Page 1

Hitachi Virtual Storage Platform F700

88-02-0x

Hardware Reference Guide

This document provides information about the system hardware components and the mechanical and

environmental specifications for the Hitachi Virtual Storage Platform F700 all-flash array.

MK-97HM85017-01

September 2018

Page 2

© 2018 Hitachi, Ltd. All rights reserved.

No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including copying and

recording, or stored in a database or retrieval system for commercial purposes without the express written permission of Hitachi, Ltd., or

Hitachi Vantara Corporation (collectively “Hitachi”). Licensee may make copies of the Materials provided that any such copy is: (i) created as an

essential step in utilization of the Software as licensed and is used in no other manner; or (ii) used for archival purposes. Licensee may not

make any other copies of the Materials. “Materials” mean text, data, photographs, graphics, audio, video and documents.

Hitachi reserves the right to make changes to this Material at any time without notice and assumes no responsibility for its use. The Materials

contain the most current information available at the time of publication.

Some of the features described in the Materials might not be currently available. Refer to the most recent product announcement for

information about feature and product availability, or contact Hitachi Vantara Corporation at

us.html.

Notice: Hitachi products and services can be ordered only under the terms and conditions of the applicable Hitachi agreements. The use of

Hitachi products is governed by the terms of your agreements with Hitachi Vantara Corporation.

By using this software, you agree that you are responsible for:

1. Acquiring the relevant consents as may be required under local privacy laws or otherwise from authorized employees and other

individuals; and

2. Verifying that your data continues to be held, retrieved, deleted, or otherwise processed in accordance with relevant laws.

Notice on Export Controls. The technical data and technology inherent in this Document may be subject to U.S. export control laws, including

the U.S. Export Administration Act and its associated regulations, and may be subject to export or import regulations in other countries. Reader

agrees to comply strictly with all such regulations and acknowledges that Reader has the responsibility to obtain licenses to export, re-export, or

import the Document and any Compliant Products.

Hitachi is a registered trademark of Hitachi, Ltd., in the United States and other countries.

AIX, AS/400e, DB2, Domino, DS6000, DS8000, Enterprise Storage Server, eServer, FICON, FlashCopy, IBM, Lotus, MVS, OS/390, PowerPC, RS/6000,

S/390, System z9, System z10, Tivoli, z/OS, z9, z10, z13, z/VM, and z/VSE are registered trademarks or trademarks of International Business

Machines Corporation.

Active Directory, ActiveX, Bing, Excel, Hyper-V, Internet Explorer, the Internet Explorer logo, Microsoft, the Microsoft Corporate Logo, MS-DOS,

Outlook, PowerPoint, SharePoint, Silverlight, SmartScreen, SQL Server, Visual Basic, Visual C++, Visual Studio, Windows, the Windows logo,

Windows Azure, Windows PowerShell, Windows Server, the Windows start button, and Windows Vista are registered trademarks or trademarks

of Microsoft Corporation. Microsoft product screen shots are reprinted with permission from Microsoft Corporation.

iPad is a trademark of Apple Inc., registered in the U.S. and other countries.

All other trademarks, service marks, and company names in this document or website are properties of their respective owners.

https://support.hitachivantara.com/en_us/contact-

Hitachi Virtual Storage Platform F700 Hardware Reference Guide 2

Page 3

Contents

Preface..................................................................................................... 6

Intended audience............................................................................................... 6

UEFI Development Kit 2010................................................................................ 6

Product version....................................................................................................7

Release notes......................................................................................................7

Changes in this revision.......................................................................................7

Document conventions........................................................................................ 7

Conventions for storage capacity values............................................................. 9

Accessing product documentation.....................................................................10

Getting help........................................................................................................10

Comments..........................................................................................................11

Chapter 1: Overview ............................................................................ 12

Block configuration.............................................................................................12

Features.............................................................................................................12

Chapter 2: System controller ..............................................................14

CBL controller chassis....................................................................................... 14

CBL controller front panel bezel LEDs......................................................... 14

CBL controller front panel LEDs (without bezel).......................................... 16

CBL controller rear panel LEDs....................................................................18

CBL controller power supply unit LEDs and connectors.............................. 18

Host, Network, and Drive Tray Ports and LEDs.................................................19

Front end modules........................................................................................19

10-Gbps iSCSI board LEDs and connectors (optical).............................20

10-Gbps iSCSI board LEDs and connectors (copper)............................ 20

8-Gbps, 16-Gbps, or 32-Gbps Fibre Channel (4-port) board LEDs

and connectors........................................................................................22

16-Gbps Fibre Channel (2-port) board LEDs and connectors................ 24

Back-end module LEDs and connectors...................................................... 25

Chapter 3: Drive trays..........................................................................27

Small form-factor drive tray (DBS).....................................................................27

SFF with front panel bezel............................................................................27

SFF front panel without bezel.......................................................................28

Hitachi Virtual Storage Platform F700 Hardware Reference Guide 3

Contents

Page 4

SFF rear panel..............................................................................................29

AC power supply unit LEDs and connectors................................................ 30

Flash module drive tray (DBF)...........................................................................31

FMD with front panel bezel...........................................................................31

FMD front panel without bezel......................................................................32

FMD rear panel.............................................................................................33

Chapter 4: Service processor.............................................................. 35

Service Processor (Windows 10 Enterprise) hardware specifications...............35

Service processor description............................................................................36

SVP front panel............................................................................................ 37

SVP rear panel............................................................................................. 37

Chapter 5: Maintaining the storage system........................................39

Storing the storage system................................................................................ 39

Powering off the storage system........................................................................39

Battery unit.........................................................................................................40

Appendix A: Storage system parts list............................................... 41

VSP F700 parts list............................................................................................ 41

Drive tray and drive configuration.................................................................44

Data and power cable model list........................................................................44

Appendix B: System specifications ................................................... 48

VSP F700 mechanical specifications.................................................................48

Electrical specifications .....................................................................................52

Environmental specifications ............................................................................ 53

Shared memory................................................................................................. 59

Appendix C: Network access...............................................................62

TCP/IP port assignments...................................................................................62

Controller connections....................................................................................... 65

Physical service processor connections............................................................ 65

Appendix D: Data and power cables...................................................67

Required cables.................................................................................................67

Fibre Channel cables.........................................................................................69

iSCSI cables...................................................................................................... 72

iSCSI standards............................................................................................75

iSCSI specifications......................................................................................75

Managing cables................................................................................................78

AC power cables................................................................................................81

Power cable assemblies...............................................................................81

AC connections............................................................................................ 83

Hitachi Virtual Storage Platform F700 Hardware Reference Guide 4

Contents

Page 5

Power cable usage guidelines......................................................................85

Three-phase power considerations for racks............................................... 85

Cable management...................................................................................... 85

Appendix E: Power distribution units for Hitachi Universal V2

Rack .......................................................................................................86

Americas single-phase PDU 1P30A-8C13-3C19UL.P...................................... 86

Americas single-phase PDU 1P30A-15C13-3C19UL.P.................................... 87

Americas three-phase PDU 3P30A-8C13-3C19UL.P........................................87

Americas three-phase PDU 3P30A-15C13-3C19UL.P......................................88

Americas three-phase PDU 3P30A-24C13-6C19UL.P......................................89

APAC and EMEA single-phase PDU 1P32A-9C13-3C19CE.P......................... 90

APAC and EMEA single-phase PDU 1P32A-18C13-3C19CE.P....................... 91

APAC and EMEA three-phase PDU 3P16A-9C13-3C19CE.P...........................92

APAC and EMEA three-phase PDU 3P16A-15C13-3C19CE.P.........................93

APAC and EMEA three-phase PDU 3P32A-24C13-6C19CE.P.........................94

Appendix F: Non-Hitachi racks............................................................96

Non-Hitachi rack support .................................................................................. 96

Hitachi Universal V2 Rack rail kits..................................................................... 96

Hitachi Universal V2 Rack accessories............................................................. 97

Appendix G: Warning labels on the storage system.........................98

Small form factor drive tray................................................................................99

Flash module drive tray....................................................................................100

CBL controller.................................................................................................. 101

Battery..............................................................................................................101

Appendix H: Environmental notices................................................. 102

Appendix I: Regulatory compliance..................................................103

Hitachi Virtual Storage Platform F700 Hardware Reference Guide 5

Contents

Page 6

Preface

This guide describes the hardware features and specications of the Hitachi Virtual

Storage Platform F700.

Intended audience

This document is intended for Hitachi Vantara representatives, system administrators,

and authorized service providers who install, congure, and operate the VSP Fx00

models .

Readers of this document should be familiar with the following:

■

Data processing and RAID storage systems and their basic functions

■

RAID storage system hardware components and operational specications

UEFI Development Kit 2010

This product includes UEFI Development Kit 2010 written by the UEFI Open Source

Community. For more information, see the UEFI Development Kit website:

http://sourceforge.net/apps/mediawiki/tianocore/index.php?title=UDK2010

©

2004, Intel Corporation.

All rights reserved.

Redistribution and use in source and binary forms, with or without modication, are

permitted provided that the following conditions are met:

Redistributions of source code must retain the above copyright notice, this list of

conditions and the following disclaimer.

Redistributions in binary form must reproduce the above copyright notice, this list of

conditions and the following disclaimer in the documentation and/or other materials

provided with the distribution.

Neither the name of the Intel Corporation nor the names of its contributors might be

used to endorse or promote products derived from this software without specic prior

written permission.

Hitachi Virtual Storage Platform F700 Hardware Reference Guide 6

Preface

Page 7

THIS SOFTWARE IS PROVIDED BY THE COPYRIGHT HOLDERS AND CONTRIBUTORS “AS IS”

AND ANY EXPRESS OR IMPLIED WARRANTIES, INCLUDING, BUT NOT LIMITED TO, THE

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE

ARE DISCLAIMED. IN NO EVENT SHALL THE COPYRIGHT OWNER OR CONTRIBUTORS BE

LIABLE FOR ANY DIRECT, INDIRECT, INCIDENTAL, SPECIAL, EXEMPLARY, OR

CONSEQUENTIAL DAMAGES (INCLUDING, BUT NOT LIMITED TO, PROCUREMENT OF

SUBSTITUTE GOODS OR SERVICES; LOSS OF USE, DATA, OR PROFITS; OR BUSINESS

INTERRUPTION) HOWEVER CAUSED AND ON ANY THEORY OF LIABILITY, WHETHER IN

CONTRACT, STRICT LIABILITY, OR TORT (INCLUDING NEGLIGENCE OR OTHERWISE)

ARISING IN ANY WAY OUT OF THE USE OF THIS SOFTWARE, EVEN IF ADVISED OF THE

POSSIBILITY OF SUCH DAMAGE.

Product version

This document revision applies to VSP F700 rmware 88-02-0x or later.

Release notes

Product version

Read the release notes before installing and using this product. They may contain

requirements or restrictions that are not fully described in this document or updates or

corrections to this document. Release notes are available on Hitachi Vantara Support

Connect: https://knowledge.hitachivantara.com/Documents.

Changes in this revision

■

Added support for 15 TB SSD

Document conventions

This document uses the following storage system terminology conventions:

Convention Description

VSP Fx00 models Refers to all of the following models, unless otherwise noted.

■

■

■

■

Hitachi Virtual Storage Platform F350

Hitachi Virtual Storage Platform F370

Hitachi Virtual Storage Platform F700

Hitachi Virtual Storage Platform F900

Hitachi Virtual Storage Platform F700 Hardware Reference Guide 7

Preface

Page 8

Document conventions

Convention Description

VSP Gx00 models Refers to all of the following models, unless otherwise noted.

■

Hitachi Virtual Storage Platform G350

■

Hitachi Virtual Storage Platform G370

■

Hitachi Virtual Storage Platform G700

■

Hitachi Virtual Storage Platform G900

This document uses the following typographic conventions:

Convention Description

Bold

Italic

Monospace

< > angle

brackets

■

Indicates text in a window, including window titles, menus,

menu options, buttons, elds, and labels. Example:

Click OK.

■

Indicates emphasized words in list items.

■

Indicates a document title or emphasized words in text.

■

Indicates a variable, which is a placeholder for actual text

provided by the user or for output by the system. Example:

pairdisplay -g group

(For exceptions to this convention for variables, see the entry for

angle brackets.)

Indicates text that is displayed on screen or entered by the user.

Example: pairdisplay -g oradb

Indicates variables in the following scenarios:

■

Variables are not clearly separated from the surrounding text or

from other variables. Example:

[ ] square

brackets

{ } braces Indicates required or expected values. Example: { a | b } indicates

| vertical bar Indicates that you have a choice between two or more options or

Hitachi Virtual Storage Platform F700 Hardware Reference Guide 8

Status-<report-name><file-version>.csv

■

Variables in headings.

Indicates optional values. Example: [ a | b ] indicates that you can

choose a, b, or nothing.

that you must choose either a or b.

arguments. Examples:

Preface

Page 9

Conventions for storage capacity values

Convention Description

[ a | b ] indicates that you can choose a, b, or nothing.

{ a | b } indicates that you must choose either a or b.

This document uses the following icons to draw attention to information:

Icon Label Description

Note Calls attention to important or additional information.

Tip Provides helpful information, guidelines, or suggestions for

performing tasks more eectively.

Caution Warns the user of adverse conditions and/or consequences

(for example, disruptive operations, data loss, or a system

crash).

WARNING Warns the user of a hazardous situation which, if not

avoided, could result in death or serious injury.

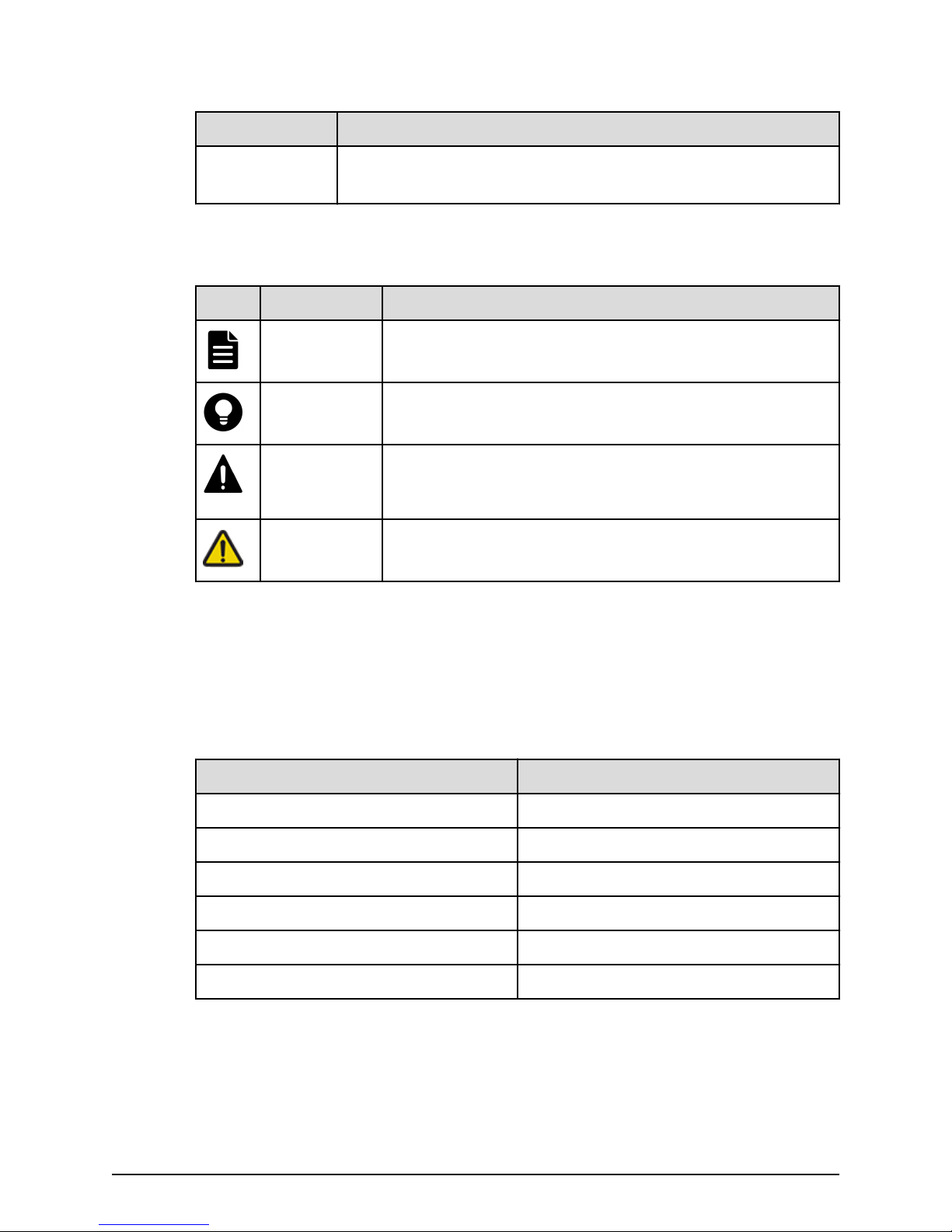

Conventions for storage capacity values

Physical storage capacity values (for example, disk drive capacity) are calculated based

on the following values:

Physical capacity unit Value

1 kilobyte (KB) 1,000 (103) bytes

1 megabyte (MB) 1,000 KB or 1,0002 bytes

1 gigabyte (GB) 1,000 MB or 1,0003 bytes

1 terabyte (TB) 1,000 GB or 1,0004 bytes

1 petabyte (PB) 1,000 TB or 1,0005 bytes

1 exabyte (EB) 1,000 PB or 1,0006 bytes

Logical capacity values (for example, logical device capacity, cache memory capacity) are

calculated based on the following values:

Hitachi Virtual Storage Platform F700 Hardware Reference Guide 9

Preface

Page 10

Accessing product documentation

Logical capacity unit Value

1 block 512 bytes

1 cylinder Mainframe: 870 KB

Open-systems:

■

OPEN-V: 960 KB

■

Others: 720 KB

1 KB 1,024 (210) bytes

1 MB 1,024 KB or 1,0242 bytes

1 GB 1,024 MB or 1,0243 bytes

1 TB 1,024 GB or 1,0244 bytes

1 PB 1,024 TB or 1,0245 bytes

1 EB 1,024 PB or 1,0246 bytes

Accessing product documentation

Product user documentation is available on Hitachi Vantara Support Connect: https://

knowledge.hitachivantara.com/Documents. Check this site for the most current

documentation, including important updates that may have been made after the release

of the product.

Getting help

Hitachi Vantara Support Connect is the destination for technical support of products and

solutions sold by Hitachi Vantara. To contact technical support, log on to Hitachi Vantara

Support Connect for contact information: https://support.hitachivantara.com/en_us/

contact-us.html.

Hitachi Vantara Community is a global online community for Hitachi Vantara customers,

partners, independent software vendors, employees, and prospects. It is the destination

to get answers, discover insights, and make connections. Join the conversation today!

Go to community.hitachivantara.com, register, and complete your prole.

Hitachi Virtual Storage Platform F700 Hardware Reference Guide 10

Preface

Page 11

Comments

Please send us your comments on this document to

doc.comments@hitachivantara.com. Include the document title and number, including

the revision level (for example, -07), and refer to specic sections and paragraphs

whenever possible. All comments become the property of Hitachi Vantara Corporation.

Thank you!

Comments

Hitachi Virtual Storage Platform F700 Hardware Reference Guide 11

Preface

Page 12

Chapter 1: Overview

The Hitachi Virtual Storage Platform F700 is a versatile modular, rack-mountable all-ash

array storage system equipped with drive boxes, supporting ash module drives, scaled

for various storage capacity congurations. To deliver consistent low latency host

response times and highest IOP performance across all host connection ports,

conventional hard-disk drives are not supported in an all-ash conguration.

The storage systems provide high performance operations by using dual controllers with

high-speed processors, dual in-line cache memory modules (DIMMs), cache ash

memory (CFM), battery, fans and ports to connect iSCSI and Fibre Channel I/O modules.

Each controller has an Ethernet connection for out-of-band management. If the data

path through one controller fails, all data drives remain available to hosts using a

redundant data path through the other controller.

For reliability, essential hardware components are implemented with a redundant

conguration so that the storage system can remain operational if a component fails.

Adding and replacing components, along with rmware upgrades, can be conducted

while the storage system is active and without interruption of data availability to the

hosts. A hot spare drive can be congured to replace a failed data drive automatically,

securing the fault-tolerant integrity of the logical drives. Self-contained, hardware-based

RAID logical drives provide maximum performance in compact external enclosures.

Block configuration

A storage system congured for block-level storage provides the ability to access and

provision raw storage volumes using protocols such as Fibre Channel and iSCSI.

A block conguration consists of the following:

■

Two controllers

■

One or more drive trays

■

Optional service processor (SVP)

Features

All storage systems are highly reliable, versatile, and able to scale its performance by

adding more drive chassis and data drives. Depending on the system conguration, the

drive chassis oerings support SAS-interface solid-state and ash module drives.

Hitachi Virtual Storage Platform F700 Hardware Reference Guide 12

Chapter 1: Overview

Page 13

High performance

■

Dual controller conguration distributes processing to each controller

■

Equipped with high capacity cache to provide a total of 1,024 GB of high-speed

processing

■

Flash drive conguration increases I/O processing speeds

■

Equipped with 32/16-Gbps Fibre Channel or 10-Gbps iSCSI interface facilitates highspeed data transfer

High reliability

■

Main system components are congured with redundancy to maintain continued

service

■

RAID 1, RAID 5, and RAID 6 support (RAID 6 including 14D+2P)

■

Provides data security by transferring data to cache ash memory at the time of a

power outage

Scalability and versatility

■

Flash drive tray (DBF): Up to 12 ash module drives (FMD) can be installed (2U size)

■

Supports system environments with mixed operating systems such as UNIX, Linux,

Windows, and VMware

Features

Hitachi Virtual Storage Platform F700 Hardware Reference Guide 13

Chapter 1: Overview

Page 14

Chapter 2: System controller

The storage systems are equipped with dual controllers for communicating with a data

host.

Each controller includes the following internal components such as a processor, dual inline cache memory modules (DIMMs), cache ash memory (CFM), battery, and fans. The

controller has an Ethernet connection for out-of-band management using Hitachi Device

Manager - Storage Navigator. If the data path through one controller fails, all drives

remain available to data hosts using a redundant data path through the other controller.

The controller is equipped with LED indicators for monitoring its operating conditions

and notifying possible component replacement.

CBL controller chassis

The controller chassis houses controllers, backup fan modules, and power supplies. The

chassis also includes specic functional LEDs located on the front and rear of controller

to provide its operating status.

The following table lists the controller board specications.

Component VSP F700

Chassis (4U) DW850-CBL

Controller board DW-F850-CTLM

Number of DIMM slot 8

Cache memory capacity 64 GiB to 256 GiB

Data encryption N/A

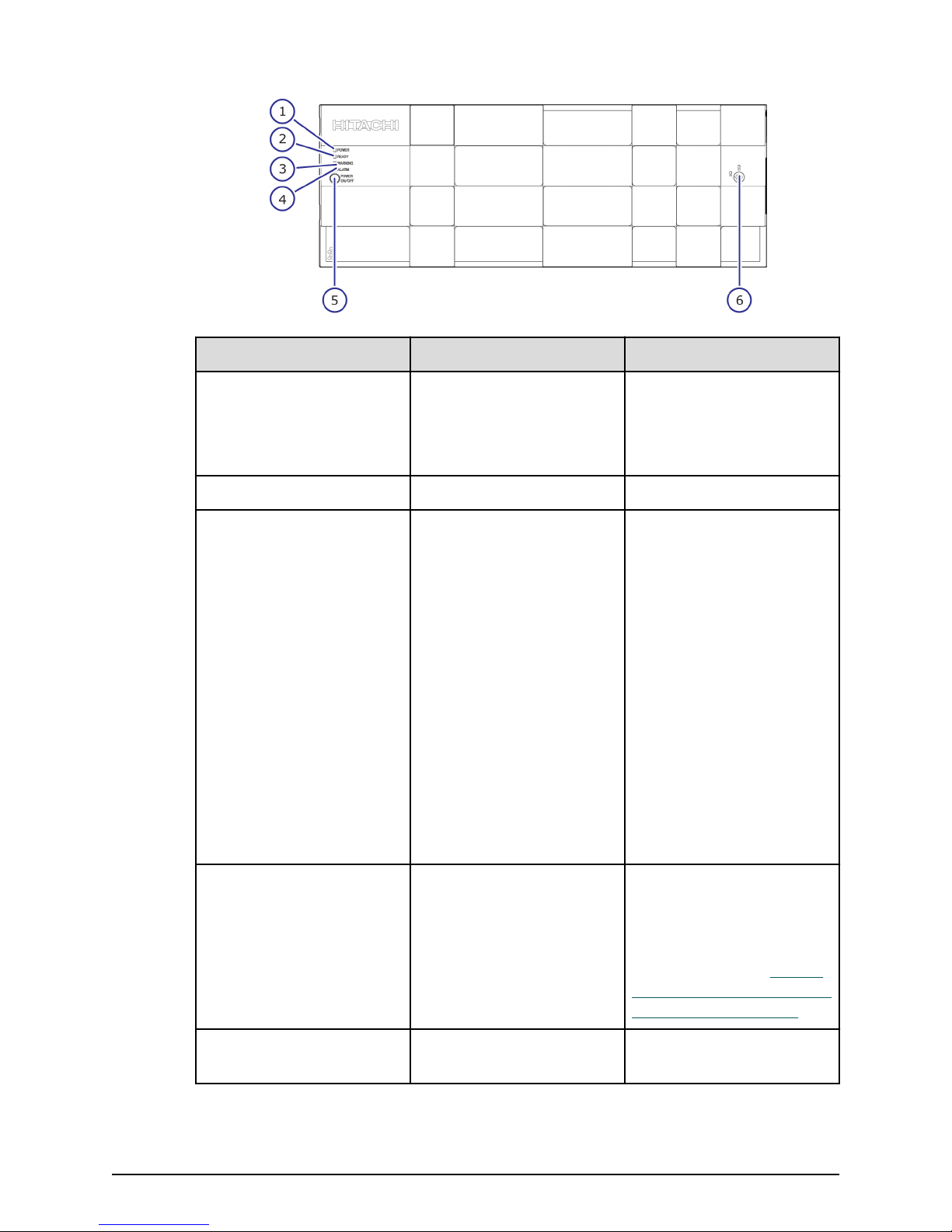

CBL controller front panel bezel LEDs

The following table describes the denitions of the CBL controller front panel bezel LEDs.

Hitachi Virtual Storage Platform F700 Hardware Reference Guide 14

Chapter 2: System controller

Page 15

CBL controller front panel bezel LEDs

Number Item Description

1 POWER LED Green: Storage system is

powered on.

Amber: Storage system is

receiving power.

2 READY LED Green: Normal operation.

3 WARNING LED O: Normal operation.

Amber: Component

requires maintenance.

Blink: Failure requires

maintenance.

Note: When System Option

Mode 1097 is set to ON,

the WARNING LED does not

blink, even if the following

failure service information

messages (SIM) are issued:

452xxx, 462xxx, 3077xx,

4100xx, and 410100.

LED might turn o during

user maintenance.

4 ALARM LED O: Normal operation.

Red: Processor failure

(system might be down).

For assistance, contact

customer support: https://

support.hitachivantara.com

/en_us/contact-us.html.

5 POWER ON/OFF (main

Hitachi Virtual Storage Platform F700 Hardware Reference Guide 15

Powers the storage system.

switch)

Chapter 2: System controller

Page 16

CBL controller front panel LEDs (without bezel)

Number Item Description

6 Lock Locks and unlocks the front

Note: Removing a controller can cause the POWER, READY, WARNING, and

ALARM LEDs on the front panel to turn o. These LEDs return to the on status

after the storage system recovers from the controller replacement.

CBL controller front panel LEDs (without bezel)

The following table describes the denitions of the CBL controller front panel LEDs.

panel bezel by using the

supplied key.

Number Item Description

1 POWER ON/OFF (main

switch)

2 POWER, READY, WARNING,

and ALARM LEDs

3 Controllers Controller 1 (bottom) and

4 Backup module N/A

Chapter 2: System controller

Hitachi Virtual Storage Platform F700 Hardware Reference Guide 16

Powers the storage system.

Note: When System Option

Mode 1097 is set to ON,

the WARNING LED does not

blink, even if the following

failure service information

messages (SIM) are issued:

452xxx, 462xxx, 3077xx,

4100xx, and 410100.

Controller 2 (top).

Page 17

CBL controller front panel LEDs (without bezel)

Number Item Description

5 BACKUP LED Green: Power restoration in

progress following power

outage.

Fast blink green: Restoring.

Slow blink green: Restoring,

or sequential shutdown in

progress.

6 Cache ash memory N/A

7 ALM LED (for cache ash

memory)

Red: Cache ash memory

can be removed.

8 CTL ALM LED Red: Controller can be

removed.

Blink red: Failure with the

power supply unit of the

controller.

Amber: LAN reset switch

was pressed.

9 LAN-RST switch Use only when instructed

by customer support.

10 STATUS LED (for BKMF) Green: Charging of the

battery in the backup

module is complete.

Red: Backup module can

be removed.

Blink red one time: Main

battery failure.

Hitachi Virtual Storage Platform F700 Hardware Reference Guide 17

Blink red two times:

Backup battery failure.

Blink red three times: Both

batteries failed or

preventive maintenance

replacement of batteries

can run.

Chapter 2: System controller

Page 18

Number Item Description

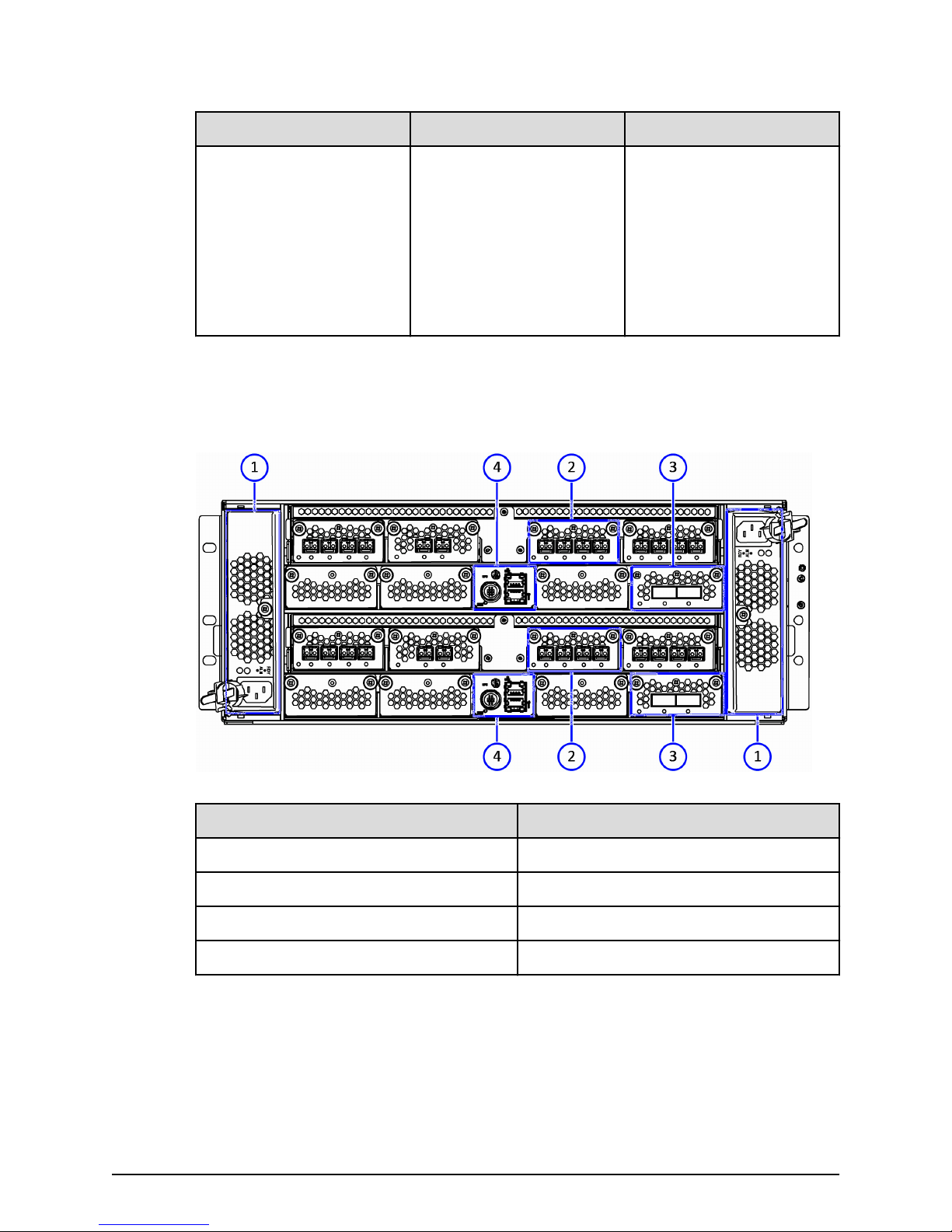

CBL controller rear panel LEDs

The following table describes the denitions of the CBL controller rear panel LEDs.

CBL controller rear panel LEDs

O: Battery is not

mounted, batterymounting failure occurred,

or rmware is being

upgraded. O is normal

status for congurations

without batteries (for

example, BKMF-10 and

BKMF-20).

1 Power supply unit

2 Front end module

3 Back end module

4 LAN blade

CBL controller power supply unit LEDs and connectors

The following table lists the denitions of the CBL controller power supply unit LEDs and

connectors.

Hitachi Virtual Storage Platform F700 Hardware Reference Guide 18

Number Item

Chapter 2: System controller

Page 19

Host, Network, and Drive Tray Ports and LEDs

Number Item Description

1 ALM / RDY LED Red: Power supply unit can

be replaced.

2 Receptacle Connects to the power

cable provided with the

storage system.

3 RDY LED Green: Normal operation.

Host, Network, and Drive Tray Ports and LEDs

The controllers are equipped with specic interfaces for connecting, powering,

conguring, and managing the storage system. The component LEDs display the

operating status of the storage system.

Front end modules

The following front end modules are available for the controllers. The LEDs display the

operating status of the module.

Hitachi Virtual Storage Platform F700 Hardware Reference Guide 19

Chapter 2: System controller

Page 20

10-Gbps iSCSI board LEDs and connectors (optical)

10-Gbps iSCSI board LEDs and connectors (optical)

Number Item Description

1 STATUS LED Green: Front end module is

2 PORT LED Red: Small form-factor

3 ISCSI connectors Connect to Ethernet cables.

10-Gbps iSCSI board LEDs and connectors (copper)

in the power-on state.

Red: Front end module can

be removed safely.

pluggable can be removed.

Blue: Normal link status.

Blink blue: Front end

module is in

communication status.

Hitachi Virtual Storage Platform F700 Hardware Reference Guide 20

Chapter 2: System controller

Page 21

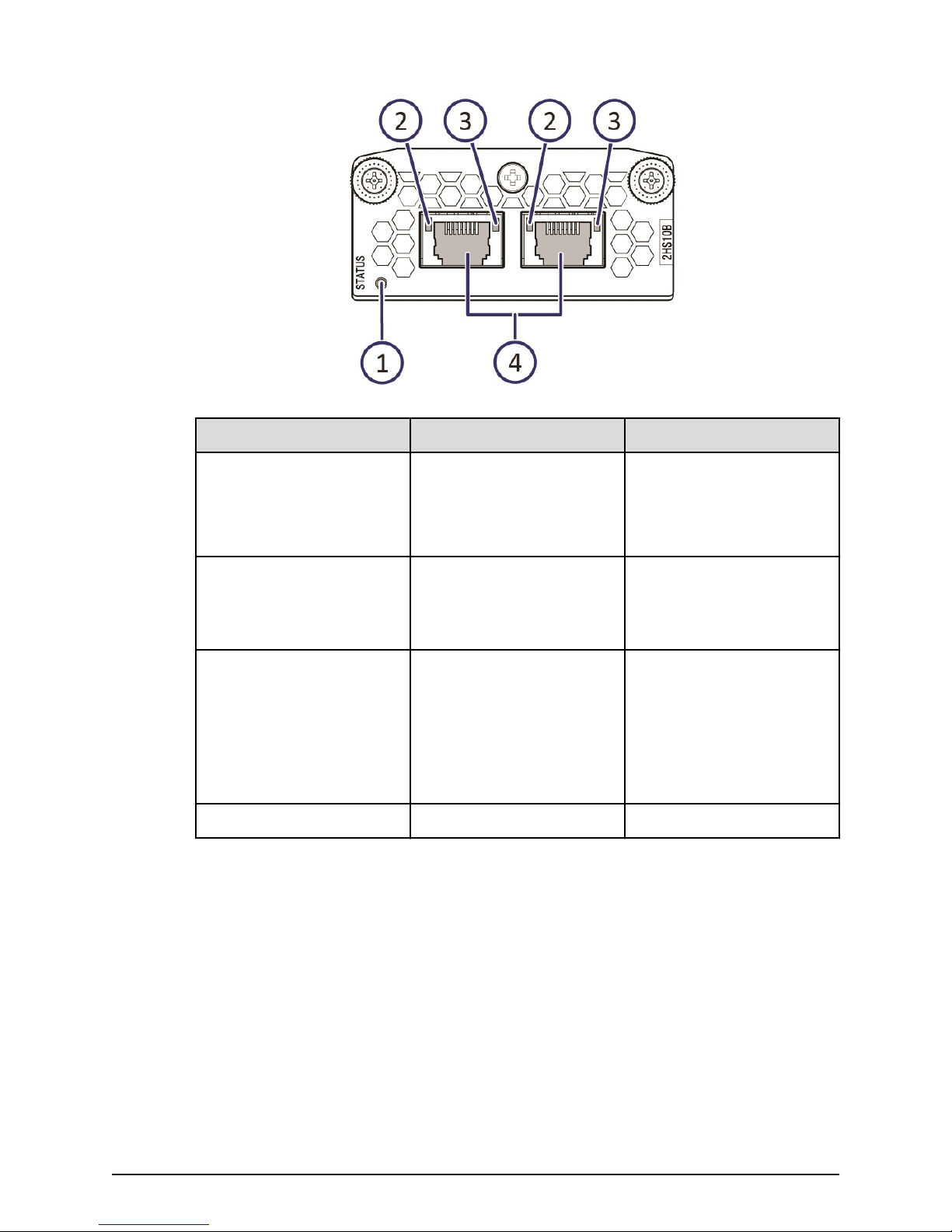

10-Gbps iSCSI board LEDs and connectors (copper)

Number Item Description

1 STATUS LED Green: Front end module is

in the power-on state.

Red: Front end module can

be removed safely.

2 PORT (Link/Speed) LED Yellow: 1-Gbps link.

Green: 10-Gbps link.

O: No link connection.

3 PORT LED Green: Link connection is

established.

Blinking: Communication is

in progress.

O: No link connection or

not ready to communicate.

4 ISCSI connectors Connect to Ethernet cables.

Hitachi Virtual Storage Platform F700 Hardware Reference Guide 21

Chapter 2: System controller

Page 22

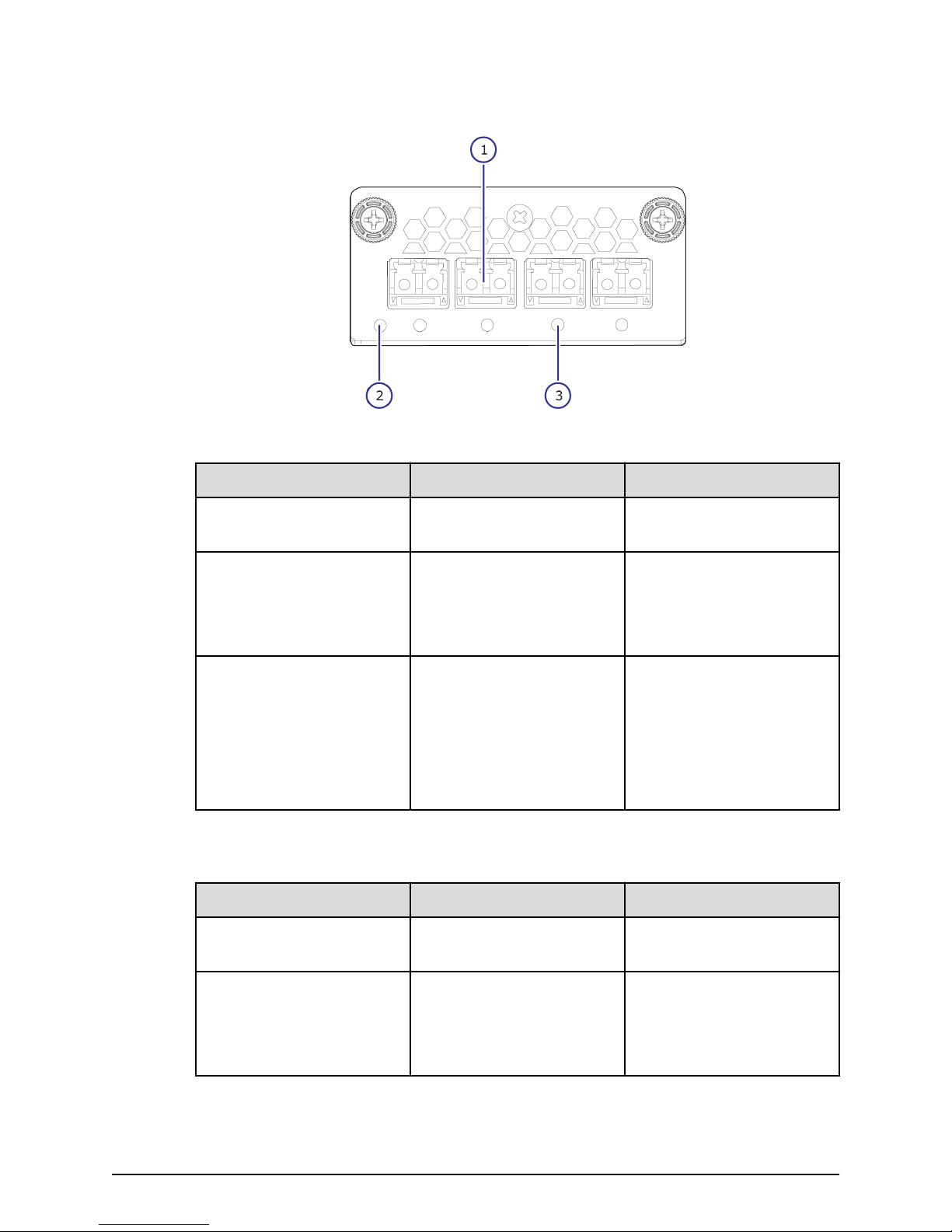

8-Gbps, 16-Gbps, or 32-Gbps Fibre Channel (4-port) board LEDs and connectors

8-Gbps, 16-Gbps, or 32-Gbps Fibre Channel (4-port) board LEDs and connectors

Table 1 8-Gbps Fibre Channel

Number Item Description

1 Fibre Channel connectors Connect to Fibre Channel

cables.

2 STATUS LED Green: Front end module is

in power-on state.

Red: Front end module can

be removed safely.

3 PORT LED Red: Small form-factor

pluggable can be removed.

Blue: Normal link status at

8-Gbps.

Green: Normal link status

at 2-Gbps or 4-Gbps.

Table 2 32-Gbps, 16-Gbps Fibre Channel

Number Item Description

1 Fibre Channel connectors Connect to Fibre Channel

cables.

2 STATUS LED Green: Front end module is

Hitachi Virtual Storage Platform F700 Hardware Reference Guide 22

in power-on state.

Red: Front end module can

be removed safely.

Chapter 2: System controller

Page 23

8-Gbps, 16-Gbps, or 32-Gbps Fibre Channel (4-port) board LEDs and connectors

Number Item Description

3 PORT LED Red: Small form-factor

pluggable can be removed.

Blue: Normal link status at

16-Gbps (16-Gbps).

Blue: Normal link status at

32-Gbps (32-Gbps).

Green: Normal link status

at 4-Gbps or 8-Gbps (16Gbps).

Green: Normal link status

at 8-Gbps or 16-Gbps (32Gbps).

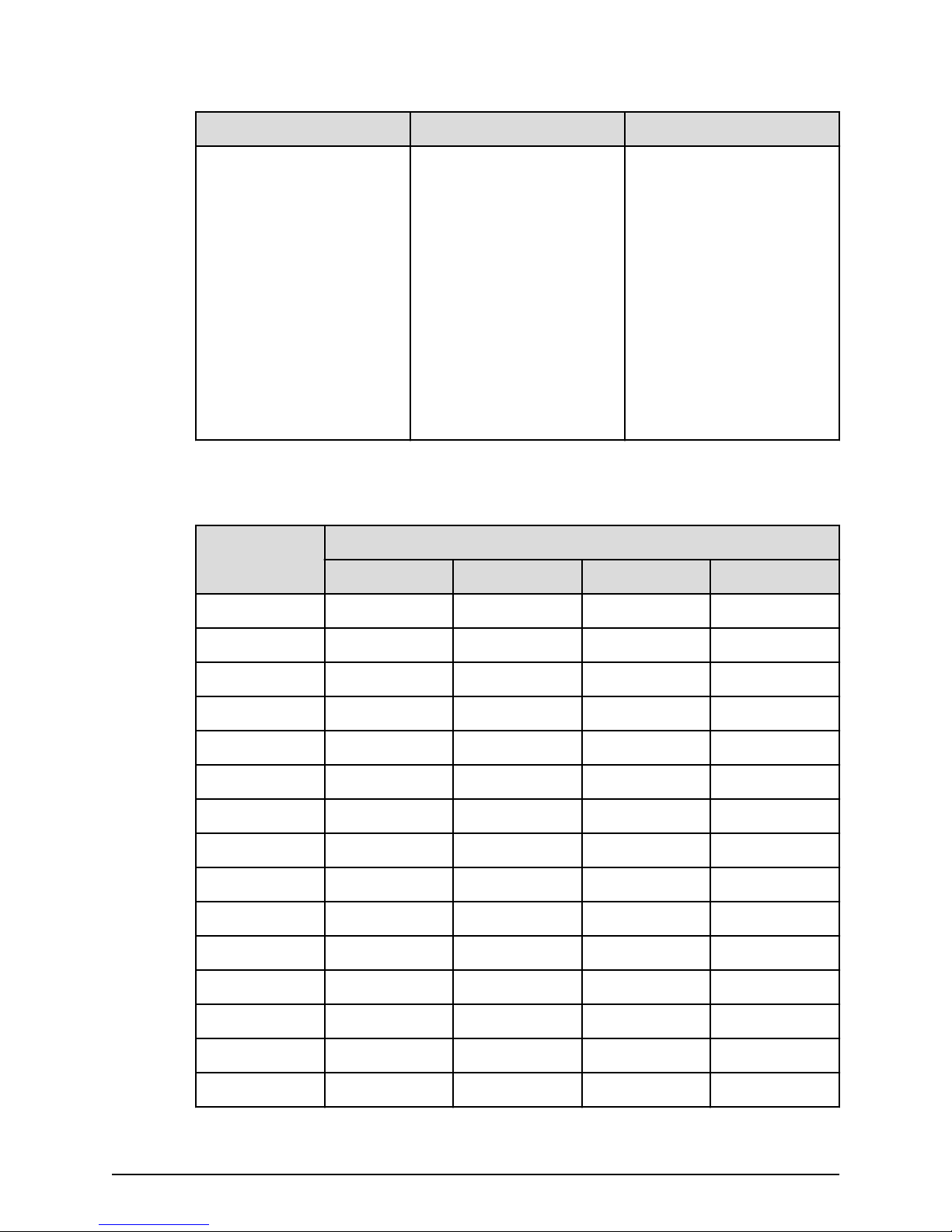

Port assignments

8-Gbps, 16-Gbps, or 32-Gbps Fibre Channel ports (left to right)

CHB number

Port 1 Port 2 Port 3 Port 4

CHB-1A 1A 3A 5A 7A

CHB-1B 1B 3B 5B 7B

CHB-1C 1C 3C 5C 7C

CHB-1D 1D 3D 5D 7D

CHB-1E 1E 3E 5E 7E

CHB-1F 1F 3F 5F 7F

CHB-1G 1G 3G 5G 7G

CHB-1H 1H 3H 5H 7H

CHB-2A 2A 4A 6A 8A

CHB-2B 2B 4B 6B 8B

CHB-2C 2C 4C 6C 8C

CHB-2D 2D 4D 6D 8D

CHB-2E 2E 4E 6E 8E

CHB-2F 2F 4F 6F 8F

CHB-2G 2G 4G 6G 8G

Hitachi Virtual Storage Platform F700 Hardware Reference Guide 23

Chapter 2: System controller

Page 24

16-Gbps Fibre Channel (2-port) board LEDs and connectors

8-Gbps, 16-Gbps, or 32-Gbps Fibre Channel ports (left to right)

CHB number

CHB-2H 2H 4H 6H 8H

Port 1 Port 2 Port 3 Port 4

16-Gbps Fibre Channel (2-port) board LEDs and connectors

Number Item Description

1 STATUS LED Green: Front end module is

in the power-on state.

Red: Front end module can

be removed safely.

2 PORT LED Red: Small form-factor

pluggable can be removed.

Blue: Normal link status at

16-Gbps.

Green: Normal link status

at 4-Gbps or 8-Gbps.

3 Fibre Channel connectors Connect to Fibre Channel

cables.

Hitachi Virtual Storage Platform F700 Hardware Reference Guide 24

Chapter 2: System controller

Page 25

Port assignments

Back-end module LEDs and connectors

16-Gbps Fibre Channel ports (left to right)

CHB number

CHB-1A 1A 3A

CHB-1B 1B 3B

CHB-1C 1C 3C

CHB-1D 1D 3D

CHB-1E 1E 3E

CHB-1F 1F 3F

CHB-1G 1G 3G

CHB-1H 1H 3H

CHB-2A 2A 4A

CHB-2B 2B 4B

CHB-2C 2C 4C

CHB-2D 2D 4D

CHB-2E 2E 4E

Port 1 Port 2

CHB-2F 2F 4F

CHB-2G 2G 4G

CHB-2H 2H 4H

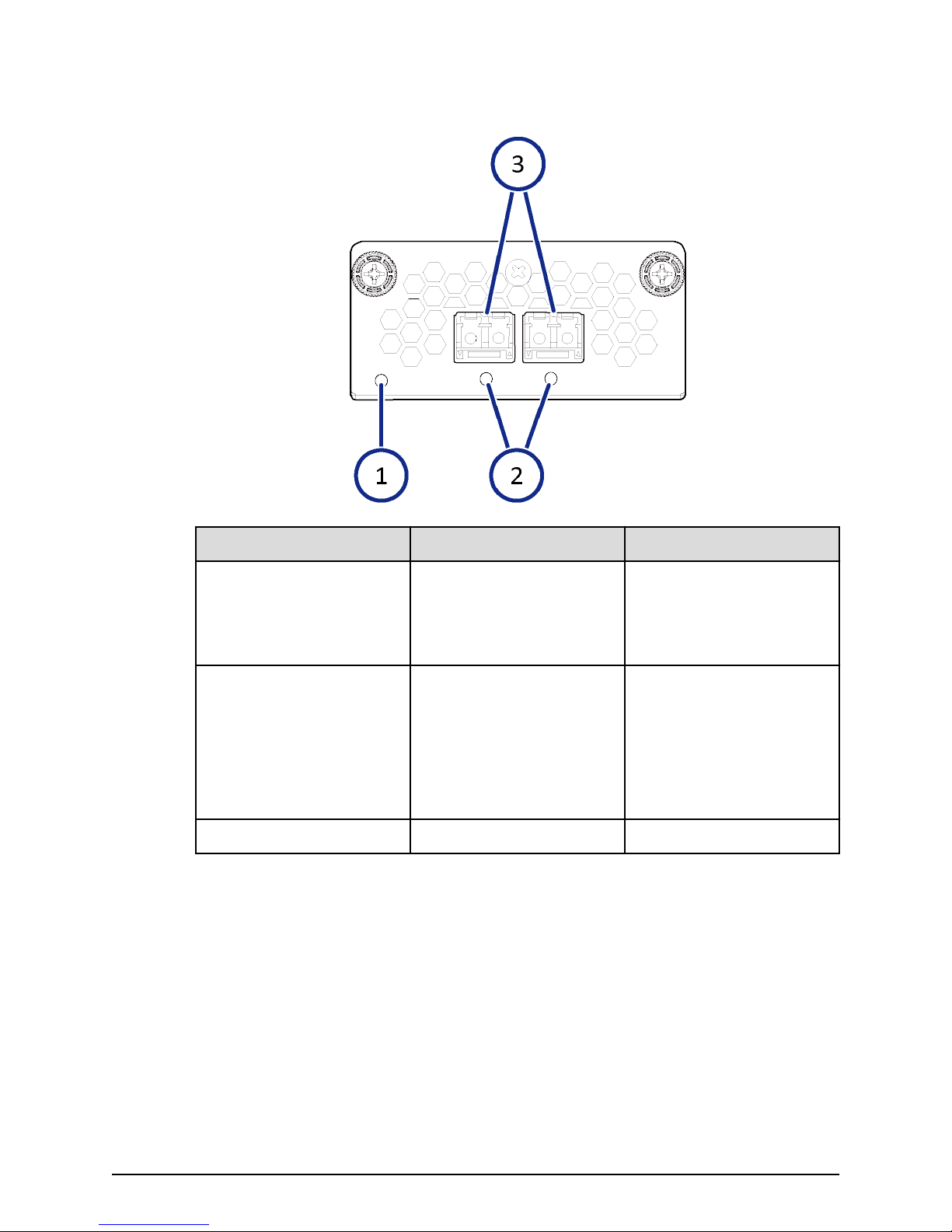

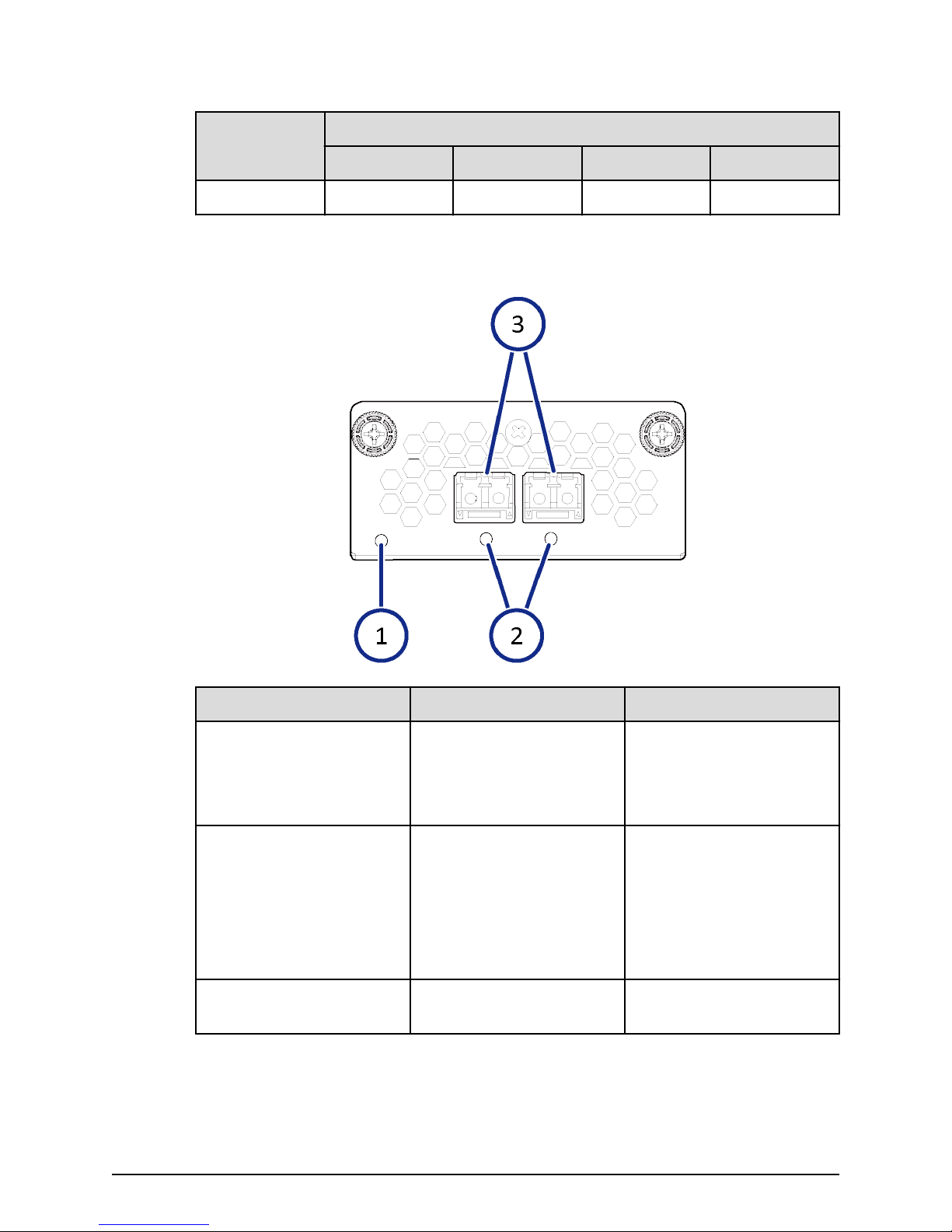

Back-end module LEDs and connectors

The back-end module LEDs display the operating status of the module.

Hitachi Virtual Storage Platform F700 Hardware Reference Guide 25

Chapter 2: System controller

Page 26

Back-end module LEDs and connectors

Number Item Description

1 STATUS LED Green: Back end module is

in the power-on state.

Red: Back end module can

be removed safely.

2 PORT LED Blue: Link status is normal.

3 PATH 0 connector Connect to a drive tray.

4 PATH 1 connector Connects to a drive tray.

Hitachi Virtual Storage Platform F700 Hardware Reference Guide 26

Chapter 2: System controller

Page 27

Chapter 3: Drive trays

The drive tray contains data drives, power supplies, fans, and status LEDs. Each drive tray

provides interfaces for connecting to controllers and other drive trays. The all-ash

storage arrays have various xed storage capacity congurations with ash storage

devices. To deliver consistent low latency host response times and highest IOP

performance across all host connection ports, conventional hard disk drives (HDD) are

not included or congurable with all-ash arrays.

Small form-factor drive tray (DBS)

The following describes the physical specications of the small form-factor drive tray.

Name Model name Height

DBS DW-F800-DBSC 2U (88.2 mm) 24 2.5 inch (SFF)

Number of

drive slots Drive type

SFF with front panel bezel

Number Item Description

1 POWER LED Green: Drive tray is

2 READY LED Green: Drive tray is

powered on.

operational.

Hitachi Virtual Storage Platform F700 Hardware Reference Guide 27

Chapter 3: Drive trays

Page 28

Number Item Description

3 Locate LED Amber:

4 Lock Locks and unlocks the front

SFF front panel without bezel

SFF front panel without bezel

■

Indicates the location of

the chassis.

■

Can be turned on or

turned o by the

maintenance utility.

panel bezel by using the

supplied key.

Number Item Description

1 POWER, READY, and

LOCATE LEDs

Green: Drive tray is

powered on.

Green: Drive tray is

operational.

Amber:

■

Indicates the location of

the chassis.

■

Can be turned on or

turned o by the

maintenance utility.

2 ALM LED Red: Drive stopped due to

a failure and can be

replaced.

3 ACT LED Green: Normal operation.

Chapter 3: Drive trays

Hitachi Virtual Storage Platform F700 Hardware Reference Guide 28

Page 29

4 Small form-factor drives The twenty-four 2.5-inch

SFF rear panel

SFF rear panel

Number Item Description

Blink green: Drive is being

accessed.

small form factor drives are

positioned vertically. The

slots are organized from 0

to 23.

Number Item Description

1 ENC N/A

2 POWER LED Green: ENC is in the power-

on state.

3 Locate LED Amber:

■

Indicates the location of

the chassis.

■

Can be turned on or

turned o by the

maintenance utility.

4 ALARM LED Red: ENC can be replaced.

5 PATH (IN) LED Blue: IN side port is linked

up.

6 PATH (IN) connector Connects to a controller or

drive tray.

Hitachi Virtual Storage Platform F700 Hardware Reference Guide 29

Chapter 3: Drive trays

Page 30

AC power supply unit LEDs and connectors

Number Item Description

7 PATH (OUT) LED Blue: OUT side port is

linked up.

8 PATH (OUT) connector Connects to a drive tray.

9 Console This port is reserved.

10 Power supply unit N/A

11 Receptacle Connects to the power

cable provided with the

storage system.

12 AC IN LED Green: Normal operation.

13 ALM LED Red: Power supply unit can

be replaced.

14 RDY LED Green: Normal operation.

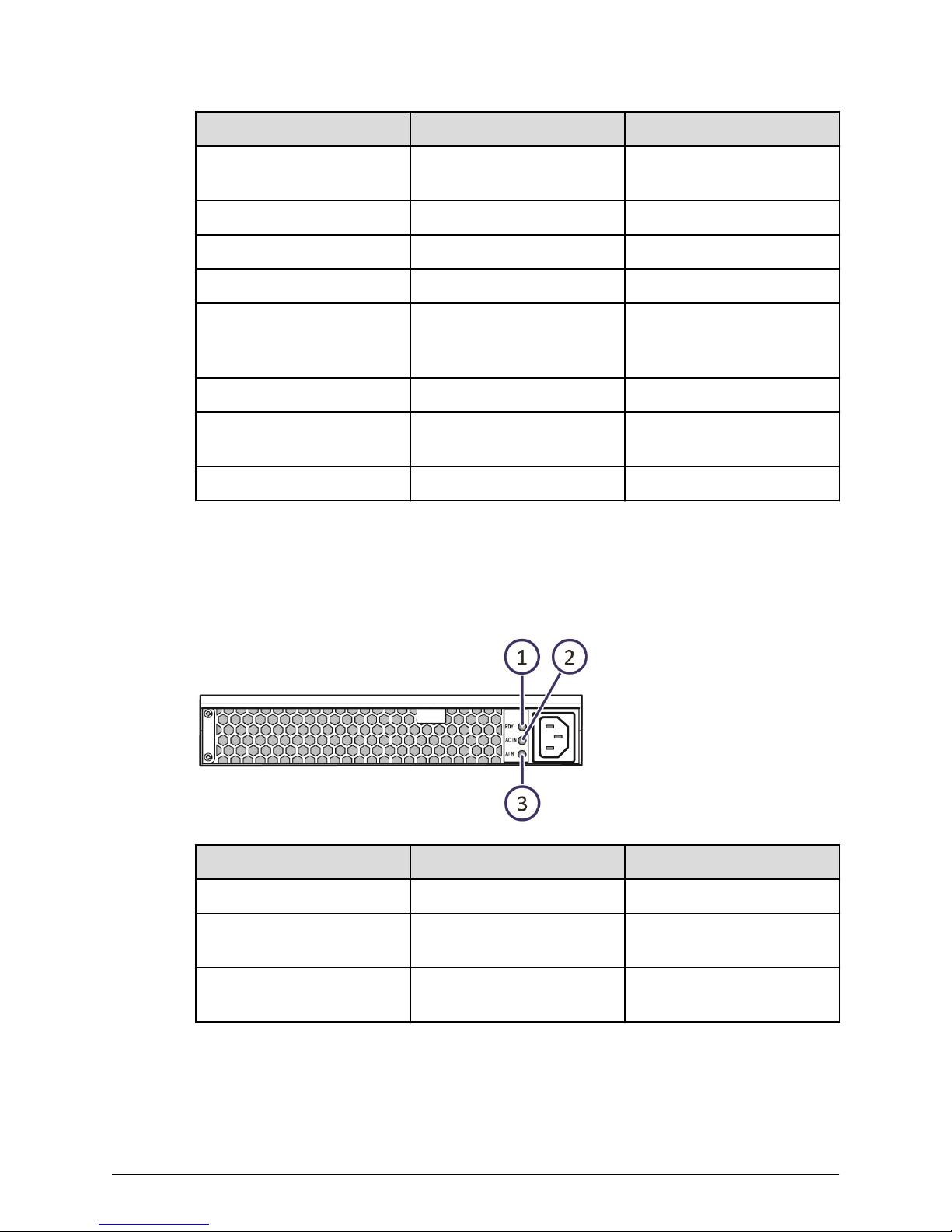

AC power supply unit LEDs and connectors

Both SFF and LFF drive trays are equipped with AC power supply units. The AC power

supply units include LEDs to display its operating status.

Number Item Description

1 RDY LED Green: Normal operation.

2 ACI IN LED Green: AC input is

3 ALM LED Red: Power supply unit can

operating normally.

be replaced.

Hitachi Virtual Storage Platform F700 Hardware Reference Guide 30

Chapter 3: Drive trays

Page 31

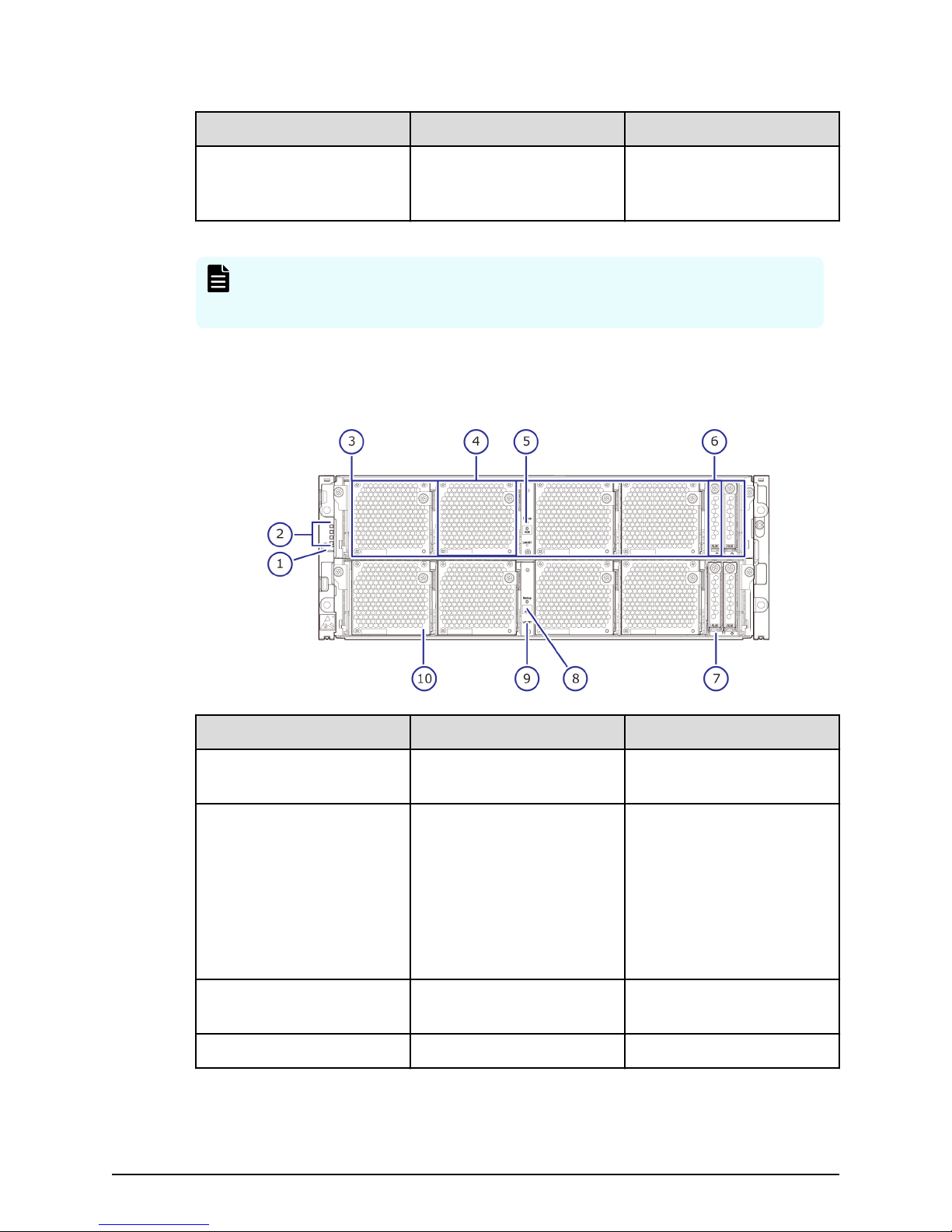

Flash module drive tray (DBF)

The following describes the physical specications of the ash module drive tray.

Name Model name Height

DBF DW-F800-DBF 2U (87 mm) 12 Flash module

FMD with front panel bezel

Flash module drive tray (DBF)

Number of

drive slots Drive type

drive (FMD)

Number Item Description

1 POWER LED Green: Drive tray is

powered on.

2 READY LED Green: Drive tray is

operational.

3 Locate LED Amber:

■

Indicates the location of

the chassis.

■

Can be turned on or

turned o by the

maintenance utility.

4 Lock Locks and unlocks the front

panel bezel by using the

supplied key.

Hitachi Virtual Storage Platform F700 Hardware Reference Guide 31

Chapter 3: Drive trays

Page 32

FMD front panel without bezel

FMD front panel without bezel

Number Item Description

1, 2 ACT LED Green: Normal operation.

Blink: Drive is being

accessed.

Slow blink indicates the

FMD is in the process of

startup. When powered,

the LED blinks for about

two to ve minutes until

the startup processing is

complete.

ALM LED Red: Drive stopped due to

a failure and can be

replaced.

Note: ACT indicator is only

printed on some types of

FMDs.

3 POWER, READY, and

LOCATE LEDs

Green: Drive tray is

powered on.

Hitachi Virtual Storage Platform F700 Hardware Reference Guide 32

Green: Drive tray is

operational.

Chapter 3: Drive trays

Page 33

FMD rear panel

Number Item Description

Amber:

■

Indicates the location of

the chassis.

■

Can be turned on or

turned o by the

maintenance utility.

4 Flash module drives Twelve ash module drives.

Slots are organized the

following way:

9, 10, 11

6, 7, 8

3, 4, 5

0, 1, 2

FMD rear panel

1 ENC N/A

2 POWER LED Green: ENC is in the power-

3 Locate LED Amber:

Number Item Description

on state.

■

Indicates the location of

the chassis.

■

Can be turned on or

turned o by the

maintenance utility.

Hitachi Virtual Storage Platform F700 Hardware Reference Guide 33

Chapter 3: Drive trays

Page 34

FMD rear panel

Number Item Description

4 ALARM LED Red: ENC can be replaced.

5 PATH (IN) LED Blue: IN side port is linked

up.

6 PATH (IN) connector Connects to a controller or

drive tray.

7 PATH (OUT) LED Blue: OUT side port is

linked up.

8 PATH (OUT) connector Connects to a drive tray.

9 Console This port is reserved.

10 Receptacle Connects to the power

cable provided with the

storage system.

11 Three LEDS, top to bottom:

RDY LED

AC IN LED

ALM REPLACE LED

Green: Power supply unit is

operating normally.

Green: Power supply unit is

operating normally.

Red: Power supply unit can

be replaced.

Hitachi Virtual Storage Platform F700 Hardware Reference Guide 34

Chapter 3: Drive trays

Page 35

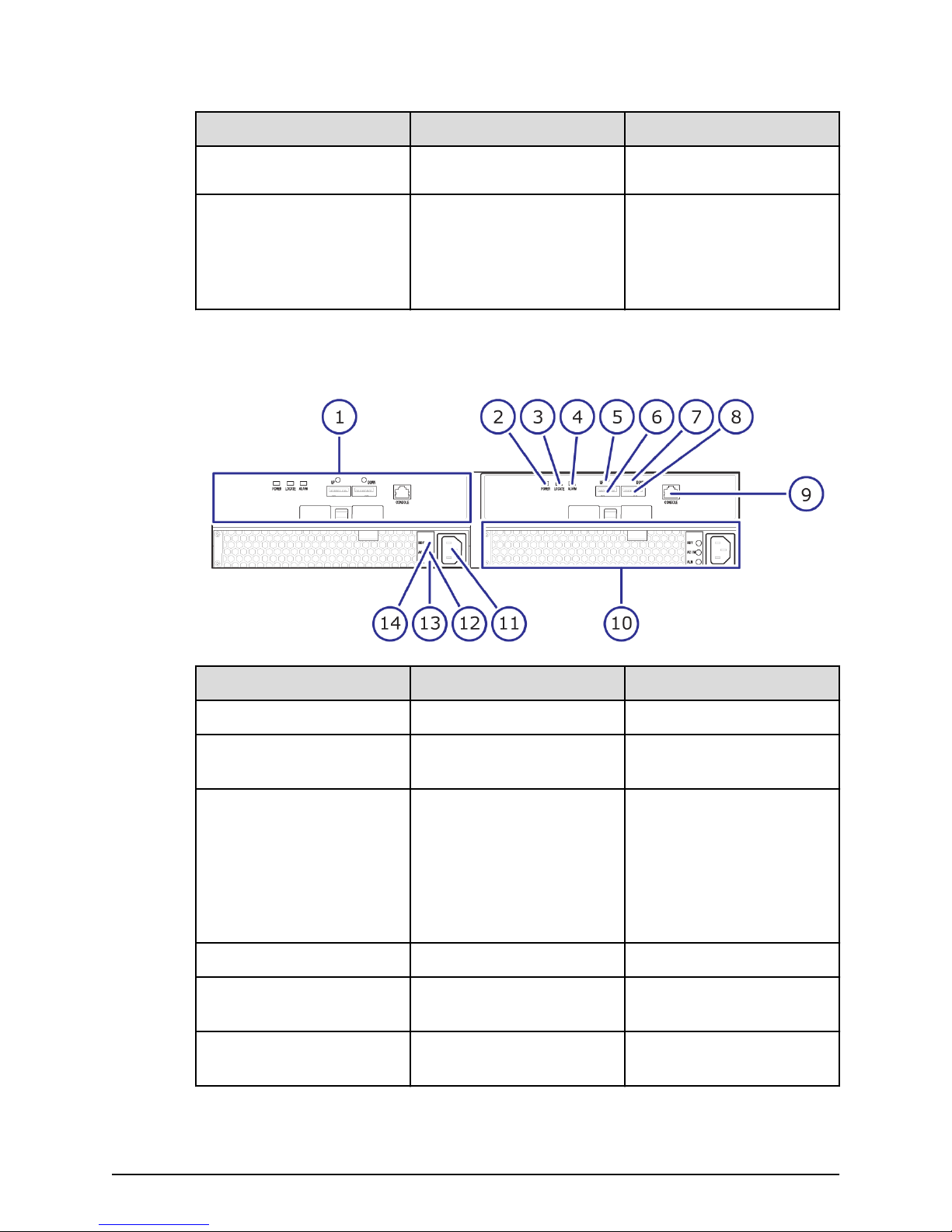

Chapter 4: Service processor

The VSP Fx00 models include an optional, separate 1U service processor (SVP) dedicated

to host an element manager (Storage Navigator). The SVP operates independently from

the CPU of the storage system and operating system, and provides out‑of‑band

conguration and management of the storage system. The SVP also monitors and

collects performance data for key components of the storage system to enable

diagnostic testing and analysis for customer support.

The SVP is also available as a 64-bit software application provided by Hitachi Vantara. For

the latest interoperability updates and details, see the SVP (Service Processor) OS and

Hypervisor support for Gx00, Fx00 report at

interoperability.html.

Service Processor (Windows 10 Enterprise) hardware

specifications

The following table lists the hardware specications for the service processor (Windows

10 Enterprise) provided by Hitachi Vantara.

https://support.hitachivantara.com/en_us/

Item Specification

Dimensions Height: 1.7 inches (43 mm)

Width: 17.2 inches (437 mm)

Depth: 9.8 inches (249 mm)

Weight: 10 lbs (4.5 kg)

Processor Intel N3710 Pentium processor 4C/4

threads 1.6 GHz 2M cache, 6W

Memory 2 x 4 GB DDR3 1600MHz

Storage media 1 TB 5400 RPM SATA HDD

LAN/Network interface card 1-GbE x 4 ports (on-board NIC)

x1 IPMI (BMC) port

Fans 2 x 4028 mm 13KPRM 4-pin PWM fans

Operating system Windows 10 Enterprise

Maximum temperature Up to 40° C (104° Fahrenheit)

Hitachi Virtual Storage Platform F700 Hardware Reference Guide 35

Chapter 4: Service processor

Page 36

Item Specification

Service processor description

The SVP provides four RJ-45 ports:

■

Two ports connect to the storage system controllers (one port for each controller).

■

One port connects to the IP network of the user.

■

One port connects to a user-supplied management console PC.

Note: This product is also designed for IT power distribution systems with

phase-to-phase voltage.

Service processor description

The SVP is supported in high-temperature

environments. Do not operate in any

location with temperatures above 40°C

(104° Fahrenheit).

Three of the four RJ-45 ports (which connect to the controllers and the IP network) are

congured as a bridge. The SVP can be addressed using the default IP address

192.168.0.15.

In the unlikely event you cannot connect to the SVP using the default IP address, use the

following emergency login: http://<default SVP IP address>/dev/storage/

<model number><system serial number>/emergency.do. For example:

Storage system model

number

Storage system serial

number URL

8320004 456789 http://192.168.0.15/dev/

storage/8320004456789/

emergency.do

8340004 456789 http://192.168.0.15/dev/

storage/8340004456789/

emergency.do

8360004 456789 http://192.168.0.15/dev/

storage/8360004456789/

emergency.do

Hitachi Virtual Storage Platform F700 Hardware Reference Guide 36

Chapter 4: Service processor

Page 37

Users are responsible for adopting the appropriate security procedures with the SVP,

including:

■

Applying Windows security patches.

■

Turning on automatic Windows updates or using the manual Windows update

method.

■

Installing antivirus software that has been tested and approved by Hitachi.

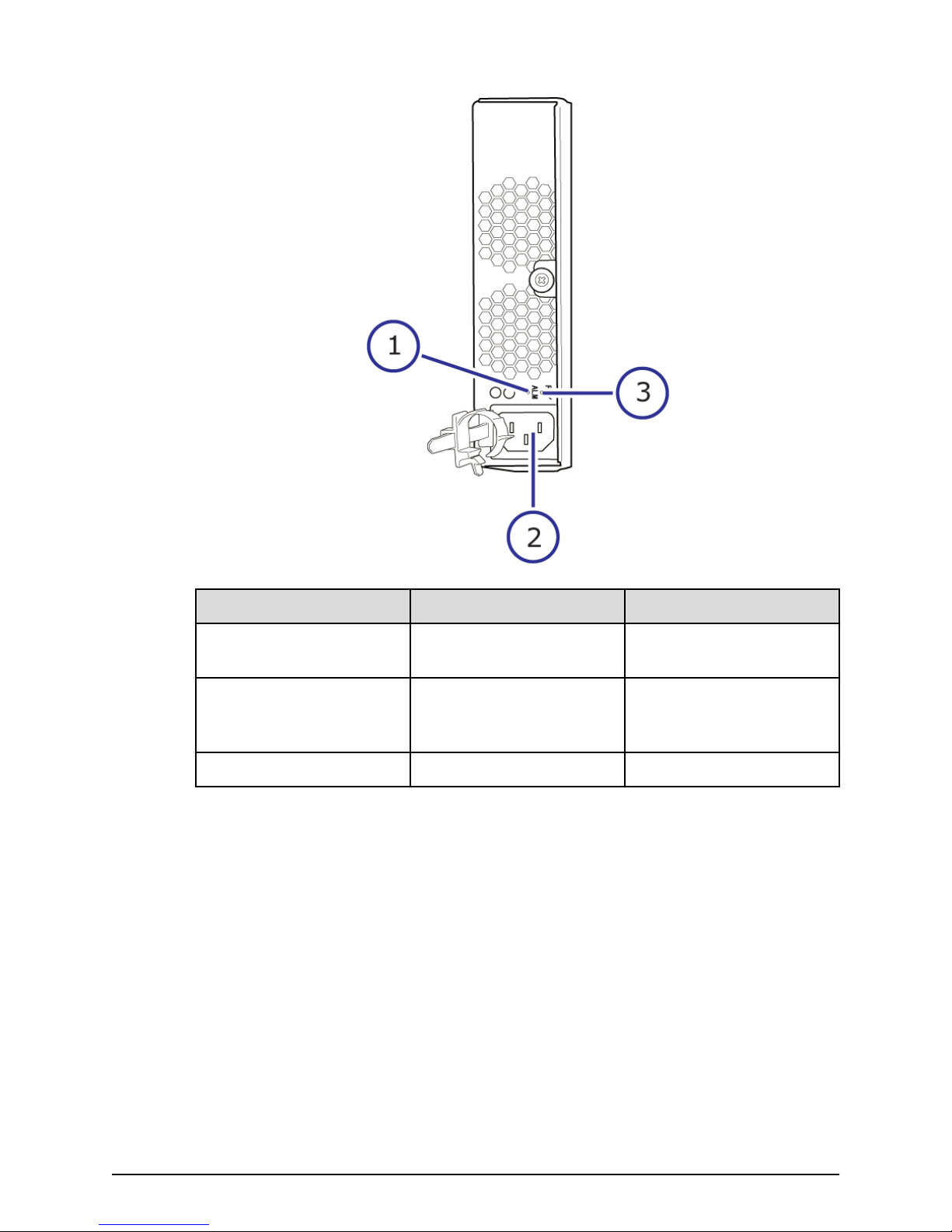

SVP front panel

The front panel of the physical SVP with Windows 10 Enterprise operating system is

equipped with LEDs, a reset button, and a power button.

SVP front panel

1 LED (Left to Right):

2 Reset button

3 Power button

SVP rear panel

The only ports used at the rear panel of the physical SVP are the power socket and the

four LAN ports. The following ports connect to your IP network, the management

console PC, and the user LAN port on each storage system controller.

Table 3 SVP (Windows 10 Enterprise) front panel

Item Description

■

N/A

■

LAN card 2

■

LAN card 1

■

Hard drive

■

System standby power

Hitachi Virtual Storage Platform F700 Hardware Reference Guide 37

Chapter 4: Service processor

Page 38

SVP rear panel

Table 4 SVP (Windows 10 Enterprise) rear panel

Item Description

1 Management (DKC CTL1) - LAN3 port

2 Management (DKC CTL2) - LAN4 port

3 Maintenance - LAN2 port

4 Management (User) - LAN1 port

Note: The SVP running Windows 10 operating system does not provide an

option to disable Spanning Tree Protocol (STP). If your network has BPDU

enabled to prevent loops, connect the user LAN port on controllers 1 and 2 to

an Ethernet switch that is also connected to the LAN1 port on the SVP.

Note: After the Initial Startup Wizard is complete, the SVP can be used in nonbridge mode. In this mode, the cables can be removed from SVP ports LAN3

and LAN4 and attached to switches. For more information, contact customer

support.

Hitachi Virtual Storage Platform F700 Hardware Reference Guide 38

Chapter 4: Service processor

Page 39

Chapter 5: Maintaining the storage system

Ongoing proper maintenance of the storage system maintains the reliability of the

storage system and its constant availability to all hosts connected to it.

For more complex maintenance activities, contact customer support.

Storing the storage system

If the storage system does not receive power for more than six months, the battery can

become discharged and possibly damaged. To avoid this situation, charge the battery for

more than three hours at least once every six months.

Note: Do not store the equipment in an environment with temperatures of

104ºF (40ºC) or higher because battery life will be shortened.

Powering off the storage system

Procedure

1. Press the main switch on the controller chassis for approximately three seconds

until the POWER LED on the front of the chassis changes from solid green to a

blinking status.

2. Release the main switch and the POWER LED returns to solid green after blinking for

approximately three seconds.

The power-o process begins. The process takes approximately 18 minutes or

longer depending on the amount of data that needs to be written. The POWER LED is

solid green during the powering o process. The POWER LED changes from green to

amber when the process is completed.

3. Verify the POWER LED on the front of the storage system changes from green to

amber.

4. To stop the power supply, remove the power cables from the power supply units on

the controller chassis and drive box.

If the storage system is connected to a PDU, you can stop the power supply by

turning o the PDU breaker.

Note: If the storage system does not receive power for more than six

months, the battery can become discharged and possibly damaged. To

avoid this situation, charge the battery for more than three hours at

least once every six months.

Hitachi Virtual Storage Platform F700 Hardware Reference Guide 39

Chapter 5: Maintaining the storage system

Page 40

Battery unit

Battery lifetime

The battery life time is aected by the battery temperature. The battery temperature

changes depending on the intake temperature and height of the storage system, the

conguration, operation of the controller boards and drives, charge-discharge count and

others. The battery lifetime will be three to ve years.

Treatment

Use the storage system in a place where the ambient temperature is 86°F (30°C) or less

on average.

Periodic parts replacement is required. If you have a maintenance service contract, parts

are replaced periodically according to the terms of the contract.

Battery unit

Note: The battery protects the data in the cache memory in an emergency,

such as a sudden power failure. In these cases, follow the normal power

down procedure. If not, the battery might reach its lifespan earlier than

expected and become unusable within three years. When replacing the

battery, follow the given procedure for disposing a used battery.

Replacement period

The battery lifetime (intake temperature is 30 degrees C or less.) in the standard

environment is as shown below.

Storage System Intake Temperature CBL

Up to 24 degrees Celsius 5 years

Up to 30 degrees Celsius 5 years

Up to 34 degrees Celsius 4 years

Up to 40 degrees Celsius 3 years

Hitachi Virtual Storage Platform F700 Hardware Reference Guide 40

Chapter 5: Maintaining the storage system

Page 41

Appendix A: Storage system parts list

The following parts list describes the standard and optional hardware components for

the storage systems.

For more information about the storage system, contact an Hitachi Vantara sales

representative.

VSP F700 parts list

The VSP F700 includes the following standard and optional components.

Table 5 CBL controller components

Model number Part description Quantity

DW850-CBL 4U chassis 1

Power supply unit 2

LAN board (LAN/UPS) 2

Backup module (BKM) 8

Front bezel (4U) 1

Binder 1

SAS cable label 2

DW-F800-RRCB Rail kit 1

DW-F800-BAT Battery 6

Hitachi Virtual Storage Platform F700 Hardware Reference Guide 41

Appendix A: Storage system parts list

Page 42

Table 6 CBL optional controller components

Model number Part description Quantity

DW-F850-CTLM Controller board 2

VSP F700 parts list

DW-F850-CM16G

DW-F850-CM32G

1

1

Cache memory (16 GB) 8-16

Cache memory (32 GB) 8-16

DW-F850-BM35 Cache ash memory (CFM) 2-4

DW-F800-2HS10S Front-end module (also

2-12

know as a channel board)

(10-Gbps SFP optic-iSCSI)

DW-F800-2HS10B Front-end (10-Gbps copper-

2-12

iSCSI)

DW-F800-4HF32R Front-end (32/16-Gbps

2-12

4port-FC)

DW-F800-1HP8 PCIe channel board 2

DW-F800-PC1F PCIe cable (1.5m) 2

DW-F800-BS12G Disk board 0-4

DW-F800-BS12GE Encryption disk board 0-4

DW-F800-1PS16 SFP for 16 Gbps Shortwave 0-48

DW-F800-1PL16 SFP for 16 Gbps Longwave 0-48

DW-F800-1PL32 SFP for 32 Gbps Longwave 0-48

DW-F800-BAT Battery 0-6

Note:

1. A DIMM of a particular capacity cannot be mixed with dierent capacities in a

storage system conguration.

Hitachi Virtual Storage Platform F700 Hardware Reference Guide 42

Appendix A: Storage system parts list

Page 43

Table 7 DBF drive tray components

Model number Part description Quantity

DW-F800-DBF 2U chassis 1

ENC 2

Power supply unit 2

Front bezel (2U) 1

DW-F800-RRDBF Rail kit 1

Table 8 DBF optional drive tray components

Model number Part description Quantity

VSP F700 parts list

DKC-F810I-3R2FN 3.5 TB, MLC 12 Gbps, ash

module drive

DKC-F810I-7R0FP 7 TB, MLC/TLC 12 Gbps,

ash module drive

DKC-F810I-14RFP 14 TB, MLC/TLC 12 Gbps,

ash module drive

Table 9 DBS drive tray components

Model number Part description Quantity

DW-F800-DBSC 2U chassis 1

ENC 2

AC Power supply unit 2

Front bezel (2U) 1

DW-F800-RRDB Rail kit 1

0-12

0-12

0-12

Hitachi Virtual Storage Platform F700 Hardware Reference Guide 43

Appendix A: Storage system parts list

Page 44

Drive tray and drive

Table 10 DBS optional drive tray components

Model number Part description Quantity

conguration

DKC-F810I-960MGM 960 GB, MLC, 12 Gbps, SFF,

ash drive

DKC-F810I-1R9MGM 1.9 TB, MLC/TLC, 12 Gbps,

SFF, ash drive

DKC-F810I-3R8MGM 3.8 TB, MLC/TLC, 12 Gbps,

SFF, ash drive

DKC-F810I-7R6MGM 7.6 TB, TLC, 12 Gbps, SFF,

ash drive

DKC-F810I-15RMGM 15 TB, TLC, 12 Gbps, SFF,

ash drive

Table 11 Optional service processor

Model number Part description Quantity

HDW2-F850-SVP.P Service processor

(Windows 10 Enterprise)

0-24

0-24

0-24

0-24

0-24

1

Drive tray and drive configuration

The following table lists the supported maximum installable drive trays and data drives

for the VSP F700 storage system.

Number of mountable drive trays

Controller

chassis

CBL DBS 36 864 N/A

Drive trays Maximum

DBF 36 N/A 432

Data and power cable model list

The following tables list the data and power cables available to the storage system.

Maximum number of mountable

drives

Solid-state

drive

Flash module

drive (FMD)

Hitachi Virtual Storage Platform F700 Hardware Reference Guide 44

Appendix A: Storage system parts list

Page 45

Data and power cable model list

Table 12 Power cables

Model number Specification

DW-F800-J1K 2.5 m, 2-pole power cable with grounding

terminal (AC 125 V, 13 A or 15 A)

DW-F800-J2H 2.5 m, 2-pole power cable with grounding

terminal (AC 250 V, 13 A or 15 A)

DW-F800-J2H5 5.0 m, 2-pole power cable with grounding

terminal (AC 250 V, 13 A or 15 A)

DW-F800-J2H10 10.0 m, 2-pole power cable with

grounding terminal (AC 250 V, 13 A or 15

A)

A-F6516-P620 Power cable for PDU (1)

A-F6516-P630 Power cable for PDU (1)

Table 13 SAS cables

Model number Specification

DW-F800-SCQ1 1 m SAS cable, including omega clip (2)

DW-F800-SCQ1F 1.5 m SAS cable, including omega clips (2)

DW-F800-SCQ3 3 m SAS cable, including omega clips (2)

DW-F800-SCQ5 5 m SAS cable, including omega clips (2)

DW-F800-SCQ10A 10 m SAS optical cable

DW-F800-SCQ30A 30 m SAS optical cable

DW-F800-SCQ1HA 100 m SAS optical cable

Hitachi Virtual Storage Platform F700 Hardware Reference Guide 45

Appendix A: Storage system parts list

Page 46

Data and power cable model list

Table 14 Optical cables

Model number Specification

A-6515-GM5L 5 m LC-LC optical cable for optical

A-6515-GM10L 10 m LC-LC optical cable for optical

A-6515-GM20L 20 m LC-LC optical cable for optical

A-6515-GM30L 30 m LC-LC optical cable for optical

A-6515-GM40L 40 m LC-LC optical cable for optical

A-6515-GM50L 50 m LC-LC optical cable for optical

A-6515-GM1JL 100 m LC-LC optical cable for optical

A-6515-GS10L 10 m LC-LC optical cable for optical

A-6515-GS20L 20 m LC-LC optical cable for optical

A-6515-GS30L 30 m LC-LC optical cable for optical

A-6515-GS50L 50 m LC-LC optical cable for optical

A-6515-GS1JL 100 m LC-LC optical cable for optical

A-6515-HM5L 5 m LC-LC optical cable for optical

A-6515-HM10L 10 m LC-LC optical cable for optical

A-6515-HM20L 20 m LC-LC optical cable for optical

A-6515-HM30L 30 m LC-LC optical cable for optical

A-6515-HM50L 50 m LC-LC optical cable for optical

A-6515-HM100L 100 m LC-LC optical cable for optical

A-6515-HM200L 200 m LC-LC optical cable for optical

A-6515-HM300L 300 m LC-LC optical cable for optical

A-6515-JM5L 5 m LC-LC optical cable for optical

A-6515-JM10L 10 m LC-LC optical cable for optical

A-6515-JM20L 20 m LC-LC optical cable for optical

A-6515-JM30L 30 m LC-LC optical cable for optical

A-6515-JM50L 50 m LC-LC optical cable for optical

A-6515-JM100L 100 m LC-LC optical cable for optical

A-6515-JM200L 200 m LC-LC optical cable for optical

Hitachi Virtual Storage Platform F700 Hardware Reference Guide 46

Appendix A: Storage system parts list

Page 47

Data and power cable model list

Model number Specification

A-6515-JM300L 300 m LC-LC optical cable for optical

Hitachi Virtual Storage Platform F700 Hardware Reference Guide 47

Appendix A: Storage system parts list

Page 48

Appendix B: System specifications

The mechanical, electrical, and environmental specications of the storage system are

listed.

VSP F700 mechanical specifications

The following tables list the system specications for VSP F700.

CBL controller chassis

Item Specification

Physical dimension

(W x D x H) (mm)

Weight/Mass (kg)

(Approximate)

Start-up time (min)

Required height

(EIA unit)

Heat output (W) 338 W

Power consumption (VA) 363 VA

Air ow (m3/min)

Notes:

1. The start-up time might be longer in proportion to the number of drive trays

2. Can be mounted on the RKU rack. For the mounting, special rails for the rack and

3. The value is at maximum level.

2

connected. With a maximum conguration 1 controller chassis and 19 drive trays,

start-up time is approximately 8 minutes.

decoration panels are required separately depending on the number of the

mounted storage systems.

1

3

483 × 808.1 × 174.3 mm

29.8 kg

5 to 10 (min)

4U

6.0 (m3/min)

Hitachi Virtual Storage Platform F700 Hardware Reference Guide 48

Appendix B: System specications

Page 49

Drive chassis

VSP F700 mechanical specications

Item Component Specification

Physical dimension

(W x D x H) (mm)

Weight/Mass (kg)

(Approximate)

Start-up time (min)

1

DBF 483 × 762 × 87 mm

DBS 482 × 565 × 88.2 mm

DBF 19.3 kg

DBS 17 kg

DBF 5 to 10 (min)

DBS 5 to 8 (min)

Required height

(EIA unit)

2

DBF 2U

DBS

Heat output (W) DBF 120 W

DBS 116 W

Power consumption (VA) DBF 130 VA

DBS 126 VA

Air ow (m3/min)

3

DBF 1.6 (m3/min)

DBS 2.2 (m3/min)

Notes:

1. The start-up time might be longer in proportion to the number of drive trays

connected. With a maximum conguration 1 controller chassis and 19 drive trays,

start-up time is approximately 8 minutes.

2. Can be mounted on the RKU rack. For the mounting, special rails for the rack and

decoration panels are required separately depending on the number of the

mounted storage systems.

3. The value is at maximum level.

Hitachi Virtual Storage Platform F700 Hardware Reference Guide 49

Appendix B: System specications

Page 50

Drive type

VSP F700 mechanical specications

Item Specification

Supported data

945.23, 1890.46, 3780.92, 7561.85, 15048.49 GB (SSD)

capacity

3518.43, 7682.17, 15364.35 GB (FMD)

Maximum storage

11,824 TiB (using 15 TB SSD)

system capacity

(physical capacity)

Maximum mountable

quantity (unit)

1

Maximum number of

spare drives

2

5,530 TiB (using 14 TB FMD)

12 (total per chassis) 432 (maximum per system)

48

Note:

1. When mounting storage system and DBF drive trays, the maximum mountable

quantity (unit) may vary.

2. Available as spare or data disks.

Host interface

Item Specification

Interface type 16/32 Gbps FC (Optical)

10 Gbps iSCSI (Optical)

10 Gbps iSCSI (Copper)

Data transfer speed

(Max. speed for transfer to host)

400 Mbps (FC)

800 Mbps (FC)

1600 Mbps (FC)

3200 Mbps (FC)

1000 Mbps (iSCSI - Optical)

1000 Mbps (iSCSI - Copper)

Number of ports 16/32 Gbps FC (Optical): 64

10 Gbps iSCSI (Optical): 32

10 Gbps iSCSI (Copper): 32

Transferred block size 512

Hitachi Virtual Storage Platform F700 Hardware Reference Guide 50

Appendix B: System specications

Page 51

Item Specification

(bytes)

Maximum number of hosts via FC switch 255

VSP F700 mechanical specications

Maximum number of hosts via network

255

switch

Battery life

Storage system intake temperature CBL

Up to 75.2º F (24º C) 5 years

Up to 86º F (30º C) 5 years

Up to 93.2º (34º C) 4 years

Up to 104º (40º C) 3 years

RAID specications

Item Specification

RAID level

1

Flash drive mounted: 1/5/6

RAID conguration RAID1: 2D+2D, 4D+4D

RAID5: 3D+1P, 4D+1P, 6D+1P, 7D+1P

RAID6: 6D+2P, 12D+2P, 14D+2P

Maximum number of parity groups 288

Maximum volume size 3 TB (when using the LDEVs of other

Storage Systems: 4TB)

Maximum volumes/host groups and iSCSI

2048

targets

Maximum volumes/parity groups 2048

Note:

1. A storage system congured with RAID6, RAID 5, or RAID 1 provides redundancy

and enhances data reliability. However, there is still a possibility of losing data

caused by unforeseeable hardware or software failure. Users should always follow

recommended best practices and back up all data.

Hitachi Virtual Storage Platform F700 Hardware Reference Guide 51

Appendix B: System specications

Page 52

Internal logic specications (CBL)

Item Specification

Control memory Flash memory: 32 MB

L3 cache memory: 4 MB

SDRAM: 1 GB

Data assurance method Data bus: Parity

Cache memory: ECC (1 bit correction, 2 bit

detection)

Drive: Data assurance code

Cache specications

Item Specification

Electrical

specications

Capacity (GB per controller) 512 GB

Control method Read LRU/Write after

Battery backup Provided

Backup duration

*

Unrestricted (Saving to a nonvolatile

memory)

*

Non-volatile data in the cache memory is protected against sudden power failure. The

backup operation writes data into a cache, even if a power interruption occurs, and

transferred to the cache ash memory.

Insulation performance

Item Specification

Insulation withstand voltage AC 1,500 V (100mA, 1min)

Insulation resistance DC 500 V, 10 MΩ or more

Electrical specifications

The electrical input power specications for the storage systems are described in the

following table.

Hitachi Virtual Storage Platform F700 Hardware Reference Guide 52

Appendix B: System specications

Page 53

Environmental specications

Item Controller Drive tray

Input voltage (operable

voltage range) (V)

AC 200-240 +6%/-11% FMD tray: AC 200-240

+6%/-11%

Frequency (Hz) 50/60 ±1

Number of phases, cabling Single-phase with protective grounding

Steady-state current 100V/

200V1,

2

Current rating of breaker/

CBL: 4.0x2 FMD tray: 2.6x2/1.3x2

16.0 (each electrical)

fuse (A)

Heat value (normal) (kJ/h) CBL: 2810 or less FMD tray: 1520 or less

Steady-state power (VA/W)3CBL: 1600/1560 or less FMD tray: 520/490 or less

Power consumption (VA/W) CBL: 840/780 or less FMD tray: 440/420 or less

Notes:

1. The power current of Nx2 described in this table is required for a single power

unit.

2. If one power unit fails, another power unit requires electric current for the two

power units. Therefore, plan the power supply facility so that the current-carrying

capacity for one power unit can provide the total capacity for two power units.

3. This table shows the power requirement (100 V or 200 V) for the maximum

conguration . The actual required power might exceed the value shown in the

table when the tolerance is included.

Environmental specifications

The environmental specications for the storage systems are described in the following

table.

Temperature

Caution: The following storage system components are not supported in

high-temperature environments. Do not operate the following components at

temperatures of 40°C or higher:

■

Hitachi Vantara-provided service processor (SVP) server

■

First-generation FMDs (non-DC2 FMDs)

Hitachi Virtual Storage Platform F700 Hardware Reference Guide 53

Appendix B: System specications

Page 54

Environmental specications

State Controller FMD tray

Operating 50°F to 104°F

(10°C to 40°C)

Non-operating 14°F to 122°F

DKC-F810I-1R6FN/3R2FN/6R4FN/7R0FP/14RFP

drive is installed: 50°F to 104°F (10°C to 40°C)

14°F to 95°F (-10°C to 35°C)

(-10°C to 50°C)

Transport,

storage

Temperature

-22°F to 140°F

(-30°C to 60°C)

10°C or less

-22°F to 122°F (-30°C to 50°C)

change rate

(°C/h)

Humidity

State FMD tray

Operating (%) 8 to 80

Non-operating (%) 8 to 90

Transport, storage (%) 5 to 95

Maximum wet bulb temperature (°C) 29°C (non-condensing)

Vibration

State FMD tray

Operating

(m/s2)

2.5 or less (5 to 300Hz)

Within 5 seconds (resonance point: 10 Hz

or less)

Non-operating

(m/s2)

5.0 or less at (5 Hz to 300 Hz: no damage

to product)

9.8 (1.0 G): Ensure own safety with fall

prevention.

Within 5 seconds (resonance point: 10 Hz

or less)

Transport (packed)

5.0 m/s or less

(m/s2)

Hitachi Virtual Storage Platform F700 Hardware Reference Guide 54

Appendix B: System specications

Page 55

Impact

Environmental

specications

State CBL controller FMD tray

Operating

(m/s2)

Non-operating

(m/s2)

Transport (packed)

20 or less

(10 ms, half sine wave)

50 or less

(10 ms, half sine wave)

80 or less

(m/s2)

Tipping angle (°)

(Storage system tips over)

15° or less

(To be measured when installed on leveling bolts.)

Altitude

State Controller FMD tray

Operating

(m)

3,050

(Environmental

3,050 (Environmental temperature: 10°C to 28°C)

temperature: 10°C

to 28°C)

1

950

950 (Environmental temperature: 10°C to 40°C)

(Environmental

temperature: 10°C

to 40°C)

Non-

-60 to 12,000

operating

(m)

Note:

1. Meets the highest allowable temperature conditions and complies with ASHRAE

(American Society of Heating, Refrigerating and Air-Conditioning Engineers) 2011

Thermal Guidelines Class A3. The maximum value of the ambient temperature

and the altitude is from 40ºC at an altitude of 950m (3000 feet) to 28ºC at an

altitude of 3050m (1000 feet).

The allowable ambient temperature is decreased by 1ºC for every 175m increase

in altitude above 950m.

Gaseous contaminant

Avoid areas exposed to corrosive gas and salty air.

Hitachi Virtual Storage Platform F700 Hardware Reference Guide 55

Appendix B: System specications

Page 56

Environmental

specications

State Controller FMD tray

Operating Gaseous contamination should be within ANSI/ISA

S71.04-2013 G1 classication levels.

1

Non-operating

1

Recommends the data centers maintain a clean operating environment by

monitoring and controlling gaseous contamination.

Acoustic Noise

The acoustic level is measured under the following conditions in accordance with

ISO7779 and the value is declared based on ISO9296. In a normal installation area (data

center / general oce), the storage system is surrounded by dierent elements from the

following measuring conditions according to ISO, such as noise sources other than the

storage system (other devices), the walls and ceilings that reect the sound. Therefore,

the values described in the table do not guarantee the acoustic level in the actual

installation area.

■

Measurement environment: In a semi-anechoic room whose ambient temperature is

23ºC±2ºC.

■

Device installation position: The Controller Chassis is at the bottom of the rack and

the Drive Box is at a height of 1.5m in the rack.

■

Measurement position: 1m away from the front, rear, left or right side of the storage

system and 1.5m high (at four points).

■

Measurement value: Energy average value of the four points (front, rear, left and

right).

The recommendation is to install the storage system in a computer room in a data

center. It is possible to install the storage system in a general oce, however, take

measures against noise as required. When you replace an existing storage system with

another system in a general oce, especially note the following: The cooling fans in the

storage system are downsized to enhance the high density of the storage system. As a

result, the rotation number of the fan is increased than before to maintain the cooling

performance. Therefore, the rate of the noise occupied by high-frequency content is

high.

Hitachi Virtual Storage Platform F700 Hardware Reference Guide 56

Appendix B: System specications

Page 57

Environmental specications

State Controller DBS drive tray

Opera

ting

60 dB

(Environmental

60 dB (Environmental temperature 32°C or less)1, 2,

temperature 32°C or

1

less)

Non-

55 dB 55 dB

opera

ting

Notes:

1. The internal temperature of the system controls the rotating speed of the fan

module. Therefore, this standard value might be exceeded if the maximum load

continues under high-temperature environment or if a failure occurs in the

system.

2. Sound pressure level (LA) changes from 66 dB or 75 dB, according to the ambient

temperature, drive conguration, and operating status. Maximum volume can

reach 79 dB during maintenance procedure for a failed ENC or power supply.

3. Acoustic power level (LwA) measured by the ISO 7779 standard is 7.2 B. This value

changes from 7.2 B to 8.1 B, according to the ambient temperature, drive

conguration, and operating status.

3

State Controller FMD tray

Opera

ting

Non-

60 dB (Environmental

60 dB (Environmental temperature 32°C or less)1, 2,

temperature 32°C or

1

less)

55 dB (Environmental temperature 32°C or less)1, 2, 3 55 dB

opera

ting

Notes:

1. The internal temperature of the system controls the rotating speed of the fan

module. Therefore, this standard value might be exceeded if the maximum load

continues under high-temperature environment or if a failure occurs in the

system.

2. Sound pressure level (LA) changes from 66 dB or 75 dB, according to the ambient

temperature, drive conguration, and operating status. Maximum volume can

reach 79 dB during maintenance procedure for a failed ENC or power supply.

3. Acoustic power level (LwA) measured by the ISO 7779 standard is 7.2 B. This value

changes from 7.2 B to 8.1 B, according to the ambient temperature, drive

conguration, and operating status.

3

Hitachi Virtual Storage Platform F700 Hardware Reference Guide 57

Appendix B: System specications

Page 58

Noise Level

Environmental

State Condition

specications

Operating (Recommended) 90 dB or less

*

Note:

*

Fire suppression systems and acoustic noise:

Some data center inert gas re suppression systems when activated release gas from

pressurized cylinders that moves through the pipes at very high velocity. The gas exits

through multiple nozzles in the data center. The release through the nozzles could

generate high-level acoustic noise. Similarly, pneumatic sirens could also generate

high-level acoustic noise. These acoustic noises may cause vibrations to the hard disk

drives in the storage systems resulting in I/O errors, performance degradation in and

to some extent damage to the hard disk drives. Hard disk drives (HDD) noise level

tolerance may vary among dierent models, designs, capacities and manufactures. The