Pursuing the Ideal Compact Inverter

Pursuing the Ideal Compact Inverter

Series

Designed for excellent performance and user friendliness

Hitachi Solar Water Pump

Inverter System

Hitachi Solar Water Pump

Inverter System

KHKSCO GROUP

Ii

Objective of this Manual:

The objective of this manual is to educate the user for proper installation and for putting the system into

use.

Scope Statement:

The scope of this manual covers only installation, commissioning and general operations of the

Solar Water Pump Inverter

How-ever, some information on primary maintenance can be found in this manual.

Ii

ii

Operation Manual

Table of Contents:

Chapter

Page

About the System

1

Overview

1-1

Solar Power and Irrigation

1-1

Safety

2

Definitions And Symbols

2-1

General Warnings and Cautions

2-2

UL Cautions, Warnings And Instructions

2-3

Installation Preparation & Requirements

3

Terminal Screw and Wire size

3-1

Fuse Size

3-2

Mounting Location

3-3

Electrical Wiring

3-4

Connection to Solar Water Pump

System

4

4

Power Wire For Solar Inverter

4-1

Control Wiring For Solar Inverter

2-8

2-9

Keypad Description

2-10

Key and Indicator Legend

2-11

Operating Principle And Hardware

5

Principle of Solar Water Pump Inverter

5-1

MPPT Over view

5-2

Motor Requirement

5-3

System Start-Up

6

Parameter Settings

6-1

Steps for setting Inverter for System

6-4

Fault Code

6-5

Monitoring System Data

6-6

PC Tools for Monitoring

6-9

Maintenance And Inspection

7

Modbus Network Communication

8

Introduction

8-1

Connecting Inverter to Modbus Network

8-2

Modbus Parameter Setting

8-3

Common Fault and Remedies

9

Contacts

About the System 1

In this chapter…

Page

About the System

Over View

1-1

Solar Power and Irrigation

1-1

For the purpose of this manual and the product the following symbols are used.

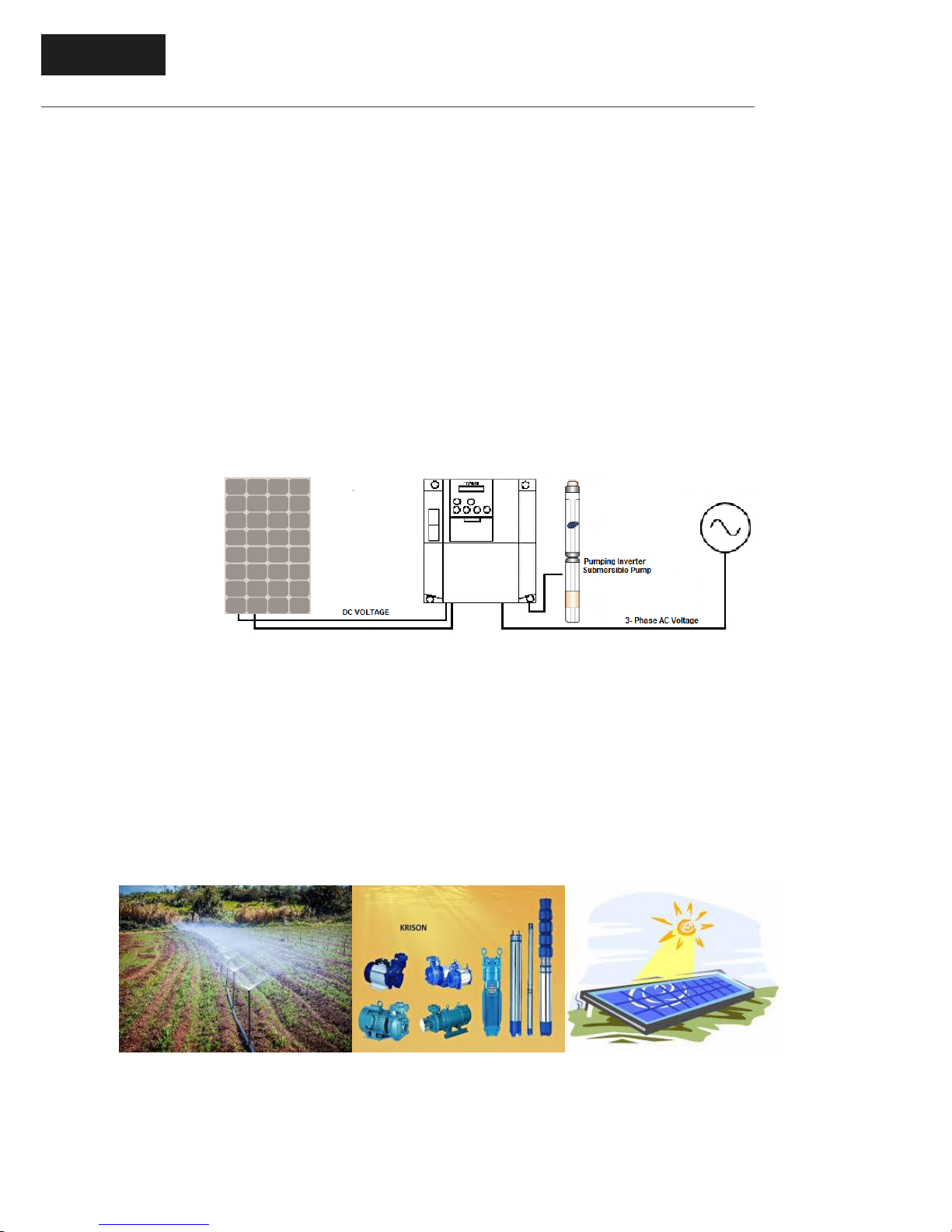

Overview:

The system operates on power generated using solar PV (photovoltaic) system. The

photovoltaic array converts the solar energy into electricity, which is used for running

the motor pump set. The pumping system draws water from the open well, bore well,

stream, pond, canal etc.

The system requires a shadow-free area for installation of the Solar Panel.

Of all the ways solar electricity benefits the people on Earth, none makes as much

difference in the daily lives as pumping water. By providing water for irrigation or

potable water have obvious benefits for people in rural areas and especially for those

in developing nations. The proper choice is determined by application specific factors

like how much water is required and whether the water should be available at night

or just during high sun hours.

Solar Power and Irrigation:

Irrigation is best utilisation of Solar power

Usually area which require more water have high solar irradiation

During summer time when more water is require, there is more sun light

Water need not be available at night

Maintenance facilities are lacking, Solar pump run maintenance free.

Solar tracking can use.

Safety 2

In this chapter…

Page

Introduction

2-1

Definition and Symbol

2-3

General warning and Cautions

2-3

UL Cautions, Warning and Instructions

2-1 Safety Information

Definitions and Symbols

HAZARDOUS HIGH VOLTAGE: Motor control equipment and electronic

controllers are connected to hazardous line voltages. When servicing drives and

electronic controllers, there may be exposed components with housing or protrusions at

or above line potential. Extreme care should be taken to protect against shock. Stand on

an insulating pad and make it a habit to use only one hand when checking components.

Always work with another person in case an emergency occurs. Disconnect power before

checking controllers or performing maintenance. Be sure equipment is properly

grounded. Wear safety glasses whenever working on electronic controllers or rotating

machinery.

WARNING: This equipment should be installed, adjusted, and serviced by qualified

electrical maintenance personnel familiar with the construction and operation of the

equipment and the hazards involved. Failure to observe this precaution could result in

bodily injury.

WARNING: For equipment protection, install a ground leakage type breaker with a

fast response circuit capable of handling large currents. The ground fault protection

circuit is not designed to protect against personal injury.

WARNING: HAZARDOUS OF ELECTRICAL SHOCK. DISCONNECT INCOMING

POWER BEFORE WORKING ON THIS CONTROL.

WARNING: Wait at least five (5) minutes after turning OFF the input power supply

before performing maintenance or an inspection. Otherwise, there is the danger of

electric shock.

CAUTION: Proper grounds, disconnecting devices and other safety devices and

their location are the responsibility of the user and are not provided by Hitachi Industrial

Equipment Systems Co., Ltd.

HIGH VOLTAGE: Dangerous voltage exists until power light is OFF. Wait at least

five (5) minutes after input power is disconnected before performing maintenance

Ii

WARNING: This equipment has high leakage current and must be permanently

(fixed) hard-wire to earth ground via two independent cables.

WARNING: Rotating shafts and above-ground electrical potentials can be

hazardous. Therefore, it is strongly recommended that all electrical work conform to

the National Electrical Codes and local regulations. Installation, alignment and

maintenance should be performed only by qualified personnel.

CAUTION:

b) Any motor used must be of a suitable rating.

c) Motors may have hazardous moving path. In this event suitable protection must be

provided.

CAUTION: Hazardous (main) terminals for any interconnection (motor, contact

breaker, filter, etc.) must be inaccessible in the final installation.

CAUTION: This equipment should be installed in IP54 or equivalent enclosure.

CAUTION: Connection to field wiring terminals must be reliably fixed having

two independent means of mechanical support. Use a termination with cable support

(figure below), or strain relief, cable clamp, etc.

Ii

General Warnings and Cautions

WARNING: Never modify the unit. Otherwise, there is a danger of electric shock and/or injury.

CAUTION: Withstand voltage test and insulation resistance tests (HIPOT) are executed before

the units are shipped, so there is no need to conduct these tests before operation.

CAUTION: Do not attach or remove wiring or connectors when power is applied. Also, do not

check signals during operation.

CAUTION: Be sure to connect the grounding terminal to earth ground.

CAUTION: When inspecting the unit, be sure to wait five minutes after turning OFF the power

supply before opening the cover.

UL Cautions, Warnings and Instructions

Warnings and Cautions for Troubleshooting and Maintenance The warnings and instructions in

this section summarizes the procedures necessary to ensure an inverter installation complies with

delines.

-001L, -002L, -004L, -007L, -015S, -

022S, -004H, -007H, -015H, -022H and -030H)

WARNING: Use 75 -001S, -002S, -004S, -007S, -015L, -

022L, -037L, -055L, -075L, -110L, -150L, -040H, -055H, -075H, -110H and -150H) WARNING: Suitable

for use on a circuit capable of delivering not more than 100,000 rms Symmetrical Amperes, 240 or

480V maximum.

WARNING: When protected by CC, G, J, or R class Fuses, or when Protected By A Circuit

Breaker Having An Interrupting Rating Not Less Than 100,000 rms Symmetrical Amperes, 240 or 480

Volts Maximum.

WARNING: Install device in pollution degree 2 environment.

WARNING: Solid state motor overload protection is provided in each model

WARNING: Integral solid state short circuit protection does not provide branch circuit protection.

Branch circuit protection must be provided in accordance with the National Electric Code and any

additional local codes

Installation Preparation 3

And Requirements

In this chapter…

Page

Installation Preparation

3-1

Mounting Location

2-3

Electrical Wiring

2-3

Ii

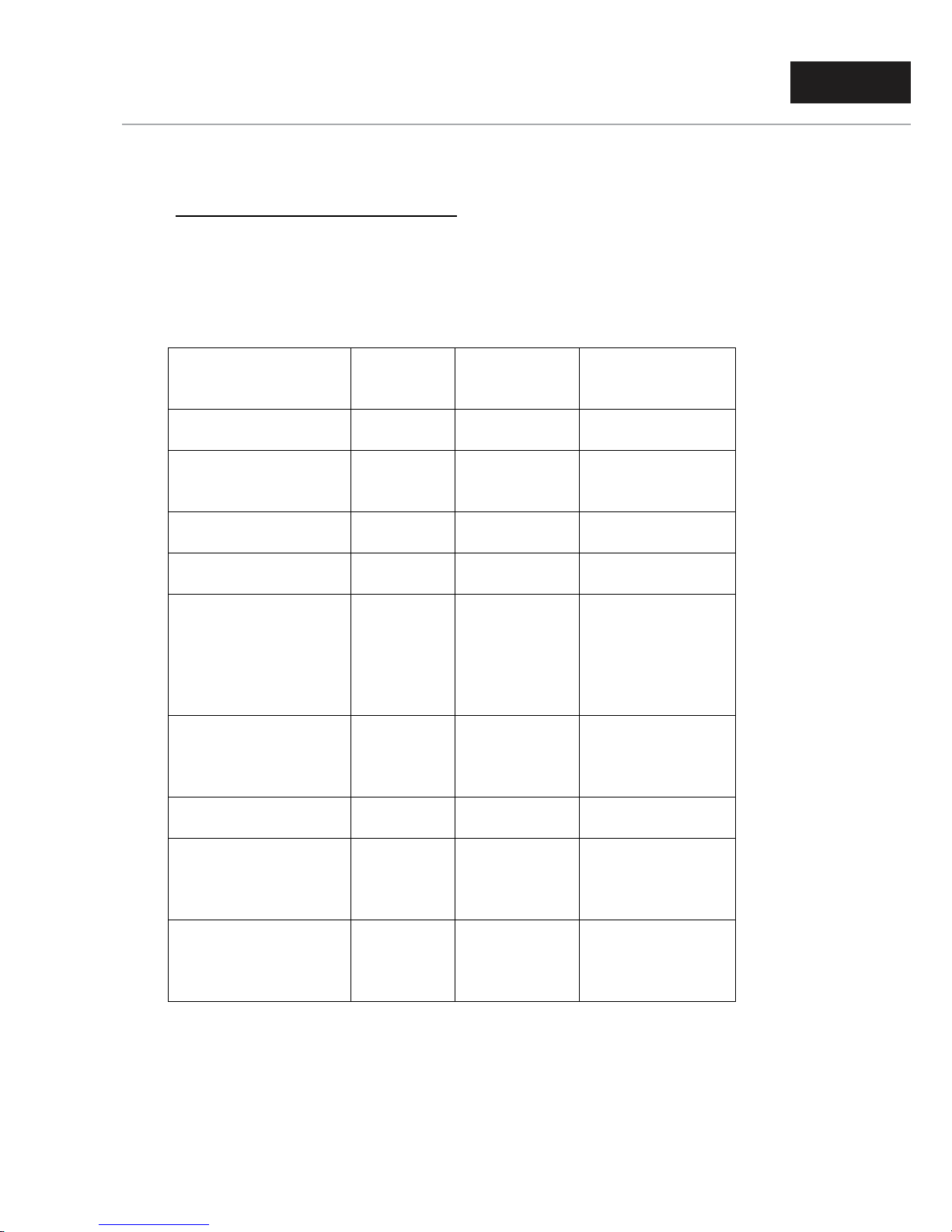

Installation Preparation

Terminal Screw and Wire Size

Inverter Model

Screw Size

Required

Torque (N-m)

Wire Range

WJ-0001S

M3.5

1.0

AWG16

(1.3mm2)

WJ-0002S

WJ-

007S

M4

1.4

AWG14

(2.1mm2)

WJ-0015S

M4

1.4

AWG12

(3.3mm2)

WJ-0022S

M4

1.4

AWG10

(5.3mm2)

WJ-0004H

WJ-0007H

WJ-0015H

M4

1.4

AWG16

(1.3mm2)

WJ-0022H

WJ-0030H

M4

1.4

AWG14

(2.1mm2)

WJ-0040H

M4

1.4

AWG12

(3.3mm2)

WJ-0055H

WJ-0075H

M5

3.0

AWG10

(5.3mm2)

WJ-0110H

WJ-0150H

M6

5.9 to 8.8

AWG6 (13mm2)

Ii

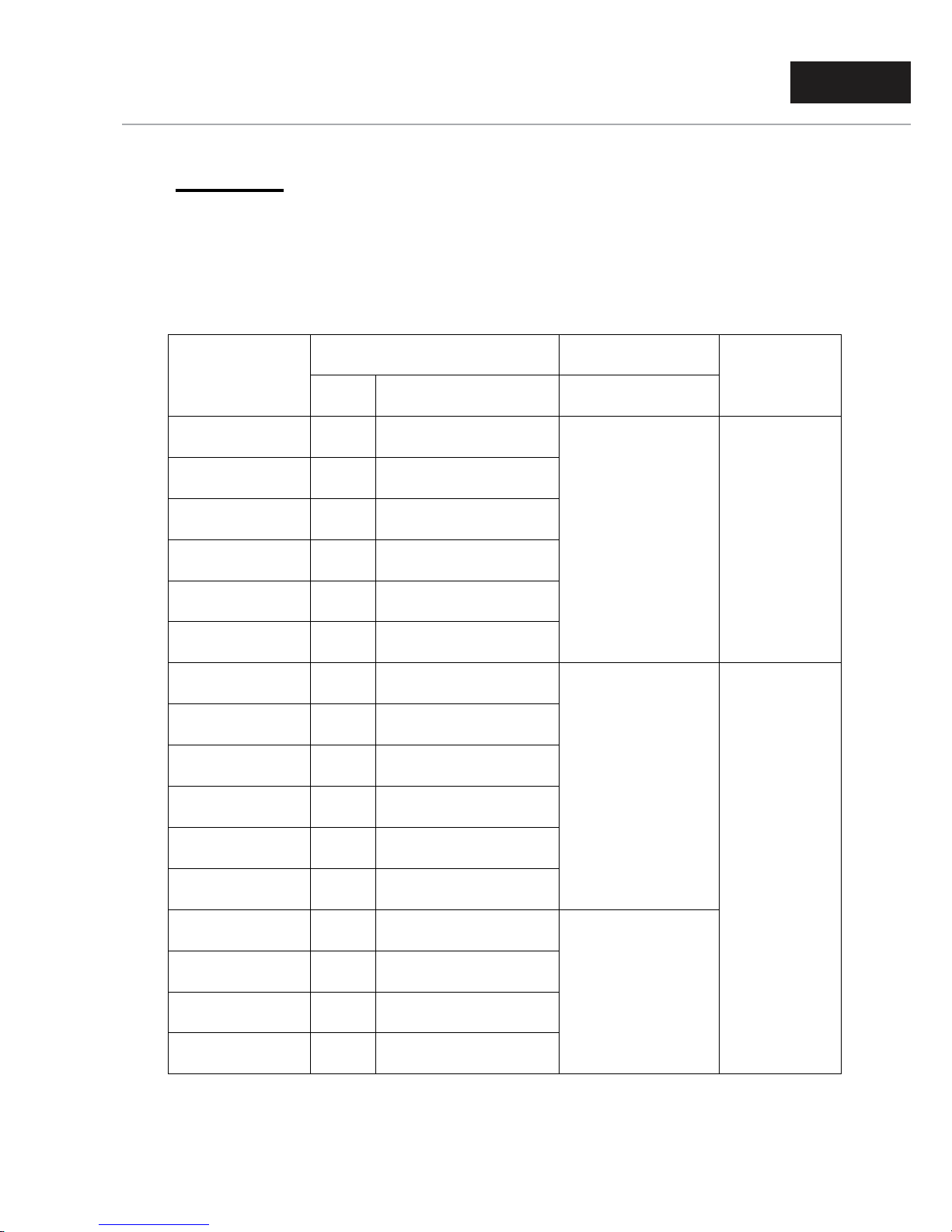

Fuse Size

The unit shall be connected with a Listed Cartridge Nonrenewable fuse or Inverse

time circuit breaker, rated 600 Vac with the current ratings as shown in the table

below

Model No.

Fuse

Inverse Time

Circuit Breaker

Type E CMC

Type

Rating(Maximum A)

Rating (Maximum

A)

WJ-0001S

Class

J

10 A, AIC 200 kA

30A

MMS-32H,

240V,40A

WJ-0002S

Class

J

10 A, AIC 200 kA

WJ-0004S

Class

J

10 A, AIC 200 kA

WJ-0007S

Class

J

15 A, AIC 200 kA

WJ-0015S

Class

J

15 A, AIC 200 kA

WJ-0022S

Class

J

20 A, AIC 200 kA

WJ-0004H

Class

J

10 A, AIC 200 kA

20A

MMS-32H,

480V,40A or

MMS-63H,

480V,52A

WJ-0007H

Class

J

10 A, AIC 200 kA

WJ-0015H

Class

J

10 A, AIC 200 kA

WJ-0022H

Class

J

10 A, AIC 200 kA

WJ-0030H

Class

J

15 A, AIC 200 kA

WJ-0040H

Class

J

15 A, AIC 200 kA

WJ-0055H

Class

J

30 A, AIC 200 kA

40A

WJ-0075H

Class

J

30 A, AIC 200 kA

WJ-0110H

Class

J

50 A, AIC 200 kA

WJ-0150H

Class

J

50 A, AIC 200 kA

Ii

Mounting location

Hardware installation

Study the following caution messages associated with mounting the inverter. This is the

time when mistakes are most likely to occur that will result in expensive rework, equipment

damage, or personal injury.

CAUTION: Be sure to install the unit on flame-resistant material such as steel plate.

Otherwise, there is the danger of fire.

CAUTION: Be sure not to place any flammable materials near the inverter.

Otherwise, there is the danger of fire.

CAUTION: Be sure not to let the foreign matter enter vent openings in the inverter

housing, such as wire clippings, spatter from welding, metal shavings, dust, etc. Otherwise,

there is the danger of fire.

CAUTION: Be sure to install the inverter in a place that can bear the weight according

to the specifications in the text. Otherwise, it may fall and cause injury to personnel.

CAUTION: Be sure to install the unit on a perpendicular wall that is not subject to

vibration. Otherwise, it may fall and cause injury to personnel.

CAUTION: Be sure not to install or operate an inverter that is damaged or has

missing parts. Otherwise, it may cause injury to personnel.

CAUTION: Be sure to install the inverter in a well-ventilated room that does not have

direct exposure to sunlight, a tendency for high temperature, high humidity or dew

condensation, high levels of dust, corrosive gas, explosive gas, inflammable gas, grindingfluid mist, salt damage, etc. Otherwise, there is the danger of fire.

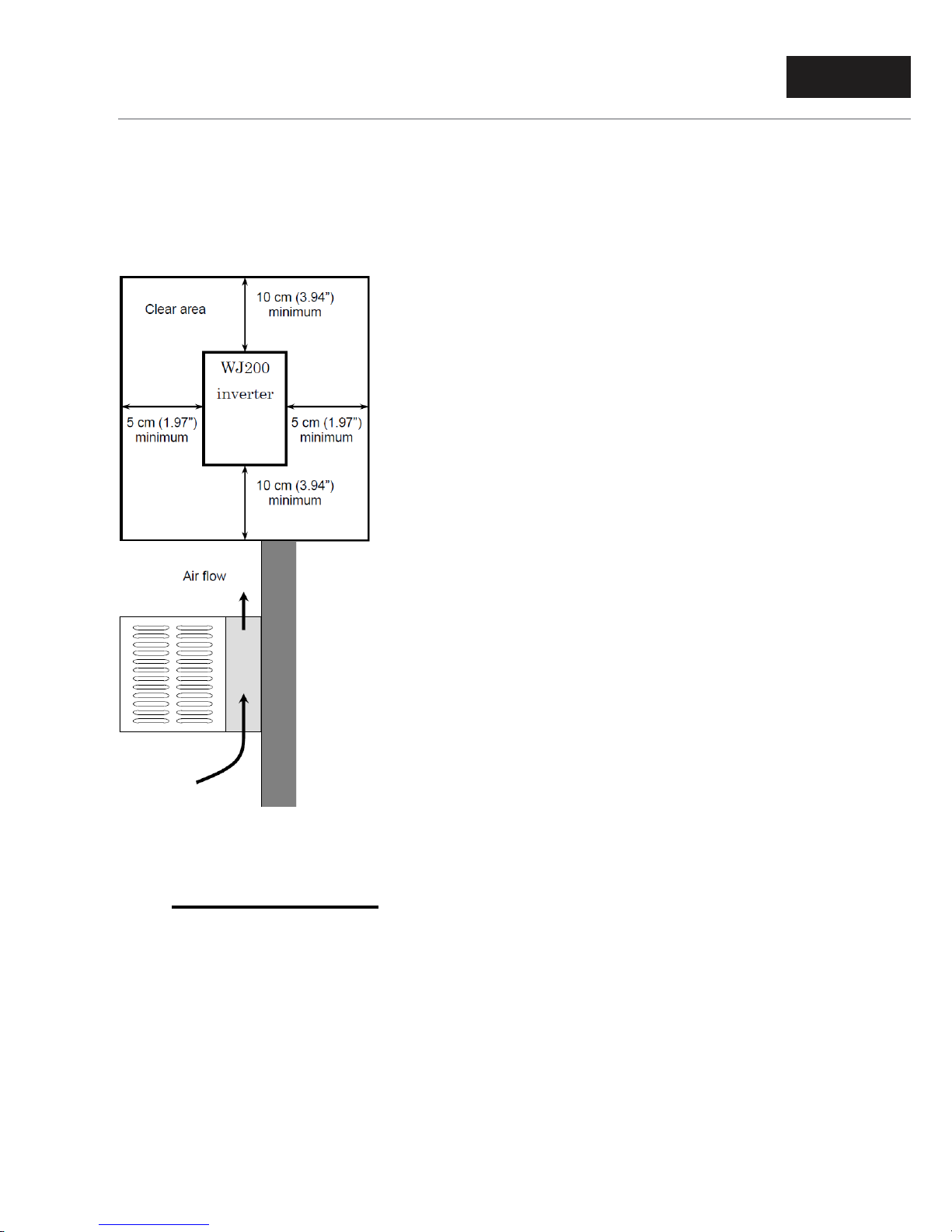

Ensure Adequate Ventilation

To summarize the caution messages – you will need to find a solid, non-flammable, vertical

surface that is in a relatively clean and dry environment. In order to ensure enough room

for air circulation around the inverter to aid in cooling, it is recommended to maintain the

specified clearance and the inverter specified in the below diagram.

CAUTION: Be sure to maintain the specified clearance area around the inverter and

to provide adequate ventilation. Otherwise, the inverter may overheat and cause equipment

damage or fire.

Ii

Ensure Adequate Ventilation

To summarize the caution messages – you will need to find a solid, non-flammable,

vertical surface that is in a relatively clean and dry environment. In order to ensure enough

room for air circulation around the inverter to aid in cooling, it is recommended to maintain

the specified clearance and the inverter specified in the below diagram

CAUTION: Be sure to maintain the specified clearance area around the inverter and to

provide adequate ventilation. Otherwise, the inverter may overheat and cause equipment

damage or fire.

Electrical Wiring

You will connect wiring to the input of the inverter. First, you must determine whether the

inverter model you have required three-phase power only, or single-phase power only. All

models have the same power connection terminals [R/L1], [S/L2], and [T/L3]. So you must

refer to the specifications label (on the side of the inverter) for the acceptable power

source types! For inverters that can accept single-phase power and are connected that

way, terminal [S/L2] will remain unconnected. Note the use of ring lug connectors for a

secure connection.

Ii

Single-phase 200V 0.1 to 0.4kW

Three-phase 200V 0.1 to 0.75kW

Ii

Ii

Solar Water System 4

Wiring details

Ii

Connection to Solar Water Pump System

DC PV Power AC Grid Power

All Type Induction motor pump and PMAC motor Pump

Hitachi Solar

Water Pump

Inverter

Ii

Power Wiring For Solar Power in Solar Water Pump Inverter

( DC Input )

SOLAR PV

MODULE DC

POWER

DC Power

Hitachi Solar Water Pump

Inverter

R S T

U V W M E

Water Submersible Pump AC

and PMAC Motor

+

-

+

-

Ii

Power Wiring For Solar Power Or Grid Power in

Solar Water Pump Inverter AC Or DC Input

Note :

When AC Grid Power and DC PV Power use with change over switch,

Alternatively AC and DC power use in Inverter

AC Grid

Power

SOLAR PV

MODULE DC

POWER

AC / DC Power

Change Over

Switch, AC MCB,

DC Fuses

Hitachi Solar Water Pump

Inverter

R

S

T

+

-

U V W M E

Water Submersible Pump AC

and PMAC Motor

Option

+

-

Ii

Power Wiring For Solar Power and Grid Power

in Solar Water Pump Inverter AC & DC Input

When AC Grid and DC PV Power use together In Inverter Where DC PV Module Total

Vmp Value should be higher than AC Grid Voltage x 1.414

AC Grid

Power

SOLAR PV

MODULE DC

POWER

Switch, AC

MCB, DC Fuses

Hitachi Solar Water Pump

Inverter

R

S

T

+

-

U V W M E

Water Submersible Pump AC

and PMAC Motor

Fuses And Diodes For

Reverse Polarity

Protection

Note :

+

-

Ii

Control Wiring for Solar Water Pump Inverter:

For Rating 0.75KW to 15KW ( WJ200 )

For Rating above 15Kw ( SJ700 )

Note:

1. For Rating 0.75kw to 15Kw, Make switch between terminal L and 1 for giving Start

command to pump and for above 15kw, It is require to put start switch between P24

and FW terminal of Control board.

2. Customer can use Push button for reset error of inverter for getting immediate

restart command.

3. There is delay restart timer inside inverter for error come while dark cloud or

suddenly power changes in PV panel. Like undervoltage

For Rating above 15Kw ( SJ700D )

Ii

Using the Front Panel Keypad

Inverter Keypad Description

Key and Indicator Legend

Items

Contents

(1) POWER

LED

Turns ON (Green) while the inverter is powered up.

(2) ALARM

LED

Turns ON (Red) when the inverter trips.

(3) Program

LED

Turns ON (Green) when the display shows changeable

parameter.

Blinks when there is a mismatch in setting.

(4) RUN LED

Turns ON (Green) when the inverter is driving the motor.

(5) Monitor

LED [Hz]

Turns ON (Green) when the displayed data is frequency related.

(6) Monitor

LED [A]

Turns ON (Green) when the displayed data is current related.

(7) Run

command LED

Turns ON (Green) when a Run command is set to the operator. (Run

key is effective.)

(8) 7-seg LED

Shows each parameter, monitors etc.

(9) Run key

Makes inverter run.

(10) Stop/reset

key

Makes inverter decelerates to a stop.

Reset the inverter when it is in trip situation

(11) ESC key

Go to the top of next function group, when a function mode is

shown

Cancel the setting and return to the function code, when a

data is shown

Moves the cursor to a digit left, when it is in digit-to-digit

setting mode

Pressing for 1 second leads to display data of d001,

regardless of current display.

(12) Up key

(13) Down key

Increase or decrease the data.

Pressing the both keys at the same time gives you the digit-to-

digit edit.

(14) SET key

Go to the data display mode when a function code is shown

Stores the data and go back to show the function code, when

data is shown.

Moves the cursor to a digit right, when it is in digit-to-digit

display mode

(15) USB

connector

Connect USB connector (mini-B) for using PC communication

Ii

SJ700 series Inverter Keypad description

Key and Indicator Legend

Name Function

Name Function

POWER lamp

Lights when the control circuit power is on.

ALARM lamp

Lights to indicate that the inverter has tripped.

RUN (operation) lamp

Lights to indicate that the inverter is operating.

PRG

(program)

lamp

Lights when the monitor shows a value set for a function.

This lamp starts blinking to indicate a warning

(when the set value is invalid).

Monitor

Displays a frequency, output current, or set value.

Monitor lamps

Indicates the type of value and units displayed on the monitor.

"Hz" (frequency), "V" (voltage), "A" (current), "kW"

(electric power), and "%" (percentage)

RUN key

enable LED

Lights up when the inverter is ready to respond to the RUN

key.

(When this lamp is on, you can start the inverter with the RUN

key on the digital

operator.)

RUN key

Starts the inverter to run the motor. This key is effective only

when the operating device is

the digital operator.

(To use this key, confirm that the operating

device indicator lamp is on.)

STOP/RESET

key

Decelerates and stops the motor or resets the

inverter from alarm status.

FUNC

(function) key

Makes the inverter enter the monitor, function, or

extended function mode.

STR (storage)

key

Stores each set value. (Always press this key

after changing a set value.)

1 (up) or 2

(down) key

Switches the inverter operation mode (among monitor,

function, and extended function

modes) or increases or decreases the value set

on the monitor for a function.

Operating Principle 5

And Hardware

Ii

Operating Principal and Hardware:

Solar Water Pump Inverter :

WJ200 & SJ700 Series of Hitachi Inverter is low voltage range AC drive and it

available for 0.4Kw to 400Kw Motor rating which is design for drawing

maximum power from PV module (Photovoltaic Cell).

Inverter has design to operate in Dual power supply AC power and DC power.

It is operating Maximum power point tracking algorithm to derive maximum power

from PV cell at any instant while in cloudy or sunny weather.

This inverter series specifically design for pump application which has special

reduce torque control mode with energy saving technology.

It is design for meet requirement of pump manufacturer and OEM to customize

application as per their requirements.

Control Mode: Reduce Torque technology is mostly utilized in pump application

where load on motor shaft have very high inertia / momentum. It operates on

starting torque is normal and afterword torque is going to reduce and increase

speed of motor. So, less power require to achieve higher speed of motor. It operate

Energy saving function while reaching nearly constant speed where optimizing input

power by reduce of output voltage and current.

Ii

MPPT overview

The Hitachi solar inverter uses maximum power pint tracking control software to

operate solar panel (PV) at maximum power generation level.

Hitachi solar inverter internal MPPT algorithm is used to derive maximum power

form PV cell at any instant and it is happen by changing output voltage and current

in PV cell until maximum power is obtained.

When inverter is in stop command then PV cell generating short circuit current and if

the PV cells are not connected to any load, then output voltage of cell is same as

open circuit voltage of PV.

See below I-V characteristic

The I-V curve is not constant for all instant, the intensity of sun ray and temperature

changes during a day time. The current changes linearly with Intensity and voltage

change very small with temperature changes. So, for constant temperature,

Maximum power varies proportionally with intensity of sun rays. The Maximum

power is obtain at knee point of I-V curve.

System Start-up 6

Ii

Parameter setting

WJ200 series Inverter parameter setting for solar water pump inverter

There are six buttons available for setting parameters.

Run button : use for start motor form operator panel/ keypad

Stop/Reset button: use for stop motor form operator panel / keypad and also to reset

alarm

ESC button: use for going back to parameter group number. Use for go out from

parameters

SET button: use for going inside of parameter and setting change value of

parameters in eeprom memory

1 UP arrow and 2 DOWN arrow button: use for changing digit value, Means change

parameter number as well as value inside parameters

Ii

WJ200 series Inverter parameter setting for solar water pump inverter

After giving power to inverter, It show 0000 value of d001 parameter (output motor Hz)

Make b049 = 01 for making inverter in Variable torque mode (Specially pump application)

Check A017 = 02 For enabling MPPT algorithm, 00 means stop, 01 means for

terminal enabling

First to set motor data inside of inverter like KW, Hz, RPM, Current, Votlage

A003 = Hz of motor

H003 = KW of motor

H004 = Pole of motor which come from RPM of motor.

A002 = 01 Terminal Run command

F002 = 100 Sec , Acceleration Time

F003 = 1 Sec , Deceleration time

A020 = Put Total Vmp of connect PV cells,

C001 = 56, Terminal 1 as Forward Run command

C006 = 18, Terminal 6 as Reset inverter

P101 = 3 min,

Auto restart delay time after inverter get any alarm, Change as per requirements

P102 = 3000, Water level sensitivity,

For 1-PHASE (2-WIRE) PUMPS MAKE :

1- P129 = 00

2- A082 = MAX

For 60Hz Pump Make :

1- A017 = 00

2- P117 = 6000

3- A061 = 60

4- A003 = 60

5- A017 = 02

Note : Make B037 = 00

Ii

SJ700 series Inverter parameter setting for solar water pump inverter

After giving power to inverter, It show 0000 value of d001 parameter (output motor Hz)

Check A017 = 01 For enabling MPPT algorithm, 00 means stop, 01 means for

terminal enabling.

And Check Short link between terminal P24 and FW where Short link seen between

PLC and CM1 terminal.

First to set motor data inside of inverter like KW, Hz, RPM, Current, Votlage

A003 = Hz of motor

H003 = KW of motor

H004 = Pole of motor which come from RPM of motor.

A002 = 01 Terminal Run command

F002 = 100 Sec , Acceleration Time

F003 = 1 Sec , Deceleration time

A020 = Put Total Vmp of connect PV cells,

C001 = 56, Terminal 1 as Forward Run command

C006 = 18, Terminal 6 as Reset inverter

P101 = 3 min,

Auto restart delay time after inverter get any alarm, Change as per requirements

P130 = 3000, Water level sensitivity,

For 60Hz Pump Make :

1- A017 = 00

2- Remove FW

3- P111 = 6000

Note : Make B037 = 00

4- A061 = 60

5- A003 = 60

6- A017 = 01

7- FW Back

Ii

SJ700D series Inverter parameter setting for solar water pump inverter

After giving power to inverter, It show 0000 value of d001 parameter (output motor

Hz)

Check A017 = 02 For enabling MPPT algorithm, 00 means stop, 02 means for

terminal enabling.

First to set motor data inside of inverter like KW, Hz, RPM, Current, Votlage

A003 = Hz of motor

H003 = KW of motor

H004 = Pole of motor which come from RPM of motor.

A002 = 01 Terminal Run command

F002 = 100 Sec , Acceleration Time

F003 = 1 Sec , Deceleration time

A020 = Put Total Vmp of connect PV cells,

C001 = 56, Terminal 1 as Forward Run command

C006 = 18, Terminal 6 as Reset inverter

P101 = 3 min,

Auto restart delay time after inverter get any alarm, Change as per requirements

P130 = 3000, Water

level sensitivity,

For 60Hz Pump Make :

A017 = 00

P111 = 6000

Note : Make B037 = 00

A061 = 60

A003 = 60

A017 = 02

Ii

Fault Codes

All fault come in parameters D081 to d086, means Hitachi drive can store last 6 fault

history.

Error

Code

Name

Cause(s)

E01

Over-current event while at

constant speed

The inverter output was short-circuited, or the

motor shaft is locked or has a heavy load. These

conditions cause excessive current for the

inverter, so the inverter output is turned OFF. The

dual-voltage motor is wired incorrectly.

E02

Over-current event during

deceleration

E03

Over-current event during

acceleration

E04

Over-current event during

other conditions

E05

Overload protection

When a motor overload is detected by the

electronic thermal function, the inverter trips and

turns OFF its output.

E06

Braking resistor overload

protection

When the BRD operation rate exceeds the

setting of "b090", this protective function shuts off

the inverter output and displays the error code.

E07

Over-voltage protection

When the DC bus voltage exceeds a threshold,

due to regenerative energy from the motor.

E08

EEPROM error

When the built-in EEPROM memory has

problems due to noise or excessive temperature,

the inverter trips and turns OFF its output to the

motor.

E09

Under-voltage error

A decrease of internal DC bus voltage below a

threshold results in a control circuit fault. This

condition can also generate excessive motor heat

or cause low torque. The inverter trips and turns

OFF its output.

E10

Current detection error

If an error occurs in the internal current detection

system, the inverter will shut off its output and

display the error code.

E11

CPU error

A malfunction in the built-in CPU has occurred,

so the inverter trips and turns OFF its output to

the motor.

E12

External trip

A signal on an intelligent input terminal

configured as EXT has occurred. The inverter

trips and turns OFF the output to the motor.

E13

USP

When the Unattended Start Protection (USP) is

enabled, an error occurred when power is applied

while a Run signal is present. The inverter trips

and does not go into Run Mode until the error is

cleared.

E14

Ground fault

The inverter is protected by the detection of

ground faults between the inverter output and the

motor upon during powerup tests. This feature

protects the inverter, and does not protect

humans.

E15

Input over-voltage

The inverter tests for input over-voltage after the

inverter has been in Stop Mode for 100 seconds.

If an over-voltage condition exists, the inverter

enters a fault state. After the fault is cleared, the

inverter can enter Run Mode again.

E21

Inverter thermal trip

When the inverter internal temperature is above

the threshold, the thermal sensor in the inverter

module detects the excessive temperature of the

power devices and trips, turning the inverter

output OFF.

E22

CPU communication error

When communication between two CPU fails,

inverter trips and displays the error code.

E25

Main circuit error (*3)

The inverter will trip if the power supply

establishment is not recognized because of a

malfunction due to noise or damage to the main

circuit element.

E30

Driver error

An internal inverter error has occurred at the

safety protection circuit between the CPU and

main driver unit. Excessive electrical noise may

be the cause. The inverter has turned OFF the

IGBT module output.

E35

Thermistor

When a thermistor is connected to terminals [5]

and [L] and the inverter has sensed the

temperature is too high, the inverter trips and

turns OFF the output.

E36

Braking error

When "01" has been specified for the Brake

Control Enable (b120), the inverter will trip if it

cannot receive the braking confirmation signal

within the Brake Wait Time for Confirmation

(b124) after the output of the brake release

signal.

E37

Safe Stop

Safe stop signal is given.

E38

Low-speed overload

protection

If overload occurs during the motor operation at a

very low speed, the inverter will detect the

overload and shut off the inverter output.

E40

Operator connection

When the connection between inverter and

operator keypad failed, inverter trips and displays

the error code.

E41

Modbus communication error

When ―trip‖ is selected (C076=00) as a

behavior in case of communication error, inverter

trips when timeout happens.

E43

EzSQ invalid instruction

The program stored in inverter memory has been

destroyed, or the PRG terminal was turned on

without a program downloaded to the inverter.

E44

EzSQ nesting count error

Subroutines, if-statement, or for-next loop are

nested in more than eight layers

E45

EzSQ instruction error

Inverter found the command which cannot be

executed.

E50

to

E59

EzSQ user trip (0 to 9)

When user –defined trip happens, inverter trips

and displays the error code.

E60

Option error (DeviceNet

Communications error)

If the disconnection due to the Bus-Off signal or

timeout occurs during the operation using

DeviceNet commands, the inverter will shut off its

output and display the error code shown on the

right. (The inverter will trip according to the

settings of "p45" and "P048".)

E61

Option error (duplicated

MACID)

If two or more devices having the same MAC ID

are detected in the same network, the inverter

will display the error code shown on the right.

E62

Option error (External trip)

If the Force Fault/Trip bit of Attribute 17 in the

Instance 1 of the Control Supervisory object is

set to "1", the inverter will shut off its output and

display the error code shown on the right.

E63

to

E68

Option error

The inverter detects errors in the option board

mounted in the optional slot. For details, refer to

the instruction manual for the mounted option

board.

E69

Option error (inverter

communication error)

If timeout occurs during the communication

between the inverter and DeviceNet option

board, the inverter will shut off its output and

display the error code shown on the right.

E80

Encoder disconnection

If the encoder wiring is disconnected, an encoder

connection error is detected, the encoder fails, or

an encoder that does not support line driver

output is used, the inverter will shut off its output

and display the error code shown on the right.

E81

Excessive speed

If the motor speed rises to "maximum frequency

(A004) x over-speed error detection level (P026)"

or more, the inverter will shut off its output and

display the error code shown on the right.

E83

Positioning range error

If current position exceeds the position range

(P072-P073), the inverter will shut off its output

and display the error code.

Ii

Motor requirement

The all type induction and submersible motor can work under Hitachi solar

inverter

200VAC Hitachi inverter can work for 0VAC to 240VAC motor

400VAC Hitachi inverter can work for 0 VDC to 460VAC motor

Motor should be three phase three wire input

DC motor can’t be work

For PMDC motor, Please contact concern Hitachi Person.

Ii

Monitoring System Data :

“D” Group parameter is use for monitor inverter data

D001 = output Hz of inverter / Speed of motor in Hz

D002 = output current to motor

D102 = DC voltage level at DC bus inside inverter

D013 = Output voltage to motor, It may be less as per energy saving mode compare

to V/F ratio

D014 = input KW power consumption

D015 = Total KW power consume by inverter/motor

D016 = Total Run time of motor in Hr

D017 = Total power on time of inverter in Hr

D018 = Heat sink temperature of inverter

PC tool for monitoring :

Ii

Maintenance and Inspection

Daily and Yearly Inspection Chart

Item Inspected

Check for…

Inspection

Cycle

Inspection

Method

Criteria

Daily

Year

Overall

Ambient

environment

Extreme

temperatures &

humidity

Thermometer,

hygrometer

Ambient temperature

between –

Humidity 90% or less

non-condensing

Major

devices

Abnormal noise

& vib.

Visual and aural

Stable environment for

electronic controls

Power

supply

voltage

Voltage tolerance

Digital volt meter,

measure

between inverter

terminals [L1],

[L2], [L3]

200V class: 50/60 Hz

200 to 240V (-15/+10%)

400V class: 50/60 Hz

380 to 460V (-15/+10%)

Main

circuit

Ground

Insulation

Adequate

resistance

5 Mohm or greater

Mounting

No loose screws

Torque wrench

M3.5: 1.0Nm M4: 1.4Nm

M5: 3.0 M6: 3.9 to

5.1Nm M8: 5.9 to 8.8Nm

Components

Overheating

Thermal trip

events

No trip events

IGBT

Resistance value

Terminal

block

Secure

connections

Visual

No abnormalities

Smoothing

capacitors

Leaking, swelling

Visual

No abnormalities

Relay(s)

Chattering

Aural

Single click when

switching ON or OFF

Resistors

Cracks or

discoloring

Visual

Check Ohms of optional

braking res.

Control

circuit

Function

Voltage balance

between phases

Measure voltage

between U,V,W

Difference must be 2%

or less.

Protection circuit

e.g. Input Ex.trip

signal and check

inverter behavior

and alarm signal.

Functions properly.

Overall

No odor,

discoloring,

corrosion

Visual

No abnormalities

Capacitor

Leaking, swelling

Visual

Undistorted appearance

Cooling

Cooling fan

Noise

Power down,

manually rotate

Rotation must be

smooth

Dust

Visual

Vacuum to clean

Mounting

Visual

Mounted firmly

Heat sink

Dust

Visual

Vacuum to clean

Display

LEDs

Legibility

Visual

All LED segments work

Ii

Note 1: The life of a capacitor is affected by the ambient temperature.

Note 2: Designed life of a cooling fan is.10 years. However, it is affected by the ambient

temperature and other environmental conditions.

Note 3: The inverter must be cleaned periodically. If dust accumulates on the fan and heat sink,

it can cause overheating of the inverter.

Network Communication 7

Ii

Modbus Network Communication

Introduction

WJ200 Series inverters have built-in RS-485 serial communications, featuring the Modbus

RTU protocol. The inverters can connect directly to existing factory networks or work with

new networked applications, without any extra interface equipment. The specifications are

in the following table.

Item

Specifications

User-selectable

Transmission speed

2400 / 4800 / 9600 / 19.2k / 38.4k /

57.6k / 76.8k / 115.2k bps

Communication mode

Asynchronous

Character code

Binary

LSB placement

Transmits LSB first

Electrical interface

RS-485 differential transceiver

Data bits

8-bit (Modbus RTU mode)

Parity

None / even / odd

Stop bits

1 or 2 bits

Startup convention

One-way start from host device

Wait time for response

0 to 1000 msec.

Connections

Station address numbers from 1 to 32

Connector

Terminal connector

Error check

Overrun, Framing block check code,

CRC-16, or horizontal parity

Cable length

500m maximum

Connecting the Inverter to Modbus

Modbus connector is in control terminal block as below. Note that RJ45 connector (RS-422)

is used for external operator only.

Ii

Inverter Parameter Setup –

The inverter has several settings related to Modbus communications. The table

below lists them together. The Required column indicates which parameters must

be set properly to allow communications. You may need to refer to the host

computer documentation in order to match some of its settings.

Func.

Code

Name

Required

Settings

A001

Frequency source

03

00…Keypad potentiometer

01…Control terminal

02…Function F001 setting

03…Modbus network input

10…Calculate function output

A002

Run command source

03

01…Control terminal

02…Run key on keypad, or digital

operator

03…Modbus network input

C071

Communication speed

05

03 2400 bps

04 4800 bps

05 9600 bps

06 19.2k bps

07 38.4k bps

08 57.6k bps

09 76.8k bps

10 115.2k bps

C072

Modbus Address

1

Network address, range is 1 to

247

C074

Communication parity

00

00…No parity

01…Even parity

02…Odd parity

C075

Communication stop bit

1

Range is 1 or 2

C076

Communication error

select

00

00…Trip (Error code E60)

01…Decelerate to a stop and trip

02…Disable

03…Free run stop (coasting)

04…Decelerate to a stop

C077

Communication error

time-out

1.00

Comm. Watchdog timer period,

range is 0.00 to 99.99 sec.

C078

Communication wait

time

10

Time the inverter waits after

receiving a message before it

transmits. Range is 0. to 1000.

ms

Ii

NOTE:

When you change any of the parameters above, the inverter power must be

rebooted in order to activate new parameters. Instead of rebooting, turning ON/OFF

of reset terminal works as same.

For Modbus data Listing, Please refer detail manual come with inverter

Common Fault and Remedies

Fault: During running pump Find E09.x – Under Voltage Alarm

Remedies: First to check x value,

Suppose E09.2, E09.3 and E09.4 means during deceleration, Constant speed and

acceleration condition

Then Check following parameters

F002 – 50second

F003 – 10 second

A017 – 02 MPPT enable

D004 – DC voltage of PV input power

Fault: If find E07.x – Over Voltage Alarm

Remedies: First to check PV module Open circuit Voltage (Voc) value and no of PV

connected in series connection. If Total Voc value is higher than 800VDC then

Inverter will show over voltage alarm. then try to reduce PV qty in series.

Now, Best selection as below for series and parallel connection

Example: If, Pump motor voltage is 415VAC, Then try to make Total Vmp value of

connected near to 585 to 600VDC. It should be 1.414 time of Pump motor voltage

Fault: If find E01, E02, E03, E04 and E05 during starting of pump

Remedies: Check following parameters

F002 – 50 second (Up to 90kw inverter)

B021 – 03 overload restriction enable

A044 – 01 Pump control mode

Try to change B049 – 01 VT mode, B022 – max value and B023 – 0.1sec

Fault: If find E14 – Ground fault

Remedies: Check motor wires and its earth cable.

Inverter has two screw terminal One cable for incoming and other for motor earth

cable

If Earthing cable is properly connected then check inverter to pump motor distance,

if it more than 100meter, please try to use output line reactor (output choke) with

minimum 3% impedance.

If there is no any motor cable and only DC power input, then asked to service

person from company.

Application Notes

FOR Best Vmpp value to set in

A020 : D004 (VOC )/1.2 OR

D004 (VOC )VOC/1.25

PV in Series

PV in

Parallel

Ii

Standard Specications

1-phase 200V class

Models WJ2 00- 00 1SF 002SF 004SF 007SF 0 15 S F 022SF

VT 0.2 0.4 0.55 1.1 2.2 3.0

kW

Applicable mot or size *

Rated capaci ty (kVA)

Input

Rating

Output

Rating

Minimum value of r esistor (Ω) 100 100 100 50 50 35

Weight

Rated input volt age (V ) 1-phase: 20 0V-15% to 240V +10%, 5 0/ 60Hz ±5%

Rated inpu t current (A)

Rated output voltage (V) *

Rated output current (A)

1

3-phase 200V class

Models WJ2 00- 001LF 002LF 004LF 007LF 015 LF 022LF 037LF 055LF 075LF 110 LF 150 LF

Applicable mot or size *

Rated capaci ty (kVA)

Input

Rating

Output

Rating

Minimum value of r esistor (Ω) 100 10 0 10 0 50 50 35 35 20 17 17 10

Weight

Rated input volt age (V ) 3-phase: 200V-15% to 240V +10%, 5 0/ 60Hz ±5%

Rated inpu t current (A)

Rated output voltage (V) *

Rated output current (A)

1

CT 0.1 0.2 0.4 0.75 1.5 2.2

VT 1/4 1/ 2 3/4 1. 5 3 4

HP

CT 1/8 1/4 1/2 1 2 3

VT 0.4 0.6 1.2 2.0 3.3 4.1

200V

CT 0.2 0.5 1.0 1.7 2.7 3.8

VT 0.4 0.7 1.4 2.4 3.9 4.9

240V

CT 0.3 0.6 1.2 2.0 3.3 4.5

VT 2.0 3.6 7.3 13.8 20.2 24.0

CT 1.3 3.0 6.3 11.5 16.8 22.0

2

VT 1. 2 1.9 3.5 6.0 9.6 12.0

CT 1.0 1.6 3.0 5.0 8.0 11.0

kg 1.0 1. 0 1.1 1.6 1.8 1.8

lb 2.2 2.2 2.4 3.5 4.0 4.0

VT 0.2 0.4 0.75 1.1 2.2 3.0 5.5 7. 5 11 15 18.5

kW

CT 0 .1 0.2 0.4 0.75 1.5 2.2 3.7 5.5 7. 5 11 15

VT 1/4 1/2 1 1.5 3 4 7.5 10 15 20 25

HP

CT 1/8 1/4 1/2 1 2 3 5 7.5 10 15 20

VT 0.4 0.6 1.2 2.0 3.3 4.1 6.7 10.3 13.8 19 .3 23.9

200V

CT 0.2 0.5 1.0 1.7 2.7 3.8 6.0 8.6 11. 4 16.2 20.7

VT 0.4 0.7 1. 4 2.4 3.9 4.9 8.1 12.4 16.6 23.2 28.6

240V

CT 0.3 0.6 1.2 2.0 3.3 4.5 7.2 10.3 13.7 19.5 24.9

VT 1.2 1.9 3.9 7. 2 10.8 13.9 23.0 3 7.0 48.0 68.0 72.0

CT 1.0 1.6 3.3 6.0 9.0 12.7 20.5 30.8 39.6 57.1 62.6

2

VT 1.2 1.9 3.5 6.0 9.6 12.0 19.6 30.0 40.0 56.0 69.0

CT 1.0 1.6 3.0 5.0 8.0 11.0 17.5 25.0 33.0 47.0 60.0

kg 1.0 1.0 1.1 1. 2 1. 6 1.8 2.0 3.3 3.4 5.1 7. 4

lb 2.2 2.2 2.4 2.6 3.5 4.0 4.4 7.3 7. 5 11. 2 16.3

3-phase: 200 to 240V (proportional to input voltage)

3-phase: 200 to 240V (proportional to input voltage)

Ii

3-phase 400V class

Models WJ2 00- 00 4HF 007HF 015HF 02 2HF 030HF 040HF 055HF 0 75HF 110HF 150HF

VT 0.75 1.5 2.2 3.0 4.0 5.5 7. 5 11 15 18.5

kW

Applicable mot or size *

Rated capaci ty (kVA)

Input

Rating

Output

Rating

Minimum value of r esistor (Ω) 180 18 0 180 100 100 100 70 70 70 35

Weight

Rated input volt age (V ) 3-phase: 380V-15% to 480 V +10%, 50 / 60Hz ±5%

Rated inpu t current (A)

Rated output voltage (V) *

Rated output current (A)

1

CT 0.4 0.75 1. 5 2.2 3.0 4.0 5.5 7.5 11 15

VT 1 2 3 4 5 7.5 10 15 20 25

HP

CT 1/2 1 2 3 4 5 7.5 10 15 20

VT 1. 3 2.6 3.5 4.5 5.7 7.3 11. 5 15 .1 20.4 25.0

200V

CT 1.1 2.2 3.1 3.6 4.7 6.0 9.7 11. 8 15.7 20.4

VT 1. 7 3.4 4.4 5.7 7. 3 9.2 14. 5 19 .1 25.7 31. 5

240V

CT 1.4 2.8 3.9 4.5 5.9 7.6 12. 3 14.9 19.9 25.7

VT 2.1 4.3 5.9 8.1 9.4 13. 3 20.0 24.0 38.0 4 4.0

CT 1. 8 3.6 5.2 6.5 7. 7 11.0 16.9 18. 8 29.4 35.9

2

VT 2.1 4.1 5.4 6.9 8.8 11.1 17.5 23.0 31.0 38.0

CT 1. 8 3.4 4.8 5.5 7. 2 9.2 14.8 18.0 24.0 31.0

kg 1. 5 1.6 1. 8 1.9 1. 9 2 .1 3.5 3.5 4.7 5.2

lb 3.3 3.5 4.0 4.2 4.2 4.6 7.7 7.7 10.4 11. 5

3-phase: 380 to 480 V (proportional to input voltage)

General Specications

Item General Specications

Protect ive housing *

3

Control method Sinusoidal Pulse Width Modulation (PW M) control

Carrier frequency 2kHz to 15kHz (derating required depending on the model)

Output f requency range *

4

Frequency accuracy

Frequency set ting resolut ion Digital: 0.01Hz; Analog: max . frequency / 1000

Volt ./ Freq. character istic

Overload capacity

Acceleration /deceleration time 0.01 to 3600 seconds, linear and S-curve accel /decel, second accel /decel setting available

Start ing torque 200% @0.5Hz (sensorless vector control)

DC braking Variable operating f requency, time, and braking force

Operator panel

Freq . setting

Ex ternal signal *

Via network RS485 ModBus RTU, other net work option

Operator panel Run /Stop (For ward /Rever se run change by command)

FW D/ REV run

Ex ternal signal *

Via network RS485 ModBus RTU, other net work option

Terminals 7 terminals, sink / source changeable by a short b ar

Intelligent input

Input signal

terminal

68 funct ions

Functions

assignable

Intelligent output

terminal

Functions

48 f unctions

assignable

Output signal

Moni tor output (analog) Output freq., output current, output torque, output voltage, input power, thermal load ratio, L AD freq., heat sink temperature, general ou tput (EzSQ)

Pulse train output

(0 – 10VDC, 32 kHz max.)

Alar m output cont act ON for inverter alar m (1c contacts, both nor mally open or closed available.)

Other functions

Protect ive funct ion

Temperature Operating (ambient): -10 to 50

Operating environment

Humidity 20 to 90% humidity (non-condensing)

Vibration *

Location Altitude 1,000m or less, indoors (no corrosive gasses or dust)

Coat ing color Black

Options Remote operator unit, cables for the units, braking unit, braking resistor, AC reactor, DC reactor, EMC lter

IP20

0.1 to 400Hz

Digital command: ±0.01% of the maximum frequency

Analog command: ±0.2% of the maximum frequency (25

°

C ±10°C)

V/f control (constant torque, reduced torque, free-V /F): b ase freq. 3 0Hz – 400Hz adjustable,

Sensorless vector control, Closed loop control with motor encoder feedback (only V/f control).

Dual rating: CT (Heavy duty): 60 sec. @150%

VT (Normal duty): 60 sec. @120%

2

1

keys / Value set tings

6

0 to 10 VDC (input impedance 10kΩ), 4 to 20mA (input imp edance 100Ω), Potentiometer (1k to 2kΩ, 2W )

6

Forward r un /stop, Reverse run / stop

FW (forward run command), RV (reverse run command), CF1 – CF4 (multi-stage speed setting), JG (jog command), DB (external braking), SET (set second

motor), 2CH (2-stage accel. /decel. command), FRS (free run stop command), E XT (exter nal trip), USP (st artup function), CS (commercial power switchover),

SFT (soft lock), AT (analog input selection), RS (reset), PTC (thermistor thermal protection), STA (start), STP (stop), F/ R (forward /reverse), PID (PID

disable), PIDC (PID reset), UP (remote control up function), DWN (remote control down function), UDC (remote control data clear), OPE (operator control),

SF1– SF7 (multi-stage speed setting; bit operation), OLR (overload restriction), TL (torque limit enable), TRQ1 (torque limit changeover1), TRQ2 (torque

limit changeover2), BOK (Braking conrmation), L AC (LAD cancellation), PCLR (position deviation clear), ADD (add frequency enable), F-TM (force terminal

mode), ATR (permission of torque command input), KHC (Cumulative power clear), MI1– MI7 (general purpose inputs for EzSQ), AHD (analog command hold),

CP1– CP3 (multistage-position switches), ORL (limit signal of zero-return), ORG (trigger signal of zero-return), SPD (speed/position changeover), GS1,GS2 (STO

inputs, safety related signals), 485 (Starting communication signal), PRG (executing E zSQ program), HLD (retain output frequency), ROK (permission of run

command), EB (rotation direction detection of B-phase), DISP (display limitation), NO (no function)

RUN (run signal), FA1 –FA 5 (frequency arrival signal), OL,OL2 (overload advance notice signal), OD (PID deviation error signal), A L (alarm signal),

OTQ (over / under torque thre shold), UV (under-voltage), TRQ (torque limit signal), RNT (run time expired), ONT (power ON time expired), THM (thermal

warning), BRK (brake release), BER (brake error), ZS (0Hz detection), DSE (speed deviation excessive), POK (positioning completion), ODc (analog

voltage input disconnection), OIDc (analog cur rent input disconnection), FB V (PID second stage output), NDc (network disconnec t detection), LOG1 –

LOG3 (Logic output signals), WAC (capacitor life warning), WA F (cooling fan warning), FR (st arting contact), OHF (heat sink overheat warning), LOC

(Low load), MO1 –MO3 (general outputs for EzSQ), IRDY (inver ter ready), FWR (forward operation), RVR (reverse operation), M JA (major failure),

WCO (window comparator O), WCOI (window comparator OI), FREF (frequency command source), REF (run command sour ce), SETM (second motor in

operation), EDM (STO (safe torque off ) per formance monitor), OP (option control signal), NO (no function)

[PW M output]

Output fre q., output current, output torque, output voltage, input power, thermal load ratio, LAD freq., heat sink temperature, general output (EzSQ)

[Pulse train output]

Output frequency, output cur rent , pulse train input monitor

Free-V/f, manual / automatic torque boost, output voltage gain adjustment, AVR function, reduced voltage start, motor data selection, autotuning, motor stabilization control, reverse r unning protection, simple position control, simple torque control, torque limiting, automatic carrier

frequency r educ tion, energy saving operation, PID function, non-stop operation at instantaneous power failure, brake control, DC inje ction

braking, dynamic braking (BRD), f requency upper and lower limiters, jump frequencies, curve accel and decel (S, U, inversed U,EL-S), 16-stage

speed prole, ne adjustment of st art frequency, accel and decel stop, process jogging, frequency calculation, frequency addition, 2-stage

accel/decel, stop mode selection, start /end freq., analog input lter, window comparators, input terminal response time, output signal delay/

hold function, rotation direction restriction, stop key sele ction, sof tware lock, safe stop function, scaling function, display restriction, passwor d

function, user p arameter, initialization, initial display selection, cooling fan control, warning, trip retry, frequency pull-in r estart, frequency

matching, overload restriction, over current restriction, DC bus voltage AVR

Over-current, over-voltage, under-voltage, overload, brake resistor overload, CPU error, memory error, external trip, USP error, ground fault detection

at power on, temperature error, internal communication error, driver error, thermistor error, brake error, safe stop, overload at low speed, modbus

communication error, option error, encoder disconnection, speed excessive, EzSQ command error, EzSQ nesting error, EzSQ execution error, EzSQ user trip

°

C / Stor age: -2 0 to 65°C *

8

5.9m/s2 (0.6G), 10 to 55 Hz

7

Ii

Loading...

Loading...