Page 1

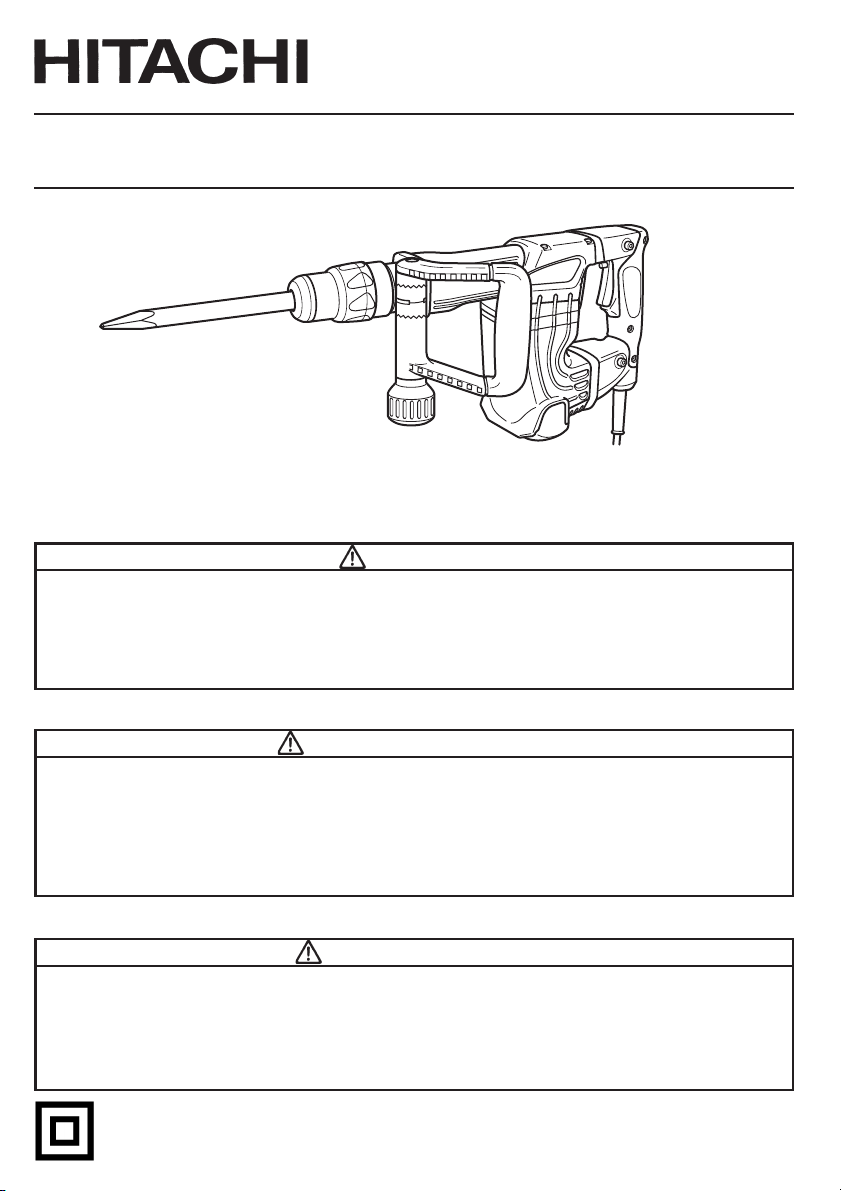

Model Demolition Hammer

Modèle Marteau piqueur

Modelo Martillo demoledor

H 45MR

SAFETY INSTRUCTIONS AND INSTRUCTION MANUAL

WARNING

IMPROPER OR UNSAFE use of this power tool can result in death or serious bodily

injury!

This manual contains important information about product safety. Please read and

understand this manual BEFORE operating the power tool. Please keep this manual

available for other users and owners before they use the power tool. This manual should

be stored in safe place.

INSTRUCTIONS DE SECURITE ET MODE D’EMPLOI

AVERTISSEMENT

Une utilisation INCORRECTE OU DANGEREUSE de cet outil motorisé peut entraîner la

mort ou de sérieuses blessures corporelles!

Ce mode d’emploi contient d’importantes informations à propos de la sécurité de ce

produit. Prière de lire et de comprendre ce mode d’emploi AVANT d’utiliser l’outil

motorisé. Garder ce mode d’emploi à la disponibilité des autres utilisateurs et propriétaires

avant qu’ils utilisent l’outil motorisé. Ce mode d’emploi doit être conservé dans un

endroit sûr.

INSTRUCCIONES DE SEGURIDAD Y MANUAL DE INSTRUCCIONES

ADVERTENCIA

¡La utilización INAPROPIADA O PELIGROSA de esta herramienta eléctrica puede

resultar en lesiones de gravedad o la muerte!

Este manual contiene información importante sobre la seguridad del producto. Lea y

comprenda este manual ANTES de utilizar la herramienta eléctrica. Guarde este manual

para que puedan leerlo otras personas antes de utilizar la herramienta eléctrica. Este

manual debe ser guardado en un lugar seguro.

DOUBLE INSULATION

DOUBLE ISOLATION

AISLAMIENTO DOBLE

1

Page 2

English

English

IMPORTANT SAFETY INFORMATION ...... 3

MEANINGS OF SIGNAL WORDS .............. 3

SAFETY ............................................................4

GENERAL SAFETY RULES ......................... 4

SPECIFIC SAFETY RULES AND

SYMBOLS.............................................. 6

DOUBLE INSULATION FOR SAFER

OPERATION .......................................... 8

FUNCTIONAL DESCRIPTION ......................... 9

NAME OF PARTS ........................................ 9

SPECIFICATIONS ........................................ 9

Français

INFORMATIONS IMPORTANTES DE

SÉCURITÉ ............................................ 18

SIGNIFICATION DES MOTS

D’AVERTISSEMENT ........................... 18

SECURITE ......................................................19

REGLES GENERALES DE SECURITE ....... 19

REGLES DE SECURITE SPECIFIQUES

ET SYMBOLES ....................................21

DOUBLE ISOLATION POUR UN

FONCTIONNEMENT PLUS SUR ........ 23

DESCRIPTION FONCTIONNELLE ................ 24

NOM DES PARTIES .................................. 24

SPECIFICATIONS ...................................... 24

TABLE DES MATIERES

CONTENTS

Page

Page

ASSEMBLY .................................................... 10

Page

OPERATION .................................................. 12

APPLICATIONS ......................................... 12

PRIOR TO OPERATION ............................. 12

HOW TO USE THE DEMOLITION

HAMMER ............................................. 13

MAINTENANCE AND INSPECTION ............. 14

ACCESSORIES .............................................. 16

STANDARD ACCESSORIES ..................... 16

OPTIONAL ACCESSORIES ....................... 16

PARTS LIST ................................................... 48

Page

ASSEMBLAGE .............................................. 25

FONCTIONNEMENT ..................................... 27

APPLICATIONS ......................................... 27

AVANT L’UTILISATION ............................ 27

COMMENT UTILISER LE MARTEAU

PIQUEUR ............................................. 28

ENTRETIEN ET INSPECTION ....................... 29

ACCESOIRES ................................................. 31

ACCESSOIRES STANDARD ..................... 31

ACCESSOIRES SUR OPTION ................... 31

LISTE DES PIECES ........................................ 48

Español

Página

INFORMACIÓN IMPORTANTE SOBRE

SEGURIDAD ........................................33

SIGNIFICADO DE LAS PALABRAS DE

SEÑALIZACIÓN................................... 33

SEGURIDAD .................................................. 34

NORMAS GENERALES DE SEGURIDAD

............................................................. 34

NORMAS Y SÍMBOLOS ESPECÍFICOS

DE SEGURIDAD .................................. 36

AISLAMIENTO DOBLE PARA OFRECER

UNA OPERACIÓN MÁS SEGURA ..... 38

DESCRIPCIÓN FUNCIONAL ......................... 39

NOMENCLATURA ..................................... 39

ESPECIFICACIONES .................................. 39

2

ÍNDICE

Página

MONTAJE ..................................................... 40

OPERACIÓN .................................................. 42

APLICACIONES ......................................... 42

ANTES DE LA OPERACIÓN ...................... 42

FORMA DE USAR EL MARTILLO

DEMOLEDOR ...................................... 43

MANTENIMIENTO E INSPECCIÓN ..............44

ACCESORIOS ................................................ 46

ACCESORIOS ESTÁNDAR ....................... 46

ACCESORIOS OPCIONALES .................... 46

LISTA DE PIEZAS .......................................... 48

Page 3

English

IMPORTANT SAFETY INFORMATION

Read and understand all of the safety precautions, warnings and operating instructions in

the Instruction Manual before operating or maintaining this power tool.

Most accidents that result from power tool operation and maintenance are caused by the

failure to observe basic safety rules or precautions. An accident can often be avoided by

recognizing a potentially hazardous situation before it occurs, and by observing appropriate

safety procedures.

Basic safety precautions are outlined in the “SAFETY” section of this Instruction Manual

and in the sections which contain the operation and maintenance instructions.

Hazards that must be avoided to prevent bodily injury or machine damage are identified by

WARNINGS on the power tool and in this Instruction Manual.

NEVER use this power tool in a manner that has not been specifically recommended by

HITACHI.

MEANINGS OF SIGNAL WORDS

WARNING indicates a potentially hazardous situation which, if ignored, could result in death

or serious injury.

CAUTION indicates a potentially hazardous situation which, if not avoided, may result in

minor or moderate injury, or may cause machine damage.

NOTE emphasizes essential information.

3

Page 4

English

SAFETY

GENERAL SAFETY RULES

WARNING: Read and understand all instructions.

Failure to follow all instructions listed below, may result in electric shock,

fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS

1. Work Area

(1) Keep your work area clean and well lit. Cluttered benches and dark areas invite

accidents.

(2) Do not operate power tools in explosive atmospheres, such as in the presence of

flammable liquids, gases, or dust. Power tools create sparks which may ignite the

dust of fumes.

(3) Keep bystanders, children, and visitors away while operating a power tool.

Distractions can cause you to lose control.

2. Electrical Safety

(1) Double Insulated tools are equipped with a polarized plug (one blade is wider than

the other.) This plug will fit in a polarized outlet only one way. If the plug does not

fit fully in the outlet, reverse the plug. If it still does not fit, contact a qualified

electrician to install a polarized outlet. Do not change the plug in any way. Double

Insulation eliminates the need for the three wire grounded power cord and

grounded power supply system.

(2) Avoid body contact with grounded surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric shock if your body is grounded.

(3) Don’t expose power tools to rain or wet conditions. Water entering a power tool

will increase the risk of electric shock.

(4) Do not abuse the cord. Never use the cord to carry the tools or pull the plug from

a receptacle. Keep cord away from heat, oil, sharp edges or moving parts. Replace

damaged cords immediately. Damaged cords increase the risk of electric shock.

(5) When operating a power tool outside, use an outdoor extension cord marked “W-

A” or “W”. These cords are rated for outdoor use and reduce the risk of electric

shock.

3. Personal Safety

(1) Stay alert, watch what you are doing and use common sense when operating a

power tool. Do not use tool while tired or under the influence of drugs, alcohol, or

medication. A moment of inattention while operating power tools may result in

serious personal injury.

(2) Dress properly. Do not wear loose clothing or jewelry. Contain long hair. Keep

your hair, clothing, and gloves away from moving parts. Loose clothes, jewelry, or

long hair can be caught in moving parts.

(3) Avoid accidental starting. Be sure switch is off before plugging in. Carrying tools

with your finger on the switch or plugging in tools that have the switch on invites

accidents.

4

Page 5

English

(4) Remove adjusting keys or wrenches before turning the tool on. A wrench or a key

that is left attached to a rotating part of the tool may result in personal injury.

(5) Do not overreach. Keep proper footing and balance at all times. Proper footing and

balance enables better control of the tool in unexpected situations.

(6) Use safety equipment. Always wear eye protection. Dust mask, non-skid safety

shoes, hard hat, or hearing protection must be used for appropriate conditions.

4. Tool Use and Care

(1) Use clamps or other practical way to secure and support the workpiece to a stable

platform. Holding the work by hand or against your body is unstable and may lead

to loss of control.

(2) Do not force tool. Use the correct tool for your application. The correct tool will do

the job better and safer at the rate for which it is designed.

(3) Do not use tool if switch does not turn it on or off. Any tool that cannot be controlled

with the switch is dangerous and must be repaired.

(4) Disconnect the plug from the power source before making any adjustments,

changing accessories, or storing the tool. Such preventive safety measures reduce

the risk of starting the tool accidentally.

(5) Store idle tools out of reach of children and other untrained persons. Tools are

dangerous in the hand of untrained users.

(6) Maintain tools with care. Keep cutting tools sharp and clean. Properly maintained

tools, with sharp cutting edges are less likely to bind and are easier to control.

(7) Check for misalignment or binding of moving parts, breakage of parts, and any

other condition that may affect the tools operation. If damaged, have the tool

serviced before using. Many accidents are caused by poorly maintained tools.

(8) Use only accessories that are recommended by the manufacturer for your model.

Accessories that may be suitable for one tool, may become hazardous when used

on another tool.

5. Service

(1) Tool service must be performed only by qualified repair personnel. Service or

maintenance performed by unqualified personnel could result in a risk of injury.

(2) When servicing a tool, use only identical replacement parts. Follow instructions in

the Maintenance section of this manual. Use of unauthorized parts or failure to

follow Maintenance Instruction may create a risk of electric shock or injury.

5

Page 6

English

SPECIFIC SAFETY RULES AND SYMBOLS

1. Hold tools by insulated gripping surfaces when performing an operation where the

tool may contact hidden wiring or its own cord. Contact with a “live” wire will make

exposed metal parts of the tool “live” and shock the operator.

2. ALWAYS wear ear protectors when using the tool for extended periods.

Prolonged exposure to high intensity noise can cause hearing loss.

3. Never touch moving parts.

Never place your hands, fingers or other body parts near the tool’s moving parts.

4. Never operate without all guards in place.

Never operate this tool without all guards or safety features in place and in proper

working order. If maintenance or servicing requires the removal of a guard or safety

feature, be sure to replace the guard or safety feature before resuming operation of the

tool.

5. Use right tool.

Don’t force small tool or attachment to do the job of a heavy-duty tool.

Don’t use tool for purpose not intended —for example— don’t use circular saw for

cutting tree limbs or logs.

6. Never use a power tool for applications other than those specified.

Never use a power tool for applications other than those specified in the Instruction

Manual.

7. Handle tool correctly.

Operate the tool according to the instructions provided herein. Do not drop or throw

the tool. Never allow the tool to be operated by children, individuals unfamiliar with its

operation or unauthorized personnel.

8. Keep all screws, bolts and covers tightly in place.

Keep all screws, bolts, and plates tightly mounted. Check their condition periodically.

9. Do not use power tools if the plastic housing or handle is cracked.

Cracks in the tool’s housing or handle can lead to electric shock. Such tools should not

be used until repaired.

10. Blades and accessories must be securely mounted to the tool.

Prevent potential injuries to youself or others. Blades, cutting implements and

accessories which have been mounted to the tool should be secure and tight.

11. Keep motor air vent clean.

The tool’s motor air vent must be kept clean so that air can freely flow at all times.

Check for dust build-up frequently.

12. Operate power tools at the rated voltage.

Operate the power tool at voltages specified on its nameplate.

If using the power tool at a higher voltage than the rated voltage, it will result in

abnormally fast motor revolution and may damage the unit and the motor may burn

out.

6

Page 7

English

13. Never use a tool which is defective or operating abnormally.

If the tool appears to be operating unusually, making strange noises, or otherwise

appears defective, stop using it immediately and arrange for repairs by a Hitachi

authorized service center.

14. Never leave tool running unattended. Turn power off.

Don’t leave tool until it comes to a complete stop.

15. Carefully handle power tools.

Should a power tool be dropped or struck against hard materials inadvertently, it may

be deformed, cracked, or damaged.

16. Do not wipe plastic parts with solvent.

Solvents such as gasoline, thinner benzine, carbon tetrachloride, and alcohol may

damage and crack plastic parts. Do not wipe them with such solvents.

Wipe plastic parts with a soft cloth lightly dampened with soapy water and dry

thoroughly.

17. ALWAYS wear eye protection that meets the requirement of the latest revision of ANSI

Standard Z87.1.

18. NEVER touch the tool bit with bare hands after operation.

19. NEVER wear gloves made from materials likely to roll up such as cotton, wool, cloth or

string, etc.

20. ALWAYS attach the side handle and securely grip the Demolition Hammer.

21. ALWAYS be careful with buried object such as an underground wiring.

Touching live wiring or electric cable with this tool may result in electric shock.

Confirm before use whether hidden objects are present, such as electric cables within

the wall, floor or ceiling.

22. Definitions for symbols used on this tool

V ............. volts

Hz ........... hertz

A ............. amperes

no .......... no load speed

W ............ watt

............ Class II Construction

---/min .... revolutions per minute

........... Alternating current

7

Page 8

English

DOUBLE INSULATION FOR SAFER OPERATION

To ensure safer operation of this power tool, HITACHI has adopted a double insulation

design. “Double insulation” means that two physically separated insulation systems have

been used to insulate the electrically conductive materials connected to the power supply

from the outer frame handled by the operator. Therefore, either the symbol “ ” or the

words and “Double insulation” appear on the power tool or on the nameplate.

Although this system has no external grounding, you must still follow the normal electrical

safety precautions given in this Instruction Manual, including not using the power tool in

wet environments.

To keep the double insulation system effective, follow these precautions:

䡬 Only HITACHI AUTHORIZED SERVICE CENTER should disassemble or assemble this

power tool, and only genuine HITACHI replacement parts should be installed.

䡬 Clean the exterior of the power tool only with a soft cloth moistened with soapy water,

and dry thoroughly.

Never use solvents, gasoline or thinners on plastic components; otherwise the plastic

may dissolve.

SAVE THESE INSTRUCTIONS

AND

MAKE THEM AVAILABLE TO

OTHER USERS

AND

OWNERS OF THIS TOOL!

8

Page 9

FUNCTIONAL DESCRIPTION

NOTE:

The information contained in this Instruction Manual is designed to assist you in the

safe operation and maintenance of the power tool.

NEVER operate, or attempt any maintenance on the tool unless you have first read and

understood all safety instructions contained in this manual.

Some illustrations in this Instruction Manual may show details or attachments that

differ from those on your own power tool.

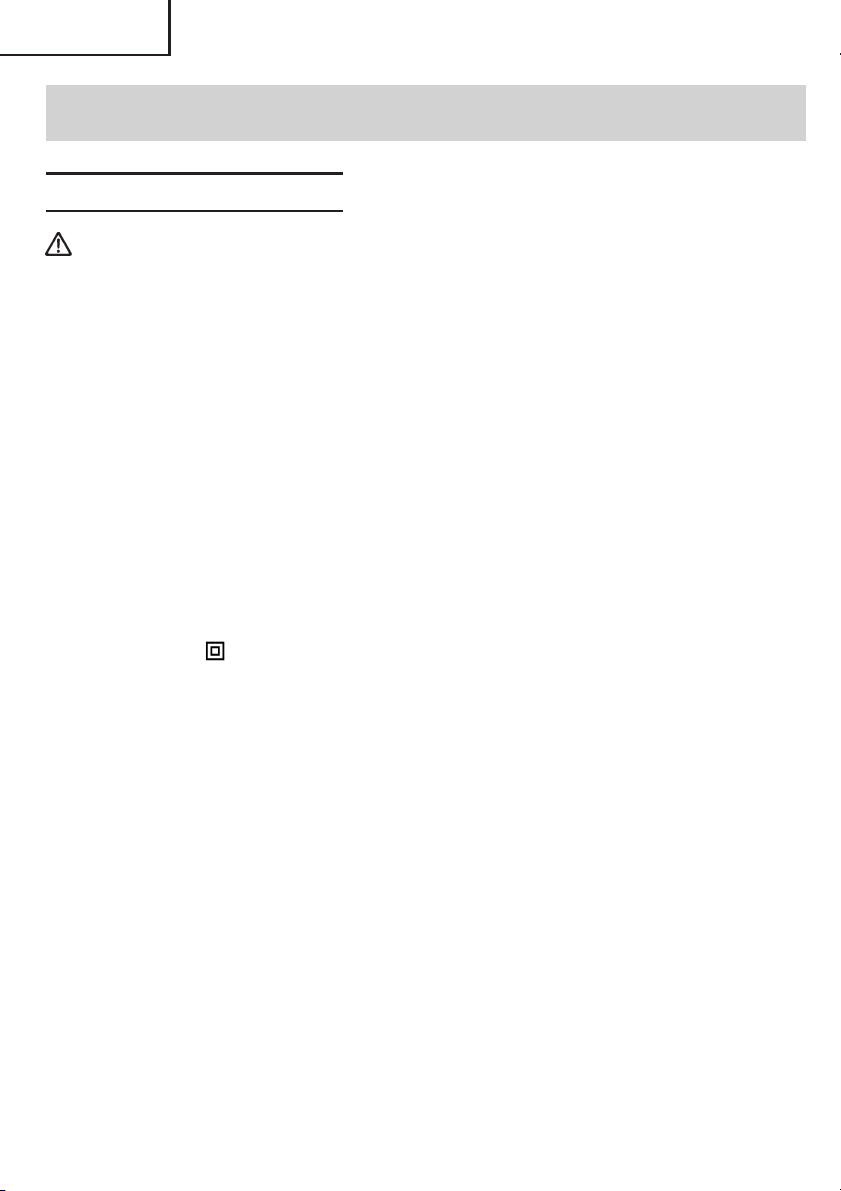

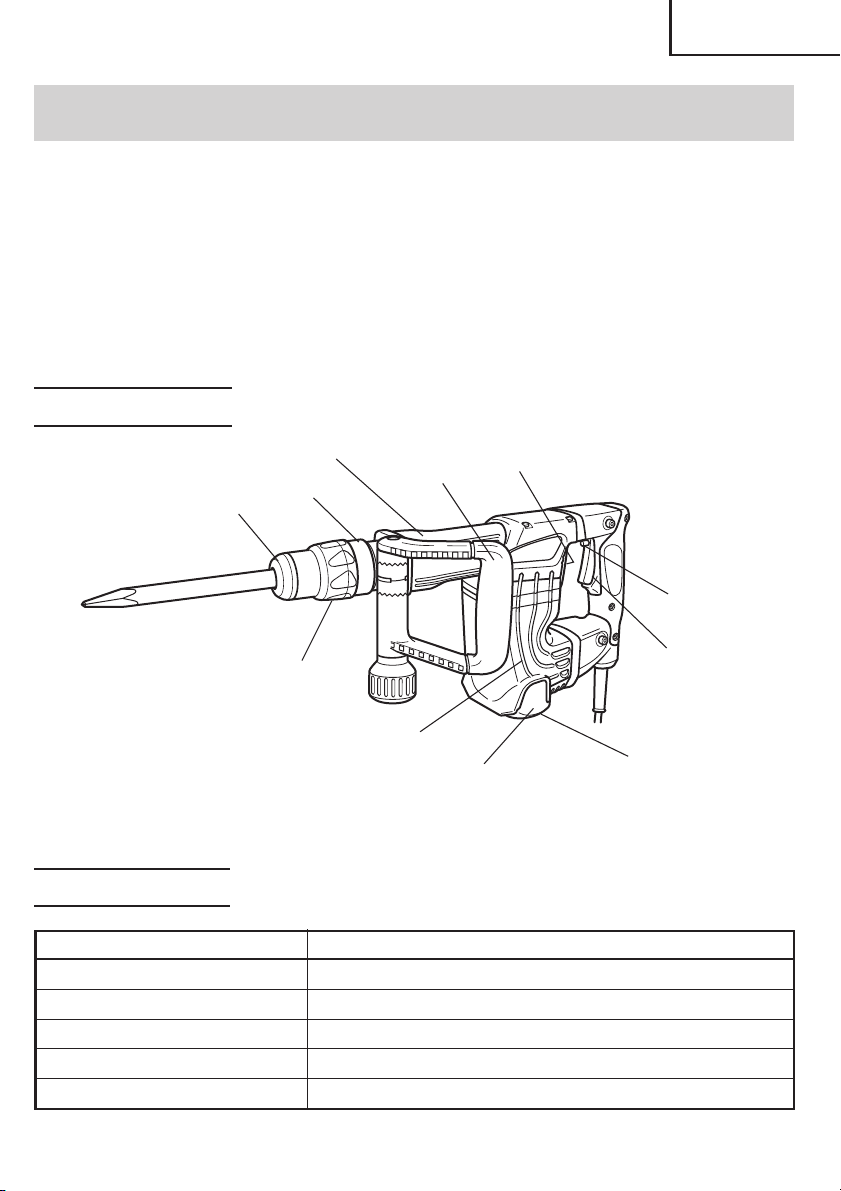

NAME OF PARTS

English

Front Cap

Cylinder Case

Side Handle

Grip (B)

Grip (A)

Housing

Brush Cap

(Under the Tail Cover)

Fig. 1

Nameplate

Stopper

Trigger

Switch

Tail Cover

SPECIFICATIONS

Model H 45MR

Motor Single-Phase, Series Commutator Motor

Power Source Single-Phase, 120 V AC 60 Hz

Current 8.3 A

Full-load Impact Rate 3000/min.

Weight 13.0 lbs (5.9 kg)

9

Page 10

English

ASSEMBLY

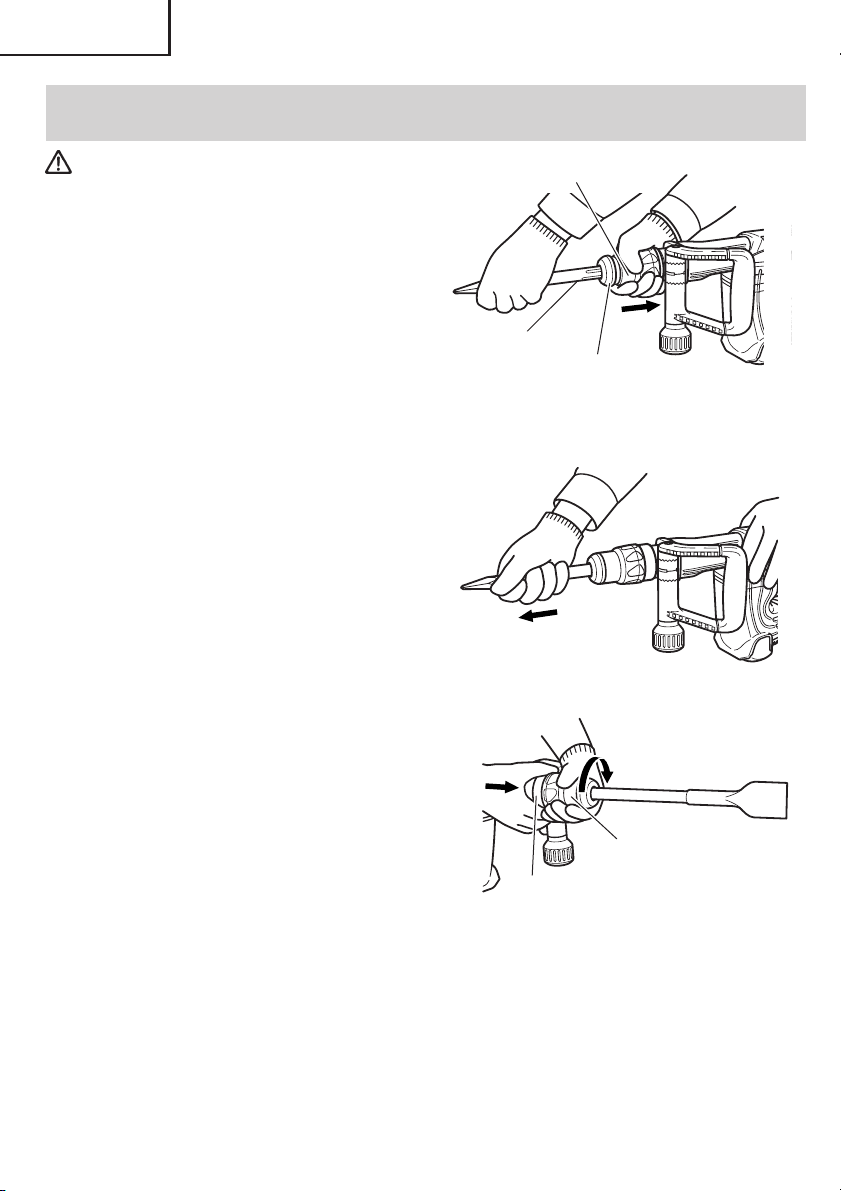

CAUTION: To prevent accidents, make

sure to turn the switch off and

disconnect the plug from the

receptacle.

NOTE:

When using tools such as bull points,

cutters, etc., make sure to use the genuine

parts designated by our company.

1. Installing Tools

(1) Clean the shank portion of the tool.

(2) As shown in Fig. 2, pull grip (A) in the

direction of A, and insert the tool into a

hole of the front cap.

(3) Adjust the groove position while turning

the tool, and furthermore insert it until it

hits the end of the hole.

(4) Return grip (A) to its original position, pull

the tool to make sure it is locked

completely. (Fig. 3)

2. Deciding Working Position of Tool

The tool can be turned every 30 degrees

and can be fixed at the position of 12

steps.

(1) As shown in Fig. 4, the blade angle can

be freely changed if the grip (A) is turned

in the direction of B in a state where grip

(B) is slid in the direction of A.

(2) Release grip (B) and turn the tool, and

make sure that it is locked completely.

3. Removing Tool

As shown in Fig. 2, pull grip (A), and pull

out the tool.

Tool

Shank

A

Grip (A)

A

Front Cap

Fig. 2

Fig. 3

B

Grip (A)

Grip (B)

Fig. 4

10

Page 11

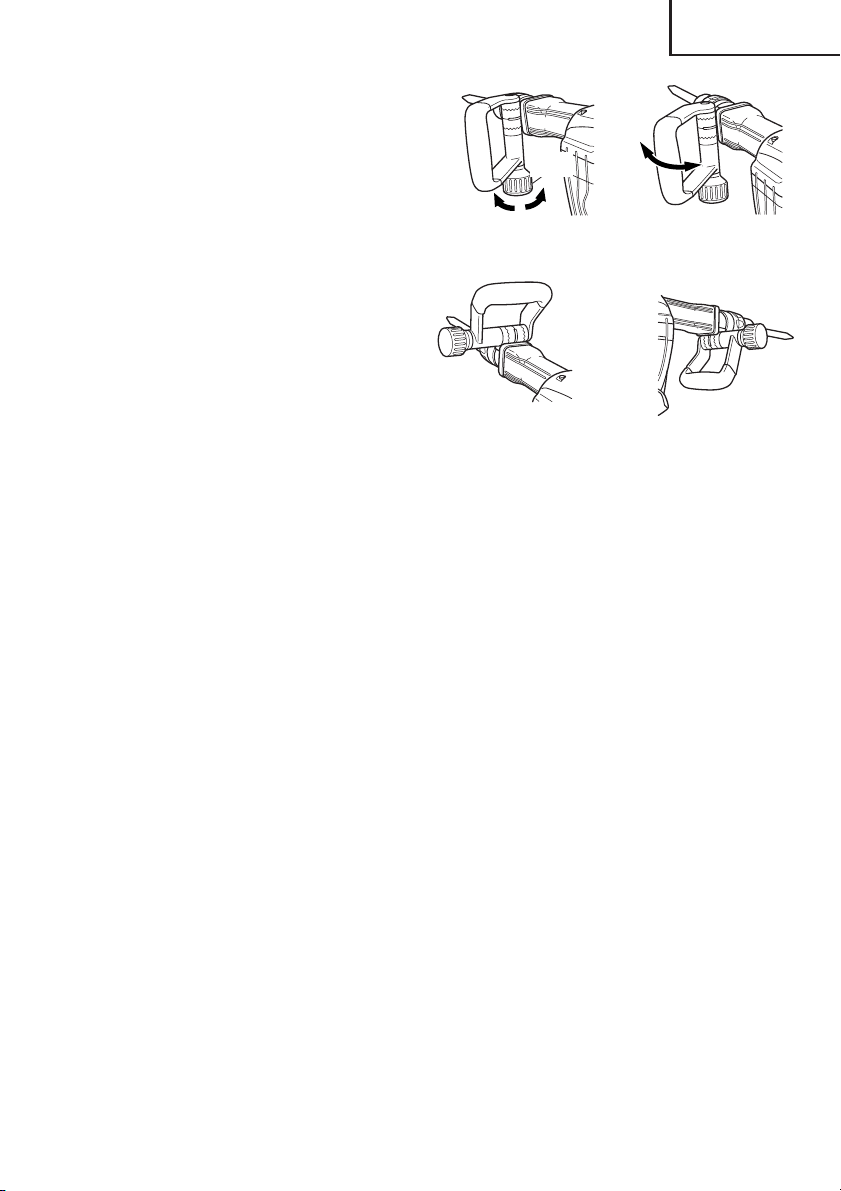

4. Move the side handle

The side handle can be fixed at any

desired position; 360 degrees, and can

also be fixed at any position in the backand-forth direction.

(1) Loosen the handle by turning the grip in

the direction of A as shown in Fig. 5.

(2) Adjust it to a position where vertical (up-

and-down) operation can be facilitated as

illustrated in Fig. 6, Fig. 7, and Fig. 8.

(3) Turn the grip in the direction of B and fix

the handle.

Grip

A

B

Fig. 5 Fig. 6

Fig. 7 Fig. 8

English

11

Page 12

English

OPERATION

APPLICATIONS

䡬 Demolishing concrete, chiseling concrete, grooving, bar cutting, and driving piles.

Application examples:

Installation of piping and wiring, sanitary facility installation, machinery installation,

water supply and drainage work, interior jobs, harbor facilities and other civil engineering

work.

PRIOR TO OPERATION

1. Power source

Ensure that the power source to be utilized conforms to the power source requirements

specified on the product nameplate.

2. Power switch

Ensure that the switch is in the OFF position. If the plug is connected to a receptacle

while the switch is in the ON position, the power tool will start operating immediately

and can cause serious injury.

3. Extension cord

When the work area is far away from the power source, use an extension cord of

sufficient thickness and rated capacity. The extension cord should be kept as short as

practicable.

WARNING: Damaged cord must be replaced or repaired.

4. Check the receptacle

If the receptacle only loosely accepts the plug, the receptacle must be repaired. Contact

a licensed electrician to make appropriate repairs.

If such a fautly receptacle is used, it may cause overheating, resulting in a serious

hazard.

5. Confirming condition of the environment:

Confirm that the work site is placed under appropriate conditions conforming to

prescribed precautions.

12

Page 13

English

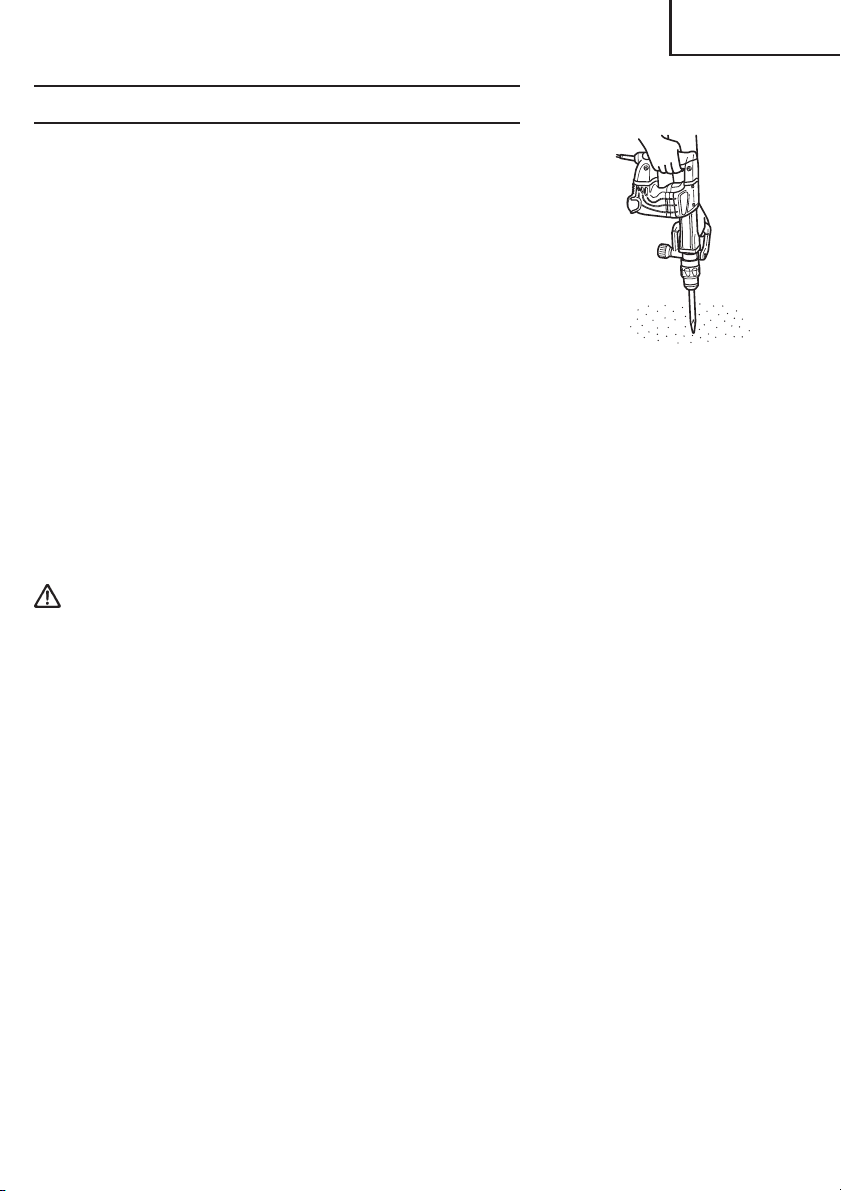

HOW TO USE THE DEMOLITION HAMMER

1. After placing the tip of the tool on concrete surface, switch

ON.

The switch can be turned ON if the trigger is pulled and OFF

when it is released.

If the stopper is pressed while the trigger for the switch is

pulled, even if your finger is released from the trigger, the

switch remains ON - convenient for continuous operation.

To turn the switch OFF, pull the trigger again, and then the

stopper comes off.

2. By utilizing the empty weight of the machine and by firmly

holding the hammer by both hands, you can effectively

control the subsequent recoil motion.

Proceed at a moderate work-rate, the use of too much

pushing force will impair efficiency.

3. Even when the switch is on, the motor is running and the tool head is pressed to the

demolition surface, the hammer sometimes does not start operating. In these instances,

turn the switch off, press the tool head against the demolition surface again, and turn

the switch on and off. This should start the hammer operating. Repeat this procedure

for several minutes, and the hammer will heat, after which it will operate when switched

to ON-LOCK.

CAUTION: After long time of use, the cylinder case becomes hot.

Therefore, be careful not to burn your hands.

Fig. 9

13

Page 14

English

73

MAINTENANCE AND INSPECTION

WARNING: Be sure to switch power OFF and disconnect the plug from the

receptacle during maintenance and inspection.

1. Inspecting the tool

Since use of a dull tool will degrade efficiency and cause possible motor malfunction,

sharpen or replace the tool as soon as abrasion is noted.

2. Inspecting the screws

Regularly inspect all screws and ensure that they are properly tightened. Should any of

the screws be loosened, retighten them immediately.

WARNING: Using this demolition hammer with loosened screws is extremely

dangerous.

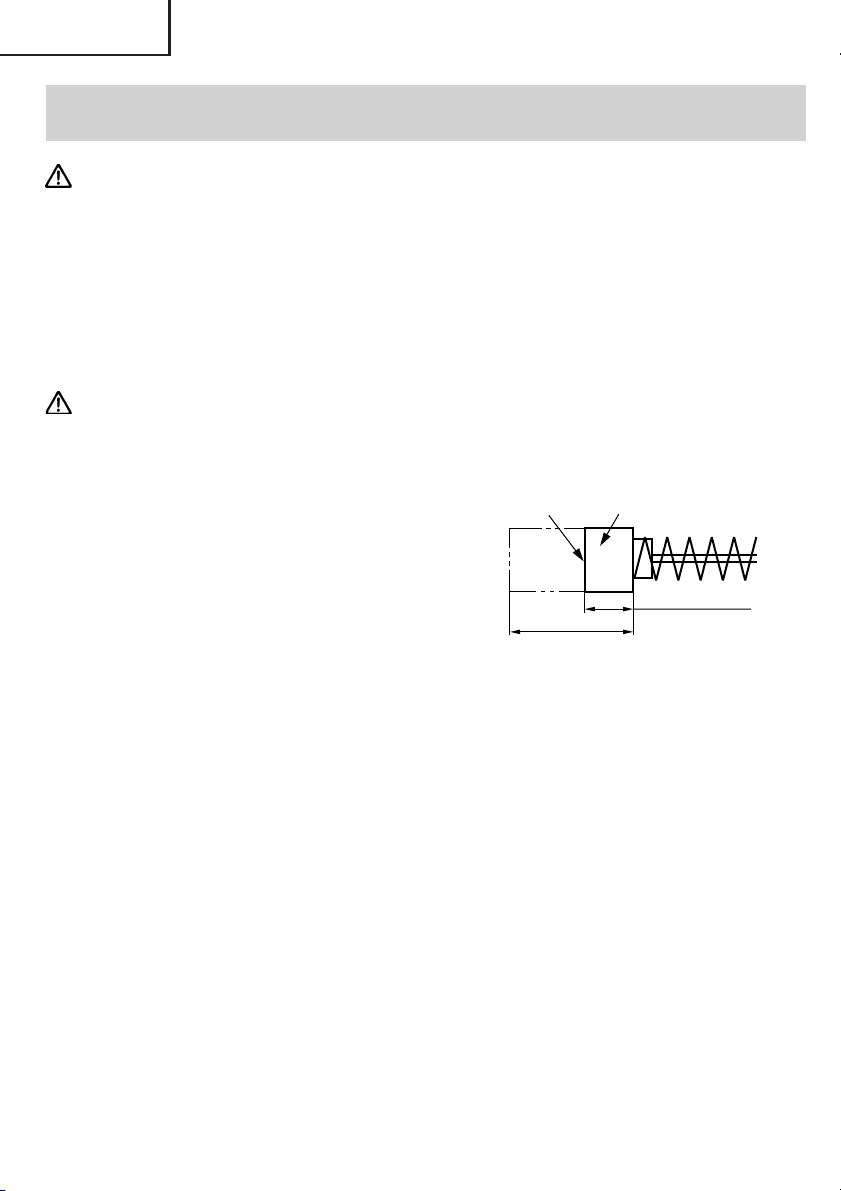

3. Inspecting the carbon brushes (Fig. 10)

The Motor employs carbon brushes which

are consumable parts. When they become

worn to or near the “wear limit”, it could

result in motor trouble. When an auto-stop

carbon brush is equipped, the motor will

stop automatically. At that time, replace

both carbon brushes with new ones which

have the same carbon brush Numbers

shown in the figure. In addition, always

keep carbon brushes clean and ensure

that they slide freely within the brush

holders.

NOTE: Use HITACHI carbon brush No. 73 indicated in Fig. 10.

Wear limit

0.67" (17 mm)

No. of carbon

brush

0.28" (7 mm)

Fig. 10

4. Replacing carbon brushes (Refer to figure for name of parts)

Loosen the set screw then remove the tail cover. By loosening the brush caps, the

carbon brushes can be removed. After fitting new carbon brushes, properly retighten

the brush caps and mount the tail cover.

5. Grease replacement

This machine is of fully oil sealed construction to protect against dust incursion and to

prevent lubricant leakage. This machine can be used without grease replenishment for

an extended period of time. However, perform the grease replacement to extend the

service life. Replace the grease as described below.

(1) Grease Replacement Period

Inspect the grease amount according to the timing replacement period of the carbon

brush. (See item 3 in the section MAINTENANCE AND INSPECTION.)

Ask for grease replacement at the nearest authorized Hitachi Service Center.

In the case that you are forced to change the grease by yourself, please follow the

following points.

14

Page 15

English

(2) How to replace grease

CAUTION:

䡬 Before replacing the grease, turn the power off and pull out the plug from the receptacle.

1 Disassenble the crank cover and thorougly

wipe off the old grease inside.

2 Supply 1.3 oz (40 g) (the standard volume

to cover the connecting rod) of Hitachi

Electric Hammer Grease A in the crank

case.

3 After replacing the grease, reassemples

the crank cover securely. At this time, do

not damage or lose the oil seal.

NOTE:

䡬 The Hitachi Electric Hammer Grease A is of the low viscosity type. When the grease is

consumed, purchase from the authorized Hitachi Service Center.

䡬 Do not excessively supply the designated amount of grease. Otherwise, the tool should

not operate accurately.

Crank Cover

Fig. 11

6. Service and repairs

All quality power tools will eventually require servicing or replacement of parts because

of wear from normal use. To assure that only authorized replacement parts will be

used, all service and repairs must be performed by a HITACHI AUTHORIZED SERVICE

CENTER, ONLY.

7. Service parts list

A: Item No.

B: Code No.

C: No. Used

D: Remarks

CAUTION: Repair, modification and inspection of Hitachi Power Tools must be carried

out by an Hitachi Authorized Service Center.

This Parts List will be helpful if presented with the tool to the Hitachi

Authorized Service Center when requesting repair or other maintenance. In

the operation and maintenance of power tools, the safety regulations and

standards prescribed in each country must be observed.

MODIFICATIONS:

Hitachi Power Tools are constantly being improved and modified to incorporate the latest

technological advancements.

Accordingly, some parts (i.e. code numbers and/or design) may be changed without prior

notice.

15

Page 16

English

ACCESSORIES

WARNING: ALWAYS use Only authorized HITACHI replacement parts and

accessories. NEVER use replacement parts or accessories which are

not intended for use with this tool. Contact HITACHI if you are not sure

whether it is safe to use a particular replacement part or accessory

with your tool.

The use of any other attachment or accessory can be dangerous and

could cause injury or mechanical damage.

NOTE:

Accessories are subject to change without any obligation on the part of the HITACHI.

STANDARD ACCESSORIES

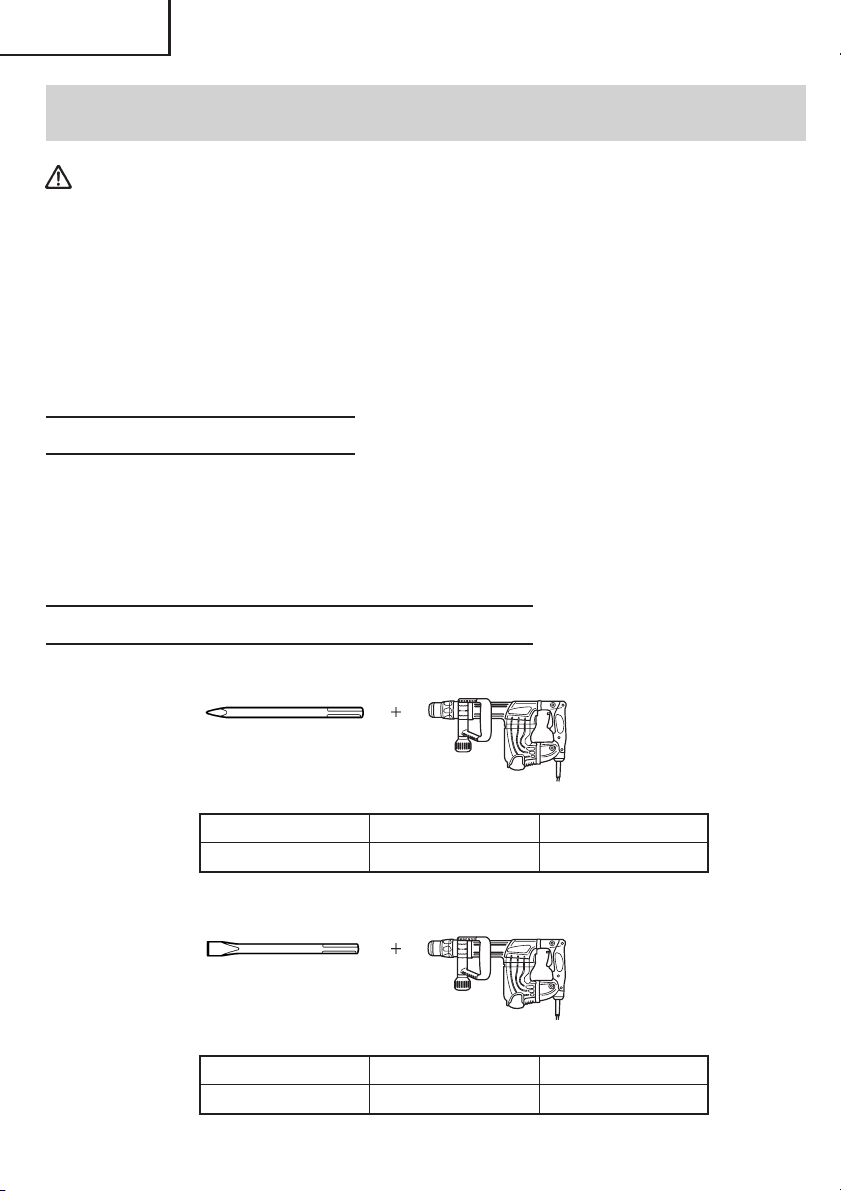

(1) Bull Point (SDS max shank) (Code No. 313471)............................................................... 1

(2) Case (Code No. 320842) ..................................................................................................... 1

(3) Side Handle (Code No. 317103)......................................................................................... 1

(4) Allen Wrench (for 6 mm screw) (Code No. 944459) ........................................................ 1

(5) Allen Wrench (for 5 mm screw) (Code No. 944458) ........................................................ 1

OPTIONAL ACCESSORIES........ sold separately

䡬 Demolitioning

(1) Bull Point (SDS max shank type)

Overall Length 11-1/32" (280 mm) 15-3/4" (400 mm)

Code No. 313471 313472

䡬 Groove digging and edging

(1) Cold chisel (SDS max shank type)

Overall Length 11-1/32" (280 mm) 15-3/4" (400 mm)

Code No. 313473 313474

16

Page 17

䡬 Asphalt Cutting

(1) Cutter (SDS max shank type)

Overall Length 15-3/4" (400 mm)

Code No. 313475

䡬 Scooping Work

(1) Scoop (SDS max shank type)

Overall Length 15-3/4" (400 mm)

Code No. 313476

䡬 Surface Roughing

English

(1) Bushing Tool

(Code No. 313477)

(2) Shank

(Code No. 313479)

䡬 Tamping

(1) Rammer

(Code No. 313478)

(2) Shank

(Code No. 313479)

䡬 Hammer Grease A

70 g (in a tube) (Code No. 981840)

30 g (in a tube) (Code No. 308471)

NOTE:

Specifications are subject to change without any obligation on the part of the HITACHI.

17

Page 18

Français

INFORMATIONS IMPORTANTES DE SÉCURITÉ

Lire et comprendre toutes les précautions de sécurité, les avertissements et les instructions

de fonctionnement dans ce mode d’emploi avant d’utiliser ou d’entretenir cet outil motorisé.

La plupart des accidents causés lors de l’utilisation ou de l’entretien de l’outil motorisé

proviennent d’un non respect des règles ou précautions de base de sécurité. Un accident

peut la plupart du temps être évité si l’on reconnaît une situation de danger potentiel avant

qu’elle ne se produise, et en observant les procédures de sécurité appropriées.

Les précautions de base de sécurité sont mises en évidence dans la section “SECURITE”

de ce mode d’emploi et dans les sections qui contiennent les instructions de fonctionnement

et d’entretien.

Les dangers qui doivent être évités pour prévenir des blessures corporelles ou un

endommagement de la machine sont identifiés par AVERTISSEMENTS sur l’outil motorisé

et dans ce mode d’emploi.

NE JAMAIS utiliser cet outil motorisé d’une manière qui n’est pas spécifiquement

recommandée par HITACHI.

SIGNIFICATION DES MOTS D’AVERTISSEMENT

AVERTISSEMENT indique des situations potentiellement dangereuses qui, si elles sont

ignorées, pourraient entraîner la mort ou de sérieuses blessures.

PRECAUTION indique des situations dangereuses potentilles qui, si elles ne sont pas évitées,

peuvent entraîner de mineures et légères blessures ou endommager la machine.

REMARQUE met en relief des informations essentielles.

18

Page 19

SECURITE

REGLES GENERALE DE SECURITE

AVERTISSEMENT: Lire et coxmprendre toutes les instructions.

Un non respect de toutes les instructions ci-dessous peut

entraîner une électrocution, un incendie et/ou de sérieuses

blessures personnelles.

CONSERVER CES INSTRUCTIONS

1. Zone de travail

(1) Garder la zone de travail propre et bien éclairée. Les établis mal rangés et les

zones sombres invitent aux accidents.

(2) Ne pas utiliser les outils motorisés dans une atmosphère explosive, telle qu’en

présence de liquides inflammables, de gaz ou de poussières. Les outils motorisés

créent des étincelles qui risquent d’enflammer la poussière ou les vapeurs.

(3) Tenir les spectateurs, les enfants et les visiteurs éloignés, lors de l’utilisation de

l’outil motorisé. Une distraction peut faire perdre le contrôle de la machine.

2. Sécurité électrique

(1) Les outils à double isolation sont équipés d’une fiche polarisée (une lame est plus

large que l’autre). Cette fiche ne pénétrera dans une prise secteur polarisée que

dans un sens. Si la fiche ne rentre pas complètement dans la prise, la retourner. Si

elle ne rentre toujours pas, contacter un électricien qualifié pour installer une prise

polarisée. Ne pas modifier la fiche d’aucune façon. La double isolation élimine

le besoin d’un cordon d’alimentation à trois fils et d’un système d’alimentation

avec mises à la terre.

(2) Eviter tout contact corporel avec les surfaces mises à la terre telles que les

canalisations, les radiateurs, les réchauds et les réfrigérateurs. Il y a un risque

accru d’électrocution si son corps est mis à la terre.

(3) Ne pas exposer les outils motorisés à la pluie ou à l’humidité. De l’eau pénétrant à

l’intérieur de l’outil motorisé augmente le risque d’électrocution.

(4) Ne pas maltraiter le cordon d’alimentation. Ne jamais utiliser le cordon pour porter

les outils ou tirer sur la fiche du réceptacle. Garder le cordon à l’écart de la chaleur,

de l’huile, des arêtes coupantes ou des pièces en mouvement. Remplacer les

cordons endommagés immédiatement. Des cordons endommagés augmentent le

risque d’électrocution.

(5) Lors de l’utilisation d’un outil motorisé, utiliser un cordon de rallonge extérieur

marqué “W-A” ou “W”. Ces cordons sont prévus pour une utilisation extérieure et

réduisent les risques d’électrocution.

3. Sécurité personnelle

(1) Rester sur ses gardes, regarder ce que l’on fait et utiliser son sens commun lors de

l’utilisation d’un outil motorisé. Ne pas utiliser un outil en état de fatigue ou sous

l’influence de drogues, d’alcool ou de médicaments. Un moment d’inattention lors

de l’utilisation de l’outil motorisé peut entraîner de sérieuses blessures personnelles.

(2) S’habiller correctement. Ne pas porter des vêtements larges ou des bijoux. Attacher

les cheveux longs. Tenir ses cheveux, vêtements et ses gants éloignés des parties

mobiles. Les vêtements larges, les bijoux et les cheveux longs peuvent se prendre

dans les parties mobiles.

Français

19

Page 20

Français

(3) Eviter tout démarrage accidentel. S’assurer que le l’interrupteur d’alimentation

est sur la position d’arrêt avant de brancher la machine. Transporter l’appareil

avec les doigts sur l’interrupteur d’alimentation ou brancher un outil avec

l’interrupteur sur la position marche invite aux accidents.

(4) Retirer les clefs d’ajustement ou les commutateurs avant de mettre l’outil sous

tension. Une clef qui est laissée attachée à une partie tournante de l’outil peut

provoquer une blessure personnelle.

(5) Ne pas trop présumer de ses forces. Garder en permanence une position et un

équilibre correct. Une position et un équilibre correct permettent un meilleur contrôle

de l’outil dans des situations inattendues.

(6) Utiliser un équipement de sécurité. Toujours porter des lunettes de protection.

Utiliser un masque à poussière, des chaussures de sécurité antidérapantes, un

couvre-chef dur ou des protections d’oreille dans les conditions appropriées.

4. Utilisation de l’outil et entretien

(1) Utiliser un étau ou toutes autres façons de fixer et maintenir la pièce à usiner sur

une plate-forme stable. Tenir la pièce avec la main ou contre son corps est instable

et peut conduire à une perte de contrôle de l’outil.

(2) Ne pas forcer sur l’outil. Utiliser l’outil correct pour l’application souhaitée. L’outil

correct réalisera un meilleur et plus sûr travail dans le domaine pour lequel il a été

conçu.

(3) Ne pas utiliser un outil s’il ne se met pas sous ou hors tension avec un interrupteur.

Un outil qui ne peut pas être commandé avec un interrupteur est dangereux et doit

être réparé.

(4) Déconnecter la fiche de la source d’alimentation avant de réaliser tout ajustement,

changement d’accessoires ou pour ranger l’outil. De telles mesures de sécurité

réduisent le risque que l’outil ne démarre accidentellement.

(5) Ranger les outils inutilisés hors de la portée des enfants et des autres personnes

inexpérimentées. Les outils sont dangereux dans les mains de personnes

inexpérimentées.

(6) Conserver les outils avec soin. Garder les outils de coupe aiguisés et propres. Des

outils bien entretenus, avec des lames coupantes aiguisées risquent moins de se

gripper et sont plus faciles à contrôler.

(7) Vérifier les défauts d’alignement ou grippage des parties mobiles, les ruptures

des pièces et toutes les autres conditions qui peuvent affecter le fonctionnement

des outils. En cas de dommage, faire réparer l’outil avant de l’utiliser. Beaucoup

d’accidents sont causés par des outils mal entretenus.

(8) Utiliser uniquement les accessoires recommandés par le fabricant pour le modèle

utilisé. Des accessoires qui peuvent convenir à un outil, peuvent devenir dangereux

lorsqu’ils sont utilisés avec un autre outil.

5. Réparation

(1) La réparation de l’outil ne doit être réalisée uniquement par un réparateur qualifié.

Une réparation ou un entretien réalisé par un personnel non qualifié peut entraîner

des risques de blessures.

(2) Lors de la réparation d’un outil, utiliser uniquement des pièces de rechange

identiques. Suivre les instructions de la section d’entretien de ce mode d’emploi.

L’utilisation de pièces non autorisées ou un non respect des instructions d’entretien

peut créer un risque d’électrocution ou de blessures.

20

Page 21

Français

REGLES DE SECURITE SPECIFIQUES ET SYMBOLES

1. Tenir les outils par les surfaces de grippage lors de la réalisation d’opération où l’outil

de coupe risque d’entrer en contact avec des câbles cachés ou son propre cordon. Un

contact avec un fil “sous tension” mettra les parties métalliques de l’outil “sous tension”

et électrocutera l’utilisateur.

2. TOUJOURS porter des protections d’oreille lors de l’utilisation de l’outil pendant de

longues périodes.

Une exposition prolongée à un son de forte intensité peut endommager

l’ouïe de l’utilisateur.

3. Ne jamais toucher les parties mobiles.

Ne jamais placer ses mains, ses doigts ou toute autre partie de son corps près des

parties mobiles de l’outil.

4. Ne jamais utiliser l’outil sans que tous les dispositifs de sécurité ne soient en place.

Ne jamais faire fonctionner cet outil sans que tous les dispositifs et caractéristiques de

sécurité ne soient en place et en état de fonctionnement. Si un entretien ou une

réparation nécessite le retrait d’un dispositif ou d’une caractéristique de sécurité,

s’assurer de bien remettre en place le dispositif ou la caractéristique de sécurité avant

de recommencer à utiliser l’outil.

5. Utiliser l’outil correct

Ne pas forcer sur un petit outil ou accessoire pour faire le travail d’un outil de grande

puissance. Ne pas utiliser un outil pour un usage pour lequel il n’a pas été prévu: par

exemple, ne pas utiliser une scie circulaire pour couper des branches d’arbre ou des

bûches.

6. Ne jamais utiliser un outil motorisé pour des applications autres que celles spécifiées.

Ne jamais utiliser un outil motorisé pour des applications autres que celles spécifiées

dans le mode d’emploi.

7. Manipuler l’outil correctement

Utiliser l’outil de la façon indiquée dans ce mode d’emploi. Ne pas laisser tomber ou

lancer l’outil. Ne jamais permettre que l’outil soit utilisé par des enfants, des personnes

non familiarisées avec son fonctionnement ou un personnel non autorisé.

8. Maintenir toutes les vis, tous les boulons et les couvercles fermement en place.

Maintenir toutes les vis, tous les boulons et les couvercles fermement montés. Vérifier

leurs conditions périodiquement.

9. Ne pas utiliser les outils motorisés si le revêtement de plastique ou la poignée est

fendu.

Des fentes dans le revêtement ou la poignée peuvent entraîner une électrocution. De

tels outils ne doivent pas être utilisés avant d’être réparé.

10. Les lames et les accessoires doivent être fermement montés sur l’outil.

Eviter les blessures potentielles personnelles et aux autres. Les lames, les instruments

de coupe et les accessoires qui ont été montés sur l’outil doivent être fixés et serrés

fermement.

21

Page 22

Français

11. Garder propres les évents d’air du moteur

Les évents d’air du moteur doivent être maintenus propres de façon que l’air puisse

circuler librement tout le temps. Vérifier les accumulations de poussière fréquemment.

12. Utiliser l’outil motorisé à la tension nominale.

Utiliser l’outil motorisé à la tension spécifiée sur sa plaque signalétique.

Si l’on utilise l’outil motorisé avec une tension supérieure à la tension nominale, il en

résultera une rotation anormalement trop rapide du moteur et cela risque

d’endommager l’outil et le moteur risque de griller.

13. Ne jamais utiliser un outil défectueux ou qui fonctionne anormalement.

Si l’outil n’a pas l’air de fonctionner normalement, fait des bruits étranges ou sans cela

paraît défectueux, arrêter de l’utiliser immédiatement et le faire réparer par un centre

de service Hitachi autorisé.

14. Ne jamais laisser fonctionner l’outil sans surveillance. Le mettre hors tension.

Ne pas abandonner l’outil avant qu’il ne soit complètement arrêté.

15. Manipuler l’outil motorisé avec précaution.

Si un outil motorisé tombe ou frappe un matériau dur accidentellement, il risque d’être

déformé, fendu ou endommagé.

16. Ne pas essuyer les parties en plastique avec du solvant.

Les solvants comme l’essence, les diluants, la benzine, le tétrachlorure de carbone et

l’alcool peuvent endommager et fissurer les parties en plastique. Ne pas les essuyer

avec de tels solvants.

Essuyer les parties en plastique avec un chiffon doux légèrement imbibé d’une solution

d’eau savonneuse et sécher minutieusement.

17. TOUJOURS porter des lunettes de protection qui respectent les dernières révisions du

Standard ANSI Z87.1.

18. NE JAMAIS toucher la mèche avec des mains nues après l’utilisation.

19. NE JAMAIS porter de gants faits d’une matière qui risque de s’enrouler, comme du

coton, de la laine, de la toile ou de la ficelle, etc.

20. TOUJOURS fixer la poignée latérale et tenir le marteau piqueur solidement.

21. TOUJOURS vérifier s’il y a des objets encastrés, par exemple des fils électriques.

Le fait de toucher avec l’outil un fil ou un câble électrique sous tension risque de

provoquer une décharge électrique.

Avant l’utilisation, vérifier s’il y a des objets dissimulés, par exemple des câbles

électriques, dans le mur, le plancher ou le plafond.

22. Définitions pour les symboles utilisés sur cet outil

V ............. volts

Hz ........... hertz

A ............. ampères

no .......... vitesse sans charge

W ............ watt

............ Construction de classe II

---/min .... tours par minute

........... Courant alternatif

22

Page 23

Français

DOUBLE ISOLATION POUR UN FONCTIONNEMENT PLUS SUR

Pour assurer un fonctionnement plus sûr de cet outil motorisé, HITACHI a adopté une

conception à double insolation. “Double isolation” signifie que deux systèmes d’isolation

physiquement séparés ont été utilisés pour isoler les matériaux conducteurs d’électricité

connectés à l’outil motorisé à partir du cadre extérieur manipulé par l’utilisateur. C’est

pourquoi, le symbole “ ” ou les mots “Double insulation” (double isolation) apparaissent

sur l’outil motorisé ou sur la plaque signalétique.

Bien que ce système n’ait pas de mise à terre extérieure, il est quand même nécessaire de

suivre les précautions de sécurité électrique données dans ce mode d’emploi, y-compris

de ne pas utiliser l’outil motorisé dans un environnement humide.

Pour garder le système de double isolation effectif, suivre ces précautions:

䡬 Seuls les CENTRES DE SERVICE AUTORISES HITACHI peuvent démonter et remonter

cet outil motorisé et uniquement des pièces de rechange HITACHI garanties d’origine

doivent être utilisées.

䡬 Nettoyer l’extérieur de l’outil motorisé uniquement avec un chiffon doux légèrement

imbibé d’une solution savonneuse et essuyer minutieusement.

Ne jamais utiliser des solvants, de l’essence ou des diluants sur les parties en plastique;

sinon le plastique risquerait de se dissoudre.

CONSERVER

CES INSTRUCTIONS

ET

LES METTRE A LA DISPOSITION

DES AUTRES UTILISATEURS

ET

PROPRIETAIRES DE CET OUTIL!

23

Page 24

Français

DESCRIPTION FONCTIONNELLE

REMARQUE:

Les informations contenues dans ce mode d’emploi sont conçues pour assister

l’utilisateur dans une utilisation sans danger et un entretien de l’outil motorisé.

NE JAMAIS utiliser ni entreprendre une révision de l’outil sans avoir d’abord lu et

compris toutes les instructions de sécurité contenues dans ce manuel.

Certaines illustrations dans ce mode d’emploi peuvent montrer des détails ou des

accessoires différents de ceux de l’outil motorisé utilisé.

NOM DES PARTIES

Plaque signalétique

Butée

Gâchette

Couvercle arrière

Capuchon avant

Carter de cylindre

Poignée (B)

Poignée (A)

Tête porte-charbon

(sous le courvercle arrière)

Poignée latérale

Carter

Fig. 1

SPECIFICATIONS

Modèle H 45MR

Moteur Moteur série monophasé à collecteur

Source d’alimentation Secteur, 120 V 60 Hz, monophasé

Courant 8,3 A

Nombre de percussions à pleine charge 3000/min.

Poids 13,0 lbs (5,9 kg)

24

Page 25

ASSEMBLAGE

Français

PRECAUTION :

Pour éviter tout risque d’accident,

s’assurer que l’outil est éteint et

débranché du secteur.

REMARQUE:

Lorsqu’on installe des outils, par exemple

des pointes à béton, des couteaux, etc.,

bien veiller à utiliser les pièces d’origine

conçues par notre société.

1. Installation des outils

(1) Nettoyer la section de la queue de l’outil.

(2) Comme indiqué sur la Fig. 2, tirer sur la

poignée (A) dans le sens A, et insérer

l’outil dans l’un des orifices du capuchon

avant.

(3) Régler la position de la rainure tout en

tournant l’outil, et l’insérer encore

davantage jusqu’à ce qu’il touche le fond

de l’orifice.

(4) Ramener la poignée (A) sur sa position

d’origine, tirer sur l’outil et vérifier qu’il

est bloqué à fond. (Fig. 3)

2. Recherche de la position de travail de

l’outil

L’outil peut tourner par paliers de 30

degrés et il peut être fixé sur l’un de ces

12 paliers.

(1) Comme indiqué sur la Fig. 4, si l’on tourne

la poignée (A) dans le sens B de telle sorte

que la poignée (B) glisse dans le sens A,

il sera possible de modifier librement

l’angle de la lame sur n’importe quelle

position.

(2) Libérer la poignée (B) et tourner l’outil, et

vérifier qu’il est bloqué à fond.

3. Retrait de l’outil

Comme indiqué sur la Fig. 2, tirer sur la

poignée (A) et sortir l’outil.

Queue

d’outil

A

Poignée (A)

A

Capuchon avant

Fig. 2

Fig. 3

B

Poignée (A)

Poignée (B)

Fig. 4

25

Page 26

Français

4. Déplacer la poignée latérale.

La poignée latérale peut se fixer à

n’importe quelle position sur 360 degrés,

et elle peut également être fixée sur

n’importe quelle position en sens avant

et arrière.

(1) Desserrer la poignée en tournant la saisie

dans le sens de A comme indiqué à la

Fig. 5.

(2) Régler la poignée à une position facilitant

le fonctionnement vertical (de haut en

bas), comme indiqué à la Fig. 6, la Fig. 7

et la Fig. 8.

(3) Tourner la saisie dans le sens de B et fixer

la poignée.

Poignée

A

B

Fig. 5 Fig. 6

Fig. 7 Fig. 8

26

Page 27

Français

FONCTIONNEMENT

APPLICATIONS

䡬 Broyage du béton, burinage, rainurage, coupe de barres, et enfoncement de pieux.

Exemples d’application:

Installation de tuyautage et de câblage, installation de facilités sanitaires, de machinerie,

d’alimentation d’eau et de drainage, travaux intérieurs, facilités de port et autres travaux

de génie civil.

AVANT L’UTILISATION

1. Source d’alimentation

S’assurer que la source d’alimentation qui doit être utilisée est conforme à la source

d’alimentation requise spécifiée sur la plaque signalétique du produit.

2. Interrupteur d’alimentation

S’assurer que l’interrupteur est sur la position OFF (arrêt). Si la fiche est connectée sur

une prise alors que l’interrupteur est sur la position ON (marche), l’outil motorisé

démarrera immédiatement risquant de causer de sérieuses blessures.

3. Cordon prolongateur

Quand la zone de travail est éloignée de la source d’alimentation, utiliser un cordon

prolongateur d’épaisseur et de capacité nominale suffisante. Le cordon prolongateur

doit être aussi court que possible.

AVERTISSEMENT:

Tout cordon endommagé devra être remplacé ou réparé.

4. Vérifier la prise

Si la prise reçoit la fiche avec beaucoup de jeu, elle doit être réparée. Contacter un

électricien licencié pour réaliser les réparations nécessaires.

Si une telle prise défectueuse est utilisée, elle peut causer une surchauffe entraînant

des dangers sérieux.

5. Vérification des conditions d’environnement

Vérifier que l’état de l’aire de travail est conforme aux précautions.

27

Page 28

Français

COMMENT UTILISER LE MARTEAU PIQUEUR

1. Après avoir placé la pointe de l’outil sur la surface du béton,

brancher l’outil sur ON.

L’interrupteur s’enclenche lorsqu’on tire la gâchette et il se

coupe quand on relâche la gâchette.

Si l’on appuie sur la butée pendant qu’on appuie sur la

gâchette de l’interrupteur, l’interrupteur reste enclenché,

même si on relâche le doigt de la gâchette, ce qui est

pratique pour un fonctionnement continu. Pour couper

l’interrupteur, tirer à nouveau sur la gâchette; la butée se

coupe.

2. En utilisant le poids à vide de la machine et en maintenant

fermement le marteau avec les deux mains, le mouvement

de recul peut être effectivement contrôle. Procéder avec un

régime modéré; l’utilisation de trop de poussée pourrait

réduire l’efficacité.

3. Même si l’interrupteur est enclenché, que le moteur tourne et que la tête de l’outil est

appuyée contre la surface de démoliton, il est possible que le marteau piqueur ne se

mette pas à fonctionner. Dans ce cas, couper l’interrupteur, appuyer à nouveau la tête

de l’outil contre la surface de démoliton, puis enclencher et couper l’interrupteur. Cela

devrait faire marcher le marteau piqueur. Recommencer ces opérations pendant

quelques minutes ; le marteau piqueur chauffera, après quoi il fonctionnera lorsqu’il

sera commuté sur ON-LOCK.

Fig. 9

PRECAUTION : Après une utilisation prolongée, le carter de cylindre devient chaud.

Faire attention de ne pas se brûler les mains.

28

Page 29

Français

73

ENTRETIEN ET INSPECTION

AVERTISSEMENT: S’assurer de mettre l’interrupteur d’alimentation sur la

position OFF et de déconnecter la fiche de la prise secteur

avant l’entretien et l’inspection de la meuleuse.

1. Inspection de l’outil

Etant donné que l’utilisation d’un outil émoussé réduira le rendement et provoquera

éventuellement un manuvais fonctionnement du moteur, aiguiser ouremplacer l’outil

dès qu’une abrasion apparaît.

2. Inspection des vis

Inspecter régulièrement toutes les vis et s’assurer qu’elles sont correctement serrées.

Si l’une des vis était desserrée, la resserrer immédiatement.

AVERTISSEMENT: Utiliser la meuleuse avec des vis desserrées est extrêmement

dangereux.

3. Contrôle des balais en carbone (Fig. 10)

Le moteur utilise des balais en carbone

qui sont des pièces qui s’usent. Quand ils

sont usés ou près de la “limite d’usure”,

il pourra en résulter un mauvais

fonctionnement du moteur.

Quand le moteur est équipé d’un balai en

carbone à arrêt automatique, il s’arrêtera

automatiquement. Remplacez alor les

balais en carbone par des nouveaux et

ayant les mêmes numéros que ceux

montré sur la figure. En outre, toujours

tenir les balais propres et veiller à ce qu’ils

coulissent librement dans les supports.

Limite

d’usure

0,67" (17 mm)

No. du balai

en carbone

0,28" (7 mm)

Fig. 10

REMARQUE: Utiliser le balai en carbone HITACHI No. 73 indiqué sur la Fig. 10.

4. Remplacement des balais carbone (Voir la figure dans la section Nom des

pièces)

Desserrer la vis de fixation puis retirer le couvercle arrière. Desserrer la tête portecharbon pour pouvoir retirer les balais carbone. Remplacer les balais carbone par des

neufs, revisser la tête porte-charbon à fond, et remonter le couvercle arrière.

5. Remplacement de graisse

Cette machine est de construction entièrement hermétique pour la protéger contre la

poussière et pour éviter les fuites de lubrifiant. Cet outil peut être utilisé sans remplissage

de graisse pendant une longue période de temps. Cependant, remplacer la graisse

pour ne pas écourter la durée de vie. Remplacer la graisse comme indiqué ci-dessous.

29

Page 30

Français

(1) Période de remplacement

Contrôler la quantité de graisse en fonction de la durée de remplacement de la brosse

de carbone. (Voir l'élément 3 de la section MAINTENANCE ET INSPECTION.)

Se procurer la graisse chez l’Agence de Service Autorisée Hitachi la plus proche.

Si vous devez changer la graisse vous-même, veuillez respecter les points suivants.

(2) Comment remplacer la graisse

PRECAUTION :

䡬 Avant de remplacer la graisse, fermer l’interrupteur et débrancher l’outil de la prise de

courant.

1 Démonter le couvercle de manivelle et

essuyer complètement la vieille graisse à

l’intérieur.

2 Appliquer 1,3 oz (40 g) (la quantité standard

pour recouvrir la tige de connexion) de

graisse pour Marteau électrique Hitachi A

dans le carter.

3 Après avoir remplacé la graisse, remonter

fermement le carter. A ce moment, ne pas

endommager ni desserrer le joint d’huile.

NOTA:

䡬 La graisse pour Marteau électrique Hitachi A est du type à viscosité faible; quand le

tube est vide, adressez-vouz à votre Agent de Service Autorisé Hitachi pour vous en

procurer un nouveau.

䡬 Ne pas mettre trop de graisse. Sinon, l’outil ne fonctionnera plus correctement.

Couvercle de manivelle

Fig. 11

6. Service apres-vente et reparations

Tous les outils motorisés de qualité auront éventuellement besoin d’une réparation ou

du remplacement d’une pièce à cause de l’usure normale de l’outil. Pour assurer que

seules des pièces de rechange autorisées seront utilisées, tous les entretiens et les

réparations doivent être effectués uniquement par UN CENTRE DE SERVICE HITACHI

AUTORISE.

7. Liste des pièces de rechange

A: No. élément

B: No. code

C: No. utilisé

D: Remarques

PRECAUCIÓN: Les réparations, modifications et inspections des outils électriques

Hitachi doivent être confiées à un service après-vente Hitachi agréé.

Il sera utile de présenter cette liste de pièces au service après-vente

Hitachi agréé lorsqu’on apporte un outil nécessitant des réparations

ou tout autre entretien.

Lors de l’utilisation et de l’entretien d’un outil électrique, respecter les

règlements et les normes de sécurité en vigueur dans le pays en

question.

MODIFICATIONS:

Les outils électriques Hitachi sont constamment améliorés et modifiés afin d’incorporer les

tous derniers progrès technologiques.

En conséquence, il est possible que certaines pièces (c.-à-d. no. de code et/ou dessin) soient

modifiées sans avis préalable.

30

Page 31

Français

ACCESSOIRES

AVERTISSEMENT: TOUJOURS utiliser UNIQUEMENT des pièces de rechange

et des accessoires HITACHI. Ne jamais utiliser de pièce de

rechange ou d’accessoires qui ne sont pas prévus pour être

utilisé avec cet outil. En cas de doute, contacter HITACHI pour

savoir si une pièce de rechange ou un accessoire particulier

peuvent être utilisés en toute sécurité avec votre outil.

L’utilisation de tout autre attachement ou accessoire peut

être dangereux et peut causer des blessures ou des

dommages mécaniques.

REMARQUE:

Les accessoires sont sujets à changement sans obligation de la part de HITACHI.

ACCESSOIRES STANDARD

(1) Pointe de broyage (Tige SDS max.) (No. de code 313471) ............................................. 1

(2) Boîter (No. de code 320842) .............................................................................................. 1

(3) Poignée latérale (No. de code 317103) ............................................................................. 1

(4) Clé Allen (pour vis de 6 mm) (No. de code 944459) ........................................................ 1

(5) Clé Allen (pour vis de 5 mm) (No. de code 944458) ........................................................ 1

ACCESSOIRES SUR OPTION..... vendus séparément

䡬 Broyage

(1) Pointe de broyage (Tige SDS max.)

Longueur hors tout 11-1/32" (280 mm) 15-3/4" (400 mm)

No. de code 313471 313472

䡬 Creusage de rainures et cassure des angles

(1) Ciseau à froid (Tige SDS max.)

Longueur hors tout 11-1/32" (280 mm) 15-3/4" (400 mm)

No. de code 313473 313474

31

Page 32

Français

䡬 Coupage d’asphalte

(1) Fraise (Tige SDS max.)

Longueur hors tout 15-3/4" (400 mm)

No. de code 313475

䡬 Puisage

(1) Scoop (Tige SDS max.)

Longueur hors tout 15-3/4" (400 mm)

No. de code 313476

䡬 Dégrossissage

(1) Boucharde

(No. de code 313477)

(2) Queue

(No. de code 313479)

䡬 Bourrage

(1) Bourroir

(No. de code 313478)

(2) Queue

(No. de code 313479)

䡬 Graisse A pour marteau

70 g (en tube) (No. de code 981840)

30 g (en tube) (No. de code 308471)

REMARQUE:

Les spécifications sont sujettes à modification sans aucune obligation de la part de HITACHI.

32

Page 33

Español

INFORMACIÓN IMPORTANTE SOBRE SEGURIDAD

Antes de utilizar o de realizar cualquier trabajo de mantenimiento de esta herramienta

eléctrica, lea y comprenda todas las precauciones de seguridad, advertencias e instrucciones

de funcionamiento de este Manual de instrucciones.

La mayoría de los accidentes producidos en la operación y el mantenimiento de una

herramienta eléctrica se deben a la falta de observación de las normas o precauciones de

seguridad. Los accidentes normalmente podrán evitarse reconociendo una situación

potencialmente peligrosa a tiempo y siguiendo los procedimientos de seguridad apropiados.

Las precauciones básicas de seguridad se describen en la sección “SEGURIDAD” de este

Manual de instrucciones y en las secciones que contienen las instrucciones de operación y

mantenimiento.

Para evitar lesiones o el daño de la herramienta eléctrica, los riesgos están identificados

con ADVERTENCIAS en dicha herramienta y en este Manual de instrucciones.

No utilice NUNCA esta herramienta eléctrica de ninguna forma que no esté específicamente

recomendada por HITACHI.

SIGNIFICADO DE LAS PALABRAS DE SEÑALIZACIÓN

ADVERTENCIA indica situaciones potencialmente peligrosas que, si se ignoran, pueden

resultar en la muerte o en lesiones de gravedad.

PRECAUCIÓN indica situaciones potencialmente peligrosas que, de no evitarse, pueden

resultar en lesiones menores o moderadas, o causar daños en la herramienta eléctrica.

NOTA acentúa información esencial.

33

Page 34

Español

SEGURIDAD

NORMAS GENERALES DE SEGURIDAD

ADVERTENCIA: Lea y entienda todas las instrucciones.

Si no sigue las instrucciones indicadas a continuación, pueden

producirse descargas eléctricas, incendios, y/o lesiones serias.

GUARDE ESTAS INSTRUCCIONES

1. Área de trabajo

(1) Mantenga el área de trabajo limpia y bien iluminada. Los bancos de trabajo

desordenados y las áreas obscuras pueden conducir a accidentes.

(2) No utilice la herramienta en atmósferas explosivas, como en presencia de líquidos

inflamables, gases, o polvo. La herramienta eléctrica crea chispas que pueden

incendiar polvo o gases.

(3) Mantenga alejadas a otras personas, niños o visitantes, cuando utilice la

herramienta eléctrica. Las distracciones pueden hacer que pierda el control de la

herramienta.

2. Seguridad eléctrica

(1) Las herramientas eléctricas con aislamiento doble poseen un enchufe polarizado

(una cuchilla es más ancha que la otra.) Este enchufe encajará en un tomacorriente

polarizado de una sola forma. Si el enchufe no entra completamente en el

tomacorriente, invierta su sentido de inserción. Si sigue sin entrar, póngase en

contacto con un electricista cualificado para que le instale un tomacorriente

polarizado. No cambie nunca el enchufe. El aislamiento doble elimina la

necesidad de un cable de alimentación de tres conductores, uno para puesta a

tierra, y del sistema de alimentación con puesta a tierra.

(2) Evite el contacto con superficies con puesta a tierra, tales como tubos, radiadores,

hornos, y refrigeradores. Si toca tierra, existe el peligro de que reciba una descarga

eléctrica.

(3) No exponga la herramienta eléctrica a la lluvia ni a la humedad. La entrada de

agua en la herramienta eléctrica aumentará el riesgos de descargas eléctricas.

(4) No maltrate el cable de alimentación. No utilice nunca el cable de alimentación

para transportar la herramienta ni para desconectarla del tomacorriente. Mantenga

el cable alejado del calor, aceite, bordes cortantes, o partes móviles. Reemplace

inmediatamente cualquier cable dañado. Un cable dañado puede ser la causa de

descargas eléctricas.

(5) Cuando utilice la herramienta eléctrica en exteriores, utilice un cable prolongador

marcado con “W-A” o “W”. Estos cables han sido diseñados para utilizarse en

exteriores y reducir el riesgo de descargas eléctricas.

3. Seguridad personal

(1) Esté siempre alerta y utilice el sentido común cuando utilice la herramienta eléctrica.

No utilice la herramienta cuando esté cansado o bajo la influencia de medicamentos

ni de alcohol. Un descuido al utilizar la herramienta eléctrica puede resultar en una

lesión seria.

(2) Vístase adecuadamente. No utilice ropa floja ni joyas. Si tiene pelo largo, recójaselo.

Mantenga su pelo, ropa, y guantes alejados de las partes móviles. La ropa floja, las

joyas, o el pelo largo pueden engancharse en las partes móviles.

34

Page 35

Español

(3) Evite la puesta en marcha accidental. Cerciórese de que la alimentación de la

herramienta eléctrica esté desconectada antes de enchufarla en una toma de la

red. Si lleva la herramienta eléctrica con el dedo colocado en el interruptor, o si la

enchufa con dicho interruptor cerrado, es posible que se produzcan accidentes.

(4) Quite las llaves de ajuste y abra los interruptores antes de poner en funcionamiento

la herramienta. Una llave dejada en una parte móvil de la herramienta podría resultar

en lesiones.

(5) No sobrepase su alcance. Mantenga en todo momento un buen equilibrio. El

conservar en todo momento el equilibrio le permitirá controlar mejor la herramienta

en situaciones inesperadas.

(6) Utilice equipos de seguridad. Póngase siempre gafas protectoras. Para conseguir

las condiciones apropiadas, utilice una mascarilla contra el polvo, zapatos no

resbaladizos, un casco duro, y protectores auditivos.

4. Utilización y cuidados de la herramienta

(1) Utilice abrazaderas u otra forma práctica de asegurar y sujetar la pieza de trabajo

sobre una plataforma estable. La sujeción de la pieza de trabajo con la mano o

contra su cuerpo puede ser inestable y conducir a la pérdida del control.

(2) No fuerce la herramienta. Utilice la herramienta correcta para su aplicación. Con la

herramienta correcta realizará mejor el trabajo y ésta será más segura para la

velocidad para la que ha sido diseñada.

(3) No utilice la herramienta si el interruptor de alimentación de la misma no funciona.

Cualquier herramienta que no pueda controlarse con el interruptor de alimentación

puede resultar peligrosa, y deberá repararse.

(4) Desconecte el enchufe del cable de alimentación antes de realizar cualquier ajuste,

cambiar accesorios, o guardar la herramienta. Tales medidas preventivas de

seguridad reducirán el riesgo de que la herramienta se ponga en funcionamiento

accidentalmente.

(5) Guarde las herramientas que no vaya a utilizar fuera del alcance de niños y de

otras personas no entrenadas. Las herramientas son peligrosas en manos de

personas inexpertas.

(6) Realice el mantenimiento cuidadoso de las herramientas. Mantenga las

herramientas afiladas y limpias. Las herramientas adecuadamente mantenidas,

con los bordes cortantes afilados, serán más fáciles de utilizar y controlar.

(7) Compruebe que las piezas móviles no estén desalineadas ni atascadas, que no

haya piezas rotas, y demás condiciones que puedan afectar la operación de las

herramientas. En caso de que una herramienta esté averiada, repárela antes de

utilizarla. Muchos de los accidentes se deben a herramientas mal cuidadas.

(8) Utilice solamente los accesorios recomendados por el fabricante para su modelo.

Los accesorios adecuados para una herramienta pueden ser peligrosos cuando se

utilicen con otra.

5. Servicio de reparación

(1) El servicio de reparación deberá realizarlo solamente personal cualificado. El servicio

de mantenimiento o de reparación realizado por personal no cualificado podría

resultar en el riesgo de lesiones.

(2) Para el servicio de mantenimiento o reparación de una herramienta, utilice

solamente piezas de repuesto idénticas. Siga las instrucciones de la sección de

mantenimiento de este manual. La utilización de piezas no autorizadas, o el no

seguir las indicaciones del Manual de instrucciones puede crear el riesgo de

descargas eléctricas u otras lesiones.

35

Page 36

Español

NORMAS Y SÍMBOLOS ESPECÍFICOS DE SEGURIDAD

1. Sujete las herramientas por las superficies de empuñadura aisladas cuando realice

una operación en la que la herramienta pueda entrar en contacto con cables ocultos o

con su propio cable de alimentación. El contacto con un conductor “activo” “activará”

las partes metálicas de la herramienta y el operador recibirá una descarga eléctrica.

2. SIEMPRE utilice protectores auditivos cuando tenga que utilizar la herramienta durante

mucho tiempo.

La exposición prolongada a ruido de gran intensidad puede causar la

sordera.

3. No toque nunca las piezas móviles.

No coloque nunca sus manos, dedos, ni demás partes del cuerpo cerca de las piezas

móviles de la herramienta.

4. No utilice nunca la herramienta sin los protectores colocados en su lugar.

No utilice nunca esta herramienta sin los protectores de seguridad correctamente

instalados. Si el trabajo de mantenimiento o de reparación requiere el desmontaje de

un protector de seguridad, cerciórese de volver a instalarlo antes de utilizar la

herramienta.

5. Utilice la herramienta correcta.

No fuerce herramientas ni accesorios pequeños para realizar un trabajo pesado.

No utilice las herramientas para fines no proyectados, por ejemplo, no utilice esta

amoladora angular para cortar madera.

6. No utilice nunca una herramienta eléctrica para aplicaciones que no sean las

especificadas.

No utilice nunca una herramienta eléctrica para aplicaciones no especificadas en este

Manual de instrucciones.

7. Maneje correctamente la herramienta.

Maneje la herramienta de acuerdo con las instrucciones ofrecidas aquí. No deje caer ni

tire la herramienta. No permita nunca que los niños ni otras personas no autorizadas ni

familiarizadas con la operación de la herramienta utilicen ésta.

8. Mantenga todos los tornillos, pernos, y cubiertas firmemente fijados en su lugar.

Mantenga todos los tornillos, pernos, y cubiertas firmemente montados. Compruebe

periódicamente su condición.

9. No utilice herramientas eléctricas si la carcasa o la empuñadura de plástico está rajada.

Las rajas en la carcasa o en la empuñadura de plástico pueden conducir a descargas

eléctricas. Tales herramientas no deberán utilizarse mientras no se hayan reparado.

10. Las cuchillas y los accesorios deberán montarse con seguridad en la herramienta.

Evite lesiones personales y de otras personas. Las cuchillas, los accesorios de corte, y

demás accesorios montados en la herramienta deberán fijarse con seguridad.

11. Mantenga limpio el conducto de ventilación del motor.

El conducto de ventilación del motor limpio para que el aire pueda circular libremente

en todo momento. Compruebe frecuentemente y limpie el polvo acumulado.

36

Page 37

Español

12. Utilice las herramientas eléctricas con la tensión de alimentación nominal.

Utilice las herramientas eléctricas con las tensiones indicadas en sus placas de

características.

La utilización e una herramienta eléctrica con una tensión superior a la nominal podría

resultar en revoluciones anormalmente altas del motor, en el daño de la herramienta,

y en la quemadura del motor.

13. No utilice nunca una herramienta defectuosa o que funcione anormalmente.

Si la herramienta parece que funciona anormalmente, produciendo ruidos extraños,

etc., deje inmediatamente de utilizarla y solicite su arreglo a un centro de reparaciones

autorizado por Hitachi.

14. No deje nunca la herramienta en funcionamiento desatendida. Desconecte su

alimentación.

No deje sola la herramientas hasta mientras no se haya parado completamente.

15. Maneje con cuidado las herramientas eléctricas.

Si una herramienta eléctrica se ha caído o ha chocado inadvertidamente contra

materiales duros, es posible que se haya deformado, rajado, o dañado.

16. No limpie las partes de plástico con disolvente.

Los disolventes, como gasolina, diluidor de pintura, bencina, tetracloruro de carbono,

y alcohol pueden dañar o rajar las partes de plástico. No las limpie con tales disolventes.

Limpie las partes de plástico con un paño suave ligeramente humedecido en agua

jabonosa y después séquelas bien.

17. SIEMPRE utilice gafas protectoras que cumplan con los requerimientos de la última

revisión de la norma ANSI Z87.1.

18. No toque NUNCA una broca de la herramienta con las manos desnucas después de la

operación.

19. NUNCA utilice guantes hechos de materiales que tiendan a enrollarse, como algodón,

lana, paño, cuerda, etc.

20. Fije SIEMPRE la empuñadura lateral del martillo demoledor y sujétela con seguridad.

21. SIEMPRE tenga cuidado con los objetos que puedan estar enterrados o emparedados,

tales como los cables subterráneos.

Si tocase un circuito activo o un cable eléctrico con esta herramienta, podría recibir

una descarga eléctrica.

Antes del uso, confirme que no haya objetos ocultos, como los cables eléctricos

enterrados en la pared, el piso o el techo.

22. Definiciones para los símbolos utilizados en esta herramienta

V ...................voltios

Hz ................. hertzios

A ................... amperios

no ................ velocidad sin carga

W .................. vatios

..................Construcción de clase II

---/min .......... revoluciones por minuto

.................Corriente alterna

37

Page 38

Español

AISLAMIENTO DOBLE PARA OFRECER UNA OPERACIÓN MÁS SEGURA

Para garantizar una operación más segura de esta herramienta eléctrica, HITACHI ha

adoptado un diseño de aislamiento doble. “Aislamiento doble” significa que se han utilizado

dos sistemas de aislamiento físicamente separados para aislar los materiales eléctricamente

conductores conectados a la fuente de alimentación del bastidor exterior manejado por el

operador. Por lo tanto, en la herramienta eléctrica o en su placa de características aparecen

el símbolo “ ” o las palabras “Double insulation” (aislamiento doble).

Aunque este sistema no posee puesta a tierra externa, usted deberá seguir las precauciones

sobre seguridad eléctrica ofrecidas en este Manual de instrucciones, incluyendo la no

utilización de la herramienta eléctrica en ambientes húmedos.

para mantener efectivo el sistema de aislamiento doble, tenga en cuenta las precauciones

siguientes:

䡬 Esta herramienta eléctrica solamente deberá desensamblar y ensamblarla un CENTRO

DE REPARACIONES AUTORIZADO POR HITACHI, y solamente deberán utilizarse con

ella piezas de reemplazo genuinas de HITACHI.

䡬 Limpie el exterior de la herramienta eléctrica solamente con un paño suave humedecido

en agua jabonosa, y después séquela bien.

No utilice disolventes, gasolina, ni diluidor de pintura para limpiar las partes de plástico,

ya que podría disolverlas.

¡GUARDE ESTAS

INSTRUCCIONES Y

PÓNGALAS A DISPOSICIÓN DE

OTROS USUARIOS

Y

PROPIETARIOS DE ESTA

HERRAMIENTA!

38

Page 39

DESCRIPCIÓN FUNCIONAL

NOTA:

La información contenida en este Manual de instrucciones ha sido diseñada para

ayudarle a utilizar con seguridad y mantener esta herramienta eléctrica.

NUNCA haga funcionar ni efectúe el mantenimiento de la herramienta antes de leer y

comprender todas las instrucciones de seguridad contenidas en este manual.

Algunas ilustraciones de este Manual de Instrucciones pueden mostrar detalles o

accesorios diferentes a los de la propia herramienta eléctrica.

NOMENCLATURA

Español

Caja del cilindro

Empuñadura (B)

Tapa frontal

Empuñadura (A)

Alojamiento

(debajo de la cubierta del extremo de las escobillas)

Mango

Lateral

Tapa de escobilla

Fig. 1

Placa de características

Retén

Interruptor

disparador

Cubierta del

extremo

ESPECIFICACIONES

Modelo H 45MR

Motor Motor conmutador en serie monofásico

Fuente de alimentación 120 V CA, 60 Hz, monofásica

Corriente 8,3 A

Frecuencia de impacto a plena carga 3000/min.

Peso 13,0 lbs (5,9 kg)

39

Page 40

Español

MONTAJE

PRECAUCIÓN:

Para evitar accidentes, cerciórese de

desconectar la alimentación y de

desenchufar el cable del tomacorriente.

NOTA:

Cuando instale herramientas tales como

barrenos, cortadores, etc., cerciórese de

utilizar pieza genuinas diseñads por

nuestra compañía.

1. Instalación de herramientas

(1) Limpie la parte del vátago de la

herramienta.

(2) Tal como se muestra en la Fig. 2, tire de

la empuñadura (A) en la dirección de A,

e inserte la herramienta en el orificio de

la tapa frontal.

(3) Ajuste la posición de la ranura girando la