Page 1

Quick Reference

© 1998, 1999 Hitachi Koki

Imaging Solutions, Inc.

1757 Tapo Canyon Rd.

Simi Valley, CA 93063

March 1999

335908-002, Rev. B

Guide

Page 2

© 1998, 1999 Hitachi Koki Imaging Solutions, Inc. All rights reserved.

No part of this document may be reproduced without the expressed permission of

Hitachi Koki Imaging Solutions, Inc.

The material in this document is for informational purposes and is subject to

change without notice. Hitachi Koki Imaging Solutions, Inc., assumes no

responsibility for error s or om issi ons i n this document . No lia bilit y is assu med for

any damages resulting from the use of the information it contains.

TRADEMARK

Hitachi Koki Imaging Solutions, Inc., Digital Document Server, DDS, DDS 50, DDS

62, DDS 50/62, Sca nCenter, a nd thei r asso ciate d logo marks , are trademar ks o f

Hitachi Koki Imaging Solutions, Inc. Hitachi and the Hitachi logo are trademarks of

Hitachi, Ltd. All rights reserved.

EFI, the EFI logo, Fiery, and the Fiery lo go are tradem arks re gistere d in the U.S.

Patent and Trademark Office. NetWise is a tradem ar k o f El ec troni c s for I mag ing ,

Inc.

Adobe, the Adobe logo, Adobe Illustra tor, PostScript, Adobe P hotoshop, Adobe

Separator, and Adobe PageMaker are trademarks of Adobe Systems

Incorporated, registered in certain jurisdictions. EPS (Encapsulated PostScript) is

a trademark of Altsys Corporation. Apple, the Apple logo, AppleShare, AppleTalk,

EtherTalk, LaserWriter, and Macintosh are registered trademarks, and MultiFinder

is a trademark of Apple Computer, Inc. Microsoft, MS, MS-DOS, and Windows are

registered tradema rks of Micro soft in the U.S. a nd oth er coun tries. Quar kXPre ss

is a registered trademark of Quark, Inc.

All other trademarks are the property of their owners.

NOTICE TO USER

In an effort to meet the demands of a rapidly changing technology, the

manufacturer is contin ually developing new feat ures and functions to meet yo ur

changing printing or printer needs. As a result, this manual may not exactly reflect

future changes made to the product. Please be sure to consult all manual updates

or addenda when using this product’s documentation.

Page 3

Table of Contents

Overview

Printer Components..................................................... ......... ......... ..................1-2

External View of the Printer...........................................................................1-4

Internal View of the Printer ............................................................................1-5

Using the Operator Control Panel

The Operator Control Panel............................................................................2-2

Restarting and Shutting Down the DDS 50/62...............................................2-6

Paper Handling

Loading Paper in Tray 1..................................................................................3-2

Loading Paper in Tray 2..................................................................................3-4

Loading Paper in Tray 3..................................................................................3-6

Loading Paper in the HCF ..............................................................................3-10

Loading Paper in the MBT..............................................................................3-13

Using the Finisher...........................................................................................3-14

Staple Positions...............................................................................................3-15

Hole Punch......................................................................................................3-17

Maintenance

Replacing the Staple Cartridge .......................................................................4-2

Replacing the Toner Bottle.............................................................................4-5

Clearing Paper Jams

From the Printer..............................................................................................5-2

From the Duplex Unit.....................................................................................5-7

From the Intelligent Multi Bypass Tray..........................................................5-11

From the Finisher............................................................................................5-13

Table of Contents i

Page 4

Messages

OCP Messages ................................................................................................6-2

Controller Messages........................................................................................6-10

Troubleshooting

Basic Troubleshooting Tips............................................................................7-2

General Printing Problems..............................................................................7-3

Problems with Print Quality............................................................................7-7

Duplex Printing Problems...............................................................................7-7

Problems with Fiery Downloader................................................................... 7-8

Problems with Fiery Webtools........................................................................7-9

ii Table of Contents

Page 5

This chapter describes:

• Printer Features

• External View of the Printer

• Internal View of the Printer

• Printer Accessories

Overview

1

Overview

Overview 1-1

Page 6

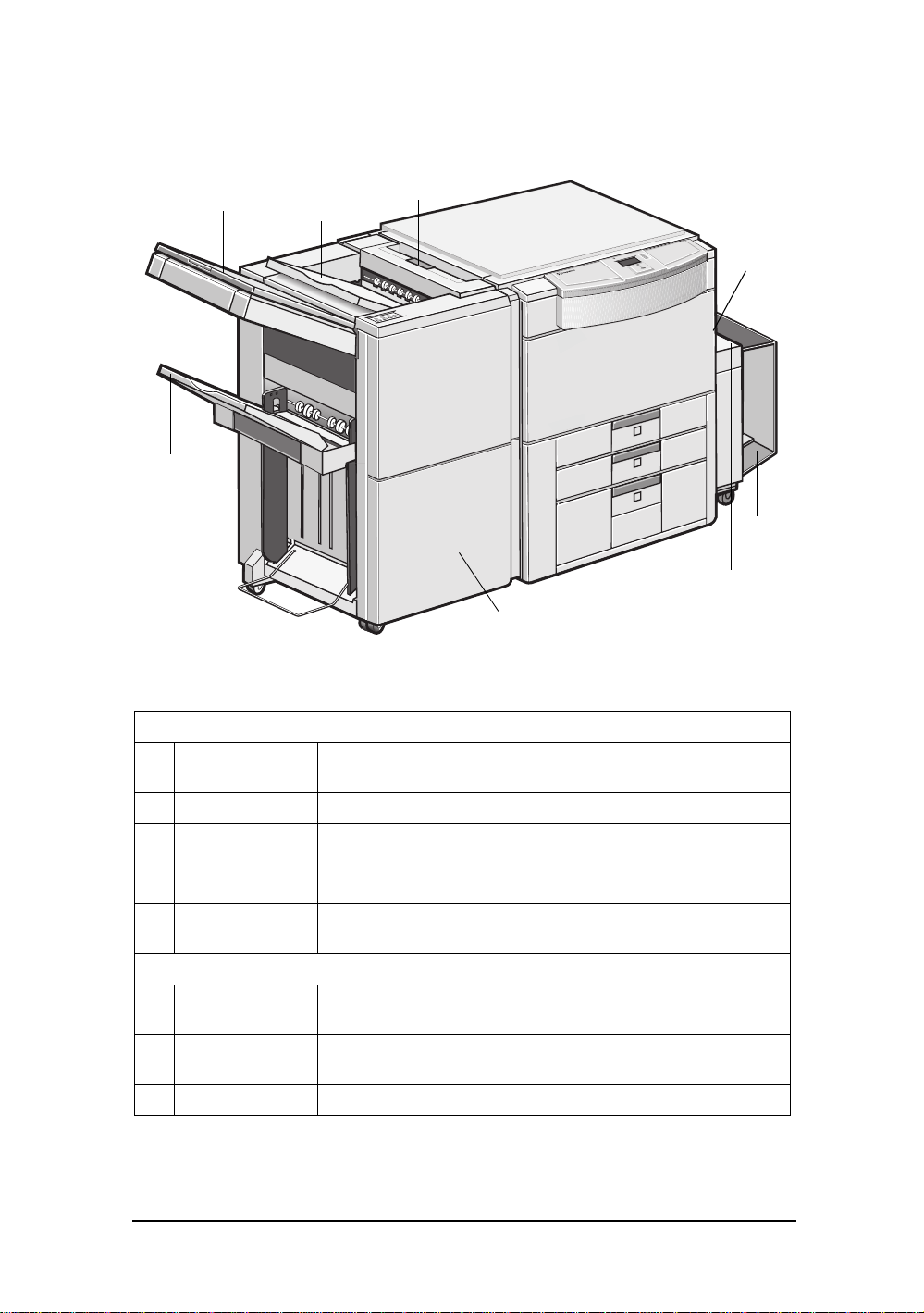

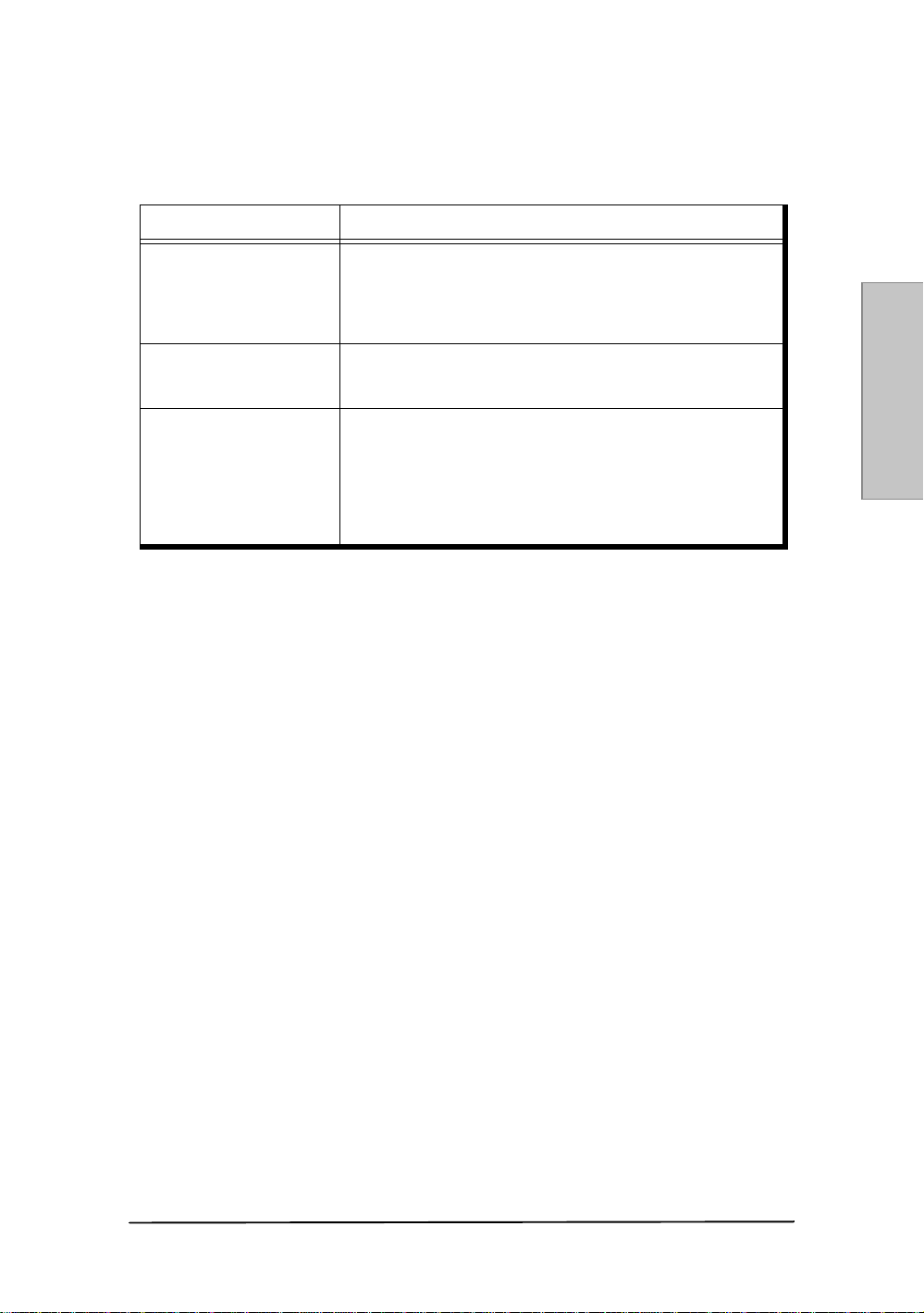

Printer Components

3

4

5

2

1

Printer shown with Finisher and High Capacity Feeder

Finisher

1 Finisher Door

2 Elevator Tray Receives finished docu m ent sets.

3 Processor Tray

4 Top Tray Receives finished docu m ent sets.

Lock Release

5

Lever

High Capacity Feeder (HCF)

Lock Release

6

Lever

Paper Plate

7

Descent Key

8 Cassette Door Open to add paper or clear a misfeed.

Open to replace the staple cartridge. Open to clear a paper

misfeed.

Open to load documents f or ma nual stapling or to clear a paper

misfeed.

Grasp and press here to sli de the finisher away from the pr i nt er to

clear a misfeed or oth er service job.

Use to unlock the cassette from the printer for clearing a misfed

sheet of paper or othe r se rvice job.

Press to lower the paper plate.

6

8

7

Overview 1-2

Page 7

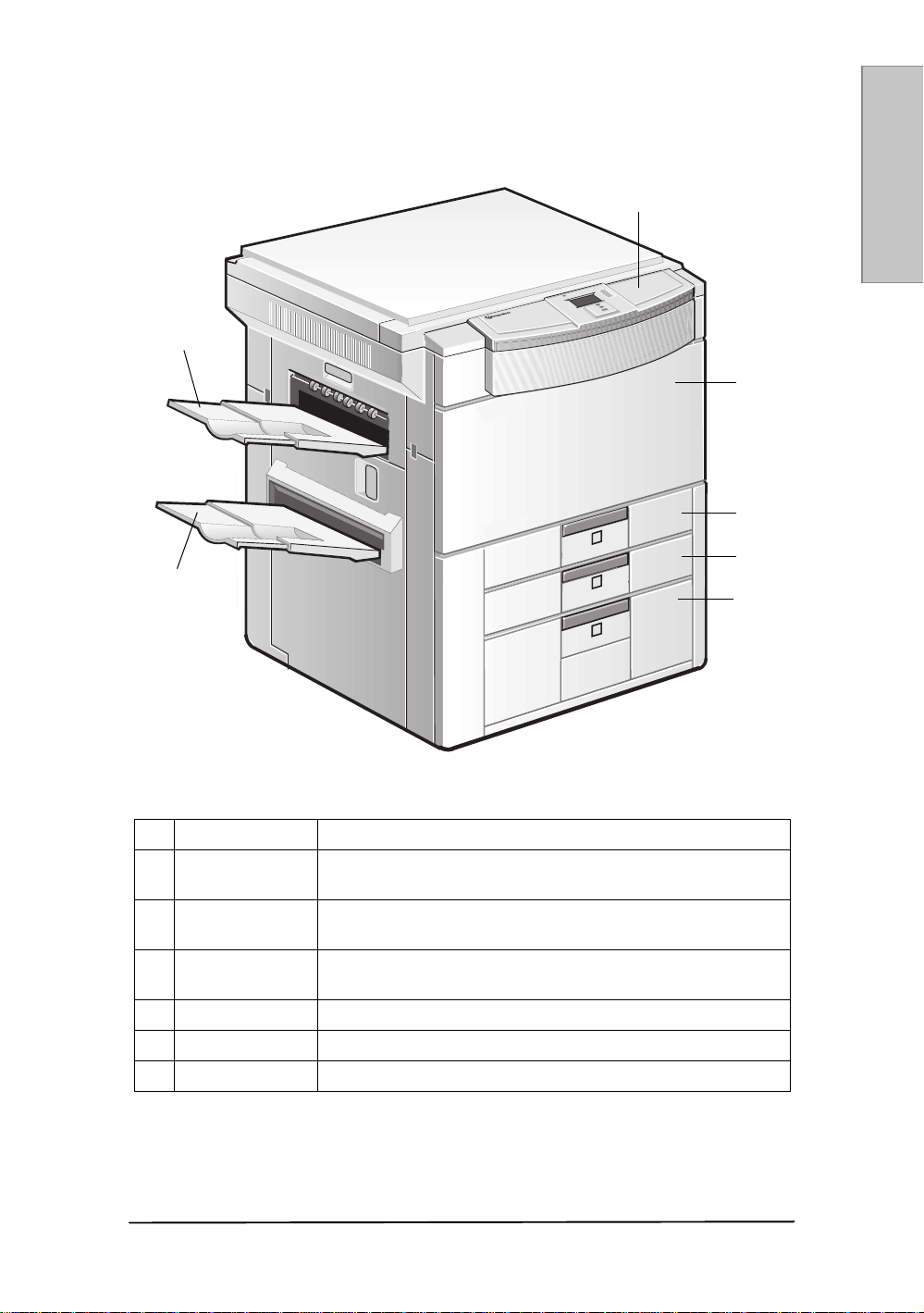

Overview

2

6

1

3

4

7

5

Printer shown with Optional Output Trays

1 Printer High speed, networked, black and white printer.

Operator Control

2

Panel

3 Tray 1

4 Tray 2

5 Tray 3 Holds up to 2,500 sheet s of paper.

6 Output Tray Face-up tray.

7 Output Tray Face-down tray.

Allows you to access all basic and special functions.

Holds up to 500 sheets of pap er. Service adjustable to

accommodate paper of different sizes.

Holds up to 500 sheets of paper. User adjustable to accommodate

paper of different sizes.

Overview 1-3

Page 8

External View of the Printer

5

4

3

6

7

2

8

1

12

9

10

11

1 Exit Tray Extender Slide this extender out wh en using large-size paper (STD 50 only).

2 Exit Tray (Optional) Holds copies fed from the printer (STD 50 only).

Open to clear a paper misfeed.

3Front Door

4 Upper Front Door Open to replenish the toner bott le .

5 Control Panel

6 Power Switch Use to turn the printer ON and OFF.

Intelligent Multi

7

Bypass Tray (MBT)

8 Extender Slide this extender out when using large-size pap er.

9 Tray 1

10 Tray 2

11 Tray 3

Paper Descent Key

12

Paper Drawer

Handle

Closing the front door after a misf eed has been cleared will turn the

misfeed warning me s sage on the control panel O FF.

Use to control and mon i to r t he printer’s statu s. S ee t he

Control Panel

Use for manual feeding of pape r i nt o t he pr i nt er. Holds up to 50

sheets of paper (20 sheet s of heavy stock).

Holds up to 500 sheets of pap er. Service adjustable to

accommodate paper of different sizes.

U.S. model opens with a pa per descent key (see item 12).

European model opens w ith a handle (see item 12).

Holds up to 500 sheets of paper. User adjustable to accommodate

paper of different sizes.

U.S. model opens with a pa per descent key (see item 12).

European model opens w ith a handle (see item 12.).

Holds up to 2,500 sheets of Let t er or A4 paper (see item 12).

U.S. and European mode l s open with a paper descent key (see

item 12).

Press before sliding the drawer out of the prin te r ( U .S model).

Pull on the handle to open (European model).

section.

Operator

Overview 1-4

Page 9

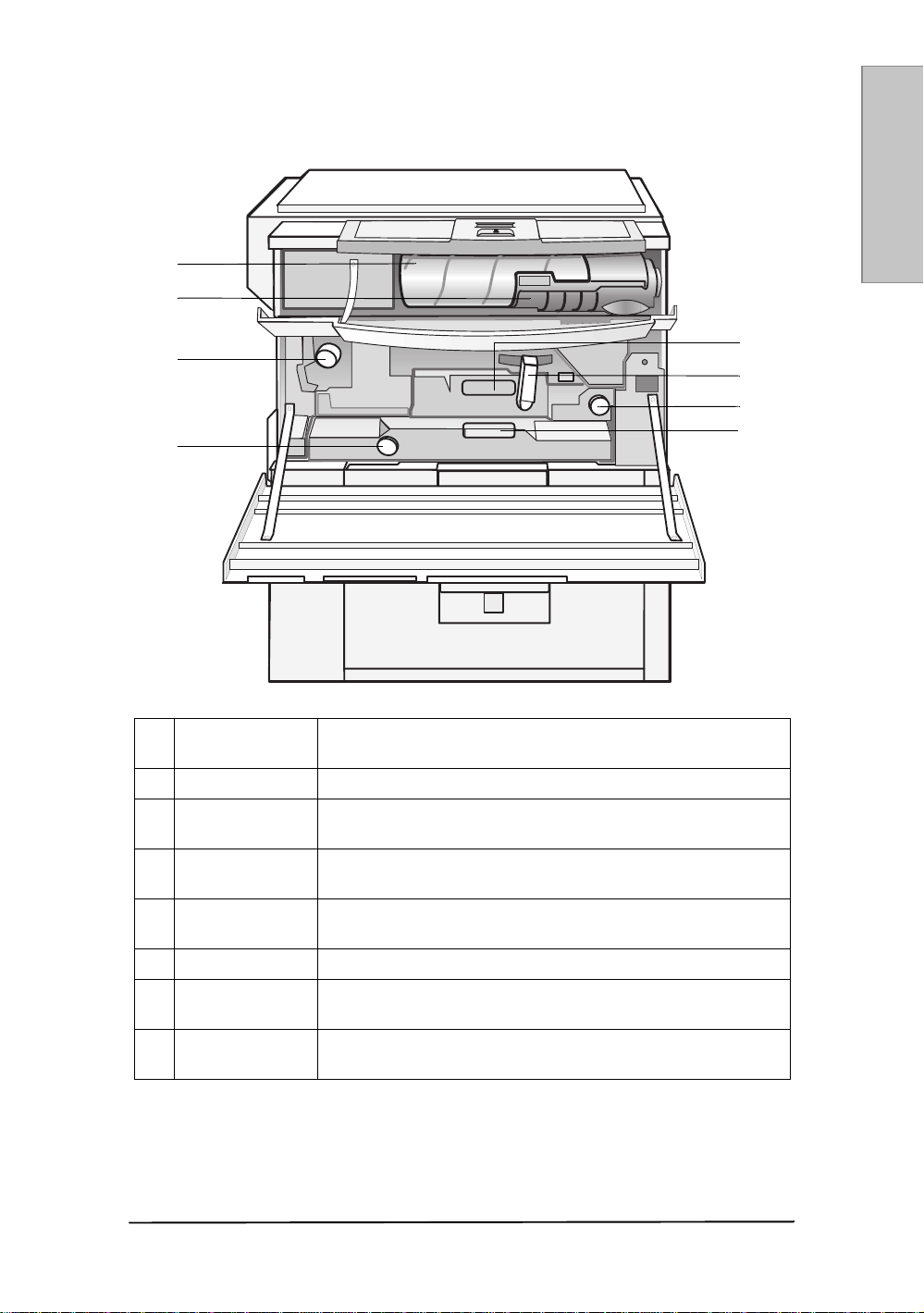

Internal View of the Printer

1

2

Overview

8

7

1 Toner Bottle

2 Toner Bottle Holder Swing open to replace the toner bottle.

Misfeed Removal

3

Guide M5

Misfeed Removal

4

Lever M4

Misfeed Removal

5

Knob M3

6 Duplex Unit D2 Slide out to clear a sheet of pap er misfed in the duplex unit.

Misfeed Removal

7

Knob D1

Misfeed Removal

8

Knob M1

Contains toner. Replace it with a new one when the warning

message appears .

Use to clear a misfed sheet of paper.

Press down to pull out the M5 unit.

Use to clear a misfed sheet of paper.

Use to clear a misfed sheet of paper.

Turn to clear a sheet of misfed pape r.

3

4

5

6

Overview 1-5

Page 10

Overview 1-6

Page 11

2

Using the Operator Control Panel

This chapter describes:

• The DDS 50/62 Control Panel

• Starting and Shutting Down the DDS 50/62

Using the OCP

Using the OCP 2-1

Page 12

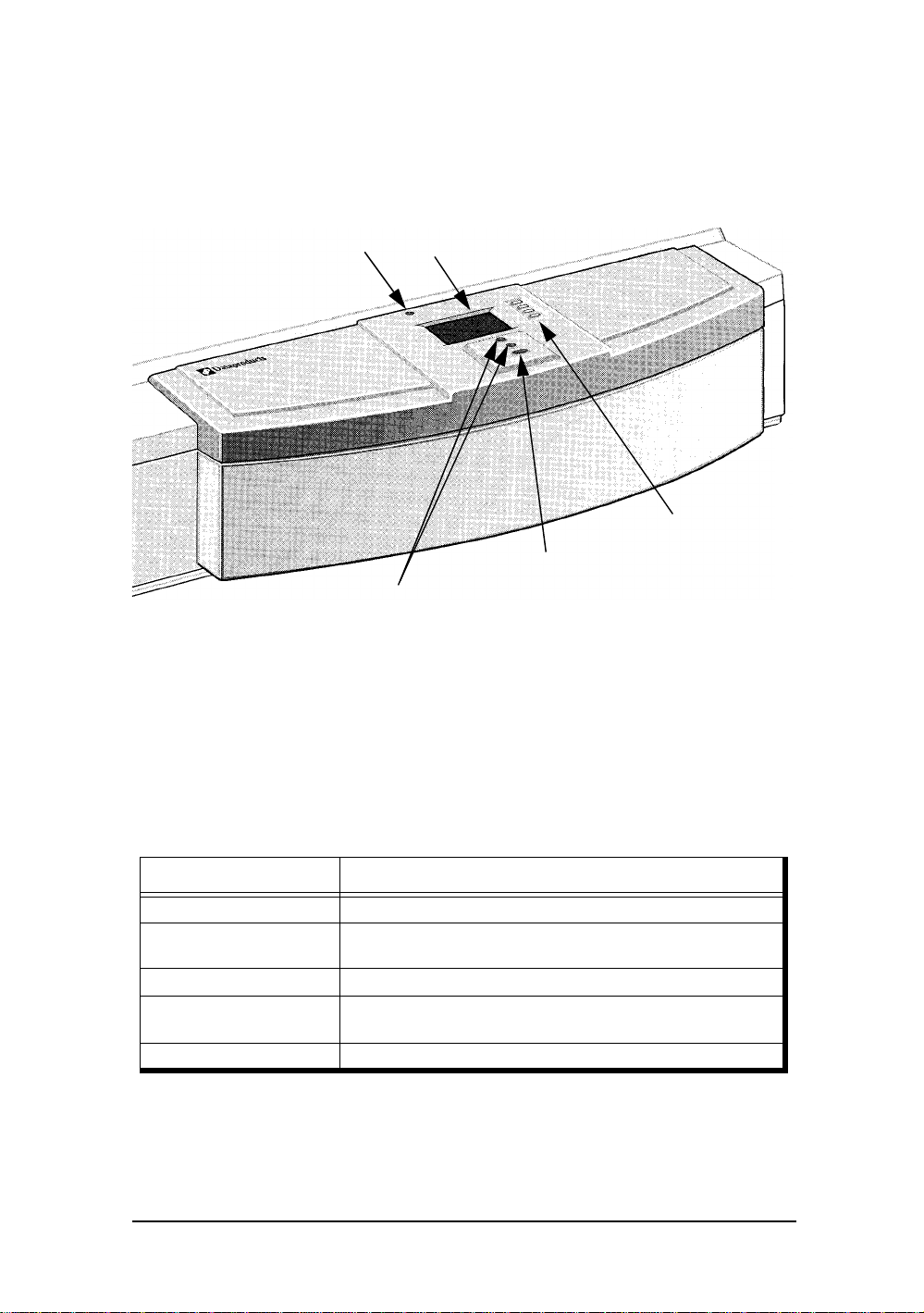

The Operator Control Panel

Activity

(LCD)

Light

Line Selection

Liquid Crystal Display

Buttons

Up/Down

Menu

Button

Buttons

The DDS 50/62 Operator Control Panel (OCP) allows you to access all basic functions, access special functions, view status and information about jobs printed,

print special pages, view error message s, run diagno stics, and co nfigure Set up options.

Activity Light

The Activity Light indicates the current DDS 50/62 activity.

Color Activity

Solid Red An error has occurred causing the DDS 50/62 to be disabled.

Flashing Red

Solid Green The DDS 50/62 is idle.

Flashing Green

No Light The DDS 50/62 is off or starting up.

2-2 Using the OCP

There is an error causing printing to be disabled, but the DDS

50/62 is capable of processing. The finisher may be busy.

The DDS 50/62 is processing or printing a job, or communicating

with a remote computer.

Page 13

Buttons

The following table describes the Operator Control Panel buttons.

Buttons Use

There are four line selection buttons on the right side of the

Line Selection Buttons

Up and Down Buttons

Menu Button

Operator Control Panel. Use these buttons to select the

command displayed on the corresponding line of the LCD. When

a button is active, a special character (>) appears in the LCD

next to the button.

Use these buttons to scroll to different screens in multi-screen

lists, to select Setup options from a list of available options, and

to scroll alphanumeric characters.

Press this button to view other screens. Under normal operation,

the Operator Control Panel displays the Info, RIP, or Print St atus

screen with information about the status of the DDS 50/62. I f you

press the Menu button, the Functions menu is displayed and you

can perform additional operations. If a job is processing or

printing, press the Menu button to cycle among the active

screens.

LCD

The LCD provides information about the status of the DDS 50/62, displays menu

information, and enables you to view and edit information in the Setup menus.

Using the OCP

The last line of the LCD indicates which screen you are looking at and highlights

one of the status icons to ind icate what the DDS 50/62 is doi ng. Only the icon s for

the screens that are current ly availa ble appea r. The Menu but ton cycle s among the

active screens.

Using the OCP 2-3

Page 14

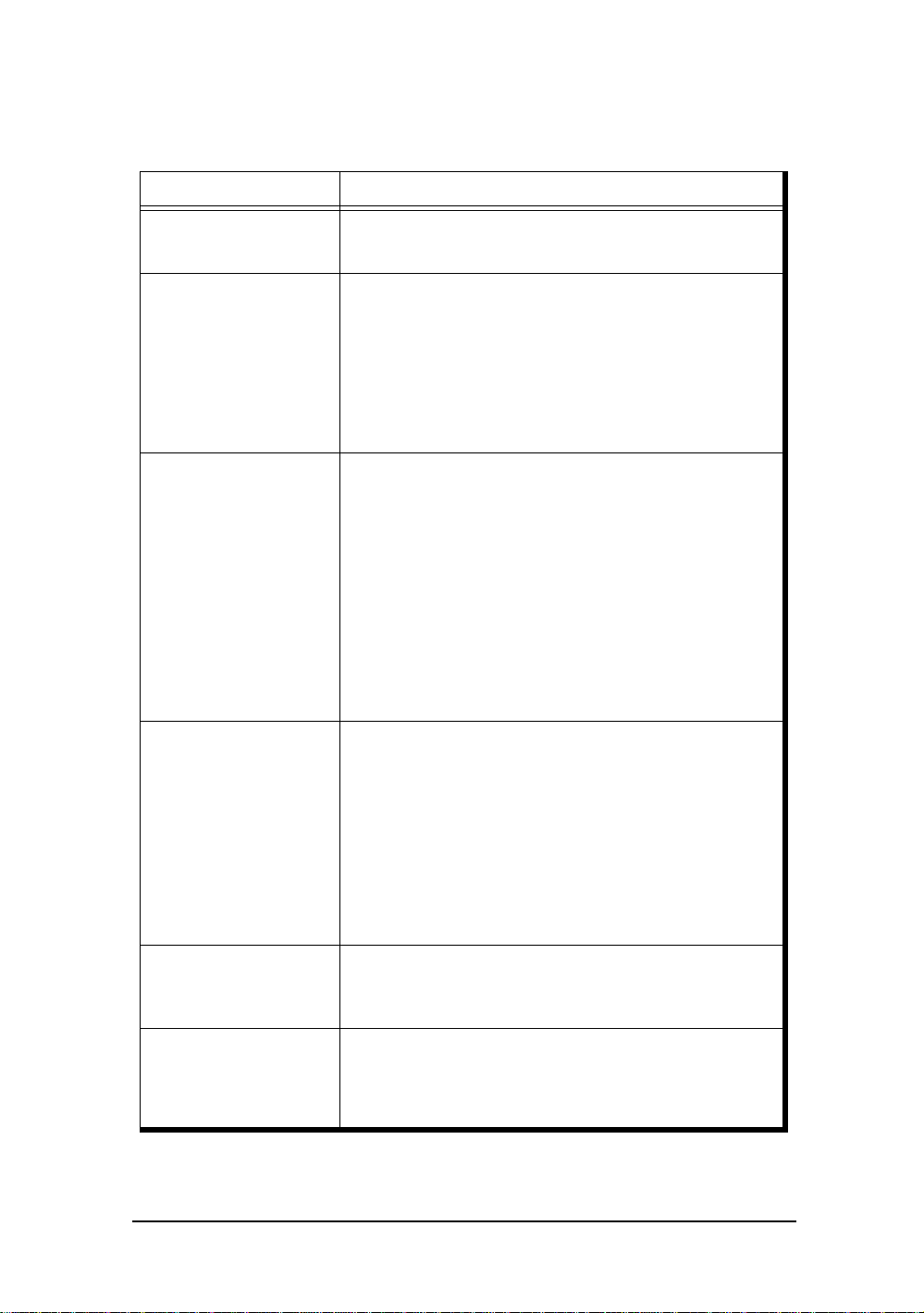

The following table describes the LCD screens.

Screen Description

Alert Status

Print Status

RIP Status

Info Status

Functions

Network

If there is a problem with processing a job or printing functions,

an error message appears on the Operator Control Panel. For

information on error messages, see the

When the DDS 50/62 is printing a job, the Print Status screen

appears. The Print Status screen displays:

Cancel Job - Press the top line selection button to cancel the job

currently printing.

User Name - The name of the user who sent the job currently

processing.

Pages/Total - The number of copies of the current job printed

and the total number of copies of the job requested.

When the DDS 50/62 is processing a job, the RIP Status screen

appears. This screen displays the following:

Cancel Job - Press the top line selection button to cancel the job

currently printing. The DDS 50/62 cancels the job before printing

begins.

Document Name - The name of the document currently printing.

User Name - The name of the user who sent the job currently

printing.

Kilobytes - The size (in kilobytes) of the job processed so far.

NOTE: This number is always displayed in kilobytes, even if

the amount goes over 1000KB; for example 10MB is

displayed as 10000KB.

When the DDS 50/62 is not processing or printing a job, it

displays information about the current server and software. It

displays the following information:

Server name - The DDS 50/62 name.

Status - The current status of the DDS 50/62. The DDS 50/62

status can be: Idle, Initializing, Busy, Processing, or Printing.

Megabytes - The space (in megabytes) available on the

DDS 50/62 hard disk, for example, 756MB.

Version - The system software version running on the

DDS 50/62.

You can press the Menu button to display the Functions menu.

Use the up and down buttons to scroll through the list. Press the

Line Selection button to the right of a command to select that

command.

The network icon appears at the bottom left of any of the other

screens when a job is being sent to the DDS 50/62, either over

the network or through the parallel port. The network icon also

appears, together with a flashing green activity light, when a

remote utility is running.

Messages

section.

2-4 Using the OCP

Page 15

Functions Menu

The Functions menu allows you to choose the following commands:

Command Description

Prints special pages from the DDS 50/62. You can print the

following pages from the submenu that appears:

Print Pages

Run Diagnostics

Reboot Server

PS Test Page - Enables you to confirm that the PostScript

interface is functioning properly. The PS Test Page provides

sample images, illustrations, point size examples, and grayscale

samples. The following information is also listed: server name,

software version, and date and time printed.

Configuration - Prints the Configuration page, which gives the

current server and device configuration. This page lists general

information about the hardware and software configuration of the

DDS 50/62, the current options for all Setup settings, information

about the current calibration, and the Ethernet and Token Ring

addresses of the DDS 50/62.

Job Log - Prints a log of the last 55 jobs. For information on the

fields in the Job Log and on printing it in other forms, see the

User’s Manual.

PS Font List - A list of all PostScript fonts resident on the DDS

50/62 hard disk.

PCL Font List - A list of all PCL fonts resident on the DDS 50/62

hard disk.

This function is provided for service representatives only.

Contact your authorized service/support technician for

information about running diagnostics.

Shut down all DDS 50/62 activity in the correct manner and then

restart.

Using the OCP

Using the OCP 2-5

Page 16

Restarting and Shutting Down the DDS 50/62

Generally, you can leave the DDS 50/62 running all the time. This section

describes how to shut down and restart the DDS 50/62 when necessary.

Restarting t he DDS 50/62

You should use the following procedure to restart the DDS 50/62 rather

than using the power switch.

To restart the DDS 50/62:

1. Make sure that the DDS 50/62 is not receiving, processing, or

printing a job.

The statu s message on the LCD should read Idle.

NOTE:

If a job from the Print queue is processing, it will

continue processing and print after DDS 50/62 is

restarted; if a job sent to the Direct connection is

processing, it will not finish processing or

printing.

2. Press the Menu button to display the Functions menu.

3. Press the Line Selection button to choose Reboot Server.

2-6 Using the OCP

Page 17

Shutting Down the DDS 50/62

You may need to shut down the DDS 50/62 for service. Fonts that have been

downloaded, print jobs in the Hold and Printed queues, and jobs that have been

processed but not printed are not deleted.

To shut down the DDS 50/62:

1. Make sure that the DDS 50/62 is not receiving, processing, or

printing a job.

The status message on the LCD should read Idl e. If a job has jus t

finished processing or printing , wait at le ast five secon ds after t he

status message switches to Idle before proceeding to step 2.

NOTE:

If a job from the Print queue is processing, it will

continue processing and print after DDS 50/62 is

restarted; if a job sent to the Direct connection is

processing, it will not finish processing or

printing.

2. Power off the DDS 50/62 by moving t he powe r swit ch to th e Of f

position.

Using the OCP

Using the OCP 2-7

Page 18

2-8 Using the OCP

Page 19

This chapter describes:

• Loading Paper in Tray 1

• Loading Paper in Tray 2

• Loading Paper in Tray 3

• Loading Paper in the HCF

• Loading Paper in the MBT

• Using the Finisher

3

Paper Handling

Paper Handling

Paper Handling 3-1

Page 20

Loading Paper in Tray 1

Tray 1 holds 500 sheets of either Letter, Legal, Ledger, A5, B5, A4,

B4, or A3. The paper size is set at t he f act or y and c an be a dju st ed by

a Service Representative to support other paper sizes.

To load paper in tray 1:

NOTE:

If the printer is in ene rgy save mode, the tray will

not open to allow paper loading. Press any

button on the Operator Control Panel to “wake”

the printer before attempting to open the tray.

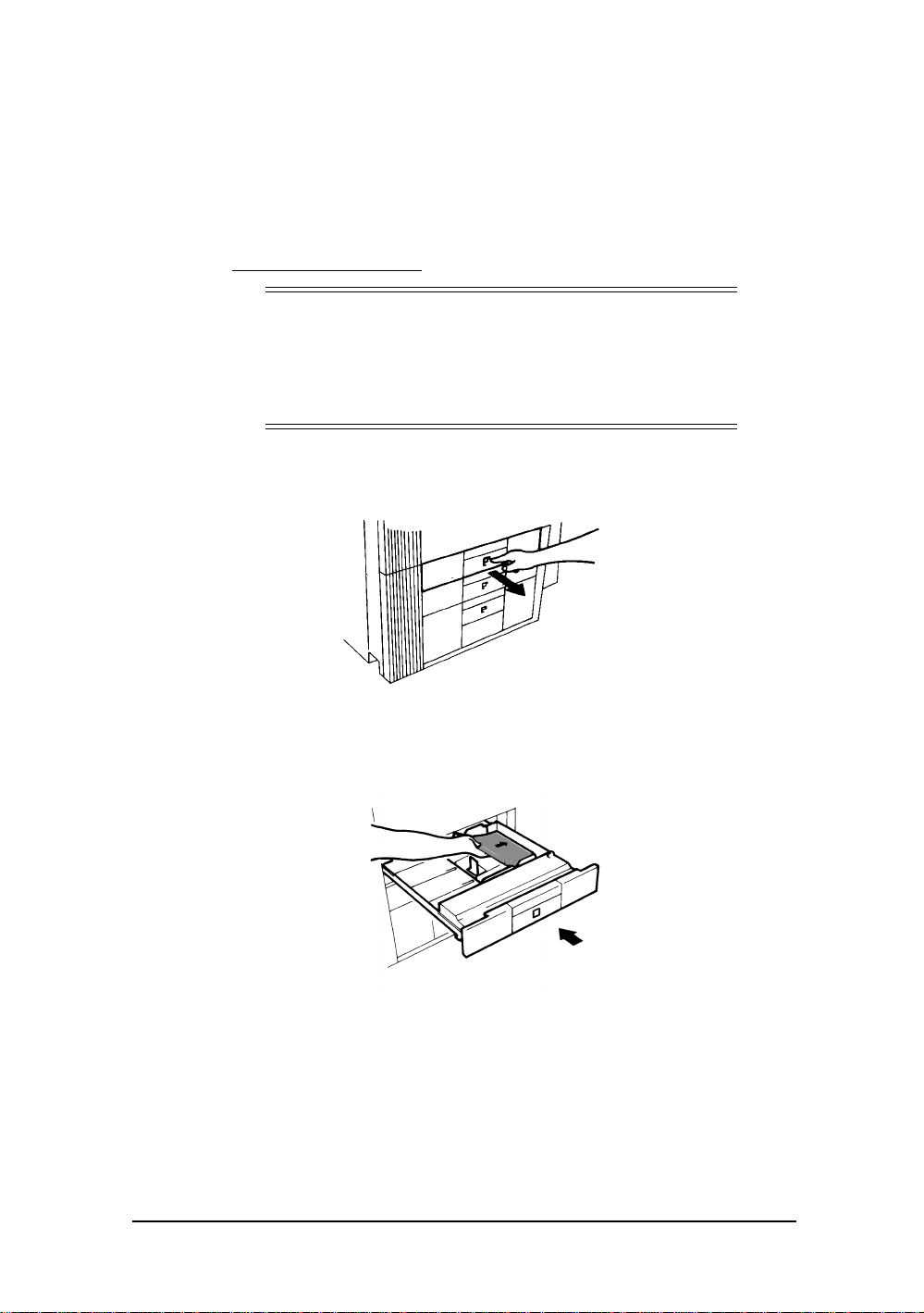

1. Press the paper descent key (US Models) or pull the handle

(European Models) and then slide out the tray.

2. Load the paper stack into the tray so that the front side (the side

3-2 Paper Handling

to be printed on) faces down.

Page 21

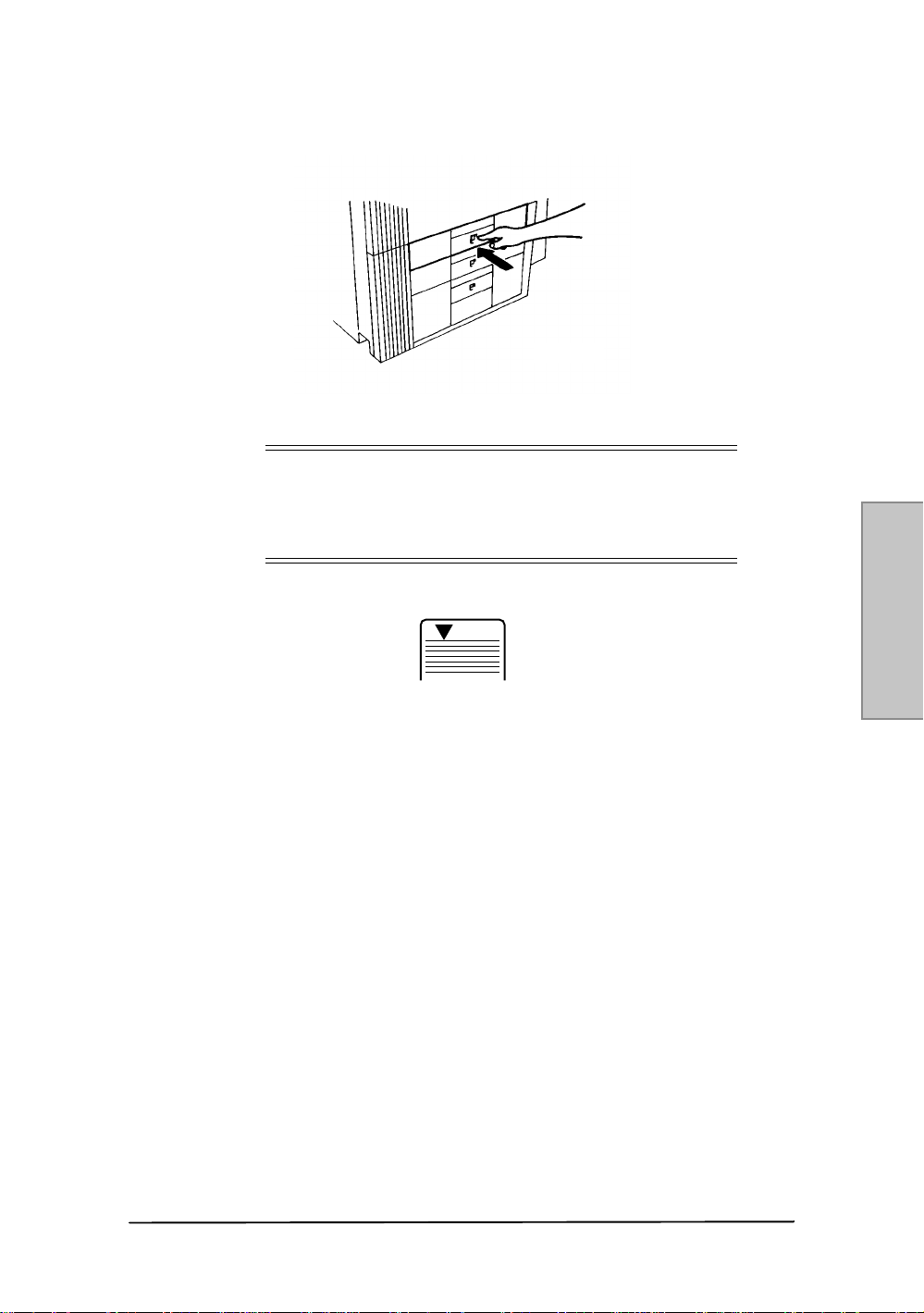

3. Slide the tray back in, and press the paper descent key.

NOTE:

The paper should be loaded no higher than the

Max. Level Indicator. The Max. Level Indicator

label is located in the tray.

Max.

Paper Handling

1145O555KA

Paper Handling 3-3

Page 22

Loading Paper in Tray 2

Tray 2 holds 500 sheets of pape r and is use r adj ust abl e to sup port all

paper sizes.

To load paper in tray 2:

NOTE:

If the printer is in ene rgy save mode, the tray will

not open to allow paper loading. Press any

button on the Operator Control Panel to “wake”

the printer before attempting to open the tray.

1. Press the paper descent key and then slide out the tray.

2. Slide the Edge Guides in the direction of the arrow to fit the

3-4 Paper Handling

paper size.

Page 23

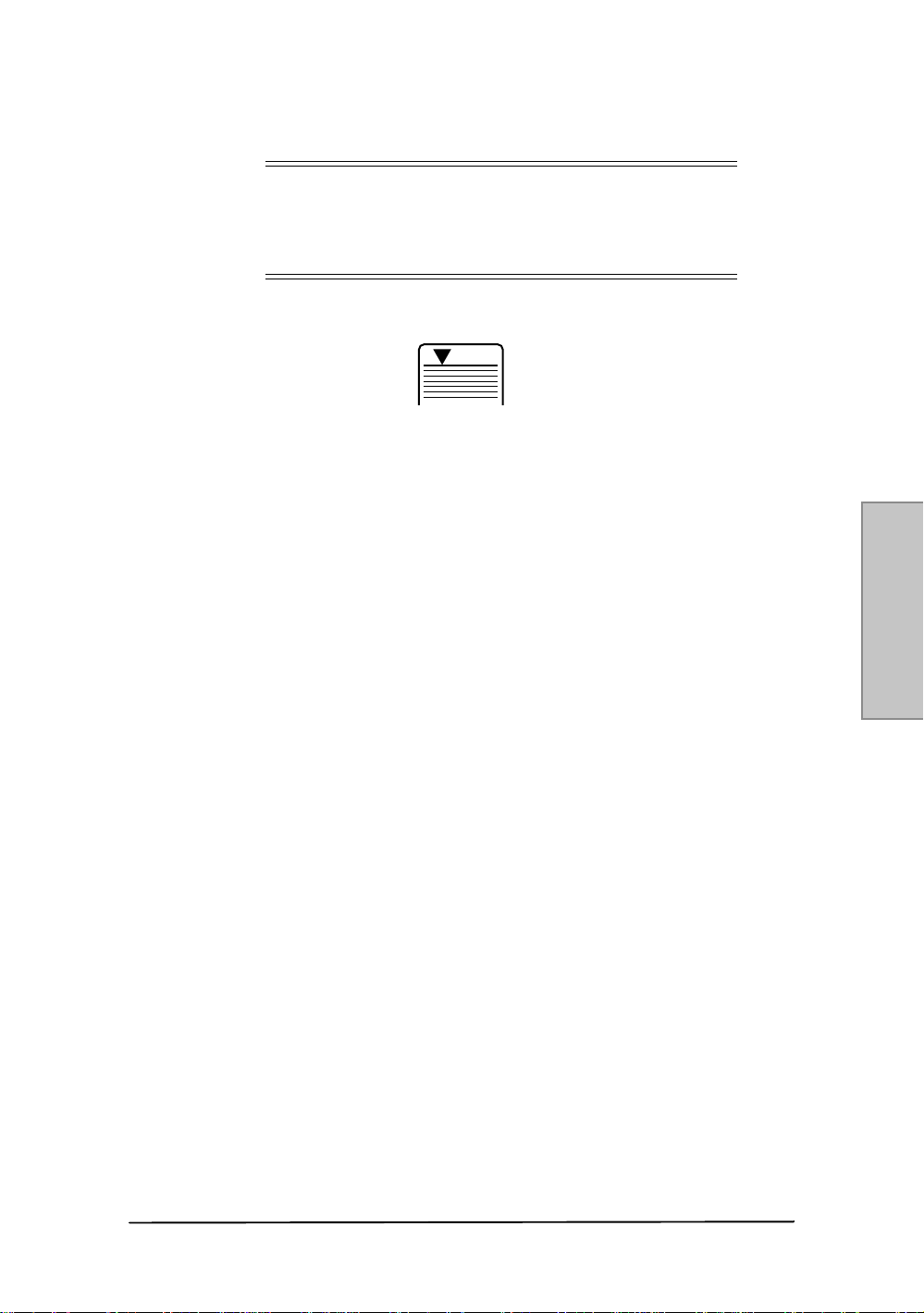

3. Load the paper stack into the tray with the front side facing

down.

NOTE:

The paper should be loade d no higher t han the Max. Leve l

Indicator. The Max. Level Indicator label is loca ted in th e

tray .

Max.

1145O555KA

Paper Handling

Paper Handling 3-5

Page 24

Loading Paper in Tray 3

Tray 3 holds 1500 sheets of Letter or A4 size paper.

To load paper in tray 3:

NOTE:

If the printer is in ene rgy save mode, the tray will

not open to allow paper loading. Press any

button on the Operator Control Panel to “wake”

the printer before attempting to open the tray.

1. Press the paper descent key and then slide out the tray.

2. Load the paper stack into the right half o f the tray, front side face

down. Press the leading edge of the paper stack tightly up

against the right side of the tray.

3-6 Paper Handling

Page 25

NOTE:

The paper should be loade d no higher t han the Max. Leve l

Indicator. The Max. Level Indicator label is loca ted in th e

tray .

Max.

1145O555KA

Paper Handling

Paper Handling 3-7

Page 26

3. Load another paper stack into the left half of the tray, front side

face down. Press the leading edge of the paper stack tightly up

against the left side of the tray.

NOTE:

The paper should be loade d no higher t han the Max. Leve l

Indicator. The Max. Level Indicator label is loca ted in th e

tray .

4. Slide the tray back in.

3-8 Paper Handling

Max.

1161O150AA

Page 27

5. Press the paper descent key.

Paper Handling

Paper Handling 3-9

Page 28

Loading Paper in the HCF

The HCF holds 3000 sheets of Letter/A4 ( LEF or SEF), Legal (SEF),

or B5 paper. It is set at the factory and can be adjusted by a service

representative.

To load paper in the HCF:

NOTE:

If the printer is in ene rgy save mode, the tray will

not open to allow paper loading. Press any

button on the Operator Control Panel to “wake”

the printer before attempting to open the tray.

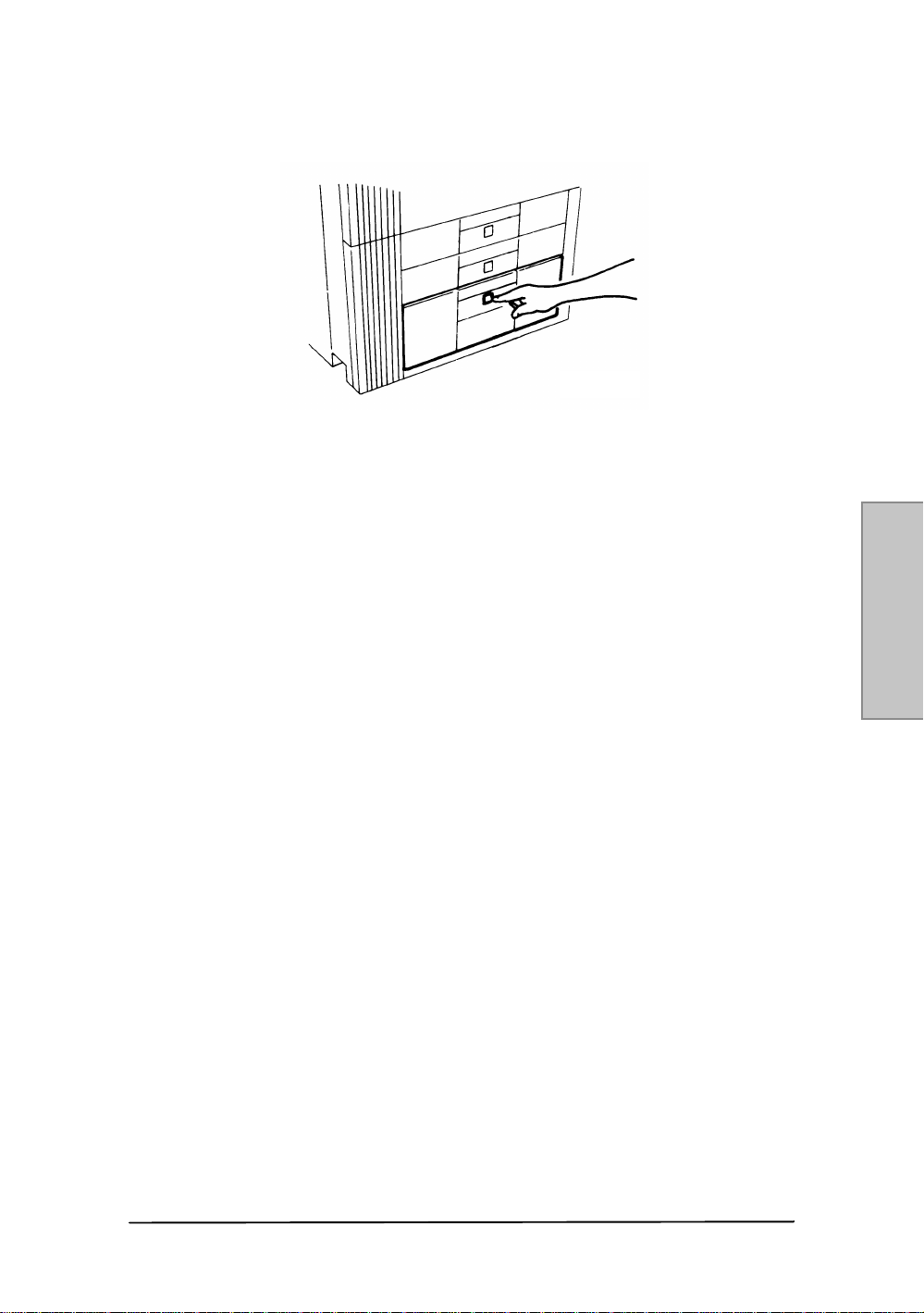

1. Press the Paper Plate Descent Key to lower the paper plate.

2. Holding the Door Lock Release Lever, open the cassette door.

3-10 Paper Handling

Page 29

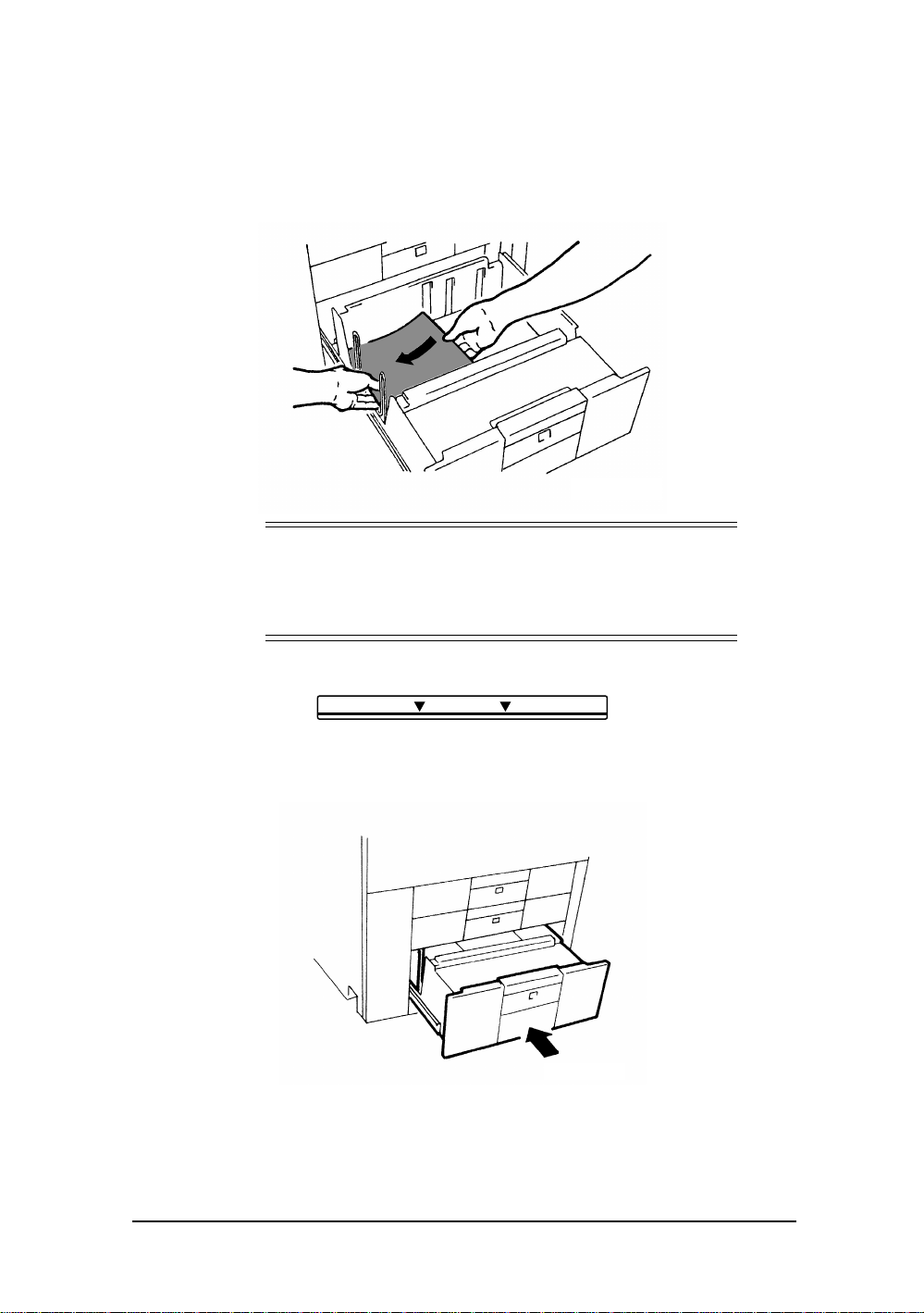

3. Place the paper stack onto the paper plate so that its front side

faces up.

NOTE:

Make sure that the leading edge of the paper stack is

pressed tightly up against the guide plate on the take-up

side of the cassette.

The paper should be loade d no higher t han the Max. Leve l

Indicator. The Max. Level Indicator label is loca ted in th e

tray.

Max.

1145O555KA

Paper Handling

Paper Handling 3-11

Page 30

4. Close the cassette door. This causes the paper plate to rise

automatically.

NOTE:

Be sure the door is completely close d, otherwise the paper

plate may not ascend.

3-12 Paper Handling

Page 31

Loading Paper in the MBT

The Intelligent Multi bypass tray allows you to manually feed paper

to the printer . T he Multi bypas s tray holds up to 50 sheets of paper (20

sheets of heavy stock).

To load paper in the MBT:

1. Lower the MBT.

2. Place the paper onto the MBT.

CAUTION:

Label stock must be loaded face up (label side up and

backing side down) and printed in simplex mode only.

Otherwise, the printer wil l be damaged and a service call

will be required.

Paper Handling

Paper Handling 3-13

Page 32

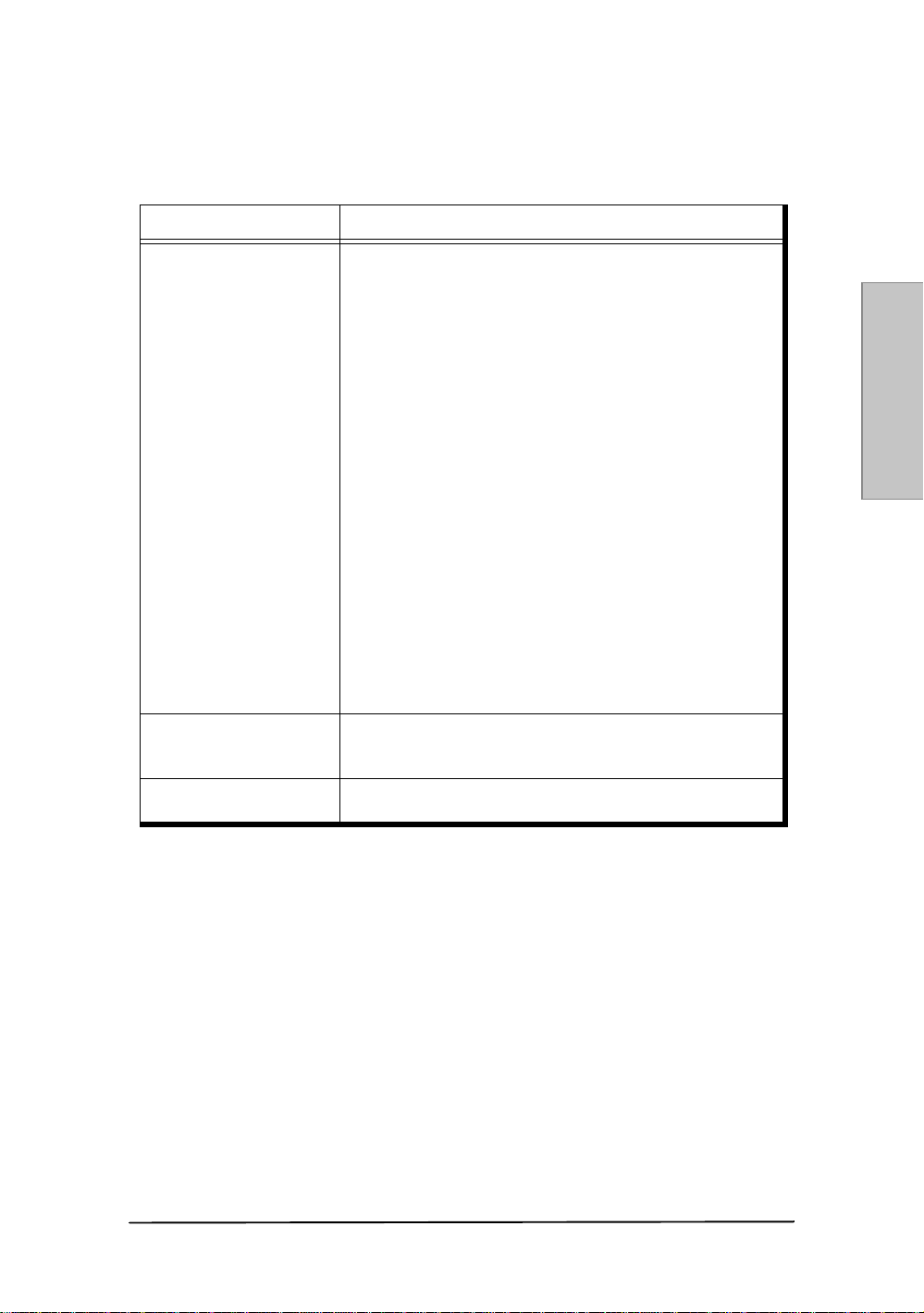

Using the Finisher

The table below shows the capabilit ies of bot h the Advance d and the

Professional Finisher.

Function Advanced Finisher Professional Finisher

Capacity

Stapling

Hole Punch

Folding None

Multiple Stapling/Hole Punching Any combination

Booklet None

100 Sheets Face Up

2,000 Sheets Fa ce Down

2 position

Corner (top left)

Two Side

Long Edge (A4/Letter)

3 holes for U.S.

4 holes for Europe

Short Edge (A3/Ledger)

3 holes for U.S.

4 holes for Europe

Short Edge (A4/Letter/Legal)

2 holes for U.S.

100 Sheets Face Up

2,000 Sheets Face Down

3 position

Corner (top left)

Two side

Saddle Stitch (2 center)

Long Edge (A4/Letter)

3 holes for U.S.

4 holes for Europe

Short Edge (A3/Ledger)

3 holes for U.S.

4 holes for Europe

Short Edge (A4/Letter/Legal)

2 holes for U.S.

Center Crease

A4/Letter - A3/Ledger

Z Folding

A3/Ledger

Yes (requires saddle stitch and folding)

3-14 Paper Handling

Page 33

Staple Positions

When stapling a job, the position of th e staple(s) dif fers depending on

three factors:

• Orientation (make sure that the Orientation setting you select

matches the actual orientation of your print job)

• Paper size of your job

• Stapler mode

Based on these three factors, the following tables illustrate where

staples are inserted into the printed page.

Paper Handling

Paper Handling 3-15

Page 34

3-16 Paper Handling

Page 35

Hole Punch

The hole punch positions ar e constrained by th e similar settings to t he

staple positions:

• Orientation

• Paper size of your job

• Hole punch mode

NOTE:

If the hole punch option is selected along with the staple

option, the staple mode required rotation overrides the

hole punch rotation. Therefore, the holes will appear on

the same side of the paper as the staples. See the table on

page 3-13 for the exact positions.

Based on these three factors, the table below illustrates where holes

are inserted into the printed page.

Paper Handling

Paper Handling 3-17

Page 36

3-18 Paper Handling

Page 37

This chapter describes:

• Replacing the Staple Cartridge

• Replacing the Toner Cartridge

4

Maintenance

Maintenance 4-1

Maintenance

Page 38

Replacing the Staple Cartridge

To replace the

Staple Cartridge:

1. Holding the finisher lock release lever, slide the finisher away

from the printer.

2. Open the finisher door

3. Slide out the staple unit.

4-2 Maintenance

Page 39

4. While pressing down the staple cartridge lever, pull the staple

cartridge out of its port.

5. Put the finisher back in place without the staple cartridge so that

the printer will recognize that the stapler needs calibrating.

6. Pull the staple sheet about 3 cm (approximately 1/8 inch) out of

the new staple cartridge and break off that portion.

NOTE:

Check that no portion of the staple sheet hangs

out of the cartridge. Break off any portion of the

sheet that hangs out of the cartridge as shown

above.

Maintenance 4-3

Maintenance

Page 40

7. Open the finisher and insert the new staple cartridge until it

clicks into position.

8.Push the staple unit back in and close the finisher front door. The

stapler will automatically calibrate.

9. Slide the finisher back against the printer. (Not shown.)

NOTE:

Replace the staple cartridge only after you are

prompted to do so by a message. Removing the

staple cartridge before then will result in stapling

trouble.

4-4 Maintenance

Page 41

Replacing the Toner Bottle

To replace the

toner bottle:

1. Swing down the upper front door.

2. Swing open the toner bottle holder, and pull out and discard the

used toner bottle.

Maintenance 4-5

Maintenance

Page 42

3. Tap a new toner bottle against a desk or other hard surface four

to five times. Then, turn the toner bottle upside down and tap it

in the same way again.

4. Shake the new toner bottle well, and turn it over lengthwise five

times.

.

5. With the UP marking on top, insert the bottle into position.

4-6 Maintenance

Page 43

6. While holding the toner bottle in place with one hand, pull the

seal off the toner bottle.

7. Swing the toner bottle holder closed and close the front door.

CAUTION:

Use ONLY the specified toner for this printer. Using any

other toner could result in trouble.

Be careful not to drop the toner bottle, because the bottle

may be damaged.

When the front door is closed, the printer

automatically starts replenishing the supply of

toner. During this period, do not attempt to turn

off the power switch or open the front door.

Maintenance 4-7

Maintenance

Page 44

4-8 Maintenance

Page 45

Clearing Paper Jams

This chapter describes clearing a paper jam from the:

•Printer

• Duplex Unit

• Intelligent Multi Bypass Tray

• Finisher

5

Clearing Paper Jams 5-1

Clearing Paper Jams

Page 46

From the Printer

1. On the left side of the printer , open the misfeed cle aring guide L1

and pull out the sheet of paper.

L1

2. Open the left door.

3. Open the front door.

5-2 Clearing Paper Jams

Page 47

4. Turning knob M1, pull out the sheet of p aper. Then turn knob D1

to return any paper to the duplex unit.

M1

D1

5. Close the left door. (Not shown.)

6. Open the right door.

7. Turning knob M2, pull out the sheet of paper.

M2

Clearing Paper Jams 5-3

Clearing Paper Jams

Page 48

8. Close the right door. (Not shown.)

9. Turn knob M3 to feed the sheet of paper.

M3

10. Lower the M4 lever and slide out the M5 unit.

M4

11. Raising the misfeed clearing guide M6, remove the sheet of

paper.

5-4 Clearing Paper Jams

M5

M6

Page 49

12. Turning knob M7, pull out the sheet of paper.

M7

13. Open misfeed clearing guide M8, and remove the sheet of paper.

M8

WARNING:

Be careful not to touch the areas on the printer

marked with “Caution” with bare hands.

14. Slide in the M5 unit, and raise the M4 lever back up again.

M4

M5

Clearing Paper Jams 5-5

Clearing Paper Jams

Page 50

15. Close the front door. (Not shown.)

16. Slide out the drawer being used and take out the paper stack.

17. Reload the paper stack and slide the drawer into the printer.

18. To reset the paper misfeed indication on the touch panel, open

and close the front door.

NOTE:

After the paper misfeed has been cleared, the

printer automatically starts a print cycle even

without pressing the Start key.

5-6 Clearing Paper Jams

Page 51

From the Duplex Unit

1. Open the left door.

2. Open the front door.

3. Turning knob M1, pull out the sheet of paper. Then, turn knob

D1 to return any paper to the duplex unit.

M1

D1

4. Close the left door.

Clearing Paper Jams 5-7

Clearing Paper Jams

Page 52

5. Open the right door.

6. Turning knob M2, pull out the sheet of paper.

M2

7. Close the right door. (Not shown.)

8. Slide out duplex unit D2.

5-8 Clearing Paper Jams

D2

Page 53

9. Raise misfeed clearing guide D3, and pull out the sheet of paper.

D3

10. Raise misfeed clearing guide D4, and pull out the sheet of paper.

D4

11. Raise misfeed clearing guide D5, and remove the sheet of paper.

D5

Clearing Paper Jams 5-9

Clearing Paper Jams

Page 54

12. Slide duplex unit D2 back into the printer.

D2

13. Close the front door.

NOTE:

After the paper misfeed has been cleared, the

printer automatically starts a print cycle even

without pressing the Start key.

5-10 Clearing Paper Jams

Page 55

From the Intelligent Multi Bypass Tray

1. Unload the paper sta ck from the Intelligent Multi Bypass Tray,

then open the right door.

2. Pull out the sheet of paper from the Paper Take-Up Section, then

close the right door.

3. Place the paper stack back on the tray.

Clearing Paper Jams

Clearing Paper Jams 5-11

Page 56

4. To reset the paper misfeed indication on the touch panel, open

and close the front door.

5-12 Clearing Paper Jams

Page 57

From the Finisher

Paper Entry Side

1. Holding the finisher Lock Release lever, slide the finisher away

from the prin ter.

2. Open misfeed clearing guide FN1, and pull out the sheet of

paper.

FN1

Clearing Paper Jams

Clearing Paper Jams 5-13

Page 58

3. Loosen two screws, open the misfeed clearing guide, then pull

out the sheet of paper.

4. Close the misfeed clearing guide and tighten the screws. (Not

shown.)

5. Open the finisher front door.

6. Raise misfeed clearing guide FN3, then pull out the sheet of

paper.

5-14 Clearing Paper Jams

FN3

Page 59

7. Turn knob FN2 to feed the sheet of paper.

FN2

8. Open misfeed clearing guide FN4.

FN4

9. Remove the sheet of paper, then close misfeed clearing guide

FN4.

FN4

Clearing Paper Jams 5-15

Clearing Paper Jams

Page 60

10. Turn knobs FN7 and FN6 to feed the sheet of paper.

FN7

FN6

11. Pinching the lever of misfeed clearing guide FN5, open FN5.

FN5

12. Remove the sheet of paper, then close FN5.

FN5

5-16 Clearing Paper Jams

Page 61

13. Close the finisher front door.

14. Slide the finisher back against the printer.

Paper Folding Area

1. Holding the finisher Lock Release lever, slide the finisher away

from the copier.

Clearing Paper Jams

Clearing Paper Jams 5-17

Page 62

2. Open the finisher front door.

3. Pinching the lever of misfeed clearing guide FN8, open FN8.

FN8

4. Remove the sheet of paper, then close FN8.

FN8

5-18 Clearing Paper Jams

Page 63

5. Turn knobs FN7 and FN6 to feed the sheet of paper.

FN7

FN6

6. Pinching the lever of misfeed clearing guide FN5, open FN5.

FN5

7. Remove the sheet of paper, then close FN5.

FN5

Clearing Paper Jams

Clearing Paper Jams 5-19

Page 64

8. Close the finisher front door.

9. Slide the finisher back against the copier.

Paper Exit Trays

1. Open Exit Tray FN9, then pull out the sheet of paper.

5-20 Clearing Paper Jams

FN9

Page 65

2. Close FN9. (Not shown.)

3. Open the Manual Staple Tray Cover FN10, then pull out the

sheet of paper.

FN10

4. Close FN10. (Not shown.)

Clearing Paper Jams 5-21

Clearing Paper Jams

Page 66

5-22 Clearing Paper Jams

Page 67

This chapter describes:

• OCP Messages

• Controller Messages

6

Messages

Error Messages

Messages 6-1

Page 68

OCP Messages

The follow ing table lis ts (in alphab etical orde r) printer erro r message s and their

appropriate corrective action.

Message Description Corrective Action

Cannot Staple The job cannot be stapled.

Caution: Toner

Empty

Checking

Sensors...

Cleaning

Wires...

Close Left Hand

Side Door

Close Left Hand

Top Door

Close Main

Body

Front Door

Close Right

Hand

Side Door

Close Toner

Door

ENGINE call

service

____

FINISHER call

serv.

____

Finisher is Busy

Finisher Not

Ready

The toner has run out.

The printer is checking the

sensors.

The printer is performing a

wire cleaning.

The printe r’s left side door

is open.

The printer’s left top door is

open.

The printe r’s main body

front door is open.

The printer’s right side door

is open.

The printer’s toner door is

open.

There is a problem with the

printer’s engine.

There is a problem with the

printer’s finisher.

You have sent a job to the

finisher, but the finisher is

busy completing anothe r

job.

You have sent a job to the

finisher, but the finisher is

not in the correct position.

Check the media type and page size of

your job.

Replace the toner bottle. See

Maintenance, page 4-5

The DDS 50/62 will be ready to print

when the check is complete.

The DDS 50/62 will be ready to print

when the check is complete.

The DDS 50/62 will resume printing when

the left side door is closed.

The DDS 50/62 will resume printing when

the left top door is closed.

The DDS 50/62 will resume printing when

the main body front door is closed.

The DDS 50/62 will resume printing when

the right side door is closed.

The DDS 50/62 will resume printing when

the toner door is closed.

Contact your authorized service

technician.

Contact your authorized service

technician.

The DDS 50/62 will send your job to the

finisher when the first job is complete.

The DDS 50/62 will send your job to the

finisher when it is reset to the ready

position.

.

6-2 Messages

Page 69

Message Description Corrective Action

The printer’s fusing roller

Fusing Roller

Not Sufficiently

Heated

Heat Roller Not

Sufficiently

Heated

Initializing... The printer is starting up. It will be ready to print in a few moments.

Initializing

Finisher...

Initializing

Status...

JAM: Clear Left

Door

JAM: Clear

Right Door

JAM: Finisher

Elevator Tray

JAM: Finisher

Folding Section

JAM: Finisher

Folding Unit

JAM: Finisher

Paper Bundle

JAM: Finisher

Processing Tray

JAM: Finisher

Punching

Sensor

JAM: Finisher

Sort Ejection

JAM: Finisher

Stapled Paper

JAM: Finisher

Staple Jam

cleaning web is empty. This

message appears after a

specific number of pages

have been printed.

The printer’s heat roller is

not warm enough to begin

printing.

The finish er is starting up.

The printer is warming up

and testing the engine

status.

There is a pap er jam in the

left door area.

There is a pap er jam in the

right door area.

There is a pap er jam in the

finisher’s elevator tray

area.

There is a pap er jam in the

finisher’s folding section.

There is a pap er jam in the

finisher’s folding unit.

There is a pap er jam in the

finisher’s stapler unit.

There is a pap er jam in the

manual staple tray.

There is a pap er jam in the

finisher’s hole punch area.

There is a pap er jam in the

finisher’s ejection area.

There is a pap er jam in the

finisher’s stapler, which

occurred after your job wa s

stapled.

There is a pap er jam in the

finisher’s stapler, which

occurred after your job wa s

stapled.

Contact your authorized service

technician.

The DDS 50/62 will begin printing when

the heat roller has heated to the

necessary temperature.

It will be ready to receive jobs in a few

moments.

It will be ready to print in a few moments.

Clear the jam and close the pr inter doors.

Clearing Paper Jams, page 5-2

See

Clear the jam and close the pr inter doors.

See

Clearing Paper Jams, page 5-3.

Clear the jam and close the pr inter doors.

Clearing Paper Jams, page 5-13

See

Clear the jam and close the pr inter doors.

See

Clearing Paper Jams, page 5-17

Clear the jam and close the pr inter doors.

See

Clearing Paper Jams, page 5-17

Clear the jam and close the pr inter doors.

See

Clearing Paper Jams, page 5-13

Clear the jam and close the pr inter doors.

See

Clearing Paper Jams, page 5-13

Clear the jam and close the pr inter doors.

See

Clearing Paper Jams, page 5-13

Clear the jam and close the pr inter doors.

See

Clearing Paper Jams, page 5-13

Clear the jam and close the pr inter doors.

Clearing Paper Jams, page 5-13

See

Clear the jam and close the pr inter doors.

See

Clearing Paper Jams, page 5-13

.

.

.

.

.

.

.

.

.

.

Messages

Messages 6-3

Page 70

Message Description Corrective Action

JAM: Finisher

Vertical

Transport

JAM: Open

Front Door

Check Duplex

Tray

JAM: Open

Front Door Clear

Both Trays

JAM: Paper

Cabinet HCF

Tray

JAM: Paper

Cabinet Manual

Tray

JAM: Paper

Cabinet

Tray____

Load____Paper

Load___Paper

in HCF Tray

Load___Paper

in Manual Tray

Load___Paper

in Tray

Load Thick___

in HCF Tray

There is a paper jam inside

the finisher.

There is a pap er jam in the

duplex tray.

There is a paper ja m in one

of the printer trays (possi bly

the duplex tray).

There is a pap er jam in the

high capacity feeder tray.

There is a pap er jam in the

high manual feed tray.

There is a paper ja m in one

of the printer trays. Check

the LCD for specific

information.

The printer is not loaded

with the type of paper

specified. Check the LCD

for specific information.

The printer’s high capacity

feeder tray is not loaded

with the type of paper

specified. Check the LCD

for specific information.

The printer’s manual feed

tray is not loaded with the

type of paper specified.

Check the LCD for specific

information.

One of the printer’s trays is

not loaded with the type of

paper specif ied. Check the

LCD for specific

information.

The printer’s high capacity

feeder tray is not loaded

with the thick paper

specified. Check the LCD

for specific information.

Clear the jam and close the pr inter doors.

Clearing Paper Jams, page 5-13

See

Clear the jam and close the pr inter doors.

Clearing Paper Jams, page 5-7

See

Clear the jam and close the pr inter doors.

Clearing Paper Jams, page 5-7

See

Clear the jam and c los e the pri nte r doors.

See the label on the inside of the printer

front door.

Clear the jam and c los e the pri nte r doors.

See

Clearing Paper Jams, page 5-11

Clear the jam and c los e the pri nte r d oors .

See the label on the inside of the printer

front door.

Load the printer with the correct paper.

Paper Handling, page 3-2.

See

Load the high capacity feeder tray with

the correct paper. See

page 3-10

Load the manual feed tray with the

correct paper. See

.

Paper Handling,

Paper Handling

.

.

.

.

,

page 3-13.

Load the manual feed tray with the

correct paper. See

page 3-2

Load the high capacity feeder tray with

the correct paper. See

page 3-10

.

.

Paper Handling,

Paper Handling,

6-4 Messages

Page 71

Message Description Corrective Action

The printer’s manual feed

Load Thick___

in Manual Tray

Load Thick___

in Tray____

Load___Transp.

in HCF Tray

Load___Transp.

in Manual Tray

Load___Transp.

Tray____

Main Power is

Off

Manual Stapler

In Use

No Waste Toner

Bottle

Paper in Output

Tray

Power Saving

Mode

Preparing Tray

3...

Processing Tray

Not Ready

tray is not loaded with the

thick paper s pecified.

Check the LCD for specific

information.

One of the printer’s trays is

not loaded with the thick

paper specif ied. Check the

LCD for specific

information.

The printer’s high capacity

feeder tray is not loaded

with the transparency

specified. Check the LCD

for specific information.

The printer’s manual feed

tray is not loaded with the

transparency specified.

Check the LCD for specific

information.

One of the printer’s trays is

not loaded with the

transparency specified.

Check the LCD for specific

information.

There is a serious problem

with the printer’s power

supply.

Someone is using the

manual stapler.

There is a no waste toner

bottle in the printer .

There is pape r in one o f the

output trays that needs to

be cleared.

The printer is in power

saving mode.

The printer is setting paper

in the correct position in

tray 3.

The processing tray is not

ready to receive your job.

Load the manual feed tray with the

correct paper. See

3-13

.

Load the specified tray with the correct

paper.

Load the high capacity feeder tray with

the correct transparency. See

Handling, page 3-10

Load the manual feed tray with the

correct transparency. See

Handling, page 3-13

Load the specified tray with the correct

transparency. See

3-2

.

Contact your authorized service

technician.

Close the manual stapler door.

Contact your service technician.

Clear all the pages from the output trays.

To print, send your job to the DDS 50/62

or press any key on the Operator Contro l

Panel.

Printing will resume in a few moments.

The DDS 50/62 will begin printing when

the proce ssing tray is in position; close

the printer doors if necessary.

Paper Handling, page

.

.

Paper Handling, page

Messages

Paper

Paper

Messages 6-5

Page 72

Message Description Corrective Action

Remove Paper

From

Processing Tray

RESTART

PRINTER Fatal

Frame Error

RESTART

PRINTER Fatal

Overrun Error

RESTART

PRINTER Fatal

Parity Error

Service

Advisory:

Cleaning

notice____

Service

Advisory:

General notice

Service

Advisory:

Life of main

body

Service

Advisory:

Replace

Develop____

Service

Advisory:

Replace Duplex

Tray

Service

Advisory:

Replace

Fusing____

There is a pap er in the

processing tray that needs

to be cleared.

There is a serious error

with the printer.

There is a serious error

with the printer.

There is a serious error

with the printer.

The specified part of the

printer needs cleaning.

This message appears

after a specific number of

pages have been printed.

The printer is due for a

general servicing. This

message appears after a

specific number of pages

have been printed.

The printe r’s main body is

due for servicing. This

message appears after a

specific number of pages

have been printed.

The specified part of the

printer’s developing unit

must be replaced. This

message appears after a

specific number of pages

have been printed.

The printer’s duplex tray

must be replaced. This

message appears after a

specific number of pages

have been printed.

The specified part of the

printer’s fusing unit must be

replaced. This message

appears after a specific

number of pages have

been printed.

Clear all the pages from the tray.

Shut down and restart the DDS 50/62

using the main power switch.

Shut down and restart the DDS 50/62

using the main power switch.

Shut down and restart the DDS 50/62

using the main power switch.

Contact your authorized service

technician.

Contact your authorized service

technician.

Contact your authorized service

technician.

Contact your authorized service

technician.

Contact your authorized service

technician.

Contact your authorized service

technician.

6-6 Messages

Page 73

Message Description Corrective Action

The printer’s high capacity

Service

Advisory:

Replace HCF

parts

Service

Advisory:

Replace HCF

Roller

Service

Advisory:

Replace

Main____

Service

Advisory:

Replace Manual

Tray

Service

Advisory:

Replace

Photo____

Service

Advisory:

Replace

Tray____

Service

Advisory:

Replace Tray 3

parts

Service

Advisory:

Replace

Tray____clutch

feeder tray or parts of the

tray must be repla ced. Thi s

message appears after a

specific number of pages

have been printed.

The printer’s high capacity

feeder roller must be

replaced. This message

appears after a specific

number of pages have

been printed.

The specified part of the

printer’s main body must

be replaced. This message

appears after a specific

number of pages have

been printed.

The printer’s manual feed

tray must be repla ced. Thi s

message appears after a

specific number of pages

have been printed.

The specified

photosensitive unit in the

printer must be replaced.

This message appears

after a specific number of

pages have been printed.

The specified printer tray

must be replaced. This

message appears after a

specific number of pages

have been printed.

The printer’s tray 3 or parts

of the tray must be

replaced. This message

appears after a specific

number of pages have

been printed.

The specified printer tray’s

clutch must be replaced.

This message appears

after a specific number of

pages have been printed.

Contact your authorized service

technician.

Contact your authorized service

technician.

Contact your authorized service

technician.

Contact your authorized service

technician.

Contact your authorized service

technician.

Contact your authorized service

technician.

Contact your authorized service

technician.

Contact your authorized service

technician.

Messages

Messages 6-7

Page 74

Message Description Corrective Action

Service

Advisory:

Repl. Tray 3

Roller

Service

Advisory:

Waste Toner

Bottle

Set Finisher

Puncher

To____Holes

Staple Cartridge

Empty

Stapling...

Toner-Boost

Activated

The printer’s tray 3 roller

must be replaced. This

message appears after a

specific number of pages

have been printed.

The printe r’s waste toner

bottle must be replaced.

This message appears

after a specific number of

pages have been printed.

Your job’s hole punch

setting does not match the

setting in the finisher.

The stapler unit is out of

staples.

The DDS 50/62 is stapling

a job.

The printer’s toner-boost

feature is in use.

Toner Empty The toner has run out.

Toner Low

The toner is about to run

out.

You have sent a job to the

Top Output Tray

Not Ready

top output tray, but the tray

is not in the correct

position.

Warming up... The printer is warming up.

Warning:

Replace

Photoconductor

Waste Toner

Bottle Almost

Full

Waste Toner

Bottle Full

The printe r’s

photoconductor must be

replaced.

The printe r’s waste toner

bottle is almost full of used

toner.

The printe r’s waste toner

bottle is full of used toner.

Contact your authorized service

technician.

Contact your authorized service

technician.

The DDS 50/62 will resume printing when

you open the finisher doors, set the hole

punch setting as spec ified, and c lose the

doors.

The DDS 50/62 will resume printing when

you have replaced the staples. See

Maintenance, page 4-2

.

The DDS 50/62 will be ready to print

when it has completed the stapling job.

The DDS is ready to print.

Replace the toner bottle. See

Maintenance, page 4-2

.

You will soon need to replace the toner

bottle, or if you cannot print, replace the

toner bottle immediately. See

Maintenance, page 4-5

.

Reset the tray to the ready position.

It will be ready to print in a maximum of 6

minutes.

Contact your authorized service

technician.

Contract your authorized service

technician to replace the waste toner

bottle.

Contact your authorized service

technician to replace the waste toner

bottle.

6-8 Messages

Page 75

Message Description Corrective Action

Messages

Service

Advisory:

Repl. Tray 3

Roller

Service

Advisory:

Waste Toner

Bottle

Set Finisher

Puncher

To____Holes

Staple Cartridge

Empty

Stapling...

Toner-Boost

Activated

Toner Empty The toner has run out.

Toner Low

Top Output Tray

Not Ready

Warming up... The printer is warming up.

Warning:

Replace

Photoconductor

Waste Toner

Bottle Almost

Full

Waste Toner

Bottle Full

The printer’s tray 3 roller

must be replaced. This

message appears after a

specific number of pages

have been printed.

The printe r’s waste toner

bottle must be replaced.

This message appears

after a specific number of

pages have been printed.

Your job’s hole punch

setting does not match the

setting in the finisher.

The stapler unit is out of

staples.

The DDS 50/62 is stapling

a job.

The printer’s toner-boost

feature is in use.

The toner is about to run

out.

You have sent a job to the

top output tray, but the tray

is not in the correct

position.

The printe r’s

photoconductor must be

replaced.

The printe r’s waste toner

bottle is almost full of used

toner.

The printe r’s waste toner

bottle is full of used toner.

Contact your authorized service

technician.

Contact your authorized service

technician.

The DDS 50/62 will resume printing when

you open the finisher doors, set the hole

punch setting as spec ified, and c lose the

doors.

The DDS 50/62 will resume printing when

you have replaced the staples. See

Maintenance, page 4-2

The DDS 50/62 will be ready to print

when it has completed the stapling job.

The DDS is ready to print.

Replace the toner bottle. See

Maintenance, page 4-5

You will soon need to replace the toner

bottle, or if you cannot print, replace the

toner bottle immediately. See

Maintenance, page 4-5

Reset the tray to the ready position.

It will be ready to print in a maximum of 6

minutes.

Contact your authorized service

technician.

Contract your authorized service

technician to replace the waste toner

bottle.

Contact your authorized service

technician to replace the waste toner

bottle.

.

.

.

Messages 6-9

Page 76

Controller Messages

The following table lists start-up diagnostics, general system, and software

installation controller error messages and their appropriate corrective action.

Start-up Diagnostics Errors

Test Name

RTC Self Test 700

RTC R/W Reg 710

RTC Start 720, 730

12C EEPROM 1100

ENET SLV REG 400, 401

IDE Chip 1001

MEM DIMM

INFO

MEM ADDRESS 301

SERIAL CHIP 3000, 3001

BOOTROM

Error

Number

300

1811, 1813,

1814, 1819

Area Tested

on

Controller

Realtime

Clock chip

Realtime

Clock chip

Realtime

Clock chip

12C

EEPROM

Ethernet

controller

chip

EIDE

controller

chip

DIMMs on

the controller

board

DIMMs on

the controller

board

PCI bus and

I/O

controllers

boot ROM

(Flash)

Corrective Action

Cycle the power off and on. If th e problem

persists, call your authorized service

technician.

Cycle the power off and on. If th e problem

persists, call your authorized service

technician.

Cycle the power off and on. If th e problem

persists, call your authorized service

technician.

Cycle the power off and on. If th e problem

persists, call your authorized service

technician.

Cycle the power off and on. If th e problem

persists, call your authorized service

technician.

Cycle the power off and on. If th e problem

persists, call your authorized service

technician.

Cycle the power off and on. If th e problem

persists, call your authorized service

technician.

Cycle the power off and on. If th e problem

persists, call your authorized service

technician.

Cycle the power off and on. If th e problem

persists, call your authorized service

technician.

Cycle the power off and on. If th e problem

persists, call your authorized service

technician.

6-10 Messages

Page 77

General Controller System Errors

Symptom Probable Cause Corrective Action

Power supply cable is not

properly connected.

Controller does

not start up.

Controller starts

up but CPU fan

is not working or

is overheating.

CPU fan is

working but

does not blow

air towards the

CPU.

Buttons do not

work on the

Operator Control

Panel.

Nothing appears

on the Operat or

Control Pa nel

when the printer

is powered on.

A “Main power is

off” message

appears on the

Operator Control

Panel.

Controller hangs

at the Loading

system... or the

Loading

settings...

screen.

Controller power supply

has failed.

The relay board may be

faulty.

CPU fan is not properly

connected.

CPU fan is installed upside

down.

Connection to the UIB is

faulty or the UIB is bad.

Faulty chip on the

controller.

Connections to the UIB are

faulty or the UIB is faulty.

Faulty controller power

supply.

Bad DIMM connections.

Communication problem

between the controller and

the engine.

System software is not

installed on the HDD.

Video interface board is

loose or faulty.

Cycle the power off and on. If th e problem

persists, call your authorized service

technician.

Cycle the power off and on. If th e problem

persists, call your authorized service

technician.

Cycle the power off and on. If th e problem

persists, call your authorized service

technician.

Cycle the power off and on. If th e problem

persists, call your authorized service

technician.

Cycle the power off and on. If th e problem

persists, call your authorized service

technician.

Cycle the power off and on. If th e problem

persists, call your authorized service

technician.

Cycle the power off and on. If th e problem

persists, call your authorized service

technician.

Messages

Messages 6-11

Page 78

System Software Installation Errors

Message Probable Cause Corrective Action

“From Drive” was selected

Installation file

not found

Not enough disk

space

Format failed

Bad file type

Wrong file size

Corrupt file size

Unpacking failed

Creating task

failed

Parallel port

timeout

Memory

allocation failed

Receiving...

appears to han g

before

completing the

file transfer.

instead of “From Parallel

Port” during software

installation.

Faulty System Software

CD or HDD.

Unnecessary files on the

controller HDD.

HDD problem when

Standard level formatting of

HDD was attempted.

Incorrect Start Up screen

option selected.

Wrong or unexpected

filename entered or

filename misspelled.

File transfer was not

completed.

Unexpected error - cause

unknown.

Unexpect error - cause

unknown.

DOS copy command

entered too late.

Installation file spooled too

late.

Using a PC r unning

Windows NT to install

system software.

Memory hardware failure.

Too little disk space on

parallel port PC.

Cycle the power off and on. If th e problem

persists, call your authorized service

technician.

Cycle the power off and on. If th e problem

persists, call your authorized service

technician.

Cycle the power off and on. If th e problem

persists, call your authorized service

technician.

Cycle the power off and on. If th e problem

persists, call your authorized service

technician.

Cycle the power off and on. If th e problem

persists, call your authorized service

technician.

Cycle the power off and on. If th e problem

persists, call your authorized service

technician.

Cycle the power off and on. If th e problem

persists, call your authorized service

technician.

Cycle the power off and on. If th e problem

persists, call your authorized service

technician.

Cycle the power off and on. If th e problem

persists, call your authorized service

technician.

Cycle the power off and on. If th e problem

persists, call your authorized service

technician.

6-12 Messages

Page 79

7

Troubleshooting

This chapter describes:

• Basic Troubleshooting Tips

• General Printing Problems

• Problems with Print Quality

• Duplex Printing Problems

• Problems with Fiery Downloader

NOTE:

The following sections provide troubleshooting

guidelines. If you are still unable to resolve a

proble m, co ntact you r auth ori zed s ervic e/supp ort

center .

Troubleshooting

Troubleshooting 7-1

Page 80

Basic Troubleshooting Tips

The following are some common situations that can cause a variety of problems.

Before you look for a spec ific problem, use the tips in this list.

• Check the power and cables to the DDS 50/62 and your

computer.

• Check the DDS 50/62 LCD and Activity Lights for

information.

• If possible, print the Configuration page from th e

Functions>Print Pages menu and make sure that the settings

match your configuration.

• Check the current status of the DDS 50/62.

The current status appears on the DDS 50/62 LCD. Press the RIP

or Print key to see status screens for jobs that are processing and/or

printing.

Look at the Status field in the Fiery Downloader or Fiery Spooler

main window, or use the Status WebTool. If the DDS 50/62 is

processing your job, the status message reflects this. If your print

job doesn’t ap pear in t he statu s message, another us er’ s job may b e

printing before you rs, or the DDS 50/62 ma y already hav e finishe d

printing your job. If the Printed queue on your DDS 50/62 is

enabled, jobs that have finished printing will appear in that list in

the Fiery WebSpooler and Fiery Spooler main window. If your job

is waiting to print, it will appear in the list for the Print queue.

If you are printing over an IPX (Novell) network, the job may be

processing on the Novell print server before it is sent to the

DDS 50/62.

• Open the Fiery WebSpooler or Fiery Spooler main window

and locate the name of the job you are trying to print.

This window provides information about the status of every job

printed to a queue, including information about jobs that do not

print becau se of PostScript error s.

7-2 Troubleshooting

Page 81

General Printing Problems

If this happens: Try this:

• On the Mac OS co m put er, make sure that the correct

zone is selected and that AppleTalk is active.

AppleTalk must be active. The DDS 50/62 may be in a different

zone from the one that’s selected (if your network doesn’t have

zones, this is not applicable). Print the Configuration page from

the Functions>Print Pages menu to view the correct AppleTalk

zone.

• Choose Control Panel from the Apple menu, ope n the

Network Control (or Ap pleTalk Control Panel), and make

sure that you have selected EtherTalk Phase 2.

You will see icons identifying the available network types. If your

Mac OS computer has built-in EtherTalk, it is EtherTalk Phase 2.

• Does the DDS 50/62 appear in the Chooser of another

Mac OS computer on th e same network.

If there is another Mac OS computer nearby, check to see if the

DDS 50/62 appears in the Chooser on that Mac OS computer. If

the DDS 50/62 is visible from one Mac OS computer, but not

The DDS 50/62 does not

appear in the Mac OS

computer’s Chooser list of

printers.

from another, there may be a problem with the way the second

Mac OS computer is connected to the network. Check all the

cabling and other connections, and verify that the network is

properly terminated. If there is a 10BaseT transceiver on the

network, make sure that its green link integrity light is on. For

more information about the network, refer to the documentation

provided with the network hardware.

Troubleshooting

• Do other printers on the network appear in the Choos er ?

If your network includes printers other than the

DDS 50/62, they should appear in the Chooser. If none of the

printers appear in the Chooser list, there is most likely a problem

with the way that the Mac OS computer is connected to the

network. Check all of the cabling and other connections. For

more information about the network, refer to the documentation

provided with the network hardware.

If other printers appear in the Chooser, there may be a problem

with the DDS 50/62 connection. Contact your DDS 50/62 system

administrator.

• Try printing a test page from the Functions>Print Pages

menu.

If you are able to print the test page, but DDS 50/62 stil l does not

appear in the Chooser, contact your authorized service/support

center.

Troubleshooting 7-3

Page 82

If this happens: Try this:

You cannot select or view

one of the Fiery

WebSpooler or Fiery

Spooler queues.

Printing seems to take too

long.

Special paper or

transparency options are

grayed out.

• Have your syste m administrator enable the queue in

DDS 50/62 Printer Setup. Only connections enabled in

Setup are available for select i on and display in Fiery

WebSpooler and Fiery Spooler.

• Print to a queue ins te ad of to t he di r ect connection.

When you print to a queue, the job is stored on the DDS 50/62

until it can be processed and printed; when you print to the direct

connection, the job cannot be sent to the DDS 50/62 until the

DDS 50/62 is done processing the previous job, so you must

wait longer to use your computer.

• Select a tray that supports printing special paper or

transparencies such as the manual feed tray.

• Did you select the DDS 50 / 62 as the current prin ter?

Before printing, you must select the DDS 50/62 as the current

printer from your Windows or Mac OS computer.

• Is the DDS 50/62 visible in the Chooser on your Mac OS

computer?

If not, see “The DDS 50/62 doesn’t appear in the Mac OS

computer’s Chooser list of printers.”

• Try printing a test page from the Functions>Print Pages

menu.

DDS 50/62 does not

respond to a Print

command.

7-4 Troubleshooting

If you are able to print the test page but still cannot print a file

from your computer, contact your system administrator or your

authorized service/support center.

• Verify that you printed to the correct queue.

View the Fiery WebSpooler or Fiery Spooler main window to see

which queue you printed to. If you printed to the Hold queue, you

must move your job to the Print queue in order to print it.

• If you are printing over an IPX (Novell) network, verify

through PCONSOLE t hat the job was sent to the Nov el l

queue and that the queue is being used by t he

DDS 50/62.

• Make sure that the job does not contain a PostScript

error.

In DDS 50/62 Printer Setup>PS Setup>Print up to PS error,

select Yes to search for PostScript errors in the file. In Fiery

WebSpooler or Fiery Spooler, check to see if the job has an error

icon next to it.

Page 83

If this happens: Try this:

• Cancel the job and do one of the following:

If you are printing a PostScript file:

Message requests a paper

size that your do not have.

In DDS 50/62 Printer Setup>PS Setup>Convert Sizes, select

Yes to convert the job to the paper size you do have. You can do

this to convert between US and metric paper sizes.

Test page or other special

Functions>Print Pages

menu pages do not print.

If you are printing a file from an application, change the page

size in the Print dialog box.

• Check the DD S 50/62 LCD.

If the LCD shows a diagnostic or error message, take the

appropriate corrective action. For more information, see the

Maintenance

If the LCD is completely blank, proceed to the following step.

section.

• Shut down and restart the DDS 50/62, and when the DDS

50/62 reaches Idle, try pri nt i ng a t est page fr om the

Functions>Print Pages menu.

If the test page still fails to print, contact your authorized

service/support center.

Troubleshooting

Troubleshooting 7-5

Page 84

If this happens: Try this:

• In DDS 50/62 Network Setup>Parallel Setup>Port

Timeout, increase the time value.

• In DDS 50/62 Network Setup>Parallel Setup>Ignore EOF:

If you are printing ASCII format PostScript only, set to No.

If you are printing Binary format PostScript, set to Yes.

• If you print using the DOS copy command, make sure to

use the /b option when printing binary files.

• Restart your Windows, enter BIOS setup, and if you have

a BIOS setting for the parallel port, make sure that it is

set to ECP and not to Bi-Directional, Compatible, EPP, or

Jobs sent to the parallel

port do not print.

any other mode.

• If you are using Windows 95, open the Syst em

Properties control panel, click t he D evice Manager tab,

click Ports, double-click the parallel port you are using,

and make sure that the driver selected is the ECP Printer

Port driver instead of the standard Printer Port, EPP

Port, or any other driver.

For information about changing this setting, see your Windows

95 documentation.

• If the PostScript Printer driver that you are using lets you

select bi-directional support, make sure that it is

disabled.

Print settings for your job

output do not match the

settings you gave.

7-6 Troubleshooting

This is generally set from the Details\Spool Settings dialog box

for the printer.

• Make sure that you did not override the setting for the

job in another place.

For information about print options, settings, and overrides, see

Appendix C

of the

DDS 50/62 User’s Manual

.

Page 85

Problems with Print Quality

If this happens: Try this:

• Make sure that you did not override the setting for the

Print settings for your job

output do not match the

settings you gave.

job in another place.

For information about print options, settings, and overrides, see

Appendix C

• Does your application require one of the DDS 50/62

printer description files?

of the

DDS 50/62 User’s Manual

.

Troubleshooting

You get poor printing

results.

Your printed file appears

too dark.

If you are printing from an application such as Adobe Separator

or PageMaker, MacroMedia Freehand, or QuarkXPress, make

sure that the DDS 50/62 printer description file is installed

correctly. For information about installing these files, see the

DDS 50/62 Getting Started

• Adjust the Brightness option.

You can use the Brightness options when printing from Fiery

Downloader to lighten your image whenever you print a

PostScript or Encapsulated postScript (EPS) file.

Duplex Printing Problems

If this happens: Try this:

• Change the Landsc ape print option.

Duplex pages print upside

down.

This option specifies how the second image is place relative to

the first. A few applications may not process the PostScript

command correctly, so when you select the opposite setting, the

correct one is used.

manual.

Troubleshooting 7-7

Page 86

Problems with Fiery Downloader

If this happens: Try this:

• Make sure that you are using the latest version of Fiery

You cannot make a

connection using Fiery

Downloader.

Downloader.

When you update your DDS 50/62 to new system software, you

should delete any existing version of Fiery Downloader from your

computer. Install the latest Fiery Downloader software from the

User Software CD to insure full compatibility.

• Try printing using the “showpag e” after EPS files

(Windows) or “showpage” (Mac OS) option in the

Options dialog box.

This option adds a showpage PostScript language command at

the end of the print job. Certain applications omit this necessary

PostScript language command when they generate EPS files.

You’ ll need to select t he Append Showpage option when printing

EPS files generated by these applications.

You cannot print an EPS

file using Fiery

Downloader.

You have problems

downloadinng a font with

Fiery Downloader

Extra blank page prints

after a Fiery Downloader

job.

If you continue having difficulties printing an EPS file with Fiery