Page 1

INSTRUCTION MANUAL

FOR

MODEL S-3400N

SCANNING ELECTRON MICROSCOPE

(User’s Operation/Maintenance Edition)

Please read through this manual carefully

before using the instrument.

• Before using the instrument, read the safety

instructions and precautions carefully.

• Keep this manual in a safe place nearby so it

can be referred to whenever needed.

Hitachi Science Systems, Ltd.

Copyright C Hitachi Science Systems, Ltd. 2004.

All rights reserved. Printed in Japan. Part No. 52E-9011-3 TG-G (HMS052008)

Page 2

NOTICE:

1. Information contained in this document is subject to

change without notice for improvement.

2. This manual is copyrighted by Hitachi High-Technologies

Corporation with all rights reserved.

No part of this manual may be reproduced, transmitted

or disclosed to a third party in any form or by any means

without the express written permission of Hitachi

High-Technologies Corporation.

3. Hitachi High-Technologies Corporation assumes no

liability for any direct, indirect, or consequential damages

arising from use not described in this manual.

Utmost care must be exercised when using the

instrument.

4. This document does not provide any warranty or

permission for industrial properties or any rights to grant

license lawfully and without infringement.

Page 3

FOREWORD

APPLICATION

CAUTION

• The S-3400N SEM utilizes an electron beam accelerated at 300V to

30kV. The instrument is designed mainly for observation and

evaluation of specimens prepared for the SEM.

• Note that Hitachi Science Systems, Ltd. will not be responsible for

injury or damage caused by usage of the instrument in a manner not

described in this manual.

The electron microscope need not conform to the “Radiation Hazard

Preventive Laws” or “Ionizing Radiation Hazard Preventive Regulations”

currently in effect throughout the world, unlike the instruments designed to

produce X-rays.

The suggestion made by the ICRP (International Committee on Radiation

Hazard Prevention), however, clearly defines that the electron

microscope, like the home television set, will potentially produce a certain

amount of X-rays as an undesirable byproduct. From a safety viewpoint,

therefore, it is essential to operate the instrument carefully taking into

account the following fundamental precautions.

(1) Use the instrument within the application range specified in the

catalog or instruction manual.

(2) Do not operate the instrument with covers or doors removed, nor use

alternatives for these components.

(3) Do not apply modifications which may possibly result in deactivation

of the built-in safety devices.

FOREWORD - 1

Page 4

Before using the equipment, read this instruction manual and pertinent instruction manuals of

relevant accessories to assure proper operation of the equipment.

Scope of Instruction Manual

This instruction manual comprises the following:

1. Installation (Requirements and Items to be prepared by User)

2. Function (Description of Controls)

3. Operation (Viewing Images, Saving Data, and Taking Photographs)

4. Maintenance (Procedures, Troubleshooting, and Action on Power Failure)

5. Replacement Parts

6. Accessory Operation

This instruction manual describes the operation, maintenance, and specific precautions pertinent

to daily operation on the model S-3400N scanning electron microscope.

First, read and get familiar with the safety precautions described in the opening pages and

General Safety Guidelines.

Ⓡ

Windows

Windows

Microsoft

Note that the

is a registered trademark of Microsoft Corp., U.S.A.

Ⓡ

XP is a registered trade name of Microsoft Corp., U.S.A.

Ⓡ

EXCEL is a registered trade name of Microsoft Corp., U.S.A.

Ⓡ

mark is not indicated in this manual.

Acronyms

Listed below are acronyms frequently used in this manual.

• SEM : Scanning Electron Microscope

• WD : Working Distance

• SE : Secondary Electron

• BSE : Backscattered Electron

• PC : Personal Computer

• GUI : Graphical User Interface

FOREWORD - 2

Page 5

GUARANTEE

Period of Guarantee

The charge-free guarantee period is one year from the date of installation.

Details of Guarantee

(a) The instrument will be repaired free of charge if it malfunctions due to a defect in

manufacture within the charge-free guarantee period.

(b) Note that a substitute part may be used for repair, or replacement with an equivalent

product may be made instead of repair.

(c) Such system components as a personal computer and printer which are frequently

modified for improvement may not be available in original versions at the time of

replacement.

(d) Maintenance procedures are provided to allow system operation for 10 years after its

delivery. During this period, the maintenance of units or parts having a rather short

product cycle such as personal computer and printer may entail the purchase of

substitute parts because of limits on the repair period of the former, for which we

request your understanding. Even when more than 10 years have elapsed after

delivery, maintenance will basically be provided as long as the relevant units and parts

are available.

Exclusions from Guarantee

The guarantee will not be valid for the following failures and/or cases even during the

charge-free guarantee period.

(a) Failure due to use in improperly installed condition.

(b) Failure due to power supply voltage/frequency other than specified by Hitachi Science

Systems Ltd. or due to power failure.

(c) Corrosion or deterioration of the tubing due to impurities contained in gas, or air

supplied by the customer.

(d) Corrosion of electric circuits or deterioration of optical elements due to corrosive gases

or much dust contained in the atmosphere.

(e) Failure due to disassembly, modification, parts replacement, or relocation not approved

by Hitachi Science Systems, Ltd.

(f) Consumables and parts having a limited period of guarantee.

(g) Failure attributable to use of non-guaranteed parts (parts not described in the

instruction manual).

(h) Failure due to acts of God, including fire, earthquake, storm, flood, lightning, social

disturbance, riot, crime, insurrection, war (declared or undeclared), radioactive

pollution, contamination with harmful substance, etc.

FOREWORD - 3

Page 6

GUARANTEE

(i) Failure of instrument or damage of basic software, application software or other data

due to a computer virus.

(j) Failure of the PC used with the instrument or damage to basic software, application

software and/or data because of momentary voltage drop caused by lightning or power

interruption.

(k) Failure of the PC used with the instrument or damage to basic software, application

software and/or data caused by turning off the PC main power without taking the

normal termination procedure.

(l) Using the system in ways that are not covered in this operating manual, or employing

operating procedures not covered in the same; or failure of the system due to repairs

performed not under control of Hitachi or under service personnel authorized by

Hitachi.

(m) Failure of the system due to relocation or transport of the system after installation, not

under Hitachi's control or under the control of service personnel authorized by Hitachi.

(n) Failure of components outside the scope of the warranty, covered by operating

manuals.

Limitations on Guarantee

HITACHI SCIENCE SYSTEMS, LTD. MAKE NO GUARANTEES, EITHER EXPRESS OR

IMPLIED, EXCEPT AS PROVIDED HEREIN, INCLUDING WITHOUT LIMITATION

THEREOF, GUARANTEES AS TO MARKETABILITY, MERCHANTABILITY, FOR A

PARTICULAR PURPOSE OR USE, OR AGAINST INFRINGEMENT OF ANY PATENT.

IN NO EVENT SHALL HITACHI SCIENCE SYSTEMS, LTD. BE LIABLE FOR ANY DIRECT,

INCIDENTAL OR CONSEQUENTIAL DAMAGES OF ANY NATURE, OR LOSSES OR

EXPENSES RESULTING FROM ANY DEFECTIVE PRODUCT OR THE USE OF ANY

PRODUCT. NO ORAL OR WRITTEN INFORMATION OR ADVICE GIVEN BY HITACHI

SCIENCE SYSTEMS, LTD., ITS DEALERS, DISTRIBUTORS, AGENTS OR EMPLOYEES

SHALL CREATE A GUARANTEE OR IN ANY WAY INCREASE THE SCOPE OF THIS

GUARANTEE.

FOREWORD - 4

Page 7

INSTALLATION AND AFTER-SALES SERVICE

Installation

• Only the persons who have been trained by a certified engineer of the manufacturer are

allowed to carry out the installation work

• Before installation, refer to section 1 and prepare the necessary utilities.

• Installation at another place after delivery will be provided at charge. Consult your

nearest Hitachi service representative for details.

After-sales Service

• For after-sales service of the instrument, contact the Hitachi sales or service

representative in charge.

• For service after the guarantee period, consult Hitachi service with regard to a

maintenance and inspection service contract.

CAUTION ON DISPOSAL OF INSTRUMENT

Although at present the instrument does not use materials that will directly harm the

environment, changes are apt to be made in relevant laws and/or regulations, so be sure to

consult a qualified specialist when planning to dispose of the instrument.

FOREWORD - 5

Page 8

Available Training Programs

Hitachi service offers various kinds of training programs at its own facilities or at the user's site

and facilities to ensure proper and safe operations of the equipment to its full performance.

Please contact your sales representative about the details of the training programs and

application to them. Applicants will be charged.

Handling of Chemicals

(1) The user is responsible for proper handling and disposal of chemicals used for cleaning of

the equipment in accordance with applicable regulations.

(2) Follow the supplier's instructions on handling, storage, and disposal of chemicals.

Instruction Manual

(1) This instruction manual and those instruction manuals for relevant accessories may be

revised for improvement without prior notice.

(2) Hitachi Science Systems, Ltd. has the copyright of this instruction manual.

(3) Reproducing or copying of part or all of this instruction manual is not allowed without our

written permission.

FOREWORD - 6

Page 9

For Safe Handling

For Safe Handling

Before operating the machine, read the following instructions

carefully.

Safety precautions are indicated with the following headings

combining the alert symbol

“Caution”, and heading words:

, words “Danger”, “Warning”, and

: This safety alert symbol calls the user’s attention

to a danger that can potentially be injurious to

people.

To avoid the hazard, or even death, that can

occur, all safety messages following the symbol

must be heeded.

DANGER: Indicates an imminently hazardous situation that, if

not avoided, will result in death or serious injury.

WARNING: Indicates a potentially hazardous situation which, if

not avoided, can result in death or serious injury.

CAUTION: Indicates a hazardous situation that, if not avoided,

will or can result in minor or moderate injury, or

serious damage of product.

IMPORTANT: Indicates a hazardous situation that, if not avoided,

can cause property damage.

In addition to the above hazard tips, precautions for safe operation

are indicated with the following headings:

NOTICE: Indicates information and descriptions for ensuring

correct usage.

SAFETY - 1

Page 10

General Precautions on Safety

Before Using the System

■ Before using this product, read the operating manual careful and

be sure to understand its contents.

■ The operating manual should be kept in a safe place near you for

ready access and reference.

■ The system should be handled according to the procedures given

in this manual.

■ Be sure to understand the safety-related instructions provided in

this manual and heed them.

■ Be sure to observe the precautions indicated on the system or in

the manual. Failure to heed such precautions can result in

equipment damage or bodily injury.

For Safe Handling

■ Be sure to observe the operating instructions on the product itself

and those provided in its operating manual.

■ Do not carry out modification of the instrument, parts

replacement, use non-specified parts, nor detach safety

mechanisms since this could be hazardous.

■ Do not perform any operation or action in any way other than as

provided in this manual. When in doubt, call the designated field

engineer.

■ The customer is responsible for proper ventilation of the room

when using chemicals. Inadequate ventilation could cause a

health hazard.

■ Most system operations are performed by viewing the monitor.

Looking at the monitor continuously for long hours can cause

fatigue-related eye problems. For the safe system operation

involving the use of display devices, adequate labor management

standards should be established and implemented.

■ Keep in mind that the hazard warnings in this manual or on the

machine cannot cover every possible case, as it is impossible to

predict and evaluate all circumstances beforehand. Be alert and

use your common sense.

The above instructions should be observed strictly. Failure to do so

can result not only in improper specimen observation and evaluation,

but also in bodily injury.

SAFETY - 2

Page 11

For Safe Handling

General Precautions on Safety (cont’d)

Precautions on Using the System

■ When leaving the system unattended, turn off the acceleration

voltage.

■ If abnormal conditions arise when the system is being used, such

as abnormal noise, noxious odor, fumes, or gas leakage,

immediately shut off the power, shut the master gas valve, and

take any other safety measures that the situation may dictate,

and call the HS Service Department.

Precautions in Installation, Maintenance, and Relocations

■ To ensure the safe and accurate use of the system, installation

will be performed by either personnel from Hitachi’s Service

Department or qualified engineers trained and certified by

Hitachi.

■ Upon completion of the installation work, when receiving the

transfer of the product, please make sure that nothing is missing

in the standard accessories that are supposed to come with the

system.

Operating the system with some standard accessories missing

can lead to system malfunction and safety problems.

If you notice anything missing, damaged, or out of the ordinary,

please discuss the matter with installation personnel, the sales

office servicing your installation, or the nearest Hitachi Service

Department.

■ Servicing operations to be performed by the customer are limited

to the items covered in this operating manual. Maintenance

services should be performed with a good understanding of the

information contained in the manual.

To avoid system malfunction, or even bodily injury, maintenance

operations not covered in the manual should not be performed.

■ To avoid below-standard performance due to vibrations, the

system should not be moved after installation.

■ If the warning labels deteriorate due to aging or are damaged,

please contact the nearest Hitachi Service Department.

SAFETY - 3

Page 12

For Safe Handling

Warnings in the Operating Manual

Warnings provided in this manual and where they occur are summarized below.

● This system does not have components that require

signs.

Warning Indicators

● Burns from the Rotary Pump

■ If it stops abnormally the rotary pump remains hot. Touching it

can cause burns. Do not touch the rotary pump in the event of

an abnormal stoppage.

(Chapter 4 Maintenance)

● Burns from Touching the Filament Assembly

■ When the filament assembly is replaced, it can be as hot at 90℃.

Touching it can cause burns. When replacing a filament

assembly, turn off the acceleration voltage, and let the assembly

stand for 30 minutes or longer after the air is let in before working

on it.

Or, execute the filament exchange by using heatproof gloves of

the clean room specification.

(Chapter 4 Maintenance)

Danger

● Beware of Electric Shock

■ Voltages up to 100 V AC and 30 kV DC are used inside this

instrument. Do not touch inside or you may receive an electric

shock.

Do not remove the covers of main unit and display unit and do

not touch internal parts or circuits while the instrument power is

turned on. There is a hazard of fatal or serious injury due to

electric shock.

(Chapter 4 Maintenance)

SAFETY - 4

Page 13

Warning Indicators (cont’d)

● Injury from Splashing Compressor Drain

■ The inside of the compressor tank is pressurized. When

draining off the compressor, jerky motion can cause the liquid to

splash, causing eye injuries.

When draining off the compressor, do not stand directly in front of

the drain. Turn the drain cock slowly.

For Safe Handling

(Chapter 4 Maintenance)

SAFETY - 5

Page 14

Caution Indicators

● Fatigue due to Long Hours of Operation

■ In operating the system while viewing the display, looking at the

display for long hours at the same posture can build up fatigue in

the eyes or body. For your health, when operating the system

for long hours, take a break 10 to 15 minutes every hour or so to

rest your eyes and body.

● Injury from Lifting Heavy Objects

■ The goniometer (stage) is a heavy object. Removing the stage

involves the risk of dropping it accidentally, injury hands or feet.

To avoid the danger, do not remove the stage from the system

unit.

■ The rotary pump is a heavy object weighing approximately 30 kg.

When moving the rotary pump, it should be lifted by at least two

persons to prevent your hands or feet from getting caught.

■ The weight is a heavy object, weighing as much as 40 kg. Any

installation or relocation of the weight must be performed by

Hitachi or a service department authorized by Hitachi. The

weight should not be lifted by customer personnel.

(Chapter 1 Specifications and Installation Requirement)

For Safe Handling

(Chapter 3 Operation)

(Chapter 2 System Configuration)

(Chapter 4 Maintenance)

● Injury from Getting Caught in a Heavy Object

■ The goniometer (stage) is a heavy object. When replacing

specimens, be sure to operate the stage by grasping the handle.

SAFETY - 6

(Chapter 3, Operation)

Page 15

For Safe Handling

Caution Indicators (cont’d)

● Burns from Touching the Heated Aperture Plates

■ Heated aperture plates after baking are hot. Touching it can cause

burns. Do not touch the heated aperture plates heated with bare

hands.

(Chapter 4 Maintenance)

SAFETY - 7

Page 16

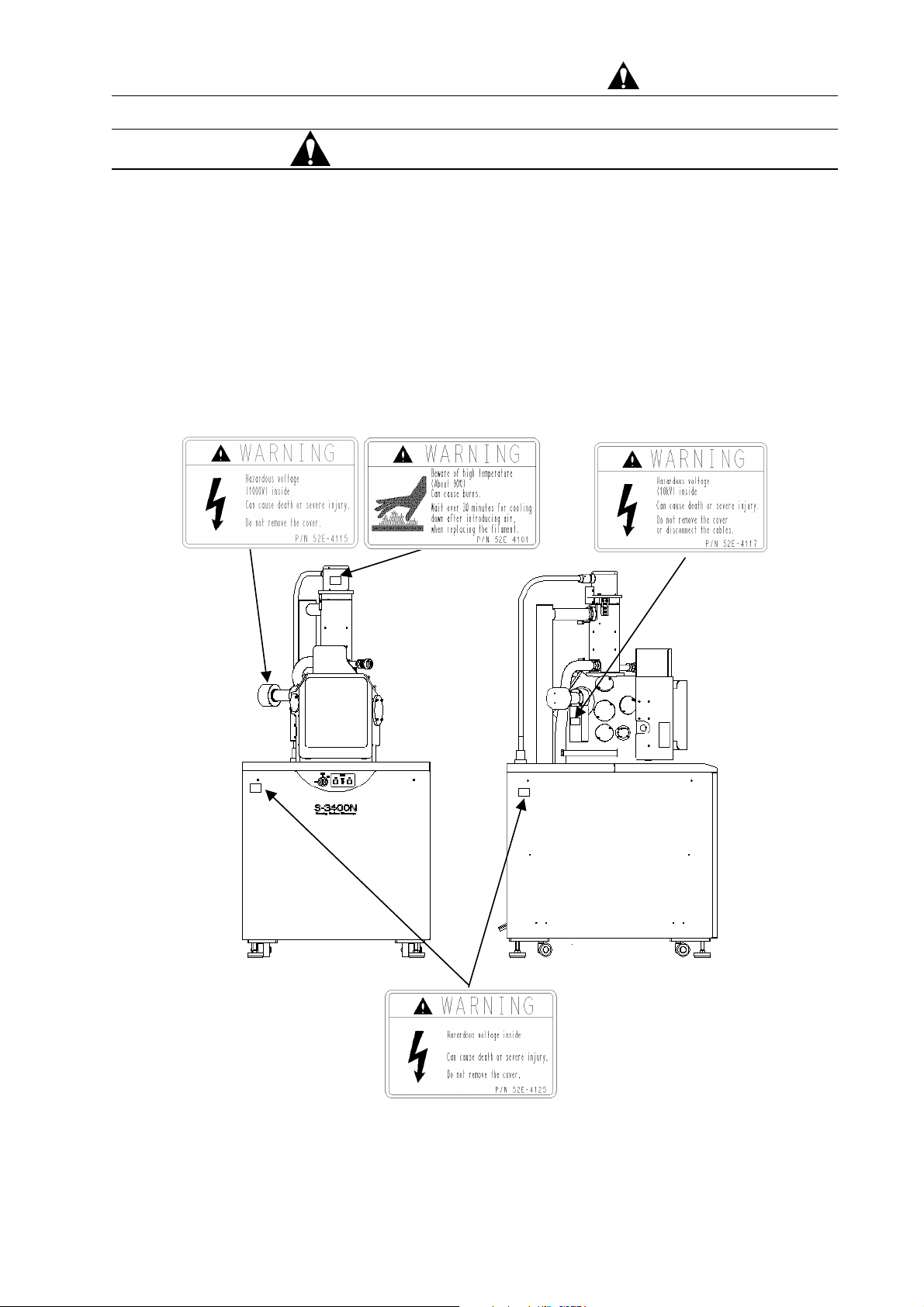

For Safe Handling

System Warning Labels

Safety pages 7 to 10 show Warning labels that are affixed to the

S-3400N. The contents of the warning labels should be checked

against the actual equipment.

Warning labels should be checked, cleaned, and maintained from

time to time so that they are clearly visible from a safe distance.

If warning labels fade and become difficult to read due to

aging, call the nearest Service Department for replacement.

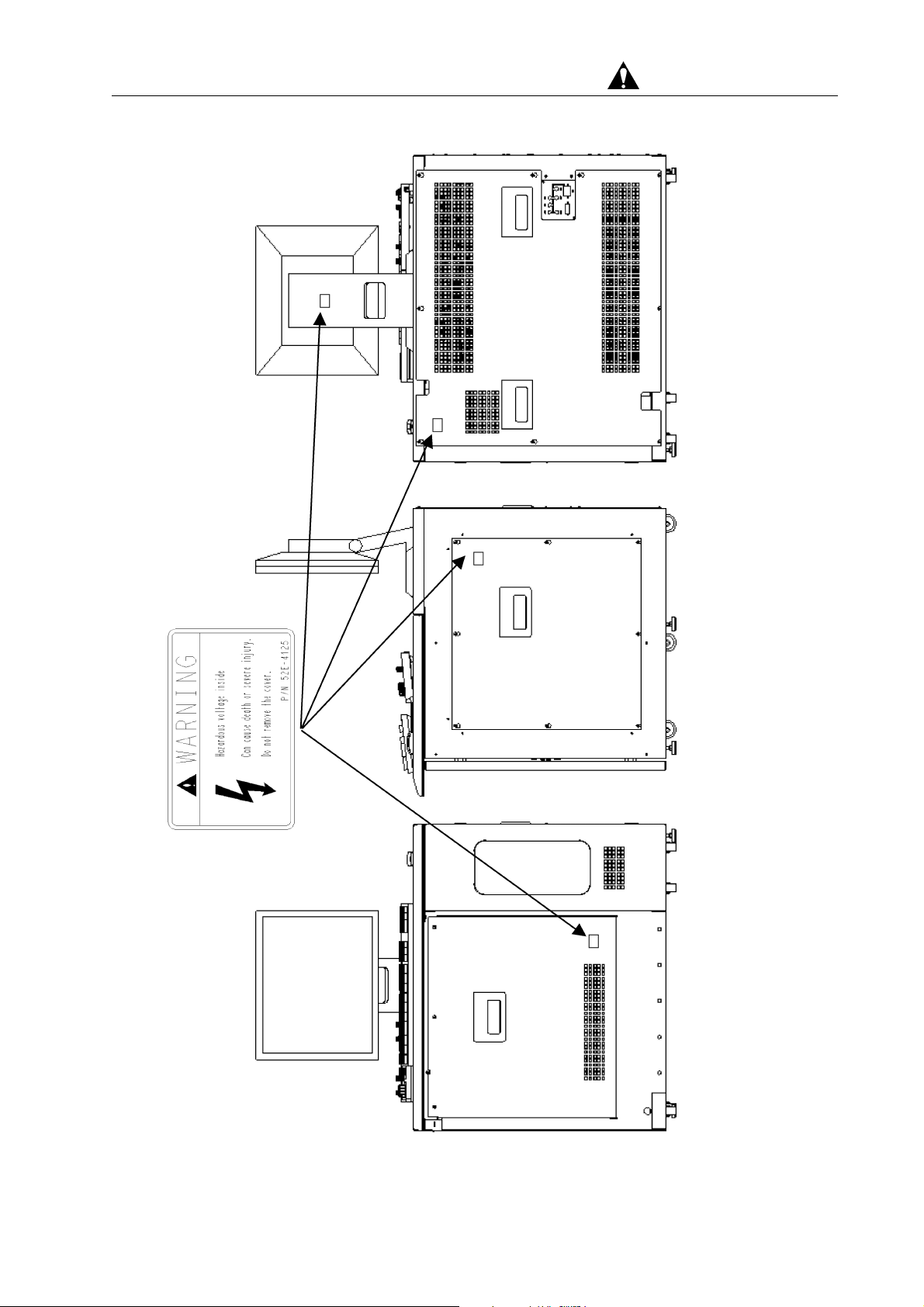

(Front view) (Left side view)

Warning Label Pasting Locations on System Unit

SAFETY - 8

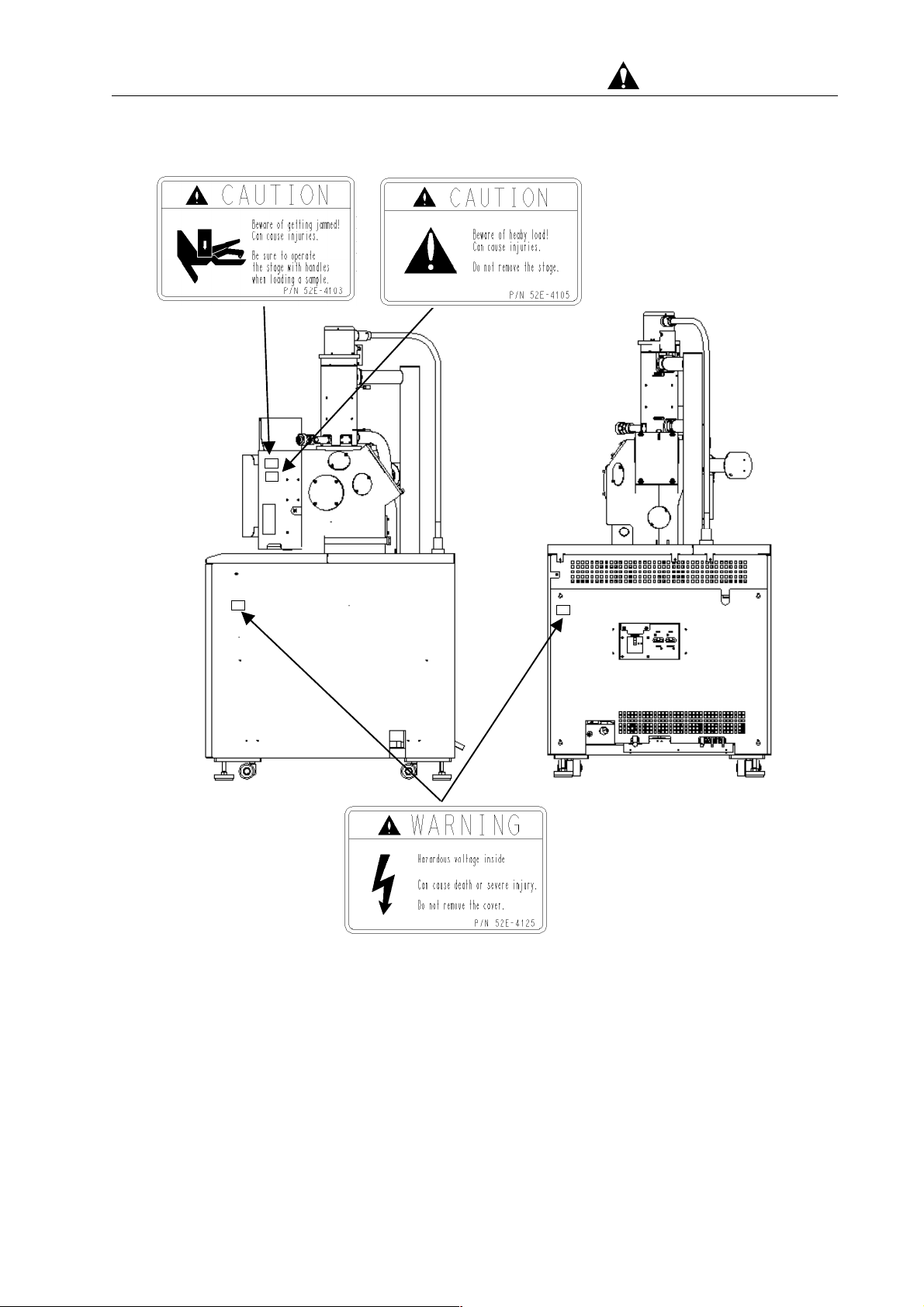

Page 17

For Safe Handling

(Right side view) (Rear view)

Warning Label Pasting Locations on System Unit

SAFETY - 9

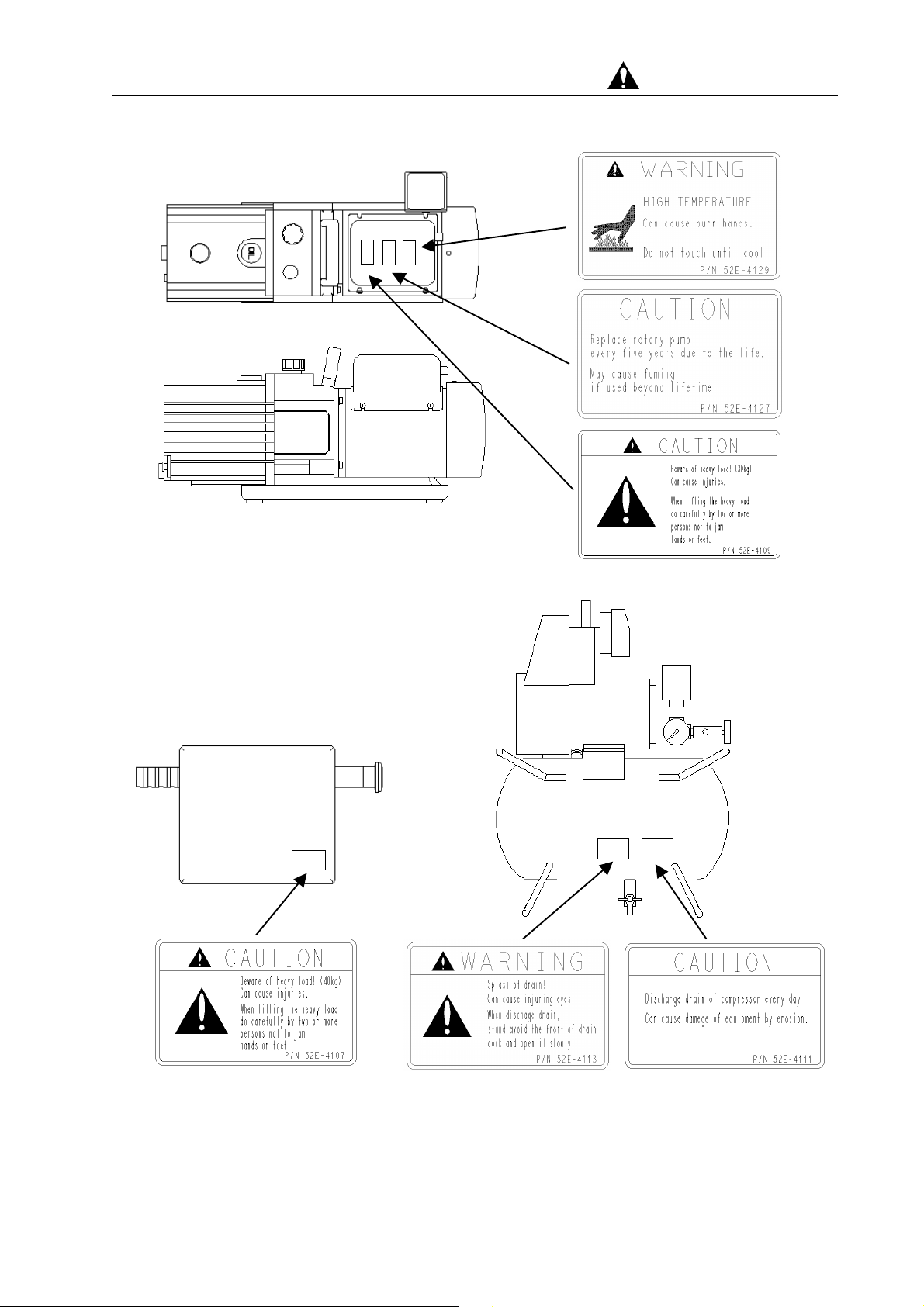

Page 18

For Safe Handling

Warning Labels Pasting Locations on Rotary Pump

Motion shielding weight Compressor

(Top view) (Back view)

Warning Label Pasting Locations on Weight/Compressor

SAFETY - 10

Page 19

For Safe Handling

Warning Label Pasting Locations Display Unit

(Front view) (Left side view)

SAFETY - 11

Page 20

For Safe Handling

Precautions for Proper Operation

― Precautions for the Proper Operation of the S-3400N ―

About Electricity

(a) Single-phase AC 100 V(±10%), 50/60 Hz, 2 kVA (for main

unit).When the supplied power line voltage is 100 V, the

instrument works by direct connection.

When the supplied power line voltage is other than 100 V (200 V

or others), use a step down transformer to step the power line

voltage down to 100 V. Refer to Chapter 1 (Specifications and

Installation Requirement) for the step down transformer

requirement.

(b) Connect the instrument to ground based on the standard of your

country to prevent electric shock hazards due to the high

voltage. Otherwise, you could suffer an electric shock or a

malfunction could occur in the instrument.

Avoid sharing the ground terminal with other power equipments.

Be sure to ground the instrument independently. The image

trouble and the malfunction of the equipment might be caused

when sharing.

Handling Volatile Solvents

When handling a volatile solvent in cleaning components of this

system, take precautions on the following points:

(a) Volatile solvent should be handled at a place which is well

ventilated and is well away from flames.

(b) For handling volatile solvents, ventilation equipment and

protective gear should be provided at the customer’s discretion.

The inhaling of a volatile solvent in excessive amounts can

results in respiratory difficulties. If volatile solvent is swallowed

or it gets onto the skin or into the eyes, symptoms of polyneuritis

including anesthesia and ataxia (difficulty in walking) may

develop.

SAFETY - 12

Page 21

Precautions on Proper Operation (cont’d)

Third Party’s Industrial or Proprietary Rights

Hitachi Science Systems, Ltd. shall not be responsible for a third

party’s claim regarding infringement of any patent rights or industrial

properties with respect either to products manufactured through the

use of equipment supplied by Hitachi or its related companies or to

applications of the Hitachi equipment.

Laser Light Hazard

The CD-ROM or CD-R/W drive in the personal computer is equipped

with a laser device. The personal computer with laser device

complies with safety standards including International

Electrotechnical Commission (IEC) 825. With specific regard to the

laser, the equipment complies with laser product performance

standards set by U.S. governmental agencies for a Class 1 laser

product. The product does not emit hazardous light; the beam is

totally enclosed during all modes of customer operation and

maintenance. Therefore be sure to observe the following warnings

when operating a product equipped with a laser device.

• Do not try to open the unit enclosure.

There are no user-serviceable components inside.

• Do not operate controls, make adjustments, or perform procedures

with the laser device other than those specified herein.

• Allow only service personnel to repair the unit.

Laser Information:

Laser type: Semiconductor GaAlAs

Wavelength: 780 ± 35 nm

Divergence angle: 53.5° ± 0.5°

Output power: Less than 0.2 mW or 10,869 W m-2 sr-1

Polarization: Circular 0.25

Numerical aperture: 0.45 ± 0.04 inches

Harmful Chemicals

For Safe Handling

This product contains chemicals, including lead, known to the State

of California to cause cancer, and birth defects or other reproductive

harm.

Wash hands after handling.

SAFETY - 13

Page 22

Precautions on Proper Operation (cont’d)

Backup of Important Data

Trouble-free operation cannot be guaranteed for the computer

system. You are recommended to copy important data on the hard

disk into floppy disks (FD) or magneto-optical disks (MO) at a regular

interval

About Computer Applications Software

Other applications software should not be installed on the PC that is

a part of this system. Such software can cause unexpected

animation screens to pop up, exert adverse impact on the system,

and interfere with the operation of the system. The warranty does

not cover situations where the system fails to run properly due to the

installation of other application software.

Protection against Computer Viruses

For Safe Handling

Computer viruses are malicious programs that sneak into the PC to

cause misbehavior or damage to data. And, a program designed to

offer protection against and eradicate computer viruses is called a

vaccine program.

Using a floppy disk or other storage medium infected by a virus can

cause virus infection. Note also that once a virus infects the PC, it

may spread to other computers through storage media. Therefore,

never use a program or storage medium that is suspected of

containing a virus.

If there is a possibility of virus infection, check for a virus using a

vaccine program.

The user is requested to prepare a proper vaccine program and carry

out virus removal on his or her own responsibility.

Note, however, that some kinds of vaccine programs may cause

incorrect operation of the S-3400N control program. If a problem

occurs after you install a vaccine program, remove it or execute virus

check when the S-3400N program is not running. It is desirable not

to set the vaccine program in the auto start-up group, or to terminate

the vaccine program before starting the S-3400N program.

SAFETY - 14

Page 23

Precautions on Proper Operation (cont’d)

About Changes in Computer Settings

Do not change the following system settings of your PC. These are

set up at the optimum conditions for operation of the S-3400N SEM

before shipping.

(a) Connection to the USB ports

This instrument uses a USB port for communication between the

PC and the internal microprocessor. The USB port number 1 is

assigned to the instrument. Therefore, if external storage devices

or printers are to be connected to USB ports, ports that are

available to users are subject to restrictions.

(b) Monitor screen setting

Monitor properties need to be set at 1280×1024 pixels for the

desktop area, true color (24 bit) mode and 60 Hz to 70 Hz for the

refresh rate. Using other resolution, faster refresh rate or 256

color mode may cause an abnormal screen display.

For Safe Handling

(c) Sub programs

This instrument operates using many DLL programs along with

the control program. Deletion of files in the Windows directory or

change of the registry will cause troubles. Also do not delete

tasks and processes using the task manager.

(d) Screen saver settings

The screen saver can cause to exert adverse impact on the

system, and to interfere with the operation of the system. For

using the screen saver, read the following carefully.

(1) Use only the screen saver of the windows standard.

The operation of the screen savers other than the Windows

standard are not guaranteed.

(2) Password Protection should not be set on a screen saver.

Password Protection can prevent SEM images to display

properly when the system wakes up from the screen saver

mode. . If you need to lock Windows when leaving your work

site, the option to activate Password Locking from the

S-3400N Control Program should be used.

See 3.9.19 Password Locking of Windows.

SAFETY - 15

Page 24

For Safe Handling

(e) Power Saving mode

Do not use the Power Saving mode. It will cause trouble in

communication between the PC and internal microprocessor.

(f) Virtual memory setting

Do not change the virtual memory setting.

(g) Any saved image data is subject to control by SEM data

Manager. Image files should not be renamed or deleted by using

Windows File Manager or Windows Explorer. The use of

Windows File Manager or Windows Explorer can cause a conflict

between the data controlled by SEM Data Manager and the actual

data. Such files generate a “Reference disabled” message on

SEM Data Manager. If such a conflict arises, the offending file

should be deleted by using the Remove List Function of the Batch

Process of SEM Data Manager. Valuable images contained in

such a file can be re-registered using the Add From File function.

SAFETY - 16

Page 25

Precautions on Proper Operation (cont’d)

OS Operation during S-3400N SEM Operation

Although the Windows Task Manager can be launched from the

Taskbar or by Ctrl+Alt+Del key operation, if Standby or Halt mode is

set or logged-off while the S-3400N control program is running, it will

not work normally when recovered from such a status. Close

S-3400N control program if setting of such mode is necessary.

USB Devices

When connecting USB devices such as external storage unit, printer

etc., take notice of the following.

(1) USB Port 1 is used by the display control unit, ports available to

users are subject to restrictions.

For Safe Handling

(2) Terminate S-3400N control program when carrying out disk

formatting or copying a large volume of image files to MO disk,

hard disk or other storage devices using USB port.

(3) By the above operation, sometimes the message “USB not

connected” will be shown. In such case, S-3400N control program

will not continue normal operation. If this message appears,

close Windows, shut down the PC, turn off the key switch for the

system unit, wait 30 seconds, and then restart the system by

turning on the power again.

SAFETY - 17

Page 26

Precautions on Proper Operation (cont’d)

Network Connection

The PC is equipped with Ethernet ports for network connectivity.

Performing a network connection using the Ethernet requires

extensive knowledge of the network environment. Such a connection

should be undertaken in consultation with the Network Administrator.

(1) Connecting a cable to an Ethernet port is carried out by Hitachi

(2) Ethernet cables are not included as part of the system. Cables

(3) For a network connection, setting in the PC should be modified

For Safe Handling

Science installation engineers or service engineers. Consult

your nearest Hitachi Science service representative for details.

should be procured as necessary. For detail, refer to About

Changes in Computer Settings in this chapter.

with adequate care. Unwittingly changing the settings required by

the operation of the system can disable the system.

(4) No special software should be installed for network connection.

Such software can adversely impact the system and even disable

it. When connecting your system to a special network, please

consult the sales representative or the Service Department that

handles your system.

(6) Connecting to an external device, such as EDX, using an optional

external communications interface requires the use of an

Etherport. Therefore, for connecting to a device other than an

external device, a branching hub should be procured. Some

external devices come equipped with a standard hub, which

should be verified with your servicing sales representative.

(7) A network connection using the Microsoft TCP/IP protocol

requires an IP address, which should be set up in consultation

with a Network Administrator. Connecting to an external device,

such as EDX, requires another IP address specifically for

connection to that device.

NOTICE The user is requested to prepare a proper Computer

viruses protection on his or her own responsibility with

consulting to the network administrator. It is not

guaranteed Failure of instrument or damage of basic

software, application software or other data due to a

computer virus.(For detail, refer to Protection against

Computer Viruses in this chapter.)

SAFETY - 18

Page 27

Precautions on Proper Operation (cont’d)

Using Other Windows Applications

Running non-SEM Windows applications (especially the Printer or

Internet Explorer) during a SEM operation, especially image capture,

transfer of saved.

Personal Computer (PC)

Do not turn off the PC power independently. If the PC power is

turned off during access to hard disk or floppy disk, the PC or data

and programs stored therein may be damaged.

Be sure to close the S-3400N control program, shut down Windows,

and after the PC is automatically shut off or a “You can now safety

turn off the computer” message has appeared, turn off the power

switch (key switch) on the S-3400N system unit.

For Safe Handling

If the PC lock up for some reason, take steps to shut down the PC

safely by referring to 4.4.9 When PC has Hung Up.

SAFETY - 19

Page 28

Precautions on Proper Operation (cont’d)

Transportation and Relocation of Instrument

(a) The transport of the system, which carries considerable risk,

should never be attempted by a customer. Any system transport

should be performed with the assistance and supervision of

Hitachi-approved engineers.

(b) Do not lift the instrument by holding the table. The strength of

table fitting is not sufficient for bearing the weight of display unit,

approximately 120 kg. Should the table be lifted, the display unit

might slip off and crash. Hence, it is recommended to remove

the table and transport the display unit independently when

moving the instrument.

Ambient Temperature and Humidity

For Safe Handling

Even when the system is not running, the room in which the system

is installed should be maintained under the following environmental

conditions:

Room temperature: 15℃ to 30℃

Humidity: 70% or lower (no condensation)

If the system is not used for a long time, the specimen chamber

should be evacuated instead of being exposed to the atmosphere.

SAFETY - 20

Page 29

Additional Information of PC Setting

Setting of Windows (r) XP Professional Service Pack2 in S-3400N

1. Outline

As of February 2005, OS of the personal computer for the PC-SEM control is Windows XP

Professional Service Pack2 (SP2). In SP2, a security function is strengthening in addition to

accumulation of the correction program published in the past. The setting of SP2 when PC-SEM

is shipped from factory is described as follows. The factory does not provide guarantee when

PC-SEM is used in the settings not described in this manual.

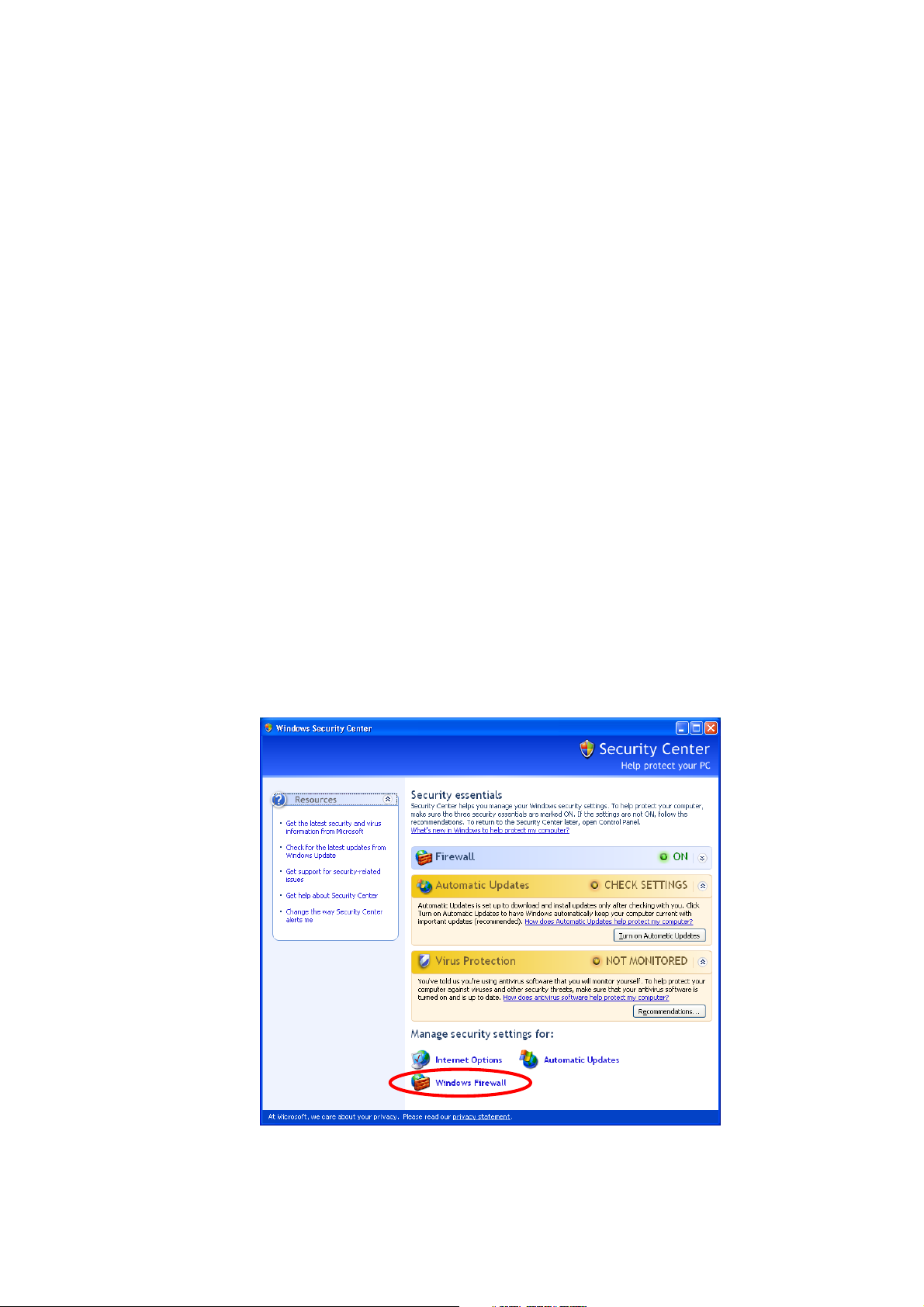

2. Setting of Security Center

(1) Click Start button, and select Control panel.

(2) Click Security Center icon.

2.1 Firewall

The Firewall is set to ON. When you confirm this setting, refer to the following procedures.

(1) Click Windows Firewall in the Windows Security Center window.

Fig. 1 The Windows Security Center Window

PC - 1

Page 30

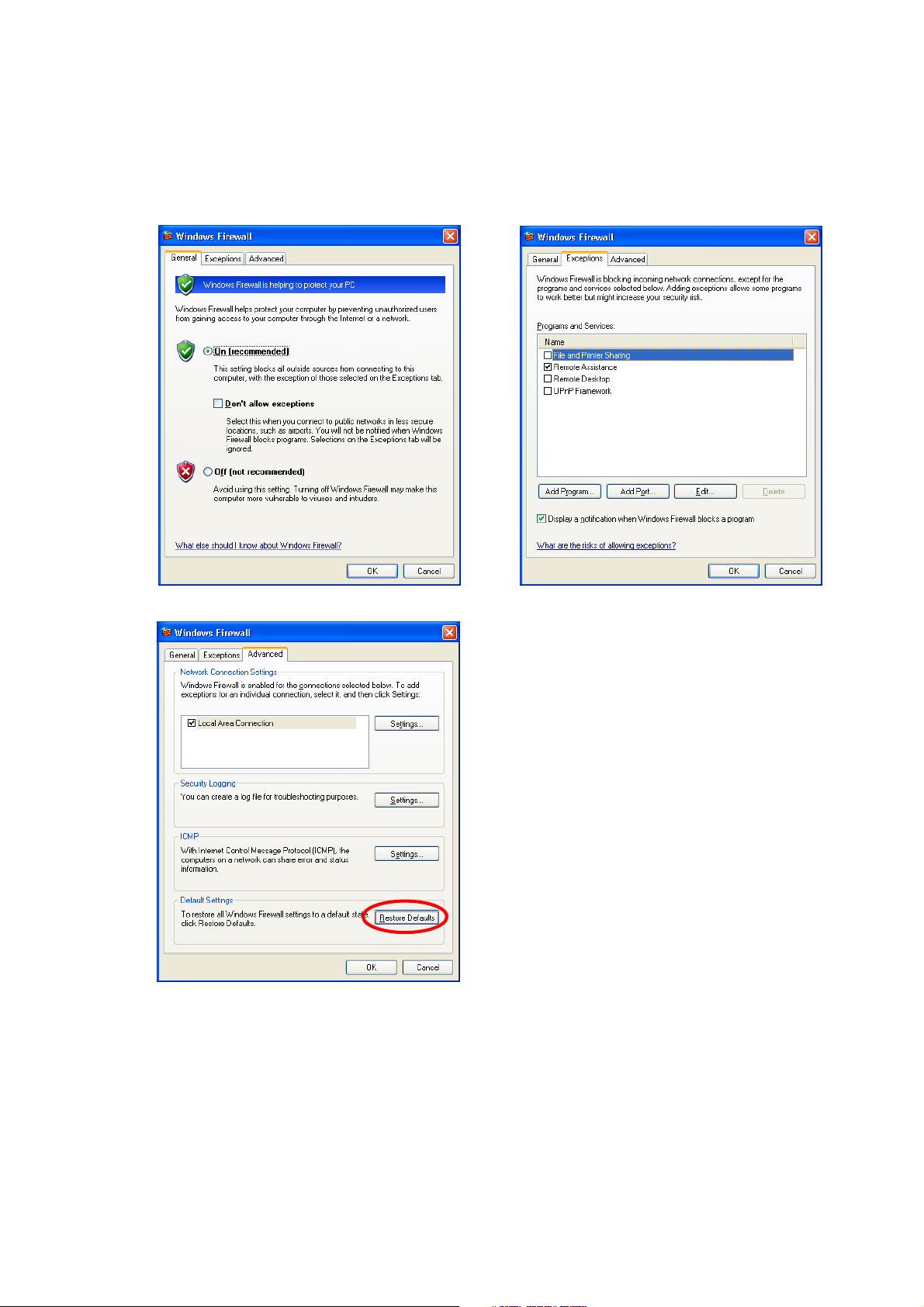

The Windows Firewall is set as shown in the figure below.

To restore all Windows Firewall settings to a default state, select the Advanced tab and click the

Restore Defaults button.

Fig. 2 The Windows Firewall Dialogs

PC - 2

Page 31

2.2 Automatic Updates

(1) Click Automatic Updates in the Windows Security Center window or click the Automatic

Updates tab in the System dialog.

Fig. 3 The Windows Security Center Window

(2) Select "Notify me but don't automatically download or install them."

Fig. 4 The Automatic Updates Dialogs

PC - 3

Page 32

2.3 Virus Protection

The anti-virus software is not installed. In SP2, if the anti-virus software is not installed or the

date of the virus definitions file is old, message is displayed when OS starts.

When the instrument is shipped from factory, the Virus Protection setting is set as follows so that

the message is not displayed.

(1) Click the Recommendations button in the Windows Security Center window.

Fig. 5 The Windows Security Center Window

(2) Check "I have an antivirus program that I'll monitor myself." and click the OK button.

Fig. 6 The Recommendation Dialog

PC - 4

Page 33

We have tested the following anti-virus software that install in the personal computer of PC-SEM,

and confirmed that the SEM control software operates correctly (as of February 2005).

Symantec Norton Anti Virus 2004

Symantec Norton Anti Virus 2005

Our company doesn't support above-mentioned anti-virus software. The user is requested to

prepare a proper Computer viruses protection on his or her own responsibility with consulting to

the network administrator. It is not guaranteed failure of instrument or damage of basic software,

application software or other data due to a computer virus.

3. Other setting

3.1 Login User Name

When the instrument is shipped from factory, the Login User Name is set as follows.

User Name Password Group Memberships Application

PC-SEM Not

registered

Power Users Used for operation of SEM.

System environment cannot be

set.

Administrator hitachi Administrators Used for system management.

System environment can be set.

SEM ∗∗∗∗ Administrators Used for maintenance of SEM.

Do not change setting.

• It is possible to set a password for users "Administrator" and "PC-SEM". For setting way of

the password, refer to the instruction manual for Windows.

• Set the Group Memberships to "Administrators" or "Power Users" when you create a new

account. The control software doesn't execute normally, when setting it to "Users".

3.2 Setting of Display Properties

Right-click on Desktop, and select Properties in the displayed menu.

(1) Desktop tab

Background: [None]

(2) Screen Saver tab

Screen saver: [None]

Monitor Power (Click the Power button):

Power schemes: Always On

Turn off monitor, Turn off hard disk, System standby, System hibernates: Set everything

to Never.

PC - 5

Page 34

(3) Appearance tab

Windows and buttons: Windows XP style

Color scheme: Default (blue)

Effects: (Click the Effects button): do not check "Use the following method to smooth edges

of screen fonts."

(If it is checked, when the SEM image with a high brightness is displayed, the character of

the data display becomes hard to see.)

(4) Settings tab

Screen resolution: 1280 by 1024 pixels

Color quality: Highest (32bit)

Monitor refresh rate (Click the Advanced button, and select the Monitor tab): 60Hz (LCD)

3.3 Setting of Hard disk drive

The hard disk drive of the Windows XP model PC-SEM is separated for two partitions of drive

letter C and drive letter D. Save the data of the SEM image etc. to drive D.

To share the data of Drive D when two or more user names to be able to log in Windows are

registered, the access permits of group Everyone is set to Full control.

To share data in Drive D, The access permit of the group "Everyone" is set to "Full control" so

that two or more user names to be able to log in Windows are registered. If you change this

setting, image data might not be able to be written in the hard disk with the SEM data manager

and so forth according to the user name. Refer to the following for the setting. (Do not change

this setting except the person who is well informed about the setting of Windows.)

(1) Select Drive D by the Explorer, and select Folder Options in the Tool menu.

(2) Select the View tab in the Folder Options dialog, and remove the check mark of "Use simple

file sharing (Recommended)" in the Advanced Settings list, and then click the OK button.

(3) Select and right-click Drive D by the Explorer, and then select Properties in the displayed

menu.

(4) Select the Security tab in the Properties dialog, and select Everyone* in the Group or User

Names list. Then check Full Control the Allow side in the Permissions for Everyone list.

Then check the Allow side of the Full control check box in the Permissions for Everyone list.

*: If there is not Everyone in the Group or User Names list, add it according to the following

procedures.

(i) Click the Add button.

(ii) Click the Advanced button in the displayed Select Users or Groups dialog.

(iii) Click the Find Now button, then the list appear.

Select Everyone from the list, and then click the OK button.

PC - 6

Page 35

3.4 Setting of Taskbar

When the instrument is shipped from factory, the setting of the taskbar is set for the following.

There is no influence in the operation of the SEM software even if this setting changes.

(1) Taskbar (Right-click on the taskbar and select Properties): Check "Auto-hide the taskbar"

(2) Start Menu (Select the Start tab in the Taskbar and [Start] Properties):Select "Start menu"

3.5 Setting of BIOS

Note that the setting of BIOS might be different in each model of PC. The following procedure is

the setting of HP Compaq Business Desktop dc7100MT (as of February 2005).

(1) Restart the PC.

(2) Press the F10 key while the logo of "HP" is displayed on the screen.

(3) The language select menu is displayed in the first. Select English and press the Enter key.

(4) The main-menu is displayed. Select "Advanced", and then select "Power-on option" and

press the Enter key.

(5) The sub-menu is displayed. Select "After power loss", and change the settings to "on"

pressing the "→" key.

Then select "Post Delay (in seconds)", and change the settings to "20" pressing the "→" key.

Then select "Hyper-Threading", and change the settings to "Disable" pressing the "→" key.

Then press the F10 key.

(6) Select "Advanced" in the main-menu, and then select "Device Options" and press the Enter

key.

(7) The sub-menu is displayed. Select "Num Lock State at Power-On", and change the settings

to "on" pressing the "→" key.

Then press the F10 key.

(8) Select "File" in the main-menu, and then select "Save Changes and Exit", and then press

the Enter key.

The Exit Message is displayed, and then press the F10 key.

PC - 7

Page 36

Table of Contents

FOREWORD ....................................................................................................... FOREWORD - 1

Scope of Instruction Manual ......................................................................... FOREWORD - 2

Acronyms...................................................................................................... FOREWORD - 2

GUARANTEE ...................................................................................................... FOREWORD - 3

INSTALLATION AND AFTER-SALES SERVICE ................................................ FOREWORD - 5

CAUTION ON DISPOSAL OF INSTRUMENT ..................................................... FOREWORD - 5

Available Training Programs......................................................................... FOREWORD - 6

Handling of Chemicals .................................................................................. FOREWORD - 6

Instruction Manual ........................................................................................ FOREWORD - 6

SAFETY SUMMARY .......................................................................................... SAFETY - 1

For Safe Handling............................................................................................... SAFETY - 1

General Precautions on Safety ........................................................................... SAFETY - 2

Before Using the System .................................................................................... SAFETY - 2

Precautions on Using the System .......................................................................SAFETY - 3

Precautions in Installation, Maintenance, and Relocations.................................. SAFETY - 3

Warning Indicators.............................................................................................. SAFETY - 4

Caution Indicators............................................................................................... SAFETY - 6

System Warning Labels...................................................................................... SAFETY - 8

Precautions for Proper Operation .......................................................................SAFETY - 12

About Electricity ..................................................................................................SAFETY - 12

Handling Volatile Solvents ..................................................................................SAFETY - 12

Third Party's Industrial or Proprietary Rights.......................................................SAFETY - 13

Laser Light Hazard .............................................................................................SAFETY - 13

Harmful Chemicals .............................................................................................SAFETY - 13

Backup of Important Data ...................................................................................SAFETY - 14

About Computer Applications Software............................................................... SAFETY - 14

Protection against Computer Viruses.................................................................. SAFETY - 14

About Changes in Computer Settings................................................................. SAFETY - 15

OS Operation during S-3400N SEM Operation...................................................SAFETY - 17

USB Devices....................................................................................................... SAFETY - 17

Network Connection............................................................................................SAFETY - 18

Using Other Windows Applications .....................................................................SAFETY - 19

Personal Computer (PC)..................................................................................... SAFETY - 19

Transportation and Relocation of Instrument ...................................................... SAFETY - 20

Ambient Temperature and Humidity ...................................................................SAFETY - 20

Additional Information of PC Setting ................................................................................PC - 1

- i -

Page 37

1 SPECIFICATIONS AND INSTALLATION REQUIREMENTS .........................................1 - 1

1.1 Specifications ........................................................................................................1 - 1

1.1.1 Resolution ................................................................................................1 - 1

1.1.2 Magnification............................................................................................1 - 1

1.1.3 Electron Optical System...........................................................................1 - 1

1.1.4 Specimen Goniometer Stage ...................................................................1 - 2

1.1.5 Evacuation System ..................................................................................1 - 2

1.1.6 Imaging Function .....................................................................................1 - 2

1.1.7 Safety Equipment.....................................................................................1 - 4

1.1.8 Size and Weight.......................................................................................1 - 4

1.2 Installation Requirements ......................................................................................1 - 5

1.2.1 General ....................................................................................................1 - 5

1.2.2 Room Temperature, Humidity and Altitude...............................................1 - 5

1.2.3 Line Power Requirement..........................................................................1 - 5

1.2.4 Grounding Terminal .................................................................................1 - 6

1.2.5 Stray Magnetic Field ................................................................................1 - 7

1.2.6 Vibrations.................................................................................................1 - 10

1.2.7 Power Line Noise and Electric Field Noise...............................................1 - 11

1.2.8 Disturbance by Sound Waves..................................................................1 - 13

1.2.9 Electro-Magnetic Compatibilitiy ................................................................1 - 13

1.2.10 Site Requirements ...................................................................................1 - 13

1.3 Customer-supplied Items.......................................................................................1 - 15

2 FUNCTIONS...................................................................................................................2 - 1

2.1 Control Knobs and Switches on Main Unit .............................................................2 - 2

2.1.1 Main Unit..................................................................................................2 - 2

2.1.2 Electron Optical Column ..........................................................................2 - 3

2.1.3 Specimen Stage (Type I) .........................................................................2 - 4

2.1.4 Specimen Stage (Type II) ........................................................................2 - 5

2.1.5 EVAC Panel .............................................................................................2 - 6

2.1.6 Evacuation System ..................................................................................2 - 7

2.1.7 System Power Distribution Board.............................................................2 - 8

2.2 Control Knobs and Switches on Display Unit .........................................................2 - 9

2.2.1 Display Console .......................................................................................2 - 9

2.2.2 PC (Personal Computer)..........................................................................2 - 10

2.2.3 Manual Operation Panel...........................................................................2 - 11

2.2.4 Mouse and Trackball................................................................................2 - 12

2.3 Graphical User Interface (GUI) ..............................................................................2 - 13

2.3.1 Starting the PC and Logging in the S-3400 Program ...............................2 - 13

2.3.2 S-3400N SEM Main Window....................................................................2 - 15

2.3.3 Control Arrangement on the Window .......................................................2 - 17

2.3.4 Menus ......................................................................................................2 - 18

2.3.5 Popup Menu.............................................................................................2 - 24

2.3.6 Control Panel ...........................................................................................2 - 26

2.3.6.1 Functional Windows on the Control Panel................................2 - 26

- ii -

Page 38

2.3.6.2 Electron Gun Control Unit ........................................................2 - 26

2.3.6.3 Scan Control Windows.............................................................2 - 27

2.3.6.4 Auto Control .............................................................................2 - 28

2.3.6.5 Magnification Control................................................................2 - 30

2.3.6.6 Capture Control........................................................................2 - 31

2.3.6.7 Image Recording Control .........................................................2 - 33

2.3.6.8 EVAC/AIR Control....................................................................2 - 35

2.3.6.9 Stage Control ...........................................................................2 - 36

2.3.6.10 Extension for Dual Screen Mode ..............................................2 - 37

2.3.7 Operation Panel .......................................................................................2 - 38

2.3.7.1 ELECTRON BEAM Window.....................................................2 - 39

2.3.7.2 Focusing Position (WD) WORKING DISTANCE Window ........2 - 40

2.3.7.3 VACUUM MODE Window ........................................................2 - 41

2.3.7.4 SCAN MODE Window..............................................................2 - 42

2.3.7.5 CONDITION LOAD/SAVE Window ..........................................2 - 43

2.3.7.6 SCREEN MODE Window.........................................................2 - 43

2.3.7.7 DETECTOR Window................................................................2 - 44

2.3.7.8 IMAGE SHIFT Window ............................................................2 - 44

2.3.7.9 R.ROTATION Window .............................................................2 - 45

2.3.7.10 SIGNAL PROCESSING Window..............................................2 - 46

2.3.7.11 DATA ENTRY Window.............................................................2 - 47

2.3.7.12 TILT COMPENSATION Window ..............................................2 - 47

2.3.7.13 Other ........................................................................................2 - 48

2.3.8 Mouse Operation on the Scanning Image ................................................2 - 49

2.3.8.1 Exchanging Mouse Control Functions ......................................2 - 49

2.3.8.2 Focus/Stigma/Contrast/Brightness Adjustment ........................2 - 49

2.3.8.3 Stage and Image Shift Tools....................................................2 - 51

2.3.9 Setup Dialog Window...............................................................................2 - 52

2.3.9.1 Optics Tab................................................................................2 - 53

2.3.9.2 Image Tab................................................................................2 - 55

2.3.9.3 Record Tab ..............................................................................2 - 56

2.3.9.4 OP. Cond Tab ..........................................................................2 - 58

2.3.10 Captured Image Window..........................................................................2 - 59

2.3.11 SEM Data Manager Window ....................................................................2 - 61

2.3.12 Alignment Dialog Window ........................................................................2 - 61

2.3.13 CD Measurement Dialog Window (option) ...............................................2 - 62

2.3.14 Login Setting Dialog Window ...................................................................2 - 62

2.3.15 Oblique Dialog Window ............................................................................2 - 63

2.3.16 Password Setting Dialog Window ............................................................2 - 63

2.3.17 Save Image Dialog Window .....................................................................2 - 64

2.3.18 Opt Signal Processing Dialog Window .....................................................2 - 64

2.3.19 Split/Dual Mag Controller .........................................................................2 - 65

2.3.20 Using Short-cut Keys ...............................................................................2 - 65

- iii -

Page 39

3 OPERATION ..................................................................................................................3 - 1

3.1 Starting the System ...............................................................................................3 - 2

3.1.1 Start-up Confirmation Items .....................................................................3 - 2

3.1.2 Startup Operation.....................................................................................3 - 2

3.2 Mounting a Specimen ............................................................................................3 - 4

3.2.1 Precautions Concerning Specimen Preparation.......................................3 - 4

3.2.2 Specimen Preparation according to Material............................................3 - 4

3.2.3 Mounting a Specimen on the Type I Stage (Manual Stage) .....................3 - 5

3.2.3.1 Setting the Specimen Stand.....................................................3 - 5

3.2.3.2 Measuring and Setting the Specimen Height ...........................3 - 5

3.2.3.3 Moving the Stage to the Specimen Exchange Position ............3 - 6

3.2.3.4 Procedure for Loading a Specimen ..........................................3 - 7

3.2.4 Mounting a Specimen on the Type II Stage (5-axis motor-driven stage) ..3 - 9

3.2.4.1 Setting the Specimen Base ......................................................3 - 9

3.2.4.2 Measuring and Setting the Specimen Height ...........................3 - 10

3.2.4.3 Moving the Stage to the Specimen Exchange Position ............3 - 12

3.2.4.4 Loading the Specimen..............................................................3 - 13

3.3 Applying the Accelerating Voltage .........................................................................3 - 15

3.3.1 Conditions under which Accelerating Voltage can be Applied ..................3 - 15

3.3.2 Setting the Accelerating Voltage and Filament Current............................3 - 15

3.4 Adjusting the Electron Optical System ...................................................................3 - 18

3.4.1 Setting Parameters for the Electron Optical System ................................3 - 18

3.4.2 Axial Alignment ........................................................................................3 - 22

3.4.2.1 Items Requiring Axial Alignment...............................................3 - 22

3.4.2.2 Axial Alignment Items in Detail .................................................3 - 23

3.5 Operation for Image Observation...........................................................................3 - 31

3.5.1 Selecting a Detector.................................................................................3 - 31

3.5.1.1 Secondary Electron Detector (SE) ...........................................3 - 32

3.5.1.2 Backscattered Electron Detector (BSE) ...................................3 - 33

3.5.1.3 Other Detectors (optional) ......................................................3 - 37

3.5.2 Selecting Magnification ............................................................................3 - 38

3.5.2.1 Notes on Using the Lowest Magnification and Conducting

Observations at a Low Magnification........................................3 - 39

3.5.3 Selecting Scanning Speed .......................................................................3 - 42

3.5.4 Image Brightness and Contrast Adjustment .............................................3 - 44

3.5.5 Focus and Astigmatism Correction ..........................................................3 - 46

3.5.6 Operation of the Specimen Stage (Type I - Manual Stage) ......................3 - 52

3.5.6.1 Movable Range and Specimen Exchange Position ..................3 - 52

3.5.6.2 Restriction on the Motion of the X and Y-axes .........................3 - 52

3.5.6.3 Allowable Range of Observation and Motion of the Tilt Axis

by Specimen Size................................................................... 3 - 52

3.5.6.4 Tilt and Z Axis Limitations ........................................................3 - 54

3.5.6.5 Operating the Z-axis (varying the Working Distance [WD]) ......3 - 55

3.5.6.6 Checking the Ranges of T-axis Tilting and Z-axis Motion

when Observing a Bulk Specimen............................................3 - 56

- iv -

Page 40

3.5.7 Operation of the Specimen Stage (Type II - 5-Axis Motorized Stage) ....3 - 57

3.5.7.1 Coordinate Notation ...............................................................3 - 57

3.5.7.2 Movable Range and Specimen Exchange Position ................3 - 58

3.5.7.3 Setting Specimen Size and Detectors in Use .........................3 - 60

3.5.7.4 Operation Methods Used to Move the Specimen Stage .........3 - 61

3.5.7.5 X, Y, R Axis Operation ...........................................................3 - 63

3.5.7.6 Z and Tilt Axis Operation........................................................3 - 66

3.5.7.7 Mouse Operation of Stage on the Scanning Image................3 - 67

3.5.7.8 Position Memory Function ......................................................3 - 75

3.5.7.9 Stage History Function ...........................................................3 - 77

3.5.7.10 Image Navigation ...................................................................3 - 79

3.5.7.11 Rotation/Tilt Eucentric Function and Calibration .....................3 - 83

3.5.7.12 Stopping Stage and Returning to Previous Stage Position .....3 - 90

3.5.7.13 Movable Range and Limitation by Optional Detectors ............3 - 90

3.6 Saving and Recording Images.............................................................................3 - 95

3.6.1 Saving and Recording Images ...............................................................3 - 95

3.6.2 Preparing Images for Recording ............................................................3 - 96

3.6.3 Image Capture .......................................................................................3 - 97

3.6.4 Saving a Scanning Image (Direct Save).................................................3 - 102

3.6.5 Saving Captured Images........................................................................3 - 105

3.6.6 Taking Photographs (Option) .................................................................3 - 106

3.6.6.1 Setting Photo Condition..........................................................3 - 106

3.6.6.2 Direct Photo Recording ..........................................................3 - 108

3.6.6.3 Memory Photo Recording.......................................................3 - 108

3.6.7 Recording Data Display with Images......................................................3 - 109

3.6.7.1 Image Recording Using Menu Commands or Buttons

on the Control Panel ..............................................................3 - 109

3.6.7.2 Captured Image Recording Using Buttons on the

Captured Image Window........................................................3 - 110

3.6.7.3 Record Captured Images without Embedding Text or

Graphic Data..........................................................................3 - 111

3.7 Using SEM Data Manager ...................................................................................3 - 111

3.8 Shutting Down .....................................................................................................3 - 112

3.8.1 Turning High Voltage Off .......................................................................3 - 112

3.8.2 Setting the Stage at the Specimen Exchange Position...........................3 - 112

3.8.3 Withdrawing the Specimen ....................................................................3 - 113

3.8.4 Closing Windows and Shutting off the Display Power ............................3 - 114

3.8.5 Termination Confirmation Items .............................................................3 - 115

3.9 Other Functions ...................................................................................................3 - 116

3.9.1 Screen Mode..........................................................................................3 - 116

3.9.2 Split Screen and Dual Mag Mode...........................................................3 - 119

3.9.3 Signal Selection and Color Mixing..........................................................3 - 120

3.9.4 X-ray Analysis Mode ..............................................................................3 - 123

3.9.5 Signal Processing ..................................................................................3 - 126

3.9.6 Operating Condition Memory .................................................................3 - 128

- v -

Page 41

3.9.7 Pseudo Color Display.............................................................................3 - 129

3.9.8 Data Entry Function ...............................................................................3 - 130

3.9.9 Raster Rotation, Dynamic Focus and Tilt Compensation .......................3 - 134

3.9.10 Printing Images Using Report Generation Function ...............................3 - 136

3.9.11 Copy Image............................................................................................3 - 143

3.9.12 Copy Image Information Text .................................................................3 - 143

3. 9.13 Oblique Image........................................................................................3 - 144

3.9.14 Optional Setting .....................................................................................3 - 145

3.9.15 Password Setting ...................................................................................3 - 150

3.9.16 Setting Login Name ...............................................................................3 - 150

3.9.17 Restoring DB..........................................................................................3 - 152

3.9.18 User Dependent Operation Condition Memory .......................................3 - 153

3.9.19 Password Locking of Windows ..............................................................3 - 154

3.9.20 Downloading Stage Control Program .....................................................3 - 155

3.10 Image Quality ......................................................................................................3 - 157

3.10.1 Accelerating Voltage and Image Quality ................................................3 - 157

3.10.2 Probe Current Setting and Image Quality...............................................3 - 158

3.10.3 Objective Lens Aperture and Image Quality ...........................................3 - 158

3.10.4 Influence of WD in Low-vacuum Mode...................................................3 - 159

3.11 Using SEM Data Manager ...................................................................................3 - 160

3.11.1 Precaution on SEM Data Manager .........................................................3 - 160

3.11.2 Functions ...............................................................................................3 - 161

3.11.2.1 Image Database.....................................................................3 - 161

3.11.2.2 Menu and Tool Buttons ..........................................................3 - 163

3.11.3 Operation ...............................................................................................3 - 167

3.11.3.1 Registering Images on SEM Data Manager Database ...........3 - 167

3.11.3.2 Selecting User Name and Opening Data Tree .......................3 - 168

3.11.3.3 Image Display ........................................................................3 - 169

3.11.3.4 Image Information ..................................................................3 - 170

3.11.3.5 Viewer Display .......................................................................3 - 170

3.11.3.6 Data Entry ..............................................................................3 - 171

3.11.3.7 Contrast Conversion...............................................................3 - 174

3.11.3.8 Image Processing ..................................................................3 - 177

3.11.3.9 Color Mixing ...........................................................................3 - 179

3.11.3.10 Printing Images ......................................................................3 - 181

3.11.3.11 Image File Operation..............................................................3 - 181

3.11.3.12 Batch Operation of Image Files ..............................................3 - 182

3.11.3.13 Slide Show .............................................................................3 - 184

3.11.3.14 Optional Setting......................................................................3 - 184

3.11.3.15 Optimizing and Repairing Database File ................................3 - 186

4 MAINTENANCE..............................................................................................................4 - 1

4.1 Maintenance of Electron Optical Column ...............................................................4 - 1

4.1.1 Filament Exchange ..................................................................................4 - 1

4.1.2 Maintenance for the Objective Lens Movable Aperture ............................4 - 6

- vi -

Page 42

4.1.3 Maintenance for the Orifice Unit...............................................................4 - 10

4.1.4 Maintenance for the Condenser Aperture ................................................4 - 15

4.1.5 Cleaning of Aperture Plates .....................................................................4 - 19

4.1.6 Ultrasonic Cleaning with Organic Solvent.................................................4 - 20

4.1.7 Replacement of Scintillator.......................................................................4 - 20

4.2 Maintenance of Rotary Pump ................................................................................4 - 21

4.2.1 Oil Change...............................................................................................4 - 21

4.2.2 Replacement of Oil Mist Trap Element.....................................................4 - 21

4.3 Maintenance of Air Compressor.............................................................................4 - 22

4.3.1 Checkup and Maintenance.......................................................................4 - 22

4.3.2 Troubleshooting of Air Compressor..........................................................4 - 24

4.3.3 Location and Functions of Major Components .........................................4 - 25

4.4 Troubleshooting.....................................................................................................4 - 26

4.4.1 The Evacuation System does not Run .....................................................4 - 26

4.4.2 The Vacuum Level in the Specimen Chamber does not Rise...................4 - 27

4.4.3 The Emission Current Fails to Flow Normally...........................................4 - 27

4.4.4 When Image is not Shown on Screen ......................................................4 - 28

4.4.5 When Image is Very Noisy.......................................................................4 - 29

4.4.6 When You cannot Correct Astigmatism ...................................................4 - 30

4.4.7 When Auto Focus or Auto Stigma does not Work Satisfactorily...............4 - 31

4.4.8 When S-3400N Control Program does not Start Up.................................4 - 31

4.4.9 When PC has Hung Up............................................................................4 - 32

4.4.10 When Error Messages are Shown ...........................................................4 - 32

4.5 What to Do in the Event of a Power Outage or the System must be Shutdown

Completely for a Long Time...................................................................................4 - 33

4.6 What to Do when the Power Failure and the System is to be Started Up ..............4 - 33

4.7 Caution on Maintenance ........................................................................................4 - 34

4.8 Electron Gun Beam Axis Maintenance...................................................................4 - 34

4.8.1 Adjusting the Electron Gun Mounting Position (for service engineers) .....4 - 34

5 REPLACEMENT PARTS................................................................................................5 - 1

5.1 Consumables.........................................................................................................5 - 1

5.2 Replacement Parts ................................................................................................5 - 2

5.3 Spare Parts............................................................................................................5 - 3

6 ACCESSORY OPERATION ...........................................................................................6 - 1

6.1 Model S-5080 Auto-Camera (Option) ....................................................................6 - 1

6.1.1 Configuration............................................................................................6 - 1

6.1.2 Specifications...........................................................................................6 - 3

6.1.3 Assembling the Camera...........................................................................6 - 5

6.1.4 Operation .................................................................................................6 - 6

6.2 Faraday Cup Device (Option) ................................................................................6 - 8

6.2.1 Range of Type II Stage Drive...................................................................6 - 8

6.1.2 Usage Method..........................................................................................6 - 8

6.3 Specification of S-3400N External Communication (Option) ..................................6 - 10

- vii -

Page 43

6.3.1 About the External Communication of S-3400N .......................................6 - 10

6.3.1.1 Communication Procedure.......................................................6 - 10

6.3.1.2 Function and Limitation ............................................................6 - 10

6.3.2 Each Command .......................................................................................6 - 11

6.3.2.1 Initialize the Communication.....................................................6 - 16

6.3.2.2 Acceleration Voltage ................................................................6 - 17

6.3.2.3 Magnification............................................................................6 - 20

6.3.2.4 Working Distance (WD) ...........................................................6 - 21

6.3.2.5 Focus Value .............................................................................6 - 22

6.3.2.6 Probe Current ..........................................................................6 - 23

6.3.2.7 Auto Functions .........................................................................6 - 24

6.3.2.8 Stage .......................................................................................6 - 26

6.3.2.9 Vacuum Setting........................................................................6 - 32

6.3.2.10 Multi-purpose Command ..........................................................6 - 34

6.3.2.11 Machine Information.................................................................6 - 34

6.3.3 Programming ...........................................................................................6 - 35

6.3.3.1 Example of Program ................................................................6 - 35