SERVICE MANUAL

MANUEL D'ENTRETIEN

WARTUNGSHANDBUCH

CAUTION:

Before servicing this chassis, it is important that the service technician read the “Safety

Precautions” and “Product Safety Notices” in this service manual.

SM7103

VMH775LE

VME578LEAU

VME578LESW

VME575LE

AC Adapter

VMACE5E

VMACE5EAU

Data contained within this Service

manual is subject to alteration for

improvement.

ATTENTION:

Avant d’effectuer l’entretien du châassis, le technicien doit lire les «Précautions de sécurité»

et les «Notices de sécurité du produit» présentés dans le présent manuel.

VORSICHT:

Vor Öffnen des Gehäuses hat der Service-Ingenieur die „Sicherheitshinweise“ und „Hinweise

zur Produktsicherheit“ in diesem Wartungshandbuch zu lesen.

When Servicing the Mechanism:

This camera/recorder uses a UH mechanism.

When servicing the UH mechanism, refer to the

following service manuals:

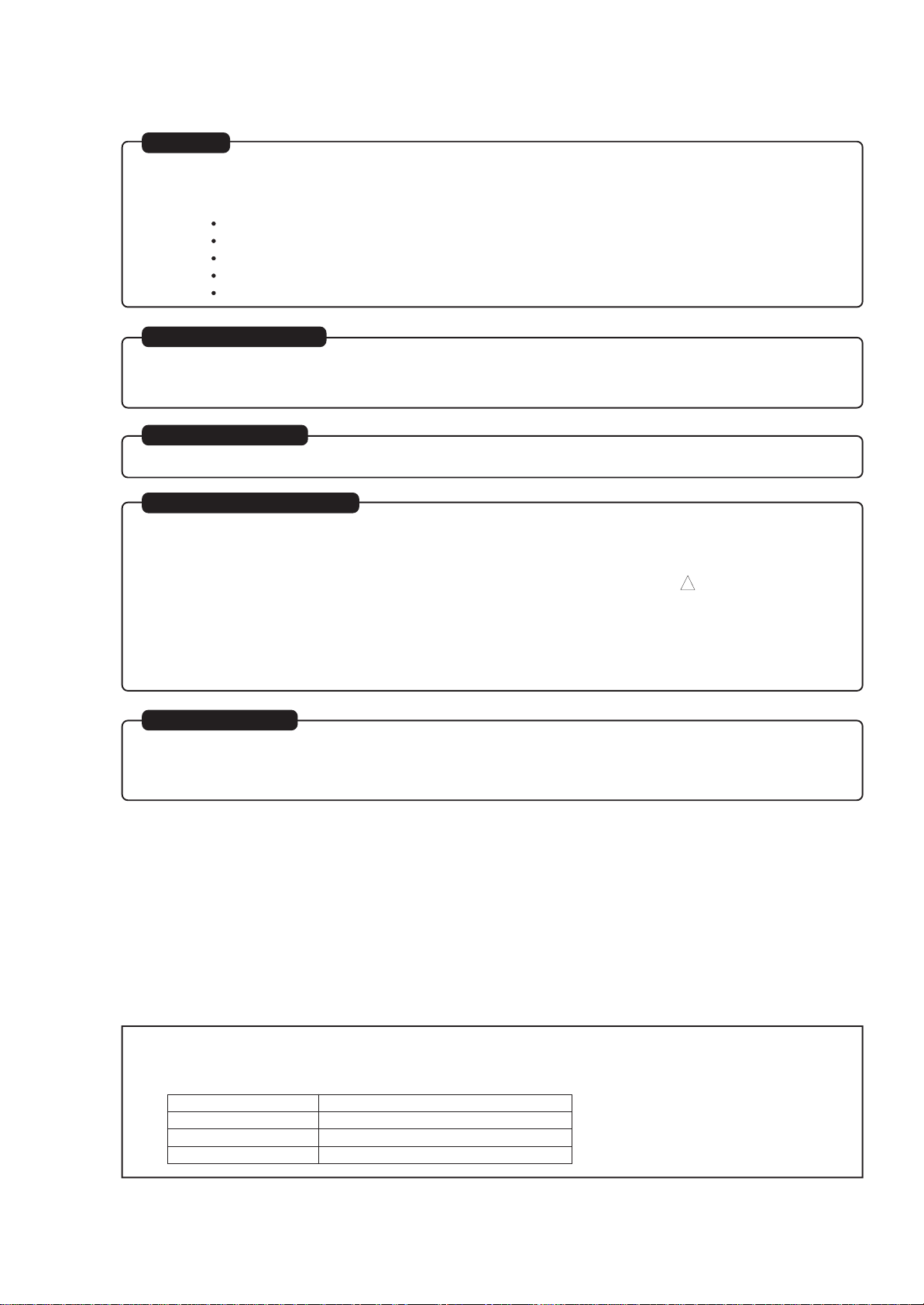

Item Manuals to be referred to

Disassembly UH Mechanism (No. 6811E)

Mechanical UH Mechanism Supplement

Adjustment (No. 6811E-1)

Maintenance/

Inspection UH mechanism (No. 6811E)

Procedure

Exploded View Chapter 4 in this manual

Les données fournies dans le présent

manuel d’entretien peuvent faire l’objet

de modifications en vue de perfectionner

le produit.

Die in diesem Wartungshandbuch

enthaltenen Spezifikationen können sich

zwecks Verbesserungen ändern.

SPECIFICATIONS AND PARTS ARE SUBJECT TO CHANGE FOR IMPROVEMENT

8mm VIDEO CAMERA/RECORDER

FEBRUARY 2001

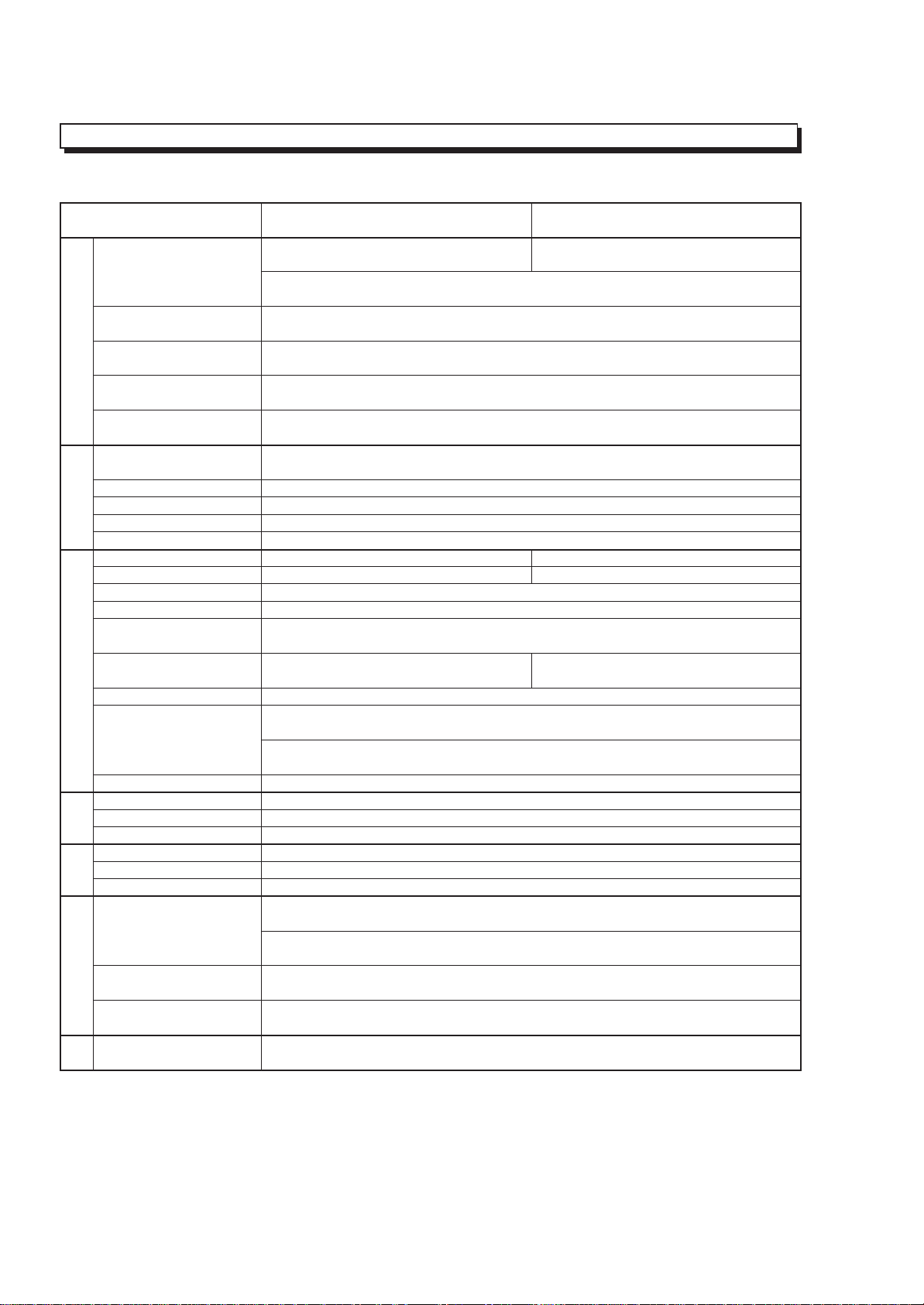

CONTENTS

CHAPTER 1 GENERAL INFORMATION

SPECIFICATIONS

COMPARISON OF FEATURES

COMPARISON OF MAIN CONTROL ICs

JIGS AND TAPES FOR SERVICE

HOW TO USE THE EXTENSION CABLE AND JIG..1-6

SERVICE POSITION

SERVICE MANUAL ABBREVIATION LIST

EXTRACT FROM THE INSTRUCTION MANUAL

IDENTIFYING CONTROLS

DATE/TIME SETTING

CHARGING THE BATTERY

ITEMS SELECTABLE WITH MENU DISPLAY

.....................................................

................................

.................

............................

.................................................

...............

.....

..................................

..........................................

................................

....

1-1

1-2

1-4

1-5

1-6

1-7

1-9

1-9

1-10

1-11

1-12

CHAPTER 2 DISASSEMBLY

1. BEFORE STARTING DISASSEMBLY

1.1 Disassembly Procedure

2. CASES AND CIRCUIT BOARDS REMOVAL

2.1 Jack Cover, Front Cover Assembly,

Lens Cover,

2.2 PSW Circuit Board, Microphone Unit,

DC Light, Front Cover

2.3 LCD Case-U, LCD Block, Cassette Lid,

Top Cover

2.4 L-Case Assembly, R-Case Assembly

2.5 Electronic Viewfinder (EVF) Assembly,

Speaker, CON Circuit Board, Fulcrum,

L-Case

2.6 Camera Chassis Assembly [Lens Frame,

Lens, SE Circuit Board, CCD Sensor],

VCR Chassis Assembly, Jack Unit, Rear

Cover, Power Terminal Unit

2.7 VCA Circuit Board, Mechanism Frame,

UH Mechanism

2.8 Hand Strap, TW/PW Switch, R-Case

2.9 LCD Circuit Board, Back light,

LCD Module, LCD Case-B

2.10 EVF Case-R, EVF Case-L, Eye Piece

3. HOW TO OPERATE THE

MECHANISM MANUALLY

..................................................

....................................................

..........................................................

.............................................

...............................

..................................

................................

.................

......

..........

.........................

..........

...........................

.........

2-1

2-1

2-2

2-2

2-2

2-3

2-4

2-5

2-6

2-7

2-7

2-8

2-8

2-9

CHAPTER 3 ELECTRIC CIRCUIT

ADJUSTMENT

1. CONNECTION FOR ADJUSTMENT

1.1 Before Starting Adjustment

2. CAMERA SECTION ADJUSTMENT

2.1 Test Equipment Necessary for

Adjustment

2.2 List of Charts for Camera Adjustment

2.3 Adjustment Conditions

2.4 Preset Positions of Switches and

Controls During Adjustment

...................................................

.................................

...................

..........................

....................

..........

.........................

3-1

3-1

3-2

3-2

3-2

3-2

3-2

2.5 Check After Replacing Major Components

in the Camera Section

2.6 Adjustment Procedure

2.6.1 Connections for Adjustment

2.6.2 How to Start the MAP

2.6.3 Initial Setting by Model

2.6.4 Digital Adjustment Procedure

(1) Auto Iris Contorl Adjustment

(2) White Balance Adjustment

(3) Chroma Gain Adjustment

2.6.5 Autofocus Adjustment Procedure

(1) Zoom Trace Adjustment

(2) AF Noise Level Adjustment

2.6.6 Stabilizer Adjustment Procedure

2.6.7 Spot Noise Adjustment

2.7 Color LCD Monitor Adjustment

2.7.1 Adjustment Procedure

(1) Flicker Adjustment

3. VCR SECTION ADJUSTMENT

3.1 Test Equipment and Alignment Tapes

Necessary for Adjustment

3.2 Adjustment Conditions

3.3 Preset Positions of Switches and

Controls During Adjustment

3.4 Check After Replacing Major Components

in the VCR Section

3.5 System Control/Servo Circuits

Adjustment

(1) Power Shut Off Level (ODC: Over

(2) Head Switching Point Adjustment

4. ERROR MESSAGES

4.1 Digital Adjustment

4.2 Autofocus Adjustment

4.3 Stabilizer Adjustment

4.4 Spot Noise Adjustment

4.5 VCR Adjustment

5. TROUBLESHOOTING OF AUTOFOCUS

(1) No Zoom and Focus Operation

(2) No Focus Lens Operation

(3) No Zoom Operation

(4) No Autofocus Operation

(5) Subject is Greatly Out-of-Focus

When Zoomed

...................................................

Discharge Control) Adjustment

.................................

.................................

..................

............................

..........................

.................

....................

......................

........................

...................

..........................

....................

...........................

.................................

............................

............................

.................................

.........................

.......................................

...........................................

........................................

..................................

...................................

................................

..........................................

...................

............................

.....................................

...............................

.............................................

CHAPTER 4 EXPLODED VIEW

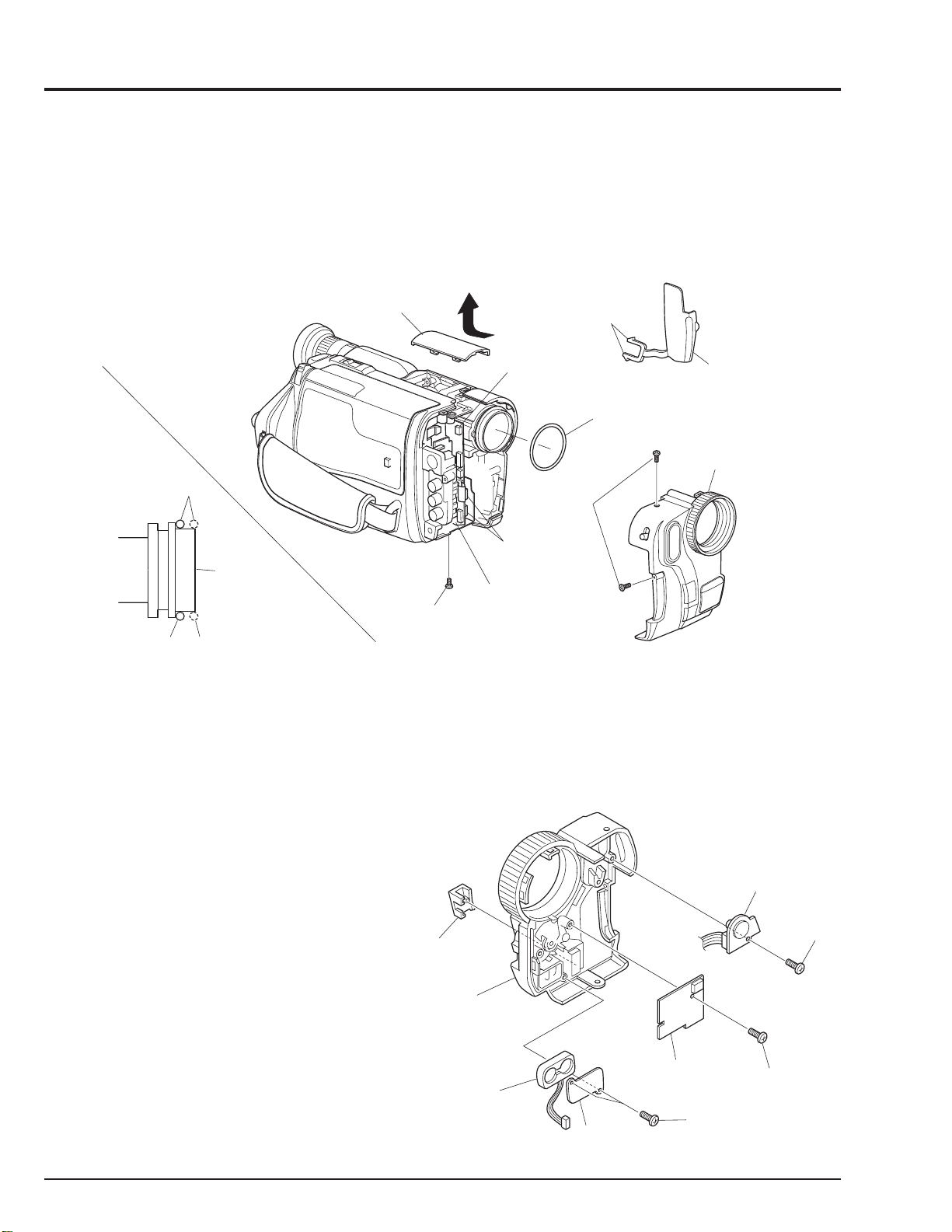

CABINET (1)

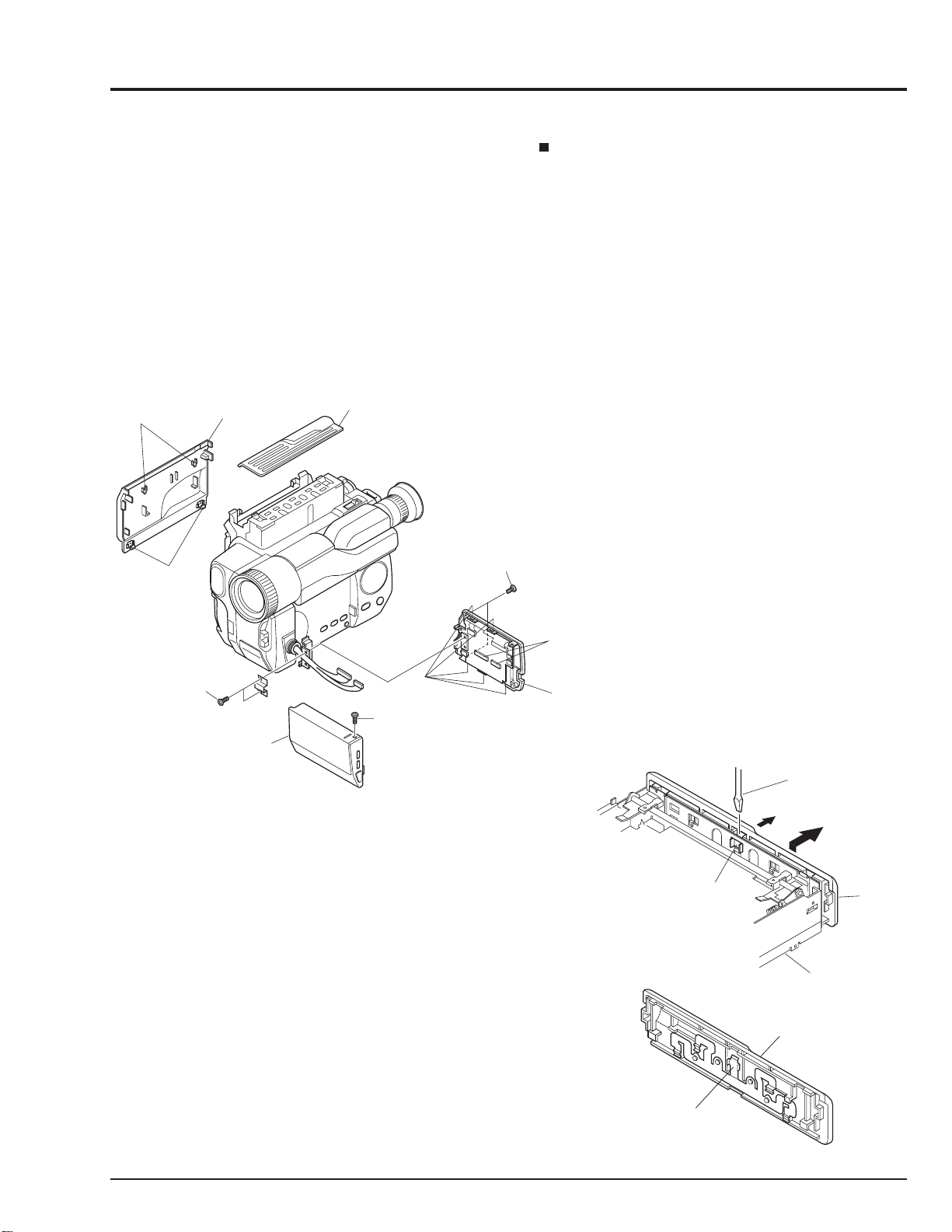

CABINET (2)

UH MECHANISM

ACCESSORIES

..............................................................

..............................................................

.......................................................

.........................................................

...............

.........

...........

.............

.........

............

3-3

3-3

3-3

3-4

3-4

3-5

3-5

3-5

3-6

3-7

3-7

3-7

3-8

3-8

3-9

3-9

3-9

3-10

3-10

3-10

3-10

3-10

3-10

3-11

3-11

3-12

3-12

3-13

3-13

3-13

3-14

3-15

3-15

3-17

3-18

3-19

3-21

4-1

4-2

4-3

4-4

CONTENTS-1

CHAPTER 5 REPLACEMENT

P ARTS LIST

1. MECHANICAL PARTS LIST

2. ELECTRICAL PARTS LIST

CHAPTER 6

SCHEMATIC, CIRCUIT BOARD

................................

.................................

AND BLOCK DIAGRAMS/

MICROPROCESSOR PIN

FUNCTION TABLE

INTERNAL WIRING DIAGRAM

SENSOR/GYRO [SE]

CAMERA PROCESS [VCA]

SYSTEM CONTROL [VCA]

MECHA. STATE SWITCH/

MECHA. SENSOR

POWER SW [PSW]

SERVO [VCA]

AUDIO -STEREO- [VCA]

AUDIO -MONAURAL- [VCA]

REGULATOR [VCA]

VIDEO PROCESS [VCA]

CHARGE [VCA]

CONTROL [CON]

LCD DRIVE [LCD]

...................................

....................................

......................................

...............................................

.....................................

............................................

.........................................

........................................

................................

Schematic / Circuit

..........................

..........................

..............................

........................

..............................

5-1

5-2

6-1

Board

6-3 / 6-33,35

6-5 / 6-37,43

6-7 / 6-37,43

6-9 / ----6-10/ 6-33,35

6-11/ 6-37,43

6-13/ 6-37,43

6-15/ 6-37,43

6-17/ 6-37,43

6-21/ 6-37,43

6-24/ 6-37,43

6-25/ 6-33,35

6-27/ 6-31

CHAPTER 7 APPENDIX

1. SELF-DIAGNOSTIC FUNCTION

1.1 Overview

1.2 Details of Display/

Detection and Applications

1.3 Setting Procedure and

Details of Diagnosis

1.3.1 Occasional Defect Self-Diagnostic

1.3.2 Mechanical Block Self-Diagnostic

2. DEMONSTRATION (DEMO) MODE

2.1 Setting the Demo Mode

2.2 Exiting the Demo Mode

2.3 Contents of Demonstration

......................................................

Function (Mode A)

Function (Mode B)

.........................

..........................

.....................................

.................................

.................................

...............................

................................

..........................

CHAPTER 8 AC ADAPTER

VM-ACE5E

................................................................

.................

7-1

7-1

7-2

7-3

7-3

7-4

7-6

7-6

7-6

7-6

8-1

WAVEFORM

SENSOR/GYRO

SYSTEM CONTROL

SERVO

VIDEO PROCESS

BLOCK DIAGRAMS

1. OVERALL BLOCK DIAGRAM

2. MAIN CONTROL BLOCK DIAGRAM

3. SERVO BLOCK DIAGRAM

4. CAMERA & VIDEO PROCESS

5. AUDIO -STEREO- BLOCK DIAGRAM

6. AUDIO -MONAURAL- BLOCK DIAGRAM

7. POWER BLOCK DIAGRAM

MICROPROCESSOR PIN FUNCTION TABLE

1. Digital Microprocessor (IC1104: D-µP)

2. System Control Microprocessor

................................................................

BLOCK DIAGRAM

(IC0901: S-µP)

.................................................

...........................................

..............................................

......................

..........................

.......................................

.........................

.............................................

...........

.........

........

6-3

6-9

6-11

6-19

6-49

6-51

6-53

6-55

6-57

...

6-59

6-61

6-63

6-65

CONTENTS-2

CAUTION

Lithium battery; danger of explosion if battery is incorrectly replaced. Replace only with the same or equivalent type

recommended by the equipment manufacturer. Discard used batteries according to manufacuturer's instructions.

When replacing the lithium battery it is important to use the same type and connect it correctly.

WARNING:

Lithium batteries contain dangerous chemicals.

Handle and dispose of with great care.

Do not throw in a fire.

Do not short circuit it.

For disposal place in a plastic bag and put in waste bin.

CAUTION (COLOR LCD)

LCD display; the liquid crystal display (LCD) panel is mode by highly precise technology.

More than 99.99% of its picture elements (pixels) are effective, but some (less than 0.01%) may appear as colored

bright dots. This mode not indicate a fault as the LCD panel stretches the limits of current technology.

CAUTION (CRT EVF)

Be careful of the section painted in white on the electronic viewfinder circuit board as it generates a high voltage.

PRODUCT SAFETY NOTICE

Many electrical and mechanical parts have special safety-related characteristics. These are often not evident from

visual inspection nor can the protection afforded by them necessarily be obtained by using replacement components rated

for a higher voltage, wattage, etc. Replacement parts which have these special safety characteristics are identified in this

Service Manual. Electrical components having such features are identified by marking with a on the schematics and the

parts list in this Service Manual. The use of a substitute replacement component which does not have the same safety

characteristics as the HITACHI recommended replacement one, shown in the parts list in this Service Manual, may create

shock, fire, or other hazards. Product safety is continuously under review and new instructions are issued from time to time.

For the latest information, always consult the current HITACHI Service Manual. A subscription to, or additional copies for,

HITACHI Service Manual may be obtained at a nominal charge from HITACHI SALES CORPORATION.

!

X-RAY RADIATION

The primary source of X-ray radiation in this viewfinder is the picture tube. The tube used in this viewfinder is specially

constructed to limit X-ray radiation emission. For continued X-ray radiation protection, the replacement tube must be

same type as the original, Hitachi approved one.

How to discriminate the "TYPE" identifications in the manual

The parts and circuits are identified by "TYPE" in this manual to discriminate the differences between models. The

TYPE numbers are the same as the model numbers. The table below shows how to read the type identifications.

TYPE identification Model name

TYPE 775 VM-H775LE

TYPE 578 VM-E578LE(AU)/E578LE(SW)

TYPE 575 VM-E575LE

CAUTION-1

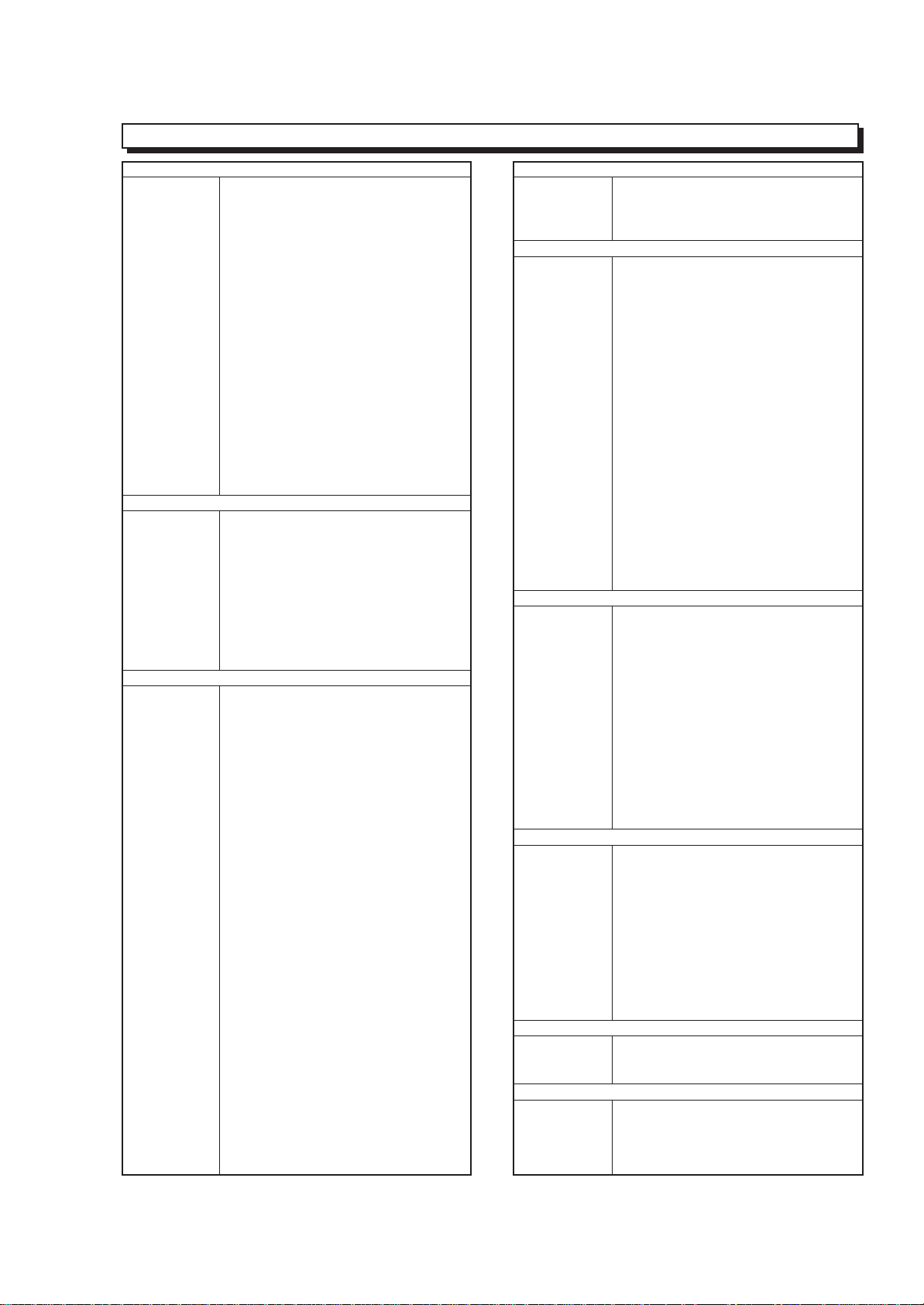

Notes When Using Service Manual

The following shows the contents to be noted when using service manual:

1. Value units used in parts list

Certain symbols are indicated below for value units of

resistors, capacitors and coils in parts list. When you read

them note the following regular indications:

Parts

Resistor

Capacitor

Coil

Indication in list Regular indication

...........................................

KOHM

................................................

UF

................................................

PF

................................................

UH

...............................................

MH

2. Values in schematic diagrams

The values, dielectric strength (power capacitance) and

tolerances of the resistors (excluding variable resistors)

and capacitors are indicated in the schematic diagrams

using abbreviations.

[Resistors]

Item

Value

Tolerance

Power

capacitance

Indication

No indication

................................................

K

...............................................

M

No indication

(All tolerances other than ±5% are

indicated in schematic diagrams)

No indication

(1/16W for leadless resistors without

indication)

All capacitances other than the above

are indicated in schematic diagrams.

...................................

.............................

............................

±5%

1/8W

k

M

k

µF

pF

µH

mH

3. Identifications of sides A/B in

circuit board diagrams

1) Board having a pattern on one side and parts on both

sides.

Side A: Shows discrete parts, viewed from the pattern

side.

Side B: Shows leadless parts, viewed from the

pattern side.

2) Board having patterns on both sides and parts on

both sides.

Side A: Shows parts and patterns which can be seen

when the case is opened.

Side B: Shows parts and the pattern on the back of

side A.

4. Table for indexing locations of parts

This table shows locations of each part on circuit board

diagrams. The locations are indicated using the guide

scales on the external lines of diagrams.

1) One diagram indicated for each board

Symbol

No.

IC

IC1201

Circuit No.

2) Two diagrams indicated for each board

Parts

Location

Type of part

2 A

Zone "A" on board diagram

Zone "2" on board diagram

[Capacitors]

Item

Value

Dielectric

strength

[Coils]

Item

Value

CAUTION-2

Indication

No indication

................................................

P

No indication

(All dielectric strengths other than 50V

are indicated in schematic diagrams)

Indication

................................................

µ

...............................................

m

.................................

..............................

µF

pF

50V

µH

mH

Symbol

No.

IC

IC1201

Circuit No.

Parts

Location

A - 2 A

A: Shows side A

B: Shows side B

Type of

part

Zone "A" on board

diagram

Zone "2" on board

diagram

CHAPTER 1 GENERAL INFORMATION

SPECIFICATIONS

General Specifications

Power requirements 7.2V DC

Power consumption VM-H775LE:

3.6W (when recording/LCD monitor OFF)

4.1W (when recording/LCD monitor ON)

VM-E578LE(AU)/E578LE(SW):

3.4W (when recording/LCD monitor OFF)

3.8W (when recording/LCD monitor ON)

VM-E575LE:

3.4W (when recording/LCD monitor OFF)

3.8W (when recording/LCD monitor ON)

Operating temperature 0°C to 40°C

Operating humidity < 80 %

Storage temperature -20°C to 60°C

Dimensions 111.5 (W) mm × 111.5 (H) mm × 200 (D) mm

Weight Approx. 836 g

Video Recorder Specifications

Format 8 mm

Record/playback system Two video record/playback heads

Video signal PAL colour & CCIR monochrome signals 625 lines

Tape speed SP: 20.05 mm/s

Video output 1.0 Vp-p, 75 ohm

Audio output -8 dBs, less than 1k ohm

Fast forward/rewind time Approx. 6 minutes with P5-90 cassette

Camera Specifications

Scanning 625 lines/50 fields/25 frames

Required minimum illumination VM-H775LE: 0.5 lx

VM-E578LE(AU)/E578LE(SW): 0.1 lx

VM-E575LE: 0.3 lx

Camera device 1/4 inch C.C.D.

Lens F1.6 to 3.8 (4 to 88 mm) 22:1 power zoom lens with auto focus

and auto iris functions

Lens diameter 46 mm

1 - 1

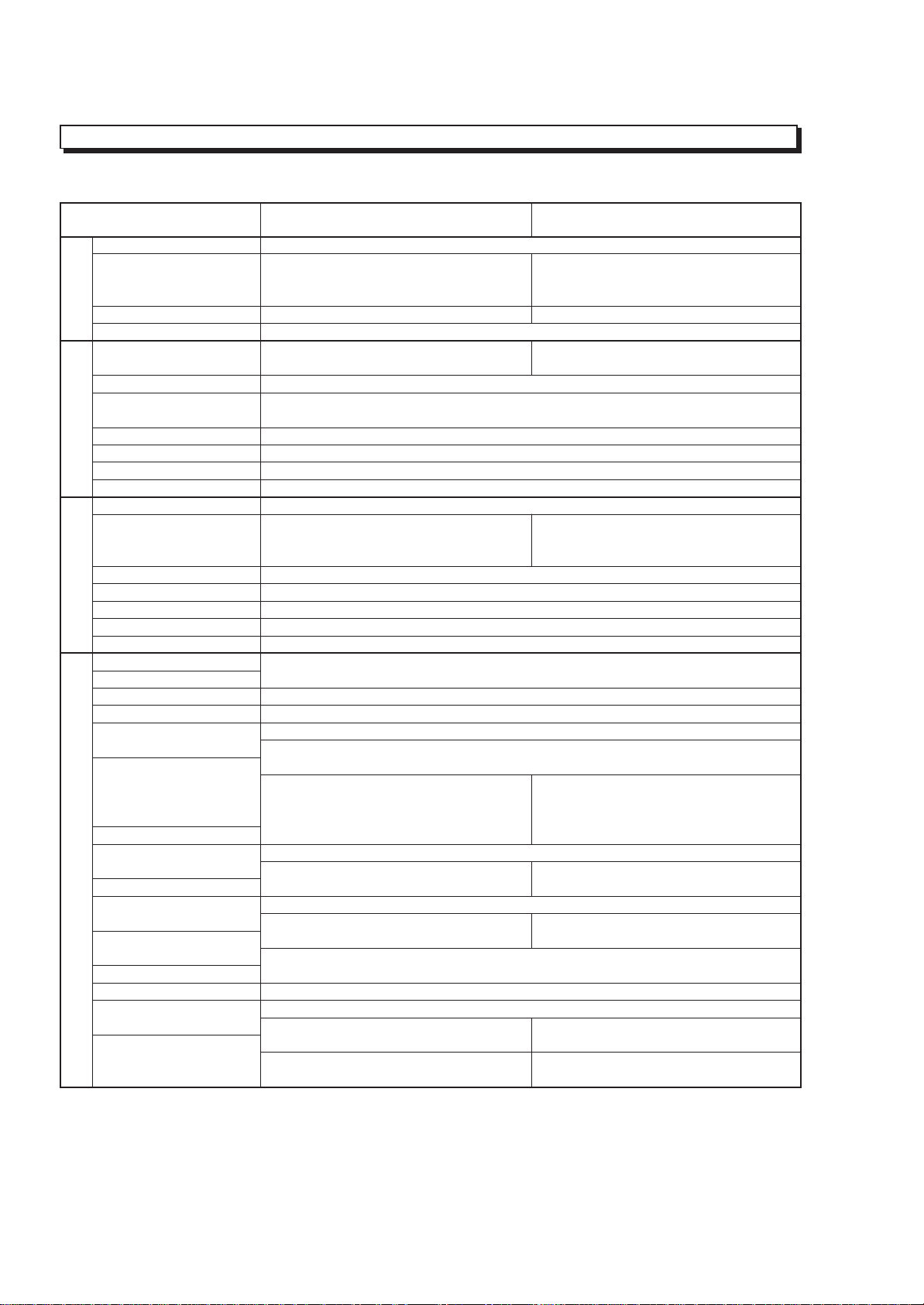

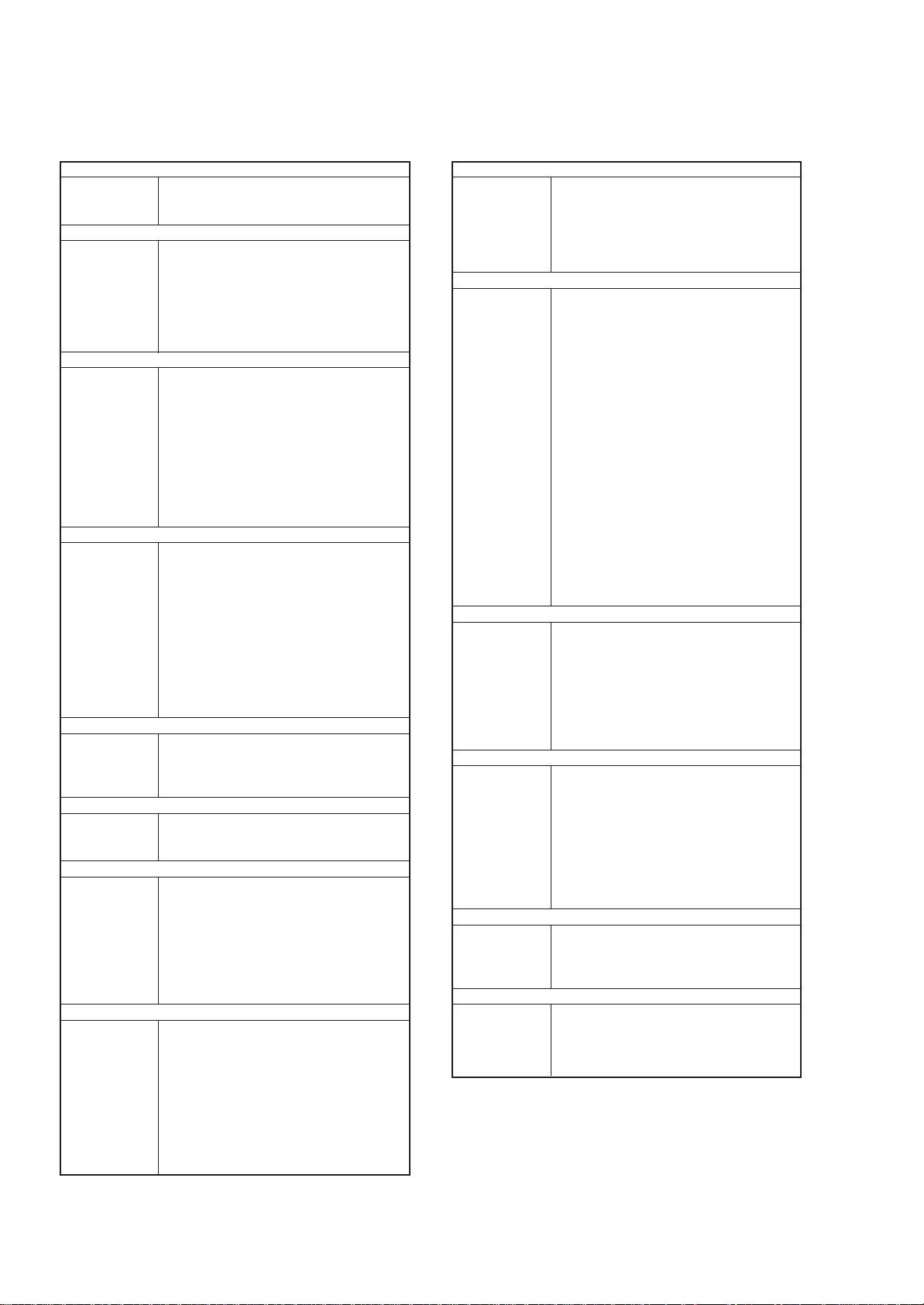

COMPARISON OF FEATURES

Note: Destinations normally added at the end of model names, (AU), (SW), (UK), etc. are omitted in this table.

ITEM

Power Requirements

Power Consumption

(when recording/LCD

monitor ON)

GENERAL

Dimensions (W × H × D )

Weight

Format

Record/Playback System

Video Signal

VIDEO

Tape Speed

F.F/Rew Time

Head Weel

Basic Chassis Type

Scanning

Required Minimum

Illumination

Camera Device

Lens Diameter

CAMERA

Zoom Ratio

Aperture

Zoom Speed

Electronic Viewfinder (EVF)

Electrical Zoom Function

INST. ZOOM Function

Autofocus System

Program AE

(Shutter Speed)

Selective Program AE

AV Input Function

S-Connector Output

AV Dubbing

FEATURES

Audio System &

Microphone

Multi Playback

(PAL 60 Conversion)

Digital Effect & Fade

Date Search

Tape Analyzer ATRS

TAPE+ Function

VM-H775LE/E578LE/E575LE

7.2 V DC

VM-H775LE: 4.1 W

VM-E578LE/E575LE: 3.8 W

111.5 mm × 111.5 mm × 200 mm

Approx. 836 g

VM-H775LE: 8 mm (Hi-8)

VM-E578LE/E575LE: 8 mm

Two video record/playback heads

PAL colour & CCIR monochrome signal

625 line

SP: 20.05 mm/s

Less than 6 minutes with P5-90 cassette

40 mm

UH

625 lines/50 fields/25 frame

VM-H775LE: 0.5 lx

VM-E578LE:0.1 lx

VM-E575LE:0.3 lx

1/4 inch C.C.D

46 mm

22 : 1 (4.0 - 88.0 mm)

F1.6 - 3.8

Adjustable speed

CRT (Black & White)

Yes [× 500 (22 × 22)]

No

Video AF System

Yes

(Program AE only)

VM-H775LE/E575LE: Yes

(AUTO, SPORTS, PORTRAIT,

SPOTLIGHT, GAIN UP)

VM-E578LE: No

No

VM-H775LE: Yes

VM-E578LE/E575LE: No

Yes (Using the remote controller)

VM-H775LE: Stereo

VM-E578LE/E575LE: Monaural

Yes (Selective)

Yse

Yes

VM-H775LE: Yes

VM-E578LE/E575LE: No

VM-H775LE: Yes

VM-E578LE/E575LE: No

VM-H765LE/E568LE/E565LE

VM-H765LE: 4.1 W

VM-E568LE/E565LE: 3.8 W

111.5 mm × 111.5 mm × 202 mm

VM-H765LE: 8 mm (Hi-8)

VM-E568/E565LE: 8 mm

VM-H765LE: 0.5 lx

VM-E568LE/E565LE: 0.3 lx

VM-H765LE/E565LE: Yes

(AUTO, SPORTS, PORTRAIT,

SPOTLIGHT, GAIN UP)

VM-E568LE: No

VM-H765LE: Yes

VM-E568LE/E565LE: No

VM-H765LE: Stereo

VM-E568LE/E565LE: Monaural

VM-H765LE: Yes

VM-E568LE/E565LE: No

VM-H765LE: Yes

VM-E568LE/E565LE: No

1 - 2

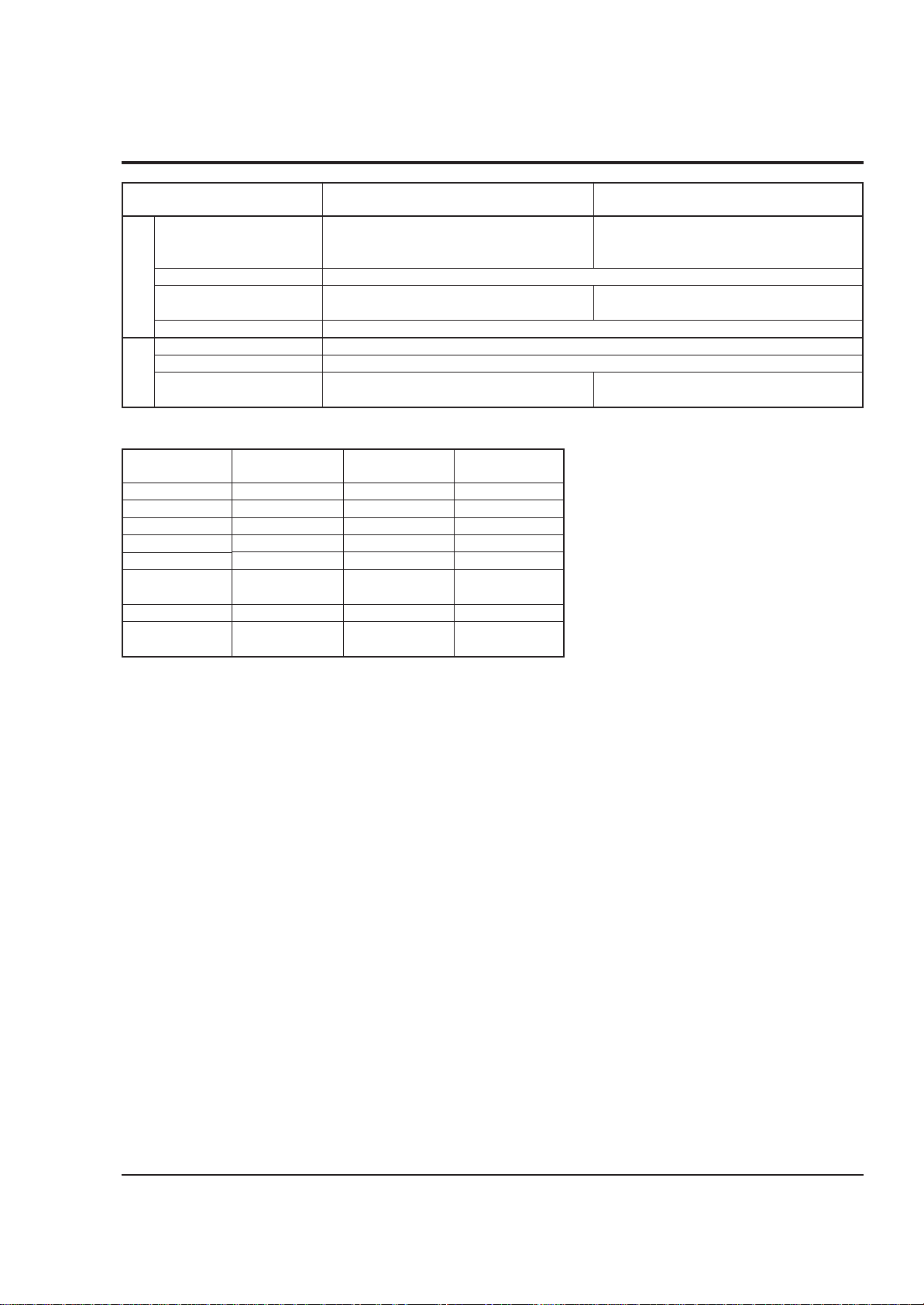

ITEM

VM-H775LE/E578LE/E575LE

VM-H765LE/E568LE/E565LE

Electronic Image Stabilizer

(EIS)

[Picture element system]

LCD Display

Internal DC Light

FEATURES

Internal Battery Charge

AC Adapter/Charger

Battery Pack

Remote Controller

ACCE-

SSORY

System

Audio

Built-in DC light

EIS function

Tape +

Programme AE

Remote control

Microphone

jack

VM-H775LE

Hi-8

Stereo

Yes

Yes

Yes

Auto/Mode

select

Provided

Yes

VM-H775LE/E575LE: Yes

VM-E578LE: No

Yes (2.5 inch)

VM-H775LE/E578LE: Yes

VM-E575LE: No

Yes

VM-ACE5E

VM-BPL13

VM-H775LE/E575LE: VM-RME611A

VM-E578LE: Not provided

VM-E578LE(AU)

VM-E578LE(SW)

Normal 8

Monaural

Yes

No

No

Auto

Not provided

No

VM-E575LE

Normal 8

Monaural

No

Yes

No

Auto/Mode

select

Provided

Yes

VM-H765LE/E565LE: Yes

VM-E568LE: No

VM-H765LE: Yes

VM-E568LE/E565LE: No

VM-H765LE/E565LE: VM-RME611A

VM-E568LE: Not provided

Memo

1 - 3

COMPARISON OF MAIN CONTROL ICs

Note: Destinations normally added at the end of model names, (AU), (SW), (UK), etc. are omitted in this table.

ITEM

CCD Sensor

V-Move (Vertical Gyro)

H-Move (Horizontal Gyro)

Gyro Amp

CCD SENSOR & GYRO

Sensor Drive (Drive Pulse

Generator)

Video DSP

(Digital Process)

CDS/AGC & A/D Conv.

Video Head Switch

VIDEO

Video Amp

PROCESS

RGB Amp

Digital µP (D-µP)

EEPROM

D/A Conv.

F Det./Iris Drive

Zoom Motor/Focus Motor

Driver

System Control µP (S-µP)

Back-up Det.

Character Gen.

SYSTEM CONTROL

CAMERA CONTROL &

IR Receiver

Cylinder Motor Drive

Capstan Motor Drive

SERVO

Loading Motor Drive

PWM

5V Reg.

CHG Current Cont.

POWER

Audio Process

Speaker Amp

AUDIOLCD

Audio Matrix

LCD SWR.

VM-H775LE/E578LE/E575LE

MN39242FT (IC1001)

[For VM-H775LE]

ICX207AK (IC1001)

[For VM-E578LE/E575LE]

ENC-03JA-07 (IC1401)

[For VM-H775LE/E575LE]

ENC-03JB-07 (IC1402)

[For VM-H775LE/E575LE]

NJU7018M (IC1403)

[For VM-H775LE/E575LE]

µPD16510GR (IC0203)

MB87L1551PMT2 (IC0201)

HD49323AF (IC0202)

HA118189MP (IC0101)

µPC5020GS129 (IC0301)

µPC5020GR-125-8JG (IC0350)

HD6432237M10TE (IC1104)

X25170S8I-2.5T3 (IC1105)

MB88347PFV (IC1111)

µPC5023GS-147-GJG (IC1201)

µPD16833AG3 (IC1301)

CXP87360-133R (IC0901)

NJU7285BV (IC0902)

µPD6461GS-947-E1 (IC0904)

[For VM-H775LE/E575LE]

µPD6461GS-941-E1 (IC0904)

[For VM-E578LE]

GP1U101X (IC0701)

LB1950V-TLR (IC0631)

LB1991V-TLR (IC0651)

BA6417F (IC0671)

BA9736KV (IC0551)

PQ20WZ51 (IC0553)

MM6564XFBE (IC0001)

HA118193F (IC0401)

[For VM-H775LE]

LA7458W (IC0401)

[For VM-E578LE/E575LE]

TDA7052AT (IC0461S)

[For VM-H775LE]

NJM2112V-TE1 (IC0471S)

[For VM-H775LE]

TL5001CD (IC5501)

VM-H765LE/E568LE/E565LE

ICX211AK (IC1001)

[For VM-H765LE]

[For VM-E568LE/E565LE]

[For VM-H765LE/E565LE]

[For VM-H765LE/E565LE]

[For VM-H765LE/E565LE]

HD6432237M08TE (IC1104)

AT25160N (IC1105)

CXP87360-132R

CXP87360-133R

[For VM-H765LE/E565LE]

[For VM-E568LE]

[For VM-H765LE]

[For VM-E568LE/E565LE]

[For VM-H765LE]

[For VM-H765LE]

(IC0901)

1 - 4

JIGS AND TAPES FOR SERVICE

1. Alignment Tape 2. Cassette Torque Meter 3. Master Plane 4. Reel Disk Height Jig

20HSC-3: No. 7099232 SRK-8T-232: No. 7099236 No.7099237 No. 7099238

SRK-8T-212: No. 7099402

5. Special Driver 6. C12 Light Balance 7. ATF-R Jig (*1,*2) 8. DSP-R jig

No. 7099239 Filter No. 7099461 No. 7099448

No. 7099369

9. DSP AV Output Jig 10.Presonal Computer 11. Personal Computer Cable

No. 7099456 [Goods on the market] RS-232C (9-pin or 25-pin)

Straight Type Cable

[Goods on the market]

12.AVOutput Cable (*3) 13.Adjustment Floppy Disk [New Jig] 14. 8 - 20 Pin Extention

[Accessory] No. TP12115 Cable

No. TS15411

15.4-Pin Extension Cable 16. ODC DC CORD 17.80-Pin Extention Board

No.7069203 No. TE13171 No. JP25461

Caution for jigs

*1. Always set SW3 on the ATF-R jig to ON.

*2. The ATF jig (No.7099386) can also be used in place of ATF-R jig to adjust this model.

*3. Either the monaural or stereo AV output cable can be used.

1 - 5

HOW TO USE THE EXTENSION CABLE AND JIG

Name of Jig Parts No. How to Use

8 - 20 Pin Extention TS15411 Used for electrical adjustment. Connected between PG905 on the VCA circuit board

Cable and DSP Output Jig (20 pins). Refer to Fig. 1-1 on the page 3-1.

4-Pin Extension Cable 7069203 Installed between the VCA circuit board and mode switch (mechanism state switch).

ODC DC Cord TE13171 Power supply cable for power shut off level (ODC) adjustment. Refer to Fig. 1-1 on the

page 3-1.

Positive: Black

Negative: Black & White

80-Pin Extension Board JP25461 Installed between the VCA circuit board and CON circuit board.

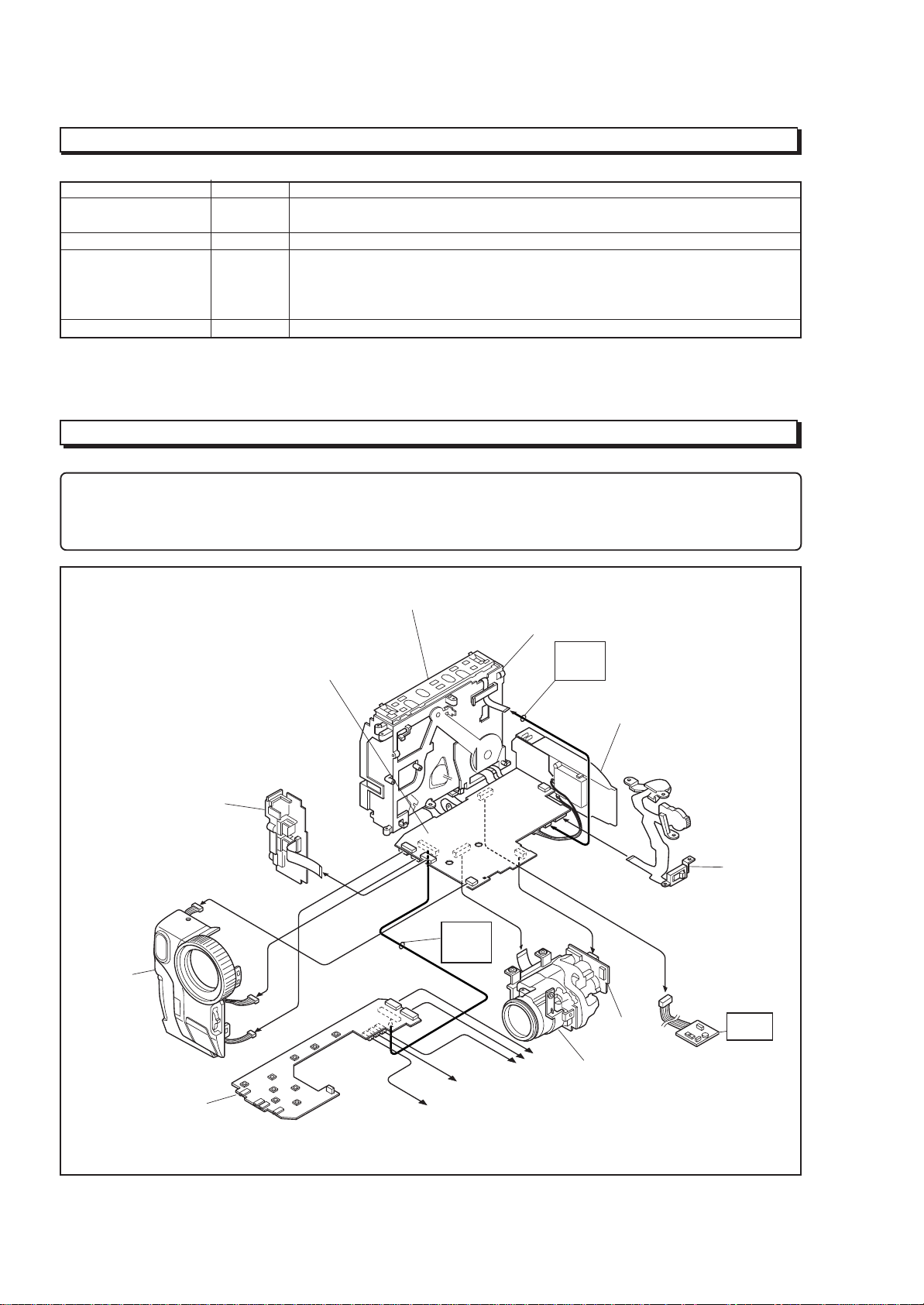

SERVICE POSITION

NOTE

1. If the front cover assembly is connected to the VCA circuit board, the provided remote control can be used to operate

the camera/recorder without connecting the CON circuit board.

2. The VCR block can be operated with the camera chassis assembly removed.

FRONT

COVER

ASSEMBLY

JACK

UNIT

CON

CIRCUIT

BOARD

VCA

CIRCUIT

BOARD

UH MECHANISM

80-PIN

EXT.

BOARD

To SPEAKER

To EVF

MECHANISM

FRAME

4-PIN

EXT.

CABLE

To LCD

REAR

UNIT

SE

CIRCUIT

BOARD

CAMERA

CHASSIS

ASSEMBLY

TW/PW

SWITCH

ATF-R

JIG

1 - 6

Fig.1-1 Service Position

SERVICE MANUAL ABBREVIATION LIST

A

A (A-) Analog

ACC Automatic Color Control

A/D Analog-to-Digital Converter

ADD Adder

ADP. Adapter (AC Adapter)

ADRS Address

A.DUB Audio Dubbing

AF Automatic focus (Autofocus)

AFC Automatic Frequency Control

AGC Automatic Gain Control

AGC KILLER AGC Killer Voltage

AI Automatic Intelligence

AIC Automatic Iris Control

ALC Automatic Level Conrol

AMP Amplifier

APC Automatic Phase Control

ASBL Assemle (Phase Matching)

ATRS Auto Tape Recording System

AUD. Audio

AUX Auxiliary

B

B (BLU) Color Signal Blue

BATT. Battery

BF Burst Flag

BG Burst Gate or Back Ground

BGP Burst Gate Pulse

BLC Backlight Compensation

BLK Blanking

BPF Bandpass Filter

BUF. Buffer Amplifier

B-YL Color Difference Signal B-YL

C

C (CHROMA) Chrominance Signal

CAM Camera

CAPST. Capstan

CARRI. Carrier

CATV Cable TV

C.BLK Composite Blanking

CCD Charge Coupled Device

CDS Correlated Double Sampling

C.FG (CFG) Capstan Frequency Generater

C.FREE RUN Capstan Free Run

CG Character Generator

CH (Ch or ch) Channel

CHARA. Character

CHD Camera Horizontal Drive Pulse

C.MEMORY Counter Memory

CNR Chroma Noise Reducer

COM. Common

COMPA. Comparator

COMPE. Compensator

COMP-EXP Compressor-Expander

COMPO Composite

CONT. Control

CONV. Converter

COUNT. Counter

CP CP

C.PAUSE Camp Pulse

C/R Capacitor/Resistor

C.RESET Countor Reset or Camera Reset

C.REVERSE Count Reverse

CS Communication Signal

C

CST Cassette

C.SYNC Composite Synchronizing Signal

CTL Control Track Pulse (Control)

CYL Cylinder

D

D (D-) Digital

DA Double Azimuth

D/A Digital to Analog Converter

D-D Direct Drive

DEEMPHA. Deephasis

DEF Deflefction

DEMOD. Demodulator

DET Detector

DIFF. AMP Differential Amplifier

Digital 8 (D8) Digital 8 mm

DISP. Display

DL Delay Line

DO Dropout

DOC Dropout Compensator

DSP Digital Signal Processor

DUB Dubbing

DV Digital Video

DVD Digital Versatile Disc

D-VHS Digital VHS

D/W Dark/White

D.ZOOM (DZ) Digital Zoom

E

EAROM Electrically Alterable Read Only

Memory

E-E Electronic-to-Electronic

EEPROM Electrical Erasable Proframmed

Memory

EIS (E.I.S.) Electronic Image Stabilizer

EMPHA. Emphasis (EMPH)

EQ Equalizer

ESS End Sensor Supply (Supply End Sensor)

EST End Sensor Take-up

(Take-up End Sensor)

EVF Electronic Viewfinder

EXT. External

E.ZOOM Electrolical Zoom

F

F.ADV Frame Advance

FB Feed back

FE Full Erase

FF (F/F) Flip Flop

F.FWD Fast Forward

FG Frequency Generator

FM Frequency Modulation

FREQ. Frequency

fsc Sub Carrier Frequency

F/V Frequency-to-Voltage Converter

FWD Forward

G

G (GRN) Color Signal Green

GEN. Generator

GND Ground

H

H (HORIZ.) Horizontal

HB Hi-Band

HBF Horizontal Burst Flag

HD Horizontal Drive

1 - 7

H

Hi-Fi High Fidelity

HPF High-pass Filter

HSW Head Switch

I

IF Intermediate Frequency or Interface

INDI. Indicator

INST. Instant

INT. Internal

INV. Inverter

I/O In/Out (Input/Output)

IR Infrared Rays

L

LB Low-Band

LCD Liquid Crystal Dissplay

LIN. Linear

LM Loading Motor

LNC Line Noise Canceller

LOG Logarithm

LP Long Play

LPF Low-pass Filter

L/R Left/Right

LUMA Luminance

M

MAN Manual

M.BRAKE Main Brake

M.CUT Monitor Cut

MEM. Memory

MIC Microphone

MIX Mixer

MMV Monostable Multivibator

MOD. Modulator

MPEG Noving Picture coding Experts Group

M.STATE Mechanism State

M.STOP Memory Stop

N

NEG Negative

NFB Negative Feed Back

NOR. (NORM) Normal

NR Noise Reduction

O

OB Optial Black

OSC Oscillator

OSD On-Screen Display

P

PB (PLAY) Playback

PCM Pulse Code Modulation

PG Pulse Generator

PLL Phase Locked Loop

POS. Positive

PROG. Program

PROT. Protector

PWM Pulse Width Modulation

R

R (RED) Color Signal Red

RAM Random Access Memory

REC Record

RECT. Rectifier

REF. Reference

REG. Regulator

REV Review

REW Rewind

RF Radio Frequency

R

ROM Read Only Memory

RSS Reel Sensor Supply

(Supply Reel Sensor)

RST Reel Sensor Take-up

(Take-up Reel Sensor)

R-YL Color Difference Signal R-YL

S

SAW Sawtooth Signal

SC1 (0°) 3.58MHz Subcarrier Signal 1

(0-degree Phase Shifted)

SC2 (90°) 3.58MHz Subcarrier Signal 2

(90-degree Phase Shifted)

SEPA. (SEP) Separator

S/H Samle and Hold

SP Standard Play or Speaker

S.REEL Supply Reel Sensor

SRCH Search

SRV Servo

STABI. Stabilizer

S.TRACK Slow Tracking

STBY Standby Mode

S-VHS Super VHS

SW Switch

SW30Hz 30Hz Head Switching Pulse

(15 or 25Hz) (15 or 25Hz Head Switching Pulse)

SYNC Synchronizing signal

SYS.CON System Control

T

T (TELE) Telephoto Angle

TAPE + Recording Hi-8 Quality Image on Normal

Tape

TBC Time Base Corrector

T.BRAKE Take-up Brake

TP Test Point

T.REEL Take-up Reel Sensor

TRS Transfer

V

V (VERT.) Vertical

V.AGC AGC Voltage

VCO Voltage Controlled Oscillator

VCXO Voltage Controlled Crystal Oscillator

VD Vertical Drive

V.DUB Video Dubbing

VHS Video Home System

VOL. Volume

VP Voltage Pulse

W

W (WIDE) Wide Angle

WHD Wide Horizontal Drive

WHT Color Sifnal White

WHT BAL. White Balance

Y

Y Luminance Signal

Y/C Luminance/Chrominance

YEL (Ye) Color Signal Yellow

YL Luminance Signal (Low Component)

1 - 8

EXTRACT FROM THE INSTRUCTION MANUAL

VM-H775LE VM-E575LE

6

ENGLISH

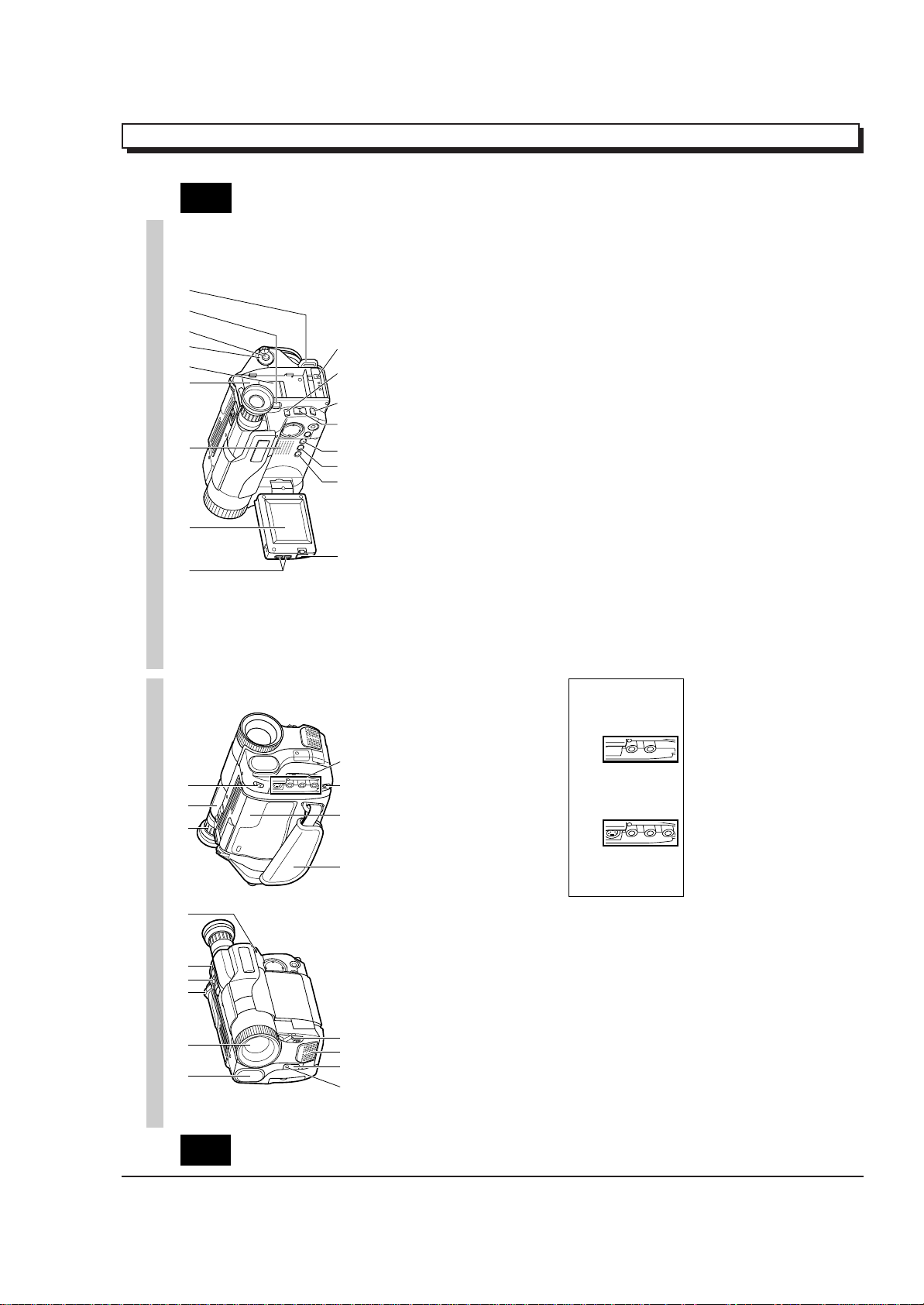

IDENTIFYING CONTROLS

18. LCD Brightness Controls (p9)

19. 2.5-inch LCD Monitor (p9)

20. Speaker (p9)

21. Power Supply Attachment Section

(p16)

22. Clock Battery Compartment (p8)

23. Sub Power Switch (p24)

STANDBY: Pressing the Start/Stop button

will start recording.

LOCK: The camera/recorder will not

enter the record mode even if

the Start/Stop button is

pressed.

24. Start/Stop Button (p24, 28)

This works as a recording Start/Stop

button in the CAM mode and as a playback

pause button in the VIDEO mode.

25. BATT. EJECT Lever (p14)

Sliding, and then holding, this switch,

remove the battery from the camera/

recorder.

26. Shoulder Strap Slot (p12)

27. LCD Monitor OPEN Button (p14)

To open the LCD monitor.

28. DATE Button (p29)

To set the date or display it.

29. TITLE Button (p43)

To select or create a title, or display one.

30. EFFECT Button (p34)

To record digitally processed image or play

back picture with digital effect added.

31. FOCUS Control Buttons (p26, 32)

CAM mode: To switch between auto

focus and manual focus, or

to control focus while in

manual focus mode.

VIDEO mode: To control playback volume.

32. BLC (Backlight Compensation) Button

(p40)

When recording a subject in bright light,

hold this button down to compensate for

lighting on tape.

33. M ENU Button (p20)

To display the menu.

34. DC IN Jack (p17)

Use this jack to power the camera/recorder

from the AC adapter or from battery in

your vehicle.

19 20 21 23 24 25 262218

27

32 343328 29 30 31

[For VM-H775LE/E575LE]

IDENTIFYING CONTROLS

2 3 4 5 11 12 136

1

ENGLISH

jack cover) (p49)

16. Microphone Jack

Connect external microphone (not

supplied) here.

17. Audio/Video Output Jacks (Behind the

9 10 14 15 16 177

8

1. Built-in DC Light (p54) (for VM-H775LE)

2. Lens Door (p24)

The lens door will open automatically

when the camera/recorder is set to the

camera (CAM) mode.

Connect the provided AV cable from this

jack to the AV input jack of your TV or VCR.

The jacks on camera/recorder differ for

each model as follows:

VM-H775LE has S-VIDEO jack and stereo

audio output jacks.

VM-E575LE has monaural audio output

jack.

3. Power Zoom Control (p32)

4. Cassette Eject Switch (p18)

5. Shoulder Strap Slot (p12)

6. Charge Indicator (p13)

7. Record Indicator (p24)

8. Infrared Receiver (p24)

9. Microphone

tape.

10. CAM/OFF/VIDEO Power Switch (p24)

CAM: Set to this position to record.

VIDEO: Set to this position to play back a

11. Diopter Control (p11)

To adjust the viewfinder eyepiece to suit

your eyesight.

12. Electronic Viewfinder (p11)

13. DC Light Switch (p54) (for VM-H775LE)

To switch the DC light between ON, OFF

and AUTO.

14. Hand Strap (p12)

15. Cassette Holder (p18)

Insert cassette here.

5

1 - 9

29

ENGLISH

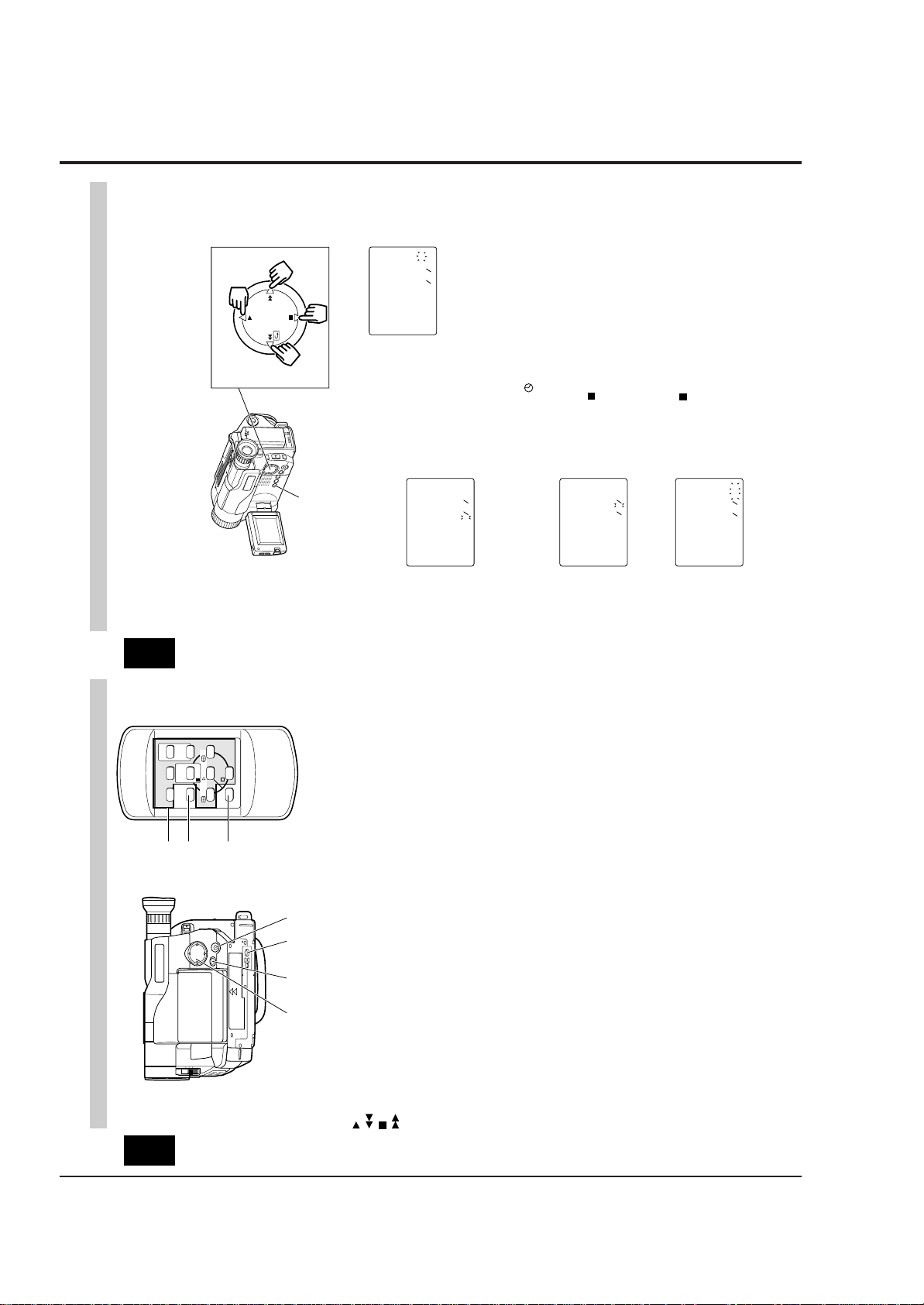

DATE/TIME SETTING

The date and time can be recorded on your tapes to act as a handy reference when

viewing them at a later time. Use the following procedure to set up this display for the

current date and time.

Make sure that the current time is displayed correctly before you start recording.

NOTE: Be sure to insert the clock battery before setting the date and time. Although the

date and time can be set without the clock battery inserted, they will disappear when the

battery providing power to the camera/recorder is removed.

1. Slide the CAM/OFF/VIDEO switch to

“CAM ” .

2. Press the DATE button.

“0:00” and “1/1/2000” appears on the

monitor screen and “ 1” flashes.

3. Press the PLAY or STOP button to select

correct date. Pressing the PLAY button

gives you higher numbers while the

STOP button gives you lower numbers.

When the correct date appears, press

the FF button.

4. Press the PLAY or STOP button to select

correct month. When the correct month

appears, press the FF button.

5. Use the PLAY, STOP and FF buttons to

select the correct year, hour and minute.

6. After setting to the correct minute, press

the DATE button to change the display

and start the internal clock.

It is recommended that you press the

DATE button to match the time signal.

NOTE: After the date and time are set,

“ AUTO” appears and the camera/

recorder enters the automatic date

recording mode. See “DATE RECORDING”

on page 30.

DATE Button

PLAY

STOP

REW FF

Date Select Buttons

000211

00:0

01021

30:6

511

0002

00:0

511

00021

00:0

511

To correct date/time after starting the

date/time

1. Hold down the DATE button for at least

3 seconds: The flashing cursor will

appear at the date.

2. Correct the incorrect digit by using the

PLAY, STOP and FF buttons.

To correct date/time during

programming

1. Press the FF button repeatedly until the

digit that is incorrect flashes.

2. Correct the incorrect digit by using the

PLAY, STOP and FF buttons.

1 - 10

T

W

ZOOM

PLAY F.FWDREW

STOP

PAUSE

TITLE

/STOP

START

ON/OFF

RESET

DISPLAY

COUNTER

A/V DUB

41

40

39

IDENTIFYING CONTROLS

ENGLISH

REMOTE CONTROL

remote control) (p48)

control) (p52)

39. Recorder Remote Control

Same functions as the corresponding

buttons on the camera/recorder.

40. COUNTER RESET Button (only on the

To reset the time counter to 0:00:00.

41. A/V DUB Button (only on the remote

To dub audio and video.

35 36 37 38

35. Tape Transport and Menu Setting

Buttons (p20, 26)

PLAY: To play back tape.

Tape Transport Buttons:

REW: To rewind tape.

FWD: To fast forward tape.

STOP: To stop tape.

Menu Setting Buttons:

To select menu items and set details.

36. FADE Button (p36)

To select the desired fade mode.

37. Tripod Mounting Threaded Socket

38. PROGRAM AE Button (p39)

To change the exposure.

7

To AC Outlet

ENGLISH

Removing the battery pack

Slide the BATT. EJECT lever in the

direction of the arrow and hold it; then

slide the battery to the upper side and

remove.

BATT. EJECT Lever

Operating time

The camera/recorder operating time

depends on how often you turn power on/

off and use start/stop and zoom.

Continuous recording

EVF: when using the viewfinder

LCD: when using the LCD monitor

14

However, if recording pause

continues for more than 5 minutes in

the CAM mode, the camera/recorder

will automatically turn off, after which

charging will start.

If the sub-power switch is set to

LOCK, charging will take place even

when the CAM/OFF/VIDEO switch is

set to CAM.

• If the DC plug is disconnected when

the battery is attached and the

CAM/OFF/VIDEO switch is set to CAM

or VIDEO, the camera/recorder will

turn off once, but then automatically

turn on again. Note that the battery

will discharge if the camera/recorder

is left as it is.

Charging time

Battery

Charging

VM-

BPL13

Full charge

75% charge

3h

1h 50 min.

VM-

BPL30

5h 30 min.

3h 40 min.

VM-

BPL60

9h 50 min.

7h

Reference of charged level

You can know the approximate charge

level of battery by observing how the

BATT. CHARGE indicator of camera/

recorder flashes or lights:

Charge level BATT. CHARGE indicator

0-50% charge

50-75% charge

More than

75% charge

Full charge

Flashes once at approx. one-

second intervals.

Flashes twice at approx. one-

second intervals.

Flashes three times at approx.

one-second intervals.

Steady light

Typical recording

EVF: when using the viewfinder

LCD: when using the LCD monitor

Notes on the battery

• It is recommended that the battery

always be left in the discharged state

when not in use, and charged before

you use it.

• Avoid storing a fully charged battery,

and do not store it in a place where the

temperature is high: this will damage

the battery.

• Do not operate the battery at

temperature below – 10 C or above 45 C.

At extremely low temperatures

operation time decreases, while at high

temperature the battery may be

damaged.

• Do not attach a hot battery to the

camera/recorder. Allow it to cool.

• There are no user-serviceable parts

inside the battery or AC adaptor.

• Throwing the battery into fire or

exposing it to excessive heat (above

60¡C) may cause injury.

• Shorting the battery’s terminal

increases risk of fire or electrical shock.

Battery

VM-BPL13 VM-BPL30 VM-BPL60

EVF

LCD

2h 40 min

2h 15 min

5h 55 min

5h

12h

10h 20 min

VM-H775LE

EVF

LCD

2h 50 min

2h 25 min

6h 15 min

5h 30 min

12h 40 min

11h 10 min

VM-E575LE

Battery

VM-BPL13 VM-BPL30 VM-BPL60

EVF

LCD

1h 35 min

1h 20 min

3h 30 min

3h

7h 10 min

6h 10 min

VM-H775LE

EVF

LCD

1h 45 min

1h 30 min

3h 45 min

3h 15 min

7h 35 min

6h 40 min

VM-E575LE

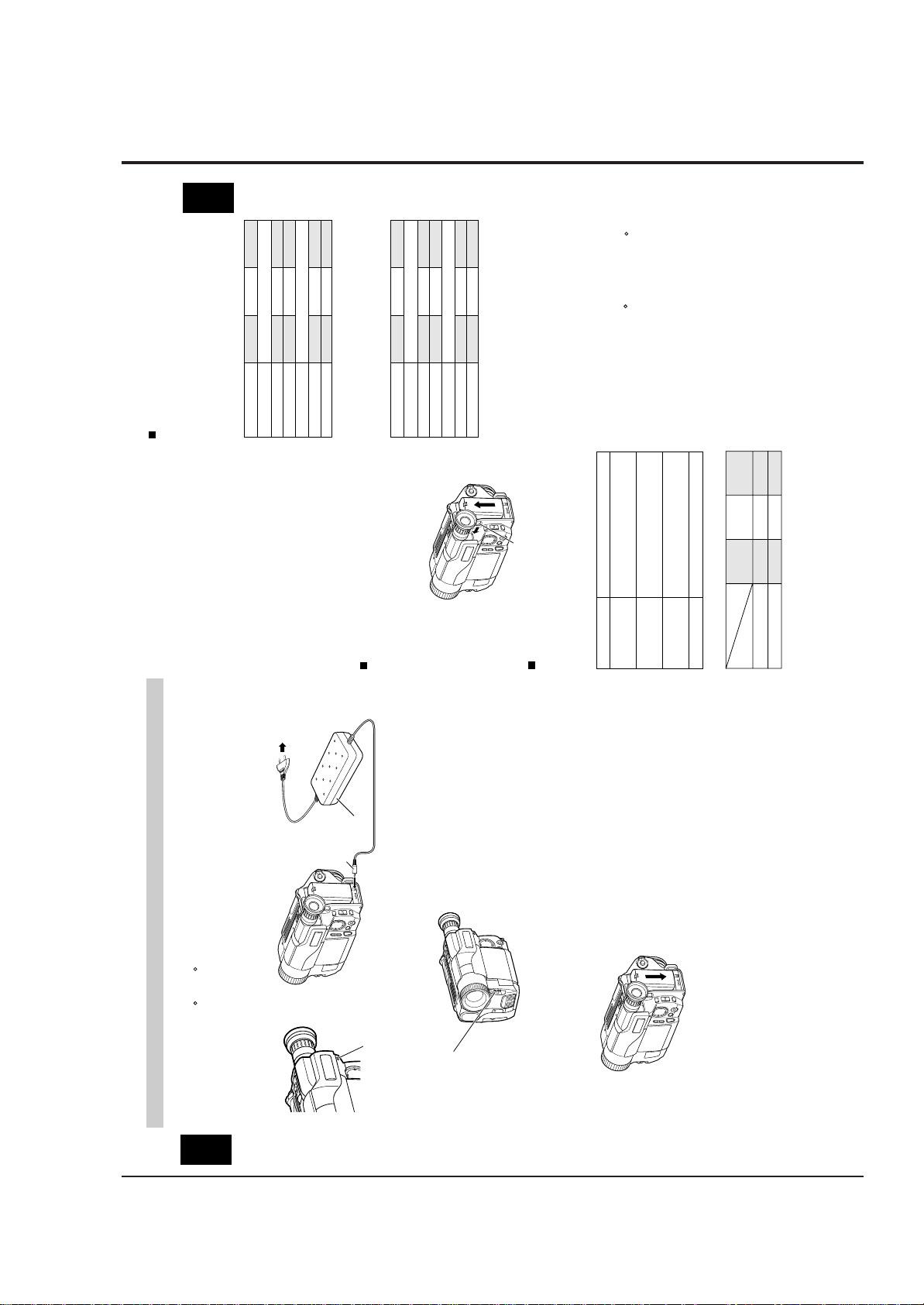

CHARGING THE BATTERY

AC Adaptor

DC Plug

indicator of the camera/recorder will

flash or light to give you a reference of

To DC IN Jack

flashes once every two seconds, the

battery could be defective.

light at all when the AC adaptor is

defective.

the charged level.

NOTES:

• If the BATT. CHARGE indicator

• The BATT. CHARGE indicator will not

completely charged.

• You can use the battery before it is

• When charging is complete, the

BATT. CHARGE Indicator

BPL30/VM-BPL60.

The first step is to set the battery for charging. To charge the battery, attach it to the

when you use battery packs other than those specified.

camera/recorder, and connect the VM-ACE5E AC adaptor. Charge the battery at a

temperature range of 10 C – 30 C to prevent damage to the battery.

NOTES:

• This camera/recorder operates with a lithium ion battery such as VM-BPL13/VM-

• We cannot be responsible for any malfunctions of the camera/recorder which occur

ENGLISH

set to OFF position.

CAM/OFF/VIDEO

Charge the battery on a flat surface that is

free of vibration.

Switch

1. Make sure the CAM/OFF/VIDEO switch is

2. Attach the battery pack to the camera/

BATT. CHARGE indicator on the

camera/recorder will light. If the fully

charged battery is removed and then

re-attached, the camera/recorder will

again enter the charge mode, and the

BATT. CHARGE indicator will flash. It

will take a few minutes for the

camera/recorder to enter the charge

complete status.

decrease charge capacity.

• Charging at low temperatures will

the AC adaptor DC plug from the

5. After charging is complete, disconnect

platform and slide it down so that it

fits into the camera/recorder.

recorder.

• Place the battery on the guide

camera/recorder after use.

OFF/VIDEO switch of the camera/

camera/recorder.

outlet.

recorder.

NOTES:

6. Disconnect the AC plug from the AC

NOTE: Always attach a battery only by

the procedure described here.

Attaching a battery forcibly could

• Always remove the battery from the

7. Detach the battery from the camera/

damage it.

AC outlet.

3. Plug the AC adaptor power cord into an

4. Connect the AC adaptor DC plug to the

recorder is set to CAM or VIDEO.

• Charging is not done when the CAM/

DC IN jack of the camera/recorder.

Charging will start within five seconds.

During charging, the BATT. CHARGE

13

1 - 11

20

ENGLISH

ITEMS SELECTABLE WITH MENU DISPLAYS

The items that can be selected depend on the position of CAM/OFF/VIDEO switch.

NOTE: The VM-H775LE menu displays are used for the following explanation. Some

items do not appear, depending on the model.

Menu selectable in the CAM mode

When the MENU button is pressed, the following menu display will appear:

M

ENU

EIS

W

H I T E BA L . AUTO

D.ZOO

M

X100

TAPE+ OFF

ATRS OFF

DISPLAY LCD

DE

M

O.

<>

END

AUTO

OFF

M

ENU

To correct camera shake (p41).

To lock the white balance

(p40).

To record in optimum status

to match tape being used

(p23) (only for VM-H775LE).

To turn the on-screen display

on or off (p22).

To select the demonstration

mode (p22).

To select the digital zoom

mode (p33).

To upgrade normal tape

(p23) (only for VM-H775LE).

Menu selectable in the VIDEO mode

Pressing the MENU button will display the following:

M

ENU

TBC

PAL CONV . OFF

DISPLAY LCD

<>

END

ON

M

ENU

To ensure playback of

stable pictures (p42).

To view NTSC tape

recorded in SP mode (p53).

To turn the on-screen

display on or off (p22).

How to select items and set them

1. Press the MENU button.

2. Press the PLAY or STOP button to select

the desired item.

3. Use the FF or REW button to select the

desired mode.

4. Press the MENU button again to

determine the mode.

PLAY

STOP

REW FF

To select an item whose

mode you wish to change.

Press PLAY to move the

cursor up.

To select the mode of the

item you have chosen.

To select an item whose

mode you wish to change.

Press STOP to move the

cursor down.

Memo

1 - 12

CHAPTER 2 DISASSEMBLY

1. BEFORE STARTING DISASSEMBLY

(1) Dismantle and reassemble the mechanism in loading

stop status, except for the following components:

Cassette Lid

Top Cover

Parts on the UH mechanism

Note: After dismantling or resembling the cassette lid

or top cover, return the mechanism to loading

stop status.

(2) For manually operating the mechanism (unloading or

loading), refer to: "How to Operate the Mechanism

Manually".

(3) Dismantle each component according to "1.1

Disassembly Procedure".

(4) For reassembly, perform the reverse procedure to

disassembly when not otherwise specified.

(5) Disconnect flat cables from connectors by the proce

dure shown in Fig. 1-1. Since many circuit boards in

the camera/recorder are connected by in-board

connectors, be sure to follow DISASSEMBLY when

removing the circuit boards.

(1) Release the lock of the connector on the left and right

simultaneously.

(2) Pull out the flat cable.

(1)

(1)

(2)

Fig. 1-1

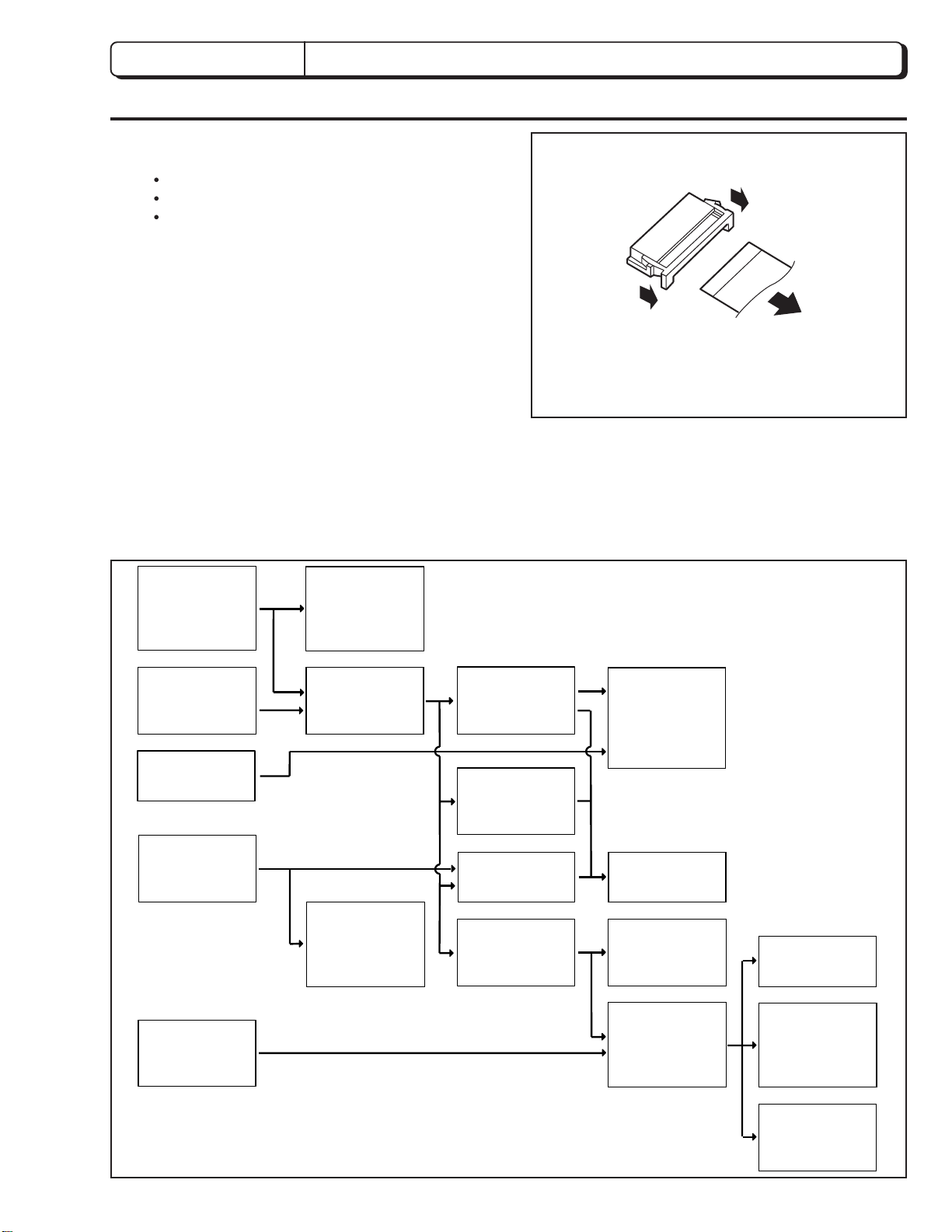

1.1 Disassembly Procedure

Jack Cover,

Front Cover

Assembly [2.1]

Lens Cover [2.1]

Eye Piece [2.10]

LCD Case-U,

LCD Block [2.3]

PSW Circuit Board,

Microphone Unit,

DC Light,

Front Cover [2.2]

L-Case Assembly,

R-Case Assembly

[2.4]

LCD Circuit Board,

Back Light,

LCD Module,

LCD Case-B [2.9]

EVF Assembly

[2.5]

Speaker,

CON Circuit Board

[2.5]

Fulcrum [2.5]

Camera Chassis

Assembly [2.6]

EVF Case-R,

EVF Case L,

[2.10]

L-Case [2.5]

Lens Frame, Lens,

SE Circuit Board,

CCD Sensor [2.6]

Power Terminal

Unit [2.6]

Cassette Lid,

Top Cover [2.3]

(Note 1)

Note 1: Dismantle or reassemble these parts in loading

stop status; after finishing, return the mechanism

to loading stop status.

VCR Chassis

Assembly,

Jack Unit,

Rear Cover [2.6]

VCA Circuit Board,

Mechanism Frame,

UH Mechanism

[2.7]

Hand Strap,

TW/PW Switch,

R-Case [2.8]

2 - 1

2. CASES AND CIRCUIT BOARDS REMOVAL

A

2.1 Jack Cover, Front Cover Assembly, Lens Cover (Fig. 2-1)

Note:Some models are not equipped with the DC light.

Cautions:

Be careful not to damage the cables of the microphone.

LENS

COVER

Reinstallation procedure and caution:

The O-ring must be installed in the position shown in Fig.

2-1.

DISCONNECT

CONNECTOR

[For DC LIGHT]

RELEASE

TWO

TABS

O-RING

JACK

COVER

FRONT COVER

ASSMBLY

GOOD

O-RING

NO GOOD

LENS

SURFACE

REMOVE

ONE

SCREW

VCA

CIRCUIT

BOARD

REMOVE

TWO

SCREWS

DISCONNECT

TWO

CONNECTORS

Fig. 2-1

2.2 PSW Circuit Board, Microphone Unit, DC Light, Front Cover (Fig. 2-2)

Note:Some models are not equipped with the DC light.

Reinstallation procedure and caution:

Take care with the orientation of the microphone when

reinstalling it: The red wire is for the left side; the white

lead is for the right side.

DJ. LID

DC

LIGHT

REMOVE

ONE

SCREW

FRONT

COVER

MICROPHONE

(MIC)

MIC

PLATE

PSW CIRCUIT

BOARD

REMOVE

TWO

SCREWS

REMOVE

ONE

SCREW

Fig. 2-2

2 - 2

2.3 LCD Case-U, LCD Block, Cassette Lid, Top Cover (Figs. 2-3-1, 2-3-2)

(C)

(B)

FLAT-BLADED

SCREW DRIVER

REMOVE

TOP

COVER

TOP

COVER

SUB CHASSIS

PLATE

SPRING

Cautions:

1. Dismantle and reassemble only the cassette lid and top

cover in loading stop status. After work is completed,

return the mechanism to loading stop status.

2. Be careful that the LCD screen is not damaged or

smudged. (If dirt adheres to it, use a soft cloth to wipe it

off.)

3. Handle the LCD module and backlight with extreme

care.

(A)

RELEASE

TWO T ABS

CASSETTE

LID

TOP COVER

REMOVE

TWO

SCREWS

Advise of Top Cover Removal

Insert a flat-bladed screwdriver between the top cover and

sub chassis, and push section (B) of the plate spring in the

direction of arrow (C), to remove the top cover in the

direction of the arrow. (See Fig. 2-3-2)

Reinstallation procedure and caution:

To install the cassette lid, first engage sections (A) with the

cassette holder.

REMOVE

TWO

SCREWS

LCD

CASE-U

REMOVE

ONE

SCREW

Fig. 2-3-1

RELEASE

FIVE T ABS

DISCONNECT

TWO

CONNECTORS

LCD BLOCK

Fig. 2-3-2

2 - 3

2.4 L-Case Assembly, R-Case Assembly (Fig. 2-4)

Caution:

Be careful so as not to damage the connectors (PG951

and PG731) between the VCA and CON circuit boards.

L-CASE

ASSEMBLY

R-CASE

ASSEMBLY

Reinstallation procedure and caution:

Connect connectors PG951 and PG731 securely.

REMOVE

TWO

SCREWS

2 - 4

PG731

CON

CIRCUIT

BOARD

REMOVE

FOUR

SCREWS

PG951

Fig. 2-4

VCA

CIRCUIT

BOARD

2.5 Electronic Viewfinder (EVF) Assembly, Speaker, CON Circuit Board, Fulcrum, L-Case

(Figs. 2-5-1, 2-5-2)

Cautions:

Be careful not to damage the LCD Open/Close switch on

the CON circuit board.

REMOVE

FULCRUM

L-CASE

TWO

SCREWS

DISCONNECT

CONNECTOR

[To SPEAKER]

EVF

ASSEMBLY

Reinstallation procedure and caution:

When reinstalling the EVF assembly, speaker, CON

circuit board and fulcrum, lay out each cable as shown

in Fig. 2-5-2.

DISCONNECT

THREE

CONNECTOR

[To LCD]

S

DISCONNECT

CONNECTOR

[To EVF]

REMOVE

THREE

SCREWS

CON

CIRCUIT

BOARD

REMOVE

THREE

SCREWS

Fig. 2-5-1

SPEAKER

EVF

ASSEMBLY

REMOVE

TWO

SCREWS

SP

BRACKET

SPEAKER

BOSS

CLOTH TAPE

CON CIRCUIT

BOARD

L-CASE

FULCRUM

Fig. 2-5-2

2 - 5

2.6 Camera Chassis Assembly (Lens Frame, Lens, SE Circuit Board, CCD Sensor),

VCR Chassis Assembly, Jack Unit, Rear Cover, Power Terminal Unit (Fig. 2-6)

Cautions:

1. Be careful so as not to damage the connectors (PG201

and PG1001) between the VCA and SE circuit boards.

2. Be careful so as not to damage the connectors

between the VCA circuit board (PG0001) and rear

cover (power terminal unit).

3. Be careful not to damage the crystal filter and CCD

sensor.

REMOVE

ONE

SCREW

VTR CHASSIS

ASSEMBLY

DISCONNECT

FLAT CABLE

DISCONNECT

CAMERA

CHASSIS

ASSEMBLY

FLAT CABLE

Reinstallation procedure and caution:

1. Connect connectors PG201 and PG1001 securely.

2. Connect connectors PG0001 and rear cover (power

terminal unit) securely.

3. The crystal filter is non-directional.

4. Fit in the CCD sensor parallel to the SE circuit board,

fix it with screws, and then solder it.

JACK

UNIT

A

R-CASE

RELEASE

PG201

DISCONNECT

CONNECTOR

ONE T AB

A

REMOVE

THREE

SCREWS

LENS

CRYSTAL

FILTER

SHADING

RUBBER

REMOVE

THREE

SCREWS

LENS

FRAME

CCD

SENSOR

UNSOLDER

FOURTEEN

POINTS

SE

CIRCUIT

BOARD

PG1001

Fig. 2-6

VCA

CIRCUIT

BOARD

REMOVE

TWO

SCREWS

REMOVE

TWO

SCREWS

DISCONNECT

FLAT CABLE

PG0001

REMOVE

ONE

SCREW

POWER

TERMINAL

UNIT

RELEASE

THREE

TABS

REAR

COVER

REMOVE

ONE

SCREW

2 - 6

2.7 VCA Circuit Board, Meacanism Frame, UH Mechanism (Fig. 2-7)

D

C

UH

MECHANISM

VCA CIRCUIT

BOARD

ISCONNECT

ONNECTOR

DISCONNECT

TWO

FLAT CABLES

REMOVE

ONE

SCREW

MECHANISM

FRAME

DISCONNECT

THREE

FLAT CABLES

HEAD

SHIELD

RELEASE

TWO T ABS

REMOVE

THREE

SCREWS

Fig. 2-7

2.8 Hand Strap, TW/PW Switch, R-Case (Fig. 2-8)

Cautions:

Be careful not to damage the flat cable of the TW/PW

switch.

HAND

STRAP

R-CASE

TW/PW

HOLDER

REMOVE

TWO

SCREWS

REMOVE

ONE

SCREW

REMOVE

TWO

SCREWS

SWITCH

HOLDER

HAND

STRAP

Fig. 2-8

2 - 7

2.9 LCD Circuit Borad, Back Light, LCD Module, LCD Case-B (Fig. 2-9)

Cautions:

1. Be careful that the LCD screen is not damaged or

smudged. (If dirt adheres to it, use a soft cloth to wipe it

off.)

2. Handle the LCD module and backlight with extreme

care.

LCD

MODULE

LCD CASE-B

REMOVE

TWO

SCREWS

DISCONNECT

TWO

FLAT CABLES

REMOVE

ONE

SCREW

LCD

CIRCUIT

BOARD

BACK

LIGHT

Fig. 2-9

2.10 EVF Case-R, EVF Case-L, Eye Piece (Fig. 2-10)

Cautions:

1. Be careful not to damage the CRT.

EVF

BASE

EVF

CASE-R

CRT

TURN

BASE

REMOVE

TWO

SCREWS

REMOVE

TWO

SCREWS

2 - 8

EVF

CASE-L

EYE PIECE

Fig. 2-10

3. HOW TO OPERATE THE MECHANISM MANUALLY

CAUTION

Perform this procedure for emergency only when

normal loading or unloading is not possible because

the electrical circuits or loading motor is defective.

(1) Remove the r-case assembly. (See Figs. 2-4-1,

2-4-2)

(2) Disconnect connector (CN604) from PG604 on the

VCA circuit board, and supply 4V DC to CN604

(directly to the loading motor). (See Fig. 3-1)

Connecting CN604 brown wire (+) and red wire (-)

results in unloading.

Connecting CN604 red wire (+) and brown wire (-)

results in loading.

R-CASE

UH

MECHANISM

Note: To unload the mechanism with a tape inserted,

manually turn the capstan motor simultaneously

to take up the tape.

If loading or unloading does not occur even when 4V DC is

directly supplied to the loading motor, perform the following procedure:

(3) Remove the camera chassis assembly and rear

cover. (See Fig. 2-6)

Note: Note that it is difficult to remove the rear cover.

VCA

CIRCUIT

BOARD

PG604

CN604

Fig. 3-1

(4) Disconnect 3 flat cables. (See Fig. 3-2)

(5) Disconnect connector. (See Fig. 3-2)

(6) Remove 1 screw holding the head shield. (See Fig.

3-2)

(7) Disconnect 2 flat cables. (See Fig. 3-2)

(8) Remove 3 screws. (See Fig. 3-2)

(9) Remove the UH mechanism in the direction of the

arrow from the r-case. (See Fig.3-2)

(10) Remove the cassette lid and top cover. (See Figs.

2-3-1, 2-3-2)

REMOVE

THREE

VCA

CIRCUIT

BOARD

DISCONNECT

CONNECTOR

DISCONNECT

TWO FLAT

CABLES

REMOVE

ONE

SCREW

MECHANISM

FRAME

DISCONNECT

THREE

FLAT CABLES

SCREWS

Fig. 3-2

(11) Release 2 tabs and pull out the loading motor from

the loading motor holder. (See Fig. 3-3)

Note: The above removal is different from normal

removal. In normal circumstances, remove the

loading motor assembled with the loading motor

holder. (The loading motor and loading motor

holder comprise an assembly.)

(12) Turn over the mechanism. (See Fig. 3-3)

Note: Do not turn over with the idler cover removed.

(13) Use a flat-bladed screwdriver, etc. to turn cam gear

(A) or (B). (See Fig. 3-3)

Turning it in the direction of the arrow will unload the

mechanism, and turning it in the opposite direction to

the arrow will load the mechanism.

Notes: 1. Be careful not to damage the cam gears.

2. To unload the mechanism with a tape inserted,

manually turn the capstan motor simultaneously

to take up the tape.

2 - 9

LOADING

MOTOR

RELEASE

TWO

TABS

LOADING

MOTOR

HOLDER

CAM

GEAR

(B)

CAM

GEAR

(A)

Memo

Fig. 3-3

2 - 10

CHAPTER 3 ELECTRIC CIRCUIT ADJUSTMENT

Trademark

MS-DOS is a registered trademark of Microsoft

Corporation.

1. CONNECTION FOR ADJUSTMENT

1.1 Before Starting Adjustment

(1) Set the date. (If the camera/recorder is left for

several minutes with no date set after power is

turned on, it will automatically enter the demo mode.)

Notes: 1. Perform the electric circuit adjustments using a

personal computer.

DC POWER

SUPPLY

(0-8V/3A)

Abbreviation

MAP: Digital adjustment program.

DSP:Digital signal processor

2. It is not necessary to remove cases for electric

circuit adjustments.

3. The ODC DC cord is a jig which is to be used in

the Power Shut Off Level (ODC) Adjustment.

For other adjustments, the AC adapter can be

used as a power supply.

ODC DC CABLE

[For ODC Adj.]

To AC ADAPTER

COLOR

VIDEO

MONITER

8 - 20PIN

EXTENSION

CABLE

DSP AV

OUTPUT

JIG

YEL

BLK

WHT

PG905

VCA

CIRCUIT

BOARD

RED

YEL

BLK

WHT

8-20PIN

EXTENSION

CABLE

DC POWER

SUPPLY

(5V/1A)

BLK

DSP-R JIG

PERSONAL

COMPUTER

RS232-C

CABLE

Fig. 1-1 Connection for adjustment

3 - 1

2. CAMERA SECTION ADJUSTMENT

2.1 Test Equipment Necessary for

Adjustment

Oscilloscope (dual trace) [& Vectorscope]

Digital Voltmeter (DVM)

Color Video Monitor

Adjustment Floppy Disk

Personal Computer

Personal Computer 9-pin or 25-pin (RS232C) Cable

DSP-R Jig

DSP AV Output Jig

8 - 20 Pin Extension Cable

Light Box (3100 K)

Light Balancing Filter C12

DC Power Supply (DC5 V/1 A)

AC Adapter or

DC power supply (DC7 V/3 A) and ODC DC code

2.2 List of Charts for Camera Adjustment

Table 2-1

Gray Scale Chart

Backfocus

Adjustmant

Chart

Color Bar Chart

Resolution Chart

2.4 Preset Positions of Switches and

Controls During Adjustment

Note: Some models do not have switches (modes)

marked "#".

CAM/OFF/VIDEO switch

SUB POWER switch

DC LIGHT switch [#]

................................................

DATE

................................................

TITLE

EFFECT

BLC

MENU

EIS on the MENU [#]

PROGRAM AE [#]

FOCUS

FADE

............................................

...................................................

...............................................

.............................................

................................................

Caution

1. Since the adjustment program is subject to change

for improvements, computer displays may be

different from those shown in this manual. In such

cases, follow the computer displays for adjustment.

2. The computer displays may be different from those

shown in this manual, depending on the destination

of models and whether or not certain functions are

provided. In such cases, follow the computer displays

for adjustment.

...................

.........................

.........................

........................

.............................

"CAM" position

"STANDBY" position

"OFF" position

Not display mode

Not display mode

OFF mode

OFF mode

Not display

OFF mode

AUTO mode

Autofocus mode

OFF mode

2.3 Adjustment Conditions

1. Check that the VCR section has been adjusted

correctly before adjusting the camera section.

2. Use a light box with minimum flickering.

Control the color temperature of the light box strictly.

3. When using the video out jack to perform adjustment,

be sure to terminate the video out jack with 75 ohms.

4. Place the light box approx. 30 cm away from the

camera (lens surface) when otherwise not specified.

5. Point the camera at the chart to full the video period

when otherwise not specified.

6. Use the 10:1 probe of the oscilloscope when otherwise

not specified.

7. When "Trigger the oscilloscope internally" is specified,

set the time base of the oscilloscope to 10µs/div.

3 - 2

2.5 Check After Replacing Major Components in the Camera Section

After replacing major components, perform adjustments, referring to the table below.

The following table shows the minimum adjustments required after major components are replaced.

The table below may not apply when several components are replaced, depending on the symptom of the defect.

Caution: When EEPROM or the VCA circuit board is replaced, initialize the EEPROM, referring to "2.6.3 Initial

Setting by Model" then perform all the camera section and system control/servo circuits adjustments.

Table 2-2

ITEM NAME OF MAJOR COMPONENTS

No. NAME OF ADJUSTMENT SE VCA IC1001 IC1104 IC1105 IC1201 IC1401 Lens

Circuit Circuit IC1402 Block

Board Board IC1403

INITIAL SETTING BY MODEL

DIGITAL ADJUSTMENT PROCEDURE

(1) Auto Iris Control Adjustment

(2) White Balance Adjustment

(3) Chroma Gain Adjustment

AUTOFOCUS ADJUSTMENT PROCEDURE

(1) Zoom Trace Adjustment

(2) AF Noise Level Adjustment

STABILIZER ADJUSTMENT

PROCEDURE [Except for VM-E578

LE(AU)/E578LE(SW)]

SPOT NOISE ADJUSTMENT

PROCEDURE

2.6 Adjustment Procedure

Notes: 1. To complete adjustment, press the [ESC]

(escape) key twice to restore the MS-DOS

screen and then turn off the camera/recorder

and jig.

2. The following describes an example of the

instructions of the personal computer and the

menu display; they are different depending on

the personal computer manufacturer and model.

Refer to the instruction manual of personal

computer.

3. When the error message appears during

adjustment, refer to "4. Error Message".

If a key is pressed after an error message

appears, the ADJUSTMENT MENU is restored.

2.6.1 Connections for Adjustment

Connect the camera/recorder, DSP jig, personal computer,

power supply, etc. as shown in Fig. 1-1.

Check that the camera/recorder is turned on.

3 - 3

2.6.2 How to Start the MAP

(1) Turn the personal computer on and start the MS-

DOS system.

Note: Refer to the instruction manual of the personal

computer for how to start computer.

(2) Load the adjustment floppy disk in to disk drive A

and press A: [ENTER]. (Display 2-1)

(3) Press MAP_IBM [SPACE] 1 [ENTER]. (Display 2-2)

Note: When you use a personal computer with two serial

interface connectors and connect the DSP jig to

serial interface connector 2, press MAP_IBM 2.

(4) Select the number accodding to the model.

(Display 2-3)

If [ESC] (escape) is pressed, the display before the

MAP starts (MS-DOS) is restored.

Notes: 1. If the required model is not found, press the P

key and select the model from the next screen.

2. If you select number without a model name by

mistake, the message shown in "MESSAGE

WHEN OPERATED BY MISTAKE" will appear

in the computer's display (Display 2-4).

Press any key to return the display to MODEL

SELECT dispaly.

(5) Press Y key. (Display 2-5)

If N key is pressed, the computer's display returns to

MODEL SELECT display.

(6) Refer to display 2-6.

2.6.3 Initial Setting by Model

Before Starting Initial Setting

1. This item describes how to initialize the EEPROM.

Be sure to perform this item after replacing EEPROM

or the VCA circuit board.

When other components are replaced, normally, it

is not necessary to initialize the EEPROM.

2. Be sure to perform the following adjustments after

completing the initial setting.

2.6.4 Digital Adjustment Procedure

2.6.5 Autofocus Adjustment Procedure

2.6.6 Stabilizer Adjustment Procedure

[Except for VM-E578LE(AU)/E578LE(SW)]

2.6.7 Spot Noise Adjustment Procedure

2.7 Color LCD Monitor Adjustment

3.5 System Control/Servo Circuits Adjustment

(1) Start the MAP.

(2) Refer to display 2-6.

(3) Press A key.

(4) Refer to display 3-1.

(5) Press Y key to start.

Note:Press N to return to MAIN MENU display.

(6) Perform adjustment according to the computer

display hereafter.

See "4. Error Messages" if an error message

appears on the computer display.

Display & Figs

Display 2-1

C>A:

A>

Display 2-2

C>A:

A>MAP_IBM 1

Display 2-3

***********************************************************

***********************************************************

MODEL SELECT

[1] ЧЧЧЧЧЧЧЧ

[2] ЧЧЧЧЧЧЧЧ

[3] ЧЧЧЧЧЧЧЧ

[4] ЧЧЧЧЧЧЧЧ

[5] ЧЧЧЧЧЧЧЧ

[P] NEXT SELECTION

[ESC] END

Please select the type of the set

Press [1] - [5] or [P] or [ESC]

3 - 4

Display 2-4

MESSAGE WHEN OPERATED BY

MISTAKE

Display 2-5

CAN NOT FIND THE DATA FILE

**** PRESS ANY KEY ****

Selected model is ЧЧЧЧЧЧЧЧ

Are you sure ? (Y/N)

Display 2-6

MAIN MENU

***********************************************************

MANUAL ADJUSTMENT PROGRAM

***********************************************************

Display 3-1

[A] DATA INITIALIZE

[B] ADJUSTMENT

[C] VCR ADJUSTMENT

[D] AUTO FOCUS

[E] STABILIZER

[F] SPOT NOISE

[G] LCD

[ESC] END

Please select [A] - [G] or [ESC]

<< DATA WRITING >>

START TO SEND DATA. (Y/N)

2.6.4 Digital Adjustment Procedure

Before Starting Adjstment

When EEPROM or the VCA circuit board is replaced,

initialize the EEPROM, referring to "2.6.3 Initial Setting By

Model" then perform all the digital adjustments.

(1) Start the MAP.

3) Refer to display 4-2.

4) Press any key to return to ADJUSTMENT MENU

display.

5) Turn the power off for 5 seconds and then on again.

(2) Refer to display 2-6.

(3) Press B key.

(4) Refer to display 4-1.

(5) Select the number of the required adjustment.

Notes: 1. If [ESC] (escape) is pressed, the computer's

display returns toMAIN MENU display.

2. To complete adjustment, press the [ESC]

(escape) twice to restore the MS-DOS screen

and then turn off the camera/recorder and jig.

(1) Auto Iris Control Adjustment

Purpose:

To set the iris control data.

Incompleted Phenomenon:

The picture becomes too bright.

The picture becomes too dark.

Condition:

Point the camera at the light box without a chart to

full the screen (at wide-angle).

Procedure:

1) Refer to display 4-1.

2) Press 1 key.

Perform adjustment according to the computer

display hereafter.

See "4. Error Messages" if an error message appears

on the computer display.

(2) White Balance Adjustment

Purpose:

To set white balance under the color temperature

which becomes a reference for the auto white balance

circuit.

Incompleted Phenomenon:

Color of the subject is different from that of the picture.

A white subject is not seen as white.

Test Point:

Video Out Jack

Condition:

Attach a C12 filter.

Point at a gray scale chart (at wide-angle).

Procedure:

1) Refer to display 4-1.

2) Press 2 key.

3) Refer to display 4-3.

4) VM-H675LA/H675LA(K):

Press 0 (ZERO) C to input the data.

VM-E575LA/E575LA(K)/E573LA/E573LA(K):

Press 0 (ZERO) C to input the data.

VM-H775LE:

Press 0 (ZERO) A to input the data.

VM-E578LE(AU)/E578LE(SW)/E575LE:

Press 0 (ZERO) D to input the data.

5) Press [Enter] key, and the display changes as follows.

Display & Figs

Display 2-6

MAIN MENU

***********************************************************

MANUAL ADJUSTMENT PROGRAM

***********************************************************

[A] DATA INITIALIZE

[B] ADJUSTMENT

[C] VCR ADJUSTMENT

[D] AUTO FOCUS

[E] STABILIZER

[F] SPOT NOISE

[G] LCD

[ESC] END

Please select [A] - [G] or [ESC]

Display 4-1

ADJUSTMENT MENU

***********************************************************

***********************************************************

ADJUSTMENT

[1] AUTO IRIS CONTROL

[2] WHITE BALANCE

[3] CHROMA GAIN

[ESC] RETURN TO MAIN MENU

Please select [1] - [3] or [ESC]

Display 4-2

Display 4-3

Display 4-4

ADJUSTMENT FINISHED

PRESS ANY KEY

<< WHITE BALANCE ADJUSTMENT >>

INPUT DATA OF OFFSET FOR R-B --> 00

<< WHITE BALANCE ADJUSTMENT >>

INPUT DATA OF OFFSET FOR Mg-G --> 00

3 - 5

6) Refer to display 4-4.

7) VM-H675LA/H675LA(K):

Press 0 (ZERO) C to input the data.

VM-E575LA/E575LA(K)/E573LA/E573LA(K):

Press 0 (ZERO) C to input the data.

VM-H775LE:

Press 1 (ZERO) 6 to input the data.

VM-E578LE(AU)/E578LE(SW)/E575LE:

Press 0 (ZERO) D to input the data.

Condition:

Attach a C12 filter.

Point at a color bar chart.

Procedure:

1) Refer to display 4-1.

2) Press 3 key.

3) Rerer to dispaly 4-5.

8) Press [Enter] key.

Perform adjustment according to the computer

displayhereafter.

See "4. Error Messages" if an error message

appears on the computer display.

(3) Chroma Gain Adjustment (Figs. 2-1, 2-2, 2-3)

Purpose:

To set the color saturation under the reference color

temperature.

Incompleted Phenomenon: