HITACHI SP 18SA User guide

MODEL SP 18SA

1. PRECAUTIONS IN DISASSEMBLY AND REASSEMBLY

The [Bold] numbers in the descriptions below correspond to the item numbers in the Parts List and exploded

assembly diagram for SP 18SA.

1-1. Disassembly of the Armature Ass'y and the Lock Lever Ass'y

(1) Loosen the two Brush Caps [27], and take out the Carbon Brushes [26].

(2) Remove the four Tapping Screws D5 x 55 [7], and remove the Gear Cover [8], and related parts.

The Armature Ass'y [17] can then be taken out together with the Inner Cover [12], the Lock Lever [14] , and

related parts.

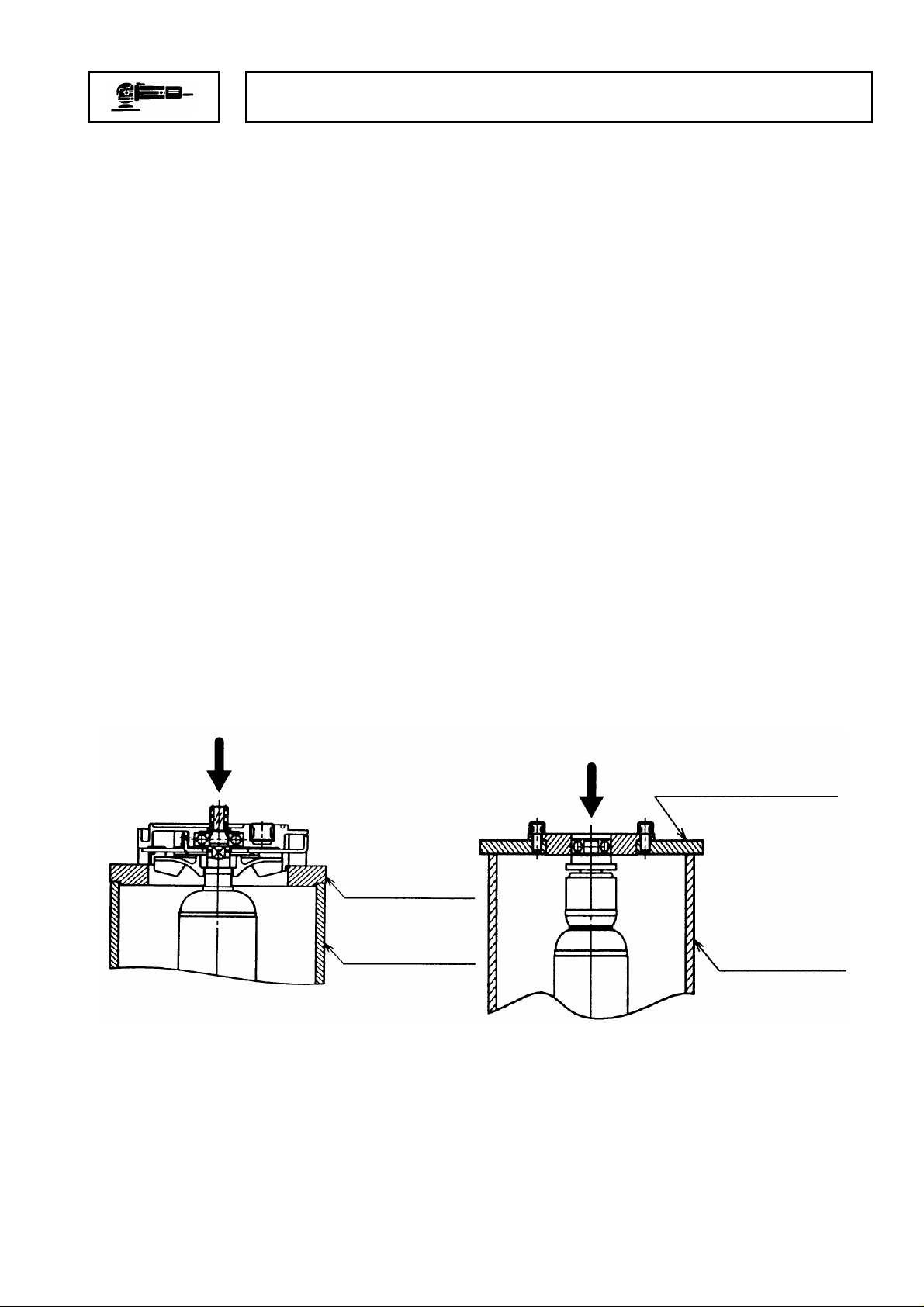

(3) As illustrated in Fig. 1, the Inner Cover [12], and related parts can be removed from the Armature Ass'y [17],

and related parts by utilizing a J-130 sleeve (special repair tool, Code No. 970907) and a J-131 plate (special

repair tool, Code No. 305711).

(4) The Ball Bearing [13] can be removed from the Armature Ass'y [17] by utilizing the J-30 bearing puller ass'y

(special repair tool, Code No. 970804).

After the Ball Bearing has been removed, the Lock Lever [14] can be easily taken off.

(5) As illustrated in Fig. 2, the Ball Bearing [19] can also be removed from the Armature Ass'y [17] by utilizing the

J-130 sleeve (special repair tool, Code No. 970907) and a J-204 bearing puller (special repair tool, Code No.

970982).

After the Ball Bearing has been removed, the Dust Seal [18] can be easily taken out.

Push the rear of the

Push

J-131 plate

(Code No. 305711)

J-130 sleeve

(Code No. 970907)

armature shaft

J-204 bearing puller

(Code No. 970982)

J-130 sleeve

(Code No. 970907)

Fig.1 Fig.2

--- 1 ---

1-2. Disassembly of the Stator Ass'y

(1) After taking off the Armature Ass'y [17], loosen the five Tapping Screws D4 X 20 [30] and remove the Tail

Cover [29], the Handle Cover [33] and the Fan Guide [20].

(2) Disconnect the lead wires of the Stator Ass'y [21] from Switch (C) [37].

Then, disconnect the lead wires of Noise Suppressor [34].

(3) Disconnect the Brush Terminals [22] from the Brush Holders [25].

(4) Loosen the two Hex. Hd. Tapping Screws [31], and remove the lead wire of the Noise Suppressor [34].

And pull out the lead wires of the Stator Ass'y [21] from the Housing Ass'y [23]. Then, the Stator Ass'y can be

taken out of the Housing Ass'y [23]. If the Stator Ass'y [21] cannot be easily taken out of the Housing Ass'y

[23], disassembly can be facilitated by heating the Housing Ass'y to a temperature of approximately 60 ˚C

(140 ˚F) in an appropriate heating oven.

1-3. Disassembly of the Final Gear and the Ball Bearing

(1) Loosen the four Tapping Screws D5 x 55 [7], and remove the Gear Cover [8], together with the Spindle [4], the

Final Gear [16], and the related parts as a single unit. Then, the Second Pinion [10] and Washer [11] can be

removed easily.

(2) Remove the Bearing Caps [3] with the J-21 wrench.

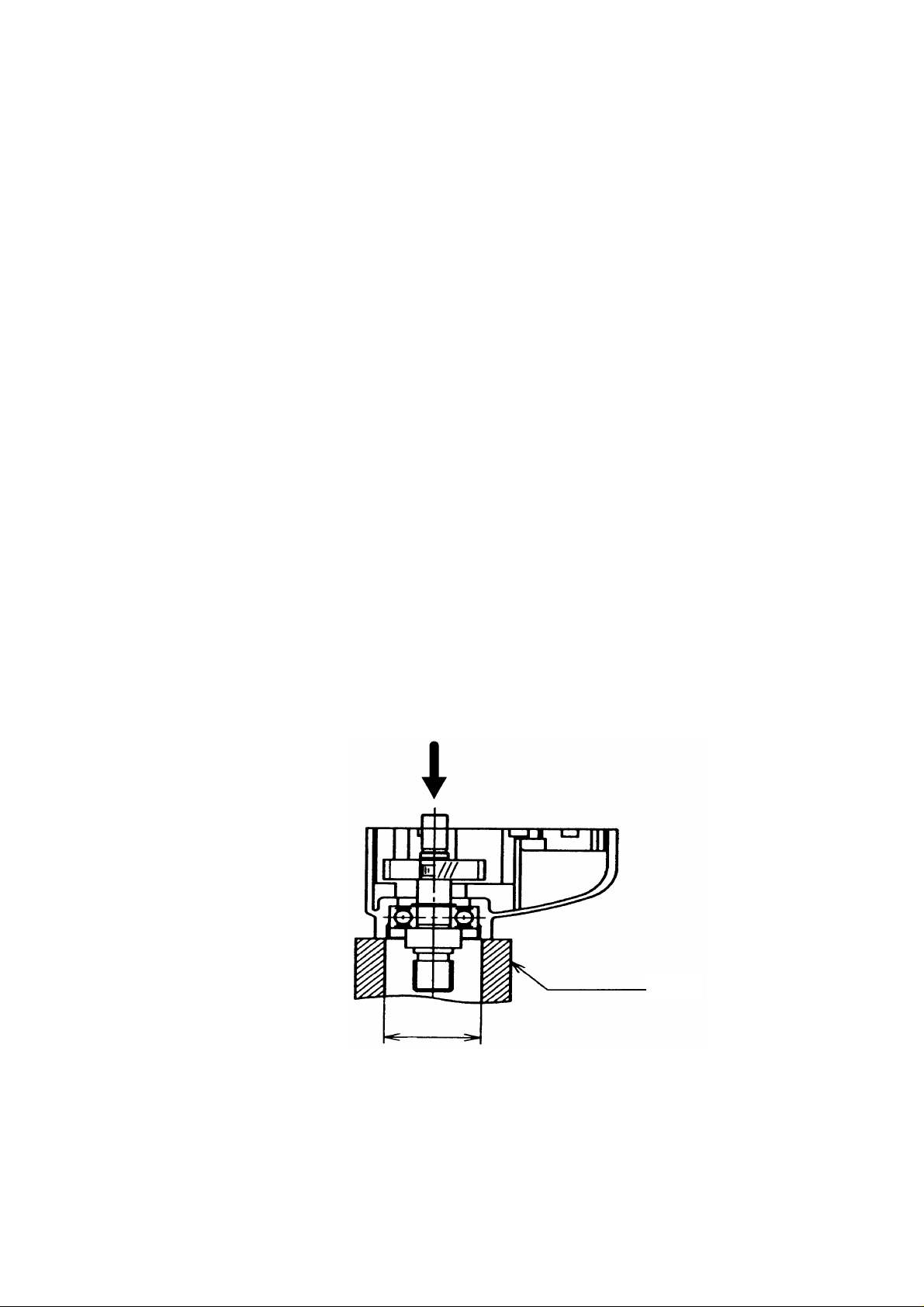

(3) As illustrated in Fig. 3, support the tip of the Gear Cover [8] with a cylindrical jig of inside diameter 35 mm or

more, and push the rear portion of the Spindle [4]. At this time, the Final Gear [16] will come off of the

Spindle.

(4) Remove the D12 Retaining Ring [6] from the Spindle [4], and the Ball Bearing [5] can be removed from the

Spindle [4] with the J-30 bearing puller ass'y (special repair tool, Code No. 970804).

Push

Cylindrical jig

35 mm dia.

Fig. 3

--- 2 ---

Loading...

Loading...