Page 1

JIG SAW

STICHSÄGE

SCIE SAUTEUSE

SEGHETTO ALTERNATIVO

DECOUPEERZAAGMACHINE

SIERRA CALADORA

FCJ 55VA • FCJ 55

FCJ 55

Read through carefully and understand these instructions before use.

Diese Anleitung vor Benutzung des Werkzeugs sorgfältig durchlesen und verstehen.

Lire soigneusement et bien assimiler ces instructions avant usage.

Prima dell’uso leggere attentamente e comprendera queste istruzioni.

Deze gebruiksaanwijzing s.v.p. voor gebruik zorgvuldig doorlezen.

Leer cuidadosamente y comprender estas instrucciones antes del uso.

Handling instructions

Bedienungsanleitung

Mode d’emploi

Istruzioni per l’uso

Gebruiksaanwijzing

Instrucciones de manejo

Page 2

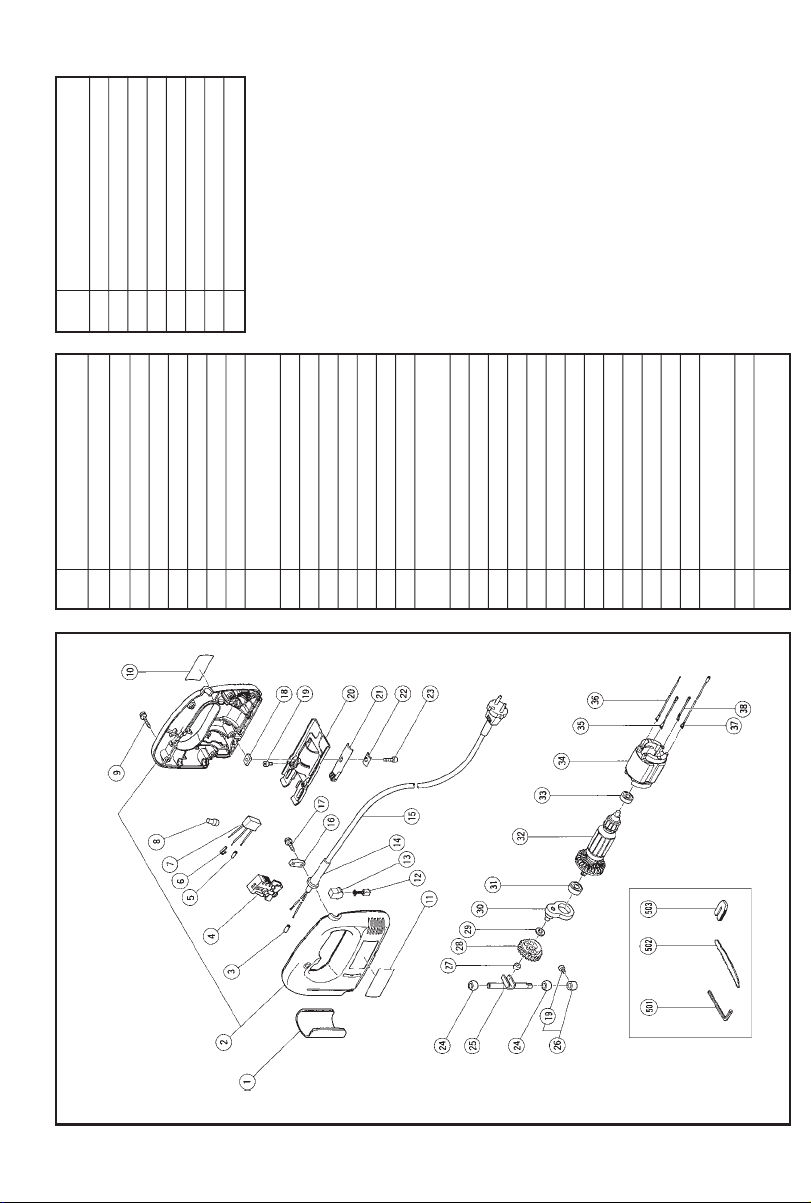

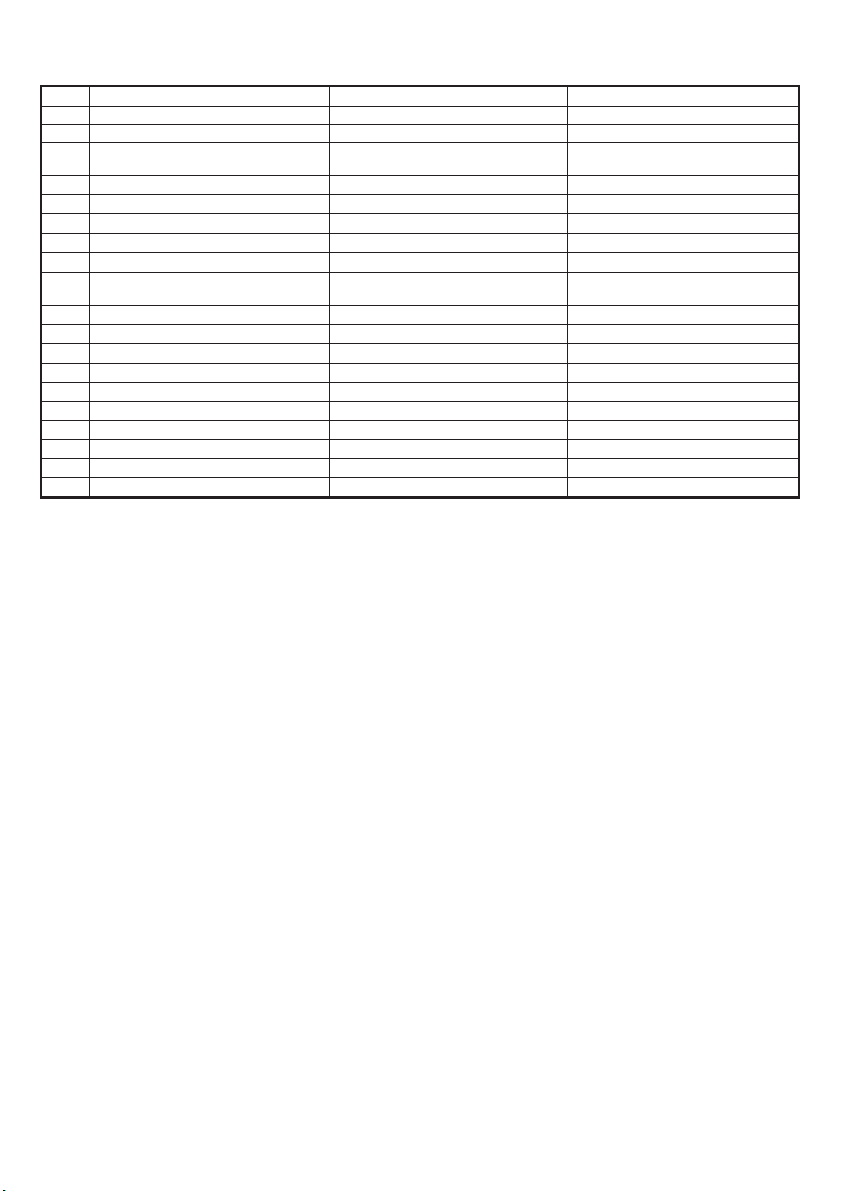

Part Name

34 Stator

No.

Item

35 Internal Wire (A)

36 Internal Wire

37 Internal Wire

38 Internal Wire (A)

501 Hex. Bar Wrench 3mm

502 Jig Saw Blades No.31

503 Splinter Guard

Parts are subject to possible

modification without notice due to

improvements.

The drawing and the list are parts

structural drawing and parts list of

model FCJ55VA.

For model FCJ55 refer to the drawing

and the list.

Part Name

No.

Item

FCJ55VA

1 Chip Cover

2 Housing (A).(B) Set

3 Tube (D)

4Switch

5 Tube (D)

D4 × 20

6 Earth Terminal

7 Noise Suppressor

8 Connector (50091)

9 Tapping Screw (W/Flange)

10 Name Plate

11 HITACHI Label

12 Carbon Brush

13 Brush Holder

14 Cord Armor

15 Cord

D4 × 16

16 Cord Clip

17 Tapping Screw (W/Flange)

18 Plate Nut

19 Hex. Socket Hd. Bolt M4 × 8

20 Base

21 Guide Roller

22 Base Locker

23 Hex. Socket Hd. Bolt M4 × 16

24 Metal

25 Plunger

26 Set Ring Ass’y

27 Connecting Piece

28 Gear

(608VVMC2EPS2L)

29 Washer (C)

30 Holder

31 Ball Bearing

(626VVMC2ERPS2S)

32 Armature

33 Ball Bearing

The exploded assembly drawing should be used only for authorized

service center.

FCJ55VA

Page 3

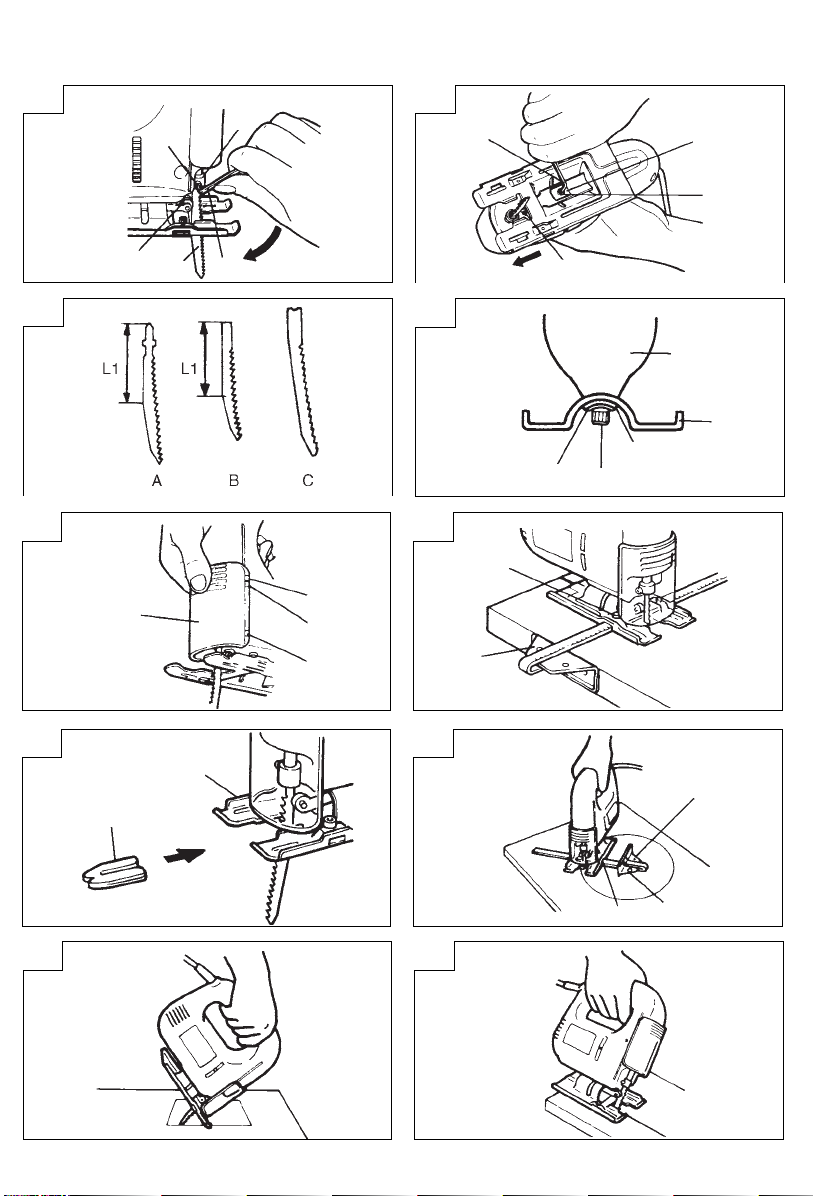

1

1

4

2

2

9

0

5

3

3

2

5

4

7

8

6

9

0

65

C

3

A

2

1

B

87

8

B

D

E

C

109

1 2 27

Page 4

11

G

F

12

B

C

C

H

13

1

Set ring Stellring Bague de réglage

2

Hexagonal bar wrench Sechskantinnenschlüssel Clef à six pans

3

Blade (blade edge must face Sägeblatt (Schnittfläche muß Lame (le bord de la lame doit être

front) nach vorne zeigen) tourné vers l’avant)

4

Blade set screw

5

Roller Führungsrolle Rouleau

6

Holder Halter Support

7

Housing Gehäuse Logement

8

Base Sägetisch Base

Base locker

9

0

4mm screw (16mm) 4mm Schraube (16mm) Vis de 4mm (16mm)

A

Chip cover Schnipseldeckel Couvercle d’éclats

B

Guide Führungsrolle Guide

C

4mm screw (8mm) 4mm Schraube (8mm) Vis de 4mm (8mm)

D

Splinter guard Splitterschutz Anti-éclats

E

Nail or wood screw Nagel oder Holzschraube Clou ou vis de bois

F

Scale Skala Echelle

G

Side groove Seitlicher Schlitz Fente latérale

H

Housing edge line Gehäusekante Arête du logement

I

Acceptable blades Verwendbare Sägeblätter Lames acceptables

I

English Deutsch Français

Klemmschraube für das Sägeblatt

Sicherungsvorrichtung für den Section de blocage de la base

Sägetisch

8

Vis de réglage de la lame

Page 5

1

Anello di fissaggio Stelring Anillo de ajuste

2

Chiave maschia esagonale Inbussleutel Llave macho hexagonal

Lama (il taglio della lama deve Zaagblad (snijkant moet naar Cuchilla (el filo tiene que mirar

3

essererivolto in avanti) voren wijzen) hacia el frente)

4

Vite di fissaggio della lama Klemschroef Tornillo de ajuste de la cuchilla

5

Rullo Geleiderol Rodillo

6

Sostegno Houder Sujetador

7

Involucro Behuizing Caja

8

Base Zaagtafel Base

9

Bloccaggio della base

0

Vite da 4mm (16mm) 4mm schroef (16mm) Tornillo 4mm (16mm)

A

Reccoglitrucioli Spaankast Cubierta de virutas

B

Guida Geleider Guía

C

Vite da 4mm (8mm) 4mm schroef (8mm) Tornillo 4mm (8mm)

D

Para-schegge Anti-splinterstuk Protector contra astillas

E

Chiodo o vite del legno Spijker of houtschroef Clavo o tornillo para madera

F

Scala graduata Schaal Escala

G

Solco laterale Gleuf aan de zijkant Hueco lateral

H

Bordo dell’involucro Behuizingshoeklijn Extremo de la caja

I

Lama accettabile Te gebruiken zaagbladen Cuchillas aceptables

Italiano Nederlands Español

Veiligheidsinrichting voor de

zaagtafel

Gaveta de base

3

Page 6

English

GENERAL OPERATIONAL PRECAUTIONS

WARNING! When using electric tools, basic safety

precautions should always be followed to reduce the

risk of fire, electric shock and personal injury, including

the following.

Read all these instructions before operating this product

and save these instructions.

For safe operations:

1. Keep work area clean. Cluttered areas and benches

invite injuries.

2. Consider work area environment. Do not expose

power tools to rain. Do not use power tools in

damp or wet locations. Keep work area well lit.

Do not use power tools where there is risk to cause

fire or explosion.

3. Guard against electric shock. Avoid body contact

with earthed or grounded surfaces. (e.g. pipes,

radiators, ranges, refrigerators).

4. Keep children and infirm persons away. Do not let

visitors touch the tool or extension cord. All visitors

should be kept away from work area.

5. Store idle tools. When not in use, tools should be

stored in a dry, high or locked up place, out of reach

of children and infirm persons.

6. Do not force the tool. It will do the job better and

safer at the rate for which it was intended.

7. Use the right tool. Do not force small tools or

attachments to do the job of a heavy duty tool. Do

not use tools for purposes not intended; for example,

do not use circular saw to cut tree limbs or logs.

8. Dress properly. Do not wear loose clothing or

jewelry, they can be caught in moving parts. Rubber

gloves and non-skid footwear are recommended

when working outdoors. Wear protecting hair

covering to contain long hair.

9. Use eye protection. Also use face or dust mask if

the cutting operation is dusty.

10. Connect dust extraction equipment.

If devices are provided for the connection of dust

extraction and collection facilities ensure these are

connected and properly used.

11. Do not abuse the cord. Never carry the tool by the

cord or yank it to disconnect it from the receptacle.

Keep the cord away from heat, oil and sharp edges.

12. Secure work. Use clamps or a vise to hold the work.

It is safer than using your hand and it frees both

hands to operate tool.

13. Do not overreach. Keep proper footing and balance

at all times.

14. Maintain tools with care. Keep cutting tools sharp

and clean for better and safer performance. Follow

instructions for lubrication and changing

accessories. Inspect tool cords periodically and if

damaged, have it repaired by authorized service

center. Inspect extension cords periodically and

replace, if damaged. Keep handles dry, clean, and

free from oil and grease.

15. Disconnect tools. When not in use, before servicing,

and when changing accessories such as blades,

bits and cutters.

16. Remove adjusting keys and wrenches. Form the

habit of checking to see that keys and adjusting

wrenches are removed from the tool before turning

it on.

17. Avoid unintentional starting. Do not carry a pluggedin tool with a finger on the switch. Ensure switch is

off when plugging in.

18. Use outdoor extension leads. When tool is used

outdoors, use only extension cords intended for

outdoor use.

19. Stay alert. Watch what you are doing. Use common

sense. Do not operate tool when you are tired.

20. Check damaged parts. Before further use of the

tool, a guard or other part that is damaged should

be carefully checked to determine that it will operate

properly and perform its intended function. Check

for alignment of moving parts, free running of

moving parts, breakage of parts, mounting and any

other conditions that may affect its operation. A

guard or other part that is damaged should be

properly repaired or replaced by an authorized

service center unless otherwise indicated in this

handling instructions. Have defective switches

replaced by an authorized service center. Do not

use the tool if the switch does not turn it on and off.

21. Warning

The use of any accessory or attachment, other than

those recommended in this handling instructions,

may present a risk of personal injury.

22. Have your tool repaired by a qualified person.

This electric tool is in accordance with the relevant

safety requirements. Repairs should only be carried

out by qualified persons using original spare parts.

Otherwise this may result in considerable danger

to the user.

4

Page 7

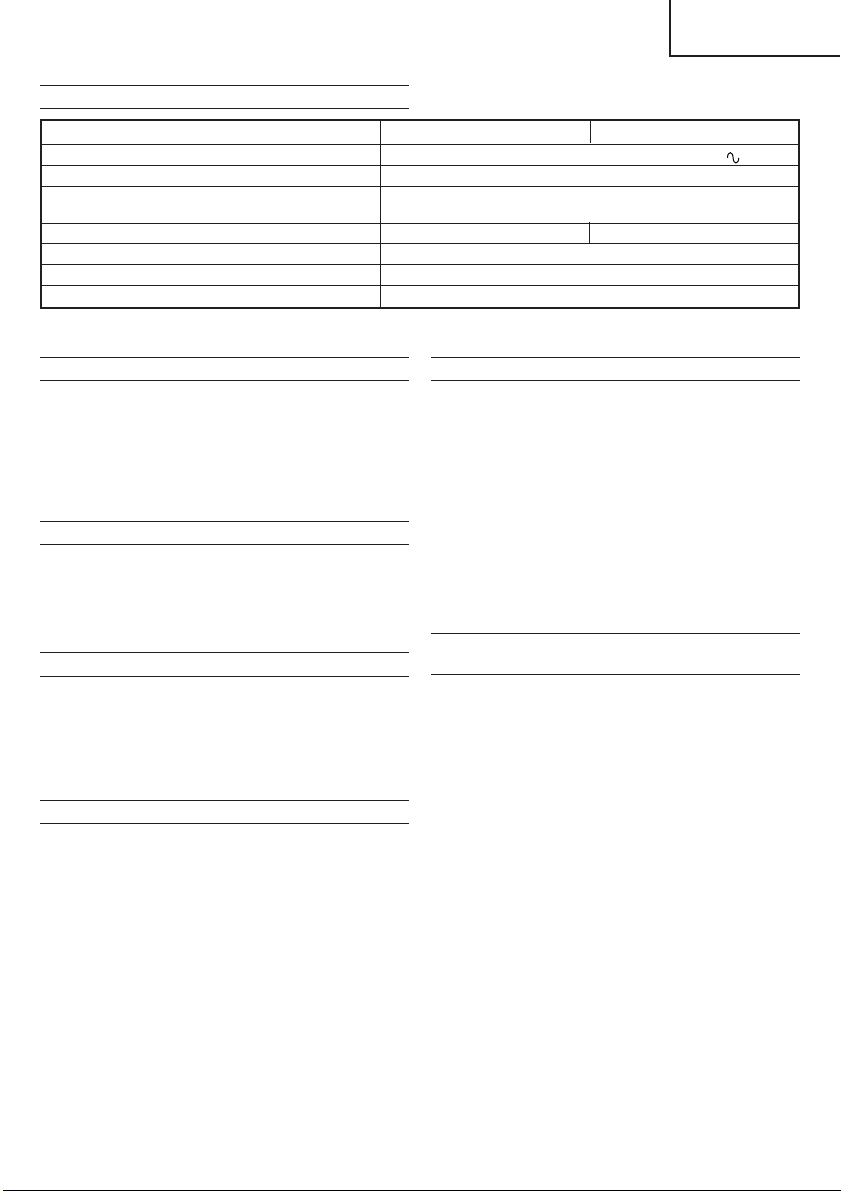

SPECIFICATIONS

Model FCJ55VA FCJ55

Voltage (by areas)* (110V, 115V, 120V, 127V, 220V, 230V, 240V)

Power input 400W*

Max. cutting depth

No-load speed 0 ~ 3000/min 3000/min

Stroke 18mm

Min. cutting radius 25mm

Weight (without cord) 1.4kg

* Be sure to check the nameplate on product as it is subject to change by areas.

Wood: 55mm

Mild steel: 3mm

English

STANDARD ACCESSORIES

(1) Blade No.31................................................................. 1

For cutting thick lumber

(2) Splinter guard ............................................................. 1

(3) Chip cover ...................................................................1

(4) Hexagonal bar wrench ............................................... 1

Standard accessories are subject to change without

notice.

OPTIONAL ACCESSORIES (sold separately)

(1) Blades, No.1 ~ No.6, 31*

* No.31 Blade is a standard accessory.

(2) Guide

(3) Dust collector

Optional accessories are subject to change without notice.

APPLICATIONS

䡬 Cutting various lumber and pocket cutting

䡬 Cutting mild steel plate, aluminum plate, and copper

plate

䡬 Cutting synthetic resins, such as phenol resin and

vinyl chloride

䡬 Cutting thin and soft construction materials

PRIOR TO OPERATION

1. Power source

Ensure that the power source to be utilized conforms

to the power requirements specified on the product

nameplate.

2. Power switch

Ensure that the power switch is in the OFF position. If

the plug is connected to a receptacle while the power

switch is in the ON position, the power tool will start

operating immediately, which could cause a serious

accident.

3. Extension cord

When the work area is removed from the power

source, use an extension cord of sufficient thickness

and rated capacity. The extension cord should be

kept as short as practicable.

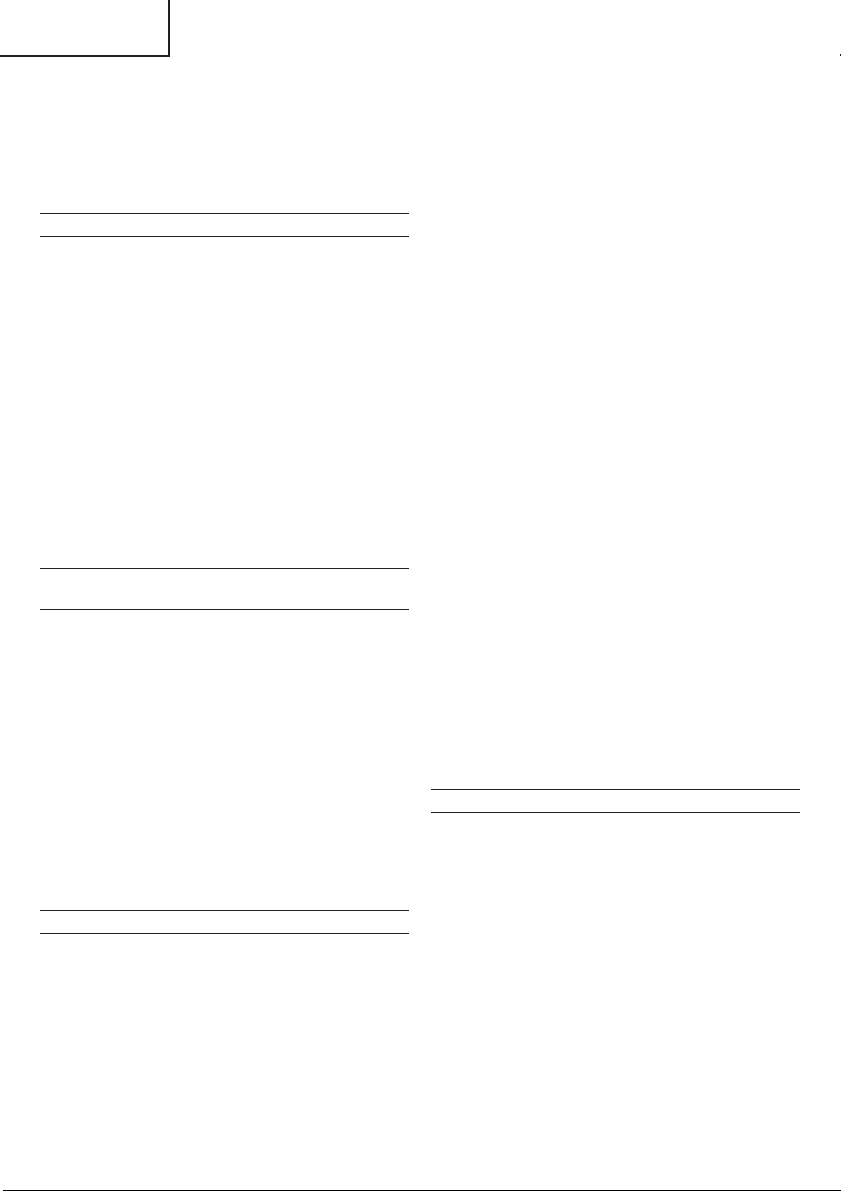

MOUNTING THE BLADE

1. Use the accessory hexagonal bar wrench to loosen

the blade set screws on the set ring, as shown in

Fig. 1.

2. Holding the blade with its cutting edge facing the

front, insert the mounting portion of the blade into

the plunger groove until it touches the bottom of the

groove.

3. As shown in Fig. 1, firmly clamp the side screw.

CAUTION

䡬 Loosened set screws may cause the blade to be

damaged. Always ensure that the set screws are

securely tightened. Always ensure that the plunger

groove is clean and clear of sawdust to ensure proper

blade mounting and set screw clamping.

ADJUSTING AND REMOVING THE GUIDE

ROLLER

1. Adjusting the guide roller

The guide roller, shown in Fig. 2, is employed to

prevent the blade from snapping. Prior to use, adjust

guide roller in accordance with the following

procedures:

(1) Loosen the holder set screw with the accessory

hexagonal bar wrench.

(2) Gently slide the guide roller until the roller groove

lightly touches the back of the blade.

NOTE

On delivery from the factory, there is a gap of about

3mm between the roller and blade.

(3) Firmly tighten the holder set screw.

CAUTION

䡬 The guide roller can be used only for Blades that

have a straight line on the rear that is longer than

50mm. (Fig. 3A and 3B) When using other types

of blades (Fig. 3C), slide the guide roller in

backwards so that the guide roller does not contact

the blade.

䡬 When cutting thick boards or performing

continuous cutting operations, use the blade

shown in the Fig. 3A, 3B and be sure to set the

guide roller.

2. Removing the guide roller

The guide roller can be removed from the jig saw

as follows:

5

Page 8

English

(1) Remove the 4mm screw, shown in Fig. 4, with the

accessory hexagonal bar wrench, and remove the

guide roller from the main body.

(2) To reassemble the main body and the base, insert

the base locker between the base and the 4mm screw,

as shown in Fig. 4, and securely clamp the 4mm

screw.

CHIP COVER POSITIONING

1. Chip cover

Use the chip cover to reduce flying of cut particles

and to easily operate the saw.

Slide the chip cover while lightly pressing its front

section.

The chip cover can be set at three positions as shown

in Fig. 5.

2. How to choose the position of the ship cover

Set the chip cover to the first step when attaching or

removing the blade.

Set the chip cover to the second step when cutting

wooden materials.

Set the chip cover to the second or third step when

cutting metal materials such as steel.

CAUTION

䡬 Keep always the chip cover in the low position when

operating the tool.

䡬 Wear protection glasses even if the chip cover is

used.

ADJUSTING THE BLADE OPERATING

SPEED .......................................... (FCJ55VA only)

NOTE

The blade operating speed cannot be adjusted for

FCJ55.

The blade operating speed can be adjusted within a

range of 0 to 3,000/min according to the degree that the

trigger switch is depressed. Select the speed appropriate

to the material being worked and/or the working

conditions.

To achieve continuous operation, pull the trigger switch

all the way back and depress the stopper. Then, turn the

speed adjustment knob to adjust the blade operating

speed as desired.

NOTE

The speed adjustment knob rotates approximately 3

turns. To turn the switch OFF, pull the trigger switch

again to disengage the stopper, and release the trigger

switch.

CUTTING

CAUTION

䡬 While sawing, the base must be firmly in contact with

the material surface, and the blade must be held at a

right angle. If the base becomes separated from the

material, it could cause the blade to break.

䡬 When cutting while holding the front surface, be

careful of the moving blade and hold the upper part

firmly.

1. Rectilinear cutting

(1) To ensure accurate rectilinear cutting, employ the

optional accessory guide as shown in Fig. 6.

(2) Use the splinter guard to reduce roughness of the

cutting surface of wooden materials. Attach the

splinter guard by inserting it from the front section of

the base until it clicks into place. (Fig. 7)

CAUTION

Set the base in the front position when using the

splinter guard.

2. Cutting a circle or a circular arc

To ensure efficient cutting, employ the optional

accessory guide and nail or wood screw as shown in

Fig. 8.

When mounting the guide, loosen the base bottom

screw, and shift the base as far forward as it will go.

3. Sawing curved lines

When sawing a small circular arc, reduce the feeding

speed of the machine. If the machine is fed too fast, it

could cause the blade to break.

4. Cutting metallic materials

Always use an appropriate cutting agent (spindle oil,

soapy water, etc.). When a liquid cutting agent is not

available, apply grease to the back surface of the

material to be cut.

5. Pocket cutting

(1) In lumber

Aligning the blade direction with the grain of the

wood, cut step by step until a window hole is cut in

the center of the lumber. (Fig. 9)

(2) In other materials

When cutting a window hole in materials other than

lumber, initially bore a hole with a drill or similar tool

from which to start cutting.

6. Angular cutting

Set the chip cover to the first step. (Fig. 5)

To adjust the angle of inclination; loosen the base

bottom screw, shift the base position to the side

groove of the semicircular portion, align the scale on

the base semicircular portion (figures engraved on

the scale indicate the angle of inclination) with the

housing edge line, and thoroughly tighten the base

bottom screw. (Fig. 10 and 11)

CAUTION

Set the screw to the opposite side of the inclining

side when using the guide. (Fig. 12)

SELECTION OF BLADES

1. Accessory blades

To ensure maximum operating efficiency and results

it is very important to select the appropriate blade

best suited to the type and thickness of the material

to be cut. One type of blade is provided as standard

accessory. The blade number is engraved in the

vicinity of the mounting portion of each blade. Select

appropriate blades by referring to Table 1.

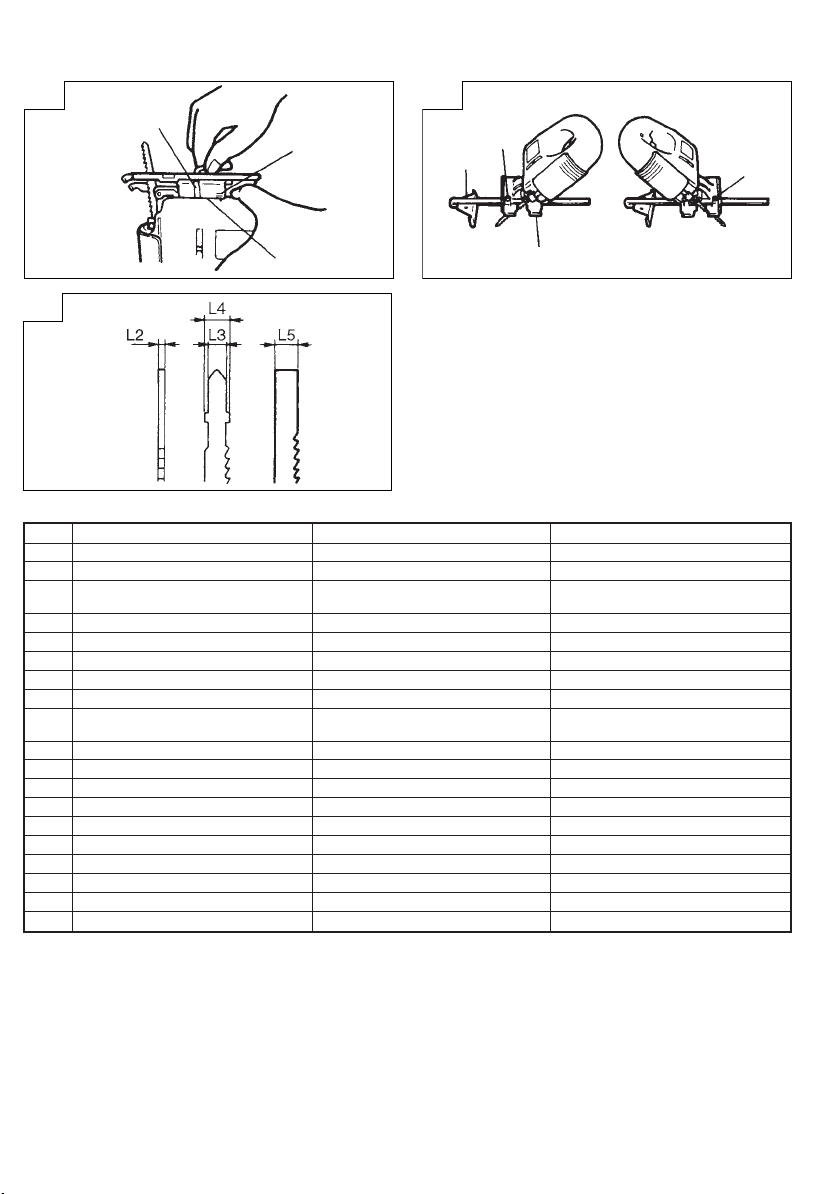

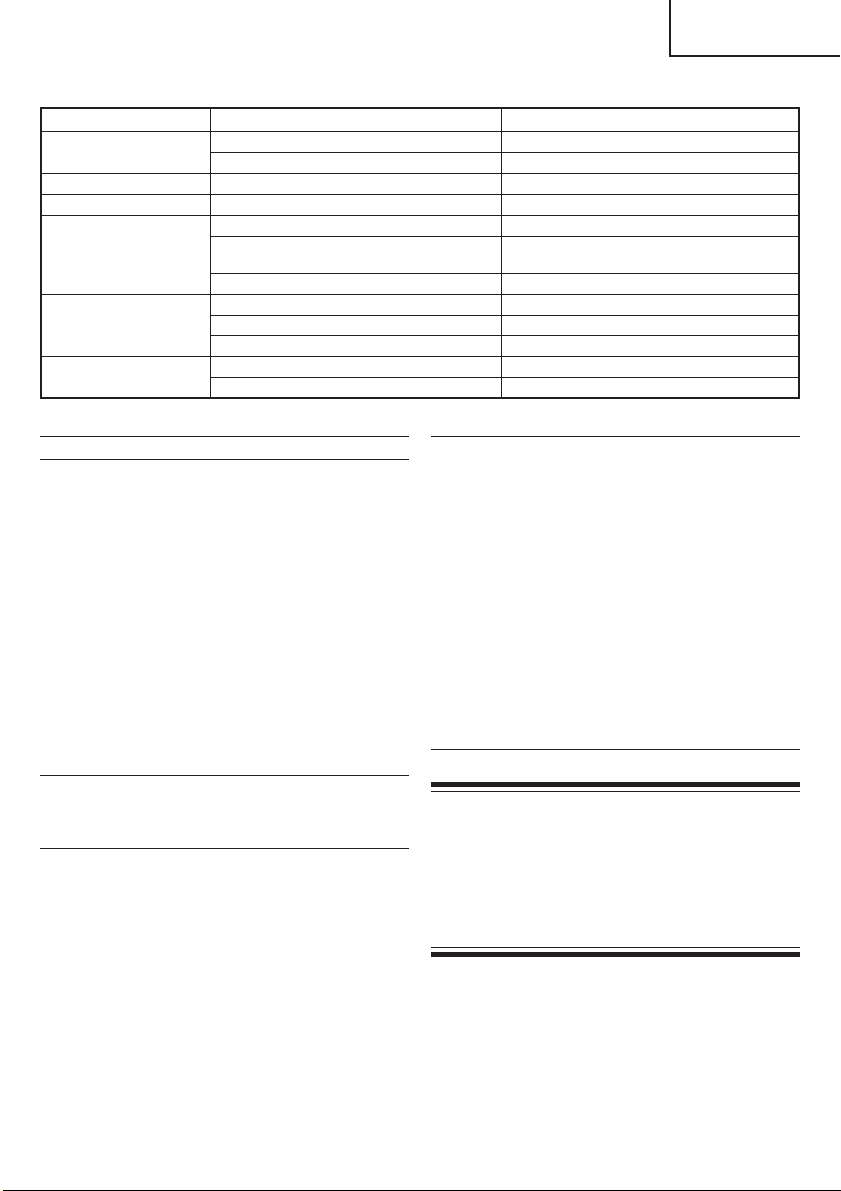

2. Acceptable commercial blades (Fig. 13)

This machine is designed to accept most blades

available on the open market. As illustrated in

Fig. 13, blade dimension restrictions are as follows:

䡬 Thickness : L2 .....Less than 1.6mm

䡬 Width : L3 ..... 6.3mm

NOTE

When cutting thick materials, use HITACHI genuine blades

which have an inclination as shown in Fig. 3-A or B.

L4 .....8mm

L5 .....7mm

6

Page 9

Table 1 List of Appropriate Blades

Material to be cut Material quality Blade No.

Lumber

Iron plate Mild steel plate No.6

Nonferrous metal Aluminum, copper, brass No.6

Synthetic resin

Pulp

Others

General lumber

Plywood No.3 or No.6

Phenol resin, melamine resin, etc. No.4 (thick plate) or No.6 (thin plate)

Vinyl chloride, acryl resin, etc.

Foamed styrol, etc. No.2

Cardboard, corrugated paper No.2

Hardboard No.5 or No.6

Fiberboard No.6

Hard rubber No.2

Slate No.5

No.1 or No.31 (thick plate) or No.2 (thin plate)

No.2 or No.4 (thick plate) or No.6

(thin plate)

English

MAINTENANCE AND INSPECTION

1. Inspecting the blade

Continued use of a dull or damaged blade will result

in reduced cutting efficiency and may cause

overloading of the motor. Replace the blade with a

new one as soon as excessive abrasion is noted.

2. Inspecting the mounting screws

Regularly inspect all mounting screws and ensure

that they are properly tightened. Should any of the

screws be loose, retighten them immediately. Failure

to do so could result in serious hazard.

3. Maintenance of the motor

The motor unit winding is the very “heart” of the

power tool. Exercise due care to ensure the winding

does not become damaged and/or wet with oil or

water.

4. Servicing

Consult an authorized Service Agent in the event of

power tool failure.

NOTE

Due to HITACHI’s continuing program of research and

development, the specifications herein are subject to

change without prior notice.

IMPORTANT

Correct connection of the plug

The wires of the main lead are coloured in accordance

with the following code:

Blue : –Neutral

Brown : –Live

As the colours of the wires in the main lead of this tool

may not correspond with the coloured markings

identifying the terminals in your plug proceed as follows:

The wire coloured blue must be connected to the terminal

marked with the letter N or coloured black. The wire

coloured brown must be connected to the terminal

marked with the letter L or coloured red. Neither core

must be connected to the earth terminal.

NOTE

This requirement is provided according to BRITISH

STANDARD 2769: 1984

Therefore, the letter code and colour code may not be

applicable to other markets except The United Kingdom.

Information concerning airborne noise and vibration

The measured values were determined according to

EN50144.

The typical A-weighted sound pressure level: 81dB (A)

Wear ear protection.

The typical weighted root mean square acceleration

value: 6.5m/s2.

7

Page 10

Deutsch

ALLGEMEINE VORSICHTSMASSNAHMEN

WARNUNG! Bei der Verwendung von Elektrowerkzeugen

müssen immer die grundlegenden Vorsichtsmaßnahmen

befolgt werden, um das Risiko von Feuer, elektrischem

Schlag und persönlicher Verletzung und den

nachfolgenden Punkten zu vermeiden.

Lesen Sie diese Anweisungen völlig, bevor Sie dieses

Erzeugnis verwenden, und bewahren Sie diese

Anweisungen auf.

Für sicheren Betrieb:

1. Der Arbeitsplatz sollte sauber gehalten werden.

Unaufgeräumte Arbeitsplätze und Werkbänke

erhöhen die Unfallgefahr.

2. Die Betriebsbedingungen beachten.

Elektrowerkzeuge sollten nicht dem Regen

ausgesetzt werden. Ebenfalls sollten Sie nicht an

feuchten oder nassen Plätzen gebraucht werden.

Der Arbeitsplatz sollte gut beleuchtet sein.

Verwenden Sie Elektrowerkzeuge nicht an Orten,

an denen die Gefahr von Feuer oder Explosion

besteht.

3. Schutzmaß nahmen gegen elektrische Schläge

treffen. Darauf achten, daß das Gehäuse nicht in

Kontakt mit geerdeten Flachen kommt, z. (z.B. Rohre,

Radiatoren, Elektroherde, Kühlschränke).

4. Kinder und gebrechliche Personen sollten vom Gerät

ferngehalten werden. Andere Personen nicht mit

dem Werkzeug oder dem Verlängerungskabel in

Kontakt kommen lassen. Besucher sollten vom

Arbeitsbereich ferngehalten werden.

5. Nicht benutzte Werkzeuge sollten sicher aufbewahrt

werden. Sie sollten an einem trockenen und

hochgelegenen oder verschließbaren Ort

aufbewahrt werden, außerhalb der Reichweite von

Kindern und gebrechlichen Personen.

6. Werkzeuge sollten nicht mit übermäßiger Gewalt

verwendet werden. Ihre Leistung ist besser und

sicherer, wenn sie mit der vorgeschriebenen

Geschwindigkeit verwendet werden.

7. Nur die korrekten Werkzeuge verwenden. Niemals

ein kleineres Werkzeug oder Zusatzgerat für

Arbeiten verwenden, die Hochleistungsgerate

erfordern. Nur Werkzeuge verwenden, die dem

Verwendungszweck entsprechen, d.h. niemals eine

Kreissäge zum Sägen von Ästen oder

Baumstämmen verwenden.

8. Die richtige Kleidung tragen. Keine lose Kleidung

oder Schmuck tragen, da sich lose Kleidungsstücke

in den bewegenden Teilen verfangen können. Bei

Arbeiten im Freien sollten Gummihandschuhe und

rutschfeste Schuhe getragen werden. Tragen Sie

eine schützende Haarabdeckung, um langes Haar

zurückzuhalten.

9. Es sollte eine Sicherheitsbrille getragen werden.

Bei Arbeiten mit Staubentwicklung sollte eine

Gesichtsoder Staubmaske getragen werden.

10. Schließen Sie eine Staubabsaugvorrichtung an.

Wenn Vorrichtungen für den Anschluß von

Staubabsaug- und -sammelvorrichtungen

vorhanden sind, so stellen Sie sicher, daß diese

angeschlossen sind und richtig verwendet werden.

11. Niemals das Kabel mißbrauchen. Ein Werkzeug

niemals am Kabel tragen oder bei Abtrennung von

der Steckdose das Kabel harausreißen. Das Kabel

sollte gegen Hitze, Öl und scharfe Kanten geschützt

werden.

8

12. Den Arbeitsplatz gut absichern. Zwingen oder einen

Schraubstock zur Befestigung des Werkstücks

verwenden. Das ist sicherer als die Benutzung der

Hände und macht beide Hände zur Bedienung des

Werkzeugs frei.

13. Sich niemals weit überbeugen. Immer einen festen

Stand und ein sicheres Gleichgewicht bewahren.

14. Die Werkzeuge sollten sorgfältig behandelt werden.

Für einen einwandfreien und sicheren Betrieb sollten

sie stets scharf sein und saubergehalten werden.

Die Anleitungen für schmierung und Austausch des

Zuehörs unbedingt einhalten. Die Kabel der Geräte

regelmäßig überprüfen und bei Beschädigung durch

eine autorisierte Kundendienststelle reparieren

lassen. Ebenfalls die Verlägerungskabel regelmäßig

überprüfen und bei Beschadigung auswechseln. Die

Handgriffe sollten stets trocken und sauber sein,

sowie keine Öl- oder Schmierfett stellen aufweisen.

15. Werkzeuge vom Netz trennen, wenn sie nicht

benutzt werden, vor Wartungsarbeiten und beim

Austausch von Zubehörteilen wie z.B. Blätter, Bohrer

und Messer.

16. Alle Stellkeile und Schraubenschlüssel entfernen.

Vor Einschaltung des Gerätes darauf achten, daß

alle Stellkeile und Schraubenschlüssel entfernt

worden sind.

17. Ein unbeabsichtigtes Einschalten sollte vermieden

werden. Niemals ein angeschlossenes Werkzeug

mit dem Finger am Schalter tragen. Vor Anschluß

überprüfen, ob das Gerät ausgeschaltet ist.

18. Im Freien ein Verlängerungskabel verwenden. Nur

ein Verlängerungskabel verwenden, das für die

Verwendung im Freien markiert ist.

19. Immer wachsam bleiben. Auferksamkeit wachen

lassen. Gesunden Menschenverstand anwenden.

Das Werkzeug nicht in ermüdetem Zustand

verwenden.

20. Beschädigte Teile überprüfen. Vor Benutzung des

Werkzeugs sollten beschädigte Teile oder

Schutzvorrichtungen sorgfältig überprüft werden,

um festzustellen, ob sie einwandfrei funktionieren

und die vorgesehene Funktion erfüllen, Ausrichtung,

Verbindungen sowie Anbringung sich bewegender

Teile überprüfen. Ebenfalls uberprufen, ob Teile

gebrochen sind. Teile oder Schutzvorrichtungen,

die beschädigt sind, sollten, wenn in dieser

Bedienungsanleitung nichts anderes erwähnt ist,

durch eine autorisierte Kundendienststelle ausge

wechselt oder repariert werden. Dasselbe gilt für

defekte Schalter. Wenn sich das Werkzeug nicht

mit dem Schalter einoder ausschalten läßt, sollte

das Werkzeug nicht verwendet werden.

21. Warnung

Die Verwendung von anderem Zubehör oder

anderen Zusätzen als in dieser Bedienungsanleitung

empfohlen kann das Risiko einer Körperverletzung

einschließen.

22. Lassen Sie Ihr Werkzeug durch qualifiziertes

Personal reparieren.

Dieses Elektrowerkzeug entspricht den zutreffenden

Sicherheitsanforderungen. Reparaturen sollten nur

von qualifiziertem Personal unter Verwendung von

Originalersatzteilen durchgeführt werden, da sonst

beträchtliche Gefahr für den Benutzer auftreten

kann.

Page 11

Deutsch

TECHNISCHE DATEN

Modell FCJ55VA FCJ55

Spannung (je nach Gebiet)* (110V, 115V, 120V, 127V, 220V, 230V, 240V)

Leistungsaufnahme 400W*

Max. Schnittiefe

Leerlaufhubzahlen 0 ~ 3000/min 3000/min

Hub 18mm

Mindestschnittradius 25mm

Gewicht (ohne kabel) 1,4kg

* Vergessen Sie nicht, die Produktangaben auf dem Typenschild zu überprüfen, da sich diese je nach Verkaufsgebiet

ändern.

Holz: 55mm

Flußstahl: 3mm

STANDARDZUBEHÖR

(1) Sägeblatt Nr.31 ........................................................... 1

Für Schneiden von dickem Bauholz

(2) Splitterschutz ..............................................................1

(3) Schnipseldeckel .......................................................... 1

(4) Innensechskantschlüssel ........................................... 1

Das Standardzubehör kann ohne vorherige

Bekanntmachung jederzeit geändert werden.

SONDERZUBEHÖR (separat zu beziehen)

(1) Sägeblätter, Nr.1 ~ Nr.6, Nr.31*

* Sägeblatt Nr.31 ist Standardzubehör.

(2) Führungsrolle

(3) Staubsauger

Das Sonderzubehör kann ohne vorherige

Bekanntmachung jederzeit geändert werden.

ANWENDUNGEN

䡬 Schneiden verschiedener Nutzhölzer (auch

Aussparungen)

䡬 Schneiden von Flußstahlblechen, Aluminiumblechen

und Kupferblechen

䡬 Schneiden von Kunstharzen wie Phenolharz und

Vinylchlorid

䡬 Schneiden von dünnen und weichen Baumaterialien

VOR DER INBETRIEBNAHME

1. Netzspannung

Prüfen, daß die zu verwendende Netzspannung der

Angabe auf dem Typenschild entspricht.

2. Netzschalter

Prüfen, daß der Netzschalter auf “AUS” steht. Wenn

der Stecker an das Netz angeschlossen wird, während

der Schalter auf “EIN” steht, beginnt das Werkzeug

sofort zu laufen, was gefährlich ist.

3. Verlängerungskabel

Wenn der Arbeitsbereich nicht in der Nähe des

Netzanschlusses liegt, ist ein Verlängerungskabel

ausreichenden Querschnitts und ausreichender

Nennleistung zu verwenden. Das Verlängerungskabel

sollte so kurz wie möglich gehalten werden.

ANBRINGEN DES SÄGEBLATTS

1. Mit dem Sechskantinnenschlüssel werden die

Klemmschrauben des Sägeblatts am Einstellring

gelöst (Abb. 1).

2. Das Sägeblatt mit der Schnittseite nach vorn halten

und den Befestigungsteil des Sägeblatts bis zum

Anschlag in den Schlitz der Schwingspule

einschieben.

3. Gemäß Abb. 1 wird die seitliche Klemmschraube fest

angezogen.

ACHTUNG

䡬 Lose Klemmschrauben können zur Beschädigung des

Sägeblattes führen. Es ist immer darauf zu achten,

daß die Klemmschrauben fest angezogen sind. Es ist

ferner darauf zu achten, daß der Schlitz der

Schwingspule sauber und ohne Sägemehl ist, um

eine richtige Befestigung des Sägeblattes und

richtiges Klemmen der Klemmschrauben zu

gewährleisten.

EINSTELLEN UND ENTFERNEN DER

FÜHRUNGSROLLE

1. Einstellen der Führungsrolle

Die Führungsrolle wird, wie in Abb. 2 gezeigt,

verwendet, um das Abspringen des Sägeblattes zu

verhindern. Vor der Benutzung wird die Führungsrolle

wie folgt eingestellt:

(1)Die Klemmschraube des Halters wird mit dem

Sechskantinnenschlüssel gelockert.

(2)Die Führungsrolle vorsichtig verschieben, bis die

Rollennut leicht die Rückseite des Sägeblatts berührt.

ANMERKUNG

Bei Lieferung ab Werk ist ein Zwischenraum von

etwa 3mm zwischen der Rolle und dem Sägeblatt

vorhanden.

(3) Die Klemmschraube des Halters wird fest angezogen.

ACHTUNG

䡬 Die Führungswalze kann nur für Sägeblätter

verwendet werden, die hinten eine gerade Linie

von mehr als 50mm Länge haben. (Abb. 3A und

3B) Bei Verwendung anderer Sägeblätter (Abb.

3C) die Führungswalze in Rückwärtsrichtung

einschieben, so daß die Führungswalze nicht das

Sägeblatt berührt.

9

Page 12

Deutsch

䡬 Beim Schneiden dicker Bretter und bei

fortgesetzten Schneidevorgängen das in Abb. 3A,

3B gezeigte Blatt verwenden und unbedingt die

Führungsrolle einstellen.

2. Entfernen der Führungsrolle

Die Führungsrolle kann wie folgt von der Stichsäge

abmontiert werden:

(1) Die 4mm Schraube wird, wie in Abb. 4 gezeigt, mit

dem Innensechskantschlüssel entfernt und dann die

Führungsrolle vom Gehäuse abgenommen.

(2) Beim Wiederzusammenbau des Gehäuses und des

Sägetisches wird die Sicherungsvorrichtung des

Sägetisches eingesetzt, zwischen Sägetisch und der

4mm Schraube aufgesetzt, wie in Abb. 4 gezeigt, und

die 4mm Schraube fest angezogen.

LAGE DES SCHNIPSELDECKELS

1. Schnipseldeckel

Den Schnipseldeckel verwenden, um das Spritzen

von Schnittpartikeln zu vermeiden und die Säge leicht

zu bedienen.

Zum Aufsetzen des Schnipseldeckels leicht die

Vorderseite drücken.

Der Schnipseldeckel kann in drei Stellungen

aufgesetzt werden, wie in Abb. 5 gezeigt.

2. Wahl der Position des Schipseldeckels

Den Schipseldeckel beim Anbringen oder Abnehmen

des Sägeblattes in die erste Stellung stellen.

Den Schipseldeckel beim Sägen von Holzmaterialien

in die zweite Stellung stellen.

Den Schnipseldeckel beim Sägen von

Metallmaterialien wie Blech in die dritte stellung

stellen.

ACHTUNG

䡬 Halten Sie die Späneabdeckung beim Betrieb des

Werkzeugs immer in der niedrigen Position.

䡬 Immer eine Schutzbrille tragen, auch wenn der

Schnipseldeckel verwendet wird.

EINSTELLEN DER ARBEITSGESCHWINDIGKEIT

DES SÄGEBLATTES .................... (Nur FCJ55VA)

ANMERKUNG

Die Sägeblattgeschwindigkeit kann beim Modell

FCJ55 nicht eingestellt werden.

Die Arbeitsgeschwindigkeit des Sägeblattes kann

innerhalb eines Bereichs von 0 bis 3000/Min. je nach

Druck auf den Drückerschalter eingestellt werden. Die

für das Material des Arbeisstückes und/oder die

Arbeitsbedingungen geeignete Geschwindigkeit wird

gewählt. Für kontinuierlichen Betrieb wird der

Drückerschalter ganz zurückgezogen und der

Arretierknopf gedrückt. Dann wird der Knopt für die

Geschwindigkeitsregelung zur Einstellung der

gewünschten Arbeitsgeschwindigkeit des Sägeblattes

eingestellt.

ANMERKUNG

Der Einstellknopf für die Geschwindigkeit hat etwa 3

Umdrehungen. Zum Ausschalten wird der

Drückerschalter erneut gezogen, so daß der Arretierknopf

freigegeben wird, und dann wird der Drückerschalter

losgelassen.

10

SCHNEIDEN

ACHTUNG

䡬 Beim Sägen muß der Sägetisch fest auf der

Oberfläche des Werkstücks auf liegen und das

Sägeblatt im rechten Winkel gehalten werden. Wenn

der Sägetisch das Material nicht berührt, kann das

zum zerbrechen des Sägeblatts führn.

䡬 Wenn Sie beim Schneiden die Vorderseite halten,

auf das sich auf-und abbewegende Sägeblatt achten

und das Oberteil festhalten.

1. Parallelschneiden

(1) Für genaues, geradliniges Schneiden den

Sonderzubehörführer wie auf Abb. 6 gezeigt

verwenden.

(2) Den Splitterschuz verwenden, um die Rauhigkeit der

Sägefläche von Holzmaterialien zu verringern. Der

Splitterschutz wird von der Vordersektion des

Sägetischs eingesetzt, bis er einrastet. (Abb. 7)

ACHTUNG

Den Sägetisch nach vorne stellen, wenn der

Splitterschutz verwendet wird.

2. Schneiden eines Kreises oder eines Kreisbogens

Um zweckmäßiges Schneiden zu erreichen,

Sonderzubehörführer, Nagel und Holzschraube wie

auf Abb. 8 gezeigt verwenden.

Zum Anbringen des Führers die Bodenschraube

lockern und den Boden soweit wie möglich nach

vorn schieben.

3. Sägen von Bogenlinienj

Beim Sägen eines kleinen Kreisbogens wird die

Schiebgeschwindigkeit der Maschine verringert.

Wenn die Maschine zu schnell geschoben wird, könnte

das zum zerbrechen des Sägeblatts führen.

4. Schneiden von Metallen

Immer ein geeignetes Schneidemittel verwenden

(Spindelöl, Seifenwasser, usw.). Wenn ein flüssiges

Schneidemittel nicht zur Verfügung steht, wird auf

die Rückseite des zu schneidenden Materials Fett

aufgetragen.

5. Schneiden von Löchern

(1) In Schnittholz

Die Schnittrichtung wird der Faserrichtung des Holzes

angepasst. Es wird Schritt für Schritt geschnitten, bis

ein Fenster in der Mitte des Schnittholzes entstanden

ist. (Abb. 9)

(2) In anderen Materialien

Beim Schneiden eines Fensters in anderen Materialien

als Holz wird zu Anfang ein Loch mit einer

Bohrmaschine oder einem ähnlichen Werkzeug

gebohrt, von dem aus das Schneiden beginnt.

6. Schrägschnitte

Den Schnipseldeckel in die erste Stellung stellen.

(Abb. 5)

Für die Einstellung des Neigungswinkels wird die

Bodenschraube gelockert, die Position des Bodens

am seitlichen Schlitz der Halbkreisführung verschoben

und die Skala auf der Halbkreisführung (die auf der

Skala eingravierten Zahlen bedeuten den

Neigungswinkel) mit der Gehäusekante eingereiht,

und die bodenschraube fest angezogen. (Abb. 10

und 11)

ACHTUNG

Bei Verwendung der Führungsrolle die Schraube in

die der Neigeseite entgegengesetzten Seite stellen.

(Abb. 12)

Page 13

Deutsch

AUSWAHL DER SÄGEBLÄTTER

1. Standardmaßiges Zubehör

Für maximale Leistung und beste Ergebnisse ist es

sehr wichtig, das richtige Sägeblatt auszuwählen,

das am besten für die Art und Dicke des zu

schneidenden Materials geeignet ist. Als

Standardzubehör wird ein Sägeblattyp geliefert. Die

Nummer des Sägeblattes ist in der Nähe der Halterung

jedes Sägeblattes eingraviert. Das geeignete Sägeblatt

wird anhand von Tabelle 1 ausgewählt.

Tabelle 1 Liste der geeigneten Sägeblätter

Zu schneidendes

Material

Schnittholz

Einseblech Flußstahlblech Nr.6

Nichteisenmetalle Aluminium, Kupfer, Messing Nr.6

Kunststoffe

Holzfasermaterial

Sonstige

Allgemeines Schnittholz

Furnierplatten Nr.3 oder Nr.6

Phenolharz, Melaminharz usw.

Vinylchlorid, Acrylharz, usw.

Geschäumtes Styrol, usw Nr.2

Pappe, Wellpappe Nr.2

Hartfaserplatte Nr.5 oder Nr.6

Faserplatte Nr.6

Hartgummi Nr.2

Schiefer Nr.5

Materialqualität Blatt-Nr.

2. Verwendbare kommerzielle Sägeblätter (Abb. 13)

Diese Maschine ist für die meisten auf dem Markt

erhältlichen Sägeblätter geeignet. Wie in Abb. 13

gezeigt, unterliegen die Sägeblattabmessungen den

folgenden Beschränkungen:

䡬 Dicke : L2 .......Weniger als 1,6mm

䡬 Breite : L3 .......6,3mm

ANMERKUNG

Beim Sägen von dicken Materialien nur echte HITACHISägeblätter mit einer Neigung wie in Abb. 3-A oder B

gezeigt verwenden.

L4 .......8mm

L5 .......7mm

Nr.1 oder Nr.31 (Dicke Platte) oder Nr.2

(Dünne Platte)

Nr.4 (Dicke Platte) oder Nr.6 (Dünnen

Platte)

Nr.2 (Dicke Platte), Nr.4 (Dicke Platte) oder

Nr.6 (Dünnen Platte)

WARTUNG UND INSPEKTION

1. Inspektion des Sägeblattes

Die Weiterverwendung eines stumpfen oder

beschädigten Sägeblattes führt zu verminderter

Schnittleistung und kann eine Überbelastung des

Motors hervorrufen. Das Sägeblatt wird durch ein

neues ersetzt, wenn übermäßige Abnutzung

festgestellt wird.

2. Inspektion der Befestigungsschraube

Alle Befestigungsschrauben werden regelmäßig

inspiziert und geprüft, ob sie gut angezogen sind.

Wenn sich eine der Schrauben lockert, muß sie sofort

wieder angezogen werden. Geschieht das nicht, kann

das zu erheblichen Gefahren führen.

3. Wartung des Motors

Die Motorwicklung ist das “Herz” des

Elektrowerkzeugs. Daher ist besonders sorgfältig

darauf zu achten, daß die Wicklung nicht beschädigt

wird und/oder mit Öl oder Wasser in Berührung

kommt.

4. Instandhaltung

Im Falle eines Versagens eine autorisierte

Wartungswerkstatt zu Rate ziehen.

ANMERKUNG

Aufgrund des ständigen Forschungs- und

Entwicklungsprogramms von HITACHI sind Änderungen

der hierin gemachten technischen Angaben nicht

ausgeschlossen.

Information über Betriebslärm und Vibration

Die Meßwerte wurden entsprechend EN50144 bestimmt.

Der typische A-gewichtete Schalldruckt ist 81dB (A)

Bei der Arbeit immer einen Ohrenschutz tragen.

Der typische gewogene quadratische Mittelwert für die

Beschleunigung ist 6,5 m/s2.

11

Page 14

Français

PRECAUTIONS GENERALES DE TRAVAIL

ATTENTION! Lors de l’utilisation d’un outillage électrique,

les précautions de base doivent être respectées de

manière à réduire les risques d’incendie, de secousse

électrique et de blessure corporelle, y compris les

précautions suivantes.

Lire ces instructions avant d’utiliser le produit et conserver

ces instructions pour référence.

Pour assurer un fonctionnement sûr:

1. Maintenir l’aire de travail propre. Des ateliers ou

des établis en désordre risquent de provoquer des

accidents.

2. Tenir compte de l’environnement de l’aire de tra

vail. Ne pas exposer les outils électriques à la pluie.

Ne pas les utiliser dans des endroits humides.

Travailler dans un endroit bien éclairé.

Ne pas utiliser d’outillage électrique s’il existe un

risque d’incendie ou d’explosion.

3. Protection contre une décharge électrique. Eviter

tout contact corporel avec des surfaces de mise à la

terre telles que les tuyaux, radiateurs, cuisinières et

réfrigérateurs.

4. Tenir les enfants et les personnes infirmes éloignés.

Ne pas laisser les visiteurs toucher l’outil ni son

cordon d’alimentation. Il est préférable de tenir les

visiteurs et les personnes infirmes à l’écart de l’aire

de travail.

5. Ranger les outils non utilisés. Quand on ne les

utilise pas, il est recommandé de ranger les outils

dans un endroit sec, verrouillé ou hors de portée

des enfants et des personnes infirmes.

6. Ne pas forcer l’outil. Il fonctionnera mieux et plus

sûrement à la vitesse pour laquelle il a été con cu.

7. Utiliser l’outil approprié. Ne pas essayer de faire

avec un petit outil le travail prevu pour un outil plus

important. Toujours utiliser l’outil adéquat; par

exemple, ne pas se servir d’une scie circulaire pour

couper des branches d’arbres ou des billots de

bois.

8. Porter des vêtements appropriés. Ne pas mettre de

vêtements flottants ou de bijoux qui risquent d’être

pris dans les pièces mobiles. Si l’on travaille à

l’extérieur, il est recommandé de porter des gants

de caoutchouc et des chaussures à semelles

antidérapantes. Veiller à s’attacher les cheveux ou

à mettre un bonnet si on a les cheveux longs.

9. Porter des lunettes protectrices. Mettre un masque

si l’opération de coupe crée de la poussière.

10. Relier l’équipement d’extraction de poussière.

Si des dispositifs sont prévus pour le raccordement

d’installations d’extraction et de collection de

poussière, s’assurer qu’ils sont correctement

raccordés et utilisés.

11. Prendre soin du fil. Ne jamais transporter l’outil en

le tenant par le fil et ne pas le débrancher en tirant

sur le fil d’un coup sec. Tenir le fil à l’abri de la

chaleur, l’éloigner de l’huile ou de bords tranchants.

12. Fixer fermement la piêce à travailler. Utiliser des

agrafes ou un étau pour la maintenir. C’est plus sûr

que d’utiliser ses mains et cela les libêre pour faire

fonctionner l’outil.

13. Ne pas présumer de ses forces. Essayer de garder

son équilibre en toute circonstance.

14. Entretenir les outils avec soin. Les conserver bien

aiguisés et les nettoyer afin d’en obtenir les

meilleures performances et de pouvoir les utiliser

sans danger. Suivre les instructions pour le

graissage et le changement des accessoires. Vérifier

régulièrement les fils et cordons et s’ils sont

endommagés, les faire réparer par une personne

compétente. Vérifier régulièrement les rallonges et

les remplacer si elles sont endommagées. Veiller à

ce que les poignées soient toujours sèches et

propres, sans huile ni graisse.

15. Debrancher les outils lorsqu’on ne les utilise pas,

avant toute opération d’entretien et lors du

changement d’accessoire; comme par exemple

quand on change les lames, les forets, le fraises,

etc.

16. Retirer les clés de réglage. Prendre l’habitude de

toujours vérifier que les clés de réglage sont bien

retirées de l’appareil avant de le mettre en marche.

17. Eviter toute mise en marche accidentelle. Ne pas

transporter l’outil branché avec un doigt sur

l’interrupteur. S’assurer que l’interrupteur est sur

la position d’arrêt quand on branche l’outil.

18. Utilisation de rallonges à l’extérieur. Quand on

utilise l’outil à l’extérieur, ne se servir que des

rallonges prévues pour l’extérieur et portant une

marque distinctive.

19. Soyez vigilant. Regardez bien ce que vous faites.

Faites appel à votre bon sens. N’utilisez pas l’outil

quand vous êtes fatigué.

20. Vérifier les pièces endommagées. Avant d’utiliser

davantage l’outil, vérifier attentivement toute pièce

endommagée afin de déterminer si l’outil peut

fonctionner correctement et effectuer le travail pour

lequel il est prévu. Vérifier l’alignement et la flexion

des piêces mobiles, la cassure des pièces, le

montage et toute autre condition risquant d’affecter

le bon fonctionnement de l’outil. Un protecteur ou

toute autre pièce endommagée devra être

correctement réparé ou remplacé par un service

d’entretien autorisé, sauf autre indication dans ce

mode d’emploi. Faire remplacer les interrupteurs

défectueux par un service d’entretien autorisé. Ne

pas utiliser l’outil si l’interrupteur ne permet pas de

le mettre en marche ou de l’arrêter.

21. Précaution

L’utilisation d’un accessoire ou dispositif annexe

autre que ceux conseillés dans ce mode d’emploi

peut entraîner un risque de blessure corporelle.

22. Confier la réparation d’un outil à un technicien

qualifié.

Cet outil électrique a été conçu conformément aux

règles de sécurité en usage. Les réparations doivent

être effectuées par du personnel qualifié utilisant

des pièces d’origine. Dans le cas contraire,

l’utilisateur s’expose à des risques graves.

12

Page 15

CARACTERISTIQUES

Modèle FCJ55VA FCJ55

Tension (par zone)* (110V, 115V, 120V, 127V, 220V, 230V, 240V)

Puissance 400W*

Profondeur max. de coupe

Vitesse sans charge 0 ~ 3000/min 3000/min

Course 18mm

Rayon min. de coupe 25mm

Poids (sans fil) 1,4kg

*Assurez-vous de vérifier la plaque signalétique sur le produit, qui peut changer suivant les régions.

Bois: 55mm

Acier doux: 3mm

Français

ACCESSOIRES STANDARD

(1) Lame No.31 ................................................................. 1

Pour couper un morceau de bois de

charpente épais.

(2) Anti-éclats ................................................................... 1

(3) Couvercle d’éclats ...................................................... 1

(4) Clef à barre à pans ..................................................... 1

Les accessoires standard sont sujets à changements

sans préavis.

ACCESSOIRES EN OPTION (vendus séparément)

(1) Lames No.1 ~ No.6, No.31*

* La lame No.31 est un accessoire standard.

(2) Guide

(3) Collecteur à poussière

Les accessoires à option sont sujets à changements sans

préavis.

APPLICATIONS

䡬 Coupe de différentes sortes de bois de charpente et

découpe d’ouvertures

䡬 Coupe de plaques en acier doux, plaques en

aluminium et en cuivre

䡬 Coupe de résines synthétiques comme résine

phénolique et chlorure de vinyl

䡬 Coupe de matériaux de construction peu épais et

tendres

AVANT LA MISE EN MARCHE

1. Source de puissance

S’assurer que la source de puissance à utiliser

correspond à la puissance indiquée sur la plaque

signalétique du produit.

2. Interrupteur de puissance

S’assurer que l’interrupteur de puissance est en

position ARRET. Si la fiche est branchée alors que

l’interrupteur est sur MARCHE, l’outil démarre

immédiatement et peut provoquer un grave accident.

3. Fil de rallonge

Lorsque la zone de travail est éloignée de la source

de puissance, utiliser un fil de rallonge d’une épaisseur

suffisante et d’une capacité nominale suffisante. Le

fil de rallonge doit être aussi court que possible.

MONTAGE DE LA LAME

1. Utiliser la clef à six pans pour desserrer les vis de

réglage de la lame sur la bague de réglage, suivant la

Fig. 1.

2. En tenant la lame avec son bord de coupe vers l’avant,

introduire la section de montage de la lame dans la

fente du piston jusqu’à ce qu’elle touche le fond de la

fente.

3. Suivant la Fig. 1, bloquer la vis de réglage latérale.

ATTENTION

䡬 Des vis de réglage desserrées peuvent provoquer

une détérioration de la lame. S’assurer toujours que

les vis sont correctement serrées. S’assurer que la

fente du piston est toujours propre et dépourvue de

sciure de manière à avoir un montage correct de la

lame et un blocage correct des vis.

REGLAGE ET DEMONTAGE DU

ROULEAUGUIDE

1. Réglage du rouleau-guide

Le rouleau-guide (montré à la Fig. 2) est utilisé pour

empêcher la lame de se casser brusquement. Avant

l’utilisation, régler ce rouleau en suivant les

instructions suivantes:

(1) Desserrer la vis de réglage du support avec la clef a

six pans.

(2) Faites glisser le rouleau-guide en douceur et jusqu’à

ce que sa rainure touche légèrement le dos de la

lame.

NOTE

A la sortie d’usine, il y a un jeu d’environ 3mm entre

le rouleau et la lame.

(3) Serrer la vis de réglage du support à fond.

ATTENTION

䡬 Le rouleau-guide ne peut être utilisé que pour des

lames dont la face arrière rectiligne ne dépasse

pas 50mm. (Fig. 3A et 3B) Lorsque d’autres types

de lames sont utilisés (Fig. 3C), pousser le rouleauguide vers l’arriàre, de sorte qu’il ne touche pas la

lame.

䡬 Pour scier des pannaux épais ou pour se livrer à

des opérations de coupe continues, utiliser la lame

montrée à la Fig. 3A, 3B et veiller à régler le

rouleau-guide.

13

Page 16

Français

2. Démontage du rouleau-guide

Le rouleau-guide peut être retiré de la scie sauteuse

de la manière suivante:

(1) Retirer la vis de 4mm, montrée à la Fig. 4 avec la clef

à six pans, et retirer le rouleau-guide du corps

principal.

(2) Pour remonter le corps principal et la base, introduire

la section de blocage de la base entre la base et la vis

de 4mm, comme montré à la Fig. 4, et serrer

fermement la vis de 4mm.

COUVERCLE D’ÉCLATS

1. Couvercle d’éclats

Utiliser le couvercle d’éclats pour réduire la dispersion

des particules coupées et pour manipuler plus

facilement la scie.

Pousser le couvercle en exerçant une légère pression

sur sa partie avant.

Le rouleau-guide peut être réglé sur 3 positions,

comme indiqué sur la Fig. 5.

2. Choix de la position du couvercle d’éclats

Régler le couvercle d’éclats sur la première position

lorsque la lame est fixée ou retirée.

Régler le couvercle d’éclats sur la deuxième position

lors de la découpe de bois.

Régler le couvercle, d’éclats sur la deuxième ou la

troisième position lors de la découpe de métal ou

d’acier.

ATTENTION

䡬 Toujours laisser le couvercle d’éclats en position

abaissée lorsqu’on utilise l’outil.

䡬 Porter des lunettes de protection même si le couvercle

d’éclats est utilisé.

REGLAGE DE LA VITESSE DE FONCTIONNEMENT

DE LA LAME .................... (FCJ55VA uniquement)

NOTE

On ne peut régler la vitesse opérationnelle de la lame

pour le modèle FCJ55.

La vitesse de fonctionnement de la lame peut être réglée

à l’intérieur d’une plage de 0 à 3000/min suivant le

pression excercée sur l’interrupteur à détente. Choisir la

vitesse appropriée au matériau de la pièce travaillée et/

ou aux conditions de travai.

Pour obtenir un fonctionnement continu, presser

entièrement la détente et appuyer sur le cliquet. Tourner

ensuite le bouton de réglage de vitesse pour régler la

vitesse souhaitée.

NOTE

Le bouton de réglage de la vitesse effectue environ 3

rotations. Pour mettre l’interrupteur sur ARRET, presser

de nouveau sur l’interrupteur à détente pour débloquer

le cliquet, et relâcher la détente.

COUPE

ATTENTION

䡬 Pendant l’opération de sciage, la base doit être

fermement en contact avec la surface de la pièce

travaillée, et la lame doit être tenue à angle droit. Si

la base se trouve separée du matériau, ceci peut

provoquera la rupture de la lame.

䡬 Lorsqu’on coupe tout en maintenant la surface avant,

rester attentif au mouvement de la lame et maintenir

fermement la partie supérieure.

1. Coupe rectiligne

(1) Pour obtenir une coupe rectiligne précise, employer

le guide-accessoire en option comme montré à la

Fig. 6.

(2) Utiliser le guide anti-éclats pour réduire l’irrégularité

de la coupe des matériaux en bois. Fixer le guide en

l’insérant par l’avant sur la base jusqu’au déclic.

(Fig. 7)

ATTENTION

Diriger la base vers l’avant lorsque le guide antiéclats

est utilisé.

2. Coupe d’un cercle ou d’un arc circulaire

Pour obtenir une coupe efficace, employer le guide

accessoire en option comme montré à la Fig. 8 et le

clou ou la vis de bois.

Pour monter le guide, desserrer la vis de la base, et

pousser la base aussi loin que possible vers l’avant.

3. Sciage de lignes courbes

Pour scier un petit arc circulaire, réduire la vitesse

d’alimentation de la machine. Une vitesse trop rapide

pourrait provoquer la rupture de la lame.

4. Coupe de matériaux métalliques

Utiliser toujours un agent de coupe qui convient

(huile pour abre, eau savonneuse etc.). Si un agent

de coupe liquide n’est pas disponible, appliquer de la

graisse au dos de la surface du matériau à couper.

5. Découpe d’ouvertures

(1) Dans du bois de charpente

En alignant la direction de la lame sur le grain du

bois, couper morceau par morceau jusqu’à ce qu’une

ouverture soit coupée au centre du bois. (Fig. 9)

(2) Dans d’autres matériaux

Pour couper une ouverture dans des matériaux autres

que le bois de charpente, percer d’abord un trou avec

une perceuse ou un outil similaire à partir duquel

commencer la coupe.

6. Coupe angulaire

Régler le couvercle d’éclats sur la première position.

(Fig. 5)

Pour régler l’angle d’inclinaison, desserrer la vis de

la base, déplacer la position de la base vers la rainure

latérale de la portion semi-circulaire, aligner l’échelle

de la portion semi-circulaire (les chiffres gravés sur

l’échelle indiquent l’angle d’inclinaison) avec l’arête

du logement, et resserrer à fond la vis de la base.

(Fig. 10 et 11)

ATTENTION

Lors de l’utilisation du guide, mettre la vis sur le côté

opposé au côté incliné. (Fig. 12)

CHOIX DES LAMES

1. Lames accessoires

Pour obtenir un fonctionnement optimal et les

meilleurs résultats possibles, il est très important de

choisir la lame la mieux appropriée au type et à

l’épaisseur du matériau à couper. Un modèle de lame

est fourni comme accessoire standard. Le numéro de

lame est gravé près de la section de montage de

chaque lame. Choisir les lames appropriées en se

référant au Tableau 1.

14

Page 17

Français

2. Lames du commerce acceptables (Fig. 13)

Cette machine est conçue pour accepter la plupart

des lames disponibles sur le marché. La Fig. 13 donne

les dimensions à respecter:

䡬 Epaisseur : L2 ..... Inférieur à 1,6mm

䡬 Largeur : L3 ..... 6,3mm

Qualité du matériau Matériau à couper No. de lame

Bois de charpente

Plaque en fer Plaque en acier doux No.6

Métal non ferreux Aluminium, cuivre, laiton No.6

Résine synthétique

Pulpe

Autres

L4 ..... 8mm

L5 ..... 7mm

Tableau 1 Liste des lames appropriées

Bois de charpente général

Contreplaqué No.3 ou No.6

Résine phénolique, résine acrylique, etc.

Chlorure de vinyl, résine acrylique, etc.

Styrène mousseux, etc. No.2

Carton, papier ondulé No.2

Isorel No.5 ou No.6

Panneau fibreux No.6

Caoutchouc dur No.2

Ardoise No.5

ENTRETIEN ET CONTROLE

1. Contrôle de la lame

L’utilisation continue d’une lame émoussée ou abîmée

peut conduire à une réduction de effecacité de coupe

et provoquer une surcharge du moteur. Remplacer la

lame par une nouvelle dès que des traces d’abrasion

apparaissent.

2. Contrôle des vis de montage

Vérifier régulièrement les vis de montage et s’assurer

qu’elles sont correctement serrées. Resserrer

immédiatement toute vis desserrée. Sinon, il y a

danger sérieux.

3. Entretien du moteur

Le bobinage de l’ensemble moteur est le “coeur”

même de l’outil électro-portatif. Veiller soigneusement

à ce que ce bobinage ne soit pas endommagé et/ou

mouillé par de l’huile ou de l’eau.

4. Entretien

Consulter un agent agréé en cas de panne de l’outil.

NOTE

Lorsque des matériaux épais sont découpés, utiliser les

lames originales HITACHI ayant l’inclinaison indiquée

sur la Fig. 3-A ou B.

No.1 ou No.31 (plaque épaisse) ou No.2

(plaque mince)

No.4 (plaque épaisse) ou No.6

(plaque mince)

No.2 (plaque épaisse), No.4 (Plaque

épaisse) ou No.6 (plaque mince)

NOTE

Par suite du programme permanent de recherche et de

développement HITACHI, ces spécifications peuvent faire

l’objet de modifications sans avis préalable.

Ce produit est conforme aux prescription 76/889/CEE et

82/499/CEE. Référence VDE 5008.6-2660-1089

Au sujet du bruit et des vibrations

Les valeurs mesurées ont été déterminées en fonction

de la norme EN50144.

Le niveau de pression acoustique pondérée A type est

de 81 dB (A)

Porter un casque de protection.

Valeur d’accélération moyenne quadratique pondérée

type: 6,5m/s2.

15

Page 18

Italiano

PRECAUZIONI GENERALI

ATTENZIONE! Quando si usano elettroutensili, bisogna

sempre seguire le precauzioni basilari di sicurezza per

ridurre il rischio di incendi, scosse elettriche e lesioni alle

persone, tra cui quanto segue.

Leggere tutte queste istruzioni prima di usare questo

prodotto e conservare le istruzioni.

Per un funzionamento sicuro:

1. Mantenere sempre pulita l’area dove si lavora.

Un’area di lavoro sempre pulita aiuta ad evitare

incidenti.

2. Tenere nella dovuta considerazione le condizioni

dell’ ambiente di lavoro. Non esporre gli

elettroutensili alla pioggia. Non usare gli

elettroutensili in luoghi molto umidi o bagnati.

Mantenere ben illuminata l’area di lavoro.

Non usare elettroutentsili dove ci sia il rischio di

causare incendi o esplosioni.

3. Fare attenzione alle scosse elettriche. Evitare il

contatto del corpo con superfici collegate a terra

(p.es. tubi, caloriferi, fornelli, frigoriferi).

4. Tenere lontani i bambini e gli infermi. Non

permettere che persone estranee ai lavori tocchino

gli elettroutensili o i cavi della corrente elettrica. Le

persone non addette al lavoro non dovrebbero

nemmeno avvicinarvisi.

5. Riporre gli elettroutensili in un luogo adatto. Quando

non utilizzati, gli elettroutensili vanno tenuti in un

luogo asciutto, chiuso a chiave o in alto, al di fuori

della portata di bambini.

6. Non forzare mai gli elettroutensili. Qualsiasi lavoro

viene eseguito meglio e più velocemente alla

velocità per la quale l’elettroutensile è stato

formulato.

7. Scegliere sempre l’utensile elettrico adatto. Non

forzare un piccolo elettroutensile o un accessorio a

fare un lavoro di un utensile o accessorio più grande.

Non usare gli elettroutensili per dei lavori per i

quali non sono stati formulati (non usare, per

esempio, una sega circolare per tagliare grossi

tronchi).

8. Vestirsi in modo adatto. Non portare abiti larghi o

gioielli, che potrebbero impigliarsi nelle parti in

movimento degli elettroutensili. Lavorando all'ester-no, si raccomanda l’uso di guanti di gomma e

di scarpe antisdrucciolo. Chi porta capelli lunghi

dovrebbe utilizzare un’apposita cuffia protettiva.

9. Usare occhiali protettivi. Esegundo dei lavori di

taglio che producono molta polvere, usare anche

una mascherina antipolvere.

10. Collegare apparecchiature di rimozione della

polvere.

Se sono forniti dispositivi per il collegamento di

apparecchiature di rimozione e raccolta della

polvere, assicurarsi che siano collegati e usati

correttamente.

11. Non maltrattare il cavo della corrente elettrica. Non

trasportare gli elettroutensili prendendoli per il cavo

della corrente e non scollegarli dalla presa in tal

modo. Tenere il cavo della corrente lontano dal

calore, olio ed oggetti taglienti.

12. Lavorare su oggetti fermi. Fissare saldamente

l’oggetto in una morsa. Èpiù sicuro che non

tenendolo fermo con le mani, che restano libere

per maneggiare l’elettroutensile.

16

13. Non squilibrare il corpo durante l’esecuzione di un

lavoro. Stare sempre su due piedi, in equilibrio

stabile.

14. Trattare gli utensili elettrici con cura. Tenerli sempre

puliti ed affilati per un funzionamento migliore e

più sicuro. Seguire le istruzioni date per la

lubrificazione e la sostituzione degli accessori.

Controllare periodicamente le condizioni del cavo

della corrente. Se dovesse essere rovinato, farlo

sostituire presso un Centro Assistenza. Non usare

cavi di prolungamento rovinati. Mantenere le

impugnature sempre pulite, libere soprattutto da

olio e grasso.

15. Quando non si usa, prima di eseguire una qualsiasi

operazione di manutenzione e prima di

intraprendere qualsiasi sostituzione di accessori

(lama, punte, ecc.), scollegare sempre

l’elettroutensile.

16. Togliere sempre le chiavi di regolazione dall’attrezzo.

E’buona abitudine controllare siste maticamente

che nessuna chiave di regolazione sia più attaccata

all’elettroutensile, prima di metterlo in funzione.

17. Evitare che l’elettroutensile possa inavvertitamente

essere messo in funzione. Non trasportare gli elet

troutensili mantenendo il dito sull’interruttore,

mentre sono collegati alla rete. Prima di collegarli,

controllare che l’interruttore sia in posizione di

spento.

18. Fare uso di cavi di prolungamento per esterni. In

questo caso, controllare che il cavo sia adatto per

l’uso all’esterno.

19. State attenti. Fate attenzione a quello che fate. Usate

il buon senso. Non usate l'utensile quando siete

stanchi.

20. Controllare qualsiasi parte che sembra danneggiata.

Prima di riprendere l’uso degli elettroutensili,

controllare attentamente che la parte

apparentemente danneggiata possa ancora essere

usata in modo da assolvere la sua funzione.

Controllare che le parti mobili siano nella loro

posizione corretta, che nessun pezzo sia rotto, che

tutti i pezzi siano montati correttamente, e

controllare altri punti importanti per il

funzionamento dell’ utensile elettrico. Qualsiasi

pezzo danneggiato deve essere ripa rato o sostituito

da un Centro Assistenza autorizzato, a meno che

dettagliate istruzioni in proposito siano date nel

presente manuale. Fare sostituire gli interruttori

difettosi presso un Centro Assistenza autorizzato.

Non usare l’elettroutensile se non può e acceso o

spento per mezzo del suo interruttore.

21. Attenzione

L’uso di qualsiasi accessorio o attacco diverso da

quelli citati nel presente manuale di istruzioni può

presentare il rischio di lesioni alle persone.

22. Far riparare l’elettroutensile da personale qualificato.

Questo elettroutensile è in conformità con le relative

norme di sicurezza. Le riparazioni devono essere

eseguite solo da personale qualificato usando

ricambi originali, altrimenti ne possono derivare

considerevoli rischi per l’utilizzatore.

Page 19

CARATTERISTICHE

Modello FCJ55VA FCJ55

Voltaggio (per zona)* (110V, 115V, 120V, 127V, 220V, 230V, 240V)

Potenza assorbita 400W*

Profondità massima di taglio

Velocità senza carico 0 ~ 3000/min 3000/min

Corsa 18mm

Raggio minimo di taglio 25mm

Peso (senza cavo) 1,4kg

*Accertatevi di aver controllato bene la piastrina perché essa varia da zona a zona.

Legno: 55mm

Acciaio tenero: 3mm

Italiano

ACCESSORI STANDARD

(1) Lama n.31.................................................................... 1

Per tagliare legno spesso

(2) Para-schegge .............................................................. 1

(3) Raccoglitrucioli ...........................................................1

(4) Chiave maschia esagonale ........................................1

Gli accessori standard possono essere soggetti a

cambiamento senza preavviso.

ACCESSORI DISPONIBILI A RICHIESTA

(venduti separatamente)

(1) Lame n.1 ~ n.6, n.31*

* La lama N.31 è un accessorio standard.

(2) Guida

(3) Raccoglipolvere

Gli accessori disponibili a richiesta possono essere

soggetti a cambiamento senza preavviso.

IMPIEGHI

䡬 Taglio di vari tipi di legno e lavori a traforo

䡬 Taglio di lamiera d’acciaio tenero, alluminio e rame

䡬 Taglio di resine sintetiche quali resine fenoliche e

cloruro di vinile

䡬 Taglio di materiali da construzione sottili e teneri

PRIMA DELL’USO

1. Alimentazione

Assicurarsi che la rete di alimentazione che si vuole

usare sia compatibile con le caratteristiche relative

all’alimentazione di corrente specificate nella piastrina

dell’apparecchio.

2. Interruttore di corrente

Mettere l’interruttore in posizione SPENTO. Se la

spina è infilata in una presa mentre l’interruttore è

acceso, l’utensile elettrico si mette immediatamente

in moto, facilitando il verificarsi di incidenti gravi.

3. Prolunga del cavo

Quando l’ambiente di lavoro è lontano da una presa

di corrente, usare una prolunga del cavo di sufficiente

spessore e di prestazione adeguata. La prolunga deve

essere più Corta possibile.

MONTAGGIO DELLA LAMA

1. Usare la chiave maschia esagonale, fornita come

accessorio, per allentare le viti di fissaggio della lama

sull’anello di fissaggio, così come indicato nella

Fig. 1.

2. Tenendo la lama con il taglio verso l’avanti, inserire

nel solco del pistone la parte della lama destinata al

fissaggio, fino a che quest’ultima tocca il fondo del

solco.

3. Come si vede dalla Fig. 1, serrare a fondo la vite

laterale di fissaggio.

ATTENZIONE

䡬 Se le viti di fissaggio non sono serrate, si può

danneggiare la lama. Assicurarsi sempre che le viti di

fissaggio siano serrate a fondo. Assicurarsi sempre

che il solco del pistone sia pulito e privo di segatura e

fare attenzione a che la lama sia montata nel modo

giusto e le viti di fissaggio siano ben serrate.

REGOLAZIONE E RIMOZIONE DEL RULLO DI

GUIDA

1. Regolazione del rullo di guida

Il rullo di guida che si vede nella Fig. 2 è usato per

impedire che la lama si spezzi. Prima dell’uso, regolare

il rullo di guida nel modo seguente:

(1) Con la chiave accessoria maschia esagonale allentare

la vite di tenuta del supporto.

(2) Spingere delicatamente il rullo di guida fino a che

l’intaglio del rullo tocchi leggermente il dorso della

lama.

NOTA

Al momento della consegna dalla fabbrica, c’è uno

spazio di circa 3mm tra rullo e lama.

(3) Serrare a fondo la vite di tenuta del supporto.

ATTENZIONE

䡬 Il rullo di guida può essere usato solo per lame

che hanno una linea diritta sul retro più lunga di

50mm. (Fig. 3A e 3B) Quando si usano altri tipi di

lame (Fig. 3C), fare scorrere il rullo di guida verso

il dietro in modo che il rullo di guida non tocchi la

lama.

䡬 Per tagliare delle tevole spesse o per eseguire

operazioni di taglio continue, usare la lama

illustrata nelle Fig. 3A, 3B assicurandosi di

posizionare il rullo della guida.

17

Page 20

Italiano

2. Rimozione del rullo di guida

Il rullo di guida può essere rimosso dal seghetto

alternativo nel modo seguente:

(1) Con la chiave accessoria maschia esagonale, togliere

la vite da 4mm di cui alla Fig. 4 e togliere il rullo di

guida dal corpo principale.

(2) Per rimontare il corpo principale e la base, inserire il

bloccaggio della base tra la base e la vite da 4mm,

come indicato nella Fig. 4, e stringere a fondo la vite

da 4mm.

POSIZIONAMENTO DEL RACCOGLITRUCIOLI

1. Raccoglitrucioli

Usare il raccoglitrucioli per ridurre lo spargimento di

parti di taglio e usare facilmente la sega.

Fare scorrere il raccoglitrucioli premendo leggermente

la sua parte anteriore.

Il raccoglitrucioli può essere regolato su tre posizioni

come illustrato nella Fig. 5.

2. Come scegliere la posizione per il raccoglitrucioli

Regolare il raccoglitrucioli sul primo passo quando si

colloca o si toglie la lama.

Regolare il raccoglitrucioli sul secondo passo quando

si tagliano materiali in legno.

Regolare il raccoglitrucioli sul secondo o terzo passo

quando si tagliano materiali di metallo come acciaio.

ATTENZIONE

䡬 Tenere sempre il paraschegge in posizione abbassata

durante l’uso dell’utensile.

䡬 Portare gli occhiali di protezione anche se si usa il

raccoglitrucioli.

REGOLAZIONE DELLA VELOCITA DI FUNZI-

ONAMENTO DELLA LAMA ........ (Solo FCJ55VA)

NOTA

La velocità a della lama dell’FCJ55 non può essere

regolata.

La velocità di funzionamento della lama può essere

regolata nel campo da 0 a 3000 giri al minuto, secondo lo

spostamento imposto all’interruttore a grilletto dalla

pressione del dito. Scegliere la velocità adeguata al

materiale dell’oggetto da lavorare e/o alle condizioni di

lavoro.

Per ottenere il funzionamento continuo, spingere fino in

fondo il grilletto e premere sul tasto di bloccaggio. Girare

quindi il tasto di regolazione della velocità per regolare

la velocità di funzionamento della lama al livello

desiderato.

NOTA

Il tasto di regolazione della velocità ruota all’incirca di 3

giri. Per spegnere l’interruttore, premere di nuovo

l’interruttore a grilletto in modo da liberare il bloccaggio

e rilasciare il grilletto.

TAGLIO

ATTENZIONE

䡬 Mentre si sega, la base deve essere bene a contatto

con la superficie dell’oggetto de lavorare e la lama

deve essere tenuta ad angolo retto. Se la base si

destacca dal materiale si può verificare la rottura

della lama.

䡬 Durante operazioni di taglio eseguite impugnando la

superficie anteriore, fare attenzione alla lama in

movimento e tenere saldamente la parte superiore.

1. Taglio rettilineo

(1) Per ottenere un taglio rettilineo accurato, impiegare

l’accessorio opzionale “guida”, come indicato nella

Fig. 6.

(2) Usare il para-schegge per ridurre la ruvidezza della

superficie di taglio di materiali in legno. Applicare il

para-schegge inserendo dalla parte anteriore della

base fino a quando scatta in posizione. (Fig. 7)

ATTENZIONE

Regolare la base sulla posizione anteriore quando si

usa il para-schegge.

2. Taglio a cerchio o ad arco di cerchio

Per ottenere un taglio efficace, usare gli accessori

opzionali “guida” e “chiodo o vite del legno” come

indicato nella Fig. 8.

Quando si monta la guida, allentare la vite inferiore

della base e far scorrere la base in avanti per tutta la

sua corsa.

3. Taglio di linee curve

Quando si sega un piccolo arco circolare, ridurre la

velocità di avanzamento dell’utensile. Se la macchina

è spinta troppo in fretta si può provocare la rottura

della lama.

4. Taglio di materiali metallici

Usare sempre una sostanza da taglio (olio lubrificante

molto fluido, acqua saponanta, ecc.). Quando non si

ha a disponsizine una solstanza da taglio, applicare

del grasso sul rovescio del materiale da tagliare.

5. Lavori a traforo

(1) Nel legno

Allineando la direzione della lama con la venatura

del legno, tagliare poco a poco fino a produrre una

apertura al centro del legno. (Fig. 9)

(2) In altri materiali

Per praticare un’apertura in materiali diversi dal legno,

fare da prima un foro con un trapano, o con un

attrezzo similare, dal quale partire per l’esecuzione

del taglio.

6. Taglio ad angolo

Regolare il raccoglitrucioli sul primo passo. (Fig. 5)

Regolazione dell’angolo d’inclinazione: allentare la

vite sul fondo della base, mettere la base sulla

scanalatura laterale della parte semicircolare, allineare

la gradazione riportata sulla parte semicircolare della

base (le cifre incise sulla scala indicano i gradi

d’inclinazione) com il bordo dell’involucro e serrare a

fondo la vite del fondo della base. (Fig. 10 e 11)

ATTENZIONE

Regolare la vite sulla parte opposta del lato inclinato

quando si usa la guida. (Fig. 12)

18

Page 21

Italiano

SCELTA DELLE LAME

1. Lame accessorie

Per assicurare la massima efficacia di funzionamento

e di risultati, è molto importante scegliere la lama

appropriata, che meglio si addice al tipo ed allo

spessore del materiale da tagliare. Un tipo di lama è

fornito come a accessorio standard. Il numero della

lama è riportato nei pressi della porzione di fissaggio

di ogni lama. Scegliere la lama opportuna facendo

riferimento alla Tabella 1.

Tabella 1 Elenco delle lame adatte

Materiale da tagliare Qualità del materiale n. della lama

Legno

Lamiera di ferro Lamiera di acciaio tenero n.6

Metalli non ferrosi Alluminio, rame, ottone n.6

Resine sintetiche

Pasta

Altri

Legno comune

Compensato n.3 o n.6

Resina fenolica, resina acrilica, ecc. n.4 (piastra spessa) o n.6 (piastra sottile)

Cloruro di vinile, resina acrilica, ecc.

Schiuma stirolica, ecc. n.2

Cartone, cartone ondulato n.2

Fibra di legno n.5 o n.6

Legno sintetico n.6

Gomma dura n.2

Ardesia n.5

2. Lame disponibili in commercio (Fig. 13)

Questo utensile è stato concepito in modo da poter

montare la maggior parte delle lame disponibili nel

commercio libero. Come si vede dalla Fig. 13, le

restrizioni sulle dimensioni delle lame sono le

seguenti:

䡬 Spessore : L2 .... Inferiore a 1,6mm

䡬 Larghezza : L3 .... 6,3mm

NOTA

Quando si tagliano materiali spessi, usare lame autentiche

HITACHI con una inclinazione come mostrato nella Fig.

3-A o B.

L4 .... 8mm

L5 .... 7mm

n.1 o n.31 (piastra spessa) o n.2

(piastra sottile)

n.2 o n.4 (piastra spessa) o

n.6 (piastra sottile)

MANUTENZIONE E CONTROLLO

1. Controllo della lama

L’uso continuativo di lame danneggiate o rovinate