INDOOR UNITS SYSTEM

RAI-50PPD, RAI-60PPD

INSTALLATION AND OPERATION MANUAL

MANUAL DE INSTALACIÓN Y FUNCIONAMIENTO

INSTALLATIONS- UND BETRIEBSHANDBUCH

MANUEL D’INSTALLATION ET DE FONCTIONNEMENT

MANUALE D’INSTALLAZIONE E D’USO

MANUAL DE INSTALAÇÃO E DE FUNCIONAMENTO

INSTALLATIONS- OG BETJENINGSVEJLEDNING

INSTALLATIE- EN BEDIENINGSHANDLEIDING

INSTALLATION- OCH DRIFTHANDBOK

ΕΓΧΕΙΡΙΔΙΟ ΕΓΚΑΤΑΣΤΑΣΗΣ ΚΑΙ ΛΕΙΤΟΥΡΓΙΑΣ

4-way cassette - R32

English

Specications in this manual are subject to change without notice in order that HITACHI may bring the latest innovations to their

customers.

Whilst every effort is made to ensure that all specications are correct, printing errors are beyond HITACHI’s control; HITACHI

cannot be held responsible for these errors.

Español

Las especicaciones de este manual están sujetas a cambios sin previo aviso a n de que HITACHI pueda ofrecer las últimas

innovaciones a sus clientes.

A pesar de que se hacen todos los esfuerzos posibles para asegurarse de que las especicaciones sean correctas, los errores

de impresión están fuera del control de HITACHI, a quien no se hará responsable de ellos.

Deutsch

Bei den technischen Angaben in diesem Handbuch sind Änderungen vorbehalten, damit HITACHI seinen Kunden die jeweils

neuesten Innovationen präsentieren kann.

Sämtliche Anstrengungen wurden unternommen, um sicherzustellen, dass alle technischen Informationen ohne Fehler

veröffentlicht worden sind. Für Druckfehler kann HITACHI jedoch keine Verantwortung übernehmen, da sie außerhalb ihrer

Kontrolle liegen.

Français

Les caractéristiques publiées dans ce manuel peuvent être modiées sans préavis, HITACHI souhaitant pouvoir toujours offrir à

ses clients les dernières innovations.

Bien que tous les efforts sont faits pour assurer l’exactitude des caractéristiques, les erreurs d’impression sont hors du contrôle

de HITACHI qui ne pourrait en être tenu responsable.

Italiano

Le speciche di questo manuale sono soggette a modica senza preavviso afnché HITACHI possa offrire ai propri clienti le

ultime novità. Sebbene sia stata posta la massima cura nel garantire la correttezza dei dati, HITACHI non è responsabile per

eventuali errori di stampa che esulano dal proprio controllo.

Português

As especicações apresentadas neste manual estão sujeitas a alterações sem aviso prévio, de modo a que a HITACHI possa

oferecer aos seus clientes, da forma mais expedita possível, as inovações mais recentes.

Apesar de serem feitos todos os esforços para assegurar que todas as especicações apresentadas são correctas, quaisquer

erros de impressão estão fora do controlo da HITACHI, que não pode ser responsabilizada por estes erros eventuais.

Dansk

Specikationerne i denne vejledning kan ændres uden varsel, for at HITACHI kan bringe de nyeste innovationer ud til kunderne.

På trods af alle anstrengelser for at sikre at alle specikationerne er korrekte, har HITACHI ikke kontrol over trykfejl, og HITACHI

kan ikke holdes ansvarlig herfor.

Nederlands

De specicaties in deze handleiding kunnen worden gewijzigd zonder verdere kennisgeving zodat HITACHI zijn klanten kan

voorzien van de nieuwste innovaties.

Iedere poging wordt ondernomen om te zorgen dat alle specicaties juist zijn. Voorkomende drukfouten kunnen echter niet door

HITACHI worden gecontroleerd, waardoor HITACHI niet aansprakelijk kan worden gesteld voor deze fouten.

Svenska

Specikationerna i den här handboken kan ändras utan föregående meddelande för att HITACHI ska kunna leverera de senaste

innovationerna till kunderna.

Vi på HITACHI gör allt vi kan för att se till att alla specikationer stämmer, men vi har ingen kontroll över tryckfel och kan därför

inte hållas ansvariga för den typen av fel.

Eλλhnika

Οι προδιαγραφές του εγχειριδίου μπορούν να αλλάξουν χωρίς προειδοποίηση, προκειμένου η HITACHI να παρέχει τις

τελευταίες καινοτομίες στους πελάτες της.

Αν και έχει γίνει κάθε προσπάθεια προκειμένου να εξασφαλιστεί ότι οι προδιαγραφές είναι σωστές, η HITACHI δεν μπορεί να

ελέγξει τα τυπογραφικά λάθη και, ως εκ τούτου, δεν φέρει καμία ευθύνη για αυτά τα λάθη.

! CAUTION

This product shall not be mixed with general house waste at the end of its life and it shall be retired according to the

appropriated local or national regulations in a environmentally correct way.

Due to the refrigerant, oil and other components contained in Air Conditioner, its dismantling must be done by a professional installer according to the applicable regulations. Contact to the corresponding authorities for more information.

! PRECAUCIÓN

Éste producto no se debe eliminar con la basura doméstica al nal de su vida útil y se debe desechar de manera respetuosa con el medio

ambiente de acuerdo con los reglamentos locales o nacionales aplicables.

Debido al refrigerante, el aceite y otros componentes contenidos en el sistema de aire acondicionado, su desmontaje debe realizarlo un

instalador profesional de acuerdo con la normativa aplicable. Para obtener más información, póngase en contacto con las autoridades

competentes.

! VORSICHT

Dass Ihr Produkt am Ende seiner Betriebsdauer nicht in den allgemeinen Hausmüll geworfen werden darf, sondern entsprechend den

geltenden örtlichen und nationalen Bestimmungen auf umweltfreundliche Weise entsorgt werden muss.

Aufgrund des Kältemittels, des Öls und anderer in der Klimaanlage enthaltener Komponenten muss die Demontage von einem Fachmann

entsprechend den geltenden Vorschriften durchgeführt werden.

Für weitere Informationen setzen Sie sich bitte mit den entsprechenden Behörden in Verbindung.

! PRECAUTION

Ne doit pas être mélangé aux ordures ménagères ordinaires à la n de sa vie utile et qu’il doit être éliminé conformément à la réglementation locale ou nationale, dans le plus strict respect de l’environnement.

En raison du frigorigène, de l’huile et des autres composants que le climatiseur contient, son démontage doit être réalisé par un instal-

lateur professionnel conformément aux réglementations en vigueur.

! ATTENZIONE

Indicazioni per il corretto smaltimento del prodotto ai sensi della Direttiva Europea 2002/96/EC e Dlgs 25 luglio 2005 n.151

Il simbolo del cassonetto barrato riportato sull’ apparecchiatura indica che il prodotto alla ne della propria vita utile deve essere raccolto

separatamente dagli altri riuti.

L’utente dovrà, pertanto, conferire l’apparecchiatura giunta a ne vita agli idonei centri di raccolta differenziata dei riuti elettronici ed

elettrotecnici, oppure riconsegnarla al rivenditore al momento dell’ acquisto di una nuova apparecchiatura di tipo equivalente.

L’adeguata raccolta differenziata delle apparecchiature dismesse, per il loro avvio al riciclaggio, al trattamento ed allo smaltimento ambientalmente compatibile, contribuisce ad evitare possibili effetti negativi sull’ ambiente e sulla salute e favorisce il riciclo dei materiali di cui

è composta l’ apparecchiatura.

Non tentate di smontare il sistema o l’unità da soli poichè ciò potrebbe causare effetti dannosi sulla vostra salute o sull’ ambiente.

Vogliate contattare l’ installatore, il rivenditore, o le autorità locali per ulteriori informazioni.

Lo smaltimento abusivo del prodotto da parte dell’utente può comportare l’applicazione delle sanzioni amministrative di cui all’articolo 50

e seguenti del D.Lgs. n. 22/1997.

! CUIDADO

O seu produto não deve ser misturado com os desperdícios domésticos de carácter geral no nal da sua duração e que deve ser eliminado de acordo com os regulamentos locais ou nacionais adequados de uma forma correcta para o meio ambiente.

Devido ao refrigerante, ao óleo e a outros componentes contidos no Ar condicionado, a desmontagem deve ser realizada por um insta-

lador prossional de acordo com os regulamentos aplicáveis. Contacte as autoridades correspondentes para obter mais informações.

! BEMÆRK:

At produktet ikke må smides ud sammen med almindeligt husholdningsaffald, men skal bortskaffes i overensstemmelse med de gældende lokale eller nationale regler på en miljømæssig korrekt måde.

Da klimaanlægget indeholder kølemiddel, olie samt andre komponenter, skal afmontering foretages af en fagmand i overensstemmelse

med de gældende bestemmelser. Kontakt de pågældende myndigheder for at få yderligere oplysninger.

! FORSIGTIG

Dit houdt in dat uw product niet wordt gemengd met gewoon huisvuil wanneer u het weg doet en dat het wordt gescheiden op een milieuvriendelijke manier volgens de geldige plaatselijke en landelijke reguleringen.

Vanwege het koelmiddel, de olie en andere onderdelen in de airconditioner moet het apparaat volgens de geldige regulering door een

professionele installateur uit elkaar gehaald worden.

Neem contact op met de betreffende overheidsdienst voor meer informatie.

! LET OP

Det innebär att produkten inte ska slängas tillsammans med vanligt hushållsavfall utan kasseras på ett miljövänligt sätt i enlighet med

gällande lokal eller nationell lagstiftning.

Luftkonditioneringsaggregatet innehåller kylmedium, olja och andra komponenter, vilket gör att det måste demonteras av en fackman i

enlighet med tillämpliga regelverk. Ta kontakt med ansvarig myndighet om du vill ha mer information.

! ΠΡΟΣΟΧΗ

Σημαίνει ότι το προϊόν δεν θα πρέπει να αναμιχθεί με τα διάφορα οικιακά απορρίμματα στο τέλος του κύκλου ζωής του και θα πρέπει να

αποσυρθεί σύμφωνα με τους κατάλληλους τοπικούς ή εθνικούς κανονισμούς και με τρόπο φιλικό προς το περιβάλλον.

Λόγω του ψυκτικού, του λαδιού και άλλων στοιχείων που περιέχονται στο κλιματιστικό, η αποσυναρμολόγησή του πρέπει να γίνει από

επαγγελματία τεχνικό και σύμφωνα με τους ισχύοντες κανονισμούς. Για περισσότερες λεπτομέρειες, επικοινωνήστε με τις αντίστοιχες αρχές.

!

DANGER – Hazards or unsafe practices which COULD result in severe personal injuries or death.

PELIGRO – Riesgos o prácticas poco seguras que PODRÍAN producir lesiones personales e incluso la muerte.

GEFAHR – Gefährliche oder unsichere Anwendung, die zu schweren Körperverletzungen oder zum Tod führen kann.

DANGER – Utilisation dangereuse ou sans garantie de sécurité qui PEUT provoquer de sévères blessures personnelles ou la

mort.

PERICOLO – Pericoli o azioni pericolose che POTREBBERO avere come esito lesioni siche gravi o il decesso.

PERIGO – Riesgos o prácticas poco seguras que PUEDEN producir lesiones personales e incluso la muerte

FARE – Farer eller farlig brug, som KAN resultere i alvorlig personskade eller dødsfald.

GEVAAR – Gevaren of onveilige praktijken die ernstig persoonlijk letsel of de dood tot gevolg KUNNEN hebben.

FARA – Risker eller osäkra tillvägagångssätt som KAN leda till svåra personskador eller dödsfall.

KINAYNO – Κίνδυνοι ή επικίνδυνες πρακτικές, οι οποίες ΜΠΟΡΕΙ να έχουν ως αποτέλεσµα σοβαρές σωµατικές βλάβες ή

θάνατο.

!

CAUTION – Hazards or unsafe practices which COULD result in minor personal injury or product or property damage.

PRECAUCIÓN – Riesgos o prácticas poco seguras que PODRÍAN provocar lesiones personales de menor importancia o daños

en el producto u otros bienes.

VORSICHT – Gefährliche oder unsichere Anwendung, die geringfügigen Personen-, Produkt- oder Sachschaden verursachen

kann.

PRECAUTION – Utilisation dangereuse ou sans garantie de sécurité qui PEUT provoquer des blessures mineures ou des

dommages au produit ou aux biens.

ATTENZIONE – Pericoli o azioni pericolose che POTREBBERO avere come esito lesioni siche minori o danni al prodotto o ad

altri beni.

CUIDADO – Perigos e procedimentos perigosos que PODERÃO PROVOCAR danos pessoais ligeiros ou danos em produtos e

bens.

FORSIGTIG – Farer eller farlig brug, som KAN resultere i mindre skade på personer, produkt eller ejendom.

LET OP – Gevaren of onveilige praktijken die licht persoonlijk letsel of beschadiging van het product of eigendommen tot gevolg

KUNNEN hebben.

VARNING – Risker eller farliga tillvägagångssätt som KAN leda till mindre personskador eller skador på produkten eller på

egendom.

ΠΡΟΣΟΧΗ – Κίνδυνοι ή επικίνδυνες πρακτικές, οι οποίες ΜΠΟΡΕΙ να έχουν ως αποτέλεσµα την πρόκληση ελαφρών

σωµατικών βλαβών ή καταστροφή περιουσίας.

?

NOTE – The text following this symbol contains information or instructions that may be of use or that require a more thorough

explanation.

NOTA – El texto que sigue a este símbolo contiene información o instrucciones que pueden ser de utilidad o requeridas para

ampliar una explicación.

HINWEIS – Der diesem Symbol folgende Text enthält konkrete Informationen und Anleitungen, die nützlich sein können oder

eine tiefergehende Erklärung benötigen.

REMARQUE – Les textes précédés de ce symbole contiennent des informations ou des indications qui peuvent être utiles, ou

qui méritent une explication plus étendue.

NOTA – I testi preceduti da questo simbolo contengono informazioni o indicazioni che possono risultare utili o che meritano una

spiegazione più estesa.

NOTA – Os textos precedidos deste símbolo contêm informações ou indicações que podem ser úteis, ou que merecem uma

explicação mais detalhada.

BEMÆRK – Den tekst, der følger efter dette symbol, indeholder oplysninger eller anvisninger, der kan være til nytte, eller som

kræver en mere grundig forklaring.

OPMERKING – De teksten waar dit symbool voorstaat bevatten nuttige informatie en aanwijzingen, of informatie en

aanwijzingen meer uitleg behoeven.

OBS – Texten efter denna symbol innehåller information och anvisningar som kan vara användbara eller som kräver en

noggrannare förklaring.

ΣΗΜΕΙΩΣΗ – Το κείμενο που ακολουθεί αυτό το σύμβολο περιέχει πληροφορίες ή οδηγίες που μπορεί να φανούν χρήσιμες ή

που απαιτούν μια πιο ενδελεχή εξήγηση.

This product contains biocidal substances according to EU Reg. 528/2012

Este producto contiene sustancias biocidas según el Reg. UE 528/2012

Dieses Produkt enthält Biozide nach EU Verordnung 528/2012

Conformément à la Reg UE 528/2012, ce produit contient des substances biocides

Questo prodotto contiene sostanze biocidi ai sensi del Reg. UE 528/2012

Este produto contém substâncias biocidas de acordo com o Regulamento (UE) N.º 528/2012

Dette produkt indeholder biocider i henhold til EU-forordning nr. 528/2012

Dit product bevat biociden volgens Europese Richtlijn 528/2012.

Denna produkt innehåller biocider i enlighet med den europeiska förordningen 528/2012

Αυτό το προϊόν περιλαμβάνει βιοκτόνες ουσίες σύμφωνα με το κανονισμό ΕΕ 528/2012

Biocide property/Propiedad biocida/Biozide Eigenschaft/Propriété biocide/Proprietà biocida/Propriedade biocida/

Biocide egenskaber/Biocide eigenschappen/Biocidegenskaper/Ιδιότητα του βιοκτόνου:

Antibacterial / Antibacteriana / Antibactérienne / Antibatterica / Antibakterielle / Antibacteriana / Antibakterielle /

Antibacteriëel / Antibakteriellt /Αντιβακτηριακές

Active substance/Sustancia activa/Aktivstoffe/ Substances actives/Principi attivi/ Substância ativa/Virksomt stof/

Actieve stof/Verksamt ämne/ Δραστική ουσία:

Silver / Plata / Silver / Argent / Argento / Prata / Sølv / Zilver / Silver / Άργυρος CAS Nº: 7440-22-4

These substances are NOT harmful to human health nor the environment

Estas sustancias no son perjudiciales para la salud humana ni el medio ambiente

Diese Stoffe sind nicht schädlich für die menschliche Gesundheit noch Umwelt

Ces substances ne sont pas nocives pour la santé humaine ni pour l’environnement

Queste sostanze non sono nocive per la salute umana o per l’ambiente

Estas substâncias NÃO são prejudiciais para a saúde humana nem para o ambiente

Disse stoffer er IKKE skadelige for hverken menneskers sundhed eller for miljøet

Deze stoffen zijn NIET schadelijk voor de menselijke gezondheid of voor het milieu.

Dessa ämnen är INTE skadliga för människors hälsa eller för miljön.

Αυτές οι ουσίες ΔΕΝ είναι επιβλαβείς στην ανθρώπινη υγεία ή στο περιβάλλον

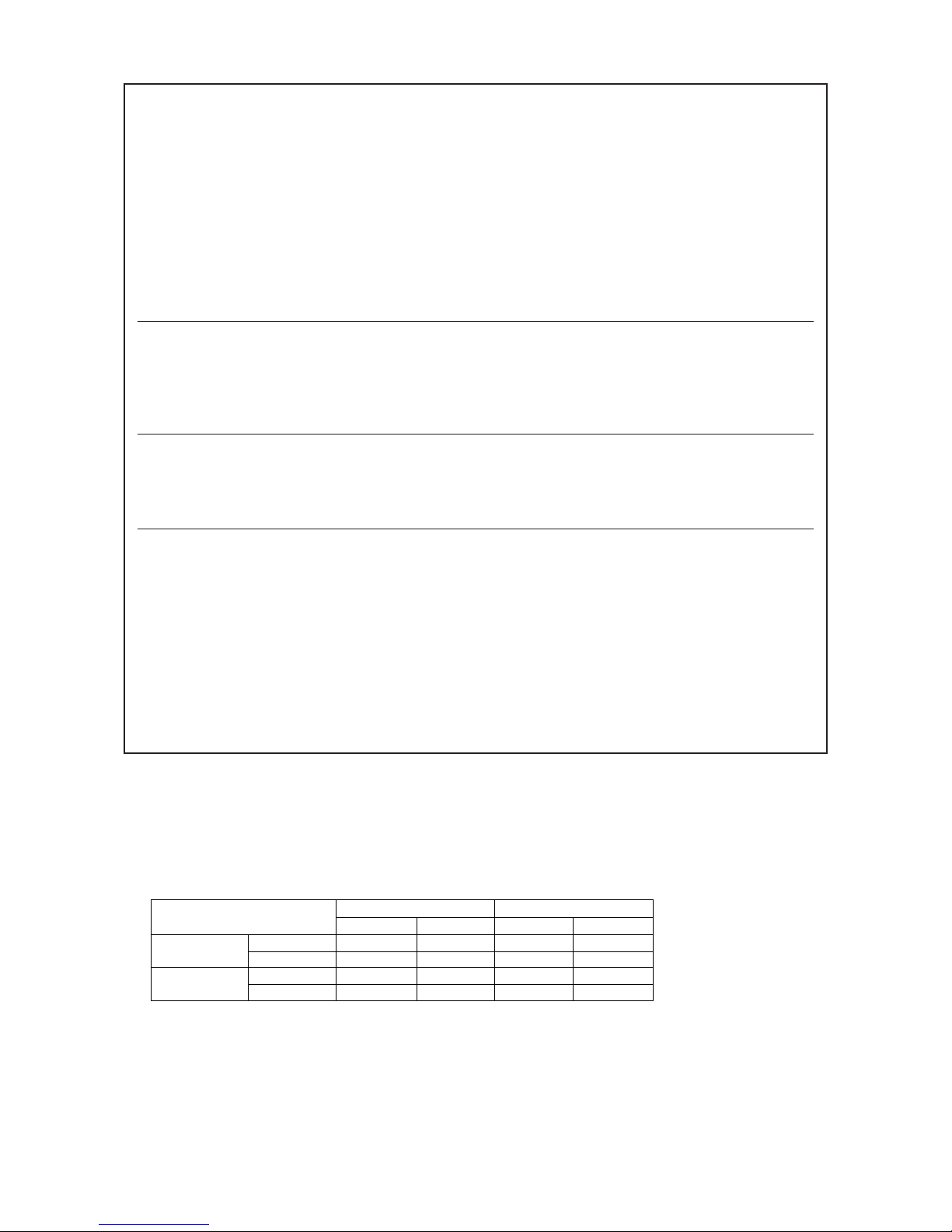

Note

●

The recommended temperatures range for safety testing should be as below:

Minimum Maximum Minimum

Indoor Dry bulb °C 21 32 20 27

Wet bulb °C 15 23 12 19

Outdoor Dry bulb °C

21

43 2 21

Wet bulb °C

15

26 1 15

Cooling Heating

Maximum

INDEX

1 GENERAL INFORMATION

2 SAFETY

3 IMPORTANT NOTICE

4 BEFORE OPERATION

5 MAINTENANCE

6 NAME OF PARTS

7 BEFORE INSTALLATION

8 INDOOR UNIT INSTALLATION

9 REFRIGERANT PIPING

10 DRAIN PIPING

11 ELECTRICAL WIRING

12 INSTALLATION OF OPTIONAL AIR PANEL: P-AP56NAMS

ÍNDICE

1 INFORMACIÓN GENERAL

2 SEGURIDAD

3 AVISO IMPORTANTE

4 ANTES DEL FUNCIONAMIENTO

5 MANTENIMIENTO

6 NOMBRE DE LOS COMPONENTES

7 ANTES DE LA INSTALACIÓN

8 INSTALACIÓN DE LA UNIDAD INTERIOR

9 TUBERÍA DE REFRIGERANTE

10 TUBERÍA DE DESAGÜE

11 CABLEADO ELÉCTRICO

12 INSTALACIÓN DEL PANEL DE AIRE OPCIONAL:

P-AP56NAMS

INHALTSVERZEICHNIS

1 ALLGEMEINE INFORMATIONEN

2 SICHERHEIT

3 WICHTIGER HINWEIS

4 VOR DER INBETRIEBNAHME

5 WARTUNG

6 TEILEBEZEICHNUNGEN

7 VOR DER INSTALLATION

8 INSTALLATION DES INNENGERÄTS

9 KÄLTEMITTELLEITUNGEN

10 ABFLUSSLEITUNGEN

11 KABELANSCHLUSS

12 INSTALLATION DER OPTIONALEN

LUFTAUSTRITTSBLENDE: P-AP56NAMS

INDEX

1 INFORMATIONS GÉNÉRALES

2 SÉCURITÉ

3 REMARQUE IMPORTANTE

4 AVANT LE FONCTIONNEMENT

5 MAINTENANCE

6 NOMENCLATURE DES PIÈCES

7 AVANT L'INSTALLATION

8 INSTALLATION DE L’UNITÉ INTÉRIEURE

9 TUYAUTERIE FRIGORIFIQUE

10 TUYAU D'ÉVACUATION

11 CÂBLAGE ÉLECTRIQUE

12 INSTALLATION DU PANNEAU DE SOUFFLAGE EN

OPTION : P-AP56NAMS

INDICE

1 INFORMAZIONI GENERALI

2 SICUREZZA

3 NOTA IMPORTANTE

4 PRIMA DEL FUNZIONAMENTO

5 MANUTENZIONE

6 NOME DEI COMPONENTI

7 PRIMA DELL'INSTALLAZIONE

8 INSTALLAZIONE DELL’UNITÀ INTERNA

9 LINEA DEL REFRIGERANTE

10 LINEA DI DRENAGGIO

11 COLLEGAMENTO DELLO SCHEMA ELETTRICO

12 INSTALLAZIONE DEL PANNELLO DI MANDATA

PZIONALE: P-AP56NAMS

ÍNDICE

1 INFORMAÇÃO GERAL

2 SEGURANÇA

3 NOTA IMPORTANTE

4 ANTES DO FUNCIONAMENTO

5 MANUTENÇÃO

6 NOME DAS PEÇAS

7 ANTES DA INSTALAÇÃO

8 INSTALAÇÃO DA UNIDADE INTERIOR

9 TUBAGEM DE REFRIGERANTE

10 TUBAGEM DE DESCARGA

11 LIGAÇÕES ELÉTRICAS

12 INSTALAÇÃO DO PAINEL DE AR OPCIONAL: P-AP56NAMS

INDHOLDSFORTEGNELSE

1 GENEREL INFORMATION

2 SIKKERHED

3 VIGTIG INFORMATION

4 FØR DRIFT

5 VEDLIGEHOLDELSE

6 NAVN PÅ DELE

7 INDEN MONTERING

8 MONTERING AF INDENDØRSENHED

9 KØLEMIDDELRØR

10 AFLØBSRØR

11 ELEKTRISK LEDNINGSFØRING

12 MONTERING AF UDLUFTNINGSPANEL (VALGFRIT

TILBEHØR): P-AP56NAMS

INHOUDSOPGAVE

1 ALGEMENE INFORMATIE

2 VEILIGHEID

3 BELANGRIJKE MEDEDELING

4 VOORDAT U HET SYSTEEM IN GEBRUIK NEEMT

5 ONDERHOUD

6 NAAM ONDERDELEN

7 VÓÓR INSTALLATIE

8 DE BINNENUNIT INSTALLEREN

9 KOUDEMIDDELLEIDING

10 AFVOERLEIDING

11 ELEKTRISCHE BEDRADING

12 HET OPTIONELE LUCHTPANEEL INSTALLEREN:

P-AP56NAMS

INNEHÅLLSFÖRTECKNING

1 ALLMÄN INFORMATION

2 SÄKERHET

3 VIKTIGT MEDDELANDE

4 FÖRE ANVÄNDNING

5 UNDERHÅLL

6 DELARNAS NAMN

7 FÖRE MONTERING

8 INSTALLATION AV INOMHUSENHET

9 KYLRÖR

10 DRÄNERINGSRÖR

11 ELEKTRISK ANSLUTNING

12 INSTALLATION AV EXTRA LUFTPANEL: P-AP56NAMS

ΕΥΡΕΤΗΡΙΟ

1 ΓΕΝΙΚΕΣ ΠΛΗΡΟΦΟΡΙΕΣ

2 ΑΣΦΑΛΕΙΑ

3 ΣΗΜΑΝΤΙΚΗ ΠΑΡΑΤΗΡΗΣΗ

4 ΠΡΙΝ ΑΠΟ ΤΗ ΛΕΙΤΟΥΡΓΙΑ

5 ΣΥΝΤΗΡΗΣΗ

6 ΟΝΟΜΑΤΑ ΕΞΑΡΤΗΜΑΤΩΝ

7 ΠΡΙΝ ΤΗΝ ΕΓΚΑΤΑΣΤΑΣΗ

8 ΕΓΚΑΤΑΣΤΑΣΗ ΕΣΩΤΕΡΙΚΗΣ ΜΟΝΑΔΑΣ

9 ΣΩΛΗΝΩΣΕΙΣ ΨΥΚΤΙΚΟΥ ΜΕΣΟΥ

10 ΣΩΛΗΝΩΣΗ ΑΠΟΧΕΤΕΥΣΗΣ

11 ΗΛΕΚΤΡΙΚΗ ΚΑΛΩΔΙΩΣΗ

12 ΕΓΚΑΤΑΣΤΑΣΗ ΤΟΥ ΠΡΟΑΙΡΕΤΙΚΟΥ ΣΤΟΜΙΟΥ ΑΕΡΑ:

P-AP56NAMS

EN English Original version

ES Español Versión traducida

DE Deutsch Übersetzte Version

FR Français Version traduite

IT Italiano Versione tradotta

PT Português Versão traduzidal

DA Dansk Oversat version

NL Nederlands Vertaalde versie

SV Svenska Översatt version

EL Ελληνικα Μεταφρασμένη έκδοση

ENGLISH

1 GENERAL INFORMATION

1.1 GENERAL NOTES

No part of this publication may be reproduced, copied, led

or transmitted in any shape or form without the permission of

Johnson Controls-Hitachi Air Conditioning Spain, S.A.U.

Within the policy of continuous improvement of its products,

Johnson Controls-Hitachi Air Conditioning Spain, S.A.U.

reserves the right to make changes at any time without prior

notication and without being compelled to introducing them into

products subsequently sold. This document may therefore have

been subject to amendments during the life of the product.

HITACHI makes every effort to offer correct, up-to-date

documentation. Despite this, printing errors cannot be controlled

by HITACHI and are not its responsibility.

As a result, some of the images or data used to illustrate this

document may not refer to specic models. No claims will be

accepted based on the data, illustrations and descriptions

included in this manual.

No type of modication must be made to the equipment without

prior, written authorisation from the manufacturer.

1.2 PRODUCT GUIDE

1.2.1 Prior check

? NOTE

Check, depending on the name of the model, the type of air conditioning

system tted, the abbreviated code and reference in this instruction

manual. This Installation and Operating Manual only refers to

RAI-(50/60)PPD units.

Check, in accordance with the Installation and Operating Manuals

included with the outdoor and indoor units, that all the information

necessary for the correct installation of the system is included. If this is

not the case, please contact your distributor.

2 SAFETY

This appliance is lled with R32

2.1 SYMBOLS USED

During normal air conditioning system design work or unit

installation, greater attention must be paid in certain situations

requiring particular care in order to avoid injuries and damage to

the unit, the installation or the building or property.

Situations that jeopardise the safety of those in the surrounding

area or that put the unit itself at risk will be clearly indicated in

this manual.

To indicate these situations, a series of special symbols will be

used to clearly identify these situations.

Pay close attention to these symbols and to the messages

following them, as your safety and that of others depends on it.

! DANGER

• The text following this symbol contains information and

instructions relating directly to your safety and physical

wellbeing.

• Not taking these instructions into account could lead to serious,

very serious or even fatal injuries to you and others in the

proximities of the unit.

In the texts following the danger symbol you can also nd

information on safe procedures during unit installation.

! CAUTION

• The text following this symbol contains information and instructions

relating directly to your safety and physical wellbeing.

• Not taking these instructions into account could lead to minor injuries

to you and others in the proximities of the unit.

• Not taking these instructions into account could lead to unit damage.

In the texts following the caution symbol you can also nd

information on safe procedures during unit installation.

? NOTE

• The text following this symbol contains information or instructions that

may be of use or that require a more thorough explanation.

• Instructions regarding inspections to be made on unit parts or systems

may also be included.

GENERAL INFORMATION

PMML0477 rev.0 - 07/2017

1

2.2 ADDITIONAL INFORMATION ABOUT SAFETY

! DANGER

• HITACHI is not able to foresee all the circumstances which may

result in a potential danger.

• Do not pour water in the indoor or outdoor unit. These products

are tted with electric components. If water comes into contact

with electric components, this will cause a serious electric

shock.

• Do not handle or adjust the safety devices inside the indoor and

outdoor units. The handling or adjustment of these devices may

result in serious accident.

• Do not open the service cover or access panel of the indoor and

outdoor units without disconnecting the main supply.

• In the event of re, switch off the mains, put out the re

immediately and contact your service supplier.

• Check that the earth cable is correctly connected.

• Connect the unit to a circuit breaker of the specied capacity.

! CAUTION

• Refrigerant leaks may hinder respiration as the gas displaces the air

in the room.

• Fit the indoor unit, the outdoor unit, the remote control and the cable

at a minimum of 3 metres away from sources of strong radiation from

electromagnetic waves, such as medical equipment.

• Do not use sprays, such as insecticides, varnishes or enamels or any

other inammable gas within a metre of the system.

• If the circuit breaker or supply fuse of the unit comes on frequently,

stop the system and contact the service suppler.

• Do not carry out maintenance or inspection work yourself. This work

must be carried out by qualied service personnel with suitable tools

and resources for the work.

• Do not place any foreign material (branches, sticks, etc.) in the air

inlet or outlet of the unit. These units are tted with high speed fans

and contact with any object is dangerous.

• This appliance must be used only by adult and capable people,

having received the technical information or instructions to handle

this appliance properly and safely.

• Children should be supervised to ensure that they do not play with

the appliance.

? NOTE

• The air in the room should be renewed and the room ventilated every

3 or 4 hours.

• The system tter and specialist shall provide anti-leak safety in

accordance with local regulations.

3 IMPORTANT NOTICE

This air conditioner has been designed for standard air

conditioning for human beings. For use in other applications,

please contact your HITACHI dealer or service contractor.

The air conditioning system should only be installed by qualied

personnel, with the necessary resources, tools and equipment,

who are familiar with the safety procedures required to

successfully carry out the installation.

PLEASE READ AND FAMILIARISE YOURSELF

WITH THE MANUAL BEFORE STARTING WORK ON THE

INSTALLATION OF THE AIR CONDITIONING SYSTEM.

Failure to observe the instructions for installation, use and

operation described in this Manual may result in operating

failure including potentially serious faults, or even the

destruction of the air conditioning system.

It is assumed that the air conditioning system will be installed

and maintained by responsible personnel trained for the

purpose. The customer should include all the safety, caution

and operating signs in the native language of the personnel

responsible.

Do not install the unit in the following places, as this may lead to

a re, deformities, rusting or faults:

• Places where oil is present (including oil for machinery).

• Places with a high concentration of sulphurous gas, such as

spas.

• Places where ammable gases may be generated or

circulate.

• Places with a saline, acidic or alkaline atmosphere.

Do not install the unit in places where silicon gas is present. Any

silicon gas deposited on the surface of the heat exchanger will

repel water. As a result, the condensate water will splash out

of the collection tray and into the electrical box. Water leaks or

electrical faults may eventually be caused.

Do not install the unit in a place where the current of expelled

air directly affects animals or plants as they could be adversely

affected.

Do not reconstruct the unit. Water leakage, fault, short circuit or

re may occur if you reconstruct the unit by yourself.

Please use an earth wire. Do not place the earth wire near

water or gas pipes, lightning conductors, or the earth wire of

a telephone. Improper installation of earth wiring may cause

electric shock or re.

Should an abnormal situation occur (like a burning smell),

please stop operating the unit and turn off the circuit breaker.

Fire may occur if you continue to operate the unit in an

abnormal situation.

Please contact your agent if you need to remove and reinstall

the unit. Electric shock or re may occur if you remove and

reinstall the unit improperly by yourself.

If the power supply cord is damaged, it must be replaced with

the special cord obtainable at authorized service/parts centres.

Please consult with your dealer if the air conditioner does not

cool, since refrigerant leakage may be considered as one of

the causes. The refrigerant gas used in the air conditioner is

harmless. However, harmful by-products may be generated if

the refrigerant gas leaks into the room and enters in contact with

re or a source of heat such as a stove heater. In the event of a

gas leakage, immediately stop the air conditioner, open doors

and windows to ventilate the room thoroughly and contact your

dealer.

IMPORTANT NOTICE

PMML0477 rev.0 - 07/2017

2

ENGLISH

During operation:

• Avoid an extended period of exposure to a direct air ow.

• Do not insert ngers, rods or other objects into the air outlet

or inlet. As the fan is rotating at high speed, it will cause

injury. Before cleaning, be sure to stop the operation and turn

the breaker OFF.

• Do not use any conductor as fuse wire. This could cause a

fatal accident.

• During thunderstorms, disconnect and turn off the circuit

breaker.

• Do not attempt to operate the unit with wet hands. This could

cause fatal accident.

• Do not direct the cool air coming out from the air conditioner

to household heating appliances (stoves, electric kettles,

ovens, etc.), as this may affect their operation.

• Please ensure that the outdoor mounting frame is always

stable, rm and without defects. Otherwise, the outdoor unit

may collapse and cause damage and injury.

• Do not splash or direct water to the body of the units when

cleaning them, as this may cause short circuit.

• Do not use any aerosol or hair sprays near the indoor unit.

Their chemicals can adhere to the ns of the heat exchanger

and block the ow of evaporation water to the drain pan.

Water will drop on the tangential fan and splash out from the

indoor unit.

• Switch off the units and turn off the circuit breaker during

cleaning.

• Do not climb on the outdoor unit or put objects on it.

• Do not put water containers (like a vase) on the indoor unit. If

water drips into the unit, it will damage the inside and cause

short circuit.

• When operating the unit with the door and windows opened

(relative humidity constantly above 80%) and with the air

deector facing down or moving automatically for a long

period of time, water will condense on the air deector

and drip down occasionally. This will wet your furniture.

Therefore, do not operate under such condition for an

extended time.

• The preset room temperature cannot be achieved if the

amount of heat in the room exceeds the cooling or heating

capacity of the unit (for example, if more people enters in the

room, if heating equipment is used, etc.).

4 BEFORE OPERATION

! CAUTION

• Supply electrical power to the system for approximately 12 hours

before start-up after long shutdown. Do not start the system

immediately after power supply, it may cause a compressor failure,

because the compressor is not heated well.

• Make sure that the outdoor unit is not covered with snow or ice. If

covered, remove it by using hot water (approximately 50ºC). If the water

temperature is higher than 50ºC, it will cause damage to plastic parts.

• When the system is started after a shutdown longer than approximately

3 months, it is recommended that the system be checked by your

service contractor.

• Turn OFF the main switch when the system is stopped for a long

period of time. If the main switch is not turned OFF, electricity is

consumed, because the oil heater is always energized during

compressor stopping.

4.1 EFFICIENT USE OF INDOOR UNIT

• Do not leave a window or a door open.

The operating efciency will be decreased.

It may cause dew condensation of the indoor unit. (Ventilate

a room sufciently too.)

• Attach a curtain or a blind to a window.

Direct sunlight is prevented and the cooling efciency will be

increased.

• Do not use heating appliances during the cooling operation

as possible.

The cooling efciency will be decreased. It may cause dew

condensation and dropping dew.

• Use a circulator if warm air stays around ceiling.

The comfortability will be increased. Contact your distributor

for the detail.

• Change the air ow direction downward if the ceiling surface

gets dirty.

It is recommended to change the air ow direction by approx.

30º downward from the levelness.

• Turn OFF the main power source if the indoor unit is not

used for a long time.

If not, the standby electricity charges will have to be paid

even if the indoor unit is unused.

BEFORE OPERATION

PMML0477 rev.0 - 07/2017

3

4.2 EFFICIENT USE OF COOLING AND HEATING

COOLING HEATING

1 Air ow direction: the appropriate air outlet angle is approx.

35º. If the cooling is not sufcient, change the air ow

direction. Pay attention to dew drop which may occur due to

the long cooling operation with low louvre angle.

35°

35°

Louver

angle

Air outlet angle (above center)

2 Air ow volume: ”AUTO” should be usually used.

3 Temperature: the recommended set temperature is 27 to 29ºC.

If the cooling is not sufcient, set the lower temperature.

1 Air ow direction: the appropriate air outlet angle is approx.

60º. If the heating is not sufcient, change the air ow

direction.

60° 60°

Louver

angle

Air outlet angle (above center)

2 Air ow volume: ”AUTO” should be usually used.

3 Temperature: the recommended set temperature is 18 to 20ºC.

If the heating is not sufcient, set the higher temperature.

? NOTE

About Multi-Split system

When the number of indoor unit or the operating mode is changed, the air outlet temperature may be changed and the indoor temperature is changed.

In this case, set as follows.

• During cooling: lower slightly the temperature setting.

• During heating: raise slightly the temperature setting.

5 MAINTENANCE

! DANGER

• Turn OFF the power source before the maintenance work. If not,

it may cause a re or an electric shock.

• Perform the maintenance work with stable footing. If not, it may

cause falling or injury.

! CAUTION

Hold the air lter and the air inlet grille securely by hand when opening,

closing, attaching or removing them. If not, it may cause the product

falling, resulting in an injury.

? NOTE

Do not operate the system without the air lter, to prevent the indoor unit

heat exchanger from being clogged.

5.1 DAILY MAINTENANCE

5.1.1 Cleaning Air Filter

1 Open the air inlet grille.

While sliding the knobs on both side of the air inlet grille in

the arrow direction, open the air inlet grille.

Air inlet grille

Knobs

2 Remove the air lter.

Hold the lower side of the air inlet grille and release the lter

lock. While sliding the air lter in the arrow direction, release

4 catches on both sides to remove the air lter from the air

inlet grille.

Upper Part of Filter

Hook

Hook

Air Filter

A

ir Inlet Grille

Air lter

Air inlet grille

Lower part of lter

Hook

Hook

Upper part of lter

3 Clean the air lter.

• Vacuum dust with a cleaner, or wash the air lter with water

or neutral detergent.

• Dry the air lter in the shade.

MAINTENANCE

PMML0477 rev.0 - 07/2017

4

ENGLISH

? NOTE

• Do not use hot water more than 50ºC. The air lter may be deformed

by heat.

• Do not dry the air lter with an open re, a dryer or a heater. The air

lter may be deformed.

4 Attach the air lter.

After the air lter is dried, attach it correctly to the air inlet

grille.

5 Close the air inlet grille.

? NOTE

• Be sure to attach the air lter. If the indoor unit is operated without the

air lter, it may cause malfunction of the indoor unit.

• Make sure that the air inlet grille is securely locked with the knobs. If

it is not properly locked, it might open suddenly, resulting in the grille

falling.

5.1.2 Removing, attaching and cleaning air

inlet grille

? NOTE

• Wipe the air inlet grille with a soft cloth soaked in lukewarm water

and squeezed.

• Use a soft cloth to clean the air inlet grille and the air panel. If

benzine, thinner or detergent (with surfactant) is used to cleaning, the

resin part may get discoloured or deformed. In addition, note that the

parts around the air outlet (louvre, guide, etc.) may be damaged if an

excessive force is applied.

The air inlet grille can be removed and cleaned.

1 Open the air inlet grille.

While sliding the knobs on both side of the air inlet grille in

the arrow direction, open the air inlet grille.

Knobs

Air inlet grille

2 Remove the air inlet grille.

• Remove the supporting string from the air panel.

Supporting

string

• Open the air inlet grille at an approximately 45° angle from

the air panel surface.

• Tilting the air inlet grille, lift it up to remove it.

? NOTE

Although the air inlet grille can be opened up to 90°, it cannot be removed

from the air panel at the angle. Tilt it at a 45° angle when removing it.

45

o

Air panel

Ceiling

Tilting the air inlet grille, lift it up to remove it

3 Clean the air inlet grille.

4 Attach the air inlet grille.

Attach the air inlet grille in the reverse procedure to

removing.

5.2 MAINTENANCE AT BEGINNING AND END OF USE

At beginning of use

• Remove obstacles around the air inlet grilles and the air

outlet of the indoor unit and outdoor unit.

• Check that the air lter is not clogged with dust and dirt.

At end of use

• Clean the air lter, the air inlet grille and the air panel.

MAINTENANCE

PMML0477 rev.0 - 07/2017

5

6 NAME OF PARTS

10

8

9

7

14

5

4

3

13

12

11

2

1

620

30 285

620

17

6

16 15 19 18

20

A

Human Detection Sensor

21

Internal gure of A

Nº Part Name

1 Fan

2 Fan motor (DC)

3 Heat exchanger

4 Distributor

5 Strainer

6 Micro-Computer control expansion valve

7 Electrical control box

8 Refrigerant gas pipe connection (with Øa are nut)

9 Refrigerant liquid pipe connection (with Øb are nut)

10 Drain pipe connection (VP25)

11 Drain discharge mechanism

12 Float switch

13 Drain pan

14 Rubber plug

15 Air panel: P-AP56NAMS (Optional)

16 Air inlet grille

17 Air lter

18 Air outlet

19 Air inlet

20 Cover for corner pocket

21 Motion sensor

(mm)

Model a b

RAI-50PPD 12,7 6,35

RAI-60PPD 12,7 6,35

? NOTE

Regarding the refrigerant cycle drawings and diagrams, refer to Technical Catalogue.

NAME OF PARTS

PMML0477 rev.0 - 07/2017

6

ENGLISH

7 BEFORE INSTALLATION

7.1 TRANSPORTATION AND HANDLING

! CAUTION

• Do not put any material on the product.

• Do not step on the product.

7.1.1 Transportation of indoor unit

• Transport the product as close to the installation location as

possible before unpacking.

• Do not put any material on the indoor unit.

• The indoor unit is packed upside down and therefore the

foamed polyethylene drain pan is exposed at the upper side.

Do NOT put the indoor unit with the drain pan side down

during the process from unpacking the indoor unit to hanging

up the unit to a ceiling. In addition, do NOT handle the indoor

unit by the drain pan portion or the air outlet portions.

• As foamed polyethylene is used for the indoor unit, take care

when handling the indoor unit. Applying an excessive force

to the unit may cause a breakage.

7.1.2 Handling of indoor unit

! DANGER

Do not put any foreign material into the indoor unit and check to

ensure that no foreign material exists in the indoor unit before

installation and the test run. Otherwise, a re or failure, etc. may

occur.

! CAUTION

• Do not hold the resin covers when holding or lifting the indoor unit.

• To avoid damage to the resin covers, put a cloth on them before lifting

or moving the indoor unit.

? NOTE

When lifting or moving the indoor unit, use appropriate slings to avoid

damage and be careful not to damage the insulation material on units

surface.

8 INDOOR UNIT INSTALLATION

! DANGER

• Do not install the indoor units outdoors. If installed outdoors, an

electric hazard or electric leakage will occur.

• Consider the air distribution from each indoor unit to the space

of the room, and select a suitable location so that uniform air

temperature in the room can be obtained.

• Avoid obstacles which may hamper the air intake or the air

discharge ow.

• Pay attention to the following points when the indoor units are

installed in a hospital or other places where there are electronic

waves from medical equipment, etc.:

- Do not install the indoor units where electromagnetic wave is

directly radiated to the electrical box, remote control cable

or remote control switch.

- Prepare a steel box and install the remote control switch in

it. Prepare a steel conduit tube and wire the remote control

cable in it. Then connect the ground wire with the box and

tube.

- Install a noise lter when the power supply emits harmful

noises.

- Do not install the indoor units, outdoor unit, remote control

switch and cable within approximately 3 meters of strong

electromagnetic wave radiators such as medical equipment.

• This unit is exclusive non electrical heater type indoor unit. It is

prohibited to install an electrical heater in the eld.

• Do not put any foreign material into the indoor unit and check to

ensure that none exist in the indoor unit before the installation

and test running. Otherwise a re or failure, etc., may occur.

• Do not perform installation work, refrigerant piping work, drain

pumping, drain piping and electrical wiring connecting work

without referring to the installation manual. If the instructions

are not followed, it may result in a water leakage, an electric

shock, a re and an injury.

• Mount suspension bolts using M10 (W3/8) as size, as shown

below:

I-Beam

Suspension bolts

(W3/8 or M10)

For concrete slab

150~160mm

Steel

Anchor bolt

Wooden beam

Concrete

Wooden bar

(60mm to 90mm square)

Nuts

Sling bolt

(W3/8 or M10)

Square

washers

! CAUTION

• Do not install the indoor units in a ammable environment to avoid a

re or an explosion.

• Check to ensure that the ceiling slab is strong enough. If not strong

enough, the indoor unit may fall down on you.

• Do not install the indoor units in a machinery shop or kitchen where

vapour from oil or mist ows to the indoor units. The oil will deposit

on the heat exchanger, thereby reducing the indoor unit performance,

and may deform. In the worst case, the oil damages the plastic parts

of the indoor unit.

• To avoid any corrosive action to the heat exchangers, do not install

the indoor units in an acid or alkaline environment.

• When lifting or moving the indoor unit, use appropriate slings to avoid

damage and be careful not to damage the insulation material on units

surface.

BEFORE INSTALLATION

PMML0477 rev.0 - 07/2017

7

8.1 FACTORY-SUPPLIED ACCESSORIES

Check to ensure that the following accessories are packed with the indoor unit.

The hose band, screws, washers and plastic bands are put in the pipe insulation.

Accessory Qty. Purpose

Checking scale

(cut and take out it from the carton board)

Q'ty

Purpose

1

For Adjusting Space of False

Ceiling Opening and

1

For adjusting space of false ceiling opening and position of

the unit

Cross recessed head screws (M5)

Q'ty

Purpose

4

1

For Adjusting Space of False

Ceiling Opening and

Position of the Unit

For Fitting Paper Pattern

4 For tting paper pattern

Washer with insulation material (M10)

Q'ty

Purpose

4

4

1

For Adjusting Space of False

Ceiling Opening and

Position of the Unit

For Fitting Paper Pattern

4

For unit installation

Washer (M10)

Q'ty

Purpose

4

4

4

1

For Adjusting Space of False

Ceiling Opening and

Position of the Unit

For Fitting Paper Pattern

For Unit Installation

4

Drain hose

Q'ty

Purpose

4

4

4

1

1

For Adjusting Space of False

Ceiling Opening and

Position of the Unit

For Fitting Paper Pattern

For Unit Installation

1

For drain hose connection

Hose clamp

Q'ty

Purpose

4

4

4

1

1

1

For Adjusting Space of False

Ceiling Opening and

Position of the Unit

For Fitting Paper Pattern

For Unit Installation

For Drain Hose Connection

1

Insulation

(5Tx50x200)

Q'ty

Purpose

4

4

4

2

6

1

1

1

1

1

1

For Adjusting Space of False

Ceiling Opening and

Position of the Unit

For Fitting Paper Pattern

For Unit Installation

For Refrigerant Piping

Connection

For Drain Hose Connection

For Fixing Remote Control

Switch Wiring, Louver Sensor

and Insulation of Piping

For Covering Wiring

Connection

1 For covering wiring connection

Insulation

(5Tx100x500)

Q'ty

Purpose

4

4

4

2

6

1

1

1

1

1

1

1

For Adjusting Space of False

Ceiling Opening and

Position of the Unit

For Fitting Paper Pattern

For Unit Installation

For Refrigerant Piping

Connection

For Drain Hose Connection

For Fixing Remote Control

Switch Wiring, Louver Sensor

and Insulation of Piping

For Covering Drain

Connection

For Covering Wiring

Connection

1 For covering drain connection

Insulation

(5Tx25x500)

Q'ty

Purpose

4

4

4

2

6

1

1

1

1

1

1

1

1

For Adjusting Space of False

Ceiling Opening and

Position of the Unit

For Fitting Paper Pattern

For Unit Installation

For Refrigerant Piping

Connection

For Drain Hose Connection

For Fixing Remote Control

Switch Wiring, Louver Sensor

and Insulation of Piping

For Covering Drain

Connection

For Covering Wiring

Connection

For Covering Drain

Connection

1 For covering drain connection

Flare nut 1 For refrigerant liquid pipe connection

? NOTE

• If any of these accessories are not packed with the unit, please contact your contractor.

• The air panel, remote control switch and branch pipes are optional accessories and so are not included.

INDOOR UNIT INSTALLATION

PMML0477 rev.0 - 07/2017

8

ENGLISH

8.2 INITIAL CHECK

• Install the indoor unit with a proper clearance around it

paying careful attention of installation direction for the piping,

wiring and maintenance working space, as shown below.

• The electrical box is located to the side surface of the unit

body. When installing the indoor unit, set up a service

access door at the electrical box side for servicing. For

servicing of the electrical box, make sure not to install the

refrigerant and drain piping in front of the electrical box.

• When equipping the duct adapter (optional), setup a service

access door at the duct adapter side in order to install the

duct adapter. Refer to the installation manual of the duct

adapter for details.

Min.

1500

Min.

1500

Min.

1500

Min.

1500

Min.

1500

Min.

1500

Min.

1500

Min.

1500

Min.

1500

Min.

1500

Min.

3000

Min. 500 Min. 100

Min. 500

Min. 1000

Min. 100

Min.

2400

Distance from wall side

Service access door

Access door for duct adapter (optional)

Piping connection

Piping connection

Piping connection

Minimum service space

Piping connection side

Electrical box side

Electrical box

Service access door

Service access door

Electrical box

Electrical box

Access door for duct adapter (optional)

• Check space between ceiling and false ceiling is enough as

indicated below.

285mm

Clearance:

Min. 30 mm

Unit height in

false ceiling

• The drain piping shall be installed on a downward slope

of 1/25 to 1/100 as shown in the gure below. Refer to the

Chapter "10 Drain piping" for details.

Downward slope:

1/25 to 1/100

Drain piping

• Check that the ceiling surface is at and suitable for the air

panel installation. If the ceiling is not at, drain water could

not ow smoothly.

? NOTE

In the case installing the indoor unit to a grid ceiling, do not touch the unit

body, the electrical wiring and refrigerant piping to a suspension bolt of a

grid. Check the location of suspension bolts of a grid ceiling and indoor

unit mounting position before installing of the indoor unit.

Suspension bolt for

indoor unit

Suspension Bolt

for Indoor Unit

Suspension bolt

for grid ceiling

Grid ceiling

• Select a suitable installation location, considering the air

distribution from each indoor unit to the whole room so that

room temperature will be uniform.

• Install the unit where there is no obstacles which may

hamper the suction air and discharged air.

• Do not install the unit near a door or a window where the

indoor unit may contact humid outside air. Otherwise, dew

condensation may occur.

• In case temperature and humidity inside the ceiling exceeds

30ºC/RH (Relative Humidity) 80%, apply additional insulation

materials to the external surface of the indoor unit to avoid

dew condensation.

• If installing the indoor unit to a high ceiling, the warmed air

may stay around the ceiling during heating operation. Thus,

the parallel installing of a circulator is recommended.

• Do not install the indoor unit where the airow from the air

outlet blows directly to the temperature detecting devices

such an alarm device or a control device. It may cause a

failure of an alarm device or a control device.

• Multiple Combinations. For simultaneous operation of

multiple units, the units must be installed in the same room

and be operated under the same conditions. If the room is

partitioned by a wall, furniture or a curtain, etc., it may cause

an operation failure. Take care when rearranging furniture or

remodelling the room after installation as well.

• When installing the receiver kit (optional) or the motion

sensor (optional), refer to their respective Installation

manuals.

• "STATIC PRESSURE SW" on the PCB must be set to HIGH

PRESSURE when installing the indoor unit at a height

of more than 2500 mm from the oor. It must be set to

NORMAL when installing the indoor unit at a height of less

than 2500 mm from the oor.

Ceiling height

STATIC PRESSURE SW

SW504

RAI-(50/60)PPD

≤ 2.5 m NORMAL

≤ 3.5 m HIGH

INDOOR UNIT INSTALLATION

PMML0477 rev.0 - 07/2017

9

8.3 INSTALLATION

Opening of false ceiling and location of

suspension bolts

• Determine the nal location and installation direction of

the indoor unit paying attention to the space for the piping,

wiring and maintenance.

• Then cut out the false ceiling for the indoor unit installation

and install suspension bolts, as shown below:

(mm)

Unit size: 570

Dimension of

suspension bolts: 530

4-positions of

suspension bolts

Dimension of opening: 576~590

Piping

connection side

Drain piping

connection side

Optional panel

Unit size: 570

Dimension of

suspension bolts: 530

Dimension of opening: 576~590

? NOTE

• Ceiling work differs depending on the building structure. Consult with

a building constructor or an interior nish worker for more information.

• Do not install electric light and the indoor unit to the same furring

of the ceiling. Otherwise, electric lights may icker or vibrate due to

indoor unit operation.

Mounting of suspension bolts

• Strengthen the opening parts of the false ceiling. Using a

steel C-prole makes the work easier.

• Mount suspension bolts, as shown.

• Strengthen suspension bolts with support plates as required

in preparation for an earthquake. Suspension bolts and

support plates shall be M10 (eld-supplied).

For concrete slab:

150 to 160mm

Insert

(100 to 150kg)

Steel

Concrete

Anchor Bolt

Anchor bolt

(W3/8 or M10)

Concrete

Steel

150 to 160mm

Insert

(100 to 150kg)

For steel beam:

I-Beam

Suspension bolt

(W3/8 or M10)

For wooden beam:

Install the indoor unit to the tie beam (for single-storied building)

or to the second oor girder (for two-storied building), and use

sufciently strong squared timber shown below.

Interval between beams Squared timber

< 90 cm 6 square

< 180 cm 9 square

Mounting indoor unit

1 Pattern board for installation and scale for dimension of

opening

a. For installation work, the pattern board is required. The

pattern board for installation and the checking scale are

printed on the back side of the packing.

b. Cut off the checking scale for dimension of opening from

the packing. The usage is shown in the item (5).

Checking scale for

dimension of opening

Packing

(Corrugated board)

Pattern board for

installation

2 Mounting position of the indoor unit

a. Check the mounting position of the indoor unit shown in

gure below:

? NOTE

The air panel (optional) may be deformed if the levelness of the indoor

unit and the position of the suspension brackets are incorrect, and dew

condensation may occur due to air leakage from the gap between the

indoor unit and the air panel.

INDOOR UNIT INSTALLATION

PMML0477 rev.0 - 07/2017

10

ENGLISH

b. The positional relation between the indoor unit and the

air panel (optional) is shown in gure below:

285

90

30

*16

Min.30

Surface of ceiling

Washer

(accessory)

Double nut

(eld-supplied)

4-positions of suspension bolts (M10 or W3/8)

(eld-supplied)

(mm)

* Dimension between bottom side of unit and ceiling surface

177

140

180

145

94

521

Wiring connection

Drain pipe

connection

Refrigerant liquid pipe

connection

Refrigerant gas pipe

connection

(Drain pipe)

(Drain pipe)

(Gas pipe)

(Liquid pipe)

(Gas pipe)

(Liquid pipe)

3 Mounting nuts and washers

Screw nuts and washers on the suspension bolts before

mounting the indoor unit.

? NOTE

Make sure to use washers (accessories) for xing the suspension

bolts to the suspension brackets. The washer with insulation must

be tted with the insulation side downward to facilitate hanging work.

90

(mm)

Nut (eld-supplied)

Suspension bolt

(eld-supplied)

Washer with insulation

(accessory)

Approx

45

Surface of ceiling

Suspension bracket

(attached indoor unit)

Washer

(accessory)

Nut (eld-supplied)

Approx

50

4 Mounting indoor unit

a. Lift up the indoor unit by a hoist, and do not apply any

force to the drain pan (the air outlet portions and the

drain pan portion).

Drain Pan

Drain pan

Suspension bolt

Suspension bracket

? NOTE

For the grid ceiling, incline the unit and then mount the unit from the

refrigerant pipe side as shown in the gure below.

Refrigerant pipe side

Grid ceiling

b. Insert the suspension bolts into the notches of the

suspension brackets to hook the indoor unit.

c. Secure the indoor unit using nuts and washers. Then

check that the washers serve as stoppers at the rising

parts of the suspension brackets.

? NOTE

After hooking up the indoor unit, piping and wiring work inside the ceiling

are required. Thus, especially if the false ceiling has already been

installed, determine the pipe direction and complete the rest of the piping

and wiring work before hooking the indoor unit.

5 Adjusting indoor unit position

Adjust the position of the indoor unit with the checking scale

as required.

a. For false ceiling with opening.

When installing the indoor unit to the false ceiling with an

opening, check the dimension of opening and adjust the

clearance between the indoor unit and the opening.

Attach the scale to the bottom side of the unit.

Attach the scale to the face of ceiling.

.

Adjust the height of

the ceiling and the

unit at each corner.

Attach the scale to the face of ceiling

Attach the scale to the bottom side of the unit

INDOOR UNIT INSTALLATION

PMML0477 rev.0 - 07/2017

11

b. For false ceiling without opening

If there is no opening in the existing false ceiling, provide

an opening in it before mounting the indoor unit. Cut out

the false ceiling. After hooking up the indoor unit, adjust

the position according to the procedure (a).

5

5

5

576~590

576~590

570

570

5

Dimension of opening

Indoor unit

Surface

of ange

Dimension of opening

Electrical box

6 Tighten two nuts of each suspension bolt after the

adjustment is completed. Apply LOCK-TIGHT paint to the

suspension bolts and nuts in order to prevent them from

loosening. Adjust the indoor unit to the correct position,

using the checking scale.

? NOTE

While adjusting the space between the indoor unit and the ceiling

surface, keep the indoor unit level. Otherwise, it may cause a

malfunction of the oat switch. Check the levelness of the unit with

a level.

Level

Vinyl tube

Drain pipe

Corrugated board

Check the levelness at each corner (•) of the unit with a

level or by pouring water to the clear vinyl tube as shown in

the gure. Make the corner at the drain pipe side 1 to 3mm

lower.

7 The upper surface of the unit is protected by corrugated

cardboard to prevent the unit from being damaged by

spatter, etc. When mounting the air panel (optional), check

to ensure that welding around the unit has been nished

before removing the corrugated cardboard.

Installation of air panel

Refer to "12 Installation of optional air panel: P-AP56NAMS".

1 Check the distance between the indoor unit and the false

ceiling. It is 16

+3

0

mm as shown in the gure. If not, adjust the

distance by using the checking scale with maintaining the

levelness of the indoor unit.

2 Check that the xing screws for the panel are tightened.

Tighten the xing screws for the panel until touching the

stopper to the suspension bracket.

? NOTE

Pay attention to the distance between the indoor unit and the false

ceiling. If it is 19mm or more, it may cause dew condensation by

leaking air from the seal packing (Field-Supplied).

3 Check the indoor unit height from the false ceiling surface.

For air panel P-AP56NAMS

3

Indoor unit

Ceiling surface

Installation of remote control switch

For details on installation of the remote control switch, refer to

Installation and Operation Manual of the product.

INDOOR UNIT INSTALLATION

PMML0477 rev.0 - 07/2017

12

ENGLISH

9 REFRIGERANT PIPING

Before refrigerant piping work, drain piping work and insulation

are required. Refer to the "10 Drain piping" for details.

! DANGER

• Do not perform refrigerant piping work, drain pumping, and

refrigerant charge without referring to Installation and Operation

Manual of the outdoor unit.

• Use the specied refrigerant (R32) to the outdoor unit in the

refrigerant cycle. Do not charge the unit with material other than

R32 such as hydrocarbon refrigerants (propane or etc.), oxygen,

ammable gases (acetylene or etc.) or poisonous gases when

installing, maintaining and moving the unit. These ammables

are extremely dangerous and may cause an explosion, a re,

and injury.

9.1 PIPING POSITION

177

140

180

145

94

521

Wiring connection

Drain pipe

connection

Refrigerant liquid pipe

connection

Refrigerant gas pipe

connection

(Drain pipe)

(Drain pipe)

(Gas pipe)

(Liquid pipe)

(Gas pipe)

(Liquid pipe)

? NOTE

Refrigerant liquid pipe connection

3

2

1

9.2 PIPING CONNECTION SIZE

1 Prepare locally-supplied copper pipes.

2 Select the appropriate pipe size according to the table

below:

mm (in.)

Model Gas Pipe Liquid Pipe

RAI-50PPD

RAI-60PPD

Ø12.7 (1/2) Ø6.35 (1/4)

3 Select clean copper pipes. Make sure there is no dust and

water inside. Use a pipe cutter when cutting the pipes, to

avoid a grind swarf generation. Do not use a saw or a grind

stone to cut pipes. Blow the inside of the pipes with nitrogen

or dry air, to remove any dust or foreign materials before

connecting pipes.

? NOTE

• Refer to Installation and Operation Manual of the outdoor unit for

detail on allowable pipe length.

• Notice for refrigerant pipe ends.

• Attach a cap or put a plastic bag over the pipe end.

In case of getting the pipe through a hole in the wall.

In Case of Getting the Pipe

Through a Hole in the Wall

Correct

CorrectIncorrect Incorrect

HoleHole

Do not place the pipe

directly on the ground.

Correct

Incorrect

Hole

Hole

Cap or plastic bag

Do not place the pipe directly on the ground.

Do not place the pipe

directly on the ground.

Correct

Incorrect

Cap or plastic bag

In case of rain

CorrectIncorrect Incorrect

HoleHole

Attach a cap or put a plastic

bag over the pipe end.

Do not place the pipe

directly on the ground.

Rain water

can come in.

In Case of Rain

Correct

Incorrect

Rain water can

come in

Rubber band

Cap or plastic bag

• Due to the change of refrigerant oil, the refrigerant cycle is more

subject to the entrance of foreign matters such as moisture, oxide

lm and grease. Be careful that these substances do not enter

the refrigerant cycle during installation work. Otherwise, they may

be trapped into such parts as the expansion valve, hindering the

operation.

REFRIGERANT PIPING

PMML0477 rev.0 - 07/2017

13

9.3 PIPING CONNECTION SIZE

Perform aring work according to the gures and tables below:

Flare pipe dimensions

mm (in.)

0.4 ~ 0.8R

φA

φd

90

o

+

2

o

45

o

+

2

o

Diameter (∅ d)

A

+0

-0.4

6.35 (1/4) 9.1

9.52 (3/8) 13.2

12.7 (1/2) 16.6

15.88 (5/8) 19.7

Thickness of copper pipes

mm (in.)

Diameter (∅ d)

Thickness

6.35 (1/4) 0.8

9.52 (3/8) 0.8

12.7 (1/2) 0.8

15.88 (5/8) 1.0

Flare nut dimensions

mm (in.)

B

Flare nut

Diameter (∅ d)

B

6.35 (1/4) 17

9.52 (3/8) 22

12.7 (1/2) 26

15.88 (5/8) 29

Check that there are no scratches, adhered grinding swarf,

deformation or surface unevenness at the aring part.

Before tightening the are nut, apply the refrigerant oil (eldsupplied) in thin layer over the aring part. Do not apply the oil

on other portions. Tighten the are nut for the liquid pipe to the

specied torque with two spanners. Then, tighten the are nut

for the gas pipe in the same way. After tightening work, check

that there is no refrigerant leakage.

Do not apply the

refrigerant oil to

the outside of the

aring part.

Apply Refrigerant Oil.

Apply refrigerant oil

Required tightening torque

Pipe Size Tightening Torque

Ø6.35 mm (1/4) 14 - 18 (N-m)

Ø9.52 mm (3/8) 34 - 42 (N-m)

Ø12.7 mm (1/2) 49 - 61 (N-m)

Ø15.88 mm (5/8) 68 - 82 (N-m)

? NOTE

• If the refrigerant oil contacts the air panel, it may cause a crack. Be

careful that the refrigerant oil does not contact the air panel.

! CAUTION

Tighten the are nuts according to the specied torque. If an excessive

force is applied, the are nuts may crack due to aging degradation,

causing refrigerant leakage.

If temperature and humidity inside the ceiling exceed 27ºC/

RH80%, dew condensation occurs on the surface of the

accessory insulation. Wrap additional insulation (approx.

5~ 10mm thickness) around the accessory insulation of the

refrigerant pipe as a preventive measure.

For buried pipe with joints such as an elbow or a socket, provide

service access doors to facilitate the check for connection.

The pipes must be reinforced by an earthquake resistant

support so that they will not be damaged by an external force.

Do not clamp the refrigerant pipe tightly when supporting them

for prevention of heat stress.

When connecting indoor/outdoor units with refrigerant pipes, x

the pipes as required so that the pipes may not to contact weak

portions of the wall, ceiling, etc. Failure to take this measure

may lead to an abnormal sound caused by the vibration of the

pipe.

Perform the air tight test according to Installation and Operation

Manual of the outdoor unit.

REFRIGERANT PIPING

PMML0477 rev.0 - 07/2017

14

ENGLISH

Insulate each are connection without gap with eld-supplied

insulations to prevent dew condensation. Then insulate each

refrigerant pipe as well.

Fasten securely cord clamps and

the vinyl tape in order to prevent the

pipe from dew condensation

Fix the vinyl tape position at the vertical part

(Insulation for refrigerant pipe (eld-supplied)).

Refrigerant pipe

(eld-supplied)

Fasten 3 places of the

pipe by cord clamps

(eld-supplied)

Insulation for refrigerant pipe

(eld-supplied)

Insulation material

(factory-supplied)

Check no clearance between the

indoor unit and the insulation

Unit

side

If coating the optional air panel with a forming agent

(recommended Gupoex) after installation, make sure that the

forming agent does not contact it. Otherwise, it could cause

a breakage of the panel, resulting in the panel falling. If the

forming agent contacts the air panel, completely wipe it off.

10 DRAIN PIPING

10.1 GENERAL INFORMATION

! CAUTION

• Do not put the drain pipe for the indoor unit into the drainage trench

where corrosive gases occur. Otherwise, poisonous gases ow into

the room, which may cause poisoning.

• Do not create an upper-slope or rise for the drain piping, since drain

water will ow back to the unit and leakage to the room will occur

when the unit operation is stopped.

• Do not connect the drain pipe with sanitary or sewage piping or any

other drainage piping.

• When the common drain piping is connected with other indoor units,

the connected position of each indoor unit must be higher than the

common piping. The pipe size of the common drain pipe must be

large enough according to the unit size and number of units.

• Drain piping will require insulating if the drain is installed in a location

where condensation forming on the outside of drain pipe may drop

and cause damage. The insulation for the drain pipe must be selected

to insure vapour sealing and prevent condensation forming.

• Drain trap should be installed next to indoor unit. This trap must be

designed to good practice and be checked with water (charged)

and tested for correct ow. Do not tie or clamp the drain pipe and

refrigerant pipe together.

? NOTE

• Install drainage in accordance with national and local codes.

• Pay attention to the thickness of the insulation when the left side

piping is performed. If it is too thick, piping can not be installed in

the unit.

10.2 DRAIN PIPE CONNECTION

1 The position of the drain pipe connection is shown below.

36

49

177

Drain pipe connection

2 Prepare a polyvinyl chloride pipe with a 32mm outer

diameter (VP25).

3 Fasten the tubing to the drain hose with an adhesive and the

factory-supplied clamp. The drain piping must be performed

with a down-slope pitch of 1/25 to 1/100.

4 Do not apply excessive force to the drain pipe connection. It

could cause a damage.

5 Connect the factory-supplied drain hose to the drain pipe

connection with the polyvinyl chloride adhesive. When

cleaning the connection surface, applying the adhesive,

inserting, retaining and curing the pipe, refer to information

given by the adhesive manufacturer.

DRAIN PIPING

PMML0477 rev.0 - 07/2017

15

6 Insert the drain hose completely. If it is not inserted properly,

or if it is twisted, water leakage may occur.

CORRECT

Drain pipe

connection

Drain hose

(Accessory)

INCORRECT

(Correct)

Drain Hose

(Accessory)

Drain hose

(Accessory)

Twisted

Incompletely insertion

Twisted, incompletely insertion

7 In case of raising the drain pipe, install it according to the

dimension shown in the gure below. The total drain piping

length of a+b+c shall be within 1100mm.

b

F

Ceiling

Drain hose

(accessory)

Support part

1 to 1.5m

(Max. 50mm, shorter

as possible)

1/25 to 1/100

Down-slope

a (Max. 300mm)

Hose band (accessory)

Max. 850mm

8 Attach the factory-supplied hose clamp to the vinyl tape

(gray) attached to the drain hose. The hose clamp shall

be 20mm away from the end face of the drain hose. Then

tighten the hose clamp to make sure that it is approximately

28mm in length from the screw to the edge of the hose

clamp as shown:

20+5mm

Hose band (accessory)

Tightening torque: 3.0-3.5 N.m

Elbow or vinyl chloride VP25

(Field-supplied)

Drain hose (accessory)

Vinyl tape (gray)

Drain pipe connection

for checking drainage

(transparent)

Use vinyl chloride

type adhesive

Tightening torque: 3.0-3.5 N.m

Min. 28mm

Max. 300mm

? NOTE

• If connecting the factory-supplied drain hose to the drain pipe

connection without adhesive, for future relocation, follow the

procedure (6) and (8).

• Use the factory-supplied drain hose and the hose clamp. Others may

cause water leakage.

• Do not bend or twist the factory supplied drain hose. It will cause

water leakage.

• Do not apply an excessive force to the drain pipe connection. It could

cause a damage.

On-site drain piping work

• Connect the factory-supplied drain hose to the drain pipe

connection using the polyvinyl chloride adhesive.

• When cleaning the connection surface, applying the

adhesive, inserting, retaining and curing the drain pipe, refer

to information given by the adhesive manufacturer.

• Install the support parts at an interval of 1m to 1.5m in order

not to bend the drain pipe.

• Install the drain hose horizontally or slightly on an upward

slope to prevent air pockets from forming inside it. If air

pockets form, the drain water will ow back into the unit,

which could cause an abnormal noise and leakage to the

room when the unit operation is stopped.

Drain Hose

Install the drain hose horizontally or

with an upward slope.

Drain hose

Installing common drain pipe

• Install the common drain pipe on a downward slope to make

sure that it is lower than each rising part of the drain pipe

from the indoor unit.

• The pipe size of the common drain pipe must be larger

than VP30 (nominal diameter 30mm, outer diameter 38mm)

according to the number of the connected indoor units.

Example

This drain pipe shall

be separating from

other pipes

Vinyl Chloride Pipe (VP25)

Min. 100mm

(higher as possible)

1/25 to 1/100

downward slope

Common drain piping (Min. VP30)

(Downward slope from rising part)

Drain piping of unit side

? NOTE

• Do not provide an upward slope or a rising part for the drain pipe.

Otherwise, the drain water will ow back into the unit and it may

cause the water leakage when the unit operation is stopped.

Incorrect installation of drain piping

Rising part

Upward slope

• Do not connect the drain pipe with sanitary or sewage pipe or any

other drainage pipe.

DRAIN PIPING

PMML0477 rev.0 - 07/2017

16

ENGLISH

Drainage and water leakage check

After performing drain piping work and the electrical wiring and

before installing the air panel, check to ensure that water ows

smoothly according to the following procedure.

• Drainage operation by oat switch

The following is regular procedure to check the oat switch

operation.