Hitachi WJ200-007SF, WJ200-002SF, WJ200-0015SF, WJ200-0022SF, WJ200-001LF User Manual

...

Pursuing the Ideal Compact Inverter

Stöwer Antriebstechnik GmbH, Enneststrasse 3, 51702 Bergneustadt, tel: 02261-40970, Fax: 02261-41309

Pursuing the Ideal Compact Inverter

Series

Designed for excellent performance and user friendliness

2 3

3

4

5

0.5

1 3

6 10 20 30 40 50 60Hz

-100

-200

200

100

0

Speed (min-1)

(%)

Torque

Deceleration Time:

4.2 sec.

Deceleration Time:

1.9 sec.

OFF ON

Motor Current

DC Voltage

Output Frequency

DC Voltage

Output Frequency

Motor Current

Pursuing the Ideal Compact Inverter

Designed for excellent performance and user friendliness

Industry-leading Levels of Performance

High starting torque of 200% or greater achieved

by sensorless vector control

(when sized for heavy duty

).

Speed regulation at low-speed is greatly impro ved.

–

Fluctuation is 1/2* compar ed with the previous model.

–

Trip avoidance functions

Conformity to global st andards

Sink / source logic is standard

Wide input power voltage range

Simple positioning contr ol

(when feedbac k signal is used.)

Induction motor & Permanent magnetic motor *

control with one inverter

(corresponds more than Ver.2.0)

1

2

1

2

3

Integrated auto-tuning function for easy sensorless vector cont rol

realizes high torque suit able for applications requiring it s uch as crane

hoists, lifts, elev ators, etc.

Minimum time deceleration function, over-current suppress function

and DC bus AVR function are incorporated. The functions reduce

nuisance t ripping. Improv ed torque limiting/current limiting function

enables a load limit to prot ect machine and equipment.

Speed regulation at low spe ed has been dras tically improve d to

enhance proce ss stability and precision.

CE, UL, c-UL, c-Tick approvals.

Logic input and output terminal can be congured for sink or source logic.

Input voltage 240V for 200V class and 480V for 40 0V class as standard.

When simple positioning function is activated, speed control operation or

positioning contr ol operation is select able via intellient input. W hile the [SPD]

input is ON, the current position counter is held at 0. When [SPD] is OFF, the

inverter enters positioning control operation and the position counter is active.

The WJ 200 inverter can drive both induc tion motors (IM) and permanent

magnetic mot ors (PM). Energy conservat ion and miniaturi zation can be

achieved using PM motors. Moreover, one inverter used for two types of motor.

Output Frequency

Start position counting

Speed control Position control

Target position

DB

Time

SPD input

ON

Example of Torque Char acteristic s

Model ConfigurationModel Name Indication

WJ200 – 001 L F

with Digit al Operator

Power Source

S: 1-phase 200V class

L: 3-phase 200V class

H: 3-phase 4 00V class

Applied Mot or Capacity

001: 0.1k W – 150 : 15kW

Series Name

PM

WJ200

IM

IM + Inverter

PM + Dedicat ed Contro ller

Auto-tuning to perform sensorles s vector control can now be easily done.

Model Name

WJ200-xxx

1-phase 2 00V clas s 3-phase 200V cla ss 3-phas e 400V c lass

VT CT VT CT VT CT

001 0.2 0.1 0.2 0.1

002 0.4 0.2 0.4 0.2

004 0.55 0.4 0.75 0.4 0.75 0.4

007 1.1 0.75 1.1 0.75 1. 5 0.75

015 2.2 1.5 2.2 1. 5 2.2 1.5

022 3.0 2.2 3.0 2.2 3.0 2.2

030 4.0 3.0

037 5.5 3.7

040 5.5 4.0

055 7.5 5.5 7. 5 5.5

075 11 7.5 11 7. 5

110 15 11 15 11

150 18.5 15 18.5 15

(Example of WJ20 0-055 LF)

• Frequency c ommanded by t he invert er: 0.5H z.

• Motor: H itachi's st andard 3- phase 5.5 kW 4-pol e totally en closed ty pe motor.

Example of Hi tachi's standar d motor. (7.5k W 4-pole)

2.3 sec. re duction of decelera tion time wit hout a braking

resistor i s achieved when the func tion is active.

Over-current Suppress Func tion*

Minimum time deceleration Funct ion

(Example of W J200- 075LF)

* WJ200: 5mi n-1, Previous mo del: 13min

-1

*Turn off this f unction for li fting equip ment.

*Permanen t magnet mot or control f unction of WJ 200 is for va riable torqu e applicatio n such as fan and p ump.

EC97J1095

Features P2–5

Standard Specicatio ns P6

General Specications P7

Dimensions P8

Operation and Programming P9

Termin al (Arrangements /Functions) P 1 0 – 11

Functi on List P 12– 2 0

Protectiv e Functions P 21

Connecting Diagram P 22– 23

OFF ON

Motor Current

Output Frequency

Motor Current

Output Frequency

Trip

Connecting to PLC P24

Wiring and Accessories P 25

For Correct Operation P 26 –27

Global standards

Index

3

Stöwer Antriebstechnik GmbH, Enneststrasse 3, 51702 Bergneustadt, tel: 02261-40970, Fax: 02261-41309

4 5

2

3

3

Watt-hour monitor

Output monitor ing

(2 terminals)

Improvement

of environmen t

2

EU RoHS

compliant

Environment-fr iendly

inverter meet s RoHS

requirements

(ordered items).

Energy consump tion is displayed in kwh.

Two monit or outpu t terminals

(A nal og 0 –10 VDC

(10-bit), pulse train (0–10VDC, max 32kHz))

.

5

EzCOM (Peer-to-Peer communication)

WJ200 supports Peer-to-Peer communication between multiple

inverters. One administrator inver ter is necessary in the networ k, and

the other inverters act as master or slave.

Varnish coating of

internal PC boar d is

standard.

(Logic PCB an d I/ F PCB ar e

excluded.)

Dual rating

1

WJ200 can be used for both heavy and

normal duty. One-frame-size smaller WJ200

can be applicable to cer tain applications.

Built-in BRD circuit

4

Built-in BRD circuit for all models (Op tional resist or).

1

6

5 7

4

Network compatibility & Ex ternal port s

2

3

Safe stop fun ction

(planning)

Password function

1

Easy sequence [EzS Q]

programming function

Pursuit of Ease of Use

Ease of Maintenance Environmental Friendliness

Long life time components

(Design life time 10 years or more*)

Easy-removable

cooling fan

Micro surge voltage suppress

function

(Patent re gistered)

Life time warning function

1 3

2

Sequence oper ation is realized by dow nloading to an inverter a

program crea ted with Hitachi's Ez SQ software. Us er program can

be compiled on E zSQ software on a PC. Exter nal components can

be simplied or eliminat ed, resulting in cost-sa vings.

Design lifetime 10 Years or more for D C bus

capacitors and c ooling fan.

Cooling fan ON /O FF control function fo r longer

fan life.

*Ambient temp erature : Av erage 40ºC (

no corrosiv e gases, oil mis t or dust

)

Design lifet ime is calculat ed, and not gua ranteed.

The cooler fan can b e exchanged

without special t ools.

Hitachi original P WM control method

limits motor termin al voltage to less than

twice inver ter DC bus voltage.

Lower than Hit achi motor max. insulation

voltage (1,250V )

(During rege neration, t he motor ter minal volta ge may exceed

the motor ma ximum insulat ion voltage (1, 250V))

WJ200 diagnoses lif etime of DC bus capacitors

and cooling fan(s).

The WJ200 inverter has a pas sword function t o prevent changing

parameters or to hide some or all par ameters.

Only one MC is enough

•Reduction in costs.

•Miniaturization

Safety Module

ST01 (GS1)

ST02 (GS2)

EDM

Safety terminal

(In/ output)

Emergency output

shut-down

via hardware

Safety SW

(Emergency Stop)

Top cover can

be removed

with nger tips.

Remove cooling

fan after

disconnect ing

power plug.

Motor ter minal voltag e

Easy to maintain

Easy select ion of displayed par ameters

●

Data compar ison function

Display paramete rs changed from def ault setting.

●

Basic display

Display most fre quently used parame ters.

●

Quick display

Display 32 user-selec ted parameters.

●

User-changed parameter display

Store automa tically and display the par ameters changed by

the user (Up to 32 sets); can also be used as change histor y.

●

Active pa rameter display

Display those par ameters which are en abled.

Inverters can be ins talled

with no space between them

to save space in the panel.

*Ambient temp erature 4 0ºC max.,

individual mounting.

Side-by-side ins tallation

6

Automatic r eturn to the initial display: 10 min. a fter the last

key operation , display returns to th e initial parameter se t.

Display limitatio n:

Show only the con tents of display par ameter.

Dual monitor: Two arbi trary monitor it ems can be set. Par ameters

are switche d by up/down keys.

Flexible display funct ions

Various Versatile Functions

Ease of wiring

Screw-less t erminals (control circuit

terminals) spring-lo aded, for use with

solid or strande d wire with ferrules.

Screw-less terminals

(Control circui t terminals)

E=625V cable:100m

A serial RS-4 85 Modbus/RT U port is stand ard. The WJ200 can

communicate via DeviceNet, CompoNe t, PROFIBUS and C ANopen

with optional e xpansion card

(planned) . USB (Mini-B c onnector) port

and RS-42 2 (RJ45 connect or) port are stan dard.

USB port

RS42 2 port

1st 2nd 3rd 4th 5th 6th 7th

Night time

Standard driving

(Frequency is constant.)

WJ200 driving

Motor Speed

date

●

EzSQ E xample: Energy cos t saving by speed r eduction.

■Daytime: Motor speed is automatically reduced to reduce demand during peak hours.

■Nighttime: Motor spee d is increased to t ake a advantag e of off-peak p ower rates.

Example of d riving progra m

Operation panel

(Switc h/tim er etc.)

Panel lead

Standard Inverter WJ200 U sing EzSQ

RUN

STOP

RESET

POWER

Hz

A

RUN

PRG

MAX

MIN

WJ200 confor ms to the applicable safet y standards and cor responds

to Machinery Dire ctive of Europe. Shut s down the inverter b y

hardware, byp assing the CPU, to achieve r eliable safe stop function.

The safet y standard can be met at a low cost.

(ISO13849 -1 Category 3 / IE C60204 -1 Stop Categor y 0)

One network ex pansion card can

be installed ins ide the WJ2 00.

Inverter

WJ200

Operation panel

(Switc h/tim er etc.)

Rely seque nce

Conventional

Inverter

Panel lead

Stöwer Antriebstechnik GmbH, Enneststrasse 3, 51702 Bergneustadt, tel: 02261-40970, Fax: 02261-41309

Standard Specications

Stöwer Antriebstechnik GmbH, Enneststrasse 3, 51702 Bergneustadt, tel: 02261-40970, Fax: 02261-41309

1-phase 200V class

Models WJ2 00- 00 1SF 002SF 004SF 007SF 0 15 S F 022SF

VT 0.2 0.4 0.55 1.1 2.2 3.0

kW

Applicable mot or size *

Rated capaci ty (kVA)

Input

Rating

Output

Rating

Minimum value of r esistor (Ω) 10 0 100 100 50 50 35

Weight

Rated input volt age (V ) 1-phase: 20 0V-15% to 240 V +10%, 50 / 60Hz ±5%

Rated inpu t current (A)

Rated output voltage (V) *

Rated output current (A)

1

3-phase 200V class

Models WJ2 00- 001L F 002LF 004LF 007LF 015 LF 022LF 037LF 055LF 075LF 110 LF 150 LF

Applicable mot or size *

Rated capaci ty (kVA)

Input

Rating

Output

Rating

Minimum value of r esistor (Ω) 100 10 0 100 50 50 35 35 20 17 17 10

Weight

Rated input volt age (V ) 3-phase: 200V-15% to 240V +10%, 5 0/ 60Hz ±5%

Rated inpu t current (A)

Rated output voltage (V) *

Rated output current (A)

1

CT 0.1 0.2 0.4 0.75 1.5 2.2

VT 1/4 1/2 3/4 1.5 3 4

HP

CT 1/8 1/4 1/2 1 2 3

VT 0.4 0.6 1. 2 2.0 3.3 4 .1

200V

CT 0.2 0.5 1.0 1.7 2.7 3.8

VT 0.4 0.7 1.4 2.4 3.9 4.9

240V

CT 0.3 0.6 1.2 2.0 3.3 4.5

VT 2.0 3.6 7.3 13.8 20.2 24.0

CT 1.3 3.0 6.3 11.5 16 .8 22.0

2

VT 1.2 1.9 3.5 6.0 9.6 12. 0

CT 1.0 1.6 3.0 5.0 8.0 11.0

kg 1.0 1.0 1.1 1.6 1.8 1. 8

lb 2.2 2.2 2.4 3.5 4.0 4.0

VT 0.2 0.4 0.75 1.1 2.2 3.0 5.5 7.5 11 15 18.5

kW

CT 0.1 0.2 0.4 0.75 1.5 2.2 3.7 5.5 7. 5 11 15

VT 1/4 1/2 1 1.5 3 4 7. 5 10 15 20 25

HP

CT 1/8 1/4 1/2 1 2 3 5 7. 5 10 15 20

VT 0.4 0.6 1.2 2.0 3.3 4.1 6.7 10. 3 13.8 19.3 23.9

200V

CT 0.2 0.5 1.0 1.7 2.7 3.8 6.0 8.6 11. 4 16. 2 20.7

VT 0.4 0.7 1.4 2.4 3.9 4.9 8.1 12.4 16.6 23.2 28.6

240V

CT 0.3 0.6 1.2 2.0 3.3 4.5 7.2 10.3 13.7 19.5 24.9

VT 1.2 1.9 3.9 7.2 10.8 13.9 23.0 3 7.0 48.0 68.0 72.0

CT 1.0 1.6 3.3 6.0 9.0 12 .7 20.5 30.8 39.6 57.1 62.6

2

VT 1.2 1.9 3.5 6.0 9.6 12. 0 19.6 30.0 40.0 56.0 69.0

CT 1.0 1.6 3.0 5.0 8.0 11.0 17.5 25.0 33.0 47. 0 60.0

kg 1.0 1.0 1.1 1.2 1.6 1.8 2.0 3.3 3.4 5.1 7.4

lb 2.2 2.2 2.4 2.6 3.5 4.0 4.4 7.3 7. 5 11. 2 16.3

3-phase: 200 to 240V (proportional to input voltage)

3-phase: 200 to 240V (proportional to input voltage)

3-phase 400V class

Models WJ2 00- 004HF 007HF 015HF 022HF 030HF 040HF 05 5HF 075HF 110HF 15 0HF

VT 0.75 1. 5 2.2 3.0 4.0 5.5 7. 5 11 15 18 .5

kW

Applicable mot or size *

Rated capaci ty (kVA)

Input

Rating

Output

Rating

Minimum value of r esistor (Ω) 180 180 180 100 100 100 70 70 70 35

Weight

*1: The ap plicable mot or refers t o Hitachi st andard 3- phase mot or (4p). Whe n using other motors, ca re must be ta ken to prev ent the rat ed motor cur rent (50/ 60Hz) fr om exceedi ng the rate d output cu rrent of th e inverte r.

*2: Th e output vo ltage vari es as the main s upply volt age varies (e xcept when using the AVR f unction). In any case, t he output v oltage can not exceed the input po wer supply v oltage.

6

Rated input volt age (V ) 3-phase: 380V-15% to 480 V +10%, 50 / 60Hz ±5%

Rated inpu t current (A)

Rated output voltage (V) *

Rated output current (A)

1

CT 0.4 0.75 1.5 2.2 3.0 4.0 5.5 7.5 11 15

VT 1 2 3 4 5 7. 5 10 15 20 25

HP

CT 1/2 1 2 3 4 5 7. 5 10 15 20

VT 1. 3 2.6 3.5 4.5 5.7 7.3 11.5 15.1 20.4 25.0

200V

CT 1.1 2.2 3.1 3.6 4.7 6.0 9.7 11. 8 15.7 20.4

VT 1. 7 3.4 4.4 5.7 7.3 9.2 14.5 19.1 25.7 3 1.5

240V

CT 1.4 2.8 3.9 4.5 5.9 7. 6 12.3 14.9 19.9 25.7

VT 2.1 4.3 5.9 8.1 9.4 13.3 20.0 24.0 38.0 44.0

CT 1.8 3.6 5.2 6.5 7.7 11.0 16.9 18.8 29.4 35.9

2

VT 2.1 4.1 5.4 6.9 8.8 11.1 17.5 23.0 31.0 38.0

CT 1.8 3.4 4.8 5.5 7.2 9.2 14.8 18. 0 24.0 31.0

kg 1.5 1.6 1.8 1.9 1. 9 2.1 3.5 3.5 4.7 5.2

lb 3.3 3.5 4.0 4.2 4.2 4.6 7.7 7. 7 10.4 11. 5

3-phase: 380 to 480 V (proportional to input voltage)

General Specications

Stöwer Antriebstechnik GmbH, Enneststrasse 3, 51702 Bergneustadt, tel: 02261-40970, Fax: 02261-41309

Item General Specications

Protect ive housing *

3

Control method Sinusoidal Pulse Width Modulation (PW M) control

Carrier frequency 2kHz to 15kHz (derating required depending on the model)

Output f requency range *

4

Frequency accuracy

Frequency set ting resolut ion Digital: 0.01Hz; Analog: max . frequency / 1000

Volt ./ Freq. character istic

Overload capacity

Acceleration /deceleration time 0.01 to 3600 seconds, linear and S-curve accel /decel, second accel /decel setting available

Start ing torque 200% @0.5Hz (sensorless ve ctor control)

DC braking Variable operating f requency, time, and braking force

Operator panel

Freq . setting

Ex ternal signal *

Via network RS485 ModBus RT U, other net work option

Operator panel Run / Stop (For ward /Reverse run change by command)

FW D/ REV run

Ex ternal signal *

Via network RS485 ModBus RT U, other net work option

Terminals 7 terminals, sink / source changeable by a short bar

Intelligent input

Input signal

terminal

68 funct ions

Functions

assignable

Intelligent output

terminal

Functions

48 f unctions

assignable

Output signal

Moni tor output (analog) Output freq., output current, output torque, output voltage, input power, thermal load ratio, L AD freq., heat sink temperature, general ou tput (EzSQ)

Pulse train output

(0 – 10VDC, 32 kHz max.)

Alar m output cont act ON for inverter alar m (1c contacts, both normally open or closed available.)

Other functions

Protect ive funct ion

Temperature Op erating (ambient): -10 to 50

Operating environment

Humidity 20 to 90% humidity (non-condensing)

Vibration *

Location Altitude 1,000m or less, indoors (no corrosive gasses or dust)

Coat ing color Black

Options Remote operator unit, cables for the units, braking unit, braking resistor, AC reactor, DC reactor, EMC lter

IP20

0.1 to 400Hz

Digital command: ±0.01% of the maximum frequency

Analog command: ±0.2% of the maximum frequency (25

°

C ±10°C)

V/f control (constant torque, reduced torque, free-V /F): b ase freq. 3 0Hz – 400Hz adjustable,

Sensorless vector control, Closed loop control with motor encoder feedback (only V/f control).

Dual rating: CT (Heavy duty): 60 sec. @150%

VT (Normal dut y): 60 sec. @120%

2

1

keys / Value set tings

6

0 to 10 VDC (input impedance 10kΩ), 4 to 20mA (input imp edance 100Ω), Potentiometer (1k to 2kΩ, 2W )

6

Forward r un /stop, Reverse run / stop

FW (forward run command), RV (reverse run command), CF1 – CF4 (multi-stage speed setting), JG (jog command), DB (external braking), SET (set second

motor), 2CH (2-stage accel. /decel. command), FRS (free run stop command), E XT (exter nal trip), USP (st artup function), CS (commercial power switchover),

SFT (soft lock), AT (analog input selection), RS (reset), P TC (thermistor thermal protection), STA (start), STP (stop), F /R (forward /reverse), PID (PID

disable), PIDC (PID reset), UP (remote control up function), DWN (remote control down function), UDC (remote control data clear), OPE (operator control),

SF1– SF7 (multi-stage speed setting; bit operation), OLR (overload restriction), TL (torque limit enable), TRQ1 (torque limit changeover1), TRQ2 (torque

limit changeover2), BOK (Braking conrmation), L AC (LAD cancellation), PCLR (position deviation clear), ADD (add frequency enable), F-TM (force terminal

mode), ATR (permission of torque command input), KHC (Cumulative power clear), MI1– MI7 (general purpose inputs for EzSQ), AHD (analog command hold),

CP1– CP3 (multistage-position switches), ORL (limit signal of zero-return), ORG (trigger signal of zero-return), SPD (speed/position changeover), GS1,GS2 (STO

inputs, safety related signals), 485 (Starting communication signal), PRG (executing EzSQ program), HLD (retain output frequency), ROK (permission of run

command), EB (rotation direction detection of B-phase), DISP (display limitation), NO (no function)

RUN (run signal), FA1 –FA 5 (frequency arrival signal), OL,OL2 (overload advance notice signal), OD (PID deviation error signal), A L (alarm signal),

OTQ (over / under torque thre shold), UV (under-voltage), TRQ (torque limit signal), RNT (run time expired), ONT (power ON time expired), THM (thermal

warning), BRK (brake release), BER (brake error), ZS (0Hz detection), DSE (speed deviation excessive), POK (positioning completion), ODc (analog

voltage input disconnection), OIDc (analog cur rent input disconnection), FB V (PID second stage output), NDc (network disconnec t detection), LOG1 –

LOG3 (Logic output signals), WAC (capacitor life warning), WA F (cooling fan warning), FR (st arting contact), OHF (heat sink overheat warning), LOC

(Low load), MO1 –MO3 (general outputs for EzSQ), IRDY (inver ter ready), FWR (forward operation), RVR (reverse operation), M JA (major failure),

WCO (window comparator O), WCOI (window comparator OI), FREF (frequency command source), REF (run command sour ce), SETM (second motor in

operation), EDM (STO (safe torque off ) per formance monitor), OP (option control signal), NO (no function)

[PW M output]

Output fre q., output current, output torque, output voltage, input power, thermal load ratio, LAD freq., heat sink temperature, general output (EzSQ)

[Pulse train output]

Output frequency, output cur rent , pulse train input monitor

Free-V/f, manual / automatic torque boost, output voltage gain adjustment, AVR function, reduced voltage start, motor data selection, autotuning, motor stabilization control, reverse r unning protection, simple position control, simple torque control, torque limiting, automatic carrier

frequency r educ tion, energy saving operation, PID function, non-stop operation at instantaneous power failure, brake control, DC inje ction

braking, dynamic braking (BRD), f requency upper and lower limiters, jump frequencies, curve accel and decel (S, U, inversed U,EL-S), 16-stage

speed prole, ne adjustment of st art frequency, accel and decel stop, process jogging, frequency calculation, frequency addition, 2-stage

accel/decel, stop mode selection, start /end freq., analog input lter, window comparators, input terminal response time, output signal delay/

hold function, rotation direction restriction, stop key sele ction, sof tware lock, safe stop function, scaling function, display restriction, passwor d

function, user p arameter, initialization, initial display selection, cooling fan control, warning, trip retry, frequency pull-in r estart, frequency

matching, overload restriction, over current restriction, DC bus voltage AVR

Over-current, over-voltage, under-voltage, overload, brake resistor overload, CPU error, memory error, external trip, USP error, ground fault detection

at power on, temperature error, internal communication error, driver error, thermistor error, brake error, safe stop, overload at low speed, modbus

communication error, option error, encoder disconnection, speed excessive, EzSQ command error, EzSQ nesting error, EzSQ execution error, EzSQ user trip

°

C / Stor age: -2 0 to 65°C *

8

5.9m/s2 (0.6G), 10 to 55 Hz

7

*3: Th e protect ion method conforms t o JEM 1030.

*4: To operat e the motor b eyond 50 / 60Hz, c onsult the m otor manuf acturer f or the maxim um allowable r otation sp eed.

*5: Th e brakin g torque via ca pacitive feedbac k is th e averag e decele ration t orque at the sh ortest deceler ation (st opping f rom 50 / 60Hz as indic ated). I t is no t continu ous rege nerative braking torque. The a verage d ecelerati on

torqu e varies wit h motor los s. This value d ecreases w hen opera ting beyon d 50Hz. If a large rege nerative t orque is req uired, the o ptional reg enerativ e braking uni t and a resis tor should be u sed.

*6: T he frequenc y command is t he maximum f requency a t 9.8V for inp ut voltage 0 t o 10VDC , or at 19.6mA fo r input curr ent 4 to 20mA . If this char acterist ic is not satis factory f or your applic ation, cont act your Hit achi repre sentativ e.

*7: The stora ge tempera ture refe rs to the sho rt-term t emperatur e during tr ansport ation.

*8: Co nforms to t he test met hod speci ed in JIS C0 040 (1999) . For the mo del types excluded in t he standar d specic ations, con tact your H itachi sale s represe ntative.

7

Dimensions

Stöwer Antriebstechnik GmbH, Enneststrasse 3, 51702 Bergneustadt, tel: 02261-40970, Fax: 02261-41309

• WJ200-001LF – 007LF

• WJ200-001SF – 004SF

68 (2.68)

WJ200 INVERTER

PWR

RUN

Hz

ALM

A PRG

STOP

RUN

1

RESET

ESC

2 SET

128 (5.04)

118 (4.65)

5 (0.20)

56 (2.20)

D

Ø4.5 (0.18)

Model D

001LF, 002LF

001SF, 00 2SF

109 (4. 29)

004 LF, 004SF 122. 5 (4.82)

007LF 145.5 ( 5.73)

• WJ200-055LF

• WJ200-075LF

• WJ200-055HF

• WJ200-075HF

248 (9.76)

260 (10.24)

155 (6.10)

140 (5.51)

6 (0.24)

122 (4.80)

[Unit : mm(inch)]

Inche s for refere nce only

Ø6 (0.24)

WJ200 INVERTER

PWR

RUN

Hz

ALM

A

PRG

STOP

RUN

1

RESET

ESC

2 SET

• WJ200-015LF, 022LF

• WJ200-007SF – 022SF

• WJ200-004HF – 030HF

108 (4.25)

WJ200 INVERTER

RUN

Hz

A PRG

STOP

RUN

1

RESET

ESC2SET

128 (5.04)

118 (4.65)

5 (0.20)

96 (3.78)

D

• WJ200-037LF

• WJ200-040HF

140 (5.51)

WJ200 INVERTER

RUN

1

ESC2SET

128 (5.04)

118 (4.65)

• WJ200-110LF

• WJ200-110HF

• WJ200-150HF

Ø4.5 (0.18)

PWR

ALM

296 (11.65)

Model D

004HF 143.5 ( 5.65)

Other 170.5 (6.7 1)

175 (6.89)

284 (11.18)

7 (0.28)

180 (7.09)

WJ200 INVERTER

STOP

RUN

1

RESET

ESC2SET

160 (6.30)

Ø7 (0.28)

RUN

PWR

Hz

ALM

A

PRG

• WJ200-150LF

220 (8.66)

Ø7 (0.28)

WJ200 INVERTER

RUN

PWR

Hz

ALM

A

PRG

STOP

RUN

PWR

RUN

Hz

ALM

A PRG

STOP

RESET

Ø4.5 (0.18)

336 (13.23)

350 (13.78)

ESC2SET

1

RESET

5 (0.20)

128 (5.04)

170.5 (6.71)

8

175 (6.89)

7 (0.28)

192 (7.56)

Operation and Programming

Stöwer Antriebstechnik GmbH, Enneststrasse 3, 51702 Bergneustadt, tel: 02261-40970, Fax: 02261-41309

Operation Panel

WJ200 Series can be easily operated with the digital operator provided as standard.

( 4 ) Run LED

ON when inverter is in RUN mode.

( 5 ) Monitor L ED [Hz]

ON (Green) when the displayed data is

frequency related.

( 6 ) Monitor LED [A]

ON (Green) when the displayed dat a is

current related.

( 8 ) 7-segment L ED

Shows each parame ter, monitors etc.

( 7 ) Run command LED

ON (Green) when the Run command is set to the

operator. (Run key is enabled.)

( 9 ) RUN key

Makes inver ter run.

(11) Escape key

Go to the top of next function group,

when function mode is displayed.

(12) Up key (13) Down key

Press up or down to sequence through parameters and functions

shown on the display, and increment/decrement values.

(1 ) POWER LED

ON (Green) while t he inverter is receiving

input power.

( 2 ) AL ARM LED

ON (Red) when the inver ter trips.

( 3 ) Program L ED

ON (Green) when the display shows

editable parameter.

(15) USB port

USB connector (mini-B) for PC communication.

(10) Stop /reset key

Makes inverter stop.

(16) RS-422 port

RJ4 5 jack for remote operator.

(14) Set key

Function code: Moves to the data display.

Data code: Press to write the new value

to EEPROM.

Keypad Navigation Map Single-Digit Edit Mode

If a target function code or data is far from current

posit ion, using the single-digit edit mode makes it

quicker to navigate there. Pressing the up key and

down key at the same time brings you into the

digit-by-digi t navigation mode.

Press both up key and down key at

Step1:

the same.

1st digit will be blinking.

Group "d"

Function co de

Group "F "

Function co de

Func tion code di splay

:

Moves to dat a display

Data display

Func tion code di splay

: Chang e the value of fun ction code.

Pressing the up key at the bot tom of the group returns to the top of the group.

Func tion code di splay

: Jumps t o the next gr oup

Save

Data display

d001: Output frequency monitoring

F001: Output frequency setting

Function group "d" is a monitor,

data c annot be changed.

Data display (F001 to F003)

Data d oes not blink becaus e of real time s ynchronizing

Save s the data in EE PROM and re turns to functio n code display.

Group "A"

Function co de

Group "b"

Group " C"

Group " H"

Group " P"

Group " U"

Group "d"

return to d 001

)

Data display

Function group "U" return to function group "d" next.

A001: Frequency source setting

Data display

When data is changed, the display starts blinking, which

means that new data has not been stored yet.

: Saves the data in EEPROM and returns to function code display.

: Cancels the data change and returns to function code display.

The blinking digit is moved by the

Step2:

ESC

and

SET

key right and left.

Use up/down keys to change the value

of the digit.

+1

SETESC

Move cursor to left. Move cursor to right.

Step3:

-1

When the least signicant digit is

blinking, the

SET

key selects

that parameter.

SET

9

Terminal (

Stöwer Antriebstechnik GmbH, Enneststrasse 3, 51702 Bergneustadt, tel: 02261-40970, Fax: 02261-41309

Arrangements / Functions

Terminal Description

Symbol Terminal Name

R/L1, S/L 2, T/L3 Main power supply input terminals

U/T1, V/T2, W/T3 Inver ter output terminals

PD/+1, P/+ DC reactor connection terminals

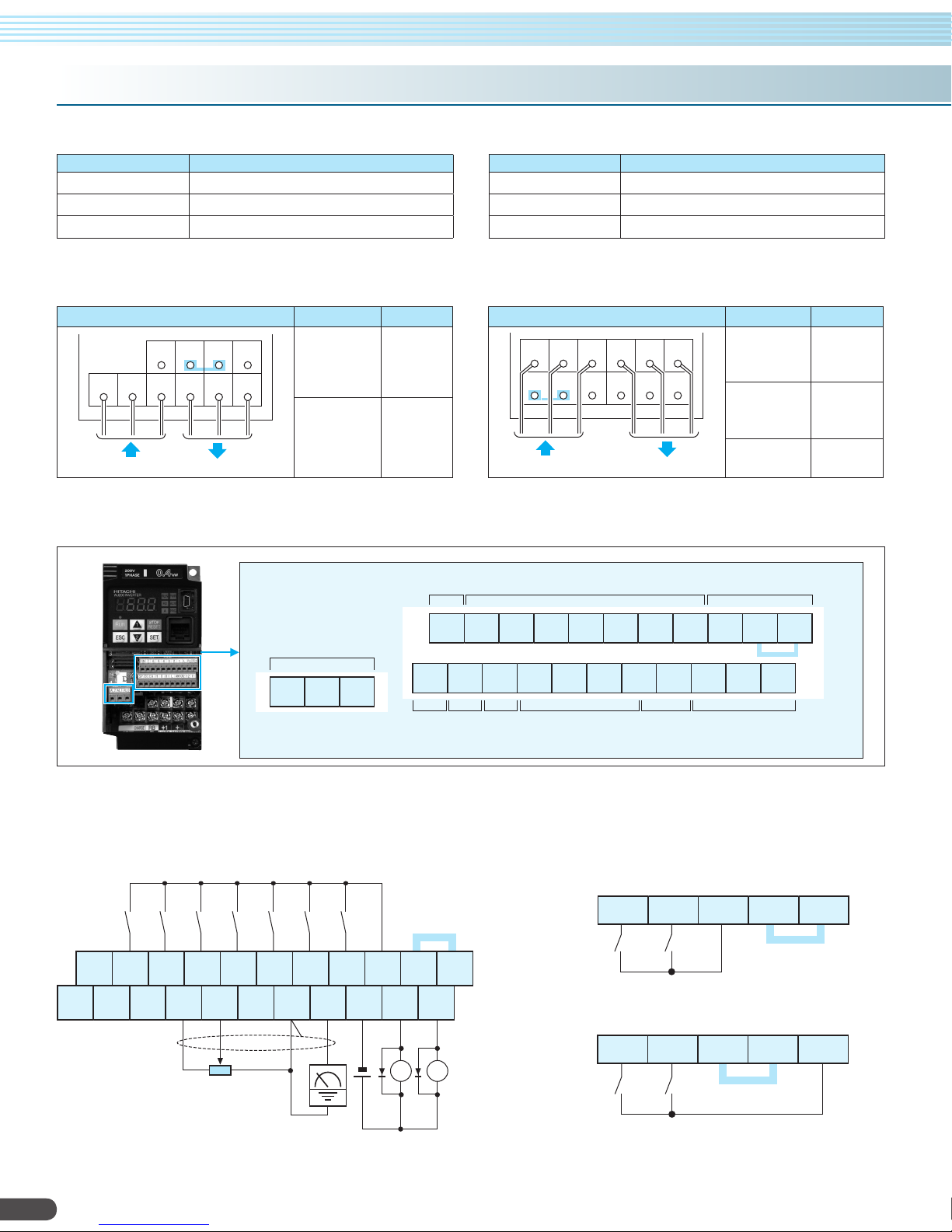

Terminal Arrangement and Screw Diameter

Terminal Model

Screw Diameter

)

Symbol Terminal Name

P/+, RB External braking resistor connection terminals

P/+, N/- External braking unit connection terminals

G Ground connection terminal

Terminal Model

Screw Diameter

RB

PD/+1

P/+ N/-

R/L1 S/L2 T/L3 U/T1 V/T2 W/T3

001 – 007LF

001 – 004SF

M3.5

015 – 037LF

007– 022SF

Power input Output to motor

004 –040HF

Terminal Arrangement of Control Circuit Terminals

Relay contacts

AL2 AL1 AL0

M4

RS-485

comm.

R/L1 S/L2

PD/+ P/+

Power input Output to motor

RS-485

comm.

SN

7 6 5 4 3 2 1 L PLC P24

SP

EO EA H O OI L AM CM2 12 11

Pulse

Pulse

Train

Train

output

input

T/L3 U/T1 V/T2 W/T3

N/-

RB G G

Logic inputs

Analog input A nalog output Logic outputs

055 – 075LF

055 – 075HF

110LF

110 – 150HF

150 LF M8

Logic common

and power supply

M5

M6

Short bar

Wiring sample of control logic terminal (Sink logic)

Sink /source logic of intelligent input terminals

Sink or source logic is switched by a short bar as below.

Sink logic

Short bar

(Sink logic)

SN 7 6 5 4 3 2 1 L PLC P24

SP EO EA H O OI L AM CM2 12 11

Variable resistor

for freq. set tting

(1kΩ –2kΩ)

10

Freq. meter

(27Vdc 50m A max.)

RYRY

Source logic

2 1 L PLC P24

Short bar

2 1 L PLC P24

Short bar

Loading...

Loading...