Page 1

Model Planer

1/2

C

M

INCH

2-

1/2

1-1/2

1

3

1414

11

12

10

5-

1/

25-1/2

3-

1

/2

171

7

6-

1

/2

Modele

P 13F

Raboteuse

Modelo Cepilladora

1

7

2

1/

6-

16

6

15

14

1/2

5-

131

3

55

121

2

1111

44

1010

99

2

2

/

/

-1

-1

3

3

88

33

77

/2

/2

-1

-1

2

2

66

22

55

44

2

2

/

/

1

-1

-

1

1

33

11

22

2

2

/

/

1

1

11

00

00

CMCM

H

H

NC

NC

I

I

INSTRUCTION MANUAL AND SAFETY INSTRUCTIONS

WARNING

Improper and unsafe use of this power tool can result in death or serious bodily injury!

This manual contains important information about product safety. Please read and understand

this manual before operating the power tool. Please keep this manual available for others before

they use the power tool.

MODE D'EMPLOI ET INSTRUCTIONS DE SECURITE

AVERTISSEMENT

Une utilisation incorrecte et dangereuse de cet outil motorisé peut entraîner la mort ou de

sérieuses blessures corporelles!

Ce mode d’emploi contient d’importantes informations à propos de la sécurité de ce produit.

Prière de lire et d’assimiler ce mode d’emploi avant d’utiliser l’outil motorisé. Garder ce mode

d’emploi à la disponibilité des autres utilisateurs avant qu’ils utilisent I'outil motorisé.

MANUAL DE INSTRUCCIONES E INSTRUCCIONES DE SEGURIDAD

ADVERTENCIA

¡La utilización inapropiada e insegura de esta herramienta eléctrica puede resultar en lesiones

serias o en la muerte!

Este manual contiene información importante sobre la seguridad del producto. Lea y comprenda

este manual antes de utiIizar la herramienta eléctrica. Guarde este manual para que puedan

leerlo otras personas antes de que utilicen la herramienta eléctrica.

Page 2

English

SECTION PAGE

Technical Data .........................................................................3

General safety rules ................................................................4

Specific Safety instructions for the planer ............................5

Electrical information ............................................................. 7

Know your planer ....................................................................8

Assembly and adjustments ................................................... 9

TABLE OF CONTENTS

SECTION PAGE

Operations ............................................................................. 13

Maintenance ..........................................................................16

Troubleshooting guide ......................................................... 17

Parts list .................................................................................48

HITACHI AUTHORIZED SERVICE CENTERS

Service under this warranty is available from Hitachi Koki U.S.A., Ltd. at :

IN THE U.S.A.

3950 Steve Reynolds Blvd. Norcross, GA 30093

9409 Owensmouth Ave. Chatsworth, CA 91311

OR CALL: (800) 546-1666 for a service center nearest you.

IN CANADA

6395 Kestrel Road Mississauga, ON L5T 1Z5

OR CALL: (800) 970-2299 for a service center nearest you.

Français

SECTION PAGE

Spécifications techniques .....................................................18

Consignes de sécurité ...........................................................19

Consignes de sécurité spécifiques à la raboteuse .............20

Informations relatives à l'électricité ....................................22

Connaître votre raboteuse ....................................................23

Montage et réglages .............................................................24

TABLE DE MATIERES

SECTION PAGE

Opération ...............................................................................28

Entretien .................................................................................31

Guide de dépannage .............................................................32

Liste des pièces ..................................................................... 48

CENTRES TECHNIQUES HITACHI AGREES

La réparation est réalisée dans le cadre de cette garantie par Hitachi Koki U.S.A., Ltd. :

AUX ETATS-UNIS

3950 Steve Reynolds Blvd. Norcross, GA 30093

9409 Owensmouth Ave. Chatsworth, CA 91311

OU APPELEZ LE : (800) 546-1666 pour connaître le centre

technique le plus proche de chez vous.

Español

SECCIÓNPÁGINA

Datos técnicos ....................................................................... 33

Normas de seguridad generales ..........................................34

Instrucciones De Seguridad Específicas Para La Cepilladora

Información eléctrica ............................................................ 37

Conozca su cepilladora .........................................................38

Montaje y ajustes ..................................................................39

....35

ÍNDICE

AU CANADA

6395 Kestrel Road Mississauga, ON L5T 1Z5

OU APPELEZ LE : (800) 970-2299 pour connaître le centre

technique le plus proche de chez vous.

SECCIÓNPÁGINA

Funcionamiento ....................................................................43

Mantenimiento ......................................................................46

Guía de solución de problemas ...........................................47

Lista de piezas ....................................................................... 48

CENTROS DE SERVICIO AUTORIZADOS DE HITACHI

Hitachi Koki U.S.A. Ltd. proporciona un servicio de reparaciones bajo esta garantía en:

EN EE.UU.

3950 Steve Reynolds Blvd. Norcross, GA 30093

9409 Owensmouth Ave. Chatsworth, CA 91311

O LLAME AL: (800) 546-1666 para informarse del centro de

reparaciones más cercano.

— 2 —

EN CANADA

6395 Kestrel Road Mississauga, ON L5T 1Z5

O LLAME AL: (800) 970-2299 para informarse del centro de

reparaciones más cercano.

Page 3

English

WARNING

Some dust created by power sanding, sawing, grinding, drilling and other construction activities contains chemicals

known to the state of California to cause cancer, birth defects or other reproductive harm. Some examples of these

chemicals are:

• Lead from lead-based paints

• Crystalline silica from bricks, cement and other masonry products

• Arsenic and chromium from chemically treated lumber

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your exposure to

these chemicals, work in a well-ventilated area and work with approved safety equipment such as dust masks that are

specially designed to filter out microscopic particles.

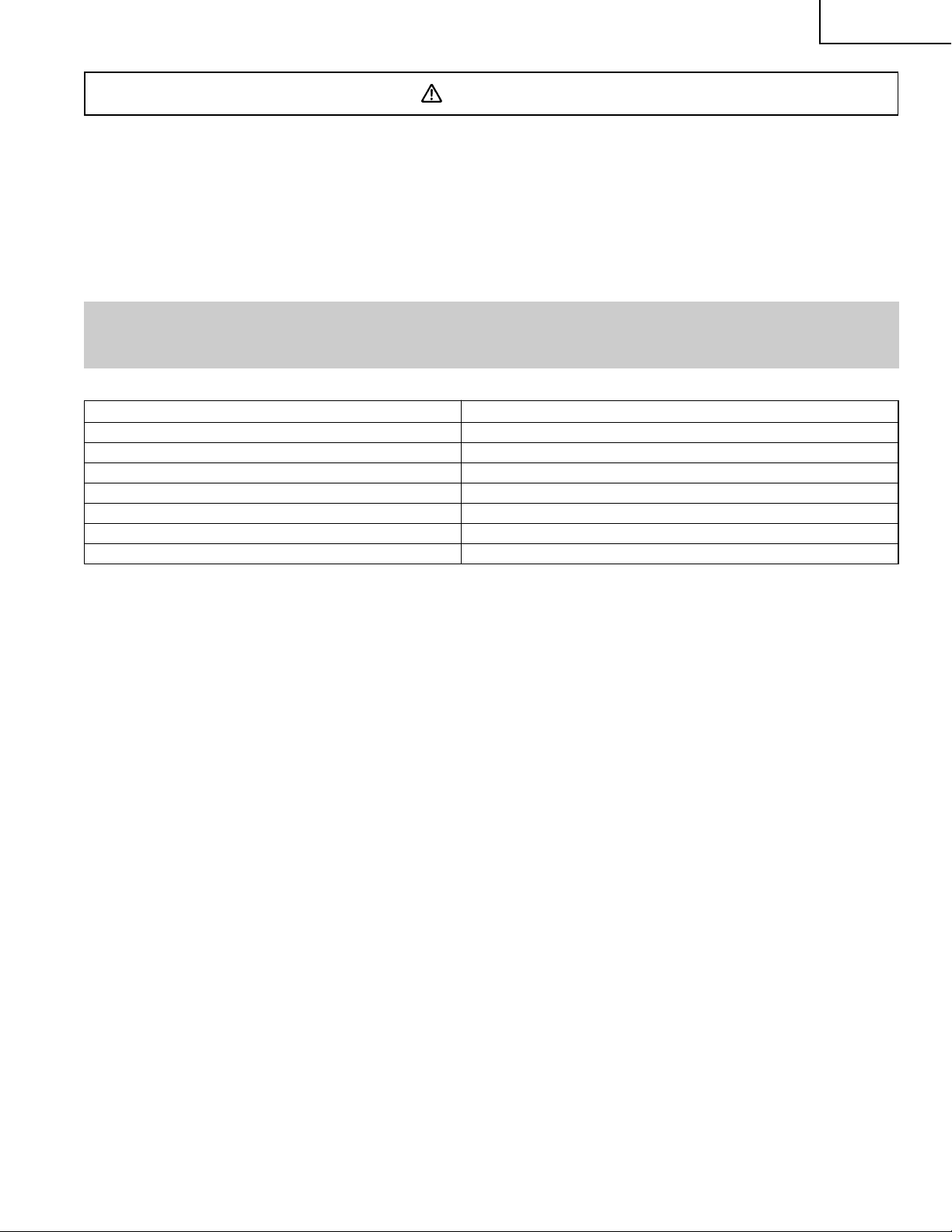

TECHNICAL DATA

13” PLANER

Motor 15A, 120V, 60Hz

Maximum stock width 13”

Thickness of cut Min. 1/8”

Maximum depth of cut 3/32”

Feed speed 24.08 ft/min

Number of blade 2

RPM (no load) 8000 min

Weight 101.4 lb (46 kg)

-1

— 3 —

Page 4

English

GENERAL SAFTY RULES

Safety is a combination of common sense, staying alert and knowing how your planer works.

WARNING

TO AVOID MISTAKES THAT COULD CAUSE SERIOUS INJURY, DO NOT PLUG IN THE PLANER UNTIL THE FOLLOWING

STEPS HAVE BEEN READ AND UNDERSTOOD.

1. READ and become familiar with this entire

instruction manual. LEARN the tool’s applications,

limitations, and possible hazards.

2. AVOID DANGEROUS CONDITIONS. DO NOT use

power tools in wet or damp areas or expose them to

rain. Keep work areas well-lit.

3. DO NOT use power tools in the presence of flammable

liquids or gases.

4. ALWAYS keep your work area clean, uncluttered, and

well-lit. DO NOT wok on floor surfaces that are

slippery with sawdust or wax.

5. KEEP BYSTANDERS AT A SAFE DISTANCE FROM the

work area, especially when the tool is operating.

NEVER allow children near the tool.

6. DO NOT FORCE THE TOOL to do a job for which it was

not designed.

7. DRESS FOR SAFETY. DO NOT wear loose clothing,

gloves, neckties, or jewellery (rings, watches) when

operating the tool. They can get caught and draw you

into moving parts. ALWAYS wear non-slip footwear,

and tie back long hair.

8. WEAR A FACE MASK OR DUST MASK. Tool operation

produces dust.

9. ALWAYS remove the power cord plug from the

electrical source when making adjustments, changing

parts, cleaning or working on the tool.

10. KEEP GUARDS IN PLACE AND IN WORKING ORDER.

11. ADOID ACCIDENTAL START-UPS. Make sure the

power switch is in the OFF position before plugging in

the power cord.

12. REMOVE ADJUSTING TOOLS. ALWAYS MAKE SURE

all tools are removed from the planer before turning it

on.

13. NEVER LEAVE TOOL ON WHILE UNATTENDED. Turn

the power switch to OFF. DO NOT leave the tool until

it has come to a complete stop.

14. NEVER STAND ON THE TOOL. Serious injury could

result if the tool tips or is accidentally hit. DO NOT

store anything above or near the tool.

15. DON’T OVERREACH. Keep proper footing and balance

at all times. Wear oil-resistant rubber-soled footwear.

Keep the floor clear of oil, scrap, and other debris.

16. MAINTAIN TOOLS PROPERLY. ALWAYS keep tools

clean and in good working order. Follow instructions

for lubricating and changing accessories.

17. CHECK FOR DAMAGED PARTS. Check moving parts

for alignment, jamming, breakage, improper

mounting, or any other condition that may affect the

tool’s operation. Any part that is damaged should be

properly repaired or replaced before use.

18. MAKE THE WORKSHOP CHILDPROOF. Use padlocks,

master switches, and ALWAYS remove starter keys.

19. DO NOT operate the tool if you are under the

influence of drugs, alcohol or medication that could

affect your ability to use the tool properly.

20. WHEN SERVICING USE ONLY IDENTICAL

REPLACEMENT PARTS.

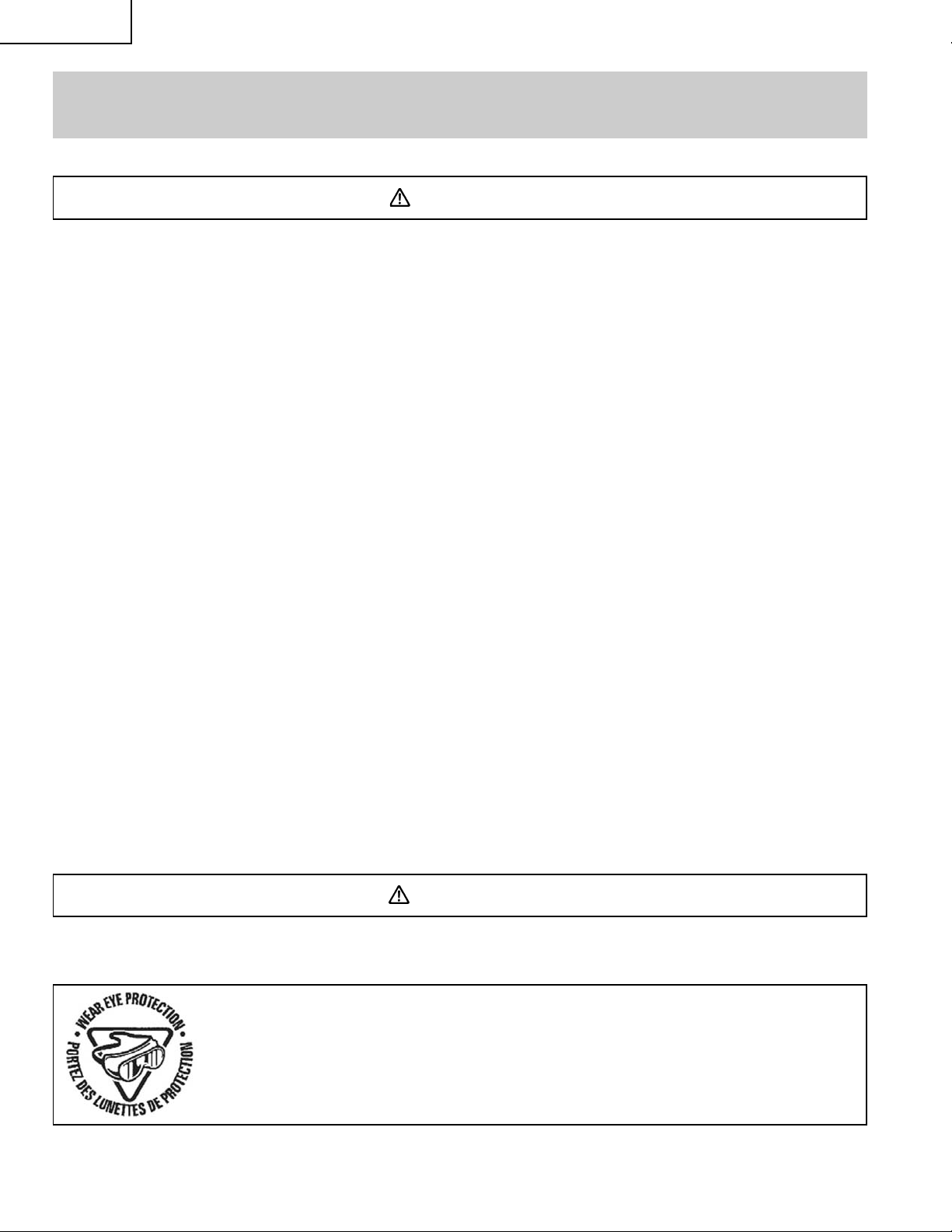

WARNING

DUST GENERATED FROM CERTAIN MATERIALS CAN BE HAZARDOUS TO YOUR HEALTH. ALWAYS OPERATE THE

PLANER IN A WELL-VENTILATED AREA AND PROVIDE FOR PROPER DUST REMOVAL. USE DUST COLLECTION

SYSTEMS WHENEVER POSSIBLE.

ALWAYS WEAR EYE PROTECTION.

A planer can throw foreign objects into your eyes which could cause permanent eye damage.

ALWAYS wear safety goggles (not glasses). Ordinary eyeglasses have only impact-resistant

lenses…they are NOT safety goggles.

SAVE THESE SAFETY INSTRUCTIONS

— 4 —

Page 5

English

SPECIFIC SAFETY INSTRUCTIONS FOR THE PLANER

BEFORE USING THE PLANER

WARNING

TO AVOID MISTAKES THAT COULD CAUSE SERIOUS,

PERMANENT INJURY, DO NOT PLUG IN THE PLANER

UNTIL THE FOLLOWING STEPS HAVE BEEN READ AND

UNDERSTOOD.

1. Your planer comes completely assembled. The only

assembly required is the cutterhead depth adjustment

handle. Mount your planer to a work bench or an

adequate surface.

2. Learn to use the function of the ON/OFF switch,

elevation handle, cutterhead guard, outfeed table,

infeed table and push blocks.

3. Review and understand all safety instructions and

operating procedures in this instruction manual.

4. Review the maintenance methods for this planer.

5. Find and read all the warning labels found on the

planer:

䢇 Read manual before using planer.

䢇 Wear safety goggles.

䢇 Never perform planning operation with cutterhead

guard or belt guard removed.

䢇 Never make planning cuts greater than 1/32”

(0.8 mm).

䢇 Never perform planning cuts on workpieces

shorter than 14” (35.6 cm) in length.

䢇 Turn power OFF, wait for blade to stop and

remove power cord from power source before

adjusting or servicing.

WHEN INSTALLING OR MOVING THE PLANER

1. AVOID A DANGEROUS ENVIRONMENT:

䢇 Use the planer in a dry, indoor place protected

from rain.

䢇 Keep work area well-lit.

2. TO AVOID INJURY FROM UNEXPECTED PLANER

MOVEMENT:

䢇 Bolt or clamp the planer to a firm level surface

where there is plenty of room to move the

workpiece through the entire cut.

䢇 Support the planer so the tables are level and

planer does not rock.

䢇 Put the planer where operators nor bystanders

will stand in line with the wood while planning.

䢇 To avoid injury from electrical shock, make sure

your fingers do not touch the plug’s metal prongs

when plugging in or unplugging the planer.

䢇 Turn OFF and unplug the planer before moving it

to a new area. To avoid back injury, get help when

you need to lift the planer.

䢇 Bolt the planer to the floor if it tends to move

when planning long, heavy boards.

䢇 DO NOT STAND ON THE PLANER. Do not store

materials above or near it. Standing on the tool to

reach materials could result in serious injury if it

tips or is accidentally contacted.

BEFORE EACH USE

1. INSPECT YOUR PLANER:

䢇 If any part is missing, bent or broken in any way,

or any electrical part does not work properly, turn

the planer OFF and unplug the planer.

䢇 Replace damaged or missing parts before using

the planer.

䢇 Make sure the cutterhead turns in the right

direction. They should move toward the infeed

table.

2. AVOID INJURY FROM JAMS, SLIPS OR THROWN

PLECES (KICKBACKS):

䢇 Use this planer to cut wood only.

䢇 Plan your hand placement so your fingers will not

be in a place where a sudden slip could cause

them to slide or fall into the cutterhead. When

using only one push block to feed the wood, do

not put your other hand on the planer or

workpiece.

䢇 Avoid injury from thrown pieces. Make sure the

blades are properly installed and the cutter blade

wedge screws are tight.

䢇 Adjust the depth of cut to between 1/32” or less

(0.8 mm or less) for best results. A deep cut makes

feeding the wood harder and can cause the wood

to kickback.

䢇 Use the right tool. Do not force the tool to do a job

it is not intended to do.

3. INSPECT YOUR WORK AREA:

䢇 Keep the work area clean.

䢇 Cluttered area and benches invite accidents. The

floor must not be slippery from wax or sawdust.

䢇 Avoid burns or other fire damage. Do not use the

planer near flammable liquids, vapours or gases.

䢇 Before using the planer, clear the table of all

objects not needed to feed the workpiece.

䢇 Avoid injury. Do not perform layout, assembly, or

setup work on the planer.

4. PLAN YOUR WORK:

䢇 Before trying a new or not often used operation,

carefully plan your hand placement. Make sure

you have proper push blocks, jigs, fixtures, stops,

and other items ready to use.

䢇 Avoid injury form unsafe accessories. Use only

recommended accessories.

SAVE THESE SAFETY INSTRUCTIONS

— 5 —

Page 6

English

SPECIFIC SAFETY INSTRUCTIONS FOR THE PLANER _Continued

5. DRESS FOR SAFETY:

䢇 Plan ahead to protect your eyes, hands, face and

ears.

䢇 Do not wear loose clothing, gloves, neckties or

jewellery (rings, wrist watches). They can get

caught and draw you into moving parts.

䢇 Wear nonslip footwear.

䢇 Tie back long hair.

䢇 Roll long sleeves above the elbow.

䢇 Noise levels vary widely. To avoid possible

hearing damage, wear ear plugs or muffs when

using the planer for hours at a time.

䢇 Planer can throw foreign objects into your eyes.

This can result in permanent eye damage. Wear

safety goggles (not glasses) that comply with

CSA Standards. Regular eyeglasses have only

impact-resistant lenses. They are not safety

glasses.

䢇 For dusty operations, wear a dust mask along

with safety goggles.

6. INSPECT YOUR WORKPIECE:

䢇 Make sure there are no nails or foreign objects in

the part of the workpiece to be planed.

7. PLAN YOUR CUT:

䢇 Small or thin workpieces can kickback when they

tip over on the tables or the cutterhead.

䢇 To avoid cutterhead contact or workpiece

kickback, do not plane workpieces shorter than

14” (35.6 cm).

䢇 Do not plane wood thinner than 1/2” (13 mm).

䢇 Do not cut freehand. Guide your workpiece

solidly against the fence and table top. Make sure

there in no debris between the workpiece and its

supports.

䢇 Use extra caution with large, small or awkward

workpieces.

䢇 Use extra support (tables, sawhorses, blocks) if

your workpiece is hard to hold down to the table.

Do not use another person as additional support

or to help feed, support or pull the workpiece.

䢇 Do not cut more than one workpiece at a time.

䢇 Do not turn your planer ON before clearing

everything except the workpiece and related

support devices off the table.

8. AVOID ACCIDENTAL STARTING:

䢇 Make sure the switch is OFF before plugging the

planer into a power source.

WHEN THE PLANER IS RUNNING

WARNING

DO NOT ALLOW FAMILIARITY (GAINED FROM

FREQUENT USE OF YOUR PLANER) TO CAUSE A

CARELESS MISTAKE. REMEMBER THAT A CARELESS

FRACTION OF A SECOND IS ENOUGH TO CAUSE A

SEVERE INJURY.

1. KEEP CHILDREN AWAY:

䢇 Make sure bystanders are clear of the planer.

䢇 Before actually cutting with the planer, let it run

for a while. If it makes an unfamiliar noise or

vibrates, stop immediately. Turn the planer OFF.

Unplug the planer. Do not restart it until finding

and correcting the problem.

2. DO NOT FORCE THE TOOL:

䢇 Feed the workpiece into the planer only fast

enough to let the tool cut without bogging down

or jamming.

3. BEFORE FREEING JAMMED MATERIAL:

䢇 Turn the switch OFF.

䢇 Wait for all moving parts to stop.

䢇 Unplug the planer.

4. BEFORE LEAVING THE PLANER:

䢇 Turn the planer OFF.

䢇 Unplug the planer.

䢇 Make the workshop childproof. Lock the shop.

Disconnect master switches. Remove the ON/OFF

switch key. Store it away from children and others

not qualified to use the tool.

SAVE THESE SAFETY INSTRUCTIONS

— 6 —

Page 7

ELECTRICAL INFORMATION

English

GROUNDING INSTRUCTIONS

IN THE EVENT OF A MALFUNCTION OR BREAKDOWN,

grounding provides a path of least resistance for electric

current and reduces the risk of electric shock. This tool is

equipped with an electric cord that has an equipment

grounding conductor and a grounding plug. The plug

MUST be plugged into a matching outlet that is properly

installed and grounded in accordance with ALL local

codes and ordinances.

DO NOT MODIFY THE PLUG PROVIDED. If it will not fit the

outlet, have the proper outlet installed by an electrician.

IMPROPER CONNECTION of the equipment grounding

conductor can result in electric shock. The conductor with

the green insulation (with or without yellow stripes) is the

equipment grounding conductor. If repair or replacement

of the electric cord or plug is necessary, DO NOT connect

the equipment grounding conductor to a live terminal.

CHECK with a qualified electrician or service personnel if

you do not completely understand the grounding

instructions, or if you are not sure if the tool is properly

grounded.

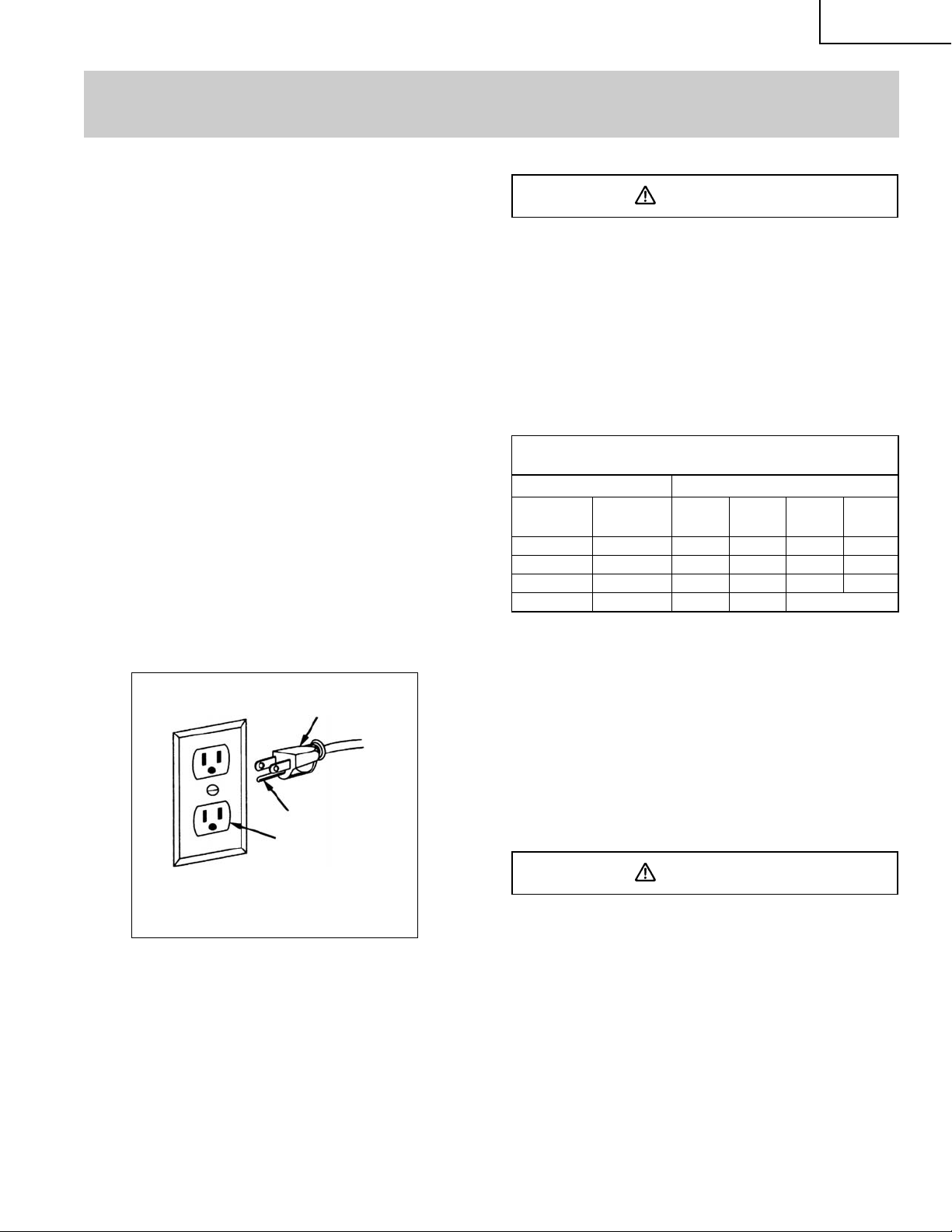

USE ONLY 3-WIRE EXTENSION CORDS that have 3-prong

plugs and 3-prong outlets that accept the tool’s plug as

shown in Fig. A. Repair or replace damaged or worn cords

immediately.

1

3

2

GUIDELINES FOR USING EXTENSION CORDS

WARNING

THIS PLANER IS FOR INDOOR USE ONLY. DO NOT

EXPOSE TO RAIN OR USE IN DAMP LOCATIONS.

Make sure your extension cord is in good condition. When

using an extension cord, be sure to use one heavy enough

to carry the current your product will draw. An undersized

cord will cause a drop in line voltage resulting in loss of

power and overheating. The table below shows the

correct size to be used according to cord length and

nameplate ampere rating. If in doubt, use the next heavier

gauge. The smaller the gauge number, the heavier the

cord.

MINIMUM GAUGE FOR EXTENSION CORDS (AWG)

(when using 120 V only)

Ampere Rating Total length in feet

Not

More Than More Than 25’ 50’ 100’ 150’

0 6 18 16 16 14

6 10 18161412

10 12 16 16 14 12

12 16 14 12

Make sure your extension cord is properly wired and in

good condition. Always replace a damaged extension

cord or have it repaired by a qualified person before using

it. Protect your extension cords from sharp objects,

excessive heat and damp or wet areas.

Use a separate electrical circuit for your tools. This circuit

must not be less than a #12 wire and should be protected

with a 15 A time lag fuse. Before connecting the motor to

the power line, make sure the switch is in the OFF position

and the electric current is rated the same as the current

stamped on the motor nameplate. Running at a lower

voltage will damage the motor.

Not Recommended

1-3-prong plug 2-properly grounded outlet

3-grounding prong

CAUTION: IN ALL CASES, MAKE CERTAIN THE

RECEPTACLE IN QUESTION IS PROPERLY GROUNDED. IF

YOU ARE NOT SURE IF IT IS, HAVE A CERTIFIED

ELECTRICIAN CHECK THE RECEPTACLE.

SAVE THESE SAFETY INSTRUCTIONS

WARNING

THIS TOOL MUST BE GROUNDED WHILE IN USE TO

PROTECT THE OPERATOR FROM ELECTRICAL SHOCK.

— 7 —

Page 8

English

CAPACITIES

1/2

2-1/2

1-1/2

13

11

12

10

5-1/25-1/2

3-1/2

6-1/2

Cutting width 13"

Cutting height 6"

Depth of cutting 3/32"

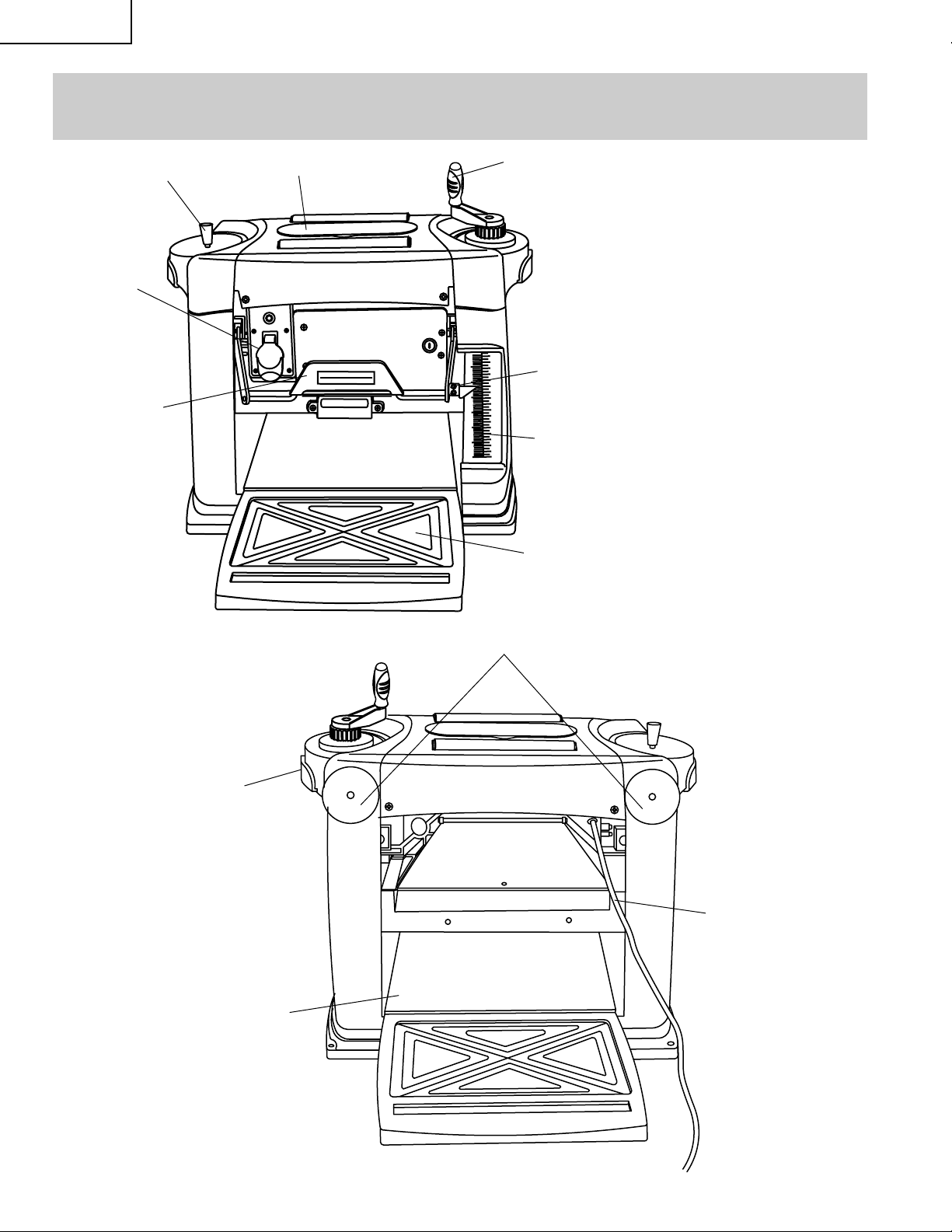

KNOW YOUR PLANER

ON/OFF switch

Depth lock lever

Cap

Tool storage

CAPACITIESCAPACITIES

Cutting width 13"

Cutting width 13"

Cutting height 6"

Cutting height 6"

Depth of cutting 3/32"

Depth of cutting 3/32"

Depth adjustment handle

17

-1/2

6

16

6

15

14

5-1/2

1313

55

1212

1111

44

1010

99

3-1/23-1/2

88

33

77

/2

/2

-1

-1

2

2

66

22

55

44

1-1/21-1/2

33

11

22

/2

1/21

11

00

00

CMCM

INCHINCH

Depth scale

pointer

Depth scale

Front extension

table

Carrying handle

Main table

Cord brackets

Power cord

— 8 —

Page 9

English

ASSEMBLY AND ADJUSTMENTS

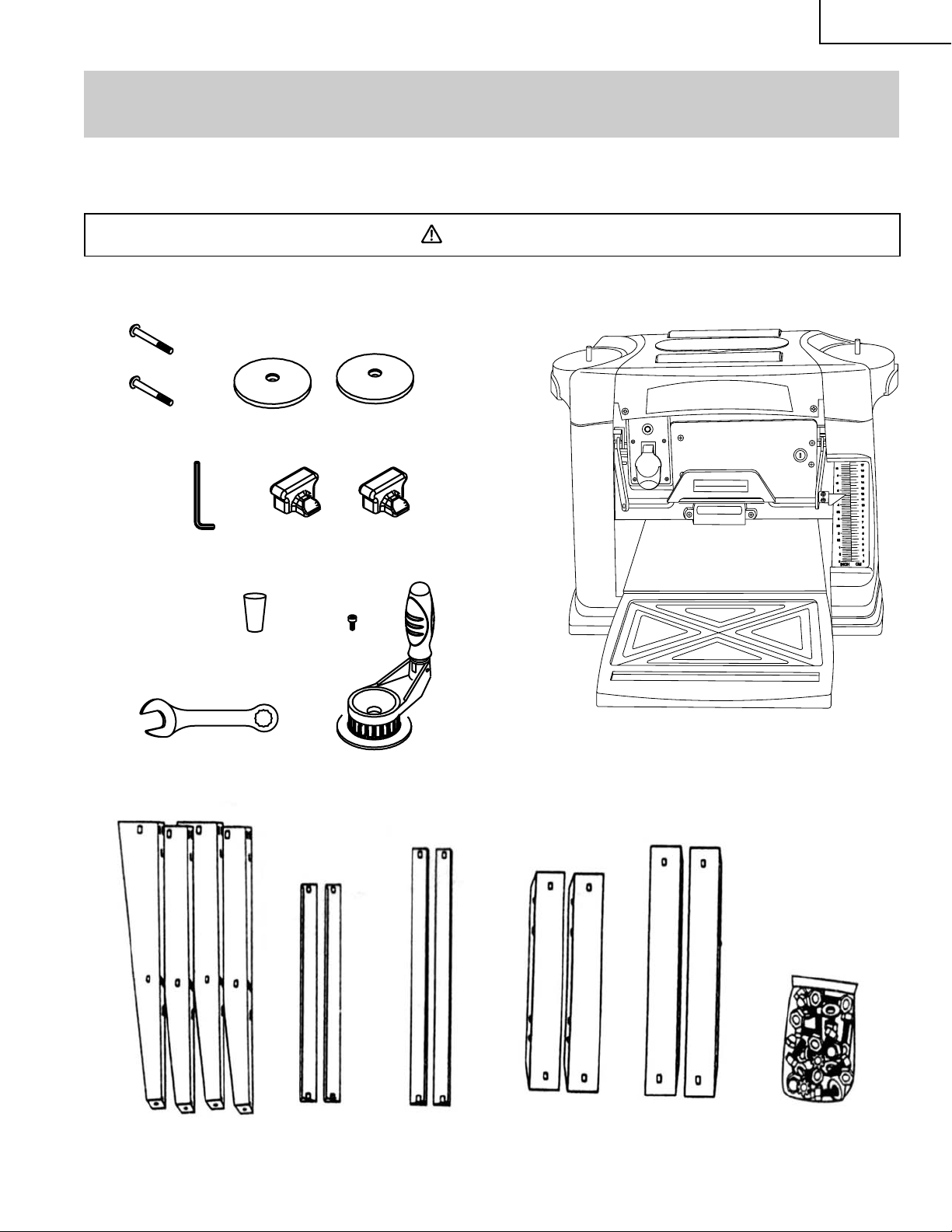

UNPACKING ESTIMATED ASSEMBLY TIME 20 ~ 35 MINUTES

Carefully unpack the planer and all its parts, and compare it to the list below. Do not discard the carton or any packaging

until the planer is completely assembled.

WARNING

IF ANY PART IS MISSING OR DAMAGED, DO NOT PLUG IN THE PLANER UNTIL THE MISSING OR DAMAGED

PART IS REPLACED.

Bolts

Power Cord Bracket

Hex Key Setting Gauges

Cap Bolt

Wrench

Crank Handle

Planer

Stand Legs

Short

Lower

Crossbar

Long

Lower

Crossbar

— 9 —

Short

Upper

Crossbar

Long

Upper

Crossbar

Mounting

Hardware

Page 10

English

ASSEMBLY AND ADJUSTMENTS_Continued

WARNING

Never connect the plug to the power source outlet until all installations and adjustments are completed and you have

read and understood the safety and operational instructions.

ASSEMBLY INSTRUCTIONS

Lift the tool from the packaging and place it on your

workbench. Carefully open the front and rear extension

tables and take out the loose parts bag and power cord.

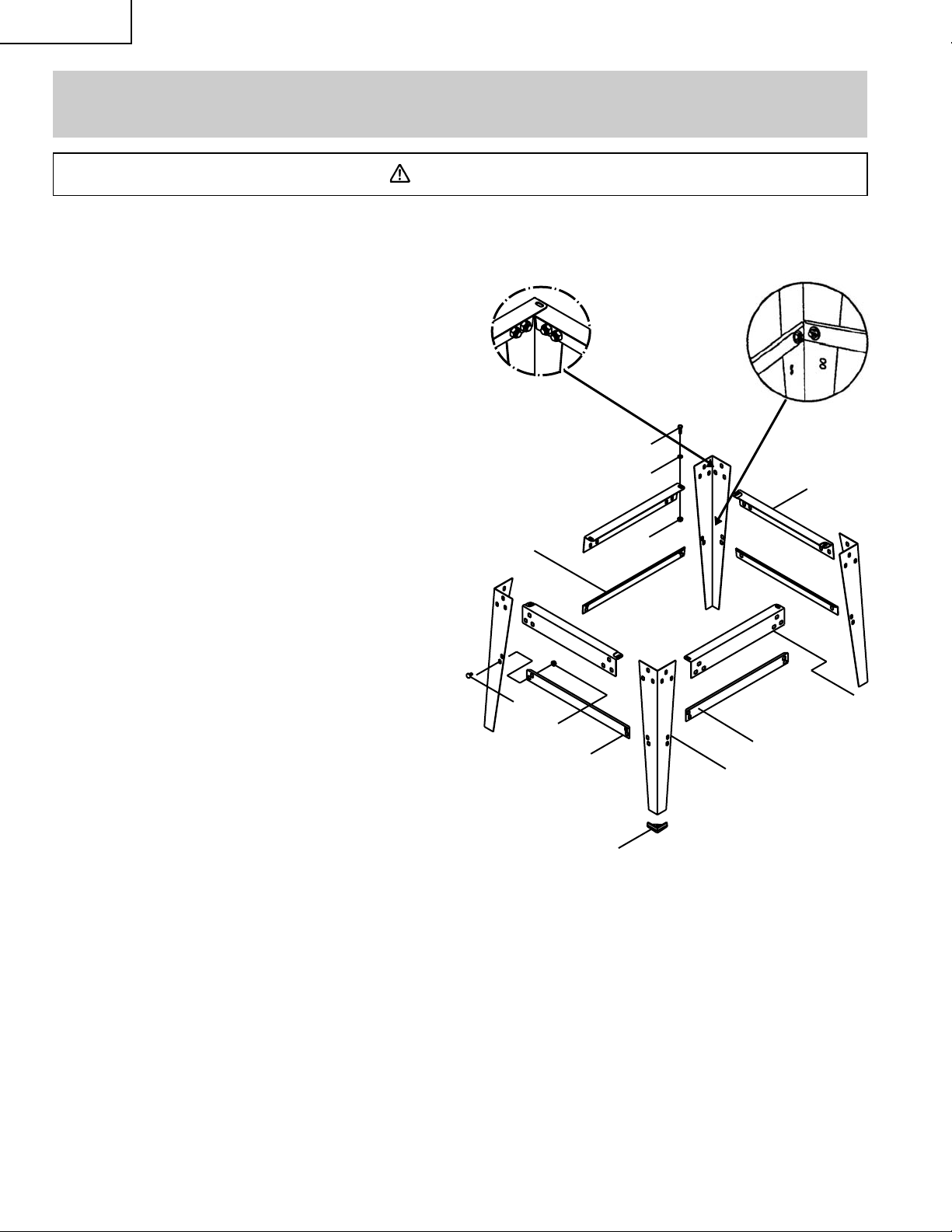

ASSEMBLE STAND (Fig. A)

1. Unpack all parts and sort by type and size.

Refer to the parts list on page 18 for correct

quantities.

2. Attach long upper crossbar (4) to top of

leg (1) and adjacent leg using carriage bolts (2) and

nuts (5).

12

NOTE: Do not tighten bolts until step 7.

3. Attach long lower crossbar (3) to bottom of leg (1) and

adjacent leg using carriage bolts and nuts.

4. Repeat on opposite side of stand.

5. Join the front and back of stand, using short upper

(11) and lower (10) crossbars, carriage bolts and nuts.

6. Place end caps (7) on legs.

7. Place the stand on a level surface and make sure all

legs are contacting the floor and are at similar angles

to the floor. Tighten all bolts.

ASSEMBLE PLANER TO STAND

1. Carefully place planer on top of stand.

2. Line up the four mounting holes on tool base with

those on the stand.

3. Fasten the planer to the stand using mounting bolts

(12), washers (13) and nuts (14)(see Fig. A).

4. Tighten all nuts.

NOTE: DO NOT OVER TIGHTEN NUTS.

13

6

2

5

10

14

3

1

7

11

4

Fig. A

— 10 —

Page 11

English

ASSEMBLY AND ADJUSTMENTS_Continued

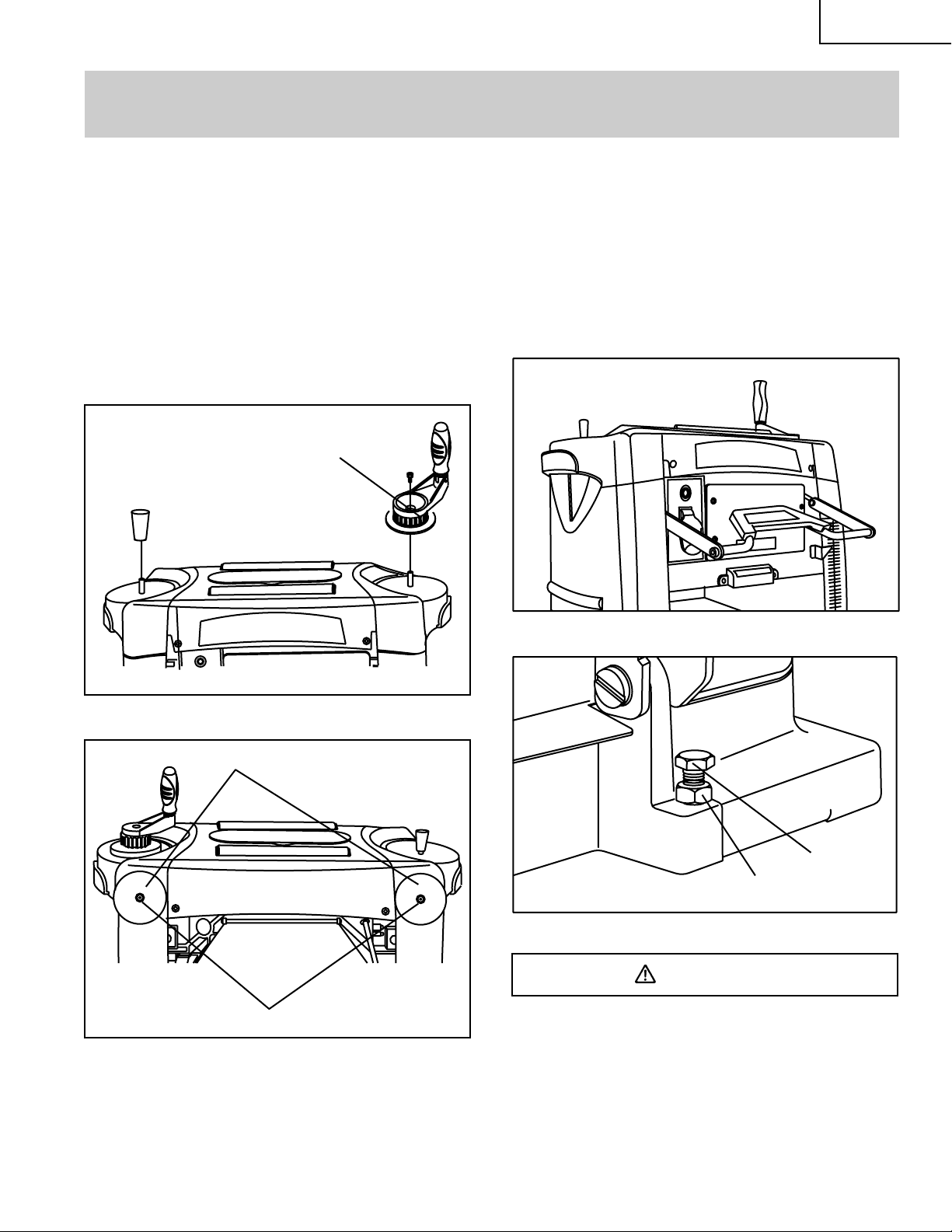

Installing the Depth Adjustment Handle (Fig. 1)

1. Place the depth adjustment handle (1) on the right

hand side, on top of the machine.

2. Insert the hex socket screw into the handle. Tighten.

3. Press the cap on the left hand side.

NOTE: The depth adjustment handle can be installed on

either the right-hand side or left-hand side. The illustration

shows the crank handle on the right-hand side.

Install Power Cord Brackets (Fig. 2)

Power cord brackets (1) are provided for convenient cord

storage. Attach the power cord brackets to the back of the

tool body, as shown, with two screws (2). Tighten.

1

Adjusting the Extension Table (Fig. 4, 5)

1. Pull out the cutterhead lock lever.

2. Unlock the head.

3. Turn the depth adjustment handle to raise the head.

4. Place a straight edge over the extension tables and

the main table.

5. Press down the edge against the table extensions to

remove any play.

6. If adjustment is required, fold up the extension table

and loosen the nut (1) and adjust the bolt (2) until the

tables are level.

13-In. Planer

Fig. 1

1

2

Fig. 2

Fig. 4

2

1

Fig. 5

WARNING

To avoid injury from an accidental start-up, make sure the

switch is in the OFF position and the plug is not connected

to the power source.

ADJUSTMENT

NOTE: This tool was accurately adjusted before shipping

from the factory. Check the following accuracy and

readjust them if necessary in order to obtain the best

results in operation.

— 11 —

Page 12

English

ASSEMBLY AND ADJUSTMENTS_Continued

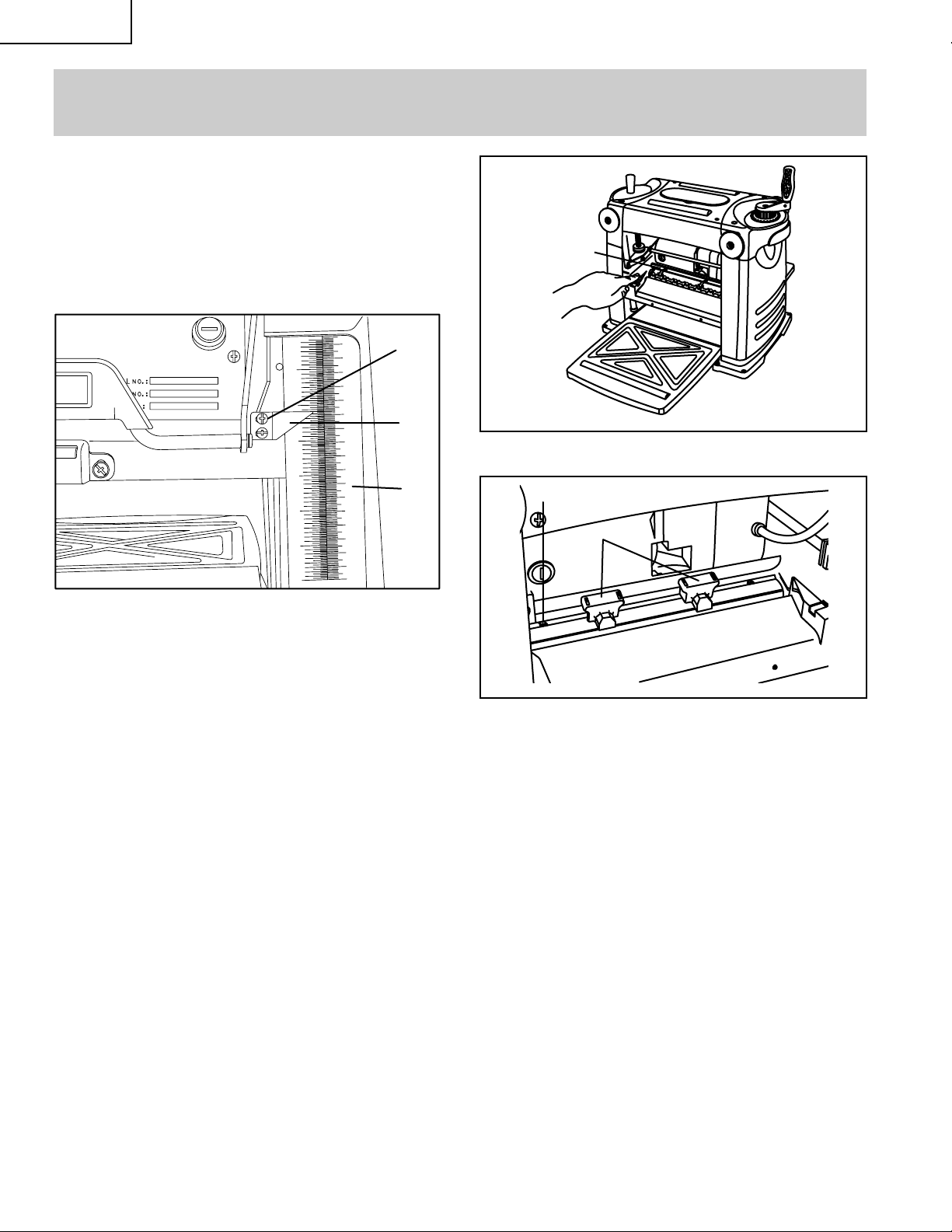

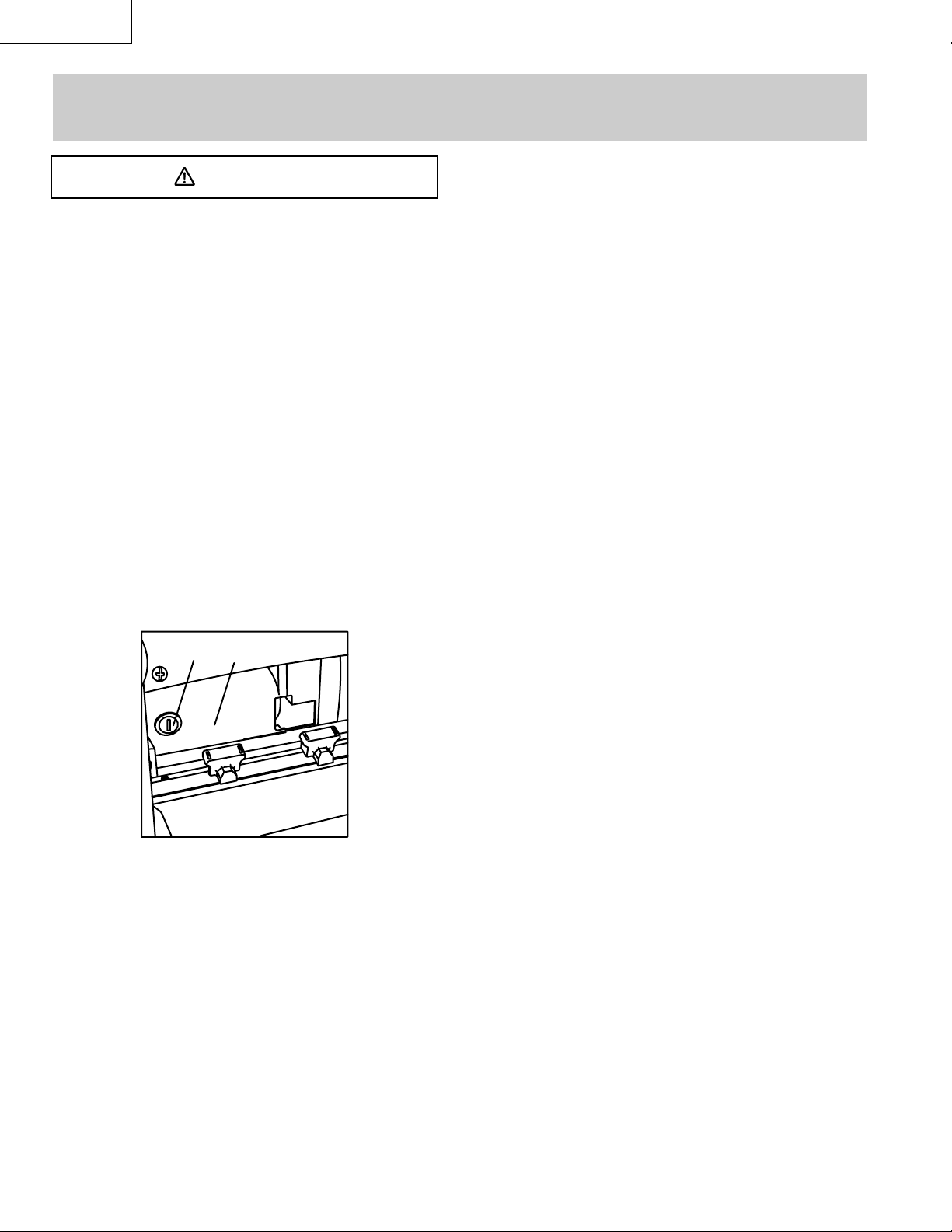

Adjusting the Depth Scale (Fig. 6)

1. Try to plane a board.

2. Compare the measured thickness of the board to the

reading on the depth scale (2).

3. If the reading on the depth scale is incorrect, loosen

the screws (1) that tighten the pointer (3) and adjust

until the proper measurement is displayed.

4. Test the reading again by planing another scrap wood.

Double check it and re-adjust if necessary.

1

INCH

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

CM

1

3

2

6-1/2

6

5-1/2

5

4

3-1/2

3

2-1/2

2

1-1/2

1

1/2

0

Fig. 6

Setting the Knife Height (Fig. 7, 8)

1. Remove the two screws with a screwdriver, then

remove the dust cover. (Fig. 13)

2. Loosen the eight hex-head screws (1) with supplied

wrench.

3. Press the arbor lock latch and turn the cutterhead until

exposing two hex bolts (1).

4. Place the knife setting gauge (2) (Fig. 8) on the

cutterhead with both guides resting firmly against the

knife.

5. Loosen or tighten the hex bolts (1) (Fig. 8) until the

knife touches the knife setting gauge.

6. Fasten the eight hex-head screws with the supplied

wrench.

7. Replace the dust cover and secure it with the two

screws.

Fig. 7

1

2

Fig. 8

— 12 —

Page 13

OPERATION

English

WARNING

Never connect the plug to the power source outlet until all

installations and adjustments are completed and you have

read and understood the safety and operational

instructions.

Remove the switch key whenever the saw is not in use.

Place it in a safe place and out of reach of children.

Thickness Planer Operations

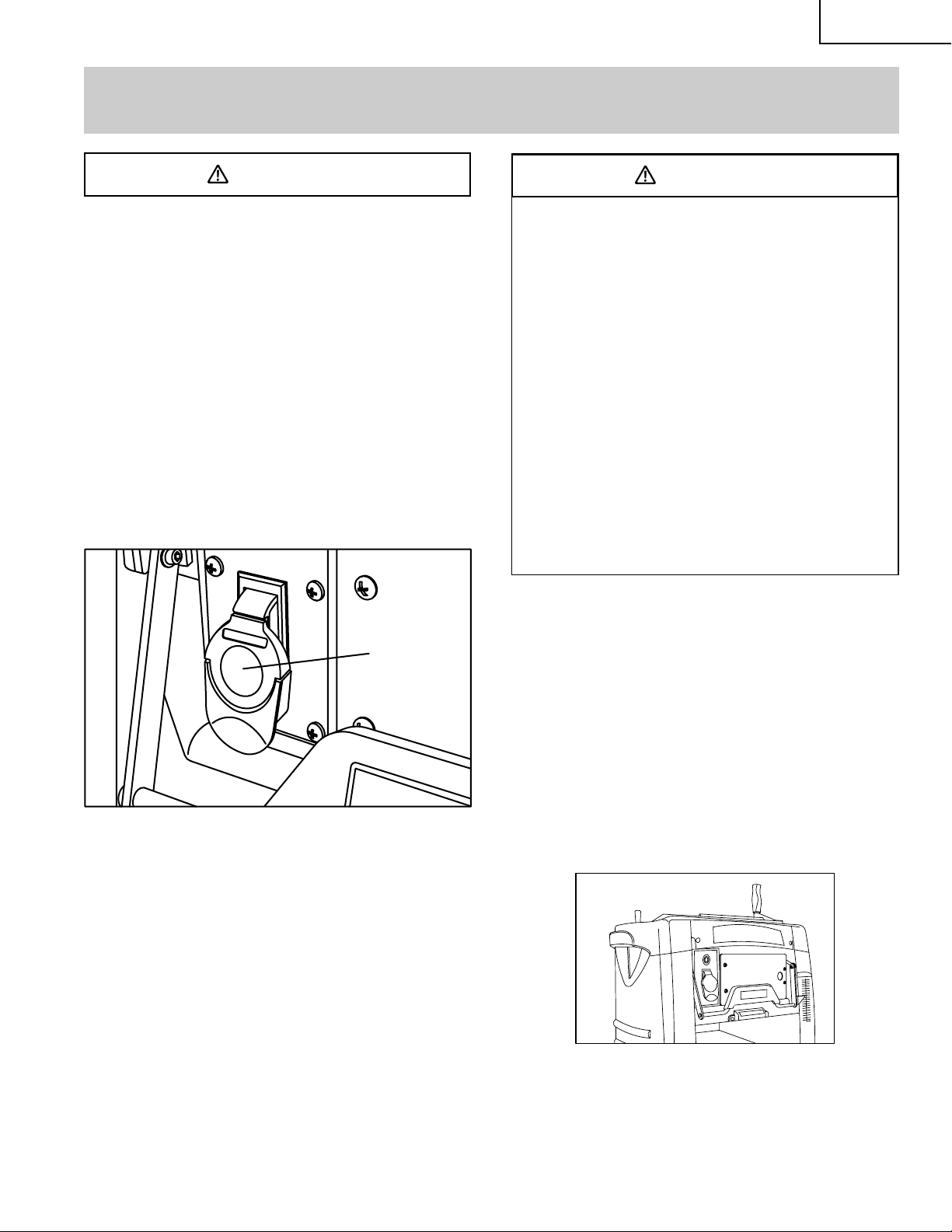

“ON/OFF” SWITCH (Fig. 9)

The keyed switch is intended to prevent unauthorized use

of the planer.

1. To turn the planer ON insert the yellow key (1) into the

key slot in the centre of the switch.

2. Push the key firmly into the slot, then push switch to

the ON position to start the planer.

3. To turn the planer OFF push the switch to the down

position.

4. Remove yellow safety key when saw is not in use to

prevent unauthorized usage.

1

Fig. 9

WARNING

1. Allow the motor to come up to full speed before

starting cut.

2. Always feed the work in the direction that allows the

planer blades to cut with the grain. Feeding against

the grain will cause the blades to lift fibres from the

work surface causing a fuzzy appearance.

3. Remove all foreign objects from the workpiece. Do

not plane wood that is severely knotted or warped.

4. The planer works best with at least one flat surface.

Place the flat surface downward on the table.

5. Do not plane more than 3 mm in one pass.

6. Proper depth of cut is judged by the width of the

board and hardness of the board.

7. Make sure long boards are supported level with table

at front and rear of the planer. Use extension roller

stand if necessary.

8. Do not receive the board with your hands toward

inside of the rear extension table.

9. If you need cutting to a specific height (3/4”, 1/4”, 1/2”).

Move the right side of the height level to the desired

position. (Fig. 12)

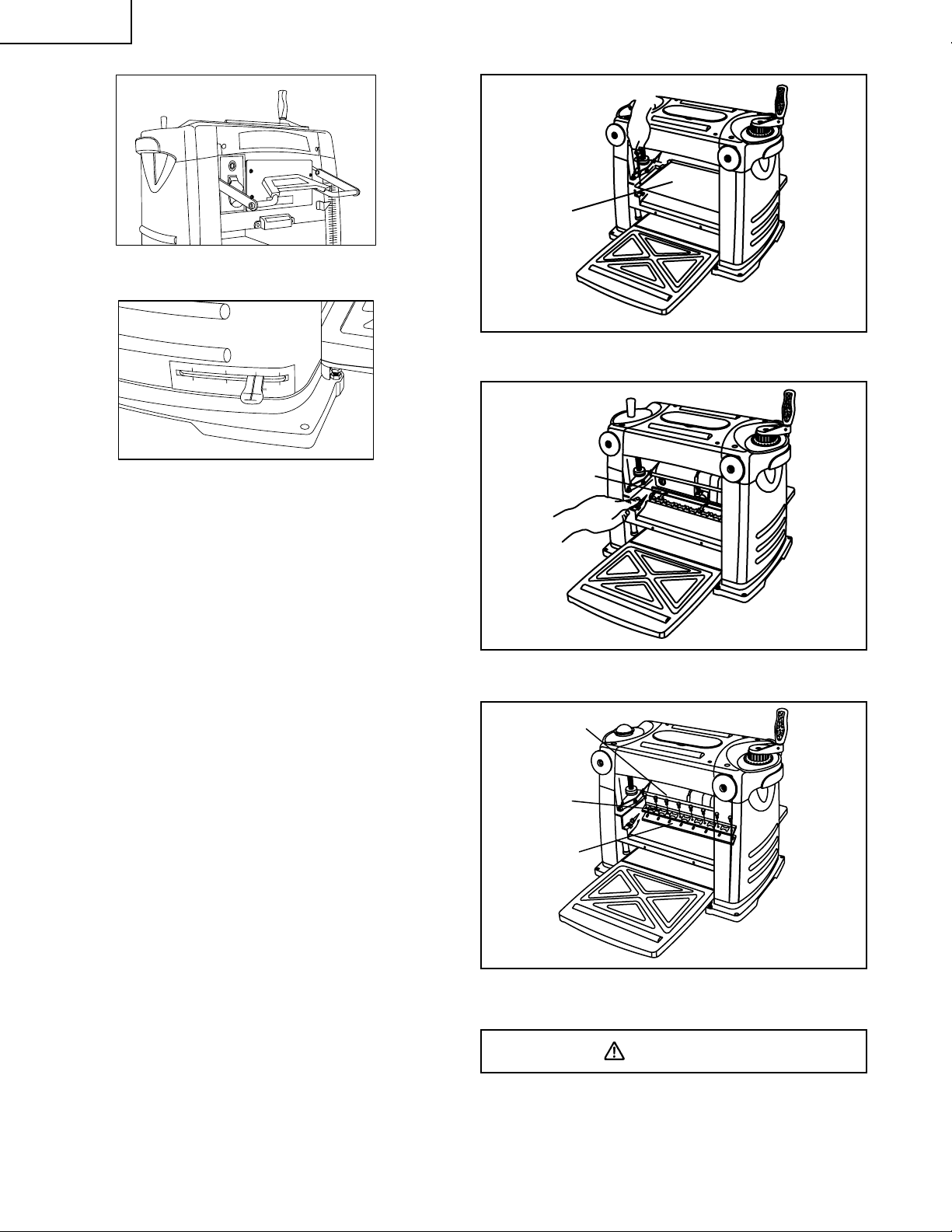

1. Pull out the cutterhead lock lever. (Fig. 10)

2. Unlock the cutterhead.

3. Lower the cutter head until it touches the workpiece.

4. Set the cutting depth dial to “0” mark.

5. Raise the cutterhead a little and remove the

workpiece.

6. Adjust the depth of cut to the desired finished

thickness of the board.

7. Lock the cutterhead.

8. Push in the cutterhead lock lever. (Fig. 11)

9. Start board under the infeed roller so it travels

straight. When infeed roller takes hold, release board

and stand aside (out of the way of any possible

kickback).

10. If the board is long, place it on the top of the planer

and roll it to the front for replaning.

— 13 —

Fig. 10

Page 14

English

1

Fig. 11

3/4

0

1/4

1/2

3/4"

0

1/2"

Fig. 12

NOTE:

1. Planing for a smooth finish as well as thickness is best

accomplished by taking light cuts on the board.

2. For the best result, plane both sides of your workpiece

to reach the desired thickness.

3. If snipe happens, (snipe is a depression made when

the ends of the workpiece contact the cutters) make

sure the extension tables and support stands are level

with the main table and the flat side of the workpiece

is against the tables.

4. For bowed workpiece, removing the bow with a jointer

is recommended.

5. For cupped or warped workpieces, plane the top flat

and then turn it over and plane the bottom flat.

Changing Blades

NOTE: The blades changing accessories are stored in the

tool storage.

Fig. 13

1

Fig. 14

3

4

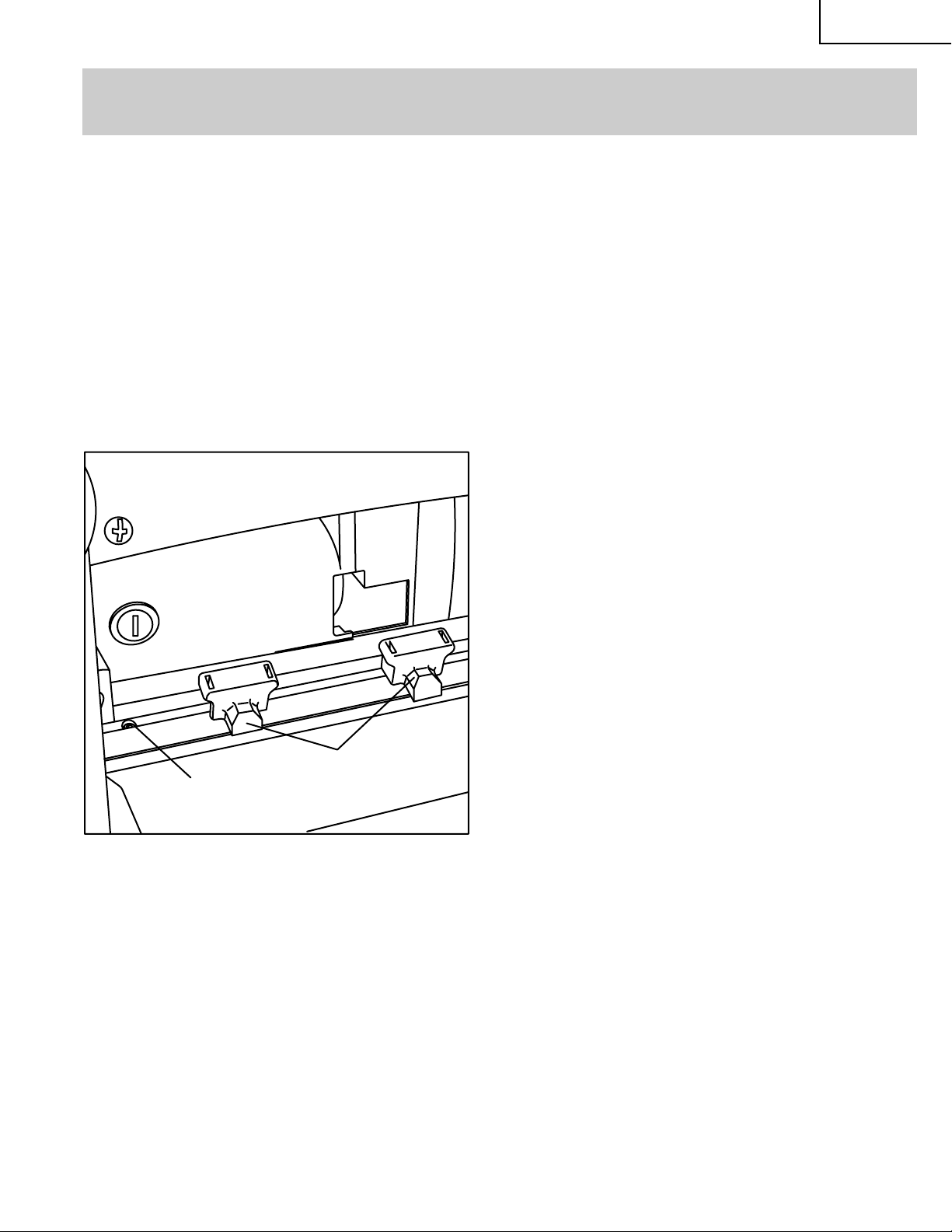

1. Rotate the handle to lower down the cutterhead to 2”

(50 mm) height.

2. Remove all screws to remove the dust hood and dust

cover (1) (Fig. 13).

3. Press the arbor lock latch (2) and turn the cutter head

until it exposes eight hex head screws (Fig. 14).

4. Remove the eight hex head bolts (3) with the supplied

wrench (Fig. 15).

5. Carefully remove the hold-down plate (4) by lifting

straight up (Fig. 15).

6. Carefully remove the blade (5) by lifting both ends

straight up (Fig. 15).

7. The blade has two cutting edges. If using the other

side of the blade or replacing the blade, place the

blade on the cutterhead by locating the two slotted

holes in the blade over the locating pins on the

cutterhead (Fig. 15).

5

Fig. 15

WARNING

To avoid injury from on accidental start-up, always turn

the switch off and remove the power plug from the power

source before changing the blades.

— 14 —

Page 15

OPERATION_Continued

8. Slightly adjust the blade position so that it is

positioned uniformly in the centre of cutterhead.

9. Replace the hold-down plate (4), screw the eight hex

head-bolts (3) in, but do not tighten.

10. Place the blade setting gauges (6) on the cutterhead

with both gauges resting firmly against the blade.

(Fig. 16)

11. Turn both of the adjusting screws (7) until the blade

touches the blade setting gauges.

12. Remove the blade setting gauges and then rotate the

cutterhead to expose the eight hex-head blots (3).

Tighten all bolts with supplied hex wrench.

13. Replace the dust hood and secure it with the two

screws.

NOTE: The planer will not start until the dust cover and

cutterhead guard are properly installed.

English

6

7

Fig. 16

— 15 —

Page 16

English

MAINTENANCE

WARNING

Never put lubricants on the blade while it is spinning.

To avoid fire or toxic reaction, never use gasoline,

naphtha acetone, lacquer thinner or similar highly volatile

solvents to clean the planer.

To avoid injury from unexpected starting or electrical

shock, unplug the power cord before working on the tool.

For your safety, this tool is double-insulated. To avoid

electrical shock, fire or injury, use only parts identical to

those identified in the parts list. Reassemble exactly as the

original assembly to avoid electrical shock.

REPLACING CARBON BRUSHES (Fig. 17)

The carbon brushes furnished will last approximately 50

hours of running time, or 10,000 ON/OFF cycles. Replace

both carbon brushes when either has less than 1/4” length

of carbon remaining, or if the spring or wire is damaged or

burned. To inspect or replace brushes, first unplug the tool.

Then remove the black plastic cap (1) on the side of the

motor (2). Remove the cap cautiously, because it is

spring-loaded. Then pull out the brush and replace.

Replace for the other side. To reassemble reverse the

procedure. The ears on the metal end of the assembly go

in the same slots the carbon part fits into. Tighten the cap

snugly, but do not overtighten.

䢇 Make sure the belt is evenly seated all the way on

the motor and drive pulley grooves.

䢇 Replace and secure right panel.

LUBRICATION

䢇 Motor and cutterhead bearings are sealed and

need no lubrication.

䢇 Gears and elevation screws should be cleaned of

debris and grease

䢇 The tables can be coated with a lubricant such as

furniture wax, to make the workpiece feed

smoother. Make sure the lubricant used does not

affect the ability to finish the workpiece with

varnish, sealer, etc. Do not use any silicone-base

lubricants.

CLEAN PLANER

Keep planer clean. After 10 hours of operation, remove

wood chips, dust, dirt and debris.

1

2

Fig 17

NOTE: To reinstall the same brushes, first make sure the

brushes go back in the way they came out. This will avoid

a break-in period that reduces motor performance and

increases wear.

REPLACING V-BELT

Inadequate tension in the V-belt will cause the belt to slip

from the motor pulley or drive pulley. A loose belt must

be replaced. To replace V-belt:

䢇 Turn planer OFF and unplug from power source.

䢇 Loosen and remove screws on right panel.

Remove panel.

䢇 Remove old belt by walking the belt from motor

and drive pulleys alternatively. Gently pull the belt

while turning the pulleys at the same time.

䢇 Replace with new belt. Walk the belt onto the

pulleys in the reverse manner as when removing

the belt.

— 16 —

Page 17

English

TROUBLESHOOTING GUIDE

WARNING

To avoid injury from an accidental start-up, always turn switch OFF and unplug the planer before moving, replacing the

blade or making adjustments.

PROBLEM

Snipe

(gouging at ends of

board)

Fuzzy grain

Torn grain

Rough raised grain

Uneven depth of cut

(side to side)

Rollercase elevation

adjusts with difficulty

Board feeds inside, but

stops moving past the

outfeed roller

Board thickness does

not match depth of cut

scale

Chain jumping

Planer will not operate

Belt slipping

Rollercase connot be

lowered

CAUSE

1. Dull blades.

2. Inadequate support of long boards.

3. Uneven force on cutterhead.

4. Rollercase not level with base.

5. Lumber not butted properly.

Planing wood with a high moisture

content

1. Too heavy a cut

2. Blades cutting against grain

3. Dull blades

1. Dull blades

2. Too heavy a cut

3. Moisture content too high

Rollercase not level with Planer

1. Gears dirty

2. Elevation screws dirty

3. Gears, elevation screws worn

4. Friction between rollercase and covers

5. Rollercase not parallel with planer base

6. Rollercase lock engaged

1. Outfeed rollers cannot rotate due

to clogging of chips

2. Too much pressure on the

cutterhead from long workpiece

Indicator not set correctly

1. Sprockets worn

2. Chain worn

1. No power to planer

2. Motor overload protection

tripped

3. Defective or loose switch or

wiring.

Loose belt

Workpiece thickness gauge setting

restricts rollercase movement.

SUGGESTED REMEDY

1. Replace blades per instructions.

See CHANGING THE BLADE.

2. Support long boards. See Avoiding Snipe.

3. Gently push board when board is in contact

with only one feed roller. See Avoiding

Snipe.

4. Adjust rollercase. See Adjusting.

5. Butt each piece of stock end-to-end as

boards pass through planer.

Remove high moisture content from wood

by drying

1. Review OPERATION.

2. Review OPERATION.

3. Replace blades per instructions. See

CHANGING THE BLADES.

1. Replace blades per instructions. See

CHANGING THE BLADES.

2. Review OPERATION.

3. Dry the wood or use dried wood.

Rollercase not level. See ADJUSTING.

1. Clean and lubricate gears.

2. Clean and lubricate elevation screws.

3. Replace gears, elevation screw.

4. Clean and lubricate.

5. Adjust rollercase. See ADJUSTING.

6. Release rollercase lock

1. Clear the clogging, use dust collector chip

chute.

2. Use support stands to support workpiece

longer than 24”.

Adjust indicator and tighten securely.

1. Replace sprockets.

2. Replace chain.

1. Check power source by qualified electrician.

2. Turn planer off. Reset motor overload

protection.

3. Check switch and wiring by qualified

electrician.

Replace belt, see Replacing V-Belt.

Reset thickness gauge setting.

— 17 —

Page 18

Français

AVERTISSEMENT

La poussière engendrée par le sablage, le sciage, le broyage et le forage électriques et autres activités de construction

contient des agents chimiques qui, selon l’Etat de Californie, sont susceptibles de provoquer le cancer, des malformations

de naissance ou autres troubles de la reproduction. Parmi les exemples des agents chimiques:

• Plomb issu des peintures à base de plomb

• Silice cristalline des briques, du ciment et autres produits de maçonnerie

• Arsenic et chrome du bois d’œuvre traité chimiquement

Le risque inhérent à ces expositions varie selon la fréquence à laquelle vous réalisez ce type de travaux. Pour réduire votre

exposition à ces agents chimiques, travaillez dans une zone bien aérée et avec l’équipement de sécurité agréé tel que des

masques anti-poussière spécialement conçus pour filtrer les particules microscopiques.

SPECIFICATIONS TECHNIQUES

RABOTEUSE DE 13”

Moteur 15A, 120V, 60Hz

Largeur maximum de pièce 13”

Epaisseur de la coupe Min. 1/8”

Profondeur maximum de coupe 3/32”

Vitesse d'alimentation 24,08 pieds/min

Nombre de lames 2

T/M (à vide) 8000 min

Poids 101,4 lb (46 kg)

-1

— 18 —

Page 19

Français

CONSIGNES DE SECURITE

La sécurité est une combinaison de sens commun, de rester alerte et de comprendre comment utiliser votre raboteuse.

AVERTISSEMENT

POUR EVITER LES ERREURS QUI POURRAIENT PROVOQUER DES BLESSURES GRAVES, NE BRANCHEZ PAS LA

RABOTEUSE AVANT D'AVOIR LU ET COMPRIS LES CONSIGNES DE SECURITE SUIVANTES.

1. BIEN LIRE et se familiariser avec ce Manuel

d’utilisation. DECOUVRIR les applications de l’outil,

ses limitations et les dangers potentiels.

2. NE PAS UTILISER DANS UN ENVIRONNEMENT

DANGEREUX comme les lieux humides ou mouillés

ou exposés à la pluie. Maintenez l’aire de travail bien

éclairée.

3. NE PAS UTILISER d’outils électriques en présence de

liquides ou de gaz inflammables.

4. TOUJOURS maintenir l’aire de travail propre, non

encombrée et bien éclairée. NE PAS travailler sur des

sols glissants à cause de la sciure ou de la cire.

5. INTERDIRE L’ACCES A L’AIRE DE TRAVAIL à tout le

monde, plus particulièrement lorsque l’outil est en

marche. NE JAMAIS laisser les enfants s’approcher de

l’outil.

6. NE JAMAIS FORCER L’OUTIL à effectuer un travail

pour lequel il n’a pas été conçu.

7. PORTER DES VÊTEMENTS APPROPRIÉS. Ne jamais

porter de vêtements lâches ni de gants, cravate,

bijoux (bagues, montres) pendant le travail. Ils

pourraient se coincer dans les pièces en rotation.

TOUJOURS porter des chaussures anti-dérapantes et

attacher les cheveux longs.

8. PORTER UN MASQUE FACIAL OU UN MASQUE ANTIPOUSSIERE. L’outil produit de la poussière.

9. TOUJOURS débrancher l’outil avant de procéder à

des réglages, remplacer des pièces, nettoyer ou

procéder à l’entretien de l’outil.

10. TOUJOURS MAINTENIR LES PROTECTIONS EN

PLACE ET EN BON ETAT DE MARCHE.

11. EVITER LES DEMARRAGES ACCIDENTELS. Veiller à

ce que l’interrupteur soit en position OFF avant de

brancher le cordon d’alimentation.

12. RETIRER LES OUTILS DE REGLAGES. TOUJOURS

VERIFIER que tous les outils sont retirés de la

raboteuse avant de l’allumer.

13. NE JAMAIS LAISSER L’OUTIL EN MARCHE SANS

SURVEILLANCE. Le mettre hors tension. NE PAS laisser

l’outil avant qu’il ne soit totalement hors tension.

14. NE JAMAIS MONTER SUR L’OUTIL. Il y a risque de

blessure grave en cas de renversement de l’outil ou

en cas de contact accidentel. NE RIEN stocker audessus ou près de l’outil.

15. NE JAMAIS TROP SE PENCHER. Toujours garder une

bonne assise et un bon équilibre pendant le travail.

Porter des chaussures en caoutchouc résistantes à

l’huile. Maintenir le sol exempt d’huile, de ferraille ou

autres débris.

16. ENTRETENIR LES OUTILS AVEC SOIN. TOUJOURS

maintenir les outils propres et en bon état de marche.

Suivre les instructions de graissage et de

remplacement des accessoires.

17. TOUJOURS VÉRIFIER SI L’OUTIL A DES PIÈCES

ENDOMMAGÉES. Vérifier si toutes les pièces mobiles

sont bien alignées, non voilées, ou toute autre condition

qui pourrait entraver leur bon fonctionnement. Toujours

réparer ou remplacer les protections ou les autres pièces

endommagées avant d’utiliser l’outil.

18. RENDRE L’ATELIER INACCESSIBLE AUX ENFANTS.

Utiliser des cadenas, des interrupteurs généraux, et

TOUJOURS retirer les clés de sécurité.

19. NE JAMAIS utiliser l’outil si vous êtes sous l’influence

de drogues, d’alcool ou de médicaments pouvant

réduire votre capacité d’utiliser l’outil en toute

sécurité.

20. PENDANT L’ENTRETIEN, TOUJOURS UTILISER DES

PIECES DE RECHANGE IDENTIQUES.

AVERTISSEMENT

LA POUSSIERE GENEREE PAR CERTAINS MATERIAUX PEUVENT NUIRE A VOTRE SANTE. TOUJOURS UTILISER LA

RABOTEUSE DANS UNE ZONE BIEN VENTILEE ET UTILISER UNE BONNE ELIMINATION DE LA POUSSIERE. UTILISER

DES SYSTEMES DE RECUPERATION DE LA POUSSIERE LORSQUE CELA EST POSSIBLE.

TOUJOURS PORTER UNE PROTECTION POUR LES YEUX.

Une raboteuse peut vous projeter des corps étrangers dans les yeux, ce qui pourrait entraîner

des troubles oculaires permanents.

TOUJOURS porter des verres de sécurité (non pas des lunettes ordinaires). Les lunettes ordinaires

n’assurent pas une protection suffisante parce que leurs verres sont uniquement résistants aux

chocs… Ce NE SONT PAS des verres de sécurité.

CONSERVER CES INSTRUCTIONS

— 19 —

Page 20

Français

CONSIGNES DE SECURITE SPECIFIQUES A LA RABOTEUSE

AVANT D’UTILISER LA RABOTEUSE

AVERTISSEMENT

POUR EVITER TOUTE ERREUR POUVANT ENGENDRER

DES BLESSURES PERMANENTES GRAVES, NE PAS

BRANCHER LA RABOTEUSE AVANT D’AVOIR LU ET

COMPRIS LES CONSIGNES SUIVANTES.

1. La raboteuse est livrée déjà montée. Le seul montage

requis est celui de la poignée de réglage de la

profondeur de la lame. Monter la raboteuse sur un

établi ou une surface adéquate.

2. Apprendre à utiliser l’interrupteur ON/OFF, la poignée

d’élévation, le protecteur de lame, la table de sortie, la

table d’entrée et les blocs de poussée.

3. Prendre connaissance et comprendre l’ensemble des

consignes de sécurité et procédures d’utilisation de ce

manuel d’instructions.

4. Prendre connaissance des méthodes d’entretien de

cette raboteuse.

5. Trouver et lire l’ensemble des étiquettes

d’avertissement situées sur la raboteuse:

䢇 Lire le manuel avant d’utiliser la raboteuse.

䢇 Porter des lunettes de sécurité.

䢇 Ne jamais raboter si le protecteur de la lame ou le

protecteur de la ceinture est retiré.

䢇 Ne jamais effectuer de coupes de rabotage

supérieures à 1/32”(0,8 mm).

䢇

Ne jamais effectuer de coupes de rabotage sur des

pièces dont la longueur est inférieure à 14” (35,6 cm).

䢇 Mettre l’interrupteur sur OFF, attendre que la lame

s’arrête et débrancher le cordon d’alimentation

avant de procéder à des réglages ou à l’entretien.

LORS DE L’INSTALLATION OU DU DEPLACEMENT DE LA

RABOTEUSE

1. EVITER LES ENVIRONNEMENTS DANGEREUX:

䢇 Utiliser la raboteuse dans un lieu sec et abrité

contre la pluie.

䢇 Maintenir l’aire de travail bien éclairée.

2. Pour EVITER TOUTE BLESSURE DUE A UN

MOUVEMENT INATTENDU DE LA RABOTEUSE:

䢇 Visser ou serrer la raboteuse sur une surface

solide avec suffisamment de place pour déplacer

la pièce pendant l’opération de coupe.

䢇 Soutenir la raboteuse de manière à ce que les

tables soient à niveau et que la raboteuse ne

bascule pas.

䢇 Mettre la raboteuse à un endroit où ni les

opérateurs, ni les visiteurs ne sont dans la

trajectoire de la planche pendant le rabotage.

䢇 Pour éviter tout risque de choc électrique, veiller à

ce que les doigts ne soient pas en contact avec les

bornes métalliques en branchant ou en

débranchant la raboteuse.

䢇 Mettre la raboteuse sur OFF et la débrancher

avant de la déplacer à un autre endroit. Pour

éviter les maux de dos, se faire aider pour

soulever la raboteuse.

䢇 Visser la au sol si elle a tendance à bouger lors du

rabotage de panneaux longs et lourds.

䢇 NE PAS MONTER SUR LA RABOTEUSE. Ne pas

stocker d’objets dessus ou près de la raboteuse. Il y a

risque de blessure grave en cas de renversement de

l’outil ou en cas de contact accidentel.

AVANT CHAQUE UTILISATION

1. INSPECTER LA RABOTEUSE:

䢇

Si une pièce est manquante, voilée ou cassée, ou

qu’une pièce électrique ne fonctionne pas

correctement, éteindre la raboteuse et la débrancher.

䢇 Remplacer les pièces endommagées ou

manquantes avant d’utiliser la raboteuse.

䢇 Veiller à ce que les lames tournent dans la bonne

direction. Elles doivent tourner vers la table d’entrée.

2. EVITER LES BLESSURES DUES AU RENVERSEMENT,

AU GLISSEMENT OU A LA PROJECTION DE PIECES

(RETOURS):

䢇 Utiliser cette raboteuse pour couper de bois

uniquement.

䢇 Planifier le positionnement des mains de manière

à ne pas placer ses doigts dans un endroit où un

glissement soudain pourrait les faire glisser ou

tomber dans la lame. En cas d’utilisation d’un seul

bloc de poussée pour pousser le bois, ne pas

mettre l’autre main sur la raboteuse ou la pièce.

䢇 Eviter les blessures dues à la projection de pièces.

Veiller à ce que les lames soient correctement

installées et que les vis du dos de la lame sont

bien vissées.

䢇 Régler la profondeur de coupe à 1/32”(0,8 mm) ou

moins pour de meilleurs résultats. Une coupe

profonde rend la poussée du bois plus difficile et

peut engendrer le retour du bois.

䢇 Utiliser le bon outil. Ne pas forcer l’outil à faire un

travail pour lequel il n’a pas été conçu.

3. INSPECTER L’AIRE DE TRAVAIL:

䢇 Maintenir l’aire de travail propre.

䢇 Les zones et établis encombrés sont propices aux

accidents. Le sol ne doit pas être glissant à cause

de la cire ou de la sciure.

䢇 Eviter les brûlures ou autres problèmes d’incendie.

Ne pas utiliser la raboteuse à proximité de liquides,

vapeur ou gaz inflammables.

䢇 Avant d’utiliser la raboteuse, retirer tous les objets

non nécessaires pour pousser la pièce de la table.

䢇 Eviter les blessures. Ne pas déballer, monter ou

installer le travail sur la raboteuse.

4. PLANIFIER LE TRAVAIL:

䢇 Avant d’essayer une nouvelle opération ou une

opération peu fréquente, planifier soigneusement

le positionnement des mains. Veiller à disposer

des blocs de poussée, fixation, butées et autres

éléments prêts à l’emploi adéquats.

䢇

Eviter les blessures dues à l’utilisation d’accessoires

non sûrs. N’utiliser que les accessoires recommandés.

CONSERVER CES INSTRUCTIONS

— 20 —

Page 21

Français

CONSIGNES DE SECURITE SPECIFIQUES A LA RABOTEUSE _ Suite

5. PORTER DES VETEMENTS APPROPRIES:

䢇 Planifier de se protéger les yeux, les mains, le

visage et les oreilles.

䢇 Ne pas porter de vêtements amples, de gants, de

cravates ou de bijoux (bagues, montres de poignet).

Ils pourraient se coincer dans les pièces en rotation.

䢇 Porter des chaussures anti-dérapantes.

䢇 Attacher les cheveux longs.

䢇 Enrouler les longues manches au dessus du coude.

䢇 Les niveaux sonores varient considérablement.

Pour éviter tout trouble auditif, porter des

bouchons d’oreille ou des manchons en utilisant

la raboteuse pendant longtemps.

䢇 Une raboteuse peut vous projeter des corps

étrangers dans les yeux, ce qui pourrait entraîner

des troubles oculaires permanents. Porter des

verres de sécurité (non pas des lunettes ordinaires)

conformes aux Normes CSA. Les lunettes

ordinaires n’assurent pas une protection suffisante

parce que leurs verres sont uniquement résistants

aux chocs. Ce ne sont pas des verres de sécurité.

䢇 Pour les opérations poussiéreuses, porter un

masque anti-poussière ainsi que des verres de

sécurité.

6. INSPECTER LA PIECE:

䢇 Veiller à ce qu’il n’y ait pas de clous ou d’objets

étrangers dans la pièce à raboter.

7. PLANIFIER LA COUPE:

䢇 Les pièces petites ou fines peuvent revenir si elles

culbutent au dessus des tables ou de la lame.

䢇 Pour éviter tout contact avec la lame ou le retour

de la pièce, ne pas raboter les pièces dont la

longueur est inférieure à 14” (35,6 cm).

䢇 Ne pas raboter du bois dont l’épaisseur est

inférieure à 1/2” (13 mm).

䢇 Ne jamais effectuer des travaux à “mains libres”.

Toujours utiliser le guide pour positionner et

guider la pièce. Veiller à ce qu’il n’y ait pas de

débris entre la pièce et ses supports.

䢇 Faire très attention avec les pièces grandes,

petites ou encombrantes.

䢇 Utiliser un support supplémentaire (tables,

tréteaux, blocs) si la pièce est difficile à tenir sur

la table. Ne pas demander l’aide de quelqu’un

d’autre pour pousser, soutenir ou tirer la pièce.

䢇 Ne pas couper plus d’une pièce à la fois.

䢇 Ne pas mettre la raboteuse sur ON avant d’avoir

retiré tous les objets, sauf la pièce et les

dispositifs de soutien de la table.

8. EVITER LES DEMARRAGES ACCIDENTELS:

䢇 Veiller à ce que l’interrupteur soit sur OFF avant

de brancher la raboteuse dans la prise secteur.

LORSQUE LA RABOTEUSE EST EN MARCHE

AVERTISSEMENT

NE PAS LAISSER LA FAMILIARITE (DUE A L’USAGE

FREQUENT DE LA RABOTEUSE) ENGENDRER DES

ERREURS D’INATTENTION. SOUVENEZ-VOUS QU’UNE

FRACTION DE SECONDE D’INATTENTION EST

SUSCEPTIBLE DE PROVOQUER DES BLESSURES GRAVES.

1. NE JAMAIS LAISSER LES ENFANTS S’APPROCHER

DE LA RABOTEUSE:

䢇 Veiller à ce que l’ensemble des visiteurs reste à

distance de la raboteuse.

䢇 Avant de procéder à la coupe avec la raboteuse, la

laisser fonctionner un moment. Si elle émet un

son non familier ou qu’elle vibre, l’arrêter

immédiatement. Eteindre la raboteuse et la

débrancher. Ne pas la redémarrer avant d’avoir

trouvé et réparé le problème.

2. NE PAS FORCER L’OUTIL:

䢇 Pousser la pièce dans la raboteuse assez

rapidement pour que l’outil coupe sans se coincer

ou se bourrer.

3. AVANT DE LIBERER LE MATERIEL BOURRE:

䢇 Mettre l’interrupteur sur OFF.

䢇 Attendre que toutes les pièces mobiles s’arrêtent.

䢇 Débrancher la raboteuse.

4. AVANT DE LAISSER LA RABOTEUSE SANS

SURVEILLANCE:

䢇 Mettre l’interrupteur sur OFF.

䢇 Débrancher la raboteuse.

䢇 La mettre hors de la portée des enfants.

Verrouiller l’atelier. Débrancher les interrupteurs

principaux. Retirer la clé de sécurité ON/OFF. La

stocker hors de la portée des enfants et d’autres

personnes non qualifiées pour utiliser cet outil.

CONSERVER CES INSTRUCTIONS

— 21 —

Page 22

Français

INFORMATIONS RELATIVES A L’ELECTRICITE

INSTRUCTIONS DE MISE A LA MASSE

EN CAS D’ANOMALIE OU DE PANNE, la mise à la masse offre

un trajet peu résistant au courant électrique de manière à

réduire les risques de secousse électrique. Cette scie est dotée

d’un cordon électrique ayant un conducteur de mise à la

masse de l’outil électrique et d’une prise avec mise à la masse.

La prise DOIT être branchée sur une prise secteur convenable,

correctement installée, et mise à la masse conformément à

TOUS les règlements et ordonnances locaux.

NE PAS MODIFIER LA PRISE FOURNIE. Si elle ne peut pas

être branchée sur la prise secteur, faire installer par un

technicien compétent la prise secteur qui convient.

UN RACCORDEMENT INCORRECT du conducteur de mise

à la masse de l’outil électrique peut se traduire par un

choc électrique. Le conducteur (câble) dont l’isolant est

vert (avec ou sans filets jaunes), est le conducteur de mise

à la masse de l’outil électrique. Si la réparation ou le

remplacement du cordon ou de la prise électriques sont

nécessaires. NE PAS RELIER le conducteur de mise à la

masse à une borne sous tension.

VERIFIER auprès d’un électricien compétent ou du

personnel d’entretien que les instructions de mise à la

masse ont été comprises et que l’outil électrique est

correctement mis à la masse.

N’UTILISER QUE DES RALLONGES A 3 CONDUCTEURS

munies de prises à 3 bornes dont une pour la mise à la

masse et pouvant recevoir la prise du cordon de l’outil

électrique, tel que cela est indiqué sur la Fig. A. Remplacer

ou réparer immédiatement tout cordon endommagé ou usé.

DIRECTRICES PARA UTILIZAR ALARGADORES

AVERTISSEMENT

CETTE RABOTEUSE EST DESTINEE A UN USAGE

INTERIEUR. NE PAS L’EXPOSER A LA PLUIE OU A DES

ENVIRONNEMENTS MOUILLES.

Veiller à ce que le cordon de rallonge soit en bon état.

Lorsqu’on utilise un cordon de rallonge, veiller à ce qu’il soit

suffisamment lourd pour supporter le courant dont l’appareil

aura besoin. Un cordon trop petit provoquera une chute de

la tension de ligne, ce qui entraînera une perte de puissance

et une surchauffe. Le tableau indique le calibre à utiliser en

fonction de la longueur du cordon et de l’intensité nominale

indiquée sur la plaque signalétique. En cas de doute, utiliser

un calibre supérieur. Plus le numéro du calibre est petit, plus

le cordon est lourd.

CALIBRE MINIMUM POUR LES RALLONGES (AWG)

(120 V uniquement)

Intensité nominale Longueur totale en pieds

Supérieure à

0 6 18 16 16 14

6 10 18161412

10 12 16 16 14 12

12 16 14 12

Veiller à ce que le cordon de rallonge soit correctement

câblé et en bon état. Toujours remplacer un cordon de

rallonge endommagé ou le faire réparer par un technicien

qualifié avant de l’utiliser. Protéger vos cordons de

rallonge contre les objets pointus, les excès de chaleur et

des zones humides ou mouillées.

Inférieure à

25’ 50’ 100’ 150’

Non recommandée

1

3

2

1-prise à 3 bornes

2- prise correctement mise à la masse

3- borne de mise à la masse

ATTENTION: DANS TOUS LES CAS, S’ASSURER QUE LE

RECEPTACLE EN QUESTION EST CORRECTEMENT MIS A

LA MASSE. EN CAS D’INCERTITUDE, FAIRE VERIFIER LE

RECEPTACLE PAR UN ELECTRICIEN QUALIFIE.

CONSERVER CES INSTRUCTIONS

Utiliser un circuit électrique séparé pour les outils. Ce

circuit ne doit pas être inférieur à un câble #12 et doit être

protégé par un fusible retardé de 15 A. Avant de brancher

le moteur au cordon d’alimentation, veiller à ce que

l’interrupteur soit en position OFF et que la tension du

courant électrique soit identique à celle indiquée sur la

plaque signalétique du moteur. Une tension plus faible

endommagerait le moteur.

AVERTISSEMENT

CET OUTIL DOIT ETRE MIS A LA MASSE PENDANT

L’UTILISATION POUR PROTEGER L’OPERATEUR CONTRE

LES CHOCS ELECTRIQUES.

— 22 —

Page 23

CONNAITRE LA RABOTEUSE

CAPACITIES

1/2

2-1/2

1-1/2

13

11

12

10

5-1/25-1/2

3-1/2

6-1/2

Cutting width 13"

Cutting height 6"

Depth of cutting 3/32"

Français

Capuchon

Interrupteur

ON/OFF

Levier de verrouillage

de profondeur

Stockage de l’outil

CAPACITIESCAPACITIES

Cutting width 13"

Cutting width 13"

Cutting height 6"

Cutting height 6"

Depth of cutting 3/32"

Depth of cutting 3/32"

Poignée de réglage

de profondeur

17

/2

-1

6

16

6

15

14

5-1/2

1313

55

1212

1111

44

1010

99

3-1/23-1/2

88

33

77

/2

/2

-1

-1

2

2

66

22

55

44

1-1/21-1/2

33

11

22

/2

1/21

11

00

00

CMCM

INCHINCH

Repère échelle

de profondeur

Echelle de

profondeur

Rallonge de

table avant

Poignée de

transport

Table principale

Crochets cordon

Cordon

d’alimentation

— 23 —

Page 24

Français

MONTAGE ET REGLAGES

DEBALLAGE TEMPS D’ASSEMBLAGE ESTIME A 25~35 MINUTES

Soigneusement déballer la raboteuse et l’ensemble de ses pièces, et les comparer à la liste ci-dessous. Ne pas jeter le

carton ou l’emballage avant que la raboteuse soit complètement montée.

AVERTISSEMENT

SI UNE PIECE EST MANQUANTE OU ENDOMMAGEE, NE PAS BRANCHER LA RABOTEUSE AVANT QUE LA

PIECE MANQUANTE OU ENDOMMAGEE SOIR REMPLACEE.

Boulons

Clé hexagonale Guides de réglage

Clé ouverte

Crocher cordon d’alimentation

Capuchon Boulon

Poignée de la manivelle

Raboteuse

Pieds de support

Barre

transversale

courte inférieure

Barre

transversale

longue inférieure

— 24 —

Barre

transversale

courte supérieure

Barre

transversale

longue inférieure

Matériel de montage

Page 25

Français

MONTAGE ET REGLAGES _ Suite

AVERTISSEMENT

Ne jamais brancher l’appareil à la prise secteur avant d’avoir terminé les installations et les réglages et lu et compris les

consignes de sécurité et d’opération.

INSTRUCTIONS RELATIVES AU MONTAGE

Soulever l’outil de son emballage et le placer sur l’établi.

Soigneusement ouvrir les rallonges de table avant et

arrière et sortir le sachet d’accessoires et le cordon

d’alimentation.

MONTAGE DU SUPPORT (Fig. A)

1. Déballer toutes les pièces et les trier par type et par

taille. Se reporter à la liste page 48 pour les quantités.

2. Attacher la barre transversale longue supérieure (4) au

haut du pied (1) et du pied adjacent à l’aide de

boulons à tête ronde (2) et d’écrous (5).

12

NOTE: Ne pas serrer les boulons avant l’étape 7.

3. Attacher la barre transversale longue inférieure (3) au

bas du pied (1) et au pied adjacent à l’aide de boulons

à tête ronde et d’écrous.

4. Répéter l’opération de l’autre côté du support.

5. Joindre l’avant et l’arrière du support à l’aide des

barres transversales courtes supérieure (11) et

inférieure (10), de boulons à tête ronde et d’écrous.

6. Mettre les capuchons (7) sur les pieds.

7. Mettre le support sur une surface plane et veiller à ce

que tous les pieds soient en contact avec le sol et à

raison d’angles similaires au niveau du sol. Serrer

tous les boulons.

MONTAGE DE LA RABOTEUSE SUR LE SUPPORT

1. Soigneusement mettre la raboteuse sur le dessus du

support.

2. Aligner les quatre trous de montage situés sur l’outil

avec ceux du support.

3. Fixer la raboteuse au support à l’aide de boulons (12),

de rondelles (13) et d’écrous (14)(voir Fig. A).

4. Serrer tous les écrous.

NOTE: NE PAS TROP SERRER LES ECROUS.

13

6

2

5

10

14

3

1

7

11

4

Fig. A

— 25 —

Page 26

Français

MONTAGE ET REGLAGES _ Suite

Installation de la poignée de réglage de profondeur (Fig. 1)

1. Mettre la poignée de réglage de profondeur (1) en

haut à droite de la machine.

2. Insérer les vis à tête hexagonale dans la poignée. Serrer.

3. Appuyer sur le capuchon à gauche.

NOTE: La poignée de réglage de profondeur peut être

installée soit à droite, soit à gauche. L’illustration indique

la poignée de la manivelle à droite.

Installation des crochets du cordon d’alimentation (Fig. 2)

Les crochets du cordon d’alimentation (1) sont fournis à

des fins de stockage. Attacher les crochets du cordon

d’alimentation à l’arrière de l’outil, tel que cela est

indiqué, au moyen de deux vis (2). Serrer.

1

Réglage de la rallonge de table (Fig. 4, 5)

1. Tirer sur le levier de verrouillage de lame.

2. Déverrouiller la tête.

3. Tourner la poignée de réglage de profondeur pour

élever la tête.

4. Placer une équerre sur les rallonges de table et sur la

table principale.

5. Appuyer l’équerre sur les rallonges de table pour

supprimer le jeu.

6. Si des réglages sont nécessaires, plier la rallonge de

table et dévisser l’écrou (1), puis régler le boulon (2)

jusqu’à ce que les tables soient à niveau.

13-Raboteuse In.

Fig. 1

1

2

Fig. 2

REGLAGE

NOTE: Cet outil a été réglé en usine avant son expédition.

Vérifier l’exactitude de ces réglages et procéder à de

nouveaux réglages si nécessaire afin d’obtenir de

meilleurs résultats.

Fig. 4

2

1

Fig. 5

AVERTISSEMENT

Pour éviter toute blessure inhérente à un démarrage

accidentel, s’assurer que l’interrupteur est en position

d’arrêt (OFF) et que la prise n’est pas branchée à la prise

secteur.

— 26 —

Page 27

MONTAGE ET REGLAGES _ Suite

Réglage de l’échelle de profondeur (Fig. 6)

1. Essayer de raboter une planche.

2. Comparer l’épaisseur mesurée de la planche à

l’affichage de l’échelle de profondeur (2).

3. Si l’affichage de l’échelle de profondeur est incorrect,

dévisser les vis (1) qui serrent le repère (3), puis régler

jusqu’à affichage de la bonne mesure.

4. Tester l’affichage en rabotant un autre morceau de

bois. Vérifier et régler à nouveau si nécessaire.

Français

1

INCH

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

CM

1

3

2

6-1/2

6

5-1/2

5

4

3-1/2

3

2-1/2

2

1-1/2

1

1/2

0

Fig. 6

Réglage de la hauteur de la lame (Fig. 7, 8)

1. Retirer les deux vis avec un tournevis et retirer le

couvercle de poussière. (Fig. 13)

2. Dévisser les huit vis à tête hexagonale (1) avec la clé

ouverte fournie.

3.

Appuyer sur le tourniquet de verrouillage de l’arbre et

tourner la lame jusqu’à exposer les deux boulons hex (1).

4. Mettre le guide de réglage de la lame (2) (Fig. 8) sur le

porte-outil avec les deux guides reposant fermement

contre la lame.

5. Dévisser ou serrer les boulons hex (1) (Fig. 8) jusqu’à

ce que la lame touche le guide de réglage de la lame.

6. Serrer les huit vis à tête hexagonale à l’aide de la clé

fournie.

7. Remplacer le couvercle de poussière et le fixer avec

deux vis.

Fig. 7

1

2

Fig. 8

— 27 —

Page 28

Français

OPERATION

AVERTISSEMENT

Ne jamais brancher l’appareil à la prise secteur avant

d’avoir terminé les installations et les réglages et lu et

compris les consignes de sécurité et d’opération.

Retirer la clé de sécurité lorsque la scie n’est pas utilisée. La

ranger dans un lieu sûr et hors de la portée des enfants.

Opérations de la raboteuse

INTERRUPTEUR “ON/OFF” (Fig. 9)

L’interrupteur à clé est destiné à éviter toute utilisation

non autorisée de la raboteuse.

1. Pour allumer la raboteuse, insérer la clé de sécurité

jaune (1) dans la fente située au centre du contacteur.

2. Pousser fermement la clé dans la fente et mettre

l’interrupteur en position ON pour démarrer la

raboteuse.

3. Pour éteindre la raboteuse, mettre l’interrupteur en

position OFF (en bas).

4. Retirer la clé de sécurité jaune lorsque la scie n’est pas

utilisée pour éviter toute utilisation non autorisée.

1

Fig. 9

AVERTISSEMENT

1. Attendre que le moteur ait atteint sa vitesse de

régime avant d’entamer une coupe.

2. Toujours pousser la pièce dans une direction qui

permette aux lames de la raboteuse de couper dans le

sens du grain. Pousser la pièce dans le sens contraire

du grain fera en sorte que les lames soulèveront des

fibres de la surface de travail, ce qui donnera un

aspect imprécis.

3. Retirer tous les objets étrangers de la pièce. Ne pas

raboter de bois qui soit strié ou gauchi.

4. La raboteuse fonctionne mieux avec au moins une

surface plane. Mettre la surface plane vers le bas sur

la table.

5. Ne pas raboter plus de 3 mm à la fois.

6. La bonne profondeur de coupe dépend de la largeur

et de la dureté de la planche.

7. Veiller à ce que les longs panneaux soient supportés

à niveau avec la table à l’avant et à l’arrière de la

raboteuse. Utiliser une rallonge de support si

nécessaire.

8. Ne pas recevoir le panneau dans les mains vers

l’intérieur de l’arrière de la rallonge de table.

9. En cas de besoin d’une coupe à une hauteur spécifique

(3/4”, 1/4”, 1/2”). Déplacer le côté droit du niveau de

hauteur dans la position souhaitée. (Fig. 12)

1. Tirer le levier de verrouillage de lame. (Fig. 10)

2. Déverrouiller la lame.

3. Baisser la lame jusqu’à ce qu’elle touche la pièce.

4. Régler le cadran de profondeur de coupe sur “0”.

5. Elever la lame légèrement et retirer la pièce.

6. Régler la profondeur de coupe à l’épaisseur souhaitée

du panneau.

7. Verrouiller la lame.

8. Pousser le levier de verrouillage de lame. (Fig. 11)

9. Pousser le panneau dans le rouleau d’entrée de

manière à ce qu’il aille droit. Lorsque le rouleau

d’entrée s’arrête, retirer le panneau et le mettre de

côté (hors de la trajectoire d’un retour possible).

10. Si le panneau est long, le mettre ay dessus de la

raboteuse et la faire rouler vers l’avant pour la raboter

à nouveau.

— 28 —

Fig. 10

Page 29

Fig. 11

Français

1

3/4

0

1/4

1/2

3/4"

0

1/2"

Fig. 12

NOTE:

1.

Le rabotage pour un fini et une épaisseur doux est mieux

réalisé en procédant à des coupes légères sur le panneau

2. Pour de meilleurs résultats, raboter les deux côtés de

la pièce pour obtenir l’épaisseur souhaitée.

3. En cas de fossette (une fossette est une dépression qui a

lieu lorsque les extrémités de la pièce entrent en contact

avec les lames), veiller à ce que les rallonges de table et

les supports soient à niveau avec la table principale et

que la surface plate de la pièce soit contre les tables.

4. En cas de pièce arquée, il est conseillé de retirer l’arc

avec un rabot.

5. Pour les pièces creuses ou gauchies, raboter la face

supérieure, retourner la pièce et raboter la face inférieure.

Remplacement des lames

NOTE: Les accessoires de remplacement des lames sont

rangés dans le stockage de l’outil.

Fig. 13

1

.

Fig. 14

3

4

1. Faire tourner la poignée pour baisser la lame à une

hauteur de 2” (50 mm).

2. Retirer toutes les vis pour retirer le capot à poussière

et le capuchon à poussière (1) (Fig. 13).

3. Appuyer sur le tourniquet de verrouillage de l’arbre (2)

et tourner la lame jusqu’à exposer les huit boulons vis

à tête hexagonale (Fig. 14).

4. Retirer les huit boulons à tête hexagonale (3) à l’aide

de la clé fournie (Fig. 15).

5. Soigneusement retirer la plaque de soutien (4) en la

soulevant droit (Fig. 15).

6. Soigneusement retirer la lame (5) en soulevant les

deux extrémités droit (Fig. 15).

7.

La lame a deux extrémités coupantes. En cas d’utilisation

de l’autre extrémité de la lame ou de remplacement de la

lame, mettre la lame sur le porte-outil en situant les deux

trous de la lame sur les aiguilles de localisation du porteoutil (Fig. 15).

— 29 —

5

Fig. 15

AVERTISSEMENT

Pour éviter toute blessure inhérente à un démarrage

accidentel, s’assurer que l’interrupteur est en position

d’arrêt (OFF) et que la prise n’est pas branchée à la prise

secteur avant de remplacer les lames.

Page 30

Français

OPERATION _ Suite

8. Régler légèrement la position de la lame de manière à

ce qu’elle soit uniformément positionnée au centre du

porte-outil.

9. Remettre la plaque de soutien (4), visser les huit

boulons à tête hexagonale (3), mais ne pas serrer.

10. Mettre les guides de réglages de lame (6) sur le porte-

outil avec les deux guides reposant fermement contre

la lame. (Fig. 16)

11. Tourner les deux vis de réglage (7) jusqu’à ce que la

lame touche les guides de réglage de lame.

12. Retirer les guides de réglage de lame et faire tourner

le porte-outil de manière à exposer les huit boulons à

tête hexagonale (3). Serrer tous les boulons avec la

clé fournie.

13. Remettre le capot de poussière et le fixer avec deux vis.

NOTE: La raboteuse ne démarrera pas avant que le

couvercle de poussière et le protecteur du porte-outil

soient correctement installés.

6

7

Fig. 16

— 30 —

Page 31

ENTRETIEN

AVERTISSEMENT

Ne jamais lubrifier la lame lorsqu’elle tourne.

Pur éviter les risques d’incendie ou de réaction toxique, ne

jamais utiliser de gasoil, d’acétone naphtha, de diluant ou

autres solvants hautement volatiles pour nettoyer la

raboteuse.

Afin d’éviter toute blessure inhérente au démarrage

inattendu ou tout choc électrique, débrancher le cordon

d’alimentation avant d’entretenir l’outil.

Pour des raisons de sécurité, cet outil est doublement isolé.

Pour éviter les risques de choc électrique, d’incendie ou de

blessure, n’utiliser que des pièces identiques à celles

identifiées dans la liste des pièces. Remonter exactement

comme le montage initial pour éviter les chocs électriques.

REMPLACEMENT DES BALAIS CARBONE (Fig. 17)

Les balais carbone sont fournis avec une durée de vie

d’environ 50 heures, ou 10 000 cycles ON/OFF. Si les deux

balais carbone si l’un dispose de moins de 1/4” de carbone,

ou si le ressort ou le câble est endommagé ou brûlé. Pour

inspecter ou remplacer les balais, débrancher l’outil. Ensuite,

retirer le capuchon en plastique (1) sur le côté du moteur (2).

Retirer le capuchon soigneusement car il est monté sur

ressort. Ensuite, retirer le balai et le remplacer. Le mettre de

l’autre côté. Pour remonter, suivre la procédure inverse. Les

oreilles sur l’extrémité métallique du montage vont dans les

mêmes fentes que les pièces en carbone. Serrer le capuchon

sans trop serrer.

Français

䢇 Retirer l’ancienne courroie en la faisant passer

alternativement dans la poulie du moteur et la

poulie motrice. Tirer légèrement sur la courroie

tout en tournant les poulies.

䢇 Remplacer par la nouvelle courroie. Faire passer

la courroie dans les poulies dans le sens contraire

du retrait de la courroie.

䢇 Veiller à ce que la courroie soit positionnée de

façon homogène sur l’ensemble du moteur et des

rainures de la poulie motrice.

䢇 Remettre et fixer le panneau droit.

LUBRIFICATION

䢇 L’ensemble des accessoires du moteur et du

porte-outil sont étanches et ne requièrent pas de

lubrification.