Page 1

SCREW DRIVER

MODEL

W 6VB2

W 8VB

POWER TOOLS

TECHNICAL DATA

AND

W 6VB2, W 8VB

SERVICE MANUAL

W

LIST Nos. W 6VB2: 0780

W 8VB: 0781

SPECIFICATIONS AND PARTS ARE SUBJECT TO CHANGE FOR IMPROVEMENT

Jul. 1999

Page 2

REMARK:

Throughout this TECHNICAL DATA AND SERVICE MANUAL, a symbol(s)

is(are) used in the place of company name(s) and model name(s) of our

competitor(s). The symbol(s) utilized here is(are) as follows:

Model: W 6VB2

Competitors

Symbols Utilized

Company Name

Model Name

Model: W 8VB

Symbol Utilized

C

B BOSCH

P

P

MAKITA

DeWALT

Company Name

DeWALT

6802BV

GSR6-20TE

(1423VSR)

DW266

Competitor

Model Name

DW265

Page 3

CONTENTS

[ Business Section ]

1. PRODUCT NAME

2. MARKETING OBJECTIVE

3. APPLICA TIONS

4. SELLING POINTS

5. SPECIFICATIONS

5-1. Specifications

5-2. Optional Accessories

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

6. COMPARISONS WITH SIMILAR PRODUCTS

6-1. W 6VB2

6-2. W 8VB

6-3. Screw tightening time

7. PRECAUTIONS IN SALES PROMOTION

7-1. Handling Instructions

7-2. Caution Plates

7-3. Screw Driving-Depth Adjustment

7-4. Self-Drilling Screws

7-5. Dry-Wall Screws

7-6. Variable-Speed Switch

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

Page

1

1

1

1

2

2

3

4

4

4

5

6

6

6

6

7

7

8

8. PRECAUTIONS IN DISASSEMBLY AND REASSEMBLY

8-1. Disassembly

8-2. Reassembly

8-3. Wiring Diagrams

8-4. Internal Wire Arrangement and Wiring Work

8-5. Insulation Tests

8-6. No-load Current Values

9. STANDARD REPAIR TIME (UNIT) SCHEDULES

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

[ Appendix ]

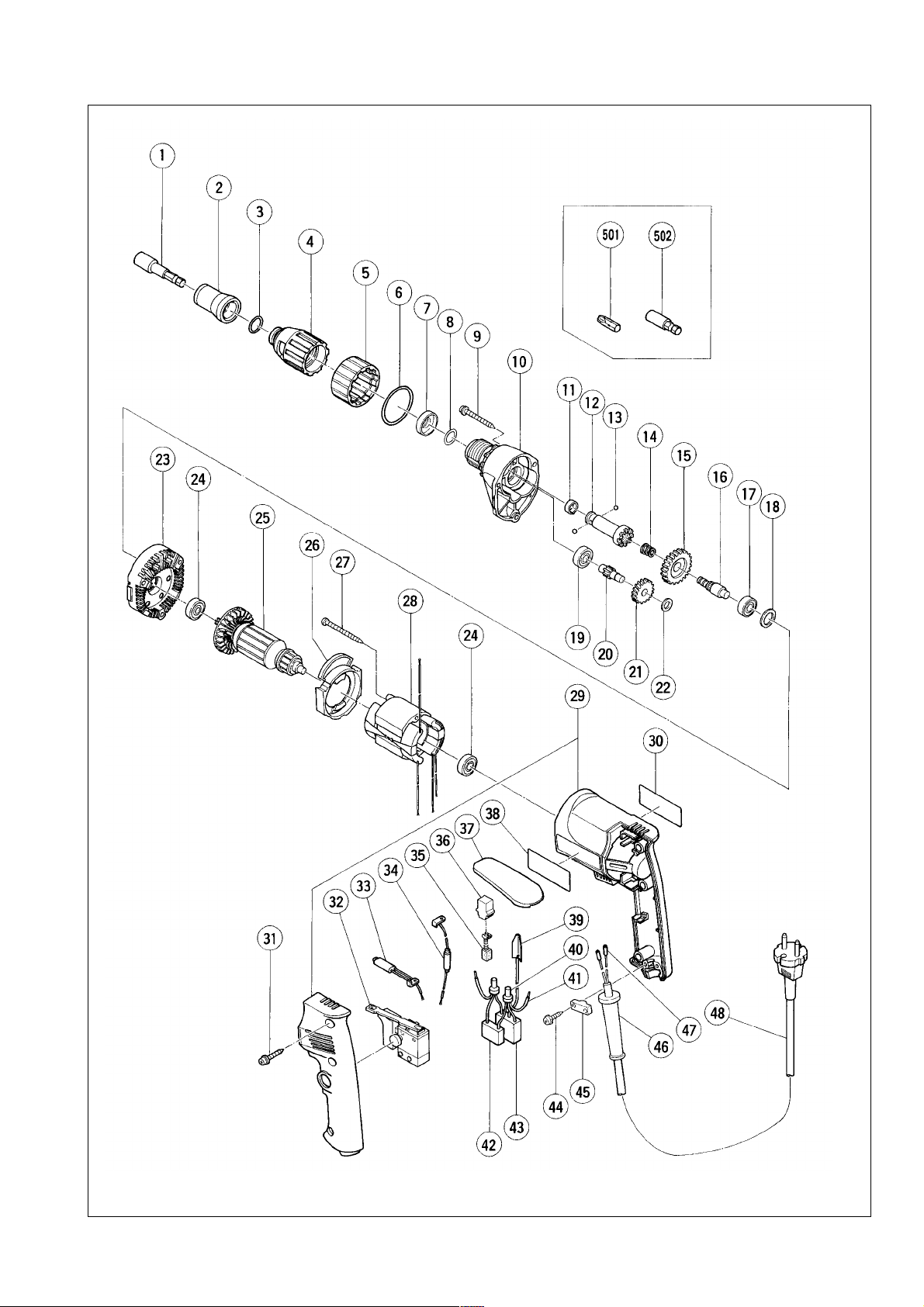

Assembly Diagram for W 6VB2

Assembly Diagram for W 8VB

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

8

8

9

10

11

13

13

14

15

19

Page 4

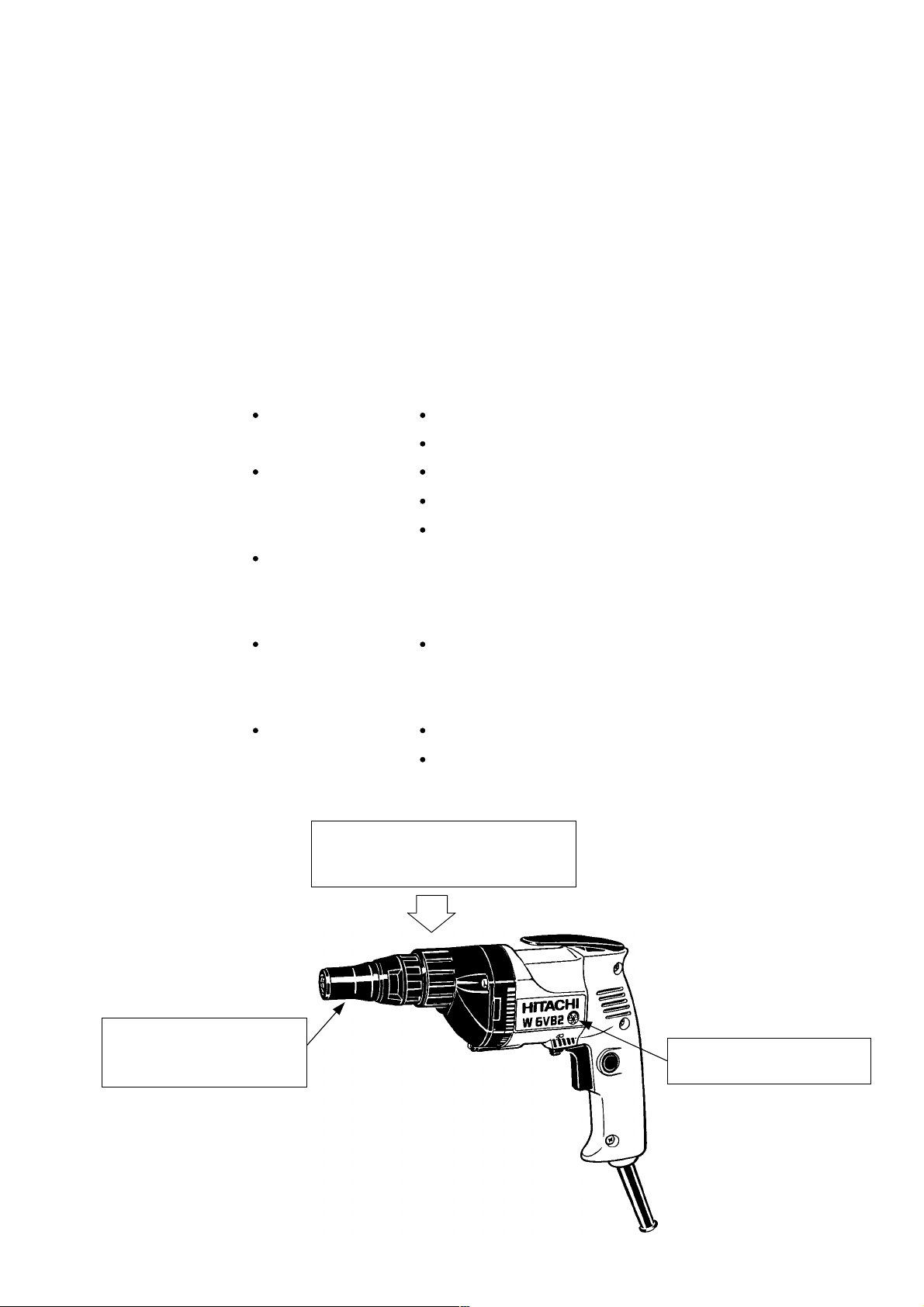

1. PRODUCT NAME

Hitachi Screw Driver, Models W 6VB2

W 8VB

2. MARKETING OBJECTIVE

The W 6VB screw driver has been on the market for 14 years. The new W 6VB2/W 8VB are totally redesigned

with an easy-to-grip body structure and other features in response to the diverse needs of customers. In

particular, the W 8VB has been introduced to meet the demand for higher torque. Our market share is expected

to grow with the release of these new models which broaden our lineup of screw drivers.

3. APPLICA TIONS

Hex. and Teks screws: Fastening metal onto metal, or metal onto wood

Exterior construction Installation of siding on buildings

Installation of galvanized iron sheet or corrugated sheet roofing

Plate assembly Assembly and mounting of advertising billboards

Assembly of metal frames for vinyl greenhouses

Assembly and installation of automobile stamped sections

Various other interior/exterior construction and plate assembly jobs

Drywall screws: Fastening metal studs and drywall

Interior construction Installation of ceilings, paneling or partitions in offices,

shops, supermarkets, apartment houses, schools, factories, etc.

Wood screws: Interior construction Assembly and installation of interior wood paneling,

Installation of flooring in gymnasiums and similar buildings

4. SELLING POINTS

Compact and lightweight

Overall length: 285 mm (11-1/4")

Weight: 1.4 kg (3.1 Ibs)

Detachable nosepiece for:

Easy unscrewing

Easy bit changes

High-power motor:

Speedy screw fastening

--- 1 ---

Page 5

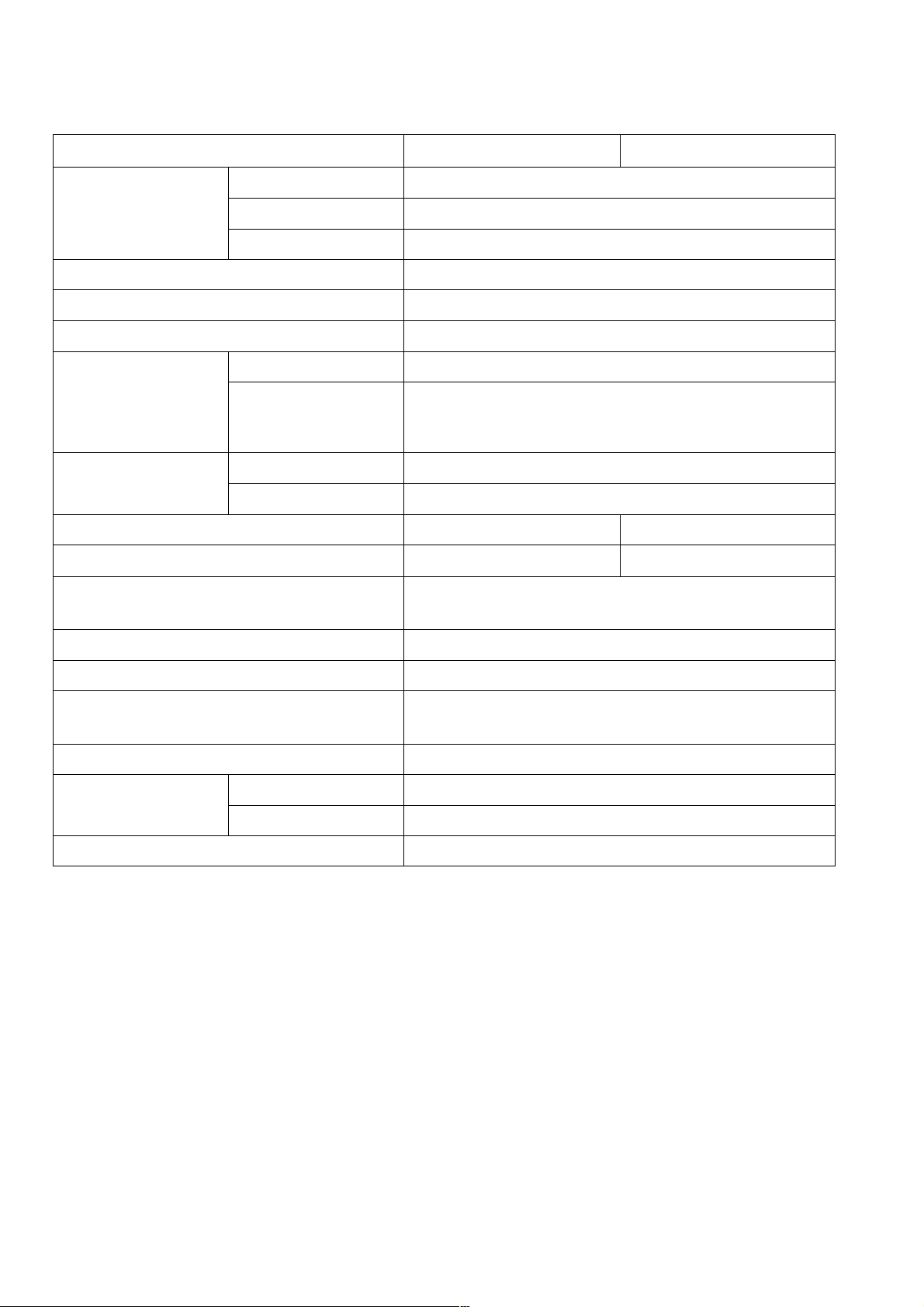

5. SPECIFICATIONS

5-1. Specifications

Model

Capacity

Bit mounting size

Power source

Type of motor

Full-load current

Power input

No-load speed

Full-load speed

Enclosure

Drywall screw

Self-drilling screw

Wood screw

U.S.A., Canada

Other areas

U.S.A., Canada

Other areas

W 6VB2

W 8VB

6 mm (1/4")

6 mm (1/4")

5.8 mm dia. x 50 mm ( 7/32" dia. x 2")

6.35 mm (1/4")

Single phase, AC 50 Hz or 60 Hz

Single phase, AC commutator motor

6.4 A (115 V)

2.9 A (220 V)

5.9 A (110 V) 2.8 A (230 V)

2.7 A (240 V)

640 W

600 W

0 --- 2,600 /min

0 --- 1,700 /min

0 --- 2,000 /min 0 --- 1,200 /min

Housing, Handle cover, Inner cover and Gear cover

••••••••••••••••••••••••••••••••••••••••••••••••••••

Polyamide resin

Switch

Handle

Weight

Packaging

Cord

Standard accessory

Type

Overall length

Variable switch with reversing switch

Pistol grip handle

•••••••••••••••

Net

Gross

•••••••••••

1.4 kg (3.1 Ibs) (without cord)

1.9 kg (4.2 Ibs)

Corrugated cardboard box

Two core cabtire cable

2.5 m (8.2 ft.)

Magnetic hexagon socket

••••••••••••••••••••••••••••••••••••••••

1

--- 2 ---

Page 6

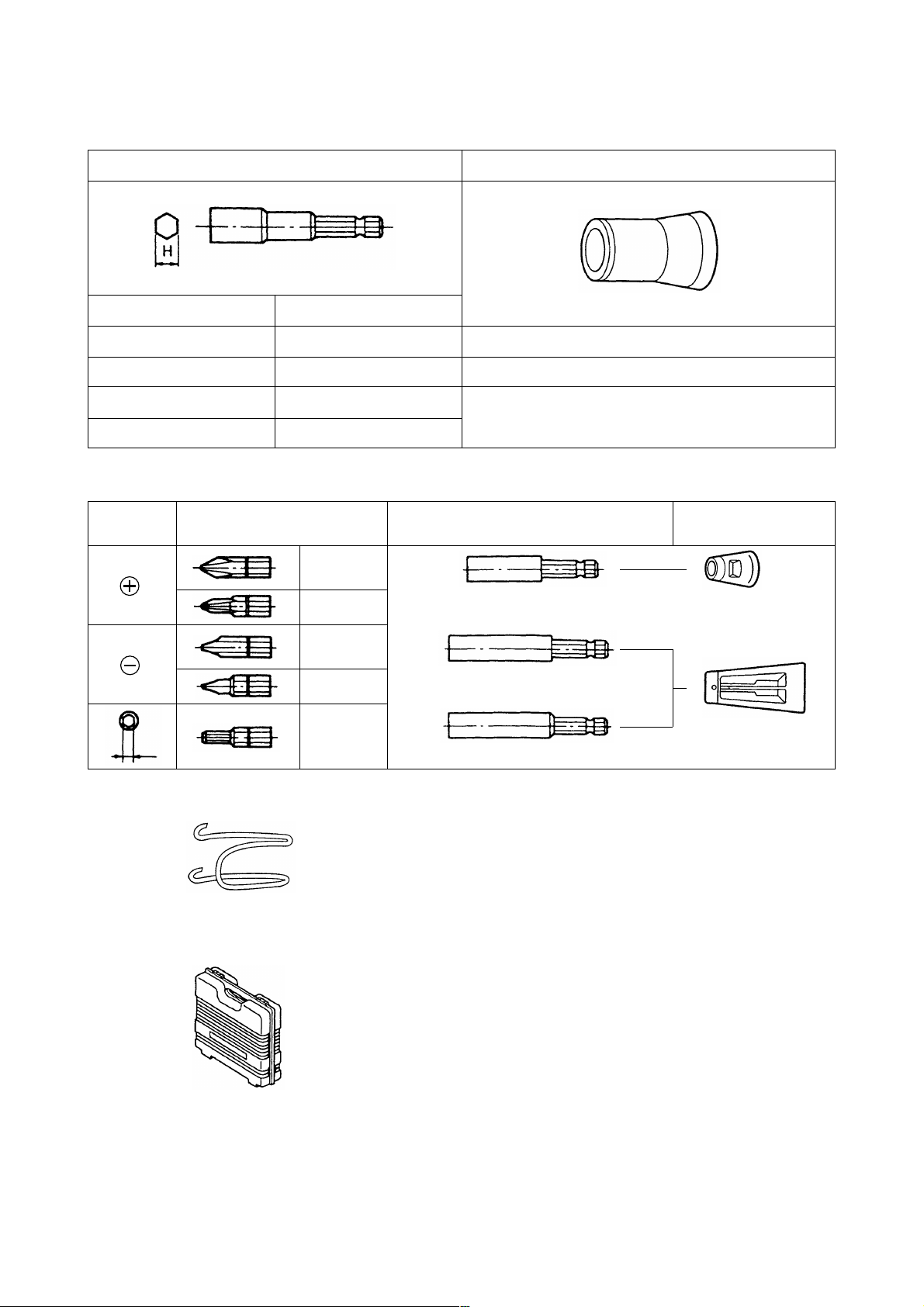

5-2. Optional Accessories

(1) For hex-head screws

Sub-stopper (B)Hex-socket

Magnetic type

H = 6.35 mm

H = 7.94 mm H = 7.94 mm

H = 9.53 mm

H = 10 mm H = 10 mm

(2) For other screws

Screw

head

B

Non magnetic type

H = 6.35 mm

H = 9.53 mm

Bit type Bit holder

No.1

No.2

No.3

No.1

No.2

No.1

No.2

No.3

No.1

No.2

B size

4 mm

5 mm

Magnetic bit holder

(Short type)

Magnetic bit holder

Non-magnetic bit bolder

H 1/4

H 5/16

H 3/8

Sub-stopper

Sub-stopper (A)

Sub-stopper (C)

(3) Hook

(4) Plastic case

Optional accessories are subject to change without notice.

--- 3 ---

Page 7

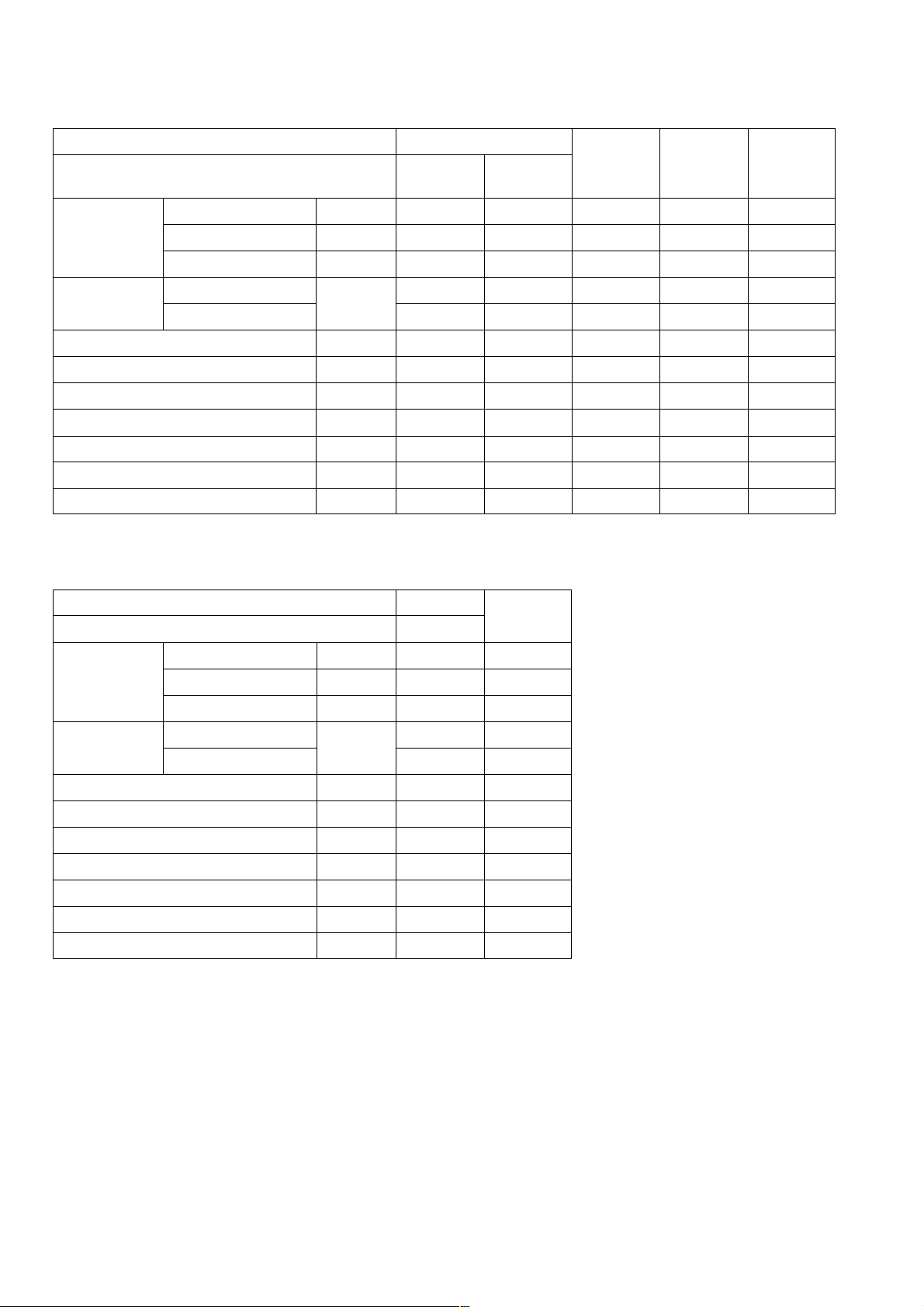

6. COMPARISONS WITH SIMILAR PRODUCTS

6-1. W 6VB2

Maker

Model

Capacity Self-drilling screw

Dry-wall screw

Wood screw

Power input U.S.A.

Other areas

Voltage, Full-load current

No-load rotation

No-load noise level

Max. output

Overall length

Cord length

Weight

6-2. W 8VB

mm

mm

mm

W

V, A

/min

dB (A)

W

mm

m

kg

HITACHI

W 6VB2 W 6VB

666 66.3

665------

5.8 dia. x 50 5.8 dia. x 50

680

600

115, 6.4

0 --- 2600

79

640

285

2.5

1.4

520

520

115, 5.0

0 --- 2600

81

550

290

2.5 2.5

1.7

CBP

---

---

510 600

115, 4.8 120, 5.5 120, 6.5

80 82 82

485 560 540

265 305 300

1.7 1.9 1.6

---

---

2.5

---

---

---

0 --- 26000 --- 2500 0 --- 2000

2.4

Maker

Model

Capacity

Power input U.S.A.

Voltage, Full-load current

No-load rotation

No-load noise level

Max. output

Overall length

Cord length

Weight

Self-drilling screw

Dry-wall screw

Wood screw

Other Areas

mm

mm

mm

W

V, A

/min

dB (A)

W

mm

m

kg

HITACHI

W 8VB

88

6

6.2 dia. x 50

680

600

115, 6.4

0 --- 1700

79

640

285

2.5

1.4

P

---

---

---

---

120, 6.5

0 --- 2000

83

540

300

2.4

1.6

--- 4 ---

Page 8

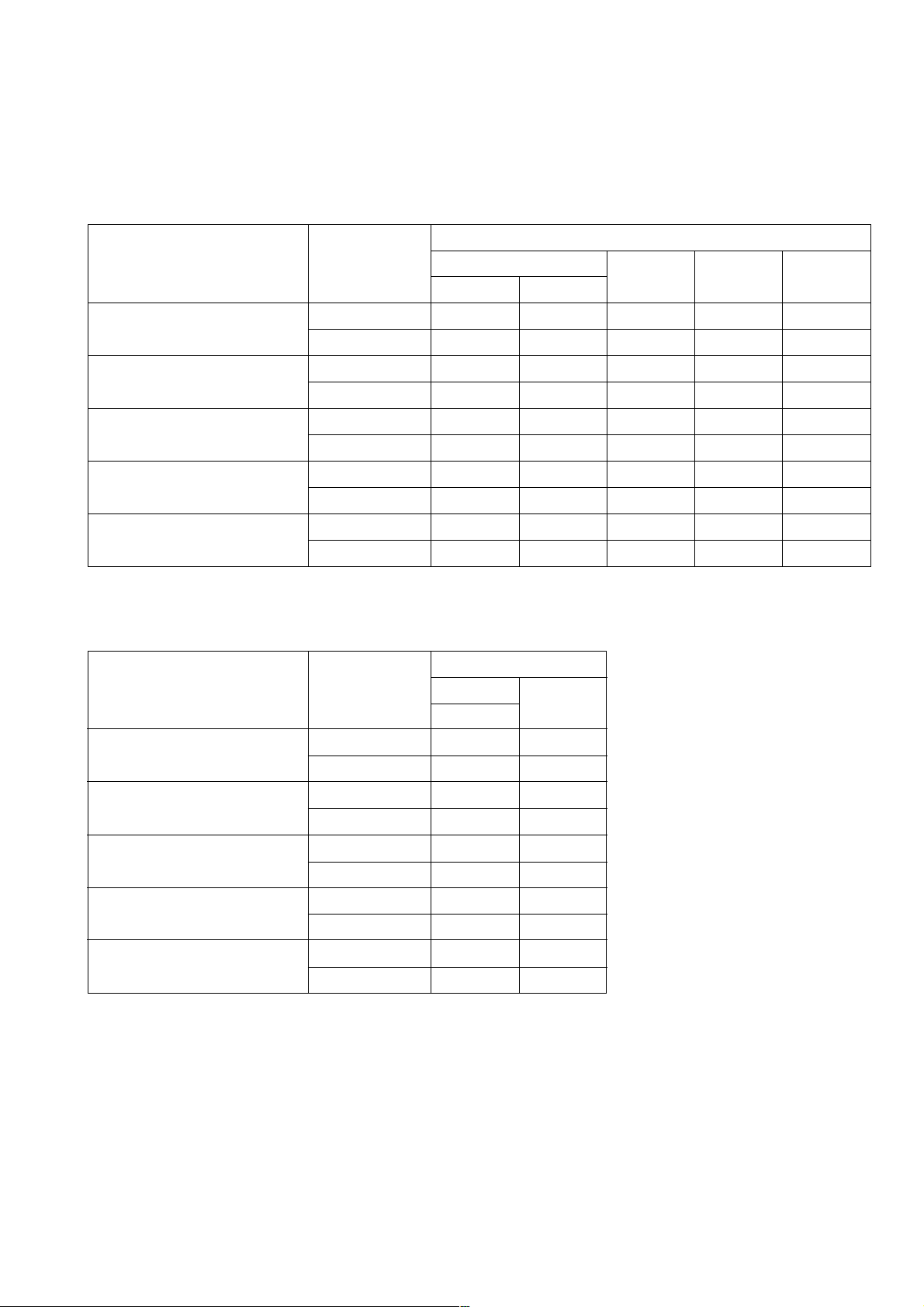

6-3. Screw tightening time

Tables 1 and 2 show the relationship between thrust and tightening time based on factory tests. The tightening

time may vary a little as screws are not necessarily uniform. The time information is for reference.

<W 6VB2>

Table 1

Mean tightening time (sec.)

Tightening condition

Teks screw:

5 dia. x 25L (13/64" x 1")

Mild steel plate: T3.2 (1/8")

Teks screw:

5 dia. x 25L (13/64" x 1")

Mild steel plate: T5 (13/64")

Teks screw:

6 dia. x 25L (15/64" x 1")

Mild steel plate: T3.2 (1/8")

Teks screw:

6 dia. x 25L (15/64" x 1")

Mild steel plate: T5 (13/64")

Wood screw

5.8 dia. x 38L (7/32" x 1-1/2")

Wood: Lauan

<W 8VB>

Tightening condition

Teks screw:

5 dia. x 25L (13/64" x 1")

Mild steel plate: T3.2 (1/8")

Teks screw:

5 dia. x 25L (13/64" x 1")

Mild steel plate: T5 (13/64")

Teks screw:

6 dia. x 25L (15/64" x 1")

Mild steel plate: T3.2 (1/8")

Teks screw:

6 dia. x 25L (15/64" x 1")

Mild steel plate: T5 (13/64")

Wood screw:

5.8 dia. x 38L (7/32" x 1-1/2")

Wood: Lauan

Power source HITACHI

W 6VB2 W 6VB

120 V 60 Hz

230 V 50 Hz

120 V 60 Hz

230 V 50 Hz

120 V 60 Hz

230 V 50 Hz

120 V 60 Hz

230 V 50 Hz

120 V 60 Hz

230 V 50 Hz

Table 2

Power source

120 V 60 Hz

230 V 50 Hz

120 V 60 Hz

230 V 50 Hz

120 V 60 Hz

230 V 50 Hz

120 V 60 Hz

230 V 50 Hz

120 V 60 Hz

230 V 50 Hz

2.70 3.00 2.90

3.20 ---

3.60

2.70

3.20

4.00

4.20

0.40

0.60

Mean tightening time (sec.)

HITACHI

W 8VB

3.90

4.00 ---

5.30 4.90

5.30

4.40

4.00

5.50

6.30

0.70

0.70

CBP

---

3.60

3.40

---

2.90

---

3.90

---

0.55 --- 0.75

P

3.80

---

3.90

---

5.40

---

0.60

---

---

--- 3.80

--- 5.70

0.50 0.40

---

3.502.60 ---2.40

---

4.80

---

---

---

4.00

---

3.302.80 ---

---

4.304.00

---

---

--- 5 ---

Page 9

7. PRECAUTIONS IN SALES PROMOTION

In the interest of promoting the safest and most efficient use of the Models W 6VB2 and W 8VB electric

screwdrivers by all of our customers, it is very important that at the time of sales the salesperson carefully ensures

that the buyer seriously recognizes the importance of the contents of the Handling Instructions, and fully

understands the meaning of the precautions listed on the Caution Plate attached to each tool.

7-1. Handling Instructions

Although every effort is made in each step of design, manufacture and inspection to provide protection against

safety hazards, the dangers inherent in the use of any electric power tool cannot be completely eliminated.

Accordingly, general precautions and suggestions for the use of electric power tools, and specific precautions and

suggestions for the use of the electric screwdriver are listed in the Handling Instructions to enhance the safe and

efficient use of the tool by the customer. Salespersons must be thoroughly familiar with the contents of the

Handling Instructions to be able to offer appropriate guidance to the customer during sales promotion.

7-2. Caution Plates

The following basic safety precautions are listed on the Name Plate attached to the main body of each tool.

However, these precautions are not listed for European countries.

For Asia and Oceania

CAUTION

Read thoroughly HANDLING INSTRUCTIONS before use.

For the U.S.A. and Canada

WARNING

To reduce the risk of injury, user must read and

understand instruction manual

AVERTISSEMENT

Afin de reduire le risque de blessures, l'utilisateur doit

lire et bien comprendre le mode d'emloi.

7-3. Screw Driving-Depth Adjustment

Information and suggestions for screw driving-depth selection for applicable screws are described in the Handling

Instructions. The salesperson must be thoroughly familiar with screw driving-depth adjustment procedures to be

able to instruct the customer/user in performing adjustment so that the screw neither protrudes above nor sinks

excessively below the surface of the workpiece into which the screw is driven.

--- 6 ---

Page 10

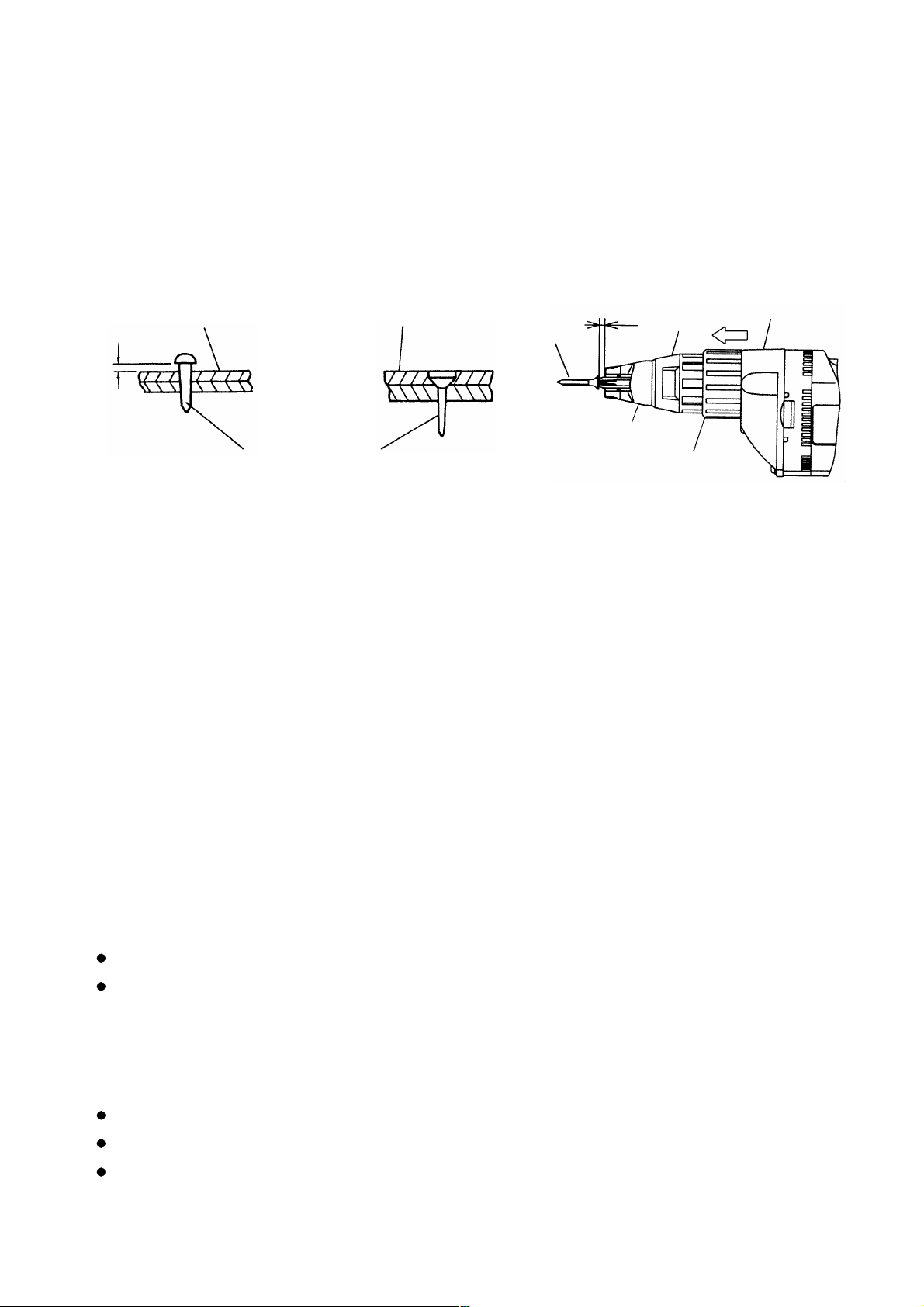

Specific adjustment procedures are as follows

(1) Head of screw protrudes above workpiece surface (Fig. 1)

If dimension A in Fig. 3 is excessively small, the head of the driven screw will protrude above the surface of the

workpiece material as shown in Fig. 1. To adjust dimension A, pull the lock sleeve in the direction indicated by

the arrow in Fig. 3 to disengage the lock sleeve from the gear cover spline, and rotate the lock sleeve

clockwise as viewed from the screw mounting end (see Note below). Repeat adjustment as necessary until

the head of the driven screw is properly aligned with the surface of the workpiece.

Material into which screw

is driven

B

Screw

Fig. 1 Fig. 2 Fig. 3

(2) Head of screw sinks below workpiece (Fig. 2)

If dimension A in Fig. 3 is excessively large, the head of the driven screw will sink below the surface of the

workpiece as shown in Fig. 2. To perform adjustment, follow the procedures described in item (1) above, but

rotate the lock sleeve counter-clockwise.

Should Hex and Teks screws be driven when dimension A is excessively large, both the screws and bits may

be easily damaged. Instruct customers/users to perform adjustment correctly without fail.

(NOTE) By turning the lock sleeve clockwise or counter-clockwise, dimension A in Fig. 3 can be adjusted

within a maximum dimension of 1.5 mm (0.059"). One complete rotation of the lock sleeve is

Material into which screw

is driven

Screw

Screw

A

Sub-stopper

Gear cover

Locator

Lock sleeve

divided into ten settings, each setting permitting an adjustment of 0.15 mm (0.006"). Accordingly,

if dimension B in Fig. 1 is 0.3 mm (0.012"), rotate the lock sleeve by two settings.

7-4. Self-Drilling Screws

Self-drilling screws are most suitable for joining wooden and metal materials, mounting metallic components onto

iron sheets, or installing roofing materials. Self-drilling and self-tapping, they are commonly employed in the

construction industry because:

Separate drilling and tapping processes are not required when securing wooden materials to metal materials.

Consequently, job costs and processes can be drastically reduced.

7-5. Drywall Screws

Drywall screws are most suitable for interior decorating and construction utilizing such materials as gypsum board

and plastic board. Their main features are:

Like Hex and Teks screws, drywall screws are self-drilling, and can reduce work time.

Wall panels can be mounted cleanly without cracks or chips.

Drywall screws display far stronger holding power than conventional screws when applied to materials

composed of powder or particles, such as gypsum board.

--- 7 ---

Page 11

7-6. Variable-Speed Switch

This switch is equipped with a variable speed control circuit. Through the control circuit, the speed can be

controlled up to 75 % of maximum speed according to the degree at which the switch is depressed.

A disadvantage of this system is that if the bit becomes locked resulting in stoppage of the motor, the speed

control circuit may be burnt out. In such a case, the switch should be released immediately or turned OFF. To

avoid damage to the switch circuit, the customer should be advised to increase driving speed gradually until the

screw is driven approximately halfway into the workpiece, then depress the trigger to obtain optimum speed.

100 %

75 %

speed

0

Trigger stroke

Fig. 4

Switch characteristics (Approximately shown converted into the linear line)

Maximum speed change point

8. PRECAUTIONS IN DISASSEMBLY AND REASSEMBLY

The [BOLD] numbers in the descriptions below correspond to the item numbers in the Parts List and the exploded

assembly diagram.

8-1. Disassembly

A. Disassembly of the parts within the handle

(1) Removal of the Handle Cover

Loosen the three Tapping Screws D4 x 20 [31], and remove the Handle Cover [29].

(2) Removal of the Carbon Brushes

With a small flat-blade screwdriver, lift up on the Brush Holder [36], and pull it out slightly.

Next, pull out the terminal portion which connects the two Carbon Brushes [35] and the lead wires from the

Speed Control Switch [32]. When pulling the terminal, it is best to push the Carbon Brushes fully into the

Brush Holder.

(3) Removal of the Cord

Loosen the two Tapping Screws D4 x 16 [44] which retain the Cord Clip [45], and remove the Cord [48]

together with the Cord Armor [46].

B. Removal of the armature and stator

(1) Removal of the Armature

Remove the three Tapping Screws D4 x 40 [9] from the Gear Cover Ass'y [10], and remove the Inner

Cover Ass'y [23] from the Housing [29]. The Armature [25] can then be taken out.

(2) Removal of the Stator

First, remove the Fan Guide [26] from the inside of the Housing.

Then, loosen the two Tapping Screws D4 x 50 [27], and lightly tap the end surface of the Housing [29] with

a wooden hammer to loosen and remove the Stator [28].

--- 8 ---

Page 12

C. Removal of the socket (B) ass'y, gear ass'y and second pinion ass'y

(1) Remove the Gear Cover Ass'y [10] and the Inner Cover Ass'y [23], then the Socket (B) Ass'y [12], Gear

Ass'y [15] and Second Pinion Ass'y [20] can be removed. If the Gear Ass'y [15] is hard to remove, lightly

tap the end surface of the Inner Cover Ass'y [23] with a wood hammer. If the Second Pinion Ass'y [20] is

hard to remove, lightly tap the end surface of the Gear Cover Ass'y [10] with a wood hammer. Be careful

not to lose the Spring [14] on the outer circumference of the Gear Shaft [16] and the Washer [22] on the

outer circumference of the Second Pinion Ass'y [20].

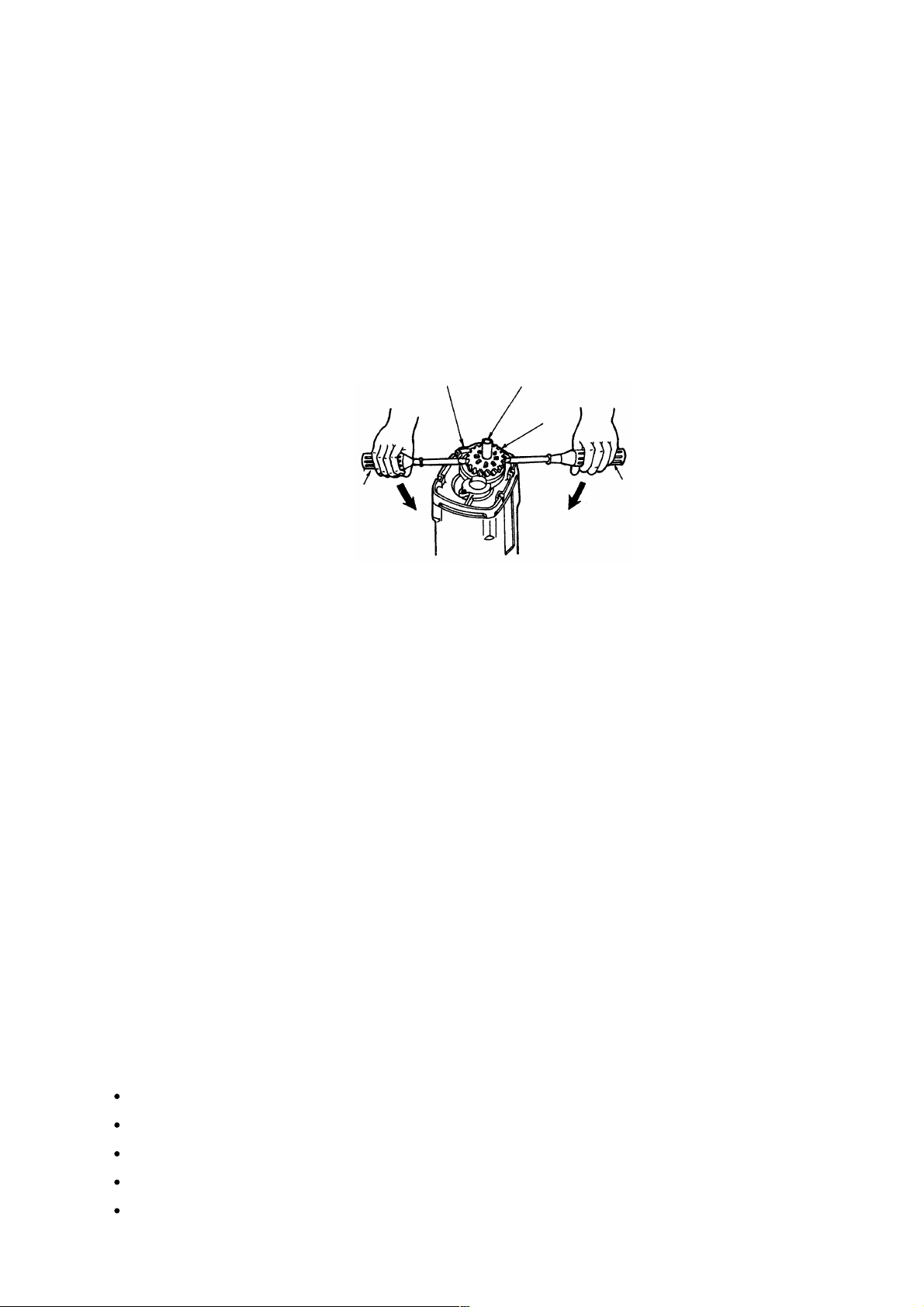

As shown in Fig. 5, insert two flat-blade screwdrivers between the Inner Cover Ass'y [23] and Gear Ass'y

[15] at each side and remove the Gear Ass'y [15], Gear Shaft [16] and Ball Bearing [17] from the Inner

Cover Ass'y as a single unit.

Inner Cover Ass'y [23]

Gear Shaft [16]

Gear

Ass'y [15]

Flat-blade screwdriver

Flat-blade screwdriver

Fig. 5

8-2. Reassembly

Reassembly can be accomplished by following the disassembly procedures in reverse. However, special

attention should be given to the following items.

(1) Lubrication

Grease: Hitachi Motor Grease (Code No. 930035)

Application:

(a) Fill a moderate amount of grease in the Gear Cover Ass'y [10]. (If the Gear Cover Ass'y is new, fill it with

7 g of grease.)

(b) Outer circumference and clutch of the Socket (B) Ass'y [12]

(c) Teeth and clutch of the Gear Ass'y [15]

(d) Outer circumference of the Gear Shaft [16]

(e) Teeth and outer circumference of the Second Pinion Ass'y [20]

(f) Teeth of the First Gear [21]

(g) Pinion of the Armature [25]

(2) Tightening torque

Handle cover retaining screws

Cord clip retaining screws

Gear cover retaining screws

Stator retaining screws

Speed control switch retaining screws

••••••••••••••••••••••••••••••••••••••••••••••••••••••

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

••••••••••••••••••••••••••••••••••••••••••••

--- 9 ---

15 --- 25 kg•cm (13.0 --- 21.7 Ibs-in)

15 --- 25 kg•cm (13.0 --- 21.7 Ibs-in)

15 --- 25 kg•cm (13.0 --- 21.7 Ibs-in)

15 --- 25 kg•cm (13.0 --- 21.7 Ibs-in)

4 --- 8 kg•cm (3.5 --- 6.9 Ibs-in)

Page 13

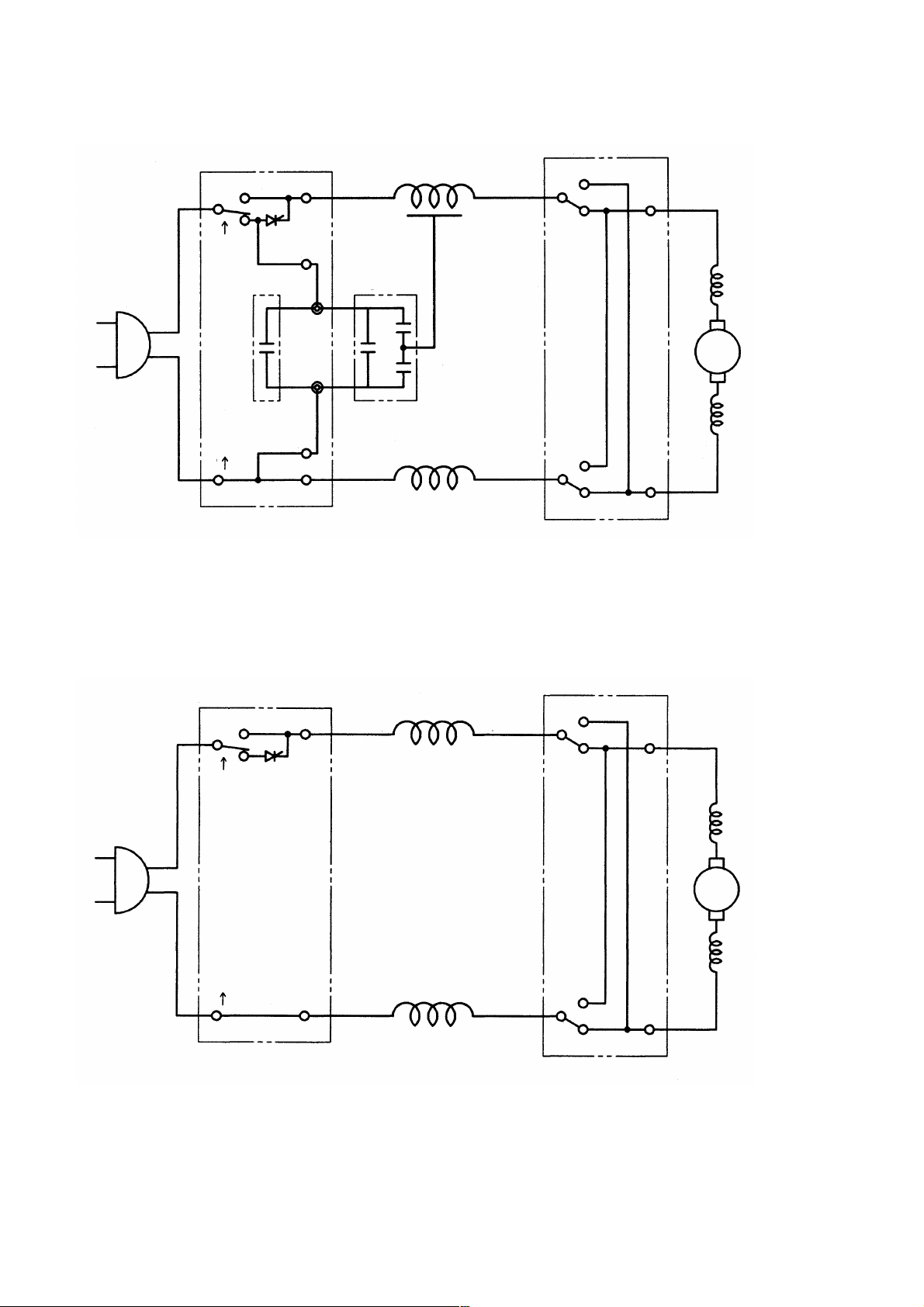

8-3. Wiring Diagrams

(1) Products with noise suppressor

Power source

Variable switch

1

Capacitor

C2

2

M1

C1

M2

White Gray

Noise

suppressor

Stator

Stator

Fig. 6

RedYellow

Reversing switch

2

1

4

3

Blue

Choke coil

Ar

Choke coil

Brown

(2) Products without noise suppressor

V ariable switch

M1

1

Power source

2

M2

White

Yellow

Stator

Stator

Gray

Red

Reversing switch

2

1

4

3

Blue

Choke coil

Ar

Choke coil

Brown

Fig. 7

--- 10 ---

Page 14

8-4. Internal Wire Arrangement and Wiring Work

A. Internal wire arrangement

Insert earth terminal between

stator core and housing

White

(Stator)

Brown

(Carbon brush)

Blue

(Carbon brush)

Yellow

(Stator)

Gray

(Stator)

Blue

(Carbon brush)

White

(Stator)

Noise suppressor

Fig. 8 Schematic diagram

--- 11 ---

Page 15

B. Additional wiring work

General internal wiring can be accomplished by

referring to paragraph 8-3 and 8-4-A. The followings

are special instructions for switch connection.

(1) Wiring of reversing switch

Insert the lead wire (red) coming from the stator

into the terminal (1) of the reversing switch, and

the lead wire (gray) into the terminal (2) as shown

in Fig. 9. Insert the lead wire (brown) coming

from the carbon brush into the terminal (3) and

the lead wire (blue) into the terminal (4). After

insertion, pull each lead wire slightly to check that

the lead wires do not come off. To disconnect the

lead wires, insert a small flat-blade screwdriver

into the slots near the terminals and pull out the

lead wires.

(Stator) (Carbon brush)

Red

Blue

(Carbon brush) (Stator)

Fig. 9 Wiring of reversing switch

Brown

Gray

--- 12 ---

Page 16

(2) Wiring of variable speed control switch

Insert each cord into the terminal 1 ↑ and

terminal 2 ↑ of the speed control switch as shown

in Fig. 10, and tighten the screw [tightening

torque: 0.6 _+ 0.2 N•m (6 _+ 2 kgf•cm, 5.2 _+ 1.7

Ibs-in)]. Insert the lead wire (white) coming from

the stator into the terminal M1 and the lead wire

(yellow) into the terminal M2. Insert each lead

wire (white) coming from the noise suppressor

into the terminal C1 and C2. After insertion, pull

each lead wire slightly to check the lead wires do

not come off. To disconnect the lead wires, insert

a small flat-blade screwdriver into the slots near

the terminals and pull out the lead wires.

(Stator)

(Noise suppressor)

White

Yellow

White

(Noise suppressor)

(Stator)

White

(Cord) (Cord)

Fig. 10 Wiring of speed control switch

8-5. Insulation Tests

On completion of reassembly after repair, measure the insulation resistance and conduct the dielectric strength

test.

Insulation resistance: 7 M Ω or more with DC 500 V Megohm Tester

Dielectric strength: AC 4,000 V/1 minute, with no abnormalities

AC 2,500 V/1 minute, with no abnormalities

••••••••

220 V --- 240 V (

••••••••

110 V --- 127 V (except for U.K. products)

and 110 V for U.K. products

8-6. No-load Current Values

After no-load operation for 30 minutes, the no-load current value should be as follows

Voltage (V) 110

115 120 220 230 240

)

Current (A) max.

2.5

2.5 2.5 1.2 1.2 1.1

--- 13 ---

Page 17

9. STANDARD REPAIR TIME (UNIT) SCHEDULES

MODEL 10 20 30 40 50 60 min.

Fixed

Variable

Work Flow

W 6VB2

W 8VB

Speed control

Cord Armor

Cord

Carbon Brush

General Assembly

switch

Housing.Handle

Cover Set

Stator

x 2

Armature

Ball Bearing

(608VV) x 2

Inner Cover

Ass'y

Spring

Gear Ass'y

Gear Shaft

Ball Bearing

(608VV) x 2

Second Pinion

Ass'y

First Gear

Sub Stopper(B)

Locator (A)

Lock Sleeve (A)

O-Ring (S-28)

Fringer (A)

O-Ring (F)

Gear Cover

Ass'y

Set Ring

Socket (B)

Ass'y

Steel Ball

D3.175

--- 14 ---

Page 18

Assembly Diagram for W 6VB2

--- 15 ---

Page 19

PARTS

ITEM

CODE NO. DESCRIPTION

NO.

* 1 985-322 MAGNETIC HEX. SOCKET 5/16"X65L 1 FOR AUS,GBR,NOR,USA

* 1 985-321 MAGNETIC HEX. SOCKET 10MMX65L 1 FOR HOL,FIN,CHN

* 2 317-670

* 2 317-671

* 2 317-673

* 2 317-672

* 2 317-899

3 876-031 O-RING (S-16) 1

4 317-666 LOCATOR (A) 1

5 317-665 LOCK SLEEVE (A) 1

6 873-731 O-RING (S-28) 1

7 971-468 FRINGER (A) 1

8 317-662 O-RING (F) 1

9 306-664 TAPPING SCREW (W/FLANGE) D4X40 3

10 317-661 GEAR COVER ASS’Y 1 INCLUD.8,19

11 872-573 SET RING 1

12 317-664 SOCKET (B) ASS’Y 1 INCLUD.11,13

13 959-148 STEEL BALL D3.175 (10 PCS.) 2

14 306-024 SPRING 1

15 317-771 GEAR ASS’Y 1 INCLUD.16

16 307-340 GEAR SHAFT 1

17 608-VVM BALL BEARING 608VVMC2EPS2L 1

18 987-641 WASHER (A) 1

19 608-VVM BALL BEARING 608VVMC2EPS2L 1

20 317-770 SECOND PINION ASS’Y 1 INCLUD.21

21 317-772 FIRST GEAR 1

22 317-663 WASHER 1

23 317-660 INNER COVER ASS’Y 1 INCLUD.17,18

24 608-VVM BALL BEARING 608VVMC2EPS2L 2

* 25 360-492C ARMATURE 110V 1

* 25 360-492U ARMATURE ASS’Y 115V 1 INCLUD.24

* 25 360-492E ARMATURE 220V-230V 1

* 25 360-492F ARMATURE 240V 1

26 305-398 FAN GUIDE (B) 1

27 950-515 TAPPING SCREW D4X50 2

* 28 340-436C STATOR 110V-115V 1

* 28 340-436E STATOR 220V-230V 1

* 28 340-224F STATOR 240V 1

29 317-659 HOUSING.HANDLE COVER SET 1

30 NAME PLATE 1

31 302-086 TAPPING SCREW (W/FLANGE) D4X20 (BLACK) 3

* 32 314-916 SPEED CONTROL SWITCH (2P) 100V-115V 1 FOR GBR (110V),USA

* 32 314-921 SPEED CONTROL SWITCH (2P) 220V-240V 1

* 33 317-668 INTERNAL WIRE (A) 1 FOR AUS,GBR,FRG,FRA,HOL,FIN,AUT,NOR

* 33 314-917 INTERNAL WIRE (B) (BLUE) 1 FOR USA

* 34 317-669 INTERNAL WIRE (B) 1 FOR AUS,GBR,FRG,FRA,HOL,FIN,AUT,NOR

* 34 314-918 INTERNAL WIRE (B) (BROWN) 1 FOR USA

35 999-041 CARBON BRUSH (1 PAIR) 2

36 955-203 BRUSH HOLDER 2

37 317-676 HOOK (A) 1

38 HITACHI LABEL 1

----

2

99

SUB STOPPER (B) FOR H3/8,H10 HEX. SOCKET

SUB STOPPER (B) FOR H5/16 HEX. SOCKET

SUB STOPPER (C) FOR BIT HOLDER (75L)

SUB STOPPER (A) FOR BIT HOLDER (41L)

SUB STOPPER (D) FOR HEX. SOCKET

: ALTERNATIVE PARTS

*

--- 16 ---

NO.

USED

1 FOR HOL,FIN,CHN

1 FOR AUS,GBR,NOR,USA

1 FOR FRG

1 FOR FRG,FRA,HOL,AUT

1 FOR FRA

REMARKS

W 6VB2

Page 20

PARTS

ITEM

* 42 930-039 NOISE SUPPRESSOR 1 EXCEPT FOR USA

* 43 994-273 NOISE SUPPRESSOR 1 EXCEPT FOR USA

* 48 500-409Z CORD 1 (CORD ARMOR D8.8)

* 48 500-439Z CORD 1 (CORD ARMOR D8.8) FOR AUS

* 48 500-436Z CORD 1 (CORD ARMOR D8.8) FOR GBR (230V)

* 48 971-675Z CORD 1 (CORD ARMOR D8.8) FOR GBR (110V)

* 48 500-240Z CORD 1 (CORD ARMOR D8.8) FOR USA

* 48 500-456Z CORD 1 (CORD ARMOR D8.8) FOR CHN

CODE NO. DESCRIPTION

NO.

39 992-635 EARTH TERMINAL 1 FOR NOISE SUPPRESSOR

40 959-140 CONNECTOR 50091 (10 PCS.) 2

41 317-667 INTERNAL WIRE 2

44 305-812 TAPPING SCREW (W/FLANGE) D4X16 (BLACK) 2

45 937-631 CORD CLIP 1

46 953-327 CORD ARMOR D8.8 1

47 981-373 TUBE (D) 2 FOR CORD

NO.

USED

REMARKS

W 6VB2

: ALTERNATIVE PARTS

*

--- 17 ---

----

2

99

Page 21

STANDARD ACCESSORIES

ITEM

CODE NO. DESCRIPTION

NO.

501 971-511Z + DRIVER BIT (A) NO.2 25L 1

* 502 317-674 MAGNETIC BIT HOLDER ASS’Y (41L) 1 INCLUD.501 FOR FRG,FRA,HOL,AUT

* 502 982-554Z MAGNETIC BIT HOLDER (75L) 1 FOR FRG

NO.

USED

REMARKS

OPTIONAL ACCESSORIES

ITEM

CODE NO. DESCRIPTION

NO.

601 317-827 SUB STOPPER (B) H1/4 HEX. SOCKET 1

602 985-326 NON-MAGNETIC HEX. SOCKET 3/8" 65L 1

603 985-327 NON-MAGNETIC HEX. SOCKET 5/16" 65L 1

604 985-328 NON-MAGNETIC HEX. SOCKET 1/4" 65L 1

605 985-329 NON-MAGNETIC HEX. SOCKET 10MM 65L 1

606 982-563Z NON-MAGNETIC BIT HOLDER 1

607 982-554Z MAGNETIC BIT HOLDER (75L) 1

608 985-333 + DRIVER BIT NO.1 25L 1

609 971-512Z + DRIVER BIT (A) NO.3 25L 1

610 985-334 + DRIVER BIT NO.1 25L W/STEPPED ROD 1

611 985-335 + DRIVER BIT NO.2 25L W/STEPPED ROD 1

612 985-336

613 985-337

614 985-338

615 985-339

616 985-340

617 985-341

618 985-342 HEX. BIT 4MMX25L 1

619 985-343 HEX. BIT 5MMX25L 1

620 985-344 HEX. BIT 6MMX25L 1

621 985-330 MAGNETIC HEX. SOCKET 3/8"X65L 1

622 985-332 MAGNETIC HEX. SOCKET 1/4"X65L 1

623 310-904 CASE 1

-

DRIVER BIT 4MMX25 1

-

DRIVER BIT 5MMX25 1

-

DRIVER BIT 6MMX25 1

-

DRIVER BIT 8MMX25 1

-

DRIVER BIT 4MMX25 (W/STEPPED ROD) 1

-

DRIVER BIT 5MMX25 (W/STEPPED ROD) 1

NO.

USED

REMARKS

W 6VB2

Printed in Japan

(990225 N)

----

2

99

: ALTERNATIVE PARTS

*

--- 18 ---

Page 22

Assembly Diagram for W 8VB

--- 19 ---

Page 23

PARTS

ITEM

CODE NO. DESCRIPTION

NO.

* 1 985-321 MAGNETIC HEX. SOCKET 10MMX65L 1 FOR HOL,FIN,ESP,CHN

* 1 985-322 MAGNETIC HEX. SOCKET 5/16"X65L 1 FOR AUS,NOR,USA

* 2 317-670

* 2 317-671

* 2 317-672

* 2 317-673

* 2 317-899

3 876-031 O-RING (S-16) 1

4 317-666 LOCATOR (A) 1

5 317-665 LOCK SLEEVE (A) 1

6 873-731 O-RING (S-28) 1

7 971-468 FRINGER (A) 1

8 317-662 O-RING (F) 1

9 306-664 TAPPING SCREW (W/FLANGE) D4X40 3

10 317-661 GEAR COVER ASS’Y 1 INCLUD.8,19

11 872-573 SET RING 1

12 317-664 SOCKET (B) ASS’Y 1 INCLUD.11,13

13 959-148 STEEL BALL D3.175 (10 PCS.) 2

14 306-024 SPRING 1

15 307-339 GEAR ASS’Y 1 INCLUD.16

16 307-340 GEAR SHAFT 1

17 608-VVM BALL BEARING 608VVMC2EPS2L 1

18 987-641 WASHER (A) 1

19 608-VVM BALL BEARING 608VVMC2EPS2L 1

20 317-887 SECOND PINION ASS’Y 1 INCLUD.21

21 317-772 FIRST GEAR 1

22 317-663 WASHER 1

23 317-660 INNER COVER ASS’Y 1 INCLUD.17,18

24 608-VVM BALL BEARING 608VVMC2EPS2L 2

* 25 360-492U ARMATURE ASS’Y 115V 1 INCLUD.24

* 25 360-492E ARMATURE 220V-230V 1

* 25 360-492F ARMATURE 240V 1

26 305-398 FAN GUIDE (B) 1

27 950-515 TAPPING SCREW D4X50 2

* 28 340-436C STATOR 110V-115V 1

* 28 340-436E STATOR 220V-230V 1

* 28 340-224F STATOR 240V 1

29 317-659 HOUSING.HANDLE COVER SET 1

30 NAME PLATE 1

31 302-086 TAPPING SCREW (W/FLANGE) D4X20 (BLACK) 3

* 32 314-916 SPEED CONTROL SWITCH (2P) 100V-115V 1 FOR USA

* 32 314-921 SPEED CONTROL SWITCH (2P) 220V-240V 1

* 33 317-668 INTERNAL WIRE (A) 1 EXCEPT FOR USA

* 33 314-917 INTERNAL WIRE (B) (BLUE) 1 FOR USA

* 34 317-669 INTERNAL WIRE (B) 1 EXCEPT FOR USA

* 34 314-918 INTERNAL WIRE (B) (BROWN) 1 FOR USA

35 999-041 CARBON BRUSH (1 PAIR) 2

36 955-203 BRUSH HOLDER 2

37 317-676 HOOK (A) 1

38 HITACHI LABEL 1

* 39 992-635 EARTH TERMINAL 1 FOR NOISE SUPPRESSOR

----

2

99

SUB STOPPER (B) FOR H3/8,H10 HEX. SOCKET

SUB STOPPER (B) FOR H5/16 HEX. SOCKET

SUB STOPPER (A) FOR BIT HOLDER (41L)

SUB STOPPER (C) FOR BIT HOLDER (75L)

SUB STOPPER (D) FOR HEX. SOCKET

: ALTERNATIVE PARTS

*

--- 20 ---

NO.

USED

1 FOR HOL,FIN,ESP,CHN

1 FOR AUS,NOR,USA

1 FOR FRG,FRA,HOL

1 FOR FRG

1 FOR FRA

REMARKS

W 8VB

Page 24

PARTS

ITEM

* 40 959-140 CONNECTOR 50091 (10 PCS.) 2 EXCEPT FOR USA

* 41 317-667 INTERNAL WIRE 2 EXCEPT FOR USA

* 42 930-039 NOISE SUPPRESSOR 1 EXCEPT FOR USA

* 43 994-273 NOISE SUPPRESSOR 1 EXCEPT FOR USA

* 47 981-373 TUBE (D) 2 FOR CORD

* 48 500-409Z CORD 1 (CORD ARMOR D8.8)

* 48 500-439Z CORD 1 (CORD ARMOR D8.8) FOR AUS

* 48 500-240Z CORD 1 (CORD ARMOR D8.8) FOR USA

* 48 500-456Z CORD 1 (CORD ARMOR D8.8) FOR CHN

CODE NO. DESCRIPTION

NO.

44 305-812 TAPPING SCREW (W/FLANGE) D4X16 (BLACK) 2

45 937-631 CORD CLIP 1

46 953-327 CORD ARMOR D8.8 1

NO.

USED

REMARKS

W 8VB

: ALTERNATIVE PARTS

*

--- 21 ---

----

2

99

Page 25

STANDARD ACCESSORIES

ITEM

CODE NO. DESCRIPTION

NO.

* 501 971-511Z + DRIVER BIT (A) NO.2 25L 1 FOR FRG,FRA,HOL

* 502 317-674 MAGNETIC BIT HOLDER ASS’Y (41L) 1 INCLUD.501 FOR FRG,FRA,HOL

* 502 982-554Z MAGNETIC BIT HOLDER (75L) 1 FOR FRG

NO.

USED

REMARKS

OPTIONAL ACCESSORIES

ITEM

CODE NO. DESCRIPTION

NO.

601 317-827 SUB STOPPER (B) H1/4 HEX. SOCKET 1

602 985-326 NON-MAGNETIC HEX. SOCKET 3/8" 65L 1

603 985-327 NON-MAGNETIC HEX. SOCKET 5/16" 65L 1

604 985-328 NON-MAGNETIC HEX. SOCKET 1/4" 65L 1

605 985-329 NON-MAGNETIC HEX. SOCKET 10MM 65L 1

606 985-330 MAGNETIC HEX. SOCKET 3/8" X65L 1

607 985-332 MAGNETIC HEX. SOCKET 1/4" X65L 1

608 982-563Z NON-MAGNETIC BIT HOLDER 1

609 982-554Z MAGNETIC BIT HOLDER (75L) 1

610 985-333 + DRIVER BIT NO.1 25L 1

611 971-511Z + DRIVER BIT (A) NO.2 25L 1

612 971-512Z + DRIVER BIT (A) NO.3 25L 1

613 985-334 + DRIVER BIT NO.1 25L W/STEPPED ROD 1

614 985-335 + DRIVER BIT NO.2 25L W/STEPPED ROD 1

615 985-336

616 985-337

617 985-338

618 985-339

619 985-340

620 985-341

621 985-342 HEX. BIT 4MMX25L 1

622 985-343 HEX. BIT 5MMX25L 1

623 985-344 HEX. BIT 6MMX25L 1

624 310-904 CASE 1

-

DRIVER BIT 4MMX25 1

DRIVER BIT 5MMX25 1

-

-

DRIVER BIT 6MMX25 1

DRIVER BIT 8MMX25 1

-

-

DRIVER BIT 4MMX25 (W/STEPPED ROD) 1

-

DRIVER BIT 5MMX25 (W/STEPPED ROD) 1

NO.

USED

REMARKS

W 8VB

Printed in Japan

(990225 N)

----

2

99

: ALTERNATIVE PARTS

*

--- 22 ---

Loading...

Loading...