SERVICE MANUAL

VORSICHT:

Data contained within this Service

Verbesserungen

ä

ndern.

MANUEL D’ ENTRETIEN

WARTUNGSHANDBUCH

No. 0301

VTMX900ECT

VTMX900EUK

VTMX905EUK

VTMX905EVPS

VTMX910EUK

VTMX902EL

VTMX930EVPS

VTMX932EL

CAUTION:

Before servicing this chassis, it is important that the service technician read

the “ Safety Precautions” and “ Product Safety Notices” in this service manual.

ATTENTION:

Avant d’ effectuer l’ entretien du châassis, le technicien doit lire les

«Précautions de sécurité» et les «Notices de sécurité du produit» présentés

dans le présent manuel.

Vor Öffnen des Gehäuses hat der Service-Ingenieur die „ Sicherheitshinweise“

und „ Hinweise zur Produktsicherheit“ in diesem Wartungshandbuch zu lesen

.

VTFX2000ELN

VTFX940EVPS

VTFX940EUKN

VTFX940ENA

VTFX942ELN

VTFX940ELN

VTFX952ELN

manual is subject to alteration for

improvement.

Les données fournies dans le

présent manuel d’ entretien

peuvent faire l’ objet de

modifications en vue de

perfectionner le produit.

Die in diesem Wartungshandbuch

enthaltenen Spezifikationen

können sich zwecks

June 2000

1-6

Safety instructions

– Safety regulations demand that the set be restored to its

original condition and that components identical with the

original types be used.

Safety components are marked by the symbol

– All ICs and many other semi-conductors are susceptible to

electrostatic discharges (ESD). Careless handling during repair

may reduce life drastically. When repairing, make sure that you

are conneted with the same potential as the mass of the set via

a wrist wrap with resistance. Keep components and tools on

the same potential.

– A set to be repaired should always be connected to the mains

via a suitable isolating transformer.

– Never replace any modules or any other parts while the set is

switched on.

– Use plastic instead of metal alignment tools. This in order to

prelude short-circuit or to prevent a specific circuit from being

rendered unstable.

GB

!

Remarks

– The direct voltages and oscillograms ought to be measured

relative to the set mass.

EXCEPTION

At the power supply, the DC voltages and the oscillograms at

the primary side are measured to LIVE GND.

– The direct voltages and oscillograms mentioned in the

diagrams ought to be measured with a colour bar signal and

the picture carrier at 503.25 MHz (C25).

– The oscillograms and direct voltages have been measured in

RECORD or PLAY mode.

– The semiconductors, which are mentioned in the circuit

diagram and in the parts lists, are fully exchangeable per

position with the semiconductors in the set, irrespective of the

type designation of these semiconductors.

Sicherheitshinweise

– Die Sicherheitsvorschriften erfordern es, daß sich das Gerät

nach der Reparatur in seinem originalen Zustand befindet und

daß die zur Reparatur benutzten Ersatzteile mit den

Originalersatzteilen identisch sind.

Sicherheits-Bauteile sind mit der Markierung versehen

– Alle IC’s und Halbleiter sind empfindlich gegen elektrostatische

Entladungen (ESD). Unvorschriftmässige Behandlung von

Halbleitern im Reparaturfall kann zur Zerstörung dieser

Bauteile oder zu einer drastischen Reduzierung der

Lebensdauer führen. Sorgen Sie dafür, daß Sie sich im

Reparaturfall über ein Armband mit Widerstand auf dem

gleichen Potential, wie die Masse des Gerätes befinden. Alle

Bauteile, Werkzeuge und Hilfsmittel sind auf das gleiche

Potential zu legen.

– Ein zu reparierendes Gerät ist immer über einen

Trenntransformator an die Netzspannung anzuschließen.

– Bei eingeschaltetem Gerät dürfen keine Module oder sonstige

Einzelteile ausgetauscht werden.

– Zum Abgleich sind ausschließlich Kunststoffwerkzeuge zu

benutzen (keine Metallwerkzeuge verwenden). Dadurch wird

vermieden, daß ein Kurzschluß entstehen kann oder eine

Schaltung instabil wird.

D

!

Anmerkungen

– Die Gleichspannung und Oszillogramme sind gegen

Gerätemasse zu messen.

AUSNAHME

Beim Netzteil sind die Gleichspannungen und Oszillogramme

auf der Primärseite gegen Live GND gemessen.

– Die Gleichspannungen und Oszillogramme angeführt in den

Schaltbildern sollen unter folgenden Bedingungen gemessen

werden: Farbbalkensignal, Bildträger auf 503.25 MHz (C25)

– Die Oszillogramme und Gleichspannungen sind in RECORD

oder PLAY gemessen. Die in den Stücklisten aufgeführten

Bauteile sind positionsweise voll auswechselbar gegen die

Bauteile in dem Gerät, ungeachtet der etwaigen

Typenbezeichungen.

Avertissements

– Les normes de sécurité exigent qu’aprés réparation I’appareil

soit remis dans son état d’origine et que soient utilisées les

piéces de rechange identiques à celles spécifiées.

Les composants de sécurité sont marqués

– Tout les IC et beaucoup d’autres semi-conducteurs sont

sensibles aux décharger statiques (ESD). Leur longévité

pourrait étre considérablement écourté par le fait qu’aucune

précaution n’est prise à leur manipulation. Lors de réparations

s’assurer de bien étre relié au méme potential que la masse de

l’appareil et enfiler le bracelet serti d’une résistance de

sécurité. Veiller à ce que les composants ainsi que les outils

que I’on utilise soient également à ce potentiel.

– Toujours alimenter un appareil à réparer à travers un transfo

d’isolement.

– Ne jamais remplacer les modules ni d’autres composants

quand I’appareil est sous tension.

– Pour l’ajustage, utiliser des outils en plastique au lieu

d’instruments métalliques. Ceci afin d’éviter les court-circuits et

exclure I’instabilité dans certains circuits.

F

!

Observations

– La mésure des tensions continues et des oscillogrammes doit

se faire par rapport à la terre de l’appareil.

EXCEPTION

Sur l’unité d’alimentation la tension continue et l’oscillogramme

sont mesurés sur le côte primaire en Live GND.

– La mésure des tensions continues et des oscillogrammes

figurant sur le schéma doit se faire dans un signal de barre

couleur porteuse image sur 503.25 MHz (C25).

– Les oscillogrammes et tension sont mésurées en mode

RECORD ou PLAY.

– Les semi-conducteurs indiqués dans le schéma de principe et

à la liste des compostants, sont interchangeables par repère

sur ce chassis avec les semi-conducteurs de l’appareil quelle

que soit la désignation de type donnée sur ces semiconducteurs.

Veiligheidsinstructies

– Veiligheidsbepalingen vereisen, dat het apparaat in zijn

oorspronkelijke toestand wordt teruggebracht en dat

onderdelen, indentiek aan de oorspronkelijke, worden

toegepast.

De veiligheidsonderdelen zijn aangeduid met het symbool

– Alle IC’s en vele andere halfgeleiders zijn gevoelig voor

elektrostatische ontladingen (ESD). Onzorgvuldig behandelen

tijdens reparatie kan de levensduur drastisch doen

verminderen. Zorg ervoor, dat U tijdens reparatie via een

polsband met weerstand verbonden bent met hetzelfde

potentiaal als de massa van het apparaat. Houd componenten

en hulpmiddelen ook op ditzelfde potentiaal.

– Sluit een apparaat dat gerepareerd wordt altijd via een

scheidingstransformator aan op de netspanning.

– Verwissel nooit modules of andere onderdelen terwijl het

apparaat is ingeschakeld.

– Gebruik voor het afregelen plastic i.p.v metalen gereedschap.

Dit om mogelijke kortsluiting te voorkomen of een bepaalde

schakeling instabiel te maken.

NL

Opmerkingen

– De gelijksspanningen en oscillogrammen dienen gemeten te

worden ten opzichte van de apparaat aarde.

– De gelijksspanningen en oscillogrammen vermeld in de

schema’s dienen gemeten te worden met een

kleurbalkensignaal beelddraaggolf op 503.25 MHz (C25).

– De oscillogrammen en gelijksspanningen zijn in RECORD of

PLAY mode gemeten.

– De halfgeleiders, die in het pricipeschema en in de stuklijsten,

zijn vermeld, zijn per positie volledig uitwisselbaar met de

halfgeleiders in het apparaat, ongeacht de typeaanduiding op

deze halfgeleiders.

!

1-7

Avvertimenti

– Le prescrizioni di sicurezza richiedono che l’apparecchio sia

ricondotto alle condizioni originali e che siano usati ricambi

originali.

Componenti di sicurezza sono marcati con

– Tutti gli IC e semiconduttori sono sensibili a scariche

elettrostatiche (ESD). Noncuranze durante la riparazione di

semiconduttori possono danneggiarli o condurre ad una

riduzione drastica della durata. Durante la riparazione

assicurarsi di essere collegati allo stesso potenziale attraverso

un bracciale di protezione contro scariche elettrostatiche.

Inoltre tenere anche tutti i componenti e gli attrezzi a questo

potenziale.

– Apparecchi da riparare bisogna collegarli sempre via un

trasformatore isolante (separatore) alla tensione normale.

– Non scambiare moduli o altri componenti quando l’apparecchio

è in funzione.

– Per l’accordo usare soltanto attrezzi di plastica (non usare

attrezzi metallici). Cosí si evitano cortocircuiti e collegamenti

instabili.

I

!

Osservazioni

– Misurare le tensioni continue e gli oscillogrammi riferiendosi

alla massa dell’apparecchio.

ECCEZIONE

Le tensioni continue e gli oscillogrammi dall’alimentatore sono

misurati sulla parte primaria contro GND-Live.

– Le tensioni continue e gli oscillogrammi indicati negli schemi di

collegamento devono essere misurati secondo le condizioni

seguenti: segnale barre colore, portante dell’immagine su:

503.25 MHz (C25).

– Gli oscillogrammi e le tensioni continue sono misurati in

RECORD o PLAYBACK.

– I componenti indicati nelle liste sono intercambiabili con quelli

nell’apparecchio nonostante l’eventuale denominazione di

modelli.

Avisos

– Las instrucciones de seguridad exigen que después de la

reparación el aparato se encuentre en el estado original y que

las piezas de repuesto, utilizadas para la reparación, sean

idénticas a las originales.

Los componentes de seguridad estan marcados con

– Todos los IC y semiconductores son sensibles a descargas

electrostáticas (ESD). Un tratamiento no conforme a las

instrucciones de semiconductores en caso de reparación,

podría llevar a la destrucción de estos componentes, o a una

reducción drástica de la duración. Tenga cuidado de que, en

caso de reparación, estar al mismo potencial que la masa del

aparato, por una pulsera con resistencia. Ponga todos los

componentes, herramientas y recursos al mismo potencial.

– Para reparar un aparato hay que conectarlo siempre a la

alimentación a traves de un transformador de aislamiento.

– Cuando un aparato está en marcha no pueden ser cambiados

módulos u otras piezas de repuesto.

– Para los ajustes hay que utilizar exclusivamente herramientas

de plástico (nunca herramientas metálicas). Así se evitaran

cortocircuitos y circuitos inestables.

E

!

Notas

– Hay que medir las tensiones continuas y los oscilogramas

contra la masa del aparato.

UITZONDERING:

Bij het netgedeelte zijn de gelijkspanningen en oscillogrammen

aan de primaire kant tegen Live GND gemeten.

– Las tensiones continuas y los oscilogramas mencionados en

los esquemas tienen que ser medidos de manera siguiente:

señal barra de color portadora de imagen en 503.25MHz (C25)

– Los oscilogramas y las tensiones continuas son medidas en

„RECORD“ y „PLAYBACK“

– Los componentes mencionados en las listas se los puede

cambiar por los componentes en el aparato, a pesar de

eventuales designaciones de tipos.

1-8

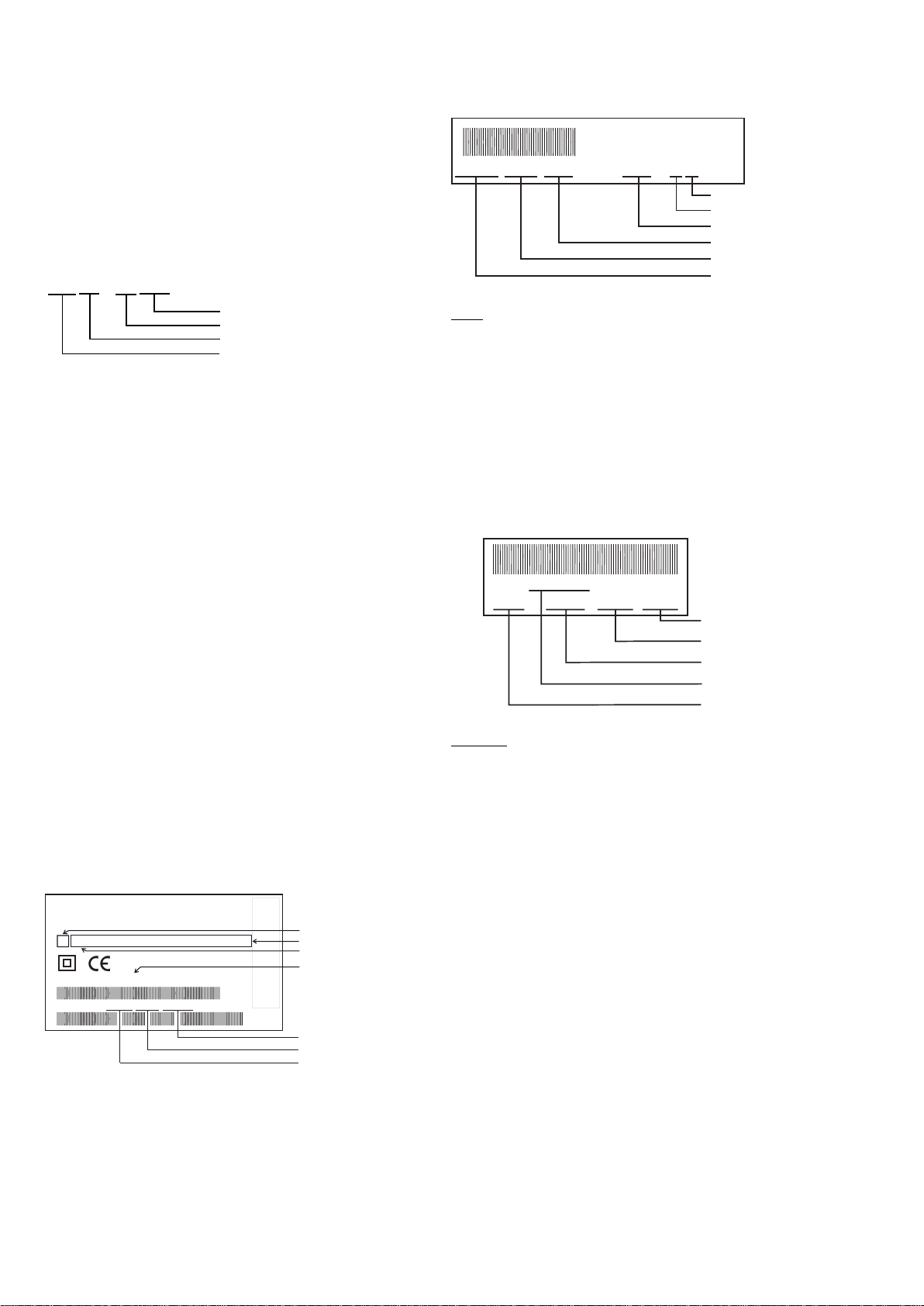

Modifications

Description of the system used for publishing

modification data and supplements to the

service manual.

All modification data and supplements to the Service Manual are

published by means of Service Information bulletins.

Each Service information has a number, for example :

VR 00 - 01 GB

Language

Sequence number

Y ear

Video cassette recorder

A Service Information bulletin concists of a front sheet, as the case

may be followed by supplementary and/or replacement sheets.

Replacement sheets serve to replace existing sheets in the Service

Manual. These sheets are identified by an additional letter after the

page number, for example 5-1a. Page 5-1a then takes the place of

page 5-1.

Supplementary sheets are inserted between the existing sheets in

the Service Manual. These sheets can be identified by an additional

figure following the page number, for example 5-1-1.

Sheet 5-1-1 should be inserted after page 5-1.

Description of the system by means of which

modifications are indicated in the recorder.

All important parts of the recorder, such as tape deck, p.c. boards

and modules, are provided with a sticker. These stickers specify a

number of product data. The meaning of this data will now be

explained for the most important sections.

Tape deck

12345678 009271 AT-P2/0 00151 10WD51

Production code

Factory indication

Production date

T ape deck type

Factory code number

Serial number

Note :

The production code and the serial number on the tape deck need

not correspond to the production code and the serial number on the

type plate.

Printed panels

The stickers are generally located on the track side of the module.

Example :

AVR 01102

12345 KW 015 WD 01 123456

Serial number

Production code

Production week

Printed board name

Factory code

Remarks :

The complete recorder

The type plate is located at the back of the recorder, below an

example of such a type plate is given.

Type plate :

.FOR BY GEMSTARDEVELOPMENT CORP.

P

D

D

R

E

IE

.GEMSTARDEVELOPMENT CORP.

O

MADE IN EUROPEMADE IN EUROPE

220-240 V ~220-240 V ~

AAA BBB CCC DDD EEE FFF GGG

AA

S

MODEL NO:MODEL NO:

PROD.NO:PROD.NO:

VN 37 0015 123456VN 37 123456

50Hz50Hz

VR110/02

Note :

- In the case of an important modification to the recorder the

production code on the type plate is increased by one.

E.g. 37 becomes 38.

- In the case of an important modification to the service

documentation the evolution code on the type plate is increased

by one.

E.g. AA becomes AB.

R

P

L

C

U

P

R

T

T

P

O

C

N

A

C

A

E

M

T

K

F

M

Service

O

N

R

U

P

R

E

A

N

F

O

A

M

M

L

Option codes (A-G)

E

P

E

E

S

O

D

V

N

L

IS M

A

E

E

E

Evolution code

R

D

M

V

IC

E

E

R

L

T

AT

D

A

R

S

T

E

R

Y

S

IS

Type number

D

A

S

M

T

W

N

E

S

W

UNDER LICENSE FROM

U

IE

M

G

IE

V

E

Y

V

W

G

B

W

O

O

R

H

H

S

SHOWVIEW IS A TRADEMARK APPLIED

O

S

SHOWVIEW SYSTEM IS MANUFACTURED

F

Serial number

Production date

Production center (VN),

Production code

The production code number will not always be mentioned.

In case of an important modification, the last figure of the factory code

number (point number) is increased by one. E.g. 6635.1 becomes

6635.2.

GB

1-9

GB D

F

TECHNICAL DATA TECHNISCHE DATEN CARACTERISTIQUES

Mains voltage.................................. Netzspannung ...................................... Tension secteur ............................. 220 - 240 V, +/- 10%

Mains frequency ............................. Netzfrequenz ....................................... Fréquence...................................... 45 - 65 Hz

Power consumption: ...................... Leistungsaufnahme:.............................. Puissance absorbée: ..................... mono 12.5 W during operation

HiFi 16 W during operation

without Low Power Standby...... Standby................................................ mode veille normal ........................ mono 4 W during standby

HiFi 4.4 W during standby

with Low Power Standby ........... Standby mit geringem Verbrauch ........ mode veille faible consommation .. < 4 W standby

Ambient temperature ...................... Raumtemperatur .................................. Température ambiante .................. +10°C to +35°C

Relative humidity ............................ Relative Luftfeuchtigkeit ...................... Humidité relative ............................ 20 - 80 %

Dimensions ..................................... Abmessungen ...................................... Encombrement .............................. 380 x 260 x 94 mm

Weight............................................. Gewicht ................................................ Poids .............................................. 3,7 kg

Fast forward/rewind time (turbo) ... Vor-/Rückspulzeit (turbo) ..................... Temps (re-)bobinage (turbo) ......... typ. 100s (E180 cass.)

Position of use ................................ Betriebslage ......................................... Position d'emploi ........................... horizontally, max. 15°

Video resolution .............................. Video-Auflösung .................................. Puissance absorbée ...................... ≥240 lines

Audio............................................... Audio.................................................... Audio SP: Linear Audio ................. 80Hz - 10kHz (+/−6 dB)

Audio LP: Linear Audio.................. 80Hz - 5kHz (+/−6 dB)

Stereo FM Audio............................ 20Hz - 20kHz (+/−3dB)

NL E I

TECHNISCHE GEGEVENS DATOS TECNICOS DATI TECNICI

Netspanning.................................... Tensión de red ..................................... Tensione di alimentazione............. 220 - 240 V

Netfrequentie .................................. Frecuencia de red ................................ Frequenza di rete .......................... 45 - 65 Hz

Opgenomen vermogen: .................. Consumo de potencia:......................... Potenza assorbita: ......................... mono 12.5 W during operation

HiFi 16 W during operation

zonder Low Power Standby ...... sin standby de bajo consumo .............. in attesa non a basso consumo .... mono 4 W during standby

HiFi 4.4 W during standby

met Low Power Standby ........... con standby de bajo consumo............. in attesa a basso consumo............ < 4 W standby

Omgevingstemperatuur .................. Temperatura ambiente ........................ Temperatura ambiente .................. +10°C to +35°C

Relatieve vochtigheid ..................... Humedad relativa ................................ Umiditá relativa .............................. 20 - 80 %

Afmetingen...................................... Dimensiones ........................................ Dimensioni ..................................... 380 x 260 x 94 mm

Gewicht ........................................... Peso ..................................................... Peso ............................................... 3,7 kg

Vooruit/terugspoeltijd (turbo) .......... tiempo de (re-)bobinado (turbo) .......... Tempo di (ri-)avvolgimento (turbo) typ. 100s (E180 cass.)

Gebruikspositie ............................... Posición de uso ................................... Posizione di funzionamento .......... horizontally, max. 15°

Opplossend vermogen ................... Resolución video ................................. Risoluzione video .......................... ≥240 lines

Audio............................................... Audio.................................................... Audio SP: Linear Audio ................. 80Hz - 10kHz (+/−6 dB)

Audio LP: Linear Audio.................. 80Hz - 5kHz (+/−6 dB)

Stereo FM Audio ............................ 20Hz - 20kHz (+/−3dB)

Euroconnector (AV1) SCART plug 1

Connection to TV, monitor, projection TV ...

Pin 1 ARO (audio right out) 500 mV

Pin 2 ARI (audio right in) 0,2 V

Pin 3 ALO (audio left out) 500 mV

Pin 6 ALI (audio left in) 0,2 V

Pin 7 Blue (out) **)

Pin 8 Switching output: (with R

low: 2 V

+/- 3 dB R

rms

to 2V

rms

+/- 3 dB R

rms

to 2 V

rms

= 10kOhm, C

load

rms

rms

1 kOhm

out

Rin 10 kOhm

1 kOhm

out

Rin 10 kOhm

< 2nF)

load

high: 9.5 V

rise time: 5 ms

Pin 11 Green (out) **)

Pin 15 Red (out) **)

Pin 16 Blanking (out) **) loop through enabled during

standby, view-mode

Pin 19 CVBS II (video out) 1 Vpp +1/-2dB R

Pin 20 CVBS I (video in) 1 Vpp +3/-3dB Rin 75 Ohm

75 Ohm

out

**) passive loop through from AV2

Cinch Audio/Video input on front panel (OPTION)

Audio:

AINFR (audio right in) red 0.2 V

AINFL (audio left in) white 0.2 V

Input impedance 47 kOhm

to 2 V

rms

to 2 V

rms

typ. 500 mV

rms

typ. 500 mV

rms

rms

rms

Video:

VFR yellow 1 Vpp + 3 / -3 dB

Input impedance 75 Ohm

Cinch Audio Out Rear (OPTION)

AOUT1R (audio right out) red 500 mV

AOUT1L (audio left out) white 500 mV

This outputs are in parallel with the corresponding outputs on

Euroconnector 1.

+/- 3 dB R

rms

+/- 3 dB R

rms

1 kOhm

out

1 kOhm

out

Euroconnector (AV2) SCART plug 2

Connection to decoder, SAT tuner, video disc, 2nd VCR ....

Pin 1 ARO (audio right out) 500 mV

Pin 2 ARI (audio right in) 0,2 V

Pin 3 ALO (audio left out) 500 mV

Pin 6 ALI (audio left in) 0,2 V

Pin 7 Blue (in) *)

Pin 8 Switching input only low: 2 V (low) Rin 10 kOhm

high: 4.5 V (high) R

Pin 11 Green (in) *)

Pin 15 Red (in) *)

Pin 16 Blanking (in) *) loop through enabled during

standby, view-mode

Pin 19 CVBS II (video out) 1 Vpp +1/- 2dB R

Pin 20 CVBS I (video in) 1 Vpp +3/-3 dB Rin 75 Ohm

*) passive loop through to Euroconnector AV1

+/- 3 dB R

rms

to 2 V

rms

+/- 3 dB R

rms

to 2 V

rms

rmsRin

rmsRin

1 kOhm

out

10 kOhm

1 kOhm

out

10 kOhm

10kOhm

in

75 Ohm

out

TUMOD

Modulator:

Frequency range loop through 45 MHz - 860 MHz

Gain: ANT IN - TV OUT 2 dB + 3 / -2 dB

ANT IN - TUN OUT 2 dB + 3 / -2 dB

Switch for RF input attenuation NO

Frequency range out (tuned by IIC bus) Ch 21 - Ch55

Tuner:

Frequency range 43 MHz - 860 MHz

for UK 450 MHz - 860MHz

Input voltage max. < 100 dBµV

min. > 60 dBµV

2-1

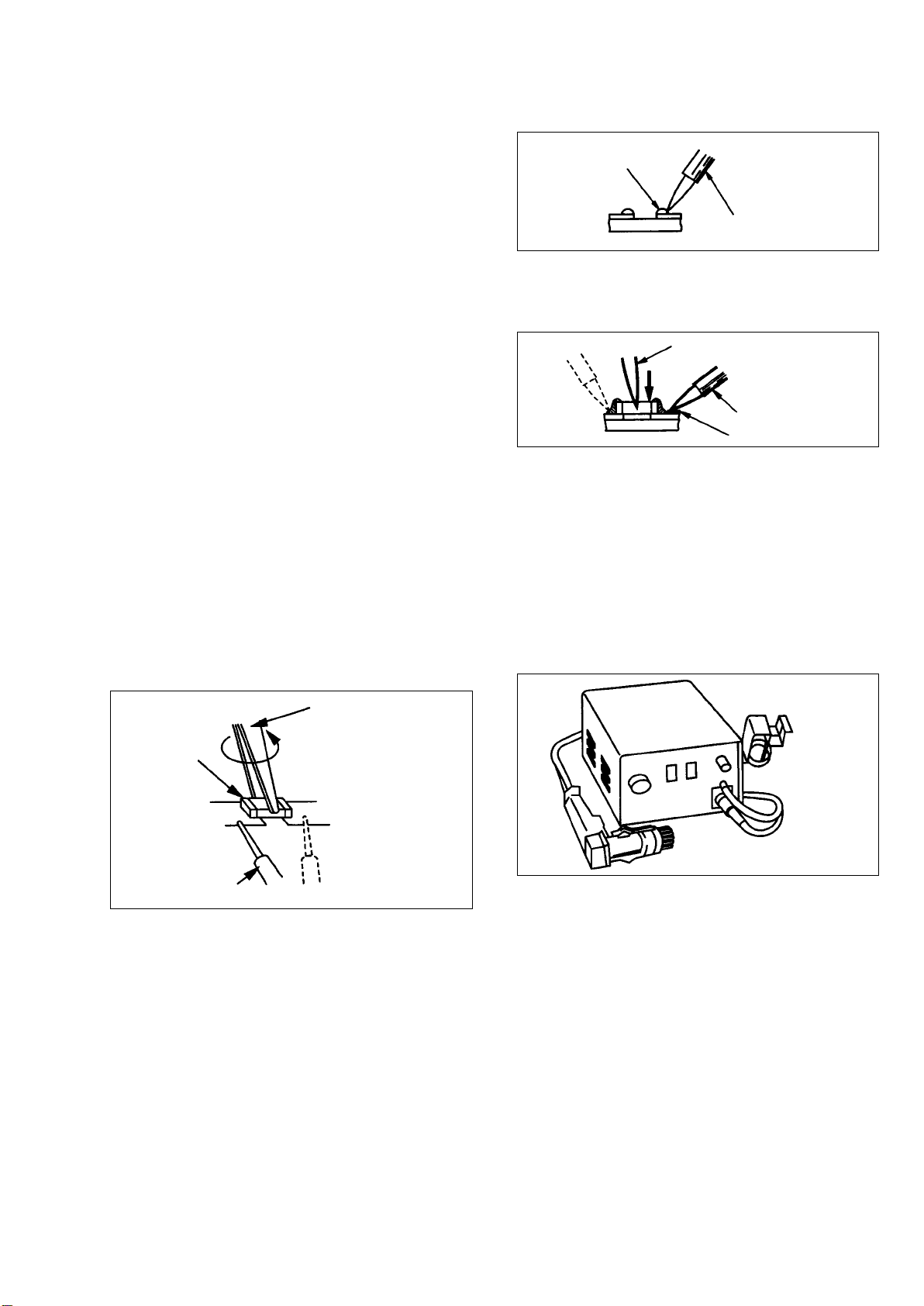

TOOLS FOR ERROR DIAGNOSIS

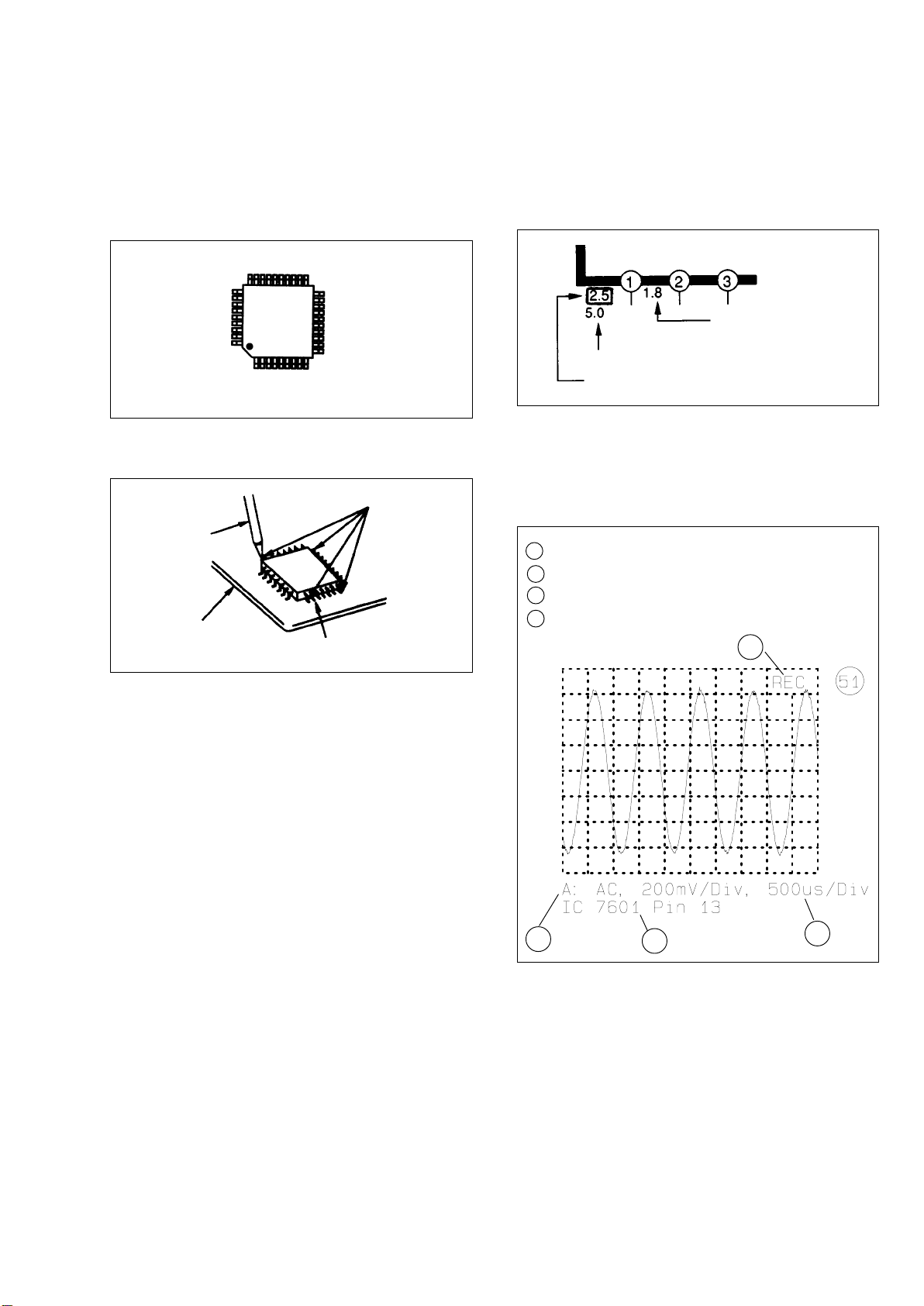

Replacement procedure for leadless

components (chip)

The following procedures are recommended for replacing leadless

components used in this unit.

1. Preparation for replacement

a. Soldering iron

Use a pencil-type soldering iron that uses less than 30W.

b. Solder

Use Eutectic solder

(Tin 63%, Lead 37%)

c. Soldering time

Maximum 4 seconds.

Note:

a. Leadless components must not be re-used after removal.

b. Excessive mechanical stress and rubbing of the component

electrode must be avoided.

2. Removing the leadless components

Grasp the leadless component body with tweezers and alternately

apply heat to both electrodes. When the solder on both electrodes

has melted, remove leadless component with a twisting motion.

Note:

a. Do not attempt to lift the component off the board until the

component is completely disconnected from the board with a

twisting motion.

3. Installation of leadless components

a. Presolder the contact points on the circuit board.

Presolder

Soldering iron

Fig. 2-2

b. Using tweezers press down the part and solder both electrodes

as shown below.

Tweezers

Soldering iron

solder

Fig. 2-3

Note:

Do not glue the replacement component to the circuit board.

How to remove/install the FLA T PACK IC

1. How to remove the Flat Pack IC

• Using a hot air Flat Pack IC unsoldering equipment

b. Be careful not to break the copper foil on the printed circuit

board.

Tweezers

Chip

Soldering iron

Fig. 2-1

EXAMPLE

Fig. 2-4

GB

2-2

a. Prepare the hot air Flat Pack IC unsoldering equipment. Then

apply hot air to Flat Pack lC for 5 - 8 seconds.

b. Remove the Flat Pack lC with tweezers while applying the hot

air.

CAUTION:

To avoid damage, do not apply the hot air to the chip parts around

the Flat Pack lC for long periods.

C.B.A.

Masking

tape

Tweezers

Fig. 2-5

Put masking tape around the Flat Pack lC to protect adjacent parts.

2. The Flat Pack IC is fixed to the P.C.B. with glue; therefore take

care not to break or damage any foil under the lC or on each pin

when removing it.

Hot air Flat Pack

IC unsoldering

equipment

FLAT PACK IC

b. Lift up each lead of the Flat Pack IC individually, using a sharp

pin or non-solder wire (iron wire), while heating the pins using a fine

tip soldering iron or a hot air blower.

Sharp pin

Soldering iron

Fig. 2-7

• Using iron wire

a. Use unsoldering braid to remove the solder from all pins of the

Flat Pack IC. Apply solder flux to all pins of the Flat Pack IC, to

allow easy removal.

b. Affix the wire to workbench or solid mounting point (see Fig. 2-8)

c. Pull up the wire as the solder melts in order to lift the IC lead from

the P.C.B. contact pad, while heating the pins using a fine-tip

soldering iron or hot air blower.

• Using a soldering iron

a. Use unsoldering braid to remove the solder from all pins of the

Flat Pack IC.

Apply solder flux to all pins of the Flat Pack IC, to allow easy

removal.

FLA T P ACK

IC

Unsoldering

braid

Soldering iron

Fig. 2-6

Hot air

blower ...

Pull up gently

to remove

Fig. 2-8

Note:

When using a soldering iron care must be taken to ensure that the

Flat Pack lC is not held by glue or the P.C.B. may be damaged if

force is used.

If the IC is glued, heat the IC with hot air to loosen the glue.

Solid mounting

point

Iron wire

... or soldering iron

GB

2-3

2. How to install the FLA T PACK IC

a. Use unsoldering braid to remove the solder from the foil of each

pin of the Flat Pack lC on the P.C.B. in order to install the

replacement Flat Pack IC more easily.

b. The “•” mark on the Flat Pack IC indicates pin 1.

Make sure this mark matches the 1 on the P.C.B. when positioning

for installation. Then pre-solder the four corners of the Flat Pack IC.

(see Fig. 2-9).

EXAMPLE

Pin 1 on FLAT PACK IC is marked by a "•".

Fig. 2-9

Presolder

Soldering iron

C.B.A.

FLA T P ACK

IC

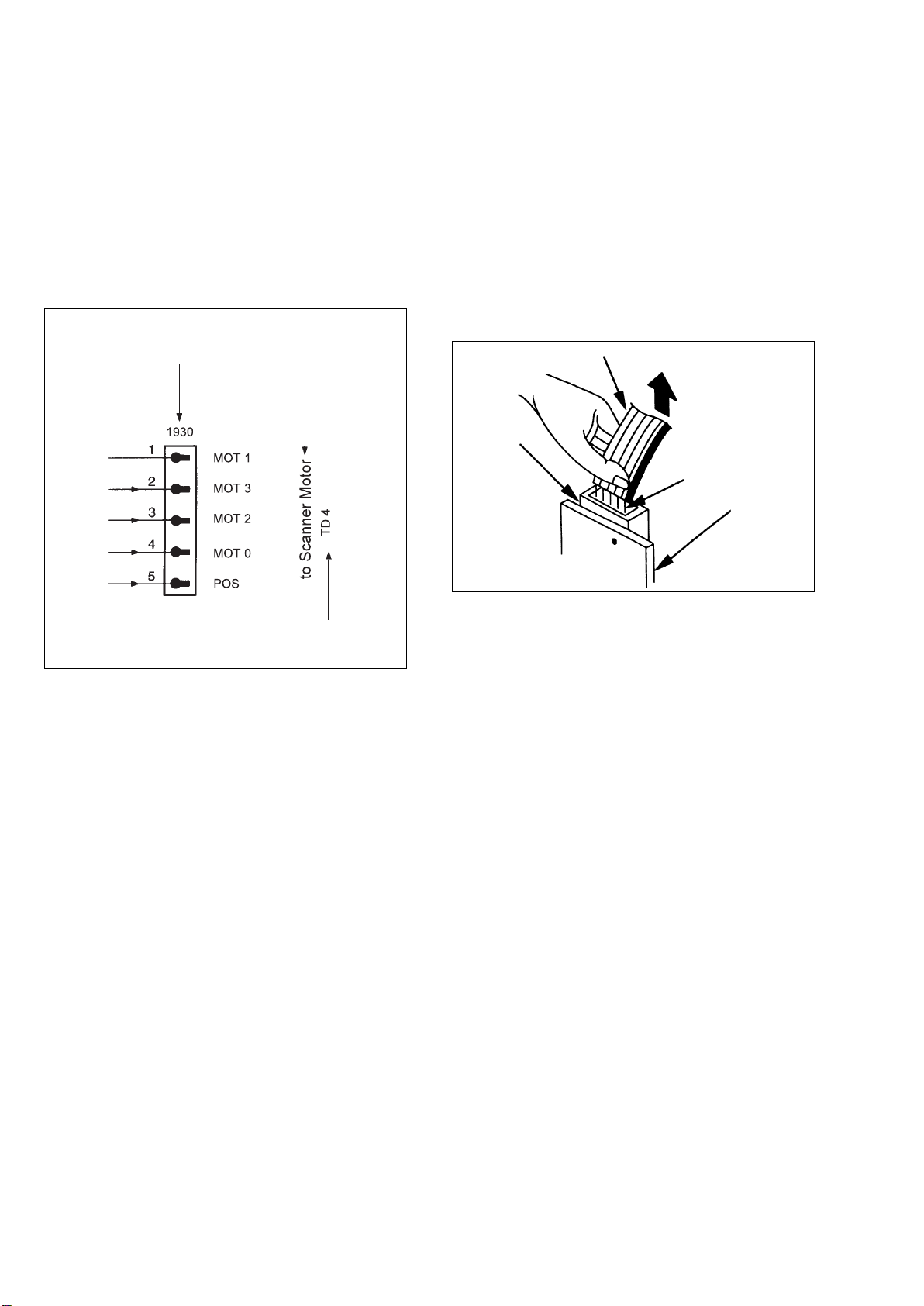

V oltage measurements

Color bar signal in SP REC and PB modes.

Note:

Voltage indications for the REC. and PB mode on the schematic

diagrams are shown below:

REC. and PLAY mode

(Identical voltages for

both modes).

PLAY mode

REC. mode

Fig. 2-11

How to read wave forms

1 Connecting point

2 Amplitude

3 Time base

4 Operating mode of the VCR

4

Fig. 2-10

c. Solder all pins of the Flat Pack IC. Make sure that none of the

pins have solder bridges between pins on the Flat Pack IC.

Note

All integrated circuits and many other semiconductor devices are

electrostatically sensitive and therefore require the special

handling techniques described in the “SAFETY INSTRUCTIONS”

section of this manual.

2

1

Fig. 2-12

3

Voltage indication of Zener diodes

The Zener voltage of Zener diodes is indicated as such on

schematic diagrams:

Example:

BZX79C20............Zener voltage: 20 Volts

GB

2-4

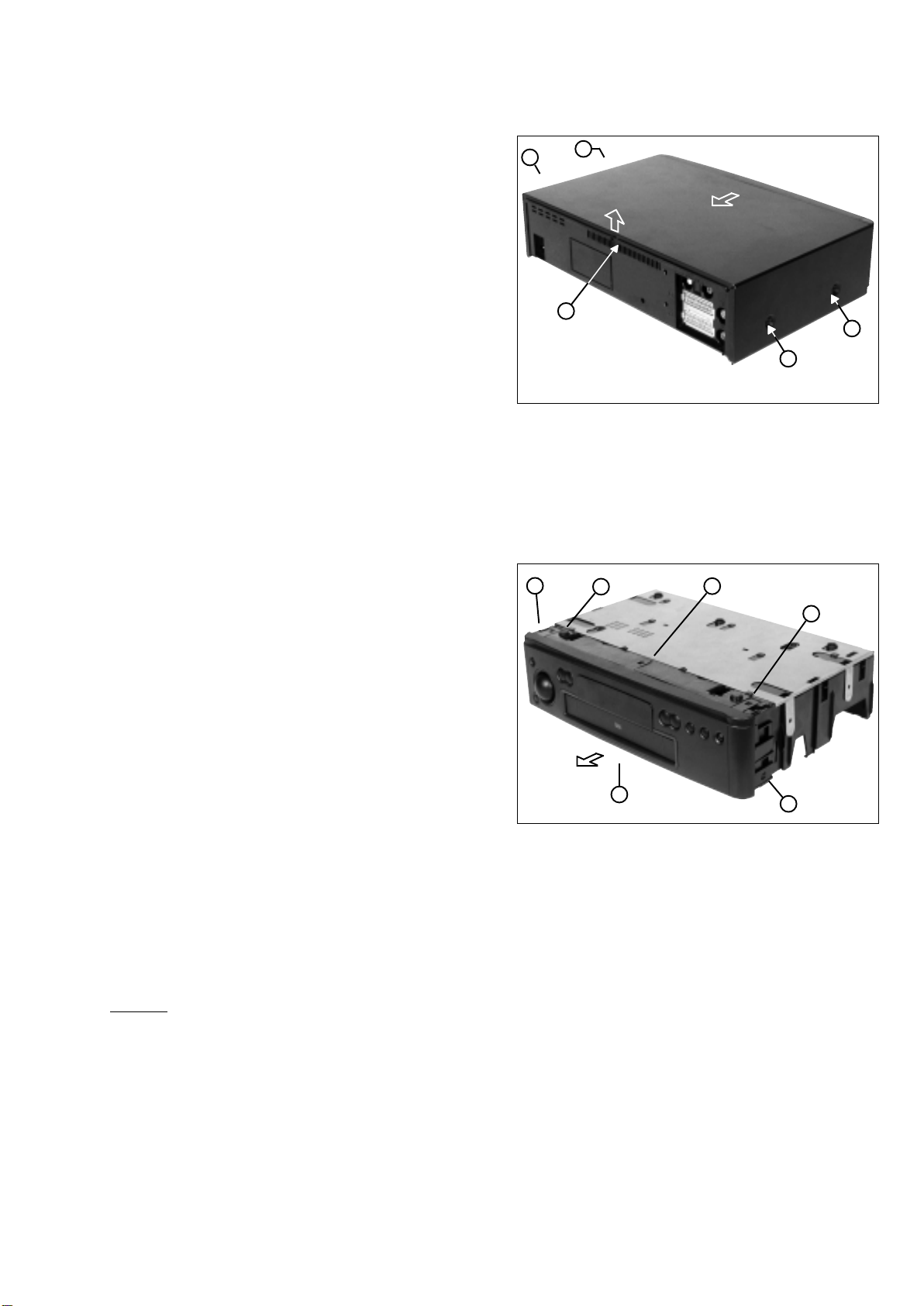

How to identify connectors on schematic

diagrams

Each connector is labeled with a connector number and a pin

number indicating to what component it is connected; in other

words, its counterpart.

Use the Connecting Wiring Diagram to find the connections

between associated connectors.

Example:

The connections between C.B.A.s are shown below:

Connector no.

and Pin no.

on PCB

PCB to which this

connector is connected

Test point information

With this model, test pin or components leads are used as contact

points for adjustment and checking. In case of other test points

with no test pin or components leads, use the foil solder pad to

connect the measuring equipment.

Removal or installation of flat cables

a. Removal

Pull out the flat cable, holding it securely to avoid damaging

individual wires (see fig. 2-14).

Flat cable

PULL

Connector

Pin 1

Board

Fig. 2-13

Connector no. to which

the left connector is

connected

1

Fig. 2-14

b. Installation

1. Adjust the position of the flat cable so that the lines on the flat

cable align with the pins X of the trap connector (see fig. 2-14).

2. Align individual wires with its individual trap connector

hole. Then insert the flat cable wire into the trap

connector.

CAUTION: After installation, inspect the connection to

insure that individual wires are not bent or touching other

wires.

GB

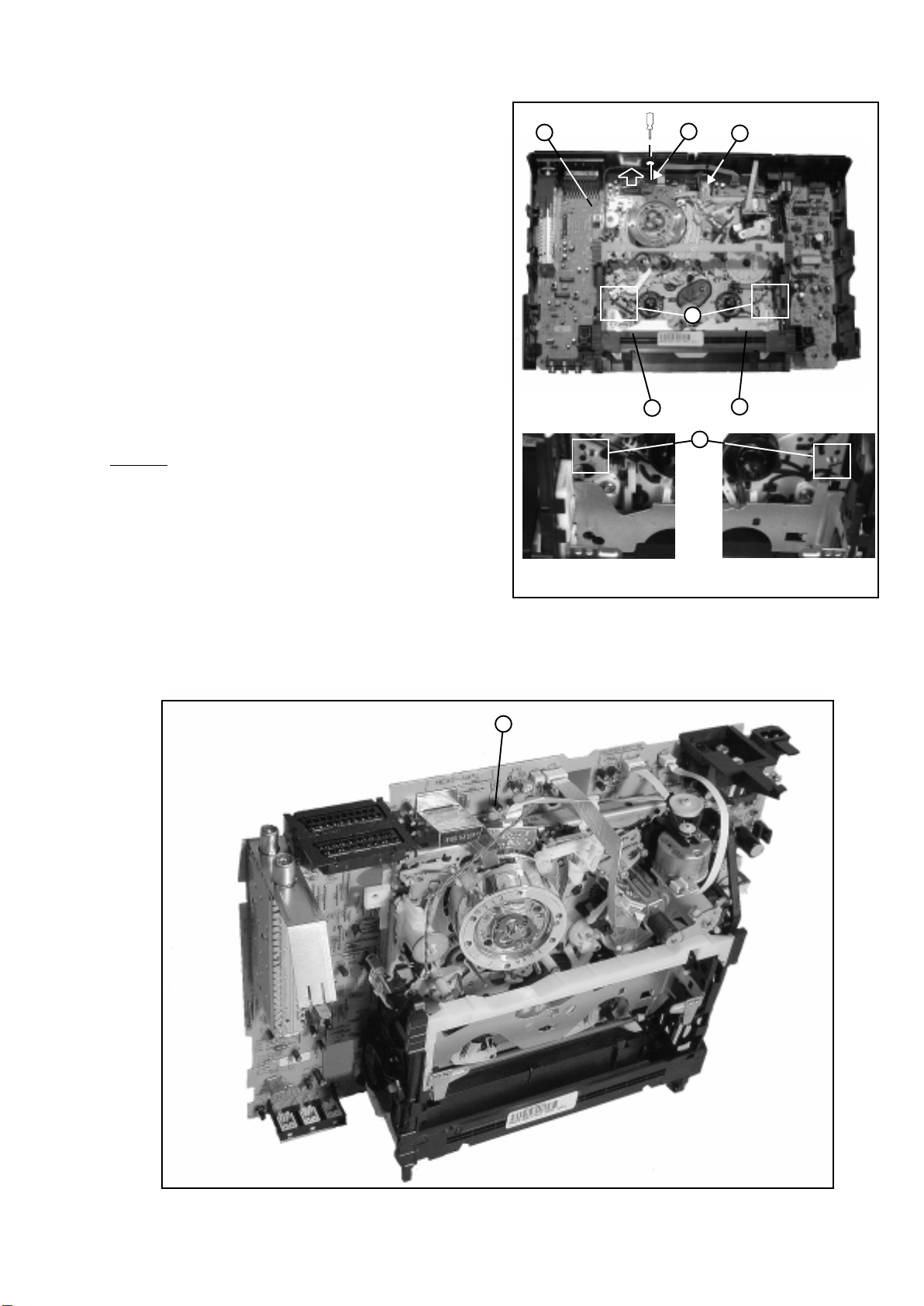

Dismantling instructions

2-5

General guidelines for dismantling housing

components, electronic parts and the drive

mechanism

Always disconnect from mains before dismantling or

assembly.

Due to the supply voltages (hot circuit) on the primary

side of the switched-mode power supply, an isolating

transformer is required for the operation of the device.

The drive or the drive/motherboard unit must not be

pulled out by the cross struts!

Components placed below the tape deck has to be

inserted exactly.

The use of a regulating isolating transformer is

recommended for detecting faults around the power

supply.

All screws of the video recorder can be removed or

tightened with a 10* torx screwdriver .

1. Housing cover (Fig. 1)

- Remove the four screws (A).

- Push catch (S) inwards, lifting lid at the same time to move out

of groove.

- Slide housing cover back by approx. 1 cm.

- Push centre of housing cover sides on underside approx. 1 cm

outwards and lift up the housing cover.

Assembly

Assemble in reverse order.

A

ä

Fig. 1

S

ä

S

ä

A

ä

A

A

S

S

S

ä

ä

2. Base plate (Fig. 2)

The base plate may not be removed from the frame!

3. Front panel (Fig. 2)

Preparation

Dismantle the housing lid as described in section 1.

- Position the device with the base plate facing upwards.

- Undo the six catches (S) one after the other, starting from the

left or the right.

- Remove the front panel by pulling it forwards.

- For devices with shuttle print or socket print, disconnect the

cabling to the motherboard.

Assembly

Assemble in reverse order (device in operational position).

Important

- The lift flap lever should be connected to the lift flap guide.

- Check that all catches are engaged.

Fig. 2

ä

S

ä

S

* …available from dealers

GB

2-6

4. Dismantling of the motherboard/drive

combination (Fig. 3) (Fig. 4)

Preparation

Remove the housing cover as described in section 1.

Remove the front panel as described in section 3.

- Move device into operational position (Fig. 3).

- Undo the two screws (B) of the stay and pull it up to remove it.

- Push back the lift by 5 cm after releasing both lift stops.

- Undo and remove the four fastening screws (C) of the drive.

- Detach the Cinch socket cable (K) and ground cable (M) from

the socket print (if present).

- Remove the cables (K1; K2; K3) from the guides on the rear of

the frame.

- Pull the Cinch socket holder with the socket and print up and

out of the frame (if present).

- Position the device with the base plate facing up.

- Undo the 8 catches (S) from the rear right to the rear front and

then from the rear left to the front left.

- After the weight of the motherboard/drive unit has released it

from the frame, the catch (S) at the mains socket has to be

released for a second time.

- The frame can be removed by lifting it off.

- Turn the motherboard/drive unit and move it into the service

position (Fig. 5), if necessary.

The device is operational in this position

”Eject” must NOT be used !!!

M/K

ä

B

ä

K1

C K2 K3

ä

ä

C

ä

ä

C C B

Lift protection

ä

ä

ä

Caution:

Adjustments can not be made in the service position.

”Eject” must NOT be used !!!

Assembly

- Position the frame with the top open onto a level surface.

- Hold the drive on the side at the lift and insert the motherboard/

drive unit into the frame, pushing it down lightly. Observe that

the power supply and Scart sockets are positioned in

openings.

- Check that all 8 catches (S) are engaged.

- Secure the drive with the four holding screws (C).

- Move the lift into the ”Eject” position.

- Push the stay onto the frame with the chamfered side facing to

the rear and secure with both screws (B).

- Insert the Cinch socket into the opening and ensure that it

engages.

- Connect the Cinch socket and the ground cable (K ; M)

(if present).

- Insert the cables (K1; K2; K3) into the supports provided in

the frame.

- Replace the front panel and the housing cover.

Fig. 3

ä

ä

ä

ä

SS

ä

GB

Fig. 4

ä

ä

5. Dismantling the drive (Fig. 3)(Fig. 5)(Fig. 6)

Preparation

Remove the housing cover as described in section 1.

Remove the front panel as described in section 3.

- Undo the two screws (B) of the stay and pull it up to remove it.

- Push back lift by 5 cm after releasing both lift stops.

- Undo and remove the four fastening screws (C) of the drive.

- Undo and remove the ground screw (D) at the rear.

(For this purpose, insert the screwdriver through the hole in the

back panel).

- Remove the cables from the drive.

- Bend back the guard of the scanner cable.

- Remove the scanner cable from the socket.

- Return the lift into the ”Eject” position.

- Slightly lift the left rear side of the drive to undo the connector

to the capstan motor.

- Press both catches (S) together with fine pliers and lift the drive

around the snapholders.

- The drive may be separated from the motherboard.

Assembly

Assemble in reverse order.

Important

Observe that the cables (K1; K2; K3) are positioned in the

supports on the rear of the frame and that the ground

screw (D) is screwed in!

C

Fig. 6

ä

ä

C

2-7

D

C

S

ä

C

S

Fig. 5

Service position

D

ä

GB

2-8

Circuit descriptions

1. Switched-mode power supply PS (PS Part) ................................................................................................................................................9

1.1 Technical data:................................................................................................................................................................................................9

1.2 Functional principle: .......................................................................................................................................................................................9

1.3 Supply voltage part.........................................................................................................................................................................................9

1.4 Start-up with Mains-on: ..................................................................................................................................................................................9

1.5 Normal mode: .................................................................................................................................................................................................9

1.6 Overload, power limitation, burst mode: ......................................................................................................................................................10

1.7 Standby mode: .............................................................................................................................................................................................10

2. Operating unit DC (DC part) ........................................................................................................................................................................10

2.1 Evaluation of the keyboard matrix................................................................................................................................................................10

2.2 IR receiver and signal evaluation .................................................................................................................................................................10

2.3 Activation and function of the VFD display ..................................................................................................................................................10

3. Central Control AIO (AIO part) .................................................................................................................................................................... 11

3.1 Analogue interface to the µC:.......................................................................................................................................................................11

3.2 Tape end - LED control : ............................................................................................................................................................................... 11

3.3 CMT detection (video detection with CSYNC) ............................................................................................................................................. 11

3.4 EE-PROM ..................................................................................................................................................................................................... 11

3.5 Easy link (P50) .............................................................................................................................................................................................11

3.6 Shuttle: .........................................................................................................................................................................................................11

3.7 Satmouse...................................................................................................................................................................................................... 11

4. Deck electronics DE (DE part) ....................................................................................................................................................................11

4.1 CTL stage .....................................................................................................................................................................................................11

4.2 Power on reset (POR) generator ................................................................................................................................................................. 12

4.3 The sensor interface :...................................................................................................................................................................................12

4.4 Interface to the head drum motor driver part ............................................................................................................................................... 12

4.5 Interface to the loading motor driver part:....................................................................................................................................................12

4.6 Interface to the capstan motor .....................................................................................................................................................................12

5. Front end FV (FV part) .................................................................................................................................................................................13

5.1 The front end comprises the following parts : ..............................................................................................................................................13

5.2 The front end has been designed to receive the following systems:...........................................................................................................13

5.3 Tuner modulator (TUMOD) ...........................................................................................................................................................................13

5.4 IF selection ...................................................................................................................................................................................................13

5.5 IF demodulator .............................................................................................................................................................................................13

5.6 Audio demodulator .......................................................................................................................................................................................13

6. Video signal processing VS (VS part) ........................................................................................................................................................13

6.1 Switchover functions in the signal electronics IC LA71595M [7004]: ..........................................................................................................13

6.2 Recording : ...................................................................................................................................................................................................14

6.2.1 Luminance .................................................................................................................................................................................................14

6.2.2 Chrominance PAL......................................................................................................................................................................................14

6.2.3 MESECAM ................................................................................................................................................................................................14

6.2.4 SECAM L ...................................................................................................................................................................................................14

6.2.5 FM signal ...................................................................................................................................................................................................14

6.3. Playback: ..................................................................................................................................................................................................... 15

6.3.1 FM signal ...................................................................................................................................................................................................15

6.3.2 Luminance .................................................................................................................................................................................................15

6.3.3 Chroma PAL ..............................................................................................................................................................................................15

6.3.4 Chroma MESECAM...................................................................................................................................................................................15

6.3.5 Chroma SECAM L .....................................................................................................................................................................................15

6.3.6 NTSC .........................................................................................................................................................................................................15

6.3.7 PAL M,N.....................................................................................................................................................................................................15

6.4 General .........................................................................................................................................................................................................15

7. Audio linear (AL part)...................................................................................................................................................................................16

7.1 Audio I/O for the 1-scart version...................................................................................................................................................................16

7.2 Audio I/O for the 2-scart version...................................................................................................................................................................16

7.3 Audio linear recording...................................................................................................................................................................................16

7.4 Audio linear playback....................................................................................................................................................................................16

7.5 Audio linear muting.......................................................................................................................................................................................16

8. Audio HiFi - for stereo units (AF part)........................................................................................................................................................16

8.1 General .........................................................................................................................................................................................................16

8.2 Audio I/O .......................................................................................................................................................................................................16

8.3 Audio HiFi recording .....................................................................................................................................................................................16

8.4 Audio HiFi playback......................................................................................................................................................................................16

8.5 Interface to the audio linear..........................................................................................................................................................................16

9. IN/OUT (IO part) ............................................................................................................................................................................................17

9.1 Video:............................................................................................................................................................................................................17

9.1.1 Audio for the 2-scart version: ....................................................................................................................................................................17

9.2 Decoder mode: (REC or STOP)...................................................................................................................................................................17

9.2.1 Program position with decoder (front end)................................................................................................................................................17

9.2.2 External input with decoder .......................................................................................................................................................................17

10. Follow Me (FOME part) ..............................................................................................................................................................................17

11. VPS/PDC, on-screen display (VPO part) ..................................................................................................................................................17

11.1 VPS/PDC ....................................................................................................................................................................................................17

11.2 OSD-PART..................................................................................................................................................................................................17

GB

2-9

1. Switched-mode power supply PS (PS Part)

1.1 Technical data:

Mains voltage: 195-264 V

Maximum output: 15W / 40W (continuous / maximum output)

Operating frequency:40 kHz

Efficiency: approx. 75 % at maximum output

Six different direct voltages are supplied on the power supply

outputs.

1.2 Functional principle:

This power supply functions in a similar way to a blocking oscillator.

In the supply voltage part [1300 to 2318], the mains voltage is

rectified and buffered in the capacitor [2318]. From this direct

voltage [2318] energy is transferred into the transformer [5301,

pins 1-3] during the conductive phase of the switching transistor

[7302] and is stored there as magnetic energy. This energy is

passed to the secondary outputs on the power supply in the in the

blocking phase of the switching transistor [7302]. With the switchon time of the switching transistor [7302], the energy transferred in

every cycle is regulated in such a way that the output voltages

remain constant regardless of changes in the load or input

voltages. The power transistor is activated using the integrated

switch [7303] Fig.1.

1.3 Supply voltage part

The supply voltage part extends from the mains socket [1300] to

the capacitor [2318]. Using the diodes [6310, 6311, 6312 and 6313]

the a.c. supply voltage is rectified and buffered using the capacitor

[2318]. The line reactor [5305] and capacitor [2316] create a filter to

keep interference arising in the power supply away from the mains.

Components [1302], [3326] and [3323] protect the power supply

against short-term overvoltages in the mains, e.g. caused by

indirect effects from lightning.

MC44608

start - up

phase

200 µA

0

1

ISENSE

2

NC

7

VI

start - up

management

Vcc

management

switching phase

&

stand - by

200 µA

8

10

leading edge

blanking

rms

3318

C demag

latched off phase

start up phase

stand - by

management

+

65mV/45mV

&

PWM

comp

1

DEMAG

current mirror

current mirror

&

Fig. 1

OVP - out

1.4 Start-up with Mains-on:

Following connection to the mains, the capacitor [2310] is loaded

via the start-up resistor [3318] and a current source between pin 8

and pin 6 on the IC [7303]. Once the voltage on [2310] and

therefore the supply voltage Vcc on the IC [7303] has reached

approx. 13V, the IC starts up and issues pulses to its output on pin

5. These pulses are used to control the gate on the power transistor

[7302] (see Fig.2). The frequency has a fixed setting in the IC

(approx. 40 kHz). The current input on the IC is approx. 5 mA in

normal mode.

If Vcc drops to below approx. 10V (e.g. with power limitation) or if

Vcc exceeds around 15V (interruption of the control loop), the

output on the IC [7303, pin 5] is blocked. All output voltages on the

power supply, and therefore also Vcc, decrease. Once Vcc has

dropped to below approx. 6.5V, a new start-up cycle begins. (See

also “Overload, Power Limitation, Burst Mode“ section)

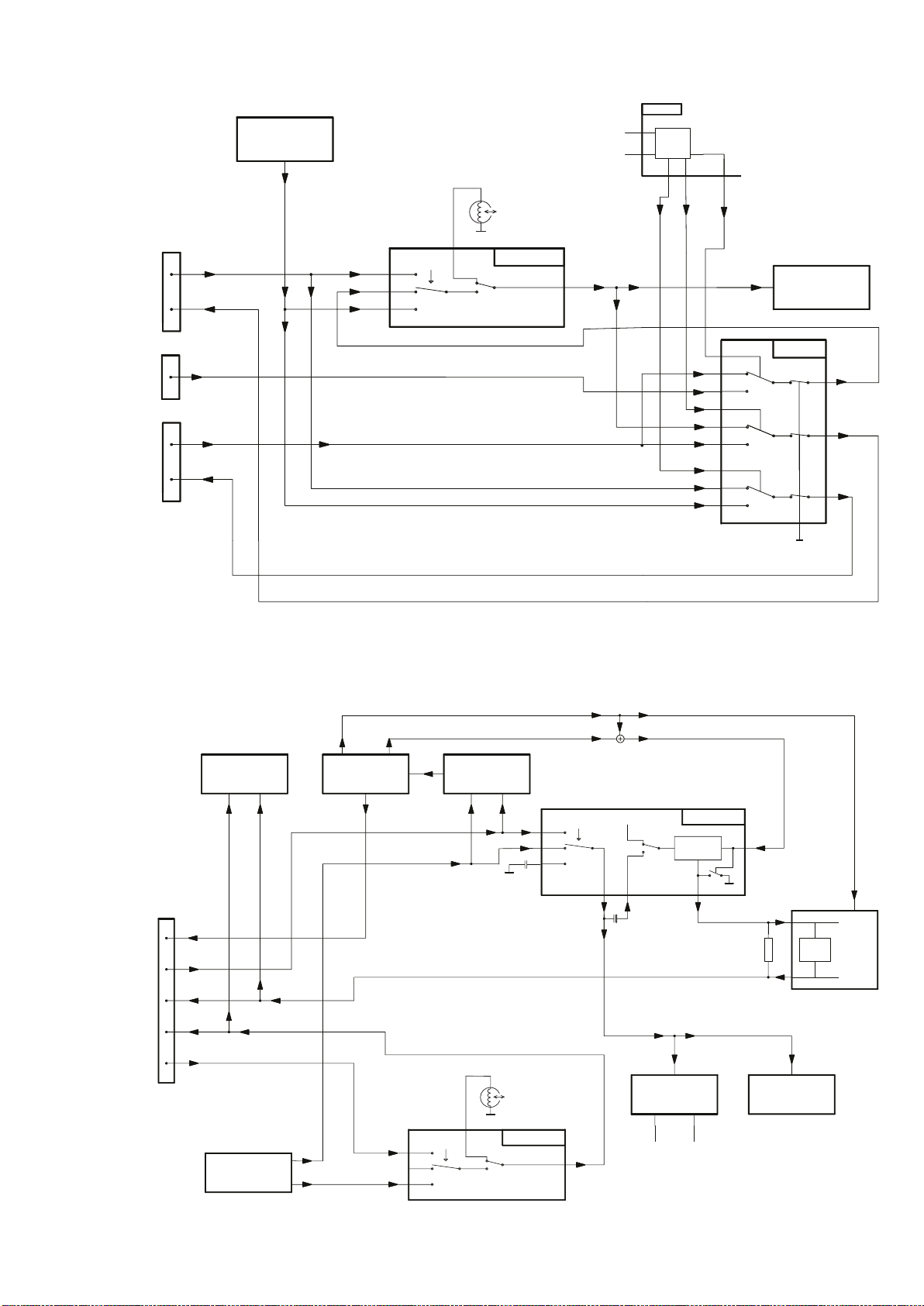

1.5 Normal mode:

With the power supply in normal mode, the periodic sequences in

the circuit are divided primarily into the conductive and blocking

phase of the switching transistor [7302]. During the conductive

phase of the switching transistor [7302], current flows from the

rectified mains voltage to the capacitor [2318] through the primary

coil on the transformer [5301, pins 1-3], the transistor [7302] and

resistors [3314, 3331] to earth (see Fig.1). The positive voltage on

pin 1 of the transformer [5301] can be assumed to be constant for a

switching cycle. The current in the primary coil on the transformer

[5301] increases linearly in the pattern of U=L*di/dt. A magnetic

field representing a certain volume of the primary current is formed

inside the transformer. In this phase, the voltages on the secondary

coils are polarised in such a way that the diodes [6300, 6301, 6306,

6308 and 6309] block. From the controller on [7301], a current is

supplied to the CTRL input on the IC [pin 3, 7303] via optocoupler

[7300]. Once the switch-on time for the switching transistor [7302]

has been reached, which corresponds to the current supplied on

the CTRL input, the switching transistor is switched off.

Once the switching transistor has been switched off, the blocking

phase begins. No more energy will be transferred into the

transformer. The inductivity of the transformer will still attempt to

maintain the current which has flowed through it (U=L*di/dt) at a

constant level. As the primary current circuit is interrupted by the

shut-off switching transistor [7302], the current will flow through the

secondary coils.

current and voltage

quick OVP

PWM

latch

stand by

UVL01

references

&

output

buffer

DRIVER

01

VCC

GND

CTRL

7300

6307

3314

7302

6304

+

6305

6

2310

5

4

3

t

regulation

block

200 µA

thermal shutdown

&

latch OFF phase

5301

GB

2-10

The polarity of the voltages on the transformer is reversed, which

means that the diodes [6300, 6301, 6306, 6308 and 6309] become

conductive and current flows into the capacitors [2301, 2305, 2309,

2311 and 2312] and the load. This current is also ramp-shaped (di/

dt negative, therefore decreasing).

The control adjustment for the switched-mode power supply is

made by changing the conductive phase of the switching transistor

(see Fig.2), so that either more or less energy is transferred from

the rectified mains voltage to [2318] in the transformer. The control

information is provided by the control element [7301]. This element

compares the 5V output voltage via the voltage dividers [3300,

3306, 3336] with an internal 2.5V reference voltage. The output

voltage from [7301] passes via an optocoupler [7300] (for the metallic isolation of the primary and secondary parts) as the current

value to pin 3 on the IC [7303]. The switch-on time for the switching

transistor [7302] is inversely proportional to the value of this

current.

1.6 Overload, power limitation, burst mode:

With an increasing load on one or more power supply outputs, the

switch-on time for the power transistor [7302] also increases, and

thus also the peak value of the delta-shaped current through this

power transistor. The equivalent voltage circuit for this current

profile is passed from resistors [3314] and [3331] via [3312] and

[3347] to pin 2 on the IC [7305]. If the voltage on pin 2 reaches 1V

in one switching cycle, the conductive phase of the switching

transistor is ended immediately. This check is made in each

individual switching cycle. This process ensures that no more than

approx. 48W can be taken out of the mains ( = power limitation ).

If the power supply reaches the power limit, the output voltages

and the supply voltage Vcc on pin 6 of the IC [7303] will be reduced

following further loading. If Vcc is less than approx. 10V at any point

during this process, the output on the IC [7303, pin 5] is blocked. All

output voltages and Vcc are reduced. Once Vcc has dropped to

below approx. 6.5V, a new start-up cycle begins. If the overload

status or short-circuit remains, the power limitation will be activated

immediately and the voltages will continue to be reduced, followed

by another start-up attempt ( Burst Mode ). The amount of power

taken up from the mains in burst mode is low.

1.7 Standby mode:

In the ‘Standby‘ operating mode on the device, the ’STBY‘ control

line is used to shut off the output voltages 14AL, 5VA and 5VD on

the power supply to minimise the amount of power taken up from

the mains. The supply to the display heating can also be switched

off using the ‘I1WSTBY‘ control line. The power supply itself will

continue to function continuously in the ‘Standby‘ operating mode

with a switching frequency of 40kHz.

U

3

= UGS

t

I

Dmax

point of reversal

t

UDS

I

D

t

Fig. 2

2. Operating unit DC (DC part)

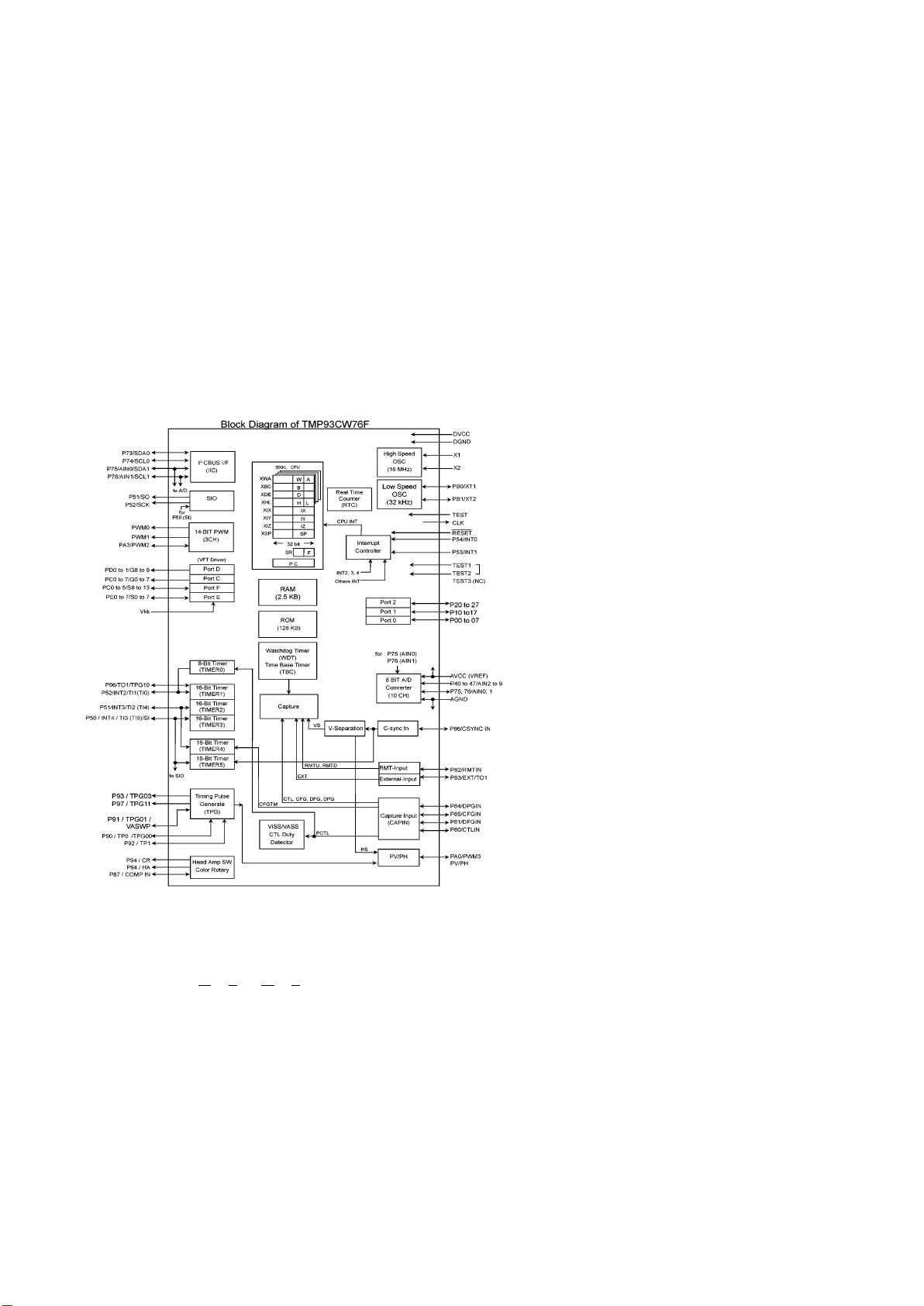

The microcontroller TMP93CT76F [7899-A] is a 16 bit

microcontroller fitted with 128Kb ROM and 2.5Kb RAM.

It is the core element of the operating unit, fulfilling the following

tasks with the respective functional groups:

• Integrated VFD driver

• Timer

• Evaluation of the keyboard matrix

• Decoding the remote control commands from the infra-red

receiver pos. 6170

• Activation of the display

• Back-up mode

In normal operation, the µP is operated in dual-clock mode, i.e.

both quartzes [1170, 1171] oscillate. The time is derived from the

slow quartz [1170] (32.768 kHz), and the fast quartz [1171]

(16MHz) is used to generate the system clock frequency.

In case of a mains failure (back-up mode) the µP is not reset, but

instead the mains failure is registered by the IPOR interrupt 3

[7899-B] (pin 67) and the µP is moved into “Sleep mode” (low

power consumption). The 16MHz quartz is turned off and the

32kHz quartz is then used as the clock and system clock frequency.

The operating voltage for the AIO is buffered by a back-up cell [pos.

2174, 2172]. A diode [6171] prevents this gold capacity from

discharging.

2.1 Evaluation of the keyboard matrix

There are 12 different keys. Each key function is assigned a fixed

voltage value. This value is decoded using an analogue/digital (A/

D) port (7899-B, pin 56). Each mechanical key position on the

printed board can adopt any key function via a coding resistor.

Pressing keys simultaneously may lead to undesired functions!

Schematic:

10K

DC-KEY

[7899-B, pin56]

100K

Y

C

B

E

T

R

S

2.2 IR receiver and signal evaluation

The IR receiver [6170] includes a selective, controlled amplifier in

addition to a photo-diode. The photo-diode changes the received

transmission (approx. 940nm) in electrical pulses, which are then

amplified and demodulated. On the output of the IR receiver [7220]

a level lift 0V/5V pulse sequence, which corresponds to the

envelope curve of the received IR remote control command, can be

measured. This pulse sequence is input into the controller for further signal evaluation via input IRR [7899-B, pin 46].

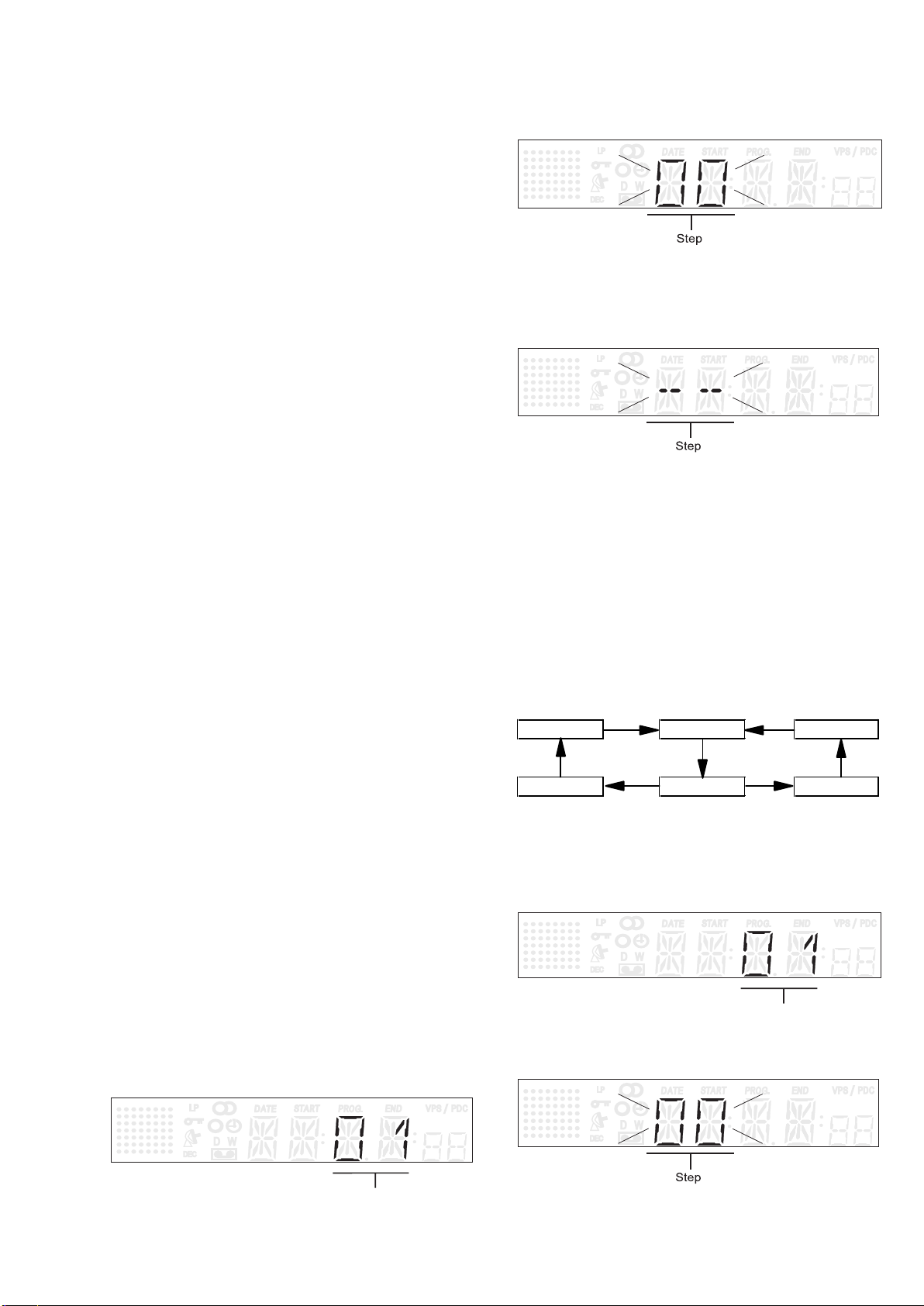

2.3 Activation and function of the VFD display

In principle, the VFD display [7170] is a tube triode in which the

heating filaments in the tube serve as cathodes (F+,F-). The 7 grids

(G1 - G7) are activated via PC2 - PC7, PD0 on the controller, and

the 16 anodes (P1 - P16) are controlled via ports PE0 - PE7, PF0 PF7, PC0, PC1 on the controller, each with a positive potential

compared to the cathode.

The grids and anodes (digits and symbols to be displayed) are

activated in the time-multiplex procedure, voltage lift 5V/-18V. A

dimmer function is generated using pulse-width modulation of the

grid control signals. At maximum display brightness, the pulse

width for each grid is 2.16 ms. It can be reduced, controlled using

software, which reduces the visual brightness of the VFD display

accordingly.

A digit or symbol is only illuminated if the corresponding anode and

the surrounding grid are switched simultaneously to 5V for a certain

time within a scanning period. The electrons emitted from the

cathode are accelerated by the positively charged grid and hit the

luminous layer of the anode which is also positively charged.

T

C

JE

T

27K

/E

47K

18K

12K

P

P

O

O

T

T

S

S

8K2

C

JE

E

D

Y

IN

LA

W

P

R

O

5K6

3K9

IT

N

W

O

E

M

R

1K2

2K2

470E

N

ILL

T

S

W

O

P

D

U

0E

GB

2-11

During the remainder of the scanning period, the corresponding

grid and parts of the anode are at -18V, due to the internal pulldown resistors in the controller. This potential is still lower than the

average cathode potential of approx. -15V, prevents the

acceleration of electrons, thus causing the relevant grid and anode

segments to go dark.

The heating direct voltage of the display (U = 3.5V) is supplied from

the power supply via lines HELO or HEHI to pins F+ and F- to the

VFD display. Resistors [3070] and [3071] restrict F- to approx. 15V.

3. Central Control AIO (AIO part)

The microcontroller (µC) TMP93CT76F [7899-B] includes the

following functions:

• PWM outputs

• A/D converters

• Composite sync input

• Special servo inputs for VCR functions

• I²C-BUS interface

• Shuttle evaluation

3.3 CMT detection (video detection with CSYNC)

This has been extended due to identification problems with weak

transmission signals and video signals not conforming to the

STANDARD (common channel interference). The CSYNC line is

supplied to the µP [7899-B] on pin 50. A hardware integration

[7807,7808,7809] of the video pulse compensates the interference

generated by the common channels and weak signals.

3.4 EE-PROM

The EE-PROM [7818] is a non-volatile memory which can be

erased and written to electrically. (Data remains

even if the operating voltage fails). Data specific to the device such

as the X distance, head changeover position, preset stations, optional bytes etc. is stored in the EE-PROM [7818].

The data is accessed by the µP via the I²C bus.

3.5 Easy link (P50)

For the communication between the TV set, video recorder and the

peripheral devices, a bi-directional single-wire bus is used, which

runs via pin 10 to scart socket 1.

The output signal is generated on pin 84 of the µC [7899-B], pin 68

is the signal input.

3.6 Shuttle:

The shuttle is connected to the motherboard on plug pos.1982. It is

a binary coded rotary switch with a rotation angle of +/- 70 degrees

and 16 switch positions. These are input and evaluated via four

lines (shuttle b1 – shuttle b4) to the input ports P24 – P27 [7899B

pins 2-5].

3.1 Analogue interface to the µC:

The following analogue levels are supplied to the µC’s

internal analogue/digital (A/D) converter:

• TAE/TAS Tape End / Tape Start Detection

• TRIV Tracking Information Video

• TRIA Tracking Information Audio

• AGC Automatic Gain Control

• AFC Automatic Frequency Control

• 8SC1/2 Pin 8 Scart1 or Scart2 switching voltage

• Key-in Keypad evaluation

3.2 Tape end - LED control :

The LED current is switched using transistor [7804]. The ON time is

approx. 1 msec and the OFF time approx. 12 msec during playback

and 1msec to 5.5msec during the winding functions.

The LED current is typically 150 mA. In order to prevent

interference from the relatively high pulsed current ‘spreading’

through the entire unit, the LED is fed from the 14VM1, and filtered

by 2 resistors [3800, 3805] with 10R each and a 220µF electrolytic

capacitor [2803].

3.7 Satmouse

For activating a sat-receiver via an external infrared electronic

transmission unit (Satmouse) a bi-directional data line, a shortcircuit proof +5V and earth are provided via a 3-pin 3.5mm jack

[1941].

The +5V is limited to approx. 140 mA using a current limiting switch

[7812 and peripherals].

4. Deck electronics DE (DE part)

The deck interface IC MP63100FP [7463] contains the

following functional groups:

• CTL stage (tape synchronisation)

• Sensor interface

• Power on reset

• Head drum motor driver

• Loading motor driver

• Capstan motor control

4.1 CTL stage

The IC M63100FP [7463] contains a read/write stage for the CTL

track with the option of overwriting an existing CTL track without

any interference. The playback stage is fitted with a “digital” fivestage AGC. This logic circuit identifies the size of the output signal

supplied by the CTL head, and then selects the best amplification

ratio in the playback stage using comparators.

The CTL head voltage can therefore vary greatly, if Vmax / Vmin is

great. The slowest tape speed is in LP mode. The fastest speed is

adjusted during rewind. To ensure that the duty cycle in the tape

sync is always reproduced correctly in the conditions mentioned

above (important for detecting VISS marks), the amplifier must not

be overdriven.

The five-stage AGC alone cannot cover the large dynamic range of

the input voltage. The amplifier is therefore also equipped with a

low pass characteristic (fg = 3kHz typ.; internal).

GB

2-12

In parallel with the CTL head is the RC cell comprising capacitor

[2479] and resistor [3471]. The capacitor [2479], together with the

CTL head inductivity, causes a resonance step-up at around 10

kHz and the resistor [3471] suppresses this step-up. This creates

an aperiodic transient response in the resonance. Beyond the

resonance frequency , there is an adjustment in terms of a steep fall

in the frequency transmission characteristic. This effectively

suppresses high-frequency pick-ups. The CTL head signal

amplitude in standard play is around 1mVp (typ.) which means that

the amplification for the playback amplifier must be

correspondingly high. To avoid offset problems, a 100 µF

electrolytic capacitor [2490] is fitted in the negative feedback

branch for DC decoupling.

The polarity of the playback amplifier can be changed using the

Video Index Search System (VISS) voltage. This is the only way in

which the µP can write a VISS mark on the tape without spikes. The

Write/Read (W/R) signal is used to switch over between record and

playback:

W = “H“, R = “L“.

4.2 Power on reset (POR) generator

The POR generator contained in the M63100FP [7463] requires

only one external capacitor [2477], which specifies the length of the

POR pulse. For 33 nF, tPOR is approx. 30ms.

The response threshold of the reset circuit is between 4.5 and 4.8

V. Supply fluctuations which are shorter than tPOR/100 area and

which do not fall below 4.0 V, do not trigger the POR. The µP is

reset using the inverted POR.

4.3 The sensor interface :

The four comparators in the M63100FP [7463] are used to convert

sensor signals to the logic level. The outputs are overload

protected by a current limiter and thermal overload protection. Only

the non-inverting input on each comparator is accessible from the

outside. The other inputs are connected to an internal reference of

2.5V. The fixed hysteresis of the comparators of approx. 18 mV is

also located internally.

The comparators are connected as follows:

Comparator 1: In = FTA, pin 39; Out = FTAD, pin 34:

FTA

= threading tachometer. This signal comes from a forked light

barrier in the deck. An infra-red light beam is interrupted by a 4blade impeller (butterfly). The output amplitude for the light barriers

should be less than 2V for the low level and greater than 3V in the

high level to ensure a correct evaluation process. An additional

hysteresis is created with a resistor [3476]. For unit versions <1W

and FOME the external operation amplifier [7530B] is used to

reduce the power consumption in <1W mode.

Comparator 2: In = WTR, pin 38; Out = WTRD, pin 33:

WTR

= Winding tachometer right, from a reflection photoelectric

barrier. The level is the same as for the FTA.

Comparator 3: In = WTL, pin 37; Out = WTLD, pin 31 :

WTL

= Winding tachometer left, from a reflection photoelectric

barrier. The level is the same as for the FTA.

Comparator 4: In = FG, pin 35; Out = FGD, pin 30:

FG

= capstan tachometer. This signal stems from an amplifier for

the tachometer hall sensor on the motor unit [1946 pin 4]. The

output impedance is 10 kOhm. The amplitude of the virtually

sinusoidal signal is normally 1 Vp. It should not fall below 300

mVpp. It is AC-coupled via a capacitor [2485]. In order for a bias

current to flow, the input pin 31 must be passed via a resistor [3474]

to the reference voltage on pin 4. A capacitor [2480] for filtering out

high-frequency interference is arranged in parallel to the bias

resistor.

4.4 Interface to the head drum motor driver part

The head drum control voltage (speed and phase control

information) is output via a µP-output (7899-B pin 35; PWM 14-bit).

This pulse-wide modulated signal is fed to the motor driver IC

M63100FP [7463 pin 11] and integrated with the capacitor [2469].

This IC already has a completely integrated ‘start-up’ circuit fitted.

For the commutation, the head drum motor driver uses the e.m.f.

on the non-current carrying motor coil (transformer principle). The

motor speed is also discharged from there at the same time. The

phase of the head disc is discharged from a position coil. The

speed and phase are multiplexed into one signal [7463 pin 6] and

output, which means that the falling edge of the signal is available

with a positive edge for the speed (FG/450Hz) and at 25Hz for the

position pulse (PG).

The motor driver M63100FP [7463] is connected to the head drum

motor on the motherboard using plug [1948].

• DRUM is the speed-phase control signal. The resolution is

14 bit.

• PG/FG is the combined POS/tachometer signal from the

M63100FP [7463].

4.5 Interface to the loading motor driver part:

The loading motor driver part is constructed for use as a bridged

dual power operations amplifier (OPAMP). It can supply max. +/-

0.8A output current. The output current is limited to approx. 0.7A by

the internal resistance of the loading motor (18 Ohm typ.) (start-up

or motor is blocked).

Between the IC outputs [7463, pins 22 and 24] there is a

“Boucherot” circuit [3467] 1E, [2474] 100 nF for suppressing a

spurious 3MHz oscillation from the output stage. One half of the

bridge is controlled via the TMO line on pin 27 and acts as a

comparator. The other half is an amplifier integrator with a 3.9 gain.

A change in the input voltage (THIO) of between 0 and 5V on pin 25

results in a change in the output voltage of between 0V and almost

Ub. With 50% modulation (THIO = 2.5 V) pin 24 has approx. 7 V.

The 100nF capacitor [2473] in the negative feedback of the op-amp

filters out the PWM frequency of approx. 39kHz. During POR, the

µP issues “L” to the THIO line, whilst TMO is “H”. This ensures that

no current flows in the motor for the duration of the POR pulse. This

prevents the motor being destroyed in case of prolonged running or

blockage. This arrangement also has a disadvantage, however.

This is that if the 5 V supply fails (e.g. because the 5V fuse has

blown), residual voltages may be passed to the IC inputs via the

adjacent 14 V voltages. These residual voltages trigger the

comparator and the op-amp in opposite ways, causing a shortcircuit in the blocked loading motor after about a minute. To get

around this problem, a separate voltage divider is used internally

for the comparator. Both outputs on the M63100FP [7463] are then

in “common mode” if this error occurs.

4.6 Interface to the capstan motor

The driver IC on the capstan motor is activated via connector

[1946].

CAP is the signal for the capstan speed. This voltage may vary

without load between 0 and 5 V.

The rotational direction of the motor is determined using CREV

(capstan reverse). The maximum current input for the motor is

limited to 1A. Typical values in PLAY mode are 0.2 ... 0.3 A.

GB

2-13

5. Front end FV (FV part)

5.1 The front end comprises the following parts :

• TUMOD = Tuner (+ Modulator Option) (+Booster Option)

(+Passive Loop Through Option)

• IF amplifier & video demodulator IC TDA 9817, [7705] with FM

- PLL demodulator

• IF amplifier & video demodulator IC TDA 9818, [7705] with FM

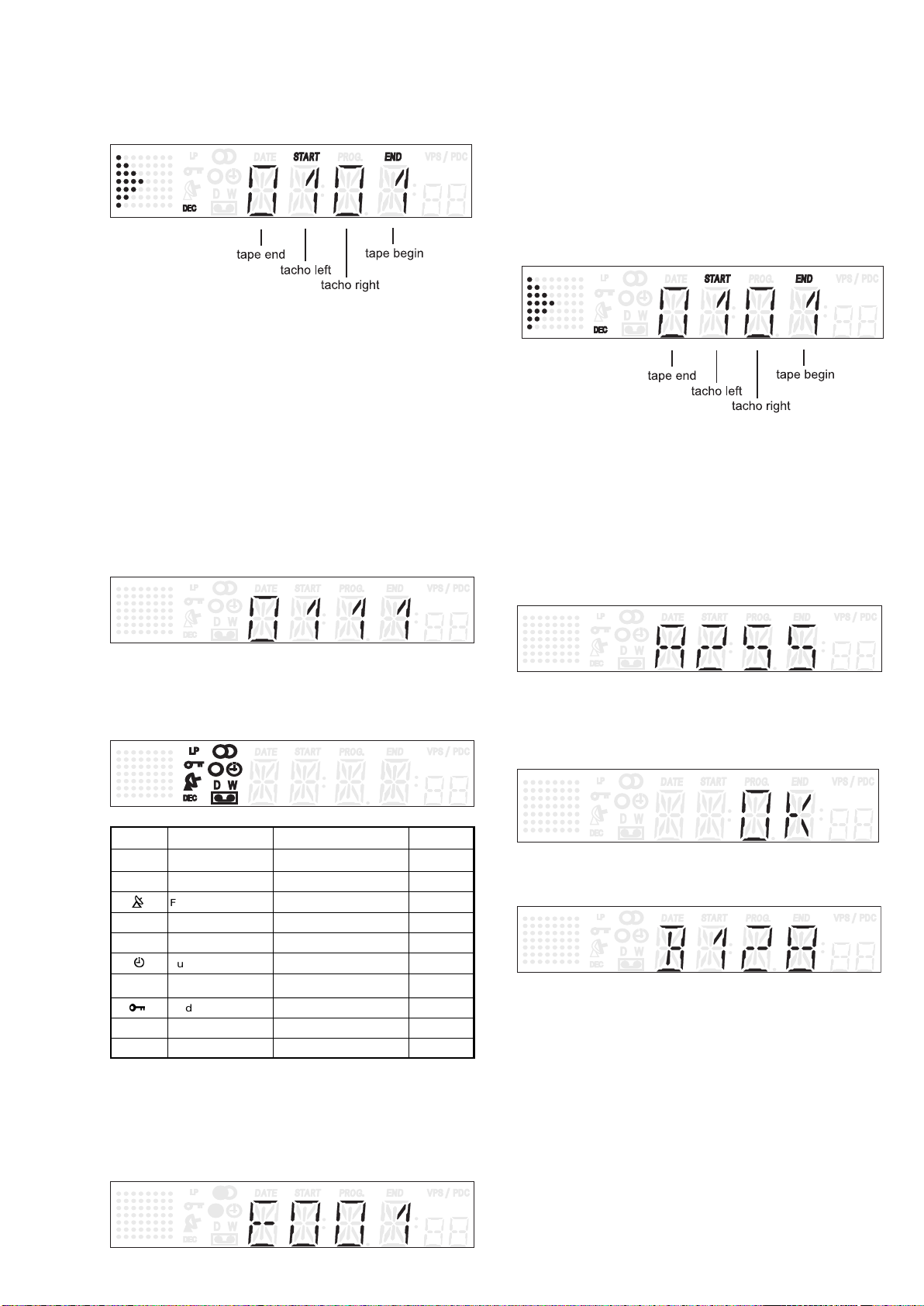

- PLL and AM demodulator