Page 1

SERVICE MANUAL

DVD / VCR Combo DV-PF5E(UK

)

SM0425

DV-PF5E(UK)

PAL

DO NOT RESELL OR DIVERT IMPROPERLY.DO NOT RESELL OR DIVERT IMPROPERLY.

SPECIFICATIONS AND PARTS ARE SUBJECT TO CHANGE FOR IMPROVEMENT

DVD PLAYER & VIDEO CASSETTE RECORDER

2004 Digital Media Division, TokaiDecember

Page 2

CONTENTS

1 CAUTIONS FOR SAFETY IN PERFORMING

REPAIR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1-1 LASER BEAM SAFETY PRECAUTIONS . . . . . . . 1-1

1-2 IMPORTANT SAFETY PRECAUTIONS . . . . . . . . 1-2

1-2-1 Product Safety Notice . . . . . . . . . . . . . . . . . . . . 1-2

1-2-2 Precautions during Servicing . . . . . . . . . . . . . . 1-2

1-2-3 Safety Check after Servicing. . . . . . . . . . . . . . . 1-3

1-3 STANDARD NOTES FOR SERVICING . . . . . . . . . 1-4

1-3-1 Circuit Board Indications . . . . . . . . . . . . . . . . . . 1-4

1-3-2 Instructions for Connectors . . . . . . . . . . . . . . . . 1-4

1-3-3 Pb (Lead) Free Solder. . . . . . . . . . . . . . . . . . . . 1-4

1-3-4 Instructions for Handling Semi-conductors . . . . 1-4

2 GENERAL INFORMATION . . . . . . . . . . . . . . . 2-1

2-1 SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2-2 COMPARISON OF MODELS. . . . . . . . . . . . . . . . . 2-2

2-2-1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2-2-2 VCR Section . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2-2-3 DVD Section . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2-3 COMPARISON OF MAIN CONTROL ICS. . . . . . . 2-4

2-4 LIST OF ABBREVIATIONS AND TERMS

FOR DVD PLAYER . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2-5 FUNCTION INDICATOR SYMBOLS . . . . . . . . . . . 2-6

2-6 OPERATING CONTROLS AND FUNCTIONS. . . . 2-7

3 MAINTENANCE AND INSPECTION. . . . . . . . 3-1

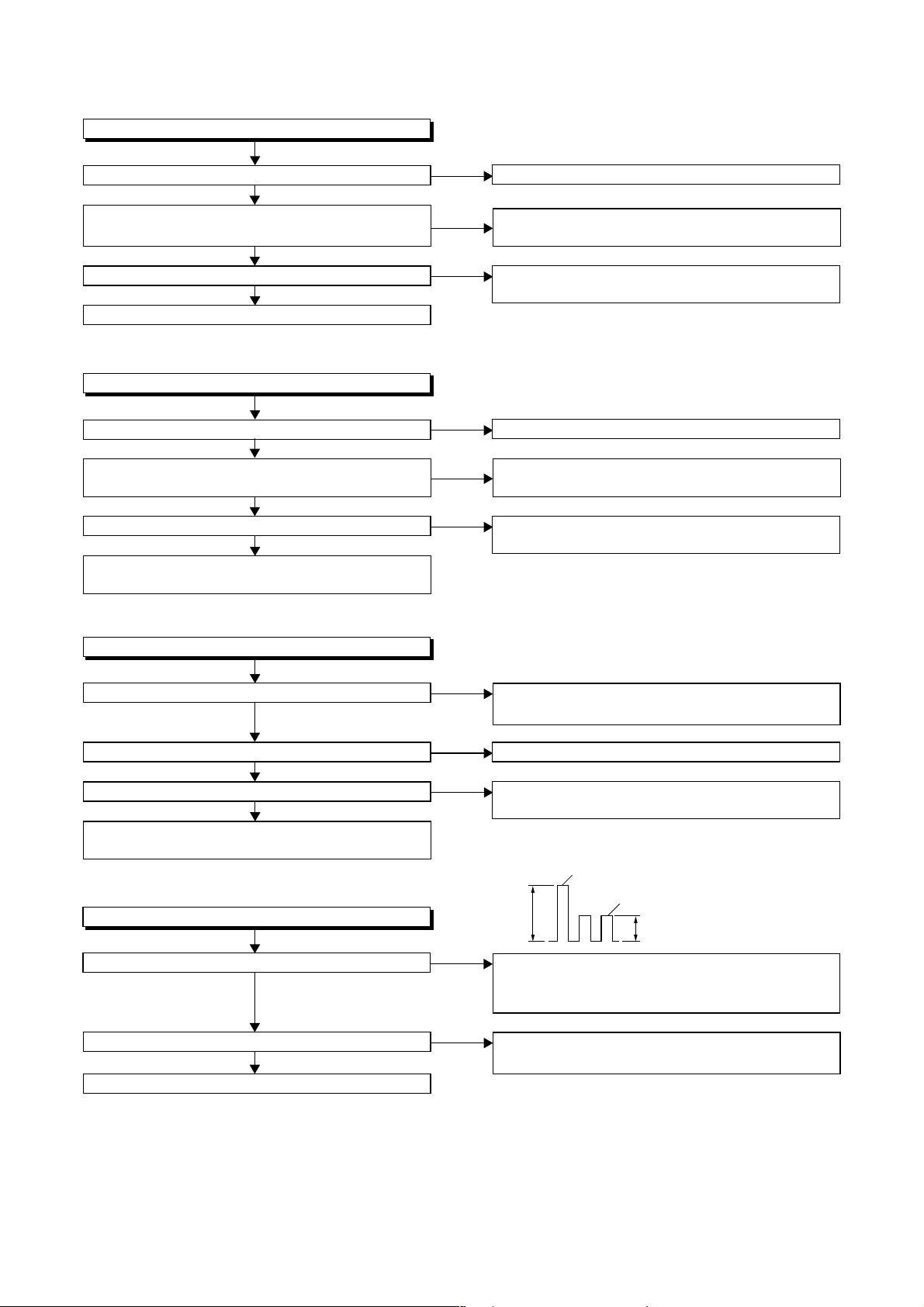

3-1 TROUBLESHOOTING. . . . . . . . . . . . . . . . . . . . . . 3-1

3-1-1 Power Supply Section. . . . . . . . . . . . . . . . . . . . 3-1

3-1-2 DVD Section . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3-1-3 VCR Section . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3-2 FIRMWARE RENEWAL MODE. . . . . . . . . . . . . . 3-15

3-2-1 How to Update the Firmware Version . . . . . . . 3-15

3-2-2 How to Verify the Firmware Version . . . . . . . . 3-16

3-3 STANDARD MAINTENANCE. . . . . . . . . . . . . . . . 3-17

3-3-1 Service Schedule of Components. . . . . . . . . . 3-17

3-3-2 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

4 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4-1 CABINET DISASSEMBLY INSTRUCTIONS . . . . . 4-1

4-1-1 Disassembly Flowchart . . . . . . . . . . . . . . . . . . . 4-1

4-1-2 Disassembly Method. . . . . . . . . . . . . . . . . . . . . 4-1

4-1-3 How to Eject Manualy . . . . . . . . . . . . . . . . . . . . 4-5

4-2 DISASSEMBLY/ASSEMBLY PROCEDURES

OF DECK MECHANISM . . . . . . . . . . . . . . . . . . . . 4-6

4-3 ALIGNMENT PROCEDURES OF MECHANISM. 4-15

5 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5-1 PREPARATION FOR SERVICING. . . . . . . . . . . . . 5-1

5-1-1 How to Enter the Service Mode. . . . . . . . . . . . . 5-1

5-2 FIXTURE AND TAPE FOR ADJUSTMENT . . . . . . 5-2

5-2-1 How To Use The Fixtures And Tape . . . . . . . . . 5-2

5-3 ELECTRICAL ADJUSTMENT INSTRUCTIONS . . 5-3

5-3-1 Test Equipment Required . . . . . . . . . . . . . . . . . 5-3

5-3-2 Head Switching Position Adjustment. . . . . . . . . 5-3

5-4 MECHANICAL ALIGNMENT PROCEDURES. . . . 5-4

5-4-1 Service Information. . . . . . . . . . . . . . . . . . . . . . 5-4

5-4-2 Tape Interchangeability Alignment . . . . . . . . . . 5-5

1-A. Preliminary/Final Check ing and

Alignment of Tape Path. . . . . . . . . . . . . . . . . . . 5-6

1-B. X Value Alignment. . . . . . . . . . . . . . . . . . . . . . . 5-6

1-C. Checking/Adjustment of Envelope Waveform . . 5-7

1-D. Azimuth Alignment of

Audio/Control/Erase Head. . . . . . . . . . . . . . . . . 5-8

1-E. Checking and Alignment of

Tape Path during reversing . . . . . . . . . . . . . . . . 5-8

6 EXPLODEDS VIEWS AND PARTS LIST . . . . 6-1

6-1 EXPLODED VIEWS. . . . . . . . . . . . . . . . . . . . . . . . 6-1

6-1-1 Cabinet Section. . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6-1-2 Deck Mechanism View 1 Section . . . . . . . . . . . 6-2

6-1-3 Deck Mechanism View 2 Section . . . . . . . . . . . 6-2

6-1-4 Deck Mechanism View 3 Section . . . . . . . . . . . 6-3

6-2 REPLACEMENT PARTS LIST. . . . . . . . . . . . . . . . 6-4

6-2-1 Mechanical Parts List . . . . . . . . . . . . . . . . . . . . 6-4

6-2-2 Electrical Parts List . . . . . . . . . . . . . . . . . . . . . . 6-6

7 APPENDIX. . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7-1 SYSTEM CONTROL TIMING CHARTS . . . . . . . . 7-1

7-2 IC PIN FUNCTION DESCRIPTIONS. . . . . . . . . . . 7-7

7-3 LEAD IDENTIFICATIONS . . . . . . . . . . . . . . . . . . 7-10

S SCHEMATIC, WIRING DIAGRAMS

S-1 Schematic Diagrams/CBA’s and Test Points . . . . . S-1

S-2 Wiring Diagrams < VCR Section >. . . . . . . . . . . . . S-3

S-3 Wiring Diagrams < DVD Section >. . . . . . . . . . . . . S-4

S-4 Main 1/9 Schematic Diagram. . . . . . . . . . . . . . . . . S-5

S-5 Main 2/9, Sensor & Power SW

Schematic Diagrams . . . . . . . . . . . . . . . . . . . . . . . S-6

S-6 Main 3/9 Schematic Diagram. . . . . . . . . . . . . . . . . S-7

S-7 Main 4/9 Schematic Diagram. . . . . . . . . . . . . . . . . S-8

S-8 Main 5/9 Schematic Diagram. . . . . . . . . . . . . . . . . S-9

S-9 Main 6/9 Schematic Diagram. . . . . . . . . . . . . . . . S-10

S-10Main 7/9 & DVD Open/Close

Schematic Diagram . . . . . . . . . . . . . . . . . . . . . . . S-11

S-11Main 8/9 Schematic Diagram. . . . . . . . . . . . . . . . S-12

S-12Main 9/9 Schematic Diagram. . . . . . . . . . . . . . . . S-13

S-13Power Supply & Junction Schematic Diagrams. . S-14

S-14Jack-A Schematic Diagram . . . . . . . . . . . . . . . . . S-15

S-15AFV Schematic Diagram . . . . . . . . . . . . . . . . . . . S-16

S-16DVD Main 1/3 Schematic Diagram. . . . . . . . . . . . S-17

S-17DVD Main 2/3 Schematic Diagram. . . . . . . . . . . . S-18

S-18IC101 Voltage Chart. . . . . . . . . . . . . . . . . . . . . . . S-19

S-19DVD Main 3/3 Schematic Diagram. . . . . . . . . . . . S-20

S-20Waveforms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . S-21

C CIRCUIT BOARD DIAGRAMS

C-1 Main CBA Top View & Sensor CBA Top View . . . . C-1

C-2 Main CBA Bottom View . . . . . . . . . . . . . . . . . . . . .C-2

C-3 Power SW CBA Top/Bottom View &

DVD Open/Close CBA Top/Bottom View . . . . . . . . C-3

C-4 Power Supply CBA Top/Bottom View &

Junction CBA Top/Bottom View. . . . . . . . . . . . . . .C-4

C-5 Jack-A CBA Top/Bottom View

AFV CBA Top/Bottom View . . . . . . . . . . . . . . . . . . C-

&

B BLOCK DIAGRAMS

B-1 Servo/System Control Block Diagram . . . . . . . . . . B-1

B-2 Video Block Diagram . . . . . . . . . . . . . . . . . . . . . . . B-2

B-3 Audio Block Diagram . . . . . . . . . . . . . . . . . . . . . . . B-3

B-4 Hi-Fi Audio Block Diagram. . . . . . . . . . . . . . . . . . . B-4

B-5 Power Supply Block Diagram. . . . . . . . . . . . . . . . . B-5

B-6 DVD System Control/Servo Block Diagram . . . . . . B-6

B-7 Digital Signal Process Block Diagram . . . . . . . . . . B-7

B-8 DVD Video / Audio Block Diagram. . . . . . . . . . . . . B-8

5

Page 3

1

CAUTION FOR SAFETY IN PERFORMING REPAIR

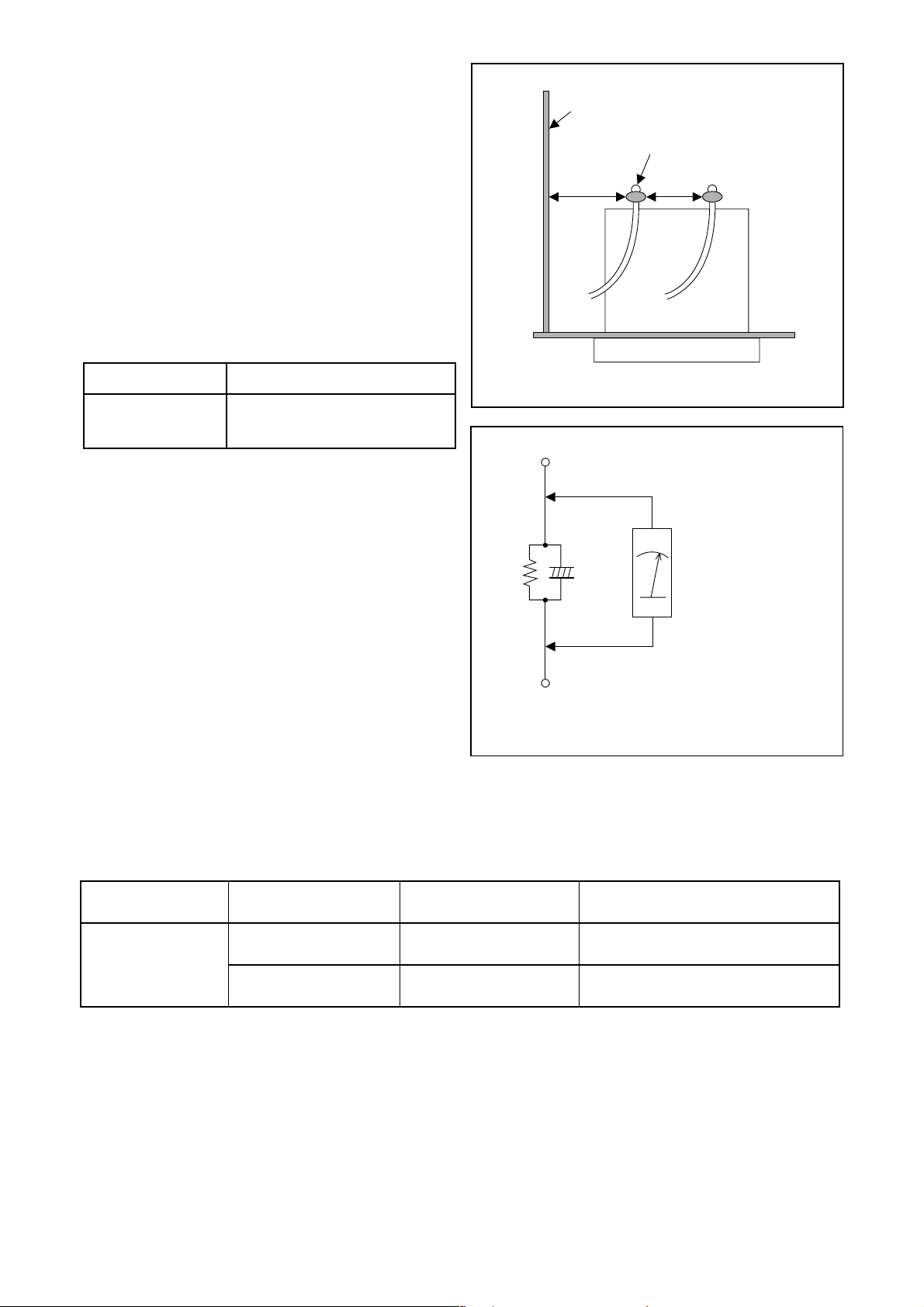

1-1 LASER BEAM SAFETY PRECAUTIONS

This DVD player uses a pickup that emits a laser beam.

Do not look directly at the laser beam coming

from the pickup or allow it to strike against

your skin.

The laser beam is emitted from th e location shown in the figure. When checking the laser dio de, be sure to

keep your eyes at least 30cm away from the pickup lens when the diode is turned on. Do not look directly at the

laser beam.

Caution: Use of controls and adjustments, or doing procedures other than those specified herein, may result in

hazardous radiation exposure.

Drive Mecha Assembly

Laser Beam Radiation

Laser Pickup

Turntable

1-1

Page 4

1-2 IMPORTANT SAFETY PRECAUTIONS

1-2-1 Product Safety Notice

Some electrical and mechanical parts have special

safety-related characteris tics which are often not evident from visual inspection, nor can the protection

they give necessarily b e obtained by replacing them

with components rated for higher voltage, wattage,

etc. Parts that have special safety characteri stics are

identified by a ! on schematics and in parts lists.

Use of a substitute replacement that does not have

the same safety characteristics as the recommended

replacement part might create shock, fire, and/or

other hazards. The Product’s Safety is under review

continuously and new instructions are issued whenever appropriate. Prior to shipment from the factory,

our products are carefully inspected to confirm with

the recognized prod uct safety and electr ical codes of

the countries in which they are to be sold. However, in

order to maintain such compliance, it is equally important to implement the following precautions when a

set is being serviced.

1-2-2 Precautions during Servicing

A. Parts identified by the ! symbol are critical for

safety. Replace only with part number specified.

B. In addition to safety, other parts and assemblies

are specified for conformance with regulations

applying to spur io us radiati on. T he se must a lso be

replaced only with specified re pla ce men ts.

Examples: RF converters, RF cables, noise blocking capacitors, and noise blocking filters, etc.

C. Use specified internal wiring. Note especially:

1)Wires covered with PVC tubing

2)Double insulated wi res

3)High voltage leads

D. Use specified insulating materials for hazardous

live parts. Note especially:

1)Insulation tape

2)PVC tubing

3)Spacers

4)Insulators for transistors

E. When replacing AC primary side components

(transformers, power cord, etc.), wrap ends of

wires securely abo ut the terminals before soldering.

F. Observe that the wires do not contact heat produc-

ing parts (heatsinks, oxide metal film resistors, fusible resistors, etc.).

G. Check that replaced wires do not contact sharp

edges or pointed parts.

H. When a power cord has been repl ace d, c he ck that

5 - 6 kg of force in any direction will not loosen it.

I. Also check areas surrounding repaired locations.

J. Be careful that foreign objects (screws, solder

droplets, etc.) do not remain inside the set.

K. Crimp type wire connector

The power transformer uses crimp type connectors which connect the power cord and the primary

side of the transformer. When replacing t he transformer, follow these steps carefully and precisely

to prevent shock hazards.

Replacement procedure

1)Remove the old connector by cutting the wires at

a point close to the connector.

Important: Do not re-use a connector. (Discard

it.)

2)Strip about 15 mm of the insul ation from the ends

of the wires. If the wires are stranded, twist the

strands to avoid frayed conductors.

3)Align the lengths of the wires to be connected.

Insert the wires fully into the connector.

4)Use a cri mping tool to crimp the metal sleeve at

its center. Be sure to crimp fully to the compl ete

closure of the tool.

L. When connecting or disconnecting the internal

connectors, first, disconnec t the AC plug from the

AC outlet.

1-2

Page 5

1-2-3 Safety Check after Servicing

Examine the area surrounding the repaired location

for damage or deterioration. Observe that screws,

parts, and w ires have been returned to thei r original

positions. Afterwards, do the following tests and confirm the specified values to verify compliance with

safety standards.

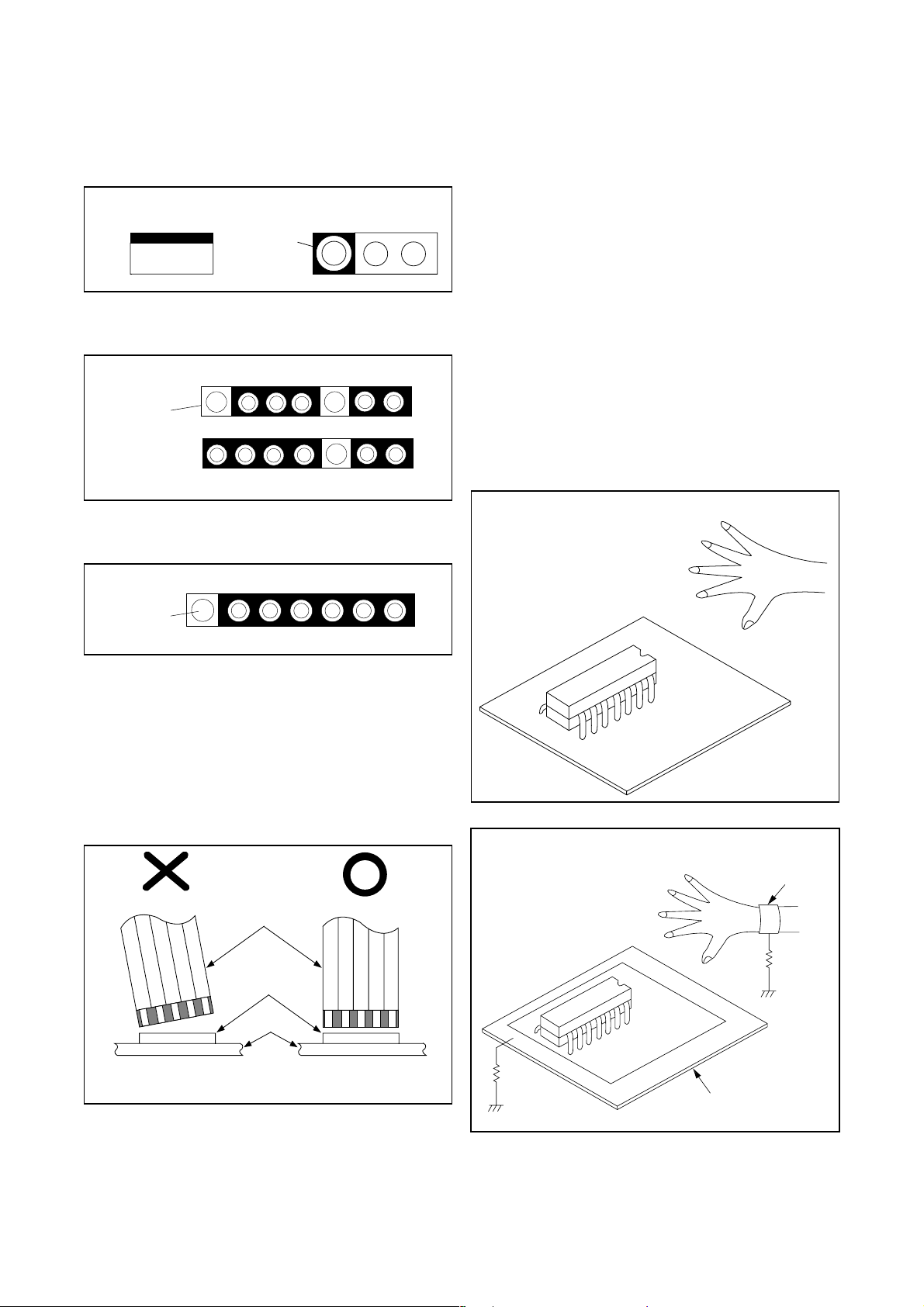

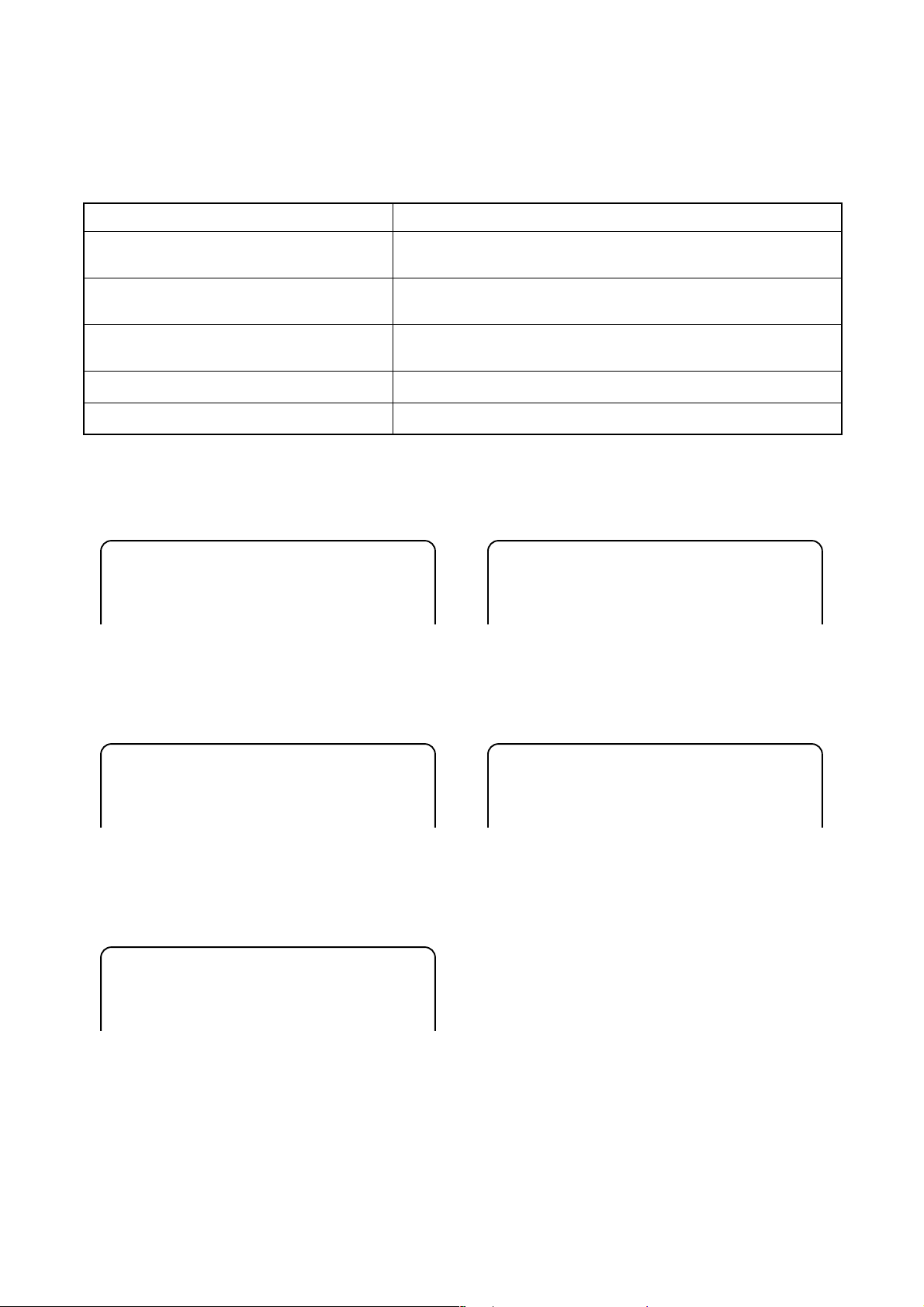

1. Clearance Distance

When replacing pr imary circuit components, confir m

specified clearance di sta nc e ( d ) and ( d’ ) between soldered terminals, and between terminals and surrounding metallic parts. (See Fig. 1-2-1)

Table 1-2-1 : Ratings for selected area

AC Line Voltage Clearance Distance (d), (d’)

220 to 240 V

Note: This table is unofficial and for reference only.

Be sure to confirm the precise values.

≥ 3 mm(d)

≥ 6 mm(d’)

2. Leakage Current Test

Confirm the specified (or lower) leakage current

between B (earth ground, power cord plug prongs)

and externally exposed accessible parts (RF terminals, antenna terminals, video and audio input and

output terminals, microphone jacks, earphone jacks,

etc.) is lower than or equal to the specified value in the

table below.

Measuring Method (Power ON) :

Insert load Z between B (ear th ground, power cord

plug prongs) and exposed accessible par ts. Use an

AC voltmeter to measure across the terminal s of load

Z. See Fig. 1-2-2 and the following table.

Chassis or Secondary Conductor

Primary Circuit Terminals

dd'

Fig. 1-2-1

Exposed Accessible Part

Z

One side of

B

Power Cord Plug Prongs

AC Voltmeter

(High Impedance)

Fig. 1-2-2

Table 1-2-2: Leakage current ratings for selected areas

AC Line Voltage Load Z Leakage Current (i)

2kΩ RES.

220 to 240 V

Note: This table is unofficial and for reference only. Be sure to confirm the precise values.

Connected in parallel

50kΩ RES.

Connected in parallel

i≤0.7mA AC Peak

i≤2mA DC

i≤0.7mA AC Peak

i≤2mA DC

1-3

One side of power cord plug

prongs (B) to:

Antenna terminals

A/V Input, Output

RF or

Page 6

1-3 STANDARD NOTES FOR SERVICING

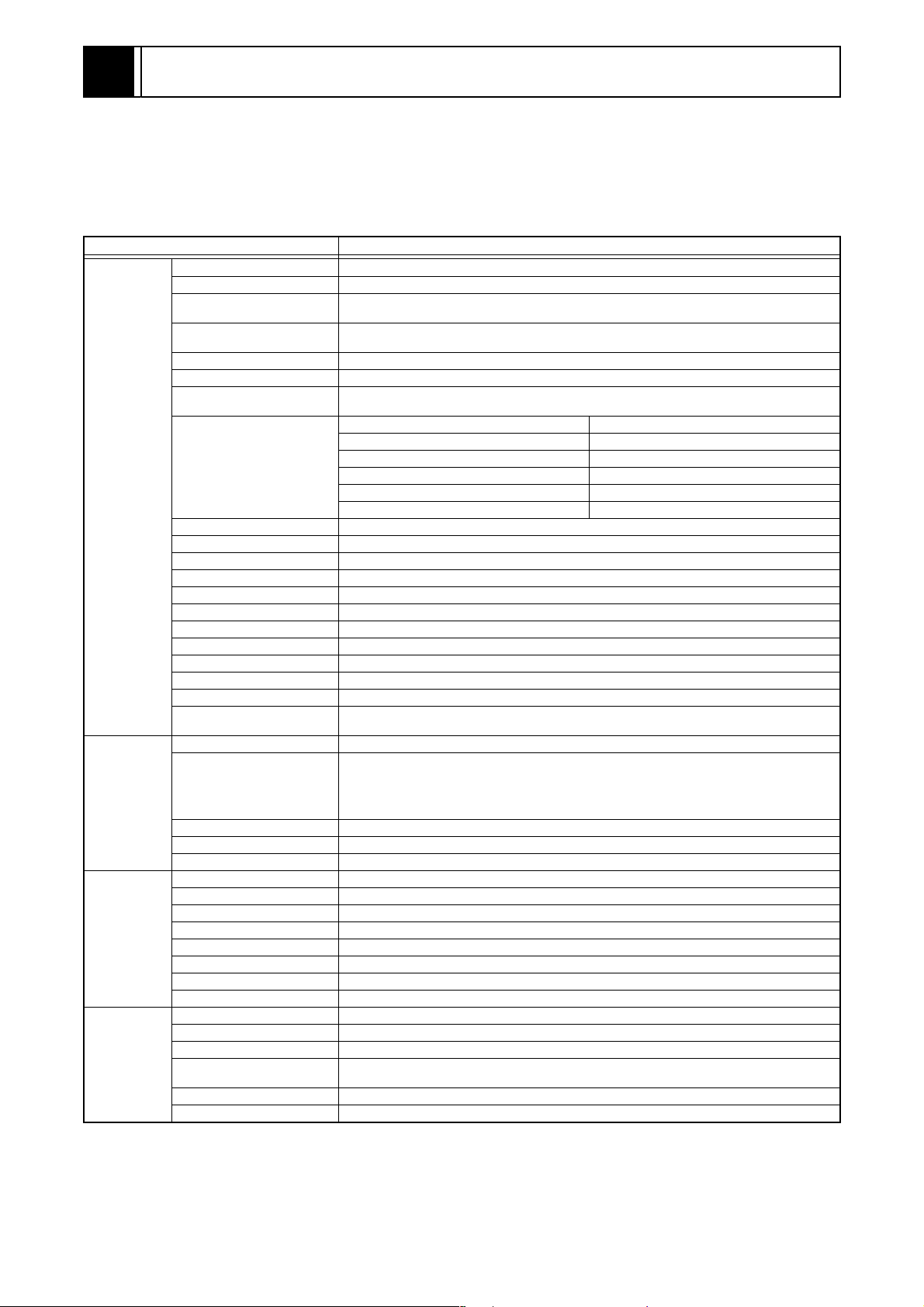

1-3-1 Circuit Board Indications

1. The output pin of the 3 p in Regulator ICs is indicated as shown.

Top View

Input

Out

2. For other ICs, pin 1 and every fifth pin are indicated as shown.

In

Pin 1

3. The 1st pi n of every male connector is indicate d a s

shown.

Bottom View

5

10

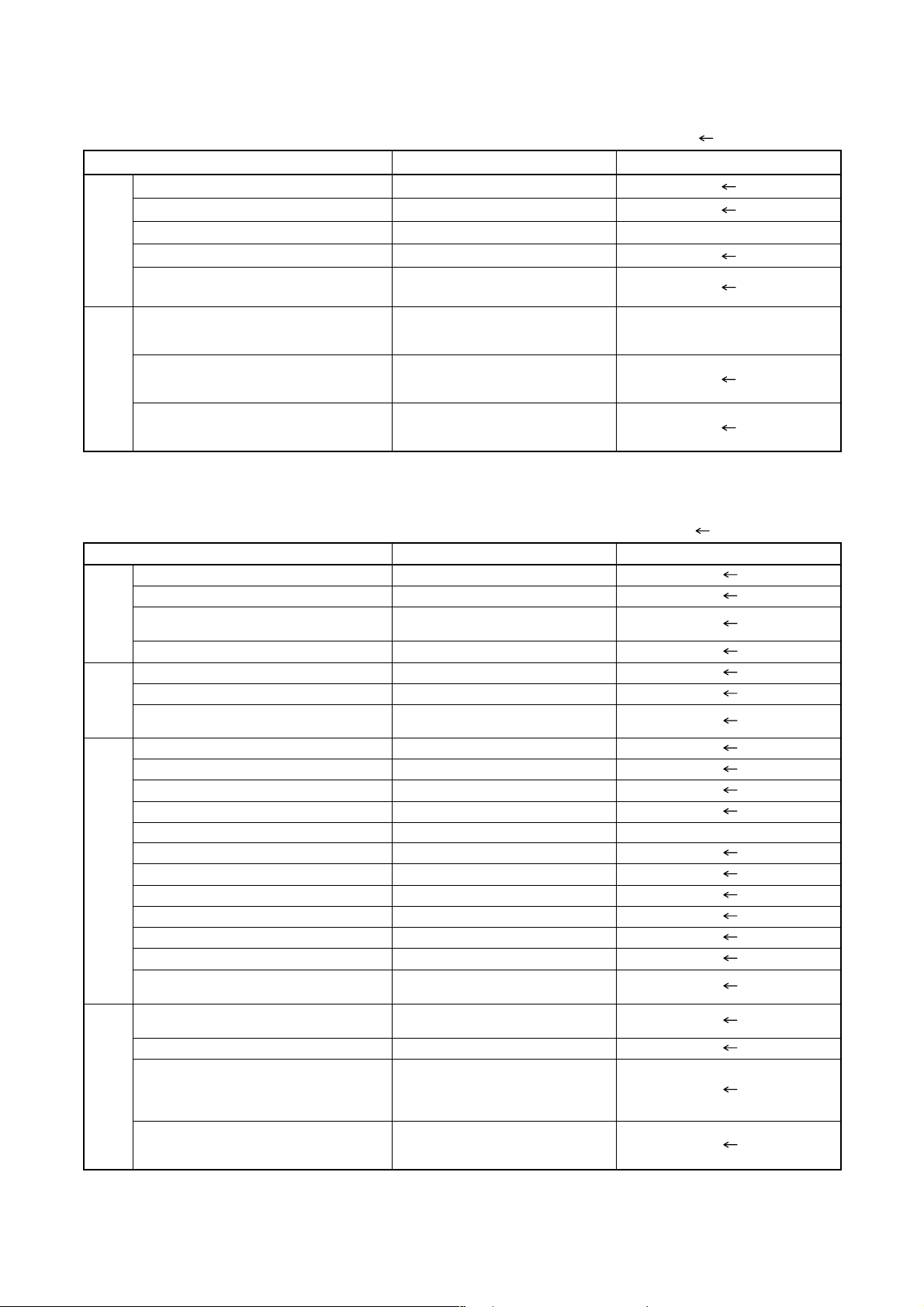

1-3-4 Instructions for Handling

Semi-conductors

Electrostatic breakd own of the semi-conductor s may

occur due to a pote ntial dif ference caused by electrostatic charge during unpacking or repair work.

1. Ground for Human Body

Be sure to wear a grounding band (1MΩ) that i s prop erly grounded to remove any static electricity that may

be charged on the body.

2. Ground for Workbench

(1) Be sure to place a conductive sheet or copper

plate with proper grounding (1MΩ) on the workbench or other surface, where the semi-conductors are to be placed. Beca us e the s tatic el ec tr ic i ty

charge on clothing will not escape through the

body grounding band, be careful t o avoid contacting semi-conductors with your clothing.

< Incorrect >

Pin 1

1-3-2 Instructions for Connectors

1. When you connect or disconnect the FFC (Flexible

Foil Connector) cable, be sure to first disconnect

the AC cord.

2. FFC (Flexible Foil Connector) cable should be

inserted parallel into the connector, not at an

angle.

FFC Cable

Connector

CBA

CBA

< Correct >

Grounding Band

1MΩ

CBA

* Be careful to avoid a short circuit.

1-3-3 Pb (Lead) Free Solder

When soldering, be sure to use the Pb free solder.

1MΩ

Conductive Sheet or

Copper Plate

1-4

Page 7

2

GENERAL INFORMATION

Overview

DV-PF5E(UK) is the model that deleted “VIDEO Plus+” function from DV-PF4E(UK).

With this, the [VIDEO Plus+] button on remote controller is also deleted.

2-1 SPECIFICATIONS

ITEM DESCRIPTION

TV system PAL

Video head Rotating 4 heads

Rotating 2 head helical scan brightness signal FM method

VHS standard for methods to directly record color signal low frequency conversions

Hi-Fi audio track: 2 channel

Normal audio track: 1 channel

{SP}: 4 hours (with E-240 used)

{LP}: 8 hours (with E-240 used)

CH Indication TV Channel

01-10 TRA-IRJ, GAP

21-69 E21-E69

74-78 X.Y.Z.Z+1.Z+2

88-99, 100 S1-S20, GAP

121-141 S21-S41

Frequency characteristic: 20-20,000 Hz

Dynamic range: 70 dB or more

DVD (linear audio)

20 Hz - 22 kHz (48 kHz sampling frequency)

20 Hz - 44 kHz (96 kHz sampling frequency)

Music CD

20 Hz - 20 kHz (JEITA)

5 °C - 40 °C

Video section

DVD section

Terminal

Others

Recording system

Audio track

Tape VHS-type videocassette

Tape speed {SP}: 23.39 mm/s {LP}: 11.70 mm/s

Maximum record and

playback time

Receiving channel

Reception system Up-heterodyne

RF converter RF CONVERTER

Converter output UHF 22 - 69 ch, I: 35 ch

Timer display 24-hour system

Video output impedance 75 Ω

Video output level 1.0 V P-P

Audio output level -6 dB 1 kΩ unbalance (high impedance)

Video input level 0.5-2.0 V P-P

Audio input level -10 dBV

Video S/N ratio 40 dB or more

Audio S/N ratio 36 dB or more

Hi-Fi audio

Disc used DVD video disc, Music CD disc

Audio frequency

characteristic

Signal/Noise (S/N) ratio CD: 70 dB (JEITA)

Dynamic range DVD (linear audio): 70 dB, CD: 70 dB (JEITA )

Total distortion ratio DVD: 0.1%, CD: 0.1%

Antenna input DIN (input) terminal

Antenna output DIN (output) terminal

Video input SCART JACK (AV 1, 2) FRONT PIN JACK

Video output SCART JACK (AV 1, 2)

Audio input SCART JACK (AV 1, 2) FRONT PIN JACK

Audio output SCART JACK (AV 1, 2) PIN JACK (REAR)

S Video output MINI DIN 4PIN JACK (75 Ω)

Coaxial digital audio output PIN JACK

Power supply AC 220-240 V +/-10%, 50 Hz +/-0.5%

Power consumption 30 W (Standby: 5.0 W)

Back-up time 30 s

Temperature range for

operation

Dimensions 435(W) mm x 94(H) mm x 233(D) mm

Weight 3.2 kg

2-1

Page 8

2-2 COMPARISON OF MODELS

2-2-1 General

ITEM DV-PF5E(UK) DV-PF4E(UK)

Dimensional 435(W) x 94(H) x 233(D)mm

Weight 3.2 kg

Power Consumption 30W (standby: 5.0W) 30W (standby: 9.0W)

Tray Panel Silver

Color Front/Button Silver / Silver

APPEARANCE

Remote Controller Model Name DV-RMPF5E(UK) DV-RMPF4E(UK)

Jog Shuttle on Remote ---

REMOTE

TV Control ---

CONTROLLER

2-2-2 VCR Section

ITEM DV-PF5E(UK) DV-PF4E(UK)

Video Format VHS

Y/C Separation Comb Filter

YNR (Luminance Noise Reduction)

Circuit

VIDEO

Picture Control O

Video/Audio Input (Rear) 2/2 (AV1/AV2)

Video/Audio Input (Front) 1/1 (AV3)

O: Yes, ---: No, : Same as on left

O: Yes, ---: No, : Same as on left

O

Video/Audio Output (Rear) 2/2 (AV1/AV2)

INPUT/

OUTPUT

OSD languages (VCR) 1 (English)

Stereo CM Skip Feature --Auto Clock Feature O

Number of Timer Programming 8 Program / 1 year

VIDEO Plus+ --- O

Self Diagnosis Function O (4 Modes)

Back-up Time 30 s

OTHERMECHANISM

SQPB --Surge Absorber --Auto Power Off Feature O

Local Broadcast Setting O

Multi Search Feature

Search Speed

FF/REW Time (E-180 Tape)

Head Composition

Head Material

O (Index, Time Search, Quick

Find)

SP: X5/X7

LP: X5/X11

Approx. 100 s

DA4+Hi-Fi

SP: 2[49/49 µm]

LP: 2[25/25 µm]

Hi-Fi Audio: 2[28/28 µm]

SP: Ferrite

LP: Ferrite

Hi-Fi Audio: Ferrite

2-2

Page 9

2-2-3 DVD Section

ITEM DV-PF5E(UK) DV-PF4E(UK)

DVD/VCD/SVCD/CD-DA O / --- / --- / O

CD-R/CD-RW/DVD-R (Video Format) O / O / O

DVD-RAM (VR Format) --MP3 ---

GENERALVIDEOAUDIO

OSD languages (DVD)

PAL Disc NTSC Out ---

Video Out Mode NTSC/PAL/PAL60 --- / O / O

S-Video / Component / Composite O / --- / O

Video D/A Converter 10bit

Black Level Select --Picture Control --Progressive Out --Audio D/A Converter 192kHz / 24bit

Digital Audio Out Optical / Coaxial --- / O

Dolby Digital 5.1 ch Decode --DTS Digital Out --Virtual Surround O

Dynamic Range Compression (Dolby

Digital)

DVD Audio --Power on sound ---

O: Yes, ---: No, : Same as on left

7 (English , French, Spanish,

Italian, German, Dutch, Swedish)

O

Search Speed 4 Steps

Slow Speed 3 Steps

IP Search (Smooth 2x Play) O

2x Play with Audio --Step Forward / Reverse O / ---

TRICK PLAY

Still Picture Select (Frame/Field) Flame / Field / Auto

Disc Navigation O

DVD Zoom x2 / x4 O / O

Program and Random Play of DVD O

A-B Repeat O

Repeat O

Last Play ---

FEATURES

Front Panel Display Dimmer --Screen Saver O

Auto Power Off O (always ON)

2-3

Page 10

2-3 COMPARISON OF MAIN CONTROL ICS

---: No, : Same as on left

ITEM DV-PF5E(UK) DV-PF4E(UK)

VIDEO DRIVER

VIDEO/AUDIO SIGNAL

PROCESS/HEAD AMP

Hi-Fi AUDIO SIGNAL PROCESS LA72648M-MPB-E (IC451)

MICROCONTROLLER 8BIT

SERVO/SYSTEM CONTROL

MEMORY

FIP 7-BT-298N (IC611)

FIP DRIVER PT6313-S-TP (IC612) PT6313-S-TP / SC16313 (IC612)

VPS LC74793JM-TRM (IC631)

OUTPUT SELECT

1.2V REG PQ070XZ5MZP (IC1002)

3.3V REG BA3948FP-E2 (IC1003)

AMP KIA4558P / NJM4558D (IC1201)

ERROR VOLTAGE DET

IF SIGNAL PROCESS MSP3417G-QG-B8 (IC1)

MM1637XVBE (IC102)

MM1636XWRE (IC1403)

LA71750EM-MPB-E (IC301)

M3776AMCA-AA8GP (IC501) M3776AMCA-AA9GP (IC501)

CAT24WC02JI /

BR24L02F-WE2 (IC502)

TC4053BF / BU4053BCF-E2 /

CD4053BCSJX / CD4053BNSR (IC751)

EL817 / LTV-817B-F /

PS2561A-1(Q,W) (IC1001)

2-4

Page 11

2-4

LIST OF ABBREVIATIONS AND TERMS FOR DVD PLAYER

Index Abbreviation/Term Explanation

A AC3 See Dolby AC3.

C CD-R One type of DVD standard disc, to which writing once is possible (recordable type)

CD-RW One type of CD standard disc, to which writing up to 1000 times is possible

Component video

output terminals

D Dolby AC3 Audio coding format developed by Dolby Laboratories in U.S, also simply referred to as

D terminal This terminal, specified by EIAJ (currently JEITA), can automatically switch "digital hi-

DTS Digital Theater System: Sound system as for movie theaters developed by US Digital

DVD Digital Versatile Disc. A huge amount of digital data for video (movie) and audio can be

DVD-Audio One type of DVD standard disc, on which high-quality audio can be recorded

DVD-R One type of DVD standard disc, to which writing once is possible (recordable type)

DVD-RAM One type of DVD standard disc, to which writing up to 100,000 times is possible

DVD-ROM One type of DVD standard disc, to which data for computer can be recorded

DVD-RW One type of DVD standard disc, to which writing up to 1000 times is possible

DVD-Video One type of DVD standard disc, on which high-quality video and audio can be recorded

DVD Video Format Video recording/playback standard that applies to DVD-Video, DVD-R and DVD-RW

DVD Video Recording

Format

DVD Forum International organization that formulates the technical standards of DVD

E EIAJ Electronic Industries Association of Japan: An organization of manufacturers of

J JPEG Joint Photographic Expert Group: International standard format for compressing still

L Linear PCM Linear Pulse Code Modulation: LPCM is a format that digitizes analog audio signal

M MPEG Moving Picture Experts Group: Standard related to compression of digital video and

MPEG Audio Layer 2 One of three audio compression standards (layers 1-3) defined by MPEG

MP3 MPEG1 Audio Layer-3: Audio data digital compression technology.

P Progressive playback

function

S SDMI Secure Digital Musi c Initiativ e: This conf erence was estab lished b y hardware makers , the

V Virtual surround This technology localizes sound at any position using only two front speakers, by

Used for outputs of HDTV video signal format. Since signals for brightness and colors

are independently handled for components signals (Y: luminance signal; PR/PB:

chrominance signals), degrading of image will be redu ce d.

AC3 f ormat: Suppo rts 5-channel full -r ange soun d an d one cha nnel for sub-woofer sound

playback.

vision" programs of BS digital broadcast, and "digital standard broadcast" of current

image quality. A tuner and TV can easily be connected to the D terminal. There are 5

types of D terminal, depending on the different format of video signal passing thorough

the D terminal.

Theater Systems, Inc. The number of channels provided by DTS is the same for Dolby

AC3.

recorded on this disc, whose size is the same as CD.

Video recording/playback standard that applies to DVD-RAM and DVD-RW: This allows

versatile editing functions, differing from the DVD Video Format.

consumer electronic devices, industrial electronic devices and electronic components,

established in April 1948. EIAJ merged with JEIDA (Japan Electronic Industry

Development Association) in November 2000 to become JEITA (Japan Electronics and

Information Technology Industries Association).

images.

during recording and converts it back to analog signal during playback.

audio. MPEG2 is a higher standard of MPEG and is applied to video (movie) requiring

higher quality.

This function converts interlaced images to non-interlaced images and displays them. It

can play back 24-frame/second images included in DVD movie software, etc.

Recording Industry Association of America (RIAA) and music industry companies, to

protect copyrights of musical compositions.

subjecting the L and R signal s to matrix oper ation. It uses the f our tran sf er function s from

L/R speakers located at specified positions to both ears of listener located in a specified

position, taking into account the shape of head and the effect of earlobes, and the two

transfer functions from any position to both ears.

2-5

Page 12

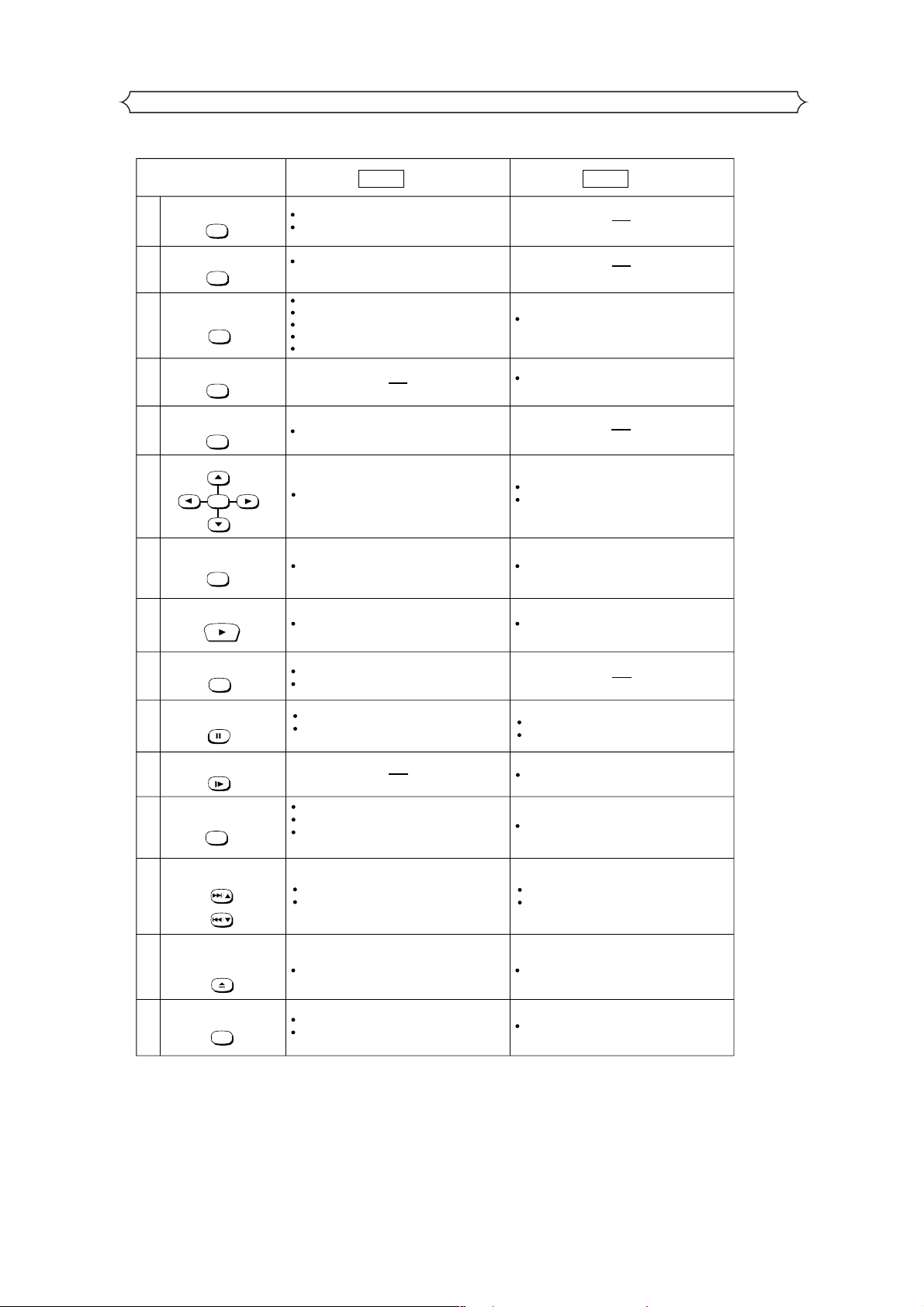

2-5 FUNCTION INDICATOR SYMBOLS

Note:

If a mechanical malf unction oc curs, the power is tur ned off. When the power com es on again after that by

pressing [y/I ] button, an error message is displayed on the TV screen for 5 seconds.

MODE INDICATOR ACTIVE

When reel or capstan mechanism is not

functioning correctly

When tape loading mechanism is not

functioning correctly

When cassette loading mechanism is not

functioning correctly

When the drum is not working properly

P-ON Power safety detection

“A R” is displayed on a TV screen. (Refer to Fig. 1.)

“A T” is displayed on a TV screen. (Refer to Fig. 2.)

“A C” is displayed on a TV screen. (Refer to Fig. 3.)

“A D” is displayed on a TV screen. (Refer to Fig. 4.)

“A P” is displayed on a TV screen. (Refer to Fig. 5.)

TV screen

When reel or capstan mechanism is not functioning

correctly

A

R

Fig. 1

When the drum is not working properly

A

D

Fig. 4

When tape loading mec hanism is not func tioning c orrectly

A

T

Fig. 2

When cassette loadin g mechanism is not functioning

correctly

A

C

Fig. 3

P-ON Power safety detection

A

P

Fig. 5

2-6

Page 13

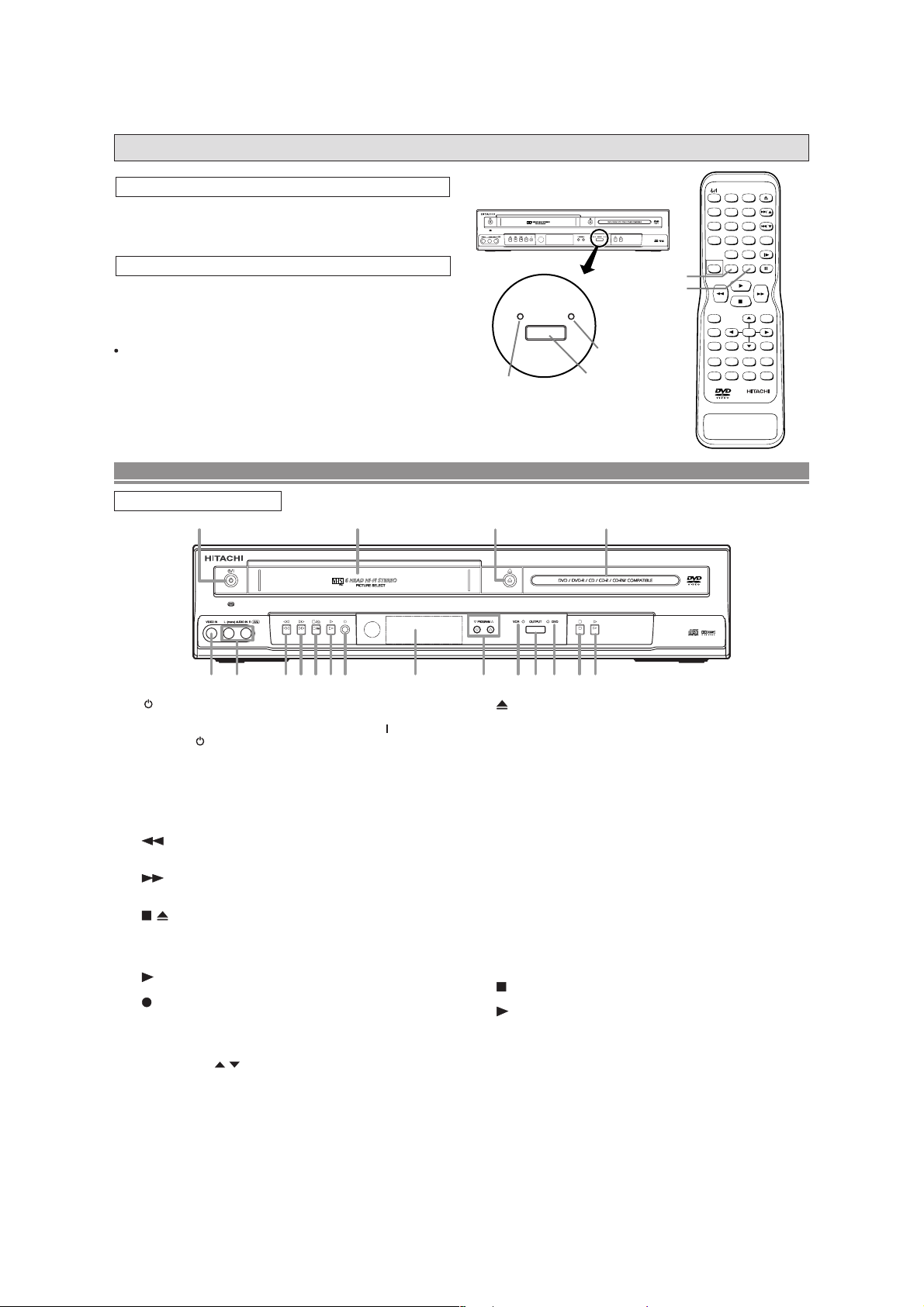

2-6 OPERATING CONTROLS AND FUNCTIONS

DVD / VCR Combo DV-PF5E(UK

)

OUTPUT

DVD

VCR

DVD / VCR Combo DV-PF5E(UK

)

OUTPUT button

VCR OUTPUT Light

DVD OUTPUT Light

+

123

56

789

010

AUDIO

SKIP/PROG

SKIP/PROG

SLOW

CLEAR

C.RESET

REC/OTR DISPLAY

RETURN

TOP MENU

MENU

SETUP

QUICK-FIND

ZOOM

MODE

A-B REPEAT

ANGLE

SEARCH MODE

REPEAT

SUBTITLE

TIMER

VCR DVD

SURROUND

SPEED

OPEN/CLOSE

EJECT

4

DISC NAVIGATION

ENTER

DV-RMPF5E(UK

)

VCR button

DVD button

Since this product comprises DVD and VCR players, it is necessary to select the correct output mode.

SWITCHING TO DVD MODE

Press DVD on the remote control.

(Verify that the DVD OUTPUT Light is lit.)

SWITCHING TO VCR MODE

Press VCR on the remote control.

(Verify that the VCR OUTPUT Light is lit.)

NOTE

Pressing only OUTPUT on the front panel does not switch

the mode of the remote control. You always need to select

the correct mode on the remote control too.

FUNCTIONAL OVERVIEW

FRONT PANEL

1

9 12 18

432 7 85 6

1. /I (POWER/STANDBY)

Press to turn the power on and off.

(As to the indication of the Operate switch, “

ON and “ ” indicates electrical power STANDBY.)

2. VIDEO In Jack

Connect a video cable coming from the video out jack

of a camcorder, another VCR, or a video source (laser

disc player, camcorder, etc.) here.

3. AUDIO In Jacks

Connect audio cables coming from the audio out jacks

of a camcorder, another VCR, or an audio source here.

4.

(REW) [VCR]

Press to rewind the tape, or to view the picture rapidly

in reverse during the playback mode (Rewind Search).

5. (F.FWD) [VCR]

Press to rapidly advance the tape, or view the picture

rapidly in forward during playback. (Forward Search).

6.

/ (STOP/EJECT) [VCR]

STOP

Press to stop the tape motion.

EJECT

Press to remove the tape from the VCR.

7.

(PLAY) [VCR]

Press to begin playback.

8. (REC) [VCR]

Press once to start a recording. Press repeatedly to

start a One Touch Recording.

9. Cassette Compartment

10. Display, Remote Sensor Window

11. PROGRAM (

In VCR mode, press to change TV programmes on the

VCR; press to adjust the tracking during normal or slow

motion playback; press to remove vertical jitter in a Still

picture.

/ ) Buttons

10 11 13 14 16 1715

12.

Press to insert discs into or remove them from the tray.

” indicates

13. VCR OUTPUT Light

This light appears when the VCR output mode is selected. You can only watch tapes when the green VCR

OUTPUT light is on. To make the green VCR OUTPUT

light come on, VCR on the remote control or OUTPUT

on the front panel.

14. OUTPUT

Press to select DVD mode or VCR mode.

You can switch the output mode either by pressing

OUTPUT on the front panel, or by pressing DVD or

VCR on the remote control. However, if you press

OUTPUT on the front panel first, you need to reselect the corresponding mode by pressing DVD or

VCR on the remote control.

15. DVD OUTPUT Light

This light appears when the DVD output mode is selected. You can only watch DVDs when the green DVD

OUTPUT Light is on. To make the green DVD OUTPUT

light come on, press DVD on the remote control or

OUTPUT on the front panel.

16.

Stops operation of the disc.

17. (PLAY) [DVD]

Press to begin playback.

18. Disc loading tray

2-7

(OPEN/CLOSE) [DVD]

(STOP) [DVD]

Page 14

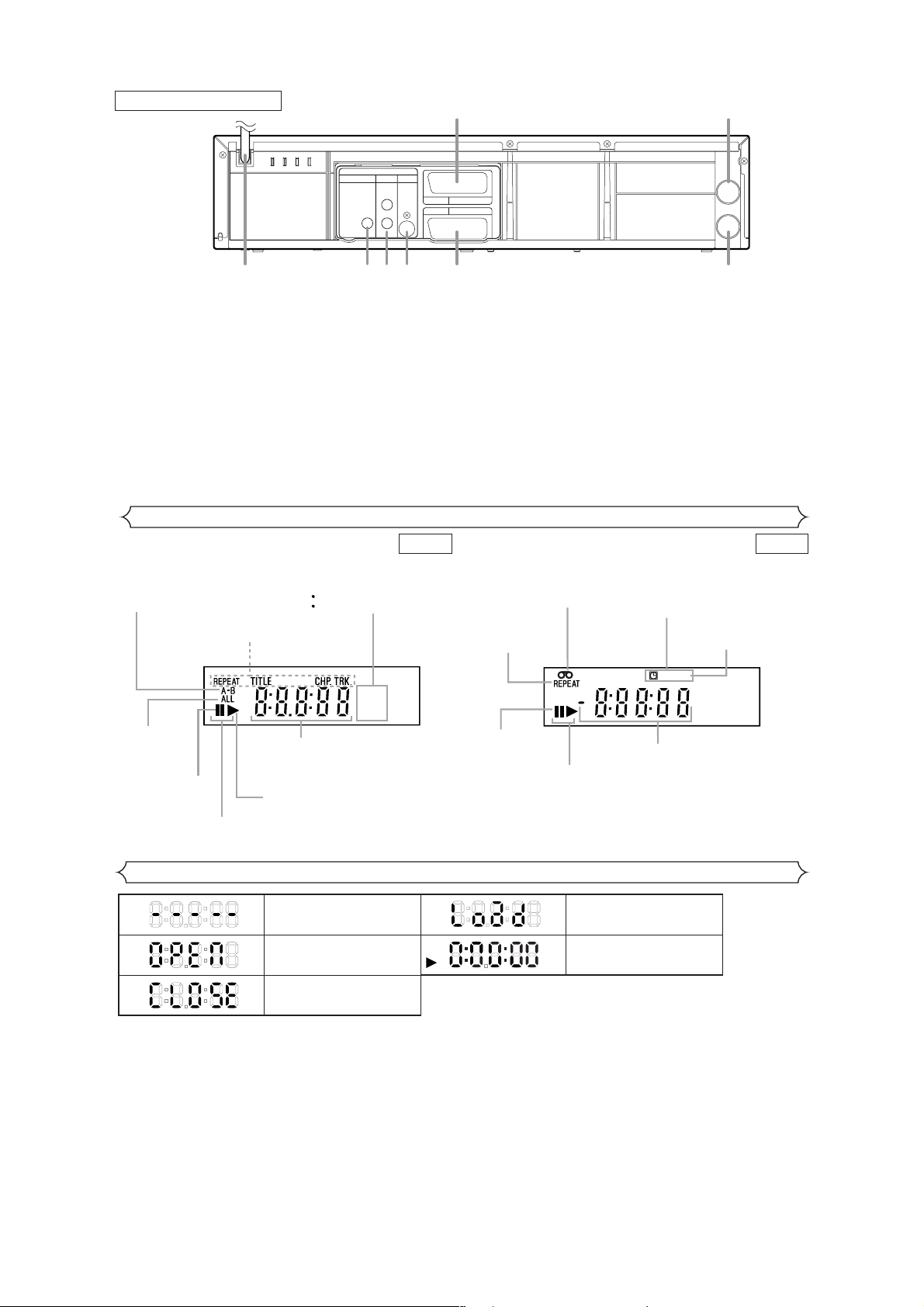

Tray open

Tray closed

When a disc is being

played back

DVD

Loading the Disc

No disc inserted or cannot

read

COAXIAL

DIGITAL

AUDIO OUT

S

-

VIDEO

OUT

DVD

DVD/VCR AV 1

(TV)

AV2(DECODER

)

VCR

ANALOG

AUDIO OUT

L

R

AERIAL

RF OUT

5

1 2 3 4 6

7

8

REAR PANEL

1. MAIN (AC Power Cord)

Connect to a standard AC plug.

2. COAXIAL DIGITAL AUDIO OUT Jack [DVD only]

Connect to a compatible Dolby Digital receiver. Use to

connect to a Dolby Digital decoder or MPEG decoder.

3. AUDIO OUT Jacks (ANALOG Left/Right)

[DVD only]

Connect to the Audio input jacks of A/V-compatible TV

or wide screen TV, Stereo system.

4. S-VIDEO OUT Jack (DVD Only)

Use the S-Video cable to connect this jack to the SVideo jack on your A/V-compatible TV or wide screen

TV for a higher quality picture.

5. EURO AV2 (DECODER) Jack [VCR only]

Use the Euro A/V (scart) cable to connect this jack to

the 21 pin scart jack on your decoder.

Display

DVD VCR

Lights up when the

A-B repeat function

is on.

Lights up when

the ALL repeat

function is on.

Lights up when the

inserted disc comes

to a pause.

Lights up when playing back

in slow mode. (DVD)

Lights up when the

repeat function is on.

Displays a type of the disc

which is inserted on the tray.

DVD disc

DVD:

Audio CD

CD:

DVD

CD

Displays how long the current title

or track has been played back. When

a chapter or track is switched, the

number of a new title, chapter or

track is displayed.

Lights up when the inserted

disc is being played back.

6. EURO AV1 (TV) Jack

Use the Euro A/V (scart) cable to connect this jack to

the 21 pin scart jack on your A/V-compatible TV or wide

screen TV for a best quality picture.

7. AERIAL Jack

Connect your antenna, Cable Box, or Direct Broadcast

System.

8. RF OUT Jack

Use the supplied aerial cable to connect this jack to the

ANTENNA IN Jack on your TV.

Caution: Do not touch the inner pins of the jacks on the rear

panel. Electrostatic discharge may cause permanent damage to the DVD/VCR.

Lights up when a tape is

in the DVD/VCR.

Lights up during

playback when

the repeat function

is on.

Lights up when

the playback is

in still or slow mode.

Lights up when the inserted

cassette is being played

back.

Lights up when

the timer recording or an

OTR recording has been set.

Lights up during a recording.

Flashes when a recording

is paused.

REC

Works as a tape counter

(hour,minute,second).

Also displays a channel number,

tape speed, remaining time for OTR or

current time.

Displays During Operation

2-8

Page 15

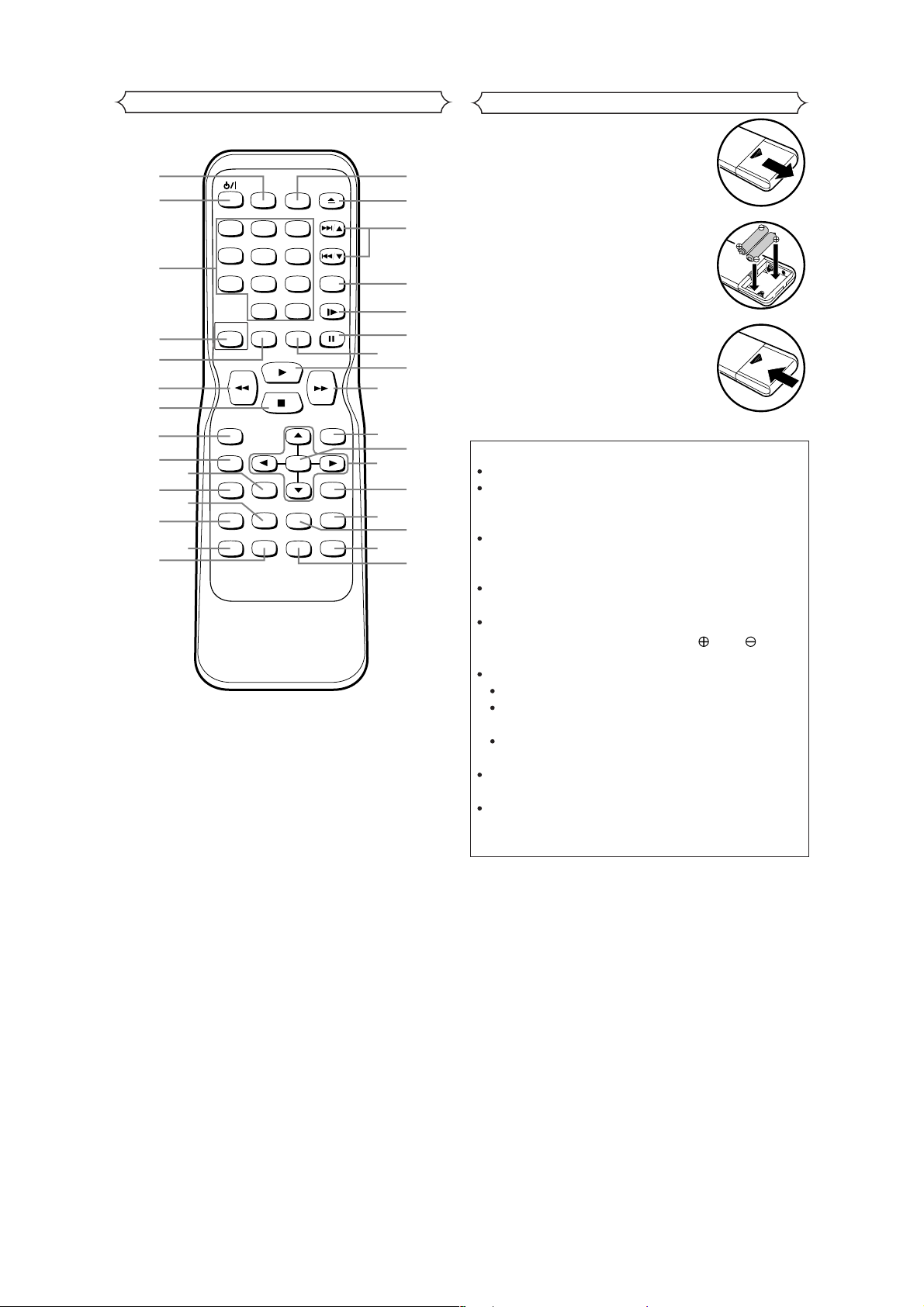

Remote Controller

Loading the Batteries

1. Open the battery compartment

cover.

11

13

15

26

24

32

31

30

29

28

27

25

2. Insert two AA batteries, with

each one oriented correctly.

3. Close the cover.

1

SURROUND

SPEED

2

123

56

4

3

789

010

VCR DVD

DISC NAVIGATION

AUDIO

+

OPEN/CLOSE

EJECT

SKIP/PROG

SKIP/PROG

CLEAR

C.RESET

SLOW

4

5

6

7

REC/OTR DISPLAY

8

9

10

12

MENU

SETUP

MODE

SUBTITLE

TIMER

TOP MENU

ZOOM

ANGLE

ENTER

SEARCH MODE

A-B REPEAT

REPEAT

RETURN

QUICK-FIND

14

23

21

19

17

22

20

18

16

Cautions On Batteries

Use “AA” (R6P) batteries in this remote control unit.

Replace the batteries with new ones approximately

once a year, though this depends on the frequency

with which the remote control unit is used.

If the remote control unit does not operate from

close to the main unit, replace the batteries with

new ones, even if less then a year has passed.

The included battery is only for verifying operation.

Replace it with a new battery as soon as possible.

When inserting the batteries, be careful to do so in

the proper direction, following the and marks

in the remote control unit’s battery compartment.

To prevent damage or battery fluid leakage:

Do not use a new battery with an old one.

Do not use two different types of batteries such

as alkaline and manganese.

Do not short-circuit, disassemble, heat or dispose

of batteries in flames.

Remove the batteries when not planning to use the

remote control unit for a long period of time.

If the batteries should leak, carefully wipe off the

fluid from the inside of the battery compartment,

then insert new batteries.

2-9

Page 16

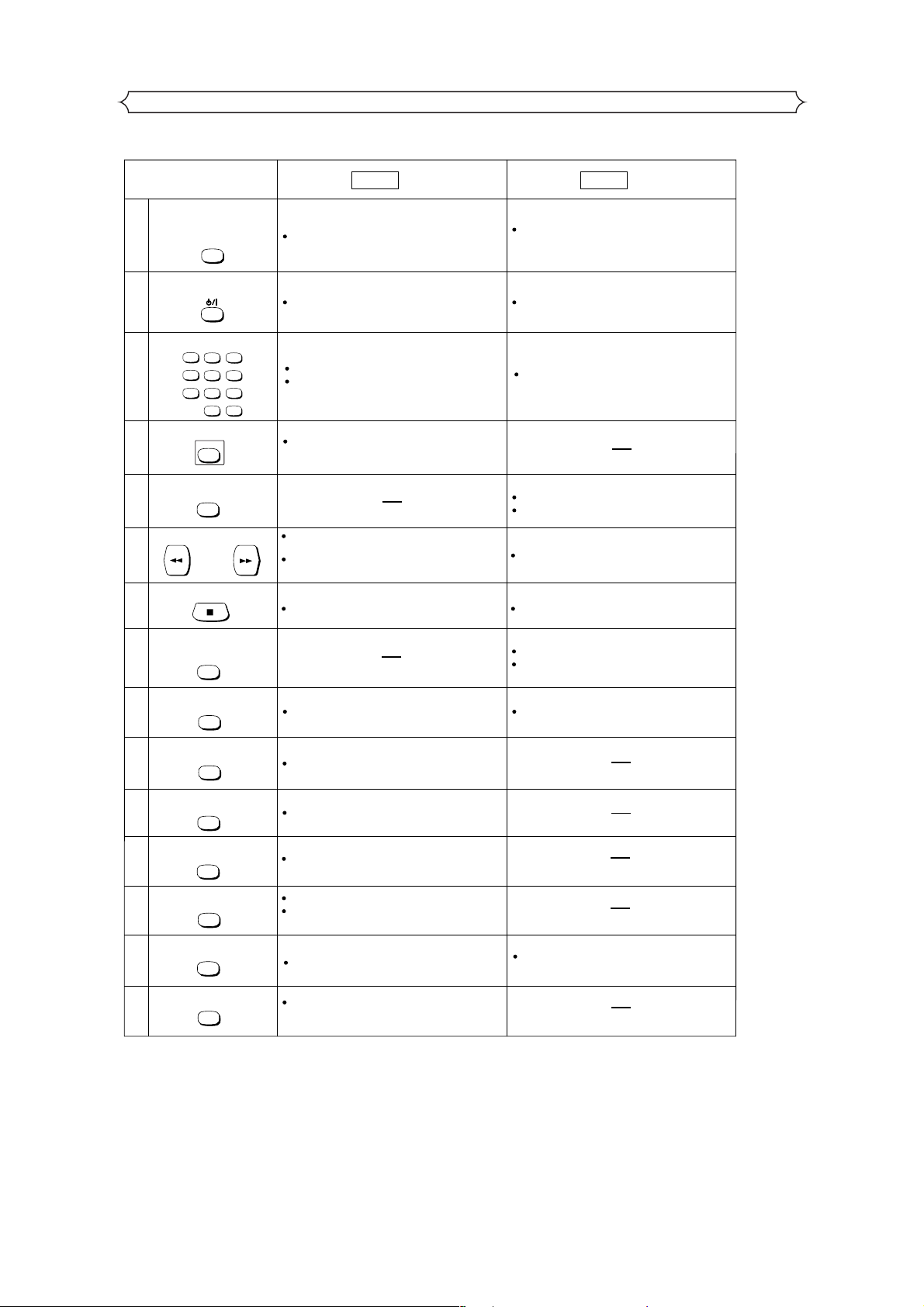

Tour of the remote controller

Buttons on remote controller work in different ways for DVD, Audio CD and VCR:

Refer to the following table for correct use.

SURROUND/

SPEED Button

SURROUND

1

SPEED

POWER/STANDBY Button

2

Number Buttons

3

123

56

4

789

010

DISC NAVIGATION Button

4

5

6

DISC NAVIGATION

VCR Button

VCR

SEARCH Buttons

24

STOP Button

7

DVD

Mode Mode

To activate virtual surround.

Turns the DVD/VCR on and off.

To select chapter or title directly. (DVD)

To select track directly. (CD)

+

To select the recording speed.

Turns the DVD/VCR on and off.

To select channel.

VCR

The first scenes of each chapter of the title being

played will be displayed. (DVD)

To select the VCR output mode.

To use the remote control in VCR mode.

Allows you to search forward/backward through

a disc.

To begin slow forward/backward through a disc.

(DVD)

Press to call up the index or time search menu.

To stop playback. To stop playback or record.

RECORD/ONE-TOUCH-

RECORDING Button

8

REC/OTR

MENU Button

9

MENU

TOP MENUButton

10

11

TOP MENU

SETUP Button

SETUP

ZOOM Button

12

13

SUBTITLE/TIMER Button

14

15

ZOOM

MODE Button

MODE

SUBTITLE

TIMER

ANGLE Button

ANGLE

Brings up the Menu on a disc. (DVD)

Brings up the Top Menu on a disc. (DVD).

Brings up the DVD player's Setup menu.

To magnify part of picture x2/x4. (DVD)

To set virtual surround on/off.

To arrange the playing order or play randomly.

(CD)

Accesses various subtitles on a disc. (DVD)

Accesses various camera angles on a disc.

(DVD)

To start a recording.

To start One Touch Recording.

Brings up the VCR Menu.

Press to put the VCR into standby mode

for a timer recording.

2-10

Page 17

Tour of the remote controller

DVD VCR

Mode Mode

REPEAT Button

16

17

REPEAT

A-B REPEAT Button

A-BREPEAT

SEARCH MODE Button

18

19

SEARCH MODE

QUICK-FIND

QUICK-FIND

RETURN Button

20

RETURN

ENTER, Cursor Buttons

21

22

ENTER

DISPLAY Button

23

DISPLAY

PLAY Button

25

Allows you to repeat play a chapter or title. (DVD)

Allows you to repeat play a track or all. (CD)

Marks a segment to repeat between A and B.

(DVD/CD)

To search chapter or title. (DVD)

To search track. (CD)

To search time. (DVD/CD)

To rapidly return to a location of disc.

Search the markers. (DVD/CD)

Returns to a previous menu. (DVD)

Moves the cursor and determines its position.

Displays the current disc mode.

Begin disc play.

Allows you to search forward/backward through

a tape.

To search and confirm the contents of the

recorded programme(s).

Moves the cursor and determines its position.

Cannot use the ENTER button.

Displays the current time, tape counter, channel.

Begin tape playback.

DVD Button

26

DVD

PAUSE/STEP Button

27

SLOW Button

28

CLEAR/C.RESET Button

29

30

31

32

SLOW

CLEAR

C.RESET

SKIP/PROG Buttons

SKIP/PROG

SKIP/PROG

OPEN/CLOSE/EJECT

Button

OPEN/CLOSE

EJECT

AUDIO Button

AUDIO

To select the DVD output mode.

To use the remote control in DVD mode.

Pause disc play.

Advances playback one frame at a time.

(DVD)

Clear the markers.

Clear the number that is entered incorrectly.

Removes status No. in programme input.

(CD)

To skip chapters. (DVD)

To skip tracks. (CD)

To open or close the disc tray.

Accesses various audio functions on a disc. (DVD)

To select STEREO, L-CH or R-CH. (CD)

Pause tape playback or recording.

Advances playback one frame at a time.

To view the tape in slow motion.

To reset the tape counter.

Press to control the TV programmes.

To adjust the tracking manually during playback.

Press to eject the video cassette from the VCR.

To select STEREO, L-CH R-CH or normal.

2-11

Page 18

3

MAINTENANCE AND INSPECTION

3-1 TROUBLESHOOTING

Troubleshooting is how to service for the specifying malfunction or poor parts.

Detect malfunction or poor parts and service as the following charts.

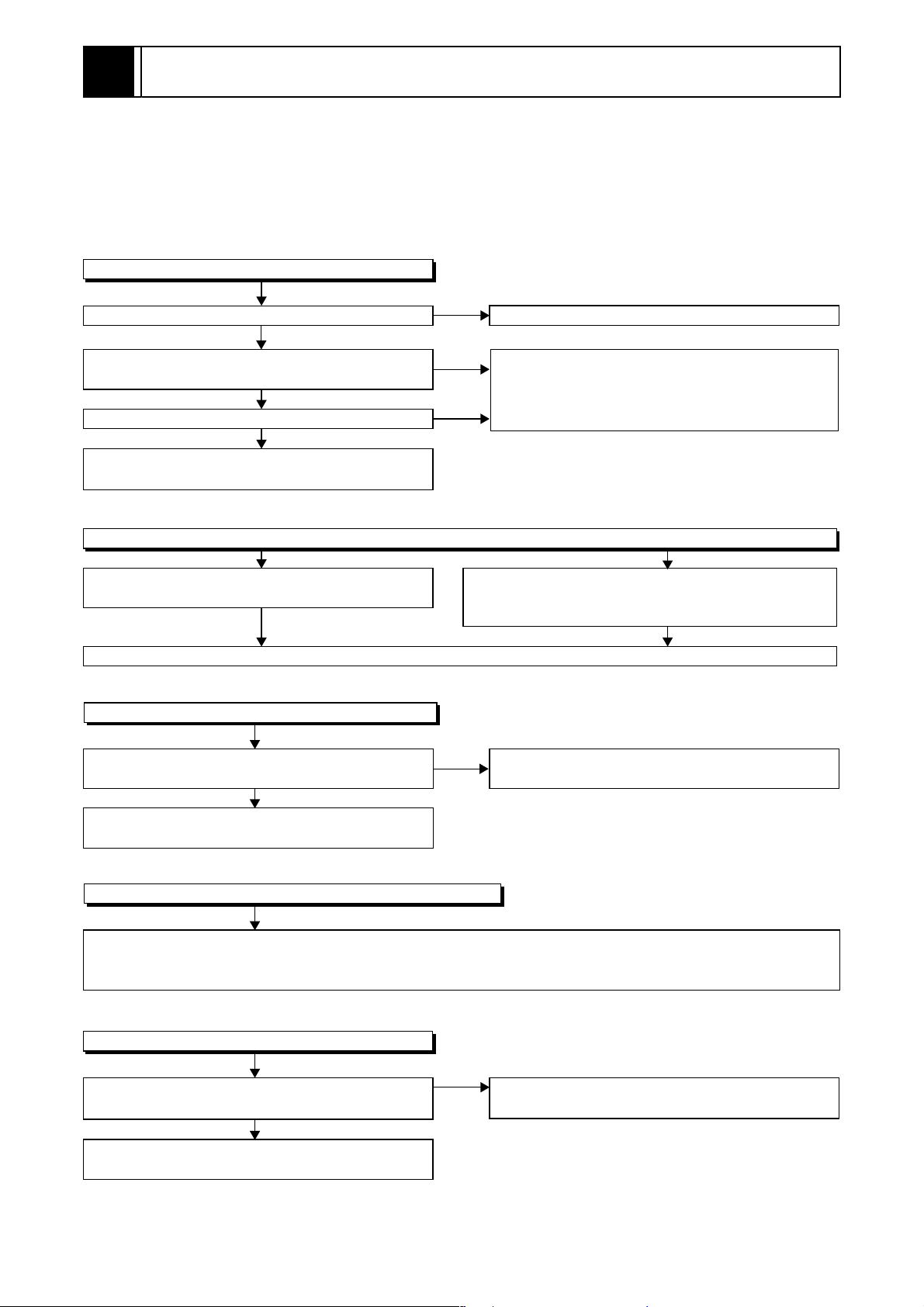

3-1-1 Power Supply Section

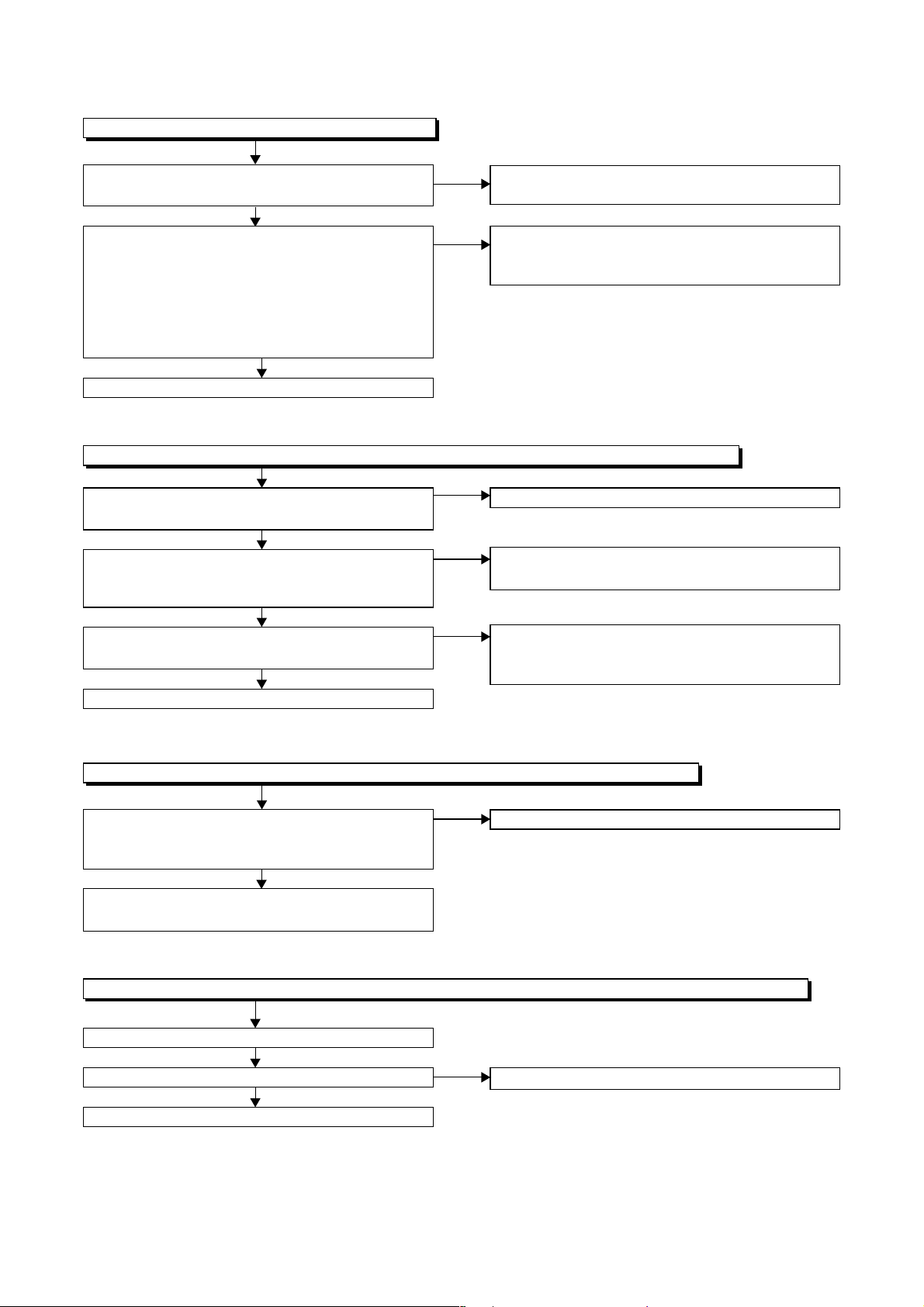

FLOW CHART NO.1

The power cannot be turned on.

Is the fuse normal?

Yes

Is normal state restored when once unplugged

power cord is plugged again after several seconds?

Yes

Is the AL+5V line voltage normal?

Yes

Check each rectifying circuit of secondary circuit

and service it if defective.

FLOW CHART NO.2

The fuse blows out.

Check the presence that the primary component

is leaking or shorted and service it if defective.

After servicing, replace the fuse.

FLOW CHART NO.3

When the output voltage fluctuates.

No

No

No

See FLOW CHART No.2 <The fuse blows out.>

Check for lead or shor-circuiting of primary

circuit component and service it if defective.

(Q1001, Q1003, T0011, D1001, D1002, D1003,

D1004, D1011, C1005, C2014)

Check the presence that the rectifying diode or circuit

is shorted in each rectifying circuit of secondary side

and service it if defective.

Does the secondary side photo coupler circuit

operate normally?

Yes

Check the circuit and service it if defective.

(IC1001, D1006, D1012, D1024)

FLOW CHART NO.4

When buzz sound can be heard in the vicinity of power circuit.

Check if there is short circuit on the rectifying diode and the circuit in each rectifying circuit of secondary side

and service it if defective. (D013, D014, D016, D018, D019, D1008, D1016, D1030, IC1002, IC1003, Q051,

Q053, Q055, Q056, Q058, Q1052, Q1053, Q1055)

FLOW CHART NO.5

-FL is not outputted.

Is the supply voltage of -30V fed to the anode of

D018?

Yes

Check for load circuit short-circuiting or leak, and

service it if defective.

No

No

Check the circuit and service it if defective.

(IC1001, Q1004, D1019)

Check D018 and their periphery, and service it if

defective.

3-1

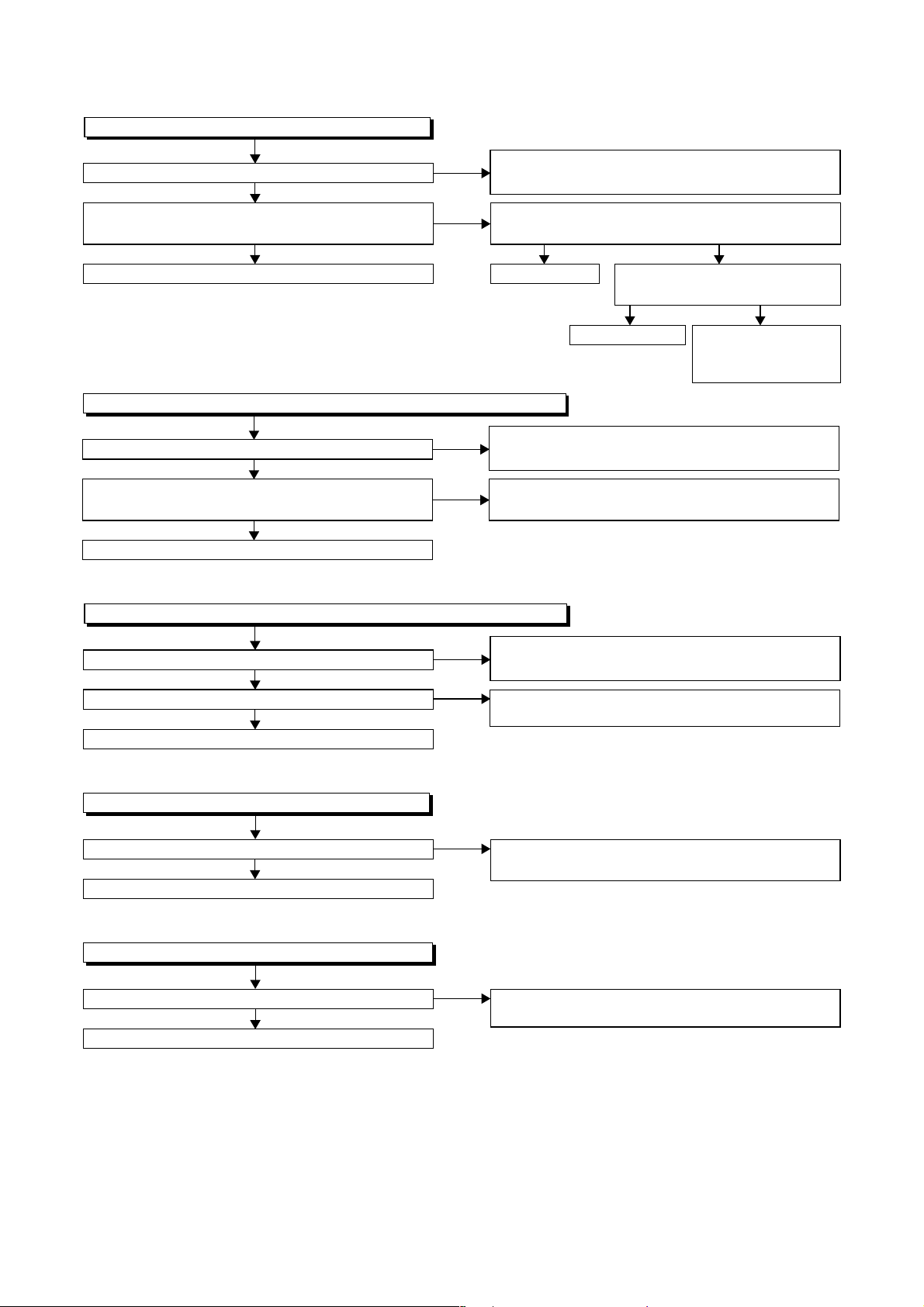

Page 19

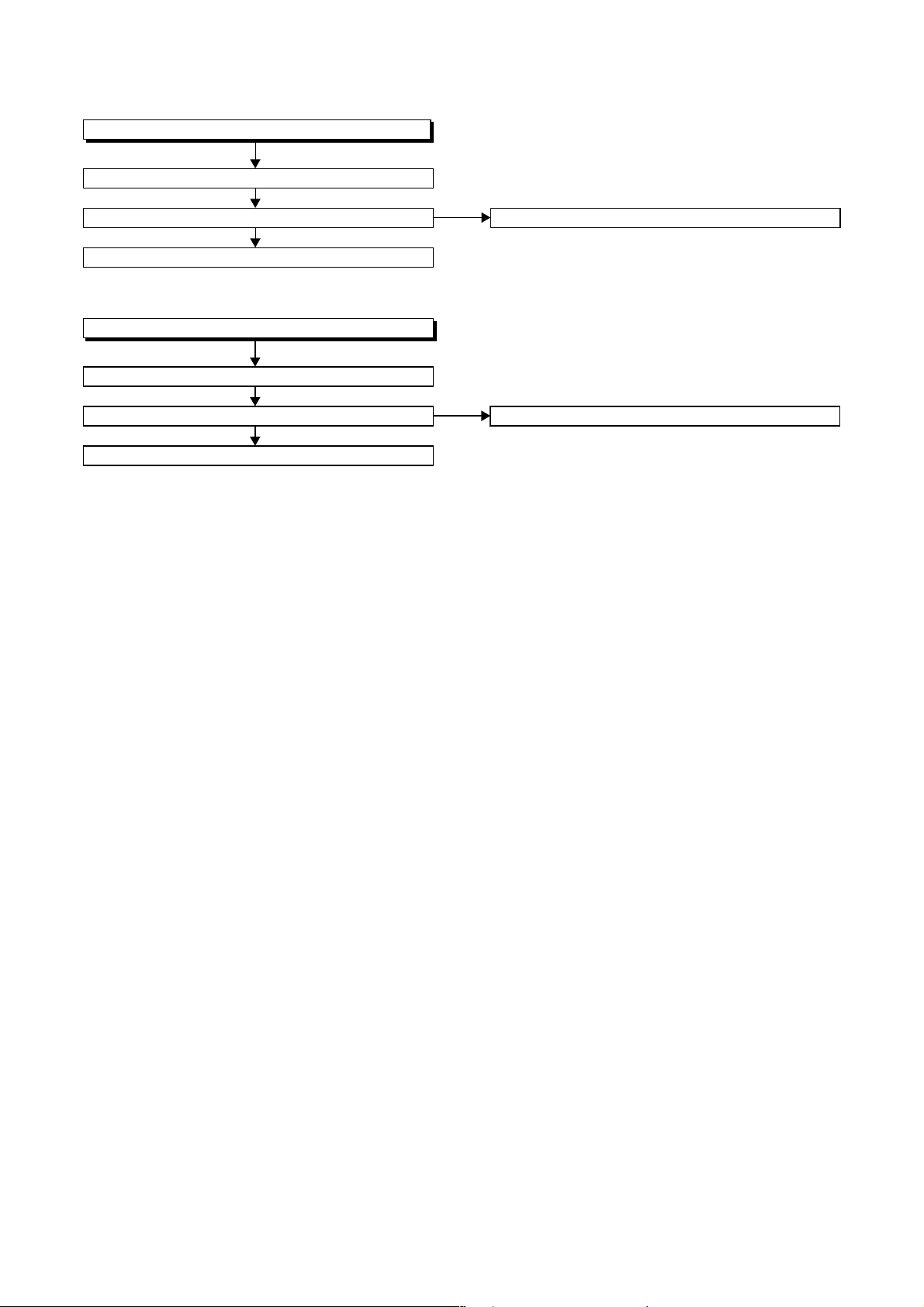

FLOW CHART NO.6

P-ON+44V is not outputted.

Is 44V voltage supplied to the emitter of Q053?

Yes

Is the "L" pulse (approximately 0V) inputted to

the base of Q053?

Yes

Replace Q053. Replace Q054.

FLOW CHART NO.7

AL+9V (AL+12V) is not outputted. (P-ON+44V is outputted normally)

Is 12V voltage supplied to the collector of Q055?

Yes

Is the "H" pulse (approximately 10V) inputted to

the base of Q055?

Yes

Replace Q055.

FLOW CHART NO.8

P-ON+5V (AL+5V) is not outputted. (P-ON+44V is outputted normally)

No

No

No

No

Check D013, C013, and their periphery, and

service it if defective.

Is the "H" pulse (approximately 5V) inputted to

the base of Q054?

Yes

Replace IC501.

Check D014, D017, L010, C015, and their

periphery, and service it if defective.

Check D054, R055, and their periphery,

and service it if defective.

No

Is 5V voltage supplied to the

Pin(37,99) of IC501.

Yes

Check AL+5V and

Timer+5V line, and

service it if defective.

No

Is 5V voltage supplied to the collector of Q056?

Yes

Is the "H" pulse inputted to the base of Q056?

Yes

Replace Q056.

FLOW CHART NO.9

EV+3.3V is not outputted.

Is 4V voltage supplied to Pin(1) of IC1003?

Yes

Replace IC1003.

FLOW CHART NO.10

EV 1.2V is not outputted.

Is 2.8V voltage supplied to Pin(1) of IC1002?

Yes

Replace IC1002.

No

No

No

No

Check D016, L013, C017, C018, and their

periphery, and service it if defective.

Check R058, R059, R060 and their periphery,

and service it if defective.

Check D1008, L1012, C1007, C2015 and

their periphery, and service it if defective.

Check D1030, L1009, C1035, C1107, and their

periphery, and service it if defective.

3-2

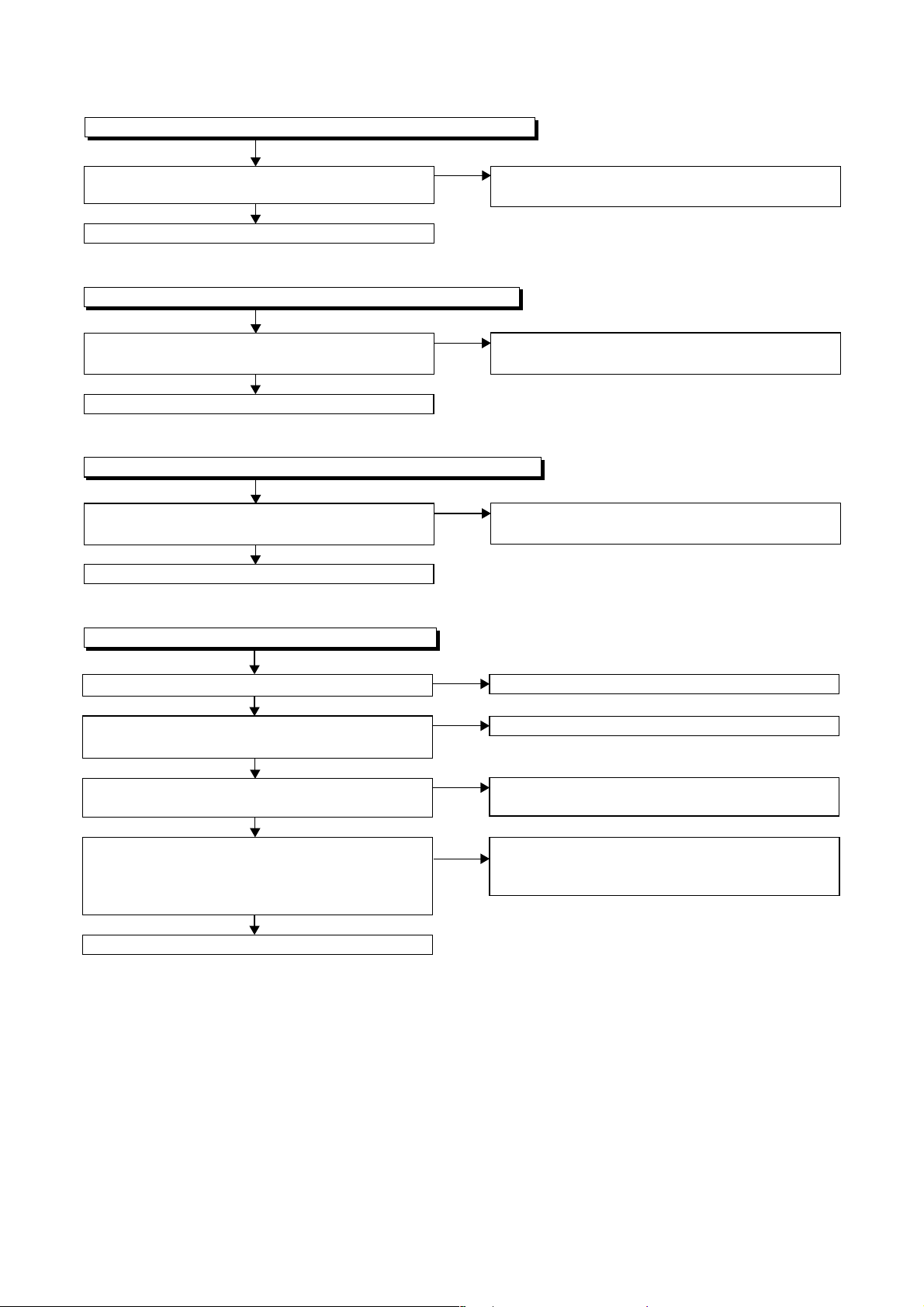

Page 20

FLOW CHART NO.11

DVD-P-ON+12V is not outputted. (AL+12V is outputted normally.)

Is the "L" pulse (approximately 0V) outputted to

the collector of Q1054?

Yes

Replace Q1053.

FLOW CHART NO.12

DVD-P-ON+5V is not outputted. (AL+5V is outputted normally.)

Is the "H" pulse (approximately 6V) inputted to

the base of Q1055?

Yes

Replace Q1055.

FLOW CHART NO.13

DVD-P-ON+3.3V is not outputted. (EV+3.3V is outputted normally.)

Is the "H" pulse (approximately 4V) inputted to

the base of Q1052?

Yes

Replace Q1052.

No

No

No

Check Q1054 and PWRCON line, and service it if

defective.

See FLOW CHART NO.11. <DVD-P-ON+12V is

not outputted. >

See FLOW CHART NO.11. <DVD-P-ON+12V is

not outputted. >

FLOW CHART NO.14

The fluorescent display tube does not light up.

Is 3.3V voltage supplied to Pin(6, 24) of IC612?

Yes

Is approximately -24V to -28V voltage supplied to

Pin(15) of IC612?

Yes

Is there approximately 500kHz oscillation to

Pin(26) of IC612?

Yes

Are the filament voltage applied between (1, 2)

and (29, 30) of the fluorescent display tube?

Also negative voltage applied between these pins

and GND?

Yes

Replace the fluorescent display tube (IC611).

No

No

No

No

Check the EV+3.3V line and service it if defective.

Check the -FL line and service it if defective.

Check R618, IC612 and their periphery, and

service it if defective.

Check the power circuit, D1016, D1017,

R1040, C1018 and their periphery, and

service it if defective.

3-3

Page 21

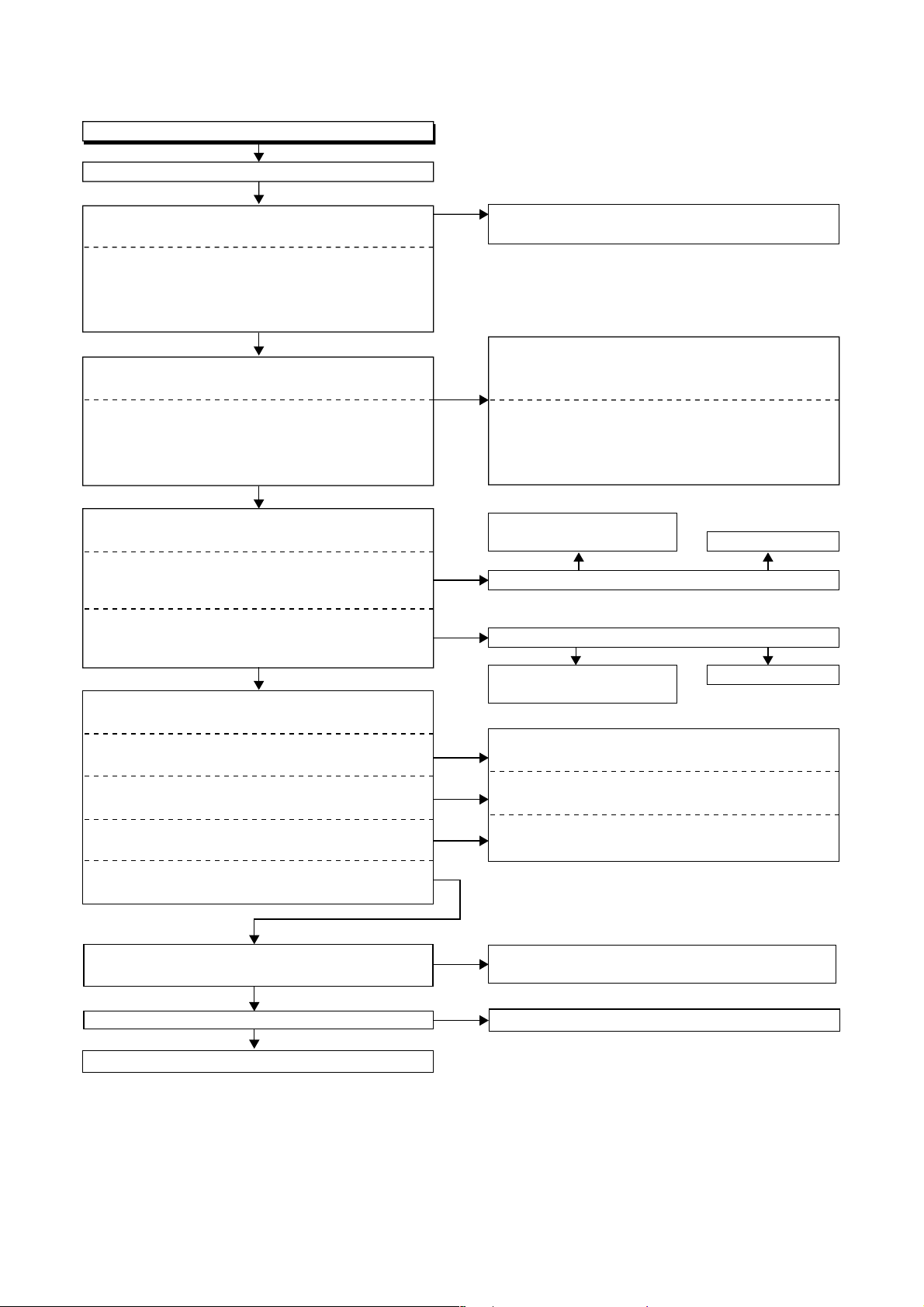

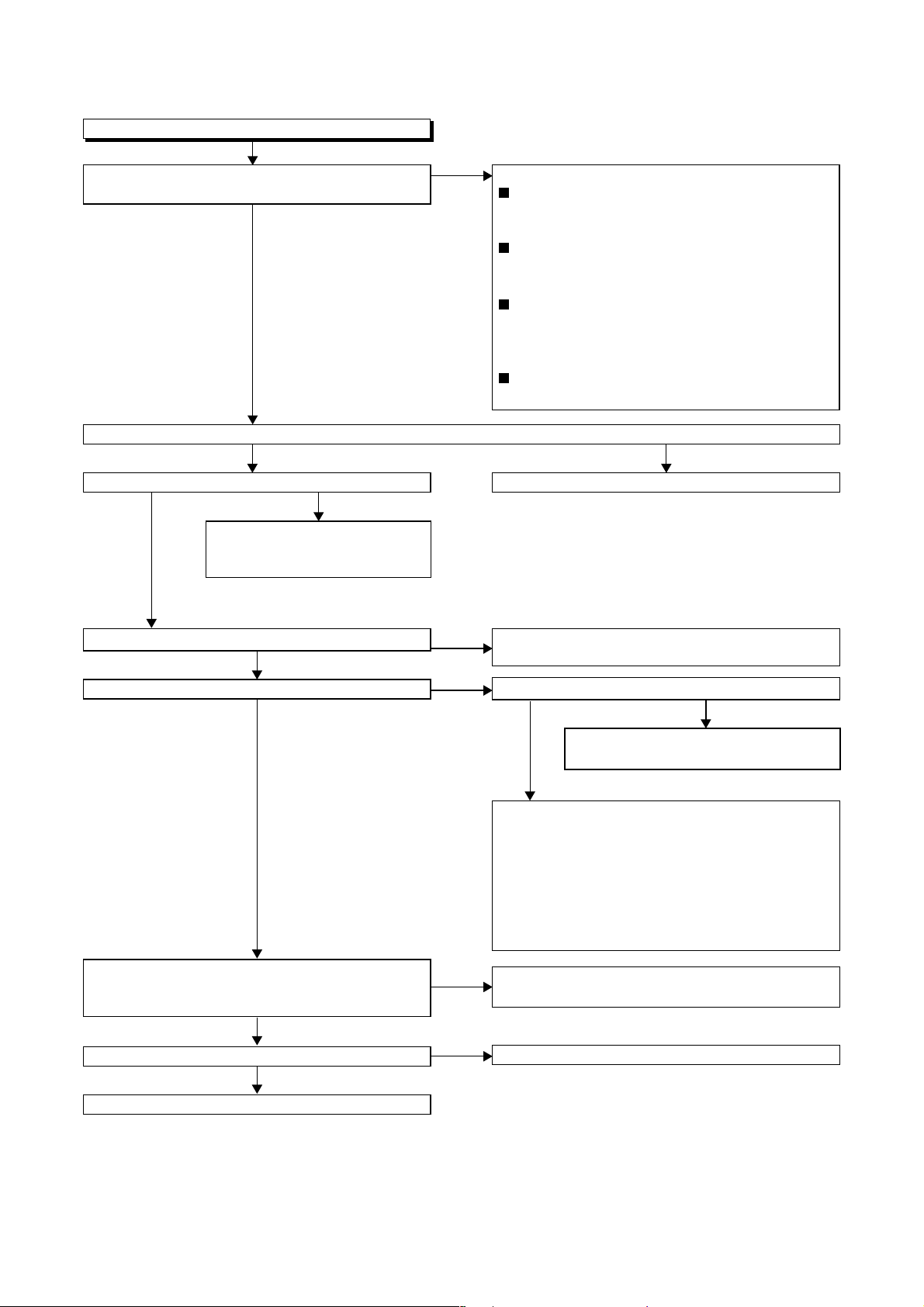

3-1-2 DVD Section

FLOW CHART NO.1

The key operation is not functioning.

Are the contact point and the installation state of

the key switches (SW2020, SW2021, SW2022) normal?

Yes

When pressing each key switches (SW2020,

SW2021, SW2022), do the voltage of each pin

of CL1051 (shown below) change to "H" (3.3V)

from "L" (0V)?

SW2020 → CL1051 24PIN

SW2021 → CL1051 26PIN

SW2022 → CL1051 25PIN

Yes

Replace DVD Main CBA.

FLOW CHART NO.2

No DVD operation is possible from the remote control unit. (

Is 5V voltage supplied to Pin(3) terminal of the

RM2001 (remote control receiver)?

Yes

Is the "L" pulse sent out from Pin(1) terminal of the

RM2001 (remote control receiver) when the remote

control unit is activated?

Yes

Is the "L" pulse signal supplied to Pin(22) of

CL1051?

Yes

Replace the DVD Main CBA.

No

No

No

No

No

Re-install the key switches (SW2020, SW2021,

SW2022) correctly or replace the poor switch.

Check the key switches (SW2020, SW2021,

SW2022) and their periphery, and service it if

defective.

Operation is possible from the unit.)

Check AL+5V line, and service it if defective.

Replace the RM2001 (remote control receiver).

Replace remote control unit if needed.

Check the line between the RM2001 (remote

control receiver) and Pin(22) of CL1051, and

service it if defective.

FLOW CHART NO.3

The disc tray cannot be opened and closed. (It can be done using the remote control unit.)

Does the voltage of Pin(24) on CL1051 become

3.3V when pressing "OPEN/CLOSE" button on

the unit?

Yes

Refer to "FLOW CHAR NO.4" <The disc tray

cannot be opened and closed.>

FLOW CHART NO.4

The disc tray cannot be opened and closed. (It can not be done using the unit and the remote control unit.)

Replace the DVD Main CBA.

No improvement can be found.

Yes

Replace the DVD Mechanism.

No

No

Replace the "OPEN/CLOSE" button (SW2020).

Original DVD Main CBA is poor.

3-4

Page 22

FLOW CHART NO.5

The [No Disc] indication.

Replace the DVD Main CBA.

No improvement can be found.

Yes

Replace the DVD Mechanism.

FLOW CHART NO.6

Both picture and sound do not operate normally.

Replace the DVD Main CBA.

No improvement can be found.

Yes

Replace the DVD Mechanism.

No

No

Original DVD Main CBA is poor.

Original DVD Main CBA is poor.

3-5

Page 23

FLOW CHART NO.7

Picture does not appear normally.

Set the disc on the disc tray, and playback.

Are the video signals outputted to each pin of

CN1601 on the Main CBA?

CN1601 1PIN S-Y

CN1601 10PIN S-C

CN1601 4PIN R

CN1601 8PIN G

CN1601 6PIN B

Yes

Are the video signals shown above inputted into

each pin of IC1403 and IC102?

IC1403 3PIN S-Y

IC1403 1PIN S-C

IC102 8PIN R

IC102 6PIN G

IC102 1PIN B

Yes

Are the video signals outputted to each pin

of IC1403 and IC102?

IC1403 6PIN CVBS

IC1403 5PIN S-Y

IC1403 7PIN S-C

IC102 10PIN R

IC102 11PIN G

IC102 15PIN B

Yes

Are the video signals outputted to the specific

output terminal?

Are the luminance signals outputted to the

S-OUT terminal (JK1401)?

Are the chroma signals outputted to the

S-OUT terminal (JK1401)?

Are the RGB video signals outputted to the

Scart jack (JK101)?

Are the composite video signals outputted to

Pin(19) of JK101 (Scart jack)?

No

No

No

No

No

No

No

Replace the DVD Main CBA or the DVD

Mechanism.

Check the line between each pin of CN1601 and

each pin of IC1403 and IC102 on the Main CBA,

and service it if defective.

CN1601 1PIN → IC1403 3PIN S-Y

CN1601 10PIN → IC1403 1PIN S-C

CN1601 4PIN → IC102 8PIN R

CN1601 8PIN → IC102 6PIN G

CN1601 6PIN → IC102 1PIN B

Check DVD-P-ON+5V line

and service it if defective.

No Yes

Is 5V voltage supplied to the Pin(4) of IC1403?

Is 5V voltage supplied to the Pin(4,12) of IC102?

No Yes

Check AL+5V line

and service it if defective.

Check the periphery of JK1401 from

Pin (5) of IC1403 and service it if defective.

Check the periphery of JK1401 from

Pin (7) of IC1403 and service it if defective.

Check the periphery of JK101 from Pins (10, 11,

15) of IC102 and service it if defective.

Replace IC1403.

Replace IC102.

No

Are the composite video signals outputted to

Pin(4) of IC751?

No

Are the "H" pulse inputted into Pins(9,10,11) of IC751?

No

Replace IC501.

Yes

Yes

Check the line between Pin(4) of IC751 and JK101

and service it if defective.

Replace IC751.

3-6

Page 24

FLOW CHART NO.8

Audio is not outputted.

Set the disc on the disc tray, and playback.

Are the analog audio signals outputted to each pin

of CN1601 on Main CBA?

CN1601 14PIN AUDIO-L

CN1601 16PIN AUDIO-R

Yes

Are the analog audio signals inputted to each pin

of IC1201.

IC1201 6PIN AUDIO-L

IC1201 2PIN AUDIO-R

Yes

Is the "H" level mute signals outputted to CN1601

on the Main CBA ?

CN1601 13PIN DVD-A-MUTE

CN1601 15PIN DVD-A(R)-MUTE

Yes

Are the analog audio signals outputted to each pin

of IC1201?

IC1201 7PIN AUDIO-L

IC1201 1PIN AUDIO-R

Yes

Are the audio signals outputted to the specific

output terminal?

Are the audio signals outputted to the L/R OUT

terminal (JK751)?

Are the audio signals outputted to Pins(1, 3) of

JK101 (Scart jack)?

No

No

No

No

No

Replace the DVD Main CBA or the DVD Mechanism.

Check each line between each pin of CN1601

and each pin of IC1201 on Main CBA, and service

it if defective.

CN1601 14PIN → IC1201 6PIN AUDIO-L

CN1601 16PIN → IC1201 2PIN AUDIO-R

Replace the DVD Main CBA or the DVD Mechanism.

Replace IC1201.

Check the periphery between Pins(1,7) of IC1201

and JK751, and service it if defective.

No

Are the audio signals outputted to Pin(14,15) of

IC751?

No

Are the "H" pulse inputted into Pins(9,10,11) of IC751?

No

Replace IC501.

Yes

Yes

Check the line between Pin(

and their periphery, and service it if defective.

Replace IC751.

14,15

) of IC751 and JK101

,

3-7

Page 25

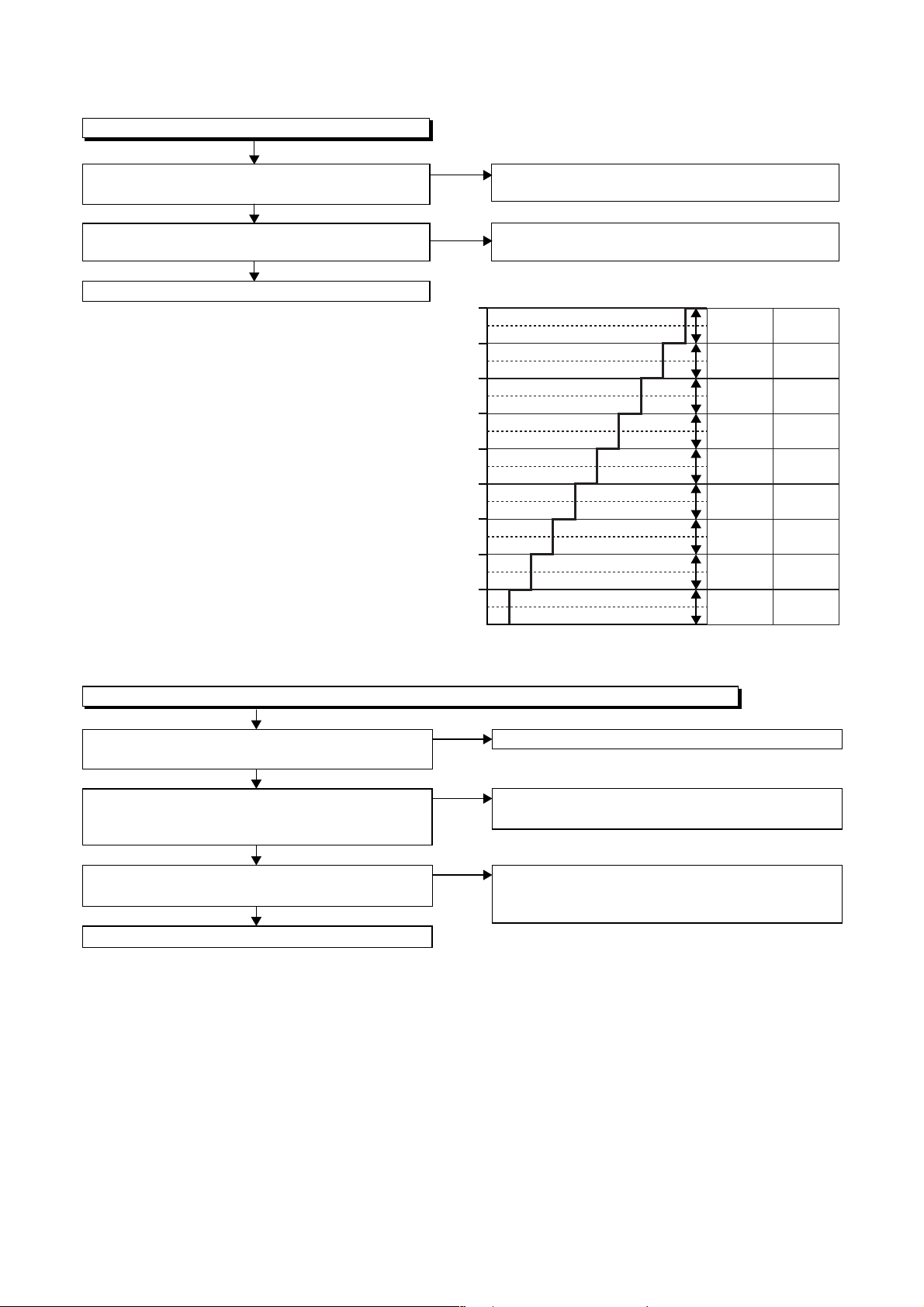

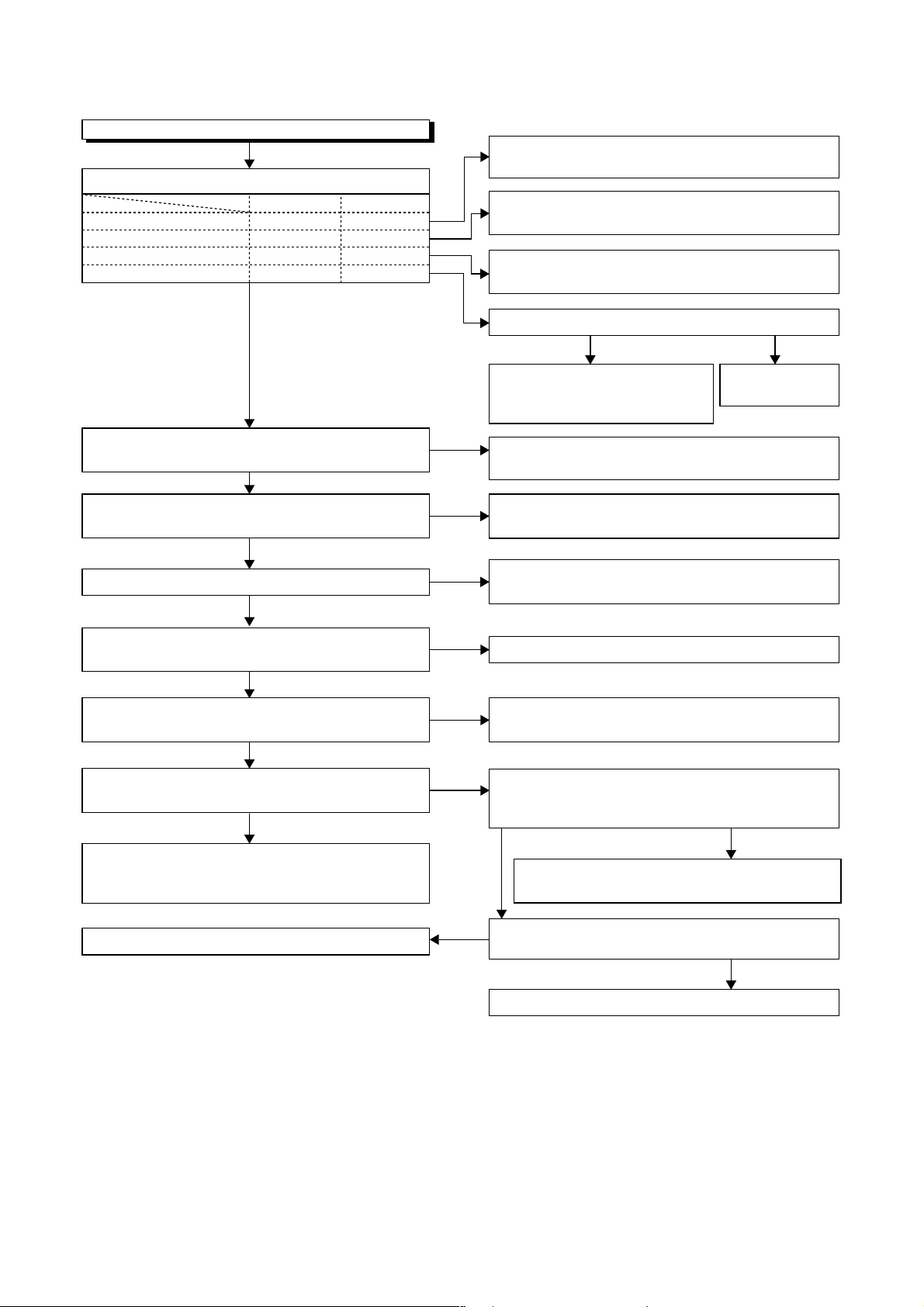

3-1-3 VCR Section

FLOW CHART NO.1

The key operation is not functioning.

Are the contact point and the installation state of

the key switches normal?

Yes

Is the control voltage normally inputted into

Pins(7,8) of IC501?

Yes

Replace IC501.

No

Re-install some key switches correctly or

replace some key switches.

No

Check the key switches and their periphery, and

service it if defective.

Terminal voltage of IC501-7,8

4.30

3.60

2.90

2.39

1.98

1.61

1.27

0.92

0.51

(V)

KEY-1

IC501-7

-----

-----

CH

DOWN

CH UP

-----

-----

OUTPUT

SELECT

POWER

REC/OTR

KEY-2

IC501-8

-----

-----

-----

S-INH

FF

REW

PLAY

STOP

/EJECT

-----

FLOW CHART NO.2

No VCR operation is possible from the remote control unit. (

Is 5V voltage supplied to the Pin(3) terminal of

No

the RM2001 (remote control receiver)?

Yes

Is the "L" pulse sent out from Pin(1) terminal of

No

the RM2001 (remote control receiver) when the

remote control unit is activated?

Yes

No

Is the "L" pulse signal supplied to the Pin(14) of

IC501?

Yes

Replace IC501.

Operation is possible from the unit.)

Check AL+5V line and service it if defective.

Replace the RM2001 (remote control receiver).

Replace remote control unit if need.

Check the line between the RM2001 (remote

control receiver) and the Pin(14) of IC501, and

service it if defective.

3-8

Page 26

FLOW CHART NO.3

Cassette tape can not be loaded.

When loading a cassette tape, on Pin(10) of

IC501, does the "L" pulse switch to the "H" pulse?

Yes

When loading a cassette tape, is the specified

voltage (approximately 13V) outputted to the

terminal of the Loading Motor Unit?

Yes

Replace the Loading Motor Unit.

FLOW CHART NO.4

Cassette tape is ejected right after the loading.

When loading a cassette tape, on Pin(10) of IC501,

does the "L" pulse switch to the "H" pulse?

Yes

When loading a cassette tape, on Pin(4) of IC501,

does the "L" pulse switch to the "H" pulse?

Yes

When loading a cassette tape, does the LD-SW

operate normally?

Yes

Replace IC501.

No

No

No

No

No

Check the line between the start sensor and

Pin(10) of IC501, and service it if defective.

Replace the Capstan Motor Unit.

Check the line between the start sensor and

Pin(10) of IC501, and service it if defective.

Check the line between the end sensor and

Pin(4) of IC501, and service it if defective.

Check the line between the LD-SW(SW507) and

Pin(9) of IC501, and service it if defective.

FLOW CHART NO.5

Cassette tape can not be ejected.

When pressing the eject button, does the Capstan

Motor start rotating?

Yes

While the Capstan Motor is rotating, is the Takeup

Reel rotating?

Yes

While the Takeup Reel is rotating, is the reel pulse

signal inputted to Pin(80) of IC501?

Yes

While the reel pulse signal is inputting, is "L" pulse

outputted to Pin(81) of IC501?

Yes

Is the specified voltage (approximately 13V)

outputted to the terminal of the Lading Motor Unit?

Yes

Is the Loading Motor rotating?

Yes

Check the Cassette Cam or Cassette Gear, etc,

and service it if defective.

No

No

No

No

No

No

Refer to "FLOW CHART NO.6 " <The Capstan

Motor does not rotate>.

Check the Reel Disc or Reel Drive Unit, and

service it if defective.

Check the line between the Takeup Reel sensor

and Pin(80) of IC501, and service it if defective.

Replace IC501.

Replace the Capstan Motor unit.

Replace the Loading Motor unit.

3-9

Page 27

FLOW CHART NO.6

Capstan Motor does not rotate.

Is 5V voltage supplied to Pin(2) of CN502?

Yes

Is over approximately 2.6V voltage supplied to

Pin(5) of CN502?

Yes

Is 12V voltage supplied to Pin(1,11) of CN502?

Yes

Replace the Capstan Motor Unit.

FLOW CHART NO.7

Drum Motor does not rotate.

Is 5V voltage supplied to Pin(2) of CN502?

Yes

Is over approximately 2.6V voltage supplied to

Pin(8) of CN502?

Yes

Is 12V voltage supplied at Pin(1,11) of CN502?

Yes

Replace the Capstan Motor Unit or Cylinder

Assembly.

No

No

No

No

No

No

Check the P-ON+5V line and service it if defective.

Check the line between Pin(5) of CN502 and

Pin(76) of IC501, and service it if defective.

Check the AL+12V line, AL+20.5V/+12V line

and service it if defective.

Check the P-ON+5V line and service it if defective.

Check the line between Pin(8) of CN502 and

Pin(77) of IC501, and service it if defective.

Check the AL+12V line, AL+20.5V/+12V line

and service it if defective.

FLOW CHART NO.8

Drum Motor rotates only for a few seconds.

Is the drum PG/FG signal inputted to Pin(90) of IC501?

Yes

Is the RF-SW signal outputted to Pin(18) of IC501?

Yes

Is 12V voltage supplied Pin(1,11) of CN 502?

No

No

No

Yes

Replace the Capstan Motor Unit or the Cylinder

Assembly.

FLOW CHART NO.9

RF-SW signal is not outputted.

No

Is the Drum Motor rotating?

Yes

Is the drum PG/FG signal inputted to Pin(90) of IC501?

No

Yes

Replace IC501.

Replace the Capstan Motor Unit or the Cylinder

Assembly.

Replace IC501.

Check the AL+12V line, AL+20.5V/+12V line

and service it if defective.

D-PG

5Vp-p

D-FG

2.5Vp-p

Refer to "FLOW CHART NO.7" <Drum Motor does

not rotate> and "FLOW CHART NO.8" <Drum

Motor rotates only for a few seconds>.

Replace the Capstan Motor Unit or the Cylinder

Assembly.

3-10

Page 28

FLOW CHART NO.10

Video E-E does not appear.

Is the Video signal inputted to Pins(48,50,52,54) of

IC301?

Yes

Is the C-SYNC signal outputted to Pin(67) of IC301?

Yes No

Is the C-SYNC signal inputted to Pin(58) of IC501?

No

Check the line between Pin(67)

of IC301 and Pin(58) of IC501,

and service it if defective.

Yes

No

1) In the external input mode

Check the line between Pin(20) of JK101 (Scart

jack) and Pin(50) of IC301, and service it if

defective.

Check the line between Pin(20) of JK1402

(Scart jack) and Pin(52) of IC301, and service it

if defective.

Check the line between the video input

terminal (front) and Pin(54) of IC301, and

service it if defective.

2) In the U/V tuner mode

Check the line between Pin(24) of the U/V tuner

and Pin(48) of IC301, and service it if defective.

Replace IC301.

Is the video signal inputted into Pin(5) of IC751?

Yes

Is the video signal outputted to Pin(4) of IC751?

No

Is approximately 5V voltage supplied to Pin(16)

of IC751, or approximately -5V voltage supplied to

Pin(7) of IC751?

Yes

Is the "L" pulse inputted into Pin(9,10,11) of IC751?

Yes

No

Yes

No

No

Check the line between Pin(61) of IC301 and

Pin(5) of IC751, and service it if defective.

Is the video signal outputted to the emitter of Q104?

No

Check the line between Pin(4) of IC751

and Q104,

Yes

When only Line signal is not outputted...

check the line between the emitter of Q104 and

Pin(19) of JK101 (Scart jack), and service it if

defective.

When only RF signal is not outputted...

check the tuner (TU701), and the line between

the emitter of Q104 and Pin(6) of the tuner,

and service it if defective.

Check the AL+5V line and the AL-30V line

(R764, R765), and service it if defective.

Replace IC501.

and service it if defective.

Replace IC751.

3-11

Page 29

FLOW CHART NO.11

Hi-Fi E-E audio does not operate normally.

Is each signal supplied to each pin of IC451 as below?

L-ch R-ch

Front input terminal

Scart jack 1 (JK101)

Scart jack 2 (JK1402)

Tuner audio signal

Pin(8) Pin(54)

Pin(6) Pin(52)

Pin(10) Pin(56)

Pin(4) Pin(50)

No

No

No

No

Check the peripheral circuit of the front input

terminal and service it if defective.

Check the peripheral circuit of the Scart jack 1

(JK101) and service it if defective.

Check the peripheral circuit of the Scart jack 2

(JK1402) and service it if defective.

Is the SIF signal outputted from Pin(22) of the tuner?

Yes

Is the 5V voltage supplied to Pins(16,32,35,36,46,55) of

IC451, or the 9V voltage supplied to Pin(69) of IC451?

Yes

Is the serial data and the clock signal supplied to

Pin(37,38) of IC451?

Yes

Is the "L" pulse inputted into the Pin(53) of IC451?

Yes

Is the audio signal outputted to Pin(65,67,74,76)

of IC451?

Yes

Is the audio signal inputted into Pin(2,12) of

IC751?

Yes

Is the audio signal outputted to Pin(14,15) of

IC751?

Yes

Check the line between Pin(14,15) of IC751 and

Pin(1,3) of JK101 (Scart jack), and service it if

defective.

No

No

No

No

No

No

Yes

Check the line between Pins(4,

50) of IC451 and Pin(22) of

tuner, and service it if defective.

Check the circuit of AL+5V, P-ON+5V and

AL+9V, and service it if defective.

Check the line between Pin(37,38) of IC451 and

Pin(71,72) of IC501, and service it if defective.

Check the line between Pin(53) of IC451 and

Pin(28) of IC501, and service it if defective.

Replace IC451.

Check the line between Pin(74,76) of IC451 and

Pin(2,12) of IC751, and service it if defective.

Is approximately 5V voltage supplied to Pin(16)

of IC751, or approximately -5V voltage supplied to

Pin(7) of IC751?

Check the AL+5V line and the AL-30V line

Yes

(R764, R765), and service it if defective.

Replace the

tuner.

No

No

Replace IC751.

Yes

Replace IC501.

3-12

Is the "L " pulse inputted into the Pins(9,10,11) of

IC751?

No

Page 30

FLOW CHART NO.12

Hi-Fi audio can not be recorded normally. (E-E mode is normal.)

Is the REC FM signal outputted to Pin(26) of IC451?

Yes

Is the line between Pin(8) of CN251 and

Pin(26) of IC451 normal?

Yes

Replace the Cylinder Assembly.

FLOW CHART NO.13

Hi-Fi audio can not be playbacked normally. (Hi-Fi E-E mode is normal.)

Is the Playback Envelope signal outputted to

Pin(33) of IC451?

Yes

Replace IC451.

FLOW CHART NO.14

Hi-Fi audio can not be recorded normally in the linear audio mode. (E-E mode is normal.)

Is the audio signal inputted into Pin(13,15,17) of IC301?

Yes

Does the Bias oscillation circuit operate normally?

Yes

Is the audio signal outputted to Pin(11) of IC301?

Yes

Is the audio signal outputted to Pin(100) of IC301?

Yes

Is CN504 and the connected cable normal?

No

No

No

No

No

No

No

No

Replace IC451.

Check the line between Pin(8) of CN251 and

Pin(26) of IC451, and service it if defective.

Is the Hi-Fi-H-SW signal inputted into to Pin(39) of IC451?

Yes

Replace

IC451.

Check the line between Pin(78) of IC451 and

Pin(13,15,17) of IC301, and service it if defective.

Check the Bias oscillation circuit (

Q404,Q405,Q406)

Replace IC301.

Replace IC301.

Replace CN504 and the connected cable.

Check the Hi-Fi-H-SW line between

Pin(39) of IC451 and Pin(19) of

IC501, and service it if defective.

and service it if defective.

No

Q401,Q403,

Replace ACE head.

Yes

3-13

Page 31

FLOW CHART NO.15

Hi-Fi audio can not be playbacked normally in the linear audio mode. (E-E mode is normal.)

Is the audio signal supplied to Pin(9) of IC301?

No

Are the CN504, the connected cable and the parts

on periphery of playback amplifier normal?

Yes

Is there no dirt on the surface of ACE head?

Yes

Is the height of ACE head appropriate?

Yes

Replace the ACE head.

Yes

No

No

No

Is the audio signal outputted to Pin(11) of IC301?

NoYes

Check the line between Pin(11) of

IC301 and Pin(80) of IC451, and

service it if defective.

Service and replace poor parts.

Clean the surface of ACE head.

Readjust the height of the ACE head.

Replace

IC301.

3-14

Page 32

3-2 FIRMWARE RENEWAL MODE

3-2-1 How to Update the Firmware

Version

Note:

If the firmware has been changed, etc., we will use

Service News, etc. to report on how to obtain new

firmware data and create an upgraded disc.

1. Turn the power on and remove the disc on the tray.

2. To put the DVD player into version up mode, press

[9], [8], [7], [6], and [SEARCH MODE] buttons on

the remote control unit in that order. The tray will

open automatically.

Fig. a appears on the screen and Fig. b app ears

on the VFD.

"

" differ depending on the models.

*******

F/W Version Up Mode Model No : *******

Please insert a DISC

for F/W Version Up.

VERSION : *.**

EXIT: POWER

The appearance shown in (*1) of Fig. c is

described as follows:

AppearanceNo. State

Reading... Sending files into the memory

1

Erasing... Erasing previous version data

2

Programming...

3 Writing new version data

5. After programming is finished, the tray opens automatically. Fig. e appears on the screen and the

checksum in (*2) of Fig. e appears on the VFD.

(Fig. f)

"

" differ depending on the models.

*******

F/W Version Up Mode

VERSION : D5****_****.ab5

Completed

*2

SUM : 7ABC

Fig. e Completed Program Mode Screen

Model No : *******

VERSION : *.**

Fig. a Version Up Mode Screen

Fig. b VFD in Version Up Mode

The DVD player can also enter the version up

mode with the tray open. In this case, Fig. a will be

shown on the screen while the tray is open.

3. Load the disc for version up.

4. The DVD player enters the F/W version up mode

automatically. Fig. c appears on the screen and

Fig. d appears on the VFD. If you enter the F/W for

different models, “Disc Error” will appear on the

screen, then the tray will open automatically.

"

" differ depending on the models.

*******

F/W Version Up Mode Model No : *******

VERSION : D5****_****.ab5

Reading...

*1

VERSION : *.**

Fig. f VFD upon Finishing the Programming Mode (Example)

At this time, no buttons are available.

6. Remove the disc on the tray.

7. Unplug the AC cord from the AC outlet. Then plug

it again.

8. Turn the power on by pressing the [y/I ] button

and the tray will close.

9. Press [1], [2], [3], [4], and [DISPLAY] buttons on

the remote control unit in that order.

Fig. g appears on the screen.

"

" differ depending on the models.

*******

MODEL : *******

Version

Region

: *.**

: *

EXIT: POWEREEPROM CLEAR : CLEAR

Fig. g

Fig. c Programming Mode Screen

Fig. d VFD in Programming Mode (Example)

3-15

Page 33

10.Press [CLEAR/C.RESET] button on the remote

control unit.

Fig. h appears on the screen.

"

" differ depending on the models.

*******

MODEL : *******

Version

Region

: *.**

: *

EXIT: POWEREEPROM CLEAR : CLEAR

EEPROM CLEAR : OK

Fig. h

When “OK” appears on the screen, the factory

default will be set. Then the firmware renewal

mode is complete.

11.To exit this mode, press [y/I ] button.

3-2-2 How to Verify the Firmware Ver-

sion

1. After making sure tha t no disc is in unit, turn the

power on.

2. Press [1], [2], [3], [4], and [DISPLAY] buttons on

the remote control uni t i n th at o rder. The Firmware

version appears on the VFD and TV screen.

3. Turn the power off to reset the unit.

3-16

Page 34

3-3 STANDARD MAINTENANCE

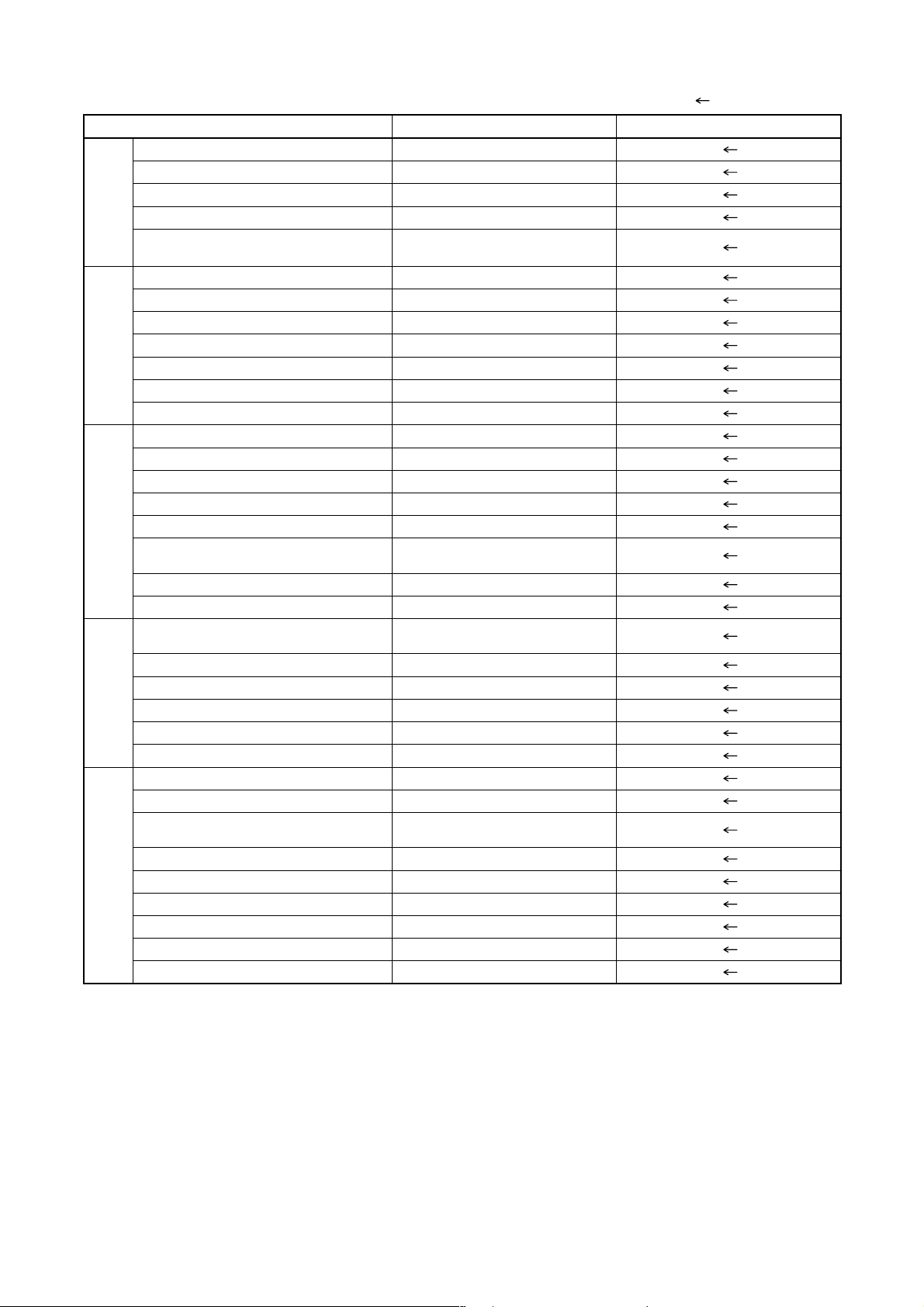

3-3-1 Service Schedule of Components

This maintenance chart shows you the standard of replacement and cleaning time for each part.

Because those may replace depending on environment and purpose for use, use the chart for reference.

h: Hours : Cleaning I: Replace

Deck Periodic Service Schedule

Ref.No. Part Name 1,000 h 2,000 h 3,000 h 4,000 h

B2

B3

B8 Pulley Assembly II

B587

B31

B573, B574 Reel S, Reel T I

B37

B52 Cap Belt II

B73 FE Head I

B86

B133 Idler Assembly (HI) II

B410

B414

B416 M Brake (TU) Assembly (HI) II

Cylinder Assembly

Loading Motor Assembly

Tension Lever Assembly

ACE Head Assembly

Capstan Motor

F Brake Assembly (HI)

Pinch Arm Assembly

M Brake (SP) Assembly (HI)

II

I

II

I

II

II

II

II

B525

Notes:

1.Clean all p ar t s for the tape transp or t ( Upper Dr um with Vide o Head / Pi nch Ro ller / ACE Head / FE Head )

using 90% lsopropyl Alcohol.

2.After cleaning the parts, do all DECK ADJUSTMENTS.

3.For the reference numbers listed above, refer to Deck Exploded Views.

LDG Belt

II

3-17

Page 35

3-3-2 Cleaning

Cleaning of Video Head

Clean the head with a h ead c leani ng s tick or c ha mois

cloth.

Procedure

1.Remove the top cabinet.

2.Put on a glove (thin type) to avoid touching the

upper and lower drum with your bare hand.

3.Put a few drops of 90% Isopropyl alcohol on the

head cleaning stick or on th e chamois cloth and,

by slightly pressing it against the head tip, turn the

upper drum to the right and to the left.

Notes:

1.The video head surface is made of very hard

material, but sinc e it is ver y thin, avoid cleaning it

vertically.

2.Wait for the cleaned part to dr y th oroughly before

operating the unit.

3.Do not reu se a stained head cleaning stick or a

stained chamois cloth.

Cleaning of ACE Head

Clean the head with a cotton swab.

Procedure

1.Remove the top cabinet.

2.Dip the cotton swab in 90% isopropyl alcohol and

clean the ACE Head. Be careful not to damage

the upper drum and other tape running parts.

Notes:

1.Avoid cleaning the ACE Head vertically.

2.Wait for the cleaned part to dr y tho roughly before

operating the unit or damage may occur.

ACE Head

Upper

Cylinder

Do Not !

Video Head

Do Not touch

with your bare

hand!

Cleaning Stick

3-18

Page 36

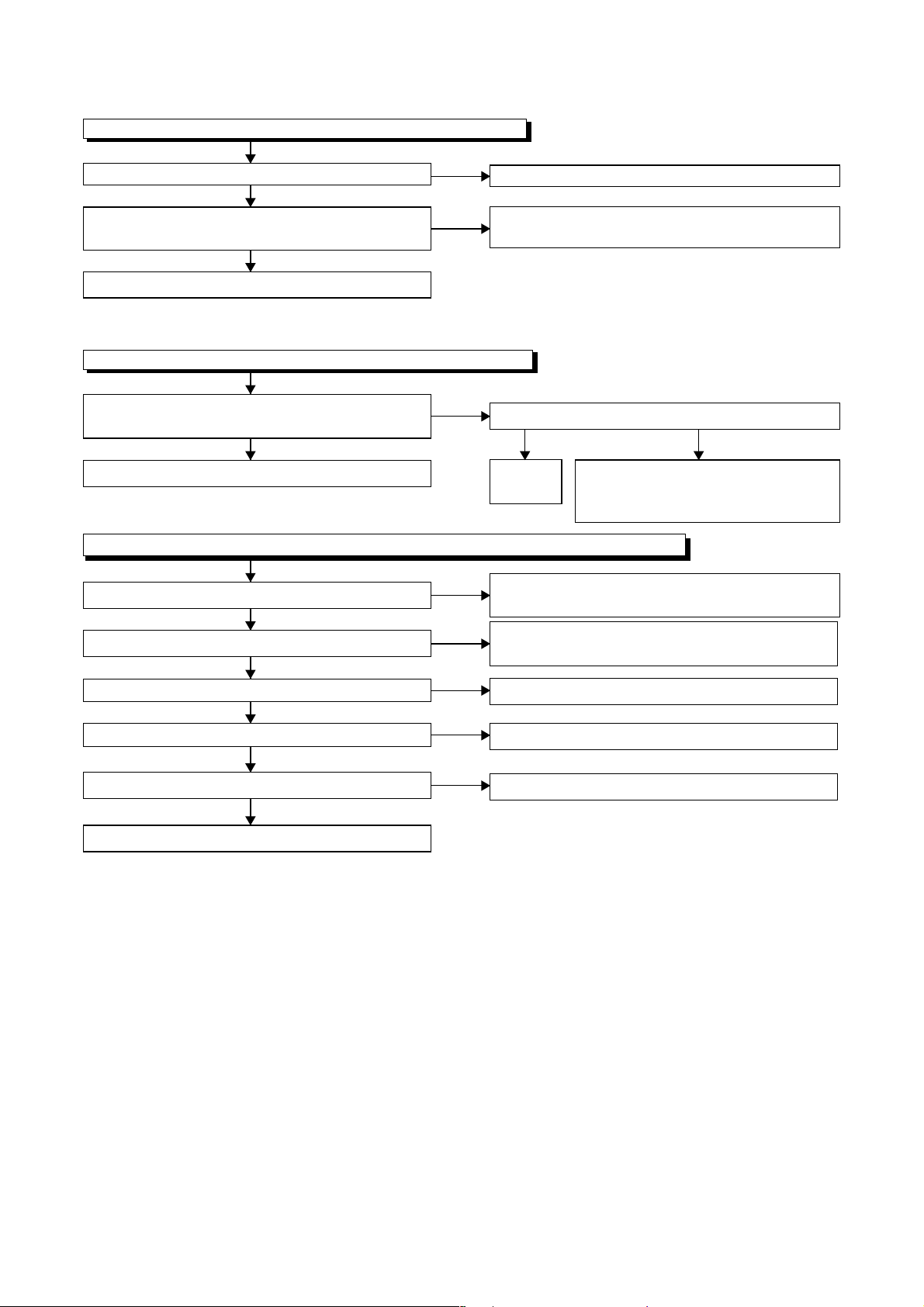

4

DISASSEMBLY

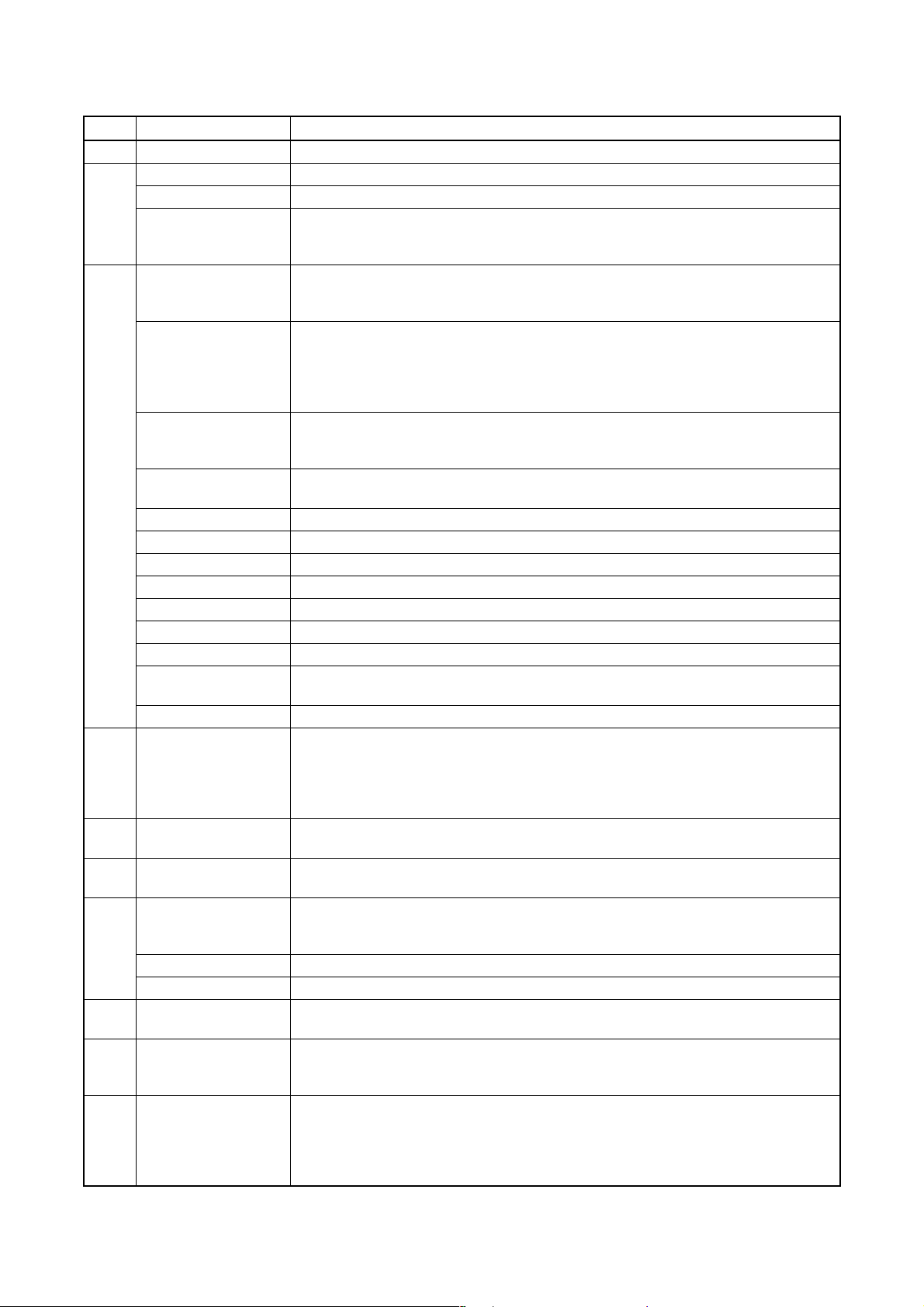

4-1 CABINET DISASSEMBLY INSTRUCTIONS

4-1-1 Disassembly Flowchart

This flowchart indicates the disassembly steps to gain

access to item(s) to be serviced. When reassembling,

follow the steps in reverse order. Bend, route, and

dress the cables as they were originally.

[1] T op Case

[2] Front Assembly

[3] T op Bracket

[4] DVD Mecha Assembly [8] DVD Main CBA

[5] Partition Plate

[6] Power Supply CBA

[7] Loader Holder

[9] VCR Chassis Unit

[10] Deck Assembly

[11] DVD Open/Close CBA

[12] Power SW CBA

[13] Main CBA

[14] Jack-A CBA

REMOVAL

ID/

LOC.

No.

[7]

[8]

[9]

[10]

[11]

[12]

[13] Main CBA D6 ---------- -

[14]

PA RT

Loader

Holder

DVD Main

CBA

VCR

Chassis

Unit

Deck

Assembly

DVD

Open/

Close

CBA

Power SW

CBA

Jack-A

CBA

REMOVE/*UNHOOK/

Fig.

UNLOCK/RELEASE/

No.

UNPLUG/DESOLDER

D3 2(S-6) -

2(S-7), *CN201,

D4

*CN301

5(S-8), 2(S-9),

D5

2(S-10), (L-3)

Desolder,

D6

2(S-11), (S-12)

D6 Desolder -

D6 Desolder -

D6 Desolder, 2(S-13) -

Note

2

2-1

2-2

3

-

4,5

4-1-2 Disassembly Method

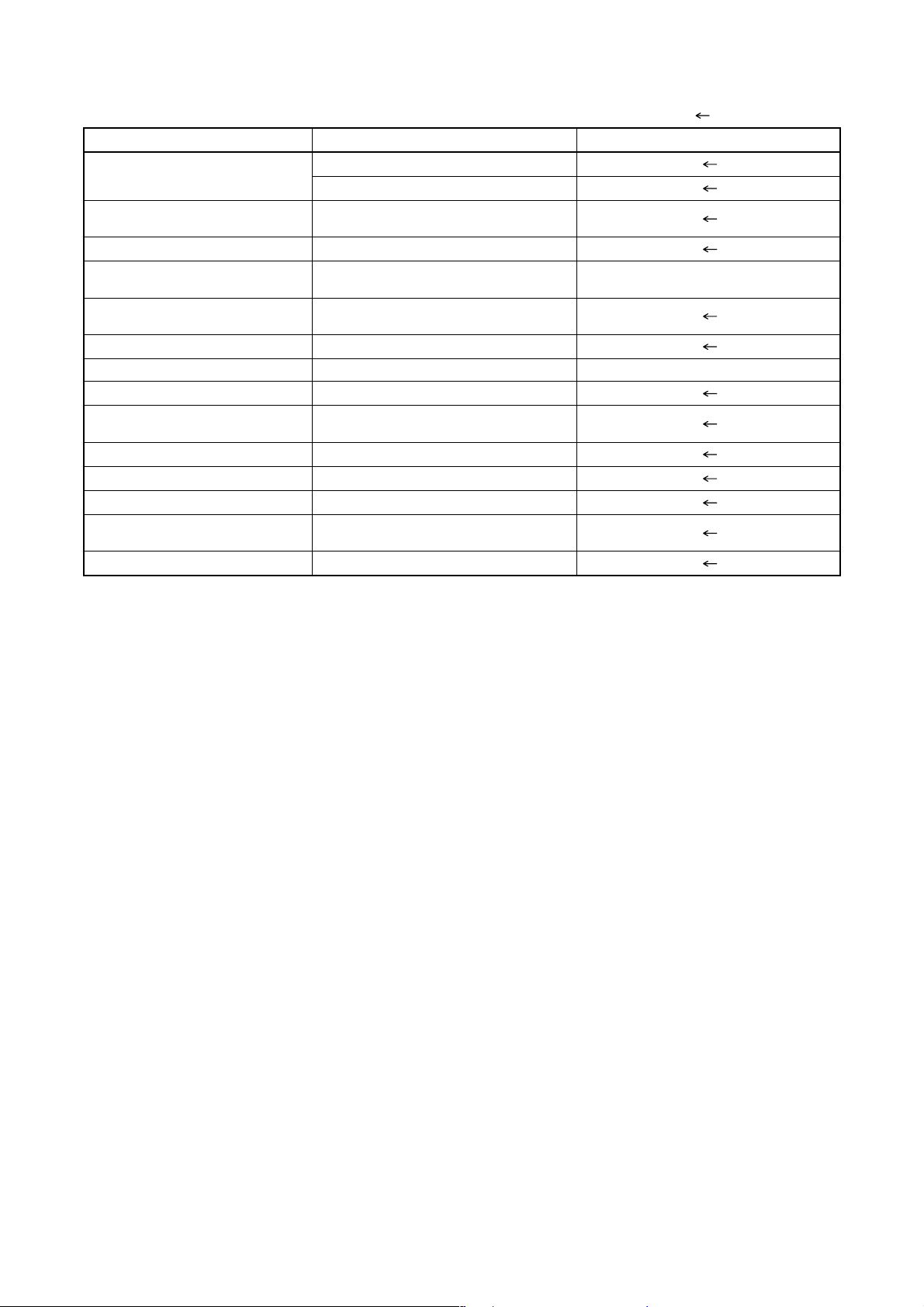

REMOVAL

ID/

LOC.

No.

[1] Top Case D1 8(S-1) -

[2]

[3]

[4]

[5]

[6]

PART

Front

Assembly

Top

Bracket

DVD

Mecha

Assembly

Partition

Plate

Power

Suppy

CBA

REMOVE/*UNHOOK/

Fig.

UNLOCK/RELEASE/

No.

UNPLUG/DESOLDER

D2 *3(L-1), *3(L-2)

D2 3(S-2) -

4(S-3), *CN401,

D3

*CN601

D3 (S-4) -

D3 2(S-5), CN501 -

Note

1

1-1

1-2

-

↓

(1)

Note:

(1):Identification (location) No. of parts in the figures

(2):Name of the part

(3):Figure Number for reference

(4): Identification of parts to be removed, unhooked,

unlocked, released, unplugged, unclamped, or

desoldered.

P=Spring, L=Locking Tab, S=Screw,

CN=Connector

*=Unhook, Unlock, Release, Unplug, or Desolder

e.g. 2(S-2) = two Screws (S-2),

2(L-2) = two Locking Tabs (L-2)

(5):Refer to “Reference Notes.”

↓