Page 1

SERVICE MANUAL

TECHNICAL INFORMATION

FOR SERVICE PERSONNEL ONLY

RAI-ECPM

RAI-25NH5

RAI-35NH5

NOTE:

This manual describes only points that differ from

RAK-18NH5, 25NH5, 35NH5 (PM NO. 0269E) and

RAM-40QH5 (PM NO. 0270E) for items not described

in this manual.

PM

NO. 0271E

RAI-25NH5

RAI-35NH5

REFER TO THE FOUNDATION MANUAL

CONTENTS

SPECIFICATIONS ------------------------------------------------------------------- 4

HOW TO USE ------------------------------------------------------------------------ 6

CONSTRUCTION AND DIMENSIONAL DIAGRAM --------------------- 27

MAIN PARTS COMPONENT --------------------------------------------------- 28

WIRING DIAGRAM ---------------------------------------------------------------- 29

CIRCUIT DIAGRAM --------------------------------------------------------------- 31

PRINTED WIRING BOARD LOCATION DIAGRAM --------------------- 35

BLOCK DIAGRAM ----------------------------------------------------------------- 37

BASIC MODE ----------------------------------------------------------------------- 39

REFRIGERATING CYCLE DIAGRAM --------------------------------------- 53

AUTO SWING FUNCTION ------------------------------------------------------ 55

DESCRIPTION OF MAIN CIRCUIT OPERATION ----------------------- 56

SERVICE CALL Q & A ---------------------------------------------------------- 61

TROUBLE SHOOTING ----------------------------------------------------------- 64

PARTS LIST AND DIAGRAM -------------------------------------------------- 69

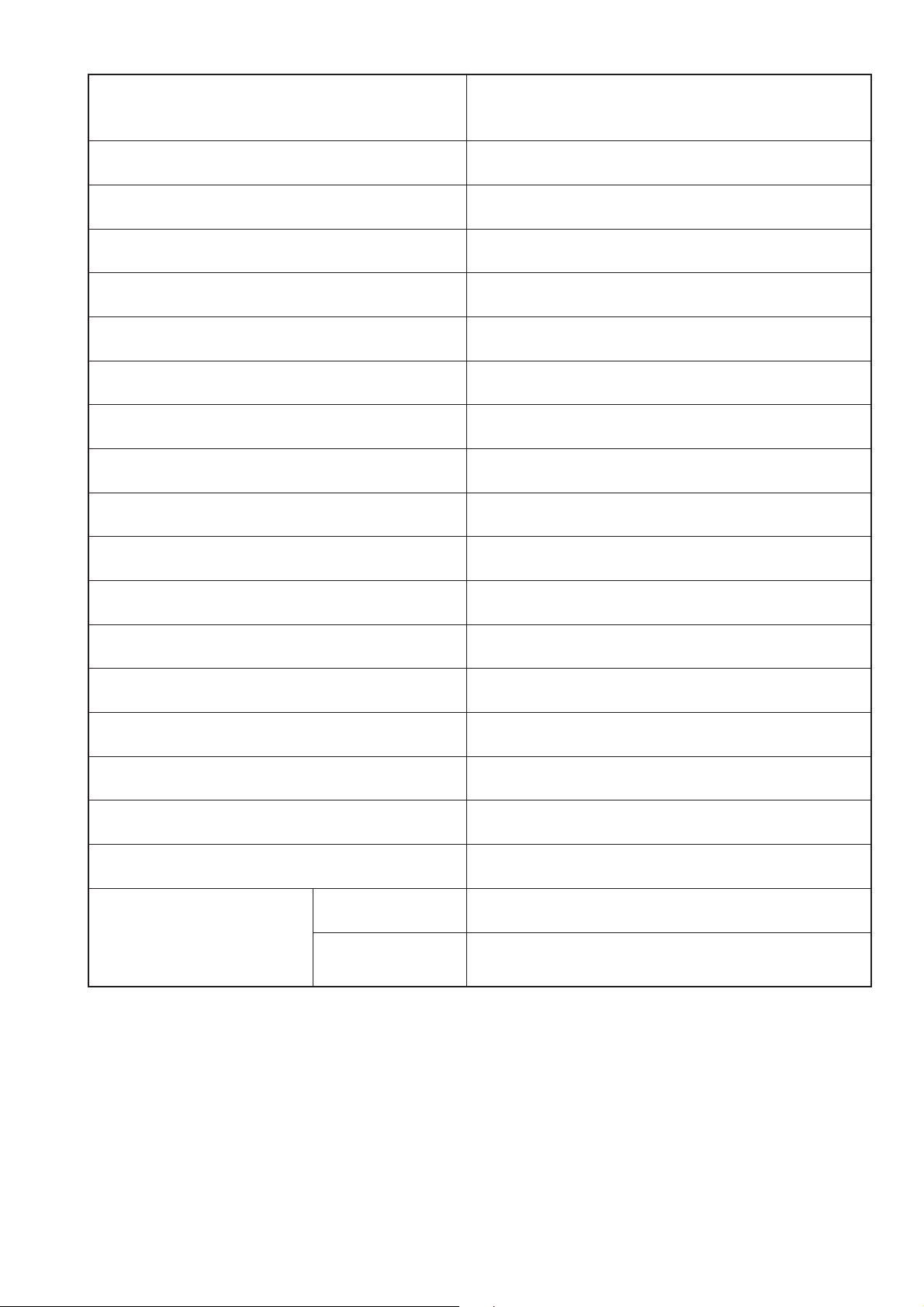

SPECIFICATIONS

TYPE

MODEL

POWER SOURCE

TOTAL INPUT

COOLING

HEATING

DIMENSIONS

(mm)

NET WEIGHT

TOTAL AMPERES

CAPACITY

TOTAL INPUT

TOTAL AMPERES

CAPACITY

1 PHASE, 50 Hz, 220-240V

(W)

(A)

(kW)

(B.T.U./h)

(W)

(A)

(kW)

(B.T.U./h)

W

H

D

(kg)

DC INVERTER (CEILING CASSETTE TYPE)

INDOOR UNIT

RAI-25NH5

1 PHASE, 50 Hz, 220-240V

REFER TO THE SPECIFICATIONS PAGE (5)

580

285

580

20

RAI-35NH5

SPECIFICATIONS AND PARTS ARE SUBJECT TO CHANGE FOR IMPROVEMENT

580

285

580

20

ROOM AIR CONDITIONER

SEPTEMBER 2005

Refrigeration & Air-Conditioning Division

INDOOR UNIT

Page 2

SAFETY DURING REPAIR WORK

1. In order to disassemble and repair

the unit in question, be sure to

disconnect the power cord plug

from the power outlet before starting

the work.

2. If it is necessary to replace any parts, they should be replaced with respective genuine parts for the unit, and

the replacement must be effected in correct manner according to the instructions in the Service Manual of

the unit.

If the contacts of electrical parts

are defective, replace the

electrical parts without trying to

repair them.

First, I must disconnect

the power cord plug

from the power outlet.

3. After completion of repairs, the initial state

should be restored.

4. Lead wires should be connected and laid as

in the initial state.

5. Modification of the unit by user himself should

absolutely be prohibited.

6. Tools and measuring instruments for use in repairs or inspection should be accurately calibrated in advance.

7. In installing the unit having been repaired, be careful to prevent the occurence of any accident such as

electrical shock, leak of current, or bodily injury due to the drop of any part.

8. To check the insulation of the unit, measure the insulation resistance between the power cord plug and

grounding terminal of the unit. The insulation resistance should be 1M

DC megger.

9. The initial location of installation such as window, floor or the other should be checked for being and safe

enough to support the repaired unit again.

If it is found not so strong and safe, the unit should be installed at the initial location reinforced or at a new

location.

10. Any inflammable thing should never

be placed about the location of

installation.

or more as measured by a 500V

DANGER

11. Check the grounding to see whether

it is proper or not, and if it is found

improper, connect the grounding

terminal to the earth.

– i –

Page 3

WORKING STANDARDS FOR PREVENTING BREAKAGE OF SEMICONDUCTORS

1. Scope

The standards provide for items to be generally observed in carrying and handling semiconductors in relative

manufacturers during maintenance and handling thereof. (They apply the same to handling of abnormal goods

such as rejected goods being returned).

2. Object parts

(1) Micro computer

(2) Integrated circuits (IC)

(3) Field-effect transistors (FET)

(4) P.C. boards or the like on which the parts mentioned in (1) and (2) of this paragraph are equipped.

3. Items to be observed in handling

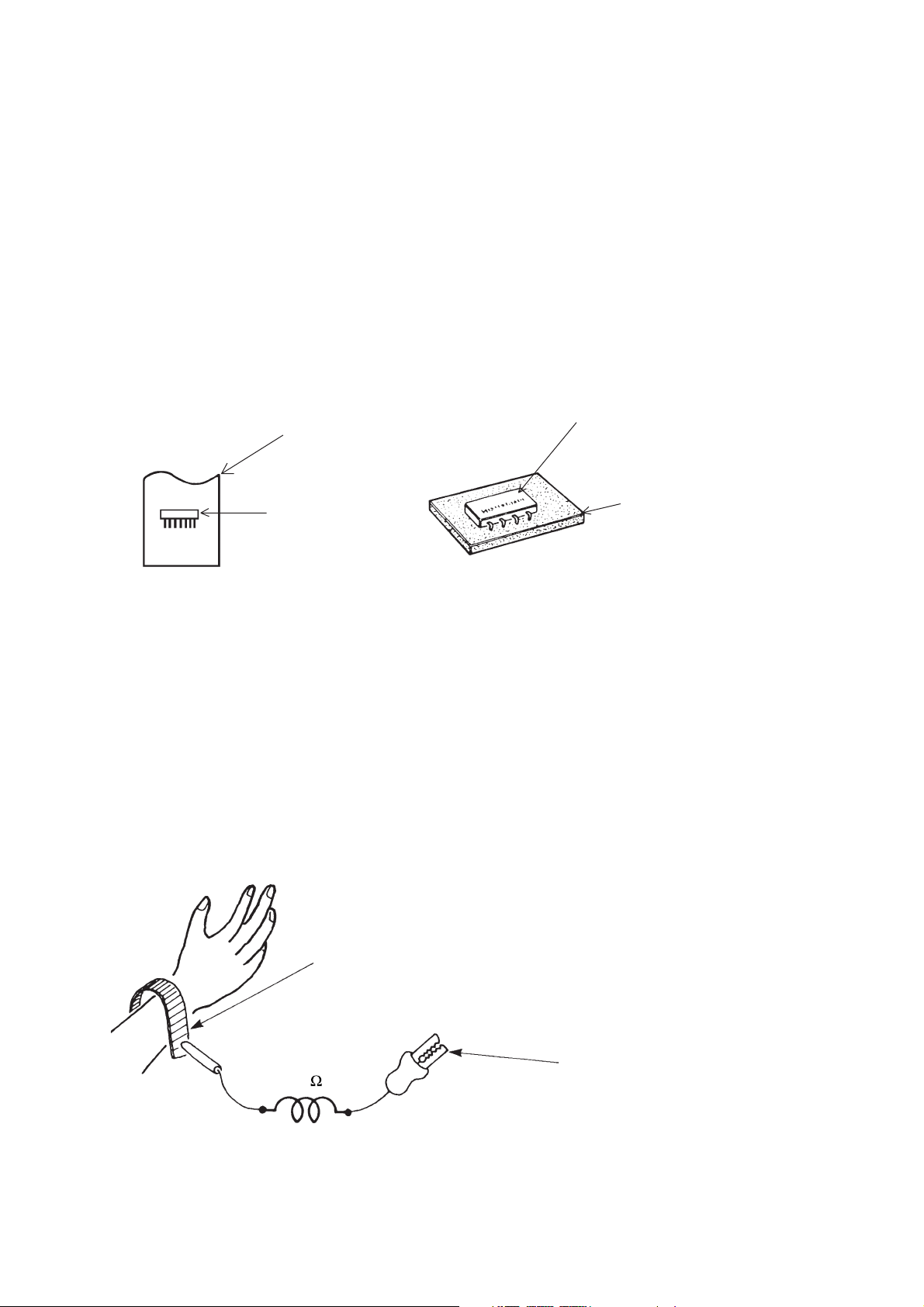

(1) Use a conductive container for carrying and storing of parts. (Even rejected goods should be handled in

the same way).

A conductive polyvinyl bag

IC

Fig. 1. Conductive Container

(2) When any part is handled uncovered (in counting, packing and the like), the handling person must always

use himself as a body earth. (Make yourself a body earth by passing one M ohm earth resistance through

a ring or bracelet).

(3) Be careful not to touch the parts with your clothing when you hold a part even if a body earth is being

taken.

(4) Be sure to place a part on a metal plate with grounding.

(5) Be careful not to fail to turn off power when you repair the printed circuit board. At the same time, try

to repair the printed circuit board on a grounded metal plate.

IC

Conductive sponge

Body earth

(Elimik conductive band)

1M

Fig. 2. Body Earth

Clip for connection with a

grounding wire

– 1 –

Page 4

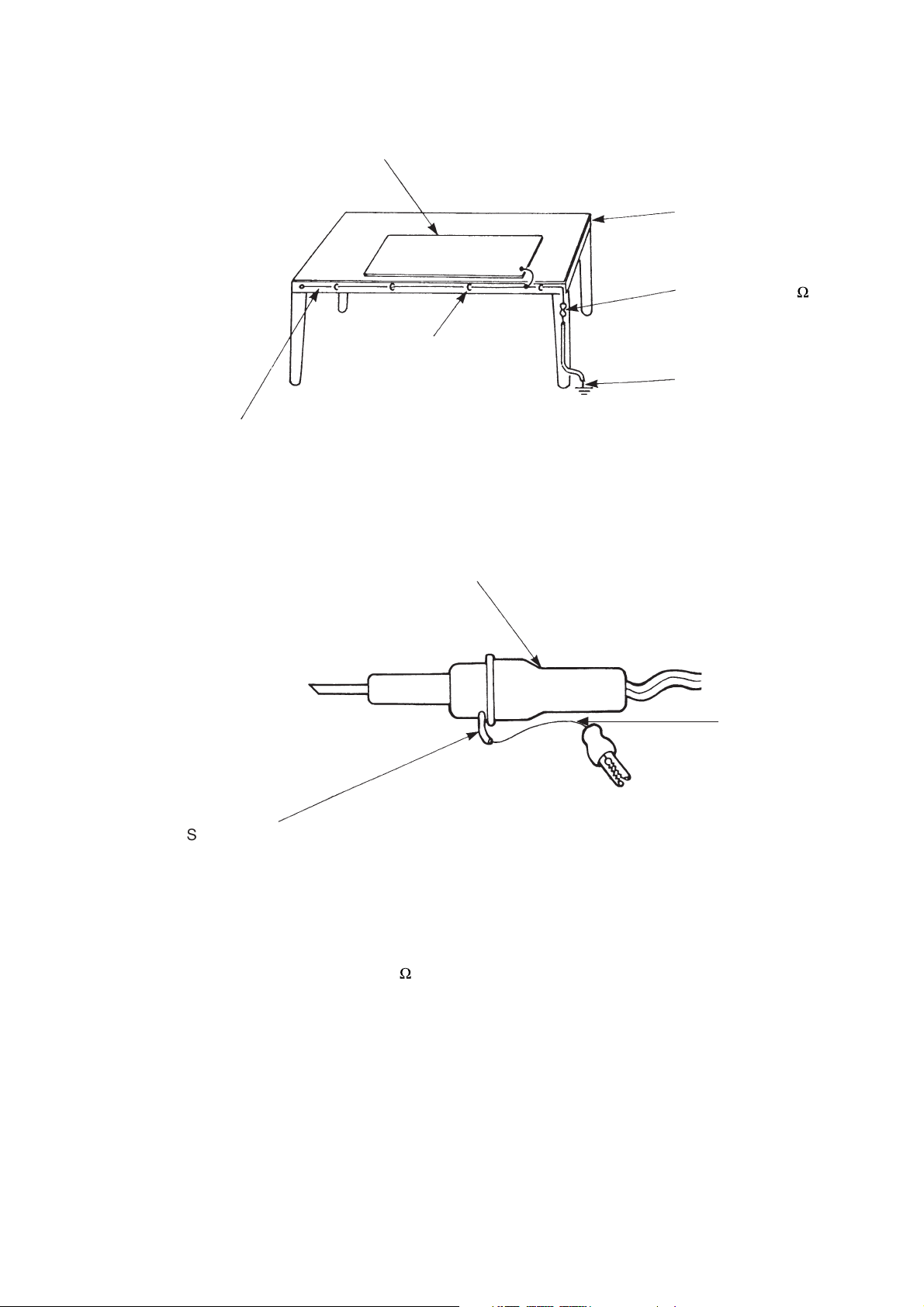

(6) Use a three wire type soldering iron including a grounding wire.

Metal plate (of aluminium, stainless steel, etc.)

Working

table

Bare copper wire (for body earth)

Staple

Fig. 3. Grounding of the working table

Soldering iron

2

Resistor of 1 M

Earth wire

Grounding

wire

(1/2W)

Screw stop at the screwed

part using a rag plate

Fig. 4. Grounding a soldering iron

Use a high insulation mode (100V, 10M

(7) In checking circuits for maintenance, inspection or some others, be careful not to have the test probes of the

measuring instrument shortcircuit a load circuit or the like.

or higher) when ordinary iron is to be used.

– 2 –

Page 5

CAUTION

!

1. In quiet operation or stopping the running, slight flowing noise of refrigerant in the refrigerating cycle is

heard occasionally, but this noise is not abnormal for the operation.

2. When it thunders near by, it is recommend to stop the operation and to disconnect the power cord plug

from the power outlet for safety.

3. The room air conditioner does not start automatically after recovery of the electric power failure for

preventing fuse blowing. Re-press START/STOP button after 3 minutes from when unit stopped.

4. If the room air conditioner is stopped by adjusting thermostat, or missoperation, and re-start in a moment,

there is occasion that the cooling and heating operation does not start for 3 minutes, it is not abnormal

and this is the result of the operation of IC delay circuit. This IC delay circuit ensures that there is no

danger of blowing fuse or damaging parts even if operation is restarted accidentally.

5. This room air conditioner should not be used at the cooling operation when the outside temperature is

below 10°C (50°F).

6. This room air conditioner (the reverse cycle) should not be used when the outside temperature is below

–15°C (5°F).

If the reverse cycle is used under this condition, the outside heat exchanger is frosted and efficiency falls.

7. When the outside heat exchanger is frosted, the frost is melted by operating the hot gas system, it is not

trouble that at this time fan stops and the vapour may rise from the outside heat exchanger.

– 3 –

Page 6

SPECIFICATIONS

MODEL

FAN MOTOR

FAN MOTOR CAPACITOR

FAN MOTOR PROTECTOR

COMPRESSOR

COMPRESSOR MOTOR CAPACITOR

OVERLOAD PROTECTOR

OVERHEAT PROTECTOR

FUSE (for MICROPROCESSOR)

POWER RELAY

RAI-25NH5

RAI-35NH5

25W

NO

NO

–

NO

NO

NO

NO

NO

POWER SWITCH

TEMPORARY SWITCH

SERVICE SWITCH

TRANSFORMER

VARISTOR

NOISE SUPPRESSOR

THERMOSTAT

REMOTE CONTROL SWITCH (LIQUID CRYSTAL)

REFRIGERANT CHARGING

VOLUME

(Refrigerant 410A)

UNIT

PIPES

NO

YES

NO

NO

NO

NO

YES(IC)

YES

----------

WITHOUT REFRIGERANT BECAUSE

COUPLING IS FLARE TYPE.

– 4 –

Page 7

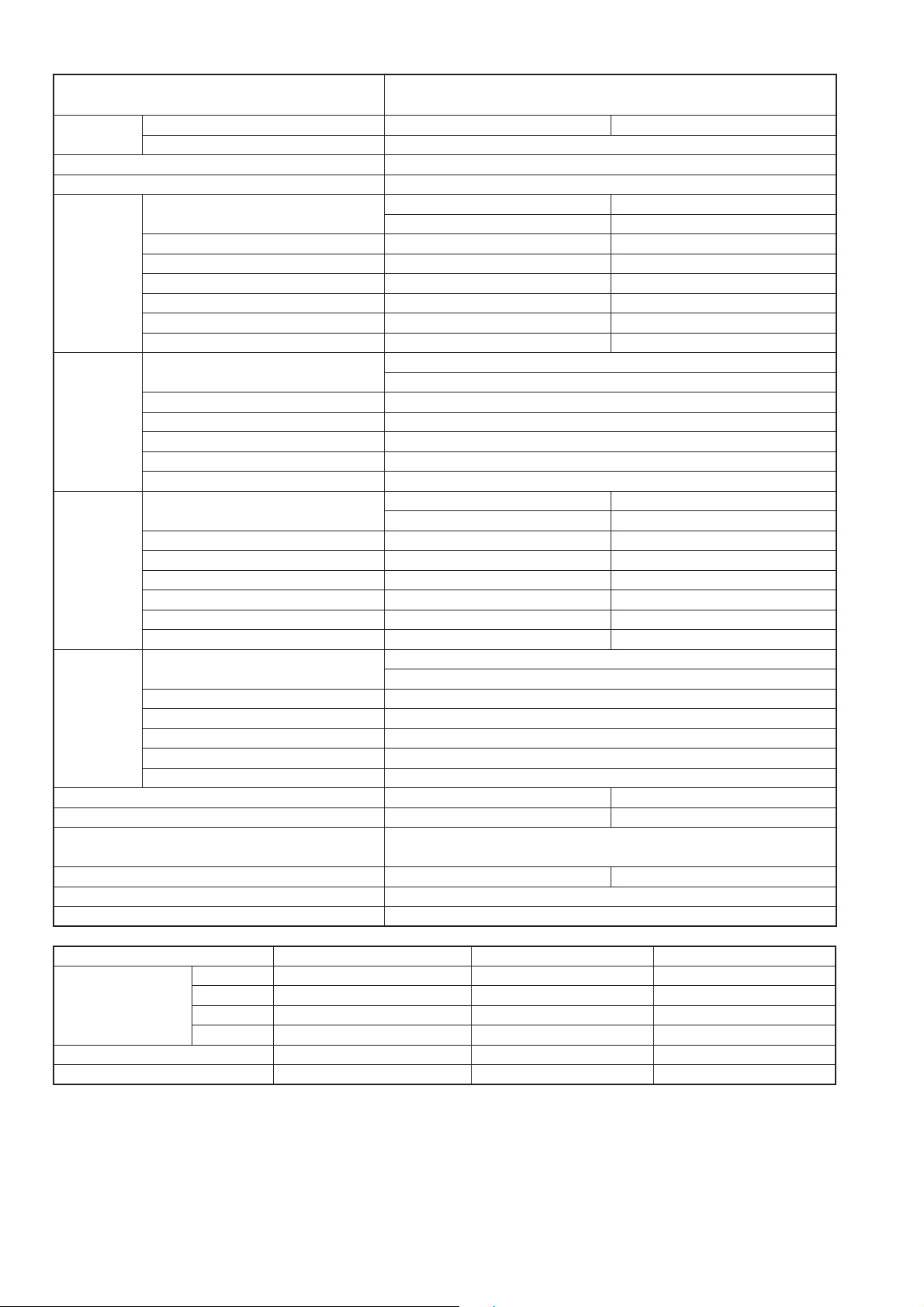

SPECIFICATIONS FOR INDOOR UNITS COMBINATIONS

CEILING CASSETTE TYPE DC INVERTER QUADRUPLE

SYSTEM MULTI COOLING AND HEATING

RAI-25NH5 RAI-35NH5

2.50 (1.00 ~ 3.00)

8540 (3412~10236)

750 (200-880)

11.39

3.44 ~ 3.16

99

35

8.5m3/min

3.40 (1.10 ~ 4.40)

11610 (3761~15026)

870 (200-1120)

13.34

3.99 ~ 3.66

99

36

3

8.5m

YES (AUTO SWING)

3

NOT PROVIDED (POWER CORD SHOULD BE PREPARED AND

CONNECTED TO OUTDOOR UNIT WHEN INSTALLED)

YES (WIRELESS) YES (WIRELESS)

MODEL

CIRCUIT AMPERES TO CONNECT (A)

COOLING

(ONE UNIT)

COOLING

(TWO UNITS)

HEATING

(ONE UNIT)

HEATING

(TWO UNITS)

TYPE

INDOOR UNIT

OUTDOOR UNIT

PHASE/VOLTAGE/FREQUENCY

CAPACITY (kW)

(B.T.U./h)

TOTAL INPUT (W)

EER (B.T.U./hW)

TOTAL AMPERES (A)

POWER FACTOR (%)

SOUND LEVEL (INDOOR)

AIR FLOW VOLUME (Hi)

CAPACITY (kW)

(B.T.U./h)

TOTAL INPUT (W)

EER (B.T.U./hW)

TOTAL AMPERES (A)

POWER FACTOR (%)

SOUND LEVEL (OUTDOOR)

CAPACITY (kW)

(B.T.U./h)

TOTAL INPUT (W)

EER (B.T.U./hW)

TOTAL AMPERES (A)

POWER FACTOR (%)

SOUND LEVEL (INDOOR)

AIR FLOW VOLUME (Hi)

CAPACITY (kW)

(B.T.U./h)

TOTAL INPUT (W)

EER (B.T.U./hW)

TOTAL AMPERES (A)

POWER FACTOR (%)

SOUND LEVEL (OUTDOOR)

AIR DEFLECTORS

FAN SPEED

LINE CORD

REMOTE CONTROL SWITCH

MAXIMUM LENGTH OF PIPING

STANDARD

RAM-40QH5

1ø, 220V-240V, 50Hz

16

11950 (3412~13660)

4.00 (1.50 ~ 4.50)

13660 (5126~15367)

1245 (200-1800)

10.97

5.72 ~ 5.24

99

49

14340 (3761~17070)

/min

5.00 (1.50 ~ 5.60)

17070 (5126~19122)

1350 (200-1780)

12.64

6.20 ~ 5.68

99

51

YES (AUTO SWING)

MAX. 35m (TWO UNITS TOTAL)

CE (EMC&LVD)

3.50 (1.00 ~ 4.00)

1090 (200-1300)

10.96

5.00 ~ 4.59

99

39

10.8m3/min

4.20 (1.10 ~ 5.00)

1080 (200-1300)

13.28

4.96 ~ 4.55

99

40

3

/min

10.8m

3

MODEL

W

PACKING

(mm)

H

D

cu.ft.

GROSSWEIGHT (kg)

FLARENUTSIZE (SMALL/LARGE)

RAI-25NH5

760

395

706

7.48

25

6.35/9.52D

– 5 –

RAI-35NH5

760

395

706

7.48

25

6.35/9.52D

RAM-40QH5

905

633

394

8.27

43

6.35/9.52D, 6.35/9.52D

Page 8

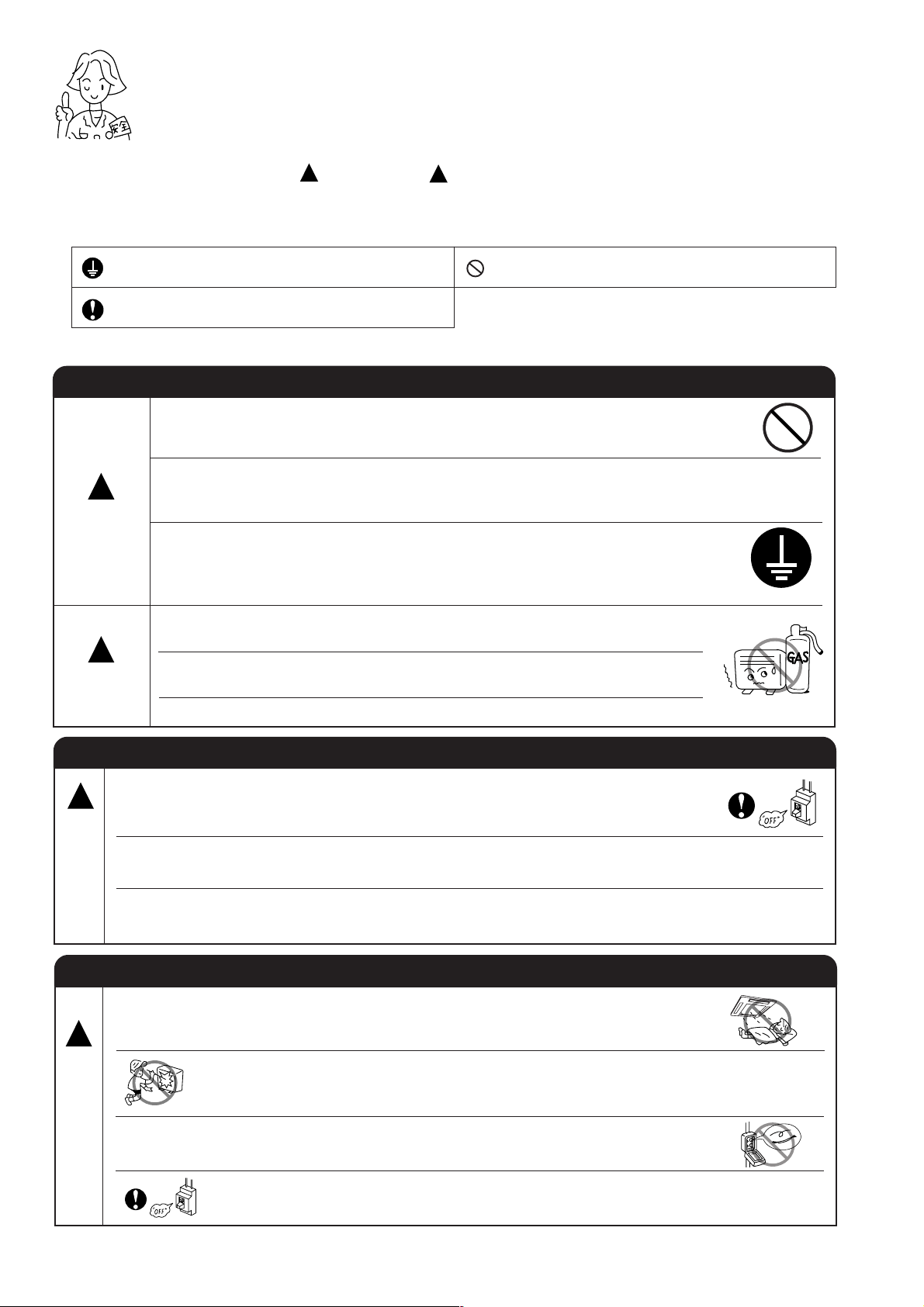

SAFETY PRECAUTION

●

Please read the “Safety Precaution” carefully before operating the unit to ensure correct usage of the unit.

●

Pay special attention to signs of “ Warning” and “ Caution”. The “Warning” section contains matters which,

if not observed strictly, may cause death or serious injury. The “Caution” section contains matters which may

result in serious consequences if not observed properly. Please observe all instructions strictly to ensure safety.

●

The sign indicate the following meanings.

!

!

Make sure to connect earth line.

Indicates the instructions that must be followed.

●

Please keep this manual after reading.

PRECAUTIONS DURING INSTALLATION

●

Do not reconstruct the unit.

Water leakage, fault, short circuit or fire may occur if you reconstruct the

unit by yourself.

●

Please ask your sales agent or qualified technician for the installation of

!

WARNING

!

CAUTION

your unit. Water leakage, short circuit or fire may occur if you install the unit

by yourself.

●

Please use earth line.

Do not place the earth line near water or gas pipes, lightning-conductor, or

the earth line of telephone. Improper installation of earth line may cause

electric shock.

●

A circuit breaker should be installed depending on the mounting site of the

unit. Without a circuit breaker, the danger of electric shock exists.

●

Do not install near location where there is flammable gas. The outdoor unit

may catch fire if flammable gas leaks around it.

●

Please ensure smooth flow of water when installing the drain hose.

The sign in the figure indicates prohibition.

W

A

R

N

N

G

W

A

R

N

N

G

PRECAUTIONS DURING SHIFTING OR MAINTENANCE

●

Should abnormal situation arises (like burning smell), please stop operating the unit

!

I

and turn off the circuit breaker. Contact your agent. Fault, short circuit or fire may

occur if you continue to operate the unit under abnormal situation.

●

Please contact your agent for maintenance. Improper self maintenance may cause

electric shock and fire.

●

Please contact your agent if you need to remove and reinstall the unit. Electric

shock or fire may occur if you remove and reinstall the unit yourself improperly.

PRECAUTIONS DURING OPERATION

●

Avoid an extended period of direct air flow for your health.

!

●

Do not insert a finger, a rod or other objects into the air outlet or inlet. As the

fan is rotating at a high speed, it will cause injury. Before cleaning, be sure

to stop the operation and turn the breaker OFF.

●

I

Do not use any conductor as fuse wire, this could cause fatal accident.

●

During thunder storm, disconnect and turn off the circuit breaker.

– 6 –

Page 9

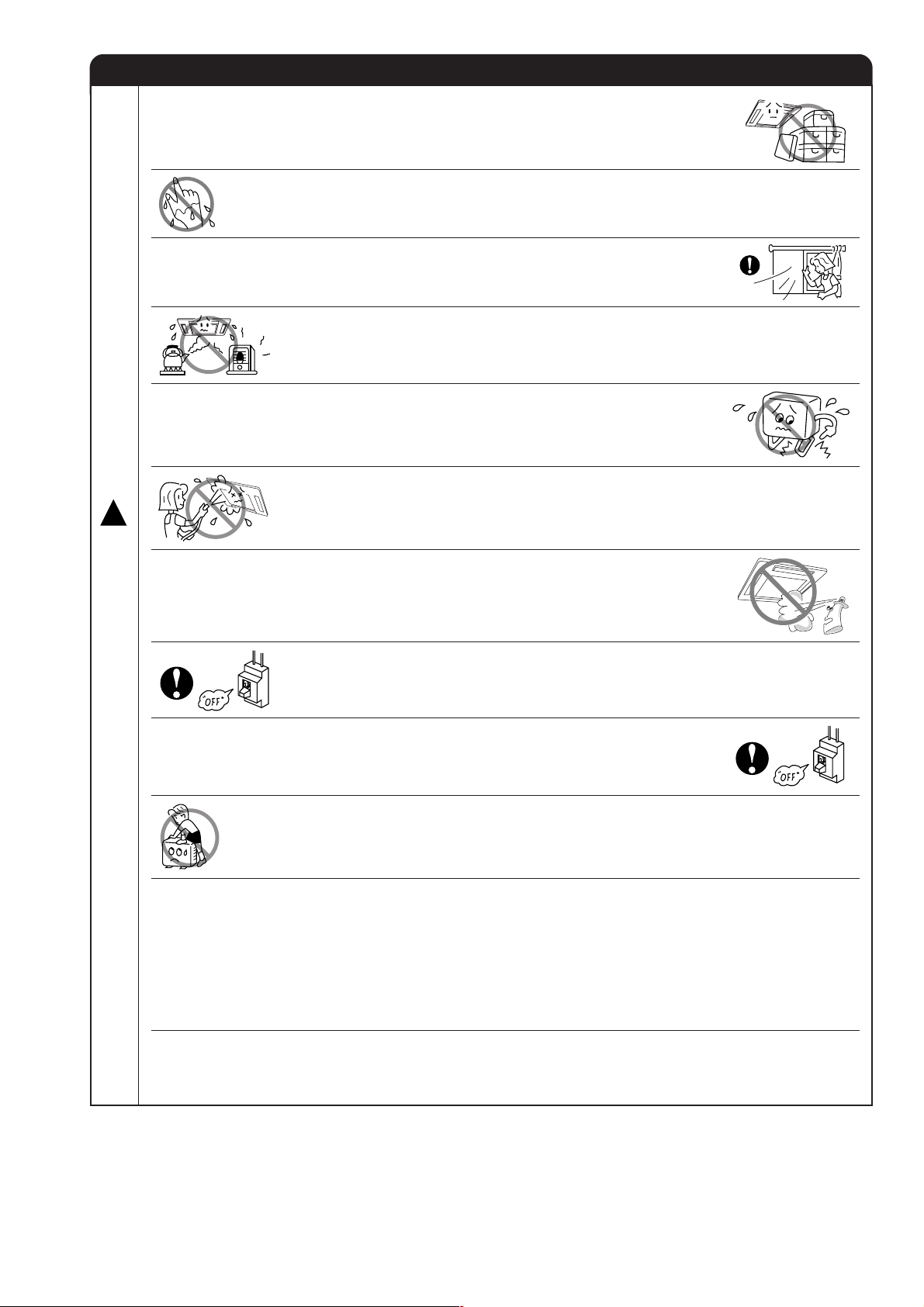

PRECAUTIONS DURING OPERATION

●

The product shall be operated under the manufacturer specification and

not for any other intended use.

●

Do not attempt to operate the unit with wet hands, this could cause fatal

accident.

●

When operating the unit with burning equipments, regularly ventilate the

room to avoid oxygen insufficiency.

●

Do not direct the cool air coming out from the air-conditioner panel to face

household heating apparatus as this may affect the working of apparatus

such as the electric kettle, oven etc.

●

Please ensure that outdoor mounting frame is always stable, firm and

without defect. If not, the outdoor unit may collapse and cause danger.

●

Do not splash or direct water to the body of the unit when cleaning it as this

!

may cause short circuit.

C

A

U

T

I

●

Do not use any aerosol or hair sprays near the indoor unit. This chemical

can adhere on heat exchanger fin and blocked the evaporation water flow

to drain pan. The water will drop on tangential fan and cause water splashing

out from indoor unit.

O

N

●

Please switch off the unit and turn off the circuit breaker during cleaning, the

high-speed fan inside the unit may cause danger.

●

Turn off the circuit breaker if the unit is not to be operated for a long period.

●

Do not climb on the outdoor unit or put objects on it.

●

When operating the unit with the door and windows opened, (the room humidity is always above

80%) and with the air deflector facing down or moving automatically for a long period of time,

water will condense on the air deflector and drips down occasionally. This will wet your furniture.

Therefore, do not operate under such condition for a long time.

●

If the amount of heat in the room is above the cooling or heating capability of the unit (for

example: more people entering the room, using heating equipments and etc.), the preset room

temperature cannot be achieved.

●

This appliance is not intended for use by young children or infirm persons unless they have been

adequately supervised by a responsible person to ensure that they can use the appliance safely.

●

Young children should be supervised to ensure that they do not play with the appliance.

– 7 –

Page 10

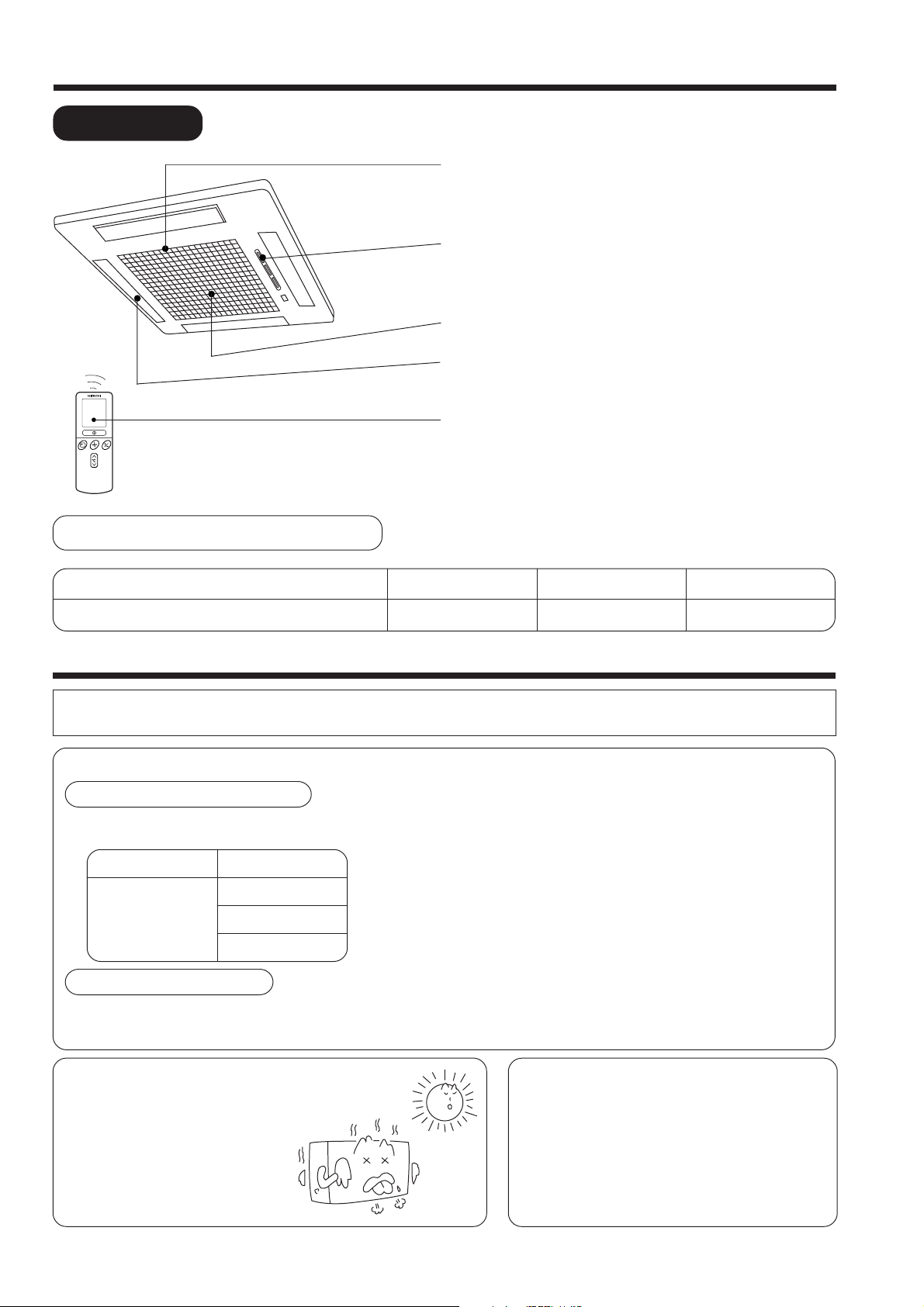

NAMES AND FUNCTIONS OF EACH PART

INDOOR UNIT

AIR FILTER

To prevent dust from coming into the indoor unit.

(Refer page 23)

INDOOR UNIT INDICATORS

Light indicator showing the operating condition.

(Refer page 9)

SUCTION GRILL (AIR INLET)

HORIZONTAL DEFLECTOR (AIR OUTLET)

(Refer page 19)

REMOTE CONTROL

Send out operation signal to the indoor unit. So as to

operate the whole unit.

(Refer page 10)

MODEL NAME AND DIMENSIONS

MODEL

RAI-25NH5 / RAI-35NH5

WIDTH (mm)

580

HEIGHT (mm)

285

DEPTH (mm)

580

MULTI-AIR CONDITIONER

With this multi-air conditioner, several indoor units can be connected to one outdoor unit to be driven. You can operate

the required number of indoor units.

Combination of Operations:

When operation mode is selected:

● You cannot operate the indoor units in the

following combinations.

One unit

Heating

During automatic operation:

● When heating operation is automatically selected for the first indoor unit, the next indoor unit will then start to heat.

Also, if cooling or dehumidifying is automatically selected for the first indoor unit, the next indoor unit will also start

to cool or dehumidify.

Other unit

Cooling

Dehumidifying

Circulating (fan)

● The indoor unit which is switched on first continues to

operate, but other indoor units which is switched on later

does not operate while the lamp lights.

● To re-start an indoor unit which was operated later, stop

the indoor unit which was operated first or later and reset

the type of operation, then perform operation again.

Adjusting the Number of Indoor Units:

Decrease the number of indoor

units to be operated especially

when it is very hot or cold or

when you want to reach the

present temperature quickly.

Stopped Indoor Units:

When an indoor unit is operated in the cooling,

heating or dehumidifying mode in the room, the

sound of refrigerant flow may be heard from a

stopped indoor unit or a stopped indoor unit may

become warm. This is because the indoor unit

returns refrigerant to the outdoor unit to be ready

for operation.

– 8 –

Page 11

OPERATION INDICATOR

TEMPORARY SWITCH

TEMPORARY

SWITCH

Use this switch to start and stop when the remote controller does not work.

[Use non-conductor stick (example toothpick)]

● By pressing the temporary switch, the operation is done in previously set

operation mode.

● When the operation is done using the temporary switch after the power

source is turned off and turn on again, the operation will be done in automatic

mode.

INDOOR UNIT INDICATORS

OPERATION LAMP

This lamp lights during operation.

The OPERATION LAMP flashes in the following

cases during heating.

(1) During preheating

For about 2–3 minutes after starting up.

(2) During defrosting

Defrosting will be performed about once an

hour when frost forms on the heat exchanger

of the outdoor unit, for 5–10 minutes each

time.

Press

Nonconducted

stick

Temporary Switch

about 5.5mm

– 9 –

TIMER LAMP

This lamp lights when the timer is working.

FILTER LAMP

When the device is operated for a total of about

200 hours, the FILTER lamp lights to indicate

that it is time to clean the filter. The lamp goes

out when the “ (AUTO SWING)” button is

pressed while the device is on “STANDBY

MODE”.

Page 12

NAMES AND FUNCTIONS OF REMOTE CONTROL UNIT

REMOTE CONTROLLER

● Operate by pointing towards the signal receptor on the indoor unit. The range of control is

about 7 meters. Signal receivable angle range is approximately 70°. However, if there is an

electronic light sensor device (inverter) in the room, signal may not be received or receivable

distance may become shorter.

● Indoor unit must be install 1 meter or more away from lighting.

● Handle the remote controller with care. Dropping it or getting it wet may compromise its

signal transmission capability.

● After new batteries are inserted into the remote controller, the unit will initially require

approximately 10 seconds to respond to commands and operate.

● Signal emitting window/transmission sign

Point this window toward the indoor unit when controlling it.

CH

˚

CH

˚

RESET

AUTO

HEAT

DEHUMIDIFY

COOL

FAN

FAN SPEED

LOW

MED

HI

SLEEPING

STOP (CANCEL)

START (RESERVE)

START/STOP

TIME

TIMER SET

TIMER SELECTOR

ON TIMER

OFF TIMER

AUTO SWING

The transmission sign blinks when a signal is sent.

● Display

This indicates the room temperature selected, current time, timer status, function

and intensity of circulation selected.

● START/STOP button

Press this button to start operation. Press it again to stop operation.

● SLEEP button

Use this button to set the sleep timer.

● TEMPERATURE buttons

Use these buttons to raise or lower the temperature setting. (Keep pressed, and

the value will change more quickly.)

● TIME button

Use this button to set and check the time and date.

● RESET buttons

● FUNCTION selector

Use this button to select the operating mode. Every time you press it,

the mode will change from (AUTO) to (HEAT) to (DEHUMIDIFY) to

(COOL) and to (FAN) cyclically.

● FAN SPEED selector

This determines the fan speed. Every time you press this button, the intensity

of circulation will change from (AUTO) to (HI) to (MED) to (LOW)

(This button allows selecting the optimal or preferred fan speed for each operation

mode).

● AUTO SWING button

Controls the angle of the horizontal air deflector.

● TIMER control

Use this button to set the timer.

● OFF-TIMER button Select the turn OFF time.

● ON-TIMER button Select the turn ON time.

● RESERVE button Time setting reservation.

● CANCEL button Cancel time reservation.

Precautions for Use

● Do not put the remote controller in the following places.

● Under direct sunlight.

● In the vicinity of a heater.

● Handle the remote controller carefully. Do not drop it on the floor,

and protect it from water.

● Once the outdoor unit stops, it will not restart for about 3 minutes

(unless you turn the power switch off and on or unplug the power

cord and plug it in again).

This is to protect the device and does not indicate a failure.

● If you press the FUNCTION selector button during operation, the

device may stop for about 3 minutes for protection.

▲

▲

Approximately 70°

– 10 –

Page 13

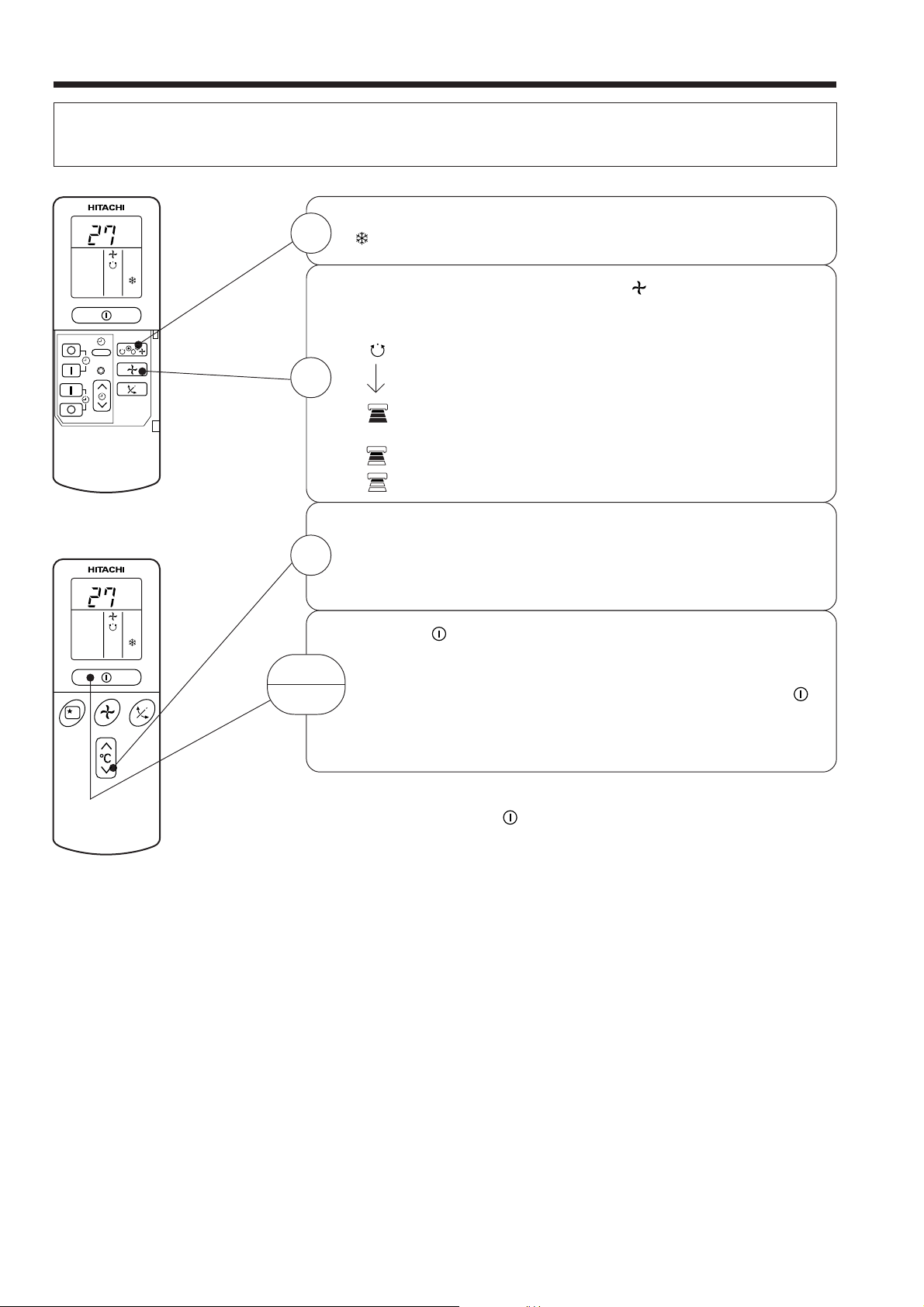

VARIOUS FUNCTIONS

■ Auto Restart Control

● If there is a power failure, operation will be automatically restarted when the power is resumed with previous operation mode

and airflow direction.

(As the operation is not stopped by remote controller.)

● If you intend not to continue the operation when the power is resumed, switch off the power supply.

When you switch on the circuit breaker, the operation will be automatically restarted with previous operation mode and airflow

direction.

Note: 1. If you do not require Auto Restart Control, please consult your sales agent or OFF by remote control.

2. Auto Restart Control is not available when Timer or Sleep Timer mode is set.

AUTOMATIC OPERATION

The device will automatically determine the mode of operation, HEAT, COOL or DEHUMIDIFY depending on the current room

temperature. The selected mode of operation will change when the room temperature varies. However the mode of operation will

not change when indoor unit connected to multi type outdoor unit.

Press the FUNCTION selector so that the display indicates the (AUTO) mode of operation.

● When AUTO has been selected, the device will automatically determine the mode of

operation, HEAT, COOL or DEHUMIDIFY depending on the current room temperature.

1

However the mode of operation will not change when indoor unit connected to multi type

outdoor unit.

● If the mode automatically selected by the unit is not satisfactory, manually change the

mode setting (heat, dehumidify, cool or fan).

RESET

START

STOP

Press the (START/STOP) button.

Operation starts with a beep.

Press the button again to stop operation.

■ As the settings are stored in memory in the remote controller, you only have to press the

(START/STOP) button next time.

You can raise or lower the temperature setting as necessary by maximum of 3°C.

°C

● The preset temperature and the actual room temperature may vary somewhat depending on

conditions.

● The display does not indicate the preset temperature in the AUTO mode. If you change the

setting, the indoor unit will produce a beep.

Press the (FAN SPEED) button, AUTO and LOW is available.

Press the temperature button and the temperature setting will change by

1°C each time.

– 11 –

Page 14

HEATING OPERATION

● Use the device for heating when the outdoor temperature is under 21°C.

When it is too warm (over 21°C), the heating function may not work in order to protect the device.

● In order to keep reliability of the device, please use this device above -15°C of the outdoor temperature.

Press the FUNCTION selector so that the display indicates

(HEAT).

Set the desired FAN SPEED with the (FAN SPEED) button

(the display indicates the setting).

(AUTO): The fan speed is HI at first and varies to

MED or LOW automatically when the preset

temperature has been reached.

(HI) : Economical as the room will become warm

quickly.

But you may feel a chill at the beginning.

(MED) : Fan speed slow.

(LOW) : Fan speed slower.

RESET

C

˚

1

2

Set the desired room temperature with the TEMPERATURE

buttons (the display indicates the setting).

3

C

˚

START

STOP

■ As the settings are stored in memory in the remote controller, you only

The temperature setting and the actual room temperature may

vary somewhat depending on conditions.

Press the (START/STOP) button. Heating operation starts

with a beep. Press the button again to stop operation.

have to press the (START/STOP) button next time.

– 12 –

Page 15

DEHUMIDIFYING OPERATION

Use the device for dehumidifying when the room temperature is over 16°C.

When it is under 15°C, the dehumidifying function will not work.

Press the FUNCTION selector so that the display indicates

(DEHUMIDIFY).

The FAN SPEED is set at LOW automatically.

The FAN SPEED button does not work.

Set the desired room temperature with the TEMPERATURE

button (the display indicates the setting).

The range of 20-26˚C is recommended as

the room temperature for dehumidifying.

RESET

C

˚

1

2

C

˚

■ Dehumidifying Function

START

STOP

■ As the settings are stored in memory in the remote controller, you

Press the (START/STOP) button. Dehumidifying operation

starts with a beep. Press the button again to stop operation.

only have to press the

(START/STOP) button next time.

When the room temperature is higher than the temperature setting: The device will dehumidify the room,

reducing the room temperature to the preset level.

When the room temperature is lower than the temperature setting: Dehumidifying will be performed at

the temperature setting slightly lower than the current room temperature, regardless of the temperature

setting. The function will stop (the indoor unit will stop emitting air) as soon as the room temperature

becomes lower than the setting temperature.

– 13 –

Page 16

COOLING OPERATION

Use the device for cooling when the outdoor temperature is 22-42°C.

If in doors humidity is very high (80%), some dew may form on the air outlet grille of the indoor unit.

Press the FUNCTION selector so that the display indicates

C

˚

1

(COOL).

RESET

Set the desired FAN SPEED with the

(the display indicates the setting).

(AUTO): The FAN SPEED is HI at first and varies to

MED or LOW automatically when the preset

2

(HI) : Economical as the room will become cool

(MED) : Fan speed slow.

(LOW) : Fan speed slower.

Set the desired room temperature with the TEMPERATURE

button (the display indicates the setting).

3

C

˚

START

STOP

The temperature setting and the actual room temperature may

vary some how depending on conditions.

Press the

with a beep. Press the button again to stop operation. The

cooling function does not start if the temperature setting is

higher than the current room temperature (even though the

(OPERATION) lamp lights). The cooling function will start as

soon as you set the temperature below the current room

temperature.

temperature has been reached.

quickly.

(START/STOP) button. Cooling operation starts

(FAN SPEED) button

■ As the settings are stored in memory in the remote controller, you

only have to press the

(START/STOP) button next time.

– 14 –

Page 17

FAN OPERATION

You can use the device simply as an air circulator. Use this function to dry the interior of the indoor

unit at the end of summer.

Press the FUNCTION selector so that the display indicates

1

(FAN).

RESET

FAN SPEED (AUTO)

For the heating operation

2

START

STOP

.....

When the AUTO fan speed mode is set in the cooling/heating operation:

● The fan speed will automatically change according to the temperature

of discharged air.

● When the difference of room temperature and setting temperature is

large, fan starts to run at HI speed.

● When the room temperature reaches setting temperature, fan speed

changes to LOW automatically.

Press the (FAN SPEED) button.

Press the (START/STOP) button. Fan operation starts with

a beep. Press the button again to stop operation.

For the cooling operation

● When the difference of room temperature and setting temperature is

large, fan starts to run at HI speed.

● After room temperature reaches the preset temperature, the cooling

operation, which changes the fan speed and room temperature to obtain

optimum conditions for natural healthful cooling will be performed.

– 15 –

Page 18

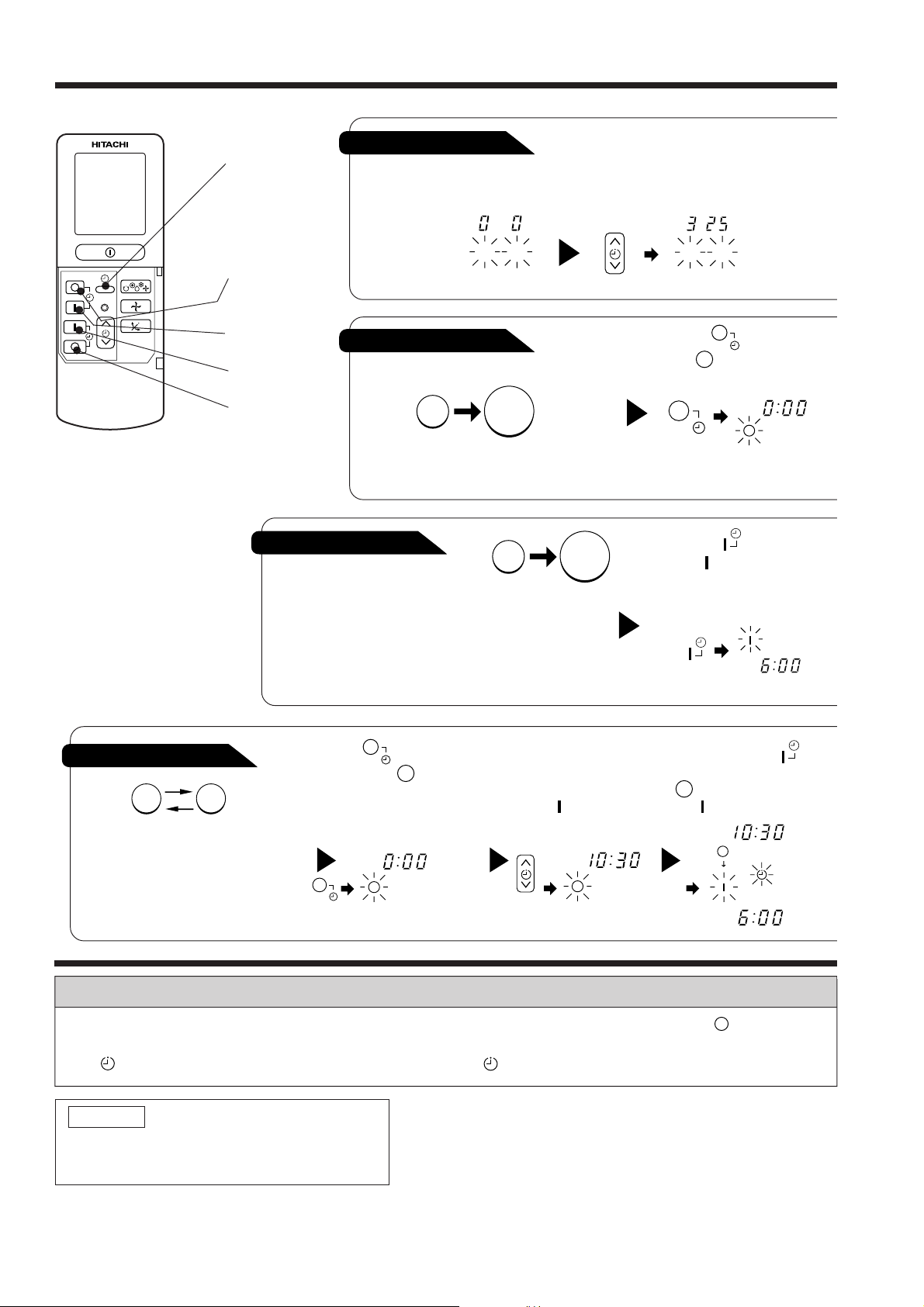

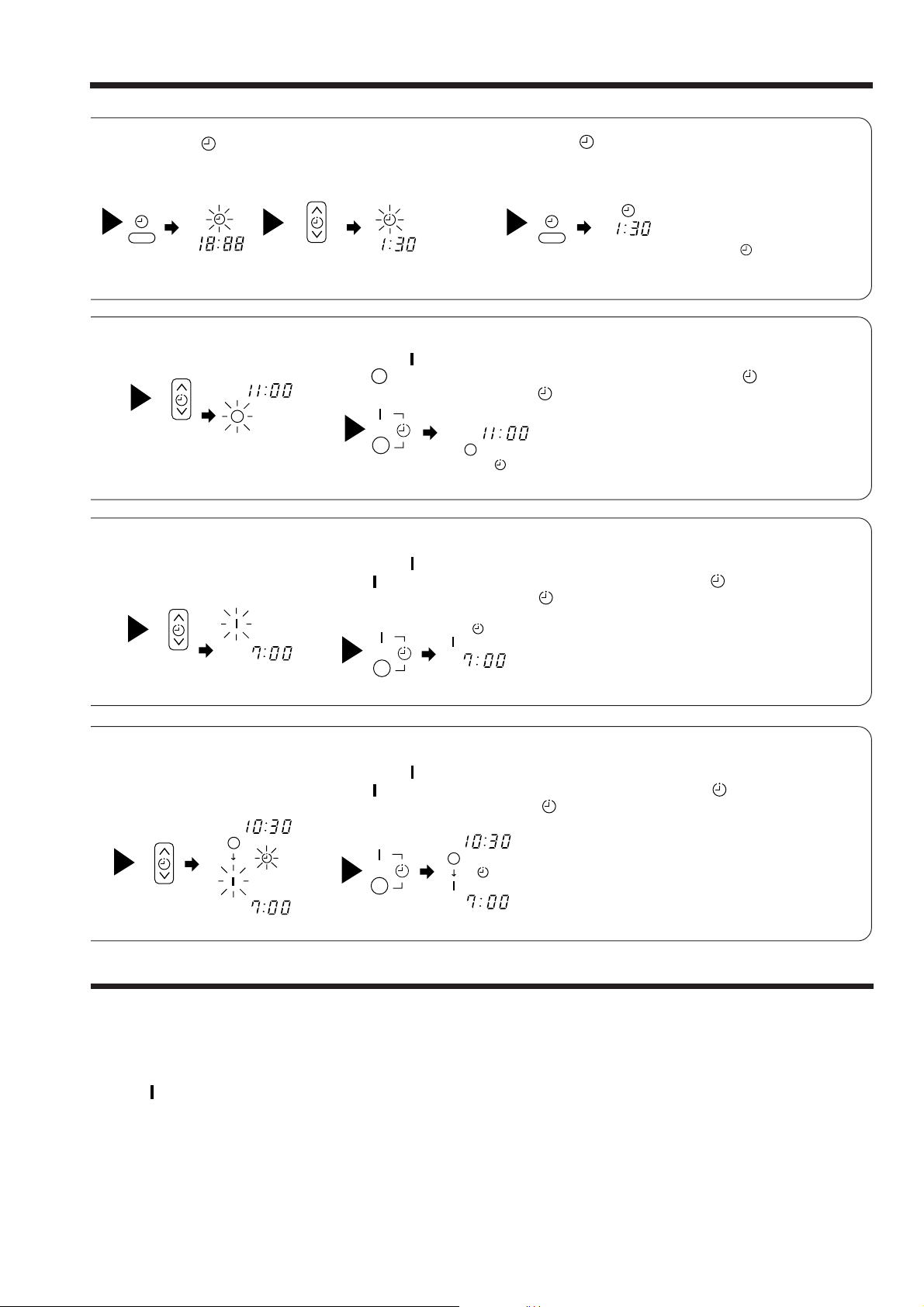

HOW TO SET THE TIMER

RESET

Time, Day, Month

TIME, DAY,

MONTH

(current time,

After you change the

batteries;

day, month)

OFF TIMER

ON TIMER

OFF-Timer

RESERVE

CANCEL

You can set the device to turn off

at the present time.

ON-Timer

● The device will turn on

at the designated times.

Start

M D

STOP

Stop

Start

1

Set the current month and

day with the TIMER control

button.

M D

1

Press the (OFF-TIMER)

button. The (OFF) mark blinks

on the display.

AM

1

Press the (ON-TIMER)

button the (ON) mark blinks

on the display.

AM

3

ON/OFF-Timer

Start Stop

● The device will turn on (off) and off

(on) at the designated times.

● The switching occurs first at the

preset time that comes earlier.

● The arrow mark appearing on the

display indicates the sequence of

switching operations.

1

Press the (ON-OFF)

button so that the (OFF)

mark blinks.

PM

2

Set the turn-off time

with the TIMER control

button.

Press the (RESERVE)

button.

PM

Press the (ON-

TIMER) button so that the

(OFF) mark lights and

the (ON) mark blinks.

PM

AM

How to Cancel Reservation

Point the signal window of the remote controller toward the indoor unit, and press the (CANCEL)

button.

The (RESERVED) sign goes out with a beep and the (TIMER) lamp turns off on the indoor unit.

NOTE

You can set only one of the OFF-timer,

ON-timer and ON/OFF-timer.

– 16 –

Page 19

2

Press the

(TIME) button.

AM

PM PM

2

Set the turn-off time with the

TIMER control button.

3

TIMER control button.

PM

Set the current time with the

Example: The current time is 1:30 p.m.

3

Point the signal window of the remote controller toward the indoor unit, and

press the (RESERVE) button.

The (OFF) mark starts lighting instead of flashing and the sign (RESERVED)

lights. A beep occurs and the (TIMER) lamp lights on the indoor unit.

4

Press the (TIME) button again.

The time indication starts lighting

instead of flashing.

● The time indication will disappear

PM

● To check the current time setting,

automatically in 10 second.

press the (TIME) button twice.

The setting of the current time is

now complete.

2

Set the turn-on time with the

TIMER control button.

AM

4

Set the turn-on time with the

TIMER control button.

PM

AM

PM

The setting of turn-off time is now complete.

3

Point the signal window of the remote controller toward the indoor unit, and

press the (RESERVE) button.

The (ON) mark starts lighting instead of flashing and the (RESERVED) sign

lights. A beep occurs and the (TIMER) lamp lights on the indoor unit.

Example:

AM

5

Point the signal window of the remote controller toward the indoor unit, and

press the (RESERVE) button.

The (ON) mark starts lighting instead of flashing and the (RESERVED) sign

lights. A beep occurs and the (TIMER) lamp lights on the indoor unit.

PM

AM

The device will turn on at 7:00 a.m.

The setting of the turn-on time is now complete.

Example:

The device will turn off at 10:30 p.m. and it will be turned on

at 7:00 a.m.

The settings of the turn-on/off times are now complete.

Example: The device will turn off at 11:00p.m.

● The timer may be used in three ways: off-timer, on-timer, and ON/OFF (OFF/ON)-timer. Set

the current time at first because it serves as a reference.

● As the time settings are stored in memory in the remote controller, you only have to press

the (RESERVE) button in order to use the same settings next time.

– 17 –

Page 20

HOW TO SET THE SLEEP TIMER

Set the current time at first if it is not set before (see the pages for setting

the current time). Press the (SLEEP) button, and the display changes as

shown below.

Mode

44 44

H

SLEEP

Sleep timer

Sleep Timer: The device will continue working for the designated

number of hours and then turn off.

Point the signal window of the remote controller toward the indoor

unit, and press the SLEEP button.

The timer information will be displayed on the remote controller.

The TIMER lamp lights with a beep from the indoor unit. When the

sleep timer has been set, the display indicates the turn-off time.

H

Sleep

timer

1

Set the ON-timer.

Start

1 hour 2 hours 3 hours 7 hours

The device will be turned off by the sleep

timer and turned on by on-timer.

Indication

Sleep timer off

Example: If you set 3 hours sleep

time at 11:38 p.m., the turn-off

time is 2:38 a.m.

1

2

Press the (SLEEP) button and set the sleep timer.

AM

H

AM

For heating:

In this case, the device will turn off

in 2 hours (at 1:38 a.m.) and turn

on early so that the preset

temperature will be almost reached

at 6:00 next morning.

How to Cancel Reservation

Point the signal window of the remote controller toward the indoor unit, and press the (CANCEL)

button.

The (RESERVED) sign goes out with a beep and the (TIMER) lamp turns off on the indoor unit.

– 18 –

Page 21

ADJUSTING THE AIR DEFLECTOR

about 45˚

SWINGING

RANGE

45˚

about 45˚

SWINGING

RANGE

45˚

Adjustment of the conditioned air in the upward and

1

downward directions.

According to “Dehumidifying” or “Cooling” operation, the

horizontal air deflector is automatically set to the proper

angle suitable for each operation. The deflector can be

swung up and down and also set to the desired angle

using the “ (AUTO SWING)” button. (If the angle

of the deflector is changed, it will not return to the autoset position after operations start unless the operation

mode is switched.)

● If the “ (AUTO SWING)” button is pressed

once, the horizontal air deflector swings up and

down. If the button is pressed again, the deflector

stops in its current position. Several seconds (about

6 seconds) may be required before the deflector

starts to move.

● Use the horizontal air deflector within the adjusting

range shown on the right.

RESET

● When the “ (AUTO SWING)” button is

pressed while the operation is stopped, the horizontal

air deflector moves and stops at the position where

the air outlet closes.

● When the auto swing operation is performed, if the

horizontal air deflector is moved manually, the

swinging range may drift. However, it will return to

the original operation range after a short time.

CAUTION

!

When operating the unit in cooling operation with the air deflector facing down and moving

automatically for a long period of time, water will condensed on the air deflector and drips down

occasionally. This will wet your furniture.

– 19 –

Page 22

HOW TO EXCHANGE THE BATTERIES IN THE REMOTE CONTROLLER

Remove the cover as shown in the figure and take out the

1

old batteries.

=

Install the new batteries.

2

The direction of the batteries should match the marks in the

case.

!

CAUTION

1. Do not use new and old batteries, or different kinds of batteries

together.

2. Take out the batteries when you do not use the remote controller

for 2 or 3 months.

Push and pull to the

direction of arrow

– 20 –

Page 23

THE IDEAL WAYS OF OPERATION

Suitable Room Temperature Install curtain or blinds

!

Warning

Freezing temperature

is bad for health and a

waste of electric power.

Ventilation Effective Usage Of Timer

It is possible to

reduce heat

entering the

room through

windows.

!

Caution

Do not close the room for a long period of

time. Occasionally open the door and windows

to allow the

entrance of

fresh air.

Do Not Forget To Clean The Air Filter

Dusty air filter will reduce the air volume and

the cooling efficiency. To prevent from wasting

electric energy, please clean the filter every 2

weeks.

At night, please use the “OFF or ON timer

operation mode”, together with your wake up

time in the morning. This will enable you to

enjoy a comfortable room temperature. Please

use the timer effectively.

Please Adjust Suitable Temperature

For Baby And Children

Please pay attention to the room temperature

and air flow direction when operating the unit

for baby, children and old folks who have

difficulty in movement.

– 21 –

Page 24

FOR USER’S INFORMATION

The Air Conditioner And The Heat Source In The Room

!

Caution

If the amount of heat in the room is above the cooling

capability of the air conditioner (for example: more

people entering the room, using heating equipments

and etc.), the preset room temperature cannot be

achieved.

Not Operating For A Long Time

When the indoor unit is not to be used for a long

period of time, please switch off the power from the

mains. If the power from mains remains “ON”, the

indoor unit still consumes about 8W in the operation

control circuit even if it is in “OFF” mode.

OFF

When Lightning Occurs

!

Warning

To protect the whole unit during lightning, please

stop operating the unit and remove the plug from the

socket.

Interference From Electrical Products

!

Caution

To avoid noise interference, please place the indoor

unit and its remote controller at least 1m away from

electrical products.

To prevent

interference,

place at least

1m away.

Inverter-type

fluorescent

lamp.

TV

– 22 –

Page 25

MAINTENANCE

!

CAUTION

Cleaning and maintenance must be carried out by qualified service personnel.

Before the cleaning, stop operation and disconnect the power supply.

Clean the filter at least once every one month. This helps save electricity cost.

1. CLEANING OF AIR FILTER

REMOVAL AND ATTACHMENT OF AIR FILTER

PROCEDURE

1

2

3

Remove the filter from indoor

● Press the mark “PUSH” on the left and

right sides of the suction grille.

● Pull out the filter from the grille.

Remove dust from the filter using a vacuum

cleaner.

If there is too much dust, use neutral

detergent. After using neutral detergent, wash

with clean water and dry in the shade.

Install the filter. (Set it with “UP SIDE” mark

facing front.)

Slot the filter to suction grille and close as

original state.

(Press the mark “PUSH” at the left and right

sides of the suction grille to fix it securely.)

Safety Cable

Air Filter

PUSH

Filter Guide

Grille

Note:

● This model has an air cleaning filter. The cooling capacity is slightly weakened and the cooling

speed becomes slower when the air cleaning filter is used. So, set the fan speed to “HIGH” when

using it in this condition.

● Recommended to replace the air cleaning filter after every 3 months for normal usage. Type number

for this air cleaning filter is <SPX-CFH5>. Please use this number for ordering when you want to

renew it.

!

CAUTION

● Do not wash with hot water at more than 40°C. The filter may shrink.

● When washing it, shake off moisture completely and dry it in the shade; do not expose it directly to

the sun. The filter may shrink.

● Do not operate the air conditioner with the filter removed. Dust may enter the air conditioner and

cause trouble.

– 23 –

Page 26

2. CLEANING OF FRONT PANEL

● Wipe it with a soft dry cloth.

● When it is excessively dirty, wipe with soft cloth soaked in lukewarm water or neutral detergent. Then

wipe thoroughly with a soft dry cloth.

!

CAUTION

● Do not splash or direct water to the body of the unit when cleaning it as

this may cause short circuit.

● Never use hot water (above 40°C), benzine, gasoline, acid, thinner or a

brush, because they will damage the plastic surface and the coating.

3. MAINTENANCE AT BEGINNING OF LONG OFF PERIOD

● Running the unit setting the operation mode to (FAN) and

the fan speed to HI for about half a day on a fine day, and

dry the whole of the unit.

● Turn off the circuit breaker.

Air

Blow

REGULAR INSPECTION

PLEASE CHECK THE FOLLOWING POINTS EITHER EVERY HALF YEARLY OR YEARLY.

CONTACT YOUR SALES AGENT SHOULD YOU NEED ANY HELP.

Is the earth line disconnected or broken?

WARNING

1

2

!

Coming off or breakage of grounding wire may cause malfunction

or electrical shock.

Is the mounting frame seriously affected by rust and is the outdoor

unit tilted or unstable?

!

WARNING

Outdoor unit may fall or drop if there is extreme rust on mounting

frame or outdoor unit is unstably installed. This may cause injury.

3

Confirm

Is the plug of power line firmly plugged into the socket?

(Please ensure no loose contact between them).

– 24 –

Page 27

AFTER SALES SERVICE AND WARRANTY

WHEN ASKING FOR SERVICE, CHECK THE FOLLOWING POINTS.

CONDITION CHECK THE FOLLOWING POINTS

● Is the fuse blown out or the circuit breaker tripped?

When it does not operate

When it does not cool well

When it does not hot well

Notes

● In quiet operation or stopping the running, the following phenomena may

occassionally occur, but they are not abnormal for the operation.

(1) Slight flowing noise of refrigerant in the refrigerating cycle.

(2) Slight rubbing noise from the fan casing which is cooled and then

● The odor will possibly be emitted from the room air conditioner because

the various odor, emitted by smoke, foodstuffs, cosmetics and so on,

sticks to it. So please clean the air filter and the evaporator regularly to

reduce the odor.

● Is the voltage normal?

● Is the circuit breaker “ON”?

● Is the air filter blocked with dust?

● Does sunlight fall directly on the outdoor unit?

● Is the air flow of the outdoor unit obstructed?

● Are the doors or windows opened, or is there any source of

heat in the room?

● Is the set temperature suitable?

gradually warmed as operation stops.

●

Please contact your sales agent immediately if the air conditioner still fails to operate normally after the above

inspections. Inform your agent of the model of your unit, production number, date of installation. Please also

inform him regarding the fault.

●

Power supply shall be connected at the rated voltage, otherwise the unit will be broken or could not reach the

specified capacity.

– 25 –

Page 28

Please note:

On switching on the equipment, particularly when the room light is dimmed, a slight brightness fluctuation

may occur. This is of no consequence.

The conditions of the local Power Supply Companies are to be observed.

Note

● Avoid to use the room air conditioner for cooling operation when the outside temperature is below

21°C (70°F).

The recommended maximum and minimum operating temperatures of the hot and cold sides

should be as below:

Cooling Heating

Minimum Maximum Minimum Maximum

Indoor

Dry bulb °C2132 2027

Wet bulb °C1523 1219

Outdoor

Dry bulb °C21 43 2 21

Wet bulb °C15 26 1 15

MEMO

.....................................................................................................................................................................................

.....................................................................................................................................................................................

.....................................................................................................................................................................................

.....................................................................................................................................................................................

.....................................................................................................................................................................................

.....................................................................................................................................................................................

.....................................................................................................................................................................................

.....................................................................................................................................................................................

.....................................................................................................................................................................................

.....................................................................................................................................................................................

.....................................................................................................................................................................................

.....................................................................................................................................................................................

.....................................................................................................................................................................................

.....................................................................................................................................................................................

.....................................................................................................................................................................................

.....................................................................................................................................................................................

.....................................................................................................................................................................................

.....................................................................................................................................................................................

.....................................................................................................................................................................................

.....................................................................................................................................................................................

.....................................................................................................................................................................................

.....................................................................................................................................................................................

.....................................................................................................................................................................................

– 26 –

Page 29

CONSTRUCTION AND DIMENSIONAL DIAGRAM

MODEL RAI-25NH5, RAI-35NH5

650 (Panel)

600 (Opening on ceiling)

580 (Indoor unit)

400 (Suspension bolt)

64

42

393 (Electric box)

580 (Indoor unit)

650 (Panel)

610 (Suspension bolt)

600 (Opening on ceiling)

Narrow pipe fl6.35

Wide pipe fl12.7

Unit : mm

147

56 18

Wireless remote controller

97 (Drain)

65

Drain outlet

42

Above 300

110

Panel (Optional part RAI-ECPM)

Ceiling

285

32

55

62

230 (Drain)

227 (Electric box)

112

Air outlet

Air inlet Air outlet

Note:

1. Insulated pipes should be used for both the narrow and wide dia. pipes.

2. Piping length is within 20m.

3. Height difference of the piping between the indoor unit and the outdoor unit should be within 10m.

4. An F-cable 1.6mm or 2.0mm dia. X 3 (control side) is used for the connection cable.

– 27 –

Page 30

MAIN PARTS COMPONENT

THERMOSTAT

Thermostat Specifications

THERMOSTAT MODEL IC

OPERATION MODE COOL HEAT

MODEL RAI-25NH5 RAI-35NH5 RAI-25NH5, RAI-35NH5

ON 15.0 (59.0) 13.0 (55.4) 20.0 (68.0)

OFF 14.7 (58.5) 12.7 (54.9) 20.3 (68.5)

ON 23.0 (73.4) 21.0 (69.8) 28.0 (82.4)

OFF 22.7 (72.9) 20.7 (69.3) 28.3 (82.9)

ON 31.0 (87.8) 29.0 (84.2) 36.0 (96.8)

OFF

30.7 (87.3) 28.7 (83.7) 36.3 (97.9)

TEMPERATURE

°C (°F)

INDICATION

16

INDICATION

24

INDICATION

32

FAN MOTOR

Fan Motor Specifications

MODEL

RAI-25NH5

RAI-35NH5

POWER SOURCE DC: 0 ~ 35V

OUTPUT 25W

RED

YEL

BLU

M

CONNECTION

0~35V

5V

(Control circuit built in)

BLU : BLUE YEL : YELLOW BRN : BROWN WHT : WHITE

GRY : GRAY ORN : ORANGE GRN : GREEN RED : RED

BLK : BLACK PNK : PINK VIO : VIOLET

– 28 –

Page 31

MODEL RAI-25NH5 / RAI-35NH5

WIRING DIAGRAM

INDOOR UNIT

– 29 –

Page 32

CIRCUIT DIAGRAM

1

2

3

4

5

6

7

8

10

11

13

14

15

16

17

19

20

9

12

18

SEG19

SEG18

SEG17

SEG16

SEG21

SEG24

SEG25

SEG26

SEG27

SEG28

NC

NC

NC

NC

NC

NC

NC

NC

NC

SEG20

SEG5

SEG0

SEG1

SEG2

SEG3

SEG4

SEG5

SEG6

SEG7

COM3

COM2

COM1

COM0

SEG14

SEG13

SEG12

SEG11

SEG13

SEG9

SEG8

40

39

38

37

36

35

34

33

31

30

28

27

26

25

24

22

21

32

29

23

40

39

38

37

36

35

34

33

31

30

28

27

26

25

32

29

64

63

62

61

60

59

58

57

56

55

54

53

52

51

50

49

48 47

46

45

44

43

41

42

65

66

67

68

69

70

71

72

74

75

77

78

79

80

73

76

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17 18

19

20

21

22

24

23

SEG20

SEG21

SEG22

SEG23

SEG24

SEG25

SEG26

SEG27

SEG28

SEG29

SEG30

SEG31

SEG32

SEG33

SEG34

SEG35

SEG19

SEG18

SEG17

SEG16

SEG15

SEG14

SEG13

SEG12

SEG11

SEG10

SEG9

SEG8

SEG7

SEG6

SEG5

SEG4

SEG3

SEG2

SEG1

SEG0

SEG43

SEG42

SEG41

SEG40

P40

P41

P42

P43

P00

P01

P02

P03

P10

P11

P12

P13

D0

D1

D2

D3

D4

D5

D6

D7

D8

D9

BEEP

P20

P30

P31

NCVL C1

VL C2

VL C3

XC IN

XC OUT

VDD

X OUT

X IN

RESET

CARR

P23

P22

P21

VSS

IC 1

M3455OM6A-504FP

LCD 1

C8

50v/1u

K 1

D3

RB425D(1/2)

K2K3

K4

K5

P10

P11

P12

K6

K7 K8

K9 K10

K11K12

K18

K17

K15 K16

K13 K14

D0

D1

D2

D3

R1

100k

SW1

R2

P

100k

R3

100k

R4

100k

R5

Q1

2SC3443

or 2SC2982

R6

R7

R9

D2D1

D1 D2

EL-1L7

D3

(1/2)

RB425D

R10

12M

K19

X1

C9

R11

R15

R16

R13

R14

910kHz

105

104

104

150k

X2

kHz

C4

C5

C6

C7

18p

22p

R12

220k

220K

220k

100k

100k

32.768

C1

C2

C3

220p

220p

334

R6 R9

24(1/8W)

R8

330

SW-187-2P

Remote Control

Key matrix table

P10

P11

P12

Output

Input

D0

Door open Automatic swingFan speed selectionOperation selectionStart/Stop

Door shut ––Automatic swingStart/Stop

Door open Day

Door shut Fan speedRoom temperature downRoom temperature up–

Door open CancelReservation–Off timer

Door shut –––Sleep

D3D2D1

• present timeHour downHour upOn timer

– 31 –

Page 33

CIRCUIT DIAGRAM

MODEL RAI-25NH5, RAI-35NH5

– 33 –

Page 34

PRINTED WIRING BOARD LOCATION DIAGRAM

MODEL RAI-25NH5, RAI-35NH5

MAIN P.W.B.

Marking on P.W.B.

COMPONENT SIDE

SOLDERING SIDE

– 35 –

Page 35

RAI-25NH5, RAI-35NH5

INDOOR UNIT 1

LCD wireless

Room temperature

thermistor

Heat exchanger

thermistor

Temporary switch

Initial setting circuit

Reset circuit

Wireless receive

circuit

Indoor microcomputer (AX-7R11)

Filter.

Operation.

Timer.

Drain Pump Motor

Auto sweep motor for

Air deflector

SPM2

L

N

Outdoor

unit

Terminal

board

Trip signal

synthesis circuit

INDOOR UNIT 2

LCD wireless

Room temperature

thermistor

Heat exchanger

thermistor

Temporary switch

Initial setting circuit

Reset circuit

Wireless receive

circuit

Indoor microcomputer (AX-7R11)

Filter.

Operation.

Timer.

Drain Pump Motor

Auto sweep motor for

Air deflector

C1

D1

C2

D2

Indoor 1/Outdoor

interface circuit

Indoor 2/Outdoor

interface circuit

Outdoor microcomputer / HIC (AX-6M01)

Electric Expansion valve

drive circuit

Electric

Expansion

valve

– 37 –

Page 36

RAI-25NH5, RAI-35NH5

47.

– 39 –

Page 37

Table 1 Mode data file

RAI-25NH5 RAI-35NH5

LABEL NAME VALUE

WMAX 4400 min

WMAX2 4500 min

WSTD 3300 min

WBEMAX 2800 min

CMAX 2900 min

CMAX2 3000 min

CSTD 2350 min

CKYMAX 2200 min

CJKMAX 1800 min

CBEMAX 1600 min

WMIN 1500 min

CMIN 1500 min

–1

–1

–1

–1

–1

–1

–1

–1

–1

–1

–1

–1

6000 min

6000 min

4250 min

3500 min

4700 min

4700 min

4100 min

3500 min

2700 min

2000 min

1800 min

1800 min

–1

–1

–1

–1

–1

–1

–1

–1

–1

–1

–1

–1

STARTMC 60 Seconds 60 Seconds

DWNRATEW 80% 80%

DWNRATEC 80% 80%

SHIFTW 4.00°C 4.00°C

SHIFTC –1.00°C –2.99°C

CLMXTP 30.00°C 30.00°C

YNEOF 21.00°C 21.00°C

TEION 2.00°C 2.00°C

TEIOF 6.00°C 6.00°C

SFTDSW 2.66°C 2.66°C

DFTIM1 50 Minutes 50 Minutes

DFTIM2 90 Minutes 90 Minutes

DFTIM3 60 Minutes 60 Minutes

– 41 –

Page 38

NOTE (9)

Reversing valve (heating “on” mode)

Notes:

(1) Condition for entering into Cool Dashed mode. When fan set to “Hi” or “Auto mode” and temperature difference between indoor temperature and set temperature has a

corresponding compressor rpm larger than WMAX.

(2) Cool Dashed will release when i) a maximum 25 minutes is lapsed and ii) room temperature is lower than set temperature –3°C (thermo off) and iii) when room temperature

has achieved setting temperature –1°C then maximum Cool Dashed time will be revised to 20 minutes. And iv) indoor fan is set to Lo and Med fan mode and v) change operation

mode.

(3) During Cool Dashed operation, thermo off temperature is set temperature (with shift value) –3°C. After thermo off, operation continue in Fuzzy control mode.

(4) Compressor minimum “ON” time and “OFF” time is 3 minutes.

(5) During normal cooling mode, compressor maximum rpm CMAX will maintain for 60 minutes if indoor temperature is lower than CLMXTP. No time constrain if indoor temperature

is higher than CLMXTP.

(6) When fan is set to “Hi”, compressor rpm will be limited to CKYMAX.

(7) When fan is set to “Med”, compressor rpm will be limited to CJKMAX.

(8) When fan is set to “Lo”, compressor rpm will be limited to CBEMAX.

(9) During Cool Dashed, when room temperature reaches set temperature –1°C compressor rpm is actual rpm x DWNRATEC.

Table 2 ∆TCMAX

Temperature Calculated

difference compressor rpm

1.66 2265 min

2 2435 min

2.33 2600 min

2.66 2765 min

3 2935 min

3.33 3100 min

3.66 3265 min

4 3435 min

4.33 3600 min

4.66 3765 min

5 3935 min

5.33 4100 min

5.66 4265 min

6 4435 min

6.33 4600 min

6.66 4765 min

7 4935 min

7.33 5100 min

7.66 5265 min

8 5435 min

8.33 5600 min

8.66 5765 min

9 5935 min

9.33 6100 min

9.66 6265 min

10 6435 min

10.33 6600 min

10.66 6765 min

11 6935 min

–1

–1

–1

–1

–1

–1

–1

–1

–1

–1

–1

–1

–1

–1

–1

–1

–1

–1

–1

–1

–1

–1

–1

–1

–1

–1

–1

–1

–1

Note:

1. See the data in Table 1 on

page 45 for each constant in

capital letters in the diagrams.

– 43 –

Page 39

Cooling Sleep Operation

Compressor speed

Horizontal air

deflector

Shut

Horizontal

Facing down

Maximum speed

Indoor fan

Outdoor fan

Timer lamp

Operation lamp

Sleep key

(Cooling/dehumidifying set

temperature = Remote control set

temperature (+) SHIFTC)

Final set temperature

(Cooling/dehumidifying set

temperature (+) sleep shift)

Set to 7 hours

0.5hr

1.5hr

3hr

P1

2.5hr 3.5hr 6hr 7hr

Hi

See basic operation

Med

Lo (sleep)

Lo

Notes:

(1) The sleep operation starts when the sleep key is pressed.

(2) When the sleep key is set, the maximum compressor speed is limited, and the indoor fan is set to “sleep Lo”.

(3) 30 minutes after the sleep key is set, the sleep shift of temperature starts, and upper shift is made at least 6 times. If 25˚C

is not reached after 6 shifts, shifts repeat unit 25˚C is reached.

(4) The sleep shift upper value of set temperature is 28˚C.

(5) After 6 hours, a shift down to the initial set temperature is made at a rate of 0.33˚C/5 min.

(6) If the operation mode is changed during sleep operation, the set temperature is cleared, and shift starts from the point when

switching is made.

(7) The indoor fan speed does not change even when the fan speed mode is changed.

(8) When operation is stopped during sleep operation, the set temperature when stopped, as well as the time, continue to be

counted.

(9) If the set lime is changed during sleep operation, all data including set temperature, time, etc. is cleared and restarted.

(10) If sleep operation is canceled by the cancel key or sleep key, all data is cleared.

– 45 –

Page 40

+

+

Delay

–1.33˚C

–0.66˚C

Notes:

(1) If the room temperature is (cooling preset temperature) - (1.33°C) or less after 30 seconds from starting the operation, the operation is done assuming

as the preset temperature = (room temperature at the time) - (2°C).

(2) The indoor fan is operated in the “Lo” mode. During thermo OFF indoor fan will be OFF for 5 minutes and ON for 1 minute.

(3) When the operation is started by the themostat turning ON, the start of the indoor fan is delayed 32 seconds after the start of compressor operation.

(4) The compressor is operated forcedly for 3 minutes after operation is started.

(5) The minimum ON time and OFF time of the compressor are 3 minutes.

– 47 –

Page 41

1.33˚C.

SFTDSW

0.66˚C.

Fan speed set to "auto"

1 min.

Hi

Lo Hi Hi Hi

ultra Hi

Basic Heating Operation

Start

Stop Start Start StopStop

Thermo

OFF

Thermo

OFF

Heating set temperature

(remote control set temperature

(+))

Start/stop switch

Thermo judgment

Indoor fan

Ultra-Hi

Hi

Med

Lo

Ultra-Lo

Operation lamp

Max.

Rating

3000

0

Compressor speed

Outdoor fan

Reversing valve (heating "on" model)

Thermo OFF

Dash period

TWMAX

Wtd

Defrost signal

Preheating judgment

30sec. 30sec.

10sec.

15sec. 15sec.

15sec. 15sec. 15sec.

10sec.

15sec.

15sec.

150sec. Delay

150sec. Delay150sec. Delay

3min.

Max. 3 min.

Preheating released

Control by

heat exchanger temperature

Control by

heat exchanger temperature

15sec.

Control by

heat exchanger temperature

Control by

heat exchanger temperature

Control by

heat exchanger temperature

18˚C

10sec.

30sec. 30sec.

10sec.

30sec. 30sec.30sec. 30sec. 30sec. 30sec.

10sec.

Preheat released

WMIN

(WSTD)

(WMAX)

NOTE (11)

WMAX2

Notes:

(1) Condition for entering into Hot Dashed mode. When fan set to “Hi” or “Auto mode” and i) Indoor temperature is lower than 18°C, and ii) outdoor temperature is lower than 10°C,

and iii) Temperature difference between indoor temperature and set temperature has a corresponding compressor rpm larger than WMAX.

(2) Hot Dashed will release when i) Room temperature has achieved the set temperature + SFTDSW. ii) Thermo off.

(3) During Hot Dashed operation, thermo off temperature is set temperature (with shift value) +3°C. After thermo off, operation continue in Fuzzy control mode.

(4) Compressor minimum “ON” time and “OFF” time is 3 minutes.

(5) During normal heating mode, compressor maximum rpm WMAX will maintain for 120 minutes if indoor temperature is higher than 18°C. No time limit constrain if indoor temperature

is lower than 18°C and outdoor temperature is lower than 2°C.

(6) During Hotkeep or Defrost mode, indoor operation lamp will blink at interval of 3 seconds “ON” and 0.5 second “OFF”.

(7) When heating mode starts, it will enter into Hotkeep mode if indoor heat exchanger temperature is lower than YNEOF + 0.33°C.

(8) When fan is set to “Med” or “Lo”, compressor rpm will be limited to WBEMAX.

(9) In “Ultra-Lo” fan mode, if indoor temperature is lower than 18°C, indoor fan will stop. If indoor temperature is higher than 18°C + 0.33°C, fan will continue in “Ultra-Lo” mode.

During Hotkeep or Defrost mode, fan will continue in “Ultra-Lo” mode.

(10) During Hot Dashed or outdoor temperature is lower than –5°C, compressor rpm is WMAX2.

(11) During Hot Dashed, when room temperature reaches set temperature + SFTDSW compressor rpm is actual rpm x DWNRATEW.

Table 3 ∆TWMAX

Temperature Calculated

difference compressor rpm

1.66 1965 min

2 2135 min

2.33 2300 min

2.66 2465 min

3 2635 min

3.33 2800 min

3.66 2965 min

4 3135 min

4.33 3300 min

4.66 3465 min

5 3635 min

5.33 3800 min

5.66 3965 min

6 4135 min

6.33 4300 min

6.66 4465 min

7 4635 min

7.33 4800 min

7.66 4965 min

8 5135 min

8.33 5300 min

8.66 5465 min

9 5635 min

9.33 5800 min

9.66 5965 min

10 6135 min

10.33 6300 min

10.66 6465 min

11 6635 min

–1

–1

–1

–1

–1

–1

–1

–1

–1

–1

–1

–1

–1

–1

–1

–1

–1

–1

–1

–1

–1

–1

–1

–1

–1

–1

–1

–1

–1

Notes:

1. See the data in Table 1 on

page 45 for each constant in

capital letters in the diagrams.

– 49 –

Page 42

1 min

WMIN

TDF TDF TDF

TDF

TDF

TDF

Setting Defrosting Inhibit Period

D F T I M 3

D F T I M 2

Time

Outdoor temperature

– 1 0 – 5˚C0˚C

D F T I M 1

Notes:

(1) The sleep operation starts when the sleep key is pressed.

(2) When the sleep key is set, the maximum compressor speed is limited to WSTD+2000/2, and the indoor fan is set

to “sleep Lo”.

(3) 30 minutes after the sleep key is set, the sleep shift of set temperature starts.

(4) The maximum sleep shift of set temperature is 5°C, and the minimum is 12°C.

(5) If the operation mode is changed during sleep operation, the changed operation mode is set and sleep control

starts.

(6) The indoor fan speed does not change even when the fan speed mode is changed. (Lo)

(7) When defrosting is to be set during sleep operation, defrosting is engaged and sleep operation is restored after

defrosting.

(8) When operation is stopped during sleep operation, the set temperature when stopped, as well as the time, continue

to be counted.

(9) If the set time is changed during sleep operation, all data including set temperature, time, etc. is cleared and

restarted.

(10) If sleep operation is canceled by the cancel key or sleep key, all data is cleared.

Notes:

(1) The first inhibit time after operation start is set to DFTIM1.

(2) From the second time onwards, the inhibit time is set according to the time required for

defrosting.

Reverse cycle operation time ≥ [DEFCOL] : DFTIM1 is set.

Reverse cycle operation time < [DEFCOL] : The time corresponding to outdoor temperature is set.

– 51 –

Page 43

Cooling, dehumidifying, defrosting

Outdoor Unit

Indoor Unit

Suction tank

Reversing

valve

Strainer

Strainer

Strainer

Service

valve (

1/4"

)

Service

valve (

3/8"

)

Service

valve (

3/8"

)

Single-ended

union (

3/8"

)

Single-ended

union (

3/8"

)

Single-ended

union (

1/4"

)

Indoor heat

exchanger

Air

Flow

Air

Flow

Indoor heat

exchanger

Single-ended

union (

1/4"

)

Charge port (

1/2"

)

Charge port (

1/2"

)

Service

valve (

1/4"

)

Electric expansion 1

valve

Electric expansion 2

valve

Strainer

Strainer

Strainer

Silencer

Compressor

REFRIGERATING CYCLE DIAGRAM

RAI-25NH5 / RAI-35NH5

– 53 –

Page 44

Heating

Outdoor Unit

Indoor Unit

Suction tank

Reversing

valve

Strainer

Strainer

Strainer

Service

valve (

1/4"

)

Service

valve (

3/8"

)

Service

valve (

3/8"

)

Single-ended

union (

3/8"

)

Single-ended

union (

3/8"

)

Single-ended

union (

1/4"

)

Indoor heat

exchanger

Air

Flow

Air

Flow

Indoor heat

exchanger

Single-ended

union (

1/4"

)

Charge port (

1/2"

)

Charge port (

1/2"

)

Service

valve (

1/4"

)

Electric expansion 1

valve

Electric expansion 2

valve

Strainer

Strainer

Strainer

Silencer

(Scroll)

Compressor

REFRIGERATING CYCLE DIAGRAM

RAI-25NH5 / RAI-35NH5

– 54 –

Page 45

REFERENCE

INITIALIZE AT NEXT

OPERATION.

OPERATING SPECIFICATION

INITIALIZE AT NEXT

OPERATION.

ONE SWING (CLOSING AIR DEFLECTOR)

PRESENT CONDITION

OPERATION OPERATION MODE AIR DEFLECTOR

STOP AT THE MOMENT.

1 DOWNWARD

2 UPWARD

STOP

DURING ONE SWING

EACH MODE

STOP

START SWINGING

1 DOWNWARD

2 UPWARD

STOP

AUTO COOL

COOL

FAN

STOP AT THE MOMENT.

3 DOWNWARD

DURING SWINGING

AUTO DRY

DRY

DURING

START SWINGING

1 DOWNWARD

2 UPWARD

3 DOWNWARD

STOP

AUTO HEAT

HEAT

CIRCULATOR

OPERATION

START SWING AGAIN.

STOP AT THE MOMENT.

DURING SWINGING

STOP SWINGING TEMPORARILY.

(SWING MODE IS CLEARED IF SWING COMMAND IS

TEMPORARY STOP

AUTO DRY

DURING SWINGING

DRY

AUTO HAET

HEAT

DURING

OPERATION

INITIALIZE

TRANSMITTED DURING TEMPORARY STOP.)

COOL

CIRCULATOR

1 DOWNWARD

2 UPWARD

INITIALIZE

STOP

DURING ONE SWING

STOP

FAN

DRY

HEAT

STOP

ONE SWING (CLOSING AIR DEFLECTOR)

1 DOWNWARD

DURING ONE SWING

STOP

CIRCULATOR

INITIALIZING CONDITION OF EACH MODE.

1 DOWNWARD

2 UPWARD

DURING SWINGING

DURING

INITIALIZING

EACH MODE

DURING

OPERATION

STOP SWINGING AND MODE BECOMES INITIALIZING

CONDITION.

STOP

DURING SWINGING

EACH MODE

DURING

OPERATION

INPUT SIGNAL

AUTO SWING FUNCTION

MODEL: RAI-25NH5, RAI-35NH5

KEY INPUT

– 55 –

THERMO. ON

(INTERNAL FAN

ON)

THERMO. ON

(INTERNAL FAN

OFF)

MAIN SWITCH

ON

MAIN SWITCH

OFF

CHANGE OF

OPERATION

Page 46

DESCRIPTION OF MAIN CIRCUIT OPERATION

MODEL RAI-25NH5, RAI-35NH5

1. Reset Circuit

5V

2

R522

1

C521

R521

5

C524

NORMAL : HI

RESET : LO

RES

7

Microcomputer

C522

Voltage

Voltage supply to

2

of IC521

pin

Reset release at 4.4V

3

IC521

0V

Fig. 1-1