Page 1

SERVICE MANUAL

Warning

The technical information and parts shown in this

manual are not to be used for: the development,

design, production, storage or use of nuclear, chemical,

biological or missile weapons or other weapons of

mass destruction; or military purposes; or purposes that

endanger global safety and peace. Moreover, do not

sell, give, or export these items, or grant permission for

use to parties with such objectives. Forward all inquiries

to Hitachi Ltd.

YK

No.0567E

ED-X10/ED-X12

(CC9XM2)

Caution

Be sure to read this manual before servicing. To assure safety from fi re, electric shock, injury, harmful

radiation and materials, various measures are provided in this Hitachi Multimedia LCD Projector. Be

sure to read cautionary items described in the manual to maintain safety before servicing.

Service Warning

1. When replace the lamp, to avoid burns to your fi ngers. The lamp becomes too hot.

2. Never touch the lamp bulb with a fi nger or anything else. Never drop it or give it a shock. They may

cause bursting of the bulb.

3. This projector is provided with a high voltage circuit for the lamp. Do not touch the electric parts of

power unit (circuit) and power unit (ballast), after turn on the projector.

4. Do not touch the exhaust fan, during operation.

5. The LCD module assembly is likely to be damaged. If replacing to the LCD LENS/PRISM assembly,

do not hold the FPC of the LCD module assembly.

6. Use the cables which are included with the projector or specifi ed.

Contents

1. Features ------------------------------------------------------ 2

2. Specifi cations ----------------------------------------------- 2

3. Names of each part ---------------------------------------- 3

4. Adjustment --------------------------------------------------- 6

5. Troubleshooting ------------------------------------------ 12

6. Service points --------------------------------------------- 17

7. Wiring diagram -------------------------------------------- 31

8. Disassembly diagram ----------------------------------- 40

9. Replacement parts list ---------------------------------- 47

10.RS-232C communication ------------------------------- 49

11. Block diagram --------------------------------------------- 59

12. Connector connection diagram ----------------------- 60

13.Basic circuit diagram ------------------------------------ 61

SPECIFICATIONS AND PARTS ARE SUBJECT TO CHANGE FOR IMPROVEMENT.

Multimedia LCD Projector

April 2006

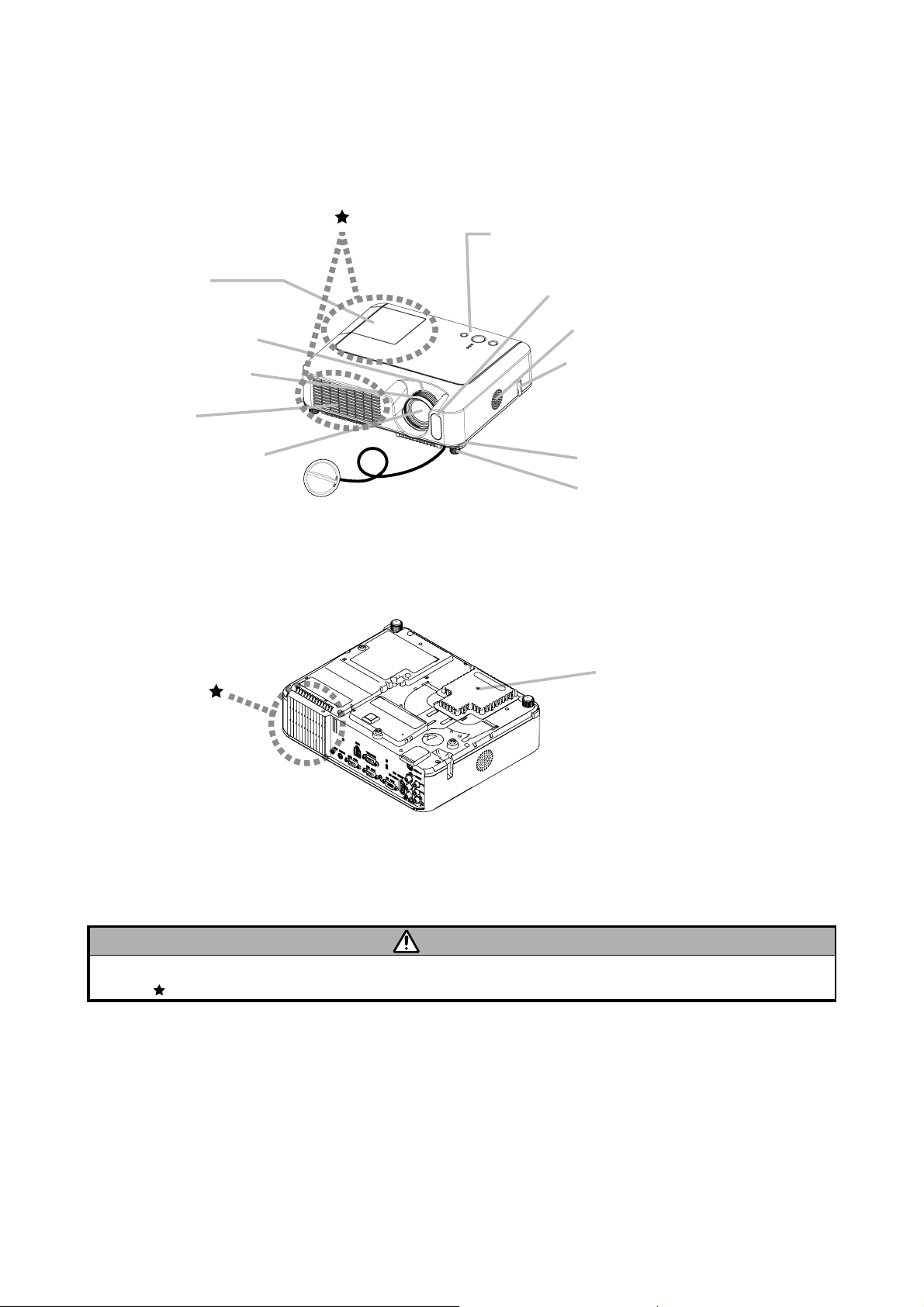

Page 2

1. Features

• High Brightness

• Low Noise

• Rich Connectivity

• Compact Body

2. Specifications

ED-X10/ED-X12(CC9XM2)

Liquid crystal

panel

Lamp 200W UHB

RGB

signal

VIDEO

signal

AUDIO

signal

Speaker output 1W x 1

Power supply AC100~120V/3.3A, AC220~240V/1.4A

Power consumption 310W

Dimensions 306 (W) x 86 (H) x 249 (D) mm (Not including protruding parts)

Weight 3.0kg

Temperature range

Accessories

Drive system TFT active matrix

Panel size 1.6cm(0.63 type)

Number of pixels 1024 (H) x 768 (V)

Video : Analog 0.7Vp-p(75 termination)

RGB IN

RGB OUT

VIDEO IN 1.0Vp-p (75 termination)

S-VIDEO IN

COMPONENT

VIDEO

AUDIO IN 1

AUDIO IN 2

AUDIO IN 3 L/R 200mVrms, 47k or more (max. 3.0Vp-p)

AUDIO OUT 0~200mVrms, output impedance 1k (max. 5.0Vp-p)

1

H/V. sync. : TTL level (positive/negative)

2

Composite sync. : TTL level

Video:Analog 0.7Vp-p, 75 output impedance (positive)

H/V. sync.: TTL level (positive/negative)

Composite sync.: TTL level

Y signal: 1.0±0.1Vp-p, (75 termination)

C signal: 0.286±0.1Vp-p (NTSC burst signal, 75 termination)

0.3±0.1Vp-p (PAL/SECAM burst signal, 75 termination)

Y 1.0±0.1Vp-p, 75 termination (positive)

B/PB

C

CR/PR0.7±0.1Vp-p, 75 termination (positive)

0.7±0.1Vp-p, 75 termination (positive)

200mVrms, 47k or more (max. 3.0Vp-p)

Operation : 5~35°C

Storage : -20~60°C

Remote control x1

RGB cable x 1

Audio/Video cable x 1

Power cords x 3

Batteries x 2

User’s manuals x 1

2

Page 3

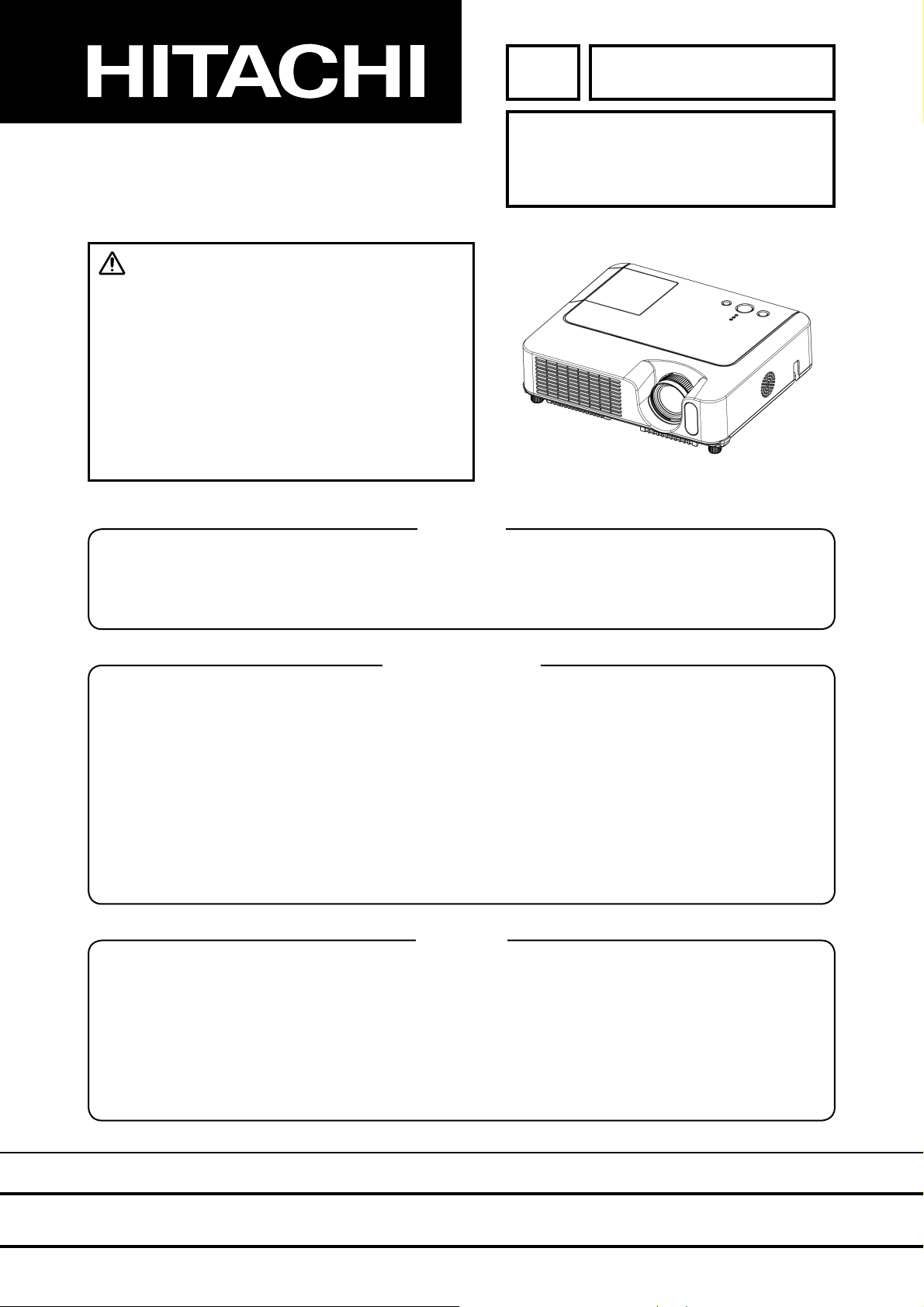

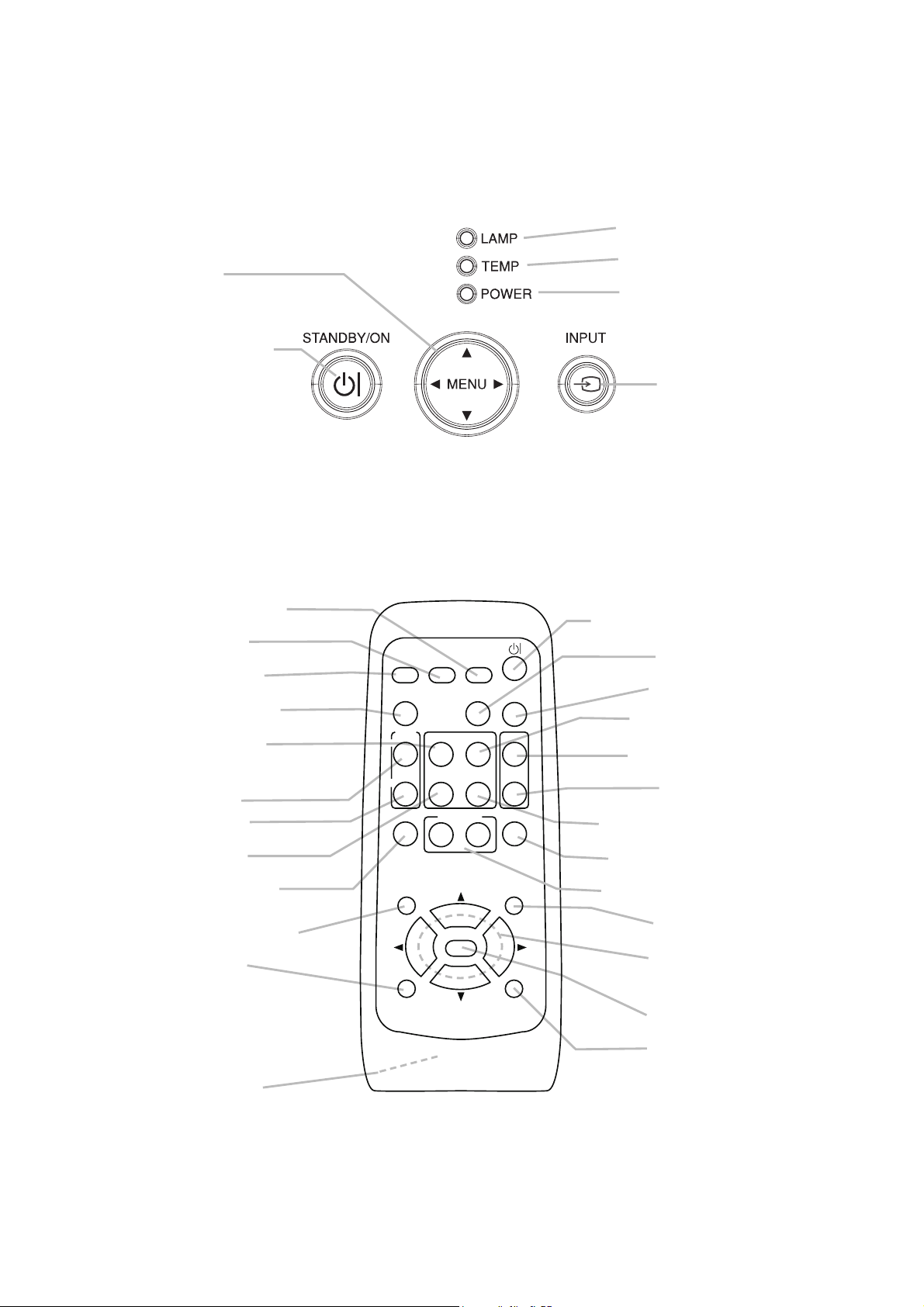

3. Names of each part

Projector

ED-X10/ED-X12(CC9XM2)

Control buttons

Lamp cover

(Lamp unit is inside.)

Zoom ring

Focus ring

Vent

Lens

Lens cover

Front-Right side

Remote sensor

Speaker

Security bar

(Use for attaching a

commercial anti-theft

chain or wire.)

Elevator button

Elevator foot

Filter cover

(Air filter and intake vent

are inside.)

Bottom side

WARNING

During use or immediately after use, do not touch around the lamp and vents of the projector. ( ) It could cause a burn.

3

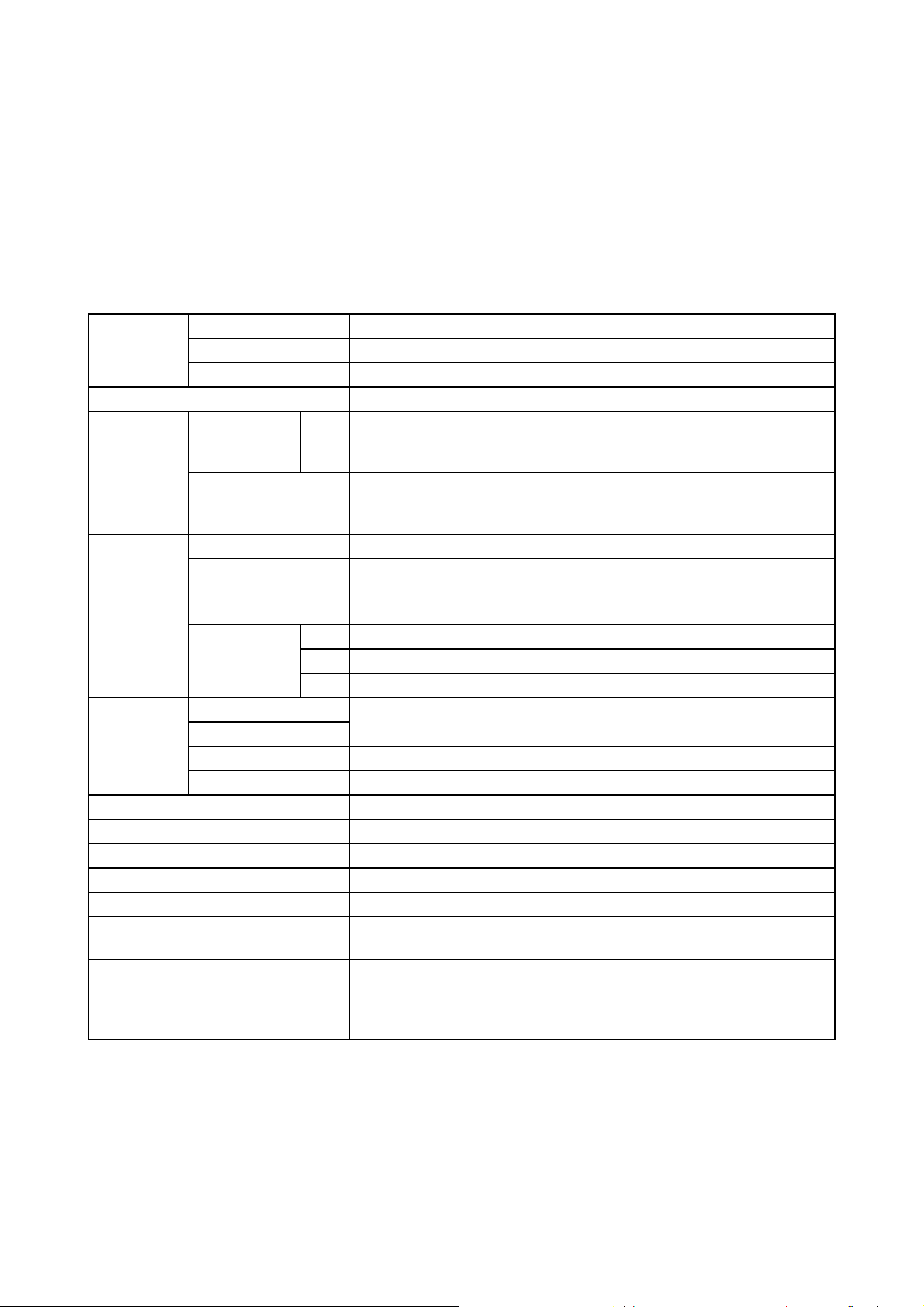

Page 4

ED-X10/ED-X12(CC9XM2)

Power switch

AC inlet

Ports (See below.)

AUDIO IN3 L/R port

(In the default setting, the

AUDIO IN3 L/R port is the audio

port for the VIDEO, S-VIDEO

and COMPONENT VIDEO

ports, however it is possible to

change the settings.)

COMPONENT

VIDEO ports

AUDIO IN3

Y R

Y

B/PB

C

CR/P

VIDEO port

R

C

B

/

P

B

C

R

/

P

R

VIDEO

S-VIDEO

L

Elevator button

Elevator foot

Rear-Left side

Vent

AUDIO IN1 port

(In the default setting, the AUDIO IN1 port is the audio

port for the RGB IN1 port, however, it is possible to

change the settings.)

RGB IN1 port

Restart switch (*)

RGB IN2 port

RGB OUT port

AUDIO OUT port

RGB IN1

AUDIO IN1

AUDIO IN2

K

RGB IN2

CONTROL

RGB OUT

USB

AUDIO OUT

Ports

S-VIDEO port

USB port

AUDIO IN2 port

(In the default setting, the AUDIO

CONTROL port

IN2 port is the audio port for

the RGB IN2 port, however, it is

Kensington lock slot

possible to change the settings.)

NOTE (*) About Restart switch: This projector is controlled by an internal

microprocessor. Under certain exceptional circumstances, the projector may not

operate correctly and the microprocessor will need to be reset. In such a case,

please push the Restart switch by using a cocktail stick or similar, and before

turning on again, make the projector cool down at least 10 minutes without

operating. Only push the Restart switch in these exceptional instances.

4

Page 5

Control buttons

Cursor buttons

,,,

STANDBY/ON button

ED-X10/ED-X12(CC9XM2)

LAMP indicator

TEMP indicator

POWER indicator

INPUT button

Remote control

SEARCH button

RGB button

VIDEO button

ASPECT button

HOME button

MAGNIFY

ON button

OFF button

END button

FREEZE button

POSITION button

ESC button

VIDEO

ASPECT AUTO

MAGNIFY

ON

OFF

FREEZE

POSITION

ESC

SEARCH

RGB

PAGE UP

HOME

PAGE DOWN

END

MY BUTTON

12

ENTER

BLANK

VOLUME

MUTE

KEYSTONE

MENU

RESET

STANDBY/ON button

AUTO button

BLANK button

PAGE UP button

VOLUME button

MUTE button

PAGE DOWN button

KEYSTONE button

MY BUTTON button

MENU button

Cursor buttons

,,,

Battery cover

(on the back)

ENTER button

RESET button

5

Page 6

ED-X10/ED-X12(CC9XM2)

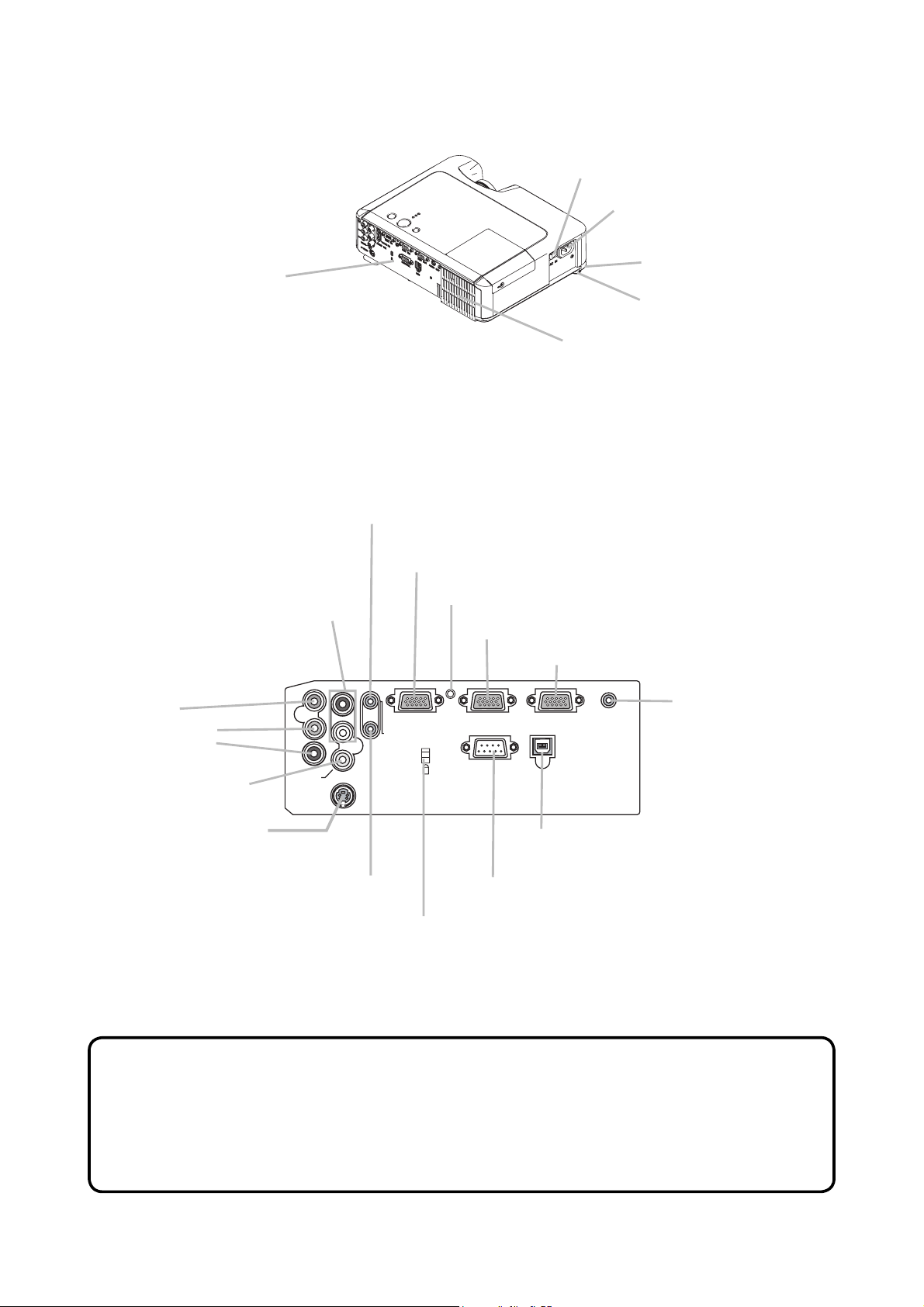

4. Adjustment

4-1 Before adjusting

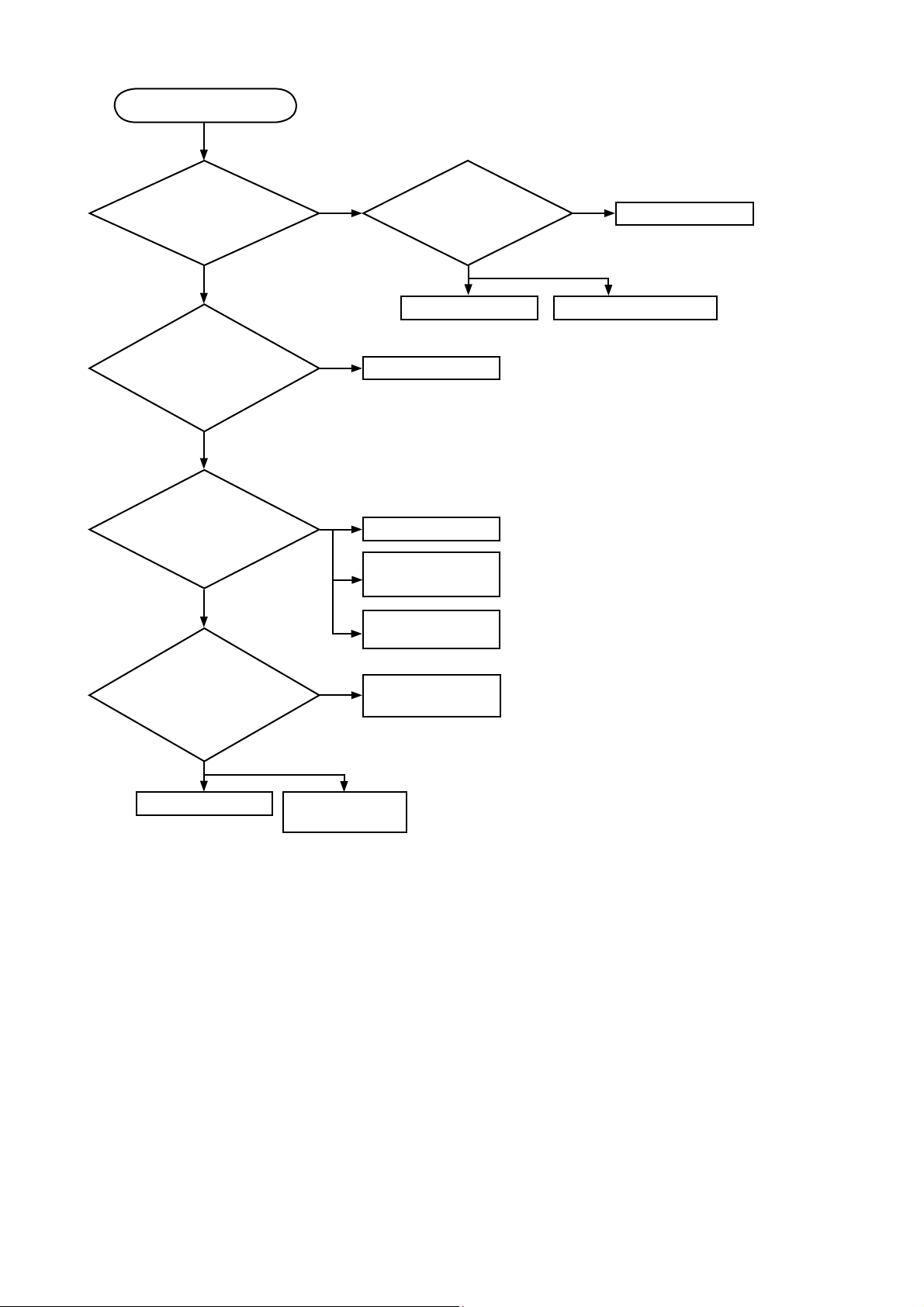

4-1-1 Selection of adjustment

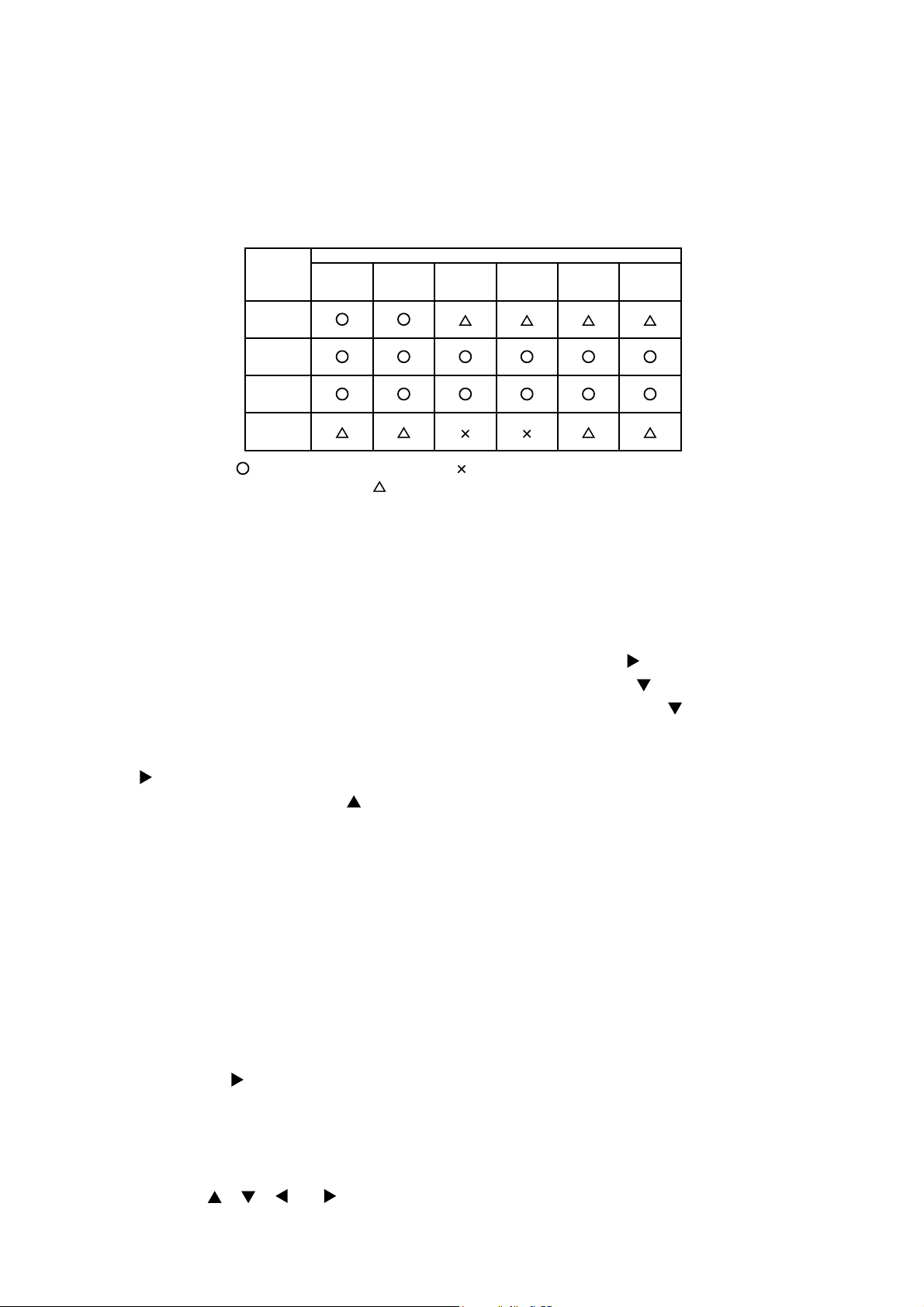

When any parts in the table 4-1 are changed, choose the proper adjusting items with the chart.

Table 4-1: Relation between the replaced part and adjustment

Replaced

part

Dichroic

optics unit

LCD/LENS

prism

assembly

PWB

assembly

Main

Lamp

unit

assembly

Flicker

(Chap.4-2)

Ghost

(Chap.4-3)

: means need for adjustment. : means not need for adjustment.

: means recommended.

Adjustment

DC OFF

(Chap.4-4)

E-POS

(Chap.4-5)

White

balance

(Chap.4-6)

Color

uniformity

(Chap.4-7)

4-1-2 Setting of condition before adjustments

1. Before starting adjustments, warm up projector

for about 10 minutes.

2. Set Zoom Wide to Max. And project an image

with more than 1m (40 inches) in diagonal size.

3. Normalizing the video adjustments

Press the [MENU] button to display the EASY

menu. If Advanced menu comes up, move to the

Easy menu.

Select the RESET in the EASY menu and press

the [ ] or [ENTER] button to open the RESET dia-

log. Choose the EXECUTE with the [ ] button.

Note that the projector will not allow you to reset

its adjustment values with no signal input.

4. Perform all adjustments from the FACTORY

MENU. Operate as follows to display the FAC-

TORY MENU.

When you use the remote control...

a. Press the [MENU] button of the remote con-

trol to display the Easy menu. (If the Ad-

vanced menu appears, move to the Easy

menu.)

b. Select the RESET in the Easy menu, and

then press the [ ] or [ENTER] button.

c. Next, press the [RESET] button one time. And

hold the [RESET] button for 3 seconds or lon-

ger (the FACTORY MENU will appear).

When you use the keypad of the projector...

[],

[],

[ ]

or [

a. Press the

] button of the

projector to display the Easy menu. (If the Ad-

vanced menu appears, move to the Easy

menu.)

b. Select the RESET in the Easy menu, and

then press the [

] or [ENTER] button.

c. Next, press the [ ] button one time. And re-

press and hold the [ ] button together with

the [INPUT] button for 3 seconds or more (the

FACTORY MENU will appear).

6

Page 7

ED-X10/ED-X12(CC9XM2)

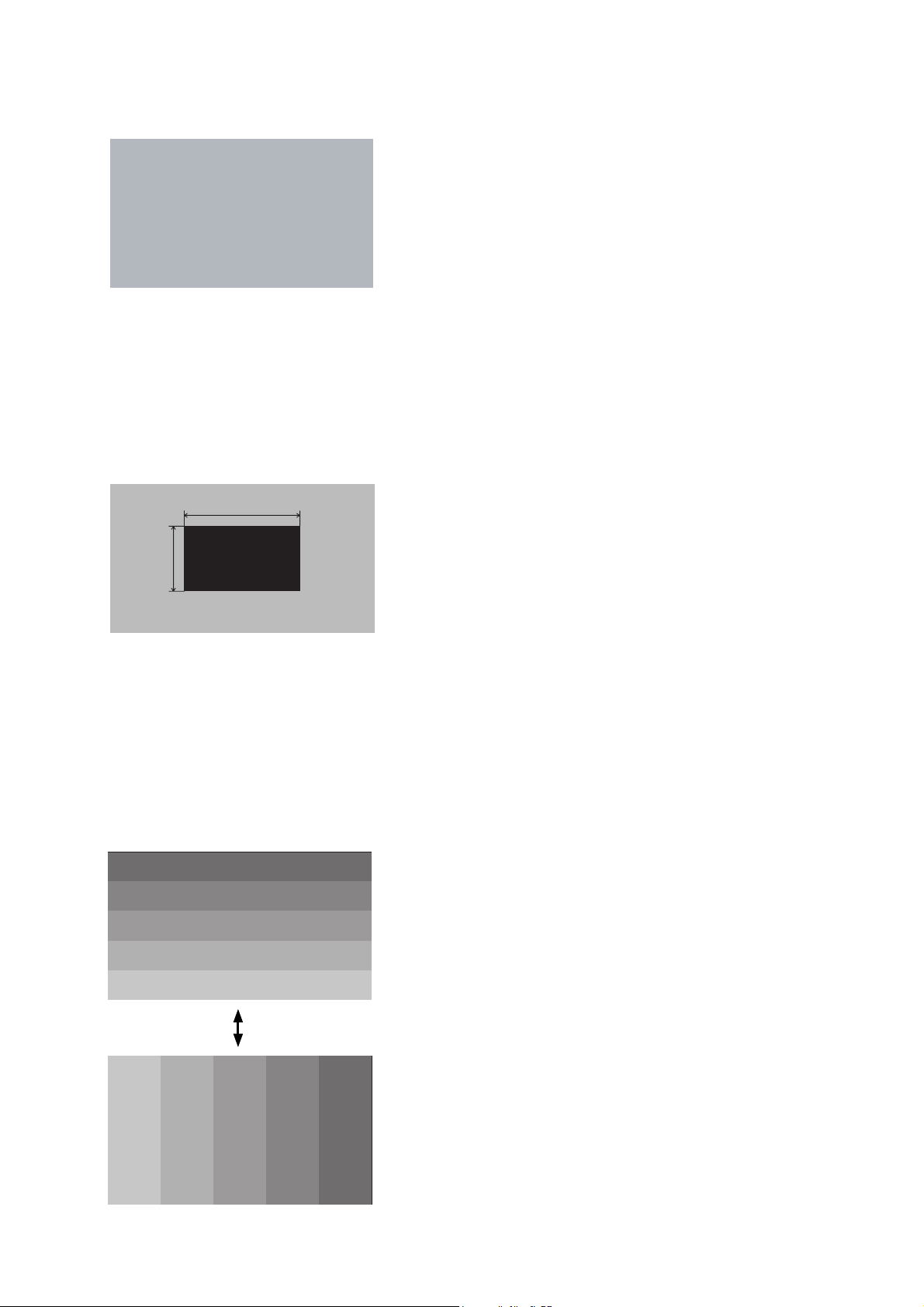

4-2 Flicker adjustment

(V.COM adjustment)

Test pattern for the adjustment

128/255

4-3 Ghost adjustment

Test pattern for the adjustment

30%

30%

0/255

112/255

Adjustment procedure

1.

Use DAC-P - V.COM - R: in the FACTORY

MENU to adjust so that the flicker at the center of

the screen is less than the flicker at the periphery.

(When the flicker is about the same across the

whole screen, adjust so that the flicker at the center

of the screen is somewhat less than elsewhere.)

2. In the same way, use DAC-P - V.COM-G: in the

FACTORY MENU to adjust the G color flicker.

3. In the same way, use DAC-P - V.COM-B: in the

FACTORY MENU to adjust the B color flicker.

NOTE: The test pattern shown on the left sometimes has a horisontal line accross the screen.

Adjustment procedure

1. Make this adjustment after completing the ad-

justment in the section 4-2.

2.

Use DAC-P - GHOST - R: in the FACTORY MENU

to adjust so that R color ghost is at a minimum.

(Set the adjustment value to default, and then

raise the value. When a ghost appears to the left

of a vertical line, reduce the value by 6 steps.)

3. In the same way, use DAC-P - GHOST-G: in

the FACTORY MENU to adjust so that G color

ghost is at a minimum.

4. In the same way, use DAC-P - GHOST-B: in

the FACTORY MENU to adjust so that B color

ghost is at a minimum.

4-4

DC OFF adjustment

(vertical bars adjustment 1)

Test pattern for the adjustment

64

/255

88

/255

112

/255

136

/255

160

/255

Press ENTER key

160

/255

136

/255

112

/25588/25564/255

Adjustment procedure

1. Make this adjustment after completing the ad-

justment in the section 4-3.

2.

Open FACTORY MENU. Select STRIPE >

DCOFF > R and use it so that vertical bars are

minimized.

3. In the same way, select

and use it so that vertical bars

4. In the same way, select

and use it so that vertical bars

STRIPE > DCOFF

are minimized.

STRIPE > DCOFF

are minimized.

> G

> B

7

Page 8

ED-X10/ED-X12(CC9XM2)

4-5

E-POS adjustment (vertical bars adjustment 2)

Test pattern for the adjustment

112/255

4-6

White balance adjustment

Preparations

1. Perform these adjustments after the adjustments described in Section 4-5.

Adjustment procedure

1. First, adjust the G color.

2.

Select GAMMA, SUB-CNT, and G: in the FACTORY

MENU. If the background is white solid, press the

[ENTER] key on the Remote control transmitter to

change to [G] monochrome in the 33-tone grayscale.

3. Adjust GAMMA, SUB-CNT, and G: in the FACTORY MENU so that brightness of 33 steps is

best.

4. Don’t adjust GAMMA, SUB-BRT, and G: in the

FACTORY MENU because we want to keep the

best contrast ratio.

5. Then adjust colors R and B.

(visual inspection)

Adjustment procedure

1. Make this adjustment after completing the ad-

justment in the section 4-4.

2.

Open FACTORY MENU. Select DAC-P > E-POS

> R and use it so that vertical bars are minimized.

3. In the same way, select DAC-P > E-POS > G

and use it so that vertical bars

4. In the same way, select DAC-P > E-POS > B

and use it so that vertical bars

2. Reset gamma correction before adjustment.

Place the cursor on [GAMMA] in the FACTORY

MENU, press the [RESET] key and select RESET.

6.

Select GAMMA, SUB-CNT, and G: in the FACTORY

MENU. If the background is white solid, press the

[ENTER] key on the remote control to change to [W]

monochrome in the 33-tone grayscale.

7. Adjust GAMMA, SUB-BRT, R: and B: in the

FACTORY MENU so that low-brightness white

balance is best.

8. Adjust GAMMA, SUB-CNT, R: and B: in the

FACTORY MENU so that middle-brightness

white balance is best.

9. Repeat steps 7 to 8 above, and adjust so that

brightness white balance of 33 steps is best.

are minimized.

are minimized.

8

Page 9

ED-X10/ED-X12(CC9XM2)

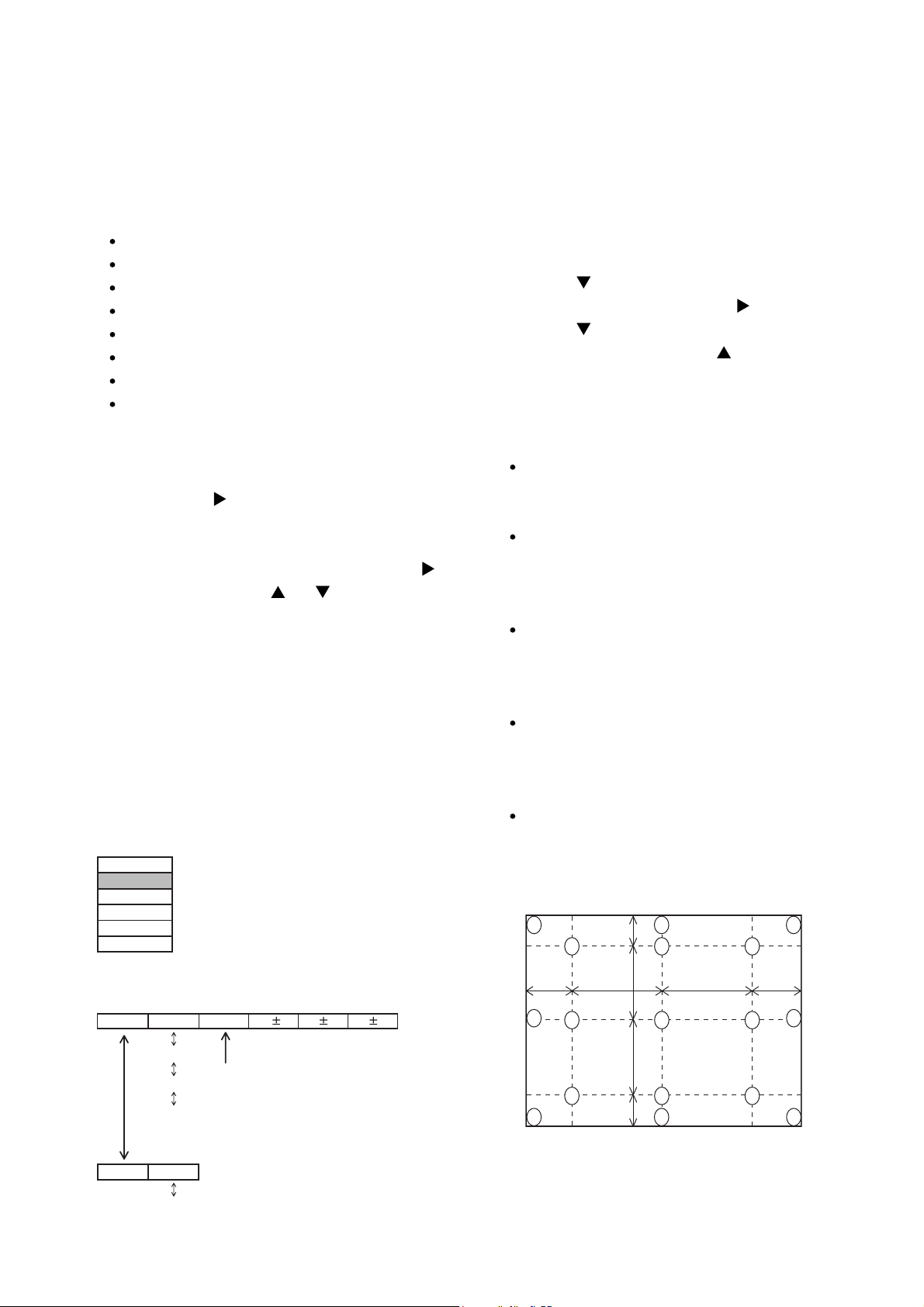

4-7 Color uniformity adjustments

Preparations

1.

Perform these adjustments after the adjustments

described in the section 4-6.

2. Make a color uniformity adjustments for the fol-

lowing tones.

MIN tone (approx. 7% input signal)

MID-1 tone (approx. 14% input signal)

MID-2 tone (approx. 21% input signal)

MID-3 tone (approx. 29% input signal)

MID-4 tone (approx. 36% input signal)

MID-5 tone (approx. 50% input signal)

MID-6 tone (approx. 61% input signal)

MAX tone (approx. 75% input signal)

NOTE: The brightness level of the test patterns

in MID-4 and MID-6 is selectable.

3. Select the [C.UNIF.] in the FACTORY MENU

and press the [ ] key. This operation displays

the Adjust Tone menu (shown below) on the

bottom of the screen.

To choose the tone to be adjusted, press the [

] key and then use the [ ] or [ ] key.

Select the major adjustment lattice point No.

and color, and then adjust them.

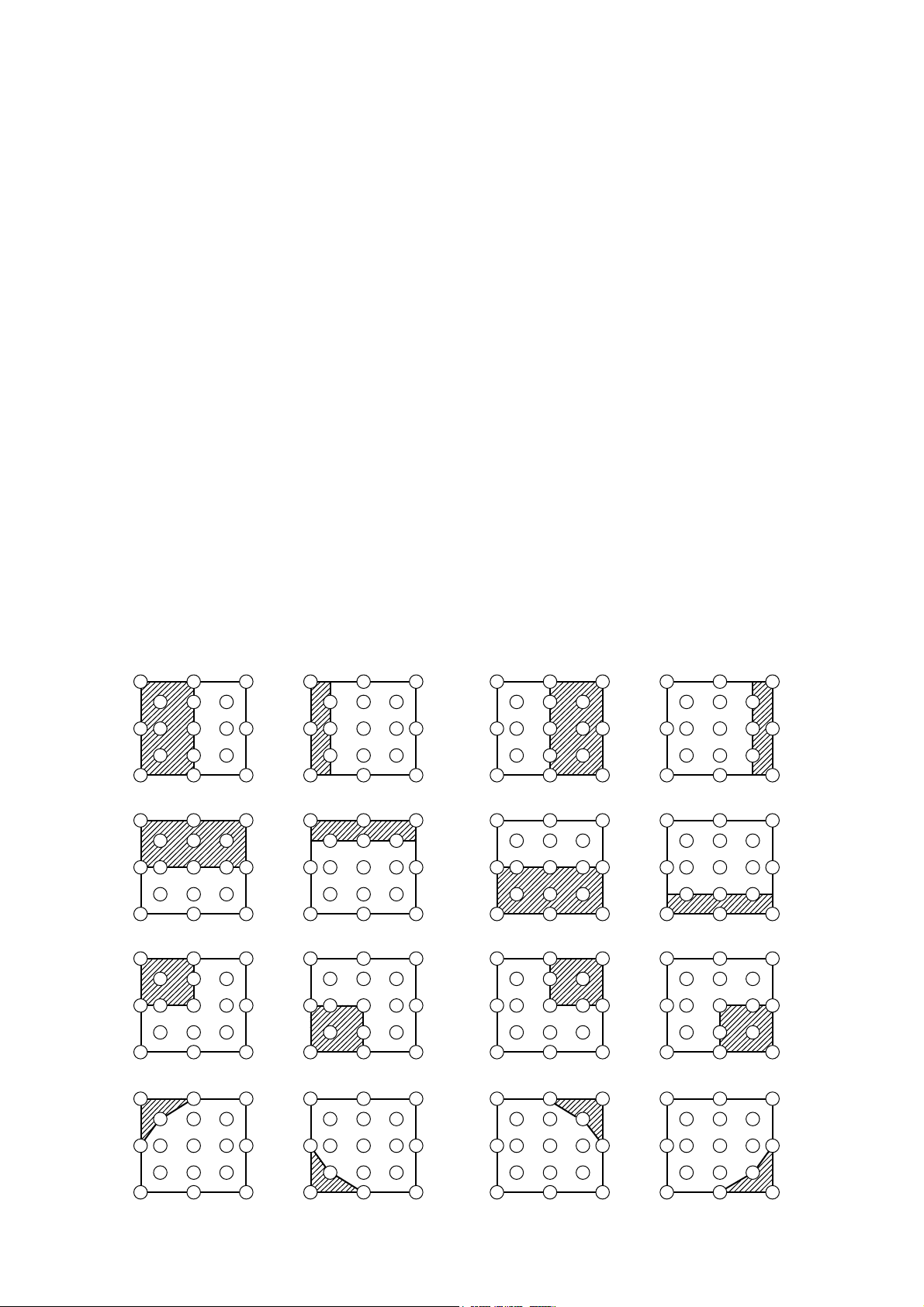

4. The major adjustment lattice point numbers (a

total of 17 points) corresponds to the major ad-

justment lattice point positions in the diagram

on the right. The color uniformity of the entire

screen can be adjusted by adjusting the white

balance for each of the points starting in order

from the low numbers.

FACTORY MENU

VID-AD

C. UNIF.

DAC-P

GAMMA

STRIPE

OPTION

Adjust tone menu

5. Adjustment point No.1 should not be adjusted,

because it controls the brightness of the entire

screen.

6.

To temporarily turn correction off, place the cur-

sor on [C.UNIF.] in the Adjust Tone menu and

press the [ ] key. The ON/OFF menu appears.

Place the cursor on [ON] with the [ ] key and

press the [ ] key. To turn it on again, place the

cursor on [OFF] and press the [ ] key.

7. Although this adjustment can also be made us-

ing internal signals, we will here use the [EN-

TER] key on the remote control to select the fol-

lowing two signals.

Solid monochrome adjustment color (use G

color adjustment when a color differential me-

ter is used).

Solid white (use for adjustment other than

above).

8. Reset color-shading correction before adjust-

ment.

When resetting all values of 8 tones and all

colors, place the cursor on [C.UNIF.] in the

FACTORY MENU, press the [RESET] key and

select RESET in the dialog.

When resetting only 1 tone, place the cursor

on the tone such as MID-1 to be reset, press

the [RESET] key and select RESET in the di-

alog.

Single tone and monochrome resets cannot

be performed.

Major adjustment lattice point position

14 12

H/6 H/3 H/3 H/6

V/6

6 4 8

V/3

16

C.UNIF

ON/OFF ON

MIN

MID-1

MID-2 ... 6

MAX

OFF

No. 1 R 0

Major adjustment lattice point No.

G 0 B 0

10 11

2 1 3

V/3

7 5 9

V/6

15 17

13

9

Page 10

ED-X10/ED-X12(CC9XM2)

Adjustment procedure 1

(When a color differential meter is used)

1. First adjust the [MID-1] tone [G:].

2. Select adjustment point [No.2][G:].

When the background is not [G] monochrome,

press the [ENTER] key on the remote control to

switch to solid [G] monochrome.

3. Measure the illumination at adjustment points

No. 2, No.3, No.10 and No.11.

The values should be:

No.2 = Y2 [lx] No.10 = Y10 [lx]

No.3 = Y3 [lx] No.11 = Y11 [lx]

4. No.2 and No.3 adjustment points have the aver-

age of Y2 and Y3.

Y2 = ( Y2 + Y3 ) / 2 ± 2 [%]

Y3 = ( Y2 + Y3 ) / 2 ± 2 [%]

5. No.10 and No.11 adjustment points have the

average of Y10 and Y11.

Y10 = ( Y10 + Y11 ) / 2 ± 2 [%]

Y11 = ( Y10 + Y11 ) / 2 ± 2 [%]

6. Then adjust the [MID-1] tone [R] and [B].

When the background is [G] monochrome,

press the [ENTER] key on the remote control to

switch to solid white.

7. Measure the color coordinates of adjustment

point [No.1] and make a note of them.

Assume that they are x = x1, y = y1.

Note: When the CL-100 color and color differ-

ence meter is used, the [ ](delta) mode

is convenient. When adjustment point

[No.1] color coordinate has been select-

ed, set the slide switch on the side to

[ ](delta) while holding down the [F] but-

ton on the front panel. The measurement

shown after this displays the deviation

from measurement point 1.

8. Measure the color coordinates of measurement

point [No.2] and adjust [No.2][R:] and [B:] so

that the coordinates are as follows.

x = x1 ± 0.005 , y = y1 ± 0.010

9. Similarly, measure adjustment points [No.3] to

[No.17] and adjust their color coordinates start-

ing in order from the small number points.

This completes adjustments required for

[MID-1].

Note: Since excessive correction may lead to a

correction data overview during internal

calculations, use the following values for

reference.

[No.2] to [No.5] ± 40 or less

[No.6] to [No.9] ± 50 or less

[No.10] to [No.13] ± 70 or less

[No.14] to [No.17] ± 120 or less

10. Then adjust the [MIN] tone [G] so that the ad-

justment values are two times as much as

MID-1] tone [G] values.

This completes [G] color adjustments.

11. Then adjust [MIN] tone [R] and [B].

Select [No.2] [B:] and press the [ENTER] key

on the Remote control transmitter to change to

solid white.

12. Measure the color coordinates of adjustment

point [No.1] and make a note of them.

Assume that they are x = x1, y = y1.

13. Now measure the color coordinates of mea-

surement point [No.2] and adjust [No.2][R:] and

[B:] so that the coordinates are as follows.

x = x1 ± 0.005 , y = y1 ± 0.010 (Target)

x = x1 ± 0.020 , y = y1 ± 0.040

14. Similarly, measure adjustment points [No.3] to

[No.17] and adjust their color coordinates start-

ing in order from the small number points.

This completes [MIN] tone adjustments.

15. Now make similar adjustments for [MID-2] tone.

(Adjust [MID-2] tone [G] so that the adjustment

data set half as many as [MID-1] tone [G].)

16. Now make similar adjustments for [MID-3],

[MID-5], [MAX] tones. (It is not necessary to ad-

just the [G] data in these tones.)

17. After comleting the step 16, set the value of the

[MID-4] tone [R]: [No.2] to the mean of the val-

ues of the [R]: [No.2] in the [MID-3] and [MID-4]

tones.

18. Set all the values for the [No.2] to [No.17] of

the [MID-4] tone [R] and [B] in the same way as

the step 17.

19. Finally, set the data of the [MID-6] tone [R] and

[B] using the values of the [MID-5] and [MAX]

tones in the same way as the [MID-4] tone [R]

and [B] adjustments in the step 17 and 18.

10

Page 11

ED-X10/ED-X12(CC9XM2)

Adjustment procedure 2

(visual inspection)

1. First adjust [MIN] tone [G:].

2. Select [No.2] [G:].

If the background is [G] monochrome, press the

[ENTER] key on the remote control to switch to

solid white.

3. View measurement point [No.2] and [No.3].

Lower the [G] color intensity only of the color

point whose [G] color is more intense than

measurement point [No.1].

4. View measurement point [No.10] and [No.11].

Lower the [G] color intensity only of the color

point whose [G] color is more intense than

measurement point [No.1], and raise the inten-

sity of the point whose color intensity is lower

than measurement point [No.1].

5. Now adjust the [MIN] tone for colors [R] and

[B].

6. View measurement points [No.2], [No.3],

[No.10] and [No.11]. Adjust the [R] and [B] of

each measurement point so that they have the

same color as measurement point [No.1].

Adjustment technique:

First, adjust [B:] of the point whose color is to

be adjusted so that it approximates that of

[No.1]. If [R:] is low at this time, the image will

have cyan cast, in which case [R:] is increased.

On the other hand, if [R:] is excessive, the im-

age will have a magenta cast, in which case

[R:] is decreased.

Overall, a cyan cast makes it easy to see color

shading.

7. Next, view measurement points [No.4], [No.5],

[No.12], [No.13] and make similar adjustments.

Then adjust measurement points [No.6], [No.7],

8.

[No.8], [No.9], [No.14], [No.15], [No.16] and [No.17].

This completes the [MIN] tone adjustments.

9. Make similar adjustments for other tones, ex-

cept the [MID-4] and [MID-6] tones, as de-

scribed in steps 1 to 8 above.

No. 2 deviation range No. 10 deviation range No. 3 deviation range No. 11 deviation range

14

10

15 13

12

6

2

7

4

1

5

16

8

3

11

9

17

14 12

6

10

2

7

15 13

4

1

5

16

8

3

11

9

17

14

10

15

12

6

4

2

1

5

7

13

16

8

3

11

9

17

14 12

6

10

2

7

15 13

16

4

8

1

3

11

5

9

17

No. 4 deviation range No. 12 deviation range No. 5 deviation range No. 13 deviation range

16

8

3 112

9

17

14 12

6

10

2

7

15 13

16

4

8

1

3

113 11210 1

9

5

17

7

15 13

1614 12

86 4 84

9

5

17

6

10 1

2

7

15 13

1614 12

3

11

9

5

17

14

10 1

15

12

6

4

5

7

13

No. 6 deviation range No. 7 deviation range No. 8 deviation range No. 9 deviation range

7

15 13

1614 12

86 4 84

3 11210 1

9

5

17

10 12

1614 12

6

3

11

9

5

7

1315

17

14

10

15

12

6

418

5

7

13

16

3 112

9

17

14 12

10

2

7

15

13

46

8

1 3 11

95

5

16

17

No. 14 deviation range No. 15 deviation range No. 16 deviation range No. 17 deviation range

1614 12

6

84 84

6

1614 12

14

12

6

4

16

8

14 12

16

46

8

10

7

15 13

3

3 112 1

9

5

17

10 12

15

5

7

13

11

9

17

10

7

15

13

32

1

5

11

9

17

10

15

2

7

1 3511

5

9

13

17

11

Page 12

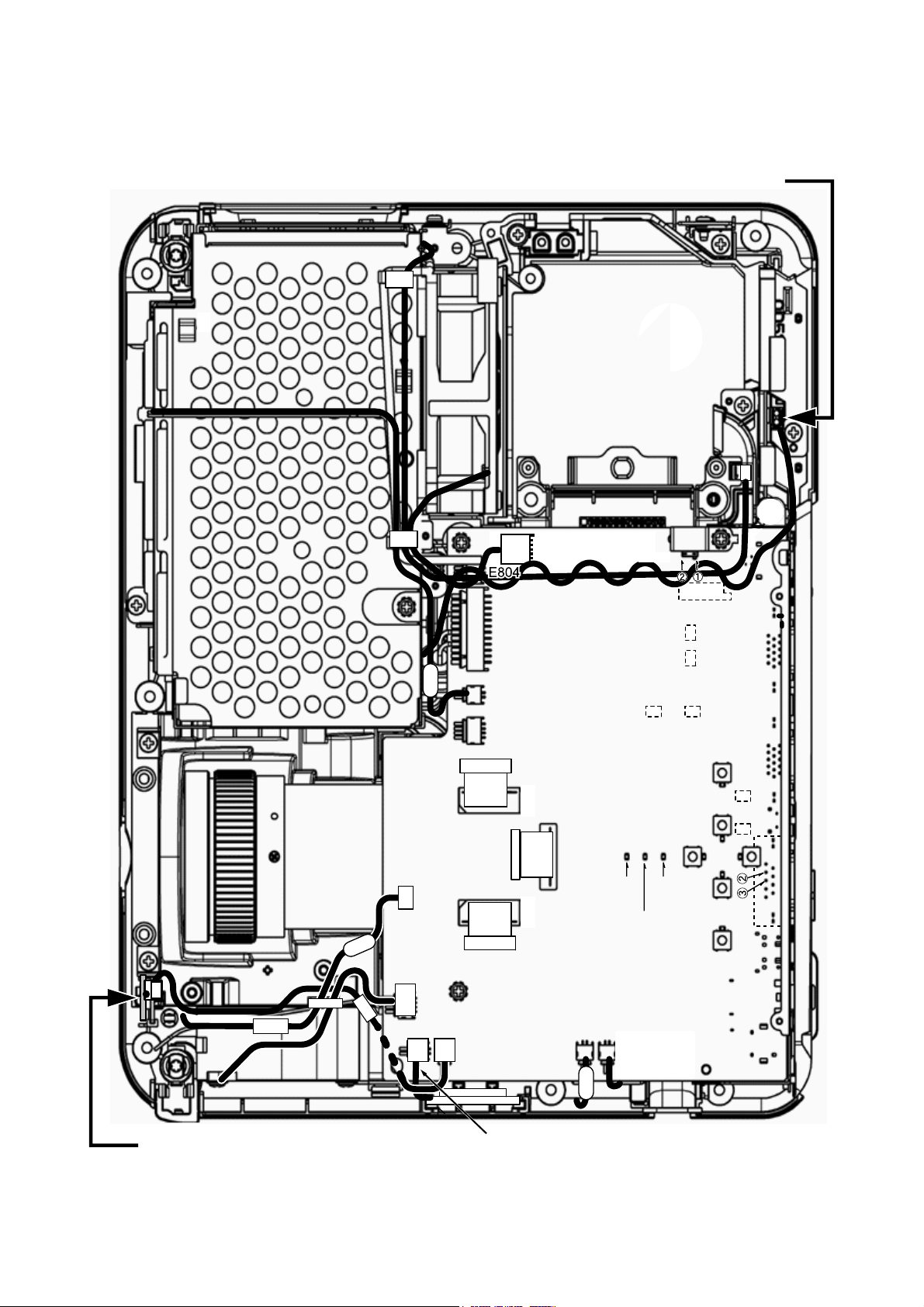

5. Troubleshooting

Check points

ED-X10/ED-X12(CC9XM2)

THERMAL SWITCH (TSW)

E1

E304

E807

E2

E301

E802

P601

P701

E801

E800

P501

D303

(LAMP)

PWB assembly MAIN

S801

IS08

D301

(POWER)

D302

(TEMP)

IS01

IS06

IS07

IS09

IS03

IS02

EK01

EASP

E805

E302 E806

PWB assembly REMOTE Speaker cable

12

E3

Page 13

ED-X10/ED-X12(CC9XM2)

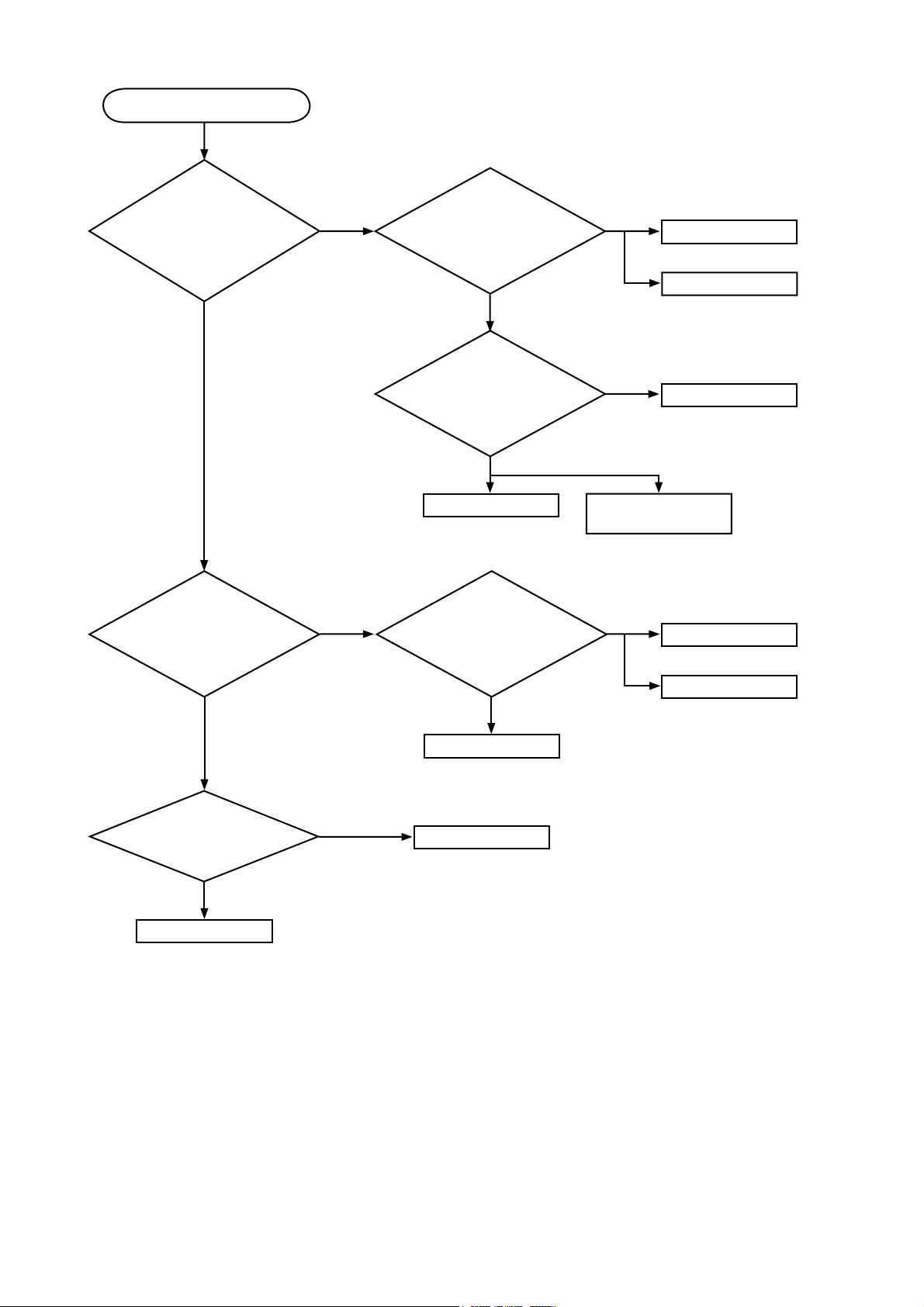

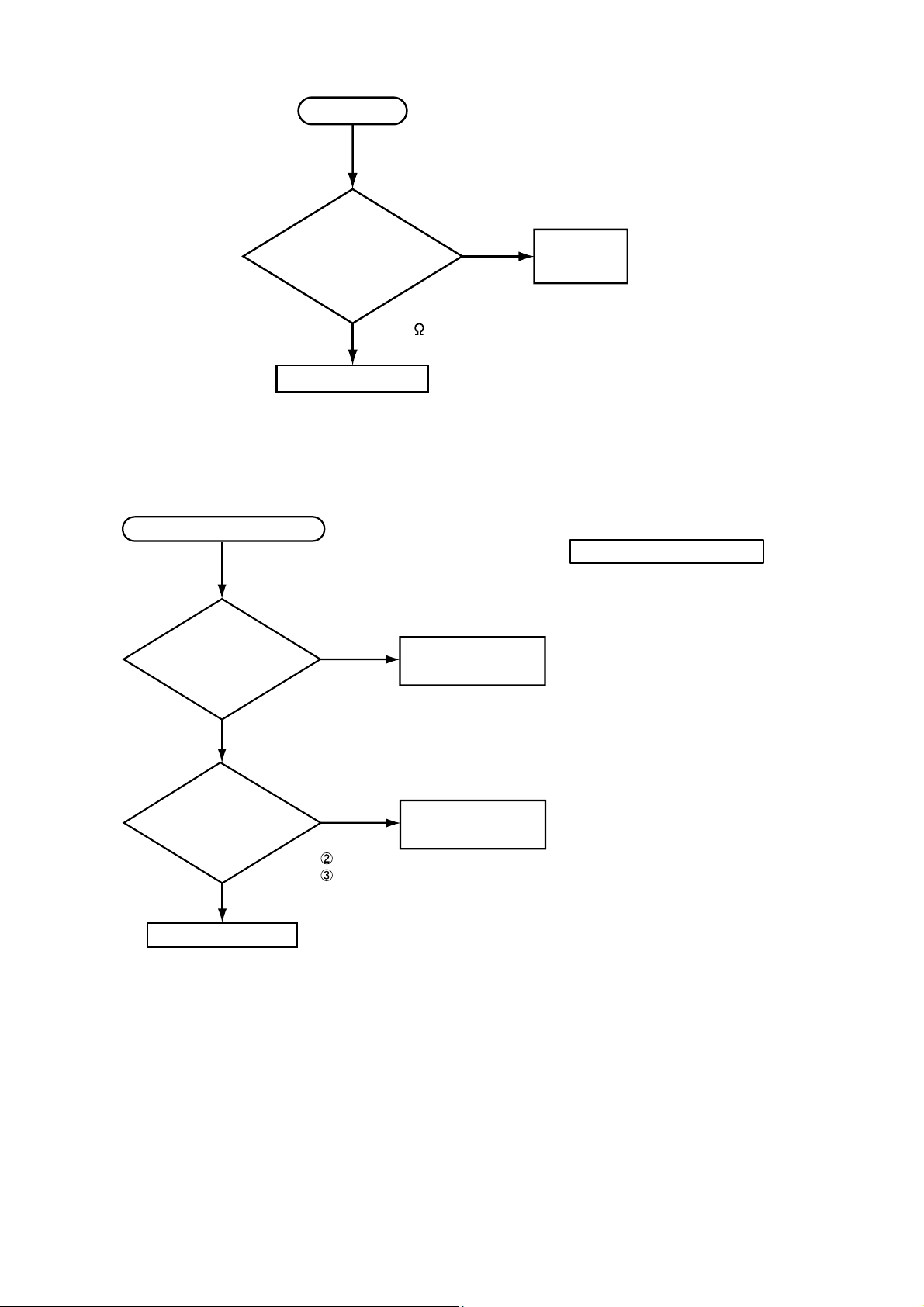

Power can not be turned on

Are

voltage

supplied at pins (6)

and (8) of E800 on the PWB

assembly MAIN in

standby mode?

(6): +6.0V

(8): +4.0V

YES

(10): GND

*: Be sure to unplug the power cord before measuring resistance.

Measure

NO

resistance* between pins

(6) and (10), and between

pins (8) and (10) of

E800.

Open

Disconnect TSW

from power unit circuit, and

measure resistance of

TSW.

Short

Power unit (circuit)

0

Open

Fuse on the power unit

(circuit)

PWB assembly MAIN

Power unit (circuit)

Termal switch (TSW)

Are

voltage supplied

at pins (1) and (4) of E800

on the PWB assembly

MAIN in standby

mode?

Does LAMP

(D303) or TEMP (D302)

indicator light or

blink?

PWB assembly MAIN

(1): +15V

(3): GND(for +15V)

YES

(4): +17V

(10): GND(for +17V)

NO

NO

YES

Mea-

sure resistance*

between pins (1) and (3),

and between pins (4) and

(10) of E800.

Open

Power unit (circuit)

Go to the next page

0

PWB assembly MAIN

Power unit (circuit)

13

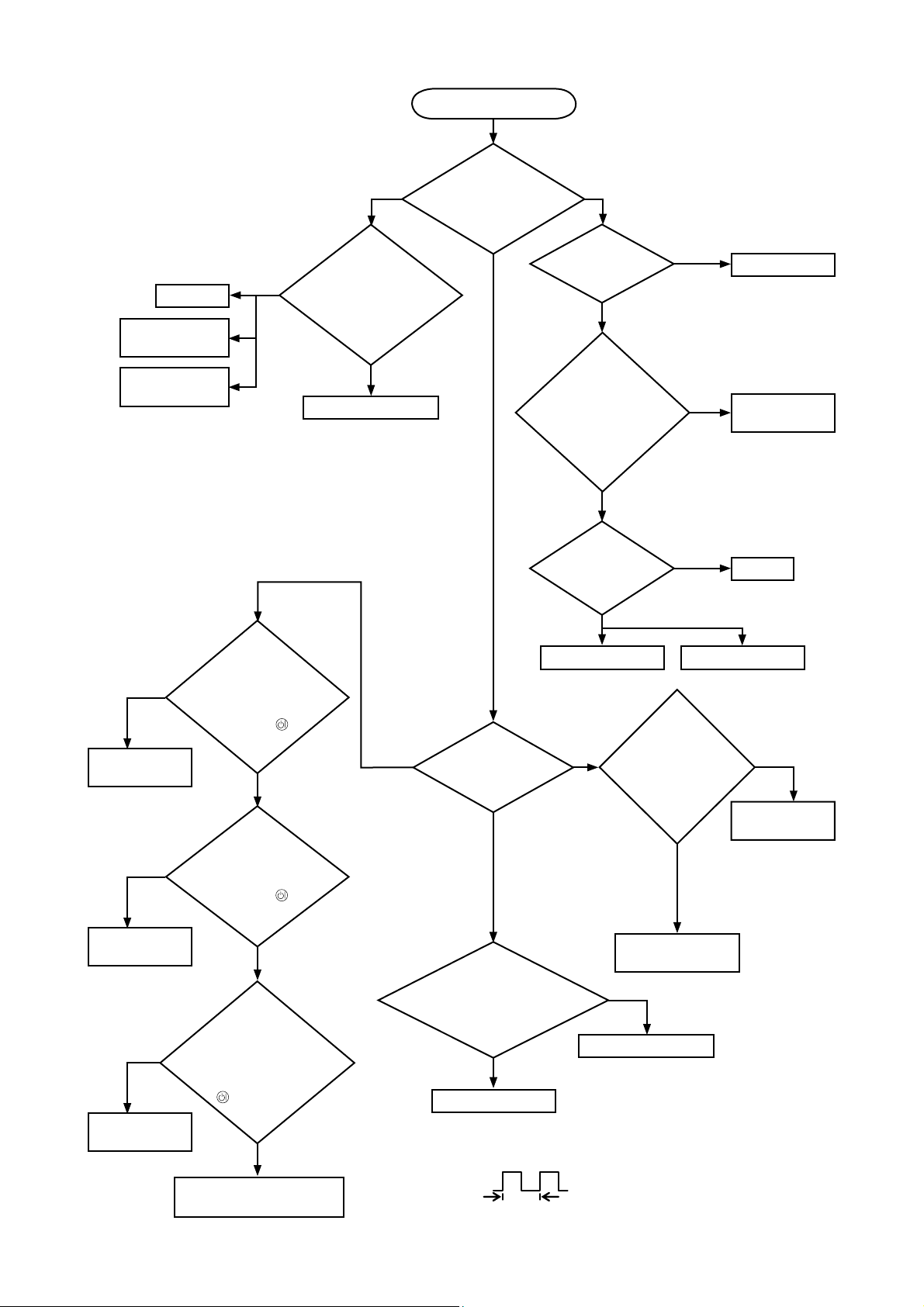

Page 14

ED-X10/ED-X12(CC9XM2)

Open

Lamp door

Re-attach lamp

door

Re-attach PWB

assembly MAIN

**: DC fan connectors are E801,

E802, E806, and E807.

Blinks

Measure

resistance* between

pins (1) and (2) of S801

when the lamp door

is secure.

0

PWB assembly MAIN

LAMP indicator D303

Lamp does not light

What

is the state of

during operation?

Not light

and blink

*: Be sure to unplug the power cord

before measuring resistance.

Light

Is the

LAMP installation

correct?

YES

Is

the voltage

at the (1) of

E804 on the PWB

assembly MAIN fixed

to "L" during

warming-

up?

Not light

Change the

lamp. Does lamp

light?

NG

install the Lamp

YES

“L” = 0V

PWB assembly

MAIN

Light

Lamp

NO (0V)

PWB assembly

MAIN

NO (0V)

PWB assembly

MAIN

Correct

PWB assembly

MAIN

Are

the voltage

supplied to the pin

(2) of connectors** for

DC fans soon after

the button is

pressed?

YES

(5V or higher)

Is

the voltage

supplied to the pin

(4) of E801 soon after

the button is

pressed?

YES

(1V or higher)

Observe

the voltage

waveforms at pin (1) of

connectors for DC fans**

soon after the button

is pressed.

incorrect

Power unit (ballast) Power unit (circuit)

Blinks

E804 on the PWB assembly

MAIN set to "L" during

Correct waveform is drawn below.

What

is the state of

TEMP indicator

D302?

Not light

and blink

Is the

voltage at the (3) of

warming-up?

No

Power unit (ballast)

No

Measure

Lights

PWB assembly MAIN

resistance of

E1, E2 and E3 after

disconnecting them

from MAIN

board.

Thermistor

(E1/E2/E3)

YES

“L” = 0V

OK

PWB assembly

MAIN

E1/E2: 5 to 20k

E3: 0.5 to 2k

NG(open/short)

DC fan

(failed in above check)

f 40Hz

14

Page 15

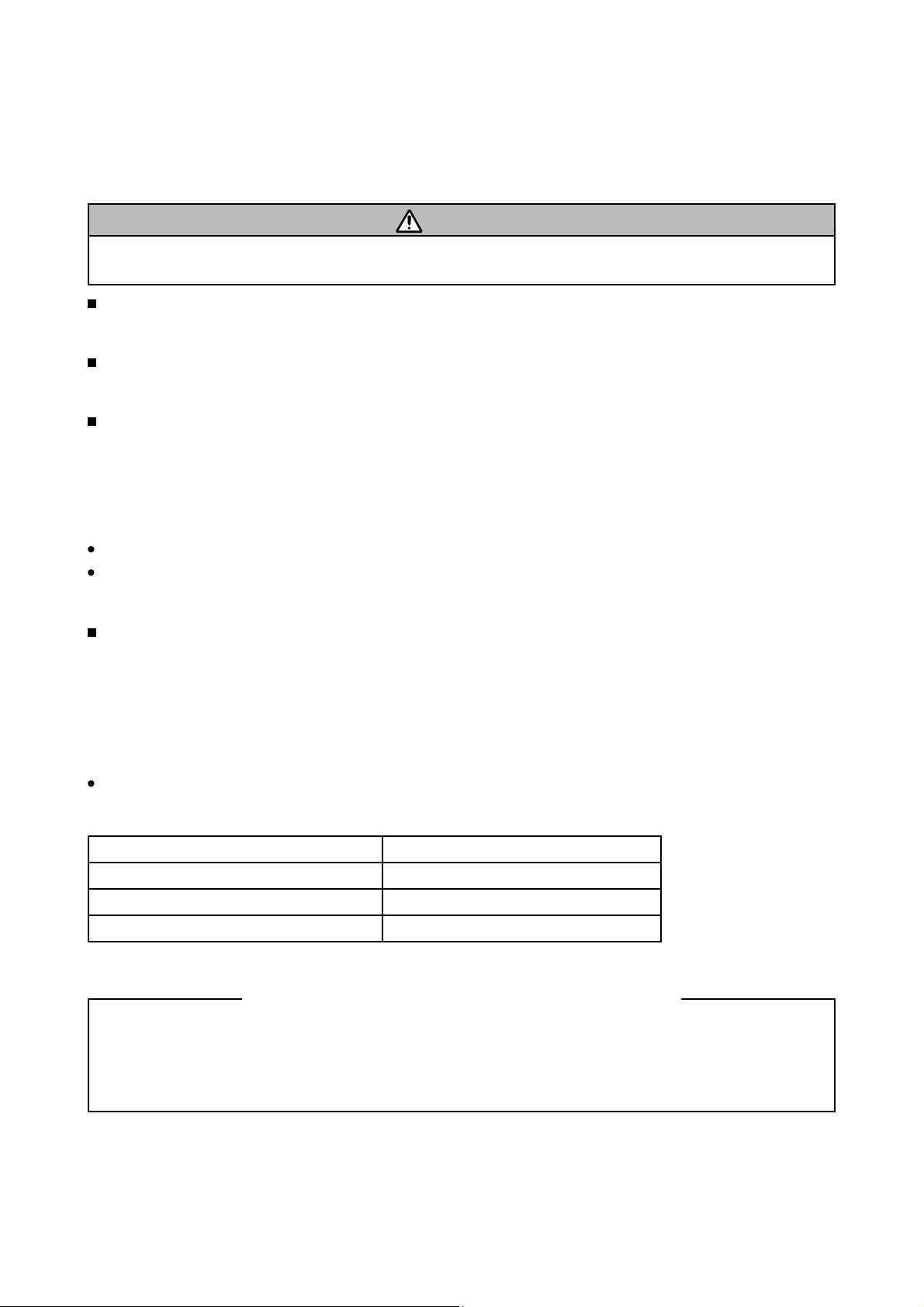

Picture is not displayed.

ED-X10/ED-X12(CC9XM2)

Are

the splash screen

and the user menu displayed

correctly?

YES

Are all

of the pictures

from video, s-video and

component video ports

displayed correctly?

YES

Is the

picture from RGB

out port displayed correctly

on another monitor

display?

YES

Is the

message of ”

No input is detected on

**” or “Sync is out of range on

**” displayed on the

screen?

No

No

No

YES

Confirm

the LCD Panels

connection to the MAIN

board.

OK

PWB assembly MAIN LCD/Lens prism assembly

PWB assembly MAIN

PWB assembly MAIN

SN74LVC1G97

(IS06/IS07)

EL8302IUZ

(IS02/IS03)

SN74LVC1G97

(IS08/IS09)

NG

CPC30 connector A/B

No

PWB assembly MAIN EL8302IUZ

(IS02/IS03)

15

Page 16

ED-X10/ED-X12(CC9XM2)

No sound

Check at operating mode

(Make sure the state of MUTE and Volume)

Disconnect

the speaker from the

PWB assembly Main, and

measure its

resistance.

about 8

PWB assembly Main

infinity

Speaker

Can not control to RS-232C

Check the

RS-232C cable.

Are pin No. 2 and 3

crossed?

YES

Are the

signals input at each

pins on the PWB assembly

Main?

EK01

YES

Make sure PC setup

EK01

NO

NO

: RX

: TX

Use cross cable

PWB assembly MAIN

The check after parts change

1. PC power supply OFF

2. Connection of cable

3. Projector starting

4. PC starting

*When not operating :

PC set up change of cable.

16

Page 17

ED-X10/ED-X12(CC9XM2)

6. Service points

6-1 Lead free solder [CAUTION]

This product uses lead free solder (unleaded) to help preserve the environment. Please read these

instructions before attempting any soldering work.

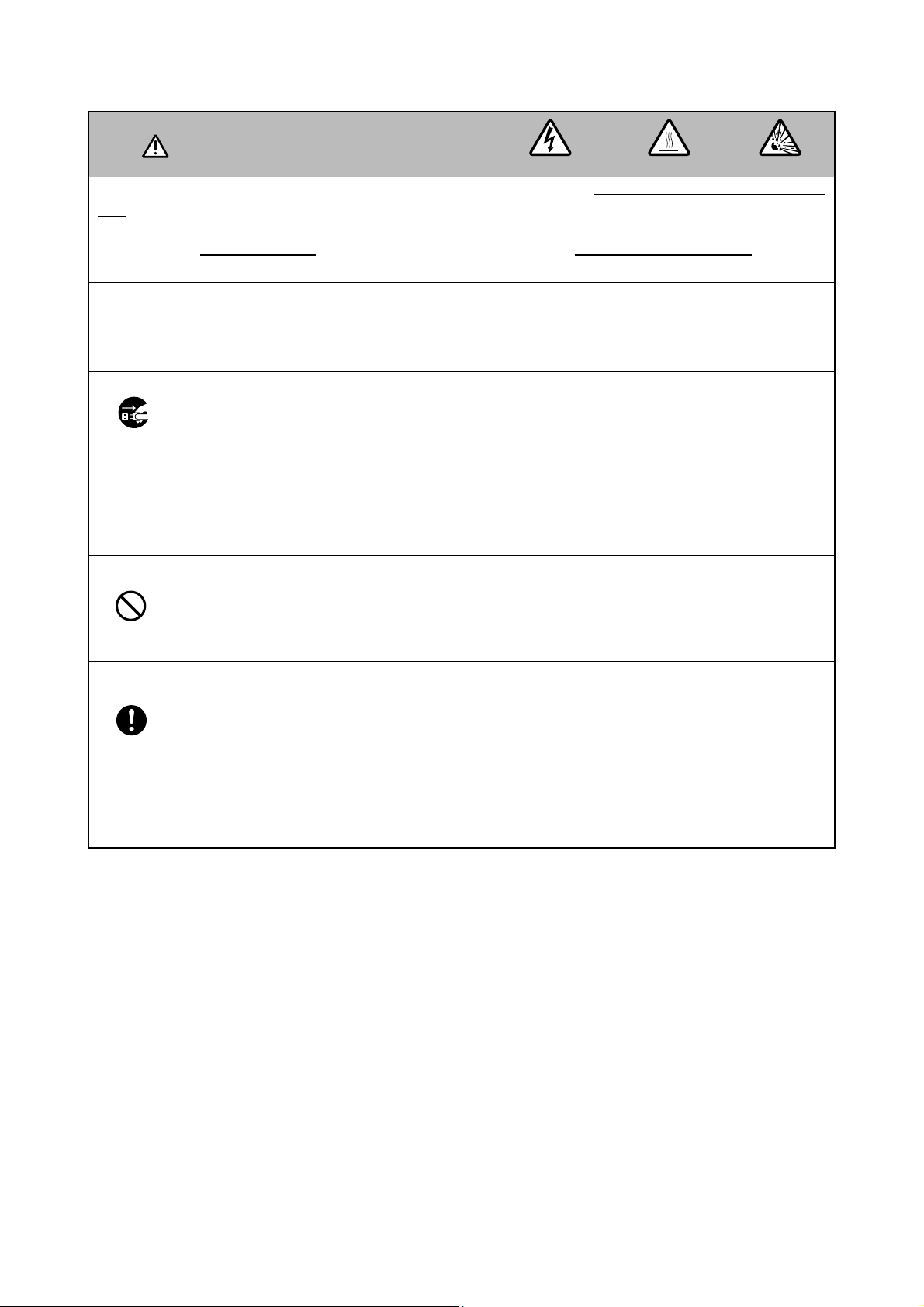

CAUTION

Always wear safety glasses to prevent fumes or molten solder from getting into the eyes. Lead free solder

can splatter at high temperatures (600˚C).

Lead free solder indicator

Printed circuit boards using lead free solder are engraved with an "F" or "LF".

Properties of lead free solder

The melting point of lead free solder is 40-50˚C higher than leaded solder.

Servicing solder

Solder with an alloy composition of Sn-3.0Ag-0.5Cu or Sn-0.7Cu is recommended.

Although servicing with leaded solder is possible, there are a few precautions that have to be taken. (Not

taking these precautions may cause the solder to not harden properly, and lead to consequent malfunctions.)

Precautions when using leaded solder

Remove all lead free solder from soldered joints when replacing components.

If leaded solder should be added to existing lead free joints, mix in the leaded solder thoroughly after the

lead free solder has been completely melted (do not apply the soldering iron without solder).

Servicing soldering iron

A soldering iron with a temperature setting capability (temperature control function) is recommended.

The melting point of lead free solder is higher than leaded solder. Use a soldering iron that maintains a high

stable temperature (large heat capacity), and that allows temperature adjustment according to the part being

serviced, to avoid poor servicing performance.

Recommended soldering iron:

Soldering iron with temperature control function (temperature range: 320-450˚C)

Recommended temperature range per part:

Part Soldering iron temperature

Mounting (chips) on mounted PCB 320˚C±30˚C

Mounting (chips) on empty PCB 380˚C±30˚C

Chassis, metallic shield, etc. 420˚C±30˚C

The PWB assembly which has used lead free solder

(1) PWB assembly MAIN

(2) PWB assembly REMOTE

(3) PWB assembly CONTROL

(4) POWER UNIT (BALLAST)

(5) POWER UNIT (CIRCUIT)

17

Page 18

ED-X10/ED-X12(CC9XM2)

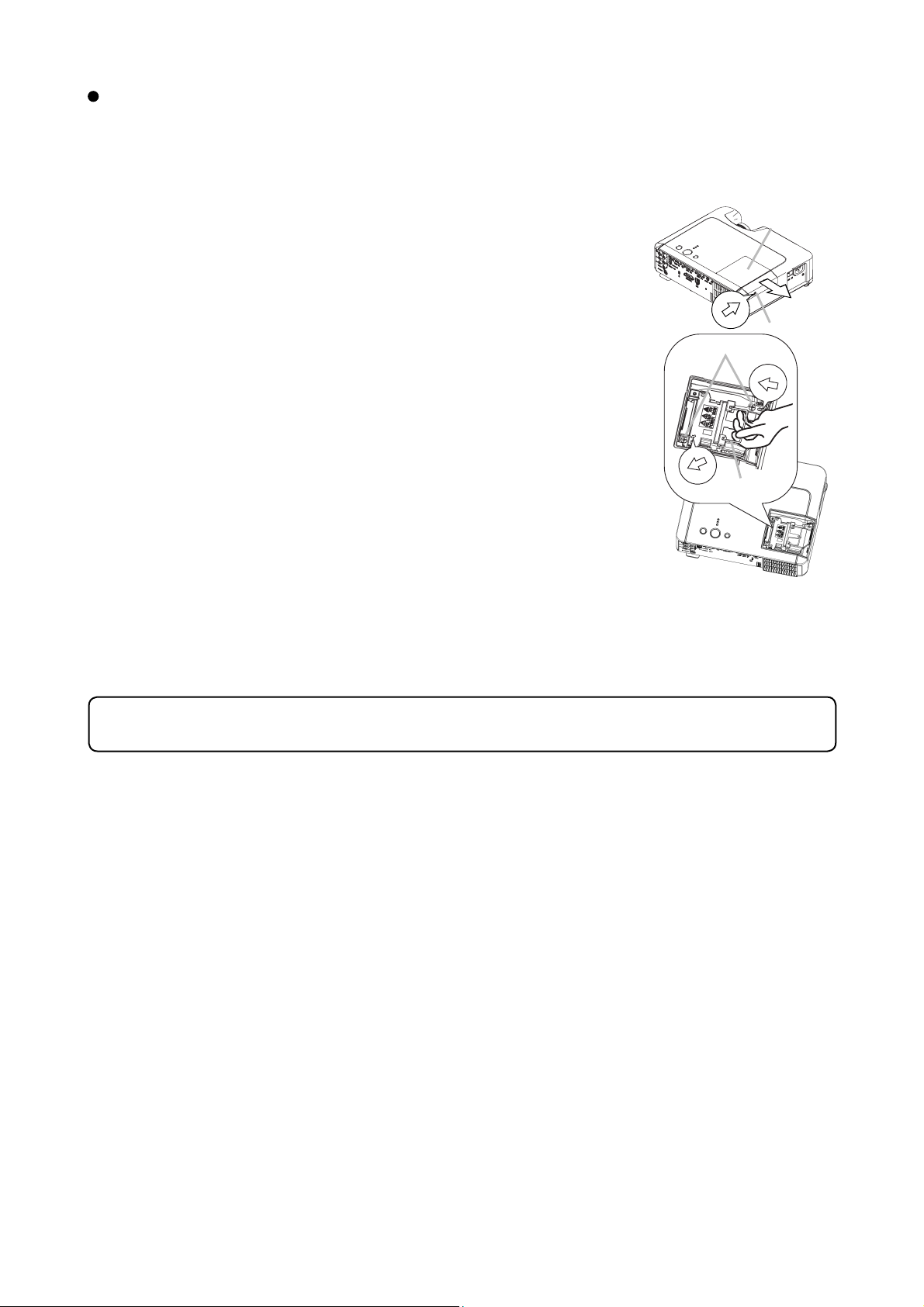

6-2 Before Replacing The LCD/Lens Prism

You should not replace separately the parts of the liquid crystal LCD/Lens prism because it works properly

only when used together. Therefore, regarding these parts, you can either replace part, LCD/Lens prism

assembly, or send the whole unit LCD/Lens prism assembly back to HITACHI, where we will replace the

malfunctioning part, recondition the device and send it back to you.

G Panel

HITACHI

DISTRIBUTOR

Do not disassemble the unit

because replacement of separate

parts is not possible.

Return

Replacement of G Panel Reconditioning

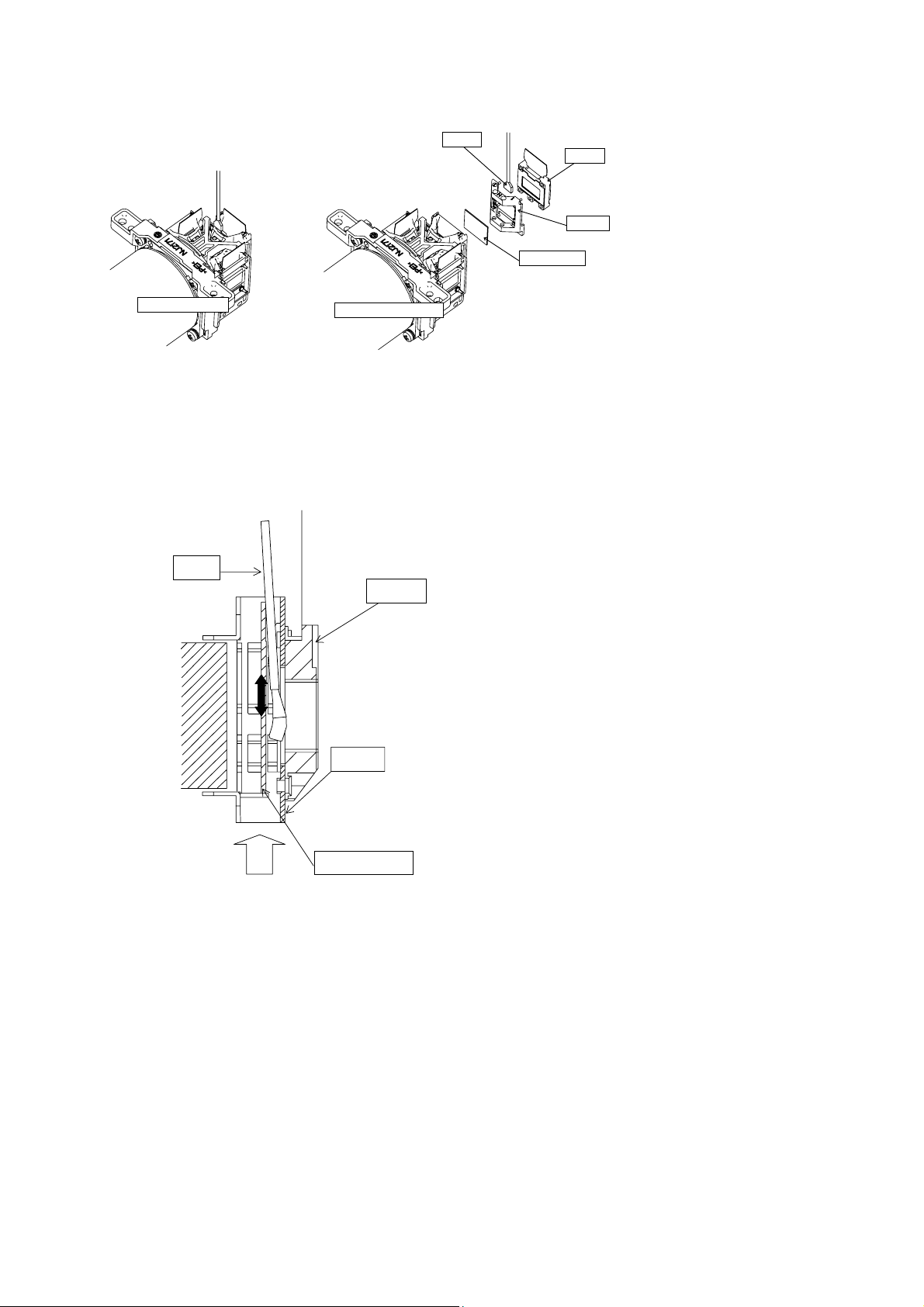

6-3 Cleaning up dust from panels and optical filters

WARNING

Wear sunglasses to protect your eyes when you maintain the projector with its lamp on.

1. Preparation

Please prepare cleaning tools and materials as follows. And prepare relatively clean room not to work in

additional dust, while removing operation.

(1) Swab for cleaning : P#: NX08061, "Cotton stick L147"

(2) Air duster (Dust blower, spray can)

(3) Vacuum cleaner

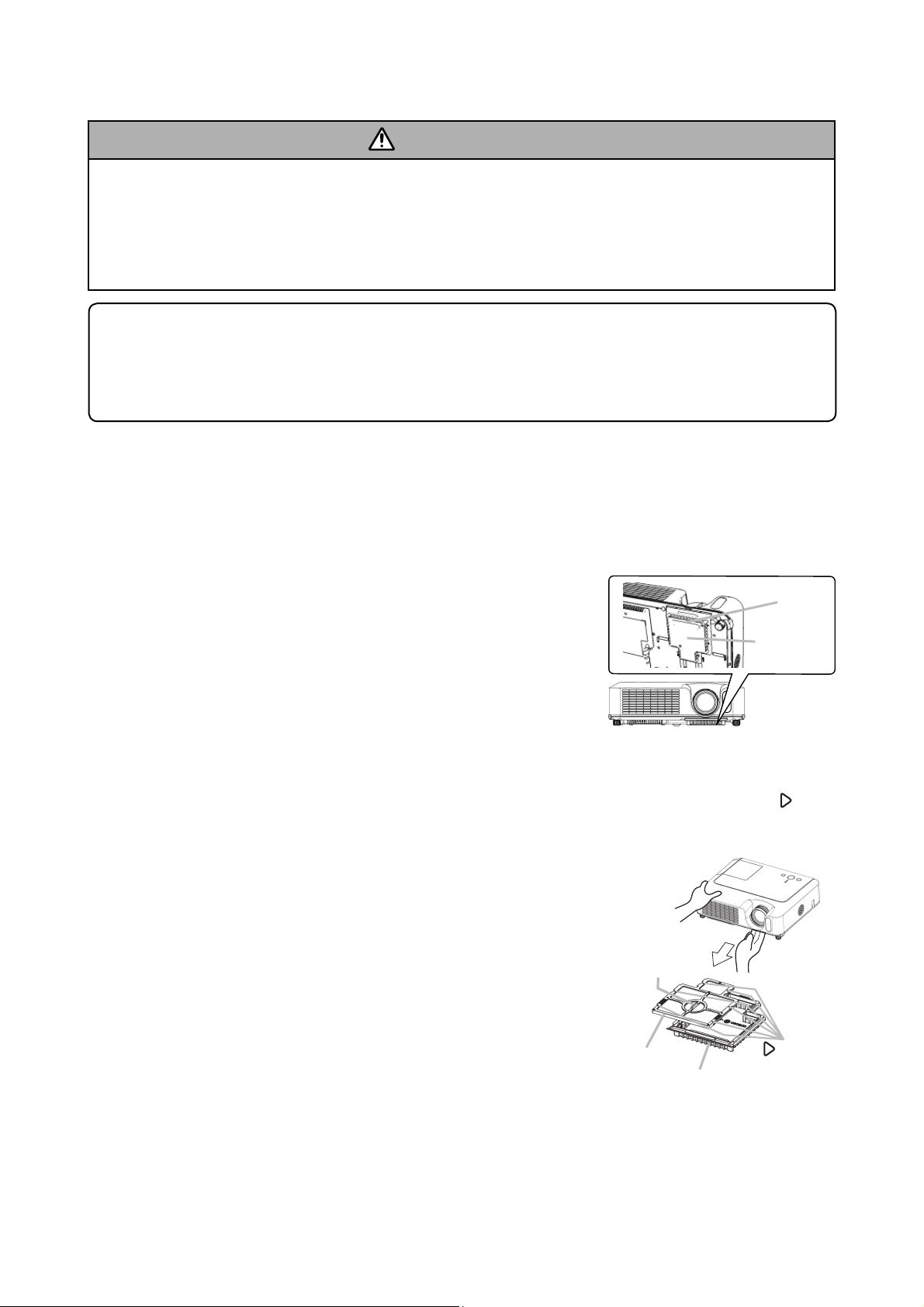

2. Disassemble and setting up.

(1) Turn off the projector, and unplug the power cord.

(2) Remove the lamp cover and upper case, according to the disassembling diagram of chapter 8.

(3) Unscrew the shield sheet and disconnect the LCD panel flexible cables.

(4) Unscrew PWB assembly MAIN to make it free.

Remove these screw

PWB assembly MAIN

Remove these screws

(5) Press and hold the switch S801 using an insulator during maintenance.

(6) Keep the unscrewed wires away from all of electric parts.

18

Flexible cables of LCD panel

Page 19

3. Maintenance point

ED-X10/ED-X12(CC9XM2)

Swab

Optical filter

Panel

Holder

Each color part has same

construction.

By using swab and air duster,

you can easily remove dust

from panel and optical filter.

Actual formation

Separatied formation

4. Cleaning the panels and optical filters

(1) Turn on the set and lit on the lamp.

(2) By using swab and air duster, remove the dust. Focusing dust makes you check the dust on screen.

Swab

Panel

• While removing the dust, separated dust will

be blown off by air cooling system.

• Please pay attention not to damage panels

and optical filters.

Holder

Air

Optical filter

5. Re-assembly

(1) Turn off the set and unplug the power cord.

(2) Remove an insulator from S801.

Screw down the PWB assembly MAIN and connect the LCD panel flexible cables to the PWB assembly MAIN.

(3)

(4) Re-assemble the set.

(5)

While re-assembling, please clean the intake filter by using a vacuum cleaner.

19

Page 20

ED-X10/ED-X12(CC9XM2)

6-4 Putting batteries

WARNING

Always handle the batteries with care and use them only as directed. Improper use may result in battery

explosion, cracking or leakage, which could result in fire, injury and/or pollution of the surrounding environment.

Be sure to use only the batteries specified. Do not use batteries of different types at the same time. Do

not mix a new battery with used one.

Make sure the plus and minus terminals are correctly aligned when loading a battery.

Keep a battery away from children and pets.

Do not recharge, short circuit, solder or disassemble a battery.

Do not allow a battery in a fire or water. Keep batteries in a dark. cool and dry place.

If you observe a leakage of a battery, wipe out the flower and then replace a battery.

If the flower adheres your body or clothes, rinse well with water immediately.

1. Remove the battery cover.

Slide back and remove the battery cover in the direction of the arrow.

2. Insert the batteries.

Align and insert the two AA batteries according to their plus and minus terminals as indicated in the

remote control.

3. Close the battery cover.

Replace the battery cover in the direction of the arrow and snap it back into place.

The signal settings for the remote control transmitter and the projector's remote sensor can be changed. If

the remote control does not function properly try changing the signal setting.

Changing the signal setting for the remote control transmitter

(1) Setting 1 (FREQ. : NORMAL)

Simultaneously press and hold the MUTE and RESET buttons for about 3 seconds.

(2) Setting 2 (FREQ. : HIGH)

Simultaneously press and hold the MAGNIFY OFF and ESC buttons for about 3 seconds.

•Setting 1 is the factory default setting.

•When the batteries are removed from the remote control, user-specified settings are saved for about half a

day. If the batteries are removed from the remote control for longer than half a day, the remote will reset to

Setting 1.

Changing the signal setting for the projector's remote sensor

Switch between Setting 1 and 2 using the SERVICE/REMOTE FREQ. item found in OPTION MENU.

Use the / button to change the Projector's remote sensor setting.

1:NORMAL 2:HIGH

Items with a checkmark are on. The factory default setting is for both 1:NORMAL and 2:HIGH to be on. If

the remote control does not function correctly set this to either only 1 or only 2. Neither can be turned off

at the same time.

NOTE: The remote control will not function properly if the remote control transmitter settings and the projec-

tor's remote sensor settings are not the same.

20

Page 21

ED-X10/ED-X12(CC9XM2)

6-5 Air filter

WARNING

• Before caring, make sure the power switch is off and the power cable is not plugged in, then allow the

projector to cool suffi ciently. The care in a high temperature state of the projector could cause an electric

shock, a burn and/or malfunction to the projector.

• Use only the air fi lter of the specifi ed type. Do not use the projector with the air fi lter and the fi lter cover

removed. It could result in a fi re and/or malfunction to the projector.

• The air fi lter should be cleaned periodically. If the air fi lter becomes clogged by dust or the like, internal

temperatures rise and could cause a fi re, a burn and/or malfunction to the projector.

NOTE

• Please replace the air fi lter when it is damaged or too soiled, and also when you replace the lamp.

• Please reset the fi lter time only when you have cleaned or replaced the air fi lter, for a suitable indication

about the air fi lter.

• The projector may display the message such as “CHECK THE AIR FLOW” or turn itself off, to prevent the

internal heat level rising.

If the air fi lter becomes clogged by dust or the like, internal temperatures rise and could cause a fi re, a burn

and/or malfunction to the projector. When the indicators or a message prompts to clean the air fi lter, clean

the air fi lter as soon as possible.

Please check and clean the air fi lter periodically, even if there is no message.Please replace the air fi lter

when it is damaged or too soiled.

And also when you replace the lamp, please replace the air filter. An air filter of specified type will come

together with a replacement lamp for this projector.

1. Turn the projector off, and unplug the power cord. Allow the lamp to

cool for at least 45 minutes.

2. When the projector is suspended from the ceiling, apply the vacuum

cleaner to and around the fi lter cover fi rst, to prevent penetration of

dust or the like.

3. While supporting the projector with one hand, use your other hand to

pull the fi lter cover forward in the direction of the arrow. Remove the

air fi lter.

4. Apply a vacuum cleaner to the air fi lter and the fi lter cover. Please replace the air fi lter when it is damaged

or too soiled.

5. Replace the air fi lter in its original position. Secure the air fi lter in place by pressing each of the six

locations.

Make sure there is no dust or dirt remaining after the cover is in place.

If any dust or dirt remains, use a vacuum cleaner to remove it as when

placing the fi lter cover on the air fi lter.

Reattach the fi lter cover to the projector by aligning the fi lter cover with

the grooves on the projector. While holding the handle, push down on

the fi lter cover until it locks fi rmly in place.

6. Turn the projector on and reset the fi lter time using the FILTER TIME

function.

(1) Press the MENU button to display a menu. When the EASY MENU

has appeared, please skip the next step (2).

(2) Point at the “OPTION” in the left column of the menu using /

button, then press the button.

(3) Point at the “FILTER TIME” using / button, then press the

button. A dialog will appear.

(4) Press the button to select “RESET” on the dialog. It performs resetting the fi lter time.

Air fi lter’s

knob

Air fi lter

Filter cover

Handle

Filter cover

mark

21

Page 22

ED-X10/ED-X12(CC9XM2)

6-6 Lamp

WARNING

The projector uses a high-pressure mercury glass lamp. The lamp can break with a loud bang, or burn

out, if jolted or scratched, handled while hot, or worn over time. Note that each lamp has a different life-

time, and some may burst or burn out soon after you start using them. In addition, when the bulb bursts, it

is possible for shards of glass to fly into the lamp housing, and for gas containing mercury to escape

from the projector’s vent holes.

About disposal of a lamp • This product contains a mercury lamp; do not put it in the trash. Dispose of

in accord with environmental laws.

For lamp recycling, go to www.lamprecycle.org. (in the US) For product disposal, contact your local government agency or www.eiae.org (in the US) or www.epsc.ca (in Canada).

• If the lamp should break (it will make a loud bang when it does), unplug the power cord from

the outlet. Note that shards of glass could damage the projector’s internals, or cause injury

during handling.

Disconnect

the plug

from the

power

outlet

• If the lamp should break (it will make a loud bang when it does), ventilate the room well, and

make sure not to breathe the gas that comes out of the projector vents, or get it in your eyes

or mouth.

• Before replacing the lamp, turn the projector off and unplug the power cord, then wait at least

45 minutes for the lamp to cool suffi ciently. Handling the lamp while hot can cause burns, as

well as damaging the lamp.

HIGH VOLTAGE HIGH TEMPERATURE HIGH PRESSURE

• Never unscrew except the appointed (marked by an arrow) screws.

• Do not open the lamp cover while the projector is suspended from above. This is dangerous,

since if the lamp’s bulb has broken, the shards will fall out when the cover is opened.

• Do not use the projector with the lamp cover removed. At the lamp replacing, make sure that

the screws are screwed in fi rmly. Loose screws could result in damage or injury.

• Use only the lamp of the specifi ed type.

• If the lamp breaks soon after the fi rst time it is used, it is possible that there are electrical

problems elsewhere besides the lamp. If this happens, contact your local dealer or a service

representative.

• Handle with care: jolting or scratching could cause the lamp bulb to burst during use.

• Using the lamp for long periods of time could cause it dark, not to light up or to burst. When

the pictures appear dark, or when the color tone is poor, please replace the lamp as soon as

possible. Do not use old (used) lamps; this is a cause of breakage.

22

Page 23

ED-X10/ED-X12(CC9XM2)

Replacing the Lamp

A lamp has a fi nite product life. Using the lamp for long periods of time could cause the pictures darker or

the color tone poor. Note that each lamp has a different lifetime, and some may burst or burn out soon after

being started using.

1. Turn the projector off, and unplug the power cord. Allow the lamp to cool for

at least 45 minutes.

2. Prepare a new lamp.

3. Loosen the lamp cover screw (marked by arrow) and then slide the lamp

cover to the side to remove it.

4. Loosen the 2 screws (marked by arrow) of the lamp, and slowly pick up the

lamp by the handles.

Screws

5. Insert the new lamp, and retighten fi rmly the two screws that are loosened in

the previous process to lock it in place.

6. Slide the lamp cover back in place and fi rmly fasten the lamp cover screw.

7. Turn the projector on and reset the lamp time using the LAMP TIME function

in the OPTION menu.

(1) Press the MENU button to display a menu. Only when the EASY MENU has

appeared, please perform the next step (2).

(2) Point at the “Go to Advanced Menu …” in the menu using / button, then

press the button.

(3) Point at the “OPTION” in the left column of the menu using / button,

then press the button.

(4) Point at the ”LAMP TIME” using / button, then press the button. A

dialog will appear.

(5) Press the button to select “RESET” on the dialog. It performs resetting the lamp time.

Lamp cover

Screw

Handle

NOTE

• Please reset the lamp time only when you have replaced the lamp, for a suitable indication about the lamp.

23

Page 24

ED-X10/ED-X12(CC9XM2)

6-7 Other care

WARNING

Before caring, make sure the power switch is off and the power cable is not plugged in, and then allow the

projector to cool suffi ciently. The care in a high temperature state of the projector could cause a burn and/

or malfunction to the projector.

Avoid wetting the projector or inserting liquids in the projector. It could result in a fi re, an electric shock, and

and/or malfunction to the projector.

• Don’t put a container containing water , cleaner or chemicals near the projector.

• Don’t use aerosols or sprays.

CAUTION

Please take right care of the projector according to the following. Incorrect care could cause not only an

injury but adverse influence such as discoloration, peeling paint, etc.

• Do not use cleaner or chemicals other than those listed below.

• Do not polish or wipe with hard objects.

Inside of the projector

In order to ensure the safe use of the projector, it needs to clean and inspect the projector about once a year.

Caring for the lens

If the lens is flawed, soiled or fogged, it could cause deterioration of display quality. Please take care of the

lens, being cautions of the handling.

1. Turn the projector off, and unplug the power cord. Allow the projector to cool sufficiently.

2. After making sure that the projector is cool adequately, lightly wipe the lens with a commercially available

lens-cleaning wipe. Do not touch the lens directly with your hand.

Caring for the cabinet and remote control

Incorrect care could have adverse influence such as discoloration, peeling paint, etc.

1. Turn the projector off, and unplug the power cord. Allow the projector to cool sufficiently.

2. After making sure that the projector is cool adequately, lightly wipe with gauze or a soft cloth.

If soiling is severe, dip soft cloth in water or a nautral cleaner dilute in water, and wipe lightly after wringing

well. Then, wipe lightly with a soft, dry cloth.

24

Page 25

ED-X10/ED-X12(CC9XM2)

6-8 Notice of AUTO adjustment

Use of AUTO adjustment with the image through RGB input optimizes V_POSI, H_POSI, H_SIZE and

H_PHASE automatically.

In case that projected image has dark tone around its peripheral, AUTO operation sometimes makes artifacts

in the image, shifts capture area and so on. Those failures are caused by period of image data is not exactly

distinguished to period of blanking on signal processing.

To avoid such phenomena, AUTO function should be used with the full size picture that has bright tone on its

peripheral.

Image when AUTO operates correctly

Note

1) The phenomenon at the failure of AUTO adjustment depends on resolution of input source, scene of pic-

ture etc.

2) There is no failure above in AUTO with video source through VIDEO, S-VIDEO or COMPONENT input. The

reason is why recognition of input signal’s standard does not need to search the capture range from input

signal itself.

Image when AUTO fails.

Noting image of top or bottom lines.

Shift of the image to East or West.

Artifacts on image. Etc.

25

Page 26

ED-X10/ED-X12(CC9XM2)

6-9 How to inactivate the security functions

This projector is equipped with security functions.

(1)MyScreen PASSWORD

The MyScreen PASSWORD function can be used to prohibit access to the MyScreen function and prevent the currently registered MyScreen image from being overwritten.

(2)PIN LOCK

PIN LOCK is a function which prevents the projector from being used unless a registered Code is input.

(3)Transition detector

Transition detector is a function which prevents the projector from being used unless the recorded vertical

angle of the projector and mirror setting is set.

64#05+6+10&'6'%61410

6JGRTQLGEVQTJCUDGGPVTCPUHGTTGF

HTQORTGXKQWUN[KPUVCNNGFRQUKVKQP

+H[QWYKUJVQJCXGCUSWCTGKOCIG

FKUCDNG6TCPUKVKQP&GVGEVQTQP/GPW

2+0$1:

QPUETGGPCICKP

Transition Detector

Alarm

It is possible to inactivate all security functions with following procedures.

(1) Go to “SECURITY” on OPTION Menu and press the button.

Then, ENTER PASSWORD box will be displayed.

(The BOX will be displayed by pressing the [MENU] button (remote) or [///] button (keypad) when

Transition Detector Alarm is displayed.)

5'%74+6;

'06'42#55914&

㪇㩷㩷㩷㪇㩷㩷㩷㪇㩷㩷㩷㪇

37+6 0':6

ENTER PASWORD box

(2) Press the [Magnify off] button once, then press [Magnify off] button of remote for 3 second or more to dis-

play SERVICE PASSWORD box.

5'48+%'

'06'42#55914&

㪄㩷㩷㩷㪄㩷㩷㩷㪄㩷㩷㩷㪄

SERVICE PASWORD box

(3) Enter the Life Key (MENU, , KEYSTONE, ). Then all security functions will be inactivated.

Note: • The Life key can be used up to 30 times. The key cannot be used thereafter. If the Life key cannot be

used, see the paragraph of SECURITY in the User’s Manual.

The frequency in which Life key is input will be set to 0 after the registered code is input.

The SECURITY Menu can not be operated if the SECURITY PASSWORD was released by Life key.

•

• The Mirror, Keystone and Auto keystone are not memorized though they are possible to operate if

Transition Detector was released by Life key.

• The MyScreen Lock on SCREEN Menu keeps “TURN ON” if MyScreen PASSWORD was set when

SECURITY PASSWORD was released by Life key.

26

Page 27

ED-X10/ED-X12(CC9XM2)

6-10 PIN LOCK System

If the following PIN BOX menu appears after power on the projector, the PIN LOCK system has been activated. Under such a condition, key operations and signal displaying are inhibited. To open the PIN LOCK system, we need to input the correct 4 digits PIN CODE. If correct PIN CODE is not input in 5 min., the lamp will

be automatically turned off.

PIN BOX

Returning repaired unit

Use the Master PIN code. See the paragraph of Releasing the PIN LOCK system inactivation.

Swap unit/Returned unit

Inactivate the PIN LOCK system. See the paragraph of the PIN LOCK system inactivation.

Releasing the PIN LOCK System

When the PIN BOX menu is displayed, sequentially enter the codes with remote controller as follows. In

accordance with remote controller button entry,

Master PIN codes

1st entry code: Press the “MENU” button.

2nd entry code: Press the “ ” button.

3rd entry code: Press the “KEYSTONE ” button.

4th entry code: Press the “ ” button.

Note: The Master PIN codes can be used up to 30 times. The codes cannot be used thereafter. If the Master

PIN codes cannot be used, see the paragraph of the PIN LOCK system inactivation.

“” mark appears in the PIN BOX menu.

The PIN LOCK System inactivation

1. When the PIN BOX menu is displayed, press “RESET” for 3 seconds or more in order to get the ID Inquiring Code.

PIN BOX

Inquiring Code

12 1234 1234

Inquiring Code

PIN BOX (ID Inquiring Code)

2. Send HITACHI sales company the Inquiring code (10 digits) to inquire the correct PIN code.

3. With the PIN BOX menu displayed, input the correct PIN code. Enter the correct PIN CODE that HITACHI

sales company informed.

4. Open menu and select “TURN OFF” from the PIN LOCK items in the SECURITY menu. Then the PIN

BOX menu appears.

5. Input the correct PIN code in the PIN BOX menu.

6. And then, PIN LOCK will be set to “TURN OFF”.

27

Page 28

ED-X10/ED-X12(CC9XM2)

6-11 Related Messages

When the unit’s power is on, messages such as those shown below may be displayed. When any such message

is displayed on the screen, please respond as described below.

Although these messages will be automatically disappeared around several minutes, it will be reappeared every

time the power is turned on.

Message Description

NO INPUT IS DETECTED

***

SYNC IS OUT OF RANGE

***

fH

*****kHz fV *****Hz

CHECK THE AIR FLOW

REMINDER

***HRS PASSED AFTER THE

LAST FILTER CHECK.

FILTER MAINTENANCE IS ESSENTIAL

TO REMOVE WARNING MESSAGE,

RESET FILTER TIMER.

SEE MANUAL FURTHER INFO.

There is no input signal.

Please confi rm the signal input connection, and the status of the signal source.

The horizontal or vertical frequency of the inputted signal is outside of the

response parameters of this unit.

Please confi rm the specs for this unit or the signal source specs.

The internal portion temperature is rising.

Please turn the power OFF, and allow the unit to cool down at least 20 minutes.

After having confi rmed the following items, please turn the power ON again.

• Is there blockage of the air passage aperture?

• Is the air fi lter dirty?

• Does the peripheral temperature exceed 35°C?

If the same indication is displayed after the remedy, please set FAN SPEED of the

SERVICE item in the OPTION menu to HIGH.

A note of precaution when cleaning the air fi lter.

Please immediately turn the power OFF, and clean or change the air filter by

referring to the “Air Filter” section of this manual. After you have cleaned or

changed the air fi lter, please be sure to reset the fi lter timer.

28

Page 29

ED-X10/ED-X12(CC9XM2)

6-12 Regarding the indicator lamps

Lighting and flashing of the POWER indicator, the LAMP indicator, and the TEMP indicator have the meanings as described in the table below. Please respond in accordance with the instructions within the table.

POWER

indicator

Lighting

In Orange

Blinking

In Green

Lighting

In Green

Blinking

In Orange

Blinking

In Red

Blinking

In Red

or

Lighting

In Red

Blinking

In Red

or

Lighting

In Red

Blinking

In Red

or

Lighting

In Red

Blinking

In Red

or

Lighting

In Red

Lighting

In Green

Lighting

In Green

LAMP

indicator

Turned

off

Turned

off

Turned

off

Turned

off

(discretionary)

Lighting

In Red

Blinking

In Red

Turned

off

Turned

off

blinking in Red

Simultaneous

blinking in Red

indicator

Alternative

TEMP

Turned

off

Turned

off

Turned

off

Turned

off

(discretionary)

Turned

off

Turned

off

Blinking

In Red

Lighting

In Red

Description

The projector is in a standby state.

The projector is warming up.

Please wait.

The projector is in an on state.

Ordinary operations may be performed.

The projector is cooling down.

Please wait.

The projector is cooling down. A certain error has been detected.

Please wait until the POWER indicator fi nishes blinking, and then perform the proper

measure using the item descriptions below.

The lamp does not light, and there is a possibility that interior portion has

become heated.

Please turn the power off, and allow the projector to cool down at least 20 minutes.

After the projector has suffi ciently cooled down, please make confi rmation of the

following items, and then turn the power on again.

• Is there blockage of the air passage aperture?

• Is the air fi lter dirty?

• Does the peripheral temperature exceed 35ºC?

If the same indication is displayed after the remedy, please change the lamp referring

to the section “Lamp”.

The lamp cover has not been properly fi xed (attached).

Please turn the power off, and allow the unit to cool down at least 45 minutes. After

the projector has suffi ciently cooled down, please make confi rmation of the attachment

state of the lamp cover. After performing any needed maintenance, turn the power on

again.

The cooling fan is not operating.

Please turn the power off, and allow the unit to cool down at least 20 minutes. After

the projector has suffi ciently cooled down, please make confi rmation that no foreign

matter has become caught in the fan, etc., and then turn the power on again.

If the same indication is displayed after the remedy, please replace a fan.

There is a possibility that the interior portion has become heated.

Please turn the power off, and allow the unit to cool down at least 20 minutes. After

the projector has suffi ciently cooled down, please make confi rmation of the following

items, and then turn the power on again.

• Is there blockage of the air passage aperture?

• Is the air fi lter dirty?

• Does the peripheral temperature exceed 35°C?

If the same indication is displayed after the remedy, please set the FAN SPEED of the

SERVICE item in the OPTION menu to HIGH.

There is a possibility that the interior portion has become overcooled.

Please use the unit within the usage temperature parameters (5°C to 35°C). After the

treatment, resent the power to ON.

If the same indication is displayed after the

treatment, please make sure that the proper cables are connected to each of

connectors E301, E302 and E304 on the PWB assembly MAIN.

It is time to clean the air fi lter.

Please immediately turn the power OFF, and clean or change the air fi lter referring to

the section “Air Filter”. After cleaning or change the air fi lter, please be sure to reset

the fi lter timer. After the remedy, resent the power to ON.

NOTE •

When the interior portion has become overheated, for safety purposes, the power source is automati-

cally turned off, and the indicator lamps may also be turned off. In such a case, press the “” (OFF) side of the

power switch, and wait at least 45 minutes. After the projector has suffi ciently cooled down, please make con-

fi rmation of the attachment state of the lamp and lamp cover, and then turn the power on again.

29

Page 30

ED-X10/ED-X12(CC9XM2)

6-13 HIDDEN SERVICE MENU

To display the OSD for “HIDDEN SERVICE MENU” set up.

HIDDEN SERVICE

AIR-SENSOR EXECUTE

LAMP ALARM NOTE

LENS TYPE 1

STARTUP TYPE

SOFT RESET

1

1. Display the Advanced menu by

2. Select the “OPTION” on the

3. Continue press the button [ ]

By the control panel By the remote control transmitter

1. Display the menu by the

the “MENU” button.(If EASY

MENU appears, choose “Go to

Advanced menu” to display

ADVANCED MENU.)

“MENU” button. (If EASY

MENU appears, choose “Go to

Advanced menu” to display

ADVANCED MENU.)

2. Select the “OPTION” on the menu.

menu.

3. Press the “MAGNIFY OFF”

button.

fi rst, then press the button [ ]

together with “INPUT”, and hold

Next hold the “MAGNIFY OFF”

button for 3 seconds.

for 3 seconds.

SOFT RESET

If this is executed, all of the user data is initialized.Never use it when not required.

6-14 RUN TIME window

Set operating time display method (accumulated lamp time display method)

1. Select “OPTION” from the Advanced menu, then place the cursor on the “LAMP TIME”.

2. Press the [ ], [ENTER] or [RESET] button.

3. Press the [Reset] button once, then press [KEYSTONE] button of the remote control for 3 seconds or

more to display the screen shown below. (The menu will close after 10 seconds if there are no further

operations.)

4. Use [ ] or [ ] to select the usage status number. (The usage status is as shown below.)

Usage status number

0 ..... Total usage status

1 ..... Current usage status

2 ..... Usage status before first reset

3 ..... Usage status before second reset

9 ..... Usage status before eighth reset

RUN TIME

LAMP Lamp time1234h

BRIGHT Lamp time(BRIGHT)1000

NORMAL Lamp time(NORMAL)234

AC 2000 AC energizing time

On Number of times on1

Off Number of times off

No.0 Usage status number(See below)

h

h

h

0

||

30

Page 31

7. Wiring diagram

ED-X10/ED-X12(CC9XM2)

Area of Importance

Attach the FB2 (ferrite core) to the CNPWR.

Make sure to completely lock the hook when attaching the FB2.

Secure the FB2 to the CNPWR with the cable tie Z2, as

indicated in the diagram.

Cut the cable tie with 2 to 3 mm of excess length remaining.

Area of Importance

The operations with this symbol have implications with

laws/standards. It is possible to be in violation of these

laws/standards in the case that these operations are not

carried out according to the instructions. Assemble

according to the operation instructions.

Heat sink

CN103

CN102

FB5

FB2

CN101

Heat

sink

CNPWR

FB2

Z2

Wiring diagram 1

50±5mm

CNPWR

Make sure to securely connect the CNPOW, TSW, and

CNPWR to the circuit power supply (as it cannot be confirmed

Wiring of the circuit power supply (1/2)

on the diagram below) when attaching the TSW.

(1)Connect the TSW. Make sure to confirm the seal (based

(2)Connect the CNPWR, attach FB2

Wiring of the circuit power supply main board

(3)Connect the CNPOW, attach FB5

whether they are securely connected in later processes).

CNPOW

TSW

Area of Importance

It is not necessary to secure the FB5

Attach the FB5 (ferrite core) to CNPOW.

Make sure to completely lock the hook

when attaching the FB5.

with a cable tie.

Make sure to confirm the print of the TSW.

31

Area of Importance

Confirm that the print indicates

Seal

Page 32

ED-X10/ED-X12(CC9XM2)

Make sure to pass the CNSH2 through

the hole indicated in the diagram below.

[CAUTION]

Make sure to attach the power supply

sheet after attaching the CNSH2.

E2

Outline of

power supply

case holes

CNSH2

Power supply case

Fastener

Lock the CNPOW, TSW by passing them through

the power supply case fastener.

Power supply sheet

FB2

Heat sink

CN101

CN103

CN102

CNSH2

CNPWR

ZTP2

Clamp Clamp

Fasten the CNSH2 and E2 with tape,

ZTP1 and ZTP2, after passing them

through the clamps of the power

supply case.

[CAUTION]

As the upper case touches the gray

areas of the diagram on the right,

make sure no wires protrude into

these areas.

Power supply

sheet

Heat sink

Luover of

the power

supply case

Fasten the E2 with tape ZTP1. Make sure to stick the tape

along the outline of the power supply case holes as shown

in the diagram.

ZTP1

Incorrect

(dotted line)

Wiring diagram 2

Correct

(solid line)

Don’t wire the E2 on the louvers.

The solid line in the diagram indicates an example of correct wiring.

The dotted lines in the diagram indicate examples of incorrect wiring.

FB5

TSW

CNPOW

Wiring of the circuit power supply (2/2)

Wiring of the circuit power supply board

(1)Style the CNPOW, TSW.

(2)Attach the CNSH2.

(3)Attach the power supply sheet.

(4)Style the CNPER.

Heat sink

Heat sink

Pass the CNPWR through

the hole in the power supply

sheet, and pull the wire out.

When pulling out the CNPWR and FB2, make sure that

they do not pass over the heat sink, as this will lift the

power supply sheet.

View from

above

32

Heat sink

Power supply sheet

Heat sink

View from

the side

Incorrect

Heat sink

Correct

Page 33

ED-X10/ED-X12(CC9XM2)

Be careful not to

pinch the wires

Area of Importance

It is not necessary to secure the FB4

Attach the FB4 (ferrite core) to the

fan

lead

Sirocco

when attaching the FB4.

CNBAR and sirocco fan lead.

Wind the CNBAR around once.

Make sure to completely lock the hook

with a cable tie.

when locking.

FB4

Sirocco fan lead

40±5mm

[CAUTION]

Be careful of where you

attach the FB4.

If the wire of the CNBAR

sags, it will get close to

the primary circuit inside

the ballast power supply.

CNBAR

Style the sirocco fan lead

Therefore, be careful of

where you attach the FB4,

as it prevents the CNBAR

wire from sagging.

FB4

by winding it around the

top, to prevent the lead

escaping the hook.

Fasten the fan lead with

tape ZTP5 after styling.

ZTP5

fan

lead

Sirocco

CNBAR

CNBAR

Sirocco

Ballast sheet

Ballast power supply

fan

FB4

Pull out the CNBAR, sirocco

fan lead, and FB4 from the

sheet hole after passing them

under the ballast sheet.

Make sure the sag in the wires

is absorbed in the direction of

the arrow.

Wiring diagram 3

Ballast power supply

FB3

Ballast sheet

Style the lamp lead of the

ballast power supply by

Wiring of the ballast power supply

Wiring of the ballast power supply board

(1)Attach and wire the FB3 to the lamp lead

(2)Attach the FB4, and wire the CNBAR and

sirocco fan.

passing it through the

groove in the bottom case.

Make sure the lamp lead of

the ballast power supply

does not touch with the

LAMP FAN BKT bracket

when styling it.

Make sure the sag in the

wires is absorbed in the

direction of the arrow.

LAMP FAN BKT Bracket

33

Pull out the lamp lead of

the ballast power supply

by passing it through the

slit in the ballast sheet.

Style by turning the boss

on the bottom case.

Attach the FB3 (ferrite core) to the lamp

Be careful when handling the ballast power supply.

Do not hold the small circuit board of the ballast power supply.

Make sure to connect the CNBAR before attaching the ballast power supply.

Insert connector straight.

The termination of the connector is likely to be bent and broken by inserting it diagonally.

Area of Importance

㊀ⷐᬺᚲ

when attaching the FB3.

lead of the ballast power supply.

Make sure to completely lock the hook

Page 34

ED-X10/ED-X12(CC9XM2)

Connect the CNPWR to the ballast power

supply.

Make sure it is securely connected.

(as it cannot be confirmed whether they are

securely connected in later processes).

[CAUTION]

Assemble the power supply block after

connecting the CNPWR.

CNPWR

lamp door bracket Power supply case bracket

㪘㪹㫊㫆㫉㪹㩷㪼㫏㪺㪼㫊㫊

㫃㪼㫅㪾㫋㪿㩷㫋㪿㫀㫊㩷㫎㪸㫐

Cross-sectional diagram

of this area

Pass the CNSH

through this gap.

Upper case

Lamp house

Bottom case

CNSH

Area of Importance

[CAUTION]

Connect the CNSH to the power supply case side only

Pass the CNSH through the hole below the lamp door

bracket, and style it by passing it through the gap between

the bottom case and lamp house.

Make sure the excess length of the wires is absorbed in

Connect the CNSH to the lamp door bracket and power

supply case bracket.

the direction of the arrow.

after assembling the power supply block.

Circuit power supply

[CAUTION]

Be careful not to pinch the CNBAR

and sirocco fan lead when attach-

ing the power supply unit.

Wiring diagram 4

Wiring of the power supply block

Wiring when assembling the power supply block

(1)Connect and style the CNPWR

(2)Wire the CNBAR and sirocco fan lead.

Attach the power supply block.

(3)Connect and wire the CNSH.

(4)Wire the lamp sirocco fan lead.

34

lead

Lamp

SIrocco

[CAUTION]

Complete the pulling out of

the lamp sirocco fan lead

before attaching the optical

engine.

Page 35

FB8

CNRM

the sirocco fan lead and E1.

Pass under the sirocco fan lead and E1.

3. Wire the CNRM passing under

ED-X10/ED-X12(CC9XM2)

FB7

ZTP7

This face is visible from outside.

Do not put the tape on this face.

the hook of duct. Attach the

FB7 to the sirocco fan by tape.

2. Hang the sirocco fan lead on

Assembly procedure of fan lead, E1, CNRM

1. Attach the FB7 to the E1. Hang

sirocco fan lead

duct

E1

the E1 on the hook of duct.

fan duct

duct

hook of duct

Little damage of the

wire is assumed to

hook of duct

FB7

Little damage of the

wire is assumed to

View from the side

be acceptable.

be acceptable.

Remote board

E1

Panel

sirocco

ZTP7

FB7

remote

board

FB8

CNRM

E3

Lamp

sirocco

main board

ZTP4

ZTP6

FB6

Hook of the

Dicroic optics unit

FB6

Set the FB6 in the corner

of Dicroic optics unit by tape.

Lamp sirocco

fan lead

E3

ZTP6

Wiring diagram 5

Attach the FB7(ferrite core) to the thermistor

Wiring of the fans

ing the main board

(1)Attach the E1 to the FB7.

(2)Style the E1, FB7, panel sirocco. Setting

them by tape.

(3)Attach the FB8 to the CNRM. Connect the

CNRM to the remote board.

(4)Attach the remote board. Style the CNRM.

Prepare the wiring of the fans before install-

(5)Attach the FB6 to the E3.

E1 lead.

(6)Style the E3 and lamp sirocco.

FB8

Area of Importance

Attach the FB8(ferrite core) to the CNRM lead.

Make sure to completely lock the hook when

attaching the FB7 and FB8.

30±10mm

CNRM

ZTP12

35

Area of Importance

Hang the E3 on the hook of Dichroic

optics unit.

Attach the E3 to the Dichroic optics

Attach the FB8 to the CNRM by ZTP12.

Wrap diagonally the tape to the FB8. Set the FB8

with both ends of tape.

See above diagram.

Attach the FB6(ferrite core) to the lamp sirocco lead.

Make sure to completely lock the hook when attaching the FB6.

unit by tape(ZTP4).

Attach the FB6 in the corner of the

Dichroic optics unit by tape(ZTP6)

Style the E3 and lamp sirocco lead

internally to prevent the protruding.

Page 36

ED-X10/ED-X12(CC9XM2)

main board

CNCO

Control board

Dichroic optics unit

Prevention of hooking the CNCO.

Prevent hooking the CNCO to the Dichroic

optics unit when installing the main board.

ZTP11

Control board

ZTP11

I/O metal

Wiring diagram 6

CNCO

main board

Preparation for attaching the main board

Wiring when attaching the control board.

(1)Attaching the control board to the I/O metal.

(2)Connect the main board and Control board by CNCO.

(3)Style and fix the CNCO.

36

Fasten the CNCO along the

control board by tape.

Page 37

ED-X10/ED-X12(CC9XM2)

CNSH2

Area of Importance

CNSH2

Fasten the end of the winding area with

tape.

Keep the prepared TSW and CNSH2 out

Wind the TSW around the CNSH2 5 times.

of the way by placing them on the top of

TSW

the power supply unit.

TSW

fan

Exhaust

E2

Wind around 5 times.

Fasten the end of the winding

area with tape ZTP3.

E804

ZTP3

When attaching the main board, keep the wires of

E2, exhaust fan, and TSW and CNSH2 (which have

been prepared) out of the way by placing them on

the top of the power supply unit.

Main board

LCD panel flexible cable

Optical unit

FB2

fan

Sirocco

E800

E802

CNPOW

n board

Mai

CNBAR

LCD panel

flexible cable

Connect the CNPOW, CNBAR, and

sirocco fan to the main board before

attaching the main board.

d

Main boar

LCD panel

flexible cable

Optical unit

Wiring diagram 7

Optical unit

fan, and TSW/CNSH2.

sirocco fan to the main board.

Wiring when attaching the main board (1/2)

Wiring when attaching the main board

(1)Prepare the TSW and CNSH2.

(2)Temporarily style the E2, FG3, exhaust

connectors.

(3)Connect the CNPOW, CNBAR, and

(4)Attach the main board, and style the

After lifting up the main board, connect the CNPOW,

CNBAR, and sirocco fan.