K6602637

Rev.3

02.27.01

- 1 -

OEM Manual

DK23CA-30F/30/15/75 Disk Drive

Specifications

REV.3

Caution for Safety

Read Safety descriptions carefully.

Read and recommend drive usage cautions to your end user.

Keep this manual with care.

(Total 104 pages)

H I T A C H I

All Rights Reserved, Copyright ©2001 Hitachi, Ltd.

K6602637

Rev.3

02.27.01

- 2 -

Rev.0: 01.30.01 Preliminary

Rev.1: 02.08.01 Preliminary

Rev.2: 02:15:01

Rev.3: 02:27:01

To use this product safely

To use the product, read safet y descript ions below and understand t hor oughly.

Keep this manual with care to insure unlimited use.

l

General Caution for Safety

The followings are general cautions for safe use of this product.

(Caution before Product Use)

- Please read and follow all instructions and cautions described on “Safety Instructions” (Page 4) and “1.2

General Caution” (Page 10 and 11) before attempting to use this product.

- Follow all instructions and cautions indicated throughout this manual and the product. Failure to follow

these instructions and cautions may cause injury, fire and product damage.

l

Advise y our end user of the safety caution

Read and recommend that your end users read the caution for drive usage in this manual.

l

Protect yourself

The safety instructions in this manual were thoroughly considered, but unexpect ed situations can occur.

Not only follow the instructions on this manual, but also be careful for t he safety of yourself.

l

Symbol of safety caution

Safety instructions and cautions are indicated as the following headline, which consist s a symbol (marking)

and word of “Caution”. The indication and meaning are as follows:

Caution:

This symbol indicates that potential danger may exist which may cause bodily

injury or damage to the product if safety instructions are not followed.

l

Safety caution in this manual

Followings are the cautions and contents described in this manual.

Items of indicating

Caution

:

-

Safety Instructions Page 4

-

General Caution Sec. 1.2, Page 10 – 11

-

Power Supply Requirements Sec.3.1, Page 14

-

Maximum Power off Interval Sec. 3.2, Page 15

-

Data Reliability Sec. 3.2, Page 16

-

Attention for HDD Installation Sec. 4.2.3, Page 21

-

Packing Sec. 5.1, Page 23

-

Handling Sec. 5.2, Page 24

K6602637

Rev.3

02.27.01

- 3 -

To use this product safely (Continued)

l

Environmental circumstance

Although this product partially scatters electro-magnetic field into the air, it has been inspected and was

installed under Electro-magnetic regulations of resident areas, such as EMC standard EN55022

(corresponding to FCC part 15 Class B, etc.). However, anything other than this product, such as an

interface cable, is excluded. Therefore, the following cases require a system side improvement for the

electro-magnetic field regulations.

1) Disturbance of operations of other products or equipment in resident area

2) Disturbance caused by other product, such as cabling, to operations of other products or equipment.

Only Hitachi trained persons should change this product Hitachi assumes no responsibility for products

which have been changed by anyone else.

l

Safety regulations

This product meets the following safety regulations, but the sy st em side should consider the safet y of the

system with this product.

Regulations: - UL1950 Third Edition dated July 28, 1995

- CSA C22.2 N0.950-M95

- IEC60950 A4: 1996

- EN60950 A11: 1992

Warranty and Limited Liability

This product is sold with a limited warranty and specific remedies are available to the original purchaser in

the event the product fails to confor m t o t he limited warranty. Hitachi’s liability may be further limited in

accordance with its sales contact.

In general, Hitachi shall not be responsible for product damages caused by natural disasters, fire, static

discharge, misuse, abuse, neglect, improper handling or installation, unauthorized repair, alteration or

accident. In no event will Hitachi be liable for loss of dat a st or ed on pr oduct.

HITACHI SHALL NOT BE LIABLE FOR ANY SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES,

EVEN IF INFORMED OF THE POSSIBILI TY THEREOF IN ADVANCE.

Please see your sales contract for a complete statement of warranty rights, remedies and limitation of

liability.

K6602637

Rev.3

02.27.01

- 4 -

Safety Instructions

1. The product is not authorized for use in life support devices or syst ems or other applicat ions that pose a

significant risk of personal injury.

2. Since the drive uses glass media for the disk platter, opening of Metal Head Disk Assembly (HDA) may

cause bodily injury. Warranty void in case of opened HDA or any broken HDA seals. Don’t open the HDA

or break any HDA seals.

3. Dropping of the HDD may cause bodily injury. Handle with care.

4. Do not cover the breather hole. If the hole was cov ered w it h any material, it shall result in permanent

damage to the drive and/or loss of data. Label or seal shall be attached on the cover avoiding the

breather hole. Warranty void if the breather hole was covered.

5. Do not hit the interface connector pins against other objects. Do not make contact w ith the interface

connector pins. Contact causes pin dent, electrical discharge distraction or contact failure. Also, pins or

HDA corners may cause bodily injury. Handle with care.

6. Observe Clause 3.3 “Drive Usage Condition Specificat ions” . Since r eliability and product life depends on

usage conditions, please consult our sales or application engineers.

7. Keep usage conditions within specifications (Power Supply, Environment, etc.). If the conditions are not

kept within the specifications, failures may occur.

8. Hot swapping (Power-on swapping) can damage the drive. The drive shall be sw apped during Pow er O ff

only.

9. Electro Static Discharge (ESD) can damage the drive. Protect the drive from ESD during handling.

10. Voltage rise time 5 - 100 ms at power on is required for power supply. The power supply v olt age must

not be under below GND level (0 V) at power off.

11. This product is required over current protection for possible combustion due to circuit or component

failure. Secondary over current protection shall be prepared by the system. The requirement of the

current limitation is max. 10 A for the protection.

12. Improper insertion of connector or wrong jumper setting may cause catastrophic failures. Referring to

this manual prior to the connector insertion or jumper setting can help to insure correct insertion.

13. If a foreign conductive substance (metallic powder, fluid, etc.) adheres to active metal of the driv e

(Printed pattern, component lead, etc. on PCBA), it may cause catast rophic failures. Cust omer should

protect the drive from the above condition.

14. The PCBA side of the drive should be covered with insulation sheet if t he active metal of host system

may contact to the PCBA of the drive. If the insulation sheet is not provided for the possible contact of the

live metal, failures may occur.

15. Shock can result in permanent damage to the drive and/or loss of data. Prevent shocks, which is often

incurred by dropping, knocking over, or hitting the drive.

16. To fix the drive, use the size of screws and the torque recommended in this manual. If nonrecommended size screws and torque are used, it may cause catastrophic failures.

17. Do not press top cover. It may cause catastrophic failures. In case of steel plate installation on HDD

cover side, the spacing between HDD cover and steel plate should be kept more than 2 mm. If this

spacing is not kept for the steel plate, it may affect Load/Unload mechanism.

18. Do not push the bottom PCBA of the drive. It may cause cat ast rophic failures.

Caution

K6602637

Rev.3

02.27.01

- 5 -

Safety Instructions

(Continued)

19. The long-term storage without power on should not exceed one year.

20. Prevent humidity when the drive is packed in a box.

21. Use original packages (50 units’ package) during drive transportation to protect from any damage.

(Keep some extra packages for the drive transportation)

22. To returning over 100 units, use original outside package with pallet or proper packaging with pallet to

protect from any damage.

23. Recorded data on the disk may be lost due to accidents such as disasters, shock damage during

handling or drive failure. To prepare for accidents, back up data. Hitachi does not perform data

recovery.

24. Data may be lost due to unexpected or accidental power loss during write operat ion.

NOTICE TO USERS

While every effort has been made to ensure that the information provided herein is correct please feel free

to notify us in the event of an error or inconsistency.

Hitachi makes no representations or warranties with respect to the contents hereof and specifically

disclaims any implied warranties or merchantability or fitness for any purpose.

Further Hitachi reserves the right to revise this publication and t o make changes from time to time in the

content hereof without obligation to notify any person of such revisions or changes.

Caution

K6602637

Rev.3

02.27.01

- 6 -

Contents Page

To use this product safely

--------------------------- 2

1. 0 General --------------------------- 9

1.1 General --------------------------- 9

1.2 General Caution --------------------------- 10

2.0 Components --------------------------- 12

3.0 Specification Summary --------------------------- 13

3.1 Principal Specifications --------------------------- 13

3.2 Environmental Specifications and Reliability --------------------------- 15

3.3 Drive Usage Condition Specifications --------------------------- 16

3.4 Load/Unload Specifications --------------------------- 17

3.4.1 Normal Load/Unload --------------------------- 17

3.4.2 Emergency Unload --------------------------- 17

3.4.3 Required Power Off Sequence --------------------------- 17

4.0 Installation --------------------------- 18

4.1 Installation Direction --------------------------- 18

4.2 Mounting HDD --------------------------- 19

4.2.1 Mounting HDD with Screws --------------------------- 19

4.2.2 Single HDD Test Condition --------------------------- 20

4.2.3 Attention for HDD Installation --------------------------- 21

4.3 Drive Address Setting(DRIVE 0/DRIVE 1) --------------------------- 21

4.4 Dimensions --------------------------- 22

5.0 Packing and Handling --------------------------- 23

5.1 Packing --------------------------- 23

5.2 Handling --------------------------- 24

6.0 Interface --------------------------- 25

6.1 Power Interface --------------------------- 25

6.2 Physical Interface --------------------------- 26

6.2.1 Connector --------------------------- 26

6.2.2 Connector Pin Assignment --------------------------- 27

6.2.3 Description of the Interface Signals --------------------------- 28

6.3 Logical Interface --------------------------- 31

6.3.1 I/O Registers --------------------------- 31

6.3.1.1 Data Register --------------------------- 31

6.3.1.2 Error Register --------------------------- 31

6.3.1.3 Features Register --------------------------- 32

6.3.1.4 Sector Count Register --------------------------- 32

6.3.1.5 Sector Number Register --------------------------- 32

6.3.1.6 Cylinder Low Register --------------------------- 32

6.3.1.7 Cylinder High Register --------------------------- 32

6.3.1.8 Device/Head Register --------------------------- 33

6.3.1.9 Status Register --------------------------- 33

6.3.1.10 Command Register --------------------------- 33

6.3.1.11 Alternate Status Register --------------------------- 34

6.3.1.12 Device Control Register --------------------------- 34

K6602637

Rev.3

02.27.01

- 7 -

6.3.2 Command --------------------------- 35

6.3.2.1 Command Summary --------------------------- 35

6.3.2.2 Command BSY Timing --------------------------- 36

6.3.2.3 PIO Data In Commands --------------------------- 37

6.3.2.3.1 Identify Device [ECh] --------------------------- 38

6.3.2.3.2 Read Buffer [E4h] --------------------------- 45

6.3.2.3.3 Read Sectors [20h, 21h] --------------------------- 45

6.3.2.3.4 Read Long [22h, 23h] --------------------------- 45

6.3.2.3.5 Read Multiple [C4h] --------------------------- 45

6.3.2.4 PIO Data Out Commands --------------------------- 46

6.3.2.4.1 Write Buffer [E8h] --------------------------- 46

6.3.2.4.2 Write Sectors [30h, 31h] --------------------------- 46

6.3.2.4.3 Write Long [32h, 33h] --------------------------- 46

6.3.2.4.4 Write Multiple [C5h] --------------------------- 46

6.3.2.4.5 Format Track [50h] --------------------------- 47

6.3.2.5 Non-Data Commands --------------------------- 47

6.3.2.5.1 Initialize Device Parameters [91h] --------------------------- 47

6.3.2.5.2. Read Verify [40h, 41h] --------------------------- 48

6.3.2.5.3 Recalibrate [1Xh] --------------------------- 48

6.3.2.5.4 Seek [7Xh] --------------------------- 48

6.3.2.5.5 Set Features [EFh] --------------------------- 48

6.3.2.5.6 Set Multiple Mode [C6h] --------------------------- 49

6.3.2.5.7 Execute Device Diagnostic [90h] --------------------------- 49

6.3.2.5.8 Flush Cache [E7h] --------------------------- 50

6.3.2.6 Power Commands --------------------------- 51

6.3.2.6.1 Power Management --------------------------- 51

6.3.2.6.2 Advanced Power Management --------------------------- 52

6.3.2.6.3 Check Power Mode [98h, E5h] --------------------------- 53

6.3.2.6.4 Idle [97h, E3h] --------------------------- 54

6.3.2.6.5 Idle Immediate [95h, E1h] --------------------------- 54

6.3.2.6.6 Sleep [99h, E6h] --------------------------- 54

6.3.2.6.7 Standby [96h, E2h] --------------------------- 54

6.3.2.6.8 Standby Immediate [94h, E0h] --------------------------- 54

6.3.2.7 DMA Data In/Out Commands --------------------------- 55

6.3.2.7.1 Read DMA [C8h, C9h] --------------------------- 55

6.3.2.7.2 Write DMA [CAh, CBh] --------------------------- 55

6.3.2.8 SMART Feature --------------------------- 56

6.3.2.8.1 Attribute Parameters --------------------------- 56

6.2.7.8.2 SMART Device Error Log Reporting --------------------------- 57

6.2.7.8.3 SMART Operation with Management Modes --------------------------- 57

6.3.2.8.4 SMART Function Default Setting --------------------------- 57

6.3.2.8.5 SMART Enable Operations [B0h, Sub D8h] --------------------------- 57

6.3.2.8.6 SMART Disable Operations [B0h, Sub D9h] --------------------------- 58

6.3.2.8.7 SMART Return Status [B0h, Sub DAh] --------------------------- 59

6.3.2.8.8 SMART Enable/Disable Attribute AUTOSAVE [B0h, Sub D2h] ------------------ 59

6.3.2.8.9 SMART Save Attribute Values [B0h, Sub D3h] ---------------------------- 60

6.3.2.8.10 SMART Enable/Disable Automatic Off-line [B0h, Sub DBh] ------------------- 61

6.3.2.8.11 SMART Execute Off-line Immediate [B0h, Sub D4h] ------------------------- 62

K6602637

Rev.3

02.27.01

- 8 -

6.3.2.8.12 SMART Read Log Sector [B0h, Sub D5h] --------------------------- 65

6.3.2.8.13 SMART Write Log Sector [B0h, Sub D6h] --------------------------- 70

6.3.2.9 Security Mode Feature --------------------------- 71

6.3.2.9.1 Security Mode Default Setting --------------------------- 71

6.3.2.9.2 Initial Setting of the User Password --------------------------- 72

6.3.2.9.3 Security Mode Operation from Power-on or Hardware Reset ---------------------- 72

6.3.2.9.4 User Password Lost --------------------------- 73

6.3.2.9.5 Security Set Password [F1h] --------------------------- 74

6.3.2.9.6 Security Unlock [F2h] --------------------------- 75

6.3.2.9.7 Security Erase Prepare [F3h] --------------------------- 76

6.3.2.9.8 Security Erase Unit [F4h] -------------------------- 76

6.3.2.9.9 Security Freeze Lock [F5h] --------------------------- 77

6.3.2.9.10 Security Disable Password [F6h] --------------------------- 77

6.3.2.9.11 Security Mode Command Action [F1h] --------------------------- 78

6.3.2.10 Protected Area Feature, Address Offset Feature --------------------------- 79

6.3.2.10.1 Protected Area Feature and Set Max Security Extension -------------------------- 79

6.3.2.10.2 Address Offset Feature --------------------------- 80

6.3.2.10.3 Read Max Address Command [F8h] --------------------------- 82

6.3.2.10.4 Set Max Address Command [F9h, Sub 00h] --------------------------- 83

6.3.2.10.5 Set Max Set Password Command [F9h, Sub 01h] --------------------------- 85

6.3.2.10.6 Set Max Lock Command [F9h, Sub 02h] --------------------------- 85

6.3.2.10.7 Set Max Unlock Command [F9h, Sub 03h] --------------------------- 86

6.3.2.10.8 Set Max Freeze Lock Command [F9h, Sub 04h] --------------------------- 86

6.3.2.11 Note for Write Cache and Auto Reallocation --------------------------- 87

6.4 Interface Signal Timing --------------------------- 88

6.4.1 Data Transfer Timing --------------------------- 88

6.4.2 Ultra DMA Data Transfer Timing --------------------------- 91

6.4.3 Power On and Hardware Reset Timing --------------------------- 101

< Glossary > --------------------------- 102

< Reference > --------------------------- 103

K6602637

Rev.3

02.27.01

- 9 -

1.0 General

1.1 Introduction

The DK23CA series disk drives reach high capacities (30,005MB, 15,103MB and 7,501MB for 9.5mm

height) in a 2.5 type form factor by applying the latest high-density recording technology. Model Names

DK23CA-xxF indicates FDB (Fluid Bering) motor type, and DK23CA-xx indicates Ball Bering motor type.

Capacity

Model (Formatted) Height Interface

DK23CA-30F/30 30,005 MB 9.5 mm ATA-5(IDE)

DK23CA-15 15,103 MB 9.5 mm ATA-5(IDE)

DK23CA-75 7,501 MB 9.5 mm ATA-5(IDE)

[Features]

-

GMR Head

-

ID-less Format

-

ME

2

PRML Read Channel

-

Data Transfer Rate

(Host-Device)

-16.6 MB/sec: PIO mode-4/Multiword DMA mode-2

- 100 MB/sec: Ultra DMA mode-5

(Device-Buffer)

- 16.5 to 28.7 MB/sec

-

CDR (Constant Density Recording)

-

On-the-fly ECC Correction

-

Buffer: 2MB(DK23CA-30F/30)/512 KB(DK23CA-15/75)

-

Read-ahead Cache/Write Cache

-

Auto Read Reassign/Auto Write Reassign

-

SMART

-

Average Access Time 12 ms

-

Embedded Sector Servo

-

FDB Motor (DK23CA-30F)/Ball Bering Motor (DK23CA-30/15/75)

-

Rotary Actuator

-

Load/Unload Mechanism

-

95 grams(DK23CA-30F/30)/91 grams(DK23CA-15/75)

-

Low Power Consumption: 0.65W(130mA) at Idle mode, 0.25W(50mA) at Standby mode

-

Advanced Power Management(APM)

-

Non-operating Shock 7,840m/S

2

(800G, 2ms, half-sine wave)

-

Operating Shock 1,764m/S

2

(180G, 2ms, half-sine wave)

-

MCC 2.5 inch Small Form Factor(9.5mm height)

[Identify Device Information for Setup]

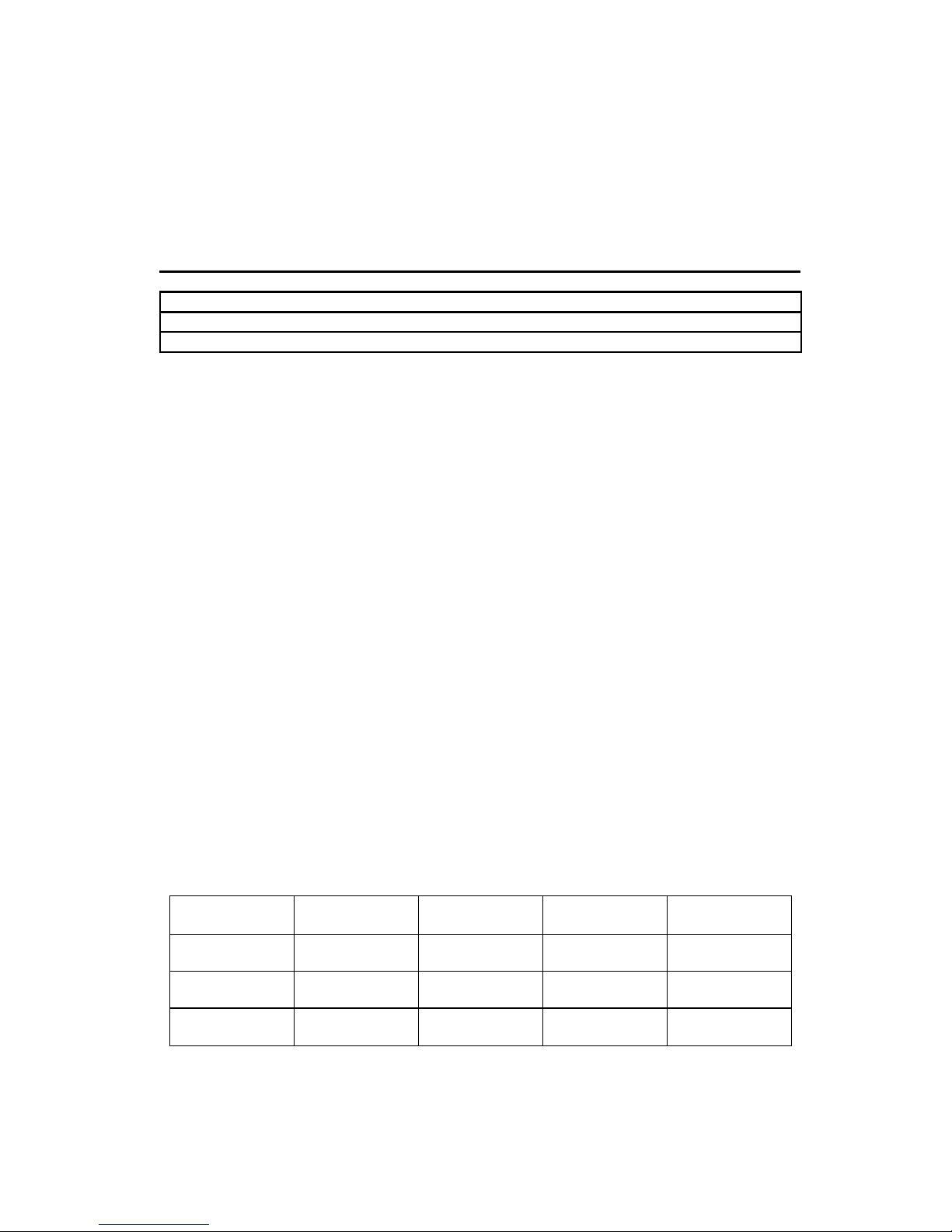

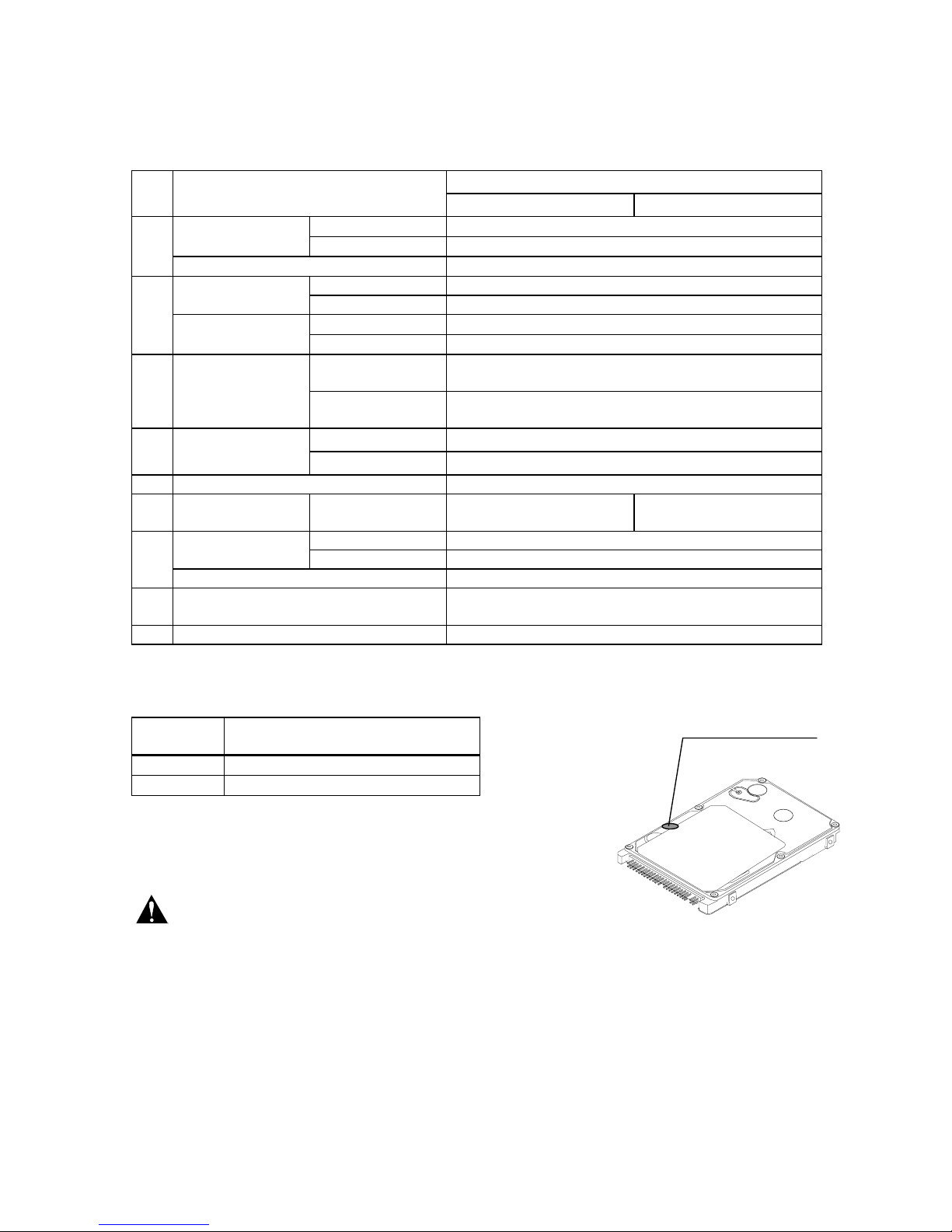

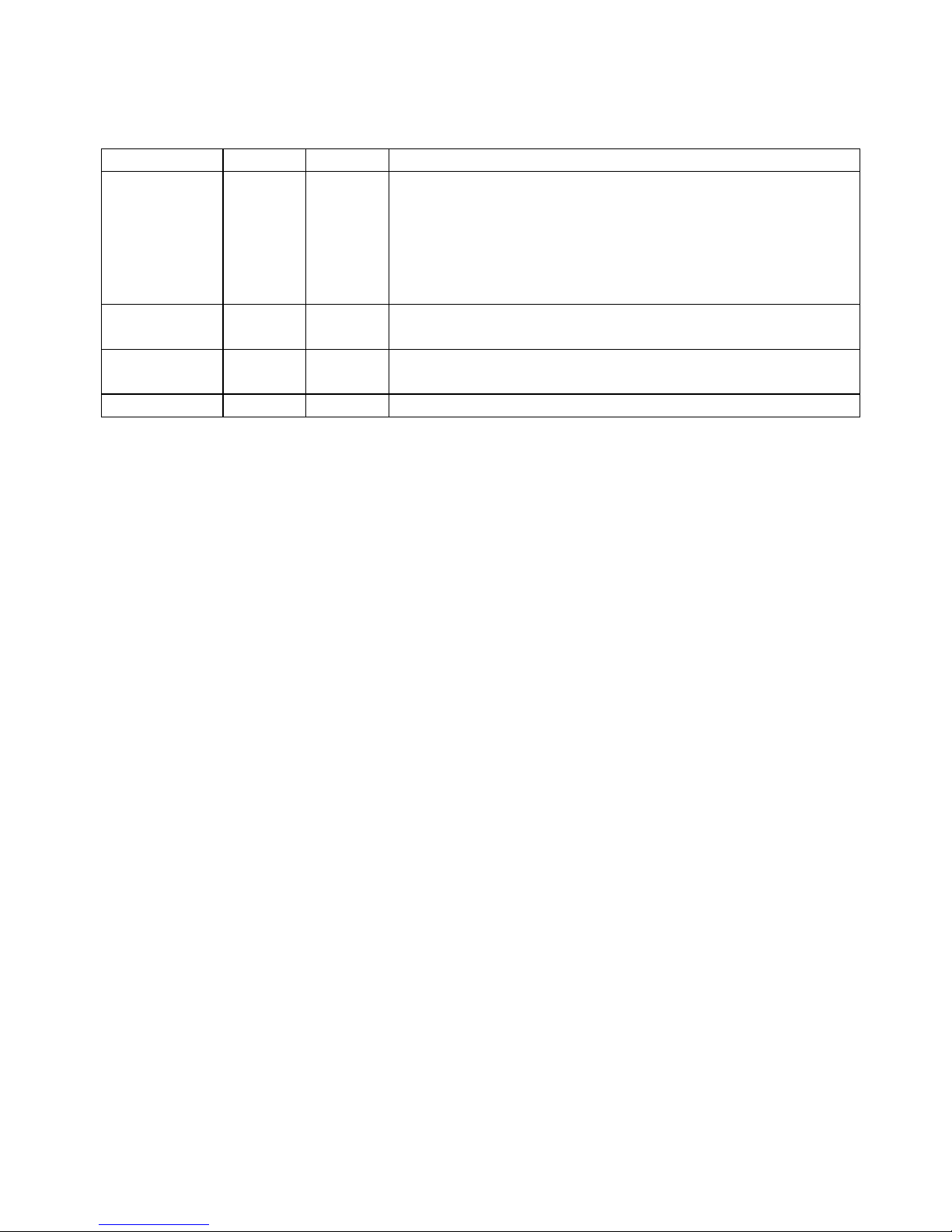

Table 1.1 Identify Device information (Addressing)

Model Word 1

Number of CYL.

Word 3

Number of HD

Word 6

Number of SPT

Word 60、61

Total LBA

DK23CA-30F/30 16383

(3FFFh)

16

(0010h)

63

(3Fh)

58605120

(037E3E40h)

DK23CA-15 16383

(3FFFh)

16

(0010h)

63

(3Fh)

29498112

(01C21B00h)

DK23CA-75

15504 (

*1)

(3C90h)

15

(000Fh)

63

(3Fh)

14651280

(00DF8F90h)

*1.

Maximum capacity in CHS mode is 8,455MB.

K6602637

Rev.3

02.27.01

- 10 -

1.2 General Caution

Adhere to the following cautions.

(a) Warranty void if Metal Head Disk Assembly (HDA) is opened, or any HDA seal/label is broken.

(b) Hot swapping (Power on) damages the drive. The drive should be swapped during Power O ff only.

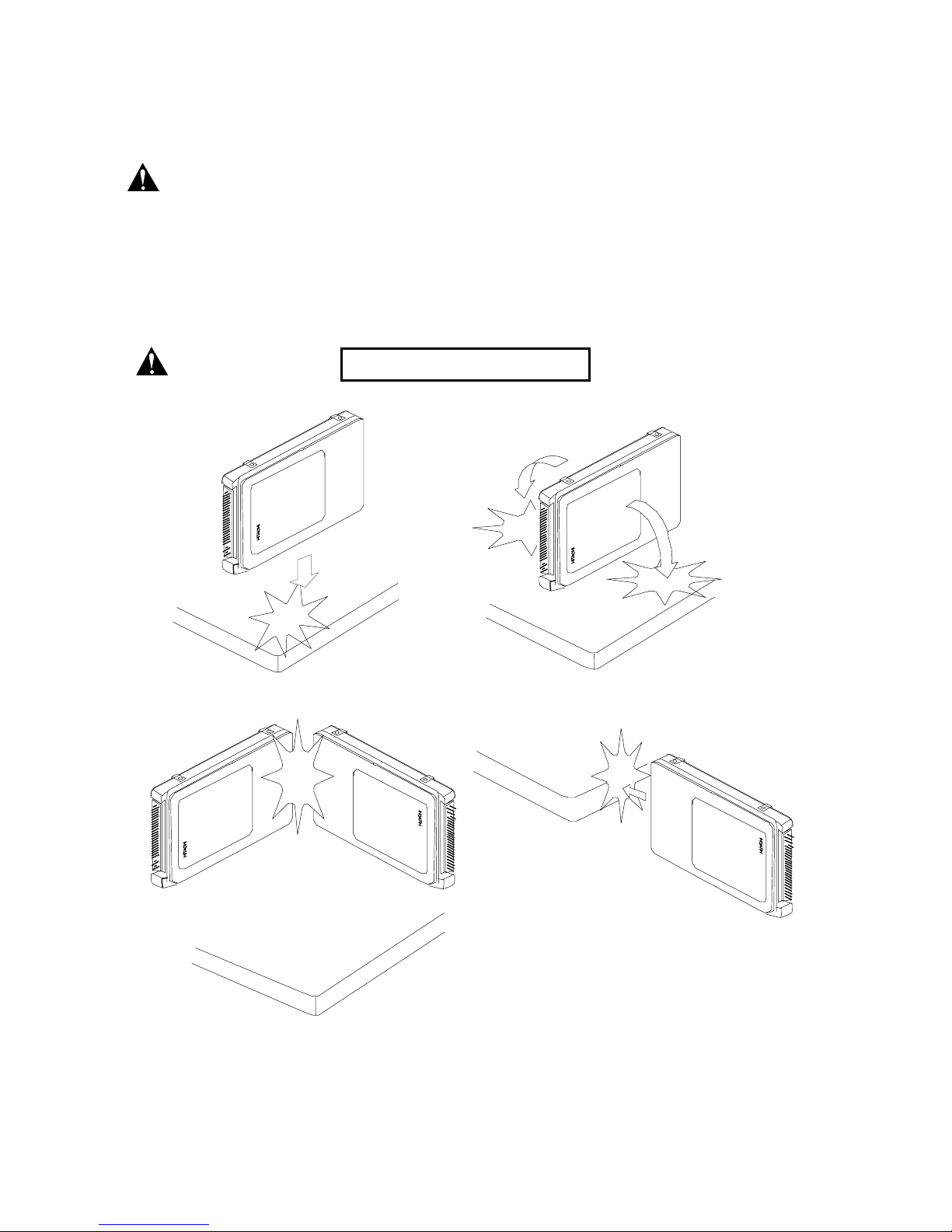

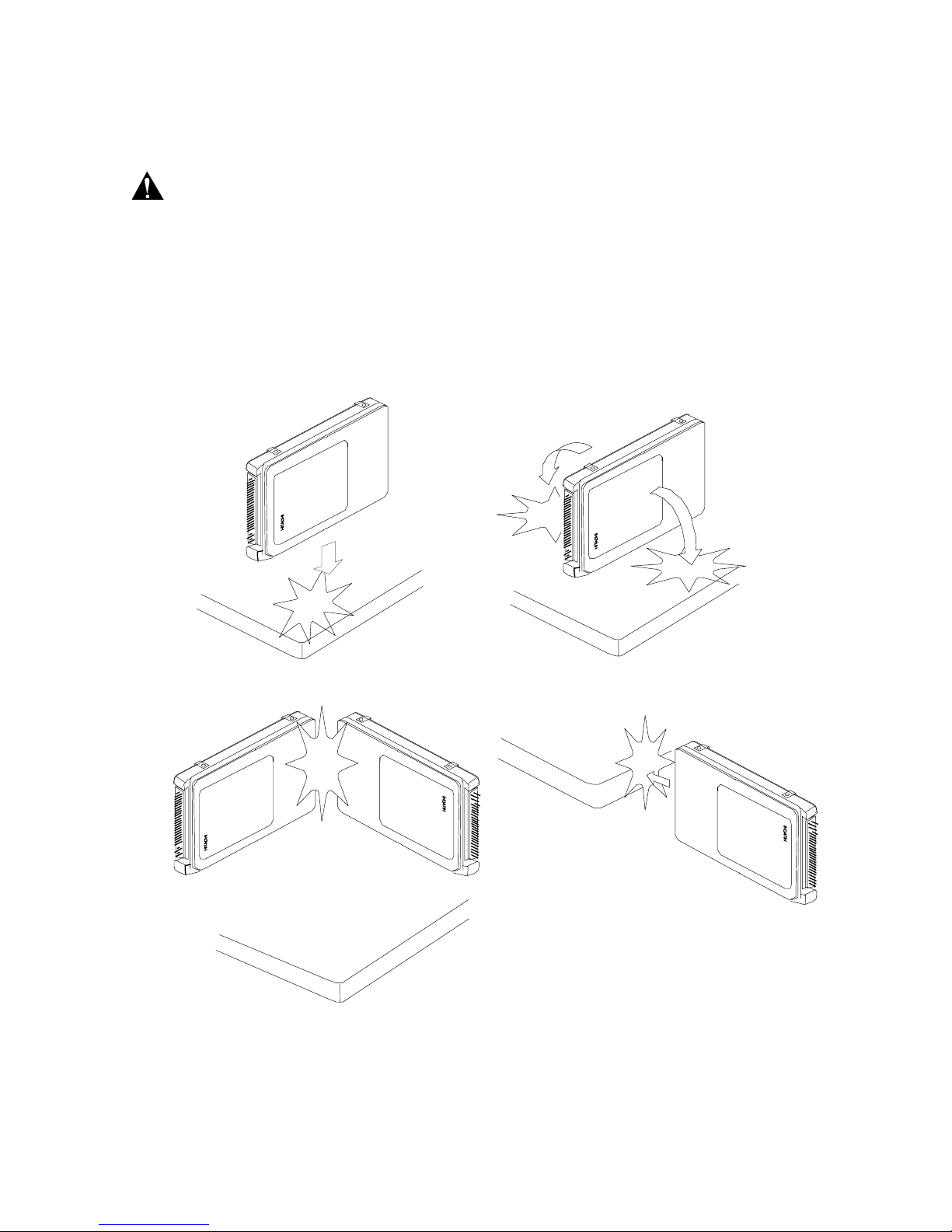

(C) Shock can result in permanent damage to the drive and/or loss of data.

Prevent shocks often incurred by dropping, knocking over, or hitting the drive.

(Dropping) (Knocking over)

(Hitting) (Hitting)

Figure 1-1

Caution

PREVENT SHO CK S

Caution

K6602637

Rev.3

02.27.01

- 11 -

(Continued)

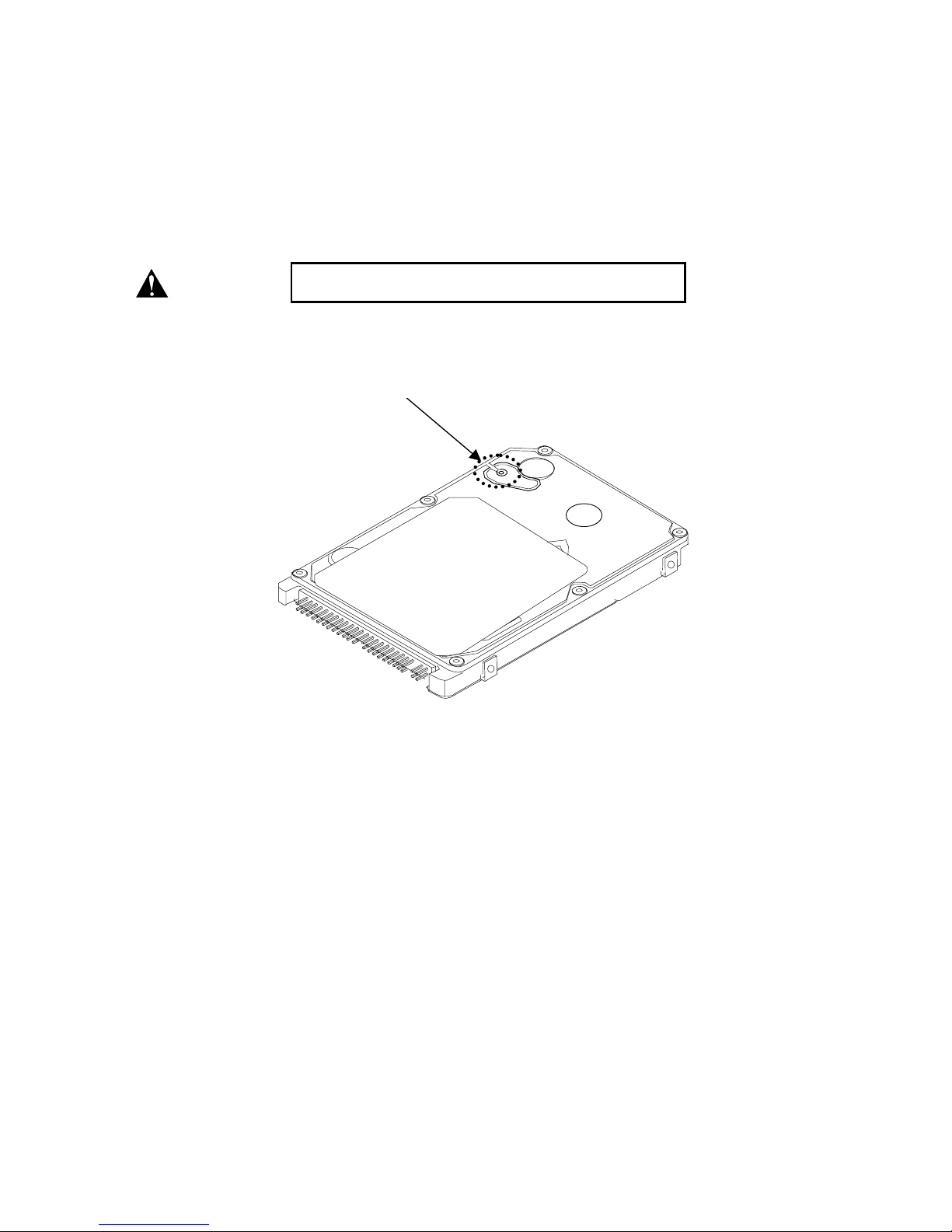

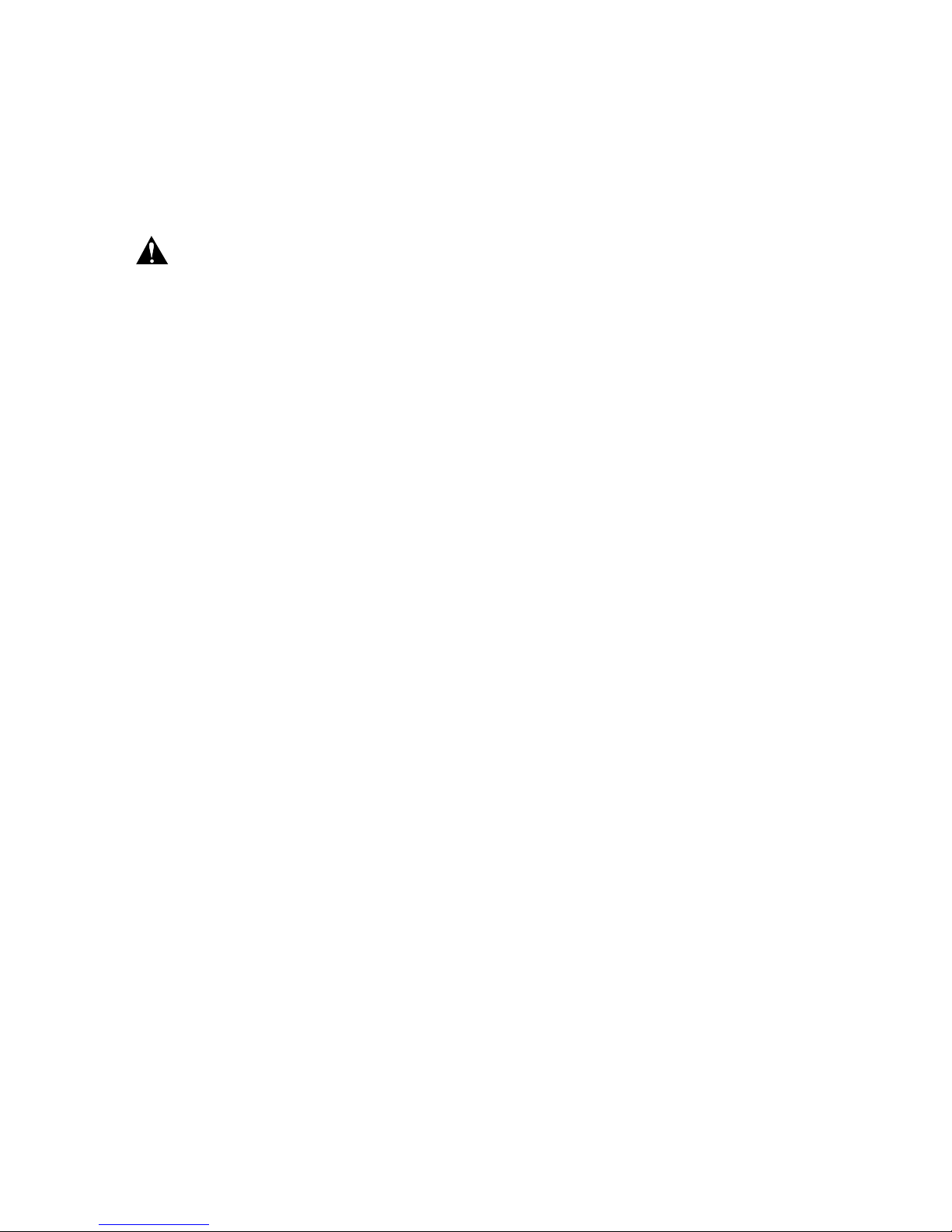

(d) Do not cover the breather hole. If the hole was covered w ith any material, it shall result in permanent

damage to the drive and/or loss of data. Label or seal shall be attached on the cover avoiding the

breather hole. Warranty void if the breather hole was covered.

Caution

Do not cover the breather hole

Breather hole

Figure 1-2 Breather hole location

K6602637

Rev.3

02.27.01

- 12 -

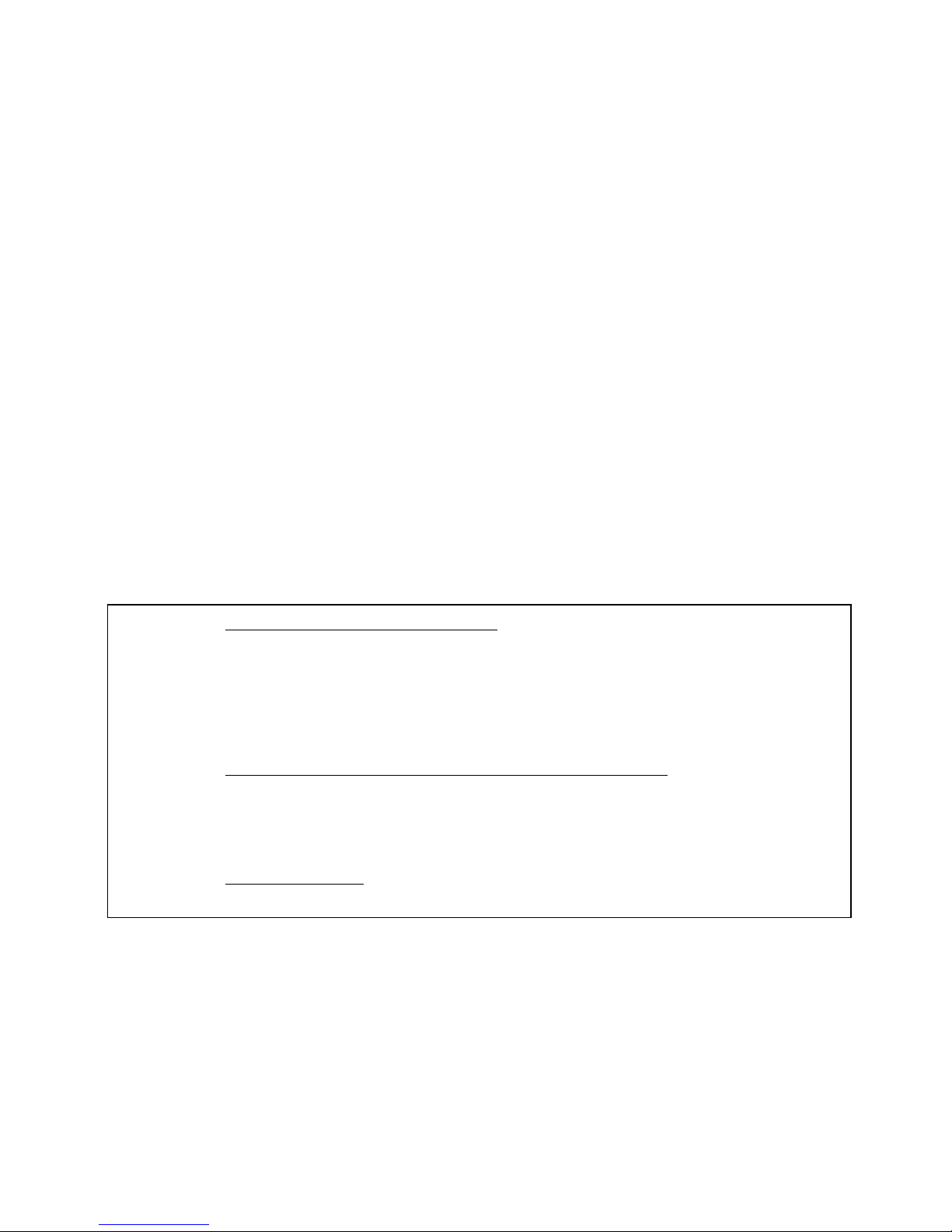

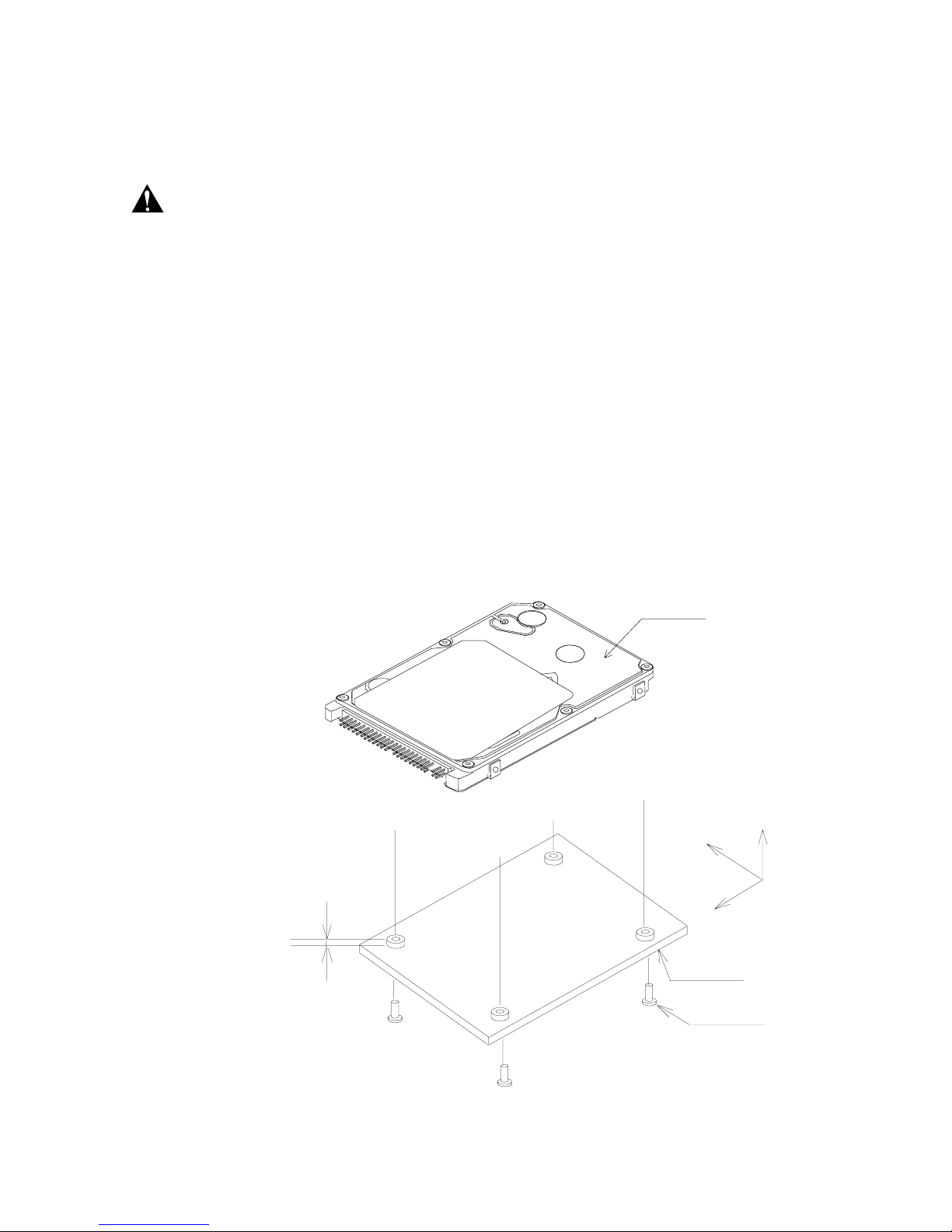

2.0 Components

DK23CA-30F/30/15/75 Disk Drive

Figure 2-1 Overview of DK23CA-30F/30/15/75 (9.5mm height)

Note: 1) Prepare connection cables referring to Sec. 6.2.

2) Mounting holes are compatible with DK237A-XX, DK238A-XX, DK239A-XX, DK23AA-XX

DK23BA-xx and DK23BA - XXE.

K6602637

Rev.3

02.27.01

- 13 -

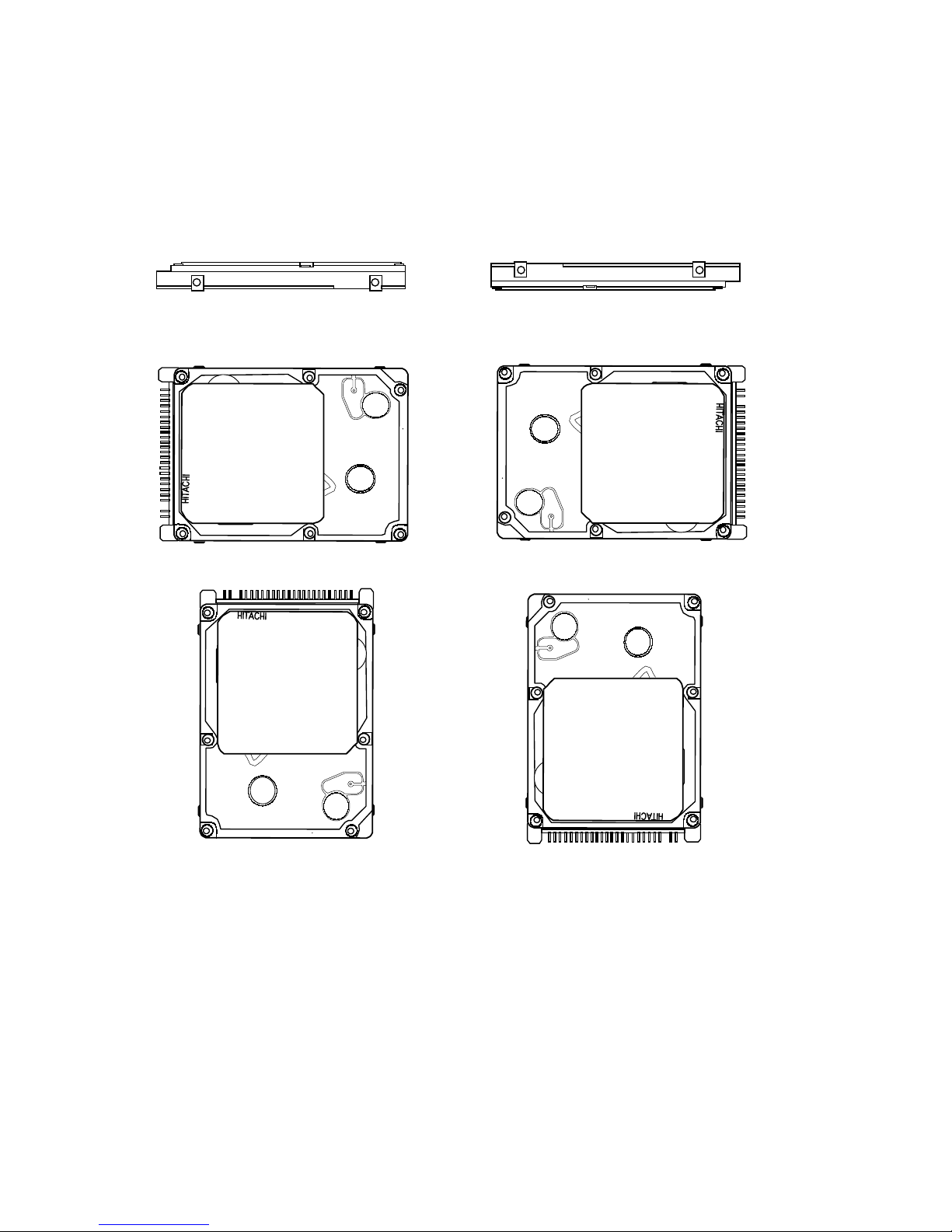

3.0 Specification Summary

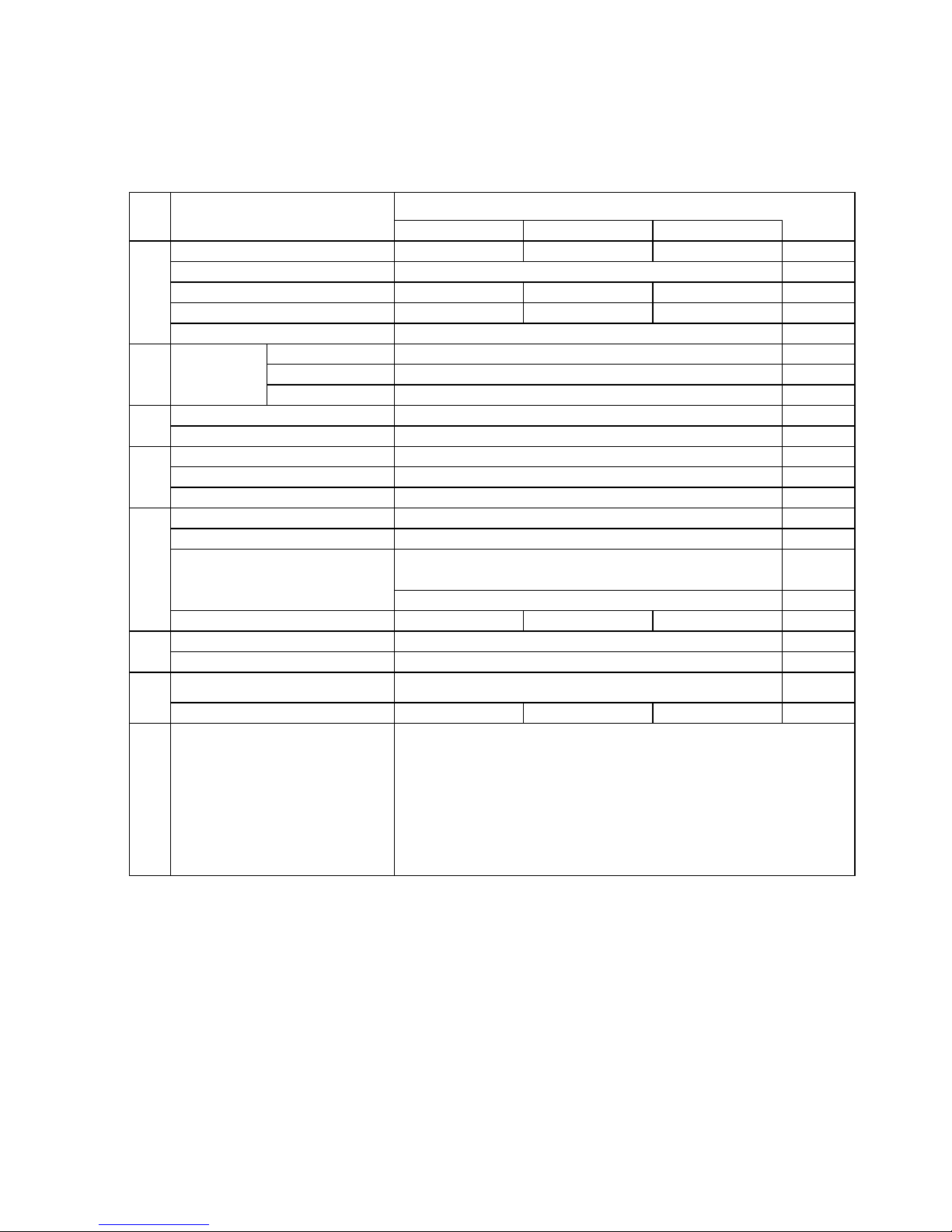

3.1 Principal Specifications

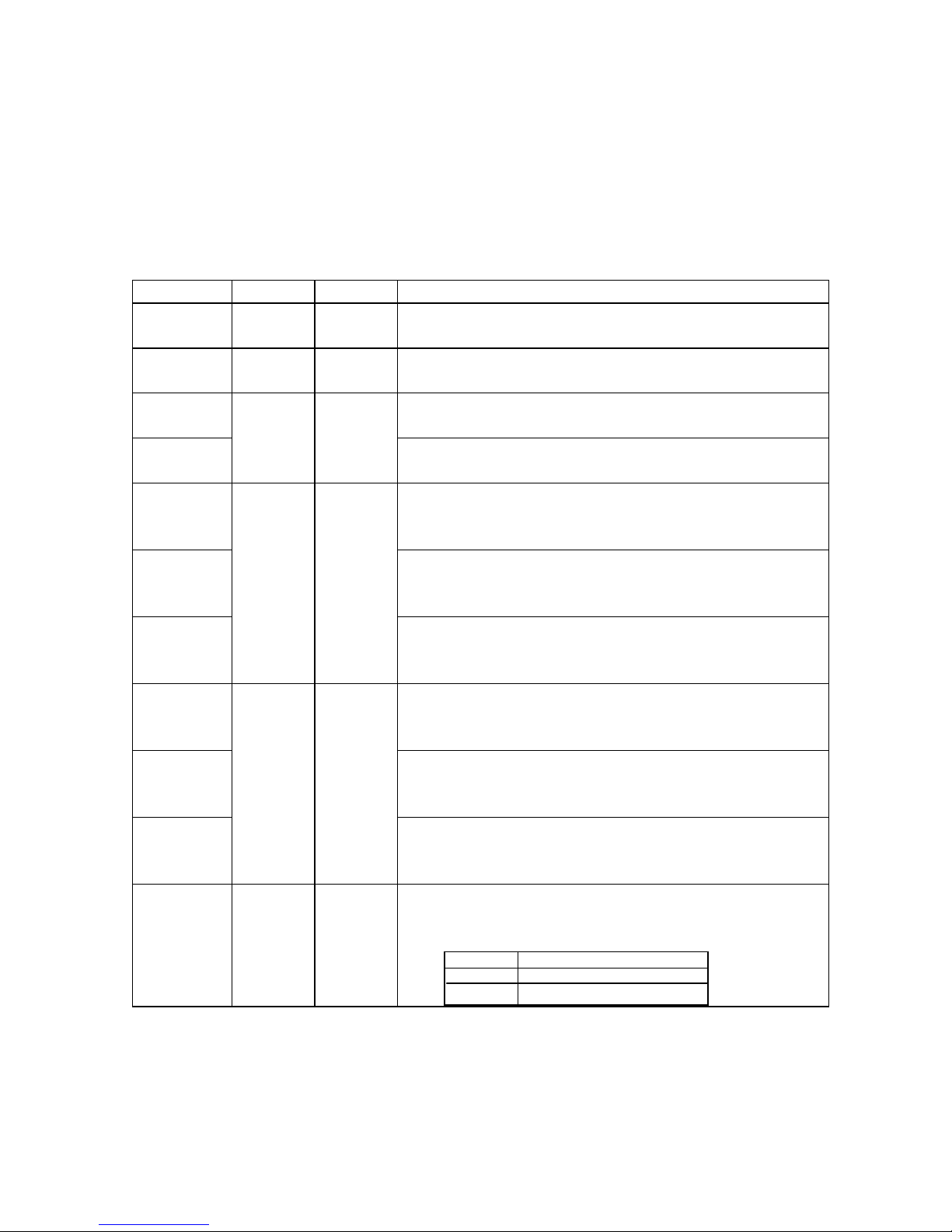

Table 3.1 Principal Specifications

Specifications

No. Item

DK23CA-30F/30 DK23CA-15 DK23CA-75

Units

1 Capacity per drive (Formatted

)

30,005 15,103 7,501 MB

Capacity per sector 512 Bytes

Disks 2 1 1

Heads 4 2 1

Cylinders 28,134

2 Seek time Average 12

*1

ms

(

Nominal Maximum 24

*1

ms

value

)

Minimum 3 ms

3Average latenc

y

7.1 ms

Disk rotational speed 4,200 RPM

4 Recording densit

y

Max. 530 kBPI

Track densit

y

46.8 kTPI

Recording method ME2PRML, ID-Less format

5 Interface ATA-5(IDE

)

Data transfer rate (Disk-Buffer

)

16.3 – 30.2 MB/sec

Data transfer rate (Host-Buffer

)

Max. 16.6 MB/sec

(

PIO mode 4/ Multiword DMA mode 2

)

Max. 100 (Ultra DMA mode 5

)

MB/sec

Buffer size 2048 512 512 kB

6 Power on - Ready

*2

5 (Typical)

*3

sec

Sleep/Standby - Ready

*2

3 (Typical)

*3

sec

7

Dimensions(W×H×D) 70W×9.5H×100D

mm

Weight (Approximate value

)

95 91 91

g

rams

8 DC Power Requirements

*4

(Typical)

+

5v ± 5% Ripple noise 100mvp-p or less

- Start up *5 0.90 A(4.5W)

- Idle *6 0.13 A(0.65W)

- Low Power Active *7 0.33 A(1.65W)

-Seek *8 0.45 A(2.25W)

- Read/Write *9 0.40/0.40 A(2.0/2.0W)

- Standby 0.050 A(0.25W)

- Sleep 0.020 A(0.1W)

K6602637

Rev.3

02.27.01

- 14 -

*1

:Average time of seek is calculated under the following condition. (Read/Write ratio: Read only)

Average of 10,000 random seeks, Voltage 5.0V, Temperature 25°C.

Maximum time of seek is calculated under the following condition.

Average of 1,000 full stroke seeks, Voltage 5.0V, Temperature 25°C.

This maximum time is not included the seek time by seek retry.

*2

: Periodically, during start up, the drive may perform a spin up retr y operation. When this operation occurs,

the start up sound will change slightly and the ready timing will also be altered from typical time.

*3

: Power on to Ready time could take up to 20 seconds in case of spin up retries under certain

conditions of the voltage specifications(Table 3.1) and environmental specifications(Table 3.2).

*4 :

For DC power input, the average current is measured at the connector of the PCBA of this drive and in

the nominal condition in which the power voltage and the temperature are 5.0V and 25°C, respectively.

Burst free (common mode). The average current may have some tolerance after power-on. The current

measurement is recommended at 5 minutes later after power-on.

Voltage rise time 5 - 100 ms at power on is required for power supply. The power

supply voltage must not be under below GND lev el ( 0 V) at power off.

This product is required over current protection for possible combustion due to

circuit or component failure. Secondary over current protection shall be prepared

by the system. The requirement of the current limitation is max. 10 A for the

protection.

*5

: For more information, refer to Section 6.1.

*6

: This value is at Low Power Idle mode. The heads are unloaded.

*7

: Power mode automatically enters to Low Power Active mode after Read/ Write operation. Head position

is kept on the same track before this power transition.

*8

: Measured during random seek , and the seek interval is 1.5 revolution times (i.e. the average latency

and one revolution).

*9

: Measured while reading or writing 16 sectors of data located on the same track.

Caution

Caution

K6602637

Rev.3

02.27.01

- 15 -

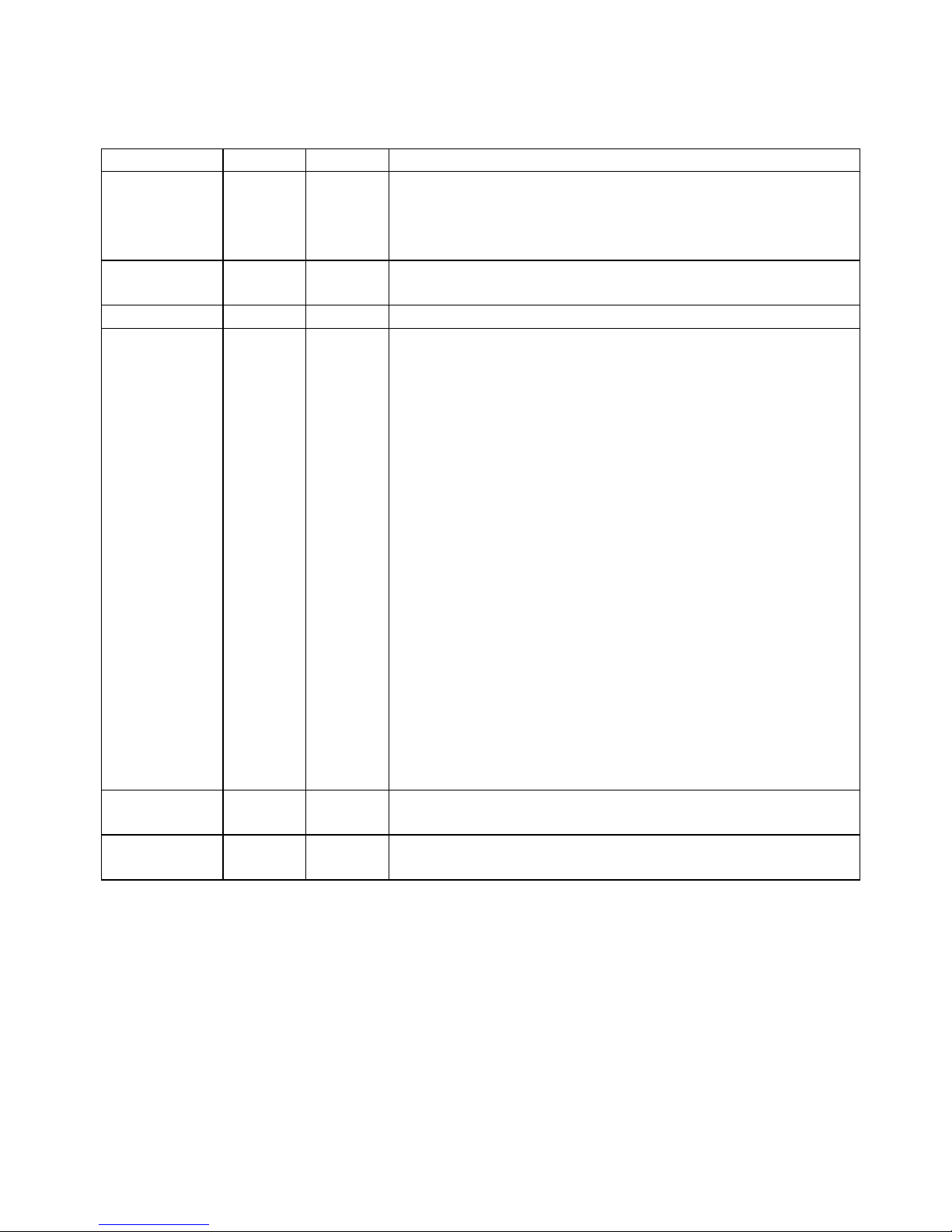

3.2 Environmental Specifications and Reliability

Table 3.2 Environmental Specification and Reliability

No. Item Specification

DK23CA-30F DK23CA-30/15/75

1

Ambient

*1

Operational

5 to 55°C

temperature Non-operational

-40 to 70°C

*2

Temperature gradient

Max. 20°C /hour

2 Relative humidity Operational 5 to 90 %

Non-operational 5 to 95 %

Maximum wet Operat ional

29°C (without condensation)

bulb Non-operational

40°C (without condensation)

*3

3 Vibration Operational 1.0mm p-p or less (5 - 22Hz)

9.8 m/s2 (1.0G) or less m/s2 (22 – 500Hz)

Non-operational 5mm p-p or less (5 – 22Hz)

49m/s2(5G) or less (22 – 500Hz)

4

Shock

*6

Operational

1,764m/s2(180G) or less (2 ms, half sine wave)

Non-operational

7,840m/s2(800G) or less (2 ms, half sine wave)

5 Atmospheric condition Without corrosive vapors or salt

6 Acoustic-noise

*4

Idle Typical 2.5 Bels Typical 2.8 Bels

7 Height Operational 3,000m or less

(Altitude) Non-operational 12,000m or less

Height gradient Max. 300m/min.(3.1kpa/min.)

8

(*5)

Data reliability

(with retries and ECC)

Less than 1 non-recoverable error in

10 E 13 bits read

9 External magnetic field 1,500 micro Tesla (DC) or less

*1

: Ambient temperature should be measured at point 10 mm away from the nameplate of the drive. If the

maximum operational ambient temperature cannot be measured at a point 10 mm away from the

nameplate, a substitution method is stipulated in the table below.

Ambient

temperature

Temperature at cover

(Point A)

55°C62

°

C

5°C5

°

C

*2

: In case the ambient temperature is -40 to 0°C, the drive should be

packed in HDD package box. Please see specification 5.1 Packing

for reference.

Maximum power-off interval is 12 months.

*3

: In case of the maximum wet bulb 40°C , the drive should be packed in HDD package box with ESD bag

and desiccant. Please see specification 5.1 Packing for reference. If the drive is not packed in the HDD

package box with ESD bag and desiccant, maximum wet bulb 29°C is applied.

Caution

Measurement point

(Point A

)

K6602637

Rev.3

02.27.01

- 16 -

*4

: 3.9 Bels are the maximum sound power levels with A-weighted . This value is specified at product

shipment, except during startup, seek, load, unload or st op. Clicking noise of releasing magnet latch will

occur at power-on and loading operation. Also, the licking noise of locking magnet latch will occur at

normal and emergency unloading operations.

*5

:

Data reliability is not to be used to compromise t he host system data backup.

For the HDD evaluation, long term operation is not r ecommended. In case of

evaluation, once or more unload operation by Power off , Standby or Sleep is

recommended within twelve hours’ power on time.

*6

: These shock specifications are defined for each axis. For non-operating rotational shock, the

specification is 15K radian/sec

2

or less (2 ms, half sine wave).

3.3 Drive Usage Condition Specifi cat i ons

The drive is designed for usage under the following conditions. Since reliability and product life depends on

usage conditions, please consult our sales representatives or application engineers if the drive may be

operated outside these conditions.

-Power on hours (POH) : Less than 160 hours/month

POH includes Sleep and Standby modes.

The heads are unloaded during Power off, Standby, Sleep or Low Power Idle

modes. The spindle motor is stopped during Standby and Sleep modes.

-Operating (Seek/Write : Less than 20% of POH

Read operations)

-Motor Start/Stop Count : Max. 100,000 times. This number includes Standby, Sleep and pow er-on/off

count.

-Environment : Within environmental specifications given in Table 3.2

-Power Requirement : Within DC power requirement specifications given in Table 3.1 “Principal

Specifications”

-Drive Grounding : Drive frame should be grounded to system ground with four screws electrically.

Grounding noise should be less than 500mVp-p. The grounding noise

should be measured between electrical ground and system frame ground

without the drive. Grounding AC current (measuring between two of side

mounting holes) should be less than 50 mAp-p (Frequency Range: less than

20MHz). The grounding current should be measured through 50 ohm resistor.

-External Magnetic Field : Within specifications given in Table 3.2

-Mounting : Mount with recommended screws and regular torque.

-Physical/Electrical Interface: ATA-5

-Handling : Do not add Electrical Static Discharge, and Vibration and Shock to the drive.

Do not press top cover and bottom PCBA surface of the drive.

Caution

K6602637

Rev.3

02.27.01

- 17 -

3.4 Load/Unload Specifications

Load /Unload is a mechanism to load/unload the heads on the disk surfaces.

3.4.1 Normal Load/Unload

Normal load/unload operations are limited to maximum 300,000 times during HDD life. The normal unload

operation is performed by the following commands.

-

Standby

-

Standby Immediate

-

Sleep

Also, the normal unload is automatically performed by control software, during Idle mode. The abov e normal

unload time does not include an emergency unload as explained in Sec. 3.4.2.

3.4.2 Emergency Unload

The emergency unload is occurred by unexpected power down, and is limited to maximum 20,000 times

during HDD life. Since normal unload can not be performed by the softwar e cont r o l aft er power off, the

heads are unloaded by a hardware control. The maximum number of emergency unload is defined

separately.

3.4.3 Required Power Off Sequence

To operate the load/unload normally, the following BIOS sequence is required by Host system before power

off.

[Sequence #1]: Execute one of following commands.

-

Standby

-

Standby Immediate

-

Sleep

Note:

Such as Soft Reset, Flush Cache command or Check Power Mode command does

not unload the heads. Soft Reset does not unload the heads from DK23CA-xx.

[Sequence #2]: Check the Status Register, and wait the command complete.

Note:

The head is unload by the sequence #1 command, and the command completion

normally takes about 400 ms. Considering the error retries, BIOS timer should be set

to over 30 sec by the Host side.

[Sequence #3]: Power off the drive

Above sequence is required for the Host system at Power off, Suspend and Hibernation operations.

K6602637

Rev.3

02.27.01

- 18 -

4.0 Installation

4.1 Installation Direction

The DK23CA-30F/30/15/75 can be installed in the 6 directions as shown below.

Figure 4-1 Installation

K6602637

Rev.3

02.27.01

- 19 -

4.2 Mounting HDD

4.2.1 Mounting HDD with screws

Mount the HDD with the screws according to the following instruction to optimize the

performance.

(a) Mount the HDD with M3 screws. Take care not t o add any distorting force to the HDD when mounting.

Using 4 screws holes, secure the HDD.

(b) Use screws with the following specifications when t he HDD is mounted.

i) M3 (screw engagement of 2.5mm max)

ii) The torque for fixing the screws is 3±0.5kgcm(2.6±0.4 lb. inch)

(c) Any distortion of HDD over 0.020mm should be avoided. Take care that the system chassis are

flat enough.

(d) Consider an appropriate cooling to keep the temperature of cent er of HDD top cover less than 62°C.

(e) The inertia of the chassis around the Z-axis of the gravity center of the device must be more than

7 X 10

-4

kg m2.

Note) In case of general Sub-Notebook PC(Weight: 1.7kg), the inertia of the chassis around the Z-axis of

the gravity center of the device is greater t han 100 X 10

-4

kg

m2. Therefore, the required inertia level

has no problem with the general electronic equipment.

Caution

(0.2)

4-M3x0.5

Chassis

X

Z

Y

(

Unit: mm

)

HDD

Figure 4-2 Mounting the HDD

K6602637

Rev.3

02.27.01

- 20 -

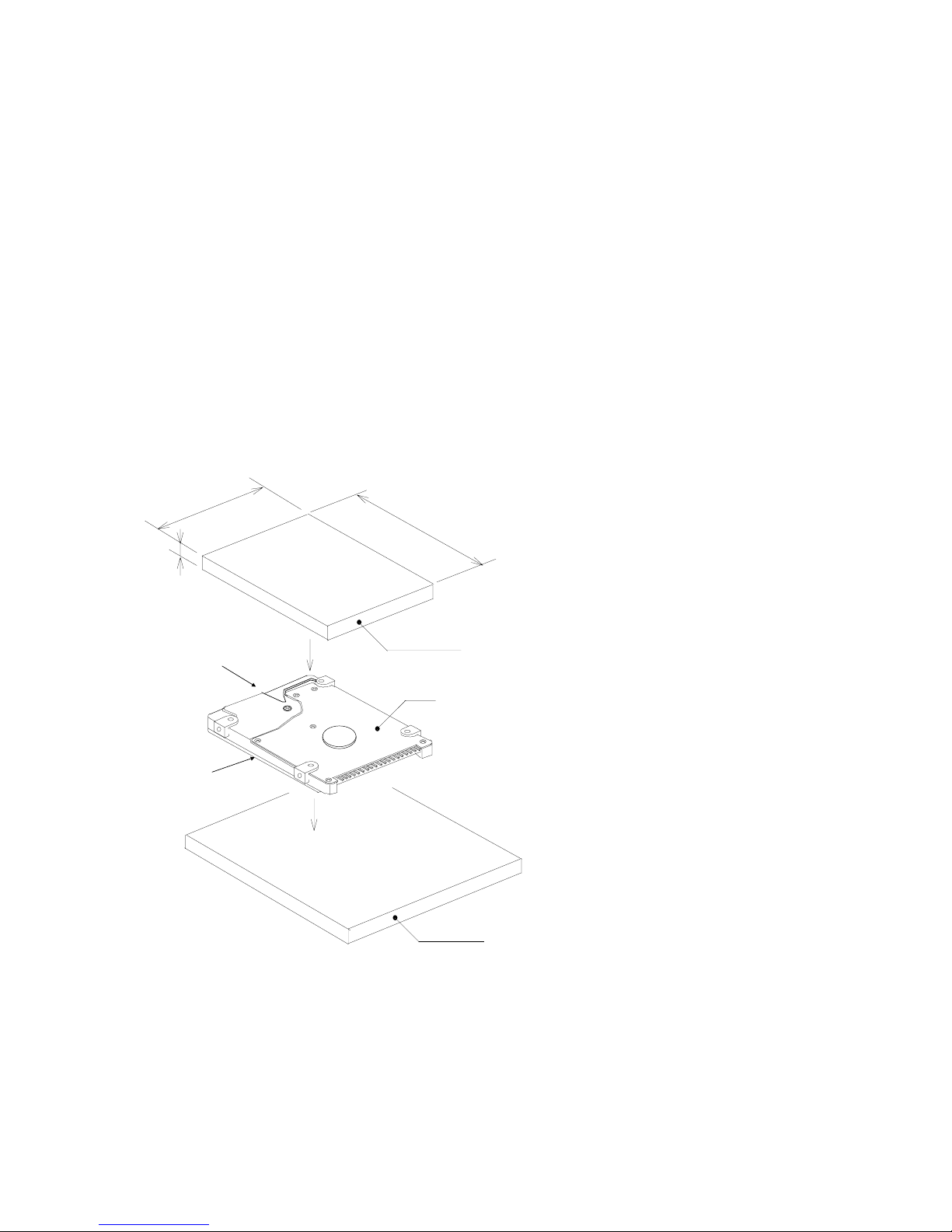

4.2.2 Single HDD Test Condition

To optimize the performance, keep the following instructions.

1) For the Single HDD test, HDD should be placed on an ABS-sheet. HDD should be place wit h

no movement by external force min. 0.39N for X axis and Y-axis directions.

2) Don’t place HDD on a soft sponge sheet or hard surface at HDD test. I f the HDD is placed on

the soft sponge sheet or slippery hard desk surface, the HDD has unstable condit ions such as HDD

self-vibration at seek operations or spindle motor rotation. It may cause performance reduction or

some errors. Also, HDD floating by t ension of I /F cabling may cause the similar symptom. The HDD

should be placed without any floating. Don’t test the HDD under these unstable conditions.

3) If the HDD cannot be fixed by the required holding torque above item 1), put a body weight on the

HDD as shown in Figure 4-3. The body weight is prov ided for pr eventing the HDD movement or HDD

floating by tension of I/F cabling.

Use the body weight as specified below.

Material : SS41 with ELP-coat

Weight : M=0.66kg

Inertia : I=7.3X10 kg m

Figure 4-3 Single HDD Test Condition

Y Axis Direction

X Axis Direction

(70)

(13)

(92)

Weight

SS41 with Insulation sheet

(m=0.66kg, I=7.3X10 kg m )

-4

2

HDD

ABS-sheet

(t = 5mm)

K6602637

Rev.3

02.27.01

- 21 -

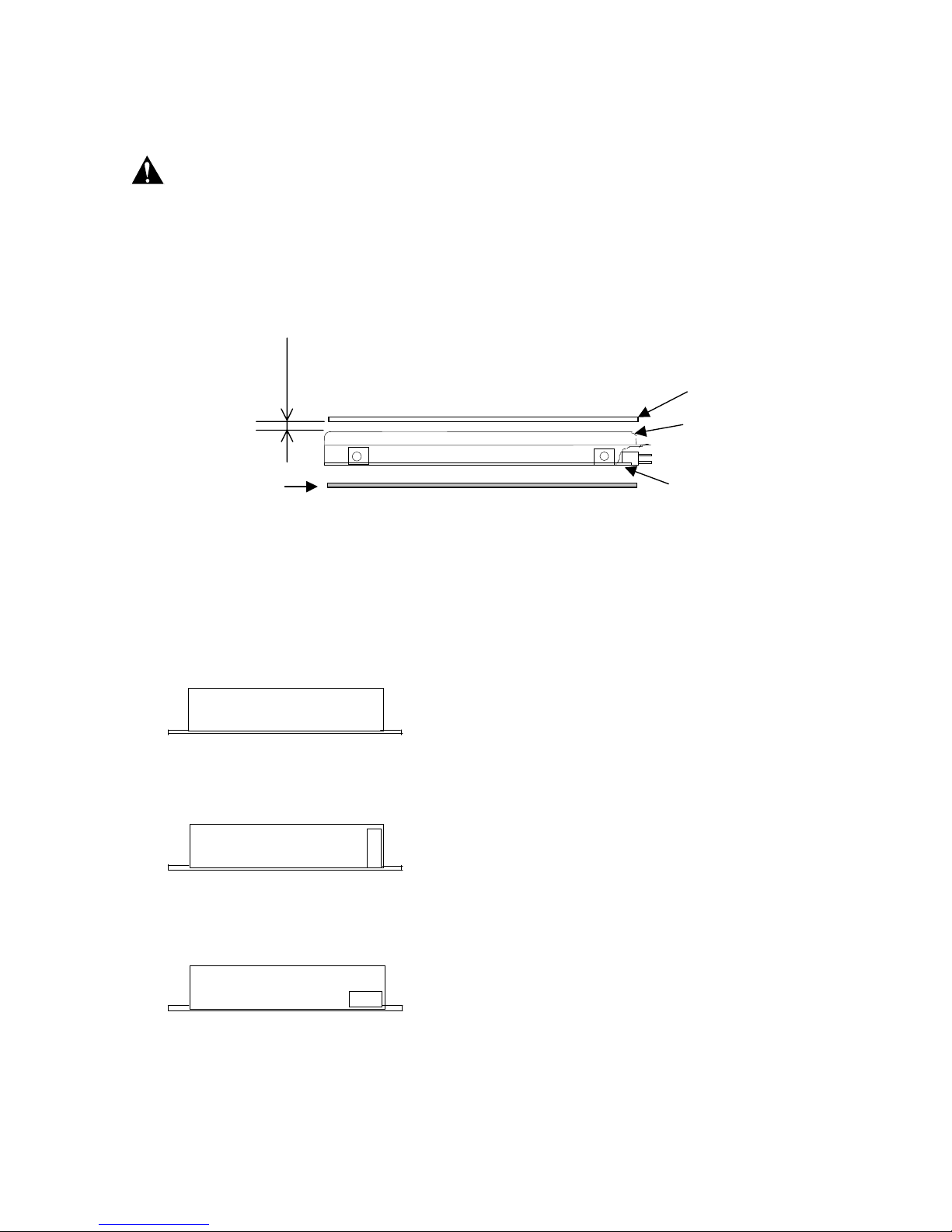

4.2.3 Attent i on f or HDD Installation

(1) In case of steel plate installation on HDD cover side, the spacing between

HDD cover and steel plate should be kept more than 2 mm. If this spacing is not

kept for the steel plate, it may affect Load/Unload mechanism.

(2) The PCBA side of the drive should be covered with insulation sheet if the active

metal of host system may contact to the PCBA of t he drive. If the insulation sheet

is not provided for the possible contact of the live metal, failures may occur.

(3) Do not push the bottom PCBA. It may cause catastrophic failures.

4.3 Device Address Setting (DRI VE 0/DRIVE 1)

When the device is connected to the host bus, Device address setting is necessary to configure

a device as DRIVE 0 or DRIVE 1. The device address setting is established bet ween drives on

the interface connector by using jumper 0-2 (pin # A, B, D)

The DRIVE 0 is assigned to device address 0, and the DRIVE 1 is assigned to device address 1.

O - - - - - - - - O O O O O

O - - - - - - - - O O O O O

43 5 3 1

CA

44

642 DB

O - - - - - - - - O O O O O

O - - - - - - - - O O O O O

43 5 3

1

CA

44 642 DB

O - - - - - - - - O O O O O

O - - - - - - - - O O O O O

43 5 3 1

CA

44 642 DB

1) DRIVE 0 (or single)

2) DRIVE 1

3) CSEL Selection

If all of pins A,B, D are open, the drive is

DRIVE 0(or single).

If jumper Position A-B is used, the driv e is

DRIVE 1.

If jumper Position B-D is used, DRIVE 0 or

DRIVE 1 settin g is deter mined b y the con dition of

CSEL signal (pin# 28).

Caution

Steel Plate

HDD Cover

2 mm

PCBA

More than

Insulation sheet

(Recommended type of jumper socket)

Vender: IRISO ELECTRONICS CO., LTD.

Vender Part Number: 9721HJ-GF

K6602637

Rev.3

02.27.01

- 22 -

±

0.25

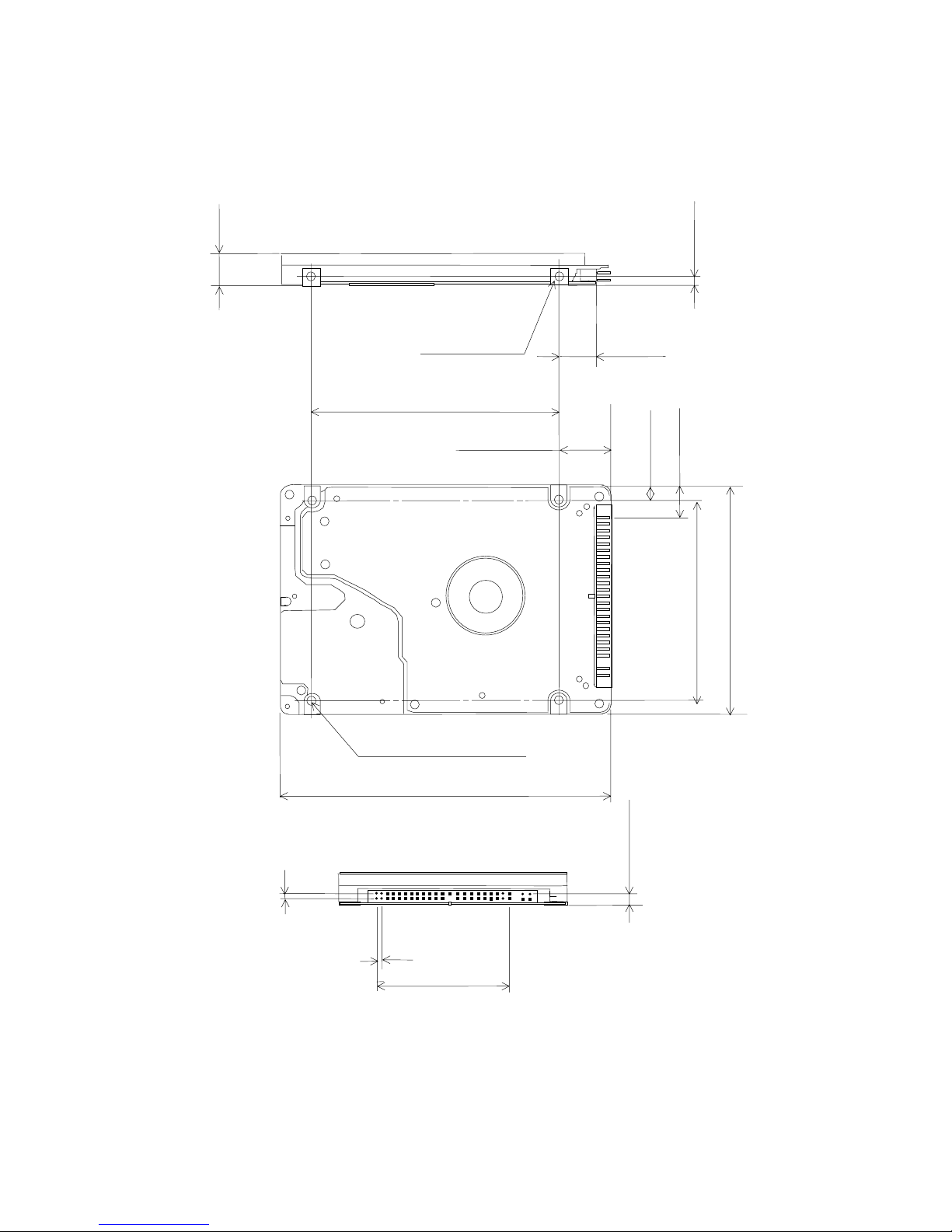

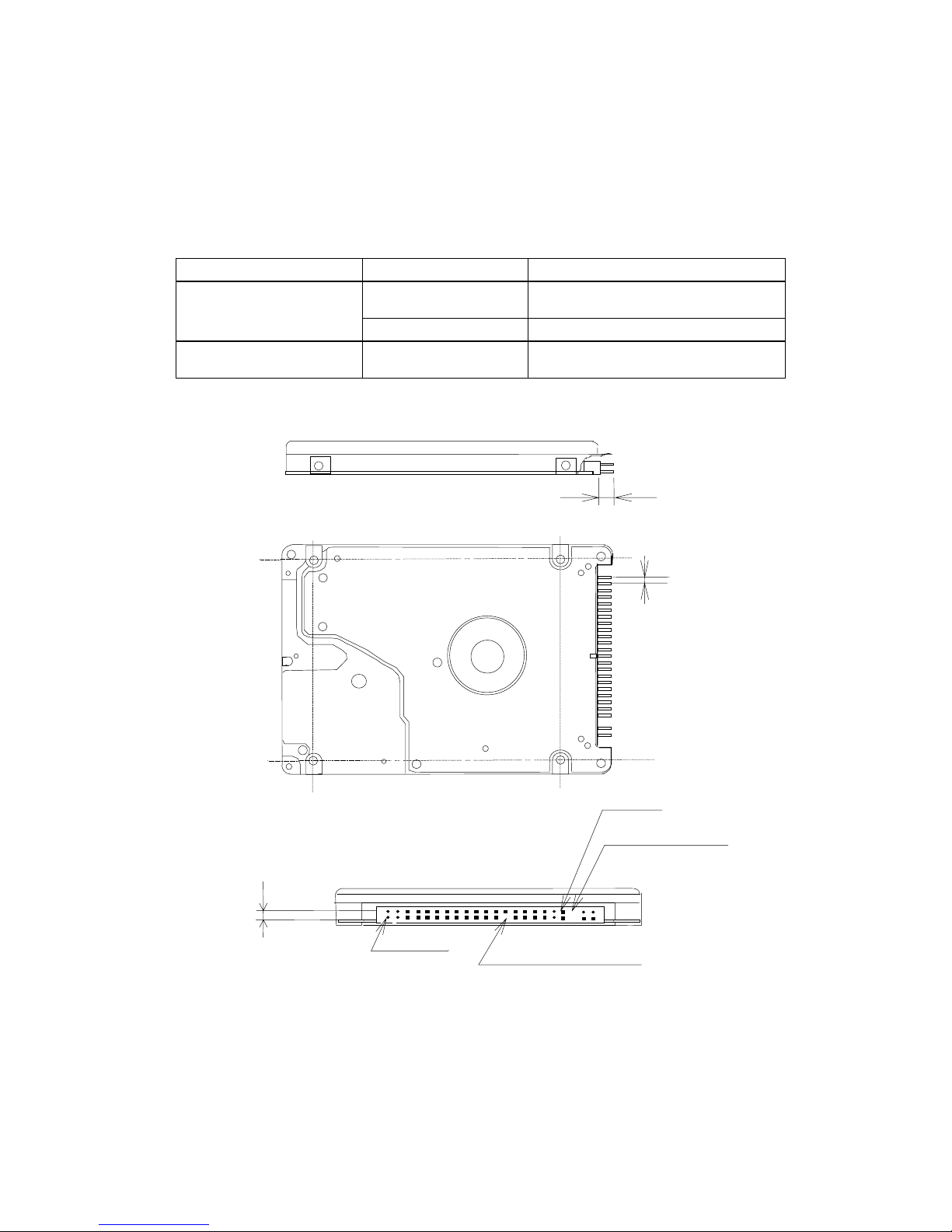

4.4 Dimensions

Figure 4-4 Dimensions (DK23CA-30F/30/15/75)

9.5

±

0.2

14.0 ± 0.25

4-M3

3.0mm min. full thread

10.14

±

0.375

100±0.45

61.72

±

0.25

(70.1

Maximum drive width

)

69.85

4.07

±

0.25

10.24 ± 0.25

3

±

0.25

4-M3

3.5mm min.

full thread

76.6 ± 0.25

2

3.99

±

0.25

2

42

(Unit : mm)

Drive width at mountin

g

K6602637

Rev.3

02.27.01

- 23 -

5.0 Packing and Handling

5.1 Packing

When you package the device, clean it and execute the following procedures

to prevent humidity and handling damage.

(1) Pack the device in an ESD protective bag with desiccant.

(2) Use the original Hitachi cardboard box and the cushioning materials or equivalent cushioning

structures to surround the above bag.

(3) Never stack or package drives next to each other with at the proper cushion material separating

them.

(4) Indicate which side is upside or downside on the exterior of the package box and attach notices

requesting careful treatment and preventing the box from being turned upside down.

(5) Prevent excessive pressure from being applied on the top and bottom of the drive(top cover and

PCBA side) when packing, unpacking, and transporting.

(6) Remember, mishandling of a drive can void the drive’s warranty.

Prevent humidity when the drive is packed in a box.

Caution

Caution

K6602637

Rev.3

02.27.01

- 24 -

5.2 Handling

Mount the HDD with the screws according to the following instructions to optimize the

performance.

It is necessary to prevent vibration, shock, and static electricity to the dr ive because it will damage the

precision parts. In particular, prevent vibration or shock generated by dropping, knocking over, or hitting the

drive. Also, avoid touching the electrical components directly, which can discharge electrostatic energy and

damage the drive.

(Dropping) (Knocking over)

(Hitting) (Hitting)

Figure 5-1

Caution

K6602637

Rev.3

02.27.01

- 25 -

6.0 Interface

6.1 Power Interface

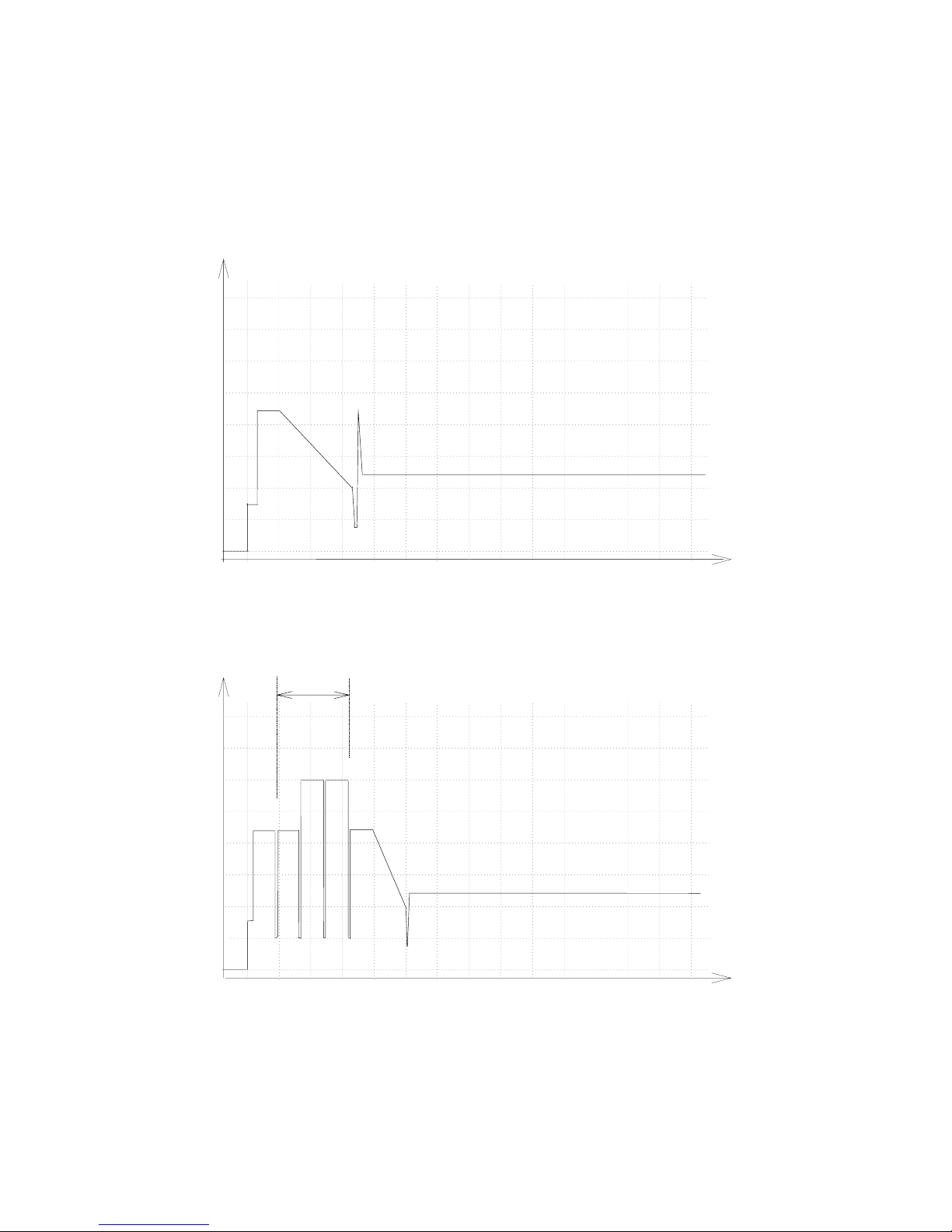

Only +5VDC power is applied to this Device. Figures 6-1 and 6-2 show power current transitions

after turning on the power.

Typical Spin-up Current Transition

1.6

1.4

1.2

1.0

0.8

0.6

0.4

0.2

0.0

0123456

7

Time (sec)

Current of

+5V power

(A)

Figure 6-1 Power Current Transition

Typical Spin-up Current Transition with Retry

1.6

1.4

1.2

1.0

0.8

0.6

0.4

0.2

0.0

0

123456

7

Time (sec)

Current of

+5V power

(A)

8

9

10 11

121413

Retry

Figure 6-2 Power Current Transition with retries

K6602637

Rev.3

02.27.01

- 26 -

6.2 Physical Interface

6.2.1 Connector

This device has a 2mm pitch interface connector which contains a power line. The connector

location is shown in Figure 6-3.

Table 6.1 Connector Parts List

Name Parts number of recommended type

Interface cable side

Signal Connector

Receptacle

Molex 87259-4413 or equivalent

Cable AWG#28 or equivalent

Drive side

Signal Connector

Plug

Molex 87400-5005 or equivalent

Figure 6-3 Connector Location

2 mm

PIN44

PIN20 REMOVED(KEY)

PINS REMOVED(KEY)

PIN1

3.86 mm

2 mm

K6602637

Rev.3

02.27.01

- 27 -

6.2.2 Connector Pin Assignment

Figure 6-4 Pin Assignments

JUMPER0

JUMPER2

KEY(Removed)

DD7

RESET-

DD6

DD5

DD4

DD3

DD2

DD1

DD0

GND

DMARQ

DIOW-

DIOR-

IORDY

DMACK-

DA1

DA0

CS0-

DASP-

5VDC(Logic)

GND(Logic)

A

C

E

1

3

5

7

9

11

13

15

17

19

21

23

25

27

29

31

33

35

37

39

41

43

B

D

F

2

4

6

8

10

12

14

18

16

20

22

24

28

32

26

30

34

36

38

40

42

44

JUMPER1

JUMPER3

KEY(Removed)

GND

DD8

DD9

DD10

DD11

DD12

DD13

DD14

DD15

KEY(Removed)

GND

GND

GND

CSEL

GND

IOCS16PDIAGDA2

CS1GND(Motor)

5VDC(Motor)

Reserved

INTRQ

PCB

K6602637

Rev.3

02.27.01

- 28 -

6.2.3 Description of the Interface Signals

The interface is an ATA(IDE) interface. Reserved pins should be left unconnected. The signal names

and the pin numbers are shown in Figure 6-4 and Table 6.2. Table 6.2 shows signal definitions.

"I" of I/O type represents an input signal from the device and "O" represents an output signal from the

device.

Table 6.2 Signal List(1/3)

Signal name Pin I/O type Description

RESET- 1 I This is a reset signal output from the host system and to be

used for interface logic circuit.

DD0-DD15 3-18 I/O This is a 16-bit bi-directional data bus. The lower 8 bits are

used for register access other than data register.

DIOW- 23 I The rising edge of this Write Strobe signal clocks data from

the host data bus into a register on the device.

STOP

*1

Assertion of this signal by the host during an Ultra DMA burst

signals the termination of the Ultra DMA burst.

DIOR- 25 I Activating this Read Strobe signal enables data from a register

on the device to be clocked onto the host data bus. The rising

edge of this signal latches data at the host.

HDMARDY-

*1

This signal is a flow control signal for Ultra DMA Read.

Host asserts this signal, and indicates that the host is ready t o

receive Ultra DMA Read data .

HSTROBE

*1

This signal is Write data strobe signal from the host for an

Ultra DMA Write. Both the rising and falling edge latch

the data from DD(15:0) into the device.

IORDY 27 O This signal is used to temporarily stop the host register access

(read or write) when the device is not ready to respond t o a

data transfer request.

DDMARDY-

*1

This signal is a flow control signal for Ultra DMA Write. Device

asserts this signal, and indicates that the device is ready t o

receive Ultra DMA Write data .

DSTROBE

*1

This signal is the data in strobe signal from the device for an

Ultra DMA Read. Both the rising and falling edge latch

the data from DD(15:0) into the host.

CSEL 28 I This signal is used to configure a device as either DRIVE 0 or

DRIVE1 when CSEL mode is selected.

This signal is pulled up inside the drive.

CSEL

GND

OPEN

0

1

Drive address

*1

: Signal name in Ultra DMA mode

K6602637

Rev.3

02.27.01

- 29 -

Table 6.2 Signal List(2/3)

Signal name Pin I/O type Description

INTRQ 31 O This is an interrupt signal for the host system. This signal is

asserted by a selected device when the nIEN bit in the Device

Control Register is "0". In other cases, this signal should be a high

impedance state.

IOCS16- 32 O This signal indicates to the host that the 16-bit data port has been

addressed and a 16-bit word can be read or written to the device.

DA0-2 33,35,36 I This is a register address signal from the host system.

PDIAG-:CBLID-

(*1)

34 I/O The PDIAG- signal is asserted by Device 1 to indicate to Device 0

that it has completed diagnostics. This signal is pulled up inside the

device.

The host may sample CBLID- after a power-on or hardware reset in

order to detect the presence or absence of an 80-conductor cable

assembly by performing the following steps:

a) The host shall wait until the power on or hardware reset

sequence is complete for all devices on the cable;

b) If Device 1 is present, the host should issue IDENTIFY DEVI CE

or IDENTIFY PACKET DEVICE and use the returned data to

determine that Device 1 is compliant with ATA-3 or subsequent

standards. Any device compliant with ATA-3 or subsequent

standards releases PDIAG- no later than after the first

command following a power on or hardware reset sequence.

If the host detects that CBLID- is connected to ground, an 80conductor cable assembly is installed in the system. If the host

detects that this signal is not connected to ground, an 80-conductor

cable assembly is not installed in the system.

CS0- 37 I This device chip selection signal is used to select the Command

Block Registers from the host system.

CS1- 38 I This device chip selection signal is used to select the Control Block

Registers from the host system.

*1

: PDIAG-:CBLID- (Passed diagnostics: Cable assembly ty pe identifier

K6602637

Rev.3

02.27.01

- 30 -

Table 6.2 Signal List(3/3)

Signal name Pin I/O type Description

DASP- 39 I/O This signal indicates that a device is active or that Drive 1 is present

when the power is turned on.

Upon receipt of a command from the host, the device asserts this

signal. At command completion, the device de-asserts this signal.

However, When a sequential read command is received from the

host, the device does not assert this signal.

DMARQ 21 O The device shall assert this signal, used for DMA data transfers

between host and device, when it is ready t o t r ansfer dat a.

DMACK- 29 I The host in response to DMARQ to either acknowledge that data

has been accepted, or that data is available shall use this signal.

JUMPER0,1,2 PIN-A,B,D - See Sec. 4.3 “ Drive Address Setting (Drive 0/Drive 1)” for the detail.

The I/O signal levels are as follows.

(1) Input signal High level +2.0V to Vcc+0.5V

Low level -0.5V to +0.8V

(2) Output signal High level +2.4V to +5.25V or an open circuit

Low level +0.4V or less (IOL=2mA), +0.5V or less (IOL=12mA)

Note) The I/F cable should be no longer than 50cm(20 inches) including the circuit pattern length in the host

system. If the cable length is not within this specification, it may cause fact ional degradat ions or some

errors.

K6602637

Rev.3

02.27.01

- 31 -

6.3 Logical Interface

6.3.1 I/O Registers

Communication between the host system and the device is done through I/O registers. The Command

Block Registers are used for sending commands to the device or posting device status. The Control

Block Registers are used for controlling the device or posting device status. The registers are listed in

Table 6.3.

Table 6.3 Register List

Addresses Functions

CS0- CS1- DA2 DA1 DA0 READ(DIOR-) WRITE(DIOW-)

Command Block Registers

01000Data Data

0 1 0 0 1 Error Features

0 1 0 1 0 Sector Count Sector Count

0 1 0 1 1 Sector Number Sector Number

0 1 1 0 0 Cyl Low Cyl Low

0 1 1 0 1 Cyl High Cyl High

0 1 1 1 0 Device/Head Dev ice/ Head

01111Status Command

Control Block Registers

1 0 1 1 0 Alt. Status Device Control

Invalid or Not Used

00

´´´

Invalid address

01

´´´

Data bus high impedance (not used)

100

´´

Data bus high impedance (not used)

1010

´

Data bus high impedance (not used)

'0' is low signal level. '1' is high signal level.

6.3.1.1 Data register

A 16-bit register to be used for transferring dat a blocks betw een the HDD's data buffer and the host.

6.3.1.2 Error register

This register stores device status when the last command has been completed or diagnostic codes

when a self-diagnostic process has been completed. The contents of this register are valid when the

error bit (ERR) is set in the Status Register. The contents of this register are diagnostic codes when

the device has just completed a self-diagnostic process requested when turning on the power or

resetting.

K6602637

Rev.3

02.27.01

- 32 -

Bit76543210

Name ICRC UNC - IDNF - ABRT TK0NF AMNF

a) AMNF(Address Mark Not Found): This bit indicates that a data address mark is not found after the

correct ID field is detected.

b) TK0NF(Track 0 Not Found): This bit indicates that Track 0 is not found during the execution of the

Recalibrate command.

c) ABRT(Aborted Command): This bit indicates that execution of a command is interrupted due to

a device error(e.g. Not Ready and Write fault) or an invalid command code.

d) IDNF (ID Not Found): This bit indicates that an ID field of the requested sect or is not found.

e) UNC(Uncorrectable Data Error): This bit indicates that an uncorrectable error has occurred.

f) ICRC(Interface CRC Error): This bit indicat es that an interface CRC error was occurred. This bit is not

applied for Multiword DMA transfers.

6.3.1.3 Features Register

By combining with the Set Features command, this register is used for enabling or disabling each

feature.

6.3.1.4 Sector Count Register

This register contains the number of sectors of data requested to be transferred on a read or write

operation. When a command has been completed and the value of this register is "0", it represents that

the command has been executed successfully. If the command has not been executed successfully,

this register indicates the number of the sectors yet to be processed. This definition cannot be applied

to all commands. For more information on commands, refer to the corresponding sections.

6.3.1.5 Sector Number Register

This register contains the starting sector number for any disk data access. This number may be from 1

to the maximum number of sectors per track. In LBA mode, this register contains Bits 7-0 of the LBA.

6.3.1.6 Cylinder Low Register

This register contains the lower 8 bits of the starting cylinder address for any disk access. When a

command has been executed; this register displays the currently specified cylinder number.

In LBA mode, this register contains Bits 15-8 of the LBA.

6.3.1.7 Cylinder High Register

This register contains the higher 8 bits of the starting cylinder address for any disk access. When a

command has been executed, this register displays the currently specified cylinder number.

In LBA mode, this register contains Bits 23-16 of the LBA.

K6602637

Rev.3

02.27.01

- 33 -

6.3.1.8 Device/Head Register

This register has the binary coded address of device and head selected. The head numbers begins

with "0".

Bit76543210

Name - L - DRV HS3 HS2 HS1 HS0

a) Bits HS3 to HS0 are head addresses to be selected. HS3 is the highest bit. The address of the

currently selected head is displayed in this register when a command is completed. In case of

LBA mode, these bits HS3 to HS0 are applied to LBA bits 27 to 24.

b) DRV is a device selection bit. 0=DRV0, 1=DRV1

c) L is the sector address mode select. 0=CHS mode, 1=LBA mode

6.3.1.9 Status Register

The current device status is reflected in this register. The contents are updat ed at the completion of each

command. If BSY=1, no other bits in this register are valid. When BSY is cleared, the other bits in this

register shall be valid within 400 ns. If the host reads this register when an int errupt is pending, it is

considered to be the interrupt acknowledge, and the pending interrupt is then cleared.

Bit76543210

Name BSY DRDY DWF DSC DRQ CORR IDX ERR

a) ERR (Error): This bit indicates that an error occurs during the execution of a command. For more

information, refer to the description of the Error register.

b) IDX(Index): This bit is set once per disk revolution.

c) CORR(Corrected Data): This bit indicates that a correctable error has occurred and data has been

corrected. The data transfer is not interrupted.

d) DRQ(Data Request): This bit indicates that the dev ice is ready to transfer data between the host and

the device.

e) DSC(Device Seek Complete): This bit indicates that the device head is located on the specified track.

If an error has occurred, the value of this bit is not changed until the host reads the Status register.

f) DFW(Device Write Fault): This bit indicates that an error has occurred during a Write operation. If an

error has occurred, the value of this bit is not changed until the host reads the St atus register.

g) DRDY(Device Ready): This bit indicat es that the device is ready to respond any command. If an error

has occurred, the value of this bit is not changed until the host reads the St atus register. This bit is

cleared when the power is turned on and then kept cleared until the device gets ready t o accept any

command.

h) BSY(Busy): This bit is specified when the device accesses t he Command Block Registers. When BSY

is 1,the host cannot access the Command Block Registers. If the Command Block Registers are read

when BSY is 1, all contents of the Status Register are returned.

6.3.1.10 Command Register

The command code is sent to this register. After it is written, execution begins.

K6602637

Rev.3

02.27.01

- 34 -

6.3.1.11 Alternate Status Register

The information in this register is a duplicate of that in the Status Register. Reading this register will not

clear the interrupt.

6.3.1.12 Device Control Register

This register includes the software reset bit and the interrupt enable bit.

Bit76543210

Name - - - - - SRST nIEN '0'

a) nIEN(Interrupt Enable): If the device is selected when nI EN is 0, t he I NTRQ signal is enabled. When

nIEN is 1 or when the device is not selected, the I NTRQ signal is in a high impedance stat e.

b) SRST (Software Reset): When this bit is set, the device is reset. When this bit is cleared, the device

exits from the reset state. When two devices are connected through one line in the daisy chain mode,

they are reset simultaneously.

K6602637

Rev.3

02.27.01

- 35 -

6666

.3.2 Commands

6.3.2.1 Command Summary

Commands are issued to the device first loading the Command Block Registers with any information

needed for the command. Then a command code is written to the Command Register, which starts

the execution of the command.

Table 6.4 Command Codes

Command Description Protocol Class Code Parameter Setup

FR SC SN CY DH

Read Commands

Read Buffer PI 1 E4h D

Read Sectors PI 1 20h, 21h V V V V

Read Long PI 1 22h, 23h V V V V

Read Multiple PI 1

C4h

VVVV

Read DMA DM 1 C8h, C9h V V V V

Read Verify ND 1 40h, 41h V V V V

Write Commands

Write Buffer PO 2 E8h D

Write Sectors PO 2 30h, 31h V V V V

Write Long PO 2 32h, 33h V V V V

Write Multiple PO 3 C5h V V V V

Write DMA DM 3 CAh,CBh V V V V

Format Track PO 2 50h V V V

Flush Cache ND 1 E7h D

Seek Commands

Recalibrate ND 1 1Xh D

Seek ND 1 7Xh V V V

Mode Set/Check, Diagnostic

Execute Device Diagnostic ND 1 90h D

Initialize Device Parameters ND 1 91h V V

Identify Device PI 1 ECh D

Set Features ND 1 EFh V D

Set Multiple Mode ND 1 C6h V D

Power Control

Check Power Mode ND 1 98h, E5h V D

Idle ND 1 97h, E3h V D

Idle Immediate ND 1 95h, E1h D

Sleep ND 1 99h, E6h D

Standby ND 1 96h, E2h V D

Standby Immediate ND 1 94h, E0h D

K6602637

Rev.3

02.27.01

- 36 -

Table 6.4 Command Codes (Continued)

Command Description Protocol Class Code Parameter Setup

FR SC SN CY DH

SMART Commands

SMART Enable/Disable Auto

Save

ND 1 B0h D2h V V D

SMART Save Attribute

Values

ND 1 B0h D3h V D

SMART Enable Operations ND 1 B0h D8h V D

SMART Disable Operations ND 1 B0h D9h V D

SMART Return Status ND 1 B0h DAh V D

SMART Enable/Disable

Automatic Off-line

ND 1 B0h DBh V V D

SMART Execute Off-line

Immediate

ND 1 B0h D4h V D

SMART Read Log Sector PI 1 B0h D5h V V V D

SMART Write Log Sector PO 3 B0h D6h V V V D

Security Commands

Security Disable Password PO 3 F6h D

Security Erase Prepare ND 1 F3h D

Security Erase Unit PO 3 F4h D

Security Freeze Lock ND 1 F5h D

Security Set Password PO 3 F1h D

Security Unlock PO 3 F2h D

Protected Area Commands

Read Max Address ND 1 F8h D

Set Max Address ND 1 F9h 00h V V V D

Set Max Set Password PO 3 F9h 01h D

Set Max Lock ND 1 F9h 02h D

Set Max Unlock PO 3 F9h 03h D

Set Max Freeze Lock ND 1 F9h 04h D

PI : PIO Data In PO : PIO Data Out

ND : Non-Data DM : DMA Data In/Out

CY : Cylinder Registers SC : Sector Count Register

DH : Device/Head Register SN : Sector Number Register

FR : Features Register

V : Valid parameter register for this command D : Only the Device parameter is valid.

K6602637

Rev.3

02.27.01

- 37 -

6.3.2.2 Command BSY Timing

The manner in which a command is accepted varies by the three classes of command acceptance all

predicated on the fact that to receive a command, BSY=0. The following describes by t he condit ions

under which busy is set after receipt of a command.

Class1 - The device sets busy within 400 ns.

Class2 - The device will set BSY within 400 ns, t hen set s up t he sector buffer for a write operation,

then sets DRQ, and clears BSY within 400 ns of setting DRQ .

Note

: DRQ may be set so quickly on classes 2 that the BSY transit ion is t oo short for BSY=1 to

be recognized.

6.3.2.3 PIO Data In Commands

Execution includes the transfer of one or more 512 byte sectors of data from the device to t he host .

1) The host writes any required parameters to the Features, Sector Count , Sect or Number, Cylinder

Low, Cylinder High, and Device/Head registers.

2) The host writes the command code to the Command Register.

3) The device sets BSY and prepares for data transfer.

4) When a sector(block) of data is available, the device sets DRQ and clears BSY prior to asserting

INTRQ.

5) After detecting INTRQ, the host reads the Status Register, t hen reads one sect or (block) of data via

the Data Register. In response to the Status Register being read, t he device negates INTRQ.

6) The device clears DRQ. If transfer of another sector (block) is required, the device also sets BSY

and the above sequence is repeated from 4).

K6602637

Rev.3

02.27.01

- 38 -

6.3.2.3.1 Identify Dev i ce [ECh]

The Identify Device command enables the host to receive parameter information from the device.

When the command is issued, the device sets BSY, stores the required parameter information in the

sector buffer, sets DRQ, and generates an interrupt. The host then reads the information from the

sector buffer through the Data Register. The parameter words are defined in Table 6.5 and 6.6.

All reserved bits or words shall be zero.

Table 6.5 Identify Device Information

Word Description Value

(HEX.)

0 General configuration 045Ah

1 Number of logical cylinders See table 6.6

2 Specific configuration C837h

3 Number of logical heads See table 6.6

4 Number of unformatted bytes per track

5 Number of unformatted bytes per sector

6 Number of logical sectors per logical track See table 6.6

7-9 Vendor specific

10-19 Serial number (20 ASCII characters)

20 Buffer type

0000h = Not specified 0001h = Single port single buffer

0002h = Dual port multi-sector buffer

0003h = Dual port multi-sector buffer with read caching capability

0003h

21 Buffer size in 512 byte increments (0000h=not specified) DK23CA-15/

75: 0400h

DK23CA-30F/

30: 1000h

22 Number of ECC bytes passed on READ/WRITE LONG commands 0004h

23-26 Firmware revision(8 ASCII Characters)

27-46 Model number(40 ASCII Characters)

47 Number of sectors on multiple commands

Bit 15 - 8 80h (fixed)

Bit 7 - 0 Number of sectors on multiple command

8010h

48 Double word I/O not supported

0000h = cannot perform double word I/O

0001h = can perform double word I/O

0000h

49 Capabilities

Bit 15 – 14 0 = Reserved

Bit 13 1 = Standby timer values as specified in ATA-2

specification supported

Bit 12 0 = Reserved

Bit 11 1 = IORDY supported

Bit 10 1 = IORDY can be disabled

Bit 9 1 = LBA supported

Bit 8 1 = DMA supported

Bit 7 – 0 Vendor Specific

0B00h

K6602637

Rev.3

02.27.01

- 39 -

Table 6.5 Identify Device Information (

Continued)

Word Description Value

(HEX.)

50 Capabilities

Bit 15 0 (fixed)

Bit 14 1 (fixed)

Bit 13 - 1 0 = Reserved

Bit 0 1 = Standby timer value is equal to or greater than

5 minutes. Reserved.

4000h

51 Bit 15 - 8 PIO data transfer cycle timing mode

Bit 7 - 0 Vendor Specific

0200h

52 Bit 15 – 8 DMA data transfer cycle timing mode

Bit 7 – 0 Vendor Specific

0200h

53 Field validity

Bit 15 - 3 0 = Reserved

Bit 2 1 = The field reported in word 88 is valid

Bit 1 1 = The fields reported words 64-70 are valid

Bit 0 1 = The fields reported words 54-58 are valid

0007h

54 Number of current cylinders

55 Number of current heads

56 Number of current sectors per track

57-58 Current capacity in sectors

59 Multiple sector setting

Bit 15-90 = Reserved

Bit 8 1 = Multiple sector setting is valid

Bit 7 - 0Current setting for number of sectors that can be

transferred per interrupt on R/W MULTIPLE command

60-61 Total addressable LBA See table 6.6

62 Single word DMA transfer

Bit 15 - 8 Single word DMA transfer mode active

Bit 7 - 0Single word DMA transfer mode supported

63 Multi-word DMA transfer

Bit 15 - 8 Multi-word DMA transfer mode active

Bit 7 - 0Multi-word DMA transfer mode supported

64 Flow control PIO transfer Modes supported

Bit 15 - 2 0 = Reserved

Bit 1 1 = PIO Mode 4 supported

Bit 0 1 = PIO Mode 3 supported

0003h

65 Minimum Multi-word DMA Transfer Cycle Time Per Word(ns) 0078h

66 Manufacturer's Recommended Multi-word DMA Cycle Time(ns) 0078h

67 Minimum PIO Transfer Cycle Time without Flow Control(ns) 0190h

68 Minimum PIO Transfer Cycle Time with IORDY(ns) 0078h

69-74 Reserved 0000h

75 Queue Depth

Bit 15 - 5 0 = Reserved

Bit 4 - 0 Maximum queue depth

0000h

76-79 Reserved 0000h

K6602637

Rev.3

02.27.01

- 40 -

Table 6.5 Identify Device Information (

Continued)

Word Description Value

(HEX.)

80 ATA Interface Major Version Number

Bit 15 - 6 Reserved for ATA-6 - 14

Bit 5 1 = Supports ATA-5

Bit 4 1 = Supports ATA-4

Bit 3 1 = Supports ATA-3

Bit 2 1 = Supports ATA-2

Bit 1 1 = Supports ATA-1

Bit 0 Reserved

003Eh

81 ATA Interface Minor Version Number 0013h

82 Command Set Supported

0000h or FFFFh = Command set notification not supported

Bit 15 0 = Reserved

Bit 14 1 = NOP command supported

Bit 13 1 = READ BUFFER command supported

Bit 12 1 = WRITE BUFFER command supported

Bit 11 0 = Reserved

Bit 10 1 = Host Protected Area feature set supported

Bit 9 1 = DEVICE RESET command supported

Bit 8 1 = SERVICE interrupt supported

Bit 7 1 = Release interrupt supported

Bit 6 1 = Look-ahead supported

Bit 5 1 = Write cache supported

Bit 4 1 = Supports PACKET command feature set

Bit 3 1 = Supports power management feature set

Bit 2 1 = Supports removable feature set

Bit 1 1 = Supports security feature set

Bit 0 1 = Supports SMART feature set

346Bh

83 Command set supported

0000h or FFFFh = Command set notification not supported

Bit 15 0 (fixed)

Bit 14 1 (fixed)

Bit 13 - 9 0 = Reserved

Bit 8 1 = SET MAX security extension supported

Bit 7 1 = Address offset mode feature supported

Bit 6 1 = SET FEATURES subcommand required to spin-up after

power-up

Bit 5 1 = Power-up in standby feature set supported

Bit 4 1 = Removable Media Status Notification feature set supported

Bit 3 1 = Advanced Power Management feature set supported

Bit 2 1 = CFA feature set supported

Bit 1 1 = READ/WRITE DMA QUEUED supported

Bit 0 1 = DOWNLOAD MICROCODE command supported

4188h

84 Command set/feature supported extension

0000h or FFFFh = Command set notification not supported

Bit 15 0 (fixed)

Bit 14 1 (fixed)

Bit 13 - 0 0 = Reserved

4000h

K6602637

Rev.3

02.27.01

- 41 -

Table 6.5 Identify Device Information (

Continued)

Word Description Value

(HEX.)

85 Command set/feature enabled

0000h or FFFFh = Command set notification not supported

Bit 15 0 = Reserved

Bit 14 1 = NOP command supported

Bit 13 1 = READ BUFFER command supported

Bit 12 1 = WRITE BUFFER command supported

Bit 11 0 = Reserved

Bit 10 1 = Host Protected Area feature set supported

Bit 9 1 = DEVICE RESET command supported

Bit 8 1 = SERVICE interrupt enabled

Bit 7 1 = Release interrupt enabled

Bit 6 1 = Look-ahead enabled

If word 85 bit 6 is set to one, read look-ahead

has been enabled via SET FEATURE command.

Bit 5 1 = Write cache enabled

If word 85 bit 5 is set to one, write cache

has been enabled via SET FEATURE command.

Bit 4 1 = Supports PACKET command feature set

Bit 3 1 = Supports power management feature set

Bit 2 1 = Supports removable feature set

Bit 1 1 = Supports Security Mode feature enabled

If word 85 bit 1 is set to one, the Security Mode

feature has been enabled via SECURITY SET PASSWORD

command.

Bit 0 1 = Supports SMART feature enabled

If word 85 bit 0 is set to one, the SMART feature

set has been enabled via SMART ENABLE OPERATIONS

command.

3468h

(at shipment)

86 Command set/feature enabled

0000h or FFFFh = Command set notification not supported

Bit 15 –9 0 = Reserved

Bit 8 1 = SET MAX security extension enabled by SET MAX

PASSWORD

Bit 7 1 = Address offset mode feature enabled

Bit 6 1 = SET FEATURES subcommand required to spin-up after

power-up

Bit 5 1 = Power-up in standby feature set enabled

Bit 4 1 = Removable Media Status Notification feature set enabled

Bit 3 1 = Advanced Power Management feature set enabled

Bit 2 1 = CFA feature set supported

Bit 1 1 = READ/WRITE DMA QUEUED supported

Bit 0 1 = DOWNLOAD MICROCODE command supported

0008h

87 Command set/feature default

0000h or FFFFh = Command set notification not supported

Bit 15 0 (fixed)

Bit 14 1 (fixed)

Bit 13 – 0 0 = Reserved

4000h

K6602637

Rev.3

02.27.01

- 42 -

Table 6.5 Identify Device Information (

Continued)

Word Description Value

(HEX.)

88 Ultra DMA transfer

Bit 15 – 14 0 = Reserved

Bit 13 0 = Ultra DMA mode 5 is selected

Bit 12 0 = Ultra DMA mode 4 is selected

Bit 11 0 = Ultra DMA mode 3 is selected

Bit 10 0 = Ultra DMA mode 2 is selected

Bit 9 0 = Ultra DMA mode 1 is selected

Bit 8 0 = Ultra DMA mode 0 is selected

Bit 7 – 6 0 = Reserved

Bit 5 0 = Ultra DMA mode 5 and below are supported

Bit 4 0 = Ultra DMA mode 4 and below are supported

Bit 3 0 = Ultra DMA mode 3 and below are supported

Bit 2 0 = Ultra DMA mode 2 and below are supported

Bit 1 0 = Ultra DMA mode 1 and below are supported

Bit 0 0 = Ultra DMA mode 0 and below are supported

XX3Fh

89 Time required for security erase unit completion

Word 89 specifies the time required for the SECURITY ERASE UNIT

command to completion. If word 90 is 0000h, the time is not specified.

SECURITY ERASE UNIT completion time = value x 2[minutes]

00XXh

90 Time required for enhanced security erase unit completion

Word 90 specifies the time required for the ENHANCED SECURITY ERASE UNIT

command to completion. ENHANCED SECURITY ERASE UNIT completion

time = value x 2[minutes]. If Word 90 is 0000h, the time is not

specified.

00XXh

91 Current advanced power management level value

Word 91 contains the current Advanced Power Management level settings.

40XXh

92 Master password revision code

Word 92 contains the value of the Master password revision code set when the

Master Password was last changed.

XXXXh

K6602637

Rev.3

02.27.01

- 43 -

Table 6.5 Identify Device Information (

Continued)

Word Description Value

(HEX.)

93 Hardware reset result

Bit 15 0 (fixed)

Bit 14 1 (fixed)

Bit 13 1 = Device detected CBLID- above V

iH

0 = Device detected CBLID- below V

iL

Bit 12 - 8 Device 1 hardware reset result. Device 1 clears these bits to zero.

Device 1 sets these bits as follows:

Bit 12 0 = Reserved

Bit 11 1 = Device 1 asserted PDIAGBit 10 - 9 These bits indicate how Device 1 determined the

device number:

00, 11 = Reserved

01 = A jumper was used

10 = the CSEL signal was used

Bit 8 1 (fixed)

Bit 7 - 0 Device 0 hardware reset result. Device 1 clears these bits to zero.

Device 0 sets these bits as follows:

Bit 7 0 = Reserved

Bit 6 1 = Device 0 responds when Device 1 is selected

Bit 5 1 = Device 0 detected the assertion of DASPBit 4 1 = Device 0 detected the assertion of PDIAG0

Bit 3 1 = Device 0 passed diagnostic

Bit 2 - 1 These bits indicate how Device 0 determined the

device number:

00, 11 = Reserved

01 = A jumper was used

10 = the CSEL signal was used

Bit 0 1 (fixed)

XXXXh

94-126 Reserved 0000h

K6602637

Rev.3

02.27.01

- 44 -

Table 6.5 Identify Device Information(

Continued)

Word Description Value

(HEX.)

127 Removable Media Status Notification feature set support

Bit 15 – 2 0 = Reserved

Bit 1 – 0 00 = Removable Media Status Notification feature set

not support

01 = Removable Media Status Notification feature

supported

10 = Reserved

11 = Reserved

0000h

128 Security Status

Bit 15 – 9 Reserved

Bit 8 Security level 0 = High, 1 = Maximum

Bit 7 – 6 Reserved

Bit 5 1 = Enhanced security erase supported

Bit 4 1 = Security count expired

Bit 3 1 = Security frozen

Bit 2 1 = Security locked

Bit 1 1 = Security enabled

Bit 0 1 = Security supported

0XXXh

129-159 Vendor Specific

160-254 Reserved 0000h

255 Integrity Word

Bit 15 - 8 Checksum.

The checksum is the two’s complement of the sum of all bytes

in word 0 through 254 and the byte consisting of bit 7:0 in

word 255. Each byte is added with unsigned arithmetic, and

overflow is ignored.

Bit 7 - 0 Signature Code “A5h”

XXA5h

Table 6.6 Identify Device information (Addressing)

Model

Word 1

Number of CYL.

Word 2

Number of HD

Word 3

Number of SPT

Word 60、61

*1

Total LBA

DK23CA-30F/30

16383

(3FFFh)

16

(000Fh/0010h)

63

(3Fh)

58605120

(037E3E40h)

DK23CA-15

16383

(3FFFh)

16

(0010h)

63

(3Fh)

29498112

(01C21B00h)

DK23CA-75

15504 (*2)

(3C90h)

15

(000Fh)

63

(3Fh)

14651280

(00DF8F90h)

*1:

Words 60-61 reflect the total number of user addressable sectors in LBA mode.

*2.

Maximum capacity in CHS mode is 8,455MB.

K6602637

Rev.3

02.27.01

- 45 -

6.3.2.3.2 Read Buffer [E4h]

The Read Buffer command enables the host to read the current contents of the device's sector buffer.

When this command is issued, the device sets BSY, sets up the sector buffer for a read operation,

sets DRQ, clears BSY, and generates an interrupt. The host t hen reads up t o 512 bytes of data from

the sector buffer.

6.3.2.3.3 Read Sectors [20h, 21h]

This command reads sectors as specified in the Sector Count Register. The read operation begins at

the sector specified in the Sector Number Register. An implied seek is done if needed, after which

the device searches for the target sector. If the target sector is not found within two index periods,

then with retries disabled an ID Not Found Error is posted, but with retr ies ot her at tempts are made

to try and read the target sector. DRQ is set prior t o dat a transfer regardless of the presence or

absence of an error condition. At command completion, the Command Block Registers contain the

cylinder, head, and sector numbers of the last sector read. If an error occurs, the read terminates at

the sector where the error occurred. The Command Block Registers contain the cylinder, head, and

sector numbers where the error occurred.

6.3.2.3.4 Read Long [22h, 23h]

The Read Long command performs similarly to the Read Sectors command except that it returns the data

and the ECC bytes contained in the data field of the desired sector. During a Read Long command, the

device does not check the ECC bytes to determine if there has been a data error. Only single sect or read

long operations are supported. The number of ECC bytes t r ansfer r ed w ill be 4 Bytes (Default). If the ECC

transfer length is changed by Feature register 44h, 24 bytes of ECC will be transferred.

6.3.2.3.5 Read Multiple [C4h]

This command is similar to the Read Sectors command, except interrupts are not generated on every sector,

but on the transfer of a block which contains the number of sectors defined by a Set Multiple command. The

number of sectors defined by a Set Multiple command is transferred without intervening interrupts. DRQ