Hitachi RAS-2WHVNP, RAS-2.5WHVNP, RAS-3WHVNP, RAS-4WHVNPE, RAS-4WHNPE Instruction And Operation Manual

...Page 1

YUTAKI SERIES

Page 2

Page 3

English

Specications in this manual are subject to change without notice in order that HITACHI may bring the latest innovations

to their customers.

Whilst every effort is made to ensure that all specications are correct, printing errors are beyond Hitachi’s control;

Hitachi cannot be held responsible for these errors.

Español

Las especicaciones de este manual están sujetas a cambios sin previo aviso a n de que HITACHI pueda ofrecer las

últimas innovaciones a sus clientes.

A pesar de que se hacen todos los esfuerzos posibles para asegurarse de que las especicaciones sean correctas, los

errores de impresión están fuera del control de HITACHI, a quien no se hará responsable de ellos.

Deutsch

Bei den technischen Angaben in diesem Handbuch sind Änderungen vorbehalten, damit HITACHI seinen Kunden die

jeweils neuesten Innovationen präsentieren kann.

Sämtliche Anstrengungen wurden unternommen, um sicherzustellen, dass alle technischen Informationen ohne Fehler

veröffentlicht worden sind. Für Druckfehler kann HITACHI jedoch keine Verantwortung übernehmen, da sie außerhalb

ihrer Kontrolle liegen.

Français

Les caractéristiques publiées dans ce manuel peuvent être modiées sans préavis, HITACHI souhaitant pouvoir toujours

offrir à ses clients les dernières innovations.

Bien que tous les efforts sont faits pour assurer l’exactitude des caractéristiques, les erreurs d’impression sont hors du

contrôle de HITACHI qui ne pourrait en être tenu responsable.

Italiano

Le speciche di questo manuale sono soggette a modica senza preavviso afnché HITACHI possa offrire ai propri

clienti le ultime novità.

Sebbene sia stata posta la massima cura nel garantire la correttezza dei dati, HITACHI non è responsabile per eventuali

errori di stampa che esulano dal proprio controllo.

Português

As especicações apresentadas neste manual estão sujeitas a alterações sem aviso prévio, de modo a que a HITACHI

possa oferecer aos seus clientes, da forma mais expedita possível, as inovações mais recentes.

Apesar de serem feitos todos os esforços para assegurar que todas as especicações apresentadas são correctas,

quaisquer erros de impressão estão fora do controlo da HITACHI, que não pode ser responsabilizada por estes erros

eventuais.

Dansk

Specikationerne i denne vejledning kan ændres uden varsel, for at HITACHI kan bringe de nyeste innovationer ud til

kunderne.

På trods af alle anstrengelser for at sikre at alle specikationerne er korrekte, har Hitachi ikke kontrol over trykfejl, og

Hitachi kan ikke holdes ansvarlig herfor.

Nederlands

De specicaties in deze handleiding kunnen worden gewijzigd zonder verdere kennisgeving zodat HITACHI zijn klanten

kan voorzien van de nieuwste innovaties.

Iedere poging wordt ondernomen om te zorgen dat alle specicaties juist zijn. Voorkomende drukfouten kunnen echter

niet door Hitachi worden gecontroleerd, waardoor Hitachi niet aansprakelijk kan worden gesteld voor deze fouten.

Svenska

Specikationerna i den här handboken kan ändras utan föregående meddelande för att HITACHI ska kunna leverera de

senaste innovationerna till kunderna.

Vi på Hitachi gör allt vi kan för att se till att alla specikationer stämmer, men vi har ingen kontroll över tryckfel och kan

därför inte hållas ansvariga för den typen av fel.

Eλλhnika

Οι προδιαγραφές του εγχειριδίου μπορούν να αλλάξουν χωρίς προειδοποίηση, προκειμένου η HITACHI να παρέχει τις

τελευταίες καινοτομίες στους πελάτες της.

Αν και έχει γίνει κάθε προσπάθεια προκειμένου να εξασφαλιστεί ότι οι προδιαγραφές είναι σωστές, η Hitachi δεν μπορεί

να ελέγξει τα τυπογραφικά λάθη και, ως εκ τούτου, δεν φέρει καμία ευθύνη για αυτά τα λάθη.

Page 4

! CAUTION

This product shall not be mixed with general house waste at the end of its life and it shall be retired according to the

appropriated local or national regulations in a environmentally correct way.

Due to the refrigerant, oil and other components contained in heat pump, its dismantling must be done by a professional

installer according to the applicable regulations. Contact to the corresponding authorities for more information.

! PRECAUCIÓN

Éste producto no se debe eliminar con la basura doméstica al nal de su vida útil y se debe desechar de manera respetuosa con el

medio ambiente de acuerdo con los reglamentos locales o nacionales aplicables.

Debido al refrigerante, el aceite y otros componentes contenidos en la bomba de calor, su desmontaje debe realizarlo un instalador

profesional de acuerdo con la normativa aplicable. Para obtener más información, póngase en contacto con las autoridades competentes.

! VORSICHT

Dass Ihr Produkt am Ende seiner Betriebsdauer nicht in den allgemeinen Hausmüll geworfen werden darf, sondern entsprechend den

geltenden örtlichen und nationalen Bestimmungen auf umweltfreundliche Weise entsorgt werden muss.

Aufgrund des Kältemittels, Öls und anderer Komponenten in der Wärmepumpe muss ihr Ausbau von einem professionellen

Installateur entsprechend der anwendbaren Vorschriften durchgeführt werden. Für weitere Informationen setzen Sie sich bitte mit den

entsprechenden Behörden in Verbindung.

! ADVERTISSEMENT

Ne doit pas être mélangé aux ordures ménagères ordinaires à la n de sa vie utile et qu’il doit être éliminé conformément à la

réglementation locale ou nationale, dans le plus strict respect de l’environnement.

En raison du frigorigène, de l’huile et des autres composants que contient la pompe à chaleur, son démontage doit être effectué par un

installateur professionnel conformément aux règlementations en vigueur.

! AVVERTENZE

Indicazioni per il corretto smaltimento del prodotto ai sensi della Direttiva Europea 2002/96/EC e Dlgs 25 luglio 2005 n.151

Il simbolo del cassonetto barrato riportato sull’ apparecchiatura indica che il prodotto alla ne della propria vita utile deve essere raccolto

separatamente dagli altri riuti.

L’utente dovrà, pertanto, conferire l’apparecchiatura giunta a ne vita agli idonei centri di raccolta differenziata dei riuti elettronici ed

elettrotecnici, oppure riconsegnarla al rivenditore al momento dell’ acquisto di una nuova apparecchiatura di tipo equivalente.

L’adeguata raccolta differenziata delle apparecchiature dismesse, per il loro avvio al riciclaggio, al trattamento ed allo smaltimento

ambientalmente compatibile, contribuisce ad evitare possibili effetti negativi sull’ ambiente e sulla salute e favorisce il riciclo dei materiali

di cui è composta l’ apparecchiatura.

Non tentate di smontare il sistema o l’unità da soli poichè ciò potrebbe causare effetti dannosi sulla vostra salute o sull’ ambiente.

Vogliate contattare l’ installatore, il rivenditore, o le autorità locali per ulteriori informazioni.

Lo smaltimento abusivo del prodotto da parte dell’utente può comportare l’applicazione delle sanzioni amministrative di cui all’articolo 50

e seguenti del D.Lgs. n. 22/1997.

! CUIDADO

O seu produto não deve ser misturado com os desperdícios domésticos de carácter geral no nal da sua duração e que deve ser

eliminado de acordo com os regulamentos locais ou nacionais adequados de uma forma correcta para o meio ambiente.

Por causa do refrigerante, do óleo e de outros componentes na bomba de calor, o desmantelamento deve ser realizado por um instalador

prossional em conformidade com os regulamentos aplicáveis. Contacte as autoridades correspondentes para obter mais informações.

! ADVASEL!

At produktet ikke må smides ud sammen med almindeligt husholdningsaffald, men skal bortskaffes i overensstemmelse med de

gældende lokale eller nationale regler på en miljømæssig korrekt måde.

Da varmepumpen indeholder kølemiddel, olie samt andre komponenter, skal afmontering foretages af en fagmand i overensstemmelse

med de gældende bestemmelser. Kontakt de pågældende myndigheder for at få yderligere oplysninger.

! VOORZICHTIG

Dit houdt in dat uw product niet wordt gemengd met gewoon huisvuil wanneer u het weg doet en dat het wordt gescheiden op een

milieuvriendelijke manier volgens de geldige plaatselijke en landelijke reguleringen.

Wegens de aanwezigheid van koelmiddel, olie en andere componenten in de warmtepomp moet het apparaat volgens de toepasselijke

regelgeving door een professionele installateur worden gedemonteerd. Neem contact op met de betreffende overheidsdienst voor meer

informatie.

! FÖRSIKTIGHET

Det innebär att produkten inte ska slängas tillsammans med vanligt hushållsavfall utan kasseras på ett miljövänligt sätt i enlighet med

gällande lokal eller nationell lagstiftning.

Eftersom värmepumpen innehåller kylmedel, oljor och andra komponenter, måste den demonteras av en behörig installatör i enlighet

med gällande föreskrifter. Ta kontakt med ansvarig myndighet om du vill ha mer information.

! ΠΡΟΣΟΧΗ

Σημαίνει ότι το προϊόν δεν θα πρέπει να αναμιχθεί με τα διάφορα οικιακά απορρίμματα στο τέλος του κύκλου ζωής του και θα πρέπει να

αποσυρθεί σύμφωνα με τους κατάλληλους τοπικούς ή εθνικούς κανονισμούς και με τρόπο φιλικό προς το περιβάλλον.

Λόγω του ψυκτικού, του λαδιού και άλλων εξαρτημάτων που περιλαμβάνονται στην αντλία θέρμανσης, η αποσυναρμολόγησή του

πρέπει να γίνει από εξουσιοδοτημένο επαγγελματία τεχνικό, σύμφωνα με τους ισχύοντες κανονισμούς. Για περισσότερες λεπτομέρειες,

επικοινωνήστε με τις αντίστοιχες αρχές.

Page 5

MODELS CODIFICATION

Important note: Please, check, according to the model name, which is your heat pump

system, how it is abbreviated and referred to in this instruction manual.

This Installation and Operation Manual is related to YUTAKI Units.

CODIFICACIÓN DE

MODELOS

MODELLCODES

CODIFICATION DES

MODÈLES

CODIFICAZIONE DEI

MODELLI

CODIFICAÇÃO DE MODELOS

MODELKODIFICERING

Nota importante: compruebe, de acuerdo con el nombre del modelo, el tipo de bomba

de calor, su abreviatura y su referencia en el presente manual de instrucciones. Este

Manual de instalación y funcionamiento está relacionado con unidades YUTAKI.

Wichtiger Hinweis: Bitte stellen Sie anhand der Modellbezeichnung den Typ der

Wärmepumpe und das entsprechende, in diesem Technischen Handbuch verwendete

Kürzel fest. Dieses Installations- und Betriebshandbuch bezieht sich auf die YUTAKI

Geräte

Note importante : veuillez déterminer, d’après le nom du modèle, quel est votre type de

pompe à chaleur et quelle est son abréviation et référence dans ce manuel d’instruction.

Ce manuel d’installation et de fonctionnement concerne les unités YUTAKI.

Nota importante: controllare in base al modello il tipo di pompa di calore, la descrizione

e il tipo di abbreviazione utilizzati nel manuale di istruzioni. Questo Manuale di

installazione e d’uso è relativo alle unità YUTAKI.

Nota Importante: de acordo com o nome do modelo, verique o tipo da sua bomba de

calor e a respetiva abreviatura e menção neste manual de instruções. Este manual de

instalação e de funcionamento está relacionado com unidades YUTAKI

Vigtig information: Kontrollér venligst din varmepumpetype i henhold til modelnavnet,

hvordan den forkortes, og hvilken reference den har i denne vejledning. Denne

installations- og betjeningsvejledning gælder for YUTAKI-enheder.

CODERING VAN DE

MODELLEN

MODELLER

ΚΩΔΙΚΟΠΟΙΗΣΗ ΜΟΝΤΕΛΩΝ

Belangrijke opmerking: Controleer aan de hand van de modelnaam welk type

warmtepomp u heeft, hoe de naam wordt afgekort en hoe ernaar wordt verwezen in deze

instructiehandleiding. Deze installatie- en gebruikshandleiding geldt voor YUTAKI-units.

Viktigt! Kontrollera med modellnamnet vilken typ av värmepump du har, hur den

förkortas och hur den anges i den här handboken. Denna Installations- och

driftshandbok gäller för YUTAKI-enheter.

Σημαντική σημείωση: Ελέγξτε, σύμφωνα με το όνομα μοντέλου, τον τύπο της δικής

σας αντλίας θέρμανσης και με ποια σύντμηση δηλώνεται και αναφέρεται σε αυτό το

εγχειρίδιο. Το παρόν εγχειρίδιο εγκατάστασης και λειτουργίας αναφέρεται στις μονάδες

YUTAKI.

EN English Original version

ES Español Versión traducida

DE Deutsch Übersetzte Version

FR Français Version traduite

IT Italiano Versione tradotta

PT Português Versão traduzidal

DA Dansk Oversat version

NL Nederlands Vertaalde versie

SV Svenska Översatt version

EL Ελληνικα Μεταφρασμένη έκδοση

Page 6

Page 7

General Index

1 GENERAL INFORMATION .............................................................................................. 1

1.1 General information ................................................................................................................................. 1

1.1.1 General notes .................................................................................................................................................. 1

1.1.2 Introduction ..................................................................................................................................................... 1

1.1.2.1 Overview of YUTAKI system .............................................................................................................. 1

1.1.2.2 Summary of operations ...................................................................................................................... 2

1.2 Applied symbols ......................................................................................................................................4

1.3 Product guide ..........................................................................................................................................5

1.3.1 Classication of the units ................................................................................................................................. 5

1.3.1.1 Split system - Outdoor unit ................................................................................................................. 5

1.3.1.2 Split system - Indoor unit .................................................................................................................... 5

1.3.1.3 Monobloc system ............................................................................................................................... 6

1.3.2 Product list ....................................................................................................................................................... 7

1.3.2.1 Split system - Outdoor unit ................................................................................................................. 7

1.3.2.2 Split system - Indoor unit .................................................................................................................... 7

1.3.2.3 Monobloc system ............................................................................................................................. 10

1.3.3 Accessory code list .........................................................................................................................................11

2 GENERAL SAFETY NOTES ..........................................................................................15

2.1 ADDITIONAL INFORMATION ABOUT Safety .......................................................................................15

2.2 Important notice.....................................................................................................................................15

3 GENERAL DATA ............................................................................................................ 16

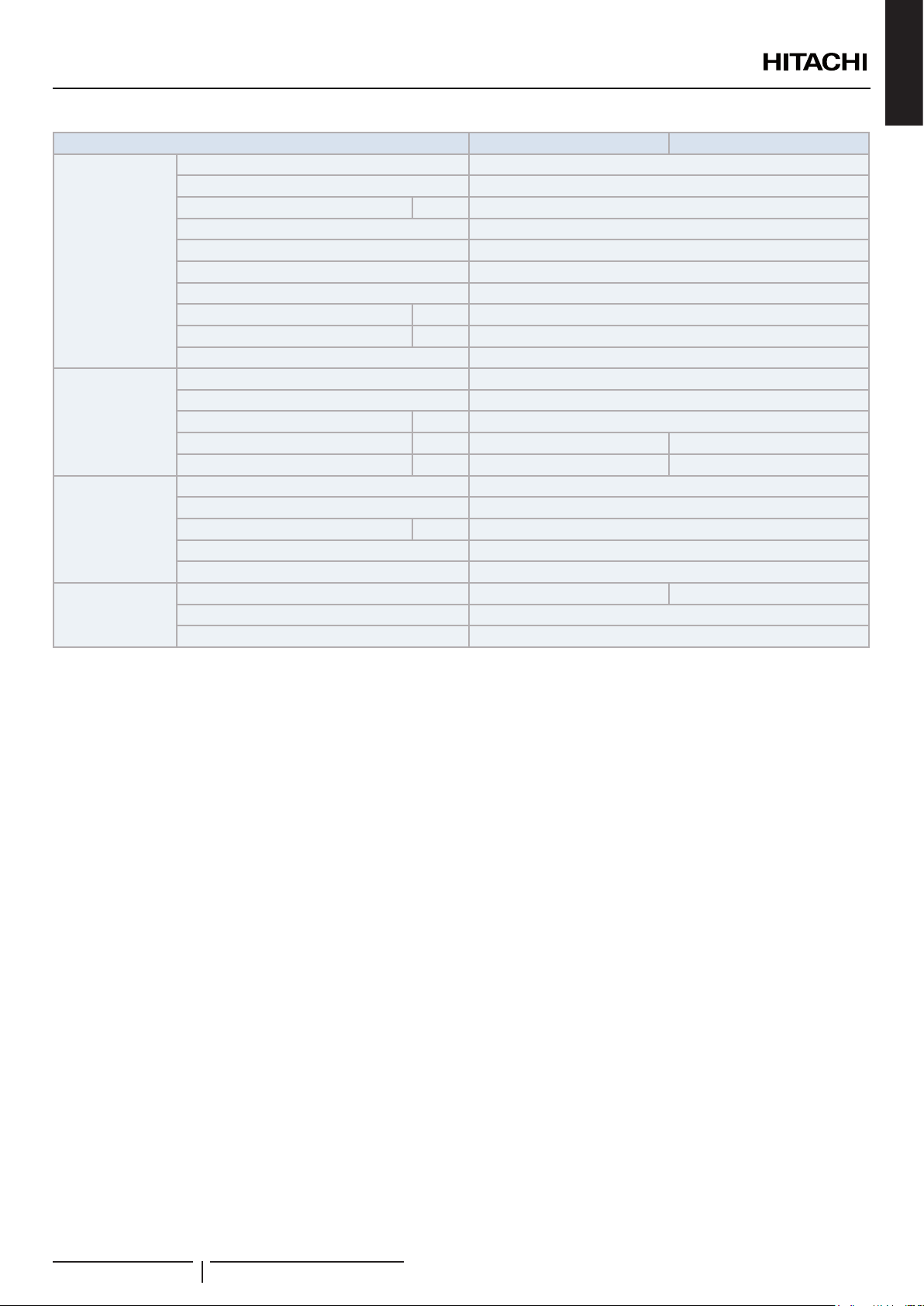

3.1 Capacity tables ...................................................................................................................................... 16

3.1.1 Nominal capacity-performance tables ........................................................................................................... 16

3.1.1.1 Considerations ................................................................................................................................. 16

3.1.1.2 Capacity-performance data .............................................................................................................. 16

3.2 ERP performance data ..........................................................................................................................19

3.2.1 General considerations ................................................................................................................................. 19

3.2.2 General ERP data for space heaters ............................................................................................................ 19

3.2.2.1 ERP data - YUTAKI S ....................................................................................................................... 19

3.2.2.2 ERP data - YUTAKI S COMBI .......................................................................................................... 23

3.2.2.3 ERP data - YUTAKI S80 ................................................................................................................... 26

3.2.2.4 ERP data - YUTAKI M ...................................................................................................................... 28

3.2.2.5 ERP additional data - YUTAKI S ...................................................................................................... 30

3.2.2.6 ERP additional data - YUTAKI S COMBI ......................................................................................... 31

3.2.2.7 ERP additional data - YUTAKI S80 .................................................................................................. 32

3.2.2.8 ERP additional data - YUTAKI M ...................................................................................................... 32

VII

PMML0335A rev.1 - 04/2016

Page 8

3.3 General specications ........................................................................................................................... 33

3.3.1 Considerations .............................................................................................................................................. 33

3.3.2 Split system - Outdoor unit ............................................................................................................................ 33

3.3.3 Split system - Indoor unit ............................................................................................................................... 36

3.3.3.1 YUTAKI S ......................................................................................................................................... 36

3.3.3.2 YUTAKI S COMBI ............................................................................................................................ 39

3.3.3.3 YUTAKI S80 ..................................................................................................................................... 45

3.3.4 Monobloc system - YUTAKI M....................................................................................................................... 48

3.4 Component data .................................................................................................................................... 50

3.4.1 Split system - Outdoor unit ............................................................................................................................ 50

3.4.2 Split system - Indoor unit ............................................................................................................................... 52

3.4.2.1 YUTAKI S ......................................................................................................................................... 52

3.4.2.2 YUTAKI S COMBI ............................................................................................................................ 53

3.4.2.3 YUTAKI S80 ..................................................................................................................................... 57

3.4.2.4 DHW tank ......................................................................................................................................... 58

3.5 Electrical data ........................................................................................................................................ 61

3.5.1 Considerations .............................................................................................................................................. 61

3.5.2 Split system - Outdoor unit ............................................................................................................................ 61

3.5.3 Split system - Indoor unit ............................................................................................................................... 62

3.5.3.1 YUTAKI S ......................................................................................................................................... 62

3.5.3.2 YUTAKI S COMBI ............................................................................................................................ 62

3.5.3.3 YUTAKI S80 ..................................................................................................................................... 63

3.5.4 Monobloc system - YUTAKI M....................................................................................................................... 64

4 WORKING RANGE ........................................................................................................ 65

4.1 Power supply working range .................................................................................................................65

4.2 Temperature working range................................................................................................................... 65

4.2.1 Space heating ............................................................................................................................................... 65

4.2.2 DHW .............................................................................................................................................................. 67

4.2.3 Swimming pool heating ................................................................................................................................. 68

4.2.4 Space cooling (Necessary cooling kit) .......................................................................................................... 68

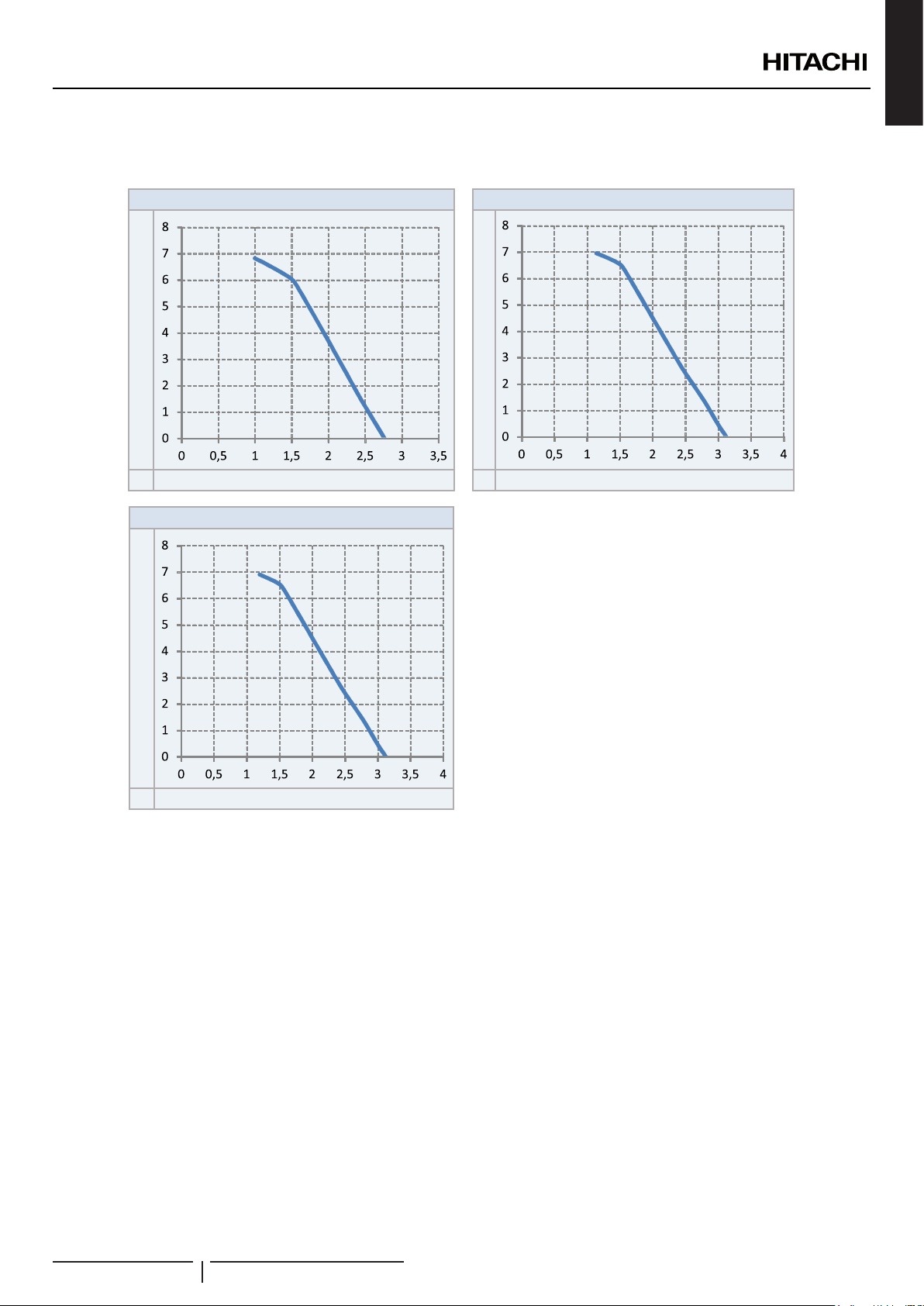

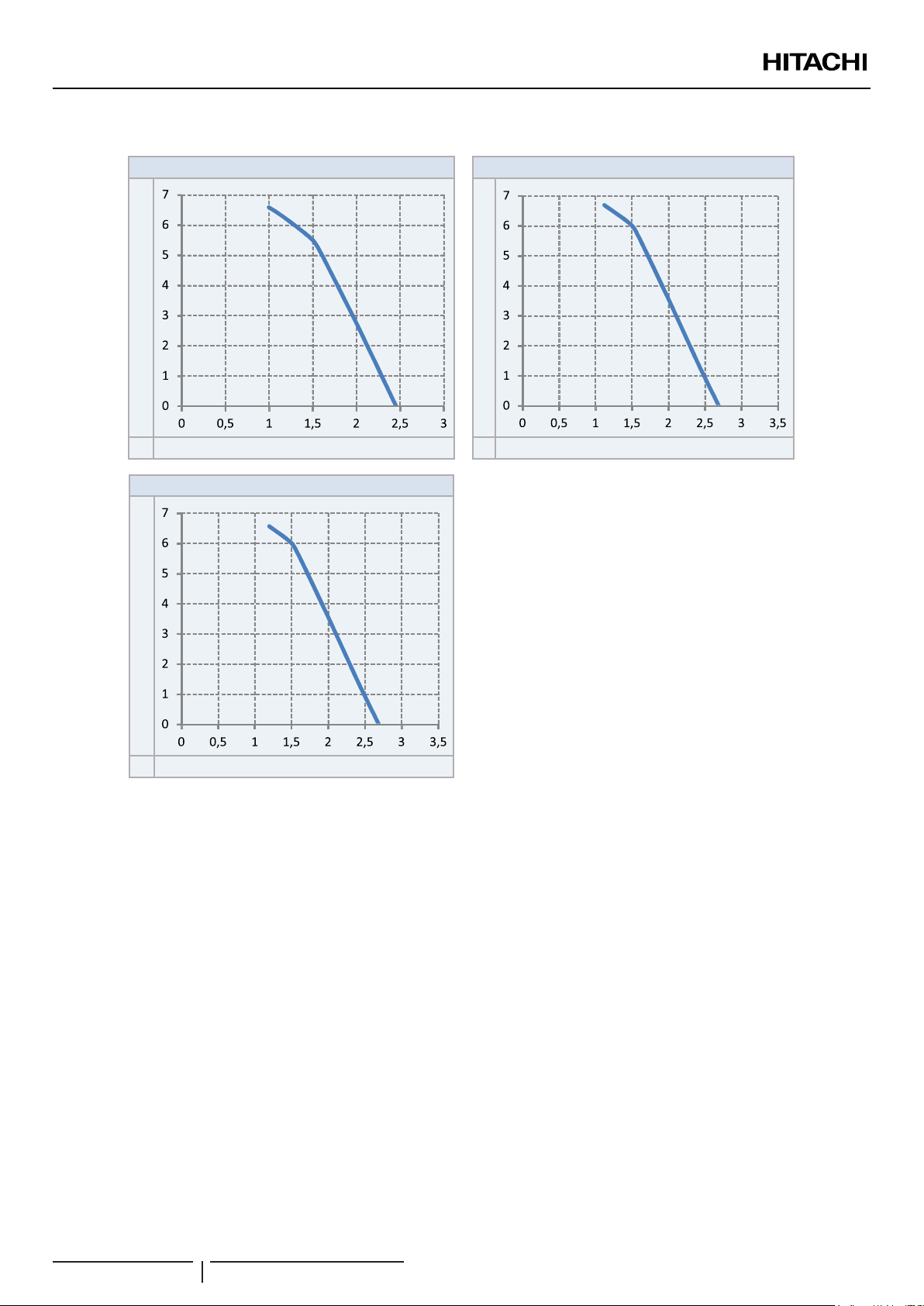

4.3 Hydraulic working range ........................................................................................................................ 69

4.3.1 Hydraulic data ............................................................................................................................................... 69

4.3.2 Pump performance curves ............................................................................................................................ 70

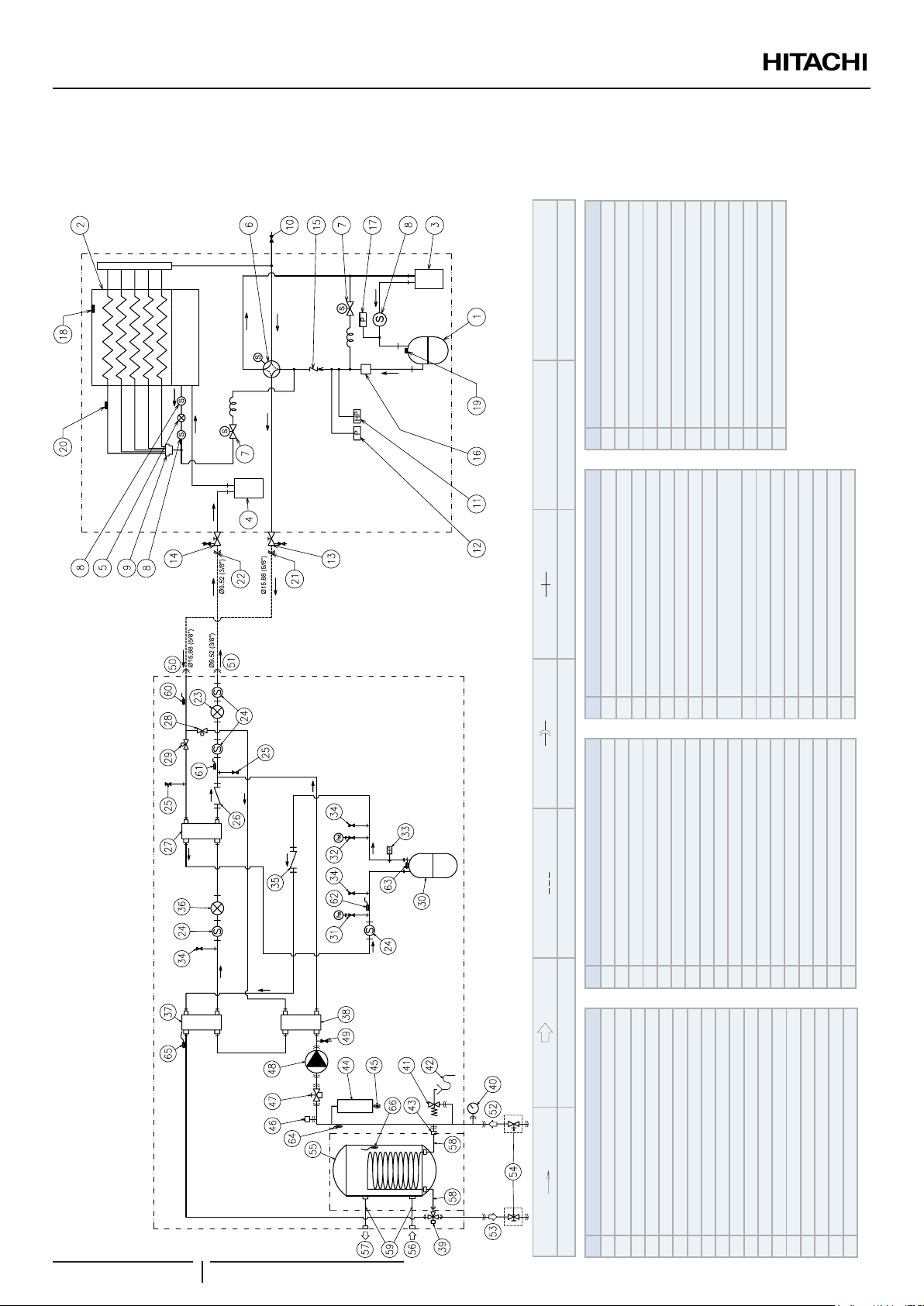

5 REFRIGERANT CYCLE AND HYDRAULIC CIRCUIT .................................................. 76

5.1 Refrigerant cycle and hydraulic circuit for Split system ......................................................................... 76

5.1.1 YUTAKI S ...................................................................................................................................................... 76

5.1.2 YUTAKI S COMBI.......................................................................................................................................... 79

5.1.3 YUTAKI S80 .................................................................................................................................................. 81

5.1.3.1 Indoor unit standalone version ......................................................................................................... 81

VIII

PMML0335A rev.1 - 04/2016

Page 9

5.1.3.2 Indoor unit for integrated tank version .............................................................................................. 82

5.2 Refrigerant cycle and hydraulic circuit for Monobloc system - YUTAKI M ............................................83

6 REFRIGERANT AND WATER PIPING ..........................................................................85

6.1 Refrigerant circuit ..................................................................................................................................85

6.1.1 Refrigerant piping .......................................................................................................................................... 85

6.1.2 Precautions in the event of gas refrigerant leaks .......................................................................................... 86

6.1.3 Water piping .................................................................................................................................................. 87

6.1.4 Water quality (Preliminary information) ....................................................................................................... 90

6.1.5 Water ow control .......................................................................................................................................... 90

7 ELECTRICAL AND CONTROL SETTINGS ...................................................................91

7.1 General check .......................................................................................................................................91

7.2 Electrical connection .............................................................................................................................94

7.2.1 Wiring size ..................................................................................................................................................... 94

7.2.2 Minimum requirements of the protection devices .......................................................................................... 96

7.3 Setting of DIP switches and RSW switches ..........................................................................................99

7.3.1 Outdoor unit ................................................................................................................................................... 99

7.3.1.1 Location of DIP switches and rotary switches .................................................................................. 99

7.3.1.2 Function of DIP switches and rotary switches ................................................................................ 100

7.3.1.3 LED indication ................................................................................................................................ 102

7.4 Terminal board connections ................................................................................................................ 103

7.4.1 Table board 1 ............................................................................................................................................... 103

7.4.2 Table board 2 ............................................................................................................................................... 104

8 UNIT CONTROLLER ................................................................................................... 110

8.1 DEFINITION OF THE SWITCHES ...................................................................................................... 11 0

8.2 Description of the icons ........................................................................................................................111

8.2.1 Common icons .............................................................................................................................................111

8.2.2 Icons for the comprehensive view ................................................................................................................112

8.2.3 Icons for the room thermostat view ..............................................................................................................113

8.3 CONTENTS ......................................................................................................................................... 114

8.4 MAIN SCREEN ................................................................................................................................... 116

8.4.1 Comprehensive view ....................................................................................................................................116

8.4.2 Room thermostat view ..................................................................................................................................117

8.5 WIZARD START-UP CONFIGURATION ............................................................................................. 11 8

8.5.1 Conguration Assistant .................................................................................................................................119

8.5.1.1 General overview ............................................................................................................................119

8.5.1.2 Questions ....................................................................................................................................... 120

8.5.1.3 Results ........................................................................................................................................... 122

IX

PMML0335A rev.1 - 04/2016

Page 10

8.5.1.4 Examples of possible congurations .............................................................................................. 124

8.5.1.5 Not allowed congurations ............................................................................................................. 129

8.5.2 Advanced Conguration .............................................................................................................................. 129

8.5.2.1 Screen 1 ......................................................................................................................................... 129

8.5.2.2 Screen 2 ......................................................................................................................................... 129

8.5.2.3 Screen 3 ........................................................................................................................................ 130

8.5.2.4 Screen 4 ......................................................................................................................................... 130

8.6 Menu navigation .................................................................................................................................. 131

8.6.1 Operation information .................................................................................................................................. 131

8.6.1.1 General .......................................................................................................................................... 132

8.6.1.2 Circuit 1 .......................................................................................................................................... 132

8.6.1.3 Circuit 2 .......................................................................................................................................... 133

8.6.1.4 DHW ............................................................................................................................................... 133

8.6.1.5 Swimming Pool .............................................................................................................................. 133

8.6.1.6 Heat Pump Details .................................................................................................................... 133

8.6.1.7 Electrical Heater ........................................................................................................................ 134

8.6.1.8 Boiler Combination .................................................................................................................... 134

8.6.1.9 Solar Combination ..................................................................................................................... 135

8.6.1.10 Alarm History ................................................................................................................................ 135

8.6.1.11 Energy data .................................................................................................................................. 135

8.6.2 System Conguration .................................................................................................................................. 136

8.6.2.1 General Options ............................................................................................................................ 136

8.6.2.2 Timer and Schedule ....................................................................................................................... 140

8.6.2.3 Water settings ............................................................................................................................... 142

8.6.2.4 Space Heating ........................................................................................................................... 144

8.6.2.5 Space Cooling ........................................................................................................................... 147

8.6.2.6 DHW ............................................................................................................................................... 150

8.6.2.7 Swimming Pool .............................................................................................................................. 152

8.6.2.8 Complementary Heating ................................................................................................................ 152

8.6.2.9 Heat Pump ................................................................................................................................ 155

8.6.2.10 Optional Functions ....................................................................................................................... 156

8.6.2.11 I/O and Sensor ......................................................................................................................... 158

8.6.3 Controller Settings ....................................................................................................................................... 161

8.6.3.1 Controller Options .......................................................................................................................... 162

8.6.3.2 Room Names ................................................................................................................................. 162

8.6.3.3 Date and Time ................................................................................................................................ 162

8.6.3.4 Screen Settings .............................................................................................................................. 164

8.6.3.5 Language selection ........................................................................................................................ 164

8.6.4 Commisioning ......................................................................................................................................... 165

8.6.4.1 Air Purge Procedure ....................................................................................................................... 165

8.6.4.2 Unit test run ............................................................................................................................... 165

8.6.4.3 Screed Drying ............................................................................................................................ 166

8.6.5 About ........................................................................................................................................................... 166

X

PMML0335A rev.1 - 04/2016

Page 11

8.6.5.1 System Information ........................................................................................................................ 166

8.6.5.2 Contact Information ........................................................................................................................ 166

8.6.6 Factory Reset ......................................................................................................................................... 167

8.6.7 Return to user mode ............................................................................................................................... 167

8.7 INDEX OF REFERENCES .................................................................................................................. 168

9 TROUBLESHOOTING ................................................................................................. 171

10 MAINTENANCE ......................................................................................................... 174

10.1 Maintenance work ............................................................................................................................... 174

10.1.1 General maintenance procedure for the outdoor unit ................................................................................ 174

10.1.2 General maintenance procedure for the indoor unit .................................................................................. 175

XI

PMML0335A rev.1 - 04/2016

Page 12

Page 13

GENERAL INFORMATION

1 GENERAL INFORMATION

1.1 GENERAL INFORMATION

1.1.1 General notes

© Copyright 2016 HITACHI Air Conditioning Products Europe, S.A.U. – All rights reserved.

No part of this publication may be reproduced, copied, led or transmitted in any shape or form without the permission of HITACHI

Air Conditioning Products Europe, S.A.U.

Within the policy of continuous improvement of its products, HITACHI Air Conditioning Products Europe, S.A.U. reserves the right to

make changes at any time without prior notication and without being compelled to introducing them into previously sold products.

This document may therefore have been subject to amendments during the life of the product.

HITACHI makes every effort to offer correct, up-to-date documentation. Despite this, printing errors cannot be controlled by HITACHI

and are not its responsibility.

As a result, some of the images or data used to illustrate this document may not refer to specic models. No claims will be accepted

based on the data, illustrations and descriptions included in this manual.

No type of modication must be made to the equipment without prior, written authorization from the manufacturer.

ENGLISH

1.1.2 Introduction

HITACHI proudly announces the newest complete range of air-to-water heat pumps in its award-winning YUTAKI range.

YUTAKI units produce heating and domestic hot water like any oil or gas boiler, but transforming renewable energy from the outside

air into heat. Air to water heat pumps extract the free energy present in the air, which is enough to heat a home up to a comfortable

temperature, even on the coldest winter day. Every kW of electricity used to power the heat pump can yield up to more than 5 kW of

energy for heating; this provides savings of up to 80% on heating expenses compared to a traditional fossil fuel boiler.

The new YUTAKI series, based on state-of-the-art technology, does not only achieve an outstanding performance in space heating

but also provides domestic hot water with high efciency. Additionally, cooling operation for summer can also be provided installing

the dedicated “Cooling kit” accessory of HITACHI.

The system is simple to control; its new user controller (PC-ARFHE) improves the acclaimed and successful design used with the

existing LCD controller and provides a great deal of new functions like: wizard start-up conguration, auto cool/heat, improved timer,

etc.

1.1.2.1 Overview of YUTAKI system

The wide range of YUTAKI products is basically divided in two types of system:

• Split system

• Monobloc system

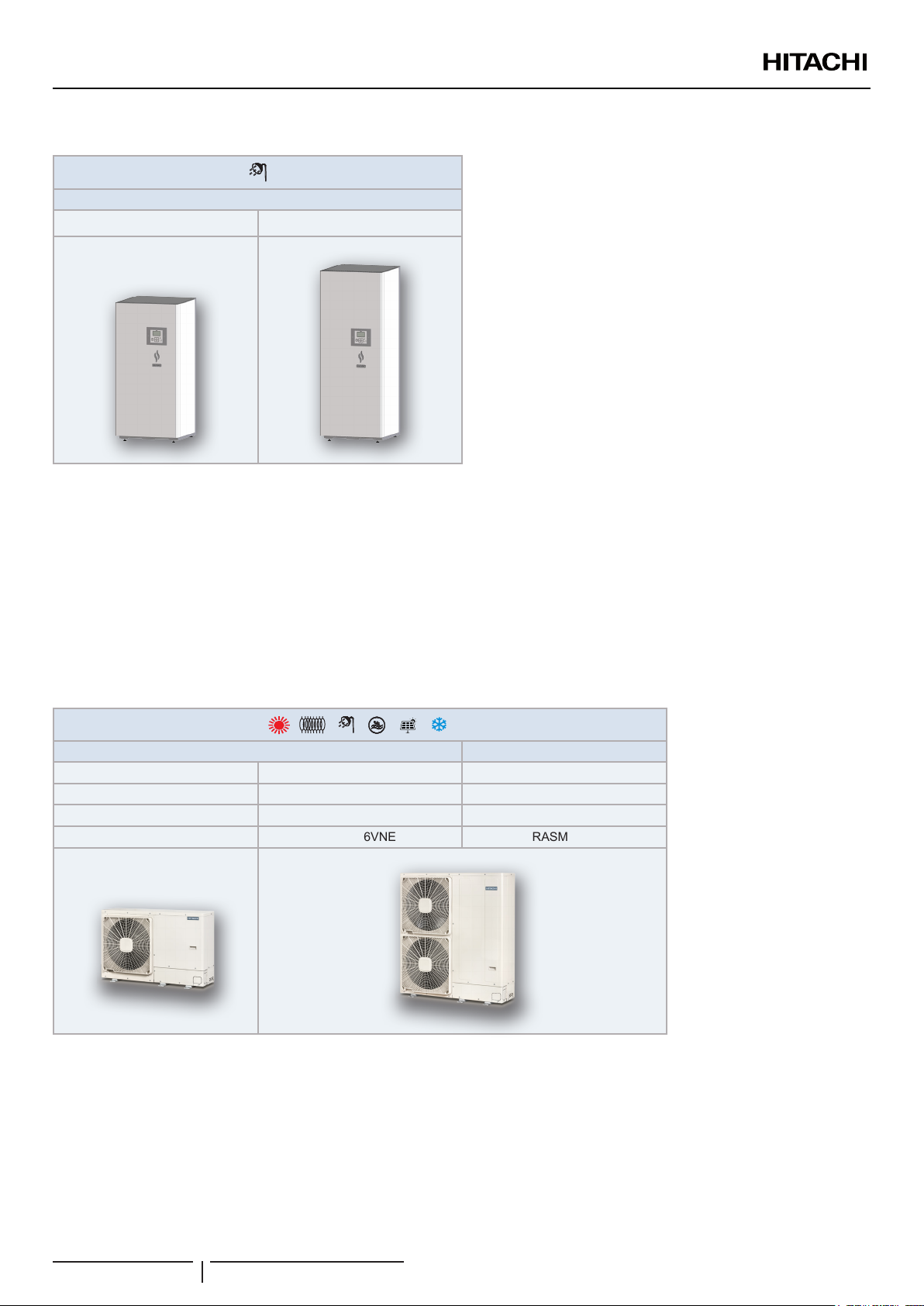

Split system - YUTAKI S, YUTAKI S COMBI, YUTAKI S80

It consists of one outdoor unit and one indoor unit. The outdoor unit extracts the heat present in the air, increases its refrigerant

temperature and transmits it to the water circuit using the plate heat exchanger of the indoor unit where the heat is taken to radiators

(fan-coils), underoor heating components or both (2nd temperature area).

Three types of indoor unit can be used in heating split systems:

YUTAKI S

The indoor unit of YUTAKI S is designed for space heating, in wall-mounted installation. It is convenient for new installations with low

capacity requirements (Well isolated installations, high efciency radiators...).

YUTAKI S COMBI

The indoor unit of YUTAKI S COMBI is conceived as a oor standing unit. It is prepared for heating operation as well as for domestic

hot water production. For this purpose, it has a built-in domestic hot water tank available in two sizes (200 or 260 L). In line with

YUTAKI S units, it meets the needs of installations with low capacity requirements.

Furthermore, special YUTAKI S COMBI models have been designed with a specic solar tank for the use of solar panels.

Also, new models of YUTAKI S Combi have been specially designed for the UK market that meet the requirements referred in the

UK Building Regulations.

1

PMML0335A rev.1 - 04/2016

Page 14

GENERAL INFORMATION

YUTAKI S80

The YUTAKI S80 is a standalone indoor unit that generates hot water up to 80ºC; the hottest water temperature in the domestic

heating market using renewable energy.

The extra innovation in the YUTAKI S80 lies in that it has two compressors, working in a smart cascade system, with two refrigerant

cycles (R-410A and R-134a). To maximize seasonal efciency, the second refrigerant cycle is only operated as a booster, when very

high water temperature is required - the rest of the time, only one cycle is used.

The YUTAKI S80 is ideal for existing properties, in particular older installations where high water supply temperatures may be

required to keep the house warm – as well as for new buildings. It is designed for the replacement of boilers, offering heating and

sanitary hot water all year round, without boiler back-up.

Two different models have been designed for different purposes: one model for space heating only and the other one for space

heating as well as for DHW operation. For DHW operation (optional), HITACHI offers two specic YUTAKI S80 DHW tanks

(DHWS200S-2.7H2E and DHWS260S-2.7H2E) which may be placed on top of the indoor unit or besides it, as an integrated unit to

provide high-temperature domestic hot water enjoying the benets of the high efciency of the heat pump.

Monobloc system - YUTAKI M

YUTAKI M is a monobloc air to water heat pump system, composed by only an special outdoor unit, which carries out the function of

an air-to-water heat pump. This results in an excellent solution when installation space available is limited.

YUTAKI M is designed to be installed outdoors, in any kind of dwelling (house, apartment, villa,…), whether in a new construction or

in an existing building. Installation work is greatly simplied thanks to the lack of refrigerant piping connections.

1.1.2.2 Summary of operations

Space heating

YUTAKI units are factory-supplied ready for space heating operation. Different heating installation congurations can be selected

providing a comfortable atmosphere all year long even in the coldest climates:

• Mono-valent system

The air to water heat pump is sized to provide 100% of the heating requirements on the coldest day the year.

• Mono-energy system

This is the most popular conguration. The air to water heat pump is sized to provide 80% of the heating requirements on the

coldest days of the year. An auxiliary electric heater is used to provide the additional heating required on cold days. This option

usually results in an ideal balance between installation costs and future energy consumption, as proven by its popularity in colder

climates than ours, such as Sweden and Norway.

• Alternating Bi-valent system

For installations with an existing heating system by boiler, and when is needed to heat the supplied water temperature to the

circuit up to high temperatures (80ºC), the boiler can be congured to alternate with the air to water heat pump.

Selecting the different conguration types it is possible to adapt the system to all customer requirements, providing a wide

application range from the simplest conguration to complete conguration: Radiator, heating oor or both (2nd temperature area).

Domestic hot water production

YUTAKI models also give the option of domestic hot water production, allowing the user to benet from the heat pump’s high

efciency and achieve domestic hot water.

This is made possible by a domestic hot water tank. In case of YUTAKI S COMBI, the domestic hot water tank is built in the indoor

unit. In YUTAKI S80, a specic DHW tank is designed for combination with the indoor unit. For YUTAKI S and YUTAKI M, the

HITACHI accessory “DHWT-(200/300)S-3.0H2E” can be used for the production of DHW.

An electric heater is incorporated inside the tank in order to allow an immediate heating of the domestic hot water in accordance with

the user’s needs.

2

PMML0335A rev.1 - 04/2016

Page 15

GENERAL INFORMATION

Space cooling

YUTAKI units can also be operated in cooling operation The dedicated “Cooling kit” accessory has been designed for this purpose.

Combining the heating only models with these cooling kits, the reversible models become available. In this case, combination with

fan-coils, refreshing oor or both (2nd temperature area) can be applied.

Combination with solar panels

YUTAKI system can be combined with solar panels. The solar combination enables to heat up the DHW by means of the sun. The

solar combination is designed to transfer the heat from the solar panels (sun radiation) to the heat exchanger of DHW tank.

In case of YUTAKI S COMBI, a specic model with integrated tank for solar combination has been designed, as explained before.

Swimming pool water heating operation

For summer session period, YUTAKI system can be used to heat the water temperature of swimming pools up to a value between

24 and 33ºC.

ENGLISH

3

PMML0335A rev.1 - 04/2016

Page 16

GENERAL INFORMATION

1.2 APPLIED SYMBOLS

During normal heat pump system design work or unit installation, greater attention must be paid in certain situations requiring

particular care in order to avoid damage the unit, the installation or the building or property.

Situations endangering the safety of those in the surrounding area or to the unit itself are clearly indicated in this manual.

Special symbols are used to clearly identify these situations.

Pay close attention to these symbols and to the messages following them, as your safety and that of others depends on it.

! DANGER

• The text following this symbol contains information and instructions relating directly to your safety.

• Not taking these instructions into account could lead to serious, very serious or even fatal injuries to you and others.

In the texts following the danger symbol you can also nd information on safety procedures during unit installation.

! CAUTION

• The text following this symbol contains information and instructions relating directly to your safety.

• Not taking these instructions into account could lead to minor injuries to you and others.

• Not taking these instructions into account could lead to unit damage.

In the texts following the caution symbol you can also nd information on safety procedures during unit installation.

? NOTE

• The text following this symbol contains information or instructions that may be of use or that requires a more thorough explanation.

• Instructions regarding inspections to be made on unit parts or systems may also be included.

4

PMML0335A rev.1 - 04/2016

Page 17

GENERAL INFORMATION

1.3 PRODUCT GUIDE

1.3.1 Classication of the units

1.3.1.1 Split system - Outdoor unit

Unit type: Outdoor unit (Split air system)

Position-separating hyphen (xed)

Compressor power (HP): 2, 2.5, 3, 4, 5, 6, 8, 10.

For water combination

Heat pump

V: Single phase unit (1~ 230V 50Hz)

—: Three phase unit (3N~ 400V 50Hz)

R410A refrigerant

Premium series

RAS - X W H (V) N P (E)

ENGLISH

E: Made in Europe

—: Made in Japan

1.3.1.2 Split system - Indoor unit

YUTAKI S

Unit type: YUTAKI S (Split system - Single water module (Indoor unit) - Medium/Low temperature)

Position-separating hyphen (xed)

Compressor power of the combined outdoor unit (HP): 2.0, 2.5, 3.0, 4.0, 5.0, 6.0, 8.0, 10.0.

—: Heating only

C: Reversible

R410A refrigerant

Made in Europe

RWM - X.X (X) N E

YUTAKI S COMBI

Unit type: YUTAKI S COMBI (Split system - Dual water module (Indoor unit + Domestic hot water tank) - Medium/Low temperature)

Position-separating hyphen (xed)

Compressor power of the combined outdoor unit (HP): 2.0, 2.5, 3.0, 4.0, 5.0, 6.0.

R-410A refrigerant

Water-to-water DHW heat exchanger

— : Standard model

S : Model for solar combination

Made in Europe

Position-separating hyphen (xed)

Tank model: 200/260 L

Tank material: Stainless steel

-K: Model for UK market

RWD - X.X N W (X) E - XXX S (-K)

5

PMML0335A rev.1 - 04/2016

Page 18

GENERAL INFORMATION

YUTAKI S80

Indoor unit

Unit type: YUTAKI S80 (Split system - Single water module (Indoor unit) - High & Very High temperature)

Position-separating hyphen (xed)

Compressor power (HP): 4.0, 5.0, 6.0.

V: Single phase unit (1~ 230V 50Hz)

—: Three phase unit (3N~ 400V 50Hz)

R-410A refrigerant

R-134a refrigerant

—: Type1: Version for operation in DHW with a remote tank

W: Type2: Version for operation with Hitachi DHW tank

Made in Europe

RWH - X.X (V) N F (W) E

Domestic hot water tank (For combination with YUTAKI S80 indoor unit standalone version)

Unit type: YUTAKI S80 domestic hot water tank

Model: 200/260 L

Tank material: Stainless steel

Position-separating hyphen (xed)

Electric heater of 2.7 kW

Series

Made in Europe

DHWS XXX S - 2.7H 2 E

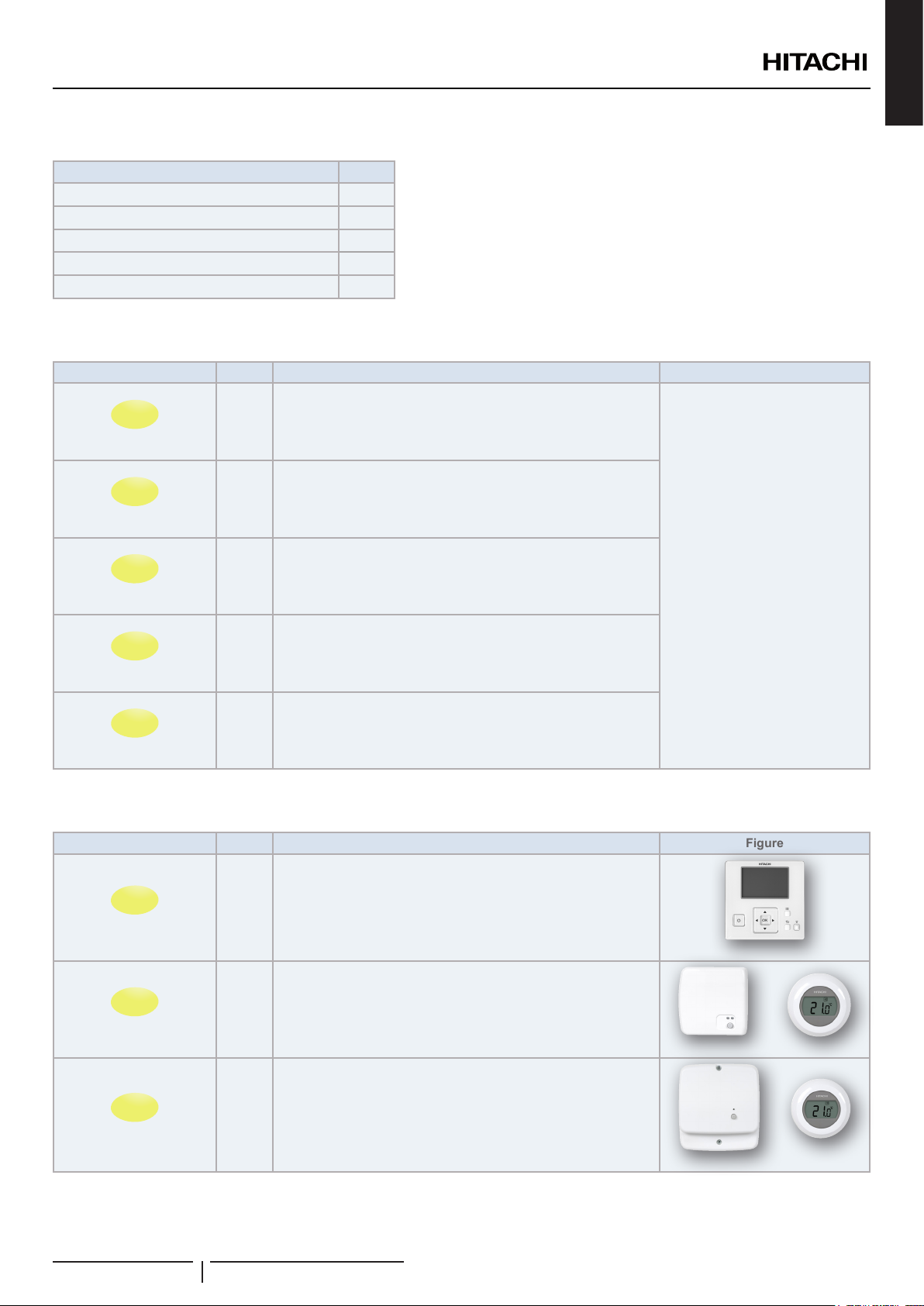

1.3.1.3 Monobloc system

YUTAKI M

Unit type: YUTAKI M (Monobloc system - Single water module (Outdoor unit) - Low/Medium temperature)

Position-separating hyphen (xed)

Compressor power (HP): 3.0, 4.0, 5.0, 6.0.

V: Single phase unit (1~ 230V 50Hz)

—: Three phase unit (3N~ 400V 50Hz)

R410 refrigerant

Made in Europe

RASM - X.X (V) N E

6

PMML0335A rev.1 - 04/2016

Page 19

GENERAL INFORMATION

1.3.2 Product list

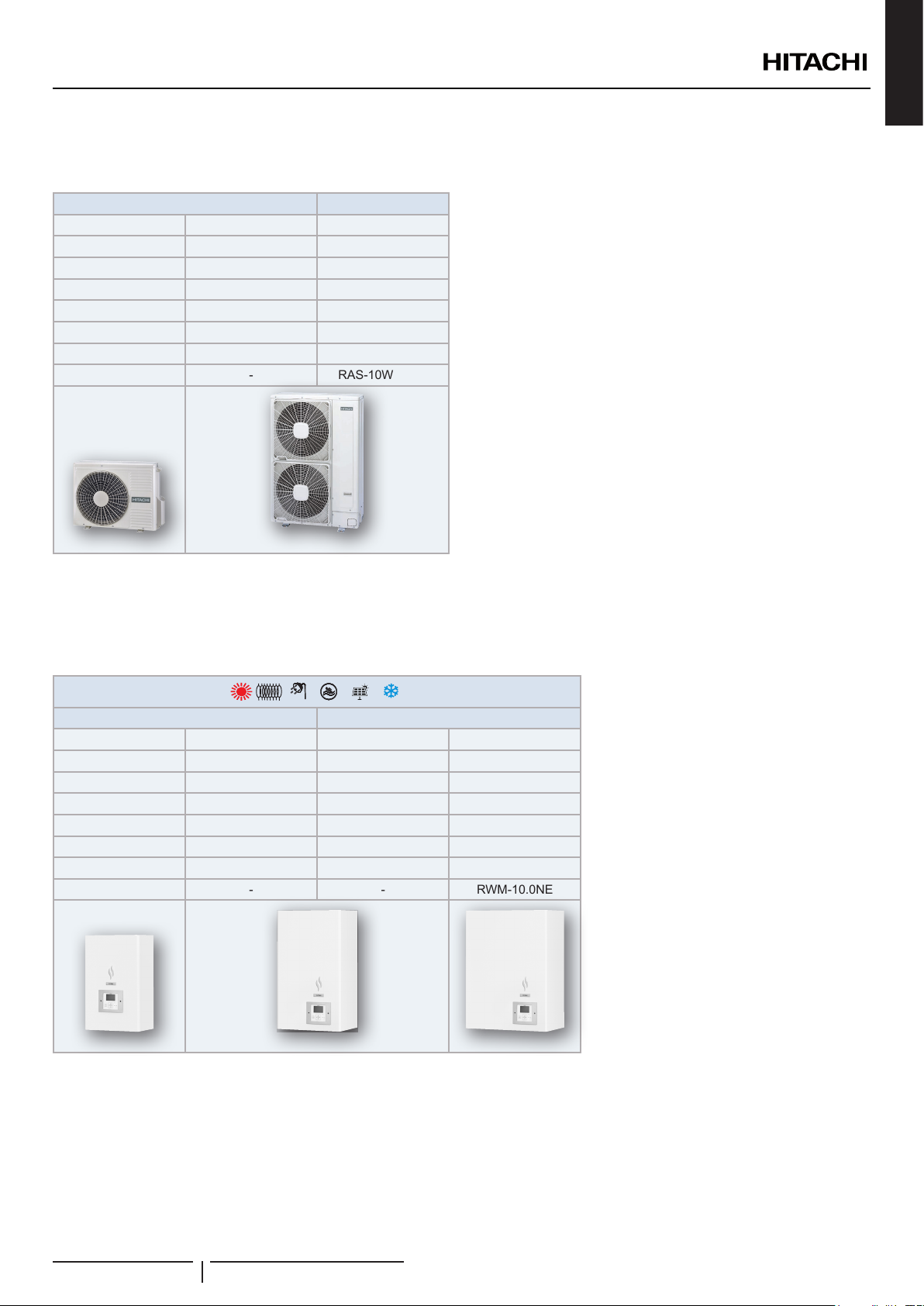

1.3.2.1 Split system - Outdoor unit

1~ 230V 50Hz 3N~ 400V 50Hz

RAS-2WHVNP - -

RAS-2.5WHVNP - -

RAS-3WHVNP - -

- RAS-4WHVNPE RAS-4WHNPE

- RAS-5WHVNPE RAS-5WHNPE

- RAS-6WHVNPE RAS-6WHNPE

- - RAS-8WHNPE

- - RAS-10WHNPE

ENGLISH

1.3.2.2 Split system - Indoor unit

YUTAKI S

(

(

(

1~ 230V 50Hz 3N~ 400V 50Hz

RWM-2.0NE - - RWM-2.5NE - - RWM-3.0NE - - -

- RWM-4.0NE RWM-4.0NE -

- RWM-5.0NE RWM-5.0NE -

- RWM-6.0NE RWM-6.0NE -

- - - RWM-8.0NE

- - - RWM-10.0NE

)

(

)

)

)

? NOTE

Icons between brackets means possible extra operations to the factory-supplied operations. For cooling operation, refer to the Cooling kit accessory

for YUTAKI S units.

7

PMML0335A rev.1 - 04/2016

Page 20

GENERAL INFORMATION

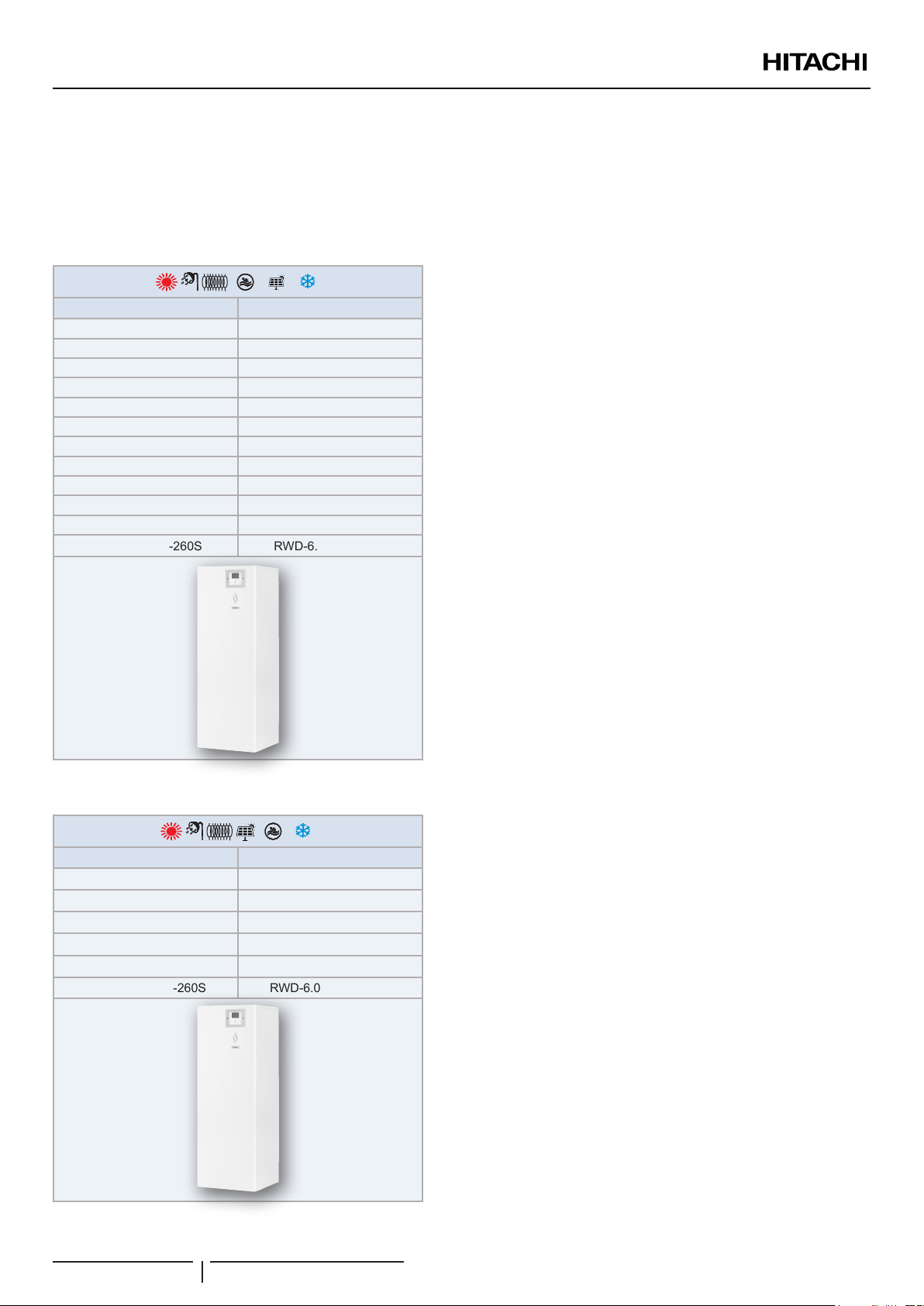

YUTAKI S COMBI

? NOTE

Icons between brackets means possible extra operations to the factory-supplied operations. For cooling operation, refer to the Cooling kit accessory

for YUTAKI S COMBI units.

Standard model

(

(

(

)

)

1~ 230V 50Hz 3N~ 400V 50Hz

RWD-2.0NWE-200S RWD-2.0NWE-260S RWD-2.5NWE-200S RWD-2.5NWE-260S RWD-3.0NWE-200S RWD-3.0NWE-260S RWD-4.0NWE-200S RWD-4.0NWE-200S

RWD-4.0NWE-260S RWD-4.0NWE-260S

RWD-5.0NWE-200S RWD-5.0NWE-200S

RWD-5.0NWE-260S RWD-5.0NWE-260S

RWD-6.0NWE-200S RWD-6.0NWE-200S

RWD-6.0NWE-260S RWD-6.0NWE-260S

)

Model for solar combination

(

(

)

1~ 230V 50Hz 3N~ 400V 50Hz

RWD-2.0NWSE-260S RWD-2.5NWSE-260S RWD-3.0NWSE-260S RWD-4.0NWSE-260S RWD-4.0NWSE-260S

RWD-5.0NWSE-260S RWD-5.0NWSE-260S

RWD-6.0NWSE-260S RWD-6.0NWSE-260S

)

8

PMML0335A rev.1 - 04/2016

Page 21

GENERAL INFORMATION

Model for UK market

(

(

1~ 230V 50Hz 3N~ 400V 50Hz

RWD-2.0NWE-200S-K RWD-2.0NWE-260S-K RWD-2.5NWE-200S-K RWD-2.5NWE-260S-K RWD-3.0NWE-200S-K RWD-3.0NWE-260S-K RWD-4.0NWE-200S-K RWD-4.0NWE-200S-K

RWD-4.0NWE-260S-K RWD-4.0NWE-260S-K

RWD-5.0NWE-200S-K RWD-5.0NWE-200S-K

RWD-5.0NWE-260S-K RWD-5.0NWE-260S-K

RWD-6.0NWE-200S-K RWD-6.0NWE-200S-K

RWD-6.0NWE-260S-K RWD-6.0NWE-260S-K

)

ENGLISH

)

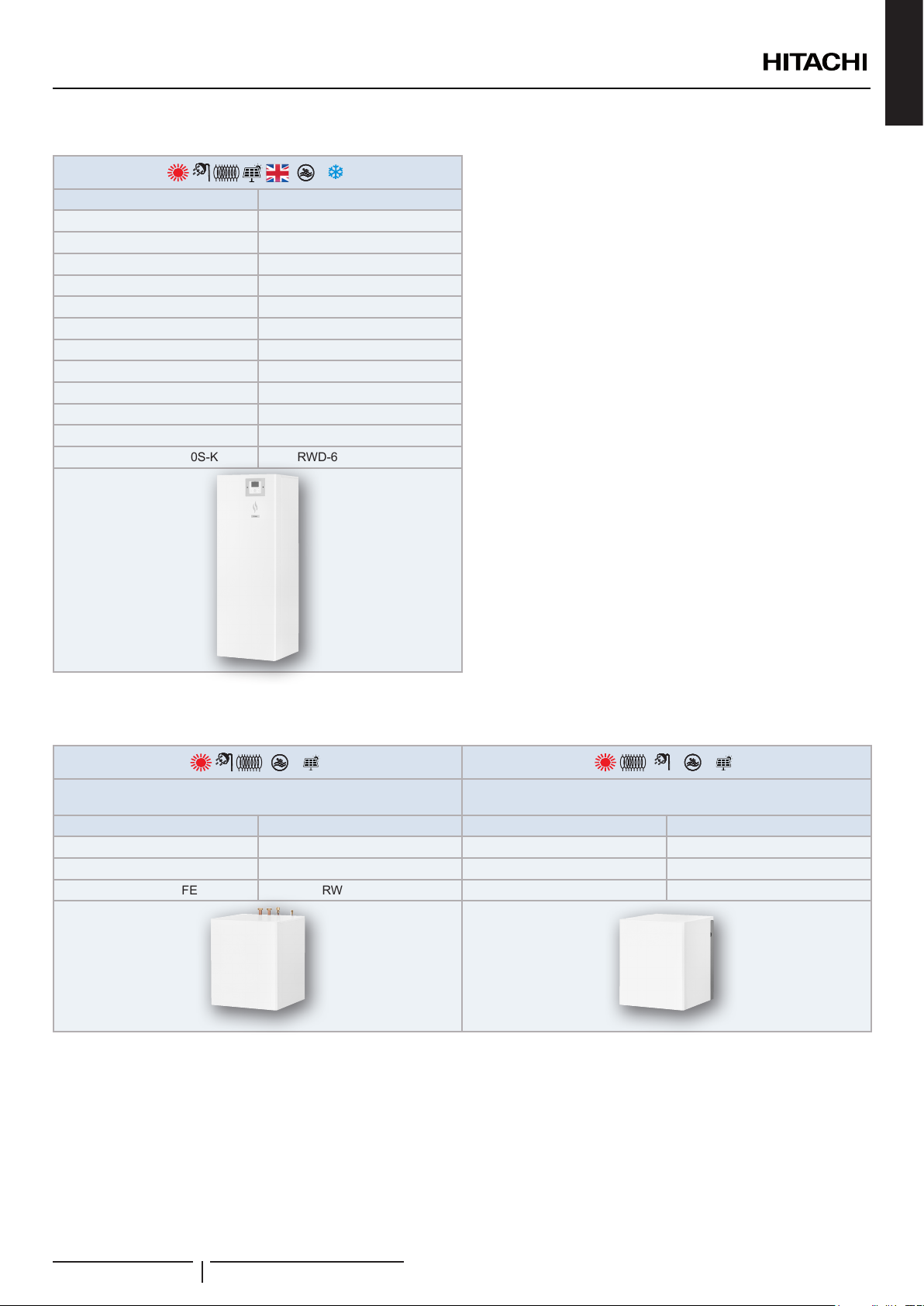

YUTAKI S80

Indoor unit

(

(

)

TYPE 1: Version for operation in DHW but with a remote tank

(Tank cannot be plugged on top of the unit)

1~ 230V 50Hz 3N~ 400V 50Hz 1~ 230V 50Hz 3N~ 400V 50Hz

RWH-4.0VNFE RWH-4.0NFE RWH-4.0VNFWE RWH-4.0NFWE

RWH-5.0VNFE RWH-5.0NFE RWH-5.0VNFWE RWH-5.0NFWE

RWH-6.0VNFE RWH-6.0NFE RWH-6.0VNFWE RWH-6.0NFWE

)

(

(

(

)

)

TYPE 2: Version for operation with Hitachi DHW tank

(Tank can be plugged on top of the unit or next to it)

)

9

PMML0335A rev.1 - 04/2016

Page 22

GENERAL INFORMATION

YUTAKI S80 domestic hot water tank

1~ 230V 50Hz

DHWS200S-2.7H2E DHWS260S-2.7H2E

? NOTE

• In “TYPE 1: Version for operation in DHW but with a remote tank”, the required unit controller(PC-ARFHE) has to be ordered as accessory.

• In “TYPE 2: Version for operation with Hitachi DHW tank”, the domestic hot water tank of model DHWS200S-2.7H2E or DHWS260S-2.7H2E is

required. The DHW tank has to be ordered separately. The unit controller (PC-ARFHE) is factory supplied with the DHW tank (integrated in the front

cover). The tank can be installed in 2 ways: on top of the indoor unit (integrated installation) or next to it. In this second case, the specic accessory

kit installation (ATW-FWP-02, ordered as an accessory) is required.

• Icons between brackets mean possible extra operations to the factory-supplied operations.

1.3.2.3 Monobloc system

YUTAKI M

(

(

(

)

1~ 230V 50Hz 3N~ 400V 50Hz

RASM-3VNE - -

- RASM-4VNE RASM-4NE

- RASM-5VNE RASM-5NE

- RASM-6VNE RASM-6NE

(

)

)

? NOTE

The unit controller has to be ordered as accessory (PC-ARFHE).

(

)

)

10

PMML0335A rev.1 - 04/2016

Page 23

GENERAL INFORMATION

1.3.3 Accessory code list

Model Ref.

For all series A

For YUTAKI S units S

For YUTAKI S COMBI units SC

For YUTAKI S80 units S80

For YUTAKI M units M

Cooling kit accessories

Accessory Ref. Name Figure

ENGLISH

NEW

NEW

NEW

NEW

NEW

ATW-CKS-01

ATW-CKS-02

ATW-CKS-03

ATW-CKSC-01

ATW-CKM-01

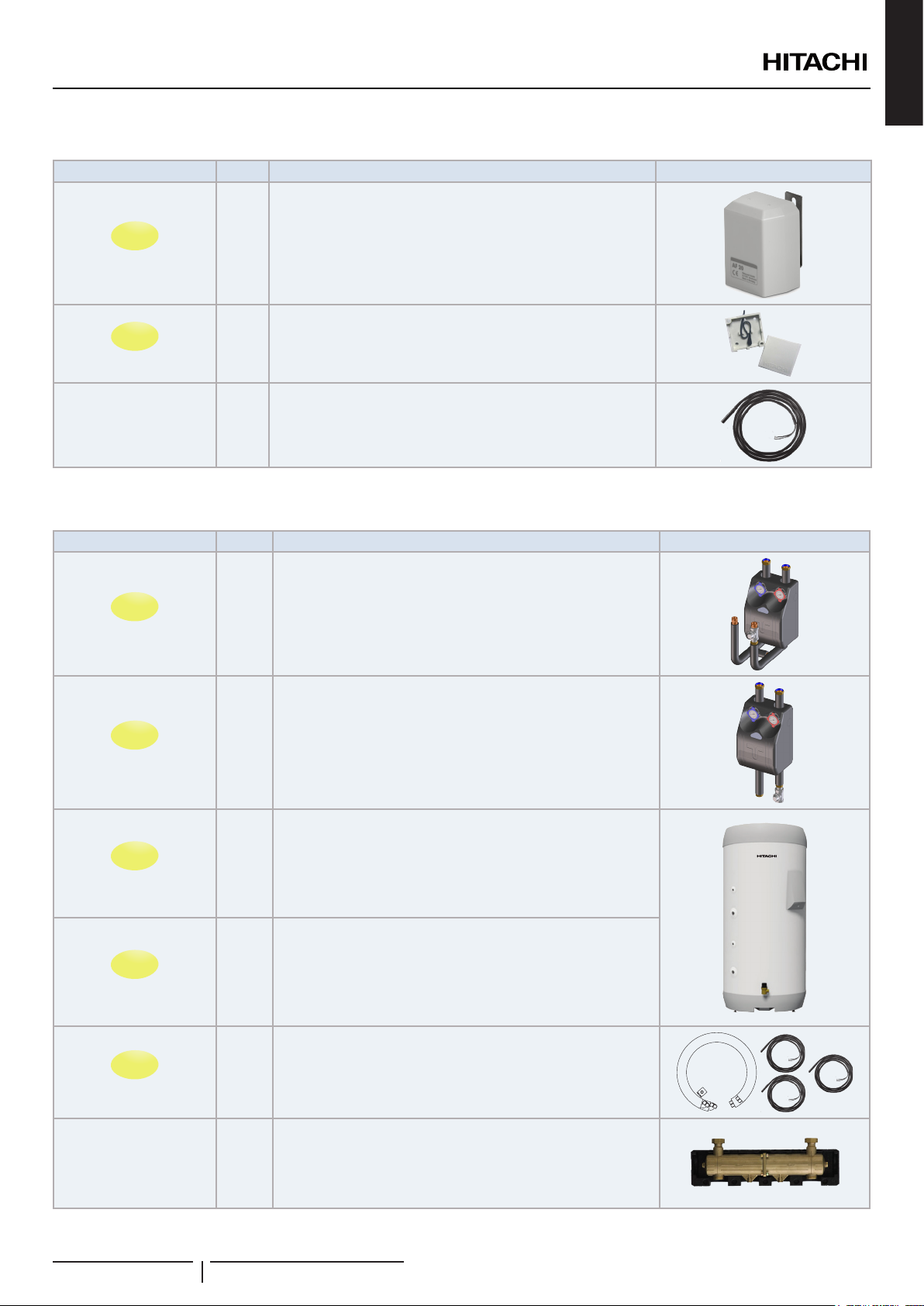

Control accessories

Accessory Ref. Name Figure

S

S

S

SC Cooling operation kit for YUTAKI S COMBI

M Cooling operation kit for YUTAKI M

Cooling operation kit for YUTAKI S

(For 2.0-3.0HP)

Cooling operation kit for YUTAKI S

(For 4.0-6.0HP)

Cooling operation kit for YUTAKI S

(For 8.0/10.0HP)

To be informed later

NEW

PC-ARFHE

NEW

ATW-RTU-04

NEW

ATW-RTU-05

11

A

A

A

PMML0335A rev.1 - 04/2016

Wired room thermostat for YUTAKI units

Unit controller

(Languages EN/ES/DE/FR/IT)

Wireless ON/OFF thermostat

(Receiver + Room thermostat)

Wireless Intelligent thermostat

(Receiver + Room thermostat)

Page 24

GENERAL INFORMATION

Accessory Ref. Name Figure

NEW

NEW

NEW

NEW

NEW

ATW-RTU-06

ATW-MBS-02

ATW-KNX-02

ATW-TAG-02

ATW-AOS-02

A

A MODBUS gateway for YUTAKI units

A KNX interface for YUTAKI units

A TaHoma gateway for YUTAKI units

A

(Only Room thermostat. For Intelligent thermostat application)

Wireless Intelligent thermostat for 2nd circuit

Auxiliary output signal box

(Relay board for additional output signals)

NEW

NEW

NEW

ATW-MAK-01

ATW-YMM-01

ATW-FCP-01

A Kit for 4-20 mA application To be informed later

M YUTAKI M remote control box (Slave)

S

SC

S80

LCD Cover

12

PMML0335A rev.1 - 04/2016

Page 25

GENERAL INFORMATION

Temperature sensor accessories

Accessory Ref. Name Figure

ENGLISH

NEW

NEW

NEW

ATW-2OS-02

ATW-ITS-01

ATW-WTS-02Y A Universal water temperature sensor

Water circuit accessories

Accessory Ref. Name Figure

ATW-2KT-03

A 2nd. outdoor temperature sensor

A Indoor wired temperature sensor

A

(Integrable in YUTAKI S COMBI 200 L model)

2nd zone mixing kit

NEW

NEW

NEW

NEW

ATW-2TK-04

DHWT-200S-3.0H2E

DHWT-300S-3.0H2E

ATW-FWP-02

ATW-HSK-01 A Hydraulic separator

SC

S

M

S

M

S80 Kit for installation with tank beside the indoor unit

2nd zone mixing kit

(Wall mounted model)

Domestic hot water tank (200 L)

Domestic hot water tank (300 L)

13

PMML0335A rev.1 - 04/2016

Page 26

GENERAL INFORMATION

Accessory Ref. Name Figure

ATW-AQT-01 A Aquastat security (for heating oor protection)

ATW-3WV-01 A

ATW-WCV-01 A Water check valve

WEH-6E

ATW-DPOV-01 A Differential pressure overow valve

NEW

ATW-FWP-03

S80

M

S80 Flexible pipe

(Internal thread and spring return)

3-way valve

Water electric heater

14

PMML0335A rev.1 - 04/2016

Page 27

GENERAL SAFETY NOTES

2 GENERAL SAFETY NOTES

2.1 ADDITIONAL INFORMATION ABOUT SAFETY

! DANGER

• DO NOT CONNECT THE POWER SUPPLY TO THE INDOOR UNIT PRIOR TO FILLING THE SPACE HEATING CIRCUIT (AND DHW CIRCUIT

IF IT WAS THE CASE) WITH WATER AND CHECKING WATER PRESSURE AND THE TOTAL ABSENCE OF ANY WATER LEAKAGE.

• Do not pour water over the indoor unit electrical parts. If the electrical components are in contact with water a seri ous electrical shock

will take place.

• Do not touch or adjust the safety devices inside the air to water heat pump. If these devices are touched or adjusted, a serious accident

can take place.

• Do not open the service cover or access inside the air to water heat pump without disconnecting the main power supply.

• In case of re Turn OFF the main switch, put out the re at once and contact your service contractor.

• It must ensure that the air to water heat pump cannot op erate accidentally without water neither with air inside hydraulic system.

! CAUTION

• Do not use any sprays such as insecticide, lacquer, hair spray or other ammable gases within approximately one meter from the system.

• If installation circuit breaker or the unit fuse is often activated, stop the system and contact your service contractor.

• Do not make service or inspections tasks by yourself. This work must be performed by a qualied service person.

• This appliance must be used only by adult and capable people, having received the technical information or instructions to handle this appliance

properly and safely.

• Children should be supervised to ensure that they do not play with the appliance.

• Do not let any foreign body into the water inlet and outlet piping of the air to water heat pump.

ENGLISH

2.2 IMPORTANT NOTICE

• PLEASE READ THE INSTRUCTION MANUAL AND THE FILES ON THE CD-ROM CAREFULLY BEFORE STARTING TO

WORK ON THE INSTALLATION OF THE AIR TO WATER HEAT PUMP SYSTEM. Failure to observe the instructions for

installation, use and operation described in this documentation may result in operating failure including potentially serious faults,

or even the destruction of the air to water heat pump system.

• Verify, in accordance with the manuals which appear in the outdoor and indoor units, that all the information required for the

correct installation of the system is included. If this is not the case, contact your distributor.

• HITACHI pursues a policy of continuous improvement in product design and performance. The right is therefore reserved to vary

specications without notice.

• HITACHI cannot anticipate every possible circumstance that might involve a potential hazard.

• This air to water heat pump has been designed for standard water heating for human beings only. Do not use this for other

purposes such as for drying clothes, heating foods or for any other heating process (except swimming pool).

• No part of this manual may be reproduced without written permission.

• If you have any questions, contact your service contractor of HITACHI.

• Check and make sure that the explanations of each part of this manual correspond to your air to water heat pump model.

• Refer to the models codication to conrm the main characteristics of your system.

• Signal words (NOTE, DANGER and CAUTION) are used to identify levels of hazard seriousness. Denitions for identifying

hazard levels are provided in initial pages of this document.

• The operation modes of these units are controlled by the unit controller.

• This manual should be considered as a permanent part of the air to water heat pump. It gives a common description of and

information for this air to water heat pump which you operate as well as for other models.

• Keep the water temperature of the system above the freezing temperature.

15

PMML0335A rev.1 - 04/2016

Page 28

GENERAL DATA

3 GENERAL DATA

3.1 CAPACITY TABLES

3.1.1 Nominal capacity-performance tables

3.1.1.1 Considerations

• The heating capacity tables show the capacity and performance data in integrated values (with defrost correction factor

included).

• The nominal heating and cooling capacities are based on the EN 14511 standard: Piping length: 7.5 meters; Piping lift: 0 meters.

Keywords:

• CAP: Nominal capacity (kW)

• COP: Coefcient of performance

• EER: Energy efciency ratio

• DB: Dry bulb; WB: Wet bulb (ºC)

• OAT: Outdoor ambient temperature (ºC)

• WIT: Water inlet temperature (ºC)

• WOT: Water outlet temperature (ºC)

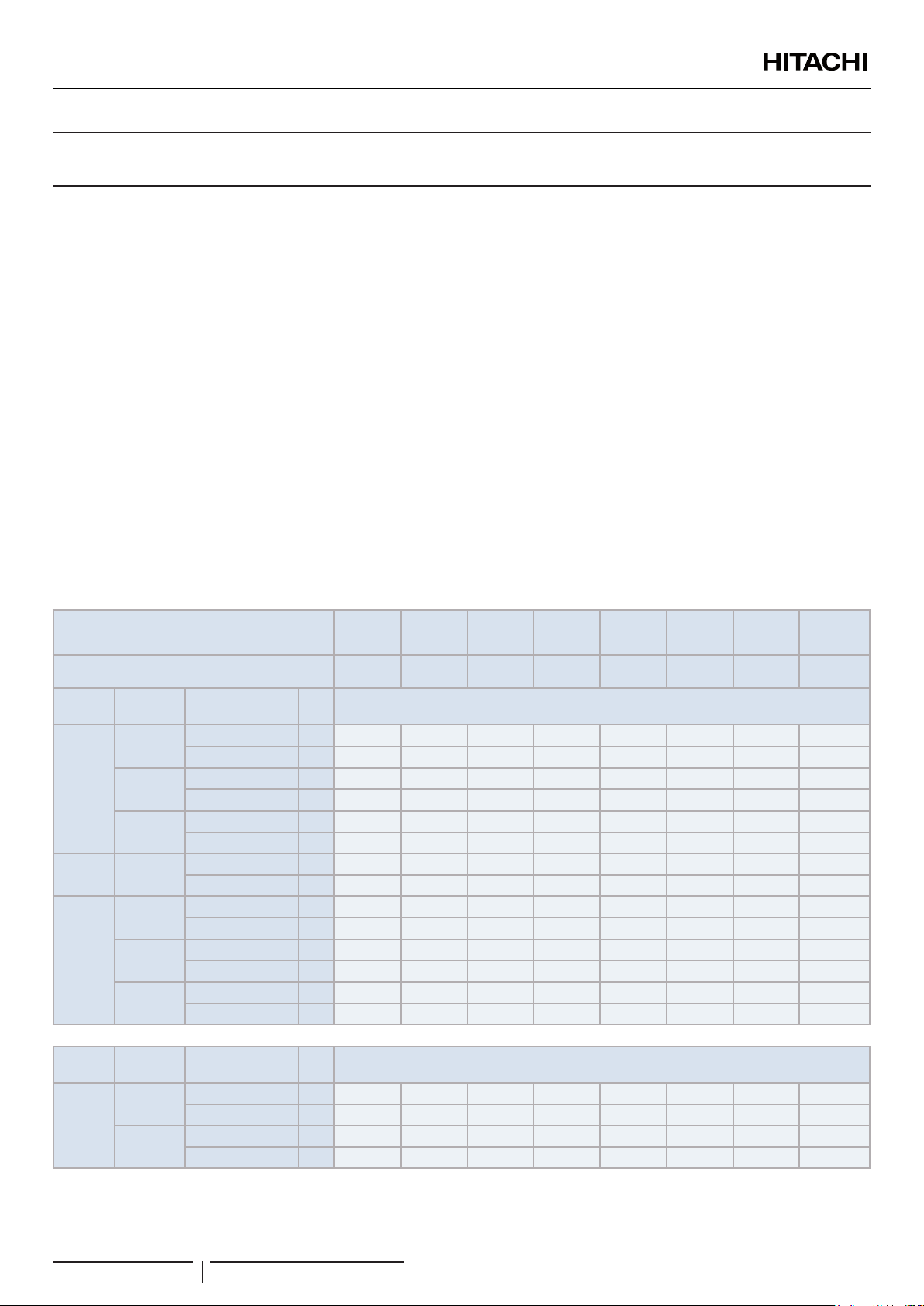

3.1.1.2 Capacity-performance data

YUTAKI S

Outdoor unit model

Indoor unit model

OAT

(DB/WB)

7 / 6 ºC

2 / 1 ºC 30 / 35 ºC

-7 / -8 ºC

WIT / WOT - Unit Heating operation

30 / 35 ºC

40 / 45 ºC

47 / 55 ºC

30 / 35 ºC

40 / 45 ºC

47 / 55 ºC

CAP (Nom./Max.) kW

COP (Nom.) CAP (Nom./Max.) kW 4.3/6.2 6.0/9.0 7.5/10.0 11.0/14.1 14.0/15.7 16.0/17.3 20.0/25.0 24.0/32.0

COP (Nom.) - 3.90 3.59 3.50 3.98 3.61 3.40 3.40 3.30

CAP (Nom./Max.) kW 4.3/6.0 6.0/8.0 7.5/9.2 11.0/13.5 14.0/15.2 16.0/17.0 20.0/24.0 24.0/32.0

COP (Nom.) - 3.00 2.89 2.57 3.00 2.80 2.50 2.72 2.65

CAP (Nom./Max.) kW

COP (Nom.) - 4.10 3.65 3.53 3.61 3.55 3.41 3.41 3.31

CAP (Nom./Max.) kW 4.3/4.7 5.3/5.7 5.8/6.7 9.7/10.6 11.5/12.0 12.0/13.0 14.2/17.9 16.5/21.0

COP (Nom.) - 2.85 2.60 2.57 2.74 2.65 2.57 2.57 2.46

CAP (Nom./Max.) kW 4.3/4.6 5.0/5.5 6.0/6.4 10.0/10.0 11.0/11.6 11.5/12.5 15.0/16.6 16.5/18.5

COP (Nom.) - 2.45 2.25 2.25 2.45 2.25 2.15 2.08 1.74

CAP (Nom./Max.) kW 4.0/4.2 4.6/5.0 5.0/5.5 8.7/9.7 9.7/11.2 10.5/12.0 12.5/14.5 15.5/17.3

COP (Nom.) - 1.93 1.82 1.60 1.78 1.85 1.75 1.70 1.50

RAS-2

WHVNP

RWM-2.0 NERWM-2.5 NERWM-3.0 NERWM-4.0 NERWM-5.0 NERWM-6.0 NERWM-8.0 NERWM-10.0

4.3/7.0 6.0/9.0 7.5/11.0 11.0/15.2 14.0/16.7 16.0/17.8 20.0/25.5 24.0/32.0

5.25 4.80 4.55 5.00 4.71 4.57 4.30 4.29

3.5/5.5 4.5/7.0 5.5/8.9 9.5/12.8 10.5/13.9 11.1/15.0 12.3/20.0 13.0/20.7

RAS-2.5

WHVNP

RAS-3

WHVNP

RAS-4

WH(V)

NPE

RAS-5

WH(V)

NPE

RAS-6

WH(V)

NPE

RAS-8

WHNPE

RAS-10

WHNPE

NE

OAT

(DB/WB)

35 / -- ºC

Blank data: To be informed later.

WIT / WOT - Unit

12 / 7 ºC

23 / 18 ºC

CAP (Nom.) kW 3.8/4.9 5.0/5.8 6.0/7.0 7.2/11.8 9.5/12.6 10.5/13.5 14.0/16.4 17.5/20.6

EER (Nom.) CAP (Nom.) kW 4.1/6.1 5.5/7.4 6.0/8.5 10.4/15.0 12.9/16.0 13.5/17.5 17.0/23.5 20.0/27.0

EER (Nom.) - 3.81 3.81 3.81 4.50 4.02 3.81 3.81 3.61

16

PMML0335A rev.1 - 04/2016

Cooling operation

(Using cooling kit accessory)

3.12 3.15 2.75 3.30 3.22 2.82 3.12 2.81

Page 29

GENERAL DATA

YUTAKI S COMBI

ENGLISH

Outdoor unit model

Indoor unit model

OAT

(DB/WB)

7 / 6 ºC

2 / 1 ºC 30 / 35 ºC

-7 / -8 ºC

WIT / WOT - Unit Heating operation

30 / 35 ºC

40 / 45 ºC

47 / 55 ºC

30 / 35 ºC

40 / 45 ºC

47 / 55 ºC

RAS-2

WHVNP

RWD-2.0

NW(S)E-

(200/260)

S(-K)

CAP (Nom./Max.) kW 4.3/7.0 6.0/9.0 7.5/11.0 11.0/15.2 14.0/16.7 16.0/17.8

COP (Nom.) - 5.25 4.80 4.55 5.00 4.71 4.57

CAP (Nom./Max.) kW 4.3/6.2 6.0/9.0 7.5/10.0 11.0/14.1 14.0/15.7 16.0/17.3

COP (Nom.) - 3.90 3.59 3.50 3.98 3.61 3.40

CAP (Nom./Max.) kW 4.3/6.0 6.0/8.0 7.5/9.2 11.0/13.5 14.0/15.2 16.0/17.0

COP (Nom.) - 3.0 2.89 2.57 3.00 2.80 2.50

CAP (Nom./Max.) kW 3.5/5.5 4.5/7.0 5.5/8.9 9.5/12.8 10.5/13.9 11.1/15.0

COP (Nom.) - 4.10 3.65 3.53 3.61 3.55 3.41

CAP (Nom./Max.) kW 4.3/4.7 5.3/5.7 5.8/6.7 9.7/10.6 11.5/12.0 12.0/13.0

COP (Nom.) - 2.85 2.60 2.57 2.74 2.65 2.57

CAP (Nom./Max.) kW 4.3/4.6 5.0/5.5 6.0/6.4 10.0/10.0 11.0/11.6 11.5/12.5

COP (Nom.) - 2.45 2.25 2.25 2.45 2.25 2.15

CAP (Nom./Max.) kW 4.0/4.2 4.6/5.0 5.0/5.5 8.7/9.7 9.7/11.2 10.5/12.0

COP (Nom.) - 1.93 1.82 1.60 1.78 1.85 1.75

RAS-2.5

WHVNP

RWD-2.5

NW(S)E-

(200/260)

S(-K)

RAS-3

WHVNP

RWD-3.0

NW(S)E-

(200/260)

S(-K)

RAS-4

WH(V)NPE

RWD-4.0

NW(S)E-

(200/260)

S(-K)

RAS-5

WH(V)NPE

RWD-5.0

NW(S)E-

(200/260)

S(-K)

RAS-6

WH(V)NPE

RWD-6.0

NW(S)E-

(200/260)

S(-K)

OAT

(DB/WB)

35 / -- ºC

WIT / WOT - Unit

12 / 7 ºC

23 / 18 ºC

CAP (Nom.) kW 3.8/4.9 5.0/5.8 6.0/7.0 7.2/11.8 9.5/12.6 10.5/13.5

EER (Nom.) - 3.12 3.15 2.75 3.30 3.22 2.82

CAP (Nom.) kW 4.1/6.1 5.5/7.4 6.0/8.5 10.4/15.0 12.9/16.0 13.5/17.5

EER (Nom.) - 3.81 3.81 3.81 4.50 4.02 3.81

Cooling operation

(Using cooling kit accessory)

17

PMML0335A rev.1 - 04/2016

Page 30

GENERAL DATA

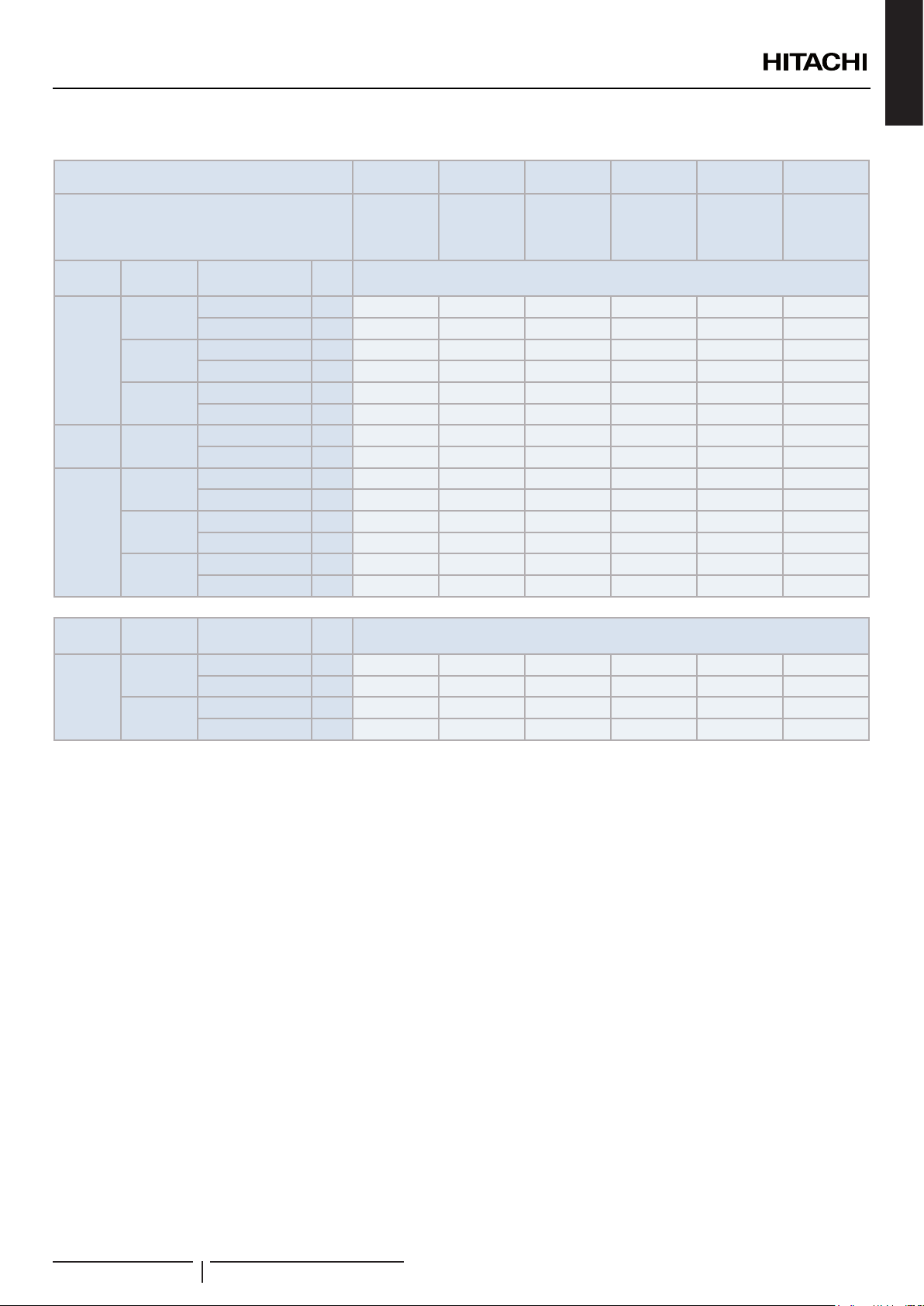

YUTAKI S80

OAT

(DB/WB)

7 / 6 ºC

-7 / -8 ºC

WIT / WOT - Unit Heating operation

Outdoor unit model RAS-4WH(V)NPE RAS-5WH(V)NPE RAS-6WH(V)NPE

Indoor unit model RWH-4.0(V)NF(W)E RWH-5.0(V)NF(W)E RWH-6.0(V)NF(W)E

30 / 35 ºC

40 / 45 ºC

47 / 55 ºC

55 / 65 ºC

30 / 35 ºC

40 / 45 ºC

47 / 55 ºC

55 / 65 ºC

CAP (Nom./Max.) kW 11.0/15.2 14.0/16.7 16.0/17.8

COP (Nom.) - 5.00 4.71 4.57

CAP (Nom./Max.) kW 11.0/14.5 14.0/17.0 16.0/18.0

COP (Nom.) - 3.90 3.78 3.60

CAP (Nom./Max.) kW 11.0/14.5 14.0/17.0 16.0/18.0

COP (Nom.) - 3.32 3.19 3.10

CAP (Nom./Max.) kW 11.0/14.5 14.0/17.0 16.0/18.0

COP (Nom.) CAP (Nom./Max.) kW 9.7/10.6 11.5/12.2 12.1/13.0

COP (Nom.) - 2.74 2.65 2.57

CAP (Nom./Max.) kW 11.0/12.5 14.0/14.5 16.0/16.0

COP (Nom.) - 2.40 2.30 2.20

CAP (Nom./Max.) kW 11.0/12.5 14.0/14.5 16.0/16.0

COP (Nom.) - 2.30 2.20 2.08

CAP (Nom./Max.) kW 11.0/12.5 14.0/14.5 16.0/16.0

COP (Nom.) - 2.10 2.05 1.95

2.90 2.88 2.73

YUTAKI M

Outdoor unit model RASM-3VNE RASM-4VNE RASM-5VNE RASM-6VNE

OAT

(DB/WB)

7 / 6 ºC

2 / 1 ºC 30 / 35 ºC

-7 / -8 ºC

OAT

(DB/WB)

35 / -- ºC

WIT / WOT - Unit Heating operation

30 / 35 ºC

40 / 45 ºC

47 / 55 ºC

30 / 35 ºC

40 / 45 ºC

47 / 55 ºC

WIT / WOT - Unit

12 / 7 ºC

23 / 18 ºC

CAP (Nom./Max.) kW 7.5/11.0 11.0/15.2 14.0/16.7 16.0/17.8

COP (Nom.) - 4.55 5.00 4.71 4.57

CAP (Nom./Max.) kW 7.5/10.0 11.0/14.1 14.0/15.7 16.0/17.3

COP (Nom.) - 3.50 3.80 3.61 3.40

CAP (Nom./Max.) kW 7.5/9.2 11.0/13.5 14.0/15.2 16.0/17.0

COP (Nom.) - 2.70 3.00 2.80 2.50

CAP (Nom./Max.) kW 5.5/8.9 9.5/12.8 10.5/13.9 11.1/15.0

COP (Nom.) - 3.53 3.70 3.55 3.41

CAP (Nom./Max.) kW 6.0/6.7 9.7/10.6 11.5/12.0 12.0/13.0

COP (Nom.) - 2.57 2.74 2.65 2.57

CAP (Nom./Max.) kW 5.5/6.4 10.0/10.3 11.0/11.6 11.5/12.5

COP (Nom.) - 2.25 2.45 2.25 2.15

CAP (Nom./Max.) kW 5.5/5.5 8.7/9.8 9.7/11.2 10.5/12.0

COP (Nom.) - 1.72 1.78 1.85 1.75

Cooling operation

(Using cooling kit accessory)

CAP (Nom.) kW 6.0/7.0 7.2/11.8 9.5/12.6 10.5/13.5

EER (Nom.) - 2.75 3.30 3.22 2.82

CAP (Nom.) kW 6.0/8.5 10.4/15.0 12.9/16.0 13.5/17.5

EER (Nom.) - 3.81 4.50 4.02 3.81

18

PMML0335A rev.1 - 04/2016

Page 31

GENERAL DATA

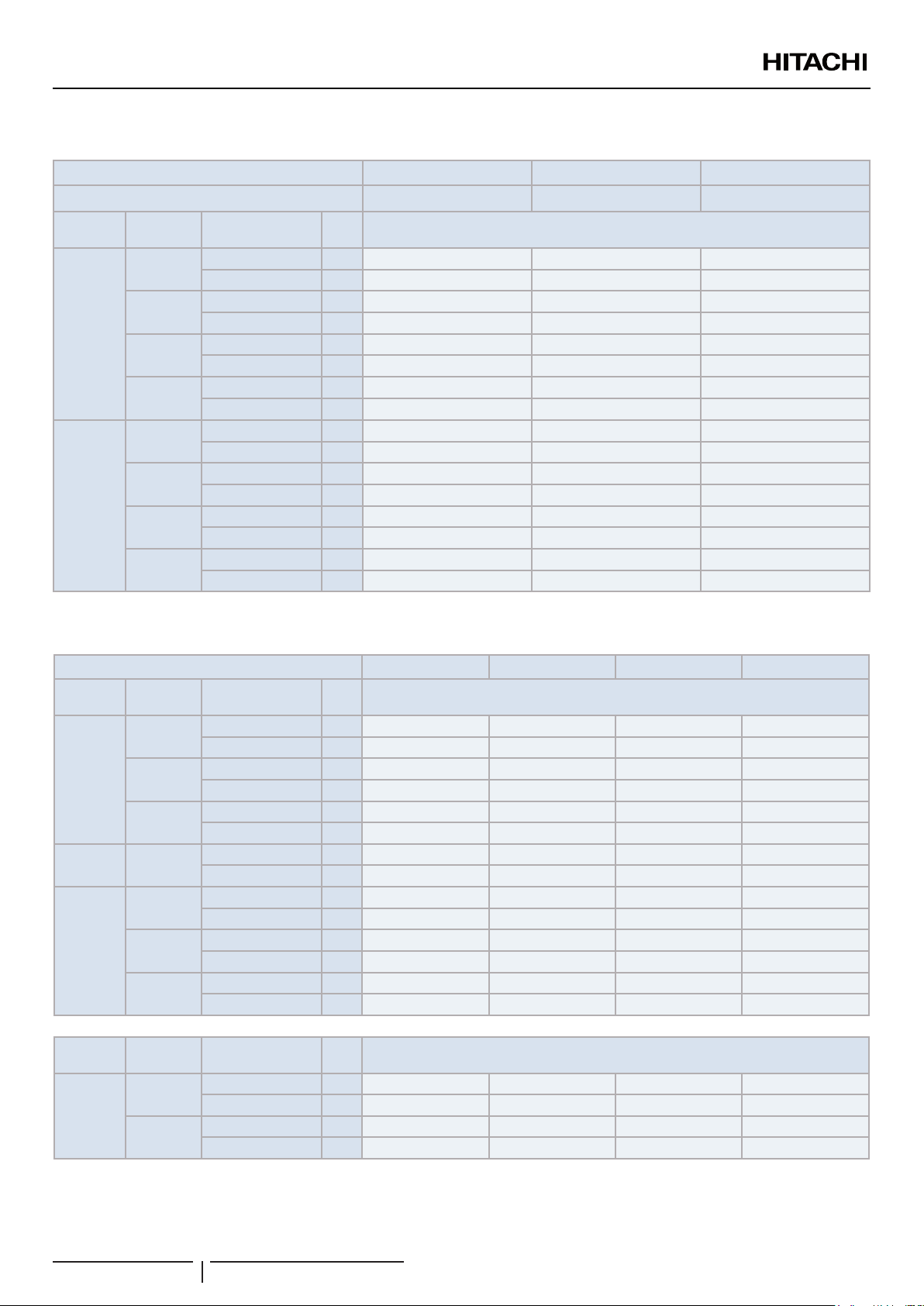

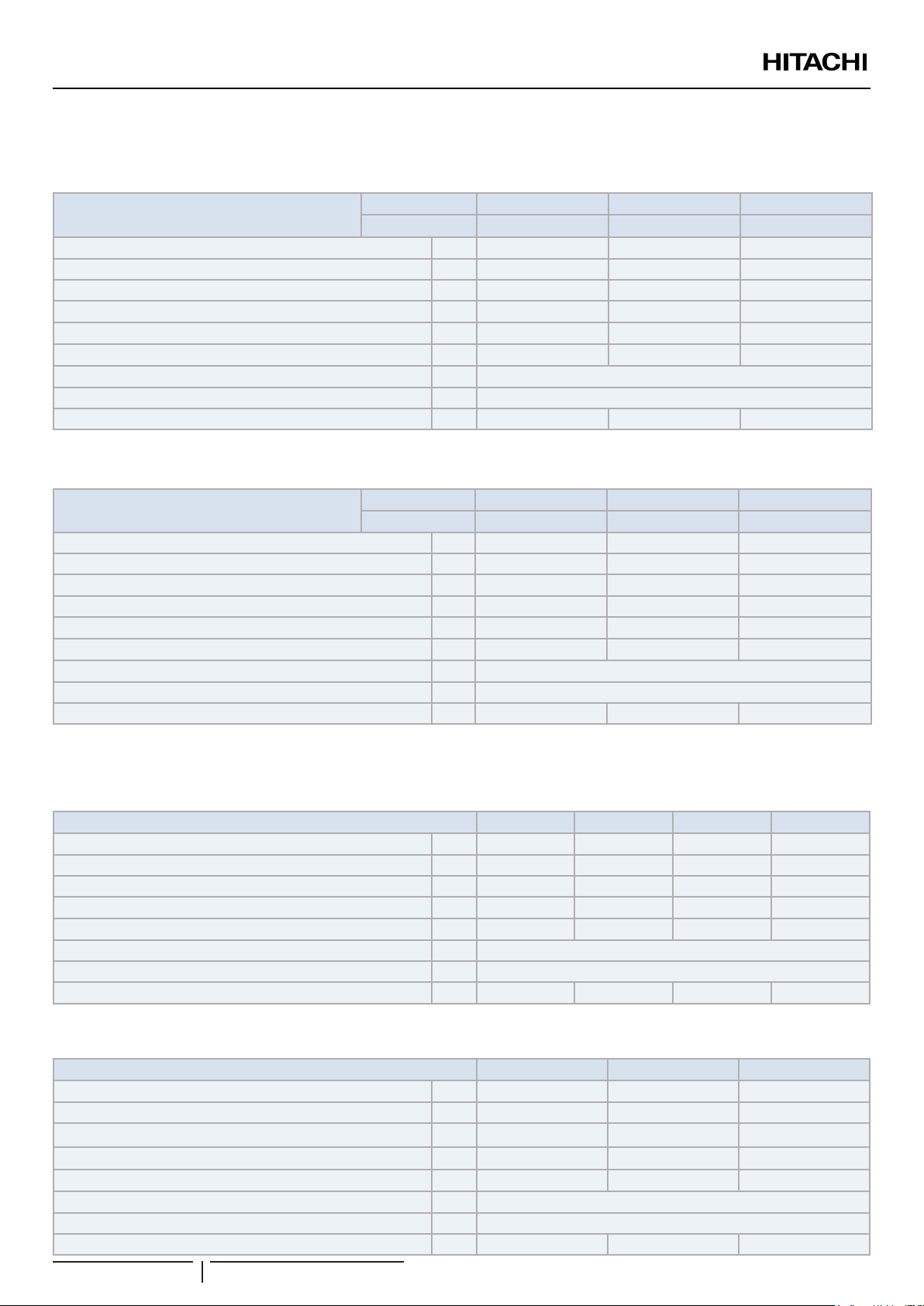

3.2 ERP PERFORMANCE DATA

3.2.1 General considerations

• This appliance must be installed, maintained and dismantled by professionals. Do not pour contained refrigerant into the

atmosphere since this refrigerant uid is a uorinated greenhouse gas regulated under European Regulation (EU) No 517/2014.

• Data with the mark (*) corresponds to the “Energy efciency contribution (ηS)” due to the use of temperature control.

Wired room thermostat (PC-ARFHE) 7E543002(*)

OTC control (Factory-supplied)

Temperature control class II Temperature control class VI

Energy efciency contribution +2% Contribution to the nominal energy efciency +4%

(*) Factory supplied in case of Yutaki S, SC and S80 DHW Tank

• Data between brackets corresponds only to heating and cooling models (“Cooling kit” accessory needed).

3.2.2 General ERP data for space heaters

3.2.2.1 ERP data - YUTAKI S

AVERAGE climate

Wireless room thermostat (ATW-RTU-04) 7E543003

Wired room sensor (ATW-ITS-01) 7E549932

ENGLISH

RAS-(2-3)WHVNP + RWM-(2.0-3.0)NE

Model

Water outlet temperature 35ºC 55ºC 35ºC 55ºC 35ºC 55ºC

Air to water heat pump -

Product

description

Design capacity (P

Nominal energy efciency (ηS) %

Nominal energy class -

Data for Packaged Fiche:

Energy efciency with OTC control (ηS) (*) %

Energy class with OTC control -

Energy efciency with thermostats/sensors (ηS) (*) %

Energy class with thermostats -

Supplementary capacity (P

Type of energy used -

Declared capacity (Pdh) and coefcient of performance (COPd) at partial load under the following outdoor temperatures:

Outdoor temperature (Tj) = -7ºC

Outdoor temperature (Tj) = +2ºC

Outdoor temperature (Tj) = +7ºC

Outdoor temperature (Tj) = +12ºC

Outdoor temperature (Tj) = Bivalent

temperature (T

Outdoor temperature (Tj) = Limit operation

temperature (TOL)

Bivalent temperature (T

Limit operation temperature (TOL) ºC

Water limit operation temperature (WTOL) ºC

Degradation coefcient (Cdh) Annual energy consumption (QHE) kW·h

Heat pump combination heater Low temperature heat pump -

Complementary heater -

) kW

DESIGN

) kW

SUP

)

biv

) ºC

biv

Outdoor unit RAS-2WHVNP RAS-2.5WHVNP RAS-3WHVNP

Indoor unit RWM-2.0NE RWM-2.5NE RWM-3.0NE

Yes

No

No

Yes

4.0 4.0 6.0 5.0 7.0 6.0

189 (194) 137 (140) 177 (180) 130 (132) 165 (167) 125 (127)

A+++ A++ A+++ A++ A++ A++

191 (196) 139 (142) 179 (182) 132 (134) 167 (169) 127 (129)

A+++ A++ A+++ A++ A++ A++

193 (198) 141 (144) 181 (184) 134 (136) 169 (171) 129 (131)

A+++ A++ A+++ A++ A++ A++

0.0 0.6 0.3 0.7 0.6 0.8

Electricity

Pdh kW

COP

d

Pdh kW

COP

d

Pdh kW

COP

d

Pdh kW

COP

d

Pdh kW

COP

d

Pdh kW

COP

d

-

-

-

-

-

-

3.54 3.50 4.95 4.42 5.90 5.10

3.20 2.20 2.70 1.85 2.50 1.84

2.15 2.10 3.01 2.69 3.59 3.10

5.20 3.73 4.60 3.45 4.40 3.20

1.70 1.60 1.90 1.84 2.31 2.00

6.05 4.40 6.00 4.20 5.35 4.45

1.75 1.60 1.80 2.06 2.10 2.30

6.25 5.00 7.20 6.90 6.15 5.96

3.54 3.50 4.95 4.42 5.90 5.10

3.20 2.30 2.70 1.85 2.50 1.84

4.00 3.40 5.30 4.30 6.40 5.20

2.75 2.10 2.50 1.80 2.30 1.65

-7 -7 -7 -7 -7 -7

-10 -10 -10 -15 -10 -15

55 55 55 55 55 55

0.9 0.9 0.9 0.9 0.9 0.9

1719 (1675) 2341 (2298) 2569 (2525) 3110 (3066) 3286 (3242) 3714 (3671)

19

PMML0335A rev.1 - 04/2016

Page 32

GENERAL DATA

RAS-(4-6)WHVNPE + RWM-(4.0-6.0)NE

Model

Outdoor

unit

RAS-4WHVNPE RAS-5WHVNPE RAS-6WHVNPE

Indoor unit RWM-4.0NE RWM-5.0NE RWM-6.0NE

Water outlet temperature 35ºC 55ºC 35ºC 55ºC 35ºC 55ºC

Air to water heat pump - Yes

Product

description

Heat pump combination heater - No

Low temperature heat pump - No

Complementary heater - Ye s

Design capacity (P

) kW 11.0 10.0 14.0 12.0 16.0 14.0

DESIGN

Nominal energy efciency (ηS) % 187 (189) 136 (137) 175 (176) 133 (134) 153 (153) 125 (126)

Nominal energy class - A+++ A++ A+++ A++ A++ A++

Data for Packaged Fiche:

Energy efciency with OTC control (ηS) (*) % 189 (191) 138 (139) 177 (178) 135 (136) 155 (155) 127 (128)

Energy class with OTC control - A+++ A++ A+++ A++ A++ A++

Energy efciency with thermostats/sensors (ηS) (*) % 191 (193) 140 (141) 179 (180) 137 (138) 157 (157) 129 (130)

Energy class with thermostats - A+++ A++ A+++ A++ A++ A++

Supplementary capacity (P

) kW 0.5 1.2 1.9 1.5 1.9 2.3

SUP

Type of energy used - Electricity

Declared capacity (Pdh) and coefcient of performance (COPd) at partial load under the following outdoor temperatures:

Outdoor temperature (Tj) = -7ºC

Outdoor temperature (Tj) = +2ºC

Outdoor temperature (Tj) = +7ºC

Outdoor temperature (Tj) = +12ºC

Outdoor temperature (Tj) = Bivalent

temperature (T

)

biv

Outdoor temperature (Tj) = Limit operation

temperature (TOL)

Bivalent temperature (T

) ºC -7 -7 -7 -7 -7 -7

biv

Limit operation temperature (TOL) ºC

Pdh kW 9.60 8.60 12.00 10.25 13.80 11.20

COP

- 2.74 1.80 2.55 1.70 2.40 1.60

d

Pdh kW 5.84 5.23 7.30 6.24 8.40 6.82

COP

- 5.20 3.60 4.70 3.60 3.90 3.35

d

Pdh kW 3.76 3.52 4.70 4.01 5.40 4.38

COP

- 5.80 4.80 5.70 4.60 5.00 4.35

d

Pdh kW 3.70 3.60 3.50 3.50 3.50 3.60

COP

- 6.40 5.80 6.00 5.50 6.00 5.50

d

Pdh kW 9.60 8.60 12.00 10.25 13.80 11.20

COP

- 2.74 1.80 2.55 1.70 2.40 1.60

d

Pdh kW 10.50 8.80 12.10 10.50 14.10 11.70

COP

- 2.65 1.90 2.50 1.70 2.30 1.55

d

-10 -10 -10 -10 -10 -10

Water limit operation temperature (WTOL) ºC 55 55 55 55 55 55