Page 1

Cordless Driver Drill

DS 18DGL

Read through carefully and understand these instructions before use.

Handling instructions

Page 2

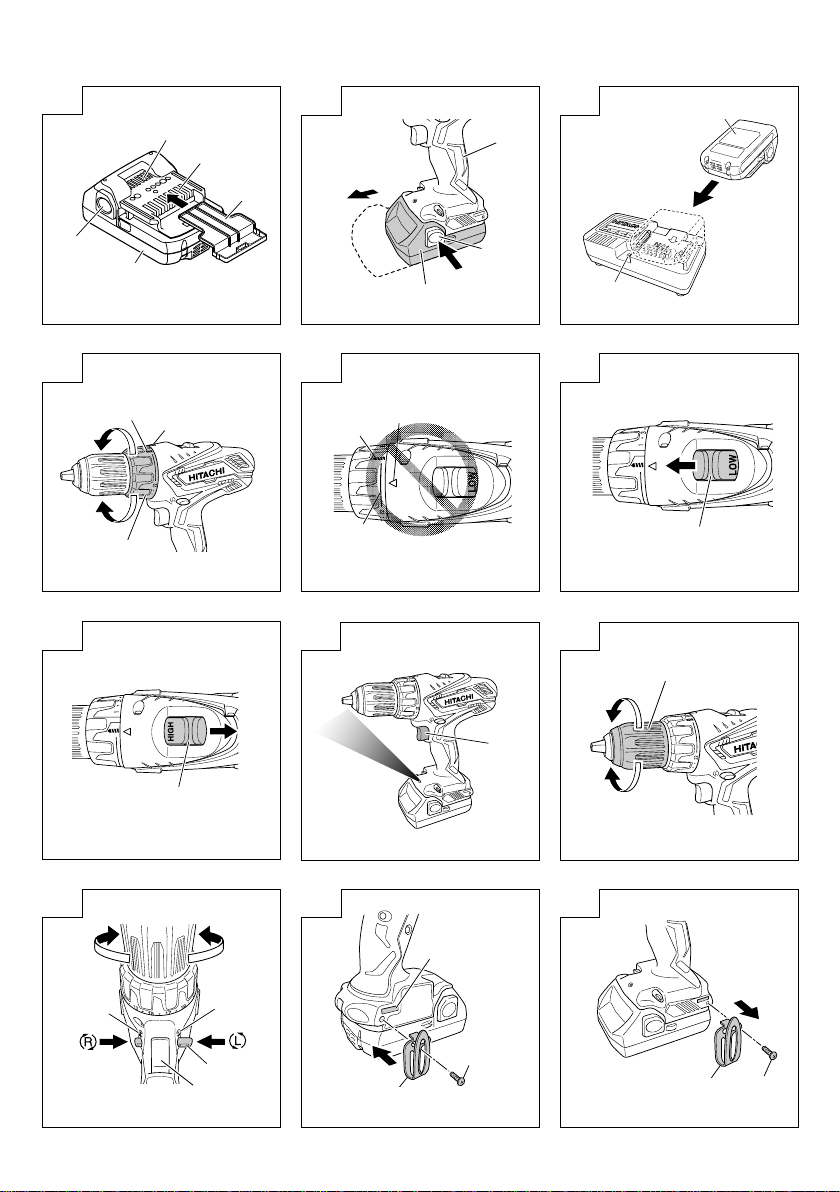

1

5

8

32

1

4

7

3

2

1

1

6

2

9

654

C

0

B

0

B

G

D

A

7

E

F

98

J

L

H

F

I

K

121110

Q

I

M

N

P

O

P

O

N

2

Page 3

1

Rechargeable battery

Latch

2

Battery cover

3

Terminal

4

Ventilator

5

Push

6

Pull out

7

Handle

8

Pilot lamp

9

Drill mark

0

Clutch dial

A

Triangle mark

B

Weak

C

Strong

D

Line

E

Shift knob

F

Low speed

G

High speed

H

Trigger switch

I

Sleeve

J

Tighten

K

Loosen

L

M

Selector button

and marks

N

O

Screw

Hook

P

Groove

Q

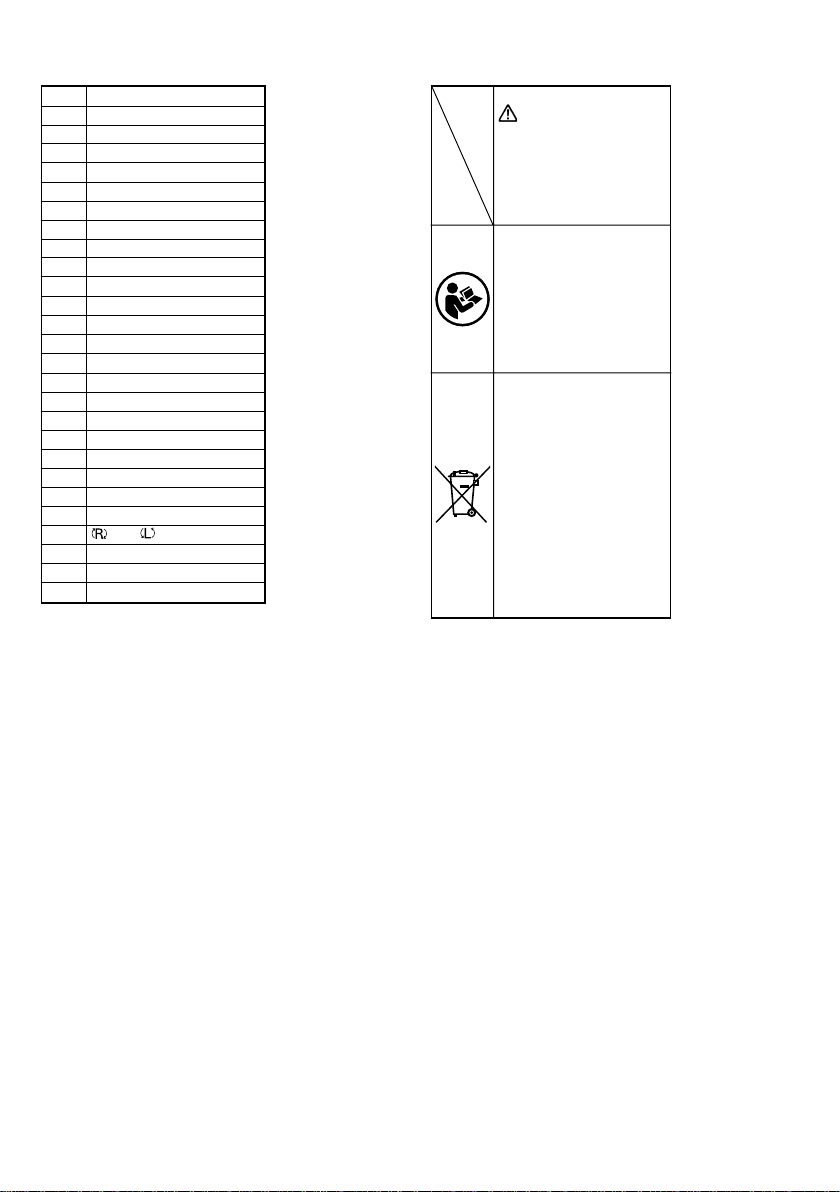

Symbols

WARNING

The following show

symbols used for the

machine. Be sure that

you understand their

meaning before use.

Read all safety

warnings and all

instructions.

Failure to follow the

warnings and

instructions may result

in electric shock, fire

and/or serious injury.

Only for EU countries

Do not dispose of electric tools

together with household waste

material!

In observance of European

Directive 2002/96/EC on waste

electrical and electronic

equipment and its

implementation in accordance

with national law, electric tools

that have reached the end of

their life must be collected

separately and returned to an

environmentally compatible

recycling facility.

3

Page 4

GENERAL POWER TOOL SAFETY WARNINGS

WARNING

Read all safety warnings and all instructions.

Failure to follow the warnings and instructions may result

in electric shock, fire and/or serious injury.

Save all warnings and instructions for future reference.

The term “power tool” in the warnings refers to your

mains-operated (corded) power tool or battery-operated

(cordless) power tool.

1) Work area safety

a) Keep work area clean and well lit.

Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust.

Power tools create sparks which may ignite the

dust or fumes.

c) Keep children and bystanders away while

operating a power tool.

Distractions can cause you to lose control.

2) Electrical safety

a) Power tool plugs must match the outlet.

Never modify the plug in any way.

Do not use any adapter plugs with earthed

(grounded) power tools.

Unmodified plugs and matching outlets will

reduce risk of electric shock.

b) Avoid body contact with earthed or grounded

surfaces, such as pipes, radiators, ranges and

refrigerators.

There is an increased risk of electric shock if

your body is earthed or grounded.

c) Do not expose power tools to rain or wet

conditions.

Water entering a power tool will increase the

risk of electric shock.

d) Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges or

moving parts.

Damaged or entangled cords increase the risk

of electric shock.

e) When operating a power tool outdoors, use an

extension cord suitable for outdoor use.

Use of a cord suitable for outdoor use reduces

the risk of electric shock.

f) If operating a power tool in a damp location

is unavoidable, use a residual current device

(RCD) protected supply.

Use of an RCD reduces the risk of electric shock.

3) Personal safety

a) Stay alert, watch what you are doing and use

common sense when operating a power tool.

Do not use a power tool while you are tired or

under the influence of drugs, alcohol or medication.

A moment of inattention while operating power

tools may result in serious personal injury.

b) Use personal protective equipment. Always wear

eye protection.

Protective equipment such as dust mask, nonskid safety shoes, hard hat, or hearing protection

used for appropriate conditions will reduce

personal injuries.

4

c) Prevent unintentional starting. Ensure the switch

is in the off-position before connecting to power

source and/or battery pack, picking up or

carrying the tool.

Carrying power tools with your finger on the

switch or energising power tools that have the

switch on invites accidents.

d) Remove any adjusting key or wrench before

turning the power tool on.

A wrench or a key left attached to a rotating part

of the power tool may result in personal injury.

e) Do not overreach. Keep proper footing and

balance at all times.

This enables better control of the power tool in

unexpected situations.

f) Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves

away from moving parts.

Loose clothes, jewellery or long hair can be

caught in moving parts.

g) If devices are provided for the connection of

dust extraction and collection facilities, ensure

these are connected and properly used.

Use of dust collection can reduce dust related hazards.

4) Power tool use and care

a) Do not force the power tool. Use the correct

power tool for your application.

The correct power tool will do the job better and

safer at the rate for which it was designed.

b) Do not use the power tool if the switch does

not turn it on and off.

Any power tool that cannot be controlled with

the switch is dangerous and must be repaired.

c) Disconnect the plug from the power source

and/or the battery pack from the power tool

before making any adjustments, changing

accessories, or storing power tools.

Such preventive safety measures reduce the risk

of starting the power tool accidentally.

d) Store idle power tools out of the reach of children

and do not allow persons unfamiliar with the

power tool or these instructions to operate the

power tool.

Power tools are dangerous in the hands of

untrained users.

e) Maintain power tools. Check for misalignment

or binding of moving parts, breakage of parts

and any other condition that may affect the

power tools operation.

If damaged, have the power tool repaired before

use.

Many accidents are caused by poorly maintained

power tools.

f) Keep cutting tools sharp and clean.

Properly maintained cutting tools with sharp

cutting edges are less likely to bind and are

easier to control.

g) Use the power tool, accessories and tool bits

etc. in accordance with these instructions, taking

into account the working conditions and the

work to be performed.

Use of the power tool for operations different from

those intended could result in a hazardous situation.

Page 5

5) Battery tool use and care

a) Recharge only with the charger specified by the

manufacturer.

A charger that is suitable for one type of battery

pack may create a risk of fire when used with

another battery pack.

b) Use power tools only with specifically designated

battery packs.

Use of any other battery packs may create a risk

of injury and fire.

c) When battery pack is not in use, keep it away

from other metal objects like paper clips, coins,

keys, nails, screws, or other small metal objects

that can make a connection from one terminal

to another.

Shorting the battery terminals together may

cause burns or a fire.

d) Under abusive conditions, liquid may be ejected

from the battery; avoid contact. If contact

accidentally occurs, flush with water. If liquid

contacts eyes, additionally seek medical help.

Liquid ejected from the battery may cause

irritation or burns.

6) Service

a) Have your power tool serviced by a qualified repair

person using only identical replacement parts.

This will ensure that the safety of the power tool

is maintained.

PRECAUTION

Keep children and infirm persons away.

When not in use, tools should be stored out of reach of

children and infirm persons.

CORDLESS DRIVER DRILL SAFETY WARNINGS

1. Use auxiliary handle(s), if supplied with the tool.

Loss of control can cause personal injury.

2. Hold power tool by insulated gripping surfaces,

when performing an operation where the cutting

accessory or fastener may contact hidden wiring.

Cutting accessory or fasteners contacting a "live"

wire may make exposed metal parts of the power

tool "live" and could give the operator an electric

shock.

3. Always charge the battery at a temperature of 0 –

40°C. A temperature of less than 0°C will result in

over charging which is dangerous. The battery

cannot be charged at a temperature higher than

40°C.

The most suitable temperature for charging is that

of 20 – 25°C.

4. When one charging is completed, leave the charger

for about 15 minutes before the next charging of

battery.

Do not charge more than two batteries

consecutively.

5. Do not allow foreign matter to enter the hole for

connecting the rechargeable battery.

6. Never disassemble the rechargeable battery and

charger.

7. Never short-circuit the rechargeable battery. Short-

circuiting the battery will cause a great electric

current and overheat. It results in burn or damage

to the battery.

8. Do not dispose of the battery in fire.

If the battery is burnt, it may explode.

9. Bring the battery to the shop from which it was

purchased as soon as the post-charging battery life

becomes too short for practical use. Do not dispose

of the exhausted battery.

10. Using an exhausted battery will damage the charger.

11. Do not insert object into the air ventilation slots of

the charger.

Inserting metal objects or inflammables into the

charger air ventilation slots will result in electrical

shock hazard or damaged charger.

12. When mounting a bit into the keyless chuck, tighten

the sleeve adequately. If the sleeve is not tight, the

bit may slip or fall out, causing injury.

13. This product contains a strong permanent magnet

in the motor.

Observe the following precautions regarding

adhering of chips to the tool and the effect of the

permanent magnet on electronic devices.

CAUTION

Do not place the tool on a workbench or work area

where metal chips are present.

The chips may adhere to the tool, resulting in injury

or malfunction.

If chips have adhered to the tool, do not touch it.

Remove the chips with a brush.

Failure to do so may result in injury.

If you use a pacemaker or other electronic medical

device, do not operate or approach the tool.

Operation of the electronic device may be affected.

Do not use the tool in the vicinity of precision

devices such as cell phones, magnetic cards or

electronic memory media.

Doing so may lead to misoperation, malfunction or

loss of data.

CAUTION ON LITHIUM-ION BATTERY

To extend the lifetime, the lithium-ion battery equips

with the protection function to stop the output.

In the cases of 1 to 3 described below, when using this

product, even if you are pulling the switch, the motor

may stop. This is not the trouble but the result of

protection function.

1. When the battery power remaining runs out, the

motor stops.

In such a case, charge it up immediately.

2. If the tool is overloaded, the motor may stop. In this

case, release the switch of tool and eliminate causes

of overloading. After that, you can use it again.

3. If the battery is overheated under overload work,

the battery power may stop.

In this case, stop using the battery and let the

battery cool. After that, you can use it again.

Furthermore, please heed the following warning and

caution.

5

Page 6

WARNING

In order to prevent any battery leakage, heat generation,

smoke emission, explosion and ignition beforehand,

please be sure to heed the following precautions.

1. Make sure that swarf and dust do not collect on the

battery.

During work make sure that swarf and dust do not

fall on the battery.

Make sure that any swarf and dust falling on the

power tool during work do not collect on the battery.

Do not store an unused battery in a location exposed

to swarf and dust.

Before storing a battery, remove any swarf and

dust that may adhere to it and do not store it together

with metal parts (screws, nails, etc.).

2. Do not pierce battery with a sharp object such as a

nail, strike with a hammer, step on, throw or subject

the battery to severe physical shock.

3. Do not use an apparently damaged or deformed

battery.

4. Do not use the battery in reverse polarity.

5. Do not connect directly to an electrical outlets or

car cigarette lighter sockets.

6. Do not use the battery for a purpose other than

those specified.

7. If the battery charging fails to complete even when

a specified recharging time has elapsed,

immediately stop further recharging.

8. Do not put or subject the battery to high

temperatures or high pressure such as into a

microwave oven, dryer, or high pressure container.

9. Keep away from fire immediately when leakage or

foul odor are detected.

10. Do not use in a location where strong static

electricity generates.

11. If there is battery leakage, foul odor, heat generated,

discolored or deformed, or in any way appears

abnormal during use, recharging or storage,

immediately remove it from the equipment or

battery charger, and stop use.

CAUTION

1. If liquid leaking from the battery gets into your

eyes, do not rub your eyes and wash them well

with fresh clean water such as tap water and contact

a doctor immediately.

If left untreated, the liquid may cause eye-problems.

2. If liquid leaks onto your skin or clothes, wash well

with clean water such as tap water immediately.

There is a possibility that this can cause skin irritation.

3. If you find rust, foul odor, overheating, discolor,

deformation, and/or other irregularities when using

the battery for the first time, do not use and return it

to your supplier or vendor.

WARNING

If a conductive foreign matter enters in the terminal of

lithium ion battery, the battery may be shorted, causing

fire. When storing the lithium ion battery, obey surely

the rules of following contents.

Do not place conductive debris, nail and wires such

as iron wire and copper wire in the storage case.

To prevent shorting from occurring, load the battery

in the tool or insert securely the battery cover for

storing until the ventilator is not seen. (Fig. 1)

SPECIFICATIONS

POWER TOOL

Model DS18DGL

No-load speed (Low / High) 0 – 450 / 0 – 1250 min

Capacity

Drilling

Driving

Wood

(Thickness 18 mm)

Metal

(Thickness 1.6 mm)

Machine screw

Wood screw

6.8 mm (diameter) × 50 mm (length)

38 mm

Steel: 13 mm,

Aluminum: 13 mm

6 mm

(Requires a pilot hole)

Rechargeable battery BSL1815: Li-ion 18 V (1.5 Ah 5 cells)

Weight* 1.7 kg

–1

* Weight: According to EPTA-Procedure 01/2003

CHARGER

Model UC18YKSL

Charging voltage 14.4 V – 18 V

Weight 0.35 kg

6

STANDARD ACCESSORIES

1 Plus driver bit (No. 2) ......................1

2

Charger ...................................................

DS18DGL

3 Battery ..............................................2

4 Plastic case .......................................1

5 Battery cover....................................1

Standard accessories are subject to change without

notice.

1

Page 7

OPTIONAL ACCESSORIES (sold separately)

Battery

BSL1815

Hook (with screw)

Optional accessories are subject to change without notice.

APPLICATIONS

Driving and removing of machine screws, wood

screws, tapping screws, etc.

Drilling of various metals

Drilling of various woods

BATTERY REMOVAL/INSTALLATION

1. Battery removal

Hold the handle tightly and push the battery latch

(2 pcs.) to remove the battery (See Figs. 1 and 2).

CAUTION

Never short-circuit the battery.

2. Battery installation

Insert the battery while observing its polarities (See

Fig. 2).

Indications of the pilot lamp

Before

charging

Blinks

Lights for 0.5 seconds. Does not light for 0.5

seconds. (off for 0.5 seconds)

CHARGING

Before using the power tool, charge the battery as follows.

1. Connect the charger’s power cord to the receptacle.

When connecting the plug of the charger to a

receptacle, the pilot lamp will blink in red (At 1second intervals).

2. Insert the battery into the charger.

Firmly insert the battery into the charger as shown in

Fig. 3.

3. Charging

When inserting a battery in the charger, charging will

commence and the pilot lamp will light up

continuously in red.

When the battery becomes fully recharged, the pilot

lamp will blink in red. (At 1-second intervals) (See

Table 1)

(1) Pilot lamp indication

The indications of the pilot lamp will be as shown in

Table 1, according to the condition of the charger or

the rechargeable battery.

Table 1

While

charging

Pilot lamp

(red)

(2) Regarding the temperatures of the rechargeable

battery

The temperatures for rechargeable batteries are as

shown in Table 2, and batteries that have become

hot should be cooled for a while before being

recharged.

Table 2 Recharging ranges of batteries

Rechargeable batteries

BSL1815 0°C – 50°C

(3) Regarding recharging time

Depending on the combination of the charger and

batteries, the charging time will become as shown in

Table 3.

Charging

complete

Overheat

standby

Charging

impossible

Lights

Blinks

Blinks

Flickers

Lights continuously

Lights for 0.5 seconds. Does not light for 0.5

seconds. (off for 0.5 seconds)

Lights for 1 second. Does not light for 0.5

seconds. (off for 0.5 seconds)

Lights for 0.1 seconds. Does not light for 0.1

seconds. (off for 0.1 seconds)

Temperatures at

which the battery

can be recharged

Battery overheated.

Unable to charge.

(Charging will commence

when battery cools)

Malfunction in the

battery or the charger

Table 3 Charging time (At 20°C)

Battery

BSL1815 Approx. 40 min.

NOTE

4. Disconnect the charger’s power cord from the

5. Hold the charger firmly and pull out the battery

NOTE

Charger

The recharging time may vary according to the

ambient temperature and power source voltage.

receptacle.

Be sure to pull out the battery from the charger after

use, and then keep it.

UC18YKSL

7

Page 8

Regarding electric discharge in case of new

batteries, etc.

As the internal chemical substance of new batteries

and batteries that have not been used for an extended

period is not activated, the electric discharge might

be low when using them the first and second time.

This is a temporary phenomenon, and normal time

required for recharging will be restored by recharging

the batteries 2 – 3 times.

How to make the batteries perform longer

(1) Recharge the batteries before they become completely

exhausted.

When you feel that the power of the tool becomes

weaker, stop using the tool and recharge its battery.

If you continue to use the tool and exhaust the electric

current, the battery may be damaged and its life will

become shorter.

(2) Avoid recharging at high temperatures.

A rechargeable battery will be hot immediately after

use. If such a battery is recharged immediately after

use, its internal chemical substance will deteriorate,

and the battery life will be shortened. Leave the battery

and recharge it after it has cooled for a while.

CAUTION

If the battery is charged while it is heated because it

has been left for a long time in a location subject to

direct sunlight or because the battery has just been

used, the pilot lamp of the charger lights for 1 second,

does not light for 0.5 seconds (off for 0.5 seconds). In

such a case, first let the battery cool, then start

charging.

When the pilot lamp flickers (at 0.2-second intervals),

check for and take out any foreign objects in the

charger’s battery connector. If there are no foreign

objects, it is probable that the battery or charger is

malfunctioning. Take it to your authorized Service

Center.

Since the built-in micro computer takes about 3

seconds to confirm that the battery being charged

with UC18YKSL is taken out, wait for a minimum of 3

seconds before reinserting it to continue charging. If

the battery is reinserted within 3 seconds, the battery

may not be properly charged.

PRIOR TO OPERATION

Setting up and checking the work environment

Check if the work environment is suitable by following

the precautions.

HOW TO USE

1. Confirm the clutch dial position (See Fig. 4)

The tightening torque of this unit can be adjusted

according to the clutch dial position, at which the

clutch dial is set.

(1) When using this unit as a screwdriver, line up the one

of the numbers “1, 3, 5 ... 22” on the clutch dial, or

the dots, with the triangle mark on the outer body.

When using this unit as a drill, align the clutch dial drill

(2)

mark “

” with the triangle mark on the outer body.

CAUTION

The clutch dial cannot be set between the numerals

“1, 3, 5 ... 22” or the dots.

Do not use with the clutch dial numeral between

“22” and the line at the middle of the drill mark.

Doing so may cause damage. (See Fig. 5)

2. Tightening torque adjustment

(1) Tightening torque

Tightening torque should correspond in its intensity

to the screw diameter. When too strong torque is

used, the screw head may be broken or be injured.

Be sure to adjust the clutch dial position according to

the screw diameter.

(2) Tightening torque indication

The tightening torque differs depending on the type

of screw and the material being tightened.

The unit indicates the tightening torque with the

numbers “1, 3, 5 ... 22” on the clutch dial , and the

dots. The tightening toque at position “1” is the

weakest and the torque is strongest at the highest

number. (See Fig. 4)

(3) Adjusting the tightening torque

Rotate the clutch dial and line up the numbers “1, 3,

5, ... 22” on the clutch dial, or the dots, with the

triangle mark on the outer body. Adjust the clutch

dial in the weak or the strong torque direction

according to the torque you need.

CAUTION

The motor rotation may be locked to cease while the

unit is used as drill. While operating the driver drill,

take care not to lock the motor.

Too long hammering may cause the screw broken

due to excessive tightening.

3. Change rotation speed

Operate the shift knob to change the rotational speed.

Move the shift knob in the direction of the arrow (see

Figs. 6 and 7).

When the shift knob is set to “LOW”, the drill

rotates at a low speed. When set to “HIGH”, the

drill rotates at a high speed.

CAUTION

When changing the rotational speed with the shift

knob, confirm that the switch is off.

Changing the speed while the motor is rotating will

damage the gears.

When setting the shift knob to “HIGH” (high speed)

and the position of the clutch dial is “17” or “22”, it

may happen that the clutch is not engaged and that

the motor is locked. In such a case, please set the

shift knob to “LOW” (low speed).

If the motor is locked, immediately turn the power

off. If the motor is locked for a while, the motor or

battery may be burnt.

Be sure to turn the shift knob.

4. The scope and suggestions for uses

The usable scope for various types of work based on

the mechanical structure of this unit is shown in

Table 4.

8

Page 9

Table 4

Work Clutch dial Position Suggestion

Wood

Drilling Steel Use for drilling purpose.

Aluminum

Driving

5. How to select tightening torque and rotational speed

Driving

Drilling

Machine screw

Wood screw 1 – Use after drilling a pilot hole.

Use

Machine screw 1 – 22

Wood screw 1 –

Wood

Metal For drilling with a metal working drill bit.

1 – 22 Use the bit or socket matching the screw diameter.

Table 5

Clutch dial Position

Rotating speed selection (Position of the shift knob)

LOW (Low speed) HIGH (High speed)

For 6 mm or smaller

diameter screws.

For 6.8 mm or smaller

nominal diameter screws.

For 38 mm or smaller

diameters.

For 6 mm or smaller

diameter screws.

For 4.8 mm or smaller

nominal diameter screws.

For 24 mm or smaller

diameters screws.

CAUTION

The selection examples shown in Table 5 should be

considered as general standard. As different types of

tightening screws and different materials to be

tightened are used in actual works proper adjustments

are naturally necessary.

When using the driver drill with a machine screw at

HIGH (high speed), a screw may damage or a bit may

loose due to the tightening torque is too strong. Use

the driver drill at LOW (low speed) when using a

machine screw.

NOTE

The use of the battery in a cold condition (below 0

degree Centigrade) can sometimes result in the

weakened tightening torque and reduced amount of

work. This, however, is a temporary phenomenon,

and returns to normal when the battery warms up.

6. Using the light

Pull the trigger switch to light up the light. The light

keeps on lighting while the trigger switch is being

pulled. The light goes out after releasing the trigger

switch. (Fig. 8)

(The light automatically goes out 10 seconds after

releasing the trigger switch.)

CAUTION

Do not expose directly your eye to the light by looking

into the light.

If your eye is continuously exposed to the light, your

eye will be hurt.

7. Mounting and dismounting of the bit

(1) Mounting the bit

Loosen the sleeve by turning it toward the left (in the

counterclockwise direction as viewed from the front)

to open the clip on the keyless chuck. After inserting

a driver bit, etc., into the keyless drill chuck, and

tighten the sleeve by turning it toward the right (in

the clockwise direction as viewed from the front).

(See Fig. 9)

If the sleeve becomes loose during operation, tighten

it further.

The tightening force becomes stronger when the

sleeve is tightened additionally.

(2) Dismounting the bit

Loosen the sleeve by turning it toward the left (in the

counterclockwise direction as viewed from the front),

and then take out the bit etc. (See Fig. 9)

NOTE

If the sleeve is tightened in a state where the clip of

the keyless chuck is opened to a maximum limit, a

click noise may occur. This is the noise that occurs

when the loosening of the keyless chuck is prevented

and is not a malfunction.

CAUTION

When it is no longer possible to loosen the sleeve,

use a vise or similar instrument to secure the bit. Set

the clutch mode between 1 and 11 and then turn the

sleeve to the loose side (left side) while operating the

clutch. It should be easy now to loosen the sleeve.

8. Automatic spindle-lock mechanism

This unit has automatic spindle-lock mechanism for

quick bit changes.

9. Confirm that the battery is mounted correctly

10. Check the rotational direction

The bit rotates clockwise (viewed from the rear side)

by pushing the R-side of the selector button.

The L-side of the selector button is pushed to turn the

bit counterclockwise. (See Fig. 10) (The

marks are provided on the body.)

11. Using the hook (Sold separately)

The hook is used to hang up the power tool to your

waist belt while working.

CAUTION

When using the hook, hang up the power tool firmly

not to drop accidentally.

If the power tool is dropped, it may lead to an accident.

and

9

Page 10

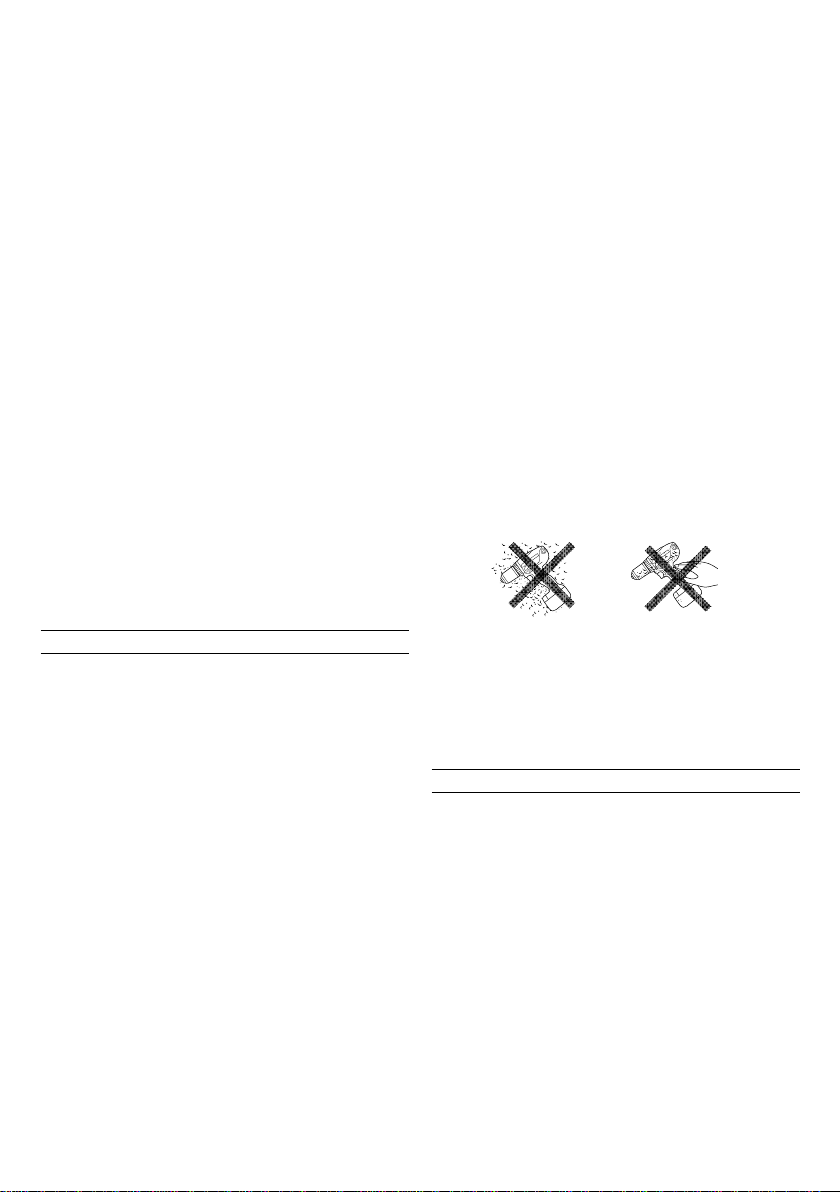

When carrying the power tool with hooked to your

waist belt, do not fit any bit to the tip of power tool. If

the sharp bit such as drill is fitted to the power tool

when carrying it with hooked to your waist belt, you

will be injured.

Install securely the hook. Unless the hook is securely

installed, it may cause an injury while using.

Placing the hook and tightening the screws.

(1)

Install securely the hook in the groove of power tool

and tighten the screws to fix the hook firmly. (Fig. 11)

(2) Removing the hook.

Remove the screws fixing the hook with Phillips screw

driver. (Fig. 12)

12. Switch operation

When the trigger switch is depressed, the tool rotates.

When the trigger is released, the tool stops.

The rotational speed of the drill can be controlled by

varying the amount that the trigger switch is pulled.

Speed is low when the trigger switch is pulled slightly

and increases as the trigger switch is pulled more.

NOTE

A buzzing noise is produced when the motor is about

to rotate; This is only a noise, not a machine failure.

MAINTENANCE AND INSPECTION

1. Inspecting the tool

Since use of a dull tool will degrade efficiency and

cause possible motor malfunction, sharpen or replace

the tool as soon as abrasion is noted.

2. Inspecting the mounting screws

Regularly inspect all mounting screws and ensure

that they are properly tightened. Should any of the

screws be loose, retighten them immediately. Failure

to do so could result in serious hazard.

3. Maintenance of the motor

The motor unit winding is the very “heart” of the

power tool.

Exercise due care to ensure the winding does not

become damaged and/or wet with oil or water.

4. Cleaning on the outside

When the driver drill is stained, wipe with a soft dry

cloth or a cloth moistened with soapy water. Do not

use chloric solvents, gasoline or paint thinner, for

they melt plastics.

5. Storage

Store the driver drill in a place in which the tempera

ture is less than 40°C and out of reach of children.

NOTE

Make sure that the battery is fully charged when

stored for a long period (3 months or more). The

battery with smaller capacity may not be able to be

charged when used, if stored for a long period.

NOTE

Storing lithium-ion batteries

Make sure the lithium-ion batteries have been fully

charged before storing them.

Prolonged storage of batteries with a low charge

may result in performance deterioration, significantly

reducing battery usage time or rendering the batteries

incapable of holding a charge.

However, significantly reduced battery usage time

may be recovered by repeatedly charging and using

the batteries two to five times.

10

If the battery usage time is extremely short despite

repeated charging and use, consider the batteries

dead and purchase new batteries.

6. Service parts list

CAUTION

Repair, modification and inspection of Hitachi Power

Tools must be carried out by a Hitachi Authorized

Service Center.

This Parts List will be helpful if presented with the

tool to the Hitachi Authorized Service Center when

requesting repair or other maintenance.

In the operation and maintenance of power tools, the

safety regulations and standards prescribed in each

country must be observed.

MODIFICATIONS

Hitachi Power Tools are constantly being improved

and modified to incorporate the latest technological

advancements.

Accordingly, some parts may be changed without

prior notice.

Important notice on the batteries for the Hitachi

cordless power tools

Please always use one of our designated genuine

batteries. We cannot guarantee the safety and

performance of our cordless power tool when

used with batteries other than these designated

by us, or when the battery is disassembled and

modified (such as disassembly and replacement

of cells or other internal parts).

GUARANTEE

We guarantee Hitachi Power Tools in accordance with

statutory/country specific regulation. This guarantee does

not cover defects or damage due to misuse, abuse, or

normal wear and tear. In case of complaint, please send

the Power Tool, undismantled, with the GUARANTEE

CERTIFICATE found at the end of this Handling instruction,

to a Hitachi Authorized Service Center.

NOTE

Due to HITACHI’s continuing program of research and

development, the specifications herein are subject to

change without prior notice.

Information concerning airborne noise and vibration

The measured values were determined according to

EN60745 and declared in accordance with ISO 4871.

Measured A-weighted sound power level: 97 dB (A)

Measured A-weighted sound pressure level: 86 dB (A)

Uncertainty Kp

Wear hearing protection.

Vibration total values (triax vector sum) determined

according to EN60745.

Drilling:

Vibration emission value

Uncertainty K = 1.5 m/s

A: 3 dB (A).

2

a

D = 4.5 m/s

h,

2

Page 11

The declared vibration total value has been measured in

accordance with a standard test method and may be

used for comparing one tool with another.

It may also be used in a preliminary assessment of

exposure.

WARNING

The vibration emission during actual use of the power

tool can differ from the declared total value depending

on the ways in which the tool is used.

Identify safety measures to protect the operator that

are based on an estimation of exposure in the actual

conditions of use (taking account of all parts of the

operating cycle such as the times when the tool is

switched off and when it is running idle in addition to

the trigger time).

11

Page 12

2

1

4

5

6

7

8

9

17

18

19

20

27

28

30

10

13

16

21

22

23

24

25

26

3

504

29

33

12

14

15

502

503

11

36

40

37

38

35

35

41

34

31

32

39

506

42

1

Q’TY

Part Name

M6×23

SPECIAL SCREW (LEFT HAND)

1

2 KEYLESS CHUCK 13MM 1

3 GEAR BOX ASS'Y (INCLUD.4-28) 1

4 CLUTCH DIAL 1

5 CLICK SPRING 1

Item

No.

6 NUT 1

2

(W/SP. WASHER) M4×6

MACHINE SCREW

7 SPRING 1

8 WASHER (D) 1

9 FRONT CASE 1

10 ROLLER SET 6

11 STEEL BALL D5 6

12 LOCK RING 1

13 RING GEAR 1

14 NEEDLE ROLLER (A) SET 6

15 CARRIER 1

16 PLANET GEAR (C) SET 3

17 WASHER (A) 1

18 REAR CASE 1

19 SCREW SET D3×12 4

20 SHIFT ARM 1

21 SLIDE RING GEAR (B) 1

22 PINION(C) 1

23 PLANET GEAR (B) SET 3

24 PINION (B) 1

25 PLANET GEAR (A) SET 3

26 FIRST RING GEAR 1

27 WASHER (B) 1

28 MOTOR SPACER 1

29 MOTOR 1

30

31 INTERNAL WIRE FERRITE SET 1

32 INTERNAL WIRE (BLACK) 1

33 HOUSING (A) (B) SET 1

34 SHIFT KNOB 1

35 LOCK NUT M4 2

36 INTERNAL WIRE (RED) 1

9

D3×16

TAPPING SCREW (W/FLANGE)

37 PUSHING BUTTON 1

38 SWITCH TERMINAL SET 1

39 SUPPORT (D) 1

40

41 NAME PLATE 1

42 BATTERY (BSL1815) 2

502 CHARGER (UC18YKSL) 1

503 PLUS DRIVER BIT NO.2 65L 1

504 BATTERY COVER 1

506 CASE 1

12

Page 13

English

GUARANTEE CERTIFICATE

1 Model No.

2 Serial No.

3 Date of Purchase

4 Customer Name and Address

5 Dealer Name and Address

(Please stamp dealer name and address)

Deutsch

GARANTIESCHEIN

1 Modell-Nr.

2 Serien-Nr.

3 Kaufdaturn

4 Name und Anschrift des Kunden

5 Name und Anschrift des Händlers

(Bitte mit Namen und Anschrift des

Handlers abstempeln)

Français Português

CERTIFICAT DE GARANTIE

1 No. de modèle

2 No. de série

3 Date d’achat

4 Nom et adresse du client

5 Nom et adresse du revendeur

(Cachet portant le nom et l'adresse du

revendeur)

Italiano

Nederlands

1 Modelnummer

2 Serienummer

3 Datum van aankoop

4 Naam en adres van de gebruiker

5 Naam en adres van de handelaar

(Stempel a.u.b. naam en adres vande de

handelaar)

Español

1 Número de modelo

2 Número de serie

3 Fecha de adquisición

4 Nombre y dirección del cliente

5 Nombre y dirección del distribudor

(Se ruega poner el sellú del distribudor

con su nombre y dirección)

1 Número do modelo

2 Número do série

3 Data de compra

4 Nome e morada do cliente

5 Nome e morada do distribuidor

(Por favor, carímbe o nome e morada

do distribuidor)

GARANTIEBEWIJS

CERTIFICADO DE GARANTIA

CERTIFICADO DE GARANTIA

CERTIFICATO DI GARANZIA

1 Modello

2 N° di serie

3 Data di acquisto

4 Nome e indirizzo dell’acquirente

5 Nome e indirizzo del rivenditore

(Si prega di apporre il timbro con questi

dati)

✄

13

Page 14

1

2

3

4

5

✄

14

Page 15

Hitachi Power Tools Europe GmbH

Siemensring 34, 47877 willich, Germany

Tel: +49 2154 49930

Fax: +49 2154 499350

URL: http://www.hitachi-powertools.de

Hitachi Power Tools Netherlands B. V.

Brabanthaven 11, 3433 PJ Nieuwegein, The Netherlands

Tel: +31 30 6084040

Fax: +31 30 6067266

URL: http://www.hitachi-powertools.nl

Hitachi Power Tools (U. K.) Ltd.

Precedent Drive, Rooksley, Milton Keynes, MK 13, 8PJ, United Kingdom

Tel: +44 1908 660663

Fax: +44 1908 606642

URL: http://www.hitachi-powertools.co.uk

Hitachi Power Tools France S. A. S.

Prac de l ’Eglantier 22, rue des Crerisiers Lisses-C. E. 1541,

91015 EVRY CEDEX, France

Tel: +33 1 69474949

Fax: +33 1 60861416

URL: http://www.hitachi-powertools.fr

Hitachi Power Tools Belgium N.V. / S.A.

Koningin Astridlaan 51, 1780 Wemmel, Belgium

Tel: +32 2 460 1720

Fax: +32 2 460 2542

URL http://www.hitachi-powertools.be

Hitachi Fercad Power Tools Italia S.p.A

Via Retrone 49, 36077, Altavilla Vicentina (VI), Italy

Tel: +39 0444 548111

Fax: +39 0444 548110

URL: http://www.hitachi-powertools.it

Hitachi Power Tools lberica, S.A.

Puigbarral, 26-28 Pol. Ind. Can Petit 08227 TERRSSA (Barcelona) Spain

Tel: +34 93 735 6722

Fax: +34 93 735 7442

URL: http://www.hitachi-powertools.es

Hitachi Power Tools Österreich GmbH

Str. 7, Objekt 58/A6, Industriezentrum NÖ –Süd 2355

Wiener Neudorf, Austria

Tel: +43 2236 64673/5

Fax: +43 2236 63373

URL: http://www.hitachi-powertools.at/

15

Page 16

Object of declaration: Hitachi Cordless Driver Drill DS18DGL

d.

We declare under our sole responsibility that this product is in conformity with standards or standardization documents

EN60745-1, EN60745-2-1, EN60745-2-2, EN60335-1, EN60335-2-29, EN55014-1, EN55014-2 and EN61000 in accordance with

Directives 2004/108/EC, 2006/95/EC and 2006/42/EC. This product also conforms to RoHS Directive 2011/65/EU.

The European Standards Manager at Hitachi Koki Europe Ltd. is authorized to compile the technical file.

This declaration is applicable to the product affixed CE marking.

EC DECLARATION OF CONFORMITY

Hitachi Koki Europe Ltd.

Clonshaugh Business & Technology Park, Dublin 17,

lreland

Representative office in Europe

Hitachi Power Tools Europe GmbH

Siemensring 34, 47877 Willich 1, F. R. Germany

Head office in Japan

Hitachi Koki Co., Ltd.

Shinagawa Intercity Tower A, 15-1, Konan 2-chome,

Minato-ku, Tokyo, Japan

28. 2. 2014

John de Loughry

European Standard Manager

28. 2. 2014

F. Tashimo

Vice-President & Director

Hitachi Koki Co., Lt

Code No. C99213411 G

402

Printed in China

Loading...

Loading...