Page 1

Trimmer

Model M 6SB

Handling instructions

Note:

Before using this Electric Power Tool, carefully read through these

HANDLING INSTRUCTIONS to ensure efficient, safe operation. It is

recommended that these INSTRUCTIONS be kept readily available

as an important reference when using this power tool.

Page 2

G

ENERAL POWER TOOL SAFETY WARNINGS

WARNING

Read all safety warnings and all instructions.

Failure to follow the warnings and instructions may result in

electric shock, fire and/or serious injury.

Save all warnings and instructions for future reference.

The term “power tool” in the warnings refers to your mainsoperated (corded) power tool or battery-operated (cordless)

power tool.

1) Work area safety

a) Keep work area clean and well lit.

Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive atmospheres,

such as in the presence of flammable liquids, gases

or dust.

Power tools create sparks which may ignite the dust

or fumes.

c) Keep children and bystanders away while operating

a power tool.

Distractions can cause you to lose control.

2) Electrical safety

a) Power tool plugs must match the outlet.

Never modify the plug in any way.

Do not use any adapter plugs with earthed (grounded)

power tools.

Unmodified plugs and matching outlets will reduce

risk of electric shock.

b) Avoid body contact with earthed or grounded surfaces,

such as pipes, radiators, ranges and refrigerators.

There is an increased risk of electric shock if your

body is earthed or grounded.

c) Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of

electric shock.

d) Do not abuse the cord. Never use the cord for carrying,

pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges or moving

parts.

Damaged or entangled cords increase the risk of

electric shock.

e) When operating a power tool outdoors, use an

extension cord suitable for outdoor use.

Use of a cord suitable for outdoor use reduces the

risk of electric shock.

f) If operating a power tool in a damp location is

unavoidable, use a residual current device (RCD)

protected supply.

4) Power tool use and care

Use of an RCD reduces the risk of electric shock.

3) Personal safety

a) Stay alert, watch what you are doing and use common

sense when operating a power tool.

Do not use a power tool while you are tired or under

the influence of drugs, alcohol or medication.

A moment of inattention while operating power tools

may result in serious personal injury.

b) Use personal protective equipment. Always wear eye

protection.

Protective equipment such as dust mask, non-skid

safety shoes, hard hat, or hearing protection used for

appropriate conditions will reduce personal injuries.

c) Prevent unintentional starting. Ensure the switch is

in the off-position before connecting to power source

and/or battery pack, picking up or carrying the tool.

2

5) Service

PRECAUTION

Keep children and infirm persons away.

When not in use, tools should be stored out of reach of children and

infirm persons.

Carrying power tools with your finger on the switch

or energising power tools that have the switch on

invites accidents.

d) Remove any adjusting key or wrench before turning

the power tool on.

A wrench or a key left attached to a rotating part of

the power tool may result in personal injury.

e) Do not overreach. Keep proper footing and balance

at all times.

This enables better control of the power tool in

unexpected situations.

f) Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves away

from moving parts.

Loose clothes, jewellery or long hair can be caught

in moving parts.

g) If devices are provided for the connection of dust

extraction and collection facilities, ensure these are

connected and properly used.

Use of dust collection can reduce dust related hazards.

a) Do not force the power tool. Use the correct power

tool for your application.

The correct power tool will do the job better and safer

at the rate for which it was designed.

b) Do not use the power tool if the switch does not

turn it on and off.

Any power tool that cannot be controlled with the

switch is dangerous and must be repaired.

c) Disconnect the plug from the power source and/or

the battery pack from the power tool before making

any adjustments, changing accessories, or storing

power tools.

Such preventive safety measures reduce the risk of

starting the power tool accidentally.

d) Store idle power tools out of the reach of children

and do not allow persons unfamiliar with the power

tool or these instructions to operate the power tool.

Power tools are dangerous in the hands of untrained

users.

e) Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts and any

other condition that may affect the power tool's

operation.

If damaged, have the power tool repaired before use.

Many accidents are caused by poorly maintained

power tools.

f) Keep cutting tools sharp and clean.

Properly maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits etc. in

accordance with these instructions, taking into

account the working conditions and the work to be

performed.

Use of the power tool for operations different from

those intended could result in a hazardous situation.

a) Have your power tool serviced by a qualified repair

person using only identical replacement parts.

This will ensure that the safety of the power tool is

maintained.

Page 3

PRECAUTIONS ON USING TRIMMER

1. Always use the bit of correct shank diameter suitable

for the speed of the tool.

2. Hold the body firmly during operation. Otherwise,

injuries can result.

3. The bit is very hot immediately after operation.

Avoid bare hand contact with the bit for any reason.

4. Avoid bringing your hand, face, etc., close to the

bit and rotary parts during operation.

5. Exercise caution as the bit remains rotating even

after the switch is turned off. Contact of your hand,

etc., with the rotating bit can result in injuries.

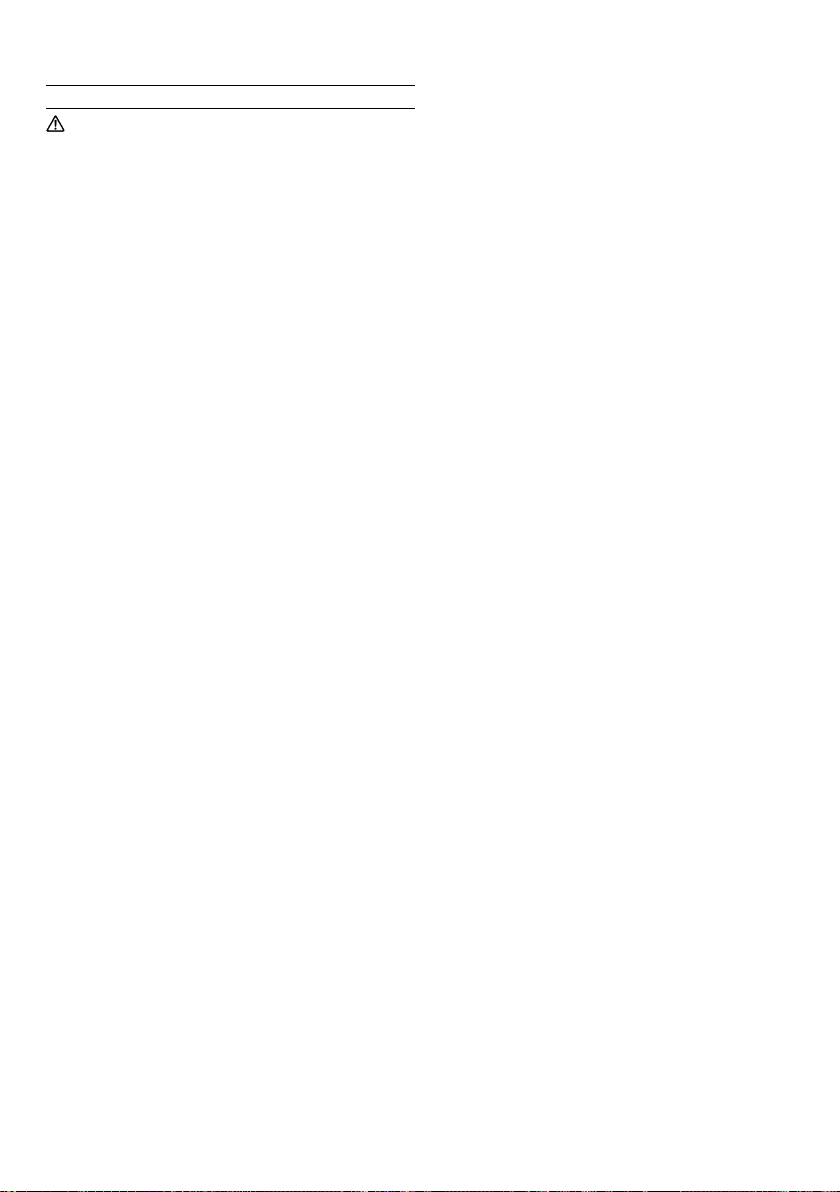

SPECIFICATIONS

Voltage (by areas)* (110 V, 230 V, 240 V)

Power Input* 440 W

No-load speed 30000/min

Collet Chuck Capacity 6 mm or 6.35 mm (1/4")

Weight (Only main body) 1.4 kg

*Be sure to check the nameplate on product as it is subject to change by areas.

STANDARD ACCESSORIES

(1) Trimmer guide ass'y ................................................ 1

(2) Straight Guide ........................................................... 1

(3) Template Guide (with two M4 screws) ................ 1

(4) Wrench 17/19 mm .................................................... 1

Standard accessories are subject to change without

notice.

APPLICATIONS

䡬

Plywood trimming

䡬 Various beveling

䡬 Various grooving

䡬 Engraving

䡬 Cut offs

PRIOR TO OPERATION

1. Power source

Ensure that the power source to be utilized conforms

to the power requirements specified on the product

nameplate.

2. Power switch

Ensure that the power switch is in the OFF position.

If the plug is connected to a receptacle while the

power switch is in the ON position, the power tool

will start operating immediately, which could cause

a serious accident.

3. Extension cord

When the work area is removed from the power

source, use an extension cord of sufficient thickness

and rated capacity. The extension cord should be

kept as short as practicable.

4. Fitting the bit

Refer to "Fitting and removal of the bit" section

given in the following. It is dangerous if the bit is

not fitted to the coIlet chuck securely. Check if the

collet chuck is sufficiently tightened.

5. Cutting using the workpiece edge as a base line

(Fig. 1)

Note that the distance between the machine center

and the hollow differs from the other three distances.

Hollow

52mm

46mm

45mm 45mm

Top view

Fig. 1

6. Confirm the spindle lock mechanism.

Confirm that the spindle lock is disengaged by

pushing the push button two or three times before

switching the power tool on. (See Fig. 2)

Tighten

Loosen

Collet chunk

Spindle lock

7. RCD

The use of a residual current device with a rated

residual current of 30mA or less at all times is

recommended.

Bit

Fig. 2

3

Page 4

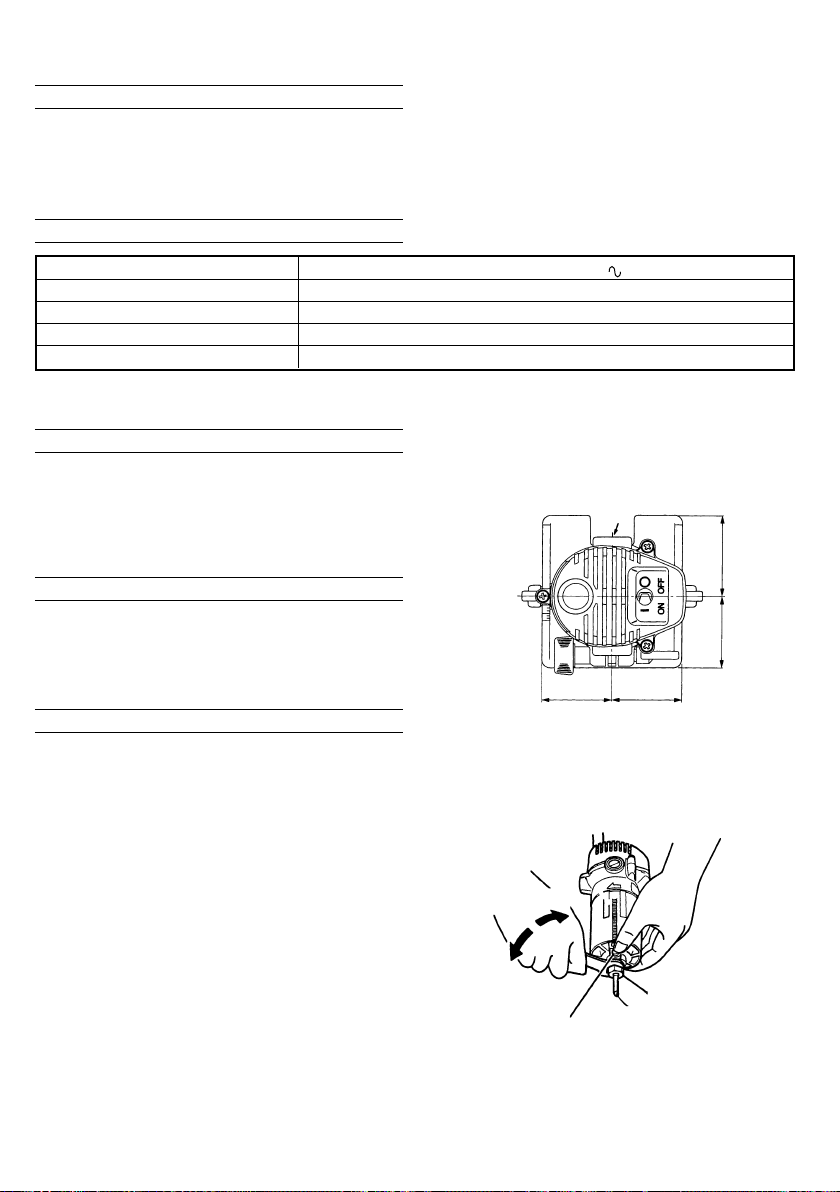

FITTING AND REMOVAL OF THE BIT

1. Fitting the bit

(1) Remove the base ass'y from the body. When

loosening the wing nut (See Fig. 3), the base ass'y

can be removed.

Rack portion

Knob bolt (A)

Scale

A

Tighten

Wing nut

Pinion

Loosen

Scale

Knob bolt (A)

Bit

Fig. 3

(2) Deeply inset the bit into the collet chuck hole. (The

distance is 15 mm or more from side of collet

chuck.)

(3) Depress spindle lock (Fig. 2) and rotate collet nut

clockwise by hand until lock engages hole in motor

spindle.

(4) While holding spindle lock engaged, tighten collet

nut securely by turning clockwise using wrench

provided.

CAUTIONS

䡬 Make sure to tighten the collet chuck after inserting

the bit. Collet chuck may be damaged if it is tightened

without inserting the bit.

䡬 Avoid depressing the lock pin while the bit is still

in rotation. Because, there is a fear that doing so

may result in an abnormal noise or damage in the

fixed section of the rotating shaft.

(5) Fit the removed base assembly to the rack provided

on the body's outer housing after adjusting the

pinion of the base assembly thereto. Then tighten

the wing nut and fix the assembly securely.

2. Removal of the bit

Loosen the collet chuck in the reverse manner as

described for the fitting the bit.

CAUTION

Bit is heated after the cutting work.

Do not touch it directly.

Wing nut

Base ass'y

Base

HOW TO USE

1. Adjustment of cutting depth

(1) Loosen the wing nut on the base ass'y.

(2) Move the base ass'y up and down by turning knob

bolt (A) and fit the front end of base with the

pointed end of the bit. (Fig. 3)

(3) Read the value indicated by the top of the base

ass'y. (A in Fig. 4)

(4) Move the base ass'y to the cutting depth.

(5) After moving the base ass'y to the cutting depth,

tighten wing nut securely. (Fig. 4)

Spindle lock

Fig. 4

2. Cutting

It is recommended that the most appropriate guide

be used which is suitable to the type of the work

in order to carry out the work exactly without failure.

(Refer to "How to use guide".) The material to be

processed should be firmly fixed.

(1) Keep the bit separated from the material and hold

the body firmly before switch is turned on. (Fig. 5)

Keep the bit separated

from the material

Fig. 5

(2) Feeding direction

The bit rotates clockwise as seen from above. Use

the unit by feeding the trimmer in the direction

shown in Fig. 6. If the trimmer is fed in the reverse

direction as shown in the figure, you will receive

reaction of the bit and finishing of the plane to be

cut becomes coarse.

For cutting the external

circumference

Fig. 6

Trimmer fedding

direction

For cutting inner

circumference

Material

4

Page 5

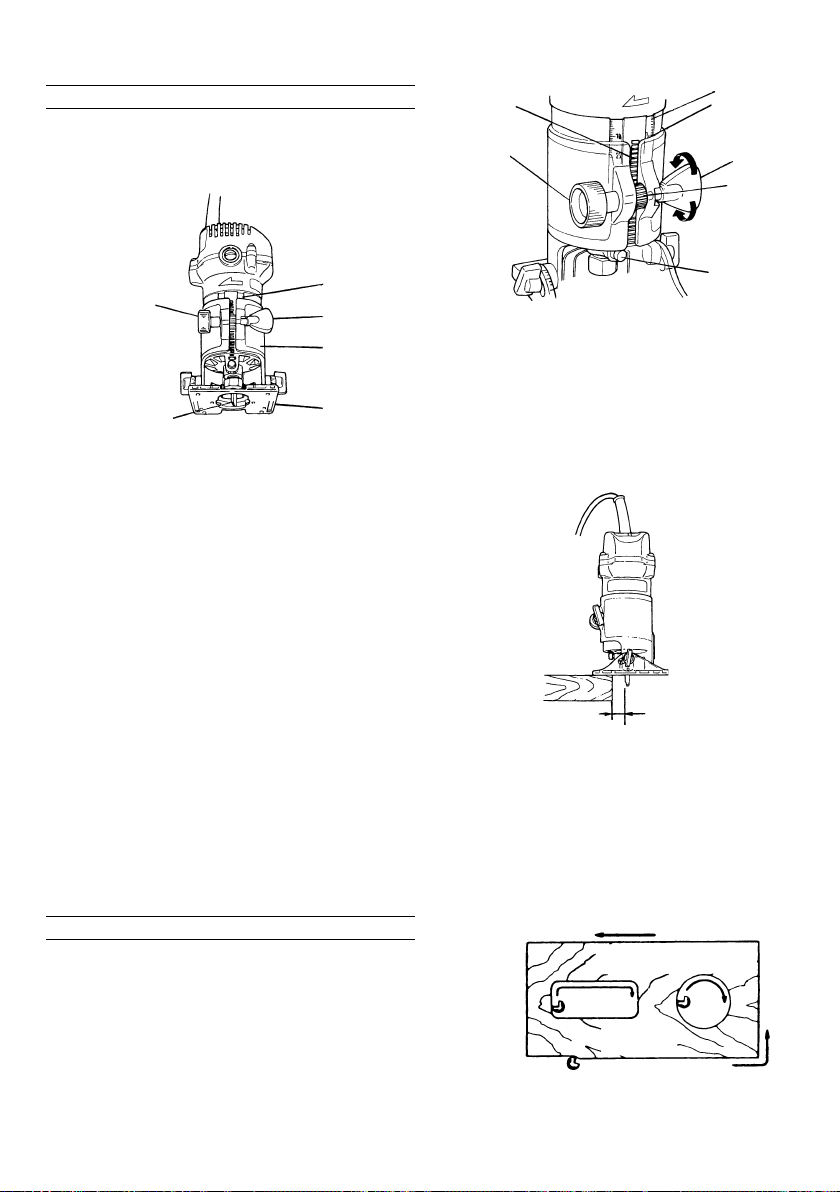

3. Base angle adjustment

Loosen the right and left wing bolts and adjust the

base angle. (Fig. 7)

The interval of the embossed graduations is 5˚. Lay

a ruler, etc., along the side of the base for use in

chamfering work.

Index mark

Base

Wing bolt

Base ass'y

Fig. 7

HOW TO USE GUIDE

NOTE:

Avoid tilting the base when the guide is used.

1. Trimmer guide

Application:

The guide is handy when used in processing of

materials such as trimming and beveling of plywood.

(1) Fit the trimmer guide on the base with knob bolt

(B).

(2) Loosen knob bolt (B) to move the trimmer guide

up and down.

(3) Loosen knob bolt (C) and turn the stop screw to

move the guide pin. (Fig. 8)

After moving the guide pin, tighten knob bolt (C)

to secure it.

Fig. 9

2. Straight guide

Application:

It is handy when used for linear processing work

such as beveling, grooving and the like.

(1) Fit the straight guide with knob bolt (B) on the base

and fix it.

(2) Adjust the length "B" from the bit to the surface

of straight guide by loosening the knob bolt (D) and

rnoving the straight guide as necessary (Fig. 10)

Straight guide

Knob bolt (B)

Knob bolt (D)

Knob bolt (B)

Guide pin

Knob bolt (C)

Fig. 8

(4) When cutting refer to term "Feeding direction" in

"How to use". (Fig. 9)

Stopscrew (B)

B

Fig. 10

(3) When cutting refer to term "Feeding direction" in

"How to use". (Fig. 11)

Fig. 11

5

Page 6

3. Template guide

Application:

It is handy to process with a template a number

of materials in one same shape.

(In this case 6 × 6 mm or 6.35 × 6.35 mm

(1/ 4" × 1/4") straight bit is usable.)

(1) Remove the base ass'y from the main unit.

(2) Loosen the right and left wing bolts and secure the

base horizontally.

(3) Install the template in the recessed part of the base

and secure it with two screws.

Base ass'y

Template

Template is referred to also as profillig mold and

is made from a plywood or a thin wooden plate.

Be careful of the following in producing a

template:

When putting following the inner edge of the

template, the workpiece is cut smaller because

of the distance between the template guide and

bit edge (with a 6 × 6 mm straight bit: 2.0 mm

or 6.35 × 6.35 mm (1/4" × 1/4"): 1.8 mm). By

following the outer edge of the template, the

workpiece is cut larger. (Figs. 14 and 15)

The thickness of the template should be 5 mm

or more.

Inner edge cutting

Template

M4 Screw

Base

Template

guide

Fig. 12

NOTE:

Tighten the two screws moderately. Optimum

tightening torque is 10-15 kg-cm.

(4) Install the base ass'y in the main unit. (Fig. 13)

CAUTION

When fit the template guide, the upper part of the

template guide must not touch the collet chuck.

(5) Securely fix the template to the workpiece. Feed the

trimmer following the template. (Fig. 13)

Fig. 13

2 mm

Cutting line

Fig. 14

Outer edge cutting

Template

2 mm

Cutting line

Fig. 15

MAINTENANCE AND INSPECTION

1. Inspecting the bit

Continued use of a dull or damaged bit will result

in reduced cutting efficiency and may cause

overloading of the motor. Replace the bit with a

new one as soon as excessive abrasion is noted.

2. Inspecting the mounting screws

Regularly inspect all mounting screws and ensure

that they are properly tightened. Should any of the

screws be loose, retighten them immediately. Failure

to do so could result in serious hazard.

3. Maintenance of the motor

The motor unit winding is the very “heart” of the

power tool. Exercise due care to ensure the winding

does not become damaged and/or wet with oil or

water.

6

Page 7

4. Inspecting the carbon brushes (Fig. 16)

The motor employs carbon brushes which are

consumable parts. Since an excessively worn carbon

brush can result in motor trouble, replace the carbon

brush with new ones having the same carbon brush

No. shown in the figure when they becomes worn

to or near the “wear limit”. In addition, always keep

carbon brushes clean and ensure that they slide

freely within the brush holders.

Wear limit

21

5 mm

12 mm

5. Replacing carbon brushes

Disassemble the brush caps with a slotted-head

screwdriver. The carbon brushes can then be easily

removed.

6. Replacing supply cord

If the supply cord of Tool is damaged, the Tool

must be returned to Hitachi Authorized Service

Center for the cord to be replaced.

7. Service parts list

A: Item No.

B: Code No.

C: No. Used

D: Remarks

CAUTION

Repair, modification and inspection of Hitachi Power

Tools must be carried out by an Hitachi Authorized

Service Center.

This Parts List will be helpful if presented with the

tool to the Hitachi Authorized Service Center when

requesting repair or other maintenance.

In the operation and maintenance of power tools,

the safety regulations and standards prescribed in

each country must be observed.

MODIFICATIONS

Hitachi Power Tools are constantly being improved

and modified to incorporate the latest technological

advancements.

Accordingly, some parts (i.e. code numbers and/or

design) may be changed without prior notice.

No. of carbon brush

Fig. 16

NOTE

Due to HITACHI’s continuing program of research and

development, the specifications herein are subject to

change without prior notice.

7

Page 8

FRA, HOL, AUT,

SUI”

(110V)”

ABC D

ABC D

38 314-027 1 “32, 33”

37-2 314-603 1 “GBR, ITA, FRG,

1 600-2DD 1 6002DDUCMPS2S

2 961-489 1

3 931-701 1

4A 314-026 1 “46-50”

39 930-630 2

40-1 340-374M 1 110V “39” “GBR

40-2 340-374L 1 220V-230V “39”

40-3 340-374G 1 230V “NZL”

5 ———— 1

7 960-096 1

8 314-019 1

6-1 960-095 1 6MM

6-2 960-114 1 6.35MM

41 627-VVM 1 627VVMC3EPS2S

42 960-111 1

43 963-388 2 D4 × 60

40-4 340-374H 1 240V “39”

9 993-609 1 M6 × 11

44-1 360-428C 1 110V

44-2 360-428E 1 220V-230V

10 961-482 1

11 314-018 1

12 961-469 1

13 314-017 1 “14, 15”

14 949-432 2 M6

46 321-207 1 M8

44-3 360-428F 1 240V

15 308-364 2 M5 × 15

16 314-029 1

47 321-206 1

17 310-386 1 M5.5

48 321-204 1

49 321-205 1

50 321-203 1

18 314-020 1 M5

19 ———— 1

20 980-063 1

51 325-506 1 “11, 12, 16-18”

501 960-058 1 M6 × 16

502 960-104 1 “501”

503 314-613 1 “504, 505”

504 960-092 1

505 960-058 1

21 ———— 1

22 307-028 3 D4 × 25

24 984-750 4 D4 × 16

25 937-631 1

23-1 953-327 1 D808

23-2 938-051 1 D10.1

507 961-478 1 D10.1

508 976-815 2 M4 × 8

26 314-021 1

27 994-273 1

509 931-161 1 17/19MM

28 980-063 2

29 959-144 1

30 937-847 2

31 999-021 2

32 937-846 2

33 938-477 2 M5 × 8

34 314-028 1

35 314-016 1

36 938-307 1

37-1 955-509 1

8

Page 9

91011

Page 10

Page 11

Page 12

Hitachi Koki Co., Ltd.

Shinagawa Intercity Tower A, 15-1, Konan 2-chome,

Minato-ku, Tokyo, Japan

410

Code No. C99076212 N

Printed in Japan

Loading...

Loading...