1HITACHI VT F641 EUKN

General Information

Also Covers

VT M610 EUK, VT M631 EUK

Matrix

Item See Model Book

Deck Exploded Parts View .......................................................... Paolina Mono 5

Deck Parts List ............................................................................. Paolina Mono 5

Mechanical Adjustments ...................................................... Turbo Mechanism 4

Mechanical Alignments ........................................................ T urbo Mechanism 4

Recommended Safety Parts

Item Part No. Description

1001 R4822 267 10577 MAINS PLUG

1350 R4822 252 11234 Fuse 100 mA

1351 R4822 071 55001 Fuse 500 mA

1352 R4822 071 55001 Fuse 500 mA

1353 R4822 070 31252 Fuse 1.25 A

1355 R4822 252 11235 Fuse 1.0 A

1356 R4822 252 11235 Fuse 1.0 A

3252 R4822 117 11593 22 R

3361 R4822 052 10479 47 R 0,33W

3384 R4822 052 10101 100 R 0,33W

3392 R4822 053 21335 3,3 M 0,5W

3393 R4822 053 21335 3,3 M 0,5W

3414 R4822 052 10109 10 R 0,33W

3415 R4822 052 10109 10 R 0,33W

3440 R4822 052 10228 2,2 R 0,33W

5080 R4822 157 11226 47uH 5%

5150 R4822 157 53906 47uH 10%

5300 R4822 157 53005 0pH33 20%

5352 R4822 157 10454 LINE FILTER

5353 R4822 146 10786 SRW32ES-E01

5355 R4822 157 53005 0pH33 20%

7350 R4822 130 63794 STP3NA60

7351 R4822 209 32126 SOC1012T

R4822 321 10886 MAINS CORD (+FUSE) for UK

R4822 321 10249 MAINS CORD

AV Sockets

PCB

Diagram

Service Modes

1. Special functions

Erasing the EEPROM

- Disconnect from mains

- Push and hold down the Standby key,

reconnect to mains and keep the Standby key

depressed for a further 3 sec.

All EEPROM data will then be erased and

initialised (timer and transmitter channels). The

internal processor RAM will also be erased, but

the option codes, deck parameters and adjustment values are maintained.

After changing the EEPROM or MOBO the

following steps must be carried out:

Step 40: Option code input

Step 51: Gap position adjustment

Step 52: ‘Studio Picture control’ adjustment

Step 53: Input of clock correction

Step 60: Level adjustment - Stereo (optional)

Step 61: Channel separation adjustment -

Stereo (optional)

Step 62: Adjustment of Audio Linear Playback

Level (optional)

Step 99: Clock frequency output

Video head cleaning

With the recorder set to PLAY, the video heads

can be cleaned by pressing the PLAY key again

for more than 5 sec. The recorder then moves to

STOP and the video head cleaning roll is

pressed against the running head drum for 10

sec. The recorder automatically returns to PLAY.

The display shows:

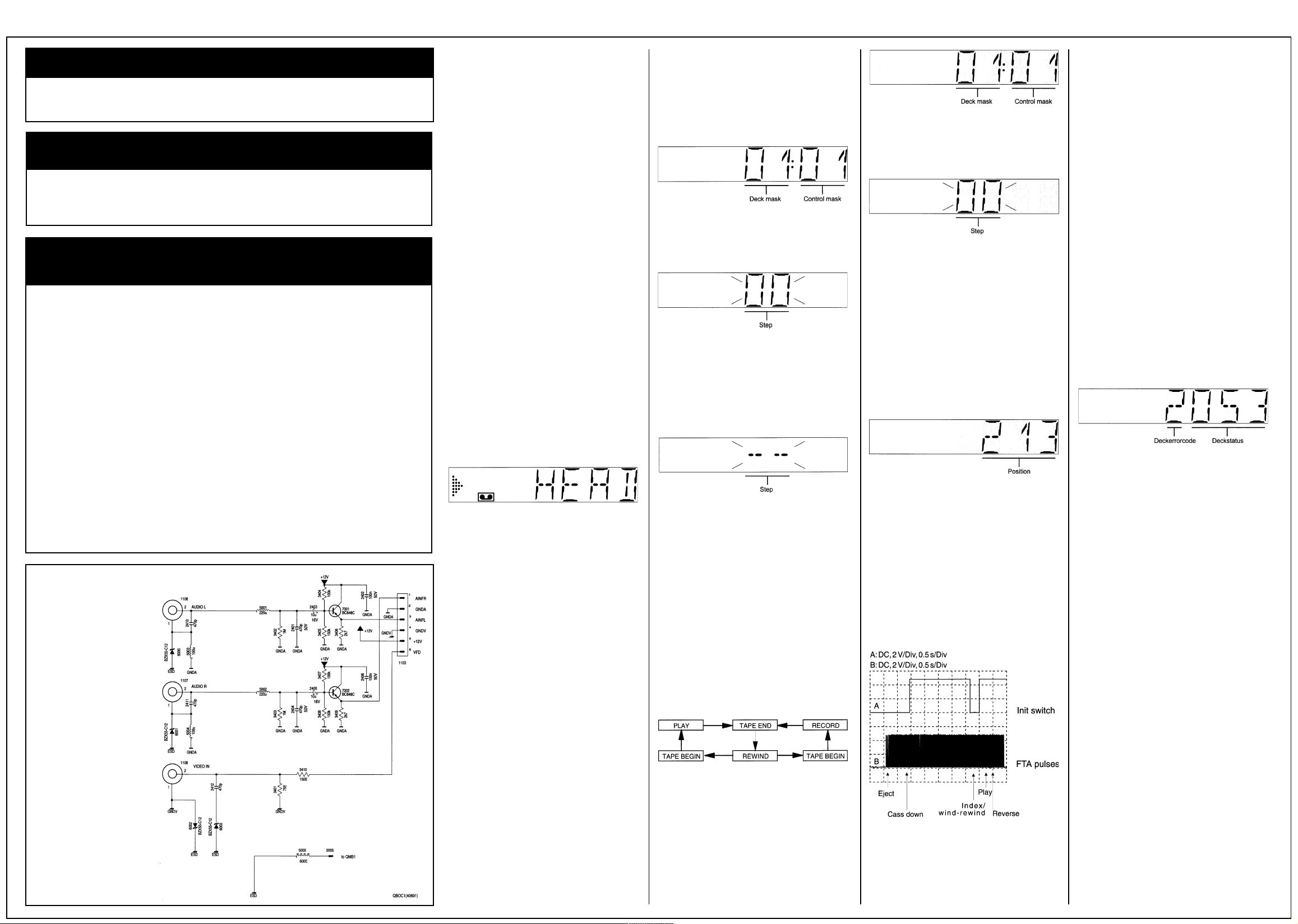

Fig. 1

2. Service test program

2.1 Introduction

The software program for the control, deck and

operating microprocessors includes a service

test program. It was divided into the following

steps, with the following ‘modes’:

Step 00: Display of mask version number

Step 01: Check of the drive positions

Step 02: Display of the deck - error codes

Step 03: Deck - sensors and manual tracking

Step 04: Display of operating hours counter

Step 10: Operation without drive - dummy mode

Step 40: Option code input

Step 51: Gap position adjustment

Step 52: ‘Studio Picture control’ adjustment

Step 53: Input of clock correction

Step 60: Level adjustment - Stereo (optional)

Step 61: Adjustment of channel separation -

Stereo (optional)

Step 62: Adjustment of Audio Linear Playback

Level (optional)

Step 99: Clock frequency output

In the service test program, all drive functions

apart from the channel search and channel

change mode can be carried out. The program

position set before entering the service test

program is maintained.

2.2 Activating the service test program

Press and hold down the STOP key on the

remote control. Then press the PLAY key on the

recorder and keep it depressed for at least 5

sec. The STOP key on the remote control may

be released whilst the PLAY key on the recorder

is pressed. The service test program can be

selected in any operating mode apart from the

channel search, install, clock set-up and

cassette length calculation mode. The recorder

and all drive functions are fully operational in the

service mode.

The display shows, for instance:

Fig. 2

By pressing the SELECT key on the remote

control, all step modes may be left and the

currently selected step number appears and

flashes.

Fig. 3

Other service steps are selected with the UP

and DOWN keys or the numerical remote control

keys. By pressing the SELECT key on the

remote control whilst the Step is flashing, the

respective mode can be entered or left.

If a step is selected to which no mode is

assigned, the displays shows - - and flashes.

Fig. 4

To leave the service program, press the STANDBY key or disconnect recorder from mains.

2.3 Service mode functions

Endurance test

In the service test program, the recorder can be

endurance tested. For this purpose, use a

cass~te and activate “PLAY” or “REC”. The

functions are then repeated continuously. In

RECORD, the recorder does not move to

EJECT at the tape end, but to REWIND, after

which it starts to RECORD again. This test

serves to detect intermittent faults. The last error

is stored in the EEPROM. (The fault remains

stored even after a power failure).

The endurance test is ended by pressing STOP

or leaving the service test program.

Fig. 5

2.4 Description of steps with modes:

Step 00: Display of mask version number

After activating the service test program, step 00

and the mask version number are automatically

displayed.

Fig. 6

The mode can be left again by pressing the

SELECT key on the remote control. The

currently selected position number appears and

flashes on the display.

Fig. 7

A step between 00 and 99 can now be selected.

Step 01: Checking the drive positions

By pressing the SELECT key whilst Step 01 is

flashing, the drive position appears on the

display.

The FTA signal from the photoelectric barriers

which controls the revolutions of the loading

motor is used to check the drive condition.

The drive position is shown as a 3-digit decimal

number by counting the FTA pulses on the

display.

(e.g. 213 = Play)

Fig. 8

Table of drive positions:

Status Position

(FTA dec)

Eject 007+2/-2

Index 191+0/-2

Stop 200+4/-4

Play 213+4/-4

Reverse 237 +2/-0

Function of the Init switch:

The diagram shows the function of the nit

switch, depending on the position of the deck.

The number of ETA pulses is important for

theposition of the drive.

Fig. 9

Step 02: Display of the deck error codes

By pressing the SELECT key whilst Step 02 is

flashing, the deck error code is shown on the

display.

Checking the drive function

Loading and unloading time

The signal (ETA) of the photoelectric barrier

which controls the revolutions of the loading

motor is used as a reference for the loading and

unloading time.

Stopping of supply or take-up reels

The tacho signals of the left (WTL) and right

(WTR) winding disks are used as control

reference.

Stopping of head drum motor

This is monitored with the PG/FG signal. The

signal is discharged from the e.m.f. of the nonconducting spools of the head cylinder motor,

showing the position of the head cylinder.

Capstan motor fault

This is monitored with the FGD signal.

If one of the above sensor signals is not

available, the recorder tries to put the lift into the

“EJECT” position.

Explanation of deck error codes and deck

error status

The last error code is stored and remains in the

EEPROM, even if the recorder is disconnected

trom the mains.

The error code can be erased by pushing the

CLEAR button on the remote control.

The display shows, for instance:

Fig. 10

The left digit shows the error:

(e.g.: Error 2 = Capstan error)

Error table:

0 no error

1 threading error

2 no capstan pulses

3 tape broken

4 no pulses left reel

5 no pulses right reel

6 head motor error

The 3 digits on the right represent the deck error

condition:

(e.g.: 053 = during Play)

012 Standby

014 Autotracking

031 Play-3

034 Slow reverse

041 Still Picture

042 Fast

044 Play-9

045 Eject

046 Play9

047 Play-1

048 Pause

050 Rewind

052 Wind

053 Play

054 Stop out

055 Record

112 lndex next

113 Index previous

114 VlSS write

115 Viss erase

125 Tuner-Stopout

126 Auto Remain Funct.

130 ATTS Function

168 Frame+

169 Frame-

2HITACHI VT F641 EUKN

Service Modes Cont’d

170 Play-11

171 Play-7

172 Play-5

173 Play5

174 Play7

175 Play11

196 Tuner-Eject

197 Standby Eject

199 Audio Dubbing

202 Audio Dubb. Pause

206 Reset Tapecounter

211 Slow motion 1/24

212 Slow motion 1/14

215 Slow motion 1/7

216 Slow motion 1/2

217 Slow motion -1/24

218 Slow motion -1/14

219 Slow motion -1/7

220 Slow motion -1/2

222 Edit Record

223 Align of Gap

238 Pause

239 SPC align

246 Edit Pause

247 Slow motion 1/10

248 Slow motion 1/18

249 Slow motion -1/10

250 Slow motion -1/18

253 Key Released

Enter the mode by pressing the SELECT key.

The motors are then switched off and the

sensors will be ignored by the deck microprocessor. The drive can now be dismantled from

the motherboard (see dismantling instructions).

Only install drive if recorder is disconnected

from mains. For signal tracking, the recorder

can be set to all drive conditions, i.e. signal

electronics, audio and IO processing are

switched to the respective operating mode.

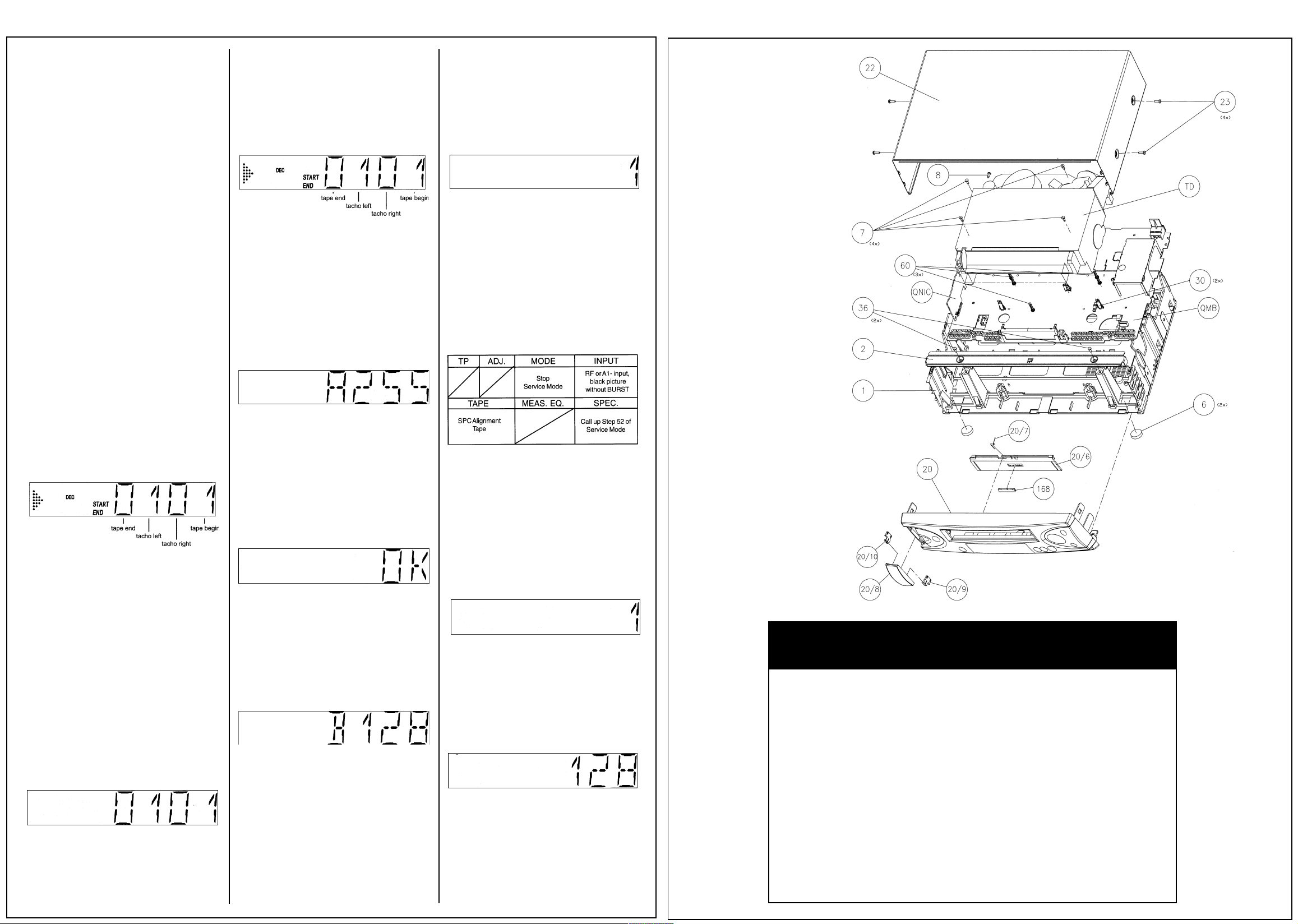

Fig. 13

START mit switch (INIT)

END record protection (RECP)

DEC loading pulses (FTA)

Step 40: Option code input

If a new EEPROM is installed in the course of

repairs, it must be initialised

By pressing the SELECT key whilst step 40 is

flashing, the decimal option A appears in the

display.

using the numerical keys.

—Insert a test cassette (e.g. 4822 397 30103)

with the standard video signal in the VCR.

—By pressing the SELECT key whilst step 51 is

flashing, the automatic adjustment is triggered

and stored in the EEPROM.

After a correct adjustment, the display shows 1;

0 when incorrect.

To leave the step, press Select.

Fig. 17

Causes of incorrect adjustment:

Incorrect standard video signal.

Scanner fault.

Microprocessor fault.

Step 52: “Studio Picture control” adjustment

Purpose:

Adjustment of the reference level for the SPC.

Symptom if incorrectly set:

The picture is played back at a lower resolution

than would be possible.

Cabinet Exploded

Parts View

The error code can be reset in this step with the

CLEAR key.

Step 03: Deck sensors and manual tracking

By pressing the SELECT key whilst step 03 is

flashing, the deck sensors will be displayed in

one digit as either 1 or 0.

Fig. 11

START init switch (INIT)

END record protection (RECP)

DEC Loading pulses (FTA)

In the service test program, the tracking is

always in the centre position.

Only in this step can the value tor the required

tape running sefting be changed, manually in

the PLAY function with the UP / DOWN keys.

After leaving the mode with the SELECT key,

the tracking value always resets itself to the

centre position and cannot be changed.

Step 04: Display of the operating hours

counter:

By pressing the SELECT key whilst step 04 is

flash jng, the operating hours counter shows

how many hours the head disk has turned. The

hours are displayed as a 4-digit decimal

number.

Fig. 12

Step 10: Operation without drive - dummy

mode

Before activating this mode with the SELECT

key, the recorder must be in the EJECT position.

Fig. 14

By entering a 3-digit decimal code, the correct

features are set. These codes are shown on the

type-plate of the recorder.

After pressing the OK key on the remote control,

the entered code is saved. The display shows

OK for approx. 3 sec. and then the stored value

in decimal format.

By pressing the UP and DOWN keys, the

available options (A to E) can be selected. The

display shows the last stored value in decimal

format.

Fig. 15

In case of an invalid entry (value >255) the

activation of the OK key causes the content of

the last stored option to be displayed and OK

does not appear in the display.

Depending on the model, some bits are software

or default protected and cannot be changed by

an entry. In this case, the display shows OK, but

the display returns to the default value.

Fig. 16

3.Adjustments in the service test program

Step 51: Setting the gap position (GAP)

Purpose:

To determine the correct head switching point

during playback.

Symptom if incorrectly set:

Head switching fault and/or vertical picture

flickers.

— Enter the service test program whilst step

display is flashing, and enter the step number

Table 1

- Video signal via Scart or aerial

- Enter the service test program and, whilst the

step is flashing, input the step number 52,

using the numerical keys.

- Insert cassette (not a SVHS cassette).

- By pressing the SELECT key whilst step 52 is

flashing, the recorder makes a recording in

SP mode (approx. 10 sec.) and in LP mode

(approx. 10 sec.), rewinds and carries out a

playback with automatic adjustment.

- After a correct adjustment, the display shows

1 and 0 for incorrect adjustments.

Fig. 18

To leave the step press SELECT.

Step 53: Inputting the clock correction

Before carrying out step 53, the correction

value must be established in step 99.

By pressing the SELECT key whilst step 53 is

flashing, the display shows, for instance:

Fig. 19

Using the numerical keys of the remote control,

the established correction value from Step 99 is

entered as a 3-digit number (value must be

between 0 and 255).

After pressing the OK key on the remote control,

the entered code is stored, the display shows

OK for approx. 3 seconds and then the stored

value in decimal format.

Mechanical Parts - Cabinet

Item Part No. Description

1 R3103 138 86070 Frame CINCH

2 R3103 141 22000 Bracket

6 R3103 184 00830 Foot

7 R3103 100 42400 Screw 3,5X16

8 R3103 100 42530 Screening screw

20 R3103 138 87120 Control panel [VT-F641EUKN]

R3103 138 86820 Control panel [VT-M610EUK]

R3103 138 87110 Control panel [VT-F631EUK]

20/6 R3103 178 21210 Lift flap [VT-F641EUKN]

R3103 178 20970 Lift flap [VT-M610EUK]

R3103 178 21220 Lift flap [VT-F631EUK]

20/7 R3103 111 02450 Leg spring

22 R3103 144 23460 Cover lacquered

23 R3112 400 40220 Screw 3,5X10

30 R3103 107 61760 Distance holder deck

36 R3103 10041320 Screw P2,9X12

60 R3103 104 20410 Distance holder MOBO

151 R8622 661 73301 Remote RT173/301

152 R3103 166 18990 Direction for use GB [VT-F641EUKN]

R3103 166 18740 Direction for use GB [VT-M610EUK]

R3103 166 18970 Direction for use GB [VT-F631EUK]

168 R3103 110 01280 Wordmark HITACHI

3HITACHI VT F641 EUKN

Service Modes Cont’d

Fig. 20

In case of an invalid entry (value >255), the

activation of the OK key causes the content of

the last stored value to be displayed and OK

does not appear in the display.

To leave the step press Select.

Step 60: Level adjustment of Stereo TDA9840

(only for stereo units)

Purpose:

Amplification adjustment of stereo demodulator

TDA9840 [7780].

Symptom if incorrectly set:

Sound is too low or too loud

Table 2

By pressing the SELECT key whilst step 60 is

flashing, the output select is switched to stereo

and the display shows, for instance:

Fig. 21

— Connect Millivoltmeter to Scart 1 Pin 3 (Audio

out left).

— The noise amplitude on Scart 1 Pin 3 (Audio

out left) can be adjusted to the lowest value

by pressing the UP(+) or DOWN (-) keys.

(The amplitude changes by 0.1 dB each time

the key is pressed). The range is shown in the

display with the numbers 0.49.

- The value is automatically stored in the EEPROM each time the button is pressed.

Fig. 22

After leaving the step with SELECT, the last

value remains stored in the EE-PROM.

Step 62: Adjustment of the Audio-LinearPlayback level (only for stereo units)

Purpose:

Adjustment of the amplification of the audio

linear playback level TDA96O4H [7850].

Symptom if incorrectly set:

The linear playback sound is too low or too loud.

Table 4

By pressing the SELECT button whilst step 62 is

flashing, the output select is switched to Mono

and the display shows, for instance:

Deviation = 1x106x (f

Determining the correction value for Step 53:

Correction value = Deviation / 0.763 + 128

(round off to whole number)

The calculated correction value must be

between 0 and 255 (change quartz otherwise),

and must be entered in Step 53 and saved.

This Step can only be left by performing a mains

reset, after which the service program must be

entered again before Step 53 can be called up.

Example:

f

=2047.97Hz f

mess

Deviation =

1x106x (2047.97- 2048) / 2048 = -14.648

Correction value =

-14.648 / 0.763 +128 = 108.80 = 109

(See Fig. 24)

nom

) /f

mess-fnom

=2048.00Hz

nom

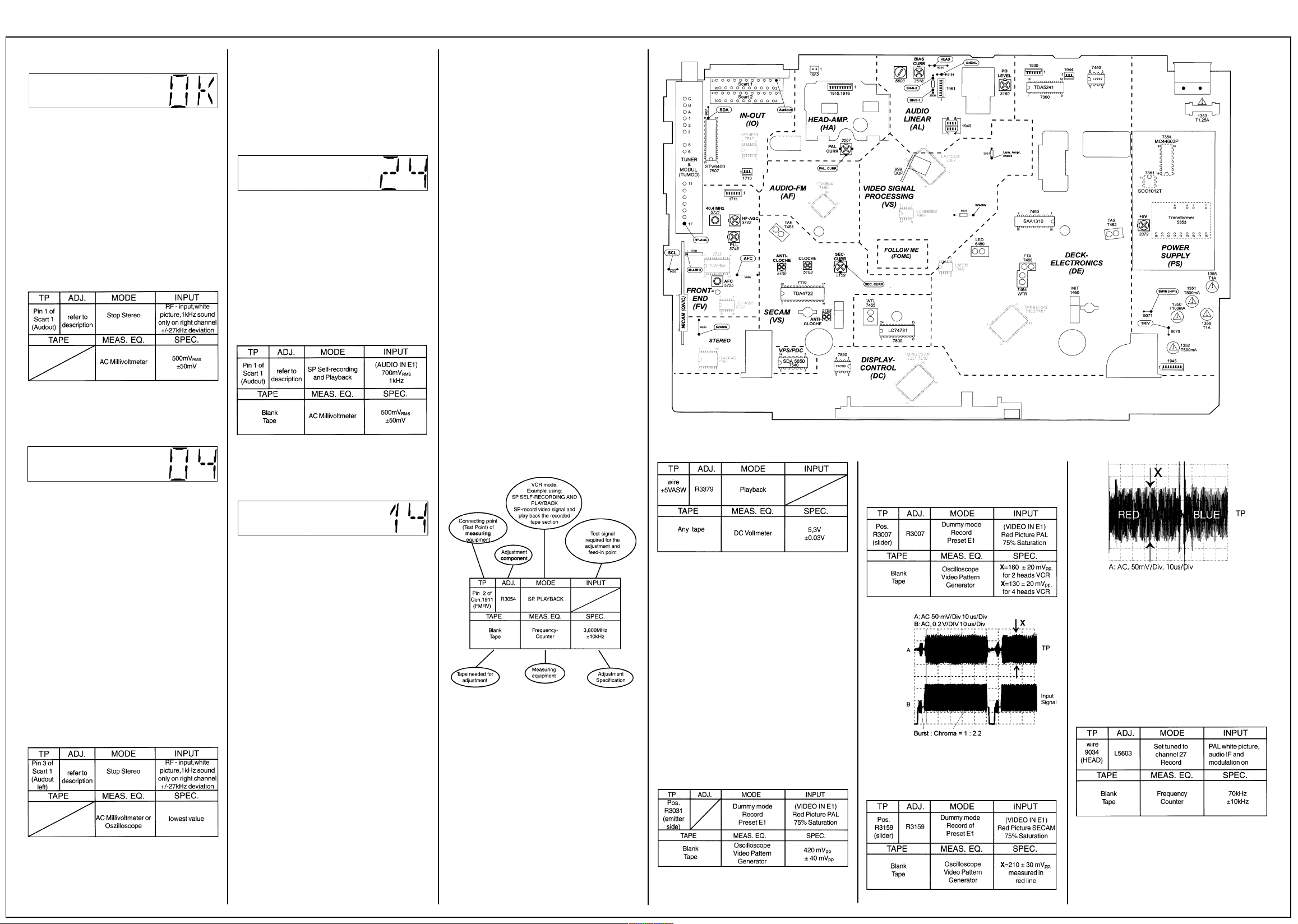

Adjustments

Test equipment:

1. Dual-trace oscilloscope

Voltage range 0.001 50 V/div

Frequency : DC -~ 50 MHz

Probe :10:1,1:1

2. DVM (Digital voltmeter)

3. Frequency counter

4. Sinus generator

Sinus : 0~50 MHz

5. Test pattern generator

6. VHS AlignmentTape 4822 397 30103

How to read the adjustment procedures:

Fig. 24

2.1 PAL chrominance record current adjustment [3007]:

Connect resistor R3031 on the emitter side

(T7006) with 5VASW of coil L5001.

—Connect the millivoltmeter to Scarti pini (Audio

out right).

— The level on Scart 1, Pin 1 (Audio out) can be

adjusted to the set value by pressing the UP

(value increases) or DOWN key (value

decreases). (The amplitude changes by 0.5

dB each time the key is pressed). The range

is shown in the display with the numbers 1-9.

— The value is automatically stored in the EE-

PROM each time the key is depressed.

After leaving the step with SELECT, the last

value will be stored in the EE-PROM.

Step 61: Adjustment of stereo channel

separation Stereo TDA9840

Purpose:

Adjustment of channel separation of the stereo

demodulator TDA9840 [7780].

Symptom if incorrectly set:

Crosstalk between left and right channel.

Table 3

By pressing the SELECT key whilst step 61 is

flashing, the output select is switched to stereo

and the display shows, for instance:

Fig. 23

—Make a recording of the audio signal on E1.

—Connect the millivoltmeterto Scarti Pin 1

(Audio out) and play the recording back.

—The level on Scart 1, Pin 1 (Audio out) can be

adjusted to the set value by pressing the UP

(value increases) or DOWN keys (value

decreases). (The amplitude changes by 1 dB

each time the key is pressed). The range is

shown in the display by the numbers 0.15.

- The value is automatically stored in the EEPROM each time the button is pressed.

Step 99: Clock frequency output

Purpose:

Setting the exact clock function.

Symptom, if incorrectly set:

The clock is too fast or too slow.

After entering with SELECT, the display is

switched off and no further function can be

carried out. At the HEST measuring point [7201

pin 80], the uncorrected clock frequency of

approx. 2048 Hz is always output.

Measure the output frequency with the calibrated counter (minimum resolution of 6 digits)

and note down the value (fmess).

Determining the deviation (in ppm):

f

...measured frequency

mess

f

...set frequency (2048,000 Hz)

nom

Fig. 25

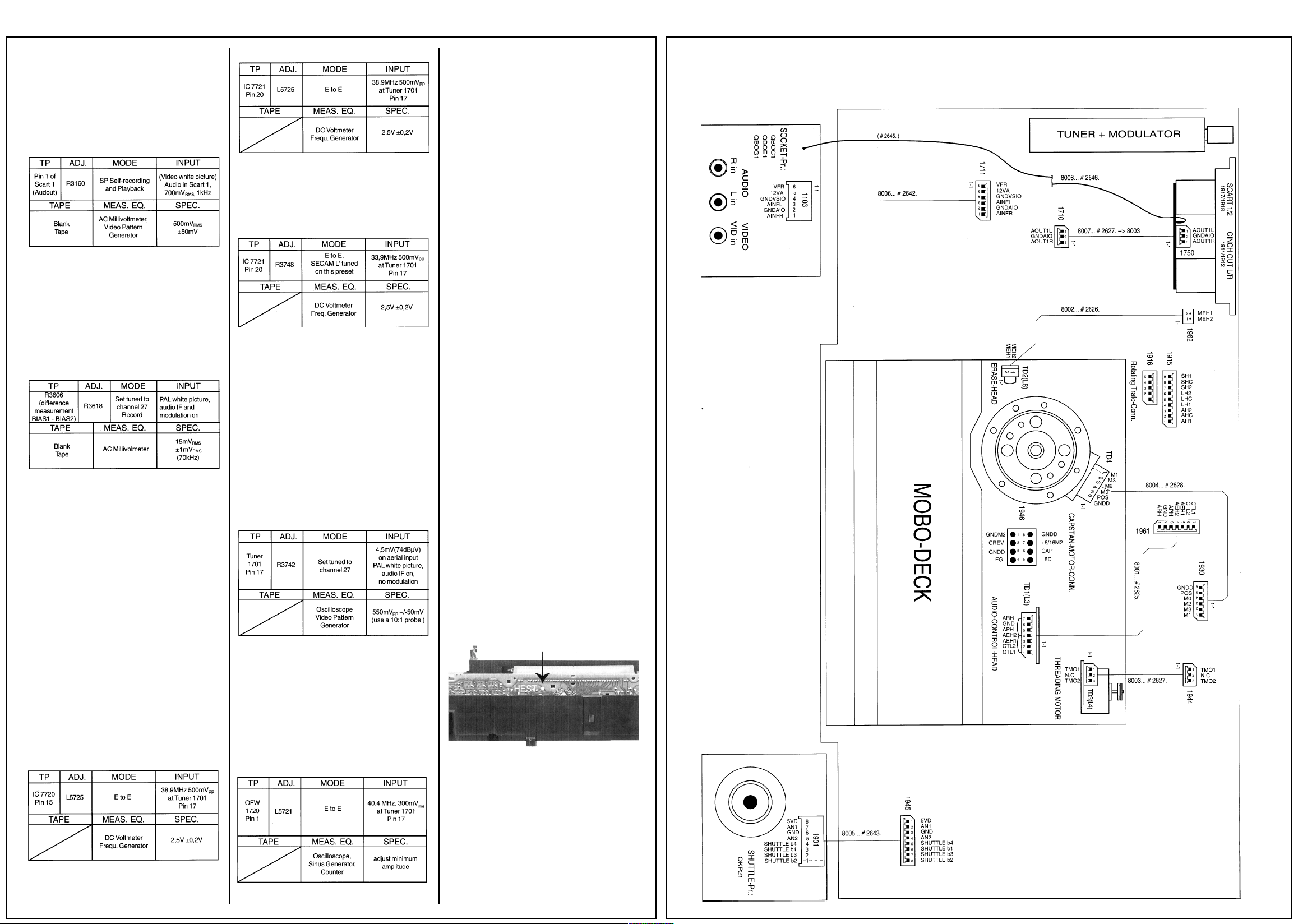

1. Power supply - QMB (PS)

Service tasks after repairing the power supply:

1.1 Setting the output voltage +5VASW

[3379]:

Purpose:

To set the correct supply voltage.

Symptom, if incorrectly set:

VCR functions are not operating correctly.

Table 5

2. Video signal processing-QMB (VS,AL,l/O)

Service tasks after replacement of ICs 7007,

7110:

Purpose:

To set the optimum record PAL or SECAM

chroma level.

Symptom, if incorrectly set:

If the record level is too high, beats may appear

on the picture. If the level is too low, the colour

may be degraded.

Before commencing adjustment:

Call the service test program and enter Step 10

(Dummy mode). Remove the drive from the

motherboard. Control the luminace amplitude on

TPR3031:

Table 6

Table 7

Fig. 26

2.2 SECAM chrominance record current

adjustment [3159]:

Connect resistor R3031 on the emitter side

(T7006) with 5VASW of coil L5001.

Table 8

Fig. 27

3. Audio linear - QMB (VS, AL, I/O)

Service tasks after replacement of coil L5603,

IC7007 or the audio heads:

3.1 Adjusting the erasing frequency [5603]:

Purpose:

To set the correct recording erasing frequency.

Symptom, if incorrectly set:

Erasing frequency or its harmonics cause audio

faults.

Table 9

Continues on next page...

4HITACHI VT F641 EUKN

Adjustments Cont’d

3.2 Adjustment of playback amplitude [3160]:

(mono only)

Purpose:

To set audio part amplification

Symptom, if incorrectly set:

Playback sounds too faint or too loud.

Table 10

3.3 Adjustment of bias current (3618]:

Purpose:

To set the optimum record bias current.

Symptom, if incorrectly set:

If the audio level is too high, the higher frequencies of the linear sound are too low.

If the level is too low, the higher frequencies are

too strong and sound distortions inrease.

Table 11

Checking the ‘bias’adjustment:

After the bias has been adjusted to the indicated

level, record some music, play back the

recording, and adjust the audio switch to

“MONO”.

Only use brand name cassettes, but not chrome

dioxide tapes. Check if sufficient treble is

reproduced and for any audio distortion. In case

of insufficient treble, reduce ‘bias’ current a little.

In case of excessive distortion, increase ‘bias’

current a little.

4. Front End - QMB (VS, AL, I/O)

Service tasks after replacement of ICs 7720,

7721, coil L5725 and TUMOD:

4.1 AFC Adjustment:

Purpose: Correct adjustment of

demodulatorAFC - circuit

Symptom, if incorrectly set:

Bad or disturbed TV channel reception.

4.1.1 PAL - AFC adjustment (5725]:

4.1.2 PAL/SECAM - AFC adjustment [5725]:

Table 13

4.2 SECAM band 1 - AFC adjustment [3748]:

(SECAM L/L’ only)

Before commencing ad]ustment:

— Switch VCR to SECAM with SYSTEM key.

Table 14

4.3 Phase offset adjustment (3743]:

(TDA9800T only)

After replacement of the ICTDA9800T [7720],

the potentiometer pos. 3748 has to be removed

from the motherboard. The demodulator IC

TDA9800T [7720] is automatically adjusted to a

default value.

4.4 HF - AGC adjustment [3742]:

Service tasks after replacement of ICs 7720,

7721 or TUMOD:

Purpose:

Set amplifier control.

Symptom, if incorrectly set:

Picture jitter if input level is too low and picture

distortion if input level is too high.

Table 15

4.5 Attenuating the 40.4 MHz [5721]:

(SECAM only)

Service tasks after replacement of coil

75721:

Purpose:

To attenuate the band I carrier rests.

Symptom, if incorrectly set:

Bad picture quality when the filter attenuates the

picture carrier (38.9MHz).

If the adjustment is correct the signal at pin 1 of

SFW [1720] must be smaller than the input

signal amplitude by at least 5 dB.

Software adjustments in the service test

program

5. Deck electronics - QMB (DE, DC)

Service tasks after replacement of the head

drum or EEPROM:

5.1 Software adjustment of gap positions:

Information about this adjustment is contained in

the Fault Locating document, Chapter 2-20, and

in the service test program in Step 51.

5.2 “Studio Picture control” adjustment:

Information about this adjustment is contained in

the Fault Locating document, Chapter 2-20, and

in the service test program in Step 52.

6. Stereo demodulator TDA9840 - QMB (FV)

Service tasks after replacement of IC7780 or the

EEPROM:

6.1 Stereo level adjustment [7780]:

Information about this adjustment is contained in

the Fault Locating document, Chapter 2-20, in

the service test program in Step 60.

6.2 Stereo channel separation adjustment

[7780]:

Information about this adjustment is contained in

the Fault Locating document, Chapter 2-20, in

the service test program in Step 61.

7. Audio HIFI TDA9604H - QMB (AF)

Service tasks after replacement of the audio

heads, IC 7007 or the EEPROM:

7.1 Audio Linear playback level adjustment

TDA9604H (7850]:

Information about this adjustment is contained in

the Fault Locating document, Chapter 2-20, in

the service test program in Step 62.

8. Display Control - QMB (DE, DC)

Service tasks after replacement of the clock

quartz [1297] or the EEPROM:

8.1 Clock frequency adjustment:

The clock is corrected via software with the

measurement of a frequency at the HEST

measuring point [7201, pin 80] and computation

of a correction factor.

Information about this adjustment is contained in

the Fault Locating document, Chapter 2-20, in

the service test program in Steps 53 and Step

99.

Fig. 28

Wiring Diagram

Table 12

Table 16

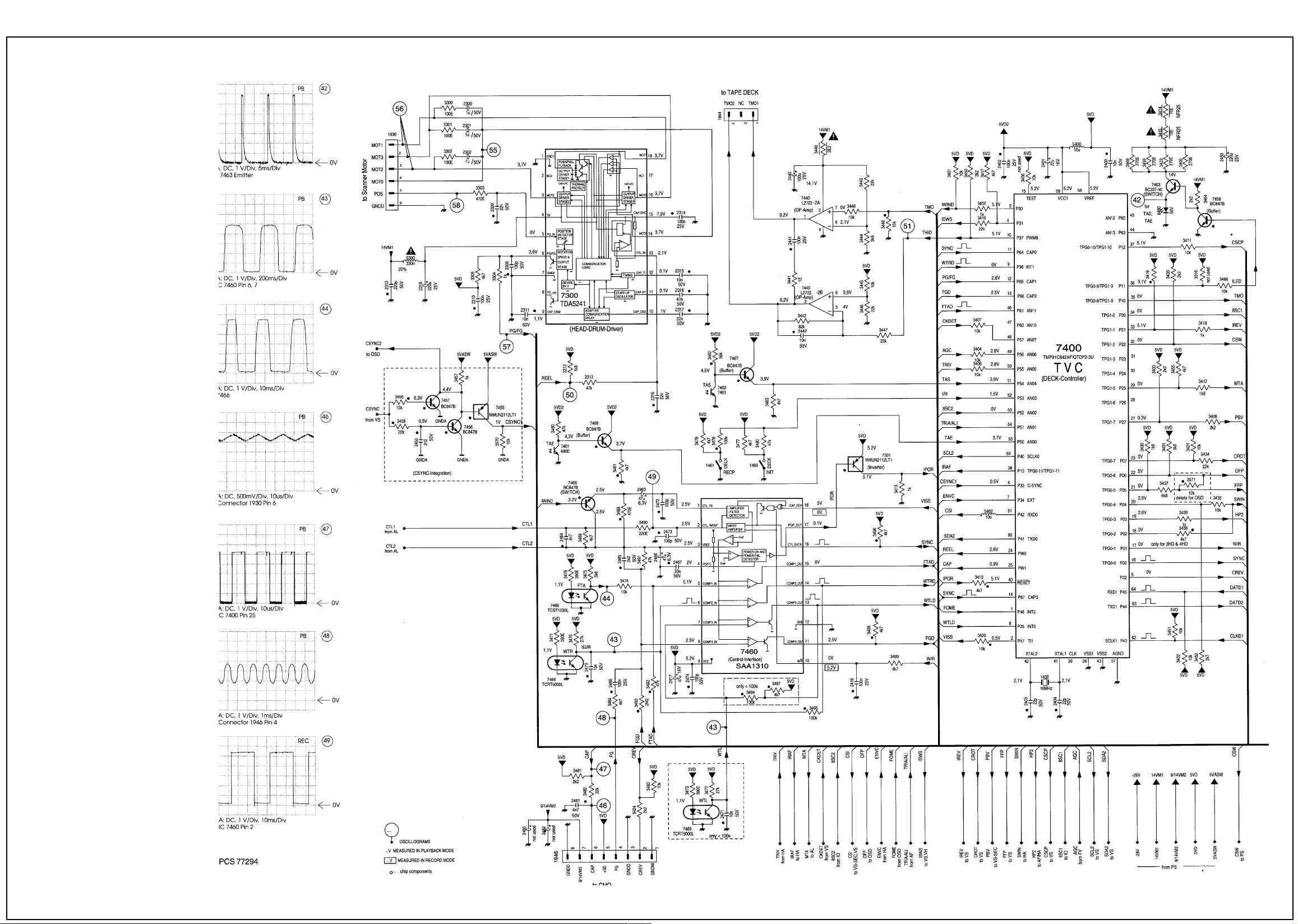

Deck Electronics

Diagram

5HITACHI VT F641 EUKN

6HITACHI VT F641 EUKN

Display Control

Diagram

Waveforms

7HITACHI VT F641 EUKN

Scart Diagram Head Amp Diagram

8HITACHI VT F641 EUKN

HiFi Audio Diagram

9HITACHI VT F641 EUKN

Nicam Diagram

10HITACHI VT F641 EUKN

OSD , VPS, PDC Diagram

11HITACHI VT F641 EUKN

Power Supply Diagram

12HITACHI VT F641 EUKN

Secam Processing Diagram

13HITACHI VT F641 EUKN

Supply Voltages & Bus Diagram

14HITACHI VT F641 EUKN

Tuner IF Diagram

15HITACHI VT F641 EUKN

Video Processing Diagram

Loading...

Loading...