Page 1

SERVICE MANUAL

SM0512

DV-RV8500E

DV-RV8500E(UK)

PAL

PAL SECAM

DO NOT RESELL OR DIVERT IMPROPERLY.

SPECIFICATIONS AND PARTS ARE SUBJECT TO CHANGE FOR IMPROVEMENT

DVD VIDEO RECORDER with VIDEO CASSETTE RECORDER

2005July

Digital Media Division,Yokohama

Page 2

Table of Contents

1 Safety Precaution for Repair ........... 1-1

1-1 Cautions ................................................. 1-1

1-2 Electrostatic Protection Measures .......... 1-2

1-3 Cautions When Handling DVD Drive....... 1-2

1-4 Lead-Free Solder.................................... 1-3

1-5 Notes When Using Service Manual ........ 1-4

2 General Description ......................... 2-1

2-1 Overview ................................................ 2-1

2-1-1 Service method ................................... 2-1

2-1-2 Disc information ................................... 2-2

2-2 Features ................................................. 2-4

2-3 Specifications ......................................... 2-5

2-4 Major Differences from Previous Model .. 2-6

2-5 Function Differences from

Previous Model ....................................... 2-7

2-6 Names of Parts....................................... 2-8

2-7 List of Abbreviations and Terms for DVD

Recorder ............................................... 2-12

3 Details of Servicing and

Troubleshooting ............................... 3-1

3-1 Details of Servicing ................................. 3-1

3-1-1 Removing Disc from Faulty Recorder ... 3-1

3-1-2 Removing Video Cassette from Faulty

Recorder ............................................... 3-1

3-1-3 Firmware .............................................. 3-2

3-1-4 Setting to defaults at the factory ........... 3-3

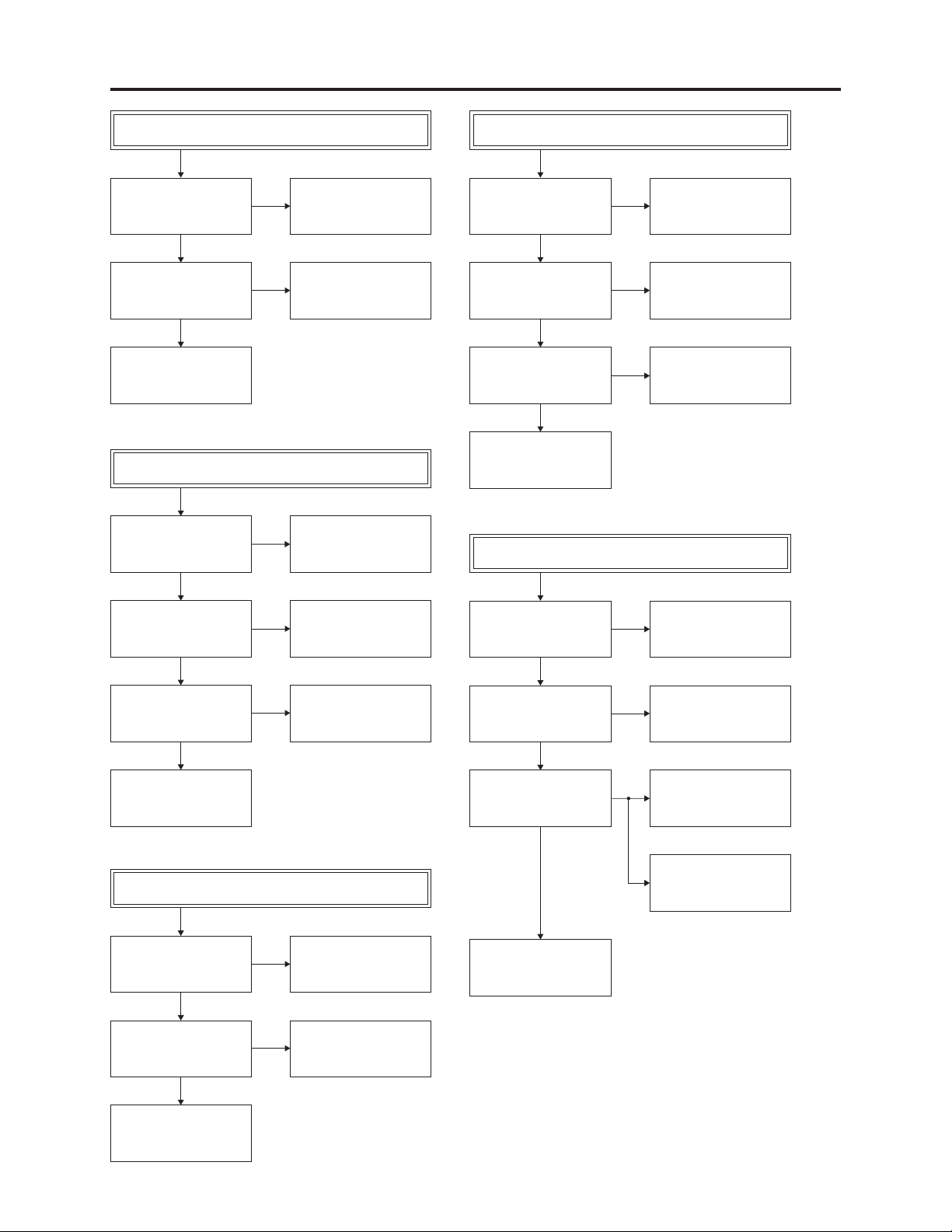

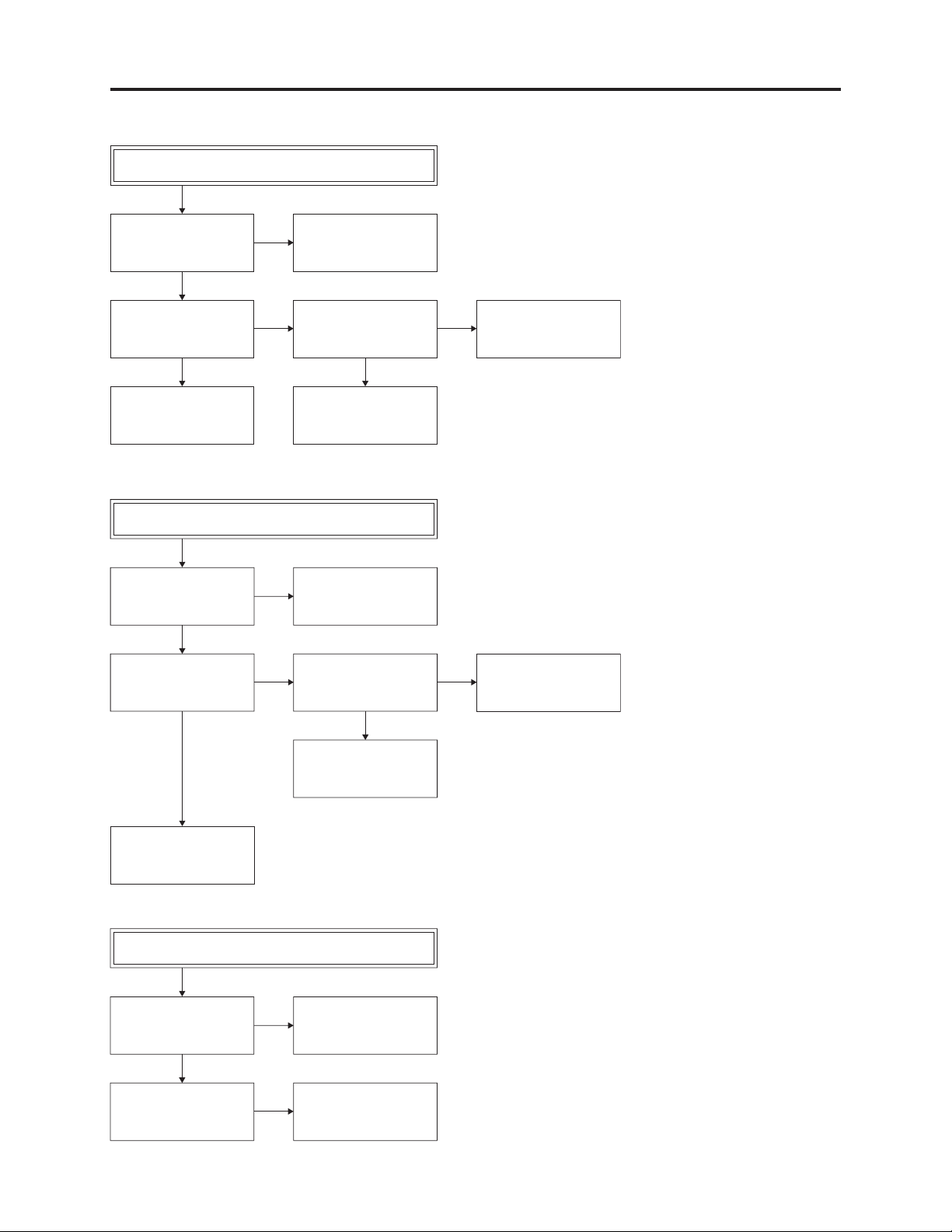

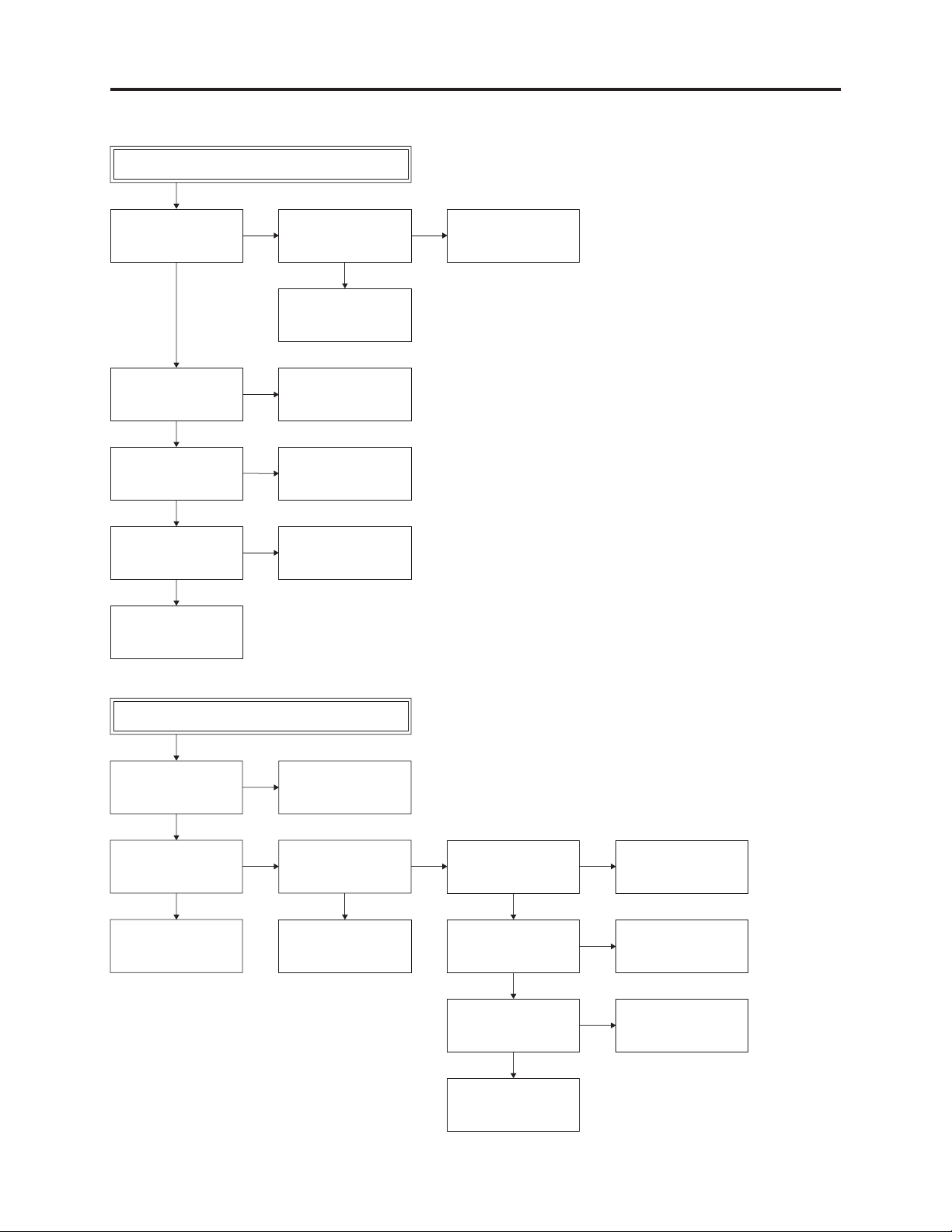

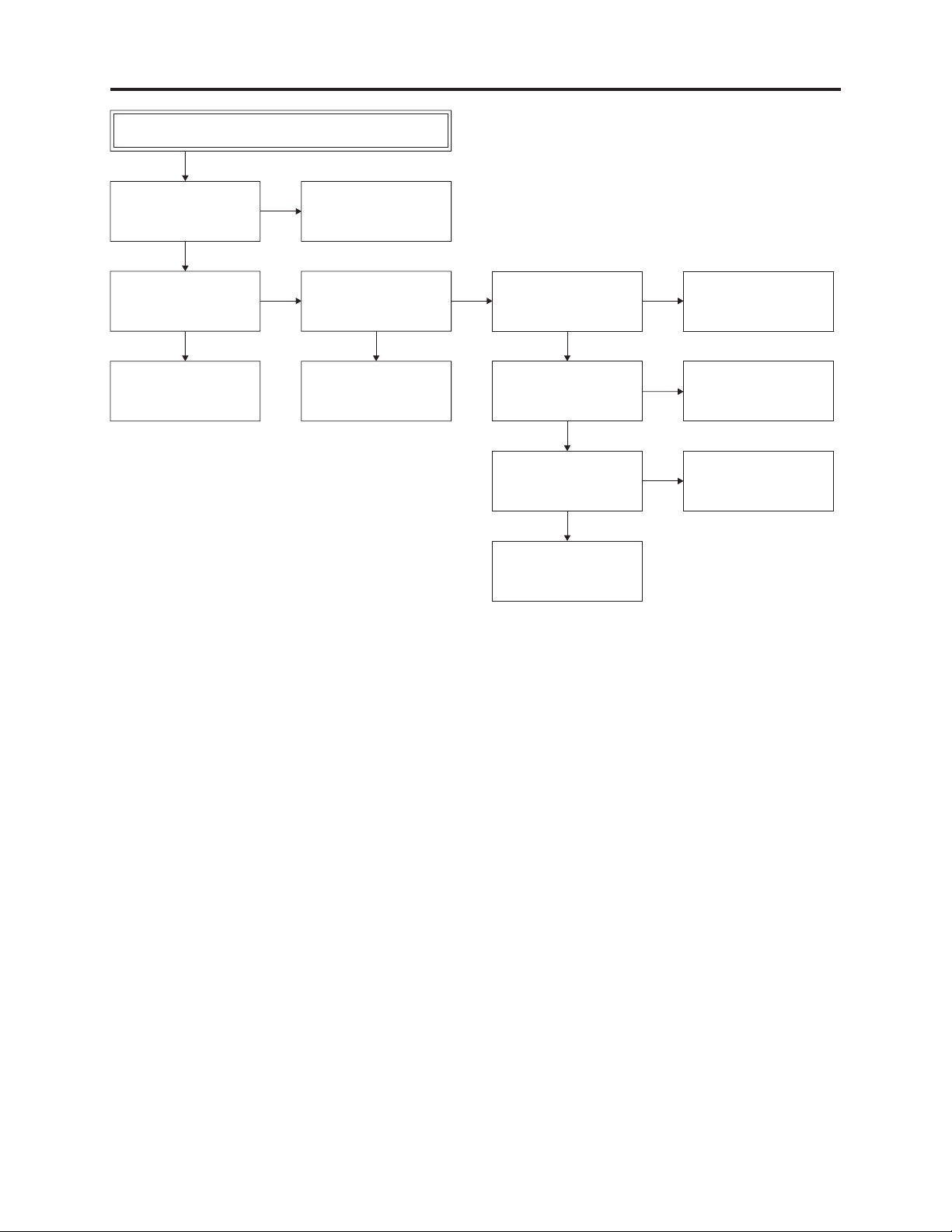

3-2 Troubleshooting ...................................... 3-4

3-2-1 Troubleshooting electronic system ........ 3-4

3-2-2 Troubleshooting mechanical block ...... 3-14

4 Disassembly and Reassembly ........ 4-1

4-1 Order of Disassembly ............................. 4-1

4-2 Cabinet Disassembly .............................. 4-1

(1) Top Cover ................................................. 4-1

(2) Front Panel ............................................... 4-2

(3) FAN Motor ................................................ 4-2

(4) SMPS P.C.B ............................................. 4-3

(5) Deck mechanism...................................... 4-4

(6) TIMER P.C.B ............................................ 4-5

(7) VCR P.C.B ................................................ 4-5

(8) DVD multi-drive ........................................ 4-6

(9) VDR, JACK and KEY P.C.Bs .................... 4-6

4-3 Deck Mechanism Parts Locations ........... 4-7

4-4 Deck Mechanism Disassembly ................ 4-8

(1) Drum assembly ........................................ 4-8

(2) Top plate ................................................... 4-9

(3) CST holder assembly ............................... 4-9

(4) F/L rack gear assembly ............................ 4-9

(5) Door opener ............................................. 4-9

(6) F/L arm assembly..................................... 4-9

(7) S/W lever assembly.................................. 4-9

(8) L/D motor assembly ............................... 4-11

(9) Wheel gear ............................................. 4-11

(10) F/E head .............................................. 4-11

(11) A/C head assembly .............................. 4-11

(12) T brake assembly ................................. 4-12

(13) Tension arm assembly .......................... 4-12

(14) S reel and T reel ................................... 4-12

(15) P4 base assembly ................................ 4-13

(16) Lid opener ............................................ 4-13

(17) Pressure arm assembly ....................... 4-13

(18) Take-up arm ......................................... 4-13

(19) Capstan supporter ............................... 4-14

(20) Capstan belt and capstan motor ........... 4-14

(21) F/R lever............................................... 4-14

(22) D37 clutch assembly ............................ 4-14

(23) Driver gear and cam gear ..................... 4-15

(24) Sector gear .......................................... 4-15

(25) Capstan brake assembly ...................... 4-15

(26) Slider plate ........................................... 4-15

(27) Tension lever ........................................ 4-15

(28) Spring lever .......................................... 4-15

(29) Brake lever ........................................... 4-15

(30) P2 gear assembly and

P3 gear assembly ................................. 4-16

(31) P2 base assembly and

P3 base assembly ................................ 4-16

(32) Loading base ........................................ 4-16

(33) Tension base ........................................ 4-17

(34) Jog idler arm assembly ........................ 4-17

4-5 Checking Mode after Reassembling Deck

Mechanism ........................................... 4-18

Contents - 1

Page 3

5 Adjustment / Maintenance ............... 5-1

5-1 Set-up for Adjustment ............................. 5-1

5-2 VCR Electrical Adjustment ..................... 5-2

5-2-1 Head switching adjustment ................... 5-2

5-3 Deck Mechanism Tape Transport System

Adjustment ............................................. 5-3

5-3-1 Guide roller height adjustment .................

5-3-2 A/C head adjustment ............................ 5-4

5-3-3 X-value adjustment ............................... 5-5

5-3-4 Adjustments after replacing

drum assembly ..................................... 5-5

5-3-5 Check after adjustment ........................ 5-6

5-3-6 Method of setting the mechanism to

loading status without inserting tape ..... 5-6

5-3-7 Reel torques ......................................... 5-7

5-4 Maintenance ............................................ 5-8

5-4-1 Maintenance and inspection ................. 5-8

5-4-2 Lubricating oil and greasing ................ 5-10

5-3

6 Exploded View and Parts List.......... 6-1

6-1 Exploded Views ...................................... 6-1

6-1-1 Cabinet Section ................................... 6-1

6-1-2 F / L Mechanism .................................. 6-2

6-1-3 Deck Mechanism Section - Top view ... 6-3

6-1-4

Deck Mechanism Section - Bottom view

6-2 Parts List ................................................. 6-5

6-2-1 Mechanical Parts List ........................... 6-5

6-2-2 Electrical Parts List ............................... 6-6

6-4

C Circuit Board Diagrams .................. C-1

C-1 VCR Circuit Board Diagram ................... C-1

C-2 S.M.P.S Circuit Board Diagram .............. C-3

C-3 JACK Circuit Board Diagram ................. C-4

C-4 TIMER Circuit Board Diagram ............... C-4

C-5 KEY Circuit Board Diagram ................... C-4

B Block Diagrams ............................... B-1

B-1 S.M.P.S Circuit Block Diagram ................B-1

B-2 VIDEO Circuit Block Diagram .................B-2

B-3 AUDIO Circuit Block Diagram .................B-3

B-4 SYSTEM Circuit Block Diagram..............B-4

B-5 VIDEO I/O Circuit Block Diagram ...........B-5

S Schematic, Wiring Diagrams .......... S-1

S-1 Wiring Diagram ....................................... S-1

S-2 S.M.P.S Schematic Diagram ................... S-2

S-3

SYSTEM Schematic Diagram(VCR P.C.B)

S-4

TUNER Schematic Diagram(VCR P.C.B) ..

S-5 A/V Schematic Diagram(VCR P.C.B) ......S-5

S-6 Hi-Fi Schematic Diagram(VCR P.C.B) ....S-6

S-7 REAR JACK Schematic Diagram

(VCR P.C.B)............................................S-7

S-8 TIMER,KEY Schematic Diagrams .......... S-8

S-9 JACK Schematic Diagram ...................... S-9

S-10 A/V,SYSTEM Circuit Waveforms ......... S-10

S-11 CIRCUIT VOLTAGE CHART ................ S-11

S-3

S-4

Contents - 2

Page 4

1

Safety Precaution for Repair

1-1 Cautions

PRODUCT SAFETY NOTICE

Many electrical and mechanical parts have special safety-related characteristics. These are often not

evident from visual inspection nor can the protection afforded by them necessarily be obtained by using

replacement components rated for a higher voltage, wattage, etc. Replacement parts which have these

special safety characteristics are identified in this Service Manual. Electrical components having such

features are identified by marking with a on the schematics and the parts list in this Service Manual.

The use of a substitute replacement component which does not have the same safety characteristics as

the HITACHI recommended replacement one, shown in the parts list in this Service Manual, may create

shock, fire, or other hazards. Product safety is continuously under review and new instructions are

issued from time to time. For the latest information, always consult the current HITACHI Service Manual.

A subscription to, or additional copies for, HITACHI Service Manual may be obtained at a nominal

charge from HITACHI SALES CORPORATION.

CAUTION

There is a high-voltage section inside the DVD video

recorder. When repairing or inspecting it, take great care

to prevent electric shock: Use an isolating transformer,

CAUTION

This product contains a laser diode of

higher class than 1. To ensure continued safety, do not remove any covers

or attempt to gain access to the inside of the product. Refer all servicing

to qualified personnel.

wear gloves, etc.

1 - 1

Page 5

Safety Precaution for Repair > Electrostatic Protection Measures / Cautions When Handling DVD Drive

1-2 Electrostatic Protection Measures

Semiconductor components can be damaged by static electricity charged on clothes, human body,

etc. Take great care when handling components to avoid electrostatic damage, and perform

servicing in an environment where grounding is complete.

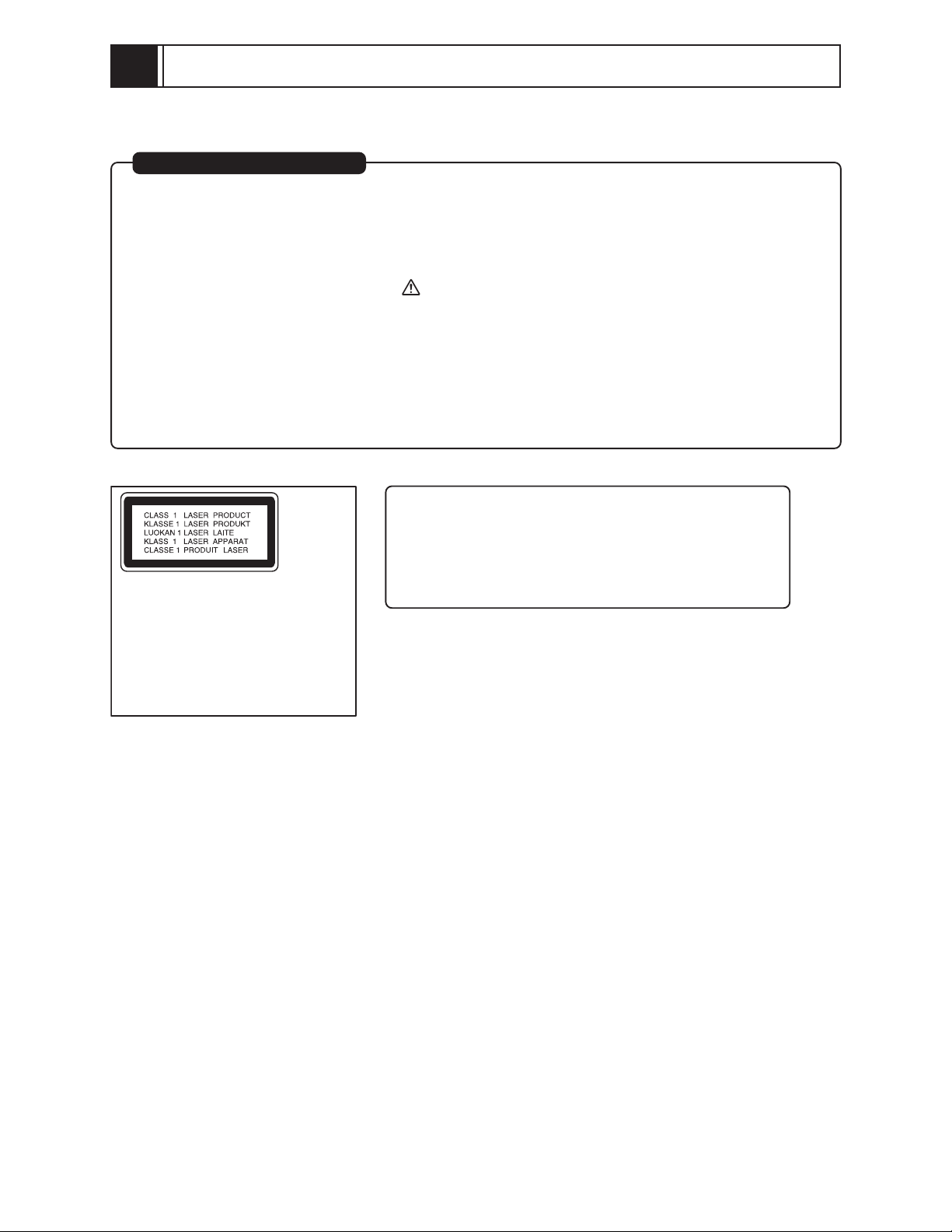

(1) Grounding work bench

Lay out an antistatic mat on work bench, and then use the ground plate to ground the work bench.

Antistatic mat

1M ohm

Ground

(2) Grounding human body

Use an antistatic wrist strap to discharge any static electricity charged on the body. Also, use a

tester for wrist strap to make sure that the wrist strap is working normally. Note, however, that

static electricity charged on clothes will not be discharged by wrist strap: Therefore do not allow

your clothes to touch the semiconductor components.

Antistatic wrist strap

1M ohm

1-3 Cautions When Handling DVD Drive

The optical pickup in DVD drive has a high precision structure: Be sure to observe the following

cautions.

1) Do not subject optical pickups to any severe vibrations or

impact during movement, installation or disassembly.

2) When performing repair work, do not perform disassembly

any further than that described in this manual.

3) Never turn the semi-variable resistors for adjustment in

optical pickup or DVD drive.

4) NEVER look into the objective lens in optical pickup or

directly view the laser light: You could lose your eyesight.

Do not directly look at laser light

from pickup.

1 - 2

Page 6

Safety Precaution for Repair > Lead-Free Solder

1-4 Lead-Free Solder

The printed circuit board that uses lead-free solder is adopted. To protect the global environment,

use the recommended lead-free solder also during servicing.

Read and observe the following before soldering:

Caution

ALWAYS wear protective goggles during soldering so that no solder smoke or scattered solder

enters the eye. Lead-free solder may scatter at high temperatures of 600°C.

(1) Characteristics of lead-free solder

The melting point of lead-free solder is 30-40°C higher than that of lead based solder.

(2) Lead-free solder for servicing

Use the following lead-free solder for servicing:

Recommended lead-free solder and composition of alloy (wt%): Sn-3.0Ag-0.5Cu or equivalent

Information:

For composition of alloy, Sn is tin; Ag is silver; Cu is copper; Bi is bismuth; Pb is lead.

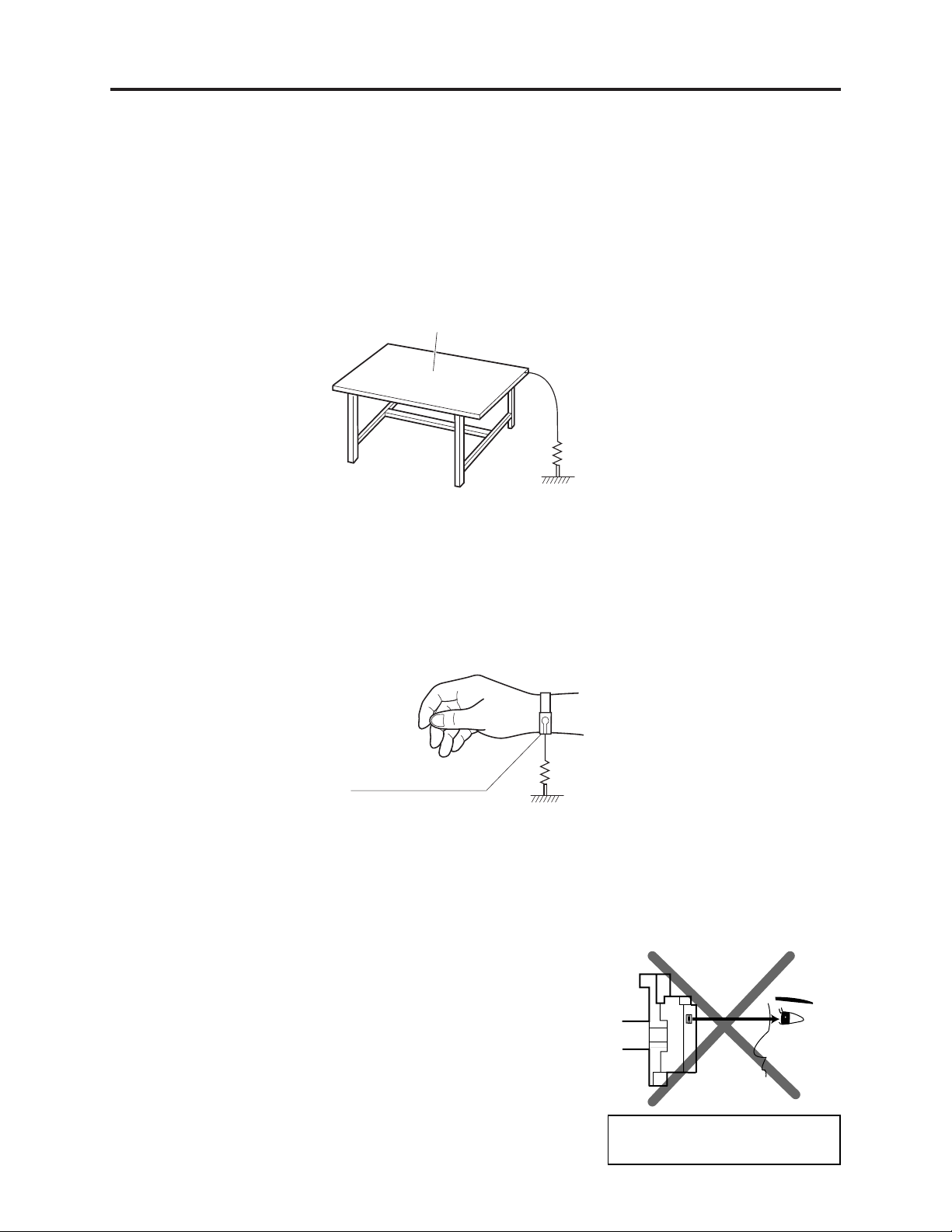

(3) Soldering iron for servicing

The temperature of soldering iron tip must be adjusted according to the points to be soldered: Use

an antistatic soldering iron with thermal control function.

When removing components, take care not to damage any surrounding component or pattern. When

attaching components, observe the heating time in the following table so that the components are

not destroyed by heat.

Tip temperatures for different soldering points:

Point to be soldered

Surface-mounted (chip) parts [other than

those shown below]

Surface-mounted (chip) parts [for DVD

cameras, cellular phones only]

Discrete parts

Chassis, metal shield, etc.

320 ± 30°C

[heating time: less than 5 seconds]

350 ± 10°C

[heating time: less than 3 seconds]

380 ± 30°C

420 ± 30°C

Tip temperature

(4) Cautions when using lead based solder

It is recommended that you use lead-free solder when servicing, but it is also possible to service

using lead based solder. However, if lead based solder is used for servicing, take care with the

following:

1) Before using lead based solder, remove the lead-free solder completely from the point to be

soldered.

2) For additional soldering for repair, set the soldering iron tip temperature for lead-free solder, mix

lead based solder and lead-free solder sufficiently. Do not perform any repair using the bare

soldering iron tip without adding solder, since it will cause secondary failure due to lack of

strength.

1 - 3

Page 7

Safety Precaution for Repair > Notes When Using Service Manual

1-5 Notes When Using Service Manual

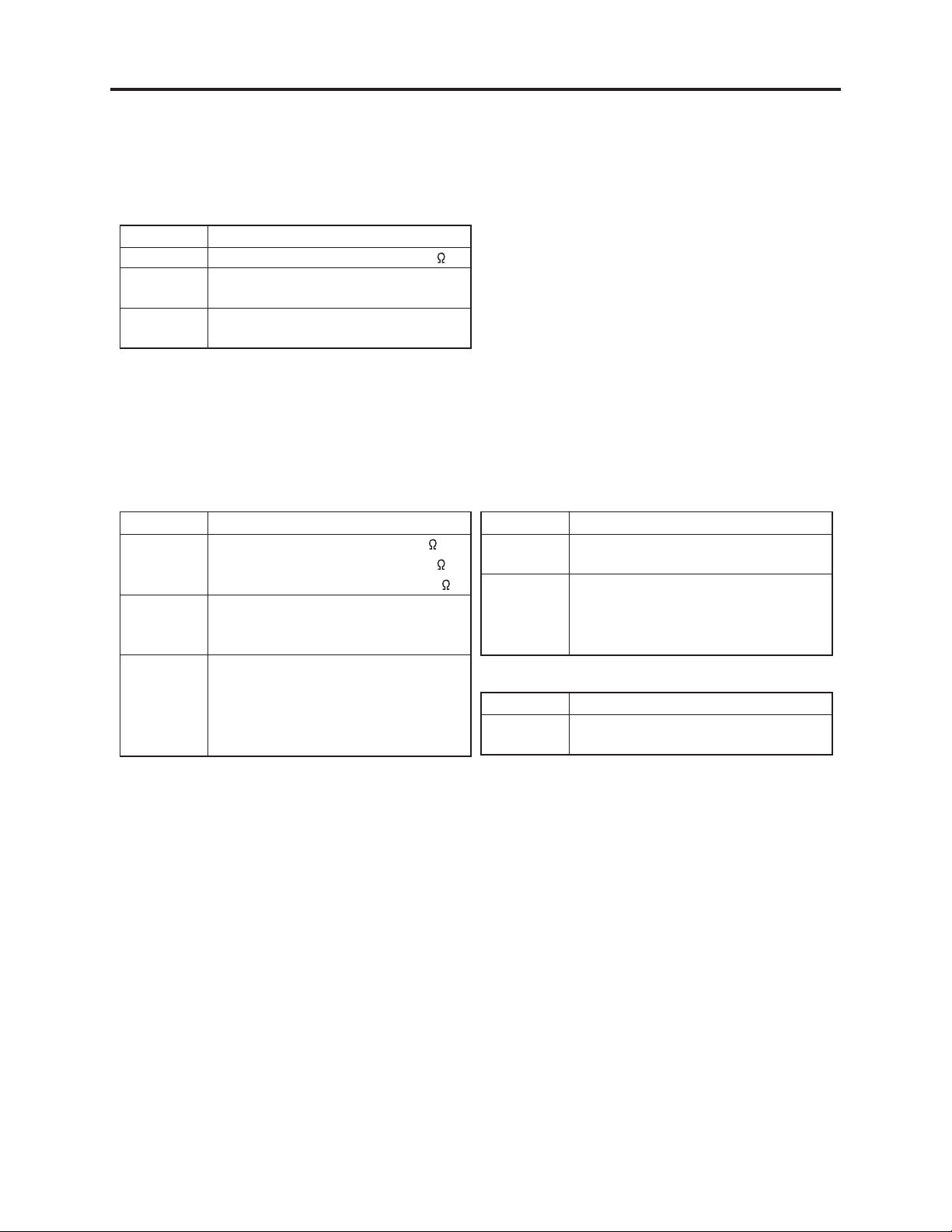

(1) Value units used in parts list

Certain symbols are indicated as shown below for value units of resistors, capacitors and coils in

parts list. When you read them, note the following regular indications:

Parts

Resistor

Capacitor

Coil

Indication in list Regular indication

KOHM

UF

PF

UH

MH

.........................................

................................................

................................................

...............................................

..............................................

k

µF

pF

µH

mH

(2) Values in schematic diagrams

The values, dielectric strength (power capacitance) and tolerances of the resistors (excluding

variable resistors) and capacitors are indicated in the schematic diagrams using abbreviations.

Certain symbols are indicated for value units: When you read them note the regular indications in

tables below:

[Resistors] [Capacitors]

Item

Value

Tolerance

Power

capacitance

No indication

..................................................

K

.................................................

M

No indication

(All tolerances other than ±5% are

indicated in schematic diagrams)

No indication

(1/16 W for leadless resistors with no

indication)

All capacitances other than the above

are indicated in schematic diagrams.

Indication

..............................

..............................

..............................

k

M

±5%

1/8W

Item

Value

Dielectric

strength

[Coils]

Item

Value

Indication

No indication

..................................................

P

No indication

(All dielectric strengths other than

50 V are indicated in schematic

diagrams)

..............................

..............................

µF

pF

50V

Indication

...................................................

µ

..................................................

m

µH

mH

1 - 4

Page 8

2

General Description

2-1 Overview

The DV-RV8500E is a DVD recorder with VHS VCR that incorporates a DVD super multi-drive:

It allows user to record and play back on +RW and +R, as well as on DVD-RAM, DVD-RW, DVD-R

and VHS videotape.

It can be used without any concern about the type of media.

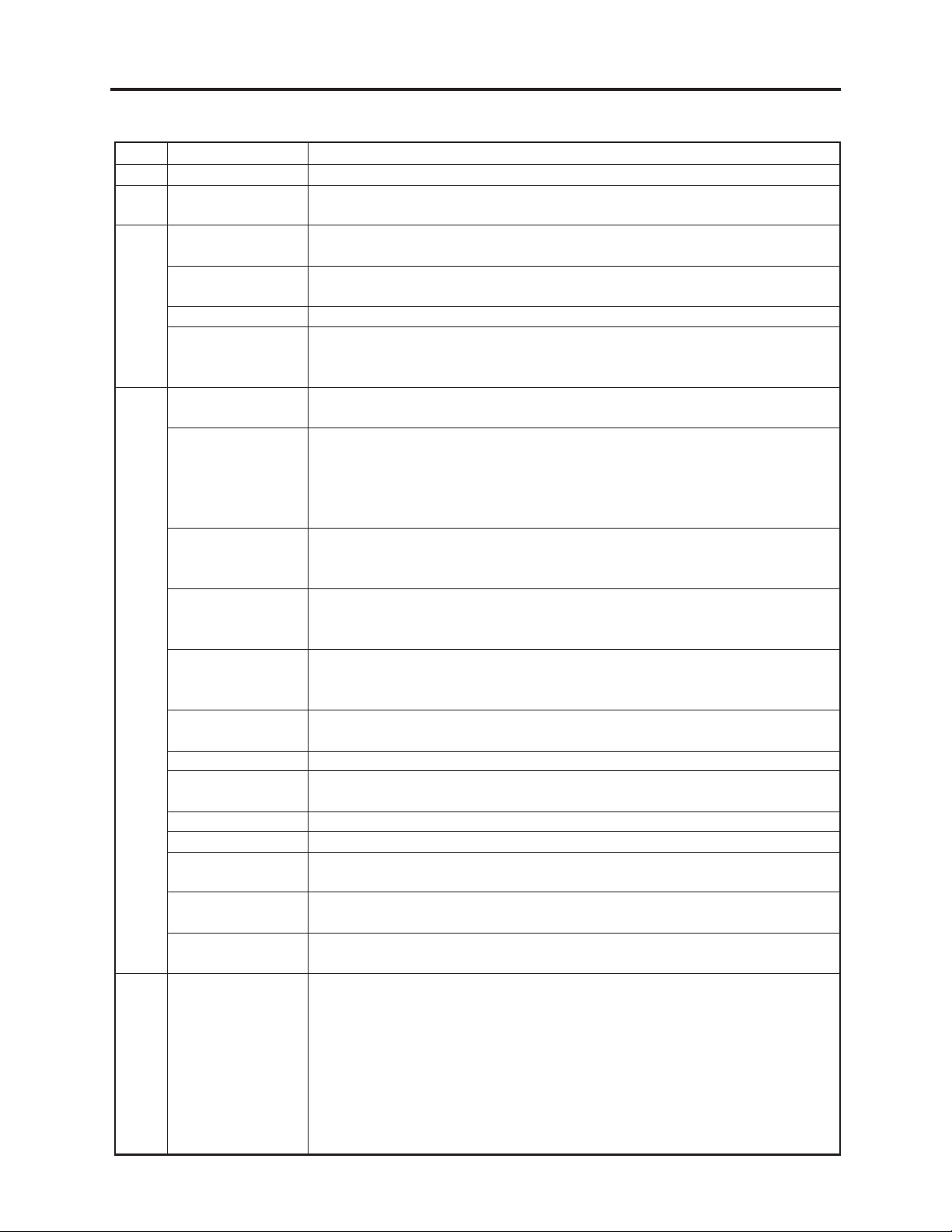

2-1-1 Service method

Basically, components are replaced when servicing the DV-RV8500E. However, the service method

is different for high-density packaging PCBs and precision components.

Refer to the following table and perform the designated, appropriate servicing. Any changes that

occur in the service method will be published using service bulletin, etc.

Do not perform any servicing other than that described in this manual.

Component

Exterior component

DVD Multi Drive

VDR P.C.B

VCR P.C.B

TIMER P.C.B

JACK P.C.B

KEY P.C.B

SMPS P.C.B

Deck mechanism

Service method

Component replacement

Unit replacement

Circuit board assembly

replacement

Component replacement

Component replacement

Component replacement

Component replacement

Component replacement

Component replacement

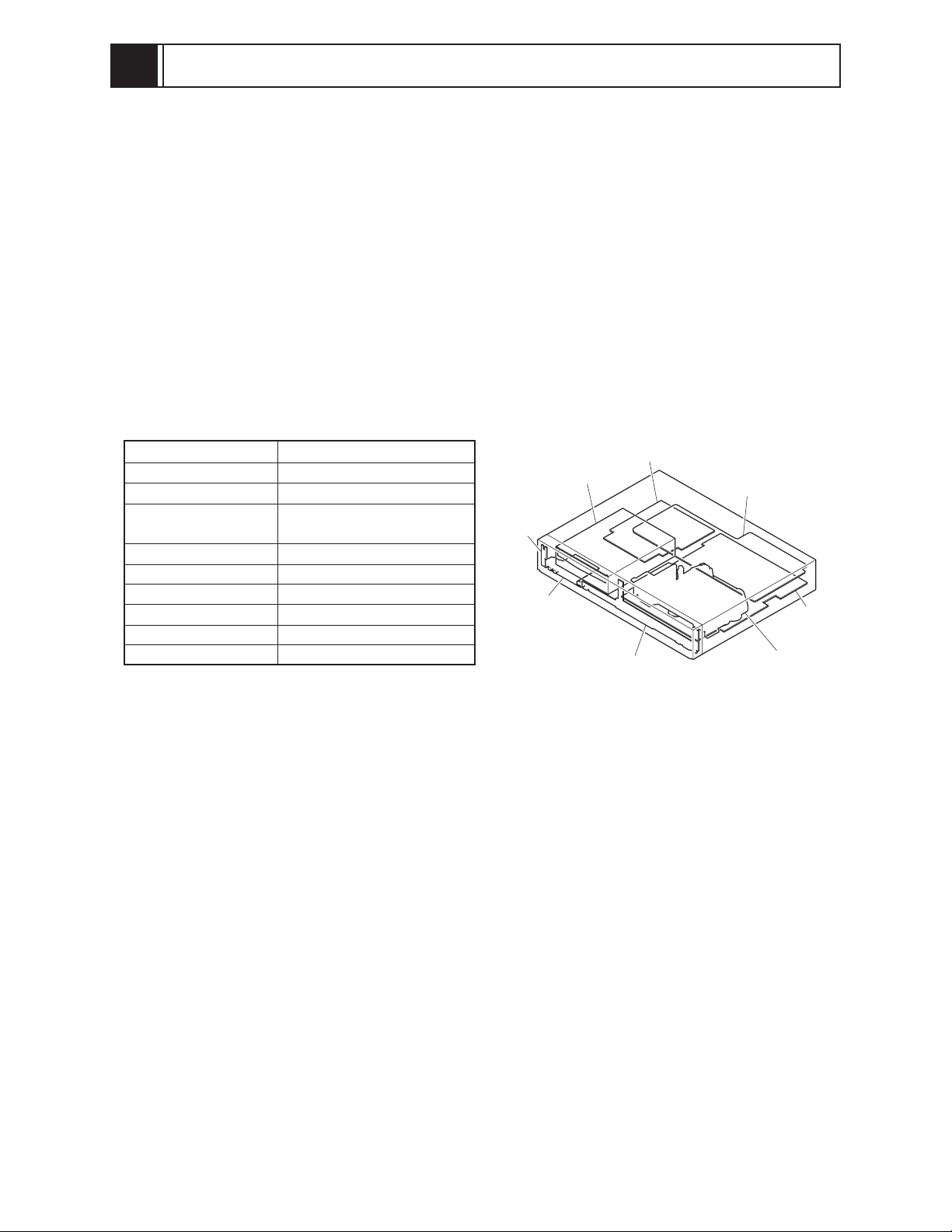

DVD Multi Drive

KEY P.C.B

JACK P.C.B

VDR P.C.B

SMPS P.C.B

TIMER P.C.B

Deck Mechanism

Fig. 2-1-1 Component Location

VCR P.C.B

2 - 1

Page 9

General Description > Overview

2-1-2 Disc information

Recordable Discs

DVD-RW (Digital Video Disc - ReWritable):

These Discs can be recorded on repeatedly.

Recordings can be erased, then you can

record again on the same Disc.

When a brand-new DVD-RW disc is inserted,

the screen for formatting the disc will appear:

Choose the VR mode or Video mode, and

then format the disc before use.

DVD-R (Digital Video Disc - Recordable):

These Discs can be recorded only once. After

you finalize a DVD-R, you cannot record on it

or edit it any more.

DVD+RW (Digital Video Disc + ReWritable):

These Discs can be recorded on repeatedly.

Recordings can be erased, then you can

record again on the same Disc.

When a brand-new DVD+RW disc is inserted,

the screen for formatting the disc will appear:

Format the disc before use.

When a DVD+RW disc recorded on this

recorder is removed, it will automatically be

finalized, but if you enter a title after finalization,

you will need to manually finalize it.

DVD+R (Digital Video Disc + Recordable):

These Discs can be recorded only once. After

you finalize a DVD+R, you cannot record on

it or edit it any more.

. DVD-RAM (DVD - Random Access

Memory)

DVD-RAM discs can be formatted for VR

mode recording.

These Discs can be recorded on repeatedly.

Recordings can be erased, then you can

record again on the same Disc.

Playable on DVD-RAM compatible players.

Recordings can be extensively edited.

Only DVD-RAM standard Version 2.0, 2.1

and 2.2 discs can be used in this unit.

You cannot use the cartridge-type DVD-RAM

disc in this unit.

When a brand-new DVD-RAM disc is

inserted, the screen for formatting the disc

will appear: Format the disc before use.

In the case of an 8-cm DVD-RAM on which

photos were recorded on a Hitachi DVD

video camera/recorder, no editing of Disc

Navigation or play list can be performed on

this recorder (recording on it and creating a

play list are possible).

otes

– This recorder cannot record CD-R or CD-RW discs.

– DVD-R/RW, DVD+R/RW and CD-R/RW discs

recorded using a personal computer or a DVD or CD

recorder may not play if the disc is damaged or dirty,

or if there is dirt or condensation on the recorder’s

lens.

– If you record a disc using a personal computer, even if

it is recorded in a compatible format, there are cases

in which it may not play because of the settings of the

application software used to create the disc. (Check

with the software publisher for more detailed

information.)

– The company does not hold any responsibility to

compensate the contents which should have been

recorded, and any losses or damages (e.g. losses of

business profit, or business intermission) that may

arise from malfunction of this recorder (not

recording/editing as intended).

Problems arising in the following situations are included.

• When a DVD disc recorded on this recorder is used

in a DVD recorder of another manufacturer, or used

(insertion, playback, recording or editing) in a

personal computer DVD drive.

• When a DVD that has been used as above is used

again in this recorder.

• When a DVD disc recorded in a DVD recorder of

another manufacturer, or in a personal computer

DVD drive is used.

Playable Discs

DVD

(8 cm/12 cm disc)

Video CD (VCD)

(8 cm / 12 cm disc)

Audio CD

(8 cm/12 cm disc)

In addition, this unit can play DVD-R/DVD-RW discs;

DVD+R/DVD+RW discs; CD-R/CD-RW discs that

contain audio titles, MP3 files, WMA files, or JPEG files;.

and VCD.

otes

– Depending on the conditions of the recording

equipment or the CD-R/RW (or DVD±R/±RW) disc

itself, some CD-R/RW (or DVD±R/±RW) discs cannot

be played on the unit.

– Do not attach any seal or label to either side (the

labelled side or the recorded side) of a disc.

– Do not use irregularly shaped CDs (e.g., heart-shaped

or octagonal). Doing so may result in malfunctions.

2 - 2

Page 10

General Description > Overview

About DVD-R and DVD-RW disc

How are DVD-R and DVD-RW discs different?

The essential difference between DVD-R and DVD-RW

is that DVD-R is a record-once medium, while DVD-RW

is a re-recordable/erasable medium. You can re-record/

erase a DVD-RW disc approximately 1,000 times.

Can I play my recordable discs in a regular DVD

player?

Generally, DVD-R discs and DVD-RW discs recorded in

Video mode are playable in a regular DVD player, but

they must be ‘finalized’ first. This process fixes the

contents of the disc to make them readable to other

DVD players as DVD-Video discs.

DVD-RW discs recorded in VR (Video Recording) mode

are playable in some players.

This indicates a product feature that is

capable of playing DVD-RW discs recorded

with Video Recording format.

What are ‘recording modes’?

There are two recording modes available using this

recorder: VR mode and Video mode. When recording to

a DVD-R disc, recordings are always in Video mode.

DVD-RW discs can be formatted for VR mode recording

or Video mode recording.

VR mode recording

• 4 different picture quality/recording time settings

available (XP, SP, LP, EP)

• Not playable on regular DVD players

• Recordings can be extensively edited

Video mode recording

• 4 different picture quality/recording time settings

available (XP, SP, LP, EP)

• Playable on regular DVD players (after finalizing)

• Limited editing features

Is editing a DVD like editing a video tape?

No. When you edit a video tape you need one video

deck to play the original tape and another to record the

edits. With DVD, you edit by making a ‘Playlist’ of what

to play and when to play it. On playback, the recorder

plays the disc according to the Playlist.

About word ‘Original’ and ‘Playlist’

Throughout this manual, you will often see the words

Original and Playlist to refer to the actual content and

the edited version.

• Original: content refers to what’s actually recorded on

the disc.

• Playlist: content refers to the edited version of the

disc — how the Original content is to be played.

About DVD+R and DVD+RW disc

How are DVD+R and DVD+RW discs different?

The essential difference between DVD+R and DVD+RW

is that DVD+R is a record-once medium, while

DVD+RW is a re-recordable/erasable medium. You can

re-record/ erase a DVD+RW disc approximately 1,000

times.

DVD+RW mode recording

• 4 different picture quality/recording time settings

available (XP, SP, LP, EP)

• Playable on regular DVD players

• The edited contents is playable on regular DVD

players only after finalizing

• Recordings can be edited the title/chapter

DVD+R mode recording

• 4 different picture quality/recording time settings

available (XP, SP, LP, EP)

• Playable on regular DVD players (after finalizing)

• Any edited contents are not be compatible on regular

DVD players. (Hide, chapter combine, added chapter

mark, etc.)

• Limited title/chapter editing features

ote

DVD-Video Format (Video mode) is a new format for

recording on DVD-R/RW and DVD+R/RW discs that

was approved by the DVD Forum in 2000. You may

therefore experience problems playing recordable DVD

discs in some players. Symptoms include video

artifacts, audio and/or video dropouts and playback

suddenly stopping.

Our company cannot take responsibility for problems

playing discs recorded on this recorder in other players.

2 - 3

Page 11

General Description > Features

2-2 Features

1. DVD super multi-drive incorporated

1) This drive is newly compatible with recording/playback on +R and +RW, in addition to DVDRAM, DVD-RW and DVD-R. DVD-RW is compatible with recording/playback in both Video mode

and VR (Video Recording) mode: DVD media can be selected to match the application.

2) The drive can play back 8 cm DVD-R recorded on a Hitachi DVD video camera/recorder and not

finalized.

3) The drive is widely compatible with reading of original CD-R/RW recorded in MP3, WMA

(Windows Media Player) and JPEG formats, as well as music CDs.

2. The Dubbing button easily dubs VHS images to create a DVD.

Simply pressing the button allows user to dub precious material recorded on VHS videotapes onto

DVD. And images edited on DVD can be dubbed onto VHS videotape.

3. High-quality image design

1) VBR (Variable Bit Rate control) format ensures both high image quality and long-time recording:

This DVD recorder uses a VBR recording format that increases the compression ratio with simple

images and decreases it with complex images of larger amounts of data, thus variably controlling

to the optimum compression ratio: It reduces deterioration in image quality and effectively

records on DVD.

2) Progressive playback makes possible the playback of generally available DVD movies, with

natural images and reduced flickering:

This DVD recorder plays back clear images even on a large screen with reduced jagging on

diagonal lines or characters, and reduced flickering.

4. Enhanced functions

1) DV input port enables digital dubbing from a digital camcorder to DVD.

2) Zoom-up function allows you to enlarge DVD images.

2 - 4

Page 12

General Description > Specifications

2-3 Specifications

General

Power requirements AC 220-240V, 50/60Hz

Power consumption 35W

Dimensions (approx.) 432 X 81.5 X 367 mm (w x h x d)

Mass (approx.) 6.6 kg

Operating temperature 5˚C to 35˚C

Operating humidity 5 % to 90 %

Television system PAL B/G, SECAM L/L' colour system [For E]

Recording format VCR : PAL, SECAM [SECAM : E only]

System

Laser Semiconductor laser, wavelength 650 nm

Video head system Double azimuth 4 heads, helical scanning

Signal system VCR : PAL, SECAM [SECAM : E only]

Recording

Recording format DVD VideoRecording, DVD-VIDEO

Recordable discs DVD-ReWritable, DVD-Recordable, DVD+ReWritable, DVD+Recordable,

Recordable time DVD (4.7GB) : Approx. 1 hour (XP mode), 2 hours (SP mode),

Video recording format

Sampling frequency 27MHz

Compression format MPEG 2

Audio recording format

Sampling frequency 48kHz

Compression format Dolby Digital

PAL I colour system [For E (UK)]

DVD : PAL

DVD : PAL

DVD-Random Access Memory

4 hours (LP mode), 6 hours (EP mode)

Playback

Frequency response DVD (PCM 48 kHz): 8 Hz to 22 kHz, CD: 8 Hz to 20 kHz

DVD (PCM 96 kHz): 8 Hz to 44 kHz

Signal-to-noise ratio More than 100 dB (AUDIO OUT connector)

Harmonic distortion Less than 0.008% (AUDIO OUT connector)

Dynamic range More than 95 dB (AUDIO OUT connector)

Inputs

AERIAL IN Aerial input, 75 ohms

VIDEO IN 1.0 Vp-p 75 ohms, sync negative, RCA jack x 1 / SCART x 2

AUDIO IN 0 dBm more than 47 kohms, RCA jack (L, R) x 1 / SCART x 2

DV IN 4 pin (i.LINK/IEEE 1394 standard)

S-VIDEO IN (Y) 1.0 V (p-p), 75 Ω, negative sync, Mini DIN 4-pin x 1

(C) 0.3 V (p-p) 75 Ω

Outputs

VIDEO OUT 1.0 Vp-p 75 ohms, sync negative, SCART x 2

S-VIDEO OUT (Y) 1.0 V (p-p), 75 Ω, negative sync, Mini DIN 4-pin x 1

(C) 0.3 V (p-p) 75 Ω

COMPONENT VIDEO OUT (Y) 1.0 V (p-p), 75 Ω, negative sync, RCA jack x 1

(C

B/PB

)/(CR/PR) 0.7 V (p-p), 75 Ω , RCA jack x 2

Audio output (digital audio) 0.5 V (p-p), 75 Ω, RCA jack x 1

Audio output (optical audio) 3 V (p-p), 75 Ω, Optical connector x 1

Audio output (analogue audio) 2.0 Vrms (1 KHz, 0 dB), 600 Ω, RCA jack (L, R) x 1 / SCART

• Design and specifications are subject to change without notice.

• Manufactured under licence from Dolby Laboratories. “Dolby” and the double-D symbol are trademarks of Dolby

Laboratories.

• DTS and DTS Digital Out are registered trademarks of Digital Theater Systems, Inc.

2 - 5

Page 13

General Description > Major Differences from Previous Model

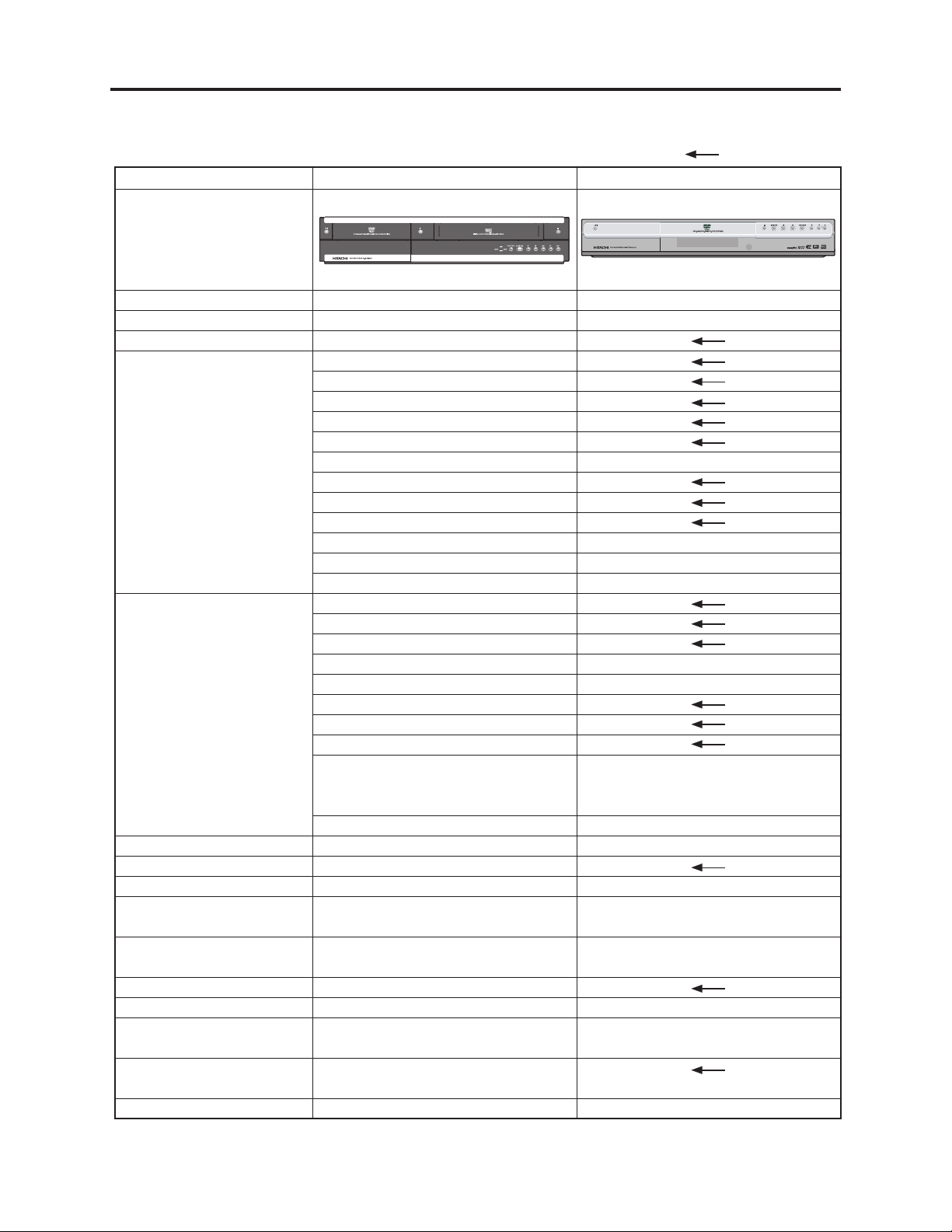

2-4 Major Differences from Previous Model

Item

Appearance

DV-RV8500E

: Same as on left

DV-RX7000E

PROGRAM

Dimensions

Power consumption

CPRM

Recordable media

Playable media

Remote control

DV input terminal

S-VIDEO input terminal

VIDEO/AUDIO input

terminals

COMPONENT VIDEO

output terminal

S-VIDEO output terminal

VIDEO output terminal

Analog AUDIO output

terminals

Digital AUDIO output

terminals

Video output switch

432(W) x 367(D) x 81.5(H)mm

Approx. 35 W

Yes

12 cm (5”) 4.7 GB DVD-RAM

12 cm (5”) 9.4 GB DVD-RAM

8 cm (3”) 1.4 GB DVD-RAM

8 cm (3”) 2.8 GB DVD-RAM

12 cm (5”) 4.7 GB DVD-RW

8 cm (3”) 1.4 GB DVD-RW

12 cm (5”) 4.7 GB DVD-R

8 cm (3”) 1.4 GB DVD-R

12 cm (5”) 4.7 GB DVD-R (4x-SPEED)

12 cm (5”) 4.7 GB DVD+RW

12 cm (5”) 4.7 GB DVD+R

VHS

DVD-RAM

DVD-RW

DVD-R

DVD+RW

DVD+R

DVD-VIDEO

Video CD (VCD)

Audio CD (CD-DA)

CD-R/CD-RW

(CD-DA, MP3,WMA,JPEG,VCD

formatted discs)

VHS/S-VHS (SQPB)

DV-RM8500E

1 (IEEE 1394/i.LINK)

1 (Mini DIN 4pin)

3 (RCA: 1, SCART: 2)

1 (RCA)

1 (Mini DIN 4pin)

2 (SCART: 2)

3 (RCA: 1, SCART: 2)

2 (Optical: 1, Coaxial: 1)

Yes (COMPONENT-RGB)

430(W) x 279(D) x 69(H)mm

Approx.35 W

---

---

---

---

---

---

CD-R/CD-RW

(CD-DA, MP3,JPEG formatted discs)

---

DV-RM7000E

2 (Mini DIN 4pin: 2)

4 (RCA: 2, SCART: 2)

---

3 (RCA: 1, SCART: 2)

4 (RCA: 2, SCART: 2)

Yes (SETUP screen)

2 - 6

Page 14

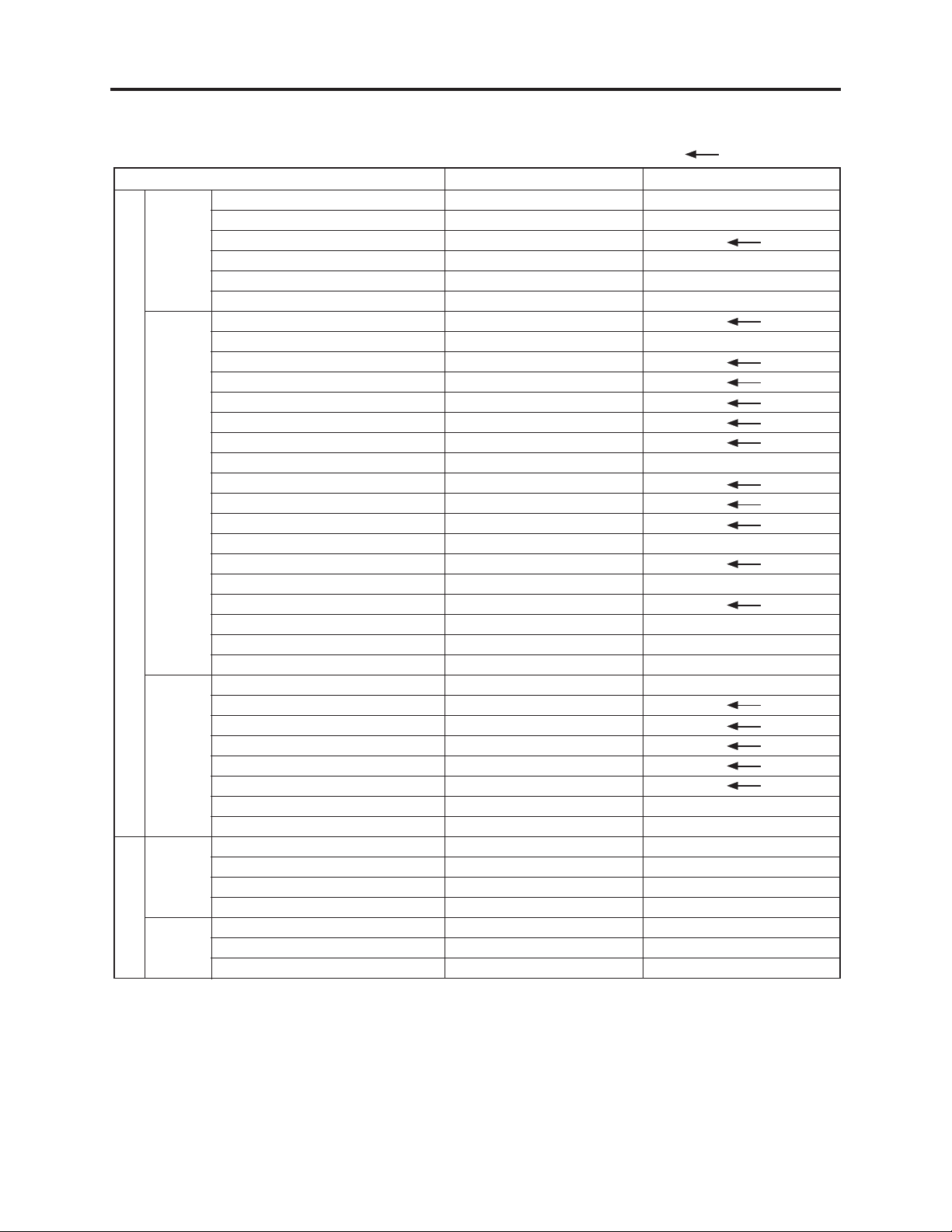

General Description > Function Differences from Previous Model

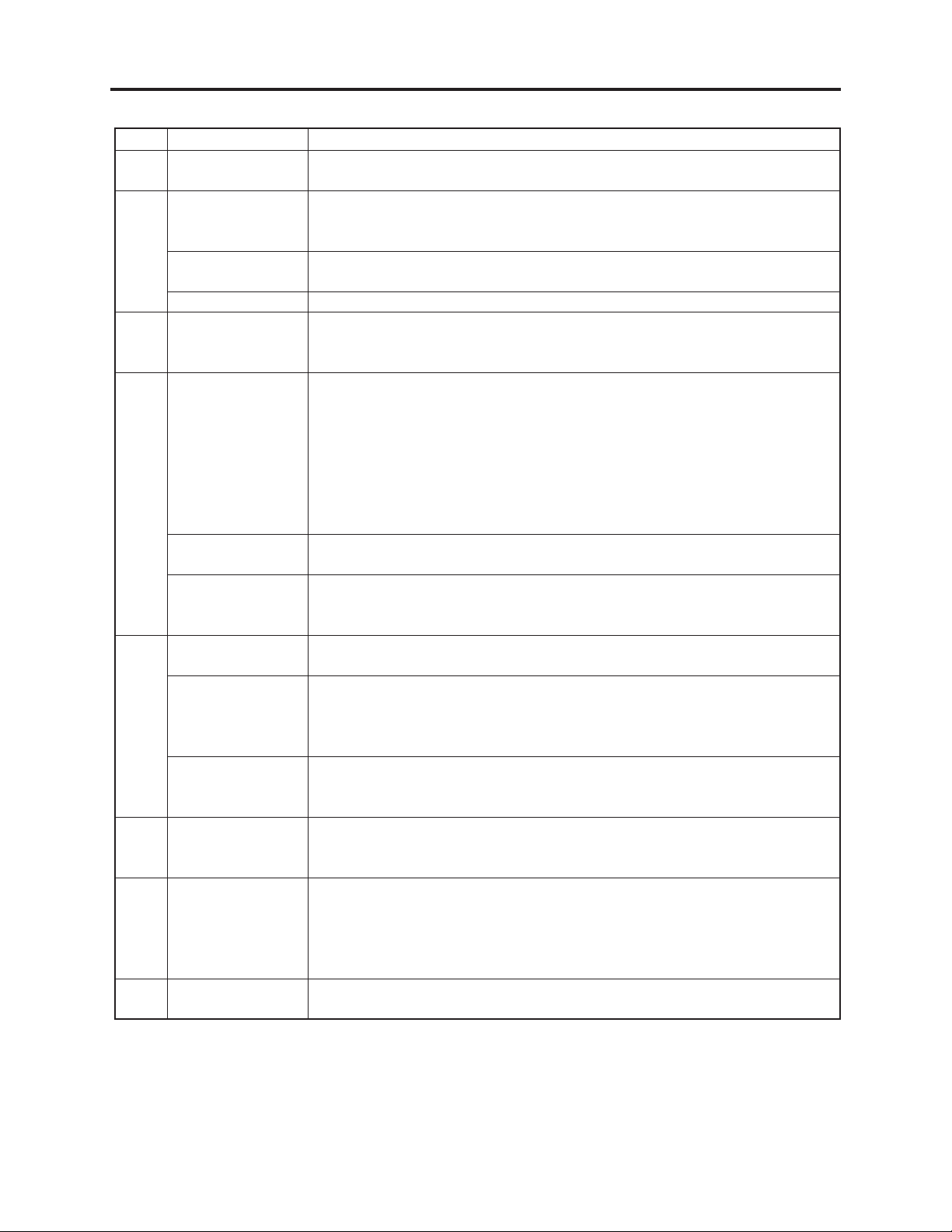

2-5 Function Differences from Previous Model

Recording

Playback

DVD sectionVCR section

Other

Recording

Playback

Item

Digital Recording (DV to DVD)

Dubbing (VCR to DVD)

Time Slip (PIP)

Instant Timer Recording

Flexible Recording Mode

Recording Mode

Title List Playback

CM Skip

Manual Skip

Marker Search

Zoom

Photo CD Playback (JPEG)

MP3 Playback

P in P

Repeat Play

Repeat A-B Play

Camera Angle

3D Surround

Slow Motion Play

Random Play

Time Search

DivX Movie Disc Playback

WMA Playback

Intro Play

Disk Menu

Title List

Chapter List

Edit Title List

Edit Chapter List

Playlist

Divide Program

Hide Program

Digital Recording (DV to VCR)

Dubbing (DVD to VCR)

Title List Dubbing (DVD to VCR)

Instant Timer Recording

Picture Search

Slow Motion

Counter [0:00:00] Stop

DV-RV8500E

Yes

Yes

Yes

Yes

No

XP, SP, LP, EP

Yes

No

Yes

Yes

Yes

Yes

Yes

No

Yes

Yes

Yes

Yes

Yes

Yes (Karaoke, VCD)

Yes

Yes

Yes

No

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

: Same as on left

DV-RX7000E

No

No

One Touch Recording (OTR)

Yes (Timer Recording Only)

XP, SP, LP, EP, FR

Yes (15, 30, 60 sec)

Yes

No

Yes

No

No

Yes

Yes (Disc Manager)

No

No

---

---

---

---

---

---

---

2 - 7

Page 15

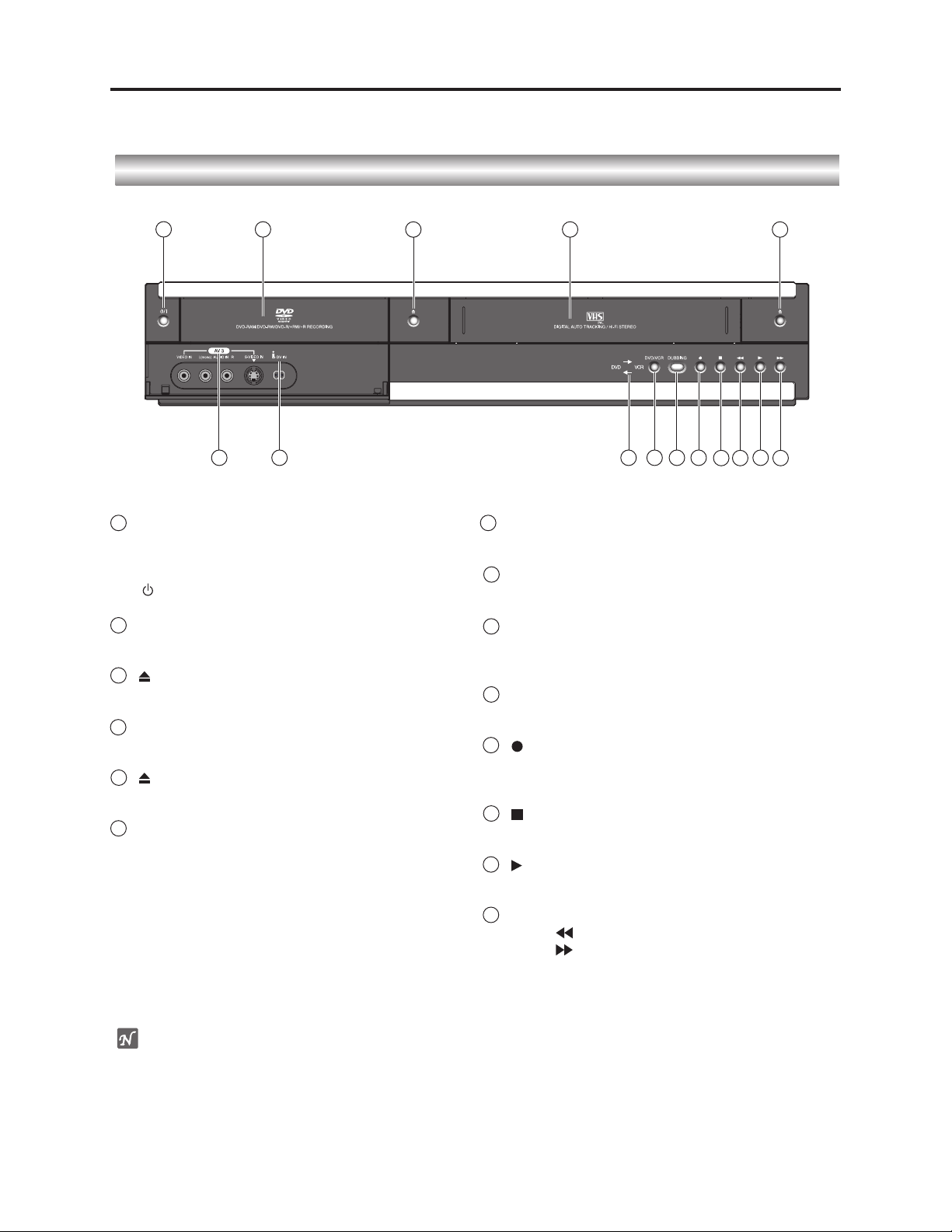

General Description > Names of Parts

2-6 Names of Parts

Front Panel

1

1

STANDBY/ON

Switches the Recorder ON and OFF.

Press to turn the power on and off.(As to the

indication of the Operate switch, “ I ” shows ON and

“ ” shows electrical power stand-by.)

Disc Tray (DVD deck)

2

Insert a disc here.

3

OPEN/CLOSE

Opens or closes the disc tray.

4

Cassette Compartment (VCR deck)

Insert a video cassette here.

5

EJECT

Ejects the tape in the VCR deck.

6

AV 3 IN

- VIDEO /AUDIO (Left/Right)

Connect the audio/video output of an external

source

(Audio system, TV/ Monitor, VCR, Camcorder, etc.).

- S-VIDEO IN

Connect the S-Video output of an external source

(TV/ Monitor, VCR, Camcorder, etc.).

2

6

7

(REC)

(STOP)

(PLAY)

4

12

10

9

8

11

14

13

5

14

3

7

DV IN

Connect the DV output of a digital camcorder.

8

DVD/VCR indicator

Indicates the active DVD or VCR deck.

DVD/VCR

9

Toggles control between the DVD deck and the VCR

deck.

10

DUBBING

Press to copy DVD to VCR (or VCR to DVD).

11

Starts recording.

Press repeatedly to set the recording time.

12

Stops playback.

13

To play back a disc or tape.

14

SEARCH

Press for fast back.

Press for fast forward.

ote

Holding down the POWER button on the front of this

recorder in the stop mode will allow you to reset the

recorder. Do not perform this during recording: Doing so

will result in flawed recording.

2 - 8

Page 16

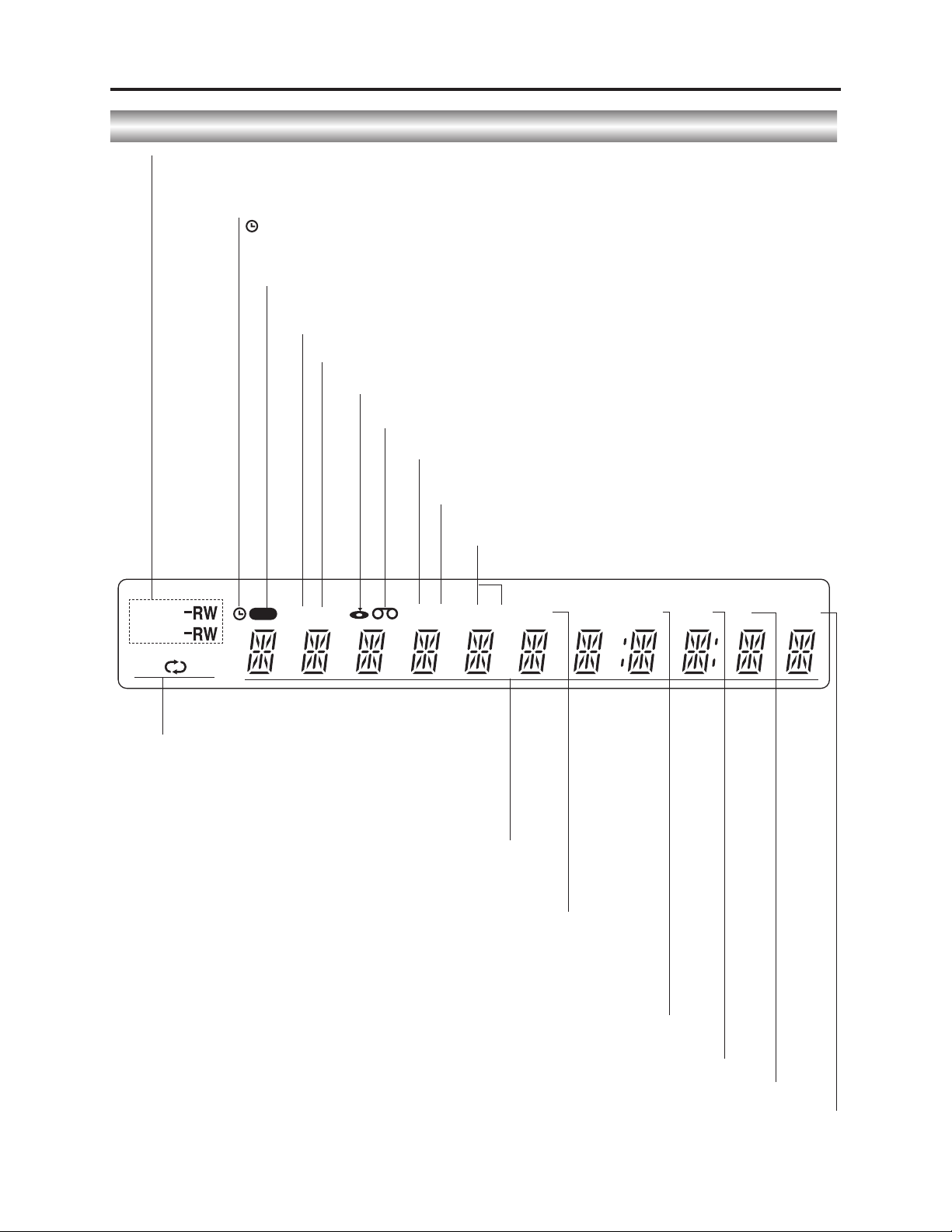

General Description > Names of Parts

Function Display Window

Disc type indicators

Indicates the type of disc loaded.

Indicates when the recorder

is in timer recording or a timer

recording is programmed.

REC The recorder is

recording.

PRG Programmed playback active.

TTL Indicates current title.

A disc is inserted in the DVD deck.

A VHS tape is inserted in the VCR deck.

Indicates a DVD-RW disc (VR mode only)

disc is inserted in the DVD deck.

TVVRIndicates when the recorder is in TV tuner mode.

DVD

REC

PRG TTL VR TRKCHP DUB

TV

VCD

AB

REPEAT Indicates repeat mode.

Character indicators

Indicates clock, total playing time, elapsed time, remaining

time, title number, chapter/track number, channel, etc.

DUB Indicates that a DVD to VCR (or VCR to DVD)

copy is in progress.

Hi-Fi Indicates when the Recorder is playing

CHP/TRK Indicates current chapter or track number.

Hi-Fi ST

a tape in Hi-Fi.

BIL

NICAM

ST Indicates a stereo broadcast is

being received.

BIL Indicates when a BILINGUAL broadcast is being received.

NICAM Indicates when a NICAM broadcast is being received.

2 - 9

Page 17

General Description > Names of Parts

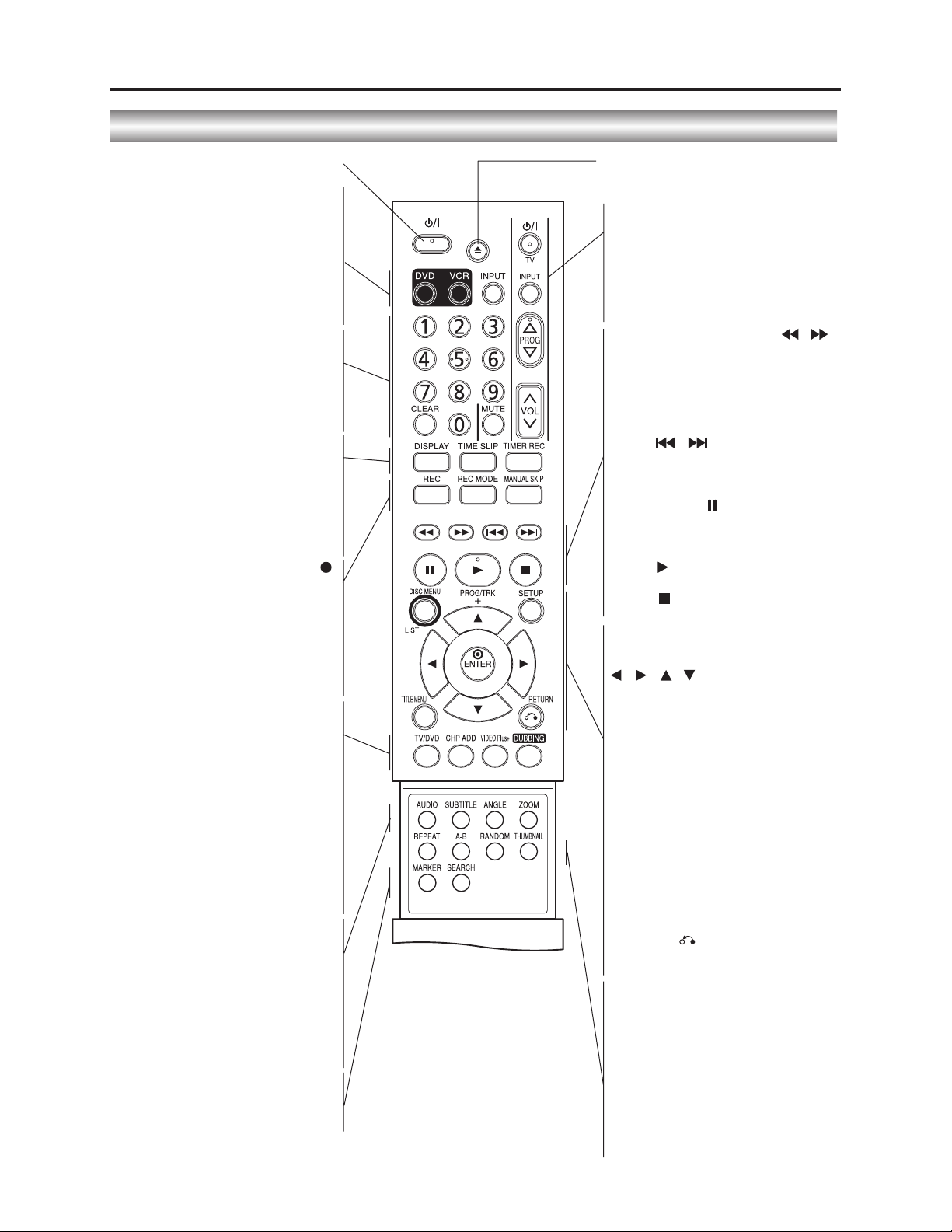

Remote Control Overview

POWER

Switches the recorder ON or OFF.

DVD

Select the Recorder’s function mode to

DVD.

VCR

Select the Recorder’s function mode to

VCR.

INPUT

Changes the input to use for recording

(Tuner, AV1-3, or DV IN).

0-9 numerical buttons

Selects numbered options in a menu.

CLEAR

- Removes a track number on the

Program List or a mark on the

Marker Search menu.

- Reset tape counter to zero.

DISPLAY

Accesses On-Screen Display.

TIME SLIP

To play the title being recorded and also

currently being recorded appears as

PIP.

TIMER REC

Displays Timer Record menu.

REC ( )

Starts recording. Press repeatedly to set

the recording time.

REC MODE

Selects the recording mode:

XP, SP, LP, or EP.

MANUAL SKIP

Pressing this button during palyback will

skip to a scene 30 seconds forward.

TV/DVD

To view channels selected by the

recorder’s tuner or by the TV tuner.

CHP ADD

Inserts a chapter marker when playing/

recording a VR mode DVD-RW (and

DVD+RW/+R) disc.

VIDEO Plus +

Pressing this button and input VIDEO

Plus + number to preset the timer for

recording.

DUBBING

Press to copy DVD to VCR (or VCR to

DVD).

AUDIO

Selects an audio language (DVD) or an

audio channel (CD).

SUBTITLE

Selects a subtitle language.

ANGLE

Selects a DVD camera angle,

if available.

ZOOM

Enlarges DVD video image.

MARKER

Marks any point during playback.

SEARCH

Displays Marker Search menu.

EJECT, OPEN/CLOSE

- Opens and closes the disc tray.

- Ejects the tape in the VCR deck.

TV Control Buttons

POWER:

INPUT:

PROG:

VOL:

MUTE:

OFF, press again to restore.

BACKWARD / FORWARD (

- DVD: Search backward or forward.

- VCR: Rewinds the tape during the

STOP mode, for fast reverse picture

search and Advances the tape during

the STOP mode, fast forward picture

search.

SKIP (

Go to next chapter or track. Returns to

beginning of current chapter or track or

go to previous chapter or track.

Turns the TV on or off.

Selects the TV’s source.

Selects TV’s channel.

Adjusts TV’s volume.

Temporarily turns TV sound

)

/

/

PAUSE/STEP ( )

Pause playback temporarily / press

repeatedly for frame-by-frame

playback.

PLAY ( )

Starts playback.

STOP ( )

Stops playback or recording.

DISC MENU / LIST

Accesses menu on a DVD disc, Title List

or Playlist menu.

///

Selects an option in the menu.

(left/right/up/down)

PROG/TRK(+/–)

- Select channel program of the

recorder.

- To adjust tracking.

- To control vertical tremble during

picture still.

ENTER

- Acknowledges menu selection.

- Displays information while viewing a

TV program.

SETUP

Accesses or removes the Setup menu.

TITLE MENU

Displays the disc’s Title menu, if

available.

RETURN ( )

- Removes the menu.

- Displays the menu of a video CD

with PBC.

REPEAT

Repeat chapter, track, title, all.

A-B

Repeat sequence.

RANDOM

Plays tracks in random order.

THUMBNAIL

Selects a thumbnail picture for the

current title and chapter for use in the

Original and Playlist menu.

)

2 - 10

Page 18

General Description > Names of Parts

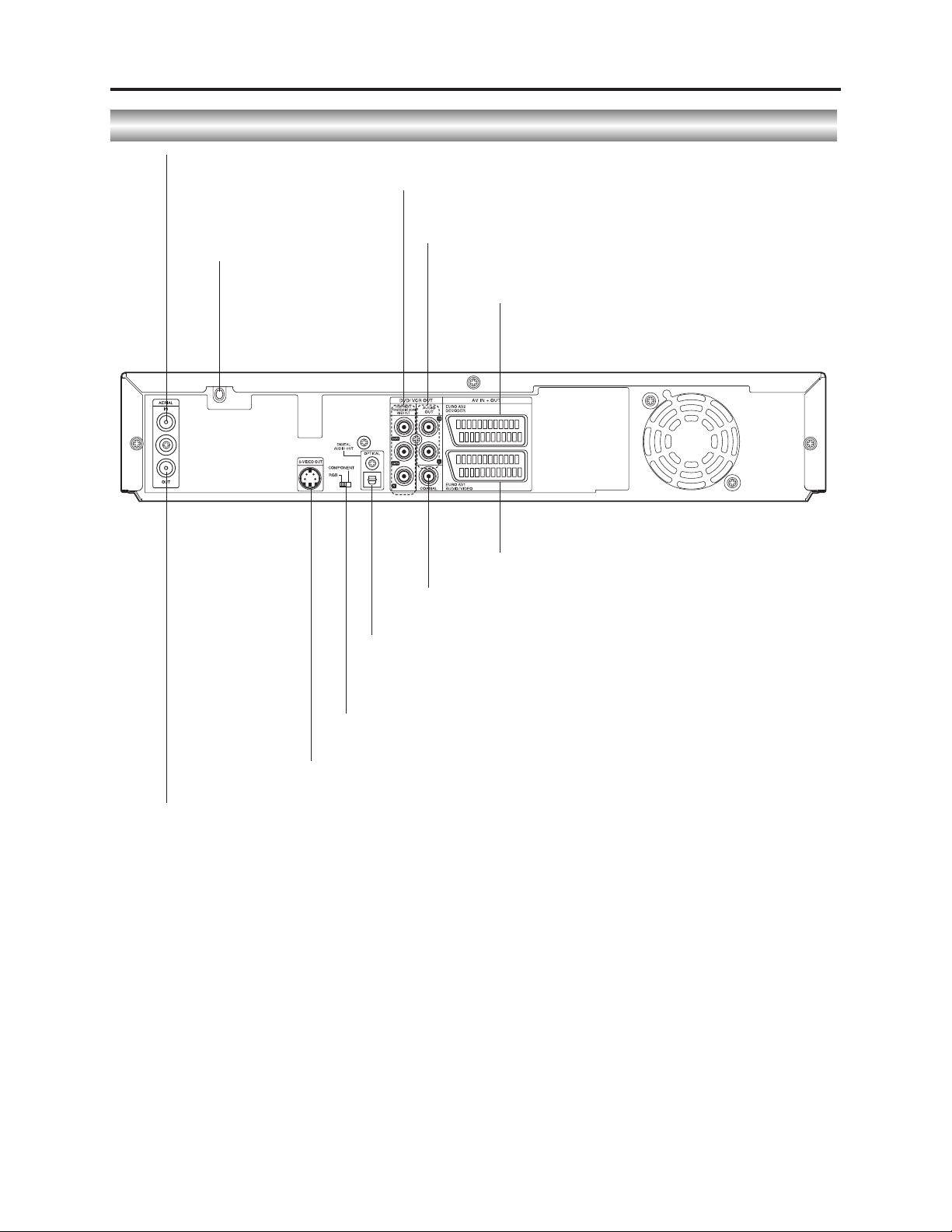

Rear Panel

AERIAL

Connect the aerial to this terminal.

Mains Lead

Plug into the power source.

COMPONENT/PROGRESSIVE SCAN VIDEO OUT (Y Pb Pr)

Connect to a TV with Y Pb Pr inputs.

AUDIO OUT (Left/Right)

Connect to an amplifier, receiver or stereo system.

EURO AV 2 DECODER

Connect the audio/video output of an external source

(Pay-TV decoder, Set Top Box, VCR, etc.).

EURO AV 1 AUDIO/VIDEO

Connect to a TV with SCART jack.

COAXIAL (Digital audio out jack)

Connect to digital (coaxial) audio equipment.

OPTICAL (Digital audio out jack)

Connect to digital (optical) audio equipment.

VIDEO OUTPUT Switch

Select either COMPONENT/PROGRESSIVE SCAN VIDEO OUT or RGB

signal of EURO AV1 AUDIO/ VIDEO terminal depending on how you connect

the Recorder to the TV.

S-VIDEO OUT

Connect to a S-Video Input on TV.

AERIAL OUT

Passes the signal from the AERIAL to your TV/monitor.

2 - 11

Page 19

General Description > List of Abbreviations and Terms for DVD Recorder

2-7 List of Abbreviations and Terms for DVD Recorder

Index

A

B

C

D

I

Abbreviation/Term

AC3

Black Level

CPRM

CD-R

CD-RW

Component video

output terminals

Decoder

Dynamic Range

Dolby AC3

DRC

DTS

DVD

DVD-Audio

DVD-R

DVD-RAM

DVD-RW

DVD-Video

DVD Video Format

DVD Video

Recording Format

I/P/B

Explanation

See Dolby AC3.

Function to correct the gradations on dark portions to make dark scenes easierto-see.

Content Protection for Recordable Media: Copyright protection function that is

suitable for online distribution of music.

One type of DVD standard disc, to which writing once is possible (recordable

type)

One type of CD standard disc, to which writing up to 1000 times is possible

Used for outputs of HDTV video signal format. Since signals for brightness and

colors are independently handled for components signals (Y: luminance signal;

PR/PB: chrominance signals), degrading of image will be reduced.

A device that decodes the data coded and recorded on DVD Video and restores it

to video and audio signals. This processing is referred to as decoding.

A difference between maximum and minimum levels of audio recorded on disc:

Measured in decibel (dB) units. If the dynamic range is compressed (audio DRC),

the minimum signal level will increase and the maximum signal level will

decrease: This will reduce the higher audio signal - such as burst sound - so that

the low-level audio signal - such as human voice - can be heard more clearly.

Audio coding format developed by Dolby Laboratories in U.S, also simply

referred as AC3 format: Supports 5-channel full-range sound and one channel

for sub-woofer sound playback.

Dynamic Range Control: Adjusting the audio range of maximum and minimum

levels (dynamic range) will improve audio signal when, for example, dialog is

hard to hear or user is watching movies late at night.

Digital Theater System: Sound system as for movie theaters developed by US

Digital Theater Systems, Inc. The number of channels provided by DTS is the

same for Dolby AC3.

Digital Versatile Disc. A huge amount of digital data for video (movie) and audio

can be recorded on this disc, whose size is the same as CD.

One type of DVD standard disc, on which high-quality audio can be recorded

One type of DVD standard disc, to which writing once is possible (recordable

type)

One type of DVD standard disc, to which writing up to 100,000 times is possible

One type of DVD standard disc, to which writing up to 1000 times is possible

One type of DVD standard disc, on which high-quality video and audio can be

recorded

Video recording/playback standard that applies to DVD-Video, DVD-R and DVDRW

Video recording/playback standard that applies to DVD-RAM and DVD-RW:

This allows versatile editing functions, differing from the DVD Video Format.

DVD recorders normally use data that is common between images, and

individually record different data for each image.

I-picture: Images recorded independently for the reference of commonly used

data.

P-picture: Images created from past I-picture or P-picture

B-picture: Images created from both I and P pictures, which interact between

both types

Since I-picture delivers the highest image quality, selecting I-picture is

recommended when adjusting image quality.

2 - 12

Page 20

General Description > List of Abbreviations and Terms for DVD Recorder

Index

J

M

O

P

S

T

Abbreviation/Term

JPEG

MPEG

MPEG Audio Layer

2

MP3

Optical digital

audio output

Pan & Scan/

Letterbox

Playback Control

(PBC)

Progressive

playback function

S-Video Output

Sampling

Frequency

SDMI

Tracking

Explanation

Joint Photographic Expert Group: International standard format for

compressing still images.

Moving Picture Experts Group: Standard related to compression of digital video

and audio. MPEG2 is a higher standard of MPEG and is applied to video (movie)

requiring higher quality.

One of three audio compression standards (layers 1-3) defined by MPEG

MPEG1 Audio Layer-3: Audio data digital compression technology.

Audio is usually converted to an electrical signal and transmitted from DVD to a

device such as amp: When audio is converted to a digital signal, this optical

digital audio output can be transmitted on optical fiber.

Most DVD videos are produced assuming that they will be displayed on wide TV

screen (aspect ratio of 16:9): If they are displayed on TV screens with 4:3 aspect

ratio, 16:9 images will not quite fit on 4:3 screens. There are two ways of

displaying 16:9 images on 4:3 TV:

· Pan & Scan: Cuts out the left and right ends of images and displays them on

whole screen.

· Letterbox: Reproduces 16:9 images on 4:3 screens with black bands across the

top and bottom of screen.

One format to play Video CD: User can select desired screens and data while

watching the displayed menu screen.

This function converts interlaced images to non-interlaced images and displays

them. It can play back 24-frame/second images included in DVD movie software,

etc.

The video signal is separated into chrominance (C) and luminance (L) signals

and transmitted to TV: This delivers clearer images.

Sampling slices audio waves (analog signal) at a specified time interval, and

digitizes the levels of the sliced waves. The slicing number per second is referred

to as the sampling frequency: The higher the number, the closer the sound to

the original.

Secure Digital Music Initiative: This conference was established by hardware

makers, the Recording Industry Association of America (RIAA) and music

industry companies, to protect copyrights of musical compositions.

To make adjustment for clearer playback image, by reducing noise that appears

on screen during videotape playback.

V

Virtual surround

W

WMA

This technology localizes sound at any position using only two front speakers, by

subjecting the L and R signals to matrix operation. It uses the four transfer

functions from L/R speakers located at specified positions to both ears of listener

located in a specified position, taking into account the shape of head and the

effect of earlobes, and the two transfer functions from any position to both ears.

Windows Media Audio: Codec that was developed by Microsoft Corporation in

USA.

2 - 13

Page 21

3

Details of Servicing and Troubleshooting

3-1 Details of Servicing

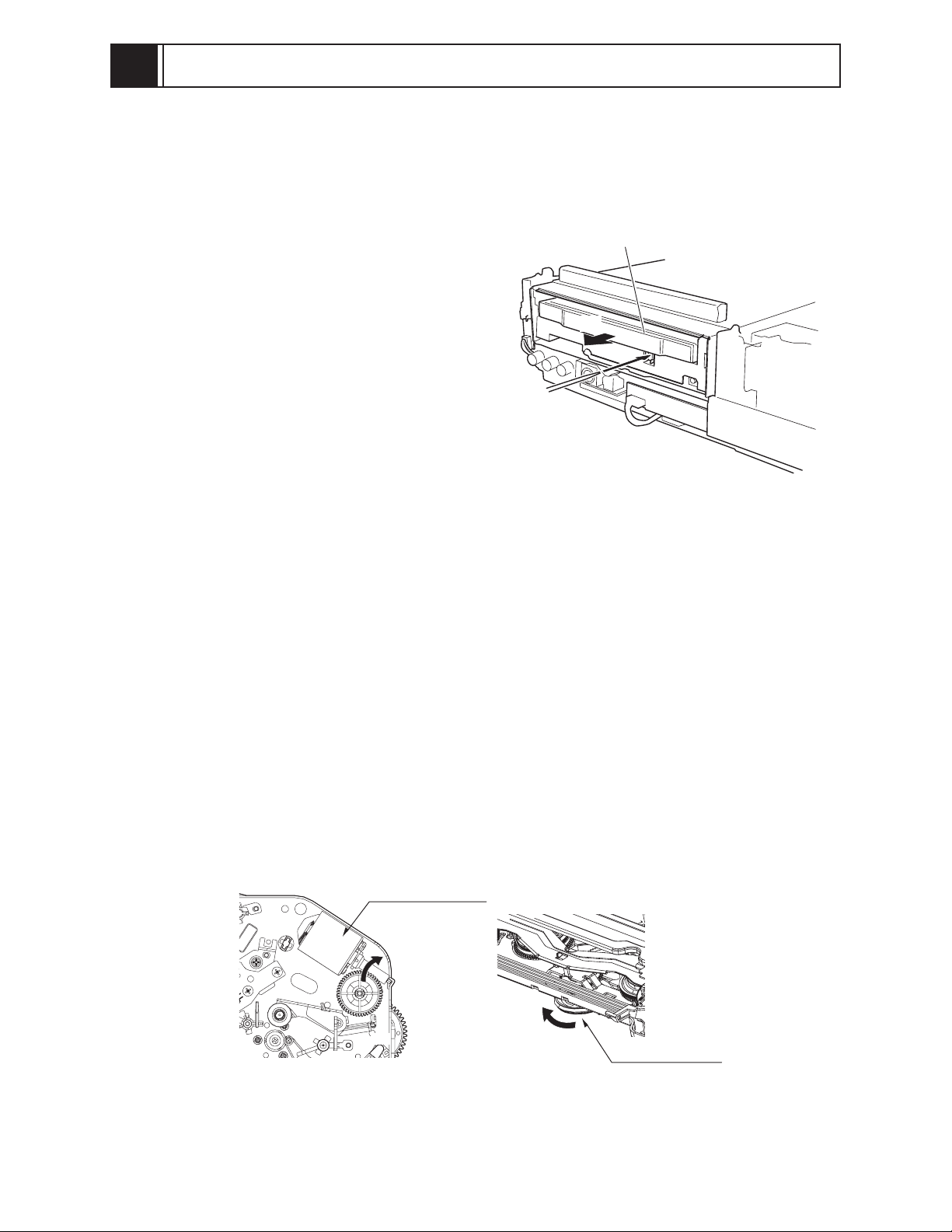

3-1-1 Removing Disc from Faulty Recorder

If disc cannot be removed due to fault, disassemble the recorder and remove the disc by the

following procedure:

1) Remove the top cover.

[See 4-2 (1) for removal procedure.]

2) Remove the front panel.

[See 4-2 (2) for removal procedure.]

3) Push the white component portion under the

disc tray strongly, and the tray will come

slightly forward.

Remove the disc tray in the direction of arrow

B. Perform this work carefully, making sure

that the disc is not scratched.

"A" PUSH

DISC TRAY

"B"

Fig. 3-1-1 Removing Disc

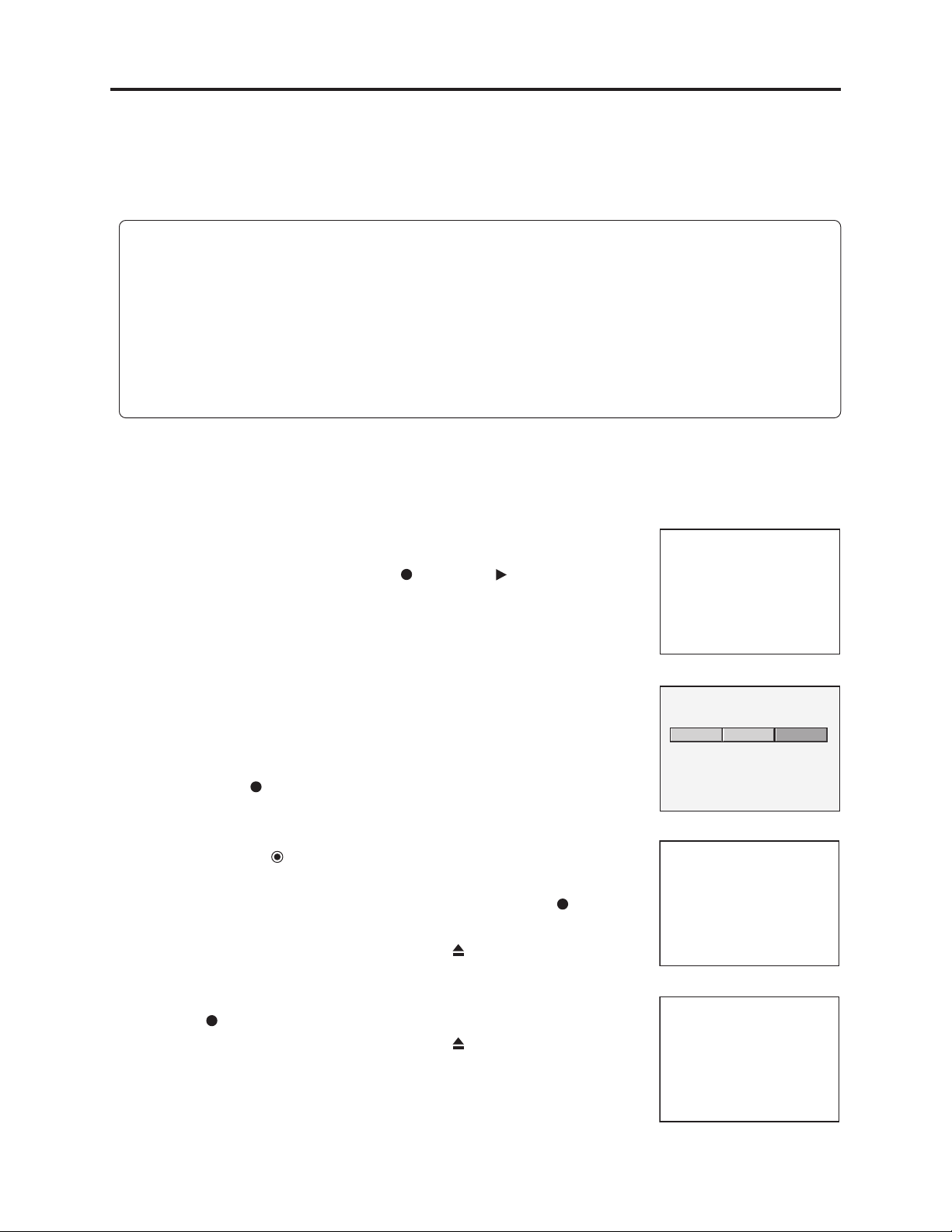

3-1-2 Removing Video Cassette from Faulty Recorder

If video cassette cannot be removed due to fault, disassemble the recorder and remove the video

cassette by the following procedure:

1) Remove the top cover. [See 4-2 (1) for removal procedure.]

2) Remove the front panel. [See 4-2 (2) for removal procedure.]

3) Remove the deck mechanism. [See 4-2 (5) for removal procedure.]

4) Turn the worm gear of L/D motor assembly in the direction of arrow A: Unloading will start.

When the tape starts to slacken, turn the D37 clutch assembly on the front of deck mechanism in

the direction of arrow B to remove the slack tape.

5) When unloading is complete, the deck mechanism will begin EJECT operation: Completely turn

the worm gear of L/D motor assembly in the direction of arrow A.

L/D MOTOR Ass'y

(A)

(B)

Fig. 3-1-2 Removing Video Cassette

3 - 1

D37 Clutch Ass'y

Page 22

Details of Servicing and Troubleshooting > Firmware

3-1-3 Firmware

The firmware is occasionally updated to improve performance.

Check whether a customer complaint can be solved by updating of firmware: If the complaint can be

solved, update the firmware.

Information:

1) If any corrections in firmware are made at the factory, information on how to obtain the

firmware data and create a disc containing upgraded firmware will be reported in technical

bulletin, etc.

2) The main and drive firmware programs in this DVD recorder can be written to one CD-R and

updated at the same time. It is also possible to write one firmware program to a CD-R and

update it individually. Note that some parts of on-screen display will be different depending on

the contents to be written to CD-R.

(1) Version check procedure

1) With the recorder turned on, make sure that no disc or tape is

inserted.

2) Connect a monitor TV to the video output terminals on this DVD

recorder.

3) Simultaneously hold down the REC and PLAY buttons on the

front of this DVD recorder for approx. 10 seconds.

4) The firmware version screen will appear on the monitor TV.

5) Turn the recorder off to switch off the display.

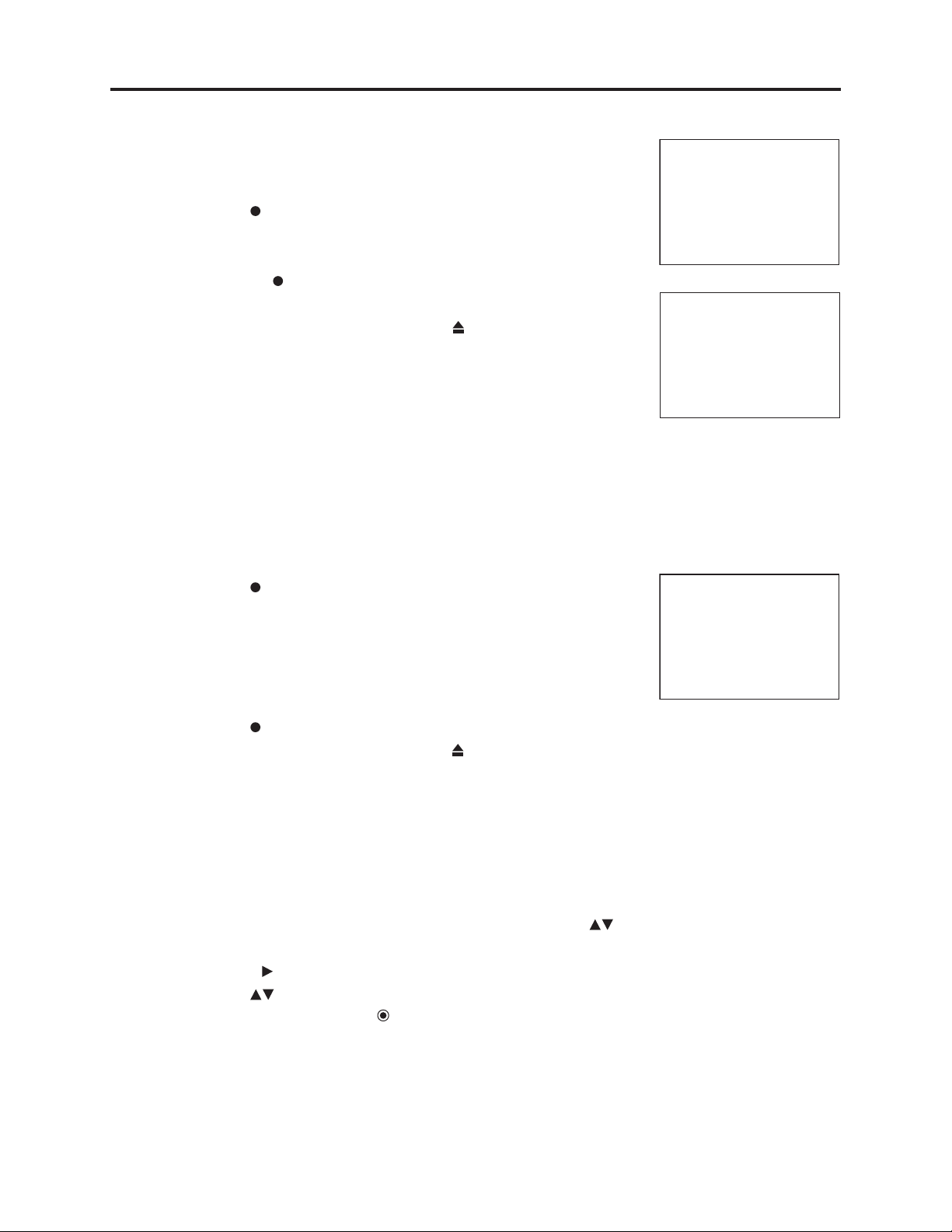

(2) Main/drive firmware simultaneous updating procedure

1) Write the main firmware data and drive firmware data to a CD-R.

2) Insert the firmware disc: The screen for verifying update will appear

(Fig. 3-1-3).

3) Press the REC button on this DVD recorder three times: The

Firmware Update screen will appear (Fig. 3-1-4).

4) Use the cursor buttons on remote control to choose “ALL”, and then

press the ENTER button.

5) The current version of drive firmware and the version of firmware on

the disc will both appear on the screen. Pressing the REC button on

this DVD recorder will start writing (Fig. 3-1-5).

To cancel writing, press the OPEN/CLOSE button and remove the

disc.

6) The main firmware version will then appear on the screen. Pressing

the REC button on this DVD recorder will start writing (Fig. 3-1-6).

To cancel writing, press the OPEN/CLOSE button and remove the

disc.

7) When updating is complete, the tray will open automatically: Remove

the disc.

8) Turn the DVD recorder off and then on: The firmware is now updated.

Update Disc.

Run: REC KEY 3 times

Open: Other KEY

Fig. 3-1-3

==== Firm Ware Update =====

ALLLoaderMain

Fig. 3-1-4

Current Loader Version

DVD+-R/RW RL-02A a.30

New CD Write Loader Version

DVD+-R/RW RL-02A a30

RECKEY:WRITE OPEN:CANCEL

Fig. 3-1-5

Current Version

Version=040731APV Cware=LG17 BSP=1

New CD Write Version

Version=040731A cware=LG17 BSP=16

RECKEY:WRITE OPEN:CANCEL

Fig. 3-1-6

3 - 2

Page 23

Details of Servicing and Troubleshooting > Firmware

Update Disc.

Run: REC KEY 3 times

Open: Other KEY

Current Version

Version=040731APV Cware=LG17 BSP=1

New CD Write Version

RECKEY:WRITE OPEN:CANCEL

Version=040731A cware=LG17 BSP=16

(3) Main firmware updating procedure

1) Write the main firmware data to a CD-R.

2) Insert the firmware disc: The screen for verifying update will appear

(Fig. 3-1-7).

3) Press the REC button on this DVD recorder three times: Both the

current version of main firmware and the version of main firmware

on the disc will appear on the screen (Fig. 3-1-8).

4) Pressing the REC button on this DVD recorder will start writing

(Fig. 3-1-8).

To cancel writing, press the OPEN/CLOSE button and remove the

disc.

5) When updating is complete, the tray will open automatically:

Remove the disc.

6) Turn the DVD recorder off and then on: The firmware is now

updated.

(4) Drive firmware updating procedure

1) Write the drive firmware data to a CD-R.

2) Insert the firmware disc: The screen for verifying update will appear

(Fig. 3-1-7).

3) Press the REC button on this DVD recorder three times: The data

on disc will be read, the Firmware Update screen will appear, and

the drive firmware version along with the version of drive firmware

on the disc, will appear on the screen (Fig. 3-1-9).

When reading the data on disc is complete, the disc tray will open

automatically: Remove the disc.

4) Press the REC button on this DVD recorder.

To cancel writing, press the OPEN/CLOSE button.

5) Turn the DVD recorder off and then on: The firmware is now

updated.

Fig. 3-1-7

Fig. 3-1-8

Current Loader Version

DVD+-R/RW RL-02A a.30

New CD Write Loader Version

DVD+-R/RW RL-02A a30

RECKEY:WRITE OPEN:CANCEL

Fig. 3-1-9

3-1-4 Setting to defaults at the factory

Perform the following procedure to reset this DVD recorder to the

initial status when it was shipped from the factory (defaults):

1) Press the SETUP button on remote control and use the cursor

buttons to choose the GENERAL menu.

2) Press the cursor button to move to the second level.

3) Use the cursor buttons to choose “Factory Set”, choose the SET

icon, and then press the ENTER button.

3 - 3

Page 24

Details of Servicing and Troubleshooting > Troubleshooting

3-2 Troubleshooting

3-2-1 Troubleshooting electronic system

(1) SMPS Circuit

No 5.3VA

F101: Normal?

Ye s

BD101: Normal? Replace BD101.

Ye s

TH01: Normal? Replace TH01.

Ye s

D121 cathode: 5.3 V?

Ye s

IC103-1: Approx. 2.5 V?

Ye s

D126 cathode: Voltage? Replace D126.

No

No

No

No

No

No

Replace F101.

Replace D121.

Replace IC103.

D127 anode: Voltage? Replace D127.

Ye s

D128 cathode: Voltage?

Ye s

Power line on

VCR PCB shorted.

No

No

Replace D128.

Ye s

D129 cathode: Voltage? Replace D129.

Ye s

D130 cathode: Voltage? Replace D130.

Ye s

No

No

3 - 4

Page 25

Details of Servicing and Troubleshooting > Troubleshooting

No 12VA

(power supply of capstan/cylinder motors)

Is 13 V supplied

to C130?

Ye s

D132 cathode: Voltage?

Ye s

No

No

Check D126, and

replace if necessary.

Replace D132.

Check capstan motor and

cylinder motor, and

replace if necessary.

FL display does not light.

R107: Normal?

No

Check R107, and

replace if necessary.

No REG12V

Is 13 V supplied

to Q126-C?

Ye s

Is 33 V supplied

to Q126-B?

Ye s

Is there "Hi" signal

on 'PWR CTL H' line

from SYSTEM circuit?

Ye s

Check D126, and

replace if necessary.

No

No

No

No CAP Vcc power supply

Check D126, and

replace if necessary.

Check 33V line.

Check

SYSTEM microprocessor.

Ye s

D128 cathode: Voltage?

Ye s

ZD151: Normal?

Ye s

Check D127, and

replace if necessary.

No 33V

Is 33 V supplied

to Q123-E?

Ye s

No

No

No

Check D128, and

replace if necessary.

Check ZD151, and

replace if necessary.

Check D130, and

replace if necessary.

Is 30 V supplied

to Q120-C?

Ye s

Is 30 V supplied

to Q120-B?

Ye s

Is 33 V supplied

to Q121-C?

Ye s

Check Q120, and

replace if necessary.

No

No

No

Check D129, and

replace if necessary.

Check ZD153, and

replace if necessary.

Check 'HSR H' line

from SYSTEM circuit?

Check Q121, Q122

and 33V line.

Q123-B: "Lo"?

Ye s

Check Q123, and

replace if necessary.

No

Check

the 'PWR CTL H' line

from SYSTEM circuit.

3 - 5

Page 26

Details of Servicing and Troubleshooting > Troubleshooting

(2) SYSTEM Circuit

Stops automatically

IC501-23: H.SW waveform?

Ye s

IC501-3: Take-up

reel pulses?

Ye s Ye s

Replace IC501. Replace RS501.

Supplement: Automatic stop may occur when grease or oil in the mechanism block has dried up.

No

No No

Check DPG/DFG signals

from cylinder motor.

Is 5.0 V supplied

to RS501?

Check power supply line.

Cassette tape does not load smoothly

Is 12 V supplied

to PMC01-8?

Ye s

Does "Hi" signal appear

at IC501-32 when

cassette is inserted?

Ye s

No

Check power supply line.

No No

Is 5.0 V supplied to

R544?

Ye s

Check 5.3VA

power supply line.

Check deck mechanism.

No key operation

Is 5 V supplied

to IC501-73?

Ye s

Does FL display change

when operation

button is pressed?

Check CS501 (CST SW)

and its peripheral circuits.

No

No

See "No 5.3VA" in

(1) SMPS circuit.

Replace any

faulty switches.

3 - 6

Page 27

Details of Servicing and Troubleshooting > Troubleshooting

(3) Servo circuit

Faulty image during playback

(noise on screen changes)

IC501-72: CTL pulses?

Ye s

IC501-67: CFG waveform?

Ye s

Does tracking operation

move CTL pulses?

Ye s

IC501-82:

Envelope waveform?

Ye s

Replace IC501.

No No

No

No

No

Is the height of

A/C head appropriate?

Ye s

Check CTL pulse line.

Check CFG line.

Replace IC501.

See "No Y signal

during playback" in

(4) VIDEO circuit.

Readjust the height

of A/C head.

Cylinder motor does not rotate.

Is 12 V supplied

to PMC01-8?

Ye s

PMC01-12: 2.8 V?

Ye s

Check connector between

PMC01 and cylinder motor.

No

No No

between IC501-34 and

See "No 12VA" in

(1) SMPS circuit.

IC501-34:

DRUM PWM pulses?

Ye s

Check for short-circuit

PMC01-12.

PMC01-11: DFG pulses?

Ye s

IC501-65: DFG pulses?

Ye s

IC501-34:

DRUM PWM pulses?

Ye s

Check for short-circuit

between IC501-34 and

PMC01-12.

No

No

No

Replace capstan motor.

Check for short-circuit

between IC501-65 and

PMC01-11.

Replace IC501.

3 - 7

Page 28

Details of Servicing and Troubleshooting > Troubleshooting

Capstan motor does not rotate.

Is 12 V supplied

to PMC01-2?

Ye s

PMC01-9: 2.8 V?

Ye s

Check for short-circuit

between PMC01 and

capstan motor.

No

No

See "No CAP Vcc power

supply" in (1) SMPS

circuit.

IC501-33:

CAP PWM pulses?

Ye s

Check for short-circuit

between IC501-33 and

PMC01-9.

No

PMC01-1:

CFG pulses?

Ye s

IC501-67: CFG pulses?

Ye s

IC501-33:

CAP PWM pulses?

Ye s

Check for short-circuit

between IC501-33 and

PMC01-9.

No

Check capstan motor.

No

No

Check for short-circuit

between IC501-67 and

PMC01-1.

Replace IC501.

3 - 8

Page 29

Details of Servicing and Troubleshooting > Troubleshooting

(4) VIDEO circuit

No image in EE mode.

Is TU-VIDEO

signal supplied

IC301-15?

Ye s

Is 5V supplied to

IC301-4, 22, 47, 50, 52,

60, 84, 92?

Ye s

Does VIDEO signal

appear at IC301-29?

Ye s

Does VIDEO signal

appear at PMD02-7

Ye s

Does VIDEO signal

appear at PMD02-5?

Ye s

Is VIDEO signal

appear at IC802-5?

Ye s

No

Check IC802 and tuner.

No

Check 5V line.

No

No

Check Q310 and Q905,

and replace if necessary.

No

Replace VDR PCB.

No

Check the line between

PMD02-5 and IC802-5.

2

C BUS signal

Is I

supplied to

IC301-73, 74?

Ye s

Check C329, and replace

if necessary: Is normal

status restored?

No

No

Check IC501, and

if necessary.

Replace IC301.

Is VIDEO signal

supplied to IC901-4?

Ye s

Replace IC901.

No

Replace IC802.

3 - 9

Page 30

Details of Servicing and Troubleshooting > Troubleshooting

No Y signal during playback

Is 5V supplied to

IC301-4, 22, 47, 50,

52, 60, 84, 92?

Ye s

2

Is I

C BUS signal

supplied to

IC301-73, 74?

Ye s

Is V.H.SW signal

to IC301-80?

Ye s

Does approx. 3.4 V

appear at IC301-80

when V.H.SW is Hi?

Ye s

Does Y signal appear

at IC301-33?

No

No

No

No

No

Check 5V line.

Check IC501, and

replace if necessary.

Check IC501, and

replace if necessary.

Check R342, and

replace if necessary.

Replace IC301.

No image during recording

Does E-E signal appear?

Ye s

Is 5V supplied to

IC301-4, 22, 47, 50,

52, 60, 84, 92?

Ye s

Does image appear

during playback?

Ye s

Does REC RF signal

appear at IC301-86, 90?

Ye s

Check cylinder motor

and connector.

No

No

No

No

See "No image in

E-E mode" in

(4) VIDEO circuit.

Check 5V line.

Check playback mode.

Replace IC301.

Ye s

Does Y signal appear

at IC301-31?

Ye s

No

Replace IC301.

Replace VDR PCB.

No chroma signal during playback

Is 5V supplied to

IC301-4, 22, 47, 50,

52, 60, 84, 92?

Ye s

Does chroma signal

appear at IC301-29?

Ye s

No

No

Check 5V line.

Does X301 (4.43 MHz)

generate a signal?

Ye s

No

Replace X301.

Replace VDR PCB.

Replace IC301.

3 - 10

Page 31

Details of Servicing and Troubleshooting > Troubleshooting

(5) AUDIO circuit

No audio in EE mode

Does signal appear at

IC801-6, 7 when AV1

audio is input?

Ye s

Does signal appear at

IC801-8, 9 when AV2

audio is input?

Ye s

Does signal appear at

IC801-10, 11 when

AV3 audio is input?

Ye s

Does signal appear at

IC801-4, 5 during

DVD playback?

Ye s

Does signal appear at

IC801-2, 3 during tuner

reception?

Ye s

Is power supplied to

IC801-34, 40?

No

Check AV1 jack (SC901).

No

Check AV2 jack (SC901).

No

Check AV3 jack (JK764)

and VDR P.C.B

No

Check VDR PCB, and

replace if necessary.

No

Check tuner (TU701).

No

Check 5.0V and

REG12V lines.

Ye s

Are control signals

supplied to

IC801-42, 43?

Ye s

Does audio signal appear

at IC801-16, 17?

Ye s

Does audio signal appear

at PMD02-19, 21?

Ye s

Does audio signal appear

at PMD02-23, 25?

Ye s

Check IC802 and

AV1 jack (SC901).

No

No

No

No

Check

SYSTEM microprocessor

(IC501), and replace

if necessary.

Replace IC801.

Check wiring between

IC801-16, 17 and

PMD02-19, 21.

Replace VDR PCB.

3 - 11

Page 32

Details of Servicing and Troubleshooting > Troubleshooting

No audio during playback

No

Is power supplied to

IC801-34, 40?

Ye s

Check 5.0V and

REG12V lines.

Envelope waveform at

IC801-44: At least

300 mVp-p?

Ye s

Are control signals

supplied to

IC801-42, 43?

Ye s

Does audio signal

appear at IC801-35, 37?

Ye s

Does audio signal

appear at IC801-16, 17?

Ye s

Does audio signal

appear at PMD02-19, 21?

Ye s

Is A. head switching

signal input to

Check P3D01 connector.

Check

No

SYSTEM microprocessor

(IC501), and replace

if necessary.

No

Check P3D01 connector.

No

Replace IC801.

Check wiring between

No

IC801-16, 17 and

PMD02-19, 21.

IC801-41?

Ye s

NoNo

Check IC501, and

replace if necessary.

Does audio signal

appear at PMD02-23, 25?

Ye s

Does audio signal

appear at IC802-21, 25?

Ye s

Check AV1 jack (SC901).

No

No

Replace VDR PCB.

Replace IC802.

3 - 12

Page 33

Details of Servicing and Troubleshooting > Troubleshooting

No Hi-Fi audio can be recorded

IIs power supplied to

IC801-34, 40?

Ye s

Are control signals

supplied to

IC801-42, 43?

Ye s

Does audio signal

appear at IC801-16, 17?

Ye s

Does FM audio signal

appear at IC801-36?

Ye s

Check P3D01 connector.

(If the connector is normal,

replace the cylinder.)

No

Check 5.0V and

REG12V lines.

Check

No

SYSTEM microprocessor

(IC501), and replace

if necessary.

Check to see if audio

No

input signal appears

for each input source

(IC801-2,3,4,5,6,7,8,9,10,11).

No

Replace IC801.

(6) TUNER circuit

No image during RF output

Is 5 V supplied to

TU701-1?

Ye s

Is Hi signal supplied

to TU701-4?

Ye s

Does video signal

appear at TU701-6?

Ye s

Replace TU701.

No

No

No

Check 5.0V line.

Check voltage at

IC501-26

(Hi: Tuner mode).

Check wiring between

IC901-23 and TU701-6.

3 - 13

Page 34

Details of Servicing and Troubleshooting > Troubleshooting

3-2-2 Troubleshooting mechanical block

(1) Deck mechanism

No auto rewind at end of tape

Does supply end sensor

(ES502) output "Hi"?

"Hi": At least 3.5V

"Lo": 0.7V or less to 1V

Ye s

IR LED (LD501):

0.8-1.5 V?

Ye s

Check SYSTEM circuit

(replace IC501)

No No

No

No fast forward or rewind

Is the position of

mode SW appropriate?

Ye s

No

Is 5 V supplied to

end sensor?

Ye s

Replace supply end

sensor (ES502).

Replace IR LED (LD501).

Align the boss of mode

SW and hole in drive

gear, and assemble them

(see page 4-4).

Check 5.0V line.

Does capstan motor

rotate?

Ye s

SYSTEM circuit

(replace IC501).

No

Is power supplied

to PMC01-2?

Replace capstan motor.

Ye s

No

Check CAP Vcc line.

Stops automatically during playback and

search

Is pressure roller

Do supply/take-up reel

sensors output pulses?

SYSTEM microprocessor,

3 - 14

compressed to

capstan shaft?

Ye s

Ye s

Check

and replace if

necessary.

No

alignment of cam gear

No

Check position

(see page 4-15).

Replace reel sensors.

Page 35

Details of Servicing and Troubleshooting > Troubleshooting

Tape transport system faulty during playback

Is pressure roller

compressed to capstan

shaft?

Ye s

Does take-up reel

rotate?

Ye s

Does capstan motor

rotate?

Ye s

Does cylinder motor

rotate?

Check position

No

alignment of cam gear

(see page 4-15).

No

No

Is capstan belt normal? Replace capstan belt.

Is power supplied to

Replace capstan motor.

No

Is power supplied to

Ye s

Check D37 clutch

assembly.

PMC01-2?

Ye s

PMC01-8?

No

No

No

Check CAP Vcc line.

Check 13.5VA

(DRUM) line.

Ye s

PMC01-11:

DPG/DFG pulses?

Ye s

Check SYSTEM circuit.

Ye s

Replace cylinder motor.

Cassette tape cannot be inserted

Insert a cassette tape.

Does S/W lever assembly

operate normally?

Ye s

Check output level of

CS501 (CST/REC SW):

Tape with record prevention

tab ("L" >"H" >"L")

Tape without record prevention

tab ("L" >"H" >"L" >"H")

Ye s

No

No

Check CST holder

assembly.

Replace CS501

(CST/REC SW).

Check SYSTEM circuit

(replace IC501).

3 - 15

Page 36

Details of Servicing and Troubleshooting > Troubleshooting

(2) Front loading mechanism

Cassette tape cannot be inserted

Does S/W lever assembly

operate normally?

Ye s Ye s

Is 5.0V power line on

VCR PCB normal?

Ye s

Does 5.0 V appear

between CS501

(CST/REC SW) and GND?

Ye s

Check mode SW or

SYSTEM circuit.

No

No

No

Is spring in S/W lever

assembly normal?

Does CS501

(CST/REC SW)

operate normally?

Check SYSTEM circuit

(replace IC501).

Check power supply line.

Is there short-circuit

between CS501

(CST/REC SW) and GND?

Repair shorted circuit.

Ye s

Ye s

No

No

No

Replace spring.

Replace CS501

(CST/REC SW).

Replace CS501

(CST/REC SW).

Cassette tape does not eject

Does L/D motor rotate?

Ye s

Does S/W lever assembly

operate normally?

Ye s

Does F/L arm assembly

operate normally?

Ye s

Does door open normally? Replace door opener.

No

No

No

No

Check L/D motor or

drive IC.

Replace S/W lever

assembly.

Replace F/L arm

assembly.

3 - 16

Page 37

4

Disassembly and Reassembly

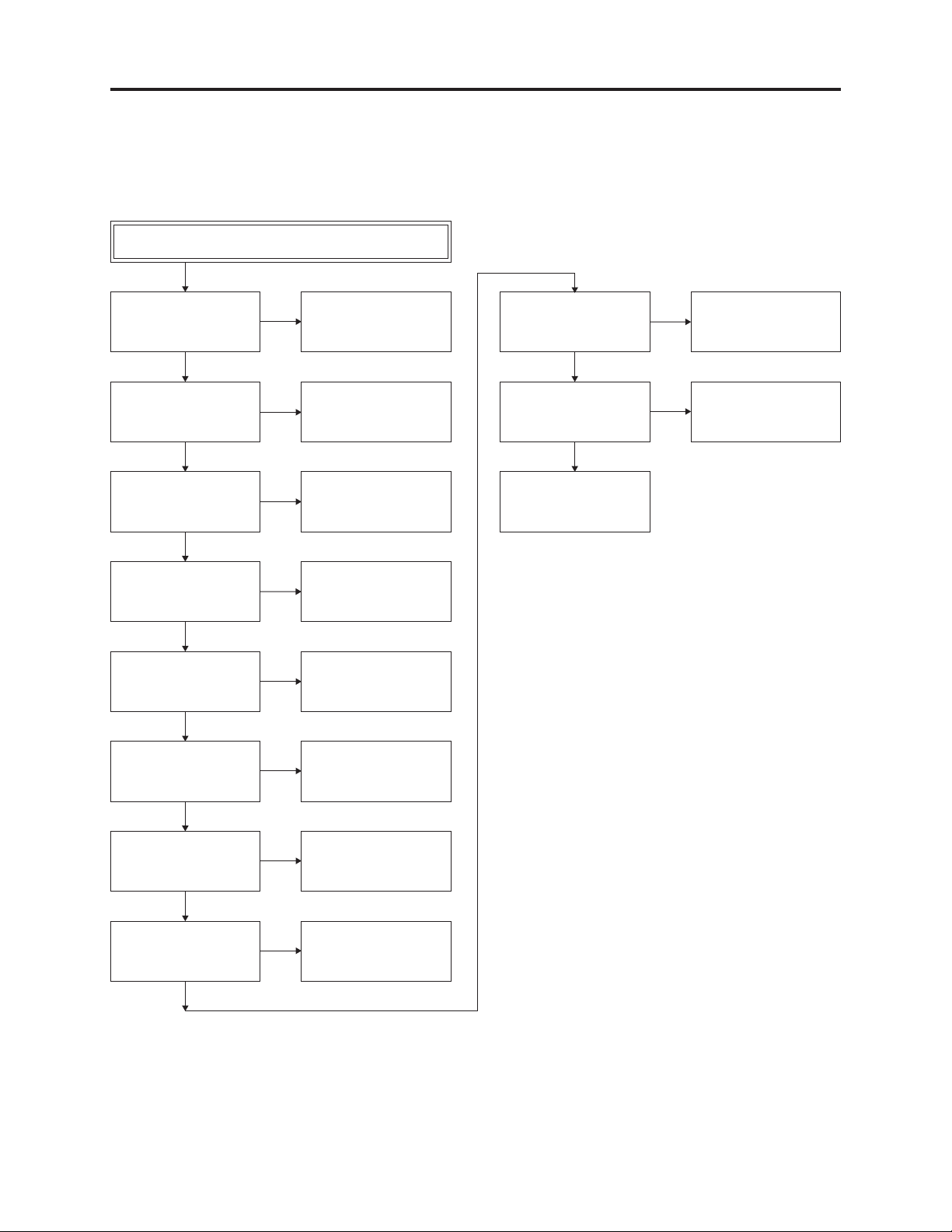

4-1 Order of Disassembly

Refer to the Disassembly Flowchart in Fig. 4-1-1 for the order of removing components. When

reassembling components, use the reverse order to removal unless otherwise specified.

Reading Disassembly Flowchart:

After locating the target component in the flowchart, remove all components of the target in

sequence, following the arrows (routes) from the top of flowchart. If multiple routes exist to the

target component from the top of flowchart, remove all the components on all the routes.

Parts to remove Item

To p cov e r

Front panel

DVD Multi drive

VDR P.C.B

4-2 (1)

4-2 (2)

4-2 (8)

4-2 (9)

Parts to remove Item Parts to remove Item

FAN motor

SMPS P.C.B

Deck mechanism

VCR P.C.B

JACK P.C.B, KEY P.C.B

4-2 (3)

4-2 (4)

4-2 (5)

4-2 (7)

4-2 (9)

TIMER P.C.B

4-2 (6)

Fig. 4-1-1 Disassembly Flowchart

4-2 Cabinet Disassembly

Information:

Numbers in figures are step numbers in disassembly procedure, and letters in brackets [ ] show the

types of screw.

(1) Top Cover

1) Remove the seven screws [A].

2) Slightly open both ends on the front side of top cover and lift the top cover in the direction of the

arrow.

To p C o v e r

1) Screw [A]

[A] M3X8 [Black]

2)

1) Screw [A]

1) Screw [A]

Fig. 4-2-1 Top cover

4 - 1

Page 38

Disassembly and Reassembly > Cabinet Disassembly

(2) Front Panel

1) Release three tabs (A), two tabs (B) and two tabs (C) in this order. (The tab (A) and the tab (C)

should be released at the same time, respectively.)

2) Slowly move the front panel forward to remove it.

Caution when reassembling front panel:

Reattach the front panel while pushing the cassette door so that the cassette door open/close lever

is positioned outside the door.

1) Tab(A)

1) Tab(B)

1) Tab(C)

1) Tab(B)

Front Panel

Cassette Door

Cassette Door

open/close lever

Fig. 4-2-2 Front Panel

(3) FAN Motor

1) Unplug the connector on SMPS P.C.B.

2) Remove two screws [B] from the rear panel.

Caution when reinstalling FAN motor:

Wind the cord of FAN motor around the cords on VDR P.C.B, as shown in the figure, to secure

them.

1) Connector

Wind around the cords.

2) Screw [B]

[B] M3X20 [Black]

FAN Motor

Fig. 4-2-3 FAN Motor

4 - 2

Page 39

Disassembly and Reassembly > Cabinet Disassembly

(4) SMPS P.C.B

1) Remove the power cable form rear panel.

2) Unplug the five connectors on SMPS P.C.B.

3) Remove screw [C] on rear panel, three screws [D] and screw [E] on the SMPS P.C.B, and then lift

the SMPS P.C.B block.

4) Remove four screws [F] that secure the heat sink, and then separate the SMPS P.C.B.

Caution when reinstalling heat sink:

Secure the heat sink, identified [Caution] in the figure, on the back of P.C.B, and make sure that a

cushion is attached between the heat sink and P.C.B.

3) Screw [D]

3) Screw [E]

2) Connector

2) Connector

SMPS P.C.B Block

3) Screw [D]

[C] M3X8 [Black]

Fig. 4-2-4 SMPS P.C.B (1)

[F] M3X6.5 [Gold]

4) Screw [F]

1) Power cable

3) Screw [C]

[D] M3X8 [Silver]

[E] M3X21 [Gold]

Caution

4) Screw [F]

Caution

Secure heat sink on

the rear of PCB.

Fig. 4-2-5 SMPS P.C.B (2)

4 - 3

Heat sink

SMPS

P. C . B

Cusion

Page 40