Hitachi dz-mv380e Service Manual

SERVICE MANUAL

TK No. 7304E

DZ-MV380E

DZ-MV380E(AU)

DZ-MV380E(SW)

DZ-MV380E(SWH)

DZ-MV380E(UK)

Contents Included and Reference Materials

Model DZ-MV380E series is basically the same

as the DZ-MV350E series: The CCD (image

sensor) and lens have been changed.

This service manual therefore includes only

differences from the DZ-MV350E series

manual.

When servicing the DZ-MV380E series , use

the DZ-MV350E series service manual (no.

7303E) along with this manual.

Refer to “2-1-1 Contents Included in Manual

and Reference Materials” on page 2-1 for

contents included in this manual and items to

be referred to in DZ-MV350E series service

manual.

MultiMediaCard

SPECIFICATIONS AND PARTS ARE SUBJECT TO CHANGE FOR IMPROVEMENT

DVD VIDEO CAMERA/RECORDER

2003April

Digital Media Division,Tokai

TM

Table of Contents

1 Safety Precaution for Repair ............. 1-1

1-1 Cautions ................................................... 1-1

1-2 Notes When Using Service Manual .......... 1-2

1-2-1 Value units used in parts list .................. 1-2

1-2-2 Values in schematic diagrams ............... 1-2

1-2-3 Identifications of sides A/B in

circuit board diagrams ........................... 1-2

1-2-4 Table for indexing locations of parts ....... 1-3

1-2-5 How to discriminate the "TYPE"

identifications in the manual .................. 1-3

1-3 Electrostatic Protection Measures ............ 1-4

1-3-1 Grounding for prevention of

electrostatic damage ............................. 1-4

1-3-2 Cautions when handling

optical pickup......................................... 1-4

1-4 Lead-Free Solder...................................... 1-5

1-4-1 Characteristics of lead-free solder ......... 1-5

1-4-2 Solder for servicing................................ 1-5

1-4-3 Soldering iron for servicing .................... 1-5

2 General Description ........................... 2-1

2-1 Overview .................................................. 2-1

2-1-1 Contents Included in Manual and

Reference Materials .............................. 2-1

2-1-2 Servicing method................................... 2-2

2-2 Features ................................................... 2-3

2-3 Specifications ........................................... 2-4

2-4 Major Differences from

Previous Models ....................................... 2-6

4 Troubleshooting.................................. 4-1

4-7 Trouble Diagnosis ..................................... 4-1

4-7-1 Selecting service position ...................... 4-1

4-7-2 Disassembly/reassembly for enabling

service position ..................................... 4-2

4-7-3 Trouble diagnosis table .......................... 4-5

4-8 Procedure for Removing Disc from

Faulty DZ-MV380E ................................... 4-8

4-8-1 Item to be checked ................................ 4-8

4-8-2 How to remove disc ............................... 4-8

5 Disassembly and Reassembly .......... 5-1

5-1 Preparations for Disassembly ................... 5-1

5-2 Order of Disassembly ............................... 5-1

5-3 Disassembly ............................................. 5-3

(1) Adjustment Cover .................................. 5-3

(2) Hood, Filter Piece, and Lens Cover ...... 5-3

(3) Eyecup, SAF Circuit Board, and

L Block .................................................. 5-4

(4) Front Block, FAF Circuit Board, and

R Block .................................................. 5-5

(5) L Cover, L Case and LCD Block ............ 5-6

(6) Microphone, Microphone Cover,

Jack Cover, Front Case, and

FRT Circuit Board.................................. 5-6

(7) LCD Case U, MR Circuit Board, and

Fulcrum Block........................................ 5-7

(8) Disc Cover ............................................. 5-8

(9) USB Circuit Board, Rear Cover, and

Hand Strap ............................................ 5-9

(10) SHE Circuit Board, Accessory

Shoe, and EVF Unit ............................... 5-10

(11) AEL and MAN Circuit Boards ................ 5-11

(12) Camera Block ........................................ 5-12

(13) LCD Circuit Board, Backlight,

LCD Unit , and LCD Case B .................. 5-13

(14) Link Bracket, Drive Block, and

R Case .................................................. 5-14

(15) Fulcrum Cover U and

Fulcrum Cover B ................................... 5-15

(16) GYR Circuit Board, Lens Frame,

Lens Unit, SEN Circuit Board and

Sensor ................................................... 5-15

(17) Loader, DRF Circuit Board,

Disc Drive Unit, and Lock Unit ............... 5-16

6 Adjustment .......................................... 6-1

Note:

The adjustment for DZ-MV380E is identical to that

for DZ-MV350E: Refer to the DZ-MV350E Service

Manual (No. 7303E).

i

7 Exploded View and Parts List............ 7-1

7-1 Exploded Views ........................................ 7-1

7-1-1 Main section .......................................... 7-1

7-1-2 LCD Block Section................................. 7-2

7-1-3 Camera Block Section ........................... 7-2

7-2 Replacement Parts List ............................ 7-3

7-2-1 Mechanical parts list .............................. 7-3

7-2-2 Electrical parts list ................................. 7-4

Schematic, Circuit Board and Block

Diagrams .................................................... 1

1 Wiring Diagram .............................................. 1

2 Schematic Diagrams ..................................... 2

2-1 SEN Schematic Diagram ........................... 2

2-2 FRT Schematic Diagram ........................... 3

2-3 FAF Schematic Diagram ............................ 3

2-4 SAF Schematic Diagram ........................... 3

2-5 GYR Schematic Diagram .......................... 4

2-6 SHE Schematic Diagram ........................... 4

2-7 Board To Board [AEL]

Schematic Diagram ................................... 5

2-8 Lens Drive [AEL] Schematic Diagram........ 6

2-9 Audio [AEL] Schematic Diagram............... 7

2-10 EVF [AEL] Schematic Diagram.................. 8

2-11 LCD Schematic Diagram ........................... 9

2-12 MR Schematic Diagram............................. 10

2-13 USB Schematic Diagram ........................... 10

2-14 DRF Schematic Diagram ........................... 10

2-15 IC Block Diagram....................................... 11

3 Circuit Board Diagrams ................................. 13

3-1 SEN Circuit Board Diagram ....................... 13

3-2 SHE Circuit Board Diagram ....................... 13

3-3 FRT Circuit Board Diagram ....................... 14

3-4 FAF, SAF Circuit Board Diagrams .............. 14

3-5 GYR Circuit Board Diagram....................... 15

3-6 DRF Circuit Board Diagram ....................... 15

3-7 MR Circuit Board Diagram ......................... 16

3-8 USB Circuit Board Diagram ....................... 16

3-9 AEL Circuit Board Diagram........................ 17

3-10 LCD Circuit Board Diagram ....................... 18

3-11 MAN Circuit Board Diagram ...................... 19

3-12 DRV Circuit Board Diagram ....................... 20

3-13 SID Circuit Board Diagram ........................ 21

3-14 HDM Circuit Board Diagram ...................... 21

3-15 Identification of Parts Location ................... 22

4 Block Diagrams ............................................. 23

4-1 Video/Audio Signal Process Section

Block Diagram ........................................... 23

4-2 Disc Drive Section Block Diagram ............. 24

4-3 Power-1 ..................................................... 25

4-4 Power-2 ..................................................... 26

Information of MAN, DRV, SID and HDM

Circuit Boards

During servicing, replace the entire MAN

circuit board, and the entire disc drive unit,

including the DRV, SID and HDM circuit

boards.

Because of this servicing method, this service

manual includes only the simplified circuit

board diagrams, and does not include any

schematic circuit diagrams.

The simplified circuit board diagrams show the

major voltage values: Refer to them during

troubleshooting.

ii

1

Safety Precaution for Repair

1-1 Cautions

CAUTION

Lithium battery; danger of explosion if battery is incorrectly replaced. Replace only with the same or

equivalent type recommended by the equipment manufacturer. Discard used batteries according to

manufacturer's instructions.

When replacing the lithium battery it is important to use the same type and connect it correctly.

WARNING:

Lithium batteries contain dangerous chemicals.

Handle and dispose of with great care.

Do not throw in a fire.

Do not short circuit it.

For disposal place in a plastic bag and put in waste bin.

PRODUCT SAFETY NOTICE

Many electrical and mechanical parts have special safety-related characteristics. These are often not

evident from visual inspection nor can the protection afforded by them necessarily be obtained by using

replacement components rated for a higher voltage, wattage, etc. Replacement parts which have these

special safety characteristics are identified in this Service Manual. Electrical components having such

features are identified by marking with a on the schematics and the parts list in this Service Manual.

The use of a substitute replacement component which does not have the same safety characteristics as

the HITACHI recommended replacement one, shown in the parts list in this Service Manual, may create

shock, fire, or other hazards. Product safety is continuously under review and new instructions are issued

from time to time. For the latest information, always consult the current HITACHI Service Manual. A

subscription to, or additional copies for, HITACHI Service Manual may be obtained at a nominal charge

from HITACHI SALES CORPORATION.

CAUTION (COLOR LCD)

LCD display; the liquid crystal display (LCD) panel is mode by highly precise technology.

More than 99.99% of its picture elements (pixels) are effective, but some (less than 0.01%) may appear

as colored bright dots. This mode not indicate a fault as the LCD panel stretches the limits of current

technology.

CLASS 1

LASER PROCTECT

CAUTION

This product contains a laser diode of

higher class than 1. To ensure continued safety, do not remove any covers

or attempt to gain access to the inside of the product. Refer all servicing

to qualified personnel.

CAUTION

There is a high-voltage section inside the DVD video

camera/recorder: When repairing or inspecting it, take

great care to prevent electric shock: Use an isolating

transformer, wear gloves, etc.

CAUTION

VISI

BLE

AND

RADIATION

LASER

EXPOSURETOBEAM.

AVOI D

INVI

BLE

SI

WHEN

OPEN.

1 - 1

Safety Precaution for Repair > Notes When Using Service Manual

1-2 Notes When Using Service Manual

The following shows the contents to be noted when using service manual:

1-2-1 Value units used in parts list

Certain symbols are indicated below for value units of resistors, capacitors and coils in parts list. When you read

them note the following regular indications:

Parts

Resistor

Capacitor

Coil

Indication in list Regular indication

...........................................

KOHM

................................................

UF

................................................

PF

................................................

UH

...............................................

MH

k

µF

pF

µH

mH

1-2-2 Values in schematic diagrams

The values, dielectric strength (power capacitance) and tolerances of the resistors (excluding

variable resistors) and capacitors are indicated in the schematic diagrams using abbreviations.

[Resistors] [Capacitors]

Item

Value

Tolerance

Power

capacitance

Indication

No indication

...................................................

K

..................................................

M

No indication

(All tolerances other than ±5% are

indicated in schematic diagrams)

No indication

(1/16W for leadless resistors without

indication)

All capacitances other than the above

are indicated in schematic diagrams.

...................................

.............................

............................

±5%

1/8W

k

M

Item

Value

Dielectric

strength

[Coils]

Item

Value

Indication

No indication

...................................................

P

No indication

(All dielectric strengths other than 50V

are indicated in schematic diagrams)

Indication

....................................................

µ

..................................................

m

.................................

..............................

µF

pF

50V

µH

mH

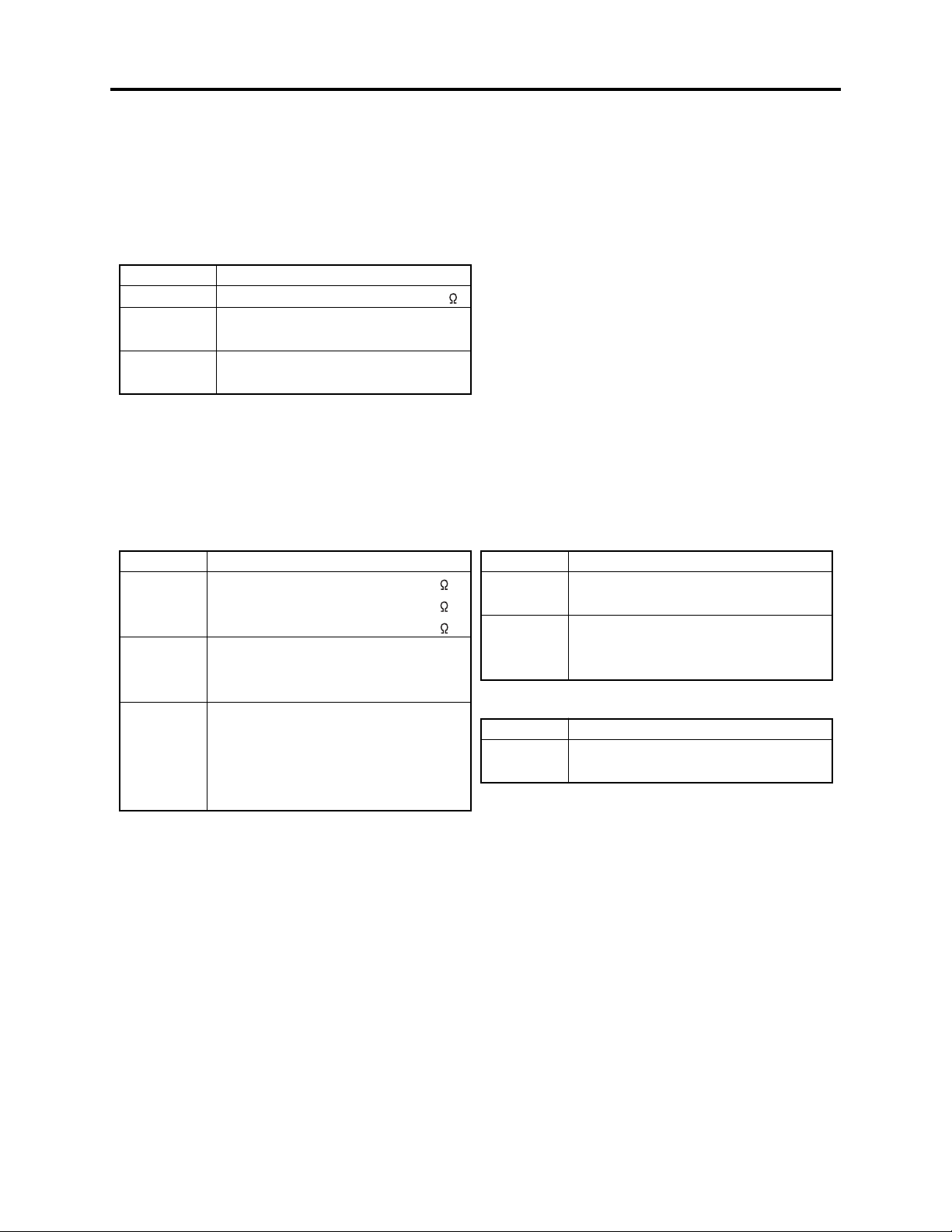

1-2-3 Identifications of sides A/B in circuit board diagrams

1) Board having a pattern on one side and parts on both sides.

Side A: Shows discrete parts, viewed from the pattern side.

Side B: Shows leadless parts, viewed from the pattern side.

2) Board having patterns on both sides and parts on both sides.

Side A: Shows parts and patterns which can be seen when the case is opened.

Side B: Shows parts and the pattern on the back of side A.

1 - 2

Safety Precaution for Repair > Notes When Using Service Manual

1-2-4 Table for indexing locations of parts

The table of “Identification of parts location” on circuit board diagrams shows locations of each part

is below explanations. The locations are indicated using the guide scales on the external lines of

diagrams.

1) One diagram indicated for each board

Symbol

No.

IC

IC1201

Circuit No.

Parts

Location

Type of part

2 A

Zone "A" on board diagram

Zone "2" on board diagram

2) Two diagrams indicated for each board

Symbol

No.

Parts

Location

IC

IC1201

A: Shows side A

B: Shows side B

A - 2 A

Zone "A" on board

diagram

Zone "2" on board

diagram

1-2-5 How to discriminate the "TYPE" identifications in the manual

The parts and circuits are identified by "TYPE" in this manual to discriminate the differences

between models. The TYPE numbers are the same as the model numbers. The table below shows

how to read the type identifications.

TYPE identification

TYPE 8A

TYPE 8E

DZ-MV380E/MV380E(AU)/MV380E(SW)/MV380E(SWH)/MV380E(UK)

Model name

Not used

1 - 3

Safety Precaution for Repair > Electrostatic Protection Measures

1-3 Electrostatic Protection Measures

Semiconductor components, including optical pickups, may be damaged by static electricity charged

on clothes, human body, etc. Take great care when handling it to avoid electrostatic damage.

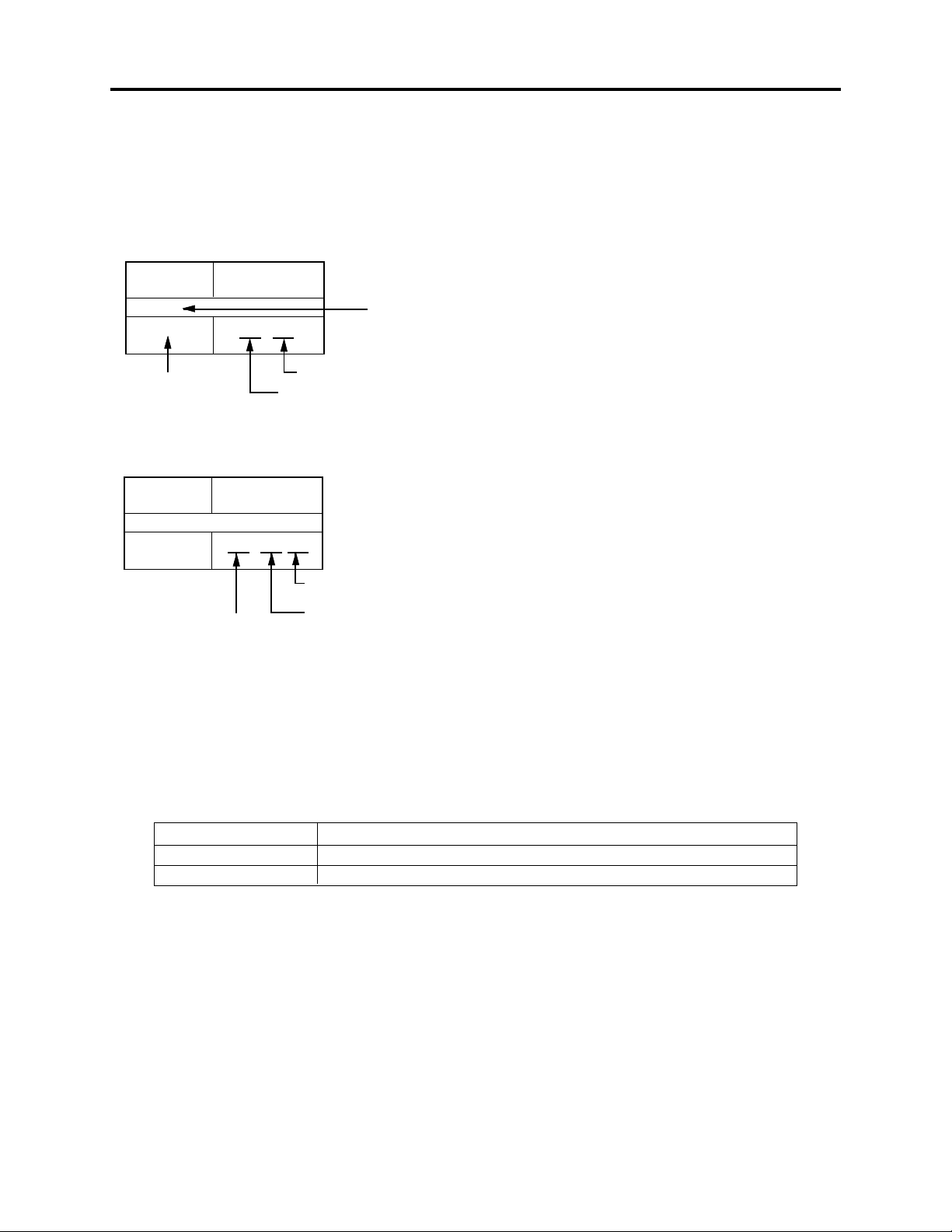

1-3-1 Grounding for prevention of electrostatic damage

Perform servicing in an environment where grounding is complete.

Grounding work bench (Fig. 1-3-1)

1) Lay out a conductive material (conductive sheet) or iron plate under the work bench on which

semiconductor components, such as optical pickups, are placed to ground the bench.

Grounding human body (Fig. 1-3-2)

1) Use an anti-static wrist strap to discharge static electricity charged on human body. Note,

however, that static electricity charged on clothes will not be discharged by anti-static wrist

strap: Be careful that your clothes do not touch the semiconductor components, such as optical

pickups.

Conductive material (conductive sheet)

or iron plate

Anti-static wrist strap

Ground

Fig. 1-3-1 Grounding work bench Fig. 1-3-2 Grounding human body

1M ohm

1-3-2 Cautions when handling optical pickup - only for DVD products

1) The optical pickup has a high precision structure: Do not subject it to any impact.

2) Do not perform disassembly further than that described in this manual.

3) Never turn the semi-variable resistors in drive unit block.

1 - 4

Safety Precaution for Repair > Lead-Free Solder

1-4 Lead-Free Solder

To protect the global environment, lead-free solder is used in this product.

Be sure to read the following before soldering.

Caution

Be sure to wear protective goggles so that no solder smoke or scattered solder enters the eye during

servicing. Lead-free solder may scatter at high temperatures (600°C).

1-4-1 Characteristics of lead-free solder

The melting point of lead-free solder is 30-40°C higher than that of lead based solder.

Composition of alloy (wt%): Sn-3.0Ag-0.5Cu

Melting temperature: Approx. 220°C

1-4-2 Solder for servicing

It is recommended that you use lead-free solder whose characteristics are the same as that used in

this product, although it is also possible to service using lead based solder. However, if lead based

solder is used for servicing, some precautions are necessary. (Neglecting these could decrease

strength, causing malfunctions.)

Cautions when using lead based solder:

When replacing components, remove the lead-free solder previously used for soldered points as far

as possible.

For additional soldering, melt lead-free solder completely and mix well with lead based solder. Never

perform repair using the bare soldering iron tip without adding solder.

1-4-3 Soldering iron for servicing

It is recommended that you use a soldering iron with thermal control function, with which the

temperature at its tip can be set.

Lead-free solder melts at a temperature 30-40°C higher than lead based solder. Therefore,

workability will be reduced unless you use a soldering iron whose temperature is high, whose

temperature at tip does not change greatly (heat capacity is large), and that can be set to match the

work points.

Recommended soldering iron:

With thermal control function (temperature setting range: 320-450°C)

Recommended tip temperatures for different work points:

Work point

Circuit board with surface-mounted (chip) parts

Circuit board without surface-mounted (chip) parts

Chassis, metal shield

Recommended tip temperature

320°C ± 30°C

380°C ± 30°C

420°C ± 30°C

1 - 5

2

General Description

Destinations normally added at the end of model names, (AU), (SW), (SWH), (UK) etc. are omitted

in this item.

2-1 Overview

The DZ-MV380E DVD video camera/recorder is equipped with mega-pixel CCD and highperformance lens. Since model DZ-MV380E is a higher version of DZ-MV350E, with the CCD and

lens changed, it has all the features and functions of DZ-MV350E.

As for external appearance, the DZ-MV380E is larger than the DZ-MV350E, since it uses a highperformance lens.

2-1-1 Contents Included in Manual and Reference Materials

This service manual includes only differences from the DZ-MV350E manual.

The following table shows the details: See “DZ-MV350E service manual (no. 7303E)” for any items

not included in this manual.

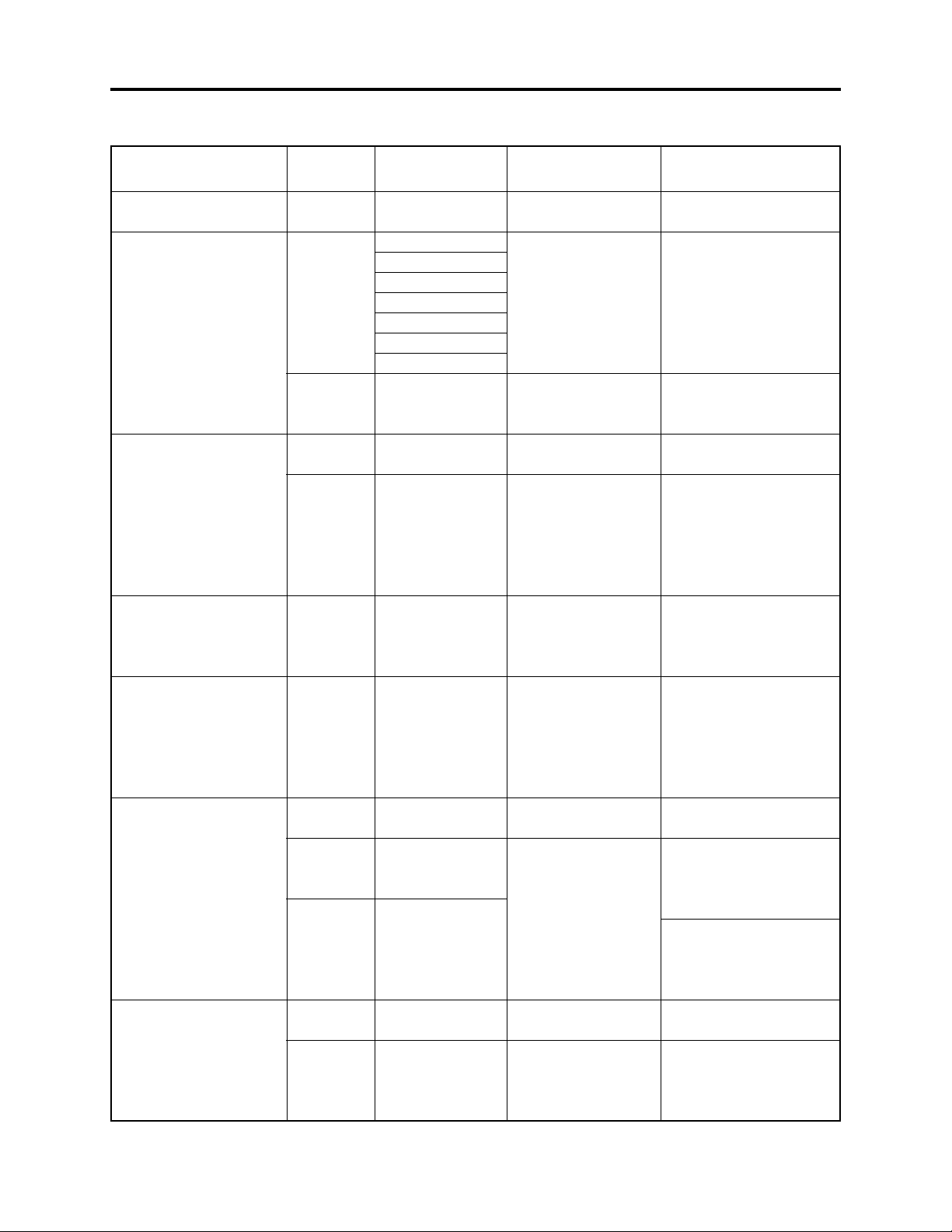

Table 2-1-1 Details Included

1 Safety Precaution for Repair

2 General Description

3 Description of

Operation

4 Troubleshooting

5 Disassembly and

Reassembly

6 Adjustment

7 Exploded View and

Parts List

Schematic, Circuit Board and Block Diagrams

2-1 Overview

2-2 Features

2-3 Specifications

2-4 Major Differences from Previous Models

2-5 List of Functions

2-6 Compatibility of Recorded Discs

2-7 Name of Parts

2-8 Inserting Disc

2-9 List of Abbreviations and Terms for DVD Video Camera/

Recorders

3-1 Description of Mechanism

3-2 Description of Newly Adopted Technology

4-1 Procedure for Troubleshooting

4-2 System Resetting/Resetting Camera Functions

4-3 Problem Guide

4-4 Messages and Troubleshooting

4-5 Self-Diagnosis Function and

Troubleshooting

4-6 Checking Versions of Firmware and Updating

4-7 Trouble Diagnosis

4-8 Procedure for Removing Disc from Faulty DZ-MV380E

4-9 Special Functions

5-1 Preparations for Disassembly

5-2 Order of Disassembly

5-3 Disassembly

7-1 Exploded Views

7-2 Replacement Parts List

Item

Inclusion

Yes

No

Yes

No

Yes

No

Yes

2 - 1

General Description > Overview

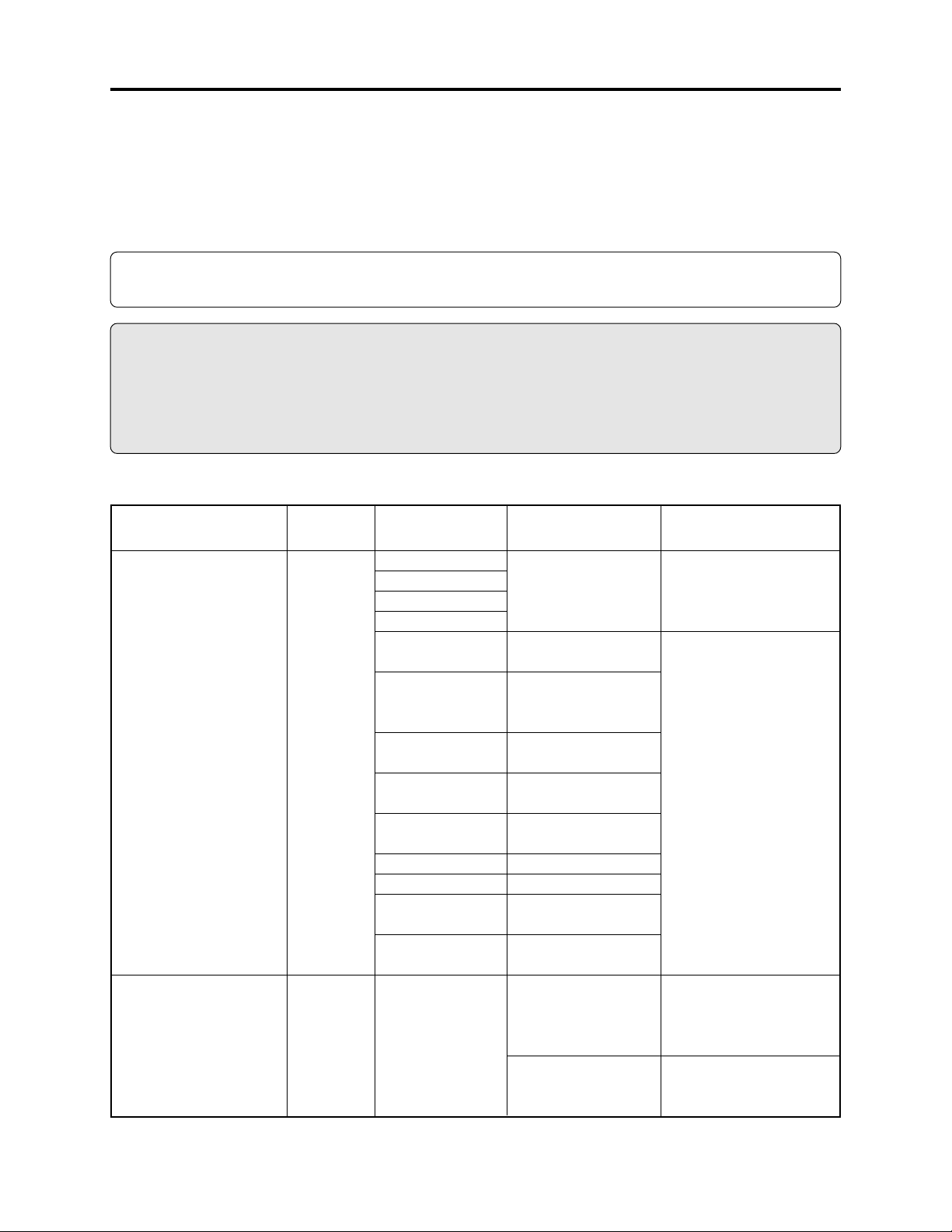

2-1-2 Servicing method

Table 2-1-2 shows the method for servicing each circuit board and each unit.

Refer to "4 Troubleshooting" for the method of judging defects in each circuit board and each unit.

Information:

These servicing methods are subject to change without notice for the purpose of facilitating service

procedures.

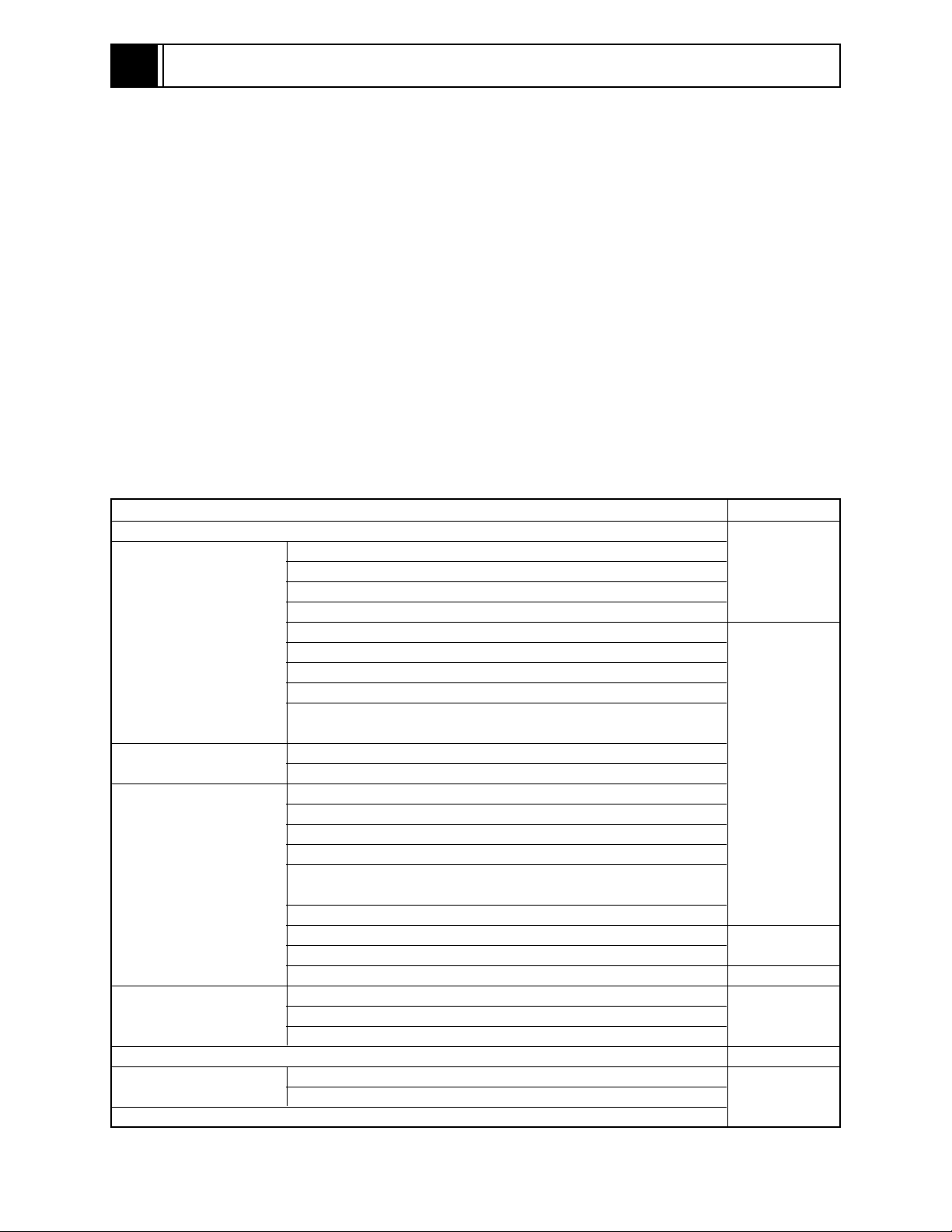

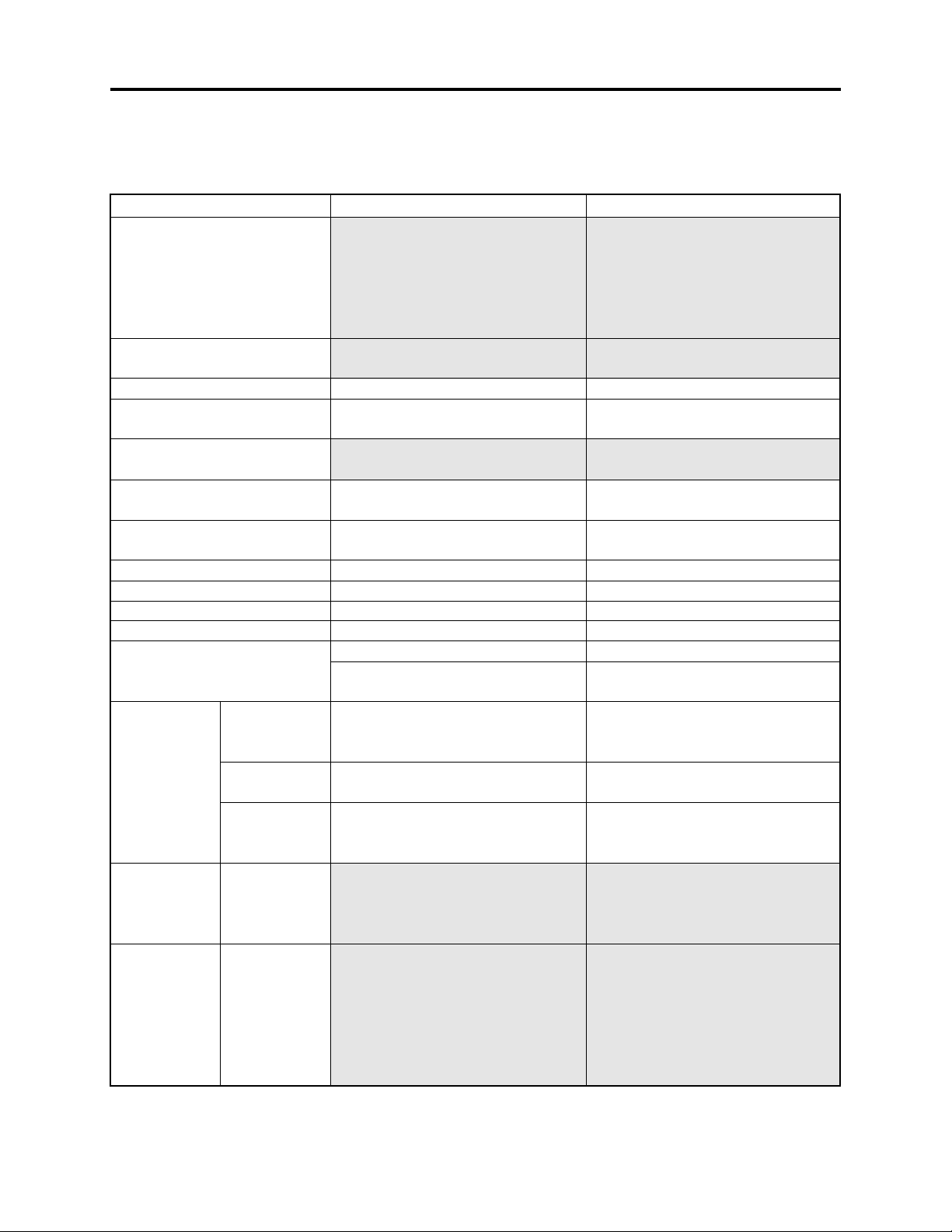

Table 2-1-2 Circuit Board and Unit Servicing

Method

Circuit board/Unit

AEL circuit board

DRF circuit board

DRV circuit board

FAF circuit board

FRT circuit board

GYR circuit board

HDM circuit board

LCD circuit board

MAN circuit board

MR circuit board

SAF circuit board

SEN circuit board

SHE circuit board

SID circuit board

USB circuit board

Disc drive unit

Servicing method

Component replacement.

Included in disc drive unit.

Component replacement.

Included in disc drive unit.

Component replacement.

Circuit board assembly

replacement (Order format).

Except for the fuse trouble.

Component replacement.

Included in disc drive unit.

Component replacement.

Unit replacement (Order

format). Which incorporates

the DRV, SID and HDM

circuit boards.

LCD

CIRCUIT

BOARD

DISC

DRIVE UNIT

SEN

CIRCUIT

*4

BOARD

AEL

CIRCUIT

BOARD

FAF CIRCUIT

BOARD

GYR

CIRCUIT

BOARD

USB

CIRCUIT

BOARD

*1

FRT

CIRCUIT

BOARD

SHE

CIRCUIT

BOARD

SAF

CIRCUIT

BOARD

MR

CIRCUIT

BOARD

DRF

CIRCUIT

BOARD

MAN

CIRCUIT

BOARD

*3

*2

*1: Film type board that connects AEL and FRT

circuit boards

*2: Film type board that connects MAN circuit

board and disc drive unit.

*3: Film type board that connects AEL circuit

board and switches in L case.

*4: The DZ-MV350E included the CCD mounting

circuit board in lens unit; the DZ-MV380E does

not.

Fig. 2-1-1 External Views of the Circuit Board/Unit

2 - 2

General Description > Features

2-2 Features

Mounting 1,020,000-pixel CCD (image

sensor)

A CCD with a total number of 1,020,000 pixels

(the number of effective pixels: 570,000 pixels

for video, 960,000 pixels for photo) is mounted

to ensure high resolution and faithful color

resolution.

Mounting a high-performance lens

A high-performance multi-coated aspheric lens

is mounted.

Multi-coating eliminates flare/ghost, and

aspheric lens reduces astigmatism, thereby

allowing maximum performance of the CCD.

1,020,000-pixel

CCD

High-performance

lens

Fig. 2-2-1 Media Storage Available on

DZ-MV380E

2 - 3

General Description > Specifications

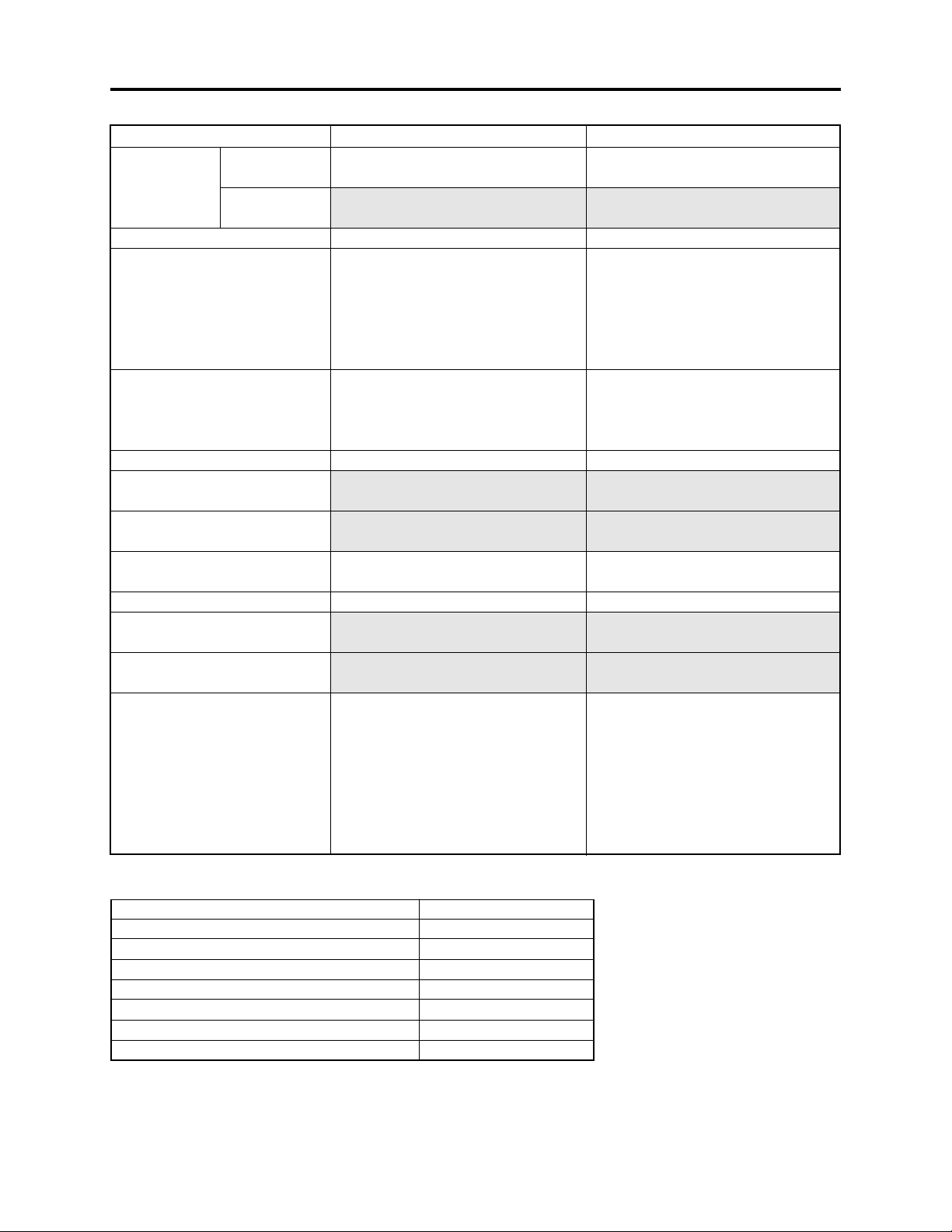

2-3 Specifications

The specifications in shaded columns are different from those of previous models.

Specifications are subject to change without notice for the purpose of improvement.

Item

CCD

Lens

Focus

Zoom

Required minimum

illumination

Viewfinder

LCD monitor

Image Stabilizer

Shutter speed

Self-timer recording

External microphone jack

Recording mode

Maximum

recordable

time

(per side)

Maximum

number of

recordable

photos

Recording

format

DVD-RAM disc

DVD-R disc

DVD-RAM disc

(per side)

Card (When

using 32MB

SD memory

card)

DVD-RAM disc

DZ-MV380E

1/3.8-inch interlaced

Total number of pixels:

Approx. 1020,000

Number of effective pixels:

Video: Approx. 570,000

Photo: Approx. 960,000

F1.8 - 2.4, f = 3.8 - 38 mm

Filter diameter: 37 mm

Auto/Manual

Optical 10×, 40 - 240× with digital

zoom added (40× for photo)

0.3 lx (When Low Light mode is

selected)

0.44-inch color TFT

(approx. 110,000 pixels)

2.5-inch color TFT

(approx. 1,200,000 pixels)

Electronic Type

1/60 - 1/4000 (video)

Photo recording only

Ø 3.5 mm stereo mini-jack

Video (with audio)

Photo (DVD-RAM disc, SD memory

card, MultiMediaCard)

XTRA mode: Approx. 18 min.

FINE mode: Approx. 30 min.

STD mode: Approx. 60 min.

FINE mode: Approx. 30 min.

STD mode: Approx. 60 min.

999 (However, if video and photo are

mixed on one disc, the recordable

number will decrease)

Approx. 50 (in FINE mode)

(Varies depending on the recording

quality and the type of card)

Video: Conforming to DVD video

recording format

Photo: Simultaneous recording,

conforming to DVD video

recording format (704 × 576

pixels) and JPEG (1280 × 960

pixels)

DZ-MV350E

1/4-inch interlaced

Total number of pixels:

Approx. 800,000

Number of effective pixels:

Video: Approx. 410,000

Photo: Approx. 410,000

F1.8 - 2.5, f = 3.15 - 31.5 mm

Filter diameter: 30.5 mm

Auto/Manual

Optical 10×, 40× - 240× with digital

zoom added (40× for photo)

0.1 lx (When Low Light mode is

selected)

0.44-inch color TFT

(approx. 110,000 pixels)

2.5-inch color TFT

(approx. 1,200,000 pixels)

Electronic Type

1/60 - 1/4000 (video)

Photo recording only

Ø 3.5-mm stereo mini-jack

Video (with audio)

Photo (DVD-RAM disc, SD memory

card, MultiMediaCard)

XTRA mode: Approx. 18 min.

FINE mode: Approx. 30 min.

STD mode: Approx. 60 min.

FINE mode: Approx. 30 min.

STD mode: Approx. 60 min.

999 (However, if video and photo are

mixed on one disc, the recordable

number will decrease)

Approx. 220 (in FINE mode)

(Varies depending on the recording

quality and the type of card)

Video: Conforming to DVD video

recording format

Photo: Simultaneous recording,

conforming to DVD video

recording format (704 × 576

pixels) and JPEG (640 × 480

pixels)

2 - 4

General Description > Specifications

Item DZ-MV380E DZ-MV350E

Recording

format

Audio playback format

Recording media

Jacks

Battery system

Power consumption (when

recording with LCD monitor off)

Dimensions (W × H × D,

excluding projections)

Operating temperature

(humidity)

Storage temperature

Weight (excluding battery and

disc)

Total weight when recording

Provided accessories

DVD-R disc

Card

Video: Conforming to DVD video

Photo: Conforming to JPEG (1280 ×

MPEG Audio layer 2, Dolby AC3

8 cm DVD-RAM disc (conforming to

8 cm DVD-R disc (conforming to

SD memory card

MultiMediaCard

Video/audio output × 1

External microphone input × 1

PC connection terminal (connected

Lithium-ion

Approx. 5.0 W (FINE mode)

Approx. 60 × 93 × 148 mm

0-40°C (less than 80%)

0-30°C when connected to PC

-20 - 60°C

Approx. 505 g

Approx. 590 g (when using DZ-BP14S

battery)

AC adapter/charger, battery, AV/S

output cable, infrared remote control,

Lithium battery for remote control,

lens cap, lens cap string, shoulder

strap, power cable, DC power cord,

ferrite core, software CD-ROM, PC

connection cable, 8cm DVD-R disc (in

round DVD holder)

format (MPEG Audio layer 2)

960 pixels) standard

DVD-RAM Ver. 2.1)

DVD-R for General Ver. 2.0)

to PC USB port) × 1

Video: Conforming to DVD video

format (MPEG Audio layer 2)

Photo: Conforming to JPEG (640 ×

480 pixels) standard

MPEG Audio layer 2, Dolby AC3

8 cm DVD-RAM disc (conforming to

DVD-RAM Ver. 2.1)

8 cm DVD-R disc (conforming to

DVD-R for General Ver. 2.0)

SD memory card

MultiMediaCard

Video/audio output × 1

External microphone input × 1

PC connection terminal (connected

to PC USB port) × 1

Lithium-ion

Approx. 4.7 W (FINE mode)

Approx. 57 × 89 × 134 mm

0-40°C (less than 80%)

0-30°C when connected to PC

-20 - 60°C

Approx. 480 g

Approx. 565g (when using DZ-BP14S

battery)

AC adapter/charger, battery, AV/S

output cable, infrared remote control,

Lithium battery for remote control,

lens cap, lens cap string, shoulder

strap, power cable, DC power cord,

ferrite core, software CD-ROM, PC

connection cable, 8cm DVD-R disc (in

round DVD holder)

Specifications of DZ-ACS1 AC Adapter/Charger (Reference)

Power supply

Input capacity

DC output (max.)

Charge output

Weight

External dimensions (W x H x D)

Ambient temperature for operation

Allowable relative humidity

100 - 240 V AC, 50/60 Hz

26 VA (at 100 V)

7.9 V, 1.4 A

8.4 V, 0.65A

105 g

61 × 32 × 91 mm

5 - 35°C

40 - 80%

2 - 5

General Description > Major Differences from Previous Models

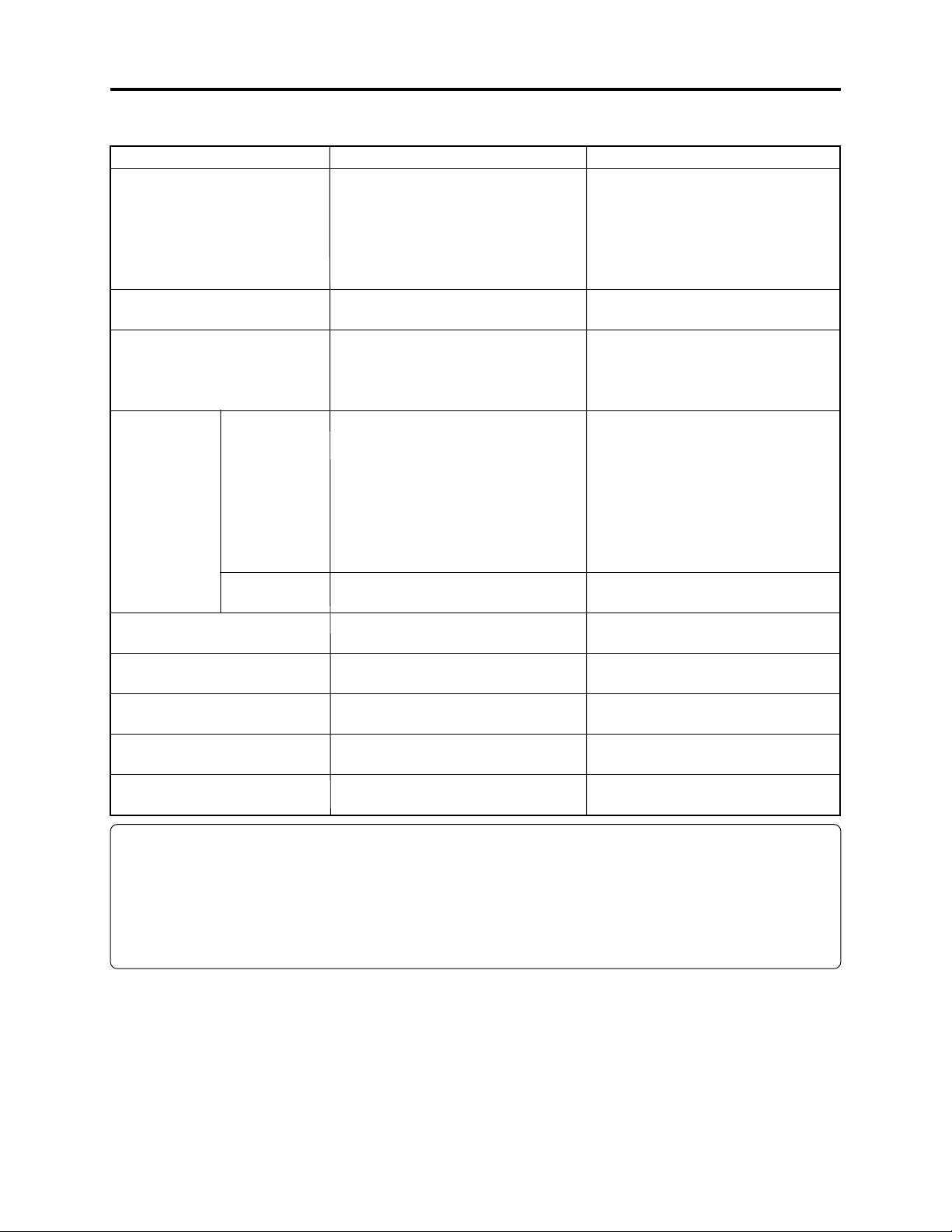

2-4 Major Differences from Previous Models

Item

CCD

Lens

Maximum number of

recordable photos for card

(When using 32MB SD memory

card)

Recording

format

Power consumption (when

recording with LCD monitor off)

Dimensions (W × H × D,

excluding projections)

Weight (excluding battery and

disc)

Total weight when recording

Accessory shoe

DVD-RAM disc

Card

DZ-MV380E

1/3.8-inch interlaced

Total number of pixels:

Approx. 1020,000

Number of effective pixels:

Video: Approx. 570,000

Photo: Approx. 960,000

F1.8 - 2.4, f = 3.8 - 38 mm

Filter diameter: 37 mm

Approx. 50 (in FINE mode)

(Varies depending on the recording

quality and the type of card)

Video: Conforming to DVD video

recording format (MPEG

Audio layer 2)

Photo: Simultaneous recording,

conforming to DVD video

recording format (704 × 576

pixels) and JPEG (1280 × 960

pixels)

Photo: Conforming to JPEG

(1280 × 960 pixels) standard

Approx. 5.0 W (FINE mode)

Approx. 60 × 93 × 148 mm

Approx. 505 g

Approx. 590 g (when using DZ-BP14S

battery)

Power/control terminal provided

(External flash: DZ-FLH3 mountable)

DZ-MV350E

1/4-inch interlaced

Total number of pixels:

Approx. 800,000

Number of effective pixels:

Video: Approx. 410,000

Photo: Approx. 410,000

F1.8 - 2.5, f = 3.15 - 31.5 mm

Filter diameter: 30.5 mm

Approx. 220 (in FINE mode)

(Varies depending on the recording

quality and the type of card)

Video: Conforming to DVD video

recording format (MPEG

Audio layer 2)

Photo: Simultaneous recording,

conforming to DVD video

recording format (704 × 576

pixels) and JPEG (640 × 480

pixels)

Photo: Conforming to JPEG

(640 × 480 pixels) standard

Approx. 4.7 W (FINE mode)

Approx. 57 × 89 × 134 mm

Approx. 480 g

Approx. 565 g (when using DZ-BP14S

battery)

Power/control terminal not provided

Information:

1) Although the DZ-MV350E included the CCD mounting circuit board in lens unit, the DZMV380E does not: With the DZ-MV380E, the lens unit and CCD mounting circuit board (SEN

circuit board) are discrete components. Also, the CCD is set as an independent part.

2) The DZ-MV380E disassembly procedure is different from that for DZ-MV350E because the lens

unit, CCD and accessory shoe have been changed.

2 - 6

4

Troubleshooting

4-7 Trouble Diagnosis

Information:

Although the procedures for disassembling and reassembling the DZ-MV380E are different from

those for DZ-MV350E, the contents in “4-7-3 Trouble diagnosis table” still apply to both devices.

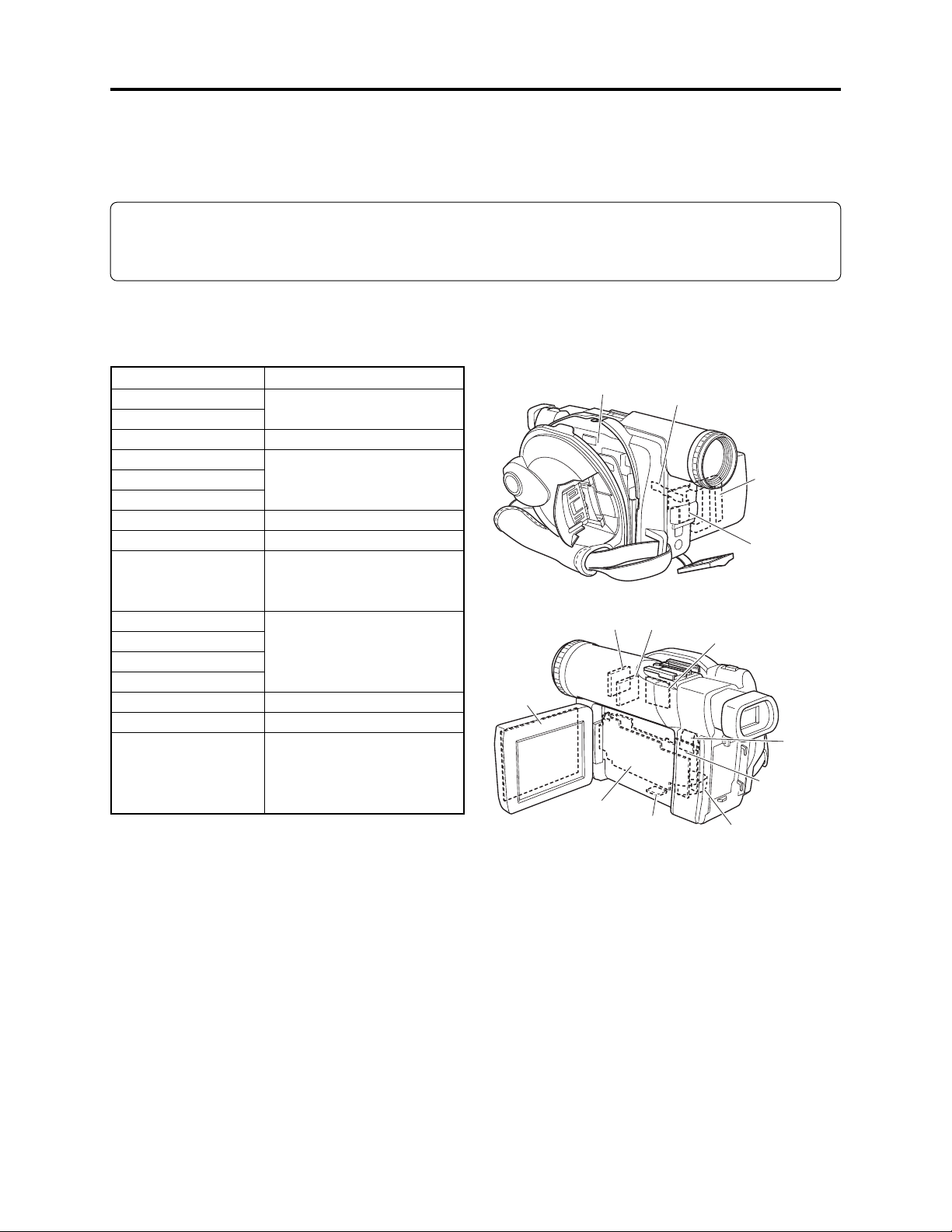

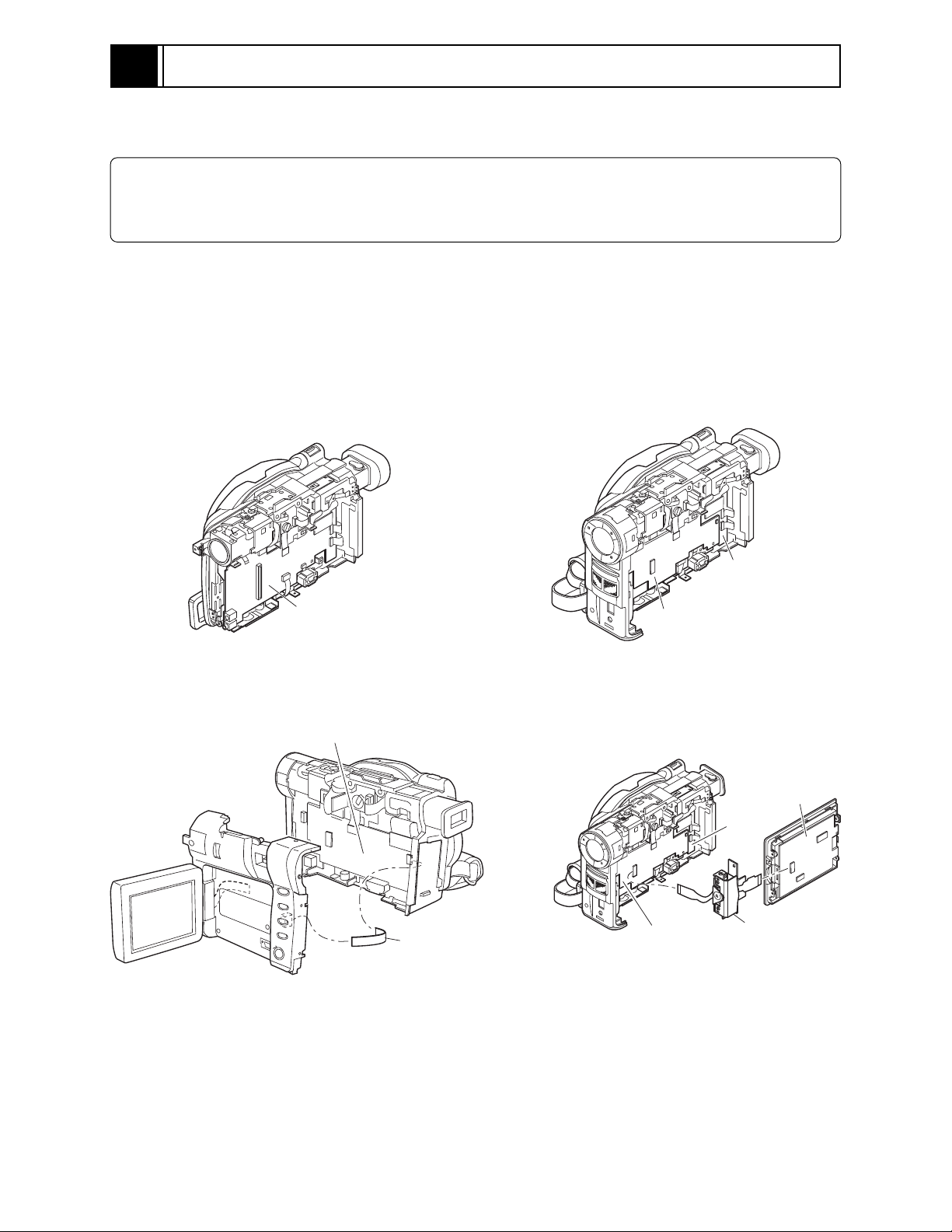

4-7-1 Selecting service position

For trouble diagnosis, with a few exceptions it is necessary to disassemble the DZ-MV380E and set it

to the service position.

There are four types of service position (A)-(D) as shown in the figures below.

Refer to Table 4-7-1 and select the appropriate service position for the defective symptom.

MAN

CIRCUIT

BOARD

MAN CIRCUIT

BOARD

AEL CIRCUIT

BOARD

Fig. 4-7-1 Service Position (A) Fig. 4-7-2 Service Position (B)

AEL CIRCUIT

BOARD

MAN

CIRCUIT

BOARD

FULCRUM

BLOCK

Fig. 4-7-3 Service Position (C)

SAF

CIRCUIT

BOARD

AEL

CIRCUIT

BOARD

Fig. 4-7-4 Service Position (D)

LCD

CIRCUIT

BOARD

4 - 1

Troubleshooting > Trouble Diagnosis

4-7-2 Disassembly/reassembly for enabling service position

Prohibition

Disconnect the AC adapter/charger of battery pack from the DZ-MV380E.

The DZ-MV380E has a built-in laser emitter block. Do not look into it: If Laser beam strikes your

eye, it could cause serious damage.

To set to service position (A), (B) or (C), remove the following components, referring to “5.

Disassembly and Reassembly”:

a) Hood, Filter Piece, and Lens Cover (Fig. 5-3-2)

b) Eyecup, SAF Circuit Board, and L Block (Figs. 5-3-3, 5-3-4)

c) Front Block, FAF Circuit Board, and R Block (Fig. 5-3-5)

d) AEL and MAN Circuit Boards (Fig. 5-3-13)

Information:

Numbers in figures are step numbers for setting procedure.

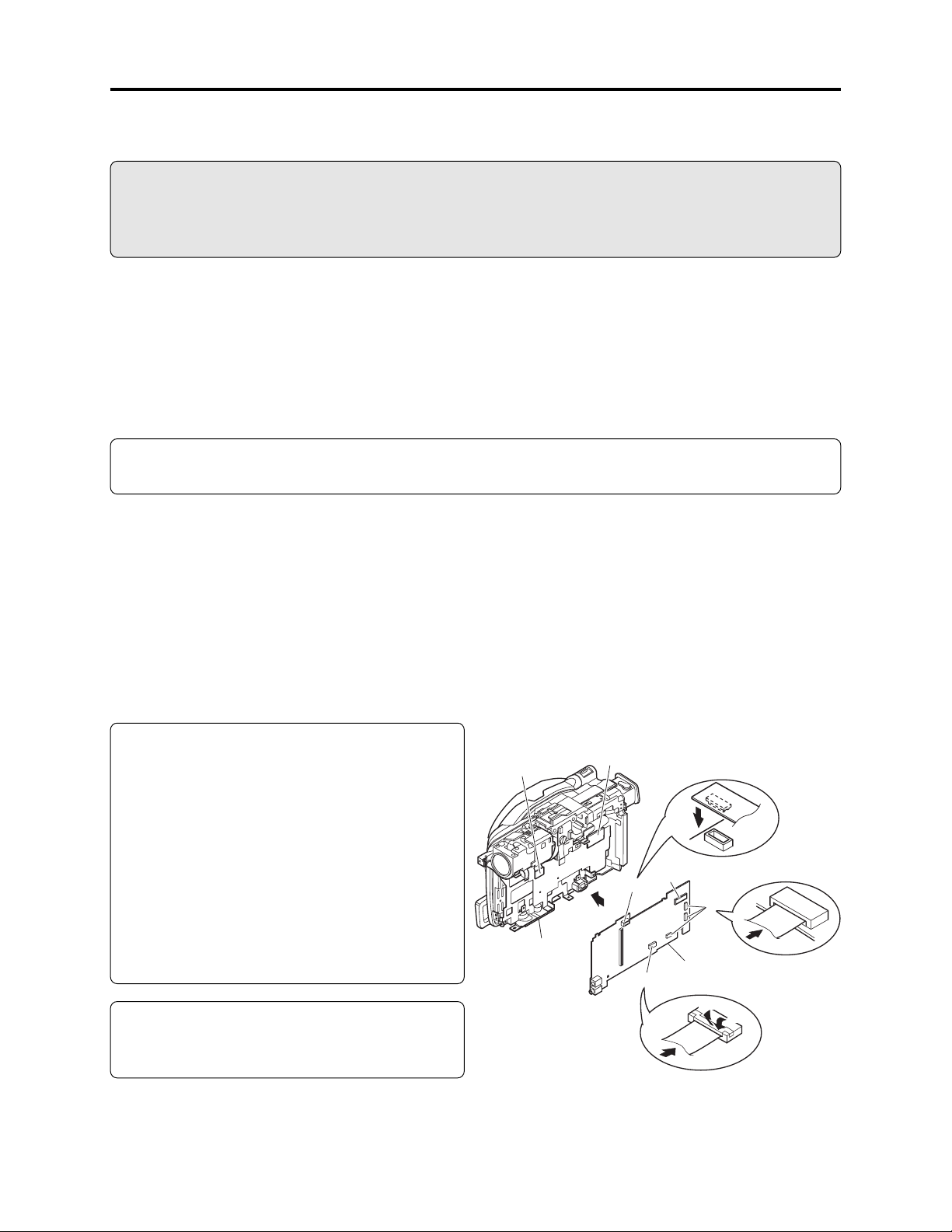

(1) Setting to service position (A) (Fig. 4-7-5)

Refer to Table 4-7-1 and the MAN circuit board diagram: Solder a lead wire of approx. 10 cm to the

check point that corresponds to the symptom (except for terminals of IC or connector/plug).

1) Assemble the MAN circuit board into R block.

2) Connect the DRF circuit board to MAN circuit board.

3) Connect the SEN circuit board to MAN circuit board.

4) Connect all the connectors on MAN circuit board.

Note:

Assemble the MAN circuit board independently

into R block only when setting to service

position (A). During normal assembly, or when

setting to service position (B), first be sure to

connect the AEL circuit board to MAN circuit

board, and then assemble them into R block.

If the AEL circuit board is connected to MAN

circuit board that is already assembled in R

block, connection error may occur, or the circuit

boards or frame could be damaged.

Information:

No button or joystick operation on unconnected

L block can be performed.

SEN CIRCUIT

BOARD

R BLOCK

DRF CIRCUIT

BOARD

2

3

1

4

4

MAN CIRCUIT

BOARD

4-1

4-3

4-2

4 - 2

Fig. 4-7-5 Setting to Service Position (A)

Troubleshooting > Trouble Diagnosis

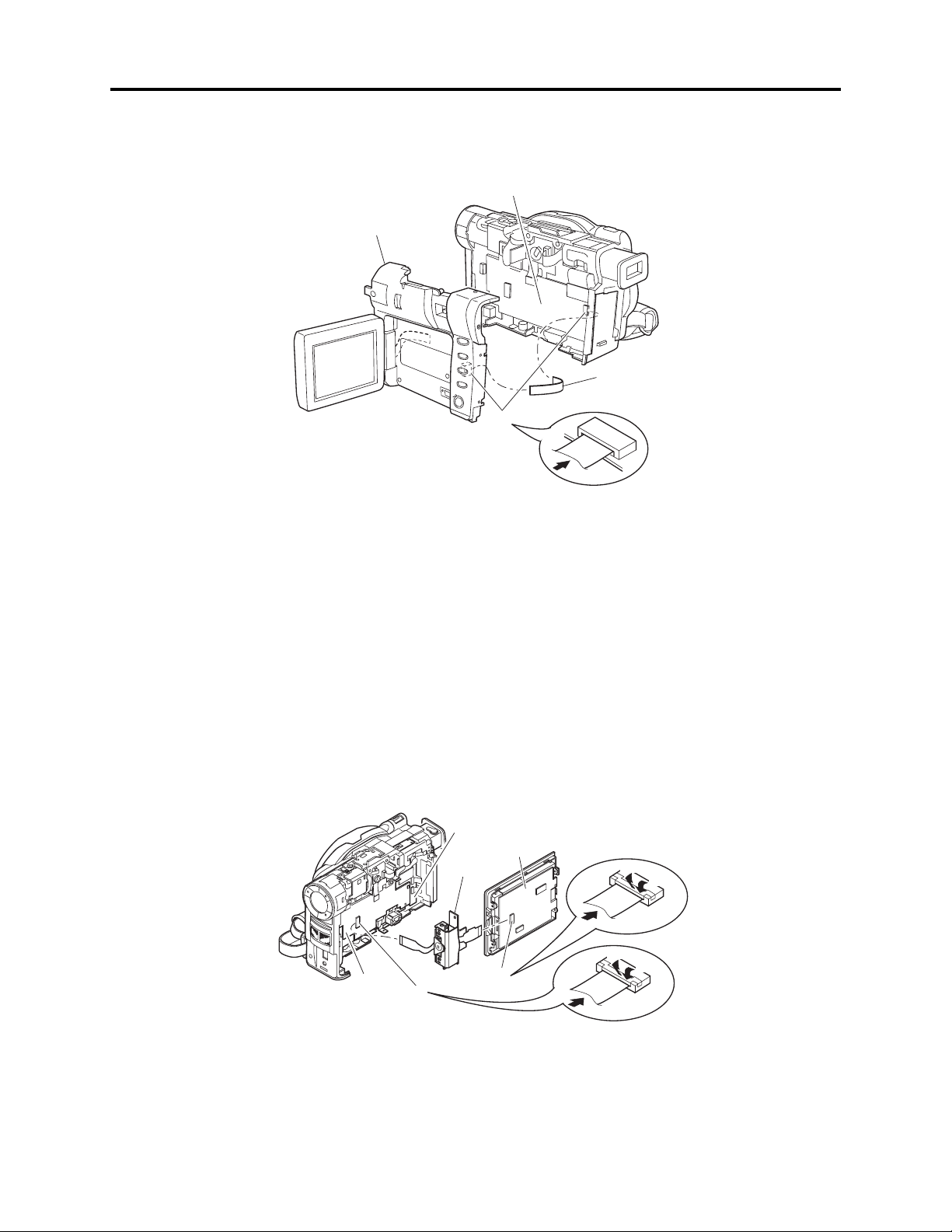

(2) Setting to service position (B) (Fig. 4-7-6)

Refer to Table 4-7-1 and the MAN and AEL circuit board diagrams: Solder a lead wire of approx. 10

cm to the check point that corresponds to the symptom (except for terminals of IC or connector/

plug).

1) Connect the MAN and AEL circuit boards.

2) Assemble the MAN and AEL circuit boards into R block.

3) Connect the DRF circuit board to MAN circuit board.

4) Connect the SEN circuit board to MAN circuit board.

5) Connect the SHE circuit board to AEL circuit board.

6) Connect all the connectors on MAN and AEL circuit boards.

7) Connect the front block and AEL circuit board via FAF circuit board.

Information:

Use the remote control for operation of button/joystick from L block that is not connected.

DRF

CIRCUIT

BOARD

4

2

MAN CIRCUIT

BOARD

3

1

6

5

6

1

AEL CIRCUIT

7

BOARD

R BLOCK

FRONT

BLOCK

7

SEN

CIRCUIT

BOARD

6-2

SHE

CIRCUIT

BOARD

6-1

6-3

FAF CIRCUIT

BOARD

Fig. 4-7-6 Setting to Service Position (B) or (C)

(3) Setting to service position (C) (Figs. 4-7-6, 4-7-7)

Refer to Table 4-7-1 and the MAN and AEL circuit board diagrams: Solder a lead wire of approx. 10

cm to the check point that corresponds to the symptom (except for terminals of IC or connector/

plug).

1) Connect the MAN and AEL circuit boards. (Fig. 4-7-6)

2) Assemble the MAN and AEL circuit boards into R block.

3) Connect the DRF circuit board to MAN circuit board.

4) Connect the SEN circuit board to MAN circuit board.

5) Connect the SHE circuit board to AEL circuit board.

6) Connect all the connectors on MAN and AEL circuit boards.

7) Connect the front block and AEL circuit board via FAF circuit board.

4 - 3

Troubleshooting > Trouble Diagnosis

8) Connect the L block and AEL circuit board via SAF circuit board. (Fig. 4-7-7)

AEL CIRCUIT

BOARD

L BLOCK

SAF

CIRCUIT

BOARD

8

Fig. 4-7-7 Setting to Service Position (C)

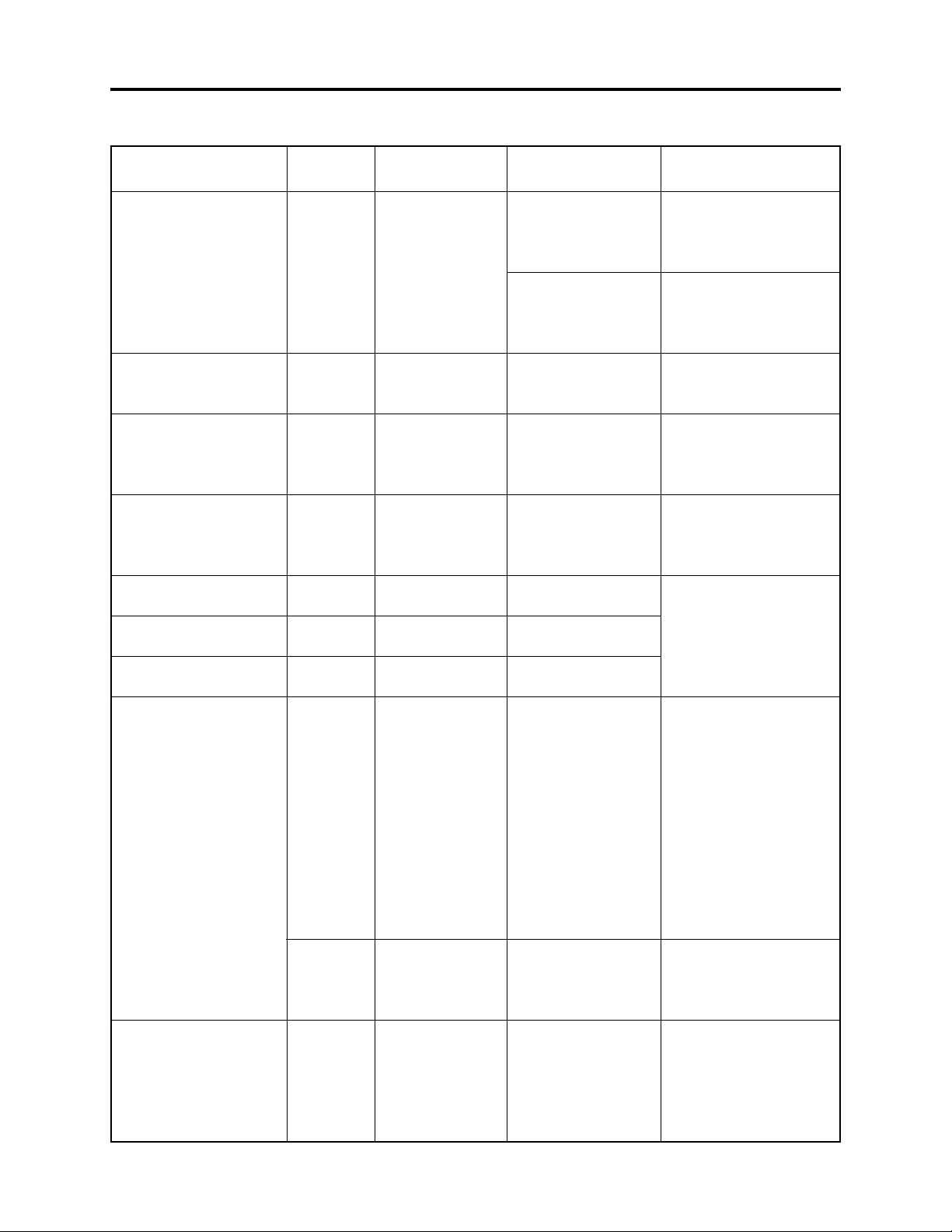

(4) Setting to service position (D) (Fig. 4-7-8)

Remove the following components, referring to “5. Disassembly and Reassembly”:

a) Hood, Filter Piece, and Lens Cover (Fig. 5-3-2)

b) Eyecup, SAF Circuit Board, and L Block (Figs. 5-3-3, 5-3-4)

c) L Cover, L Case and LCD Block (Fig. 5-3-6)

d) LCD Case U, MR Circuit Board, and Fulcrum Block (Fig. 5-3-8)

1) Connect the flat cable of the fulcrum block to the AEL circuit board.

2) Connect the flat cable of the fulcrum block to the LCD circuit board.

MAN

AEL

CIRCUIT

BOARD

1

CIRCUIT

BOARD

FULCRUM

BLOCK

LCD

CIRCUIT

BOARD

2

2-1

2-3

2-2

1-1

1-3

1-2

Fig. 4-7-8 Setting to Service Position (D)

4 - 4

Troubleshooting > Trouble Diagnosis

4-7-3 Trouble diagnosis table

Interpreting the trouble diagnosis table:

1) Letters in brackets [ ] in “check points” columns show the name and side of circuit board.

Example: [MAN-A] shows that the check point exists on side A of MAN circuit board.

2) If there are multiple check points for one symptom, check the items from the top down.

Information:

Use the DZ-ACS1 adapter/charger to power DZ-MV380E for trouble diagnosis.

Prohibition

1) The LCD circuit board has a high-voltage section: When troubleshooting it, take great care to

prevent electric shock by wearing gloves, etc.

2) During troubleshooting, never look directly into the objective lens in optical pickup block, and

take great care that the reflected laser beam does not enter your eye.

Table 4-7-1 Trouble Diagnosis Table (1/3)

Symptom

No power

Error message “DISC

ACCESS” appears and

disc is not recognized.

Service

position

(A)

-----

Check points

F0501 [MAN-B]

F0502 [MAN-B]

F0503 [MAN-B]

F0504 [MAN-B]

TL0503 [MAN-A]

IC1503-53 to 56

[MAN-B] (Do not

solder lead wire.)

TL0510 [MAN-A]

TL0511 [MAN-A]

TL0512 [MAN-A]

TL0513 [MAN-A]

TL0515 [MAN-A]

TL0517 [MAN-B]

TL0518 [MAN-B]

-----

Detail of check

Continuity check

Hi when power turns

on (REG ON)

Approx. 3V DC

(SYS3V)

Approx. 1.5V DC

(C1.6V)

Approx. 3.2V DC

(CAM3V)

Approx. 4.8V DC

(CAM5V)

Approx. 3V DC (D3V)

Approx. 5V DC (D5V)

Approx. 2.5V DC

(D2.5V)

Approx. 15V DC

(C15V)

Error message does

not disappear and

POWER switch does

not work.

Error message does

not disappear after 3

seconds or more.

Troubleshooting due to

check results

NG: Replace fuse.

NG: Replace MAN circuit

board.

Check connections of DRF

circuit board.

Replace disc drive unit.

4 - 5

Troubleshooting > Trouble Diagnosis

Table 4-7-1 Trouble Diagnosis Table (2/3)

Symptom

Error message “NO

DISC” appears even

when normal disc is

inserted

Error message “CHECK

DISC” appears

Message “Disc is not

formatted. Format the

disc now? YES NO”

appears

Date is not backed up

Zoom switch does not

work

EJECT switch does not

work

Does not enter REC

PAUSE status

No image in LCD

No image in EVF

Service

position

-----

-----

-----

(B)

(A)

(A)

(B)

(D)

-----

(B)

Check points Detail of check

-----

-----

-----

TL7041 [AEL-A]

TL1543 [MAN-B]

TL1547 [MAN-B]

TL1541 [MAN-B]

TL3418 [LCD]

-----

TL3719 [AEL-B]

Error message

appears approx. 1

second after disc is

inserted.

Error message

appears within 10

seconds after disc is

inserted

Disc is protected.

Normally initialized

disc was inserted

3V DC is not

supplied.

Switch operation

changes voltage.

Switch operation

changes voltage.

Switch operation

changes voltage.

INV5V(5V)

Check damage to flat

cable between LCD

circuit board and AEL

circuit board

Video signal

Troubleshooting due to

check results

Check connections of DRF

circuit board. If no

abnormality is found,

replace disc drive unit.

Replace disc drive unit.

Yes: Release protect.

No: Replace disc drive

unit.

Yes: Replace disc drive

unit.

No: Change or Initialize

disc.

NG: Check backup

Lithium battery

LA1801.

OK: Replace MAN board.

NG: Replace rear cover.

OK: Replace MAN circuit

board.

NG: Check cable between

LCD circuit board

and AEL circuit

board. Or replace

MAN circuit board.

OK: Check cable between

LCD circuit board

and AEL circuit

board. Or check

connections of MAN

and AEL circuit

boards.

NG: Replace fulcrum

block.

OK: Replace MAN circuit

board.

NG: IC3701 faulty.

OK: Check flat cable

between EVF, SHE

and AEL circuit

boards.

Or replace EVF unit.

4 - 6

Troubleshooting > Trouble Diagnosis

Table 4-7-1 Trouble Diagnosis Table (3/3)

Symptom

Conspicuous block noise

during movie recording

Camera image is

abnormal

No video from video

output jack

No sound from speaker

No audio from audio

output jack

Microphone sound cannot

be recorded

Sound from external

microphone cannot be

recorded

Service

position

-----

(B)

(B)

-----

(B)

(C)

(B)

-----

(B)

(B)

-----

(B)

Check points Detail of check

-----

TL2084 [MAN-A]

TL2085 [MAN-A]

TL2086 [MAN-A]

TL2089 [MAN-A]

TL2090 [MAN-A]

TL2091 [MAN-A]

TL2095 [MAN-A]

TL2082 [MAN-A]

-----

TL6010 [MAN-B]

TL1535 [MAN-B]

TL1536 [MAN-B]

TL6006 [MAN-B]

TL6009 [MAN-B]

PG1802 (Do not

solder lead wire.)

IC6101-1, 7, 8, 14

[AEL-A] (Do not

solder lead wire.)

TL6101 [AEL-B]

TL6102 [AEL-B]

Microphone jack

(JK6001)

IC6201-3,4

[AEL-A] (Do not

solder lead wire.)

Check CCD sensor

drive pulses

Check CCD output

signal

Image appears in

LCD or EVF.

Video signal

Audio signal

Audio signal

Check connections

Audio signal

Connection of

external microphone

Audio signal

-----

Troubleshooting due to

check results

Replace MAN circuit

board.

NG: Replace MAN circuit

board.

NG: Replace lens unit.

OK: Replace MAN circuit

board.

No: Replace MAN circuit

board.

NG: IC6103 or its

peripheral circuits

faulty.

OK: Check JK6002. Or

replace MAN circuit

board.

NG: IC6103 or its

peripheral circuits

faulty.

OK: Replace speaker.

NG: IC6103 or its

peripheral circuits

faulty.

OK: Check JK6002. Or

replace MAN circuit

board.

NG: Connector

connections faulty.

NG: Check IC6101 its

peripheral circuits.

Or replace

microphone.

NG: Check IC6102 and

peripheral circuits.

OK: Check IC6201 its

peripheral circuits.

NG: External microphone

connection faulty.

NG: Replace MAN circuit

board.

OK: Check IC6102 its

peripheral circuits.

4 - 7

Troubleshooting > Procedure for Removing Disc from Faulty DZ-MV380E

4-8 Procedure for Removing Disc from Faulty DZ-MV380E

Information:

DZ-MV380E has an accessory shoe equipped with the power/control terminal, and the shape and

removal of accessory shoe are different from those for DZ-MV350E.

4-8-1 Item to be checked

Connect the AC adapter/charger or charged battery pack, making sure the ACCESS/PC indicator

turns off (after the disc rotation stops and the sound showing that the disc lock has been released is

heard), and then press the DISC EJECT button again.

Even with normal product, the disc cannot be removed while the ACCESS/PC indicator is lit or

blinking.

Information:

Connect the charged battery pack or the AC adapter/charger (power supply) before pressing the

DISC EJECT button.

With conventional DVD video camera/recorders, the DISC EJECT button will work even when no

power supply is connected. However, with the DZ-MV380E, the DISC EJECT button will not work

without a power supply connected.

Prohibition

After the above check, disconnect the AC adapter/charger of battery from the DZ-MV380E.

The DZ-MV380E has a built-in laser emitter block. Do not look into it: If Laser beam strikes your

eye, it could cause serious damage.

4-8-2 How to remove disc

If the disc cannot be ejected after performing “4-8-1 Item to be checked”, remove it using the

procedure in this section.

Information:

Numbers in figures are step numbers of setting procedure, and letters in brackets [ ] show the

types of screw.

4 - 8

Troubleshooting > Procedure for Removing Disc from Faulty DZ-MV380E

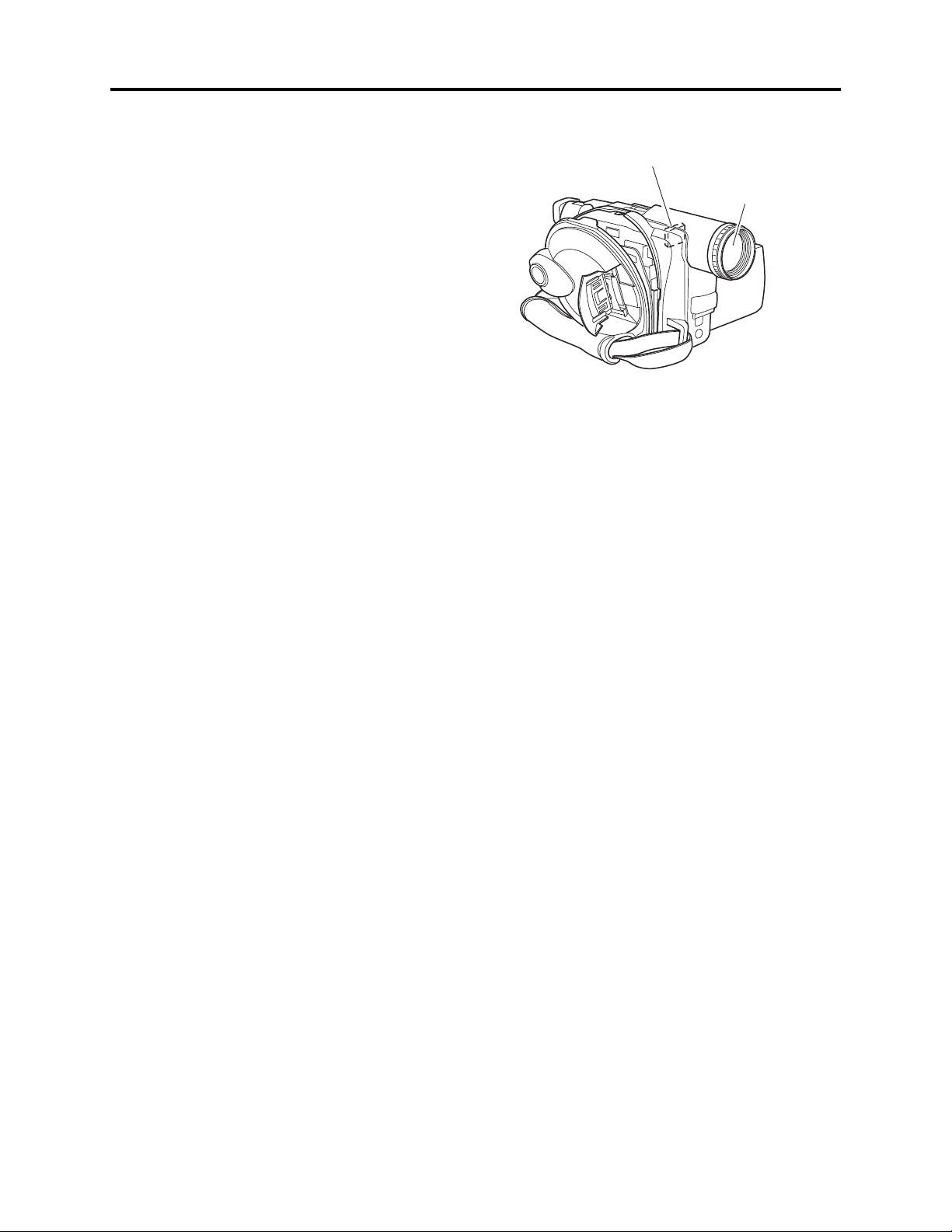

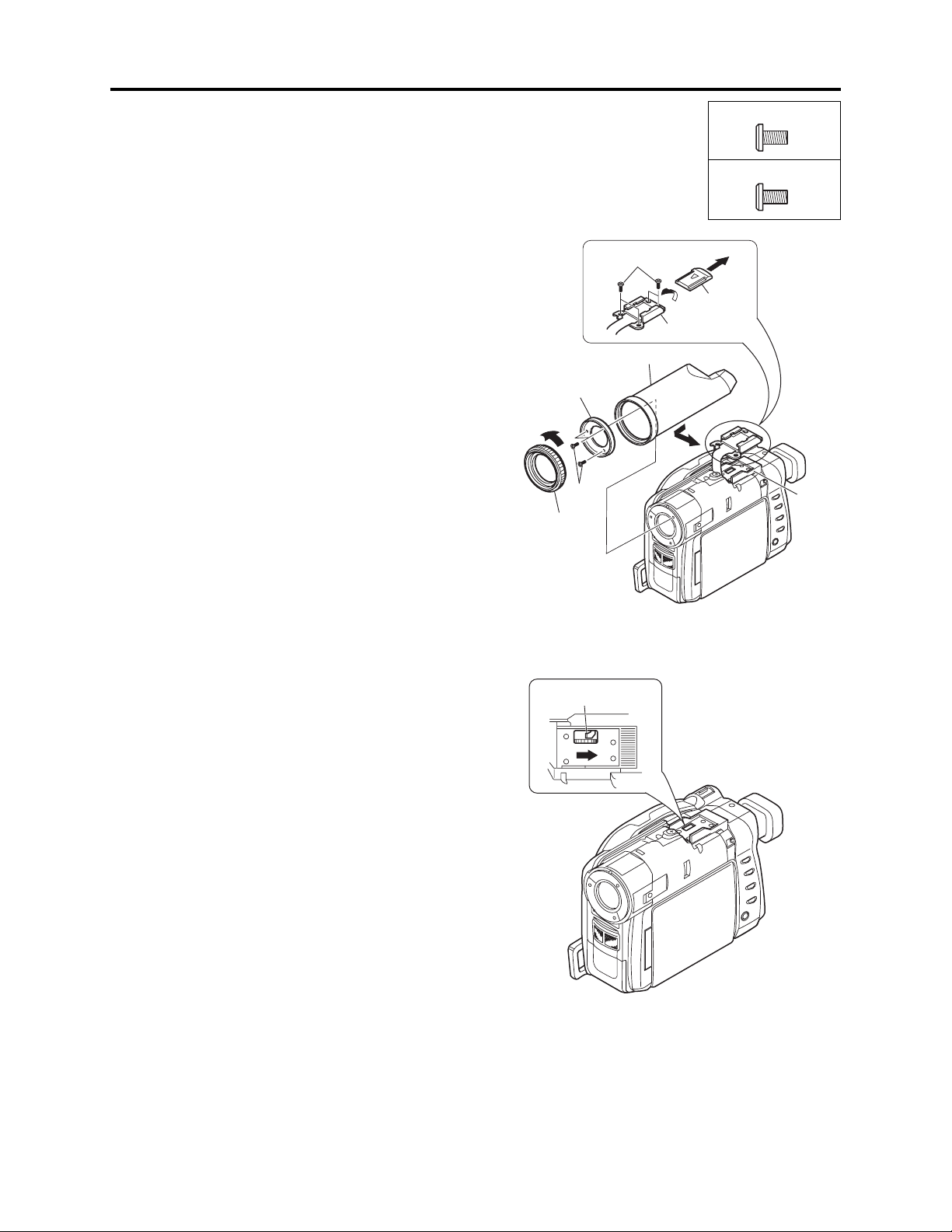

1) Turn the hood (a) in the direction of the

arrow to remove it. (See Fig. 4-8-1)

2) Remove three screws [A], and then remove

the filter piece (b). Be careful not to scratch

the lens surface with screwdriver at this

time.

3) Remove the lens cover (c) in the direction of

the arrow.

4) Remove the shoe cover in the direction of

the arrow.

5) Remove four screws [X].

6) Move the parts of the accessory shoe in the

direction of the arrow.

(a) Hood

(b) Filter Piece

(c) Lens Cover

(d) Shoe Cover

(e) Parts of Accessory

Shoe

(f) Accessory Shoe

(b)

1

2 [A]

(a)

5 [X]

(c)

(e)

[A] M1.7×4 (Black)

[X] M2×2.5 (Black)

4

(d)

6

3

(f)

7) Insert a screwdriver, etc. into the hole in

accessory shoe at the top of product, and

move the lock arm (g) in the direction of the

arrow to open the disc loading block. (See

Fig. 4-8-2)

8) After removing the disc, close the disc

loading block to protect the disc drive unit.

When reinstalling removed components, use

the reverse procedure to removal.

9) After work, reinstall part of accessory shoe

and screws [X] to the accessory shoe: The

accessory shoe is set as a service part,

including screws [X].

Fig. 4-8-1 How to Remove Disc

(g)

(g) Lock Arm

Fig. 4-8-2 How to Remove Disc

4 - 9

Loading...

Loading...