Page 1

TC

SERVICE MANUAL

TECHNICAL INFORMATION

REFER TO THE FOUNDATION MANUAL

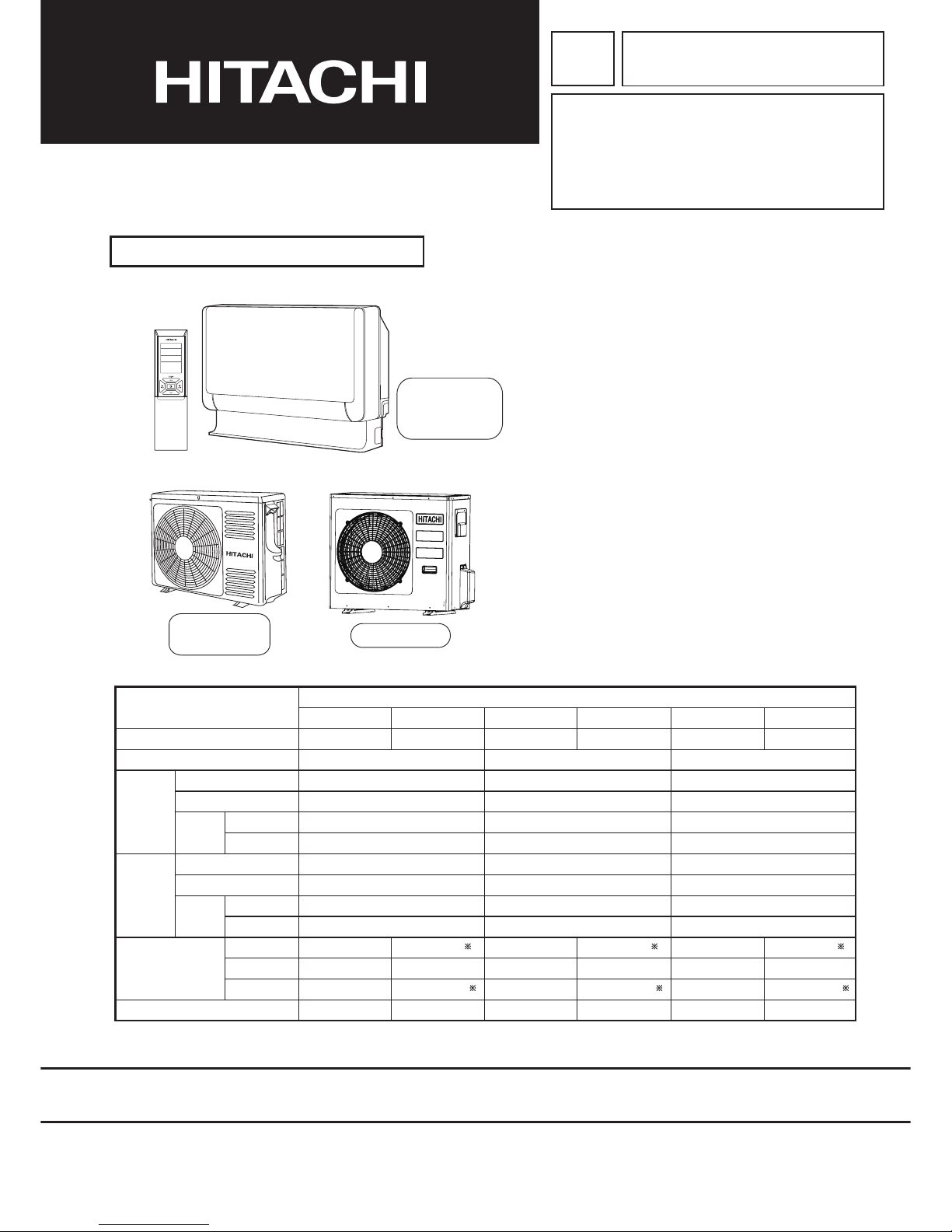

ROOM AIR CONDITIONER

SPECIFICATIONS AND PARTS ARE SUBJECT TO CHANGE FOR IMPROVEMENT

FOR SERVICE PERSONNEL ONLY

NO. 0842E

RAF-35RXB/RAC-35FXB

RAF-50RXB/RAC-50FXB

RAF-25RXB/RAC-25FXB

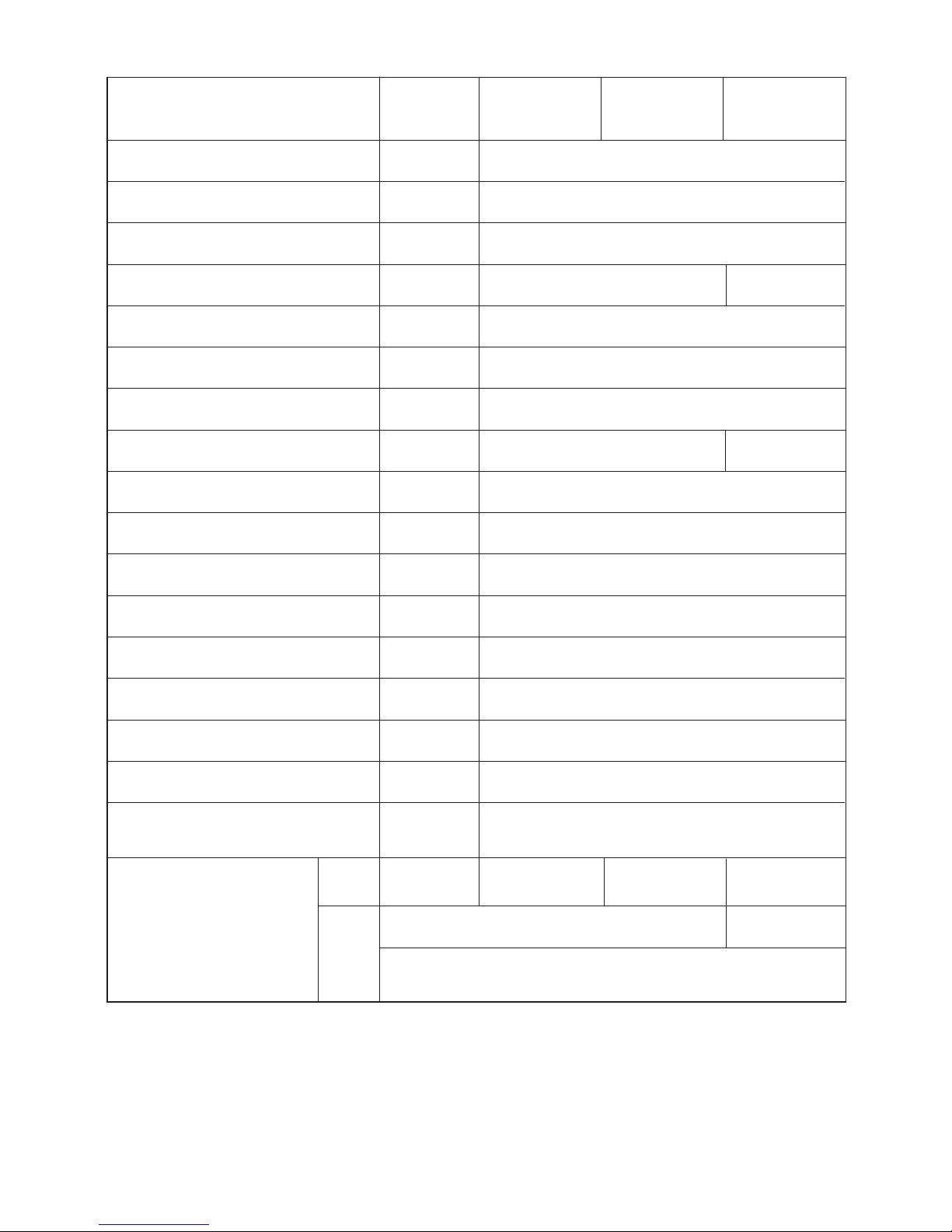

SPECIFICATIONS

INDOOR UNIT + OUTDOOR UNIT

FEBRUARY 2015 Hitachi Appliances, Inc.

※After installation

CONTENTS

SPECIFICATIONS---------------------------------------------------- 1−1

HOW TO USE---------------------------------------------------------- 2−1

CONSTRUCTION AND DIMENSIONAL DIAGRAM---------- 3−1

MAIN PARTS COMPONENT--------------------------------------- 4−1

WIRING DIAGRAM--------------------------------------------------- 5−1

CIRCUIT DIAGRAM-------------------------------------------------- 6−1

BLOCK DIAGRAM---------------------------------------------------- 7−1

BASIC MODE---------------------------------------------------------- 8−1

REFRIGERATING CYCLE DIAGRAM -------------------------- 9−1

PROCEDURE FOR DISASSEMBLY AND REASSEMBLY

----- 10−1

DESCRIPTION OF MAIN CIRCUIT OPERATION------------ 11−1

SERVICE CALL Q & A----------------------------------------------- 12−1

TROUBLE SHOOTING---------------------------------------------- 13−1

VARIOUS SETTINGS------------------------------------------------ 14−1

PARTS LIST AND DIAGRAM-------------------------------------- 15−1

INDOOR UNIT

OUTDOOR UNIT

RAC-50FXB

RAC-35FXB

RAC-25FXB

RAF-25RXB

RAF-35RXB

RAF-50RXB

INDOOR UNIT OUTDOOR UNIT INDOOR UNIT OUTDOOR UNIT INDOOR UNIT OUTDOOR UNIT

RAF-25RXB RAC-25FXB RAF-35RXB RAC-35FXB RAF-50RXB RAC-50FXB

(KW)

(B.T.U./h)

750

590

215

15

750(+65)

548

288(+27.5)

34

W

H

D

MODEL

POWER SOURCE

TOTAL INPUT (W)

TOTAL AMPERES (A)

CAPACITY

(KW)

(B.T.U./h)

TOTAL INPUT (W)

TOTAL AMPERES (A)

CAPACITY

COOLING

HEATING

DIMENSIONS

(mm)

NET WEIGHT (Kg)

TYPE

DC INVERTER

1 PHASE, 50HZ, 220-230V 1 PHASE, 50HZ, 220-230V 1 PHASE, 50HZ, 220-230V

580(155-1,180)

3.11-2.97

2.50(0.90-3.10)

8,530(3,070-10,580)

790(115-1,120)

3.99-3.82

3.4(0.9-4.4)

11,600(3,070-15,010)

750

590

215

15

750(+65)

548

288(+27.5)

34

1,020(155-1,300)

4.80-4.67

3.50(0.90-4.00)

11,940(3,070-13,650)

1,220(115-1,300)

5.84-5.58

4.5(0.9-5.0)

15,350(3,070-17,060)

750

590

215

15

800(+63)

736

350(+35.5)

49.5

1,560(155-1,950)

7.16-6.85

5.00(0.90-5.20)

17,060(3,070-17,740)

1,780(115-2,100)

8.17-7.82

6.5(0.9-8.1)

22,180(3,070-27,640)

Page 2

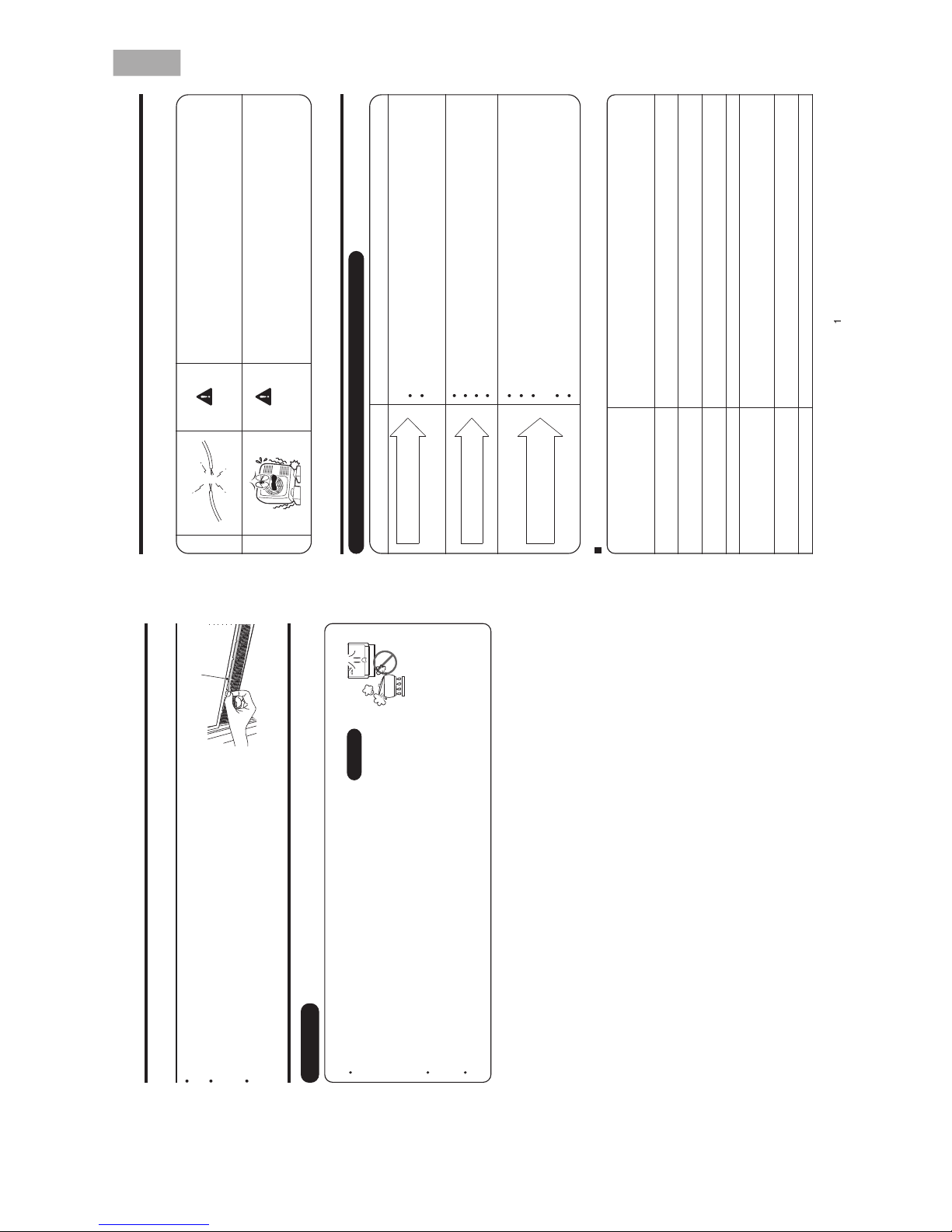

1. In order to disassemble and repair the

unit in question, be sure to disconnect the

power cord plug from the power outlet

before starting the work.

2. If it is necessary to replace any parts, they should be replaced with respective genuine parts for the unit,

and the replacement must be effected in correct manner according to the instructions in the Service

Manual of the unit.

3. After completion of repairs, the initial state should be

restored.

4. Lead wires should be connected and laid as in the

initial state.

5. Modification of the unit by the user himself should

absolutely be prohibited.

6. Tools and measuring instruments for use in repairs or inspection should be accurately calibrated in

advance.

7. In installing the unit having been repaired, be careful to prevent the occurrence of any accident such as

electrical shock, leak of current, or bodily injury due to the drop of any part.

8. To check the insulation of the unit, measure the insulation resistance between the power cord plug and

grounding terminal of the unit.

The insulation resistance should be 1MΩ or more as measured by a 500V DC megger.

9. The initial location of installation such as window, floor or the other should be checked for being safe

enough to support the repaired unit again.

If it is found not so strong and safe, the unit should be installed at the initial location after reinforced or

at a new location.

10. Any inflammable object must not be placed

about the location of installation.

11. Check the grounding to see whether it is

proper or not, and if it is found improper,

connect the grounding terminal to the earth.

Spray

gasoline

gasbombe

thinner

1. SAFETY DURING REPAIR WORK

If the contacts of electrical

parts are defective, replace

the electrical parts without

trying to repair them

1

2

3

4

5

Page 3

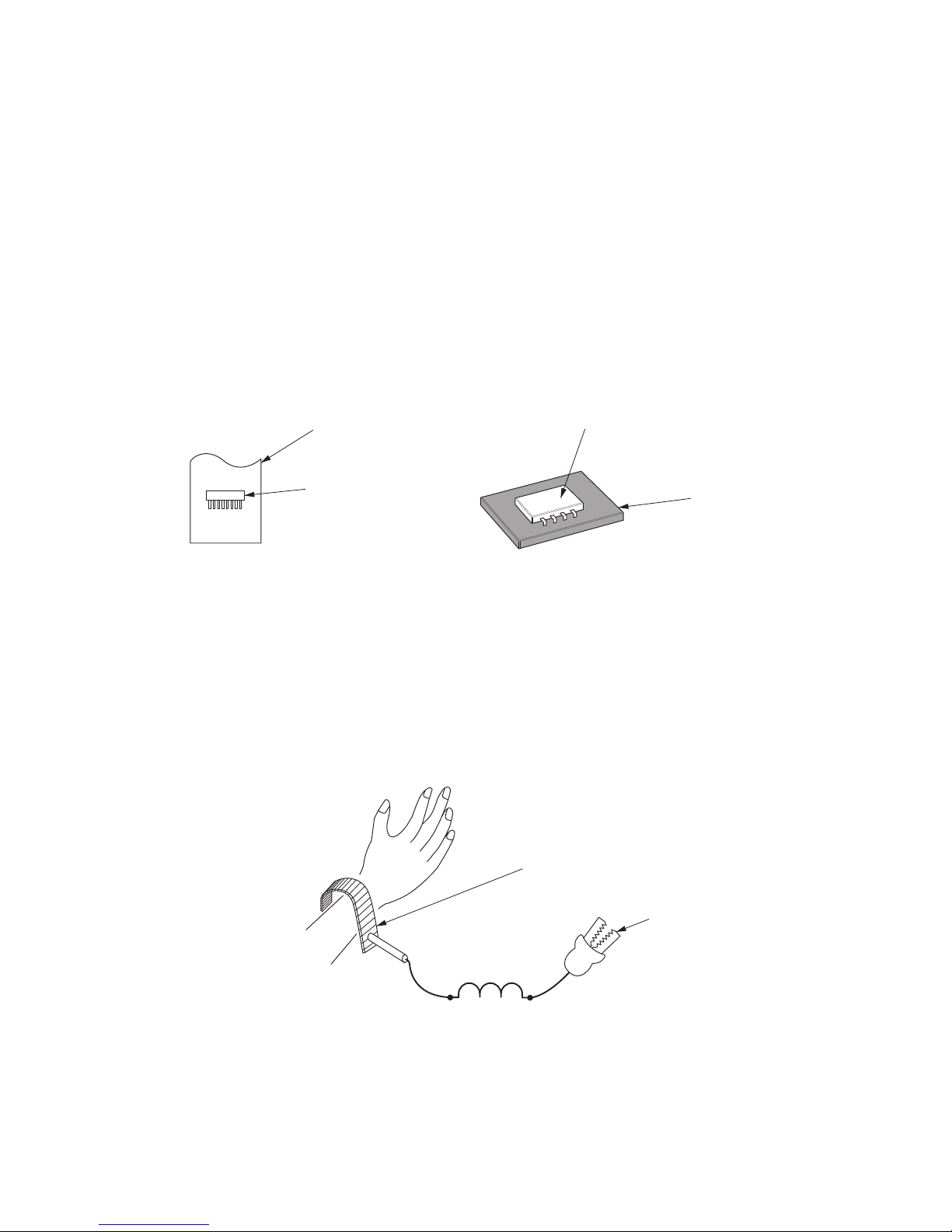

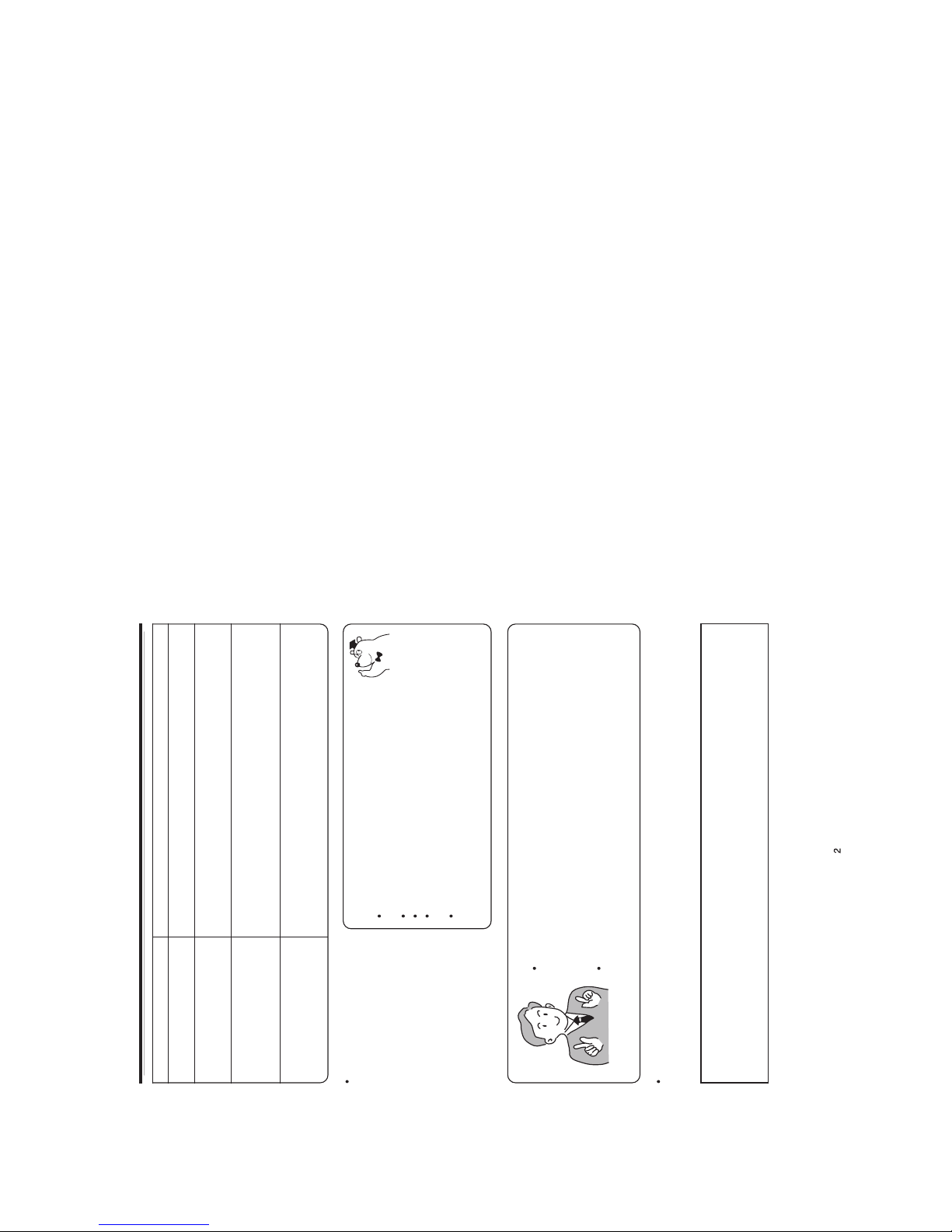

WORKING STANDARDS FOR PREVENTING BREAKAGE OF SEMICONDUCTORS

1. Scope

The standards provide for items to be generally observed in carrying and handling semiconductors in

relative manufactures during maintenance and handling thereof. (They apply the same to handling of

abnormal goods such as rejected goods being returned.)

2. Object parts

(1) Microcomputer

(2) Integrated circuits (I.C.)

(3) Field effective transistor (F.E.T.)

(4) P.C. boards or the like to which the parts mentioned in (1) and (2) of this paragraph are equipped.

3. Items to be observed in handling

(1) Use a conductive container for carrying and storing of parts. (Even rejected goods should be handled in

the same way.)

(2) When any part is handled uncovered (in counting, packing and the like), the handling person must

always use himself as a body earth. (Make yourself a body earth by passing one M ohm earth

resistance through a ring or bracelet.)

(3) Be careful not to touch the parts with your clothing when you hold a part even if a body earth is

being taken.

(4) Be sure to place a part on a metal plate with grounding.

(5) Be careful not to fail to turn off power when you repair the printed circuit board. At the same time,

try to repair the printed circuit board on a grounded metal plate.

HIT

ACH

I IC40

1TH1 ,

188UV

Fig. 1 Conductive container

A conductive polyvinyl bag

IC

IC

Conductive sponge

Fig. 2 Body earth

Body earth (Elimik conductive band)

Clip for connection with

a grounding wire

1MΩ

Page 4

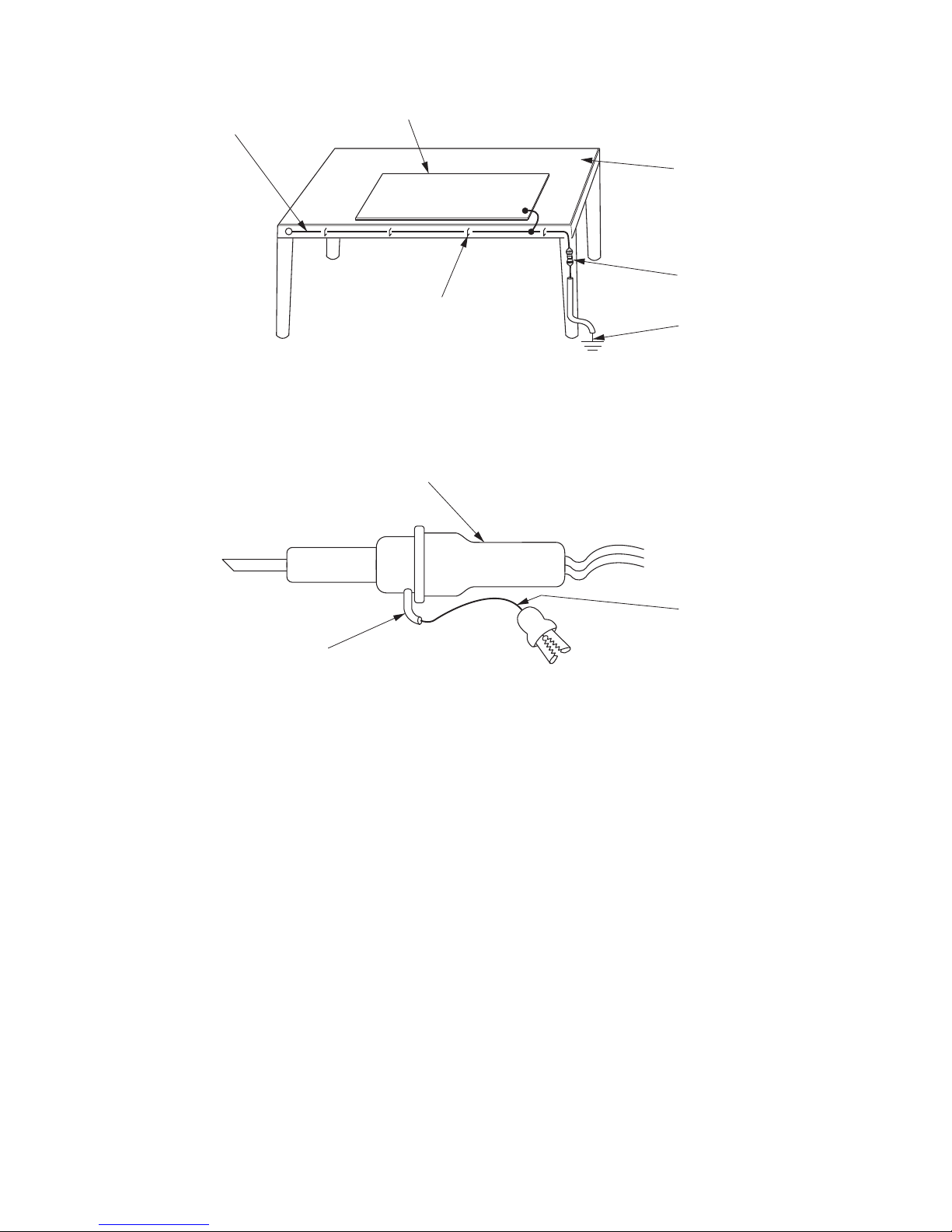

(6) Use a three wire type soldering iron including a grounding wire.

Fig.4 Grounding a solder iron

Use a high insulation mode (100V, 10MΩ or higher) when ordinary iron is to be used.

(7) In checking circuits for maintenance, inspection, or some others, be careful not to have the test probes

of the measuring instrument short circuit a load circuit or the like.

Bare copper wire (for body earth)

Metal plate (of Al. stainless steel, etc.)

Working table

Resistor 1MΩ (1/2W)

Earth wire

Staple

Fig.3 Grounding of the working table

soldering iron

Grounding wire

Screw stop at the screwed

part using a rag plate

Page 5

1.

In quiet or stop operation, slight flowing noise of refrigerant in the refrigerating cycle is heard occasionally,

but this noise is not abnormal for the operation.

2. When it thunders near by, it is recommend to stop the operation and turn off the circuit break er for safety.

3. In the event of power failure,the room air conditioner will restare automatically in the previously

mode once the power is restored. In the event of power failure during TIMER operation, the room air comditioner

will not start automatically. Re-press ON/OFF button after 3 minutes from when the unit off or power recovery.

4. If the room air conditioner is stopped by adjusting thermostat, or missoperation, and re-start in a moment,

there is occasion that the cooling and heating operation does not start for 3 minutes, it is not abnormal and

this is the result of the operation of IC delay circuit. This IC delay circuit ensures that there is no danger of

blowing fuse or damaging parts even if operation is restarted accidentally.

5. This room air conditioner should not be used at the cooling operation when the outside temperature is

below -10°C (14°F).

6. This room air conditioner (the reverse cycle) should not be used when the outside temperature is below

–15°C (5°F).

If the reverse cycle is used under this condition, the outside heat exchanger is frosted and efficiency falls.

7. When the outside heat exchanger is frosted, the frost is melted by operating the hot gas system, it is not

trouble that at this time fan stops and the vapour may rise from the outside heat exchanger.

CAUTION

selected

Page 6

This䚷manualdescribesonlypointsthatdifferfrom

RAMͲ33NP2B(PMNo.0581E)

RAMͲ40NP2B(PMNo.0582E)

RAMͲ53NP2B,RAMͲ53NP3B(PMNo.0583E)

RAMͲ68NP3B(PMNo.0584E)

RAMͲ70NP4B(PMNo.0585E)

RAMͲ90NP5B(PMNo.0586E)

RAMͲ110NP6B(PMNo.0587E)

foritemsnotdescribedinthismanual.

Combinationtable

RAFͲ25RXB RAFͲ35RXB RAFͲ50RXB

RACͲ25FXB RACͲ35FXB RACͲ50FXB

RAMͲ33NP2B

o ͲͲ

RAMͲ40NP2B

oo Ͳ

RAMͲ53NP2B

ooo

RAMͲ53NP3B

ooo

RAMͲ68NP3B

ooo

RAMͲ70NP4B

ooo

RAMͲ90NP5B

ooo

RAMͲ110NP6B

ooo

Indoorunit

Singleoutdoorunit

Multi

outdoorunit

Page 7

1ー1

SPECIFICATIONS

MODEL

FAN MOTOR

FAN MOTOR CAPACITOR

FAN MOTOR PROTECTOR

COMPRESSOR

COMPRESSOR MOTOR CAPACITOR

OVERLOAD PROTECTOR

OVERHEAT PROTECTOR

FUSE (for MICROPROCESSOR)

POWER RELAY

POWER SWITCH

TEMPORARY SWITCH

SERVICE SWITCH

TRANSFORMER

VARISTOR

NOISE SUPPRESSOR

THERMOSTAT

REMOTE CONTROL SWITCH (LIQUID

CRYSTAL)

NO

NO

NO

YES

G4A-1A

NO

NO

YES

YES

YES(IC)

NO

WITHOUT REFRIGERANT BECAUSE

COUPLING IS FLARE TYPE.

UNI T

PIPES

MAX. 30m

MIN.3m

MAX. 20m

MIN.3m

REFRIGERANT CHARGING

VOLUME

(Refrigerant 410A)

NO

NO

–

NO

NO

NO

NO

YES

NO

NO

YES(IC)

YES

----------

NO

ASG133CDNB7AT

870g 1400g

ASD084SFNA7JK1

RAF-25RXB

RAF-35RXB

RAF-50RXB

RAC-50FXBRAC-35FXBRAC-25FXB

47W (DC120~380V)

870g

30W (DC325V)

3.15A

15A, 2A, 3A, 3.15A

25A, 2A, 3A, 3.15A

450NR

YES

450NR, ERZVA431

R

YES

YES(INTERNAL)

Page 8

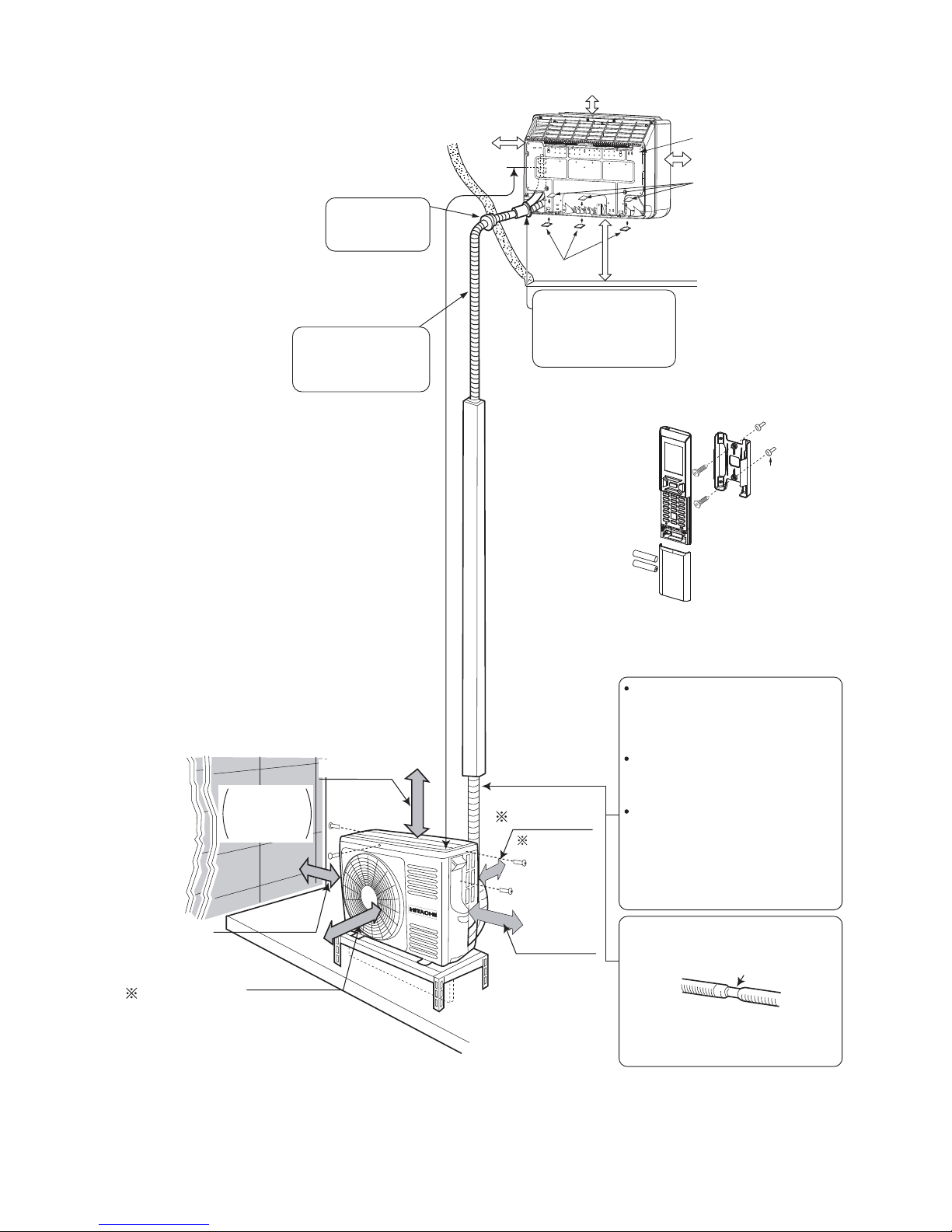

1ー2

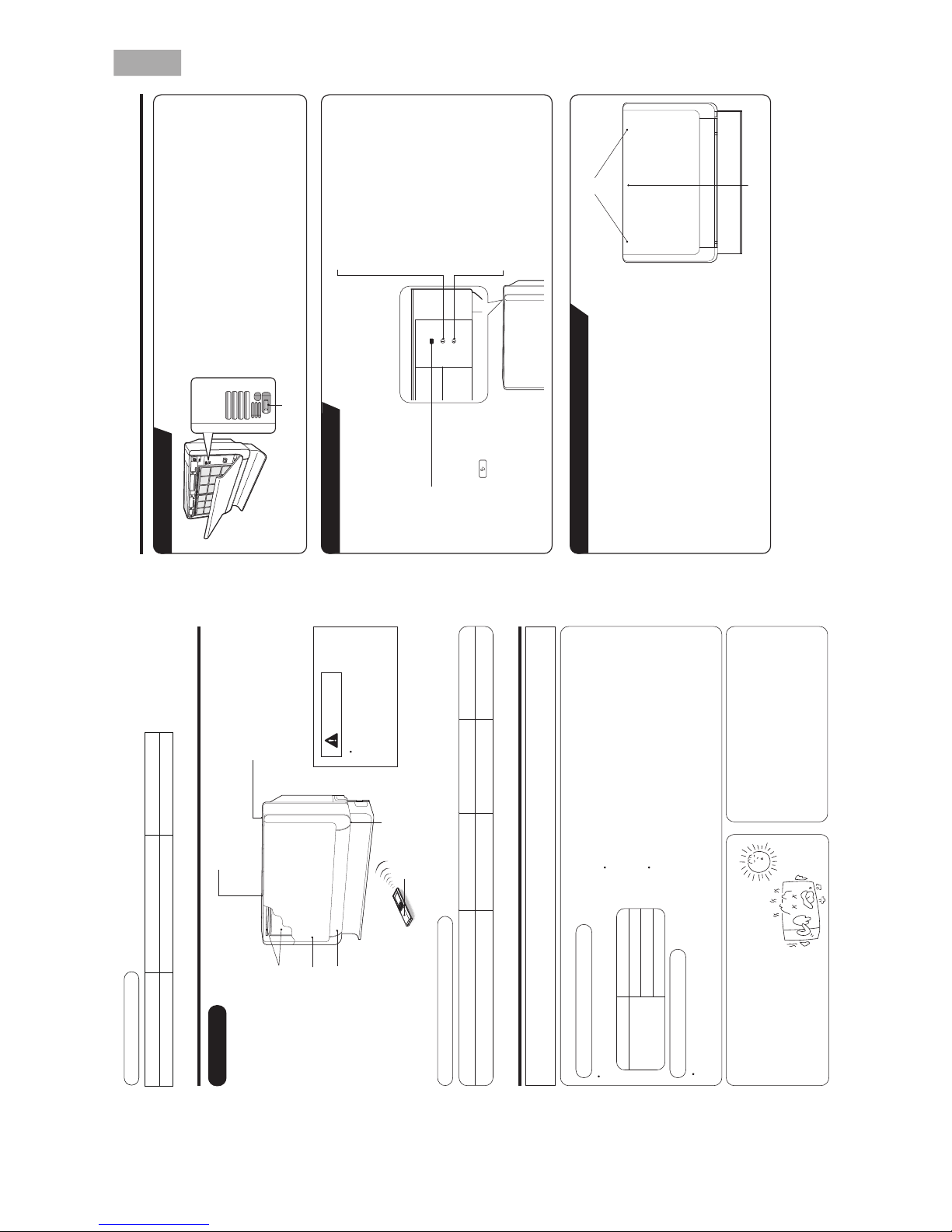

Figure showing the installation of lndoor and Outdoor unit

MODEL RAF-25RXB/RAC-25FXB

RAF-35RXB/RAC-35FXB

The refrigerating machine oil is

easily affected by moisture. Use

caution to prevent water from

entering the cycle.

The difference in height between

the indoor and outdoor unit

should be kept below 10m.

The connecting pipe, no matter

big or small, should all be

insulated with insulation pipe and

then wrapped with vinyl tape.

(The insulator will deteriorate if

it is not wrapped with tape).

The connection of insulated drain

hose.

Inner diameter 16mm

Please use insulated drain hose for

the indoor piping (commercial

product)

above 100mm

above 300mm

above 50mm

give clearance

as wide as

possible

above

200mm

above 50 mm when

installed on the

ceiling of balcony

above 200mm

Maximum pipe length 20m

Minimum pipe length 3m

Plug

Sheet

Hanger

Be sure to completely

seal any gap with

putty.

Drain pipe

Must be installed separately.

Insulate indoor part of pipe

to prevent condensation.

The indoor piping should be

insulated with the enclosed

insulation pipe. (If the insulator

is insufficient, please use

commercial products.)

Above 100mm

Above 150mm

Above 200mm

Bush

When mounting on a wall

(up to 150~500 mm from the floor surface)

(For example:wall instalation)

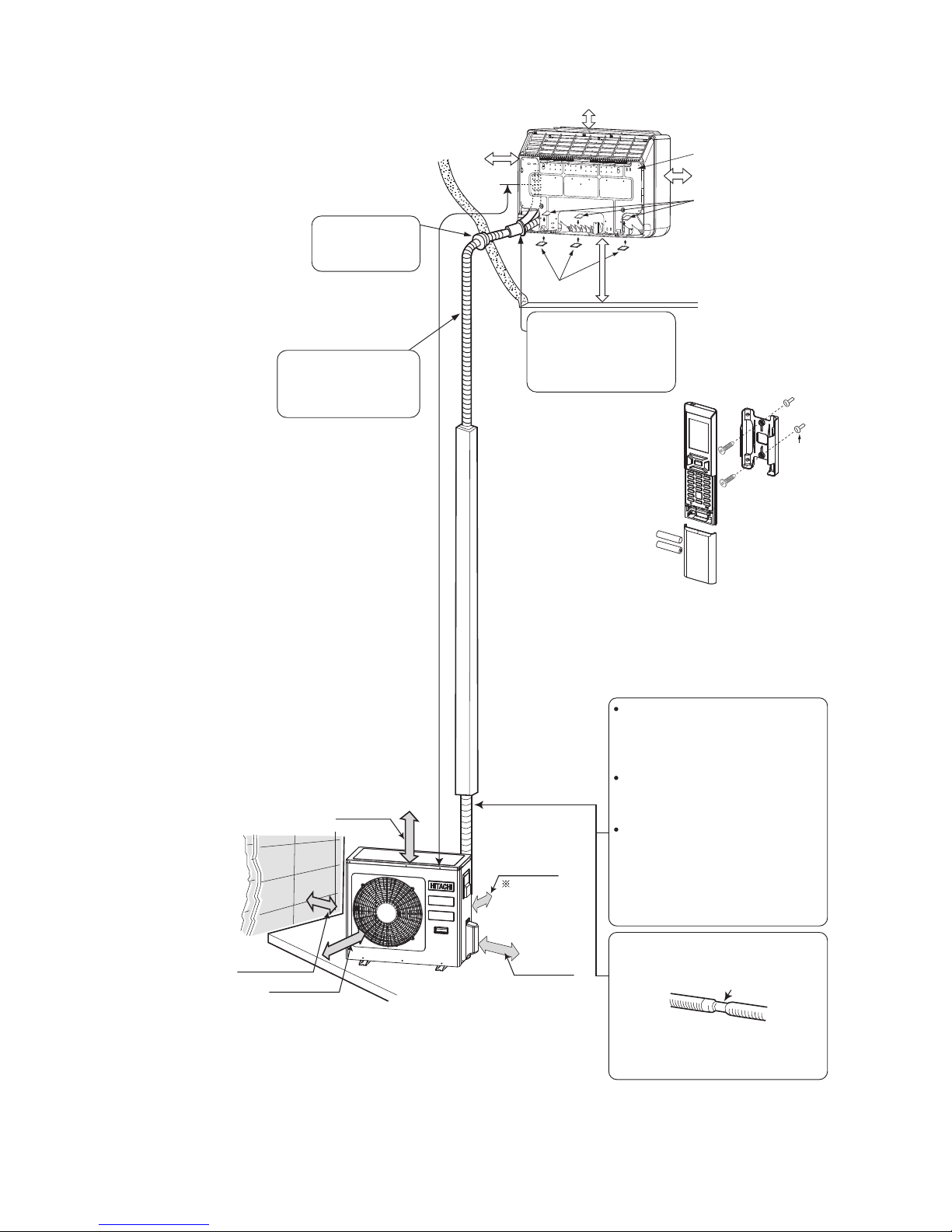

Page 9

1ー3

Figure showing the installation of lndoor and Outdoor unit

The refrigerating machine oil is

easily affected by moisture. Use

caution to prevent water from

entering the cycle.

The difference in height between

the indoor and outdoor unit

should be kept below 10m.

The connecting pipe, no matter

big or small, should all be

insulated with insulation pipe and

then wrapped with vinyl tape.

(The insulator will deteriorate if

it is not wrapped with tape).

The connection of insulated drain

hose.

Inner diameter 16mm

Please use insulated drain hose for

the indoor piping (commercial

product)

Maximum pipe length 30m

Minimum pipe length 3m

Plug

above 200mm

above

200mm

give clearance

as wide as

possible

above 300mm

above 700mm

above 150mm

Sheet

Hanger

Be sure to completely

seal any gap with

putty.

Drain pipe

Must be installed separately.

Insulate indoor part of pipe

to prevent condensation.

The indoor piping should be

insulated with the enclosed

insulation pipe. (If the insulator

is insufficient, please use

commercial products.)

Above 100mm

Above 150mm

Above 200mm

Bush

When mounting on a wall

(up to 150~500 mm from the floor surface)

(For example:wall instalation)

MODEL RAF-50RXB/RAC-50FXB

Page 10

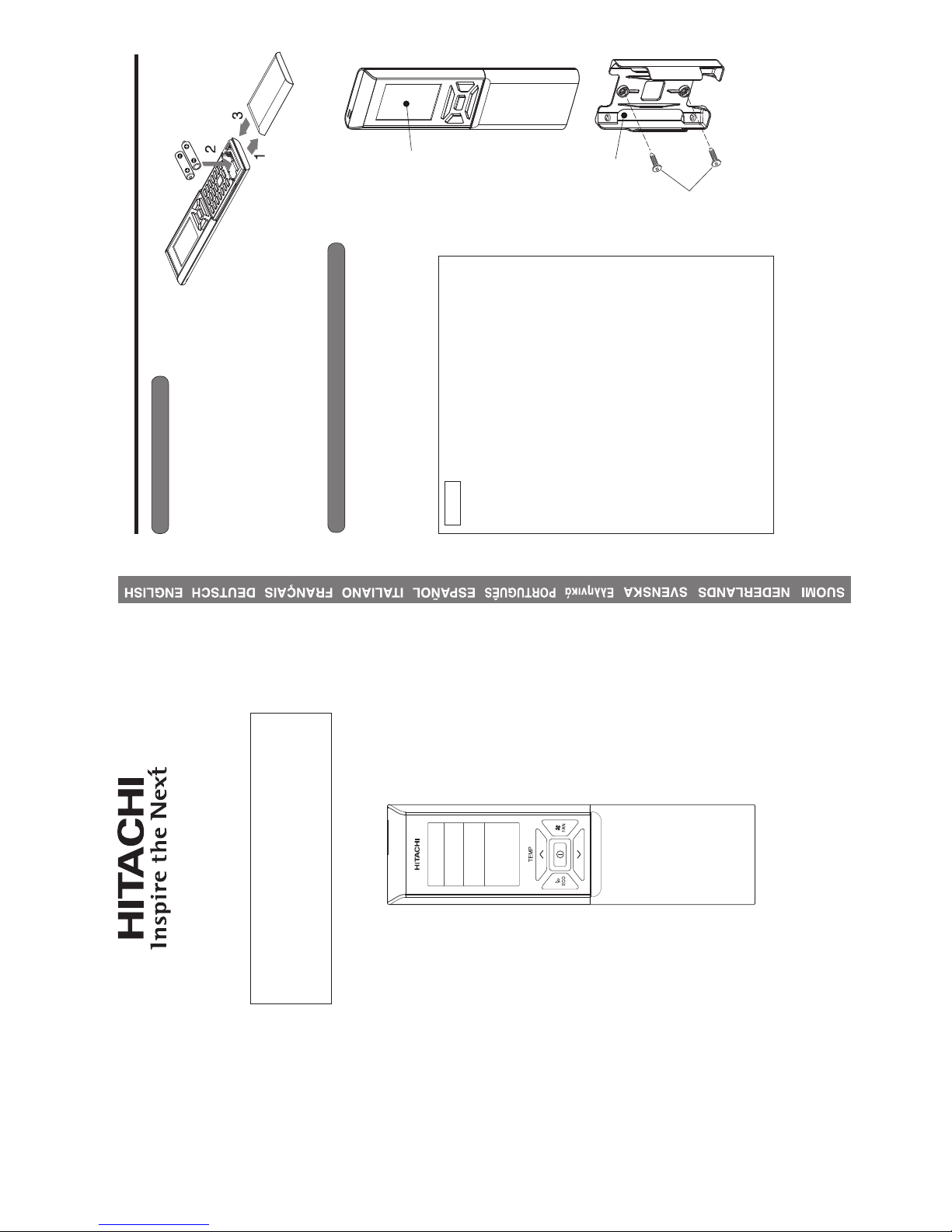

– 1 –

Remote Controller Manual

Remote Controller manual Page 1~28

To obtain the best performance and ensure years of trouble free use, please read this instruction manual completely.

MODEL

RAR-6N4

– 2 –

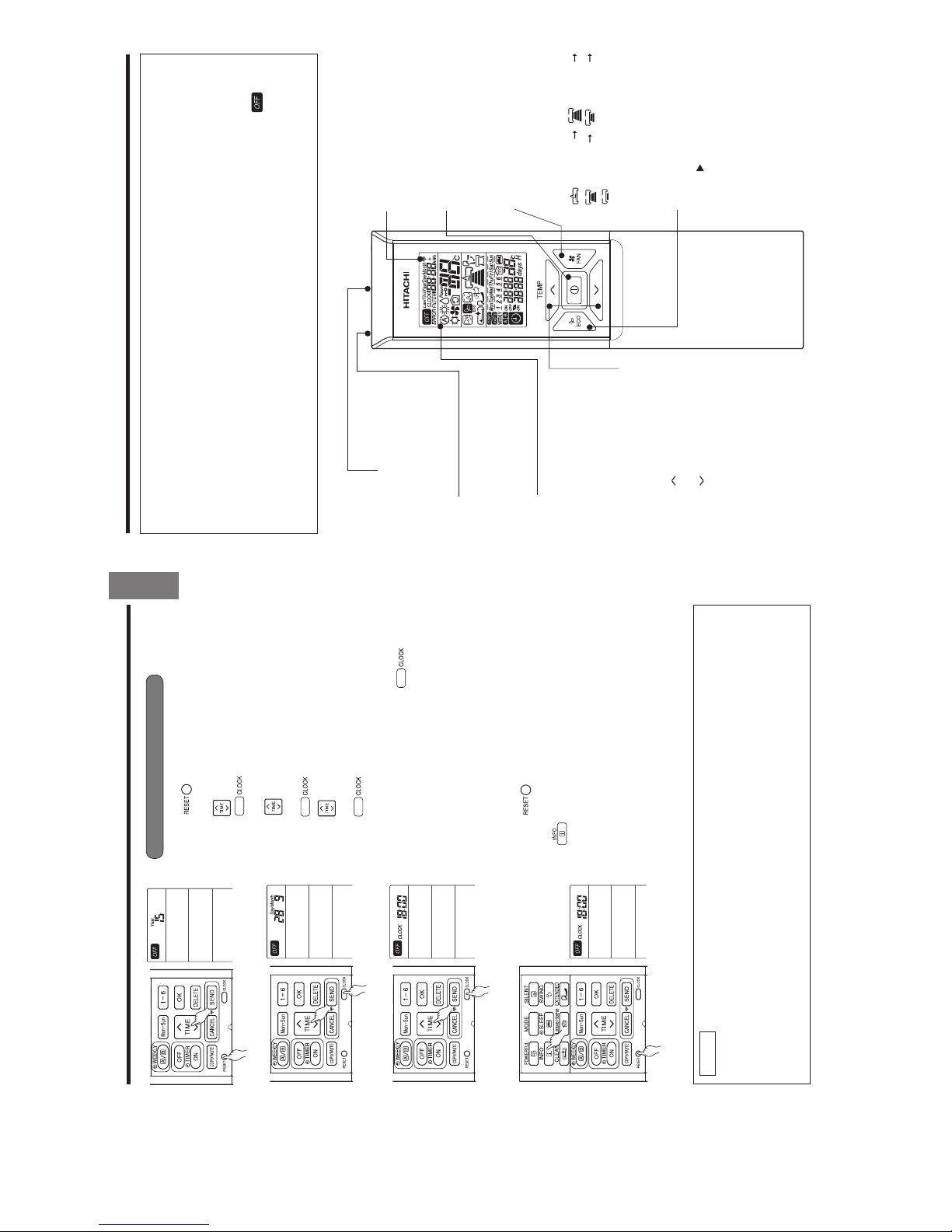

PREPARATION BEFORE OPERATION

■ To install the batteries

■ To fix the remote controller holder to the wall

1. Slide the cover to take it off.

2. Install two dry batteries AAA.LR03 (alkaline).

The direction of the batteries should match the

marks in the case.

3. Replace the cover at its original position.

1. Choose a place from where the signals can reach the unit.

2. Fix the remote controller holder to a wall, a pillar or similar

location with the provided screws.

3. Place the remote controller in the remote controller holder.

NOTE

Notes on batteries

● When replacing the batteries, use batteries of the same

type, and replace both old batteries together.

● When the system is not used for a long time, take the

batteries out.

● The batteries will last for approximately 1 year. However, if

the remote controller display begins to fade and degradation

of reception performance occurs within a year, replace both

batteries with new size AAA.LR03 (alkaline).

● The attached batteries are provided for the initial use of

the system.

The usable period of the batteries may be short depending

on the manufactured date of the air conditioner.

Notes on the remote controller

● Never expose the remote controller to direct sunlight.

● Dust on the signal transmitter or receiver will reduce the

sensitivity. Wipe off dust with soft cloth.

● Signal communication may be disabled if an electronic-

starter-type Û uorescent lamp (such as inverter-type lamps)

is in the room. Consult the shop if that is the case.

● If the remote controller signals happen to operate another

appliance, move that appliance to somewhere else, or

consult the service shop.

● When the remote controller is not in use, please close the

slide cover to prevent failure.

Remote controller

Screws

Remote

controller holder

HOW TO USE

MODEL RAF-25RXB / RAC-25FXB, RAF-35RXB / RAC-35FXB, RAF-50RXB / RAC-50FXB

2ー1

Page 11

– 3 –

ENGLISH

PREPARATION BEFORE OPERATION

■ To set calendar and clock

1. Press (RESET) button when Ú rst time setting.

"Year" blinks.

2. Press

(TIME) button to set the current year.

3. Press

(CLOCK) button. "Day" and "Month"

blink.

4. Press

(TIME) button to set the current day and

month.

5. Press

(CLOCK) button. "CLOCK" blinks.

6. Press

(TIME) button to set the clock to the current

time.

7. Press

(CLOCK) button.

Calendar and clock are set.

To modify the calendar and clock, press

(CLOCK)

button.

Then follow steps 1 to 7.

Calendar and clock need to be set again after changing

batteries.

After changing the batteries,

1. Press (RESET) button.

2. Direct remote controller towards indoor unit and press

(INFO) button.

3. The calendar and clock from indoor unit will be transmitted.

■ Calendar and clock will not be transmitted from indoor

unit when the following occurs:

● When there is a power failure.

● When breaker is OFF by user (unit is not in STANDBY

MODE).

NOTE

Note on setting the calendar and clock.

● If the calendar and clock are not set, the ON-timer, OFF-timer and Weekly Timer cannot be set.

● If the calendar and clock are not set correctly, the ON-timer, OFF-timer and Weekly Timer will not

operate correctly.

● When the ON-timer, OFF-timer and Weekly Timer are set, the calendar and clock cannot be changed.

If there is a need to change the calendar and clock, ON-timer, OFF-timer and Weekly Timer need to

be cancelled.

– 4 –

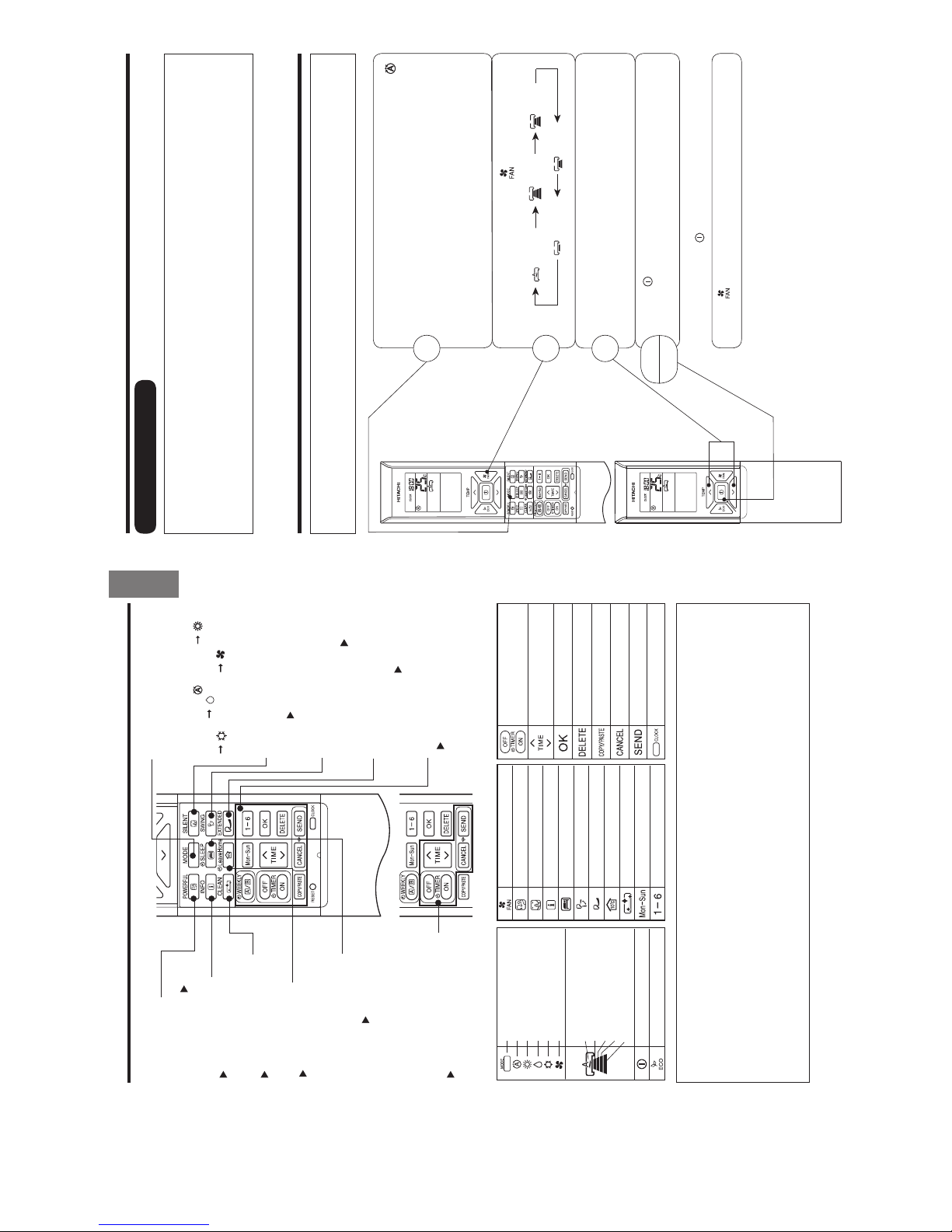

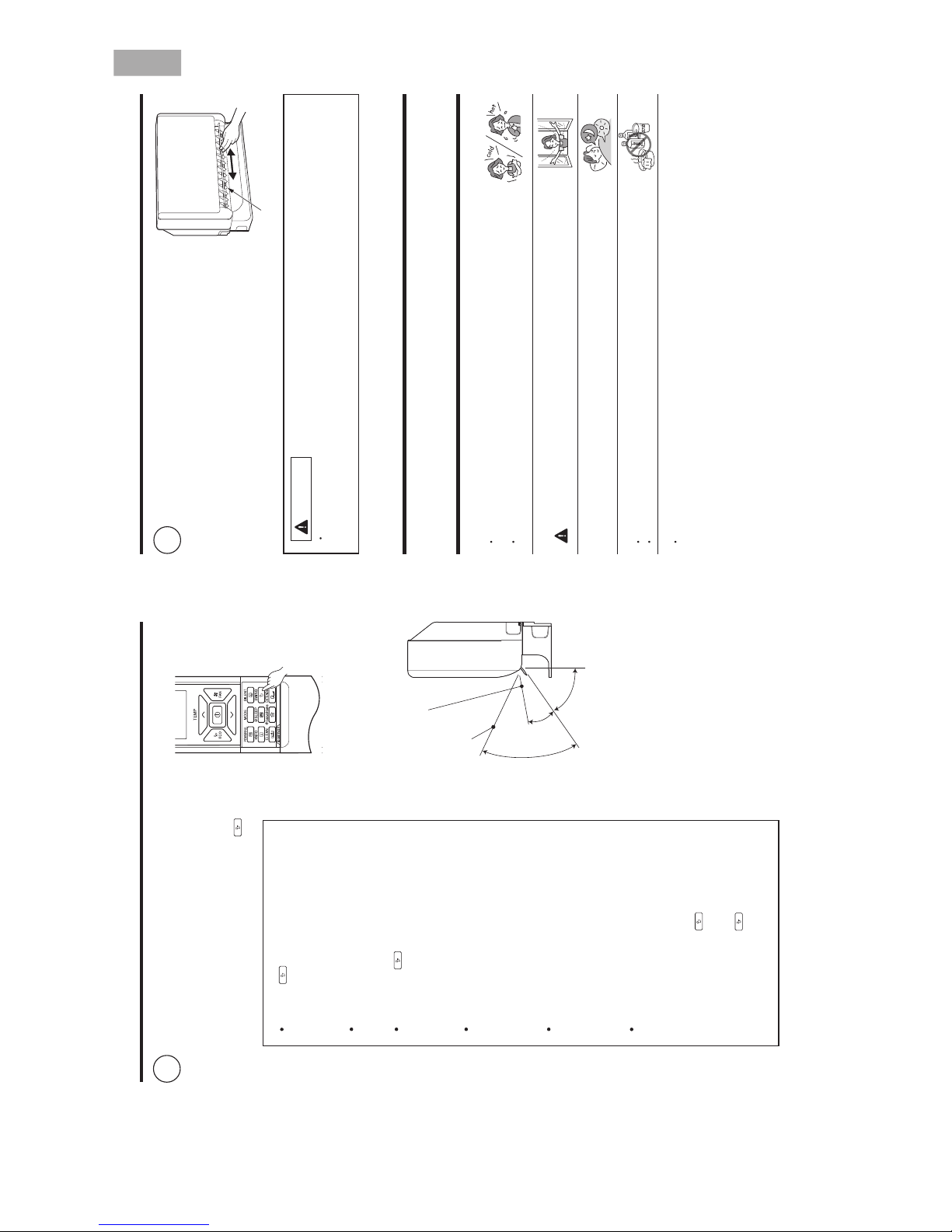

NAMES AND FUNCTIONS OF REMOTE CONTROLLER

REMOTE CONTROLLER

● This controls the operation of the indoor unit. The range of control is about 7 meters. If indoor lighting is

controlled electronically, the range of control may be shorter.

This unit can be Ú xed on a wall using the Ú xture provided. Before Ú xing it, make sure the indoor unit can

be controlled from the remote controller.

● Handle the remote controller with care. Dropping it or getting it wet may compromise its signal transmission

capability.

● After new batteries are inserted into the remote controller, the unit will initially require approximately 10

seconds to respond to commands and operate.

● When remote controller is not in use for about 3 minutes during OFF condition, indicated by on the

display, the LCD will turn off.

● During clock setting, the LCD will turn off about 10 minutes later if the remote controller is not in use.

● When pressing any button, the LCD will turn on.

● The LCD will not turn off during TIMER setting.

Signal Transmitting/Receiving

Window

Point this window towards the

indoor unit when controlling it.

Sensor

A temperature sensor inside the

remote controller senses ambient

temperature around the remote-

controller.

Display

This indicates the room temperature

selected, current time, timer status,

function and airÛ ow rate selected.

ROOM TEMPERATURE setting Buttons

Press these buttons to set the room

temperature.

Press the [

] button to raise the room

temperature.

Press the [

] button to lower the room

temperature.

Keep pressing and the value will change

more quickly.

ECO Button

Use this button to set the ECO

mode. (

p. 13)

START/STOP button

Press this button to start

operation. Press it again to stop

operation.

FAN SPEED selector Button

This determines the fan speed.

Every time you press this button,

the airÛ ow rate will change from

(AUTO) (HIGH)

(MED) (LOW)

(SILENT) (This button allows

selection of optimal or preferred fan

speed for each operation mode).

Transmission sign

The transmission sign lights up

when a signal is sent.

2ー2

Page 12

– 5 –

ENGLISH

MODE SELECTOR

AUTO

HEAT

DEHUMIDIFY

COOL

FAN

FAN SPEED

AUTO

SILENT

LOW

MED

HIGH

START / STOP

ECO

Precautions for Use

●

Do not put the remote controller in the following places.

●

Under direct sunlight.

●

In the vicinity of a heater.

●

Handle the remote controller carefully. Do not drop it on the Û oor, and protect it from water.

●

Once the outdoor unit stops, it will not restart for about 3 minutes (unless you turn the power switch

off and on or unplug the power cord and plug it in again).

This is to protect the device and does not indicate a failure.

●

If you press the MODE selector button during operation, the device may stop for about 3 minutes for

protection.

POWERFUL Button

Use this button to set the

POWERFUL mode. ( p. 11)

INFORMATION Button

(

p. 26)

ONE TOUCH CLEAN Button

(

p. 16)

ON / OFF TIMER setting Buttons

(

p. 17)

MODE selector Button

Use this button to select the

operating mode. Every time you

press this button, the mode will

change from

(AUTO)

(HEAT) (DEHUMIDIFY)

(COOL) and (FAN)

cyclically.

SILENT Button

Use this button to set the SILENT

mode. (

(

p. 12)

p. 10)

(

p. 10)

WEEKLY TIMER setting Buttons

(

p. 20)

LEAVE HOME Button

(

p. 15)

NAMES AND FUNCTIONS OF REMOTE CONTROLLER

ECO SLEEP TIMER Button

Use this button to set the ECO

sleep timer. (

p. 18)

FAN

POWERFUL

SILENT

INFO

SLEEP TIMER

AUTO SWING (VERTICAL)

LEAVE HOME

CLEAN

DAY

PROGRAM NO.

ON / OFF TIMER

TIMEOKDELETE

COPY / PASTE

CANCEL

SEND

CLOCK

EXTENDED AIRFLOW button

Pushes air out further for an

extended AIRÛow.

EXTENDED AIRFLOW button

AUTO SWING (Vertical) Button

Controls the angle of the

horizontal air deÛ ector.

p. 10)

– 6 –

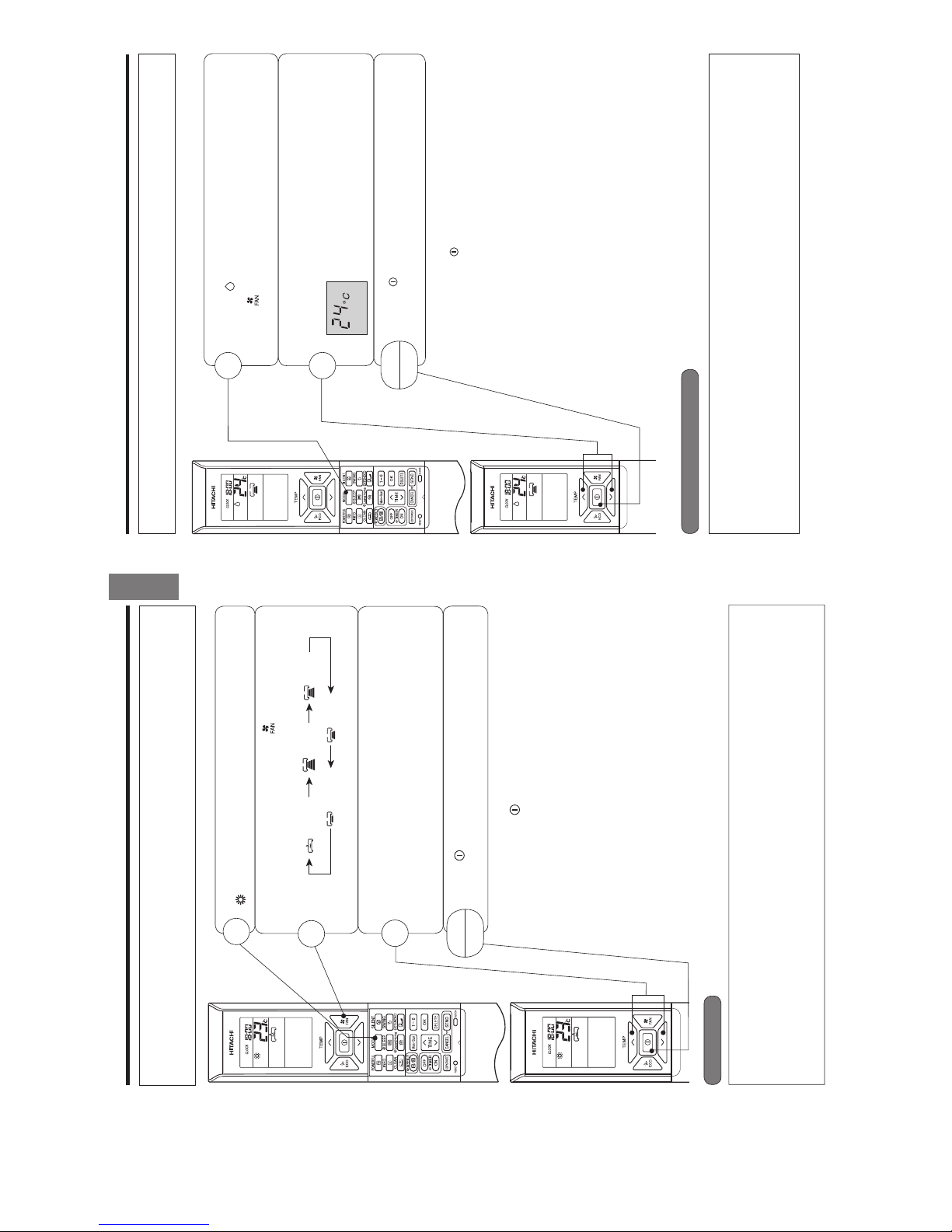

AUTOMATIC OPERATION

The device will automatically determine the mode of operation, HEAT or COOL depending on the current

room temperature. The selected mode of operation will change when the room temperature varies.

However, the mode of operation will not change when indoor unit is connected to multi type outdoor unit.

VARIOUS FUNCTIONS

■ Auto Restart Control

● If there is a power failure, operation will be automatically restarted when the power is resumed with previous operation

mode and airÛ ow direction.

(As the operation is not stopped by remote controller.)

● If you intend not to continue the operation when the power is resumed, switch off the power supply.

When you switch on the circuit breaker, the operation will be automatically restarted with previous operation mode

and airÛ ow direction.

Note: 1. If you do not require Auto Restart Control, please consult your sales agent.

2. Auto Restart Control is not available when Timer or Sleep Timer mode is set.

■ As the settings are stored in the memory of the remote controller, you

only have to press the

(START/STOP) button next time.

Press the MODE selector button so that the display indicates the

(AUTO) mode of operation.

● When AUTO has been selected, the device will automatically

determine the mode of operation, HEAT or COOL depending on

the current room temperature. However the mode of operation will

not change when indoor unit is connected to multi type outdoor

unit.

● If the mode automatically selected by the unit is not satisfactory,

manually change the mode setting (HEAT, DEHUMIDIFY, COOL

or FAN).

Press the (FAN SPEED) button to select AUTO, HIGH, MED, LOW

or SILENT.

Press the

(START/STOP) button.

Operation starts with a beep.

Press the button again to stop operation.

Set the desired room temperature with the TEMPERATURE buttons

(the display indicates the setting).

The temperature setting and the actual room temperature may vary

depending on conditions.

Temperature range can be set between 16°C and 32°C.

START

STOP

1

2

3

Set the desired FAN SPEED with the (FAN SPEED) button (the

display indicates the setting).

(AUTO) (HIGH) (MED)

(SILENT) (LOW)

2ー3

Page 13

– 7 –

ENGLISH

HEATING OPERATION

● Use the device for heating when the outdoor temperature is under 21°C.

When it is too warm (over 21°C), the heating function may not work in order to protect the device.

● In order to maintain reliability of the device, please use this device when outdoor temperature is above

–15°C.

Press the MODE selector button so that the display indicates

(HEAT).

Set the desired FAN SPEED with the (FAN SPEED) button

(the display indicates the setting).

(AUTO) (HIGH) (MED)

(SILENT) (LOW)

Set the desired room temperature with the TEMPERATURE buttons

(the display indicates the setting).

The temperature setting and the actual room temperature may

vary depending on conditions.

Temperature range can be set between 16°C and 32°C.

Press the

(START/STOP) button. Heating operation starts with

a beep. Press the button again to stop operation.

■ As the settings are stored in the memory of the remote controller, you

only have to press the (START/STOP) button next time.

■ During AUTO fan, the fan speed automatically changes as below:

● When the difference between room temperature and setting temperature

is large, fan starts to run at HI speed.

● After room temperature reaches the preset temperature, fan speed

will be changed to lower speed to obtain optimum room temperature

condition for natural healthy heating.

START

STOP

Defrosting will be performed about once an hour when frost forms on the heat exchange of the outdoor unit,

for 5~10 minutes each time.

During defrosting operation, the operation lamp blinks in a cycle of 3 seconds on and 0.5 second off.

The maximum time for defrosting is 20 minutes.

However, if the indoor unit is connected to multi type outdoor unit, the maximum time for defrosting is 15

minutes.

(If the piping length used is longer than usual, frost is likely to form.)

1

2

3

Defrosting

– 8 –

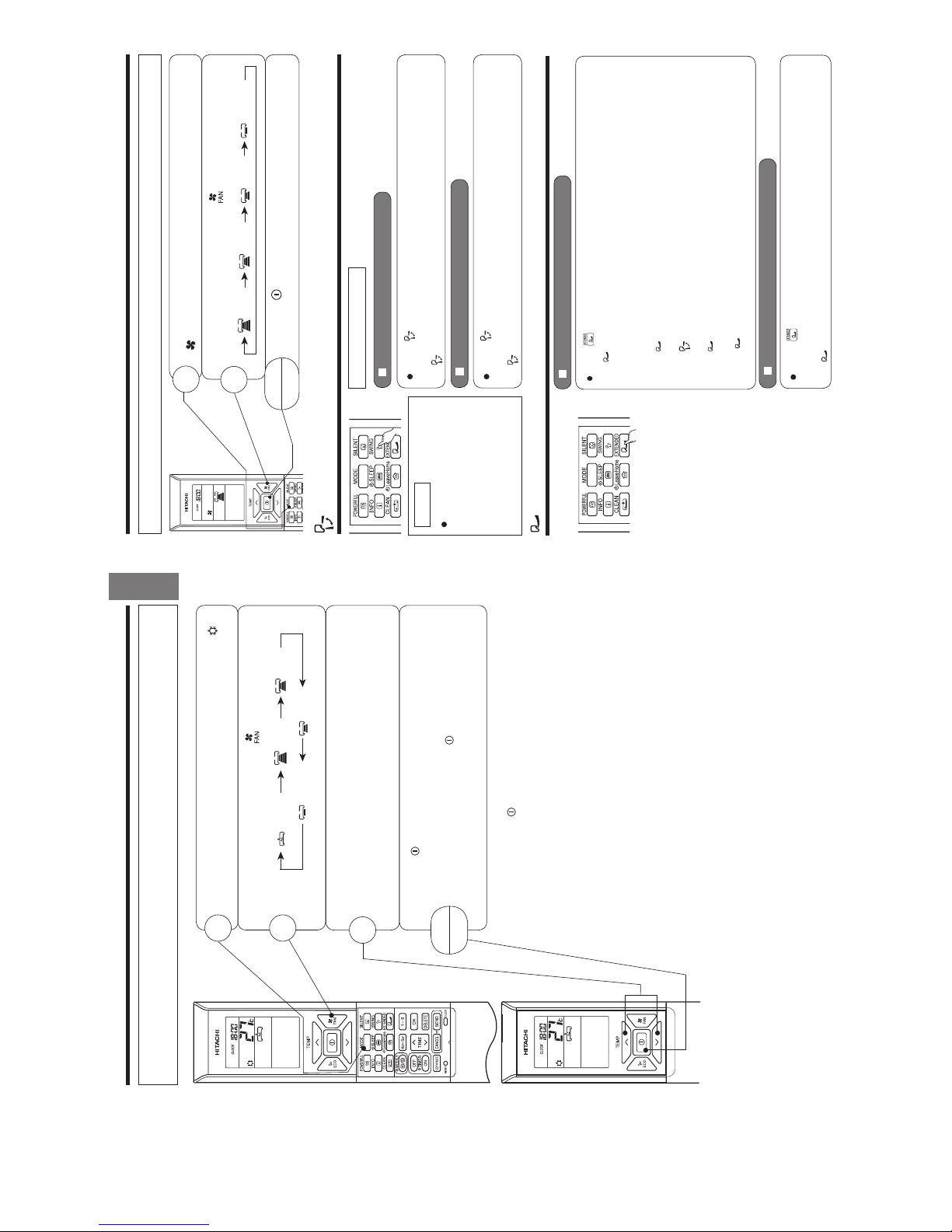

DEHUMIDIFYING OPERATION

■ Dehumidifying Function

● When the room temperature is higher than the temperature setting: The device will dehumidify the room,

reducing the room temperature to the preset level.

When the room temperature is lower than the temperature setting: Dehumidifying will be performed at the

temperature setting slightly lower than the current room temperature, regardless of the temperature setting.

● The preset room temperature may not be reached depending on the number of people present in the room

or other room conditions.

Set the desired room temperature with the ROOM

TEMPERATURE setting buttons (the display indicates the

setting).

The range of Þ# is recommended as the

room temperature for dehumidifying.

Temperature range can be set between 16°#

and #

Press the (START/STOP) button. Dehumidifying operation

starts with a beep. Press the button again to stop operation.

■ As the settings are stored in the memory of the remote controller, you

only have to press the

(START/STOP) button next time.

START

STOP

Press the MODE selector button so that the display

indicates (DEHUMIDIFY).

The fan speed is set at LOW.

Press (FAN SPEED) button to select SILENT or LOW fan

speed.

5SETHEDEVICEFORDEHUMIDIFYINGWHENTHEROOMTEMPERATUREISOVER#

7HENITISUNDER#THEDEHUMIDIFYINGFUNCTIONWILLNOTWORK

1

2

2ー4

Page 14

– 9 –

ENGLISH

COOLING OPERATION

Use the device for cooling when the outdoor temperature is -10~ 43°C.

If indoors humidity is very high (80%), some dew may form on the air outlet grille of the indoor unit.

Press the MODE selector button so that the display indicates

(COOL).

■ As the settings are stored in the memory of the remote controller, you

only have to press the

(START/STOP) button next time.

■ During AUTO fan, the fan speed automatically changes as below:

● When the difference between room temperature and setting tem-

perature is large, fan starts to run at HI speed.

● After room temperature reaches the preset temperature, fan speed

will be changed to lower speed to obtain optimum room temperature

condition for natural healthy cooling.

START

STOP

1

2

3

Set the desired FAN SPEED with the (FAN SPEED) button (the

display indicates the setting).

(AUTO) (HIGH) (MED)

(SILENT) (LOW)

Set the desired room temperature with the TEMPERATURE buttons

(the display indicates the setting).

The temperature setting and the actual room temperature may vary

depending on conditions.

Temperature range can be set between 16°C and 32°C

Press the

(START/STOP) button. Cooling operation starts with a

beep. Press the button again to stop operation. The cooling function

does not start if the temperature setting is higher than the current

room temperature (even though the (OPERATION) lamp lights).

The cooling function will start as soon as user set the temperature

below the current room temperature.

– 10 –

FAN OPERATION

User can use the device simply as an air circulator.

START

STOP

1

2

Press the MODE selector so that the display indicates

(FAN).

Set the desired FAN SPEED with the (FAN SPEED) button (the

display indicates the setting).

(HIGH) (MED) (LOW) (SILENT)

Press the (START/STOP) button. Fan operation starts with

a beep. Press the button again to stop operation.

EXTENDED AIRFLOW OPERATION

To start Extended Airflow operation

Press (EXTENDED AIRFLOW) button during operation.

“

” is displayed on the LCD.

The airflow direction will automatically set according to the type of operation and the fan speed will

change to allow air to blow further. (During cooling operation, fan speed will retur n to the original

position after 3 hours.)

s If the

(EXTENDED AIRFLOW) button is pressed while the AUTO SWING mode is set, the

AUTO SWING mode is cancelled and the EXTENDED AIRFLOW mode is set.

s If the

(AUTO SWING) button is pressed while the EXTENDED AIRFLOW mode is set, the

EXTENDED AIRFLOW mode is cancelled and the AUTO SWING mode is set.

s If the

(EXTENDED AIRFLOW) button is pressed when the horizontal air deflector stops at

your preferred angle, the deflector will change to EXTENED AIRFLOW.

s Press

(EXTENDED AIRFLOW) button to lower the room temperature quickly when the

temperature is high during the cooling operation.

NOTE

Dur ing cooling and dehumidi-

fying operation, do not keep

the deflectors swinging or in

the lower position (in the case

of vertical auto swing) for a

long time. It may cause dew

condensation on the deflectors.

AUTO SWING OPERATION

VERTICAL SWING

To start Vertical Auto Swing

To cancel Vertical Auto Swing

Press (AUTO SWING (VERTICAL)) button. The deflector(s) will start to swing

up and down.

is displayed on the LCD.

Press (AUTO SWING (VERTICAL)) button again. The deflector(s) will stop in

the current position.

disappeared from the LCD.

To cancel Extended Airflow operation

Press (EXTENDED AIRFLOW) button again.

EXTENDED AIRFLOW operation stops.

“

” disappears from LCD.

2ー5

Page 15

– 11 –

ENGLISH

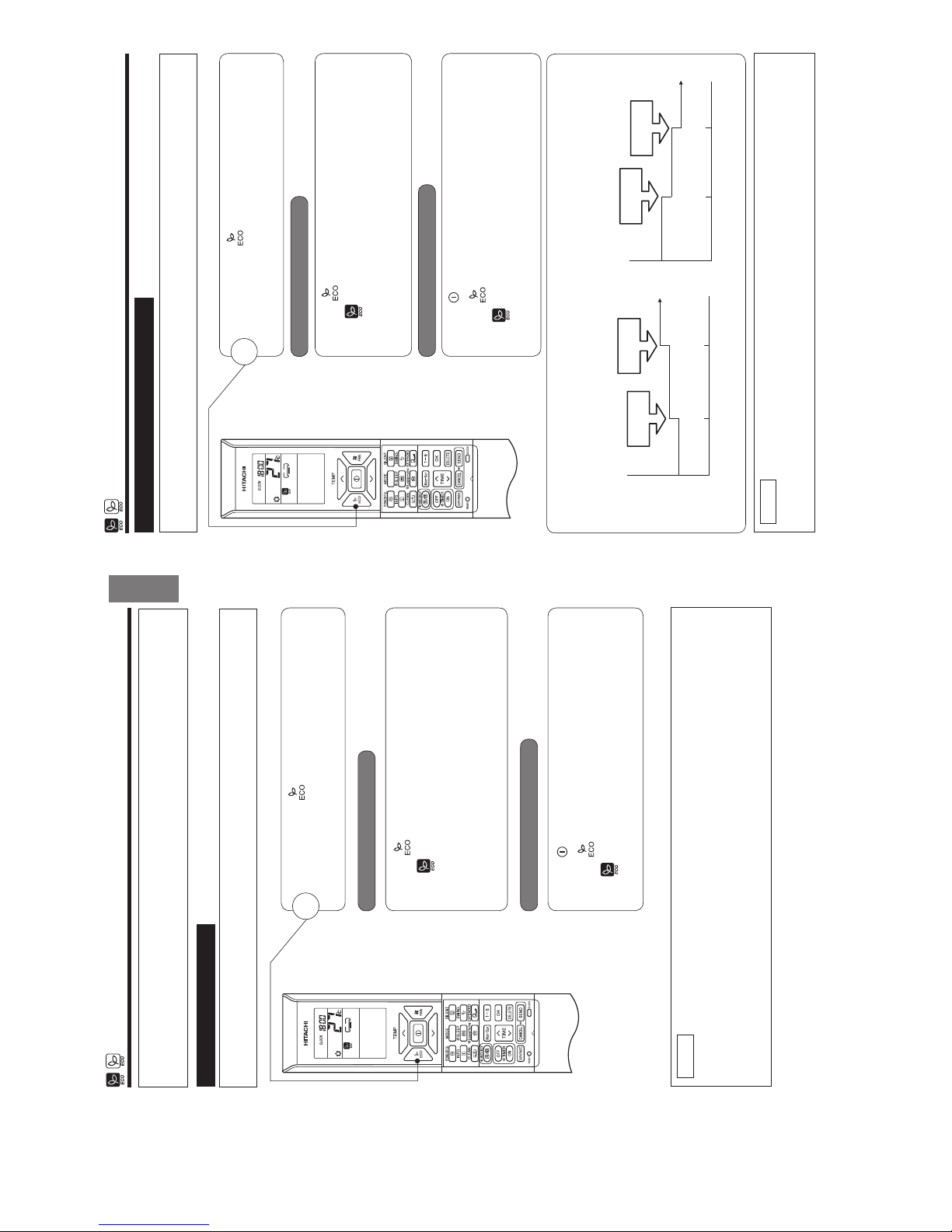

POWERFUL OPERATION

●By pressing (POWERFUL) button during AUTO, HEATING, DEHUMIDIFYING, COOLING or FAN

operation, the air conditioner performs at the maximum power.

● During POWERFUL operation, cooler or warmer air will be blown out from indoor unit for COOLING or

HEATING operation respectively.

■ To start POWERFUL operation

■ To cancel POWERFUL operation

● Press (POWERFUL) button during operation.

“ ” is displayed on the LCD.

POWERFUL operation ends in 20 minutes. Then the system

automatically operates with the previous settings used before

POWERFUL operation.

● Press the (START/STOP) button. Or

● Press (POWERFUL) button again.

POWERFUL operation stops.

“ ” disappears from the LCD.

1

NOTE

● When SLEEP mode, ECO mode, SILENT mode or LEAVE HOME mode is selected, POWERFUL

operation is cancelled.

● During POWERFUL operation, capacity of the air conditioner will not increase

– if the air conditioner is already running at maximum capacity.

– just before defrost operation (when the air conditioner is running in HEATING operation).

● After auto restart, POWERFUL operation is cancelled and previous operation shall start.

● For multi model connections, POWERFUL operation may not function depending on operation conditions.

– 12 –

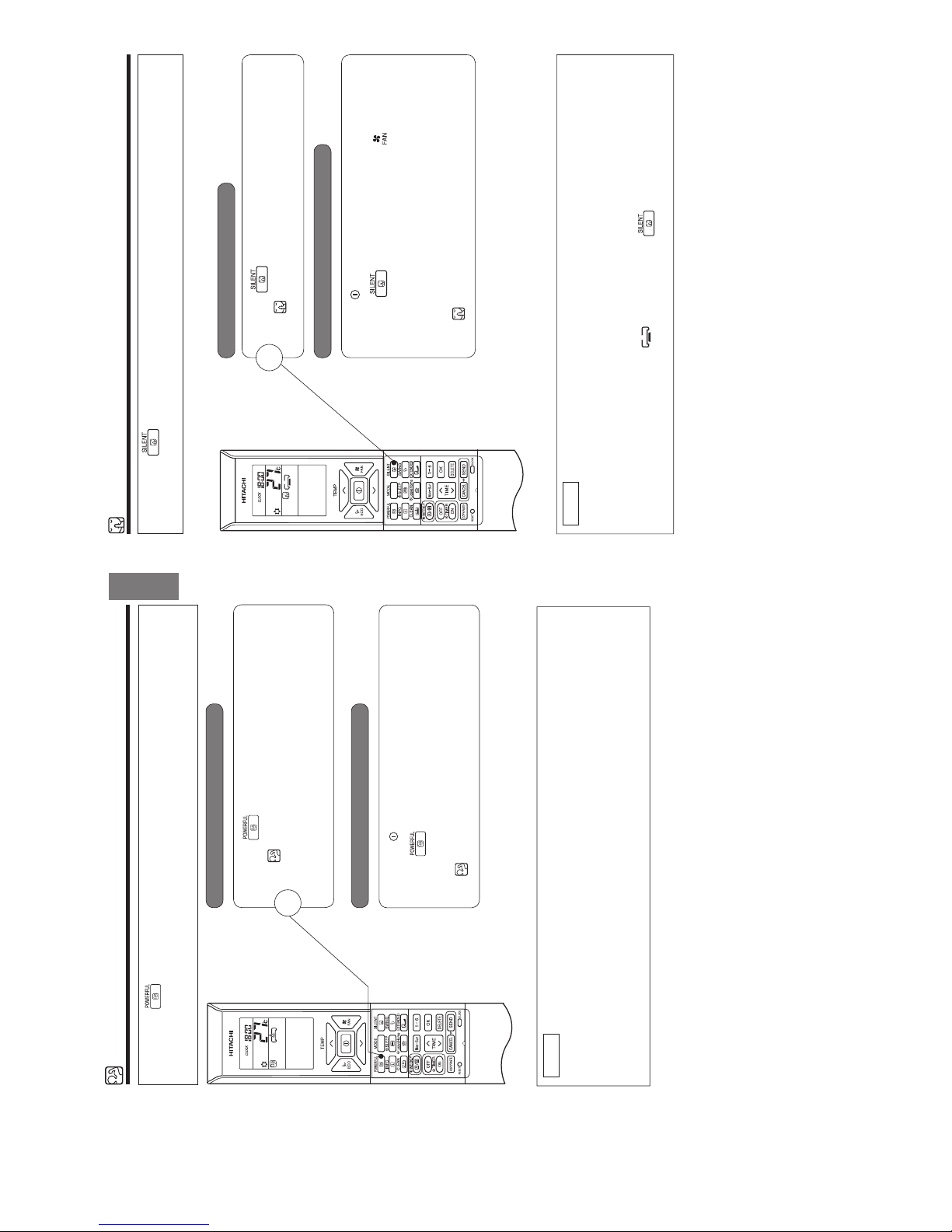

SILENT OPERATION

● By pressing (SILENT) button during AUTO, HEATING, DEHUMIDIFYING, COOLING or FAN

operation, the fan speed will change to ultra slow.

■ To start SILENT operation

■ To cancel SILENT operation

● Press (SILENT) button during operation.

“

” is displayed on the LCD. Fan speed will be ultra slow.

● Press (START/STOP) button. Or

● Press (SILENT) button again or (FAN SPEED)

button.

Fan speed will return to previous fan speed before SILENT

operation starts.

SILENT operation stops.

“ ” disappears from the LCD.

1

NOTE

● When POWERFUL operation is selected, SILENT operation is cancelled. Fan speed will return to

previous fan speed before SILENT operation.

● After auto restart, SILENT operation is cancelled. Fan speed will return to previous fan speed before

SILENT operation.

● During any operation with fan speed (SILENT), if press (SILENT) button, fan speed will

not change.

2ー6

Page 16

– 13 –

ENGLISH

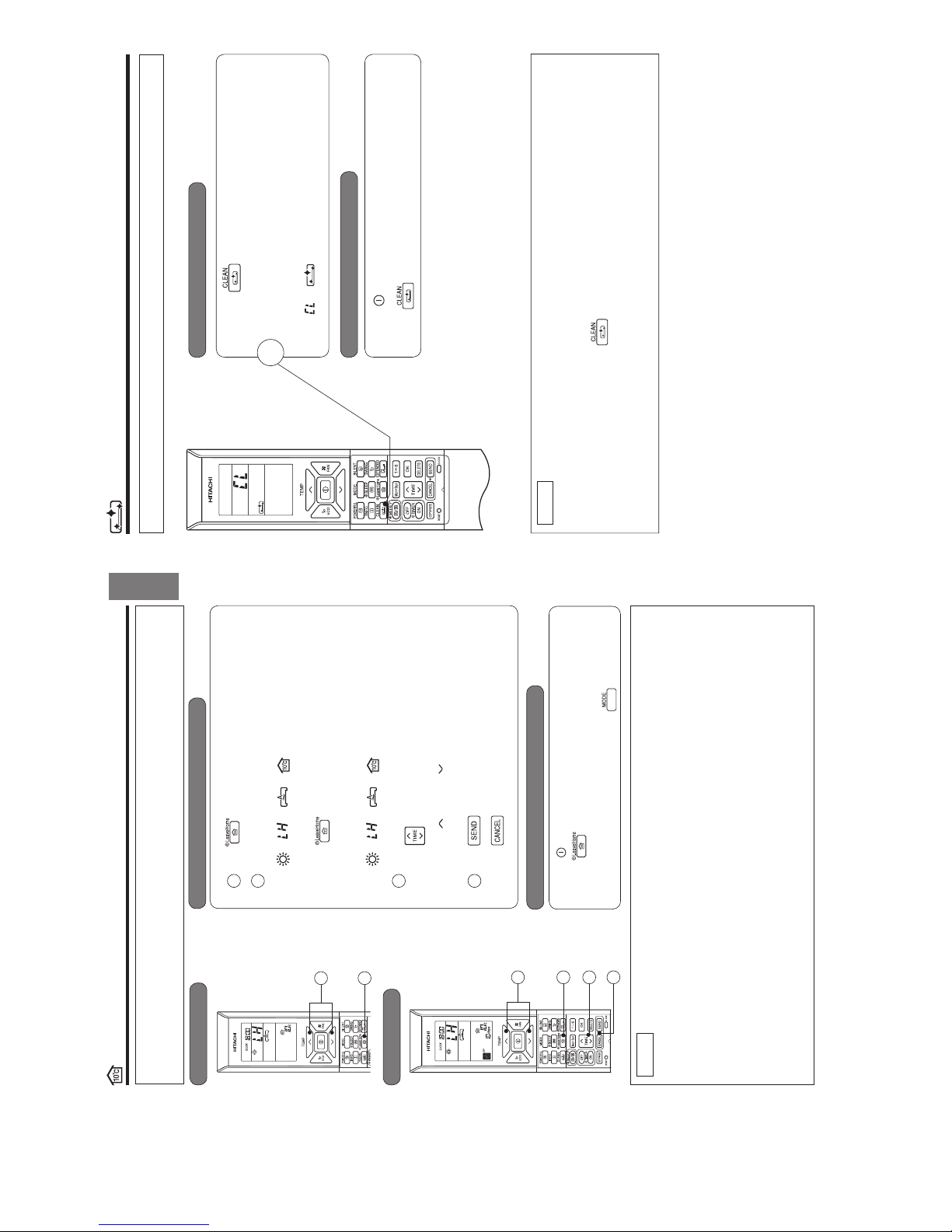

ECO OPERATION

There are two kinds of ECO OPERATION with sensor or without sensor, depending on models.

Please refer to [Names and Functions of each part] in the unit instruction manual to verify if your unit is

equipped with a sensor and read the following instruction on ECO Operation accordingly.

● By pressing the (ECO) button during AUTO, HEATING,

DEHUMIDIFYING or COOLING operation, the air conditioner

performs the "ECO" operation.

1

■ To start ECO operation

■To cancel ECO operation

● Press (ECO) button during operation.

“ ” is displayed on the LCD.

A beep sound is emitted from indoor unit.

Energy saving operation will start by changing the set temperature

higher or lower automatically and reducing operation power

consumption. This function may vary based on the connected

outdoor unit.

● Press (START/STOP) button. Or

● Press (ECO) button again.

“ ” disappears from the LCD.

A beep sound is emitted from indoor unit.

NOTE

● ECO function will not be effective when power consumption is low.

● By pressing (POWERFUL) button, ECO operation is cancelled.

● After auto restart, ECO operation is cancelled and previous operation mode shall start.

● For multi model connections, energy saving operation shall start only by changing set temperature higher

or lower automatically. However, effectiveness of ECO depends on operation conditions.

■ ECO OPERATION

ECO operation is an energy saving function by changing set temperature automatically and by limiting the

maximum power consumption value.

– 14 –

ECO OPERATION

● By pressing the (ECO) button during AUTO, HEATING,

DEHUMIDIFYING or COOLING operation, the air conditioner

performs the "ECO" operation.

1

■ To start ECO operation

■To cancel ECO operation

● Press (ECO) button during operation.

“ ” is displayed on the LCD.

A beep sound is emitted from indoor unit and the (ECO) lamp

on the indoor unit lights up.

The sensor starts to detect the presence of people in the room.

● Press (START/STOP) button. Or

● Press (ECO) button again.

“ ” disappears from the LCD.

A beep sound is emitted from indoor unit and the (ECO) lamp on

the indoor unit turns off.

NOTE

● By pressing (POWERFUL) button, ECO operation is cancelled.

● After auto restart, ECO operation is cancelled and previous operation mode shall start.

■ ECO OPERATION with sensor

The sensor detects the presence of people in the room. When nobody is detected, the unit automatically starts

enegy saving operation by shifting the set temperature in two steps.

When the presence of people is not detected for 20 minutes, the set temperature is automtatically shifted for

energy saving. If nobody is in the room for 60 minutes, the set temperature is shifted further.

Cooling operation [diagram representation

for illustrative purpose only]

Heating operation [diagram representation

for illustrative purpose only]

Setting

temperature

Shift

temperature

Shift

temperature

20 minutes 60 minutes

Setting

temperature

Shift

temperature

Shift

temperature

20 minutes 60 minutes

The unit returns to normal operation when the sensor detects human movement.

2ー7

Page 17

– 15 –

ENGLISH

LEAVE HOME (LH) OPERATION

Prevent the room temperature from falling too much when no one is at home. The initial setting temperature is 10°C and the

temperature range can be set between 10°C and 16°C.

This operation is able to operate by "Continuous operation" or "Day timer operation". Please use "Day timer operation" to

set the number of days up to 99 days.

■ To start LEAVE HOME operation

Option 1. Continuous operation.

Press (LEAVE HOME) button during stop or operation.

Room temperature is set at 10°C and heating operation starts.

Set the desired room temperature with the TEMPERATURE buttons.

Temperature range can be set between 10°C and 16°C.

“

”, “ ”, “ ”, “ ”, “SET TEMPERATURE” is displayed

on the LCD.

Option 2. Day timer operation.

Press (LEAVE HOME) button during stop or operation.

Room temperature is set at 10°C and heating operation starts.

Set the desired room temperature with the TEMPERATURE buttons.

Temperature range can be set between 10°C and 16°C.

“ ”, “ ”, “ ”, “ ”, “SET TEMPERATURE” is displayed

on the LCD.

Set number of operation days (1 to 99 days), if needed.

Press

(TIME) button to select number of days.

Number of days blink.

* Press “

(UP)” or “ (DOWN)” to set number of days from

1 day to 99 days.

* Number of day is counted when clock indicates 0:00.

Press (SEND) button to conÚ rm number of operation days.

Display for number of operation days will stop blinking.

Press (CANCEL) button to reset number of operation days

or to have continuous operation.

To cancel LEAVE HOME operation

● Press (START/STOP) button. Or

● Press (LEAVE HOME) button again.

Return to previous operation mode. Or

● Change to other operation mode by pressing (MODE) button.

NOTE

● After reaching the set number of operation days for Leave Home or by pressing the (Leave Home) button again,

the unit will operate in previous mode.

● During Leave Home operation, fan speed and horizontal air deÛ ector position cannot be changed.

● By pressing (Leave Home) button, implementation of Weekly Timer or Once Timer is cancelled.

● In case of power supply shut down, after autorestart, all setting for number of days operation will be reset and unit

shall be in continuous operation.

● POWERFUL, SILENT and ECO operations are not applicable during Leave Home operation.

● For multi connection

● FAN/COOLING/DEHUMIDIFYING and Leave Home cannot operate at the same time.

The Ú rst-run unit has a priority and other units in different mode will be in standby mode.

● Heating operation can be used with Leave Home.

● When two or more rooms are set to operate Leave Home, the temperature set by Leave Home may not be

reached. It also depends on outdoor temperature.

Continuous operation

Day timer operation

1

2

1

2

123

4

3

4

– 16 –

CLEAN (ONE TOUCH CLEAN) OPERATION

Drying indoor heat exchanger after cooling operation to prevent mildew.

■ To start CLEAN operation

■ To cancel CLEAN operation

● Press (CLEAN) button when unit is OFF.

Total time taken for One Touch Clean operation is 60 minutes.

During this operation, HEATING or FAN operation shall

operate.

During one touch clean, operation lamp is blinking.

“ ”, “ ” is displayed on the LCD.

● Press (START/STOP) button. Or

● Press (CLEAN) button again.

1

NOTE

● When CLEAN operation Ú nish, unit will switch OFF automatically.

● If Weekly Timer or Once Timer is set, there is a need to cancel those timer before operating CLEAN

function.

● For multi connections, when pressing (CLEAN) button, operation is limited to FAN operation.

● For multi connections, when one room operates CLEAN operation Ú rst, other rooms can operate

COOLING, DEHUMIDIFYING or FAN operation. However, when other rooms need to operate HEATING

operation, air conditioner will be in STANDBY mode. After CLEAN operation Ú nish, HEATING operation

will start.

2ー8

Page 18

– 17 –

ENGLISH

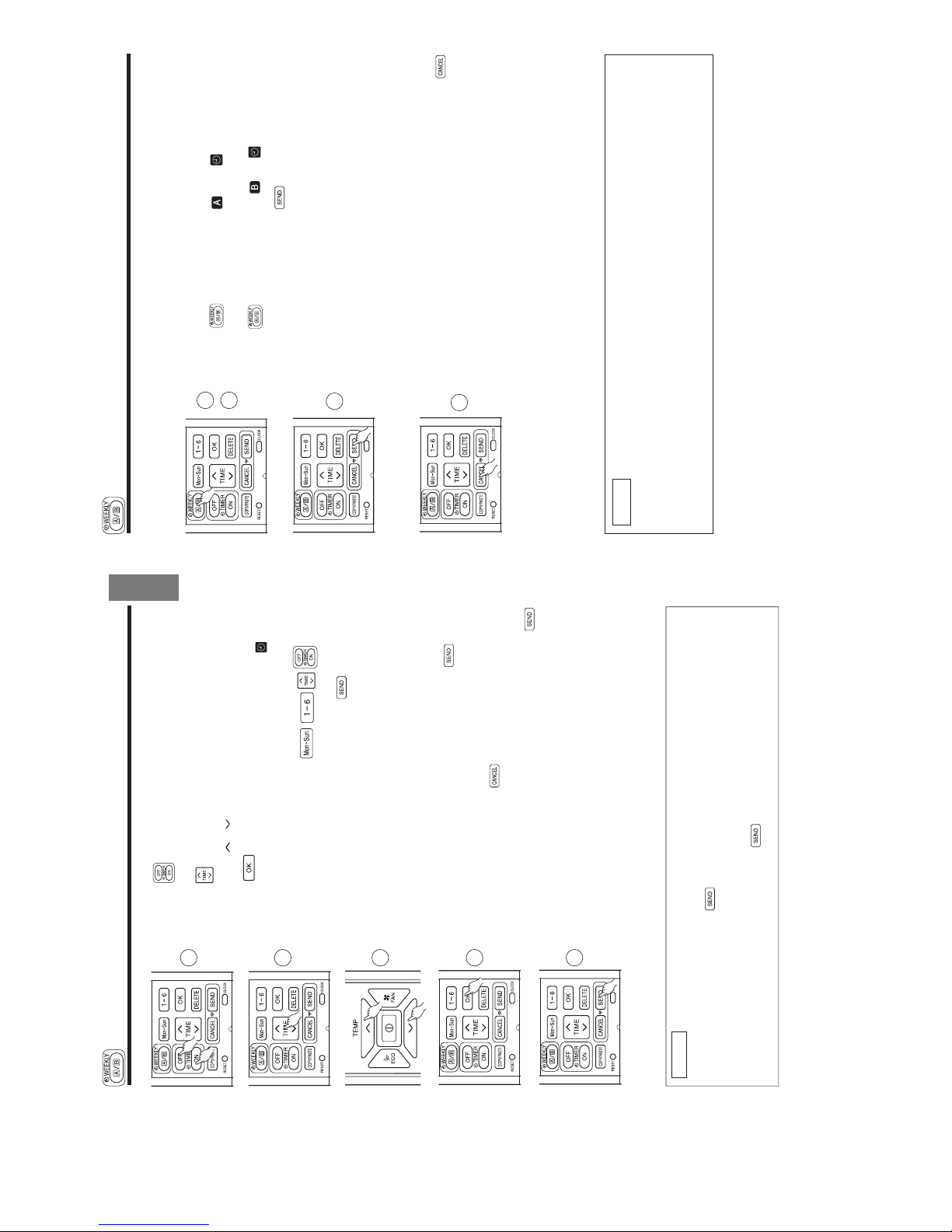

ONCE TIMER (ON/OFF TIMER) OPERATION

The device can be set to turn off at a preset time.

1. Press

(OFF-TIMER) button. and blink on the display.

2. Set the "turn-off time" with

(TIME) button.

3. After setting, direct the remote controller towards the indoor and press

(SEND) button.

and "set time" lights up instead of blinking.

A beep sound emitted from indoor unit and the (TIMER) lamp on the

indoor unit lights up.

ON TIMER

The device will turn on at a designated time.

1. Press

(ON-TIMER) button. and blink on the display.

2. Set the "turn-on time" with

(TIME) button.

3. After setting, direct the remote controller towards the indoor and press

(SEND) button.

and "set time" light up instead of blinking.

A beep sound emitted from indoor unit and the (TIMER) lamp on the indoor

unit lights up.

ON/OFF TIMER

● The device will turn on (off) and off (on) at the designated time.

● The switching occurs Ú rst at the preset time that comes earlier.

● The arrow mark appears on the display to indicate the sequence of switching

operations.

1. Press

(OFF-TIMER) button so that and blink on the

display.

2. Set the "turn-off" time with

(TIME) button. After setting, direct the remote

controller towards the indoor and press

(SEND) button.

3. Press

(ON-TIMER) button so that and set "turn-off" time light up.

The

and blink.

4. Set the "turn-on" time with

(TIME) button.

5. After setting, direct the remote controller towards the indoor and press

(SEND) button

and set "turn-on" time light up instead of blinking.

A beep sound emitted from indoor unit and the (TIMER) lamp on the indoor

unit lights up.

■The timer may be used in three ways: OFF-timer, ON-timer and ON/OFF (OFF/

/.TIMER3ETTHECURRENTTIMEÚ rst because it serves as a reference.

■ To cancel Reservation

● Point the signal window of the remote controller towards the indoor unit and press (CANCEL) button.

and "ON or OFF set time" goes out with a beep and the (TIMER) lamp on the indoor unit turns off.

NOTE

● User can set only one of the OFF-timer, ON-timer or ON/OFF-timer.

● If WEEKLY TIMER already set, by setting the ONCE TIMER, ONCE TIMER operation is prioritized. When ONCE

TIMER operation is complete, WEEKLY TIMER operation will be activated.

OFF TIMER

1

– 18 –

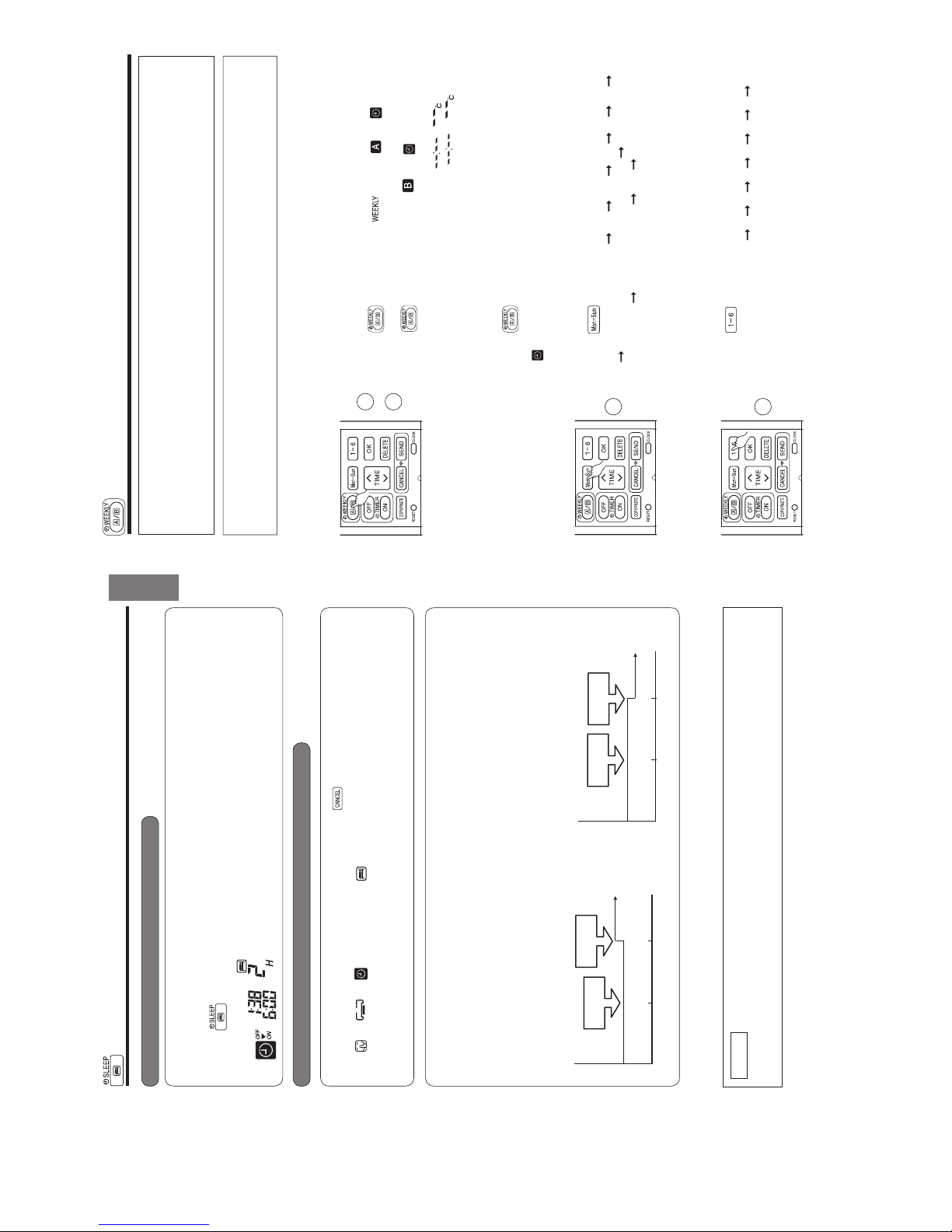

ECO SLEEP TIMER OPERATION

The timer can be set up to a duration of 7 hours.

By pressing

(SLEEP) button during AUTO, HEATING, DEHUMIDIFYING, COOLING or FAN operation,

the unit shifts the room temperature and reduces the fan speed. It results in energy saving.

Set the current time Ú rst before operating the ECO SLEEP TIMER operation.

■ To start ECO SLEEP TIMER operation

■ To cancel ECO SLEEP TIMER operation

Press (SLEEP) button during operation.

● “ ”, “ ”, “ ”, “OFF”, off time, “ ” and number

of hour are displayed on the remote controller display.

● During ECO SLEEP TIMER operation, fan speed will be ultra

slow.

● A beep sound emitted from indoor unit and the (TIMER) lamp

on the indoor unit lights up.

Pressing (SLEEP) button repeatedly, the number of hours

will change as below:

● During ECO SLEEP TIMER operation, air conditioner will

continue to operate for the designated number of hours and

then turn off.

● When the ECO SLEEP TIMER has been set, the display on

the remote controller indicates the turn off time.

Press

(START/STOP) button.

● Room air conditioner will switch off.

Press

(SLEEP) button again until “ ”, “ ”, “ ”,

off time, “ ” and number of hour disappear from the remote

controller display.

Press

(CANCEL) button.

● A beep sound emitted from indoor unit and the (TIMER) lamp

on the indoor unit turns off.

● SLEEP TIMER operation is cancelled.

1

Example: If ECO SLEEP TIMER is

set for 1 hour at 18:00, the switch

off time will be at 19:00.

1 H 2 H 3 H 7 H

SLEEP TIMER off

2ー9

Page 19

– 19 –

ENGLISH

ECO SLEEP TIMER OPERATION

■ To set ECO SLEEP TIMER and ON TIMER

■ To cancel ECO SLEEP TIMER and ON TIMER operation

The air conditioner will be turned off by ECO SLEEP TIMER and turned on by ON TIMER.

1. Set the ON TIMER.

2. Press

(SLEEP) button and set ECO SLEEP TIMER.

Direct the remote controller towards the indoor unit and press

(CANCEL) button.

● “ ”, “ ”, “ ”, “OFF”, off time, “ ”, number of hour, "ON" and ON TIMER set time disappear

from the remote controller display.

● A beep sound emitted from indoor unit and the (TIMER) lamp on the indoor unit turns off.

● ECO SLEEP TIMER and ON TIMER reservations are cancelled.

30 minutes after setting ECO SLEEP TIMER, outdoor fan speed will be reduced to lower the noise level and

to have comfort operation.

1 hour after setting ECO SLEEP TIMER, set temperature will be slightly shifted. Amount of temperature shifted

depends on type of air conditioner.

These automatic operation changes contribute to energy saving without losing comfort.

The level of energy consumption depends on outside temperature, room temperature, set temperature or air

conditioner type.

Cooling operation [diagram representation

for illustrative purpose only]

Example:

In this case, air conditioner will turn off in 2 hours (at 1:38) and it will be

turned on at 6:00 the next morning.

NOTE

● If ECO SLEEP TIMER is set when OFF TIMER or ON/OFF TIMER has been set earlier, the ECO

SLEEP TIMER becomes effective instead of the OFF TIMER or ON/OFF TIMER.

Heating operation [diagram representation for

illustrative purpose only]

Temperature

30 minutes

Outdoor fan

speed reduce

Shift

temperature

1 hour

Temperature

30 minutes

Outdoor fan

speed reduce

Shift

temperature

1 hour

– 20 –

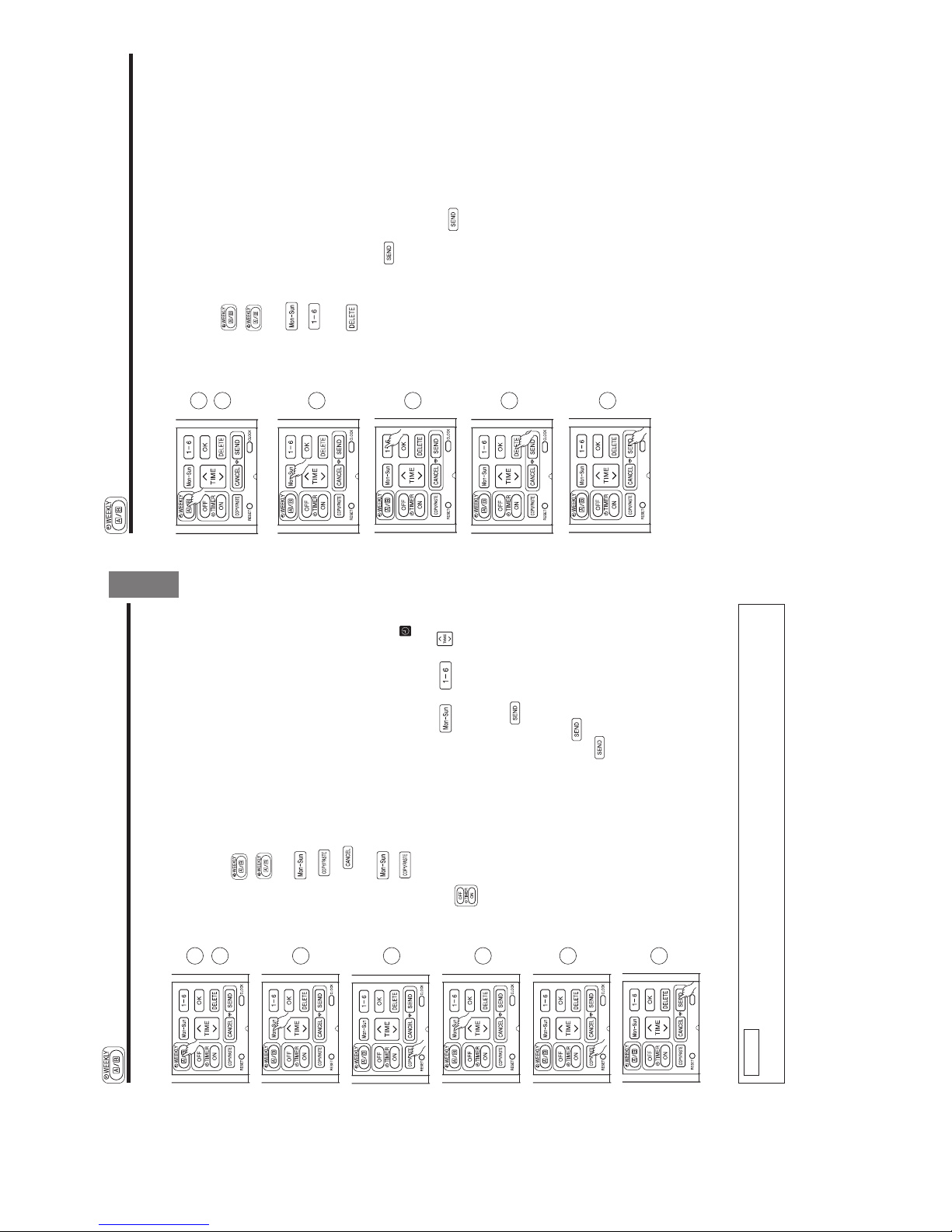

● It is possible to select Mode A or Mode B. For each mode, up to 6 programs can be set per day. In total, a

maximum of 42 programs can be set for a week for each mode.

● If calendar and clock are not set, the reservation setting for WEEKLY TIMER cannot be set.

● If calendar and clock are not set correctly, WEEKLY TIMER will not operate correctly.

● Reservation for calendar and clock shall be set Ú rst before operating WEEKLY TIMER.

WEEKLY TIMER OPERATION

■ How to set a WEEKLY TIMER.

1. Select Mode A or Mode B

Press (WEEKLY) button. lights up. and blink on the

display. (Mode A is selected).

Press (WEEKLY) button again, and blink on the display.

(Mode B is selected).

● If no reservation has been made, ON/OFF, , appear.

● If reservation has been made, ON/OFF, , will not

appear.

2. Set a program

Press (WEEKLY) button for about 3 seconds. The selection mode

can be changed.

, day: Mon, program no. : 1, ON/OFF, setting time and setting

temperature blink on the display.

3. Select the desired day of the week

Press (DAY) button.

The day changes from Mon

Tue Wed Thu Fri Sat Sun

Mon, Tue, Wed, Thu, Fri, Sat, Sun [Full days] Mon, Tue, Wed, Thu,

Fri [weekday] Sat, Sun [weekend] Mon Tue ......

Select [Full days] for daily reservation.

Select [weekday] for Monday to Friday reservation.

Select [weekend] for Saturday and Sunday reservation.

● After reservation has been set, it is easy to check and edit at the same

time.

4. Press button to select a program number.

The number changes from 1

2 3 4 5 6 1 2 .....

● If program number has been set, follow above in order to make

changes.

1

2

Step 1 : Set the reservation schedule to the remote controller. Send the registered reservation to indoor

unit and then operate.

Step 2 : Select Mode A or Mode B and activate or deactivate WEEKLY TIMER .

Step 3 : Copy and cancel the reservation schedule.

Step 1 : Set reservation schedule to the remote controller. Send the registered

reservation to indoor unit and then operate.

3

4

2ー10

Page 20

– 21 –

ENGLISH

5. Press (ON-OFF TIMER) button to select ON TIMER or OFF TIMER

reservation.

6. Press (TIME) button to set time reservation.

7. Press (TEMP or ) button to set temperature reservation.

8. Press (OK) button. The reservations are set. Day, program

number, ON reservation, setting temperature will light up. will be

continuously blinks. If reservation is not complete, settings will not be

stored in memory.

To continue with the reservation, press buttons.

Follow step 3 to 8 for reservation.

9. After all the reservations have been set, press (SEND) button

while directing the remote controller towards the indoor unit for about 3

seconds. Timer lamp on the indoor unit will blink rapidly.

After beep sound emitted from indoor unit, TIMER lamp will light up.

Please ensure that the TIMER lamp lights up.

This indicates that the reservation has been stored in the indoor unit and

Timer function has been completed.

The reservation contents will appear on the remote controller display.

● If TIMER lamp on the indoor unit does not light up, press (SEND)

button while directing the remote controller towards the indoor unit for

about 3 seconds.

● CAUTION ! Do not press (CANCEL) button during reservation

setting because this will result in all reservation contents to be lost.

● The reservation contents will not stored in the indoor unit until

(SEND) button has been pressed.

5

6

7

8

9

NOTE

● Up to 6 programs can be set per day. Setting ON TIMER or OFF TIMER for each program number

can be at random. When pressing (SEND) button, the set ON TIMER or OFF TIMER for each

program number will automatically arranged so that program number 1 shall have the earliest time and

program number 6 shall have the latest time.

If the setting time is the same, Priority will be given to the latest reservation contents.

● CAUTION ! If the remote controller is left idle and (SEND) button is not pressed within 3 minutes

after reservations have been made , all current reservations will be lost.

WEEKLY TIMER OPERATION

– 22 –

■ How to select Mode A or Mode B of WEEKLY TIMER setting.

1. Press

(WEEKLY) button. and blink on the display.

(Normally Mode A will blink Ú rst).

2. Press (WEEKLY) button again. and blink on the display.

3. Select Mode A or Mode B. Press (SEND) button while directing

the remote controller towards the indoor unit for about 3 seconds. Timer

lamp on the indoor unit will blink rapidly.

After beep sound emitted from indoor unit, TIMER lamp will light up.

Please ensure that the TIMER lamp lights up.

This indicates that Mode A or Mode B selection and active WEEKLY

TIMER have been conÚ rmed.

■ Setting non-active WEEKLY TIMER .

1. Direct the remote controller towards the indoor unit and press

(CANCEL) button.

Beep sound will be emitted from indoor unit and TIMER lamp will be

OFF. Reservation indication on remote display will also disappear.

This indicates that non-active WEEKLY TIMER has been conÚ rmed.

● To activate back the setting of WEEKLY TIMER , repeat the steps for

"How to select Mode A or Mode B of WEEKLY TIMER setting".

NOTE

● When setting ONCE TIMER, operation of WEEKLY TIMER is interrupted. After ONCE TIMER operation

is complete, WEEKLY TIMER operation will be activated.

● When ONCE TIMER is cancelled, operation of WEEKLY TIMER is also cancelled. Need to set WEEKLY

TIMER operation for activation.

● After auto restart, WEEKLY TIMER operation is cancelled. Need to set WEEKLY TIMER operation for

activation.

1

2

1

WEEKLY TIMER OPERATION

Step 2: Select Mode A or Mode B and activate or deactivate WEEKLY TIMER.

3

2ー11

Page 21

– 23 –

ENGLISH

■ How to copy and paste.

Editing the reservation schedule is easy by copying data from one day to

another day.

1. Press

(WEEKLY) button to select Mode A or Mode B.

2. Press (WEEKLY) button for about 3 seconds to start editing the

reservation schedule.

3. Press (DAY) button to select a day of the week to copy.

4. Press (COPY/PASTE) button. Then "PASTE" blinks on the

display.

* Press (CANCEL) button to cancel the COPY mode. Normal

setting mode is activated.

5. Press (DAY) button to select a day of the week to paste.

6. Press (COPY/PASTE) button one more time to paste. only

blinks on the display.

7. To continue copying to other days, press or or or

.

Then start from step 3.

8. After copy and paste completed, press (SEND) button while

directing the remote controller towards the indoor unit for about 3

seconds. Timer lamp on the indoor unit will blink rapidly.

After beep sound emitted from indoor unit, TIMER lamp will light up.

Please ensure that the TIMER lamp lights up.

If TIMER lamp does not light up, Press

(SEND) button again.

● Reservation data will not change if (SEND) button is not pressed.

Step 3: Copy and cancel the reservation schedule.

NOTE

● If there is no reservation data, copying data from one day to another day cannot be done.

1

2

3

4

5

6

8

WEEKLY TIMER OPERATION

– 24 –

Step 3: Copy and cancel the reservation schedule.

■ How to delete WEEKLY TIMER data.

[Delete one program number reservation]

1. Press

(WEEKLY) button to select Mode A or Mode B.

2. Press (WEEKLY) button for 3 seconds to start editing the reserva-

tion schedule.

3. Press (DAY) button to select a day of the week to edit.

4. Press to select program number. Selected program number will

blink.

5. Press (DELETE) button. Reservation of selected program number

is deleted.

6. After deleting, press (SEND) button while directing the remote

controller towards the indoor unit for about 3 seconds. Timer lamp on the

indoor unit will blink rapidly.

After beep sound emitted from indoor unit, TIMER lamp will light up.

Please ensure that the TIMER lamp lights up.

● Reservation will not change if (SEND) button is not pressed.

1

2

3

4

5

6

WEEKLY TIMER OPERATION

2ー12

Page 22

– 25 –

ENGLISH

Step 3: Copy and cancel the reservation schedule.

[Delete one day reservation]

1. Press

(WEEKLY) button to select Mode A or Mode B.

2. Press (WEEKLY) button for 3 seconds to start editing the

reservation schedule.

3. Press (DAY) button to select a day of the week to edit.

4. Press (DELETE) button for about 10 seconds. Reservations for all

program numbers will be deleted.

● If press for a short time, reservation for one program number will be

deleted.

5. After deleting, press (SEND) button while directing the remote

controller towards the indoor unit for about 3 seconds. Timer lamp on the

indoor unit will blink rapidly.

After beep sound emitted from indoor unit, TIMER lamp will light up.

Please ensure that the TIMER lamp lights up.

● Reservation will not change if (SEND) button is not pressed.

1

1

2

NOTE

● If all reservations in the remote controller were deleted and pressed (SEND) button, no signal will

be transmitted to indoor unit. TIMER lamp will remain off and no changes will be done to the reservations

stored in the indoor unit.

3

2

4

5

WEEKLY TIMER OPERATION

[Delete Mode A or Mode B]

1. Press (WEEKLY) button to select Mode A or Mode B.

2. Direct the remote controller towards the indoor unit and press

(DELETE) button for about 10 seconds while Mode A or Mode B display

blinks.

After beep sound emitted from indoor unit, reservations for Mode A or

Mode B will disappear.

– 26 –

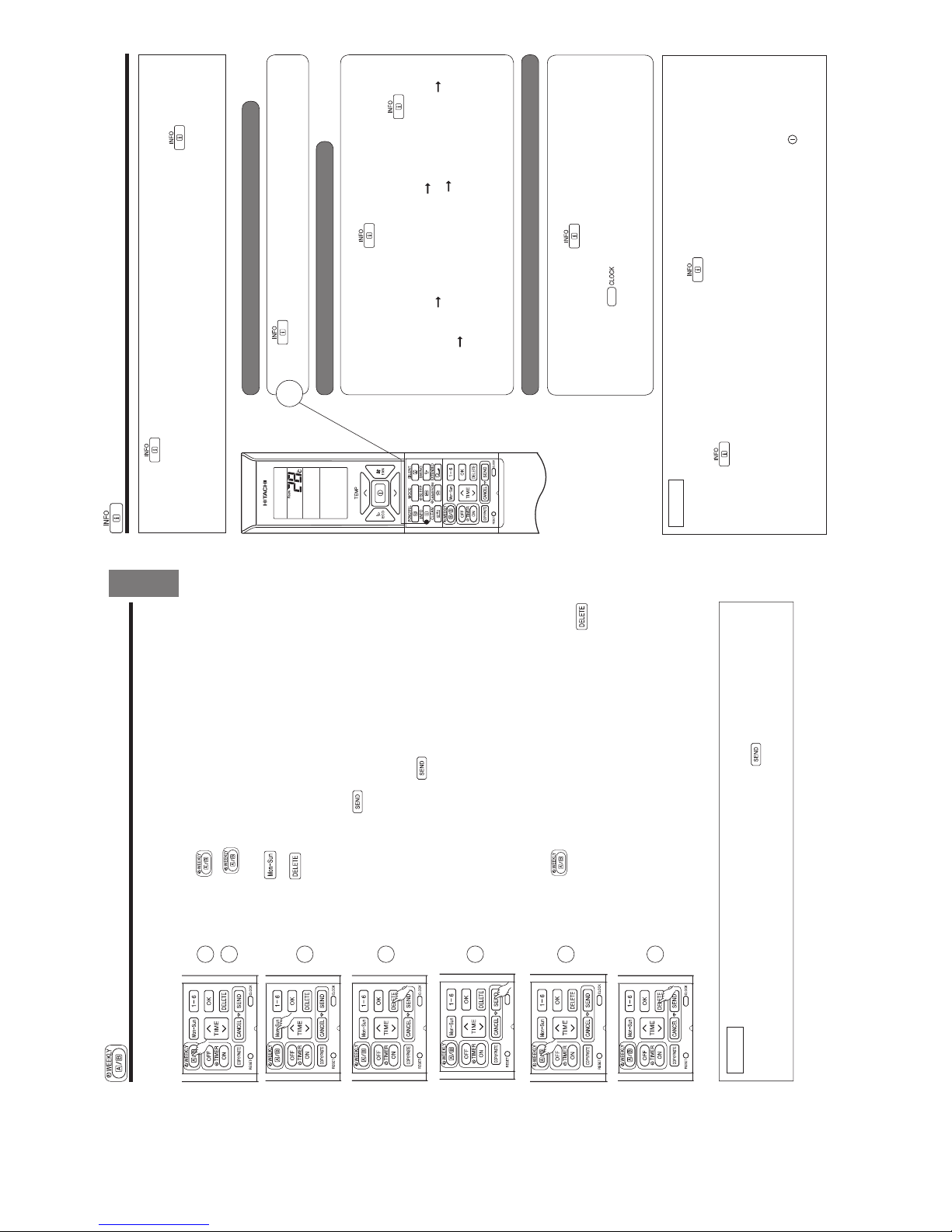

INFO FUNCTION

● By pressing (INFO) button, temperature around remote controller and monthly power consumption will

be displayed on the remote controller.

● After changing the batteries, direct the remote controller towards the indoor unit and press (INFO) button.

Current calendar and clock will be transmitted from indoor unit.

● In order to receive information from indoor unit, the distance between remote controller and receiver of indoor

units is within 2 meters.

■ To check temperature around remote controller

■ Current calendar and clock can be retrieved from indoor unit

■ To check monthly power consumption

Press (INFO) button.

Temperature will be displayed for 10 seconds.

Direct the remote controller towards the receiver of indoor unit (within 2 meters

in front of indoor unit) and press

(INFO) button. Wait for 2 seconds for

signal transmission.

Once received the current calendar and clock, check whether they are correct

or not by pressing

(CLOCK) button.

● If there is no power supply to indoor unit or calendar and clock have not been

set, INFO function cannot be used for sending or receiving information.

Direct the remote controller towards the receiver of indoor unit (within 2 meters

in front of indoor unit) and press

(INFO) button. Wait for 2 seconds for

signal transmission.

While temperature around remote controller is displayed, press

(INFO)

button repeatedly. The display will show as below:

this month power consumption amount for heating

last month power consumption

amount for heating this month power consumption amount for cooling last

month power consumption amount for cooling temperature around remote

controller this month power consumption amount for heating ...... cyclically.

● If indication is not given, bring remote controller closer to the receiver of

the indoor unit.

● Indicated value shall be regarded as a guide only.

NOTE

● In case failure occurs to the air conditioner, by pressing (INFO) button, an error code will be displayed.

Direct the remote controller towards the receiver of indoor unit (within 2 meters in front of indoor unit)

and press

(INFO) button. Wait for 2 seconds for signal transmission.

An error code will be displayed.

Call service center and inform the error code.

● Information of "Monthly power consumption" is not available for 6 rooms multi system.

● Info Function to check monthly power consumption.

During installation, in case of power failure or breaker ON / OFF, ensure to set the clock and calendar for each

indoor unit (unit in standby mode or auto restart), for single or multi connection, by pressing

(START / STOP)

button.

Failure to do the above,monthly power consumption amount will not be displayed on the remote controller.

1

2ー13

Page 23

– 27 –

ENGLISH

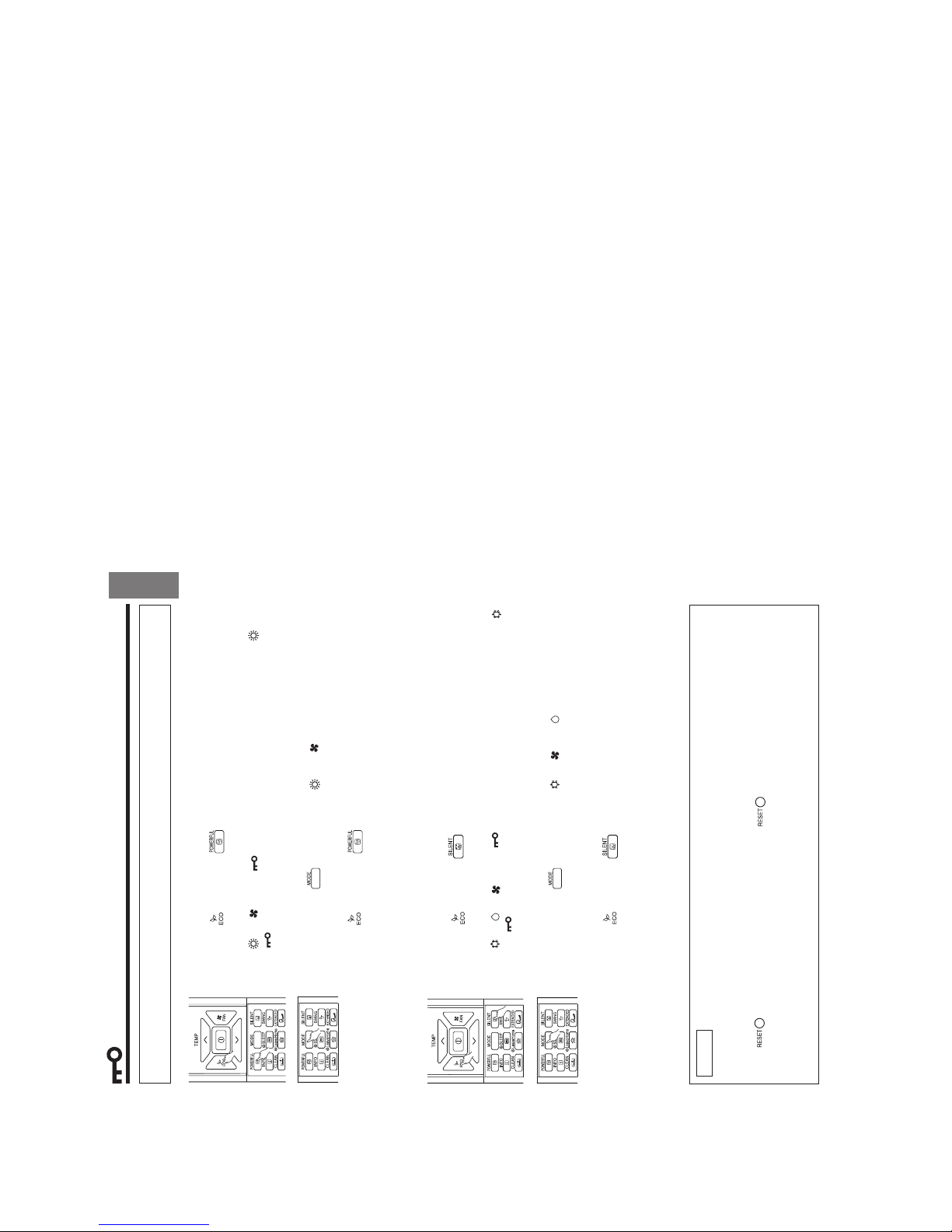

OPERATION MODE LOCK

The remote controller can be set to Ú x the HEATING mode (including FAN), COOLING mode (including FAN)

and DEHUMIDIFYING mode (including FAN) operations.

■ Method to lock HEATING mode (including FAN) operation.

Press (ECO) and (POWERFUL) buttons simultaneously for about 5

seconds when the remote controller is OFF.

“ ”, “ ” and “ ” will be displayed for about 10 seconds. Later, “ ” and

“ ” will remain.

This indicates that HEATING mode operation is locked.

When pressing (MODE) button, “ ” or “ ” will be displayed.

■ Method to unlock HEATING mode (including FAN) operation.

Press

(ECO) and (POWERFUL) buttons simultaneously for about 5

seconds when the remote controller is OFF.

All operation mode symbols will appear on the display for about 10 seconds. After

that, operation mode symbol before cancellation will be displayed.

This indicates that HEATING mode operation is unlocked.

■ Method to lock COOLING and DEHUMIDIFYING modes (including FAN)

operations.

Press

(ECO) and (SILENT) buttons simultaneously for about 5 seconds

when the remote controller is OFF.

“ ”, “ ”, “ ” and “ ” will be displayed for about 10 seconds. Later, “ ”

and “ ” will remain.

This indicates that COOLING and DEHUMIDIFYING mode operation is locked.

When pressing (MODE) button, “ ”, “ ” or “ ” will be displayed.

■ Method to unlock COOLING and DEHUMIDIFYING modes (including FAN)

operations.

Press

(ECO) and (SILENT) buttons simultaneously for about 5 seconds

when the remote controller is OFF.

All operation mode symbols will appear on the display for about 10 seconds. After

that, operation mode symbol before cancellation will be displayed.

This indicates that COOLING and DEHUMIDIFYING modes operation is unlocked.

NOTE

● Operation Mode Lock function will not activate if TIMER reservations activate.

TIMER reservations shall be deactivated Ú rst. Then, Operation Mode Lock function can be activated.

● HEATING, COOLING and DEHUMIDIFYING mode (including FAN) operations can be unlocked by pressing

the

(RESET) button. However, by pressing the (RESET) button, all the information stored

in the remote controller will disappear. You may need to set the necessary information again.

● For multi connections, unit and mode which is set to lock HEATING and switched on Ú rst shall have

higher priority. Other units which are chosen to operate at different modes shall be in STANDBY until

either the Ú rst unit operation is switched off or the mode is selected to be same as the Ú rst unit.

2ー14

Page 24

– 2 –

• Please read the “Safety Precaution” carefully before operating the unit to ensure correct usage of the unit.

• Pay special attention to signs of “

Warning” and “ Caution”. The “Warning” section contains matters which, if

not observed strictly, may cause death or serious injury. The “Caution” section contains matters which may result

in serious consequences if not observed properly. Please observe all instructions strictly to ensure safety.

• The signs indicate the following meanings. (The following are examples of signs.)

PRECAUTIONS DURING OPERATION

WARNING

WARNING

SAFETY PRECAUTION

• Do not reconstruct the unit.

yb tinu eht tcurtsnocer uoy fi rucco yam er if ro tiucric trohs ,tluaf ,egakael retaW

yourself.

• Please ask your sales agent or qualified technician for the installation of your unit.

Water leakage, short circuit or fire may occur if you install the unit by yourself.

• Please use earth line.

Do not place the earth line near water or gas pipes, lightning-conductor, or the

earth line of telephone. Improper installation of earth line may cause electric

shock or fire.

• n

i tluser yam siht ,esiwrehtO .A014R rof tes gnipip de ificeps eht esu ot erus eB

broken copper pipes or faults.

• A circuit breaker should be installed depending on the mounting site of the unit.

Without a circuit breaker, the danger of electric shock exists.

•

• .esoh niard eht

gnillatsni nehw retaw fo wo lf htooms erusne esaelP

• Make sure that a single phase power source is used.

The use of other power sources may cause electrical components to overheat

.er if ot dael dna

PRECAUTIONS DURING INSTALLATION

PROHIBITION

CONNECT EARTH LINE

PROHIBITION

WARNING

CAUTION

•

•

• Please contact your agent for maintenance. Improper self maintenance may cause electric

.er if dna kcohs

• er if ro kcohs cirtcelE .tinu eht llatsnier dna evomer ot deen uoy fi tnega ru

oy tcatnoc esaelP

may occur if you remove and reinstall the unit yourself improperly.

PRECAUTIONS DURING SHIFTING OR MAINTENANCE

• Do not use any conductor as fuse wire, this could cause fatal accident.

• During thunder storm, disconnect the plug top and turn off the circuit

breaker.

• Do not put objects like thin rods into the panel of blower and suction side

because the high-speed fan inside may cause danger.

• Spray cans and other combustibles should not be located within a meter of the

air outlets of both indoor and outdoor units.

As a spray can’s internal pressure can be increased by hot air, a rupture may result.

PROHIBITION

PROHIBITION

PROHIBITION

PROHIBITION

“OFF”

“OFF”

PROHIBITION

Avoid an extended period of direct airflow for your health.

220V-230V

Please keep this manual after reading.

Make sure to connect earth line.

Indicates the instructions that must be followed.

This sign in the figure indicates prohibition.

Do not install the unit near a location where there is flammable gas.

The outdoor unit may catch fire if flammable gas leaks around it.

Should abnormal situation arise (like burning smell), please stop operating the

unit and turn off the circuit breaker. Contact your

fire may occur if you continue to operate the unit

under abnormal situation.

agent. Fault, short circuit or

– 3 –

DEUTSCHSIAÇNARFONAILATIHSINAPSSÊUGUTROPЙИКССУР

ENGLISH

• .stnalp eht rof dab si ti sa wo lfria eht rednu yltcerid stnalp ecalp ton oD

• Do not direct the cool air coming out from the air-conditioner panel to face

household heating apparatus as this may affect the working of apparatus such

as the electric kettle, oven etc.

• ton dna noitac ific

eps rerutcafunam eht rednu detarepo eb llahs tcudorp ehT

for any other intended use.

PRECAUTIONS DURING OPERATION

CAUTION

• Do not attempt to operate the unit with wet hands, this could cause fatal

accident.

• When operating the unit with burning equipments, regularly ventilate

.ycneic iffusni negyxo diova ot moor eht

• tuohtiw dna mr if ,elbats syawla si emarf gnitnuom roo

dtuo taht erusne esaelP

defect. If not, the outdoor unit may collapse and cause danger.

• Do not wash the unit with water or place a water container such as a vase on

the indoor unit.

Electrical leakage could be present and cause electric shock.

• Be sure to stop the operation by using the remote controller and turn off the

circuit breaker during cleaning, the high-speed fan inside the unit may cause

danger.

• Turn off the circuit breaker if the unit is not be operated for a long period.

• Do not climb on the outdoor unit or put objects on it.

• When operating the unit with the door and windows opened, (the room

gnivom ro nwod gnicaf rotce lfed ria eht htiw dna )%08 evoba

syawla si ytidimuh

automatically for a long period of time, water will condense on the air deflector

and drips down occasionally. This will wet your furniture. Therefore, do not

operate under such condition for a long time.

• If the amount of heat in the room is above the cooling or heating capability of

the unit (for example: more people entering the room, using heating equipments

and etc.), the preset room temperature cannot be achieved.

• Indoor unit cleaning must be performed by authorized personnel only. Consult

This appliance is not to be used by children or persons with reduced physical, sensory or mental

instruction. Children must be supervised not to play with the appliance.

your sales agent.

capabilities, or lack of experience and knowledge, unless they have been given supervision or

Using a commercially available detergent or similar can damage the plastic parts

or clog the drain pipe, causing water to drip with potential electric shock hazard.

• roodtuo eht fo n if muinimula dna ecafrus mottob ,teltuo ria eht hcuot ton oD

unit.

You may get hurt.

Do not touch the refrigerant pipe and connecting valve.

Burns may result.

PROHIBITION

DON’T WET

PROHIBITION

PROHIBITION

PROHIBITION

DON’T TOUCH

“OFF”

PROHIBITION

PROHIBITION

PROHIBITION

PROHIBITION

PROHIBITION

DON’T TOUCH

STRICTLY OBSERVE

PRECAUTIONS

“OFF”

•

•

•

2ー15

Page 25

– 4 –

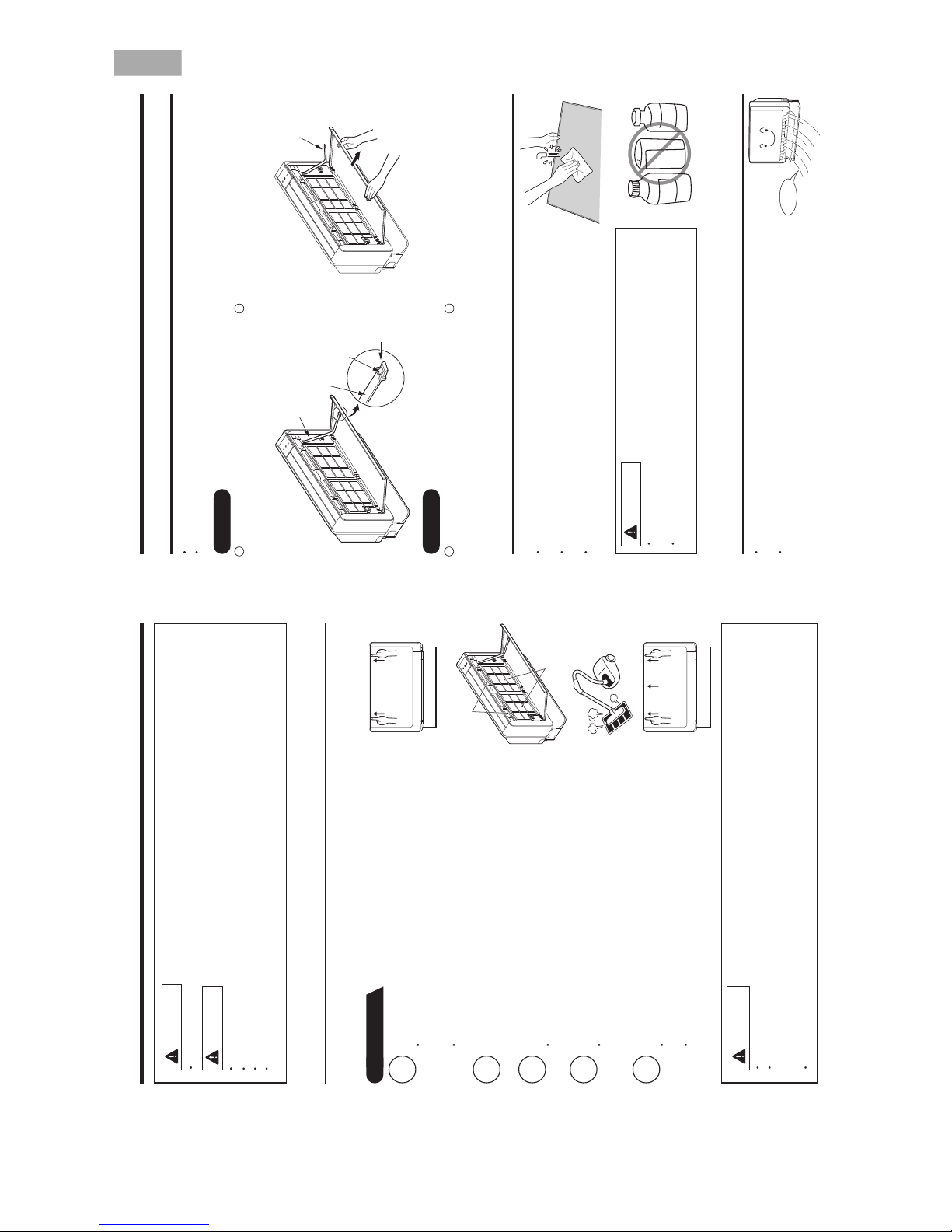

OPERATING RANGE

Operation mode Cooling / Dehumidifying Heating

Outdoor temperature

-

10 to 43°C

-

15 to 21°C

Remote controller

Send out operation signal to the indoor unit.

So as to operate the whole unit.

(Refer Remote control manual)

Indoor unit indicators

Horizontal air deflector (Air intake)

(Opens during operation and it closes

when it stops operation.)

Air filter

Front panel

Horizontal air

deflector (Air outlet)

Signal receiver

HTPEDTHGIEHHTDIWLEDOM

RAF-25RXB, RAF-35RXB, RAF-50RXB 750mm (29-17/32") 590mm (23-6/25") 215mm (8-15/32")

MODEL NAME AND DIMENSIONS

NAMES AND FUNCTIONS OF EACH PART

INDOOR UNIT

CAUTION

Do not put anything in front

of the signal receiver. Or

else, it may not receive the

signal properly.

Adjusting the number of indoor units:

Decrease the number of

indoor units to be operated

especially when it is very hot

or very cold or when you

want to reach the preset

temperature quickly.

NOTE FOR MULTI SYSTEM

Several indoor units can be connected to one outdoor unit.

You can operate only one unit or several units according to your needs.

Combination of operations:

the following combinations.

You cannot operate the indoor units in

One unit Other unit

Heating

Dehumidifying

Fan

Cooling

Other indoor units which are turned on later go into standby

The indoor unit which is turned on first continues to operate.

To operate the indoor units turned on later, set the operation

mode and the operation lamp lights.

mode as same as the indoor unit turned on first.

Stopped indoor units:

When an indoor unit is operated in the cooling,

heating or dehumidifying mode in one room,

the sound of refrigerant flow may be heard

from a stopped indoor unit or a stopped indoor

unit may become warm. This is because the

indoor unit returns refrigerant to the outdoor

unit to be ready for operation.

When operation mode is selected:

During automatic operation:

When heating operation is automatically selected for the first indoor unit, the next indoor unit will then start to

heat. Also, if cooling or dehumidifying is automatically selected for the first indoor unit, the next indoor unit will

also start to cool or dehumidify.

– 5 –

HSILGNE

DEUTSCHSIAÇNARFONAILATIHSINAPSSÊUGUTROPЙИКССУР

Open the front panel

s To open the front panel, use the remote controller to stop unit

operation. Then press at the top left and right corners of the front

panel.

s Grasp the left and right sides of the front panel and open it toward

you.

Close the front panel

s To close the front panel, press at the top left and right corners of the

front panel.

s Press the upper center part of the front panel to close properly.

TIMER lamp

This lamp lights when the timer is working.

OPERATION lamp

This lamp lights during operation.

During heating, the operation indicator may

blink, blowing very lightly or totally stopping

under the following conditions:

(1) During preheating (heating operation)

For about 2~3 minutes after start up.

(2) During defrosting (heating operation)

Defrosting will be performed about

once an hour when frost forms on the

heat exchanger of the outdoor unit, for

5~10 minutes each time. (If the piping

length used is longer than usual, frost will

likely to form.)

TEMPORARY SWITCH

Top left and right corners

TEMPORARY SWITCH

TEMPORARY SWITCH

s

s

Upper center part

INDOOR UNIT INDICATORS

HOW TO OPEN OR CLOSE THE FRONT PANEL

FILTER lamp

This lamp lights when the

device is operated for a total

of about 200 hours, it is time

to clean the filter. The lamp

goes out when the “

(AUTO

SWING)” button is pressed

while the operation is stopped.

Use this switch to start and stop when the remote

controller does not work.

By pressing the temporary switch, the operation

is done in automatic mode.

When the operation is done using the temporary

switch after the power source is turned off and

turn on again, the operation is done in automatic

mode.

ENGLISH

2ー16

Page 26

– 6 –

DEUTSCHSIAÇNARFONAILATIHSINAPSSÊUGUTROP

ЙИКССУР

ADJUSTING THE AIR DEFLECTORS

Adjustment of the conditioned air in the upward

and downward directions.

The horizontal air deflector is automatically set to

the proper angle suitable for each operation. The

deflector can be swung up and down continuously

and also set to the desired angle using the “

(AUTO SWING)” button.

1

If the “ (AUTO SWING)” button is

pressed once, the horizontal air deflector

swings up and down. If the button is

pressed again, the deflector stops in its

current position.

Use the horizontal air deflector within

the adjusting range shown in the right

figure.

When the “

(AUTO SWING)” button is

pressed while the operation is stopped,

the horizontal air deflector moves and

stops at the position where the air outlet

closes.

When the auto swing operation is

performed, if the horizontal air deflector

is moved manually, the swinging range

may drift. However, it will return to the

original operation range after a short

time.