First Edition, November 2005, SVE-3-001(B)

All Rights Reserved, Copyright © 2005, Hitachi, Ltd.

The contents of this publication may be revised without prior notice.

No part of this publication may be reproduced in any form or by any means without permission

in writing from the publisher.

Printed in Japan.

BI-SN-YS<IC-IC> (FL-MW20, AI8.0)

SAFETY PRECAUTIONS

Be sure to read this manual and all other attached documents carefully before installing,

operating inspecting or conducting maintenance on this unit. Always use this unit properly.

Be sure to carefully read the information about the device, the safety information and precautions

before using this unit. Be sure that the person(s) responsible for maintenance receives and

understands this manual completely.

This manual divides the safety precautions into DANGERs and CAUTIONs.

: Failure to observe these warnings may result in death or serious injury.

: Failure to observe these cautions may result in injury or property

Failure to observe any may lead to serious consequences.

All of these DANGERs and CAUTIONs provide very important precautions and should

always be observed.

Additional safety symbols representing a prohibition or a requirement are as follows:

DANGER

CAUTION

damage.

CAUTION

: Prohibition. For example, “Do not disassemble” is represented by:

: Requirement. For example, if a ground is required, the following will be shown:

1. Installation Precautions

REQUIREMENT

Fasten the mount base to a vertical surface. Fastening the mount base to a

horizontal surface lessens the heat dissipation effects and allows the

temperature to rise, thereby rendering the module defective or incurring

component parts deteriorati on.

Before installing the module, discharge any static buildup from your body

because static electricity may render the module defective.

Properly tighten the screws. If they are inadequately tightened, malfunction,

smoke emission, or combustion may occur.

DANGER

If an emergency stop circuit, interlock circuit, or similar circuit is to be

formulated, it must be positioned external to this module. If you do not

observe this precaution, equipment damage or accident may occur when this

module becomes defective.

Ensure that the employed external power source has overvoltage and

overcurrent protection functions.

The external power source voltage may create an electric shock hazard. If

you disconnect/connect the module or cable with the power supply switched

on, you may inadvertently touch a power supply terminal and receive an

electric shock or the equipment may become damaged due to short circuit or

noise. Switch off the power supply before disconnecting/connecting the

module or cable.

CAUTION

Use the module in an environment specified in the catalog and manual.

If you use the module in an environment where the module is subjected to high

temperature, high humidity, dust, corrosive gas, vibration, or impact, a risk of

electric shock, fire, or malfunction may result .

Observe the installation procedure stated in the manual.

If the module is improperly installed, it may drop, become defective, or

malfunction.

Do not allow wire cuttings or other foreign matter to enter the module.

The entry of foreign matter in the module may result in a fire or cause the

module to become defective or malfunction.

When the module is to be positioned at a location wher e it may become wet

with water, place it within a drip-proof enclosure to prevent it from becoming

defective.

CAUTION

The module may become defective due to a high temperature, which may

result from heat dissipation failure. It may also mal functi on du e to

electromagnetic interfer ence fro m nearby equipment. For heat dissipation

and electromagnetic radiation minimization, provide the specified clearances

among the module, its enclosure, and neighboring equipment.

The degree of temperature rise varies depending on how the module is

mounted. The mounting intervals specified in the manual should be used as

a guide only. While a test run is conducted after completion of mounting,

measure the temperature near the module to check whether it is within the

specified range. If the measured temperature is beyond the specified range,

increase the mounting intervals or provide forced air cooling with a cooling fan.

Dust or other foreign matter might accumulate on the connector, resulting in

poor contact. Immediately after the module is unpacked, perform the

mounting and wiring procedures.

To prevent the module from being dam ag ed, obser v e the foll owing precautions

when you mount or demount the module:

• Before mounting the module to the mount base connector, check that the

connector pins are properly aligned and not bent, broken, or soiled with dirt

or the like.

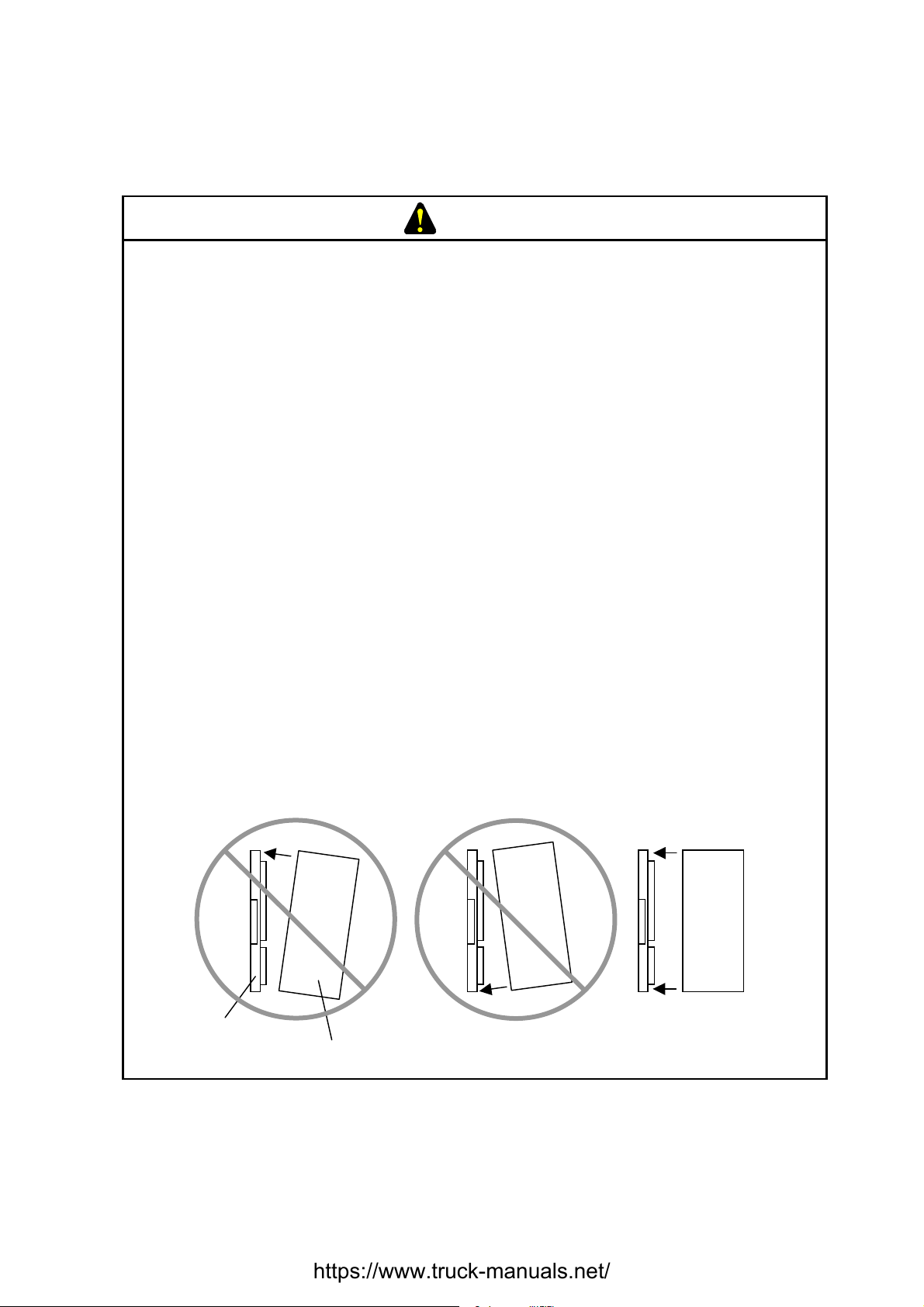

• Ensure that the module is parallel to the mount base vertical surface as

shown below when mounting. If you connect a module to or disconnect it

from its connector while it is tilted, the connector pins may become damaged.

Mount base

[Bad example]

Module

[Good example]

PROHIBITION

Do not take the insulation sheets off the mount base. These insulation sheets

electrically insulate the modules from the mount base.

PROHIBITION

Do not disassemble or modify the module. Failure to observe this precaution

may result in a fire or cause the module to become defective or malfunction.

2. Wiring Precautions

REQUIREMENT

To provide protection against short circuit, furnish the external power source

with a fuse or circuit protector. Ensure that the employed circuit protector is

rated as specified.

Before supplying power to the equipment, thoroughly check the wiring

connections.

Surge voltage may cause malfunction or damage to this product. When you

connect coils, such as relays, to the PCsOK output circuit, be sure to add

surge-absorbing diodes or the equivalent to that circuit. The peak reverse

voltages of these diodes must be at least 10 times as high as the circuit

voltage and their forward currents must be larger than the load current.

Before making power supply wiring connections, make sure that no voltage is

applied to the power cable. Immediately after completion of power supply

wiring, be sure to install the terminal cover.

Ensure that the communication, power supply, motive power, and other cables

are routed apart from each other. It is essential that the inverter, motor,

power regulator, and other motive power cables be routed at least 300 mm

away from the other types of cables. Also, be sure that the communication

and motive power cables are routed within separate conduits.

DANGER

Electric shock hazards exist so that you might suffer burns or become

electrocuted. Further, the system might malfunction due to noise interference.

Therefore, ground the line ground (LG), frame ground (FG), and shield cable

(SHD).

REQUIREMENT

Insulate the mount base from the enclosure. To keep the mount base

insulated, avoid removing the insulation sheets that are supplied with the

mount base.

The LG is a ground terminal for power supply noise. The FG and SHD are

ground terminals for the noise in the remote I/O, communication module and

other external interface lines. To avoid interference between the ground

terminals, separately ground the LG and FG.

Connect each module's FG terminal to the FG terminal provided on the mount

base and ground those terminals properly. The FG terminals for remote I/O

lines and JPCN-1 (J.NET or IR.LINK) lines must be grounded at one place

(LPU unit) for each line -- the FG terminals of remote I/O station and JPCN-1

station (J.Station or IR.Station) modules that can be grounded at the same

place as is the LPU unit must all be grounded.

CAUTION

If the input voltage for the power supply module is within the specified range

but close to the upper or lower limit, you should conclude that an input power

problem exists, and ask the power supply facility manager to conduct an

inspection.

Be sure that the power source for supplying power to various modules is rated

as specified. The use of a differently rated power source may cause a risk of

fire.

Ensure that the same power source is used for output module external power

source (for supplying power to the +V terminal) and load power supply. The

use of different power sources may cause a risk of malfunction.

Only qualified personnel should be allowed to make cable connections.

Incorrect wiring connections may cause a risk of fire, malfunction, or electric

shock.

PROHIBITION

To avoid noise-induced malfunction, do not bundle the 100 VAC/100 VDC wiring

and network cable together, but route them at least 100 mm away from each

other.

3. Operating Precautions

REQUIREMENT

Before terminating this product (by shutting down or resetting), check that all

the peripheral equipment is already stopped or will not be affected by the

termination.

Failure of an installed module may damag e the contents of memory spaces.

Be sure to make a backup copy of any important data in memory.

Overheating may cause a fire or unit failure. Where the ambient temperature

reaches 48°C or higher, lower the maximum output current that can be drawn

from the power supply module. By taking into consideration the environment

where the unit is mounted, install a cooling fan in the housing enclosure or

reduce the number of modules mounted.

DANGER

The input/output currents of I/O modules must be within their maximum

allowable current values. If an overcurrent flows in the I/O module, its

component parts may be damaged, r esulti ng i n an accident, fir e , or fail ure.

If the module emits smoke or foreign odor, immediately switch off the power

supply and investigate the problem cause.

While the power is applied, never touch a terminal strip or connector pin. If

you touch a terminal strip or connector pin while the power is applied, you may

receive an electric shock.

CAUTION

Before changing the program, generating a forced output, or performing the

RUN, STOP, or like procedure during an operation, thoroughly verify the safety

because the use of an incorrect procedure may cause equip ment d amag e or

other accident.

When you switch on the power supply, follow the specified power-on

sequence. Failure to follow the specified sequence may cause equipment

damage or other accident.

CAUTION

Do not use a transceiver, cellular phone, or similar device near the unit

because unit malfunction or system failure may occur due to noise.

The parts, which used gallium arsenic (GaAs) for a photo coupler and LED, are

included in this product. GaAs is specified as a harmful object by law. Take

special care when handling the product, in particular, scrapping it. Before

scrapping the product, ask a professional waste disposal dealer in charge of

scrapping work.

To avoid malfunction, ensure that the power supply is switched on and off at

intervals of longer than 1 second.

PROHIBITION

Do not carry out any installation, wiring, handling, and remodeling not covered

in this manual. The manufacturer is not liable to any damage to the product

and peripheral equipment and/or bodily injury due to such an improper

practice.

Never insert your finger or foreign matter into the gap between a connector

and the mount base. Disregarding this rule may result in a bodily injury..

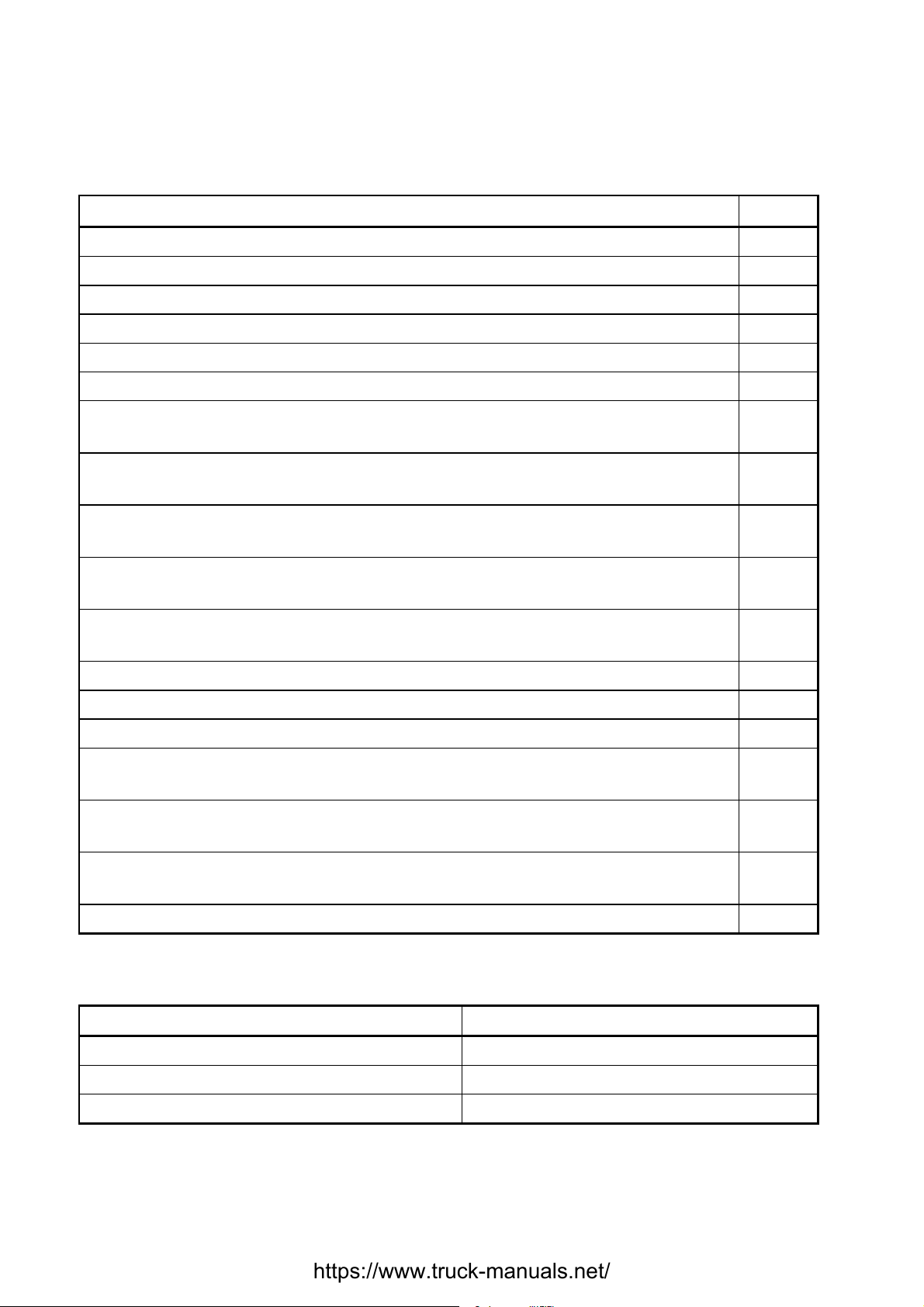

This manual provides troubleshooting information for the following hardware and program products:

(SVE-3-001(B))

<Hardware products>

LPU (LQP510) J.NET (LQE540)

CMU (LQP520) J.NET-INT (LQE545)

Power supplies (LQV000/LQV100/LQV020) IR.LINK (LQE546)

ET.NET (LQE520/LQE720) D.NET (LQE570/575)

SD.LINK (LQP530) SV.LINK (LQE521)

OD.RING (LQE510/515) EQ.LINK (LQE701)

FL.NET (LQE500/502) RI/O (LQS000)

CPU LINK (LQE550) J.Station (LQS020)

RS-232C (LQE560) IR.Station (LQS021)

RS-422 (LQE565) D.Station (LQS070)

<Program products>

S-7895-01 “S10Tools SYSTEM” 01-08

S-7895-02 “LADDER CHART SYSTEM” 01-08

S-7895-03 “HI-FLOW SYSTEM” 01-06

S-7895-07 “CPMS DEBUGGER SYSTEM” 01-01

S-7895-09 “BACKUP RESTORE SYSTEM” 01-03

S-7895-10 “RPDP/S10V SYSTEM” 01-00B

S-7895-11 “NX/ACP-S10V” 01-00

S-7895-12 “NX/Ladder” 01-00

S-7895-13 “NX/Tools-S10V SYSTEM” 01-01

S-7895-14 “NX/HOST-S10V” 01-00

S-7895-22 “CPU LINK SYSTEM” 01-00

S-7895-24 “EXTERNAL SERIAL LINK SYSTEM” 01-00

S-7895-27 “J.NET SYSTEM” 01-01

S-7895-28 “OD.RING/SD.LINK SYSTEM” 01-00

S-7895-29 “ET.NET SYSTEM” 02-00

S-7895-30 “FL.NET SYSTEM” 01-00

S-7895-31 “D.NET SYSTEM” 01-01

S-7895-36 “IR.LINK SYSTEM” 01-00

S-7895-38 “BASE SYSTEM” 01-04

S-7895-41 “EQ.LINK SYSTEM” 01-01

S-7895-60 “RCTLNET” 01-00

<Changes added to this manual>

Description of added changes Page

New information is added to Section 3.4, “Backing Up and Restoring.” 64

Section 3.16, “ET.NET (LQE720) Error Information,” is newly added. 165

Section 3.17, “Error Freeze Information,” is newly added. 168

Section 3.18, “Memory Dump Procedure,” is newly added. 173

Section 3.19, “Network Information,” is newly added. 177

Section 3.20, “Network Maintenance Commands,” is newly added. 200

Error log information is added to Subsection 4.2.2, “CMU (model LQP520) error log

info and required actions.”

Error log information is added to Subsection 4.2.13, “EQ.LINK (model LQE701)

error log info and required actions.”

Error log information is added to Subsection 4.2.14, “ET.NET (model LQE720) error

log info and required actions.”

Error log information is added to Subsection 4.2.15, “NCP-F (model LQE780-Z)

error log info and required actions.”

Error log information is added to Subsection 4.2.16, “LANCP (model LQE790-Z/

LQE795-Z) error log info and required actions.”

Section 4.3, “CMU Error Message Format,” is newly added. 255

Section 4.4, “RPDP Error Log Display Guide,” is newly added. 259

Section 4.5, “Maintenance Commands,” is newly added. 340

New error messages are added to Subsection 5.1.12, “Error messages from the

EQ.LINK SYSTEM.”

New error messages are added to Subsection 5.1.13, “Error messages from the

BACKUP RESTORE SYSTEM.”

222

244

246

249

254

370

371

New error messages are added to Subsection 5.1.14, “Error messages from the

NX/Tools-S10V SYSTEM.”

New error messages are added to Subsection 5.1.15, “Error message from the tools.” 376

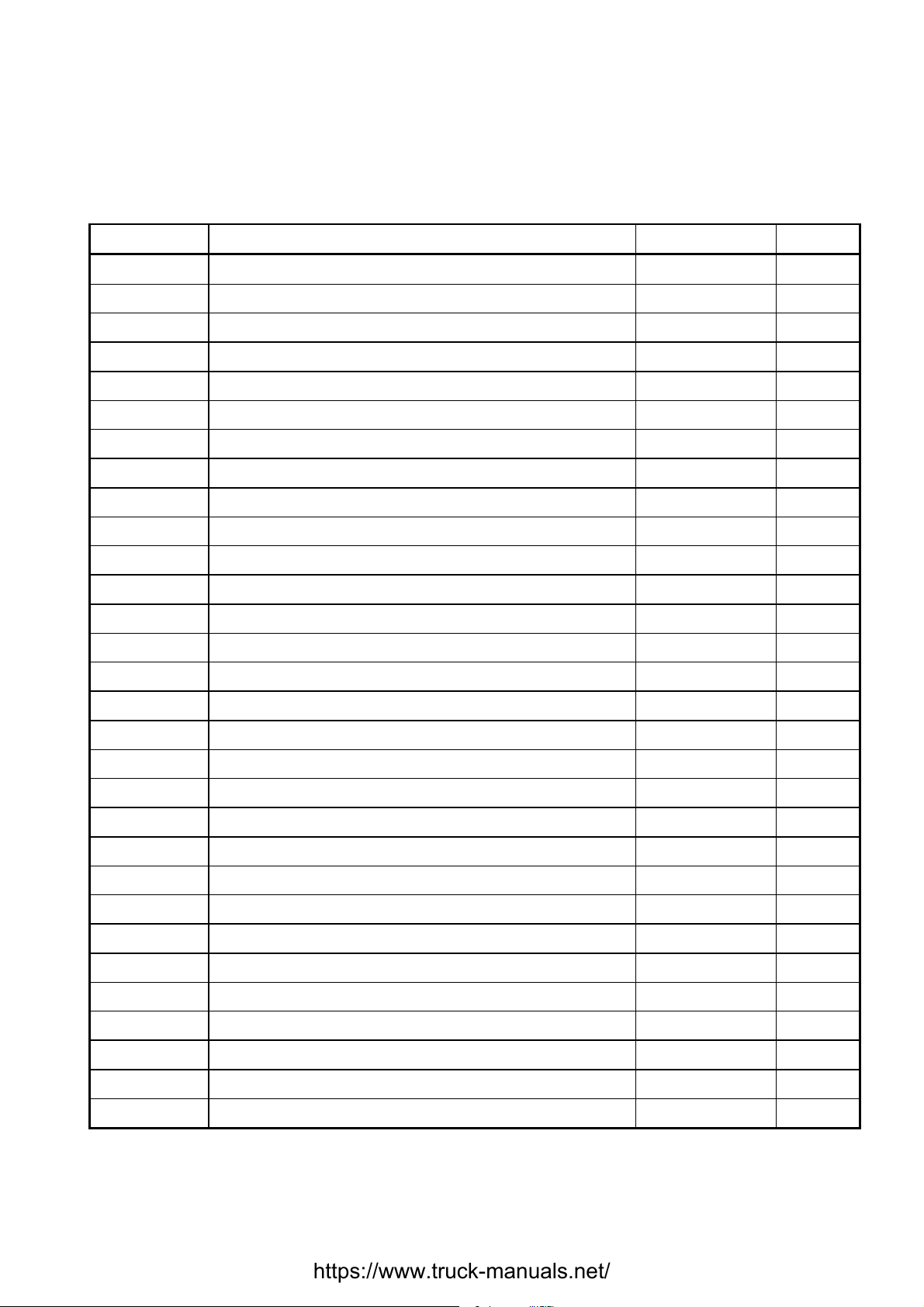

(SVE-3-001(B))

<Changes added to program products>

Program product Description of added changes

S-7895-29, “ET.NET SYSTEM”, 02-00 ET.NET (LQE720) support is newly added.

S-7895-38, “BASE SYSTEM”, 01-04 ET.NET (LQE720) support is newly added.

S-7895-41, “EQ.LINK SYSTEM”, 01-01 EQ.LINK (LQE701) support is newly added.

In addition to the above changes, all the unclear descriptions and typographical errors found are also

corrected without prior notice.

372

Revision record

Revision No. Revision Record (revision details and reason for revision) Month, Year Remarks

B First Edition November 2005

PREFACE

Thank you for purchasing Hitachi’s programmable controller (S10V).

This manual provides information on how to perform troubleshooting correctly when a problem arises

with the product. Please read this manual carefully when troubleshooting the product, and use the

product properly.

The S10V product is available in two types: standard model and environmentally resistant model.

The environmentally resistant model has thicker platings and coatings than those for the standard

model.

The model number of the environmentally resistant model is marked by adding the suffix “-Z” to the

model number of the standard model.

(Example) Standard model: LQP510

Environmentally resistant model: LQP510-Z

This manual is applicable to both the standard model and environmentally resistant models.

Although the descriptions contained in this manual are based on the standard model, follow the

instructions set forth in this manual for proper use of the product even if you use the environmentally

resistant model.

<Trademarks>

Microsoft® Windows® operating system, Microsoft® Windows® 95 operating system, Microsoft®

Windows® 98 operating system, Microsoft® Windows® 2000 operating system, Microsoft®

Windows® XP operating system are registered trademarks of Microsoft Corporation in the United

States and/or other countries.

Ethernet® is a registered trademark of Xerox Coporation.

DeviceNet is a registered trademark of ODVA (Open DeviceNet Vendor Association, Inc.)

MELSEC is a trademark of Mitsubishi Electric Corporation.

<Note for storage capacity calculations>

Memory capacities and requirements, file sizes and storage requirements, etc. must be calculated

according to the formula 2n. The following examples show the results of such calculations by 2n

(to the right of the equals signs).

1 KB (kilobyte) = 1024 bytes

1 MB (megabyte) = 1,048,576 bytes

1 GB (gigabyte) = 1,073,741,824 bytes

As for disk capacities, they must be calculated using the formula 10n. Listed below are the results

of calculating the above example capacities using 10n in place of 2n.

1 KB (kilobyte) = 1000 bytes

2

1 MB (megabyte) = 1000

1 GB (gigabyte) = 10003 bytes

bytes

i

CONTENTS

1 PRELIMINARY CHECKING.............................................................................................. 1

2 TROUBLESHOOTING........................................................................................................ 5

2.1 Troubleshooting Procedure............................................................................................... 6

2.2 Troubleshooting Maps ...................................................................................................... 7

LPU

None of the LED indicators comes on.............................................................................. 8

The ERR indicator (LED) is lit......................................................................................... 8

The remote I/O process produces outputs but does not accept inputs.............................. 9

The PCs OK output is OFF. ............................................................................................. 9

The sequence program does not run................................................................................. 10

A DI/O or AI/O module mounted on the same mount base

as is the LPU module does not run normally.................................................................... 10

CMU

Data communication is not possible with the Tool (personal computer or PC)............... 11

PS Power supply

The POWER ON indicator (LED) does not come on....................................................... 12

FL.NET

The TX and RX indicators (LEDs) do not come on normally.......................................... 13

The LER indicator (LED) is lit......................................................................................... 13

Other problems ................................................................................................................. 13

Common network problems and troubleshooting ............................................................ 14

FL.NET usage precautions ............................................................................................... 17

OD.RING, SD.LINK

The TX and RX indicators (LEDs) do not come on normally.......................................... 18

The ERR indicator (LED) is lit......................................................................................... 18

ET.NET (LQE520)

Communication is initially not possible........................................................................... 19

Communication is not possible with the Tool (PC) ......................................................... 20

SV.LINK

The TX and RX indicators (LEDs) do not come on normally.......................................... 21

The ERR indicator (LED) is lit......................................................................................... 21

Other problems ................................................................................................................. 21

ii

J.NET, J.NET-INT

The TX and RX indicators (LEDs) do not come on normally.......................................... 22

The ERR indicator (LED) is lit......................................................................................... 23

Other problems.................................................................................................................. 23

IR.LINK

The TX and RX indicators (LEDs) do not come on normally.......................................... 24

The ERR indicator (LED) is lit......................................................................................... 25

Other problems.................................................................................................................. 25

CPU LINK Inter-CPU link

The LINK indicator (LED) does not come on.................................................................. 26

RC-232C, RS-422

The TX and RX indicators (LEDs) do not come on normally.......................................... 27

The ERR indicator (LED) is lit......................................................................................... 27

D.NET

The MNS indicators (LEDs) do not come on normally.................................................... 28

Other problems.................................................................................................................. 28

EQ.LINK

The TX and RX indicators (LEDs) do not come on normally.......................................... 29

The LER indicator (LED) is lit......................................................................................... 29

Other problems.................................................................................................................. 29

Common network problems and troubleshooting............................................................. 30

EQ.LINK usage precautions. ............................................................................................ 31

ET.NET (LQE720)

Communication is initially not possible. .......................................................................... 32

Communication is not possible with the Tool (PC).......................................................... 33

Data transmission is not possible from ladder applications.............................................. 33

Data transmission is not possible from HI-FLOW applications....................................... 33

RI/O

The RI/O indicator (LED) does not come on.................................................................... 34

J.Station

The J-NET indicator (LED) does not come on normally.................................................. 35

The ERR indicator (LED) is lit......................................................................................... 35

IR.Station

The TX/RX indicator does not come on normally............................................................ 36

The ERR indicator (LED) is lit......................................................................................... 36

iii

D.Station

The MNS indicators (LEDs) do not come on normally.................................................... 37

Other problems ................................................................................................................. 37

A.INPUT Analog input

Input data cannot be input normally................................................................................. 38

A.INPUT Scan-type analog input

Input data cannot be input normally................................................................................. 39

A.OUTPUT Analog output

The output voltage and current are abnormal................................................................... 40

D.INPUT Digital input

None of the input points is turned on. .............................................................................. 41

Only a particular input point is not turned on................................................................... 41

None of the input points is turned off............................................................................... 42

The input is turned on of off irregularly........................................................................... 42

Only a particular input point is not turned off.................................................................. 42

D.OUTPUT Digital output

None of the load points is turned on................................................................................. 43

Only a particular load point is not turned on.................................................................... 43

None of the load points is turned off................................................................................ 44

Only a particular load point is not turned off. .................................................................. 44

The load is turned on of off irregularly............................................................................. 45

D.IN/OUT Digital input/output

Input or output is malfunctioning..................................................................................... 46

COUNTER Pulse counter

The counter does not count pulses.................................................................................... 47

The count value is not correct........................................................................................... 48

No external comparison output is produced..................................................................... 48

Tool (personal computer) connection

No connection can be established with the PCs (via RS-232C)....................................... 49

No connection can be established with the PCs (via Ethernet [ET.NET module]).......... 49

3 TECHNICAL SUPPORT INFORMATION ........................................................................ 51

3.1 Remote I/O Troubleshooting ............................................................................................ 52

3.2 LPU Error Information Detail Table................................................................................. 58

3.3 Clearing the Entire Memory.............................................................................................. 63

3.4 Backing Up and Restoring................................................................................................ 64

iv

3.5 Performance....................................................................................................................... 85

3.6 Address Space Maps ......................................................................................................... 88

3.7 Registers............................................................................................................................ 93

3.7.1 Ladder instructions and usable registers.................................................................... 93

3.7.2 Register numbers....................................................................................................... 95

3.7.3 System registers......................................................................................................... 97

3.8 Memory Maps for Optional Modules................................................................................ 107

3.9 FL.NET (Model LQE500/LQE502) Error Information..................................................... 116

3.10 OD.RING (Model LQE510/515) and SD.LINK (Model LQE530)

Communication Traces................................................................................................... 119

3.11 ET.NET (Model LQE520) Error Information................................................................. 126

3.11.1 Error codes from the socket handler........................................................................ 126

3.11.2 Routing information setting error table................................................................... 129

3.12 SV.LINK (Model LQE521) Error Information............................................................... 130

3.13 J.NET (Model LQE541), J.NET-INT (Model LQE547), and

IR.LINK (Model LQE548) Trace Information............................................................... 132

3.13.1 Command and response buffers .............................................................................. 132

3.13.2 Data send and data receive buffers .......................................................................... 134

3.13.3 Error counters.......................................................................................................... 136

3.13.4 Trace........................................................................................................................ 137

3.14 RS-232C (Model LQE560) and RS-422 (Model LQE565) Trace Information.............. 140

3.14.1 Communication tracing........................................................................................... 140

3.14.2 Handler tracing........................................................................................................ 142

3.14.3 H-7338 error tracing................................................................................................ 144

3.14.4 Error counters.......................................................................................................... 146

3.15 D.NET (Model LQE570/575) Statistical and Error Information.................................... 147

3.16 ET.NET (Model LQE720) Error Information................................................................. 165

3.16.1 Error codes from the socket handler........................................................................ 165

3.17 Error Freeze Information................................................................................................. 168

3.18 Memory Dump Procedure............................................................................................... 173

3.19 Network Information....................................................................................................... 177

3.19.1 Displaying network information.............................................................................. 177

3.19.2 Network information details.................................................................................... 179

3.20 Network Maintenance Commands.................................................................................. 200

3.20.1 Usage....................................................................................................................... 201

v

4 ERROR LOG INFORMATION........................................................................................... 217

4.1 Displaying Error Log Information .................................................................................... 218

4.2 Error Log Information and Required Actions................................................................... 219

4.2.1 LPU (model LQP510) error log info and required actions....................................... 219

4.2.2 CMU (model LQP520) error log info and required actions...................................... 222

4.2.3 FL.NET (model LQE500/502) error log info and required actions.......................... 226

4.2.4 OD.RING (model LQE510/515) error log info and required actions....................... 228

4.2.5 ET.NET (model LQE520) error log info and required actions................................. 229

4.2.6 SV.LINK (model LQE521) error log info and required actions............................... 230

4.2.7 SD.LINK (model LQE530) error log info and required actions............................... 231

4.2.8 J.NET (model LQE541) / J.NET-INT (model LQE547) error log info

and required actions.................................................................................................. 232

4.2.9 IR.LINK (model LQE548) error log info and required actions ................................ 235

4.2.10 CPU LINK (model LQE550) error log info and required actions ............................ 238

4.2.11 RS-232C (model LQE560) / RS-422 (model LQE565) error log info

and required actions.................................................................................................. 239

4.2.12 D.NET (model LQE570/575) error log info and required actions............................ 242

4.2.13 EQ.LINK (model LQE701) error log info and required actions............................... 244

4.2.14 ET.NET (model LQE720) error log info and required actions................................. 246

4.2.15 NCP-F (model LQE780-Z) error log info and required actions................................ 249

4.2.16 LANCP (model LQE790-Z/795-Z) error log info and required actions................... 254

4.3 CMU Error Message Formats........................................................................................... 255

4.3.1 Panic log error message formats............................................................................... 255

4.3.2 Non-panic log error message formats....................................................................... 256

4.4 RPDP Error Log Display Guide........................................................................................ 259

4.4.1 Reading the error log................................................................................................. 259

4.4.2 Types of error logs.................................................................................................... 261

4.4.3 Error log details and analysis.................................................................................... 263

(1) Program error ............................................................................................................ 263

(2) Macro parameter check error.................................................................................... 270

(3) I/O error..................................................................................................................... 272

(4) Watchdog timer timeout error................................................................................... 286

(5) Module error ............................................................................................................. 287

(6) Kernel warning.......................................................................................................... 297

(7) Kernel information.................................................................................................... 298

(8) System down -- system error..................................................................................... 299

vi

(9) System down -- kernel trap........................................................................................ 301

(10) System down -- built-in subroutine error.................................................................. 302

(11) System down -- built-in subroutine stoppage............................................................ 304

(12) ADT error.................................................................................................................. 305

(13) Memory error............................................................................................................. 310

(14) System bus error........................................................................................................ 324

(15) Other error................................................................................................................. 334

4.4.4 Reading the DHP trace information.......................................................................... 335

4.5 Maintenance Commands................................................................................................... 340

5 APPENDIX........................................................................................................................... 349

5.1 Tool Error Messages ......................................................................................................... 350

5.1.1 Error messages from the LADDER CHART SYSTEM ........................................... 350

5.1.2 Error messages from the HI-FLOW SYSTEM......................................................... 359

5.1.3 Error messages from the BASE SYSTEM................................................................ 362

5.1.4 Error messages from the FL.NET SYSTEM............................................................. 363

5.1.5 Error messages from the OD.RING/SD.LINK SYSTEM......................................... 363

5.1.6 Error messages from the ET.NET SYSTEM ............................................................ 364

5.1.7 Error messages from the J.NET SYSTEM................................................................ 365

5.1.8 Error messages from the IR.LINK SYSTEM............................................................ 366

5.1.9 Error messages from the CPU LINK SYSTEM........................................................ 367

5.1.10 Error messages from the EXTERNAL SERIAL LINK SYSTEM............................ 367

5.1.11 Error messages from the D.NET SYSTEM .............................................................. 368

5.1.12 Error messages from the EQ.LINK SYSTEM .......................................................... 370

5.1.13 Error messages from the BACKUP RESTORE SYSTEM....................................... 371

5.1.14 Error messages from the NX/Tools-S10V SYSTEM................................................ 372

5.1.15 Error messages from the tools................................................................................... 376

5.2 Trouble Report .................................................................................................................. 377

vii

FIGURES

Figure 3-1 Address Space Map of the LPU Unit.................................................................. 88

Figure 3-2 Address Space Map to the PIO-RAM Bit Area.................................................. 89

Figure 3-3 Address Space Map to the PIO-RAM Word Area (1)........................................ 90

Figure 3-4 Address Space Map to the PIO-RAM Word Area (2)........................................ 91

Figure 3-6 Trace Area Structure........................................................................................... 137

Figure 3-7 Trace Data Area Structure (for J.NET and J.NET-INT)..................................... 138

Figure 3-8 Trace Data Area Structure (for IR.LINK)........................................................... 139

Figure 3-9 Stack Frame Details (1) ...................................................................................... 171

Figure 3-10 Stack Frame Details (2) ...................................................................................... 172

Figure 3-11 Binary File Format for Memory Dumps............................................................. 174

Figure 4-1 Example of a Displayed Error Log..................................................................... 259

Figure 4-2 Program Error Analysis Procedure..................................................................... 266

viii

TABLES

Table 3-1 Memory Areas Subjected to Backing up and Restoring....................................... 64

Table 3-2 Backup Areas Used by Optional-Module Setting Tools....................................... 80

Table 3-3 Backup Areas ........................................................................................................ 82

Table 3-4 Items Displayed in the [Performance] Window.................................................... 85

Table 3-5 Usable Registers.................................................................................................... 93

Table 3-6 Register Numbers.................................................................................................. 95

Table 3-7 System Registers................................................................................................... 97

Table 3-8 Error Codes from the Socket Handler (LQE520).................................................. 126

Table 3-9 Trace Buffer Structure (for Communication Tracing).......................................... 140

Table 3-10 Trace Data Area Details (for Communication Tracing)........................................ 141

Table 3-11 Trace Buffer Structure (for Handler Tracing) ....................................................... 142

Table 3-12 Trace Data Area Details (for Handler Tracing)..................................................... 143

Table 3-13 Trace Buffer Structure (for H-7338 Error Tracing) .............................................. 144

Table 3-14 Trace Data Area Details (for H-7338 Error Tracing)............................................ 145

Table 3-15 Error Codes in H-7338 Error Trace Information .................................................. 145

Table 3-16 Error Counters....................................................................................................... 146

Table 3-17 Error Codes from the Socket Handler .................................................................. 165

Table 4-1 Panic Log Error Message Formats........................................................................ 255

Table 4-2 Panic Log Default Error Messages........................................................................ 255

Table 4-3 Non-Panic Log Error Message Formats................................................................ 256

Table 4-4 Non-Panic Log Default Error Messages ............................................................... 257

Table 4-5 Types of OS Error Logs........................................................................................ 261

Table 4-6 Types of NXACP Error Logs................................................................................ 262

Table 4-7 Program Error Message Format............................................................................ 264

Table 4-8 Error Codes, Subtitles, and Their Meanings (for Program Errors)....................... 265

Table 4-9 Macro Parameter Check Error Message Format................................................... 270

Table 4-10 Predefined Supervisory Macro Codes and Macro Names Identified by Them..... 271

Table 4-11 I/O Error Message Format..................................................................................... 272

Table 4-12 Error Detail Data for Built-in LANCE-/LANCE-Detected I/O Errors

(EC=0x078013XX)............................................................................................... 274

Table 4-13 Error Detail Data for Built-in LANCE PCI Bus I/O Errors

(EC=0x078014XX)............................................................................................... 276

Table 4-14 Error Detail Data for LANCP I/O Errors (EC=0x078016XX) ............................. 281

Table 4-15 Error Detail Data for Driver-Detected I/O Errors (EC=0x078015XX) ................ 282

ix

Table 4-16 I/O Error Message Format.................................................................................... 283

Table 4-17 Error Codes, Subtitles, and Their Meanings (for I/O Errors)............................... 284

Table 4-18 Error Detail Data for ROM Board Errors............................................................. 284

Table 4-19 Watchdog Timer Timeout Error Message Format................................................ 286

Table 4-20 Module Error Message Format............................................................................. 287

Table 4-21 Error Codes, Subtitles, and Their Meanings (for Module Errors)........................ 288

Table 4-22 MSW Detail Data for Modules............................................................................. 291

Table 4-23 Kernel Warning Message Format......................................................................... 297

Table 4-24 Error Code and Its Meaning (for Kernel Warnings)............................................. 297

Table 4-25 Kernel Information Message Format.................................................................... 298

Table 4-26 System Down (System Error) Message Format.................................................... 299

Table 4-27 Error Codes, Subtitles, and Their Meanings (for System Errors)......................... 300

Table 4-28 Kernel Trap Message Format ............................................................................... 301

Table 4-29 System Down (Built-in Subroutine Error) Message Format ................................ 302

Table 4-30 Error Codes, Subtitles, and Their Meanings (for Built-in Subroutine Errors) ..... 303

Table 4-31 System Down (Built-in Subroutine Stoppage) Message Format.......................... 304

Table 4-32 ADT Error Message Format................................................................................. 305

Table 4-33 Memory Error Message Format............................................................................ 310

Table 4-34 The Set Values of MST_TYPE and MST_INFO................................................. 323

Table 4-35 System Bus Error Message Format....................................................................... 324

Table 4-36 Error Codes........................................................................................................... 333

Table 4-37 Other-Error Message Format................................................................................ 334

Table 4-38 DHP Codes........................................................................................................... 336

x

1 PRELIMINARY

CHECKING

1 PRELIMINARY CHECKING

Perform the following preliminary checks to eliminate obvious problems before

troubleshooting the product:

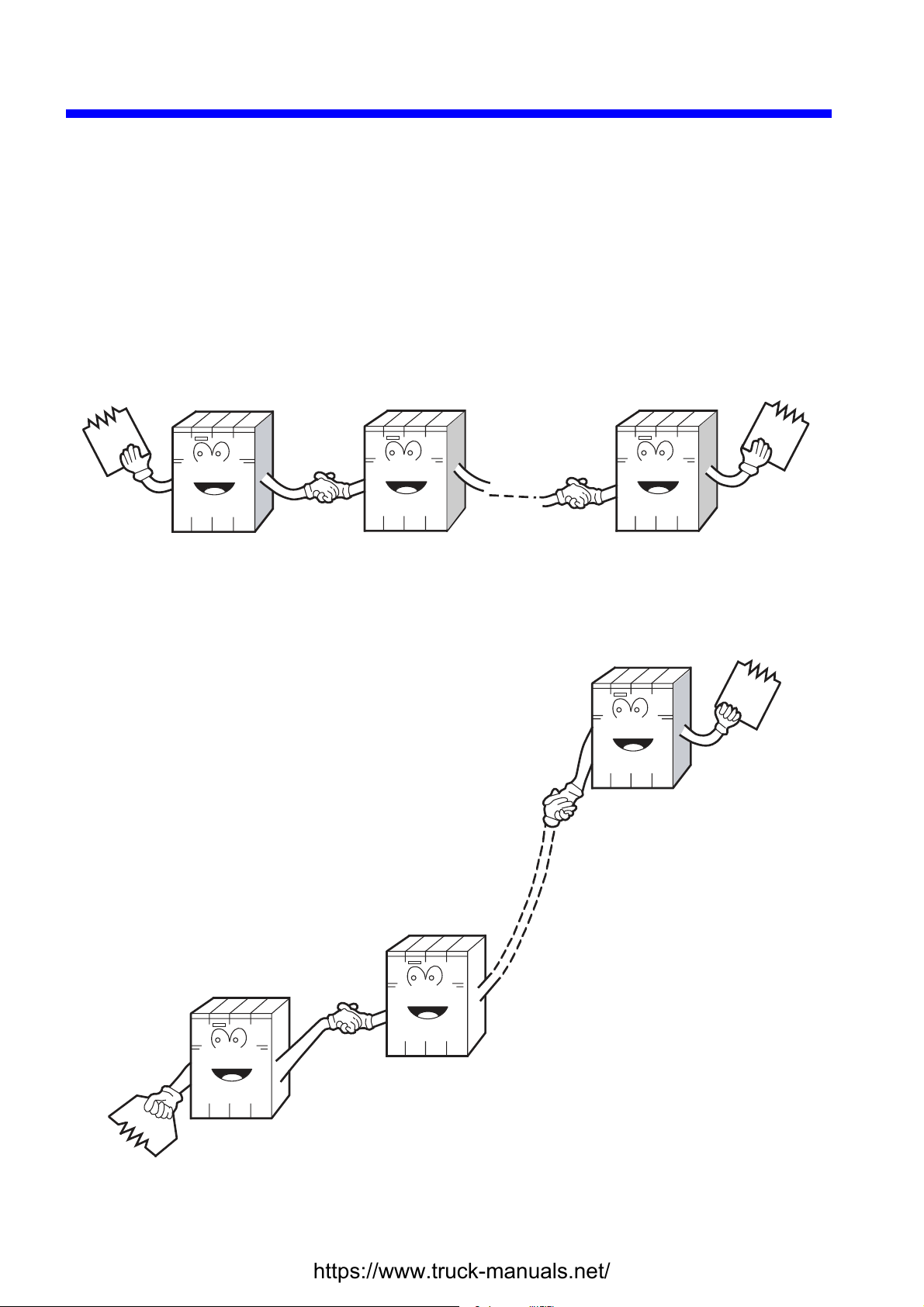

Check that terminating resistors are connected to both ends of the inter-LPU links chain

established.

Both ends of the inter-LPU link line must be terminated with terminating resistors.

Terminating

resistor

LPU LPU LPU

Terminating

resistor

Check that terminating resistors are connected to both ends of the remote I/O line.

Both ends of the remote I/O line must be terminated with terminating resistors.

LPU

Remote I/O

Remote I/O

Terminating

resistor

Terminating

resistor

- 2 -

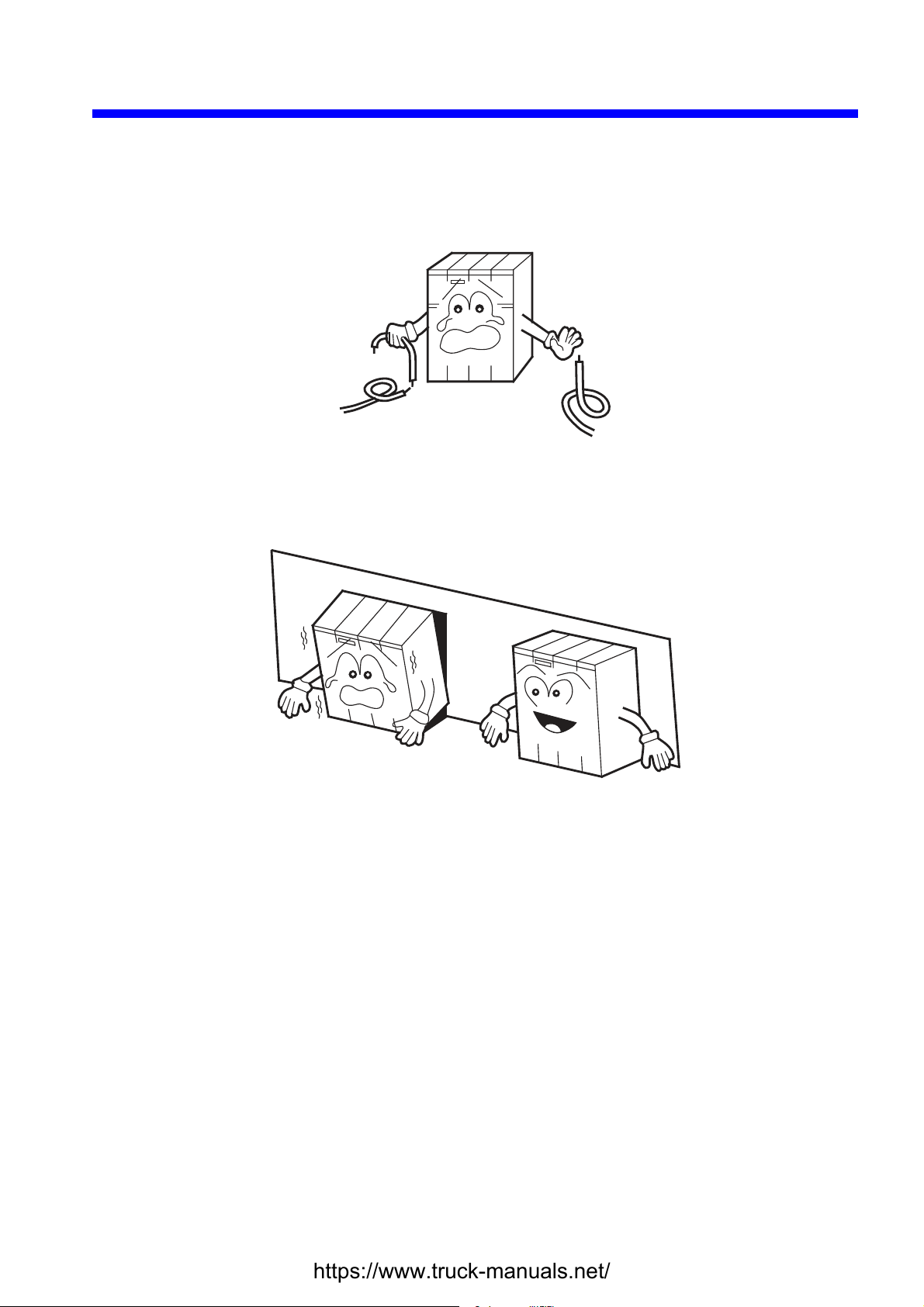

Is the cabling correct?

Check the cables for disconnection or incorrect connection.

Are the modules mounted correctly?

Check that no set screws are loosened.

1 PRELIMINARY CHECKING

- 3 -

1 PRELIMINARY CHECKING

Is grounding correct?

• Do not ground the D.NET module in the same place where high-voltage equipment is grounded.

They must be grounded in separate places.

• Perform grounding work conforming to Class D* or higher grounding standard.

Are the LG and FG separated?

• Be sure to separate the LG from the FG or vice versa because power noise enters the FG via the

LG. Failure to observe this rule may result in an equipment malfunction.

• Ground the LG at the power supply side.

LG

FG

FG

FG

LG is here!

FG is over there!

* Class D grounding is defined in the Technical Standard for Electrical Facilities of Japan. This

standard states that the grounding resistance must be 100 ohms or less for equipment operating on

300 VAC or less, and 500 ohms or less for devices that shut down automatically within 0.5

seconds when shorting occurs in low tension lines.

- 4 -

2 TROUBLESHOOTING

2 TROUBLESHOOTING

g

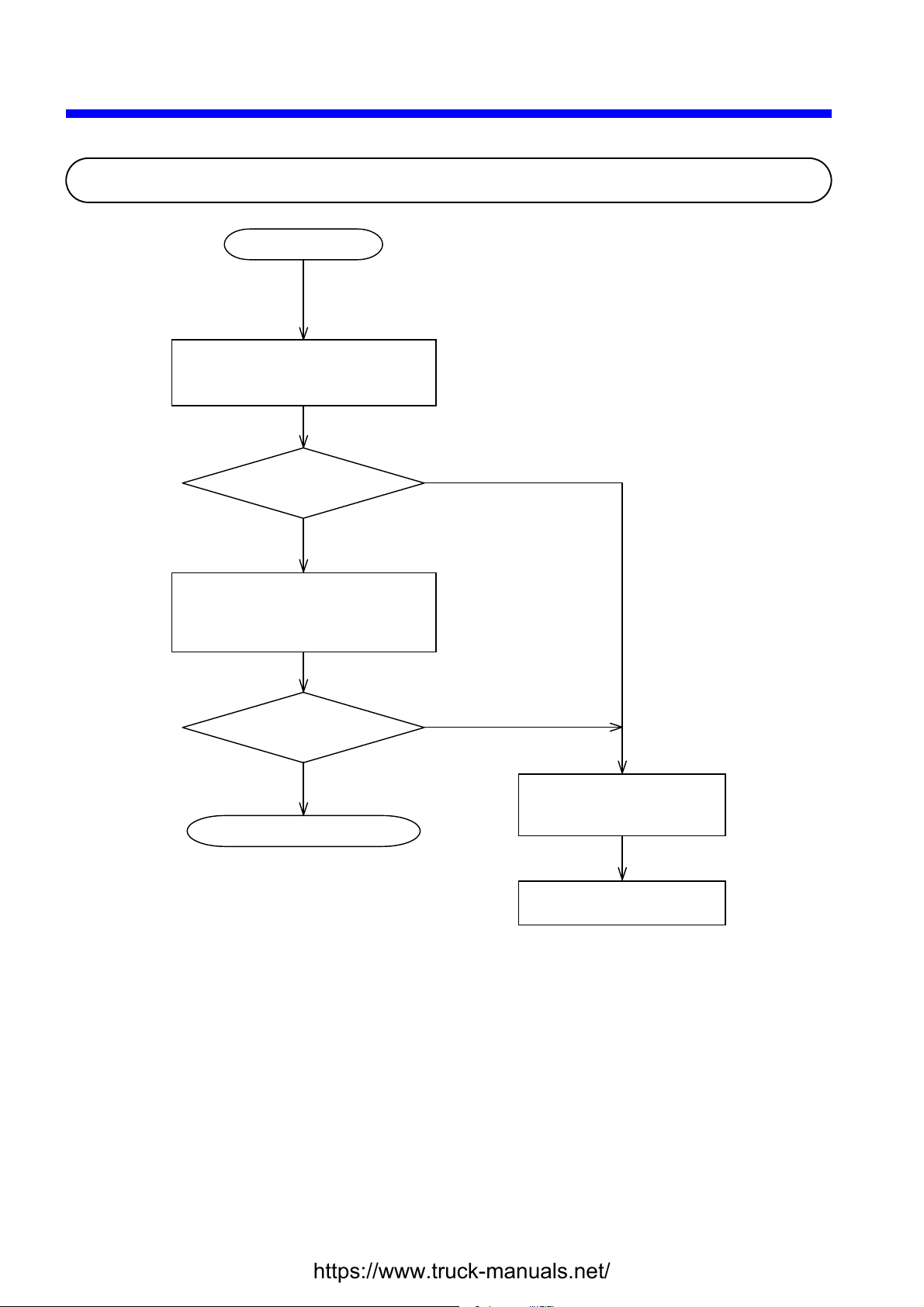

2.1 Troubleshooting Procedure

A problem occurs.

Check out indications on the

individual modules’ LEDs, error log,

and the ON/OFF status of the load.

Is an abnormal

module found?

NO

Perform all necessary checking and

take appropriate remedial action, as

described in Section 2.2,

“Troubleshootin

YES

Map.”

Is the problem

solved?

YES

End of troubleshooting

NO

Fill out a trouble report

form exemplified in Section

5.2, “Trouble Report.”

Contact your local source

of supply.

- 6 -

2 TROUBLESHOOTING

2.2 Troubleshooting Maps

The troubleshooting maps provided in this section serve as a guide to help users troubleshoot their

systems as quickly as possible in the event of a problem. Each troubleshooting map has the

following general format:

Problematic symptom or condition

None of the LED indicators comes on.

Check if: W hat to do

The power supply module is operating

abnormally.

The LPU and/or the power supply module is

installed incorrectly.

The supply voltage from the power supply

module is abnormal.

Required checks Required actions

Module name

Module model

LPU

LQP510

If true, follow the troubleshooting map

for the power supply module in order

to check out the said module.

If true, install them correctly.

If true, replace the power supply

module.

- 7 -

2 TROUBLESHOOTING

None of the LED indicators comes on.

Check if: W hat to do

LPU

LQP510

The power supply module is operating

abnormally.

The LPU and/or the power supply module is

installed incorrectly.

The supply voltage from the power supply

module is abnormal.

The ERR indicator (LED) is lit.

Check if: W hat to do

An LPU error is recorded in the error log. If true, troubleshoot according to the

If true, follow the troubleshooting map

for the power supply module in order

to check out the said module.

If true, install them correctly.

If true, replace the power supply

module.

instructions given under “4 ERROR

LOG INFORMATION.”

- 8 -

The remote I/O process produces outputs but does not accept inputs.

Check if: W hat to do

2 TROUBLESHOOTING

A terminating resistor(s) are installed between

the following terminals for the LPU:

RI/O1→ 100 Ω : Terminals A6 and A7

150 Ω : Terminals A5 and A7

RI/O2→ 100 Ω : Terminals B5 and B6

150 Ω : Terminals B4 and B6

The PCs OK output is OFF.

Check if: W hat to do

The LADDER switch is set in STOP position. If true, set it in RUN position.

The LPU module’s ERR indicator (LED) is lit. If true, check the error log to see if an

If not, install them.

LPU error is recorded. If so,

troubleshoot according to the

instructions given under “4 ERROR

LOG INFORMATION.”

The SIMU indicator (LED) is lit. If true, change the LADDER MODE

to “NORM” in the S10V BASE

SYSTEM.

The power supply module is abnormal. If true, follow the troubleshooting map

for the power supply module in order

to check out the said module.

The wiring or connections are made correctly. If not, correct them.

- 9 -

2 TROUBLESHOOTING

The sequence program does not run.

Check if: W hat to do

The LADDER switch is set in STOP position. If true, set it in RUN position.

The LPU module’s ERR indicator (LED) is lit. If true, check the error log to see if an

The SIMU indicator (LED) is lit. If true, change the LADDER MODE

External STOP input is in process. If true, turn it off.

LPU error is recorded. If so,

troubleshoot according to the

instructions given under “4 ERROR

LOG INFORMATION.”

to “NORM” in the S10V BASE

SYSTEM.

The program has a bug. If true, correct it.

A DI/O or AI/O module mounted on the same mount base as is the LPU module does not run

normally.

Check if: W hat to do

The LPU module’s I/O number setting is

missing or erroneous.

If true, set it correctly according to the

instructions given under

“7 SETTINGS” in the “S10V

USER’S MANUAL BASIC

MODULES (manual number SVE-1-

100).”

- 10 -

2 TROUBLESHOOTING

Data communication is not possible with the Tool (personal computer or PC).

Check if: W hat to do

CMU

LQP520

The ST.No. U and L

communications are

carried out by using

the CMU module

whose IP address is

set to a fixed value

of “192.192.192.1”:

switches are both set in F-

position.

The IP address of the Tool

is set to a value of

“192.192.192.***”, where

*** is a number in the

range 002 to 254.

In cases where data

communications are

carried out via a

hub:

The ST.No. U and L

switches are both set in 0-

position.

The CMU module’s IP

address setting is made.

The IP address setting of

the Tool contains the same

network address as does

that of the CMU module.

The CMU module’s T/M operational setting

switch (T/M) is set in 0-position.

If not, set both in F-position. In cases where data

If not, set it to a value of

“192.192.192.***”, where *** is a

number in the range 002 to 254.

If not, set both in 0-position.

If not, set it.

If not, use the same network

address in both.

If not, set it in 0-position.

The “Ethernet” option is selected in the

“Communication type” window on each system,

If not, choose the

“Ethernet” option.

which is displayed either at system startup time or

by clicking the Change Connection button.

The 10/100BASE-T cable used is the correct

type.

If not, use a straight cable when

connecting the CMU module to the

hub, and a cross cable when

connecting it directly to the

personal computer or PC.

The CMU module runs with one of the following IP addresses, depending on the given

settings of the ST.No. U and L switches:

ST.No. U and L : 0-position – The set IP address, if they are both set in 0-position.

: F-position – The IP address “192.192.192.1”, if they are both set in F-

position.

- 11 -

2 TROUBLESHOOTING

The POWER ON indicator (LED) does not come on.

Check if: W hat to do

The power cable is connected properly. If not, connect it properly. (For

PS

Power supply

LQV000

LQV020

LQV100

details, refer to the “S10V USER’S

MANUAL BASIC MODULES

(manual number SVE-1-100)).”

The power cable is broken. If true, replace the cable.

The external power supply is normal (in terms

If not, make it normal.

of voltage and wave form).

- 12 -

The TX and RX indicators (LEDs) do not come on normally.

Check if: What to do

The MODU number is set correctly. If not, set it correctly.

The set IP address of a remote node is duplicated with that

of another node.

The IP address of the local node is set correctly. Set the same network address for both the local

The FL.NET module’s parameters are set correctly. If not, correct them.

In cases where the FL.NET module is networked by

10BASE-T connections, the cable used is the correct one.

In cases where the FL.NET module is networked by

10BASE-5 connections, the transceiver’s SQE switch is set

correctly.

The cable connector is connected loose or about to fall off

the mating connector of the FL.NET module.

In cases where the FL.NET module is networked by

10BASE-5 connections, it is connected to the 12-V

external power supply.

A terminating resistor(s) are connected to the 10BASE-5

coaxial cable.

The 10BASE-5 coaxial cable is grounded properly. If not, ground it properly.

If true, set unique IP addresses for both nodes.

and remote nodes. The recommended network

address is “192.168.250”.

Use a straight cable if you want to connect the

FL.NET module to a given hub. If you want to

connect it directly to the destination equipment,

use a cross cable.

Turn on the SQE switch if you want to connect

the FL.NET module to a single-port transceiver.

If a multiport transceiver or repeater is connected

with a single-port transceiver, and you want to

connect the FL.NET module to that single-port

transceiver, then turn off the SQE switch.

If true, insert the connector completely into the

mating connector and lock it.

If not, connect it to the said power supply.

If not, connect them properly.

The LER indicator (LED) is lit.

Check if: What to do

An FL.NET error is recorded in the error log. If true, troubleshoot according to the instructions

given under “4 ERROR LOG

INFORMATION.”

The FL.NET module mounted in this S10V controller is

one whose parameters are previously set for use in an

S10mini controller.

If true, open the parameter-setting window in the

tool (FL.NET system) and add changes to the

parameter settings for the mounted FL.NET

module. Then, reset the controller, or turn off

the power to the controller and back on again.

Other problems

Check if: What to do

Although a device is connected to the network to which the

FL.NET module is connected, it does not support the

FL.NET module’s functions.

If true, disconnect the device from the network.

2 TROUBLESHOOTING

FL.NET

LQE500

LQE502

- 13 -

2 TROUBLESHOOTING

Common network problems and troubleshooting

(1) Network-related problems (communication not possible) and troubleshooting

Symptom

Communication not

possible

Item to be

checked

Power supply

Connection of

communication

cable and

transceiver

Connection of

transceiver cable

and transceiver

Connection of

transceiver cable

and other device

Check if: What to do

Some equipment’s main power

indicator(s) are not lit.

The power indicator of the AUI’s power

supply unit is lit.

The output voltage of the AUI’s power

supply unit is equal to its prescribed

voltage of 12 vo lts.

The power indicator of the hub is lit. If not, check the power supply and its voltage, and also

The AUI power cable is connected

properly to the equipment.

The transceiver’s cable is connected

firmly.

A transceiver installation check device

shows a problem with the transceiver.

The transceiver is electrically insulat ed

properly.

The transceiver is connected properly at

a marker on the communication cabl e.

The transceiver cable is connected

firmly.

A transceiver installation check device

shows a problem with the transceiver.

The transceiver is locked pro perly. If not, lock it prop erl y accord i ng to the instructions

The transceiver’s LED indicator(s) are

all lit normally.

The transceiver cable is connected

firmly.

The device’s TX (Transmit) and RX

(Receive) indicators (LEDs) are lit

normally.

All the media switches, such as SQE, are

set correctly.

If true, check the power supply and its voltage, and also

check the power cables for any loose connections.

If not, check the power supply and its voltage, and also

check the power cables for any loose connections.

If not, check the power supply and its voltage, and also

check the power cables for any loose connections.

check the power cables for any loose connections.

If not, check the power supply and its voltage, and also

check the power cables for any loose connections.

If not, carry out installation work again properly

according to the i nstructions given in Section 8.6 of the

FL.NET (manual number SVE-1-101).

If true, solve the problem by making necessary

adjustments. If the same problem recurs, install th e

transceiver in a different place.

If not, carry out installation work again properly

according to the i nstructions given in Section 8.6 of the

FL.NET (manual number SVE-1-101).

If not, review the connection point according to the

instructions given in Section 8.6 of the FL.NET (manual

number SVE-1-101).

If not, review the installation work according to the

instructions given in Section 8.6 of the FL.NET (manual

number SVE-1-101) and, if necessary, apply additional

tightening to the connection.

If true, check the installation work according to the

instruction manual on the check device.

given in Section 8.6 of the FL.NET (manual number

SVE-1-101).

If not, check the power supply and its voltage, and also

check the power cable for any loose connection.

If not, review the installation work according to the

instructions given in Section 8.6 of the FL.NET (manual

number SVE-1-101) and, if necessary, apply additional

tightening to the connection.

If not, troubleshoot according to the instructi ons given

in Chapter 7 of the FL.NET (manual number SVE-1-

101).

Review the settings according to the instructions given

in Section 8.6 of the FL.NET (manual number SVE-1-

101).

- 14 -

(2) Network-related problems (communication unstable) and troubleshooting

Symptom

Communication not

possible at

all, or

possible

but

unstable

Item to be

checked

Communication path

Communication station’s

equipment

settings

The external conductor of the

coaxial cable is grounded at one

place.

The shield wire of the AUI cable

is grounded properly.

There is any station not

responding correctly to a given

ping command.

The collision indicator is lit

frequently.

The number of repeaters on the

path is 4 or less.

Each segment is within the

prescribed length.

Terminating resistors are

connected to both ends of the

path.

The number of connected devices

in each segment is within the

prescribed limits.

The number of segments in which

a device(s) are connected is 3 or

less.

The power to the repeater(s) is

ON.

IP addresses are set correctly in

the network.

The station number of the

station’s equipment is set

correctly.

The equipment’s parameters are

set correctly.

The CD (Carrier Detect) indicator

is lit continuously or

intermittently.

The TX (Transmit) indicator is lit

continuously or intermittently.

The LK (Link) indicator is lit

continuously.

Check if: What to do

If not, ground it properly according to the

instructions given in Section 8.6 of the

FL.NET (manual number SVE-1-101).

If not, ground it properly according to the

instruction manual supplied by the cable

maker.

If true, check the power supply and cable

wiring of the non-responding station.

If true, check the cable wiring and connectors

for any incomplete connection. Make sure of

the nature of the problem by using a network

analyzer.

If not, review the configuration according to

the instructions given in Section 8.6 of the

FL.NET (manual number SVE-1-101).

If not, review the configuration according to

the instructions given in Section 8.6 of the

FL.NET (manual number SVE-1-101).

If not, review the configuration according to

the instructions given in Section 8.6 of the

FL.NET (manual number SVE-1-101).

If not, review the configuration according to

the instructions given in Section 8.6 of the

FL.NET (manual number SVE-1-101).

If not, review the configuration according to

the instructions given in Section 8.6 of the

FL.NET (manual number SVE-1-101).

If not, check the power supply and its voltage,

and also check the power cables for any loose

connections.

Check the set IP addresses with the support

tool and/or network analyzer.

Check the set station number with the support

tool and/or network analyzer.

Check the set parameters with the support tool.

If not, check the communication cable wiring

and power to the AUI.

If not, check the equipment settings.

If not, check the parameter settings on the

equipment side.

2 TROUBLESHOOTING

- 15 -

2 TROUBLESHOOTING

(3) IP address checking using a PC’s Ping function

Whether a given FL.NET module is networked properly or its IP address is set correctly can

be checked by using a special function of a Windows® machine (PC), commonly known as

Ping, rather than by using a special tool, such as the FL.NET network analyzer. The

description below gives an outline of check operations using the Ping function.

If an IP connection is used with the FL.NET module, check the connection by using the Ping

function, as follows:

① Choose [Start] – [Programs] – [Accessories] – [Command Prompt], and then the

command prompt appears on screen.

② Enter the Ping command to carry out a basic communication test between the link unit

(FL.NET) and PC. The form of the Ping command entered is either of the following:

Ping [IP address] or Ping [host name]

Example: Ping 192.168.250.13

It the FL.NET module under test is set up properly, the Ping command presents the

following message:

Pinging 192.168.250. 13 with 32 bytes of data:

Reply from 192.168.250. 13: bytes=32 time=2ms TTL=32

Reply from 192.168.250. 13: bytes=32 time=1ms TTL=32

Reply from 192.168.250. 13: bytes=32 time=1ms TTL=32

Reply from JEMA 192.168.250. 13 : bytes=32 time=1ms TTL=32

③ If the FL.NET module is not connected yet, the Ping command presents the following

message (timeout notifications):

Pinging 192.168.250. 13 with 32 bytes of data:

Request timed out.

Request timed out.

Request timed out.

Request timed out.

- 16 -

2 TROUBLESHOOTING

FL.NET usage precautions

There are some precautions that must be observed when using the FL.NET module. These

precautions are listed below along with the restrictions in the table below. For information on

the standard related to FL.NET communication paths, refer to the FL.NET (manual number

SVE-1-101) or IEEE802.3 standard.

Do not carry data traffic from other Ethernet networks on the FL.NET communication cable.

Do not connect the FL.NET module to any router.

It will do you any good to use a switching hub for the FL.NET module.

Use of such wireless media as infrared light and radio frequency radiation may greatly

deteriorate the realtimeness of data communications.

Use of a personal computer (PC) may greatly deteriorate the realtimeness of data communica-

tions, depending on the hardware, operating system, and applications used in the PC.

Use only the predetermined IP address.

The network address used in the IP address must be consistent throughout the network (the

standard network address is “192.168.250”). The node (station) number in the IP address

must be in the following range:

Network address Node number

192.168.250. 1 to 249

During initialization, the specified node number is not checked for any duplication. A

duplicated node number is detected only when communication is first made using that node

number. For this reason, special care must be taken when specifying a node number.

Grounding must be made properly. The grounding wire’s diameter must be sufficiently large.

Place the FL.NET module sufficiently away from any noise source. Never lay down AC

power cables near the FL.NET module.

In cases where cyclic data communication is used simultaneously with message data

communication, their realtimeness may decrease depending on the volume of data being

transmitted.

Cyclic data communication area in memory, called the common memory area, need not be

secured in a single continuous memory space.

If the transceiver is provided with an SQE switch, set the SQE switch properly according to the

instruction manual on that transceiver.

The entire system’s on-time data communicability is affected by the overall performance of the

networked equipment. In other words, data communication is performed at the transmission

speed of the lowest-speed device, as well as at the transmission speeds of all other higherspeed devices connected to the same network. Thus, addition of a single device to the

network may drastically deteriorate the realtimeness of the entire system, depending on the

transmission speed of the added device.

The header of messages transmitted by message data communication is represented in big-

endian format, whereas their data is represented in little-endian format. The only exception to

this is the data in profile read, which is the system parameters represented in big-endian format.

(The big-endian format here is a format in which the most significant bit [MSB] is first sent

out.)

- 17 -

2 TROUBLESHOOTING

The TX and RX indicators (LEDs) do not come on normally.

Check if: What t o do

OD.RING, SD.LINK

LQE510

LQE515

LQE530

The MODU No. and CPL No. switches are set

correctly.

The OD.RING/SD.LINK parameters are set

correctly by using the S10V OD.RING/SD.LINK

system.

The cable is connected properly. (For example,

check if a cable line is broken or the cable is

connected to the wrong destination.)

The cable connectors are inserted properly into the

mating connectors.

The OD.RING/SD.LINK module of the

communication destination functions normally.

The optical fiber cable is bent sharply. If true, replace the cable.

The ERR indicator (LED) is lit.

Check if: What t o do

If not, set them correctly.

If not, set them correctly.

If not, connect it properly.

Refer to Section 3.4, “Wiring,” of the

OD.RING (manual number SVE-1-102)

or SD.LINK (manual number SVE-1-

115), and connect the cable properly.

If not, start up the OD.RING/SD.LINK

module of the destination properly.

The MODU No. and CPL No. switches are set

correctly.

The specified CPL No. is duplicated with the CPL

No. of some other OD.RING/SD.LINK module.

An OD.RING/SD.LINK error is recorded in the

error log.

The OD.RING/SD.LINK module mounted in this

S10V controller is one whose parameters are

previously set for use in an S10mini controller.

- 18 -

If not, set them correctly.

If true, specify a unique CPL No.

If true, troubleshoot according to the

instructions given under “4 ERROR

LOG INFORMATION.”

If true, open the parameter-setting

window in the tool (OD.RING/SD.LINK

system) and add changes to the parameter

settings for the mounted

OD.RING/SD.LINK module. Then,

reset the controller, or turn off the power

to the controller and back on again.

Communication is initially not possible.

Check if: W hat to do

An error message is recorded in the error log. If true, troubleshoot according to the

The module number is set correctly. If not, set the rotary switch (MODU

2 TROUBLESHOOTING

ET.NET

LQE520

instructions given under “4 Error

Log Information.”

No.) at the front of the module

housing correctly according to the

instructions given under “2 NAMES

AND FUNCTIONS OF EACH

PART” in the “ET.NET (manual

number SVE-1-103).”

The cable is disconnected. If true, insert the cable connector into

the mating connector and lock it.

The IP address is set correctly. If not, set up the ET.NET module

correctly by using the S10V ET.NET

system.

The IP address of the ET.NET module is

duplicated with the IP address of some other

If true, set unique IP addresses and

subnet masks for the modules.

module.

Terminating resistors are connected to both

If not, connect them to both ends.

ends of the coaxial cable.

The ERR indicator (LED) of the ET.NET

module is lit.

If true, push the RESET switch of the

LPU module to restart it. If the ERR

indicator is lit again, replace the

ET.NET module.

In cases where the ET.NET module is

networked by 10BASE-5 connections, it is

If not, connect it to the said power

supply.

connected to the 12-V external power supply.

- 19 -

2 TROUBLESHOOTING

Communication is not possible with the Tool (PC)

Check if: What to do

Where the

Tool and

ET.NET

module are

directly

connected

together by

using a cross

cable:

Where

communication is

performed

via a hub:

The ET.NET module’s module

no. setting switch (MODU No.)

is set either in 4- or 5-position.

The IP address of the Tool is set

to a value of “192.192.192.***”,

where *** is a number in the

range 002 to 254.

The ET.NET module has its IP

address set.

The IP addresses of the Tool and

ET.NET module contain the

same network address.

The module number is set

correctly.

If not, and you are using 10BASE-T,

then set it in 4-position if the

ET.NET module is the main module,

and in 5-position if it is a submodule.

If not, set it to a value of

“192.192.192.***”, where *** is a

number in the range 002 to 254.

If not, set it.

If not, specify the same network

address in the two IP addresses.

If not, and you are using 10BASE-5,

then set it in 0-position if the ETNET module is the main module, and

in 1-position if it is a submodule. If

not, and you are using 10BASE-T,

then set it in 2-position if it is the

main module, and in 3-position if it

is a submodule.

The “Ethernet” option is selected in the

If not, choose the “Ethernet” option.

“Communication type” window on each system,

which is displayed either at system startup time

or by clicking the “Change Connection” button.

The 10BASE-T cable used is the correct type. If not, use a straight cable when

connecting the ET.NET module to

the hub, and a cross cable when

connecting it directly to the PC.

- 20 -

The TX and RX indicators (LEDs) do not come on normally.

Check if: What to do

The MODU No. switch is set correctly. If not, set it correctly.

2 TROUBLESHOOTING

SV.LINK

LQE521

The IP address of the SV.LINK module is duplicated

with the IP address of some other module.

The IP address is set correctly. If not, set it correctly.

The SV.LINK module’s parameters are set correctly. If not, correct them.

In cases where the SV.LINK module is networked by

10BASE-T connections, the cable used is the correct

one.

In cases where the SV.LINK module is networked by

10BASE-5 connections, the transceiver’s SQE switch is

set correctly.

The cable connector is connected loose or about to fall

off the mating connector of the SV.LINK module.

In cases where the SV.LINK module is networked by

10BASE-5 connections, it is connected to the 12-V

external power supply.

If true, set a unique IP address for the module.

Use a straight cable if you want to connect the

SV.LINK module to a given hub. If you

want to connect it directly to the destination