Page 1

SM017

P50XR01E

P50XR01U

P60XR01E

SERVICE MANUAL

MANUEL D'ENTRETIEN

WARTUNGSHANDBUCH

CAUTION:

Before servicing this chassis, it is important that the service technician read the “Safety

Precautions” and “Product Safety Notices” in this service manual.

ATTENTION:

Avant d’effectuer l’entretien du châassis, le technicien doit lire les «Précautions de sécurité»

et les «Notices de sécurité du produit» présentés dans le présent manuel.

VORSICHT:

Vor Öffnen des Gehäuses hat der Service-Ingenieur die „Sicherheitshinweise“ und „Hinweise

zur Produktsicherheit“ in diesem Wartungshandbuch zu lesen.

P60XR01U

Data contained within this Service

manual is subject to alteration for

improvement.

Les données fournies dans le présent

manuel d’entretien peuvent faire l’objet

de modifications en vue de perfectionner

le produit.

Die in diesem Wartungshandbuch

enthaltenen Spezifikationen können sich

zwecks Verbesserungen ändern.

SPECIFICATIONS AND PARTS ARE SUBJECT TO CHANGE FOR IMPROVEMENT

Plasma TV

November 2007

Page 2

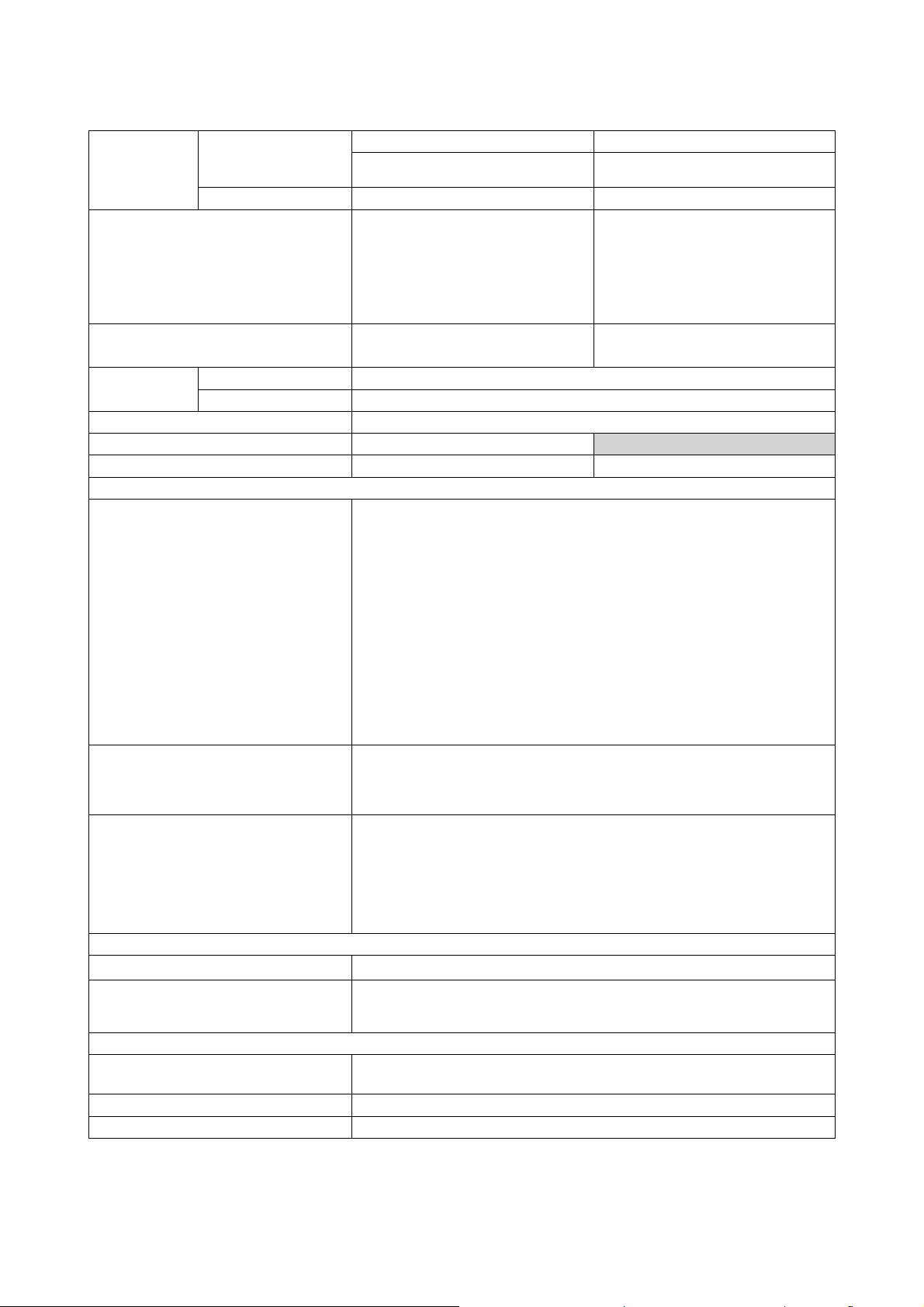

P50XR01U/E P60XR01U/E

Contents

1. Features -----------------------------------------------2

2. Specifi cations -----------------------------------------7

3. Servicing----------------------------------------------- 8

4. Component names ----------------------------------9

5. Adjustment ------------------------------------------ 15

6. Troubleshooting------------------------------------ 26

7. Self-diagnosis function --------------------------- 43

8. Waveform diagrams ------------------------------ 45

9. Block diagrams ------------------------------------- 47

10.Connection diagrams ----------------------------- 49

11.Wiring diagrams ----------------------------------- 51

12.Disassembly diagrams--------------------------- 55

13.Replacement partslist ---------------------------- 59

14.Schematic diagrams ------------------------------ 60

CAUTION FOR SAFETY

Please read this page before repairing the monitor.

This page explains the following items for keeping the safety of set and preventing accidents

during repair.

S mols Used:

Warning

Caution

This symbol means "CAUTION"

This symbol means "POSSIBILITY of

ELECTRIC SHOCK"

This symbol means "possibility of death or heavy damage"

This symbol means "possibility of damage or breakage"

Follow instructions.

Special attention parts are indicated

on cabinter, chassis and parts by label.

Please follow the notes in [Safety Instructions] in the User’s Manual.

Prevent electric shock.

Take care during working because

the monitor has high voltage parts

and power supply parts.

Possibility of electric shock if these

parts are touched.

Disconnect power plug during

overhaul, reassemble or parts change.

Daeth or injury by electric shock may

occur if live parts are touched.

Use recommended components.

Components and parts with special

characteristics for safety or reliability

are indicated in parts lists and circuit

diagrams by the

Electric shock of fire may occur if non-

recommended components or parts

are used.

mark.

This symbol means "MUST"

This symbol means "DO NOT"

WARNING

Keep the same style of wiring.

The Monitor uses insulating tubes

or tapes for safety and some comp-

nents are kept at a distance from

PCB surfaces for safety.

Internal leads kept from hot- or high

voltage parts by clampers or styling.

Return wiring to original condition after

repair to prevent electric shock or fire.

Perform safety check after finishing.

Every part (removed screws, component and wiring) should be returned to

to its original condition.

Check around the repair position for

damage and measure insulation

impedance by using a meg-ohm meter.

Confirm that the value of impedance

is more than 4M ohm.

Electric shock or fire may occur if

the value is less than 4M ohm.

The code and combination circuit of the

HDCP is not a repairable item.

Never remove the shield case that is

assembled to the code and combination

circuit of the HDCP.

1

Page 3

P50XR01U/E P60XR01U/E

PRECAUTIONS

Cleaning the plasma screen panel of the monitor

Before cleaning the monitor, turn off the monitor and disconnect the power plug from the power outlet.

To prevent scratching or damaging the plasma screen face, do not knock or rub the surface with sharp or

hard objects. Clean the screen with a soft cloth moistened with warm water and dry with a soft cloth. If it is

not enough, then use a cloth with mild detergent. Do not use harsh or abrasive cleaners.

Cleaning the cabinet of the monitor

Use a soft cloth to clean the cabinet and control panel of the monitor. When excessively soiled dilute a neutral detergent in water, wet and wring out the soft cloth and afterward wipe with a dry soft cloth.

Never use acid/alkaline detergent, alcoholic detergent, abrasive cleaner, powder soap, OA cleaner, car wax,

glass cleaner, etc. especially because they would cause discolouration, scratches or cracks.

Information for users applicable in European Union countries

This symbol on the product or on its packaging means that your electrical and electronic

equipment should be disposed at the end of life separately from your household waste.

There are separate collection systems for recycling in EU. For more information, please contact the local authority or the dealer where you purchased the product.

1. Features

Large-screen, high-definition plasma display panel

The 50-inch colour plasma display panel, with a resolution of 1920 (H) x 1080 (V) pixels, and the 60-inch colour plasma

display panel, with a resolution of 1920 (H) x 1080 (V) pixels, creates a high-definition, large-screen (aspect ratio:

16:9) and low-profile flat display. Free from electromagnetic interferences from geomagnetic sources and ambient

power lines, the panel produces high-quality display images free from colour misconvergence and display distortion.

High Performance Digital Processor

A wide range of input signals can be handed, including composite, component and HDMI. High Definition Digital

Processor creates the fine-textured image with dynamic contrast.

Easy-to-use remote control and on screen display system

The remote control included eases the work of setting display controls. Further, the on-screen display system, displays the status of signal reception and display control settings in an easy-to-view fashion.

Connecting to an Audio Visual Device

• Three Scart terminals

added. A composite video output terminal is also provided as a monitoring output.

*1

AV1 scart applies to composite/ S-video

AV2 and 3 scart applies to composite/ RGB

*2

AV5 composite/S-Video=Front Input

*3

AV4 can be connected to the equipment with either component or composite Output.

SD card slot installed

*1

, composite/S terminal*2, a component terminal*3, and two HDMI terminals have been

Power Swivel Feature (only P50XR01U/E)

It allows turning the plasma display left or right within ±30 degree using the remote control.

2

Page 4

P50XR01U/E P60XR01U/E

Digital Terrestrial Television Broadcasting

Converting into digital signals enables more channels and various useful features, such as Electric

Programme Guide, Digital Teletext, and so on. Further, digital signal can create high quality picture.

This logo indicates that the product is compliant with European Digital Broadcasting.

DVB is a registered trademark of the DVB Project.

This logo indicates that the product is set up to view digital terrestrial TV.

FREEVIEW and the FREEVIEW logo are trade marks of DVT Services Ltd and are used under license.

FREEVIEW Logo © DTV Services Ltd 2002.

3

Page 5

P50XR01U/E P60XR01U/E

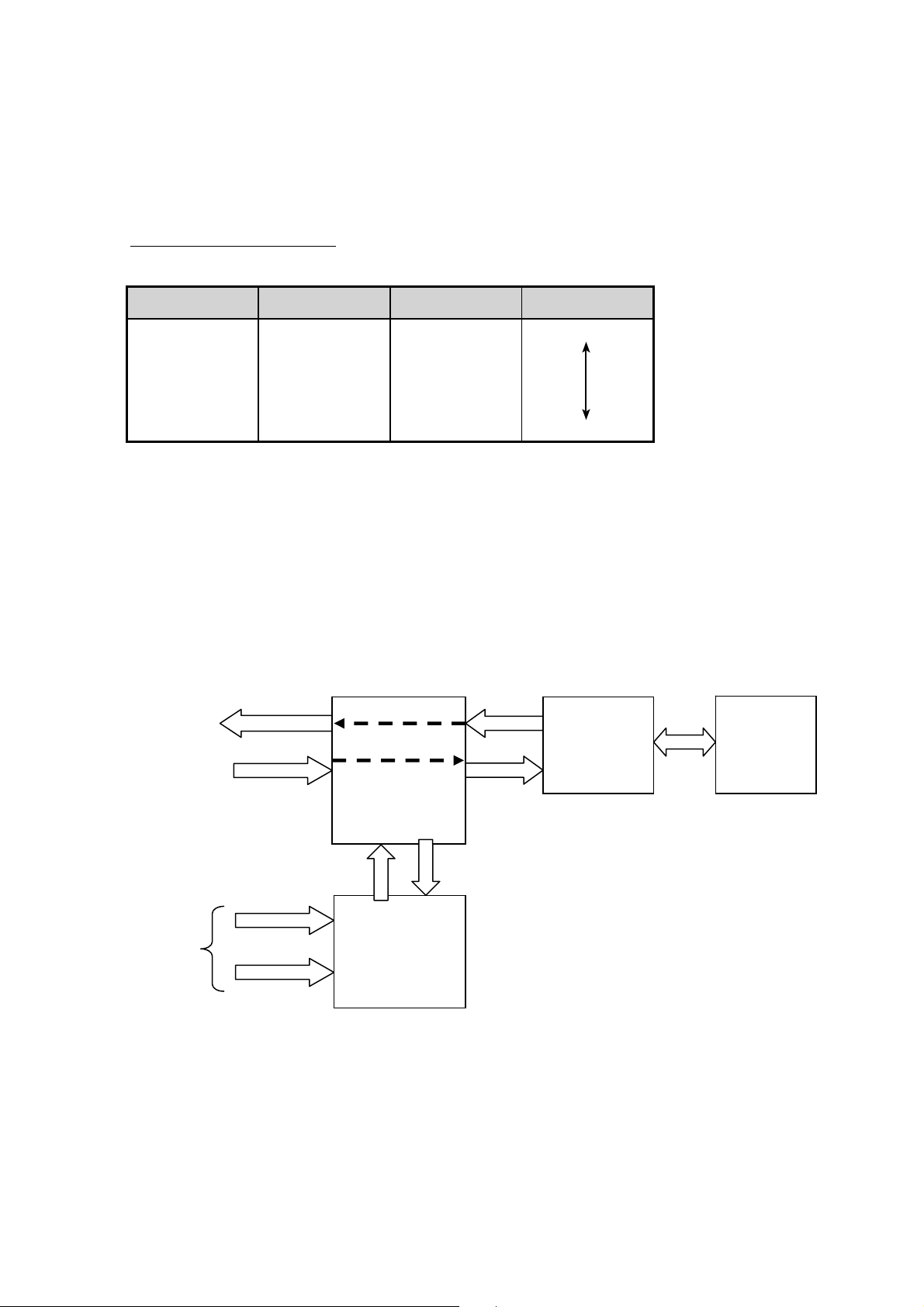

PerformanceoftheFC8(FRC)Circuit

“FC8” is a term for Hitachi’s original LSI having FRC function. “FRC” stands for Frame Rate

Converter. By using Frame Rate Converter technology for moving compensation, this circuit

creates higher picture quality and has the following functions:

1) Telecine performance (as applying “Film mode”): Judder Reduction

2) Improvement on

PDP moving image by FRC from 50Hz to 60Hz.

From the perspective of hardware, this function is actualised by newly mounting FC8 LSI and 3

sets of 256Mbit-DDR2 memories on the FC8 board (which is only for this function).

As a block component, the FC8 board is located in front of panel block. It inputs the picture signal

of the LVDS system (available: single/dual system) and then once processing the FRC as

mentioned above, it outputs the picture signal of LVDS system (available: single/dual system)

again in order to supply the panel. As the control of FC8 board, I/F of the original FC Bus system is

utilised.

2 power supplies are necessary: 5.6V and 3.2V. The other necessary power supplies are generated

on the FC8 board.

All of the above I/F are combined into 1x 160-pin BtoB connector.

FC8 Board

Reg.

DDR2

160pin㩷 BtoB

5.6V

3.3V

Nereid

Slow Bus

Seine 2D

FC8(FRC) Block

FC8

LVDS1

LVDS2

Main Board

LVDS1

LVDS2

Panel

䋨

PDP䋩

䋨LCD䋩

4

Page 6

P50XR01U/E P60XR01U/E

Handling the HDD (Hard Disk Drive)

HDD is a high precision device, and is very susceptible to vibrations or impact. Even if HDD

operates normally immediately after it has been subjected to vibrations or impact, a problem may

occur after it is used for a while: When servicing, take great care with the following.

There are two types of HDD: CSS format (head remains on disk regardless of operation status)

and ramp loading format (head moves away from disk during no operation). The impact resistance

characteristics are slightly different for the two. When servicing, observe the following cautions

regardless of the format:

(1) Cautions during unpacking

1) Do not subject the HDD to any impact when placing on desk: The head hitting against the desk

could result in damage.

2) If condensation occurs because of the environment, leave the HDD without being turned on for at

least 3 hours until it adapts to surrounding environment. If the HDD is turned on while the head

is sticking to disk because of condensation, the disk may be damaged.

(2) Cautions during transportation

An HDD is more susceptible to vibrations or impact when it is turned on or operating than during

no operation.

1) Do not move the HDD while it is turned on: If the HDD is subject to any impact while the disk is

rotating, i.e., the head hitting against the disk, breakage could result.

2) Move the HDD approximately 2 minutes (approximately 30 seconds for surveillance system

devices) after turning it off and unplugging its power cord from AC outlet. The disk will still be

rotating by inertia immediately after the HDD is turned off: Subjecting the HDD to movement at

this time could destroy it.

(3) Cautions during operation

1) Do not unplug the power cord from AC outlet during operation: This could damage the data on

HDD. Be sure to turn the HDD off before unplugging the power cord.

2) Do not hit the HDD: The head hitting the disk could result in breakage.

(4) Caution during packing

1) Use the packing material of relevant model: Material superior in impact resistance is used. Using

other packing materials could result in fault.

(5) Cautions when handling unassembled HDD

1) Hold the HDD at both sides so that the circuit board surface is facing below: Holding the HDD at

the top and bottom could cause the head to drift, which could result in fault.

2) Do not touch the terminal or pattern on circuit board.

3) Place HDD on a spot where cushion is pasted with the circuit board surface facing below.

4) Do not hold or place stacked HDDs.

5) Do not drop or hit HDD against anything: Dropping HDD from even 5 mm high on a work bench

with high stiffness could cause fault.

5

Page 7

P50XR01U/E P60XR01U/E

Performance of theX-code2U Circuit Part

X-code2U makes digital broadcasting compression efficiency and has a function to realise recording for a long time (TS

recording); in addition it possesses the MPEG encoding function to cope with analog broadcasting recording.

Recording Mode and Recording Time

There are 5 recording modes (Fig.1). The quality of the recorded picture varies depending on Recording Mode.

MODE DTT TV Quality

TS

XP

SP

LP

EP

*In EP mode, display resolution is lower. Select more than LP mode if the finer picture is preferred.

about 93 hours

-

-

-

-

about 50 hours

about 95 hours

about 190 hours

about 310 hours

Fig.1

High

Low

Following is the block diagram (Fig.2) of the recording processes.

The digital broadcasting inputs it into X-code2U after it was input into Tenko Φ. X-code2U performs transformer code

processing in real time and returns it to Tenko Φ again and passes through the SATA conversion to HDD and is

recorded. X-code2U has a separate input port for analog recording. It is recorded in the same pass on the HDD

after MPEG encoding.

TS

Play

SATA

IU06

TS

Digital

TenkoΦ

IU01

Audio LR

X-code2U

Analog input

(After ADC)

IX01

250GB

HDD

Picture

Fig.2 block diagram of the recording processing

6

Page 8

P50XR01U/E P60XR01U/E

2. Specifications

P50XR01U/E P60XR01U/E

Panel

Net dimensions

Net weight

Ambient

conditions

Display dimensions

Resolution 1920(H) x 1080 (V) pixels 1920(H) x 1080 (V) pixels

Temperature Operating : 5°C to 35°C, Storage : 0°C to 40°C

Relative humidity Operating : 20% to 80%, Storage : 20% to 90% (non-condensing)

Power supply

Power consumption/ at standby

Audio output speaker total 32W speaker total 27W

(VIDEO input)

Input terminals

Input signals

Output Signal

(RF input)

Input terminal / Receiving range ANT : 75 Unbalanced / 40~870MHz

RF Video System

(RGB input)

Input terminals

Input signals 0.7Vp-p, analog RGB (Recommended Signal)

Sync singnals H/V separate, TTL level [2k]

Approx. 50 inches

(1106(H) x 626(V) mm, diagonal 1270mm)

including Stand:

1250(W)x890(H)x423(D) mm

excluding Stand:

1250(W)x823(H)x129(D) mm

including Stand: 51.3Kg

excluding Stand: 445.2Kg

AC220 - 240V, 50Hz

540W / <0.8W W / <0.8W

AV1 : composite video input terminal (SCART)

S video input terminal (SCART)

L/R audio input terminal (SCART)

AV2•3 : composite video input terminal (SCART)

RGB video input terminal (SCART)

L/R audio input terminal (SCART)

AV4 : composite video input terminal (RCA)

component video input terminal.(RCA)

L/R audio input terminal (RCA)

AV5 : composite video input terminal (RCA)

S video input terminal (Mini DIN)

L/R audio input terminal (RCA)

HDMI 1•2•3 : HDMI input terminal

Audio input terminal (3.5mm Stereo Mini Jack)*

Photo Input : Photo Input terminal / SD card slot

Composite video: PAL, SECAM, NTSC3.58, NTSC4.43, PAL60

Component video: 480i, 576i, 480p, 576p, 720p/50, 720p/60, 1080i/50, 1080i/60

HDMI: VGA/60, 480i, 576i, 480p, 576p, 720p/50, 720p/60, 1080i/50, 1080i/60, 1080,

1080p/60, 1080p/24

OUTPUT (MONITOR): composite video monitor-output terminal (RCA)

OUTPUT (MONITOR): L/R audio monitor- output terminal (RCA)

OUTPUT (HEADPHONE): L/R audio monitor- output terminal (3.5mm Stereo Mini Jack)

OUTPUT (SUB-WOOFER): woofer output terminal (RCA)

AV1/2/3 : composite video output terminal (SCART)

L/R audio output terminal (SCART)

Optical Out: PCM/Dolby Digital

PAL B, G, H / I / D, K

SECAM B, G / K1 / L, L' / D,K

DVB-T

Analog RGB input terminal (D-sub 15pin)

Audio input terminal (3.5mm Stereo Mini Jack)*

Approx. 60 inches

(1336(H) x 751(V) , diagonal 1530mm)

including Stand&Speaker:

1773(W)x1018(H)x483(D) mm

including Speaker, excluding Stand:

1773(W)x952(H)x128(D) mm

excluding Stand:

1502(W)x1018(H)x483(D) mm

including Stand&Speaker: 100Kg

excluding Stand&Speaker: 75Kg

• The unit takes at least 30 minutes to attain the status of optimal picture quality.

* This analog audio input terminal can be used for PC (RGB) or HDMI1~3 only.

7

Page 9

P50XR01U/E P60XR01U/E

3. Servicing

Lead free solder

This product uses lead free solder (unleaded) to help preserve the environment. Please read these

instructions before attempting any soldering work.

Caution: Always wear safety glasses to prevent fumes or molten solder from getting into the eyes. Lead

free solder can splatter at high temperatures (600˚C).

Lead free solder indicator

Printed circuit boards using lead free solder are engraved with an "F."

Properties of lead free solder

The melting point of lead free solder is 40-50˚C higher than leaded solder.

Servicing solder

Solder with an alloy composition of Sn-3.0Ag-0.5Cu or Sn-0.7Cu is recommended.

Although servicing with leaded solder is possible, there are a few precautions that have to be taken. (Not

taking these precautions may cause the solder to not harden properly, and lead to consequent malfunctions.)

Precautions when using leaded solder

Remove all lead free solder from soldered joints when replacing components.

If leaded solder should be added to existing lead free joints, mix in the leaded solder thoroughly after the

lead free solder has been completely melted (do not apply the soldering iron without solder).

Servicing soldering iron

A soldering iron with a temperature setting capability (temperature control function) is recommended.

The melting point of lead free solder is higher than leaded solder. Use a soldering iron that maintains a high

stable temperature (large heat capacity), and that allows temperature adjustment according to the part being

serviced, to avoid poor servicing performance.

Recommended soldering iron:

Soldering iron with temperature control function (temperature range: 320-450˚C)

Recommended temperature range per part:

Part Soldering iron temperature

Mounting (chips) on mounted PCB 320˚C±30˚C

Mounting (chips) on empty PCB 380˚C±30˚C

Chassis, metallic shield, etc. 420˚C±30˚C

Board assemblies which use lead free solder

CONTROL PCB (Control PCB, Slot PCB, SD PCB, PC PCB)

TERMINAL PCB (Terminal PCB, LED PCB, Swivel PCB)

FILTER PCB

MAIN PCB

FC8 PCB

Readjustment Power supply voltage

When a PANEL or a Power Unit is exchanged, power supply voltage is automatically adjusted.

However, Please reconfi rm to the values of Vs and Va, as shown on the label carrently stuck on the panel

back upper parts.

Please refer to the reconfi rm the “Vs and Va” voltages on Power Unit.

8

Page 10

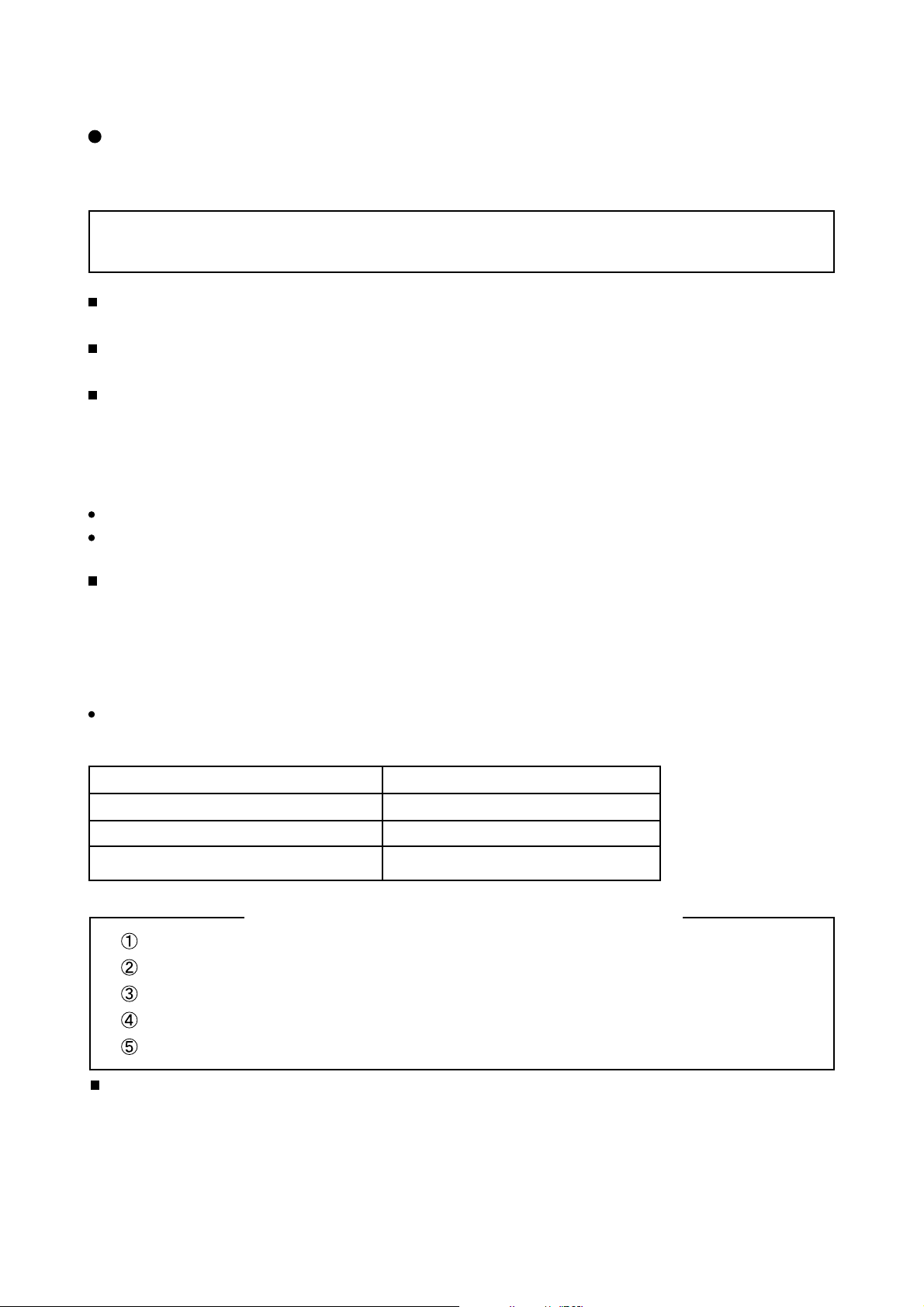

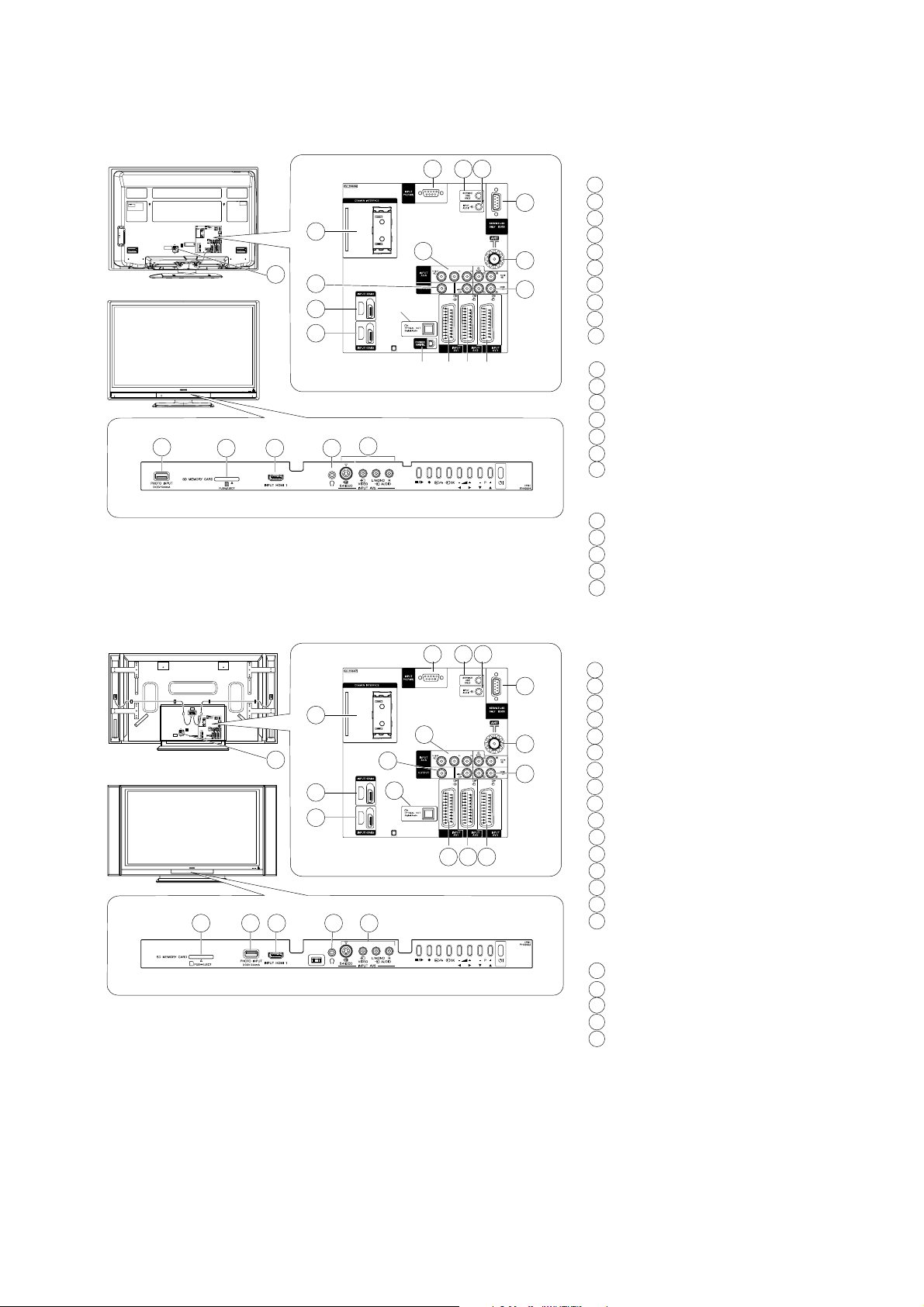

4. Component names

[Main unit]

Front Panel

P50XR01U/E P60XR01U/E

50” model

7

60” model

9

1

1

2

2

9

3

8

6

1 Cabinet

2 Panel

3 Remote Control Receiver

4 HDD/Timer Indicating Lamp

5 Power Indicating Lamp

6 Main Power Switch (On the bottom surface)

7 Control Panel and Front Input

8 Desktop Stand

9 Speaker (Option for 60” model)

4

5

7

8

6

5

3

4

Rear Panel

50” model

60” model

3

5

3

5

1

1

2

1 Terminal board (External Device Connection)

2 Power Cord Socket

3 Handgrips

4 Terminals for speaker cables on television

5 Terminals for speaker cables on speaker

2

4

9

Page 11

P50XR01U/E P60XR01U/E

Control Panel (including front input)

ledom”06ledom”05

B

50” model

A

Push here to open the door.

A Push the bottom centre of

the front door to unlock.

B Pull down the upside of the

door.

A

Push here to open the door.

B

CAUTION

Do not place your ?ngers into the

gap at the opened door. If your

?ngers are caught in the front door,

you may be injured.

A Push the bottom centre of

the front door to unlock.

B Lift it up from the

underside of the door.

* for 60” model

60” model

1

1 Front Input

2 Stop/Play button

3 Rec (Recording) button

4 Menu/Return button

5 Input Select/OK button

6 Volume Down/Żbutton

7 Volume Up/Źbutton

8 Channel Down/źbutton

9 Channel Up/Ÿbutton

10 Sub Power button

10

23456789

10

Page 12

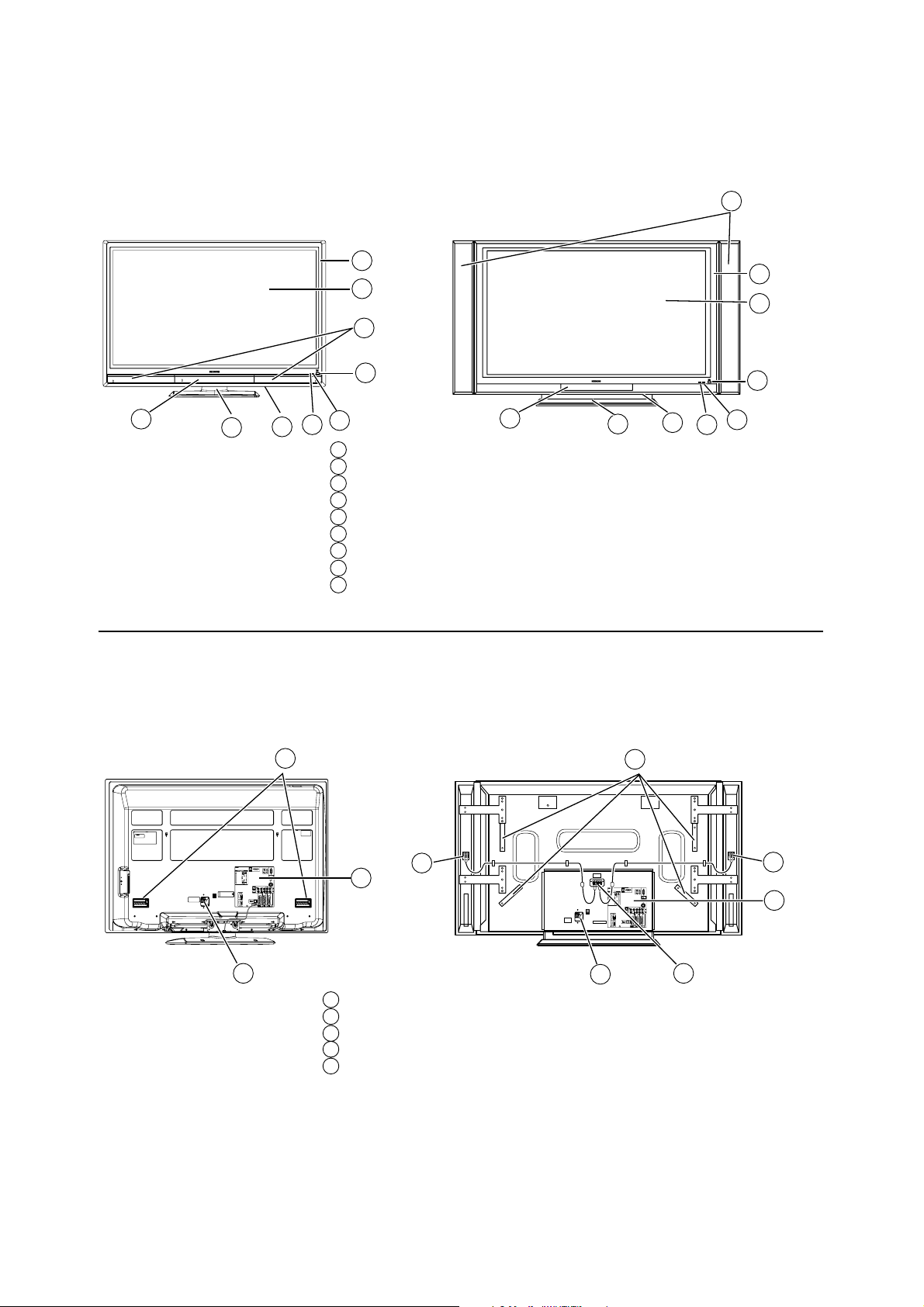

[Remote control]

P50XR01U/E P60XR01U/E

[for

***

rof[]ledomE10RX

XR01U model]

***

11

Page 13

P50XR01U/E P60XR01U/E

1 Sub Power

2 Device Select (TV/DTT, DVD, SAT)

Press these buttons to select the device (TV/DTT,

DVD, or SAT) to be controlled by this remote

control. The selected button blinks once. Normally,

select “TV/DTT”.

3

Programme Select/Input Mode [Page Select]

Press these buttons to select a TV programme directly.

You can also use these buttons when changing the

Input mode.

4 Freeze/Multi Mode [Hold]

5 CHI/II

This is exclusively for TV audio A2/NICAM mode.

Also, press this button to select Audio Language in

DTT mode.

6 Volume Up/Down

7 Colour [Colour]

8 TV/Text [TV

This switches between the TV mode and the

Teletext mode.

9 Time [Cancel]

Pressing this button can indicate the time by On-

screen display when receiving an analogue TV

programme on the screen.

10 Menu

Press this button to select Main Menu.

Cursor [Item Select]

11

OK

12

Function/Video Plus+ (

13

HOWVIEW (

S

Press this button to select Function Menu.

Pause/TIME SHIFT*

14

Play*

15

Rewind and Forward*

16

Rec*

17

TITLE LIST*

18

Recall

19

Press this button to show the input signal status.

Picture Mode

20

Picture mode can be changed each time pressed in the

following sequence. DynamicĺNaturalĺCinema

21

Swivel (with Desktop Stand)

This function is to rotate TV. Select the degree of

rotation with cursor key.

This is not available for 60” model.

Text]

XR01E model)*

***

XR01U model)/

***

Input Select

22

You can use this to change the input mode.

Multi Picture

23

Press this button to change the picture to multipicture mode. Press it again to return to normal

picture.

24

Channel Up/Down

25

Mute

[Reveal]

26

27

DVB Subtitle Language

Guide [Index]

28

Return

29

You can use this to return to the previous menu.

Stop*

30

Skip*

31

Photo Input/ 30-Second Skip*

32

Press this button to display and control the pictures

from digital still camera, USB card reader, or SD

(MMC) card.

REC MODE/10-Second Back*

33

12

Page 14

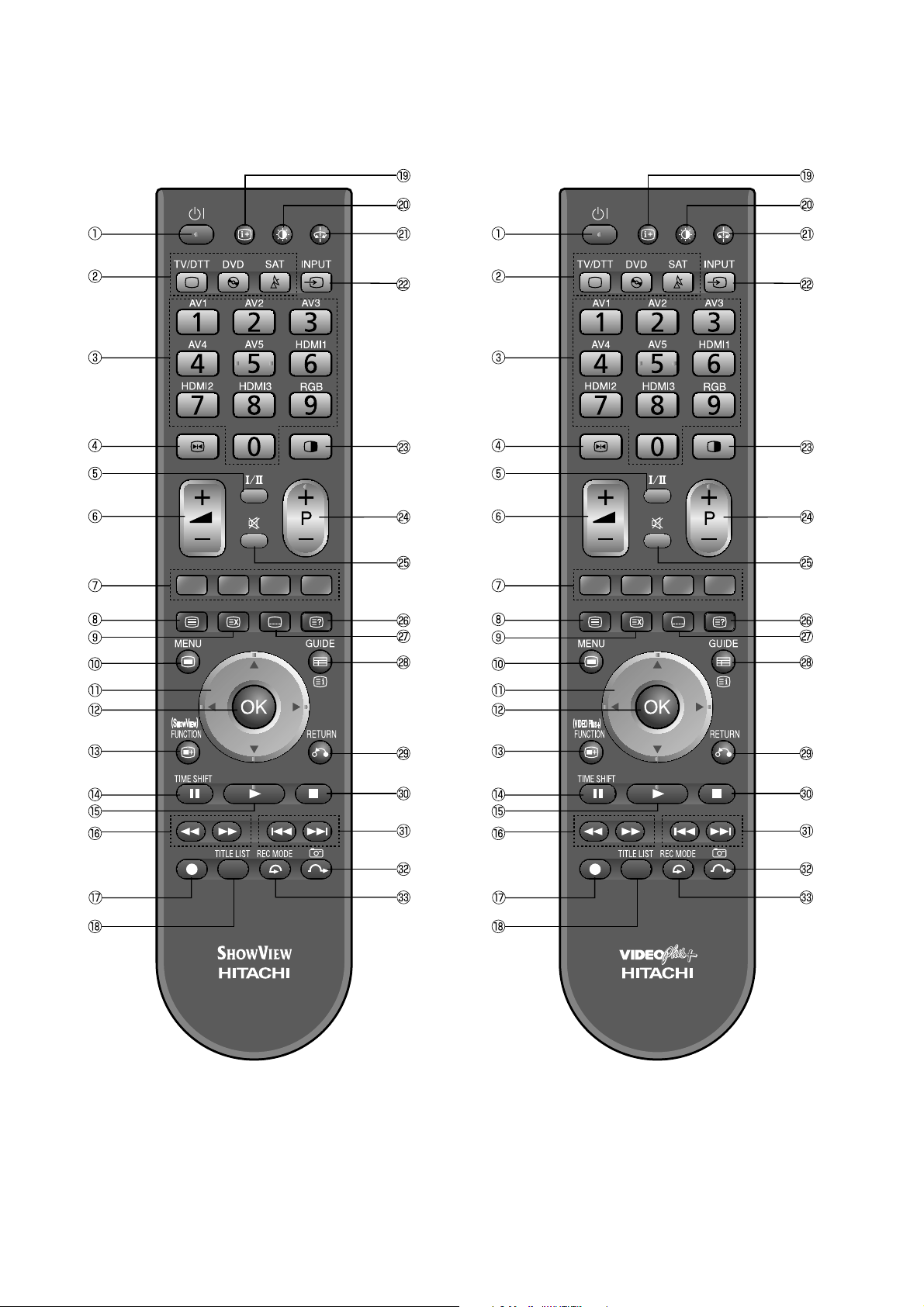

[Terminal Positions]

[

50” model]

P50XR01U/E P60XR01U/E

22

[

60” model]

14

1

17

12

13

21 19

20

18

15

9

16

8

Rear

1

Power Cord Socket

2 Aerial Socket

3AV1

4AV2

6

SUB

WOOFER

2

7

5AV3

6AV4

7 Monitor Out

8 Service use only

9 Service use only

10

Power Swivel Terminal

* Not available for 60” model.

Optical Out (Digital Audio)

11

HDMI 2

12

HDMI 3

13

Common interface slot

14

PC Terminals

15

Mini stereo for Audio

16

Sub woofer

17

Front

AV5

18

Headphone terminal

19

HDMI 1

20

SD Memory Card slot

21

Photo Input terminal

22

13

1

11

12

21 20 19 18 17

16

10

14159

6

3

SUB

WOOFER

45

Rear

1 Power Cord Socket

8

2 Aerial Socket

3AV1

4AV2

2

7

5AV3

6AV4

7 Monitor Out

8 Service use only

9 Service use only

10

Optical Out (Digital Audio)

HDMI 2

11

HDMI 3

12

Common interface slot

13

PC Terminals

14

Mini stereo for Audio

15

Sub woofer

16

Front

AV5

17

Headphone terminal

18

HDMI 1

19

Photo Input terminal

20

SD Memory Card slot

21

13

Page 15

P50XR01U/E P60XR01U/E

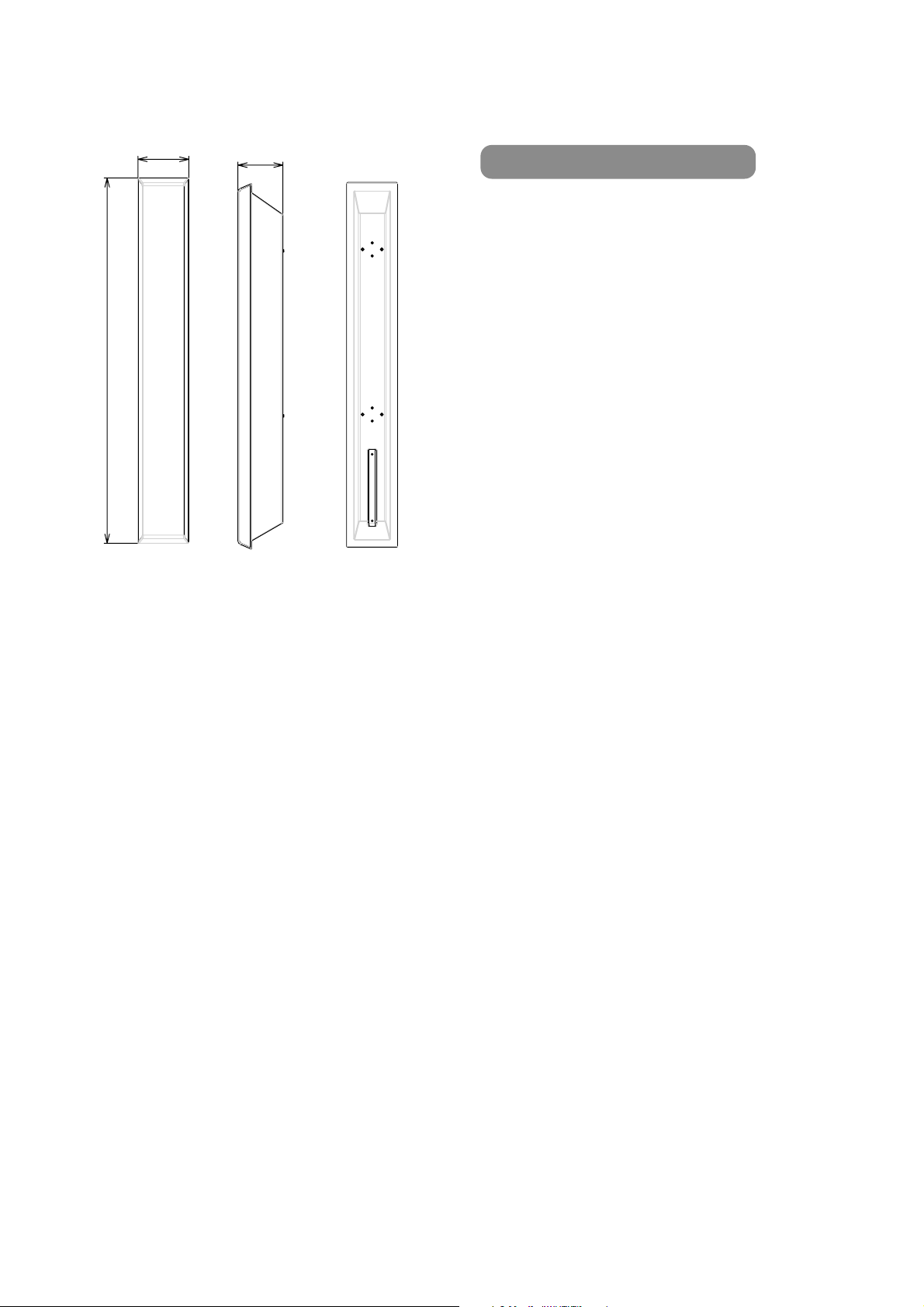

[60V SPEAKER SYSTEMS SPECIFICATION]

951.6

132.5

117.2

Specifications

Model ............................ SP01G60E

Type ............................ 2 way 3 speakers, Bass Reflex

Woofer............................ 100mm cone type ×2 each

Tweeter ........................ 25mm dome type

Impedance .................... 6ȍ

Max.input power ............ 50W

RMS input power............ 20W

External Dimensions .... 132.5(W) × 951.6(H) × 117.2(D) mm each

Weight ............................ 2.3Kg each

Specifications and design subject to possible

modification without notice,due to improvements.

14

Page 16

P50XR01U/E P60XR01U/E

e

.

.

T

A

t

.

T

.

T

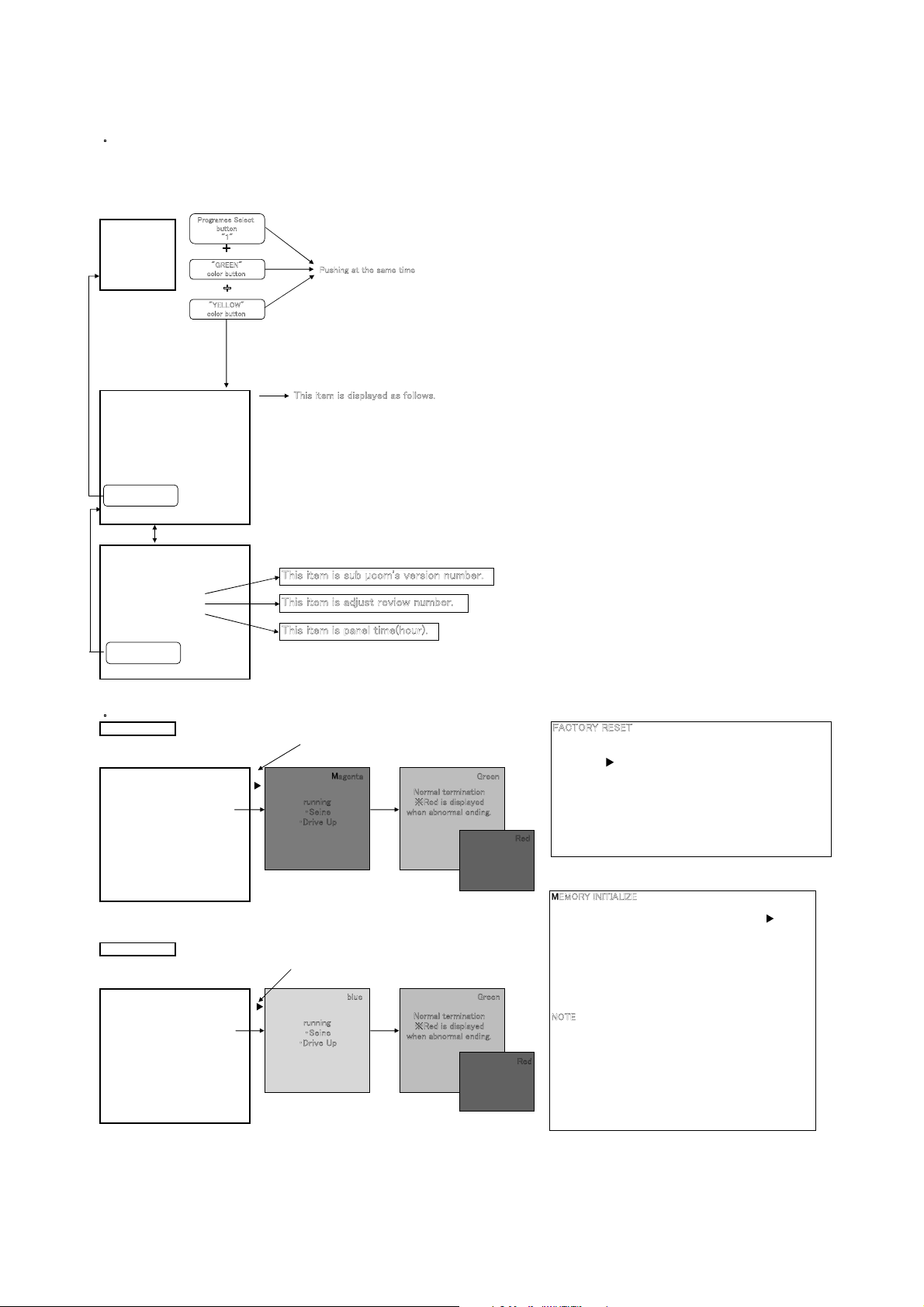

5. Adjustment

䊶How to get to Adjustment mod

Using the remote controller with the set turned on can activate it

Press the Programme Select button "1","GREEN"and "YELLOW" colour button at the same time, and hold for more than 3 seconds

The set is displayed adjustment mode.

I show the operation method of each item as follows

㪧㫉㫆㪾㫉㪸㫄㪼㪼㩷㪪㪼㫃㪼㪺㫋

normal screen

1st Page

ADJUST MODE

FACT RESET

MEMORY INI

RGB

WHITE BAL Cool

WHITE BAL Normal

WHITE BAL Warm

WHITE BAL B/W

㪩㪼㫋㫌㫉㫅

㪹㫌㫋㫋㫆㫅

㩹㪈㩹

㪂

㩹㪞㪩㪜㪜㪥㩹

㪺㫆㫃㫆㫉㩷㪹㫌㫋㫋㫆㫅

㪂

㩹㪰㪜㪣㪣㪦㪮㩹

㪺㫆㫃㫆㫉㩷㪹㫌㫋㫋㫆㫅

(***-**V-EU)ZZZZ

㪧㫌㫊㪿㫀㫅㪾㩷㪸㫋㩷㫋㪿㪼㩷㫊㪸㫄㪼㩷㫋㫀㫄㪼

㪫㪿㫀㫊㩷㫀㫋㪼㫄㩷㫀㫊㩷㪻㫀㫊㫇㫃㪸㫐㪼㪻㩷㪸㫊㩷㪽㫆㫃㫃㫆㫎㫊㪅

㪧㪌㪇㪯㪩㪇㪈㪬㩷㪑㩷㪧㪛㪧㪄㪌㪇㪭㪄㪜㪬㪲㪏㪽㪈㪇㪴

㪧㪌㪇㪯㪩㪇㪈㪜㩷㪑㩷㪧㪛㪧㪄㪌㪇㪭㪄㪜㪬㪲㪐㪽㪈㪇㪴

㪧㪍㪇㪯㪩㪇㪈㪬㩷㪑㩷㪧㪛㪧㪄㪍㪇㪭㪄㪜㪬㪲㪏㪽㪈㪋㪴

㪧㪍㪇㪯㪩㪇㪈㪜㩷㪑㩷㪧㪛㪧㪄㪍㪇㪭㪄㪜㪬㪲㪐㪽㪈㪋㪴

2nd Page

ADJUST MODE

SELF TEST

MAINTENANCE

DEVICE

M306H5 V01.00

DJ.REV. V01.01

PANEL_TIME

䂥䂯

(***-**V-EU)ZZZZ

65535

㪫㪿㫀㫊㩷㫀㫋㪼㫄㩷㫀㫊㩷㫊㫌㪹㩷㫫㪺㫆㫄㩾㫊㩷㫍㪼㫉㫊㫀㫆㫅㩷㫅㫌㫄㪹㪼㫉㪅

㪫㪿㫀㫊㩷㫀㫋㪼㫄㩷㫀㫊㩷㪸㪻㫁㫌㫊㫋㩷㫉㪼㫍㫀㪼㫎㩷㫅㫌㫄㪹㪼㫉㪅

㪫㪿㫀㫊㩷㫀㫋㪼㫄㩷㫀㫊㩷㫇㪸㫅㪼㫃㩷㫋㫀㫄㪼㩿㪿㫆㫌㫉㪀㪅

㪩㪼㫋㫌㫉㫅

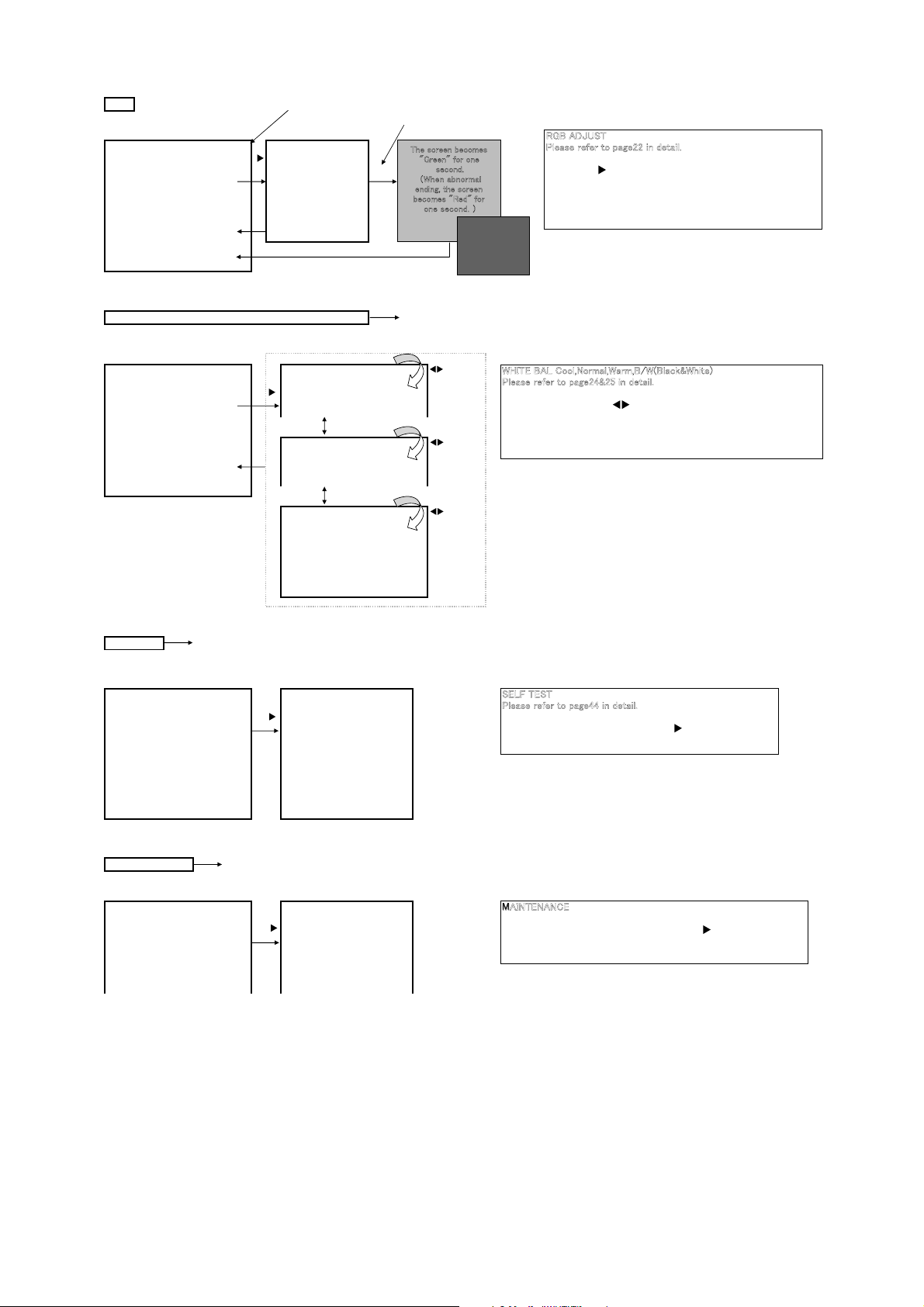

䊶Various adjustmen

FACT RESET It returns setting at the time of shipment

ADJUST MODE (***-**V-EU)ZZZZ

FACT RESET

MEMORY INI

RGB

WHITE BAL Cool

WHITE BAL Normal

WHITE BAL Warm

WHITE BAL B/W

MEMORY INIT When there were instructions, please carry it out

ADJUST MODE (***-**V-EU)ZZZZ

FACT RESET

MEMORY INI

RGB

WHITE BAL Cool

WHITE BAL Normal

WHITE BAL Warm

WHITE BAL B/W

㪚㫆㫅㫋㫀㫅㫅㪼㫊㩷㫇㫌㫊㪿㫀㫅㪾㩷㪽㫆㫉㩷㪉㩷㫊㪼㪺㫆㫅㪻㫊

㪸㪾㪼㫅㫋㪸 㪞㫉㪼㪼㫅

㪤

㫉㫌㫅㫅㫀㫅㪾

䊶㪪㪼㫀㫅㪼

䊶㪛㫉㫀㫍㪼㩷㪬㫇

㪚㫆㫅㫋㫀㫅㫅㪼㫊㩷㫇㫌㫊㪿㫀㫅㪾㩷㪽㫆㫉㩷㪉㩷㫊㪼㪺㫆㫅㪻㫊

㪹

㫃㫌㪼 㪞㫉㪼㪼㫅

㫉㫌㫅㫅㫀㫅㪾

䊶㪪㪼㫀㫅㪼

䊶㪛㫉㫀㫍㪼㩷㪬㫇

㪥㫆㫉㫄㪸㫃㩷㫋㪼㫉㫄㫀㫅㪸㫋㫀㫆㫅

㶎㪩㪼㪻㩷㫀㫊㩷㪻㫀㫊㫇㫃㪸㫐㪼㪻

㫎㪿㪼㫅㩷㪸㪹㫅㫆㫉㫄㪸㫃㩷㪼㫅㪻㫀㫅㪾㪅

㪥㫆㫉㫄㪸㫃㩷㫋㪼㫉㫄㫀㫅㪸㫋㫀㫆㫅

㶎㪩㪼㪻㩷㫀㫊㩷㪻㫀㫊㫇㫃㪸㫐㪼㪻

㫎㪿㪼㫅㩷㪸㪹㫅㫆㫉㫄㪸㫃㩷㪼㫅㪻㫀㫅㪾㪅

㪝㪘㪚㪫㪦㪩㪰㩷㪩㪜㪪㪜㪫

䋨䋱䋩㪪㪼㫃㪼㪺㫋㩷㪲㪝㪘㪚㪫㩷㪩㪜㪪㪜㪫㪴㩷㫆㪽㩷㫋㪿㪼㩷㫊㪼㫉㫍㫀㪺㪼㩷㪸㪻㫁㫌㫊㫋㫄㪼㫅㫋㩷㫄㪼㫅㫌㩷㪹㫐

㪲㩷䂯㩷㪴㩷㫂㪼㫐㩷㫆㪽㩷㫉㪼㫄㫆㫋㪼㩷㪺㫆㫅㫋㫉㫆㫃㪅

䋨䋲䋩㪧㫉㪼㫊㫊㩷㪲㩷

㪪㪼㫋㫋㫀㫅㪾㫊㩷㪹㪼㪾㫀㫅㪅

䋨䋳䋩㪤㪸㪾㪼㫅㫋㪸㩷㫀㫊㩷㪻㫀㫊㫇㫃㪸㫐㪼㪻㩷㫎㪿㫀㫃㪼㩷㪝㪸㪺㫋㫆㫉㫐㩷㪪㪿㫀㫇㫇㫀㫅㪾㩷㪪㪼㫋㫋㫀㫅㪾㫊

㫆㫇㪼㫉㪸㫋㫀㫆㫅㪅

䇭㩷㩷㩷㪞㫉㪼㪼㫅㩷㫀㫊㩷㪻㫀㫊㫇㫃㪸㫐㪼㪻㩷㫎㪿㪼㫅㩷㫅㫆㫉㫄㪸㫃㩷㪼㫅㪻㫀㫅㪾㪅

㩷㩷㩷㩷㩷㪩㪼㪻㩷㫀㫊㩷㪻㫀㫊㫇㫃㪸㫐㪼㪻㩷㫎㪿㪼㫅㩷㪸㪹㫅㫆㫉㫄㪸㫃㩷㪼㫅㪻㫀㫅㪾㪅

䋨㪋䋩㪘㫋㩷㫋㪿㪼㩷㫋㫀㫄㪼㩷㫆㪽㩷㫋㪿㪼㩷㫅㫆㫉㫄㪸㫃㩷㪼㫅㪻㪃㩷㫇㫃㪼㪸㫊㪼㩷㪻㫆㩷㪦㪝㪝㪆㪦㪥㩷㫆㪽㩷㫋㪿㪼

㪩㪼㪻

㫄㪸㫀㫅㩷㫇㫆㫎㪼㫉㩷㫊㫌㫇㫇㫃㫐㪅

㪤㪜㪤㪦㪩㪰㩷㪠㪥㪠㪫㪠㪘㪣㪠㪱㪜

䋨䋱䋩㪪㪼㫃㪼㪺㫋㩷㪲㪤㪜㪤㪦㪩㪰㩷㪠㪥㪠㪫㪴㪅

䋨䋲䋩㪤㪜㪤㪦㪩㪰㩷㪠㪥㪠㪫㪠㪘㪣㩷㫊㫋㪸㫉㫋㫊㩷㪹㫐㩷㪺㫆㫅㫋㫀㫅㫌㫀㫅㪾㩷㫇㫌㫊㪿㫀㫅㪾㩷㪲㩷

㪽㫆㫉㩷㫋㫎㫆㩷㫊㪼㪺㫆㫅㪻㫊㪅

䋨䋳䋩㪫㪿㪼㩷㫊㪺㫉㪼㪼㫅㩷㪺㪿㪸㫅㪾㪼㫊㩷㫀㫅㫋㫆㩷㪹㫃㫌㪼㩷㫎㪿㪼㫅㩷㪤㪜㪤㪦㪩㪰㩷㪠㪥㪠㪫㩷㫊㫋㪸㫉㫋㪅

䇭㩷㩷㩷㪫㪿㪼㩷㫊㪺㫉㪼㪼㫅㩷㪺㪿㪸㫅㪾㪼㫊㩷㫀㫅㫋㫆㩷㪾㫉㪼㪼㫅㩷㫎㪿㪼㫅㩷㪤㪜㪤㪦㪩㪰㩷㪠㪥㪠㪫㩷㪽㫀㫅㫀㫊㪿

㫅㫆㫉㫄㪸㫃㫃㫐㪅

㩷㩷㩷㩷㩷㪫㪿㪼㩷㫊㪺㫉㪼㪼㫅㩷㪺㪿㪸㫅㪾㪼㫊㩷㫀㫅㫋㫆㩷㫉㪼㪻㩷㫎㪿㪼㫅㩷㪤㪜㪤㪦㪩㪰㩷㪠㪥㪠㪫㩷㪽㫀㫅㫀㫊㪿

㪸㪹㫅㫆㫉㫄㪸㫃㫃㫐

䋨㪋䋩㪘㫋㩷㫋㪿㪼㩷㫋㫀㫄㪼㩷㫆㪽㩷㫋㪿㪼㩷㫅㫆㫉㫄㪸㫃㩷㪼㫅㪻㪃㩷㫇㫃㪼㪸㫊㪼㩷㪻㫆㩷㪦㪝㪝㪆㪦㪥㩷㫆㪽㩷㫋㪿㪼

㫄㪸㫀㫅㩷㫇㫆㫎㪼㫉㩷㫊㫌㫇㫇㫃㫐㪅

㪥

㪦㪫㪜㪑㪫㪿㪼㩷㪼㫏㪼㪺㫌㫋㫀㫆㫅㩷㫆㪽㩷㫋㪿㫀㫊㩷㪽㫌㫅㪺㫋㫀㫆㫅㩷㫉㪼㫋㫌㫉㫅㫊㩷㫋㪿㪼㩷㪸㪻㫁㫌㫊㫋㫄㪼㫅㫋

㪺㫆㪻㪼㫊㩷㫋㫆㩷㫋㪿㪼㩷㫇㫉㪼㫊㪼㫋㩷㫍㪸㫃㫌㪼㫊㪃㩷㫋㪿㪼㫉㪼㪽㫆㫉㪼㪃㩷㪸㪻㫁㫌㫊㫋㫄㪼㫅㫋㩷㪻㪸㫋㪸㩷㫎㫀㫃㫃㩷㪹㪼

㫃㫆㫊㫋㪅

㩷㩷㩷㪮㪿㪼㫅㩷㫐㫆㫌㩷㫇㪼㫉㪽㫆㫉㫄㩷㪤㪜㪤㪦㪩㪰㩷㪠㪥㪠㪫㪠㪘㪣㪠㪱㪜㪃㩷㫋㪿㪼㩷㪽㫆㫃㫃㫆㫎㫀㫅㪾㩷㫀㫋㪼㫄㫊

㪸㫉㪼㩷㫅㫆㫋㩷㫀㫅㫀㫋㫀㪸㫃㫀㫑㪼㪻㪅

㪩㪼㪻

㩷㩷㩷䊶㪮㪟㪠㪫㪜㩷㪙㪣㪘㪥㪚㪜㩷㪘㪛㪡㪬㪪㪫㪤㪜㪥㪫㩷㪛㪘㪫㪘

㩷㩷㩷䊶㪪㪬㪙㩷㪚㪦㪥㪫㪩㪘㪪㪫㩷㪘㪛㪡㪬㪪㪫㪤㪜㪥㪫㩷㪛㪘㪫㪘

㩷㩷㩷䊶㪚㪣㪘㪥㪧㩷㪦㪝㪝㪪㪜㪫㩷㪘㪛㪡㪬㪪㪫㪤㪜㪥㪫㩷㪛㪘㪫㪘

㩷㩷㩷㪙㫌㫋㩷㫋㪿㪼㩷㪽㫆㫃㫃㫆㫎㫀㫅㪾㩷㫀㫋㪼㫄㫊㩷㪸㫉㪼㩷㫀㫅㫀㫋㫀㪸㫃㫀㫑㪼㪻㪅

㩷㩷㩷䊶㪦㪫㪟㪜㪩㩷㪘㪛㪡㪬㪪㪫㪤㪜㪥㪫㩷㪛㪘㪫㪘

㩷㩷㩷䊶㪝㪘㪚㪫㪦㪩㪰㩷㪩㪜㪪㪜㪫㩷㪠㪫㪜㪤

㩷㪴㩷㫂㪼㫐㩷㫆㪽㩷㫉㪼㫄㫆㫋㪼㩷㪺㫆㫅㫋㫉㫆㫃㪃㩷㫋㪿㪼㫅㩷㪝㪸㪺㫋㫆㫉㫐㩷㪪㪿㫀㫇㫇㫀㫅㪾

㩷㪴㩷㪹㫌㫋㫋㫆㫅

15

Page 17

P50XR01U/E P60XR01U/E

T

(

)

)

.

A

T

R DRV Cool

.

A

.

E

A

RGB

ADJUST MODE (***-**V-EU)ZZZZ

FACT RESET

MEMORY INI

RGB

WHITE BAL Cool

WHITE BAL Normal

WHITE BAL Warm

WHITE BAL B/W

㪚㫆㫅㫋㫀㫅㫅㪼㫊㩷㫇㫌㫊㪿㫀㫅㪾㩷㪽㫆㫉㩷㪉㩷㫊㪼㪺㫆㫅㪻㫊

㩷

RGB_Amp ADJUSTING

WHITE BAL Cool,Normal,Warm,B/W(Black&White

DJUST MODE (***-**V-EU)ZZZZ ADJUST MODE (***-**V-EU)ZZZZ

FACT RESET R DRV Cool **

MEMORY INI

WHITE BAL Cool

WHITE BAL Normal

WHITE BAL Warm

WHITE BAL B/W

㪦㪢

G DRV Cool **

㩷㫆㫉㩷

ADJUST MODE

G DRV Cool **

B DRV Cool **

㪩㪼㫋㫌㫉㫅

ADJUST MODE (***-**V-EU)ZZZZ

R DRV Cool **

G DRV Cool **

B DRV Cool **

looCVRDBBGR **

䂥䂯

䂥䂯

(***-**V-EU)ZZZZ

**

㪘㪽㫋㪼㫉㩷㪺㫆㫄㫇㫃㪼㫋㫀㫅㪾㩷㫋㪿㪼㩷㪸㪻㫁㫌㫊㫋㫄㪼㫅㫋

㪫㪿㪼㩷㫊㪺㫉㪼㪼㫅㩷㪹㪼㪺㫆㫄㪼㫊

㩹㪞㫉㪼㪼㫅㩹㩷㪽㫆㫉㩷㫆㫅㪼

㫊㪼㪺㫆㫅㪻㪅

䋨㪮㪿㪼㫅㩷㪸㪹㫅㫆㫉㫄㪸㫃

㪼㫅㪻㫀㫅㪾㪃㩷㫋㪿㪼㩷㫊㪺㫉㪼㪼㫅

㪹㪼㪺㫆㫄㪼㫊㩷㩹㪩㪼㪻㩹㩷㪽㫆㫉

㫆㫅㪼㩷㫊㪼㪺㫆㫅㪻㪅㩷䋩

㪩㪞㪙㩷㪘㪛㪡㪬㪪㪫

㪧㫃㪼㪸㫊㪼㩷㫉㪼㪽㪼㫉㩷㫋㫆㩷㫇㪸㪾㪼㪉㪉㩷㫀㫅㩷㪻㪼㫋㪸㫀㫃㪅

䋨䋱䋩㪪㪼㫃㪼㪺㫋㩷㪲㪩㪞㪙㪴㪅

䋨䋲䋩㪧㫉㪼㫊㫊㩷㪲㩷

㪘㪻㫁㫌㫊㫋㫄㪼㫅㫋㩷㫊㫋㪸㫉㫋㫊㩷㪸㫌㫋㫆㫄㪸㫋㫀㪺㪸㫃㫃㫐㪅

䋨䋳䋩㪦㪪㪛㩷㪻㫀㫊㪸㫇㫇㪼㪸㫉㫊㩷㫎㪿㫀㫃㪼㩷㫋㪿㪼㩷㪸㪻㫁㫌㫊㫋㫄㪼㫅㫋㩷㫀㫊㩷㫆㫇㪼㫉㪸㫋㫀㫅㪾㪅

㩷㩷㩷㩷㩷㪦㪪㪛㩷㪸㫇㫇㪼㪸㫉㫊㩷㪸㪾㪸㫀㫅㩷㫎㪿㪼㫅㩷㫋㪿㪼㩷㪸㪻㫁㫌㫊㫋㫄㪼㫅㫋㩷㫀㫊㩷㪺㫆㫄㫇㫃㪼㫋㪼㪻㪅

Please refer to page 24&25 in detail

㪛㪘㪫㪘

㪺㪿㪸㫅㪾㪼

㪛㪘㪫㪘

㪺㪿㪸㫅㪾㪼

㪛㪘㪫㪘

㪺㪿㪸㫅㪾㪼

㪮㪟㪠㪫㪜㩷㪙㪘㪣㩷㪚㫆㫆㫃㪃㪥㫆㫉㫄㪸㫃㪃㪮㪸㫉㫄㪃㪙㪆㪮㩿㪙㫃㪸㪺㫂㩽㪮㪿㫀㫋㪼㪀

㪧㫃㪼㪸㫊㪼㩷㫉㪼㪽㪼㫉㩷㫋㫆㩷㫇㪸㪾㪼㪉㪋㩽㪉㪌㩷㫀㫅㩷㪻㪼㫋㪸㫀㫃㪅

䋨䋱䋩㪪㪼㫃㪼㪺㫋㩷㪲㪮㪟㪠㪫㪜㩷㪙㪘㪣㩷㪚㫆㫆㫃䌾㪙㪆㪮㩿㪙㫃㪸㪺㫂㩽㪮㪿㫀㫋㪼㪀㪴㪅

䋨䋲䋩㪠㫋㩷㪸㪻㫁㫌㫊㫋㫊㩷㫀㫋㩷㫎㫀㫋㪿㩷㫋㪿㪼㩷㪲

䋨䋳䋩㪮㪿㪼㫅㩷㫋㪿㪼㩷㫍㪸㫃㫌㪼㩷㫀㫊㩷㪺㪿㪸㫅㪾㪼㪻㪃㩷㪸㩷㫊㪼㫋㩷㫍㪸㫃㫌㪼㩷㫀㫊㩷㫄㪸㪻㪼㩷㪸㩷㪾㫉㪼㪼㫅㩷㪺㪿㪸㫉㪸㪺㫋㪼㫉㪅

㩷㩷㩷㩷㩷㩷㪠㫋㩷㫉㪼㫋㫌㫉㫅㫊㩷㫀㫋㩷㫋㫆㩷㪸㩷㫎㪿㫀㫋㪼㩷㪺㪿㪸㫉㪸㪺㫋㪼㫉㩷㪹㫐㩷㫋㪿㪼㩷㫄㪼㫄㫆㫉㫐㩷㫇㫉㪼㫊㪼㫉㫍㪸㫋㫀㫆㫅㪅

㩷㪴㩷㪽㫆㫉㩷㫆㫍㪼㫉㩷㪉㩷㫊㪼㪺㫆㫅㪻㫊㩷㫋㪿㪼㫅㩷㪩㪞㪙㩷㪘㫄㫇㫃㫀㫋㫌㪻㪼

㪴㩷㪹㫌㫋㫋㫆㫅㪅

SELF TEST Please refer to page 44 in detail

ADJUST MODE (***-**V-EU)ZZZZ

SELF TEST

MAINTENANCE

DEVICE

M306H5 V01.00

DJ.REV. V01.01

PANEL_TIME

65535

㩷㫆㫉㩷

㪦㪢

SELF_TEST䇭screen

MAINTENANCE Please refer to page 18 in detail

ADJUST MODE (***-**V-EU)ZZZZ

SELF TEST

MAINTENANC

DEVICE

DJ.REV. V01.01

PANEL_TIME

65535

㩷㫆㫉㩷

㪦㪢

㪪㪜㪣㪝㩷㪫㪜㪪㪫

㪧㫃㪼㪸㫊㪼㩷㫉㪼㪽㪼㫉㩷㫋㫆㩷㫇㪸㪾㪼㪋㪋㩷㫀㫅㩷㪻㪼㫋㪸㫀㫃㪅

䋨䋱䋩㪪㪼㫃㪼㪺㫋㩷㪲㪪㪜㪣㪝㩷㪫㪜㪪㪫㪴㪅

䋨䋲䋩㪠㫋㩷㪼㫅㫋㪼㫉㫊㩷㫋㪿㪼㩷㫊㪼㫃㪽㩷㫋㪼㫊㫋㩷㫊㪺㫉㪼㪼㫅㩷㫎㫀㫋㪿㩷㪲㩷

㪤㪘㪠㪥㪫㪜㪥㪘㪥㪚㪜

䋨䋱䋩㪪㪼㫃㪼㪺㫋㩷㪲㪤㪘㪠㪥㪫㪜㪥㪘㪥㪚㪜㪴㪅

䋨䋲䋩㪠㫋㩷㪼㫅㫋㪼㫉㫊㩷㫋㪿㪼㩷㪤㪘㪠㪥㪫㪜㪥㪘㪥㪚㪜㩷㫊㪺㫉㪼㪼㫅㩷㫎㫀㫋㪿㩷㪲

neercsECNANETNIAM00.10V5H603M

㩷㪴㩷㫆㫉㩷㫋㪿㪼㩷㪦㪢㩷㪹㫌㫋㫋㫆㫅㪅

㪴㩷㫆㫉㩷㫋㪿㪼㩷㪦㪢㩷㪹㫌㫋㫋㫆㫅㪅

16

Page 18

P50XR01U/E P60XR01U/E

y

A

A

A

A

A

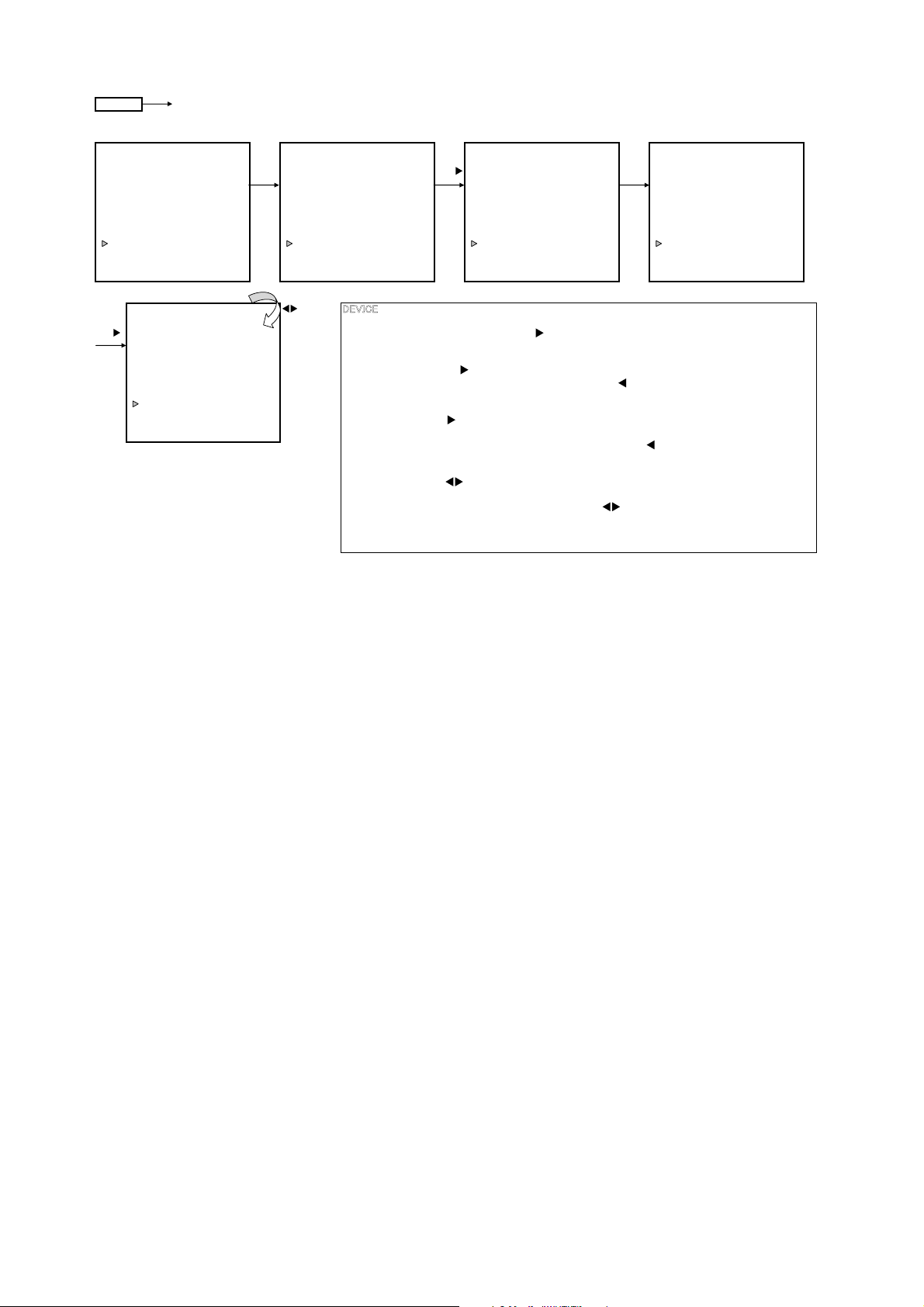

DEVICE Engineer uses onl

ADJUST MODE (***-**V-EU)ZZZZ ADJUST MODE (***-**V-EU)ZZZZ ADJUST MODE (***-**V-EU)ZZZZ ADJUST MODE (***-**V-EU)ZZZZ

DEVICE ITEM DAT

272

DEVICE ITEM DAT

㪈㪃㪈

DEVICE ITEM DAT

㪦㪢

㩷㫆㫉㩷

11__ 11 __ 11 50

DEVICE ITEM DAT

㪌㪃㪇

FFF3##1FFF3##1FFF3##1FFF3##1

E1223E1223E1223E1223

F##51F##51F##51F##51

FF139FF139FF139FF139

C272C272C272C

803803803803

D5301D5301D5301D5301

ADJUST MODE

㪦㪢

㩷㫆㫉㩷

DEVICE ITEM DAT

(***-**V-EU)ZZZZ

1 ## 3FFF

322 1E

15 ## F

931 FF

27 2C

30 8

10 3 5D

11 50 FF

㪛㪘㪫㪘

㪺㪿㪸㫅㪾㪼

㪛㪜㪭㪠㪚㪜

䋨䋱䋩㪪㪼㫃㪼㪺㫋㩷㪲㪛㪜㪭㪠㪚㪜㪴㪅

䋨䋲䋩㪠㫋㩷㪼㫅㫋㪼㫉㫊㩷㫋㪿㪼㩷㪸㪻㫁㫌㫊㫋㫄㪼㫅㫋㩷㫊㪺㫉㪼㪼㫅㩷㫎㫀㫋㪿㩷㪲㩷

䋨䋳䋩㪛㪜㪭㪠㪚㪜

㩷㽲㪫㪿㪼㩷㪺㫆㫅㫋㫉㫆㫃㩷㪻㪼㫍㫀㪺㪼㩷㫀㫊㩷㫊㪼㫃㪼㪺㫋㪼㪻㩷㫎㫀㫋㪿㩷㫋㪼㫅㩷㫂㪼㫐㫊㩷㪽㫉㫆㫄㩷㩹㪇㩹㩷㫋㫆㩷㩹㪐㪐㩹㪅

㩷㽳㪛㪜㪭㪠㪚㪜㩷㫀㫊㩷㪽㫀㫏㪼㪻㩷㫎㫀㫋㪿㩷㪲㩷

㩷㪴㩷㫆㫉㩷㫋㪿㪼㩷㪦㪢㩷㪹㫌㫋㫋㫆㫅㩷㪸㫅㪻㩷㫀㫋㩷㪺㪿㪸㫅㪾㪼㫊㩷㫋㫆㩷㪠㪫㪜㪤㪅

㩷㽴㪠㫋㩷㫉㪼㫋㫌㫉㫅㫊㩷㫋㫆㩷㪉㫅㪻㩷㫇㪸㪾㪼㩷㩹㪛㪜㪭㪠㪚㪜㩹㩷㪺㫃㪼㪸㫉㫀㫅㪾㩷㪸㫃㫃㩷㫀㫅㫇㫌㫋㩷㫎㪿㪼㫅㩷㪲㩷

䋨䋴䋩㪠㪫㪜㪤

㩷㽲㪫㪿㪼㩷㪸㪻㫁㫌㫊㫋㫄㪼㫅㫋㩷㫀㫋㪼㫄㩷㫀㫊㩷㫊㪼㫃㪼㪺㫋㪼㪻㩷㫎㫀㫋㪿㩷㫋㪼㫅㩷㫂㪼㫐㫊㩷㪽㫉㫆㫄㩷㩹㪇㩹㩷㫋㫆㩷㩹㪐㪐㪐㩹㪅

㩷㽳㪠㪫㪜㪤㩷㫀㫊㩷㪽㫀㫏㪼㪻㩷㫎㫀㫋㪿㩷㪲㩷

㫄㫆㪻㪼㪃㩷㪸㫅㪻㩷㫋㪿㪼㩷㫉㪼㪸㪻㫀㫅㪾㩷㪻㪸㫋㪸㩷㫀㫊㩷㪻㫀㫊㫇㫃㪸㫐㪼㪻㩷㪸㫅㪻㩷㫀㫋㩷㪺㪿㪸㫅㪾㪼㫊㩷㫋㫆㩷㪛㪘㪫㪘㩷㪸㫋㩷㫋㪿㪼㩷㪩㪼㪸㪻㩷㫄㫆㪻㪼㪅

㩷㽴㪠㫋㩷㫉㪼㫋㫌㫉㫅㫊㩷㫋㫆㩷㩹㪛㪜㪭㪠㪚㪜㩹㩷㫆㫅㩷㫋㪿㫀㫊㩷㫊㪺㫉㪼㪼㫅㩷㪺㫃㪼㪸㫉㫀㫅㪾㩷㫋㪿㪼㩷㫀㫅㫇㫌㫋㩷㫎㪿㪼㫅㩷㪲㩷

㫇㫌㫊㪿㪼㪻㪅

䋨䋵䋩㪛㪘㪫㪘

㩷㽲㪫㪿㪼㩷㪮㫉㫀㫋㪼㩷㫄㫆㪻㪼㩷㫀㫊㩷㪲

㫇㫌㫊㪿㪼㪻㪃㩷㫋㪿㪼㩷㪸㪻㫁㫌㫊㫋㫄㪼㫅㫋㩷㫍㪸㫃㫌㪼㩷㫄㪼㫄㫆㫉㫐㩷㫋㫆㩷㪝㪣㪘㪪㪟㪅

㩷㽳㪫㪿㪼㩷㪩㪼㪸㪻㩷㫄㫆㪻㪼㩷㫌㫇㪻㪸㫋㪼㫊㩷㫋㪿㪼㩷㪻㪼㫋㪼㪺㫋㫀㫆㫅㩷㫍㪸㫃㫌㪼㩷㫎㫀㫋㪿㩷㫋㪿㪼㩷㪲

㩷㽴㪠㫋㩷㫉㪼㫋㫌㫉㫅㫊㩷㫋㫆㩷㩹㪠㪫㪜㪤㩹㩷㫆㫅㩷㫋㪿㫀㫊㩷㫊㪺㫉㪼㪼㫅㩷㪺㫃㪼㪸㫉㫀㫅㪾㩷㫋㪿㪼㩷㫀㫅㫇㫌㫋㩷㫎㪿㪼㫅㩷㫋㪿㪼㩷㪩㪼㫋㫌㫉㫅㩷㪹㫌㫋㫋㫆㫅㩷㫀㫊㩷㫇㫌㫊㪿㪼㪻㪅

䋨䋶䋩㪛㪜㪭㪠㪚㪜㪃㩷㪠㪫㪜㪤㪃㩷㪸㫅㪻㩷㪛㪘㪫㪘㩷㪺㪸㫅㩷㪹㪼㩷㪻㫀㫊㫇㫃㪸㫐㪼㪻㩷㫌㫇㩷㫋㫆㩷㪼㫀㪾㪿㫋㩷㫃㫀㫅㪼㫊㩷㫆㫉㩷㫃㪼㫊㫊㪅

㩷㪴㩷㫆㫉㩷㫋㪿㪼㩷㪦㪢㩷㪹㫌㫋㫋㫆㫅㪃㩷㪸㫅㪻㩷㫋㪿㪼㩷㫃㪸㫊㫋㩷㪸㪻㫁㫌㫊㫋㫄㪼㫅㫋㩷㫍㪸㫃㫌㪼㩷㫀㫊㩷㪻㫀㫊㫇㫃㪸㫐㪼㪻㩷㪸㫋㩷㫋㪿㪼㩷㪮㫉㫀㫋㪼

㪴㩷㫂㪼㫐㩷㪸㫅㪻㩷㪺㪿㪸㫅㪾㪼㪸㪹㫃㪼㩷㪸㫊㩷㪽㫆㫉㩷㫋㪿㪼㩷㪸㪻㫁㫌㫊㫋㫄㪼㫅㫋㩷㫍㪸㫃㫌㪼㪅㩷㪮㪿㪼㫅㩷㫋㪿㪼㩷㪦㪢㩷㪹㫌㫋㫋㫆㫅㩷㫀㫊

㩷㪴㩷㫆㫉㩷㫋㪿㪼㩷㪦㪢㩷㪹㫌㫋㫋㫆㫅㪅

㩷㪴㩷㫆㫉㩷㫋㪿㪼㩷㪩㪼㫋㫌㫉㫅㩷㪹㫌㫋㫋㫆㫅㩷㫀㫊㩷㫇㫌㫊㪿㪼㪻㪅

㩷㪴㩷㫆㫉㩷㫋㪿㪼㩷㫉㪼㫋㫌㫉㫅㫀㫅㪾㩷㪹㫌㫋㫋㫆㫅㩷㫀㫊

㪴㩷㪸㫅㪻㩷㪦㪢㩷㫂㪼㫐㪅

17

Page 19

P50XR01U/E P60XR01U/E

HDD Check

1. Select a maintenance mode.

2. Next, select HDD.

3. It becomes the HDD check screen and the following items are displayed.

Total Size: It displays the total capacity of the HDD.

Used Size: It displays the consumption of the HDD.

Power-On Hours Count: The electricity time for HDD

Old Rec. Date: It displays the oldest date when TV recorded it to the HDD.

New Rec. Date: It displays the newest date when TV recorded it to the HDD.

Initial Date: It displays the date when TV initialised the HDD.

SMART Info.: It displays SMART of the HDD.

HDD Format: When you choose [HDD Format] and push "OK", TV initialises the HDD.

When initialisation is finished, TV displays it to right side indication as follows.

Normal end: OK

Abnormal end: NG

When you format the HDD, all the data in HDD are deleted.

HDD Log: You choose [SD] and push "OK", SD card acquire HDD log.

SMART information

[SMART info] displayed information and the poor HDD judgment standard are as follows.

When the behavior of the HDD is doubtful, please refer to this.

No item information indication range judgment standard

1 Raw Read Error Rate It displays error rate of the HDD.(decimal) 1~100 There is no problem more than 80.

2 Throughput Performance It displays Throughput performance.(decimal) 0~200 There is no judgment need.

3 Spin Up Time It displays Spin Up Time.(decimal) 0~100 There is no problem more than 50.

4 Start/Stop Count It displays Start/Stop Count.(decimal) (+)100~(-)100

5 Reallocated Sector Count It displays Reallocated Sector Count.(decimal) 1~100 There is no problem more than 90.

6 Seek Error Rates It displays Seek Error Rates.(decimal) 1~100 There is no problem more than 80.

7 Seek Time Performance It displays Seek Time Performance.(decimal) 0~200 There is no problem more than 50.

8 Power-On Hours Count It displays Power-On Hours Count.(decimal) (+)100~(-)100

9 Spin Retry Count It displays Spin Retry Count.(decimal) 50~100 There is no problem more than 80.

10 Device Power Cycle Count It displays Device Power Cycle Count. 1~100 There is no judgment need.

11 Power Off Retract Count It displays Power Off Retract Count. (+)100~(-)100

12 Load/Unload Cycle Count It displays Load/Unload Cycle Count. (+)100~(-)100

13 Device Temperature

14 Reallocation Event Count It displays Reallocation Event Count. 1~100 There is no problem more than 90.

15 Corrent Pending Sector Count It displays Corrent Pending Sector Count. 1~100 There is no problem more than 80.

Off-Line Scan Uncorectable

16

Sector Count

17 Ultra DMA CRC Error Count It displays Ultra DMA CRC Error Count. 1~200 There is no judgment need.

It displays temperature inside HDD at the ratio with

55 degrees.

It displays Off-Line Scan Uncorectable Sector Count. 1~100 There is no judgment need.

253~100

Zero indication is a life guarantee limit.

There is no problem in a plus.

Zero indication is a life guarantee limit.

There is no problem in a plus.

Zero indication is a life guarantee limit.

There is no problem in a plus.

Zero indication is a life guarantee limit.

There is no problem in a plus.

Indication at the time of 100,

the HDD inside shows 55 degrees.

There is no problem more than 100.

18

Page 20

P50XR01U/E P60XR01U/E

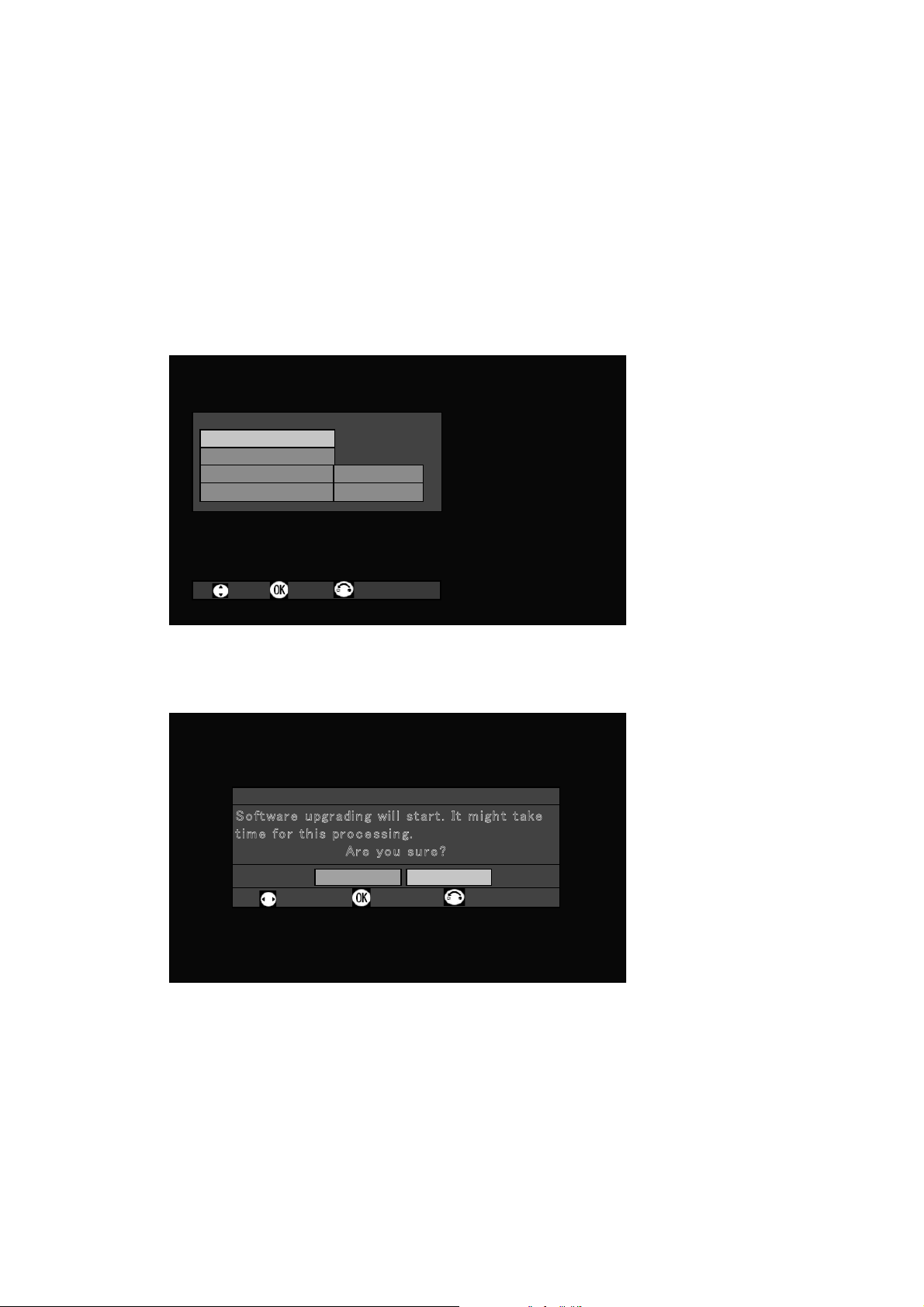

Upgrading theSD

The procedure as follows.

1. In sert the MMC/SD card on which the firmware was written to the SD slot of the TV.

When obtained from an email and/or a FTP server, a PC and a commercial SD reader/writer are

necessary.

2-1 S elect [menu] with a wireless remote controller.

2-2 S elect [Initial Setup].

2-3 The Main software version will be display Vxxx.xxxx as shown on Fig. 1.

Initial Setup

Software M aintenance

Software V ers ion 1.0000

Up gr ade ( SD)

Up gr ade ( OA D)

Auto Upgrade

Auto Picture Reset

On

Off

Select Return

2-4 S elect [Upgrade (SD)].

2-5 Fig.2 will be displayed.

㪪㫆㪽㫋㫎㪸㫉㪼㩷㫌㫇㪾㫉㪸㪻㫀㫅㪾㩷㫎㫀㫃㫃㩷㫊㫋㪸㫉㫋㪅㩷㪠㫋㩷㫄㫀㪾㪿㫋㩷㫋㪸㫂㪼

㫋㫀㫄㪼㩷㪽㫆㫉㩷㫋㪿㫀㫊㩷㫇㫉㫆㪺㪼㫊㫊㫀㫅㪾㪅

㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㪘㫉㪼㩷㫐㫆㫌㩷㫊㫌㫉㪼㪖

2-6 S elect [Continue].

Enter

Fig. 1

Confir m

Continue Cancel

Select En ter Cancel

Fig.2

19

Page 21

P50XR01U/E P60XR01U/E

)

2-7Fig.3willbedisplayed.Theupgradingprocesswillcontinueuntilthebarisfilled.

While upgrading, do not turn off the power.

Please do not turn off the pow er.

CancelUpgrade(SD

Fig.3

2-8 After upgrade completion, the TV turns off automatically. (Fig.4)

The software w as upgraded.

The receiver w ill turn off automatically.

Fig.4

2-9 Upgrade finished. C onfirm the new software version.

㶎 Abnormal Finish Message

(γ) Whhen a CARD is not inserted or accessed

Message㧦

”Please insert SD card before upgrading.”

(δ) When the version written on the SD card is the same as a present version or old

Message㧦

”New software was not found.”

(ε )Wh hen the SD card was pulled out during the upgrad process or the data from the SD card was not read.

Message㧦

”Upgrading was failed.”

20

Page 22

P50XR01U/E P60XR01U/E

ReconfirmingVsandVavoltagevaluesonthe Powerunit

P50XR01U/E and P60XR01U/E do not need adjustment. (Because P50XR01U/E and P60XR01U/E are self-adjusting.)

However, Vs and Va voltages require reconfirming on the Power Unit.

This page explains the reconfirm procedure.

(1) Turn on the TV set and apply pre-heat run more than 1 min on burn-in screen.

(2) Receive full black pattern signal.

(or no video signal; but the power will be automatically turned off after a few seconds by the power save function.)

(3) Connect a voltmeter (which has a tolerance within 0.02V) to between Vs (or Va) test pin and GND test pin on the

power unit.

Adjustment Point: Refer to the figure below

Procedures

(1) Check Vs voltage and Va voltage at CN99 test pins.

Remarks

(1) Permissible levels of voltage in sufficient time of heat-run performed is as follows.

50V PDP model 60V PDP model Reference Voltage

Vs

Va

If it is difficult to read the voltage value because of the wiring positions, make a note using a marker in a visible space in

advance.

withinr1.5V withinr3.0V

withinr1.0V withinr1.0V

Label example

<LOT>N6

Vs=80.0V Va=60.0V

Vw=140.0V Vx=60.0V

Voltage described in the label on

the PDP panel

[50V PDP]

[60V PDP]

CN99㧦Vs/Va test pins

Ԙ Va

ԙ Vs

Ԛ NC

ԛ NC

Ԝ GND

CN99㧦Vs/Va test pins

Ԙ Va

ԙ Vs

Ԛ NC

ԛ NC

Ԝ GND

21

Page 23

P50XR01U/E P60XR01U/E

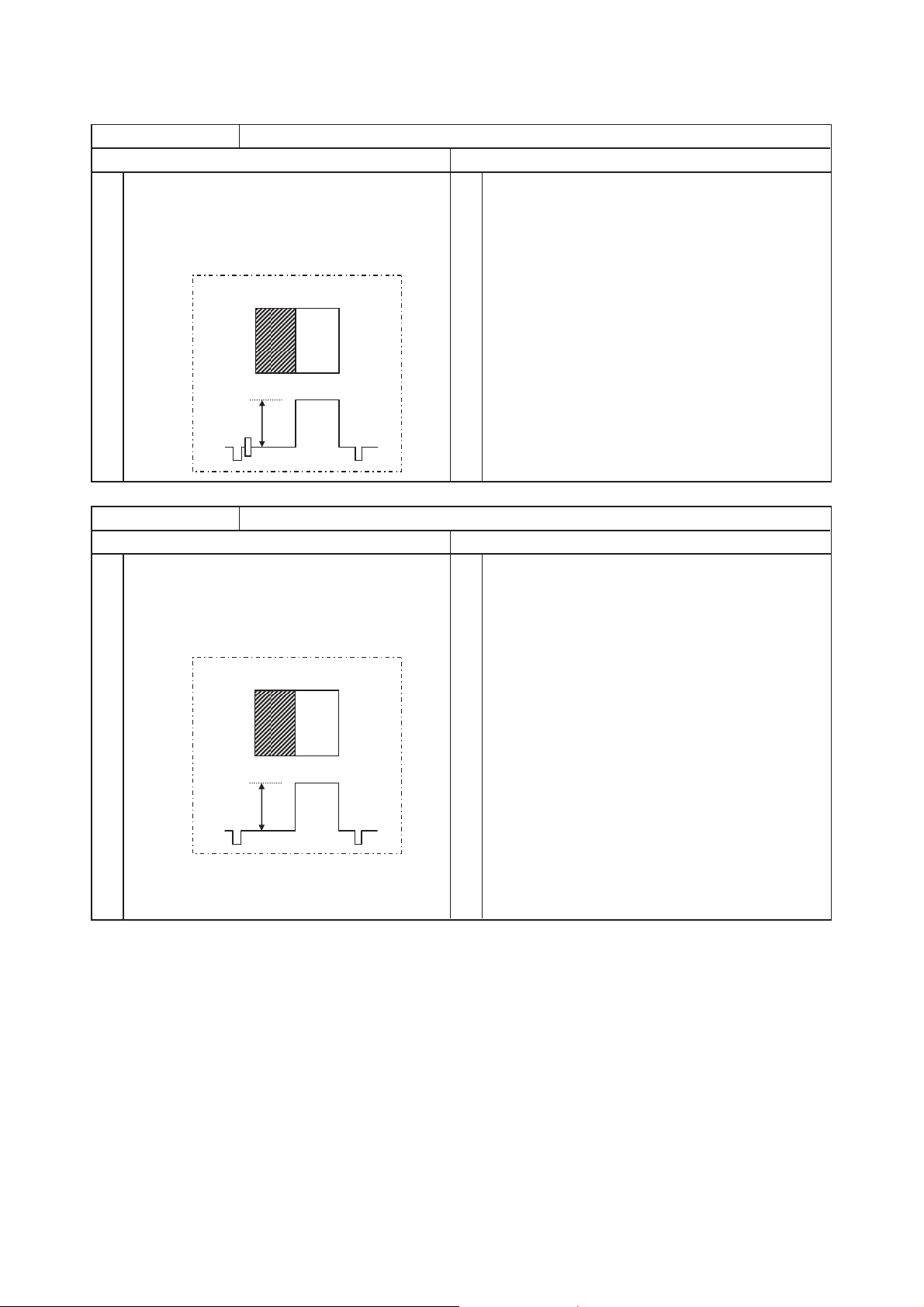

RGB Amplitude Adjustment (AV Component Input)

Item

Composite video Adjustment

Preparation Procedure

(1)

Apply heat-run to the set for more than 20 mins

before the final adjustment.

(2)

Input composite video adjustment signal into

AV1 terminal.

Adjustment signal for CVBS format

White

Black

0.7V

Item

Component 480p/480i Adjustment

Preparation Procedure

(1)

Apply heat-run to the set for more than 20 mins

before the final adjustment.

(2)

Input component 480p adjustment signal into

AV4 terminal.

Adjustment signal for 480p/480i format

White

Black

(1)

Receive composite video adjustment signal at AV1

terminal input.

Characters must not be inserted into both patterns

of Black and White.

(2)

Go into Service Adjustment Menu and select “RGB”.

(3)

Press [►] for over 2 seconds then RGB Amplitude

Adjustment starts automatically.

OSD disappears while the adjustment is operating.

OSD appears again when the adjustment is

completed.

(1)

Next, receive 480p adjustment signal at AV4

terminal input.

Characters must not be inserted into both patterns

of Black and White.

(2)

Go into Service Adjustment Menu and select “RGB”.

(3)

Press [►] for over 2 seconds then RGB Amplitude

Adjustment starts automatically.

OSD disappears while the adjustment is operating.

OSD appears again when the adjustment is

completed.

0.7V

(4)

Change signal formal from 480p to 480i.

(5)

Press [►] for over 2 seconds again, then RGB

Amplitude Adjustment starts automatically.

OSD disappears while the adjustment is operating.

OSD appears again when the adjustment is

completed.

22

Page 24

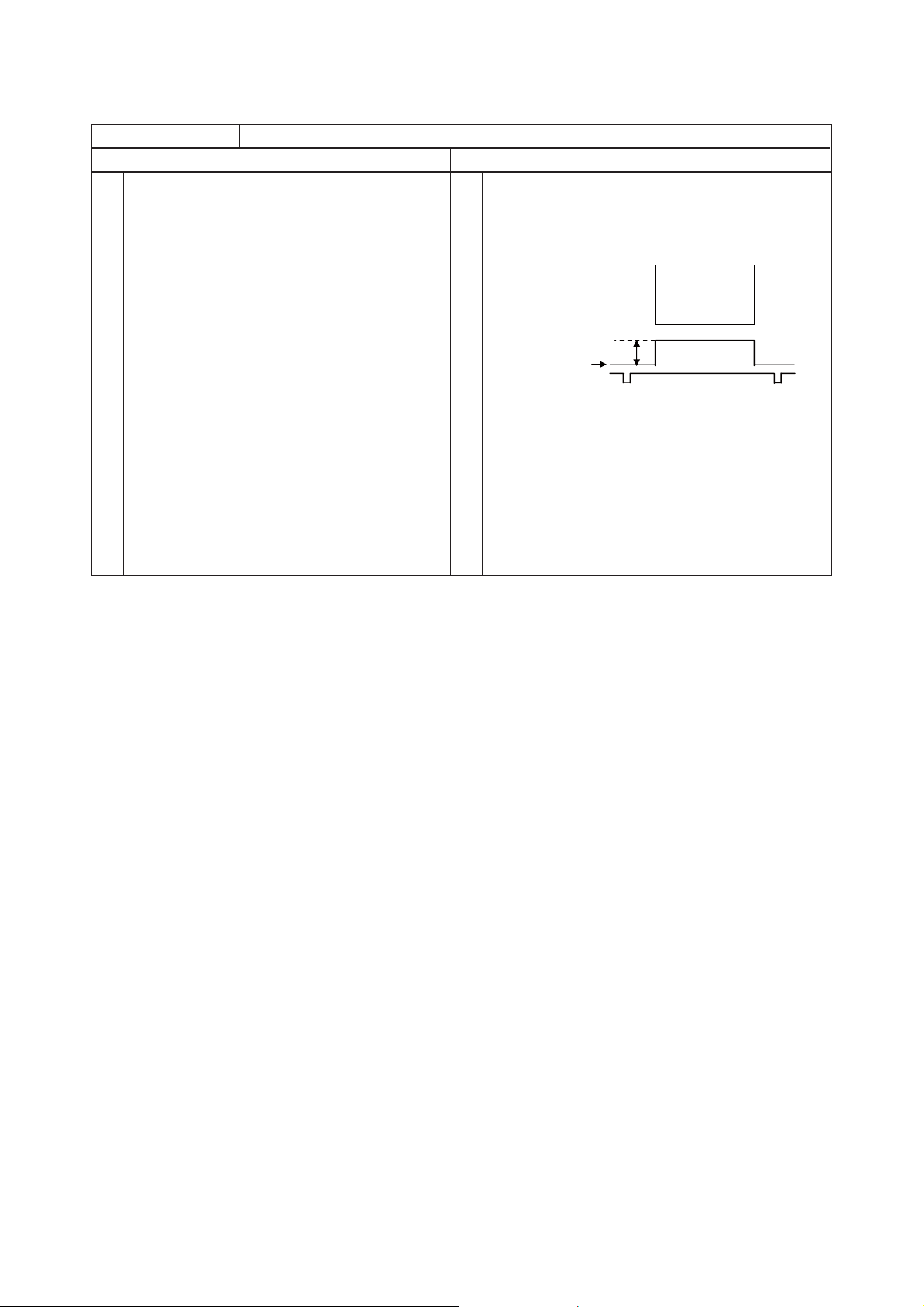

PC input Adjustment

P50XR01U/E P60XR01U/E

Item

PC input Adjustment

Preparation Procedure

(1)

Apply heat-run to the set for more than 20 mins

before the final adjustment.

(2)

Input PC VGA adjustment signal into PC input

terminal.

(1)

Receive the PC adjustment signal at PC input

terminal.

Characters must not be inserted into both patterns

of Black and White.

White

RGB

Pedestal Level

(2)

Go into Service Adjustment Menu and select “RGB”.

(3)

Press [►] for over 2 seconds then RGB Amplitude

H Sync

0.7V

Fig. Adjustment signal for PC format

Adjustment starts automatically.

OSD disappears while the adjustment is operating.

OSD appears again when the adjustment is

completed.

23

Page 25

P50XR01U/E P60XR01U/E

Video ColourTemperatureAdjustment

Item

Video Colour Temperature Adjustment (Cool)

Preparation Procedure

(1)

Set the signal generator output to white raster.

(Window ratio: 100%)

(2)

Component signal (576i or 480i)

Video level: 0.700Vp-p

Sync level: 0.300Vp-p

Setup level: 0V

(3)

Input white raster signal into AV4 Component

input terminal.

(4)

Set Picture Menu to Natural mode.

(5)

Check that the mode is set as Factory

Adjustment mode.

(6)

Set aspect to Full mode.

(1)

Perform the following adjustment with the remote

control.

(2)

Set the CRT colour analyzer (CA-100) at the centre

of the panel.

(3)

Set colour temperature to “Cool”.

(4)

Ensure that the adjustment R/G/B DRIVE (COOL)

is all set as 255.

If the values are not 255, set them to 255.

(5)

Receive white raster signal. And step down either

of R DRV_COOL, G DRV_COOL or B DRV_COOL

of the two (or, one) values and adjust to the

following value.

(Note) At least one of the data should be 255.

Specification

Video colour temperature (Cool)

x=0.266±0.005

y=0.270±0.005

14000K + 0MPCD

[Remarks]

(1) Colour temperature should be adjusted under the condition in which the screen is the brightest, thus the initial

value of adjustment is set at maximum.

(2) This adjustment only degreases brightness.

(3) Beware there is RESET in each of Picture mode.

Item

Video Colour Temperature Adjustment (Normal)

Preparation Procedure

(1)

Set the signal generator output to white raster.

(Window ratio: 100%)

(2)

Component signal (576i or 480i)

Video level: 0.700Vp-p

(1)

Perform the following adjustment with the remote

control.

(2)

Set the CRT colour analyzer (CA-100) at the centre

of the panel.

Sync level: 0.300Vp-p

Setup level: 0V

(3)

Input white raster signal into AV4 Component

input terminal.

(3)

Set colour temperature to “Normal”.

Ensure that the adjustment R/G/B DRIVE (NORMAL)

(4)

is all set as 255.

If the values are not 255, set them to 255.

(4)

Set Picture Menu to Natural mode.

Receive white raster signal. And step down either

(5)

(5)

Check that the mode is set as Factory

Adjustment mode.

of R DRV_NORMAL, G DRV_NORMAL or B

DRV_NORMAL of the two (or, one) values and

adjust to the following value.

(6)

Set aspect to Full mode.

(Note) At least one of the data should be 255.

Specification

Video colour temperature (Normal)

x=0.285±0.005

y=0.293±0.005

9300K + 0MPCD

[Remarks]

(1) Colour temperature should be adjusted under the condition in which the screen is the brightest, thus the initial

value of adjustment is set at maximum.

(2) This adjustment only degreases brightness.

(3) Beware there is RESET in each of Picture mode.

24

Page 26

P50XR01U/E P60XR01U/E

Item

Video Colour Temperature Adjustment (Warm)

Preparation Procedure

(1)

Set the signal generator output to white raster.

(Window ratio: 100%)

(2)

Component signal (576i or 480i)

Video level: 0.700Vp-p

Sync level: 0.300Vp-p

Setup level: 0V

(3)

Input white raster signal into AV4 Component

input terminal.

(4)

Set Picture Menu to Natural mode.

(5)

Check that the mode is set as Factory

Adjustment mode.

(6)

Set aspect to Full mode.

(1)

Perform the following adjustment with the remote

control.

(2)

Set the CRT colour analyzer (CA-100) at the centre

of the panel.

(3)

Set colour temperature to “Warm”.

(4)

Ensure that the adjustment R/G/B DRIVE (WARM)

is all set as 255.

If the values are not 255, set them to 255.

(5)

Receive white raster signal. And step down either

of R DRV_WARM, G DRV_WARM or B DRV_WARM

of the two (or, one) values and adjust to the following

value.

(Note) At least one of the data should be 255.

Specification

Video colour temperature (Warm)

x=0.314±0.005

y=0.323±0.005

6500K + 0MPCD

[Remarks]

(1) Colour temperature should be adjusted under the condition in which the screen is the brightest, thus the initial value of

adjustment is set at maximum.

(2) This adjustment only degreases brightness.

(3) Beware there is RESET in each of Picture mode.

Item

Video Colour Temperature Adjustment (B&W)

Preparation Procedure

(1)

(1)

Set signal generator output as All White.

(Window ratio: 100%)

(2)

Component signal (480i)

Video level: 0.700Vp-p

Perform the following adjustment with remote

control.

(2)

Set the CRT Colour Analyzer (CA-100) at the centre

of the panel.

Sync level: 0.300Vp-p

(3)

Setup level: 0V

(3)

Input white raster signal into AV4 Component

input terminal.

Set colour temperature to “Black&White”.

Ensure that the adjustment R/G/B DRIVE (B/W) is all

(4)

set as 255.

If the values are not 255, set them to 255.

(4)

Set Picture Menu to Natural mode.

Receive white raster signal. And step down either

(5)

Check that the mode is set as Factory Adjustment

(5)

mode.

Set aspect to Full mode.

(6)

of R DRV_B/W, G DRV_B/W or B DRV_B/W of the

two (or, one) values and adjust to the following value.

(Note) At least one of the data should be 255.

Specification

Video colour temperature (B/W)

x=0.335±0.005

y=0.343±0.005

5400K + 0MPCD

[Remarks]

(1) Colour temperature should be adjusted under the condition in which the screen is the brightest, thus the initial

adjustment value is set at maximum.

(2) This adjustment only degreases brightness.

(3) Beware there is RESET in each of Picture mode.

25

Page 27

P50XR01U/E P60XR01U/E

6. Troubleshooting

Burn-in mode

This mode displays test patterns of a single colour raster in turn. These signals are from the built-in generator

of the panel. So it can be presumed that the panel has a problem when the screen of Burn-in

mode is abnormal.

Using the remote control with the set turned on can activate the mode.

Press the “MENU”, “recall”, “9”, “OK” in turn for less than 2 seconds.

The set turns on with single colour raster and the OSD off [BURN IN: ON].

To escape from this mode, press the “MENU”, “recall”, “9”, “OK” in turn for less than 2 seconds.

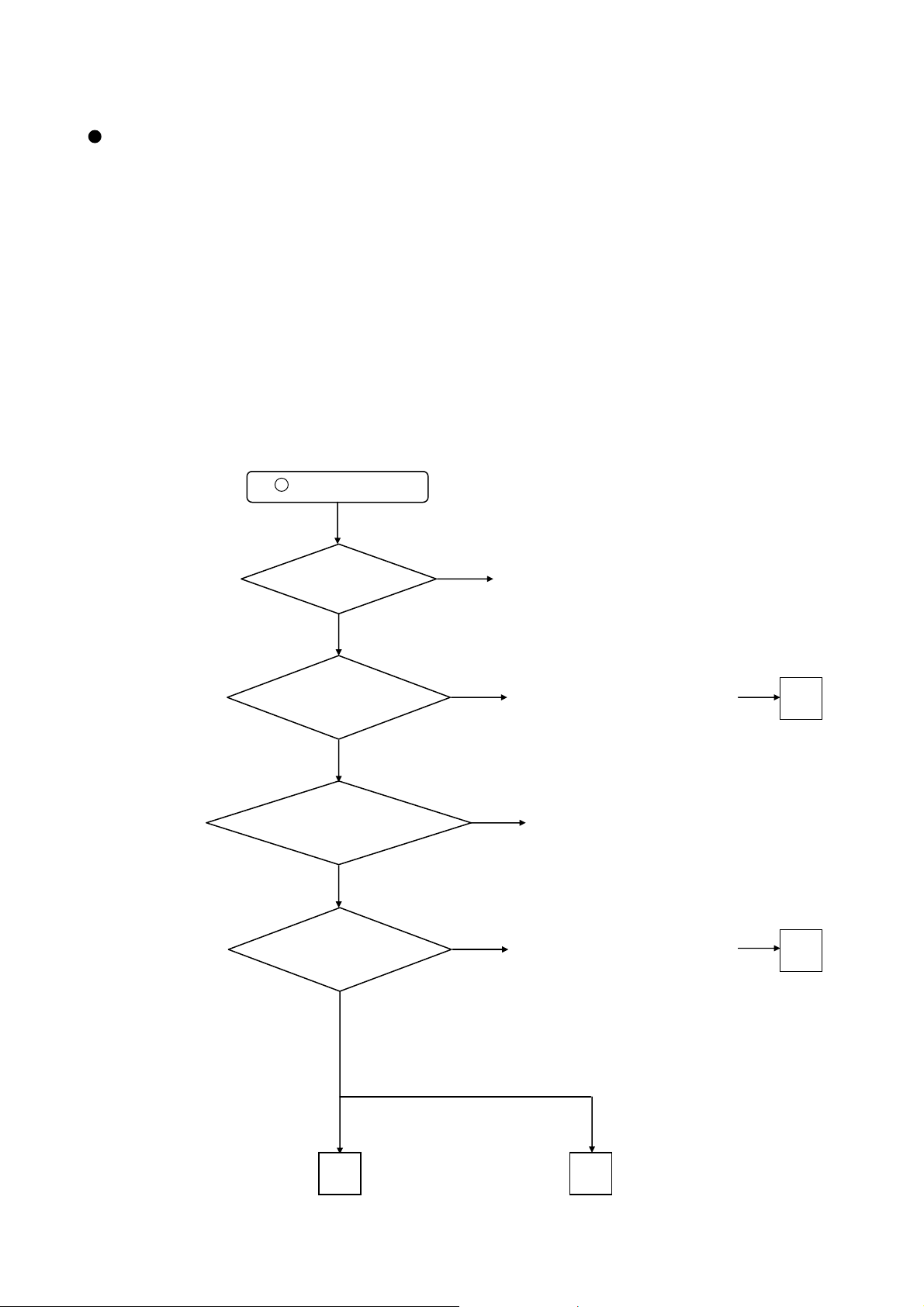

[No picture, No sound]

Confirm a state of LED and examine according to the following Flowcharts:

LED does not light.

1

Is AC Fuse

F9A2 T6.3AH 250V of Filter

PCB normal?

Ye s

Is the voltage of pin1(+5.0V)

of PPM1 connector of MAIN

PCB normal?

Ye s

Are the voltages of

pin6(+5.0V)/7(+3.3V) of PPM1

connector of MAIN

PCB normal?

Ye s

Are the voltages of

pin1/2/3(+5.6V) of PPM2

connector of MAIN PCB

normal?

Ye s

No

Change AC Fuse of Filter PCB

No

No

Change MAIN PCB or EPM1 (cable).

If no improvement, go to

Power Supply Unit Troubleshooting

No

Change MAIN PCB or EPM1 (cable)

Change MAIN PCB or EPM2 (cable).

If no improvement, go to

Power Supply Unit Troubleshooting

A

A

B C

Go to Picture Troubleshooting

Go to Sound Troubleshooting

26

Page 28

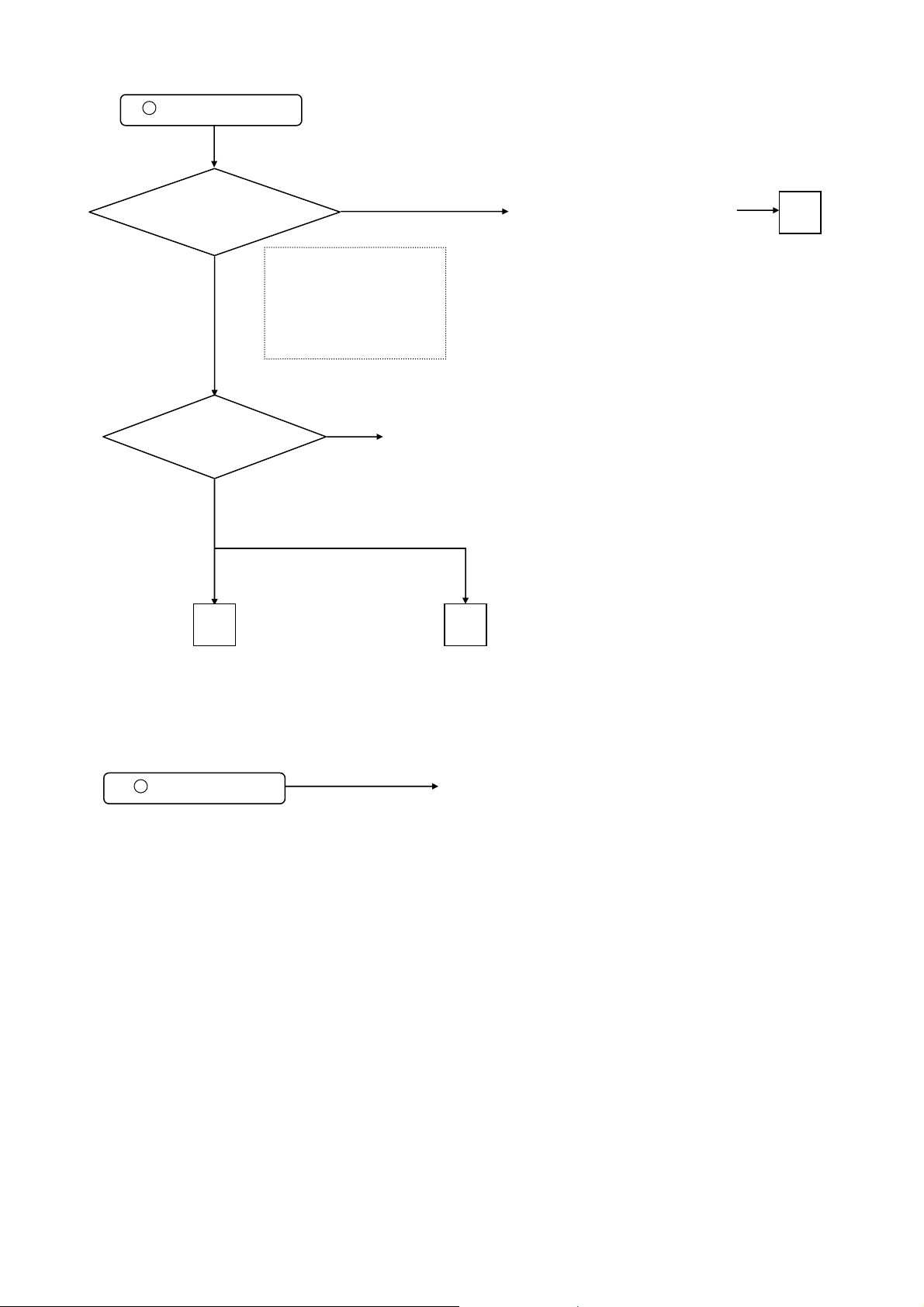

LED lights blue.

2

P50XR01U/E P60XR01U/E

Are the voltages of PPM1 and PPM2

connector of MAIN PCB normal?

Ye s

Does PDP Burn-In mode

operate normally?

[PPM1] Pin1/4/5/6(+5.0V)

Pin7/8(+3.3V)

[PPM2] Pin1/2/3(+5.6V)

Ye s

B C

No

Pin7(+10V)

Pin9(+16V)

Pin13/14/15(+12V)

No

PDP module breaks down

Change MAIN PCB or EPM1/2 (cable).

If no improvement, go to

Power Supply Unit Troubleshooting

A

Go to Picture Troubleshooting

LED blinks blue.

3

Go to Sound Troubleshooting

In Video Input Power Save mode - no fault present.

27

Page 29

P50XR01U/E P60XR01U/E

㪲㪌㪇㪧㪛㪧㩷㪧㫆㫎㪼㫉㩷㫌㫅㫀㫋㪴

#

㪧㫆㫎㪼㫉

㪠㫊㩷㫋㪿㪼㩷㫀㫅㫇㫌㫋㩷㫍㫆㫃㫋㪸㪾㪼

㪸㫇㫇㫃㫀㪼㪻㩷㫋㫆㩷㪧㫆㫎㪼㫉㩷㫊㫌㫇㫇㫃㫐

㫌㫅㫀㫋㪖㩿㪚㪥㪍㪈㩷㪣㪃㪥䋩

㪰㪼㫊

㪘㫉㪼㩷㫋㪿㪼㩷㫍㫆㫃㫋㪸㪾㪼㫊㩷㪸㫇㫇㫃㫀㪼㪻㩷㫋㫆

㪚㪥㪍㪊㩿㪈㪀㫇㫀㫅㪃㩷㪸㫅㪻

㪚㪥㪧㪧㪪㩿㪈㪀㩿㪎㪀㩿㪐㪀㩿㪈㪊㪀㫇㫀㫅㫊㩷㫆㪽

㪧㫆㫎㪼㫉㩷㫊㫌㫇㫇㫃㫐㩷㫌㫅㫀㫋㩷㪖

㪰㪼㫊

㪞㫆㩷㫋㫆㩷㪧㫀㪺㫋㫌㫉㪼㩷㫋㫉㫆㫌㪹㫃㪼㫊㪿㫆㫆㫋㫀㫅㪾

㪲㪚㪥㪍㪊㪴㩷㩷㩷䇭㩿㪈㪀㩷㪂㪌㪅㪇㪭

㪲㪚㪥㪧㪧㪪㪴㩷㩷㩷㩿㪈㪀㩷㪂㪌㪅㪋㪭㩷㩷㩷㪆㩷㩿㪎㪀㩷㪂㪈㪇㪅㪇㪭

㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩿㪐㪀㩷㪂㪈㪍㪅㪇㪭㩷㪆㩷㩿㪈㪊㪀㩷㪂㪈㪌㪅㪇㪭

Caution: When taking off a PPU1 connector.

At first take off the filter board and pull up PPU1 connector.

㪥㫆

㪚㪿㪸㫅㪾㪼㩷㪘㪚㩷㪝㫌㫊㪼㩷㪝㪐㪘㪉

㪥㫆

㪚㪿㪸㫅㪾㪼㩷㪧㫆㫎㪼㫉㩷㫊㫌㫇㫇㫃㫐

㪁㪩㪼㪄㪸㪻㫁㫌㫊㫋㫄㪼㫅㫋㩷㫀㫊㩷㫅㫆㫋

㫅㪼㪺㪼㫊㫊㪸㫉㫐㪅㪧㫃㪼㪸㫊㪼㩷㫉㪼㪽㪼㫉㩷㫋㫆

㩹㪩㪼㪺㫆㫅㪽㫀㫉㫄㩷㫋㪿㪼㩷㪭㫊㩷㪸㫅㪻㩷㪭㪸

㫍㫆㫃㫋㪸㪾㪼㩷㫆㫅㩷㪧㫆㫎㪼㫉㩷㫌㫅㫀㫋㩾㩾

㫇㪸㪾㪼㪅

㪭㪸㪃㪭㫊㩷㪸㫉㪼㩷㪸㫌㫋㫆㫄㪸㫋㫀㪺㪸㫃㫃㫐

㪸㪻㫁㫌㫊㫋㪼㪻㪅㩷㪟㫆㫎㪼㫍㪼㫉㪃㩷㫅㪼㪼㪻㩷㫋㫆

㫉㪼㪺㫆㫅㪽㫀㫉㫄㩷㫋㪿㪼㩷㪭㫊㩷㪸㫅㪻㩷㪭㪸

㪧㫆㫎㪼㫉㩷㪺㪸㫅㫅㫆㫋㩷㪹㪼㩷㫋㫌㫉㫅㪼㪻㩷㫆㫅㩷㩿㪣㪜㪛㩷㪻㫆㪼㫊㩷㫅㫆㫋㩷㫃㫀㪾㪿㫋㪀

㩷㩷㩷㩷㩷㪠㫊㩷㫋㪿㪼㩷㫀㫅㫇㫌㫋㩷㫍㫆㫃㫋㪸㪾㪼

㪸㫇㫇㫃㫀㪼㪻㩷㫋㫆㩷㪧㫆㫎㪼㫉㩷㫊㫌㫇㫇㫃㫐㩷㫌㫅㫀㫋㩷㪖

㩷㩷㩷䇭䇭䇭㩿㪚㪥㪍㪈㩷㩿㪈㪀㪃㩿㪊㪀䋩

㪰㪼㫊

㩷

㩷

㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㪘㫉㪼㩷㫋㪿㪼㩷㫍㫆㫃㫋㪸㪾㪼㫊

㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㪸㫇㫇㫃㫀㪼㪻㩷㫋㫆㩷㪚㪥㪍㪊㩿㪈㪀㫇㫀㫅㪃

㩷㩷㩷㩷㩷㩷㩷㩷㩷㪸㫅㪻㩷㪚㪥㪧㪧㪪㩿㪈㪀㩿㪎㪀㩿㪐㪀㩿㪈㪊㪀㫇㫀㫅㫊㩷㫆㪽

㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㪧㫆㫎㪼㫉㩷㫊㫌㫇㫇㫃㫐㩷㫌㫅㫀㫋㩷㪖

㪰㪼㫊

Check MAIN/TERMINAL PCB

Caution: When taking off a PPU1 connector.

At first take off the filter board and pull up PPU1 connector.

㪥㫆

䇭䇭䇭㪘㪚㩷㪝㫌㫊㪼

㪝㪐㪘㪉㩷㪫㪍㪅㪊㪘㪟㩷㩷㪉㪌㪇㪭

㪥㫆

㪲㪚㪥㪍㪊㪴㩷㩷㩷䇭㩿㪈㪀㩷㪂㪌㪅㪊㪭

㪲㪚㪥㪧㪧㪪㪴㩷㩷㩷㩿㪈㪀㩷㪂㪌㪅㪍㪭㩷㩷㩷㪆㩷㩿㪎㪀㩷㪂㪈㪇㪅㪍㪭

㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩿㪐㪀㩷㪂㪈㪍㪅㪌㪭㩷㪆㩷㩿㪈㪊㪀㩷㪂㪈㪇㪅㪍㪭

FILTER PCB

㪧㫆㫎㪼㫉㩷㫊㫌㫇㫇㫃㫐㩷㫌㫅㫀㫋

㪁㪩㪼㪄㪸㪻㫁㫌㫊㫋㫄㪼㫅㫋㩷㫀㫊㩷㫅㫆㫋㩷㫉㪼㫈㫌㫀㫉㪼㪻㪅

㩷㪭㫊㩷㪃㪭㪸㩷㪘㪻㫁㫌㫊㫋㫄㪼㫅㫋㩷㫀㫊

㪸㫌㫋㫆㫄㪸㫋㫀㪺㪸㫃㫃㫐

28

Page 30

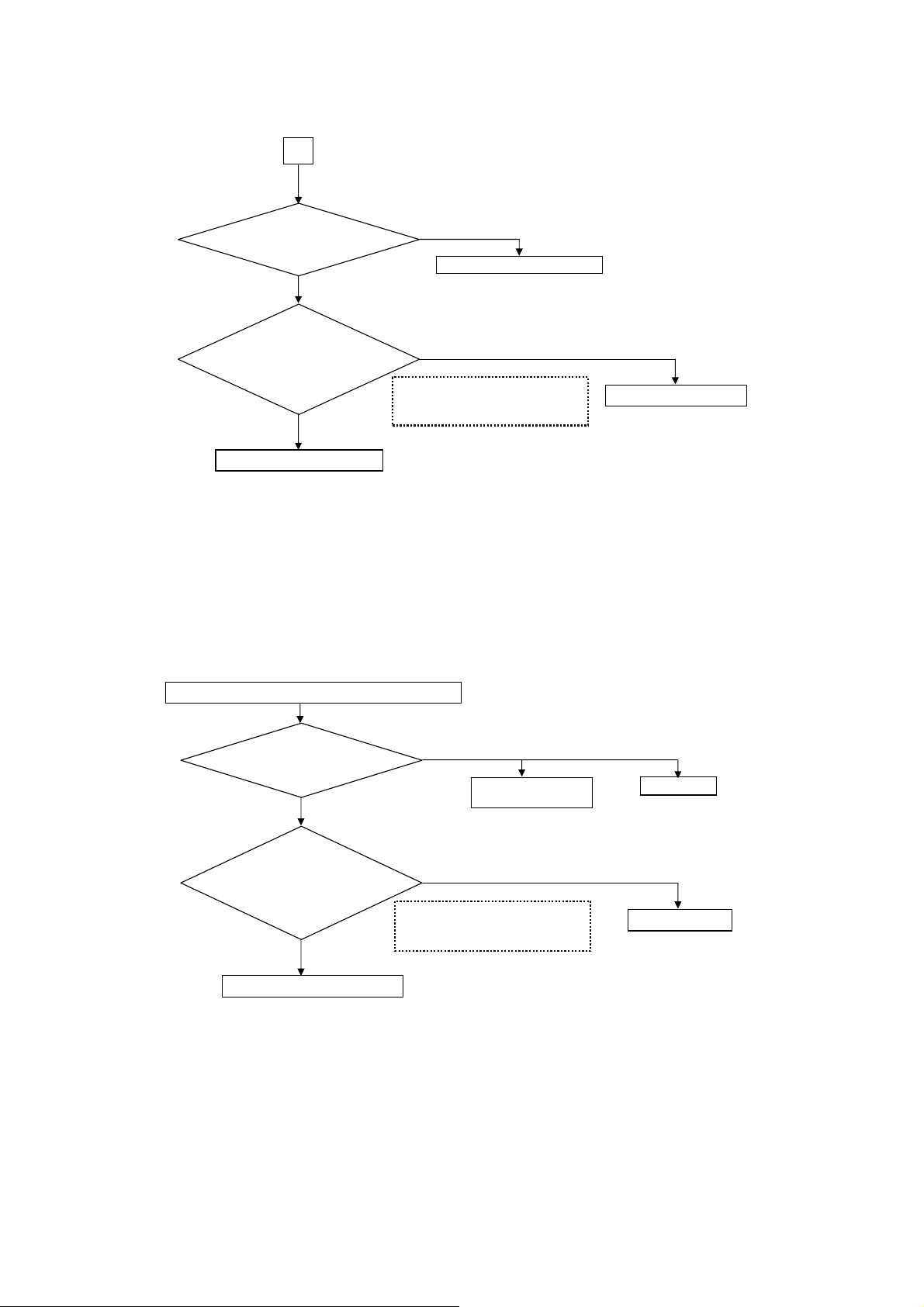

[Picture troubleshooting]

a

B

a

c

d

b

g

b

g

e

g

g

g

f

g

f

h

g

i

P50XR01U/E P60XR01U/E

No picture, Nocolour or dark

Analog format signals

Are all Analog format

signals abnormal?

Ye s

Change MAIN PCB.

Are all input no reflected?

Change MAIN PCB

What is the input abnormal?

No

Ye s

HDMI

Go to HDMI

troubleshooting

No

Which is Digital format

signal abnormal?

Digital format signals

DTT

Go to DTT

troubleshooting

Go to RF (analog tuner)

troubleshootin

What is the input

abnormal?

Go to Composite

troubleshootin

Go to S-video

troubleshootin

Go to RGB (SCART)

29

troubleshootin

Go to Component

troubleshootin

Go to PC RGB

troubleshootin

Page 31

[Picture: RF (analog) troubleshooting]

e

P50XR01U/E P60XR01U/E

RF (analog tuner)

Main tuner

Main tuner

Are the voltages of

pin2(+5V)/3(+30V)/12(+5V)/15(+5V) of

UT01(tuner) of Terminal PCB normal?

Ye s

Are waveforms at

Pin9 (SCL) /10(SDA) of UT01 (tuner) of

Terminal PCB normal?

Ye s

Is the waveform at

pin17 (VIDEO_OUT) of UT01(tuner) of

Terminal PCB normal?

Which is tuner abnormal?

No

Change UT01 of Terminal PCB

No

Change Terminal PCB

If no improvement,

exchange MAIN PCB

No

Sub tuner

Sub tuner

Are the voltages of

pin2(+5V)/3(+30V)/12(+5V)/15(+5V) of

UT02(tuner) of Terminal PCB normal?

Ye s

Are waveforms at

Pin9 (SCL) /10(SDA) of UT02 (tuner) of

Terminal PCB normal?

Ye s

Is the waveform at

pin17 (VIDEO_OUT) of UT02(tuner) of

Terminal PCB normal?

No

Change UT02 of Terminal PCB

No

Change Terminal PCB

If no improvement,

exchange MAIN PCB

No

Ye s

Is the waveform at

Pin2(CV output) of IM06 of MAIN PCB

normal?

Change UT01 of Terminal PCB

Ye s Change MAIN PCB

Change MAIN PCB

No

If no improvement,

exchange Terminal PCB

Ye s

Is the waveform at

Q005(CV output) of MAIN PCB normal?

Change UT02 of Terminal PCB

Ye s Change MAIN PCB

Change MAIN PCB

No

If no improvement,

exchange Terminal PCB

30

Page 32

P50XR01U/E P60XR01U/E

f

g

h

[Picture: composite & S-video troubleshooting]

Composite and s-video

Does the fault appear

if you change a RCA or Mini

DIN cable?

Ye s

Pin2(CV output) of IM06 of MAIN PCB

Are waveforms at

normal?

Ye s

Change MAIN PCB

[Picture: RGB (SCART) & component troubleshooting]

RGB (SCART)

No

Change RCA or Mini DIN cable

No

Component

Change MAIN PCB

If no improvement,

exchange Terminal PCB

Does the fault appear

if you change a SCART

cable?

Are waveforms at

Pin5(R output), 6(G output),

3(B output) of IM04 of MAIN

PCB normal?

Change MAIN PCB

Ye s

Ye s

No

Change SCART cable

No

Change MAIN PCB

If no improvement,

exchange Terminal PCB

Does the fault appear

if you change a RCA cable?

Ye s

Are waveforms at

Q002 (Pb output)/Q003 (Pr

output)/Q005 (Y output) of MAIN

PCB normal?

Ye s

Change MAIN PCB

No

Change RCA cable

No

Change MAIN PCB

If no improvement,

exchange Terminal PCB

31

Page 33

P50XR01U/E P60XR01U/E

i

[Picture: PC RGB troubleshooting]

PC RGB

Does the fault appear

if you change a D-sub

cable?

Ye s

Are waveforms at

Pin4(B input), 10(G input), 16(R

input),68(HSYNC),69(VSYNC) of

I202 of FC8 PCB OK?

Ye s

Change MAIN PCB

No

Change D-sub cable

No

Change FC8 PCB

If no improvement,

exchange Terminal PCB

32

Page 34

[Picture: DTT troubleshooting]

d

)

P50XR01U/E P60XR01U/E

DTT (MAIN Tuner)

[IWP1] Pin4 (+3.3V)/5(+5.6V)

[IWP2] Pin2/3 (+5.6V)/7/8(+3.3V)

[IW02] Pin2 (+5.6V)/4(+3.3V)

[IW03] Pin1/3 (+2.5V)/5(+1.2V)

[IW04] Pin1/5 (+3.3V)/4(+2.5V)

Check DW01 of SLOT PCB lighting?

No

IWP1/IWP2/IW02/IW03IW04 of SLOT

Are the voltages of

PCB normal?

Ye s

pin10(SDA)/9(SCL)/18(IFD_OUT1)/1

Are the signals of

9(IFD_OUT2) of UT01 of Terminal

PCB normal?

Ye s

pin37(MCLKo)/35(Mdo0)/27(MoVAL)/26(M

oSYNC)/46(MPEG_PD7) of PW01 of

Are the signals of

SLOT PCB normal?

Ye s

pin44(MCLKo)/45(Mdo_0)/46(MoVAL)/48(

MoSYNC)/61(MPEG_PDAT_7) of IW01 of

Are the signals of

SLOT PCB normal?

Ye s

Change MAIN PCB or SLOT PCB

No

Change SLOT PCB

No

Change UT01 of Terminal PCB

No

No

Change MAIN PCB

If no improvement,

exchange SLOT PCB or EMP0 (FFC

Change SLOT PCB

cable

.

Ye s

Change MAIN PCB

If no improvement,

exchange FC8 PCB.

33

Page 35

P50XR01U/E P60XR01U/E

d

DTT (Sub Tuner)

Are the voltages of pin2

(+5V)/3(+30V)/12(+5V)/15(+5

V) of UT02 (tuner) of Terminal

PCB normal?

Ye s

Are the signals of pin10

(SDA)/9(SCL)/18(IFD_OUT1)/19(IFD

_OUT2) of UT02 of Terminal PCB

normal?

Ye s

Are the signals of

R0C1(SUB_SYNC,SUB_EN,SUB

_CLK,SUB_DO) of MAIN PCB

normal?

Ye s

Change MAIN PCB

If no improvement,

exchange FC8 PCB.

No

Change UT02 of Terminal PCB

No

Change UT02 of Terminal PCB

No

Change Terminal PCB

34

Page 36

[Picture: HDMI troubleshooting]

c

g

P50XR01U/E P60XR01U/E

HDMI

HDMI1

HDMI1

Are waveforms at

pin13/14/16/17/20/21/23/24 of I405 of

MAIN PCB normal?

Does the fault appear

if you change a HDMI

cable?

No

Are both inputs abnormal?

No

Which is input abnormal?

No

Ye s

Change HDMI cable

Ye s

Change MAIN PCB

HDMI2/3

HDMI2/3

Change MAIN PCB

Ye s

Change MAIN PCB

Change SD PCB or EMH (FFC cable)

If no improvement,

exchan

eMAIN PCB

35

Page 37

P50XR01U/E P60XR01U/E

[Sub Picture troubleshooting]

No picture, Nocolour or dark

exchange Terminal PCB

[Teletext troubleshooting]

Change MAIN PCB

If no improvement,

No Teletext (analog)

Are the signals of

QM14/15(CV input) of MAIN

PCB normal?

Ye s

Change MAIN PCB

If no improvement,

exchange Terminal PCB

No

Change MAIN PCB

36

Page 38

[Sound troubleshooting]

C

D

d

c

E

P50XR01U/E P60XR01U/E

RF (analog)/ AV1/2/3/4/5

Are all analog inputs no

sound?

No

Sound is abnormal

Are all inputs no sound?

No

What is the input abnormal?

HDMI

Same as HDMI (Picture)

troubleshooting

Ye s

DTT

Same as DTT (Picture)

troubleshooting

Ye s

Change MAIN PCB

If no improvement,

exchange Terminal PCB

AV1/2/3/4/5

AV1/2/3/4/5

Change Terminal PCB

If no improvement,

exchange MAIN PCB

What is the input abnormal?

RF(analog tuner)

RF(analog tuner)

37

Page 39

P50XR01U/E P60XR01U/E

D

E

Main tuner

Main tuner

Are the voltages of pin3

(+5V)/15(+30V) of UT01 (tuner) of

Terminal PCB normal?

Are the signals

of a PSPK connector of the

MAIN PCB normal?

Change MAIN PCB

If no improvement,

exchange Terminal PCB

Which is tuner abnormal?

No

No

Ye s

Change Speaker or ESP1 (cable)

Sub tuner

Sub tuner

Are the voltages of pin3

(+5V)/15(+30V) of UT02 (tuner) of

Terminal PCB normal?

No

Ye s

Is the signal of

Pin6(SIF_OUT) of UT01(tuner) of

Terminal PCB normal?

Ye s

Are the signals of

Pin35 (L input)/36(R input) of

IX01 of Terminal PCB

normal?

Ye s

Change MAIN PCB

If no improvement,

exchange Terminal PCB

Change UT01 of Terminal PCB

No

Change UT01 of Terminal PCB

No

Change Terminal PCB

Ye s

Are the signals of

Pin6(SIF_OUT) of UT02(tuner) of

Terminal PCB normal?

Ye s

Are the signals of

Pin33 (L input)/34(R input) of

IX01 of Terminal PCB

normal?

Ye s

Change MAIN PCB

If no improvement,

exchange Terminal PCB

Change UT02 of Terminal PCB

No

Change UT02 of Terminal PCB

No

Change Terminal PCB

38

Page 40

P50XR01U/E P60XR01U/E

[Optical Out (Digital Audio) troubleshooting]

Optical Out (Digital Audio) is no sound

Are the voltages of

pin1/2/3(+5.6V) of PPM2

connector of MAIN PCB

normal?

Ye s

Is the voltage of pin2 (+5.0V) of

HV01 of Terminal PCB normal?

Ye s

Change Optical cable

If no improvement,

Change MAIN or Terminal PCB

No

No

Change MAIN PCB

Check Power Supply Unit

Change Terminal PCB

If no improvement,

39

Page 41

[USB troubleshooting]

(

P50XR01U/E P60XR01U/E

No Picture

Does the fault appear

if you change a USB cable &

EMH

FFC cable)?

No

Change USB cable or EMH (FFC cable)

Ye s

Are the voltages of

pin4(+5.6V)/5(+5.0V) of I4U1

of MAIN PCB normal?

No

Change MAIN PCB

Ye s

Change SD PCB

If no improvement,

exchange MAIN PCB

[SD Card troubleshooting] [SWIVEL troubleshooting (Only 50V Model)]

No Picture

Are the voltages of

pin4/5/6/7(+3.3V) of PSHL

connector of MAIN PCB

normal?

Ye s

No

Change MAIN PCB

SWIVEL does not move

When you pushed Swivel

button of a wireless remote

controller, is "Not Available"

Ye s

No

Change Terminal PCBor

Swivel cable

Change SD PCB

If no improvement,

exchange MAIN PCB or ESL

(cable)

A cable is not connected to the stands or it

is thought that a plug is incomplete.

This is not a fault.

40

Page 42

[FAN troubleshooting]

pp

P50XR01U/E P60XR01U/E

FAN does not work

Are FAN cables

connected?

Ye s

Are all the FANs' outward

earances normal?

a

Ye s

Change all the FANs.

No

No

Connect cables.

Change the abnormal FAN.

Do all FANs work?

Ye s

Check all exchanged FANs using

external power.

No

Change Terminal PCB.

41

Page 43

[HDD troubleshooting]

HDD cannot record and play.

P50XR01U/E P60XR01U/E

Do you hear an allophone sound

from the HDD?

No

Do you hear rotary sound from

the HDD?

Ye s

Does LED (DU01) of MAIN

PCB light?

Ye s

Ye s

No

No

Change the HDD.

Change MAIN PCB.

Put back

the HDD.

No

Does HDD work normally?

Ye s

Repair completed.

42

Page 44

P50XR01U/E P60XR01U/E

7. Self-Diagnosis Function

PDP panel self-diagnosis function

This function is for a PDP panel failure with no picture.

It is automatically self-diagnosed that the panel failure occurs.

It is shown by power indicator light blinks (blue).

The next table shows the PDP PCB in which failure most probably would be indicated according to the

number of blinks.

Number of blue blinks

of power indicator light

1 Logic

2 X-SUS

3 Y-SUS, SDM

4 X-SUS, Y-SUS, SDM, PSU

5 ABUS, ADM, PSU

6 ADM temperature

7 ADM temperature

8

[Number of blinks power indication light]

Ex. 2 blinks

1 sec 1 sec 2 sec OFF Repeat

Presumed failing PCB

All of above-mentioned

of PDP panel

PCBs

SDM: Scan Driver Module

PSU: Power Supply Unit

ABUS: Address Bus Module

ADM: Address Driver Module

Note) SDM is in permanent contact with

glass part.

Note)

1) Main Power switch-off operation cancels the Self-Diagnosis mode.

2) Priority is given whenaFAN error occurs (shown by red blinks).

43

Page 45

P50XR01U/E P60XR01U/E

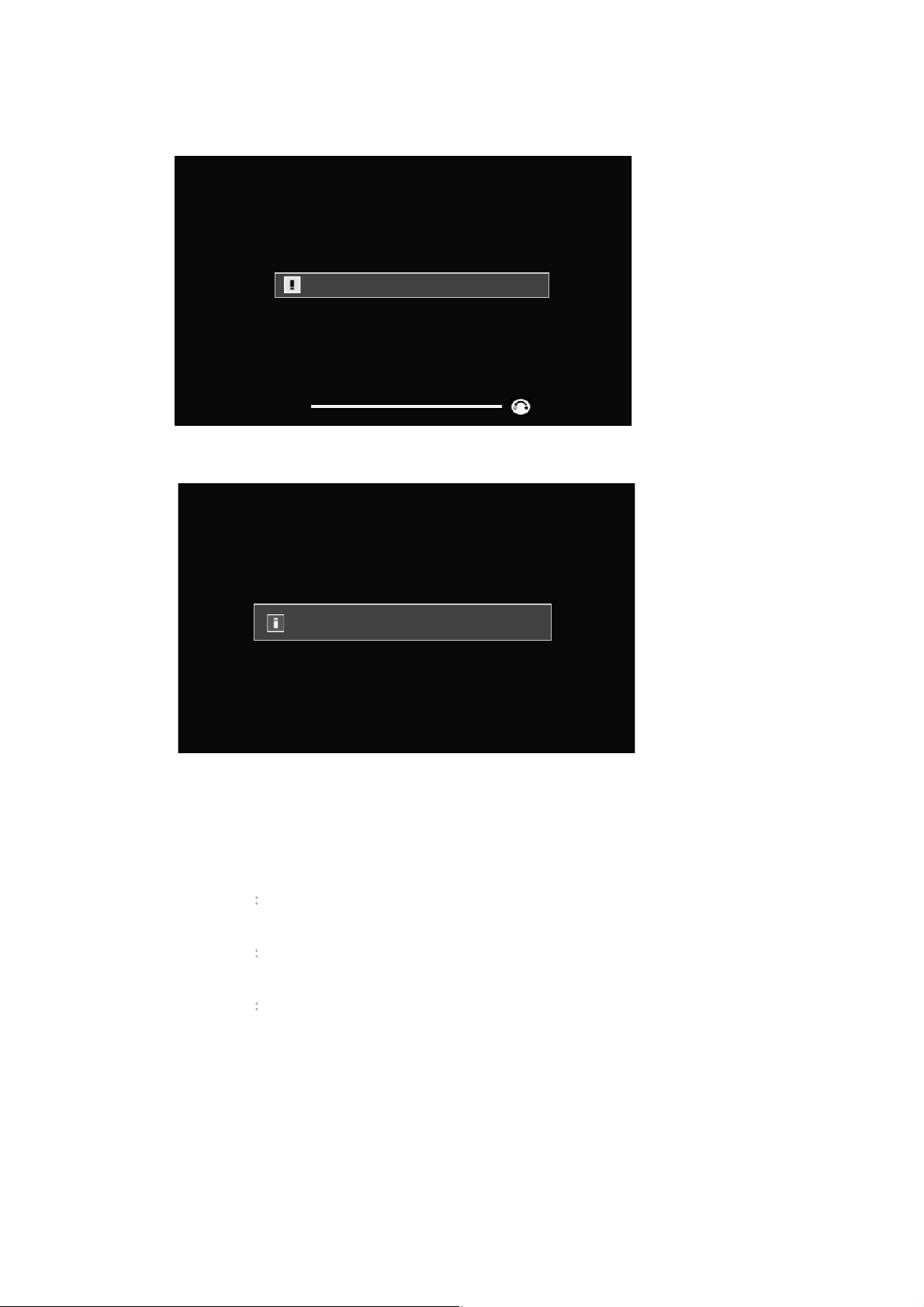

䃂㪛㫀㪾㫀㫋㪸㫃㩷㫄㫆㪻㫌㫃㪼㩷㫇㪸㫉㫋㩷㫊㪼㫃㪽㪄㪻㫀㪸㪾㫅㫆㫊㫀㫊㩷㪽㫌㫅㪺㫋㫀㫆㫅

㪧㫉㫆㪺㪼㪻㫌㫉㪼

㪉

㫉

䌓䌅䌌䌆䇭䌔 䌅䌓䌔

㪘㫋㩷㫋㪿㪼㩷㫋㫀㫄㪼㩷㫆㪽㩷㫄㪸㫀㫅㩷㫄㫀㪺㫉㫆㪺㫆㫄㫇㫌㫋㪼㫉㩷㫊㫋㪸㫉㫋㪃㩷㪺㪿㪼㪺㫂㩷㪿㪸㫉㪻㫎㪸㫉㪼㩷㩿㫄㪸㫀㫅㫃㫐㩷㪣㪪㪠㪀㩷㪹㫐㩷㪸㩷㩷㫊㪼㫃㪽㩷㪻㫀㪸㪾㫅㫆㫊㫀㫊㩷㫇㫉㫆㪾㫉㪸㫄㪅

㪫㫆㩷㪼㫅㫋㪼㫉㩷㫋㫆㩷㫋㪿㫀㫊㩷㪪㪼㫃㪽㪄㪛㫀㪸㪾㫅㫆㫊㫀㫊㩷㫄㫆㪻㪼㪃㩷㪽㫆㫃㫃㫆㫎㩷㫋㪿㪼㩷㫅㪼㫏㫋㩷㫊㫋㪼㫇㫊㪑

㪈㪀㪜㫅㫋㪼㫉㩷㪘㪻㫁㫌㫊㫋㫄㪼㫅㫋㩷㪤㫆㪻㪼㪅

㪉㪀㪪㪼㫃㪼㪺㫋㩷㪪㪜㪣㪝㩷㪫㪜㪪㪫㩷㪸㫅㪻㩷㫇㫉㪼㫊㫊㩷㪦㪢㩷㪹㫌㫋㫋㫆㫅㪅

㪊㪀㪪㪜㪣㪝㩷㪫㪜㪪㪫㩷㫊㪺㫉㪼㪼㫅㩷㫀㫊㩷㪻㫀㫊㫇㫃㪸㫐㪼㪻㪅

㪋㪀㪜㪸㪺㪿㩷㪺㫆㫉㪻㩷㫀㫊㩷㪻㫀㫊㫇㫃㪸㫐㪼㪻㩷㫋㫆㩷㪸㩷㪪㪜㪣㪝㩷㪫㪜㪪㪫㩷㫊㪺㫉㪼㪼㫅㪅

䇭㪘㩷㪻㫀㪸㪾㫅㫆㫊㫀㫊㩷㫉㪼㫊㫌㫃㫋㩷㫀㫊㩷㪻㫀㫊㫇㫃㪸㫐㪼㪻㩷㫎㫀㫋㪿㩷㫅㫌㫄㪼㫉㫀㪺㪸㫃㩷㫍㪸㫃㫌㪼㩷㫀㫅㩷㫋㪿㪼㩷㫉㫀㪾㪿㫋㩷㫊㫀㪻㪼㩷㫆㪽㩷㪼㪸㪺㪿㩷㪺㫆㫉㪻㪅

䇭㪥㫌㫄㪼㫉㫀㪺㪸㫃㩷㫍㪸㫃㫌㪼㩷㫊㪿㫆㫎㫊㩷㫋㪿㪸㫋㩷㫅㫆㫉㫄㪸㫃㩷㫄㫆㫍㪼㫄㪼㫅㫋㩷㫀㫅㩷㫋㪿㪼㩷㪺㪸㫊㪼㩷㫆㪽㩷㪇㪃㩷㪸㩷㪺㪸㫊㪼㩷㪼㫏㪺㪼㫇㫋㩷㪇㩷㪸㫉㪼㩷㪼㫉㫉㫆㫉㫊㪅

䌐䌄䌐䇭䌁䌄䌊䌕䌓䌔䇭䌍䌏䌄䌅

䇭䇭䌏䌐䌔䌉䌏䌎

䇭䇭䌍䌁䌉䌎䌔䌅䌎䌁䌎䌃䌅

䇭䇭䌓

䇭䇭䌌䌉䌎䌅䇭䌍䌏䌄䌅

䇭䇭䌍䌍䌃䇭䌄䌅䌍䌏

䇭䇭䌍䌅䌍䌏䌒䌙䇭䌉䌎䌉䌔

㪦㪢

㪩㪼㫋㫌㫉㫅

㪻㪻㪹

䇭䇭䇭䇭䇭䋺㪇

㪻㫊㫄

䇭䇭䇭䇭䇭䋺㪇

㪻㫃㪼

䇭䇭䇭䇭䇭䋺㪇

㪻㪽㫃

䇭䇭䇭䇭䇭䋺㪇

㪻㫄㫇

䇭䇭䇭䇭䇭䋺㪇

㪻㪻㫄

䇭䇭䇭䇭䇭䋺㪇

㪻㪺㪻

䇭䇭䇭䇭䇭䋺㪇

㪻㫉㫄

䇭䇭䇭䇭䇭䋺㪇

㪻㫇㪺㫀

䇭䇭䇭䇭䇭䋺㪇

㪻㫃㪸㫅

䇭䇭䇭䇭䇭䋺㪇

㪻㫊㫀

䇭䇭䇭䇭䇭䋺㪇

㪪㪜㪣㪝㩷㩷㪫㪜㪪㪫

㩷㩷䇭㪇䇭㩷㩷䋺㪦㪢

䌯䌴䌨䌥䌲䌳䋺㪥㪞

㪘㪻㫁㫌㫊㫋㫄㪼㫅㫋㩷㪤㫆㪻㪼㩷㫊㪺㫉㪼㪼㫅

㪪㪜㪣㪝㩷㪫㪜㪪㪫㩷㫊㪺㫉㪼㪼㫅

䇭䇭䇭㩷㩷㩷㩷㩷㩷䇭㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷 䇭䇭䇭䇭䇭䇭䇭

䃂

㪘㩷㫃㫀㫊㫋㩷㫆㪽㩷㫀㫅㪻㫀㪺㪸㫋㫀㫆㫅㩷㪺㫆㪻㪼㫊

㪺㫆㪻㪼 㪽㫌㫅㪺㫋㫀㫆㫅 㪺㫀㫉㪺㫌㫀㫋㩷㪥㫆㪅 PCB㩷㫅㪸㫄㪼 㪜㫉㫉㫆㫉㩷㪺㫆㫅㫋㪼㫅㫋㫊

㪻㪻㪹 㪛㪼㪹㫌㪾 㪠㪈㪇㪈 㪤㪘㪠㪥 㫇㪸㫉㪸㫄㪼㫋㪼㫉㩷㪼㫉㫉㫆㫉㪃㩷㫊㫐㫊㫋㪼㫄㩷㪼㫉㫉㫆㫉

㪻㫊㫄 㪪㫌㪹㪄㫄㫀㪺㫉㫆㪺㫆㫄㫇㫌㫋㪼㫉 㪠㪟㪇㪋 㪤㪘㪠㪥 㫊㫐㫊㫋㪼㫄㩷㪼㫉㫉㫆㫉㩿㪄㪈㪀

㪻㫃㪼 㪣㪜㪛 㪠㪟㪇㪋 㪤㪘㪠㪥 㫊㪼㫀㫅㪼㩷㪾㪼㫅㪼㫉㪸㫃㪄㫇㫌㫉㫇㫆㫊㪼㩷㫇㫆㫉㫋㩷㫃㪼㪸㪻㩷㪼㫉㫉㫆㫉䇮㫃㫀㪾㪿㫋㫀㫅㪾㩷㫋㫀㫄㪼㩷㪼㫉㫉㫆㫉䇮㫊㫐㫊㫋㪼㫄㩷㪼㫉㫉㫆㫉㩷

㪻㪽㫃 㪽㫃㪸㫊㪿 㪠㪈㪇㪊 㪤㪘㪠㪥 㫇㪸㫉㪸㫄㪼㫋㪼㫉㩷㪼㫉㫉㫆㫉䇮㪻㪼㫍㫀㪺㪼㩷㪼㫉㫉㫆㫉䇮㫊㫐㫊㫋㪼㫄㩷㪼㫉㫉㫆㫉

㪻㫄㫇 㪤㪧㪜㪞 㪠㪈㪇㪈 㪤㪘㪠㪥 㪭㫀㪻㪼㫆㩷㪼㫉㫉㫆㫉㩿㪉㪀䇮㪘㫌㪻㫀㫆㩷㪼㫉㫉㫆㫉㩿㪋㪀

㪻㪻㫄 㪻㪼㫄㫌㫃㫋㫀 㪄 㪄 㪼㫉㫉㫆㫉

㪻㫉㫄 㫂㪼㫐㩷㫊㪺㪸㫅 㪠㪟㪇㪋 㪤㪘㪠㪥 㫊㫐㫊㫋㪼㫄㩷㪼㫉㫉㫆㫉㩿㪄㪈㪀㪆㫆㫋㪿㪼㫉㫊㩷㪼㫉㫉㫆㫉㩿㪊㪀

㪻㫀㪺 䌉䌉䌃㪹㫌㫊㩷㪻㫉㫀㫍㪼㫉 㪠㪈㪇㪈 㪤㪘㪠㪥 㪩㪶㪪㪰㪪㪶㪜㪩㪩㪦㪩㩿㪄㪈㪀㪃㪛㪠㪚㪶㪩㪶㪛㪜㪭㪠㪚㪜㪶㪜㪩㪩㪦㪩㩿㪉㪀

㪻㫍㪸㪻 㪘㪛㪚 㪠㪈㪇㪈 㪤㪘㪠㪥 㫊㫐㫊㫋㪼㫄㩷㪼㫉㫉㫆㫉㩿㪄㪈㪀㪆㪻㪼㫍㫀㪺㪼㩿㪠㪉㪚㪀㪼㫉㫉㫆㫉㩿㪉㪀㪆㪻㫉㫀㫍㪼㫉㩷㪼㫉㫉㫆㫉㩿㪍㪀

㪻㪽㪺 㪝㪚 㪠㪈㪇㪈 㪤㪘㪠㪥 㪽㫀㫉㫄㫎㪸㫉㪼㩷㪼㫉㫉㫆㫉㩷㪺㫆㪻㪼䇮㫊㫐㫊㫋㪼㫄㩷㪼㫉㫉㫆㫉

㪻㪿㪻㫄 㪟㪛㪤㪠 㪠㪈㪇㪉 㪤㪘㪠㪥 㫊㫐㫊㫋㪼㫄㩷㪼㫉㫉㫆㫉㩿㪄㪈㪀㪆㫇㪸㫉㪸㫄㪼㫋㪼㫉㩷㪼㫉㫉㫆㫉㩿㪈㪀㪆㪻㪼㫍㫀㪺㪼㩿㪠㪉㪚㪀㪼㫉㫉㫆㫉㩿㪉㪀

㪻㫍㪻㪺 㪭㫀㪻㪼㫆㩷㪻㪼㪺㫆㪻㪼㫉 㪠㪈㪇㪉 㪤㪘㪠㪥 㪻㪼㫍㫀㪺㪼㩷㪼㫉㫉㫆㫉䇮㫊㫐㫊㫋㪼㫄㩷㪼㫉㫉㫆㫉

㪻㫇㪻㫇 㪧㪛㪧㫇㪸㫅㪼㫃䋨㪽㫆㫉㩷䌐䌄䌐䋩 㪄 㪧㪛㪧㩷㫇㪸㫅㪼㫃 㫊㫐㫊㫋㪼㫄㩷㪼㫉㫉㫆㫉

㪻㫃㪻㫇 㪣㪚㪛㫇㪸㫅㪼㫃䋨㪽㫆㫉㩷䌌䌃䌄䋩 㪄 㪣㪚㪛㩷㫇㪸㫅㪼㫃 㫊㫋㪸㫋㪼㩷㫀㫄㫇㫆㫊㫊㫀㪹㫃㪼㩷㫆㪽㩷㪺㫆㫄㫄㪸㫅㪻㩷㪸㪺㪺㪼㫇㫋㪸㫅㪺㪼䇮㫊㫋㪸㫅㪻㪹㫐䇮㫇㪸㫉㪸㫄㪼㫋㪼㫉㩷㪼㫉㫉㫆㫉㩷 㩷㩷

㪻㫍㫀 㪭㫀㪻㪼㫆 㪠㪈㪇㪈 㪤㪘㪠㪥 㪻㪼㫍㫀㪺㪼㩷㪼㫉㫉㫆㫉㩿㪽㫀㫉㫄㫎㪸㫉㪼㩷㪼㫉㫉㫆㫉㪀䇮㫊㫐㫊㫋㪼㫄㩷㪼㫉㫉㫆㫉

㪻㫍㪹㫀 㪭㪙㪠㩷㫊㫃㫀㪺㪼㫉 㪠㪈㪇㪉 㪤㪘㪠㪥 㫊㫐㫊㫋㪼㫄㩷㪼㫉㫉㫆㫉

㪻㫊㫃 㪭㫀㪻㪼㫆㩷㪪㫎㫀㫋㪺㪿 㪠㪈㪇㪈 㪤㪘㪠㪥 㫊㫐㫊㫋㪼㫄㩷㪼㫉㫉㫆㫉

㪻㪸㪻㪸 䌁䌵䌤䌩䌯㩷㪸㫄㫇㫃㫀㪽㫀㪼㫉 㪠㪝㪇㪎 㪤㪘㪠㪥 㫇㪸㫉㪸㫄㪼㫋㪼㫉㩷㪼㫉㫉㫆㫉䇮㫊㪼㫋㫋㫀㫅㪾㩷㪼㫉㫉㫆㫉㩷㫀㫅㩷㫊㫌㫊㫇㪼㫅㪻䇮㫊㫐㫊㫋㪼㫄㩷㪼㫉㫉㫆㫉

㪠㪉㪚㩷㪺㫆㫄㫄㫌㫅㫀㪺㪸㫋㫀㫆㫅㩷㪼㫉㫉㫆㫉㩷㫎㫀㫋㪿㩷㪫㪘㪪㪊㪈㪇㪊㩷㫆㫉㩷㪫㪘㪪㪌㪌㪇㪏

㪻㪸㫌 㪘㫌㪻㫀㫆 㪠㪈㪇㪈 㪤㪘㪠㪥 㫊㫐㫊㫋㪼㫄㩷㪼㫉㫉㫆㫉

㪻㪿㫇㪸 㪟㪼㪸㪻㫇㪿㫆㫅㪼㫊㩷㪸㫄㫇㫃㫀㪽㫀㪼㫉 㪠㪇㪇㪊 㪪㪬㪙 㫊㫋㪸㫅㪻㪹㫐䇮㫊㫋㪸㫋㪼㩷㪼㫉㫉㫆㫉㩷

㪻㫋㫌 㪛㫀㪾㫀㫋㪸㫃㩷㪆㩷㪘㫅㪸㫃㫆㪾㩷㫋㫌㫅㪼㫉 㪬㪫㪇㪈㪃㪬㪫㪇

㪫㪼㫉㫄㫀㫅㪸㫃 㪽㪸㫀㫃㩷㫀㫅㩷㫀㫅㫀㫋㫀㪸㫃㫀㫑㪸㫋㫀㫆㫅䇮㫊㫐㫊㫋㪼㫄㩷㪼㫉㫉㫆㫉

㪻㫊㫎㫍 㪪㫎㫀㫍㪼㫃 㪠㪟㪇㪋 㪤㪘㪠㪥 㫊㫐㫊㫋㪼㫄㩷㪼㫉㫉㫆㫉㩿㪄㪈㪀㪆㫇㪸㫉㪸㫄㪼㫋㪼㫉㩷㪼㫉㫉㫆㫉㩿㪈㪀㪆

㫊㫌㪹㪄㫄㫀㪺㫉㫆㪺㫆㫄㫇㫌㫋㪼㫉㩷㪻㫉㫀㫍㪼㫉㩷㪺㫆㫄㫄㫌㫅㫀㪺㪸㫋㫀㫆㫅㩷㪼㫉㫉㫆㫉㩿㪉㪀㪆

㪼㫉㫉㫆㫉㩷㫀㫄㫇㫆㫊㫊㫀㪹㫃㪼㩷㫆㪽㩷㫀㫅㫀㫋㫀㪸㫃㫀㫑㪸㫋㫀㫆㫅㩷㫉㪼㪾㫀㫊㫋㫉㪸㫋㫀㫆㫅㩿㪋㪀

㪻㫄㫄㪺 㪤㪤㪚 㪄 㪄 㪻㫉㫀㫍㪼㫉㩷㫀㫅㫀㫋㫀㪸㫃㫀㫑㪸㫋㫀㫆㫅㩷㪼㫉㫉㫆㫉䇮㫊㫐㫊㫋㪼㫄㩷㪼㫉㫉㫆㫉

㪻㫇㫋㫇 䌐䌔䌐㩷㪻㫉㫀㫍㪼㫉 㪠㪈㪇㪈 㪤㪘㪠㪥 㪩㪶㪪㪰㪪㪶㪜㪩㪩㪦㪩㩿㪄㪈㪀㫆㫋㪿㪼㫉㩷㪼㫉㫉㫆㫉㫊㩿㪈㪇㪀

㪻㫇㫈 㪧㫀㪺㫋㫌㫉㪼㩷㪺㫆㫅㫋㫉㫆㫃㩷㪻㫉㫀㫍㪼㫉 㪠㪈㪇㪉㪃㪠㪤㪇㪈 㪤㪘㪠㪥㪃㪪㪬㪙 㫇㪸㫉㪸㫄㪼㫋㪼㫉㩷㪼㫉㫉㫆㫉䇮㫊㫐㫊㫋㪼㫄㩷㪼㫉㫉㫆㫉䇮㫊㫌㫊㫇㪼㫅㪻㩷㪼㫉㫉㫆㫉䇮㪻㪼㫍㫀㪺㪼㩷㪼㫉㫉㫆㫉

㪻㪻㫇 㪛㫀㫊㫇㫃㪸㫐㩷㪻㫉㫀㫍㪼㫉 㪠㪈㪇㪈 㪤㪘㪠㪥 㫊㫐㫊㫋㪼㫄㩷㪼㫉㫉㫆㫉

㪻㫋㫋㪺 㪘㫅㪸㫃㫆㪾㩷㪫㪼㫃㪼㪫㪼㫏㫋 㪠㪩㪇㪈 㪪㪬㪙 㪻㪼㫍㫀㪺㪼㩷㪼㫉㫉㫆㫉䇮㫊㫐㫊㫋㪼㫄㩷㪼㫉㫉㫆㫉

㪻㫇㫐㪺 㪧㪘㪣㪊㪛㪰㪆㪚㩷㪭㫀㪻㪼㫆㩷㪻㪼㪺㫆㪻㪼

㪠㪤㪇㪈 㪪㪬㪙 㪻㪼㫍㫀㪺㪼㩷㪼㫉㫉㫆㫉䇮㫊㫐㫊㫋㪼㫄㩷㪼㫉㫉㫆㫉

㪻㫊㫇 㪤㫌㫃㫋㫀㫇㫃㪼㫏㩷㪻㫉㫀㫍㪼㫉 㪠㪰㪇㪈 㪪㪬㪙 㫊㫐㫊㫋㪼㫄㩷㪼㫉㫉㫆㫉㩿㪄㪈㪀㪆㪠㪉㪚㩷㪺㫆㫄㫄㫌㫅㫀㪺㪸㫋㫀㫆㫅㩷㪼㫉㫉㫆㫉㩿㪉㪀

㪻㪺㫀㪺 㪚㪠㩷㪻㫉㫀㫍㪼㫉 㪠㪮㪇㪈 㪪㪣㪦㪫 㫊㫐㫊㫋㪼㫄㩷㪼㫉㫉㫆㫉㩿㪄㪈㪀

44

Page 46

8. Waveform diagrams

㪠㪤㪇㪈㩿㪚㪭㪙㪪㪀㩷㪉㪈㫇㫀㫅 㪚㪏㪉㪏㩿㪚㪭㪙㪪㪀㩷㪘㪄㪚㪿㫀㫇㩷㫀㫅

P50XR01U/E P60XR01U/E

㪈㪅㪉㪭

㫇㪄㫇

㪈㪟 㪈㪟

㪠㪤㪇㪈㩿㪪㪄㪰㪀㩷㪉㪈㫇㫀㫅 㪚㪏㪉㪏㩿㪪㪄㪰㪀㩷㪘㪄㪚㪿㫀㫇㩷㫀㫅

㪈㪅㪉㪭

㫇㪄㫇

㪈㪟 㪈㪟

㪠㪤㪇㪈㩿㪪㪄㪚㪀㩷㪊㪇㫇㫀㫅

㪚㪏㪊㪉㩿㪪㪄㪚㪀㩷㪘㪄㪚㪿㫀㫇㩷㫀㫅 㪚㪏㪉㪏㩿㪰㪀㩷㪘㪄㪚㪿㫀㫇㩷㫀㫅

㪇㪅㪎㪭

㪇㪅㪎㪭

㫇㪄㫇

㫇㪄㫇

㪇㪅㪊㪭

㫇㪄㫇

㪈㪟 㪈㪟

㪚㪏㪊㪊㩿㪧㪹㪀㩷㪘㪄㪚㪿㫀㫇㩷㫀㫅 㪚㪏㪊㪌㩿㪧㫉㪀㩷㪘㪄㪚㪿㫀㫇㩷㫀㫅

㪇㪅㪎㪭

㫇㪄㫇

㪈㪟 㪈㪟

㪇㪅㪎㪭

㪇㪅㪎㪭

㫇㪄㫇

㫇㪄㫇

45

Page 47

P50XR01U/E P60XR01U/E

㪠㪤㪇㪈㩿㪩㪀㩷㪈㪌㫇㫀㫅 㪠㪤㪇㪈㩿㪞㪀㩷㪏㫇㫀㫅

㩷㩷㩷㪈㪟 㩷㩷㩷㪈㪟

㪠㪤㪇㪈㩿㪙㪀㩷㪊㫇㫀㫅 㪚㪏㪊㪍㩿㪩㪀㩷㪘㪄㪚㪿㫀㫇㩷㫀㫅

㩷㩷㪈㪟 㪈㪟

㪚㪏㪊㪈㩿㪞㪀㩷㪘㪄㪚㪿㫀㫇㩷㫀㫅 㪚㪏㪊㪋㩿㪙㪀㩷㪘㪄㪚㪿㫀㫇

㩷㫀㫅

㪈㪟 㪈㪟

㪩㪤㪊㪉㩷㩿㪟㪀㩷㪠㪤㪇㪈㩷㫆㫌㫋 㪩㪤㪊㪊㩷㩿㪭㪀㩷㪠㪤㪇㪈㩷㫆㫌㫋

㪈㪟 㪈㪭

㪈㪅㪈㪎㪭

㫇㪄㫇

㪈㪅㪈㪎㪭

㫇㪄㫇

㪈㪅㪍㪎㪭

㫇㪄㫇

㪇㪅㪎㪭

㫇㪄㫇

㪇㪅㪎㪭

㫇㪄㫇

㪇㪅㪎㪭

㫇㪄㫇

㪊㪅㪊㪭

㫇㪄㫇

㪊㪅㪊㪭

㫇㪄㫇

46

Page 48

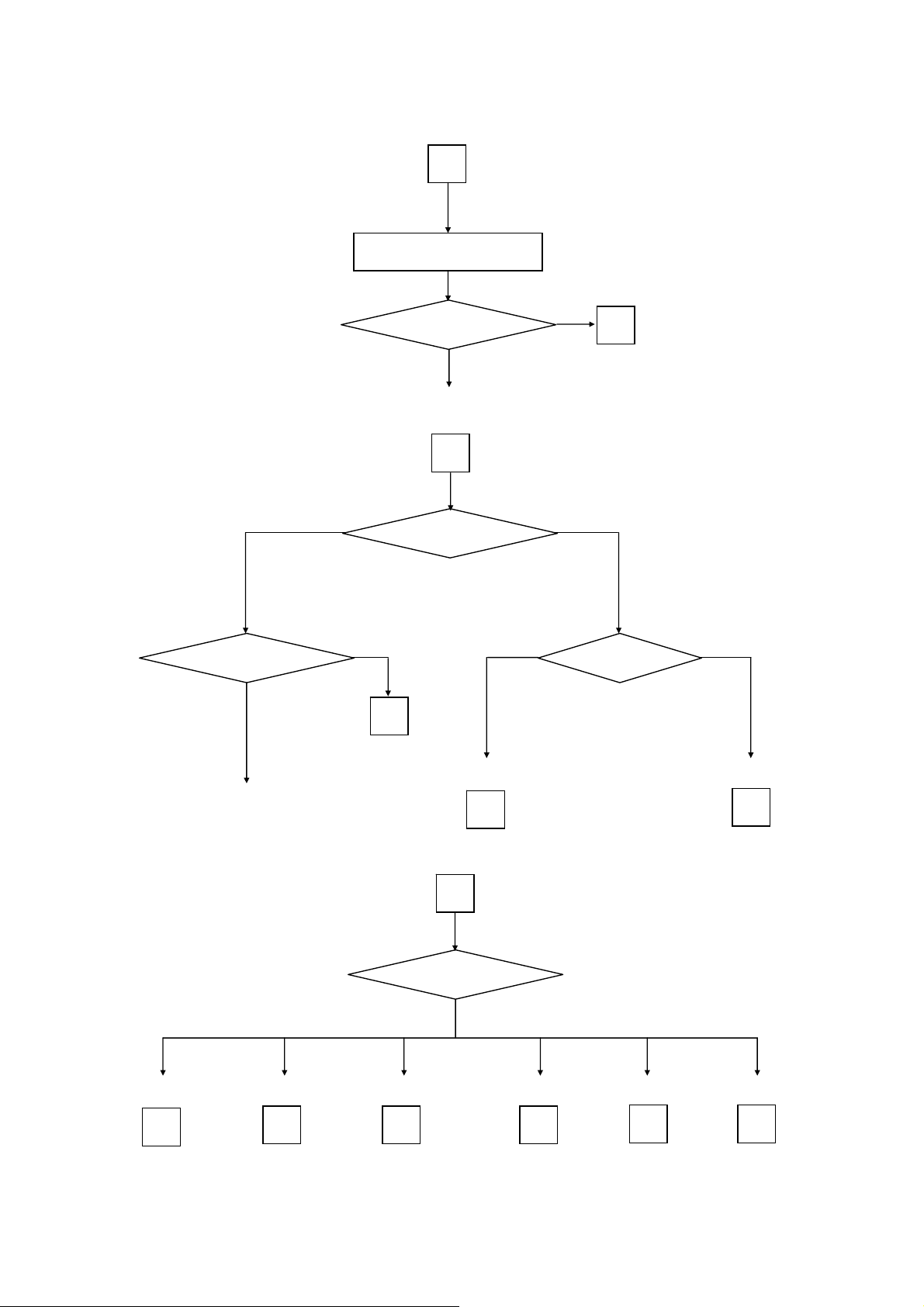

9. Block diagram [For P50XR01U/E]

P50XR01U/E P60XR01U/E

50-INCH

PDP PANEL

FC8 BOARD

MAIN BOARD

STORAGE

SLOT BOARD

MAIN BOARD

MAIN AREA

MAIN BOARD

SUB AREA

SENSOR

BOARD

PC PCB

TERMINAL PCB

INTERNAL

iVDR

EXTERNAL

iVDR

POWER

UNIT

FILTER

BOARD

AC INLET

SD BOARD

LED

BOARD

SWIVEL

STAND

CONTROL BOARD

SM017

BLOCK DIAGRAM

47

Page 49

[For P60XR01U/E]

P50XR01U/E P60XR01U/E

60-INCH

PDP FULL

HD PANEL

FC8 BOARD

MAIN BOARD

STORAGE

SLOT BOARD

MAIN BOARD

MAIN AREA

MAIN BOARD

SUB AREA

SENSOR

BOARD

PC PCB

TERMINAL PCB

INTERNAL

iVDR

EXTERNAL

iVDR

POWER

UNIT

FILTER

BOARD

AC INLET

SP TRM

BOARD

SD BOARD

LED

BOARD

CONTROL BOARD

SM017

BLOCK DIAGRAM

48

Page 50

10. Connection diagram [For P50XR01U/E]

P50XR01U/E P60XR01U/E

AC

FILTER

BOARD

POWER

UNIT

NOTE:

PARTS MARKED WITH HATCHING ARE NOT MOUNTED IN THIS MODEL.

SLOT BOARD

SENSOR

BOARD

FC8 BOARD

TERMINAL

BOARD

50-INCH

PDP FULL

HD PANEL

FRONT

FILTER

SD BOARD

MAIN BOARD

LED

BOARD

SWIVEL

BOARD

CONTROL

BOARD

SWIVEL

STAND

SM017

iVDR

LED

EXTERNAL iVDR

INTERNAL iVDR

SPEAKER

USB

CABLE

CONNECTION DIAGRAM

49

Page 51

[For P60XR01U/E]

P50XR01U/E P60XR01U/E

AC

FILTER

BOARD

POWER

UNIT

NOTE:

PARTS MARKED WITH HATCHING ARE NOT MOUNTED IN THIS MODEL.

SLOT BOARD

SENSOR

BOARD

FC8 BOARD

TERMINAL

BOARD

60-INCH

PDP

PANEL

FRONT

FILTER

SD BOARD

MAIN BOARD

LED

BOARD

CONTROL

BOARD

SM017

iVDR

LED

EXTERNAL iVDR

INTERNAL iVDR

SP TRM

BOARD

SPEAKER

CONNECTION DIAGRAM

50

Page 52

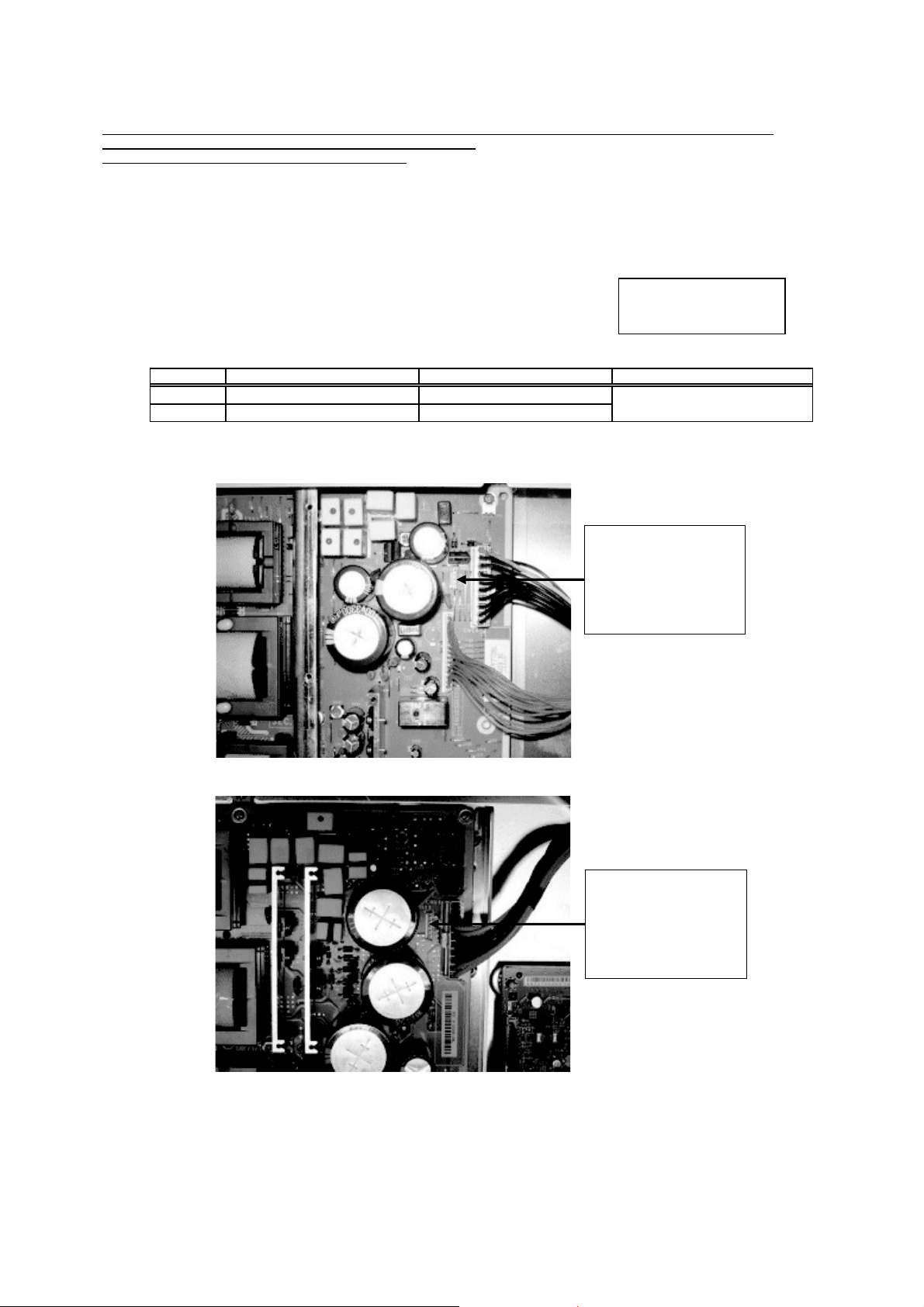

11. Wiring diagram [For P50XR01U/E only]

P50XR01U/E P60XR01U/E

Install NVS02, NVS03, NVS04, NVS05 & NVS11 beforehand at the positions shown.

NVS04

To Power Unit

CN63

20mm

To Panel Logic

CN8

PURSE LOCK

5.0mm (P/N 3749612)Æ

Ferrite Core Sizes:

Large (P/N GX00734): NVS02, NVS05, NVS09, NVS11.

Medium (P/N GX00732): NVS03, NVS04, NVS06, NVS07, NVS10, NVS12.

Small (P/N GX00731): NVS08.

For PPC (P/N GX00791): NVS01.

Use 12 in total when 1 includes a harness product ferrite core.

EPM1

ECN6

80mm

Connection Point

Name

EC01

CN68

CN64

PSC

E901

PFA1

PFA2

PFA3

PFA4

P601

EU01

PU01

PFA1

PA01

P201

CN63

CNPPS

PPU1

PSHL

PSPK

JU01

MAIN Board

Power Unit

Power Unit

MAIN Board

AC Inlet

TERMINAL Board

TERMINAL Board

TERMINAL Board

TERMINAL Board

FC8 Board

MAIN Board

MAIN Board

MAIN Board

MAIN Board

FC8 Board

Power Unit

Power Unit

FILTER Board

MAIN Board

MAIN Board

SD Board

ECN1

ECN6

ECN23

ECONT

EFAC

EFA1

EFA2

EFA3

EFA4

EFC8

EH001

EH002

EMH

EMP0

EPC

EPM1

EPM2

EPU1

ESL

ESP1

ESUB

NOTES:

1. This drawing shows connection and wire styling.

2. This drawing shows the rear view of the set.

3. Securely lock the lead holder in place.

4. Cores and SK binders with ( ) round brackets

should be delivered integrated with harness.

Serial ATA

NameName Board

CN1

CNB

CN23

PCS

PF11

----

----

----

----

----

PMF2

POWER

PH01

PW01

PPC

PPM1

PPM2

PPM3

CN61

PDS

PLS

----

---

---

Board or

Location

Panel Logic

Panel Logic

Panel X-SUS

CONTROL Board

FILTER Board

Chassis Metal

FAN Unit UFA1

FAN Unit UFA2

FAN Unit UFA3

FAN Unit UFA4

MAIN Board

HDD Unit

UHDD1

SD Board

SLOT Board

TERMINAL Board

MAIN Board

MAIN Board

Power Unit

SD Board

LED Board

SPL (Left Speaker)

SPR (Right Speaker)

USB Cable

NVS03

To MAIN Board

PPM1

To Power Unit

CN68

LED Board

PLS

To Power Unit

CNPPS

To Power Unit

CN61