Page 1

INSTRUCTIONS-P

This

manual contains

W

ARNINGS and INFORMA

READ AND RETAIN FOR REFERENCE

ARTS LIST

IMPORTANT

TION

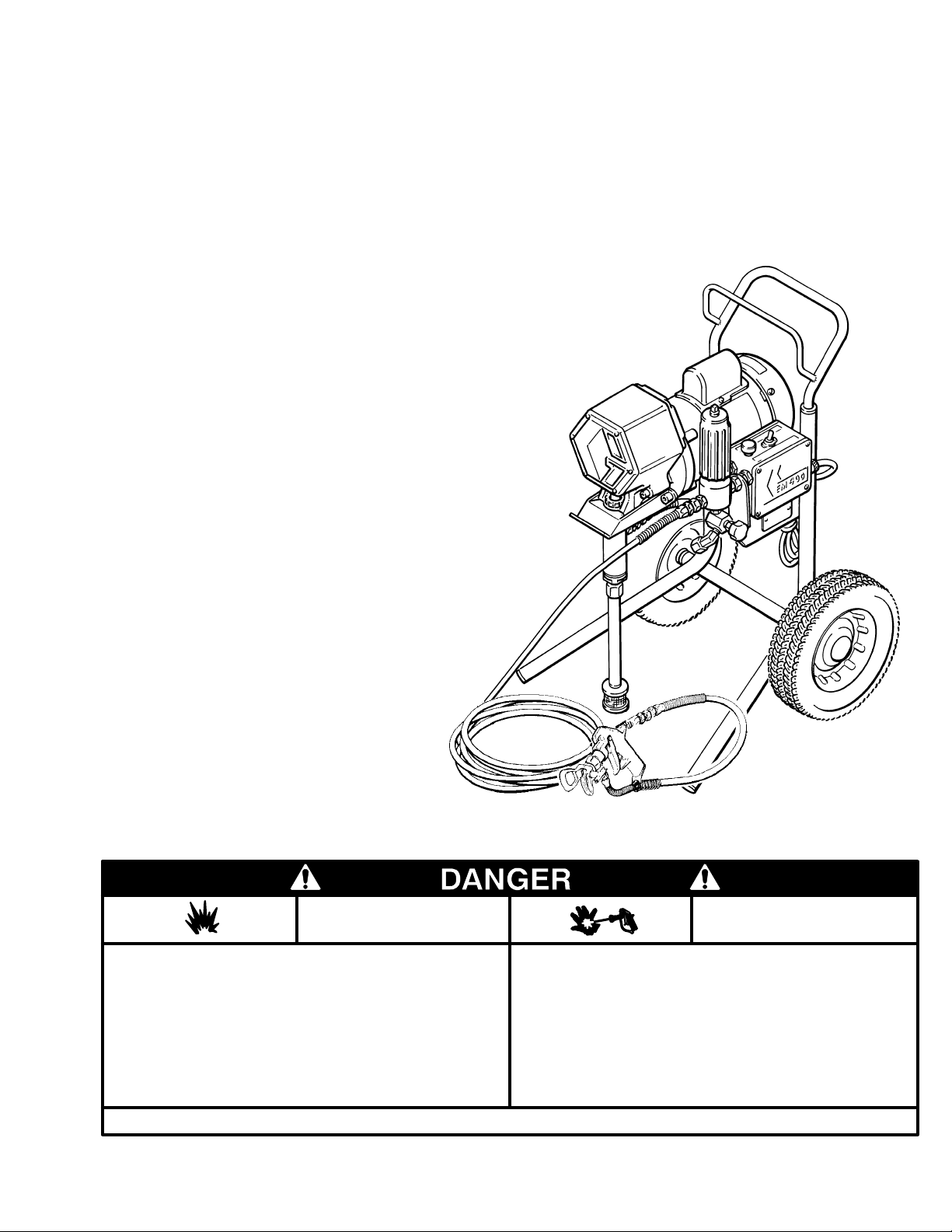

EM 490

PORTABLE/ELECTRIC

307–735

Rev G

Supersedes F

AIRLESS P

2750

psi (190 bar) MAXIMUM WORKING PRESSURE

AINT SPRA

Model 231–002, Series C

Basic

sprayer

, without hose or gun

Model 231–490

Complete sprayer with hose, “FLEX” gun, Reverse–A–

Clean

IV Dripless T

ip Guard, and 517 size SwitchT

ip

Model 220–679, Series C

Same

as Model 231–002 except has low–profile cart.

Model 231–050

Same

as Model 231–490 except has low–profile cart.

Warnings

English 2.

French (Avertissement) 4.

Spanish

Setup 8

Operation 19

Shutdown & Care 11.

Flushing

Application

Troubleshooting

Repair 16

Parts

Lists and Drawings

Accessories 30

Technical

Warranty Back Cover.

CONTENTS

. . . . . . . . . . . . . . . . . . . . . . . .

(Advertencia)6. . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

Guidelines

Methods

Guide

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

Data & Dimensions

. . . . . . . . . . . . . .

. . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . .

. . . . . . . . . . .

. . . . . . . . .

. . . . . . .

. . .

12.

13.

14.

24.

31.

YER

NOTE: This

is an example of the DANGER label on your sprayer

This label is available in other languages, free of charge.

See page 30 to order

.

FIRE

AND

EXPLOSION HAZARD

Spray

painting,

in confined areas can result in fire or explosion.

uids

Use outdoors or in extremely well ventilated areas. Ground equip

hoses, containers and objects being sprayed.

ment,

Avoid

all ignition sources such as

cloths,

open flames

arcs from

rettes,

light switches on and off.

ing

Failure

to follow this warning can result in death or serious injury

flushing or cleaning equipment with flammable liq

static electricity from plastic drop

such as pilot lights, hot objects such as ciga

connecting or disconnecting power cords or turn

READ AND UNDERSTAND ALL LABELS AND INSTRUCTION MANUALS BEFORE USE

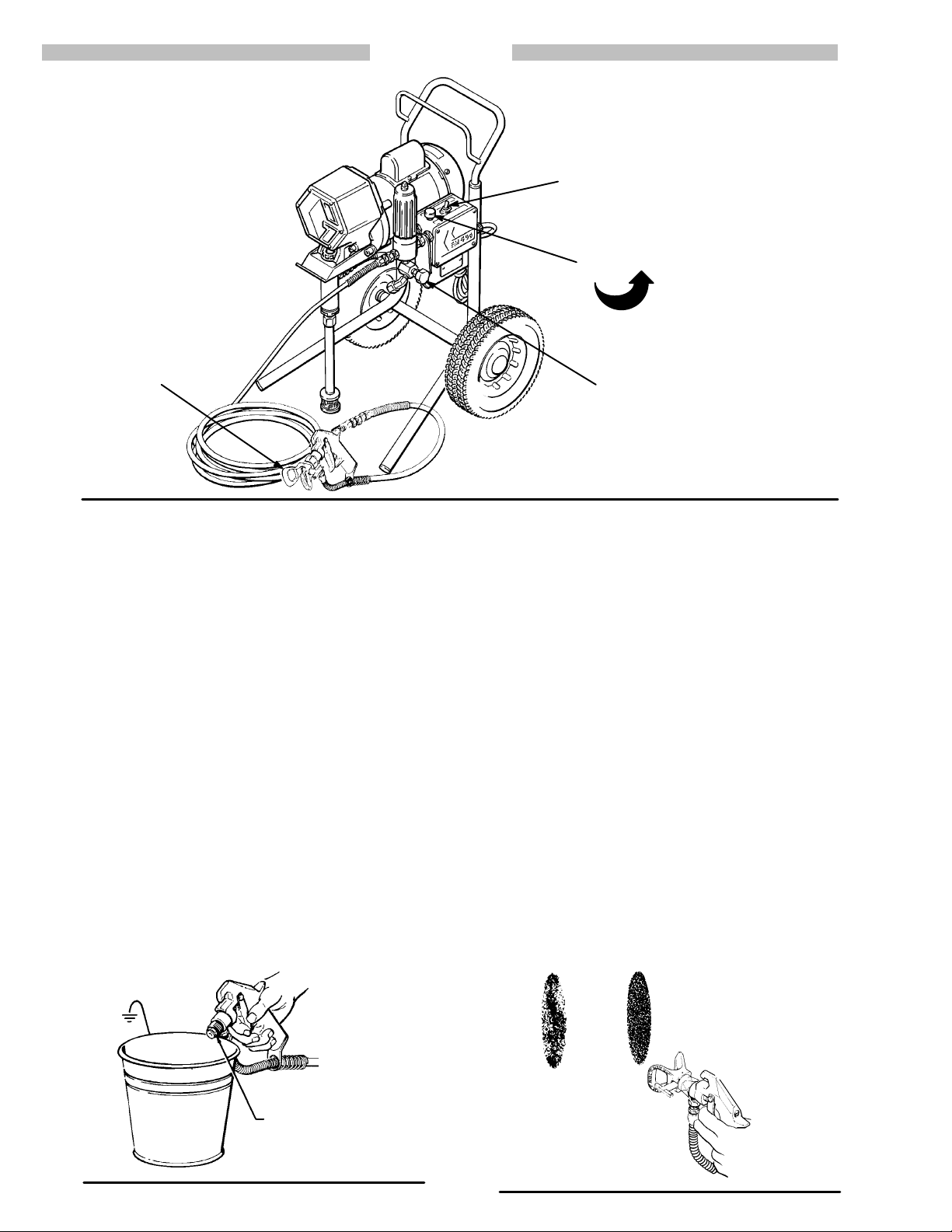

Model

231–490 shown

.

SKIN INJECTION

HAZARD

Liquids

-

-

-

-

.

can be injected into the body by high

or

leaks – especially hose leaks.

Keep

body clear of the nozzle. Never stop leaks with any part of the

body.

Drain all pressure before removing parts.A

gering

of gun by always setting safety latch when not spraying.

Never spray without a tip guard.

In case of accidental skin injection, seek immediate

“Surgical

Failure to follow this warning can result in amputation or serious

injury.

T

reatment”.

pressure airless spray

void accidental trig

-

Page 2

SAFETY

W

HIGH PRESSURE SPRAY CAN CAUSE SERIOUS INJURY.

FOR PROFESSIONAL USE ONLY. OBSERVE ALL WARNINGS.

Read and understand all instruction manuals before operating the equipment.

FLUID INJECTION HAZARD

General

This

the gun, leaks or ruptured components can inject fluid through

your

injury, including the need for amputation. Also, fluid injected or

splashed

NEVER

NEVER

to “blow back” paint; this is NOT an air spray system.

ALWAYS have the tip guard in place on the spray gun when

spraying.

ALWAYS

before cleaning or removing the spray tip or servicing any system equipment.

NEVER try to stop or deflect leaks with your hand or body

Be

each

Medical

If any fluid appears to penetrate your skin, get EMERGENCY

MEDICAL CARE AT ONCE. DO NOT TREAT AS A SIMPLE

CUT.

Spray

Be sure all gun safety devices are operating properly before

each

cause

Safety

equipment generates very high fluid pressure. Spray from

skin and into your body

into the eyes or on the

point the spray gun at any one or at any part of the body

put your

sure

equipment safety devices are operating properly before

use.

hand or fingers over the spray tip. NEVER try

follow the

PRESSURE RELIEF PROCEDURE

Alert––Airless Spray W

T

ell the doctor exactly what fluid was injected.

Note

to Physician

is important to treat the injury surgically as soon as possible.

Do not delay treatment to research toxicity. Toxicity is a

concern with some exotic coatings injected directly into the

blood

stream. Consultation with a plastic surgeon or reconstru

ctive

hand surgeon may be advisable

, and cause extremely serious bodily

skin can cause serious damage.

, below

ounds

:

Injection in the skin is a traumatic injury

.

.

. It

Gun Safety Devices

use. Do not remove or modify any part of the gun; this can

a malfunction and result in serious bodily injury

.

ARNINGS

Safety

Latch

Whenever

gun

inoperative.

triggering

Diffuser

.

The

jection when the tip is not installed. Check diffuser operation

regularly. Follow the PRESSURE RELIEF PROCEDURE, below,

ing

trigger the gun. If the fluid emitted

,

stream,

Tip

ALWAYS have the tip guard in place on the spray gun while

spraying. The tip guard alerts you to the fluid injection hazard

and

placing

tip.

Trigger

Always

to reduce the risk of accidentally triggering the gun if it is dropped

or

bumped.

Spray T

Use

-

spray tip

mediately. ALWAYS follow the PRESSURE RELIEF PROCE-

DURE,

NEVER

is

fully relieves and the gun safety is engaged.

you stop spraying, even for a moment, always set the

safety latch in the closed or “safe” position, making the gun

gun dif

then remove the spray tip. Aim the gun

the gun firmly to the pail. Using the lowest possible pressure,

Failure to set the safety latch can result in accidental

of the gun.

fuser breaks up spray and reduces the risk of fluid in

into a metal pail, hold

is

not

dif

replace the dif

fuser immediately

fused into an irregular

.

Guard

helps reduce, but does not prevent, the risk of accidentally

your fingers or any part of your body close

to the spray

Guard

have the trigger guard in place

on the gun when spraying

ip Safety

extreme caution when cleaning or changing spray tips. If the

clogs while spraying, engage the gun safety latch im

below, and then remove the spray tip to clean it.

wipe of

f build–up

around the spray tip until the pressure

-

-

-

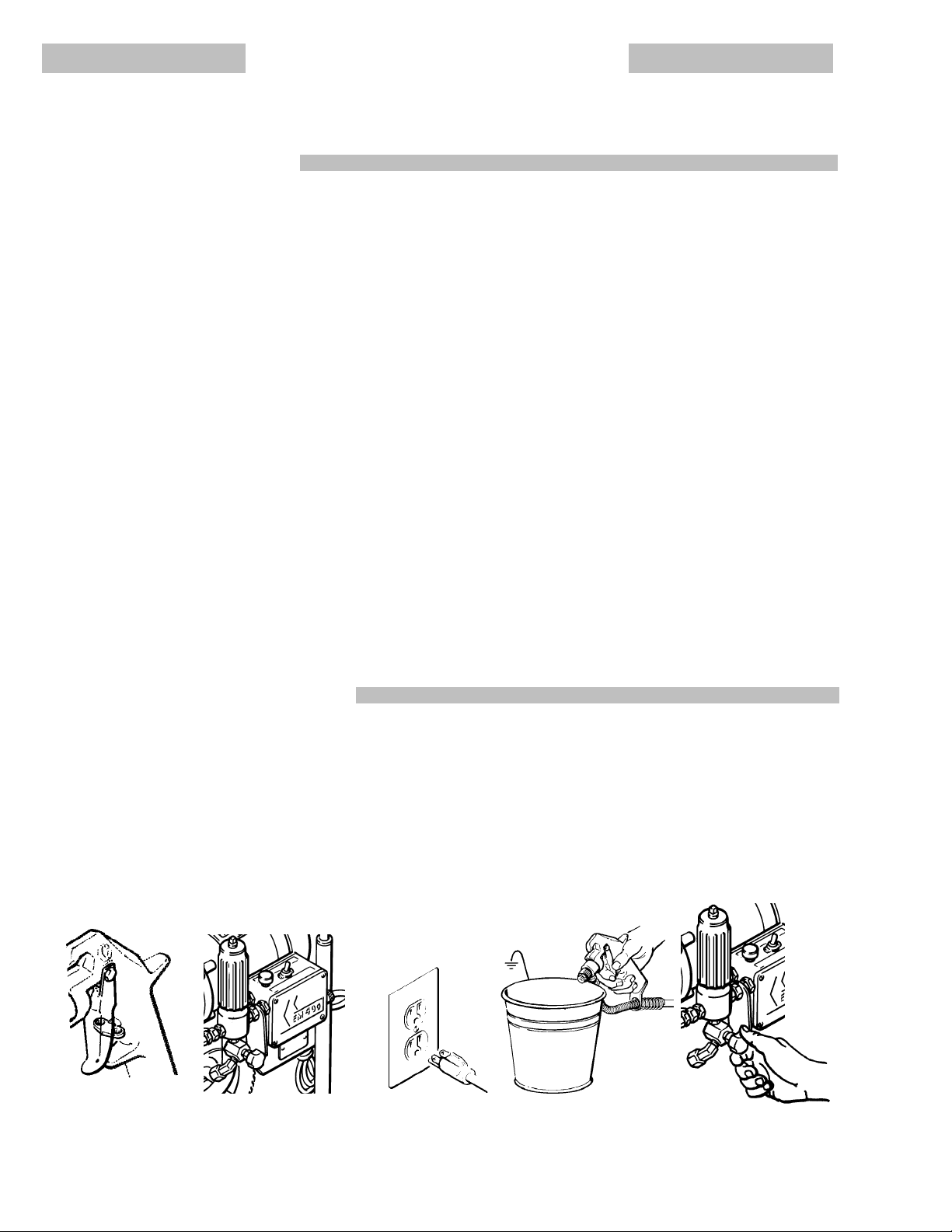

PRESSURE RELIEF PROCEDURE

To

reduce the risk of serious bodily injury

splashing

moving parts or electric shock, always follow this procedure

whenever

any

ing

1.

2. Turn the ON/OFF switch to OFF.

3.

fluid or

solvent in the eyes or on the skin, or injury from

you shut

part

of the spray system, when installing, cleaning or chang

spray tips, and whenever you stop spraying.

Engage the gun safety latch.

Unplug the power supply cord.

of

f the sprayer

1,4,5 2 3 4 6

, including fluid

, when checking or servicing

injection,

4. Disengage

firmly

to

relieve pressure.

5.

-

Engage the gun safety latch.

6. Open the pressure drain valve, having a container ready to

catch

to

spray again.

If you suspect

or that pressure has not been fully relieved after following the

steps

above,

or

hose end coupling to relieve pressure gradually

completely.

the gun safety latch. Hold a metal part of the gun

to the side of a

the drainage. Leave the valve open until you are ready

that the spray tip or hose is completely clogged,

VER

Now clear the tip or hose.

grounded metal pail, and trigger the gun

Y SLOWL

Y loosen the tip guard retaining nut

, then loosen

Page 3

MOVING PARTS HAZARD

Moving

parts can pinch or amputate

parts.

KEEP CLEAR of moving

the sprayer

before

it

from starting accidentally

. Follow the

checking or servicing any part

Pressure

.

your fingers or other body

parts when starting or operating

Relief Procedure

of the sprayer

on page 2

, to prevent

EQUIPMENT MISUSE HAZARD

General

Any misuse of the spray equipment or accessories, such as

overpressurizing, modifying parts, using incompatible chemicals

to

the

erty

NEVER

cause

CHECK

or

Always

as

System

This

ING

used

the

used

Fluid and Solvent Compatibility

All

with

31.

Do

logenated hydrocarbon solvents or fluids containing such solvents in this equipment, which contains aluminum and/or zinc

parts.

the possibility of explosion, which could cause death, serious

bodily

Safety

and fluids, or using worn or damaged parts, can cause them

rupture

and result in fluid injection, splashing in the eyes or on

skin, or other serious bodily injury

damage.

alter or modify any part of this equipment; doing so could

it to malfunction.

all spray equipment regularly and repair or replace worn

damaged parts immediately

wear protective

recommended by the fluid and solvent manufacturer

eyewear

, or fire, explosion or prop

.

, gloves, clothing and respirator

.

Pressure

sprayer can develop 2750

PRESSURE.

are rated to

maximum working pressure of any component or accessory

in the system.

chemicals used in the sprayer must be chemically

the wetted parts shown in the

Consult your chemical supplier to ensure compatibility

not use 1,1,1-trichloroethane, methylene chloride, other

Such use could result in

injury and/or substantial property damage.

Be sure all spray equipment and accessories

withstand the this pressure. DO NOT exceed

psi (190 bar)

TECHNICAL DATA on

a serious chemical reaction, with

MAXIMUM WORK

compatible

page

.

ha

HOSE SAFETY

High pressure fluid in the hoses can be very dangerous. If the

hose develops a leak, split or rupture due to any kind of wear,

damage

cause

erty

ALL

ENDS!

at

TIGHTEN all fluid connections securely before each use. High

pressure

sure

NEVER

hose for cuts, leaks, abrasion, bulging cover, or damage or

movement

replace

sure hose or mend it with tape or any other device. A repaired

hose

HANDLE AND ROUTE HOSES CAREFULLY. Do not pull on

hoses to move equipment. Keep hoses clear of moving parts

and

-

or solvents which are not compatible with the inner tube and

cover of the hose. DO NOT expose Graco hoses to temperatures

Hose Grounding Continuity

Proper hose grounding continuity is essential to maintaining a

grounded

fluid hoses at least once a week. If your hose does not have a

tag

tact the hose supplier or manufacturer for the maximum resis-

tance

your hose

recommended

poorly grounded hose can make your system hazardous. Also

read

or misuse, the high pressure spray emitted from it can

a fluid injection injury or other serious bodily injury or prop

damage.

FLUID HOSES MUST HA

The strain reliefs help protect the hose from kinks or bends

or close to the coupling which can result in hose rupture.

fluid can dislodge a loose coupling or allow high pres

spray to be emitted from the coupling.

use

a damaged hose. Before each use, check the entire

of the hose couplings. If any of these conditions

the hose immediately

cannot contain the high pressure fluid.

hot surfaces of the pump and gas engine. Do not use fluids

above 180 F (82 C) or below –40 F (–40

spray

system. Check the electrical resistance of your

on it which specifies the maximum

limits. Use a resistance meter in the appropriate range for

to check the resistance. If the resistance exceeds the

limits, replace it immediately

FIRE OR EXPLOSION HAZARD, below.

VE STRAIN RELIEFS ON BOTH

. DO NOT try to recouple high pres

C).

electrical resistance, con

. An ungrounded or

-

-

exist,

-

-

FIRE OR EXPLOSION HAZARD

Static

electricity is created by the flow of fluid through the pump

and hose. If every part of the spray equipment is not properly

grounded,

ardous.

a

power supply cord or using a gasoline engine. Sparks can ignite

fumes

and

doors

bodily injury and property damage. Always plug the sprayer into

an

outlet at least 20 feet

area.

area

If

you experience any static sparking or even a slight shock while

using

the entire system for proper grounding. Do not use the system

again

sparking may occur

Sparking may also occur when plugging in or unplugging

from solvents and the

other

flammable substances, whether you are spraying in

or outdoors, and can cause a fire or explosion and serious

Do not plug in or unplug any power supply cords in the spray

when there is any chance of igniting fumes still in the air

this equipment,

until the problem has been identified and corrected.

STOP

, and the system may become

fluid being sprayed, dust particles

(6 m) away from the sprayer and the spray

SPRA

YING IMMEDIA

TELY

haz

. Check

-

-

.

Grounding

To

reduce the risk of

other spray equipment used or located in the spray area.

CHECK

tions

all

1.

your local electrical code for detailed grounding instruc

for your area and type of equipment. BE SURE to ground

of this spray equipment:

Sprayer:

equipped

erly grounded outlet. Do not use an adapter. All extension

cords

plug the power supply cord, or extension cord – each

with an undamaged, three–prong plug,

must have three wires and be rated for 15 Amps.

static sparking, ground the sprayer and all

into a prop

-

-

IMPORTANT

2.

Fluid

hoses:

ft (150 m) combined hose length to ensure grounding continu

ity.

See

3.

Spray

grounded

4.

Object being sprayed:

5.

Fluid supply container:

6.

All

solvent pails used when flushing,

Use

only metal pails,

pail on a non–conductive surface, such as paper or cardboard,

To maintain grounding continuity when flushing or relieving

7.

pressure

of

a grounded metal pail, then trigger the gun.

Flushing

Reduce

by following the flushing procedure given on page 12 of this

ing

manual. Follow the PRESSURE RELIEF PROCEDURE on

page

2, and remove the spray tip before flushing. Hold a metal

part

of the gun firmly to

the

lowest possible fluid pressure during flushing.

use only grounded hoses with a maximumf 500

Hose Grounding Continuity

gun:

obtain grounding through connection

fluid hose and sprayer

according to local code.

according to local code.

which are conductive. Do not place the

which interrupts the grounding continuity

,

always hold a metal part

on page 3.

.

according to local code.

of the gun firmly to the side

Safety

the risk of fluid injection injury

the side of a grounded metal pail and use

, static sparking, or splash

to a properly

.

-

-

United

States Government safety standards have been adopted

under the Occupational Safety and Health Act.

– particularly the General Standards, Part 1910, and the Construction

Standards, Part 1926 – should be consulted.

These

standards

Page 4

AVERTISSEMENT

La

pulvérisation à haute pression peut causer de blessures très graves.

Réservé exclusivement à l’usage professionnel. Observer toutes les consignes de sécurité.

Bien lire et bien comprendre tous les manuels d’instructions avant d’utiliser le matériel.

RISQUES D’INJECTION

Consignes

Cet

appareil produit un fluide à très haute pression. Le fluide pul

vérisé

ou

de ruptures peut pénétrer sou la peau ou à

et

entraîner des blessures très

tion. Même sans être sous pression, le fluide éclaboussant ou

entrant

NE

JAMAIS pointer le pistolet vers quelqu’un ou vers une partie

quelconque

sur

l’ajutage

la

peinture. Cet appareil N’est P

que.

TOUJOURS garder la protection de l’ajutage en place sure le

pistolet

TOUJOURS observer la Marche à Suivre Pour Détendre la

Pression

tage du pulvérisateur, ou d’effectuer un travail quelconque sur

une

partie de l’appareil.

NE

JAMAIS essayer d’arrêter ou de dévier

ou

le corps.

Avant

curité

Soins

En

cas de pénétration de fluide sous la peau:

MEDIATEMENT DES SOINS MÉDICAUX D’URGENCE. NE

PAS SOIGNER CETTE BLESSURE COMME UNE SIMPLE

COUPURE.

Avis

un

traumatisme.

cette blessure immédiatement.

ment

vêtements exotiques sont dangereusement

sont injectés directement dans le sang. Il est souhaitable de

consulter

sé

dans la reconstruction des mains.

Dispositifs de sécurité du pistolet

Avant chaque utilisation, bien s’assure que tous les dispositifs

sécurité du pistolet fonctionnent correctement. Ne pas enle

de

ver

ni modifier une partie quelconque du pistolet; ceci risquerait

d’entraîner un mauvais fonctionnement et des blessures graves.

générales de sécurité

par le pistolet ou le fluide

dans les yeux peut

du corps. NE JAMAIS mettre le main

du pulvérisateur

pendant la pulvérisation.

donnée plus loin,

chaque utilisation, bien s’assurer que les dispositifs de sé

fonctionnent correctement.

sous pression provenant de fuites

graves, voir même une amputa

aussi entraîner des blessures graves.

. NE JAMAIS essayer de “refouler”

AS un compresseur pneumati

avant

de nettoyer ou d’enlever l’aju

l’intérieur du corps

ou les doigts

le fuites avec la main

médicaux

DEMANDER IM

au médecin:

pour effectuer des recherches sur la toxicité. Certains re

un chirurgien

La pénétration des fluides sous la peau est

Il est important

de traiter chirurgicalement

Ne pas retarder le traite-

toxiques quand ils

esthétiques ou un chirurgien spéciali

Verrou

-

-

de sécurité

A

chaque fois que l’on s’arrête de pulvériser

court

instant, toujours mettre le verrou

la position, “fermée” ou “sécurité” (“safe”), pour empêcher le pis

tolet

de fonctionner

tolet

peut se déclencher accidentellement.

. si le verrou de sécurité

, même s’il s’agit

de sécurité du pistolet sur

n’est pas mis, le pis

Diffuseur

Le

dif

fuseur du pistolet sert à diviser le jet et à réduire les risques

d’injection

fier

-

rification,

Pour

du

pulvérisateur

maintenant

sion

Si le fluide projeté

remplacer

Protection

TOUJOURS

pistolet du pulvérisateur pendant la pulvérisation. La protection

-

de

l’ajutage attire l’attention sur les risques d’injection let contri

bue à réduire, mai n’évite pas le risque, que les doigts ou une

partie quelconque du corps ne passent accidentellement à

proximité

-

accidentelle quand l’ajutage n’est pas en place. Véri

le fonctionnement du dif

détendre la pression en observant la

Détendre la Pression donnée plus

. Pointer le pistolet dans un seau en métal, en le

fermement contre le seau. puis, en utilisant la pres

la plus faible possible, appuyer sur la gâchette du pistolet.

n’est pas

immédiatement le dif

fuseur régulièrement. Pour cette vé

dif

fusé sous forme de jet irrégulier

fuseur.

Marche à Suivre

loin enlever l’ajutage

de l’ajutage

maintenir la protection de l’ajutage en place sur le

immédiate de l’ajutage du pulvérisateur

.

Consignes de sécurité concernant l’ajutage

du pulvérisateur

Faire extrêmement attention à l’occasion du nettoyage ou due

remplacement des ajutages du pulvérisateur. Si l’ajutage se

bouche

pendent la

rou

-

-

-

de sécurité du pistolet. T

à

Suivre Pour Détendre la Pression

pulvérisateur

NE JAMAIS essuyer ce qui s’est accumulé autour de l’ajutage

du pulvérisateur avant que la pression ne soit complètement

tombée

et que le verrou de sécurité du pistolet ne soit engagé.

pulvérisation, mettre immédiatement le ver

pour le nettoyer

OUJOURS bien observe la

.

puis

enlever l’ajutage du

d’un

-

-

-

-

,

-

-

Marche

MARCHE

Pour

réduire

sures

sures

ment, toujours bien

que

l’on arrête le

Égale

ajutages.

1. Engager

2.

Mettre le levier d’arrêt du moteur sur ARRET (OFF).

3.

Débrancher le cord d’alimentation.

À SUIVRE POUR DÉTENDRE LA PRESSION

les risques de blessures graves, y compris les bles

par projection de fluide ou celles causées par de éclabous

dans les yeux ou sur la peau, par des pièces en mouve

ou du nettoyage du système ou lors du changement des

le verrou de sécurité du pistolet.

observe cette marche à suivre chaque fois

pulvérisateur

, à l’occasion de la vérification, du

1,4,5 2 3 4 6

-

4. Désengager

nant

-

-

une partie métallique du pistolet fermement appuyé con

tre

le côte d’un seau en métal, actionner le pistolet pour

la

pression.

5.

Engager le verrou de sécurité du pistolet.

6. Ouvrir

que

l’on soit prêt à se servir de nouveau du pulvérisateur

Si

l’on soupconne que le tuyau ou l’ajutage est complètement bou

ché

o

u qu

avoir procédé aux opérations ci–dessus, desserrer TRES LEN

TEMENT

protection

le verrou de sécurité du pistolet. T

la soupape de sécurité et la laisser

e l

a p

ressio

n n

’

a p

a

s é

t

é c

omplètemen

un

raccord de bout de tuyau ou l’écrou de retenue de la

de l’ajutage et libérer progressivement la pression.

out en mainte

ouverte jusqu’à ce

t l

ibéré

libérer

e

après

-

-

.

-

-

Page 5

RISQUES

Consignes

toute utilisation anormale de l’appareil du pulvérisation ou des

accessoires comme, par exemple, la mise sous une pression

excessive, les modifications de pièces, l’utilisation de produits

chimiques

usées ou abîmées peut causer des dégâts à l’appareil ou des

ruptures

tres

blessures sérieuses, un incendie, une explosion ou

dégâts.

Toujours

ments protecteur et un dispositif pour

dant

aux recommandations des fabricants de fluides et

EN CAS DE MAUV

AISE UTILISA

TION DU MATERIAL

générales de sécurité

et de matières incompatibles et l’utilisation de pièces

de pièces et entraîner une injection de liquide ou

porter une protection pour les yeux, de

la respiration correspon

gants, des vête

d‘au

d’autres

solvants.

Pression

Ce

pulvérisateur peut produire une

TRAVAIL

du

la

passer

accessoires

Compatibilité

BIEN

chimiquement

dans les “Données techniques”, à page 31. Toujours lire soigneusement les documents et brochures du fabricant des fluides et solvants utilisés avant de s’en servir dans ce pulvérisateur.

Le

dangereux.

rupture

tion,

peuvent

peau

190 bar (2750 lb/po.

pulvérisateur et ses accessoires sont conçus pour résister à

pression maximum de

la pression maximum de travail d’aucun des éléments ou

utilisés avec cet appareil.

travail de ce pulvérisateur

chimique des corps

S’ASSURER que tous les corps des solvants utilisés sont

fluide à haute pression circulant dans les tuyaux peut être très

les projections de fluide haute pression qui en proviennent

ou par contact, ainsi que des dégâts matériels.

compatibles avec les parties mouillées indiquées

En cas de fuite sur le tuyau, de fissure, déchirure ou

à la

suite de l’usure, de dégâts ou d’une mauvaise utilisa

entraîner des blessures

PRESSION MAXIMUM DE

)

S’assurer que tous les éléments

. NE P

AS dé

graves par pénétration sous la

TOUS

LES TUY

SORTS

les

boucles

rupture

SERRER

-

tion.

ré ou produire un jet à haute pression s’échappant par le raccord.

-

NE

-

refaire le raccord d’un tuyau haute pression ni de réparer le

tuyau

réparé

MANIPULER

SOIGNEUSEMENT

en

ne sont pas compatibles avec l’enveloppe intérieur ou extérieure

de

supérieures

SPIRALE

de protection contribuent à éviter la formation de pliures, de

ou de nœuds sur les tuyaux qui pourraient entraîner la

du tuyau à l’endroit du raccord ou à son voisinage.

Le fluide sous

JAMAIS utiliser un tuyau endommagé. NE PAS essayer de

avec du ruban adhésif ou par tout autre moyen. Un tuyau

ne peut pas résister au fluide sous pression.

tirant sur le tuyau. Ne pas utiliser de fluides ou de solvants que

tuyau. NE P

Continuité

Une

bonne continuité de la mise à la terre des tuyaux est essen

tielle

pour maintenir la mise à la terre de l’ensemble de

tion.

Vérifiez la résistance

à

air

, au moines une fois par semaine. Si votre tuyau ne

te

pas d’étiquette qui précise la

prenez

contact avec le fournisseur de tuyaux ou la fabricant

avoir

les limites de résistance maximum. Utilisez un

sistance

résistance.

placez

avec une mise à la terre incorrecte peut entraîner des risques

pour votre système. Lisez aussi LES RISQUES D’INCENDIE

OU D’EXPLOSION.

de

le tuyau immédiatement. Un tuyau sans mise à la terre ou

AUX FLEXIBLES DOIVENT AVOIR DES RES

DE PROTECTION AUX 2 BOUTS!

FERMEMENT tous les raccords avant chaque utilisa

pression peut faire sauter un raccord desser

LES TUY

AS exposer le tuyau à fluides des températures

à 82C (180F) ou inférieures à –40C (–40

AUX A

VEC

LEUR CHEMIN. Ne pas déplacer le fluide

PRECAUTION ET CHOISIR

de la mise à la terre des tuyaux

électrique de vos tuyaux à fluides et

résistance électrique maximum,

la gamme appropriée pour votre tuyau et vérifiez la

Si celle–ci dépasse les

limites recommandées, rem

mètre de ré

Les spira

F).

vaporisa

compor

pour

-

-

-

-

-

-

-

-

-

RISQUES

De l’électricité statique est produite par le passage du fluide à

grande

pièces de l’appareil de pulvérisation ne sont pas convenablement

se

produire et l’appareil risques d’être dangereux. Des étincelles

peuvent

du débranchement du cordon d’alimentation ou de l’utilisation

d’un

moteur à essence. Les étincelles sont suf

mer

les vapeurs de solvants et le fluide pulvérisé, les fines particu

les de poussière ainsi que d’autres substances inflammables,

quand

causer un incendie ou une explosion, ainsi que des blessures

graves

teur

dans une prise se trouvant

pareil

ou débrancher un cordon d’alimentation quel qu’il soit dans la

zone

ds

vapeurs encore présentes dans l’air prennent feu.

S’il

se

sentez

PULVERISATION.

soit

identifié et corrigé.

Mise

Pour réduire les risques de production d’étincelles d’électricité

statique, le pulvérisateur et tous les équipement utilisés ou se

trouvant

re ou à la masse. Pour connaître le détail des instructions de

mise

CONSULTER le code ou les réglementations électriques locales.

S’ASSURER que tous le équipements de pulvérisation

vants

D’INCENDIE OU D’EXPLOSION

vitesse dans la pompe et dans les tuyaux. Si toutes les

reliées ou à la masse ou à la terre, des étincelles peuvent

Également

on pulvérisé à l’intérieur ou à l’extérieur

et des dégâts matériels. T

et de l’endroit où se fait la pulvérisation. Ne pas brancher

où se fait la pulvérisation quand il y

produit des étincelles d’électricité statique, ou si vous res

la moindre décharge,

à la terre ou à la masse

dans la zone de pulvérisation doivent être reliés

à la terre dans la région et le type particulier d’équipement,

sont bien reliés à la terre:

se produire à l’occasion du branchement ou

fisantes pour allu

à au moins 6 m (20 pieds) de l’ap

ARRETEZ IMMEDIA

Vérifiez que le

, et elles

oujours brancher le pulvérisa

a le moindre risque que

système avant que le problème

peuvent

TEMENT LA

à la ter

sui

1.

Pulvérisateur:

rallonge

état,

dans une prise de courant convenablement mis à la ter

re. Ne pas utiliser d’adapteur. Toutes les rallonges doivent

avoir

3 fils et être prévues pour 15 ampères.

2.

Pistolet:

tuyau

-

-

3.

-

-

4.

5.

6.

-

7.

-

flexible et à une pulvérisateur déjà convenablement re

liés

à la terre.

Tuyaux flexibles:

terre,

n’utiliser que des tuyaux comportant une mise à la

et ayant une longueur maximum combinée de 150 m (1500

pieds). Se reporter également au paragraphe, “Continuité

du

circuit de mis à la terre des tuyaux”.

Récipient

tions

locales.

Objets,

ver

le code ou les réglementations locales.

Tous

le seaux de solvant

code

ou les réglementations

métallique

sur

une surface non

carton

Pour

conserver la continuité de la mise à la terre quand on rin

cé

le

matériel ou quand on libère la pression,

nir

une

le côté d’un

tre

pistolet.

Mesures

Pour

réduire les risques de blessures

et les risques dûs aux étincelles d’électricité statique ou aux

éclaboussures,

née

à la page 12 de ce manuel.

Brancher le cordon d’alimentation ou la

qui doivent être équipes d’une prise à 3 fiches en bon

Réaliser la mise à la terre en le raccordant à une

Afin d’assurer la continuité de la mise à la

d’alimentation:

observer le code

ou les réglementa

matériel ou surfaces recevant la pulvérisation:

utilisés pour le rinçage: observer le

conducteurs de l’électricité. Ne pas mettre le seau

conductrice comme sur du papier ou du

car cela interromprait la continuité de la mise à la terre.

partie métallique du pistolet fermement appuyée con

seau

locales.

en métal

N’utiliser que des seaux

toujours mainte

puis appuyer sur la détente du

de Sécurité concernant le Rinçage

par pénétration de la peau

observe la marche à

suivre pour le rinçage don

terre

obser

-

-

-

-

-

-

-

-

Page 6

ADVERTENCIA

EL

ROCIADO A ALTA PRESION PUEDE CAUSAR GRA

SOLO P

PELIGRO

Seguridad

Este

equipo general un fluido a una presión muy

de

la pistola, los escapes de fluido

pueden

tremadamente

putación. También, el fluido inyectado o salpicado en los ojos

puede causar graves daños.

NUNCA

po.

NUNCA colocar la mano o los dedos encima de la boquilla.

NUNCA

ma

de rociado de aire.

SIEMPRE

mientras

SIEMPRE seguir el procedimiento de descarga de presión,

dado

vicio

a cualquier del sistema.

NUNCA

cuerpo.

Asegurar

funcionando

Tratamiento

Si pareciera que un poco de fluido penetró la piel, conseguir

TRATAMIENTO

TRAT

dico

exactamente cua fluido fue.

Aviso

causa

camente

tamiento

sumar

yectan

consultar

de

las manos.

DE INYECCION DE FLUIDO

general

inyectar fluido en la piel y el cuerpo y causar lesiones ex

graves, incluyendo a

apuntar la pistola hacia alguien o alguna

tratar de “hacer retornar la pintura”; este NO

tener colocado el protector de

se está pulverizando.

más abajo,

tratar de parar o desviar los escapes con la mano o el

AR LA HERIDA COMO UN SIMPLE CORTE.

al médico:

una lesión traumática.

importancia en algunas pinturas exóticas cuando se

directamente

antes

que todos los aparatos de seguridad del equipo están

bien antes de cada uso.

médico

MEDICO DE URGENCIA DE INMEDIATO. NO

la lesión a la brevedad posible.

para investigar la toxicidad. La toxicidad es algo de

a un especialista

PROCEDIMIENTO

Para

reducir el riesgo de sufrir graves

yendo

la inyección de fluidos, salpicaduras en los ojos o la piel,

o lesiones causadas por piezas en movimiento, siempre seguir

este procedimiento al apagar la máquina pulverizadora, al revi

ajustar o limpiar el sistema, o al cambiar las boquillas.

sar,

1. Enganchar

2.

Mover el interruptor de parada del motor a OFF

Desenchufar el cordón eléctrico.

3.

4.

Desenganchar el pestillo

ner

de

un

sión.

el pestillo de seguridad de la pistola.

una parte metálica de la pistola firmemente contra el lado

balde de metal y activar la pistola para descargar la pre

ARA USO PROFESIONAL. RESPECTE LOS A

Lea y entienda todo el manual de instrucciones antes de manejar el equipo.

alta. El rociado

o roturas de los componentes

veces la necesidad de am

parte del cuer

es un siste

la boquilla en la pistola

de limpiar o sacar la boquilla o de dar ser

Decir al mé

Si se llega a inyectar este fluido en la piel se

Es importante tratar quirúrgi

No demorar el tra

in

al torrente sanguíneo. Sirá conveniente

en cirugía plástica o reconstructiva

DE DESCARGA DE PRESION

lesiones corporales, inclu

.

de seguridad de la pistola. Mante-

VES LESIONES.

VISOS DE ADVERTENCIA.

Aparatos

Asegurar

funcionando

-

guna

to

-

de la misma con las consiguientes lesiones personales.

Pestillo

Cada vez que se deje de pulverizar, aunque sea por un breve

-

momento, siempre colocar el pestillo de seguridad en la posición “cerrada”, lo que deja la pistola inoperante. El no hacerlo

-

puede

de seguridad de la pistola pulverizadora

que todos los aparatos protectores de

bien antes de

pieza de la pistola pues podría causar el malfuncionamien

cada uso. No sacar ni modificar nin

la pistola están

de seguridad

llevar al disparo imprevisto de la pistola.

Difusor

El difusor de la pistola dispersa el chorro pulverizado y reduce

riesgo de inyección cuando no está instalada la boquilla. Revi

el

sar

-

-

-

-

-

-

-

-

con regularidad el funcionamiento del difusor

cedimiento

pués sacar la boquilla. Apuntar la pistola a un balde metálico,

sosteniéndola

posible, disparar la pistola.

jo

en

un chorro irregular

Protector

SIEMPRE

mientras

contra el peligro de inyección y ayuda a reducir, pero no evita,

la

colocación accidental de los dedos o cualquier otra parte del

cuerpo

Seguridad

Tener

ra

a obstruirse mientras está pulverizando, enganchar el pestillo

de

la pistola de inmediato. SIEMPRE

de descarga de presión

piarla

NUNCA

antes de

lla

el

pestillo esté enganchado.

5. Volver

6. Abrir

se

Si

se sospecha que la boquilla o la manguera esté completamente

obstruida,

pués

LENTAMENTE

ca

de renención del protector de lay punta y descargar

mente la presión.

de descarga de presión,

bien firme contra él. Utilizando la presión más ba

Si el fluido emitido

, reemplazar de inmediato el difusor

dado más

de la boquilla

tener el protector de la

se está pulverizando. Este protector llama la atención

cerca de la boquilla.

boquilla colocado en la pistola

de la boquilla pulverizadora

mucho cuidado al limpiar o cambiar las boquillas. Si llega

y después sacar la boquilla para lim

limpiar la acumulación de pintura alrededor de la boqui

que se haya descargado por completo la presión y

a enganchar el pestillo de seguridad de la pistola.

la válvula de alivio de presión y dejarla abierta hasta que

esté nuevamente listo para pulverizar

o que no se ha descargado por completo la presión des

d

e h

abe

r s

eguido

e

l p

un adaptador de extremo de la manguera o la tuer

rocedimient

seguir el

o a

. Seguir el

abajo, y des

no sale disperso

procedimiento

.

nterior

, a

floja

r

gradual

-

-

-

pro-

-

-

.

-

-

-

-

MUY

-

-

1,4,5 2 3 4 6

Page 7

PELIGRO

Seguridad

Cualquier

como

riales

zas dañadas o desgastadas, puede hacen que se rompan y

causen

incendio,

Siempre

piradero, tal como recomiendan los fabricantes del fluido y del

solvente.

SEGURIDAD

El

fluido que escapa a alta presión por las mangueras puede ser

muy

peligroso. Si en la manguera se desarrola un escape, una

rotura o rajadura debido a cualquier tipo de desgaste, daño o

maltrato, el chorro a alta presión emitido por allí puede causar

una lesión por inyección u otras lesiones corporales graves o

daños

¡TODAS LAS MANGUERAS PARA FLUIDOS TIENEN QUE

TENER GUARDAS DE RESORTE EN AMBOS EXTREMOS!

Estas

en

los acoplamientos o cerca de ellos, los

se

en roturas de la manguera.

Antes

El fluido a lata presión puede desalojar un acoplamiento suelto

o

dejar que pro él escape un chorro a alta presión.

NUNCA

en

busca de cortaduras, escapes, abrasión, cubierta abultada,

acoplamientos

quiera

ra.

NO intentar reacoplar una manguera de alta presión o enmen

darla

ha

sido remendada no aguante el fluido al alta presión.

POR MAL USO DEL EQUIPO

general

mal uso del equipo pulverizador o

sobre presurización, modificación de piezas,

y

productos químicos incompatibles, o utilización de pie

la inyección de fluido u otras

explosión o daños a la propiedad.

usar gafas, guantes, vestimentas protectoras y un res

lesiones corporales graves,

los accesorios, tal

uso de mate

EN EL USO DE LAS MANGUERAS

a la propiedad.

protegen las mangueras contra dobleces o retorceduras

de usarlas, APRET

usar una manguera que está

de estas condiciones, reemplazar de inmediato la

con

sueltos o dañados. Si llegara a encontrarse cual

cinta adhesiva u otro material similar

AR bien firmes todas las conexiones.

que podrían traducir

dañada. Siempre revisarla

mangue

. Una manguera que

o

Presión

Esta pulverizadora puede desarrollar 190 barías (2750 psi) de

-

PRESION

-

pulverizador

tar

sorio

Compatibilidad de fluido

Siempre

antes

MANEJAR

No

o

solventes que sean incompatibles con el

bierta

ras

Continuidad

del sistema

DE TRABAJO MAXIMA.

la

presión máxima de trabajo de ningún componente o acce

tirar de las mangueras para mover el equipo.

sobre 82

y sus accesorios tienen la capacidad para aguan

de este sistema.

leer las instrucciones del fabricante del fluido y solvente

de usarlos en esta pulverizadora.

Y P

ASAR CUIDADOSAMENTE LAS

de la manguera. NO exponer las mangueras a temperatu

) C

(180_F) o bajo -40

Asegurar que todo el equipo

MANGUERAS.

No usar fluidos

tubo interno y la cu

_C (-40_

F).

del circuito de puesta a tierra de la

guera

La

continuidad del circuito de puesta a tierra

cial para mantener conectado a tierra el sistema pulverizador.

-

Es

indispensable revisar la resistencia eléctrica máxima de las

mangueras

Si

la manguera no tiene una etiqueta en la cual se especifica la

resistencia

veedor o fabricante de la manguera para la información sobre

los

límites de resistencia. Usar

ma

apropiada para comprobar la resistencia; si

recomendados, reemplazarla de inmediato. Es muy arriesgado

-

tener

-

en

-

malas

GO DE INCENDIO O EXPLOSION

de aire y de fluido por lo menos una vez a la semana.

eléctrica máximum, ponerse

un metro de resistencia en la ga

una

manguera sin puesta a tierra o con la puesta a tierra

condiciones. Leer también la información sobre

, más arriba.

apropiado es esen

en contacto con el pro

excede los lites

man

RIES-

-

-

-

-

-

-

-

-

PELIGRO

El

flujo a alta velocidad del fluido al pasar por la bomba y mangue

ra

crea electricidad estática. Si todas las partes del equipo pulve

rizador

do al sistema en algo peligroso. También, pueden producirse

chispas

un

motor de gasolina. Estas chispas pueden inflamar los vapores

de

los solventes y el chorro de fluido pulverizado, partículas de

polvo

lo

que podría causar una explosión o incendio y graves lesiones

corporales

zadora a un tomacorriente que se encuentre a por lo menos 6

m

(20 pies) de la máquina y del área

far

o desenchufar ningún cordón eléctrico en el lugar donde se

está rociando cuando todavía exista la posibilidad de que que

den

vapores inflamables en el aire.

Si

ocurre una chispa de electricidad estática o incluso un ligero

choque

RIZAR

tierra

cado

Puesta

Para

pulverizadora y todo el otro equipo de pulverizar que se use o

se

encuentre en el lugar que se va a rociar

go

eléctrico de la localidad para las instrucciones sobre las

nexiones

RAR

1.

Pulverizadora:

cada

tomacorriente con puesta a tierra apropiado. No usar un

adaptador.

hilos

DE INCENDIO O EXPLOSION

no tienen buena tierra, pueden ocurrir chispas, convirtién

al enchufar o desenchufar el cordón eléctrico o al

y otras sustancias inflamables, sea al aire libre o bajo techo,

y daños a la propiedad. Enchufar siempre la pulveris

que se va a rociar

eléctrico mientras se usa el equipo, DEJAR DE

DE INMEDIATO. Revisar todo el sistema en busca de una

apropiado. No usar

y solucionado el problema.

de nuevo el sistema hasta haber identifi

a tierra

reducir el riesgo

a tierra exigidas para la zona y tipo de equipo. ASEGU

de conectar a tierra todo este equipo pulverizador:

uno con un enchuf de tres patas en buen estado, a un

T

y una capacidad de 15 amperios.

de chispas estáticas, conectar a tierra la

. CONSULTAR el códi

enchufar el cordón eléctrico, o cable estensor

otos los cables extensores tienen que tener tres

usar

. No enchu

PUL

VE-

co

-

2.

Mangueras para fluidos:

-

-

-

-

-

-

puesta a tierra de una longitud combinada de 150 m (500

pies), para asegurar buena continuidad a tierra. Referirse

también

ra.

Pistola:

3.

ra

4.

Suministrar un recipiente:

solamente

car el balde en una superficie no conductiva, como papel o

cartón,

5.

Objeto que se está rociando:

local.

Todos los baldes de solvente

6.

conformidad

7.

Para

carga de presión,

pistola bien firme contra el costado de

pués

al párrafo

hacer la puesta a tierra conectándola a una mangue

de fluido y pulverizadora bien conectadas a tierra.

sobre

baldes de metal,

que interrumpe la continuidad a tierra.

con el código local.

mantener la continuidad a tierra

siempre apoyar una parte metálica de la

apretar el gatillo.

usar solamente mangueras con

continuidad a tierra de la mangue

de acuerdo al código local. Usar

que sean

de conformidad con el código

usados durante el lavado, de

conductivos. No colo

durante el lavado o des

balde de metal

Seguridad durante el lavado

Para

reducir el riesgo de que se inyecte o salpique fluido en

piel,

o que ocurra una descarga de electricidad estática, siempre

seguir las INSTRUCCIONES PARA EL LAVADO, dadas en la

-

-

,

12. Seguir el

página

en la página 6, y quitar la

baja

posible de fluido durante el lavado.

procedimiento de descarga de presión

boquilla de metal

y usar le presión más

-

-

-

-

, des-

la

Page 8

SETUP

WARNING

If

you are supplying your own hoses and spray

be sure the

the

gun has a tip guard, and that each part is rated

for at least

Pressure

injury caused by static sparking, fluid injection or

over-pressurization

To avoid damaging the pressure control, which

may result in poor equipment performance and

component

1. Always use nylon spray hose at least 50 ft.

(15.2

2. Never

as

3. Never

ter

4. Always

eration.

1. Connect the hose and gun

a. Remove

b. Connect the 3 ft (0.9 m) hose between the main

c. DO

hoses are electrically conductive, that

2750 psi (190 bar) Maximum Working

.

This is to reduce the risk of serious

and rupture of the hose or

CAUTION

damage, follow these precautions.

m) long.

use a wire braid hose; it is too

a pulsation dampener

install any shutof

and the main hose.

use the main filter outlet for one gun op

Never plug this outlet.

.

f device between the

See Fig 1.

bodily

rigid to act

(See Fig 1)

the plastic cap plug from the filter outlet

nipple and screw the 50 ft. (15.2 m) main fluid

hose

onto the nipple.

hose and the gun inlet adapter

fluid

NOT

use thread sealant, and DO NOT install

the

spray tip yet!

.

gun,

gun.

fil

4. Be

5.

-

6. Flush the pump

-

sure your system is properly grounded before

operating it. Read and follow the warning section,

FIRE

OR EXPLOSION HAZARD

Plug in the sprayer

a.

Be sure the ON/OFF switch is OFF

b. Plug

c. Do

was left in the pump to protect it from rust.

a. Before

b. Before using oil-base paint, flush with mineral

c. See FLUSHING GUIDELINES, on page 12, for

the power supply cord into a grounded

outlet that is at least 20

trical

the

spray area to reduce the chance of a spark ig

niting

the spray vapors.

not remove the third prong of

ply

cord plug, which is the grounding prong,

do

not use an adapter

to remove the lightweight oil which

using water-base paint, flush with

spirits,

followed by a soapy water flush, and

flush

with clean water

spirits,

only

.

flushing procedure.

the

.

.

, on page 3.

.

See Fig 1.

elec

ft (6 m) aways from

the power sup

and

mineral

then

-

-

-

2. Fill the packing nut/wet–cup 1/3 full with Graco

Throat

Seal Liquid (TSL), supplied.

3.

Check the electrical service

a. Be

b. DO

c. Use

sure the electrical service

15 Amp (minimum), and that the outlet you use

properly grounded.

is

NOT remove the grounding prong of the

and

do not use an adapter

a grounded extension

having a 12 gauge size, and a maximum length

of

200 ft (61 m). Longer lengths or smaller gauges

may

af

fect sprayer performance.

See Fig 1.

is 120 V

.

cord which has 3 wires

, 60 HzAC,

plug,

7. Prepare the paint according to the manufacturer’s

recommendations.

a. Remove

b.

Stir the paint to mix pigments.

c. Strain the paint through a fine nylon mesh bag

(available at most paint dealers) to remove particles

probably

free

any skin that may have formed.

that could clog the filter or spray tip. This is

the most important step toward trouble-

spraying.

Page 9

DO

NOT INST

A SHUT OFF

DEVICE HERE

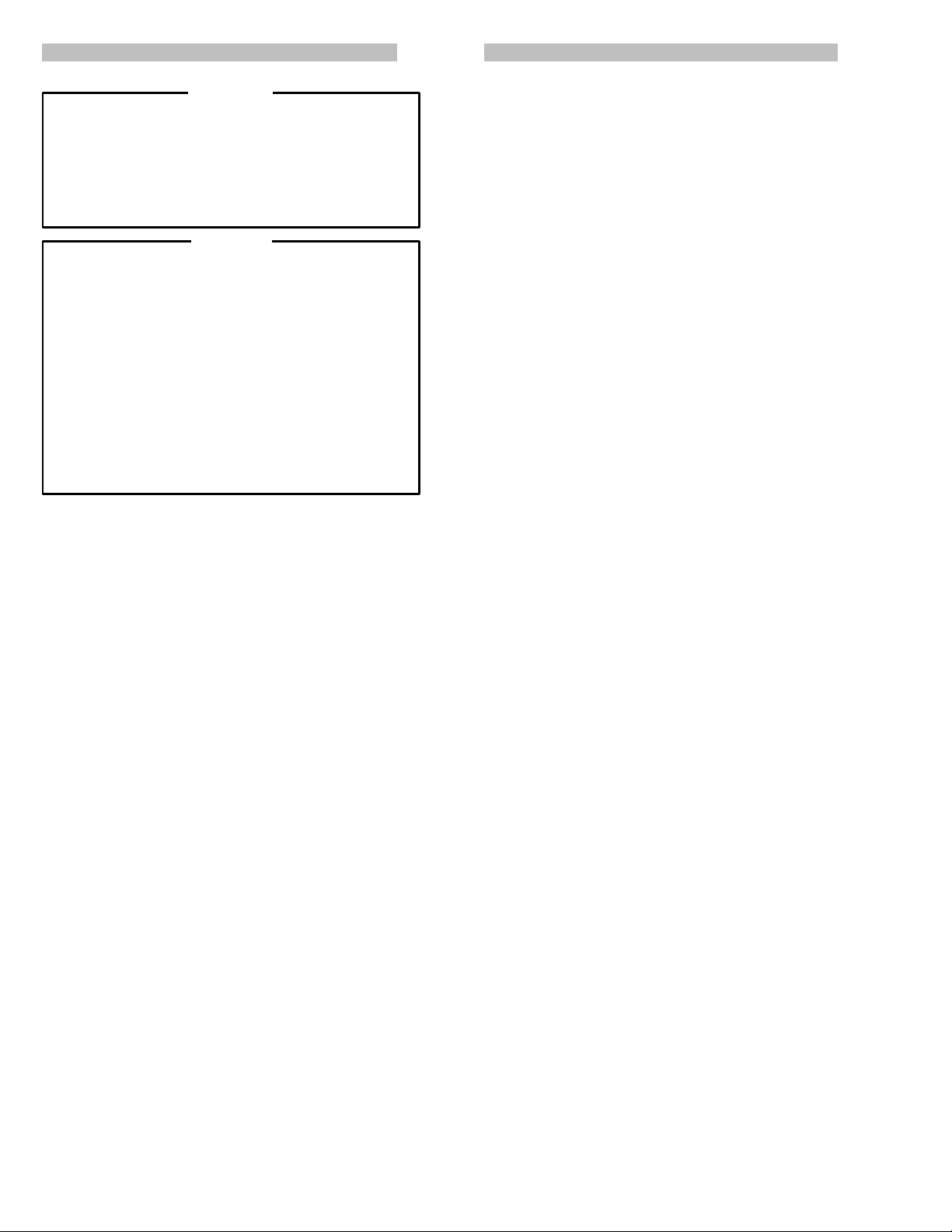

SETUP

FILTER

ALL

ON/OFF SWITCH

Fig

1

PACKING

MAIN FLUID HOSE

NUT/WETCUP

Keep filled with TSL

50 ft. (15.2 m)

PRESSURE CONTROL KNOB

3 ft (0.9 m) HOSE

RAC IV DripLess TIP GUARD and SwitchT

ip

OPERATION

WARNING

Pressure Relief Procedure

To

reduce the risk of serious bodily injury

jection;

moving

splashing in the

eyes or on the skin; injury from

parts or electric shock, always

cedure whenever you shut off the sprayer, when

checking or servicing any part of the spray system,

when installing, cleaning or changing spray tips, and

whenever

1.

2. T

3.

4. Disengage

you stop spraying.

Engage the gun safety latch.

urn the ON/OFF switch to OFF

Unplug the power supply cord.

the gun safety

latch. Hold a metal part

of the gun firmly to the side of a grounded metal

pail,

and trigger the gun to relieve pressure.

, including

follow this pro

.

in

5.

Engage the gun safety latch.

-

6. Open

the pressure drain valve, having a container

ready to catch the drainage. Leave the pressure

-

valve open

drain

sprayer

If

you suspect that the spray tip or hose is completely

clogged,

ter

following the steps above,

the

tip guard retaining nut or hose end coupling and re

again.

or that

until you are ready to operate the

pressure has not been fully relieved af

VER

Y SLOWL

lieve pressure gradually. Then loosen the nut completely.

Now clear the tip or hose obstruction.

-

Y

loosen

-

Page 10

OPERATION

RAC

IV DripLess

TIP GUARD and

SwitchTip

Fig 2

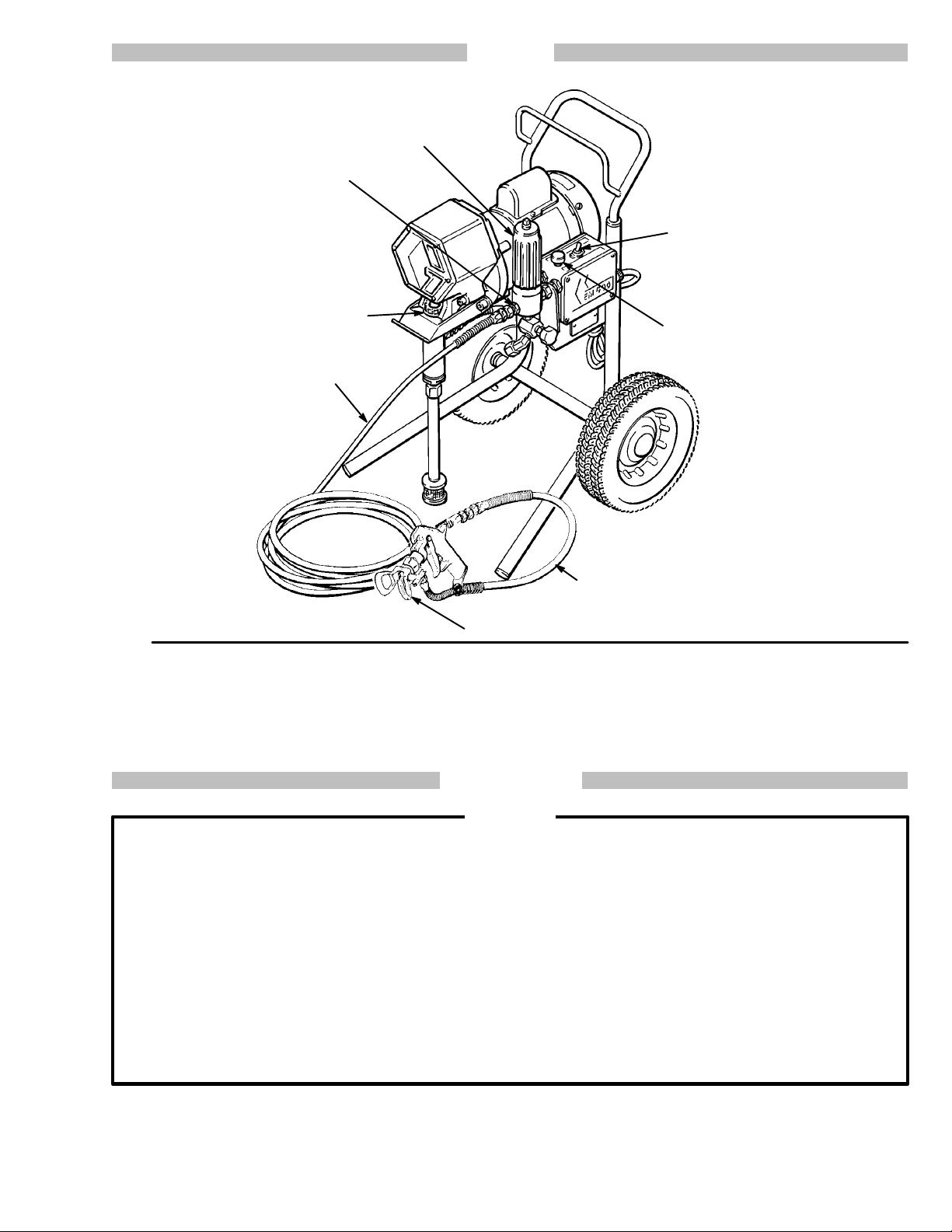

1. Prime

the sprayer with paint.

a.

Close the pressure drain valve.

b.

Don’t install the spray tip yet!

c.

Put the suction tube into the paint container

d. Turn the pressure adjusting knob all the way

counterclockwise

e.

Disengage the gun safety latch.

f.

Hold a metal part of the gun firmly against and

to lower the pressure

aimed into a grounded metal waste container.

See

Fig 3.

Squeeze the trigger and hold it open,

turn the sprayer ON, and slowly increase the

pressure

gun

setting until the sprayer

triggered until all air is forced out of the sys

starts. Keep the

tem and the paint flows freely from the gun. Release

the trigger and engage the gun safety

NOTE: If

the pump is hard to prime, place a container un

der

the pressure drain valve and open the valve.

When fluid comes from the valve, close it. Then

disengage

Step

the gun safety

1f, above.

latch and proceed as in

.

latch.

g. Check

sure

before tightening connections.

ON/OFF

all fluid connections for

SWITCH

PRESSURE CONTROL KNOB

PRESSURE DRAIN V

2. Install the spray tip and tip guard

a.

Be sure the gun safety latch is engaged.

b. Install the spray tip. If using the RAC IV, refer to

manual 307–848, supplied with the gun, for installation

instructions.

3. Adjusting the spray pattern

a.

Increase

the

the pressure setting just until spray from

gun is completely atomized. To avoid

sive overspray and fogging, and to decrease tip

wear and extend the life of the sprayer, always

use the lowest possible pressure needed to get

the

desired results.

-

b. If more coverage is needed, use a larger tip rather

than

increasing the pressure.

c. Test the spray pattern. To adjust the direction of

-

the spray pattern, engage the gun safety latch

and loosen the retaining nut. Position the tip

guard

horizontally for a horizontal pattern or verti

for a vertical

cally

ing

nut.

pattern. Then tighten the retain

TURN CCW T

LOWER PRESURE

O

ALVE

leaks; relieve pres

(Refer to Fig 4. )

exces

-

-

-

-

GROUND

WIRE

Fig 3

MAINTAIN

METAL-TO-METAL

CONT

GUN AND GROUNDED

MET

FIRM

ACT BETWEEN

AL CONT

AINER

SPOTTY

PATTERN

–

INCREASE

PRESSURE

Fig

4

GOOD

FULL

PATTERN

Page 11

OPERATION

4. Cleaning a Clogged Tip

WARNING

reduce the risk of serious bodily injury from injec

To

tion,

use extreme

ing

spray tips. If the

caution when cleaning or chang

spray tip clogs while spraying,

engage the gun safety latch immediately, then follow

the procedure in Steps 4a to 4e, below

.

NEVER wipe off buildup around the spray tip until

pressure

is fully relieved and the gun safety latch is

engaged.

a. Clean

eration.

use

a solvent–soaked brush to clean the tip and

front of the tip frequently

First relieve pressure; see page 9. Then

during op

the

to reduce fluid build up and tip clogging.

b. If

the spray tip does

and engage the gun safety latch.

ger,

clog,

release the gun trig

c. If using the RAC IV Spray Tip Kit, rotate the

RAC IV handle 180.

gun

safety latch. T

See Fig 5.

Disengage the

rigger the gun into a grounded

waste container. Engage the gun safety latch

again.

Return the handle to

the original position.

If

using a spray tip kit which is not self-clean

ing,

VER

Y SLOWL

ing

nut or hose coupling to

-

-

ually, then loosen the part completely. Clear the

tip

or hose, and then reassemble it.

Y loosen the tip guard retain

relieve pressure grad

-

-

-

d. Disengage the gun safety latch, and resume

spraying.

e. If

the tip is still clogged,

engage the gun safety

latch, shutoff and unplug the sprayer, and open

the

pressure drain valve to relieve pressure.

move

the spray tip and clean it.

f. Instructions

in

manual 307–848.

for cleaning

the RAC IV

Re

are given

-

-

-

ROTATE

HANDLE

180

Fig 5

SHUTDOWN

1. Check

pressure; see page 9. Be sure the wet–cup is 1/3 full

of

piston rod and premature wear of packings. The

packing nut should be tight enough to stop leakage,

but

excessive

2. Clean the fluid filter often and before storing the

sprayer.

ual 307–273, supplied, for the filter cleaning procedure.

3. Flush

fill it with mineral spirits to help prevent pump corrosion

page

Never

night

fluid

which

sprayer

Always

pressure

the packing nut/wet–cup daily. First relieve

TSL at all times

no tighter

packing wear

to help prevent fluid buildup on the

. Overtightening may cause binding and

.

See Fig 6.

First relieve pressure; see page 9. See man

the sprayer at the end of each work day

and

freezing. See

FLUSHING GUIDELINES

12.

CAUTION

leave water or any paint in the sprayer

to: (1) prevent pump corrosion;

(2) prevent the

over

from freezing in the pump and pressure control

can

cause loss of pressure, stalling or serious

damage.

use mineral spirits for the final flush, relieve

and leave the mineral spirits in the

sprayer

and

on

-

.

AND CARE

4. For very short shutoff periods, leave the suction

tube in the paint, relieve pressure, and clean the

spray

tip.

5. Coil

6. For the low–profile cart, use the brackets on the

-

Fig 6

the hose

ing

it, even for overnight, to

kinking,

side

of the cart to hold the suction assembly

and hang it on the hose rack when stor

help protect the hose from

abrasion, coupling damage, etc.

WARNING

Refer to the warning section HOSE SAFETY on

3 for information on the hazard of using dam

page

aged

hoses.

PACKING

Keep filled with TSL during

operation. Tighten nut by

NUT/WETCUP

turning clockwise

-

.

-

Page 12

FLUSHING GUIDELINES

NOTE: The Pressure Relief Procedure W

page

14.

arning

is on

When To Flush

CAUTION

NEVER leave water in the sprayer if there is the

slightest

with

control tube, it prevents the sprayer from being

started, and causes serious damage to the pressure

1. New

2. Changing Colors. Flush with a compatible solvent

3. Changing from water-base to oil-base paint.

4. Changing

5. Storage.

6.

change it could freeze. Flush out the

water

mineral spirits. If water freezes in the pressure

control.

Sprayer. The sprayer

oil,which was left in to protect the pump

weight

Before using water-base paint,

was factory tested in light

parts.

flush with mineral

spirits, followed by a soapy water flush, and then a

clean

water flush.

Before

its,

such

Flush

using oil-base paint,

only

.

as mineral spirits or water

with warm, soapy water

from oil-base

to water-base paint.

flush with mineral spir

.

, then mineral spirits.

Flush

with mineral spirits, followed by warm, soapy water,

and

then a clean water flush.

Water-base

paint:

Flush with water, and then miner

al spirits. Leave the pump, hose and gun filled with

mineral spirits. Shut off the sprayer and open the

pressure

Oil-base paint:

and

to

relieve pressure.

drain valve to relieve pressure.

Flush with mineral spirits. Shut off

unplug the sprayer, open the pressure drain valve

Startup after storage.

Before

al

When using oil-based paint,

spirits

using water-base paint

spirits with soapy water

with the paint to be sprayed.

SCREEN

,

flush out the miner

, and then with clean

flush out the mineral

water

How To Flush

1. Relieve

2. Remove the filter bowl and screen; see instruction

manual 307–273, supplied. Clean the screen separately

the

3.

Close the pressure drain valve.

4. Pour one–half gallon (2 liters) of compatible solvent

into

pail.

5. Remove

-

To reduce the risk of static sparking and splashing

when flushing, always remove the spray tip from

the gun, and hold a metal part of the gun firmly to

the

6. Disengage the gun safety latch. Point the gun into a

-

metal

touching

See Fig 8

sparking and splashing. Start the sprayer, trigger the

gun,

wise

until

trigger

7. Check all fluid connections for leaks. If any connections

tions.

leaks.

8. Remove

-

gun

the hose. Do not run the pump dry for more than 30

seconds

lieve pressure.

9. Leave the pressure drain valve open until you are

ready to use the sprayer again. Unscrew the filter

bowl and reinstall the clean screen. Reinstall the

bowl,

10. If

.

a

a

pressure.

and install the bowl, without the screen, to flush

bowl.

See Fig 7.

a grounded metal pail. Put

the suction tube in the

the spray tip from the gun.

WARNING

side of, and aimed into, a grounded metal pail

w

ast

e c

ontainer. Wit

the m

eta

l c

h m

ontainer

eta

l part o

, s

queeze th

f the gun f

e gun t

. This procedure reduces the risk of static

and s

lowl

y turn the p

just u

nti

l the pump s

c

lea

n s

olven

t c

and e

ngag

leak, first relieve pressure. T

Start the sprayer

ressur

e a

djustin

g knob c

tarts

. Keep the gun t

ome

s from the n

e the gun s

afet

y l

ozzle

atch.

. R

ighten the connec

. Recheck the connections for

the suction tube from the pail. Disengage the

safety latch. T

rigger the gun to force solvent from

to avoid damaging the pump packings! Re

hand tight only

you flushed with mineral spirits and are

.

going to use

water-base paint, flush with soapy water followed

clean water flush. Relieve pressure.

GROUND

WIRE

rigger.

riggered

eleas

irmly

locke t

he

by

-

-

Fig

7

FILTER

BOWL

PRESSURE

DRAIN

V

FILTER

SUPPORT

ALVE

Fig 8

MAINTAIN

METAL-TO-METAL

CONT

GUN AND GROUNDED

MET

FIRM

ACT BETWEEN

AL CONT

AINER

Page 13

APPLICATION METHODS

Always hold the gun perpendicular to the work surface

and

at an even12 to 14 in. (300–356 mm)

you

are spraying.

Begin

moving the gun in a horizontal direction at a steady

rate.

Start the spray stroke of

the

trigger as the gun is moving. Then, while the

moving,

surface, release the trigger. This method avoids excess

paint

and as you approach the other edge of the

buildup at the end of each stroke.

See Fig 9.

f the target surface and pull

CORRECT

from the surface

gun is still

work

The best way to control the rate of coverage is with the

gun

tip size. A small tip orifice applies less paint. A

tip

orifice applies more paint. The width of the pattern de

on the fan pattern of the tip you choose.

pends

Do not try to increase coverage by increasing the fluid

pressure!

desired

sprayer

For interior corners,

the

way, the edges on both sides are sprayed evenly.

See

Using the lowest pressure necessary to get the

paint atomization will help prolong the life of your

and minimize paint lost by overspray

aim the gun toward the center of

corner to be sprayed. By dividing the spray pattern this

Fig 1

1.

larger

.

-

Fig 9

Move

the gun at

to

be applied without runs or sags. Lap each stroke 50%

over

the previous stroke to produce a uniform paint thick

ness.

Spray in a uniform pattern alternately from right to

left and then left to right to get a professional finish.

See

Fig 10.

Fig 10

a speed that provides a full, wet coating

WRONG

Fig 11

-

If

there is a

minimize

Shrubs.

them

the area. Remove the dropcloth as soon as the area is

painted

Concrete

them

a

plastic dropcloth can be used.

Electrical outlets and lamps.

with

masking tape. Cover lamps with

with

masking tape.

Nearby

be sprayed. If there is a nearby home, make a

barrier

wind,

angle the spray pattern into the wind to

drifting. Paint from the ground to the roof.

Tie back shrubs with rope and stakes. Cover

with a canvas dropcloth as the painter

to prevent damage to the shrubs.

walks.

with a canvas dropcloth to avoid slipping. Otherwise

objects.

by hanging plastic between two long poles.

If the walkways will be walked on, cover

Protect electrical outlets

plastic bags secured

Move portable upwind of the surface to

approaches

protective

Page 14

TROUBLESHOOTING GUIDE

WARNING

Pressure

To

reduce the risk of serious bodily injury

injection,

from moving parts, always follow this procedure when

you

cleaning

1.

2. T

3.

Relief Procedure

, including fluid

splashing in the eyes or on the skin, or injury

shut of

f the sprayer

, when checking, adjusting

the system, and when changing spray tips.

Engage the gun safety latch.

urn the ON/OFF switch to OFF

.

Unplug the power supply cord.

or

4. Disengage

the gun safety latch. Hold a metal part

of the gun firmly to the side of a grounded metal

pail,

and trigger the gun.

5.

Engage the gun safety latch.

6. Open the fluid pressure drain valve and leave it

open

until you start the sprayer again.

If you suspect the hose or spray tip is completely

clogged

lowing

or that pressure is

the steps above,

not fully relieved after fol

VER

Y SLOWL

Y loosen the tip

-

guard retaining nut or hose end coupling and relieve

pressure

gradually

. Now clear the tip or hose.

Check everything in the chart before disassembling the sprayer

PROBLEM

Electric

motor won’t run

Electric

motor

stops while spraying

CAUSE SOLUTION

Power

cord or extension cord unplugged,

or

damaged, or building circuit breaker

fuse

has tripped

Motor overload switch1 has opened

Pressure setting too low

Pressure control frozen2 or damaged by

over–pressurization

Power

cord or extension cord unplugged,

or damaged, or building circuit or fuse is

blown

Motor overload switch1 has opened

Pressure setting too low

Spray tip or filter plugged

W

rong type extension cord

3

.

Check, reset or replace.

or

Unplug power supply cord, relieve pressure, allow motor to cool, decrease pressure.

Increase pressure.

Try

to thaw

Check,

Unplug power supply cord, relieve pressure, allow motor to cool, decrease pressure.

Increase pressure.

Remove and clean.

Use

grounded

, or replace pressure control.

reset or replace.

maximum 200 ft (61 m), 3 wires, 12 gauge,

extension cord.

Electric motor runs, but low paint

output

or no paint output;

or pump is not stroking

See the PROBLEM, “Not enough

paint

pressure”, on page 15, also

.

Electric

motor labors when starting,

and

trips building circuit breaker or

fuse

Piston ball check not seating

Piston packings worn or damaged

Intake valve ball check not seating

Pump is frozen

Filter element installed upside down

Pressure control frozen2 or damaged by

over–pressurization

Drive assembly damaged

Displacement pump worn or damaged

Sprayer is not primed.

Motor

capacitor has failed

Circuit board has failed

3

Service the pump. See page 16.

Replace the piston. See page 16.

Service the pump. See page 16.

2

Thaw

Install

element correctly

307–273.

Try

to thaw

Replace drive housing. See page 19.

Replace displacement pump. See page 16.

Prime sprayer

Replace the capacitor

Replace the circuit board. See page 21.

, or replace pressure control.

. See page 10.

. See page 12 or manual

. See page 20.

Page 15

PROBLEM CAUSE SOLUTION

Paint leaks into wet–cup

Excessive surging from spray gun

Not enough paint pressure

T

ails or fingers in spray pattern

Throat packings are worn or damaged

Spray tip or fluid filter is plugged

Spray tip too big or worn

Paint too viscous

W

rong type hose

Pressure setting too low

Spray tip too big or worn

Pressure control frozen2 or damaged by

over–pressurization

Displacement pump worn or damaged

Pressure setting too low

Fluid outlet filter is dirty or clogged

Spray

tip too big or worn

Fluid supply is low or empty

Paint too viscous

W

rong type hose

3

Replace the packings. See page 16.

Disassemble and clean.

Change the spray tip.

Thin the paint.

Use minimum 50 ft (15.2 m), static–free nylon

hose

(wire braid hose is unacceptable).

Increase pressure.

Change the spray tip.

Try

to thaw

Replace the displacement pump. See page 16.

Increase pressure.

Clean

Change the spray tip.

Refill

fluid supply often to prevent running the pump

dry.

Thin the paint.

Use minimum 50 ft (15.2 m), static–free nylon

hose

, or replace pressure control.

the filter

and prime the pump. See page 10. Check

(wire braid hose is unacceptable).

. See page 12 or manual

307–273.

Paint runs or sags

Spitting from gun

Static

sparking from the gun

1

The electric motor has an over–temperature switch

Spray tip too big or worn

Air in fluid pump or hose

T

ip partially clogged

Fluid supply is low or empty

Spray

or work being sprayed is not prop

erly

grounded

which automatically resets upon cooling. If it opens and

the

electric motor shuts itself of

cord

and let the sprayer cool for 30 to 60 minutes. Always

use

the lowest pressure setting needed when spraying.

2

Freezing

results from failure to replace the water–base

f, unplug the power supply

paint or flushing water with mineral spirits, and usually

causes

permanent damage to the pressure control.

DISPLACEMENT PUMP

WARNING

To

reduce the risk of

Pressure Relief Procedure Warning on page 14

before checking or repairing any part of the spray

system.

Unplug the sprayer!

serious bodily injury

, follow the

Change the spray tip.

Check

for loose connections at pump intake

tighten.

Then prime the pump. See page 10.

Clear the tip. See page 1

Refill

and prime the pump. See page 10. Check

fluid supply often to prevent running the pump

dry.

-

Correct problem before continuing. Follow the

warning section, FIRE OR EXPLOSION HAZ-

ARD

on page 3.

3

Over–pressurization

ft

(15.2 m) of nylon spray hose, (2)

spray

hose, (3) from adding a shutof

pump

outlet and the spray gun, (4) from attaching a spray

results from (1) using less than

1.

from using a wire braid

f device between the

and

50

hose to the pressure drain valve, or (5) from using a

clogged

2. Hold

3.

or incorrectly assembled filter

the intake valve (222) steady with

unscrew

the adapter (38).

Unscrew the hose (52).

.

a wrench and

Removing the Pump.

1.

Flush the sprayer

. Relieve pressure.

See Fig 12.

4. Use a screwdriver to push the retaining spring (33)

aside,

and then push out the pin (34).

5. Loosen

the locknut (1

12) and unscrew the pump

(58).

Page 16

54

A

2. Torque

the locknut (1

3. Reassemble

of

removal.

12) to 70 ft–lb (95 N.m).

the remaining parts, in

the reverse order

36

33

34

223

55

215

*207

58

38

10

52

See

TORQUE TO

Fig 12.

*204

*206

222

80 ft–lb

(107 N.m)

112

TORQUE

TO

70

ft–lb

(95 N.m)

Fig

12

Reinstalling the Pump.

1. Rotate

the crankshaft (A) so the connecting rod (54)

is in its lowest position. (Rotate the fan blades at the

rear

of the motor with a screwdriver.) The pump piston

rod

(223) should protrude about 1 in. (25 mm) above

the pump cylinder. Screw the pump into the pump

coupling

pin

of the pin. Screw the pump

(36) until the pin holes are aligned. Insert the