Page 1

PLANER

HOBEL

RABOT

PIALLETTO

SCHAAFMACHINE

CEPILLO

Read through carefully and understand these instructions before use.

Diese Anleitung vor Benutzung des Werkzeugs sorgfältig durchlesen und verstehen.

Lire soigneusement et bien assimiler ces instructions avant usage.

Prima dell’uso leggere attentamente e comprendere queste istruzioni.

Deze gebruiksaanwijzing s.v.p. voor gebruik zorgvuldig doorlezen.

Leer cuidadosamente y comprender estas instrucciones antes del uso.

Handling instructions

Bedienungsanleitung

Mode d’emploi

Istruzioni per l’uso

Gebruiksaanwijzing

Instrucciones de manejo

P 20SD THROW-AWAY TYPE

Page 2

4

1

56

8

7

9

11

10 12

23

321

4

82mm (Max)

10mm (Max)

10mm (Max)

20mm (Max)

20mm (Max)

6

5

7

8

9

=

A

0

C

A

B

1

Page 3

➤

2

16

13

17 18

19

14 15

D

E

F

G

D

I

G

J

B

A

C

M

K

H

44

17

mm

6

mm

➤

L

Page 4

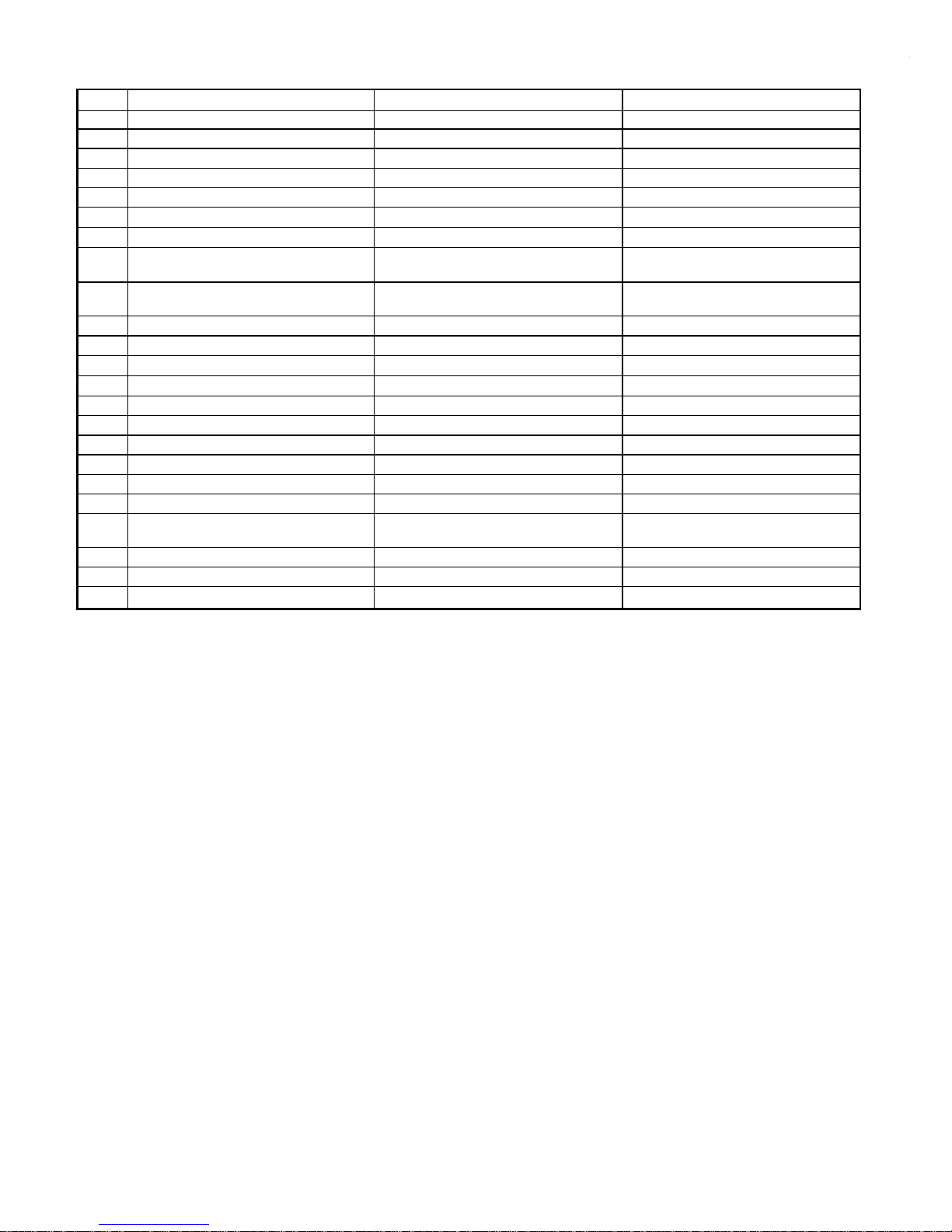

1

2

3

4

5

6

7

8

9

;

A

B

C

D

E

F

G

H

I

J

K

L

M

3

English Deutsch Français

Planing Hobeln Rabotage

Beveling Abkanten Biseautage

Rabberting Falzen Formation de feuillure

Tapering Abschrägen Formation de biais

Knob Knopf Bouton

Scale Skala Échelle

Mark Markierung Marque

Beginning of cutting operation Beginn des Hobelns Début de l’opération de coupe

End of cutting operation Ende des Hobelns Fin de l’opération de coupe

Box wrench Steckschlüssel Clef à béquille

Blade holder Hobeleisenhalter Support de lame

Cutter blade Hobeleisen Lame de coupe

Bolt Schraube Boulon

Set plate (B) Einstellplatte (B) Plaque de fixation (B)

Machine screw Maschinenschraube Vis machine

Turned surface Gebogene Oberfläche Surface tournée

Set plate (A) Einstellplatte (A) Plaque de fixation (A)

Set gauge Einstell-Lehre Jauge de fixation

Wall surface b Wandoberfläche b Surface du mur b

Flat portion of the cutter block Flacher Teil des Schneidblocks Section plate du bloc de lame

Groove Nut Encoche

Wear limit Verschleißgrenze Limite d’usure

No. of carbon brush Nr. der Kohlebürste N˚ du balai en carbone

Page 5

4

English

Italiano Nederlands Español

Piallatura Schaven Cepillar

Smussatura Afbramen Biselar

Scanalatura Groeven Ensamblar

Rastrematura Afschuinen Renatar

Manopola Knop Botón

Scala graduata Schaal Escala

Segno Merkteken Marca

Inizio dell’operazione di piallatura Begin van het schaven

Principio de la operación de

corte

Termine dell’operazione di

Einde van het schaven Fin de la operación de corte

piallatura

Chiave fissa a collare Steeksleutel Llave anular

Porta-lama Schaafijzerhouder Sujetador de cuchilla

Lama Schaafijzer Cuchilla

Bulloni Schroef Perno

Piastra di impostazione (B) Gemonteerde plaat (B) Placa de ajuste (B)

Vite Machineschroef Tornillo de máquina

Superficie curva Gedraaid oppervlak Superficie girada

Piastra di impostazione (A) Gemonteerde plaat (A) Placa de ajuste (A)

Calibro di impostazione Gemonteerd meetinstrument Manómetro de ajuste

Superficie parete b Muuroppervlak b Superficie de pared b

Parte piatta del blocco taglierina Vlakke gedeelte van freeszwart

Parte plana del bloque del

cortador

Scanalatura Groef Ranura

Limite di usura Slijtagegrens Límite de uso

N. della spazzola di carbone Nr. van de koolborstel N° de carbón de contacto

1

2

3

4

5

6

7

8

9

0

A

B

C

D

E

F

G

H

I

J

K

L

M

Page 6

English

5

GENERAL OPERATIONAL PRECAUTIONS

WARNING! When using electric tools, basic safety

precautions should always be followed to reduce the risk

of fire, electric shock and personal injury, including the

following.

Read all these instructions before operating this product

and save these instructions.

For safe operations:

1. Keep work area clean. Cluttered areas and benches

invite injuries.

2. Consider work area environment. Do not expose

power tools to rain. Do not use power tools in

damp or wet locations. Keep work area well lit.

Do not use power tools where there is risk to

cause fire or explosion.

3. Guard against electric shock. Avoid body contact

with earthed or grounded surfaces. (e.g. pipes,

radiators, ranges, refrigerators).

4. Keep children away. Do not let visitors touch the

tool or extension cord. All visitors should be kept

away from work area.

5. Store idle tools. When not in use, tools should

be stored in a dry, high or locked up place, out

of reach of children.

6. Do not force the tool. It will do the job better and

safer at the rate for which it was intended.

7. Use the right tool. Do not force small tools or

attachments to do the job of a heavy duty tool.

Do not use tools for purposes not intended; for

example, do not use circular saw to cut tree

limbs or logs.

8. Dress properly. Do not wear loose clothing or

jewellery, they can be caught in moving parts.

Rubber gloves and non-skid footwear are

recommended when working outdoors. Wear

protecting hair covering to contain long hair.

9. Use eye protection. Also use face or dust mask

if the cutting operation is dusty.

10. Connect dust extraction equipment.

If devices are provided for the connection of dust

extraction and collection facilities ensure these are

connected and properly used.

11. Do not abuse the cord. Never carry the tool by

the cord or yank it to disconnect it from the

receptacle. Keep the cord away from heat, oil and

sharp edges.

12. Secure work. Use clamps or a vise to hold the

work. It is safer than using your hand and it frees

both hands to operate tool.

13. Do not overreach. Keep proper footing and balance

at all times.

14. Maintain tools with care. Keep cutting tools sharp

and clean for better and safer performance. Follow

instructions for lubrication and changing

accessories. Inspect tool cords periodically and if

damaged, have it repaired by authorized service

center. Inspect extension cords periodically and

replace, if damaged. Keep handles dry, clean, and

free from oil and grease.

15. Disconnect tools. When not in use, before servicing,

and when changing accessories such as blades,

bits and cutters.

16. Remove adjusting keys and wrenches. Form the

habit of checking to see that keys and adjusting

wrenches are removed from the tool before turning

it on.

17. Avoid unintentional starting. Do not carry a

plugged-in tool with a finger on the switch. Ensure

switch is off when plugging in.

18. Use outdoor extension leads. When tool is used

outdoors, use only extension cords intended for

outdoor use.

19. Stay alert. Watch what you are doing. Use common

sense. Do not operate tool when you are tired.

20. Check damaged parts. Before further use of the

tool, a guard or other part that is damaged should

be carefully checked to determine that it will

operate properly and perform its intended function.

Check for alignment of moving parts, free running

of moving parts, breakage of parts, mounting and

any other conditions that may affect its operation.

A guard or other part that is damaged should be

properly repaired or replaced by an authorized

service center unless otherwise indicated in this

handling instructions. Have defective switches

replaced by an authorized service center. Do not

use the tool if the switch does not turn it on and

off.

21. Warning

The use of any accessory or attachment, other

than those recommended in this handling

instructions, may present a risk of personal injury.

22. Have your tool repaired by a qualified person.

This electric tool is in accordance with the relevant

safety requirements. Repairs should only be carried

out by qualified persons using original spare parts.

Otherwise this may result in considerable danger

to the user.

PRECAUTIONS ON USING PLANER

䡬 Do not use the Planer with the blades facing upward

(as stationary type planer).

Page 7

6

English

STANDARD ACCESSORIES

1. Box Wrench (for securing cutter blade) ............. 1

2. Set Gauge (for adjusting cutter height) .............. 1

3. Guide (with set screw) ........................................... 1

4. Depth Guide .............................................................. 1

5. Carrying case ............................................................ 1

Standard accessories are subject to change without notice.

OPTIONAL ACCESSORIES (sold separately)

1. Blade Sharpening Ass’y

2. Dust collection adapter

Optional accessories are subject to change without notice.

APPLICATIONS

䡬 Planing various wooden planks and panels.

(See Fig. 1-4)

PRIOR TO OPERATION

1. Power source

Ensure that the power source to be utilized conforms

to the power requirements specified on the product

nameplate.

2. Power switch

Ensure that the power switch is in the OFF position.

If the plug is connected to a receptacle while the

power switch is in the ON position, the power tool

will start operating immediately, which could cause

a serious accident.

3. Extension cord

When the work area is removed from the power

source, use an extension cord of sufficient thickness

and rated capacity. The extension cord should be

kept as short as practicable.

4. Prepare a stable wooden workstand suitable for

planing operation. As a poorly balanced workstand

creates a hazard, ensure it is securely positioned

on firm, level ground.

PLANING PROCEDURES

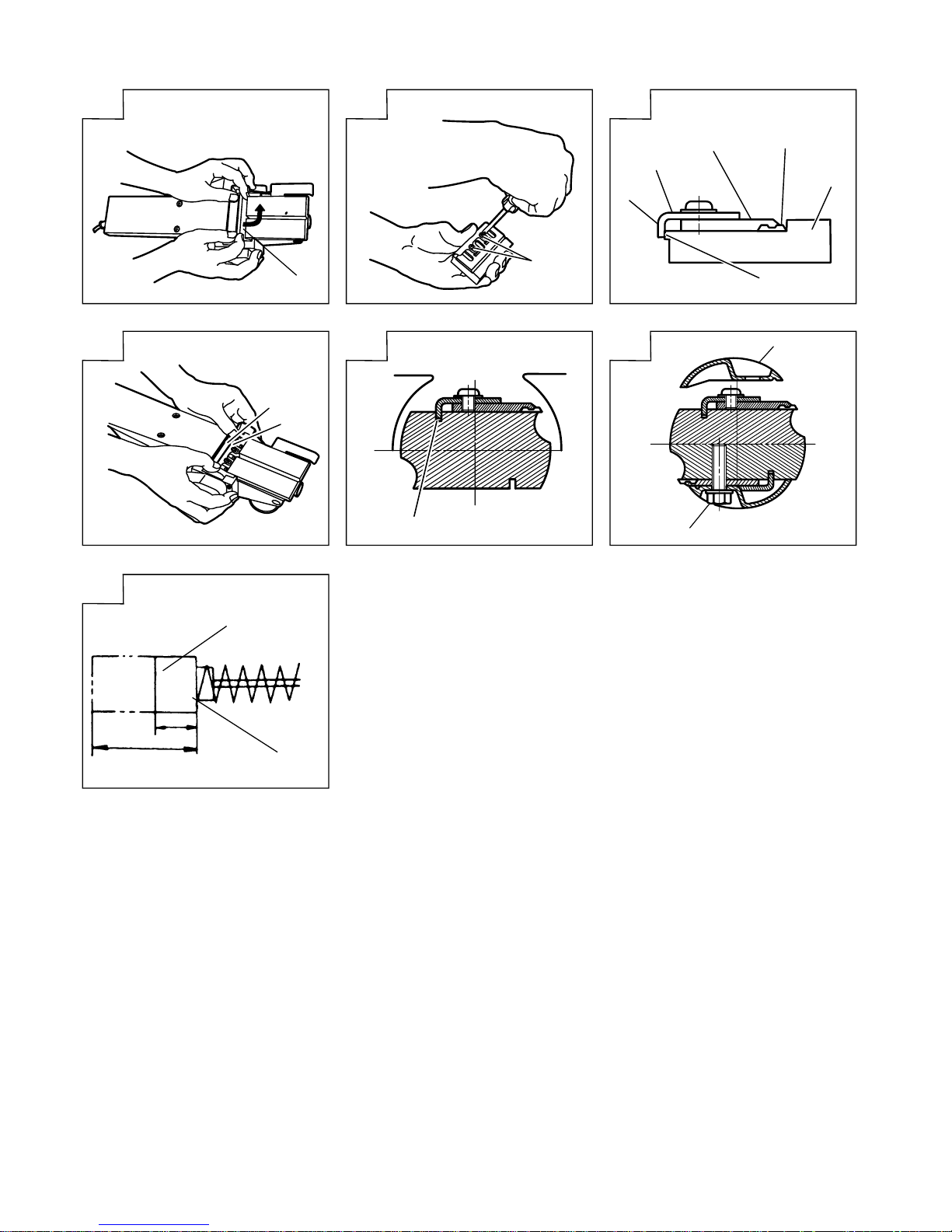

1. Adjusting the cutter depth:

(1) Turn the knob in the direction indicated by the

arrow in Fig. 5 (clockwise), until the triangular mark

is aligned with the desired cutting depth on the

scale. The scale unit is graduated in millimeters.

(2) The cutting depth can be adjusted within a range

of 0-3mm.

2. Surface cutting

Rough cutting should be accomplished at large

cutting depths and at a suitable speed so that

shavings are smoothly ejected from the machine.

To ensure a smoothly finished surface, finish cutting

should be accomplished at small cutting depths and

at low speed.

3. Beginning and ending the cutting operation:

As shown in Fig. 6, place the front base of the

planer on the material and support the planer

horizontally. Turn ON the power switch, and slowly

operate the planer toward the leading edge of the

material. Firmly depress the front half of the planer

at the first stage of cutting, as shown in Fig. 7,

depress the rear half of the planer at the end of

the cutting operation. The planer must always be

kept flat throughout the entire cutting operation.

4. Precaution after finishing the planing operation:

When the planer is suspended with one hand after

finishing the planing operation, ensure that the

cutting blades (base) of the planer do not contact

or come too near your body. Failure to do so could

result in serious injury.

CUTTER BLADE ASSEMBLY AND

DISASSEMBLY AND ADJUSTMENT OF

CUTTER BLADE HEIGHT

1. Cutter blade disassembly:

(1) As shown in Fig 8, loosen the blade holder with

the attached box wrench.

(2) As shown in Fig 9, remove the cutter blade by

sliding it with the attached box wrench.

CAUTION

䡬 Be careful not to injure your hands.

SPECIFICATIONS

Voltage (by areas)* (110V, 115V, 120V, 127V, 220V, 230V, 240V)

Power Input 1100W*

Cutting Width 82mm

Max. Cutting Depth 3mm

Weight (without cord and guide) 4.9kg

No-Load Speed 16000/min

* Be sure to check the nameplate on product as it is subject to change by areas.

Page 8

English

7

2. Cutter blade assembly:

CAUTION

䡬 Prior to assembly, thoroughly wipe off all awarf

accumulated on the cutter blade.

(1) As shown in Fig 10, mount the new cutter blade

by sliding it on the set plate (B) so that the blade

tip projects by 1mm from the end of the cutter

block.

(2) As shown in Fig 11, fix the bolt at the blade holder

and blade replacement is completed.

(3) Turn the cutter block over, and set the other side

in the same manner.

3. Adjustment of cutter blade height:

(1) As shown in Fig 12, use the box wrench to loosen

the three bolts used to ratain the cutter blade, and

remove the blade holder.

(2) As shown in Fig 13, after removing the cutter blade,

slide the set plate (B) in the direction indicated by

the arrow to disassemble set plate (B).

(3) Loosen the 2 screws holding on the cutter blade

and the set plate (A), set plate (B).

(4) As shown in Fig 14, 15, press the turned surface

of the set plate (A) to the wall surface b while

adjusting the cutter blade edge to the wall surface

a of the set gauge. Then, tighten them with the 2

screws.

(5) As shown in Fig 16, 17, insert a turned portion of

the set plate (A) attached to the set plate (B) into

a groove on the flat portion of the cutter block.

(6) As shown in Fig 18, place the blade holder on the

completed assembly and fasten it with the three

bolts. Ensure that the bolts are securely tightened.

MAINTENANCE AND INSPECTION

1. Inspecting the cutter blades:

Continued use of dull or damaged cutter blades will

result in reduced cutting efficiency and may cause

overloading of the motor. Sharpen or replace the

cutter blades as often as necessary.

2. Handling

CAUTION

The front base, rear base, and cutting depth control

knob are precisely machined to obtain specifically

high precision. If these parts are roughly handled

or subjected to heavy mechanical impact, it may

cause deteriorated precision and reduced cutting

performance. These parts must be handled with

particular care.

3. Inspecting the mounting screws:

Regularly inspect all mounting screws and ensure

that they are properly tightened. Should any of the

screws be loose, retighten them immediately. Failure

to do so could result in serious hazard.

4. Inspecting the carbon brushes (Fig. 19)

The motor employs carbon brushes which are

consumable parts. Since an excessively worn carbon

brush can result in motor trouble, replace the carbon

brush with a new one having the same carbon

brush No. shown in the figure when it becomes

worn to or near the “wear limit”. In addition, always

keep carbon brushes clean and ensure that they

slide freely within the brush holders.

5. Replacing a carbon brush:

After removing the chip cover, use a screwdriver

to disassemble the brush cap. The carbon brush can

then be easily removed with the spring.

6. Maintenance of the motor

The motor unit winding is the very “heart” of the

power tool.

Exercise due care to ensure the winding does not

become damaged and/or wet with oil or water.

NOTE

Due to HITACHI’s continuing program of research and

development, the specifications herein are subject to

change without prior notice.

IMPORTANT

Correct connection of the plug

The wires of the main lead are coloured in accordance

with the following code:

Blue: -- Neutral

Brown: -- Live

As the colours of the wires in the main lead of this tool

may not correspond with the coloured markings

identifying the terminals in your plug proceed as follows:

The wire coloured blue must be connected to the terminal

marked with the letter N or coloured black.

The wire coloured brown must be connected to the

terminal marked with the letter L or coloured red.

Neither core must be connected to the earth terminal.

NOTE

This requirement is provided according to BRITISH

STANDARD 2769: 1984.

Therefore, the letter code and colour code may not be

applicable to other markets except The United Kingdom.

Information concerning airborne noise and vibration

The measured values were determined according to

EN50144.

The typical A-weighted sound pressure level: 94dB (A).

The typical A-weighted sound poweer level: 107dB (A).

Wear ear protection.

The typical weighted root mean square acceleration

value does not exceed 2.5m/s2.

Page 9

8

Deutsch

ALLGEMEINE VORSICHTSMASSNAHMEN

WARNUNG! Bei der Verwendung von Elektrowerkzeugen

müssen immer die grundlegenden Vorsichtsmaßnahmen

befolgt werden, um das Risiko von Feuer, elektrischem

Schlag und persönlicher Verletzung und den

nachfolgenden Punkten zu vermeiden.

Lesen Sie diese Anweisungen völlig, bevor Sie dieses

Erzeugnis verwenden, und bewahren Sie diese

Anweisungen auf.

Für sicheren Betrieb:

1. Der Arbeitsplatz sollte sauber gehalten werden.

Unaufgeräumte Arbeitsplätze und Werkbänke

erhöhen die Unfallgefahr.

2. Die Betriebsbedingungen beachten.

Elektrowerkzeuge sollten nicht dem Regen

ausgesetzt werden.

Ebenfalls sollten Sie nicht an feuchten oder nassen

Plätzen gebraucht werden.

Der Arbeitsplatz sollte gut beleuchtet sein.

Verwenden Sie Elektrowerkzeuge nicht an Orten,

an denen die Gefahr von Feuer oder Explosion

besteht.

3. Schutzmaß nahmen gegen elektrische Schläge

treffen. Darauf achten, daß das Gehäuse nicht in

Kontakt mit geerdeten Flachen kommt, z. (z.B.

Rohre, Radiatoren, Elektroherde, Kühlschränke).

4. Kinder sollten vom Gerät ferngehalten werden.

Vermeiden, daß andere Personen mit dem

Werkzeung oder Verlängerungskabel in Kontakt

kommen.

5. Nicht benutzte Werkzeuge sollten sicher aufbewahrt

werden. Sie sollten an einem trockenen und

verschließbaren Ort aufbewahrt werden, damit

Kinder sie nicht in die Hände bekommen.

6. Werkzeuge sollten nicht mit übermäßiger Gewalt

verwendet werden. Ihre Leistung ist besser und

sicherer, wenn sie mit der vorgeschriebenen

Geschwindigkeit verwendet werden.

7. Nur die korrekten Werkzeuge verwenden. Niemals

ein kleineres Werkzeug oder Zusatzgerat für

Arbeiten verwenden, die Hochleistungsgerate

erfordern. Nur Werkzeuge verwenden, die dem

Verwendungszweck entsprechen, d.h. niemals eine

Kreissäge zum Sägen von Ästen oder

Baumstämmen verwenden.

8. Die richtige Kleidung tragen. Keine lose Kleidung

oder Schmuck tragen, da sich lose Kleidungsstücke

in den bewegenden Teilen verfangen kònnen. Bei

Arbeiten im Freien sollten Gummihandschuhe und

rutschfeste Schuhe getragen werden.

9. Es sollte eine Sicherheitsbrille getragen werden.

Bei Arbeiten mit Staubentwicklung sollte eine

Gesichtsoder Staubmaske getragen werden.

10. Schließen Sie eine Staubabsaugvorrichtung an.

Wenn Vorrichtungen für den Anschluß von

Staubabsaug- und -sammelvorrichtungen

vorhanden sind, so stellen Sie sicher, daß diese

angeschlossen sind und richtig verwendet werden.

11. Niemals das Kabel mißbrauchen. Ein Werkzeug

niemals am Kabel tragen oder bei Abtrennung

von der Steckdose das Kabel harausreißen. Das

Kabel sollte gegen Hitze, Öl und scharfe Kanten

geschützt werden.

12. Den Arbeitsplatz gut absichern. Zwingen oder einen

Schraubstock zur Befestigung des Werkstücks

verwenden. Das ist sicherer als die Benutzung der

Hände und macht beide Hände zur Bedienung des

Werkzeugs frei.

13. Sich niemals weit überbeugen. Immer einen festen

Stand und ein sicheres Gleichgewicht bewahren.

14. Die Werkzeuge sollten sorgfältig behandelt werden.

Für einen einwandfreien und sicheren Betrieb

sollten sie stets scharf sein und saubergehalten

werden. Die Anleitungen für schmierung und

Austausch des Zuehörs unbedingt einhalten. Die

Kabel der Geräte regelmäßig überprüfen und bei

Beschädigung durch eine autorisierte

Kundendienststelle reparieren lassen.

Ebenfalls die Verlägerungskabel regelmäßig

überprüfen und bei Beschadigung auswechseln.

Die Handgriffe sollten stets trocken und sauber

sein, sowie keine Ol- oder Schmierfett stellen

aufweisen.

15. Werkzeuge vom Netz trennen, wenn sie nicht

benutzt werden, vor Wartungsarbeiten und beim

Austausch von Zubehörteilen wie z.B. Blätter,

Bohrer und Messer.

16. Alle Stellkeile und Schraubenschlüssel entfernen.

Vor Einschaltung des Gerätes darauf achten, daß

alle Stellkeile und Schraubenschlüssel entfernt

worden sind.

17. Ein unbeabsichtigtes Einschalten sollte vermieden

werden. Niemals ein angeschlossenes Werkzeug

mit dem Finger am Schalter tragen. Vor Anschluß

überprüfen, ob das Gerät ausgeschaltet ist.

18. Im Freien ein Verlängerungskabel verwenden. Nur

ein Verlängerungskabel verwenden, das für die

Verwendung im Freien markiert ist.

19. Den Arbeitsvorgang immer unter Kontrolle haben.

Das Gerät niemals in einem abgespannten Zustand

verwenden.

20. Beschädigte Teile überprüfen. Vor Benutzung des

Werkzeugs sollten beschädigte Teile oder

Schutzvorrichtungen sorgfältig überprüft werden,

um festzustellen, ob sie einwandfrei funktionieren

und die vorgesehene Funktion erfüllen,

Ausrichtung, Verbindungen sowie Anbringung sich

bewegender Teile überprüfen. Ebenfalls

uberprufen, ob Teile gebrochen sind. Teile oder

Schutzvorrichtungen, die beschädigt sind, sollten,

wenn in dieser Bedienungsanleitung nichts anderes

erwähnt ist, durch eine autorisierte

Kundendienststelle ausge wechselt oder repariert

werden. Dasselbe gilt für defekte Schalter.

Wenn sich das Werkzeug nicht mit dem Schalter

einoder ausschalten läßt, sollte das Werkzeug nicht

verwendet werden.

21. Warnung

Die Verwendung von anderem Zubehör oder

anderen Zusätzen als in dieser Bedienungsanleitung empfohlen kann das Risiko einer

Körperverletzung einschließen.

22. Lassen Sie Ihr Werkzeug durch qualifiziertes

Personal reparieren. Dieses Elektrowerkzeug

entspricht den zutreffenden Sicherheitsanforderungen. Reparaturen sollten nur von

qualifiziertem Personal unter Verwendung von

Originalersatzteilen durchgeführt werden, da sonst

beträchtliche Gefahr für den Benutzer auftreten

kann.

Page 10

Deutsch

9

VORSICHTSMASSNAHMEN BEI DER

BENUTZUNG DES HOBELS

䡬 Die Hobelmaschine nicht mit dem Messer nach

oben verwenden (als stationäre Hobelmaschine

maschine zu verwenden).

TECHNISCHE DATEN

Spannung (je nach Gebiet)* (110V, 115V, 120V, 127V, 220V, 230V, 240V)

Leistungsaufnahme 1100W*

Hobelbreite 82mm

Max. Spantiefe 3mm

Gewicht (ohne Kabel und Führung) 4,9kg

Leerlaufgeschwindigkeit 16000 U/min

* Vergessen Sie nicht, die Produktangaben auf dem Typenschild zu überprüfen, da sich diese

je nach Verkaufsgebiet ändern.

STANDARDZUBEHÖR

1. Steckschlüssel (zum Festziehen des Hobelmes-

sers) ........................................................................... 1

2. Einstellehre ................................................................ 1

3. Führung (mit Stellschraube) ................................... 1

4. Tiefenführung ............................................................ 1

5. Tragebehälter ............................................................ 1

Das Standardzubehör kann ohne vorherige

Bekanntmachung jederzeit geändert werden.

SONDERZUBEHÖR - separat zu beziehen

1. Schärfvorrichtung für das Messer

2. Staubfangadapter

Das Sonderzubehör kann ohne vorherige

Bekanntmachung jederzeit geändert werden.

ANWENDUNGSGEBIETE

䡬 Hobeln von verchiedenen Holzplanken und Paneelen.

(s. Abb. 1-4)

VOR INBETRIEBNAHME

1. Netzspannung

Prüfen, ob die zu verwendende Netzspannung der

Angabe auf dem Typenschild entspricht.

2. Netzschalter

Prüfen, ob der Netzschalter auf “AUS” steht. Wenn

der Stecker an das Netz angeschlossen wird,

während der Schalter auf “EIN” steht, beginnt das

Werkzeug sofort zu laufen, was gefährlich wäre.

3. Verlängerungskabel

Wenn der Arbeitsbereich nicht in der Nähe des

Netzanschlusses liegt, ist ein Verlängerungskabel

ausreichenden Querschnitts und ausreichender

Nennleistung zu verwende. Das Verlängerungskabel

sollte so kurz wie möglich gehalten werden.

4. Es ist eine stabile hölzerne Arbeitsunterlage

anzufertigen, die für Hobelarbeiten geeignet ist. Eine

schlecht ausbalancierte Arbeitsunterlage bildet eine

Gefahrenquelle. Es ist darauf zu achten, daß sie auf

einem festen, ebenen Untergrund sicher aufgestellt

ist.

HOBELARBEITEN

1. Einstellen der Spantiefe:

(1) Der Knopf wird in der durch den Pfeil in Abb. 5

(im Uhrzeigersinn) angedeuteten Richtung gedreht,

bis das dreieckige Zeichen auf der Skala auf die

gewünschte Spantiefe zeigt. Die Skala ist in mm

abgestuft.

(2) Die Spantiefe in einem Bereich von 0-3mm, ingestellt

werden.

2. Flächenhobeln:

Das Grobhobeln sollte mit großer Spantiefe und in

einer geeigneten Geschwindigkeit durchgeführt

werden, so daß die Hobelspäne gleichmäßig aus

der Maschine ausgeworfen werden. Zur Erzielung

einer glatten Oberfläche sollte das abschließende

Hobeln mit geringer Spantiefe und niedriger

Geschwindigkeit durchgeführt werden.

3. Beginn und Ende der Spanarbeiten:

Wie in Abb. 6 gezeigt, wird der vordere Teil des

Hobels auf das Werkstück gesetzt und horizontal

abgestützt. Der Motor wird eingeschaltet und der

Hobel langsam zur Kante des Werkstücks

vorgeschoben. Der vordere Teil des Hobels wird zu

Beginn des Spanens, wie in Abb. 7 gezeigt, fest

aufgedrückt, während zum Ende der Spanarbeit die

hintere Hälfte des Hobels fest aufgedrückt wird. Der

Hobel muß während der gesamten Hobelarbeit flach

gehalten werden.

4. Vorsichtsmaßnahmen nach Beendigung der

Hobelarbeiten:

Wenn der Hobel nach Beendigung der Hobelarbeit

mit einer Hand abgenommen wird, ist darauf zu

achten, daß das Hobeleisen (Unterseite) des Hobels

nicht mit dem Körper in Berührung kommt. Sonst

können ernsthafte Verletzungen entstehen.

Page 11

10

Deutsch

EIN- UND AUSBAU DES HOBELEISENS UND

EINSTELLEN DER SCHNEIDTIEFE

1. Ausbau des Hobeleisens:

(1) Den Hobeleisenhalter mit dem Steckschlüssel des

Zubehörs wie in Abb. 8 gezeigt lösen.

(2) Das Hobeleisen wie in Abb. 9 gezeigt durch Schieben

mit dem Steckschlüssel des Zubehörs entfernen.

ACHTUNG

䡬 Es ist darauf zu achten, daß man sich die Hände

nicht verletzt.

2. Einbau des Hobeleisens:

ACHTUNG

䡬 Vor dem Einbau wird sorgfältig sämtlicher Staub,

der sich auf dem Hobeleisen abgesetzt hat,

entfernt.

(1) Das neue Hobeleisen wie in Abb. 10 gezeigt durch

Verschieben auf der Einstellplatte (B) so anbringen,

daß die Klingenspitze 1 mm über das Ende des

Schneidblocks hervorsteht.

(2) Die Schraube wie in Abb. 11 gezeigt am

Hobeleisenhalter fixieren, um das Auswechseln des

Hobeleisens zu beenden.

(3) Der Messerkopf wird umgedreht und die andere

Seite auf die gleiche Weise befestigt.

3. Einstellen der Höhe des Hobeleisens:

(1) Den Steckschlüssel wie in Abb. 12 gezeigt

verwenden, um die drei Schrauben zu lösen, die

das Hobeleisen halten, und dann den

Hobeleisenhalter entfernen.

(2) Nach Entfernen des Hobeleisens die Einstellplatte

(B) wie in Abb. 13 gezeigt in Pfeilrichtung schieben,

um die Einstellplatte (B) auszubauen.

(3) Die zwei Schrauben lösen, die das Hobeleisen auf

der Einstellplatte (A) und der Einstellplatte (B) halten.

(4) Die gebogene Oberfläche der Einstellplatte (A) wie

in Abb. 14 und 15 gezeigt zur Wandoberfläche b

drücken, während die Hobeleisenkante auf die

Wandoberfläche a der Einstell-Lehre ausgerichtet

wird. Dann mit den beiden Schrauben anziehen.

(5) Den gebogenen Teil der an der Einstellpaltte (B)

angebrachten Einstellplatte (A) wie in Abb. 16 und

17 gezeigt am flachen Teil des Schneidblocks

einschieben.

(6) Den Hobeleisenhalter wie in Abb. 18 gezeigt auf die

fertige Montage setzen und ihn mit den drei

Schrauben befestigen. Sicherstellen, daß die

Schrauben fest angezogen sind.

WARTUNG UND INSPEKTION

1. Inspektion der Hobeleisen

Die Weiterverwendung von stumpfen oder

beschädigten Hobeleisen führt zu verminderter

Hobelleistung und kann eine Überbelastung des

Motors verursachen. Die Hobeleisen werden so oft

wie notwendig ersetzt.

2. Behandlung

ACHTUNG

Die vordere Platte, die hintere Platte und der

Einstelknopf für die Spantiefe sind zur Erzielung

besonders großer Präzision exakt bearbeitet. Wenn

diese Teile grob behandelt oder starken

mechanischen Schlägen ausgesetzt werden, kann

das zu verminderter Präzision und verringerter

Hobelleistung führen. Diese Teile müssen mit

besonderer Sorgfalt behandelt werden.

3. Inspektion der Befestigungsschrauben:

Alle Befestigungsschrauben werden regelmäßig

inspiziert und geprüft, ob sie gut angezogen sind.

Wenn sich eine der Schrauben lockert, muß sie

sofort wieder angezogen werden. Geschieht das

nicht, kann das zu erheblichen Gefahren führen.

4. Inspektion der Kohlebürsten: (Abb. 19)

Im Motor sind Kohlebürsten verwendet, die

Verbrauchsteile sind. Übermäßig abgenutzte

Kohlebürsten führen zu Motorproblemen. Deshalb

wird eine Kohlebürste durch eine neue ersetzt, die

dieselbe Nummer trägt, wie auf der Abbildung

gezeigt, wenn sie teilweise oder ganz verbraucht ist.

Darüber hinaus müssen die Kohlebürsten immer

sauber gehalten werden, und sie müssen sich in

der Halterung frei bewegen können.

5. Austausch einer Kohlebürste:

Nach dem Entfernen der Schnipseldeckung mit

einem Negativkopf-Schraubenzieher die

Bürstenkappe abbauen. Die Kohlebürste kann dann

zusammen mit der Feder leicht entfernt werden.

6. Wartung des Motors:

Die Motorwicklung ist das “Herz” des

Elektrowerkzeugs. Daher ist besonders sorgfältig

darauf zu achten, daß die Wicklung nicht beschädigt

wird und/oder mit Öl oder Wasser in Berührung

kommt.

ANMERKUNG

Aufgrund des ständigen Forschungs- und

Entwicklungsprogramms von HITACHI sind Änderungen

den hierin gemachten technischen Angaben nicht

ausgeschlossen.

Information über Betriebslärm und Vibration

Die Meßwerte wurden entsprechend EN50144 bestimmt.

Der typische A-gewichtete Schalldruckt ist 94dB (A).

Der typische A-gewichtete Schalleistungspegel ist 107dB

(A).

Bei der Arbeit immer einen Ohrenschutz tragen.

Der typische gewichtete Effektiv-Beschleunigungswert

überschreitet nicht 2,5 m/s2.

Page 12

11

Français

PRECAUTIONS GENERALES DE TRAVAIL

ATTENTION! Lors de l’utilisation d’un outillage

électrique, les précautions de base doivent être

respectées de manière à réduire les risques d’incendie,

de secousse électrique et de blessure corporelle, y

compris les précautions suivantes.

Lire ces instructions avant d’utiliser le produit et

conserver ces instructions pour référence.

Pour assurer un fonctionnement sûr:

1. Maintenir l’aire de travail propre. Des ateliers ou

des établis en désordre risquent de provoquer des

accidents.

2. Tenir compte de l’environnement de l’aire de tra

vail. Ne pas exposer les outils électriques à la

pluie.

Ne pas les utiliser dans des endroits humides.

Travailler dans un endroit bien éclairé.

Ne pas utiliser d’outillage électrique s’il existe un

risque d’incendie ou d’explosion.

3. Protection contre une décharge électrique. Eviter

tout contact corporel avec des surfaces de mise

à la terre telles que les tuyaux, radiateurs,

cuisinières et réfrigérateurs.

4. Tenir les enfants éloignés. Ne pas laisser les

visiteurs toucher l’outil ou son cordon

d’alimentation. Il est préférable de tenir les visiteurs

à l’écart de l’aire de travail.

5. Ranger les outils non utilisés. Quand on ne les

utilise pas, il est recommandé de ranger les outils

dans un endroit sec, verrouillé ou hors de portée

des enfants.

6. Ne pas forcer l’outil. Il fonctionnera mieux et plus

sûrement à la vitesse pour laquelle il a été con

cu.

7. Utiliser l’outil approprié. Ne pas essayer de faire

avec un petit outil le travail prevu pour un outil

plus important. Toujours utiliser l’outil adéquat;

par exemple, ne pas se servir d’une scie circulaire

pour couper des branches d’arbres ou des billots

de bois.

8. Porter des vêtements appropriés. Ne pas mettre

de vêtements flottants ou de bijoux qui risquent

d’être pris dans les pièces mobiles. Si l’on travaille

à l’extérieur, il est recommandé de porter des

gants de caoutchouc et des chaussures à semelles

antidérapantes. Veiller à s’attacher les cheveux ou

à mettre un bonnet si on a les cheveux longs.

9. Porter des lunettes protectrices. Mettre un masque

si l’opération de coupe crée de la poussière.

10. Relier l’équipement d’extraction de poussière.

Si des dispositifs sont prévus pour le raccordement

d’installations d’extraction et de collection de

poussière, s’assurer qu’ils sont correctement

raccordés et utilisés.

11. Prendre soin du fil. Ne jamais transporter l’outil

en le tenant par le fil et ne pas le débrancher en

tirant sur le fil d’un coup sec. Tenir le fil à l’abri

de la chaleur, l’éloigner de l’huile ou de bords

tranchants.

12. Fixer fermement la piêce à travailler. Utiliser des

agrafes ou un étau pour la maintenir, C’est plus

sûr que d’utiliser ses mains et cela les libêre pour

faire fonctionner l’outil.

13. Ne pas présumer de ses forces. Essayer de garder

son équilibre en toute circonstance.

14. Entretenir les outils avec soin. Les conserver bien

aiguisés et les nettoyer afin d’en obtenir les

meilleures performances et de pouvoir les utiliser

sans danger. Suivre les instructions pour le

graissage et le changement des accessoires.

Vérifier régulièrement les fils et cordons et s’ils

sont endommagés, les faire réparer par une

personne compétente. Vérifier régulièrement les

rallonges et les remplacer si elles sont

endommagées. Veiller à ce que les poignées soient

toujours sèches et propres, sans huile ni graisse.

15. Debrancher les outils lorsqu’on ne les utilise pas,

avant toute opération d’entretien et lors du

changement d’accessoire; comme par exemple

quand on change les lames, les forets, le fraises,

etc.

16. Retirer les clés de réglage. Prendre l’habitude de

toujours vérifier que les clés de réglage sont bien

retirées de l’appareil avant de le mettre en marche.

17. Eviter toute mise en marche accidentelle. Ne pas

transporter l’outil branché avec un doigt sur

l’interrupteur. S’assurer que l’interrupteur est sur

la position d’arrêt quand on branche l’outil.

18. Utilisation de rallonges à l’extérieur. Quand on

utilise l’outil à l’extérieur, ne se servir que des

rallonges prévues pour l’extérieur et portant une

marque distinctive.

19. Soyez vigilant. Regardez bien ce que vous faites.

Faites appel à votre bon sens. N’utilisez pas l’outil

quand vous êtes fatigué.

20. Vérifier les pièces endommagées. Avant d’utiliser

davantage l’outil, vérifier attentivement toute pièce

endommagée afin de déterminer si l’outil peut

fonctionner correctement et effectuer le travail

pour lequel il est prévu. Vérifier l’alignement et

la flexion des piêces mobiles, la cassure des pièces,

le montage et toute autre condition risquant

d’affecter le bon fonctionnement de l’outil. Un

protecteur ou toute autre pièce endommagée devra

être correctement réparé ou remplacé par un

service d’entretien autorisé, sauf autre indication

dans ce mode d’emploi. Faire remplacer les

interrupteurs défectueux par un service d’entretien

autorisé. Ne pas utiliser l’outil si l’interrupteur ne

permet pas de le mettre en marche ou de l’arrêter.

21. Précaution

L’utilisation d’un accessoire ou dispositif annexe

autre que ceux conseillés dans ce mode d’emploi

peut entraîner un risque de blessure corporelle.

22. Confier la réparation d’un outil à un technicien

qualifié. Cet outil électrique a été conçu

conformément aux règles de sécurité en usage.

Les réparations doivent être effectuées par du

personnel qualifié utilisant des pièces d’origine.

Dans le cas contraire, l’utilisateur s’expose à des

risques graves.

PRECAUTIONS POUR L’UTILISATION DU

RABOT

䡬 Ne pas utiliser le rabot avec les lames tournées vers

le haut (comme machine de type stationnaire).

Page 13

Français

12

SPECIFICATIONS

Tension (par zone)* (110V, 115V, 120V, 127V, 220V, 230V, 240V)

Puissance 1100W*

Largeur de coupe 82mm

Profondeur max. de coupe 3mm

Poids (sans fil et guide) 4,9kg

Vitesse sans charge 16000/min

* Assurez-vous de vérifier la plaque signalétique sur le produit qui peut changer suivant les zones.

ACCESSOIRES STANDARD

1. Cléf à béquille (pour fixer la lame de coupe) .. 1

2. Jauge de fixation (pour le réglage de la hauteur de

lame) ........................................................................... 1

3. Guide (avec vis de fixation) .................................. 1

4. Guide de profondeur ............................................... 1

5. Trousse de transport ............................................... 1

Les accessoires standard sont sujets à changement sans

préavis.

ACCESSOIRES A OPTION (vedus séparément)

1. Dispositif d’affûtage de la lame

2. Adaptateur de recupération des poussières

Les accessoires à option sont sujets à changement sans

právis.

APPLICATIONS

䡬 Rabotage de différents madriers et panneaux en

bois. (Voir Fig. 1-4)

AVANT LA MISE EN MARCHE

1. Source de puissance

S’assurer que la source de puissance à utiliser

correspond à la puissance indiquée sur la plaque

signalétique du produit.

2. Interrupteur de puissance

S’assurer que l’interrupteur de puissance est en

position ARRET.

Si la fiche est branchée alors que l’interrupteur est

sur MARCHE, l’outil démarre immédiatement et peut

provoquer un grave accident.

3. Fil de rallonge

Lorsque la zone de travail est éloignée de la source

de puissance, utiliser un fil de rallonge d’une

épaisseur suffisante et d’une capacité nominale

suffisante. Le fil de rallonge doit être aussi court

que possible.

4. Préparer un support stable en bois pour le rabotage.

Comme un support mal équilibré peut créer un

danger, s’assurer qu’il est fermement positionné

sur un sol plat et dur.

RABOTAGE

1. Réglage de la profondeur de coupe de la lame:

(1) Tourner le bouton dans la direction indiquée par

la flèche à la Fig. 5 (sens des aiguilles d’une montre),

jusqu’à ce que la marque triangulaire soit alignée

sur la profondeur de coupe souhaitée sur l’échelle.

L’échelle est graduée en millimètres.

(2) La profondeur de coupe peut être réglée de 0-3mm.

2. Coupe de surface:

La taille grosse doit se faire avec une importante

profondeur de coupe et à une vitesse convenable

de manière à ce que les copeaux soient éjectés

doucement de la machine. Pour obtenir une surface

finie lisse, la finition de la coupe doit se faire à une

faible profondeur et à une vitesse faible.

3. Commencement et fin de l’opération de coupe:

Suivant la Fig. 6, placer la base avant du rabot sur

la pièce travaillée et supporter le rabot

horizontalement. Mettre l’interrupteur sur MARCHE

et faire fonctionner lentement le rabot vers le bord

d’attaque de la pièce. Appuyer fermement sur la

moitié avant du rabot au début de la coupe et,

suivant la Fig. 7, appuyer sur la partie arrière du

rabot à la fin de l’opération de coupe. Le rabot doit

être tenue plate pendant toute l’opération de coupe.

4. Précaution à prendre à la fin de l’opération de

rabotage:

Lorsque le rabot est tenue avec une main après la

fin de l’opération de rabotage, s’assurer que les

lames de coupe (base) du rabot ne sont pas en

contact avec votre corps ou ne l’approchent pas de

trop. Il y a sinon risque d’accident grave.

MONTAGE ET DEMONTAGE DE LA LAME

DE COUPE ET REGLAGE DE LA HAUTEUR

DE LA LAME DE COUPE

1. Démontage de la lame de coupe:

(1) Comme indiqué à la Fig. 8, desserrer le support de

lame à l’aide de la clé à béquille fournie.

(2) Comme indiqué à la Fig. 9, retirer la lame de coupe

en la glissant à l’aide de la clé à béquille fournie.

PRECAUTIONS

䡬 Attention de nes pas bleisser vos mains.

Page 14

13

Français

2. Montage de la lame de coupe:

ATTENTION

䡬 Avant l’assemblage, essuyer à fond tous les

copeaux accumulés sur la lame de coupe.

(1) Comme indiqué à la Fig. 10, monter la nouvelle

lame de coupe en la glissant sur la plaque de

fixation (B) de façon que l’extrémité de la lame

dépasse de 1 mm de l’extrémité du bloc de lame.

(2) Comme indiqué à la Fig. 11, fixer le boulon sur le

support de lame. Le remplacement de la lame est

maintenant terminé.

(3) Retouner le bloc de coupe, et régler l’autre côté de

la même manière.

3. Réglage de la hauteur de la lame de coupe:

(1) Comme indiqué à la Fig. 12, desserrer les trois

boulons de fixation de la lame de coupe à l’aide

de la clé à béquille, et retirer le support de lame.

(2) Comme indiqué à la Fig. 13, après avoir retiré la

lame de coupe, glisser la plaque de fixation (B) dans

le sens de la flèche pour démonter la plaque de

fixation (B).

(3) Desserrer les 2 vis de fixation de la lame de coupe,

puis la plaque de fixation (A) et la plaque de fixation

(B).

(4) Comme indiqué aux Fig. 14 et 15, appuyer la face

tournée de la plaque de fixation (A) sur la surface

du mur b tout en ajustant le tranchant de la lame

de coupe sur la surface du mur a de la jauge de

fixation. Puis, serrer avec les 2 vis.

(5) Comme indiqué aux Fig. 16 et 17, insérer la section

tournée de la plaque de fixation (A) fixée à la plaque

de fixation (B) dans une encoche de la section plate

du bloc de lame.

(6) Comme indiqué à la Fig. 18, placer le support de

lame sur l’ensemble terminé et le serrer avec les

trois boulons. Veiller à bien serrer les boulons à

fond.

ENTRETIEN ET INSPECTION

1. Contrôle des lames

L’utilisation continue de lames usées ou abîmées

peut conduire à une réduction de l’efficacité de

coupe et provoquer une surcharge du moteur.

Affûter ou remplacer les lames aussi souvent que

possible.

2. Maniement:

ATTENTION

䡬 La base avant, la base arrière et le bouton de

commande de la profondeur de coupe sont usinés

de manière précise afin d’obtenir une précision

spécialement élevée. Si ces pièces sont maniées

brutalement ou soumises à des chocs mécaniques

importants, il peut en résulter une diminution de

la précision et une réduction de l’efficacité de

coupe. Ces parties doivent être maniées avec les

plus grand soin.

3. Contrôle des vis de montage:

Vérifier régulièrement les vis de montage et s’assurer

qu’elles sont correctement serrées. Resserrer

immédiatement toute vis desserrée. Sinon, il y a

danger sérieux.

4. Contrôle des balais en carbone: (Fig. 19)

Le moteur utilise des balais en carbone qui sont

des pièces qui s’usent.

Comme un balai en carbone trop usé peut détériorer

le moteur, le remplacer par un nouveau du même

No. que celui montré à la figure quand il est usé

ou à la limite d’usure. En outre, toujours tenir les

balais propres et veiller à ce qu’ils coulissent

librement dans les supports.

5. Remplacement d’un balai en carbone:

Après avoir enlevé le couvercle d’éclats, se servir

d’un tournevis ordinaire por démonter le capuchon

des balais. Les balai en carbone peuvent alors

s’enlever facilement avec le ressort.

6. Entretien du moteur:

Le bobinage de l’ensemble moteur est le “coeur”

même de l’outil électro-portatif. Veiller

soigneusement à ce que ce bobinage ne soit pas

endommagé et/ou mouillé par de l’huile ou de

l’eau.

NOTE

Par suite du programme permanent de recherche et de

développement HITACHI, ces spécifications peuvent

faire l’objet de modifications sans avis préalable.

Au sujet du bruit et des vibrations

Les valeurs mesurées ont été déterminées en fonction de

la norme EN50144.

Le niveau de pression acoustique pondérée A type est de

94 dB (A)

Le niveau de puissance sonore pondérée A type est de

107 dB (A)

Porter un casque de protection.

L’accélération quadratique pondérée typique n’excède

pas 2,5m/s2.

Page 15

14

Italiano

PRECAUZIONI GENERALI

ATTENZIONE!

Quando si usano elettroutensili, bisogna sempre seguire

le precauzioni basilari di sicurezza per ridurre il rischio

di incendi, scosse elettriche e lesioni alle persone, tra

cui quanto segue.

Leggere tutte queste istruzioni prima di usare questo

prodotto e conservare le istruzioni.

Per un funzionamento sicuro:

1. Mantenere sempre pulita l’area dove si lavora.

Un’area di lavoro sempre pulita aiuta ad evitare

incidenti.

2. Tenere nella dovuta considerazione le condizioni

dell’ ambiente di lavoro.

Non esporre gli elettroutensili alla pioggia.

Non usare gli elettroutensili in luoghi molto umidi

o bagnati.

Mantenere ben illuminata l’area di lavoro.

Non usare elettroutentsili dove ci sia il rischio di

causare incendi o esplosioni.

3. Fare attenzione alle scosse elettriche. Evitare il

contatto del corpo con superfici collegate a terra

(p.es. tubi, caloriferi, fornelli, frigoriferi)

4. Tenere lontano i bambini. Non permettere che

persone estranee ai lavori tocchino gli elettrouten

sili o i cavi della corrente elettrica. Le persone non

addette al lavoro non dovrebbero nemmeno

avvicinarvisi.

5. Riporre gli elettroutensili non usati in luogo adatto.

Quando non utilizzati, gli elettroutensili vanno

tenuti in un luogo asciutto, chiusi a chiave o in

alto, fuori dalla portata dei bambini.

6. Non forzare mai gli elettroutensili. Qualsiasi lavoro

viene eseguito meglio e più velocemente alla

velocità per la quale l’elettroutensile è stato

formulato.

7. Scegliere sempre l’utensile elettrico adatto. Non

forzare un piccolo elettroutensile o un accessorio

a fare un lavoro di un utensile o accessorio più

grande. Non usare gli elettroutensili per dei lavori

per i quali non sono stati formulati (non usare,

per esempio, una sega circolare per tagliare grossi

tronchi).

8. Vestirsi in modo adatto. Non portare abiti larghi

o gioielli, che potrebbero impigliarsi nelle parti in

movimento degli elettroutensili. Lavorando all'ester-no, si raccomanda l’uso di guanti di gomma

e di scarpe antisdrucciolo. Chi porta capelli lunghi

dovrebbe utilizzare un’apposita cuffia protettiva.

9. Usare occhiali protettivi. Esegundo dei lavori di

taglio che producono molta polvere, usare anche

una mascherina antipolvere.

10. Collegare apparecchiature di rimozione della

polvere. Se sono forniti dispositivi per il

collegamento di apparecchiature di rimozione e

raccolta della polvere, assicurarsi che siano

collegati e usati correttamente.

11. Non maltrattare il cavo della corrente elettrica.

Non trasportare gli elettroutensili prendendoli per

il cavo della corrente e non scollegarli dalla presa

in tal modo. Tenere il cavo della corrente lontano

dal calore, olio ed oggetti taglienti.

12. Lavorare su oggetti fermi. Fissare saldamente

l’oggetto in una morsa. Èpiù sicuro che non

tenendolo fermo con le mani, che restano libere

per maneggiare l’elettroutensile.

13. Non squilibrare il corpo durante l’esecuzione di

un lavoro. Stare sempre su due piedi, in equilibrio

stabile.

14. Trattare gli utensili elettrici con cura. Tenerli sempre

puliti ed affilati per un funzionamento migliore e

più sicuro. Seguire le istruzioni date per la

lubrificazione e la sostituzione degli accessori.

Controllare periodicamente le condizioni del cavo

della corrente. Se dovesse essere rovinato, farlo

sostituire presso un Centro Assistenza. Non usare

cavi di prolungamento rovinati. Mantenere le

impugnature sempre pulite, libere soprattutto da

olio e grasso.

15. Quando non si usa, prima di eseguire una qualsiasi

operazione di manutenzione e prima di

intraprendere qualsiasi sostituzione di accessori

(lama, punte, ecc.), scollegare sempre

l’elettroutensile.

16. Togliere sempre le chiavi di regolazione

dall’attrezzo. E’buona abitudine controllare siste

maticamente che nessuna chiave di regolazione

sia più attaccata all’elettroutensile, prima di

metterlo in funzione.

17. Evitare che l’elettroutensile possa inavvertitamente

essere messo in funzione. Non trasportare gli elet

troutensili mantenendo il dito sull’interruttore,

mentre sono collegati alla rete. Prima di collegarli,

controllare che l’interruttore sia in posizione di

spento.

18. Fare uso di cavi di prolungamento per esterni. In

questo caso, controllare che il cavo sia adatto per

l’uso all’esterno.

19. Stare sempre attenti. Guardare sempre nel punto

in cui si esegue il lavoro. Non usare utensili

elettrici se si è stanchi.

20. Controllare qualsiasi parte che sembra danneggiata. Prima di riprendere l’uso degli elettroutensili,

controllare attentamente che la parte

apparentemente danneggiata possa ancora essere

usata in modo da assolvere la sua funzione.

Controllare che le parti mobili siano nella loro

posizione corretta, che nessun pezzo sia rotto, che

tutti i pezzi siano montati correttamente, e

controllare altri punti importanti per il

funzionamento dell’ utensile elettrico. Qualsiasi

pezzo danneggiato deve essere ripa rato o sostituito

da un Centro Assistenza autorizzato, a meno che

dettagliate istruzioni in proposito siano date nel

presente manuale.

Non usare l’elettroutensile se non può e acceso

o spento per mezzo del suo interruttore.

21. Attenzione

L’uso di qualsiasi accessorio o attacco diverso da

quelli citati nel presente manuale di istruzioni può

presentare il rischio di lesioni alle persone.

22. Far riparare l’elettroutensile da personale

qualificato. Questo elettroutensile è in conformità

con le relative norme di sicurezza. Le riparazioni

devono essere eseguite solo da personale

qualificato usando ricambi originali, altrimenti ne

possono derivare considerevoli rischi per

l’utilizzatore.

PRECAUZIONI PER L’USO DEL PIALLETO

䡬 Non usare il pialleto con le lame rivolte verso l’alto

(come una pialla di tipo fisso).

Page 16

Italiano

15

Voltaggio (per zona)* (110V, 115V, 120V, 127V, 220V, 230V, 240V)

Potenza assorbita 1100W*

Larghezza del taglio 82mm

Profondità massima di taglio 3mm

Peso (senza cavo e guida) 4,9kg

Velocità senza carico 16000/min

* Accertatevi di aver controllato bene la piastrina perché essa varia da zona a zona.

CARATTERISTICHE

ACCESSORI STANDARD

1. Chiave fissa a collare (per fissare la lama della

pialla) .......................................................................... 1

2. Calibro di impostazione (per regolare l’altezza della

taglierina) ................................................................... 1

3. Guida (con vite di fissaggio) ................................. 1

4. Guida di profondità ................................................. 1

5. Valigetta di transporto ............................................ 1

Gli accessori standard possono essere soggeti a

cambiamento senza preavviso.

ACCESSORI DISPONIBILI A RICHIESTA

(venduti separatamente)

1. Complesso per affilare le lame

2. Adattatore raccoglipoltere

Gli accessori disponibili a richiesta possono essere soggetti

a cambiamento senza preavviso.

IMPIEGHI

䡬 Piallare tavole e pannelli vari in legno. (Vds. Fig.

1-4)

PRIMA DELL’USO

1. Alimentazione

Assicurarsi che la rete di alimentazione che si vuole

usare sia compatibile con le caratteristiche relative

all’alimentazione di corrente specificate nella

piastrina dell’apparecchio.

2. Interruttore di corrente

Mettere l’interruttore in posizione SPENTO. Se la

spina è infilata in una presa mentre l’interruttore

è acceso, l’utensile elettrico si mette immediatamente

in moto, facilitando il verificarsi di incidenti gravi.

3. Prolunga del cavo

Quando l’ambiente di lavoro è lontano da una presa

di corrente, usare una prolunga del cavo di sufficiente

spessore e di prestazione adeguata.

La prolunga deve essere più corta possibile.

4. Preparare un banco di lavoro in legno, stabile e

adatto a lavori di piallatura. Poiché un banco di

lavoro scarsamente bilanciato crea pericolo, fare in

modo che esso sia poggiato su un piano stabile

e livellato.

COME SI PIALLA

1. Regolazione della profondità della pialla

(1) Girare la manopola nel senso indicato dalla freccia

nella Fig. 5 (senso orario), fino a che il segno

triangolare sia allineato con la profondità di piallatura

desiderata, segnata sulla scala graduata. L’unità

della scala è graduata in millimetri.

(2) La profondità di piallatura può essere regolata tra

0 e 3mm.

2. Piallatura di superfici:

La sgrossatura deve essere fatta con una profondità

di piallatura elevata ed una appropriata velocità in

modo che i trucioli siano facilmente spulsi dalla

macchina. Per ottenere una superficie rifinita e liscia,

la piallatura di rifinitura deve essere eseguita con

una profondità limitata ed a bassa velocità.

3. Inizio e termine dell’operazione di piallatura:

Come indicato nella Fig. 6, mettere la parte anteriore

della base del pialletto sul pezzo da lavorare e

tenere il pialleto orizzontale. Accendere l’interruttore

della messa in moto (posiz. ON) e manovrare

leggermente il pialleto verso il bordo di guida del

pezzo da lavorare. Premere forte la metà anteriore

del pialleto nella prima fase della piallatura, come

indicato nella Fig. 7 e premere forte la metà

posteriore del pialleto alla fine dell’operazione di

piallatura. Il pialleto deve essere sempre tenuto

piatto durante tutta l’operazione di piallatura.

4. Precauzione da prendere al termine dell’operazione

di piallatura:

Quando il pialleto è sospeso con una mano, dopo

aver ultimato l’operazione di piallatura, fate

attenzione a che le lame (la base) del pialleto non

vengano a contatto o si avvicinino troppo al vostro

corpo. In caso contrario si potrebbe verificare una

grave lesione.

SMONTAGGIO E MONTAGGIO DELLA PIALLA

E REGOLAZIONE DELLA ALTEZZA DELLA

LAMA

1. Smontaggio della lama:

(1) Come mostrato nella Fig.8, allentare il porta-lama

con la chiave fissa a collare in dotazione.

(2) Come mostrato nella Fig.9, rimuovere la lama della

taglierina facendola scorrere con la chiave fissa a

collare in dotazione.

ATTENZIONE

䡬 Fare attenzione a non ferirsi le mani.

Page 17

16

Italiano

2. Montaggio della lama:

ATTENZIONE

䡬 Prima di montare la lama, togliere completamente

tutta la segatura accumulata sulla lama.

(1) Come mostrato nella Fig.10, montare la nuova lama

della taglierina facendola scorrere sulla piastra di

impostazione (B) in modo che la punta della lama

sporga di 1 mm dall’estremità del blocco taglierina.

(2) Come mostrato nella Fig.11, fissare il bullone sul

porta-lama e la sostituzione della lama è completa.

(3) Girare sottosopra in blocco nella pialla e montare

l’altro lato allo stesso modo.

3. Regolazione dell’altezza della lama:

(1) Come mostrato nella Fig.12, usare la chiave fissa

a collare per allentare i tre bulloni usati per trattenere

la lama della taglierina e rimuovere il porta-lama.

(2) Come mostrato nella Fig.13, Dopo aver rimosso la

lama della taglierina, far scorrere la piastra di

impostazione (B) nella direzione indicata dalla freccia

per smontare la piastra di impostazione (B).

(3) Allentare le due viti che trattengono la lama della

taglierina e la piastra di impostazione (A), piastra

di impostazione (B).

(4) Come mostrato nella Fig.14, 15, premere la superficie

curva della piastra di impostazione (A) sulla

superficie parete b regolando il bordo della lama

della taglierina sulla superficie parete a del calibro

di impostazione. Quindi serrare con le 2 viti.

(5) Come mostrato nella Fig.16, 17, inserire una parte

curva della piastra di impostazione (A) applicata alla

piastra di impostazione (B) in una scanalatura della

parte piatta del blocco taglierina.

(6) Come mostrato nella Fig.18, collocare il porta-lama

sull’insieme completato e fissarlo con tre bulloni.

Assicurarsi che i bulloni siano serrati saldamente.

4. Controllo della spazzola di carbone (Fig. 19)

Il motore fa uso di una spazzola di carbone, la quale

con il tempo si consuma.

La spazzola eccessivamente consumata può causare

dei danni; quindi bisogna sostituirla con una nuova,

dello stesso numero indicato nella figura, non

appena è consumata o è vicina al limite di usura.

Inoltre bisogna mantenere la spazzola sempre pulita

e controllare che si sposti liberamente sul

portaspazzola.

5. Sostituzione di una spazzola di carbone:

Dopo aver rimosso il raccoglitrucioli, usare un

cacciavite a testa piatta per smontare il contenitore

di spazzola. Dopodiché la spazzola di carbone potrá

essere rimossa facilmente assieme alla molla.

6. Manutenzione del motore:

L’avvolgimento del motore il vero e proprio “cuore”

degli attrezzi elettrici. Fare attenzione a non

danneggiare l’avvolgimento e/o non bagnarlo con

olio o acqua.

NOTA

A causa del continuo programma di ricerca e sviluppo

della HITACHI, le caratteristiche riportate in questo

foglio sono soggette a cambiamenti senza preventiva

comunicazione.

Informazioni riguardanti i rumori trasmessi dall’aria e

le vibrazioni.

I valori misurati sono stati determinati in conformitá a

EN50144.

Il livello di pressione sonora pesato A tipico è di 94 dB (A)

Il livello di potenza sonora pesato A tipico è di 107 dB (A)

Indossare protezioni per le orecchie.

Il valore tipico di accelerazione quadrata media a radice

pesata non supera 2,5 m/s2.

MANUTENZIONE E CONTROLLI

1. Controllo delle lame

L’uso continuativo di lame logore o danneggiate

provoca una riduzione nell’efficacia della piallatura

e può causare un sovraccarico del motore. Affilare

o sostituire le lame ogni qualvolta sia necessario.

2. Maneggio

ATTENZIONE

䡬 Il basamento anteriore, quello posteriore e la

manopola di regolazione della profondità del taglio

sono prodotti con precisione, per ottenere una

precisione specificatamente elevata. Se queste

componenti sono maneggiate rudemente o

soggette a pesante impatto meccanico, ne può

risultare una minore precisione ed una ridotta

prestazione nella piallatura. Queste parti devono

essere trattate con cura particolare.

3. Controllo delle viti di tenuta:

Controllare regolarmente tutte le viti di tenuta e

assicurarsi che siano esclusivamente serrate. Nel

caso che una di queste viti dovesse allentarsi

riserrarla immediatamente. Se ciò non avviene si

può causare un grave incidente.

Page 18

17

Nederlands

ALGEMENE VOORZORGMAATREGELEN

WAARSCHUWING! Bij gebruik van elektrisch

gereedschap moet u altijd de normale basisvoorzorgen

voor de veiligheid in acht nemen om de kans op brand,

elektrische schokken en letsel te verminderen. Let tevens

op de volgende punten.

Lees al de aanwijzingen door alvorens het gereedschap

in gebruik te nemen. Bewaar deze aanwijzingen.

Voor een veilige werking:

1. Houd de plaats waar gewerkt wordt schoon. Niet

opgeruimde werkplaatsen en werkbanken

verhogen het gevaar van ongelukken.

2. Kies een geschikte omgeving om te werken. Stel

electrisch gereedschap niet aan regen bloot.

Gebruik electrisch gereedschap niet op vochtige

of natte plaatsen.

Zorg dat de werkplaats goed verlicht is.

Gebruik elektrisch gereedschap niet op plaatsen

waar brand- of explosiegevaar is.

3. Vermijd een electrische schok. Let er daarom op

dat er geen contact is met geaarde oppervlakken

zoals pijpen, radiators, keukenfornuis of ijskast.

4. Houd kinderen uit de buurt. Laat bezoekers het

gereedschap of snoer niet aanraken. Alle bezoekers

moeten een veilige afstand tot de werkplaats

aanhouden.

5. Ruim overbodig gereedschap op. Gereedschap dat

niet gebruikt wordt moet op een droge,

hooggelegen of af te sluiten plaats buiten het

bereik van kinderen opgeborgen worden.

6. Forceer het gereedschap niet. Het levert een betere

en veiligere prestatie op de snelheid waarvoor zij

werd ontworpen.

7. Gebruik het juiste gereedschap. Gebruik een klein

gereedschap of hulpstuk niet voor werkzaamheden

waarvoor een apparaat met groot vermogen vereist

is. Gebruik het gereedschap niet voor doeleinden

waarvoor dit niet bestemd is (bijvoorbeeld gebruik

van de cirkelzaag voor het zagen van bomen).

8. Draag de juiste kleding. Draag geen loszittende

kleren of armbanden e.d. daar deze in de

bewegende delen verstrikt kunnen raken. Bij het

werken buitenshuis wordt het gebruik van rubber

handschoenen en stevige, niet glijdende schoenen

aanbevolen.

9. Draag een veiligheidsbril. Ontstaat er veel stof

tijdens het werken, draag dan eveneens een

gezichtsbeschermer en/of stofmasker.

10. Sluit apparatuur voor het verzamelen van stof

aan.

Indien apparatuur voor het verzamelen van stof

is bijgeleverd, moet u deze apparatuur op de

vereiste wijze verbinden en gebruiken zoals wordt

beschreven.

11. Behandel het snoer voorzichtig. Draag het gereed

schap nooit door dit bij het snoer vast te houden.

Bescherm het snoer tegen hitte, olie en scherpe

hoeken.

12. Neem de uiterste veiligheid in acht. Gebruik

klemmen of een bankschroef om het werkstuk

vast te zetten. Hierdoor heeft u uw handen vrij

om het gereedschap te bedienen.

13. Buig u nooit te ver naar voren. Kies een goede

plaats en behoud altijd uw evenwicht.

14. Behandel het gereedschap voorzichtig. Zorg ervoor

dat het gereedschap scherp en schoon is zodat

een goed en veilig prestatievermogen wordt

verkregen. Volg de gebruiksaanwijzing voor het

smeren en het verwisselen van toebehoren.

Inspecteer de snoeren regelmatig op beschadiging

en laat deze zonodig door een erkend servicecenter

repareren. Controleer de verlengsnoeren ook

regelmatig en vervang deze bij beschadiging. Houd

alle handgrepen droog en schoon en vrij van olie

en vet.

15. Trek de stekker uit het stopcontact als het gereed

schap niet wordt gebruikt en ook bij

onderhoudsbeurten, het verwisselen van

toebehoren zoals bladen, boren, messen e.d.

16. Verwijder sleutels en moersleutels. Maak er een

gewoonte van voor het inschakelen te controleren

of alle sleutels en moersleutels verwijderd zijn.

17. Schakel het gereedschap niet onverwacht in. Draag

geen aangesloten gereedschap met de vinger op

de schakelaar. Controleer altijd of het gereedschap

uitgeschakeld staat alvorens dit aan te sluiten.

18. Bij het werken buitenshuis dient een verlengsnoer

te worden gebruikt. Gebruik dan alleen

verlengsnoeren die geschikt zijn voor het werken

buitenshuis en desbetreffend gemerkt zijn.

19. Let altijd goed op tijdens het werken. Kijk uit wat

u doet en gebruik het gereedschap niet als u moe

bent.

20. Bij beschadiging van een van de onderdelen dient

dit nauwkeurig te worden nagekeken en gerepa

reerd alvorens het gereedschap opnieuw in gebruik

wordt genomen. Let erop dat het betreffende on

derdeel zijn functie goed vervult. Controleer of de

bewegende delen goed zijn gemonteerd en vrij

kunnen bewegen. Dit om een foutief functioneren

van het gereedschap te voorkomen. Bij de

beschadiging van een onderdeel dient de reparatie

altijd te worden overgelaten aan een erkend ser

vice-center, tenzij in deze gebruiksaanwijzing an

ders wordt voorgeschreven. Laat ook defekte

schakelaars vervangen door een erkend servicecenter. Gebruik het gereedschap niet als de aan/

uit-schakelaar niet werkt.

21. Waarschuwing

Het gebruik van toebehoren of verlengstukken

waarvan het gebruik niet in deze

gebruiksaanwijzing is aangegeven, veroorzaakt

mogelijk letsel.

22. Laat het elektrisch gereedschap door een vakman

repararen.

Dit elektrisch gereedschap voldoet aan de vereiste

eisen voor de veiligheid. Voorkom mogelijk zeer

ernstige ongelukken en laat derhalve reparatie

over aan een erkend vakman die de originele

reserve-onderdelen gebruikt.

Page 19

Nederlands

18

VOORZORGSMAATREGELEN VOOR GEBRUIK

VAN DE SCHAAFMACHINE

䡬 De schaafmachine niet met het mes naar boven

gebruiken (zoals bij een stationair type).

TECHNISCHE GEGEVENS

Voltage (verschillend van gebied tot gebied)* (110V, 115V, 120V, 127V, 220V, 230V, 240V)

Opgenomen vermogen 1100W*

Schaafbreedte 82mm

Max. spaandikte 3mm

Gewicht (zonder kabel en voring) 4,9kg

Toerental onbelast 16000/min

* Controleer het naamplatje op het apparaat daar het apparaat afhankelijk vas het gebied waar het verkocht

wordt gewijzigd kan worden.

STANDAARD TOEBEHOREN

1.

Steeksleutel (om het schaafmes vast te draaien) ..

1

2. Stel meter in (voor instellen van snijhoogte) .... 1

3. Geleider (met stelschroef) ...................................... 1

4. Diepte-geleider .......................................................... 1

5. Draaghouder .............................................................. 1

De standaard toebehoren kunnen zonder aankondiging

op ieder moment worden veranderd.

EXTRA TOEBEHOREN (los te verkrijgen)

1. Slijpinrichting voor het mes

2. Adapter voor stofopvang

De extra toebehoren kunnen zonder aankonding op ieder

moment worden veranderd.

TOEPASSINGSGEBIEDEN

䡬 Het schaven van verschillende houten planken en

panelen. (Afb. 1-4)

VOOR BEGIN VAN HET WERK

1. Netspanning

Controleren of de netspanning overeenkomt met de

opgave op het naamplaatje.

2. Netschakelaar

Controleren of de netschakelaar op “UIT” staat.

Wanneer de stekker op het net aangesloten is, terwijl

de schakelaar op “AAN” staat, begint het

gereedschap onmiddellijk te draaien, hetwelk ernstig

gevaar betekent.

3. Verlengsnoer

Wanneer het werkterrein niet in de buurt van een

stopcontact ligt, dan moet men gebruik maken van

een verlengsnoer, dat voldoende dwarsprofiel en

voldoende nominaal vermogen heeft. Het

verlengsnoer moet zo kort mogelijk gehouden

worden.

4. Er moet een stabiele houten ondergrond vervaardigd

worden, welke geschikt is voor schaafwerkzaamheden.

Een slecht uitgebalanceerde ondergrond kan gevaar

veroorzaken en er moet op gelet worden, dat het

op een stevige, vlakke vloer veilig is opgesteld.

SCHAAFWERKZAAMHEDEN

1. Het instellen van de spaandikte

(1) De knop wordt in de door de pijl in Afb. 5 (met

de klok mee) aangeduide richting gedraaid, totdat

het driehoekige teken op de schaal op de gewenste

spaandikte wijst. De schaal is ingedeeld in mm.

(2) De spaandikte in een bereik van 0-3mm, worden

ingesteld.

2. Het schaven van oppervlakten:

Het grofschaven moet uitgevoerd worden met grote

spaandikte en een geschikte snelheid, zodat de

schaafspanen gelijkmatig uit de machine geworpen

worden. Om een glad oppervlak te verkrijgen moet

het naschaven uitgevoerd worden met een geringere

spaandikte en lagere snelheid.

3. Begin en einde van de schaafwerkzaamheden:

Zoals aangetoond in Afb. 6, wordt het voorste

gedeelte van de schaaf op het werkstuk gezet en

horizontaal gesteund. De motor wordt aangeschakeld

en men schuift de schaaf langzaam naar de kant

van het werkstuk. Het voorste gedeelte van de schaaf

wordt bij begin van het schaven, zoals aangetoond

in Afb. 7, er stevig opgedrukt, terwijl bij het einde

van het schaafwerk de achterste helft van de schaaf

er stevig opgedrukt wordt. De schaaf moet tijdens

het totale schaafwerk vlak gehouden worden.

4. Voorzichtig, ook na beëindiging van het schaafwerk:

Wanneer de schaaf na beëindiging van het

schaafwerk met één hand verwijderd wordt, moet

er op gelet worden, dat het schaafijzer (onderkant)

van de schaaf niet in aanraking komt met het

lichaam.

Anders kunnen er ernstige verwondingen optreden.

Page 20

19

Nederlands

HET MONTEREN EN DEMONTEREN VAN

HET SCHAAFIJZER EN HET INSTELLEN VAN

DE SNIJDIEPTE

1. Demontage van het schaafijzer:

(1) Maak de snijvlakhouder los met de bijgeleverde

steeksleutel, als aangegeven in Afb. 8.

(2) Verwijder het freessnijvlak door het te schuiven met

de bijgeleverde steeksleutel, als aangegeven in Afb.

9.

LET OP

䡬 Er moet op gelet worden, dat de handen niet

verwond worden.

2. Montage van het schaafijzer:

LET OP

䡬 Voor het monteren verwijdert men zorgvuldig al

het stof, dat zich op het schaafijzer afgezet heeft.

(1) Monteer het nieuwe freessnijvlak door het op de

gemonteerde plaat (B) te schuiven zodat de punt

van het snijvlak met 1 mm uit het einde van het

freeszwart steekt, als aangegeven in Afb. 10.

(2) Bevestig de moer aan de snijvlakhouder, als

aangegeven in Afb. 11, en het vervangen van het

snijvlak is gebeurd.

(3) De snijkop wordt omgedraaid en men bevestigt de

andere kant op dezelfde manier.

3. Het instellen van de hoogte van het schaafijzer:

(1) Gebruik de bijgeleverde steeksleutel om de drie

moertjes die het freessnijvlak tegenhouden los te

maken en verwijder de snijvlakhouder, als

aangegeven in Afb. 12.

(2) Schuif, nadat het freessnijvlak is verwijderd, de

gemonteerde plaat (B) in de richting van de pijl,

als aangegeven in Afb. 13, om de gemonteerde

plaat (B) te demonteren.

(3) Maak de twee schroeven los die het freessnijvlak,

de gemonteerde plaat (A) en de gemonteerde plaat

(B) op hun plaats houden.

(4) Duw het gedraaide oppervlak van de gemonteerde

plaat (A) richting het muuroppervlak b, terwijl u

ondertussen de snijkant van het freessnijvlak afstelt

op het muuroppervlak a van het gemonteerde

meetinstrument, als aangegeven in Afb. 14 en 15.

Zet ze vervolgens vast met de 2 schroeven.

(5) Plaats een gedraaid gedeelte van de gemonteerde

plaat (A) bevestigd aan de gemonteerde plaat (B)

in een groef op het vlakke gedeelte van het

freeszwart, als aangegeven in Afb. 16 en 17.

(6) Plaats de snijvlakhouder op de afgemaakte montage

en zet hem vast met de drie moertjes. Zorg beslist

dat de moertjes stevig vast zitten.

ONDERHOUD EN INSPECTIE

1. Inspectie van het schaafijzer:

Het verder gebruik van stompe of beschadigde

schaafijzers leidt tot verminderd schaafeffect en kan

overbelasting van de motor veroorzaken. De

schaafijzer moeten zo dikwijls mogelijk vernieuwd

worden.

2. Behandeling

LET OP

䡬 De voorste plaat, de achterste plaat en de

instelknop voor de spaandikte zijn voor het

bereiken van een bijzonder grote precisie exact

bewerkt. Wanneer deze delen ruw behandeld

worden of blootgesteld worden aan sterke

mechanische slagen, kan dat leiden tot een

verminderde precisie en schaafeffect.

Deze delen moeten met bijzondere zorgvuldigheid

worden behandeld.

3. Inspectie van de bevestigingsschroef:

Alle bevestigingsschroeven worden regelmatig

geinspecteerd en gecontroleerd of zij juist

aangedraaid zijn. Wanneer één van de schroeven

losraakt, dan moet deze onmiddellijk opnieuw

aangedraaid worden. Gebeurt dat niet, dan kan dat

tot aanzienlijke gevaren leiden.

4. Inspectie van de koolborstels (Afb. 19)

Bij de motor zijn koolborstels gebruikt, die

onderhevig zijn aan slijtage.

Versleten koolborstels leiden tot problemen bij de

motor. Dientengevolge dienen de koolborstels

vervangen te worden door borstels die hetzelfde

nummer hebben als de afbeelding aantoont,

wanneer de koolborstel versleten, of bijna versleten

zijn. Bovendien moeten de koolborstels altijd schoon

zijn en zich vrij in de borstelhouders kunnen

bewegen.

5. Het wisselen van de koolborstel:

Na het verwijderen van de spaankast kan de

koolborstel en veer gemakkelijk met een

schroevedraaier verwijderd worden.

6. Onderhoud van de motor

De motorwikkeling is het “hart” van het electrische

gereedschap. Er moet daarom bijzonder zorgvuldig

op gelet worden, dat de wikkeling niet beschadigt

en/of met olie of water bevochtigd wordt.

AANTEKENING

Op grond van het voortdurende research- en

ontwikkelingsprogramma van HITACHI zijn

veranderingen van de hierin genoemde technische

opgaven voorbehouden.

Informatie betreffende luchtgeluid en trillingen

De gemeten waarden zijn verkregen overeenkomstig

EN50144.

Het doorsnee A-gewogen geluiddruknivo is 94 dB (A)

Het standaard A-gewogen geluiddruknivo is 107 dB (A)

Draag gehoorbescherming.

De doorsnee gewogen effektieve acceleratiewaarde is

gelijk aan of minder dan 2,5 m/s2.

Page 21

Español

20

PRECAUCION ES GENERAL ES PARA