CORDLESS DRIVER DRILL

AKKU-BOHRSCHRAUBER

PERCEUSE-VISSEUSE À BATTERIE

TRAPANO-AVVITATORE A BATTERIA

SNOERLOZE

BOOR-SCHROEFMACHINE

TALADRO ATORNILLADOR

SIN CABLE DE CONEXION

Two speed Variable speed

DS 7DT DS 7DV

1

2

3

4

5

DS 7DT

Read through carefully and understand these instructions before use.

Diese Anleitung vor Benutzung des Werkzeugs sorgfältig durchlesen und verstehen.

Lire soigneusement et bien assimiler ces instructions avant usage.

Prima dell’uso leggere attentamente e comprendere queste instruzioni.

Deze gebruiksaanwijzing s.v.p. voor gebruik zorgvuldig doorlezen.

Leer cuidadosamente y comprender estas instrucciones antes del uso.

Handling instructions

Bedienungsanleitung

Mode d’emploi

Instruzioni per l’uso

Gebruiksaanwijzing

Instrucciones de manejo

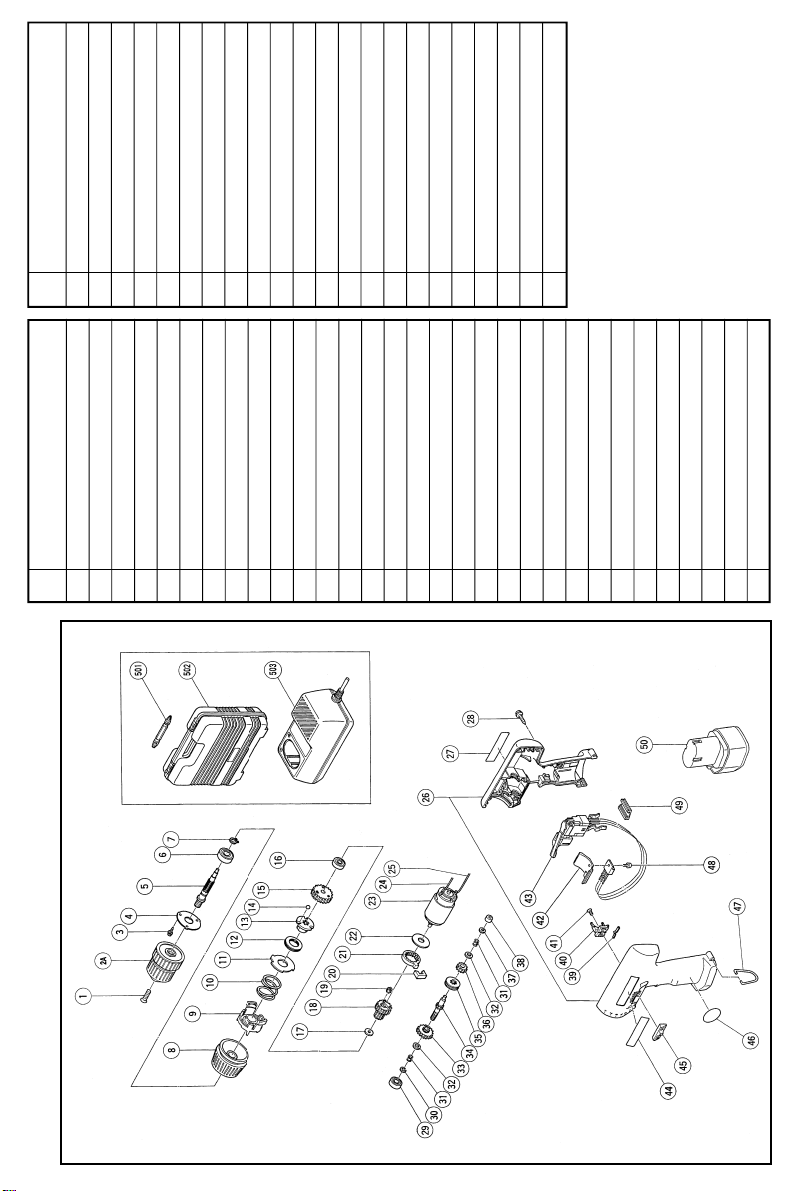

Part Name

32 Washer

No.

Item

Part Name

33 Low Speed Gear

34 Second Pinion

35 Clutch Plate

36 High Speed Gear

37 Washer

6

×

38 Metal D4

39 Shift Spring

8

×

40 Shift Arm

41 Flat Hd. Screw M4

42 Fin

7

×

43 DC-Speed Control Switch

44 HITACHI Label

45 Shift Knob

46 Mark Plate

47 Hook

48 Bind Screw M3

49 Terminal Support

50 Battery EB7

501 + Driver Bit No.2 65L

502 Case

503 Charger (Model UC7SB)

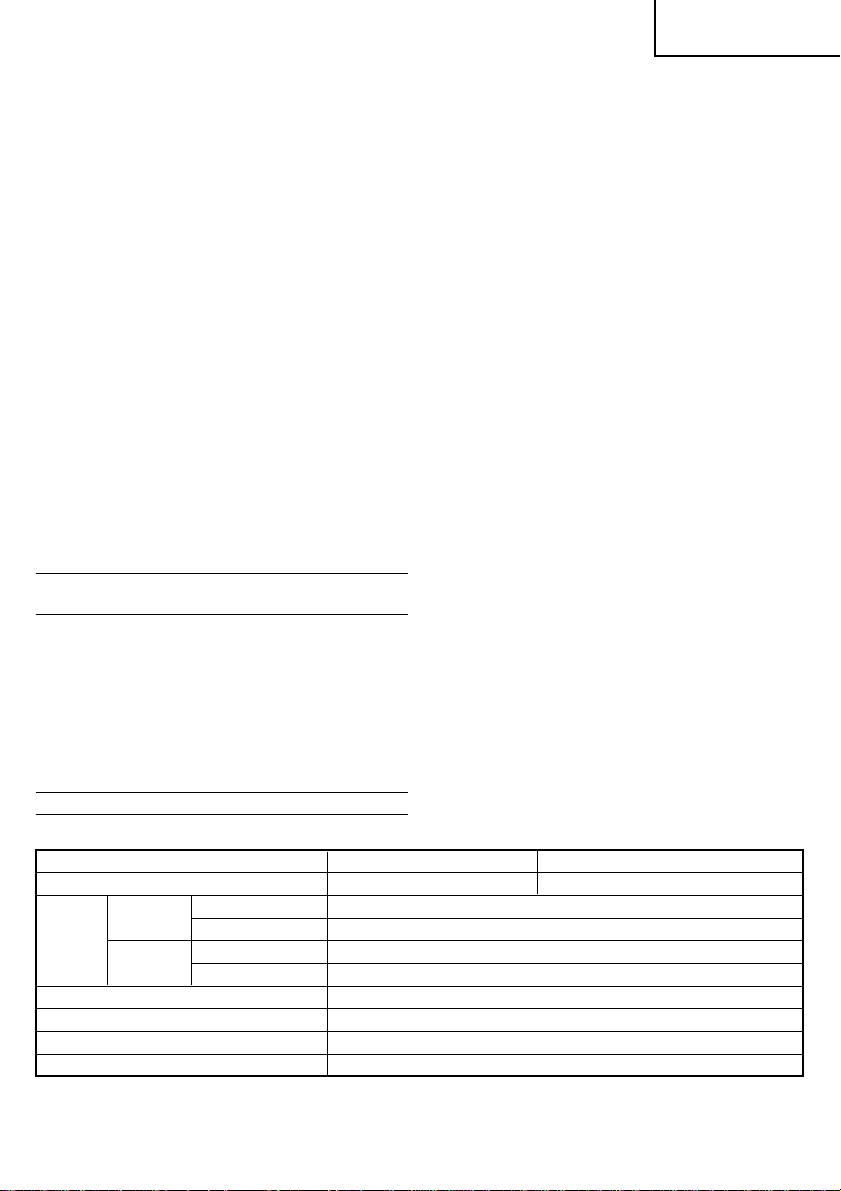

Parts are subject to possible modification

without notice due to improvements.

The drawing and the list are parts structural

drawing and parts list of model DS7DV.

For model DS7DT refer to the drawing and

the list.

Item

Tapping Screw (W/Sp. Washer) D3 × 8

1 Flat Hd. Screw (Left Hand) M5 × 17

3

2A Drill Chuck 10TLRA-N

No.

4 Plate

5 Spindle

6 Ball Bearing (6000VVCMPS2S)

7 Retaining Ring for D10 Shaft

8 Cap

9 Spring Holder

10 Spring

11 Thrust Plate

12 Thrust Needle Bearing

13 Ball Holder

14 Steel Ball D4.76

15 Final Gear

Damper

16 Ball Bearing (626VVMC2ERPS2S)

17 Washer

18 Gear Holder

19 Idle Gear

20

21 Ring Gear

22 Washer

23 Motor

24 Internal Wire (B) (Red)

Retaining Ring (E-Type) For D5 Shaft

25 Internal Wire (B) (Black)

26 Housing (A). (B) Set

27 Name Plate

28 Tapping Screw (W/Washer) D3 × 16

29 Ball Bearing (607MC3)

30

31 Spring (A)

The exploded assembly drawing should be used only for authorized service center.

DS7DV

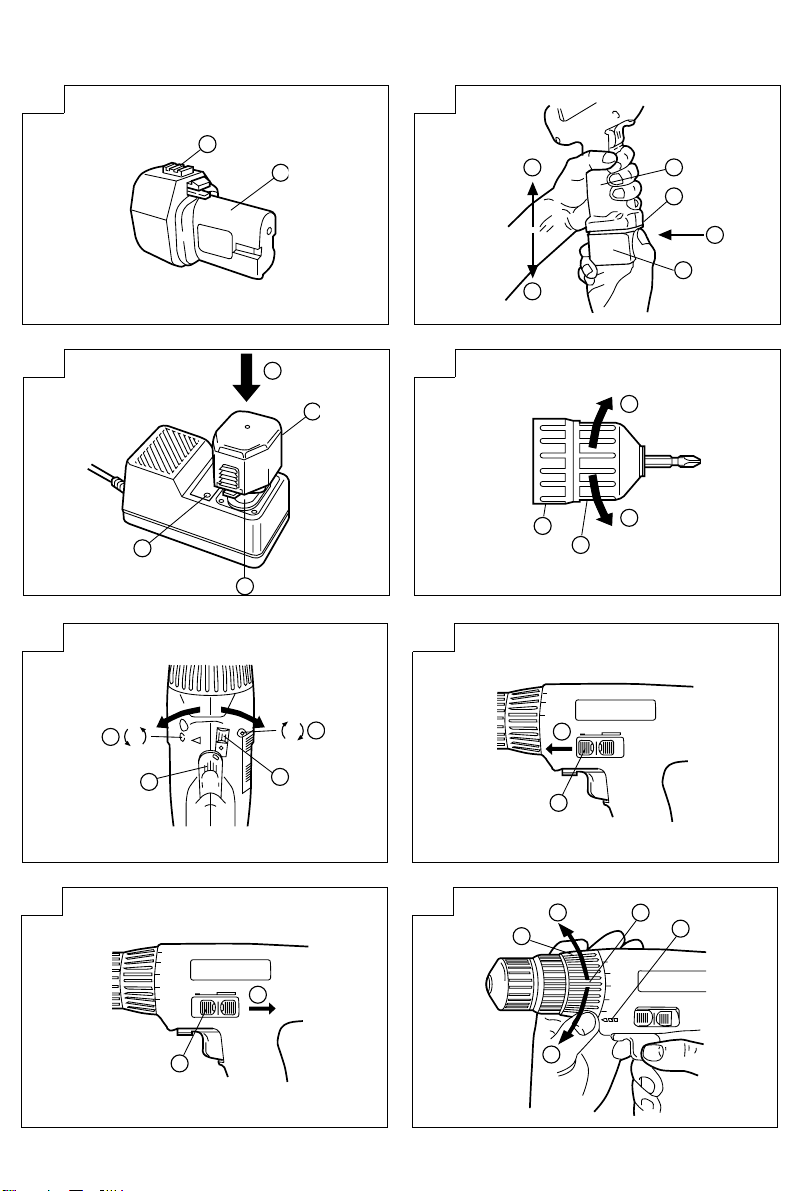

1

5

2

6

1

4

3

12

11

10

13

17

18

1

2

3

LOW

HIGH

1

2

3

4

5

24

22

21

20

23

2

2

1

3 4

7

1

8

9

5 6

15

L

15

14

R

16

7 8

1

2

3

HIGH

4

LOW

5

17

19

1

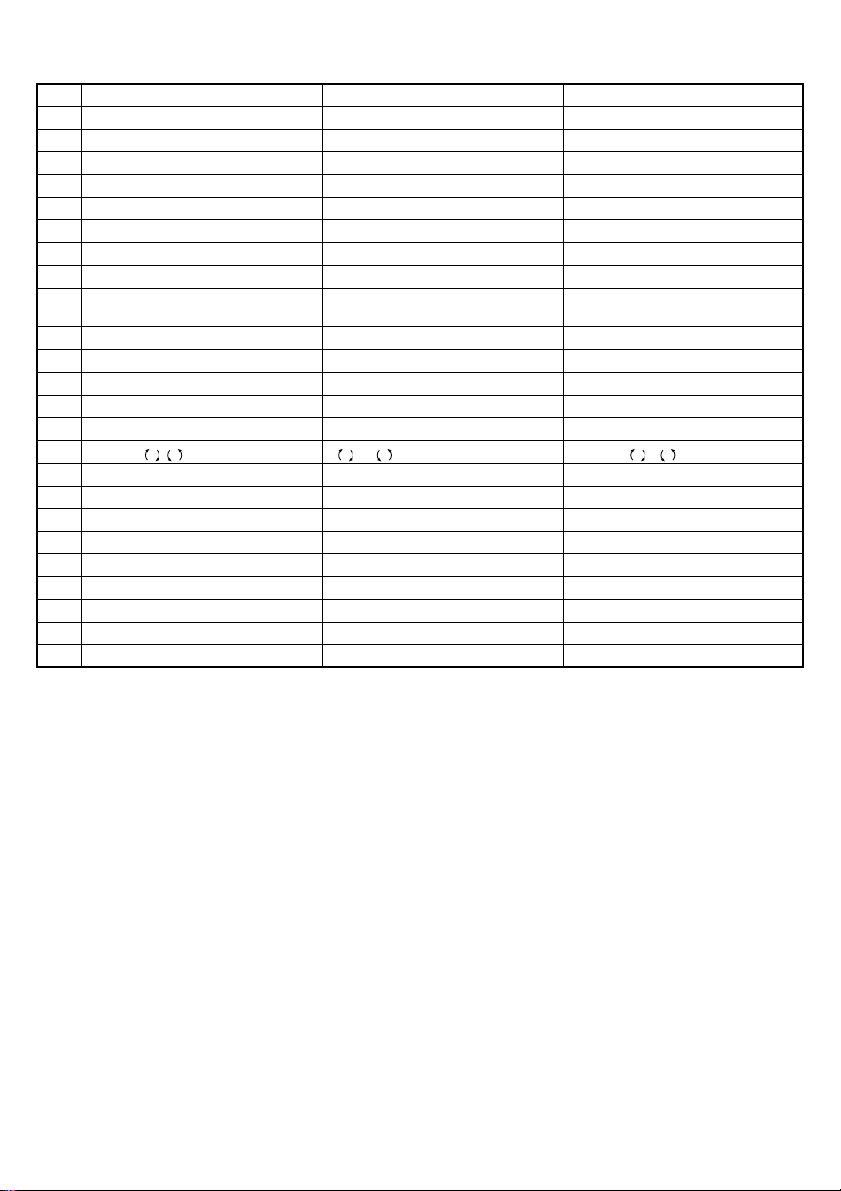

English Deutsch Français

q

Rechargeable battery Akkumulator Batterie rechargeable

w

Latch Verriegelung Taquet

e

Pull out Herausziehen Tirer vers l‘extérieur

r

Insert Einsatzen Insérer

t

Handle Handgriff Poignée

y

Push Drücken Pousser

u

Insert Einsetzen Insérer

i

Pilot lamp Kontrollampe Lampe témoin

Hole for connecting the

o

rechargeable battery batterie rechargeable

!0

Ring Ring Anneau

!1

Sleeve Manschette Manchon

!2

Tighten Anziehen Serrer

!3

Loosen Lösen Desserrer

!4

Trigger switch Trigger Déclencheur

!5

and L marks

R

!6

Selector lever Wählhel Levier-sélecteur

!7

Shift knob Schaltknopf Bouton de décalage

!8

Low speed Kleine geschwindigkeit Vitesse ralentie

!9

High speed Große geschwindigkeit Vitesse élevée

@0

Cap Kappe Capot

@1

White line Weiße linie Filet blanc

@2

Drill mark Bohrer-zeichen Indice de forage

@3

Weak Schwach Faible

@4

Strong Stark Fort

Anschlußloch für Akkumulator

und L zeichen Indices R et

R

Orifice de raccordement de la

L

Italiano Nederlands Español

Batteria ricaricabile Oplaadbare accu Batería recargable

1

2

Fermo Vergrendeling Cierre

Estrarre Uittrekken Sacar

3

4

Inserire Insteken Insertar

Impugnatura Handgreep Asidero

5

Spingere Drukken Presionar

6

Inserire Insteken Insertar

7

Spia Kontrolelampje Lámpara piloto

8

Foro di collegamento della bat- Aansluiting voor oplaadbare Agujero para conectar la batería

9

teria ricaricabili accu la recargable

0

Anello Ring Anillo

-

Collare Klembus Manguito

=

Stringere Aandraaien Apretar

~

Allentare Losdraaien Aflojar

!

Interruttore Trekkerschakelaar Conmutador de gatillo

@

Segno R,

#

Levetta Keuzeschakelaar Palanca selectora

$

Manopola di comando Toerenschakelaar Mando de cambio

%

Bassa velocità Lage toerental Velocidad alta

^

Alta velocità Hoog toerental Velocidad baja

&

Cappuccio Kap Tapa

*

Linea bianca Wit streepje Línea blanca

(

Simbolo di foratura Boor-markering Marca del taladro

)

Debol Zwak Débil

_

Forte Sterk Fuerte

L

en L merktekens Marcas R y

R

L

English

3

English

GENERAL OPERATIONAL PRECAUTIONS

1. Keep work area clean. Cluttered areas and benches

invite accidents.

2. Avoid dangerous environment. Don’t expose power

tools and charger to rain. Don’t use power tools

and charger in damp or wet locations. And keep

work area well lit. Never use power tools and

charger near flammable or explosive materials. Do

not use tool and charger in presence of flammable

liquids or gases.

3. Keep children away. All visitors should be kept

safe distance from work area.

4. Store idle tools and charger. When not in use,

tools and charger should be stored in dry, high

or locked-up place-out of reach of children. Store

tools and charger in a place where the temperature is less than 40°C.

5. Don’t force tool. It will do the job better and safer

at the rate for which it was designed.

6. Use right tool. Don’t force small tool or attachment to do the job of a heavy duty tool.

7. Wear proper apparel. Do not wear clothing or

jewelry. They can be caught in moving parts.

Rubber gloves and footwear are recommended

when working outdoor.

8. Use eye protection with most tools. Also use face

or dust mask if cutting operation is dusty.

9. Don’t abuse cord. Never carry charger by cord or

yank it to disconnect from receptacle. Keep cord

from heat, oil and sharp edges.

10. Secure work. Use clamps or a vise to hold work.

It’s safer than using your hand and it frees both

hands to operate tool.

11. Don’t overreach. Keep proper footing and balance

at all times.

12. Maintain tools with care. Keep tools sharp at all

times, and clean for best and safest performance.

Follow instructions for lubricating and changing

accessories.

13. When the charger is not in use, or when being

maintained and inspected, disconnect its power

cord from the AC outlet.

14. Remove chuck wrenches and wrenches. Form habit

of checking to see that wrenches are removed

from tool before turning it on.

15. Avoid accidental starting. Don’t carry tool with

finger on switch.

16. To avoid danger, always use only the specified

charger.

17. Use only original HITACHI replacement parts.

18. Do not use power tools for applications other than

those specified in the Handling Instructions.

19. To avoid personal injury, use only the accessories

or attachment recommended in these handling

instructions or in the HITACHI catalog.

20. Let only the authorized service facility do the

repairing. The Manufacturer will not be responsible for any damages or injuries caused by repair

by the unauthorized persons or by mishandling

of the tool.

21. To ensure the designed operational integrity of

power tools and charger, do not remove installed

covers or screws.

22. Always use the charger at the voltage specified

on the nameplate.

23. Do not touch movable parts or accessories unless

the power source has been disconnected.

24. Always charge the battery before use.

25. Never use a battery other than that specified. Do

not connect a usual dry cell, a rechargeable battery

other than that specified or a car battery to the

power tool.

26. Do not use any transformer that has a booster.

27. Do not charge the battery from an engine electric

generator or DC power supply.

28. Always charge indoors. Because the charger and

battery heat slightly during charging, charge the

battery in a place not exposed to direct sunlight;

where the humidity is low and the ventilation

good.

29. Before starting to work in a high place, pay attention to the activities below to make sure there

are no people below.

30. Use the exploded assembly drawing on this

handling instructions only for authorized servicing.

PRECAUTIONS FOR CORDLESS DRIVER DRILL

1. Always charge the battery at a temperature of 10 –

40°C. A temperature of less than 10°C will result

in over charging which is dangerous. The battery

cannot be charged at a temperature higher than

40°C. The most suitable temperature for charging

is that of 20 – 25°C.

2. Do not use the charger continuously.

When one charging is completed, leave the charger

for about 15 minutes before the next charging of

battery.

3. Do not charge the battery for more than 1 hour.

The battery will be fully charged in about 1 hour

and charging should be stopped when 1 hour has

elapsed from commencement. Disconnect the

charger power cord from the AC outlet.

4. Do not allow foreign matter to enter the hole for

connecting the rechargeable battery.

5. Never disassemble the rechargeable battery and

charger.

6. Never short-circuit the rechargeable battery. Shortcircuiting the battery will cause a great electric

current and overheat. It results in burn or damage

to the battery.

7. Do not dispose of the battery in fire.

If the battery is burnt, it may explode.

8. When drilling in wall, floor or ceiling, check for

buried electric power cord, etc.

9. Bring the battery to the shop from which it was

purchased as soon as the post-charging battery

life becomes too short for practical use. Do not

dispose of the exhausted battery.

10. Using an exhausted battery will damage the

charger.

11. Do not insert object into the air ventilation slots

of the charger.

Inserting metal objects or inflammables into the

charger air ventilation slots will result in electrical

shock hazard or damaged charger.

12. When mounting a bit into the keyless chuck, tighten

the sleeve adequately. If the sleeve is not tight,

the bit may slip or fall out, causing injury.

4

SPECIFICATIONS

POWER TOOL

Model DS7DT DS7DV

No-load speed (Low/High) 300/850/min. 0 – 300/0 – 850/min.

Drilling

Capacity

Driving

Rechargeable battery (EB7) Ni-Cd battery, 7.2 V

Weight 1.35 kg

Sound presser level Not exceed 70 dB (A)

Vibration level Not exceed 2.5 m/S

CHARGER

Model UC7SB

Charging time Approx. 1 hour (at 20°C)

Charging voltage 7.2 V

Weight 1.0 kg

Wood 15 mm

Metal Steel: 10 mm, Aluminum: 10 mm

Machine screw 6 mm

Wood screw 5.1 mm (diameter) x 35 mm (length)

2

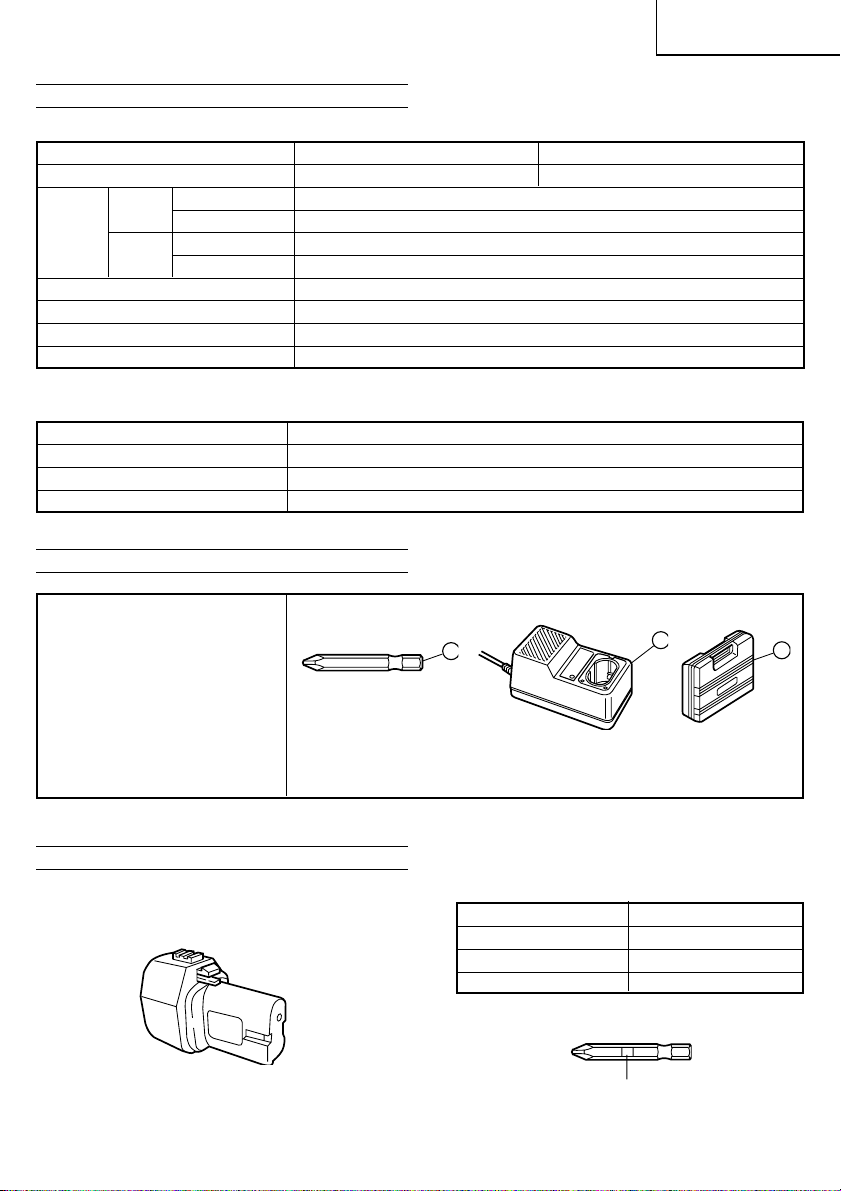

STANDARD ACCESSORIES

English

DS7DT (1HCK)

DS7DV (1HCK)

1 Plus driver bit (No. 2) ...................................................................... 1

2 Charger (UC7SB) ............................................................................. 1

3 Plastic case ....................................................................................... 1

Standard accessories are subject to change without notice.

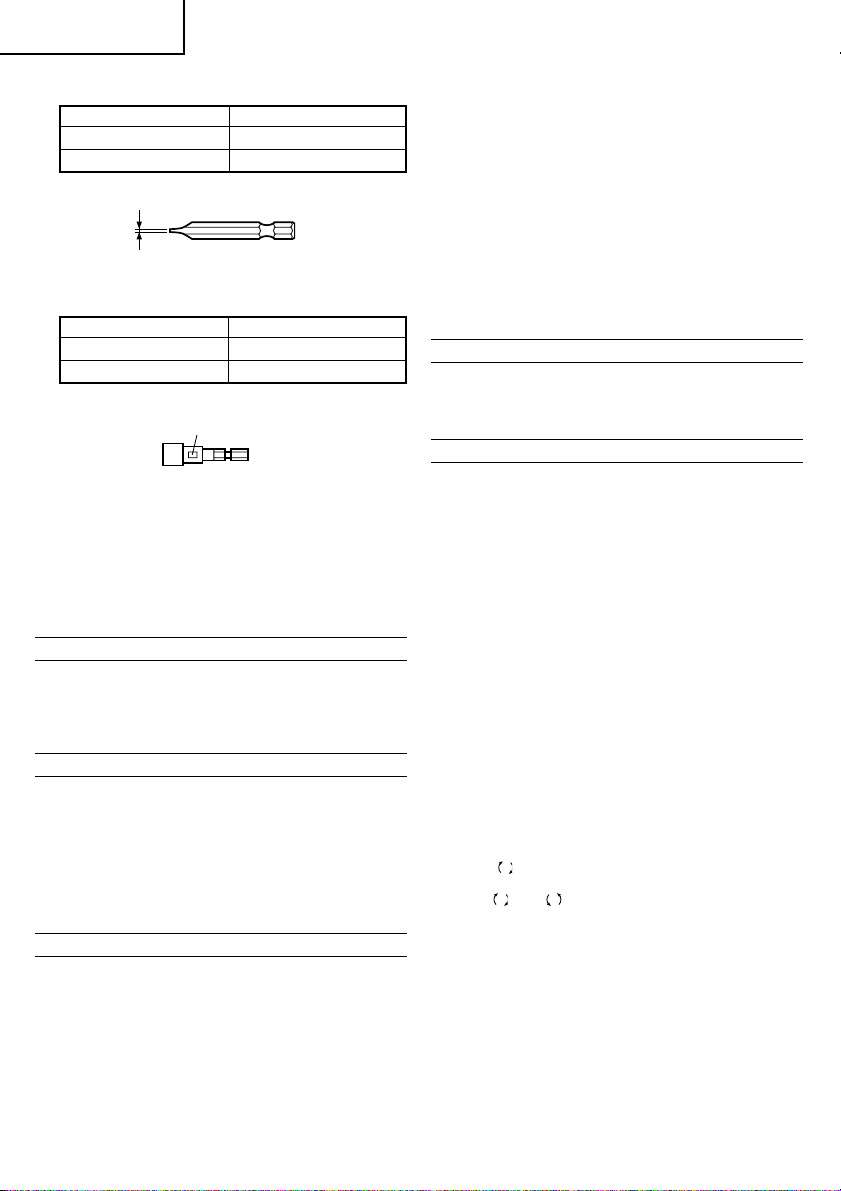

OPTIONAL ACCESSORIES ......(sold separately)

1. Battery (EB7)

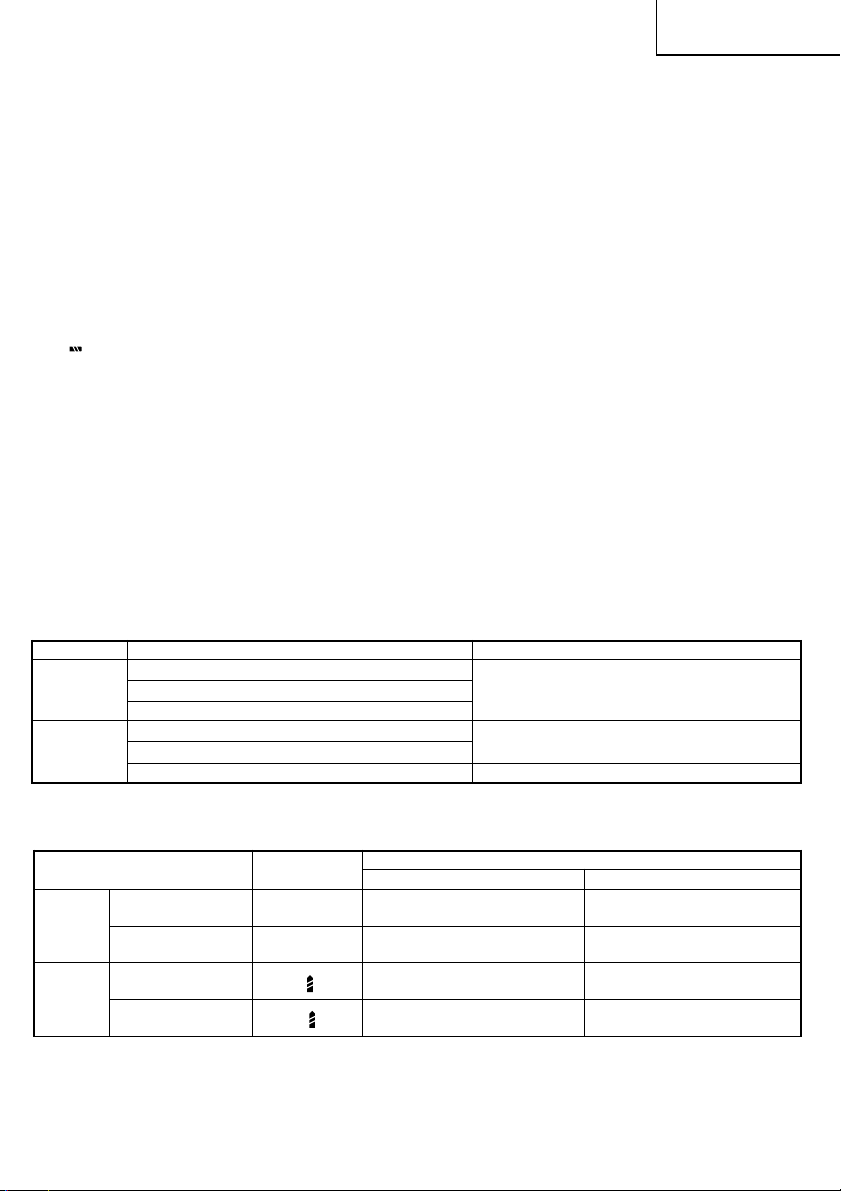

2. Plus driver bit

1

Bit No. Screw size

No. 1 2 – 2.5 mm

No. 2 3 – 5 mm

No. 3 6 – 8 mm

2

Bit No.

3

5

English

3. Minus driver bit

a Screw size

0.8 mm 4 mm

1 mm 5 – 6 mm

a

4. Hexagon socket (for nuts and bolts)

Socket No. Screw size

74 mm

85 mm

Socket No.

5. Drill bit for steel

Diameter, 2 mm, 5 mm, 6 mm.

6. Drill bit for wood

Diameter, 10 mm, 13 mm.

Optional accessories are subject to change without notice.

APPLICATIONS

䡬 Driving and removing of machine screws, wood

screws, tapping screws, etc.

䡬 Drilling of various metals.

䡬 Drilling of various woods.

BATTERY REMOVAL/INSTALLATION

1. Battery removal

Hold the handle tightly and push the battery latch

to remove the battery (see Figs. 1 and 2).

CAUTION

Never short-circuit the battery.

2. Battery installation

Insert the battery while observing its polarities (see

Fig. 2).

CHARGING

Before using the driver drill, charge the battery as follows.

1. Insert the battery in the charger.

Position the battery so that the nameplate faces

toward the nameplate of the charger and press in

the battery until it comes into contact with the

bottom plate. (See Figs. 1 and 3.)

2. Connect the charger power cord to the AC outlet.

Connecting the power cord will turn on the charger

(the pilot lamp lights).

CAUTION

If the pilot lamp does not light, pull out the power

cord from the AC outlet and check the battery

mounting condition.

About 1 hour is required to fully charge the battery

at a temperature of about 20°C. The pilot lamp goes

off to indicate that the batterry is fully charged.

CAUTION

If the battery is heated due to direct sunlight, etc.,

just after operation, the charger pilot lamp may

not light. At that time cool the battery first, then

start charging.

3. Disconnect the charger power cord from the AC

outlet.

4. Hold the charger tight and pull out the battery.

PRIOR TO OPERATION

1. Setting up and checking the work environment

Check if the work environment is suitable by following the precautions.

HOW TO USE

1. Mounting and dismounting of the bit.

(1) Mounting the bit

After inserting a driver bit, etc. into the keyless drill

chuck, firmly grasp the ring and tighten the sleeve

by turning it toward the right (in the clockwise

direction as viewed from the front). (See Fig. 4)

䡬 If the sleeve becomes loose during operation, tighten

it further. The tightening force becomes stronger

when the sleeve is tightened.

(2) Dismounting the bit

Firmly grasp the ring and loosen the sleeve by

turning it toward the left (in the counter-clockwise

direction as viewed from the front). (See Fig. 4)

CAUTION:

When it is no longer possible to loosen the sleeve,

use a vise or similar instrument to secure the bit.

Set the clutch mode between 1 and 3 and then turn

the sleeve to the loose side (left side ) while operating

the clutch. It should be easy now to loosen the

sleeve.

2. Confirm that the battery is mounted correctly.

3. Check the rotational direction

When the selector lever is set to the drill rotates

clockwise when viewed from the drill rear. When

, the drill rotates counterclockwise (see Fig.

set to

R

5).

and L marks are provided on the body.)

(The

䡬 When the trigger switch is depressed, the tool rotates.

䡬 The rotational speed of the drill can be controlled

4. Change rotation speed

R

When the trigger is released, the tool stops.

by varying the amount that the trigger switch is

pulled.

Speed is low when the trigger switch is pulled

slightly and increases as the switch is pulled more.

(DS7DV, only.)

Operate the shift knob to change the rotational

speed. Move the shift knob in the direction of the

arrow (see Figs. 6 and 7).

6

English

When the shift knob is set to “LOW”, the drill

rotates at a low speed. When set to “HIGH”, the

drill rotates at a high speed.

CAUTION

When changing the rotational speed with the shift

knob, confirm that the switch is off.

Changing the speed while the motor is rotating will

damage the gears.

5. Confirm the cap position (see Fig. 8)

The tightening power of this unit can be adjusted

according to the cap position, at which the cap is

set.

(1) For using the unit as a screw driver, set the cap

white line to one of the numerals “1” to “5” on

the outer frame.

(2) For use as a drill, set the white line at the drill mark

” (see Fig. 8).

“

CAUTION

䡬 Set the cap white line at one of either the numerals

or drill marks.

6. Tightening power adjustment

(1) Tightening power

Tightening power should correspond in its intensity

to the screw diameter. When too strong power is

used, the screw head may be broken or be injured.

Be sure to adjust the cap position according to the

screw diameter.

(2) Tightening power indication

Tightening power should be changed according to

the screw type and the materials to be tightened.

Guidance of the tightening power is indicated on

“3”, “4” and “5”. The minimum power is from “1”

position and bigger the value the stronger is the

power (see Fig. 8).

(3) How to adjust the tightening power

Rotate the cap and set to one of the numerals.

Adjust the power by cap rotation in such a way that

when the power is too strong, set to the next

smaller numeral and set to the next larger numeral

when too weak.

CAUTIONS

䡬 The motor rotation may be locked to cease while

the unit is used as drill. While operating the driver

drill, take care not to lock the motor.

䡬 When setting the shift knob to “HIGH” (high speed)

and the position of the cap is “4” or “5”, it may

happen that the clutch does not engaged and that

the motor is locked. In such a case, please set the

shift knob to “LOW” (low speed).

䡬 If the motor is locked, immediately turn the power

off. If the motor is locked for a while, the motor

or battery may be burnt.

䡬 Too long hammering may cause the screw broken

due to excessive tightening.

䡬 A buzzing noise is produced when the motor is

about to rotate; This is only a noise, not a machine

failure. (DS7DV only)

7. The scope and suggestions for uses

The usable scope for various types of work based

on the mechanical structure of this unit is shown

below.

the outer frame of this unit with numerals “1”, “2”,

Table 1

Work Usable range Suggestions

Drilling

Driving

Wood: 15 mm

Use for drilling purpose.Steel: 10 mm

Aluminum: 10 mm

Machine screw: 6 mm

Nut: 5 mm

Wood screw: 5.1 mm (diameter) x 35 mm (length) Use after drilling a preparatory hole.

Use the bit and socket matching the screw

diameter.

8. How to select tightening power and rotational speed

Table 2

Use Cap Position

Machine screw 1 – 5

Driving

Wood screw 1 – 5

Wood For 13 mm or larger diameters.

Drilling

Metal ––––––

Rotating speed selection (Position of the shift knob)

LOW (Low speed) HIGH (High speed)

For 4 mm or smaller diameter

screws.

For 3.5 mm or smaller nominal

diameter screws.

For 5 mm or larger diameter

screws.

For 3.8 mm or larger nominal

diameter screws.

For 13 mm or smaller

diameters.

For drilling with an iron

working drill.

CAUTION

䡬 The selection examples shown in Table 2 should be considered as general standard. As different types of

tightening screws and different materials to be tightened are used in actual works proper adjustments are

naturally necessary.

7

English

Deutsch

MAINTENANCE AND INSPECTION

1. Inspecting the tool

Since use of as dull tool will degrade efficiency and

cause possible motor malfunction, sharpen or replace the tool as soon as abrasion is noted.

2. Inspecting the mounting screws

Regularly inspect all mounting screws and ensure

that they are properly tightened. Should any of the

screws be loose, retighten them immediately. Failure to do so could result in serious hazard.

3. Cleaning on the outside

When the driver drill is stained, wipe with a soft

dry cloth or a cloth moistened with soapy water.

Do not use chloric solvents, gasoline or paint thinner, for they melt plastics.

4. Storage

Store the driver drill in a place in which the temperature is less than 40°C and out of reach of

children.

NOTE

Due to HITACHI’s continuing program of reserch and

development, the specifications herein are subject to

change without prior notice.

This appliance is produced to conform to the requirements of B. S. 800: 1977*.

* This requirement is applicable to appliances for

UNITED KINGDOM.

IMPORTANT

Correct connection of the plug

The wires of the mains lead are coloured in accordance

with the following code:

Blue: –Neutral

Brown: –Live

As the colours of the wires in the mains lead of this

tool may not correspond with the coloured markings

identifying the terminals in your plug proceed as follows:

The wire coloured blue must be connected to the

terminal marked with the letter N or coloured black.

The wire coloured brown must be connected to the

terminal marked with the letter L or coloured red.

Neither core must be connected to the earth terminal.

NOTE

This requirement is provided according to BRITISH

STANDARD 2769: 1984.

Therefore, the letter code and colour code may not be

applicable to other markets except United Kingdom.

The noise emitted by this power tool is measured in

accordance with IEC 59 (CO) 11, IEC 704, DIN 45 635

Part 21, NFS 31-031 (84/537/EEC for concrete breakers).

The sound pressure level at the workplace can exceed

85 dB (A); in this case noise protection for the operator

is required.

ALLGEMEINE VORSICHTSMASSNAHMEN

1. Den Arbeitsplatz stets sauber halten. Unaufgeräumte Arbeitsplätze und Werkbänke erhöhen die

Unfallgefahr.

2. Gefährliche Umgebungen vermeiden. Die Maschi-

ne und das Ladegerät keiner Feuchtigkeit aussetzen oder an nassen Stellen benutzen.

Achten Sie auf einen hellen, wenn erforderlich gut

beleuchteten Arbeitsplatz. Maschine und Ladegerät

niemals in der Nähe von brennbaren oder explosiven Materialien, Flüssigkeiten oder Gasen verwenden.

3. Außer Reichweite von Kindern halten. Nicht an der

Arbeit beteiligte Personen sollten einen Sicherheitsabstand einhalten.

4. Unbenutztes Werkzeug und Ladegerät an einen

trockenen und verschlossenen Ort wegräumen;

außerhalb der Reichweite von Kindern aufbewahren.

Die Temperatur sollte weniger als 40°C betragen.

5. Das Werkzeug nicht überlasten. Es arbeitet sich

besser und sicherer bei angemessenen Geschwindigkeiten und Belastungen.

6. Das richtige Werkzeug zur Arbeit verwenden. Erwarten Sie nicht, daß ein zu kleines Werkzeug

oder Zubehör die Arbeit einer Hochleistungsmaschine verrichtet.

7. Achten Sie auf die richtige Kleidung. Lose oder

zu weite Kleidung bzw. und/oder Schmuck (z.B.

Ketten, Ringe, usw.) könnten sich in rotierenden

oder bewegenden Teilen verfangen. Schutzhandschuhe und Arbeitsschutzschuhe sind bei

denArbeiten zu tragen.

8. Vergessen Sie nicht bei Arbeiten mit Werkzeugen

eine Sicherheitsbrille zu tragen, ebenfalls, wenn

erforderlich eine Gesichts-oder Staubmaske.

9. Schonen Sie das Anschlußkabel. Tragen Sie nie-

mals das Ladegerät am Kabel und ziehen Sie nicht

daran, um den Stecker von der Steckdose zu

trennen.

Das Kabel gegen übermäßige Hitze, Öl und scharfe Kanten schützen.

10. Das zu bearbeitende Werkstück gut sichern. Zwin-

gen oder Schraubstock für die Befestigung des

Werkstücks benutzen. Es erhöht die Sicherheit und

schafft freie Hände zur Bedienung des Werkzeugs

.

11. Verschaffen Sie sich einen festen Stand, er garantiert Sicherheit und optimales Gleichgewicht bei

der Arbeit.

12. Das Werkzeug in gutem Zustand behalten. Stets

sauber halten, pflegen und warten, damit es immer

die beste Leistung bringt. Beachten Sie die Anweisungen für Schmieren oder eventuelle Auswechselungen.

13. Wird das Ladegerät nicht benutzt oder einer Prü-

fung unterzogen, entfernen Sie den Stecker aus

Ihrem Wechselstro-manschluß.

14. Spannschlüssel und/oder Bohrfutterschlüssel vor

dem Gebrauch des Werkzeugs aus der Maschine

entfernen .

15. Zufälliges Einschalten vermeiden. Das Werkzeug

nicht mit dem Finger am Schalter tragen.

16. Um Gefahren zu vermeiden, verwenden Sie nur

das vorgeschriebene Ladegerät.

17. Nur Original-HITACHI-Ersatzteile verwenden.

18. Das Werkzeug und Ladegerät nicht anders als in

der Gebrauchsanweisung vorgeschrieben verwenden.

19. Die Benutzung von Zubehör und Sonderzubehör,

die nicht im HITACHI-Katalog oder in der

Bedienungsanleitung aufgeführt sind, erhöhen das

Risiko von Verletzungen.

8

Deutsch

20. Reparaturen sollten nur in autorisierten HITACHIService-Werkstätten durchgeführt werden.

Der Hersteller haftet nicht für Schäden und Unfälle, die auf unautorisierte Fachkräfte oder auf

den Mißbrauch des Werkzeugs zurückgeführt

werden können.

21. Um den ursprünglichen Zustand des Werkzeugs

und Ladegerätes zu erhalten, entfernen Sie keine

Hinweisschilder, Abdeckungen oder Schrauben.

22. Nehmen Sie das Ladegerät immer nur mit der auf

dem Typenschild vorgeschriebenen Spannung in

Gebrauch.

23. Bewegliche Teile und Zubehöre nicht berühren,

wenn das Werkzeug nicht vom Netz abgetrennt

ist.

24. Immer vor der Benutzung die Batterie aufladen.

25. Nur die vorgeschriebene Batterie verwenden.

Keine gewöhnlichen Trockenbatterien oder AutoBatterien, für das Elektro-Werkzeug verwenden.

26. Keinen Transformator mit Puffersatz verwenden.

27. Die Batterie nicht an einem elektrischen Generator

oder einer Gleichstromversorgung aufladen.

28. Die Batterie immer drinnen aufladen. Da sich beim

Laden Ladegerät und Batterie erwärmen, an einem Ort aufladen, der nicht direkter Sonnenbestrahlung ausgesetzt und trocken ist.

29. Wenn an hochliegenden Stellen gearbeitet

wird,(z.B. Gerüst, Treppe) vergewissern Sie sich

vor Arbeitsbeginn, daß sich under Ihnen keiner im

Arbeits-bzw. Gefahrenkreis aufhält.

30. Die detaillierte Bestandsteilzeichnung, die der

Bedienungsanleitung beigefügt ist, ist nur für die

autorisierte Service-Werkstätte bestimmt.

VORSICHTSMASSNAHMEN FÜR DEN

AKKU-BOHRSCHRAUBER

1. Die Batterie immer bei einer Temperatur von 10 –

40°C laden. Laden bei einer Temperatur die nied-

riger als 10°C ist wird gefährliche Überladung

verursachen. Die Batterie kann nicht bei einer

Temperatur über 40°C geladen werden. Die beste

Temperatur zum Laden wäre von 20 – 25°C.

2. Das Ladegerät nicht fortlaufend laden.

Nach Beendung einer Ladung, lassen Sie das Ladegerät ungefähr 15 Minuten ruhen bevor die nächste Batterieladung unternommen wird.

3. Die Batterie nicht länger als eine Stunde laden.

Sie wird ungefähr in einer Stunde vollgeladen sein

und deshalb sollte die Ladung nach einer Stunde

vom Anfang der Ladung ab angehalten werden.

Das Ladekabel vom Wechselstromausgang trennen.

4. Keine Fremdkörper durch das Anschlußloch der

Batterie eindringen lassen.

5. Niemals die Batterie und das Ladegerät auseinandernehmen.

6. Niemals die Batterie kurzschließen.

Kurzschluß der Batterie verursacht eine zu große

Stromzufuhr und Überhitzung, wodurch Durchbrennen oder Schaden beider Batterie entsteht.

7. Die Batterie nicht ins Feuer werfen. Sie könnte

dabei explodieren.

8. Beim Bohren von Wand, Boden oder Decke, nachprüfen ob keine versenkten Kabel, usw. vorhanden

sind.

9. Bringen Sie die Batterie zum Geschäft, wo Sie ihn

gekauft haben sobald die Lebensdauer der Batterie abrinnt. Die erschöpfte Batterie nicht wegwerfen.

10. Benutzung verbrauchter Batterie beschädigt den

Auflader.

11. Darauf achten, daß keine Gegenstände durch

Belüftungsschlitze des Aufladers in das Gerät eindringen. Wenn Metallobjekte oder entzündliche

Gegenstände durch die Belüftungsschlitze des

Aufladers eindringen, kann dies zu elektrischen

Schlägen führen oder den Auflader beschadigen.

12. Beim Einspannen von Bohrspitzen oder Stangen

bohrern in das schlüssellose Spannfutter, die Bohr

hülse ausreichend festdrehen. Bei nicht ausreichend festgedrehter Bohrhülse kann die Bohrspitze

verrutschen oder herausfallen und Verletzungen

verursachen.

TECHNISCHE DATEN

ELEKTRO-WERKZEUG

Modell DS7DT DS7DV

Leerlaufdrehzahl (Niedrig/Schnell) 300/850/min. 0 – 300/0 – 850/min.

Bohren

Kapazität

Wiederaufladbare Batterie(EB7) Ni-Cd Batterie, 7,2 V

Weight 1,35 kg

Schalldruckpegel Überschreitet nicht 70 dB (A)

Vibrationspegel Überschreitet nicht 2,5 m/S

Einschrau- Maschineschraube 6 mm

ben

Holz (weich) 15 mm

Metall Stahl: 10 mm, Aluminum: 10 mm

Holzschraube 5,1 mm (Durchschnitt) x 35 mm (Långe)

2

9

Deutsch

LADEGERÄT

Modell UC7SB

Ladedauer Ungefähr 1 Stunde (bei 20°C)

Ladespannung 7,2 V

Gewicht 1,0 kg

STANDARDZUBEHÖR

1

DS7DT (1HCK)

DS7DV (1HCK)

1 Plusschrauber (Nr. 2) ...................................................................... 1

2 Ladegerät (UC7SB).......................................................................... 1

3 Plastikgehäuse ................................................................................. 1

Das Standardzubehör kann ohne vorherige Bekanntmachung jederzeit geändert werden.

SONDERZUBEHÖR (separat zu beziehen)

1. Batterie (EB7)

2. Plusschrauber

Schrauber Nr. Schraubengröße

Nr. 1 2 – 2,5 mm

Nr. 2 3 – 5 mm

Nr. 3 6 – 8 mm

Schrauber Nr.

4. Sechskantsteckhülse (für Mutter und Bolzen)

Hülsen Nr. Schraubengröße

74 mm

85 mm

Hülsen Nr.

5. Bohrerspitze für stahl

Durchschnitt, 2 mm, 5 mm, 6 mm.

6. Bohrerspitze für Holz

Durchschnitt, 10 mm, 13 mm.

Das Sonderzubehör kann ohne vorherige Bekanntmachung jederzeit geändert werden.

VERWENDUNG

䡬 Einschrauben und Entfernung von Maschinen-

schrauben, Holzschrauben, Schneidschrauben, etc.

䡬 Bohren von verschiedenen Metallen.

䡬 Bohren von verschiedenen Hölzern.

2

3

3. Minusschrauber

a Schraubengröße

0,8 mm 4 mm

1 mm 5 – 6 mm

a

10

ERAUSNEHMEN/EINSETZEN DER BATTERIE

1. Herausnehmen der Batterie

Den Handgriff fest halten und die AkkumulatorVerriegelung drücken, um den Akkumulator heraus

zunehmen. (Siehe Abb. 1 und 2).

ACHTUNG

Die Kontakte des Akkumulators niemals kurzschließen.

2. Einsetzen des Akkumulators Batterie

Den Akkumulator unter Beachtung der richtigen

Richtung in das Gerät einsetzen. (Siehe Abb. 2).

Deutsch

LADEN

Vor Gebrauch des Akku-Bohrschraubers, den

Akkumulator wie folgt laden.

1. Die Batterie in das Ladegerät einlegen. Die Batterie

so ausrichten, daß ihr Typenschild gegen das Typenschild des Ladegeräts weist und die Batterie

hineindrücken, bis sie die Grundplatte berührt (siehe

Abb. 1 und 3).

2. Das Ladegerätkabel an den Wechselstromausgang

schließen.

Dadurch wird das Ladegerät eingeschaltet (die

Kontrollampe leuchtet auf).

ACHTUNG

Wenn die Kontrollampe nicht aufleuchtet, das

Netzkbel von der Steckdose abtrennen und die

Einsetzrichtung der Batterie prüfen.

Ungefähr eine Stunde ist erforderlich um die Batterie bei einer Temperatur von 20°C vollzuladen. Die

Kontrollampe erlischt, wenn die Batterie vollgeladen

ist.

ACHTUNG

Falls die Batterie wegen direkten Sonnenstrahlen,

usw., gleich nach Betrieb überhitzt wird, mag es

vorkommen, daß die Ladekontrollampe nicht auf-

leuchtet. In diesem Fall, die Batterie zuerst

abkühlen lassen, und danach laden.

3. Das Ladegerät vom Wechselstromausgang trennen.

4. Das Ladegerät festhalten und den Batterie heraus-

ziehen.

VOR INBETRIEBNAHME

1. Aufstellung und Überprüfung der Arbeitsumgebung

Prüfen Sie, ob die Arbeitsumgebung folgenden

Vorsichtsbedingungen entspricht.

ANWENDUNG

1. Anbringen und Abnehmen der Werkzeugspitze

(1) Anbringen der Werkzeugspitze

Nach dem Einsetzen einer Schraubenzieherspitze o.

dergl. oder eines entsprechenden Teils in das Schnellspann-Bohrfutter den Ring fest greifen und die

Manschette durch Drehung nahc rechts (im

Unrzeigersinn von vorne gesehen) festdrehen. (Siehe Abb. 4)

䡬 Sollte sich die Manschette während des Betriebs

lockern, ist diese wieder festzudrehen. Eine fest

zugedrehte gewährleistet erhöhte Spannkraft.

(2) Abnehmen der Werkzeugspitze

Den Ring fest greifen und die Manschette durch

Drehung nach links (gegen den Uhrzeigersinn von

vorne gesehen) lösen. (Siehe Abb. 4)

ACHTUNG

Wenn die Manschette nicht losgeschraubt werden

kann, das eingesteckte Werkzeug in einem Schraubstock o.ä. befestigen, die Kupplung auf 1 – 3 stellen

und die Manschette gegen den Uhrzeigersinn drehen, während die.

2. Sich vergewissern, daß die Batterie richtig angebracht

ist.

3. Die Drehrichtung nachprüfen.

Wenn der Wählhebel auf

sich der Bohrer nach rechts.

Wenn auf R eingestellt, dreht sich der Bohrer nach

links (Siehe Abb. 5) (Die

auf dem Körper markiert).

䡬 Wenn der Schaltertrigger gedrückt ist, dreht sich

das Werkzeug. Wenn ausgelöst, wird das Werkzeug

abgestellt.

䡬 Die Drehgeschwindigkeit des Bohrers kann durch

Verändern des Betrags des Ziehens am Auslöser

geregelt werden. Die Geschwindigkeit ist niedrig,

wenn der Auslöser nur gering gezogen wird und

nimmt zu, wenn er stärker gezogen. (nur DS7DV)

4. Wechsel der Aufrichtgeschwindigkeit

Die Aufrichtgeschwindigkeit mit dem Schaltknopf

wechseln.

Den Schaltknopf in Richtung Pfeil bewegen (Siehe

Abb. 6 und 7).

Wenn der Schaltknopdreht auf “LOW” eingestellt

ist, dreht sich der Bohrer langsamladreht. Wenn auf

“HIGH” eingestellt, dreht sich der Bohrer schnellaufend.

ACHTUNG

Beim Wechseln der Aufrichtgeschwindigkeit mit dem

Schaltknopf, sich vergewissern, daß der Schalter

auf-ZU-eingestellt und gesperrt ist.

Ändern der Geschwindigkeit bei laufendem Motor

beschädigt das Getriebe.

5. Nachprüfen der Kappeneinstellung (Siehe Abb. 8)

Die Anziehkraft dieses Werkzeuges kann durch Einstellung der Kappe reguliert werden.

(1) Wenn das Werkzeug als Schrauber benützt wird, das

Weiße link der kappe auf eine der Ziffern von ,,1“

bis ,,5“ der Außenfassung einstellen.

(2) Wenn das Werkzeug als Bohrer gebraucht wird, das

Weiße link, auf die Bohrerzeichen ,, “ (Siehe Abb. 8).

ACHTUNG

䡬 Die Weiße link der Kappe entweder auf eine der

Ziffern oder Bohrmarkierungen einstellen.

6. Einstellung der Anziehkraft

(1) Anziehkraft

Die Anziehkraft sollte dem Schraubendurchschnitt

entsprechen.

Wenn zuviel Kraft angewandt wird, kann die chraube

brechen oder am Kopf beschädigt werden. Sich

vergewissern, daß die Pfeilmarkierung der Kappe

dem Schraubendurchschnitt entsprechend eingestellt

wurde.

(2) Angaben für die Anziehkraft

Die Anziehkraft sollte je nach Schraubentyp und

gebrauchtes Schraubmaterial gewechselt werden.

Angaben für Anziehkraft sind an der Außenfassung

des Werkzeuges mit den Ziffern ,,1“, ,,2“, ,,3“, ,,4“

und ,,5“ angegeben. Die kleinste Anziehkraft liegt

bei Lage ,,1“ und erhört sich entsprechend mit den

angegebenen Werten. (Siehe Abb. 8).

(3) Wie die Anziehkraft eingestellt wird

Die Kappe drehen und eine der Ziffern am PfeilZeichen einstellen.

Die Kraft durch Kappendrehung so einstellen, daß

wenn die Kraft zu stark ist, die nächste kleine Ziffer

an das Pfeil-Zeichen eingestellt wird, und falls zu

schwach an die nächste große Ziffer einstellen.

L

eingestellt ist, dreht

R

und L Zeichen sind

11

Deutsch

ACHTUNGS

䡬 Die Motordrehung kann anhalten, während das

Werkzeug als Bohrer verwendet wird.

Bei Gebrauch des Bohrschraubers, aufpassen daß

der Motor nicht gesperrt ist.

䡬 Beim Einstellen des Schaltknopfes auf “HIGH” (hohe

Geschwindigkeit), und wenn die Position der Kappe

“4” oder “5” ist, kann es vorkommen, daß die

kupplung nicht einrastet oder daß der Motor blokkiert.

In diesem Fall den Schaltknopf auf “LOW” (niedrige

Geschwindigkeit) stellen.

䡬 Falls der Motor gesperrt ist, sofort abstellen.

Falls der Motor auf längerer Zeit in gesperrtem.

䡬 Eine zu lange Schlagbewegung könnte wegen zu

starkem Anziehen der Schraube die Schraube brechen.

䡬 Wenn der Motor beginnt, zu rotieren, ist ein Sum-

men zu bören. Dabei handelt es sich nicht um eine

störung. (nur DS7DV)

7. Gebrauchs-Weite und Angaben

Die Gebrauchsweite für verschiedene Arbeitsleistungen, auf die mechanische Struktur dieses

Werkzeuges basiert, ist auf der folgenden Tafel

gezeigt:

Zustand bleibt, mag es vorkommen, daß er oder der

Akkumulator überhitzt werden.

Tafel 1

Arbeit Gebrauschweite Anweisung

Bohren

Einschrauben

8. Wahl von Anziehkraft und Drehfrequenz

Einschrauben

Bohren

Holz: 15 mm

Aluminum: 10 mm

Maschineschraube: 6 mm

Mutter: 5 mm

Holzschraube:

5,1 mm (Durchschnitt) x 35 mm (Länge)

Tafel 2

Verwendung Kappenlage

Maschineschraube 1 – 5

Holzschraube 1 – 5

Holz

Metall ––––––

Wahl der Drehgeschwindigkeit (Stellung des Schaltknopfs)

LOW (niedrige

Geschwindigkeit)

Für Schrauben von 4 mm

Durchschnitt oder weniger

Für 3,5 mm Durchschnitt oder

weniger Nenndurchschnitt

Für 13 mm Durchschnitt oder

mehr

Für bohrarbeit verwenden.Stahl: 10 mm

Bohrerspitze und Hülse dem Schraubendurchschnitt verwenden.

Nach bohren von Führungsloch verwenden.

HIGH (hohe Geschwindigkeit)

Für Schraube von 5 mm

Durchscnitt oder mehr

Für 3,8 mm Durchschnitt oder

mehr Nenndurchschnitt

Für 13 mm Durchschnitt oder

weniger

Für Bohren mit Eisenbearbeitungsbohrer

VORSICHT

䡬 Die Wahlbeispiele die in Tafel 2 angezeigt sind sollten als allgemeines Standard angesehen werden, da

verschiedene Anziehschrauben und verschiedenes Material in Wirklichkeit verwendet werden, für die rechtmäßige anpassung natürlich erforderlich sein wird.

WARTUNG UND INSPEKTION

1. Nachprüfen des Werkzeuges

Da ein stumpfes Werkzeug die Leistung vermindern

wird und eventuell ein schlechtes Funktionieren des

Motors verursachen wird, das Werkzeug schärfen

oder es wechseln sobald Verschleiß sichtbar wird.

2. Nachprüfen der Befestigungsschrauben

Alle Befestigungsschrauben regelmäßig auf gute

Festschraubung nachprüfen. Falls irgendeine der

3. Außenreinigung

Wenn der Bohrschrauber schmutzig ist, ihn mit einem

weichen und trockenen Tuch abwischen oder mit

einem in Seifenwasser benetzten Tuch. Kein

Chlorsolvent, Benzin oder Farbsolvent verwenden

da sie plastik-Material schmelzen.

4. Lagern

Den Bohrschrauber an einen Ort aufbewahren wo

die Temperatur unter 40°C ist und außer Reichweite

der Kinder.

Schrauben locker sein sollte, sofort anziehen. Vernachlässigung dieses Punktes kann zu erheblicher

Gefahr führen.

ANMERKUNG

Aufgrund des ständigen Forschungs und Entwicklungsprogramms von HITACHI sind Änderungen der hierin

gemachten technischen Angaben vorbehalten.

12

Deutsch

Deutsch

Français

Die Geräusche unserer Elektrowerkzeuge werden nach

IEC 59 (CO) 11, IEC 704, DIN 45 635 Teil 21, NFS 31031 (84/537/EWG für Aufbruchhämmer) gemessen.

Der Schalldruckpegel am Arbeitsplatz kann 85 dB (A)

überschreiten; in dem Fall sind Schallschutzmaßnahmen

für den Bedienenden erforerlich.

PRECAUTIONS GENERALES

1. Maintenir la zone de travail propre.

Des surfaces et des bancs de travail encombrés

sont propices aux accidents.

2. Eviter des alentours dangereux. Ne pas exposer

l’outil et le chargeur à la pluie. Ne pas utiliser

l’outil ou le chargeur en des endroits humides ou

mouillés. Maintenir la zone de travail bien éclairée. Ne jamais utiliser d’outils électro-portatifs et

de chargeur à proximité de matières inflammables

ou explosives. Ne pas utiliser l’outil et le chargeur

en présence de gaz ou de liquide inflammables.

3. Maintenir les enfants à l’écart. Tous les visiteurs

devront être maintenus à une distance sûre de la

zone de travail.

4. Ranger l’outil et le chargeur quand ils sont hors

service. Quand vous ne les utilisez pas, l’outil et

le chargeur seront rangés dans un endroit sec et

surélevé ou fermé à clef, c’est-à-dire hors de portée

des enfants. Ranger l’outil et le chargeur dans un

endroit où la température est inférieure à 40°C.

5. Ne pas forcer l’outil. Il travaillera mieux et plus

sûrement au régime pour lequel il a été conçu.

6. Utiliser l’outil qui convient. Ne pas forcer un petit

outil ou accessoire à faire le travail d’un outil de

haute puissance.

7. Porter les vêtements appropriés. Pas de vêtements

flous ou d’accessoires qui risqueraient d’être pris

dans les pièces mobiles. Des gants et chaussures

en caoutchouc sont recommandés pour les travaux effectués l’extérieur.

8. Porter des lunettes de sécurité avec la plupart des

outils. Et aussi un masque si le travail de coupage

dégage de la poussière.

9. Ne pas fatiguer le cordon. Ne jamais porter le

chargeur par le cordon, et pour le débrancher de

la prise ne pas tirer le cordon. Maintenir le cordon

à l’écart de la chaleur, de l’huile et des arrêtes

pointues.

10. Fixer la pièce de travail. Utiliser des crampons ou

un étau pour fixer la pièce de travail. Ceci est plus

sûr que d’utiliser vos mains qui seront libres pour

manipuler l’outil.

11. Ne pas se pencher de trop. Maintenir un bon

équilibre en toutes circonstances.

12. Veiller soigneusement à l’entretien de l’outil.

Garder le toujours bien aiguisé, et le nettoyer pour

assurer la meilleure performance possible.

Bien suivre les instructions de lubrification et de

remplacement des accessoires.

13. Quand le chargeur n’est pas utilisé ou quand il

est soumis à l’entretien ou à une vérification,

débrancher le cordon du chargeur de la prise

secteur.

14. Enlever la clef à mandrin et les clefs. Prendre

l’habitude de vérifier si la clef a été enlevée de

l’outil avant la mise en marche.

15. Eviter une mise en marche accidentelle. Ne pas

porter l’outil avec le doigt sur l’interrupteur.

16. Utiliser toujours le chargeur spécifié.

Ne jamais utiliser un chargeur autre que celui

spécifié pour éviter les dangers.

17. N’utiliser que des pièces de rechange HITACHI

d’origine.

18. Ne pas utiliser l’outil et le chargeur pour une

application autre que celles spécifiées dans le

mode d’emploi.

19. L’utilisation d’accessoires ou fixations autres que

ceux préconisés dans le manuel d’instructions ou

le catalogue HITACHI peut présenter un danger

pour l’utilisateur.

13

Français

20. Toute réparation doit être effectuée par un

réparateur agréé. Le fabricant ne peut être tenu

responsable des dommages ou blessures dûs à

une réparation effectuée par une personne non

autorisée ou par une mauvaise utilisation de l’outil.

21. Pour assurer l’intégrité de la conception de fonctionnement de l’outil et du chargeur, ne pas enlever

les couvercles ou les vis qui ont été installés.

22. Utiliser toujours le chargeur à la tension spécifiée

sur la plaque indicatrice.

23. Ne pas toucher les piàces mobiles quand l’outil

n’est pas débranché de la source d’alimentation.

24. Charger toujours la batterie avant utilisation.

25. Ne jamais utiliser une batterie autre que celle

spécifiée. Ne pas connecter une pile sèche ordinaire, une batterie rechargeable autre que celle

spécifiée ou une batterie d’auto à l’outil électroportatif.

26. Ne pas utiliser de transformateur élévateur.

27. Ne pas charger la batterie à partir d’un générateur

électrique ou d’une alimentation en courant continu.

28. Charger toujours à l’intérieur. Etant donné que le

chargeur et la batterie chauffent légérement pendant l’opération de charge, charger la batterie

dans un endroit non exposé aux rayons du soleil,

à basse humidité et bien aéré.

29. Quand vous travaillez dans un endroit surélevé ,

faire attention à ce qui se passe au-dessous de

vous.

Avant de commencer le travail, s’assurer qu’il n’y

a personne au-dessous.

30. La vue éclatée contenue dans ce manuel d’instructions doit être utilisée seulement dans un centre

de réparation agréé.

PRECAUTIONS POUR PERCEUSE-VISSEUSE A

BATTERIE

1. Chargez toujours la batterie à une température de

10-40°C. Une température inférieure à 10°C

entrainera une surcharge dangereuse.

La batterie ne peut pas être chargée à une température supérieure à 40°C.

La température la plus appropriée serait de 20–

25°C.

2. N’utilisez pas le chargeur continuellement.

Quand une charge a été effectuée, laissez le

chargeur au repos pendant environ 15 minutes

avant de commencer la prochaine charge de

batterie.

3. Ne chargez pas la batterie pendant plus d’une

heure.

La batterie sera complètement chargée en une

heure environ, et la charge devra être arrêtée

quand une heure s’est écoulée à partir du commencement de la charge. Débranchez le cordon

de la prise secteur.

4. Ne laissez pas de corps étrangers pénétrer par le

trou de raccord de la batterie rechargeable.

5. Ne désassemblez jamais la batterie rechargeable

et le chargeur.

6. Ne court-circuitez jamais la batterie rechargeable.

Le fait de court-circuiter la batterie génèrera un

courant électrique élevé et une surchauffe, ce qui

entrainera la brûlure ou l’endommagement de la

batterie.

7. Ne jetez pas la batterie au feu. Elle pourrait

exploser.

8. Pour le forage dans un mur, le sol ou le plafond,

vérifiez s’il n’y a pas présence de cordons électriques enfouis, etc.

9. Apportez la batterie au magasin où vous l’avez

achetée dès que la durée de vie de post-charge

de la batterie devient trop courte pour une utilisation pratique. Ne jetez pas de batterie usagée.

10. L’utilisaiton d’une batterie usagée endommagera

le chargeur.

11. Ne pas introduire d’objets métalliques ou des pro

duits inflammables dans les fentes d’aération du

chargeur, cela provoquera un choc électrique ou

endommagera le chargeur.

12. Lorsque vous montez un foret ou une mèche dans

le plateau de serrage sans clavettes, serrez suffisamment le manchon. Si ce dernier est trop

léche, le foret ou la mèche risque de glisser ou

de tomber et blesser quelqu’un.

SPECIFICATIONS

OUTIL ELECTRIQUE

Modèle DS7DT DS7DV

Vitesse à vide (Basse/Grande) 300/850/min. 0 – 300/0 – 850/min.

Perçage

Capacité

Batterie rechargeable (EB7) Ni-Cd batterie, 7,2 V

Poids 1,35 kg

Niveau de pression acoustique Ne dépasse pas 70 dB (A)

Niveau de vibration Ne dépasse pas 2,5 m/S

14

Enfonce- Vis mécanique 6 mm

ment

Bois (mou) 15 mm

Métal Acier: 10 mm, Aluminum: 10 mm

Vis de bois 5,1 mm (diamètre) x 35 mm (Longueur)

2

CHARGEUR

Modèle UC7SB

Temps de charge env. 1 heure (à 20°C)

Tension de charge 7,2 V

Poids 1,0 kg

ACCESSOIRES STANDARD

Français

1

DS7DT (1HCK)

DS7DV (1HCK)

1 Mèche-visseuse cruciforme (No.2) ............................................... 1

2 Chargeur (UC7SB) ........................................................................... 1

3 Boîtier en plastique ......................................................................... 1

Les accessoires standard sont sujets à changement sans préavis.

ACCESSOIRES SUR OPTION

4. Douille heagonale (pour écrous et boulons)

(vendus séparément)

1. Batterie (EB7)

5. Mèche pour acier

2. Mèche-Visseuse cruciforme

No. de mèche Dimension de vis

No. 1 2 – 2,5 mm

No. 2 3 – 5 mm

No. 3 6 – 8 mm

No. de mèche

3. Mèche-Visseuse ordinaire

a Dimension de vis

0,8 mm 4 mm

1 mm 5 – 6 mm

a

Diamètre, 2 mm, 5 mm, 6 mm

6. Mèche pour bois

Diamètre, 10 mm, 13 mm

Les accessoires à option sont sujettes à changement

sans préavis.

APPLICATION

䡬 Enfoncement et extraction de vis mécaniques, vis

de bois, vis de taraudage, etc.

䡬 Forage de différents métaux.

䡬 Forage de différents bois.

EXTRACTION ET INSTALLATION DE LA

BATTERIE

1. Retrait de la batterie

Maintenir fermement la poignée et pousser le taquet de la batterie pour l’enlever. (Voir Fig. 1 et

2).

ATTENTION

Ne jamais court-circuiter la batterie.

2. Mise en place de la batterie

Insérer la batterie tout en respectant la polarité.

(Voir la Fig. 2).

2

No. de douille Dimension d‘écrou

74 mm

85 mm

No. de douille

3

15

Français

CHARGE

Avant d’utiliser la perceuseà visseuse, chargez la batterie

comme suit.

1. Insérer la batterie dans le chargeur. Installer la

batterie de manière à ce que la plaque nominale

se trouve en face de la plaque nominale du chargeur

et appuyer sur la batterie jusqu’à ce qu’elle entre

en contact avec la plaque du fond du chargeur (voir

Fig. 1 et 3).

2. Brancher le cordon d’alimentation du chargeur à la

prise secteur.

Le fait de connecter le cordon mettra le chargeur

sous tension (la lampe témoin s’allumera).

ATTENTION

Si la lampe témoin ne s’éclaire pas, retirer le

cordon d’alimentation de la prise secteur et vé-

rifier le sens de montage de la batterie.

Une heure environ sera requise pour charger complètement la batterie à une température d’environ

20°C. La lampe témoin s‘éteint pour indiquer que

la batterie est complètement chargée.

ATTENTION

Si la batterie est échauffée à cause de l‘exposition

directe au soleil, etc. juste apres le fonctionne-

ment, il se peut que la lampe témoin du chargeur

ne s‘allume pas.

Das ce cas, laissez d‘abord refroidir la batterie

avant de commencer la charge.

3. Déconnectez le cordon du chargeur de la prise

secteur.

4. Tenez le chargeur fermement et enlevez la batterie.

Après avoir terminé la charge, fermez le couvercle

du chargeur.

AVANT LA MISE EN MARCHE

1. Installation et vérification de l’environnement de tra-

vail

Vérifier si l’environnement de travail est adéquat en

suivant les précautions.

UTILISATION

1. Montage et démontage des forets.

(1) Montage de la foret

Aprés avoir mis un foret de tournevis etc dans le

mandrin sans clè, maintenir fermement l’anneau et

serrre le manchon en le tournant vers la droite (dans

le sens des aiguilles d’une montre, vu de l’avant).

(Voir en Fig. 4)

䡬 Si le manchon se desserre pendant le fonctionne-

ment, le resserrer. La force de serrage augmente

lorsque le manchon est resserré.

(2) Démontage de la foret

Maintenir fermement l’anneau et desserrer le manchon en le tournant vers la gauche (dans le sens

contraire des aiguilles d’une montre, vu de l’avant).

(Voir en Fig. 4)

ATTENTION

Lorsque le manchon ne peut pas être dévissé,

bloquer l’outil emmanché dans un étau, etc., mettre

l’embrayage sur 1 à 3 et tourner le manchon dans

le sens contraire des aiguilles d’une montre tout en

faisant fonctionner l’embrayage.

16

2. Vérfiez se la batterie a été correctement installée.

3. Vérifiez la direction de rotation.

Quand le levier-sélecteur est mis sur

tourne dans le sens horaire quand vue de l’arrière

de la perceuse. Quand le sélecteur est sur L, la

perceuse tourne dans le sens antihoraire (Voir la

Fig. 5). (Les repères

corps).

䡬 Quand le trigger de l’interrupteur est tiré, l’outil

tourne. Quand le trigger est reléché, l’outil s’arrête.

䡬 La vitesse de rotation de la foreuse peut être contrìlée

en faisant varier la force avec laquelle on appuie

sur l’interrupteur. En appuyant légèrement sut l’in-

terrupteur, la vitesse est basse et elle augmente

lorsqu’on appuie plus fort. (DS7DV uniquement)

4. Changement de vitesse de rotation

Actionnez le bouton de décalage pour changer la

vitesse de rotation. Enfoncez le bouton de blocage

pour ralécher le blocage et déplacez le bouton de

décalage dans la direction de la flèche (Voir les Fig.

6 et 7).

Quand le bouton de décalage est mis sur “LOW”

(petite vitesse), la perceuse tourne à petite vitesse.

Quand mis sur “HIGH” (grande vitesse), la perceuse

tourne à grande vitesse.

ATTENTION

Lors du changement de la vitesse de rotation à

l’aide du bouton de décalage, assurez-vous que

l’interrupteur est sur arrêt et que le sélecteur est

mis sur “0” (ARRET).

Le fait de changer la vitesse quand le moteur tourne

endommagera l’engrenage.

5. Vérification de la position du capuchon. (Voir Fig. 8)

La force de serrage de cet outil peut être réglée

suivant la position du capuchon.

(1) Quand vous utilisez l’outil en tant que visseuse,

réglez la flèche repère du capuchon sur l’un des

chiffre de “1” à “5” du cadre extérieur.

(2) Quand vous l’utilisez en tant que perceuse, réglez

la filet blanc sur le repère-perceuse “

8).

ATTENTION

䡬 Régler la filet blanc du capuchon soit sur l’un des

repères numériques, soit sur l‘un des repères perceuse.

6. Réglage de la force de serrage

(1) Force de serrage

La force de serrage devra correspondre au diamètre

de la vis utilisée. Si trop de force est utilisée, il se

peut que la vis se casse ou s’endommage dans la

partie de sa tête. Ne manquez pas de régler le

capuchon en conformité avec le diamètre de la vis

utilisée.

(2) Indication de force de serrage

La force de serrage sera modifiée suivant le type

de vis utilisée et le matériel devant être serré. Le

mode d’emploi pour la force de serrage est indiqué

sur le cadre extérieur de cet outil suivant la

numérotation “1”, “2”, “3”, “4” et “5”. La force

minimale est en position “1” et augmente suivant

la valeur numérique indiquée (Voir la Fig. 8).

(3) Réglage de la force de serrage

Pour régler la force de serrage, faites tourner le

capuchon pour l’amener sur l’un des repères numériques. Vous pourrez régler la force de serrage

en faisant tourner le capuchon soit vers la valeur

et R sont marqués sur le

L

, la perceuse

R

” (Voir Fig.

Français

inférieure, quand la force est trop forte, soit vers

la valeur supérieure, quand la force est trop faible.

ATTENTIONS

䡬 Il se peut que la rotation du moteur se vérouille et

s’arrête pendant que l’outil est utililsé en tant que

perceuse.

Pendant le fonctionnement de la perceuse-visseuse,

faites attention à ne pas vérouiller le moteur.

䡬 Lorsque le bouton de décalage est sur “HIGH” et

que la position du capot est de “4” ou “5”, il arrive

que l’embrayage ne s’enclenche pas et que le moteur

soit bloqué. Dans ce cas, veuillez mettre le bouton

de décalage sur “LOW” (petite vitesse).

pendant un certain temps, le moteur ou la batterie

en seront brûlés.

䡬 Une percussion trop prolongée peut casser la vis

par suite d’un serrage excessif.

䡬 La vitesse de rotation de la foreuse peut être contrìlée

en faisant varier la force avec laquelle on appuie

sur I’interrupteur. En appuyant Iégèrement sur

I’interrupteur, Ia vitesse est basse et elle augmente

lorsqu’on appuie plus fort (DS7DV uniquement).

7. Portée et recommandations pour l’utillsation

La portée de l’utilisation pour les différents types

de travaux basée sur la structure mécanique de cet

outil est indiquée ci-dessous:

䡬 Si le moteur a été vérouillé, débranchez immédia-

tement l’alimentation. Si le moteur reste vérouillé

Tableau 1

Travail Utilisation Recommandations

Forage

Enfoncement

Bois: 15 mm

Aluminum: 10 mm

Vis mécanique: 6 mm

Ecrou: 5 mm

Vis de bois:

5,1 mm (diamètre) x 35 mm (longueur)

Utiliser pour opération de forageAcier: 10 mm

Utiliser la mèche et la douille adaptés au

diamètre de la vis.

Utiliser après forage d‘un trou de préparation.

8. Sélection de la force de serrage et de la fréquence de rotation

Tableau 2

Sélection de vitesse de rotation (Position du bouton de

changement)

LOW (Petite) HIGH (Grande vitesse)

Pour vis de 4 mm ou moins

diamètre

Pour vis de 3,5 mm ou moins,

diamètre nominal

Pour diamètre de 13 mm ou

plus

Pour vis de 5 mm ou plus

diamètre

Pour vis de 3,8 mm ou plus

diamètre nominal

Pour diamètre de 13 mm ou

moins

Für Bohren mit Eisenbearbeitungsbohrer

Enfoncement

Forage

Utilisation

Vis mécanique 1 – 5

Vis de bois 1 – 5

Bois

Métal ––––––

Position du

capuchon

ATTENTION

䡬 Les exemples choisis et montrés au Tableau 2, seront pris en tant qu’exemples standards étant donné que

différentes vis de serrages et différents matériels devant être serrés seront utilisés réellement, et pour lesquels

un réglage approprié sera évidemment requis.

ENTRETIEN ET VERIFICATION

1. Vérification de l’outil

Etant donné que l’utilisation d’un outil émoussé

réduira le rendement et entrainera éventuellement

un mauvais foncitionnement du moteur, aiguisez

dès qu’une abrasion apparait.

2. Vérifiez régulièrement toutes les vis de fixation

Vérifiez régulièrement toutes les vis de fixation et

assurez-vous qu’elles sont bien serrées. S’il advient

3. Nettoyage de l’extérieur

Quand la perceuse-visseuse eset sale, essuyez la

avec un chiffon sec et doux ou un chiffon imbibé

d’eau savoneuse.

N’utilisez pas de solvant au chlore, d’essence ou de

diluant, car ils font fondre les matières plastiques.

4. Rangement

Rangez la perceuse-visseuse dans un endroit où la

température est inférieure à 40°C et hors de portée

des enfants.

qu’une vis se desserre, la resserrer immédiatement.

Le fait de négliger ce point pourrait entrainer de

sérieux dangers.

NOTE

Par suite du programme permanent de recherche et de

développement HITACHI, ces spéciications peuvent faire

l’objet de modifications sans avis préalable.

17

Français Italiano

L’intensité sonore de cet outil électrique portatif est

mesurée selon IEC 59 (CO) 11, IEC 704, DIN 45 635 part

21, NFS 31-031 (84/537/CEE pour marteaux piqueurs).

Au poste de travail le niveau de la pression acoustique

peut dépasser 85 dB (A); dans ce cas des mesures

individuelles de protection contre le bruit sont

nécessaires.

PRECAUZIONI PER LE OPERAZIONI GENERALI

1. Tenere pulita l’area di lavoro. Aree in disordine

e banchi ingombri, invitano gli incidenti.

2. Evitare ambienti pericolosi. Non esporre gli utensili elettrici e il caricabatterie alla pioggia. Non

usare gli utensili elettrici e il caricabatterie

all’umidità e al bagnato. Tenere l’area di lavoro

ben illuminata.

Non usare mai gli utensili elettrici e il caricabatterie

vicino a sostanze infiammàbili o esplosive.

Non usare gli utensili e il caricabatterie in presenza di gas o liquidi infiammàbili.

3. Tenere lontani i bambini. Tutti gli estranei devono

essere tenuti a distanza dall’area di lavoro.

4. Riporre il caricabatterie e gli utensili non utilizzati.

Quando non utilizzati, il caricabatterie e gli utensili

devono essere riposti in un luogo secco ed elevato

o chiuso a chiave e comunque fuori dalla portata

dei bambini.

Sistemare gli utensili ed il caricabatterie in luoghi

con temperatura inferiore ai 40°C.

5. Non forzare l’utensile. Farà il suo lavoro meglio

e con maggior sicurezza alla velocità per la quale

è stato concepito.

6. Usare l’utensile giusto. Non forzare utensili o ac-

cessori minori a compiere il lavoro di utensili per

grandi prestazioni.

7. Indossare indumenti adatti: nessun indumento troppo largo né bigiotteria che possano restare impigliati nelle parti in movimento. Quando si lavora

all’aperto si consiglia di indossare guanti e calzature di gomma.

8. Con la maggior parte degli utensili occorre indossare occhiali protettivi. Se l’operazione di taglio

comporta la formazione di polvere occorre usare

anche maschere facciali o anti-polvere.

9. Non maltrattare il cavo. Non portare mai utensili

per il cavo né tirare per togliere la spina dalla

presa.

Tenere il cavo lontano dal calore, dalle lame taglienti e da olio.

10. Fissare l’oggetto da lavorare. Usare staffe o morse

per fissare il lavoro. Entrambe le mani devono

essere libere di maneggiare l’utensile.

11. Non sporgersi durante il lavoro. Stare su due piedi

ed in equilibrio stabile in ogni momento.

12. Tenere sempre in buone condizioni gli utensili.

Tenerli sempre affilati e puliti per ottenerne la

migliore e pió sicura prestazione. Seguire le istruzioni per la lubrificazione e per il cambio degli

accessori.

13. Quando il caricatore non viene usato, o quando

si stanno svolgendo le operazioni di manutenzione ed ispezione, staccare il cavo della corrente del

caricatore dalla presa AC.

14. Togliere le chiavi e la chiave del mandrino. Prendere l’abitudine di controllare che non ci siano

chiavi in vicinanza prima di accendere l’attrezzo.

15. Evitare la messa in marcia accidentale. Non portare

l’attrezzo con il dito sull’interruttore.

16. Usare sempre il caricabatterie specificato, in modo

da impedire incidenti, non usare mai caricabatterie

d’altro tipo.

17. Usare solo parti di ricambio originali HITACHI.

18. Non usare gli utensili elettrici e il caricabatterie

per impieghi diversi da quelli specificati nelle istruzioni per l’uso.

19. L’uso di ogni altro accessorio o dispositivo di

attacco raccomandato in queste istruzioni di

impiego o nel catalogo HITACHI potrebbe causare

18

Italiano

20. La riparazione deve essere fatta solamente dal

personale autorizzato. II produttore non è responsabile per danni o incidenti causati da persone

non autorizzate, nè dell’eventuale malutilizzo

del’utensile.

21. Per ottenere l’integrità di funzionamento per la

quale gli utensili e il caricabatterie sono stati

concepiti, non togliere le protezioni e le viti installate.

22. Usare il caricabatterie sempre e solo al voltaggio

specificato sulla targhetta.

23. Non toccare parti muoventi o gli accessori prima

che la corrente non sia stata staccata.

24. Caricare sempre la batteria prima dell’uso.

25. Non usare mai batterie diverse da quelle specificate.

Non collegare un elemento secco uguale, una

batteria ricaricabile diversa da quella specificata

o una batteria da automobile all’utensile elettrico.

26. Non usare trasformatori con alimentatori stabilizzati.

27. Non caricare la batteria da un motogeneratore o

da una fonte di corrente DC.

28. Effettuare le operazioni di ricarico sempre all’interno. Sia il caricabatterie che la batteria si surriscaldano durante il ricaricamento. Portare la

batteria in un posto non esposto direttamente al

raggio del sole e che sia ben ventilato.

29. Quando si lavora in alto, fare attenzione a quanto

si svolge al di sotto. Assicurarsi che non ci siano

persone prima di iniziare le operazioni.

30. II disegno completo dello spaccato inserito su

queste istruzioni di impiego dovrebbe essere

utilizzato solo dal personale autorizzato.

PRECAUZION PER L’USO DEL TRAPANOAVVITATORE A BATTERIA

1. Caricare la batterie ad una temperatura di 10-40°C.

Una temperatura minore può provocare sovraccarico, il che è pericoloso. La batteria non può

essere ricaricata ad una temperatura superiore ai

40°C. La temperatura ideale è compresa 20-25°C

gradi.

2. Non usare il caricatore in continuazione.

Quando un’operazione di caricatura è terminata,

prima di iniziarne una seconda, lasciare che il

caricatore riposi per 15 minuti.

3. Non caricare la batteria per pió di un’ora. In quel

periodo la batteria sarà completamente ricaricata

e quindi passato tale limite l’operazione deve essere

interrotta. Staccare quindi il cavo della corrente

dalla presa.

4. Non permettere che sostanze estranee entrino nel

foro di collegamento della batteria ricaricabile.

5. Non smontare mai la batteria ricaricabile e il

caricatore.

6. Non provocare assolutamente mai dei corto-circuiti alla batteria ricaricabile. Il fenomeno provoca

surriscaldamento e grande corrente elettrica. Può

quindi causare bruciature o danni alla batteria.

7. Non gettare la batteria nel fuoco. Può esplodere.

8. Quando si fanno fori sulle pareti, pavimenti o

soffitti, controllare che non ci siano cavi elettrici

nascosti.

9. Non appena la vita della batteria dopo le operazioni di ricaricatura diventa troppo breve per fini

pratici, si porti la batteria al negozio dove è stata

acquistata. Non la si getti mai via.

10. Usando una batteria scarica, il caricatore può venir

danneggiato.

11. Non inserire nessun oggetto nelle fessure di ventilazione del caricatore.

Inserendo oggetti metallici o infiammabili nelle

fessure di ventilazione, si possono causare facilmente delle scosse electtriche, o si può danneggiare il caricatore.

12. Per montare una punta o una trivella da trapano

nel mandrino senza chiave, stringere il manicotto

in maniera adeguata. Se il manicotto non è ben

stretto, la punta o la trivella da trapano può

scivolare o cadere, con il pericolo di lesioni alle

persone.

CARATTERISTICHE

UTENSILE ELETTRICO

Modello DS7DT DS7DV

Velocità a vuoto (Bassa/Alta) 300/850/min. 0 – 300/0 – 850/min.

Perfora- Legno (molle) 15 mm

Capacità

Batteria ricaricabile (EB7) Ni-Cd batteria, 7,2 V

Peso 1,35 kg

Livello di pressione sonora Non supera i 70 dB (A)

Livello di vibrazione Non supera i 2,5 m/S

zione

Avvita- Vite di macchina 6 mm

mento

Metallo Acciaino: 10 mm, Alluminio: 10 mm

Vite per legno 5,1 mm (diametro) x 35 mm (lunghezza)

2

19

Italiano

CARICATORE

Modello UC7SB

Tempo di ricarica Approssimativamente un‘ora (a 20°C)

Voltaggio di carica 7,2 V

Peso 1,0 kg

ACCESSORI STANDARD

1

DS7DT (1HCK)

DS7DV (1HCK)

1 Cacciavite a croce (n.2) ................................................................... 1

2 Caricatore (UC7SB) ......................................................................... 1

3 Custodia in plastica ......................................................................... 1

Gli accessori standard possono essere cambiati senza preavviso.

ACCESSORI FACOLTATIVI (venduti a parte)

1. Batteria (EB7)

2. Cacciavite a croce

n. della punta Misura della vite

n. 1 2 – 2,5 mm

n. 2 3 – 5 mm

n. 3 6 – 8 mm

n. della punta

4. Chiave esagonale a tubo (per dadi e bulloni)

5. Punta da trapano per acciaio

Diametro, 2 mm, 5 mm, 6 mm

6. Punta da trapano per legno

Diametro, 10 mm, 13 mm

Gli accessori disponibili a richiesta possono essere cambiati senza preavviso.

APPLICAZIONI

䡬 Per stringere o togliere delle viti di macchina, delle

viti per legno, delle viti mordenti etc.

䡬 Per la foratura di metalli diversi

䡬 Per la foratura di legni diversi

2

n. della chiave Misura della vite

74 mm

85 mm

n. della chiave

3

3. Cacciavite a lama

a Misura della vite

0,8 mm 4 mm

1 mm 5 – 6 mm

a

20

RIMOZIONE E INSTALLAZIONE DELLA

BATTERIA

1. Smontaggio della batteria

Tenere saldamente l’impugnatura e spingere il fermo

della batteria, in modo da smontarla (Ved. Fig. 1

e 2).

ATTENZIONE

Non mettere la batteria in corto circuito.

2. Montaggio della batteria

Inserire la batteria facendo attenzione alla corretta

collocazione delle polarità (Ved. Fig. 2).

Italiano

RICARICA

Prima di usare il trapano avvitatore, caricare la batteria

come di seguito indicato.

1. Inserire la batteria nel caricatore. Sistemare la batteria

in modo che abbia l‘etichetta rivolta verso l‘etichetta

del caricatore e premerla fino a quando non venga

in contatto con la piastrina inferiore. (Vedere le Fig.

1 e 3)

2. Collegare il cavo del caricatore alla presa AC.

In tal modo si accenderà il caricatore e anche la

lampada spia si illuminerà.

ATTENZIONE

Se la lampada spia non si illumina, togliere il cavo

di corrente dalla presa di rete e controllare come

è inserita la batteria.

Occorre un‘ora circa per caricare la batteria ad una

temperatura di circa 20°C. La lampada spia si spegne

quando la batteria è caricata appieno.

ATTENZIONE

Se la batteria è calda a causa dei raggi diretti del

sole ad operazione eseguita, la lampada spia del

caricatore a volte non si illumina.

Prima di iniziare le operazioni di carico raffreddare

la batteria.

3. Staccare il caricatore dalla presa AC.

4. Tenere il caricatore stretto e tirare fuori la batteria.

A ricarica avvenuta, chiudere la copertina del

caricatore.

PRIMA DI INIZIARE LE OPERAZIONI

1. Stabilire e controllare l’ambiente di lavoro.

Controllare che l’ambiente di lavoro sia adatto seguendo le necessarie precauzioni.

OPERAZIONE

1. Installazione e rimozione delle punte.

(1) Per montare un attrezzo sulla punta

Dopo aver inserito una punta di trapano, ecc. nel

mandrino autoserrante, afferrare saldamente l’anel-

lo e stringere il collare girandolo verso destra (in

senso orario quando visto da davanti). (Vedere Fig.

4)

䡬 Se il collare dovesse allentarsi durante il funziona-

mento, stringerlo ulteriormente. La forza serrante

aumenta quando il collare viene stretto.

(2) Per staccare l’attrezzo dalla punta

Afferrare saldamente l’anello e allentare il collare

girandolo verso sinistra (in senso antiorario quando

visto da davanti). (Vedere Fig. 4)

ATTENZIONE

Quando non è possibile svitare il collare, stringere

l’attrezzo inserito in una morsa, ecc., regolare il

modo frizione su 1-3 e girare il collare in senso

antiorario usando la frizione.

2. Assicurarsi che la batteria sia montata in modo

corretto.

3. Controllare la direzione della rotazione.

Quando la levetta si trova su

in senso orario, come visto dal retro dello stesso.

Quando la manopola è impostata su L il trapano

ruota in senso antiorario (Ved. Fig. 5). I contrassegni L ed R sono apportati sul corpo dell’attrez-

zo.

il trapano ruota

R

䡬 Premendo il grilletto interruttore, l’utensile si mette

in movimento.

Lasciando andare il grilletto, il motore si ferma.

䡬 La velocit† di rotazione del trapano può essere

dell’interruttore viene premuto. La velocità è bassa

quando il grilletto dell’interruttore viene premuto

leggermente, e aumenta a mano a mano che l’inter-

rutoore viene premuto maggiormente. (Solo DS7DV)

4. Cambio della velocità di rotazione

Usare la manopola d’intercambio per cambiare la

velocità di rotazione. Premere il pulsante di blocco

per liberare e spostare la manopola d’intercambio

in direzione della freccia (Ved. Figs. 6 e 7).

Quando la manopola d’intercambio è portata su

“LOW” il trapano rota a bassa velocità. Su “HIGH”

il trapano rota ad alta velocità.

ATTENZIONE

Quando si cambia la velocità di rotazione con la

manopola d’intercambio, assicurarsi che l’interrut-

tore sia spento e che la manopola di selezione sia

in posizione “0” (OFF).

Se si cambia la velocità con il motore in moto si

causeranno danni agli ingranaggi.

5. Controllare la posizione del tappo. (Ved. Fig. 8)

La forza di serraggio di questo utensile può essere

regolata modificando la posizione del tappo.

(1) Per usare l’utensile come cacciavite, portare il segno

a linea bianca sul tappo in corrispondenza di uno

dei numeri, da 1 e 5, sulla carcassa dell’apparecchio.

(2) Per usare l’utensile come trapano, portare il segno

a Linea bianca sul tappo in corrispondenza del

simbolo de trapanazione “

ATTENZIONE

䡬 Portare il segno della Linea bianca sul tappo

incorrispondenza di uno dei numeri o sul segno del

trapano.

6. Regolazione della forza di serraggio

(1) Forza di serraggio

La forza di serraggio deve essere regolata in corrispondenza del diametro della vite. Se la forza di

serraggio è troppo elevata, la vite si può rompere

o la testa ne può risultare danneggiata. Controllare

che la forza di serraggio sia adatta per il diametro

della vite usata.

(2) Indicazione della direzione di serraggio

La direzione di serraggio deve essere scelta a usato.

Dei valori guida per la forza di serraggio sono

indicati con le cifre “1”, “2”, “3”, “4” e “5”, sulla

carcassa dell’utensile. La potenza minima è ottenuta

con la posizione “1”. Pió alta la cifra, pió elevata

è la forza di serraggio (Ved. Fig. 8).

(3) Regolazione della forza di serraggio

Far girare il tappo e portarlo in corrispondenza di

una delle cifre indicanti la forza di serraggio. Regolare la forza di serraggio facendo girare il tappo

in modo tale da portarlo su un valore pió piccolo

se la forza di serraggio è troppo elevata ed in modo

tale da portarlo su un valore pió grande se la forza

di serraggio non è sufficiente.

ATTENZIONES

䡬 La rotazione del motore può essere bloccata, quan-