Page 1

INSTRUCTION MANUAL

FOR

MODEL S-4800

FIELD EMISSION

SCANNING ELECTRON MICROSCOPE

Please read through this manual carefully

before using the instrument.

• Before using the instrument, read the safety

instructions and precautions carefully.

• Keep this manual in a safe place nearby so it

can be referred to whenever needed.

Copyright © Hitachi High-Technologies Corporation. 2002. All rights reserved. Printed in Japan. Part No. 539-8050

Page 2

NOTICE:

1. Information contained in this document is subject to

change without notice for improvement.

2. This manual is copyrighted by Hitachi High-Technologies

Corporation with all rights reserved.

No part of this manual may be reproduced, transmitted

or disclosed to a third party in any form or by any means

without the express written permission of Hitachi

High-Technologies Corporation.

3. Hitachi High-Technologies Corporation assumes no

liability for any direct, indirect, or consequential damages

arising from use not described in this manual.

Utmost care must be exercised when using the

instrument.

4. This document does not provide any warranty or

permission for industrial properties or any rights to grant

license lawfully and without infringement.

Page 3

FOREWORD

APPLICATION

CAUTION

• The S-4800 SEM utilizes electron beam accelerated at 500 V to 30 kV.

The instrument is designed mainly for observation and evaluation of

specimens prepared for observation using SEM.

• Note that Hitachi High-Technologies Corporation will not be responsible

for injury or damage caused by usage of the instrument in a manner not

described in this manual.

The electron microscope need not conform to the “Radiation Hazard

Preventive Laws” or “Ionizing Radiation Hazard Preventive Regulations”

currently in effect throughout the world, unlike the instruments

designed to produce x-rays.

The suggestion made by the ICRP (International Committee on Radiation

Hazard Prevention), however, clearly defines that the electron

microscope, like the home television set, will potentially produce a certain

amount of x-rays as an undesirable byproduct. From a safety viewpoint,

therefore, it is essential to operate the instrument carefully taking into

account the following fundamental precautions.

(1) Use the instrument within the application range specified in the

catalog or instruction manual.

(2) Do not operate the instrument with covers or doors removed, nor use

alternatives for these components.

(3) Do not apply modifications which may possibly result in deactivation

of the built-in safety devices.

CAUTION

Viewing the screen of the computer monitor and/or operating the computer

keyboard for prolonged, uninterrupted periods of time may result in fatigue

or other problems such as eye strain or repetitive motion injuries.

Therefore, Hitachi High-Technologies Corporation recommends that the

user carefully consider these potential risks when establishing guidelines

for proper use of this instrument in their workplace.

FOREWORD - 1

Page 4

Before using the equipment, read this instruction manual and pertinent instruction manuals of

relevant accessories to assure proper operation of the equipment.

Scope of Instruction Manual

This instruction manual comprises the following:

1. Installation (Requirements and Items to be Prepared by User)

2. Function (Description of Controls)

3. Operation (Viewing Images, Saving Data, and Taking Photographs)

4. Maintenance (Procedures, Troubleshooting, and Action on Power Failure)

5. Replacement Parts

6. Accessory Operation

This instruction manual describes the operation, maintenance, and specific precautions pertinent

to daily operation on the model S-4800 scanning electron microscope.

First, read and get familiar with the safety precautions described in the opening pages and

General Safety Guidelines.

FOREWORD - 2

Page 5

GUARANTEE

Period of Guarantee

The charge-free guarantee period is one year from the date of installation.

Details of Guarantee

(a) The instrument will be repaired free of charge if it malfunctions due to a defect in

manufacture within the charge-free guarantee period.

(b) Note that a substitute part may be used for repair, or replacement with an equivalent

product may be made instead of repair.

(c) Such system components as a personal computer and printer which are frequently

modified for improvement may not be available in original versions at the time of

replacement.

(d) Maintenance procedures are provided to allow system operation for 10 years after its

delivery. During this period, the maintenance of units or parts having a rather short

product cycle such as personal computer and printer may entail the purchase of

substitute parts because of limits on the repair period of the former, for which we

request your understanding. Even when more than 10 years have elapsed after

delivery, maintenance will basically be provided as long as the relevant units and parts

are available.

Exclusions from Guarantee

The guarantee will not be valid for the following failures and/or cases even during the

charge-free guarantee period.

(a) Failure due to use in improperly installed condition.

(b) Failure due to power supply voltage/frequency other than specified by Hitachi

High-Technologies Corporation or due to power failure.

(c) Corrosion or deterioration of the tubing due to impurities contained in gas, air or cooling

water supplied by the customer.

(d) Corrosion of electric circuits or deterioration of optical elements due to corrosive gases

or much dust contained in the atmosphere.

(e) Failure due to disassembly, modification, parts replacement, or relocation not approved

by Hitachi High-Technologies Corporation.

(f) Consumables and parts having a limited period of guarantee.

(g) Failure attributable to use of non-guaranteed parts (parts not described in the

instruction manual).

(h) Failure due to acts of God, including fire, earthquake, storm, flood, lightning, social

disturbance, riot, crime, insurrection, war (declared or undeclared), radioactive

pollution, contamination with harmful substance, etc.

FOREWORD - 3

Page 6

GUARANTEE

(i) Failure of instrument or damage of basic software, application software or other data

due to a computer virus.

(j) Failure of the PC used with the instrument or damage to basic software, application

software and/or data because of momentary voltage drop caused by lightning or power

interruption.

(k) Failure of the PC used with the instrument or damage to basic software, application

software and/or data caused by turning off the PC main power without taking the

normal termination procedure.

Limitations on Guarantee

HITACHI HIGH-TECHNOLOGIES CORPORATION MAKES NO GUARANTEES, EITHER

EXPRESS OR IMPLIED, EXCEPT AS PROVIDED HEREIN, INCLUDING WITHOUT

LIMITATION THEREOF, GUARANTEES AS TO MARKETABILITY, MERCHANTABILITY,

FOR A PARTICULAR PURPOSE OR USE, OR AGAINST INFRINGEMENT OF ANY

PATENT. IN NO EVENT SHALL HITACHI HIGH-TECHNOLOGIES CORPORATION BE

LIABLE FOR ANY DIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES OF ANY

NATURE, OR LOSSES OR EXPENSES RESULTING FROM ANY DEFECTIVE PRODUCT

OR THE USE OF ANY PRODUCT. NO ORAL OR WRITTEN INFORMATION OR

ADVICE GIVEN BY HITACHI HIGH-TECHNOLOGIES CORPORATION, ITS DEALERS,

DISTRIBUTORS, AGENTS OR EMPLOYEES SHALL CREATE A GUARANTEE OR IN

ANY WAY INCREASE THE SCOPE OF THIS GUARANTEE.

FOREWORD - 4

Page 7

INSTALLATION AND AFTER-SALES SERVICE

Installation

• Installation at delivery will be carried out by Hitachi High-Technologies Corporation

installation engineers.

• Before installation, refer to section 1 and prepare the necessary utilities.

• Installation at another place after delivery will be provided at charge. Consult your

nearest Hitachi High-Technologies Corporation service representative for details.

After-sales Service

• For after-sales service of the instrument, contact the Hitachi High-Technologies

Corporation sales or service representative in charge.

• For service after the guarantee period, consult Hitachi High-Technologies Corporation with

regard to a maintenance and inspection service contract.

CAUTION ON DISPOSAL OF INSTRUMENT

Although at present the instrument does not use materials that will directly harm the

environment, changes are apt to be made in relevant laws and/or regulations, so be sure to

consult a qualified specialist when planning to dispose of the instrument.

FOREWORD - 5

Page 8

Available Training Programs

Hitachi High-Technologies Corporation offers various kinds of training programs at its own

facilities or at the user’s site and facilities to ensure proper and safe operations of the equipment

to its full performance.

Please contact your sales representative about the details of the training programs and

application to them. Applicants will be charged.

Handling of Chemicals

(1) The user is responsible for proper handling and disposal of chemicals used for cleaning of

the equipment in accordance with applicable regulations.

(2) Follow the supplier’s instructions on handling, storage, and disposal of chemicals.

Instruction Manual

(1) This instruction manual and those instruction manuals for relevant accessories may be

revised for improvement without prior notice.

(2) Hitachi High-Technologies Corporation has the copyright of this instruction manual.

(3) Reproducing or copying of part or all of this instruction manual is not allowed without our

written permission.

FOREWORD - 6

Page 9

SAFETY SUMMARY

General Safety Guidelines

Before operating the machine, read the following instructions carefully:

• Follow all the operating procedures provided in this manual.

• Installation and maintenance must be entrusted to personnel who have received training

at and are authorized by Hitachi High-Technologies Corporation.

• Pay special attention to and follow all the hazard warnings on the machine and in the

manual. Failure to do so can cause injury to yourself or damage to the machine.

• The hazard warnings which appear on the warning labels on the machine or in the manual

have one of the following alert headings consisting of an alert symbol and a signal word,

DANGER, WARNING, or CAUTION.

DANGER

WARNING

CAUTION

CAUTION

NOTICE

Indicates an imminently hazardous situation which, if not

:

avoided, will result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided,

:

can result in death or serious injury

Indicates a hazardous situation which, if not avoided, will or can

:

result in minor or moderate injury, or serious damage of

product.

The alert symbol shown at left precedes every signal word for

:

hazard warnings, and appears in safety related descriptions in

the manual.

Indicates instructions for preventing possible damage to the

:

instrument.

Indicates information and descriptions for ensuring correct

:

usage.

• Do not perform any operation or action in any way other than as provided in this manual.

When in doubt, call the designated field engineer.

• Keep in mind that the hazard warnings in this manual or on the machine cannot cover

every possible case, as it is impossible to predict and evaluate all circumstances

beforehand. Be alert and use your common sense.

SAFETY - 1

Page 10

SAFETY SUMMARY(cont’d)

• Installation at delivery, maintenance and/or relocation must be carried out under the

supervision of Hitachi-approved specialists.

• The customer is responsible for proper ventilation of the room when using chemicals.

Inadequate ventilation could cause a health hazard.

• Maintenance up to 4.4 in section 4 must be entrusted to the service engineers (of Hitachi

Instrument Service). The user should not carry out these procedures.

• Do not carry out modification of the instrument, parts replacement, use non-specified

parts, nor detach safety mechanisms since this could be hazardous.

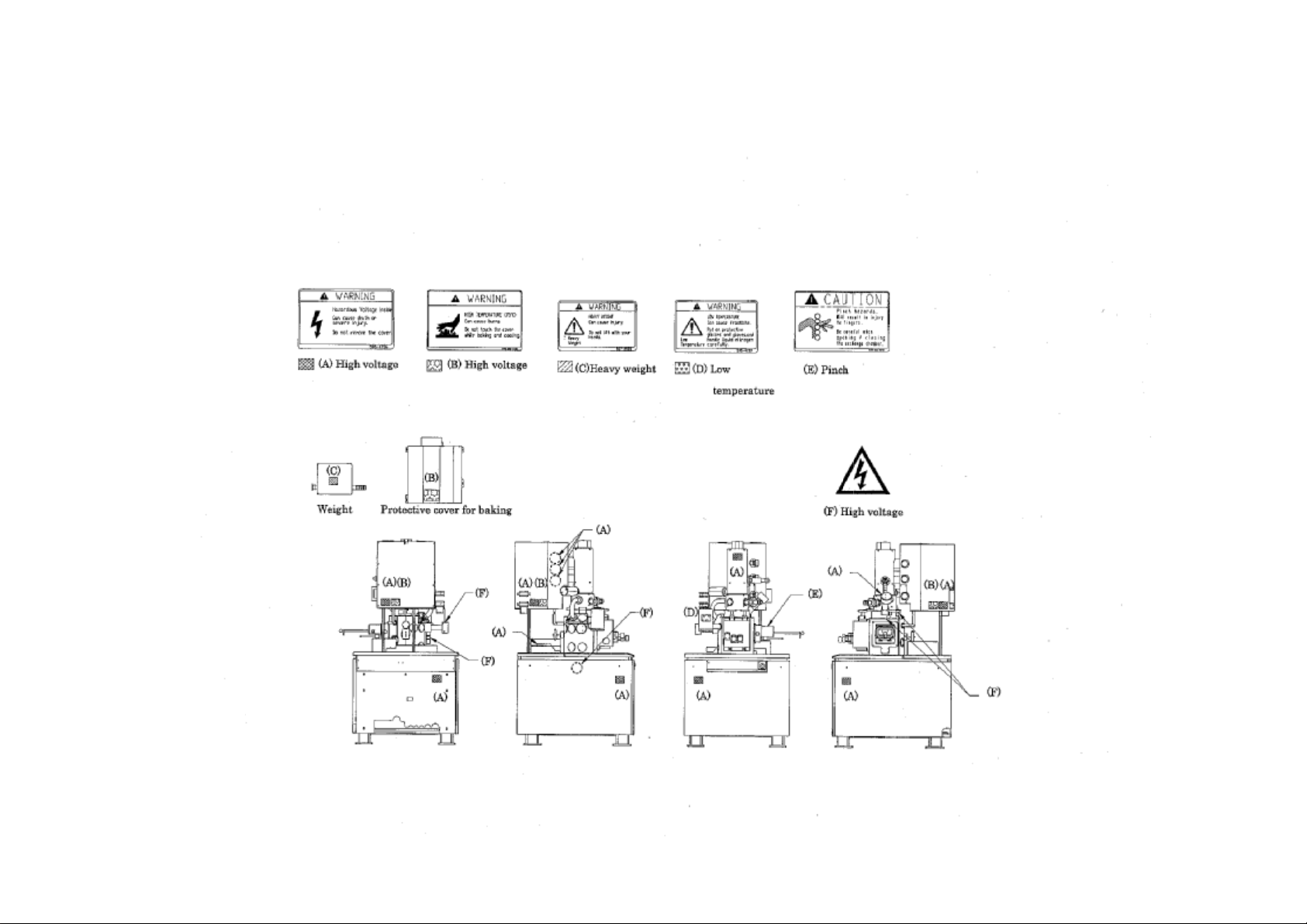

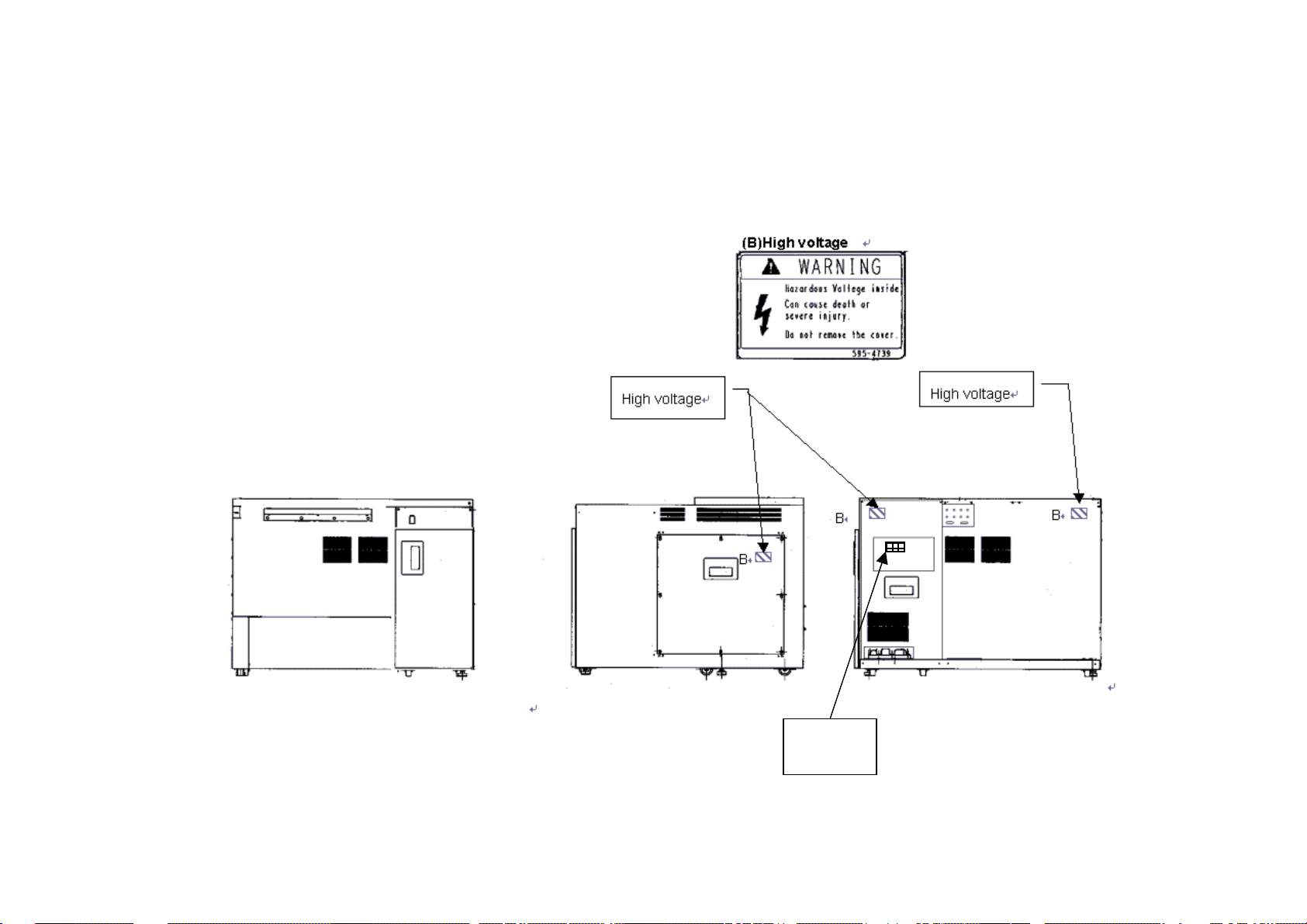

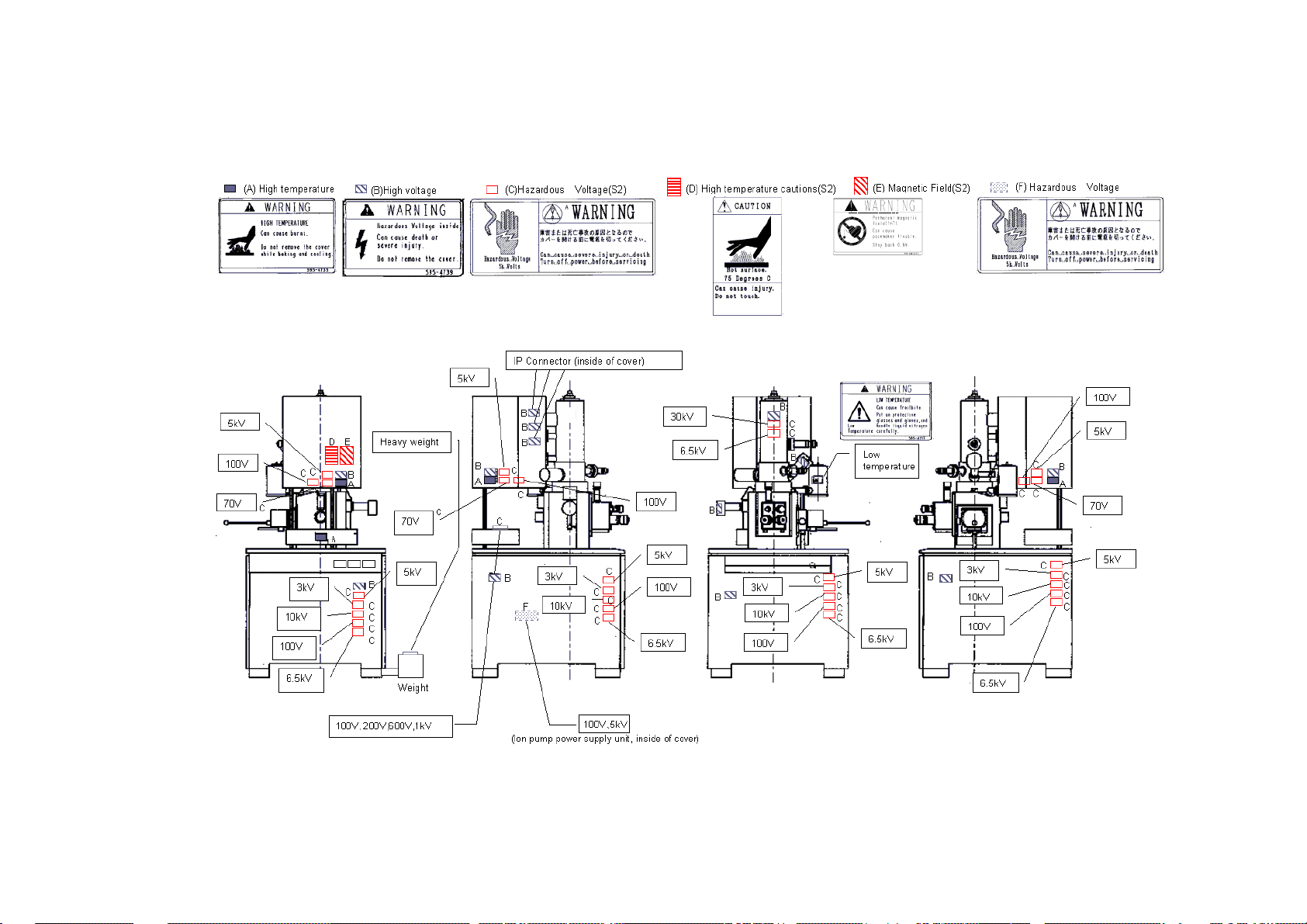

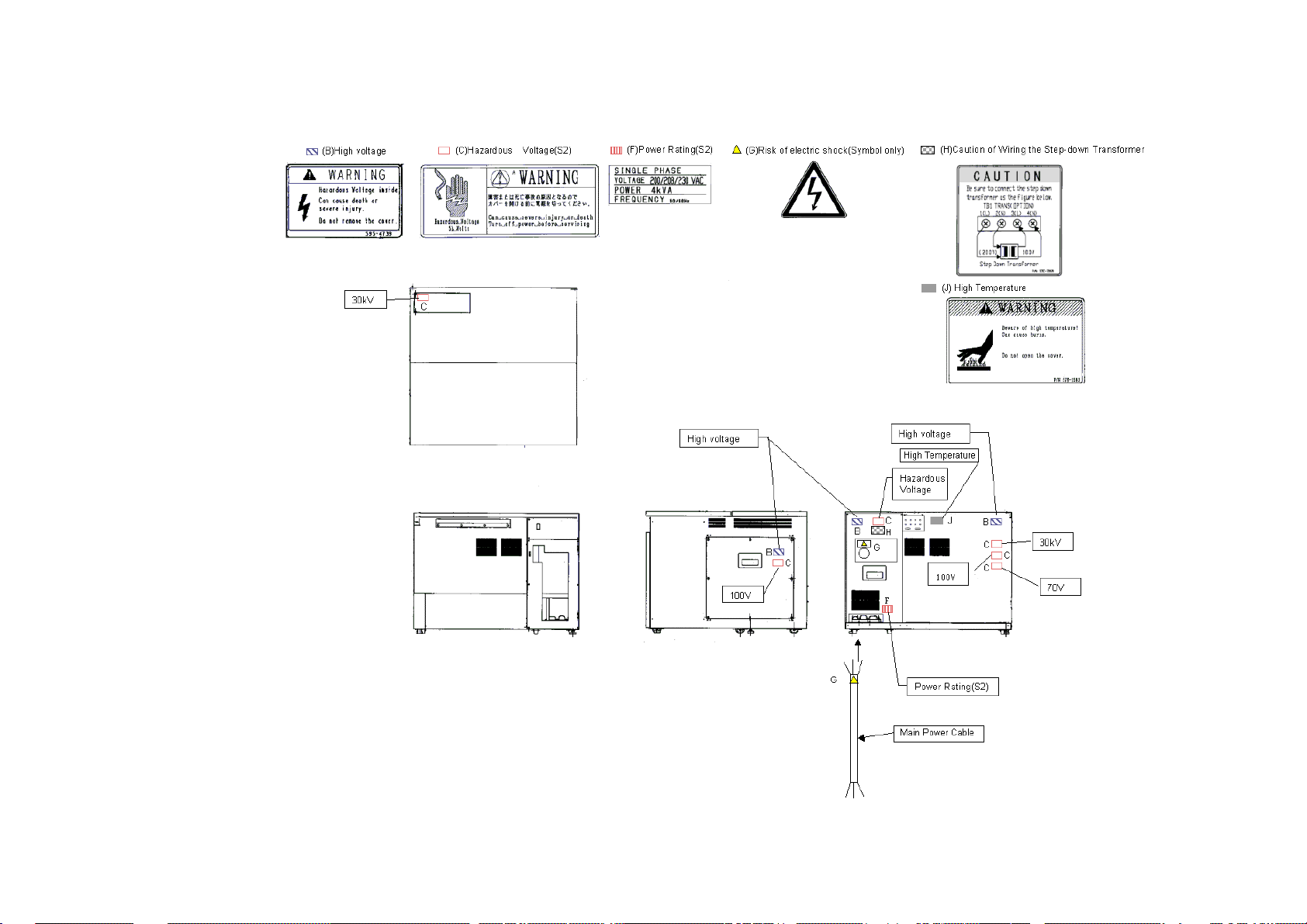

Locations of Warning Labels on the equipment are illustrated on the next pages.

Maintenance of Warning Labels

Contact your nearest Hitachi High-Technologies Corporation service representative for

maintenance of deteriorated or damaged warning labels.

Locations of Warning Labels on the equipment are illustrated on the next pages.

SEMI S2 modification including ANSI style labels is provided as option. Refer to fig S-1

and S-2 for standard version and S-3 and S-4 for ANSI style labels.

SAFETY - 2

Page 11

Electrical Hazard

Electrical hazards exist due to the following:

Electron Gun : 0.5 to 30 kV DC

Ion Pump : 5 kV DC

Photomultiplier : 1 kV DC

Scintillator of secondary electron detector : 10 kV DC

Electrode 1 : 50 V DC

Electrode 2 : 200 V (Max) DC

Electrode 3 : 100 V (Max) DC

ExB : 30 V (Max)DC

Penning gauge : 3 kV

Photo CRT : 10 kV DC

An enclosure is provided for each high voltage power supply sub-unit. These enclosures are

fixed by screws and electrically connected to the protective grounding, so electrical hazards by

direct contact are prevented.

At the high voltage power supply sub-units, warning labels are attached to prevent hazards

during maintenance. The maintenance should be carried out only by the service personnel

specified and trained by the manufacturer.

The operator should not open the enclosure of the high voltage power supply sub-units in the

main unit, display unit or ion pump power supply unit.

• If you touch a terminal board, you may receive an electric shock.

• If you touch a high-voltage section also, you may receive an electric shock.

SAFETY - 3

Page 12

High Temperature Hazard

Baking the electron gun part is carried out about once per 6 months to keep high vacuum inside

the part. When baking, the surface of the gun housing and ion pumps reaches around 250 °C.

The electron gun part is surrounded by a metal guard to prevent high temperature hazard caused

by direct contact. However, the temperature of the upper stage surface rises up to

100 °C and the temperature of the side cover surface also rises up to 75 °C. The maintenance

work of baking should be carried out by personnel trained by the manufacturer.

The operator should not touch the covers when the electron gun and ion pumps are heated up to

about 250 °C in order to keep the electron gun in ultra high vacuum. Touching these sections

would result in burns.

Note that the above heated parts are still hot even after stopping heating. Cooling down to close

to room temperature needs about 6 hours.

Magnetic Field Hazard

The ion pumps are constructed with permanent magnets. There is a fringing magnetic field of

about 10 mT at the ion pump surface and about 1 mT at the outside of the ion pump cover.

• Any person who carries a pacemaker embedded is not allowed to approach the ion-pump.

• Do not bring near the ion pump wristwatches and magnetic cards that are susceptible to

magnetic fields.

SAFETY - 4

Page 13

Laser light Hazard

The CD-ROM or CD R/W drive in the personal computer provides with a laser device.

Personal Computer with a laser device complies with safety standards, including International

Electrotechnical Commission (IEC) 825.

With specific regard to the laser, the equipment complies with laser product performance

standards set by US government agencies for a Class 1 laser product.

The product does not emit hazardous light; the beam is totally enclosed during all modes of

customer operation and maintenance.

Therefore, be sure to observe the following warnings when operating a product equipped with a

laser device.

・Do not try to open the unit enclosure. There are no user-serviceable components inside.

・Do not operate controls, make adjustments, or perform procedures to the laser device other

than those specified herein.

・Allow only Service persons to repair the unit.

Laser Information

Laser Type Semiconductor GaAlAs

Wave Length 780 nm +/- 35 nm

Divergence Angle 53.5 degrees +/- 0.5 degrees

Output Power Less than 0.2 mW or 10,869 W m-2 sr-1

Polarization Circular 0.25

Numerical Aperture 0.45 inches +/- 0.04 inche

SAFETY - 5

Page 14

SAFETY - 6

Fig S-1 Warning labels on the Main unit (standard version)

Page 15

SAFETY - 7

Fig S-2 Warning labels on the Display unit (standard version)

Page 16

Fig S-3 Warning labels on the Main unit (ANSI style labels)

SAFETY - 8

(NOTICE : (Labels with(S2) are put to SEMI-S2 guideline conforming version)

Page 17

SAFETY - 9

(NOTICE : (Labels with(S2) are put to SEMI-S2 guideline conforming version)

Fig S-3 Warning labels on the Display unit (ANSI style labels)

Page 18

Beware of

electric shock

Beware of high

temperature

WARNING

• Voltages up to 100 V AC and 30 kV DC are used inside this

instrument. Do not touch inside or you may receive an electric shock.

• Do not remove the covers of column unit, control unit or power unit

and do not touch internal parts or circuits while the instrument power

is turned on. There is a hazard of fatal or serious injury due to

electric shock.

• Avoid removing the covers of the instrument. If they must be

removed, make sure to first turn off all power to the instrument.

Electron Gun / Ion pump Baking

• The electron gun and ion pump are heated to about 250°C in order to

keep the electron gun in a high vacuum. Touching these sections

would result in burns.

Rotary Pump

• The temperature of the oil rotary pump rises up to about 70°C, while it

is operating. Touching the pump may also result in burns.

Beware of low

temperature

Magnetic Fields

Liquid Nitrogen

• When you replenish liquid nitrogen in the cold-trap of DP and the

anti-contamination trap, be sure to wear eye-protection glasses and

protective gloves to keep liquid nitrogen from splashing on the eyes or

the skin.

• Anyone working on the electrical part of the system should follow the

correct lock-out tag-out procedures for that location.

• The user should prepare a mains switch box on which the lock-out

and the tag-out procedures are provided.

• Electrical hazards can occur if lock-out tag-out procedures are not

followed.

• The ion-pump produces magnetic fields. There are fringing magnetic

fields of about 100 Gauss from the ion-pump and 10 Gauss at the

outside of the ion-pump cover.

Any person who has a pacemaker embedded is not allowed to

approach the ion-pump.

Do not bring near to the ion-pump wristwatches and magnetic cards

that are susceptible to magnetic fields.

SAFETY - 10

Page 19

Laser Light

WARNING (cont’d)

The CD-ROM or CD R/W drive in the personal computer provides with a

laser device.

Be sure to observe the following warnings when operating a product

equipped with a laser device.

・ Do not try to open the unit enclosure. There are no user-serviceable

components inside.

・ Do not operate controls, make adjustments, or perform procedures to

the laser device other than those specified herein.

・ Allow only Service persons to repair the unit.

SAFETY - 11

Page 20

Other Relevant Precautions

• Water Leakage Detection

A water-leakage detector is not provided with this equipment. Water leakage may be

caused by corrosion and cracks along the water flow system developed by changes in

cooling-water quality and pressure. If a cooling-water circulating system is not installed,

you should install a water-supply kit; the water-supply kit is provided with a pressurereducing valve and a water-leakage sensor, preventing an accident of water pooling.

• Third Party’s Industrial or Proprietary Rights

Hitachi shall not be responsible for a third party’s claim regarding infringement of any

patent rights or industrial properties with respect either to products manufactured through

the use of equipment supplied by Hitachi or its related companies or to applications of the

Hitachi equipment.

• Cooling Water

(a) You can use city water of which chlorine concentration is less than 0.5 ppm for

cooling water. If the chlorine concentration is higher, use a cooling-water circulating

system to prevent water-leakage due to corrosion of the water flow system.

(b) Necessary flow rate of the cooling water is about 1.5 L/min.

(c) Use a pipe taper-thread to fix the hose to the water faucet.

(d) Be sure to secure the drain hose to the drainage. Loose drain hose can be

responsible for a water pool.

(e) Close the supply valve of the cooling water when not in use.

(f) Soft polyvinyl chloride is used for the supply and drain hoses. These hoses may

become hardened and less flexible after a long period of time. Therefore, regular

replacement is recommended, and be sure to check against water leakage before

use.

(g) If you anticipate the cooling water to freeze in winter, use antifreeze on a cooling-

water circulating system.

(h) Cooling water temperature should be controlled so it is not more than 7 °C below the

room temperature. If the temperature difference is greater than this, condensation

may form along the cooling water flow path. And long use under this condition may

cause rusting of the important cooled parts such as objective lens magnetic path and

eventually result in damage to them, whereby the complete set of objective lens will

require replacement. It is thus recommended to use a closed water circulator and

maintain a suitable water temperature.

• Backup of Important Data

Trouble-free operation cannot be guaranteed for the computer system. You are

recommended to copy important data on the hard disk into floppy disks (FD) or magnetooptical disks (MO) at a regular interval.

SAFETY - 12

Page 21

Other Relevant Precautions (cont’d)

• Third Party’s Application Programs

Do not install a third party’s application programs into the PC of the equipment.

Those application programs can be responsible for display of unexpected windows,

adverse effects on the equipment, and interference in the operation of the system

program. Hitachi shall not be liable for the troubles caused by such application

programs.

• Protection against Computer Viruses

Computer viruses are malicious programs that sneak into the PC to cause misbehavior or

damage to data. And, a program designed to offer protection against and eradicate

computer viruses is called a vaccine program.

Virus infection can be caused by using a floppy disk or other storage medium infected by

a virus. Note also that once the PC is infected by a virus, it may spread to other

computers through storage medium. Therefore, never use a program or storage

medium that is suspected of containing a virus.

If there is a possibility of virus infection, check for a virus using a vaccine program. The

user is requested to prepare a proper vaccine program and carry out virus removal on his

or her own responsibility.

Note, however, that some kinds of vaccine programs may cause incorrect operation of

the S-4800 control program. If a problem occurs after you install a vaccine program,

remove it or execute virus check when the S-4800 program is not running. It is desirable

not to set the vaccine program in the auto start-up group, or to terminate the vaccine

program before starting the S-4800 program.

• Do Not Change Computer Settings

Do not change the following system settings of your PC. These are set up at the optimum

conditions for operation of the S-4800 SEM before shipping.

(a) Connection to the USB ports

This instrument uses a USB port for communication between the PC and the

internal microprocessor. The USB port number 1 is occupied for the instrument.

Use USB ports on the installed additional USB board for external storage devices,

printer etc. Do not connect these units to the standard USB ports of PC even if

these are open.

(b) Display screen setting

Display properties need to be set at 1280x1024 pixels for the desktop area, true

color (24 bit) mode and 60Hz to 70Hz for the refresh rate. Using other resolution,

faster refresh rate or 256 color mode may cause an abnormal screen display.

(c) Sub programs

This instrument operates using many of dll programs along with control program.

Deletion of files in the Windows directory or change of the registry will cause

troubles. Also do not delete tasks and processes using the task manager.

SAFETY - 13

Page 22

Other Relevant Precautions (cont’d)

(d) Power Saving mode

Do not use the Power Saving mode. It will cause trouble for communication

between the PC and internal microprocessor.

(f) Virtual memory setting

Do not change the virtual memory setting.

• OS operation during S-4800 SEM operation

Although the Windows Task Manager can be launched from the Taskbar or using

Ctrl+Alt+Del key operation, if Standby or Halt mode is set or logged-off during S-4800

control program is running, it will not work normally when recovered from such a status.

Close S-4800 control program If setting such mode is necessary.

• USB devices

When connecting USB devices such as external storage unit, printer etc., take notice to

followings.

(1) Terminate S-4800 control program when carrying out disk formatting or copying large

volume of image files to MO disk, hard disk or other storage devices using USB port.

(2) By above operation, sometimes the message “USB not connected” will be shown. In

the case, S-4800 control program will not continue normal operation. Terminate Windows

and shut the PC down. Then turn the DISPLAY switch OFF. Turn it on again after waiting

about half a minute.

• Power Failure

Instantaneous drop in the line voltage caused by power failure or lightning can be

responsible for malfunction of the PC or damage to system programs, application

programs, or data. An uninterruptible power supply unit is recommended to protect your

system from such instantaneous drop in the line voltage.

• Personal Computer (PC)

Do not turn off the PC power independently. If the PC power is turned off during access

to HD or FD, the PC or data and programs stored therein may be damaged.

Be sure to terminate the SEM system software and Windows 2000 software, and then

turn off the PC by means of the DISPLAY switch.

If the PC should become locked, press the Alt, Ctrl and Delete keys simultaneously,

select the process related to locking, then press the Exit button.

• Other Precautions for operation

Refer to “Precautions When Using the S-4800 SEM” in the PC-SEM Help shown by

selecting Help menu.

• Do not forget other precautions described in the text of the instruction manual.

NOTICE

:The model S-4800 has two nameplates. The nameplate at the back of the main unit

indicates production serial number, production date, manufacturer name and AC

power input. The nameplate at the back of the display unit idicates rated voltage,

current and frequency of AC power input.

SAFETY - 14

Page 23

Emergency Off Button

The Emergency Off button (EMO) is a red, mushroom shaped pushbutton switche, that is located

on the Evacuation control panel of Main unit. Its purpose is to shut off all power in the system

when pushed, and it is a non- momentary switch which is never be overridden even during

servicing of the system.

Fig S- 5 Location of Emergency Off button

It is recommended to check the function of Emergency Off circuit during the regular maintenance.

NOTE : When pushing the EMO, the whole power line is cut off. Since a battery backed up

power supply for the PC is not mounted the PC can not finish the shutdown sequence,

thus possibly causing serious damage to the PC file system.

RECOVER OF EMERGENCY OFF

1. Check the whole system. If the system has something wrong, call service personnel

(Hitachi High-Technologies Corporation service engineer etc.) and execute maintenance.

2. Turn all breakers on the back og the display unit.

3. Unlock EMO switch. (Turn clockwise for unlocking)

4. Refer to section 4 for starting up.

SAFETY - 15

Page 24

Main Power Disconnect

Lock out/tag out procedure are very important safety concern.

The purpose of the lock out/tag out procedure is to insure safety while working on electrical and

mechanical equipment. Make sure you get introduced to the person responsible for the

equipment at the site. When you need to power down the system and work on it in that state,

you must lock out/tag out. If the main Disconnect is a knife switch, turn it off and place your pad

lock in the hole provided. Place a tag that is clearly readable with your name and how you can

be reached on it, remember you are the only person that has a key to unlock this Disconnect. If

the main Disconnect is a receptacle type, remove it and place a lockable box cover over it and

tag it, again you keep the only key. If there is no disconnect you should turn off main breaker at

power supply and physically disconnect the power output of the main breaker.

Power Supply and Grounding Connection

This instrument is designed to operate on AC 100 V input power voltage. If other than 100 V

input power must be used, it is required to use the double installation transformer.

Refer to <1.3.1 Power and Ground Wirings> for connection of the transformer.

In this case, using a voltage meter, make sure that the output voltage of the transformer is 100 V.

Connect the instrument to ground based on the standard of your country.

Avoid sharing the ground terminal with other power equipments. Be sure to ground the

instrument independently.

SAFETY - 16

Page 25

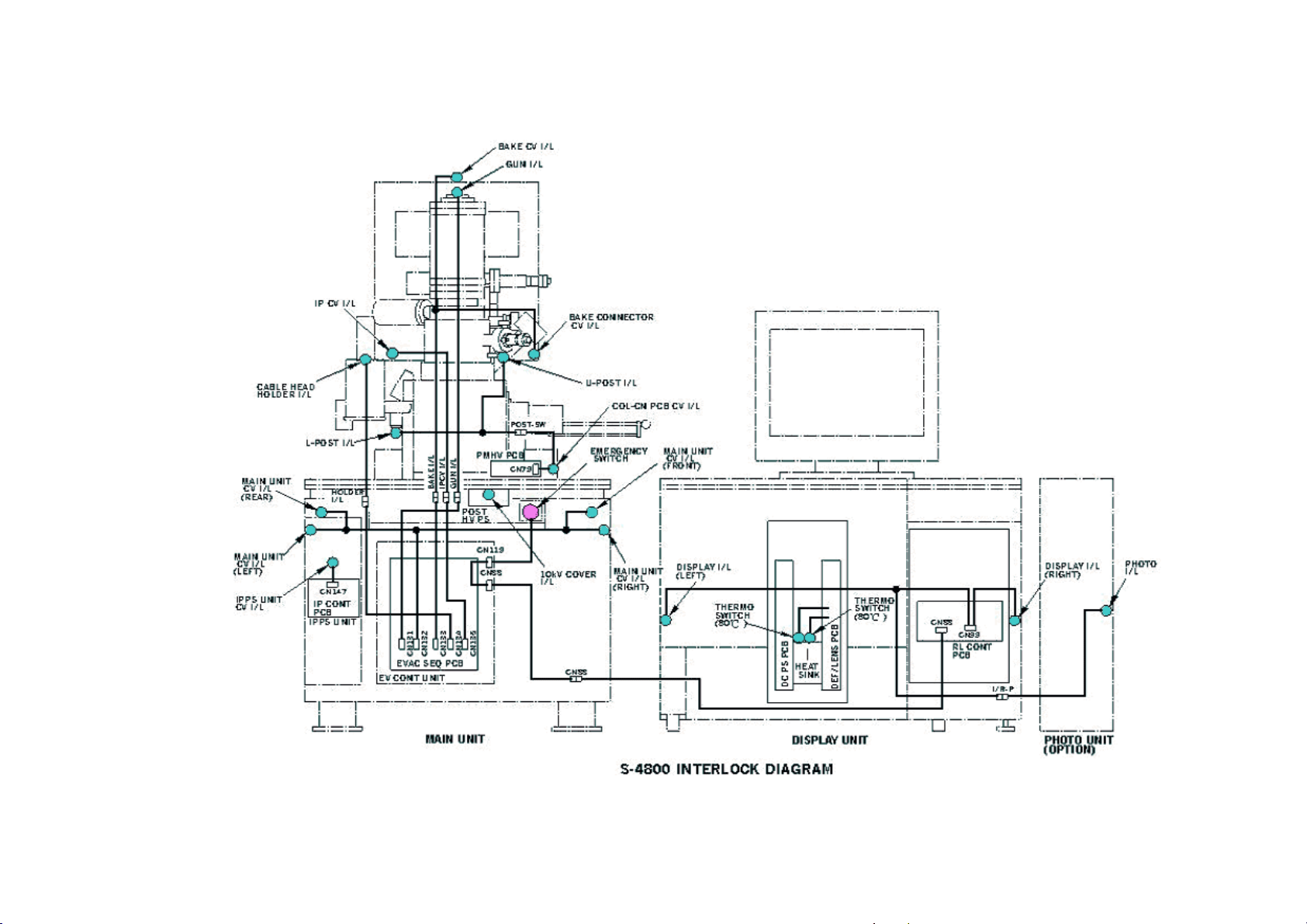

INTERLOCK

Electron Gun The Gun cable is now interlocked with a momentary switch.

If the cover at the top of the electron gun is removed to

disconnect gun cable, the High Voltage applied to the electron

gun is shut off. This switch can be overridden for service.

However, if the cable is replaced the service override is removed.

Ion Pump The ion pump cover at the back of the electron optical column

has a safety interlock switch. If the cover is removed, the High

Voltage supplied to the ion pumps is shut off and lamps in the

RESET switches for ion pumps located on the evacuation control

panel will go off. For service the switches can be overridden,

but as soon as the ion pump cover is put again, the service

override is removed.

Other High Voltages High voltage power supply for photo multipliers and electrodes

are placed inside of a box located at the behind of the specimen

chamber. The cover of the box has a safety interlock switch. If

the cover is removed, the High Voltage supplied to the photo

multipliers and electrodes is shut off. For service the switches

can be overridden, but as soon as the cover is put again, the

interlock is functional.

Baking power supply Baking heater power supply connectors are placed at the right

side of the ion pumps cover. To connect heater connectors, the

box cover of the connector must be removed. The box cover of

the connector has a safety interlock switch. The baking power is

shut off when the cover is removed. After connecting connectors,

put the cover again. The baking power then becomes applicable.

Unit power supply Four side covers of the Main unit have safety interlock switches

one for each. If one of the side covers is removed, AC power

supply for the Main unit (for evacuation system, ion pump power

supply and stage controller) will be shut off. The switches can be

overridden for service. However, if the covers are put again, the

service override is removed.

The interlock location is shown in fig S-6

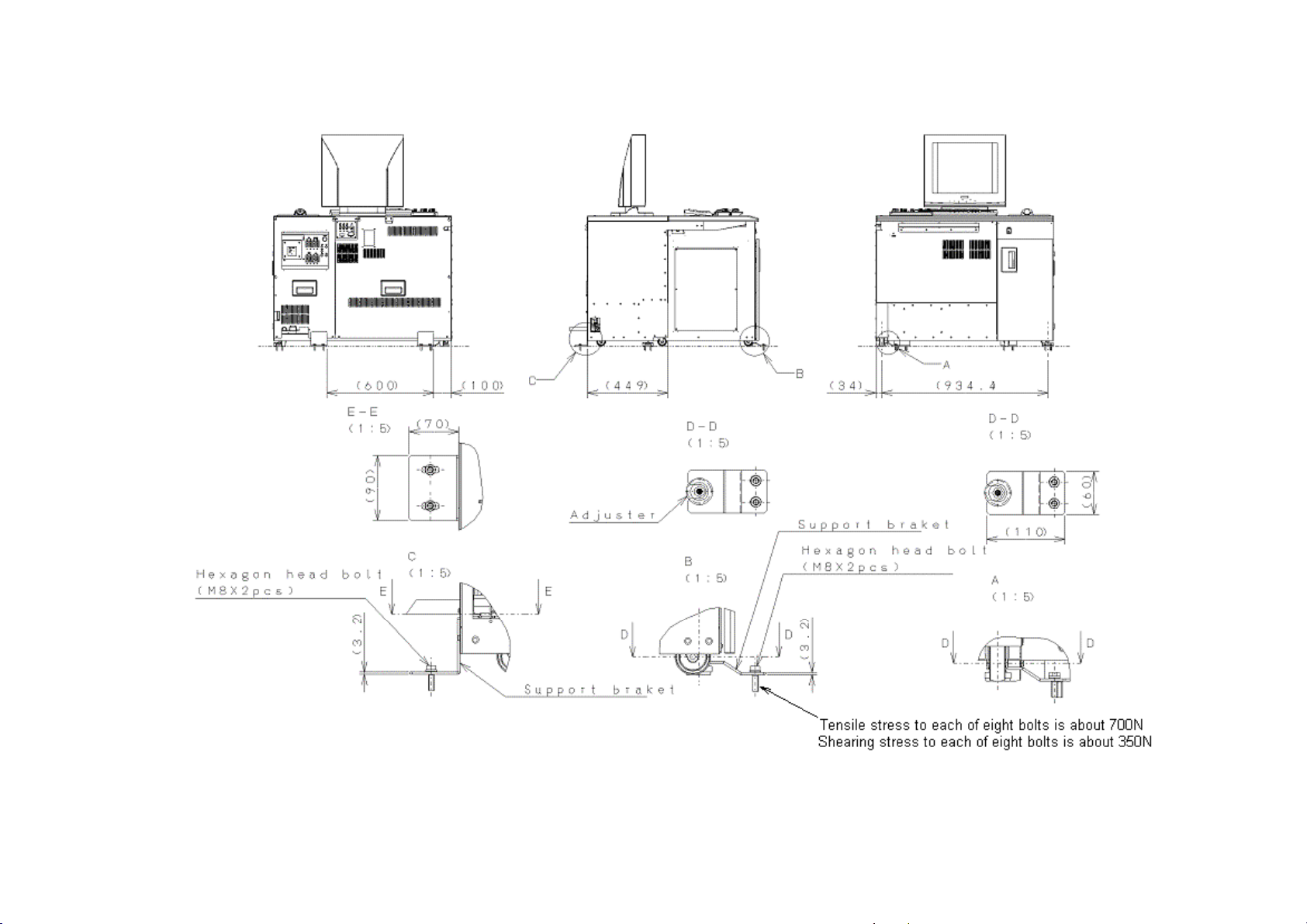

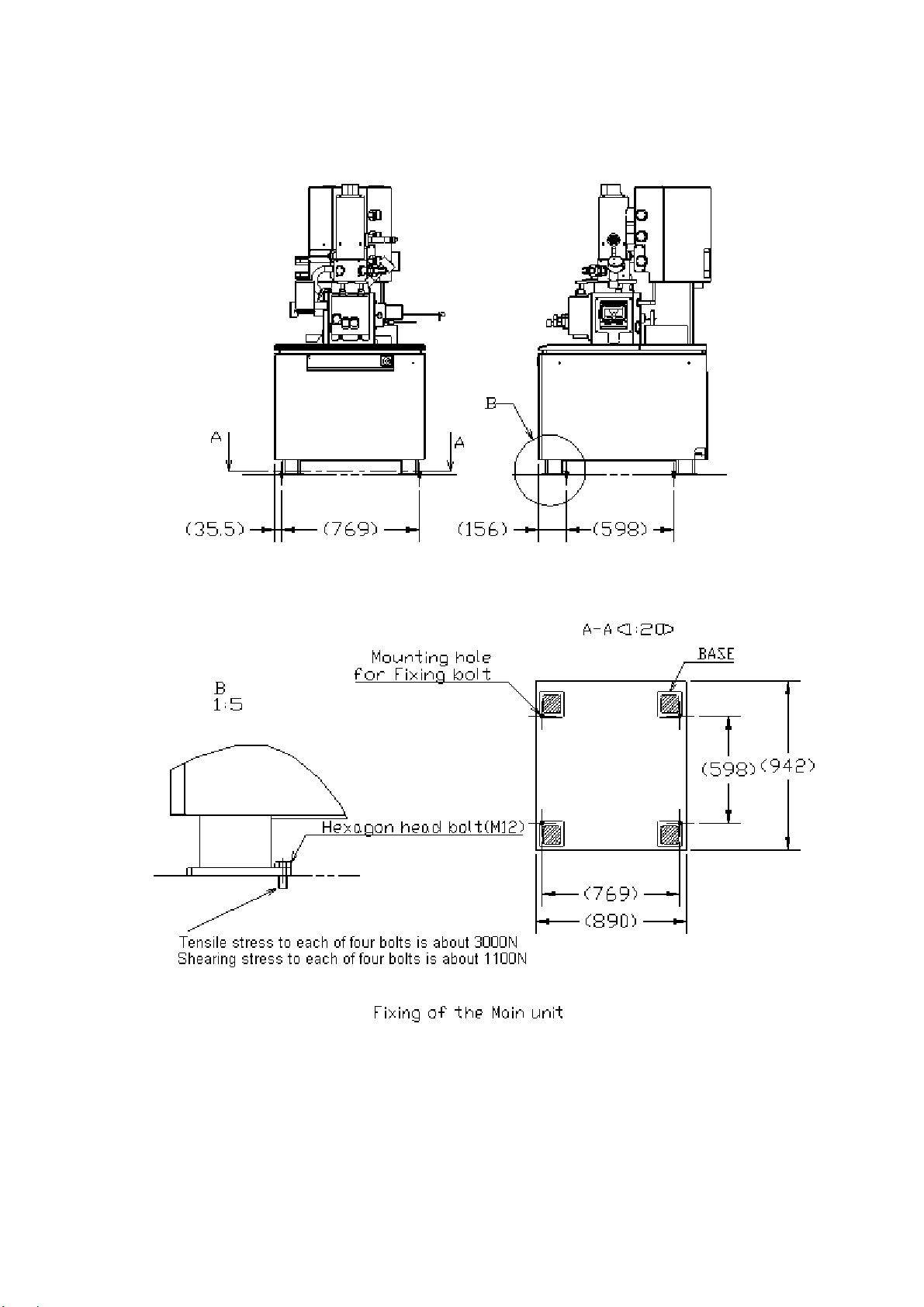

Protection for Earthquakes It is recommended that the protection for movement of Main unit

and Display unit during earthquakes is to be provided by user as

shown in figures S-7 and S-8.

Gravity location of units The gravity location of Main and Display unit are shown in fig S-

9 through S-11.

Water-leakage detection It is recommended that the water–leakage detector is to be

provided by user. Figure S-12 shows an example of the water–

leakage detector.

SAFETY - 17

Page 26

SAFETY - 18

Fig S- 6 Location of safety interlock

Page 27

Fig S- 7 Protection from movement during earthquakes (Display unit)

SAFETY - 19

Page 28

Fig S- 8 Protection from movement during earthquakes (Main unit)

SAFETY - 20

Page 29

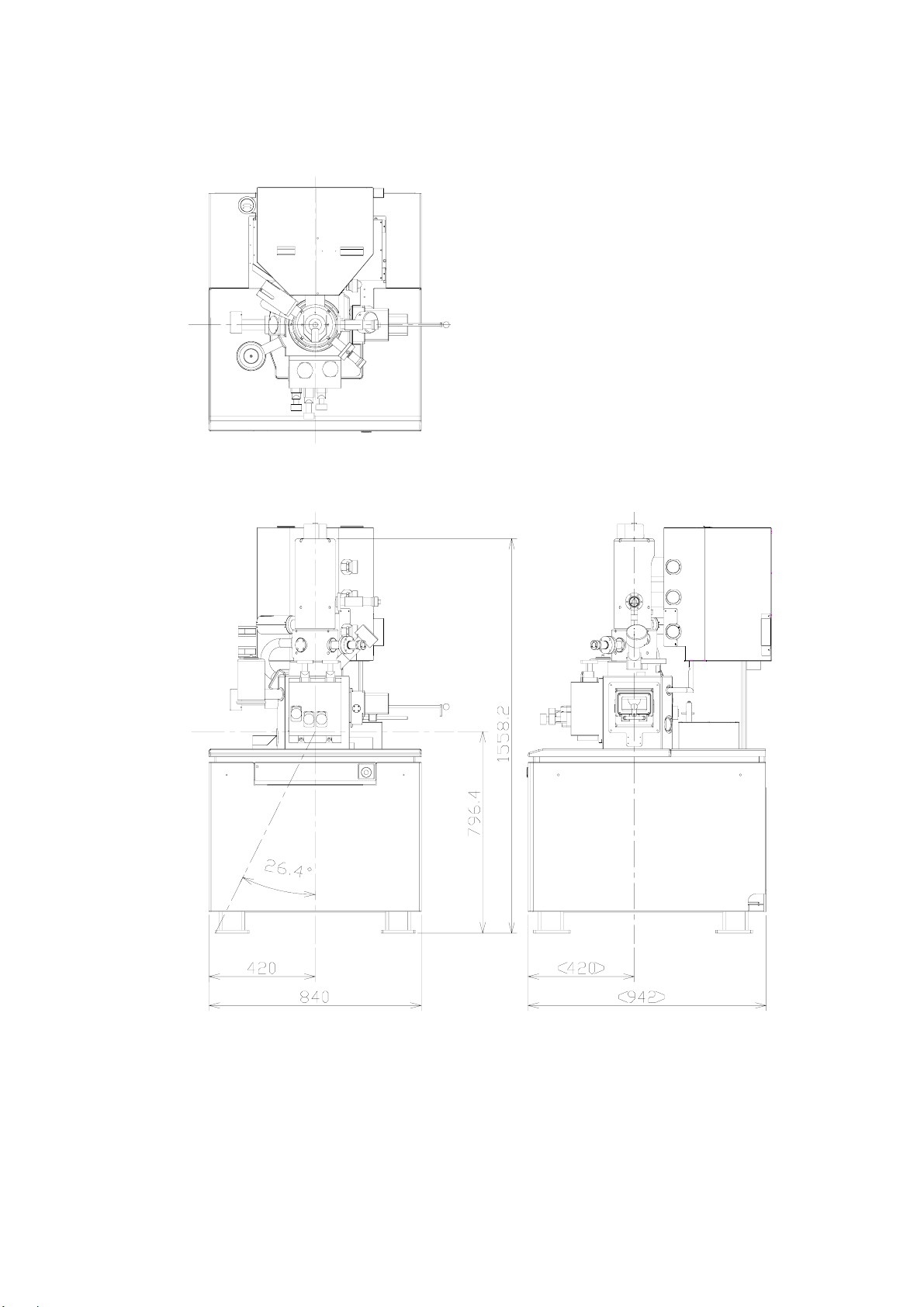

Fig S- 9 Gravity location of Main unit (Type1)

SAFETY - 21

Page 30

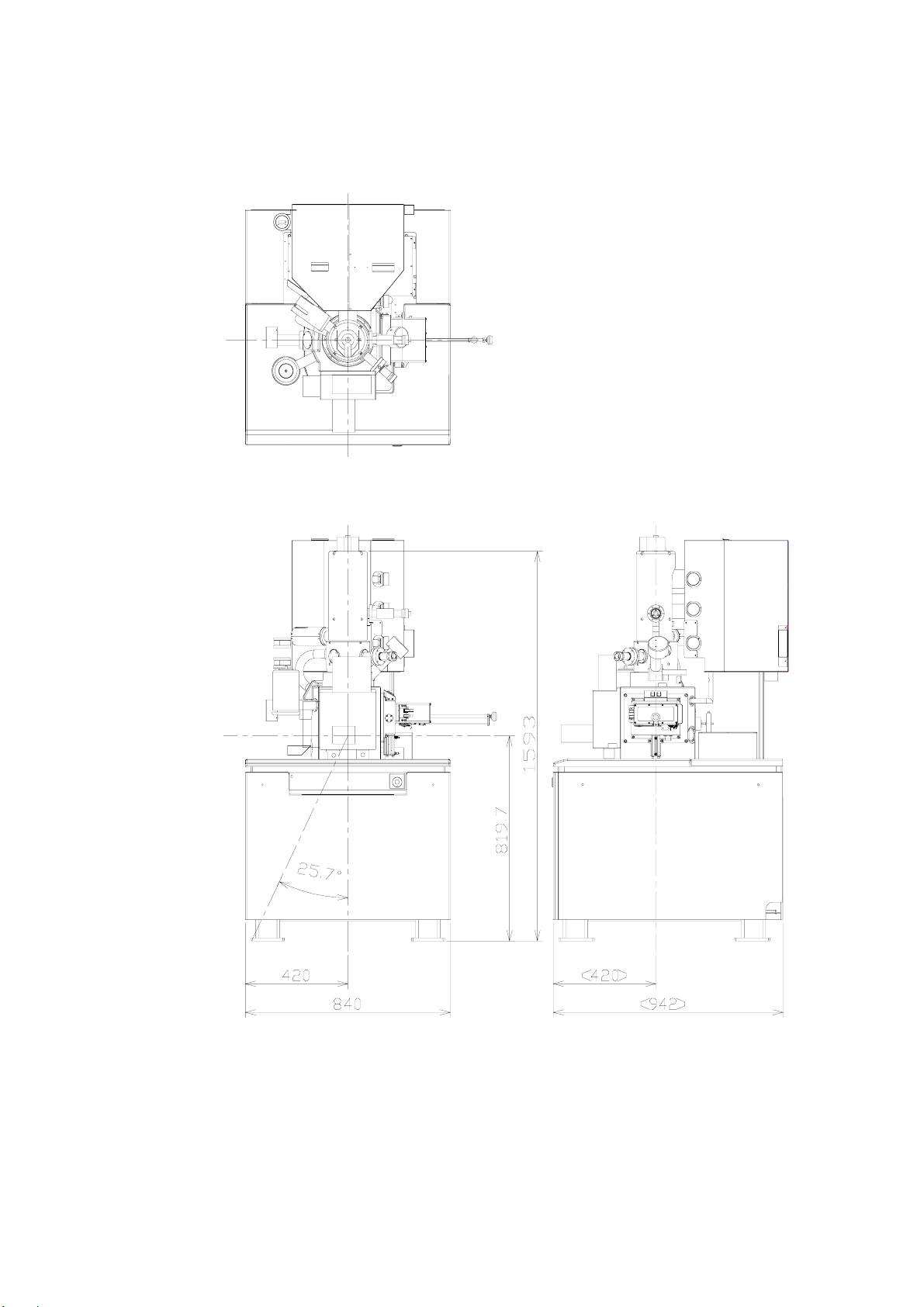

Fig S- 10 Gravity location of Main unit (Type2)

SAFETY - 22

Page 31

Fig S- 11 Gravity location of Display unit

(Not include monitor display)

SAFETY - 23

Page 32

Fig S- 12 An example of the water-leakage detector

SAFETY - 24

Page 33

PRECAUTIONS ON HANDLING

For the sake of safety, the following points should be taken into consideration.

1. PRECAUTIONS FOR TRANSPORT

CAUTION

(1) Do not lift the instrument by holding the table. The strength of table fitting is not sufficient

for bearing the weight of display unit, approximately 200 kg. Should the table be lifted, the

display unit might slip off and crash. Hence, it is recommended to remove the table and

transport the display unit independently when moving the instrument.

(2) The housing supports should be fitted in place before transport.

2. PRECAUTIONS FOR POWER CONNECTION

WARNING

(1) When removing the front, rear and top covers of housing and display unit, turn off the AC

power. The high voltage circuit within the unit constitutes a shock hazard.

(2) Connect the grounding wire correctly. Otherwise, not only will the instrument fail to

operate normally but there is a shock hazard.

(3) Avoid touching the connector of high voltage unit and the cable head of high voltage

transformer. The high voltage unit and the high voltage transformer are at voltages as

high as 30 kV, so handling of dangerous parts such as high voltage connector and cable

head should be left to the service engineer.

(4) Do not touch the areas marked HAZARD. These areas are supplied with high voltage.

(5) When replacing a fuse, turn off the main switch on the distribution board and make sure

that the AC power supply is cut off. If not the AC power line near the fuse box may cause

shock.

PRECAUTION - 1

Page 34

CAUTION

(1) Never touch the electron gun with bare hands in the course of baking and cooling.

High temperature during baking may cause burns.

(2) When using liquid nitrogen, wear leather gloves and protective glasses. There is danger if

it touches the skin as it can cause low temperature burns. Also, make sure there is

enough ventilation in the room to prevent oxygen deficiency.

(3) When the anti-contamination trap is filled with liquid nitrogen, do not allow an air leak in the

specimen chamber. This will cause the deterioration of vacuum, leading to frost in the

anti-contamination trap.

(4) When setting the specimen tilt and the stage Z to minimum, there is a danger of contact

that could scratch the specimen or objective lens. Be sure to use the special level gauge

for setting the specimen and set the specimen height to be not more than 0.5 mm higher

than the level gauge.

(5) Be careful not to hit your head when checking the specimen chamber because the beam

monitor aperture, secondary electron detector, etc. are sticking out of the top area of the

specimen exchange chamber.

(6) Do not place objects containing a magnetic powder in the specimen chamber.

The magnetism of the objective lens attracts the powder and it will attach to the magnetic

pole of objective lens separating from the specimen stage. This causes a deterioration of

performance.

(7) Since a magnetic specimen is strongly attracted by the magnetic field of the objective lens,

secure it tightly to the specimen stage. If it is not tight enough, it may be drawn to the

objective lens and cause problems.

(8) When the specimen stage is being manually operated, set it so as not to go over the limit in

the Z axis or the Tilt (T) axis adjustments. Exceeding these limits may damage the

specimen or parts of the specimen chamber.

(9) If the specimen stage is being manually operated, do not operate Z and T axes in the stage

locked condition. This damages the stage lock system and causes deterioration of stage

precision.

(10) The oil rotary pump is a heavy object that weighs 30 kg. Be very careful if it must be lifted

or moved when performing maintenance.

(11) When performing maintenance on the compressor, open the drain valve slowly and drain

the condensed water from the tank gradually. High air pressure inside the tank can cause

dangerous splashing and spraying of the condensate if the drain is opened too quickly.

PRECAUTION - 2

Page 35

NOTICE

(1) Allow an interval of at least 20 seconds between turning on or off the EVAC POWER and

DISPLAY POWER switches.

(2) Replace the oil filter of the oil-sealed rotary pump every six months.

(3) For the air compressor and oil-sealed rotary pump, perform draining of water, check of oil

level etc. with reference to the check card attached to the instrument.

(4) Do not press the EMERGENCY switch except in emergencies. Using this switch causes a

complete instrument shutdown that will necessitate a complete instrument restarting.

(5) When attaching the electron gun cover, make sure the lead wires are not in contact with the

heater.

3. GENERAL PRECAUTIONS

(1) Maintenance items other than those described in this manual should be left to the service

engineer.

(2) Any replacement of the FE (field emission) tip should be performed by a Hitachi

High-Technologies Corporation service representative.

4. MEASURES FOR EMERGENCY

(1) Turn off the main switch on the distribution board.

(2) If water is leaking, close the valve of cooling water to cut off the water supply.

(3) After taking steps (1) and (2), carry out other suitable measures.

(4) Inform the service shop.

PRECAUTION - 3

Page 36

5. CAUTIONS ON OPERATION

(1) During operation, occasionally confirm that the ion pumps are in a stable state.

-7

IP-1 2 × 10

IP-2 2 × 10

IP-3 5 × 10

Pa or better

-6

Pa or better

-5

Pa or better

(2) When emission current varies widely during operation depress the HV OFF switch to cut off

high voltage of the electron gun. Then, set the flashing intensity to ‘2’ or ‘3’, and carry out

flashing.

(3) When leaving the instrument depress the HV OFF switch.

(4) Avoid using excessive fixing agent (conductive paste or the like) when setting the specimen

onto the specimen stub.

6. OTHERS

(1) Keep the instrument installation room under the following conditions even when the

instrument is not in operation.

Room temperature : 5 to 25 °C

(temperature of diffusion pump cooling water also)

Humidity : Less than 60%

Evacuation must be performed continuously even when the instrument is not used for a

long time. An uninterruptible power supply must be provided for this purpose.

(2) The DP drain port should be located at a height of less than 20 cm from the floor.

PRECAUTION - 4

Page 37

7. FLASHING

A

(d)

(c)

(b)

(a)

(1) Principle of Field Emission Electron Gun

Figure 1 shows the principle of the field emission electron gun. The gun consists of

cathode, first anode and second anode.

An extracting voltage (Vext) is applied between the cathode and first anode, and electrons

are emitted from the cathode. The electrons are accelerated by an accelerating voltage

(Vacc). The cathode need be cleaned occasionally by turning on the flashing power

supply in order to remove adsorbed gas on the surface of the cathode.

Flashing power supply

First anode

Second anode

Cathode

Extracting voltage

(Vext)

ccelerating voltage(Vacc)

Fig. 1 Principle of Field Emission Gun

Figure 2 plots a usual change of emission current with time after flashing. The abscissa

and ordinate represent time and emission current, respectively.

Figure 3 sketches a status transition of gas molecules adsorbed on the cathode tip.

The status (a) through (b) correspond to (a) through (d) on the curve in Fig. 2.

A, B and C in Fig. 2 are generally called an “Initial Reduction Period”, “Stable Period” and

“Unstable Period”, respectively.

A

Emission current

Initial

Reduction Period

Stable Period

Time

C B

Unstable Period

Fig. 2 Change of Emission Current with Time

PRECAUTION - 5

Page 38

Cathode Tip

Gas Molecules

(a)

(b)

(c)

(d)

Fig. 3 Status Transition of Adsorbed Gas Molecules on Cathode Tip

A : In the initial reduction period, or just after flashing, gas is completely discharged from

the cathode tip. (See (a) of Fig. 3.) As gas molecules are gradually adsorbed onto

the cathode, emission current decreases. In this stage, gas molecules are

desorbed, adsorbed and transferred. So noise (fluctuation of emission current)

occurs. (See (b) of Fig. 3.)

B : In the stable period approximately one layer of gas molecules is adsorbed onto the

cathode. In this status a stable emission current is usually available. (See (c) of

Fig. 3.) Although noise (fluctuation of emission current) may appear occasionally

due to desorption and adsorption of gas molecules a stable status returns in a

comparatively short time. So record an image after confirming the stable status.

In this period emission current slightly decreases with time.

C : In the unstable period a large quantity of gas molecules repeat desorption and

adsorption. In consequence emission current fluctuates considerably while

increasing. (See (d) of Fig. 3.)

Images are observed usually in the stable period.

The periods sectioned on the time axis in Fig. 2 vary depending on electron gun vacuum,

residual gas component, cathode/anode cleanliness and emission current value.

With the Model S-4800, they are roughly given as follows.

• Initial reduction period : 30 min to 3 hours

• Stable period : 2 to 12 hours

When the initial reduction period is half an hour, the stable period lasts 2 to 4 hours, and 4

to 10 hours when the initial reduction period is 1 to 2 hours (approximate values). Even in

the unstable period, flashing cleans the surface of the cathode as shown in Fig. 3 (a) and

emission current changes again as illustrated in Fig. 2, whereby the stable period returns.

(2) Flashing Practice

The flashing may be practiced in either of the following two fashions:

(a) Carry out flashing once at the start of use.

Then when the emission current becomes unstable after two to eight hours of use

(cumulative time of beam turn-on), perform flashing again.

(b) Carry out flashing once on completion of daily operation. On the next day start

operation without flashing, and perform flashing if the emission current becomes

unstable during use.

PRECAUTION - 6

Page 39

(3) Flashing Procedure

(a) Check and set up intensity of flashing as follows:

Click the HV display area on the control panel. The HV control dialog window will open.

(b) Click the Flashing button on it. The Flashing execution dialog window will open.

Set Intensity to “2” and click Execute button.

The emission current value caused by flashing will be displayed on the Ie part of the

HV Display area about 2 seconds.

Usually flashing is set at Intensity ‘2’. However when the stable period is short or

extracting voltage (Vext) rises at about 1 hour after pressing HV ON (because a large

quantity of gas molecules are adsorbed on the cathode), set intensity ‘3’. There may be a

case where noise (bright or dark lateral stripes on CRT) appears in the initial reduction

period. But this does not constitute a problem since noise will disappear in the stable

period. Even if noise appears in the stable period, it will be suppressed in a short time.

In this case wait until the stable status returns before recording an image. In the stable

period, emission current slightly decreases. If noise becomes conspicuous during image

observation upon entering the unstable period, press the HV OFF switch, and set intensity

‘2’ for flashing again. Emission current repeats a change as traced in Fig. 2, so image

observation is enabled in the stable period again.

NOTICE

A message will appear when 8 hours of cumulative operation time or 24 hours of total time

have passed after flashing, as a reminder to flash the tip again.

If the tip is not flashed within 30 minutes, the HV will be turned off automatically.

(These time periods can be set at other values if necessary. Contact a service engineer

to change them.)

PRECAUTION - 7

Page 40

SPECIFICATION

Specifications for Hitachi Model S-4800, Field Emission Scanning Electron Microscope

1. Resolution:

Accelerating voltage 15 kV

Working distance = 4 mm..............................1.0 nm

Accelerating voltage 1 kV

Working distance = 1.5 mm...........................2.0 nm

2. Magnification:

High magnification mode ...............................100× to 800,000×

Low magnification mode................................30× to 2,000×

3. Electron Optics:

(1) Electron gun ..........................................Cold cathode field emission type

(2) Extracting voltage (Vext) .......................0 to 6.5 kV

(3) Accelerating voltage (Vacc)...................0.5 to 30 kV (in 100 V steps)

(4) Lens.......................................................3-stage electromagnetic lens, reduction type

(5) Objective lens aperture..........................Movable aperture (4 openings selectable/

alignable outside column).

Self-cleaning thin aperture

(6) Astigmatism correction coil

(stigmator) .............................................Electromagnetic type

(7) Scanning coil.........................................2-stage electromagnetic-deflection type

PRECAUTION - 8

Page 41

4. Specimen Stage

Motion Model S-4800, Type I Model S-4800, Type II

X Traverse 0 to 50 mm (continuous) 0 to 110 mm (continuous)

Y Traverse 0 to 50 mm (continuous) 0 to 110 mm (continuous)

Z Traverse 1.5 to 30.0 mm (continuous) 1.5 to 40.0 mm (continuous)

Tilt

Rotation

Specimen size Max. 100 mm (diameter)

-5° to +70° -5° to +70°

360° (continuous) 360° (continuous)

Max. 150 mm (diameter)

(airlock type specimen exchange)

(airlock type specimen exchange)

5. Display Unit

(1) Display type.........................................Flicker- free image on PC monitor

(full scanning speeds)

(2) Viewing monitor...................................Type 18.1 LCD (Type 21 Color CRT: Option)

(1280 × 1024 pixels)

(3) Photo CRT (Option).............................Ultra-high resolution type

(effective field of view 120 × 90 mm)

(4) Scanning modes..................................Normal scan,

Reduced area scan,

Line scan,

Spot analysis,

Average concentration analysis,

Split/Dual magnification,

(5) Scanning speeds .................................TV (640×480 pixels display : 25 / 30 flames/s)

Fast (Full screen display : 25 / 30 flames/s)

Slow (Full screen display :

1/0.9, 4/3.3, 20/16, 40/32, 80/64 s/flame)

(640×480 pixels display :

0.5/0.4, 2/1.7, 10/8, 20/16, 40/32 s/flame)

For Photograph (2560×1920 pixels display :

40/32, 80/64, 160/128, 320/256 s/flame)

Value of (50 Hz)/(60 Hz)

TV : NTSC or PAL signal

PRECAUTION - 9

Page 42

(6) Signal processing modes ....................Automatic brightness control,

Gamma control,

Automatic focus,

Automatic stigmator

(7) Automatic data display ........................Image number, accelerating voltage, magnification,

micron bar, micron value, date/time and working

distance can be printed on the film.

(8) Data entry............................................Alphanumeric characters, numbers, and marks can

be written on the image from the keyboard.

(9) Electrical image shift............................±12 µm (WD = 8 mm)

6. Evacuation System

(1) System type.........................................Fully automatic pneumatic-valve system

(2) Ultimate vacuum levels........................Specimen chamber : 7 × 10

-4

Pa

Electron gun chamber :

IP-1 1 × 10

IP-2 2 × 10

IP-3 7 × 10

-7

Pa or better

-6

Pa or better

-5

Pa or better

(3) Vacuum pumps....................................Electron optical system : 3 ion pumps

Specimen chamber : Turbo molecular pump

1 oil rotary pump should be provided by user.

(4) Compressor.........................................Oil-less type compressor should be provided by user.

7. Protection Devices

Warning devices ..........................................Power failure, Cooling-water interruption, Inadequate

vacuum

PRECAUTION - 10

Page 43

INSTALLATION CONDITIONS

1. Power Requirements

100 V AC (±10%), single phase, 50/60 Hz, 4 kVA

In case to use other voltage than 100V AC, a double insulation transformer should be provided

by user.

Exclusive grounding of less than 100 ohms in ground resistance should be provided by user.

2. Physical Dimensions

Main unit .............................S-4800I 840 (W) × 966 (D) × 1620 (H) mm: 583 kg

S-4800II 840 (W) × 966 (D) × 1660 (H) mm: 651 kg

Display unit ...........................................1000 (W) × 960 (D) × 1200 (H) mm: 205 kg

3. Installation Environment

(1) Ambient temperature...............15 °C to 25 °C (temperature variation 0.5 °C/10 min)

(2) Relative humidity.....................Less than 60%, without condensation

(3) Stray magnetic field

Frequency

Component

Asynchronous with

Power Supply DC

Magnetic Field

Fluctuation

320 nT (horizontal)

240 nT (vertical)

170 nT (horizontal)

150 nT (vertical)

Change with Time

(drift)

600 nT/min (horizontal)

450 nT/min (vertical)

310 nT/min (horizontal)

280 nT/min (vertical)

Allowable

value

Accelerating

Voltage

15 kV 4.0 mm

1 kV 1.5 mm

Working

Distance

Magnification

220,000×

120,000×

Frequency

Component

Synchronous with

Power Supply AC

Magnetic Field

(effective value)

290 nT (horizontal)

220 nT (vertical)

150 nT (horizontal)

130 nT (vertical)

nT: Nano Tesla

PRECAUTION - 11

Page 44

(4) Floor vibration

S-4800 Type I

Oscillation

Frequency

(Hz)

1.0 Less than 7.0

1.4 Less than 2.0

2.0 Less than 2.0

3.0 Less than 4.0

4.0 Less than 4.5

5.0 Less than 4.5

6.0 Less than 4.0

10.0 Less than 3.0

Allowable Amplitude (X, Y)

(µm Peak to Peak)

Oscillation

Allowable Amplitude (Z)

Frequency

(Hz)

(µm Peak to Peak)

1.0 Less than 25.0

2.0 Less than 14.0

3.0 Less than 5.0

3.5 Less than 2.9

4.0 Less than 1.8

5.0 Less than 1.0

6.0 Less than 1.1

10.0 Less than 1.2

S-4800 Type II

Oscillation

Frequency

(Hz)

1.0 Less than 8.0

1.5 Less than 3.0

2.0 Less than 1.4

2.4 Less than 1.4

3.0 Less than 3.0

5.0 Less than 4.0

6.0 Less than 3.5

10.0 Less than 3.5

Allowable Amplitude (X, Y)

(µm Peak to Peak)

Oscillation

Allowable Amplitude (Z)

Frequency

(Hz)

(µm Peak to Peak)

1.0 Less than 20.0

2.0 Less than 10.0

3.0 Less than 5.0

4.0 Less than 2.7

5.0 Less than 1.8

6.0 Less than 1.0

7.0 Less than 1.0

10.0 Less than 1.0

The allowable amplitude corresponds to an image deviation of less than 0.2 mm on a

micrograph at magnification 220,000×

(5) Acoustic noise ..................The following table shows the relation between allowable noise

level (C characteristic) and frequency at the S-4800 installation

site. The allowable amplitude corresponds to an image

deviation of less than 0.2 mm on a micrograph at magnification

220,000×.

Frequency : f (Hz)

f≦150

150≦f≦800

800≦f≦2000

Allowable Noise Level(Type I) Allowable Noise Level (Type II)

75 dB or less 72 dB or less

60 dB or less 60 dB or less

54 dB or less 52 dB or less

PRECAUTION - 12

Page 45

4. Water Supply and Drain

(1) Water flow rate ........................1 to 1.5 L/min

(2) Water pressure........................50 to 100 kPa

(3) Water temperature...................10 to 20 °C (temperature variation: less than 0.5 °C/10 min)

(4) Water supply port ....................One port, with Rc 3/8 taper internal thread.

(If water contains significant deposit or impurities, consult

Hitachi High-Technologies Corporation separately.)

(5) Water drain port.......................One port, more than 20 mm in diameter

(natural drainage type)

PRECAUTION - 13

Page 46

MODEL S-4800 FIELD EMISSION

SCANNING ELECTRON MICROSCOPE

Table of Contents

FOREWORD...................................................................................................... FOREWORD-1

Scope of Instruction Manual ....................................................................... FOREWORD-2

GUARANTEE..................................................................................................... FOREWORD-3

INSTALLATION AND AFTER-SALES SERVICE............................................... FOREWORD-5

CAUTION ON DISPOSAL OF INSTRUMENT................................................... FOREWORD-5

Available Training Programs....................................................................... FOREWORD-6

Handling of Chemicals................................................................................ FOREWORD-6

Instruction Manual....................................................................................... FOREWORD-6

SAFETY SUMMARY........................................................................................... SAFETY-1

General Safety Guideline............................................................................. SAFETY-1

Electrical Hazard.......................................................................................... SAFETY-3

High Temperature Hazard........................................................................... SAFETY-4

Magnetic Field Hazard................................................................................. SAFETY-4

Laser light Hazards...................................................................................... SAFETY-5

Warning Labels on the Main Unit (standard version)................................... SAFETY-6

Warning Labels on the Display Unit (standard version)............................... SAFETY-7

Warning Labels on the Main Unit (ANSI style labels).................................. SAFETY-8

Warning Labels on the Display Unit (ANSI style labels).............................. SAFETY-9

WARNING.................................................................................................... SAFETY-10

Other Relevant Precautions......................................................................... SAFETY-12

Emergency Off Button.................................................................................. SAFETY-15

Main Power Disconnect............................................................................... SAFETY-16

Power Supply and Grounding Connection................................................... SAFETY-14

INTERLOCK ....................................................................................................... SAFETY-17

Location of safety interlock .......................................................................... SAFETY-18

Protection from movement during earthquakes (Display unit)..................... SAFETY-19

Protection from movement during earthquakes (Main unit)......................... SAFETY-20

Gravity Location of Main unit (Type1).......................................................... SAFETY-21

Gravity Location of Main unit (Type2).......................................................... SAFETY-22

Gravity Location of Display unit ................................................................... SAFETY-23

An example of the water-leakage detector .................................................. SAFETY-24

- i -

Page 47

Table of Contents (Cont’d)

PRECAUTIONS ON HANDLING......................................................................PRECAUTION-1

1. Precautions for Transport ...................................................................PRECAUTION-1

2. Precautions for Power Connection .....................................................PRECAUTION-1

3. General Precautions...........................................................................PRECAUTION-3

4. Measures for Emergency....................................................................PRECAUTION-3

5. Cautions on Operation ....................................................................... PRECAUTION-4

6. Others................................................................................................. PRECAUTION-4

7. Flashing.............................................................................................. PRECAUTION-5

SPECIFICATION ............................................................................................. PRECAUTION-8

INSTALLATION CONDITIONS........................................................................PRECAUTION-11

1. INSTALLATION ............................................................................................................. 1-1

1.1 Installation Requirements.....................................................................................1-1

1.1.1 General...................................................................................................1-1

1.1.2 Room Temperature and Humidity........................................................... 1-1

1.1.3 Line Power Requirement........................................................................ 1-2

1.1.4 Grounding...............................................................................................1-2

1.1.5 Water Supply and Drain.......................................................................... 1-2

1.1.6 Stray Magnetic Field...............................................................................1-3

1.1.7 Floor Vibration ........................................................................................ 1-4

1.1.8 Power Line Noise and Electric Field Due to Noise................................. 1-6

1.1.9 Disturbance by Sound Waves ................................................................ 1-7

1.1.10 Site Requirements .................................................................................. 1-7

1.2 Materials or Instruments to be prepared by User................................................. 1-9

1.3 Wiring ................................................................................................................... 1-9

1.3.1 Power and Ground Wirings..................................................................... 1-10

- ii -

Page 48

Table of Contents (Cont’d)

2. FUNCTIONS..................................................................................................................2-1

2.1 Control Knobs and Switches on Main Unit........................................................... 2-2

2.1.1 Main unit (column).................................................................................. 2-2

2.2 Control Knobs and Switches on Display Unit.......................................................... 2-13

2.2.1 Display.................................................................................................... 2-13

2.3 Graphical User Interface (GUI)............................................................................. 2-16

2.3.1 Starting the PC and Logging in the S-4800 Program ............................. 2-16

2.3.2 S-4800 SEM Main Window..................................................................... 2-18

2.3.3 Control arrangement on the window....................................................... 2-19

2.3.4 Menu....................................................................................................... 2-21

2.3.5 Control Panel..........................................................................................2-26

2.3.6 Operation Panel...................................................................................... 2-33

2.3.7 Mouse operation on the scanning image................................................ 2-42

2.3.8 Setup dialog window............................................................................... 2-44

2.3.9 Captured Image Window........................................................................ 2-51

2.3.10 SEM Data Manager Window .................................................................. 2-52

2.3.11 Alignment Dialog Window.......................................................................2-52

2.3.12 CD Measurement dialog window (option)............................................... 2-53

2.3.13 Comm Port Setting Dialog Window ........................................................ 2-53

2.3.14 Login Setting Dialog Window..................................................................2-53

2.3.15 Oblique Dialog Window .......................................................................... 2-54

2.3.16 Password Setting Dialog Window...........................................................2-54

2.3.17 Save Image Dialog Window.................................................................... 2-55

2.3.18 Opt Signal Processing Dialog Window................................................... 2-55

2.3.19 Split/Dual Mag Controller........................................................................2-55

2.3.20 Using Short-Cut Keys............................................................................. 2-56

3. OPERATION.................................................................................................................. 3-1

3.1 Preliminary Operation........................................................................................... 3-3

3.1.1 Check of Column Vacuum......................................................................3-3

3.1.2 Flow the cooling water............................................................................3-4

3.1.3 Starting the Display................................................................................. 3-5

3.1.4 Use of Anti-Contamination Trap ............................................................. 3-6

3.2 Specimen Setting and Specimen Exchange.........................................................3-7

3.2.1 Cautions on Specimen Preparation........................................................3-7

3.2.2 Specimen Preparation for Materials ....................................................... 3-7

3.2.3 Adjustment of Specimen Height ............................................................. 3-8

3.2.4 Specimen Exchange Position.................................................................3-8

3.2.5 How to Set Specimen............................................................................. 3-9

- iii -

Page 49

Table of Contents (Cont’d)

3.3 Application of High Voltage .................................................................................. 3-12

3.3.1 Condition where the gun high voltage is applicable................................ 3-12

3.3.2 Flashing.................................................................................................. 3-12

3.3.3 Setting of Accelerating Voltage and Emission Current...........................3-13

3.3.4 Application of High Voltage..................................................................... 3-14

3.4 Optimizing the Electron Beam..............................................................................3-15

3.4.1 Selecting a Magnification Mode.............................................................. 3-15

3.4.2 Selecting Electron Optical Column Condition.........................................3-15

3.4.3 Column Alignment Operation.................................................................. 3-20

3.5 Operation for Image Observation......................................................................... 3-24

3.5.1 SE detector............................................................................................. 3-24

3.5.2 Selecting Magnification...........................................................................3-18

3.5.3 Selecting Scanning Speed...................................................................... 3-29

3.5.4 Image Brightness and Contrast Adjustment........................................... 3-31

3.5.5 Focus and Astigmatism Correction......................................................... 3-34

3.5.6 Operation of the Specimen Stage (Type I - Manual Stage).................... 3-37

3.5.7 Operation of the Specimen Stage (Type 2 - 5-Axis Motorized Stage).... 3-41

3.6 Saving and Recording Images..............................................................................3-71

3.6.1 Saving and Recording Images................................................................ 3-71

3.6.2 Preparing Images for Recording............................................................. 3-72

3.6.3 Setting Conditions for Image Capturing.................................................. 3-73

3.6.4 Image Capturing..................................................................................... 3-74

3.6.5 Saving a Scanning Image (Direct Save)................................................. 3-75

3.6.6 Saving Captured Images........................................................................ 3-76

3.6.7 Taking Photographs (Option).................................................................. 3-76

3.7 Using SEM Data Manager.................................................................................... 3-79

3.8 At the End of Daily Use.........................................................................................3-80

3.8.1 Turning High Voltage Off........................................................................ 3-80

3.8.2 Setting the Stage at the Specimen Exchange Position .......................... 3-80

3.8.3 Taking Out a Specimen.......................................................................... 3-80

3.8.4 Closing Windows and Shutting the Display Power.................................3-82

3.9 Using Other Functions.......................................................................................... 3-83

3.9.1 Screen Mode .......................................................................................... 3-83

3.9.2 Split Screen and Dual Mag Mode...........................................................3-85

3.9.3 Signal Selection and Color Mixing..........................................................3-86

3.9.4 X-ray Analysis Mode............................................................................... 3-88

3.9.5 Signal Processing................................................................................... 3-90

3.9.6 Operating Condition Memory.................................................................. 3-92

3.9.7 Pseudo Color Display............................................................................. 3-94

- iv -

Page 50

Table of Contents (Cont’d)

3.9.8 Data Entry Function................................................................................3-94

3.9.9 Raster Rotation, Dynamic Focus and Tilt Compensation.......................3-97

3.9.11 Printing images using Report generation function.................................. 3-99

3.9.12 Copy Image ............................................................................................ 3-101

3.9.13 Copy Image information text................................................................... 3-101

3.9.14 Oblique Image ........................................................................................ 3-102

3.9.15 Optional setting....................................................................................... 3-103

3.9.16 Password Setting.................................................................................... 3-105

3.9.17 Setting Login Name................................................................................ 3-105

3.10 Image Quality........................................................................................................3-107

3.10.1 Accelerating Voltage and Image Quality................................................. 3-107

3.10.2 Condenser Lens Setting and Image Quality........................................... 3-108

3.10.3 Objective Lens Aperture Size and Image Quality...................................3-108

3.11 Mechanical Column Alignment ............................................................................. 3-109

3.11.1 Preparative Operation for Alignment ...................................................... 3-109

3.11.2 Mechanical Alignment of the Electron Gun............................................. 3-110

3.11.3 Alignment of the Beam Monitor Aperture................................................ 3-110

3.11.4 Alignment of the Objective Lens Aperture.............................................. 3-111

3.11.5 Mechanical Alignment of the First Condenser Lens............................... 3-111

3.11.6 Mechanical Alignment of the Second Condenser Lens.......................... 3-111

3.11.7 Stigma Alignment (electro-magnetic alignment).....................................3-112

3.11.8 Aperture Alignment (electro-magnetic alignment) .................................. 3-112

3.12 Using SEM Data Manager.................................................................................... 3-114

3.12.1 Precaution About SEM Data Manager.................................................... 3-114

3.12.2 Functions................................................................................................ 3-115

3.12.3 Operation................................................................................................3-119

4. MAINTENANCE............................................................................................................. 4-1

4.1 Maintenance of Electron optical Column..............................................................4-1

4.1.1 Maintaining Vacuum of Electron Gun and Intermediate Chamber ......... 4-1

4.1.2 Replacement and Cleaning of Objective Lens Aperture......................... 4-1

4.1.3 Cleaning of Aperture Plates.................................................................... 4-3

4.2 Maintenance of Rotary Pump...............................................................................4-5

4.2.1 Oil Change.............................................................................................. 4-5

4.2.2 Replacement of Oil Mist Trap................................................................. 4-6

4.2.3 Troubleshooting...................................................................................... 4-7

4.3 Maintenance of Air Compressor...........................................................................4-8

4.3.1 Checkup and Maintenance.....................................................................4-8

4.3.2 Troubleshooting of Air Compressor........................................................4-10

4.3.3 Location and Functions of Major Components....................................... 4-11

- v -

Page 51

Table of Contents (Cont’d)

4.4 Troubleshooting.................................................................................................... 4-12

4.4.1 When Column Evacuation does not Work..............................................4-12

4.4.2 When Specimen Exchange Chamber Vacuum is not Good................... 4-12

4.4.3 When Specimen Chamber Vacuum is not Good.................................... 4-13

4.4.4 When Ion Pump Vacuum Degraded.......................................................4-13

4.4.5 When Emission Current is not Set at Normal Value...............................4-14

4.4.6 When Image is not Shown on Screen .................................................... 4-14

4.4.7 When Image is Very Noisy ..................................................................... 4-15

4.4.8 When You cannot Correct Astigmatism.................................................. 4-16

4.4.9 When Auto Focus or Auto Stigma does not Work Satisfactorily............. 4-16

4.4.10 When S-4800 control program does not start up....................................4-17

4.4.11 When PC has Hanged up....................................................................... 4-17

4.4.12 When Error Messages are shown .......................................................... 4-18

4.5 Operation for shutting down all power supply of S-4800......................................4-18

4.6 Operation when power was shut down by power line failure................................ 4-18

4.7 Operation for Starting S-4800 ...........................................................................4-19

4.8 Operation when power line failure recovered.......................................................4-20

4.9 Operation when Water supply stopped by failure................................................. 4-20

4.10 Gun Baking operation........................................................................................... 4-21

4.11 Caution on Maintenance....................................................................................... 4-25

5. REPLACEMENT PARTS............................................................................................... 5-1

5.1 Consumables and Spare Parts............................................................................. 5-1

5.1.1 Consumables.......................................................................................... 5-1

5.1.2 Replacement Parts................................................................................. 5-2

5.1.3 Spare Parts............................................................................................. 5-3

6. ACCESSORY OPERATION .......................................................................................... 6-1