TECHNICAL DATA

AND

SERVICE MANUAL

DISC SANDER

S 18SB

S 15SB

SPECIFICATIONS AND PARTS ARE SUBJECT TO CHANGE FOR IMPROVEMENT

LIST Nos. S 18SB: 0360

S 15SB: 0359

Feb. 2006

S

MODELS

S 18SB

S 15SB

Hitachi

Power Tools

Page

CONTENTS

1. PRODUCT NAME .............................................................................................................................. 1

2. MARKETING OBJECTIVE ................................................................................................................ 1

3. APPLICATIONS ................................................................................................................................. 1

4. SELLING POINTS ............................................................................................................................. 1

4-1. Completely Novel Design and Comfortable Grip Handle Covered with Elastomer ...........................2

4-2. Bearing Bushing ................................................................................................................................. 2

4-3. Spindle Lock .......................................................................................................................................2

4-4. Air Cover .............................................................................................................................................2

4-5. Wear-resistant Tail Cover.................................................................................................................... 3

5. SPECIFICATIONS ............................................................................................................................. 3

6. COMPARISONS WITH SIMILAR PRODUCTS ................................................................................. 4

6-1. Specification Comparisons ................................................................................................................. 4

7. PRECAUTIONS IN SALES PROMOTION ........................................................................................ 5

7-1. Handling Instructions ..........................................................................................................................5

7-2. Caution on Name Plate ....................................................................................................................... 5

7-3. Precautions on Usage ........................................................................................................................ 5

8. PRECAUTIONS IN DISASSEMBLY AND REASSEMBLY ............................................................... 6

8-1. Disassembly ....................................................................................................................................... 6

8-2. Wiring Diagram ...................................................................................................................................8

8-3. Reassembly ......................................................................................................................................12

8-4. Tightening Torque .............................................................................................................................13

8-5. Insulation Tests .................................................................................................................................13

8-6. No-load Current Values .....................................................................................................................13

9. STANDARD REPAIR TIME (UNIT) SCHEDULES .......................................................................... 14

Assembly Diagram for S 18SB

Assembly Diagram for S 15SB

--- 1 ---

1. PRODUCT NAME

Hitachi Disc Sander, Model S 18SB [180 mm (7")]

Hitachi Disc Sander, Model S 15SB [150 mm (6")]

2. MARKETING OBJECTIVE

The conventional Models S 15, S 18SA and S 15SA have obtained high evaluation as sturdy and durable disc

sanders since they were released. However, recent disc sander market is fiercely competitive due to a price war

and various sophisticated products are posing a challenge to Hitachi's share.

To address the severe situation, we have developed the newly-designed disc sanders Models S 18SB and

S 15SB. Please expand the sales of the new Models S 18SB and S 15SB.

Owing to the sales start of these models, the sales of the conventional Models S 15, S 18SA and S 15SA are

discontinued.

3. APPLICATIONS

4. SELLING POINTS

Optional accessories required

Applications

Sanding disc

Sanding of metal surfaces

(For finely finished surface with minimum sanding)

Preliminary sanding of metal surfaces before painting, rust removal,

and removing old paint before repainting

Finishing of wood surfaces, and reducing projections of joints or assemblies

Preliminary sanding of wood surfaces before painting

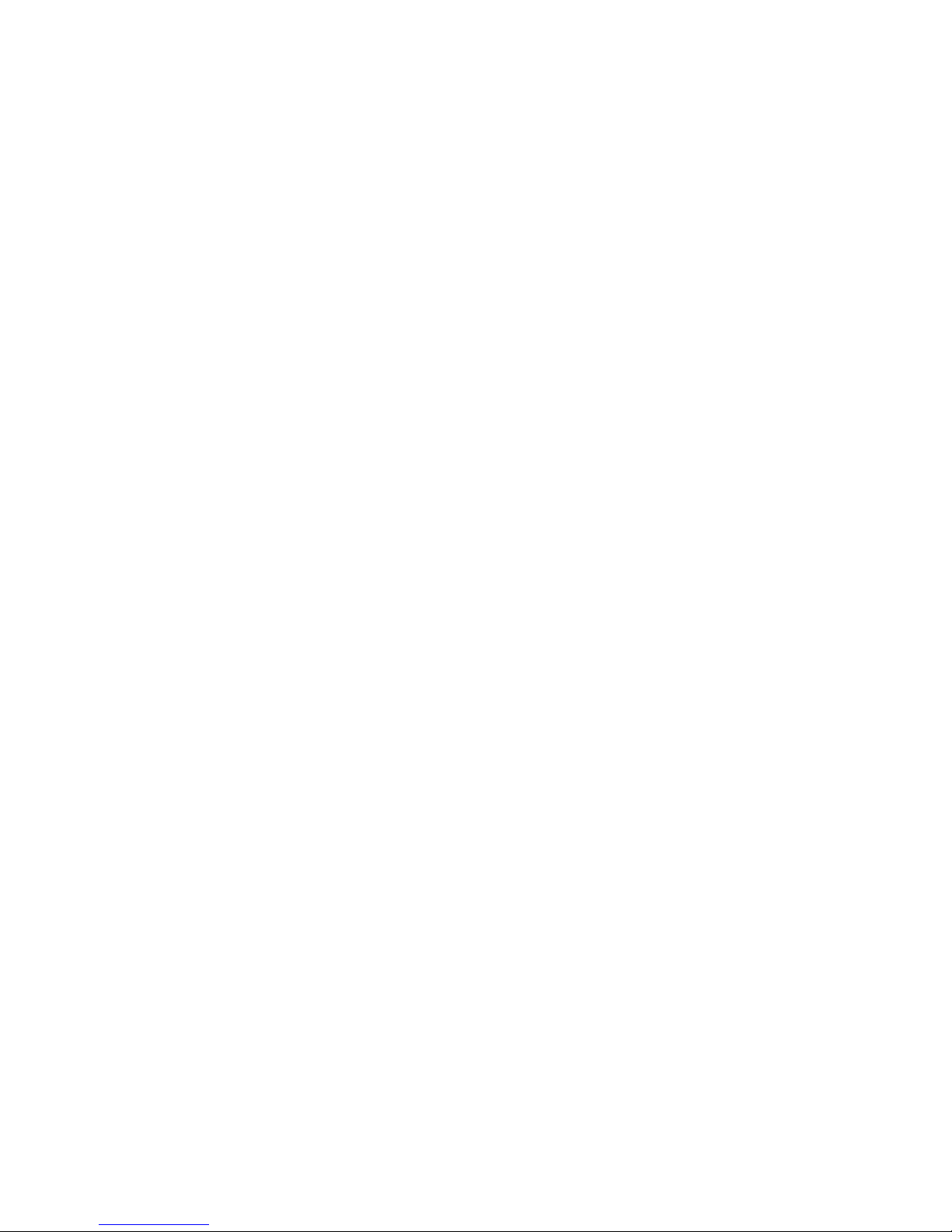

Air cover

Spindle lock

Bearing bushing

Wear-resistant tail cover

Completely novel design and

comfortable grip handle

covered with elastomer

--- 2 ---

Fig. 1

4-1. Completely Novel Design and Comfortable Grip Handle Covered with Elastomer

The Models S 18SB and S 15SB are of a completely novel design. In addition, the grip handle is covered with

elastomer. The handle is not only comfortable but also nonslip and easy to operate.

Maker

•Model

HITACHI

Grip handle

S 18SA/S 15SA

S 18SB/S 15SB

Soft (Elastomer)

S 15

Item

Hard (Aluminum)

Hard (Resin)

(Model S 15: Aluminum housing)

4-2. Bearing Bushing

Thanks to the adoption of the bearing bushing, the ball bearing chamber of the commutator side is durable.

Fig. 2

Maker•Model

HITACHI

Bearing bushing

S 18SB/S 15SB

Provided

S 18SA/S 15SA

Item

Not provided

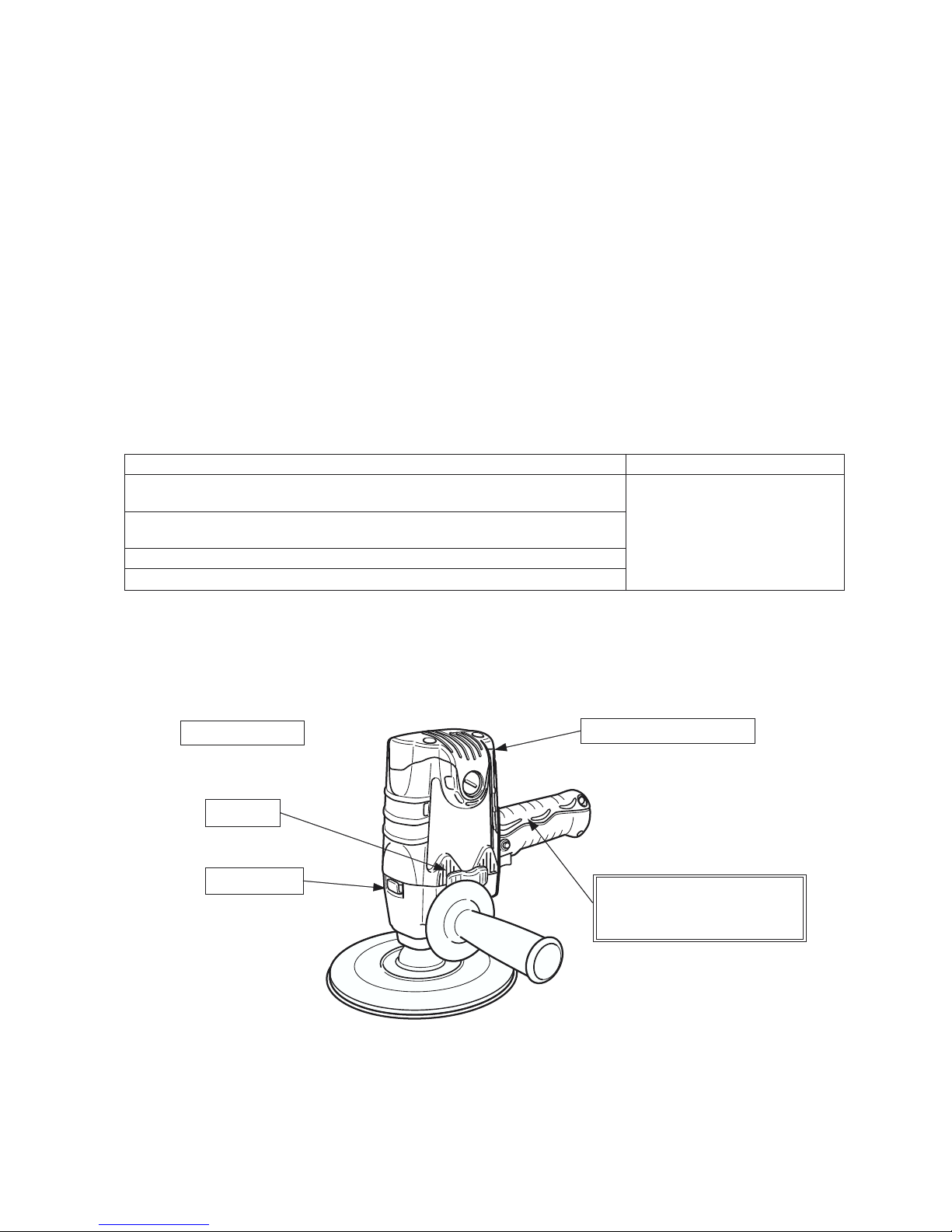

4-3. Spindle Lock

Thanks to the adoption of the spindle lock, tools can be easily replaced.

Spindle lock

Maker•Model

HITACHI

Spindle lock

S 18SA/S 15SA

S 18SB/S 15SB

Provided

S 15

Item

Not provided

Provided

Fig. 4

Fig. 3

4-4. Air Cover

The air cover made of elastomer is attached to the vent hole on the side where the side handle is installed to

prevent discharging the motor cooling air toward the operator for comfortable operation. The soft air cover can be

easily attached and detached by hand or a flat-blade screwdriver.

Fig. 5

Air cover

Hand or a flat-blade screwdriver

Maker•Model

HITACHI

Air cover

S 18SA/S 15SA

S 18SB/S 15SB

Provided

S 15

Item

Not provided

Fig. 6

(An elastomer air cover is

attached to the vent hole.)

Not provided

--- 3 ---

4-5. Wear-resistant Tail Cover

The CB holder is completely covered with the round-edge tail cover. Thanks to the new shape, the CB holder is

wear-resistant even if making a three-point rest at the side handle, handle and the tail portion.

4,500/min.

2.0 kg (4.4 lbs.)

2.17 kg (4.9 lbs.)

3.4 kg (7.5 lbs.)

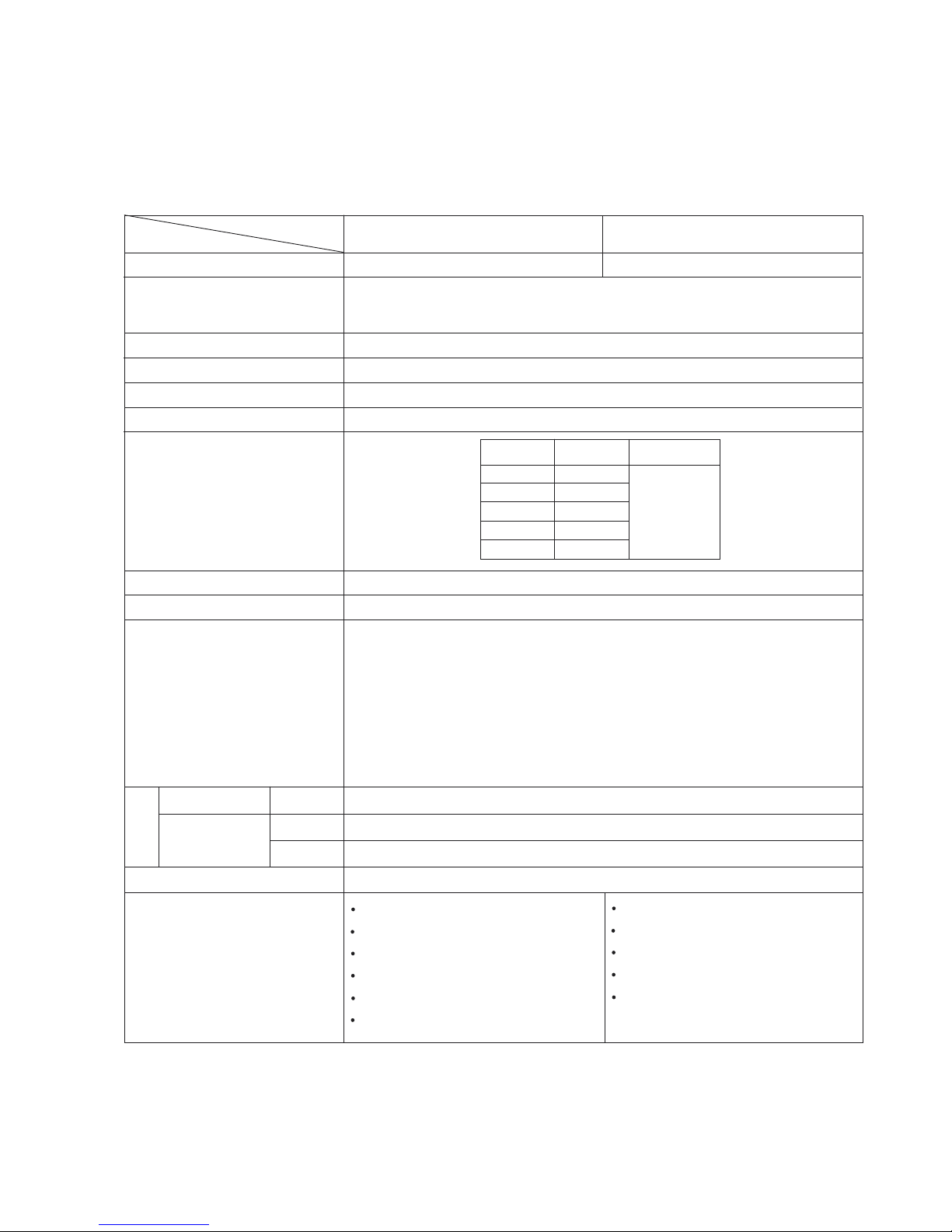

5. SPECIFICATIONS

Double insulation

AC single phase 50 or 60 Hz

Single-phase series commutator motor

Trigger switch

Capacity

Model

Item

Screw diameter of the spindle

Insulation method

S 18SB S 15SB

Type of motor

No-load rotation speed

Standard accessories

Type of switch

Workpiece: Housing .............. Glassfiber reinforced polyamide resin (black)

Handle cover ...... Glassfiber reinforced polyamide resin (black)

Grip cover .......... Glassfiber reinforced polycarbonate resin (black)

and elastomer resin (green)

Tail cover ............ Glassfiber reinforced polyamide resin (green)

Gear cover and inner cover .......... Aluminum alloy die casting

Painting: Gear cover and inner cover .......... Gunmetallic color

Rubber pad 180 mm (7") ............... 1

Side handle ................................... 1

Wrench .......................................... 1

Washer nut .................................... 1

Air cover ........................................ 1

Sanding disc 180 mm (7") ............. 1

* Net weight excludes cord, rubber pad, sanding disc, washer nut and side handle.

Power source

Voltage, current and power

input

Enclosure

Maximum output

180 mm (7")

U. S. A., Canada: 5/8-11 UNC

Europe: M14 x 2

Other countries: M16 x 2

Voltage (V)

Current (A)

110

120

220

230

240

Power input (W)

6.7

6.2

3.3

3.2

3.1

705

900 W

Corrugated cardboard box

Catalog

Actual

Net*

Net*

Gross

Weight

Packaging

150 mm (6")

Rubber pad 150 mm (6") ............. 1

Side handle ................................. 1

Wrench ........................................ 1

Washer nut .................................. 1

Air cover ...................................... 1

--- 4 ---

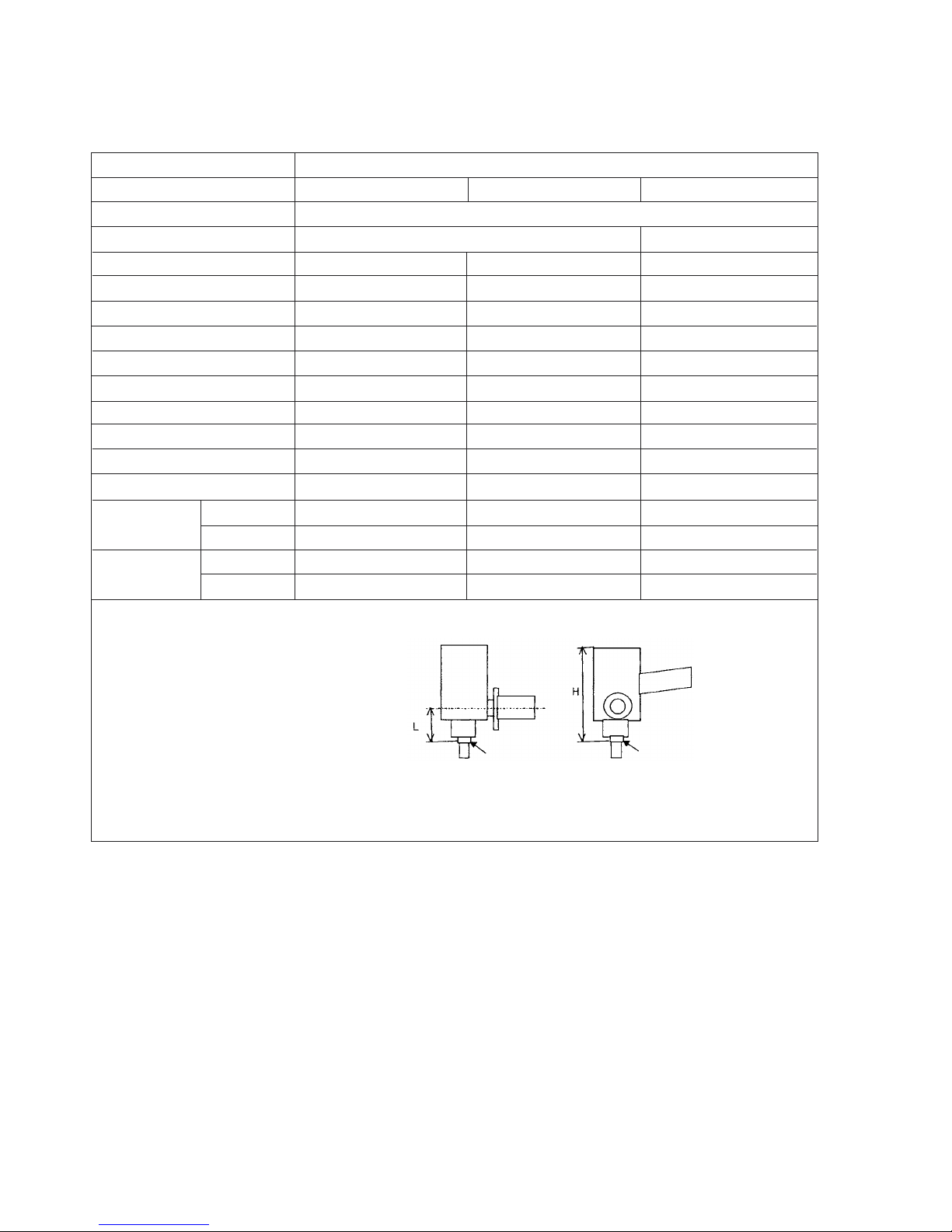

6. COMPARISONS WITH SIMILAR PRODUCTS

6-1. Specification Comparisons

Maker

Model

Capacity (mm)

Insulation type

Power input (W)

Max. power output (W)

No-load speed (/min.)

No-load noise level (dB)

Spindle lock

Bearing bushing

Air cover

Material of housing

Material of grip handle

Material of side handle

530

605

4,000

82

Not provided

Not provided

Not provided

Aluminum

Aluminum

Resin

3.2 (7.1 lbs.)

2.60 (5.7 lbs.)

185 (7-9/32")

45 (1-49/64")

Catalog (kg)

Actual (kg)

H (mm)

L (mm)

HITACHI

S 18SB/S 15SB

680

940/810

4,000

85

Provided

Not provided

Not provided

Resin

Resin

Resin

2.7 (6.0 lbs.)

2.70 (6.0 lbs.)

193 (7-39/64")

71 (2-51/64")

*: Weight without cord, side handle,

rubber pad, washer nut and sanding

disc.

180 (7")/150 (6")

705

900

4,500

83

Provided

Provided

Provided

Resin

Elastomer

Rubber

2.0 (4.4 lbs.)

2.17 (4.9 lbs.)

194 (7-41/64")

44 (1-47/64")

S 18SA/S 15SA S 15

Double insulation Single insulation

To ol contacting

portion of the

spindle

Tool contacting

portion of the

spindle

Dimensions

Weight *

--- 5 ---

7. PRECAUTIONS IN SALES PROMOTION

In the interest of promoting the safest and most efficient use of the Models S 18SB and S 15SB Disc Sanders by

all of our customers, it is very important that at the time of sale, the salesperson carefully ensures that the buyer

seriously recognizes the importance of the contents of the Handling Instructions, and fully understands the

meaning of the precautions listed on the Name Plate attached to each tool.

7-1. Handling Instructions

Although every effort is made in each step of design, manufacture and inspection to provide protection against

safety hazards, the dangers inherent in the use of any electric power tool cannot be completely eliminated.

Accordingly, general precautions and suggestions for the use of the disc sanders are listed in the Handling

Instructions to enhance the safe and efficient use of the tool by the customer. Salespersons must be thoroughly

familiar with the contents of the Handling Instructions to be able to offer appropriate guidance to the customer

during sales promotion.

7-2. Caution on Name Plate

The following basic precautions are listed on the Name Plate attached to the main body of each tool.

(1) For Taiwan

(3) For European countries

(2) For the U. S. A. and Canada

-- WARNING --

To reduce the risk of injury, user must read and understand instruction manual.

AVERTISSEMENT

Afine de reduire le risque de blessures, I'utilisateur doit lire et bien comprendre le

mode d'emploi.

(4) For China

7-3. Precautions on Usage

Never press the lock lever while the spindle is rotating:

If the lock lever is pressed while the spindle is rotating, the spindle will stop immediately.

In such a case, there is a danger that the wheel washer may be loosened so that the rubber pad and the sanding

disc fly off unexpectedly to cause possible serious injury.

CAUTION

Read thoroughly HANDLING INSTRUCTIONS before use.

--- 6 ---

8. PRECAUTIONS IN DISASSEMBLY AND REASSEMBLY

The [Bold] numbers in the descriptions below correspond to the numbers in the Parts List and the exploded

assembly diagram for the Model S 18SB, and the <Bold> numbers to those in the Parts List and the exploded

assembly diagram for the Model S 15SB.

8-1. Disassembly

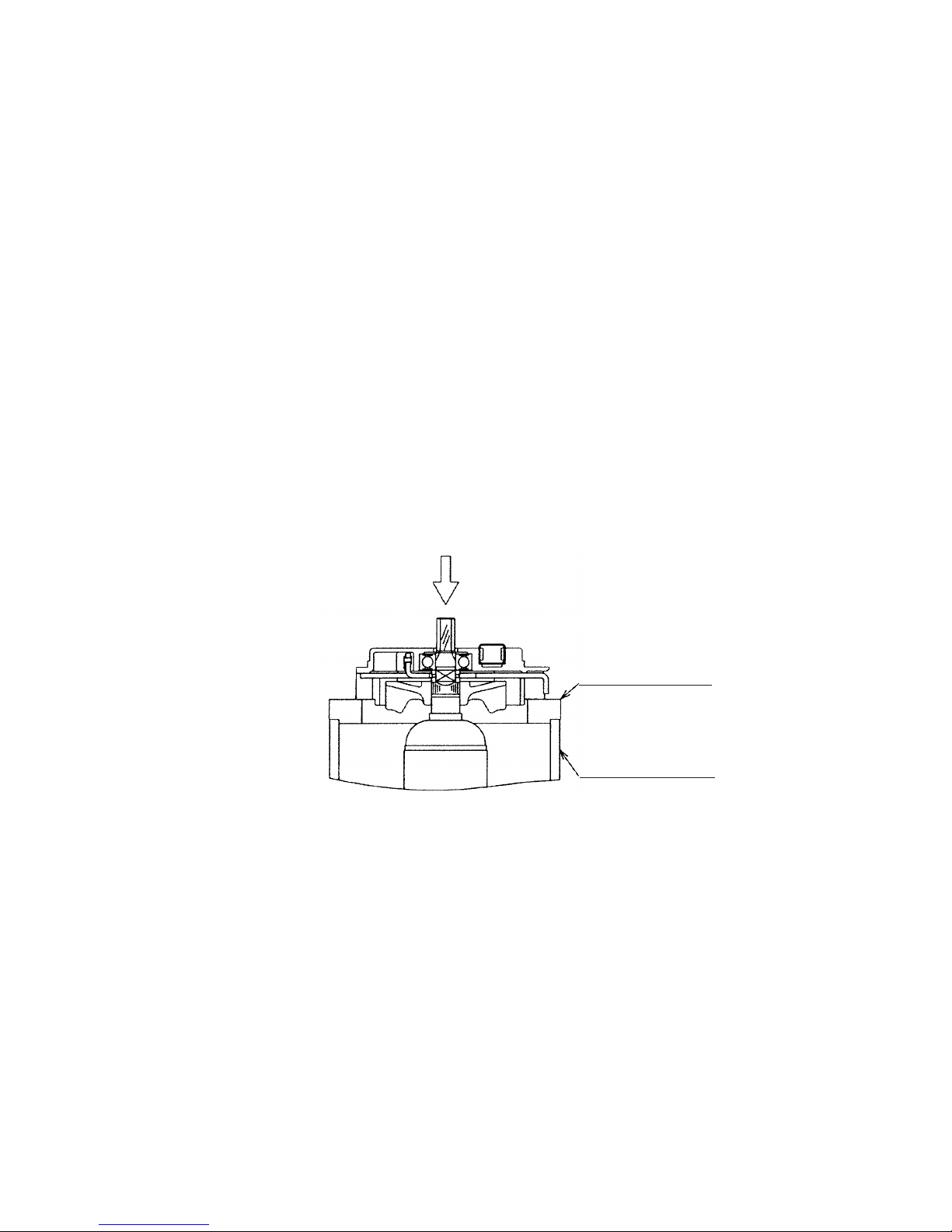

(1) Replacement of the armature and the lock lever

1. Remove the Brush Cap [33] <33> and remove the Carbon Brush [34] <34> from the Brush Holder [35] <35>.

2. Remove the Tapping Screw (W/Flange) D5 x 55 (Black) [7] <7> and the Tapping Screw (W/Flange) D5 x 35

(Black) [15] <15>. Remove the Armature [12] <12> from the Housing Ass'y [24] <24> together with the Gear

Cover Ass'y [8] <8> and the Inner Cover [9] <9>.

3. Remove the Gear Cover Ass'y [8] <8> from the Inner Cover [9] <9>.

4. As shown in Fig. 7, remove the Armature [12] <12> and the Lock Lever [11] <11> from the Inner Cover [9] <9>

using the J-130-2 Sleeve (Code No. 970908) and the J-131-2 Plate (Code No. 970910).

5. If the Ball Bearing 6000DDCMPS2L [10] <10> and the Lock Lever [11] <11> are remainded in the Armature

[12] <12>, remove the Ball Bearing 6000DDCMPS2L [10] <10> from the Armature [12] <12> using the J-30

Bearing Puller (Code No. 970804) and then remove the Lock Lever [11] <11>.

J-131-2 Plate

(Code No. 970910)

Push

J-130-2 Sleeve

(Code No. 970908)

Fig. 7

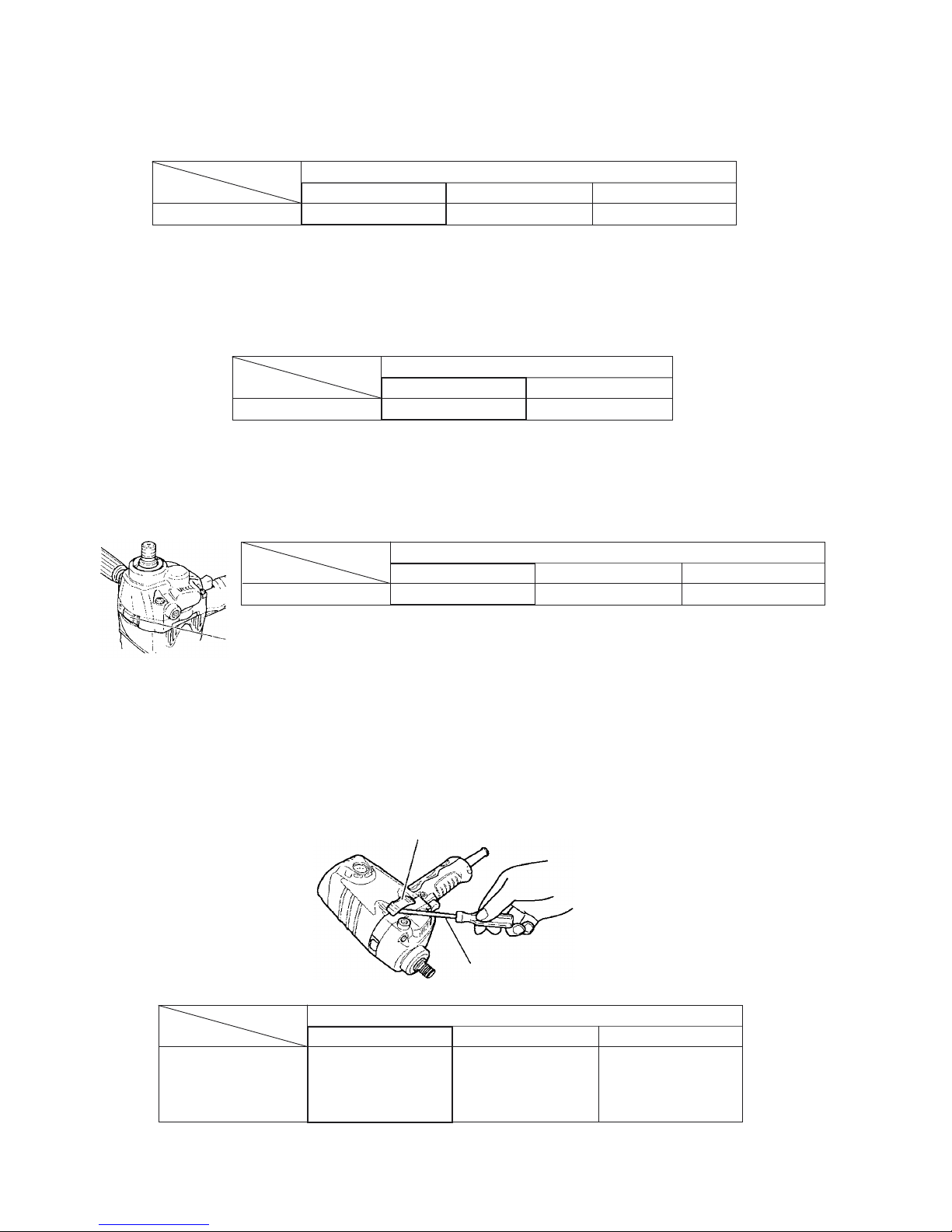

(2) Replacement of the Dust Seal [22] <22>

1. Insert the hooks of the J-204 Bearing Puller (Code No. 970982) into the clearances between the Ball Bearing

608VVC2PS2L [23] <23> and the Dust Seal [22] <22> at both ends and fix it with the bolt. At this time, be

careful not to insert the hooks excessively.

2. As shown in Fig. 8, put the J-204 Bearing Puller (Code No. 970982) on the J-130-2 Sleeve (Code No. 970908)

and push the armature shaft with a hand press to pull out the Ball Bearing 608VVC2PS2L [23] <23>.

3. Pull out the Dust Seal [22] <22> from the armature shaft.

--- 7 ---

Fig. 8

J-204 Bearing Puller

(Code No. 970982)

Push

J-130-2 Sleeve

(Code No. 970908)

(3) Replacement of Stator Ass'y (D) [20] <20>

1. Pull out the Armature [12] <12>, then pull out the Fan Guide [13] <13> from the Housing Ass'y [24] <24>.

2. Loosen the Tapping Screw (W/Flange) D4 x 20 (Black) [48] <48> and remove the Tail Cover [47] <47>, Grip

Cover [49] <49> and Handle Cover [28] <28>.

3. Loosen the Machine Screw (W/Washer) M3.5 x 6 [29] <29> and remove the Terminal [26] <26> connected to

Switch (A) [32] <32>.

4. Cut the internal wire connected to the Connector [31] <31> with nippers or loosen the screw of the Pillar

Terminal [39] <39> and disconnect the internal wire of Stator Ass'y (D) [20] <20> from the Pillar Terminal [39]

<39>.

5. Remove the Brush Terminal [21] <21> from the Brush Holder [35] <35>.

6. Remove the Hex. Hd. Tapping Screw D5 x 45 [19] <19> and remove Stator Ass'y (D) [20] <20> from the

Housing Ass'y [24] <24>. If it is difficult to remove Stator Ass'y (D) [20] <20> from the Housing Ass'y [24]

<24>, heat the Housing Ass'y [24] <24> to about 60ûC to make the removal work easier.

(4) Replacement of the First Gear [17] <17> and the Ball Bearing 6201DDCMPS2L [5] <5>

1. Remove the Gear Cover Ass'y [8] <8> from the Inner Cover [9] <9>.

2. Fix the Gear Cover Ass'y [8] <8> to the vise and remove the Bearing Cap [3] <3> with an J-21 Wrench or a

flat-blade screwdriver and a hammer. At this time, be careful that the Bearing Cap [3] <3> has a left-hand

thread.

3. As shown in Fig. 9, support the end surface of the Gear Cover Ass'y [8] <8> with an appropriate cylindrical jig

(about 35 mm inside dia.). Push the end surface of Spindle (B) [4] <4> with a hand press to remove the First

Gear [17] <17>.

4. Remove the Retaining Ring for D12 Shaft [6] <6> from Spindle (B) [4] <4>.

5. Remove the Ball Bearing 6201DDCMPS2L [5] <5> from Spindle (B) [4] <4> using the J-30 Bearing Puller

(Code No. 970804).

--- 8 ---

Fig. 9

Push

35 mm inside dia.

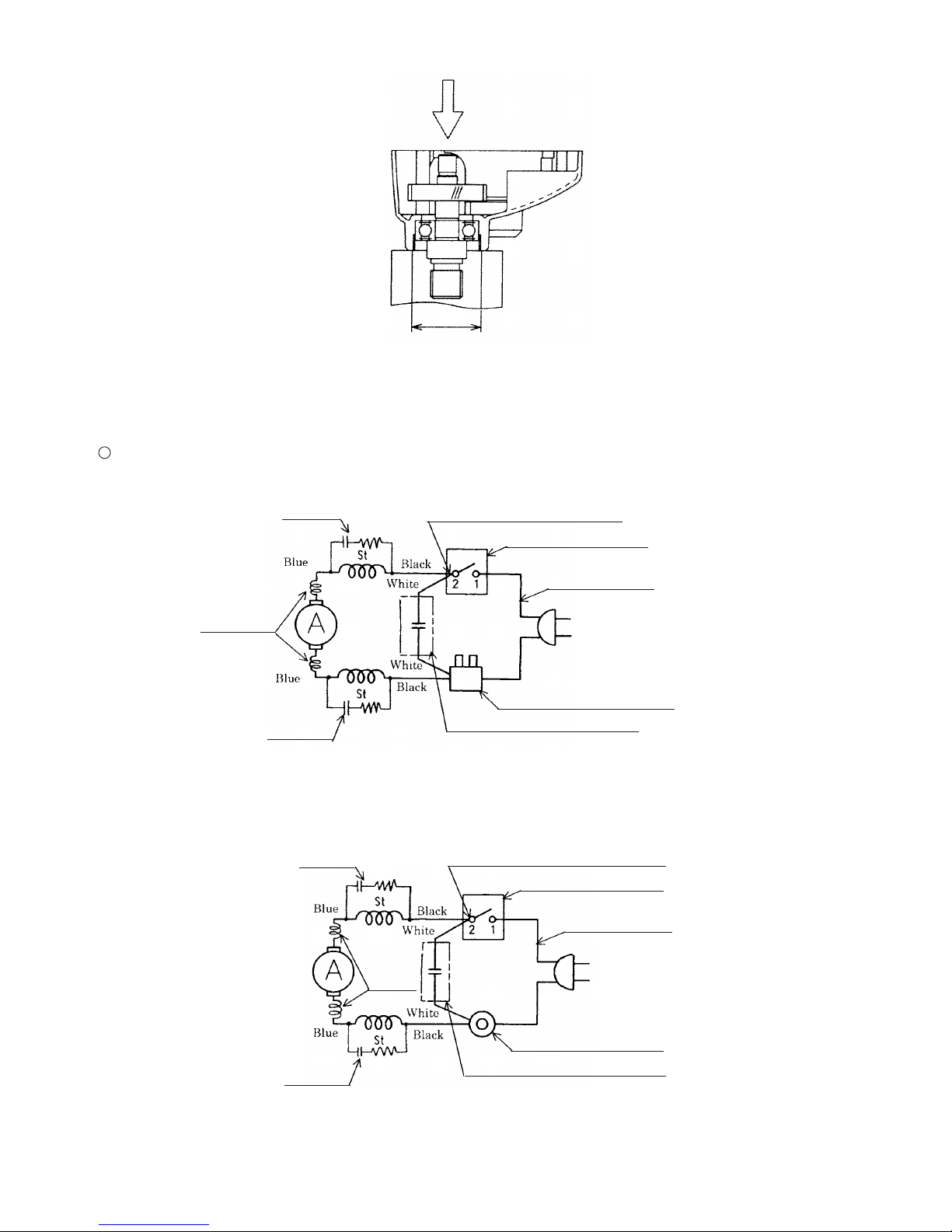

8-2. Wiring Diagram

Wiring diagram

For Europe and China

For Taiwan

Fig. 10

Fig. 11

Switch (A) [32] <32>

Cord [43] <43>

Pillar Terminal [39] <39>

Noise Suppressor [38] <38>

CR unit

Choke coil

CR unit

Terminal [26] [30] <26> <30>

Switch (A) [32] <32>

Cord [43] <43>

Connector [31] <31>

Noise Suppressor [38] <38>

CR unit

CR unit

Terminal [26] [30] <26> <30>

Choke

coil

--- 9 ---

For Malaysia

Fig. 12

Terminal [26] <26>

Switch (A) [32] <32>

Cord [43] <43>

Pillar Terminal [39] <39>

For other countries

Fig. 13

Terminal [26] <26>

Switch (A) [32] <32>

Cord [43] <43>

Connector [31] <31>

--- 10 ---

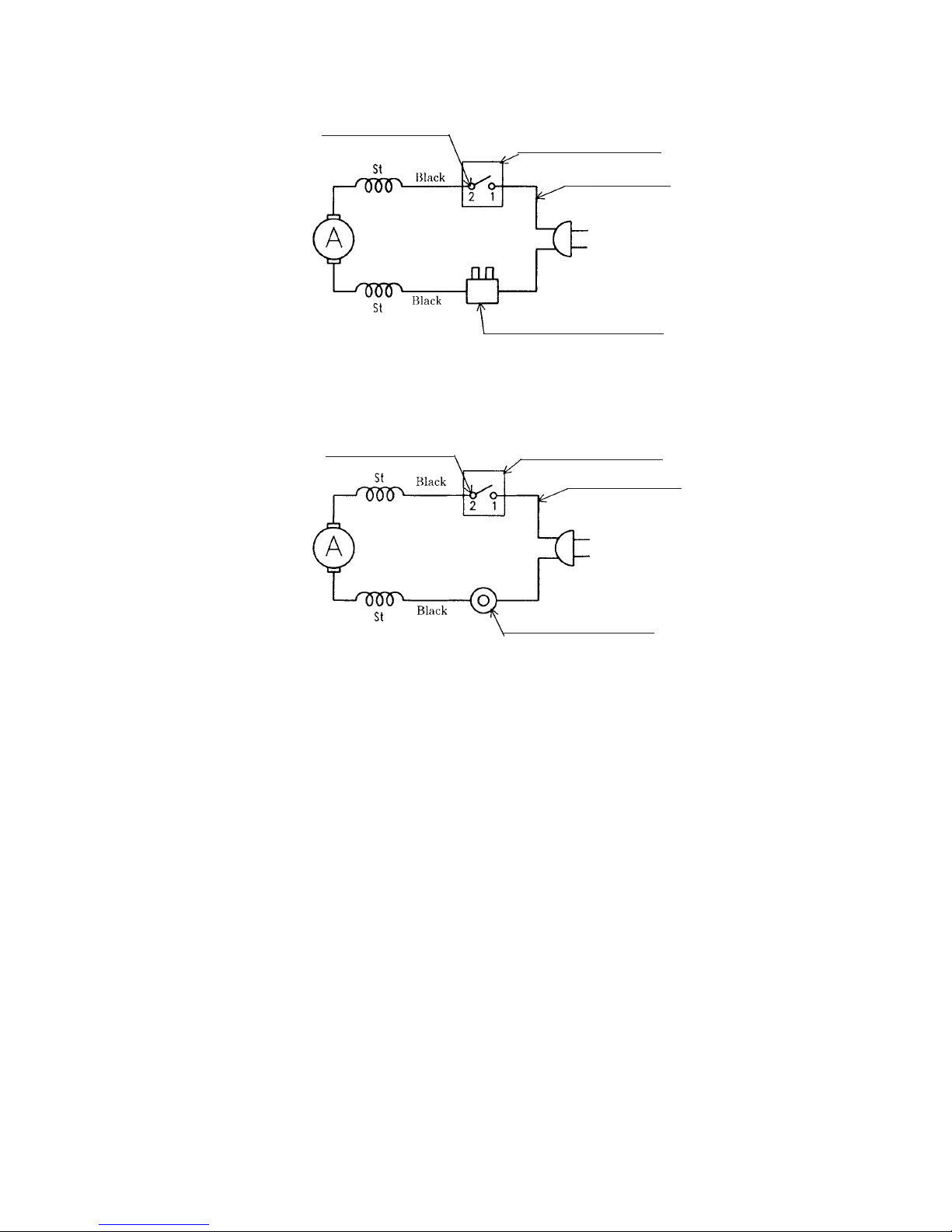

Wiring diagram

For Europe and China

Noise Suppressor [38] <38>

Switch (A) [32] <32>

Fig. 14

Pillar Terminal [39] <39>

Fig. 15

Push the choke coil into

the groove securely.

Insert the internal wires

of the choke coil into

the grooves securely.

--- 11 ---

For Taiwan

Noise Suppressor [38] <38>

Switch (A) [32] <32>

Fig. 16

Caulk the internal wire of the

cord and the internal wire (black)

of Stator Ass'y (D) [20] <20>

with the Connector [31] <31>.

Fig. 17

Insert the internal wires

of the choke coil into the

grooves securely.

Insert the choke coil into

the groove securely.

--- 12 ---

8-3. Reassembly

Reassembly can be accomplished by following the disassembly procedures in reverse. However, special attention

should be given to the following items.

(1) Check that the internal wires are wired and arranged properly as shown in Fig. 14 to Fig. 19.

(2) Insert each internal wire into the grooves of the Housing Ass'y [24] <24> securely and be careful not to pinch

the internal wires when mounting the Handle Cover [28] <28> and the Tail Cover [47] <47>.

(3) If degradation is found on the grease inside the Gear Cover Ass'y [8] <8> at reassembly, remove the grease

and apply 30 g of new grease to the inside of the Gear Cover Ass'y [8] <8>. Applicable grease is Nippeco

JF-375 (Code No. 930036). Apply it to the First Gear [17] <17>, tooth portion of the Armature [12] <12> and

the inner circumference of the needle bearing in the Inner Cover [9] <9>.

(4) When replacing the Dust Seal [22] <22> and the Ball Bearing 608VVC2PS2L [23] <23>, be careful of the

mounting direction of the Dust Seal [22] <22> so that the convex side faces the ball bearing and the concave

side faces the commutator. When press-fitting the Ball Bearing 608VVC2PS2L [23] <23>, be careful of the

press-fitting load. After press-fitting, check the Ball Bearing 608VVC2PS2L [23] <23> rotates smoothly.

The Dust Seal [22] <22> is an important element to protect the Ball Bearing 608VVC2PS2L [23] <23> from

dust. Be sure to mount the new Ball Bearing 608VVC2PS2L [23] <23> after disassembly.

Fig. 18

Pillar terminal

[39] <39>

For Malaysia

Switch (A) [32] <32>

Fig. 19

Caulk the internal wire of

the cord and the internal

wire (brown) of Stator

Ass'y (D) [20] <20> with

the Connector [31] <31>.

For other countries

Switch (A) [32] <32>

--- 13 ---

8-4. Tightening Torque

(1) Tapping Screws (W/Flange) D4 [40] [48] <40> <48> ................................ 1.5 to 2.5 N•m (15 to 25 kgf•cm)

(2) Tapping Screws D5 [7] [15] [19] <7> <15> <19> ...................................... 2.4 to 3.4 N•m (25 to 35 kgf•cm)

(3) Machine Screw (W/Washer) M3.5 x 6 [29] <29>....................................... 0.45 to 0.75 N•m (4.5 to 7.5 kgf•cm)

8-5. Insulation Tests

On completion of disassembly and repair, measure the insulation resistance, and conduct the dielectric strength

test.

Insulation resistance: 7 M Ω or more with DC 500 V megohm tester

Dielectric strength: AC 2,500 V for 1 minute, with no abnormalities .............. 110 V --- 127 V

AC 4,000 V for 1 minute, with no abnormalities .............. 220 V --- 240 V

8-6. No-load Current Values

After no-load operation for 30 minutes, the no-load current values should be as follows.

Voltage (V)

Current (A) max.

110

3.7

120

3.5

220

1.8

230

1.8

240

1.7

--- 14 ---

9. STANDARD REPAIR TIME (UNIT) SCHEDULES

MODEL 10 20 30 40

Fixed

Variable

Work Flow

Gear Cover

First Gear

Ball Bearing

(6201DD)

Spindle

Bearing Cap

60 min.

50

Housing Ass'y

Stator

Switch

Cord

General Assembly

S 15SB

S 18SB

Armature Ass'y

Ball Bearing

(6000DD)

Ball Bearing

(608VV)

Dust Seal

Inner Cover

ELECTRIC TOOL PARTS LIST

LIST NO. 0360

DISC SANDER

Model S 18SB

2006 • 2 •1

(E1)

Hitachi Power Tools

3

4

5

6

7

8

9

11

12

15

17

18

13

19

20

21

22

23

24

25

47

48

27

28

29

38

30

31

32

34

40

41

42

43

45

44

35

33

46

49

48

48

501

1

2

14

502

26

39

37

16

10

*

ALTERNATIVE PARTS--- 2 ---

ITEM

NO.

CODE NO.

DESCRIPTION REMARKS

NO.

USED

PARTS

2 -- 06

S 18SB

*1953-381 WASHER NUT 1

*1953-246Z WASHER NUT M14 1 FOR EUROPE

*1953-254P WASHER NUT 5/8”-11UNC 1 FOR USA, CAN

*2953-255 RUBBER PAD (D16 HOLE) 1

*2953-247Z RUBBER PAD (D14 HOLE) 1 FOR EUROPE

3 325-857 BEARING CAP 1

*4325-501 SPINDLE (B) 1

*4325-502 SPINDLE (B) 1 FOR EUROPE

*4325-503 SPINDLE (B) 1 FOR USA, CAN

5 620-1DD BALL BEARING 6201DDCMPS2L 1

6 939-542

RETAINING RING FOR D12 SHAFT (10 PCS.) 1

7 309-778

TAPPING SCREW (W/FLANGE) D5X55 (BLACK)

2

8 325-499 GEAR COVER ASS’Y 1 INCLUD. 16

9 325-498 INNER COVER 1

10 600-0DD BALL BEARING 6000DDCMPS2L 1

11 325-477 LOCK LEVER 1

*12 360-758U ARMATURE ASS’Y (D) 120V 1 INCLUD. 10, 22, 23

*12 360-758E ARMATURE (D) 220V-230V 1

*12 360-758F ARMATURE (D) 240V 1

13 325-474 FAN GUIDE 1

14 994-322 SIDE HANDLE 1

15 323-209

TAPPING SCREW (W/FLANGE) D5X35 (BLACK) 2

16 937-033 FELT WASHER 2

17 325-500 FIRST GEAR 1

18 328-483 AIR COVER 1

19 992-509 HEX. HD. TAPPING SCREW D5X45 2

*20 340-656C STATOR ASS’Y (D) 120V 1 INCLUD. 21, 26

*20 340-656E STATOR ASS’Y (D) 220V-230V 1 INCLUD. 21, 26

*20 340-656G STATOR ASS’Y (D) 220V-230V 1 INCLUD. 21, 26 FOR EUROPE, CHN

*20 340-656F STATOR ASS’Y (D) 240V 1 INCLUD. 21, 26

21 930-703 BRUSH TERMINAL 2

22 315-877 DUST SEAL 1

23 608-VVM BALL BEARING 608VVC2PS2L 1

24 325-492 HOUSING ASS’Y 1 INCLUD. 35, 44-46

25 NAME PLATE 1

26 980-063 TERMINAL 1

27 HITACHI LABEL 1

28 325-481 HANDLE COVER 1

29 305-499 MACHINE SCREW (W/WASHER) M3.5X6 2

*30 980-063 TERMINAL 1 FOR NOISE SUPPRESSOR

*31 959-140 CONNECTOR 50091 (10 PCS.) 1 FOR USA, CAN, INA, SIN

32 305-409

SWITCH (A) (1P PLUG IN TYPE) W/O LOCK

1 INCLUD. 29

33 945-161 BRUSH CAP 2

34 999-043 CARBON BRUSH (1 PAIR) 2

35 958-900 BRUSH HOLDER 2

37 980-063 TERMINAL 1 FOR CORD

*38 930-039 NOISE SUPPRESSOR 1 FOR EUROPE, CHN

*39 938-307 PILLAR TERMINAL 1 FOR EUROPE, MAL, CHN

40 984-750 TAPPING SCREW (W/FLANGE) D4X16 2

41 937-631 CORD CLIP 1

42 953-327 CORD ARMOR D8.8 1

*

ALTERNATIVE PARTS --- 3 ---

ITEM

NO.

CODE NO.

DESCRIPTION

REMARKS

NO.

USED

PARTS

2 -- 06

S 18SB

*43 500-409Z CORD 1 (CORD ARMOR D8.8)

*43 500-240Z CORD 1 (CORD ARMOR D8.8) FOR USA, CAN

*43 500-468Z CORD 1 (CORD ARMOR D8.8) FOR CHN

*43 500-423Z CORD 1 (CORD ARMOR D8.8) MAL, SIN

44 938-477 HEX. SOCKET SET SCREW M5X8 2

45 995-662 RUBBER RING 1

46 315-069 BEARING BUSHING 1

47 325-494 TAIL COVER 1

48 301-653

TAPPING SCREW (W/FLANGE) D4X20 (BLACK) 7

49 325-490 GRIP COVER 1

*

ALTERNATIVE PARTS

--- 4 --- 2 -- 06

OPTIONAL ACCESSORIES

ITEM

NO.

CODE NO.

DESCRIPTION

REMARKS

NO.

USED

STANDARD ACCESSORIES

ITEM

NO.

CODE NO.

DESCRIPTION

REMARKS

NO.

USED

S 18SB

Printed in Japan

(060201N)

501 325-491 WRENCH 1

* 502 314-090 SANDING DISCS 180MM C-P50 (10 PCS.) 1

* 502 314-084 SANDING DISCS 180MM C-P16 (10 PCS.) 1 FOR ESP

601 314-084 SANDING DISCS 180MM C-P16 (10 PCS.) 1

602 314-085 SANDING DISCS 180MM C-P20 (10 PCS.) 1

603 314-086 SANDING DISCS 180MM C-P24 (10 PCS.) 1

604 314-087 SANDING DISCS 180MM C-P30 (10 PCS.) 1

605 314-088 SANDING DISCS 180MM C-P36 (10 PCS.) 1

606 314-089 SANDING DISCS 180MM C-P40 (10 PCS.) 1

607 314-090 SANDING DISCS 180MM C-P50 (10 PCS.) 1

608 314-091 SANDING DISCS 180MM C-P60 (10 PCS.) 1

609 314-092 SANDING DISCS 180MM C-P80 (10 PCS.) 1

610 314-093 SANDING DISCS 180MM C-P100 (10 PCS.) 1

611 314-094 SANDING DISCS 180MM C-P120 (10 PCS.) 1

ELECTRIC TOOL PARTS LIST

LIST NO. 0359

DISC SANDER

Model S 15SB

2006 • 2 •1

(E1)

Hitachi Power Tools

3

4

5

6

7

8

9

11

12

15

17

18

13

19

20

21

22

23

24

25

47

48

27

28

29

38

30

31

32

34

40

41

42

43

45

44

35

33

46

49

48

48

501

1

2

14

502

26

39

37

10

16

*

ALTERNATIVE PARTS--- 2 ---

ITEM

NO.

CODE NO.

DESCRIPTION REMARKS

NO.

USED

PARTS

2 -- 06

S 15SB

1 953-381 WASHER NUT 1

2 935-652 RUBBER PAD 1

3 325-857 BEARING CAP 1

4 325-501 SPINDLE (B) 1

5 620-1DD BALL BEARING 6201DDCMPS2L 1

6 939-542

RETAINING RING FOR D12 SHAFT (10 PCS.)

1

7 309-778

TAPPING SCREW (W/FLANGE) D5X55 (BLACK) 2

8 325-499 GEAR COVER ASS’Y 1 INCLUD. 16

9 325-498 INNER COVER 1

10 600-0DD BALL BEARING 6000DDCMPS2L 1

11 325-477 LOCK LEVER 1

*12 360-758C ARMATURE (D) 110V 1

*12 360-758E ARMATURE (D) 220V-230V 1

*12 360-758F ARMATURE (D) 240V 1

13 325-474 FAN GUIDE 1

14 994-322 SIDE HANDLE 1

15 323-209

TAPPING SCREW (W/FLANGE) D5X35 (BLACK) 2

16 937-033 FELT WASHER 2

17 325-500 FIRST GEAR 1

18 328-483 AIR COVER 1

19 992-509 HEX. HD. TAPPING SCREW D5X45 2

*20 340-656D STATOR ASS’Y (D) 110V 1 INCLUD. 21, 26

*20 340-656E STATOR ASS’Y (D) 220V-230V 1 INCLUD. 21, 26

*20 340-656G STATOR ASS’Y (D) 220V-230V 1 INCLUD. 21, 26 FOR CHN

*20 340-656F STATOR ASS’Y (D) 240V 1 INCLUD. 21, 26

21 930-703 BRUSH TERMINAL 2

22 315-877 DUST SEAL 1

23 608-VVM BALL BEARING 608VVC2PS2L 1

24 325-492 HOUSING ASS’Y 1 INCLUD. 35, 44-46

25 NAME PLATE 1

26 980-063 TERMINAL 1

27 HITACHI LABEL 1

28 325-481 HANDLE COVER 1

29 305-499 MACHINE SCREW (W/WASHER) M3.5X6 2

*30 980-063 TERMINAL 1 FOR NOISE SUPPRESSOR

*31 959-140 CONNECTOR 50091 (10 PCS.) 1 FOR INA, SIN, TPE

32 305-409

SWITCH (A) (1P PLUG IN TYPE) W/O LOCK

1 INCLUD. 29

33 945-161 BRUSH CAP 2

34 999-043 CARBON BRUSH (1 PAIR) 2

35 958-900 BRUSH HOLDER 2

37 980-063 TERMINAL 1 FOR CORD

*38 930-039 NOISE SUPPRESSOR 1 FOR CHN, TPE

*39 938-307 PILLAR TERMINAL 1 FOR MAL, CHN

40 984-750 TAPPING SCREW (W/FLANGE) D4X16 2

41 937-631 CORD CLIP 1

42 953-327 CORD ARMOR D8.8 1

*43 500-409Z CORD 1 (CORD ARMOR D8.8)

*43 500-423Z CORD 1 (CORD ARMOR D8.8) FOR MAL, SIN

*43 500-468Z CORD 1 (CORD ARMOR D8.8) FOR CHN

*43 500-470Z CORD 1 (CORD ARMOR D8.8) FOR TPE

44 938-477 HEX. SOCKET SET SCREW M5X8 2

*

ALTERNATIVE PARTS --- 3 ---

ITEM

NO.

CODE NO.

DESCRIPTION

REMARKS

NO.

USED

PARTS

2 -- 06

S 15SB

45 995-662 RUBBER RING 1

46 315-069 BEARING BUSHING 1

47 325-495 SPINDLE (A) 1 CODE NO. 325-494 TAIL COVER

48 301-653

TAPPING SCREW (W/FLANGE) D4X20 (BLACK) 7

49 325-490 GRIP COVER 1

*

ALTERNATIVE PARTS

--- 4 --- 2 -- 06

OPTIONAL ACCESSORIES

ITEM

NO.

CODE NO.

DESCRIPTION

REMARKS

NO.

USED

STANDARD ACCESSORIES

ITEM

NO.

CODE NO.

DESCRIPTION

REMARKS

NO.

USED

S 15SB

Printed in Japan

(060201N)

501 325-491 WRENCH 1

502 314-079 SANDING DISCS 150MM C-P50 (10 PCS.) 1

601 314-073 SANDING DISCS 150MM C-P16 (10 PCS.) 1

602 314-074 SANDING DISCS 150MM C-P20 (10 PCS.) 1

603 314-075 SANDING DISCS 150MM C-P24 (10 PCS.) 1

604 314-076 SANDING DISCS 150MM C-P30 (10 PCS.) 1

605 314-077 SANDING DISCS 150MM C-P36 (10 PCS.) 1

606 314-078 SANDING DISCS 150MM C-P40 (10 PCS.) 1

607 314-080 SANDING DISCS 150MM C-P60 (10 PCS.) 1

608 314-081 SANDING DISCS 150MM C-P80 (10 PCS.) 1

609 314-082 SANDING DISCS 150MM C-P100 (10 PCS.) 1

610 314-083 SANDING DISCS 150MM C-P120 (10 PCS.) 1

Loading...

Loading...