MODEL NV 65AH

1. DISASSEMBLY AND REASSEMBLY

The items particularly necessary for disassembly and reassembly are described below. The

numbers in the descriptions below correspond to the item numbers in the Parts List and exploded assembly

diagram.

[CAUTION]

Before disassembly or reassembly , be sure to di sconnect the ai r hose from the nai ler (with your

z#

finger released from the trigger) to exhaust all the compressed air and remove all nails.

1-1. General Precautions in Disassembly and Reassembly

z#

Apply grease (Nippeco SEP-3A, Code No.930035) to the o-rings and o-rings’ sliding portion. When

installing the o-rings, be careful not to damage the o-rings and prevent dirt entry.

z#

Oil required: Hitachi pneumatic tool lubricant

1 oz (30 cc) Oil feeder (Code No.877153)

4 oz (120 cc) Oil feeder (Code No.874042)

1 quart (1ltr) Can (Code No.876212)

z#

If the Gasket

z#

Be especially careful to prevent the entry of foreign part icles into the control valve section.

z#

Tightening torque for each part

[6]

is damaged, replace it and check that no air is leaking.

[Bold]

Bolt, screw and cap

Nylock High Tension Bolt M6

Hex. Socket Hd. Bolt M6

Hex. Socket Hd. Bolt M5

Nylock Hex. Socket Hd. Bolt M4

Hex. Socket Hd. Bolt M4

Machine Screw M5

Machine Screw M4

Cap

[30]

[1], [43]

[4]

[102]

[90]

[44]

[87]

[49]

Tightening torque

[N·m (kgf·cm, ft-lbs)]

16.2±1.5 (165±15, 11.9±1.1)

12.7±0.8 (130±8, 9.4±0.6)

8.3±0.5 (85±5, 6.1±0.4)

4.4±0.3 (45±3, 3.2±0.2)

4.4±0.3 (45±3, 3.2±0.2)

2.0±0.5 (20±5, 1.5±0.4)

0.5 - 1.0 (5 - 10, 0.36 - 0.72)

24.5±4.9 (250±50, 18±3.6)

−

−

1

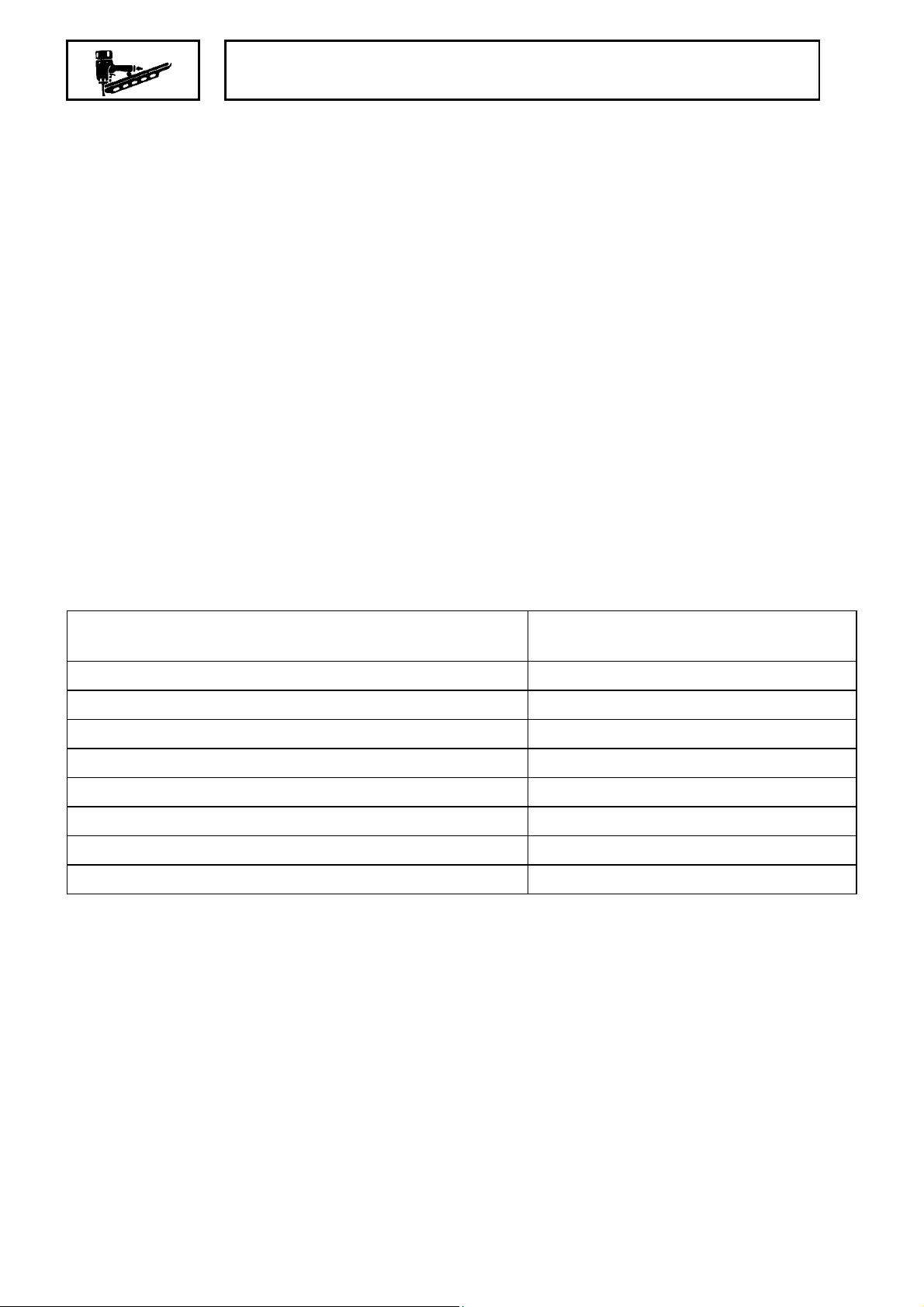

2-2. Disassembly and Reassembly of the Output Section

(1) Disassembly and reassembly of the Exhaust Cover

(A)

, etc. (See Fig. 12A and Fig. 12B)

[7]

Hex. Socket Hd. Bolt

M6 x 16

Top Cover

Plate

[1]

[2]

[3]

Hex. Socket Hd. Bolt

M5 x 35

[4]

[Tools required]

Hex. bar wrench (5 mm and 4 mm)

z#

Hammer

z#

(a) Disassembly

Remove the four Hex. Socket Hd. Bolts M5 x 35

z#

a hex. bar wrench (4 mm). The entire Exhaust Cove r

can now be removed from the Body Ass’y

Remove the Hex. Socket Hd. Bolt M6 x 16

z#

bar wrench (5 mm). The Plate

Exhaust Cover

Gasket

[5]

[6]

now be removed.

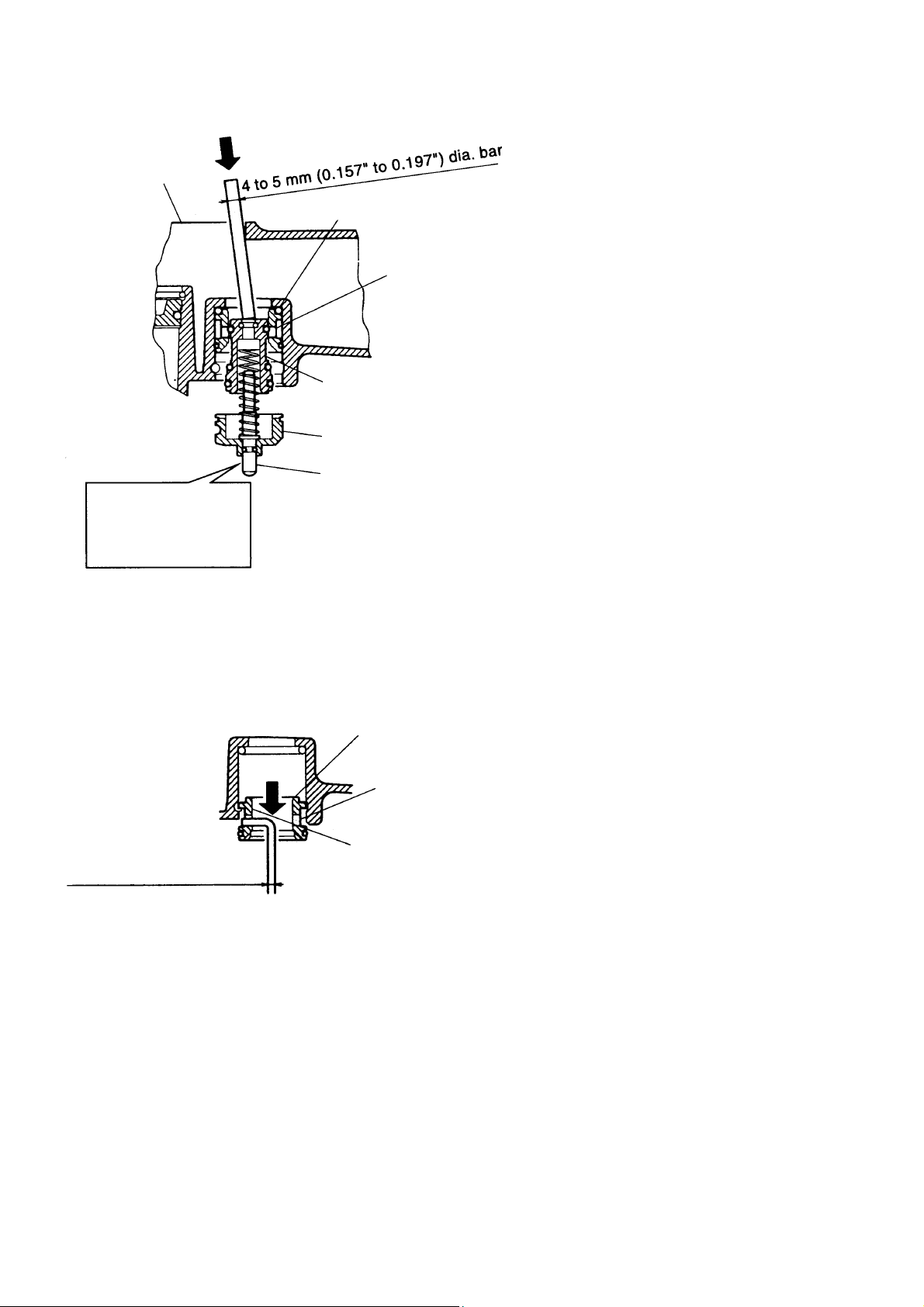

As shown in Fig. 12B, insert a 4 to 5 mm (0.157″ to

z#

0.197″) dia. bar into the M6 screw hole in the Exhaust

Cover

Exhaust Valve

Rubber (A)

[7]

with a hammer. Now, the parts forming the Exhaust

Cover

[CAUTION]

Do not use a pointed bar or a bar with a diameter of

Head Valve Spring

[8]

less than 4 mm (0.157

Valve Rubber (A) [ 7] .

the Head Valve

[5],

the Exhaust Valve Rubber

[10],

[23]

[1]

and Top Cover

[2]

and force out Exhaust Valve Rubber (A)

[5]

can be taken out.

[5]

″″″″

) to prevent damage to Exhaust

with

[4]

[5]

.

with a hex.

can

[3]

[7]

O-Ring (S-34)

Head Valve

[9]

[10]

Cylinder O-Ring (C)

(I.D 44.7)

[11]

Head Valve

Rubber

Body Ass’y

[12]

[23]

Fig. 12A Disassembly and reassembly of the

exhaust cover, head valve, exhust v al ve

rubber (A), etc.

Hammer

Exhaust Cover

Exhaust

Valve

Rubber

(A)

[7]

[5]

Fig. 12B

Force out

4 to 5 mm dia. bar

(0.157″to 0.197″)

− 2 −

Exhaust Valve Rubber (A)

Head Valve

[10]

Exhaust

Cover

Charge with 3

grams of grease.

[5]

Push in until the rubber is fully

seated over the projection.

Fig. 13

[7]

Push in

(b) Reassembly

Disassembly procedures should be followed in the

reverse order. Note the following points:

Lubricate the sliding portion of the Head Valve

z#

the Exhaust Cover

with about 3 grams of grease and

[5]

apply grease to each surface of the O-Ring

As shown in Fig. 13, firmly push in Exhaust Valve

z#

Rubber (A)

of the Exhaust Cover

until it is fully seated over the projection

[7]

.

[5]

[10]

[9] [11]

in

.

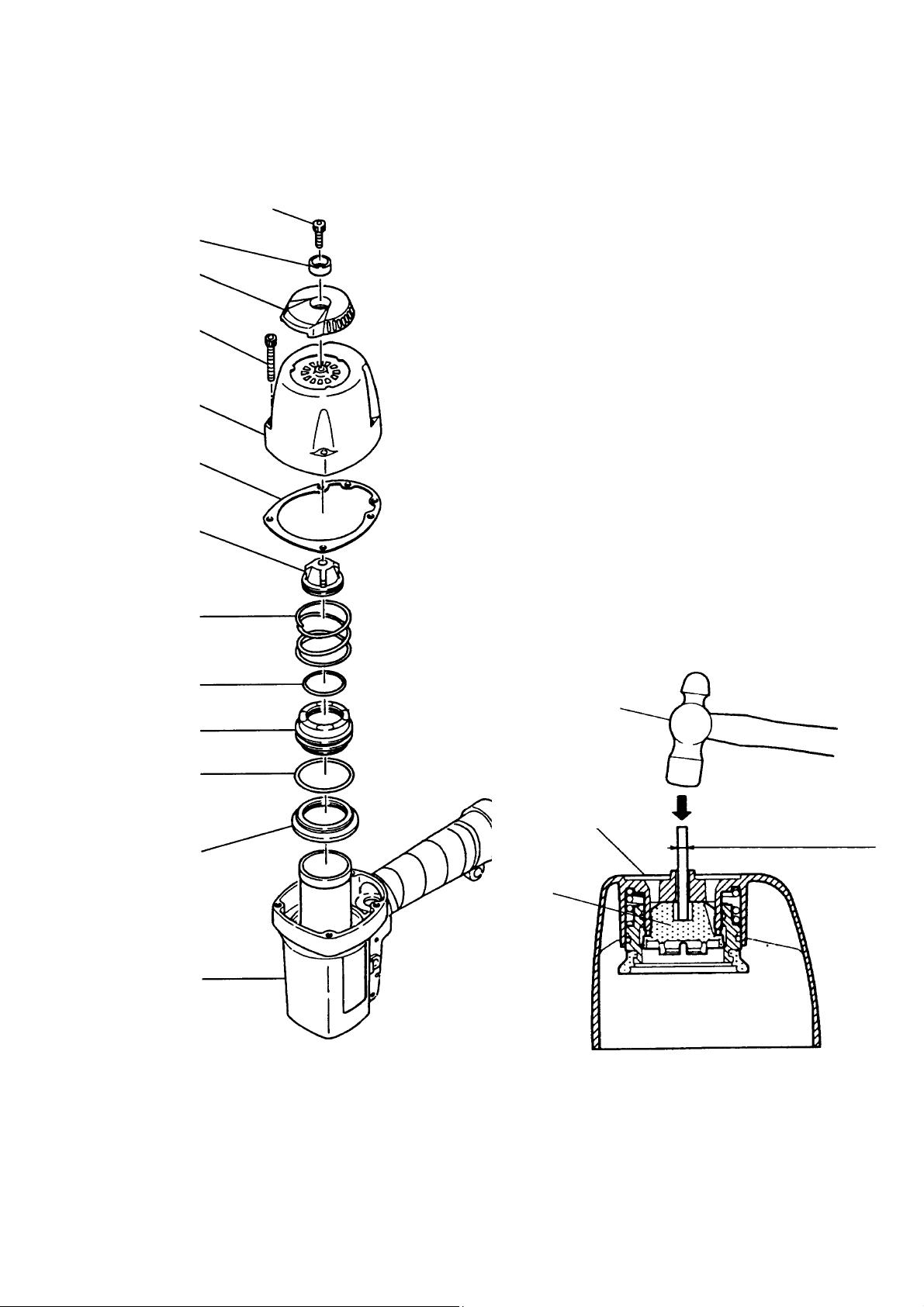

(2) Disassembly and reassembly of the Cylinder

(See Fig. 14)

O-Ring (I.D 34.2)

Retaining Ring

Cylinder Plate

Piston Ring

Piston

[20]

[13]

[14]

[18]

[9]

Cylinder O-ring

(I.D 63.1)

[15]

Cylinder O-ring (C)

(I.D 44.7)

O-ring (P-46)

[11]

Cylinder

Concave

[16]

[17]

Retaining ring

detaching groove

Piston Bumper

When assembling,

push in the Cylinder

Plate

[14]

Retaining Ring

is surely seated in

the groove in the

Body Ass’y

Body Ass’y

[26]

until the

[13]

.

[23]

[23]

Fig.14 Disassemblyandreassemblyofthe

Cylinder, Piston, Pistonbumper, etc.

, the Piston

[17]

, the Piston Bumper

[20]

[26]

[Tools required]

Hex. bar wrench (4 mm)

z#

Flatblade head screwdriver

z#

(a) Disassembly

Remove the Exhaust Cover

z#

as described in

[5]

section (1), remove the Retaining Ring

Body Ass’y

, insert the blade of the screwdriver

[23]

into the retaining ring detaching groove in the Body

Ass’y

Now, the Cylinder

Piston

, and remove the Retaining Ring

[23]

, the Cylinder Plate

[17]

, the Piston Bumper

[20]

[26]

, etc. can be

taken out.

(b) Reassembly

Disassembly procedures should be followed in the

reverse order. Note the following points:

Apply the supplied oil (Hitachi pneumatic tool

z#

lubricant) to the Piston Ring

34.2)

[17]

Apply grease to the Cylinder O-Ring (I.D 63.1)

z#

, and the internal side of the Cylinder

[19]

.

the Cylinder O-Ring (C) (I.D 44.7)

Facing the concave side of the Cylinder Plate

z#

upward, fit and push the Cylinder

Ass’y

until the Retaining Ring

[23]

, the O-Rinq (I.D

[18]

[11]

[17]

[13]

seated in the groove of the Body Ass’y.

Remember that when putting the Retaining Ring

z#

into the groove of the Body Ass’y

[13]

opening of the Retaining Ring

must not overlap

[13]

with the retaining ring detaching groove.

, etc.

in the

[13]

.

[13]

, the

[14]

[15]

and install.

[14]

in the Body

is correctly

, the

[23]

,

− 3 −

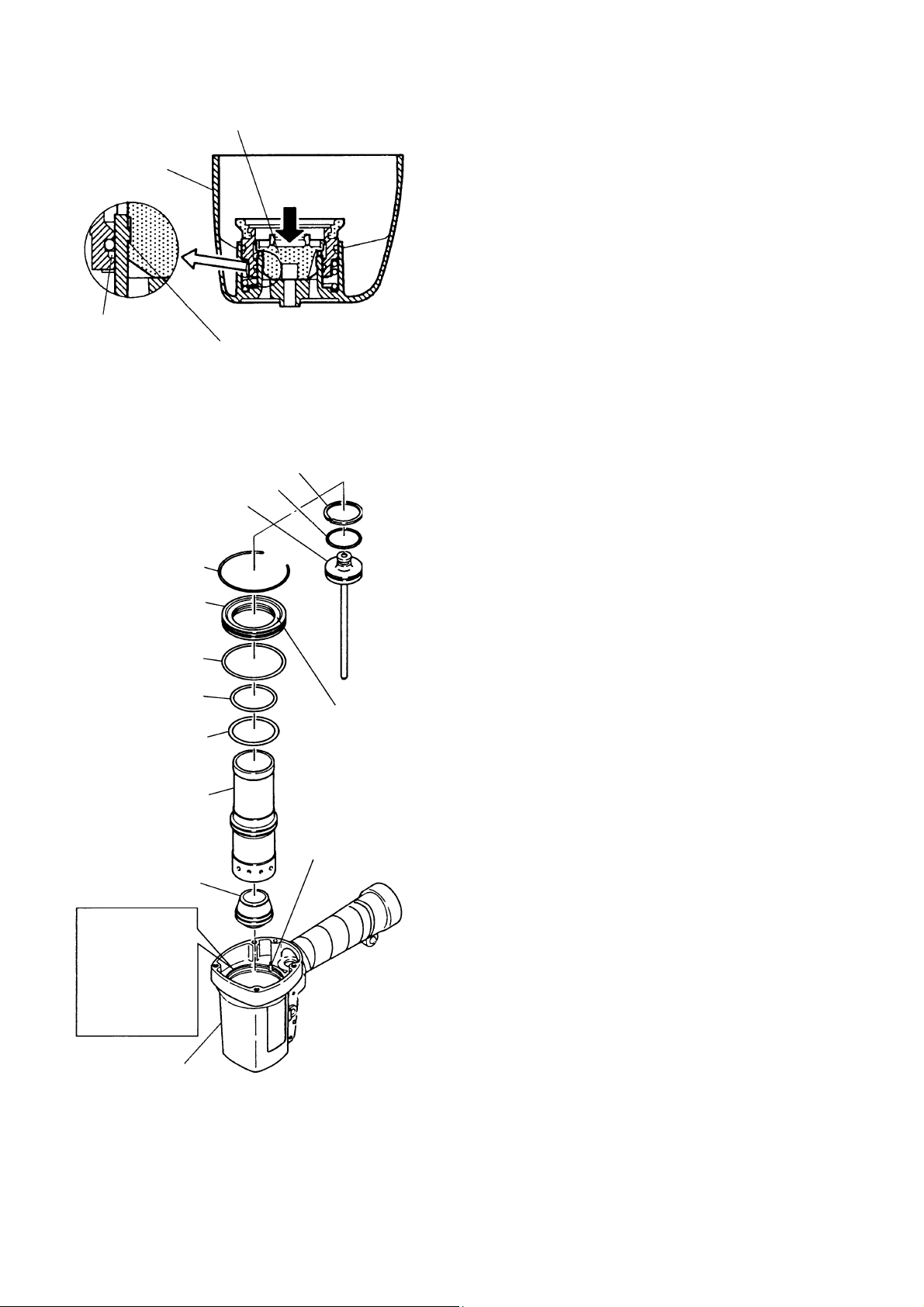

1-3.Disassembly and Reassembly of the Control Valve Section

(See Fig. 15)

Retaining Ring (E-type)

for D6 Shaft

Body Ass’y

[21]

[23]

Head Valve O-ring

(I.D 16.8)

[55]

Valve Bushing (B)

O-ring (S-18)

O-ring (I.D 8.8)

O-ring (I.D 11)

O-ring (S-4)

Valve Piston (B)

Plunger Spring

Plunger (A)

O-ring (I.D l.8)

[56]

[57]

[58]

[59]

[60]

[61]

[62]

[63]

[64]

Roll Pin

D3 x 28

Trigger (A)

Trigger Pin

[Tools required]

Flatblade head screwdriver

z#

Roll pin puller (3 mm dia.)

z#

[51]

Hex. bar wrench (4 mm)

z#

[52]

[53]

(a) Disassembly

Remove the Retaining Ring (E-Type) for D6 Shaft

z#

with the blade of a screw driver and remove

[21]

the Triqger Pin

, and Trigger (A)

[53]

removed.

To remove Trigger (A)

z#

driving Section (Pushing Lever (B)

,etc.), remove Trigger (A)

[29]

down Plunger (A)

[63]

together with the

[52]

[37]

while forcing

[52]

with the blade of a

screwdriver, as shown in Fig. 16.

can be

[52]

, the Nose

Valve Bushing (A)

[65]

Fig. 15 Disassembly and reassembly of the

control valve section

Remove

Trigger (A)

[52]

Force down

Screwdriver

Push Lever (B)

Plunger (A)

[37]

[63]

Fig. 16

− 4 −

Body Ass’y

[23]

Push

Head Valve O-Ring

(I.D 16.8)

[55]

Valve Bushing

(B)

[56]

Valve Piston (B)

Valve Bushing (A)

[61]

[65]

Pull out the Roll Pin D3 x 28

z#

with the roll

[51]

pin puller (3 mm dia.), and take out the

control valve in the following manner.

1) Remove the Exhaust Cover

[5]

by

following the procedure in (1), section

1-2.

2) As shown in Fig. 17, put a 4 to 5 mm

(0.157 to 0.197″) dia. bar in from the upper

side of the Body Ass’y

top of Valve Piston (B)

and push the

[23]

. Now, the

[61]

parts forming the control valve can be

taken out except Valve Bushing (A)

and the Head Valve O-Ring (I.D 16.8)

.

[55]

[65]

When disassembling,

do not pull out this

part by gripping it

with the pliers.

Wire with 1.5 to 3 mm dia.

(0.059″ to 0.118″)

Fig. 17

Plunger (A)

[63]

Valve Bushing (B)

Hole

Be careful not to

damage the internal

surface.

[56]

[CAUTIONS]

z#

z#Be careful not to damage Valve Pist on ( B)

z#z#

[61], Valve Bushing (A) [65] and (B) [56],

etc.

z#

z#Do not pull out the end of Plunger (A) [63]

z#z#

with pliers.

3) To take out Valve Bushing (B)

[56]

, put a

1.5 to 3 mm (0.059″ to 0.118″) dia. wire

with its end hooked into the hole in the

bushing and pull it out while being careful

not to damage the internal surface of

Valve Bushing (B)

, as shown in

[56]

Fig. 18.

Fig. 18

− 5 −

(b) Reassembly

Disassembly procedures should be followed in the reverse order. Note the following points:

Be extremely careful to prevent the entry of foreign particles into the control valve section.

z#

Thoroughly apply grease to the O-Ring (I.D 1.8)

z#

and(I.D 11)

[58]

As shown in Fig. 19, install Valve Bushing (A)

z#

on Valve Piston (B)

[59]

, and the shaft of Plunger (A)

[61]

will be aligned with the roll pin hole in the Body Ass’y

on Plunger (A)

[64]

so that the roll pin groove in Valve Bushing (A)

[65]

. First, insert a roll pin puller (3 mm dia.) into

[23]

, O-Ring (S-4)

[63]

[63]

[60]

, as shown in Fig.19.

, (I.D 8.8)

the roll pin hole. Then, upon confirming that the puIler passes through the hole, drive in the Roll Pin

D3 x 28

[51]

.

[65]

If an attempt is made to drive the roll pin with force when the roII pin groove in Valve Bushing (A)

is not aligned with the roll pin hole in the Body Ass’y

Bushing (A)

and prevent disassembly or reassembly.

[65]

, it will damage the periphery of Valve

[23]

Coat the O-ring

groove’s shaft with

Body Ass’y

[23]

Roll Pin D3 x 28

Assemble

Apply grease to the stem.

[51]

grease.

Plunger (A)

[63]

Roll pin hole

Valve Bushing (A)

[65]

Valve Bushing (A)

[65]

[65]

Roll pin groove

After assembling, check that Plunger (A)

z#

Fig. 19

moves smoothly.

[63]

− 6 −

[73]

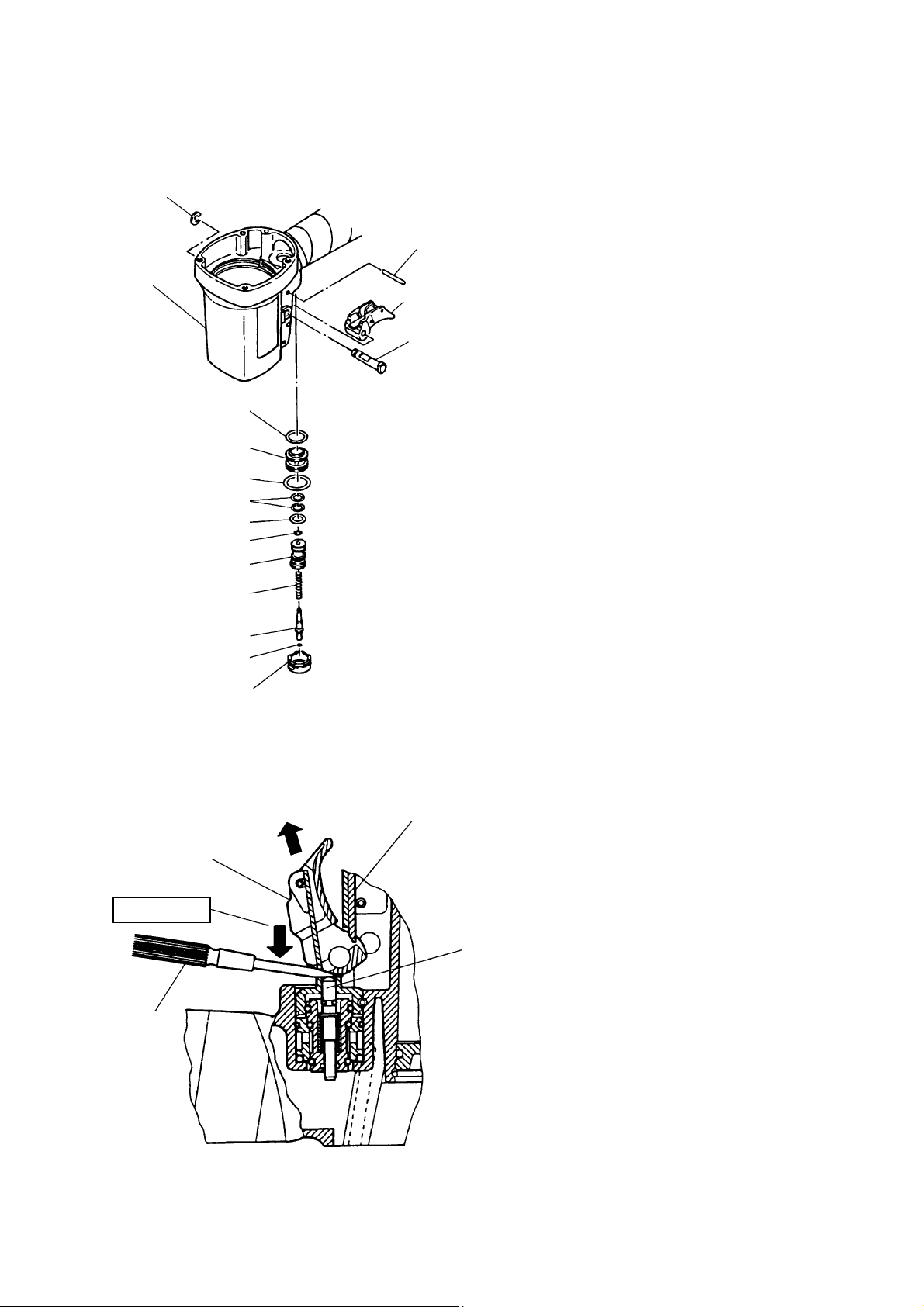

1-4. Disassembly and Reassembly of the Driving Section (See Fig. 20)

[Tools required]

Hex. Bar wrench (3 mm and 5 mm)

z#

Roll pin pulller (3 mm dia. and 4 mm dia.)

z#

Phillips screwdriver

z#

Puller for Retaining Ring (C-Type) for Hole

z#

Open ended wrench (10 mm)

z#

Machine Screw M5 x 20 (Black)

Washer

[44]

[45]

Nylon Nut M5

[74]

Body Ass’y

O-Ring (S-44)

Piston Bumper

O-Ring (P-4)

Washer

Nose

[23]

[25]

[26]

[29]

[28]

[29]

Nylock Hex. High Tensin

Bolt M6 x 20

Roll Pin D4 x 14

Needle Roller

Feeder Arm

Feeder Spring

[30]

[31]

[32]

[33]

[34]

Magazine Ass’y

Roll Pin D3 x 28

[51]

Pushing Lever Guide

Retaining Ring for

D28 Hole

Magazine Bushing

Feed Piston cover

Bumper

Feed Spring

Feed Piston

O-Ring (P-21)

O-Ring (P-9)

Cover

[100]

Sleeve (B)

[70]

[69]

[68]

[67]

[66]

[89]

Hex. Socket Hd. Bolt M4 x 6

[88]

[54]

[72]

[71]

[90]

Safety Spring

Pushing Lever (B)

Don’t lose these

parts during

disassembly.

Push Lever (A)

Hex. Socket Hd. Bolt

M6 x 12

Feeder

[35]

[36]

[37]

Adjuster (B)

[38]

Hexagonal portion

Adjuster

Spring

[39]

Steel Ball

D3.175

[40]

[41]

Washer

[42]

[43]

Fig. 20 Disassembly and reassembly of the driving section

− 7 −

(1) Disassembly and Reassembly of the Nose

, Pushing Levers (A)

[29]

[41]

, and (B)

[37],

(a) Disassembly

Remove the Machine Screw M5 x 20 (black)

z#

Magazine Ass’y

then remove the Cover

Remove the four Nylock High Tension Bolts M6 x 20

z#

mm).Now, the Nose

Tension Bolts M6 x 20

the Feeder

Hold the hexagonal portion of the Adjuster (B)

z#

[35]

the Hex. Socket Hd. Bolt M6 x 12

Ball D3.175

[40]

.Remove the Hex. Socket Hd. Bolt M4 x 6

[88]

from the Nose

[100]

, Pushing Levers (A)

[29]

in the feed piston section can be easily removed by inserting a bar betw een

[30]

and the Nose

and the Adjuster Spring

to lower the Feeder

[29]

with ahex. bar wrench (5 mm) being careful not to lose the Steel

[43]

[39]

with a Phillips screwdriver and then remove the

[44]

with a hex. bar wrench (3 mm) and

[90]

.

[29]

from the Nose

[30]

and (B)

[41]

[35]

with an open ended wrench (10 mm), then remove

[38]

. Now, Adjuster (B)

can be removed. (The Nylock High

[37]

.)

and Pushing Lever (A)

[38]

with a hex. bar wrench (5

[29]

removed.

Pull out the two Roll Pins D3 x 28

z#

can be removed.

[54]

with a roll pin puller (3 mm dia.). Then the Pushing Lever Guide

[51]

(b) Reassembly

Disassembly procedures should be followed in the reverse order. Note the following points:

Before assembling, appIy grease to the Adjuster Spring

z#

Apply grease to the O-Ring (S-44)

z#

After reassembly, check that the components of the Pushing Lever and Adjuster (B)

z#

and then fit it in the groove of the Nose

[25]

[39]

.

.

[29]

[38]

smoothly.

etc. (See Fig. 20)

can be

[41]

operate

(2) DisassembIy and reassembIy of the Piston Bumper

, the Feeder

[26]

, the Feed Piston

[35]

(See Fig. 20)

(a) Disassembly

Remove the Magazine Ass’y

z#

section according to the procedure of section 1-4 (1). Then the Piston Bumper

Pull out the Retaining Ring for D28 Hole

z#

pressing the Feed Piston Cover

and the Feed Spring

[70]

Pull out the Roll Pin D4 x 14

z#

Feeder Arm

Push out the Needle Roller

z#

Feeder

[35]

can be removed.

[33]

and the Feeder Spring

[69]

[88]

, Nose

and the components of the Pushing Lever from the output

[29]

[26]

with the puller for retaining ring (C-type) for hole while

[73]

with your fingers. Then the Feed Piston Cove

[71]

can be removed.

with a roll pin puller (4 mm dia.). Then the Feed Piston

[31]

with the roll pin puller (4 mm dia.). Then the Feeder Arm

[32]

can be removed.

[34]

can be removed.

, the Bumper

[71]

(b) ReassembIy

Disassembly procedures should be followed in the reverse order. Note the following points:

When replacing the Piston Bumper

z#

packed in the passages of the Body Ass’y

piston chamber as shown in Fig. 22 so that the Feed Piston

#

, completely remove the broken pieces of the Piston Bumper

[26]

and the Nose

[23]

as shown in Fig. 21 or in the feed

[29]

works smoothly.

[68]

[68]

[33]

, etc.

[68]

and the

, the

[26]

− 8 −

Body

Ass’y

Nose

[23]

Piston Bumper

[29]

Roll Pin

[26]

Feeder Arm

D4 x 14

[33]

Feed Piston

[31]

Split

[68]

Groove

Passage

O-Ring (P-4)

O-Ring (P-9)

Washer

[23]

[27]

[66]

A surface

Feed piston

Passage

O-Ring (P-21)

[67]

chamber

Fig. 21 Fig. 22

Nose

Groove

[29]

Retaining

Ring for D28

Hole

[73]

Magazine

Bumper

Flat surface

[70]

Apply grease to the O-Ring (P-9)

z#

Charge grease in the groove of the Feed Piston

z#

Apply grease to the O-Ring sliding surfaces of the Feed Piston

z#

and O-Ring (P-21)

[66]

[68]

[67]

(Fig. 22).

before reassembly.

and Nose

[68]

[29]

before reassembly.

Be careful not to apply too much grease to the A surface (Fig. 22). Too much grease can impair the

operation of the Feed Piston

Put the Roll Pin D4 x 14

z#

[31]

(at low pressure).

[68]

in the Feeder Arm

facing the split to the Magazine as shown in

[33]

Fig. 22.

Mount the Bumper

z#

Check that the Retaining Ring for D28 Hole

z#

(3) Disassembly and reassembly of the Nail Guide

facing the flat surface to the Magazine as shown in Fig. 22.

[70]

fits securely in the groove of the Nose

[73]

, Nail Stoppers (A)

[93]

[96]

, and (B)

[29]

[98]

.

, etc.

(See Fig. 23)

[Tools required]

Hex. bar wrench (3 mm)

z#

Flatblade screwdriver

z#

Nail Guide Shaft

Nose

Shaft Ring

[29]

[91]

[92]

O-Ring (P-4)

[27]

Sleeve (B)

[89]

Hex. Socket Hd. Bolt M4 x 6

Guide Lock

Spring

[95]

[94]

.

Nail Stopper (A)

Spring (F)

[97]

Nail Stoppers (B)

Stopper Spring

Shaft Ring

[90]

[96]

[98]

[99]

[91]

Nail Guide Cover

Nail Guide

[93]

Nylock Hex. Socket

Hd. Bolt M4 x 10

[101]

[102]

Slottted holes

Cover

[100]

Fig. 23 Disassembly and reassembly of the nail guide, nail stoppers (A) and (B), etc.

− 9 −

(a) Disassembly

Remove the Hex. Socket Hd. Bolt M4 x 6

z#

from the Nose

[100]

Remove the Shaft Ring

z#

Nail Guide Shaft

Remove the Nylock Hex. Socket Hd. Bolt M4 x 10

z#

Guide Cover

Remove the Shaft Ring

z#

Guide Lock

[92]

[101]

. Then Nail Stoppers (A)

[94]

.

[29]

from the Nail Guide Shaft

[91]

. Then the Nail Guide

Sring (F)

[91]

, the Stopper Spring

[97]

from the Guide Lock

with a hex. bar wrench (3 mm) and remove the Cover

[90]

with a flatblade screwdriver and pull out the

[92]

assembled with other components can be removed.

[93]

with the hex. bar wrench (3 mm). Then the Nail

[102]

[96]

[94]

and (B)

and the Cover

[99]

with the flatblade screwdriver and pull out the

can be removed.

[98]

can be removed.

[100]

(b) Reassembly

Disassembly procedures should be followed in the reverse order. Note the following points

Remove dust from the claw groove of the Nail Guide

z#

Securely engage Spring (F)

z#

(A)

Engage the two slotted holes of the Cover

z#

[96]

and (B)

to assemble.

[98]

and the Stopper Spring

[97]

[100]

with the convex portions of the Nail Guide

and then assemble it.

[93]

with the convex portions of Nail Stoppers

[99]

[93]

to

assemble.

1-5. Disassembly and Reassembly of the Cap and the Magazine Section

(1) Disassembly and reassembly of the Cap

(See Fig. 24)

[49]

[Tools required]

Wrench (23 mm)

z#

(a) DisassembIy

The Cap

z#

mm) and turn the Cap

has an M42 mm screw portion. Hold the two flat portions of the Cap

[49]

to remove it.

[49]

with a wrench (23

[49]

(b) Reassembly

Disassembly procedures should be followed in the reverse order. Apply grease to the O - Ring (I . D 37. 2)

z#

before reassembly.

[48]

Body Ass’y

[23]

O-Ring (I.D 37.2)

Fig. 24 Disassembly and reassembly of the cap

− 10 −

Cap

[49]

[48]

(2) Disassembly and reassembly of the magazine section (See Fig. 25)

[Tools required]

Phillips screwdriver

z#

Flatblade screwdriver

z#

Machine Screw

M5 x 20 (black)

[44]

Washer

[45]

Nylon Nut M5

[74]

Feeder Shaft

Ring

[76]

Magazine Stopper

Stopper Spring

Pin D4 x 35.5

Magazine

[75]

Nylon Nut M4

Holder Shaft

Ratchet Spring

Nail Holder

lnstalI with the

chamfered side

facing inward.

[77]

[78]

[79]

[80]

[81]

[82]

[83]

Feeder Shaft

Ring

[76]

Magazine cover

lnstalI with the

chamfered side

facing inward.

Washer M4

Pin D4 x 40

Machine Screw

M4 x 50

[87]

Fig. 25 Disassembly and reassembly of the magazine section

[84]

[85]

[86]

− 11 −

(a) Disassembly

Remove the Machine Screw M5 x 20 (black)

z#

Ass’y

can be removed.

[88]

with the Phillips screwdriver. Then the Magazine

[44]

(b) Reassembly

Disassembly procedures should be followed in the reverse order.

z#

(3) Disassembly and reassembly of the Magazine Stopper

(See Fig. 25)

[77]

(a) Disassembly

Remove the Feeder Shaft Ring

z#

the Pin D4 x 35.5

Stopper

and the Stopper Spring

[77]

pressing the Magazine Stopper

[79]

from the Pin D4 x 35.5

[76]

can be removed.

[78]

with a flatblade screwdriver. Pull out

[79]

with your fingers. Then the Magazine

[77]

(b) Reassembly

Disassembly procedures should be followed in the reverse order. Note the following points:

Mount the Feeder Shaft Ring

z#

(4) Disassembly and reassembly of the Magazine Cover

facing the chamfered side inward as shown in Fig. 25.

[76]

(See Fig. 25)

[84]

(a) Disassembly

Remove the Feeder Shaft Ring

z#

the Pin D4 x 40

. Then the Magazine Cover

[86]

from the Pin D4 x 40

[76]

[84]

with the flatblade screwdriver and pull out

[86]

can be removed in an assembly state.

(b) Reassembly

Disassembly procedures should be followed in the reverse order. Note the following points:

Mount the Feeder Shaft Ring

z#

(5) Disassembly and reassembly of the Nail Holder

facing the chamfered side inward as shown in Fig. 25.

[76]

and the Holder Shaft

[83]

[81]

(See Fig. 25)

(a) Disassembly

Open the Magazine Cover

z#

Then the Nail Holder

[83]

and remove the Machine Screw M4 x 50

[84]

and the Holder Shaft

can be removed.

[81]

with a Phillips screwdriver.

[87]

(b) Reassembly

Disassembly procedures should be followed in the reverse order.

z#

− 12 −

2. INSPECTION AND CONFIRMATION AFTER REASSEMBLY

Check that Plunger (A)

z#

Check that there is no air leakage from each part.

z#

While driving nails with an air pressure of 4.5 kgf/cm2 (63 psi), check that there is no idle driving and

z#

bending of nails.

Note: Before conducting the driving test, turn Adjuster (B)

Recheck the tightening torque of each screw.

z#

Check that Pushing Lever (A)

z#

Check that the machine will not operate only by pulling Tr igger ( A)

z#

not operate only by depressing Pushing Lever (A)

#

#

moves smoothly.

[63]

slides smoothly.

[41]

[41]

to the deepest position.

[38]

[52]

.

. Also check that the machine will

− 13 −

3. STANDARD REPAIR TIME (UNIT) SCHEDULES

MODEL 10 20 30 40 50 60 min.

NV 65AH

Fixed

General Assembly

Fixed Costs

Safety Ass’y: 0 min

Others: 20 min.

Work Flow

Safety Ass’y

Feed Piston

Feed Spring

Exhaust Cover

Ass’y

Valve Rubber

Ass’y

Valve O-Ring

Head Cap A ss’y

Trigger Plunger

Plunger O-Ring

Safety Plunger (A)

Plunger Spring

Urethane Ball

Piston Ass’y

Piston O-Ring

Damper Ring

Piston Damper

Cylinder Damper

Cylinder Plate

Cylinder Guide

Cylinder

Cylinder Ring

Cylinder

O-Ring x 7

Body Ass’y

Variable

Adjustment

Cylinder,

Body and

Valve

Tail Cove r As s’y

Magazine Ass’y

− 14 −

Loading...

Loading...