SPECIFICATIONS AND PARTS ARE SUBJECT TO CHANGE FOR IMPROVEMENT

POWER TOOLS

TECHNICAL DATA

AND

SERVICE MANUAL

DISC GRINDER

G 18SE3, G 18UA2, G 18SG2, G 18UB2,

G 23SC3, G 23UA2, G 23SE2, G 23UB2

LIST Nos. G 18SE3: E250, G 18UA2: E251,

G 18SG2: E252, G 18UB2: E253,

G 23SC3: E254, G 23UA2: E255,

G 23SE2: E256, G 23UB2: E257

Nov. 2002

G

MODELS

G 18SE3, G 18UA2, G 18SG2, G 18UB2,

G 23SC3, G 23UA2, G 23SE2, G 23UB2

REMARK:

Throughout this TECHNICAL DATA AND SERVICE MANUAL, a symbol(s)

is(are) used in the place of company name(s) and model name(s) of our

competitor(s). The symbol(s) utilized here is(are) as follows:

Symbols Utilized

Competitors

Company Name

Model Name

MAKITA

9047, 9047SF, 9049, 9049SF,

9057, 9057SF, 9059, 9059SF

C

BOSCH

GWS24-180, GWS24-180JB,

GWS24-230, GWS24-230JB,

GWS26-180, GWS26-180JB,

GWS26-230, GWS26-230JB

B

Page

CONTENTS

1. PRODUCT NAME........................................................................................................................... 1

2. MARKETING OBJECTIVE ............................................................................................................. 1

3. APPLICA TIONS.............................................................................................................................. 1

4. SELLING POINTS .......................................................................................................................... 2

4-1. Class-top Overload Durability ......................................................................................................... 2

4-2. Prolonged Service Life of the Carbon Brushes Thanks to the New Construction .......................... 3

4-3. Wear Resistance of Armature Coil.................................................................................................. 3

4-4. Dust-proof Ball Bearing Thanks to the Labyrinth Construction....................................................... 4

4-5. Durable Ball Bearing Retainer Thanks to the Iron Bushing ............................................................ 4

4-6. New Construction to Protect Grease Leakage ............................................................................... 4

4-7. Wheel Guard Angle-Adjustable without Using a Tool ..................................................................... 5

5. SPECIFICATIONS .......................................................................................................................... 6

6. COMPARISONS WITH SIMILAR PRODUCTS.............................................................................. 8

6-1. Specification Comparisons ............................................................................................................. 8

6-2. Practical Test Data........................................................................................................................ 10

7. PRECAUTIONS IN SALES PROMOTION ....................................................................................11

7-1. Handling Instructions .....................................................................................................................11

7-2. Caution on Name Plate..................................................................................................................11

7-3. Precautions on Usage .................................................................................................................. 12

8. PRECAUTIONS IN DISASSEMBLY AND REASSEMBLY .......................................................... 13

8-1. Disassembly ................................................................................................................................. 13

8-2. Reassembly .................................................................................................................................. 15

8-3. Lubrication Points and Types of Lubricant.................................................................................... 17

8-4. Tightening Torque ......................................................................................................................... 17

8-5. Wiring Diagram ............................................................................................................................. 18

8-6. Insulation Tests ............................................................................................................................. 18

8-7. No-load Current Value .................................................................................................................. 18

9. STANDARD REPAIR TIME (UNIT) SCHEDULES ....................................................................... 19

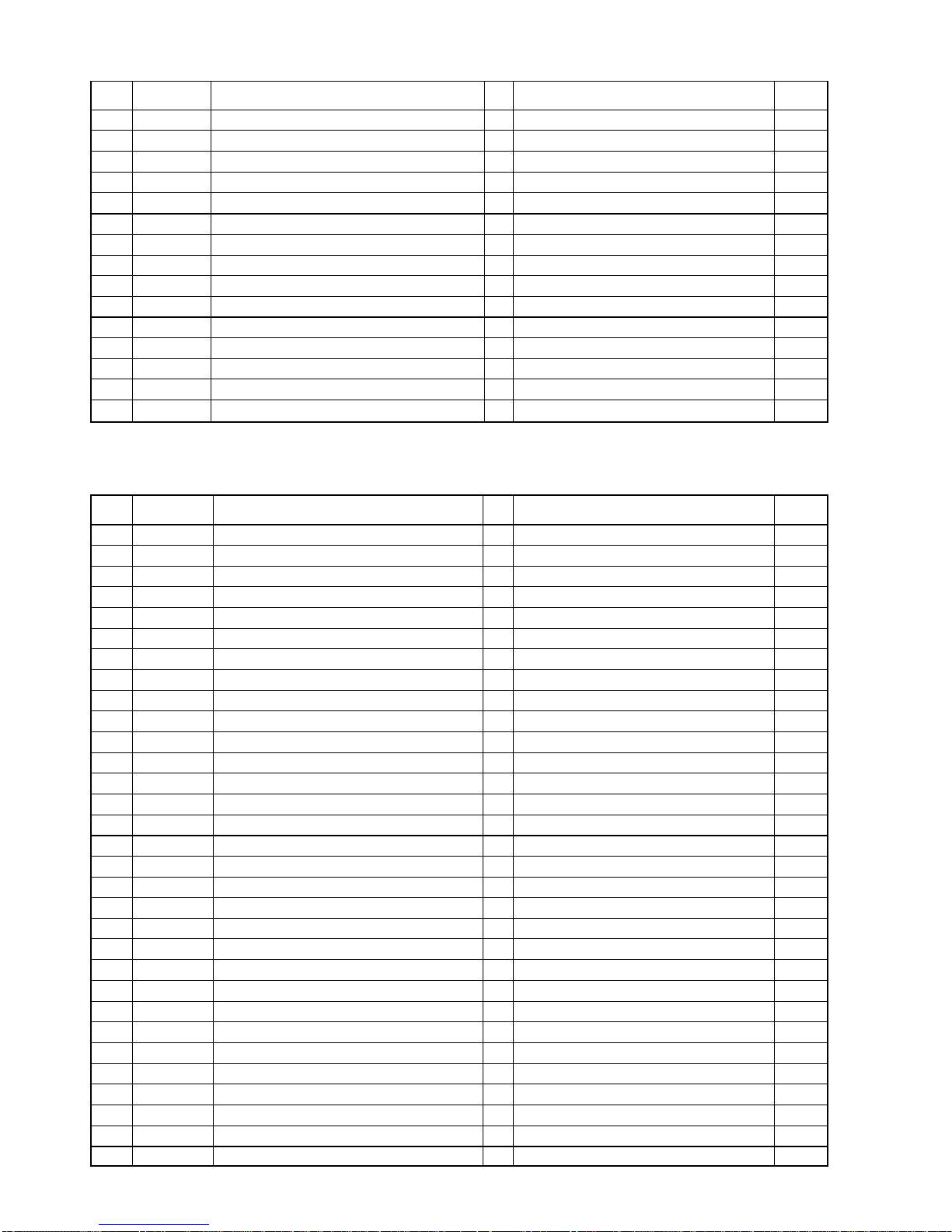

Assembly Diagram for G 18SE3

Assembly Diagram for G 18UA2

Assembly Diagram for G 18SG2

Assembly Diagram for G 18UB2

Assembly Diagram for G 23SC3

Assembly Diagram for G 23UA2

Assembly Diagram for G 23SE2

Assembly Diagram for G 23UB2

--- 1 ---

1. PRODUCT NAME

1) Hitachi 180 mm (7") Disc Grinder, Model G 18SE3

2) Hitachi 180 mm (7") Disc Grinder, Model G 18UA2 (With soft start)

3) Hitachi 180 mm (7") Disc Grinder, Model G 18SG2

4) Hitachi 180 mm (7") Disc Grinder, Model G 18UB2 (With soft start)

5) Hitachi 230 mm (9") Disc Grinder, Model G 23SC3

6) Hitachi 230 mm (9") Disc Grinder, Model G 23UA2 (With soft start)

7) Hitachi 230 mm (9") Disc Grinder, Model G 23SE2

8) Hitachi 230 mm (9") Disc Grinder, Model G 23UB2 (With soft start)

2. MARKETING OBJECTIVE

Large disc grinders are the markets where Europe is main, and HITACHI products have obtained high evaluation

in power, durability and quality. However, some improvements are requested to HITACHI's current G 23SC2

series disc grinders because about ten years passed since their development, and the competitors are introducing

high-power products with 2200 W or more input. To correspond to the request for improved powerful products

with 2200 W or more input, the Models G 18SE3, G 18UA2, G 18SG2, G 18UB2, G 23SC3, G 23UA2, G 23SE2

and G 23UB2 have been developed to upgrade and replace the current Models G 18SE2, G 18UA, G 18SG,

G 18UB, G 23SC2, G 23UA, G 23SE and G 23UB. In addition, the Models G 18UA2, G 18UB2, G 23UA2 and

G 23UB2 are equipped with a soft start. The key features of the Models G 18SE3, G 18UA2, G 18SG2, G 18UB2,

G 23SC3, G 23UA2, G 23SE2 and G 23UB2 in comparison with the current models are as follows:

1) 100 W higher input compared to the current models

2) Prolonged service life of the carbon brushes

3) Wear resistance of armature coil

4) Dust-proof labyrinth construction

5) Durable ball bearing retainer of the housing

6) New construction to protect grease leakage

7) Tool-less wheel guard

3. APPLICA TIONS

Deburring diecast products and finishing iron, bronze, aluminum and diecast products

Finishing welds and torch-cut surfaces

Cutting soft steel materials

Grooving and cutting concrete and other stone materials

--- 2 ---

4-1. Class-top Overload Durability

The Models G 18SE3, G 18UA2, G 23SC3, G 23UA2, G 18SG2, G 18UB2, G 23SE2 and G 23UB2 provide

excellent overload durability thanks to the improved motor winding and carbon brush material in common with the

current models (the service life of the carbon brushes is also prolonged). Figure 1 shows the comparison of

overload durability when the stator coil temperature rise is 200˚K using the Model G 23SC3 as the reference.

As is evident from this, the Models G 18SE3, G 18UA2, G 23SC3, G 23UA2, G 18SG2, G 18UB2, G 23SE2 and

G 23UB2 are superior to the competitors in overload durability.

Fig. 1

100

50

0

C

B

G 18SE3/G 18UA2/G 18SG2/G 18UB2/

G 23SC3/G 23UB2/G 23SE2/G 23UB2

G 18SE2/G 18UA/G 18SG/G 18UB/

G 23SC2/G 23UB/G 23SE/G 23UB

4. SELLING POINTS

Power 2,300 W motor design

(G 18SE3, G 18UA2, G 23SC3, G 23UA2)

Power 2,500 W motor design

(G 18SG2, G 18UB2, G 23SE2, G 23UB2)

Maker B's model: 2400 W

: 2600 W

Maker C's model: 2300 W

: 2500 W

Durable ball bearing retainer

thanks to the iron bushing

Dust-proof ball bearing thanks

to the labyrinth construction

Wear resistance of armature coil:

1.5 times higher compared to the current models

Prolonged service life of the carbon brushes

thanks to the new construction:

1.5 times higher compared to the current models

Class-top overload durability

1.2 times higher compared to maker C's model

1.1 times higher compared to maker B's model

Tool-less wheel guard

--- 3 ---

Fig. 2

4-2. Prolonged Service Life of the Carbon Brushes Thanks to the New Construction

The service life of the carbon brushes is 1.5 times longer than the current models thanks to the adoption of the

new carbon brush retainer construction. The service life of the carbon brushes is equivalent to that of the

competitors.

100

50

0

C

B

G 18SE3/G 18UA2/G 18SG2/G 18UB2/

G 23SC3/G 23UB2/G 23SE2/G 23UB2

G 18SE2/G 18UA/G 18SG/G 18UB/

G 23SC2/G 23UB/G 23SE/G 23UB

Protect tape winding

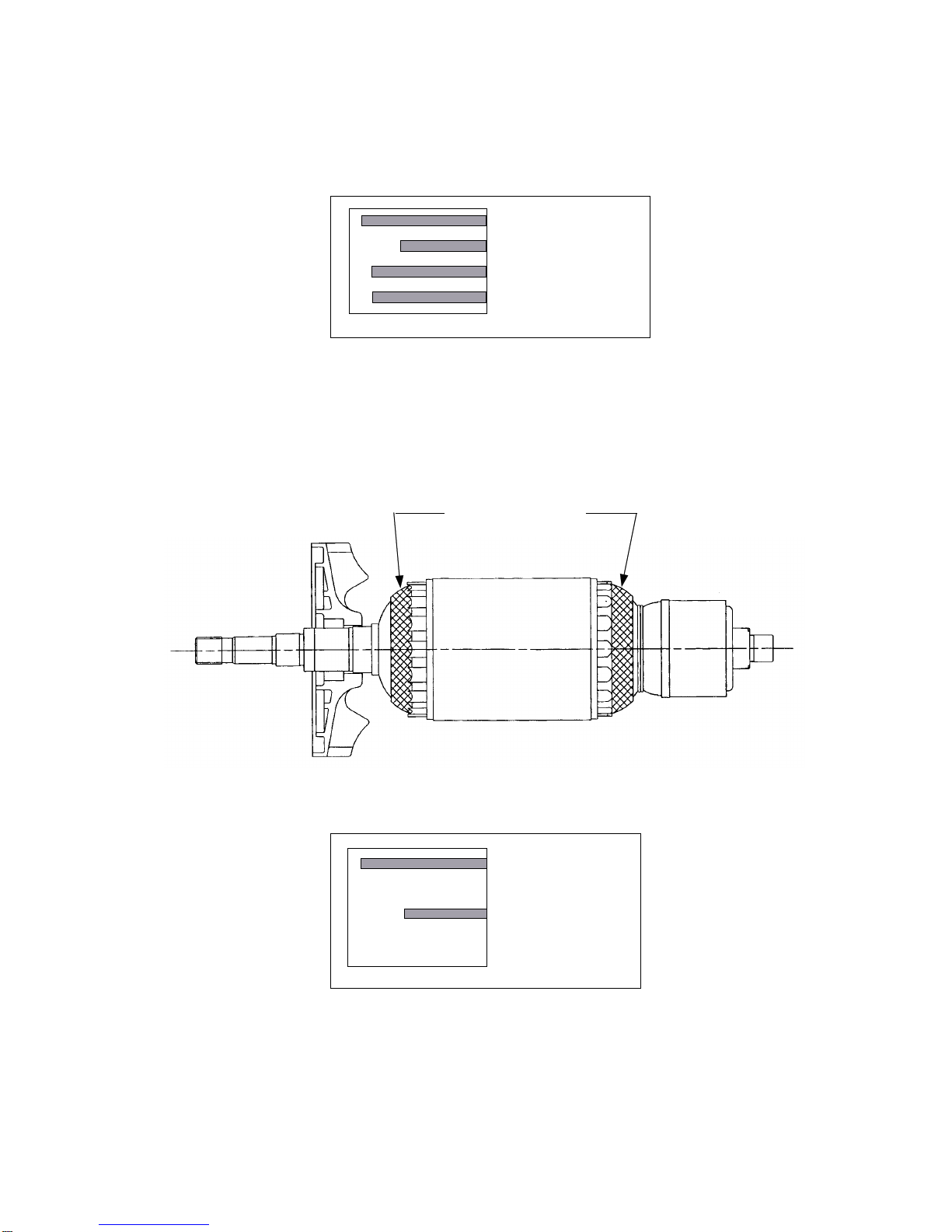

4-3. Wear Resistance of Armature Coil

Both ends of the armature coil are sealed with protect tape in addition to varnish treatment to minimize wear of the

armature coil caused by dust.

(a)

100

50

0

G 18SE3/G 18UA2/G 18SG2/G 18UB2/

G 23SC3/G 23UB2/G 23SE2/G 23UB2

G 18SE2/G 18UA/G 18SG/G 18UB/

G 23SC2/G 23UB/G 23SE/G 23UB

(b)

Fig. 3

--- 4 ---

4-4. Dust-proof Ball Bearing Thanks to the Labyrinth Construction

The ball bearing retainers at both sides of the armature have a labyrinth construction to make the ball bearings

dust-proof.

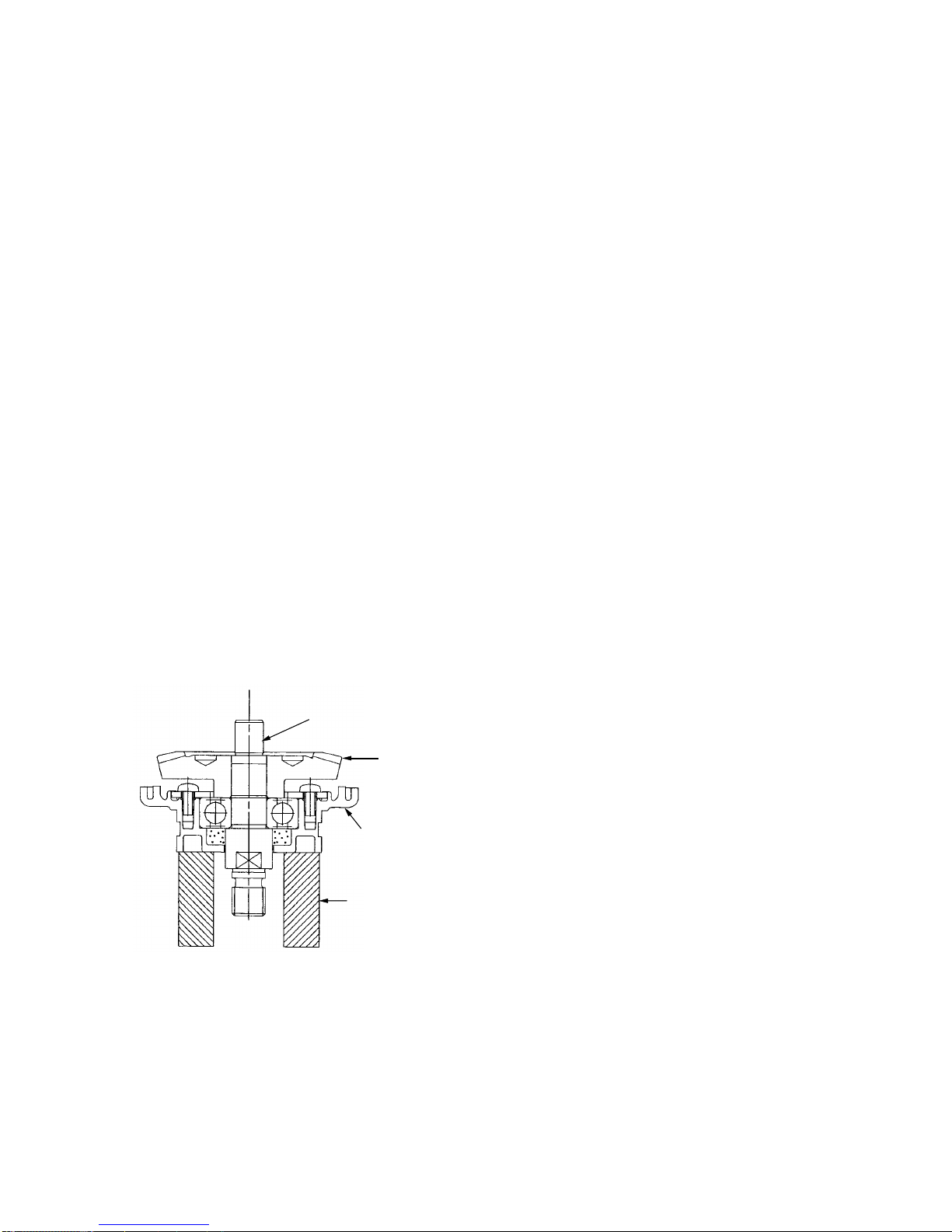

Fig. 4

Bearing cover (A)

Fan

Labyrinth

Ball bearing (6301DDCM)

Armature shaft

Ball bearing

(6000VVCM)

Commutator

Housing

Bearing bushing

Labyrinth

Dust seal

Housing

Bearing bushing

Fig. 5

4-5. Durable Ball Bearing Retainer Thanks to the Iron Bushing

The Models G 18SE3, G 18UA2, G 23SC3, G 23UA2, G 18SG2, G 18UB2, G 23SE2 and G 23UB2 are equipped

with the iron bushing in the ball bearing retainer at the commutator side of the housing to improve the durability of

the ball bearing retainer.

4-6. New Construction to Protect Grease Leakage

1) A rubber ring is added to the ball bearing section of the fan side to protect grease leakage.

2) An O-ring is added to the spindle lock section to protect grease leakage.

O-ring

Fig. 6

Fig. 7

Felt packing

Seal washer

Rubber ring (B)

Pinion

Pushing button

Spring

Metal

Gear cover

Ball bearing section of the fan side

Spindle lock section

M10 special nut

Rubber

ring (A)

--- 5 ---

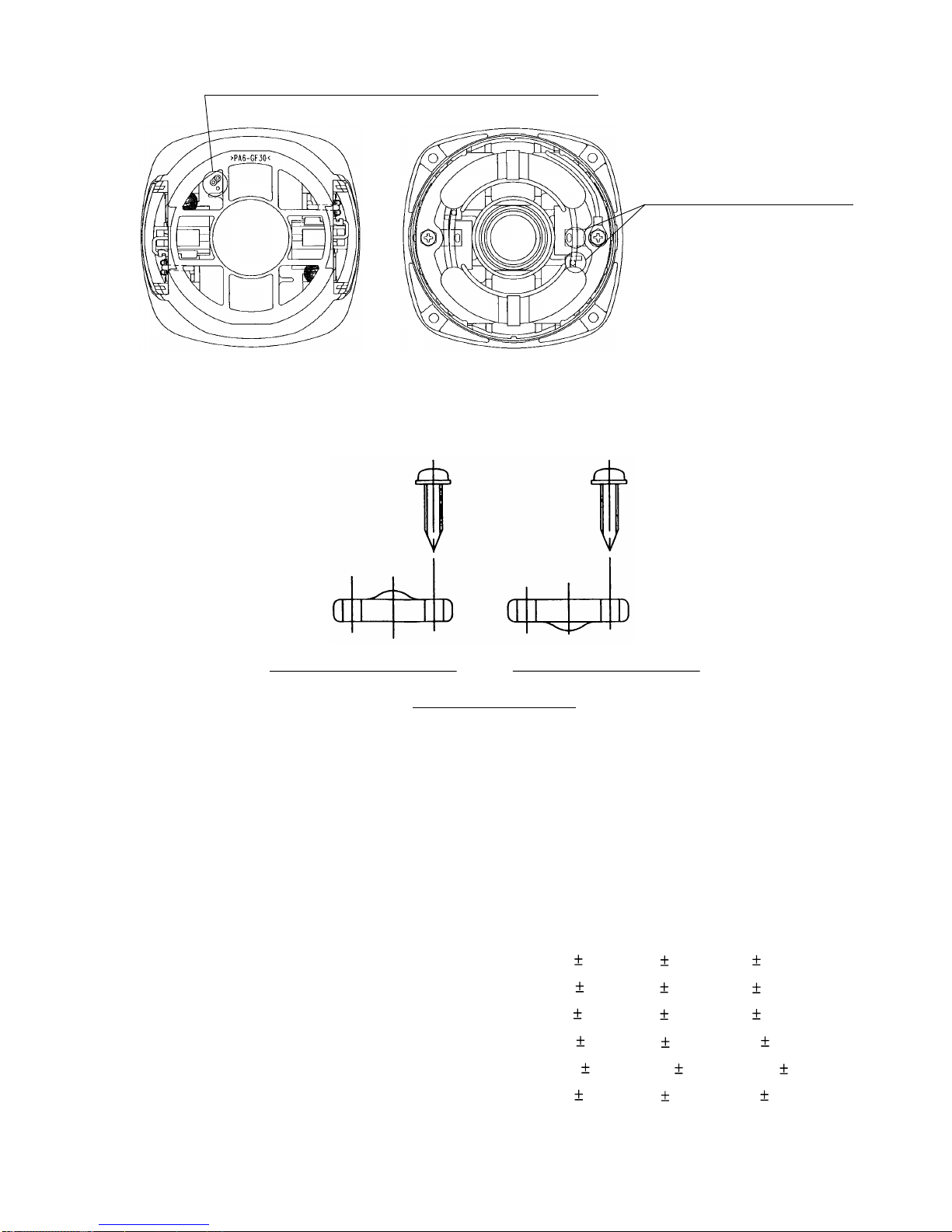

4-7. Wheel Guard Angle-Adjustable without Using a Tool

By following the procedure described below once, the newly developed tool-less wheel guard can be adjusted to a

desired angle without using any tool.

[Installation and adjustment of the wheel guard]

Set the Wheel Guard Ass'y [36] <36> (36) on the Packing Gland [27] <27> (27).

With the Lever [31] <31> (31) closed, tighten the Bolt M8 x 22 [32] <32> (32) until the wheel guard is locked in

position.

Open the Lever [31] <31> (31) for angle adjustment of the wheel guard. (If the wheel guard is difficult to turn,

loosen the Bolt M8 x 22 [32] <32> (32) and readjust the wheel guard.)

Be sure to close the Lever [31] <31> (31) after finishing adjustment before starting operation.

When the Lever [31] <31> (31) becomes dull in motion, lubricate the sliding area between the Set Piece [34]

<34> (34) and the Lever [31] <31> (31).

Fig. 8

--- 6 ---

80 m/s (15,800 ft/min)

A, 24, R, B

*

1

M14 x 2 *1 M14 x 2

Depressedcenter

wheels

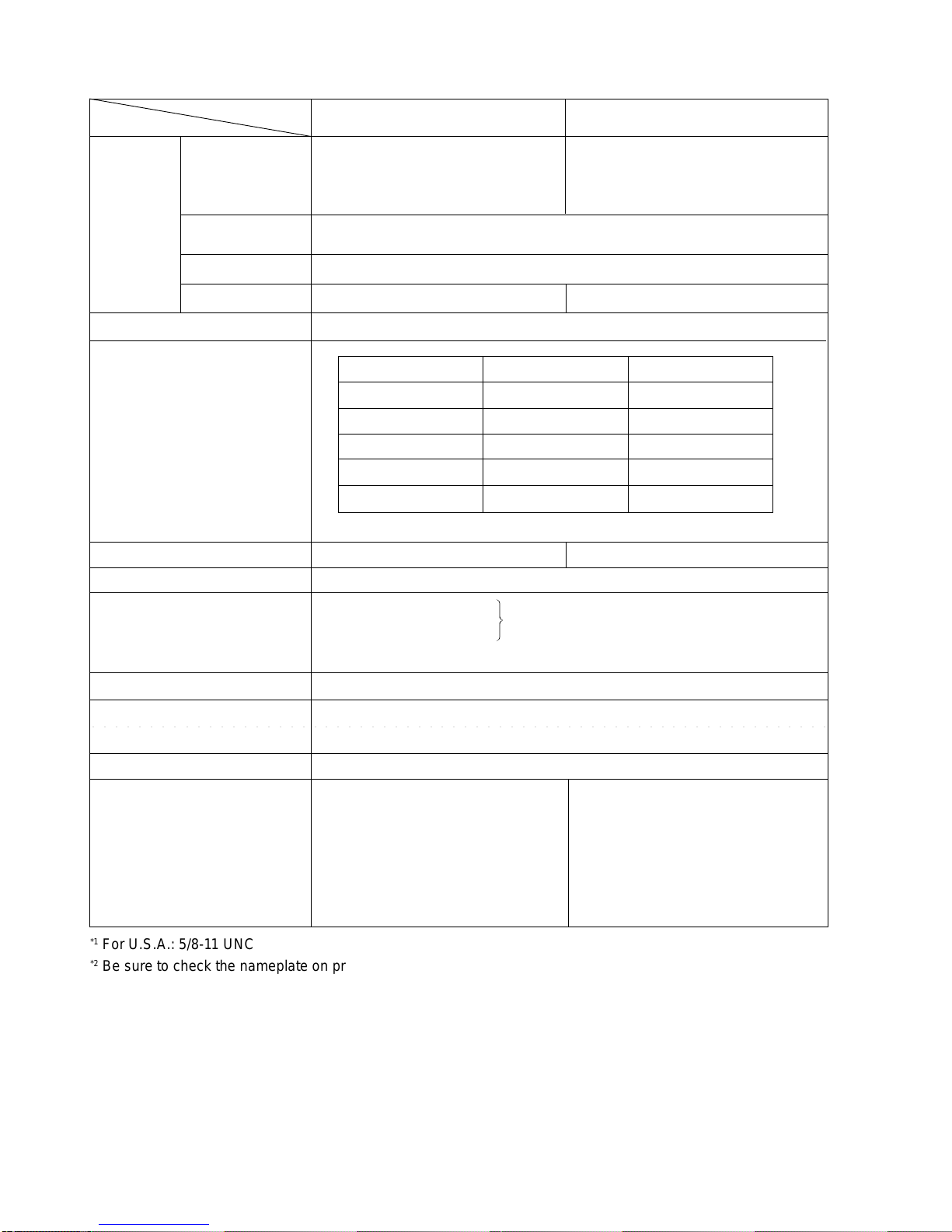

5. SPECIFICATIONS

Model

Item

O.D. 180 mm (7")

x Thickness 6 mm (1/4")

x I.D. 22.2 mm (7/8")

O.D. 230 mm (9")

x Thickness 6 mm (1/4")

x I.D. 22.2 mm (7/8")

G 18SE3/G 18UA2

G 23SC3/G 23UA2

AC single phase 50 or 60 Hz

Power source

Trigger switch

5.0 kg (11.0 lbs.)

8.2 kg (18.1 lbs.)

Corrugated cardboard box

No-load speed

Type of motor

Enclosure

Type of switch

Weight Net: *4 (main body)

Gross:

Type of packing

Standard accessories

Depressed-center wheel 180 mm (7")

(Code No. 316824) ........................1

*5

Side handle (Code No. 937981) ....1

Wrench (Code No. 937913Z).........1

Voltage and power input *

2

*

3

8,500/min *3 6,600/min

AC single phase commutator motor

Housing (Green)

Handle (Black)

Gear cover, packing gland ........................... Aluminum alloy diecasting

........................Polyamide resin with glassfiber

Depressed-center wheel 230 mm (9")

(Code No. 316825) ..........................

1

*5

Side handle (Code No. 937981) ...1

Wrench (Code No. 937913Z) ........1

Wheel nut (B) (Code No. 937917Z)

......................................................1

*5

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

*1

For U.S.A.: 5/8-11 UNC

*2

Be sure to check the nameplate on product as it is subject to change by areas.

*3

For U.S.A.: 6,000/min

*4

Net weight excludes cord, side handle, depressed-center wheel, wheel nut, wheel washer and wheel guard.

*5

Standard accessories may vary depending on market areas.

Dimensions

Max. practical

peripheral speed

Type

Spindle thread

Voltage (V) Current (A) Power input (W)

110

220

2,300

2,300

20.9

11.0

230

2,300

10.5

240

2,300

10.0

120

1,700

15

--- 7 ---

2,500

2,500

*1

Be sure to check the nameplate on product as it is subject to change by areas.

*2

Net weight excludes cord, side handle, depressed-center wheel, wheel nut, wheel washer and wheel guard.

*3

Standard accessories may vary depending on market areas.

80 m/s (15,800 ft/min)

A, 24, R, B

M14 x 2 M14 x 2

Depressedcenter

wheels

Model

Item

O.D. 180 mm (7")

x Thickness 6 mm (1/4")

x I.D. 22.2 mm (7/8")

O.D. 230 mm (9")

x Thickness 6 mm (1/4")

x I.D. 22.2 mm (7/8")

G 18SG2/G 18UB2

G 23SE2/G 23UB2

AC single phase 50 or 60 Hz

Power source

Trigger switch

5.0 kg (11.0 lbs.)

8.2 kg (18.1 lbs.)

Corrugated cardboard box

No-load speed

Type of motor

Enclosure

Type of switch

Weight Net: *2 (main body)

Gross:

Type of packing

Standard accessories

Depressed-center wheel 180 mm (7")

(Code No. 316824) ........................1

*3

Side handle (Code No. 937981) ....1

Wrench (Code No. 937913Z).........1

Voltage and power input *

1

8,500/min 6,600/min

AC single phase commutator motor

Housing (Green)

Handle (Black)

Gear cover, packing gland ........................... Aluminum alloy diecasting

........................Polyamide resin with glassfiber

Depressed-center wheel 230 mm (9")

(Code No. 316825) ..........................

1

*3

Side handle (Code No. 937981) ...1

Wrench (Code No. 937913Z)........1

Wheel nut (B) (Code No. 937917Z)

......................................................1

*3

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Dimensions

Max. practical

peripheral speed

Type

Spindle thread

Voltage (V) Current (A) Power input (W)

110

2,500

22.7

230

11.5

240

10.0

--- 8 ---

6. COMPARISONS WITH SIMILAR PRODUCTS

6-1. Specification Comparisons

*1 Depends on market

*2 Service life of carbon brushes in the

continuous rated load test

*3 Weight without cord, side handle, depressed center wheel, wheel nut, wheel washer and

wheel guard

G 18SE3

G 18UA2

180

(7")

2300

1500

4600

8500

88

175

5.0 (11.0 lbs.)

5.2 (11.5 lbs.)

478 (18-13/16)

83 (3-9/32)

180

(7")

2400

1500

4100

8500

89

160

5.1 (11.2 lbs.)

5.2 (11.5 lbs.)

470 (18-1/2)

92 (3-10/16)

HITACHI

Maker

Model name

Capacity:

Depressed-center wheel dia. (mm)

Power input *1 (W)

Power output *1 (W)

Max. power output *1 (W)

No-load speed (/min)

No-load sound pressure level (dB (A))

Service life of carbon brushes *2 (hr)

Weight *3 (kg)

(Actual weight) (kg)

Dimensions L mm (inch)

H mm (inch)

G 18SE2

G 18UA

180

(7")

2200

1450

4000

8500

86

120

5.0 (11.0 lbs.)

5.2 (11.5 lbs.)

481 (18-15/16)

83 (3-9/32)

B

G 23SC3

G 23UA2

230

(9")

2300

1500

4600

6600

88

175

5.0 (11.0 lbs.)

5.2 (11.5 lbs.)

478 (18-13/16)

83 (3-9/32)

HITACHI

Maker

Model name

Capacity:

Depressed-center wheel dia. (mm)

Power input *1 (W)

Power output *1 (W)

Max. power output *1 (W)

No-load speed (/min)

No-load sound pressure level (dB (A))

Service life of carbon brushes *2 (hr)

Weight *3 (kg)

(Actual weight) (kg)

Dimensions L mm (inch)

H mm (inch)

G 23SC2

G 23UA

230

(9")

2200

1450

4000

6600

86

120

5.0 (11.0 lbs.)

5.2 (11.5 lbs.)

481 (18-15/16)

83 (3-9/32)

230

(9")

2400

1500

4100

6600

89

160

5.1 (11.2 lbs.)

5.2 (11.5 lbs.)

470 (18-1/2)

85 (3-11/32)

B

--- 9 ---

G 18SG2

G 18UB2

180

(7")

2500

1680

4600

8500

88

165

5.0 (11.0 lbs.)

5.2 (11.5 lbs.)

478 (18-13/16)

83 (3-9/32)

180

(7")

2600

1600

4200

8500

89

150

5.1 (11.2 lbs.)

5.2 (11.5 lbs.)

470 (18-1/2)

85 (3-11/32)

HITACHI

Maker

Model name

Capacity:

Depressed-center wheel dia. (mm)

Power input *1 (W)

Power output *1 (W)

Max. power output *1 (W)

No-load speed (/min)

No-load sound pressure level (dB (A))

Service life of carbon brushes *2 (hr)

Weight *3 (kg)

(Actual weight) (kg)

Dimensions L mm (inch)

H mm (inch)

G 18SG

G 18UB

180

(7")

2400

1530

4000

8500

86

110

5.0 (11.0 lbs.)

5.2 (11.5 lbs.)

481 (18-15/16)

83 (3-9/32)

B

G 23SE2

G 23UB2

230

(9")

2500

1680

4600

6600

88

165

5.0 (11.0 lbs.)

5.2 (11.5 lbs.)

478 (18-13/16)

83 (3-9/32)

HITACHI

Maker

Model name

Capacity:

Depressed-center wheel dia. (mm)

Power input *1 (W)

Power output *1 (W)

Max. power output *1 (W)

No-load speed (/min)

No-load sound pressure level (dB (A))

Service life of carbon brushes *2 (hr)

Weight *3 (kg)

(Actual weight) (kg)

Dimensions L mm (inch)

H mm (inch)

G 23SE

G 23UB

230

(9")

2400

1530

4000

6600

86

110

5.0 (11.0 lbs.)

5.2 (11.5 lbs.)

481 (18-15/16)

83 (3-9/32)

230

(9")

2600

1600

4200

6500

89

150

5.1 (11.2 lbs.)

5.2 (11.5 lbs.)

470 (18-1/2)

85 (3-11/32)

B

*1 Depends on market

*2 Service life of carbon brushes in the

continuous rated load test

*3 Weight without cord, side handle, depressed center wheel, wheel nut, wheel washer and

wheel guard

--- 10 ---

6-2. Practical Test Data

Comparison of temperature rise of stator coil section:

The graph below shows the relationship between load and temperature rise of the stator coil. The temperature

rise of the Models G 23SC3 is the lowest among the competitive models. This means that the resistance to

overload usage of the Model G 23SC3 is superior to other maker's models.

Fig. 9

Fig. 10

The temperature rise of Model G 23SE2 is lower than the Model G 23SE.

(B is the lowest.)

Load

Stator coil temperature rise (K)

200

100

0

C

G 23SC3

B (2400 W product)

300

400

X

X

X

X: Burn-out point

2300 2400 W

G 23SC2

X

Load

Stator coil temperature rise (K)

200

100

0

G 23SE2

B (2600 W product)

300

400

X

X

X: Burn-out point

2500 2600 W

G 23SE

X

--- 11 ---

7. PRECAUTIONS IN SALES PROMOTION

In the interest of promoting the safest and most efficient use of the Models G 18SE3, G 18UA2, G 18SG2,

G 18UB2, G 23SC3, G 23UA2, G 23SE2 and G 23UB2 Disc Grinders by all of our customers, it is very important

that at the time of sale, the salesperson carefully ensures that the buyer seriously recognizes the importance of

the contents of the Handling Instructions, and fully understands the meaning of the precautions listed on the

Name Plate.

7-1. Handling Instructions

Although every effort is made in each step of design, manufacture and inspection to provide protection against

safety hazards, the dangers inherent in the use of any electric power tool cannot be completely eliminated.

Accordingly, general precautions and suggestions for the use of electric power tools, and specific precautions and

suggestions for the use of the disc grinders are listed in the Handling Instructions to enhance the safe and efficient

use of the tool by the customer. Salespersons must be thoroughly familiar with the contents of the Handling

Instructions to be able to offer appropriate guidance to the customer during sales promotion.

7-2. Caution on Name Plate

Each tool is provided with a Name Plate which contains the following basic safety precautions in the use of the

tool.

WARNING

To reduce the risk of injury, user must read and understand instruction manual.

Always use proper guards when grinding and wear eye protection.

Use only accessories rated at least * /min.

AVERTISSEMENT

Afin de reduire le risque de blessures, I'utilisateur doit lire et bien comprendre le mode d'emploi.

Utilisez toujours un outil muni d'un protecteur adequat et portez des lunettes on une visiere.

N'utilisez que des accessoires prevus pour au moins * /min.

(2) For Australia and New Zealand

CAUTION

Read thoroughly HANDLING INSTRUCTIONS before use.

(3) For U.S.A. and Canada

(5) For Taiwan

(4) For China

* G 23SC3 For U.S.A.: 6,600

For CAN: 6,600

* G 18SE3 For U.S.A.: 6,600

For CAN: 8,500

(1)

For U.K., Germany, Belgium, France, Netherlands, Austria, Spain, Italy, Finland, Norway and Switzerland

--- 12 ---

7-3. Precautions on Usage

Never press the pushing button while the depressed-center wheel is rotating.

If the pushing button is pressed while the depressed-center wheel is rotating, the spindle will stop immediately.

In such a case, there is a danger that the wheel nut may be loosened so that the depressed-center wheel flies off

unexpectedly to cause possible serious injury.

--- 13 ---

8. PRECAUTIONS IN DISASSEMBLY AND REASSEMBLY

The [Bold] numbers in the descriptions below correspond to the numbers in the Parts List and the exploded

assembly diagram for the Models G 23SC3, G 23SE2, G 18SE3 and G 18SG2, and the <Bold> numbers to those

in the Parts List and the exploded assembly diagram for the Models G 23UA2, G 18UA2, and G 18UB2, and the

(Bold) numbers to those in the Parts List and the exploded assembly diagram for the Model G 23UB2.

8-1. Disassembly

(1) Removal of the Armature [13] <13> (13)

1. Open the Lever [31] <31> (31) and loosen the Bolt M8 x 22 [32] <32> (32), and remove the Wheel Guard

Ass'y [36] <36> (36).

2. Loosen the Tapping Screw (W/Flange) D4 x 16 (Black) [49] <48> (49), and remove the Brush Cover [48] <47>

(48).

3. Remove the two Carbon Brushes [50] <49> (50) from the Brush Holders [53] <52> (53).

4. Remove the four Tapping Screws (W/Flange) D5 x 35 [2] <2> (2). The Armature [13] <13> (13) can then be

taken out simultaneously with the Gear Cover Ass'y [5] <5> (5), Packing Gland [27] <27> (27) and related

parts.

5. Remove the four Hex. Socket Hd. Bolts (W/Flange) M5 x 16 [28] <28> (28).

6. After removing the two Seal Lock Screws (W/Sp. Washer) M5 x 14 (Black) [1] <1> (1), the Armature [13] <13>

(13) can be extracted together with the Bearing Cover (A) [12] <12> (12) and related parts.

7. Carefully wrap the Armature [13] <13> (13) with a soft, clean rag to protect it from being damaged, and clamp

it securely in a vise. Then, remove the Special Nut M10 [6] <6> (6), and extract the Pinion [7] <7> (7).

8. For the models indicated under Fig. 11, the Ball Bearing 6301DDCMPS2L [10] <10> (10) can be removed from

the Armature [13] <13> (13) by utilizing a J-204 Bearing Puller (special repair tool, Code No. 970982) as

illustrated. After the ball bearing has been removed, Bearing Cover (A) [12] <12> (12) can be easily taken off.

Bearing Puller (Code No. 970982)

Push

Fig. 11

--- 14 ---

(2) Removal of the Dust Seal [43] <42> (43)

1. Insert the hooks of the J-204 bearing puller between the commutator and the Dust Seal [43] <42> (43) from

both sides, and fix the hooks with the wing bolts.

2. Place the J-204 bearing puller on a supporting jig and push down on the armature shaft with a hand press to

remove the Dust Seal [43] <42> (43) together with the Ball Bearing 6000VVCMPS2L [44] <43> (44).

Replace the Dust Seal [43] <42> (43) with new one because it is damaged by the removal of the Ball Bearing

6000VVCMPS2L [44] <43> (44).

(3) Removal of the Stator [16] <16> (16)

1. After removing the Armature [13] <13> (13), disconnect the internal wires connected to the Brush Holders [53]

<52> (53) and the Switch [55] <55> (56) .

2. Loosen the two Hex. Hd. Tapping Screws D5 x 75 [15] <15> (15) and remove the Stator [16] <16> (16) from

the Housing Ass'y [46] <45> (46). If the Stator [16] <16> (16) cannot be easily removed from the Housing

Ass'y [46] <45> (46), disassembly can be facilitated by heating the Housing Ass'y [46] <45> (46) to a

temperature of approximately 60˚C (140˚F) with an appropriate heating device.

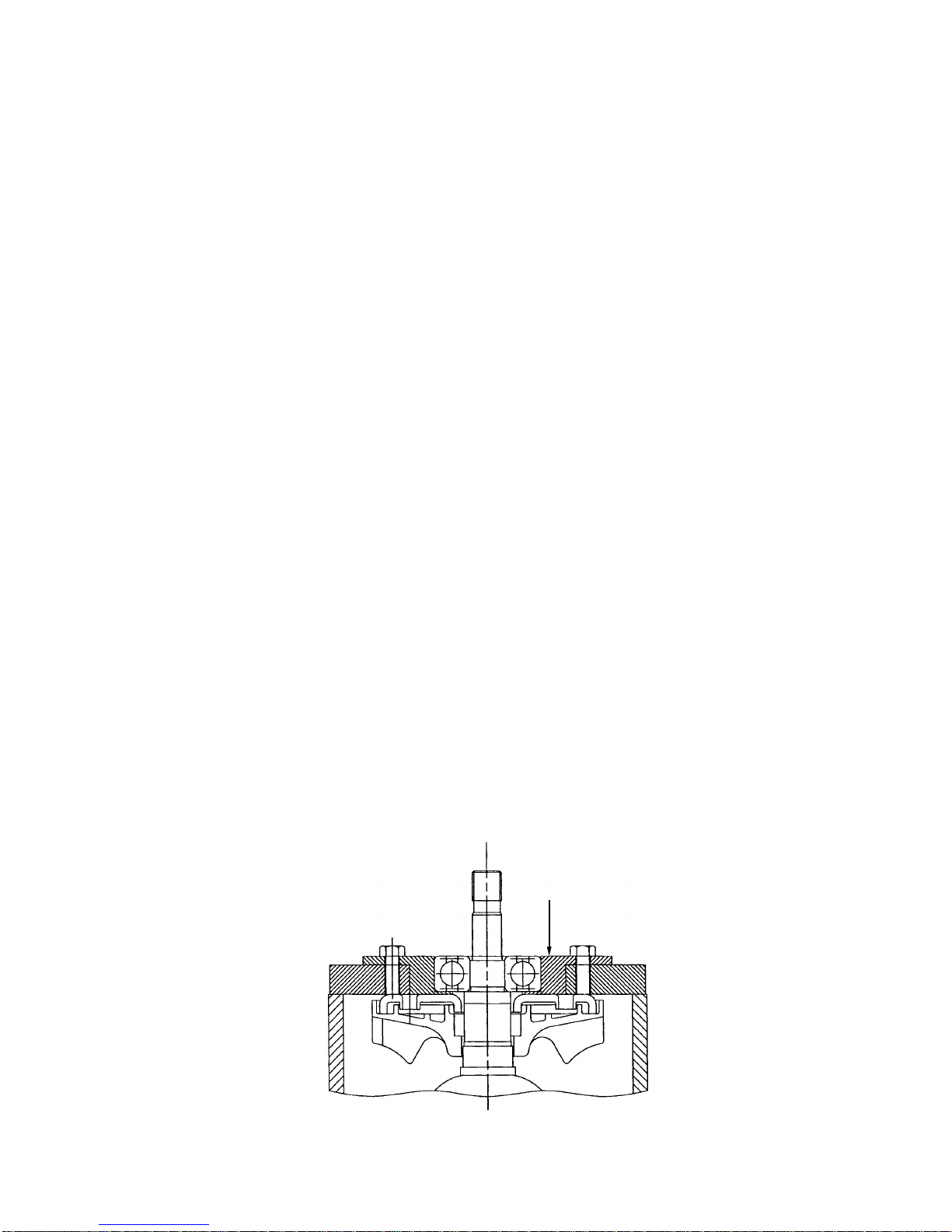

(4) Removal of the Gear [20] <20> (20)

1. Loosen the four Hex. Socket Hd. Bolts (W/Flange) M5 x 16 [28] <28> (28), and remove the Packing Gland

[27] <27> (27) together with the Spindle [25] <25> (25) and Gear [20] <20> (20) from the Gear Cover Ass'y

[5] <5> (5) in a single body.

2. Remove the Retaning Ring for D12 Shaft [19] <19> (19) from the Spindle [25] <25> (25).

3. When it is necessary to remove the Gear [20] <20> (20) from the Spindle [25] <25> (25), it is highly

recommended that the special repair tools described below are utilized.

Place the assembly on a sleeve that matches the

dimension of the Packing Gland [27] <27> (27) and

push down on the top of the Spindle [25] <25> (25)

with a hand press to remove the Gear [20] <20>

(20) as shown in Fig. 12.

Spindle

Push

Gear

Fig. 12

Packing gland

Sleeve

--- 15 ---

Fig. 14

(2) When replacing the Armature [13] <13> (13) and the

Ball Bearing 6000VVCMPS2L [44] <43> (44) on the

commutator side, press inward on the Dust Seal [43]

<42> (43) while taking care of its direction until the end

face of the Dust Seal [43] <42> (43) hits against the

butting surface of the Armature [13] <13> (13) and

make sure that the Dust Seal [43] <42> (43) cannot

turn freely. (See Fig. 13.)

The Dust Seal [43] <42> (43) is an important element

for improved dust protection of the Ball Bearing

6000VVCMPS2L [44] <43> (44). Be sure to use a new

one at every disassembly work of the Ball Bearing

6000VVCMPS2L [44] <43> (44).

Fig. 13

Dust Seal

(3) Apply Three Bond TB 1406 Screw Locking Agent to the following screws.

Two Seal Lock Screws (W/Sp. Washer) M5 x 14 (Black) [1] <1> (1) which fix Bearing Cover (A) [12] <12> (12)

in place.

Four Hex. Socket Hd. Bolt (W/Flange) M5 x 16 [28] <28> (28) which fix Packing Gland [27] <27> (27) in

place.

Armature Shaft

Ball Bearing

(6000VVCMPS2L)

(4) Check that the spring end does not hold the terminal when mounting the carbon brush. Do not catch the

terminal in the brush cover when mounting the brush cover.

8-2. Reassembly

Put the parts together in the reverse order of disassembly, with the precautions given below.

(1) Generously lubricate the teeth of Gear [20] <20> (20) and Pinion [7] <7> (7) with grease. Rub grease onto the

teeth with your fingers so that the grease reaches each tooth bottom. Note that under-lubricated Gear [20]

<20> (20) and Pinion [7] <7> (7) may wear at a faster rate.

--- 16 ---

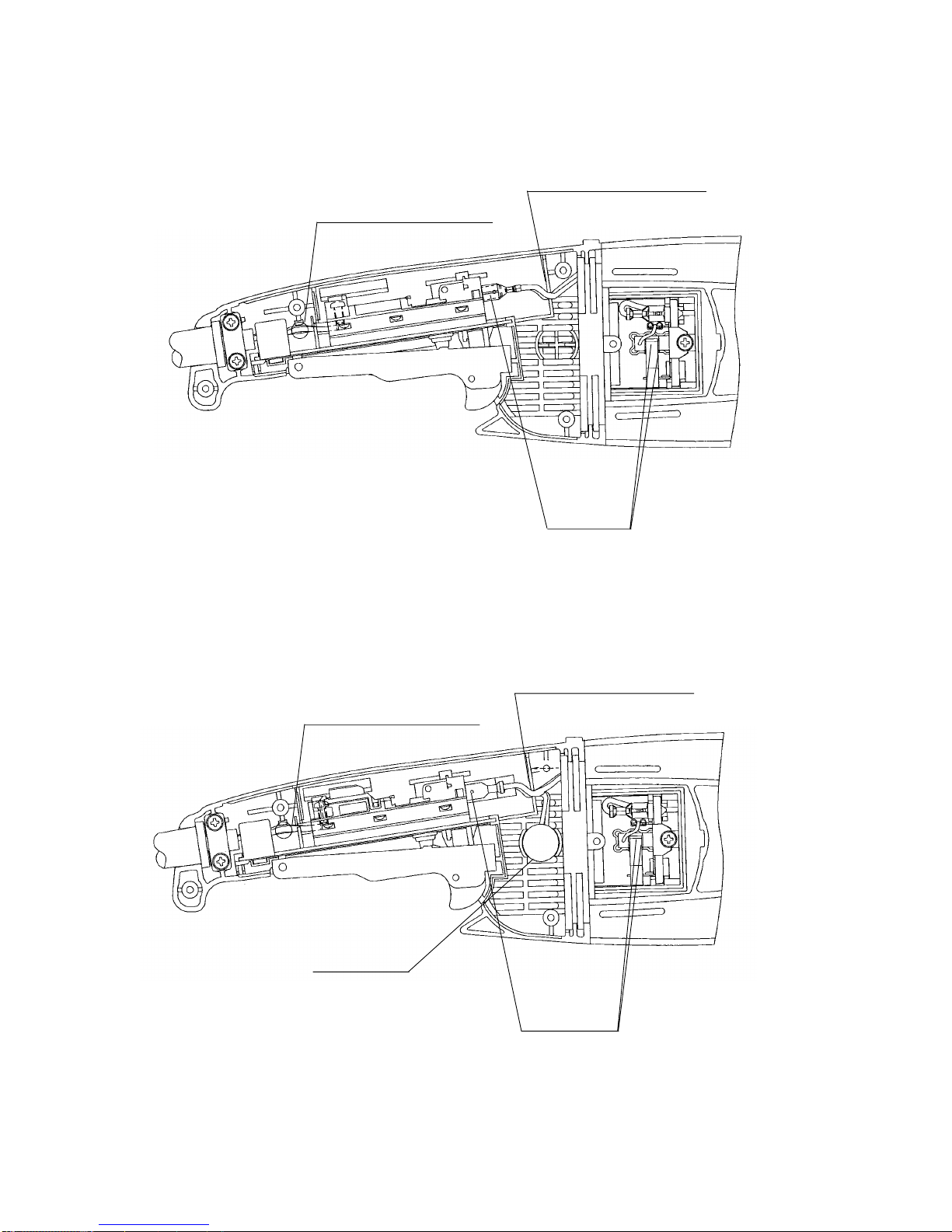

(5) Arrange the internal wires as shown in Figs. 15 and 16 being careful not to connect in wrong direction or

position and not to get the internal wires caught in parts.

Fig. 15

(a) G 18SE3/G 23SC3/G 18SG2/G 23SE2

(b) G 18UA2/G 23UA2/G 18UB2/G 23UB2

Insert the

terminal

securely.

Pass the internal wire of

the cord through this area.

Fit the internal wire in

the groove securely.

Insert the

terminal

securely.

Fit the internal wire in

the groove securely.

Pass the internal wire of

the cord through this area.

Resistor ass'y

--- 17 ---

Fig. 16

Fig. 17

(6) Mount the cord clip as shown in Fig. 17 being careful of the direction.

The internal wire with tube of stator shall pass this groove.

Cord dia.: Over 8.5 mm dia.

The internal wire of stator

shall pass this area. (2 pcs.)

Cord clip mounting diag.

Cord dia.: Max. 8.5 mm dia.

8-3. Lubrication Points and Types of Lubricant

Pinion chamber of Gear Cover Ass'y [5] <5> (5)................... ALVANIA grease EP (LF) O 35 g

Generously rub grease onto the gear and pinion

and inner circumference of metal.

8-4. Tightening Torque

Tapping Screws (W/Flange) D4 x 16

[49] <48> (49) [57] <57> (58).........................................................2.0 0.5 N

•m (20 5 kgf•cm, 1.5 0.4 ft-lbs.)

Seal Lock Screws (W/Sp. Washer) M5 x 14 [1] <1> (1)................. 2.9 0.5 N

•m (30 5 kgf•cm, 2.2 0.4 ft-lbs.)

Tapping Screw (W/Flange) D5 x 35 [2] <2> (2) .............................. 3.4 0.7 N

•m (35 7 kgf•cm, 2.5 0.5 ft-lbs.)

Hex. Socket Hd. Bolt (W/Flange) M5 x 16 [28] <28> (28) .............. 7.8 1.5 N

•m (80 15 kgf•cm, 5.8 1.1 ft-lbs.)

Special Nut M10 [6] <6> (6) ...........................................................

15.3 3.1 N•m (150 30 kgf•cm, 10.8 2.2 ft-lbs.)

Machine Screw M5 x 10 [21] <21> (21) ......................................... 5.9 1.5 N•m (60 15 kgf•cm, 4.3 1.1 ft-lbs.)

--- 18 ---

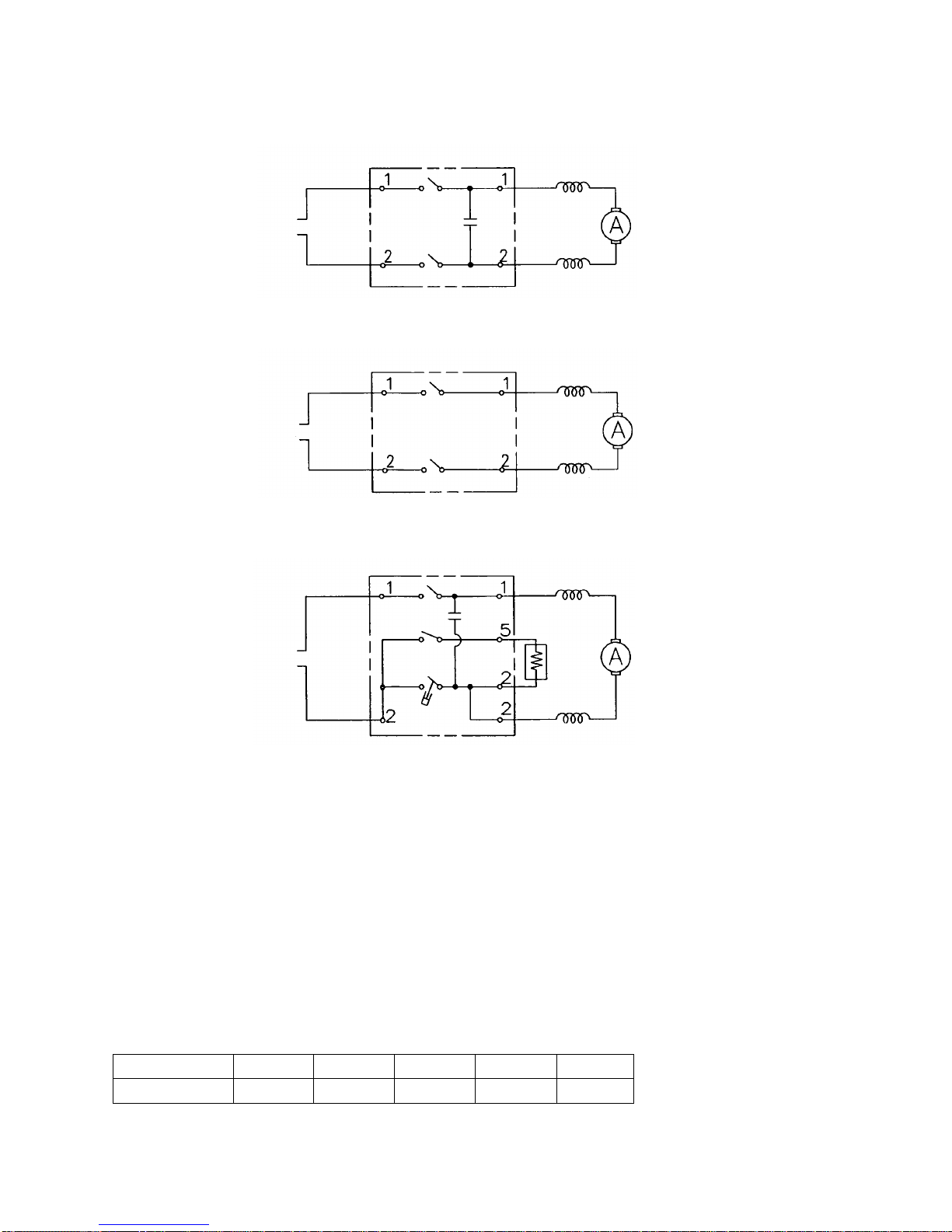

8-5. Wiring Diagram

(1) G 18SE3/G 23SC3

G 18SG2/G 23SE2

(2) G 18UA2/G 23UA2

G 18UB2/G 23UB2

Wiring dia.

8-6. Insulation Tests

On completion of disassembly and repair, measure the insulation resistance, and conduct the dielectric strength

test.

Insulation resistance: 7 M Ω or more with DC 500 V Megohm Tester

Dielectric strength test: AC 4,000 V/1 minute, with no abnormalities ...................220 V --- 240 V products

AC 2,500 V/1 minute, with no abnormalities ................... 110 V --- 127 V products

8-7. No-load Current Value

After no-load operation for 30 minutes, the no-load current value should be as follows.

(a)

(b)

(c)

<For U.S.A.>

Fig. 18

230

3.8

Voltage (V)

Current (A) max.

110

6.3

220

3.6

240

3.7

120

6.8

Field Coil

Field Coil

Switch

Condensor

Ass'y (0.22µF)

Power

Source

Field Coil

Field Coil

Switch

Damper

Power

Source

Condensor

Ass'y (0.22µF)

Resistor

Ass'y

Field Coil

Field Coil

Power

Source

Switch

--- 19 ---

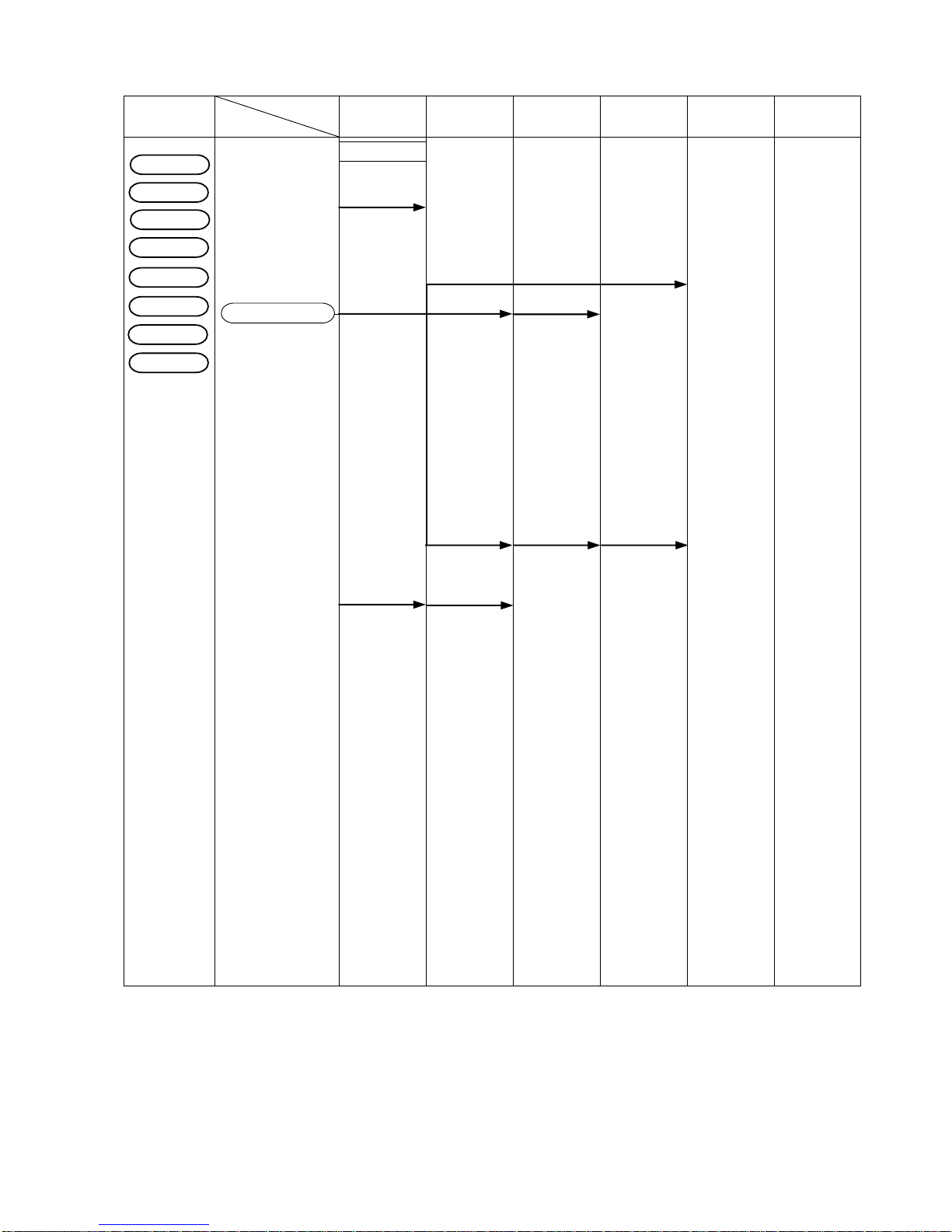

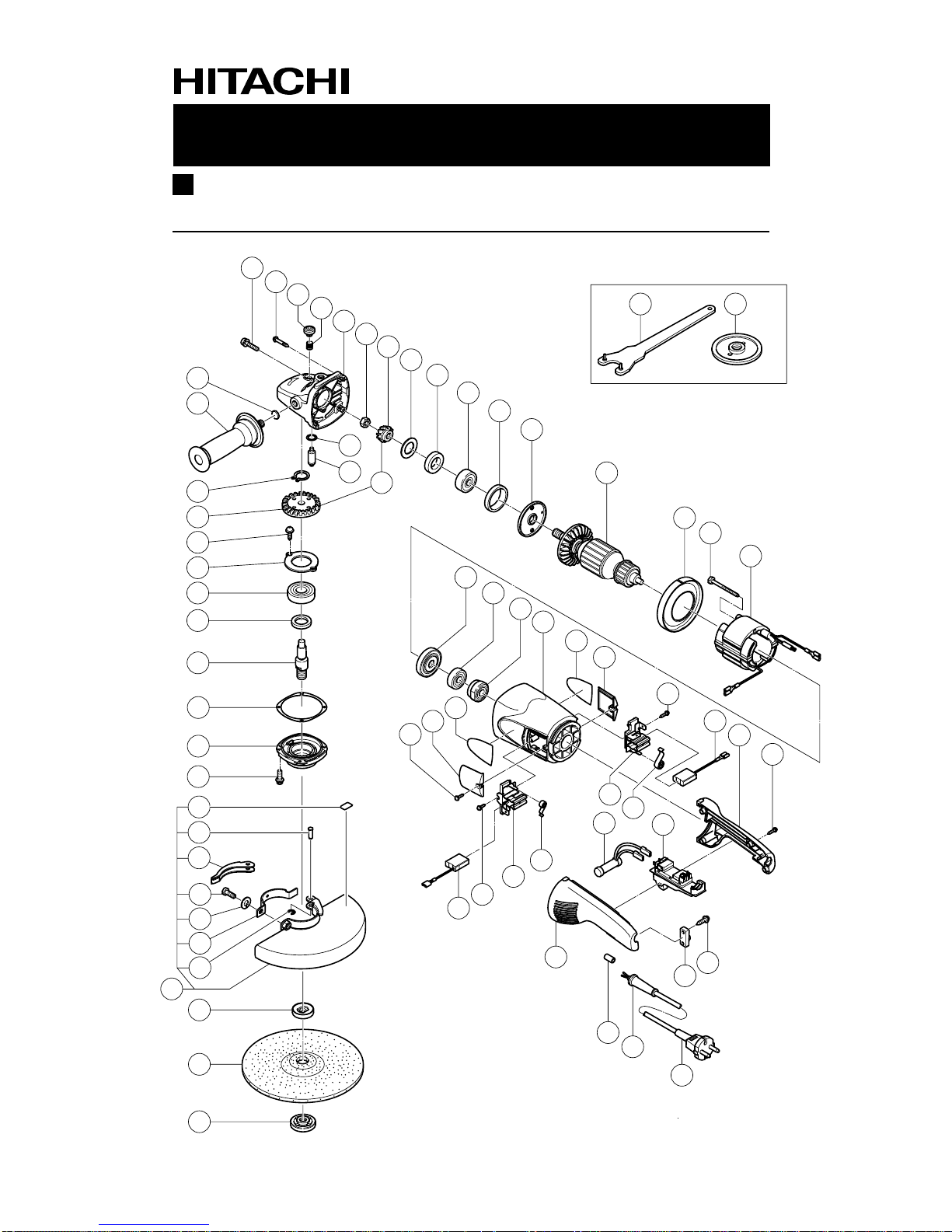

9. STANDARD REPAIR TIME (UNIT) SCHEDULES

MODEL 10 20 30 40

Fixed

Variable

Work Flow

Handle (A)

Switch

Cord

60 min.

50

Gear

Housing Ass'y

Stator

Wheel Guard

Ass'y

Handle (B)

Gear Cover

Ass'y

Rubber Ring (B)

General Assembly

G 18SE3

G 18SG2

G 23SC3

G 23SE2

Pinion

Armature

Ball Bearing

(6301DD)

Ball Bearing

(6200VV)

Seal Washer

Felt Packing

Bearing

Cover (A)

Dust Seal

Bearing Bushing

Bearing

Cover (B)

Ball Bearing

(6302DD)

Felt Packing (B)

Packing Gland

Spindle

Seal Plate

G 23UB2

G 23UA2

G 18UA2

G 18UB2

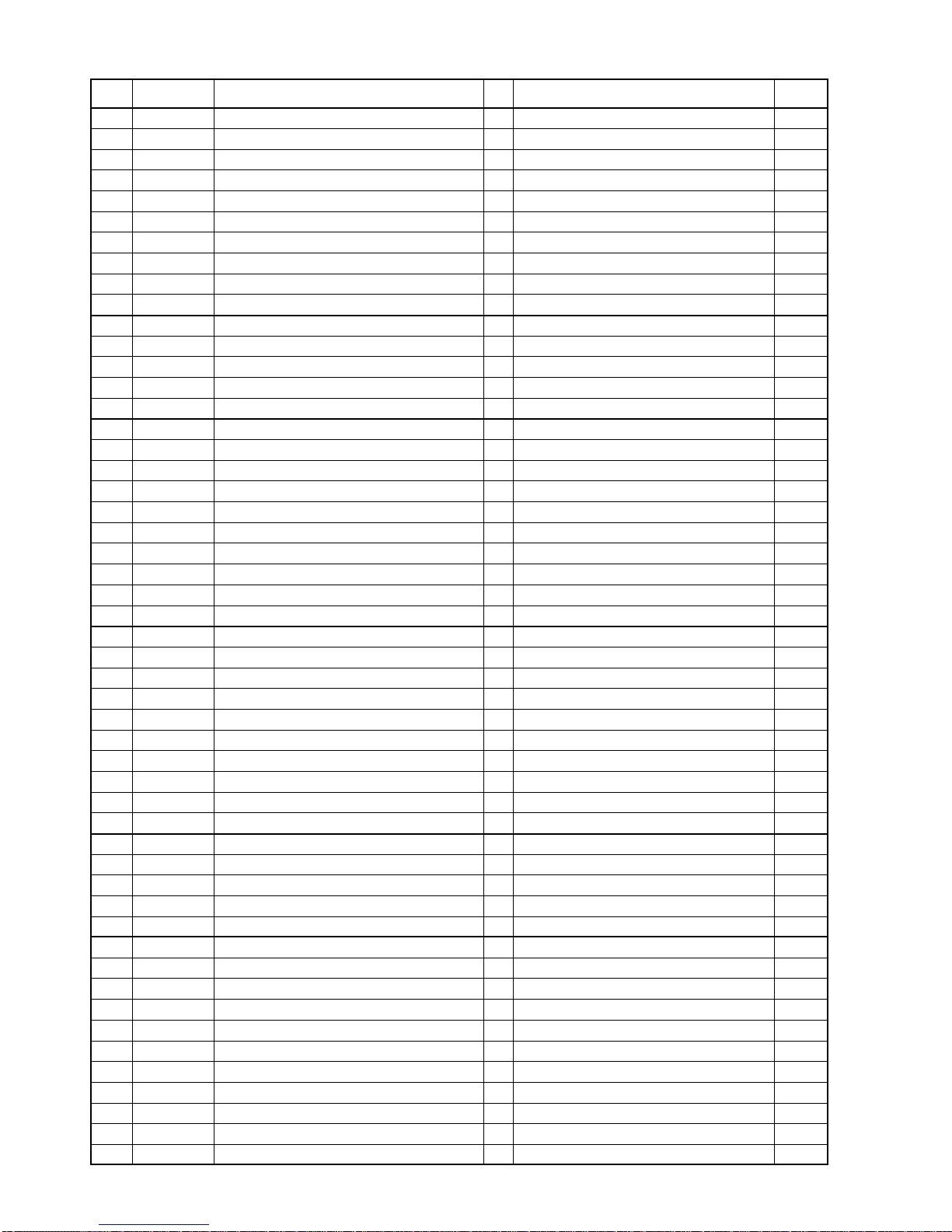

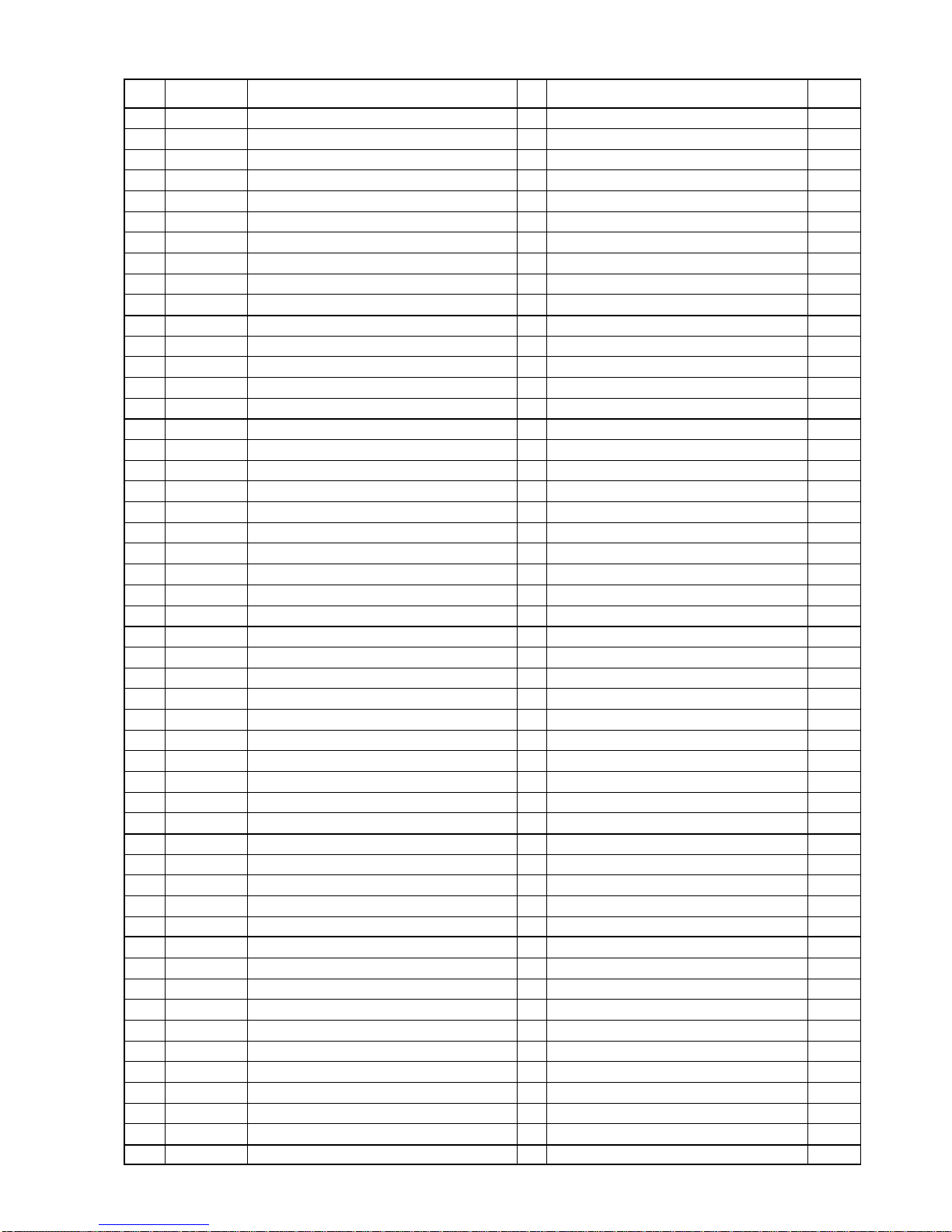

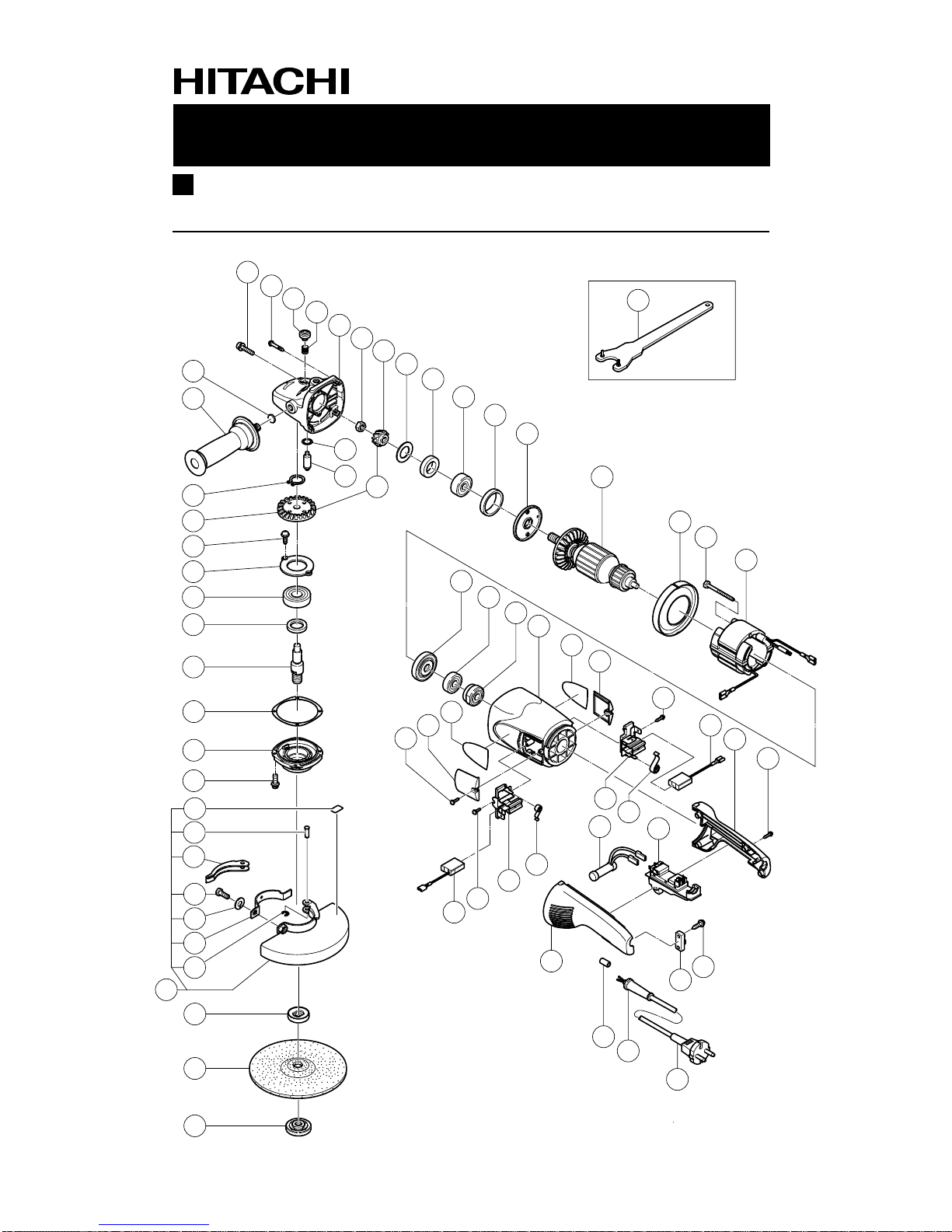

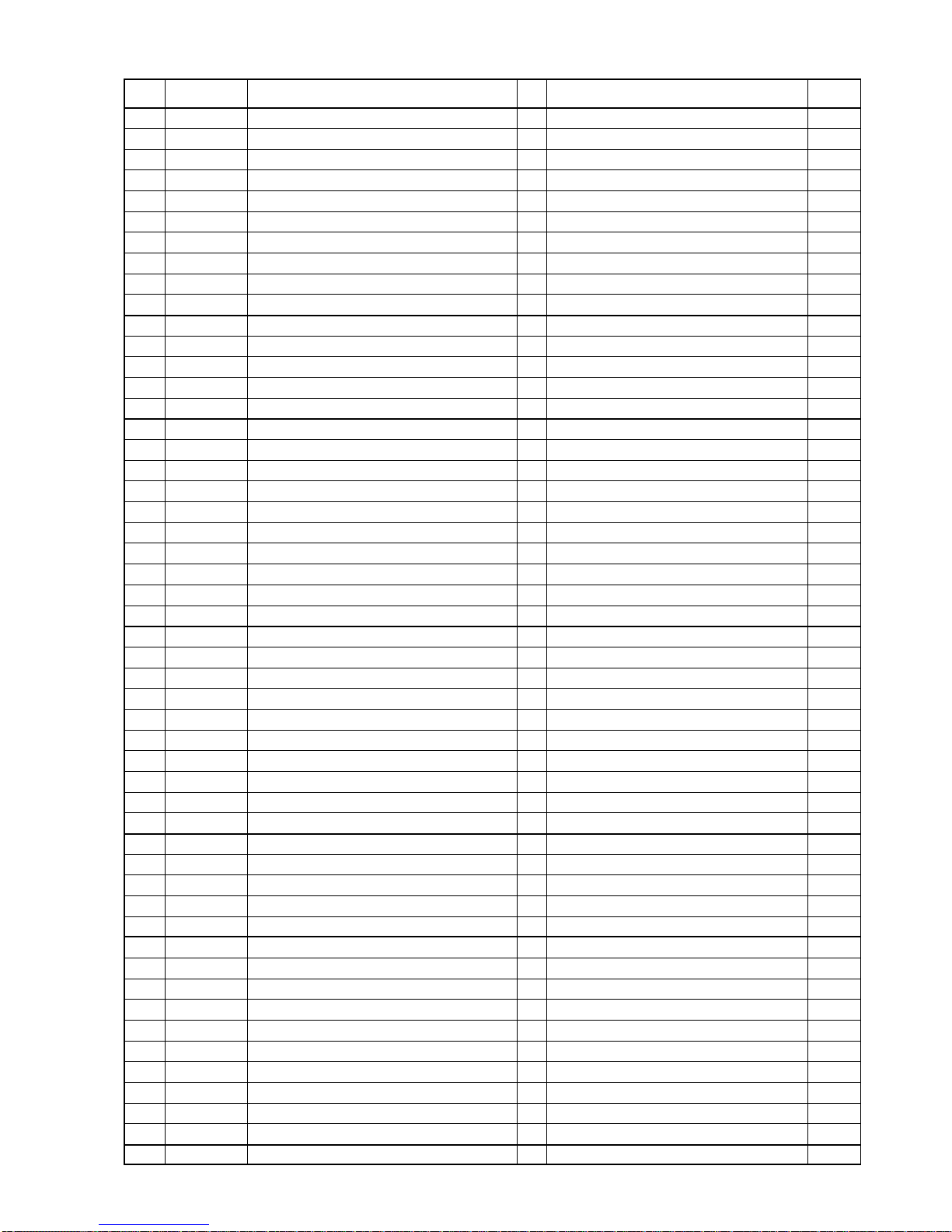

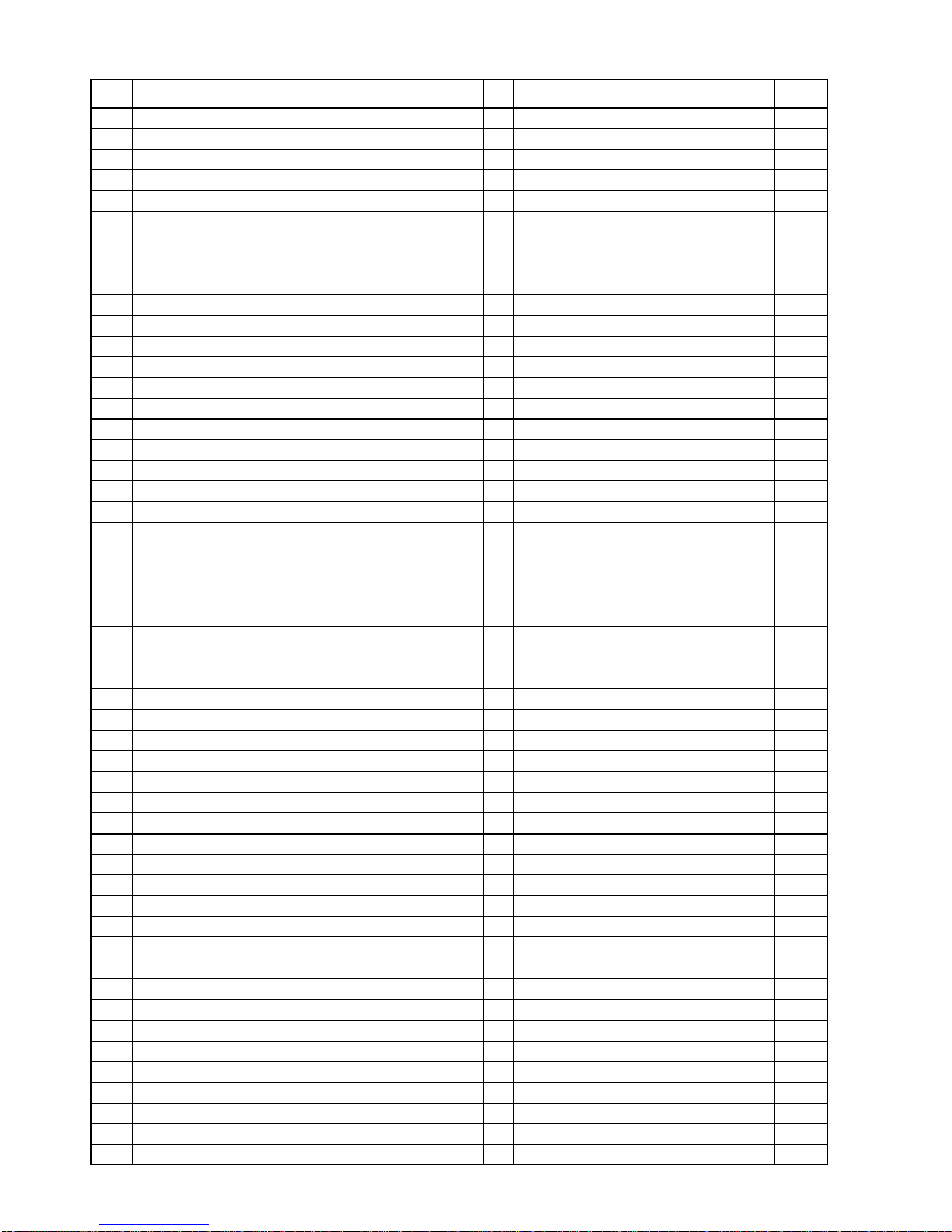

ELECTRIC TOOL PARTS LIST

LIST NO.

DISC GRINDER

Model G 18SE3

2002 • 11•30

(E1)

E250

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

27

28

29

26

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

49

49

48

52

50

49

53

54

53

54

55

56

57

58

59

60

61

501 502

*

ALTERNATIVE PARTS

--- 2 ---

ITEM

NO.

CODE NO.

DESCRIPTION REMARKS

NO.

USED

PARTS

11 -- 02

G 18SE3

1 315-636

SEAL LOCK SCREW (W/SP.WASHER) M5X14 (BLACK)

2

2 301-654 TAPPING SCREW (W/FLANGE) D5X35 4

3 306-888 PUSHING BUTTON 1

4 320-219 SPRING 1

5 320-217 GEAR COVER ASS’Y 1 INCLUD.3,4,17,40,41

6 320-226 SPECIAL NUT M10 1

* 7 320-243 PINION 1

* 7 320-225 PINION 1 FOR USA

8 320-221 SEAL WASHER 1

9 320-222 FELT PACKING 1

10 630-1DD BALL BEARING 6301DDCMPS2L 1

11 994-208 RUBBER RING (B) 1

12 320-220 BEARING COVER (A) 1

* 13 360-594U ARMATURE ASS’Y 110V-120V 1 INCLUD.9,10,43,44

* 13 360-594E ARMATURE 220V-230V 1

* 13 360-594F ARMA TURE 240V 1

14 320-215 FAN GUIDE 1

15 984-271 HEX. HD. TAPPING SCREW D5X75 2

* 16 340-546C STATOR 110V-120V 1

* 16 340-546E STATOR 220V-230V 1

* 16 340-546F STATOR 240V 1

17 937-033 FELT WASHER 1

18 321-542 SIDE HANDLE 1

19 939-542

RETAINING RING FOR D12 SHAFT (10 PCS.)

1

* 20 320-242 GEAR 1

* 20 320-224 GEAR 1 FOR USA

21 949-236 MACHINE SCREW M5X10 (10 PCS.) 2

22 320-229 BEARING COVER (B) 1

23 630-2DD BALL BEARING 6302DDCMPS2L 1

24 990-852 FELT PACKING (B) 1

* 25 320-234 SPINDLE 1

* 25 321-541 SPINDLE 1 FOR USA,CAN

26 320-228 SEAL PLATE 1

27 320-227 PACKING GLAND 1

28 994-192

HEX. SOCKET HD. BOLT (W/FLANGE) M5X16

4

29 311-492 LABEL 1

30 321-546 SET PIN 1

31 321-545 LEVER 1

32 306-887 BOLT M8X22 1

33 949-457 SPRING WASHER M8 (10 PCS.) 1

34 321-544 SET PIECE 1

35 673-489

RETAINING RING (E-TYPE) FOR D5 SHAFT

1

36 321-543 WHEEL GUARD ASS’Y 1 INCLUD.29-35

* 37 937-907Z WHEEL WASHER (A) 1

* 37 937-922P WHEEL WASHER (B) FOR D5/8” HOLE 1 FOR USA,CAN

* 37 937-908Z WHEEL WASHER (B) 1 FOR AUS

* 38 316-824 D. C. WHEELS 180MM A24R (25 PCS.) 1

EXCEPT FOR GBR, HOL, ESP, FRG, AUT, USA

* 39 937-909Z WHEEL NUT M14X2 1

* 39 937-923P WHEEL NUT 5/8”-11UNC 1 FOR USA,CAN

40 320-218 O-RING 1

41 306-890 LOCK PIN 1

*

ALTERNATIVE PARTS --- 3 ---

ITEM

NO.

CODE NO.

DESCRIPTION REMARKS

NO.

USED

PARTS

11 -- 02

G 18SE3

* 42 320-241 GEAR ASS’Y 1 INCLUD. 7, 20

* 42 320-223 GEAR AND PINION ASS’Y 1 INCLUD. 7, 20 FOR USA

43 320-216 DUST SEAL 1

44 600-0VV BALL BEARING 6000VVCMPS2L 1

45 321-536 BEARING BUSHING 1

46 321-535 HOUSING ASS’Y 1 INCLUD. 45

47 NAME PLATE 1

48 320-232 BRUSH COVER 2

49 305-812

TAPPING SCREW (W/FLANGE) D4X16 (BLACK)

8

* 50 999-061 CARBON BRUSH 7X17X22.5 (1 PAIR) 2

* 50 999-061 CARBON BRUSH 7X17X22.5 (1 PAIR) 1 FOR HOL, ESP, FRG, AUT

* 50 999-089

CARBON BRUSH (AUTO STOP TYPE) (1 PAIR)

1 FOR HOL, ESP, FRG, AUT

51 320-231 HANDLE (B) 1

52 HITACHI LABEL 1

53 320-233 BRUSH HOLDER 2

54 320-245 SPRING 2

* 55 320-239

SWITCH (2P PILLAR TYPE) W/SAFETY LOCK

1 W/LOCK

* 55 320-238

SWITCH (2P PILLAR TYPE) W/SAFETY LOCK

1 FOR AUS, GBR, HOL

* 55 321-540

SWITCH (2P PILLER TYPE) W/SAFETY LOCK

1 W/LOCK FOR USA, CAN

56 960-266 CORD CLIP 1

57 984-750 TAPPING SCREW (W/FLANGE) D4X16 2

58 320-230 HANDLE (A) 1

* 59 981-373 TUBE (D) 2 FOR CORD

* 60 940-778 CORD ARMOR D10.7 1

* 60 958-049 CORD ARMOR D8.2 1

* 61 500-245Z CORD 1 (CORD ARMOR D10.7)

* 61 500-423Z CORD 1

(CORD ARMOR D8.2) FOR SIN, MAL, SRI,

KUW, CYP, KEN, QAT, MLT, UAE

* 61 500-234Z CORD 1 (CORD ARMOR D10.7) FOR INA, EGY,

TUR, NGR, SAU, MAR, VIE

* 61 321-537 CORD 1

(CORD ARMOR D10.7) FOR HOL, ESP, FRG, AUT

* 61 321-538 CORD 1 (CORD ARMOR D10.7) FOR USA, CAN

* 61 321-539 CORD 1 (CORD ARMOR D10.7) FOR GBR (110V)

* 61 500-446Z CORD 1 (CORD ARMOR D10.7) FOR GBR (230V)

* 61 500-408Z CORD 1 (CORD ARMOR D8.2) FOR AUS

* 61 500-435Z CORD 1 (CORD ARMOR D8.2) FOR HKG

* 61 500-438Z CORD 1 (CORD ARMOR D10.7) FOR CHN

* 61 500-214Z CORD 1 (CORD ARMOR D10.7) FOR TPE

*

ALTERNATIVE PARTS

--- 4 ---

STANDARD ACCESSORIES

OPTIONAL ACCESSORIES

ITEM

NO.

CODE NO.

DESCRIPTION REMARKS

NO.

USED

ITEM

NO.

CODE NO.

DESCRIPTION

REMARKS

NO.

USED

11 -- 02

G 18SE3

Printed in Japan

(021130N)

501 937-913Z WRENCH 1

* 502 937-917Z WHEEL NUT (B) 1 FOR AUS

601 310-337 SUPER WASHER 1

* 602 937-960Z WHEEL GUARD 1 FOR USA, CAN

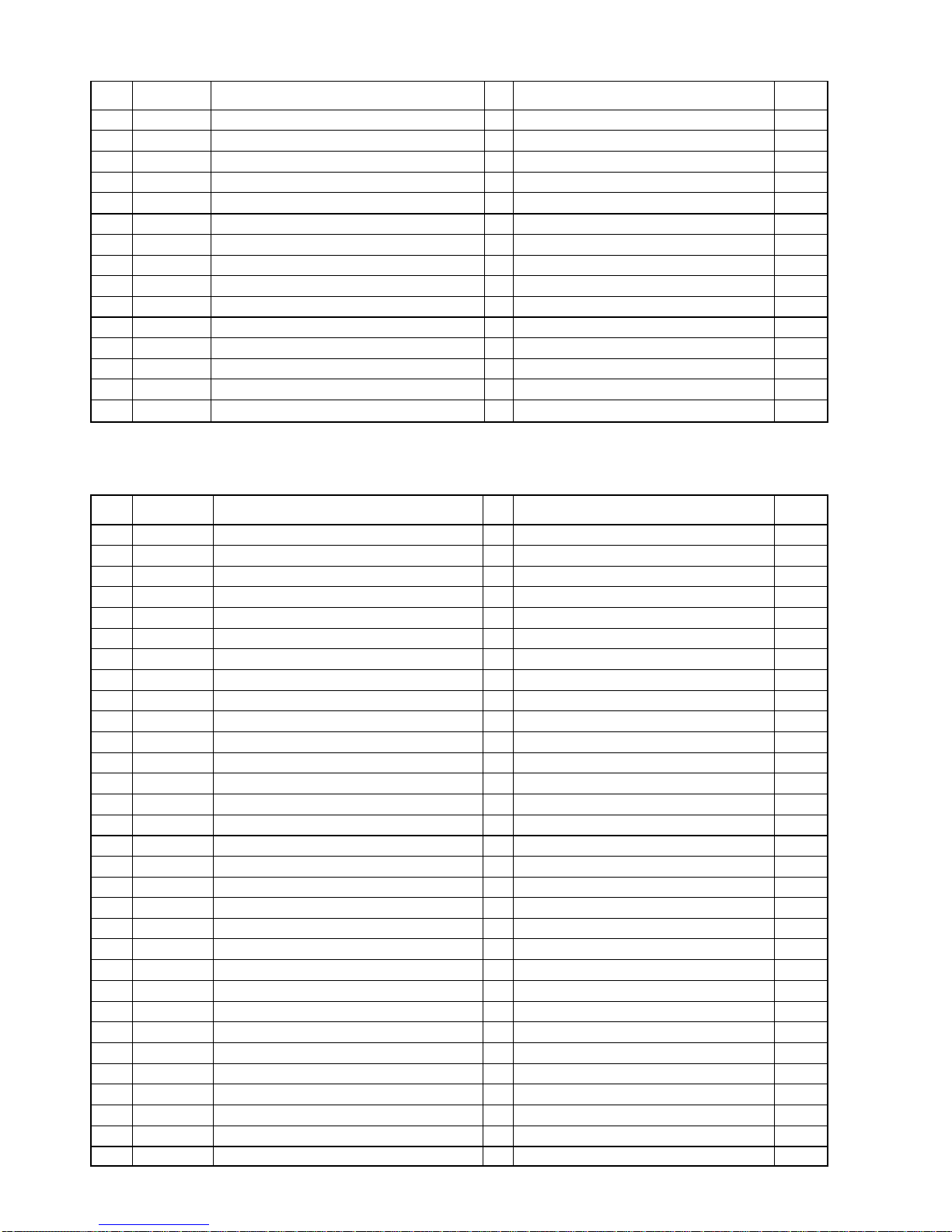

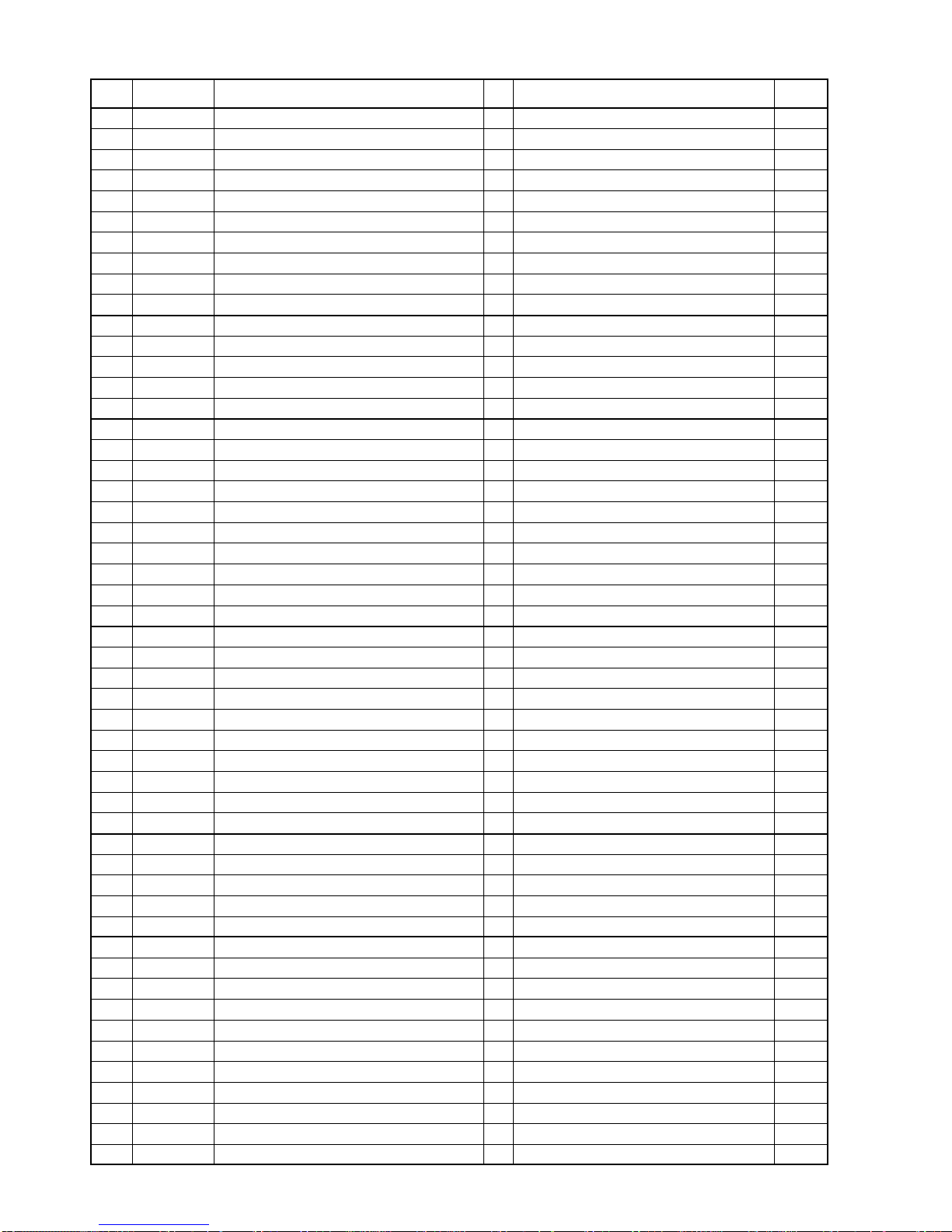

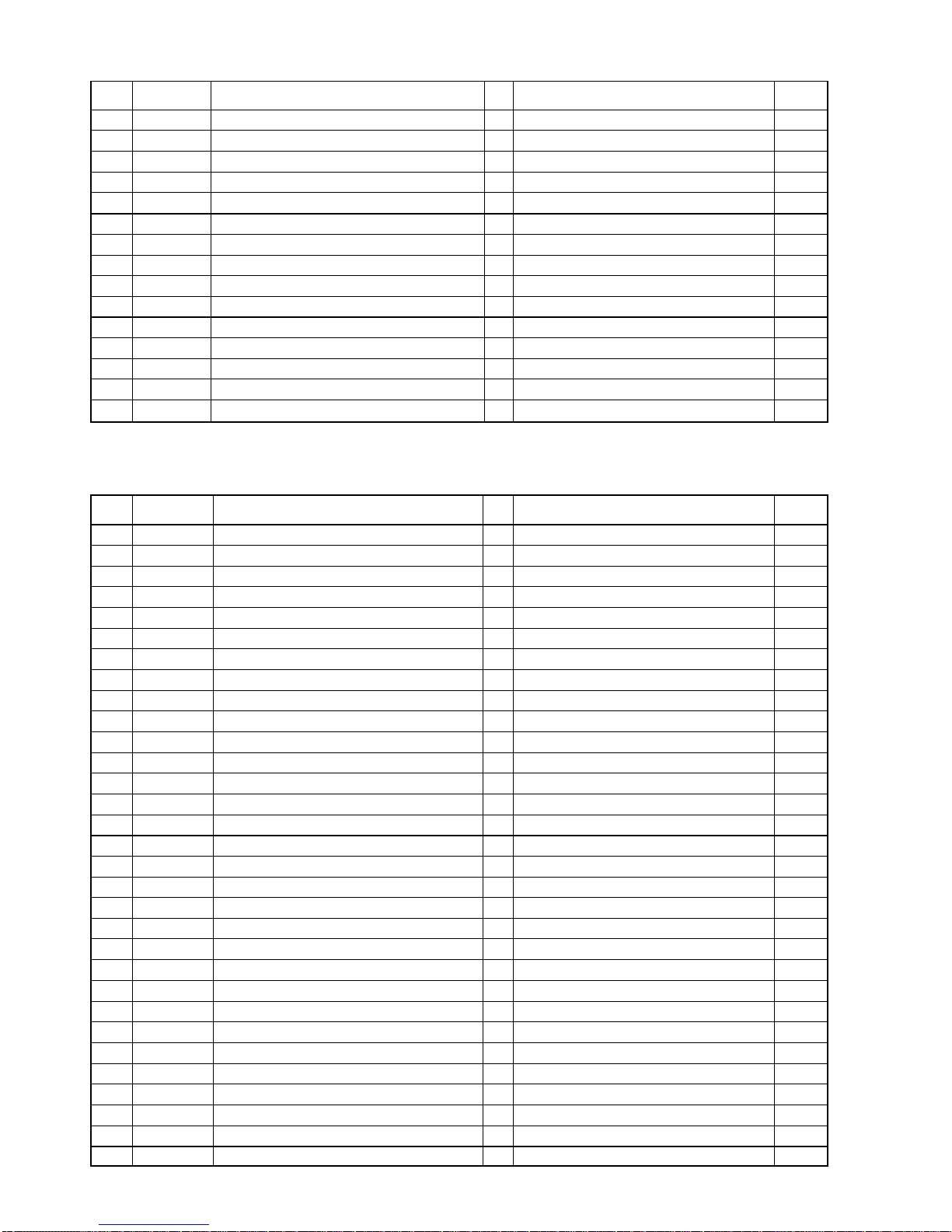

ELECTRIC TOOL PARTS LIST

LIST NO.

DISC GRINDER

Model G 18UA2

2002 • 11•30

(E1)

E251

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

27

28

29

26

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

48

52

53

54

53

55

56

57

58

59

60

61

501

601

48

48

47

49

52

*

ALTERNATIVE PARTS

--- 2 ---

ITEM

NO.

CODE NO.

DESCRIPTION REMARKS

NO.

USED

PARTS

11 -- 02

G 18UA2

1 315-636

SEAL LOCK SCREW (W/SP.WASHER) M5X14 (BLACK)

2

2 301-654 TAPPING SCREW (W/FLANGE) D5X35 4

3 306-888 PUSHING BUTTON 1

4 320-219 SPRING 1

5 320-217 GEAR COVER ASS’Y 1 INCLUD. 3, 4, 17, 39, 40

6 320-226 SPECIAL NUT M10 1

7 320-243 PINION 1

8 320-221 SEAL WASHER 1

9 320-222 FELT PACKING 1

10 630-1DD BALL BEARING 6301DDCMPS2L 1

11 994-208 RUBBER RING (B) 1

12 320-220 BEARING COVER (A) 1

13 360-594E ARMATURE 220V-230V 1

14 320-215 FAN GUIDE 1

15 984-271 HEX. HD. TAPPING SCREW D5X75 2

16 340-546E STATOR 220V-230V 1

17 937-033 FELT WASHER 1

18 321-542 SIDE HANDLE 1

19 939-542

RETAINING RING FOR D12 SHAFT (10 PCS.)

1

20 320-242 GEAR 1

21 949-236 MACHINE SCREW M5X10 (10 PCS.) 2

22 320-229 BEARING COVER (B) 1

23 630-2DD BALL BEARING 6302DDCMPS2L 1

24 990-852 FELT PACKING (B) 1

25 320-234 SPINDLE 1

26 320-228 SEAL PLATE 1

27 320-227 PACKING GLAND 1

28 994-192

HEX. SOCKET HD. BOLT (W/FLANGE) M5X16

4

29 311-492 LABEL 1

30 321-546 SET PIN 1

31 321-545 LEVER 1

32 306-887 BOLT M8X22 1

33 949-457 SPRING WASHER M8 (10 PCS.) 1

34 321-544 SET PIECE 1

35 673-489

RETAINING RING (E-TYPE) FOR D5 SHAFT

1

36 321-543 WHEEL GUARD ASS’Y 1 INCLUD. 29-35

37 937-907Z WHEEL WASHER (A) 1

38 937-909Z WHEEL NUT M14X2 1

39 320-218 O-RING 1

40 306-890 LOCK PIN 1

41 320-241 GEAR ASS’Y 1 INCLUD. 7, 20

42 320-216 DUST SEAL 1

43 600-0VV BALL BEARING 6000VVCMPS2L 1

44 321-536 BEARING BUSHING 1

45 321-535 HOUSING ASS’Y 1 INCLUD. 44

46 NAME PLATE 1

47 320-232 BRUSH COVER 2

48 305-812

TAPPING SCREW (W/FLANGE) D4X16 (BLACK)

8

* 49 999-061 CARBON BRUSH 7X17X22.5 (1 PAIR) 1

* 49 999-089

CARBON BRUSH (AUTO STOP TYPE) (1 PAIR) 1

50 320-231 HANDLE (B) 1

*

ALTERNATIVE PARTS --- 3 ---

ITEM

NO.

CODE NO.

DESCRIPTION REMARKS

NO.

USED

PARTS

11 -- 02

G 18UA2

51 HITACHI LABEL 1

52 320-233 BRUSH HOLDER 2

53 320-245 SPRING 2

54 320-236 RESISTOR 1

* 55 320-371

SWITCH (2P PILLAR TYPE) W/SAFETY LOCK

1

* 55 320-235

SWITCH (2P PILLAR TYPE) W/SAFETY LOCK

1 W/LOCK FOR FRG

56 960-266 CORD CLIP 1

57 984-750 TAPPING SCREW (W/FLANGE) D4X16 2

58 320-230 HANDLE (A) 1

* 59 981-373 TUBE (D) 2 FOR CORD

60 940-778 CORD ARMOR D10.7 1

61 321-537 CORD 1 (CORD ARMOR D10.7)

*

ALTERNATIVE PARTS

--- 4 ---

STANDARD ACCESSORIES

OPTIONAL ACCESSORIES

ITEM

NO.

CODE NO.

DESCRIPTION REMARKS

NO.

USED

ITEM

NO.

CODE NO.

DESCRIPTION

REMARKS

NO.

USED

11 -- 02

G 18UA2

Printed in Japan

(021130N)

501 937-913Z WRENCH 1

601 316-824 D. C. WHEELS 180MM A24R (25 PCS.) 1

602 310-337 SUPER WASHER 1

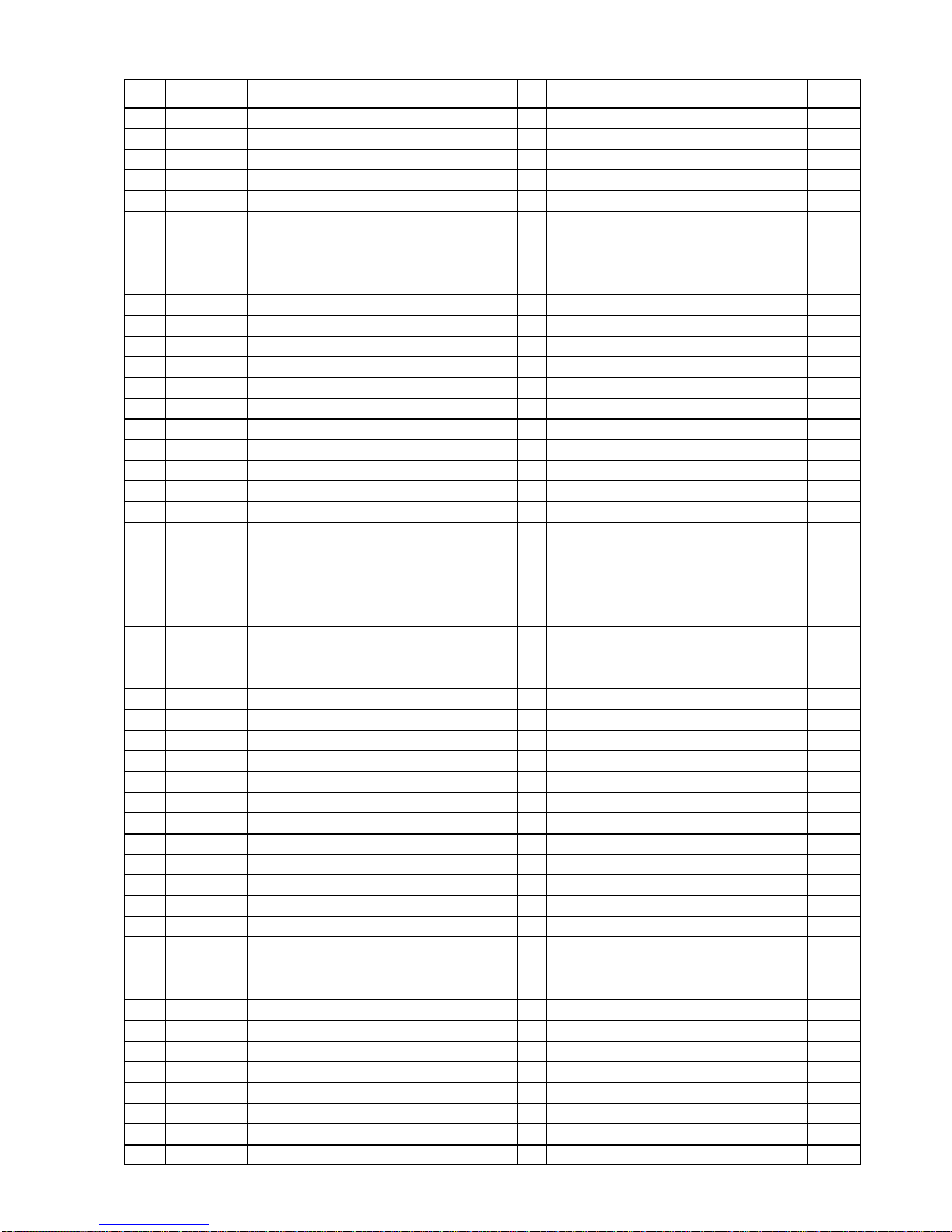

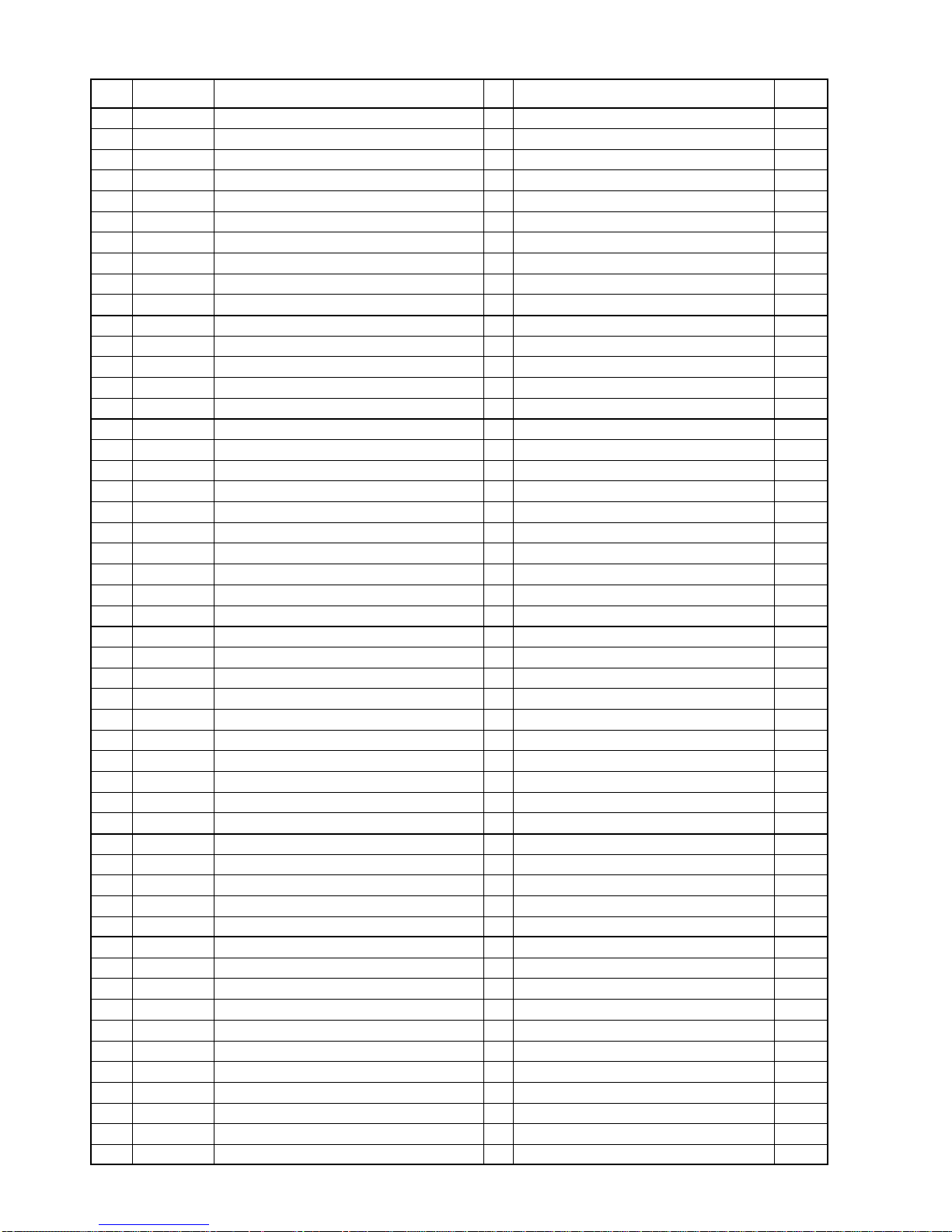

ELECTRIC TOOL PARTS LIST

LIST NO.

DISC GRINDER

Model G 18SG2

2002 • 11•30

(E1)

E252

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

27

28

29

26

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

49

49

48

52

50

49

53

54

53

54

55

56

57

58

59

60

61

501 502

*

ALTERNATIVE PARTS

--- 2 ---

ITEM

NO.

CODE NO.

DESCRIPTION REMARKS

NO.

USED

PARTS

11 -- 02

G 18SG2

1 315-636

SEAL LOCK SCREW (W/SP.WASHER) M5X14 (BLACK)

2

2 301-654 TAPPING SCREW (W/FLANGE) D5X35 4

3 306-888 PUSHING BUTTON 1

4 320-219 SPRING 1

5 320-217 GEAR COVER ASS’Y 1 INCLUD. 3, 4, 17, 40, 41

6 320-226 SPECIAL NUT M10 1

7 320-243 PINION 1

8 320-221 SEAL WASHER 1

9 320-222 FELT PACKING 1

10 630-1DD BALL BEARING 6301DDCMPS2L 1

11 994-208 RUBBER RING (B) 1

12 320-220 BEARING COVER (A) 1

13 360-594E ARMATURE 220V-230V 1

14 320-215 FAN GUIDE 1

15 984-271 HEX. HD. TAPPING SCREW D5X75 2

16 340-546E STATOR 220V-230V 1

17 937-033 FELT WASHER 1

18 321-542 SIDE HANDLE 1

19 939-542

RETAINING RING FOR D12 SHAFT (10 PCS.)

1

20 320-242 GEAR 1

21 949-236 MACHINE SCREW M5X10 (10 PCS.) 2

22 320-229 BEARING COVER (B) 1

23 630-2DD BALL BEARING 6302DDCMPS2L 1

24 990-852 FELT PACKING (B) 1

25 320-234 SPINDLE 1

26 320-228 SEAL PLATE 1

27 320-227 PACKING GLAND 1

28 994-192

HEX. SOCKET HD. BOLT (W/FLANGE) M5X16

4

29 311-492 LABEL 1

30 321-546 SET PIN 1

31 321-545 LEVER 1

32 306-887 BOLT M8X22 1

33 949-457 SPRING WASHER M8 (10 PCS.) 1

34 321-544 SET PIECE 1

35 673-489

RETAINING RING (E-TYPE) FOR D5 SHAFT

1

36 321-543 WHEEL GUARD ASS’Y 1 INCLUD. 29-35

* 37 937-907Z WHEEL WASHER (A) 1

* 37 937-908Z WHEEL WASHER (B) 1 FOR NZL

* 38 316-824 D. C. WHEELS 180MM A24R (25 PCS.) 1 FOR NZL

39 937-909Z WHEEL NUT M14X2 1

40 320-218 O-RING 1

41 306-890 LOCK PIN 1

42 320-241 GEAR ASS’Y 1 INCLUD. 7, 20

43 320-216 DUST SEAL 1

44 600-0VV BALL BEARING 6000VVCMPS2L 1

45 321-536 BEARING BUSHING 1

46 321-535 HOUSING ASS’Y 1 INCLUD. 45

47 NAME PLATE 1

48 320-232 BRUSH COVER 2

49 305-812

TAPPING SCREW (W/FLANGE) D4X16 (BLACK) 8

* 50 999-061 CARBON BRUSH 7X17X22.5 (1 PAIR) 1

*

ALTERNATIVE PARTS --- 3 ---

ITEM

NO.

CODE NO.

DESCRIPTION REMARKS

NO.

USED

PARTS

11 -- 02

G 18SG2

* 50 999-089 CARBON BRUSH (AUTO STOP TYPE) (1 PAIR) 1

51 320-231 HANDLE (B) 1

52 HITACHI LABEL 1

53 320-233 BRUSH HOLDER 2

54 320-245 SPRING 2

* 55 320-238

SWITCH (2P PILLAR TYPE) W/SAFETY LOCK 1

55 320-239

SWITCH (2P PILLAR TYPE) W/SAFETY LOCK 1 W/LOCK FOR ESP, AUT

56 960-266 CORD CLIP 1

57 984-750 TAPPING SCREW (W/FLANGE) D4X16 2

58 320-230 HANDLE (A) 1

* 59 981-373 TUBE (D) 2 FOR CORD

* 60 940-778 CORD ARMOR D10.7 1

* 60 958-049 CORD ARMOR D8.2 1

* 61 321-537 CORD 1 (CORD ARMOR D10.7)

* 61 500-408Z CORD 1 (CORD ARMOR D8.2) FOR NZL

*

ALTERNATIVE PARTS

--- 4 ---

STANDARD ACCESSORIES

OPTIONAL ACCESSORIES

ITEM

NO.

CODE NO.

DESCRIPTION REMARKS

NO.

USED

ITEM

NO.

CODE NO.

DESCRIPTION

REMARKS

NO.

USED

11 -- 02

G 18SG2

Printed in Japan

(021130N)

501 937-913Z WRENCH 1

* 502 937-917Z WHEEL NUT (B) 1 FOR NZL

601 310-337 SUPER WASHER 1

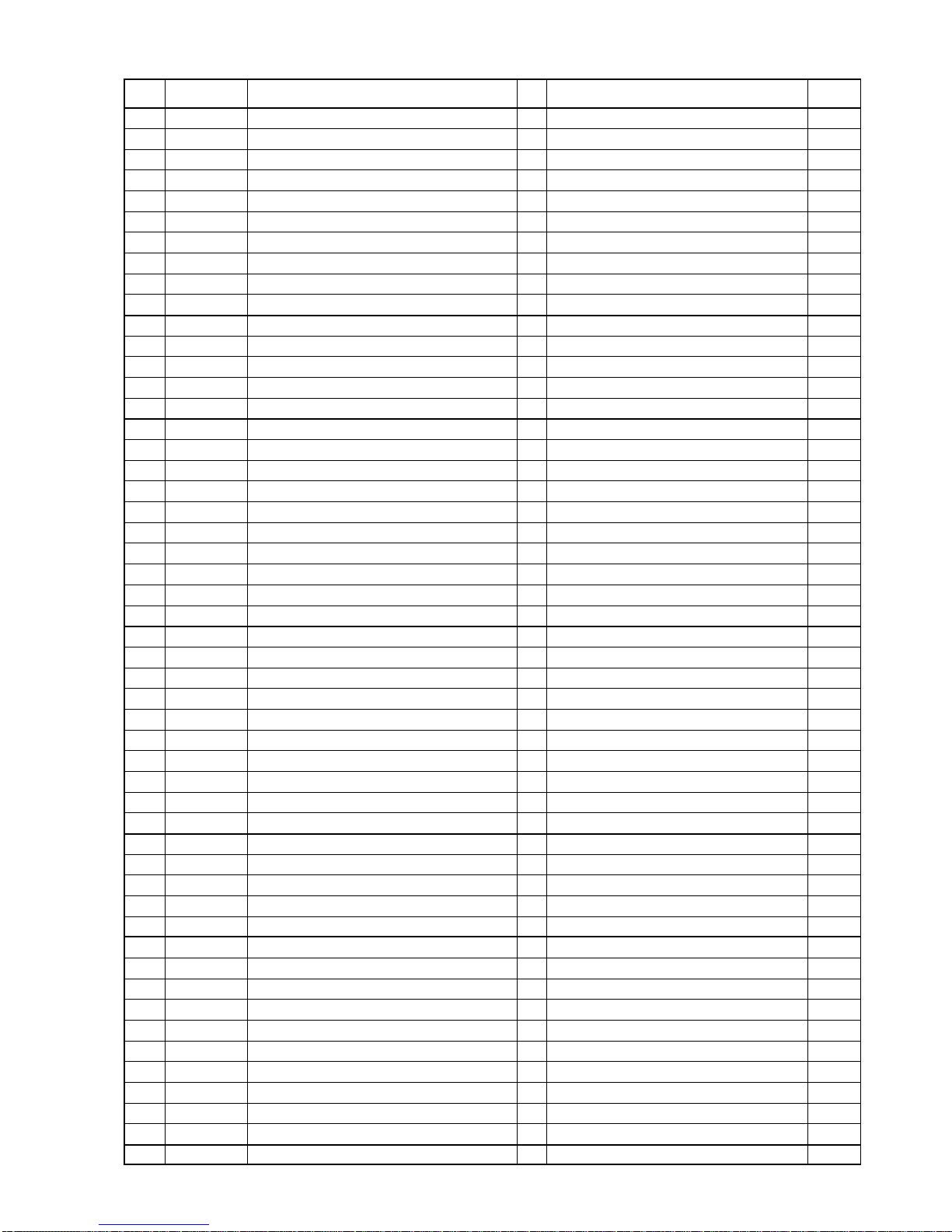

ELECTRIC TOOL PARTS LIST

LIST NO.

DISC GRINDER

Model G 18UB2

2002 • 11•30

(E1)

E253

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

27

28

29

26

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

48

52

53

54

53

55

56

57

58

59

60

61

501

601

48

48

47

49

52

*

ALTERNATIVE PARTS

--- 2 ---

ITEM

NO.

CODE NO.

DESCRIPTION REMARKS

NO.

USED

PARTS

11 -- 02

G 18UB2

1 315-636

SEAL LOCK SCREW (W/SP.WASHER) M5X14 (BLACK)

2

2 301-654 TAPPING SCREW (W/FLANGE) D5X35 4

3 306-888 PUSHING BUTTON 1

4 320-219 SPRING 1

5 320-217 GEAR COVER ASS’Y 1 INCLUD. 3, 4, 17, 39, 40

6 320-226 SPECIAL NUT M10 1

7 320-243 PINION 1

8 320-221 SEAL WASHER 1

9 320-222 FELT PACKING 1

10 630-1DD BALL BEARING 6301DDCMPS2L 1

11 994-208 RUBBER RING (B) 1

12 320-220 BEARING COVER (A) 1

13 360-594E ARMATURE 220V-230V 1

14 320-215 FAN GUIDE 1

15 984-271 HEX. HD. TAPPING SCREW D5X75 2

16 340-546E STATOR 220V-230V 1

17 937-033 FELT WASHER 1

18 321-542 SIDE HANDLE 1

19 939-542

RETAINING RING FOR D12 SHAFT (10 PCS.)

1

20 320-242 GEAR 1

21 949-236 MACHINE SCREW M5X10 (10 PCS.) 2

22 320-229 BEARING COVER (B) 1

23 630-2DD BALL BEARING 6302DDCMPS2L 1

24 990-852 FELT PACKING (B) 1

25 320-234 SPINDLE 1

26 320-228 SEAL PLATE 1

27 320-227 PACKING GLAND 1

28 994-192

HEX. SOCKET HD. BOLT (W/FLANGE) M5X16 4

29 311-492 LABEL 1

30 321-546 SET PIN 1

31 321-545 LEVER 1

32 306-887 BOLT M8X22 1

33 949-457 SPRING WASHER M8 (10 PCS.) 1

34 321-544 SET PIECE 1

35 673-489

RETAINING RING (E-TYPE) FOR D5 SHAFT

1

36 321-543 WHEEL GUARD ASS’Y 1 INCLUD. 29-35

37 937-907Z WHEEL WASHER (A) 1

38 937-909Z WHEEL NUT M14X2 1

39 320-218 O-RING 1

40 306-890 LOCK PIN 1

41 320-241 GEAR ASS’Y 1 INCLUD. 7, 20

42 320-216 DUST SEAL 1

43 600-0VV BALL BEARING 6000VVCMPS2L 1

44 321-536 BEARING BUSHING 1

45 321-535 HOUSING ASS’Y 1 INCLUD. 44

46 NAME PLATE 1

47 320-232 BRUSH COVER 2

48 305-812

TAPPING SCREW (W/FLANGE) D4X16 (BLACK) 8

* 49 999-061 CARBON BRUSH 7X17X22.5 (1 PAIR) 1

* 49 999-089

CARBON BRUSH (AUTO STOP TYPE) (1 PAIR) 1

* 49 999-061 CARBON BRUSH 7X17X22.5 (1 PAIR) 2 FOR NOR

*

ALTERNATIVE PARTS --- 3 ---

ITEM

NO.

CODE NO.

DESCRIPTION REMARKS

NO.

USED

PARTS

11 -- 02

G 18UB2

50 320-231 HANDLE (B) 1

51 HITACHI LABEL 1

52 320-233 BRUSH HOLDER 2

53 320-245 SPRING 2

54 320-236 RESISTOR 1

* 55 320-371

SWITCH (2P PILLAR TYPE) W/SAFETY LOCK 1

* 55 320-235

SWITCH (2P PILLAR TYPE) W/SAFETY LOCK 1 W/LOCK FOR FRG,AUT

56 960-266 CORD CLIP 1

57 984-750 TAPPING SCREW (W/FLANGE) D4X16 2

58 320-230 HANDLE (A) 1

* 59 981-373 TUBE (D) 2 FOR CORD

60 940-778 CORD ARMOR D10.7 1

61 321-537 CORD 1 (CORD ARMOR D10.7)

*

ALTERNATIVE PARTS

--- 4 ---

STANDARD ACCESSORIES

OPTIONAL ACCESSORIES

ITEM

NO.

CODE NO.

DESCRIPTION REMARKS

NO.

USED

ITEM

NO.

CODE NO.

DESCRIPTION

REMARKS

NO.

USED

11 -- 02

G 18UB2

Printed in Japan

(021130N)

501 937-913Z WRENCH 1

601 316-824 D. C. WHEELS 180MM A24R (25 PCS.) 1

602 310-337 SUPER WASHER 1

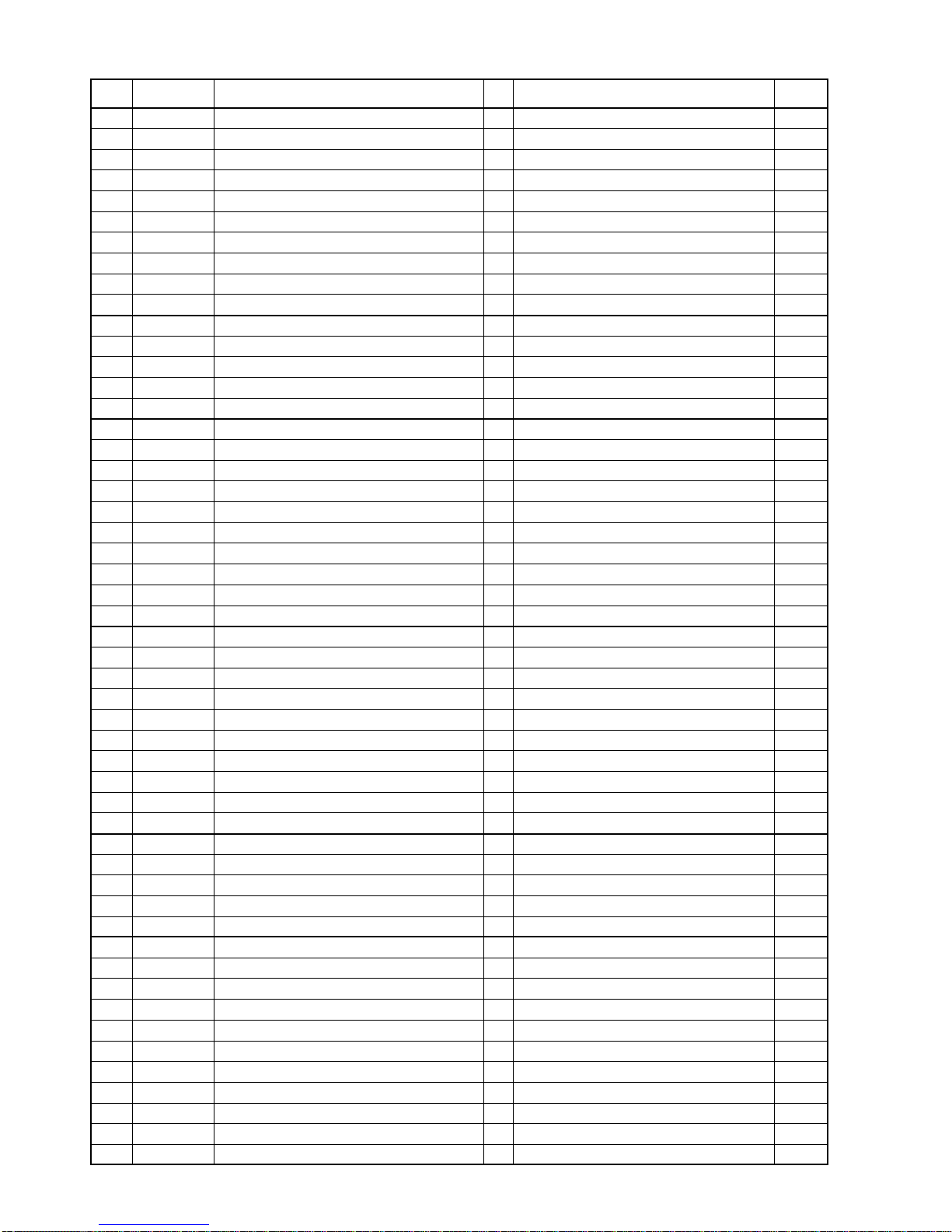

ELECTRIC TOOL PARTS LIST

LIST NO.

DISC GRINDER

Model G 23SC3

2002 • 11•30

(E1)

E254

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

49

49

48

52

50

49

53

54

53

54

55

56

57

58

59

60

61

501

*

ALTERNATIVE PARTS

--- 2 ---

ITEM

NO.

CODE NO.

DESCRIPTION REMARKS

NO.

USED

PARTS

11 -- 02

G 23SC3

1 315-636

SEAL LOCK SCREW (W/SP.WASHER) M5X14 (BLACK)

2

2 301-654 TAPPING SCREW (W/FLANGE) D5X35 4

3 306-888 PUSHING BUTTON 1

4 320-219 SPRING 1

5 320-217 GEAR COVER ASS’Y 1 INCLUD. 3, 4, 17, 40, 41

6 320-226 SPECIAL NUT M10 1

7 320-225 PINION 1

8 320-221 SEAL WASHER 1

9 320-222 FELT PACKING 1

10 630-1DD BALL BEARING 6301DDCMPS2L 1

11 994-208 RUBBER RING (B) 1

12 320-220 BEARING COVER (A) 1

* 13 360-594U ARMATURE ASS’Y 110V-120V 1 INCLUD. 9, 10, 43, 44

* 13 360-594E ARMATURE 220V-230V 1

* 13 360-594F ARMATURE 240V 1

14 320-215 FAN GUIDE 1

15 984-271 HEX. HD. TAPPING SCREW D5X75 2

* 16 340-546C STATOR 110V-120V 1

* 16 340-546E STATOR 220V-230V 1

* 16 340-546F STATOR 240V 1

17 937-033 FELT WASHER 1

18 321-542 SIDE HANDLE 1

19 939-542

RETAINING RING FOR D12 SHAFT (10 PCS.) 1

20 320-224 GEAR 1

21 949-236 MACHINE SCREW M5X10 (10 PCS.) 2

22 320-229 BEARING COVER (B) 1

23 630-2DD BALL BEARING 6302DDCMPS2L 1

24 990-852 FELT PACKING (B) 1

25 320-234 SPINDLE 1

* 25 321-541 SPINDLE 1 FOR USA, CAN

26 320-228 SEAL PLATE 1

27 320-227 PACKING GLAND 1

28 994-192

HEX. SOCKET HD. BOLT (W/FLANGE) M5X16 4

29 311-492 LABEL 1

30 321-546 SET PIN 1

31 321-545 LEVER 1

32 306-887 BOLT M8X22 1

33 949-457 SPRING WASHER M8 (10 PCS.) 1

34 321-544 SET PIECE 1

35 673-489

RETAINING RING (E-TYPE) FOR D5 SHAFT

1

36 321-547 WHEEL GUARD ASS’Y 1 INCLUD. 29-35

* 37 937-907Z WHEEL WASHER (A) 1

* 37 937-922P WHEEL WASHER (B) FOR D5/8” HOLE 1 FOR USA, CAN

* 38 316-825 D. C. WHEELS 230MM A24R (25 PCS.) 1 EXCEPT FOR GBR, EUROPE, USA

* 39 937-909Z WHEEL NUT M14X 2 1

* 39 937-923P WHEEL NUT 5/8”-11UNC 1 FOR USA, CAN

40 320-218 O-RING 1

41 306-890 LOCK PIN 1

42 320-223 GEAR AND PINION ASS’Y 1 INCLUD. 7, 20

43 320-216 DUST SEAL 1

44 600-0VV BALL BEARING 6000VVCMPS2L 1

*

ALTERNATIVE PARTS --- 3 ---

ITEM

NO.

CODE NO.

DESCRIPTION REMARKS

NO.

USED

PARTS

11 -- 02

G 23SC3

45 321-536 BEARING BUSHING 1

46 321-535 HOUSING ASS’Y 1 INCLUD. 45

* 47 NAME PLATE 1

48 320-232 BRUSH COVER 2

49 305-812

TAPPING SCREW (W/FLANGE) D4X16 (BLACK)

8

* 50 999-061 CARBON BRUSH 7X17X22.5 (1 PAIR) 2

* 50 999-061 CARBON BRUSH 7X17X22.5 (1 PAIR) 1 FOR EUROPE, SAF

* 50 999-089

CARBON BRUSH (AUTO STOP TYPE) (1 PAIR) 1 FOR EUROPE, SAF

51 320-231 HANDLE (B) 1

52 HITACHI LABEL 1

53 320-233 BRUSH HOLDER 2

54 320-245 SPRING 2

* 55 320-239

SWITCH (2P PILLAR TYPE) W/SAFETY LOCK 1 W/LOCK

* 55 320-238

SWITCH (2P PILLAR TYPE) W/SAFETY LOCK 1 FOR GBR, FRA, HOL, ITA

* 55 321-540

SWITCH (2P PILLER TYPE) W/SAFETY LOCK 1 W/LOCK FOR USA, CAN

56 960-266 CORD CLIP 1

57 984-750 TAPPING SCREW (W/FLANGE) D4X16 2

58 320-230 HANDLE (A) 1

* 59 981-373 TUBE (D) 2 FOR CORD

* 60 958-049 CORD ARMOR D8.2 1

* 60 940-778 CORD ARMOR D10.7 1

* 61 500-214Z CORD 1 (CORD ARMOR D10.7)

* 61 500-234Z CORD 1 (CORD ARMOR D10.7) FOR INA

* 61 500-245Z CORD 1 (CORD ARMOR D10.7) FOR SYR

* 61 500-423Z CORD 1 (CORD ARMOR D8.2) FOR SIN, KUW

* 61 500-435Z CORD 1 (CORD ARMOR D8.2) FOR HKG

* 61 500-446Z CORD 1 (CORD ARMOR D10.7) FOR GBR (230V)

* 61 321-539 CORD 1 (CORD ARMOR D10.7) FOR GBR (110V)

* 61 321-537 CORD 1

(CORD ARMOR D10.7) FOR EUROPE, SAF

* 61 321-538 CORD 1 (CORD ARMOR D10.7) FOR USA, CAN

*

ALTERNATIVE PARTS

--- 4 ---

STANDARD ACCESSORIES

OPTIONAL ACCESSORIES

ITEM

NO.

CODE NO.

DESCRIPTION REMARKS

NO.

USED

ITEM

NO.

CODE NO.

DESCRIPTION

REMARKS

NO.

USED

11 -- 02

G 23SC3

Printed in Japan

(021130N)

501 937-913Z WRENCH 1

601 310-337 SUPER WASHER 1

* 602 937-984Z WHEEL GUARD 1 FOR USA, CAN

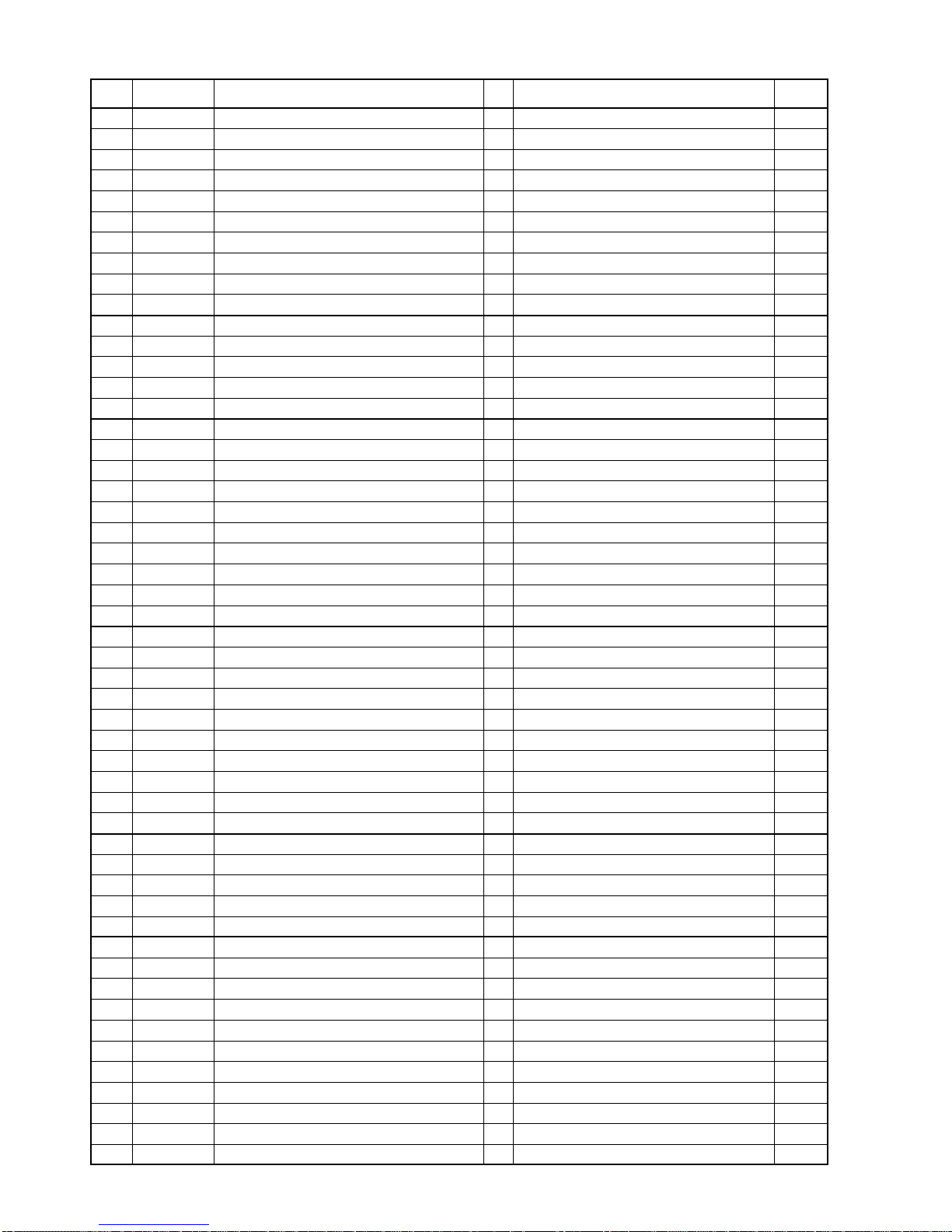

ELECTRIC TOOL PARTS LIST

LIST NO.

DISC GRINDER

Model G 23UA2

2002 • 11•30

(E1)

E255

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

49

52

53

54

55

56

57

58

59

60

61

501

47

48

48

48

601

52

53

*

ALTERNATIVE PARTS

--- 2 ---

ITEM

NO.

CODE NO.

DESCRIPTION REMARKS

NO.

USED

PARTS

11 -- 02

G 23UA2

1 315-636

SEAL LOCK SCREW (W/SP.WASHER) M5X14 (BLACK)

2

2 301-654 TAPPING SCREW (W/FLANGE) D5X35 4

3 306-888 PUSHING BUTTON 1

4 320-219 SPRING 1

5 320-217 GEAR COVER ASS’Y 1 INCLUD. 3, 4, 17, 39, 40

6 320-226 SPECIAL NUT M10 1

7 320-225 PINION 1

8 320-221 SEAL WASHER 1

9 320-222 FELT PACKING 1

10 630-1DD BALL BEARING 6301DDCMPS2L 1

11 994-208 RUBBER RING (B) 1

12 320-220 BEARING COVER (A) 1

13 360-594E ARMATURE 220V-230V 1

14 320-215 FAN GUIDE 1

15 984-271 HEX. HD. TAPPING SCREW D5X75 2

16 340-546E STATOR 220V-230V 1

17 937-033 FELT WASHER 1

18 321-542 SIDE HANDLE 1

19 939-542

RETAINING RING FOR D12 SHAFT (10 PCS.)

1

20 320-224 GEAR 1

21 949-236 MACHINE SCREW M5X10 (10 PCS.) 2

22 320-229 BEARING COVER (B) 1

23 630-2DD BALL BEARING 6302DDCMPS2L 1

24 990-852 FELT PACKING (B) 1

25 320-234 SPINDLE 1

26 320-228 SEAL PLATE 1

27 320-227 PACKING GLAND 1

28 994-192

HEX. SOCKET HD. BOLT (W/FLANGE) M5X16

4

29 311-492 LABEL 1

30 321-546 SET PIN 1

31 321-545 LEVER 1

32 306-887 BOLT M8X22 1

33 949-457 SPRING WASHER M8 (10 PCS.) 1

34 321-544 SET PIECE 1

35 673-489

RETAINING RING (E-TYPE) FOR D5 SHAFT

1

36 321-547 WHEEL GUARD ASS’Y 1 INCLUD. 29-35

37 937-907Z WHEEL WASHER (A) 1

38 937-909Z WHEEL NUT M14X2 1

39 320-218 O-RING 1

40 306-890 LOCK PIN 1

41 320-223 GEAR AND PINION ASS’Y 1 INCLUD. 7, 20

42 320-216 DUST SEAL 1

43 600-0VV BALL BEARING 6000VVCMPS2L 1

44 321-536 BEARING BUSHING 1

45 321-535 HOUSING ASS’Y 1 INCLUD. 44

* 46 NAME PLATE 1

47 320-232 BRUSH COVER 2

48 305-812

TAPPING SCREW (W/FLANGE) D4X16 (BLACK)

8

* 49 999-061 CARBON BRUSH 7X17X22.5 (1 PAIR) 1

* 49 999-089

CARBON BRUSH (AUTO STOP TYPE) (1 PAIR) 1

* 49 999-061 CARBON BRUSH 7X17X22.5 (1 PAIR) 2 FOR SUI

*

ALTERNATIVE PARTS --- 3 ---

ITEM

NO.

CODE NO.

DESCRIPTION REMARKS

NO.

USED

PARTS

11 -- 02

G 23UA2

50 320-231 HANDLE (B) 1

51 HITACHI LABEL 1

52 320-233 BRUSH HOLDER 2

53 320-245 SPRING 2

54 320-236 RESISTOR 1

* 55 320-235

SWITCH (2P PILLAR TYPE) W/SAFETY LOCK 1 W/LOCK

* 55 320-371

SWITCH (2P PILLAR TYPE) W/SAFETY LOCK 1 FOR HOL

56 960-266 CORD CLIP 1

57 984-750 TAPPING SCREW (W/FLANGE) D4X16 2

58 320-230 HANDLE (A) 1

59 981-373 TUBE (D) 2

60 940-778 CORD ARMOR D10.7 1

* 61 321-537 CORD 1 (CORD ARMOR D10.7)

* 61 500-391Z CORD 1 (CORD ARMOR D10.7) FOR SUI

*

ALTERNATIVE PARTS

--- 4 ---

STANDARD ACCESSORIES

OPTIONAL ACCESSORIES

ITEM

NO.

CODE NO.

DESCRIPTION REMARKS

NO.

USED

ITEM

NO.

CODE NO.

DESCRIPTION

REMARKS

NO.

USED

11 -- 02

G 23UA2

Printed in Japan

(021130N)

501 937-913Z WRENCH 1

601 316-825 D. C. WHEELS 230MM A24R (25 PCS.) 1

602 310-337 SUPER WASHER 1

ELECTRIC TOOL PARTS LIST

LIST NO.

DISC GRINDER

Model G 23SE2

2002 • 11•30

(E1)

E256

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

49

49

48

52

50

49

53

54

53

54

55

56

57

58

59

60

61

501

502

*

ALTERNATIVE PARTS

--- 2 ---

ITEM

NO.

CODE NO.

DESCRIPTION REMARKS

NO.

USED

PARTS

11 -- 02

G 23SE2

1 315-636

SEAL LOCK SCREW (W/SP.WASHER) M5X14 (BLACK)

2

2 301-654 TAPPING SCREW (W/FLANGE) D5X35 4

3 306-888 PUSHING BUTTON 1

4 320-219 SPRING 1

5 320-217 GEAR COVER ASS’Y 1 INCLUD. 3, 4, 17, 40, 41

6 320-226 SPECIAL NUT M10 1

7 320-225 PINION 1

8 320-221 SEAL WASHER 1

9 320-222 FELT PACKING 1

10 630-1DD BALL BEARING 6301DDCMPS2L 1

11 994-208 RUBBER RING (B) 1

12 320-220 BEARING COVER (A) 1

* 13 360-594E ARMATURE 220V-230V 1

* 13 360-594F ARMATURE 240V 1

14 320-215 FAN GUIDE 1

15 984-271 HEX. HD. TAPPING SCREW D5X75 2

* 16 340-546E STATOR 220V-230V 1

* 16 340-546F STATOR 240V 1

17 937-033 FELT WASHER 1

18 321-542 SIDE HANDLE 1

19 939-542

RETAINING RING FOR D12 SHAFT (10 PCS.)

1

20 320-224 GEAR 1

21 949-236 MACHINE SCREW M5X10 (10 PCS.) 2

22 320-229 BEARING COVER (B) 1

23 630-2DD BALL BEARING 6302DDCMPS2L 1

24 990-852 FELT PACKING (B) 1

25 320-234 SPINDLE 1

26 320-228 SEAL PLATE 1

27 320-227 PACKING GLAND 1

28 994-192

HEX. SOCKET HD. BOLT (W/FLANGE) M5X16 4

29 311-492 LABEL 1

30 321-546 SET PIN 1

31 321-545 LEVER 1

32 306-887 BOLT M8X22 1

33 949-457 SPRING WASHER M8 (10 PCS.) 1

34 321-544 SET PIECE 1

35 673-489

RETAINING RING (E-TYPE) FOR D5 SHAFT

1

36 321-547 WHEEL GUARD ASS’Y 1 INCLUD. 29-35

* 37 937-907Z WHEEL WASHER (A) 1

* 37 937-908Z WHEEL WASHER (B) 1 FOR NZL, AUS

* 38 316-825 D. C. WHEELS 230MM A24R (25 PCS.) 1 FOR NZL, AUS, SAF

39 937-909Z WHEEL NUT M14X2 1

40 320-218 O-RING 1

41 306-890 LOCK PIN 1

42 320-223 GEAR AND PINION ASS’Y 1 INCLUD. 7, 20

43 320-216 DUST SEAL 1

44 600-0VV BALL BEARING 6000VVCMPS2L 1

45 321-536 BEARING BUSHING 1

46 321-535 HOUSING ASS’Y 1 INCLUD.45

* 47 NAME PLATE 1

48 320-232 BRUSH COVER 2

*

ALTERNATIVE PARTS --- 3 ---

ITEM

NO.

CODE NO.

DESCRIPTION REMARKS

NO.

USED

PARTS

11 -- 02

G 23SE2

49 305-812 TAPPING SCREW (W/FLANGE) D4X16 (BLACK) 8

* 50 999-061 CARBON BRUSH 7X17X22.5 (1 PAIR) 2

* 50 999-061 CARBON BRUSH 7X17X22.5 (1 PAIR) 1

FOR NZL, FRA, HOL, ITA, FRG, BEL, AUT, ESP

* 50 999-089 CARBON BRUSH (AUTO STOP TYPE) (1 PAIR) 1

FOR NZL, FRA, HOL, ITA, FRG, BEL, AUT, ESP

51 320-231 HANDLE (B) 1

52 HITACHI LABEL 1

53 320-233 BRUSH HOLDER 2

54 320-245 SPRING 2

* 55 320-238

SWITCH (2P PILLAR TYPE) W/SAFETY LOCK 1

* 55 320-239

SWITCH (2P PILLAR TYPE) W/SAFETY LOCK 1 W/LOCK FOR SAF, FRG, BEL, AUT, ESP

56 960-266 CORD CLIP 1

57 984-750 TAPPING SCREW (W/FLANGE) D4X16 2

58 320-230 HANDLE (A) 1

* 59 981-373 TUBE (D) 2 FOR CORD

* 60 958-049 CORD ARMOR D8.2 1

* 60 940-778 CORD ARMOR D10.7 1

* 61 321-537 CORD 1 (CORD ARMOR D10.7)

* 61 500-408Z CORD 1 (CORD ARMOR D8.2) FOR NZL, AUS

*

ALTERNATIVE PARTS

--- 4 ---

STANDARD ACCESSORIES

OPTIONAL ACCESSORIES

ITEM

NO.

CODE NO.

DESCRIPTION REMARKS

NO.

USED

ITEM

NO.

CODE NO.

DESCRIPTION

REMARKS

NO.

USED

11 -- 02

G 23SE2

Printed in Japan

(021130N)

501 937-913Z WRENCH 1

* 502 937-917Z WHEEL NUT (B) 1 FOR AUS, NZL

601 310-337 SUPER WASHER 1

ELECTRIC TOOL PARTS LIST

LIST NO.

DISC GRINDER

Model G 23UB2

2002 • 11•30

(E1)

E257

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

53

501

502

48

49

49

49

50

54

62

*

ALTERNATIVE PARTS

--- 2 ---

ITEM

NO.

CODE NO.

DESCRIPTION REMARKS

NO.

USED

PARTS

11 -- 02

G 23UB2

1 315-636

SEAL LOCK SCREW (W/SP.WASHER) M5X14 (BLACK)

2

2 301-654 TAPPING SCREW (W/FLANGE) D5X35 4

3 306-888 PUSHING BUTTON 1

4 320-219 SPRING 1

5 320-217 GEAR COVER ASS’Y 1 INCLUD. 3, 4, 17, 40, 41

6 320-226 SPECIAL NUT M10 1

7 320-225 PINION 1

8 320-221 SEAL WASHER 1

9 320-222 FELT PACKING 1

10 630-1DD BALL BEARING 6301DDCMPS2L 1

11 994-208 RUBBER RING (B) 1

12 320-220 BEARING COVER (A) 1

* 13 360-594U ARMATURE ASS’Y 110V-120V 1 INCLUD. 9, 10, 43, 44

* 13 360-594E ARMATURE 220V-230V 1

* 13 360-594F ARMATURE 240V 1

14 320-215 FAN GUIDE 1

15 984-271 HEX. HD. TAPPING SCREW D5X75 2

* 16 340-546C STATOR 110V-120V 1

* 16 340-546E STATOR 220V-230V 1

* 16 340-546F STATOR 240V 1

17 937-033 FELT WASHER 1

18 321-542 SIDE HANDLE 1

19 939-542

RETAINING RING FOR D12 SHAFT (10 PCS.)

1

20 320-224 GEAR 1

21 949-236 MACHINE SCREW M5X10 (10 PCS.) 2

22 320-229 BEARING COVER (B) 1

23 630-2DD BALL BEARING 6302DDCMPS2L 1

24 990-852 FELT PACKING (B) 1

25 320-234 SPINDLE 1

26 320-228 SEAL PLATE 1

27 320-227 PACKING GLAND 1

28 994-192

HEX. SOCKET HD. BOLT (W/FLANGE) M5X16

4

29 311-492 LABEL 1

30 321-546 SET PIN 1

31 321-545 LEVER 1

32 306-887 BOLT M8X22 1

33 949-457 SPRING WASHER M8 (10 PCS.) 1

34 321-544 SET PIECE 1

35 673-489

RETAINING RING (E-TYPE) FOR D5 SHAFT

1

36 321-547 WHEEL GUARD ASS’Y 1 INCLUD. 29-35

* 37 937-907Z WHEEL WASHER (A) 1

* 37 937-908Z WHEEL WASHER (B) 1 FOR AUS

* 38 316-825 D. C. WHEELS 230MM A24R (25 PCS.) 1 FOR AUS

39 937-909Z WHEEL NUT M14X2 1

40 320-218 O-RING 1

41 306-890 LOCK PIN 1

42 320-223 GEAR AND PINION ASS’Y 1 INCLUD. 7, 20

43 320-216 DUST SEAL 1

44 600-0VV BALL BEARING 6000VVCMPS2L 1

45 321-536 BEARING BUSHING 1

46 321-535 HOUSING ASS’Y 1 INCLUD. 45

*

ALTERNATIVE PARTS --- 3 ---

ITEM

NO.

CODE NO.

DESCRIPTION REMARKS

NO.

USED

PARTS

11 -- 02

G 23UB2

* 47 NAME PLATE 1

48 320-232 BRUSH COVER 2

49 305-812 TAPPING SCREW (W/FLANGE) D4X16 (BLACK) 8

* 50 999-061 CARBON BRUSH 7X17X22.5 (1 PAIR) 1

* 50 999-089

CARBON BRUSH (AUTO STOP TYPE) (1 PAIR) 1

* 50 999-061 CARBON BRUSH 7X17X22.5 (1 PAIR) 2 FOR AUS, GBR, NOR, FIN

51 320-231 HANDLE (B) 1

52 HITACHI LABEL 1

53 320-233 BRUSH HOLDER 2

54 320-245 SPRING 2

55 320-236 RESISTOR 1

* 56 320-371

SWITCH (2P PILLAR TYPE) W/SAFETY LOCK 1

* 56 320-235

SWITCH (2P PILLAR TYPE) W/SAFETY LOCK 1 W/LOCK FOR FRG, BEL, AUT, ESP

57 960-266 CORD CLIP 1

58 984-750 TAPPING SCREW (W/FLANGE) D4X16 2

59 320-230 HANDLE (A) 1

60 981-373 TUBE (D) 2

* 61 958-049 CORD ARMOR D8.2 1

* 61 940-778 CORD ARMOR D10.7 1

* 62 321-537 CORD 1 (CORD ARMOR D10.7)

* 62 500-408Z CORD 1 (CORD ARMOR D8.2) FOR AUS

* 62 500-460Z CORD 1 (CORD ARMOR D10.7) FOR GBR (230V)

* 62 321-539 CORD 1 (CORD ARMOR D10.7) FOR GBR (110V)

*

ALTERNATIVE PARTS

--- 4 ---

STANDARD ACCESSORIES

OPTIONAL ACCESSORIES

ITEM

NO.

CODE NO.

DESCRIPTION REMARKS

NO.

USED

ITEM

NO.

CODE NO.

DESCRIPTION

REMARKS

NO.

USED

11 -- 02

G 23UB2

Printed in Japan

(021130N)

501 937-913Z WRENCH 1

* 502 937-917Z WHEEL NUT (B) 1 FOR AUS

601 310-337 SUPER WASHER 1

Loading...

Loading...