion and

Deceleration

OFF Frequency output uses the initial acceleration 1 and

deceleration 1 values

Valid for inputs:

C001~C007

Required settings

A092, A093, A094=00

Notes:

Function A094 selects the method for second

stage acceleration. It must be set = 00 to select

the input terminal method in order for the [2CH]

terminal assignment to operate.

Example (default input configuration shown see

page 59):

See I/O specs on page 16,17.

[2CH]

1

0

Output

frequency

t

[FW,RV]

1

0

Target

fre

q

uency

initial

second

2CH

7654321L

PCS

P24

PLC

28

Unattended Start Protection

If the Run command is already set when power is turned ON, the inverter starts running

immediately after powerup. The Unattended Start Protection (USP) function prevents that

automatic startup, so that the inverter will not run without outside intervention. When USP

is active and you need to reset an alarm and resume running, either turn the Run

command OFF, or perform a reset operation by the terminal [RS] input or the keypad

Stop/reset key.

In the figure below, the [USP] feature is enabled. When the inverter power turns ON, the

motor does not start, even though the Run command is already active. Instead, it enters

the USP trip state, and displays E 13 error code. This requires outside intervention to reset

the alarm by turning OFF the Run command per this example (or applying a reset). Then

the Run command can turn ON again and start the inverter output.

Option

Code

Terminal

Symbol

Function Name State Description

ON On powerup, the inverter will not resume a Run

command (mostly used in the US)

13

USP Unattended Start

Protection

OFF On powerup, the inverter will resume a Run

command that was active before power loss

Valid for inputs:

C001~C007

Required settings

(none)

Notes:

Note that when a USP error occurs and it is

canceled by a reset from a [RS] terminal input, the

inverter restarts running immediately.

Even when the trip state is canceled by turning

the terminal [RS] ON and OFF after an under

voltage protection E09 occurs, the USP function

will be performed.

When the running command is active

immediately after the power is turned ON, a USP

error will occur. When this function is used, wait

for at least three (3) seconds after the powerup to

generate a Run command.

Example (default input configuration shown see

page 59):

See I/O specs on page 16,17.

Inverter output frequency

0

t

Inverter power supply

1

0

Alarm output terminal

1

0

[USP] terminal

1

0

Run command [FW,RV]

1

0

Events:

E13

Alarm

cleared

Run

command

USP

7654321L

PCS

P24

PLC

29

Reset Inverter

The [RS] terminal causes the inverter to execute

the reset operation. If the inverter is in Trip Mode,

the reset cancels the Trip state. When the signal

[RS] is turned ON and OFF, the inverter executes

the reset operation. The minimum pulse width for

[RS] must be 12 ms or greater. The alarm output

will be cleared within 30 ms after the onset of the

Reset command.

WARNING: After the Reset command is given and the alarm reset occurs, the motor will

restart suddenly if the Run command is already active. Be sure to set the alarm reset after

verifying that the Run command is OFF to prevent injury to personnel.

Option

Code

Terminal

Symbol

Function Name State Description

ON The motor output is turned OFF, the Trip Mode is

cleared (if it exists), and powerup reset is applied

18

RS Reset Inverter

OFF Normal power ON operation

Valid for inputs:

C001~C007

Required settings

(none)

Notes:

While the control terminal [RS] input is ON, the

keypad displays alternating segments. After RS

turns OFF, the display recovers automatically.

Pressing the Stop/Reset key of the digital

operator can generate a reset operation only

when an alarm occurs.

Example (default input configuration shown see

page 59):

See I/O specs on page 16,17.

A terminal configured with the [RS] function can only be configured for normally open operation. The

terminal cannot be used in the normally closed contact state.

When input power is turned ON, the inverter performs the same reset operation as it does when a

pulse on the [RS] terminal occurs.

The Stop/Reset key on the inverter is only operational for a few seconds after inverter powerup when

a hand-held remote operator is connected to the inverter.

If the [RS] terminal is turned ON while the motor is running, the motor will be free running (coasting).

If you are using the output terminal OFF delay feature (any of C145, C147, C149 > 0.0 sec.), the [RS]

terminal affects the ON-to-OFF transition slightly. Normally (without using OFF delays), the [RS] input

causes the motor output and the logic outputs to turn OFF together, immediately. However, when any

output uses an OFF delay, then after the [RS] input turns ON, that output will remain ON for an additional

1 sec. period (approximate) before turning OFF.

[RS]

1

0

t

Alarm

signal

1

0

Approx. 30 ms

12 ms

minimum

RS

7654321L

PCS

P24

PLC

30

Using Intelligent Output Terminals

Run Signal

When the [RUN] signal is selected as an

intelligent output terminal, the inverter outputs

a signal on that terminal when it is in Run

Mode. The output logic is active low, and is

the open collector type (switch to ground).

Option

Code

Terminal

Symbol

Function Name State Description

ON when inverter is in Run Mode

00

RUN Run Signal

OFF when inverter is in Stop Mode

Valid for inputs:

11, 12, AL0 – AL2

Required settings

(none)

Notes:

The inverter outputs the [RUN] signal

whenever the inverter output exceeds the start

frequency specified by parameter B082. The start

frequency is the initial inverter output frequency

when it turns ON.

The example circuit for terminal [11] drives a

relay coil. Note the use of a diode to prevent the

negative going turn-off spike generated by the coil

from damaging the inverter’s output transistor.

Example for terminal [11] (default output

configuration shown see page 59):

Example for terminal [AL0], [AL1], [AL2] (requires

output configuration see page 59):

See I/O specs on page 16,17.

RY

Inverter output

terminal circuit

CM2 11

RUN

AL1

Power

supply

Load

AL0 AL2

Inverter logic

circuit board

RUN

[FW,RV]

1

0

Output

frequency

t

Run

signal

start freq.

B082

ON

31

Frequency Arrival Signals

The Frequency Arrival group of outputs helps coordinate external systems with the current

velocity profile of the inverter. As the name implies, output [FA1] turns ON when the output

frequency arrives at the standard set frequency (parameter F001). Output [FA2] relies on

programmable accel/ decel thresholds for increased flexibility. For example, you can have

an output turn ON at one frequency during acceleration, and have it turn OFF at a different

frequency during deceleration. All transitions have hysteresis to avoid output chatter if the

output frequency is near one of the thresholds.

Option

Code

Terminal

Symbol

Function Name State Description

ON when output to motor is at the constant frequency

01

FA1 Frequency Arrival

Type 1 – Constant

Speed

OFF when output to motor is OFF, or in any acceleration or

deceleration ramp

ON when output to motor is at or above the set frequency

thresholds for, even if in acceleration or decel ramps

02

FA2 Frequency Arrival

Type 2 – Over

frequency

OFF when output to motor is OFF, or during accel or decel

before the respective thresholds are crossed

ON when output to motor is at the set frequency

06

FA3 Frequency Arrival

Type 3 – Set

frequency

OFF when output to motor is OFF, or in any acceleration or

deceleration ramp

ON when output to motor is at or above the set frequency

thresholds for, even if in acceleration or decel ramps

24

FA4 Frequency Arrival

Type 4 – Over

frequency (2)

OFF when output to motor is OFF, or during accel or decel

before the respective thresholds are crossed

ON when output to motor is at the set frequency

25

FA5 Frequency Arrival

Type 5 – Set

frequency (2)

OFF when output to motor is OFF, or in any acceleration or

deceleration ramp

Valid for inputs:

11, 12, AL0 – AL2

Required

settings

C042, C043, C045, C046,

Notes:

For most applications you will need to use

only one type of frequency arrival outputs (see

examples). However, it is possible assign both

output terminals to output functions [FA1] and

[FA2]

For each frequency arrival threshold, the

output anticipates the threshold (turns ON early)

by 1.5Hz

The output turns OFF as the output

frequency moves away from the threshold,

delayed by 0.5Hz

The example circuit for terminal [11] drives a

relay coil. Note the use of a diode to prevent the

negative going turn-off spike generated by the

coil from damaging the inverter’s output

transistor

Example for terminal [11] (default output configuration

shown see page 59):

Example for terminal [AL0], [AL1], [AL2] (requires

output configuration see page 59):

See I/O specs on page 16,17.

RY

Inverter output

terminal circuit

CM2 11

FA1

AL1

Power

supply

Load

AL0 AL2

Inverter logic

circuit board

FA1

32

Frequency arrival output [FA1] uses the

standard output frequency (parameter

F001) as the threshold for switching. In

the figure to the right, Frequency Arrival

[FA1] turns ON when the output

frequency gets within Fon Hz below or

Fon Hz above the target constant

frequency, where Fon is 1% of the set

maximum frequency and Foff is 2% of

the set maximum frequency. This

provides hysteresis that prevents output

chatter near the threshold value. The

hysteresis effect causes the output to

turn ON slightly early as the speed

approaches the threshold. Then the

turn-OFF point is slightly delayed. Note

the active low nature of the signal, due to

the open collector output.

Frequency arrival output [FA2/FA4]

works the same way; it just uses two

separate thresholds as shown in the

figure to the right. These provide for

separate acceleration and deceleration

thresholds to provide more flexibility than

for [FA1]. [FA2/FA4] uses C042/C045

during acceleration for the ON threshold,

and C043/C046 during deceleration for the

OFF threshold. This signal also is active

low. Having different accel and decel

thresholds provides an asymmetrical

output function. However, you can use

equal ON and OFF thresholds, if desired.

Frequency arrival output [FA3/FA5] works

also the same way, only difference is

arriving at set frequency.

FA1

signal

Output

freq.

Fon

F001

F001

Foff

Fon

ON

Foff

ON

0

Fon=1% of max. frequency

Foff=2% of max. frequency

FA2/FA4

signal

Output

freq.

thresholds

C042/C045

ON

0

C043/C046

Fon

Foff

Fon=1% of max. frequency

Foff=2% of max. frequency

FA3/FA5

signal

Output

freq.

thresholds

C042/C045

0

C043/C046

Fon

Foff

Fon=1% of max. frequency

Foff=2% of max. frequency

Foff

Fon

ON ON

33

Alarm Signal

The inverter alarm signal is active when a fault has

occurred and it is in the Trip Mode (refer to the

diagram at right). When the fault is cleared the alarm

signal becomes inactive.

We must make a distinction between the alarm signal

AL and the alarm relay contacts [AL0], [AL1] and [AL2].

The signal AL is a logic function, which you can assign

to the open collector output terminals [11], [12], or the

relay outputs.

The most common (and default) use of the relay is for AL, thus the labeling of its terminals.

Use an open collector output (terminal [11] or [12]) for a low-current logic signal interface

or to energize a small relay (50 mA maximum). Use the relay output to interface to higher

voltage and current devices (10 mA minimum).

Option

Code

Terminal

Symbol

Function Name State Description

ON when an alarm signal has occurred and has not

been cleared

05

AL Alarm Signal

OFF when no alarm has occurred since the last clearing

of alarm(s)

Valid for inputs:

11, 12, AL0 – AL2

Required settings

C031, C032, C036

Notes:

By default, the relay is configured as normally

closed (C036=01). Refer to the next page for an

explanation.

In the default relay configuration, an inverter

power loss turns ON the alarm output. the alarm

signal remains ON as long as the external control

circuit has power.

When the relay output is set to normally

closed, a time delay of less than 2 seconds occurs

after powerup before the contact is closed.

Terminals [11] and [12] are open collector

outputs, so the electric specifications of [AL] are

different from the contact output terminals [AL0],

[AL1], [AL2].

This signal output has the delay time (300 ms

nominal) from the fault alarm output.

The relay contact specifications are in “Control

Logic Signal Specifications” on page 4–6. The

contact diagrams for different conditions are on

the next page.

Example for terminal [11] (default output

configuration shown see page 59):

Example for terminal [AL0], [AL1], [AL2] (requires

output configuration see page 59):

See I/O specs on page 16,17.

Run Stop

RUN

STOP

RESET

Trip

STOP

RESET

Fault

Fault

A

larm signal active

RY

Inverter output

terminal circuit

CM2 11

A

L

AL1

Power

supply

Load

AL0 AL2

Inverter logic

circuit board

A

L

34

The alarm relay output can be configured in two main ways:

Trip/Power Loss Alarm – The alarm relay is configured as normally closed (C036=01)

by default, shown below (left). An external alarm circuit that detects broken wiring also

as an alarm connects to [AL0] and [AL1]. After powerup and short delay (< 2 seconds),

the relay energizes and the alarm circuit is OFF. Then, either an inverter trip event or

an inverter power loss will de-energize the relay and open the alarm circuit

Trip Alarm – Alternatively, you can configure the relay as normally open (C036=00),

shown below (right). An external alarm circuit that detects broken wiring also as an

alarm connects to [AL0] and [AL2]. After powerup, the relay energizes only when an

inverter trip event occurs, opening the alarm circuit. However, in this configuration, an

inverter power loss does not open the alarm circuit.

Be sure to use the relay configuration that is appropriate for your system design. Note that

the external circuits shown assume that a closed circuit = no alarm condition (so that a

broken wire also causes an alarm). However, some systems may require a closed circuit =

alarm condition. In that case, then use the opposite terminal [AL1] or [AL2] from the ones

shown.

N.C. contacts (C036=01) N.O. contacts (C036=00)

During normal operation When an alarm occurs or

when power is OFF

During normal operation

or when power is OFF

When an alarm occurs

Power Run Mode AL0-AL1 AL0-AL2 Power Run Mode AL0-AL1 AL0-AL2

ON Normal Closed Open ON Normal Open Closed

ON Trip Open Closed ON Trip Closed Open

OFF – Open Closed OFF – Open Closed

AL1

Power

supply

Load

AL0 AL2

AL1

Power

supply

Load

AL0 AL2

AL1

Power

supply

Load

AL0 AL2

AL1

Power

supply

Load

AL0 AL2

35

Analog Input Operation

The WJ200 inverters provide for analog input to

command the inverter frequency output value.

The analog input terminal group includes the [L],

[OI], [O], and [H] terminals on the control

connector, which provide for Voltage [O] or

Current [OI] input. All analog input signals must

use the analog ground [L].

If you use either the voltage or current analog

input, you must select one of them using the logic

input terminal function [AT] analog type. Refer to

the table on next page showing the activation of

each analog input by combination of A005 set

parameter and [AT] terminal condition. The [AT]

terminal function is covered in “Analog Input

Current/Voltage Select” in section 4. Remember

that you must also set A001 = 01 to select analog

input as the frequency source.

NOTE: If no logic input terminal is configured for the [AT] function, then inverter recognizes

that [AT]=OFF and MCU recognizes [O]+[OI] as analog input.

Using an external potentiometer is a common way to

control the inverter output frequency (and a good way

to learn how to use the analog inputs). The

potentiometer uses the built-in 10V reference [H] and

the analog ground [L] for excitation, and the voltage

input [O] for the signal. By default, the [AT] terminal

selects the voltage input when it is OFF.

Take care to use the proper resistance for the

potentiometer, which is 1~2 k

, 2 Watts.

Voltage Input – The voltage input circuit uses

terminals [L] and [O]. Attach the signal cable’s

shield wire only to terminal [L] on the inverter.

Maintain the voltage within specifications (do not

apply negative voltage).

Current Input – The current input circuit uses

terminals [OI] and [L]. The current comes from a

sourcing type transmitter; a sinking type will not

work! This means the current must flow into

terminal [OI], and terminal [L] is the return back to

the transmitter. The input impedance from [OI] to

[L] is 100 Ohms. Attach the cable shield wire only

to terminal [L] on the inverter.

AM H O OI L

+V Ref.

Voltage input

Current input

A

GND

AM H O OI L

Freq.

settin

g

A001

V/I input

select

[AT]

Å

+

-

4-20 mA

0-10 V

AM H O OI L

1 to 2k, 2W

0 to 9.6 VDC,

0 to 10V nominal

AM H O OI L

+

-

4 to 19.6 mA DC,

4 to 20mA nominal

AM H O OI L

Å

See I/O specs on page 21,22.

36

The following table shows the available analog input settings. Parameter A005 and the

input terminal [AT] determine the External Frequency Command input terminals that are

available, and how they function. The analog inputs [O] and [OI] use terminal [L] as the

reference (signal return).

A005

[AT] Input Analog Input Configuration

ON [OI]

00

OFF [O]

ON Integrated POT on external panel

02

OFF [O]

ON Integrated POT on external panel

03

OFF [OI]

Other Analog Input-related topics:

· “Analog Input Settings”

· “Additional Analog Input Settings”

· “Analog Signal Calibration Settings”

· “Analog Input Current/Voltage Select”

· “ADD Frequency Enable”

· “Analog Input Disconnect Detect”

37

Pulse Train Input Operation

The WJ200 inverter is capable of accepting pulse train input signals, that are used for

frequency command, process variable (feedback) for PID control, and simple positioning.

The dedicated terminal is called “EA” and “EB”. Terminal “EA” is a dedicated terminal, and

the terminal “EB” is an intelligent terminal, that has to be changed by a parameter setting.

Terminal Name Description Ratings

EA Pulse train input A For frequency command, 32kHz max.

Reference voltage: Common is [L]

EB

(Input terminal 7)

Pulse train input B

(Set C007 to 85 )

27Vdc max.

For frequency command, 2kHz max.

Reference voltage: Common is [PLC]

(1) Frequency Command by pulse train input

When using this mode, you should set A001 to 06. In this case the frequency is detected by

input-capture, and calculated based on the ratio of designated max. frequency (under

32kHz). Only an input terminal “EA” will be used in this case.

(2) Using for process variable of PID control

You can use the pulse train input for process variable (feedback) of PID control. In this

case you need to set A076 to 03. Only “EA” input terminal is to be used.

(3) Simple positioning by pulse train input