Page 1

L300P Inverter Specifications

L300P Inverter Specifications

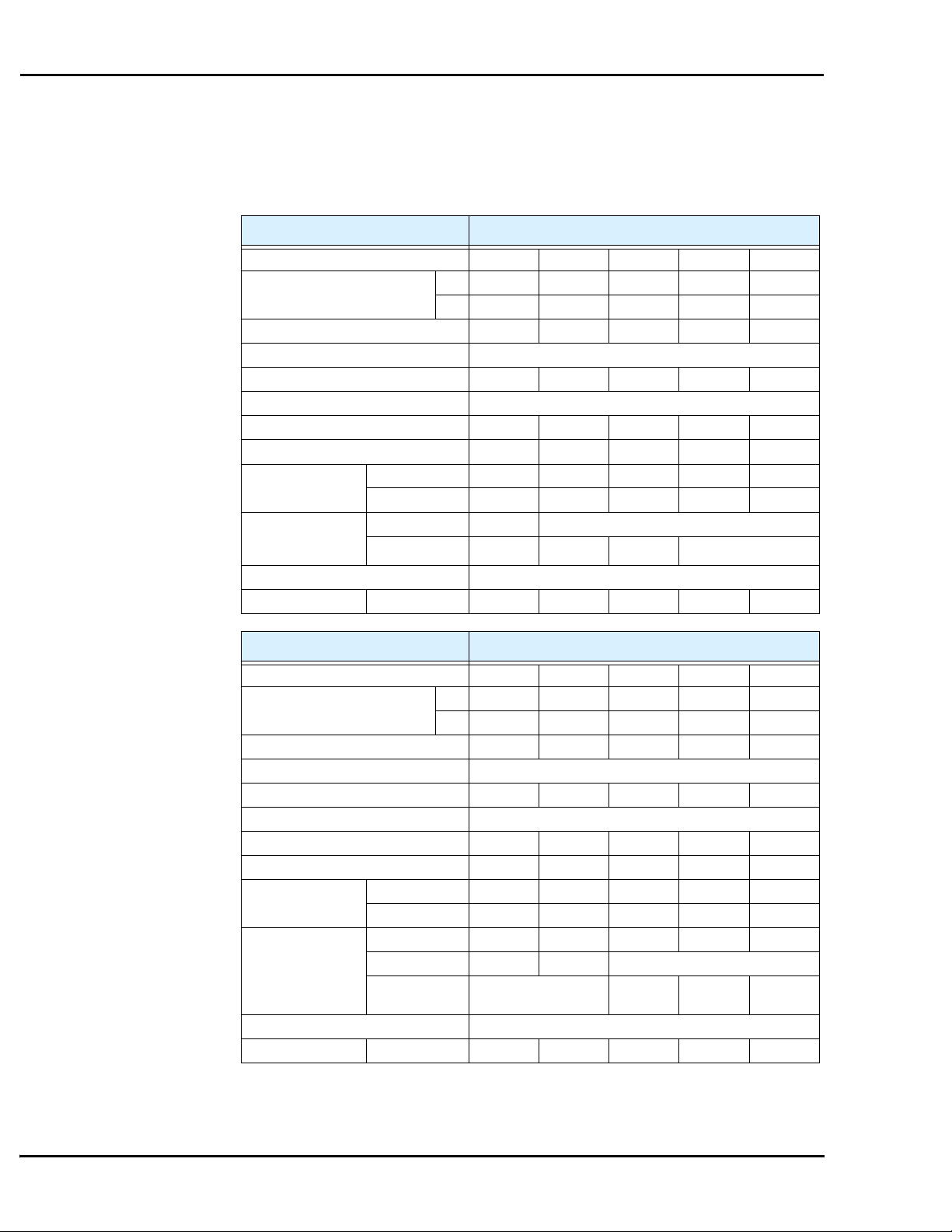

Tables for 200V

class inverters

Note that “General Specifications” on page 1–9 covers all L300P inverters, followed by

footnotes for all specifications tables. Seven 200V models in the tables below (2 to 20 hp) have

internal dynamic braking units (see “Dynamic Braking” on page 5–6).

Item 200V Class Specifications

L300P inverters, 200V models, UL ver. 015LFU2 022LFU2 037LFU2 055LFU2 075LFU2

Applicable motor size, 4-pole *2 HP 2 3 5 7.5 10

kW 1.5 2.2 3.7 5.5 7.5

Rated capacity (200/240V) kVA 2.5 / 3.1 3.6 / 4.3 5.7 / 6.8 8.3 / 9.9 11 / 13.3

Rated input voltage 3-phase: 200 to 240V ±10%, 50/60 Hz ±5%

Rated input current (A) 8.3 12 18 26 35

Rated output voltage *3 3-phase (3-wire) 200 to 240V (corresponding to input voltage)

Rated output current (A) 7.5 10.5 16.5 24 32

Efficiency at 100% rated output, % 92.3 93.2 94.0 94.4 94.6

Watt loss,

approximate (W)

Dynamic braking

approx. % torque,

short time stop *7

DC braking Variable operating frequency, time, and braking force

Weight kg / lb 3.5 / 7.7 3.5 / 7.7 3.5 / 7.7 3.5 / 7.7 5 / 11

at 70% output 102 127 179 242 312

at 100% output 125 160 235 325 425

without ext. res. 50% 20%

with external res. 200% 160% 100% 80%

Item 200V Class Specifications

L300P inverters, 200V models, UL ver. 110LFU2 150LFU2 185LFU2 220LFU2 300LFU2

Applicable motor size, 4-pole *2 HP 15 20 25 30 40

kW 11 15 18.5 22 30

Rated capacity (200/240V) kVA 15.2 / 18.2 20.0 / 24.1 25.2 / 30.3 29.4 / 35.3 39.1 / 46.9

Rated input voltage 3-phase: 200 to 240V ±10%, 50/60 Hz ±5%

Rated input current (A) 48 64 80 94 124

Rated output voltage *3 3-phase (3-wire) 200 to 240V (corresponding to input voltage)

Rated output current (A) 44 58 73 85 113

Efficiency at 100% rated output, % 94.8 94.9 95 95 95

Watt loss,

approximate (W)

Dynamic braking

approx. % torque,

short time stop *7

DC braking Variable operating frequency, time, and braking force

Weight kg / lb 5 / 11 5 / 11 12 / 26.4 12 / 26.4 12 / 26.4

at 70% output 435 575 698 820 1100

at 100% output 600 800 975 1150 1550

without ext. res. 10% 10% 10% 10% 10%

with external res. 55% 50% —

with external res.

and braking unit

— 25–170% 25–150% 55–110%

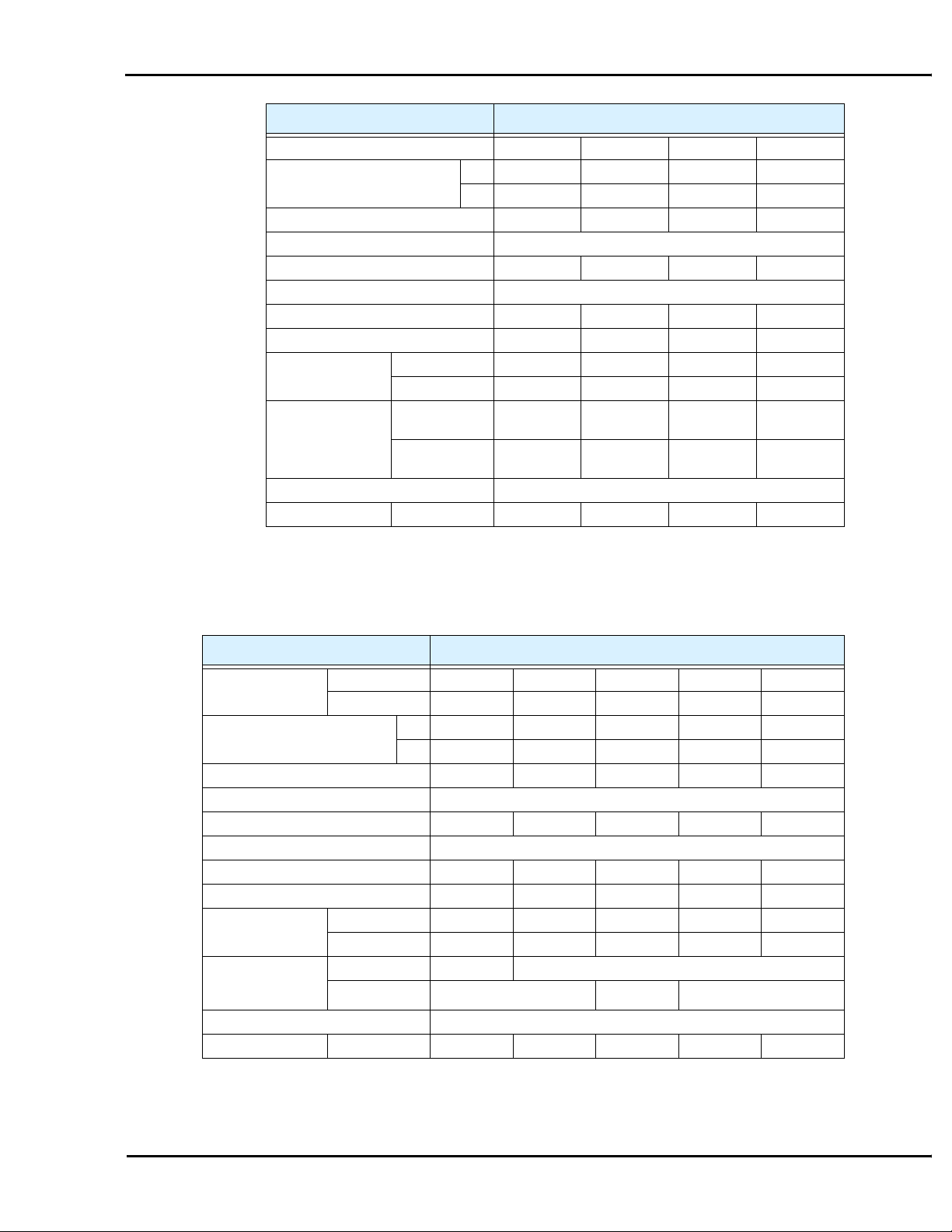

Page 2

L300P Inverter

Item 200V Class Specifications, continued

L300P inverters, 200V models, UL ver. 370LFU2 450LFU2 550LFU2 750LFU2

Applicable motor size *2 HP 50 60 75 100

kW 37 45 55 75

Rated capacity (200/240V) kVA 48.4 / 58.1 58.5 / 70.2 72.7 / 87.2 93.5 / 112.2

Rated input voltage 3-phase: 200 to 240V ±10%, 50/60 Hz ±5%

Rated input current (A) 154 186 231 297

Rated output voltage *3 3-phase (3-wire) 200 to 240V (corresponding to input voltage)

Rated output current (A) 140 169 210 270

Efficiency at 100% rated output, % 95.1 95.1 95.1 95.1

Watt loss,

approximate (W)

Dynamic braking

approx. % torque,

short time stop *7

DC braking Variable operating frequency, time, and braking force

Weight kg / lb 20 / 44 30 / 66 30 / 66 50 / 110

at 70% output 1345 1625 1975 2675

at 100% output 1900 2300 2800 3800

without external

braking unit

with external res.

and braking unit

10% 10% 10% 10%

45–90% 35–75% 30–60% 30–60%

Tables for 400V

class inverters

L300P inverters,

400V models

Applicable motor size *2 HP 2 3 5 7.5 10

Rated capacity (400 / 480V) kVA 2.6 / 3.1 3.6 / 4.4 5.9 / 7.1 8.3 / 9.9 11 / 13.3

Rated input voltage 3-phase (3-wire) 380 to 480V ±10%, 50/60 Hz ±5%

Rated input current (A) 4.2 5.8 9.5 13 18

Rated output voltage *3 3-phase (3-wire): 380 to 480V (corresponding to input voltage)

Rated output current (A) 3.8 5.3 8.6 12 16

Efficiency at 100% rated output, % 92.3 93.2 94.0 94.4 94.6

Watt loss,

approximate (W)

Dynamic braking

approx. % torque,

short time stop *7

DC braking Variable operating frequency, time, and braking force

Weight kg / lb 3.5 / 7.7 3.5 / 7.7 3.5 / 7.7 3.5 / 7.7 55 / 121

Note that “General Specifications” on page 1–9 covers all L300P inverters, followed by

footnotes for all specifications tables. Seven 400V models in the tables below (2 to 20 hp) have

internal dynamic braking units (see “Dynamic Braking” on page 5–6).

Item 400V Class Specifications

UL version 015HFU2 022HFU2 040HFU2 055HFU2 075HFU2

CE version 015HFE2 022HFE2 040HFE2 055HFE2 075HFE2

kW 1.5 2.2 4.0 5.5 7.5

at 70% output 102 127 179 242 312

at 100% output 125 160 235 325 425

without ext. res. 50% 20%

with external res. 200% 140% 100%

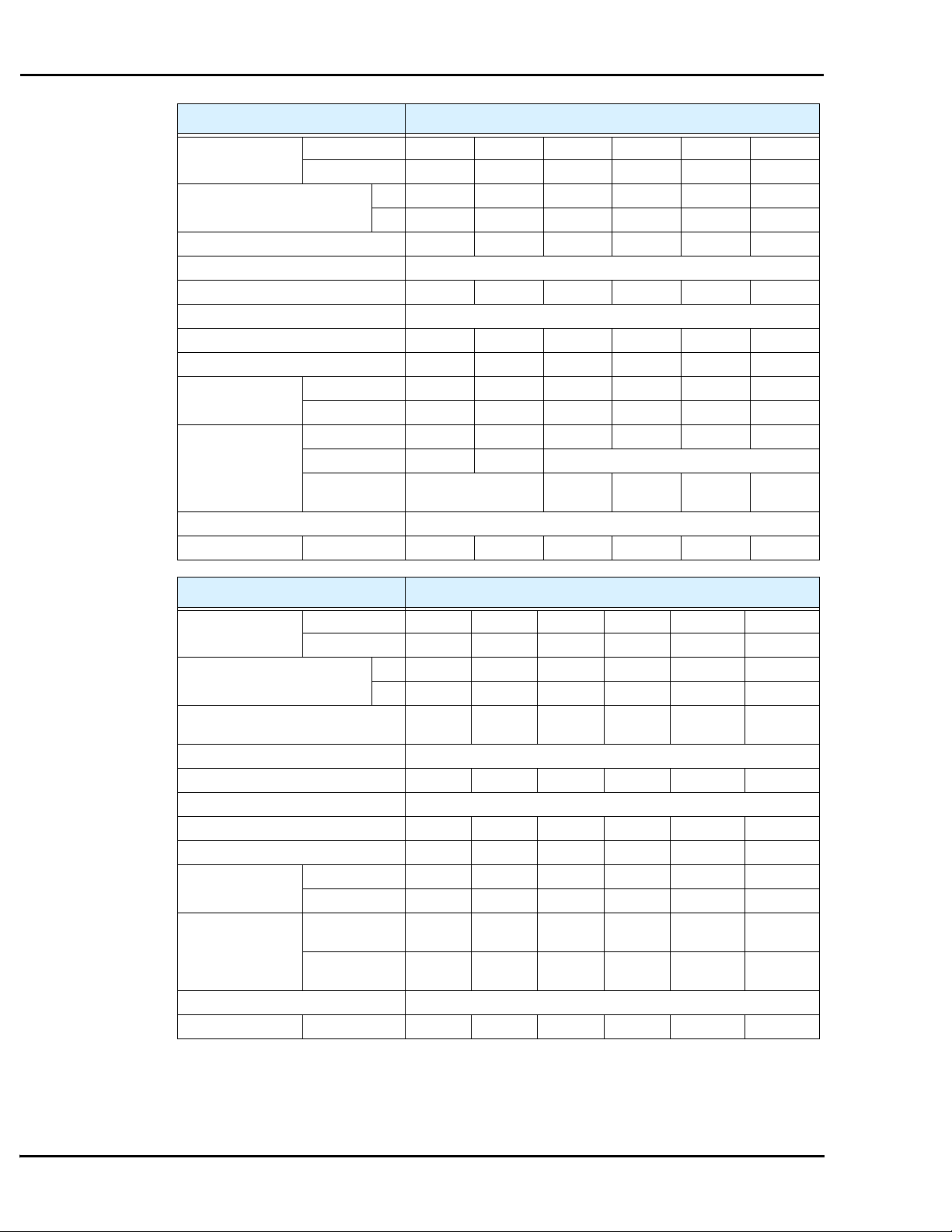

Page 3

L300P Inverter Specifications

Item 400V Class Specifications

L300P inverters,

400V models

Applicable motor size *2 HP 15 20 25 30 40 50

Rated capacity (400 / 480V) kVA 15.2 / 18.2 20.0 / 24.1 25.6 / 30.7 29.7 / 35.7 39.4 / 47.3 48.4 / 58.1

Rated input voltage 3-phase (3-wire) 380 to 480V ±10%, 50/60 Hz ±5%

Rated input current (A) 243241476377

Rated output voltage *3 3-phase (3-wire): 380 to 480V (corresponding to input voltage)

Rated output current (A) 22 29 37 43 57 70

Efficiency at 100% rated output, % 94.8 94.9 95 95 95 95.1

Watt loss,

approximate (W)

Dynamic braking

approx. % torque,

short time stop *7

DC braking Variable operating frequency, time, and braking force

Weight kg / lb 5 / 11 5 / 11 12 / 26.4 12 / 26.4 12 / 26.4 20 / 44

UL version 110HFU2 150HFU2 185HFU2 220HFU2 300HFU2 370HFU2

CE version 110HFE2 150HFE2 185HFE2 220HFE2 300HFE2 370HFE2

kW 11 15 18.5 22 30 37

at 70% output 435 575 698 820 1100 1345

at 100% output 600 800 975 1150 1550 1900

without ext. res. 10% 10% 10% 10% 10% 10%

with external res. 55% 50% —

with external res.

and braking unit

— 40–200% 35–200% 110–170% 90–150%

Item 400V Class Specifications

L300P inverters,

400V models

Applicable motor size *2 HP 60 75 100 125 150 175

Rated capacity (400 / 480V) kVA 58.8 /

Rated input voltage 3-phase (3-wire) 380 to 480V ±10%, 50/60 Hz ±5%

Rated input current (A) 94 116 149 176 215 253

Rated output voltage *3 3-phase (3-wire): 380 to 480V (corresponding to input voltage)

Rated output current (A) 85 105 135 160 195 230

Efficiency at 100% rated output, % 95.1 95.1 95.1 95.2 95.2 95.2

Watt loss,

approximate (W)

Dynamic braking

approx. % torque,

short time stop *7

DC braking Variable operating frequency, time, and braking force

Weight kg / lb 30 / 66 30 / 66 30 / 66 60 / 132 60 / 132 80 / 176

UL version 450HFU2 550HFU2 750HFU2 900HFU2 1100HFU2 1320HFU2

CE version 450HFE2 550HFE2 750HFE2 900HFE2 1100HFE2 1320HFE2

kW 45 55 75 90 110 132

70.1

at 70% output 1625 1975 2675 3375 3900 4670

at 100% output 2300 2800 3800 4800 5550 6650

without external

braking unit

with external res.

and braking unit

10% 10% 10% 10% 10% 10%

70–120% 60–100% 45–70% 40–60% 30–50% 25–40%

72.7 /

87.2

93.5 / 112 111 / 133 135 / 162 159 / 191

Page 4

L300P Inverter

General

The following table (continued on next page) applies to all L300P inverter models.

Specifications

Item General Specifications

Protective enclosure *1 *11 Models L300P–110xxx to 750xxx: IP20 (NEMA 1)

Control method Line-to-line sine wave pulse-width modulation (PWM) control

Output frequency range *4 0.1 to 400 Hz

Frequency accuracy Digital command: ± 0.01% of the maximum frequency

Frequency setting resolution Digital: ± 0.01 Hz; Analog: (max. frequency)/4000, [O] terminal: 12-bit, 0 to 10V;

Volt./Freq. characteristic V/F optionally variable (30 to 400Hz base frequency), V/F control (constant torque,

Overload capacity (output current) 120% for 60 seconds, 150% for 0.5 seconds

Acceleration/deceleration time 0.01 to 3600 sec., (linear curve profiles, accel./decel. selection), two-stage accel./decel.

Input

signal

Output

signal

Display monitor Output frequency, output current, motor torque, scaled value of output frequency, trip

Other user-settable parameters V/F free-setting (up to 7 points), frequency upper/lower limit, frequency jump, accel/

Carrier frequency range Models L300P–015xxx to 750xxx: 0.5 to 12 kHz

Freq.

setting

FW/RV

Run

Intelligent Input

terminals (assign eight

functions to terminals)

Thermistor input One terminal (PTC characteristics)

Intelligent Output terminals

(assign three functions to two

relay N.O. (1 Form A)

outputs and one relay N.O.N.C. (1 Form C) contact

Intelligent monitor output

terminals

Operator keypad Up and Down keys / Value settings

Potentiometer Analog setting via potentiometer on operator keypad

External signal *8 0 to 10 VDC (input impedance 10k Ohms), 4 to 20 mA (input impedance 100 Ohms),

Serial port RS485 interface

Operator panel Run key / Stop key (change FW/RV by function command)

External signal FW Run/Stop (NO contact), RV set by terminal assignment (NC/NO),

Models L300P–900xx to 1320xxx: IP00

Analog command: ± 0.2% (25°C ± 10°C)

[OI] terminal: 12-bit, 4-20mA; 12 bit [O2] terminal: 12 bit –10 to +10V

reduced torque)

Potentiometer (1k to 2k Ohms, 2W)

3-wire input available

RV (reverse run/stop), CF1~CF4 (multi-speed select), JG (jogging), DB (external DC

braking), SET (set 2nd motor data), 2CH (2-stage accel./decel.), FRS (free-run stop),

EXT (external trip), USP (unattended start protection), CS (commercial power source),

SFT (software lock), AT (analog input voltage/current select), RS (reset inverter), STA

(start, 3-wire interface), STP (stop, 3-wire interface), F/R (FW/RV 3-wire interface),

PID (PID ON/OFF), PIDC (PID reset), CAS (control gain setting), UP (remote control

Up function, motorized speed pot.), DWN (remote control Down function, motorized

speed pot.), UDC (remote control data clearing), OPE (Operator control), SF1-SF7

(Multispeed bits 0-7), OLR (Overload limit change)

RUN (run signal), FA1 (Frequency arrival type 1 – constant speed), FA2 (Frequency

arrival type 2 – over-frequency), OL (overload advance notice signal 1), OD (Output

deviation for PID control), AL (alarm signal), FA3 (Frequency arrival type 3 – atfrequency), IP (Instantaneous power failure signal), UV (Under-voltage signal), RNT

(Run time over), ONT (Power-ON time over), THM (thermal alarm)

Analog voltage monitor, analog current monitor (8-bit resolution), and PWM output, on

terminals [AM], [AMI], and [FM]

history, I/O terminal condition, input power, output voltage

decel curve selection, manual torque boost value and frequency adjustment, analog

meter tuning, start frequency, carrier frequency, electronic thermal protection level,

external frequency output zero/span reference, external frequency input bias start/end,

analog input selection, retry after trip, restart after instantaneous power failure, overload

restriction, default value setting (US, Europe, Japan)

Models L300P–900Hxx to 1320Hxx: 0.5 to 8 kHz

Page 5

L300P Inverter Specifications

Item General Specifications

Protective functions Over-current, overload, braking resistor overload, over-voltage, EEPROM error, under-

Environment

Coating color Models L300P–110xxx to 750xxx: Blue (D.I C14 version No. 436)

Accessories Digital input PCB SJ-DG (4-digit BCD / 16-bit binary)

Operator input devices *9 OPE–SRE (4-digit LED with potentiometer) / OPE–S (4-digit LED w/o potentiometer),

Temperature *10 Operating (ambient): -10 to 40°C / Storage: -20 to 65°C

Humidity 20 to 90% humidity (non-condensing)

Vibration *7

Location *8 Altitude 1,000 m or less, indoors (no corrosive gasses or dust)

Others EMI filters, input/output reactors, DC reactors, radio noise filters, braking resistors,

voltage error, CT (current transformer) error, CPU error, external trip, USP error,

ground fault, input over-voltage, instantaneous power failure, inverter thermal trip,

phase failure detection, IGBT error, thermistor error, expansion card 1 error, expansion

card 2 error, under-voltage waiting error

2

Models L300P–110xxx to 300xxx: 5.9 m/s

Models L300P–370xx to 1320xxx: 2.94 m/s

Models L300P–900xx to 1320xxx: Gray (MUNSELL 8.5YR6.2/0.2)

braking units, LCR filter, communication cables, factory I/O network interface cards

Optional: OPE-SR (4-digit LED with potentiometer, Japanese/English overlay),

SRW–0EX Multilingual operator with copy function (English, French, German, Italian,

Spanish, and Portuguese)

(0.6G), 10 to 55 Hz

2

(0.3G), 10 to 55 Hz

Footnotes for the preceding tables:

Note 1: The protection method conforms to JEM 1030.

Note 2: The applicable motor refers to Hitachi standard 3-phase motor (4-pole). When using

other motors, care must be taken to prevent the rated motor current (50/60 Hz) from

exceeding the rated output current of the inverter.

Note 3: The output voltage decreases as the main supply voltage decreases (except when

using the AVR function). In any case, the output voltage cannot exceed the input

power supply voltage.

Note 4: To operate the motor beyond 50/60 Hz, consult the motor manufacturer for the

maximum allowable rotation speed.

Note 5: The braking resistor is not installed in the inverter. When your application requires a

high regenerative torque, use the optional regenerative braking unit and resistor (see

Chapter 5).

Note 6: The storage temperature refers to the short-term temperature during transport.

Note 7: Conforms to the test method specified in JIS C0911 (1984). For the model types

excluded in the standard specifications, contact your Hitachi sales representative.

Note 8: When using the inverter in a dust-prone area, we recommend the optional varnish

coating specification for the inverter.

Note 9: When using a remote operator keypad and cable, be sure to remove the RJ45 modular

interconnect from the inverter’s keypad port before connecting the cable.

Note 10: When using the inverter from 40° to 50°C ambient, the output current of the inverter

must be derated (see the next section on derating curves).

Note 11: NEMA 1 applies to inverter models up to 30kW (–300xxx). An optional wire-entry

conduit box is required for inverter models 37kW to 75kW (–370 to –750xxx) to

meet the NEMA 1 rating.

Page 6

L300P Inverter

Derating Curves The maximum available inverter current output is limited by the carrier frequency and ambient

temperature. The carrier frequency is the inverter’s internal power switching frequency, settable

from 0.5 kHz to 12 kHz, or 0.5 kHz to 8 kHz for higher horsepower models. Choosing a higher

carrier frequency tends to decrease audible noise, but it also increases the internal heating of the

inverter, thus decreasing (derating) the maximum current output capability. Ambient temperature is the temperature just outside the inverter housing—such as inside the control cabinet

where the inverter is mounted. A higher ambient temperature decreases (derates) the inverter’s

maximum current output capacity.

Use the following derating curves to help determine the optimal carrier frequency setting for

your inverter, and to find the output current derating. Be sure to use the proper curve for your

particular L300P inverter model number.

% of Drive’s Rated Amps

100%

95%

90%

85%

80%

75%

70%

65%

60%

55%

Legend:

Output current at 40 °C ambient

Output current at 50 °C ambient

L300P 1.5 to 22 kW 200V class

015L, 022L,

037L, 055L,

075L, 110L,

150L, 185L

220L

185L

220L

150L

110L

246810120.5

Carrier Frequency (kHz)

Page 7

L300P Inverter Specifications

Derating curves, continued...

L300P 30 to 37 kW 200V class

100%

95%

90%

85%

% of Drive’s Rated Amps

80%

75%

70%

65%

60%

55%

100%

95%

90%

85%

80%

246810120.5

Carrier Frequency (kHz)

L300P 45 to 75 kW 200V class

750L

550L

370L

370L

300L

300L

450L

450L

% of Drive’s Rated Amps

75%

70%

65%

60%

55%

550L

750L

550L

750L

246810120.5

Carrier Frequency (kHz)

Page 8

Derating curves, continued...

L300P Inverter

% of Drive’s Rated Amps

95%

90%

85%

80%

75%

70%

65%

60%

55%

L300P 1.5 to 22 kW 400V class

246810120.5

Carrier Frequency (kHz)

015H, 022H,

030H, 040H,

055H, 075H,

110H, 150H,

185H, 220H

185H, 220H

150H

110H

95%

90%

85%

80%

75%

70%

% of Drive’s Rated Amps

65%

60%

55%

L300P 30 to 37 kW 400V class

300H

370H

370H

300H

246810120.5

Carrier Frequency (kHz)

Page 9

L300P Inverter Specifications

Derating curves, continued...

L300P 45 to 75 kW 400V class

% of Drive’s Rated Amps

95%

90%

85%

80%

75%

70%

65%

60%

55%

450H, 550H

450H

550H

750H

750H

246810120.5

Carrier Frequency (kHz)

L300P 90 to 132 kW 400V class

100%

95%

90%

85%

80%

75%

70%

% of Drive’s Rated Amps

65%

60%

55%

900H

900H

1100H, 1320H

1100H, 1320H

123456780.5

Carrier Frequency (kHz)

Loading...

Loading...