Page 1

Publishing Finisher

User’s Guide

© 2004 Ricoh Printing Systems America, Inc.

2635-A Park Center Drive

Simi Valley, CA 93065

October 2004

337466-003, Revision A

Page 2

© 2004 Ricoh Printing Systems America, Inc. All rights reserved.

No part of this document may be reproduced without the express permission of Ricoh

Printing Systems America, Inc.

The material in this document is for informational purposes and is subject to change

without notice. Ricoh Printing Systems America, Inc., assumes no responsibility for

errors or omissions in this document. No liability is assumed for any damages resulting

from the use of the information it contains.

TRADEMARK

Digital Document Publisher, DDP, DDP 70, DDP 70e, DDP 92, DDP 184, and their

associated logo marks are trademarks of Ricoh Printing Systems America, Inc. All

rights reserved.

All other terms and product names may be trademarks or registered trademarks of their

respective owners, and are hereby acknowledged.

NOTICE TO USER

In an effort to meet the demands of a rapidly changing technology, the manufacturer is

continually developing new features and functions to meet your changing printing or

printer needs. As a result, this manual may not exactly reflect future changes made to

the product. Please be sure to consult all manual updates or addenda when using this

product’s documentation.

Page 3

Safety Precautions

- The signal word WARNING indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

- The signal word CAUTION indicates a potentially hazardous situation which, if not

avoided, may result in damage of machines. It may also be used to alert against unsafe

practices.

- Read and understand all safety instructions with signal words such as WARNING and

CAUTION. If safety instructions are ignored, personal injury may result.

- All equipment shall be locked out or tagged out to protect against accidental or

inadvertent operation when such operation could cause injury to personnel. Do not

attempt to operate any switch, valve, or other energy isolating device where it is locked

or tagged out.

- Do not operate the machines when any covers are removed.

- Keep your hands and fingers off any moving parts during operation. Moving parts can

cause severe personal injury.

- Some of the drawings in this manual show the machine uncovered for explaining the

detail or inside of machine.

iii

Page 4

iv

Page 5

CONTENTS

Safety Precautions ......................................................................................................iii

1. How the Publishing Finisher Works ...................................... 1

1-1 Making Booklets ..................................................................................................1

1-2 Transport Sheets to the Advanced Finisher .........................................................2

1-3 Sheet Folding and Punching Options...................................................................3

2. Machine Description ............................................................... 5

2-1 Unit Description................................................................................................. 5

2-2 Staple Section / Sheet Accumulate Section ........................................................6

2-3 Sheet Inserter 1,2 ................................................................................................ 7

2-4 Booklet Stacker ...................................................................................................8

3. Making Booklets ..................................................................... 9

3-1 Power On ............................................................................................................. 9

3-2 Sheet Preparation .................................................................................................9

3-3 Booklet Stacker Preparation ................................................................................ 11

3-4 Printer Preparation ...............................................................................................11

3-5 Submit Print Job................................................................................................... 11

3-6 Remove Booklets .................................................................................................12

4. Troubleshooting ....................................................................... 13

4-1 Error Messages .................................................................................................... 13

4-2 Removing Jammed Sheets ................................................................................... 16

4-2-1 Interface Section .............................................................................................16

4-2-2 Sheet Inserter 1,2 ............................................................................................ 17

4-2-3 Sheet Entrance Section ................................................................................... 17

4-2-4 Staple Section .................................................................................................18

4-2-5 Fold Section For Stapled Sheets ..................................................................... 19

4-2-6 Trim Section ...................................................................................................20

4-2-7 Finisher Delivery Section ...............................................................................21

4-2-8 Transport Gate Section ................................................................................... 21

4-2-9 Delivery Path of Sheet Inserter 1,2 ................................................................22

v

Page 6

4-3 When Sheet Jams Occur Frequently .................................................................... 23

4-4 When Cover or Guide is Open............................................................................. 24

4-5 When Staples Run Out ......................................................................................... 25

4-6 When Staple is Jammed .......................................................................................27

4-7 When Trimming Trash Box Is Full...................................................................... 28

4-8 When Fold Line is Not Aligned ........................................................................... 28

4-9 When the Fold and Stitch Line Are Not Aligned ................................................29

4-10 When the Fore-edge is Not Trimmed Completely............................................. 29

4-11 When the Fore-edge is Not Trimmed At All .....................................................29

4-12 When the Sheet is Not Folded ........................................................................... 29

5. Cleaning .................................................................................... 31

5-1 Cleaning the Sheet Transport Path....................................................................... 31

Appendix ...................................................................................... 33

A-1 Specifications ......................................................................................................33

A-2 Consumables ....................................................................................................... 34

vi

Page 7

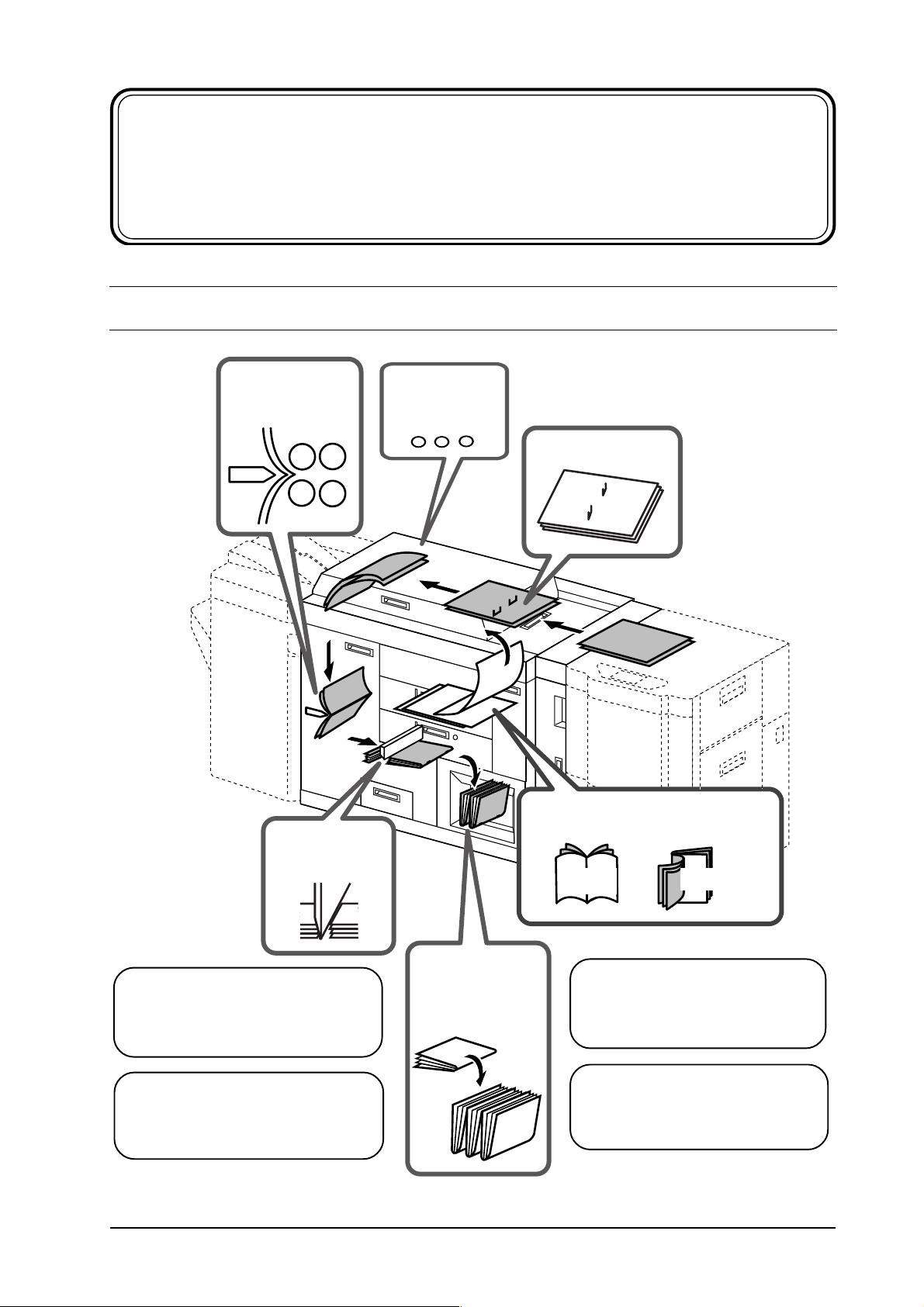

1. How the Publishing Finisher Works

This section shows how the Publishing Finisher works.

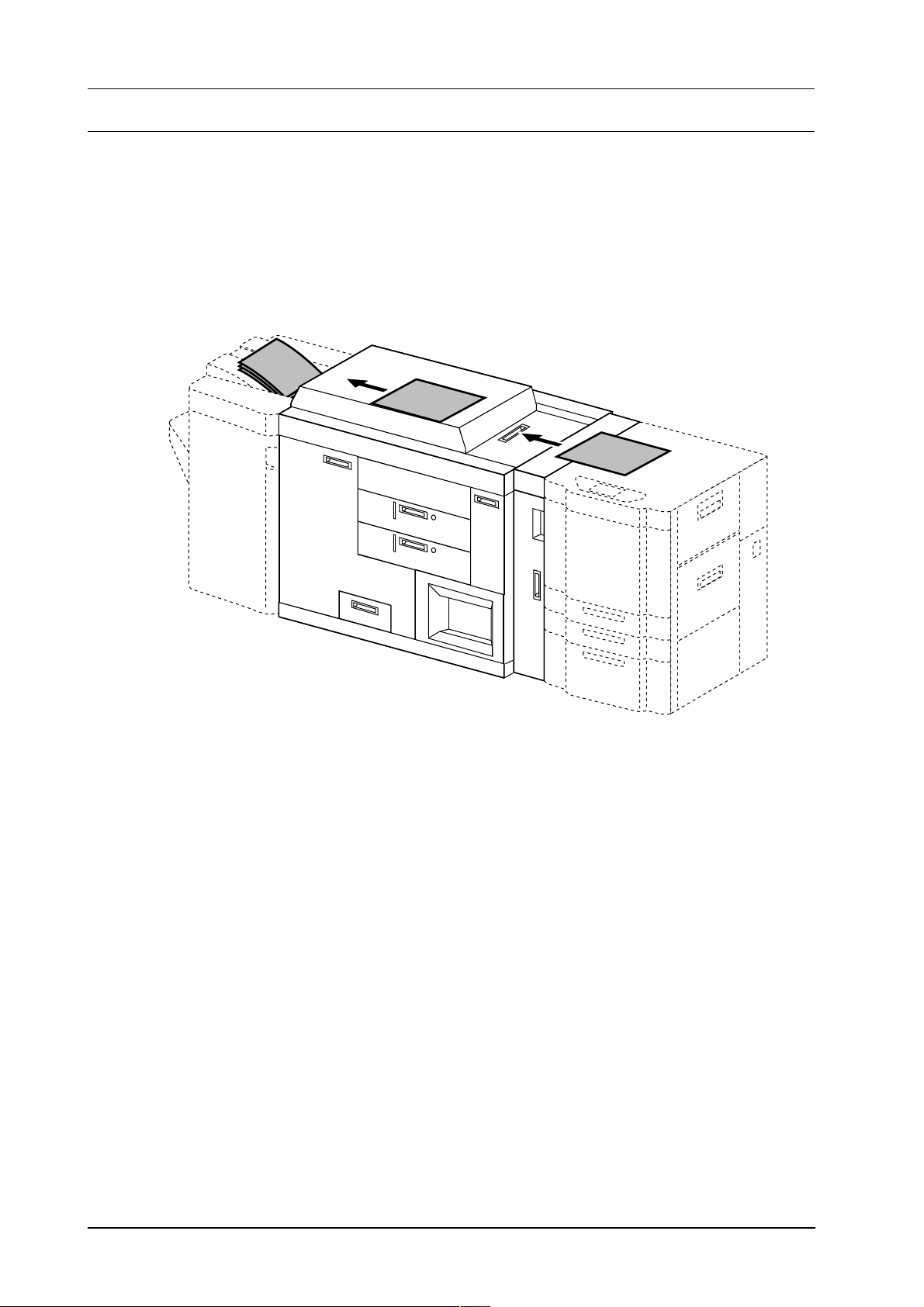

1-1 Making Booklets

4. Fold stapled

sheets in half.

5. Trim fore-edge

of booklet.

1

3. Punch sheets

(optional).

2. Staple stacked

sheets.

1. Insert cover or insert sheet into

stacked sheets.

Cover

Insert Sheet

Definition

Staple

To staple in the middle of sheets.

Definition

Insert sheet

A sheet inserted into stacked sheets.

1

Unstapled sheets can be folded with DDP 92 only.

6. Stack finished

booklet.

Definition

Fold

To fold stapled sheets in half.

Definition

Trim

To cut the fore-edge of a booklet.

1

1

Page 8

1-2 Transport Sheets to the Advanced Finisher

Printed sheets that will not be made into

booklets are transported to the Advanced

Finisher.

2

Page 9

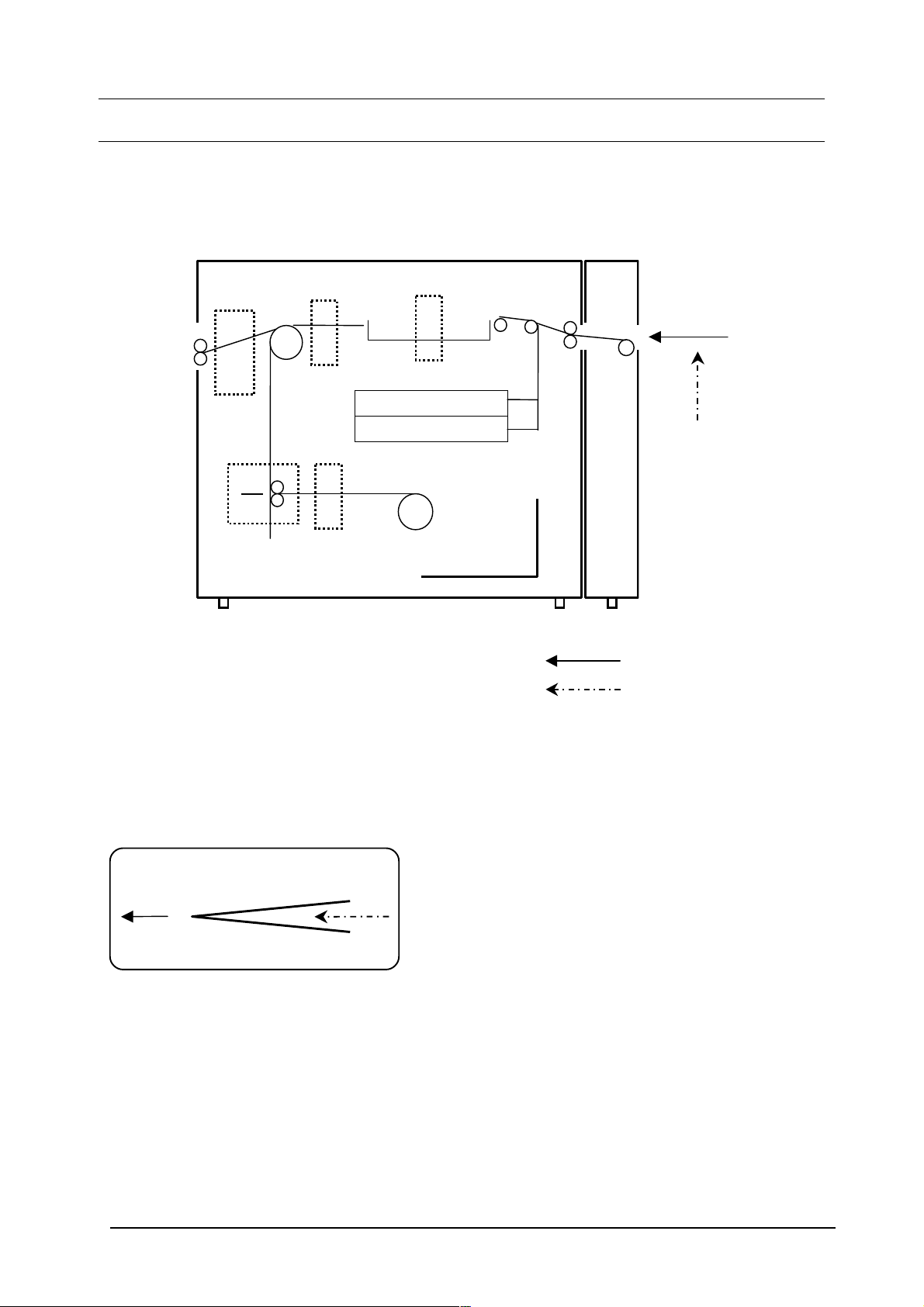

1-3 Sheet Folding and Punching Options

The diagram below shows the location of the

folding and punching options,

sheet paths of the Publishing Finisher.

as well as the

Fold

Center

Fold

Punch

Trim

Staple

Sheet from printer

Sheet Inserter 1

Sheet Inserter 2

Booklet Stacker

Sheet feed direction.

Printing surface.

The folding capability of the Publishing

Finisher is illustrated below.

Center Fold

3

Page 10

4

Page 11

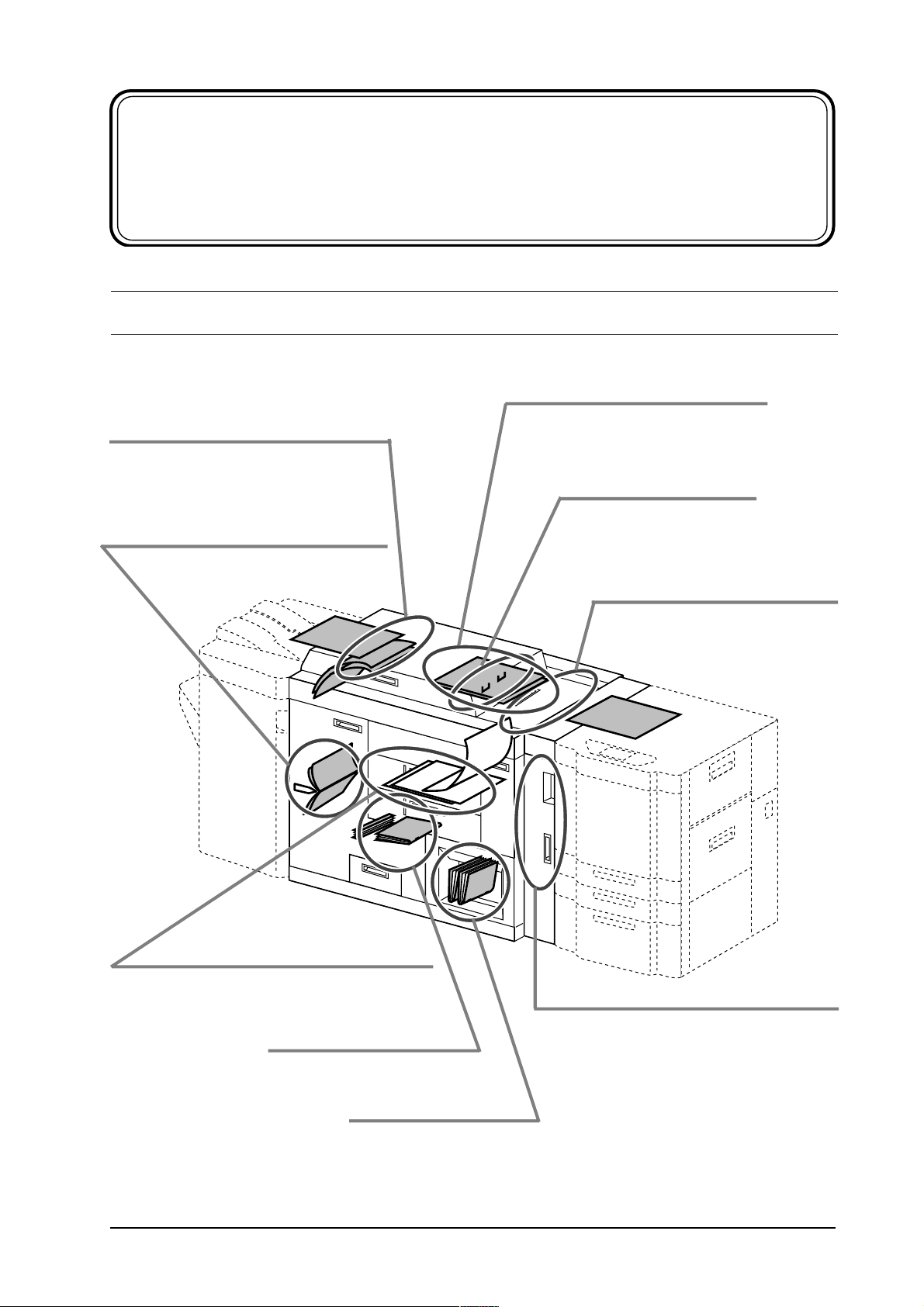

2. Machine Description

This section shows and describes the parts of the Publishing Finisher.

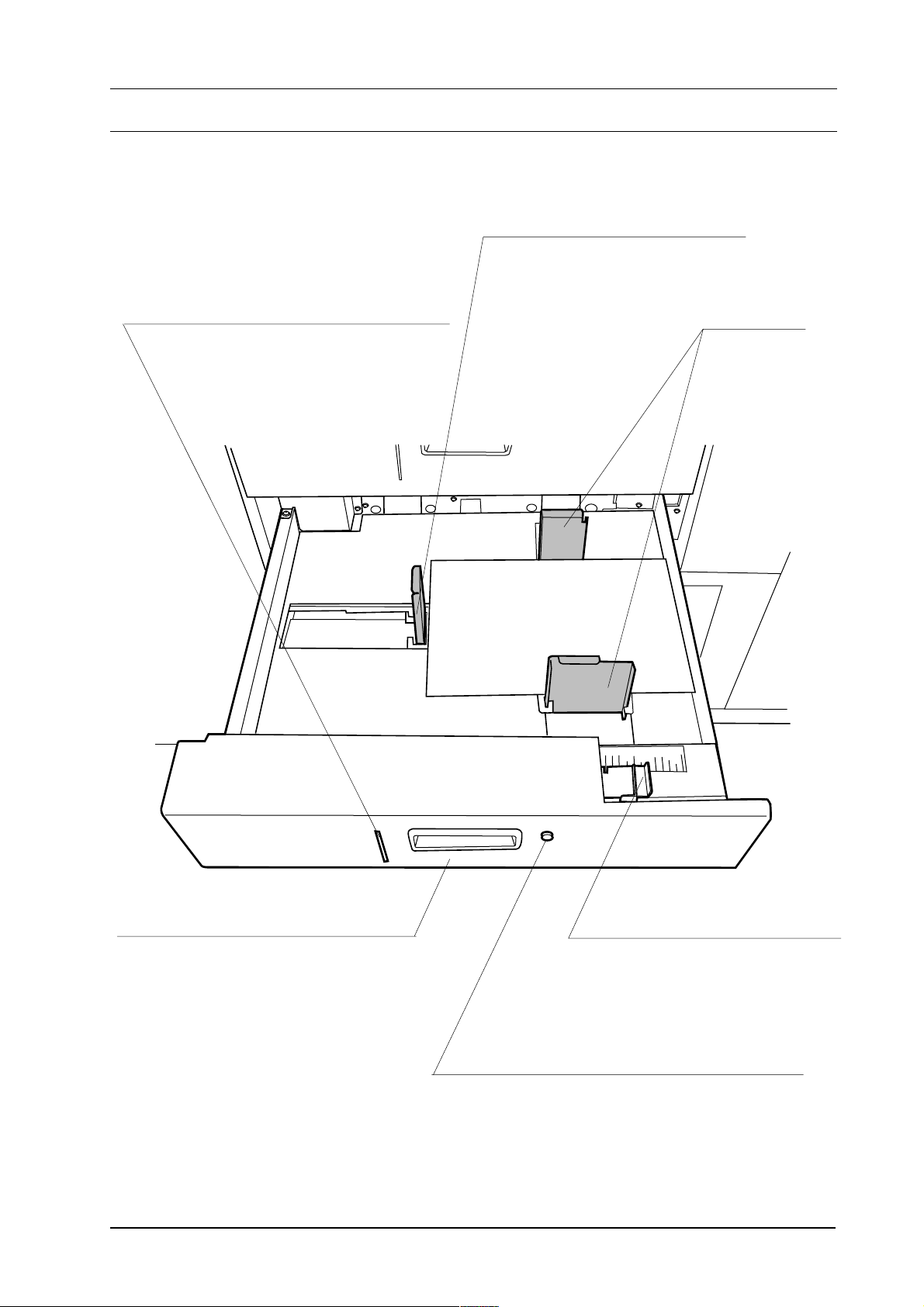

2-1 Unit Description

Transport Gate Section

Single sheets are sent to the Advanced

Finisher and stapled booklets are

transported to the fold section.

Fold Section for Stapled Sheets

The stapled sheets are folded.

Sheet Accumulate Section

Sheets from the printer are

accumulated and arranged.

Staple Section

A set of sheets is stapled.

Sheet Entrance Section

The sheets delivered from the

printer are received.

Sheet Inserter 1,2

The insert sheets are fed to the sheet

accumulate section and merged with the

sheets from the printer.

Trim Section

The fore-edge of the booklet

is trimmed.

Booklet Stacker

The trimmed booklets are

stacked.

Interface Section

This section connects the printer and

Publishing Finisher. The sheets from the

printer are transported to the Publishing

Finisher.

5

Page 12

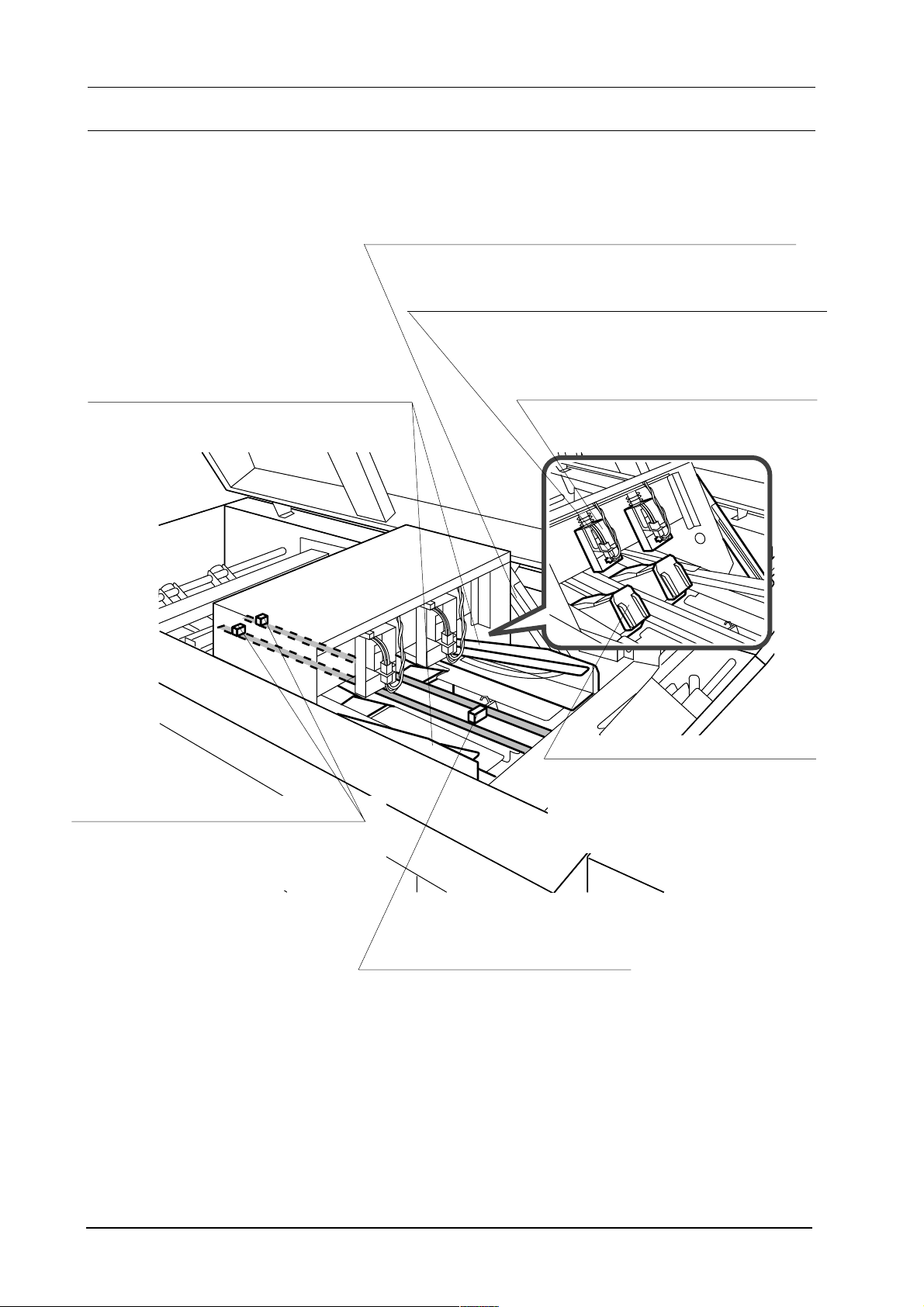

2-2 Staple Section / Sheet Accumulate Section

Stay

This stay is used to hold the staple section when it is tilted.

Staple Eject Lever

This lever is used to remove a staple jammed

inside of the clincher.

Jog Guide (Operation side and drive side)

Jog sheets at top and bottom sides.

Head Stoppers

These stoppers are used to jog

accumulated sheets.

Clincher

This clincher is used to press the

staples stitched out from the booklet.

Staple Cartridge

There are 5,000 staples in the

cartridge. When the cartridge is

empty, it can be replaced.

Transport Hook

This stopper is a pair with the head

stoppers and is used to jog sheets in

the sheet accumulate section.

6

Page 13

2-3 Sheet Inserter 1,2

End Fence

This is set according to sheet size.

Sheet Level Check Window

This window is used to check the level of

sheets in the sheet inserter.

Side Guide

Sheet Inserter 1,2

This tray is used to feed the cover or insert

sheets. The sheets in this tray must be the

same size as the sheets fed in the printer.

Sheet Size Lever

This lever is set according to the sheet

size in the sheet inserter.

Feeding Lamp

This lamp illuminates when sheets in the sheet

inserter tray are feeding or are ready to be fed. The

sheet inserter tray cannot be opened.

7

Page 14

2-4 Booklet Stacker

Stopper

This stopper is used to stack the trimmed

booklets.

Stopper Release Lever

Push the stopper release lever to move the stopper

to the left.

8

Page 15

3. Making Booklets

This section shows how booklets are made.

3-1 Power On

Turn on the printers power switch.

-This turns on power to the Publishing

Finisher and Advanced Finisher.

Power switch

Advanced Finisher

Publishing Finisher

Printer

3-2 Sheet Preparation

The following sheet sizes and weights can

be fed from the sheet inserter trays.

Sheet Size

A4

7.3" x 10.5" (185.4 x 266.7 mm)

8.5" x 11" (215.9 x 279.4 mm)

8.5" x 14" (215.9 x 355.6 mm)

11" x 17" (279.4 x 431.8 mm)

11" x 8.5" (279.4 x 215.9 mm)

Maximum size (Width X Length)

12" x 18" (305 x 457 mm)

Minimum size (Width X Length)

7.2" x 10.1" (182 x 256.5 mm)

, A3 , B4

Make sure the feeding lamp is not

illuminated.

-Do not open the sheet inserter

tray while the feeding lamp is on.

Open the sheet inserter tray.

Feeding Lamp

Sheet Inserter Tray

Insert sheet weight range

16 lb. to 53 lb.

9

Page 16

3-2 Sheet Preparation

Fan sheets well and set sheets in tray.

3

-Do not load sheets higher than

the Max line on side guide.

Max Line

Set side guides and end fence according

to sheet size.

4

Side Guide

End Fence

Side Guide

Set sheet size lever according to sheets

set on inserter tray.

5

-Pinch sheet size lever and slide it left or

right to the appropriate size.

Sheet Size Lever

- The Publishing Finisher trays

and the Printer trays must both

be set for either a Standard/

Special setting or a Custom

setting.

In some instances the paper size

settings in the Publishing

Finisher trays and the Printer

trays do not match. For

example: Letter (SEF) can be

selected in the Publishing

Finisher trays, but there is no

Letter (SEF) setting in the

Printer paper trays. In this case,

the Printer paper tray should be

set at the Special (triangle)

setting and Letter (SEF) should

be selected from the Printer

menu on the OCP or WEB page.

In this type of situation, it is

never correct to use the Custom

setting on the OCP or WEB

page.

10

Page 17

Close sheet inserter tray completely.

6

Sheet Inserter Tray

11

Page 18

3-3 Booklet Stacker Preparation

Push the stopper release lever and move

the stopper to the far left.

Stopper

Stopper Release Lever

3-4 Printer Preparation

See the documentation for the printer.

3-5 Submit Print Job

Submit print job from the printer.

-The printed sheet is delivered to

Publishing Finisher to be stapled,

folded, trimmed, and stacked side by

side in the booklet stacker.

12

Page 19

3-6 Remove Booklets

When the booklet stacker is full, the printer

and Publishing Finisher stop operating. An

explanatory message is displayed on the

printer.

Remove the booklets from the booklet

stacker.

Booklets

[Booklet Stacker]

Push the stopper release lever and move

the stopper to the far left.

Stopper

Stopper Release Lever

13

Page 20

4. Troubleshooting

This section provides troubleshooting guidelines.

4-1 Error Messages

OCP Line 1

Invalid Booklet Clear Paper Path Clear paper path. The system cannot create the

Invalid Booklet Cancel Job Correct the error or

Call for Service Exxx Contact your

Out of PF Rear

Out of PF Front

Inserter 1 Open C lose Tray E025 Close tray. Insert tray 1 is open.

Inserter 2 Open C lose Tray E026 Close tray. Insert tray 2 is open.

Booklet Staker

Paper Full

Trimm ing Trash

Box Full

Trimm ing Trash

Bo x No t S et

PF Front Cover R

Open

PF Front Cover L

Open

PF Front Cover C

Open

PF Top C over L

Open

PF Top C over R

Open

Entrance Paper

Guide Open

Inserter Guide 1

Open

Staple

Staple

Rem ove Paper E027 Rem ove paper. Stacker 4 is full.

Clean Trash Box E028 Rem ove trash. The trimming trash box is full.

Check Trash Box E02F Set trash box The trash box is not set in the

Close Cover E030 Close cover. Front Cover R of the Publishing

Close Cover E031 Close cover. Front Cover L of the Publishing

Close Cover E032 Close cover. Front Cover C of the Publishing

Close Cover E033 Close cover. Top Cover L of the Publishing

Close Cover E034 Close cover. Top Cover R of the Publishing

Close Guide E035 Close guide. The guide of entrance path 1 in the

Check Guide E036 Close guide. The upper guide of the inserter in

OCP Line 2

Error

Code

cancel job.

authorized Service

Technician and

provide the error code

displayed on the OCP.

E01B Replace the staple

cartridge.

E01C Replace the staple

cartridge.

Remedy

booklet. The remaining paper

needs to be removed.

The system cannot create the

booklet. Job needs to be canceled.

Any Call for Service error message

requires a service call for problem

resolution. Exxx is the error code.

The staples in the rear stapler of the

Publishing Finisher have run low.

The staples in the front stapler of

the Publishing Finisher have run

low .

Publishing Finisher.

Finisher is open.

Finisher is open.

Finisher is open.

Finisher is open.

Finisher is open.

Publishing Finisher is open.

the Publishing Finisher is open.

Description

13

Page 21

A pap

4-1 Error Messages

Inserter G uid e 2

Open

Fold ing Guid e 1

Open

Fold ing Guid e 2

Open

Paper in

Co n n e ctin g Un it

Paper in PF

Entrance

Paper in PF Stapler Rem ove Pa per E075 R em ove pa per. A paper in the stapler entrance path

Paper in PF Stapler Rem ove Pa per E076 R em ove pa per. A paper in the stapler unit of the

Paper in PF Folder Rem ove P aper E077 Remove paper. A paper in the folding unit of the

Paper in PF

Trimmer

Paper in PF Exit Rem ove Pa per E079 R em ove pa per. A paper in the exit path of the

Paper in PF

Puncher

Paper in PF

Inserter 1

Paper in PF

Inserter 2

Paper Jam PF

Stapler

Pape r Jam Inse rter 1 Rem ove Pa per E1E0 Rem o ve paper. A paper was not fed from insert

Pape r Jam Inse rter 1 Rem ove Pa per E1E1 Rem o ve paper. A double feeding occurred in insert

Pape r Jam Inse rter 1 Rem ove Pa per E1E2 R em ove paper. A paper jam occurred in insert tray

Pape r Jam Inse rter 2 Rem ove Pa per E1E5 Rem o ve paper. A paper was not fed from insert

Check G uide E 037 Close guide. The lower guide of the inserter in

Check G uide E 038 Close guide. The upper guide of the folding

Check G uide E 039 Close guide. The lower guide of the folding unit

Rem ove Pa per E073 R em ove pa per. A paper in the connecting unit of

Rem ove Pa per E074 R em ove pa per. A paper in the entrance path of the

Rem ove Pa per E078 R em ove pa per. A paper in the trimm ing unit of the

Rem ove Pa per E07A Rem ove paper. A paper in the punching of the

Rem ove Pa per E07B R em ove paper. A paper in inserter path 1 of the

Rem ove Pa per E07C R em ove paper. A paper in inserter path 2 of the

Rem ove Pa per E1D 4 Rem ove paper.

the Publishing Finisher is open.

guide in the Publishing Finisher is

open.

in the P u b lis h in g F i nis he r is o p en .

the Publishing Finisher needs to be

removed.

Publishing Finisher needs to be

removed.

of the Publishing Finisher needs to

be removed.

Publishing Finisher needs to be

removed.

Publishing Finisher needs to be

removed.

Publishing Finisher needs to be

removed.

Publishing Finisher needs to be

removed.

Publishing Finisher needs to be

removed.

Publishing Finisher needs to be

removed.

Publishing Finisher needs to be

removed.

er jam occ urred on the stapler

tray .

tray 1.

tray 1.

1.

tray 2.

14

Page 22

4-1 Error Messages

Pa pe r Jam Inserter 2 Rem ove Paper E 1E6 Rem ove paper. A double feeding occurred in insert

Pa pe r Jam Inserter 2 Rem ove Paper E 1E7 Rem ove paper. A paper jam occurred in insert tray

Paper Jam

Connecting Unit

Paper Jam PF

Entrance

Paper Jam PF

Stapler

Paper Jam PF

Stapler

Paper Jam PF

Folder

Paper Jam PF

Trimmer

Paper Jam PF E xit R em ove Paper E 1F0 R em ove paper. The paper did not get to the exit

Paper Jam PF

Puncher

Paper Jam

Connecting Unit

Paper Jam PF

Entrance

Paper Jam PF

Stapler

Paper Jam PF

Stapler

Paper Jam PF

Folder

Paper Jam PF

Trimmer

Paper Jam PF E xit R em ove Paper E 1F8 R em ove paper. A paper jam occurred in the exit

Paper Jam PF

Puncher

Rem ove Paper E 1EA R em ove paper. The paper did not get to the

Rem ove Paper E 1EB Rem ove paper. The paper did not get to the

Rem ove Paper E 1EC Rem ove paper. The paper did not get to the stapler

Rem ove Paper E 1ED R em ove paper. The paper did not get to the stapler

Rem ove Paper E 1EE R em ove paper. The paper did not get to the folding

Rem ove Paper E 1EF Rem ove paper. T he paper did not get to the

Rem ove Paper E 1F1 R em ove paper. The paper did not get to the

Rem ove Paper E 1F2 R em ove paper. A paper jam occurred in the

Rem ove Paper E 1F3 R em ove paper. A paper jam occurred in the

Rem ove Paper E 1F4 R em ove paper. A paper jam occurred in the stapler

Rem ove Paper E 1F5 R em ove paper. A paper jam occurred in the stapler

Rem ove Paper E 1F6 R em ove paper. A paper jam occurred in the folding

Rem ove Paper E 1F7 R em ove paper. A paper jam occurred in the

Rem ove Paper E 1F9 R em ove paper. A paper jam occurred in the

tray 2 .

2.

connecting unit of the Publishing

Finisher.

entrance path of the Publishing

Finisher.

entrance of the Publishing Finisher.

unit of the Publishing Finisher.

unit of the Publishing Finisher.

trim m ing u nit o f th e P u blis hin g

Finisher.

path of the Publishing Finisher.

punching unit of the P ublishing

Finisher.

connecting unit of the Publishing

Finisher.

connecting unit of the Publishing

Finisher.

entrance of the Publishing Finisher.

unit of the Publishing Finisher.

unit of the Publishing Finisher.

trim m ing u nit o f th e P u blis hin g

Finisher.

path of the Publishing Finisher.

punching unit of the P ublishing

Finisher.

15

Page 23

4-2 Removing Jammed Sheets

4-2-1 Interface Section

Open Front Cover R.

Front Cover R

Open the entrance paper guide and

remove the sheet.

Entrance Paper Guide

Close the guide and cover.

-Close the entrance paper guide

completely after removing sheet.

-If the sheet jam message does not

disappear, a sheet is still jammed in

the other section. Remove the sheet.

16

-Open the delivery section of the

printer and remove the sheet.

Printer Side

Page 24

4-2 Removing Jammed Sheets

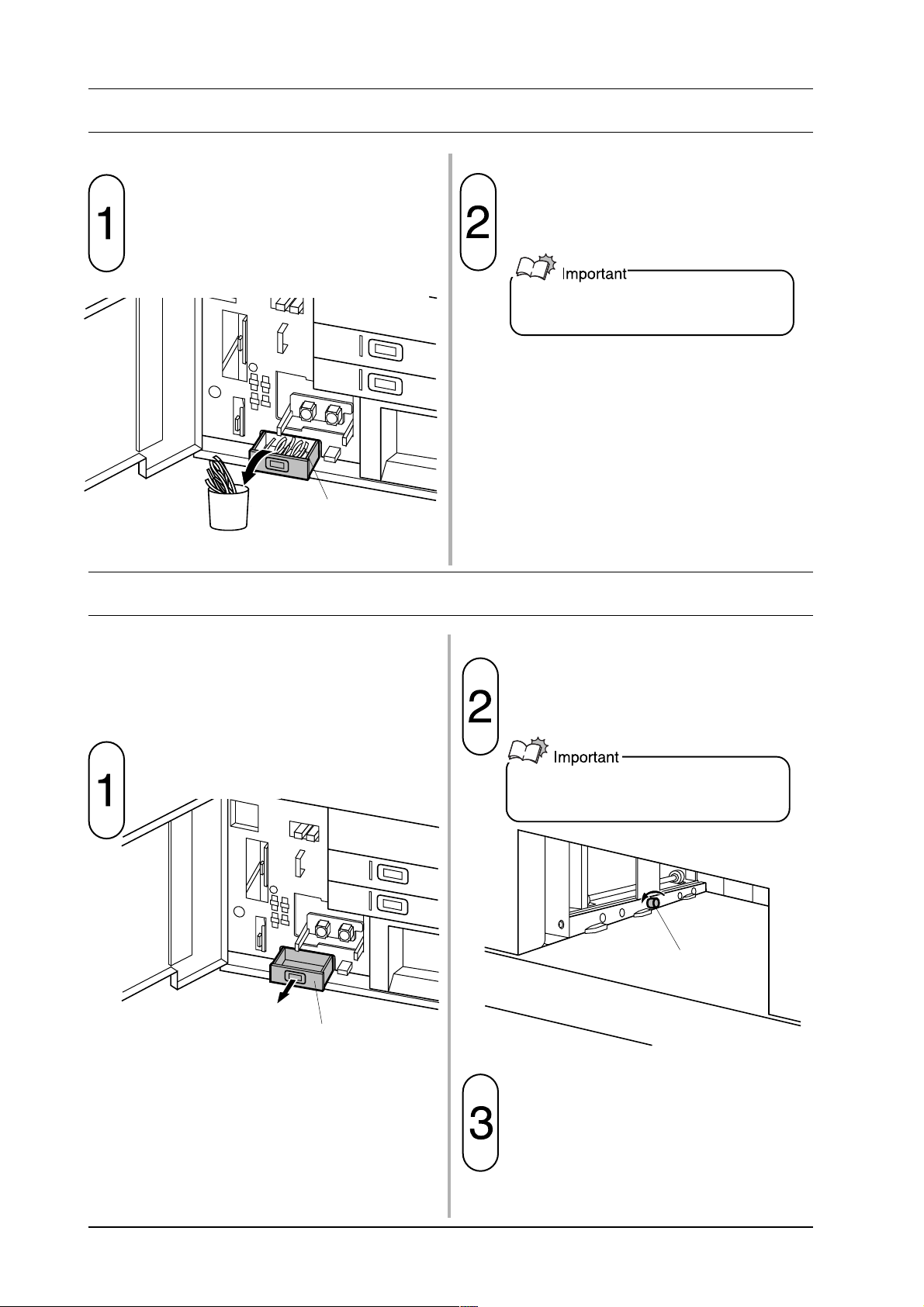

4-2-2

Sheet Inserter 1,2

Remove the sheet inserter tray.

Sheet Inserter Tray

4-2-3 Sheet Entrance Section

Open Top Cover R and remove the

sheet.

Top Cover R

Remove the jammed sheet inside the

sheet inserter.

Sheet

Replace the sheet inserter tray.

Close the cover.

17

Page 25

4-2 Removing Jammed Sheets

4-2-4 Staple Section

Open Top Cover L and Top Cover R.

Remove the jammed sheet.

Top Cover L

Top Cover R

Sheet

Close the top covers.

18

Page 26

4-2 Removing Jammed Sheets

4-2-5 Fold Section For Stapled Sheets

Open Front Cover L.

Front Cover L

Open guide 6,7 and remove sheets.

Close the guides.

-Close guides 6 ,7 completely after

removing sheet.

Close the cover.

-If sheet jams occur frequently,

the gap set between guides may

be too thin. Refer to Section 4-3.

Guide 6

Guide 7

19

Page 27

4-2 Removing Jammed Sheets

4-2-6 Trim Section

Open Front Cover L.

Front Cover L

-If the jammed sheet cannot be removed

or the transport belt comes off while

removing the sheet, follow the procedure

below to pull out the trim section. Be

very careful and do not touch the knife.

CAUTION

-Do not touch the trim section when it

is pulled out. The knife is very sharp

and can cause severe personal injury.

Remove the jammed sheet.

Sheet

Stopper

1) Remove stopper fixing screws.

2) Slowly pull out the trim section.

3) Remove jammed sheet or attach

transport belt.

4) Slowly push the trim section to original

position.

5) Attach stopper fixing screws.

Transport Belt

Knife

Close the cover.

20

Trim Section

Page 28

4-2 Removing Jammed Sheets

4-2-7 Finisher Delivery Section

Open Top Cover L.

Top Cover L

Open guide 8 and remove sheet.

4-2-8 Transport Gate Section

Open Top Cover L.

Top Cover L

Open guides 4, 5 and remove sheet.

-Close guide 8 completely after

removing sheet.

Guide 8

Close the cover.

-Close guides 4, 5 completely after

removing sheet.

Guide 5 Guide 4

Close the cover.

21

Page 29

4-2 Removing Jammed Sheets

4-2-9 Delivery Path of Sheet Inserter 1,2

Open Front Cover C.

Open guide 1,2 and remove sheet.

-Close guide 1,2 completely after

removing sheet.

Guide 1

Guide 2

Close the cover.

Front Cover C

22

Page 30

4-3 When Sheet Jams Occur Frequently

If sheet jams occur frequently in the fold

section for stapled sheets, the gap set between

guides may be too thin.

Open Front Cover L.

Guide 6

-If the sheets do not move smoothly,

pull out the trimmings box and turn

the guide adjust knob clockwise to

widen the gap between guides.

Front Cover L

Open guide 6 and place sheets between

the guides to check that the sheets pass

between the guides smoothly.

Guide 6

Trimming Trash Box

Guide Adjust Knob

23

Page 31

4-4 When Cover or Guide is Open

Symptom

Cover or guide is open.

1) Front Cover C

2) Front Cover L

3) Top Cover L

4) Top Cover R

5) Trimming trash box

6) Sheet Inserter Tray 1,2

7) Front Cover R

8) Entrance paper guide

Remedy

Close the cover or guide that is open.

3

4

6

2

5

6

8

1

7

24

Page 32

4-5 When Staples Run Out

Follow the steps below to replace the staple

cartridge.

Open Top Cover L.

Top Cover L

Lift the staple unit.

-Staple unit is held with stay 3.

Pull up on the staple cartridge.

-Approximately10 staples will be

left in the staple cartridge. They

cannot be used.

Staple Cartridge

Stay 3

Staple Unit

-When the staple unit interferes with

the jog guides, widen the jog guides

outward handling near the fulcrum

shaft.

Push the staples to the end of the cartridge.

Otherwise, the stapling function will not

work immediately.

End of the Cartridge

25

Page 33

4-5 When Staples Run Out

Push the new staple cartridge in until it

clicks.

Staple Cartridge

Place the staple unit back to the original

position.

1) Hold up staple unit with one hand.

2) Pull up stay 3 with the other hand.

3) Lower staple unit to original position.

Stay 3

Staple Unit

26

Close the cover.

Page 34

4-6 When Staple is Jammed

Follow the proedure below to remove a

jammed staple.

Open Top Cover L.

Top Cover L

Lift the staple unit.

-The staple unit is held with stay 3.

Stay 3

Press the staple eject lever and remove

any jammed staples.

[Staple Unit]

Staple Eject Lever

Place staple unit back to the original

position.

Staple Unit

Place a sheet under the unit to catch any

falling staples.

Sheet

1) Hold up staple unit with one hand.

2) Pull up stay 3 with the other hand.

3) Lower staple unit to original position.

Stay 3

Staple Unit

Close the cover.

27

Page 35

4-7 When Trimming Trash Box Is Full

Pull out the trimming trash box and

remove the trash.

Trimming Trash Box

4-8 When Fold Line is Not Aligned

Push the trimming trash box back to its

original position.

-Push the trimming trash box back

firmly and completely.

The fold line will not align properly if the gap

between the guides is too wide. Follow the

procedure below to reduce the size of the gap.

Pull out the trimming trash box.

Trimming Trash Box

Turn the guide adjust knob counterclockwise to reduce the gap between the

guides.

-Do not make the gap too small as

this can cause sheets to jam.

Guide Adjust Knob

Push the trimming trash box back firmly

and completely.

28

Page 36

4-9 When the Fold and Stitch Line Are Not Aligned

Adjustments may be necessary based on sheet

quality, direction, and thickness.

Adjust the fold position at printer set up.

4-10 When the Fore-edge is Not Trimmed Completely

The trimming length is set shorter than the

fore-edge of the booklet.

Adjust the trimming length at printer set

up.

If the problem is not cleared, the

knives might be dulled. Please call

your service representative.

4-11 When the Fore-edge is Not Trimmed At All

The trimming function is not selected.

Select the trimming function at printer

set up.

If the problem is not cleared, the

knives might be dulled. Please call

your service representative.

4-12 When the Sheet is Not Folded

The booklet thickness is over 2 mm.

Use sheets within specification and make

booklet thickness within 2 mm.

29

Page 37

30

Page 38

5. Cleaning

This section shows how to clean the Publishing Finisher.

5-1 Cleaning the Sheet Transport Path

CAUTION

-Do not use thinner, alcohol or benzin

for cleaning.

Open the cover or door necessary to

access the area to clean.

Guide 8

Guide 6

Open the guide and clean the sheet

transport path with soft and dry cloth.

- When the sheet transport path is not

cleaned with dry cloth, clean it with

cloth soaked alcohol or detergent and

wipe moisture with dry cloth.

Guide 5

Staple Section

Trim Section

Entrance Paper Guide

Guide 1

31

Page 39

32

Page 40

Appendix

This appendix shows specifications and consumables.

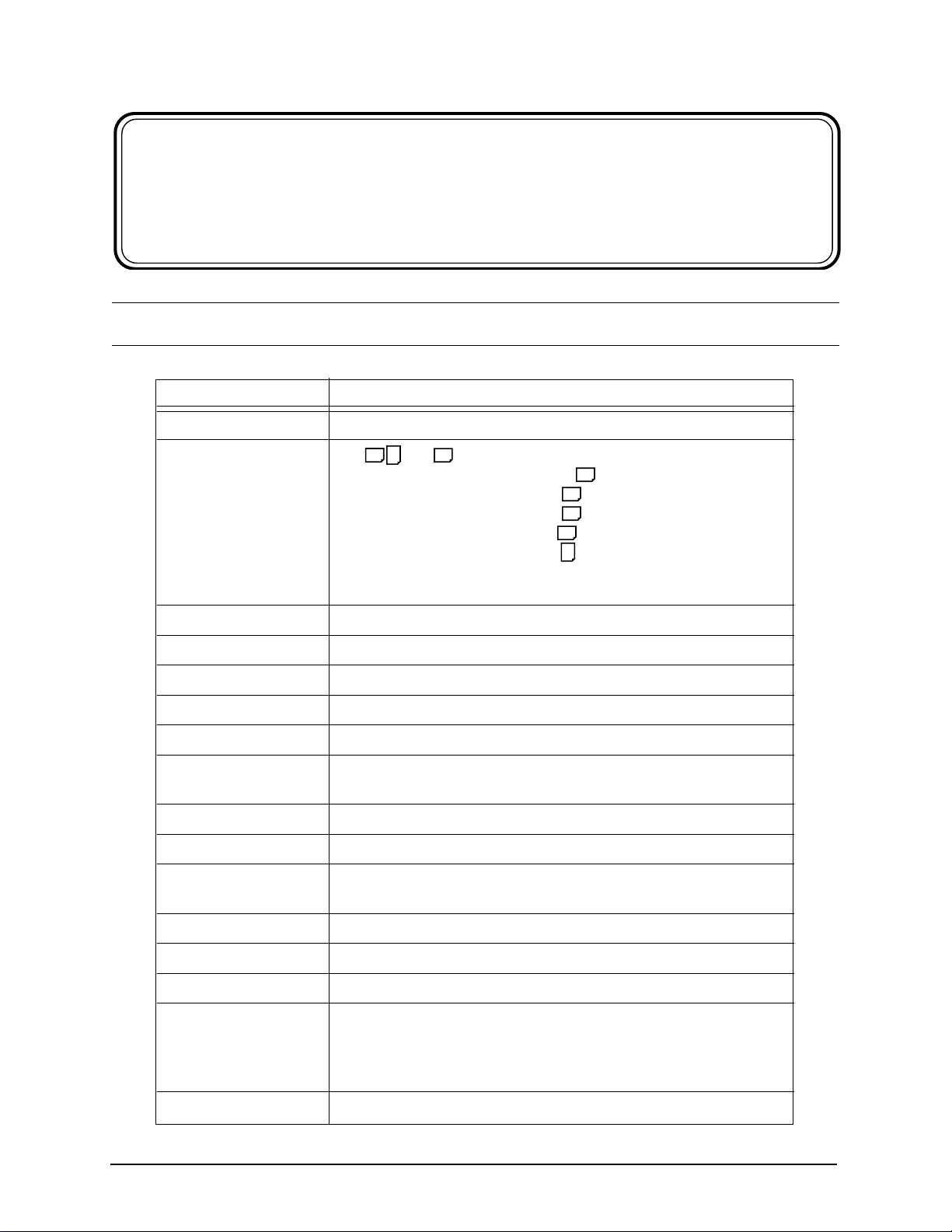

A-1 Specifications

Item Specification

Function Folding, Stapling, and Trimming

Sheet Size A4 , A3 ,

7.3" x 10.5" (185.4 x 266.7 mm) ,

8.5" x 11" (215.9 x 279.4 mm) ,

8.5" x 14" (215.9 x 355.6 mm) ,

11" x 17" (279.4 x 431.8 mm) ,

11" x 8.5" (279.4 x 215.9 mm) ,

Maximum 12" (width) x 18" (length) (305 x 457 mm)

Minimum 7.2" x 7.2" (182 x 182 mm)

Sheet Weight 16 to 24 lb (60 to 90 g/m2)

Insert Sheet Weight 16 to 53 lb (60 to 198.8 g/m2)

Tray Pile Height Maximum 50 mm (2.0)/Less than 90 g/m2 450 sheets

Trimming Width Less than 13 mm (0.5)

Production Speed Up to 800 booklets per hour

Stack Amount Maximum 250 mm (9.8)

Stapling and folding/100 booklets (80 g/m2, 5 sheets)

Staple Distance 120 mm (4.7) (fixed)

Staple Cartridge 5,000 staples

Sensors Sheet jam, sheet inside, sheet misfeed, full stack, low staple,

empty staple, cover open, guide open, trimming trash box full

Noise Level 70 dBA

Dimensions 1,268 mm x 670 mm x 1,081 mm (W x D x H)

Weight 270 kg (Publishing Finisher only)

Power Single phase 200 V / 50 Hz (4.7 A)

Single phase 220 V / 60 Hz (4.9 A)

Single phase 230 V / 50 Hz (4.6 A)

Single phase 240 V / 60 Hz (4.6 A)

Ambient Temperature 10 to 32 degrees Celsius

33

Page 41

The table below lists the maximum number of

sheets allowed per booklet. Specifications are

given for booklets without insert sheets and

booklets with one 53 lb insert sheet.

Number of Sheets Number of Sheets

Paper Weight (no insert sheets) (with 53 lb insert sheet)

16 lb (60 g/m2) 20 sheets 16 sheets

17 lb (64 g/m2) 19 sheets 15 sheets

18 lb (64 g/m2) 18 sheets 14 sheets

19 lb (64 g/m2) 17 sheets 14 sheets

20 lb (64 g/m2) 16 sheets 13 sheets

21 lb (64 g/m2) 15 sheets 12 sheets

22 lb (64 g/m2) 14 sheets 12 sheets

23 lb (64 g/m2) 14 sheets 11 sheets

24 lb (90 g/m2) 13 sheets 11 sheets

Note for DDP 92 only: When folding stacked sheets (not stapled sheets),

the maximum number of sheets is 3.

A-2 Consumables

Staple Cartridge 2 pc

Knife (U) (M072808-01) 1 pc

Knife (L) (M072822-03) 1 pc

Double Feed Stop Plate (A924697-00) 2 pc

34

Loading...

Loading...