Page 1

SJ2-CO

Hitachi Inverter

SJ200-2/L200-2 SERIES

(CANopen Interface Option)

INSTRUCTION MANUAL

Thank you for purchase of “SJ2-CO (CANopen Interface Option)”.

This manual explains about treatment of “SJ2-CO”. By reading this

manual and an instruction manual of inverter use practically for

installation, maintenance, and inspection. After reading this manual,

keep it handy for future reference.

Make sure to deliver this manual to the end user.

Table of Contents

Chapter1 Introduction 1

Chapter2 Mounting method of option 4

Chapter3 Wiring, Connecting 7

Chapter4 Setting 9

Chapter5 CANopen communication function 11

Chapter6 Countermeasure for abnormality 21

Chapter7 Communication Objects Lists 23

Chapter8

Chapter9 Contact information 31

After reading this manual, keep it at handy for future reference.

Specifications 30

NB 654 X

Page 2

- Request -

Thank you for purchase of “SJ2-CO (CANopen Interface Option)”.

This instruction manual explains about treatment and maintenance of “SJ2-CO”. Before using the product,

carefully read this manual with the instruction manual of inverter, and keeps it handy for quick reference of

operator and maintenance inspector. Before installing, operating, maintenance and inspection read this

manual carefully and follow the instructions exactly.

Always keep various kinds of specifications mentioned in this manual and use exactly. And make sure to

prevent trouble by correct inspection and maintenance. Make sure to reach this manual to the end user.

- About treatment of this manual -

(1)Please consent that mentioned items of this manual may be change without permission.

(2)Keep this manual carefully not to lose because it can not be reissued

(3)All right reserved.

(4)Please contact the Hitachi inverter dealer from whom you purchased the unit, if you have some

doubts about spelling mistakes, omitted word etc.

(5)Please agree that there is no responsibility for effects resulted, in spite of contents above

mentioned.

Revision History Table

No.

1. Initial release of Manual NB654X June. 2006 NB654X

Except this table, revised only spelling mistakes omitted words, and error writings without notice.

Revision contents The date of issued Manual No.

Page 3

SAFETY PRECAUTIONS

CAUTION

SAFTY PRECAUTIONS

Carefully read this manual and all of the warning labels attached to the inverter before installing,

operating, maintaining, inspecting, it. Safety precautions are classified into “Warning” and “Caution” in this

manual.

!

WARNING

!

The situation described in may, if not avoided, lead to serious results. Important safety

measures are described in CAUTION (as well as WARNING) so be sure observe them.

Notes are described in this manual in “(Note)”. Carefully read the contents and follow them exactly.

In all the illustrations in this manual, covers and safely device are occasionally removed to describe the

details. When the product is operated, make sure that the covers and safety devices are placed as they

were specified originally and operate it according to the instruction manual.

:Indicates a potentially hazardous situation which, if not avoided, can result in serious

injury or death.

:Indicates a potentially hazardous situation which, if not avoided, can result in minor to

CAUTIO

moderate injury, or serous damage to the product

!

CAUTION

!

Page 4

SAFETY PRECAUTIONS

WARNING

!

Wiring:

Wiring work shall be carried out by electrical experts.

Otherwise, there is a danger of electric shock, fire and/or damage of product.

Implement wiring after checking that the power supply is off.

Otherwise, there is a danger of electric shock and/or fire.

Operating:

Be sure not to touch the surface or the terminal of option board while energizing.

Otherwise, there is a danger of electric shock and/or fire.

Be sure not to remove the Canopen option printed board while operating.

Otherwise, there is a danger of electric shock and/or fire.

Maintenance, Inspection and Part Replacement:

Wait at least 5 minutes after turning off the input power supply before performing maintenance and

inspection.

(Make sure the “POW” LED display on the inverter is off and DC voltage between P-N terminals is less

than 45V)

Otherwise, there is a danger of electric shock.

Make sure that only qualified persons will perform maintenance, inspection, and part replacement

(Before starting the work, remove metallic objects from your person (wristwatch, bracelet, etc.).

Be sure to use tools protected with insulation.)

Otherwise, there is a danger of electric shock and/or injury.

Note:

Never modify the unit.

Otherwise, there is a danger of electric shock and/or injury.

CAUTION

!

Installation:

Be sure not to let the foreign matter enter such as wire clippings, spatter from welding, metal shaving,

dust etc.

Otherwise, there is a danger of fire.

Be sure to fix inverter to option printed board with an attached fixed screw.

Otherwise, there is a danger of connecting error.

Be sure to fasten the screws connecting signal wire in side of option printed board. Check for any

loosening of screw.

Otherwise, there is a danger of connecting error.

Wiring:

Be sure to fasten the screws not to loose.

Otherwise, there is a danger of connecting error.

Operation:

Check rotary direction, abnormal motor noise and vibrations during operating.

Otherwise, there is a danger of injury to personnel and/or machine breakage

Page 5

CHAPTER 1 INTRODUCTION

1.1 INSPECTION UPON UNPACKING

Make sure to treat the product carefully not to give shock and vibration while unpacking. Check that the

product is the one you ordered, no defect, and that there is no damage during transportation.

(Contents of packing)

(1) SJ2-CO(CANopen Interface option ):1

(2) Instruction manual:1

(3) CANopen connector:1

(4) The screw which fixes a facecover (M3 times 8 mm):1

(5) Bus resister(120Ω):1

If you discover any problems, contact the Hitachi inverter dealer from whom you purchased the unit

immediately.

1.2 INQUIRY OF THE PRODUCT AND WARRANTY FOR THE PRODUCT

1.2.1 Request upon inquiring

If inquiry of breakage, question, damage etc. is needed, please tell the following information to the supplier

you ordered.

(1) Type(SJ2-CO)

(2) Manufacturing number (MFG No. (See 1.5

(3) Date of purchasing

(4) Contents of inquiry

・ Damage parts and its condition etc.

・ Question parts and their contents etc.

In order to shorten impossible working time, standing spare unit is recommended.

SJ2-CO Specifications Label

))

1.2.2 Warranty of the product

This product is guaranteed one year after the purchase. But, the next case is toll repair, even if within

warranty period.

(1) In case caused by operating mistake, and incorrect repair and modification.

(2) Trouble caused by reasons except the shipped product.

(3) In case of using in range over the value of specifications.

(4) In case caused by natural calamity, disaster, and secondary disaster.

Warranty mentioned here means warranty for shipped product itself. Damage caused by trouble of shipped

product is not guaranteed.

[Replacement]

Any inspection and replacement after the expiration of warranty period (one-year) shall be charged to the

purchaser. And also any inspection and replacement which are not covered in warranty mentioned above,

even if it is within warranty period, it shall be charged to the purchaser. If you require the replacement,

please contact the Hitachi inverter dealer from whom you purchased the unit.

1

Page 6

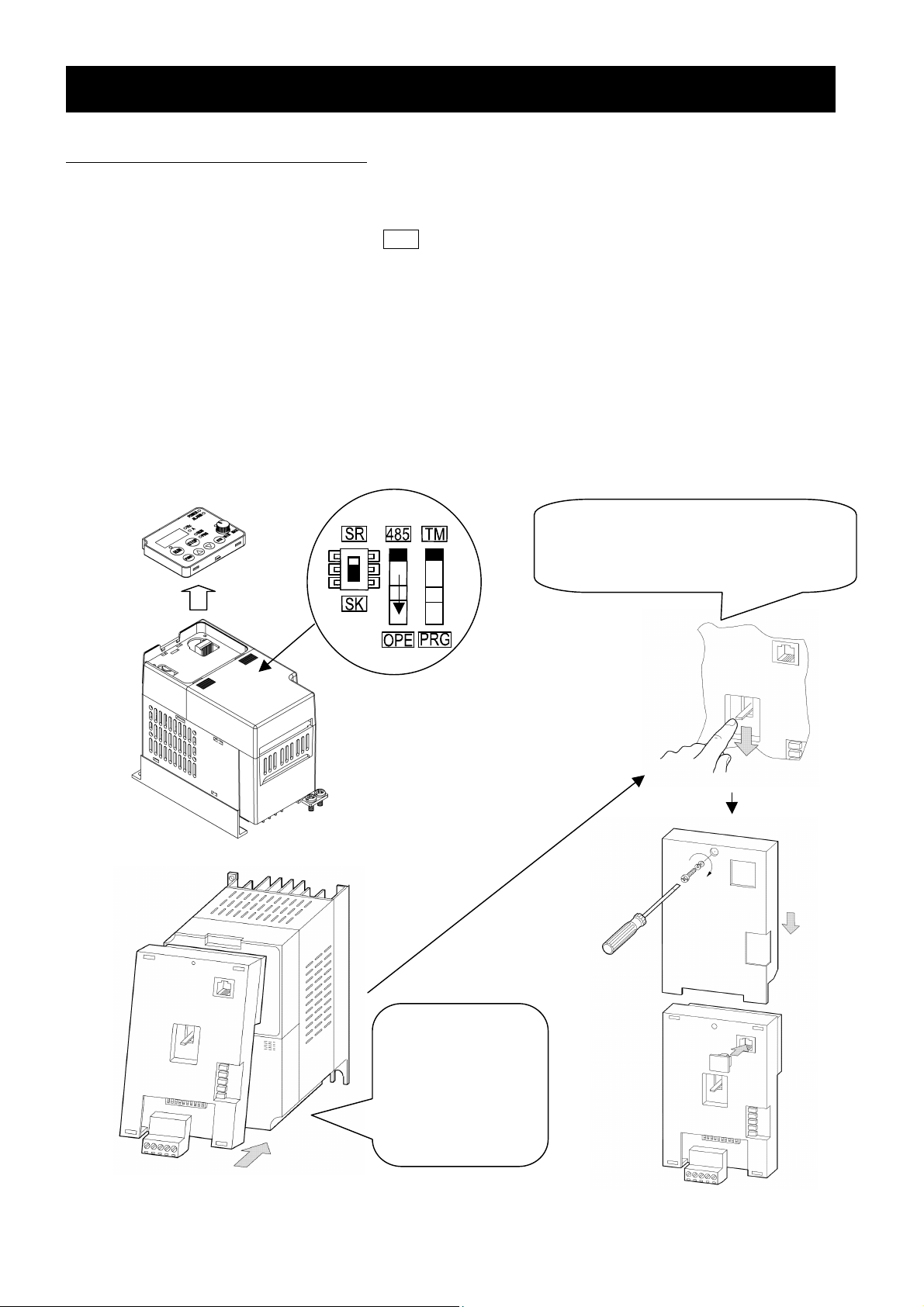

1.3 Appearance and Names of Parts

CHAPTER 1 INTRODUCTION

LED display

Power supply(POW)

Inverter Status(RUN)

Inverter condition mode(MOD)

CANbus Status(CAN)

Bus ready

(in CANopen this LED always green)

Baud rate & Node ID setting(See 4.1.2)

CAN bus Interface

Figure 1-1 Appearance of SJ2-CO

2

Page 7

1.4 CANopen Support Version

Production time

SJ2-CO can use following Inverter model of SJ200-2/L200-2.

SJ200-2 -0.2-7.5kW

L200-2 -0.2-7.5kW

How to distinguish SJ200-2(L200-2) from SJ200(L200)

CHAPTER 1 INTRODUCTION

SJ200(L200)

Series

name

Applicable

motor

004 H F E F 2

Configuration

EMC filter

type

Input

voltage

Restricted

distribution

1.5 Specifications Label

There is the Specifications Label of SJ2-CO on the back side.

model name

Manufacturing No.

A

6 7

year month

MFG No. 67A T25724B6 0001

Hitachi Industrial Equipment Systems Co.,Ltd.

MADE IN JAPAN

other model names :SJ2-MF,SJ2-CCV

SJ2-CO

Version: 2=SJ200-2(L200-2)

space=SJ200 (L200)

NEXXXXX

1.6 LED display

LED Function Color State

Power Supply

Inverter Status

Inverter condition mode(MOD) - See 6.4 LED display and Countermeasure

CAN condition/status(CAN) - See 6.4 LED display and Countermeasure

CAN bus power supply(DC+24V)

(Internal power supply)

Orange Inverter Main power supply is ON.

Blank Both power supplies are OFF.

Red Alarm or Inverter main power supply is OFF.

Green Run

Stop Stop (Normal)

Green ON

Blank OFF

3

Page 8

CHAPTER 2 MOUNTING METHOD OF OPTION

the main body of

2.1 Mounting method of option

Please connect the following cables first, and then attach the SJ2-CO to the front cover of SJ/L200-2.

[Installation step]

(1) mounting location

(2) Change the dipswitch position to lower ( OPE

(3) Connecting the cables

The cables are shown as bellow:

Power input cable, Motor output cable, Input terminal cable, Output terminal cable, Analog input cable,

Analog output cable etc

Because the following cables cannot be connected, after the instllation of SJ2-CO.

Figure 2-1 describes how to mount the SJ2-CO to the SJ200-2.

Figure 2-2 describes how to mount the SJ2-CO to the L200-2.

Figure 2-3 describes how to remove the SJ2-CO to the SJ200-2.

Figure 2-4 describes how to mount the SJ2-CO and operator(OPE-SRmini) to the SJ200-2

Note: Optional operator

(SRW-0J/0EX) cannot be used via SJ2-CO

)

.

If the lever is not dropped down,

please lift up the lever, and remount

the unit again.

Note : Please move the OPE/485 dip switch

bottom position labeled “OPE”.

Please mount the

SJ2-CO tightly to

the inverter.

Then lift down the

plastic lever.

Figure 2-1 Installation of SJ2-CO (SJ200-2 + SJ2-CO)

4

Page 9

CHAPTER 2 MOUNTING METHOD OF OPTION

Note : Please move the OPE/485

dip switch bottom position

labeled “OPE”.

SJ2-MF

*1:The CANopen connector is connected to the bottom side of the SJ2-CO

SJ2-MF Specifications Label: See 1.5 Specifications Label

Figure 2-2 Installation of SJ2-CO (L200-2 + SJ2-CO + SJ2-MF)

*1

Figure 2-3 Remove of SJ2-CO (SJ200-2 + SJ2-CO)

5

Page 10

SJ2-CCV (Optional)

CHAPTER 2 MOUNTING METHOD OF OPTION

OPE-SRmini

HITAC HI

SJ2-CCV

SJ200-2

SJ2-CO

SJ2-CCV

SJ2-CCV Specifications Label: See 1.5 Specifications Label

Figure 2-4 Installation of option unit (SJ200-2 + SJ2-CO + SJ2-CCV)

6

Page 11

CHAPTER 3 WIRING, CONNECTING

Dimension in mm

3.1 Connection for CANopen connector

SJ2-CO has a Pluggable open connector (Male contacts), and a Network connector (Female contacts)

attached. The inverter and attach connector have a seal which is color coordinated to correspond to the

network cable. Ensure the cable and contact are wired in the same color cable.

Cable side connector (attached connector)

Maker

Phoenix contact co, Ltd. MSTB 2.5/5ST-5.08 AU

Type

Dimension

18.2

Wiring of CANopen

Communication connector

Figure 3-1 Connector specifications

Blue

Black

White

Red

Color label

No.1

8.3

2.54

5.0

20.3

25.4

No.Signal

mark

1 Ground Internal power supply(-) Black

2 CAN_L CAN L bus line(dominant low) Blue

3 DRAIN Optional CAN shield Bare

4 CAN_H CAN H bus line(dominant high) White

5 NC No connect Red

Type of signal

No.5

Cable

color

Note:Communication power supply(DC 24V) of SJ2-CO is not required.

Please don’t make a short circuit between PIN 1(Black) and 5(Red).

3.2 Communication cable for CANopen

Use the connector which conforms to CANopen specifications or five conductor cable and also make sure

that cable, connector and Network distance conform to CANopen specifications.

Baud rate(kbps) Maximum Bus length(m)

1000

(1M)

800 50

500 100

250 250

125 500

50 1000

20 2500

10 5000

25

7

Page 12

CHAPTER 3 WIRING, CONNECTING

3.3 Wiring note

1.Installing the cable to Network connector must be done after checking the power supply off and “POW”

LED is “OFF”.

2.Wiring should not have bare cables exposed between connector contacts.

3.Network cables should be fixed without tension. Cables fixed under tension have potential of causing a

communication fault by to be removed a connector.

4.A terminating resistor is not built-in the unit. Please use the accessory of Bus resister(120

5.Ensure external emergency stop measures are taken to stop the inverter, in the event of a network fault.

(a) Remove the Power supply of the Inverter when the network master detects a communication fault.

(b) When the master detects a communication fault, turn on the intelligent input terminal which would be

allocated (FRS), (RS) and/or (EXT) function.

(c) Setting command P045 to except “02”.

In this setting, the inverter is tripped, deceleration or free run stop when it detects a communication

fault itself. (Factory initialization of command P045 is trip after deceleration stop (code: 01).)

See “4.2 Setting of the Inverter”.

6.Basic components for construction of CANopen application are shown bellow.

Refer to the master’s description manuals when CANopen Network system comes into operation.

Ω

).

CANopen Master UNIT

Terminating

Resistor (120Ω )

(PLC)

Trunk line

SJ200-2

HITAC HI

Configurater (PC)

Drop

line

Multi port Tap

SJ200-2

HITAC HI

Multiple Node branching drop line.

DC24V

Power

Supply

Other slave units

Trunk line

Terminating

resistor

(120Ω)

Terminating

resistor

(120Ω)

Figure 3-2 Example of components for construction of CANopen application

Note:Communication power supply(DC 24V) of SJ2-CO is not required.

Please don’t make a short circuit between PIN 1(Black) and 5(Red).

8

Page 13

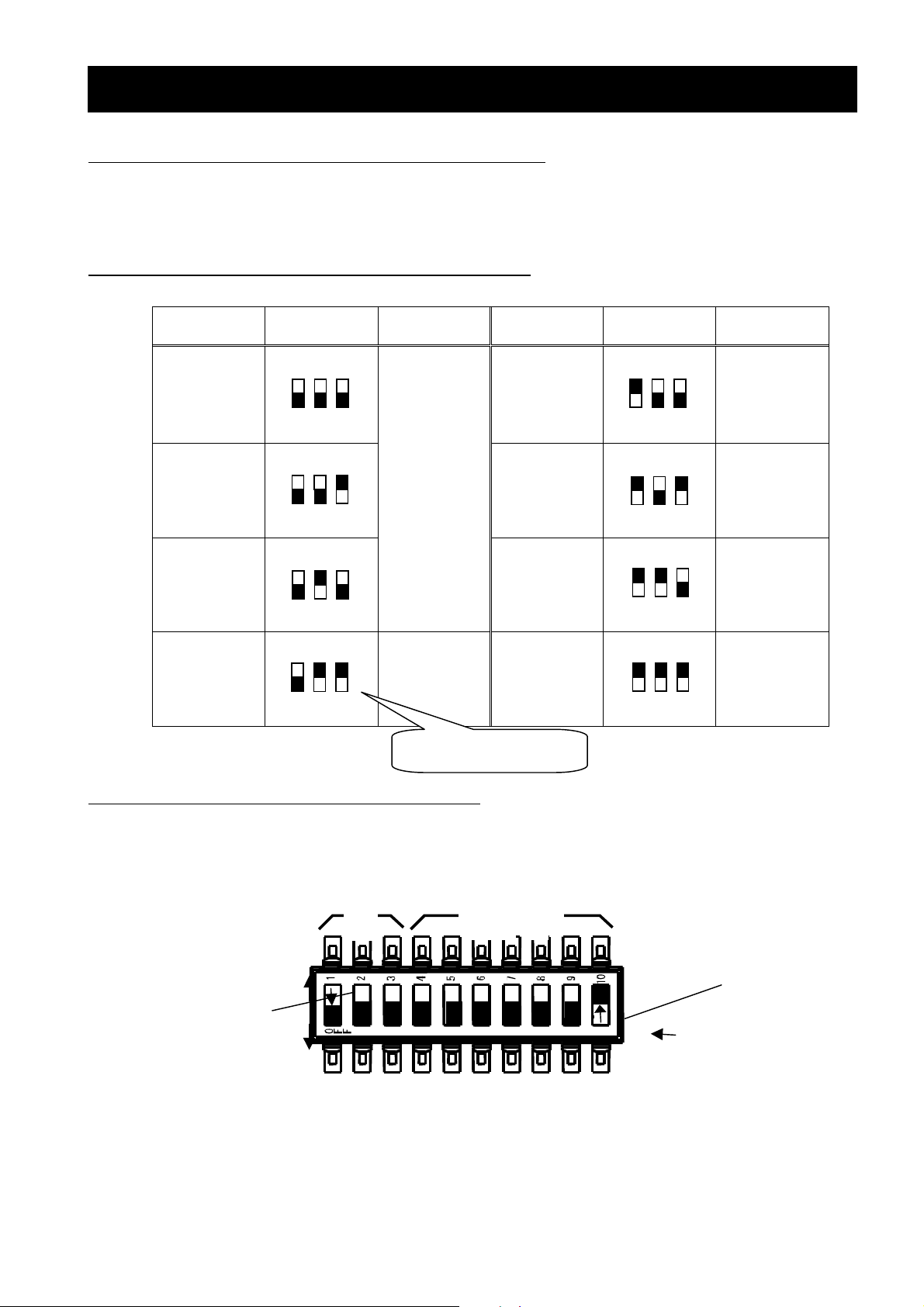

CHAPTER4 SETTING

4.1 Setting methods of Baud rate and Node ID

Follow the procedure below to set Baud rate in CANopen and Node ID, reset the power supply after

changing the setting (setting will be reflected after resetting power supply.). Initial Baud rate: 125kbps,

Initial Node ID: 2.

4.1.1 Setting method of CANopen Baud rate

The table below is setting method of Baud rate with Dip switch.

Baud rate

(kbps)

Dip switch

Setting

Note

Baud rate

(kbps)

Dip switch

Setting

Note

2

1

3

10 250

F

F

O

For bus

2

1

25 500

F

O

2

1

length

3

greater than

1km bridge

or repeater

F

device may

be needed

3

.

50

F

F

O

2

1

3

125 1000

F

F

O

1=OFF 2=ON 3=ON

4.1.2 Setting method of CANopen Node

800

2

1

3

F

F

O

2

1

3

F

F

O

2

1

3

F

F

O

2

1

3

F

F

O

Figure left describes the direction of Dip Switches. See below

ON: 1 OFF: 0

Bit increases from right to left switches. Figure formula below.

DR

NODE ID

ON

ON

OFF

1-9 = OFF, 10=ON:

OFF

NA64 NA16NA32 NA08 NA04 NA02 NA01

NODE ID = 1

NODE ID = NA64*26+ NA32*25+ NA16*24+ NA08*23+ NA04*22+ NA02*21+ NA01*2

9

0

Page 14

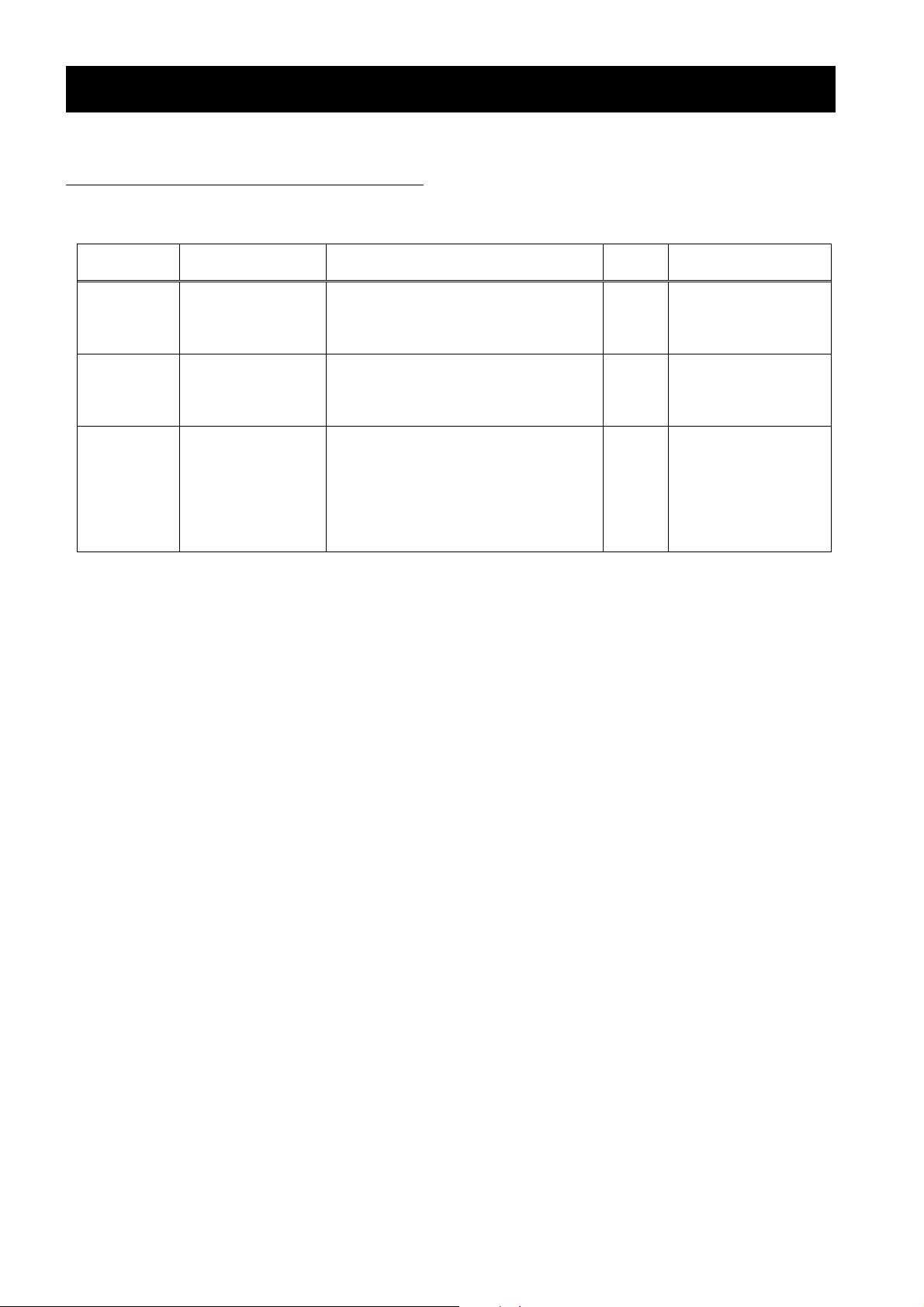

CHAPTER4 SETTING

4.2 Parameter setting of the Inverter

Following table describes setting items relate SJ200-2/L200-2 series Inverter with connecting SJ2-CO.

Following parameter will appear with connecting SJ2-CO to SJ200-2/L200-2 Inverter.

Parameter Function Range of DATA

Timer setting of

P044

P045

P049*

Communication

timeout W hilst

running

Inverter action

when

communication

error

Motor Poles

setting for

revolution per

minutes

/ 02(ignore) / 03(Free-RUN)

(It is possible to set only even

Setting value ‘0’, monitoring unit is

Setting value except ‘0’, monitoring

0.00~99.99 0.00 **

00(TRIP) / 01(TRIP after

deceleration stop)

/ 04(deceleration stop)

0 to 38

number )

Hz.

-1

unit is min

.

Initial

DATA

It is effective when

01

0

Note

“Object #6007”

setting is ‘-3’.

Note*: As “P049 Command” value is setting ‘0’, unit of “Index 6042,6043,6044,6046,6048-1,6049-1”

is ‘Hz’.

Note**: CANopen Interface Option cannot detect bus-off status with heartbeat. Using P045 command,

set value of P044 instead of detecting bus-off status.

4.3 Power Supply LED check

If the Power Supply LED(See 1.3) is not ON ,please remount(See 2.1) the SJ2-CO unit again.

10

Page 15

CHAPTER5 CANOPEN COMMUNICATION FUNCTION

5.1 Feature of CANopen communication function

5.1.1 SDO(Service Data Object)

When using the segmented SDO download and upload services, the communication software will be

responsible the SDO as a sequence of segments.

Explicit transfer has to be supported. Segmented transfer has to be supported if objects lager than 4

bytes are supported. Optionally the following SDO services for doing a block transfer with higher bus

utilization and performance for large data set size can be implemented.

The model for the SDO communication is the Client/Sever model.

CANopen Interface Option uploads and downloads inverter parameters using Object Dictionary

1200h.

Sub-Index Type Meaning Notes

0 UNSIGNED8 Number of supported entries in the record default: 2

1 UNSIGNED32 COB-ID Client -> Server (Receive ID)

2 UNSIGNED32 COB-ID Server -> Client (Transmit ID)

Abort Code

This protocol is used to implement the abort SDO Transfer Service.

The abort code is standard code of CANopen specifications.

Abort code Description Notes

0503 0000h Toggle bit not alternated.

0504 0000h SDO protocol time out.

0504 0001h Client/server command specifier not valid or unknown.

0504 0005h Out of memory.

0601 0000h Unsupported access to an object.

0601 0001h Attempt to read a write only object.

0601 0002h Attempt to write a read only object.

0602 0000h Object does not exist in the object dictionary.

0604 0041h Object cannot be mapped to the PDO.

0604 0042h

0604 0043h General parameter incompatibility reason.

0606 0000h Access failed due to an hardware error.

0607 0010h

0607 0012h Data type does not match, length of service parameter too high

0607 0013h Data type does not match, length of service parameter too low

0609 0011h Sub-index does not exist.

0609 0030h Value range of parameter exceeded (only for write access)

0609 0031h Value of parameter written too high.

0609 0032h Value of parameter written too low.

0609 0036h Maximum value is less than minimum value.

0800 0000h general error

0800 0020h Data cannot be transferred or stored to the application.

0800 0021h

0800 0022h

0800 0023h

The number and length of the objects to be mapped would exceed

PDO length.

Data type does not match, length of service parameter does not

match

Data cannot be transferred or stored to the application because of

local control.

Data cannot be transferred or stored to the application because of

the present device state.

Object dictionary dynamic generation fails or no object dictionary is

present (e.g. object dictionary is generated from file and generation

fails because of an file error).

11

Page 16

CHAPTER5 CANOPEN COMMUNICATION FUNCTION

5.1.2 PDO(Process Data Object)

The real-time data transfer is using the PDOs.

There are two kinds of PDO transmission modes. One is a synchronization (SYNC), the other is

asynchronization message (Remotely Request, Event Driven, Timer Driven).

These PDO services use the push / pull models. The PDOs have Transmit-PDOs (maximum data size is 8

bytes) and Receive-PDOs (maximum data size is 8 bytes). These data type and these mapping are

defined by the Object Dictionary.

The following table is the PDO parameter indexes, the data types and the objects.

Index Type Object Notes

1400h 20h 1st receive PDO communication parameter

1401h 20h 2nd receive PDO communication parameter

1402h 20h 3rd receive PDO communication parameter

1403h 20h 4th receive PDO communication parameter

1600h 21h 1st receive PDO mapping parameter

1601h 21h 2nd receive PDO mapping parameter

1602h 21h 3rd receive PDO mapping parameter

1603h 21h 4th receive PDO mapping parameter

1800h 20h 1st transmit PDO communication parameter

1801h 20h 2nd transmit PDO communication parameter

1802h 10h 3rd transmit PDO communication parameter

1803h 20h 4th transmit PDO communication parameter

1A00h 21h 1st transmit PDO mapping parameter

1A01h 21h 2nd transmit PDO mapping parameter

1A02h 21h 3rd transmit PDO mapping parameter

1A03h 21h 4th transmit PDO mapping parameter

Data type “20h” is a record, which defines the PDO communication parameter, and it is of the following

format:

Sub-Index Type Meaning Notes

0h UNSIGNED8

1h UNSIGNED32 COB-ID

2h UNSIGNED8 transmit type Default: 255

3h UNSIGNED16 inhibit time TPDO only

4h UNSIGNED8 CMS priority group Default: 3

Data type “21h” is a record, which defines the PDO mapping parameter and it is of the following

format:

Sub-Index Type Meaning Notes

0h UNSIGNED8

1h

or

1h, 2h

UNSIGNED32

Number of supported entries in the

record

Number of supported entries in the

record

Structure consisting of mapped

object index (16 bit), sub-index (8

bits) and object data length in bits.

For example “20010010h” defines

object “2001h”, sub-index “0h”, and

data length of16 bits (=word).

Default: 2

Default: 2

12

Page 17

CHAPTER5 CANOPEN COMMUNICATION FUNCTION

5.1.3 Device Control

CAN open interface option can use "Velocity Mode" DSP-402 V2.0 drive control profile.

5.1.4 Object Dictionary for Standardized Device Profile Area

CAN open interface option is supported following objects.

Index Meaning Type

6007h abort_connection_option_code Integer16

6040h control word Unsigned16

6041h status word Unsigned16

6042h vl_target_velocity Integer16

6043h vl_velocity_demand Integer16

6044h vl_control_effort Integer16

6046h vl_velocity_min_max_amount Unsigned 32

6048h vl_velocity_acceleration Ramp

6049h vl_velocity_deceleration Ramp

6060h modes_of_operation Integer8

6061h modes_of_operation_display Integer8

5.1.5 abort_connection_option_code (Index: 6007h)

When communications between CANopen interface option and HOST cannot be active, inverter

actions will decide following this object setting.

value Action Notes

0 No action Same as"P045 setting value 02”

1 No action Same as"P045 setting value 02”

2 Disable voltage-(FRS) Same as"P045 setting value 03”

3 Quick stop (Deceleration with 2nd setting)

-3

-4 No Action

-5 No Action

In new CANopen Interface Option, the trigger of this function is timer out in P044 instead of bus-off

condition.

manufacturer specific:

Enable switch for “P045 setting”.

See 5.1.5 Parameter setting of

SJ200

Enable P045 setting.

13

Page 18

CHAPTER5 CANOPEN COMMUNICATION FUNCTION

5.1.6 Control word (Index: 6040h)

The control word is used to send control commands to the inverter. (HOST-> Inverter)

Bit Description Note

0

1

2

3

4 RFG Enable Mode Specific

5 RFG Unlock Mode Specific

6 RFG Usr ref Mode Specific

7 Reset Fault (raising edge) Mandatory

8 Halt Mode Specific

9 (Undefined) Reserved

10 (Undefined) Reserved

11 RDY Function Enable Manufacturer Specific

12 NetRef Manufacturer Specific

13 NetCtrl Manufacturer Specific

14 Move forward Manufacturer Specific

15 Move reverse Manufacturer Specific

Switch On-Stop

Disable Voltage-Free Run Stop

Quick stop-Stop using 2CH setting

Enable Operation-Run

Mandatory

Mandatory

Mandatory

Mandatory

To use setting frequency from CANopen, please set bit NetRef(bit 12). An inverter parameter A001

is set 10(Calculate function output) with setting NetRef bit is 1, Calculate function output will not

work.

To handle RUN/STOP command form CANopen, you have to set a bit NetCtrl.

14

Page 19

CHAPTER5 CANOPEN COMMUNICATION FUNCTION

5.1.7 Status word (Index: 6041h)

The status word indicates the current state of the inverter.

Bit Description Note

0 Ready to switch on Mandatory

1 Switched on Mandatory

2 Operation enabled Mandatory

3 Fault Mandatory

4 Voltage enabled (~V1.04) Voltage disable -> enabled Mandatory

5 Quick stop Mandatory

6 Switch on disabled Mandatory

7 Warning Unsupported

8 Manufacturer Specific Unsupported

9 Remote Mandatory

10 Target reached Mandatory

11 Internal Limit Active “Index 6046” influences this bit. Mandatory

12 (reserved) (reserved) Mode Specific

13 (reserved) (reserved) Mode Specific

14 Moving forwards

15 Moving backwards

Bitmapping of Status word

Bit 6 Bit 5 Bit 3 Bit 2 Bit 1 Bit 0

Inverter

Not Ready to

Switch On

Switch On

Disabled

Ready to

Switch On

Switched On 0 1 0 0 1 1

Operation Enabled 0 1 0 1 1 1

Fault 0 X 1 1 1 1

Fault Reaction

Active

Quick Stop 0 0 0 1 1 1

‘X’ means that any value is allowed.

Switch On

Disable

0 X 0 0 0 0

1 X 0 0 0 0

0 1 0 0 0 1

0 X 1 1 1 1

Quick

Stop

Fault

Operation

Enable

Switch On

Ready to

Switch On

15

Page 20

5.1.8 State Machine

012736984511161012151413

Power

Power

PowerPower

Disabled

Disabled

DisabledDisabled

CHAPTER5 CANOPEN COMMUNICATION FUNCTION

Power

Power

PowerPower

Enabled

Enabled

EnabledEnabled

Start up

Not Ready to

Switch On

Switch On

Disabled

Ready to

Switch On

Fault

Reaction Active

Fault

Switched On

Operation

Enable

Command bit of

Control word

Shutdown 0 X 1 1 0 2,6,8

Switch On 0 X 1 1 1 3

Disable Voltage 0 X X 0 X 7,9,10,12

Quick Stop 0 X 0 1 X 7,10,11

Disable Operation 0 0 1 1 1 5

Enable Operation 0 1 1 1 1 4,16

Fault Reset 0 -> 1 X X X X 15

‘X’ means that any value is allowed.

Bit 7 Bit 3 Bit 2 Bit 1 Bit 0

Fault Reset

Enable

Operation

Quick Stop

Disable

Voltage

Quick Stop

Active

Transition

Switch On

16

Page 21

CHAPTER5 CANOPEN COMMUNICATION FUNCTION

time

∆

5.1.9 Using RFG(Ramp Function Generator)

Purpose of using RFG is selecting RAMP (frequency generator) sources. The method of selecting

RAMP sources is using STW. It is shown diagram below.

vl_velocity _acceleration

(#6048)

Index 1

Index 2

Conv. Hz

Cal.

speed

vl_velocity _deceleration

(#6049)

vl_target_veloci ty

(#6042)

Index 1

Index 2

Conv. Hz

RFG usr ref (STW:bit6)

0

0

1

F002/F003

A004

∆

RFG

INV

RFG unlock (STW:bit 5)

0

HOLD

1

vl_velocity _min_max_amount

(#6046)

Index 1

Index 2

Limiter

A061/A062

RFG enable (STW:bit 4)

1

0

HALT (STW: bit8)

0

1

Conv.

RPM

vl_velocity_demand

(#6043)

vl_velocity _effort

(#6044)

If you use RFG, Please set parameter shown below.

B021(Overload restriction operation mode) 00(OFF)

B130(Over-Voltage LADSTOP enable) 00(OFF)

B140(Over-current trip suppression) 00(OFF)

In purpose of setting parameter above, these parameters are automatically decelerated output

velocity in condition of these functions. It is not satisfied that specifications of CANopen. In

selecting RFG mode, it doesn’t work the functions Overload restriction, Over-Voltage LADSTOP

and Over-current trip suppression. W hen you want to use these functions, please don’t select

RFG mode.

17

Page 22

CHAPTER5 CANOPEN COMMUNICATION FUNCTION

5.1.10 vl_target_velocity (Index: 6042h)

The vl target velocity is the required velocity of the system. It is multiplied the vl dimension factor

and the vl set-point factor, if these are implemented.

Inverter parameter = output frequency setting (Multi-speed0) (A020)

(unit: min

-1

Minimum unit: 1dig= 1min-1)

5.1.11 vl_velocity_demand (Index: 6043h)

The vl velocity demand is the instantaneous velocity provided by ramp function, scaled to the unit of

the vl target velocity.

Inverter parameter = output frequency monitor (d001)

-1

(unit: min

Minimum unit: 1dig= 1min-1)

5.1.12 vl_velocity_effort (Index: 6044h)

The vl velocity effort is the velocity at the motor spindle or load, scaled to the unit of the vl target

velocity.

-1

(unit: min

Minimum unit: 1dig= 1min-1)

5.1.13 vl_velocity_min_max_amount (Index: 6046h)

The vl velocity min-max amount index is composed of the vl velocity min(Sub-index1) amount and vl

velocity max(sub-index2) amount sub-index. (32bit length)

Sub-index1 = 1st frequency minimum limiter (A062)

Sub-index2 = 1st frequency maximum limiter (A061)

-1

(unit: min

Minimum unit: 1dig= 1min-1)

+vl_velocity_max_amount

+vl_velocity_min_amount

0

-vl_velocity_min_amount

-vl_velocity_max_amount

output

input

18

Page 23

CHAPTER5 CANOPEN COMMUNICATION FUNCTION

5.1.14 vl_velocity_acceleration (Index: 6048h)

The vl velocity acceleration index specifies the slope of acceleration ramp for RFG. (32bit length)

It is generated as the quotient of the delta speed(Sub-index1) and delta time(sub-index2) sub-

index.

Sub-index1 = delta speed (unit: min

Sub-index2 = delta time (unit: sec Minimum unit: 1dig= 1sec)

vl_velocity_acceleration = delta_speed / delta_time

This Index is effective only RFG mode.

velocity

-1

Minimum unit: 1dig= 1min-1)

delta spe ed

delta time

5.1.15 vl_velocity_deceleration (Index: 6049h)

The vl velocity deceleration index specifies the slope of deceleration ramp for RFG. (32bit length)

It is generated as the quotient of the delta speed(Sub-index1) and delta time(sub-index2) sub-

index.

-1

Sub-index1 = delta speed (unit: min

Sub-index2 = delta time (unit: sec Minimum unit: 1dig= 1sec)

vl_velocity_acceleration = delta_speed / delta_time

This Index is effective only RFG mode.

velocity

Minimum unit: 1dig= 1min-1)

time

delta speed

delta time

time

19

Page 24

CHAPTER5 CANOPEN COMMUNICATION FUNCTION

5.1.16 modes_of_operation (Index: 6060h/6061h)

The actual mode is reflected in the modes of operation display (index 6061h), and not in the mode

of operation(index 6060h). But CANopen Interface Option supported only Velocity Mode. These

objects are always stored “2(Velocity mode)”.

5.2 Keypad display(OPTIONAL OPERATOR:OPE-SRMINI)

In status of initializing CANopen option, the keypad shows following display.

Note: This display appears during initializing which is follow conditions;

Initializing with b084

Trip reset

CANopen option initializing when power is lunched.

“RS” terminal is lunched up.

Occurring un-expected matter.

Black:Segment is “ON”

20

Page 25

CHAPTER6 COUNTERMEASURE FOR ABNORMALITY

Trip

6.1 Trip display

When the inverter is in a tripped state, the inverter displays an error code (See table below). The trip history

monitor (d081 to d086) also displays the same error code as the inverter.

6.2 Protection function list

The table below describes an error code for protecting the inverter and the motor.

No. Function Error

Display

1 Network option’s

communication error

2 External trip E12 This error is displayed, when Halt is set to 1 toward control

With regard to the other errors except table above, refer to Inverter instruction manual chapter 4

Explanation of function.

E70 This error is displayed, disconnection occurs when timeout is

Action

occurred, while the inverter is operating with CANopen. (Trip

is caused by P045 setting)

word(Index:6040h) in BIT8(Halt).

6.3 Countermeasure for a trip state

The table below only corresponds to additional trip codes, with regard to the other countermeasures refer to

Inverter instruction manual chapter 4 Explanation of function.

Trip

code

E70 CANopen

E12 External

Name of trip Cause Conformation Countermeasure

Communication

error

Baud rate is

different.

Wiring distance does

not match with Baud

rate

Defective connector

for signal cable

Check Baud

rate

Check the wiring

distance

Check the area of

connection.

Install correct Baud rate and

then reset the power supply.

Adjust the setting to the

matching Baud rate.

Adjust Wiring distance.

Improve the connection and

then reset the power supply.

causes connection

fail.

Terminating resistor

is not connected.

Check the

Connection

Connect the terminating

Resistor and then reset the

power supply

Trip

Control

word(Index:6040h)

Check as mentioned

left.

Set Halt to 0 toward Control

word(Index:6040h)Bit8(Halt).

Bit8:Halt

21

Page 26

CHAPTER6 COUNTERMEASURE FOR ABNORMALITY

6.4 LED display and Countermeasure

Following states are indicated by Module LED and CANopen status LED.

MOD (Module status) LED: It indicates Inverter condition.

CAN (CANopen status) LED: it indicates CANopen status.

LED Color State Countermeasure Category

Green ON

Green

single flash

Red ON

MOD

Red single

flash

OFF Power off - Mandatory

Green ON OPERATIONAL - Mandatory

Green

single flash

Green

Blinking

CAN

notes

LED ON:

LED OFF:

LED blinking:

LED single flash:

LED double flash:

OFF no error - Mandatory

Red single

flash

Red double

flash

constantly on

constantly off

iso-phase on and off with a frequency of approximately 2.5Hz:

on for approximately 200ms and off for approximately 200ms.

one short flash (approximately 200ms) followed by a long off phase (approximately 1000ms).

a sequence of two short flashes (approximately 200ms),

separated by an off phase (approximately 200ms).

The sequence is finished by a long off phase (approximately 1000ms).

The inverter is in Normal

condition.

The inverter is in Stand-by

condition.

An abnormality occurred

which is impossible to restore.

An abnormality occurred

which is possible to restore.

Mostly this state occurs, when

the inverter is in trip condition.

But except status below.

User initializing with b084 set

to 01 or 02.

STOPPED - Mandatory

PRE-OPERATINAL - Mandatory

Warning limit reached Any Flaming error Mandatory

Error Control Event

- Mandatory

- Mandatory

Need to fix the inverter. Mandatory

When in trip, remove the trip

causes.

When initializing, the inverter

starts up automatically the

BOOTUP process after the

initializing.

The Guarding Protocol or the

Heartbeat Protocol is

processing.

Mandatory

Mandatory

22

Page 27

CHAPTER7 COMMUNICATION OBJECTS LISTS

7.Communication Objects

Communication Objects are grouped 3 areas.

Index Profile Area

1000-1FFF Communication Profile Area

2000-5FFF Manufacturer Specific Profile Area(Inverter's parameter area)

6000-9FFF Device Profile Area

7.1 Device Profile Area

Supported Communication Object by CANopen interface option ( ) =initial value

Index Sub-Index Object name Data type Note

6007h abort_connection_option_code INTEGER16 *

6040h control word UNSIGNED16 *

6041h status word UNSIGNED16 *

6042h vl_target_velocity INTEGER16 *

6043h vl_velocity_demand INTEGER16 *

6044h vl_control_effort INTEGER16 *

6046h vl_velocity_min_max_amount UNSIGNED32

0 Number of entries(=2) INTEGER8 *

1 vl_velocity_min_amount UNSIGNED16 *

2 vl_velocity_max_amount UNSIGNED16

6048h vl_velocity_acceleration Ramp

0 Number of entries(=2) INTEGER8 *

1 delta_speed UNSIGNED16 *

2 delta_time UNSIGNED32 *

6049h vl_velocity_deceleration Ramp

0 Number of entries(=2) INTEGER8 *

1 delta_speed UNSIGNED16 *

2 delta_time UNSIGNED32 *

6060h modes_of_operation INTEGER8 *

6061h modes_of_operation_display INTEGER8 *

Note : This object cannot store to EEPROM.

23

Page 28

CHAPTER7 COMMUNICATION OBJECTS LISTS

7.2 Profile Manufacyure Objects (d,F group)

INDEX Parameter Function Name Size Unit Note

0x2001 d001 Output frequency monitor

0x2002 d002 Output current monitor

0x2003 d003 rotation direction monitor

0x2004 d004 PID feedback monitor

0x2005 d005 Intelligent input terminal status

0x2006 d006 Intelligent output terminal status

0x2007 d007 Frequency conversion monitor

0x2013 d013 Output voltage monitor

0x2016 d016 Accumulated time monitor during RUN

0x2017 d017 Power ON time monitor

0x2080 d080 Number of trip time monitor

0x2081 d081 -

sub 0 Number of element = 2

sub 1 Factor

sub 2 Output frequency in TRIP

0x20A1 - -

sub 0 Number of element = 3

sub 1 Factor

sub 2 Output current in TRIP

sub 3 DC-bus voltage in TRIP

0x20B1 - -

sub 0 Number of element = 2

sub 1 Factor

sub 2 RUN time

0x20C1 - -

sub 0 Number of element = 2

sub 1 Factor

sub 2 ON time

0x2202 F002 1st acceleration time

0x2302 F202 2nd acceleration time

0x2203 F003 1st deceleration time

0x2303 F203 2nd deceleration time

0x2204 F004

Keypad Run Key routing

(Operation direction selection) 1 -

2 0.1Hz

2 0.1%

1 -

4 0.01%

1 -

1 -

4 -

2 0.01%

4 1.hr

4 1.hr

2

4 0.01sec

4 0.01sec

4 0.01sec

4 0.01sec

*1

*2

Note *1: “d002 monitor” has to calculate shown below:

Output Current(A) = [“Value of Index 0x2002” * rated current(A)] / 100

Note *2: ”d013 monitor” has to calculate shown below:

Output Voltage(V) = [“Value of Index 0x2013” * Voltage class (200V or 400V)] / 10000

24

Page 29

CHAPTER7 COMMUNICATION OBJECTS LISTS

7.3 Profile Manufacture Objects (A,b,C,H,P group)

INDEX Parameter Function Name Size Unit Note

0x2401 A001 Frequency source setting

0x2501 A201 Frequency source setting,2nd motor

0x2402 A002 Run command source setting

0x2502 A202 Run command source setting,2nd motor

0x2403 A003 Base frequency

0x2503 A203 Base frequency, 2nd motor

0x2404 A004 Maximum frequency

0x2504 A204 Maximum frequency, 2nd motor

0x2405 A005

0x2411 A011 O start

0x2412 A012 O end

0x2413 A013 O start rate

0x2414 A014 O end rate

0x2415 A015 O start selection

0x2416 A016 O, OI sampling

0x2420 A020 Multi-speed 0

0x2520 A220 Multi-speed 0, 2nd motor

0x2421 A021 Multi-speed1

0x2422 A022 Multi-speed2

0x2423 A023 Multi-speed3

0x2424 A024 Multi-speed4

0x2425 A025 Multi-speed5

0x2426 A026 Multi-speed6

0x2427 A027 Multi-speed7

0x2428 A028 Multi-speed8

0x2429 A029 Multi-speed9

0x2430 A030 Multi-speed10

0x2431 A031 Multi-speed11

0x2432 A032 Multi-speed12

0x2433 A033 Multi-speed13

0x2434 A034 Multi-speed14

0x2435 A035 Multi-speed15

0x2438 A038 Jogging frequency

0x2439 A039 Jog stop mode

0x2441 A041 Torque boost method selection

0x2541 A241 Torque boost method selection, 2nd motor

0x2442 A042 Manual torque boost

0x2542 A242 Manual torque boost, 2nd motor

0x2443 A043 Manual torque boost point

0x2543 A243 Manual torque boost point,2nd motor

0x2444 A044 V/f characteristic curve selection

0x2544 A244 V/f characteristic curve selection 2nd motor

“AT” terminal selection

1 -

1 -

1 -

1 -

2 1.Hz

2 1.Hz

2 1.Hz

2 1.Hz

1 -

2 0.1Hz

2 0.1Hz

1 1.%

1 1.%

1 -

1 times

2 0.1Hz

2 0.1Hz

2 0.1Hz

2 0.1Hz

2 0.1Hz

2 0.1Hz

2 0.1Hz

2 0.1Hz

2 0.1Hz

2 0.1Hz

2 0.1Hz

2 0.1Hz

2 0.1Hz

2 0.1Hz

2 0.1Hz

2 0.1Hz

2 0.1Hz

2 0.1Hz

1 -

1 -

1 -

1 1.%

1 1.%

2 0.1%

2 0.1%

1 -

1 -

25

Page 30

CHAPTER7 COMMUNICATION OBJECTS LISTS

INDEX

0x2445 A045 Output voltage gain

0x2545 A245 Output voltage gain,2nd motor

0x2446 A046 I-SLV Voltage compensate gain

0x2546 A246 I-SLV Voltage compensate gain, 2nd motor

0x2447 A047 I-SLV Slip compensate gain

0x2547 A247 I-SLV Slip compensate gain,2nd motor

0x2451 A051 DC braking enable

0x2452 A052 DC braking frequency setting

0x2453 A053 DC braking wait time

0x2454 A054 DC braking during decelerating

0x2455 A055 DC braking time for deceleration

0x2456 A056 DC braking enable input signal edge/level selection

0x2461 A061 1st frequency upper limit setting

0x2561 A261 2nd frequency upper limit setting

0x2462 A062 1st frequency upper limit setting

0x2562 A262 2nd frequency upper limit setting

0x2463 A063 Jump frequency1

0x2464 A064 Jump frequency Width 1

0x2465 A065 Jump frequency2

0x2466 A066 Jump frequency Width 2

0x2467 A067 Jump frequency3

0x2468 A068 Jump frequency Width 3

0x2471 A071 PID enable

0x2472 A072 PID-P gain

0x2473 A073 PID-I gain

0x2474 A074 PID-D gain

0x2475 A075 PID scale

0x2476 A076 PID feedback selection

0x2477 A077 Reverse PID

0x2478 A078 PID Output limiter

0x2481 A081 AVR selection

0x2482 A082 Motor voltage selection

0x2492 A092 Acceleration time2

0x2592 A292 Acceleration time2(2nd motor)

0x2493 A093 Deceleration time2

0x2593 A293 Deceleration time2(2nd motor)

0x2494 A094 Select method to switch to Acc2/Dcc2 profile

0x2594 A294

0x2495 A095 Acc1 to Acc2 frequency transition point

0x2595 A295 Acc1 to Acc2 frequency transition point(2nd motor)

0x2496 A096 Dcc1 to Dcc2 frequency transition point

0x2596 A296 Dcc1 to Dcc2 frequency transition point(2nd motor)

0x2497 A097 Acceleration curve selection

0x2498 A098 Deceleration curve selection

Parameter

Function Name Size Unit

Select method to switch to Acc2/Dcc2 profile

(2nd motor) 1 -

Note

1 1.%

1 1.%

2 1.%

2 1.%

2 1.%

2 1.%

1 -

2 0.1Hz

1 1.0

1 1.

2 0.1Hz

1 -

2 0.1Hz

2 0.1Hz

2 0.1Hz

2 0.1Hz

2 0.1Hz

2 0.1Hz

2 0.1Hz

2 0.1Hz

2 0.1Hz

2 0.1Hz

1 -

1 0.1

2 0.1

2 0.01

2 0.01

1 -

1 -

2 0.1%

1 -

2 1.V

4 0.01sec

4 0.01sec

4 0.01sec

4 0.01sec

1 -

2 0.1Hz

2 0.1Hz

2 0.1Hz

2 0.1Hz

1 -

1 -

26

Page 31

CHAPTER7 COMMUNICATION OBJECTS LISTS

INDEX Parameter Function Name Size Unit Note

0x24A1 A101 OI start

0x24A2 A102 OI end

0x24A3 A103 OI start rate

0x24A4 A104 OI end rate

0x24A5 A105 OI start selection

0x24E1 A141 Cal.frequency1

0x24E2 A142 Cal.frequency2

0x24E3 A143 Cal. select

0x24E5 A145 Set point frequency

0x24E6 A146 Plus/Minus select

0x24F1 A151 Pot start

0x24F2 A152 Pot end

0x24F3 A153 Pot start rate

0x24F4 A154 Pot end rate

0x24F5 A155 Pot start selection

0x2601 b001 Automatic Restart Selection

0x2602 b002 Allowable under-voltage power failure time

0x2603 b003 Retry wait time

0x2604 b004

0x2605 b005

0x2612 b012 Electronic thermal level

0x2712 b212 Electronic thermal level(2nd motor)

0x2613 b013 1st electronic thermal characteristic selection

0x2713 b213 2nd electronic thermal characteristic selection

0x2621 b021 Overload restriction operation mode

0x2721 b221 Overload restriction operation mode,2nd motor

0x2622 b022 Overload restriction setting

0x2722 b222 Overload restriction setting,2nd motor

0x2623 b023 Deceleration rate at Overload restriction

0x2723 b223

0x2628 b028 Overload restriction source selection

0x2728 b228 Overload restriction source selection, 2nd motor

0x2631 b031 Software lock mode selection

0x2680 b080 AM adjustment

0x2682 b082 Start frequency adjustment

0x2683 b083 Carrier Frequency setting

0x2684 b084 Initialization mode

0x2685 b085 Country code for initialization

0x2686 b086 Frequency scaling conversion factor

0x2687 b087 STOP key enable

0x2688 b088 Restart mode after FRS

0x2689 b089 Monitoring selection

0x2690 b090 Dynamic braking usage

Instantaneous power failure/under-voltage trip

during stop 1 Instantaneous power failure/under-voltage retry

time selection 1 -

Deceleration rate at Overload restriction,2nd

motor 2 0.1sec

2 0.1Hz

2 0.1Hz

1 1.%

1 1.%

1 -

1 -

1 -

1 -

2 0.1Hz

1 -

2 0.1Hz

2 0.1Hz

1 1.%

1 1.%

1 -

1 -

1 0.1

2 0.1sec

2 0.01%

2 0.01%

1 -

1 -

1 -

1 -

2 0.01%

2 0.01%

2 0.1sec

1 -

1 -

1 -

1 1.%

2 0.1Hz

1 0.1kHz

1 -

1 -

2 0.1

1 -

1 -

1 -

2 0.1%

27

Page 32

CHAPTER7 COMMUNICATION OBJECTS LISTS

INDEX Parameter Function Name Size Unit Note

0x2691 b091 Stop mode selection

0x2692 b092 Cooling fan control

0x2695 b095 BRD selection

0x2696 b096 BRD ON level

0x26D0 b130 OV LAD STOP selection

0x26D1 b131 OVLAD STOP level

0x26E0 b140 Over current prevention

0x26F0 b150 Carrier Mode

0x2801 C001 Intelligent terminal 1 function setting

0x2901 C201 Intelligent terminal 1 function setting,2nd motor

0x2802 C002 Intelligent terminal 2 function setting

0x2902 C202 Intelligent terminal 2 function setting,2nd motor

0x2803 C003 Intelligent terminal 3 function setting

0x2903 C203 Intelligent terminal 3 function setting,2nd motor

0x2804 C004 Intelligent terminal 4 function setting

0x2904 C204 Intelligent terminal 4 function setting,2nd motor

0x2805 C005 Intelligent terminal 5 function setting

0x2905 C205 Intelligent terminal 5 function setting,2nd motor

0x2806 C006 Intelligent terminal 6 function setting

0x2906 C206 Intelligent terminal 6 function setting,2nd motor

0x2811 C011 Intelligent terminal 1 active state

0x2812 C012 Intelligent terminal 2 active state

0x2813 C013 Intelligent terminal 3 active state

0x2814 C014 Intelligent terminal 4 active state

0x2815 C015 Intelligent terminal 5 active state

0x2816 C016 Intelligent terminal 6 active state

0x2821 C021 Intelligent output 11 setting

0x2822 C022 Intelligent output 12 setting

0x2826 C026 Alarm relay output

0x2828 C028 AM selection

0x2831 C031 Terminal 11 active state

0x2832 C032 Terminal 12 active state

0x2836 C036 Alarm relay active state

0x2841 C041 Overload advance notice level

0x2941 C241 Overload advance notice level,2nd motor

0x2842 C042 Frequency arrival setting for acceleration.

0x2843 C043 Arrival frequency setting for deceleration.

0x2844 C044 PID deviation level setting

0x2852 C052 PID feedback High-LIM

0x2853 C053 PID feedback Low-LIM

0x2871 C071 Communicating transmission speed

0x2872 C072 Communication code

0x2874 C074 Communication parity

0x2875 C075 Communication stop bit

0x2876 C076 Comm. Error select

Note *1: Please transmit twice continuously at the change of the value of C001 to C006.

28

1 -

1 -

1 -

2 1.V

1 -

2 1.V

1 -

1 -

1 -

1 -

1 -

1 -

1 -

1 -

1 -

1 -

1 -

1 -

1 -

1 -

1 -

1 -

1 -

1 -

1 -

1 -

1 -

1 -

1 -

1 -

1 -

1 -

1 -

2 0.01%

2 0.01%

2 0.1Hz

2 0.1Hz

2 0.1Hz

2 0.1Hz

2 0.1Hz

1 -

1 1.Node

1 -

1 -

1 -

*1

*1

*1

*1

*1

*1

*1

*1

*1

*1

*1

*1

Page 33

CHAPTER7 COMMUNICATION OBJECTS LISTS

INDEX Parameter Function Name Size Unit Note

0x2877 C077 Comm. Error time

0x2878 C078 Communication waiting time

0x2881 C081 O input scan calibration

0x2882 C082 OI input scan calibration

0x2885 C085 Thermistor adj.

0x2886 C086 AM offset adjustment

0x2891 C091 Debug mode enable

0x28A1 C101 UP/DWN selection

0x28A2 C102 Reset selection

0x28E1 C141 Logic output1

0x28E2 C142 Logic output2

0x28E3 C143 AND/OR/XOR select

0x28E4 C144 ON delay time (OUTPUT11)

0x28E5 C145 OFF delay time (OUTPUT11)

0x28E6 C146 ON delay time (OUTPUT12)

0x28E7 C147 OFF delay time (OUTPUT12)

0x28E8 C148 ON delay time (RY)

0x28E9 C149 OFF delay time (RY)

0x2A03 H003 1st allowable motor capacity

0x2B03 H203 2nd allowable motor capacity

0x2A04 H004 1st motor pole setting

0x2B04 H204 2nd motor pole setting

0x2A06 H006 1st stabilizing factor

0x2B06 H206 2nd stabilizing factor

0x2A07 H007 1st motor voltage select

0x2B07 H207 2nd motor voltage select

0x2F44 P044

0x2F45 P045 Inverter action W hen communication error.

0x2F46 P046 Polled I/O OUTPUT Instance number

0x2F47 P047 Polled I/O INPUT Instance number

0x2F48 P048 Inverter action W hen Idle mode detected.

0x2F49 P049 Motor poles setting for revolution per minute

Timer setting of communication timeout Whilst

running 2 0.1sec

2 0.01sec

2 1.msec

2 0.1%

2 0.1%

2 0.1%

2 0.1V

1 -

1 -

1 -

1 -

1 -

1 -

2 0.1sec

2 0.1sec

2 0.1sec

2 0.1sec

2 0.1sec

2 0.1sec

1 -

1 -

1 -

1 -

2 1.%

2 1.%

1 -

1 -

1 -

1 -

1 -

1 -

1 -

7.4 Saving Parameters to EEPROM

The purpose of this object is to save all inverter parameter to the Inverter’s EEPROM.

INDEX Function Name Size Note

0x2F00 EEPROM write command 1

The object 0x2F00 is a placeholder for issuing the EEPROM write command. A rising edge 0 -> 1

will start the EEPROM writing process. The method of making edge is write “0” this object then

write “1”. While the object 0x2F00 is set “1”, the inverter is writing data to EEPROM. When

finished writing to EEPROM, this object is going to set “0” in automatically. Please surveillance

this object, during writing data to EEPROM.

29

Page 34

CHAPTER8 SPECIFICATIONS

8.1 CANopen Specifications of SJ200-2/L200-2 Series CANopen Option

The table below describes CANopen specifications of “CANopen interface option”.

Item Specifications

Communication Profile DS-301 V4.01

Device Profile DS-402 V2.0

Synchronization Object (SYNC) Yes

Time Stamp Object (TIME) No

Emergency Object (EMCY) Yes

Network Management Object Yes

Number of PDO’s 4Rx / 4Tx

PDO Modes Sync(cyclic) / Sync(acyclic)

PDO Linking No

PDO Mapping Variable

Number of SDO’s 1 Server / 0 Client

Emergency Message Yes

Pre-Defined Connection Set No

10kbps/20kbps/50kbps

/125kbps/250kbps/500kbpsSupported baud rates

/800kbps/1Mbps

Supported LED

Network Connector Open Connector

Supported Node ID/Default 1~127/0

Baud rates/Node ID setting Dip Switches

Module Status LED(MOD)

CANopen Status LED(CAN)

8.2 Dimension

(mm)

30

Page 35

9.1 Contact Information

CHAPTER9 CONTACT INFORMATION

Hitachi Europe GmbH

Am Seestern 18

D-40547 Dusseldorf

Germany

Phone:+49-211-5283-0

Fax: +49-211-5283-649

Hitachi America, Ltd

Power and Industrial Division

50 Prospect Avenue

Tarrytown, NY 10591

U.S.A.

Phone:+1-914-631-0600

Fax: +1-914-631-3672

Hitachi Asia, Ltd

16 Collyer Quay

#20-00 Hitachi Tower,

Tarrytown, NY 10591

U.S.A.

Phone:+1-914-631-0600

Fax: +1-914-631-3672

Hitachi Australia, Ltd

Level 3,82 Waterloo Road

North Ryde, N.S.W.2113

Australia

Phone:+61-2-9888-4100

Fax: +61-2-9888-4188

Hitachi Industrial Equipment System Co., Ltd

International Sales Department

ASK Bldg., 3,kanda Neribei-cho

Chiyodaku, Tokyo, 101-0022

Japan

Phone:+81-3-4345-6063

Fax: +81-3-4345-6913

Hitachi Industrial Equipment System Co., Ltd

Narashino Division

1-1, Higashi-Narashino 7-chome

Narashino-shi, chiba 275-8611

Japan

Phone:+81-47-474-9921

Fax: +81-47-476-9517

Hitachi Asia(Hong Kong) Ltd

th

7

Floor, North Tower

World Finance Centre, Harbour City

Canton Road, Tsimshatsui, Kowloon

Hong Kong

Phone:+852-2735-9218

Fax: +852-2735-6793

31

Loading...

Loading...